Patents

Literature

1466results about How to "Facilitate subsequent processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

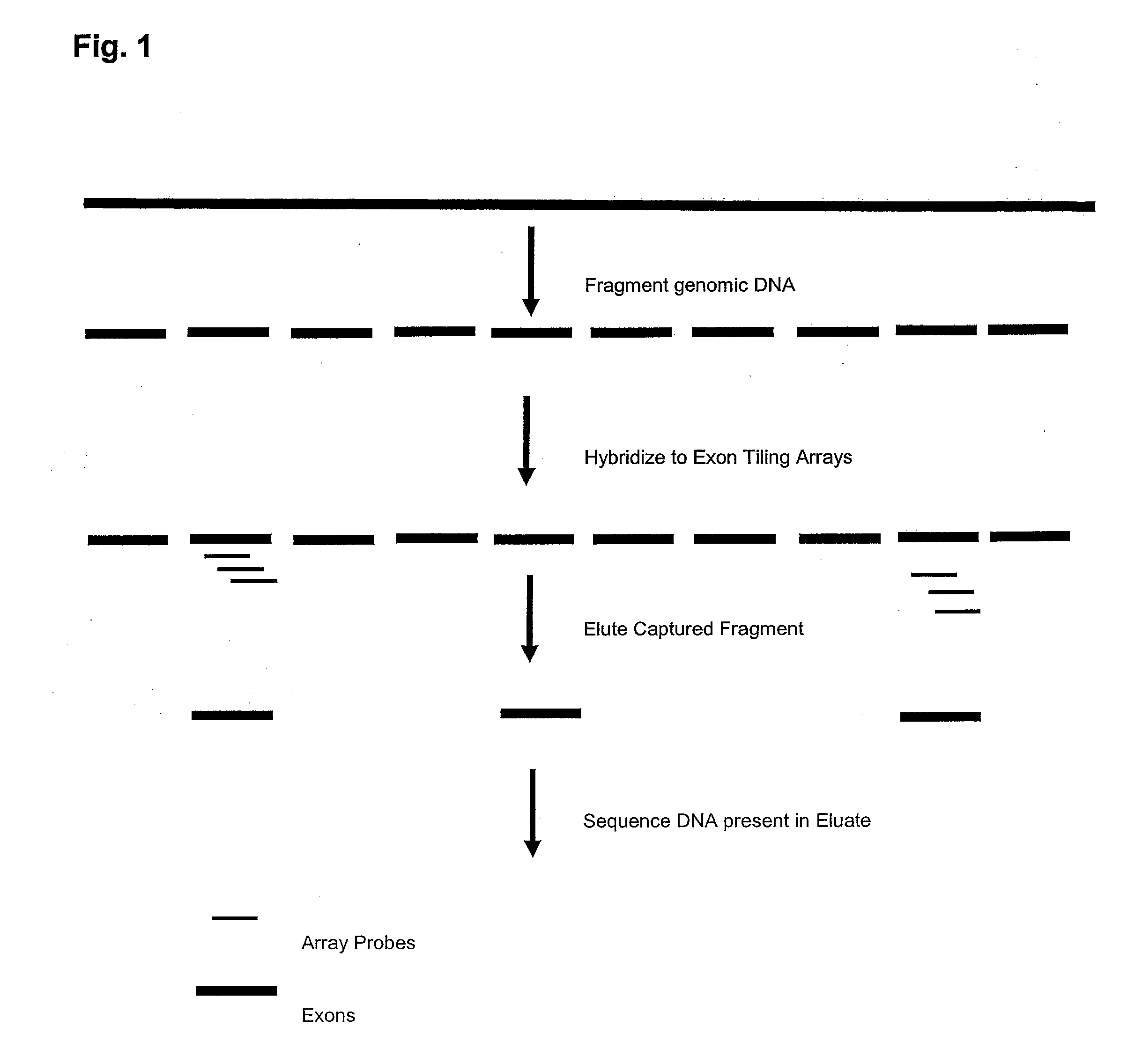

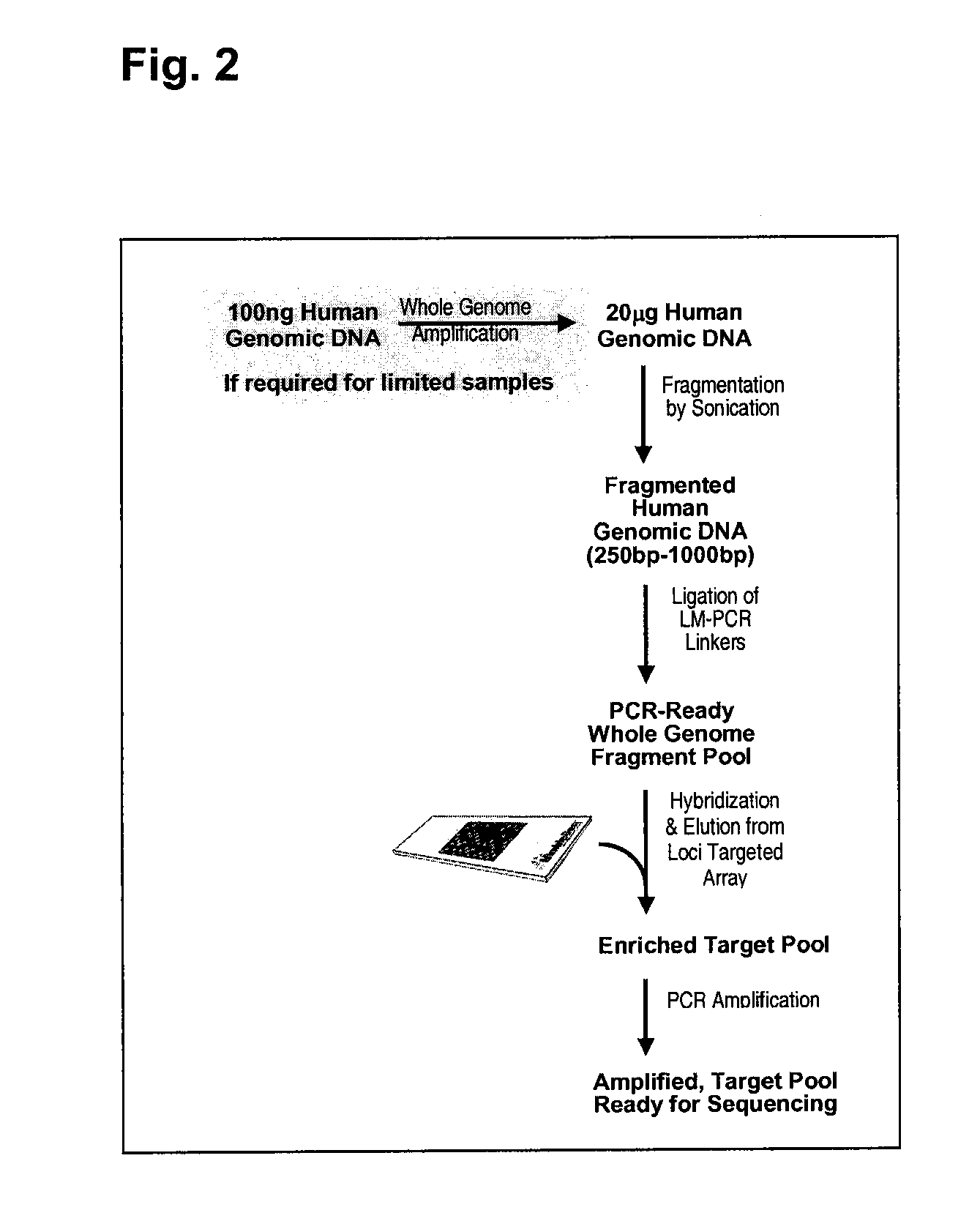

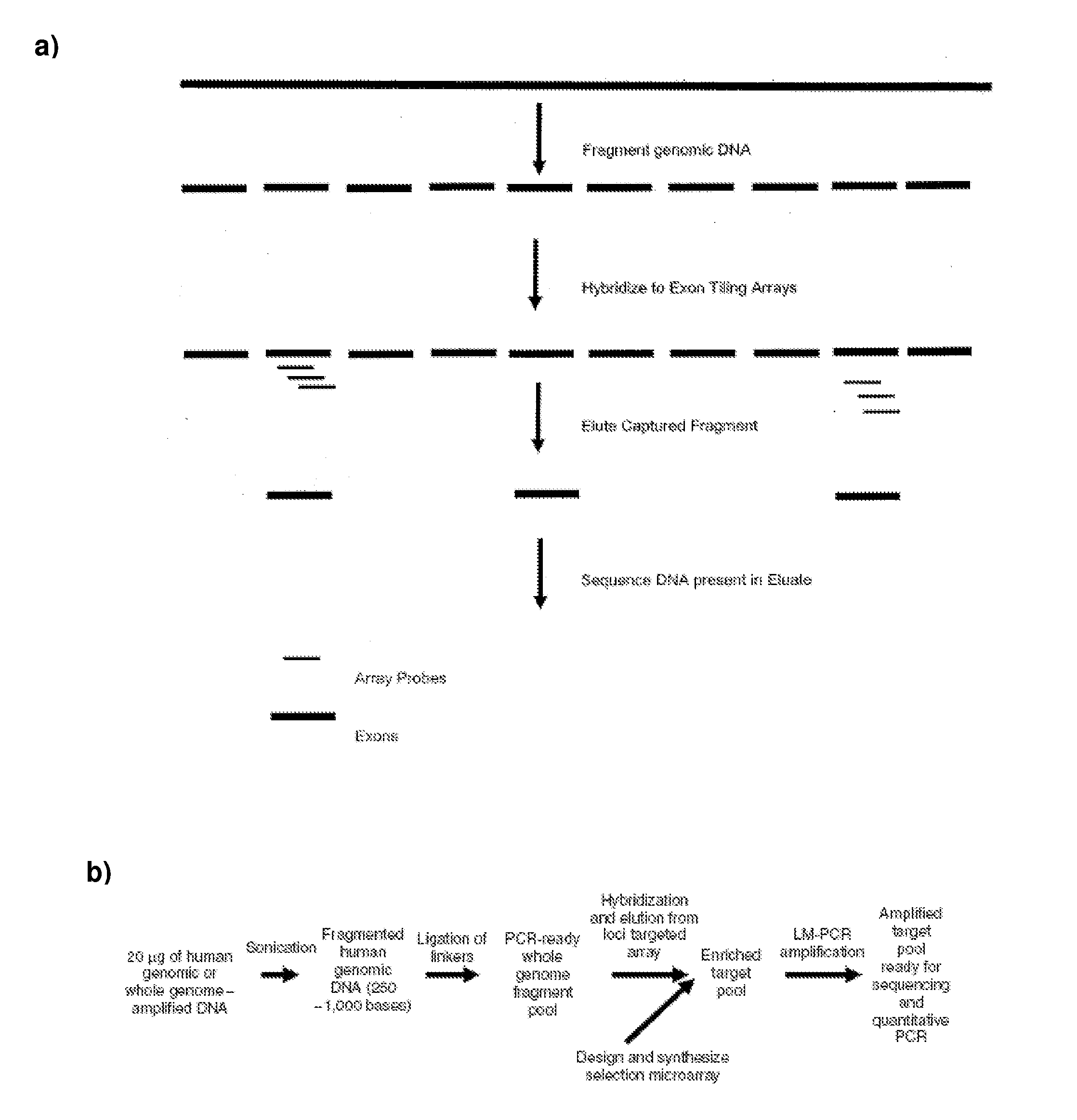

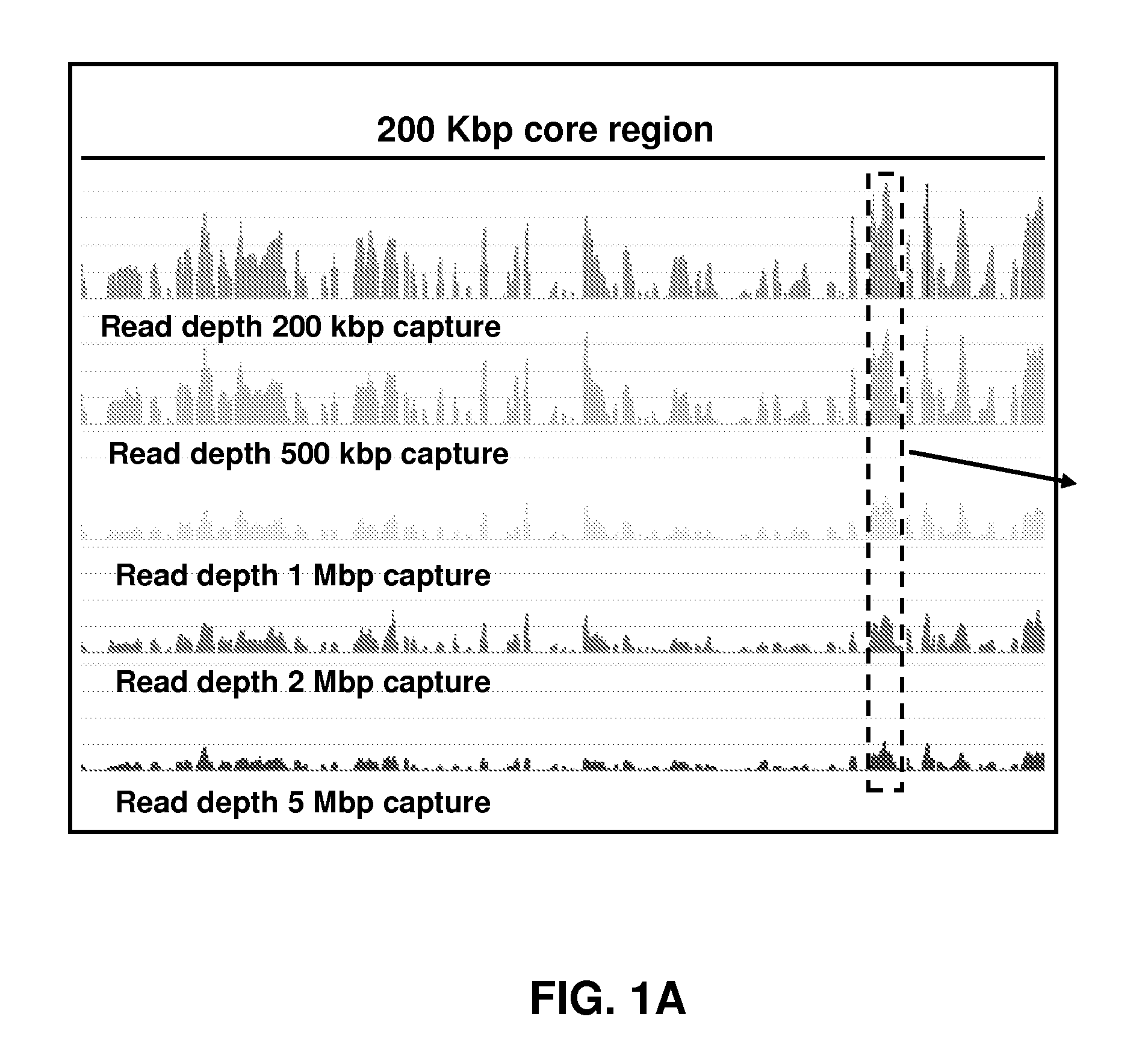

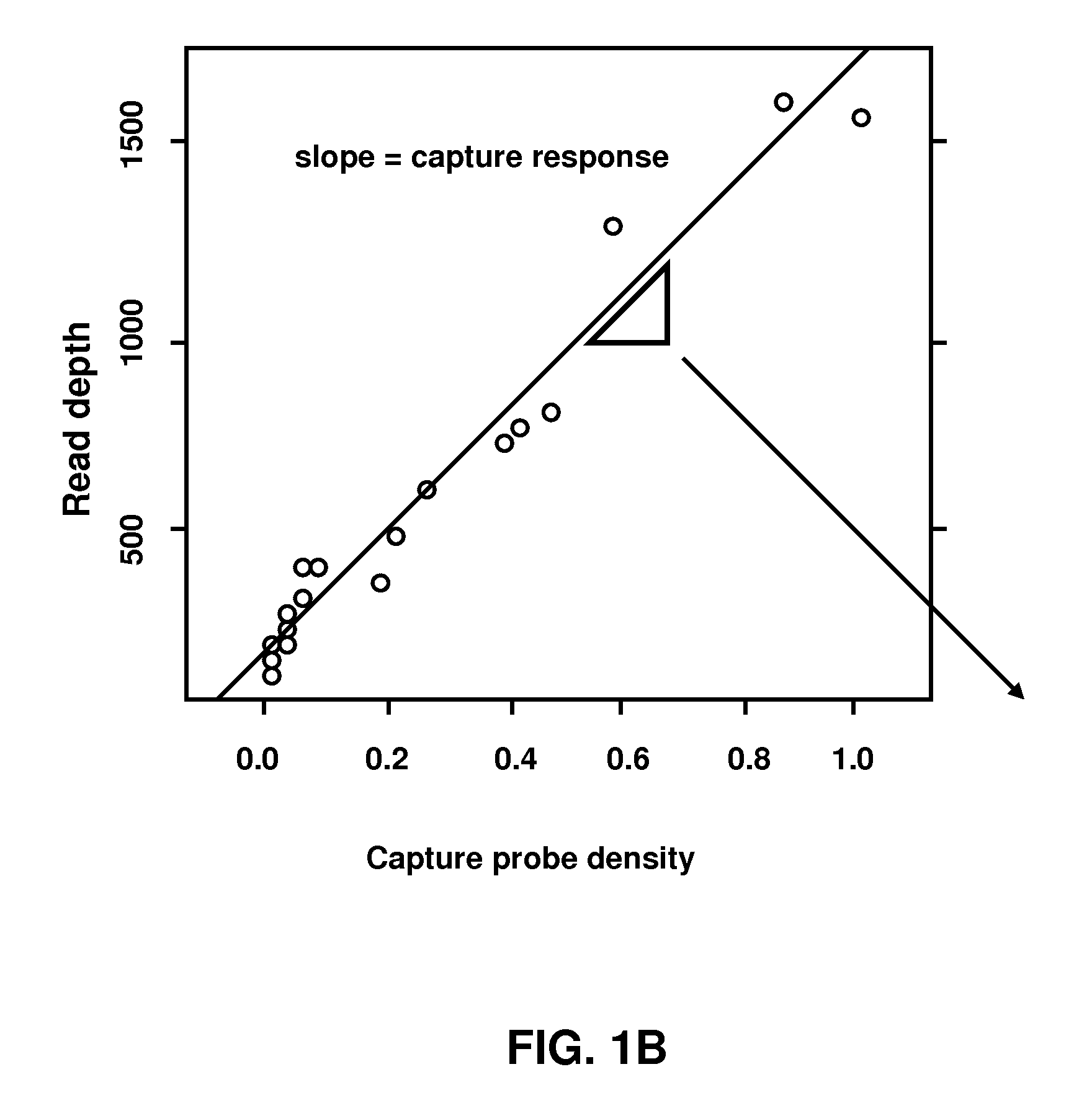

Enrichment and sequence analysis of genomic regions

InactiveUS20080194414A1Significant complexityFacilitate subsequent processingMicrobiological testing/measurementLibrary screeningSequence analysisAs Directed

The present invention provides novel methods for reducing the complexity of preferably a genomic sample for further analysis such as direct DNA sequencing, resequencing or SNP calling. The methods use pre-selected immobilized oligonucleotide probes to capture target nucleic acid molecules from a sample containing denatured, fragmented (genomic) nucleic acids for reducing the genetic complexity of the original population of nucleic acid molecules.

Owner:ALBERT THOMAS J +8

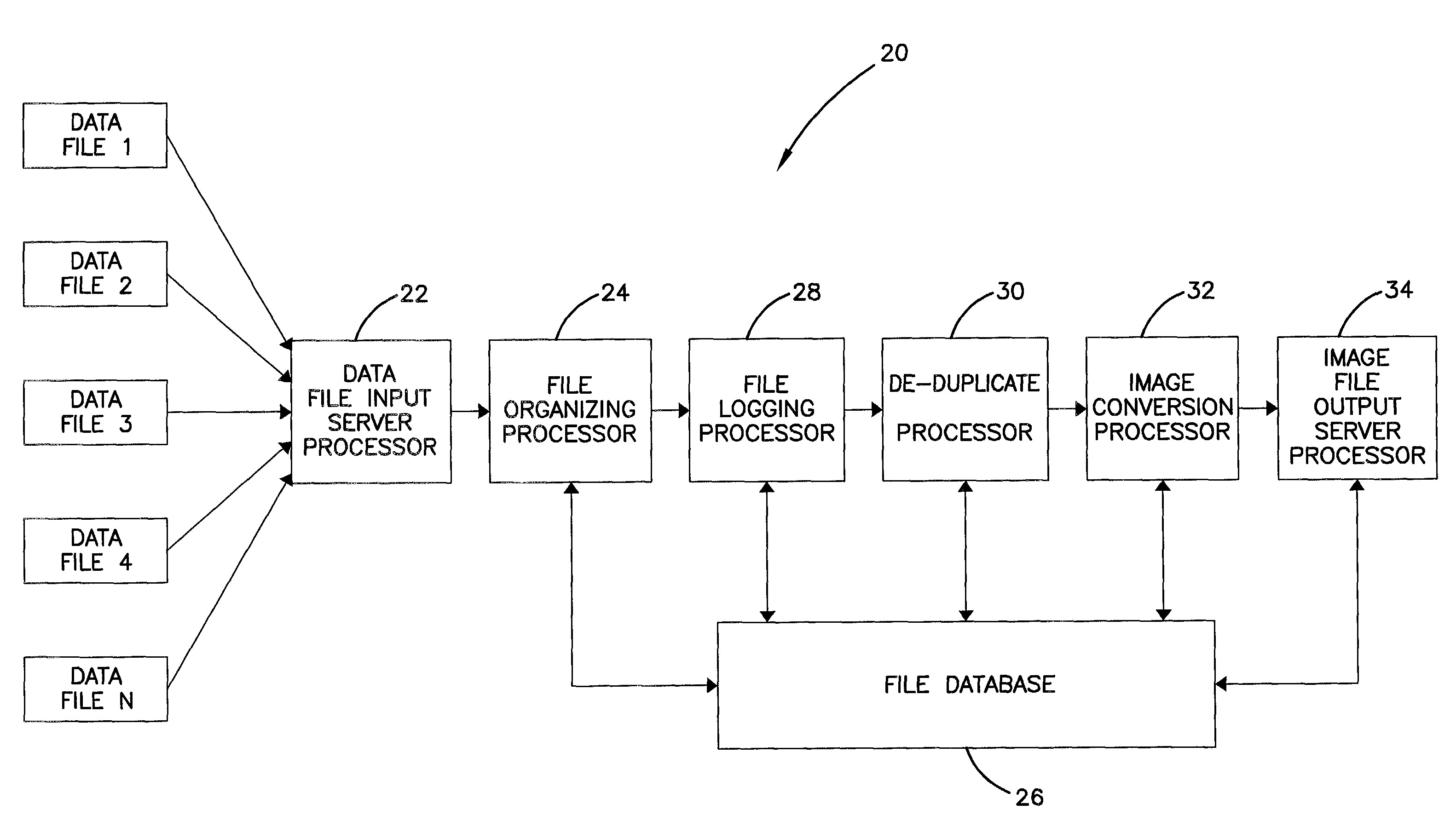

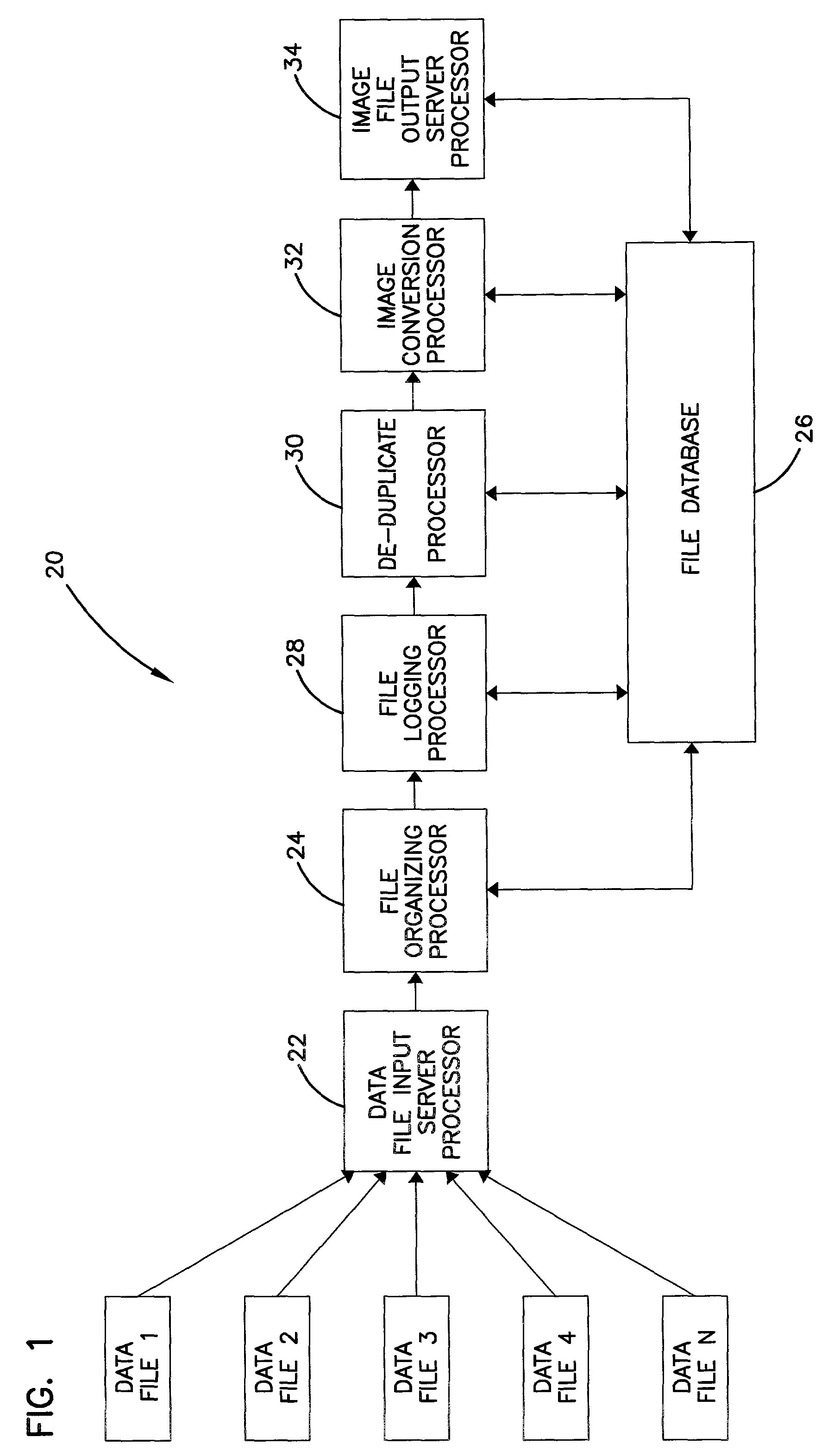

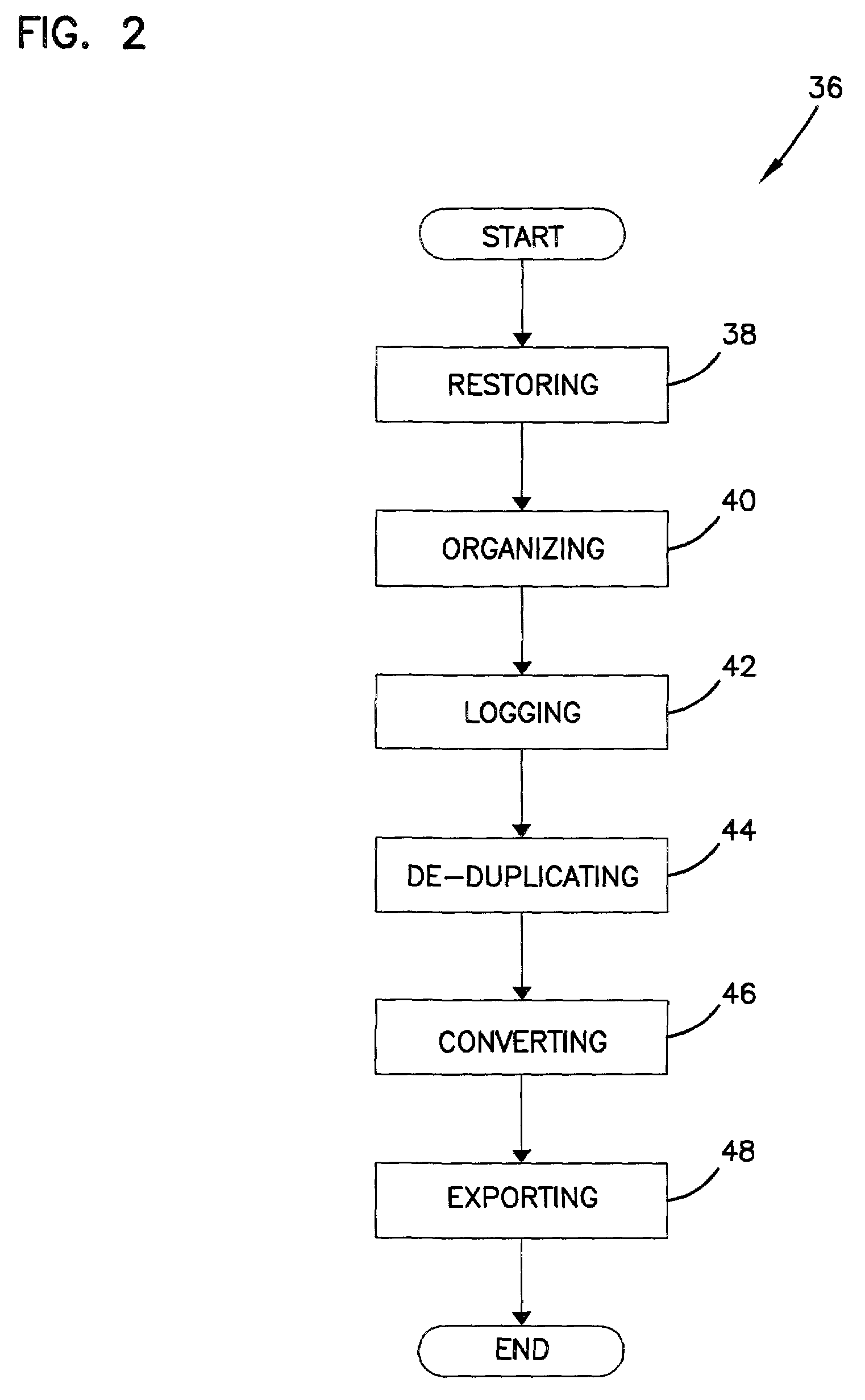

System and method for data management

InactiveUS7103602B2Exclude dataSmall sizeData processing applicationsSpecial data processing applicationsOperational systemData file

An automated data management system and method for logging, processing, and reporting a large volume of data having different file types, stored on different media, and / or run by different operating systems, includes a first server processor for restoring a plurality of received data files, the data files being capable of being different file types; a file organizing / categorizing processor for organizing the received data files, based on a predetermined user list, into a source directory structure and a destination directory structure; a file logging processor for logging the received data files into a database formed by the source and destination directory structures and identifying a file type of the received data files; a de-duplicate processor for calculating a SHA value of the received data files to determine whether the received data files have duplicates and flagging duplicated data files in the database; an image conversion processor for converting the remaining data files into image files, respectively; and a second server processor for exporting the image files.

Owner:KLDISCOVERY ONTRACK LLC

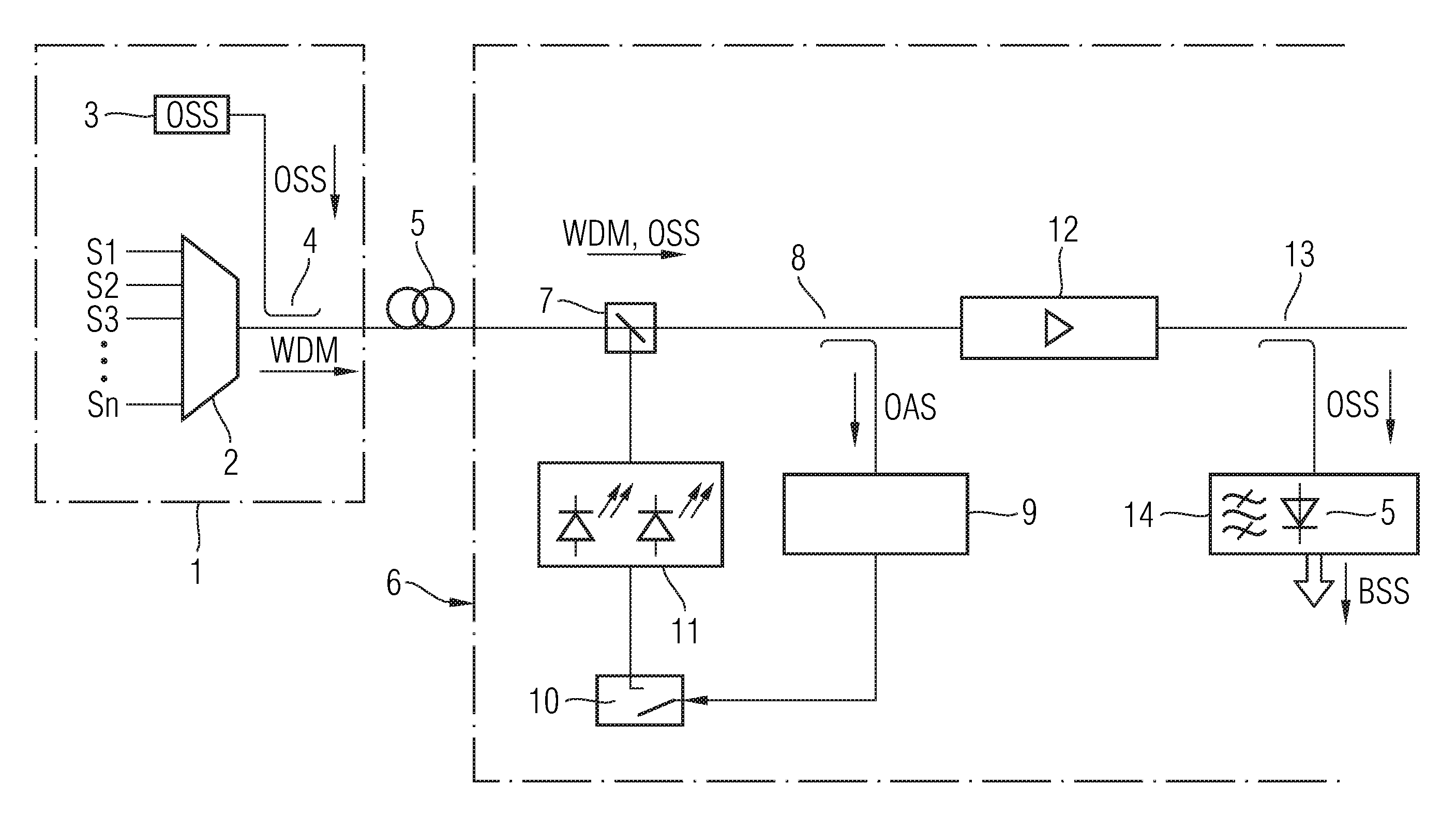

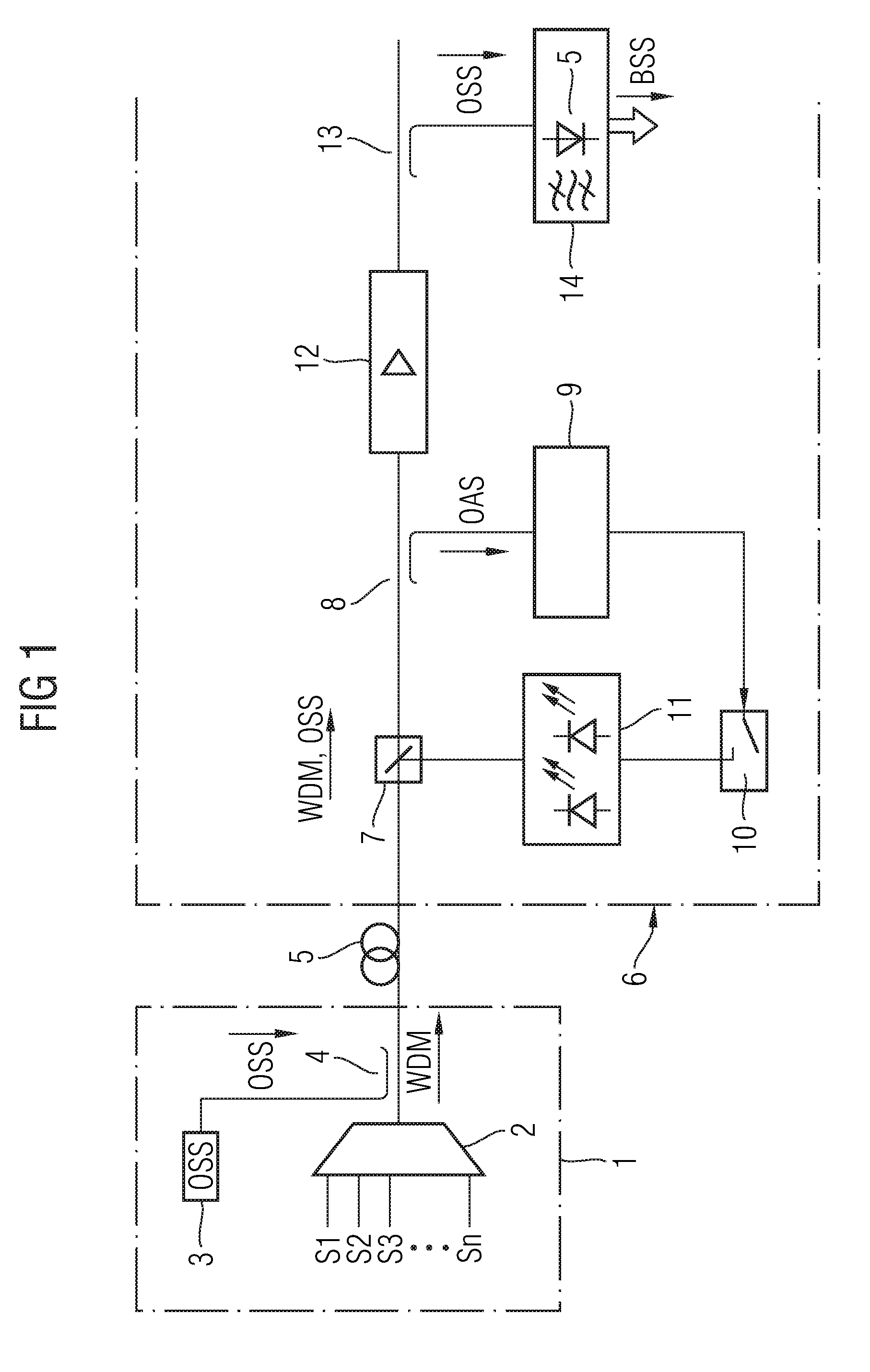

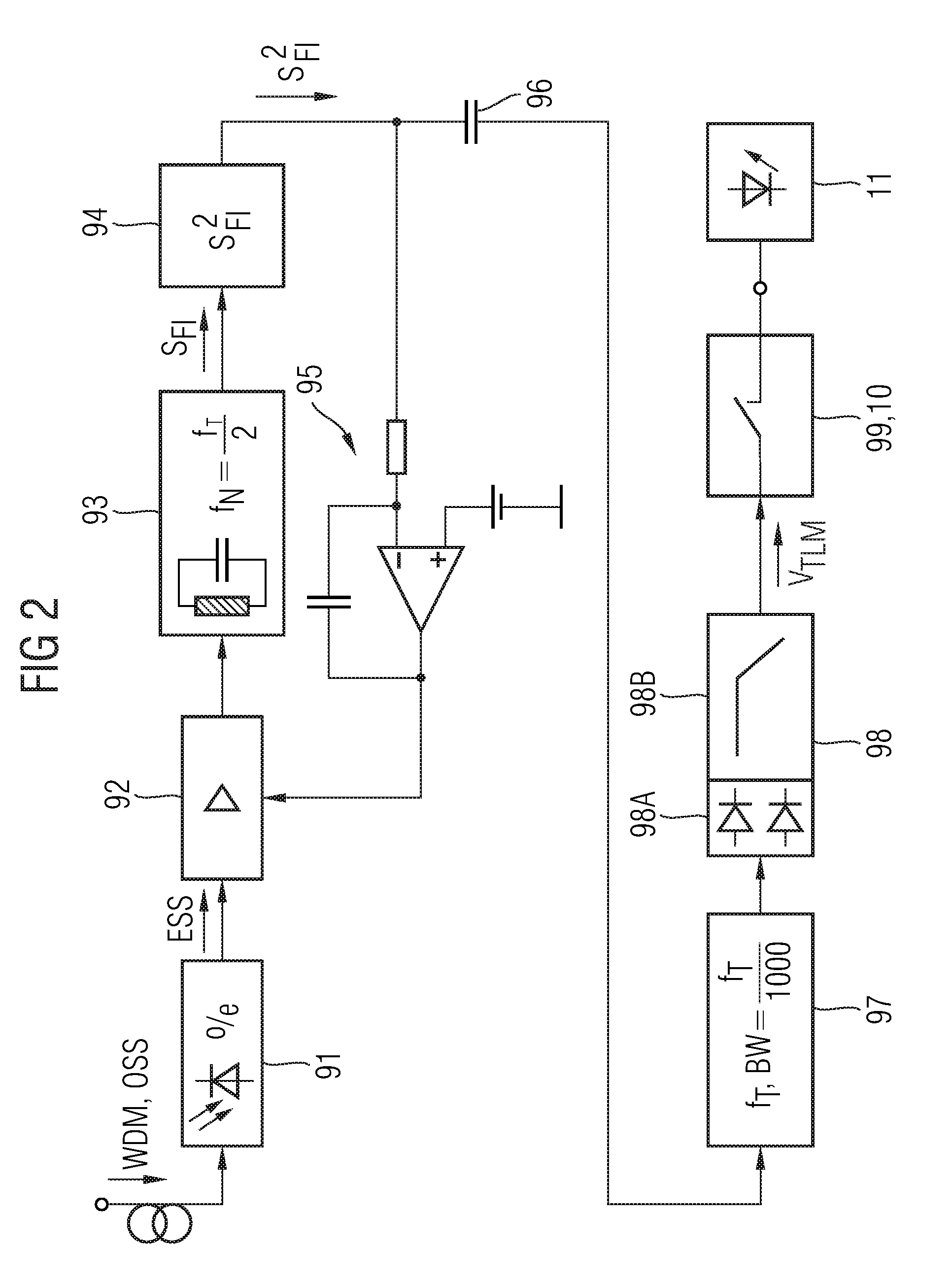

Method and arrangement for switching a Raman pump laser on and/or off

ActiveUS8301031B2Facilitate subsequent processingImprove the level ofElectromagnetic transmissionBandpass filteringClock rate

Owner:XIEON NETWORKS SARL

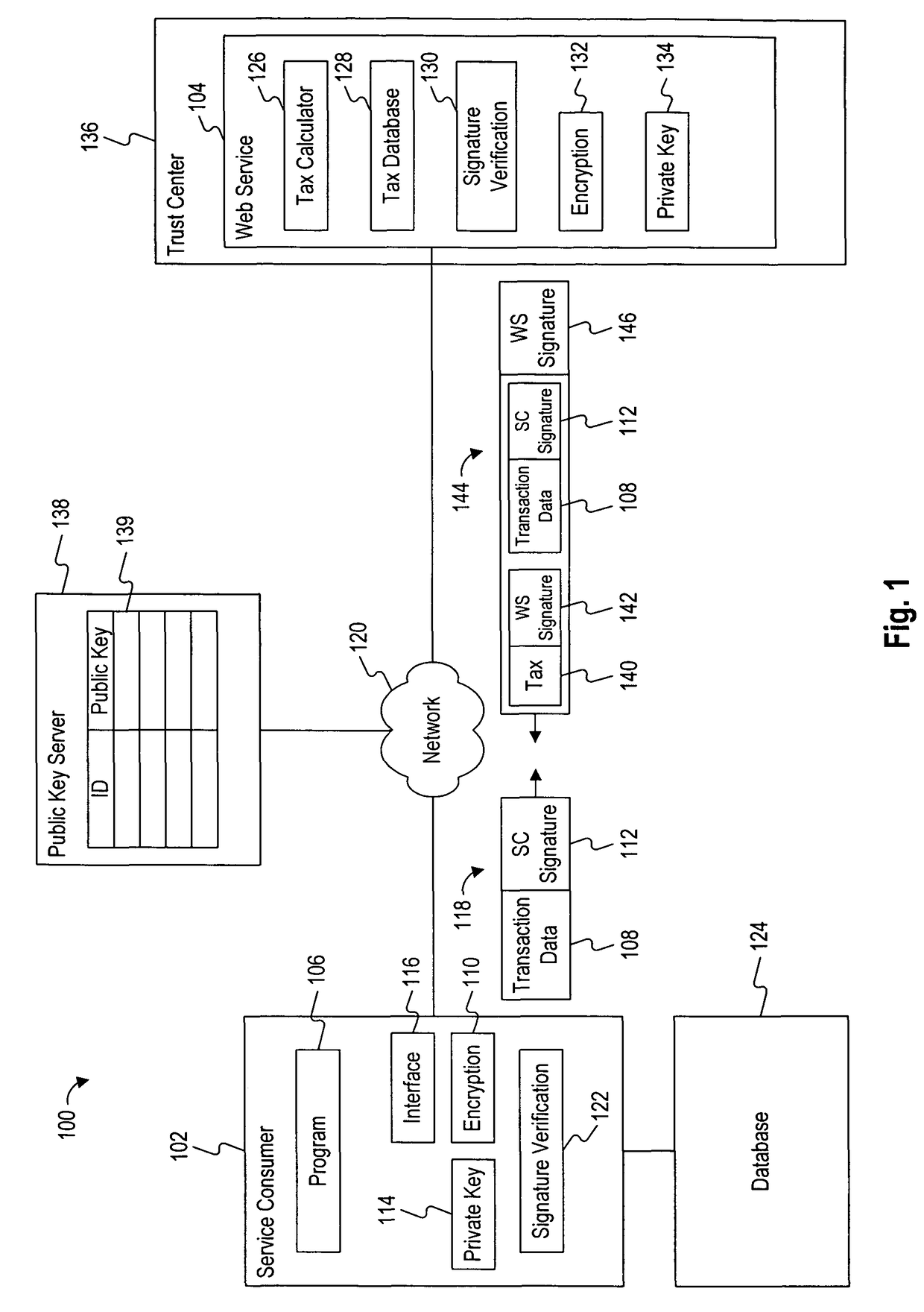

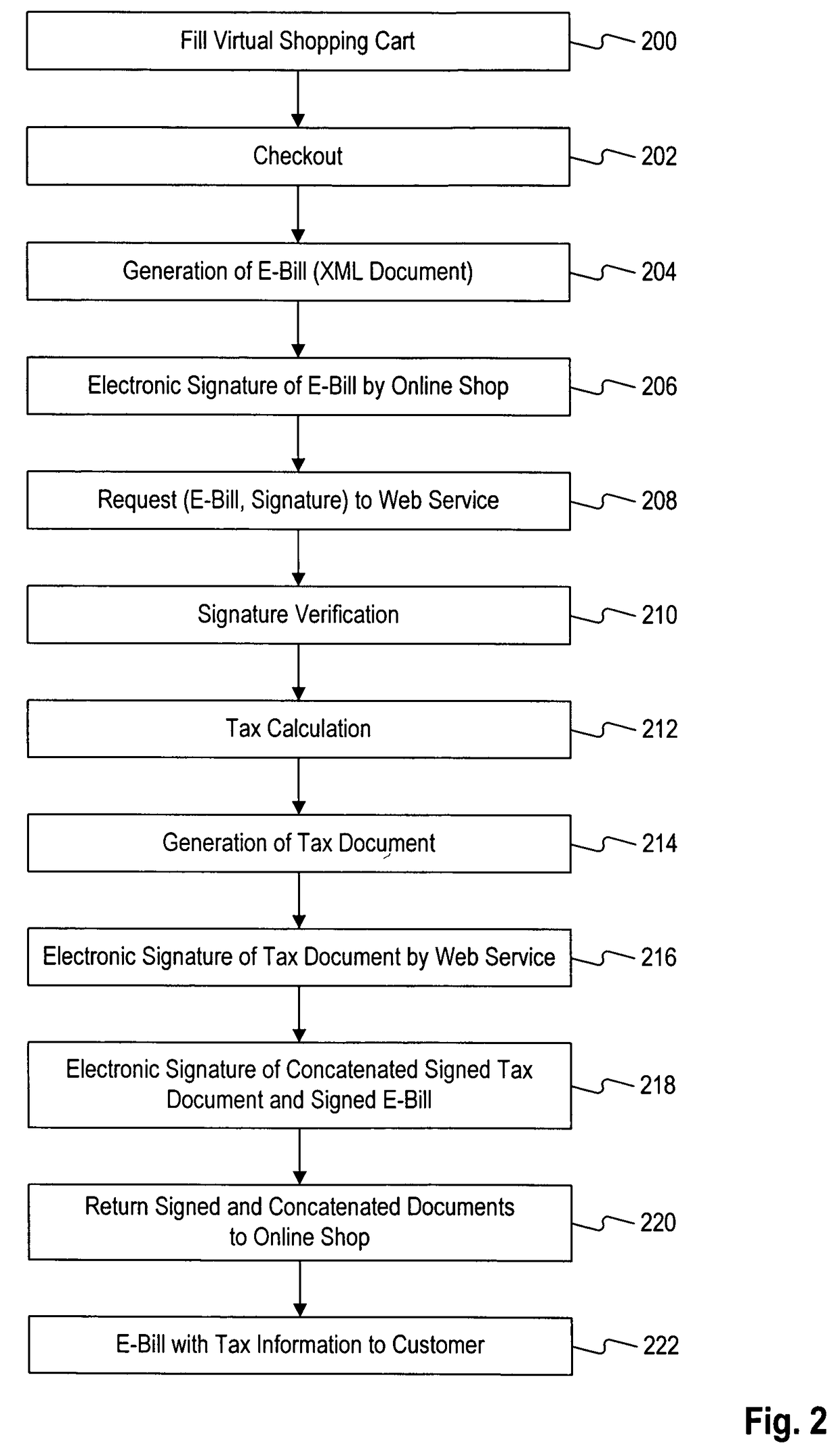

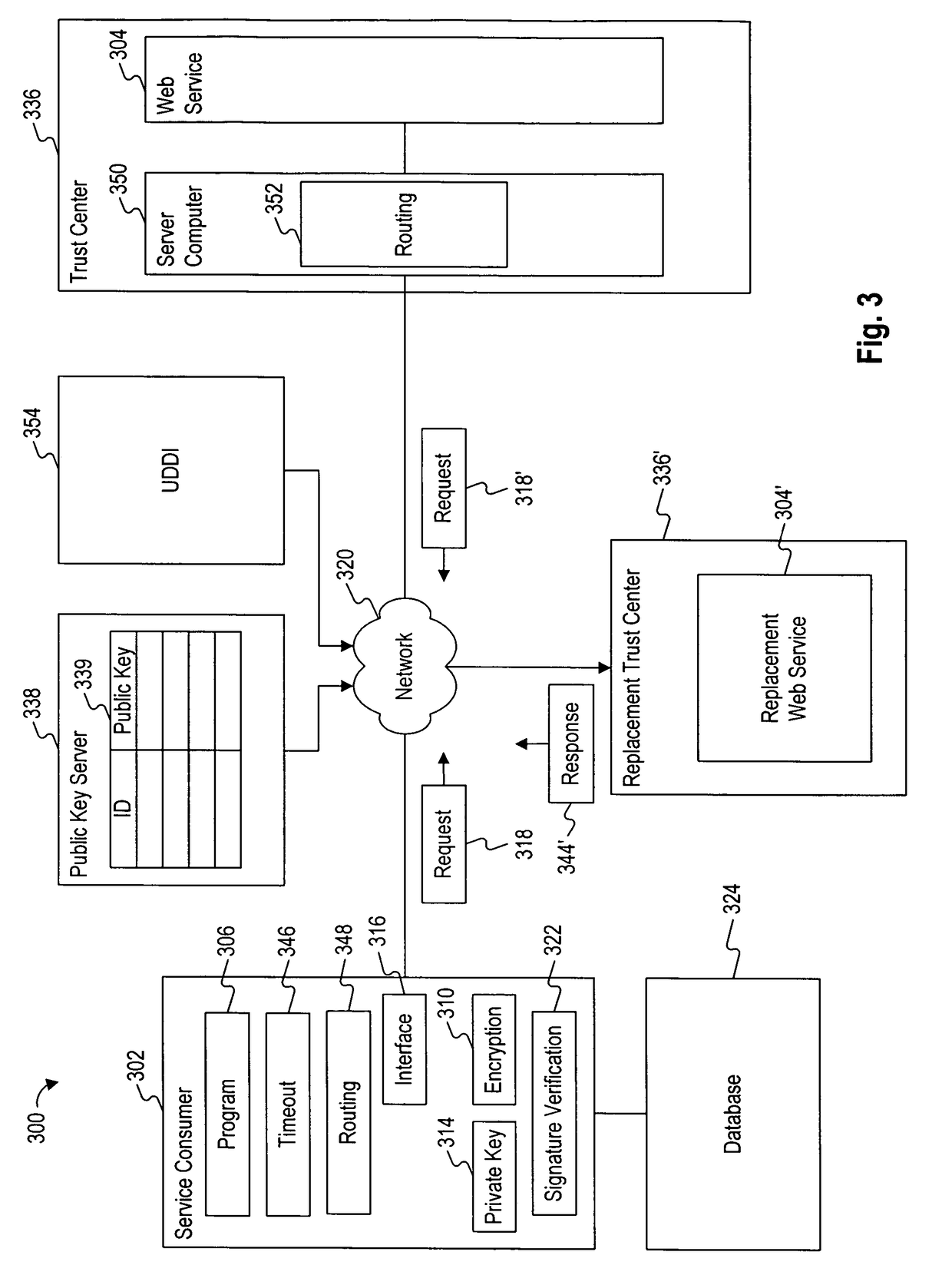

Systems and methods for applying tax legislation

ActiveUS7908190B2Facilitate subsequent processingComplete banking machinesFinanceTransaction dataDocumentation

Systems and methods are provided for applying tax legislation. In one implementation, a system is provided that includes means for receiving a request for performing a tax calculation, the request including a first mark-up language document containing transaction data. The system also includes means for performing the tax calculation and means for generating a response, wherein the response includes the first mark-up language document and a result of the tax calculation.

Owner:SAP AG

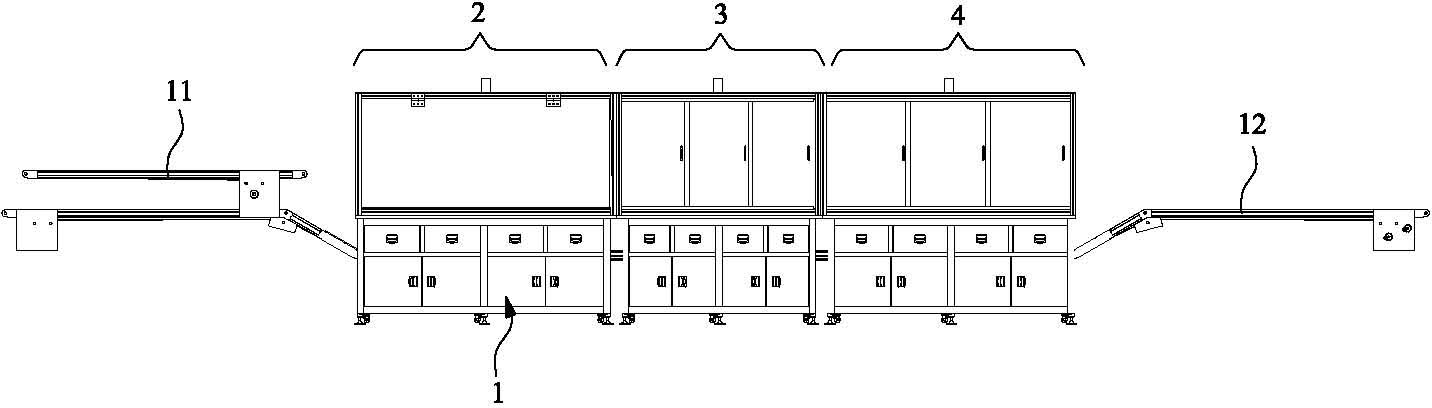

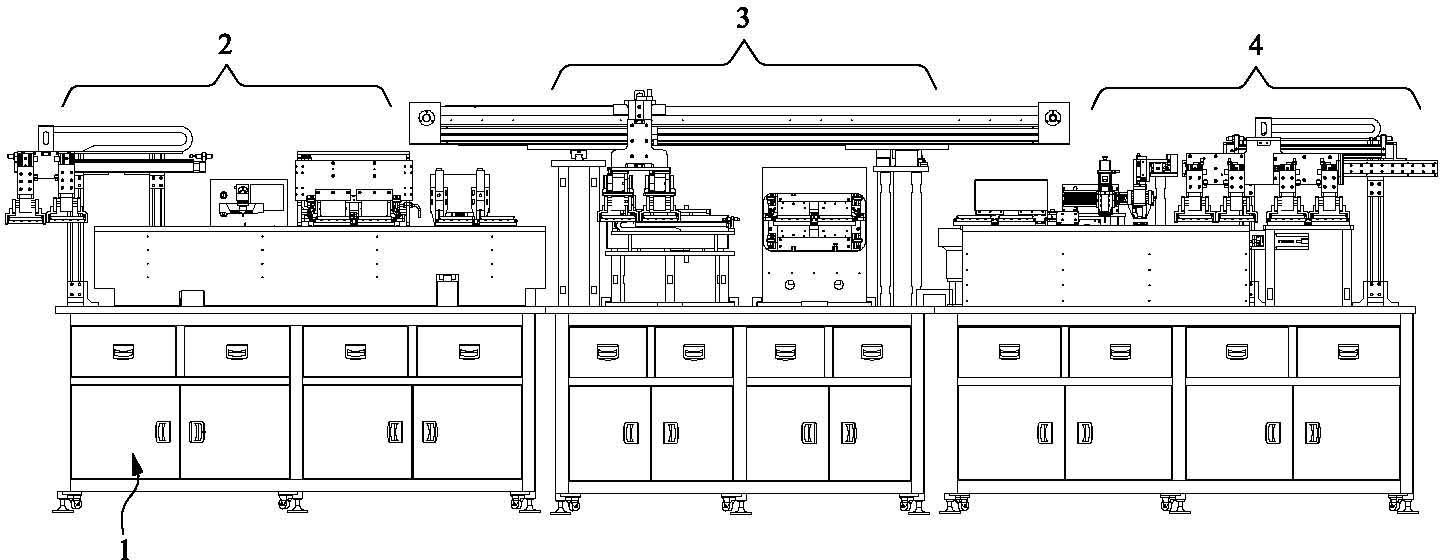

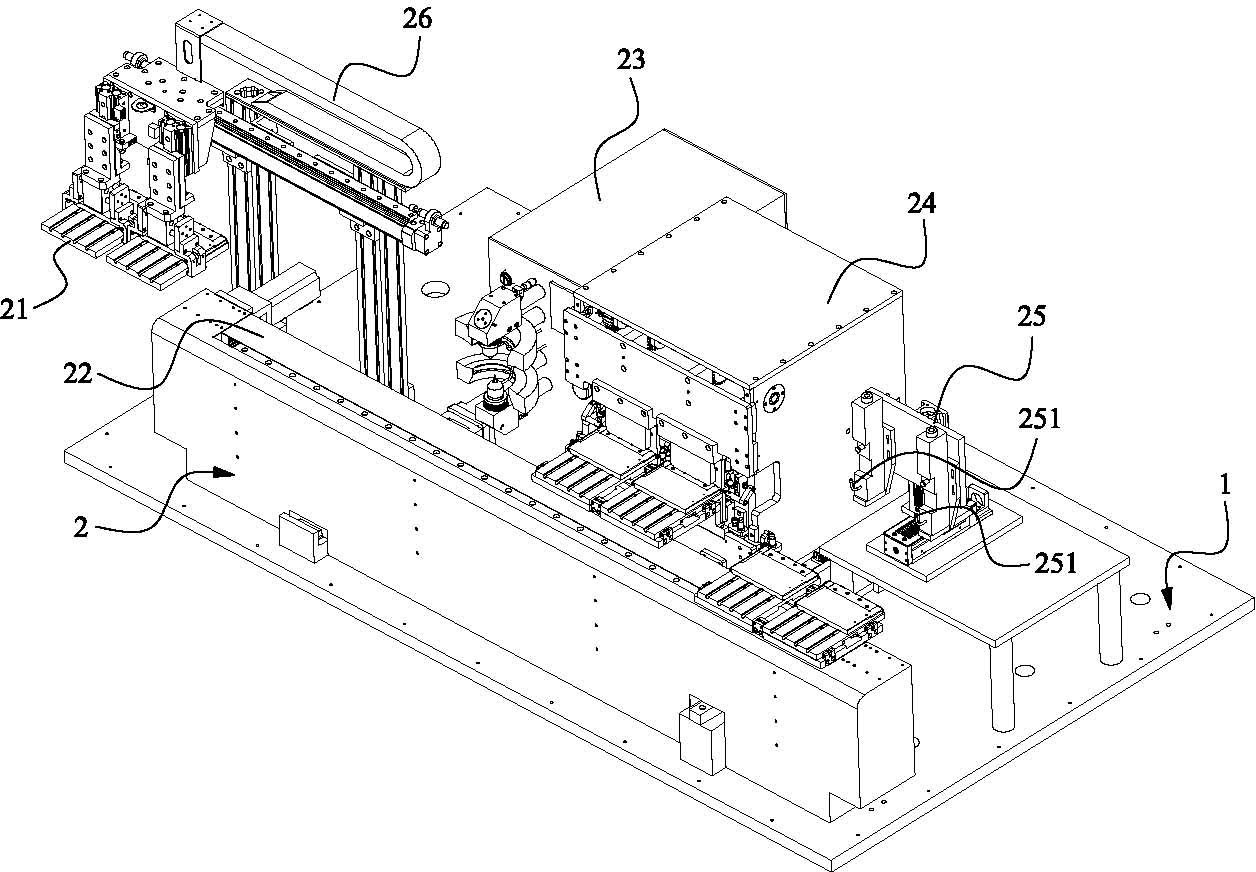

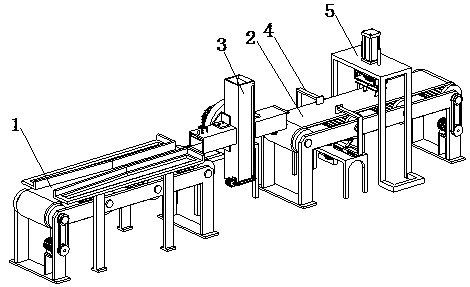

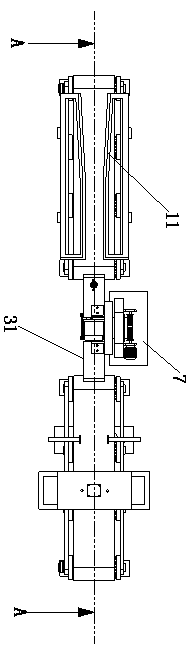

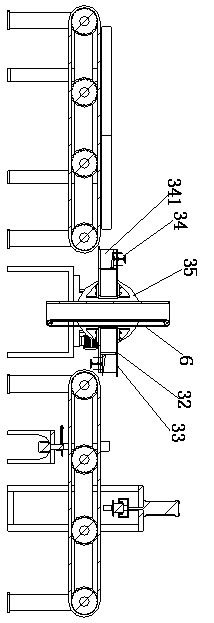

Automatic cable and connector processing, welding and assembling machine

InactiveCN102637988AEliminate weldsEliminate quality problemsLine/current collector detailsEconomic benefitsEngineering

The invention discloses an automatic cable and connector processing, welding and assembling machine, comprising a rack as well as a laser peeling module, an adhered tin trimming module and a plug welding module sequentially arranged on the rack, wherein the laser peeling module comprises a jig, a first transmission device, a laser device, a peeling device and a flux spraying device; the adhered tin trimming module comprises a clamping-jaw feeding device, a tin pot and a trimming device; and the plug welding module comprises a soldering device, a plugging device, a welding device and a clamping-jaw laying-off device. Therefore, the automatic machining on a cable is finished by virtue of the laser peeling module and the adhered tin trimming module, the laser peeling module, the adhered tin trimming module and the plug welding module are matched to weld and connect a connector and the cable together, and a core wire of the cable is kept to be straight in processes of processing and welding the core wire, so that the quality problems of insufficient soldering, leaving out of welding, short circuit and the like during the connection between the cable and the connector are eliminated, and the unmanned automatic processing, welding and assembling procedures are realized to effectively improve the production efficiency of products and to bring more economic benefits to enterprises.

Owner:DONGGUAN SANXIN PRECISION MACHINERY

Composite wear-resisting shoe sole

A composite wear-resisting shoe sole is prepared from, by weight, 60-100 parts of natural rubber, 10-50 parts of styrene butadiene rubber, 5-20 parts of polar rubber, 10-60 parts of modified white carbon black, 1-10 parts of zinc oxide, 1-4 parts of accelerant, 0.1-0.5 part of antioxidant, 2.5-4.5 parts of active agent, 5-20 parts of filler and 1-10 parts of sulfur .The filler is tetrapod-like zinc oxide whiskers .According to the composite wear-resisting shoe sole, the natural rubber and a small amount of polar rubber are jointly used as main rubber materials, the white carbon black subjected to toluene diisocyanate graft modification is added to serve as a reinforcing material, the tetrapod-like zinc oxide whiskers of a highly regular structure are used as a filling frame, the accelerant, the composite antioxidant and the active agent are added in sequence, and the composite wear-resisting shoe sole with high slippery resistance and tear strength and a remarkably improved frictional coefficient is prepared.

Owner:宁波市富罗迷鞋业有限公司

Half-dry rice noodle and preparation method thereof

ActiveCN105410624AMuscular strengthGood elasticityFood ingredient as mouthfeel improving agentLoss ratePowder mixture

The invention discloses a half-dry rice noodle and a preparation method thereof. The half-dry rice noodle comprises the following raw materials: rice, a starch mixture, a fresh fruit and vegetable paste mixture and a fruit and vegetable powder mixture and is prepared by the following steps of fermentation and preprocessing of the rice, mixing of all raw materials, twin-screw extrusion forming, aging, re-steaming, washing and cutting oof noodles, measuring and packing, post-sterilization, cooling and the like. The half-dry rice noodle prepared by the invention has the advantages of smooth and bright appearance, strong gluten power, good elasticity, natural flavor, long shelf time, clear finished product soup and the like, the breaking rate is controlled to be lower than 2%, and the loss rate of cooking is controlled to be lower than 4%. According to the half-dry rice noodle and the preparation method thereof, the problem of the existing rice noodle of single nutrition is solved; the ingredients rich in protein and vitamins are added in the formula, so that the product has comprehensive nutrients; in addition, any preservative, brightening agent and thickening agent are not added in the product, so that the product prepared by the preparation method has excellent taste and is nutrient and healthy.

Owner:GAEA GEM RICE

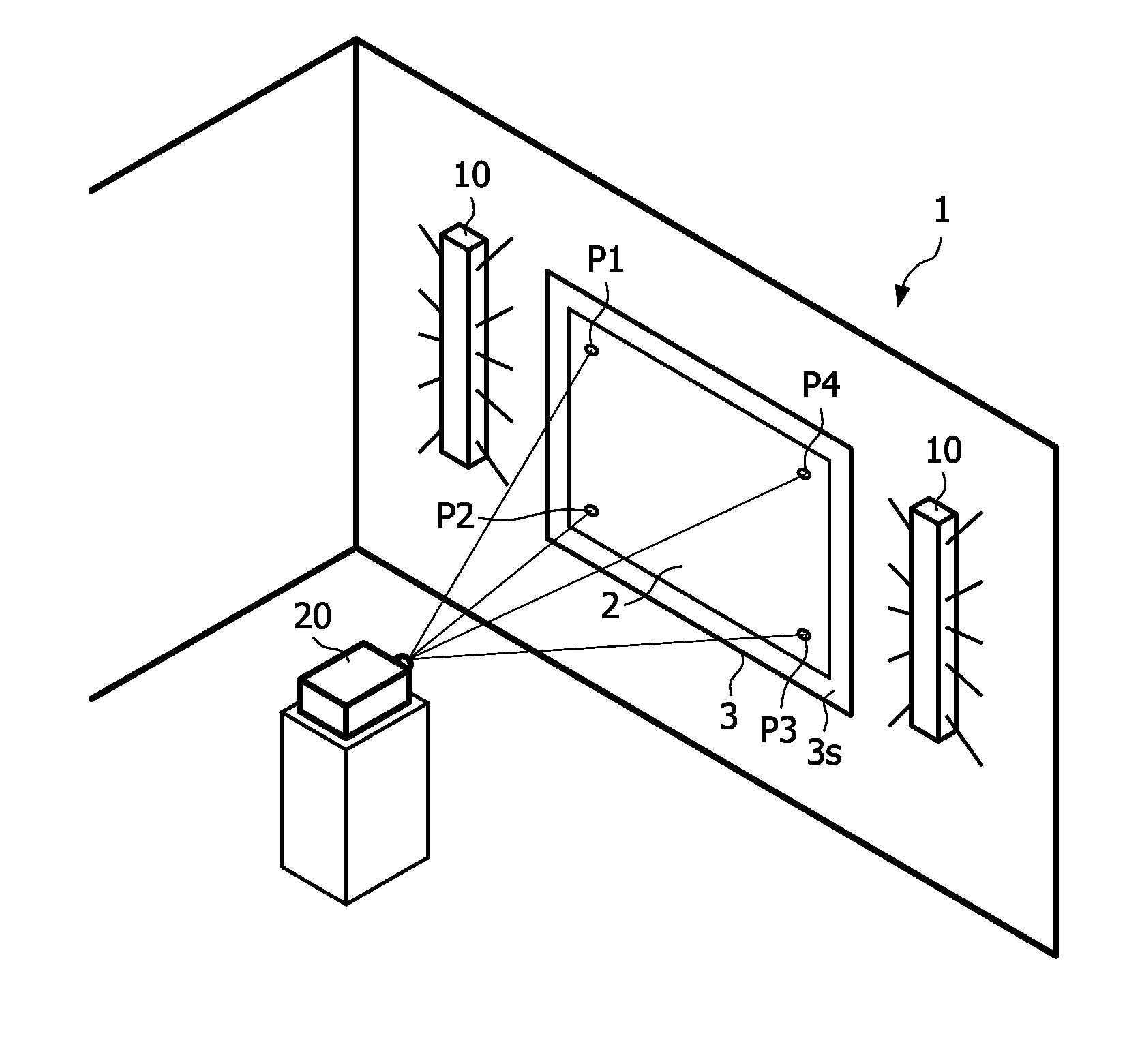

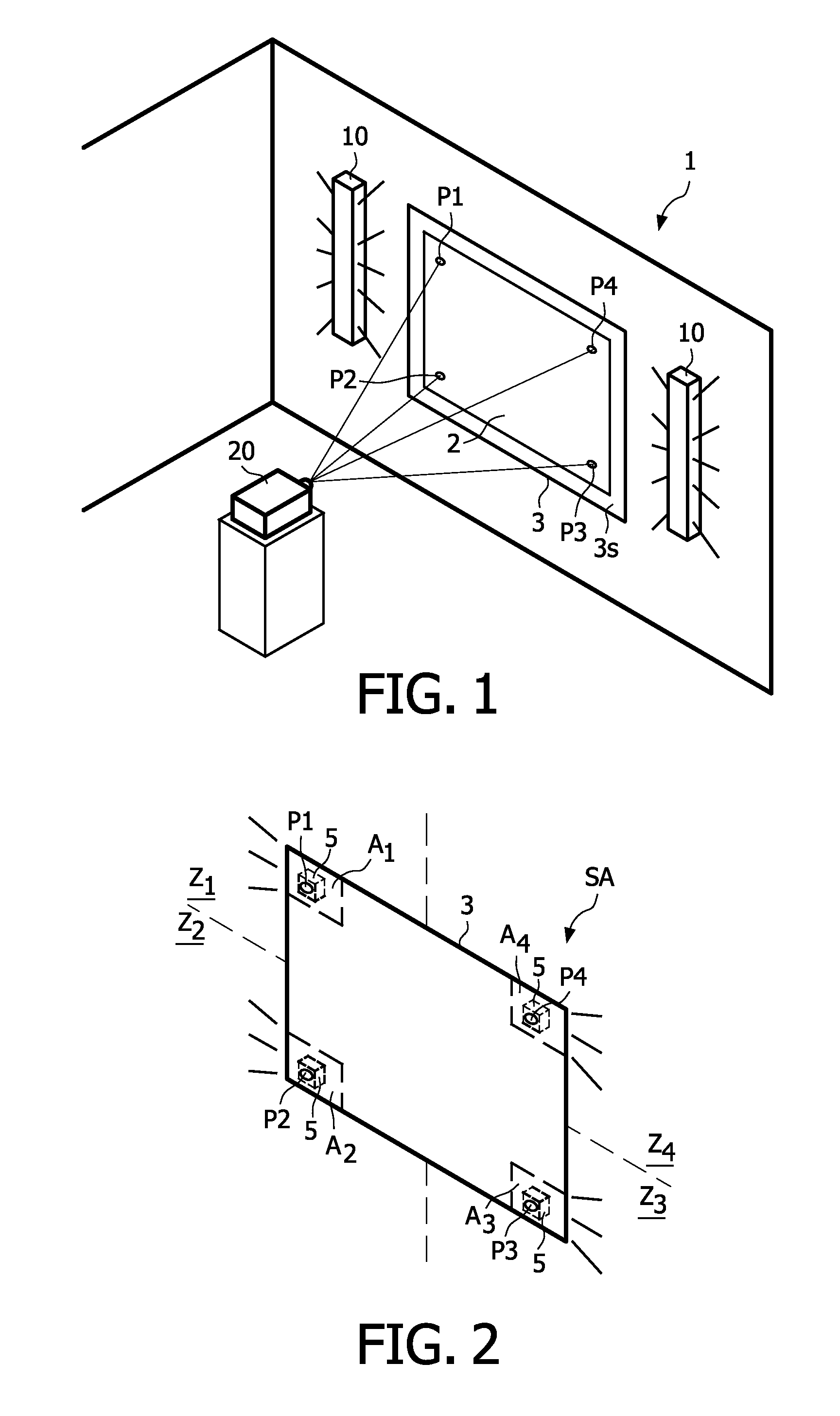

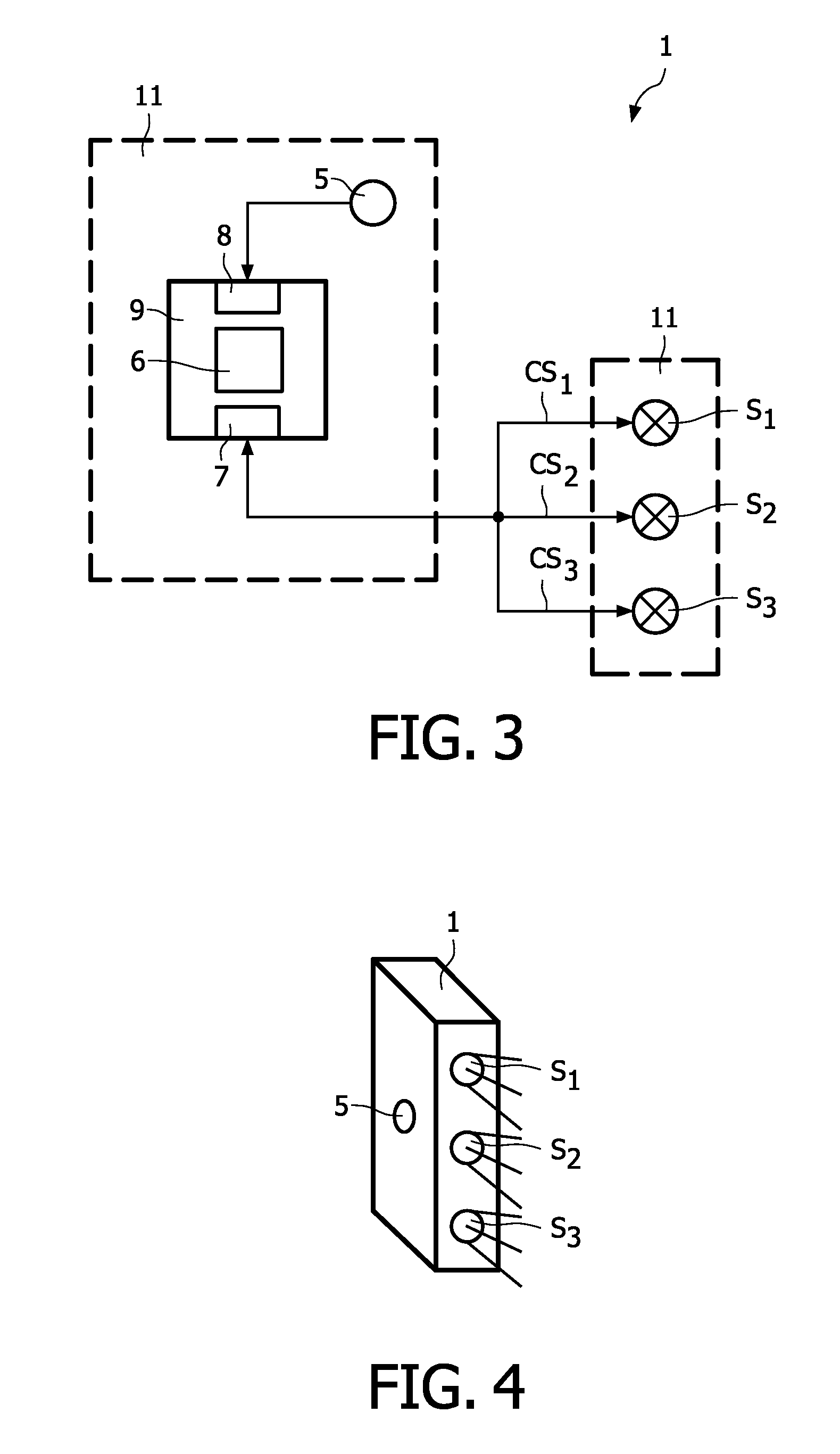

Method of controlling the lighting of a room in accordance with an image projected onto a projection surface

InactiveUS8690362B2Facilitate subsequent processingSimple control unitTelevision system detailsPhotometry using reference valueProjection screenEffect light

The invention describes a method of controlling a lighting of a room (1) in accordance with a still or moving image (2) projected onto a projection surface (3s), which method comprises optically measuring a number of characteristic features (f) of the projected image and adjusting the room lighting of the room on the basis of the measured characteristic features (f). Furthermore, the invention relates to a system for controlling the lighting of a room (1) in accordance with an image (2) projected onto a projection surface (3s), to a control device (9) for use in such a system, and to a projection screen device (3) for use in such a system. Moreover, the invention relates to a room lighting system (1) for lighting of a room in accordance with an image (2) projected onto a projection surface (3s).

Owner:KONINK PHILIPS ELECTRONICS NV +1

Efficient ore pulverizing device

The invention discloses a high-efficiency ore crushing device, which comprises a base. Support plates are arranged on the left and right sides of the base. A top plate is arranged on the top of the support plate. A crushing box is connected to the bottom of the top plate through a bracket. The limit rod is slidingly connected in the position sleeve. The top of the limit rod is connected to the top of the crushing box through a tension spring. The bottom of the limit rod is fixedly connected with a lifting plate. A pressing plate is also provided, and several through holes are evenly arranged on the pressing plate. A crankshaft cooperating with the lifting plate is arranged on the top of the crushing box, and the right end of the crankshaft passes through the right side wall of the crushing box and a second pulley is installed. The invention rotates the crankshaft so that the crushing plate moves downward to perform preliminary crushing of the ore. During the crushing, the ore is initially screened, the smaller particles fall through the through hole of the pressing plate, and the larger ore continues to be crushed. The crushing effect is good and the crushing efficiency is high.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

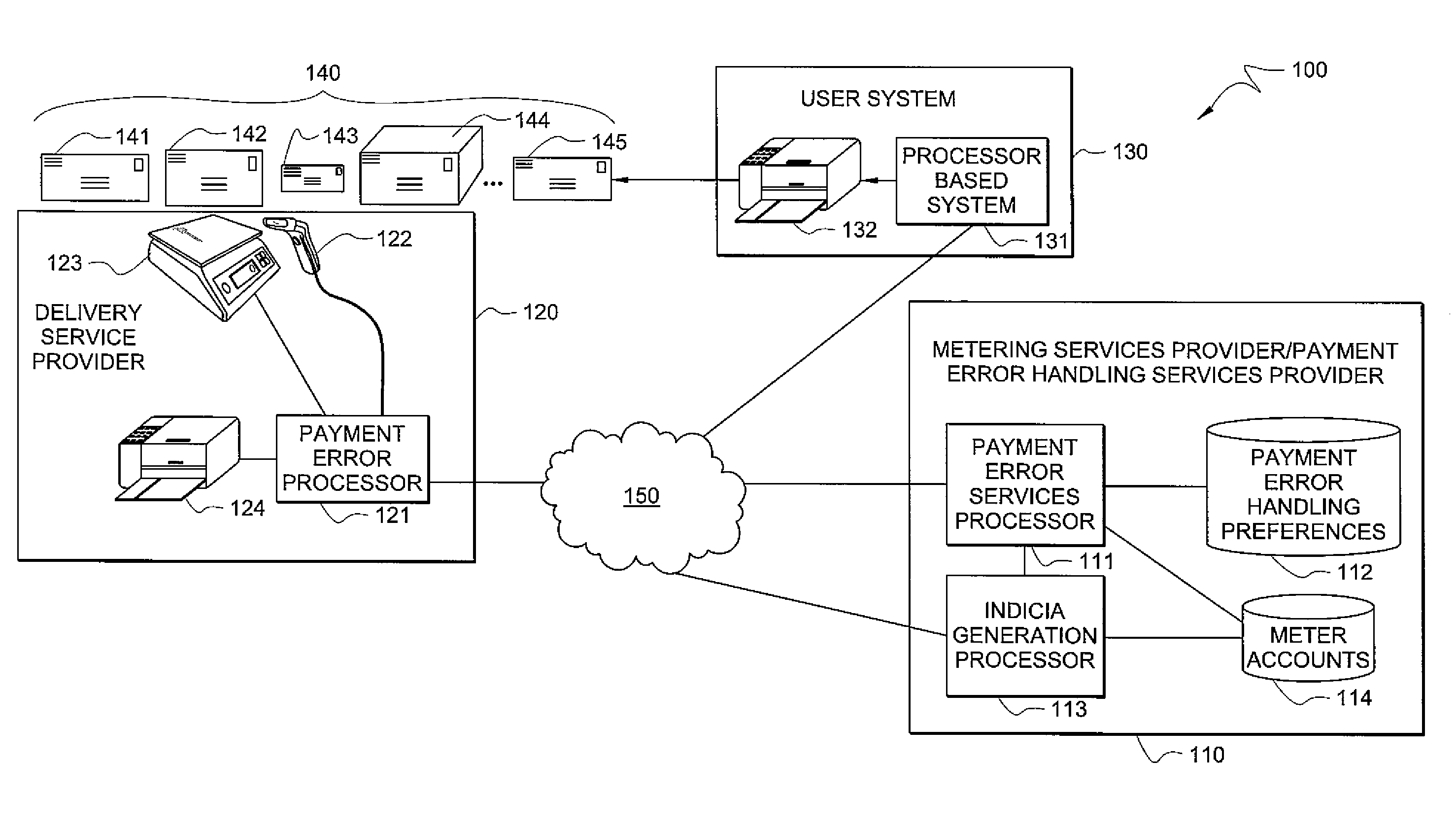

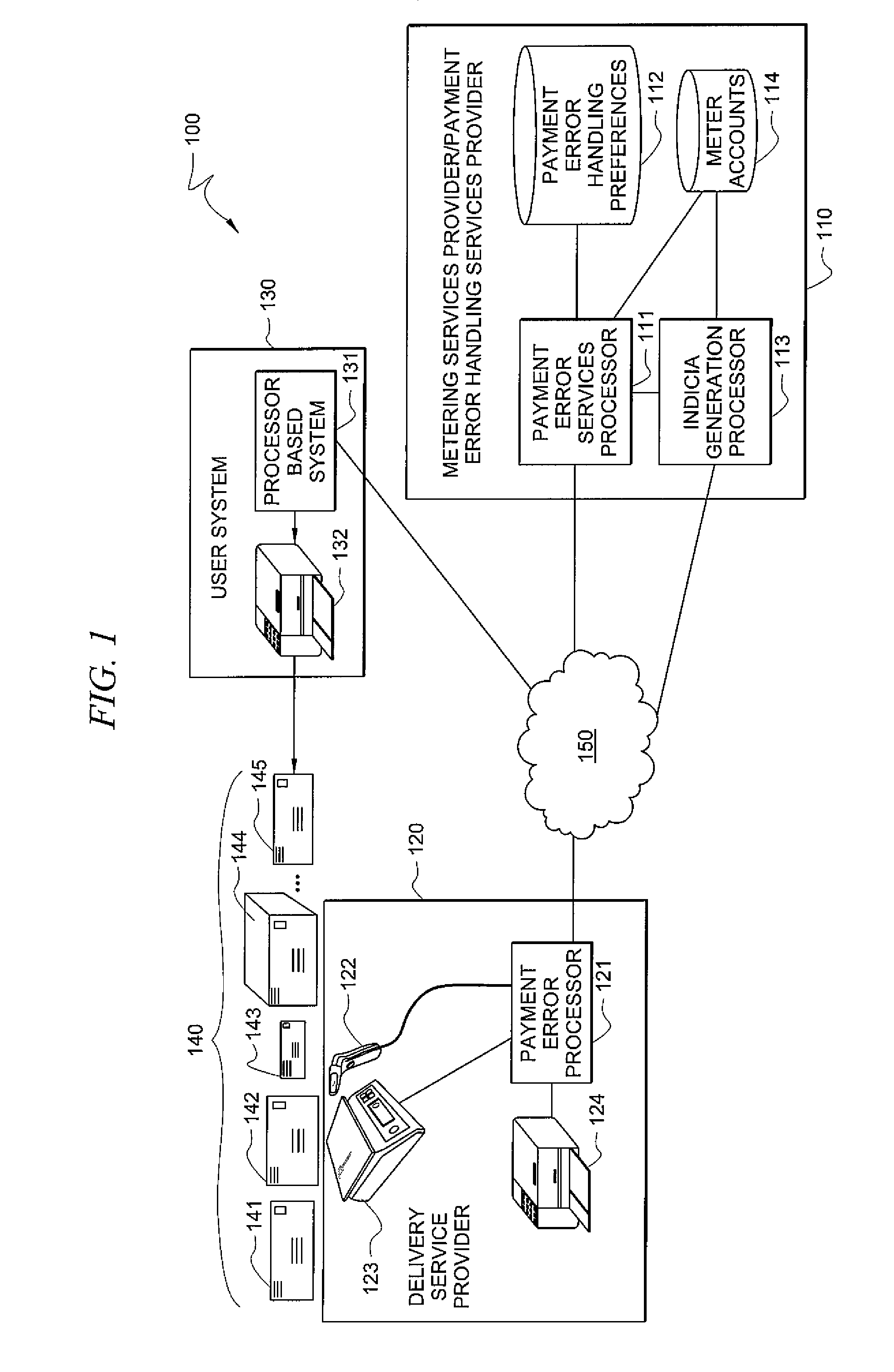

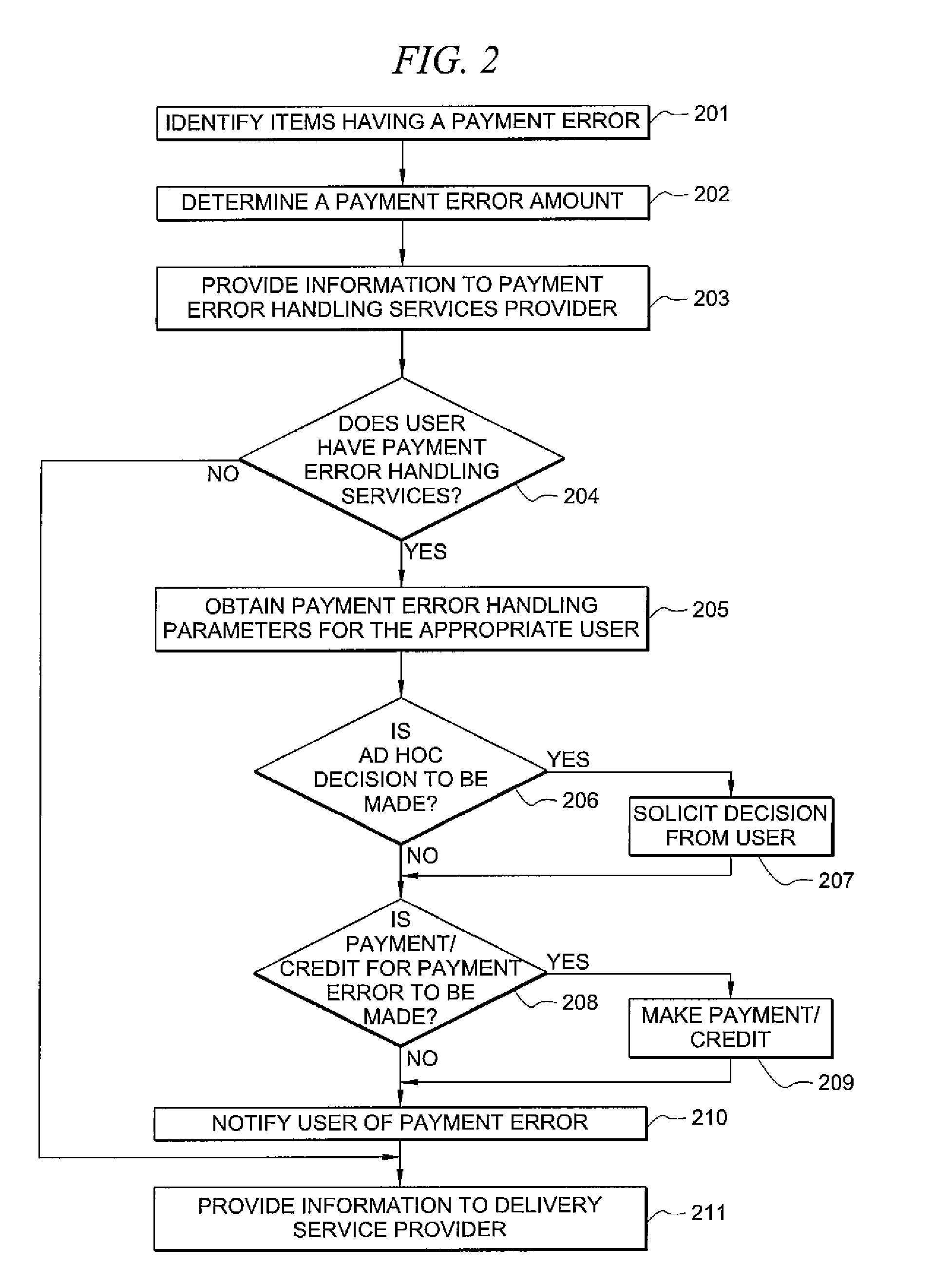

System and method for handling payment errors with respect to delivery services

ActiveUS8612361B1Facilitate subsequent processingDelay in delivery of the itemPayment architectureFranking apparatusPaymentService user

Systems and methods which provide processing of payment errors with respect to delivery services in accordance with user preferences are disclosed herein. According to embodiments, a delivery service user provides information with respect to how payment errors with respect to delivery services provided to the user are to be handled to facilitate electronic and / or automated processing of such payment errors. A user may authorize payment shortages on the user's behalf, may request notification for an ad hoc determination as to how the shortage is to be handled, or may elect to have postal items returned in the case of payment shortage. Various levels of payment error handling services may be provided with respect to users. Detailed information, such as statistics with respect to users' payment errors, the numbers and types of payment errors, user's preferences in handling payment errors, etcetera, may be provided.

Owner:AUCTANE INC

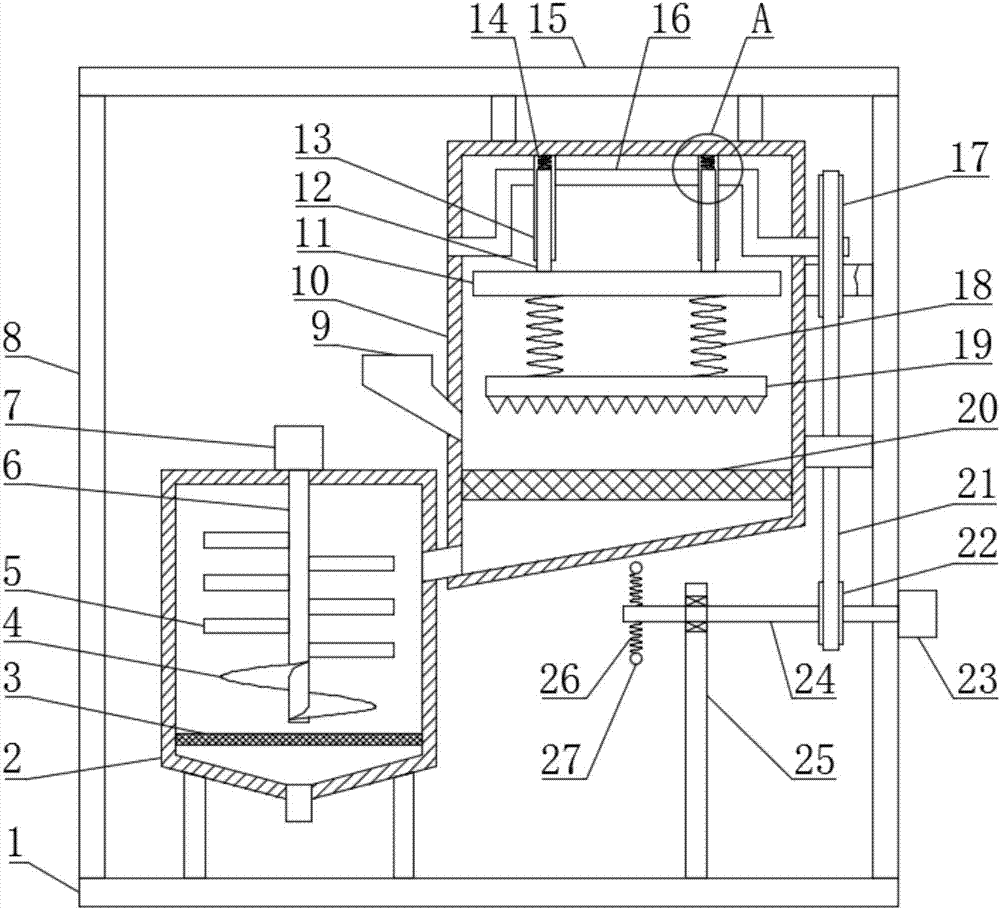

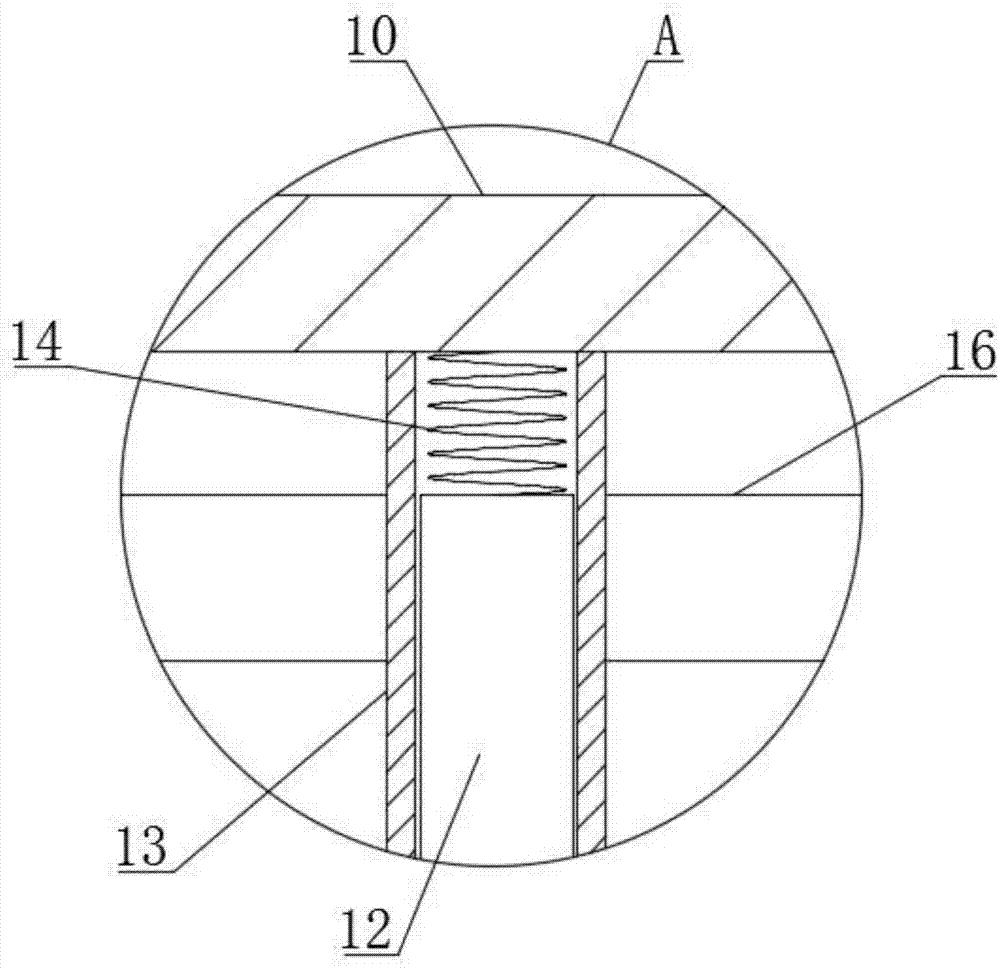

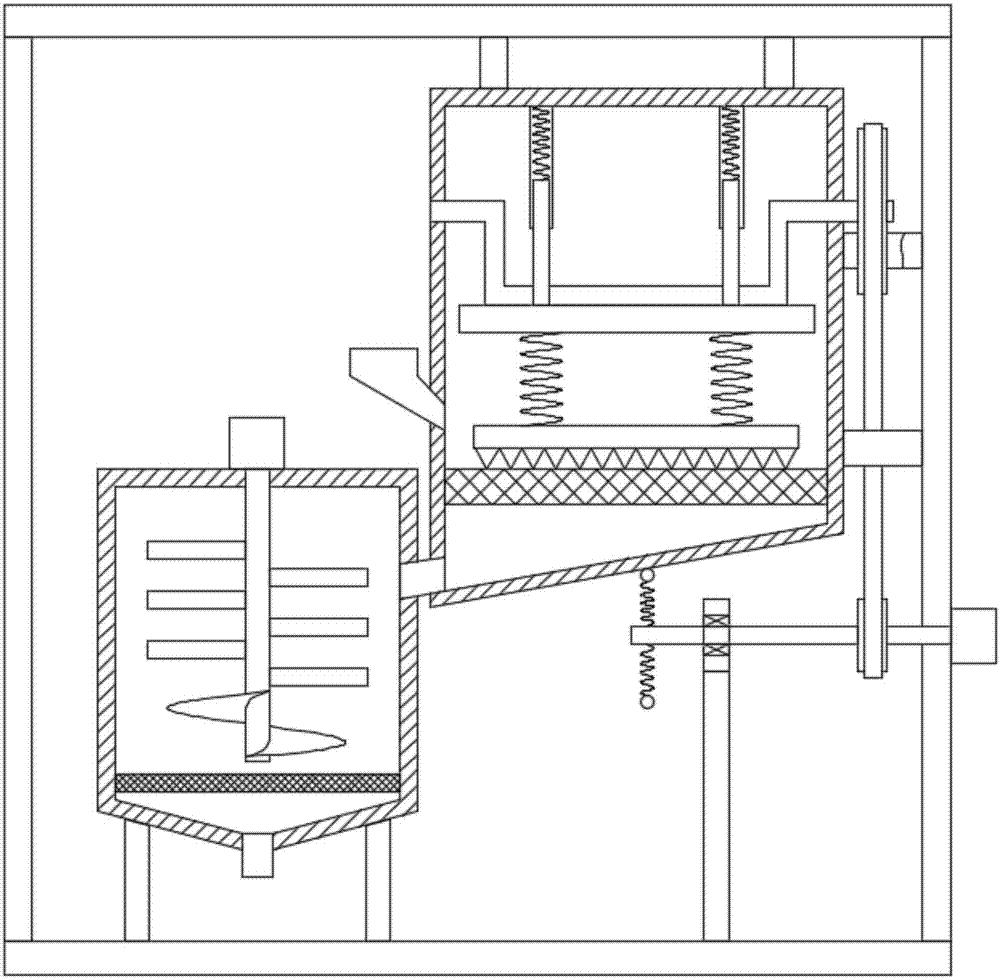

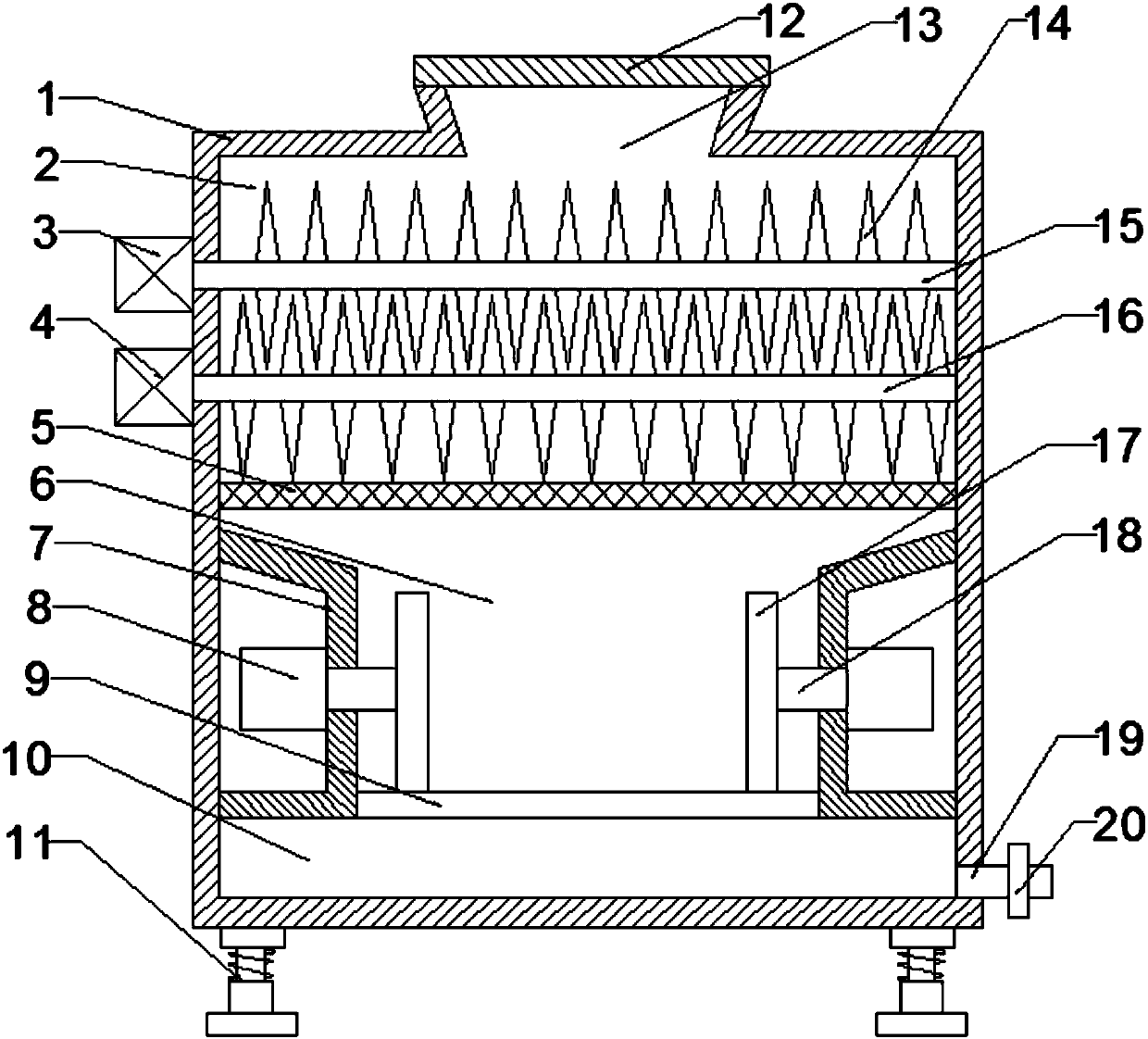

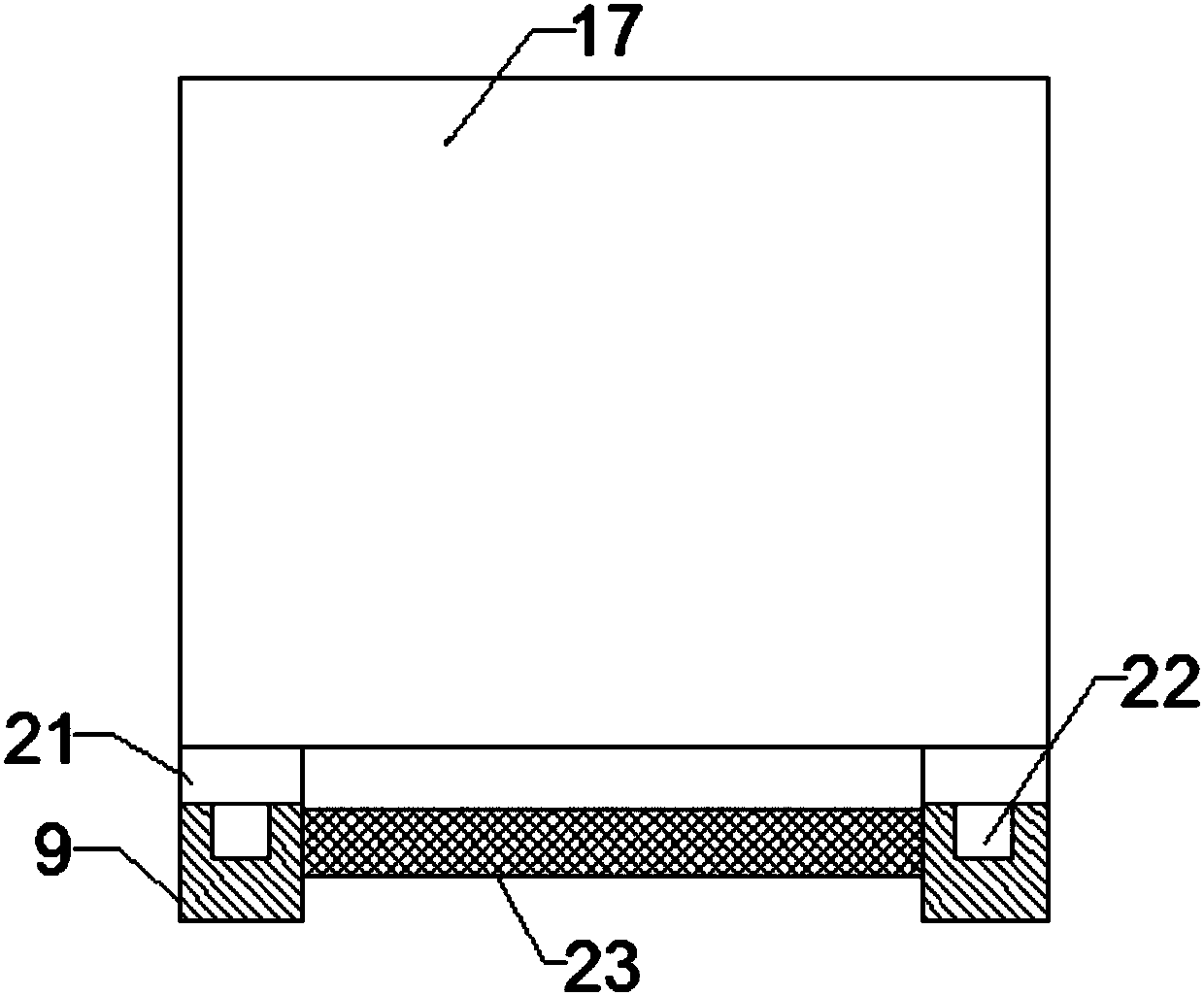

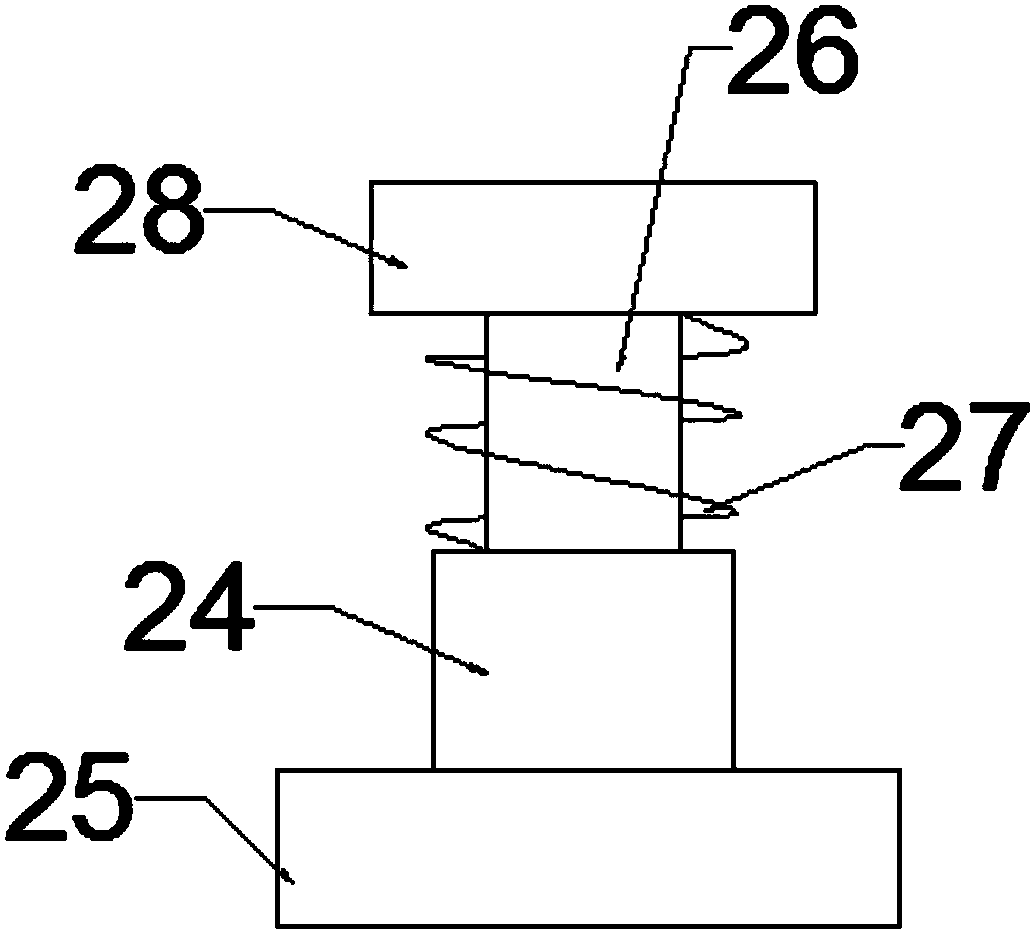

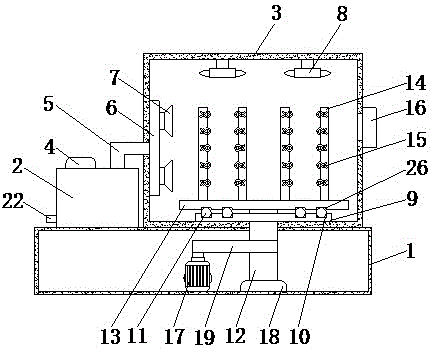

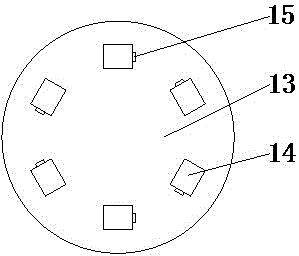

Medical garbage smashing and extrusion-forming device

InactiveCN107552537ASqueeze fullyFast crushingSolid waste disposalGrain treatmentsElectric machineryLiquid storage tank

The invention discloses a medical garbage smashing and extrusion-forming device and belongs to the technical field of medical garbage treatment. The medical garbage smashing and extrusion-forming device comprises a box body. A smashing cavity, an extruding cavity and a liquid storage tank are formed inside the box body; a feeding hopper is arranged at the bottom of the box body and communicates with the smashing cavity; a cover plate is arranged on the top of the feeding hopper through a hinge; smashing blades, a first rotating shaft and a second rotating shaft are arranged in the smashing cavity; the first rotating shaft is horizontally arranged on the upper side of the smashing cavity, and the left end of the first rotating shaft is connected with an output shaft of a first motor; and the second rotating shaft is horizontally arranged below the first rotating shaft, and the left end of the second rotating shaft is connected with an output shaft of a second motor. The structural design is reasonable, an arranged double-smashing device can smash medical garbage thoroughly, and the smashing efficiency is high; and arranged extruding plates fully extrude the medical garbage, so thatthe garbage is flattened, and subsequent machining can be conveniently conducted.

Owner:郑州莉迪亚医药科技有限公司

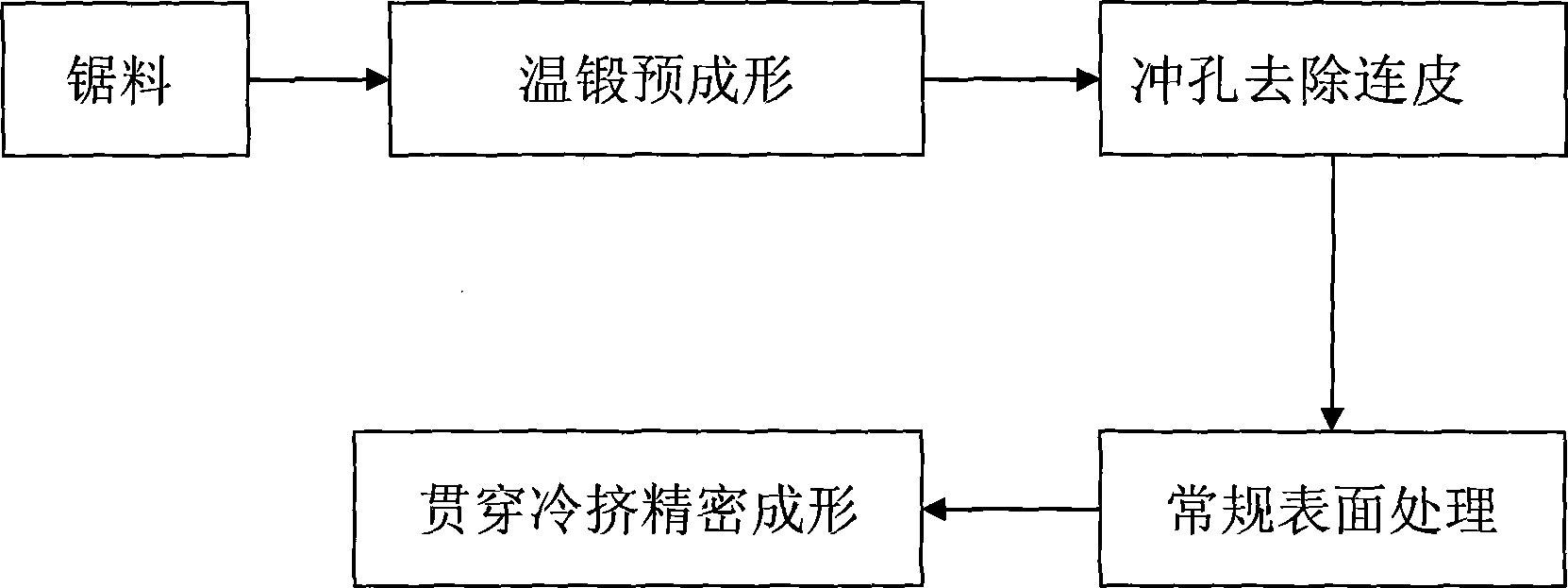

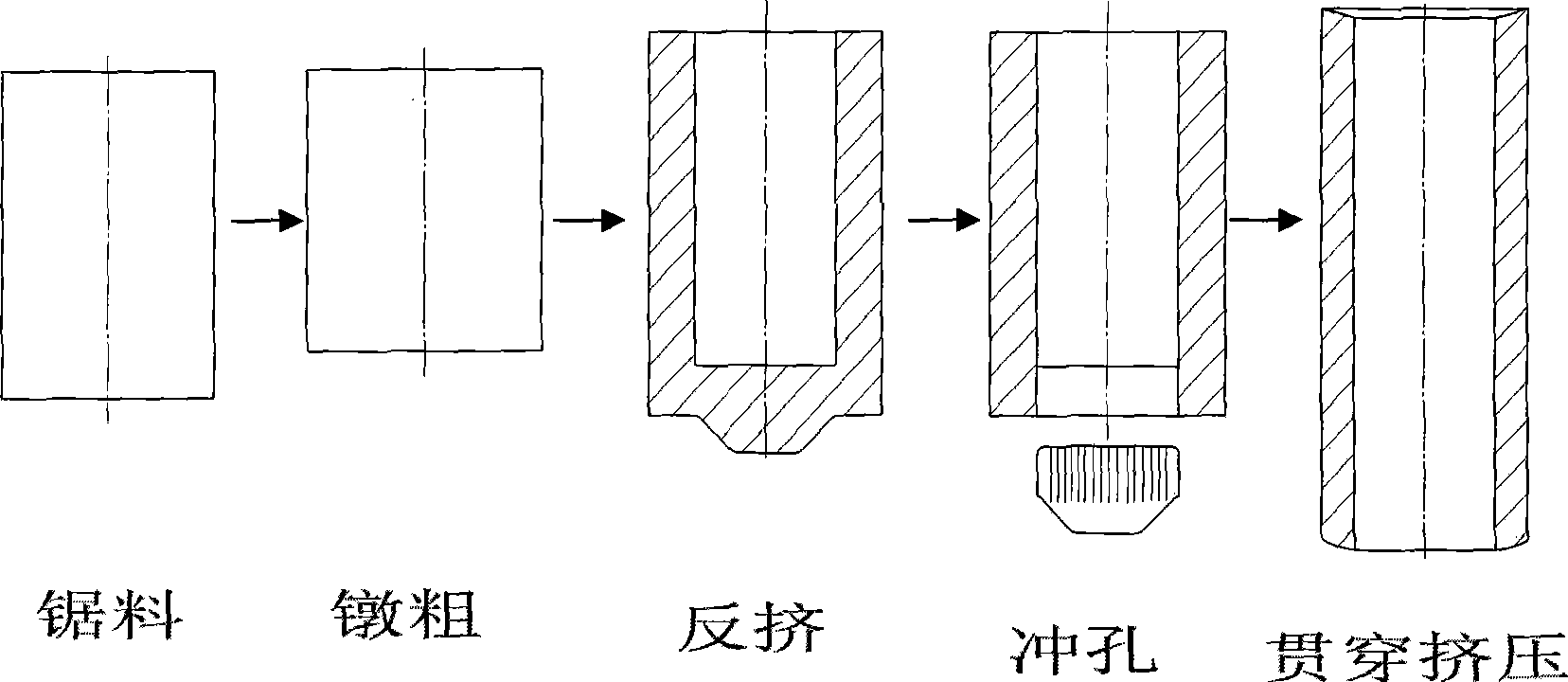

Processing method of deep-hole pin bush parts

InactiveCN101391368ASolve the problem of difficult cold forgingIncrease profitMetal-working apparatusBiochemical engineeringUltimate tensile strength

The invention provides a deep-hole pin bush parts processing method, relating to a metal plasticity modeling technology and belonging to a precise cold warm-forging modeling technology field of the deep-hole pin bush parts. The process step at least includes: 1, cutting materials; 2, warm-forging the material to form a cylinder shape; 3, punching and removing the connected skin of one end of the cylinder blank; 4, processing the surface conventionally; 5, accurately forming the shape by cold extrusion through a run-through extrusion process and finally obtaining a product which suffices the structural performance and the size accuracy requirements. The method has the advantages of a high utilization rate, easy processing, and capability of meeting mass production requirements, and the produced product has a perfect metal streamline and high fatigue resistance.

Owner:JIANGSU SUNWAY PRECISION FORGING

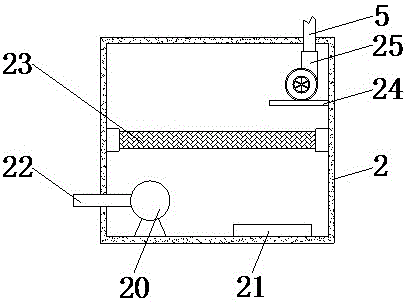

Leather drying device with high efficiency

InactiveCN106282431AImprove efficiencyDry fastDrying gas arrangementsDrying chambers/containersEngineeringDrying time

The invention discloses a leather drying device with high efficiency, relating to the technical field of leather processing equipment. The leather drying device with high efficiency comprises a base, a heating box and a drying box are installed at the top of the base in sequence from left to right, a controller and an air supply pipe are arranged at the top of the heating box in sequence from left to right, one end of the air supply pipe, close to the heating box, penetrates through the heating box and extends into the heating box, the other end of the air supply pipe, away from the heating box, penetrates through the drying box and extends into the drying box, and a ventilation plate is fixedly connected to one side of the inner wall of the drying box. The leather drying device with high efficiency adopts an exhaust fan, a blower, a fan and an air heater, wherein the air heater can heat air sucked into the heating box, and the blower and the fan can blow air to dry leather, so that the leather can be quickly dried, so that not only is the leather drying time reduced and also the working efficiency is also improved.

Owner:陈明

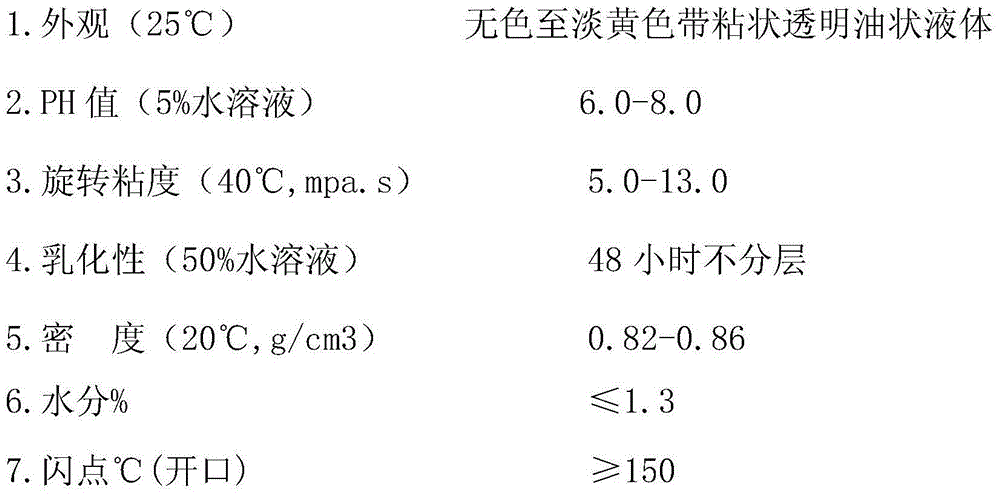

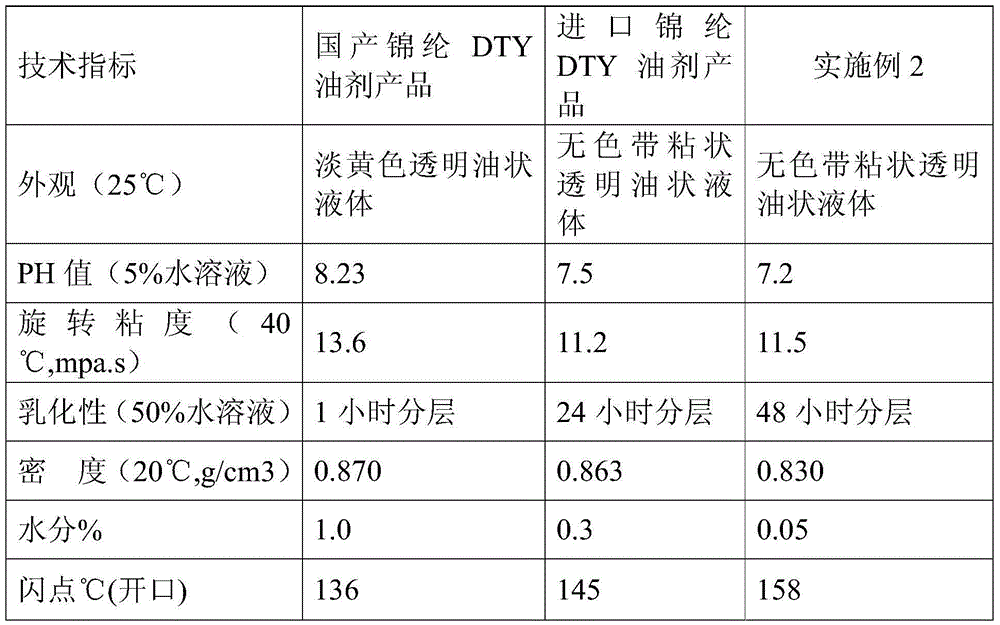

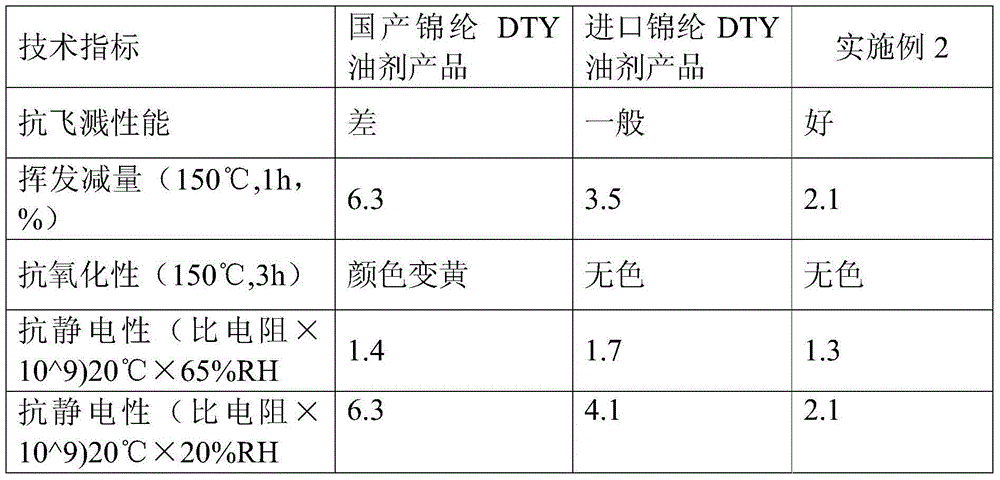

Anti-splashing chinlon DTY oil agent and preparation method thereof

The invention discloses an anti-splashing chinlon DTY oil agent and a preparation method thereof. A conventional chinlon DTY oil agent splashes on various parts when spinning processing speed increases. The anti-splashing chinlon DTY oil agent is composed of following components, by weight, 60-80% of a high-temperature resistance smooth agent, 10-25% of an environment-friendly emulsifier, 3-10% of a bundling agent, 4-6% of a compound antistatic agent, 1-2% of an anti-splashing agent and the balance polymeric additive. The anti-splashing agent is a mixture of an ethene-propylene copolymer and polyisobutylene or polybutene. The anti-splashing agent is good in anti-splashing performance, is free from splashing and causing oil-stained fibers during a production process, is free of APEO and is non-pollution and nontoxic to environment.

Owner:HANGZHOU TRANSFAR CHEM LTD

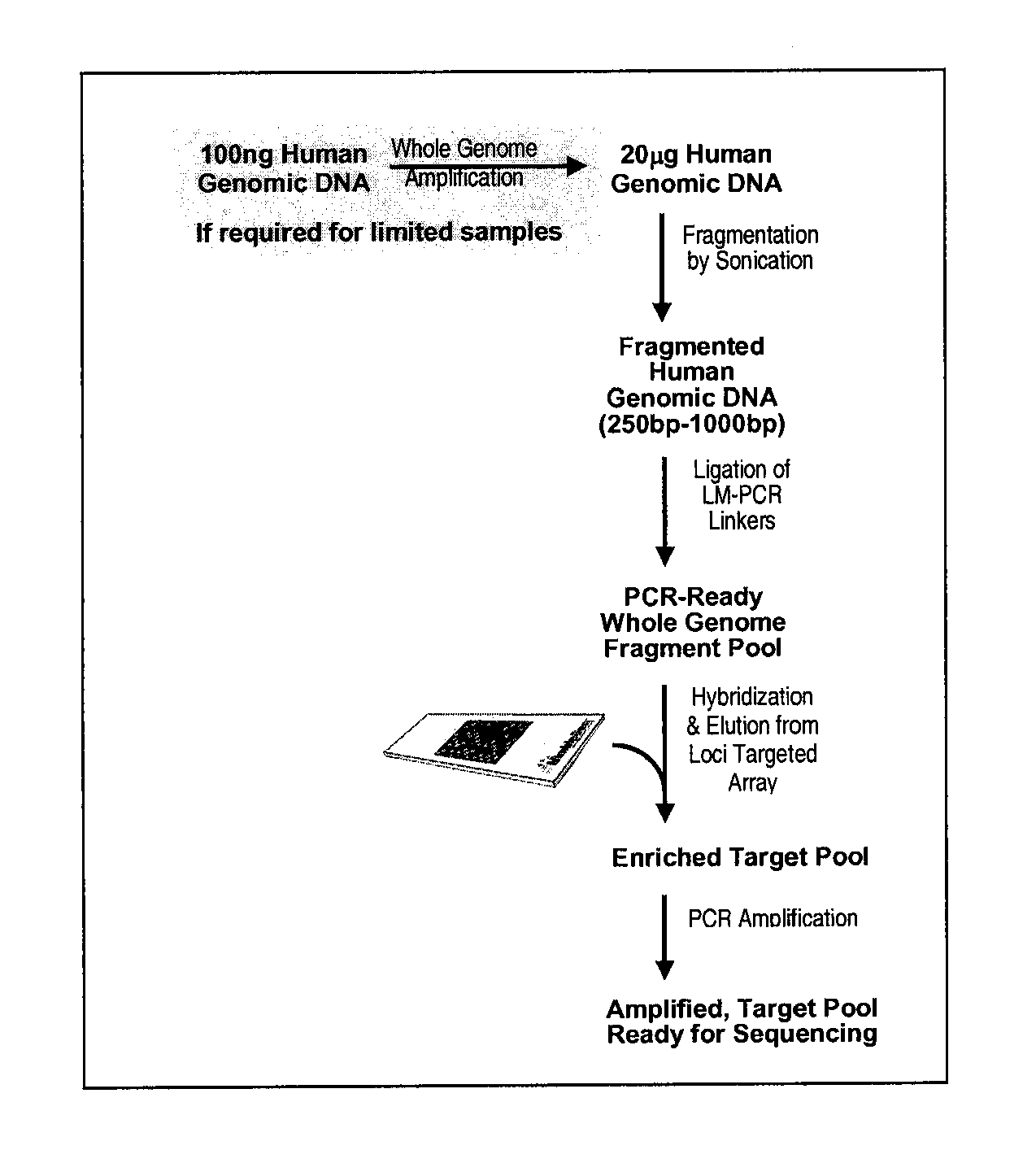

Methods and systems for uniform enrichment of genomic regions

ActiveUS20090221438A1Reduce complexityFacilitate subsequent processingSugar derivativesMicrobiological testing/measurementGenomeComputational biology

The present invention provides methods and compositions for the enrichment of target nucleic acids in a microarray system. In particular, the present invention provides methods and compositions for uniform enrichment of target nucleic acid molecules in a microarray format. The present invention also provides for intentionally non-uniform enrichment among target nucleic acid molecules.

Owner:ROCHE NIMBLEGEN

Method for producing fruit juice of germinant unpolished rice and ganoderma lucidum, and production

InactiveCN1759760ASimple processing methodHigh degree of industrializationFood preparationPlant ingredientsFruit juiceAdditive ingredient

A nutritive health-care fruit juice is prepared through choosing Korean ganoderma as bacterial strain, preparing culture medium from germinated long-grained non-glutinous rice mild, malt juice and germinated soybean juice for deep ferment, slant culture, stage-one shaker culture, stage-two seeding tank culture, deep fermenting, mixing the fermented liquid with grape jice, apple juice and orange juice, homogenizing, degassing, sterilizing and cooling. Its advantage is rich bioactive substances (ganoderma polyose, gamma-aminobutanoic acid, etc).

Owner:SUZHOU JINJI FOODS

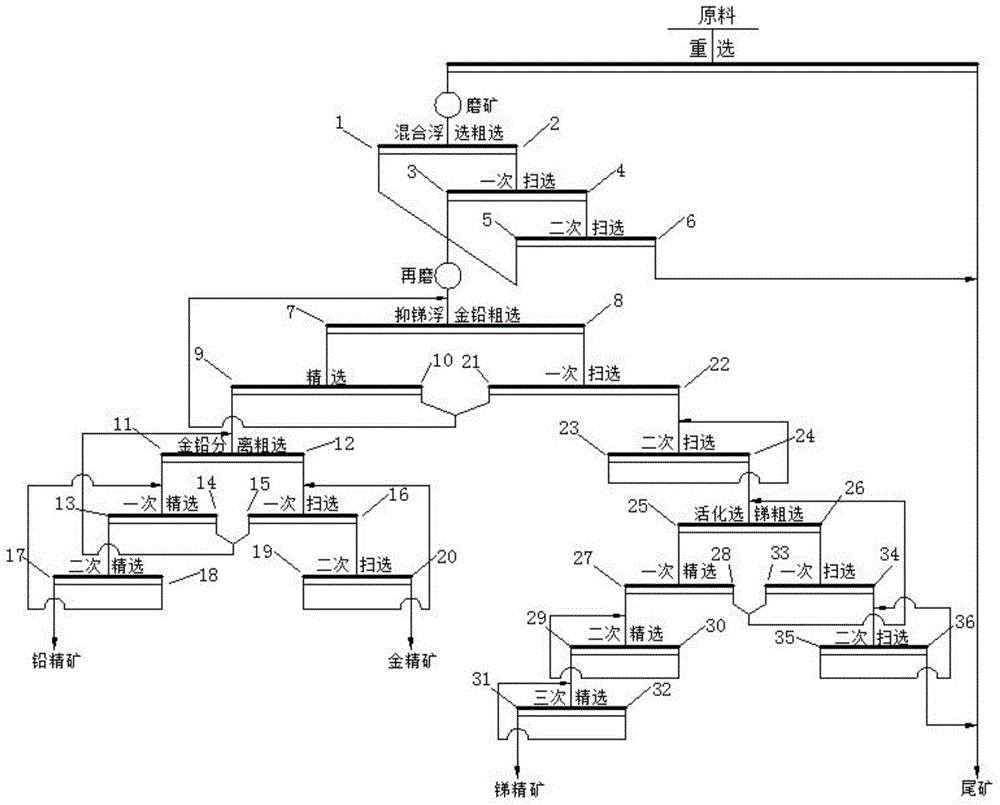

Method for recovering gold, antimony and lead from floatation tailings

ActiveCN104624363AHigh recovery rateReduce adverse effectsFlotationWet separationMaceralCoarse particle

The invention provides a method for recovering gold, antimony and lead from floatation tailings, and belongs to the technical field of resource comprehensive utilization. The method comprises the steps of first removing slime in the floatation tailings through gravity separation, then grinding gravity concentrates and carrying out gold, antimony and lead bulk flotation, re-grinding the concentrates obtained through bulk floatation to suppress antimony and float gold and lead, carrying out gold and lead separating flotation on the obtained concentrates, carrying out activated antimony separation on the obtained floatation tailings, and finally obtaining gold concentrates, lead concentrates and antimony concentrates. According to the method, coarse particle minerals are enriched in advance through the open path flow of gravity concentration, a large amount of slime in the floatation tailings is got rid of, and the negative influence of the slime on the follow-up flotation is avoided; the full open path flow of bulk flotation is favorable for making coenobia to enter the concentrates, the recovery rate of gold, antimony and lead is greatly increased, and secondary slime formed by re-grinding is prevented from entering the concentrates. The method has important economic value and environment benefits to reuse of the floatation tailings.

Owner:JIANGXI YIYUAN REGENERATION RESOURCE CO LTD

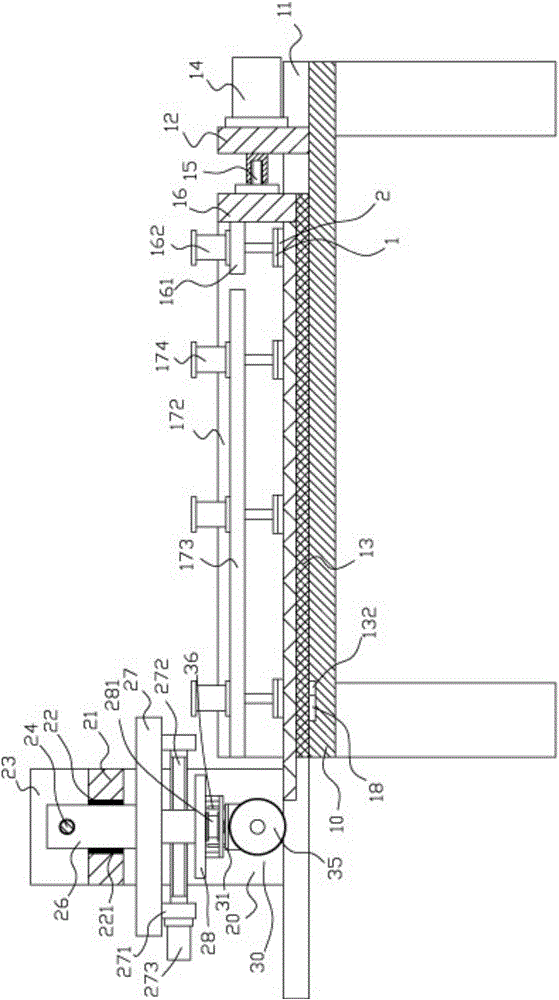

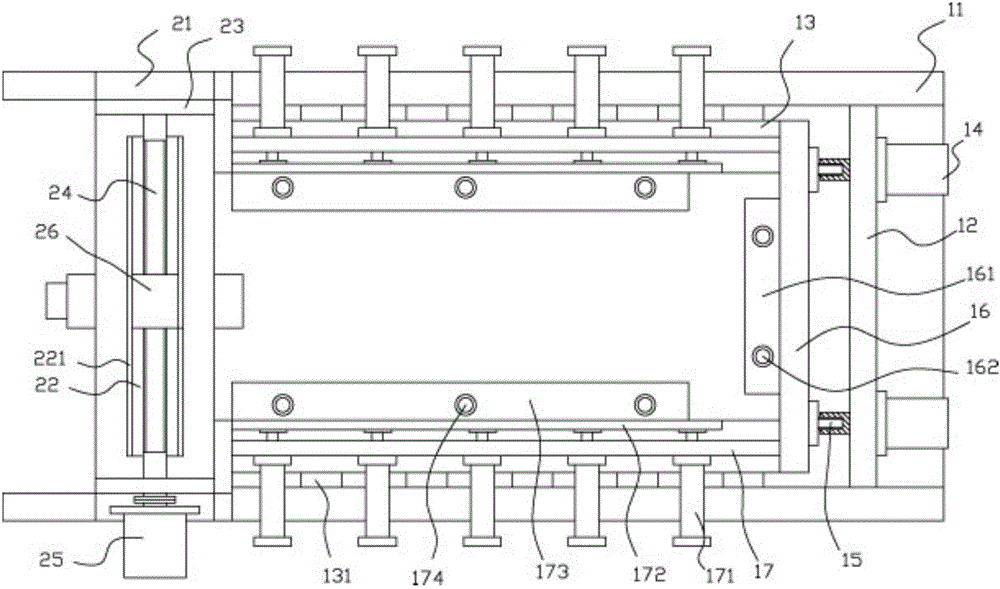

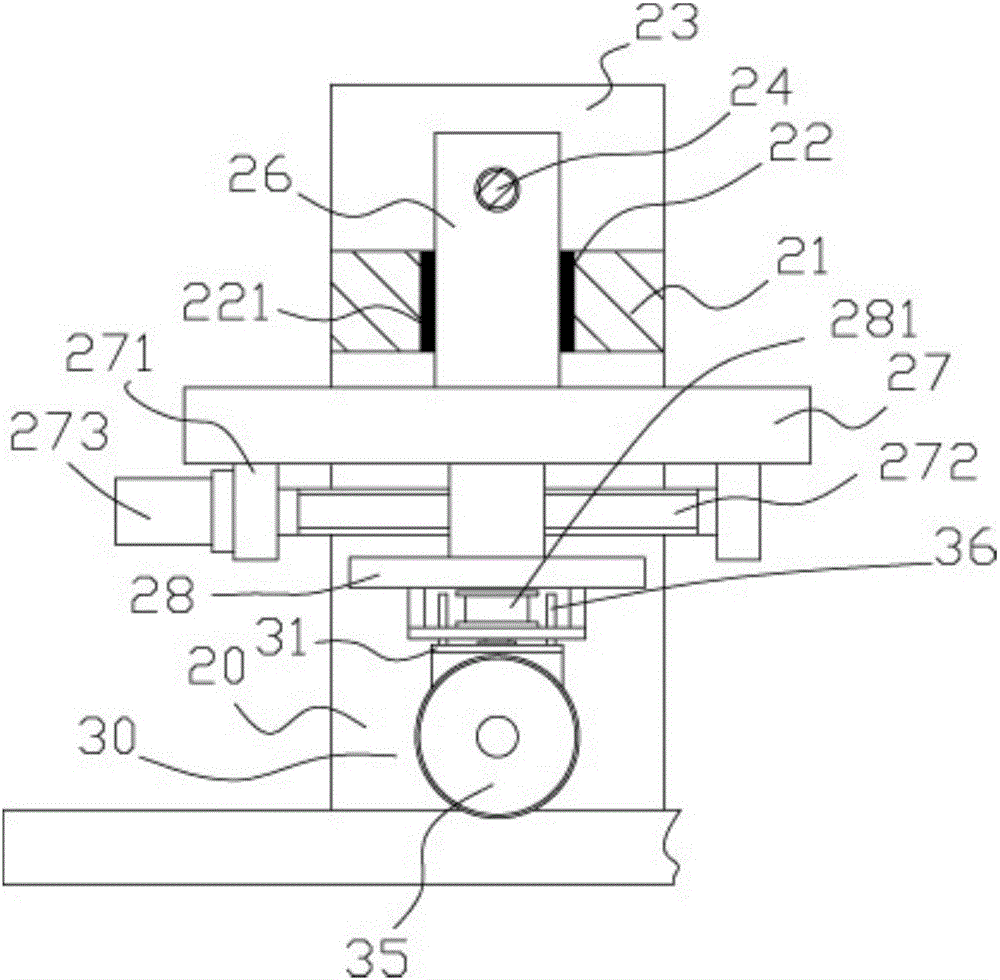

Installation, positioning and grooving mechanism for plastic plates

ActiveCN106078873AFacilitate subsequent processingGood effectMetal working apparatusCouplingWear resistant

The invention discloses an installation, positioning and grooving mechanism for plastic plates. The installation, positioning and grooving mechanism comprises a rack, wherein guide plates are respectively fixed to the front and back sides of the top surface of a top plate of the rack, a right connecting plate is fixed to the right side of the top surface of the top plate of the rack, the right connecting plate is positioned between the two guide plates, vertical support plates are respectively fixed to the front and back ends of the left side wall of the top plate of the rack, an upper horizontal adjusting plate is fixed to the top surfaces of the two vertical support plates, a moving through groove is formed in the middle of the upper horizontal adjusting plate, wear resistant layer are respectively fixed to the left and right inner side walls of the moving through groove, upper support blocks are respectively fixed to the front and back ends of the moving through groove in the upper horizontal adjusting plate, both ends of a moving screw are respectively hinged to the two upper support blocks, a moving motor is fixed to the upper horizontal adjusting plate, an output shaft of the moving motor is connected to one end, which extends from the corresponding upper support block, of the moving screw by virtue of a coupling, and a moving block is screwed on the moving screw. The installation, positioning and grooving mechanism has the advantages of convenience in subsequent processing, good effect and high degree of automation, and the plastic plates can be automatically fixed and cut.

Owner:NANTONG HUALONG MICROELECTRONICS

Processing method of freshwater crayfish pre-prepared products

The invention discloses a processing method of freshwater crayfish pre-prepared products. The method includes the steps of firstly, selecting and grading; secondly, cleaning; thirdly, frying; fourthly, vacuum cooling; fifthly, soaking with seasoning liquids; sixthly, nitrogen-filled packing; seventhly, quick-freezing; eighthly, performing cold storage. The method has the advantages that the crayfish is soaked with special cleaning fluids to allow the crayfish to spit out dirt in the intestine line, and complex manual intestine line removing is avoided; high-temperature fast frying and special soaking with special seasoning liquids are used, and the difficulties that crayfish meat protein deteriorates easily, flavor substances lose easily and flavor cannot enter the crayfish in subsequent processing are solved; the vacuumizing and nitrogen filling freshness keeping technology is used, and the crayfish is prevented from being oxidized by oil acid during storage.

Owner:洪湖市万农水产食品有限公司

Production line with automatic overturning function

ActiveCN110877817AFacilitate automated processing operationsSmall activity gapConveyor partsProduction lineTransmission belt

The invention discloses a production line with an automatic overturning function, and belongs to the technical field of conveying devices. A first conveying belt, an inverted workpiece overturning mechanism, a second conveying belt, a centering straightening mechanism and an automatic U-turn mechanism are included. The inverted workpiece overturning mechanism comprises a first image collecting unit, a controller, an inverted workpiece overturning assembly, a rotation disc and a workpiece conveying assembly. The inverted workpiece overturning assembly comprises two workpiece limiting components. Each workpiece limiting component comprises a fixing square pipe, a space size adjusting piece, a limiting space and a compression material guiding plate which is of a trapezoid structure. Through the inverted workpiece overturning assembly, an inverted workpiece can be overturned by 180 degrees, the workpiece with the wrong direction can be turned and reversed under the action of the automaticU-turn mechanism, the straightened workpiece can be located at the center position of the top face of the second conveying belt through the centering straightening mechanism, accordingly, the workpiece is straightened in one straight line direction, and workpiece conveying tidiness is improved.

Owner:烟台锐腾智能科技有限公司

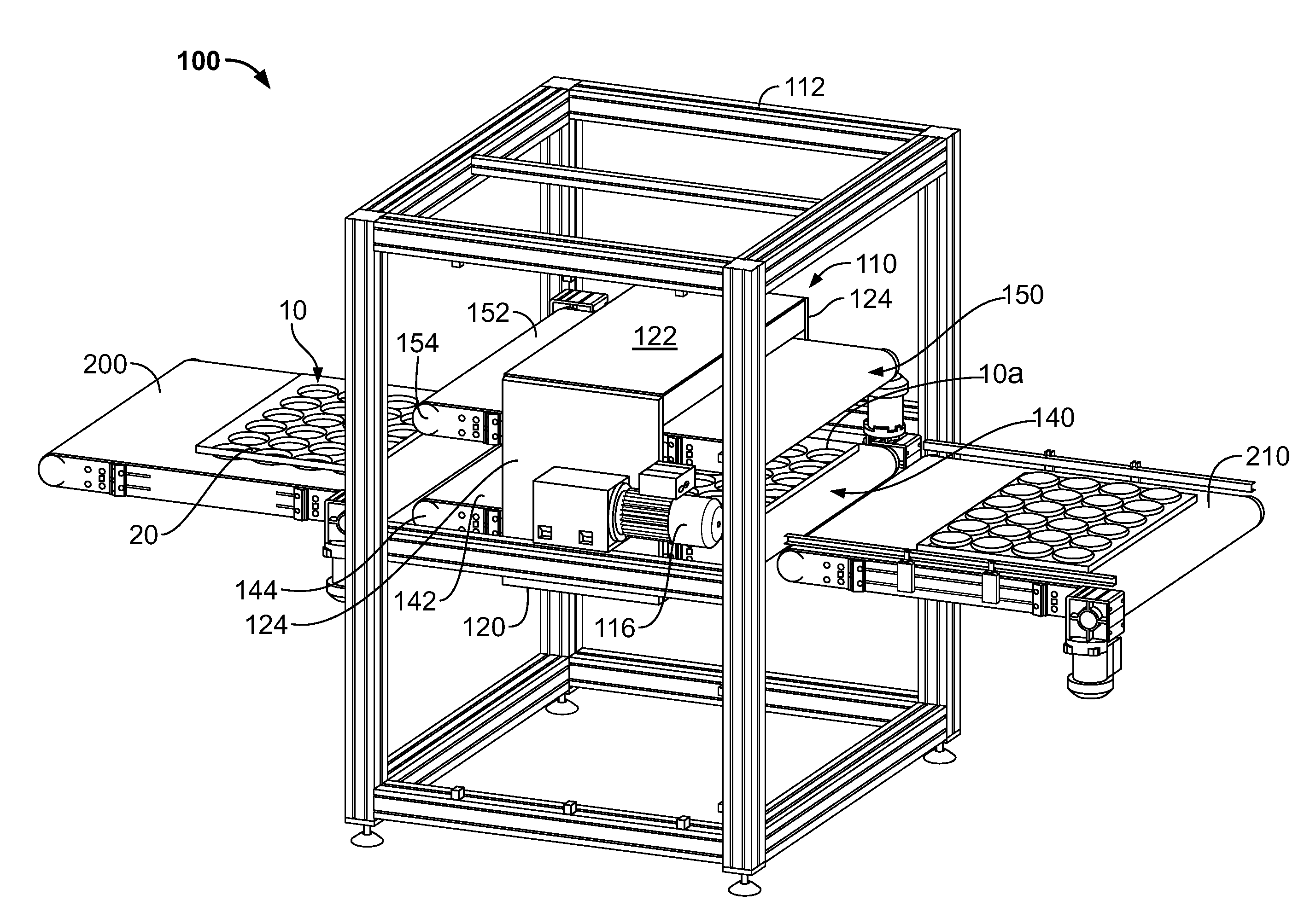

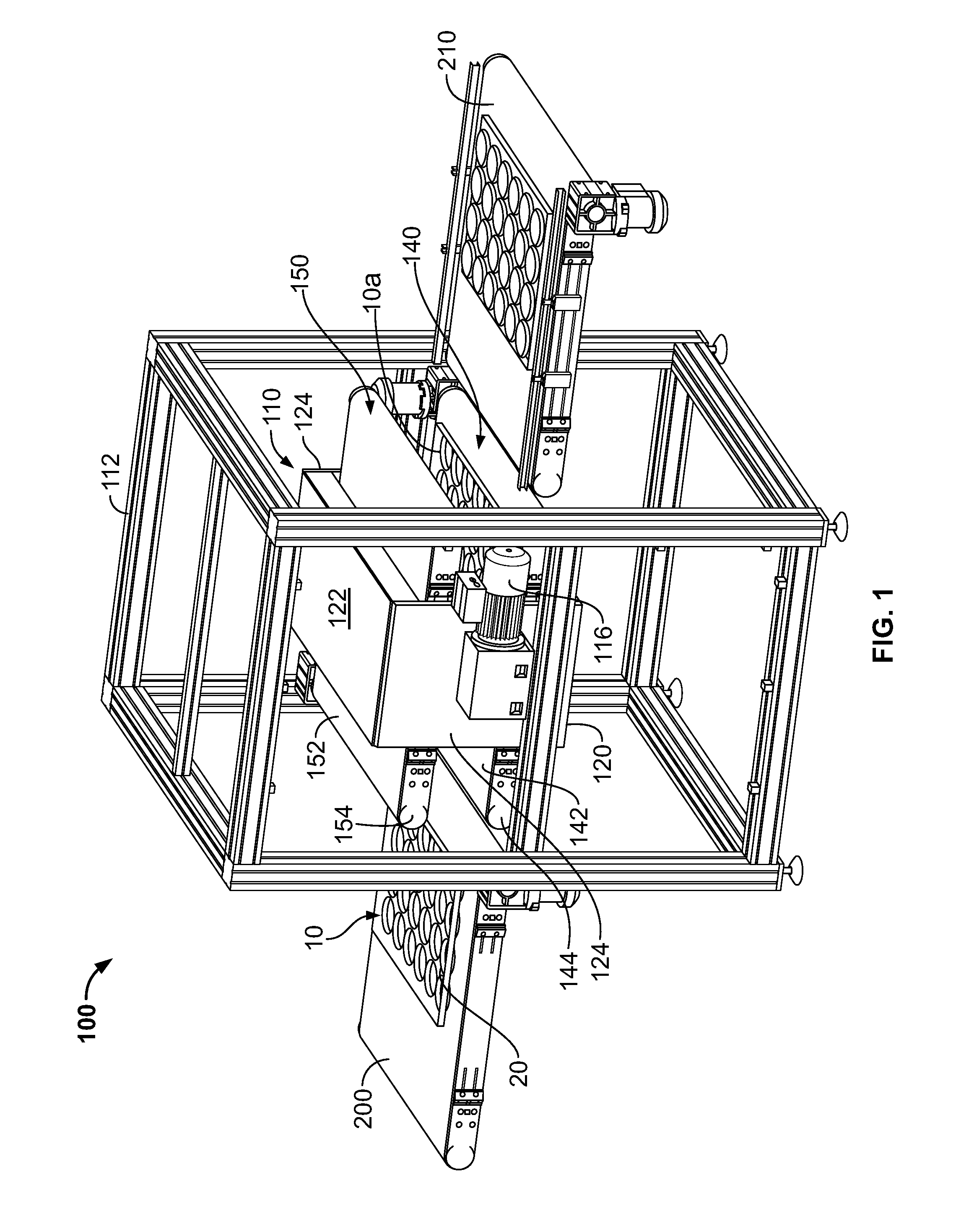

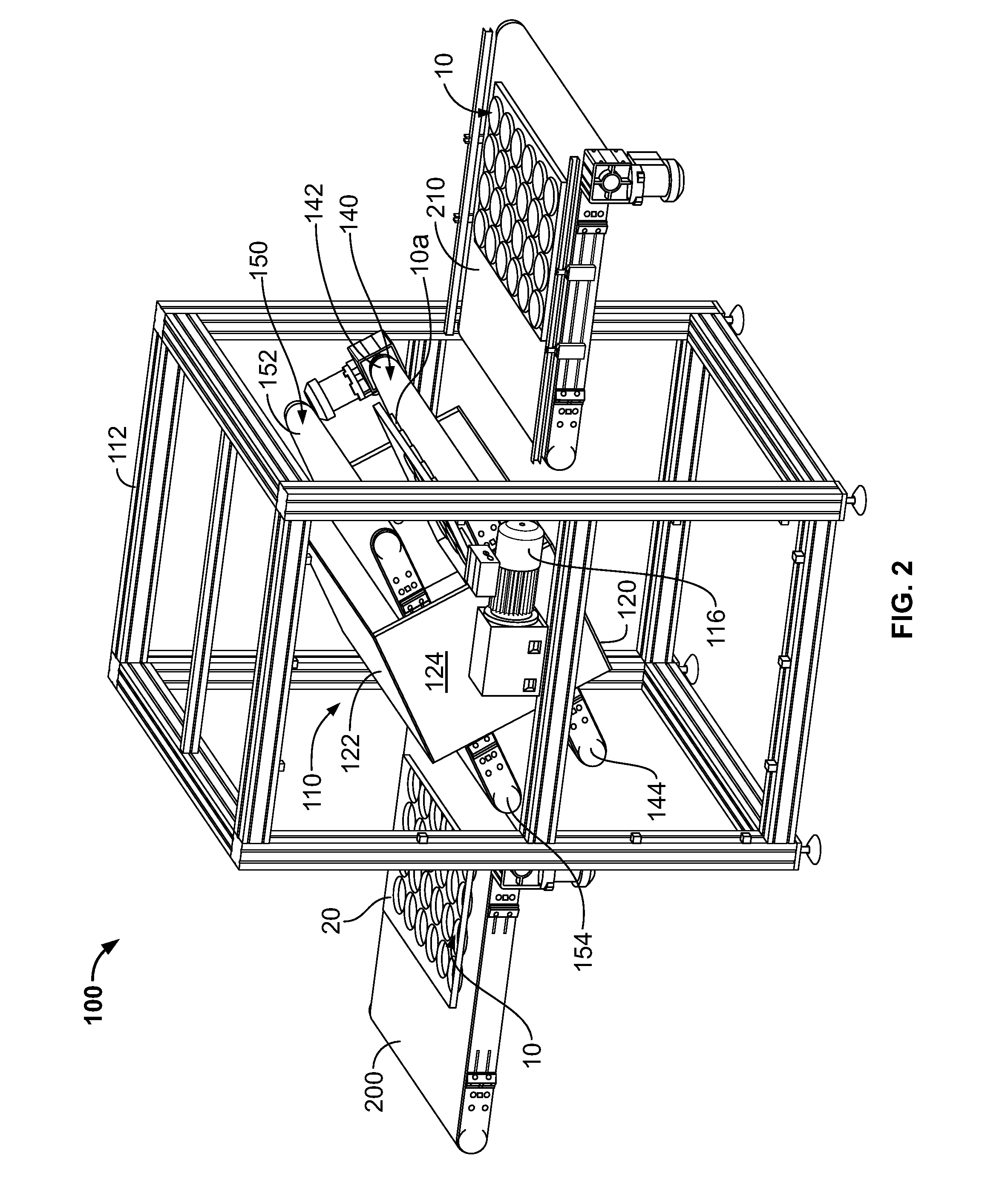

Product inverting mechanism

ActiveUS8181767B2Facilitate subsequent processingPromote sportsBaked articles handlingMeat processingTransverse axisMechanical engineering

The invention is directed to an inverting device which takes one or more articles from a first device, inverts the article(s), and discharges the article(s) onto a second device that may be at essentially the same relative height as the first device. The inverting device has a rotating device with two opposed surfaces that are spaced apart a distance slightly greater than the height of the article. Once the article(s) has been moved into position in the rotating device, the rotating device rotates 180 degrees about a transverse axis, resulting in the inversion of the article. The new orientation of the article may facilitate further processing in a manufacturing environment, such as cleaning, filling, labeling, stacking or any other activity that relies on a specific product disposition.

Owner:WELDON MACHINE TOOL

Impurity removal filtering device for sewage treatment

InactiveCN107321051AQuality assuranceFacilitate subsequent processingTreatment involving filtrationMultistage water/sewage treatmentFiltrationSewage

The invention discloses a miscellaneous filtering device for sewage treatment, which includes a miscellaneous discharge chamber, a primary sedimentation chamber and a secondary sedimentation chamber, a water inlet pipe is installed above the left end of the miscellaneous discharge chamber, and the waste discharge chamber The middle position of the left side wall of the miscellaneous room is provided with a first motor, and the right end of the first motor is equipped with a first rotating shaft. filter screen, the bottom plane of the miscellaneous room is provided with a miscellaneous bucket, the bottom end of the described miscellaneous bucket is provided with a miscellaneous chamber, and the described primary sedimentation chamber is located on the right side of the miscellaneous room. The miscellaneous room and the primary sedimentation chamber are communicated through the infusion tube, and the top of the primary sedimentation chamber is provided with an auxiliary material box; the beneficial effect of the present invention is: the principle of multi-stage sedimentation is adopted, and the sewage in the upper layer is repeatedly pumped out before being treated. Filtration treatment can fully ensure the quality of sewage after filtration.

Owner:深圳市花蘑菇网络科技有限公司

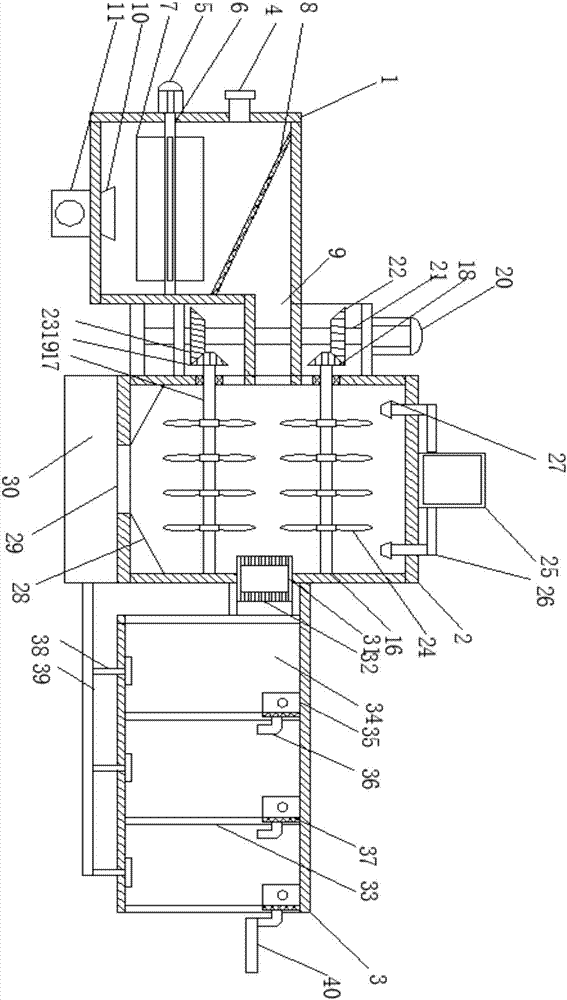

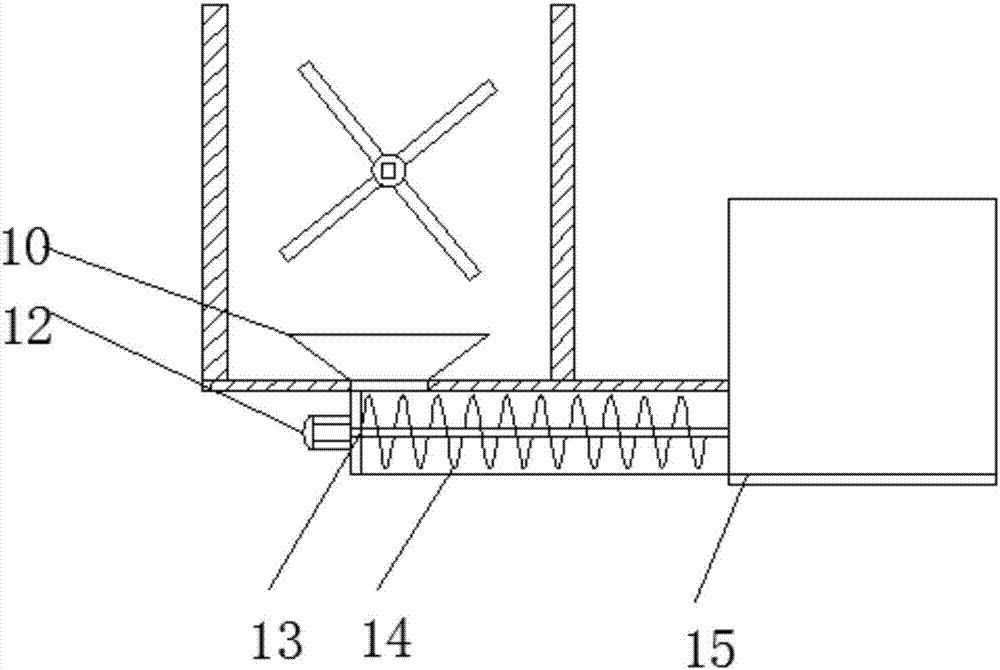

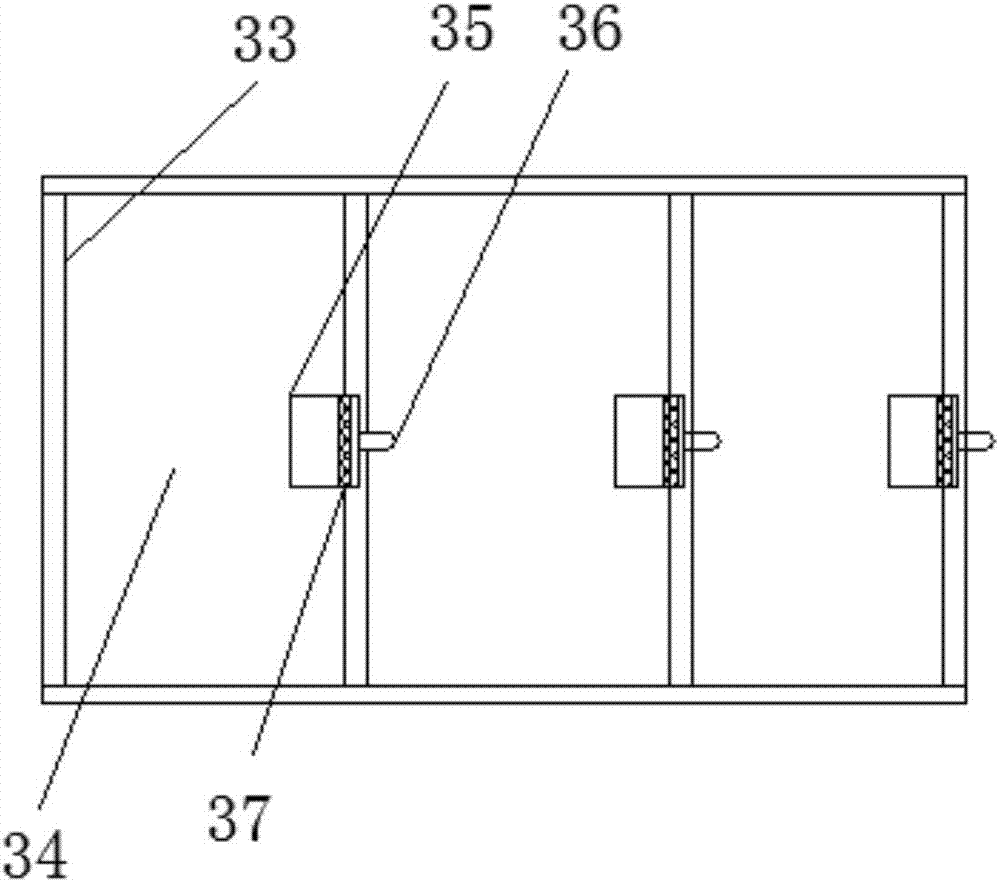

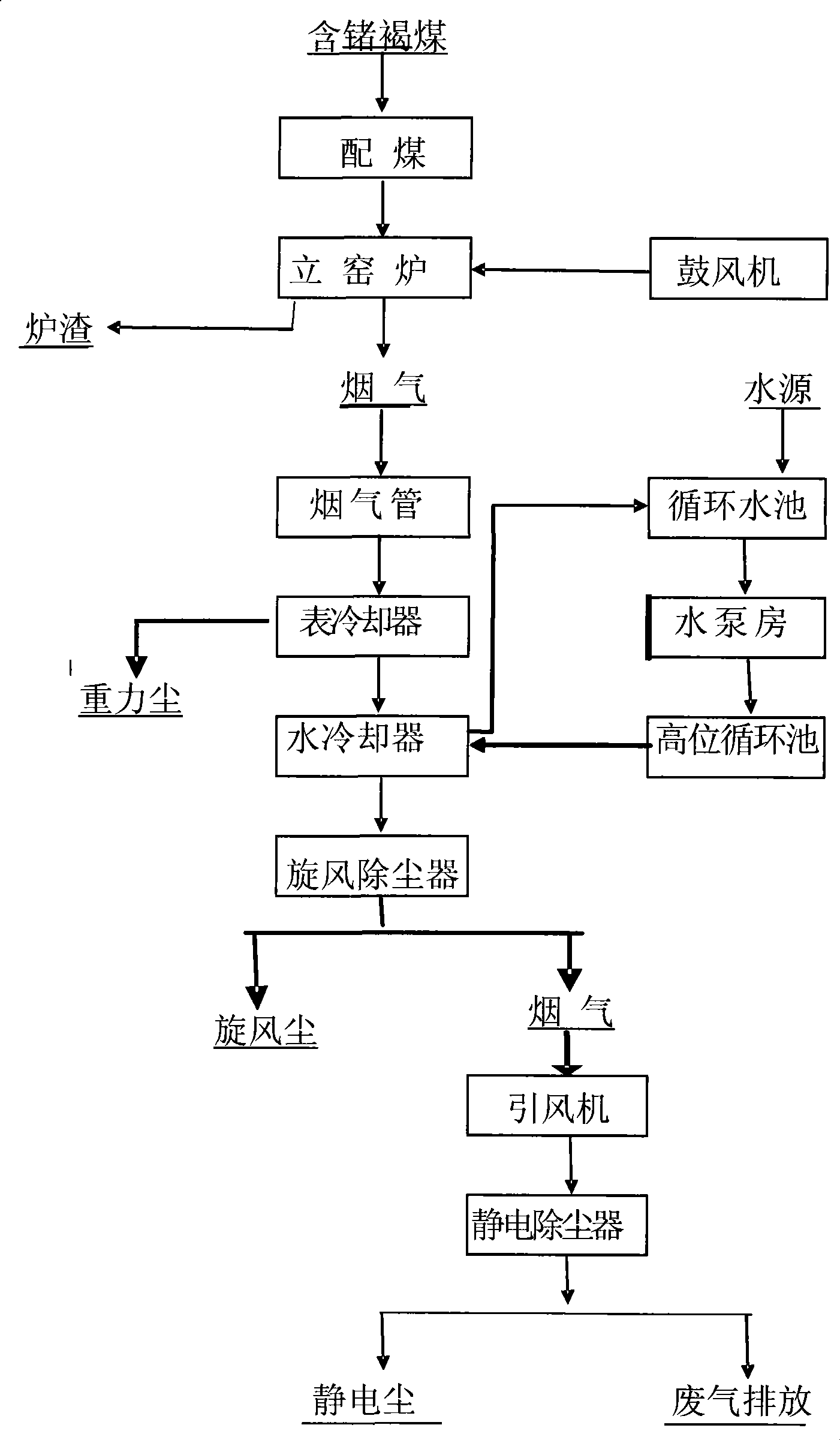

Method for extracting germanium from lignite by pyrogenic process

InactiveCN101413063AImprove direct yieldHigh germanium gradeGermanium monoxideElectrostatic precipitator

The invention provides a method for extracting germanium from lignite through a pyrogenic process. The method is characterized in that germanium-containing lignite volatilizes germanium in a pyrogenic-process smelting procedure of a vertical kiln; a control condition of volatilizing germanium is that the temperature is between 1,150 and 1,250 DEG C; in a suitable reducing atmosphere, the germanium existing as germanium dioxide generates germanium monoxide after reduction reaction through carbon particles and carbon monoxide; a suitable oxidizing atmosphere ensures that the germanium monoxide follows dust particles volatilized simultaneously to meet excessive oxygen in a flue gas tube and then is oxidized to be the germanium dioxide; the temperature of the germanium dioxide is lowered through a cooler; the generated germanium dioxide is changed into a solid state and is attached to the surfaces of the dust particles; the germanium-enriched dust particles pass an electrostatic dust catcher and then are attached to the electrostatic dust catcher; and germanium-enriched electrostatic dust is collected so as to obtain germanium concentrate. The method is advanced in technology, economical, practical and low in cost for extracting germanium. Compared with a chain-boiler germanium extracting process and other germanium extracting methods, the method has the advantages that the method is high in germanium volatilizing efficiency, the direct recovery rate of the electrostatic dust, the germanium-containing grade of the electrostatic dust and the post wet treatment yield of the output electrostatic dust, and is convenient for subsequent processing, and the like.

Owner:JIUJIANG BAIDUN VANADIUM TECH TRADING

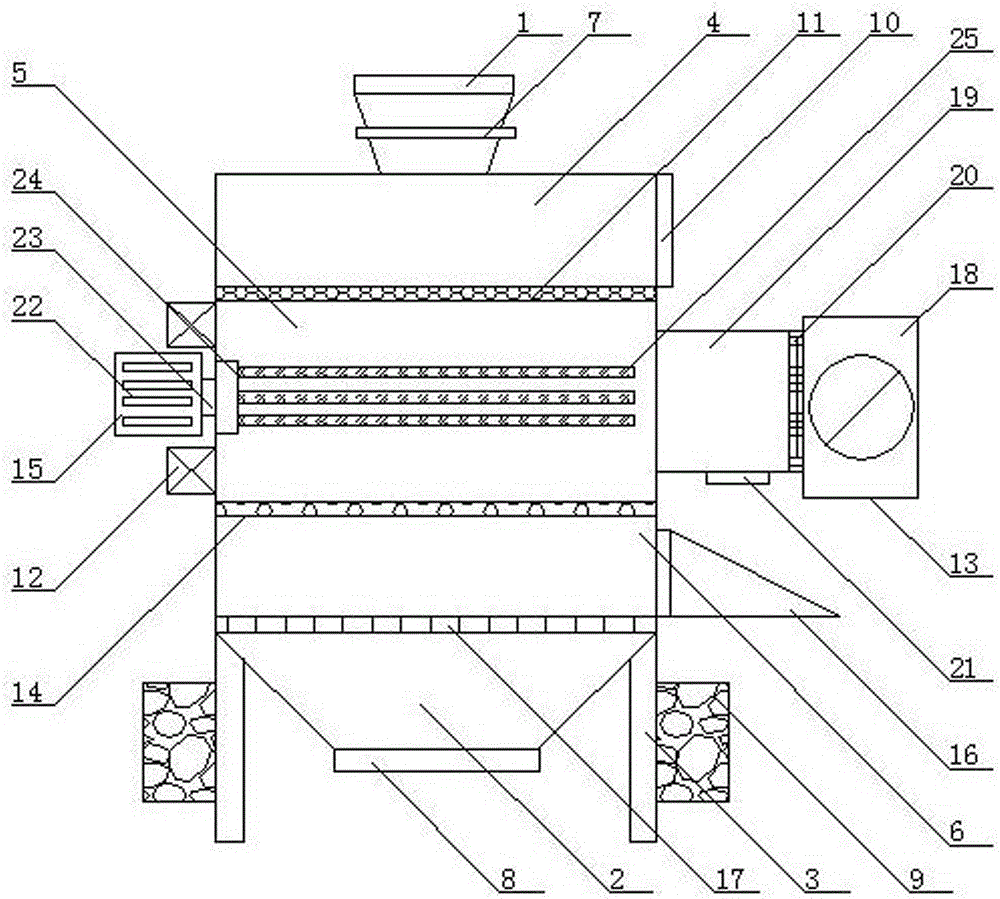

Multilevel unhusked rice dedusting device for rice processing

InactiveCN106732872AFacilitate subsequent processingEasy to removeSievingGas current separationSurface layerEngineering

The invention discloses a multilevel unhusked rice dedusting device for rice processing. The multilevel unhusked rice dedusting device comprises a device body. A feeding funnel is arranged in the middle of the top end of the device body. A conical dust collection bin is arranged in the middle of the bottom end of the device body. The left side and the right side of the bottom end of the device body are each provided with a support leg. The device body is internally provided with a first dedusting chamber, a second dedusting chamber and a third dedusting chamber in sequence from top to bottom. By means of the multilevel unhusked rice dedusting device for rice processing, the problems that in the prior art, unhusked rice cleaning modes are not high in cleaning efficiency and not good in cleaning effect are solved; the multilevel dedusting design is adopted, and dust or impurities in unhusked rice can be filtered out rapidly; meanwhile, impurities adhering to the surface layer of the unhusked rice can be effectively removed; the dedusting effect is good; in addition, material feeding and material discharging are quite convenient to conduct; and the multilevel unhusked rice dedusting device is easy to operate and high in practicability.

Owner:HARBIN MIMI RICE IND TECH CO LTD

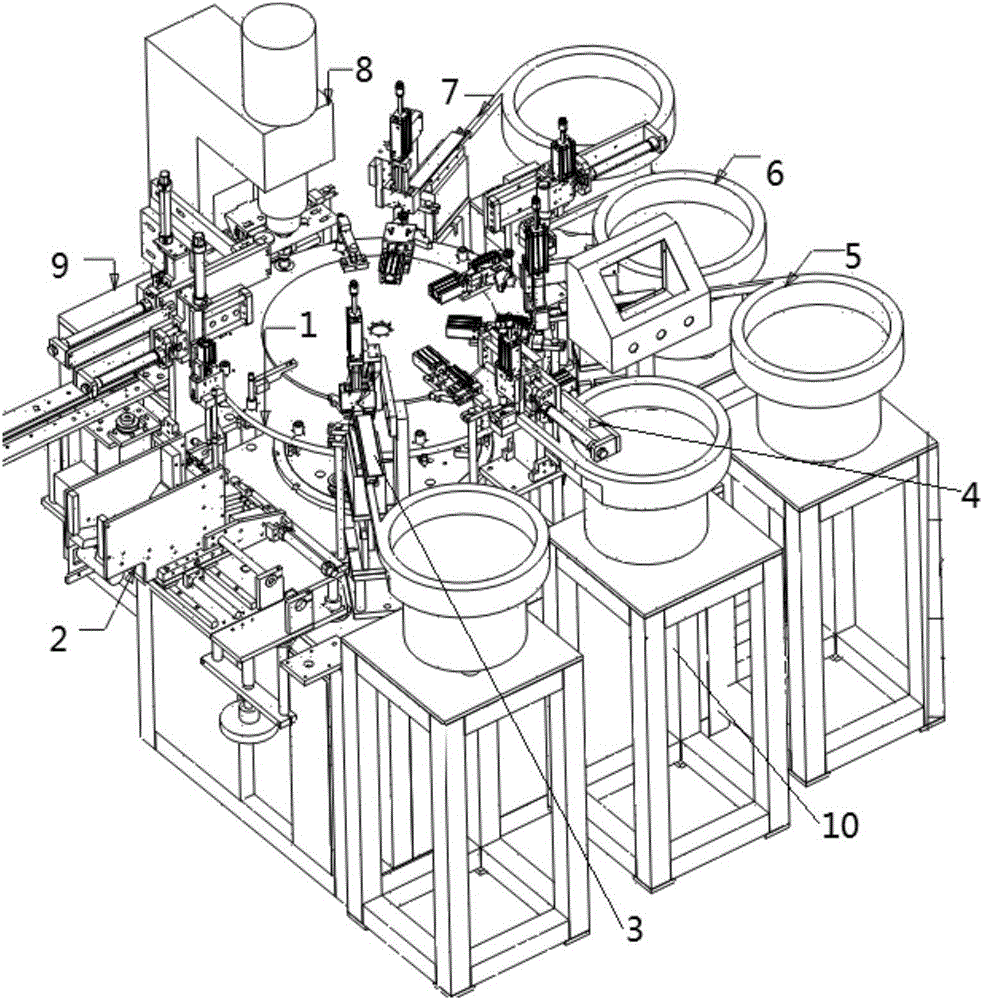

Air cylinder rod machining device and machining control method

ActiveCN105881019AImprove efficiencyImprove qualityAssembly machinesMetal working apparatusMachine controlEngineering

The invention discloses an air cylinder rod machining device and machining method, and belongs to the technical field of air cylinder rod assembly devices. The air cylinder rod machining device comprises a rotary plate cutting mechanism and an electric control system, and further comprises an air cylinder rod automatic feeding and placing mechanism, an automatic feeding and mounting mechanism, a piston rod automatic riveting mechanism and a product discharging system, wherein the electric control system is used for controlling operation execution procedures of the rotary plate cutting mechanism, the air cylinder rod automatic feeding and placing mechanism, the automatic feeding and mounting mechanism, the piston rod automatic riveting mechanism and the product discharging mechanism respectively; the rotary plate cutting mechanism is used for receiving to-be-machined air cylinder rods from the air cylinder rod automatic feeding and placing mechanism; the automatic feeding and mounting mechanism and the rotary plate cutting mechanism are matched with each other to mount and machine the to-be-machined air cylinder rods; the piston rod automatic riveting mechanism is used for riveting the air cylinder rod equipped with components; the product discharging system is used for discharging the machined air cylinder rods. According to the air cylinder rod machining device and machining method, the air cylinder rods are precisely placed by mechanical arms, so that the manual work omitted, automation is achieved, and the production efficiency and the quality are improved.

Owner:ANHUI LAITE GAS SPRING CO LTD

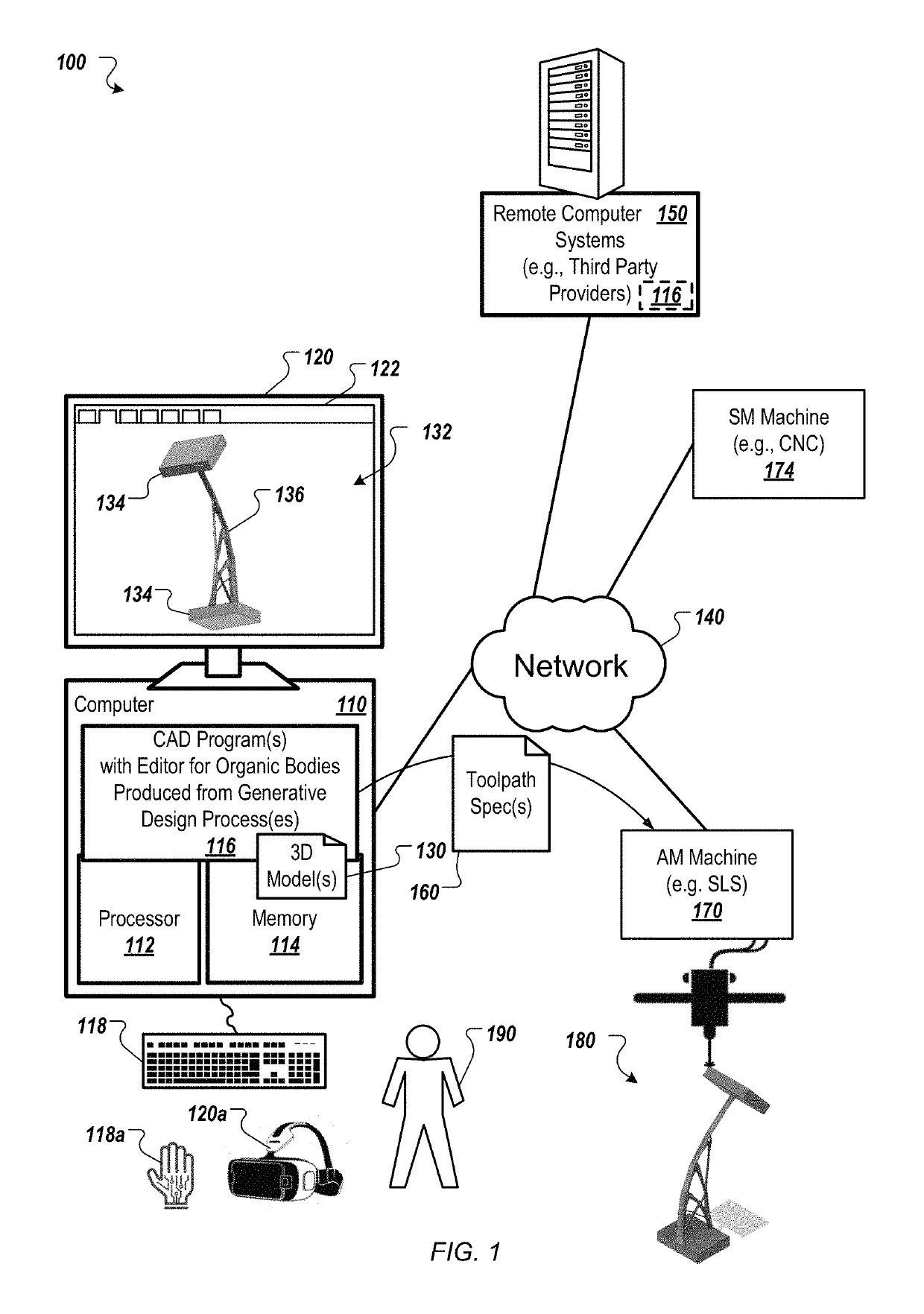

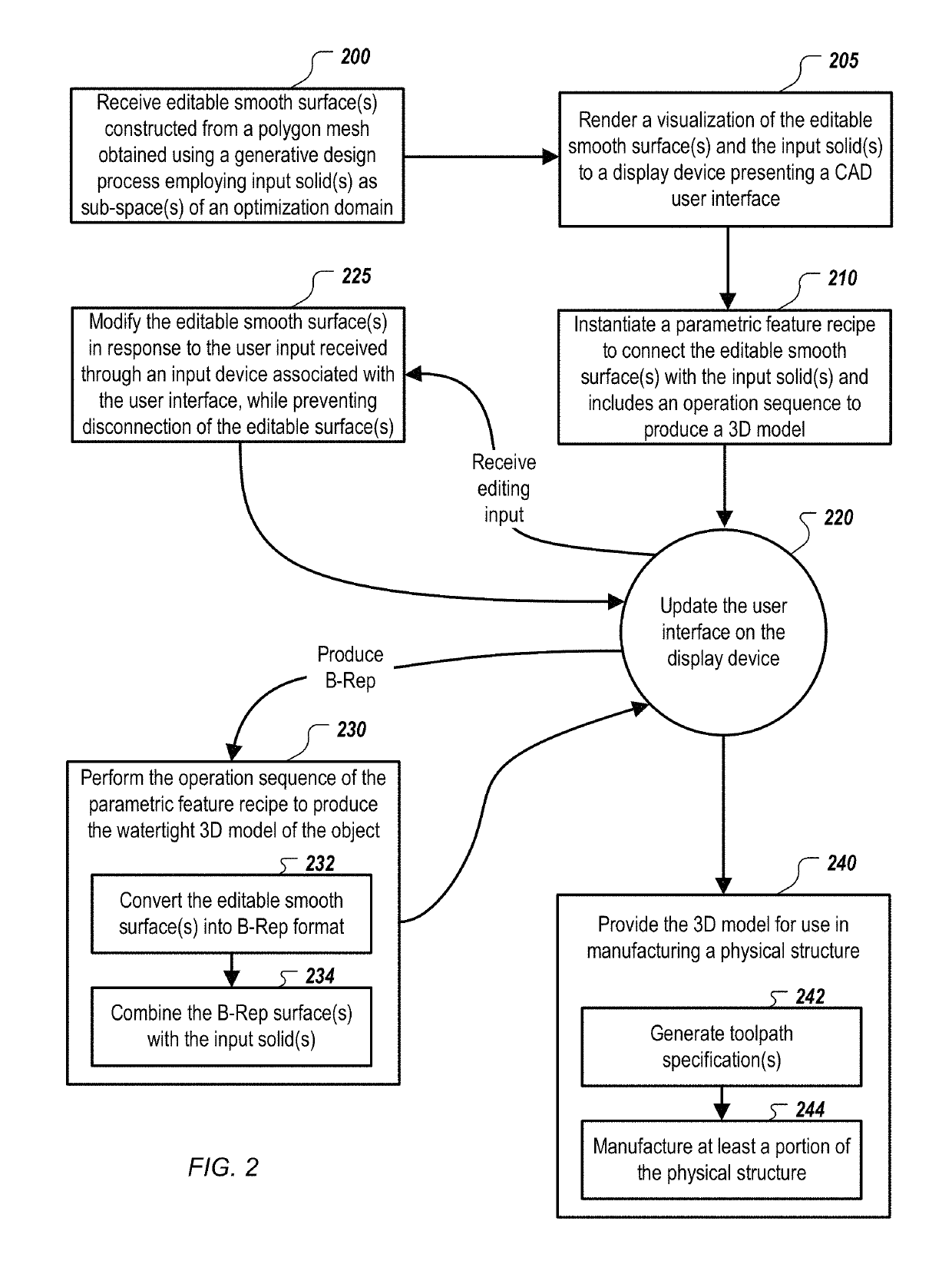

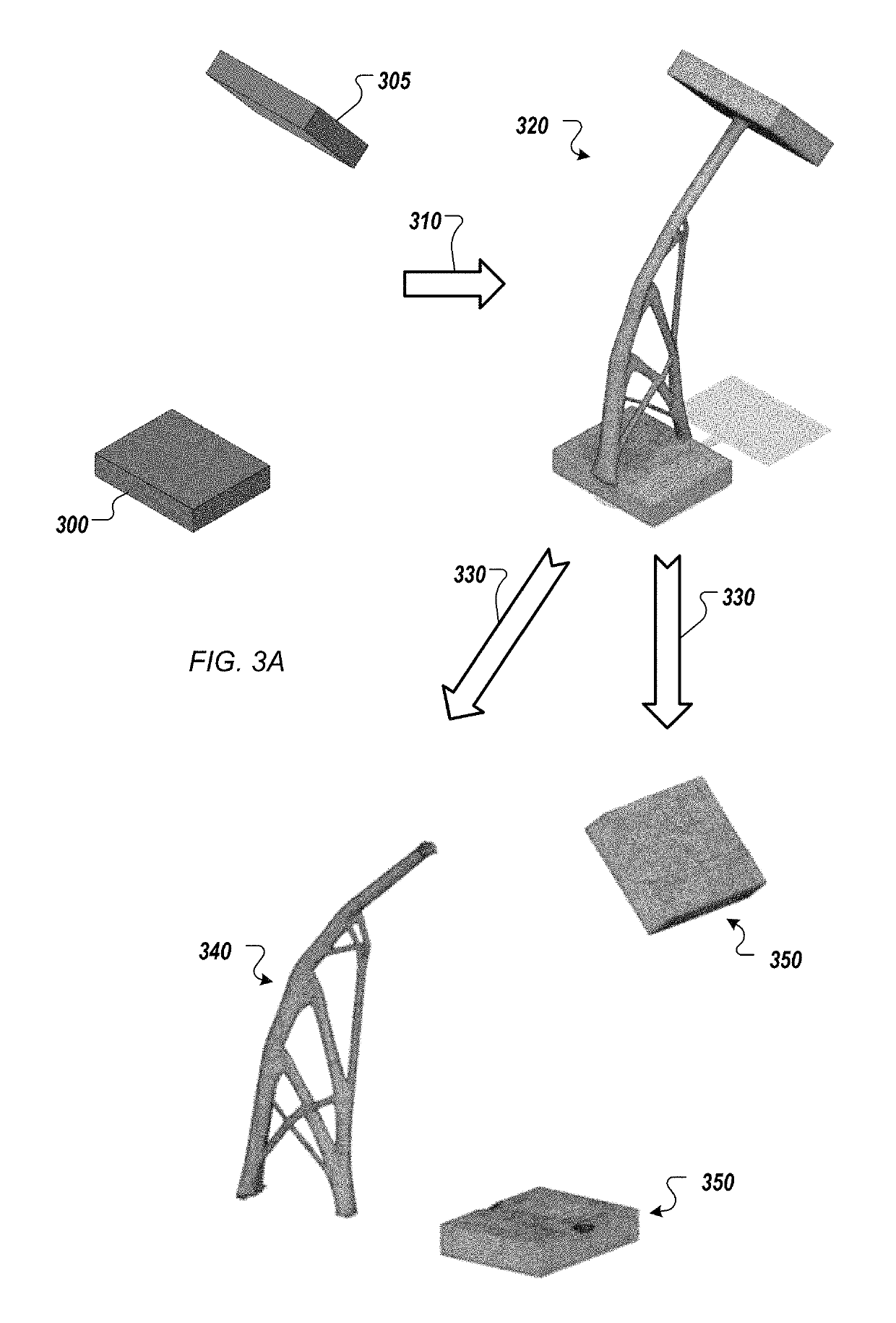

Facilitated editing of generative design geometry in computer aided design user interface

ActiveUS10467807B1Easy to editShorten the timeGeometric CADAdditive manufacturing apparatusComputer Aided DesignGenerative Design

Methods, systems, and apparatus, including medium-encoded computer program products, for facilitating editing of generative design geometry of physical structures, include a method including: receiving editable smooth surface(s), e.g., a T-Spline, constructed from a mesh obtained using a generative design process; instantiating a parametric feature recipe to connect the editable smooth surface(s) with input solid(s), wherein the parametric feature recipe includes an operation sequence that (i) converts the editable smooth surface(s) into boundary representation format and (ii) combines the boundary representation formatted smooth surface(s) with the input solid(s) to produce a watertight three dimensional model of an object; modifying the editable smooth surface(s) in response to input, while preventing disconnection of the editable smooth surface(s) from the input solid(s); updating a visualization thereof in a user interface; and performing the operation sequence of the parametric feature recipe to produce the watertight three dimensional model of the object.

Owner:AUTODESK INC

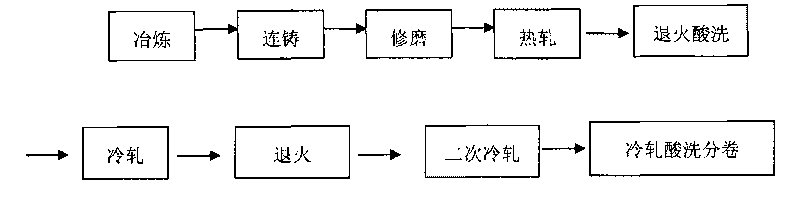

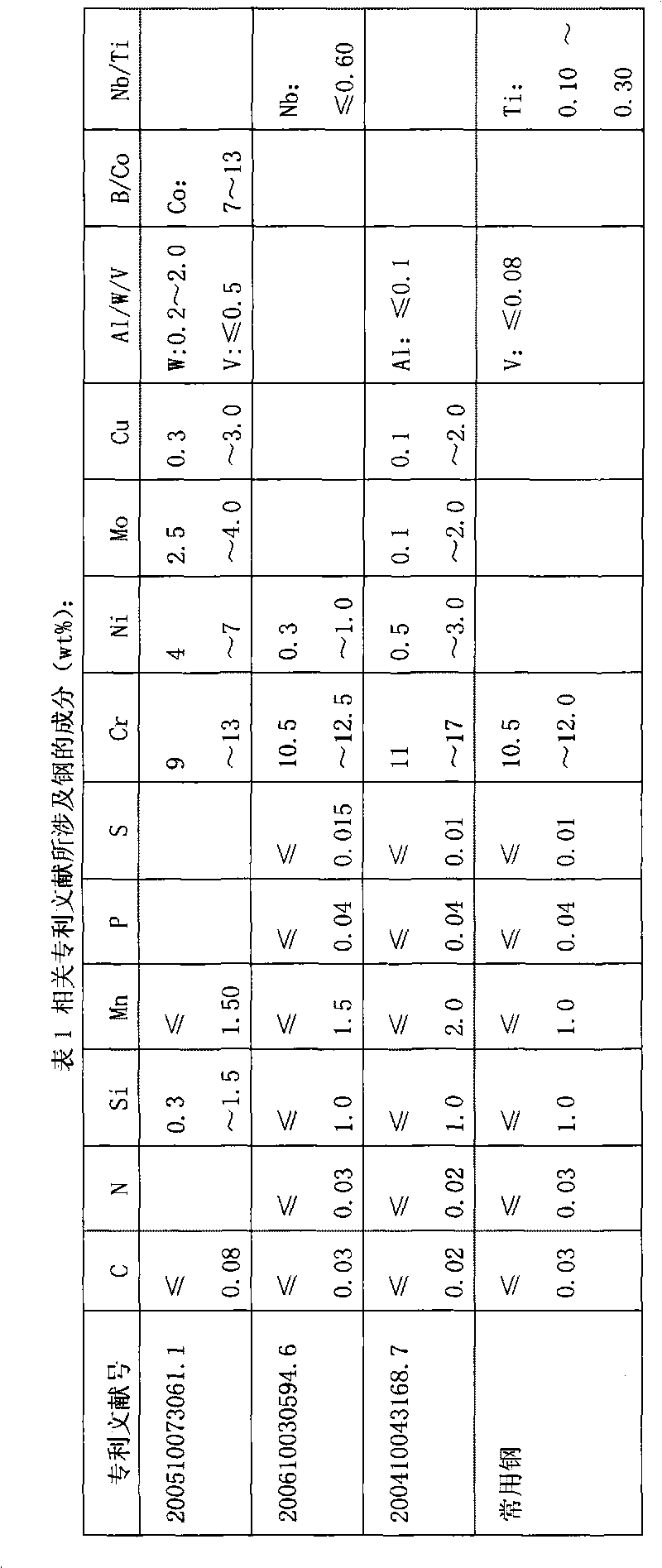

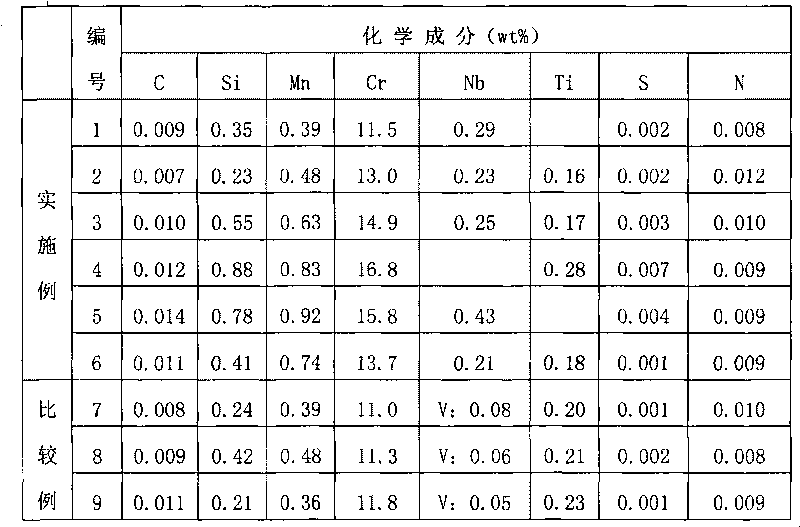

High-strength ferritic stainless steel band and manufacturing method thereof

InactiveCN101748339AHigh strengthImprove corrosion resistanceTemperature control deviceMetal rolling arrangementsHigh intensityUltimate tensile strength

The invention provides a high-strength ferritic stainless steel band, which comprises the following components in percentage by weight: less than or equal to 0.015 percent of C; less than or equal to 1.0 percent of Si; less than or equal to 1.0 percent of Mn; 10.5 to 17.0 percent of Cr; less than or equal to 0.03 percent of P; less than or equal to 0.01 percent of S; less than or equal to 0.1 percent of Ni; less than or equal to 0.015 percent of N; less than or equal to 0.03 percent of Al; less than or equal to 0.006 percent of O; less than or equal to 0.025 percent of C+N; 10(C+N) to 0.60 percent of Nb or 8(C+N) to 0.30 percent of Ti or more than or equal to 10(C+N) to 0.60 percent of Ti+0.5Nb, wherein the ratio of Nb to Ti is between 1.0 and 2.0; the balance of Fe and unavoidable impurities. The invention also provides a method for manufacturing the steel band, which comprises the steps of smelting, continuous casting, coping, hot rolling, annealing and pickling, cold rolling and pickling and bundling. The steel band has higher strength and lower cost and belongs to the environmental-friendly material.

Owner:BAOSHAN IRON & STEEL CO LTD

Totally degradable foam buffer packaging material and its manufacturing method

The invention provides a complete biodegradable foam cushioning packing material and method for preparation, characterized in that starch over 80% content is used as base-material, ultra-fine polyvinyl alcohol is used as film forming intensifier, water is used as foaming agent, and core forming agent and flow modifier are added, wherein the mixture is amalgamated through blending homogeneous machine and fed into reverse-flighted screw extrusion machine for one-shot extrusion forming. The product can be used to substitute polystyrene foam for filling with no requirement on shapes.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

High-performance silicone-acrylate-modified water-based epoxy emulsion and production method thereof

InactiveCN102336874AImprove adhesionExcellent closed shielding performanceAnti-corrosive paintsFilling pastesWater basedChemical industry

The invention discloses a high-performance silicone-acrylate-modified water-based epoxy emulsion and a production method thereof, relating to the technical field of production of coatings used in the chemical industry field. The emulsion is prepared with a core-shell mechanism process; in a core layer, a grafted polymer consists of low molecular bisphenol A epoxy resin, epoxy group siloxane and acrylic ester; a shell body consists of hydroxyl-containing siloxane and acrylic ester; and the shell body and the core layer are subjected to interpenetration graft polymerization. In the invention, epoxy resin is modified with an organic silicon acrylic acid monomer, so that a dense crosslinked netlike structure with a special interpenetration network and excellent enclosed shielding performance is obtained. Multiple series of anti-corrosive paints can be prepared on the basis of the high-performance silicone-acrylate-modified water-based epoxy emulsion provided by the invention by taking mixed modified amine as a curing agent. The emulsion has the advantages of easy and convenient production process, saving in energy, environmental friendliness, easiness for coating construction, low sensitivity to water vapor and temperature, extremely high substrate adhesion, high corrosion resistance, high chemical stability and wide formula adjusting range.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com