Anti-splashing chinlon DTY oil agent and preparation method thereof

An anti-splashing agent and anti-splashing technology, applied in the direction of fiber type, textile and papermaking, fiber processing, etc., can solve the problems of nylon DTY yarn yellowing, incomplete antistatic property of oil agent, poor emulsifying property, etc., and achieve antistatic performance. Excellent, good splash resistance, good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

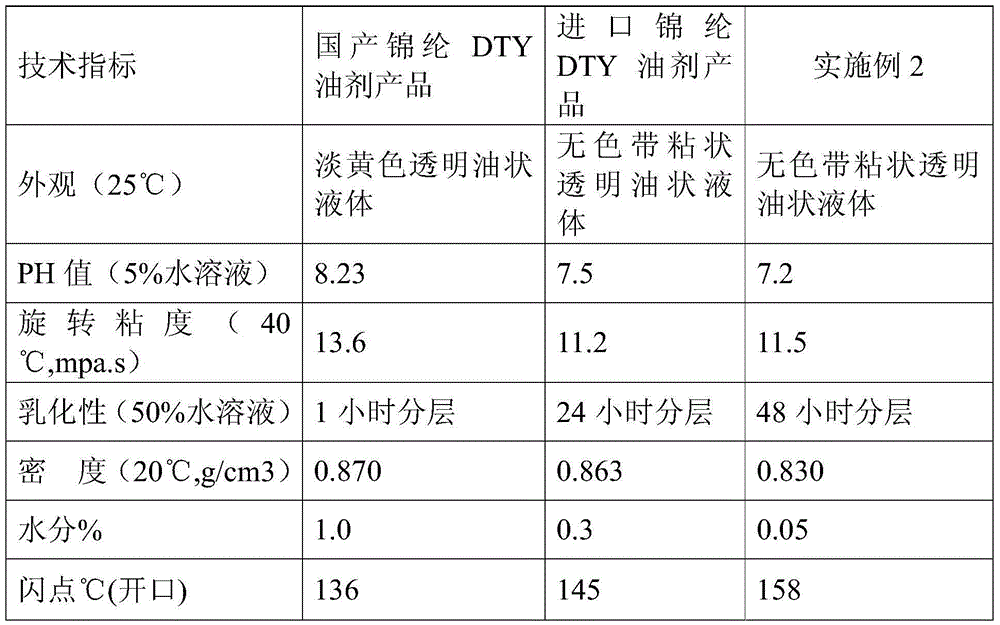

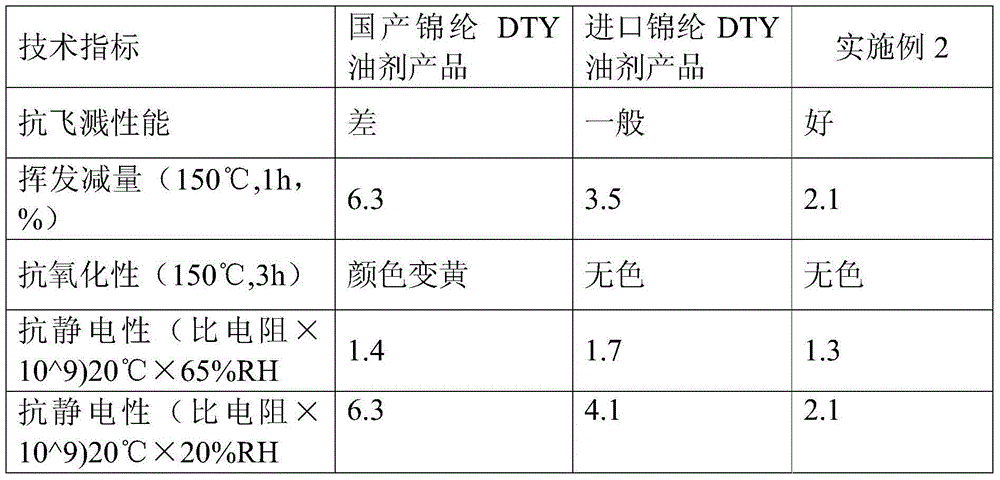

Embodiment 1

[0021] Each component and weight percentage of oil agent are as follows:

[0022] High temperature resistant smoothing agent 60%, of which synthetic oil 1# 50%, synthetic oil 2# 10%.

[0023] Environmentally friendly emulsifier 21%, including high molecular weight random polyether 6%, fatty alcohol polyoxyethylene ether 11%, sorbitan monooleate 4%.

[0024] 10% sizing agent, 7% high molecular weight polyoxypropylene ether and oleic acid polyethylene glycol 400 diester, 3% polysorbate fatty acid ester.

[0025] Composite antistatic agent 5%, high carbon alcohol polyoxyethylene ether phosphate potassium salt 3%, β-alkyl sulfonate 2%.

[0026] Anti-splash agent 2% (ethylene-propylene copolymer 60%, polyisobutylene 40%), additive 2%.

Embodiment 2

[0028] Each component and weight percentage of oil agent are as follows:

[0029] High temperature resistant smoothing agent 70%, of which synthetic oil 1# 50%, synthetic oil 2# 20%.

[0030] 10% environmentally friendly emulsifier, including 2% sorbitan monooleate, 7% fatty alcohol polyoxyethylene ether, and 1% fatty acid diethanolamide.

[0031] Sizing agent 9%, high molecular weight polyoxypropylene ether and oleic acid polyethylene glycol 400 diester 4%, polypropylene glycol alkyl phosphate 3%, polysorbate fatty acid ester 2%.

[0032] Composite antistatic agent 8%, high carbon alcohol polyoxyethylene ether phosphate potassium salt 5%, β-alkyl sulfonate 3%.

[0033] Anti-splash agent 2% (ethylene-propylene copolymer 40%, polyisobutylene 60%), additive 1%.

Embodiment 3

[0035] Each component and weight percentage of oil agent are as follows:

[0036] High temperature resistant smoothing agent 60%, of which synthetic oil 1# 30%, synthetic oil 2# 30%.

[0037] 25% environmentally friendly emulsifier, including 8% sorbitan oleic acid monoester, 15% fatty alcohol polyoxyethylene ether, and 2% fatty acid diethanolamide.

[0038] 3% sizing agent, 2% high molecular weight polyoxypropylene ether and oleic acid polyethylene glycol 400 diester, 1% polysorbate fatty acid ester.

[0039] Composite antistatic agent 8%, isomeric alcohol polyoxyethylene ether phosphate potassium salt 5%, β-alkyl sulfonate 3%.

[0040] Anti-splash agent 2% (ethylene-propylene copolymer 20%, polybutene 80%), additive 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com