Patents

Literature

115 results about "Material Deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In materials science, deformation refers to any changes in the shape or size of an object due to- an applied force (the deformation energy in this case is transferred through work) or a change in temperature (the deformation energy in this case is transferred through heat).

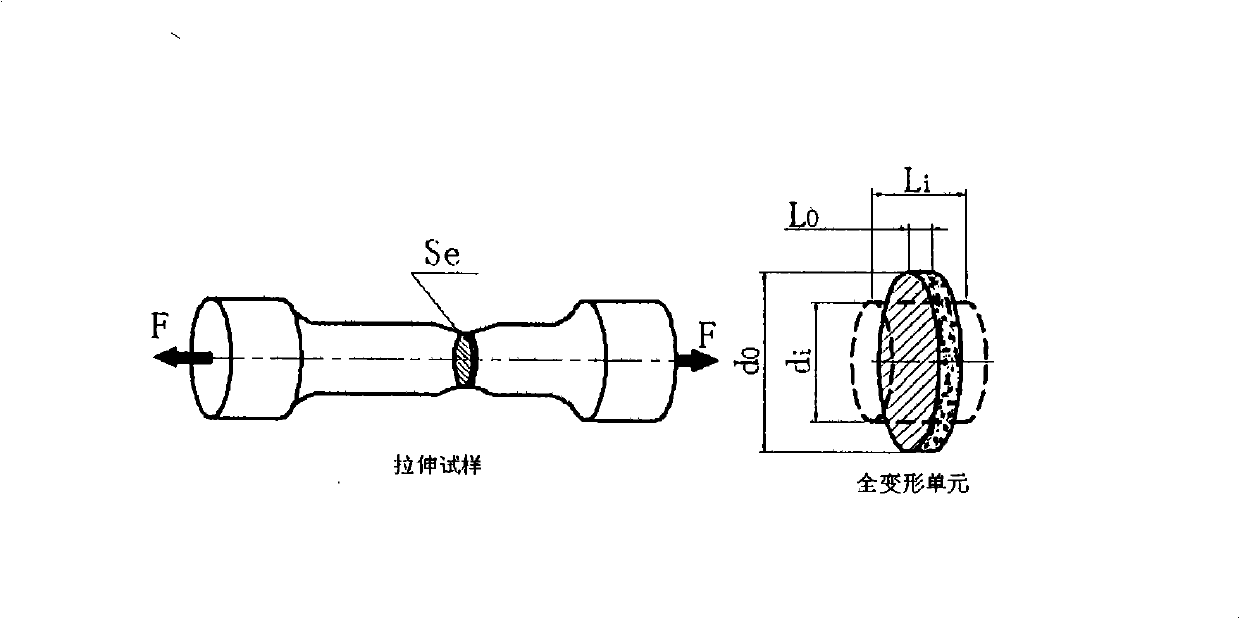

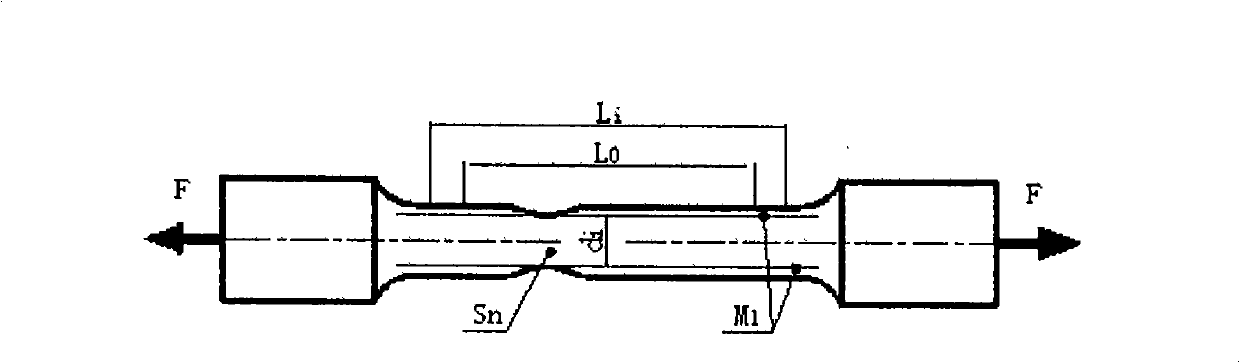

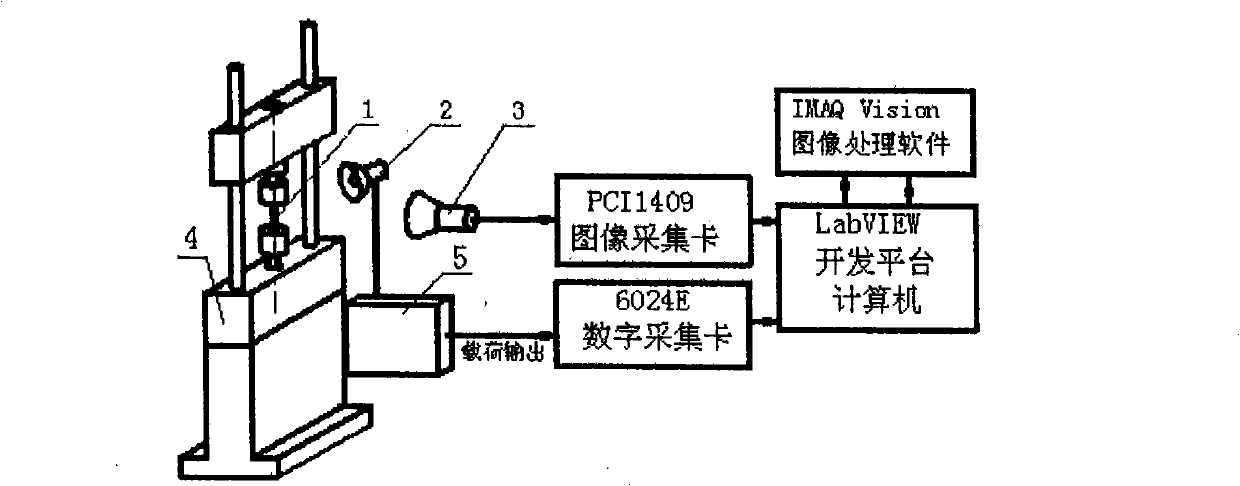

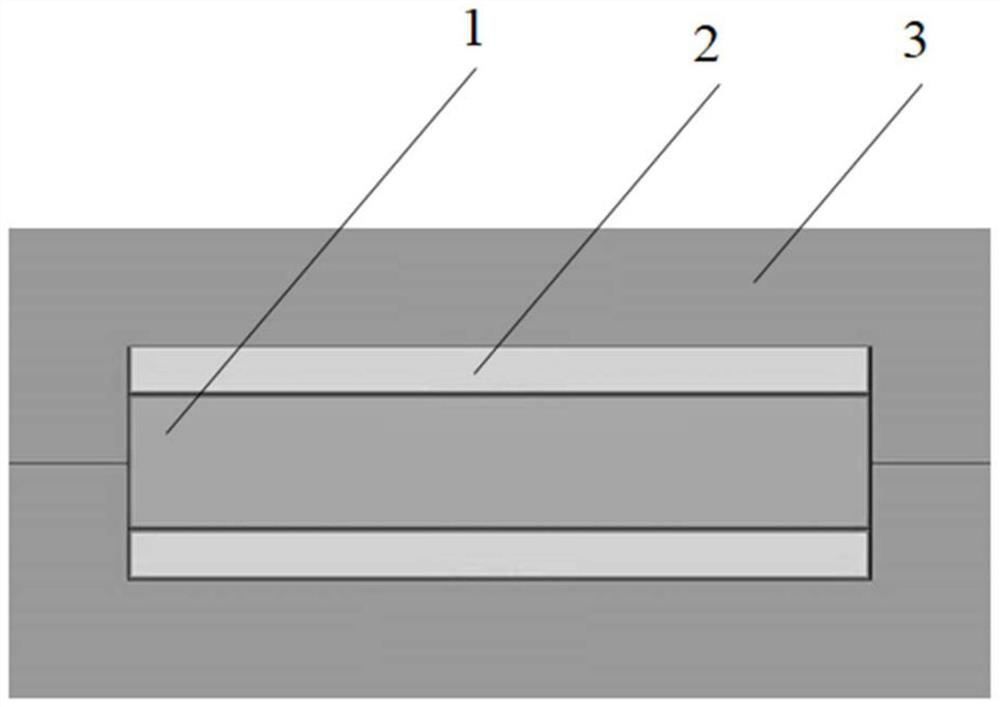

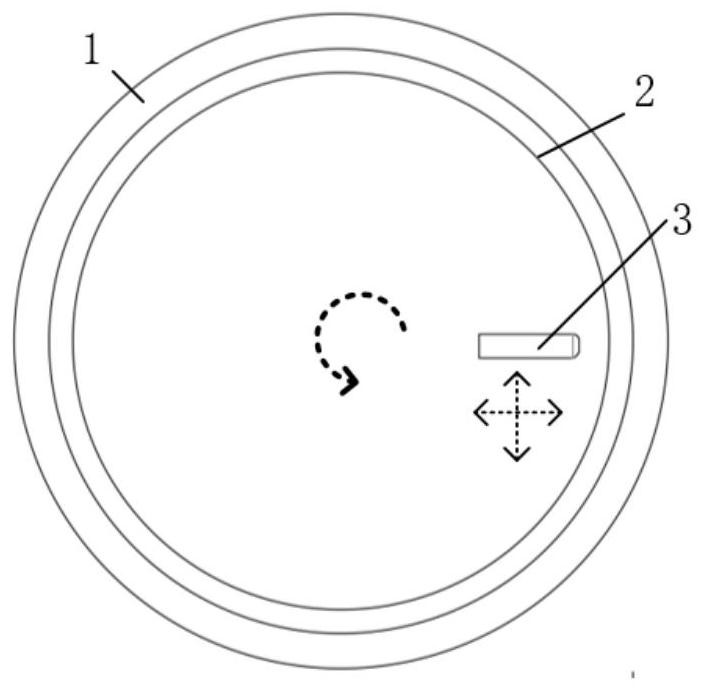

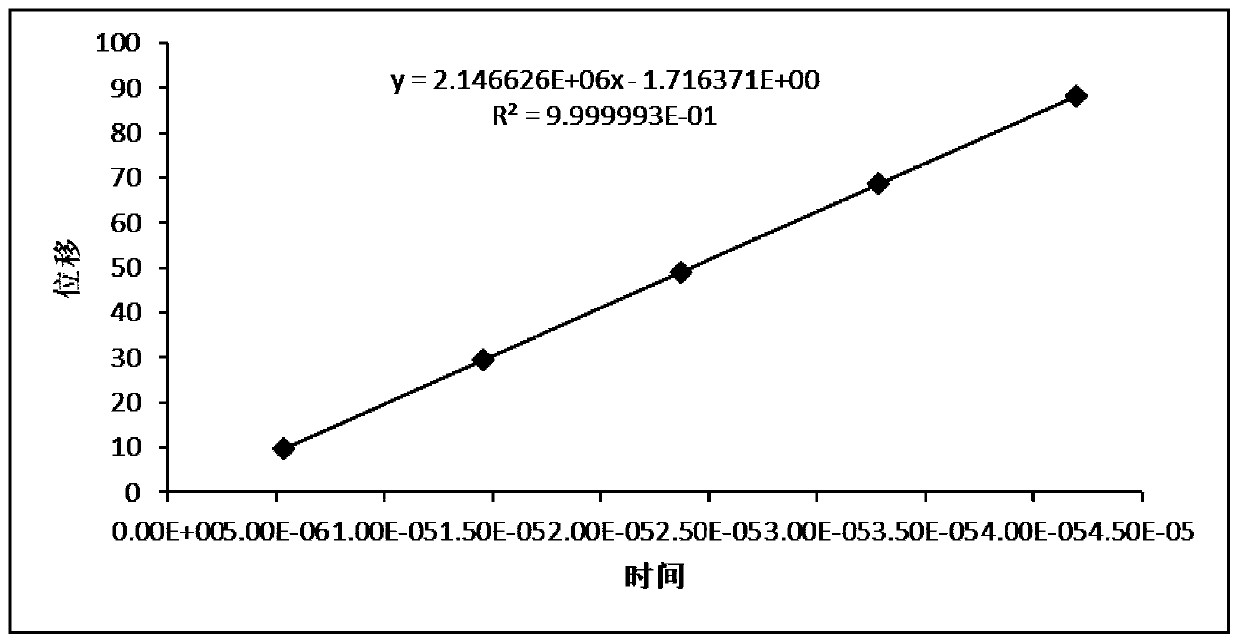

True stress-true strain computation model and test system

InactiveCN101319977AAccurate performance characteristics of mechanical behaviorExpress mechanical behavior characteristicsSpecial data processing applicationsStrength propertiesVisual technologySoftware system

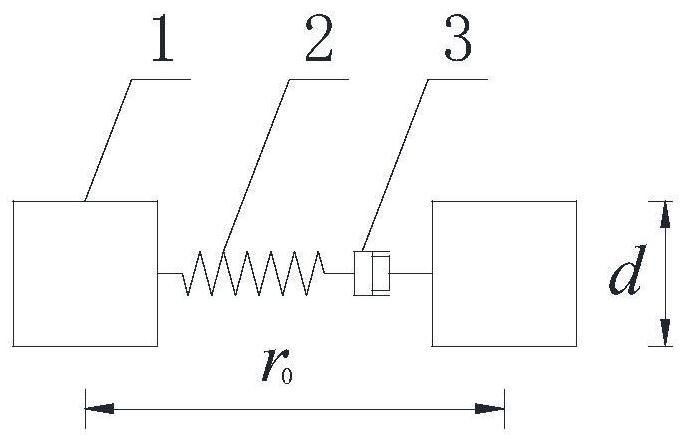

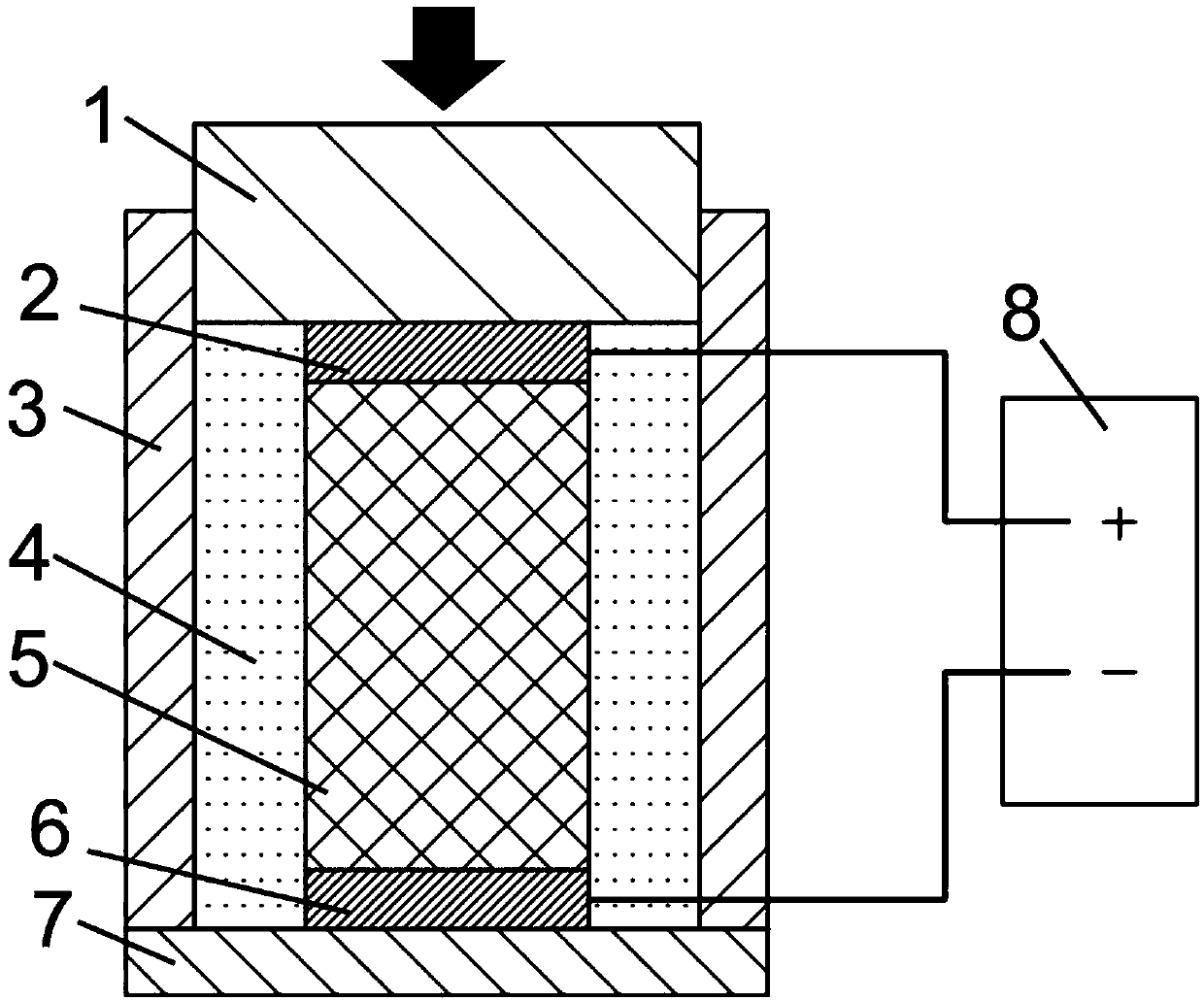

The invention researches the substantive characteristics of material deformation to aim at the practical problem of measuring real stress-real strain and discloses a real stress-real strain calculating model and a practical testing system: 1, based on the analysis on the deformation of a tension specimen, taking a unit body the special part of which is provided with characteristics as the object for the stress-strain analysis, building a unique full-deformation unit model, firstly solving the theory analysis problem of real stress-real strain, establishing a theory foundation and building a novel real stress-real strain calculating formula: Sigma i is equal to 4Fi / Pi d<2>I and Epsilon is equal to (d<2>0 / d<2>i) minus 1; 2, adopting a machine visual technology and an image processing method to develop a practical software system and a practical hardware system that are compatible with the machine visual technology and the image processing method, and realizing the direct non-contact real stress-real strain measuring in real meaning; 3, the testing system includes a light source (1), CCD camera (2), an image acquisition card (3), a data acquisition card (4) and a material testing machine (5); 4,the software includes image capturing program, load data acquisition program and comprehensive calculation analysis program.

Owner:HARBIN INST OF TECH

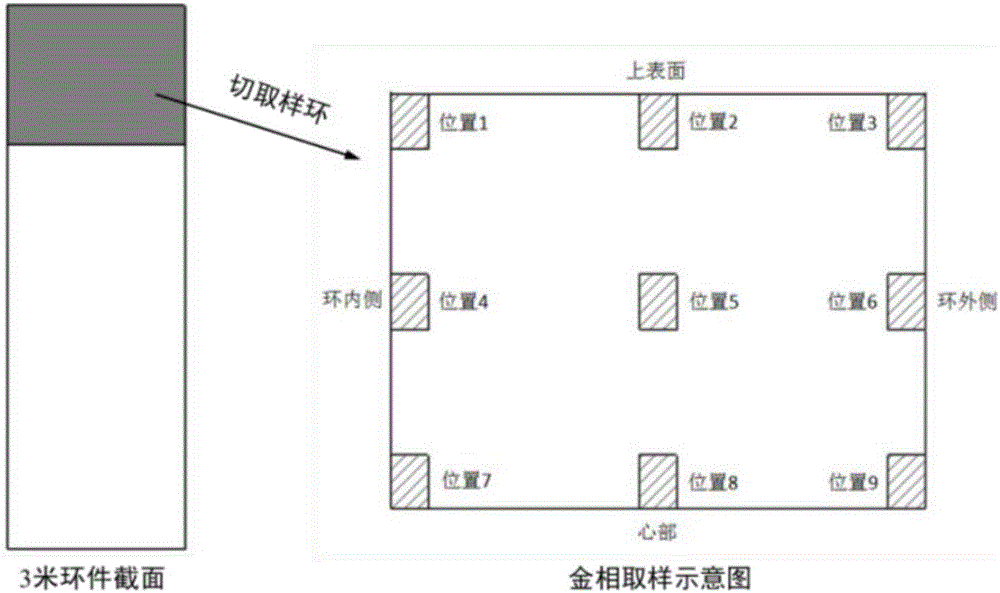

Process method for improving comprehensive mechanical property of 2219 aluminum alloy ring piece

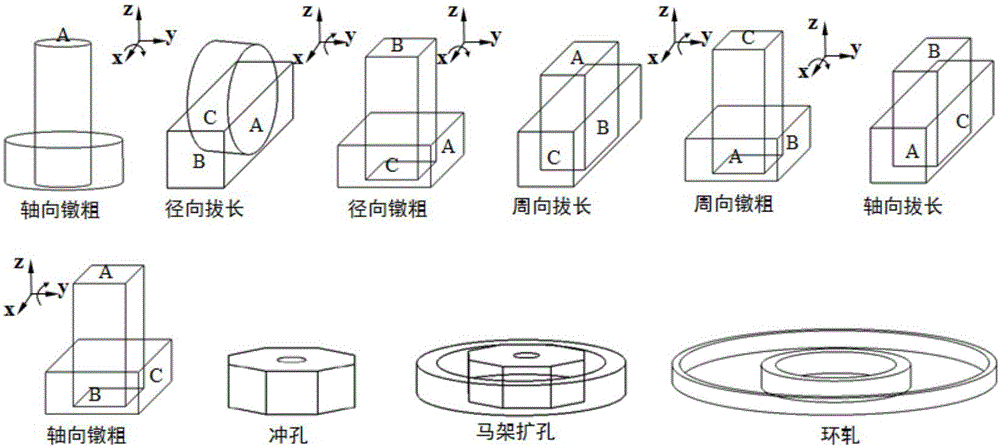

The invention relates to the technical field of metal material deformation heat treatment processes and discloses a process method for improving the comprehensive mechanical property of a 2219 aluminum alloy ring piece so that coarse residual crystalline phases of the large-size 2219 aluminum alloy ring piece can be fully crushed and crystalline grains can be refined and equiaxed, thus, the strength and the plasticity of the 2219 aluminum alloy ring piece are improved at the same time, and the anisotropy is decreased. The process method comprises the steps of multi-directional forging, punching, mandrel supporter broaching, piecewise rolling and heat treatment. In the multi-directional forging step, the heating temperature of a blank is 500 DEG C-520 DEG C, and the final forging temperature is higher than or equal to 380 DEG C. Piecewise rolling comprises the steps that in the first stage, the ring blank is heated to 420 DEG C-460 DEG C and subjected to hot rolling on a ring rolling machine, and the hot rolling deformation quantity is 30%-40%; and in the second stage, the ring piece subjected to hot rolling is air-cooled to 240 DEG C-280 DEG C and is continuously subjected to medium and low temperature rolling on the ring rolling machine, and the deformation quantity is 15%-25%.

Owner:湖南中创空天新材料股份有限公司

Forging method of TC4 titanium alloy large-specification rods

ActiveCN108097852AReduce lossIncrease the degree of deformationMetal-working apparatusIngotTitanium alloy

The invention discloses a forging method of TC4 titanium alloy large-specification rods. TC4 cast ingots are selected; TC4 are drawn to deform according to a deformation of 40-60%, and are broken to obtain multiple forgings; second heating-number forging and third heating-number forging are performed on each forging; one-upsetting and one-drawing deformation is performed on each forging in secondheating-number forging and third heating-number forging; fourth heating-number forging is performed on each forging; one-upsetting and one-drawing deformation is performed; the forgings are rounded asrods of phi 200-phi 220 mm; fifth heating-number forging is performed on each rod of phi 200-phi 220 mm; and the rods are drawn to deform according to a deformation of 40-60%, and are rounded to formrods of phi 120 mm. The one-upsetting and one-drawing operation is adopted to replace traditional three-upsetting and three-drawing operation, so that the operation is simplified, the production costand the material loss are reduced, the material deformation degree is increased, the heart structures can be crushed more sufficiently, and the equiaxial property is achieved; and the blank forging temperature is gradually lowered along with the operation, crushing of grain particles and transformation of morphologies are facilitated, and the structure uniformity of the TC4 alloy large-specification rods is improved.

Owner:西安赛特思迈钛业有限公司

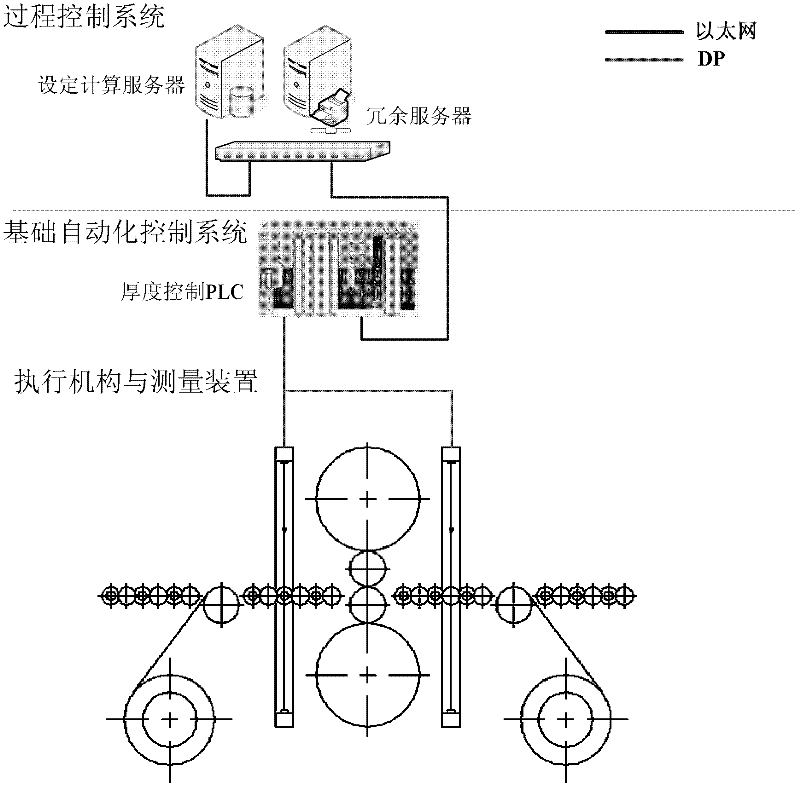

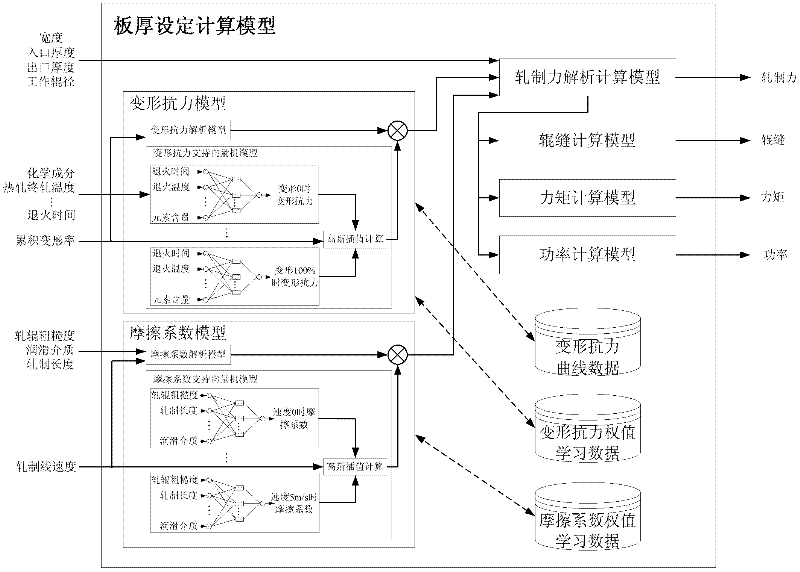

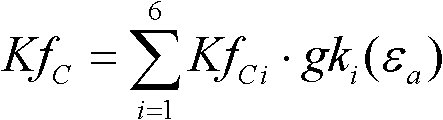

Thickness control method for single precision cold-rolled sheet thickness measuring system

ActiveCN102363159ASmall range of actionImprove calculation accuracyRoll mill control devicesMetal rolling arrangementsAnalytic modelSupport vector machine

The invention discloses a thickness control method for a single precision cold-rolled sheet thickness measuring system, and belongs to the field of mechanical automation control. Because a single sheet is short and requires short rolling time, a thickness feedback value acquired by a thickness gauge cannot be used for thickness closed-loop control. A thickness measured value is used for self-learning of a sheet thickness computation model of a process control system, the deformation resistance and a friction coefficient under the actual working condition of a material are corrected, and the thickness control accuracy is improved fundamentally by improving the set computational accuracy of the sheet thickness computation model. By an advanced support vector machine modeling method, the deformation resistance and the friction coefficient of the single sheet are subjected to statistical modeling, and an analytic model and statistical model combined model structure is formed; and a plurality of deformation resistance support vector machines are established according to different cumulative reduction ratios, and a plurality of friction coefficient support vector machines are established according to different rolling linear speeds, so that the action range of each support vector machine is narrowed, the computational accuracy of the model is effectively improved and the thickness control accuracy for single cold-rolled products can be greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

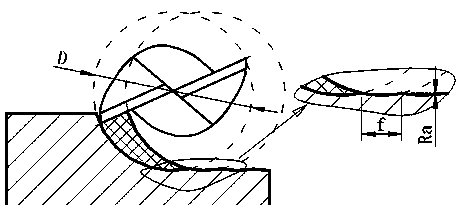

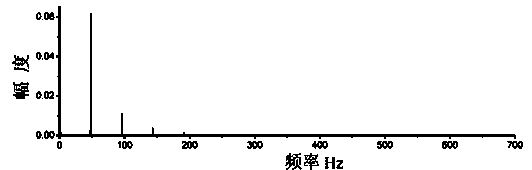

Milling surface roughness online prediction method based on acoustic emission signals

InactiveCN103394972AReduce scrap rateGood effectMeasurement/indication equipmentsAcoustic emissionMachined surface

The invention relates to a milling surface roughness online prediction method based on acoustic emission signals. An acoustic emission sensor is installed on a workpiece to be milled and used for monitoring the acoustic emission signals emitted by material deformation of the workpiece to be milled in the milling process of the workpiece. According to a theory that changes of milling thicknesses reflect milling surface roughness in a milling theory, sensitive reaction of the acoustic emission signals to the changes of the milling thicknesses in practical machining is used for analyzing and processing the detected acoustic emission signals emitted by the workpiece to be milled during milling of the workpiece so as to predict the magnitude of the milling surface roughness. According to the method, online prediction of the magnitude of the milling surface roughness during milling of the workpiece is achieved, the method has important significance on workpiece milling quality stabilizing, workpiece rejection rate reducing and milling efficiency improving, and meanwhile an important basis is provided for real-time prediction of reasonability of milling technological parameters in the milling process.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

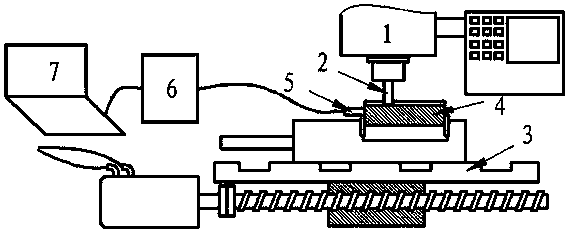

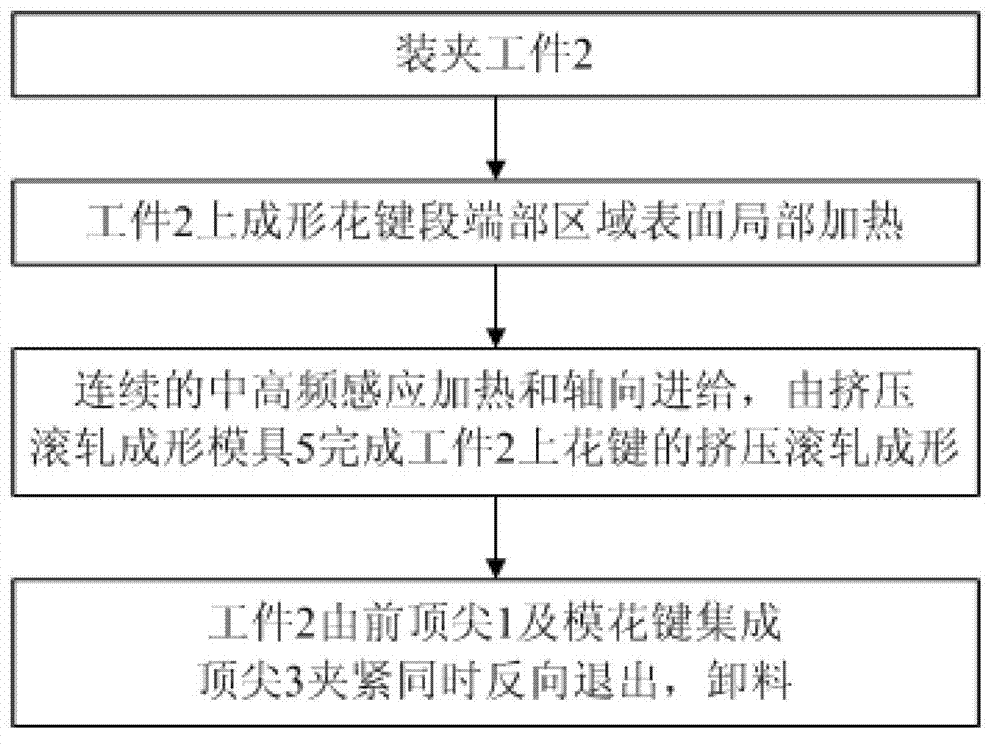

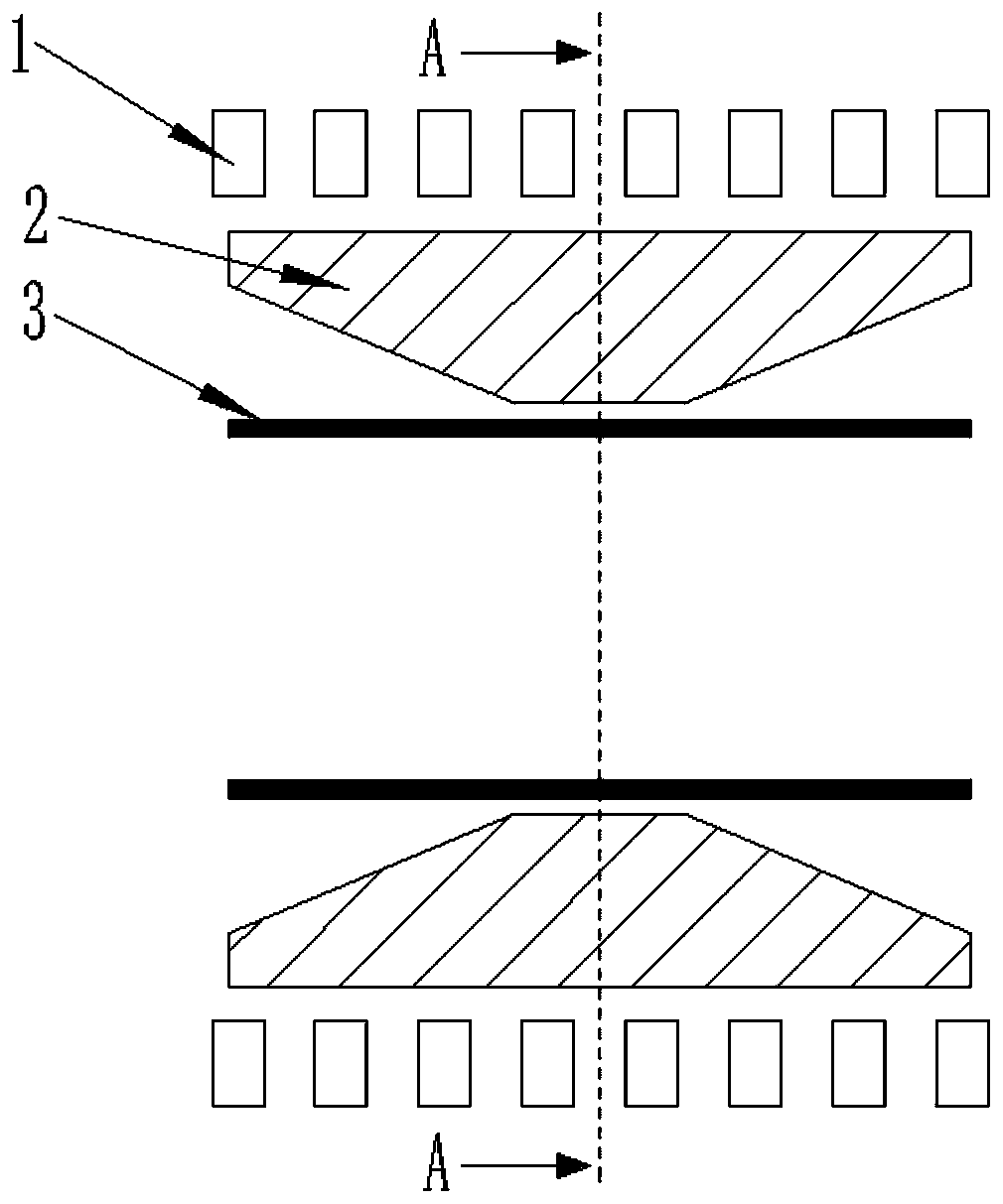

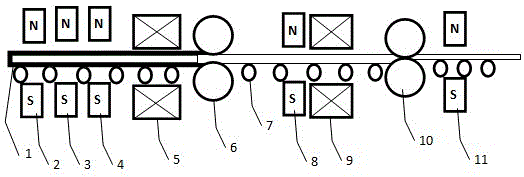

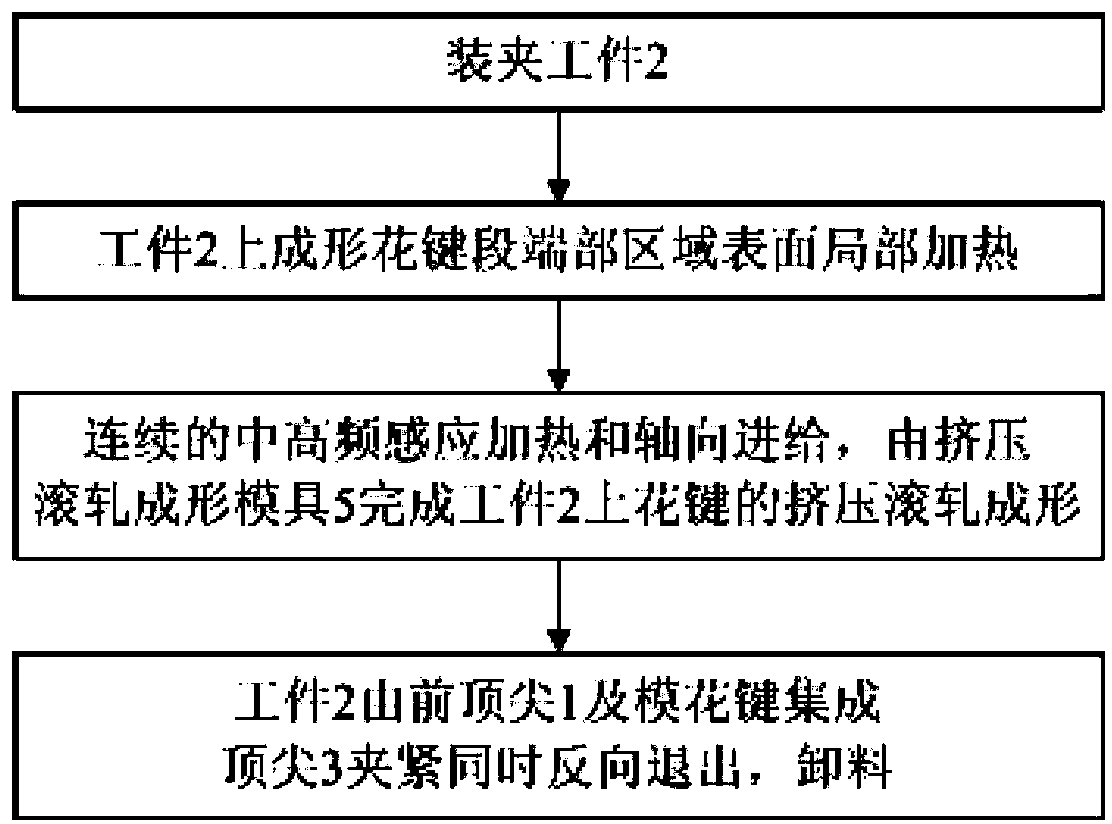

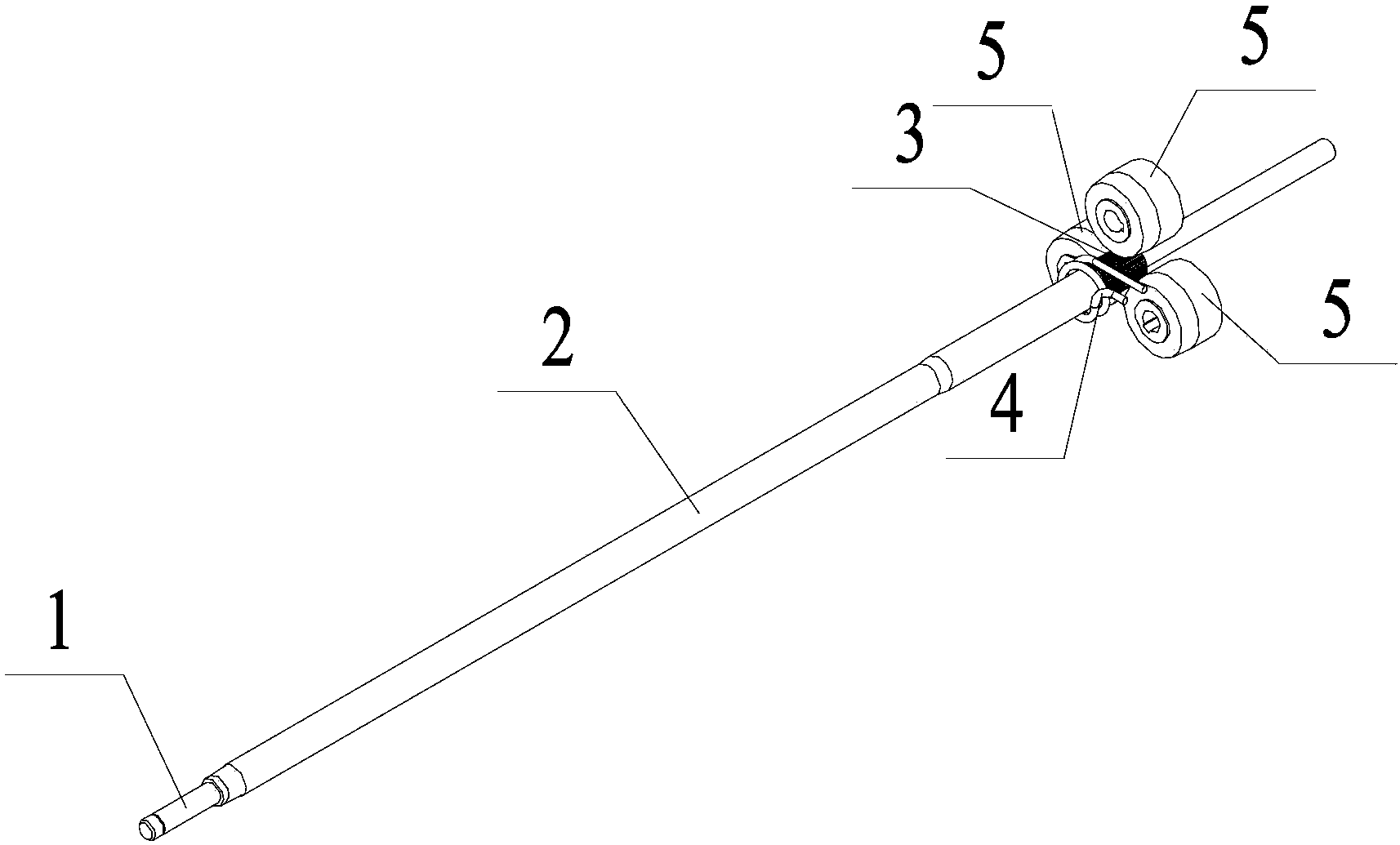

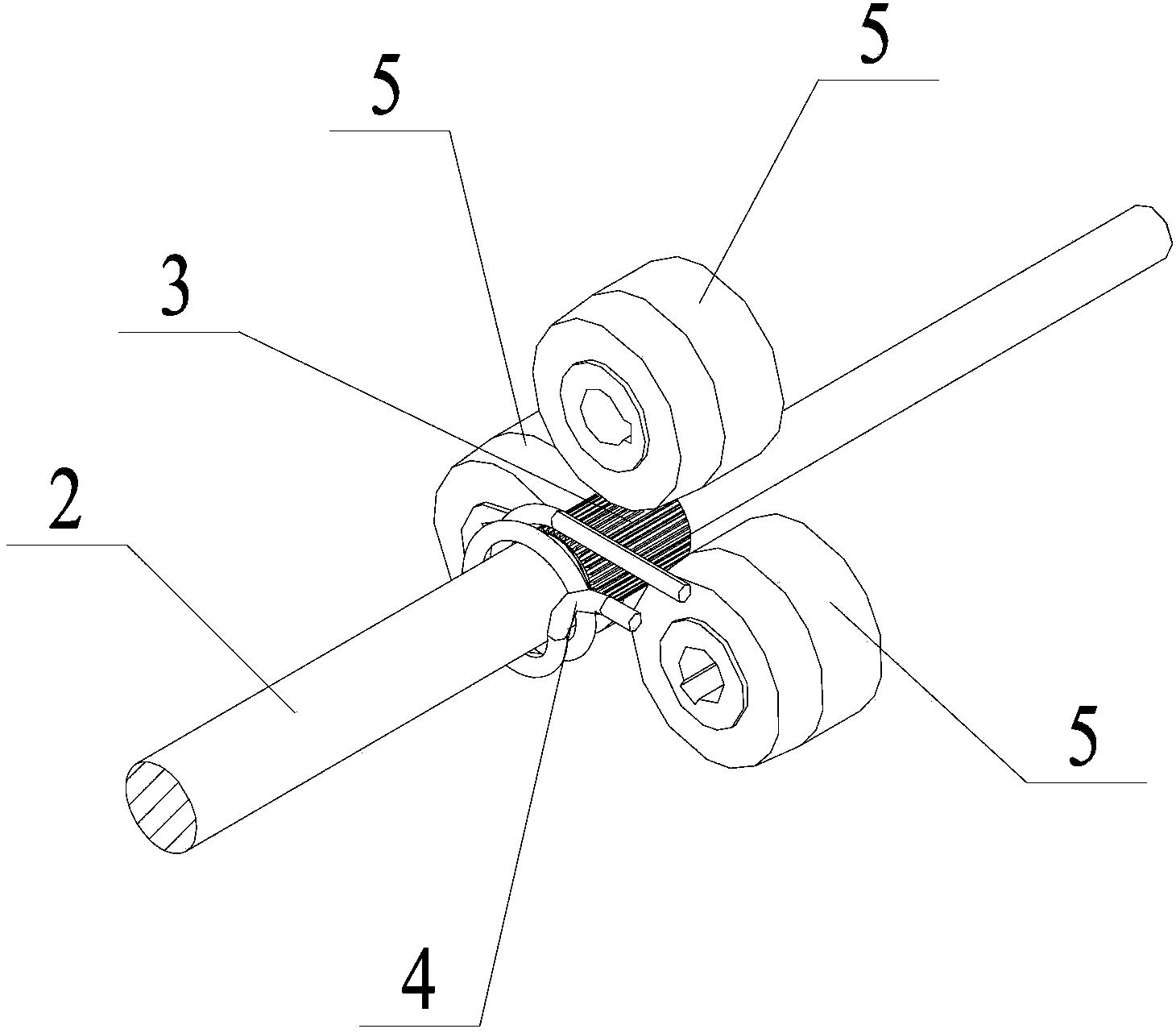

Method for axially feeding, extruding, rolling and forming spline shaft by medium-frequency and high-frequency sensing heating

ActiveCN102814434AReduce lossesReduce deformation resistanceMetal rollingInduction heaterMedium frequency

The invention discloses a method for axially feeding, extruding, rolling and forming a spline shaft by medium-frequency and high-frequency sensing heating; firstly, a work piece is clamped; the surface of an end area of a spline section which is formed on the work piece is heated; an extrusion rolling forming mould extrudes, rolls and forms a section to be heated; the section to be heated enters a forming area of a medium-frequency and high-frequency sensing heater to be continuously heated under axial feeding motion; the extrusion rolling mould completes the extrusion rolling formation to splines on the work piece; the medium-frequency and high-frequency sensing heater is arranged between the extrusion rolling forming mould and a work piece clamping position; the medium-frequency and high-frequency sensing heater only heats the local area of a surface to have plastic deformation in the forming area of a part to have extrusion rolling deformation; and the method for axially feeding, extruding, rolling and forming the spline shaft by medium-frequency and high-frequency sensing heating has the advantages of small spline forming force, little heat loss, energy saving, capability of processing spline parts with large material deformation resistance, capability of processing slender shafts and large modulus, high formation precision and surface quality, high production efficiency, wide processing scope and the like.

Owner:陕西格致精成智能制造有限公司

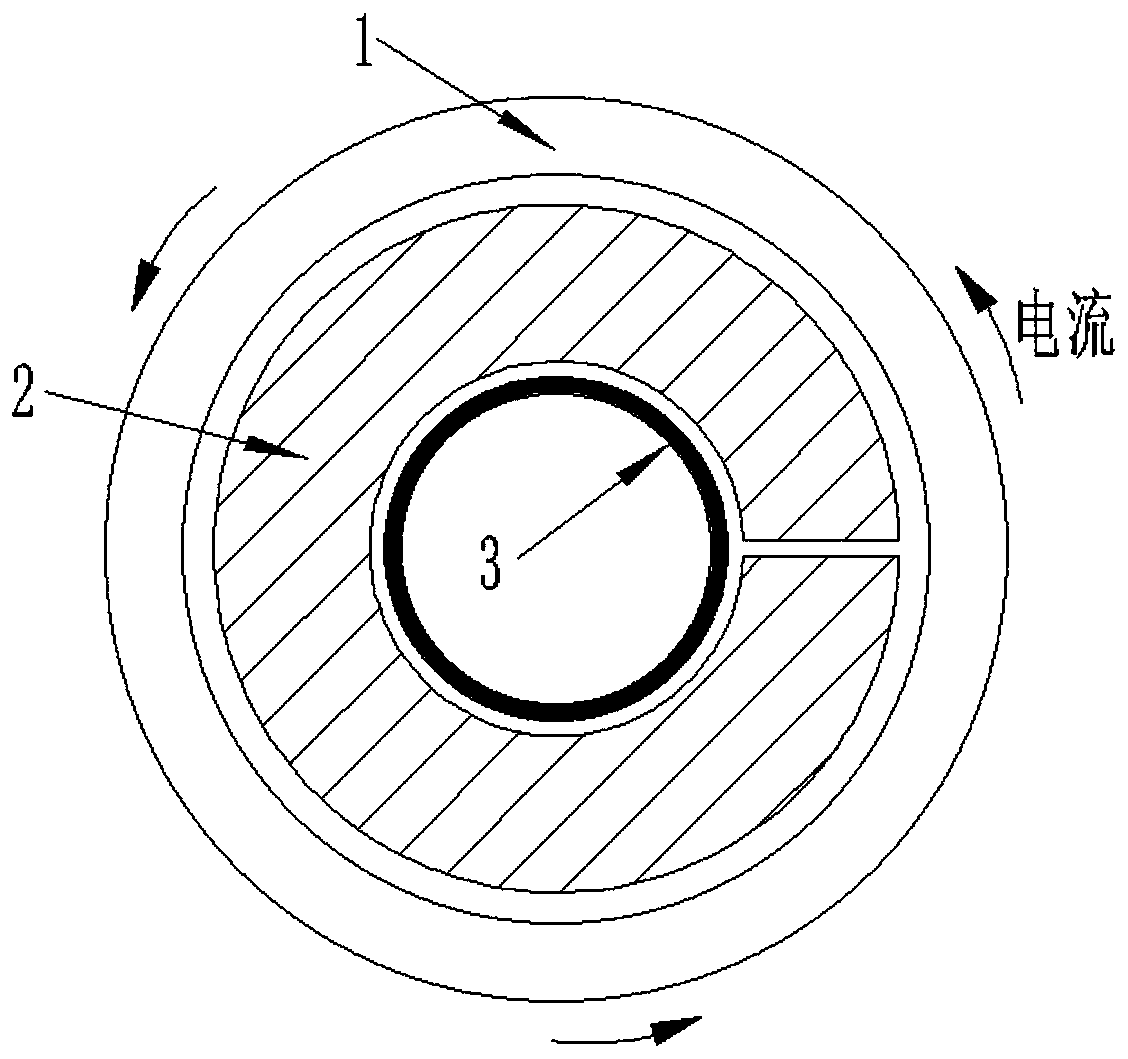

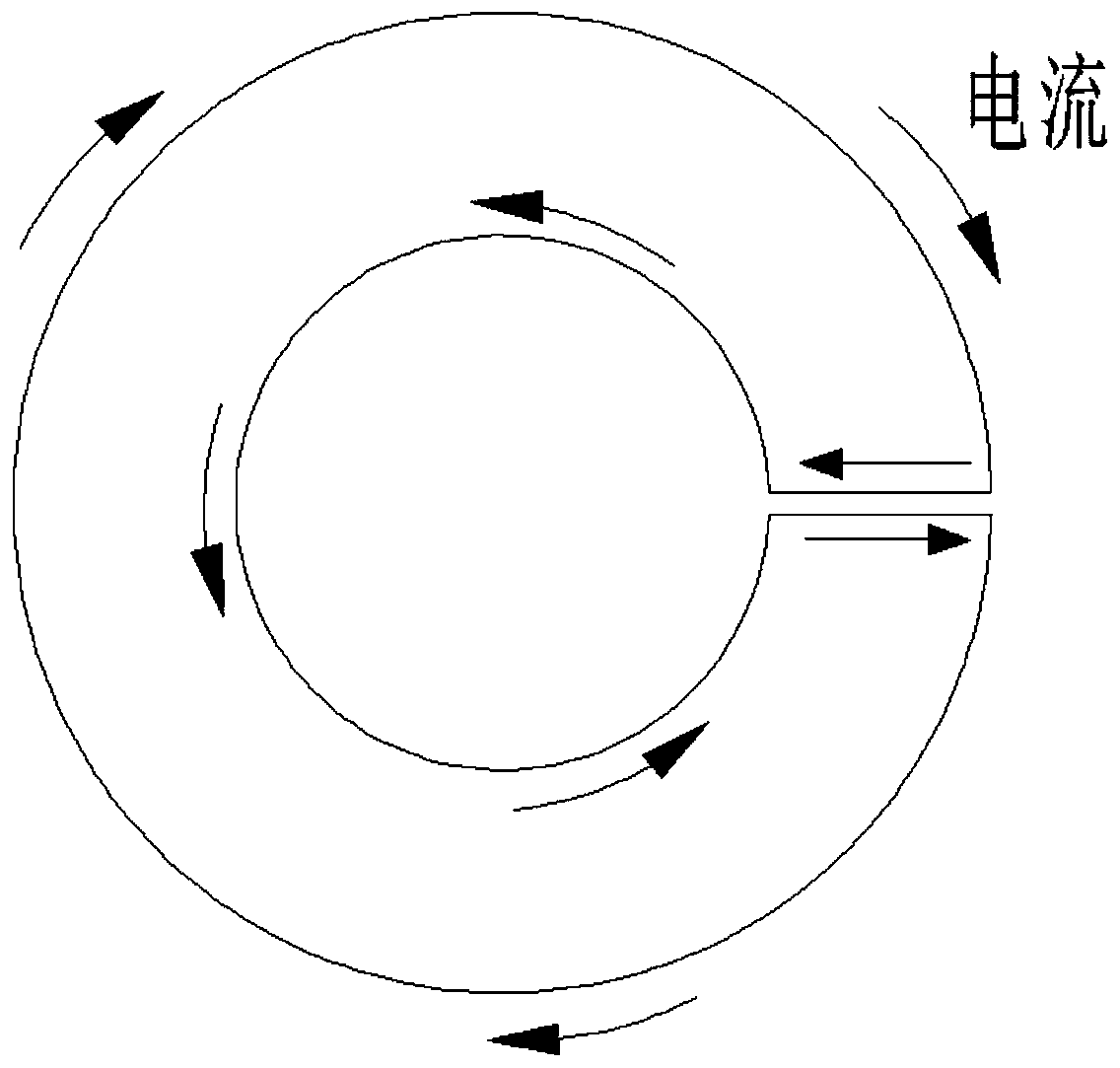

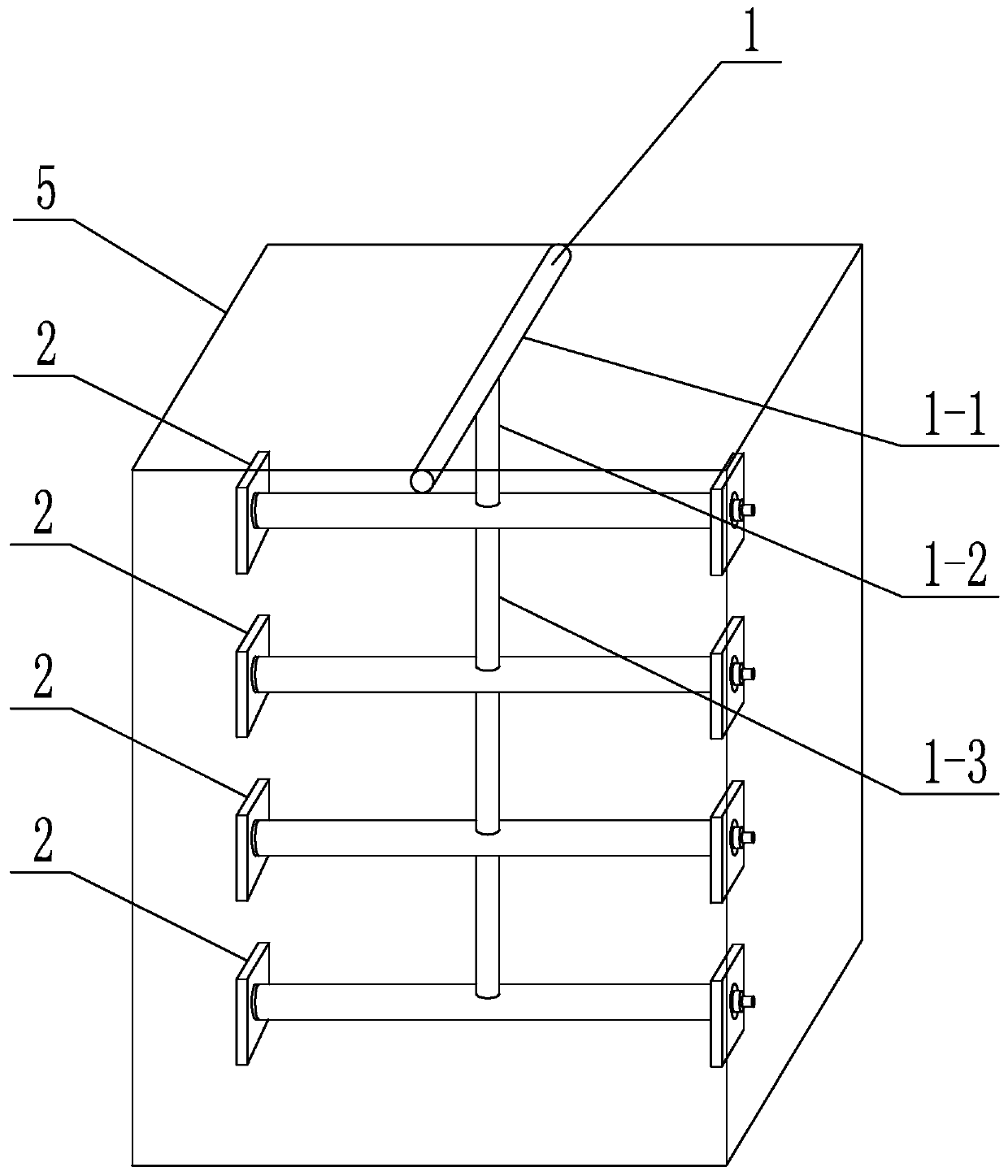

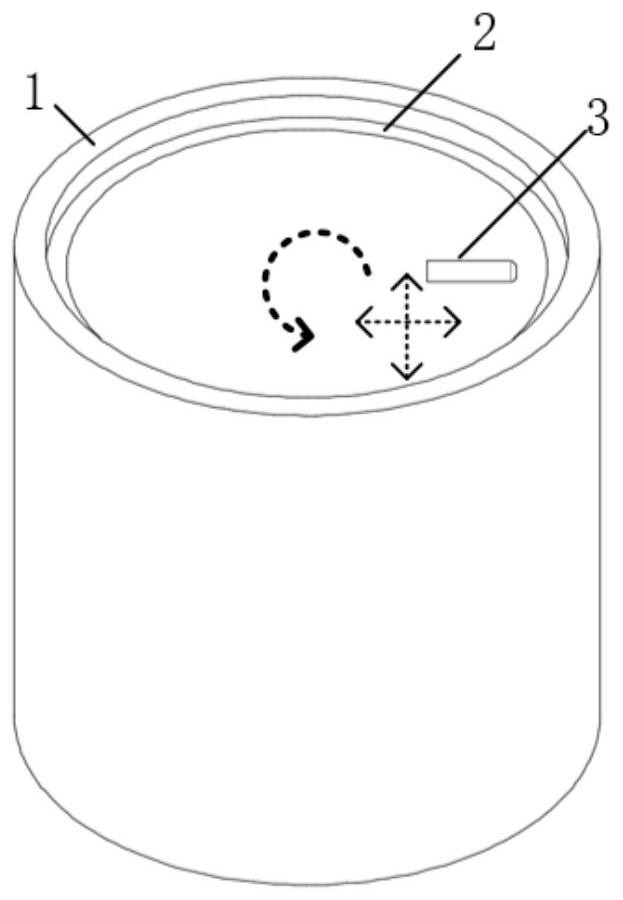

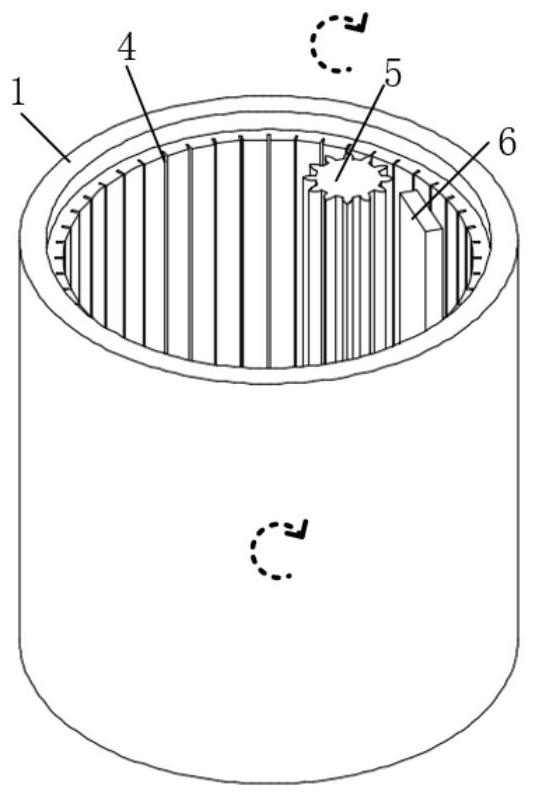

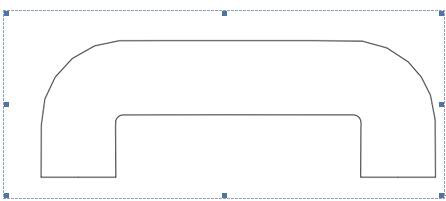

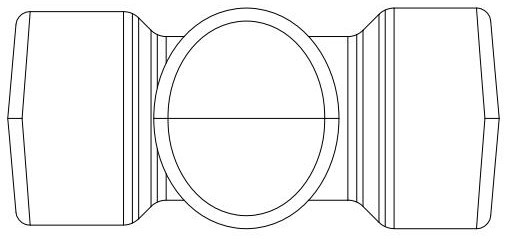

Magnetic collecting device for improving uniformity of deformation of pipe fitting and electromagnetic forming device of magnetic collecting device

The invention discloses a magnetic collecting device for improving uniformity of deformation of a pipe fitting and an electromagnetic forming device of the magnetic collecting device. The magnetic collecting device is of an annular structure with a through hole formed in the center, a gap penetrating through the side wall of the magnetic collecting device in the radical direction of the through hole is formed in the magnetic collecting device, one or more seams are further formed in the inner wall, located in the through hole, of the magnetic collector, the seams extend in the axial directionof the through hole, and the seams and the gap are evenly arranged in the circumferential direction of the through hole. The magnetic collecting device is designed to be have multiple seams, the magnetic field force corresponding to the seams is still smaller than that of the area not corresponding to the seams, so that the material has a tendency to flow to the multiple seams. Although the magnetic field force on both sides of the seams is greater than the magnetic field force of the seams, material flow is continuous, the deformation of the material on both sides of the seams drives the deformation of the material of the seams, and thus uniformity of the overall deformation is ensured. Therefore, uniformity of material deformation can be greatly improved by the multi-seam magnetic collecting device.

Owner:CENT SOUTH UNIV

Method for rolling metal wire bars under magnetostatic field auxiliary effect

ActiveCN105032926AReduce deformation resistanceImprove plastic deformation abilityMetal rolling arrangementsUltimate tensile strengthMaterial Deformation

The invention mainly relates to the technical field of extrusion rolling and drawing of metal wire bars, in particular to a method for rolling metal wire bars under a magnetostatic field auxiliary effect. The method is characterized by comprising the following steps: a magnetostatic field is installed in the advancing direction of metal wire bar blanks; before the metal wire bar blanks are rolled, extruded and drawn, the metal wire bar blanks are suffered from a magnetic field effect in the process of passing through the magnetostatic field area; the longitudinal center line of the metal wire bar blanks is consistent with the advancing direction thereof; and the blanks are rolled, extruded and drawn by rollers after the treatment of the magnetostatic field auxiliary effect. For multiple times of rolling, extrusion and drawing, the magnetostatic field treatment is performed before each time of rolling. The method has the following advantages: the material deformation resistance is prominently reduced; the rolling defects are reduced; the finished product size precision is high; the material mechanical performance, in particular the strength and the toughness are improved; and the synchronous reinforcement of the material toughness is realized.

Owner:JIANGSU UNIV

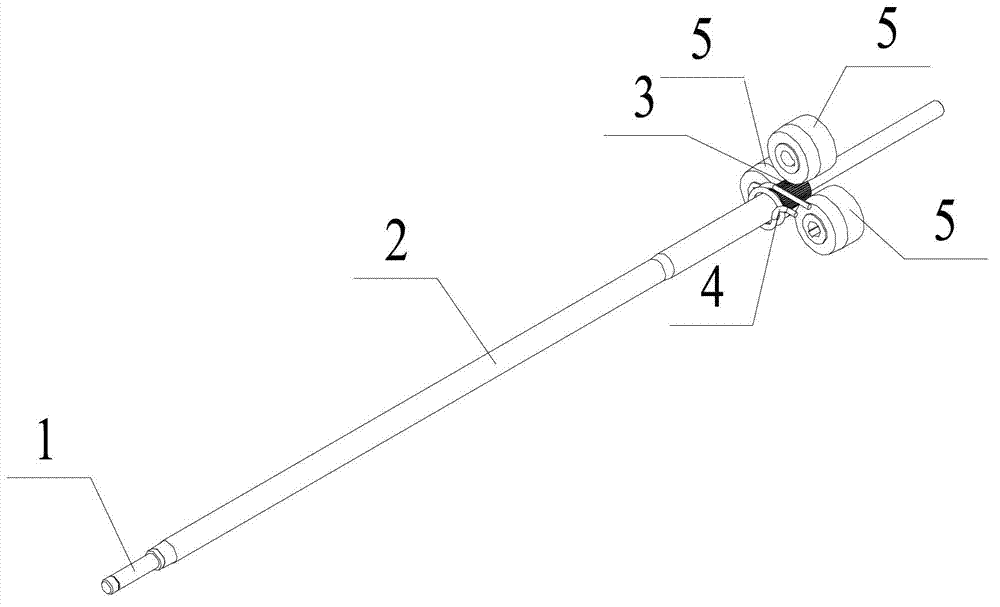

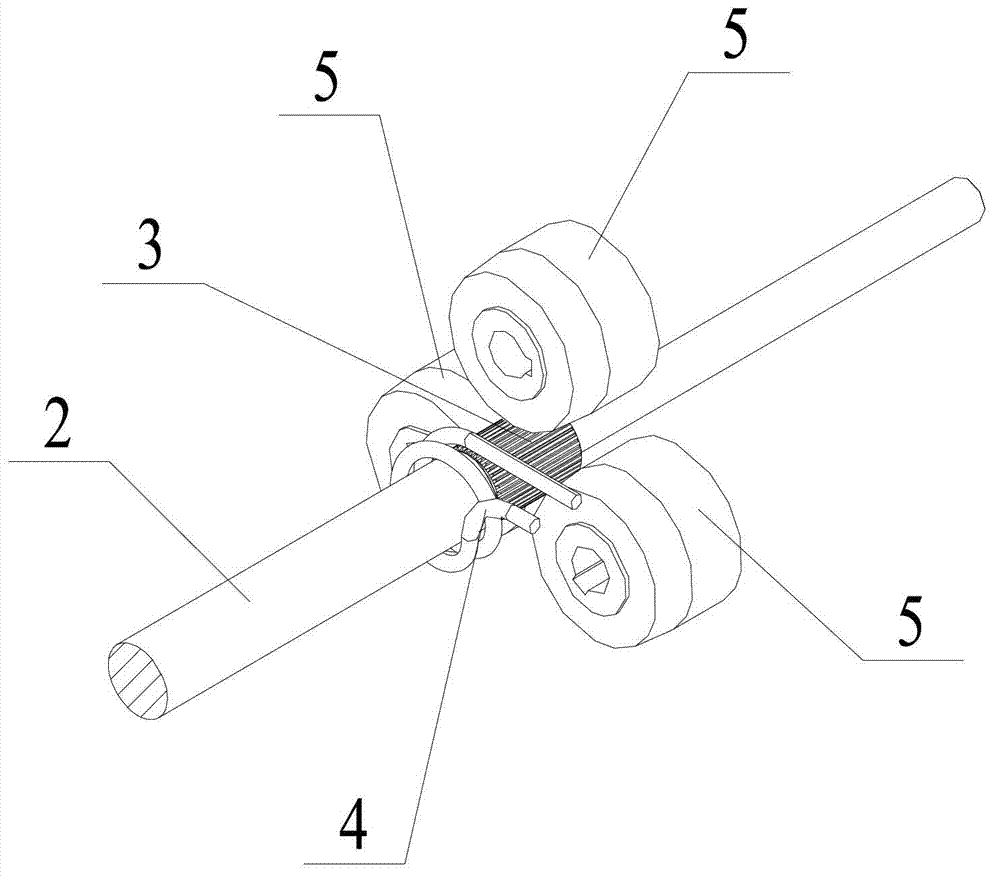

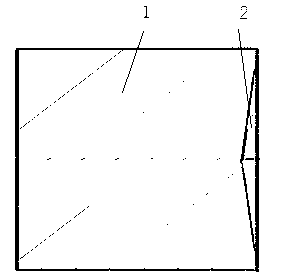

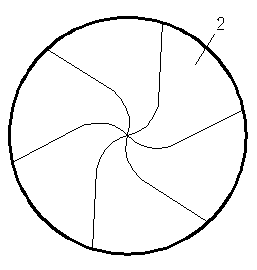

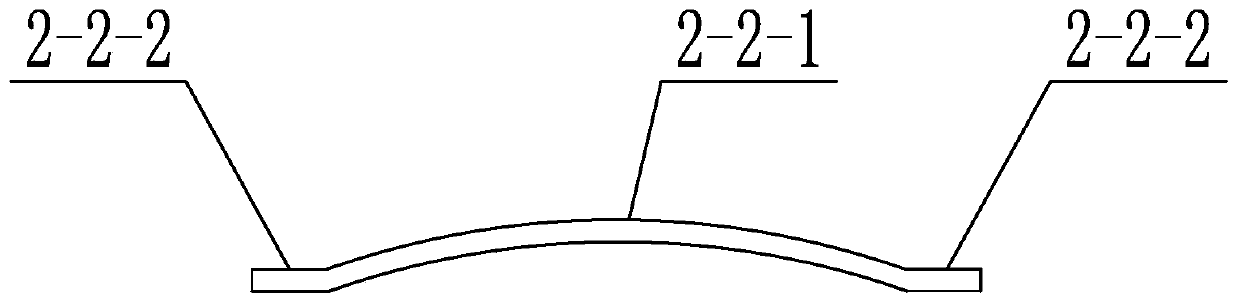

Stirring pin for surface stirring and rubbing

InactiveCN102848069AEasy to processSimple structureNon-electric welding apparatusEngineeringMachining process

A stirring pin for surface stirring and rubbing is used in a machining process for surface stirring and rubbing. The stirring pin for surface stirring and rubbing is composed of a pin body (1) and a pin head (2), wherein the pin body (1) is in a cylindrical or conical structure, and the pin head (2) is arranged at one end of the pin body (1). The stirring pin is characterized in that the pin head (2) is in a concave structure with a high edge and a lower middle and provided with stripes diverging from inside to outside. During processing, material deformation of a workpiece surface is required to be in a range of 0.02mm to 0.8mm. Corresponding processing requirements include that the rotation speed of the stirring pin is 200 to 800 turns / minute, and the transverse operating speed is 20 to 50 millimeters / minute. The stirring pin for surface stirring and rubbing is good in processing effect, simple in structure and easy to operate.

Owner:NANTONG TIANHUA HERUI TECH VENTURES

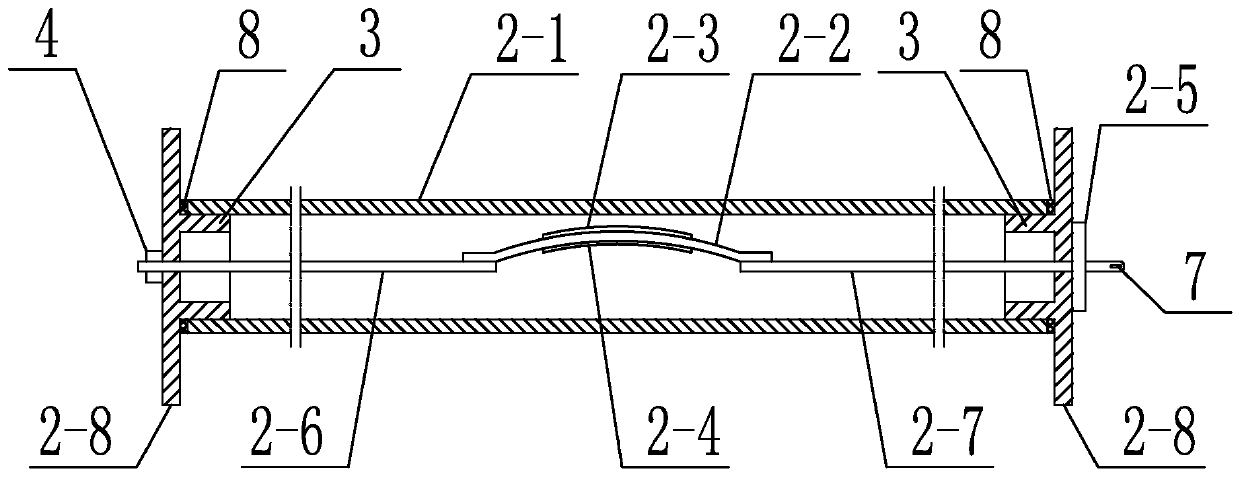

Device and method for detecting deformation stress of on-site cement-based material

PendingCN110887959AEase of evaluationReliable test resultsMaterial testing goodsApparatus for force/torque/work measurementStrain gaugeMechanical engineering

The invention discloses a device and method for detecting deformation stress of an on-site cement-based material. Due to the fact that detection of shrinkage or expansion stress generated by concretedeformation is high in precision requirement, large in difficulty, low in efficiency and poor in accuracy, a test device and method for rapidly evaluating the shrinkage or expansion stress of concreteon a construction site are deficient. The two ends of a sleeve are detachably connected with the two end covers; an arched plate is arranged in the sleeve; an upper strain gauge and a lower strain gauge are arranged on the top surface and the bottom surface of the arched plate respectively; a first slender rod and a second slender rod are arranged at two ends of the arched plate respectively; oneend of the first slender rod is fixedly connected with the arched plate, and the other end of the first slender rod penetrates through the end cover close to the first slender rod; one end of the second slender rod is fixedly connected with the arched plate, and the other end of the second slender rod penetrates through the end cover close to the second slender rod and then is detachably connected with a movable outer cover; and a hanging opening is machined in the end, matched with the movable outer cover, of the second slender rod. The detection method is realized on the basis of the detection device. The method is used for detecting the shrinkage or expansion stress of the cement-based material.

Owner:HARBIN INST OF TECH

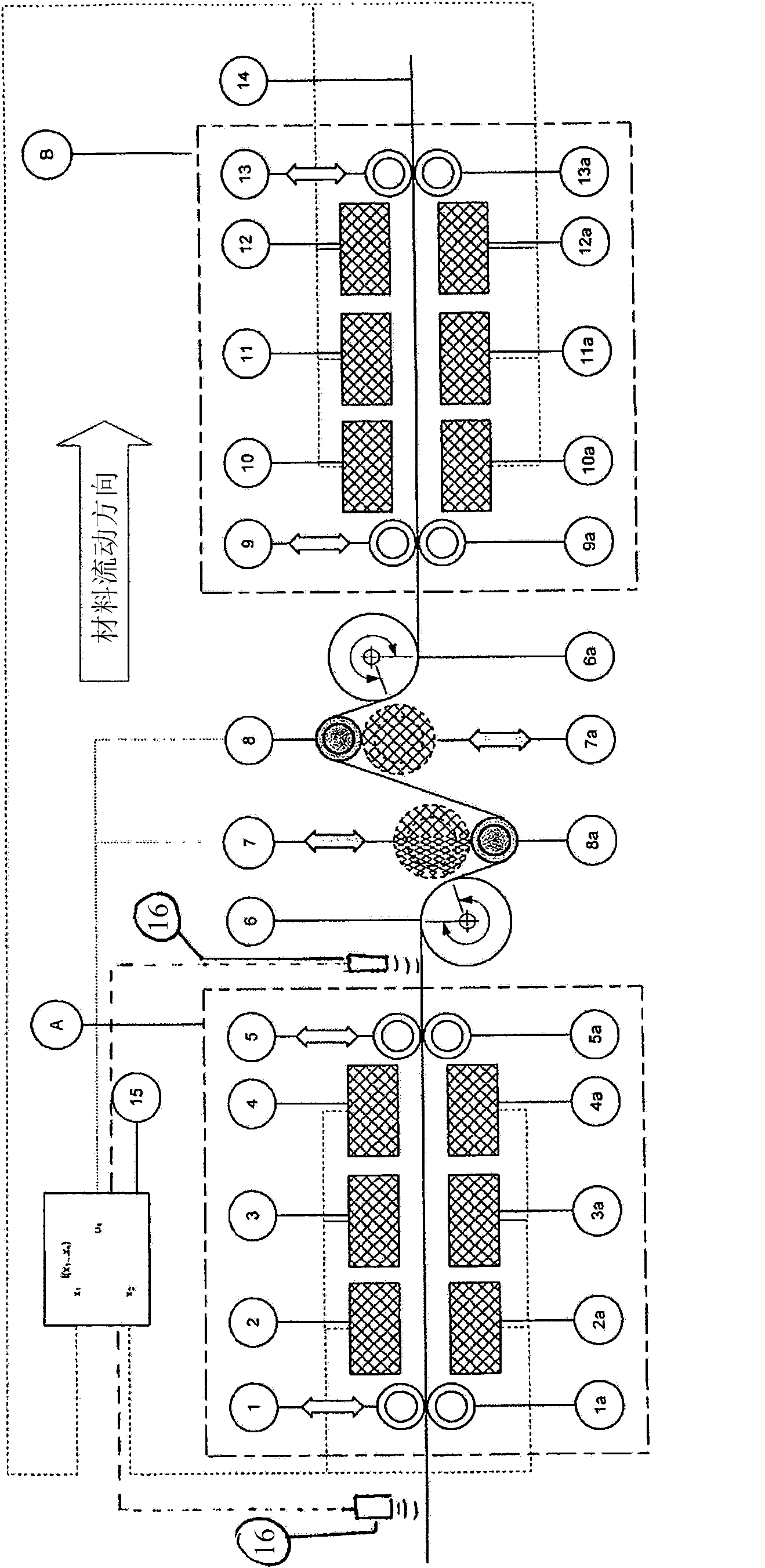

Method and apparatus for improving mechanical properties of materials that can be magnetically activated

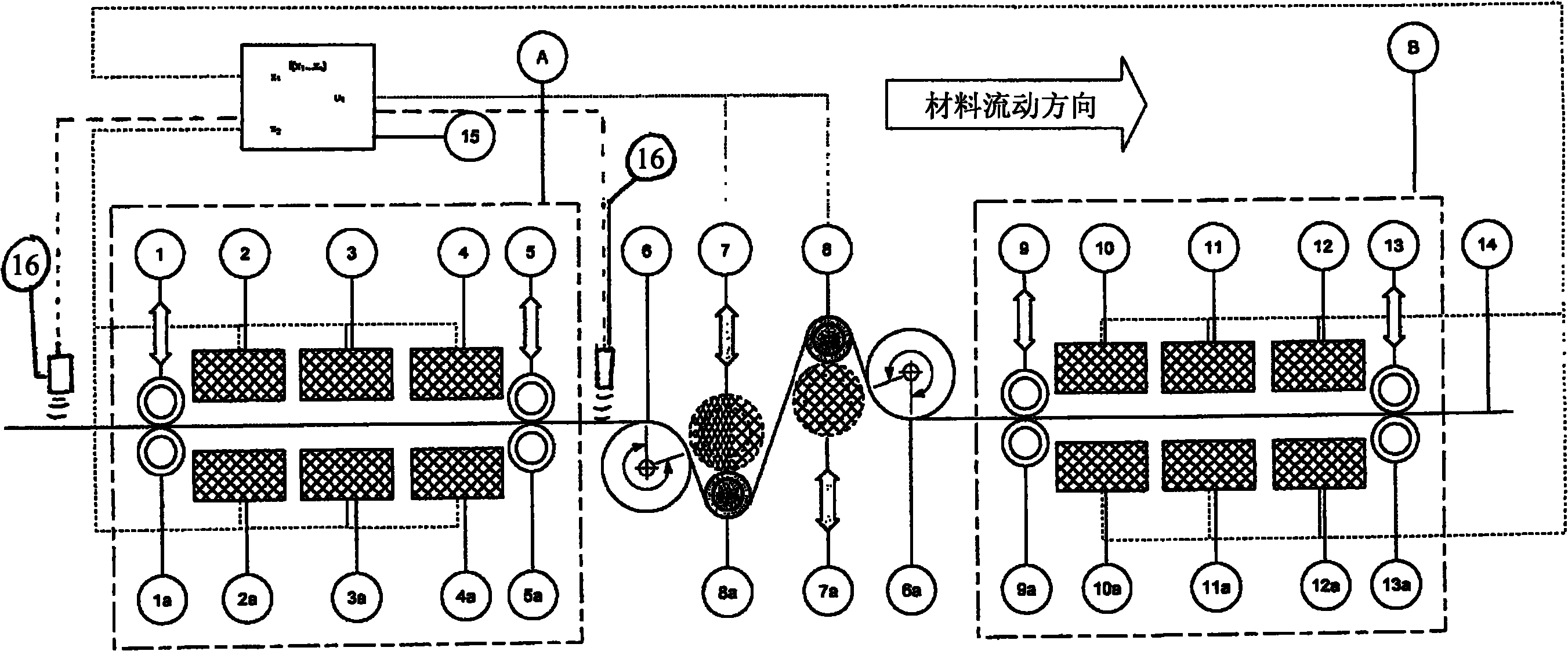

The invention relates to a method and an apparatus for improving the mechanical properties of materials that can be magnetically activated (14), comprising at least one conveying device (1, 1a; 5, 5a; 9, 9a; 13, 13a) for conveying the material (14) through a machining region. In the machining region, the material is deformed due to the application of a force. As the force is applied in the machining region by at least one magnetic field (A, B) in a non-contact way and / or by at least one ultrasound device (8), a straightening process or material finishing process for metal bands and metal plates is created which meets the requirements of all interconnected upstream and downstream machining processes.

Owner:UNGERER GMBH CO KG

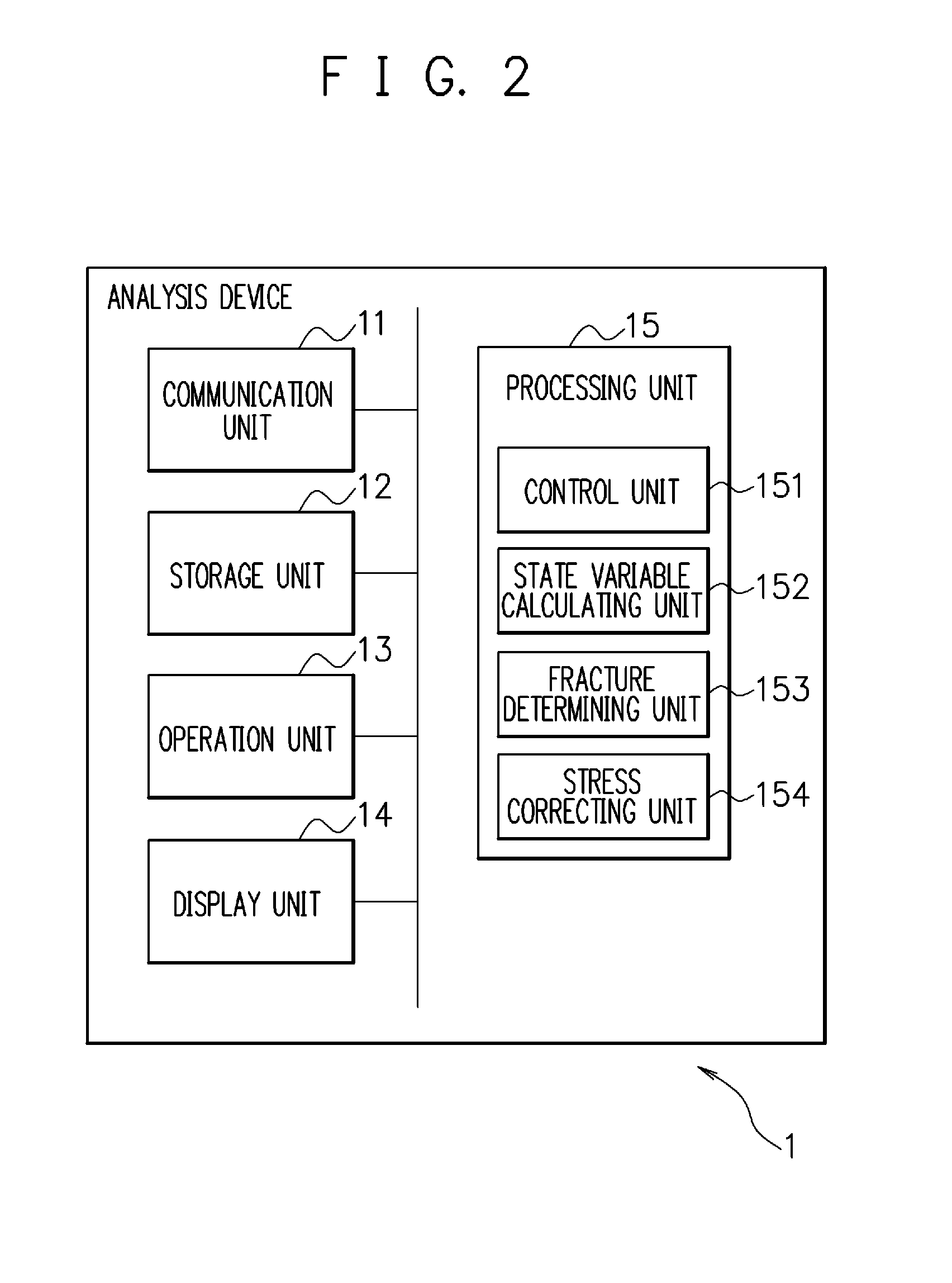

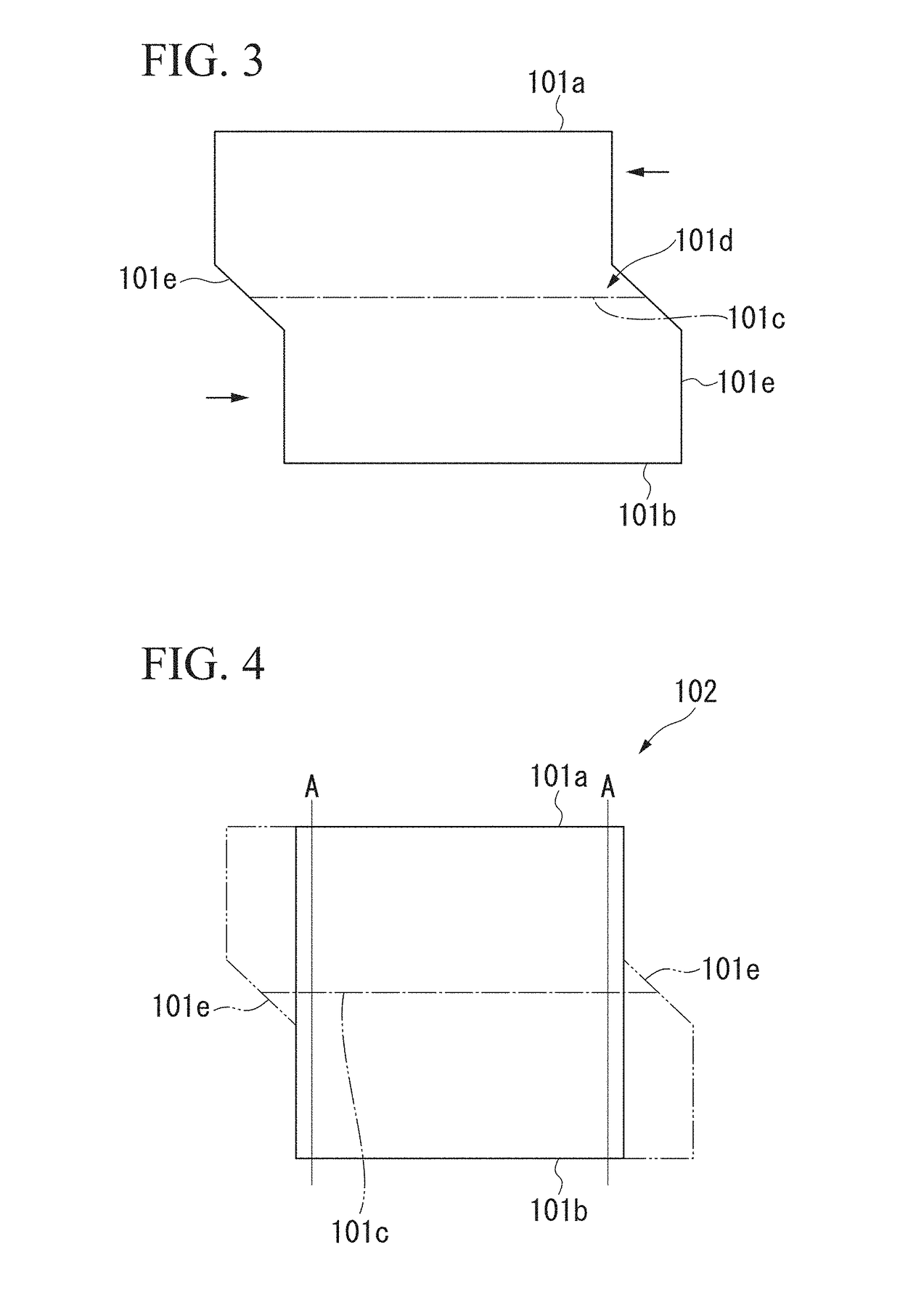

Deformation analysis device, deformation analysis method, and program

ActiveUS20150310143A1Reduce stiffnessComputation using non-denominational number representationDesign optimisation/simulationAnalysis dataStorage cell

The deformation analysis device includes: a storage unit (12) which stores analysis data of a material; a state variable calculating unit (152) which calculates stresses and other state variables of respective elements of the material at each point in time of deformation of the material, based on the analysis data; a fracture determining unit (153) which, based on the calculated state variables, determines whether or not a fracture has occurred in each of the elements of the material, based on a fracture limit stress curve which is found in advance for the material; and a stress correcting unit (154) which, regarding an element in which it is determined that the fracture has occurred, out of the elements of the material, reduces σ by the following expression σ=(1−D)σ′ where σ is a stress with a rigidity decrease taken into consideration, D is a damage variable (note that 0≦D≦1) in continuum damage mechanics, and σ′ is a stress with the rigidity decrease not taken into consideration, to thereby decrease rigidity of the relevant element, without eliminating the element, and updates the analysis data.

Owner:NIPPON STEEL CORP

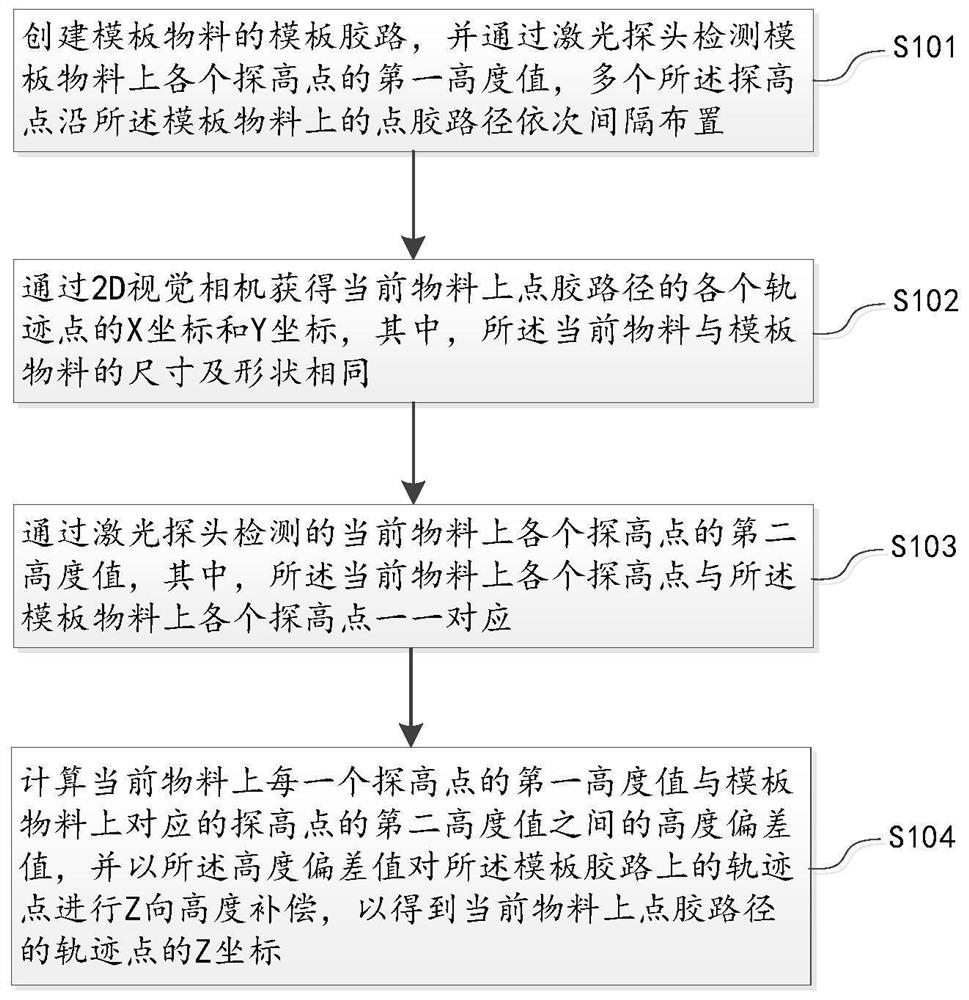

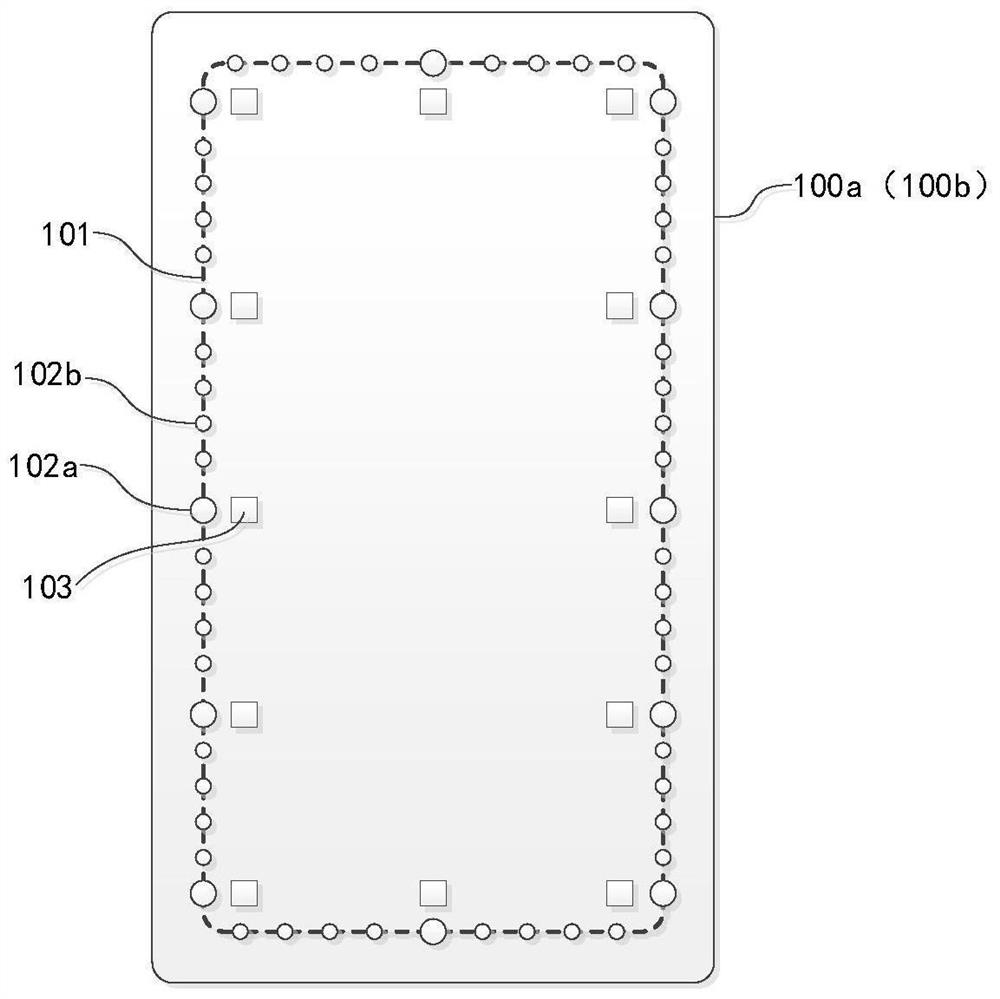

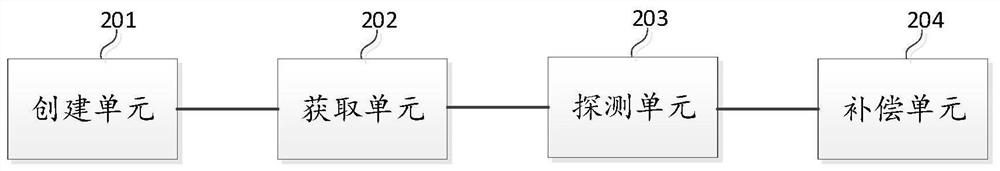

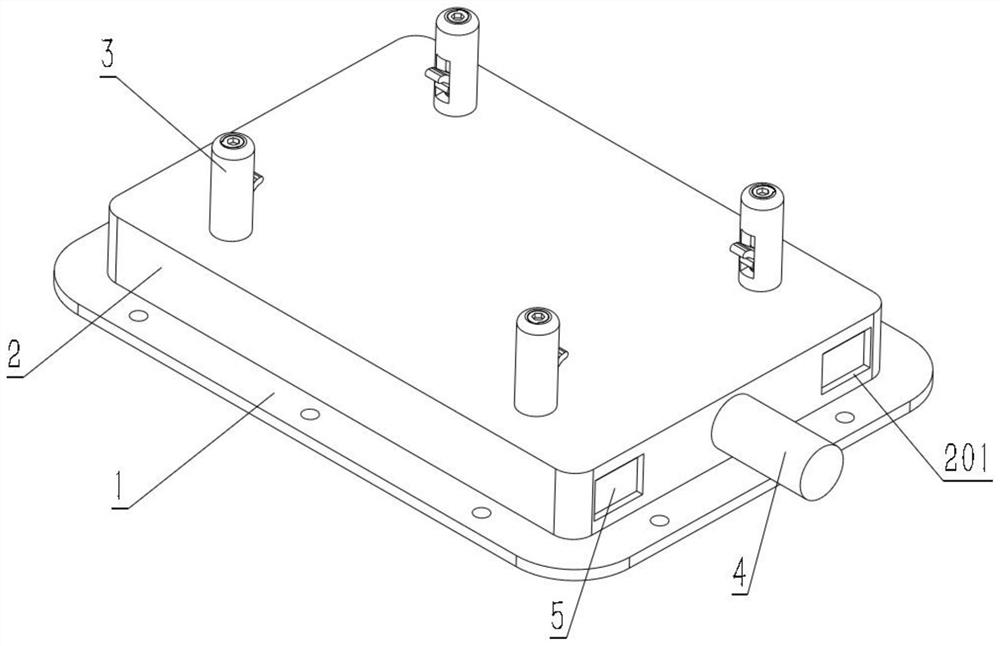

Camera and laser composite guide dispensing compensation method and related device

ActiveCN113313756AGuaranteed accuracyLower requirementLiquid surface applicatorsImage analysisLaser probeEngineering

The invention discloses a camera and laser composite guide dispensing compensation method and device, computer equipment and a storage medium thereof. The method comprises the steps of creating a template glue path of a template material, and detecting a first height value of each detection point on the template material through a laser probe; obtaining x coordinates and Y coordinates of all track points of a dispensing path on the current material through a 2D visual camera; detecting a second height value of each detection point on the current material through a laser probe; and calculating a height deviation value between the first height value of the high detection point on the current material and the second height value of the corresponding high detection point on the template material, and performing Z-direction height compensation on the track point on the template glue path according to the height deviation value to obtain a Z coordinate of the track point of the glue dispensing path on the current material. According to the method disclosed by the embodiment of the invention, the following change of the glue path and the material deformation is realized, the glue path accuracy is ensured, in addition, the quality effects of glue height, glue thickness and the like of dispensing are better due to height compensation, in addition, the cost is low, and the adaptability is better.

Owner:SHENZHEN SHIZONG AUTOMATION EQUIP CO LTD

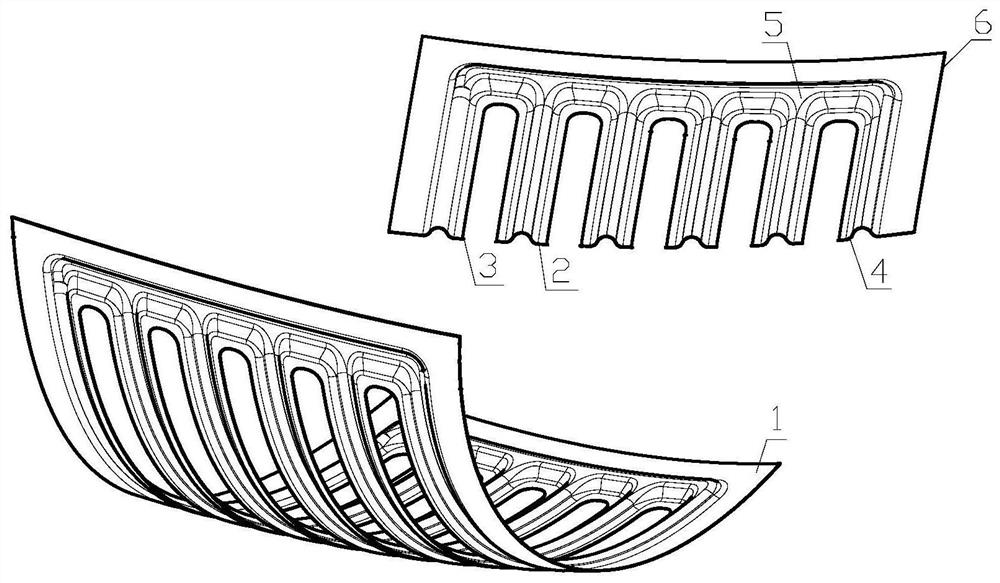

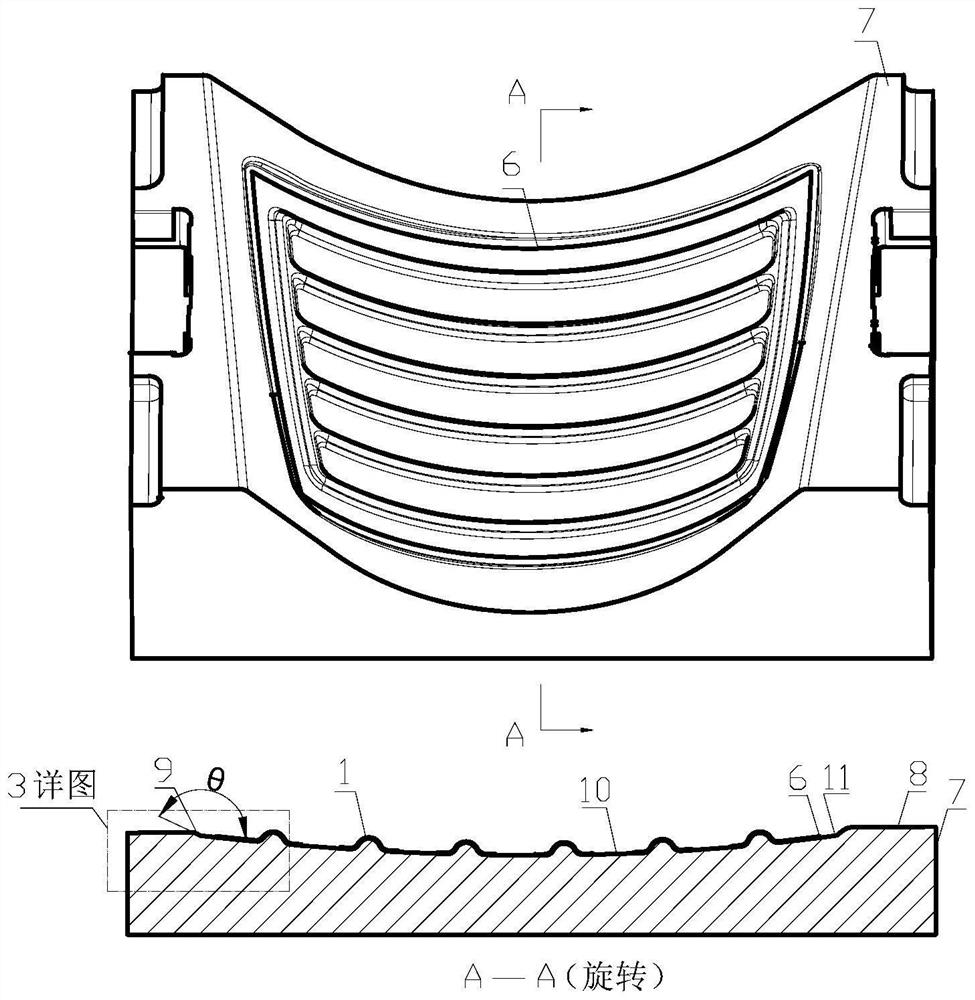

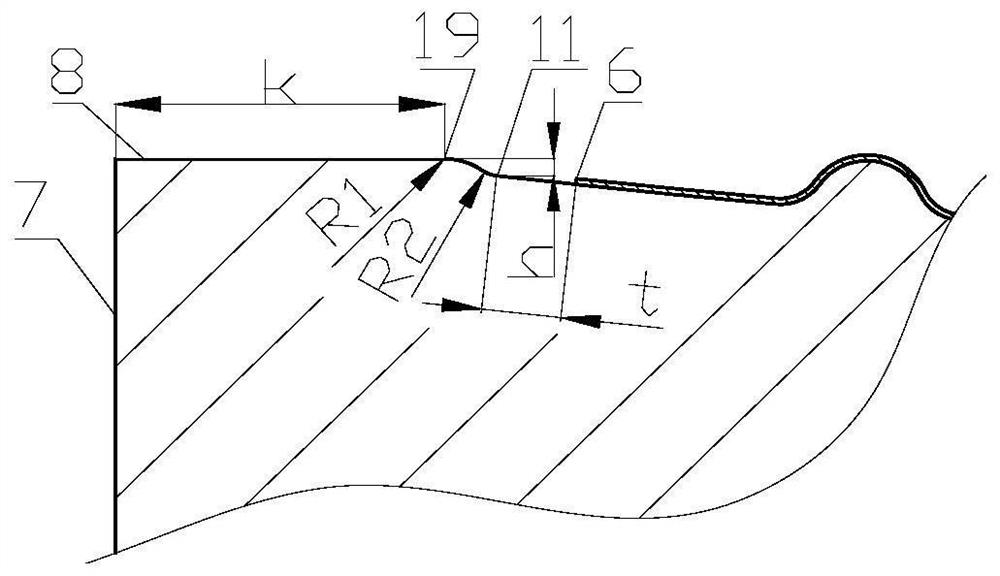

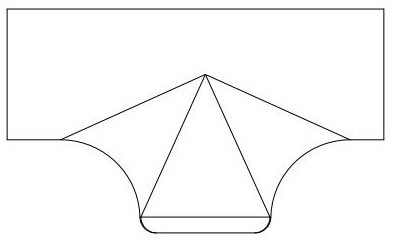

Liquid filling forming method for large-arch-height multi-cavity thin-wall opening inner skin

ActiveCN113385605AImprove unidirectional tensile deformation defectsSolve the problem of forming crackingAircraft componentsMechanical engineeringMaterial Deformation

The invention provides a liquid filling forming method for a large-arch-height multi-cavity thin-wall opening inner skin. The liquid filling forming method comprises the following steps that a liquid filling forming mold of an inner skin part is manufactured; an unfolded blank manufactured; liquid filling bulging for the first time is performed; secondary liquid filling bulging is performed; and the appearance is trimmed. A transition forming part is constructed, barbell type internal holes are designed, dangerous deformation areas prone to tearing are avoided, and the hole forming quality in the bulging pressure applying process is guaranteed. A sealing liquid chamber is created by additionally arranging the high-elastic-grade thin rubber pad, and the problem that the inner skin of the deep rib is cracked during forming is solved. The two-pass liquid-filling bulging process is designed, the material deformation limit of a conventional aluminum alloy sheet is improved, the monopoly situation that the large-arch height strengthened inner skin is pressed and formed for a long time is broken, dependence on manual operation skills is reduced, and the production efficiency and the product quality are improved.

Owner:XI'AN AIRCRAFT INTERNATIONAL

Welding method for target material and back plates

PendingCN112743216ASolve the deformationGuaranteed YieldNon-electric welding apparatusStructural engineeringUltimate tensile strength

The invention provides a welding method for a target material and back plates. The welding method comprises the steps of assembling the target material, middle layers and the back plates to obtain an assembly; enabling the target material to be located between the two middle layers, enabling the two back plates to be symmetrically arranged on the outer sides of the two middle layers, and wrapping the target material and the two middle layers; and carrying out sheath welding, degassing and hot isostatic pressing on the obtained assembly, and then stripping the back plate on one side of the sputtering face of the target material of the assembly and the middle layers to obtain a target material assembly. According to the welding method, through the design of a welding structure, the problem of target material deformation in the welding process is effectively solved, meanwhile, the welding bonding rate and the welding bonding strength are guaranteed, and good industrial application prospects are achieved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Machining process of cylinder reinforcing rib based on laser grooving and hot rolling

ActiveCN113967800ASmall thermal deformationReduce deformation resistanceShaping toolsIncreasing energy efficiencyThermal deformationWeld seam

The invention discloses a machining process of a cylinder reinforcing rib based on laser grooving and hot rolling, and belongs to the field of cylinder machining. According to the machining process of cylinder reinforcing rib based on laser grooving and hot rolling, inner rib machining of a cylinder is achieved in a laser grooving and rolling hot machining mode, and material cutting and plastic machining are comprehensively utilized. The process is high in machining efficiency, free of welding seams, good in quality, capable of saving materials and energy and low in production cost. An induction heating mode is adopted, a heating area is an inner surface of the position, needing to be machined, of the cylindrical blank, so that induction heating has the advantages of being high in heating efficiency and obvious in skin effect; only the inner side material is heated, the temperature of the inner side material is increased, the plasticity of the inner side material is enhanced, and the outer layer material is still kept at the low temperature and is high in bearing capacity and small in thermal deformation. By means of the method, the deformation resistance of the material is reduced, the plastic deformation capacity of the material is improved, the cracking problem of the cutting groove is avoided, and a high-precision workpiece can be obtained easily.

Owner:CHANGAN UNIV

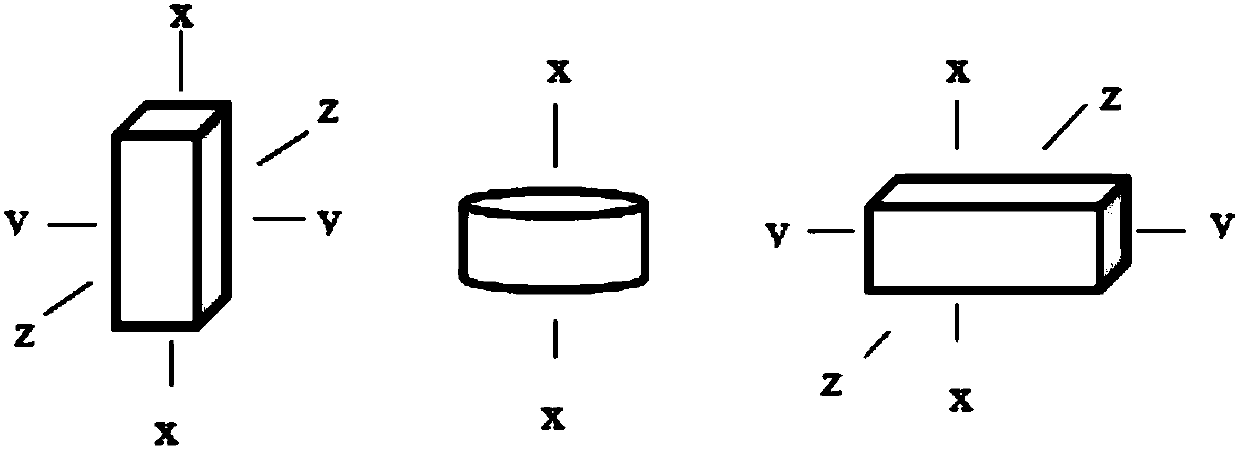

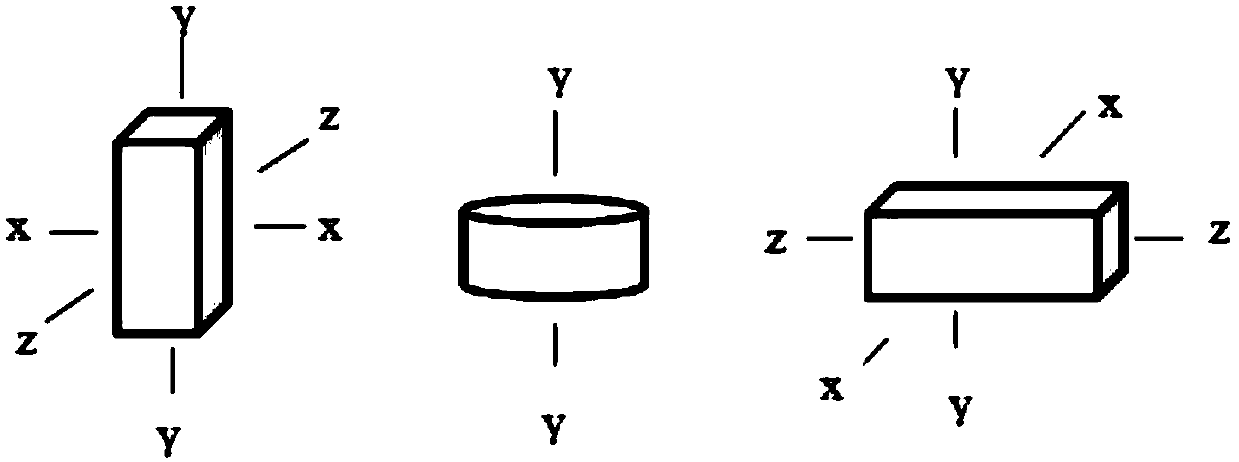

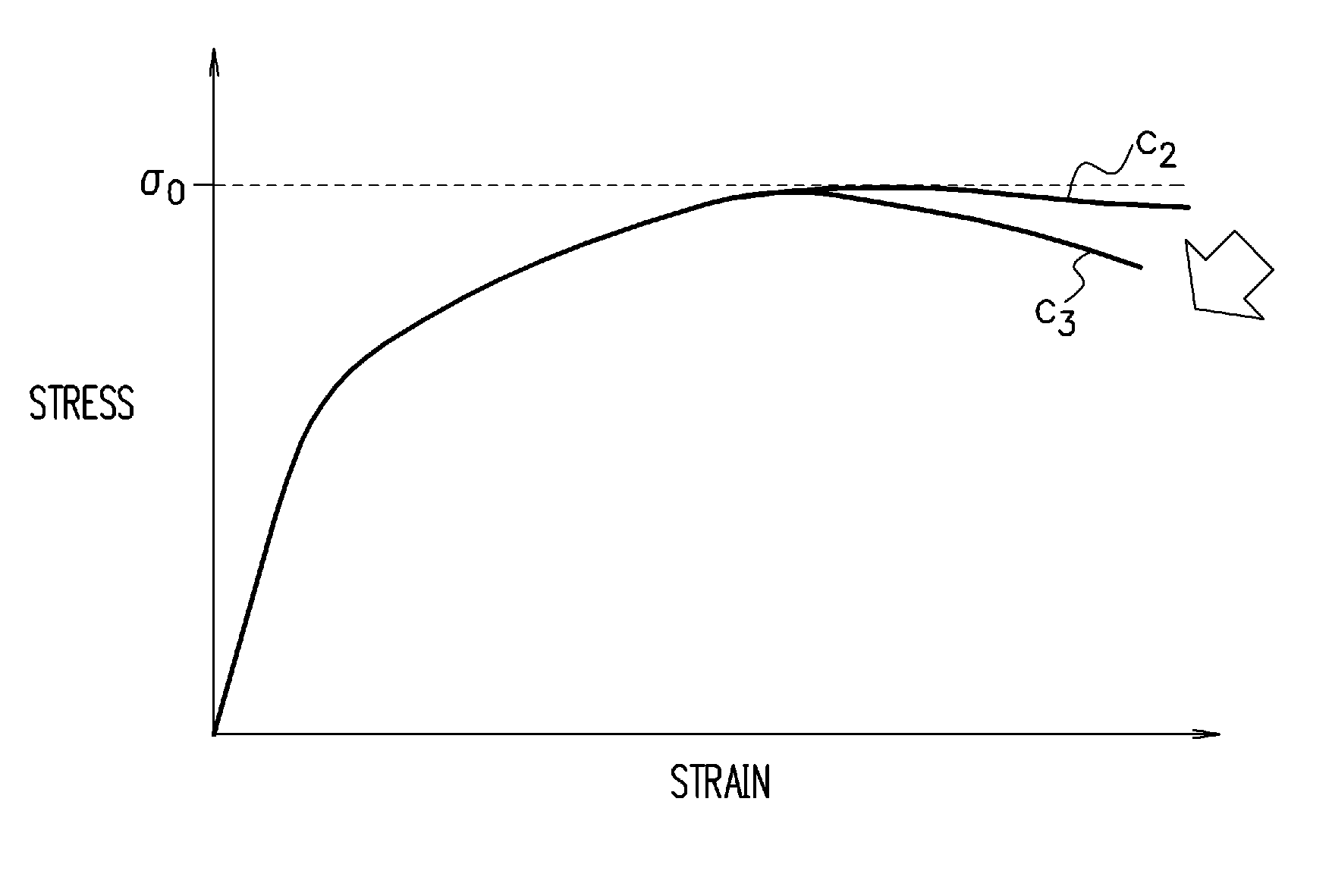

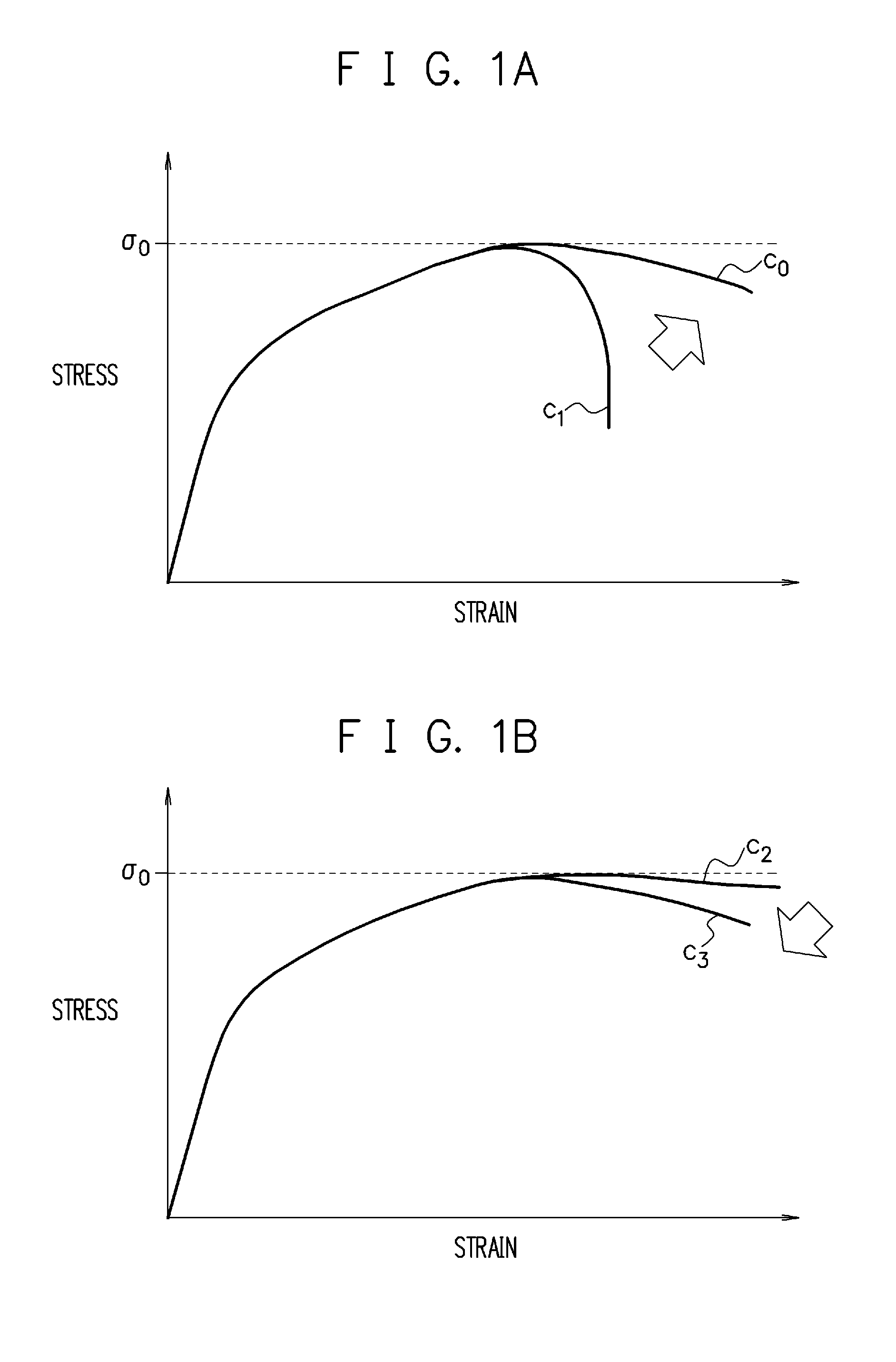

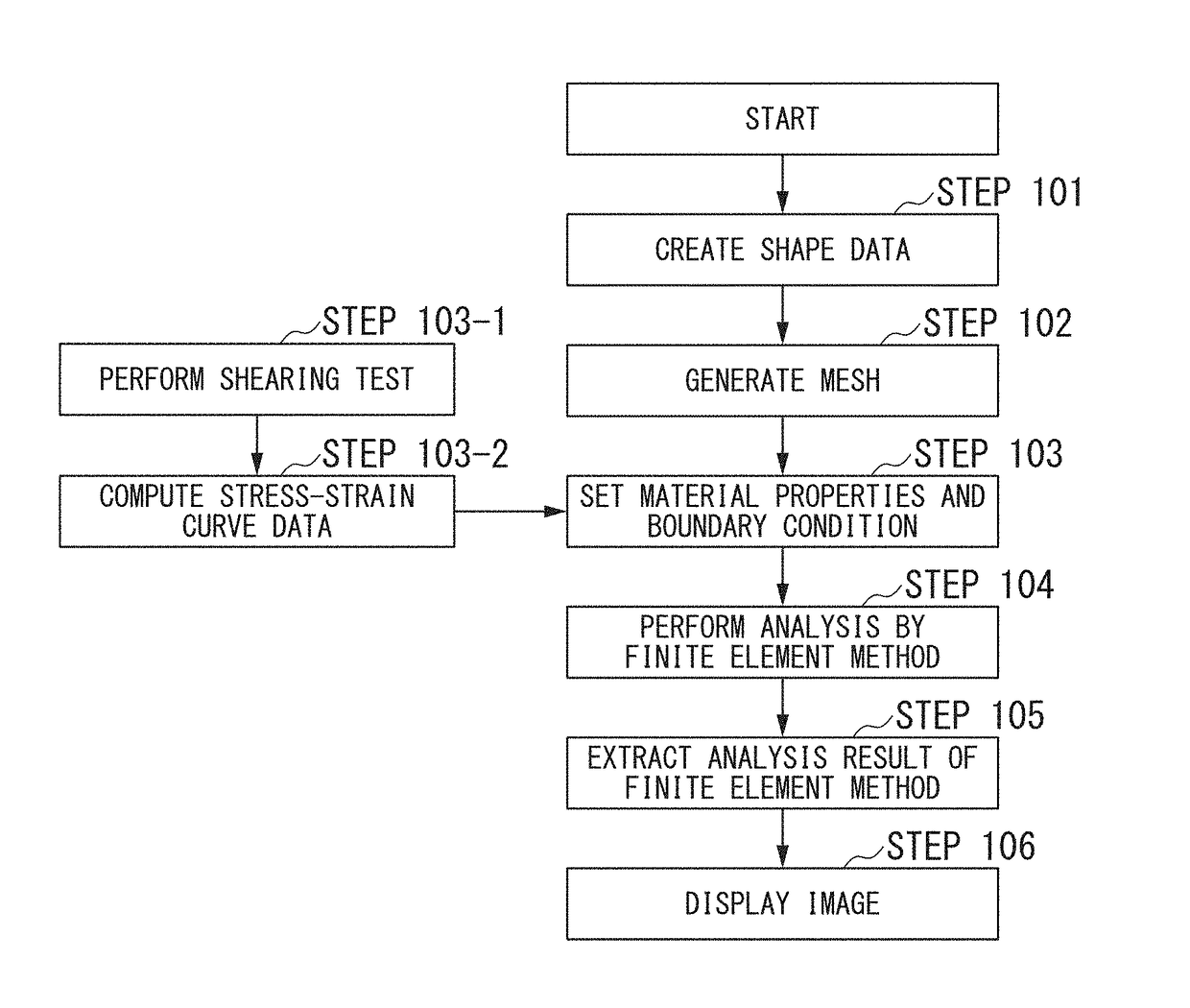

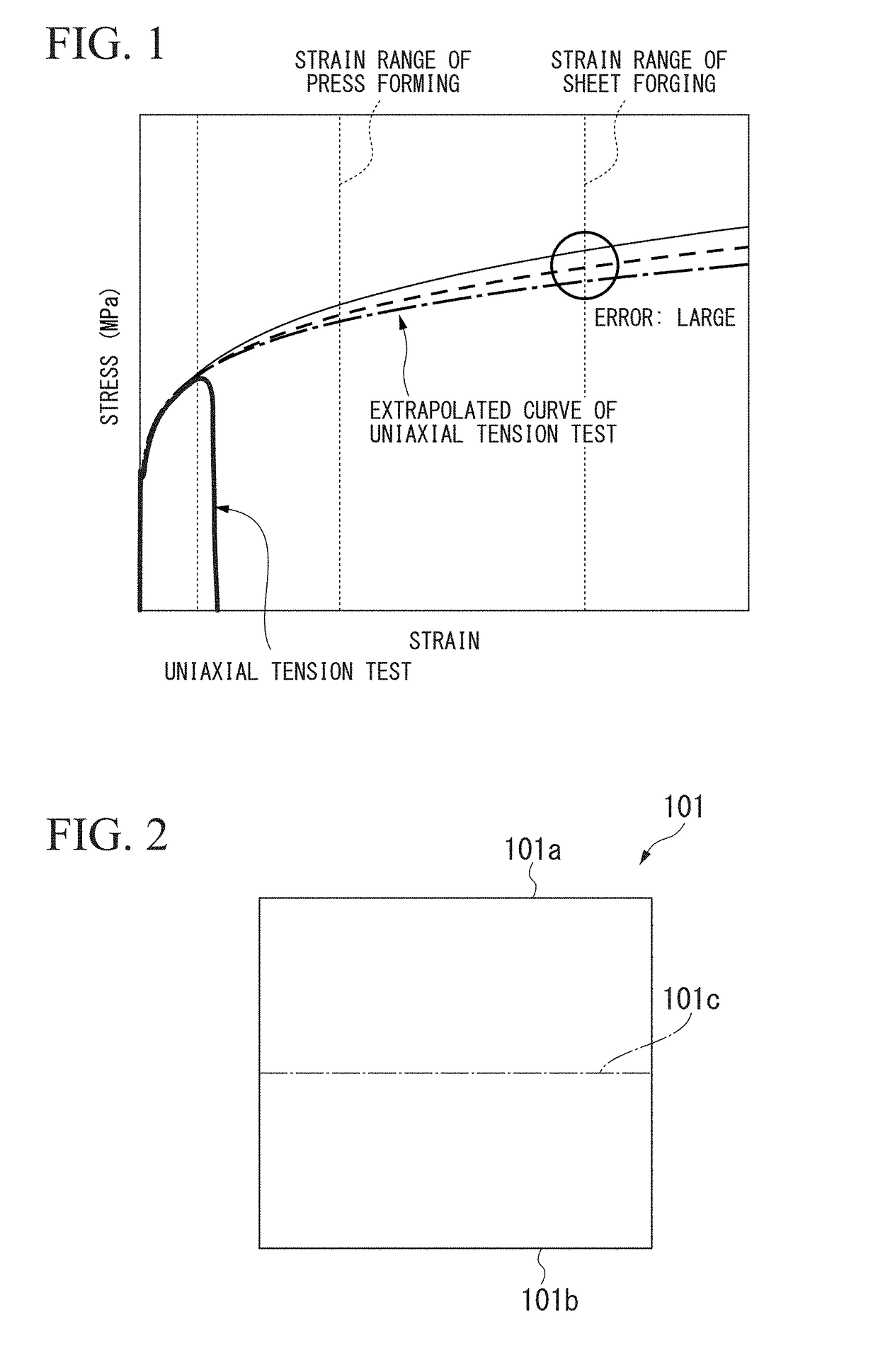

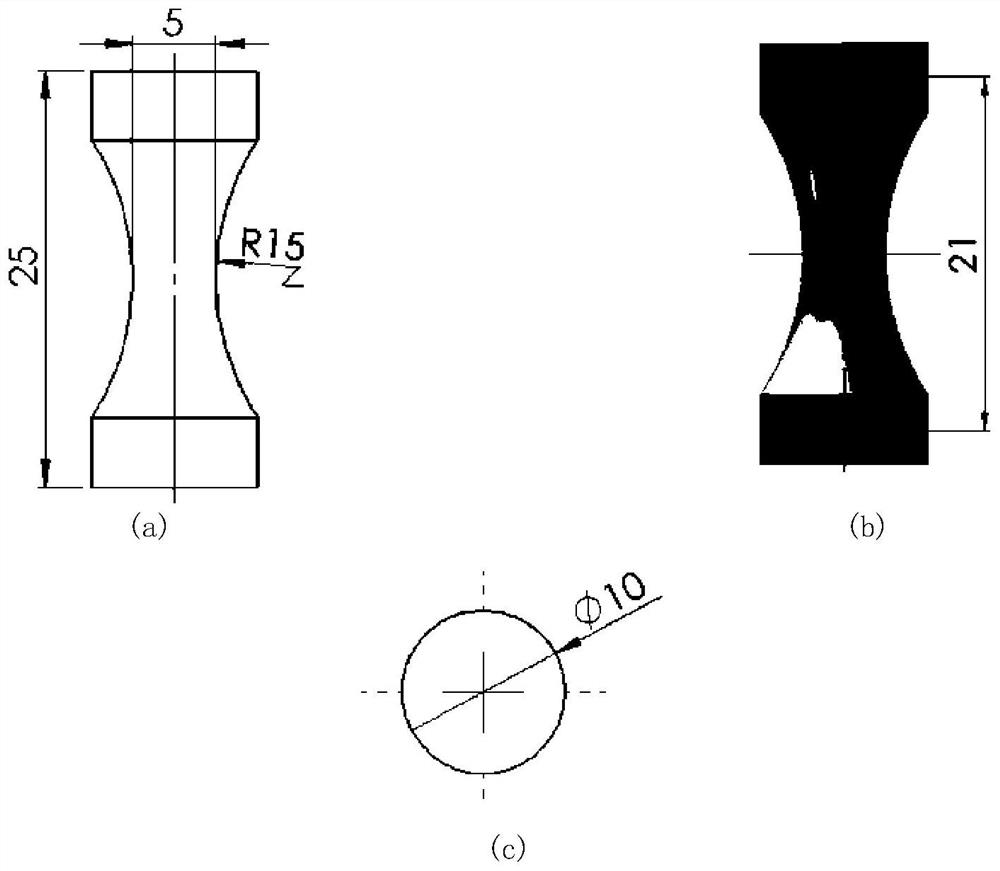

Evaluation method of plastic material and evaluation method of deformation processing of plastic material

ActiveUS20170191915A1Reduce in quantityImprove accuracyMaterial strength using steady shearing forcesDesign optimisation/simulationPlastic materialsShearing deformation

An evaluation method of a plastic material includes: a first shearing process of performing simple shearing deformation with respect to a first plastic sheet; a second shearing process of performing simple shearing deformation with respect to a second plastic sheet; a first partial stress-strain curve data obtaining process of obtaining first partial stress-strain curve data; a second partial stress-strain curve data obtaining process of obtaining second partial stress-strain curve data; and a synthesized stress-strain curve data obtaining process of obtaining synthesized stress-strain curve data based on the first partial stress-strain curve data and the second partial stress-strain curve data.

Owner:NIPPON STEEL CORP

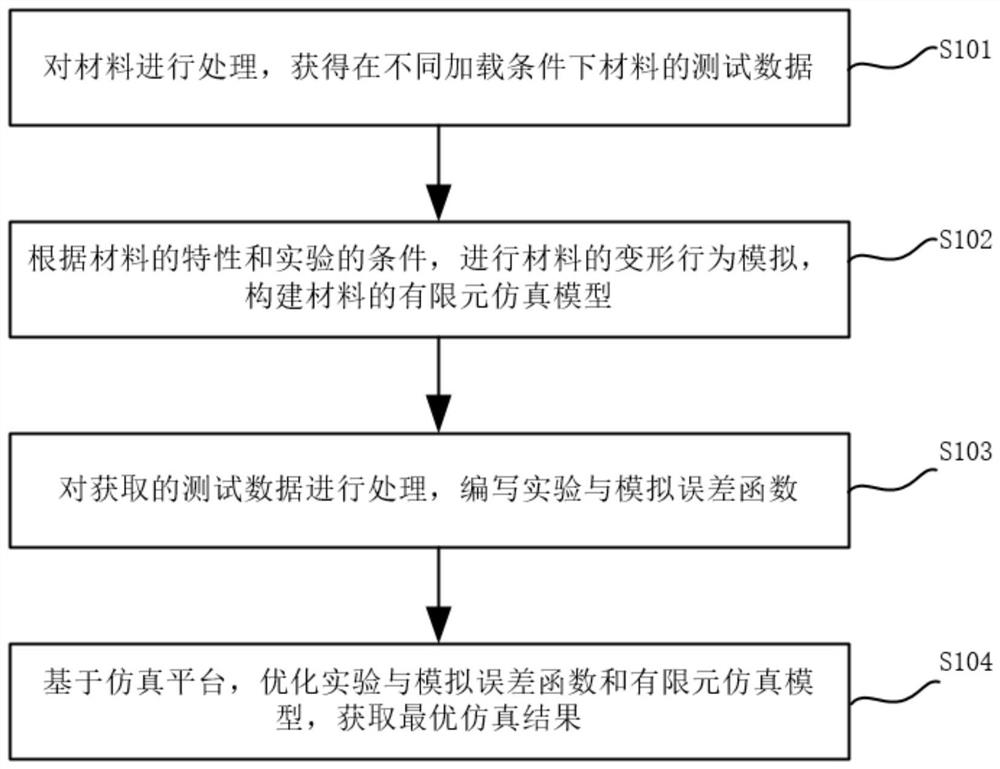

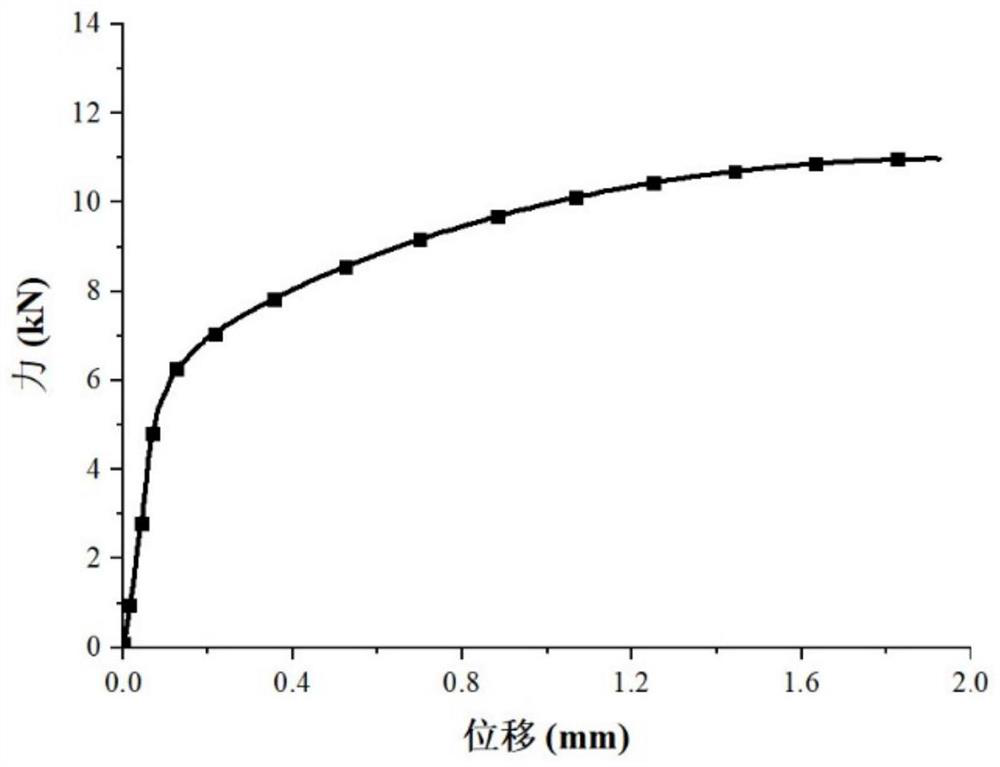

Method, system and device for calibrating deformation behavior of material and simulation platform

PendingCN113990412AMorph behavior implementationEfficient deformation behaviorDesign optimisation/simulationSpecial data processing applicationsAnalogue computationEngineering

The invention discloses a method, system and device for calibrating a deformation behavior of a material and a simulation platform, and the method comprises the steps: processing the material, and obtaining the test data of the material under different loading conditions; according to characteristics of the material and experimental conditions, carrying out deformation behavior simulation of the material, and constructing a finite element simulation model of the material; processing the obtained test data, and compiling an experiment and simulation error function; and based on the simulation platform, optimizing the experiment and simulation error function and the finite element simulation model, and obtaining an optimal simulation result. The simulation platform comprises a finite element simulation Simcode module, an MATLAB (matrix laboratory) error analysis module and an Optimization parameter optimization module. Based on the established simulation platform, simulation software is automatically operated to complete the process of simulation-optimization-parameter correction-re-simulation and re-optimization, and through multiple times of parameter optimization and finite element simulation calculation, a finite element simulation result is close to data obtained through experimental testing. And digitization and full automation of the whole material deformation mechanical behavior characterization process are realized.

Owner:XI AN JIAOTONG UNIV

Method for axially feeding, extruding, rolling and forming spline shaft by medium-frequency and high-frequency sensing heating

ActiveCN102814434BReduce lossesReduce deformation resistanceMetal rollingInduction heaterEngineering

Owner:陕西格致精成智能制造有限公司

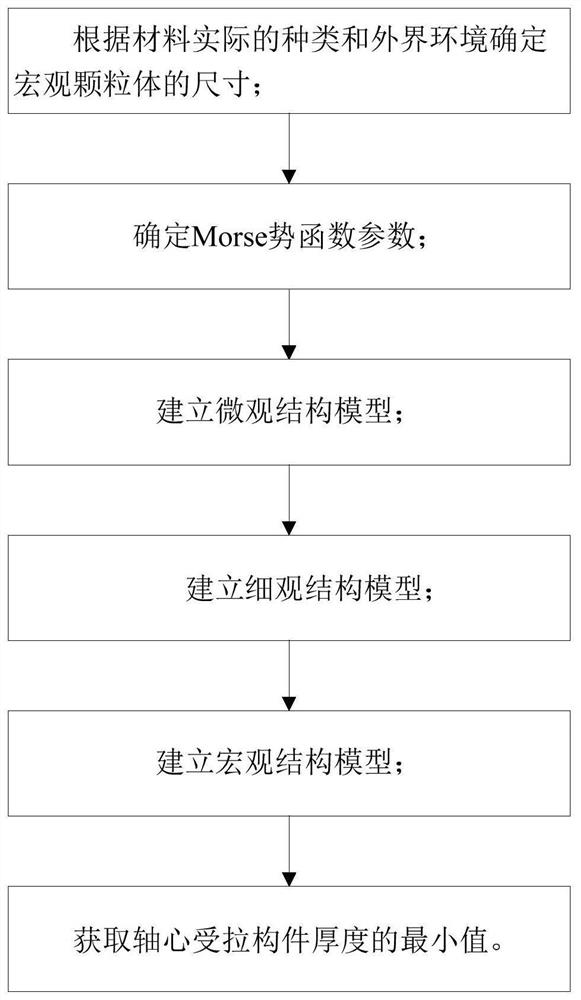

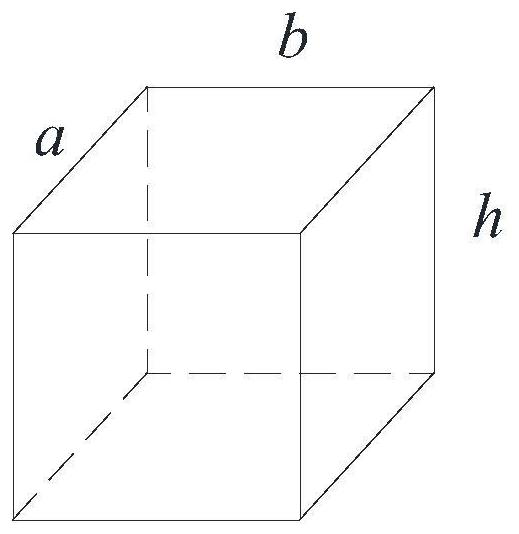

Design method of axis tension member based on microscale and axis tension member

PendingCN111783256ACorrectly designedLow costGeometric CADSpecial data processing applicationsMicro structureMacroscopic scale

The invention discloses a design method of an axis tension member based on a microscale and the axis tension member. The design method comprises the following steps: determining the size of macroscopic particles according to the actual type of a material and an external environment; then determining a Morse potential function parameter; then establishing a microstructure model, establishing a mesostructure model and establishing a macrostructure model; and finally, acquiring the minimum value of the thickness of the axis tension member. According to the method, an existing material strength calculation method is supplemented, and reasons of material deformation and damage are analyzed essentially. The design based on the design method is more accurate, and the cost can be greatly saved.

Owner:NANCHANG CAMPUS OF JIANGXI UNIV OF SCI & TECH

Hot forging forming method for titanium alloy aviation three-way elbow joint

InactiveCN112496247ASmall amount of deformationIncrease the surface treatment processEngine componentsAviationPolishing

The invention discloses a hot forging forming method for a titanium alloy aviation three-way elbow joint. The hot forging forming method comprises the steps of feeding, heating and upsetting (or bending), shot blasting, defect checking and polishing and repairing, polishing, spraying, heating and pre-forging, pre-forging and trimming, shot blasting, defect checking and polishing and repairing, polishing, spraying, heating and finish forging, finish forging and trimming and the like. The step-by-step progressive forging forming process is adopted, the material volume of each step is reasonablycalculated, the material deformation of each step is reduced, and a surface treatment process is added before each forming step, so that the generation of folding and cracks is further reduced.

Owner:无锡航亚科技股份有限公司

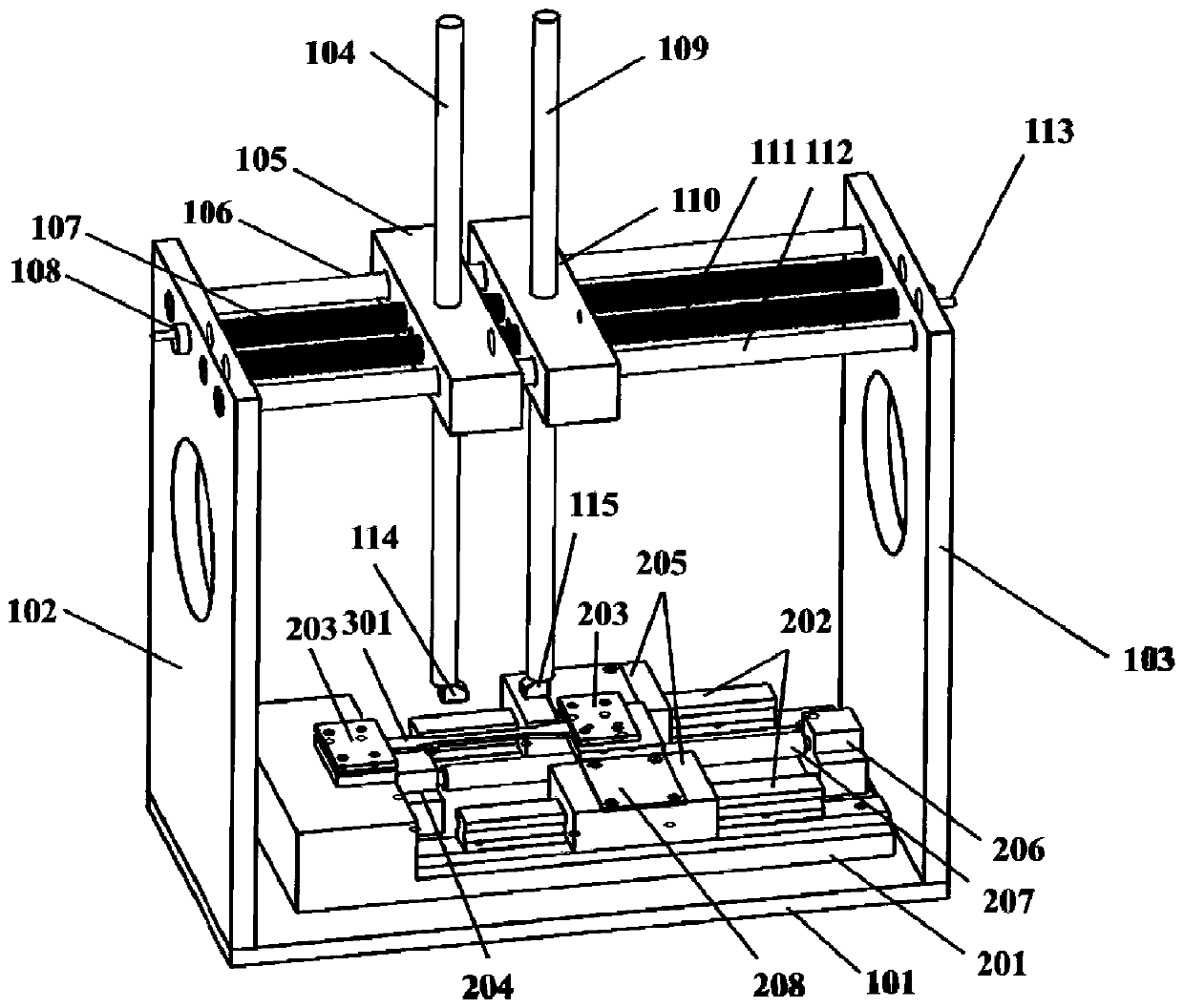

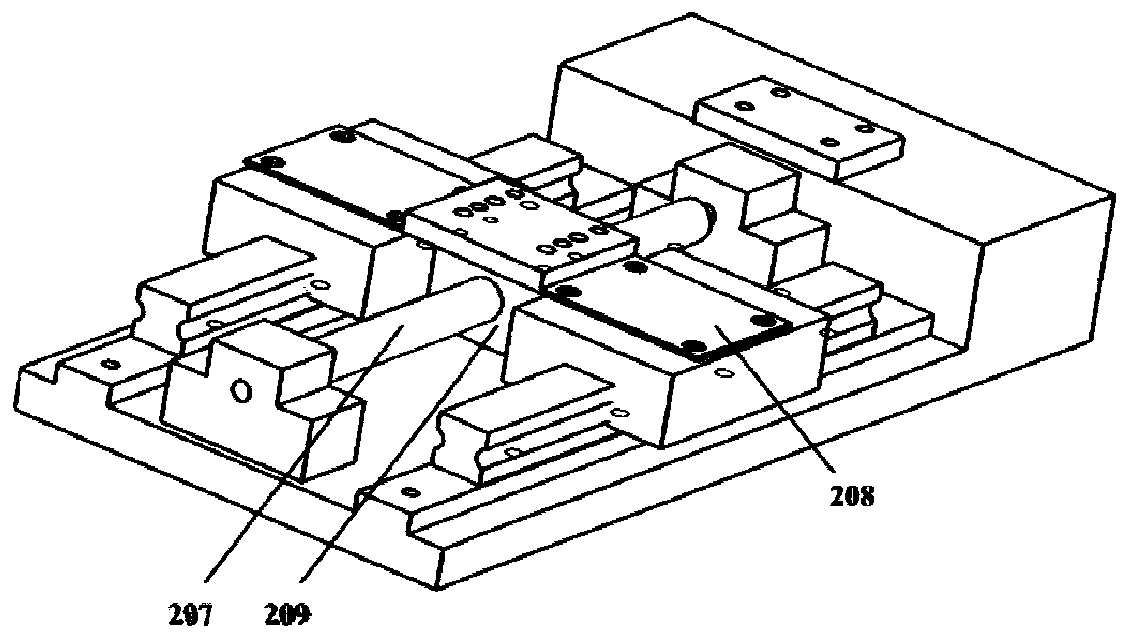

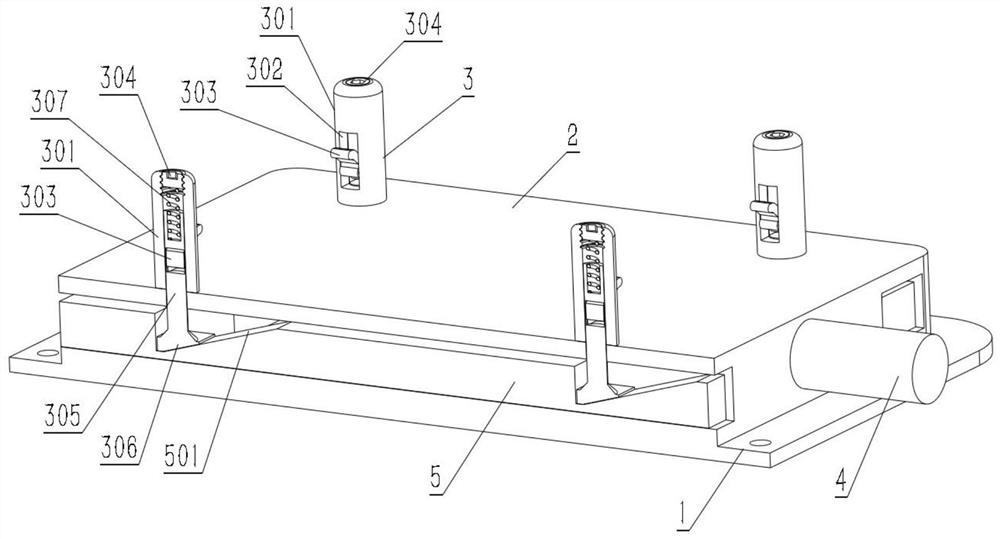

High polymer material damage in-situ test device and method based on ultrasonic waves

PendingCN111208014AHas hardnessWith characteristicsAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesAcousticsWave velocity

The invention relates to a high polymer material damage in-situ test device and method based on ultrasonic waves. The device comprises a mobile adjusting device, an ultrasonic transmitting probe and an ultrasonic receiving probe, wherein the moving adjusting device comprises an in-situ stretching base, a sliding rail sliding block and a sliding device, the sliding rail sliding block slides relative to the in-situ stretching base through the sliding device, the top of the in-situ stretching base and the top of the sliding rail sliding block are each provided with a clamp, the ultrasonic transmitting probe and the ultrasonic receiving probe are located above the moving adjusting device and located at the bottom of a first vertical rod and the bottom of a second vertical rod respectively, anda distance between two vertical rods is adjustable. The device is advantaged in that a damage value is calculated through the wave velocity of the ultrasonic waves, the defect that a traditional damage testing method can only measure damage variables after material deformation is overcome, and the internal damage condition of the material can be reflected more truly.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High-temperature and low-temperature resisting ferrite material for cold heading bolt and production technology of high-temperature and low-temperature resisting ferrite material

InactiveCN110016620AImprove plastic indexHigh elongationFurnace typesHeat treatment furnacesHardnessYield ratio

The invention provides a high-temperature and low-temperature resisting ferrite material for a cold heading bolt and a production technology of the high-temperature and low-temperature resisting ferrite material. The high-temperature and low-temperature resisting ferrite material comprises following components including, by mass percent, 0.17 wt%-0.25 wt% of C, 0.40 wt%-0.80 wt% of Mn, larger than0 and smaller than or equal to 0.4 wt% of Si, larger than 0 and smaller than or equal to 0.025 wt% of P, larger than 0 and smaller than or equal to 0.025 wt% of S, 1.20 wt%-1.50 wt% of Cr, larger than 0 and smaller than or equal to 0.60 wt% of Ni, 0.55 wt%-0.80 wt% of Mo, larger than 0 and smaller than or equal to 0.030 wt% of Al, larger than 0 and smaller than or equal to 0.030 wt% of V and thebalance Fe and inevitable impurities. The ferrite material has high plasticity indexes, elongation rate and percentage reduction of area, during cold plastic deformation, the material deformation resistance is small, the machining hardening rate is low, the material yield ratio is low, and hardness is proper.

Owner:苏州誉高紧固系统有限公司

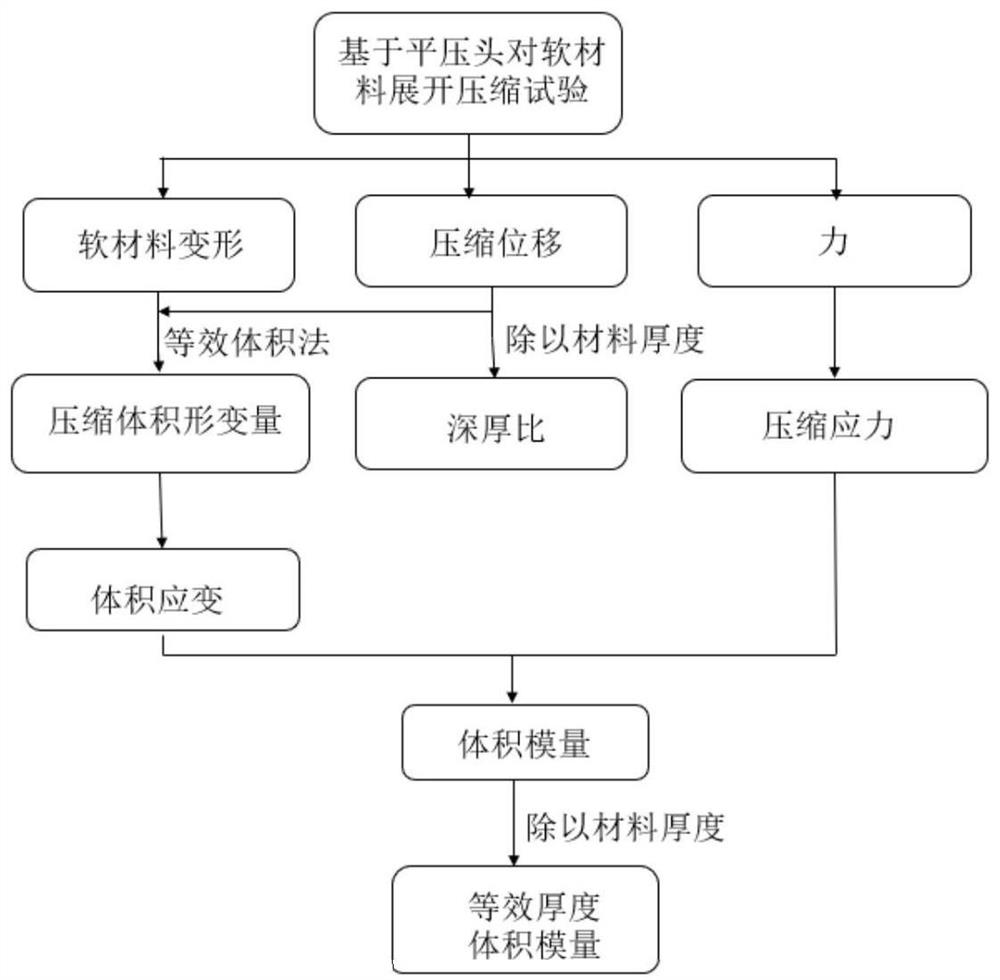

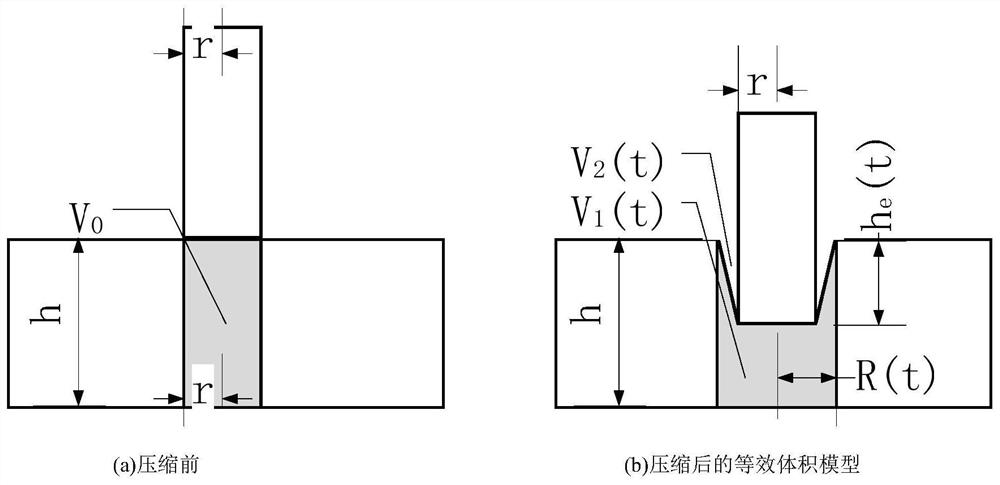

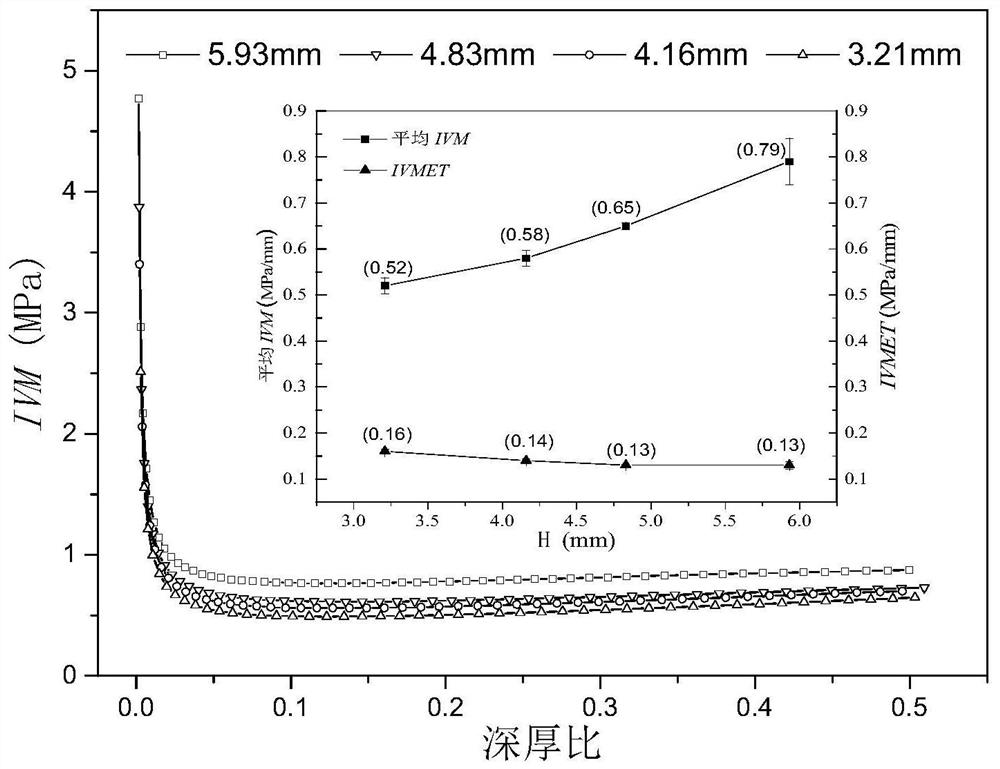

Soft material deformation characterization method based on equivalent thickness bulk modulus and application thereof

ActiveCN113075033AEliminate the effects ofReflect attributesMaterial strength using tensile/compressive forcesDesign optimisation/simulationSoft materialsMaterial Deformation

The invention discloses a soft material deformation characterization method based on equivalent thickness bulk modulus IVMET, and the method comprises the steps that an equivalent volume model is built according to the three-dimensional deformation of a soft material through employing an equivalent volume method, and the bulk modulus of the soft material is calculated more accurately; and furthermore, based on the calculation of the equivalent thickness bulk modulus, the influence of the material thickness on the material bulk modulus is eliminated, and the attribute of the soft material can be represented more accurately. Moreover, according to the soft material deformation characterization method based on the equivalent thickness bulk modulus (IVMET), the soft material containing complex added components can be characterized, so that the influence of various added components on the performance of the soft material is analyzed. The invention further discloses a method for carrying out deformation characterization on different areas of the human tongue based on the IVMET, deformation characterization can be carried out on the different areas of the human tongue, and a basis can be provided for the selection and characterization of oral cavity bionic soft materials.

Owner:JIANGNAN UNIV

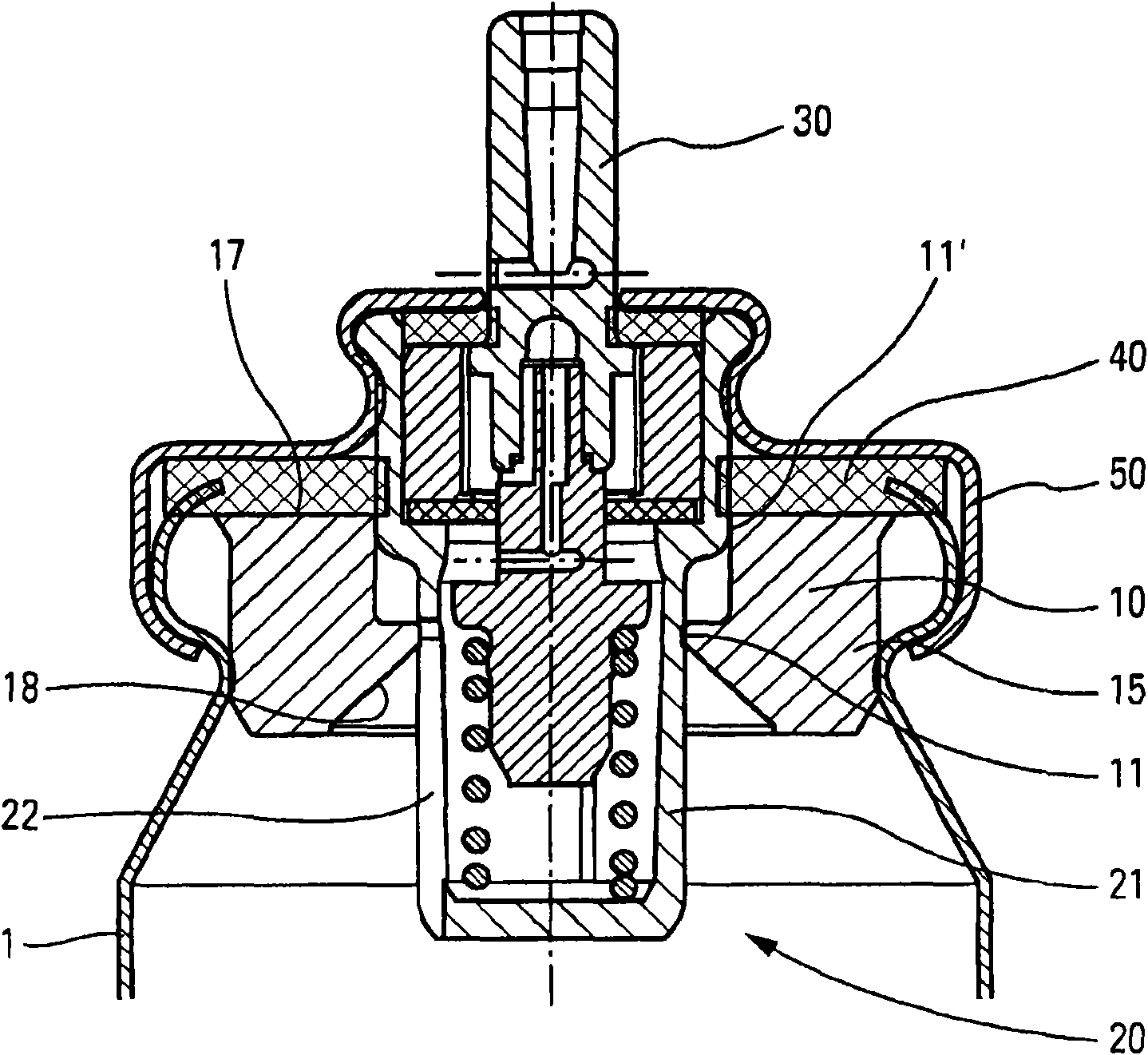

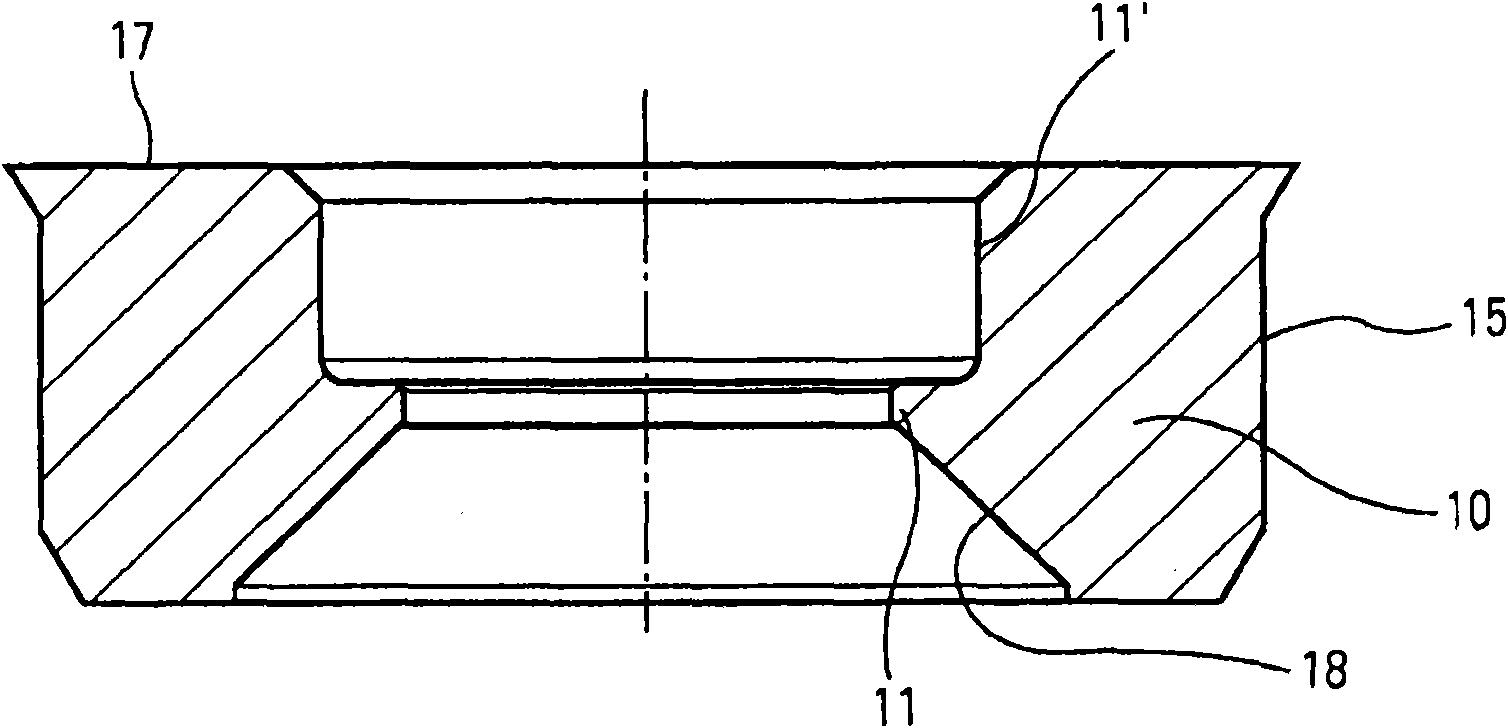

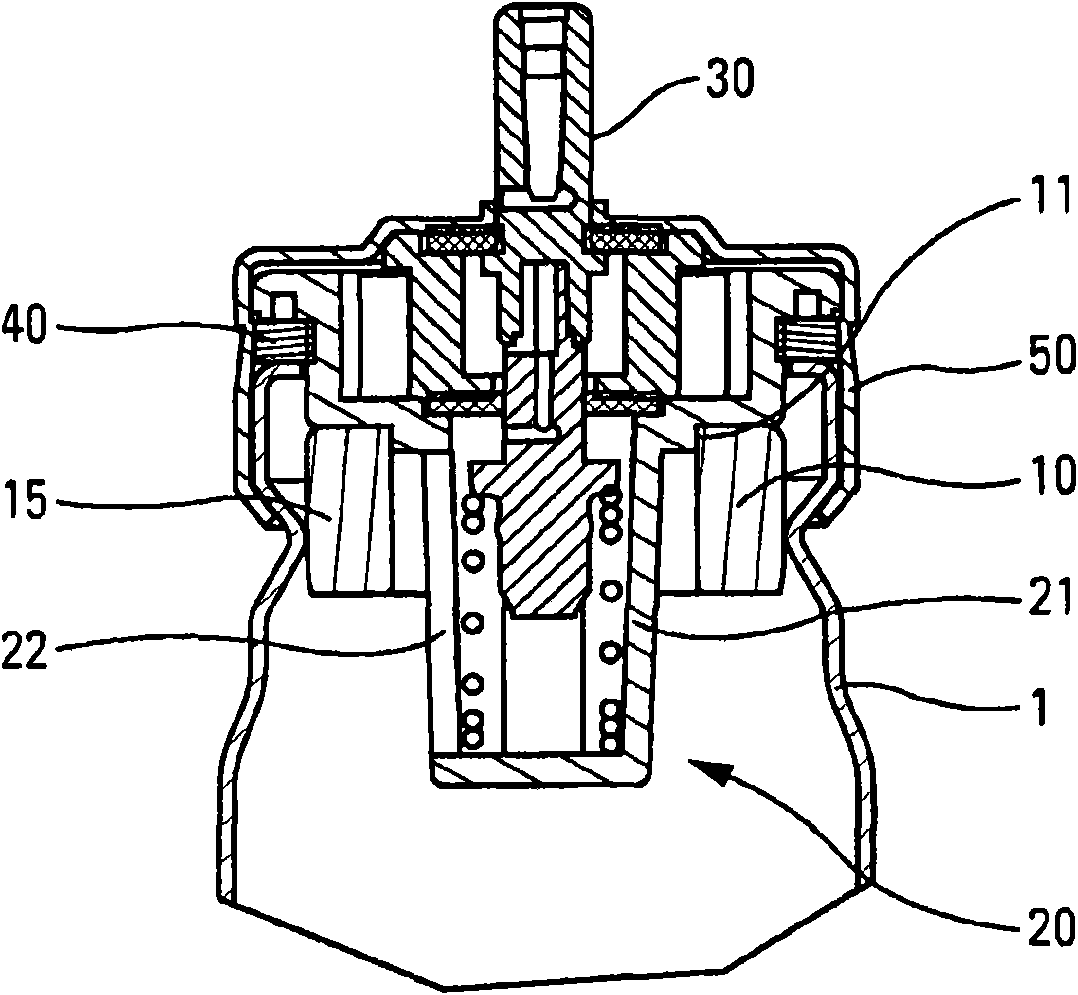

Ring for fluid production dispensing

The invention relates to a ring (10) to be provided about a valve body (21) of an aerosol dispensing valve (20) mounted via a securing member (50) such as a crimped cap, on a tank containing a productto be dispensed, wherein said ring (10) includes at least one inner portion (11, 11) interacting with said valve body (21), and an outer portion (15), said ring (10) being made of a substantially rigid single piece, and said outer portion (15) being adapted for sealed interaction by material deformation with a portion of the tank (1) upon the assembly of the securing member (50) on the tank (1).

Owner:APTAR FRANCE SAS

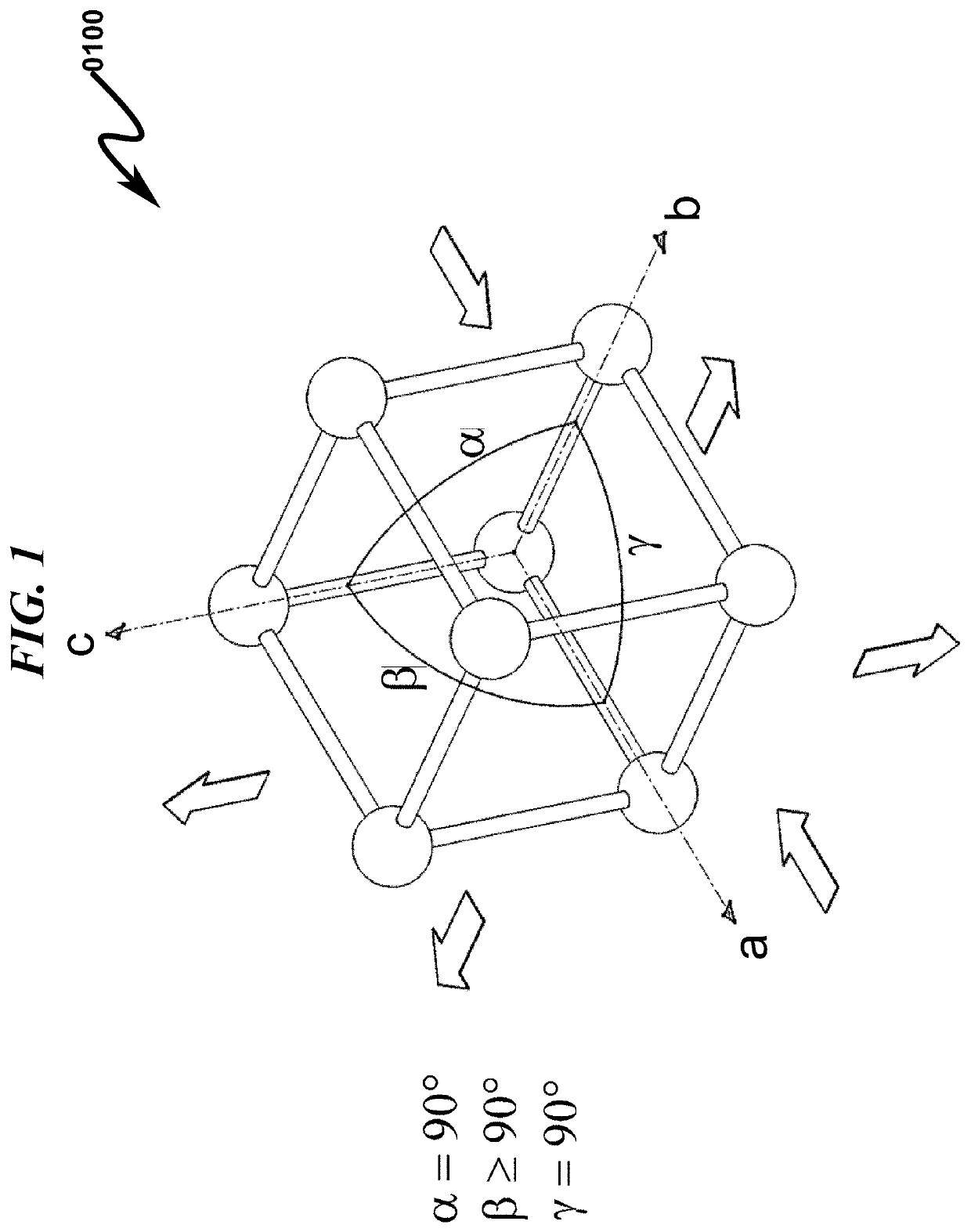

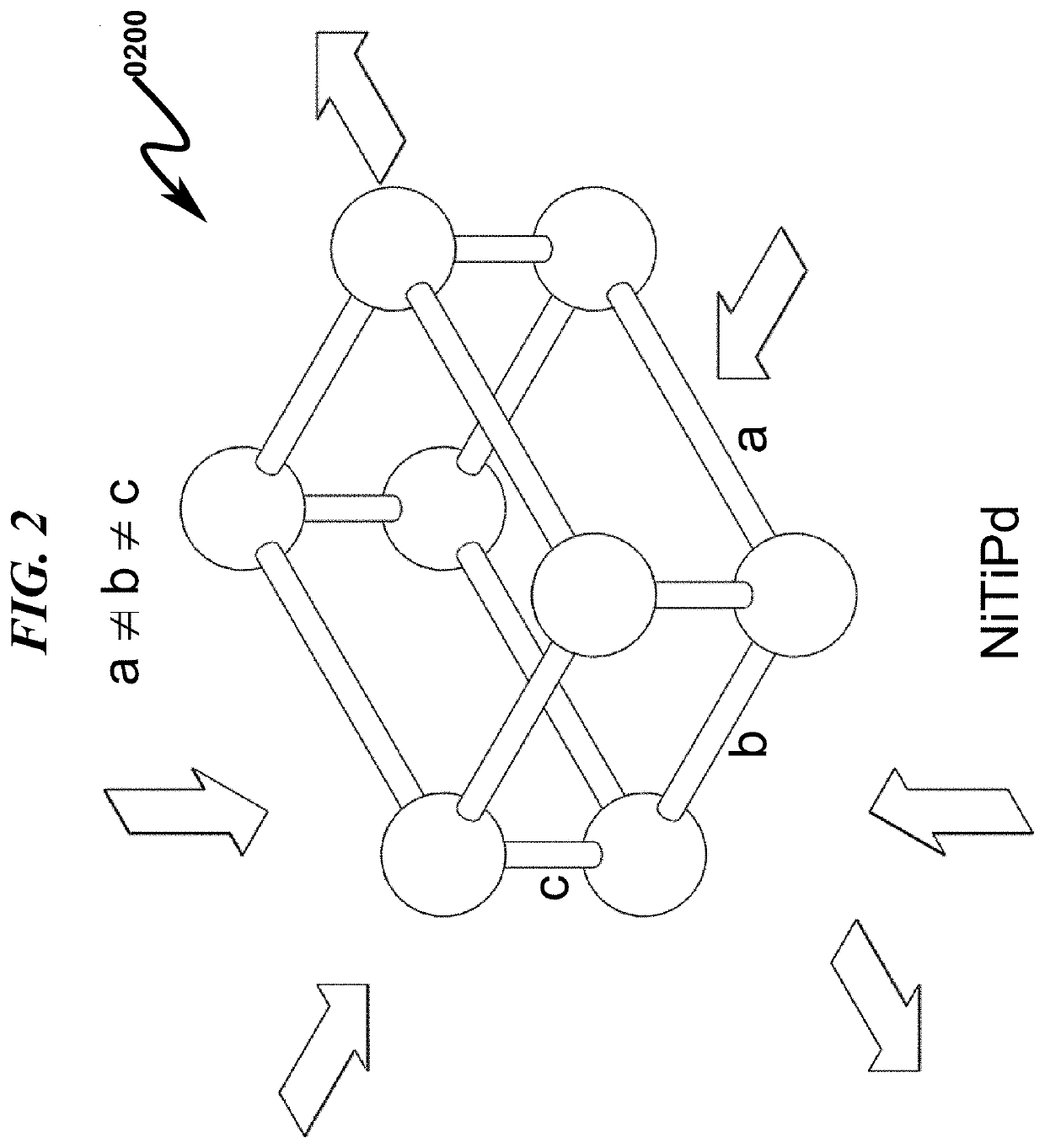

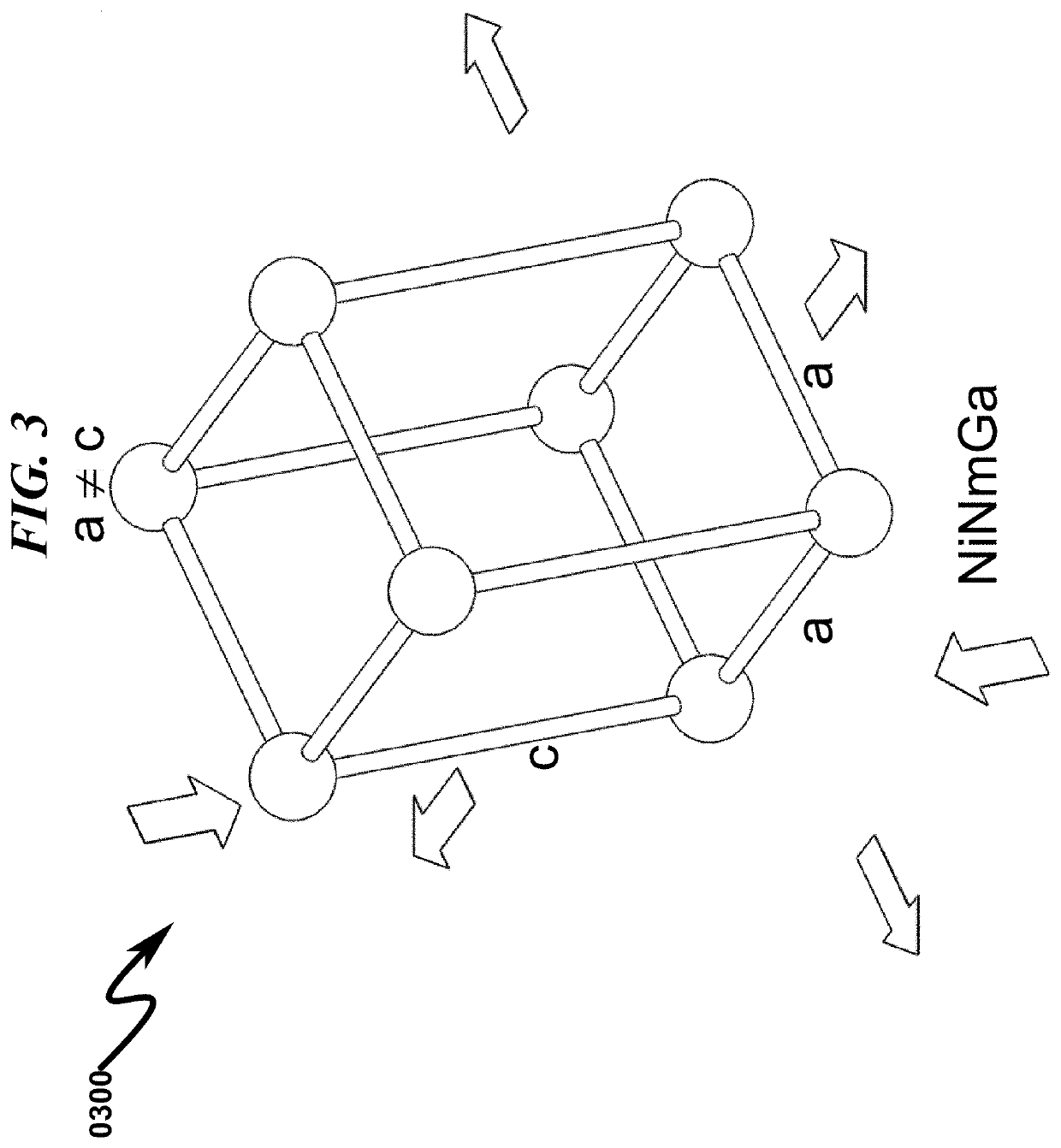

Controlled thermal coefficient product system and method

A controlled thermal coefficient product manufacturing system and method is disclosed. The disclosed product relates to the manufacture of metallic material product (MMP) having a thermal expansion coefficient (TEC) in a predetermined range. The disclosed system and method provides for a first material deformation (FMD) of the MMP that comprises at least some of a first material phase (FMP) wherein the FMP comprises martensite randomly oriented and a first thermal expansion coefficient (FTC). In response to the FMD at least some of the FMP is oriented in at least one predetermined orientation. Subsequent to deformation, the MMP comprises a second thermal expansion coefficient (STC) that is within a predetermined range and wherein the thermal expansion of the MMP is in at least one predetermined direction. The MMP may be comprised of a second material phase (SMP) that may or may not transform to the FMP in response to the FMD.

Owner:TEXAS A&M UNIVERSITY

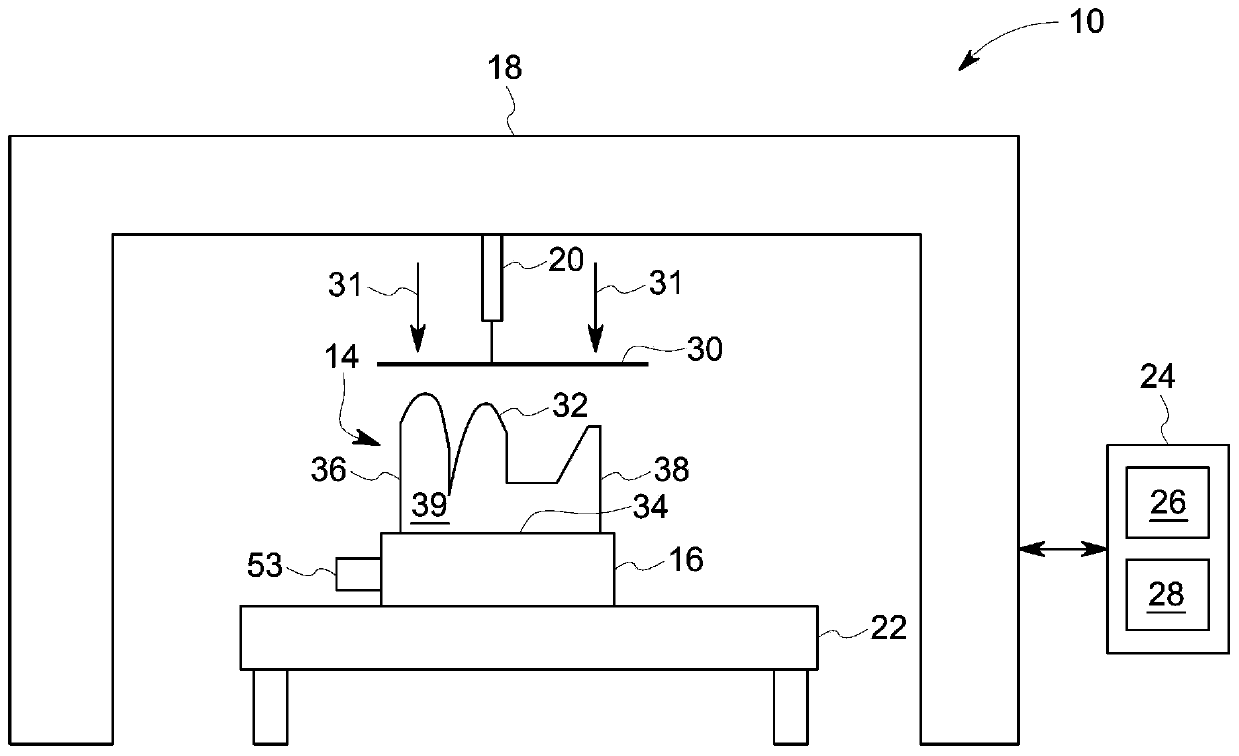

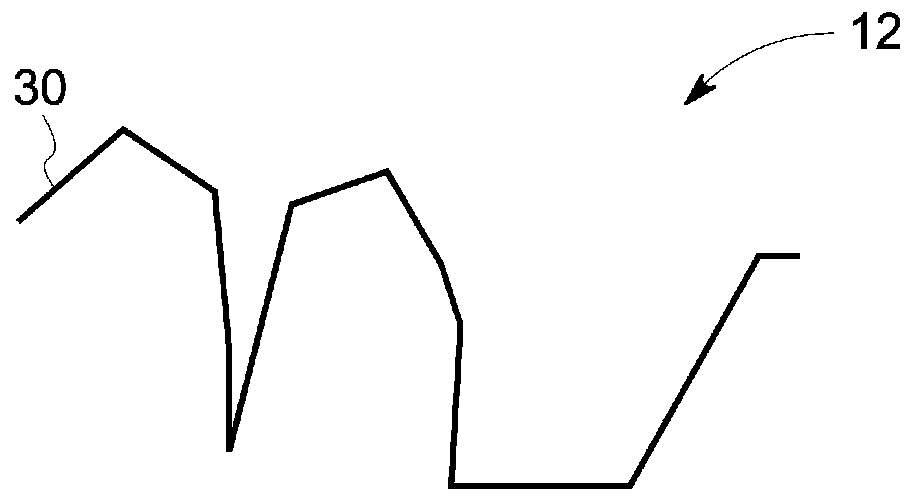

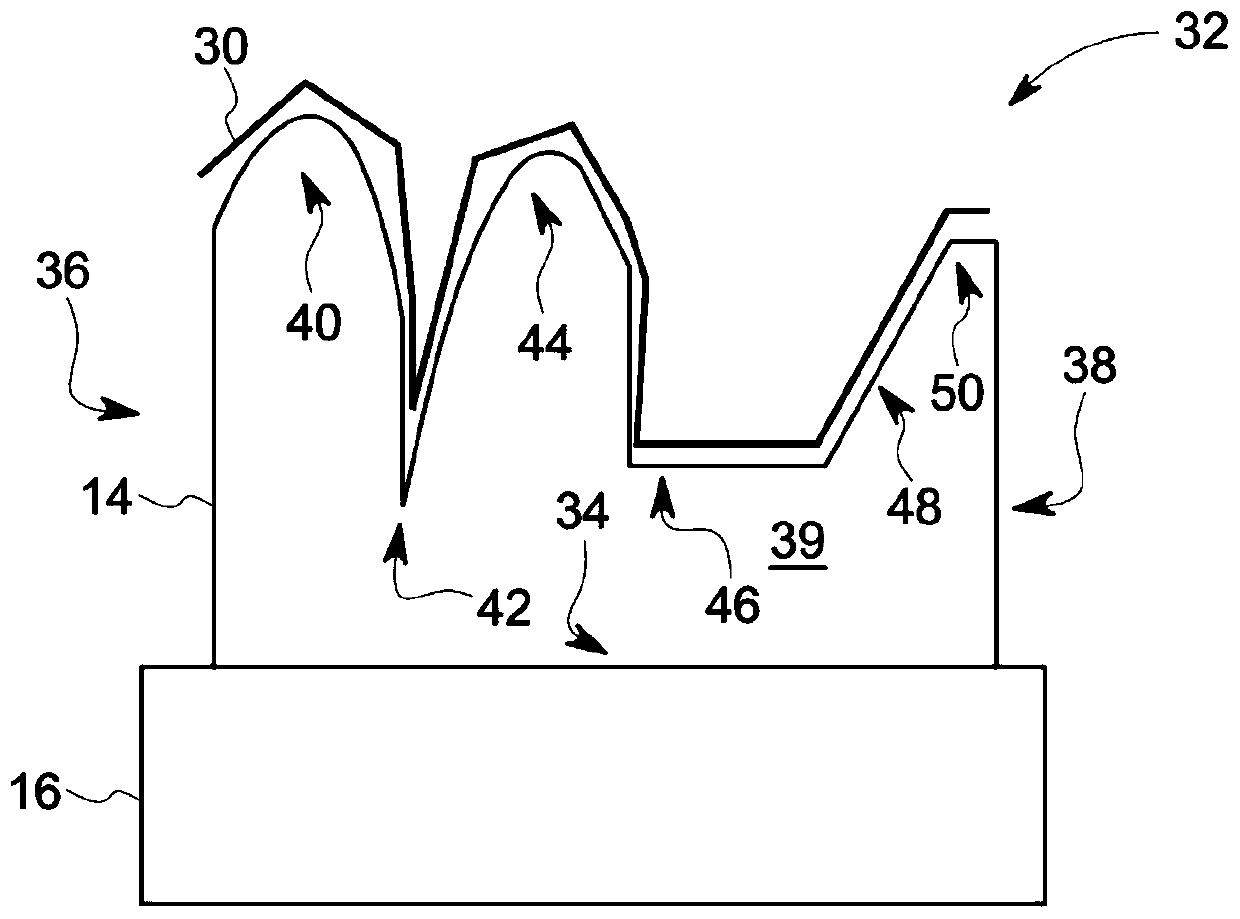

System and method for thermoforming object

The invention provides a system and a method for thermoforming object. A system 10 for thermoforming an object 12 is provided. The system 10 includes a mold 14 and a pressure-box 16. The mold 14 has asurface 32 that defines a shape of the object 12 and includes two or more portions 40, 42, 44, 46, 48, 50 of differing porosities. The pressure-box 16 is operative to generate a pressure differentialacross the surface 32. The two or more portions 40, 42, 44, 46, 48, 50 apply the pressure differential at different loads, based at least in part on the differing porosities, to a material 30 disposed onto the surface 32 so as to form the object 12 by deforming the material 30 into the shape.

Owner:GENERAL ELECTRIC CO

Material deformation spinor field test method

The invention belongs to the field of material deformation. The invention uses a digital camera to shoot the whole field photos; the two front and back frames of the whole field images or continuous multi-frame images are taken out; relevant image recognition software is used to carry out memorizing and relevant recognition on the images; the deformation spinor characteristic parameter analysis for each point of the whole filed is calculated by a spinor field computing formula; then measurement is carried out to obtain various cartoon documents and data. The invention carries out calculation and analysis on the deformation spinor field of the whole field to give out the value and the direction of the rotating spinor field of each part of the whole field during the cracking process of the deformation of a material; the invention is a novel creation in the field of metal physics.

Owner:GUOBIAO BEIJING TESTING & CERTIFICATION CO LTD

Cryogenic preparation method of ultra-fine grain material with assistance of electric pulse and confining pressure

The invention relates to the technical field of ultra-fine grain material preparation, in particular to a cryogenic preparation method of an ultra-fine grain material with assistance of electric pulseand confining pressure. The material deforms in the ultra-low temperature state, the grain recrystallization process is restrained, and due to repeated cryogenic deformation, the ultra-fine grain material is formed. In the deformation process, a large amount of dislocation is accumulated, and the strength of the material is greatly improved. During plastic deformation, a certain confining pressure is applied, the internal micro-defect in intensive deformation of the material is restrained, the material strength is further improved, and meanwhile the anti-fatigue and anti-corrosion performancecan be improved. During plastic deformation, electric pulse is applied, the low-temperature deformation plasticity of the material is improved, resistance to deformation is reduced, the processing frequency of the material is increased, and the strength and plasticity are synchronously improved.

Owner:CENT SOUTH UNIV

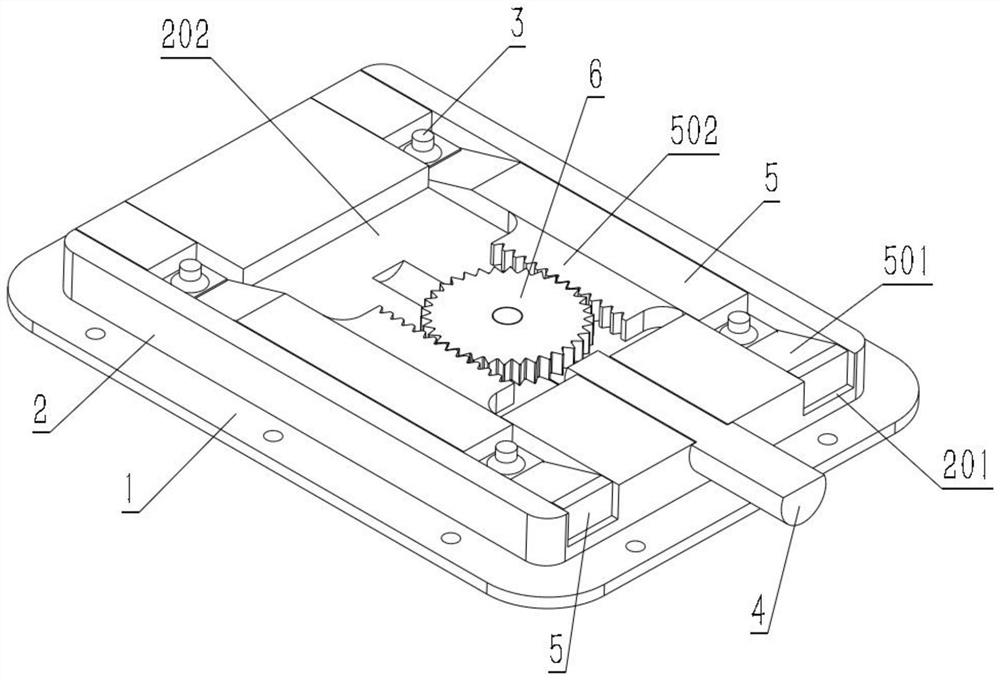

Fixing device for metal machining

InactiveCN112743361ASimple structureEasy to controlPositioning apparatusMetal-working holdersGear wheelMetal machining

The invention relates to a fixing device for metal machining. According to the technical scheme, the fixing device comprises a fixing base, a placement table, clamping devices, an electric telescopic rod, sliding base plates and a pushing gear. The pushing gear serves as a middle transmission component, the pushing gear pushes the two sliding base plates to slide, and therefore it can be guaranteed that the two sliding base plates can synchronously move and can also independently move; then, inclined faces on the sliding base plates are used for pushing the clamping devices to act, and therefore pressing block linkage is achieved to complete clamping and fixing; the multiple clamping devices are arranged on the whole device, synchronous linkage and independent actions of multiple clamping points can be achieved through transmission cooperation of the pushing gear and the sliding base plates, materials with the flat surfaces can be clamped, materials with the uneven surfaces can also be clamped, and the problem that due to material deformation or uneven surfaces, materials cannot be clamped firmly can be effectively solved. The whole device is simple in structure, convenient to control, stable in clamping and wide in application range.

Owner:陕西凌云木新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com