Cryogenic preparation method of ultra-fine grain material with assistance of electric pulse and confining pressure

An ultra-fine grain and electric pulse technology, applied in the field of cryogenic preparation of ultra-fine grain materials assisted by electric pulse and confining pressure, can solve the problems of weakening fatigue resistance and corrosion resistance, difficulty in reducing grain size, etc. Effects of improved fatigue and corrosion resistance, improved material toughness and workability, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

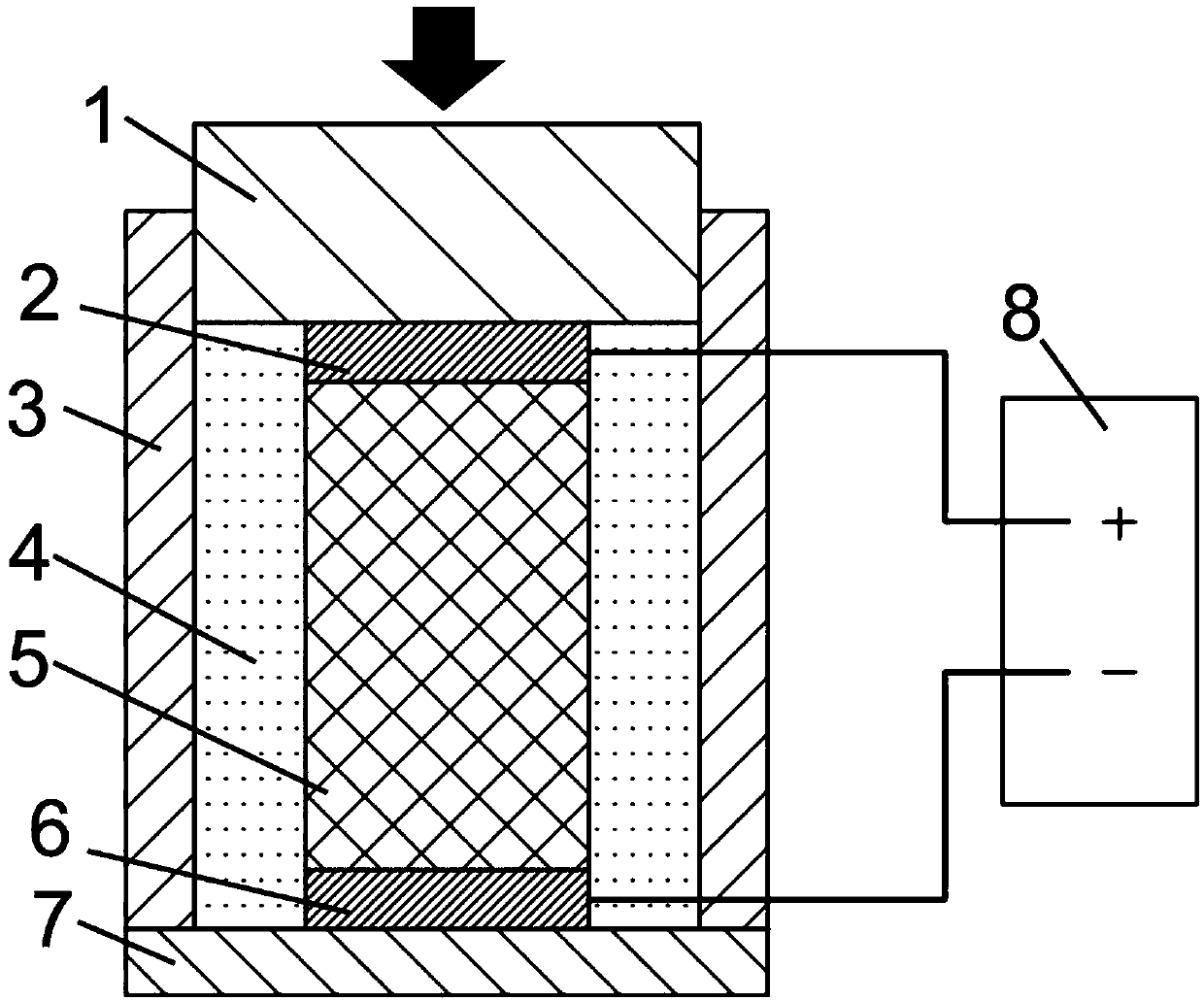

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] A cryogenic preparation method for ultrafine-grained materials assisted by electric pulses and confining pressure, using a loading piston 1 to compress and deform a cryogenically treated billet 5, the upper and lower ends of the billet 5 are in contact with electrode plates 2 and 6 respectively, and the two electrodes The plates 2 and 6 are connected with the pulse power source 8, and the blank 5 is filled with pressure fluid 4, and the blank 5 is compressed and deformed repeatedly.

[0019] The present invention comprises the following steps:

[0020] The first step: the aluminum alloy or copper alloy material in the shape of a cuboid is used as a blank 5 after annealing;

[0021] Step 2: Soak the billet 5 in liquid nitrogen and uniformly cool to -196°C;

[0022] The third step: put the blank 5 into the cylinder 3, place it on the lower electrode plate 6, insert t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com