Patents

Literature

607results about How to "Easy to bundle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

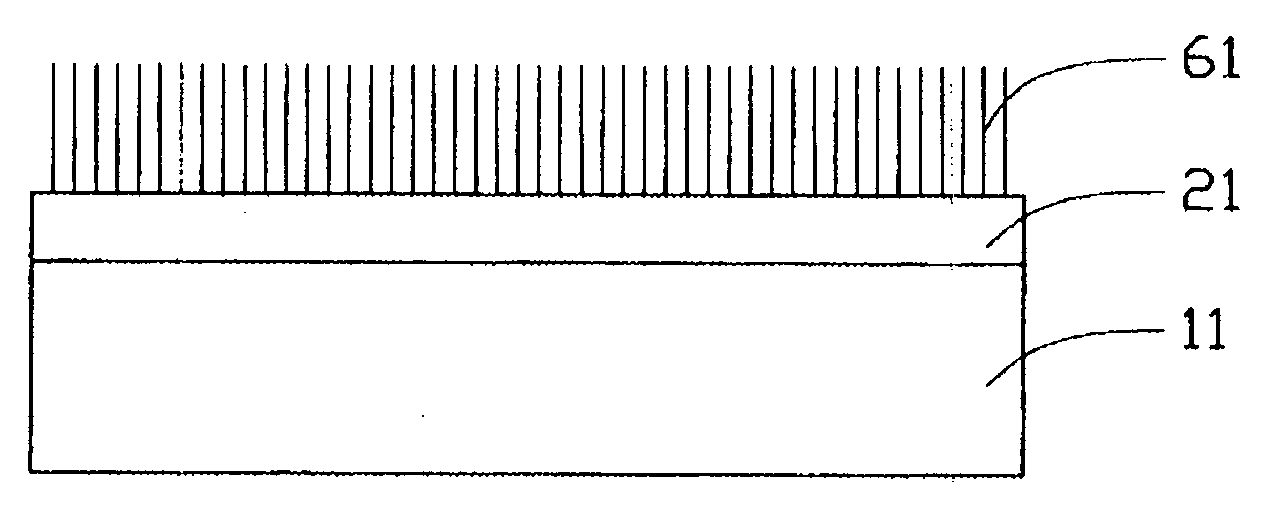

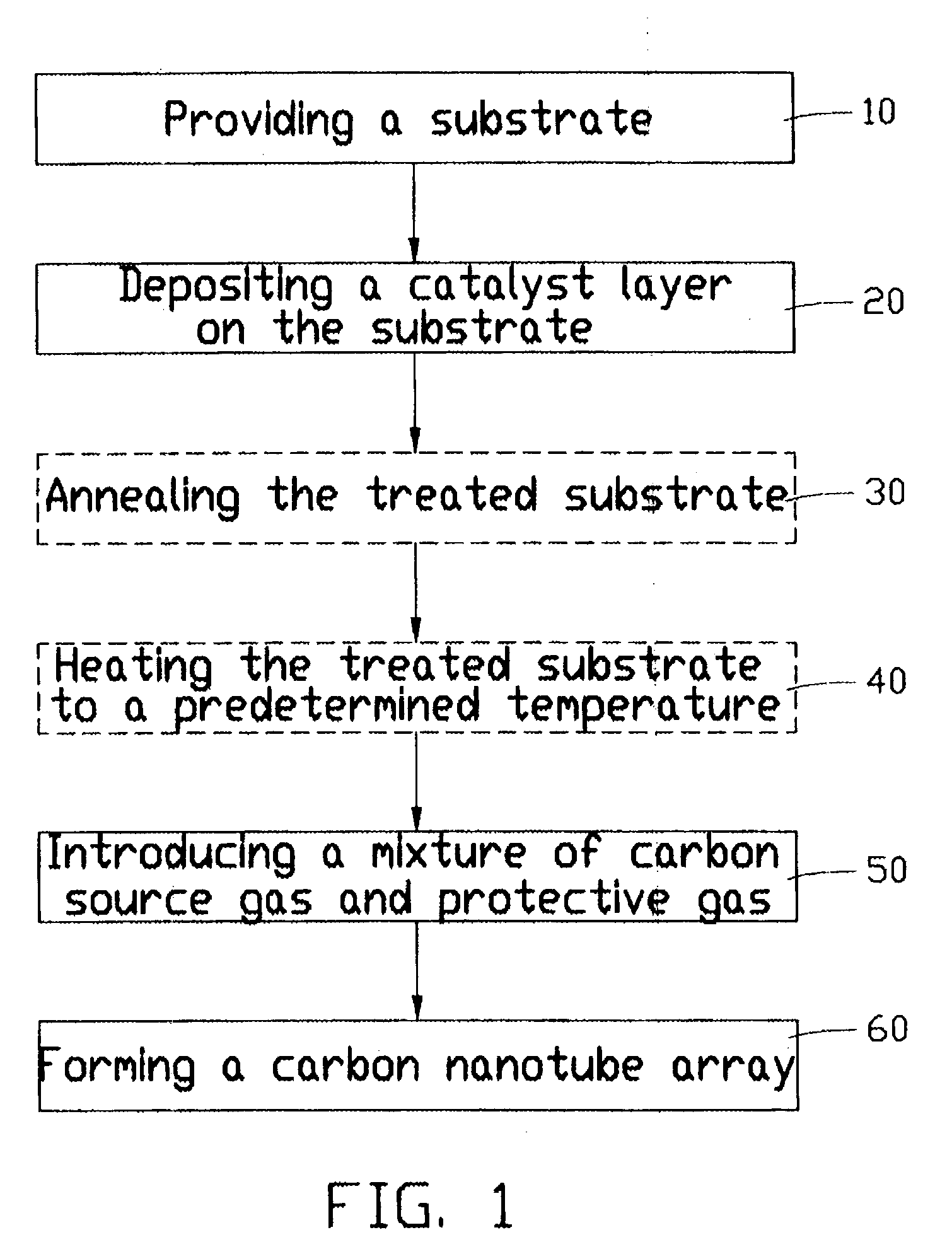

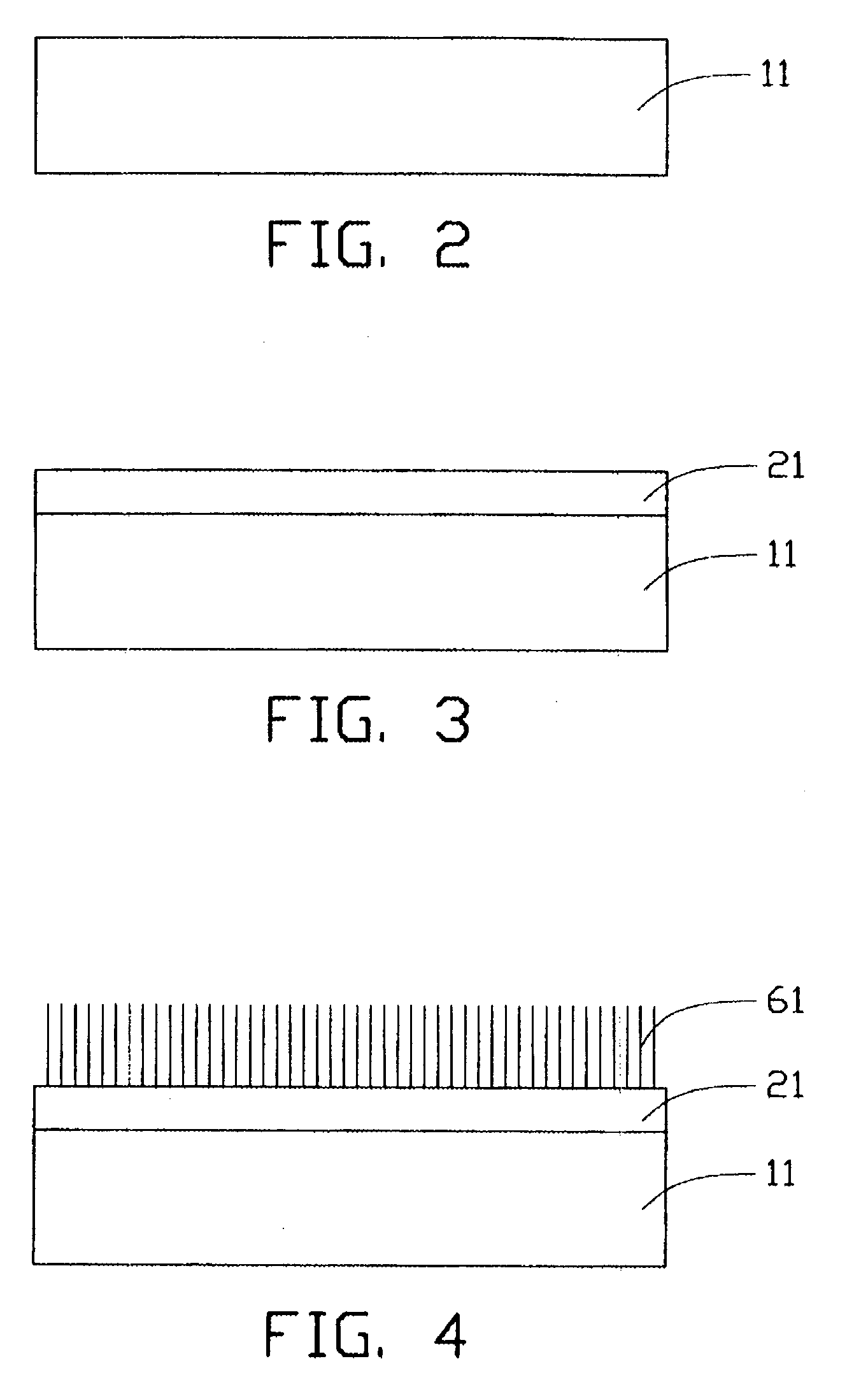

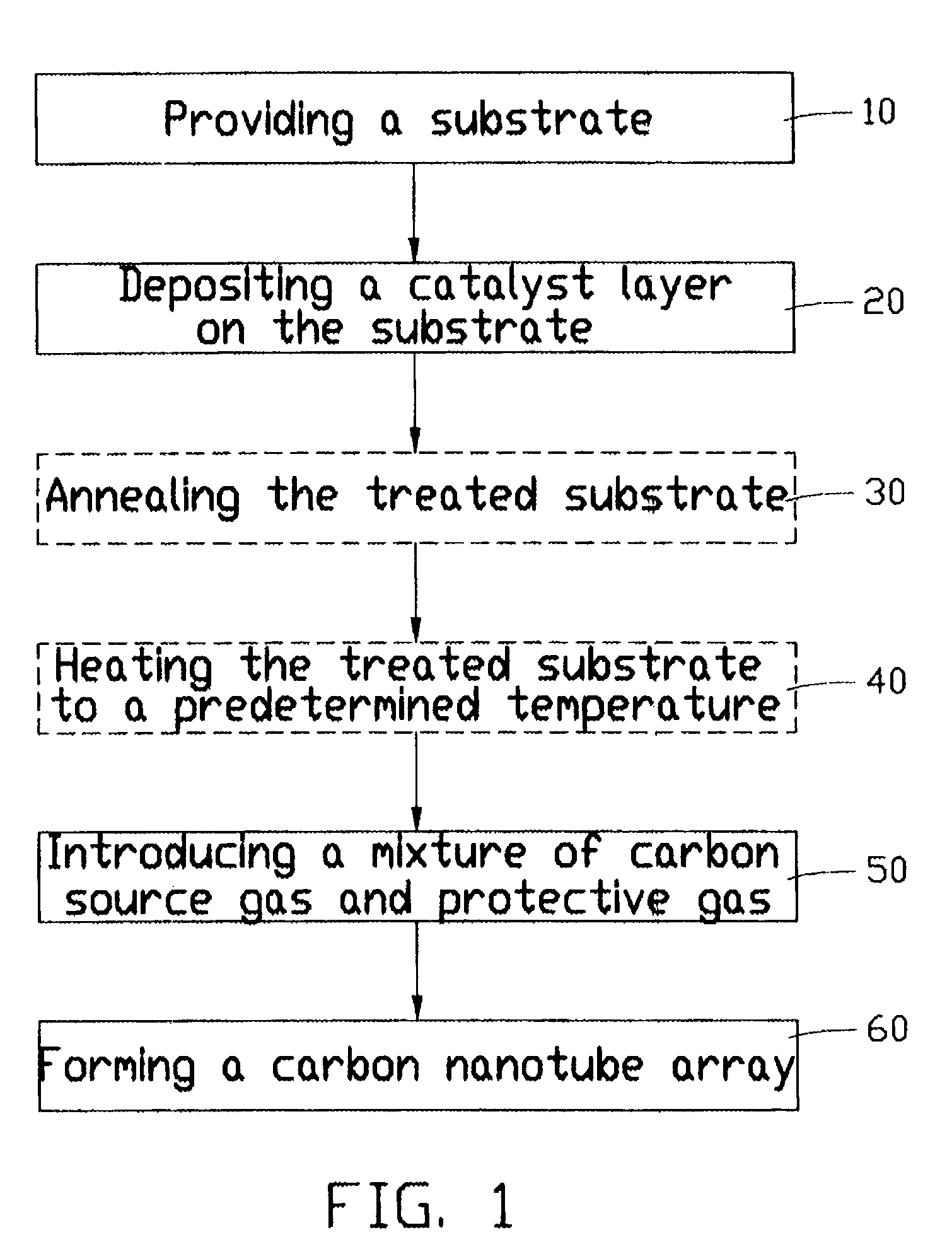

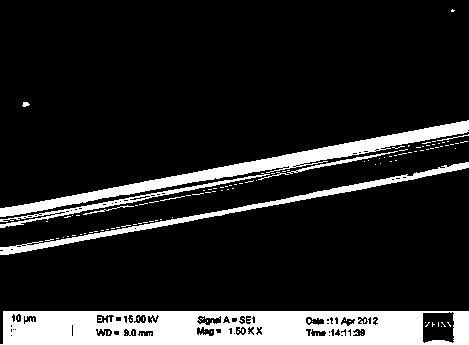

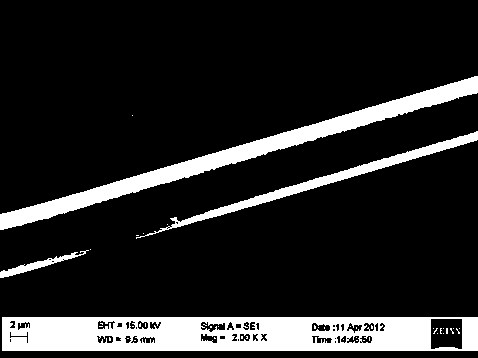

Carbon nanotube array and method for forming same

ActiveUS20040053053A1Reduce partial pressureEasy to bundleMaterial nanotechnologyPolycrystalline material growthMetal catalystCarbon nanotube

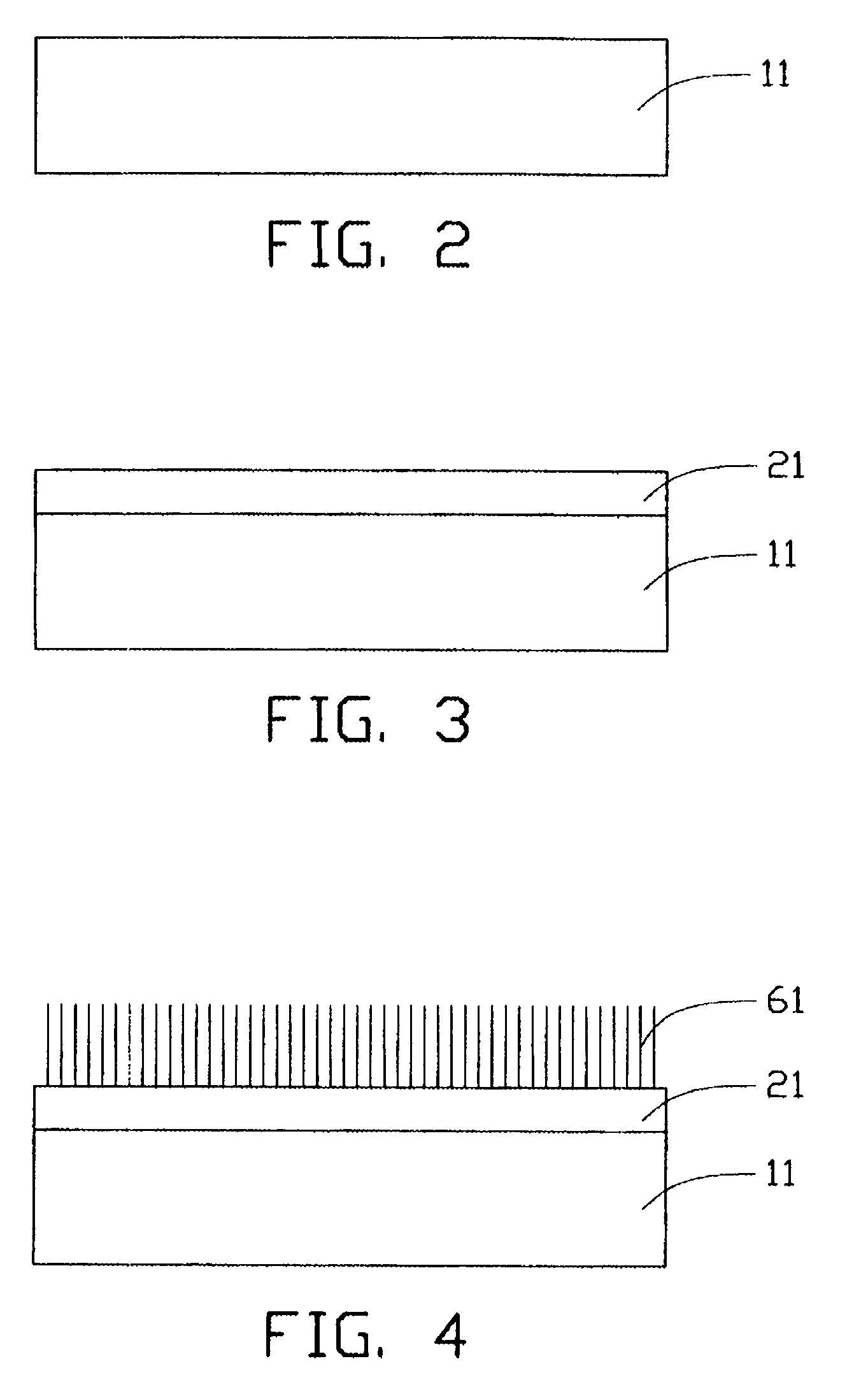

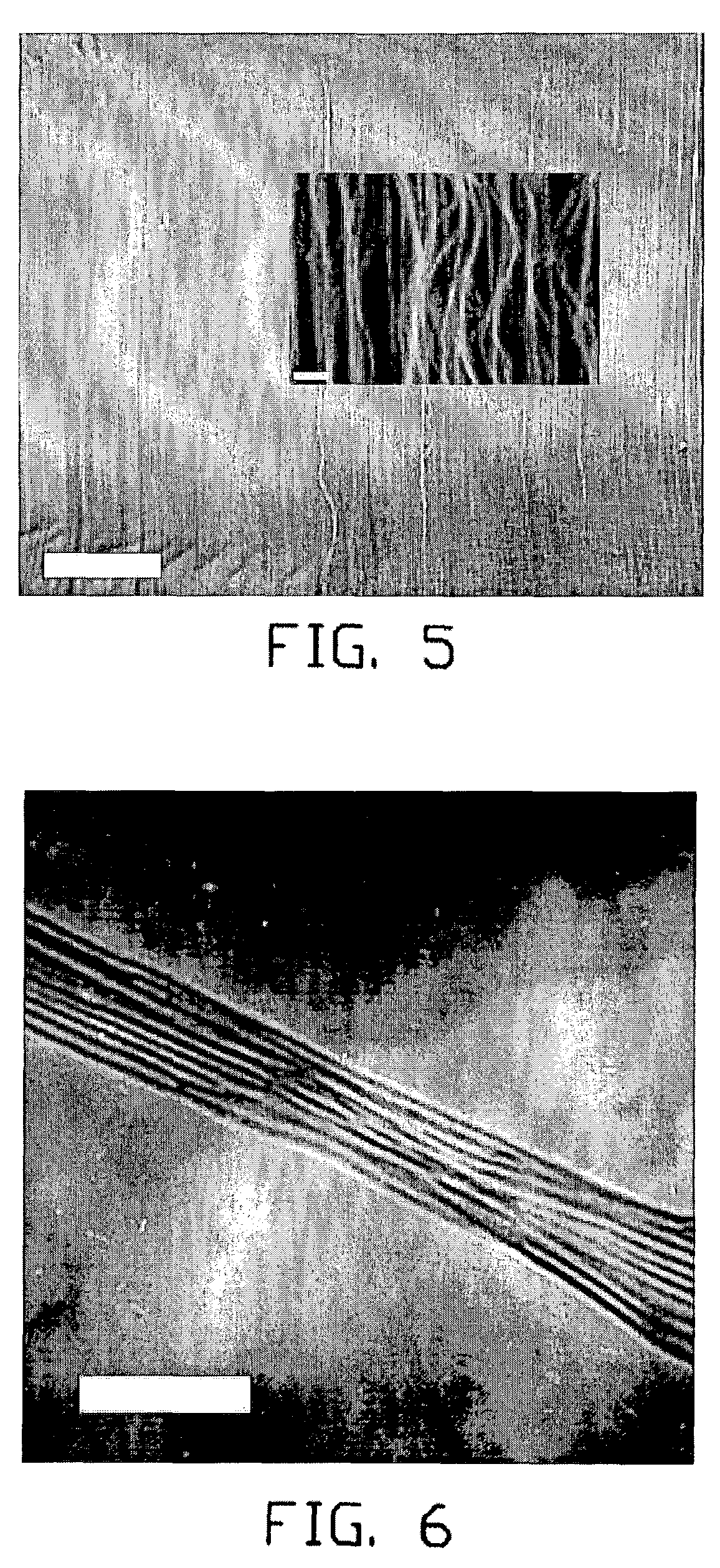

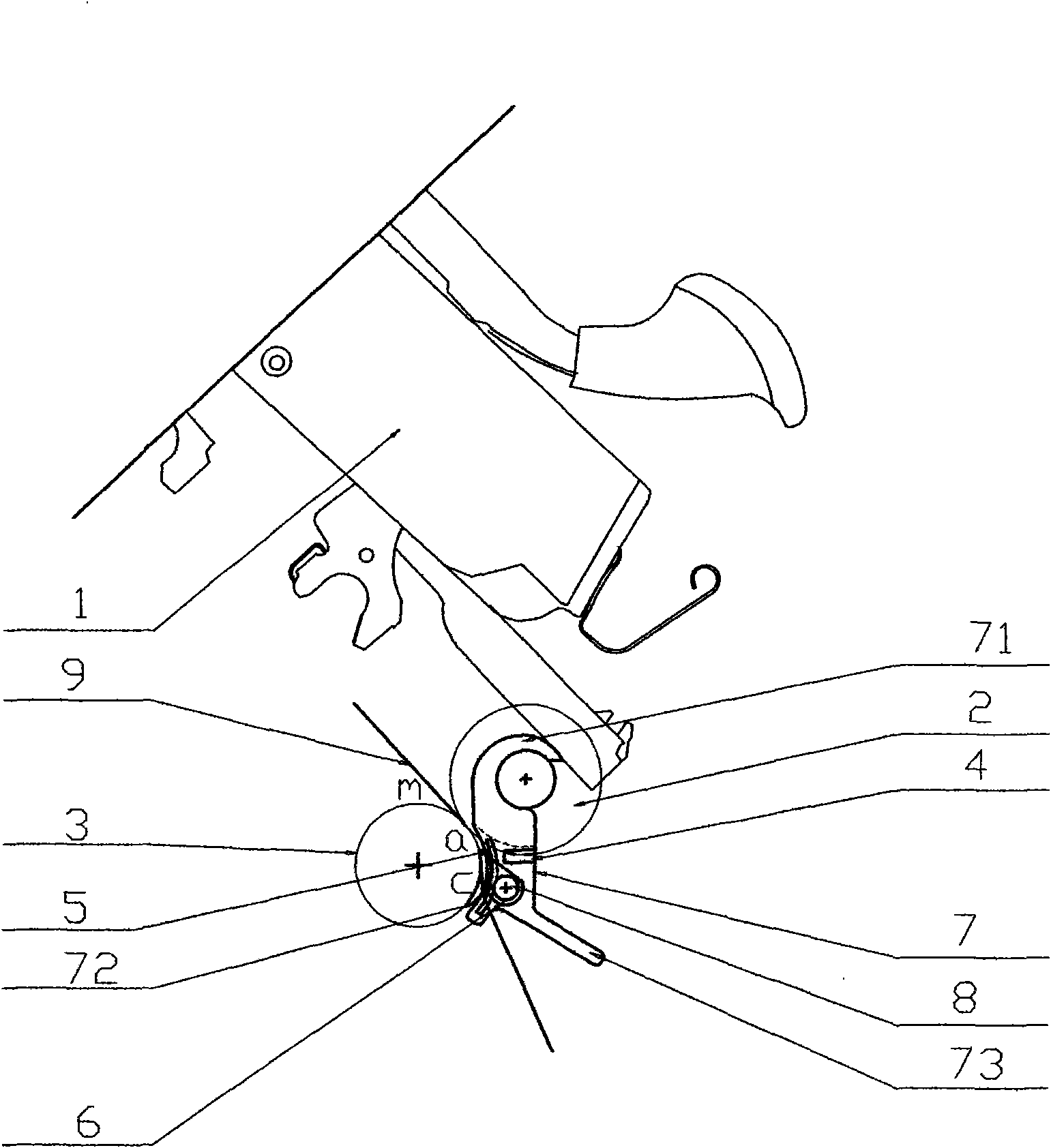

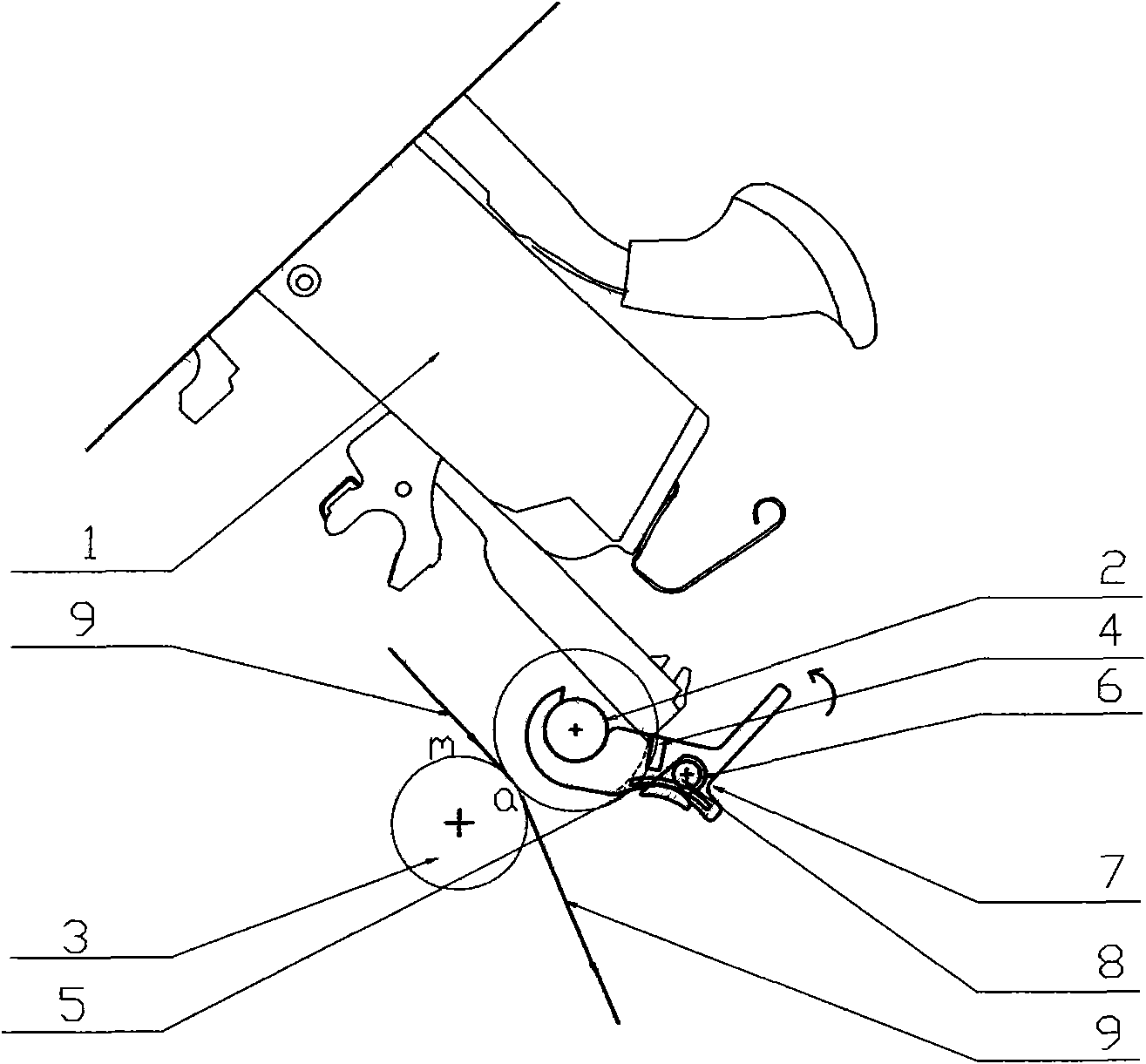

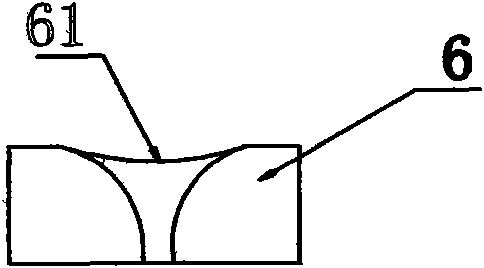

A method for forming a carbon nanotube array includes the following steps: providing a smooth substrate (11); depositing a metal catalyst layer (21) on a surface of the substrate; heating the treated substrate to a predetermined temperature in flowing protective gas; and introducing a mixture of carbon source gas and protective gas for 5-30 minutes, thus forming a carbon nanotube array (61) extending from the substrate. When the mixture of carbon source gas and protective gas is introduced, a temperature differential greater than 50° C. between the catalyst and its surrounding environment is created by adjusting a flow rate of the carbon source gas. Further, a partial pressure of the carbon source gas is maintained lower than 20%, by adjusting a ratio of the flow rates of the carbon source gas and the protective gas. The carbon nanotubes formed in the carbon nanotube array are well bundled.

Owner:HON HAI PRECISION IND CO LTD +1

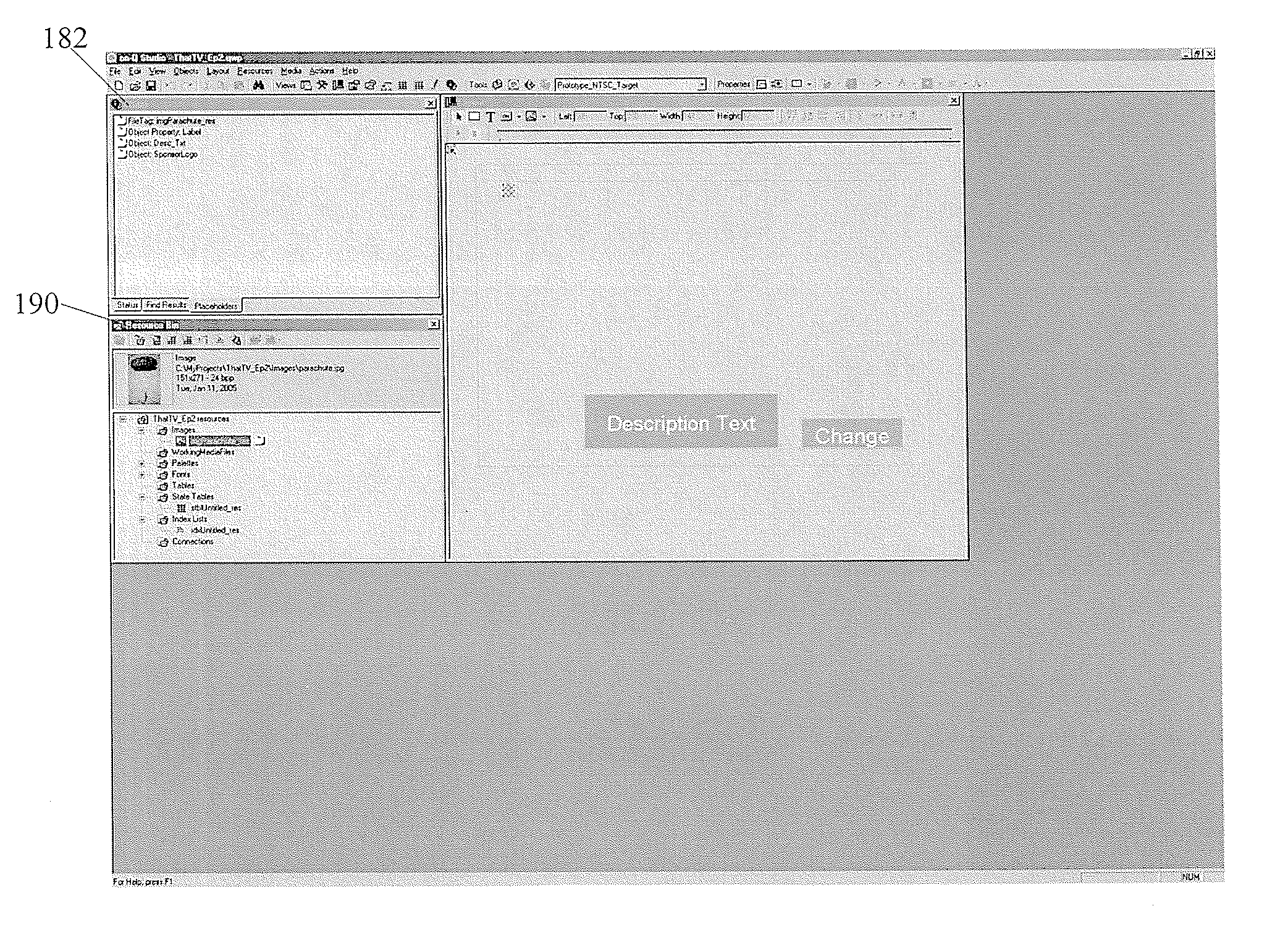

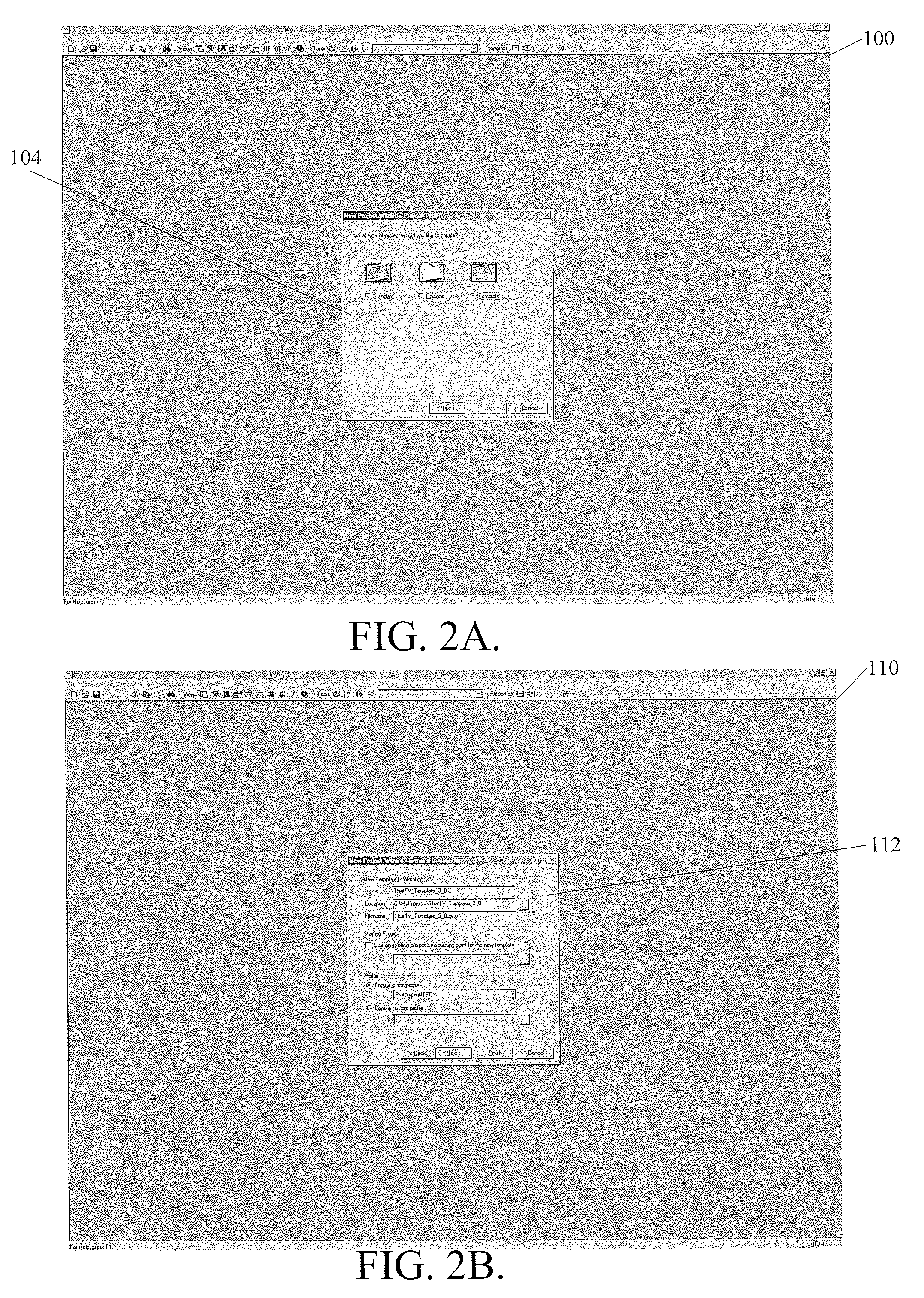

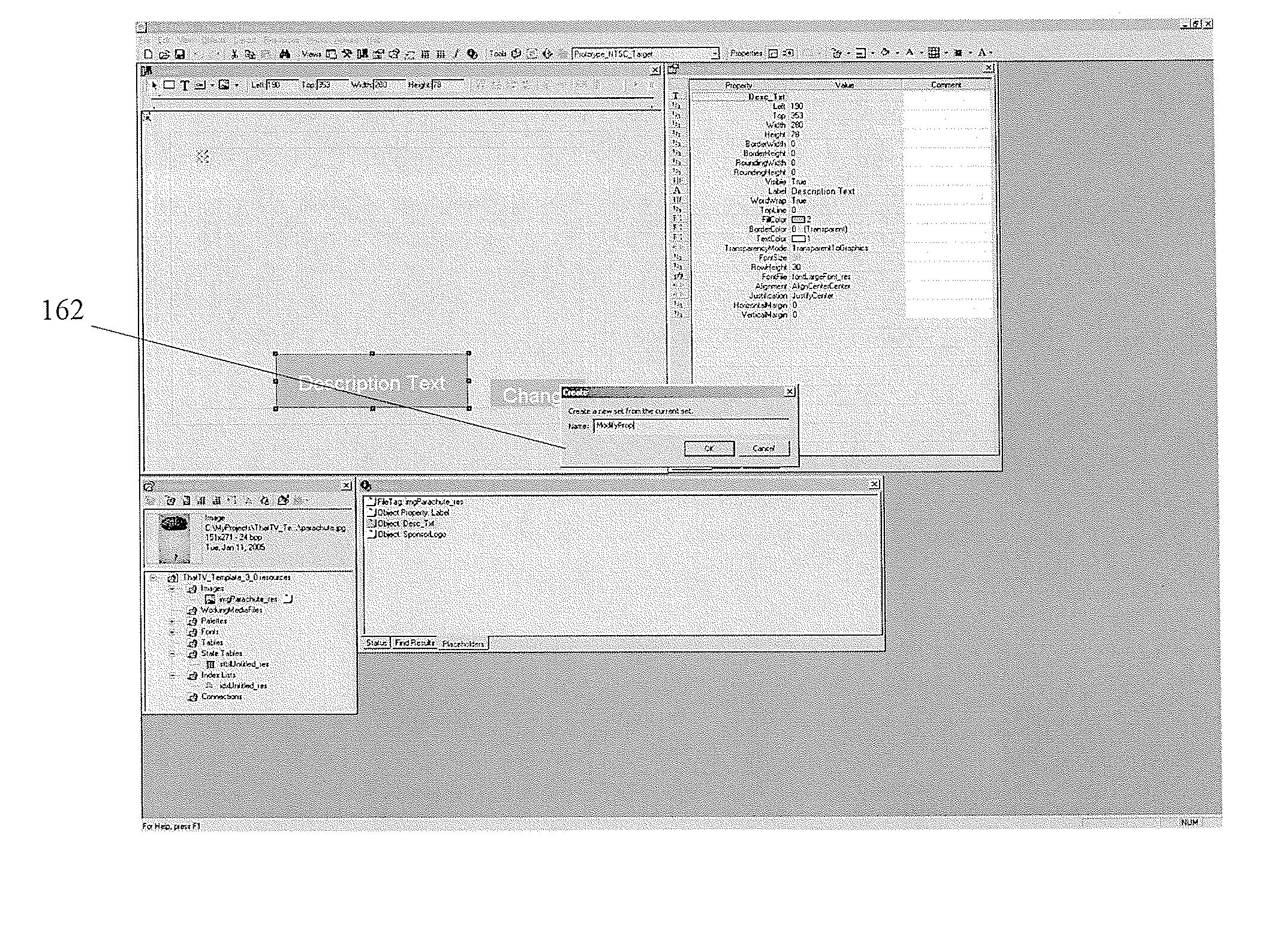

Configurable interface for template completion

ActiveUS7430718B2Easy to bundleDigital computer detailsAnalogue secracy/subscription systemsGraphicsGraphical user interface

Owner:ESW HLDG INC

Configurable interface for template completion

ActiveUS20060053390A1Easy to bundleAnalogue secracy/subscription systemsSelective content distributionGraphicsGraphical user interface

Systems, methods and graphical user interfaces for creating interactive television applications are provided. A template author creates a template application and assigns placeholder objects do display elements. An episodic creator creates an episodic application by making changes to display elements associated with a presented placeholder object.

Owner:ESW HLDG INC

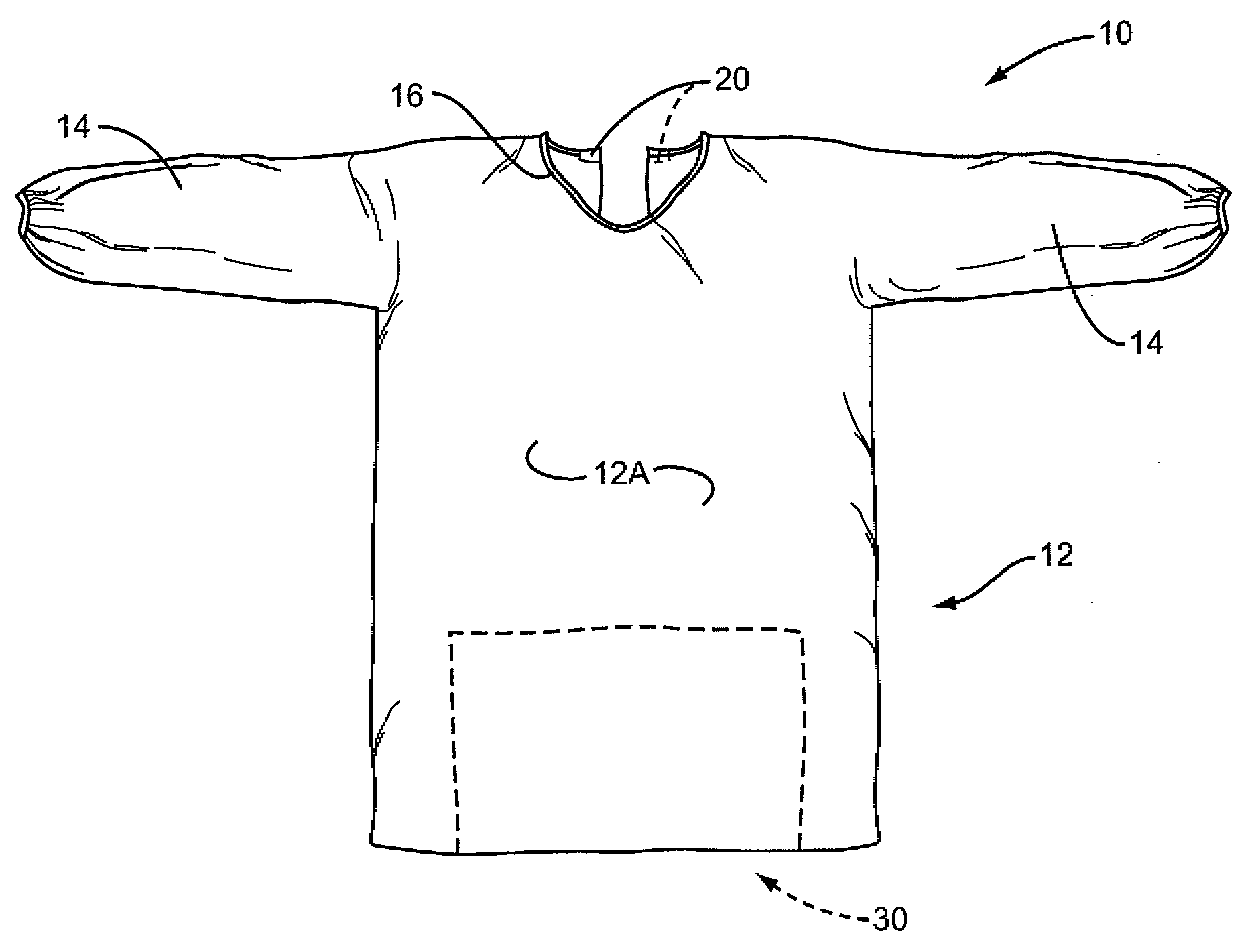

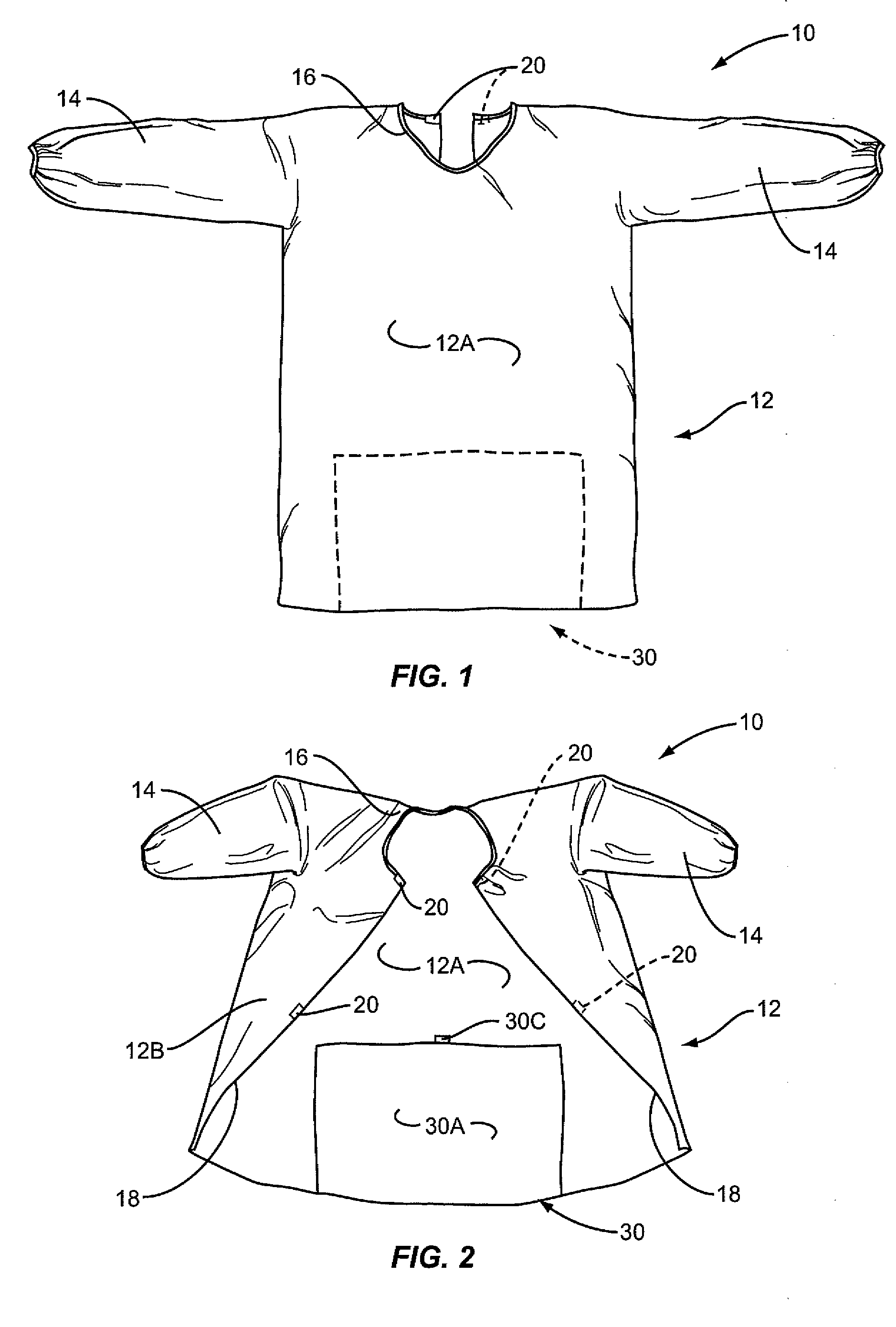

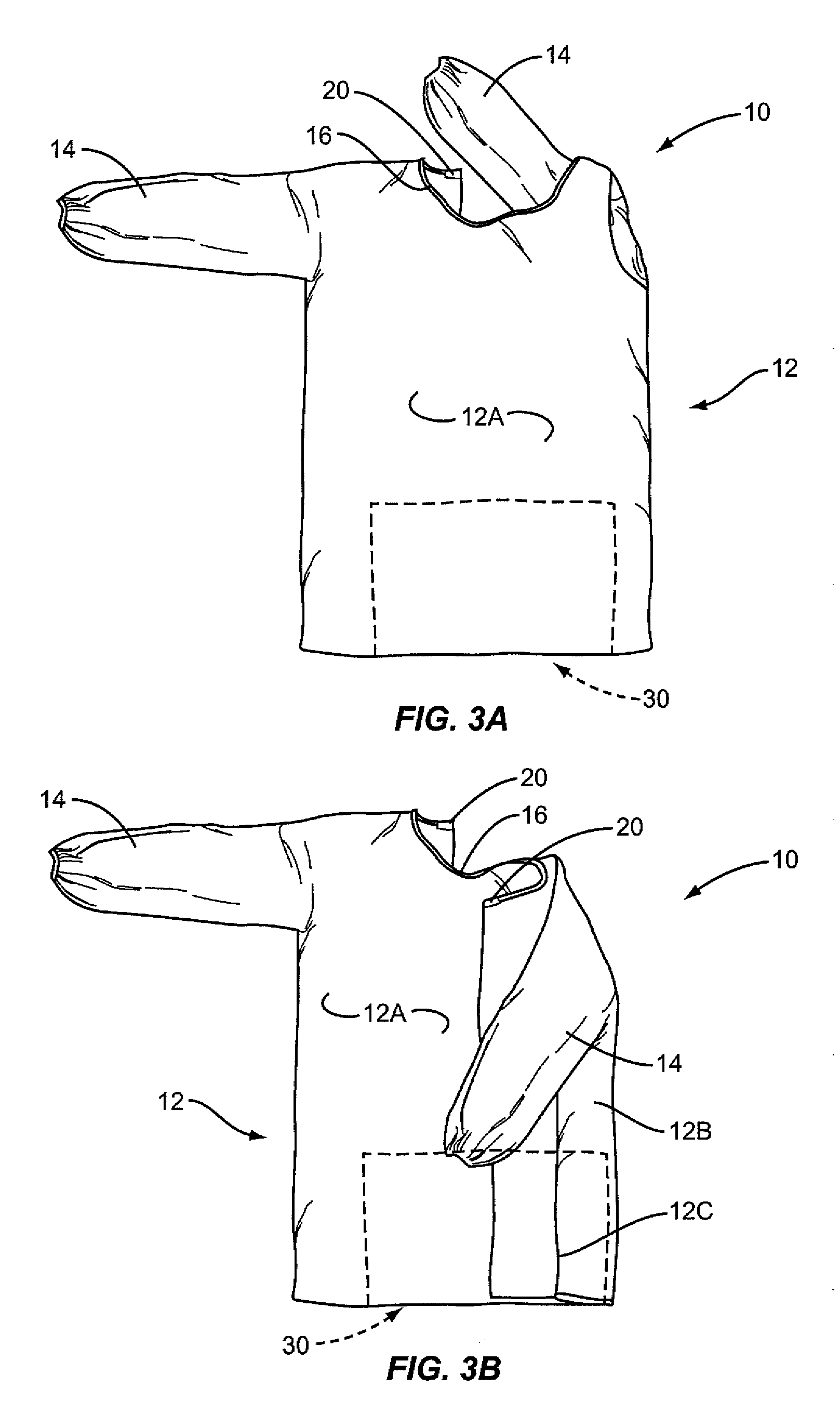

Disposable hospital gown

InactiveUS20110024485A1Easy to foldEasy to bundleGarment special featuresPyjamasSurgical GownsGeneral surgery

A disposable hospital gown is provided having a main body and a pair of sleeves. Integrally formed with the hospital gown is a disposable wrapper that is particularly positioned or placed such that the gown can be rolled or folded into a bundle, after which the disposable wrapper is reversed and in the process of reversing the disposable wrapper, the bundled gown is stuffed or placed into the reversed disposable wrapper for disposal. The disposable hospital gown is suitable for use as an isolation hospital gown, a surgical gown, or a patient disposable gown.

Owner:POROWSKI VIRGINIA

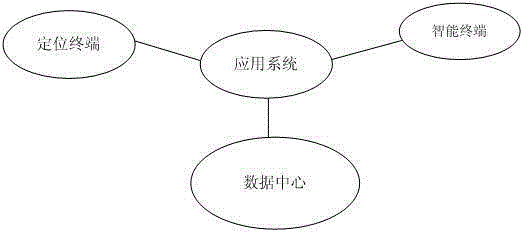

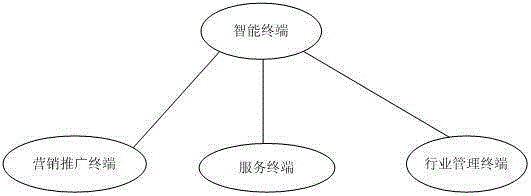

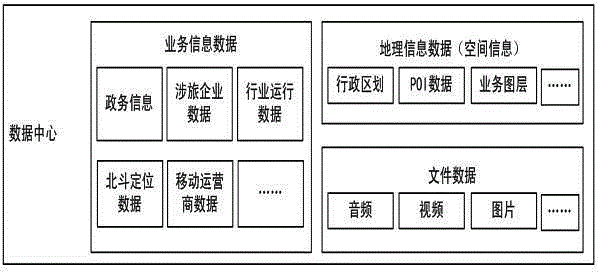

Comprehensive management system for scenic regions

The invention discloses a comprehensive management system for scenic regions. The comprehensive management system comprises an intelligent terminal, at least one data center and at least one positioning terminal; the intelligent terminal comprises a marketing promotion terminal or / and a service terminal or / and an industrial management terminal; the positioning terminal is used for collecting static position data of scenic spots and facilities in scenic regions; the positioning terminal is further used for collecting dynamic position data of touring vehicles, tourists and team tourists; the data center is for obtaining business information data and geographic information data; the data center performs centralized database-establishment and management according to the business information data and the geographic information data; the data center is provided with corresponding an industrial management module, a service module and a marketing promotion module according to the business information data and the geographic information data; the marketing promotion terminal establishes marketing promoting activities with the data center through the marketing promotion module; the industrial management terminal establishes industrial management activities with the data center through the industrial management module; and the service terminal establishes service activities with the data center through the service module.

Owner:成都中科大旗软件股份有限公司

Method for preparing self-emulsifying carbon fiber sizing agent component

InactiveCN101880967AGood compatibilityGood static stabilityCarbon fibresCarbon fibersSelf emulsifying

The invention discloses a method for preparing a self-emulsifying carbon fiber sizing agent component, which comprises the following steps of: performing graft polymerization reaction on epoxy resin by adopting an emulsion polymerization method to prepare modified epoxy emulsion; and standing the modified epoxy emulsion at 80 DEG C for two hours, adding dropwise ammonia water into the solution after demulsification to make the solution alkaline, standing the solution at 95 DEG C in a sealing way, stirring and hydrolyzing the solution for 3 hours, taking the solution out, acidifying and neutralizing the redundant ammonia water, drying and rinsing the solution to produce modified bisphenol A epoxy resin, placing the synthesis product in the step and the bisphenol A epoxy resin into a container according to a certain weight ratio, and performing phase-inversion emulsification on the mixture at 70 DEG C to prepare a modified epoxy emulsion sizing agent component with certain solid content. The prepared carbon fiber sizing agent component has the characteristics of storage time longer than 12 months, high high-temperature stability, and high dilution stability, so that the method has huge breakthrough compared with the prior art. Carbon fibers sized by the sizing agent have high machining performance and improved inter-layer shear strength.

Owner:BEIHANG UNIV

Carbon nanotube array and method for forming same

ActiveUS7754182B2Clean evenlyFlat surfaceMaterial nanotechnologyPolycrystalline material growthMetal catalystCarbon nanotube

A method for forming a carbon nanotube array includes the following steps: providing a smooth substrate (11); depositing a metal catalyst layer (21) on a surface of the substrate; heating the treated substrate to a predetermined temperature in flowing protective gas; and introducing a mixture of carbon source gas and protective gas for 5-30 minutes, thus forming a carbon nanotube array (61) extending from the substrate. When the mixture of carbon source gas and protective gas is introduced, a temperature differential greater than 50° C. between the catalyst and its surrounding environment is created by adjusting a flow rate of the carbon source gas. Further, a partial pressure of the carbon source gas is maintained lower than 20%, by adjusting a ratio of the flow rates of the carbon source gas and the protective gas. The carbon nanotubes formed in the carbon nanotube array are well bundled.

Owner:HON HAI PRECISION IND CO LTD +1

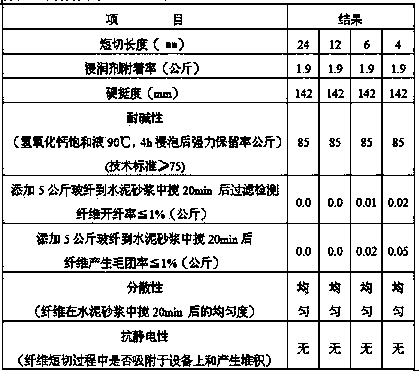

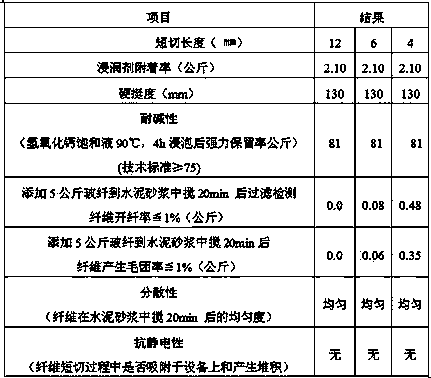

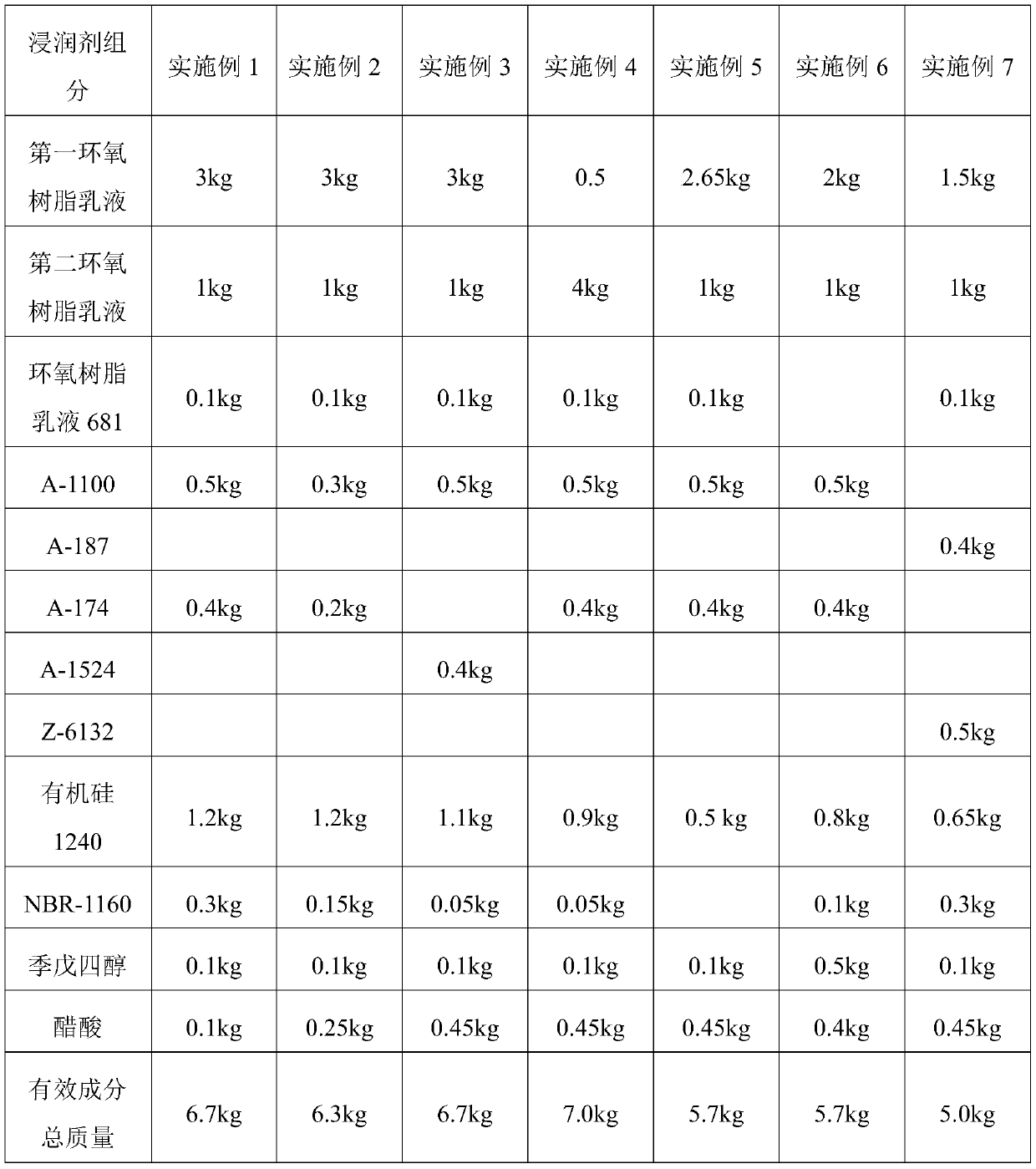

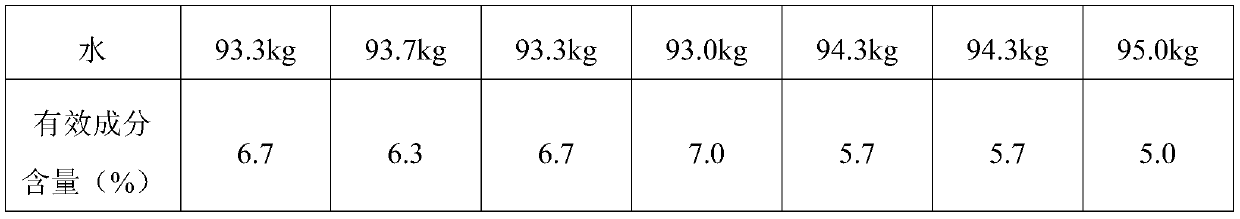

Preparation method of alkali-proof chopped glass fiber impregnating compound

The invention discloses an alkali-proof chopped glass fiber impregnating compound, and relates to a preparation method of a glass fiber surface treating agent containing an organic material. The preparation method comprises the following steps: mixing deionized water and glacial acetic acid and evenly stirring; adding a silane coupling agent, a polyacrylate film-forming agent, an epoxy resin emulsion film-forming agent, a water-soluble epoxy film-forming agent, an organosilicone lubricant and a cationic lubricant which are diluted by deionized water, and an antistatic agent diluted by deionized water; and finally adding deionized water and stirring for 15-25 minutes, wherein the stirring speed is 60r / m, wherein the film-forming agents are the polyacrylate film-forming agent, the epoxy resin emulsion film-forming agent and the water-soluble epoxy film-forming agent, the mass ratio of the polyacrylate film-forming agent to the epoxy resin emulsion film-forming agent to the water-soluble epoxy film-forming agent is (2.0-20.0) to (15.0-2.5) to (1.0-10). The alkali-proof chopped glass fiber impregnating compound disclosed by the invention is suitable for an alkali-proof chopped glass fiber of 4-24mm; the impregnated alkali-proof chopped glass fiber has good alkali resistance, bundling property, abrasive resistance, water tolerance, choppability, dispersibility and antistatic property, and cannot disperse in a cement mixing and agitating process; the bundling state of a precursor fiber is kept.

Owner:陕西汇友友基新材料有限公司

Reinforced textile type glass fiber treating compound and preparation thereof

The invention provides an impregnating compound for reinforced textile glass fibers, which takes novel organic polymer materials as a main body. The impregnating compound comprises the following compositions by weight percentage: 5 to 10 percent of polyvinyl acetate emulsion, 1 to 4 percent of polyester emulsion, 2 to 8 percent of epoxy resin, 0.2 to 2 percent of polyurethane emulsion, 0.01 to 0.2 percent of lubricant, 0.1 to 0.5 percent of coupling agent, 0.05 to 0.3 percent of antistatic agent, 0.2 to 3 percent of surfactant, 0.05 to 1 percent of acetic acid, and the balance being deionized water. The impregnating compound has good convergence, lubricity, film-forming property and antistatic property; the glass fibers which are treated by the impregnating compound have the characteristics of bending resistance, flexibility, tensile resistance, good solubility with resin and so on; and the impregnating compound is suitable for treating the surfaces of various reinforced textile glass fibers.

Owner:上海世鹏聚氨酯科技发展有限公司

Terylene FDY nano spinning finish and its preparing process

The invention relates to polyester FDY nanometer spinning oil solution and a method for preparing the polyester FDY nanometer spinning oil solution, wherein the polyester FDY nanometer spinning oil solution takes the oil solution total weight as benchmark and comprises: smoothing agent 46-48%, emulsifier 28-32%, anstatic agent 9-10%, balance adjuster 5-7% and inorganic nanometer additive 5-7%. Each component of the oil solution is rationally mixed and mutually coordinated, and the oil solution has good comprehensive property. The method for preparing the polyester FDY nanometer spinning oil solution comprises: preparing inorganic nanometer additive, adding the smoothing agent, the emulsifier and the anstatic agent into a reactor, heating and stirring until the mixture becomes even, cooling the mixture which is evenly stirred, filtering, and obtaining the oil solution products. The method for preparing is simple and easy to operate.

Owner:吴江市良燕纺织助剂厂

Lubricating antistatic high-performance oil for drawing production of carbon fibre

InactiveCN101280475AAvoid defectsReduce frictionMonocomponent synthetic polymer artificial filamentSynthetic polymer filament chemical after-treatmentFiberEpoxy

The invention relates to the chemical materials of the new material field, in particular to a high-performance anti-static lubricating finish oil used in the carbon fiber wire-drawing production process. The composition of the raw materials is calculated with the weight percentage. The quaternary ammonium salt type cationic surfactant of 3 to 10, the polyoxyethylene-polyoxy-propylene-polyether of 1 to 3, the ammonia modified silicone oil of 2 to 8, epoxy-modified silicone oil of 2 to 8, polyether modified silicone oil of 2 to 8, the fluoride silicon oil of 10 to 20, lauric acid polyoxyethylene ester of 1 to 3, laurinol polyoxyethylene of 1 to 3, polyoxyethylene hydrogenerated castor oil of 4 to 20, and the rest of high-purity deionized water are stirred in a reaction kettle for 3 to 5 hours with the temperature controlled within the range of 56 to 60 DEG degree, thus the finish oil product can be produced. The invention is applied in the carbon fiber wiredrawing production process, in which the finish oil is in the formation of a membrane on the monofilament surface, not only the adhesion and merging between the monofilaments can be avoided, but also the friction and wear of the fiber surface and the roller during the production process can be prevented. Therefore, the finish oil has excellent smoothness, antistatic property, collection property and self-emulsifying property as well.

Owner:李元杰

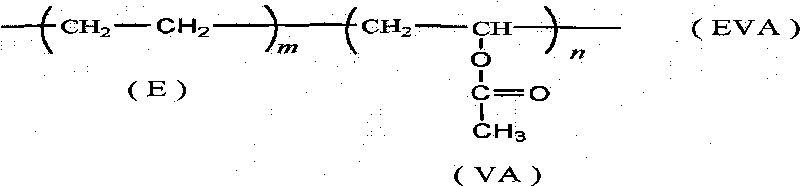

Fiber sizing agent composition

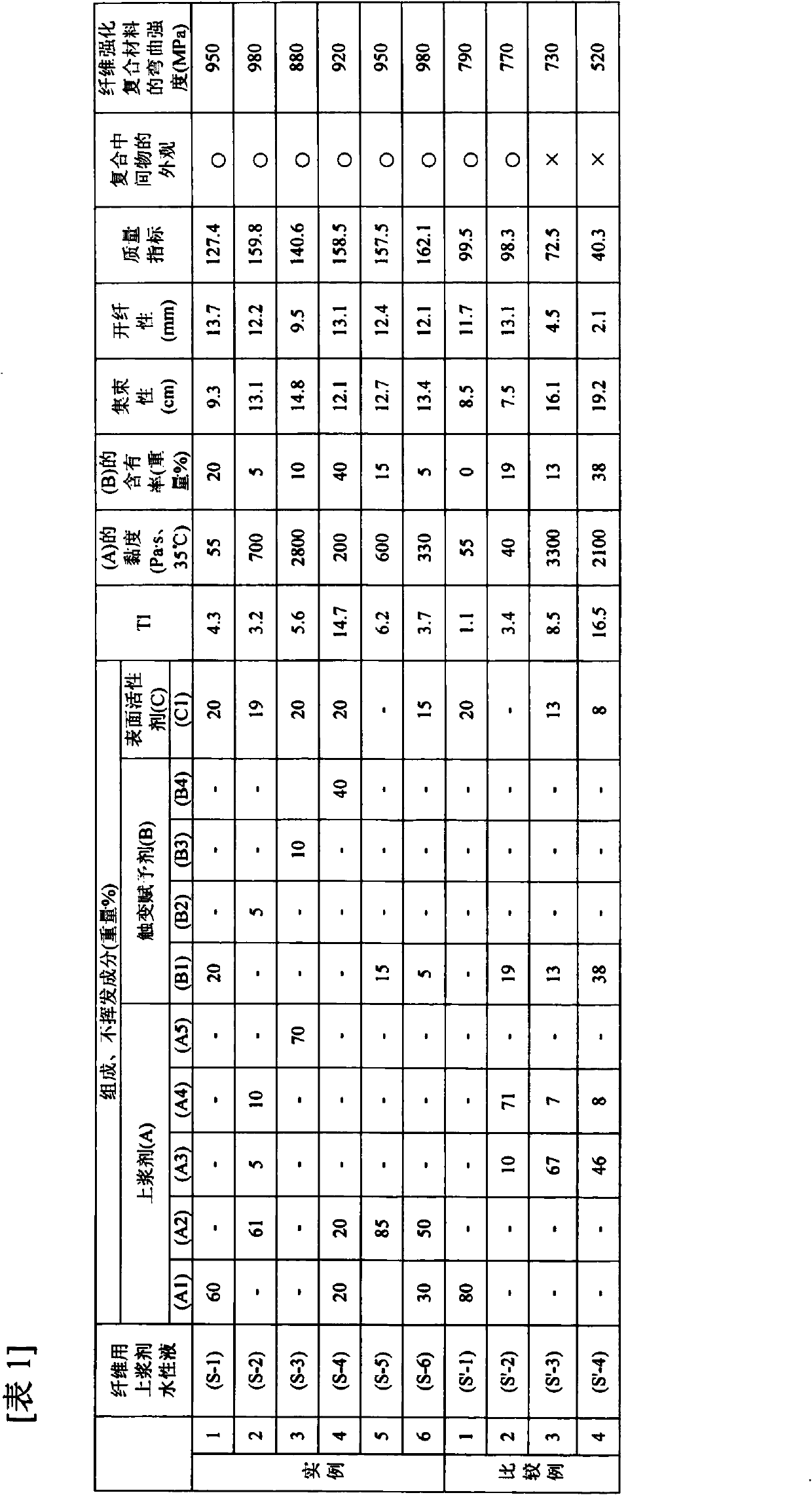

InactiveCN103797183AEasy to bundleGood fiber opening effectCarbon fibresThin material handlingEpoxyFiber bundle

Provided is a fiber sizing agent capable of imparting sufficient sizing properties and fiber spreading properties to reinforced fiber bundles for producing fiber-reinforced composite materials. A fiber sizing agent composition (E) which contains a fiber sizing agent (A), said fiber sizing agent having a viscosity at 35oC of 50-3,000 Pas, and has a thixotropic index of 3-15. As the sizing agent (A), an epoxy resin, a polyester rein, a polyurethane resin, a polyether resin and a vinyl ester resin are preferred.

Owner:SANYO CHEM IND LTD

Oil solution for spandex spinning by dry method, and preparation and use thereof

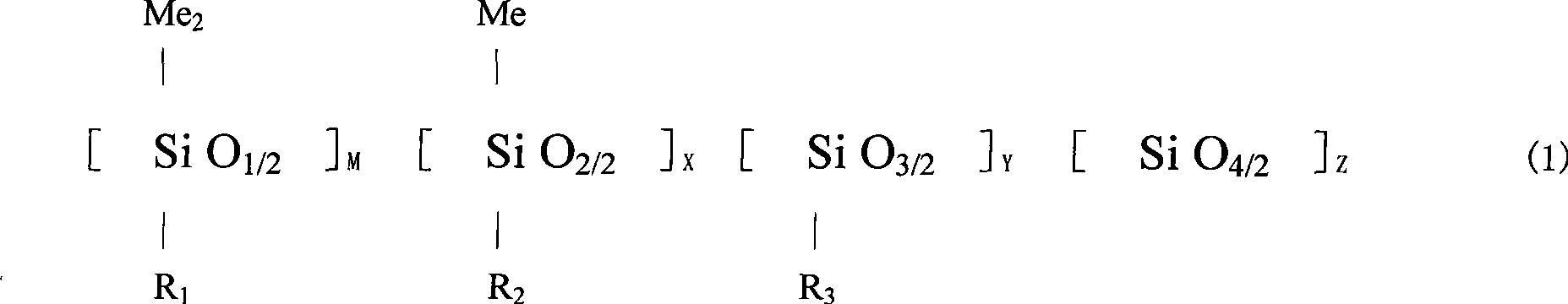

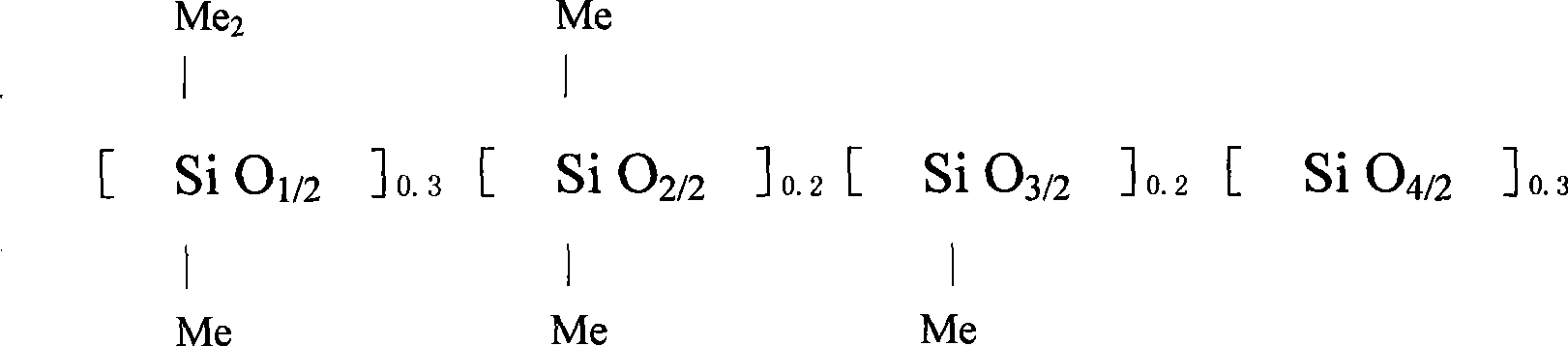

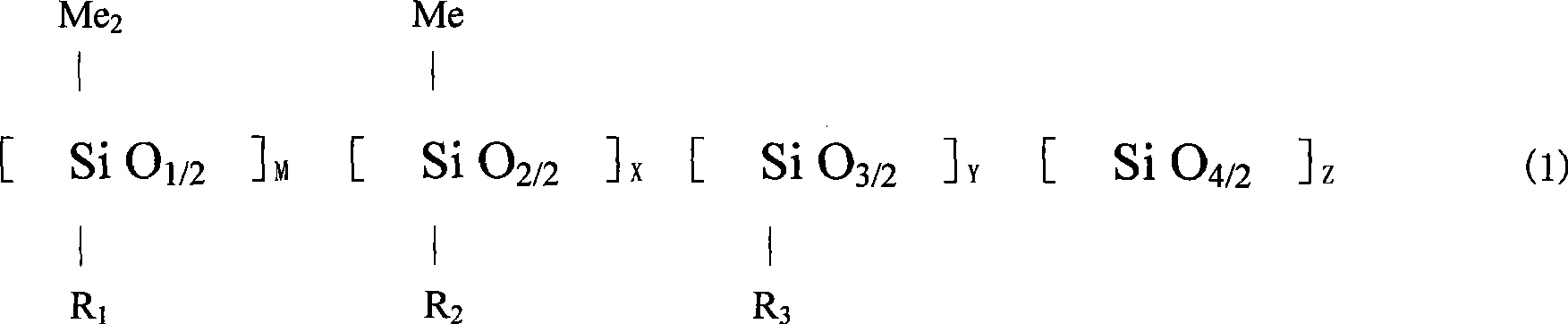

The invention relates to a preparation agent for dry method urethane elastic fiber spinning. The preparation agent comprises the following components: silicone resin, methyl silicone oil, modification silicone oil, mineral oil and antistatic agent. The preparation method comprises the following steps: 1, silicane chain links(M, X, Y and Z) are mixed and evenly stirred, started, added with acid water at a temperature of 25 DEG C and reacted for 1 hour at the temperature of between 60 and 70 DEG C, stirring stops, after layering, the resin on the lower layer is separated out, the pH value of the resin is neutral by washing, and the resin is subjected to vacuum pumping, temperature rise and dewatering to prepare the silicone resin; and 2, the silicone resin, the methyl silicone oil, the polyether modification silicone oil, the mineral oil and the antistatic agent are placed in a stirring kettle, and evenly mixed at the temperature of between 10 and 50 DEG to obtain. The application of the preparation agent is as follows: the preparation agent is put in a storage tank and transferred to an oil nozzle or roller by an oil pump, and the urethane elastic fiber is directly contacted and oiled. The preparation agent for dry method urethane elastic fiber spinning is transparent liquid, does not contain solid particle components such as hard ester acid magnesium and the like, does not plug pipes and equipment in the oiling process, and does not need power-off cleaning, thereby improving production efficiency.

Owner:NINGBO ECONOMIC & TECHN DEV ZONE SICO NEW MATERIAL

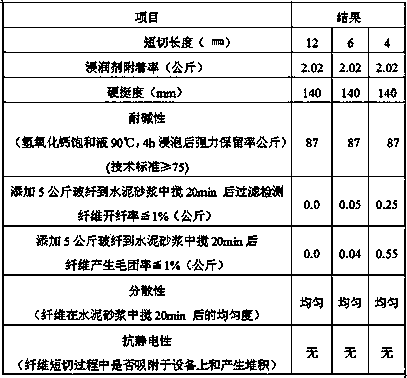

Alkali-resistant chopped glass fiber soakage agent

The invention provides an alkali-resistant chopped glass fiber soakage agent and relates to a glass fiber surface treating agent containing an organic material. The alkali-resistant chopped glass fiber soakage agent is composed of a film-forming agent, a coupling agent, a lubricant, an antistatic agent, a pH regulator and de-ionized water, wherein the film-forming agent refers to a polyacrylate film-forming agent, an epoxy resin emulsion film-forming agent and a water soluble epoxy resin film-forming agent in the mass ratio of (2.0-20.0): (15.0-2.5): (1.0-10). The alkali-resistant chopped glass fiber soakage agent provided by the invention is suitable for 4 mm to 24 mm alkali-resistant chopped glass fibers; the alkali-resistant chopped glass fibers produced through impregnation in the soakage agent are excellent in alkali resistance, bundling, wear resistance, water resistance, choppability, dispersibility and antistatic property. In the mixing and stirring process of cement, the alkali-resistant chopped glass fiber soakage agent is capable of keeping the bundled state of the previous raw yarns without loosening.

Owner:陕西汇友友基新材料有限公司

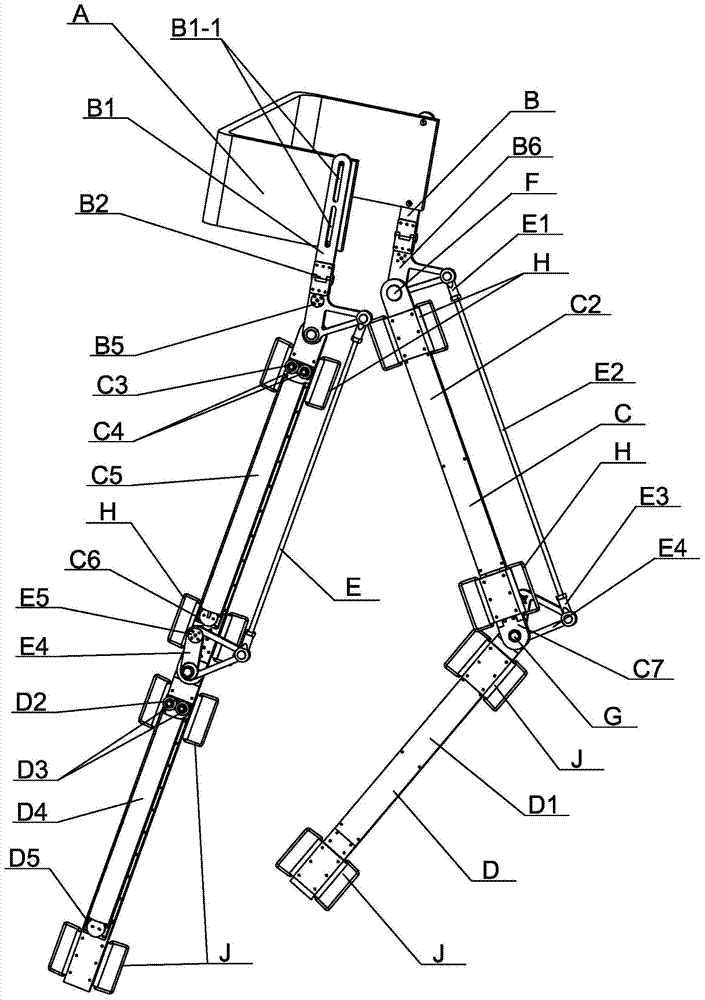

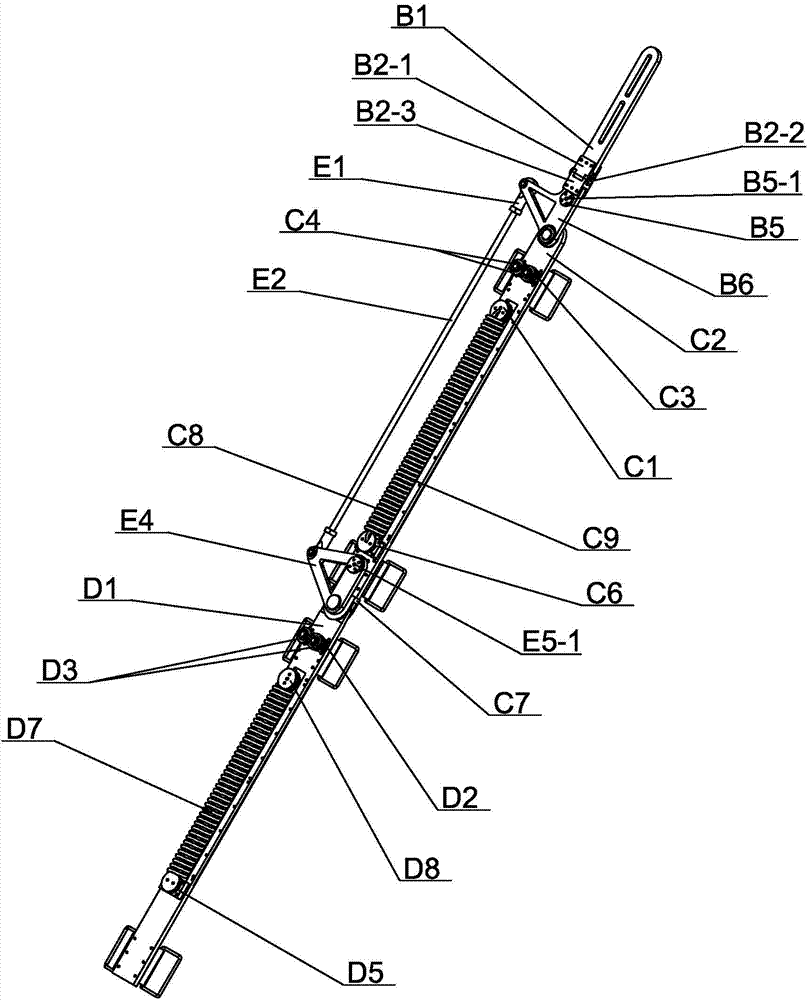

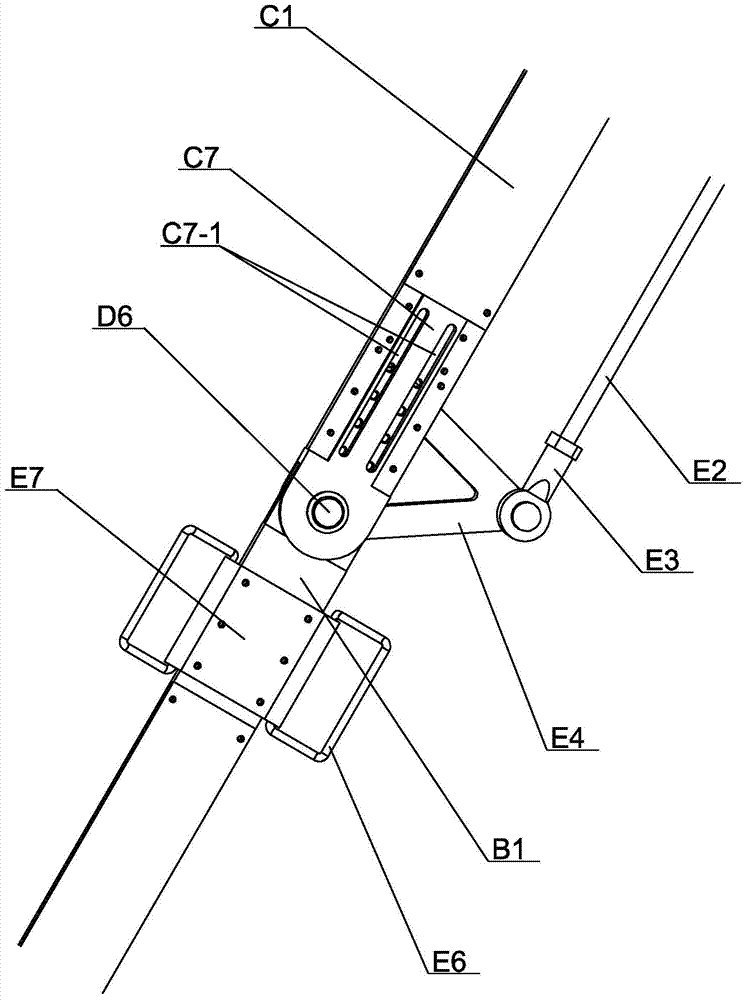

Lower limb assisting outer bone based on gravity balance

Provided is a lower limb assisting outer bone based on gravity balance. Two waists are symmetrically arranged on the two sides of a back, waist plates are fixedly connected with the back through connecting elements, upper thigh plates are hinged to the waist plates through hip joint shafts, shank plates are hinged to lower thigh plates through knee joint shafts, upper joint bearings are hinged to waist lower plates, connecting rods are hinged to the knee joint shafts, the upper end and the lower end of each upper thigh plate are each provided with a thigh binding buckle, the upper end and the lower end of each shank plate are each provided with a shank binding buckle, one ends of first steel wire ropes are arranged on the inner sides of waist upper plates and fixedly connected with the waist upper plates, the other ends of the first steel wire ropes are pulled out of first small holes of first steel wire fixing plates, wound around thigh pulley blocks and then fixedly connected with thigh connecting wheels, one ends of second steel wire ropes are arranged on the inner sides of shanks and fixedly connected with the connecting rods, and the other ends of the second steel wire ropes are pulled out of second small holes of second steel wire fixing plates, wound around shank pulley blocks and then fixedly connected with shank connecting wheels. The lower limb assisting outer bone is used for helping the aged and physically-challenged persons and used for medical rehabilitation and the like.

Owner:HARBIN INST OF TECH

Oil agent used for polyester industrial filament

This invention discloses a kind of oil applied to the polyester industry, its characteristic is that the oil is composed of the following component: (A) 5 ~ 70 weight % refining mineral oil; (B) 10 ~ 85 weight % polyatomic alcohol fatty acid esters; (C) 5 ~ 55 weight % copolymerizations ether; (D) 2 ~ 40 weight % fatty acid polyoxyethylene ester; (E) 1 ~ 15 weight % antistat; (F) 0.1 ~ 10%'s adhesion function improver. The oil can solve these defects of the present oil that both the heat resistance and the gluing function are bad. Since the heat resistance and the flatness are good, the smoke is few, the carbon build-up is few , waste thread rates is low in spinning handicraft; original silk brute force and modulus are good, maintained extension, breaking extension are low; The brute force loss in back handicraft processing is low , there is no color difference in the dyeing process.

Owner:CHINA PETROCHEMICAL CORP +1

Basalt fiber reinforced cement based material and preparation method therefor

InactiveCN105541209AReduce air bubblesReduce porositySolid waste managementInterfacial bondingBasalt

The invention relates to cement-based materials and particularly discloses a basalt fiber reinforced cement based material and a preparation method therefor. The basalt fiber reinforced cement based material contains the following ingredients: 400-800kg / m<3> of cement, 150-330kg / m<3> of active mineral admixture, 800-1,500kg / m<3> of fine aggregate, 10-40kg / m<3> of water reducing agent, 0.01-0.05kg / m<3> of setting retarder, 0.5-3.0% (volume percent) of basalt fibers and 0.2-1.0% (mass percent) of fiber surface modifier. According to the basalt fiber reinforced cement based material and the preparation method therefor, through optimizing a formula, the compactness of the material is improved, meanwhile, the property of an interface layer between the basalt fibers and a cement bonding material is improved, and the interfacial bonding strength is improved. The structure and mechanical properties of the basalt fiber reinforced cement based material disclosed by the invention are improved relatively greatly, and the compression strength, folding strength and toughness are improved greatly.

Owner:CHINA MINSHENG ZHUYOU

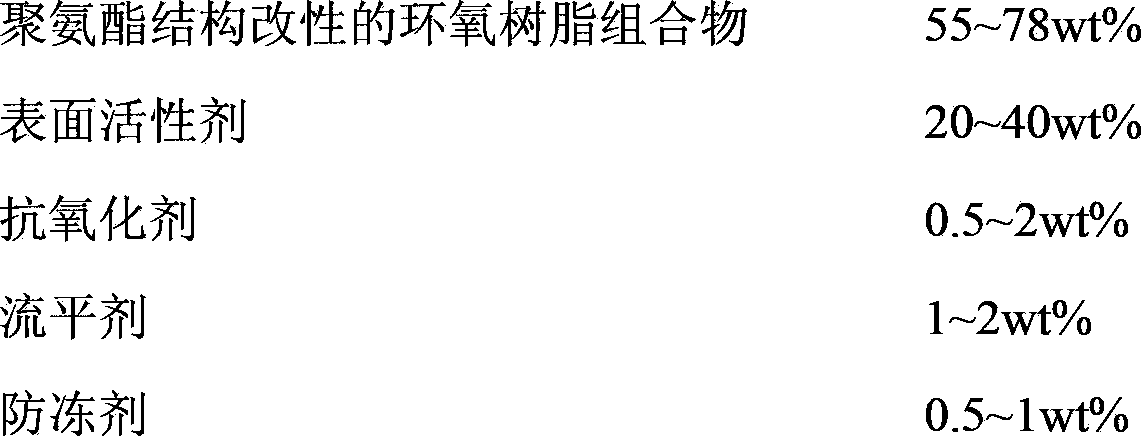

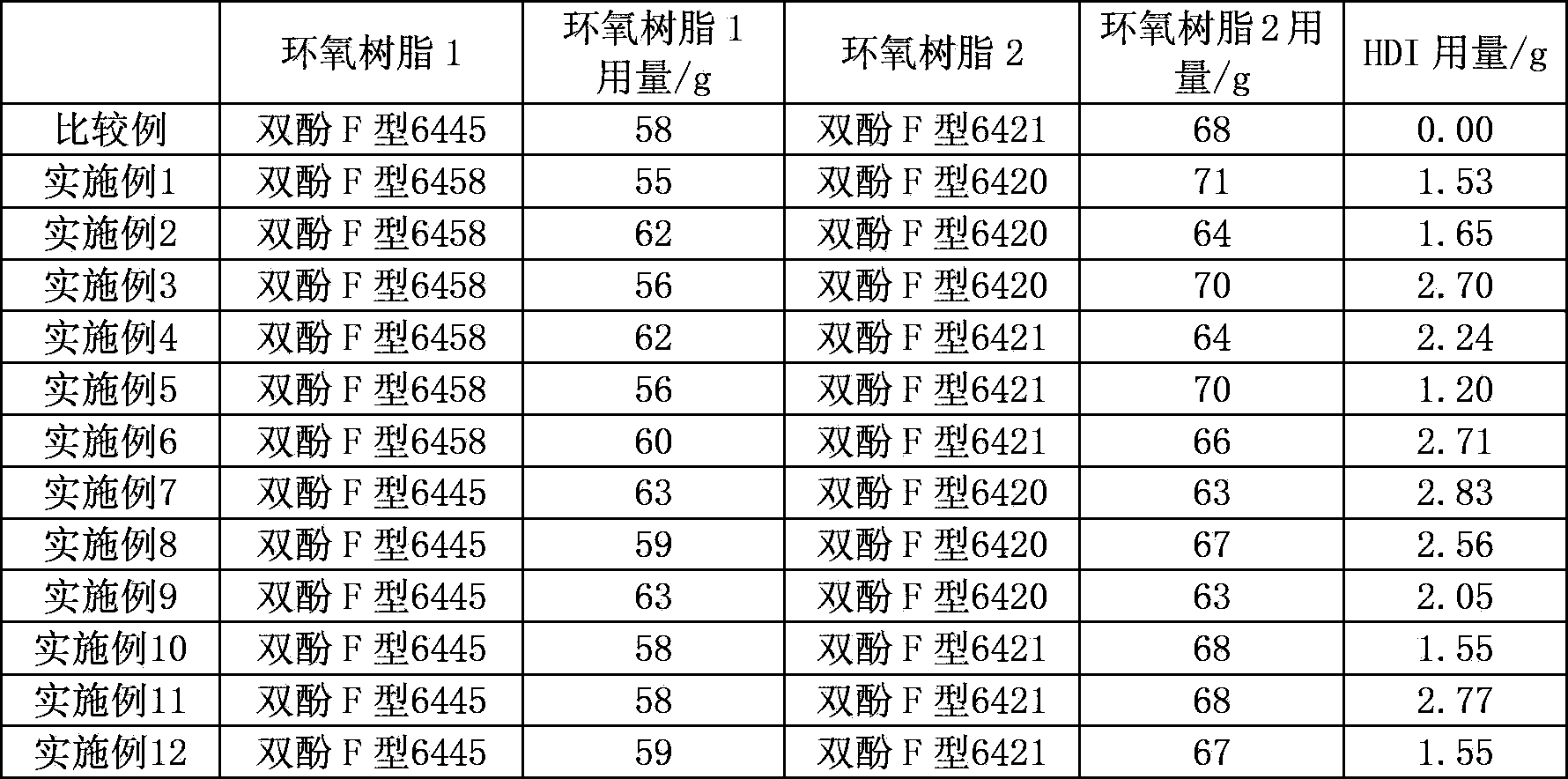

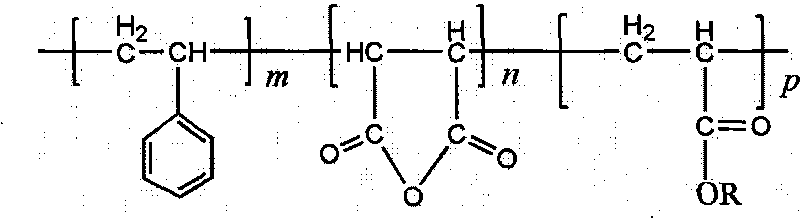

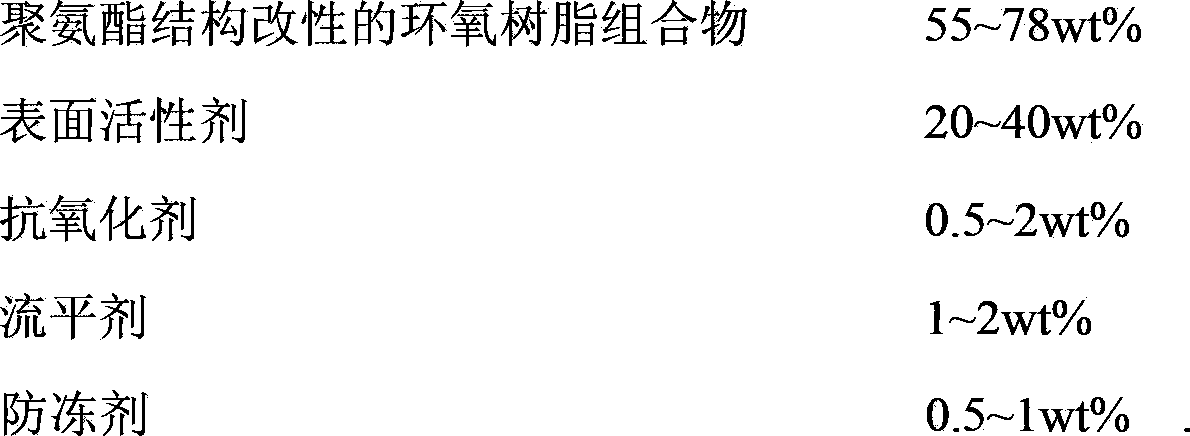

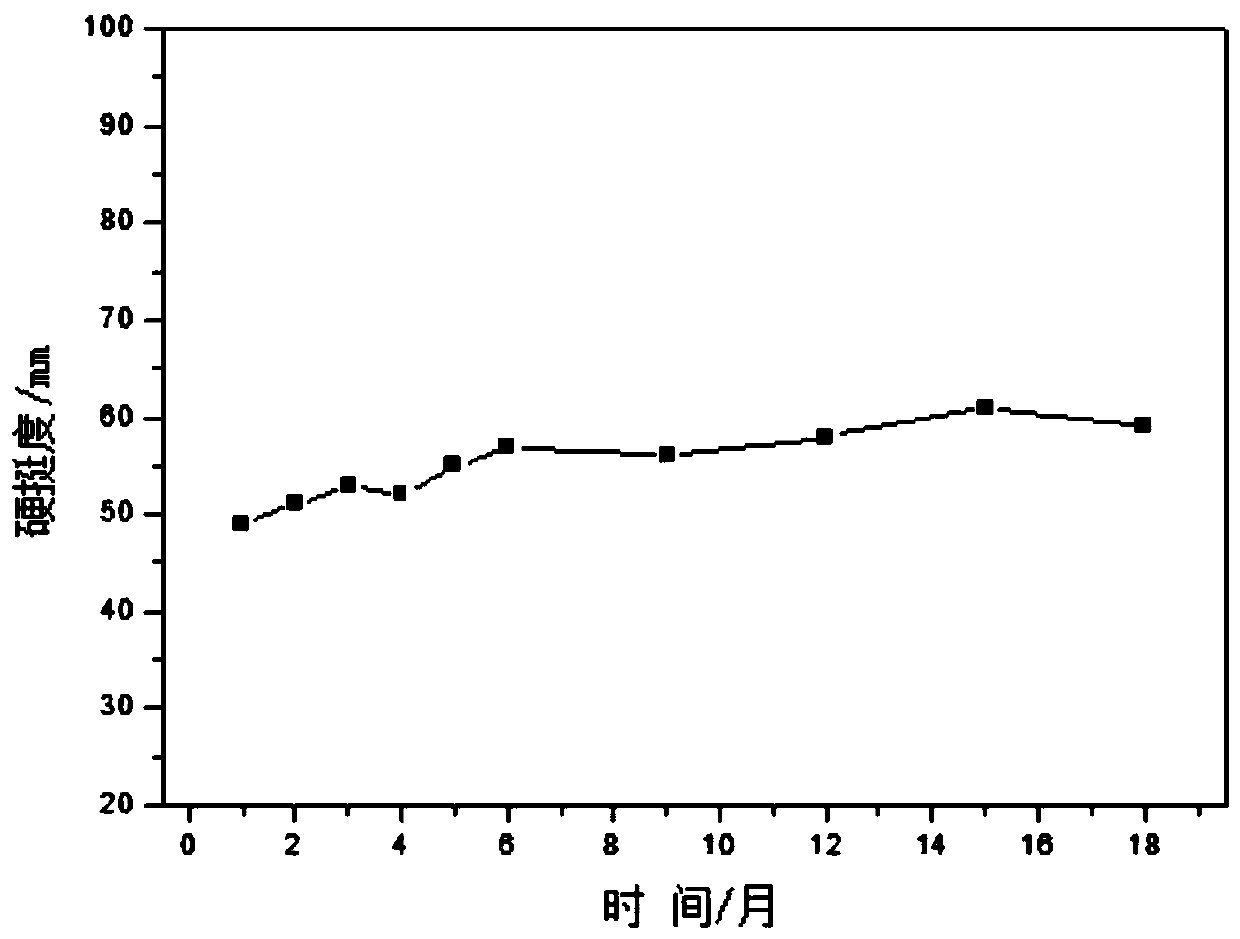

Epoxy-based carbon fiber sizing agent emulsion, its preparation method and its application

The invention relates to an epoxy-based carbon fiber sizing agent emulsion, which comprises the following components: 55-78wt% of polyurethane structure-modified epoxy resin composition, 20-30wt% of surfactant, 0.5-2wt% of anti-oxidant, 1-2wt% of levelling agent and 0.5-1wt% of antifreezing agent. A preparation method comprises the following steps: pumping a bisphenol F epoxy resin reactant under vacuum, dehydrating until no bubbles can be generated, adding an isocyanate reactant to prepare an epoxy resin composition; mixing and homogenizing the surfactant and the anti-oxidant in a reaction vessel according to the above material fraction; and then gradually adding deionized water, a levelling agent and an antifreezing agent to prepare the sizing agent emulsion. The carbon fiber from the epoxy-based carbon fiber sizing agent emulsion has good convergence, wear resistance and toughness, the sizing agent resin has good chemical stability, and is in favor of long-term storage and quality guaranteeing of sizing carbon fiber; the preparation method has the advantages of simple technology and easy operation, the reaction raw material has the advantages of convenient source and low cost, and the epoxy-based carbon fiber sizing agent emulsion is in favor of realization of industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

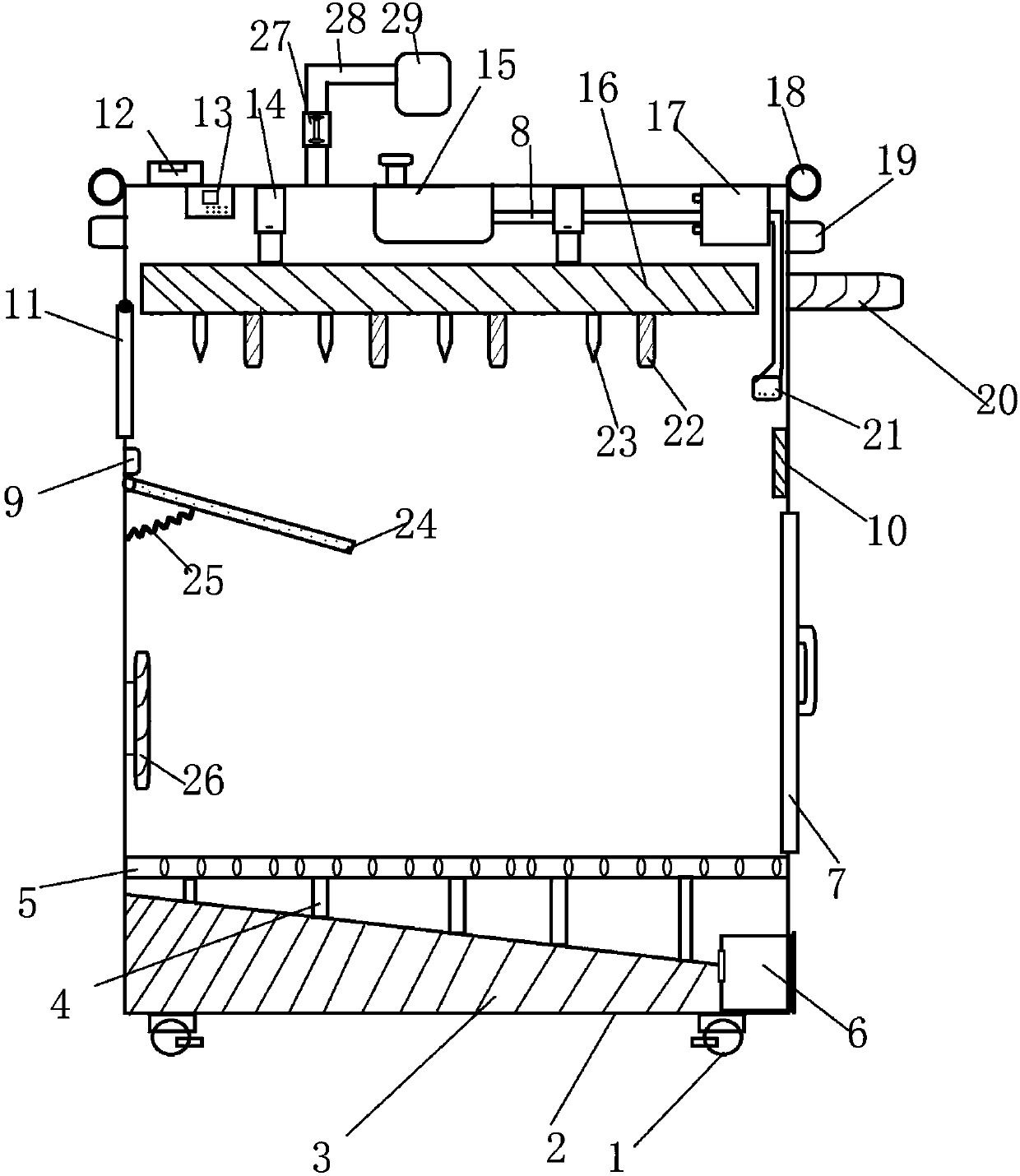

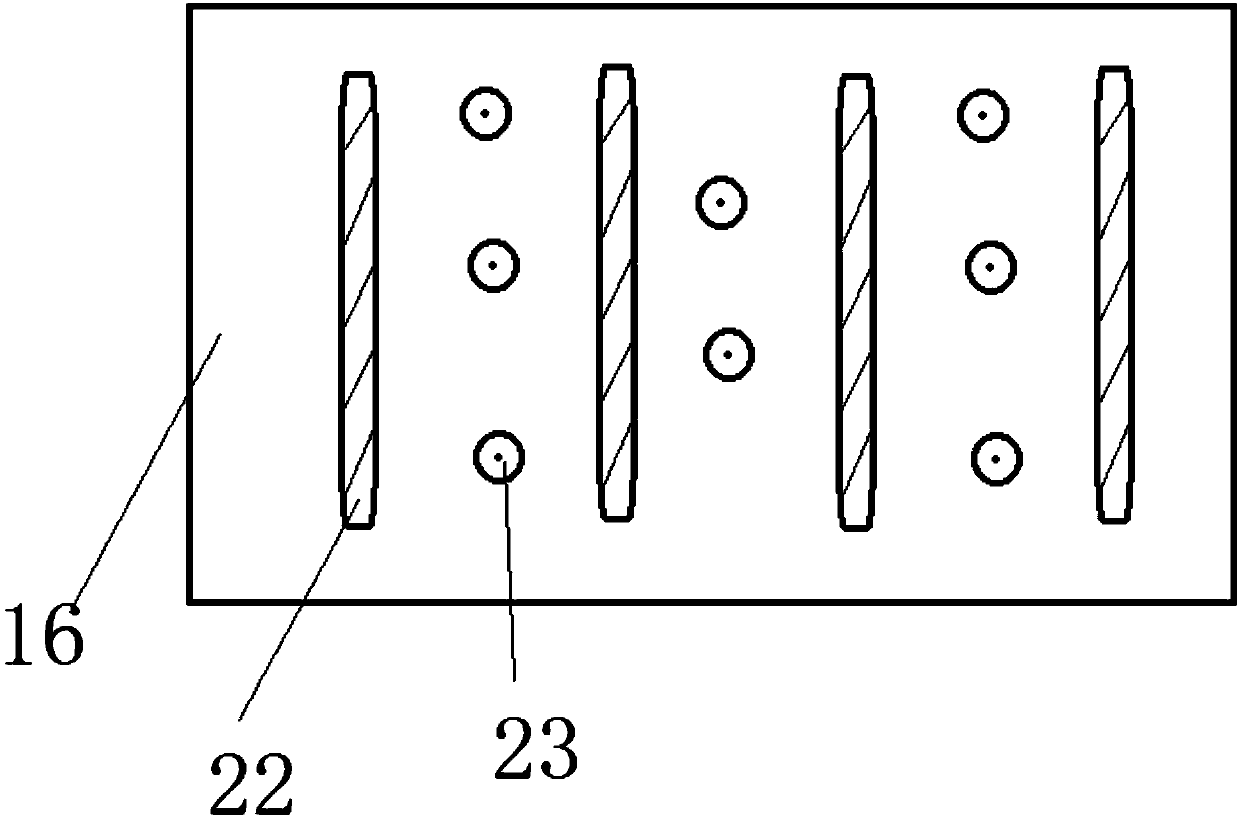

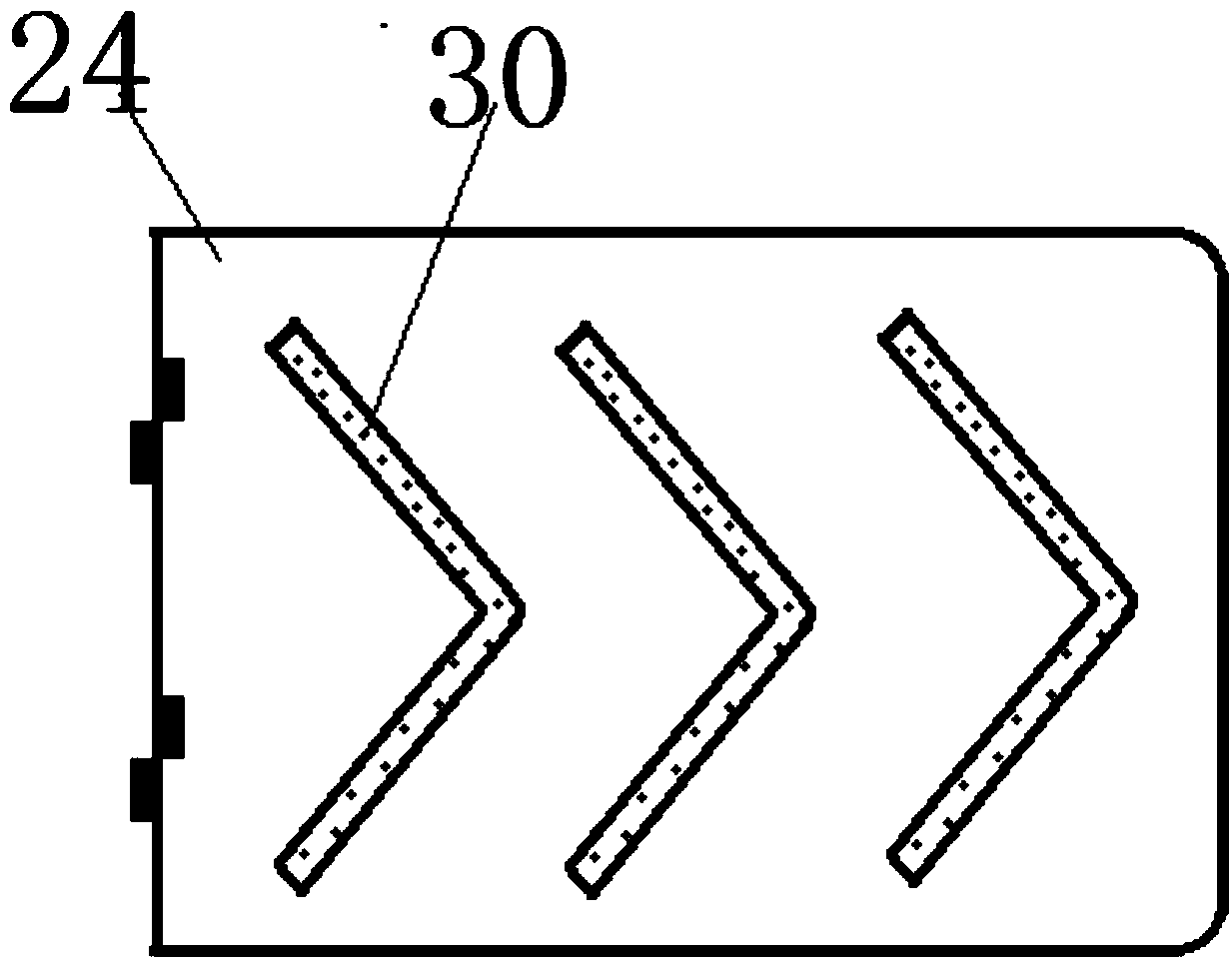

Security and environment-friendly city disinfecting and sterilizing compaction dustbin

InactiveCN107628392AEasy to separateReduce breedingRefuse receptaclesRefuse cleaningDisinfectantEngineering

The invention discloses a security and environment-friendly city disinfecting and sterilizing compaction dustbin. The security and environment-friendly city disinfecting and sterilizing compaction dustbin comprises a dustbin body, an inclined guide plate, a supporting column, a base plate, a water collecting box, an electric stretchable rod, a disinfectant tank and a pressing plate; guide wheels are arranged on the bottom face of the dustbin body, the inclined guide plate is arranged inside the bottom end of the dustbin body, the base plate is arranged above the inclined guide plate, the watercollecting box is arranged at the bottommost end of the inclined guide plate, and a garbage inlet curtain door is arranged on the side wall of the upper end of the dustbin body; and an infrared emitter and an infrared receiver are arranged on the inner wall of the dustbin body, a radio transmission device is arranged on the outer wall of the top end of the dustbin body, a microprocessor and a storage battery are arranged on the inner wall of the top end of the dustbin body, the disinfectant tank is installed on the inner wall of the top end of the dustbin body, the inner wall of the top end of the dustbin body is fixedly connected with one end of the electric stretchable rod, and the pressing plate is arranged at the other end of the electric stretchable rod. The security and environment-friendly city disinfecting and sterilizing compaction dustbin is simple in structure and convenient to use, harmful bacterium breeding is effectively reduced, the safe life environment of people is improved, meanwhile, the garbage is pushed to be compacted, the transportation cost is greatly reduced, and the appearance of a city is effectively improved.

Owner:上海申第实业有限公司

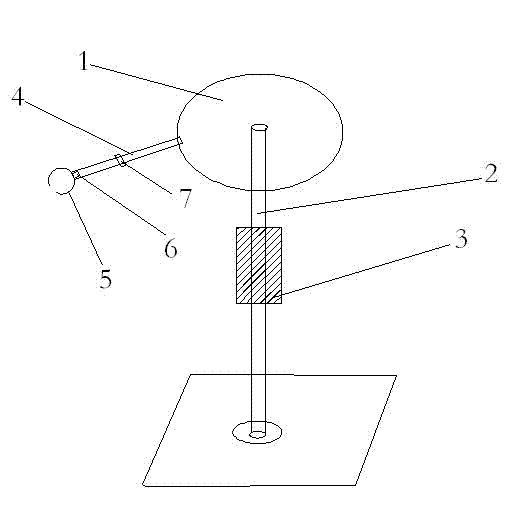

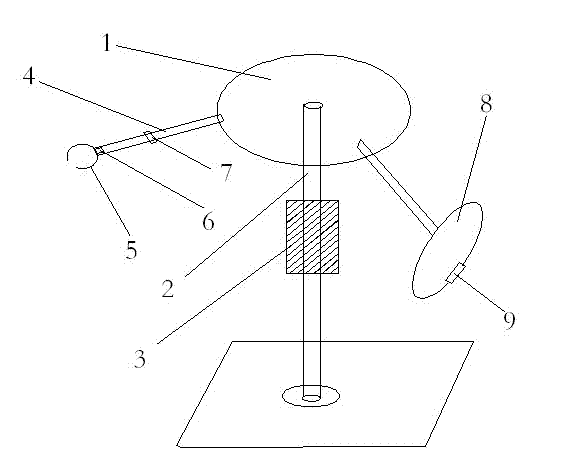

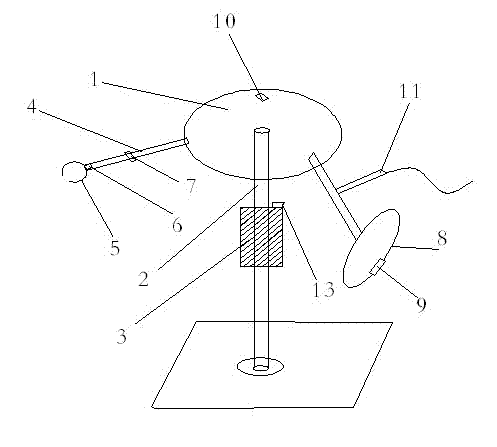

Mechanical type three-dimensional compact spinning device

The invention discloses a mechanical type three-dimensional compact spinning device, belonging to the technical field of textile machinery. A reel of a spinning frame is provided with a lower leather roller, and a bottom roll is installed on the lower leather roller pressed under the reel. The device is characterized by further comprising a retaining frame which is provided with a movable end and a handle, and the retaining frame is installed on the lower leather roller by the movable end and is provided with two groups of magnet, wherein, the first magnet is installed at the position on the retaining frame corresponding to the lower leather roller, and the second magnet is installed at the position on the retaining frame corresponding to the bottom roll; a compact part is arranged on the retaining frame by a shaft, and one side of the compact part facing to the bottom roll is cambered and clings to the bottom roll; the cambered surface of the compact part is provided with a plurality of cluster grooves which face to the coming direction of yarn, has a funnel shape and is from wide to narrow. The invention has simple structure, good cluster effect and uniform yarn strips after twisting.

Owner:绍兴华裕纺机有限公司

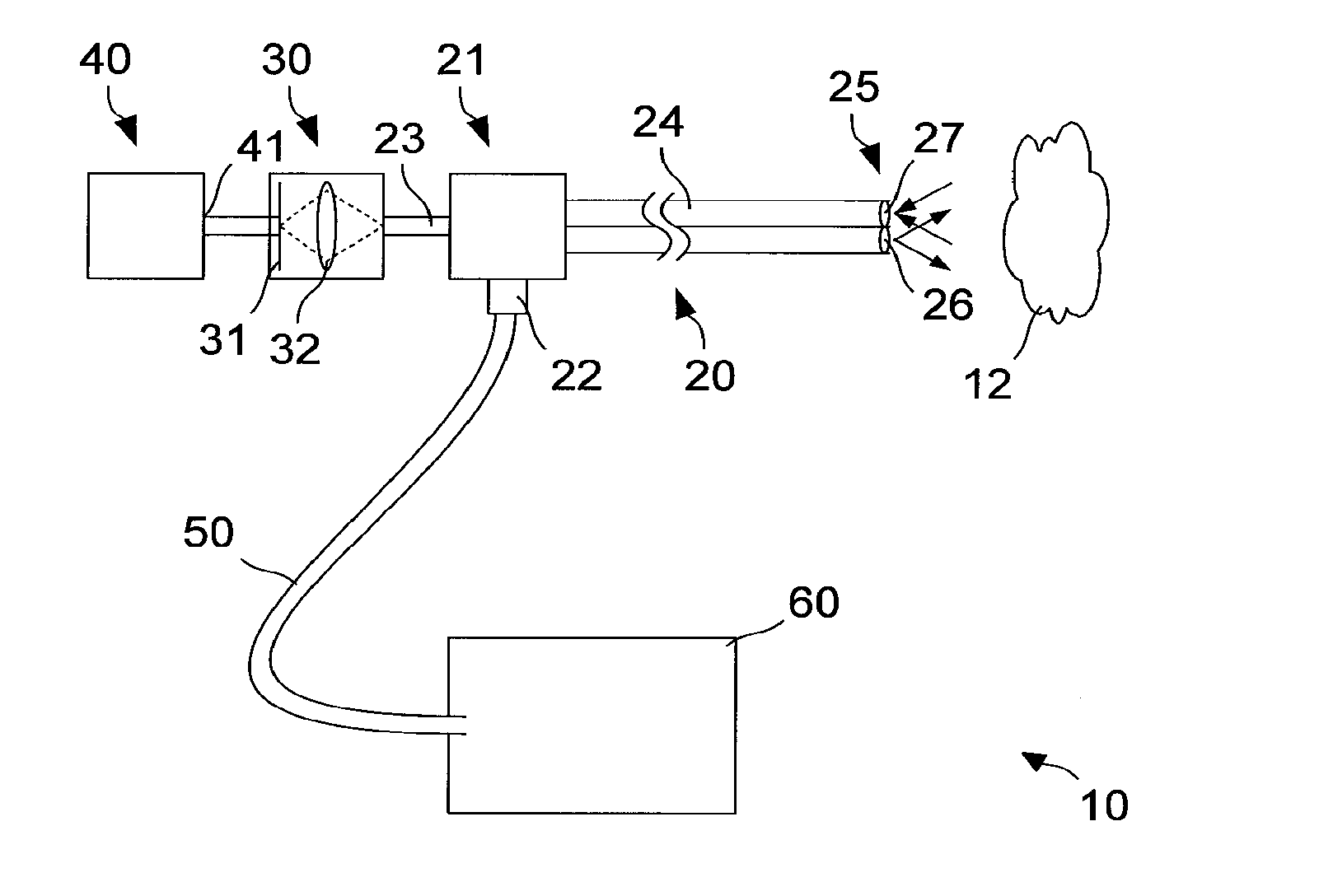

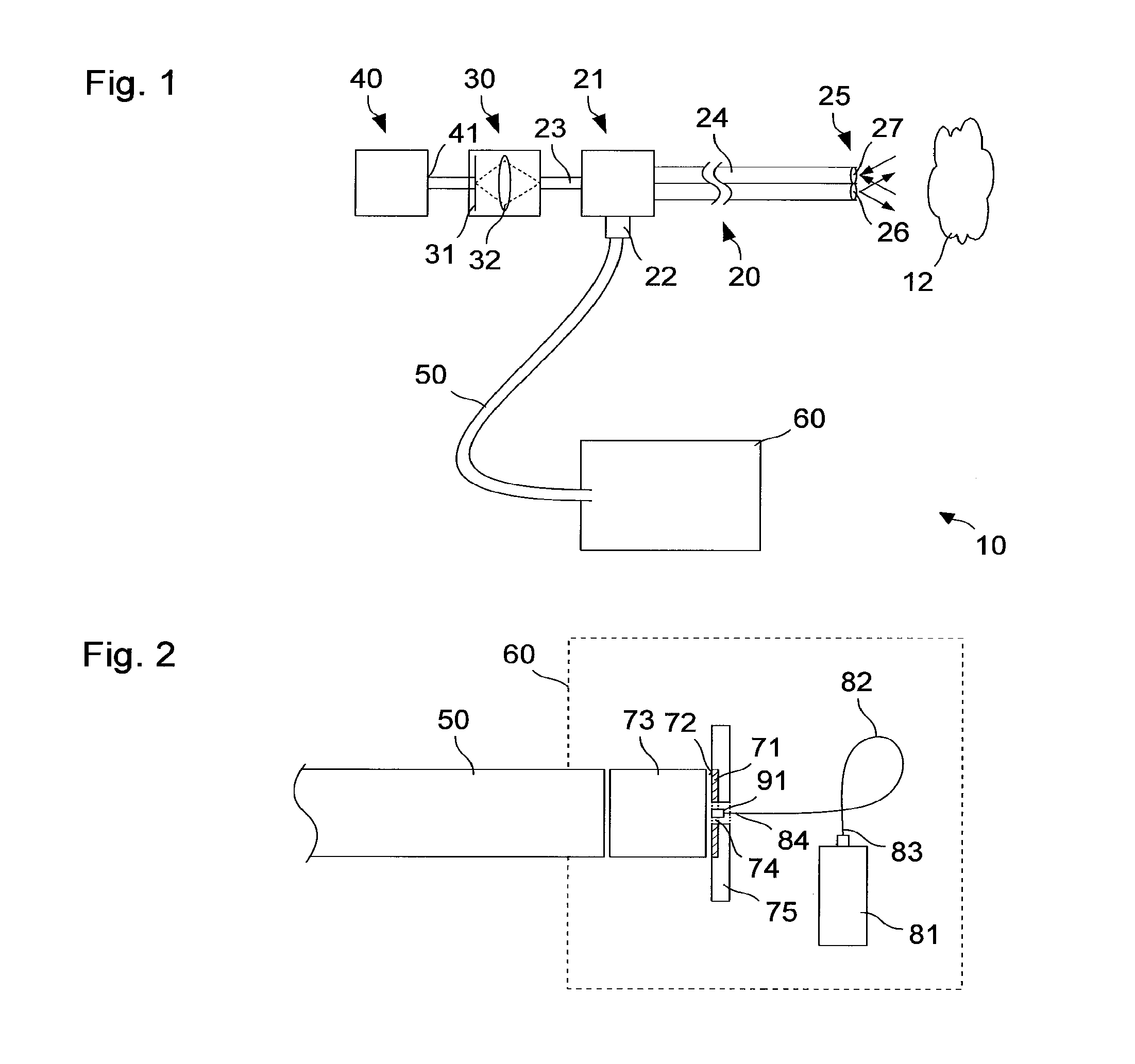

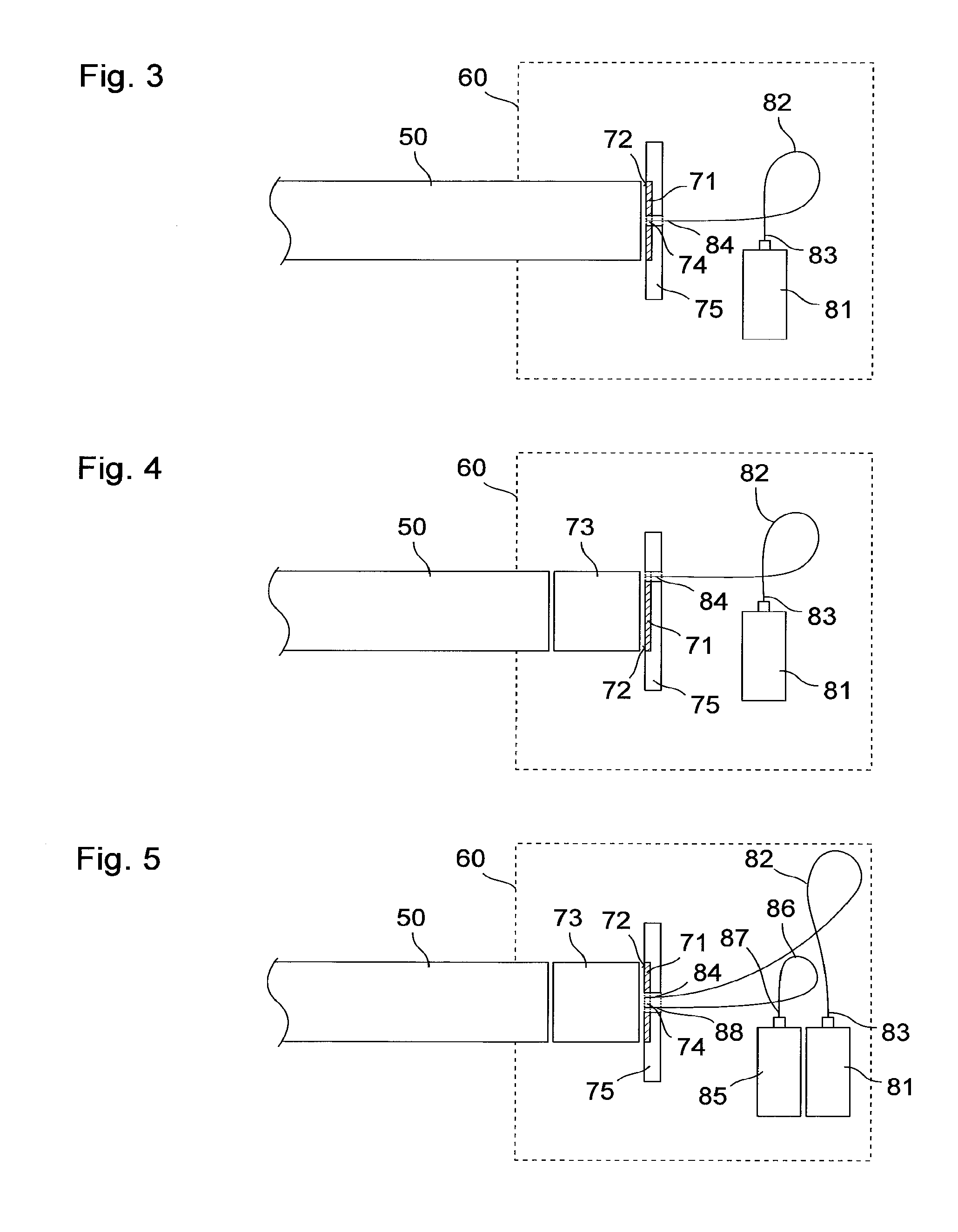

Light source device for endoscopic or exoscopic applications

ActiveUS20110235324A1Quick couplingReduce divergenceNon-electric lightingLighting support devicesCouplingLight beam

A light source device for endoscopic or exoscopic applications includes a flat first light source, a second light source, an illuminating beam path that is configured to provide a first light beam emanating from the first light source for an endoscopic or exoscopic application, and a coupling device to couple a second light beam from the second light source into the illuminating beam path, whereby the coupling device is configured in such a way that at the coupling site the cross-section surface of the second light beam is smaller than the cross-section surface of the first light beam.

Owner:KARL STORZ GMBH & CO KG

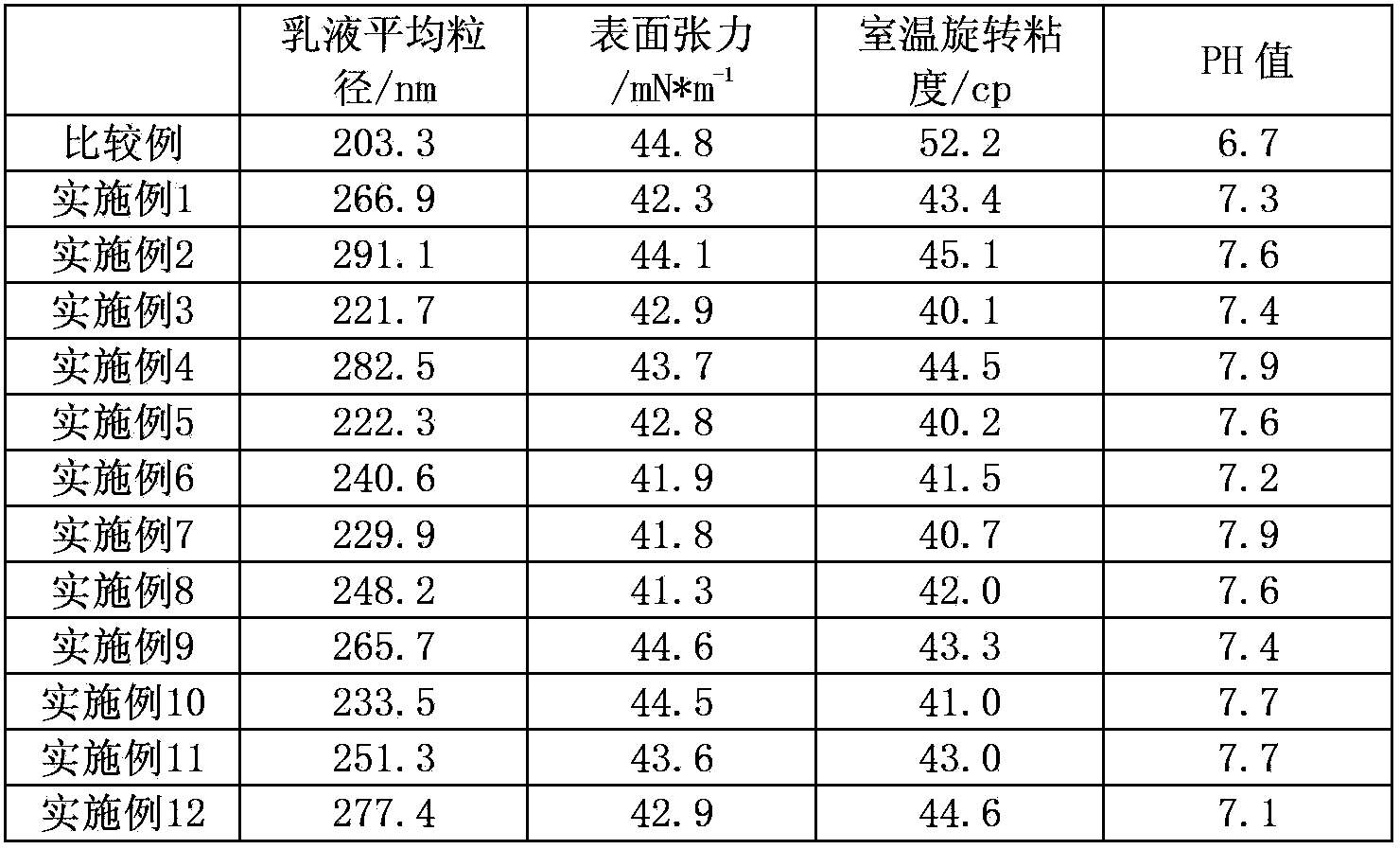

Water-based epoxy emulsion type carbon fiber sizing agent and preparation method thereof

The invention relates to a water-based epoxy emulsion type carbon fiber sizing agent and a preparation method thereof. The water-based epoxy emulsion type carbon fiber sizing agent comprises the following components in percentage by weight: 15%-35% of epoxide resin, 5%-20% of surface active agent, 0.1%-0.5% of lubricating agent, 0.1%-0.5% defoaming agent and 55%-65% of deionized water. According to the water-based epoxy emulsion type carbon fiber sizing agent and the preparation method thereof, no volatile organic compound is added, so that the harm to production equipment and operators in preparation and application processes of the sizing agent is greatly reduced, and the environment protection is facilitated. The water-based epoxy emulsion type carbon fiber sizing agent and the preparation method thereof which are disclosed by the invention have the advantages of simple emulsifying process, safety in operation, low requirement on the production equipment, easiness for raw material obtaining, low price and suitability for large-scale production.

Owner:HENGSHEN

Intellectualized animal-force power generation device

InactiveCN102444556AEasy to controlThe controller is easy to controlFrom muscle energyMachines/enginesGeneration processDrive wheel

The invention relates to an intellectualized animal-force power generation device, which comprises a driving wheel, wherein the driving wheel is connected with an electric generator through a transmission mechanism; the driving wheel is connected with an animal-force connecting rod; the animal-force connecting rod is radially arranged at the edge of the driving wheel; the animal-force connecting rod is used for connecting an animal; a magnetic separator is arranged at the end of the animal-force connecting rod; the end of the connecting rod is fixed on the body of the animal through the magnetic separator; the magnetic separator is connected with a controller; and the controller receives external control signal for releasing lock to control the separation of the magnetic separator, thus the end of the animal-force connecting rod is separated from the animal. By using the intellectualized animal-force power generation device provided by the invention, the technical problems that in the prior art, the animal-force power generation device is instable in power generation in the animal power generation process, and the animals are not easy to control and require to be artificially supervised and controlled are solved; and the intellectualized animal-force power generation device has better stability and can control the animals.

Owner:钱成结

Andalusite fiber size and preparation method thereof

The invention provides a multifunctional size for andalusite fibers, which uses an organic compound containing flexible chains in molecules as a main body and compounds a plurality of auxiliary agents. The size comprises the following components in percentage by weight: 0.5-1.5 percent of film forming agent, 1-10 percent of softening agent (penetrating agent), 0.05-0.3 percent of antistatic agent(antiseptic), 0.01-0.2 percent of dispersant, 0.01-0.07 percent of coupling agent, 0.05-0.1 percent of catalyst and the balance of tap water. The size has good convergence, lubricating property, filmforming property, antistatic property and antiseptic characteristic. Not only fibers processed through the size have flexible, anti-bending and anti-stretching characteristics, but also the fibers sprayed with the size have good dispersive property in water and can be used for the surface soakage treatment of multiple silicate fibers.

Owner:甘肃紫鑫矿业煤化工有限公司

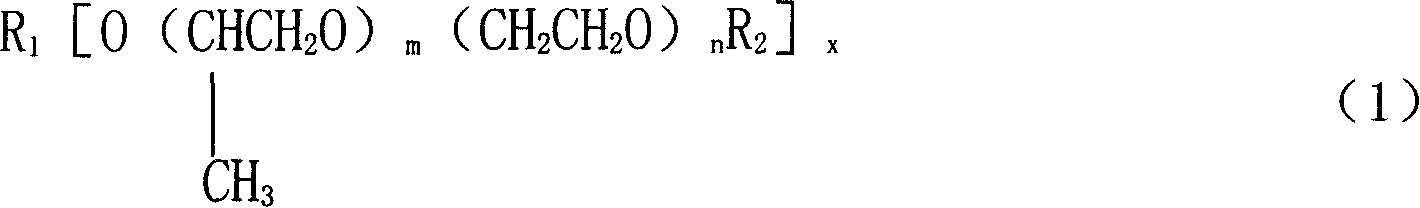

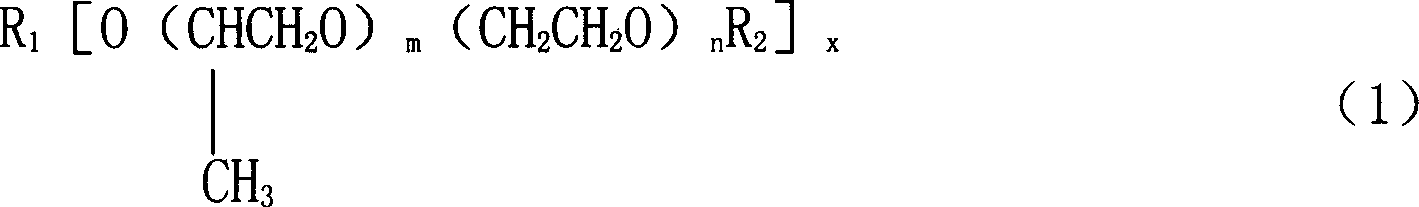

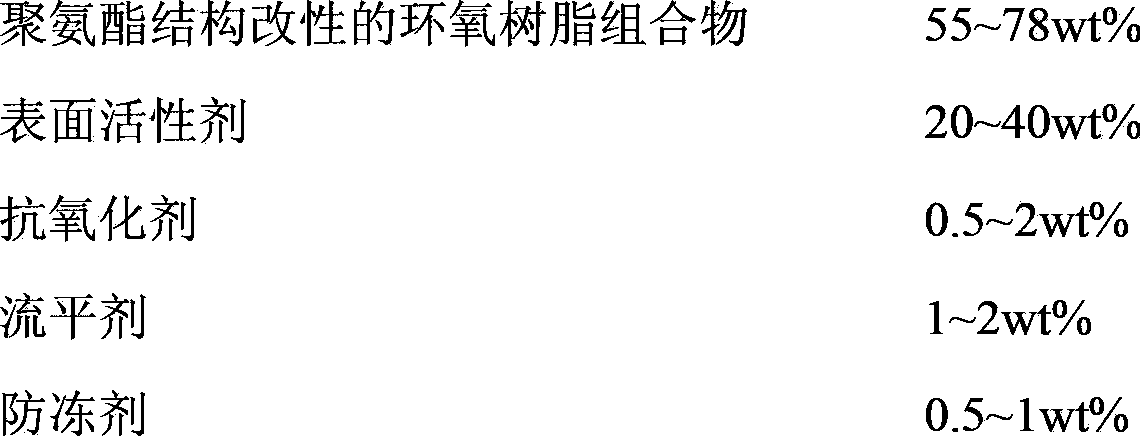

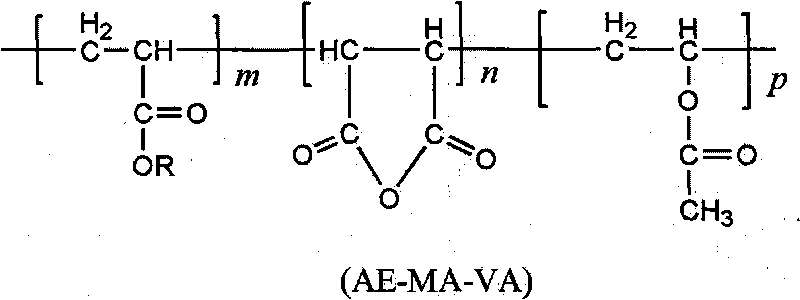

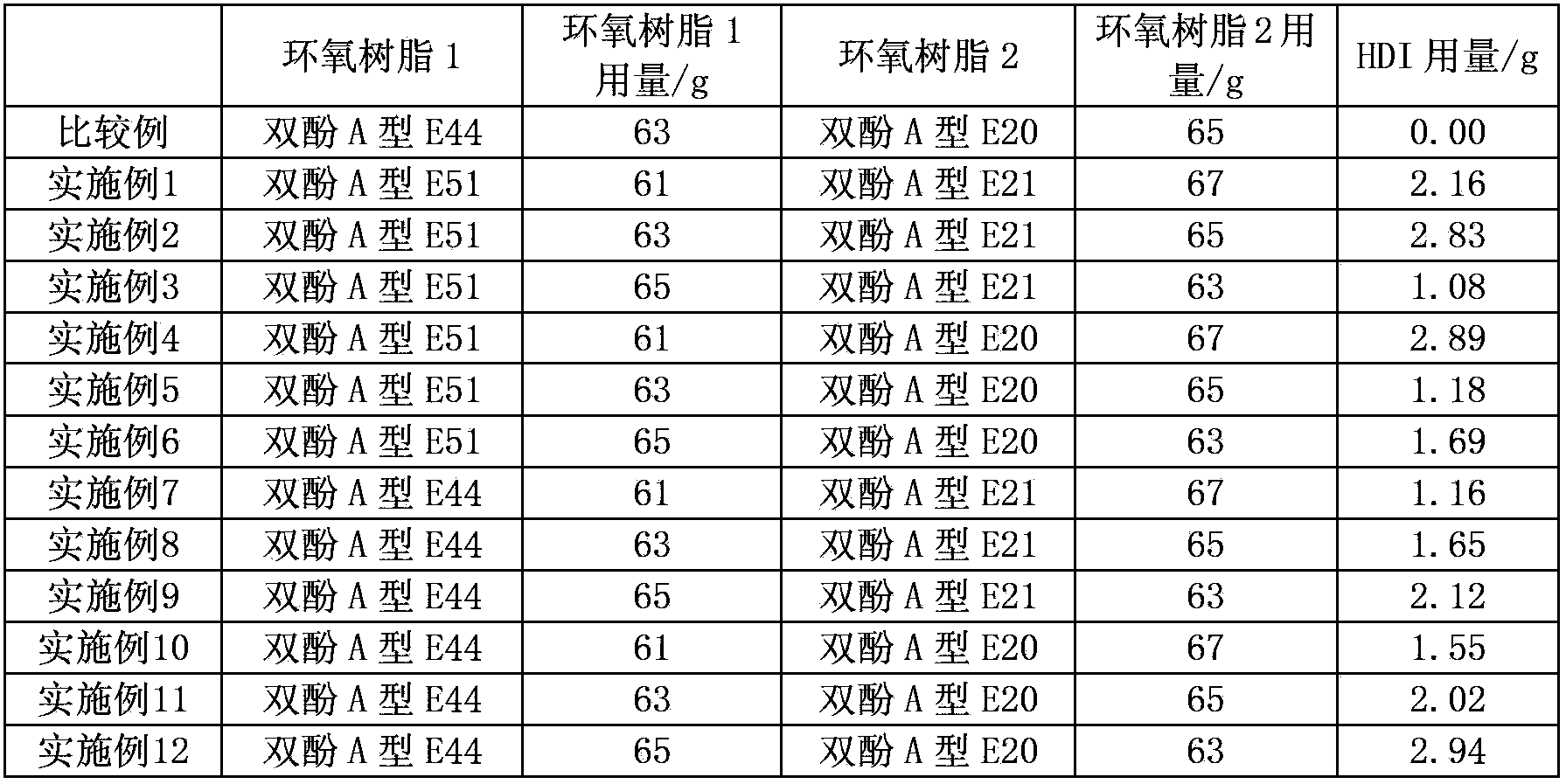

Polyurethane structure modified epoxy resin sizing agent emulsion, and preparation and application

The invention relates to a polyurethane structure modified epoxy resin sizing agent emulsion, which comprises the following ingredients: 55-78wt% of polyurethane structure modified epoxy resin composition, 20-40wt% of surfactant, 0.5-2wt% of anti-oxidant, 1-2wt% of levelling agent and 0.5-1wt% of antifreezing agent. The preparation method comprises the following steps: performing vacuum-pumping and dehydrating the bisphenol A epoxy resin to the condition that no bubbles can be generated, cooling and adding isocyanate to prepare a epoxy resin composition; mixing a surfactant and an antioxidant are mixed and homogenized in a reaction vessel according to the above material fraction, then adding deionized water, a levelling agent and an antifreezing agent gradually to obtain the polyurethane structure modified epoxy resin sizing agent emulsion. The carbon fiber prepared by the polyurethane structure modified epoxy resin sizing agent emulsion has good convergence, wear resistance and toughness, the convergence and wear resistance are easily and freely adjusted through the isocyanate component; a cluster agent is not required at the anaphase of the carbon fiber sizing agent, and on-site secondary mixing is not required, the application stability is good, the carbon fiber pasting wellability is good, and the polyurethane structure modified epoxy resin sizing agent emulsion is benefit for industrial stabilization and production of carbon fiber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Glass fiber impregnating compound and preparation method and application thereof

The invention belongs to the technical field of impregnating compounds, and discloses a glass fiber impregnating compound and a preparation method and application thereof. The impregnating compound comprises a film-forming agent, a coupling agent, a lubricant, a wetting agent and a pH regulator, wherein the film-forming agent comprises two bisphenol A type epoxy resin emulsions with different epoxy equivalents. Compared with usage of an epoxy resin emulsion with a single epoxy equivalent as a film-forming agent, the film-forming agent disclosed by the invention has the advantages that the film-forming agent can ensure sufficient coating force of the epoxy resin emulsions on the surfaces of yarns and allow the yarns to have better softness; even if the yarns are stored for a long time, theyarns still have low stiffness, which is beneficial for subsequent processing and mechanical strength of a composite material; and meanwhile, the yarns have better damp-heat resistance and still havea good strength retention rate in a high-temperature and high-humidity environment due to matched use of the film-forming agent and the coupling agent.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

Preparation method of nano modified soaking agent used for basalt fiber

The invention discloses a preparation method of a nano modified soaking agent used for basalt fiber. The preparation method includes: adopting a mixed emulsion of the nano modified soaking agent prepared by film former, coupling agent, lubricant, modified nano SiO2 particle and water; taking the film former as a main material; using water to dilute binder; adding the coupling agent, the lubricant and the modified nano SiO2 particle; stirring after being fully mixed to obtain a finished nano modified soaking agent product. The nano modified soaking agent is mainly used for coating the basalt fiber, is high in impregnability and stability, has effect of improving clustering performance and wear resistance of the basalt fiber and can improve mechanical performance of the basalt fiber, and cracking strength, drawing performance and shearing strength are all improved.

Owner:SICHUAN AEROSPACE WU YUAN COMPOSITE

Spinning finish for polyvinyl alcohol fiber for toughening cement concrete

InactiveCN102619091AAppropriate adhesionAvoid stress concentrationFibre treatmentDispersityStress concentration

The invention relates to a spinning finish for polyvinyl alcohol fiber for toughening cement concrete. The active ingredient comprises the following components: 16-30 parts of antistatic agent-fatty alkyl alcohol amine, 12-28 parts of smoothing agent-unsaturated fatty acid, 32-55 parts of stabilizer-alkyl polyoxyethylene ether and 3-10 parts of additive-nonpolar alkyl alkoxy silane or halogenatedalkyl alkoxy silane. The spinning finish can maintain the advantages of relatively high strength and modulus, strong cohesive force, good dispersity, high light resistance, alkali resistance and the like of polyvinyl alcohol fiber; and the key is that the nonpolar substance in the spinning finish can realize a certain 'shielding effect' on the polar group on the surface of the polyvinyl alcohol fiber so as to avoid stress concentration on the substrate interface and improve the toughness of the cement concrete. The components of the spinning finish are mutually coordinated and reasonably blended, thus the comprehensive performance is good, and the fiber obtains perfect characteristics of smoothness, bundling and the like.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

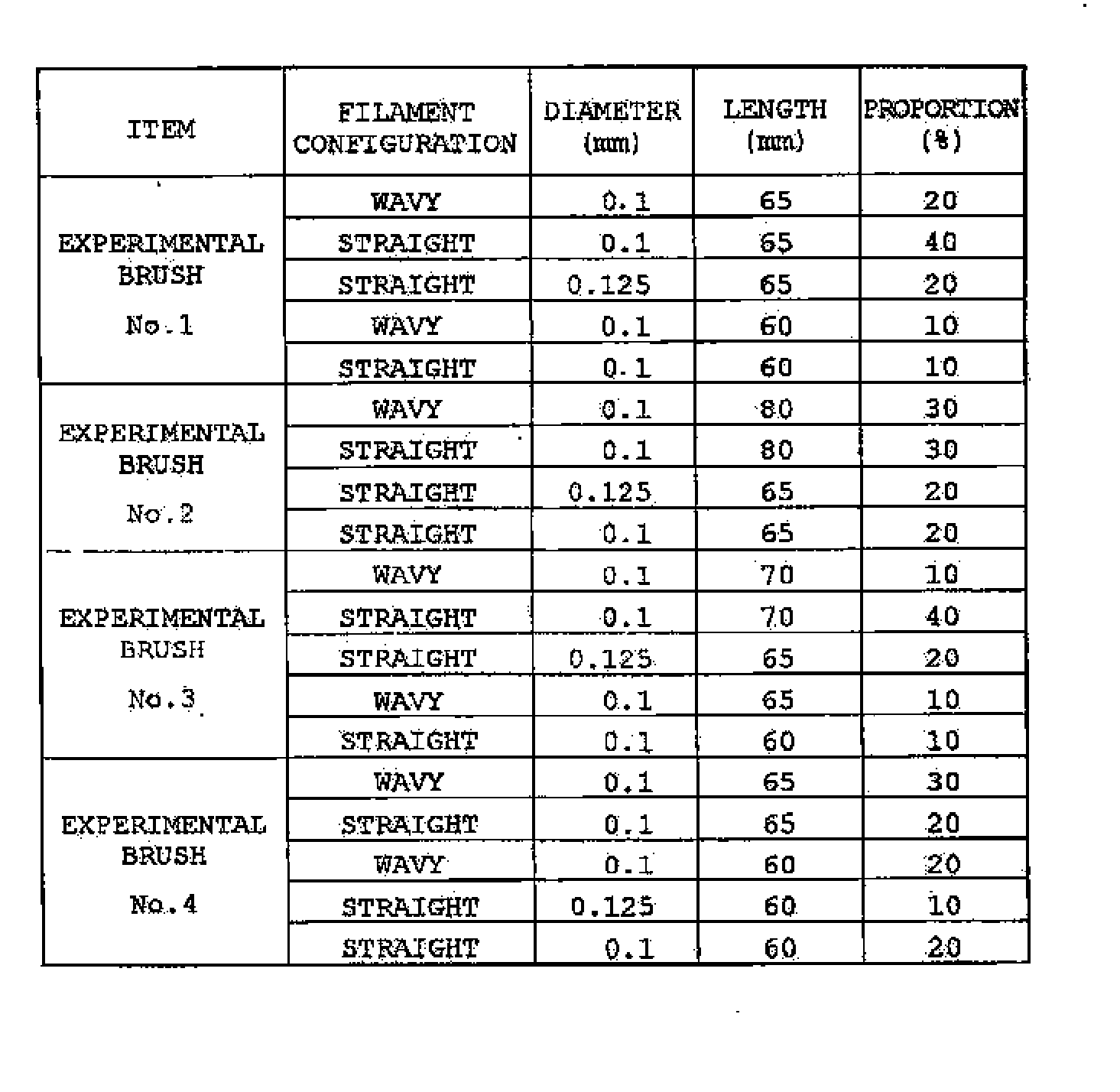

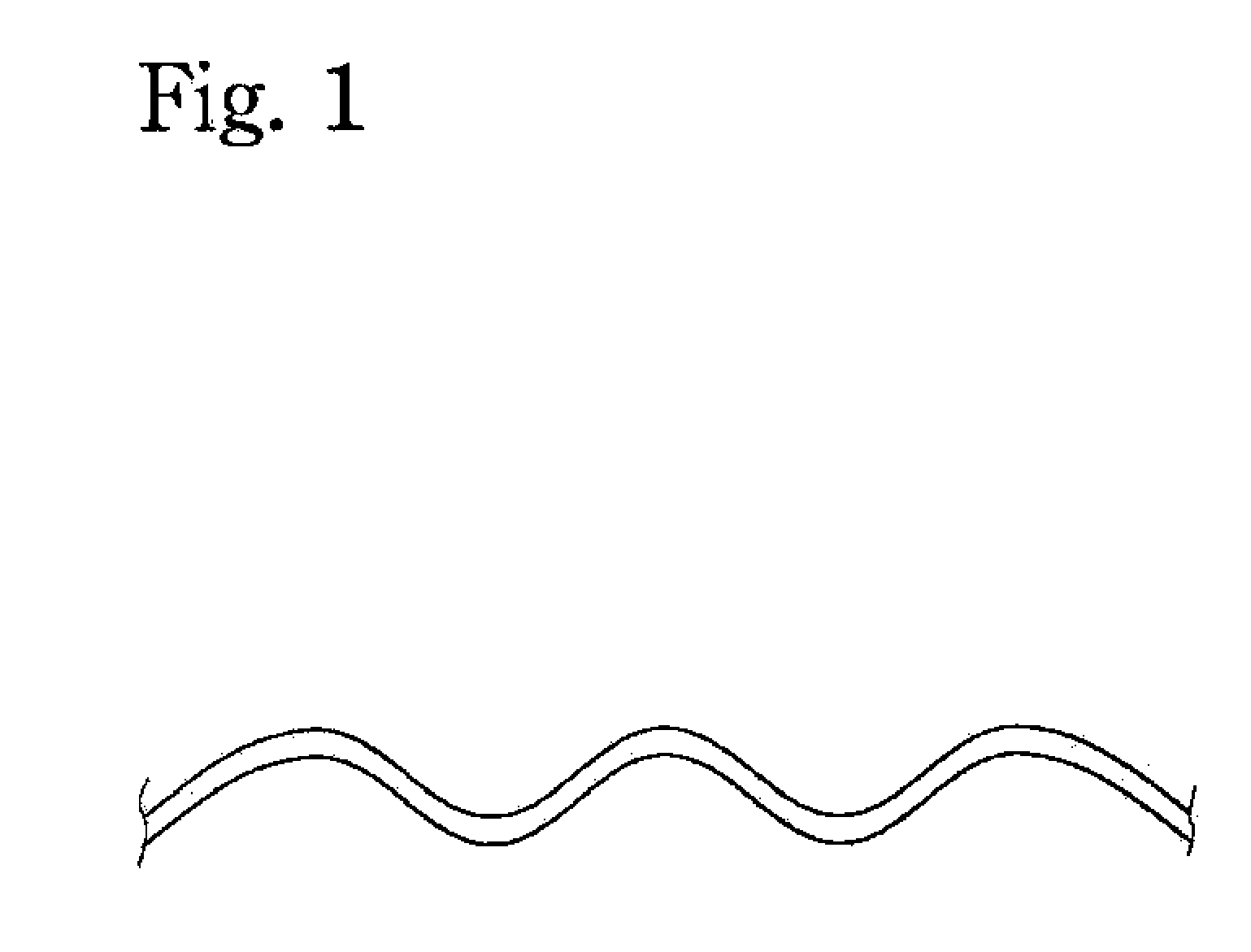

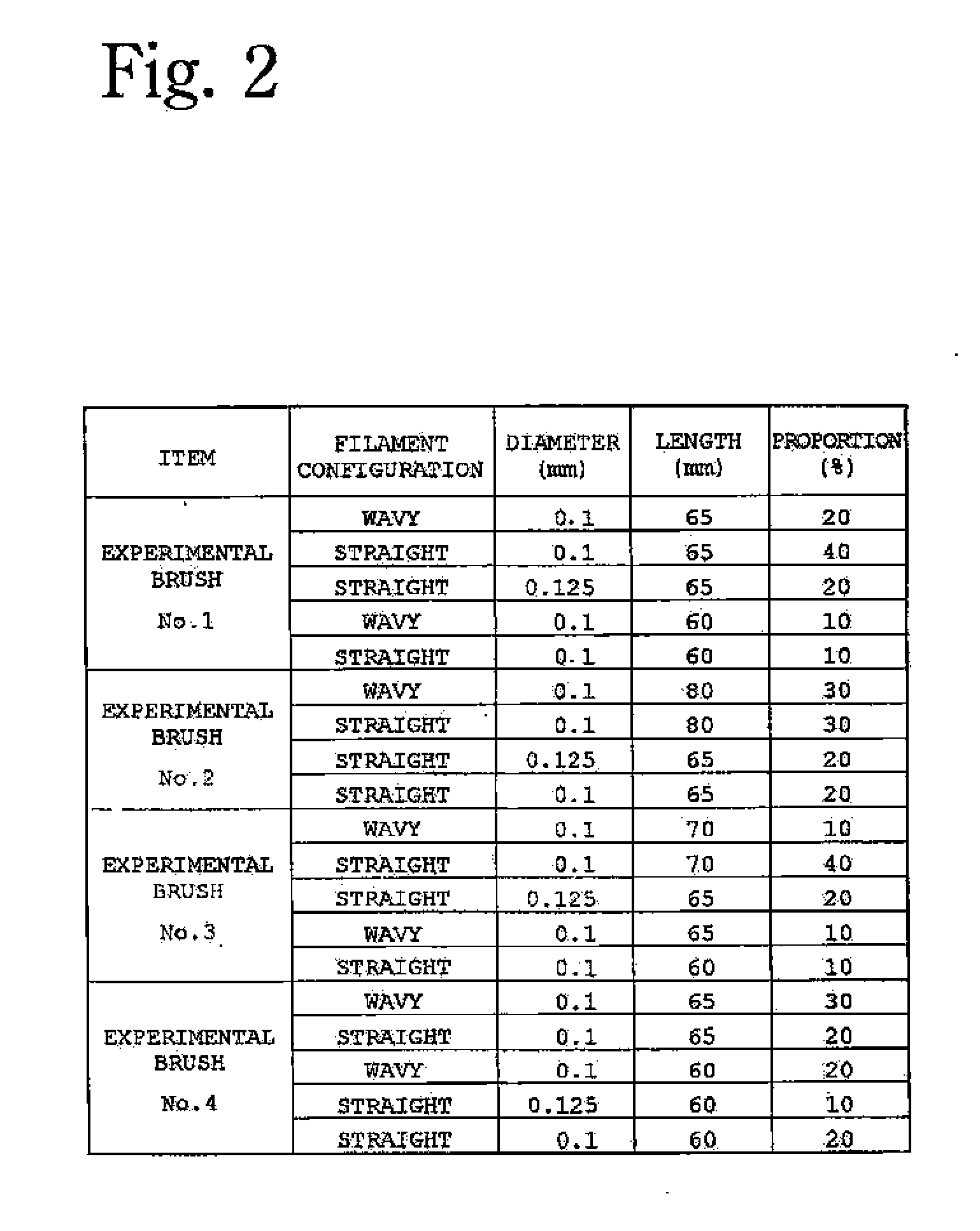

Painting Brush

The chemical-fiber-made brush is capable of providing sufficient amounts of coating material picked up and released to improve the working efficiency of the coating operation. The brush is provided with bristles 1 made up of a bundle of chemical-fiber monofilaments including wavy monofilaments. By mixing wavy monofilaments and non-wavy monofilaments, the amount picked up can be increased as compared with the case of bristles made up of non-wavy monofilaments, and the spreading out of the leading ends of the bristles can be prevented as compared with bristles made up of wavy monofilaments alone.

Owner:MARU T OHTSUKA

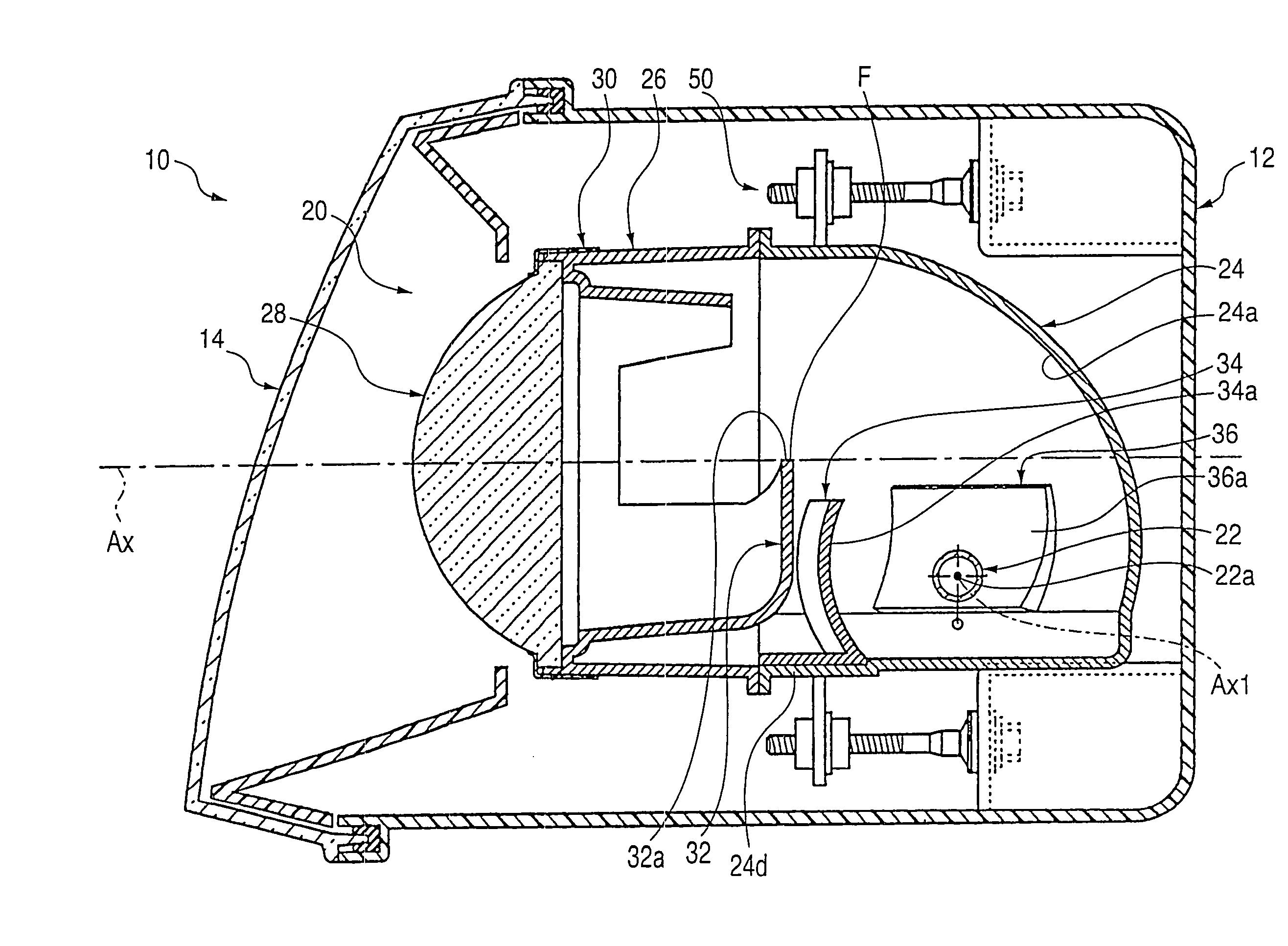

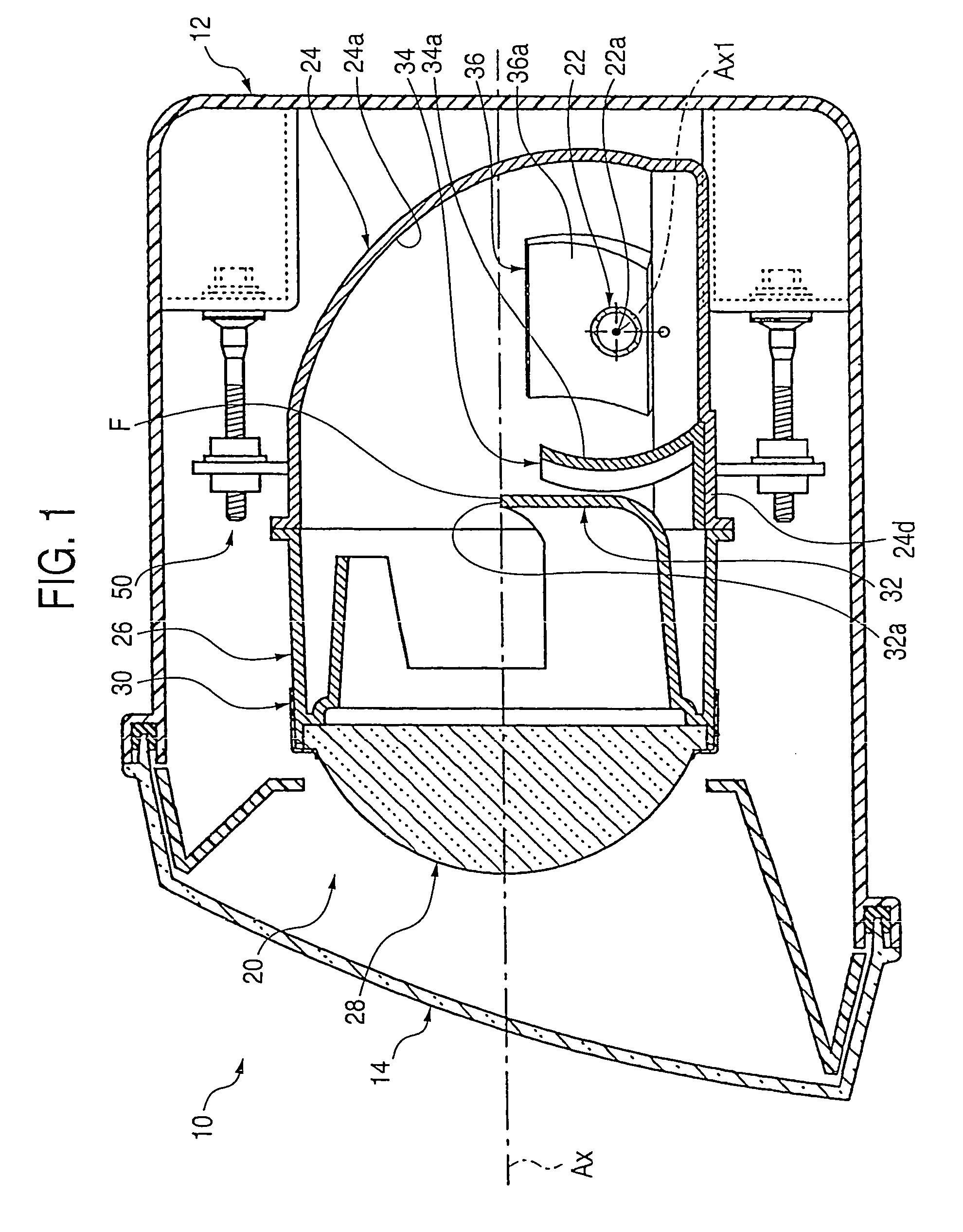

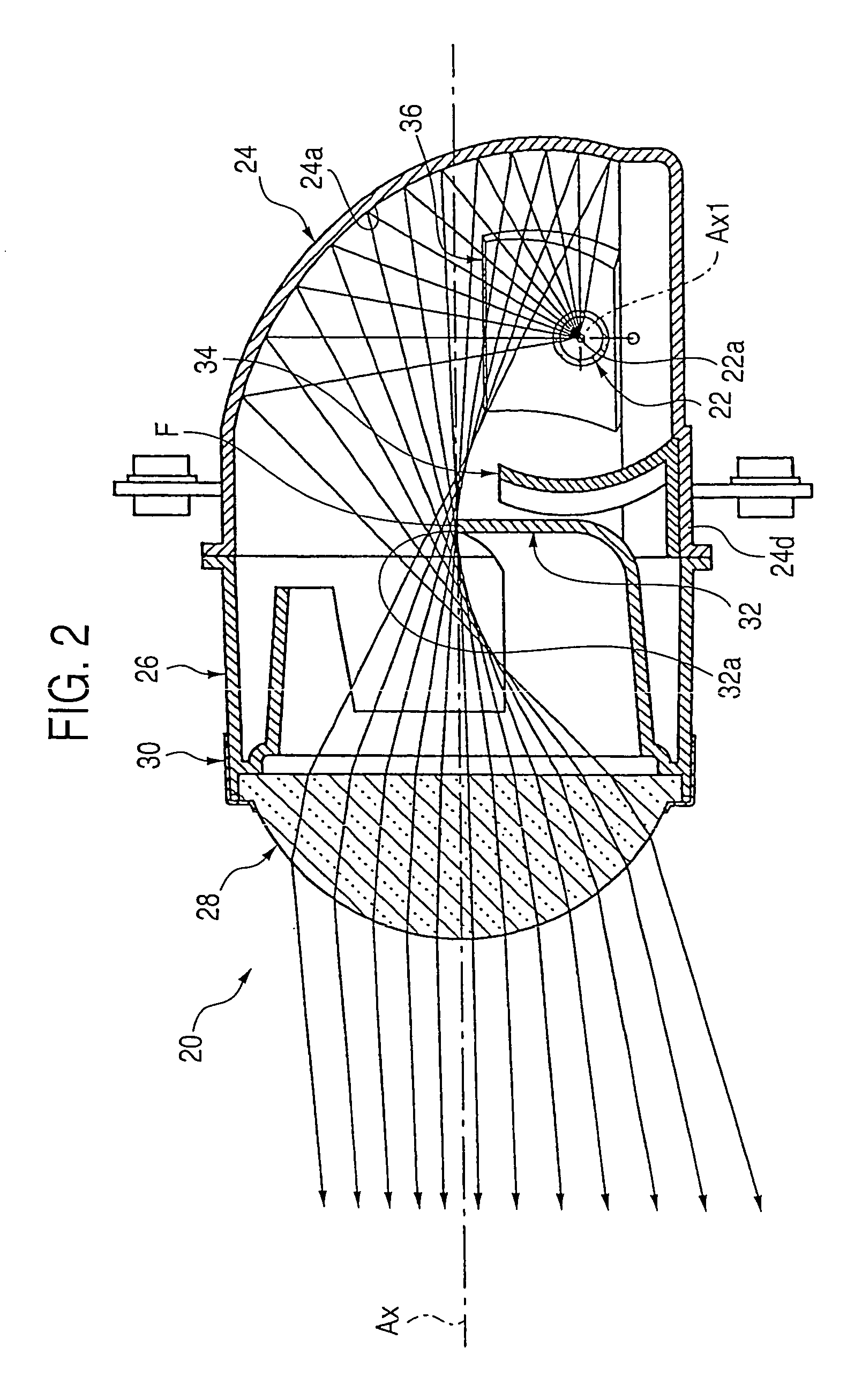

Vehicle headlamp

InactiveUS7093966B2Compact processShorten the lengthVehicle headlampsPoint-like light sourceOptical axisOptoelectronics

A first additional reflector 34 is provided between a light source bulb 22 and a shade 32 and used for reflecting light from a light source 22a to an area in front in the direction of inserting the bulb on the reflective surface 24a of a reflector 24. Further, the area in front in the direction of inserting the bulb on the reflective surface 24a of the reflector 24 is formed as a second additional reflector 36 for reflecting the light reflected from the first additional reflector 34 forward and closer to an optical axis Ax. Thus, direct light from the light source 22a which is to be shielded by the shade 32 is caused to be incident on a projection lens 28 by using the first and second additional reflectors 34 and 36, whereby the direct light can effectively be utilized as forward irradiation light.

Owner:KOITO MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com