Patents

Literature

999results about How to "Effective supervision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

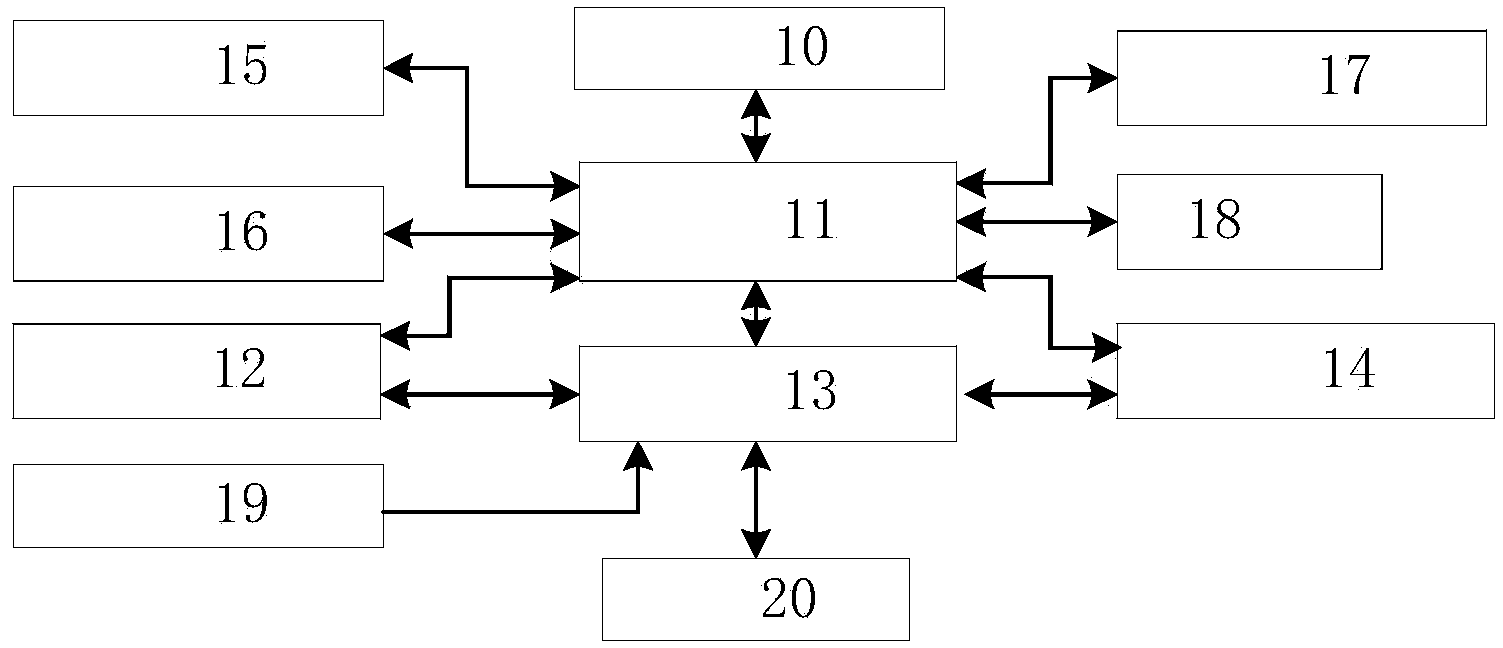

Intelligent inspection system and inspection method for electric transmission line by unmanned aerial vehicle

ActiveCN103824340AReduce idle rateImplement configurationRegistering/indicating working of machinesMonitoring systemUncrewed vehicle

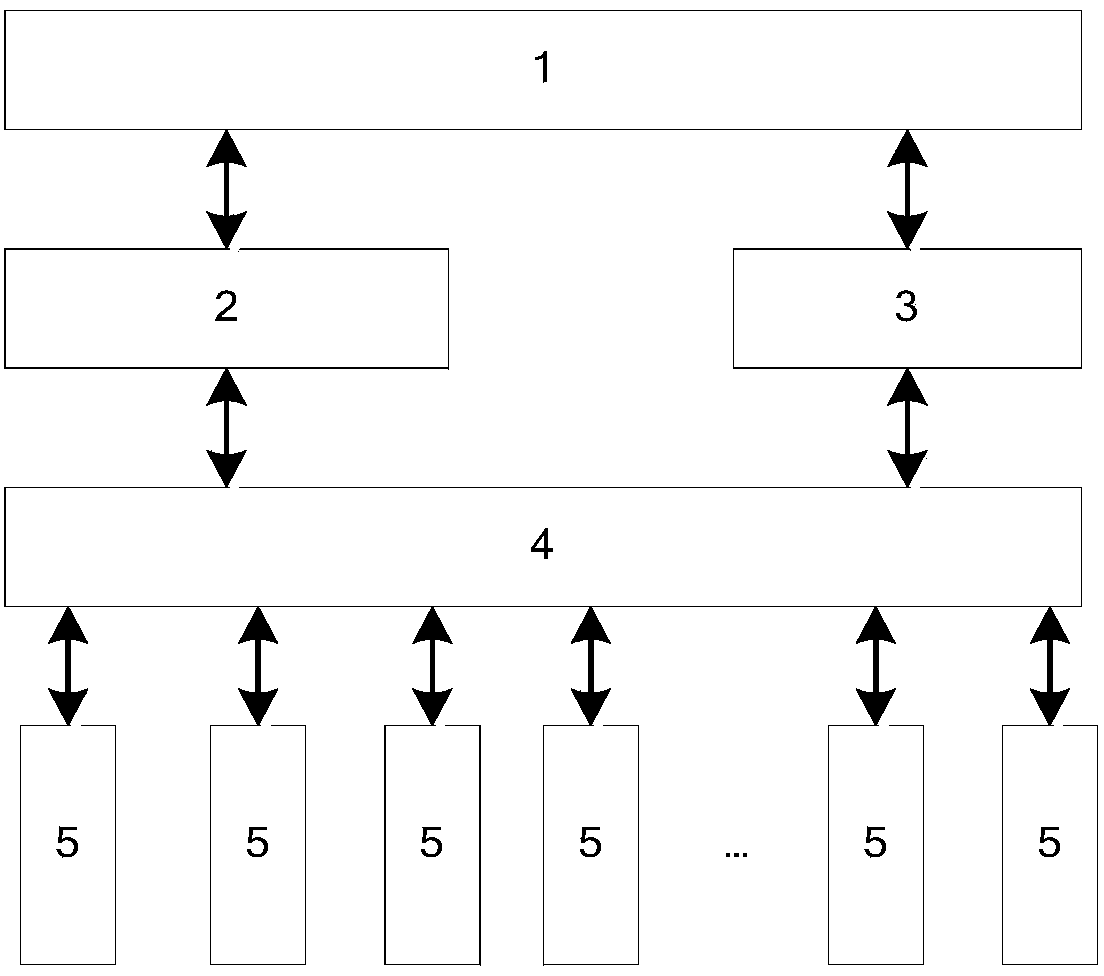

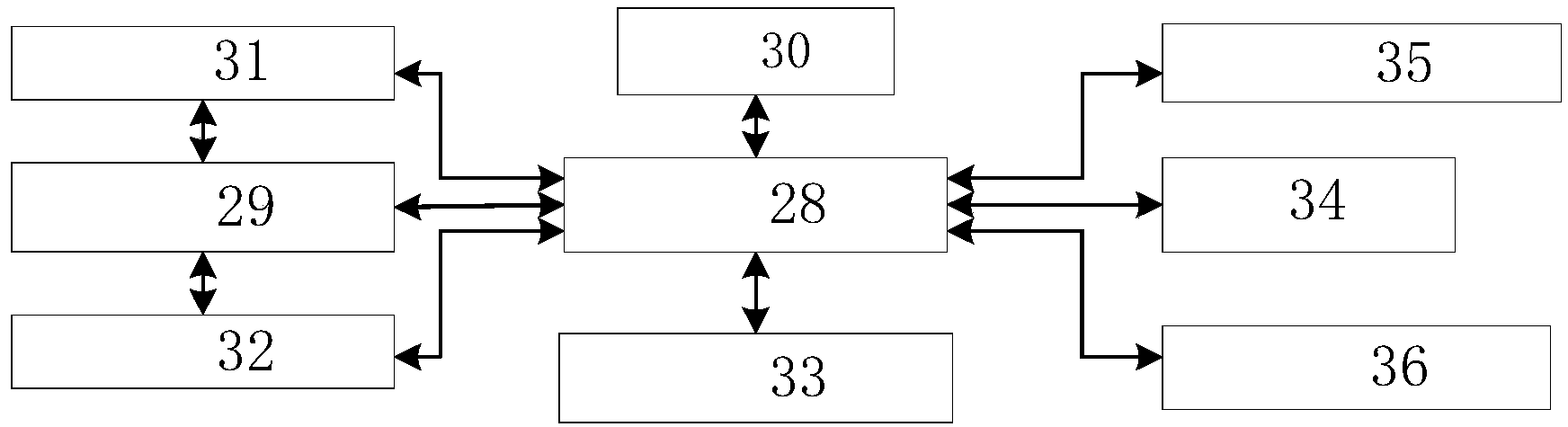

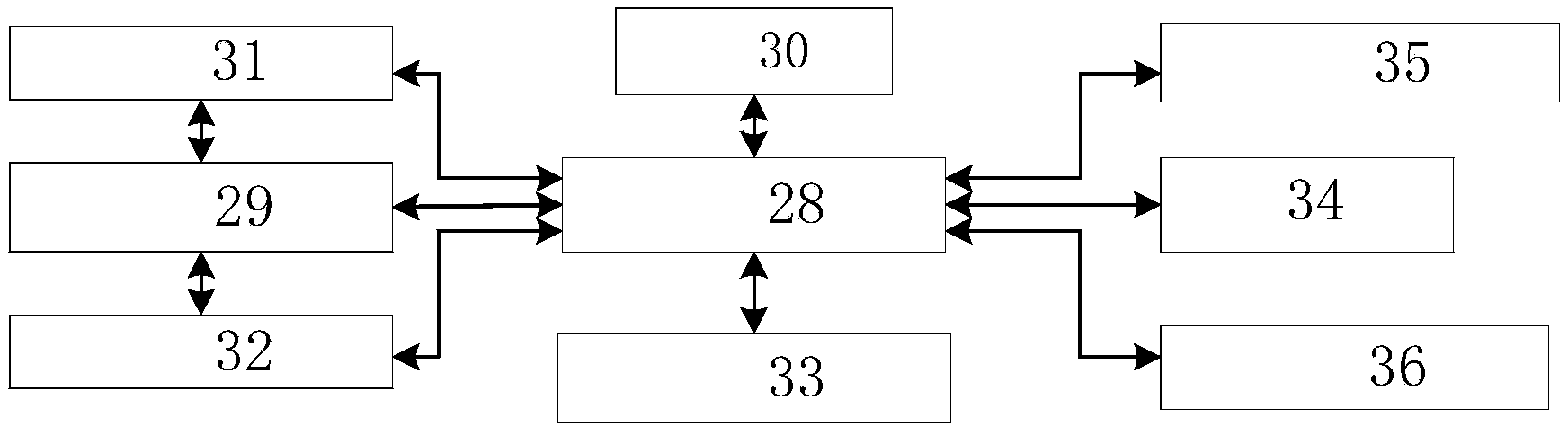

The invention discloses an intelligent inspection system and an inspection method for an electric transmission line by an unmanned aerial vehicle. The intelligent inspection system comprises an inspection mission planning system, a dispatching system, a monitoring system, an inspection result processing platform and mobile branch stations, wherein the inspection mission planning system communicates with the inspection result processing platform and the dispatching system respectively; the inspection result processing platform and the dispatching system communicates with the monitoring system respectively; the monitoring system is connected and communicate with the mobile branch stations. The inspection method has the benefits that factors of the inspection unmanned aerial vehicle, inspection equipment, an inspector, and the like accessing the dispatching platform through a dispatching terminal can be dispatched effectively to realize equipped configuration of unmanned aerial vehicle inspection resource; the usage rates of personnel and equipment can be improved; the no-load rate and vacancy rate of the inspection equipment are reduced; through centralized monitoring of condition information inspected by the unmanned aerial vehicle, unmanned aerial vehicle inspection dispatching personnel can master unmanned aerial vehicle inspection in the large effectively; the service life of the unmanned aerial vehicle is prolonged.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

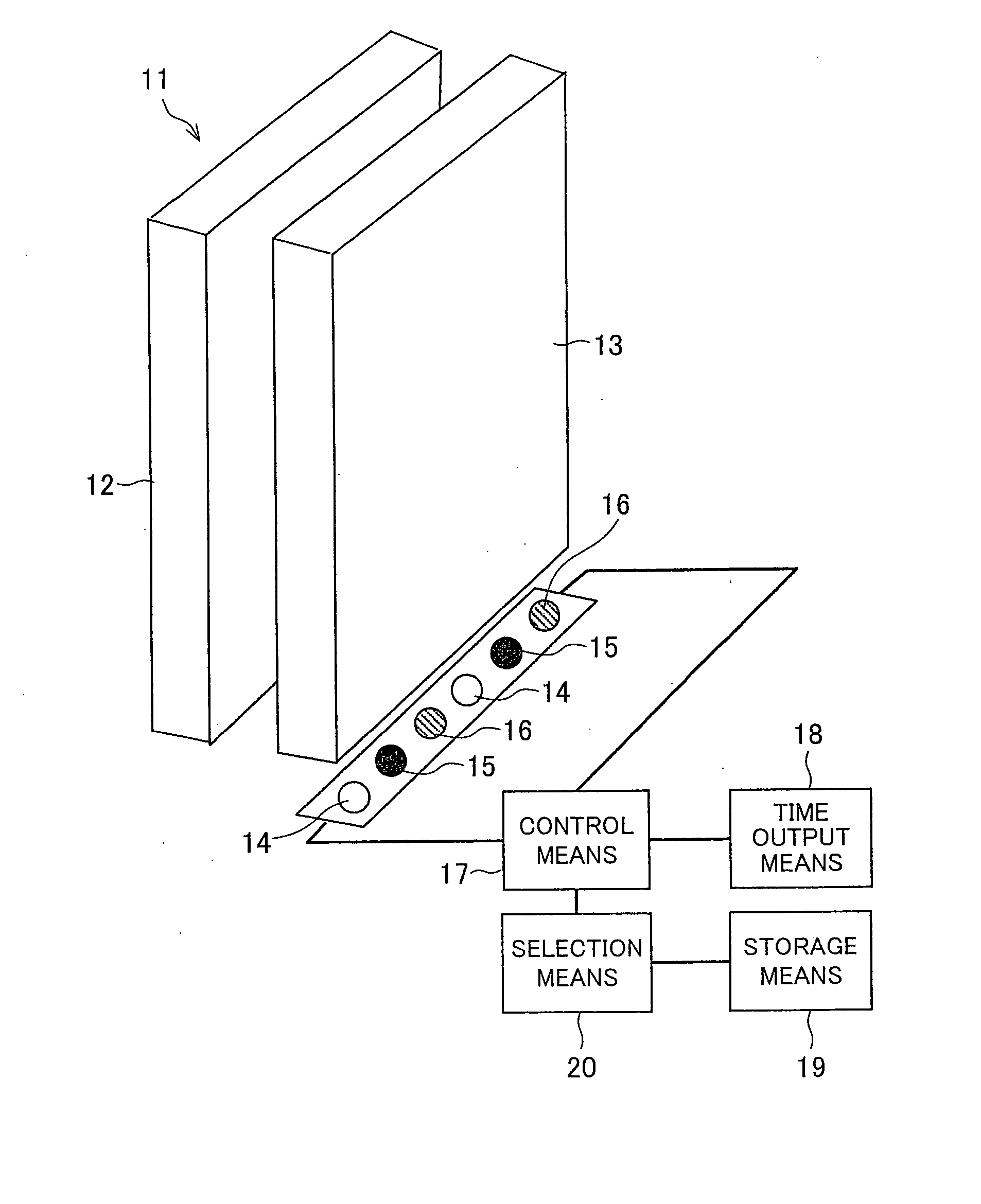

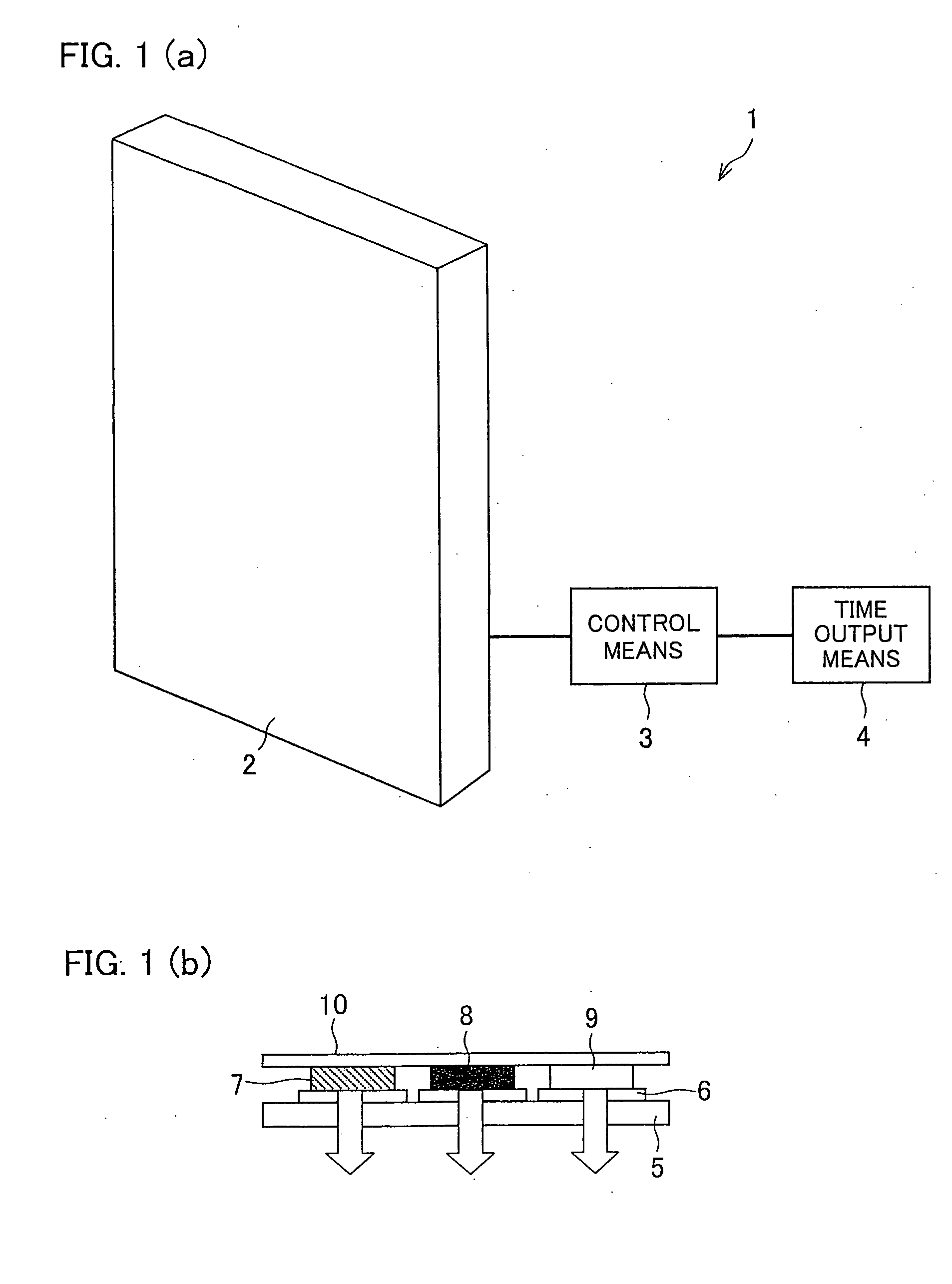

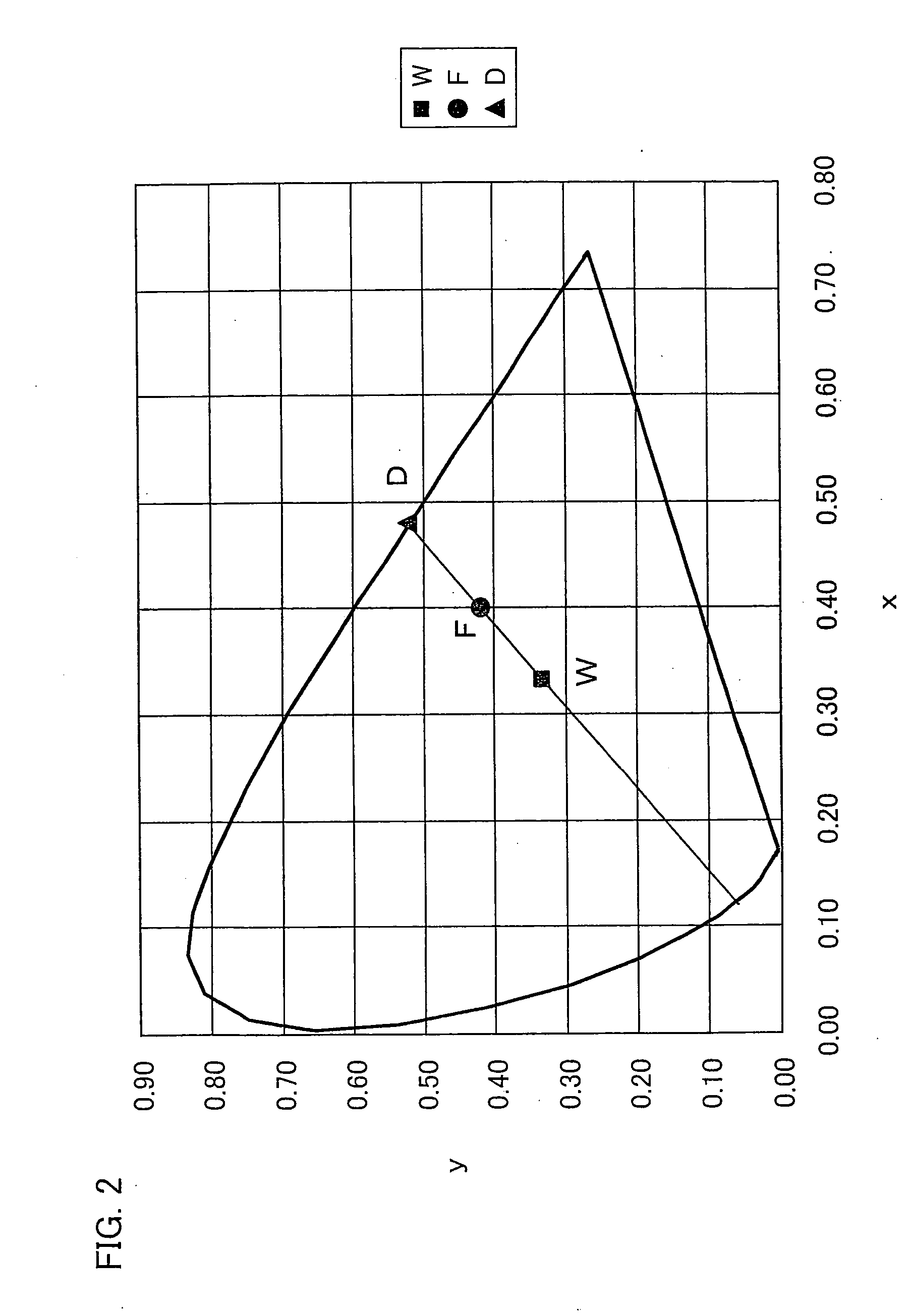

Display Device

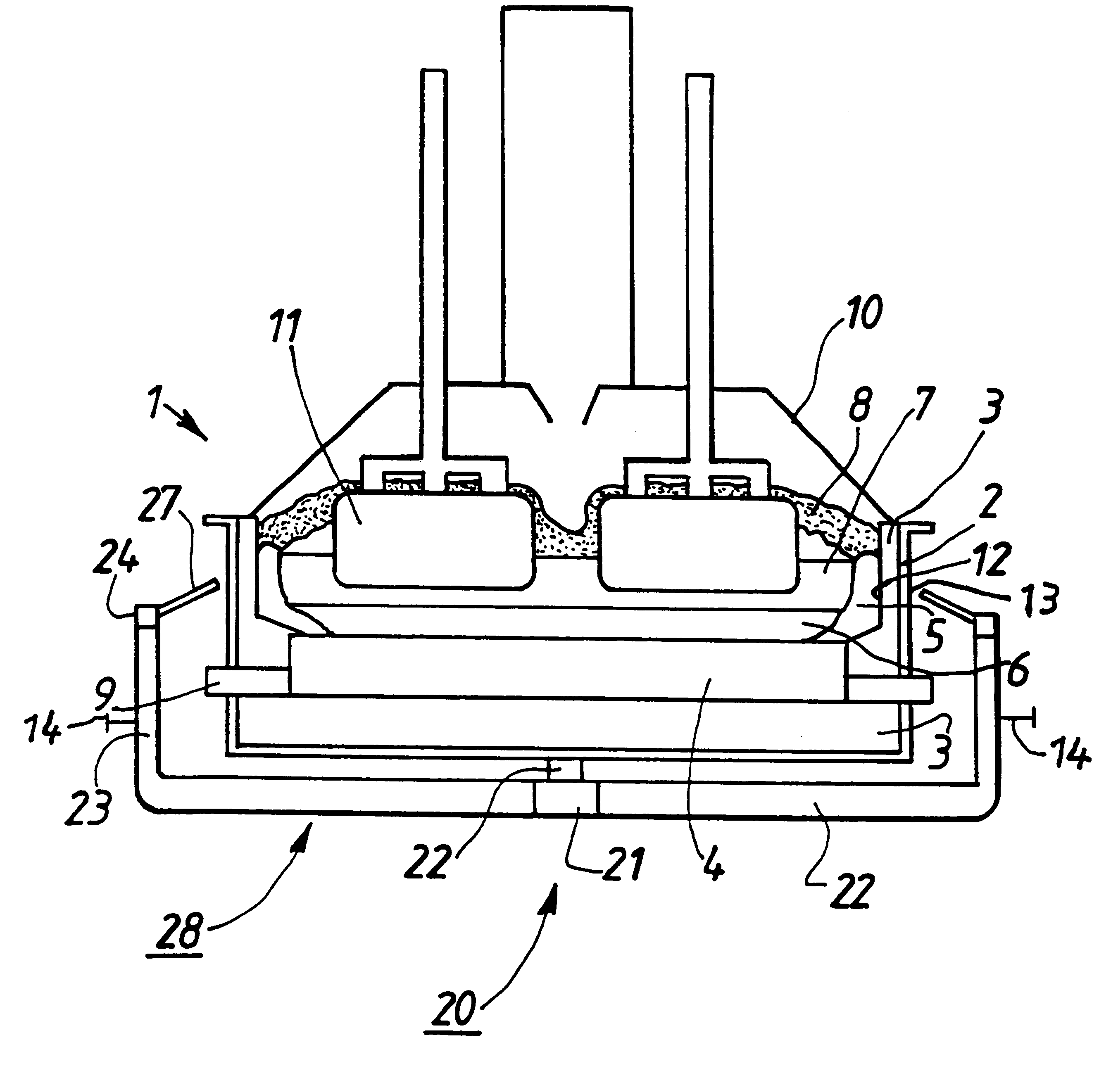

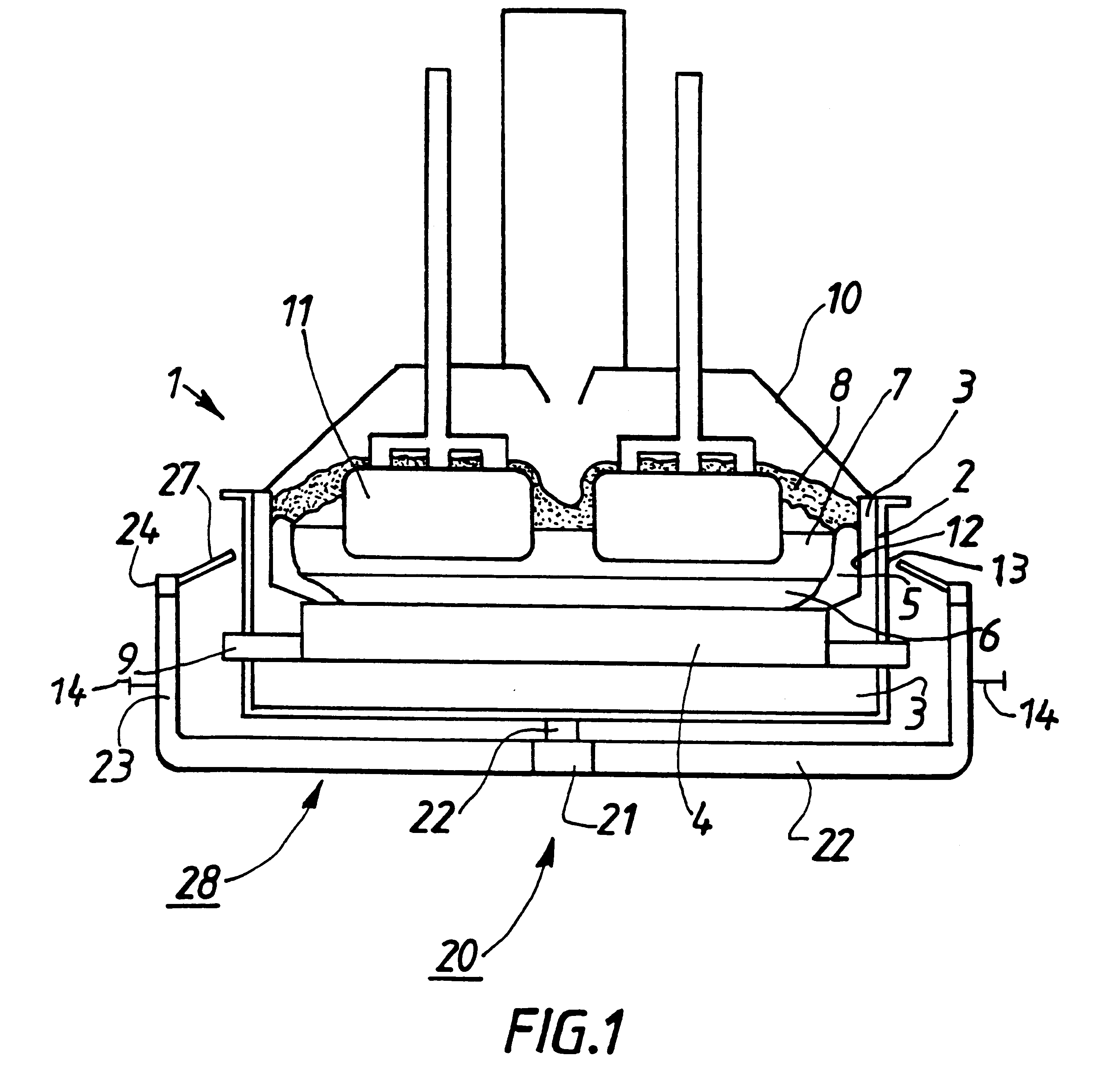

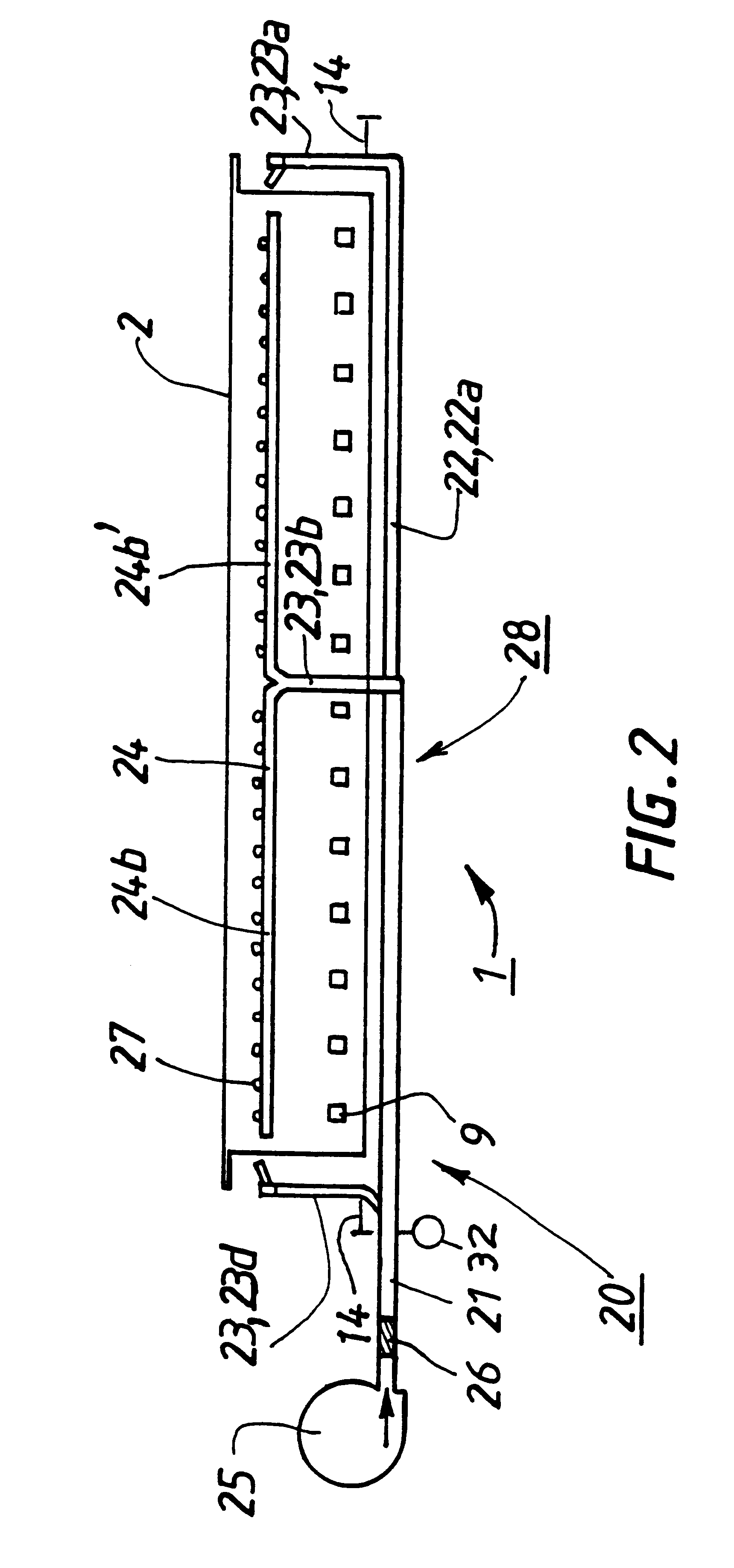

InactiveUS20070268234A1Profound effectEffective regulationStatic indicating devicesSleep inducing/ending devicesDisplay deviceOrganic layer

A display device (1) of the present invention displays an image by using an organic layer (9) which emits light having such a wavelength that affects a biorhythm, and the display device (1) controls a luminous intensity of the organic layer (9).

Owner:SHARP KK

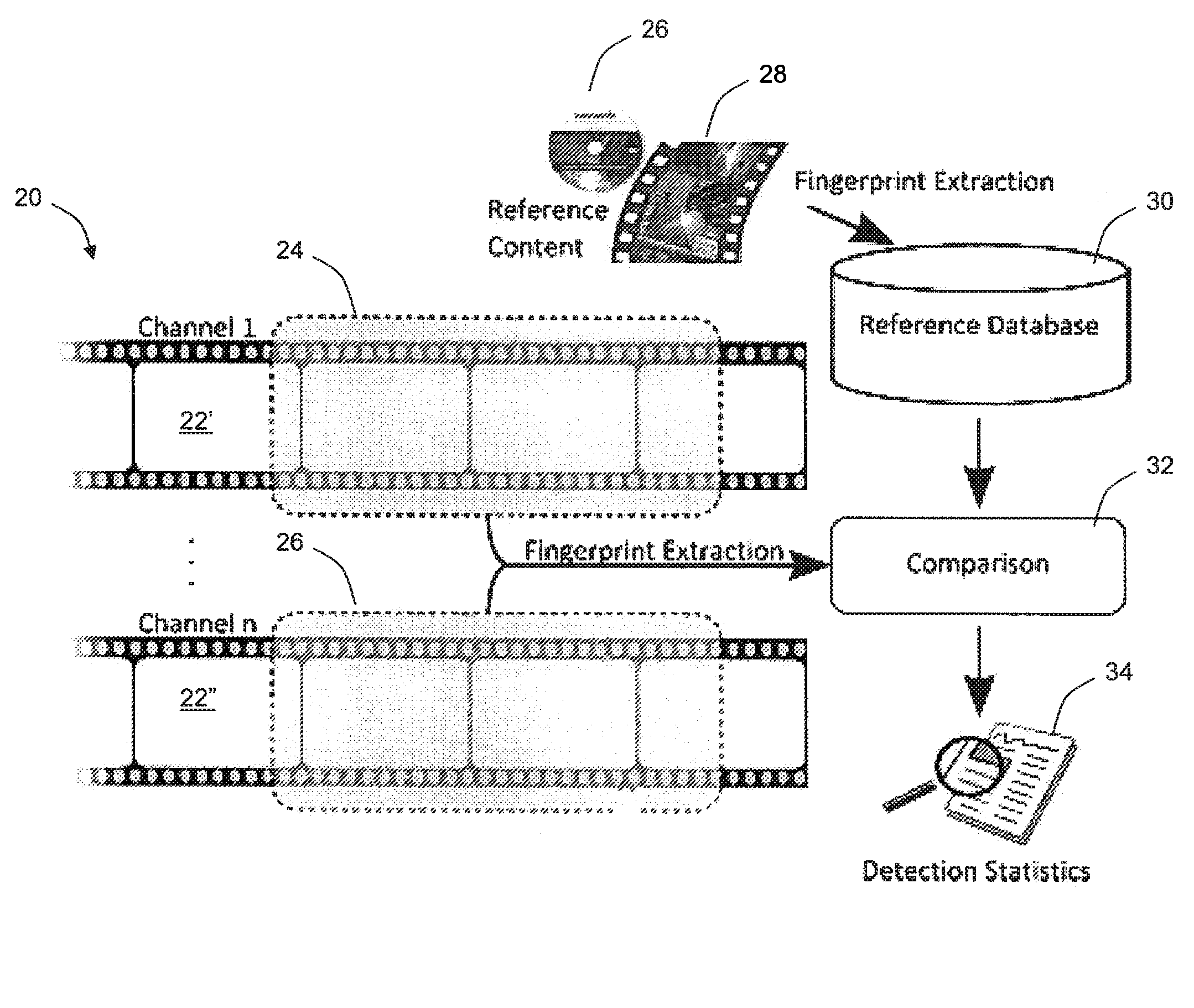

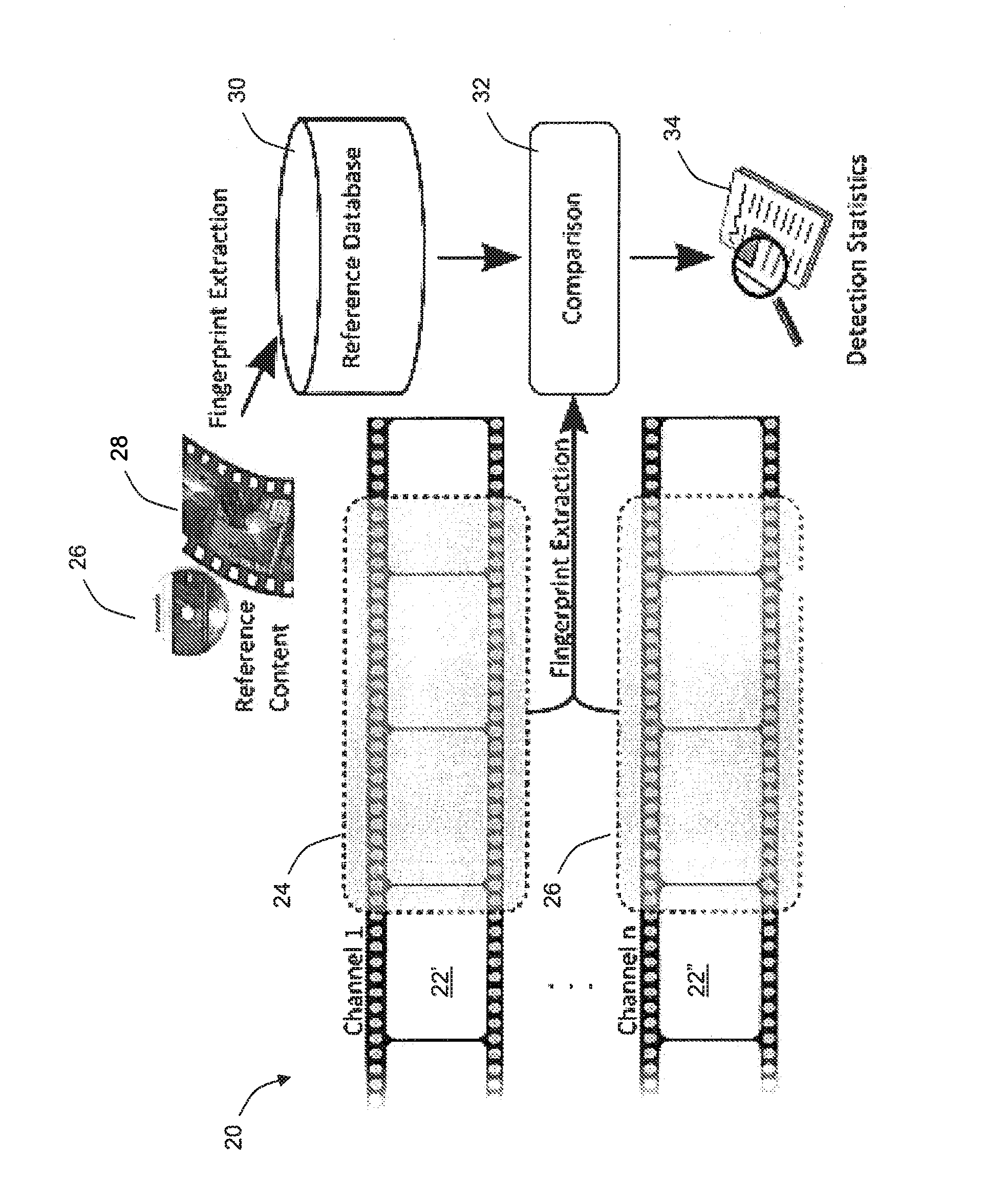

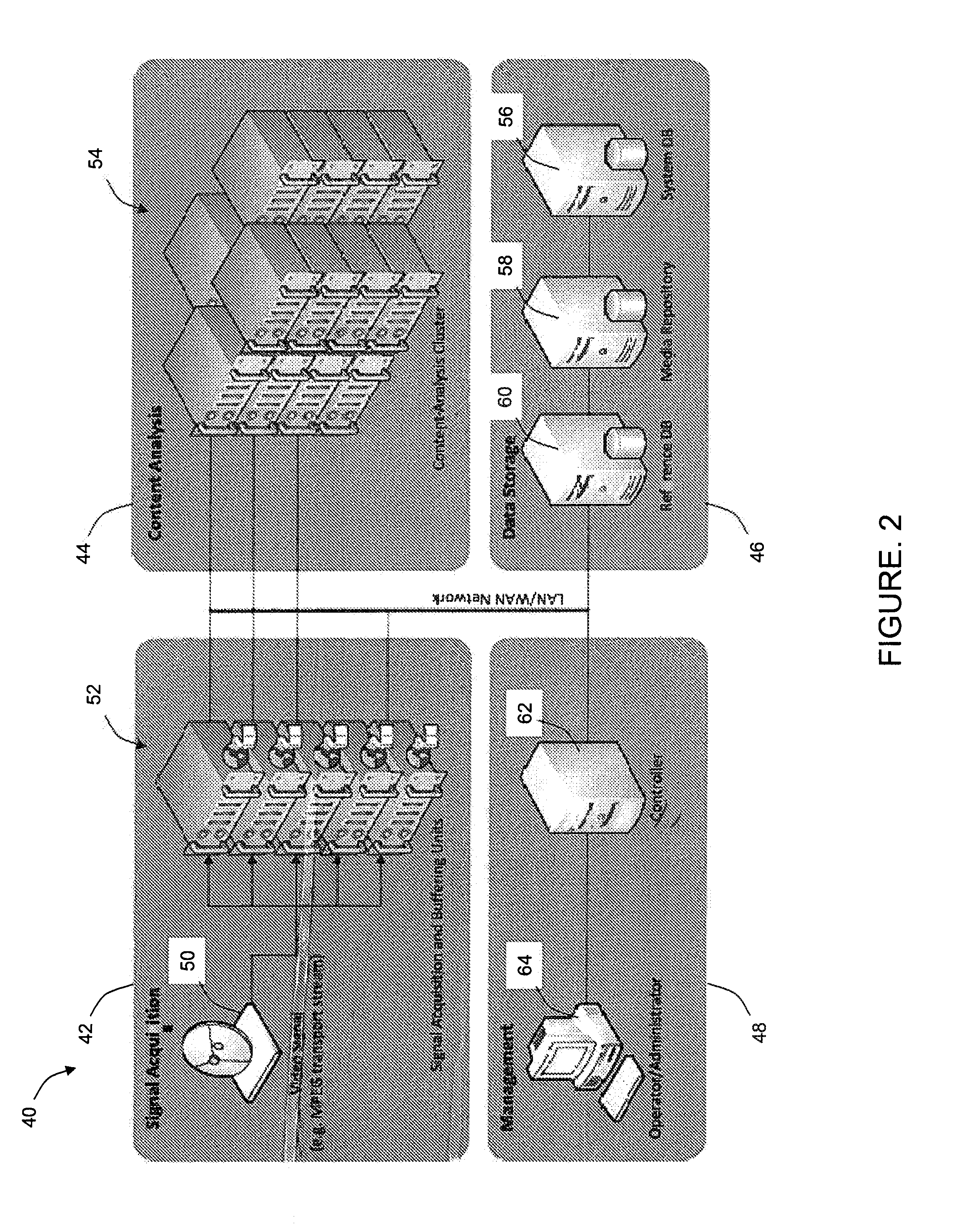

Video detection system and methods

ActiveUS20100329547A1Improve scalabilityEffective supervisionDigital data information retrievalDigital data processing detailsImage resolutionDigital image

A video detection system and method compares a queried video segment to one or more stored video samples. Each of the queried video segments and stored video samples can be represented by respective digital image sets. A first and second comparison comprises comparing a set of low and high resolution temporal and spatial statistical moments in a COLOR9 space, and eliminating file digital image sets that do not match the queried digital image set. A third comparison generates a set of matching files by comparing a set of wavelet transform coefficients in a COLOR9 space. RGB bit-wise registration and comparison of one or more subframes of specific frames in the queried digital image set to a corresponding set of matching file subframes determines queried subframe changes. In the event of a change in a queried subframe, the changed subframe is added to the set of matching file subframes.

Owner:IVITEC GMBH

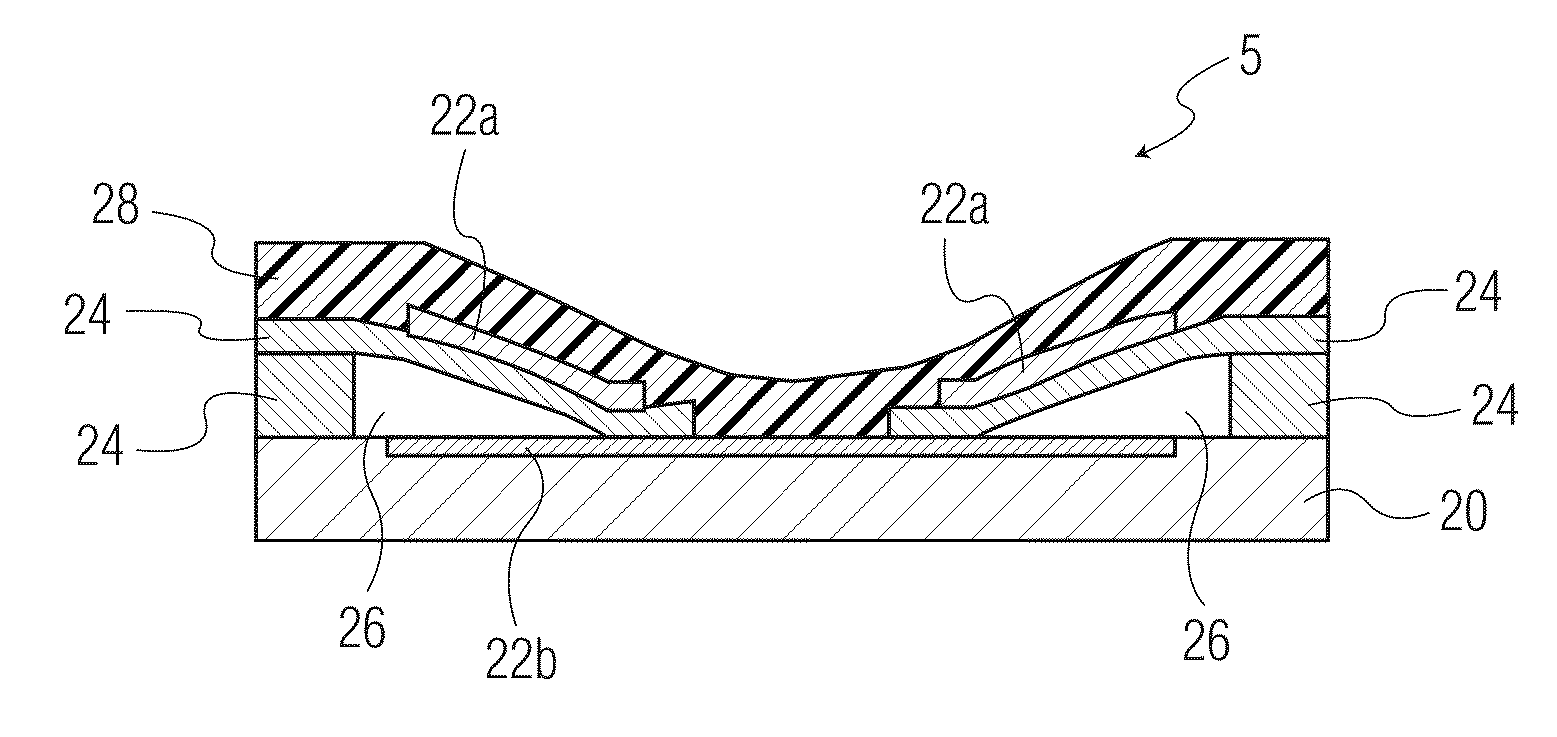

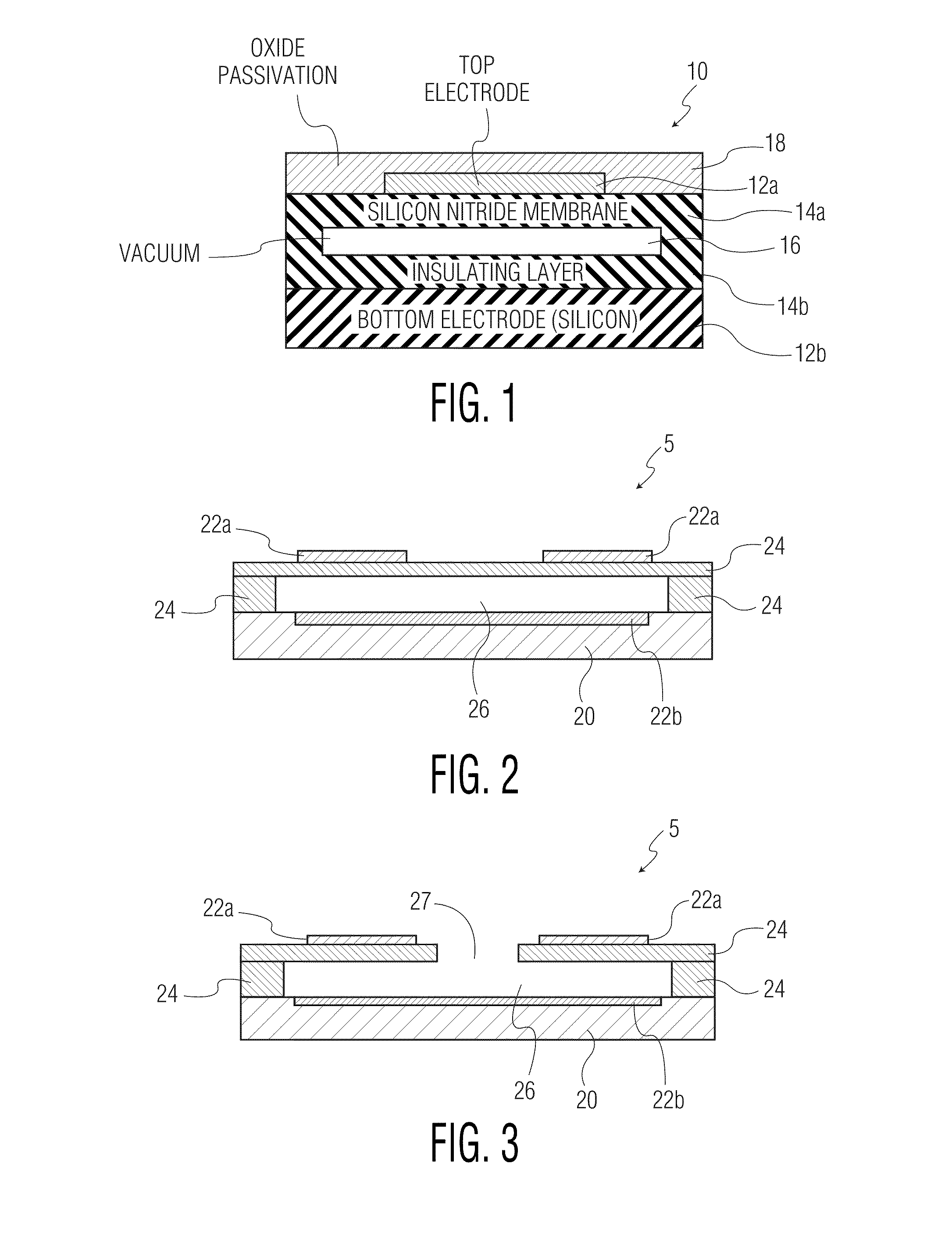

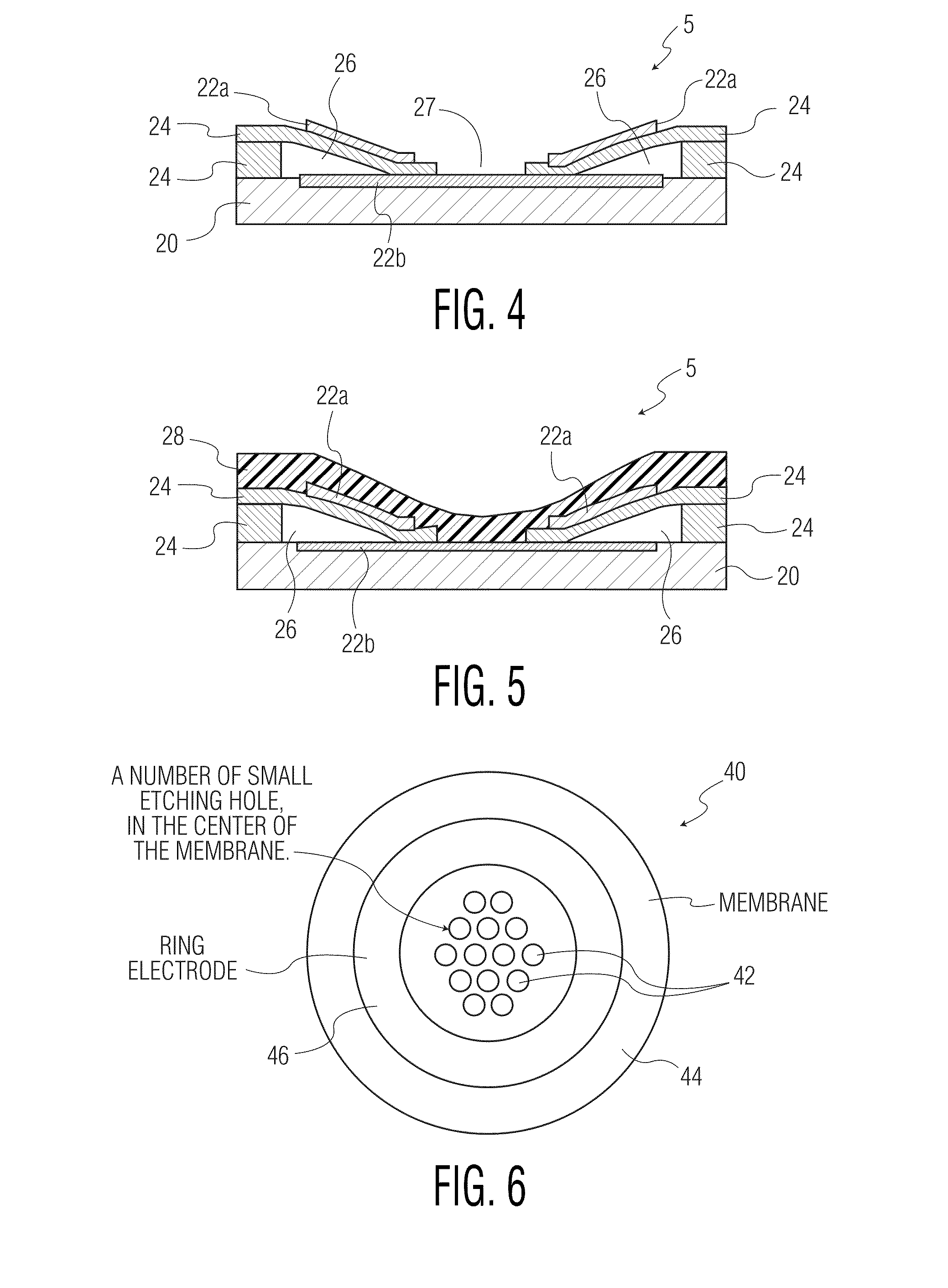

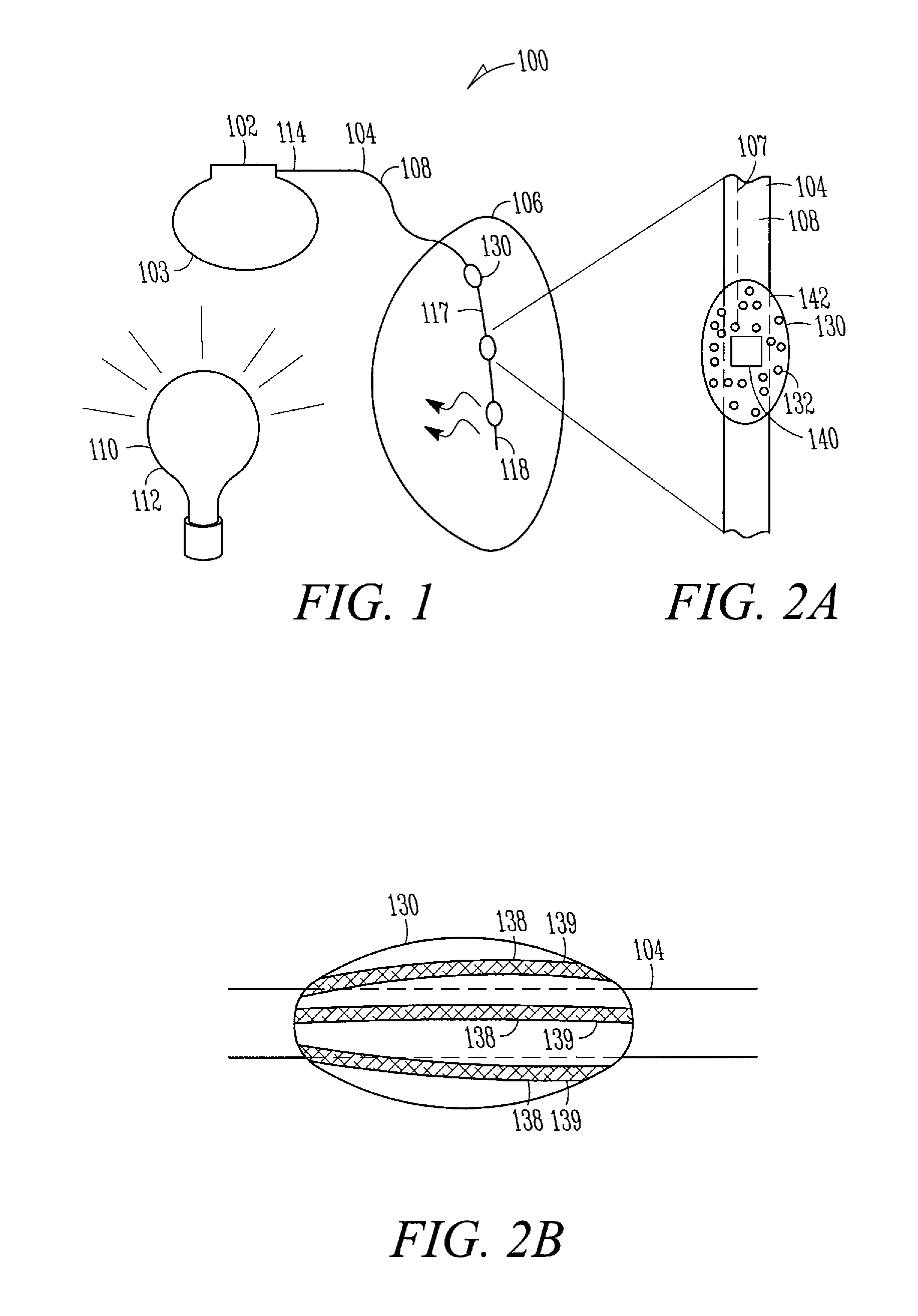

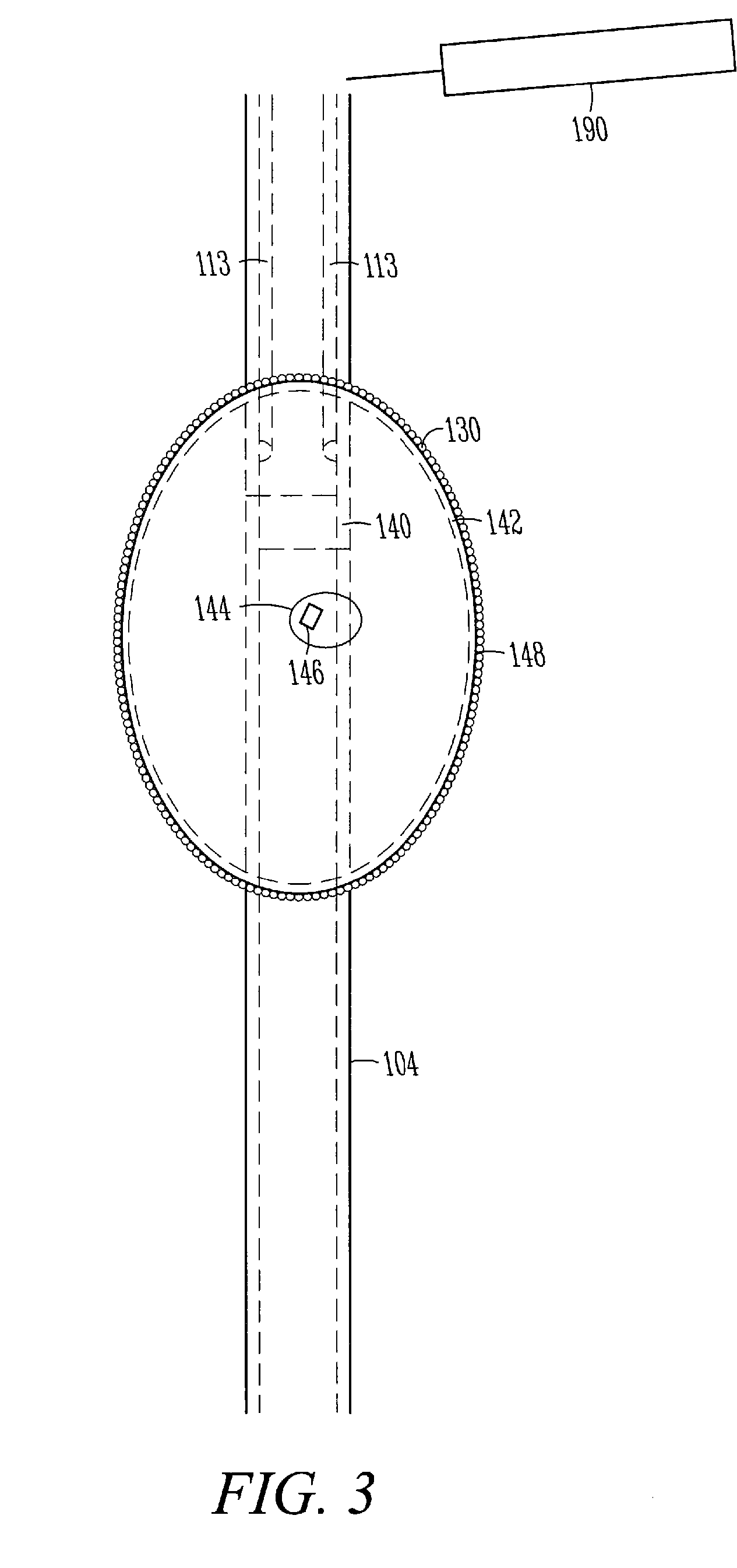

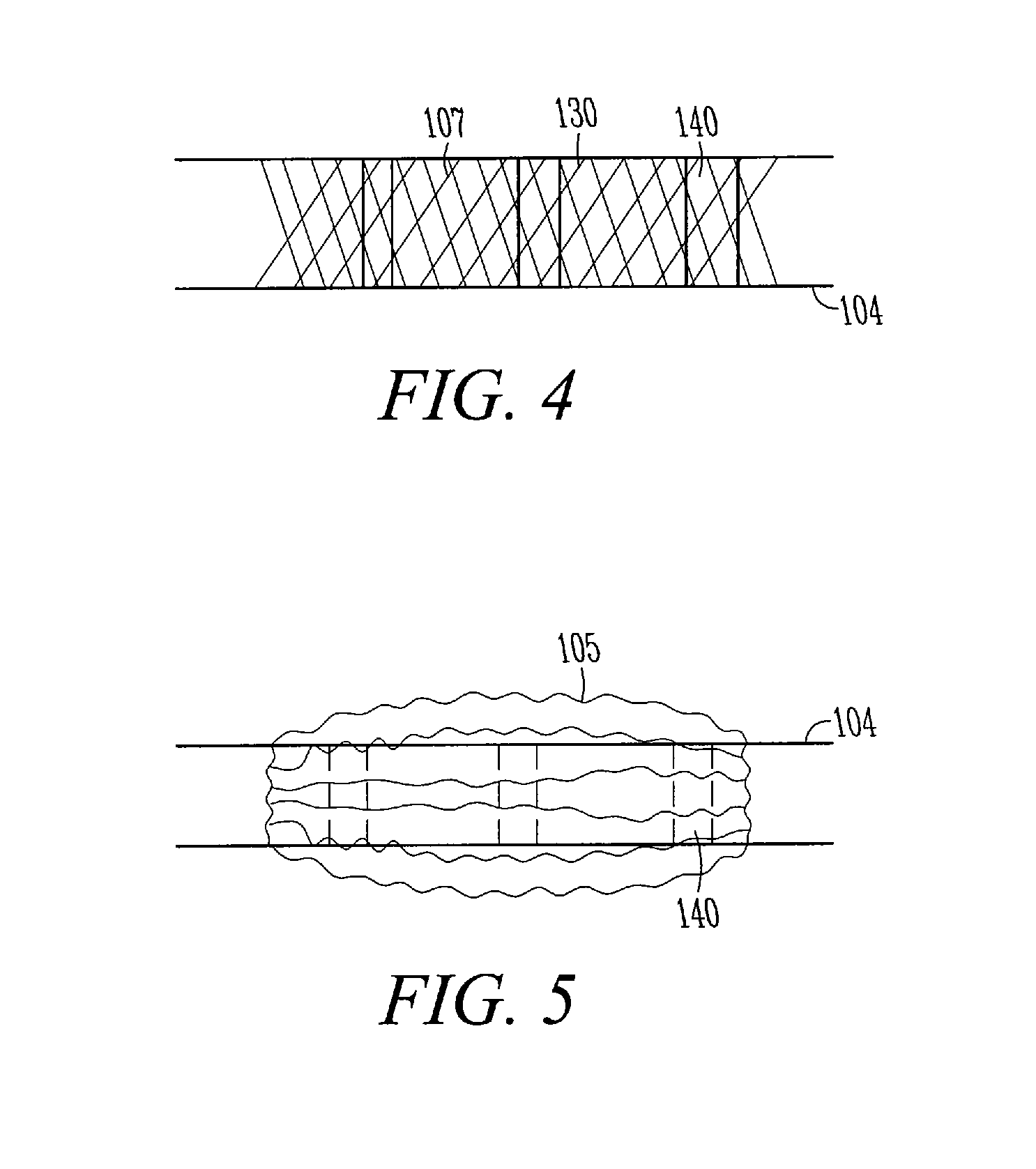

Method for production and using a capacitive micro-machined ultrasonic transducer

ActiveUS8327521B2Easy to manufactureHigh voltageUltrasonic/sonic/infrasonic diagnosticsSemiconductor electrostatic transducersCapacitive micromachined ultrasonic transducersMedicine

Owner:KONINK PHILIPS ELECTRONICS NV

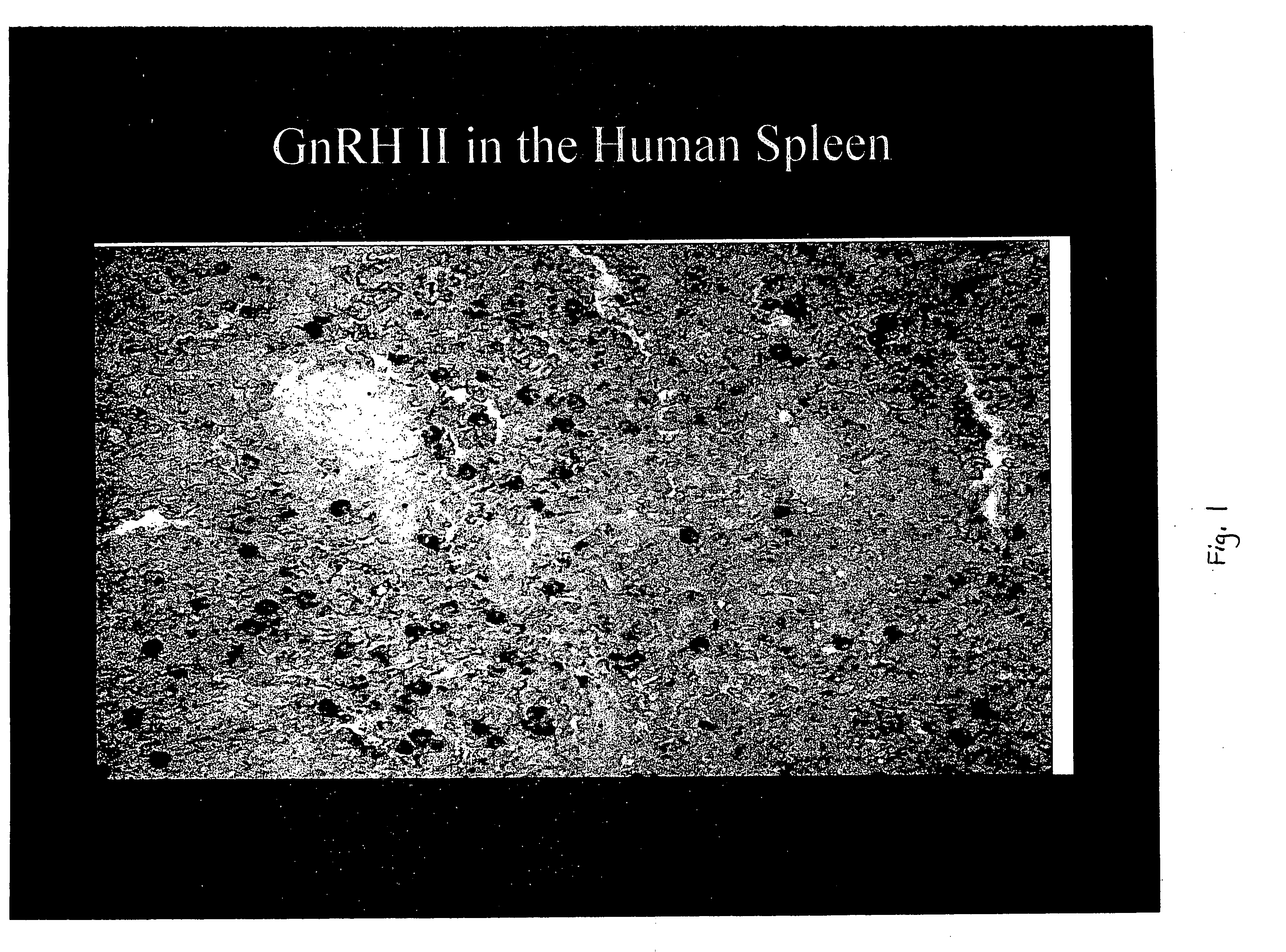

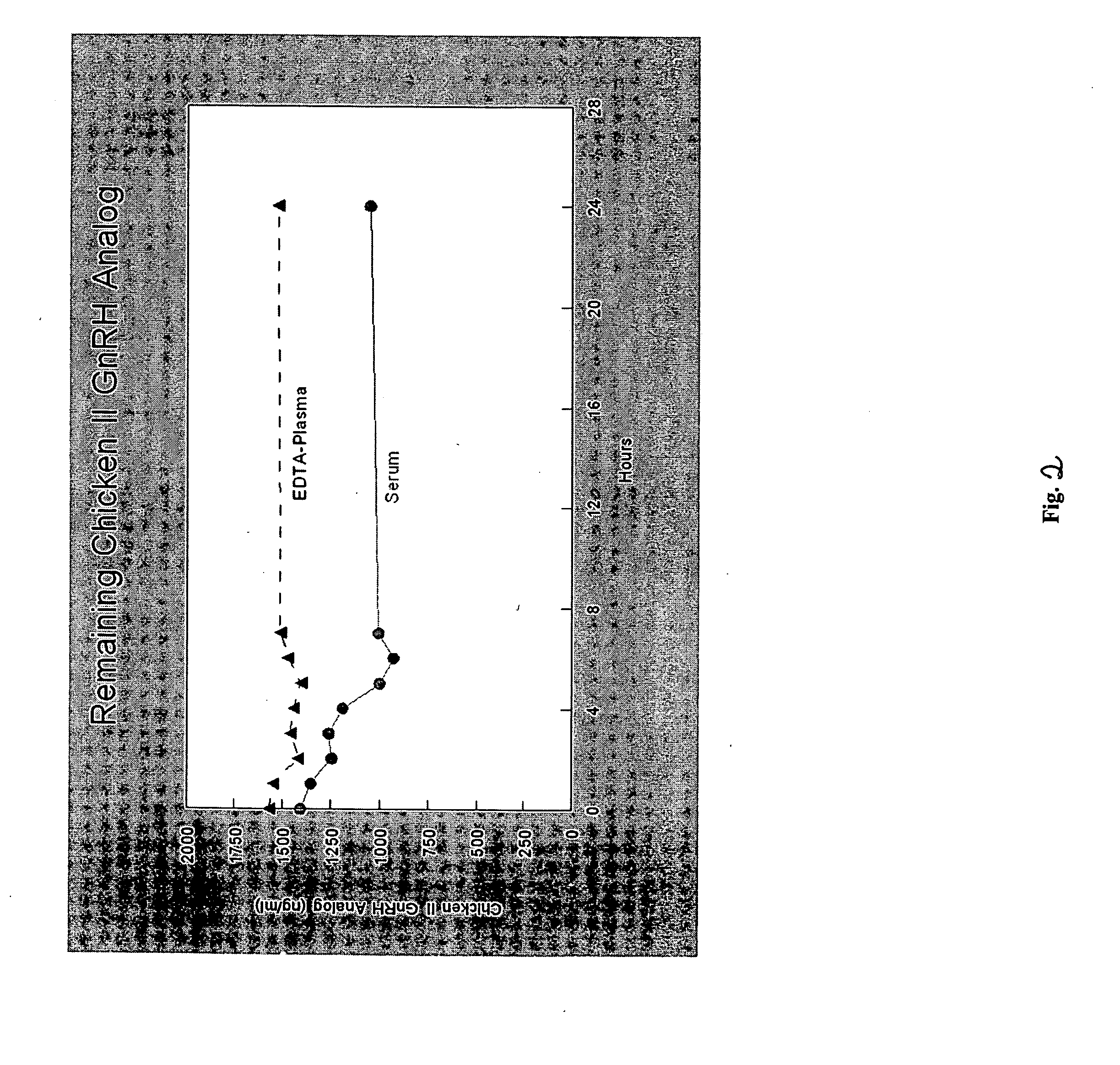

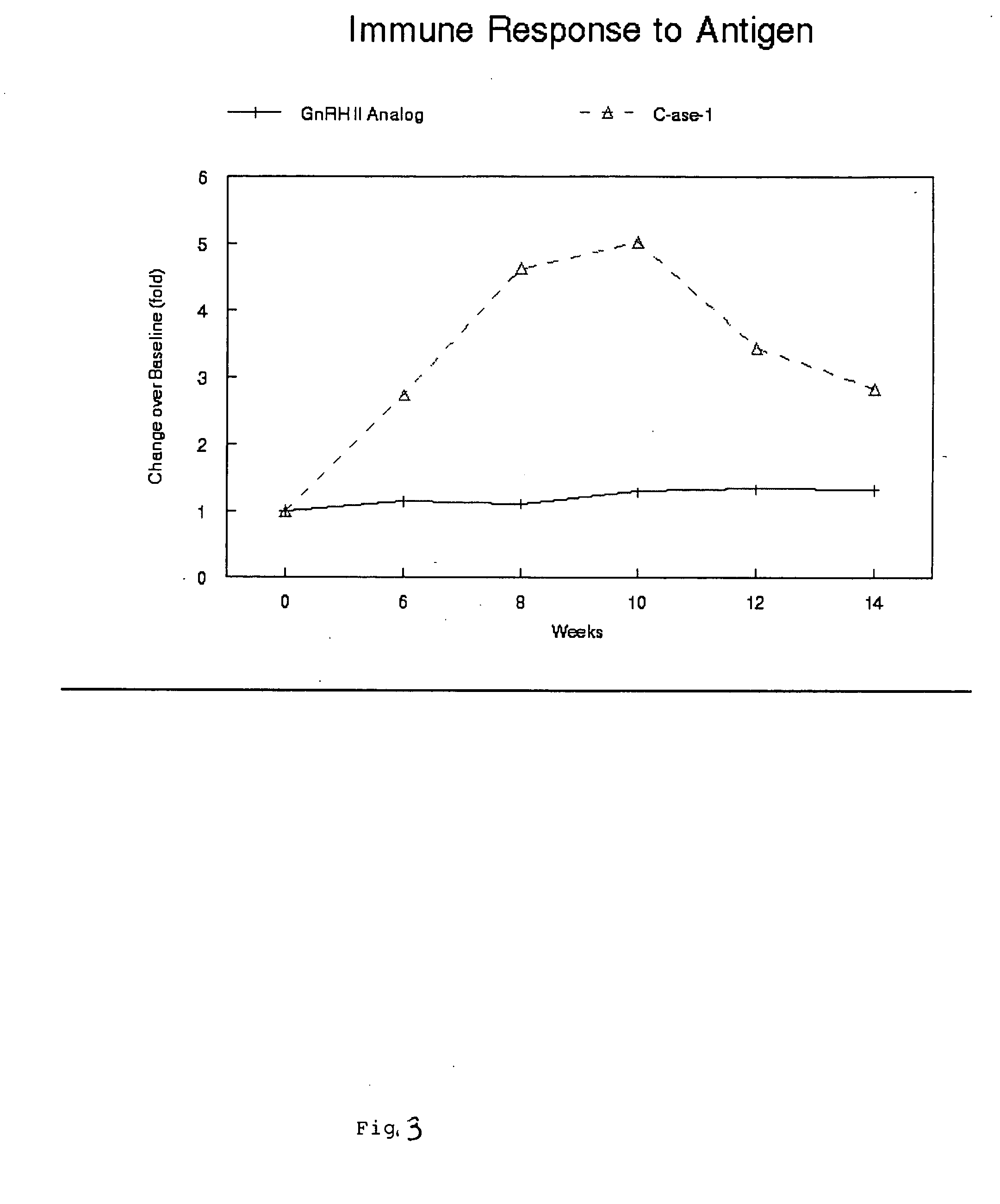

Non-mammalian GnRH analogs and uses thereof in the immune system

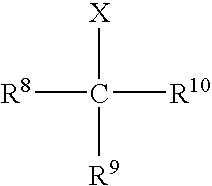

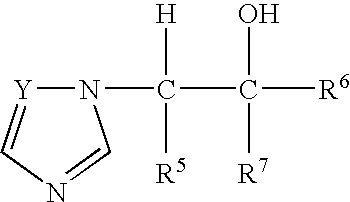

InactiveUS20050043245A1High affinityGreat affinityPeptide/protein ingredientsLuteinising hormone-releasing hormoneGnRH AnalogChemistry

Specially designed non-mammalian GnRH, its analogs, or biometics resistant to degradation by peptidase, are disclosed. The GnRH analogs are further defined as analogs of GnRH II or salmon GnRH. These non-mammalian analogs incorporate D-arginine, D-leucine, D-tBu-Serine, D-Trp or other active D amino acids at position 6 and ethylamide, aza-Gly-amide or other Gly amide at position 10. The D-Arg (6)—GnRH II-ethylamide, D-Arg (6)—GnRH II-aza-Gly (10)-amide, the D-Arg (6)—salmon GnRH ethylamide, and D-Arg (6)—salmon GnRH-aza-Gly (10)-amide analogs are also provided, and demonstrate preferential binding to immune system non-mammalian GnRH receptors. These non-mammalian GnRH or its analogs, or long-acting preparation, biometics or their antibodies may be used in pharmaceutical preparation, and specifically in treatment of various immune system disorders. The non-mammalian GnRH or its analogs are also provided in pharmaceutical preparations that may be used clinically for treating immune system disorders when used in very low doses and administered in pulsatile fashion. The aza-Gly (10) amide non-mammalian analogs are yet other embodiments of the non-mammalian GnRH or its analogs provided as a part of the invention. The use of agents that regulate the production or antibodies or In addition, the detection of non-mammalian GnRH or GnRH II or the non-mammalian GnRH receptors may be used as a diagnostic tool.

Owner:SILER KHODR THERESA

Optical stitch regulator system

InactiveUS6959657B1Effective supervisionProgramme-controlled sewing machinesSewing-machine casingsEngineeringControl unit

An optical stitch regulator system for efficiently regulating the stitch length and stitch frequency of a sewing machine. The optical stitch regulator system includes at least one optical sensor within or external of the sewing platform of a sewing machine for sensing the motion of the fabric being sewn. The motion data is communicated to a control unit which communicates with the sewing machine for controlling the stitch length and frequency.

Owner:DUVAL RICHARD J

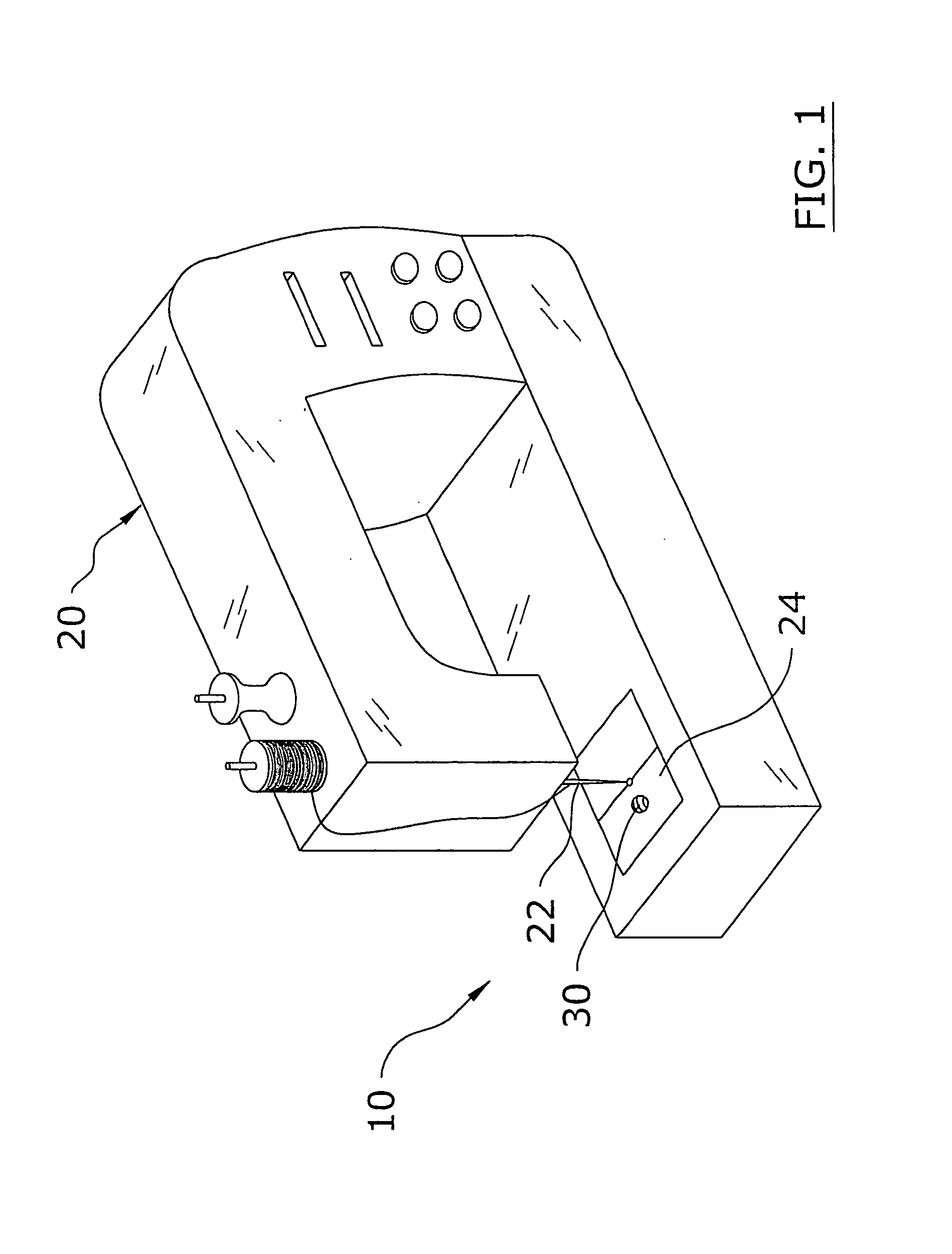

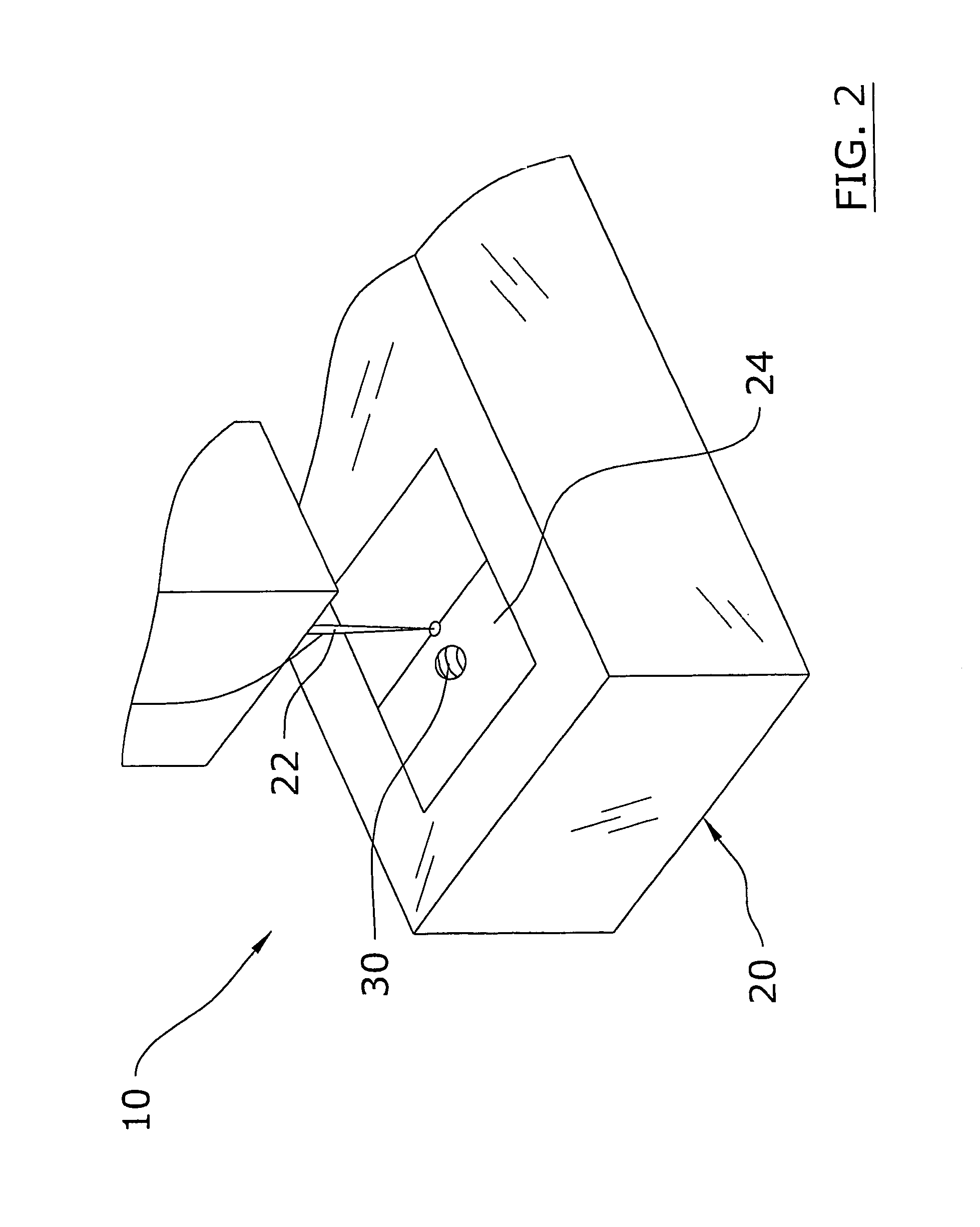

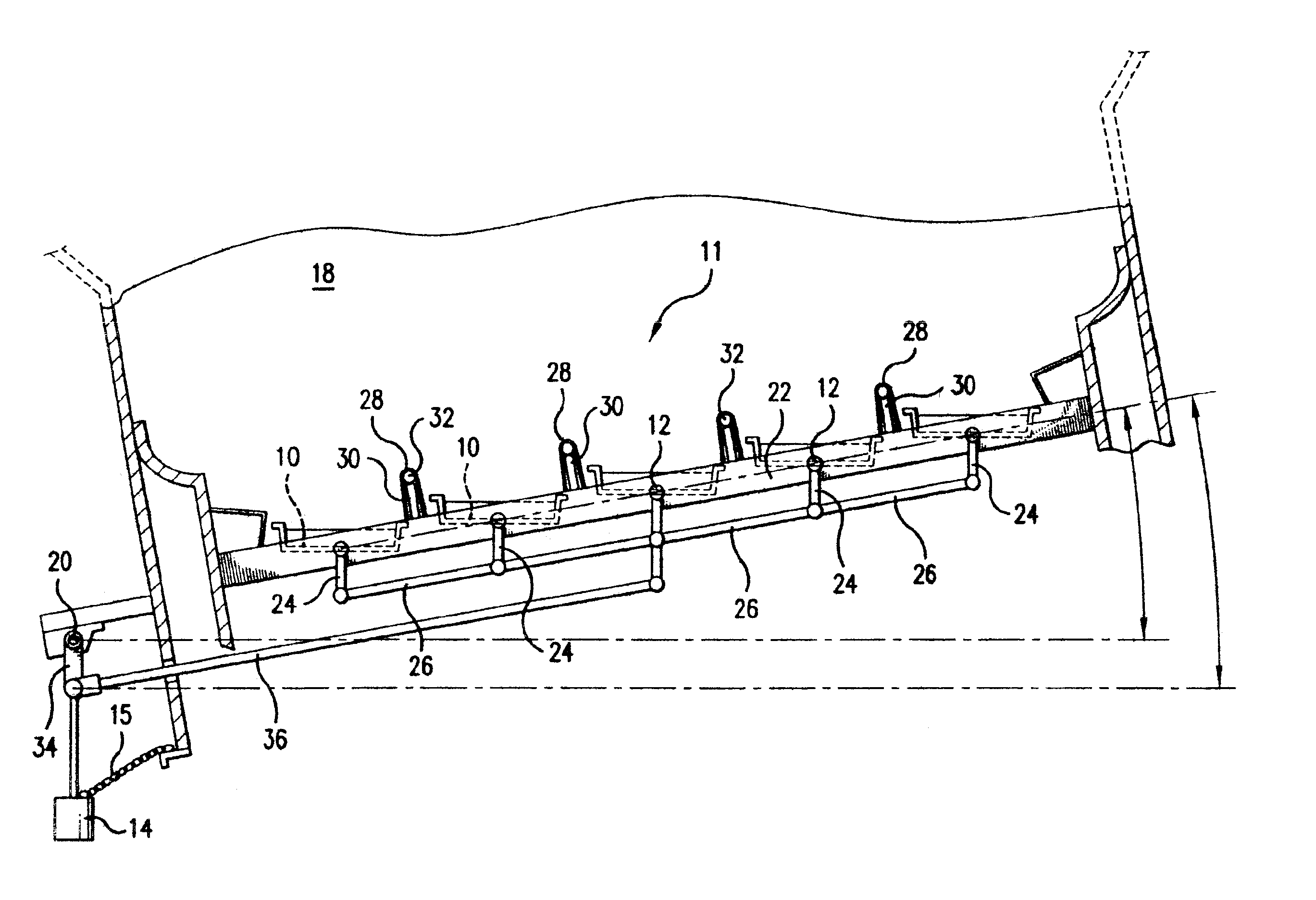

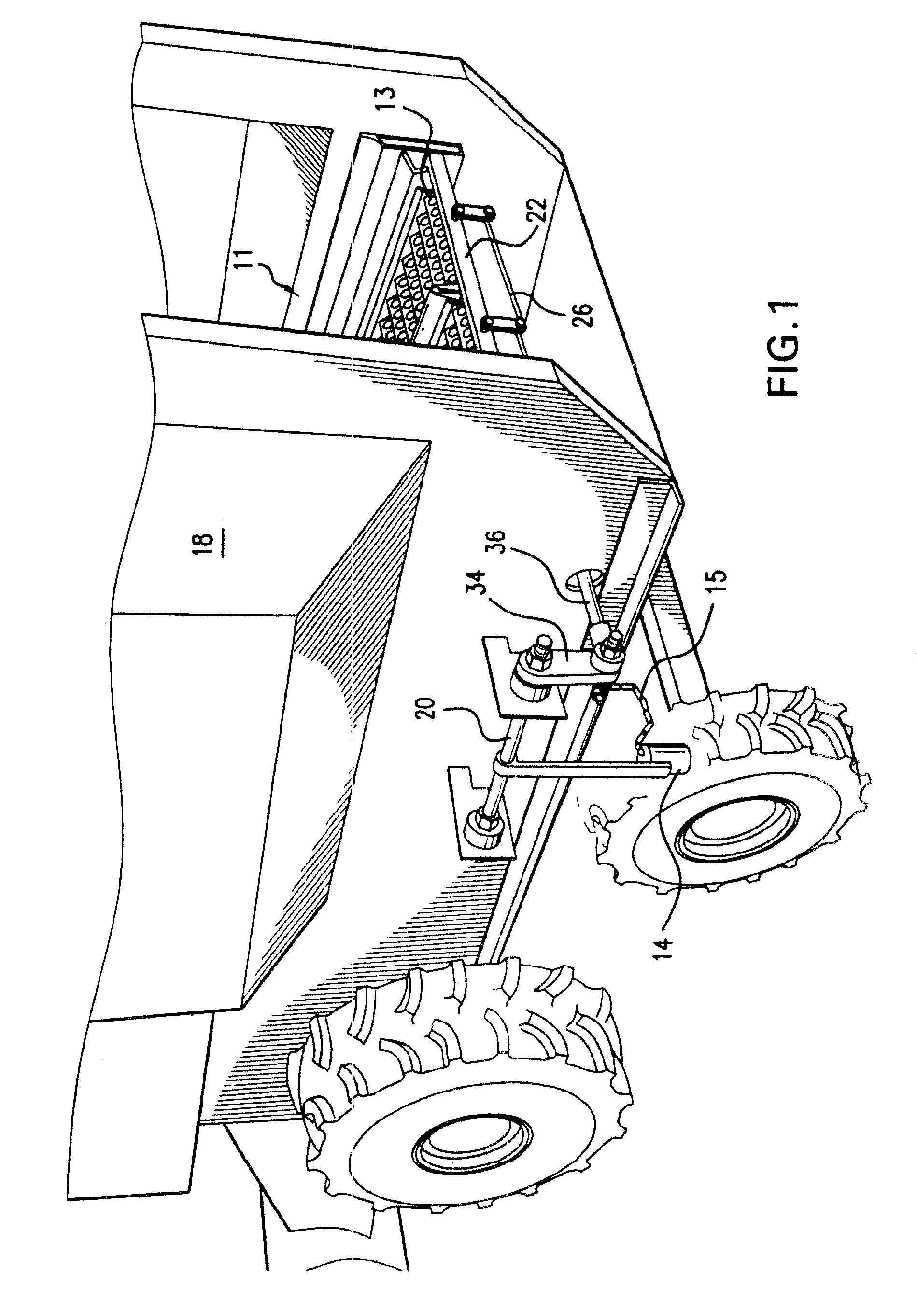

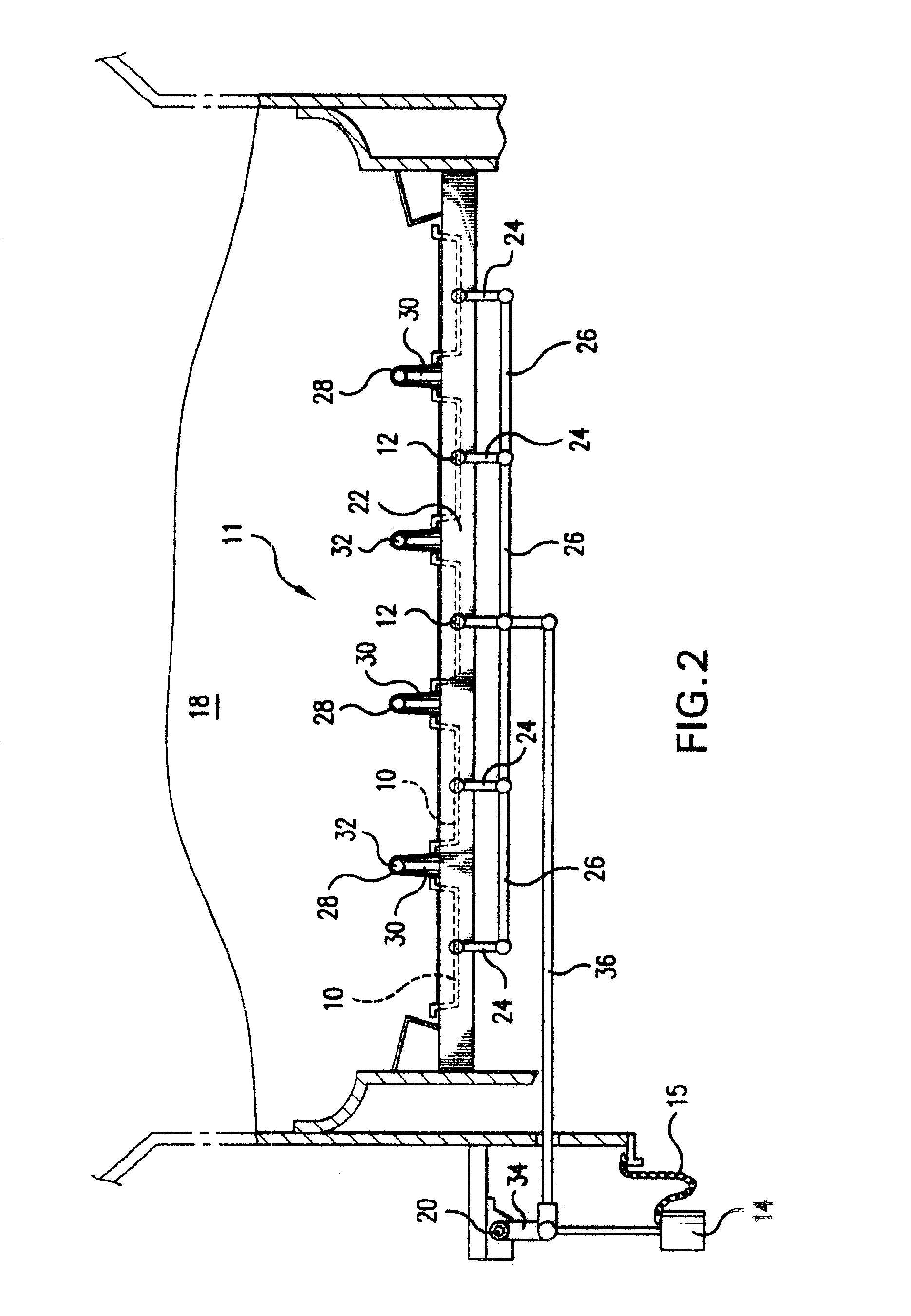

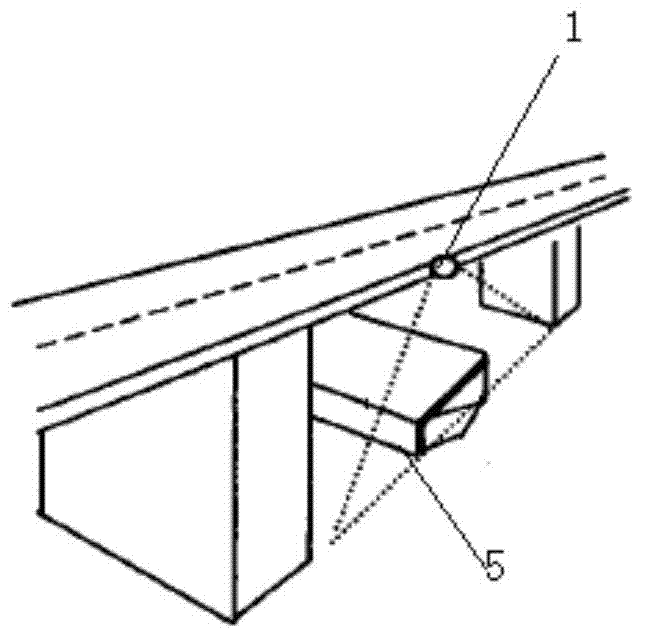

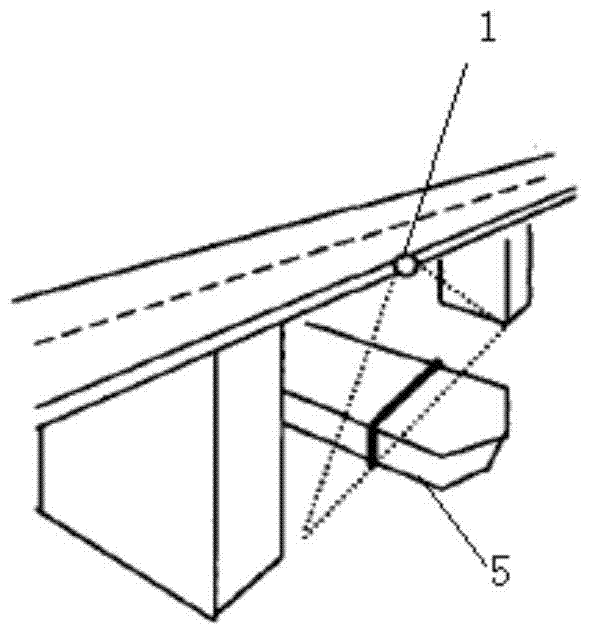

Floating combine sieve assembly

InactiveUS6843719B1Improve efficiencySeparation efficiency can be improvedSievingScreeningEngineeringCombine harvester

A sieve assembly for separating grain from chaff inside of a combine. The sieve assembly comprises a plurality of longitudinal sieve planks that pivot on their longitudinal axis. A hanging weighted member combined with the sieve planks regulates the angle of the sieve planks relative to the combine. As the combine becomes laterally inclined on a hillside, the weighted member changes its angular position relative to the combine. In doing so, the weighted member causes the sieve planks to pivot on their longitudinal axis so that the sieve planks remain level relative to the horizon. Dividers extend between each sieve plank.

Owner:SACQUITNE DAVID

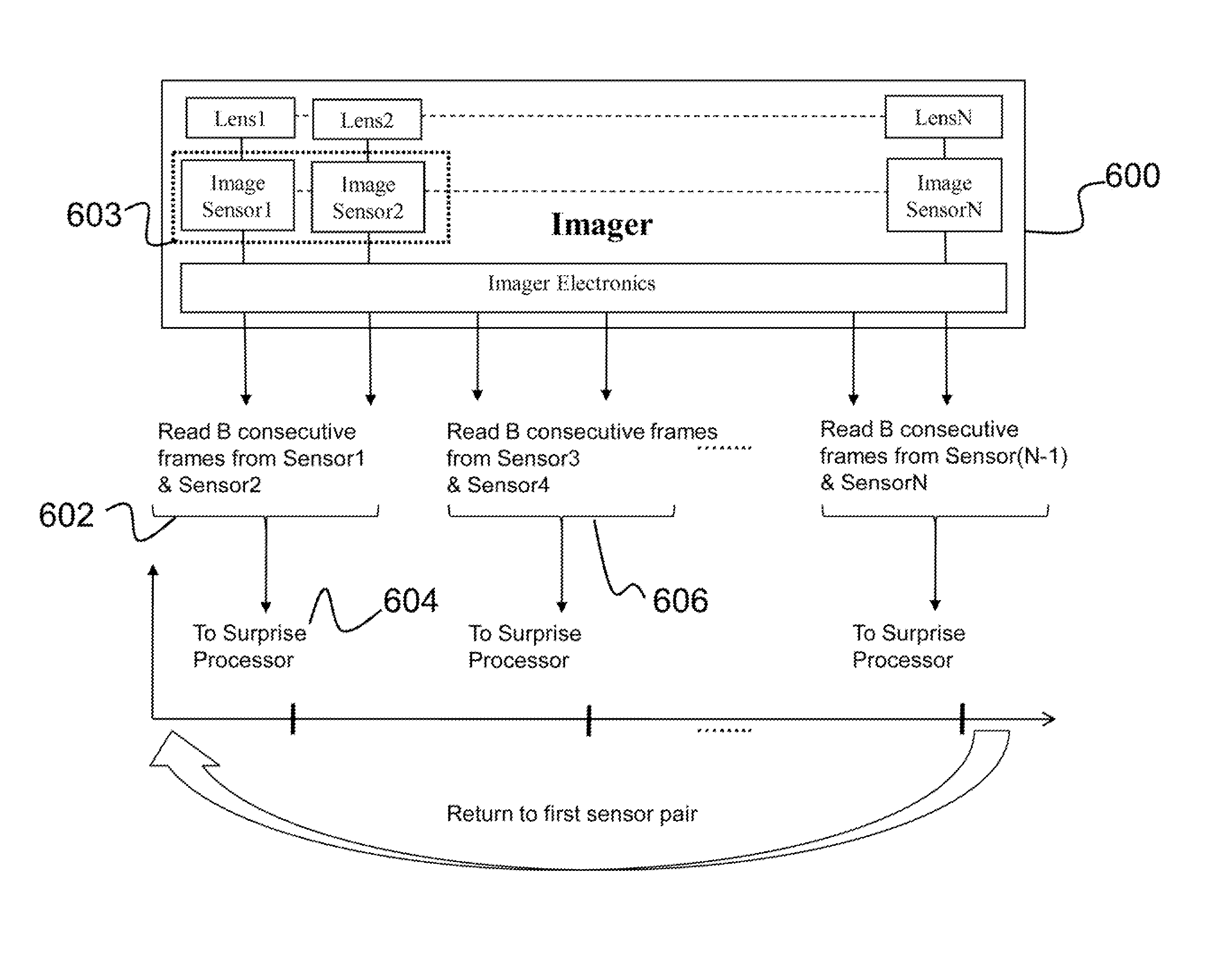

System for identifying regions of interest in visual imagery

ActiveUS8774517B1Low computational costEffective supervisionCharacter and pattern recognitionRegion of interestFeature generation

The present invention relates to a system for identifying regions of interest in visual imagery. The system is configured to receive a series of consecutive frames representing a scene as captured from N sensors. The frames include at least a current frame and a previous frame. A surprise map can be generated based on features found in the current frame and the previous frame. The surprise map having a plurality of values corresponding to spatial locations within the scene. Based on the values, a surprise in the scene can be identified if a value in the surprise map exceeds a predetermined threshold.

Owner:HRL LAB

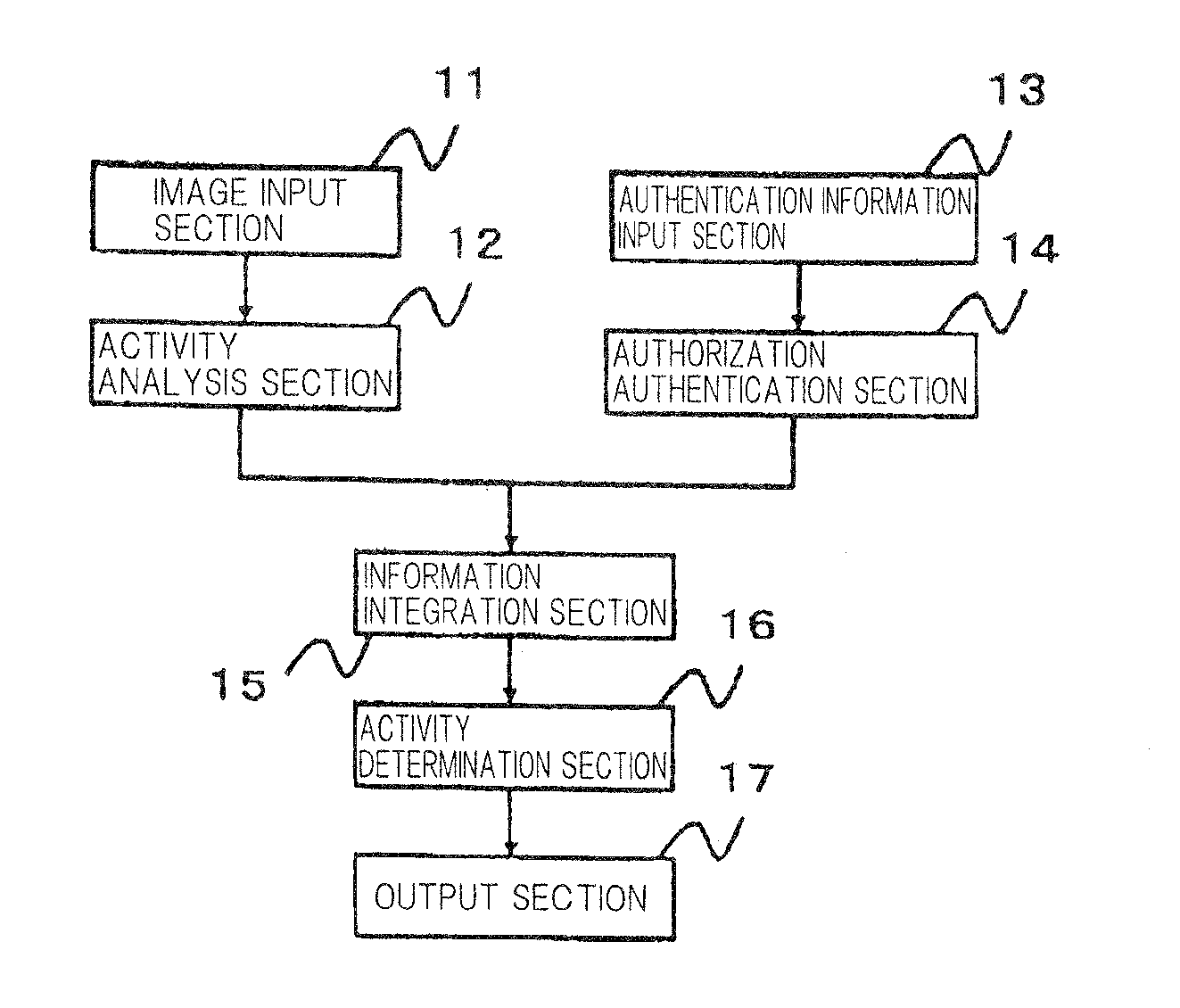

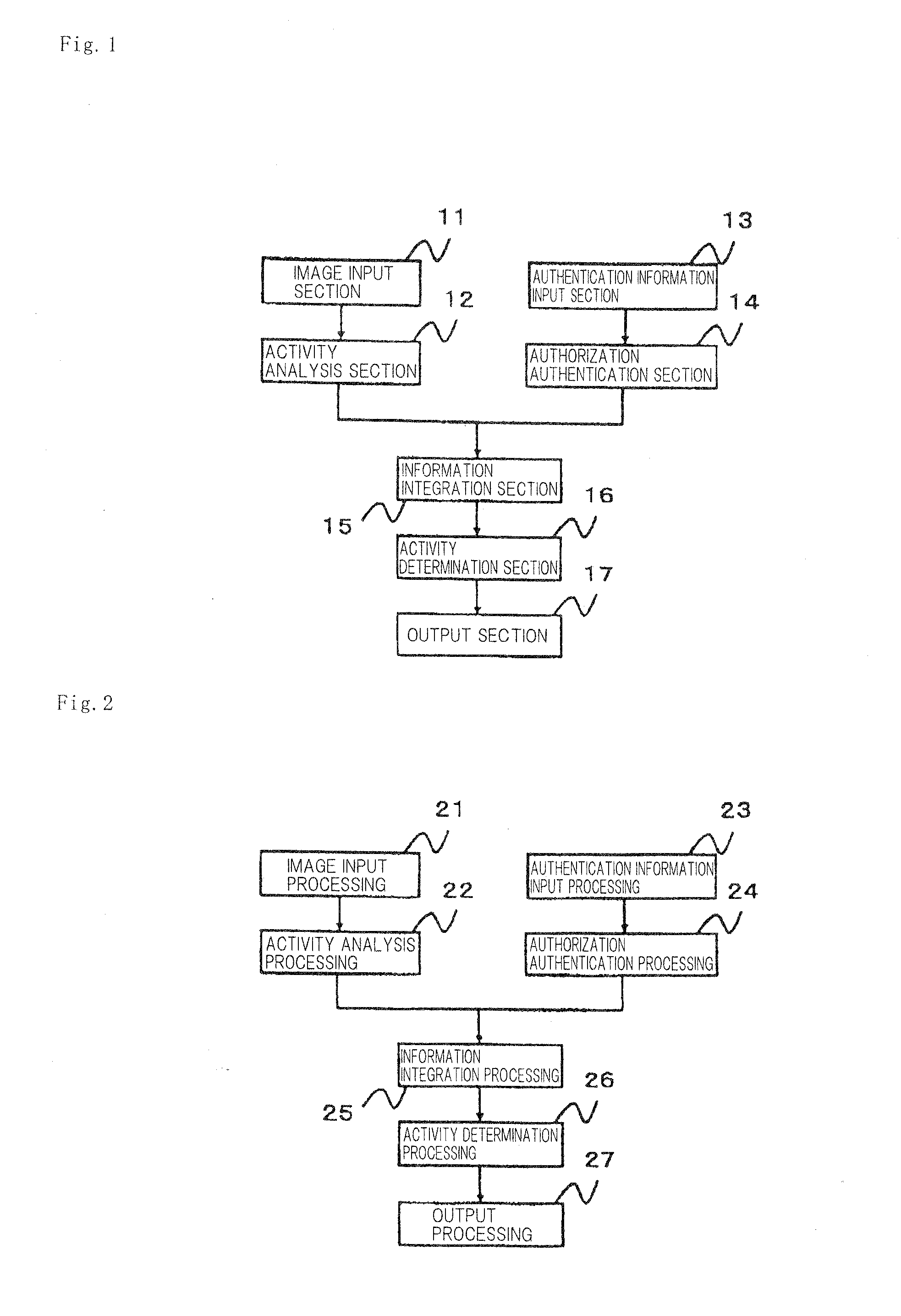

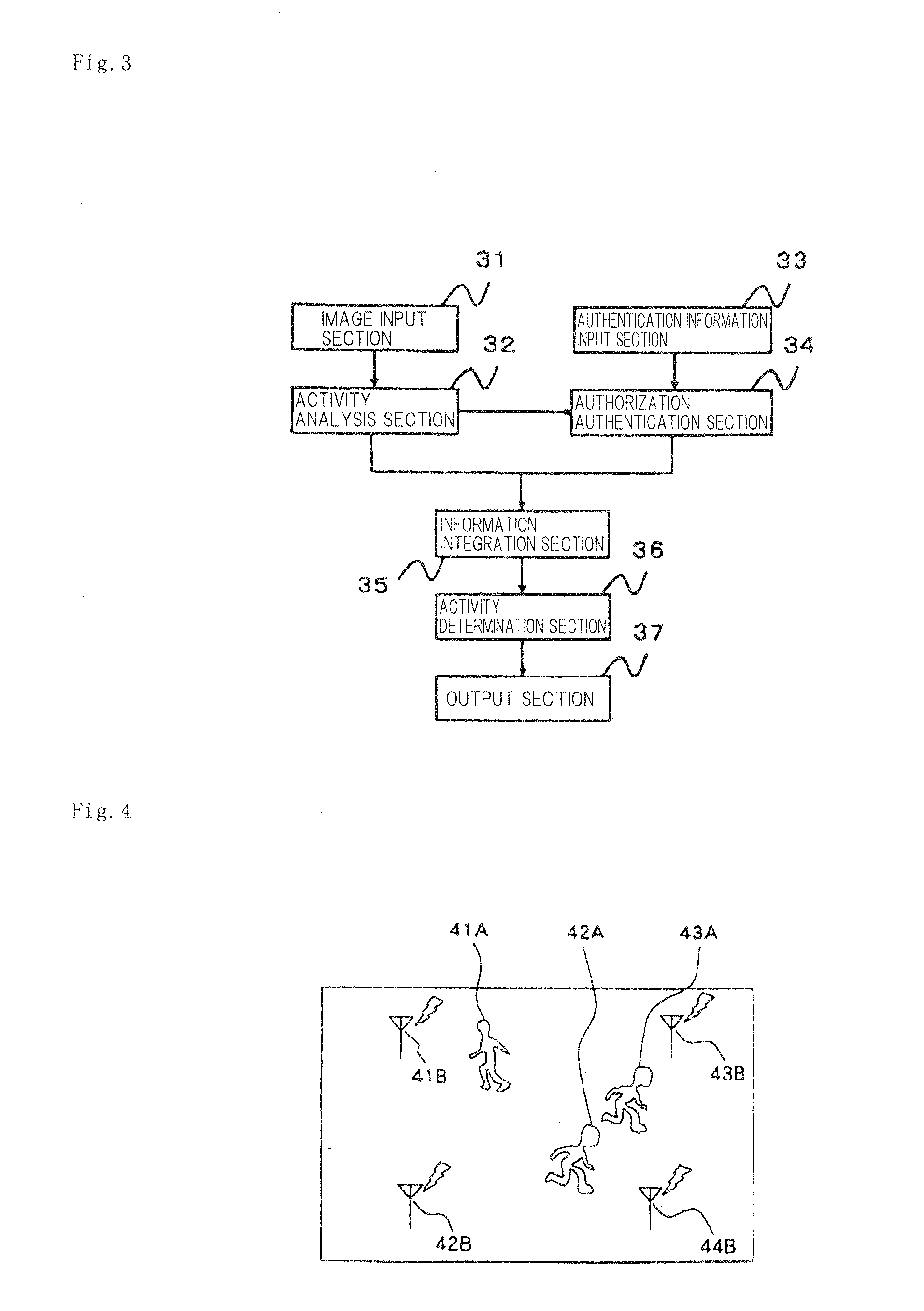

Suspicious activity detection apparatus and method, and program and recording medium

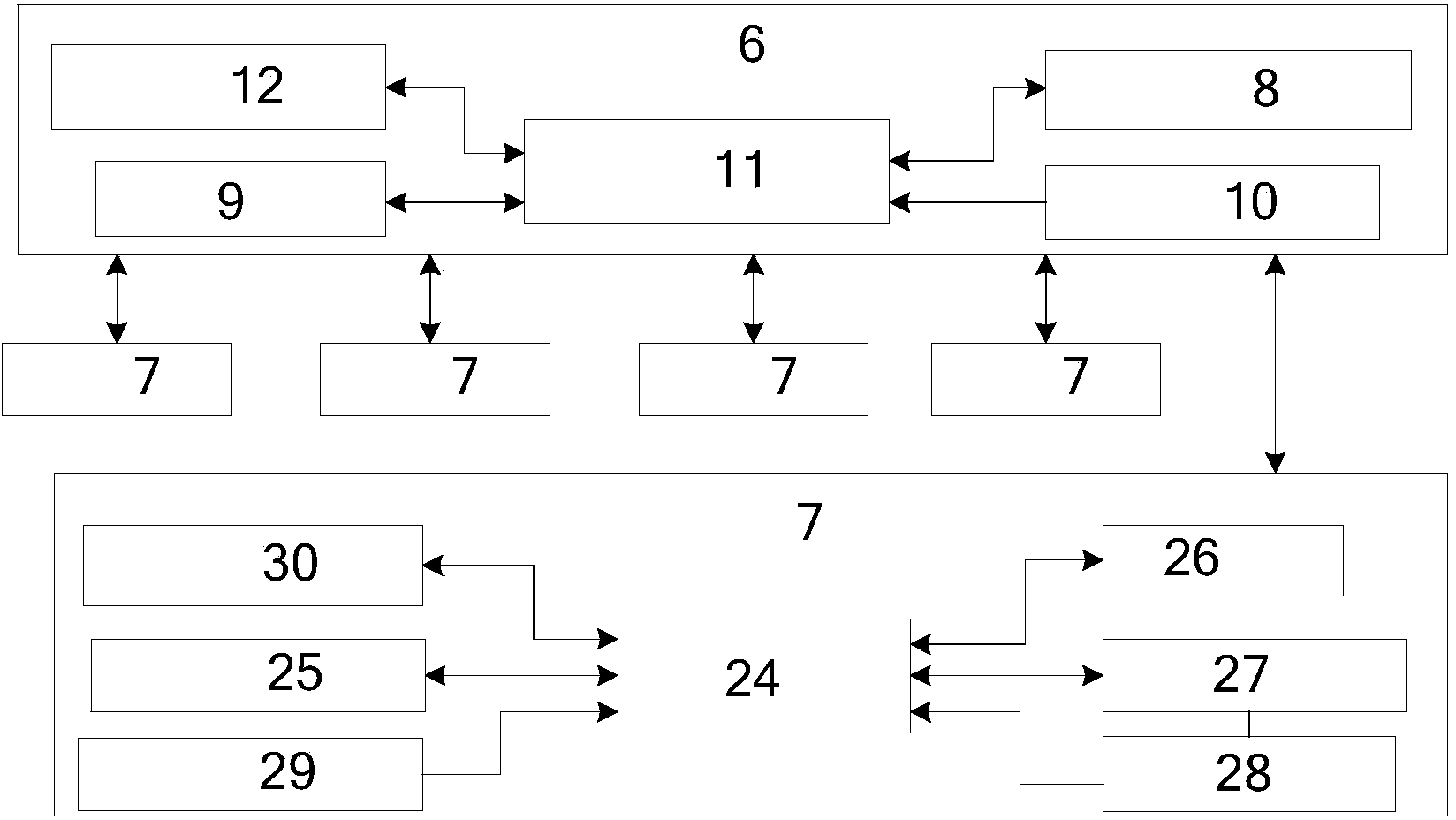

ActiveUS20090243844A1Efficient surveillanceAccurate analysisCharacter and pattern recognitionClosed circuit television systemsSurveillance cameraVideo camera

A device for detecting a suspicious activity, efficiently performing surveillance of a person and vehicle detected by a surveillance camera. The device uses signal generation means, a sensor for receiving a signal from the signal generation means, and image data taken by the camera. The device detects mobile bodies, such as a person and a vehicle, included in an image taken by the camera and uses them as mobile body information, uses as authentication information an ID number represented by a signal received by the sensor, defines permitted activities and prohibited activities according to authorized activities corresponding to authentication information, and issues an alarm when the device detects that an activity represented by mobile body activity information is a illegal or prohibited activity.

Owner:NEC CORP

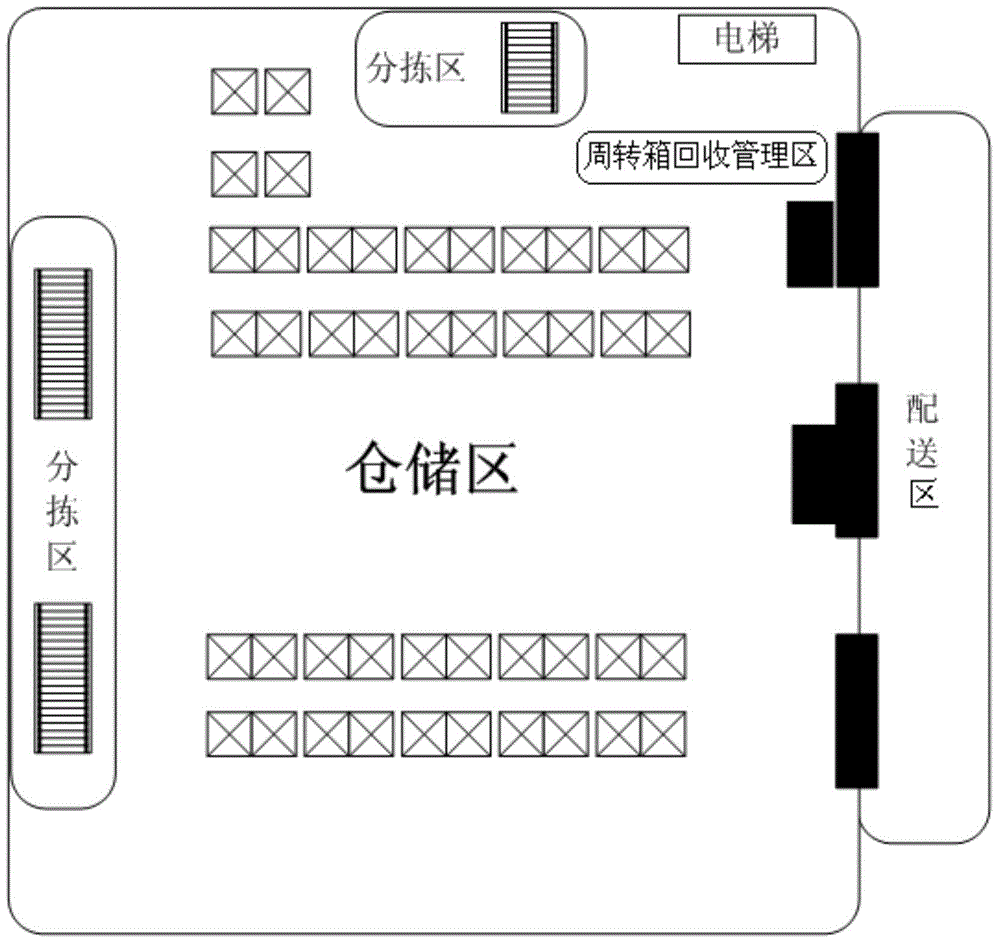

Tobacco logistics distribution system and method

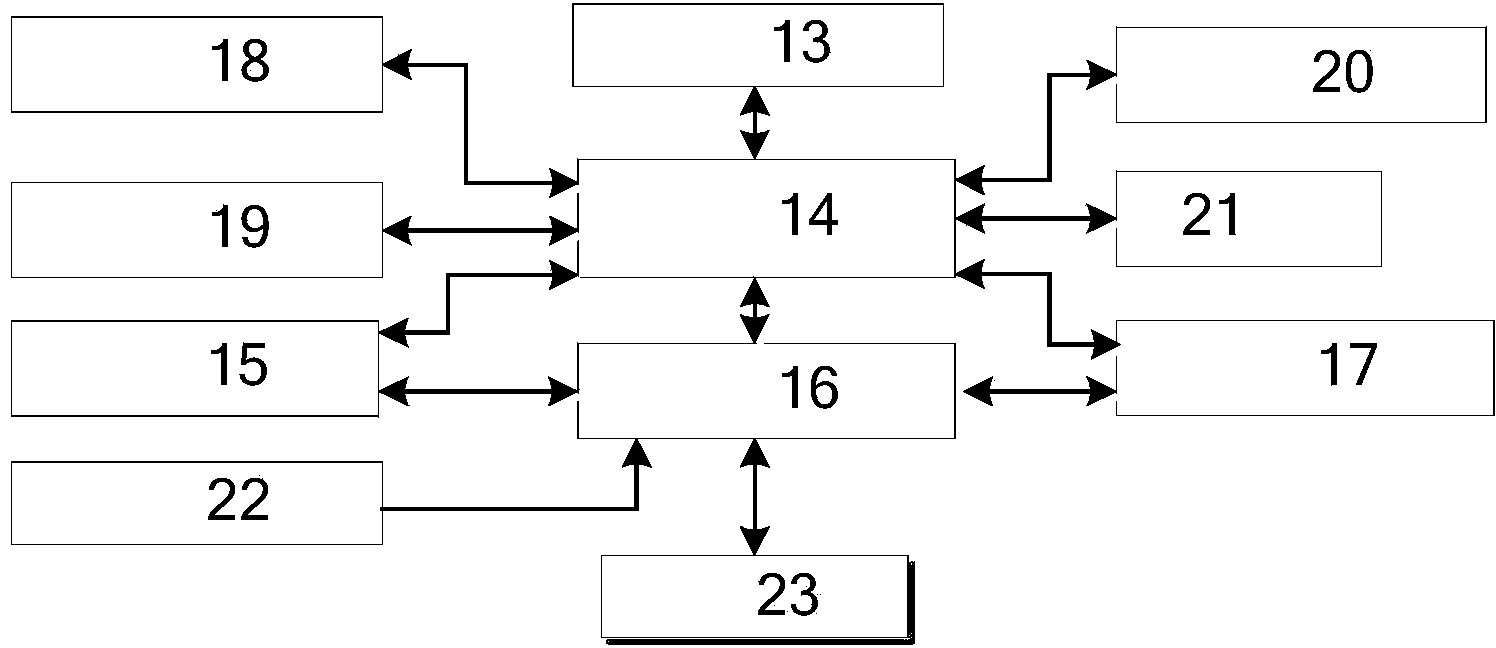

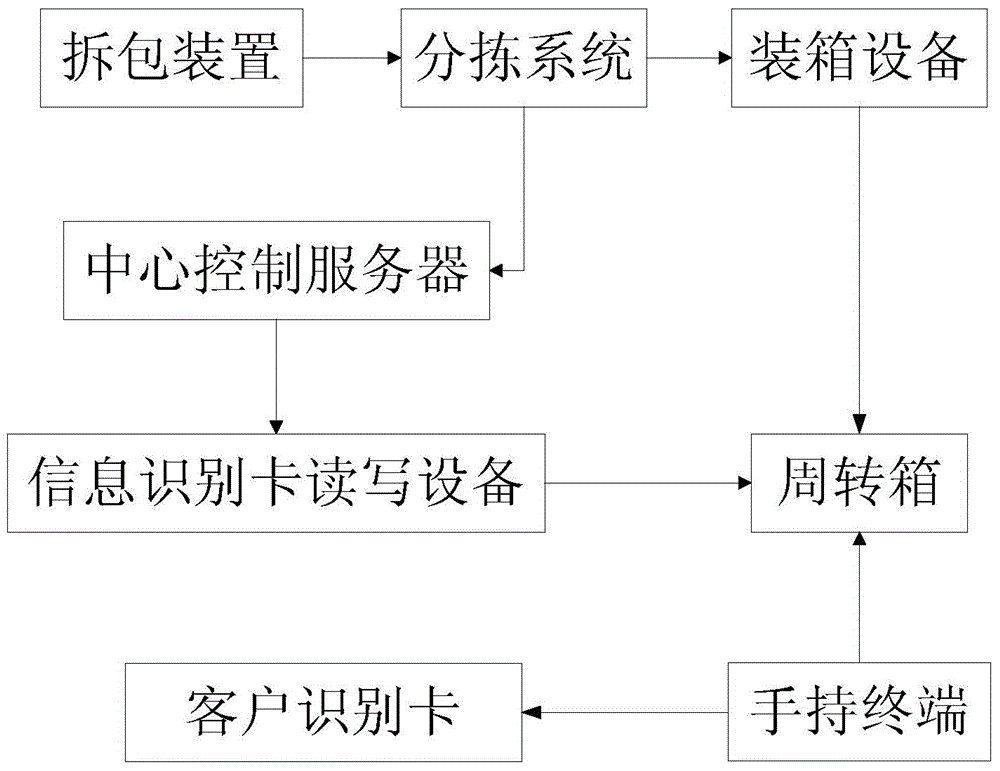

ActiveCN104574027AEffective supervisionAchieve perceptionCo-operative working arrangementsLogisticsLogistics managementDistribution system

The invention provides a tobacco logistics distribution system and method. The tobacco logistics distribution system comprises an unpacking device, a sorting system, transfer containers, casing equipment, an information identity card reader-writer, a central control server and a handheld terminal. The tobacco logistics distribution system is used for sorting and distributing tobacco for customer orders in a tobacco logistics center, the transfer containers with RFID (radio frequency identity) tags are used for distributing the tobacco, and full sensing during cigarette distribution is realized. Each transfer container is provided with an RFID tag, and cigarette order information of the transfer containers is written into the RFID. In order to distribute customer identity cards to the customers, scanning time and places are recorded by scanning the RFID tags of the transfer containers and the customer identity cards during distribution, and orders can be distributed within the preset time and places and are well documented, so that tobacco distribution time and places are monitored, and tobacco logistics distribution speed is effectively guaranteed. By reading and checking the RFID content of the transfer containers in important logistics sites, cigarette in the transfer containers can be traced and managed.

Owner:中国烟草总公司北京市公司物流中心

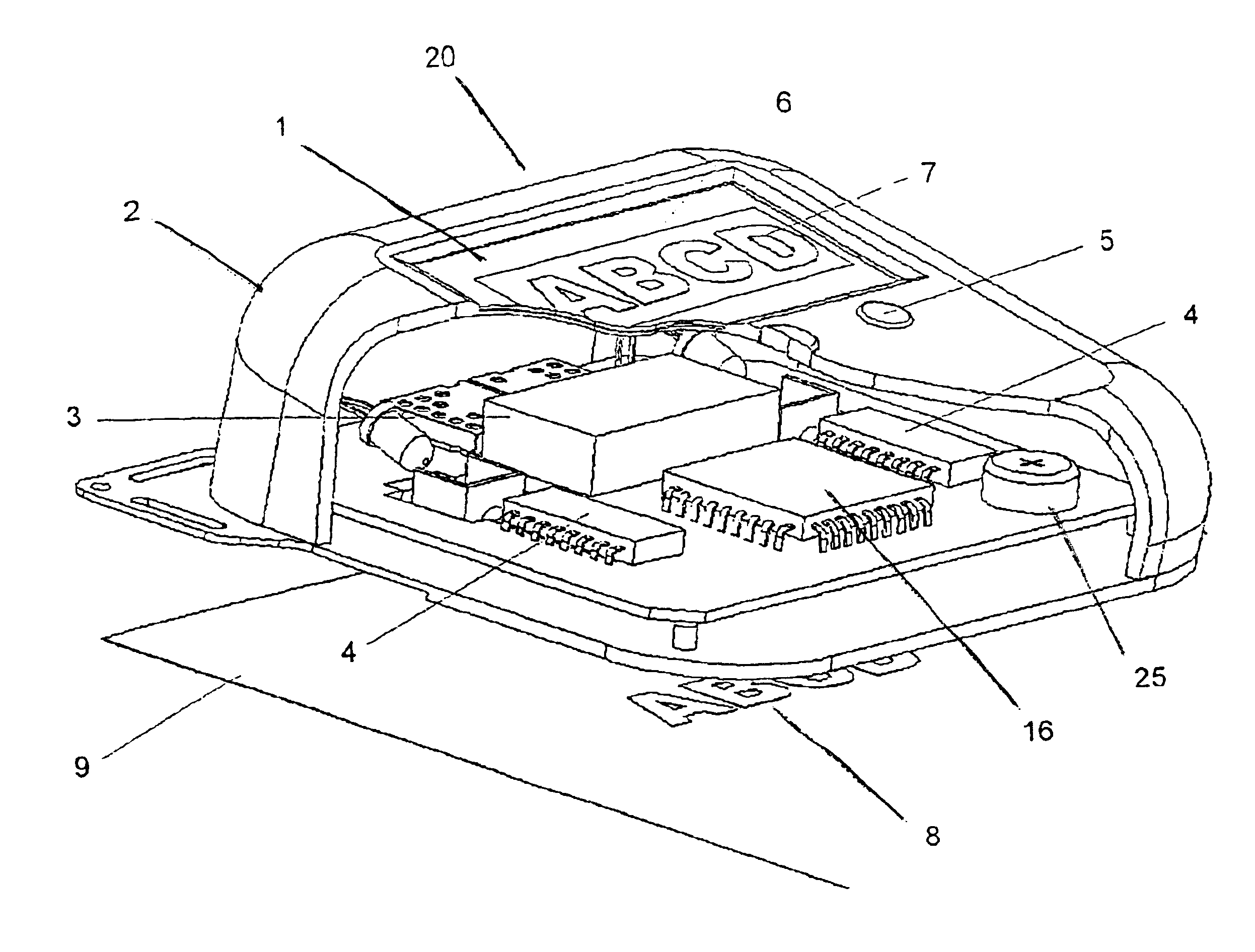

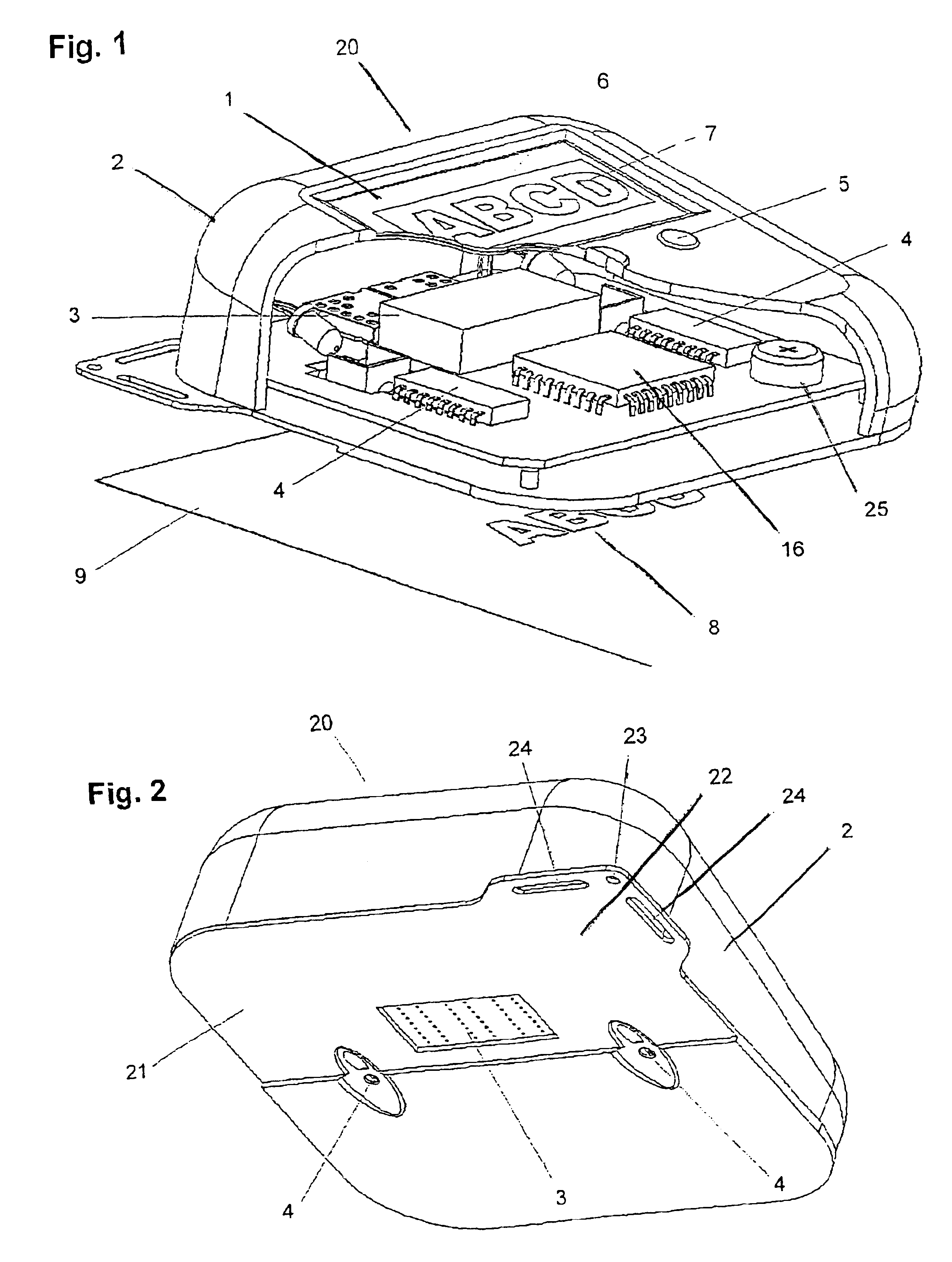

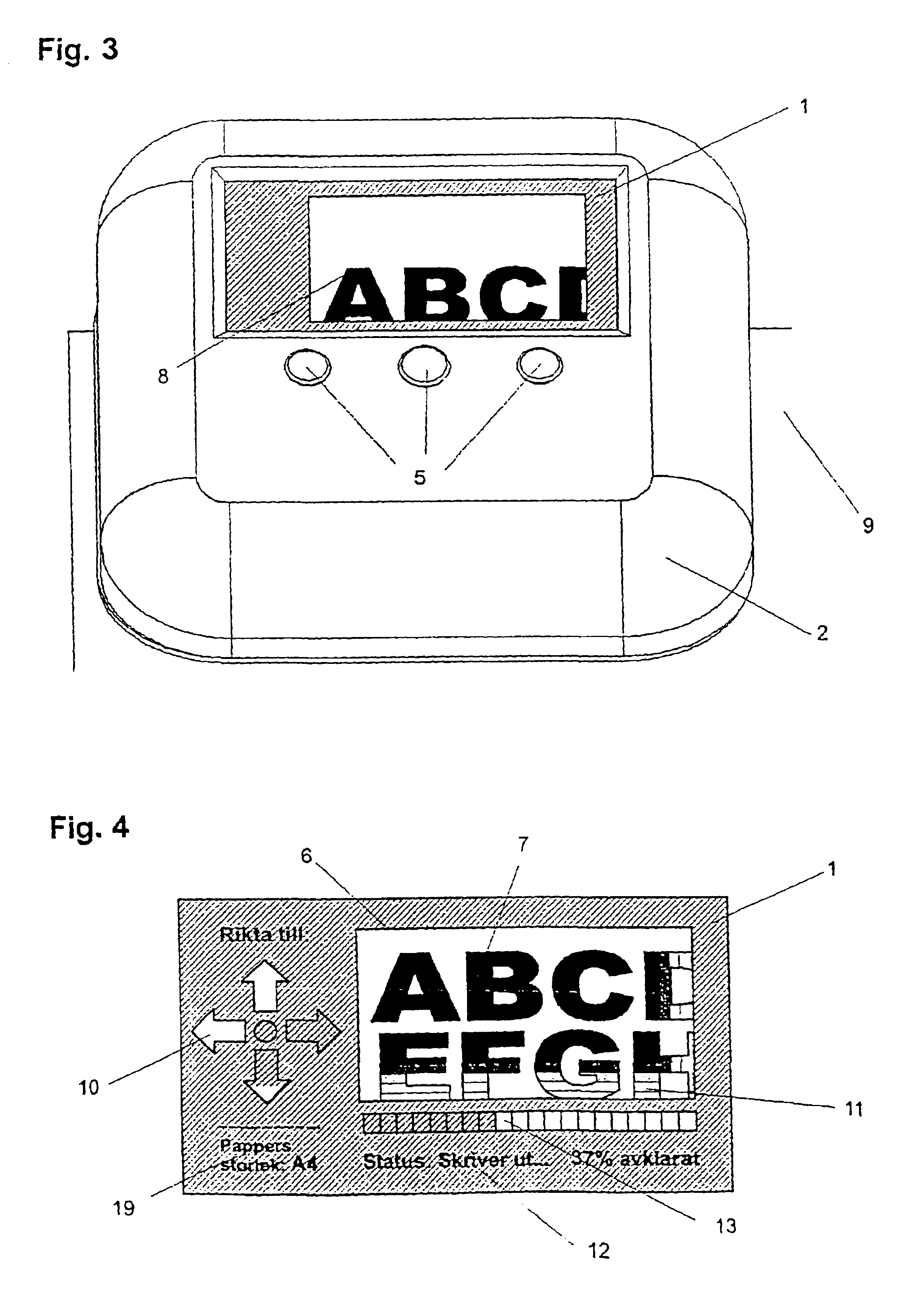

Method and handheld device for printing

InactiveUS6846119B2High-qualityEnsure correct executionTypewritersOther printing apparatusAutomatic steeringHead parts

Owner:PRINT DREAMS EURO

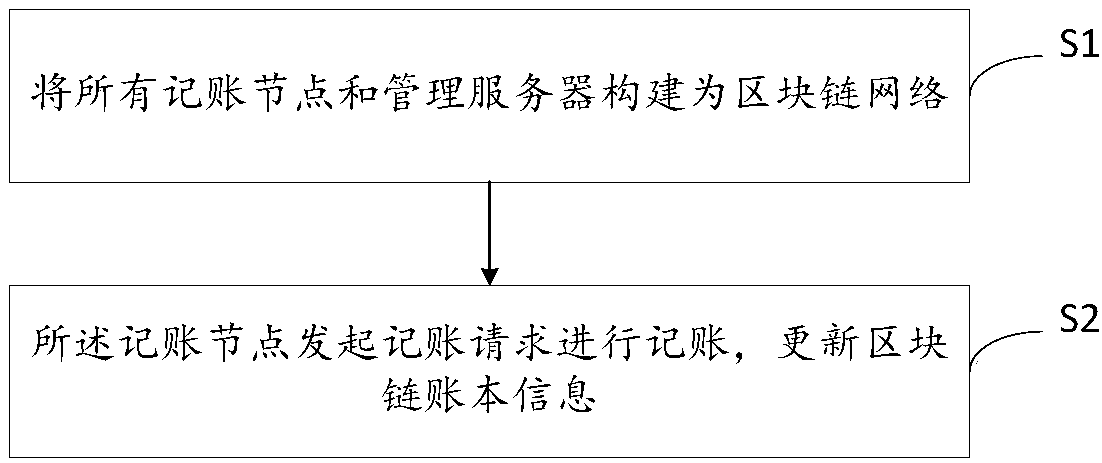

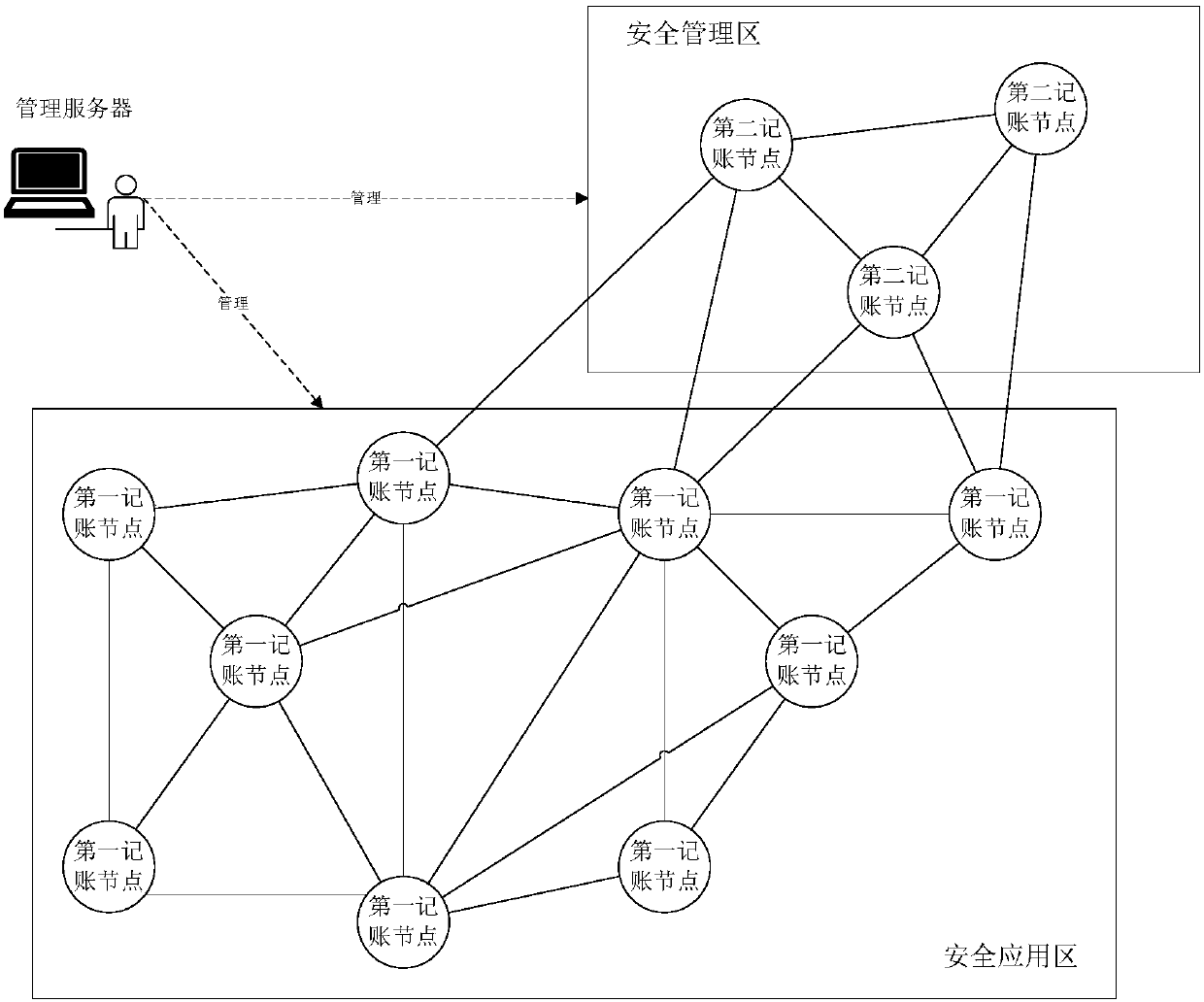

Application distribution recording method and system based on block chain

ActiveCN108055138AWidely used valueRetroactiveFinanceUser identity/authority verificationChain networkDistributed computing

The invention relates to an application distribution recording method and system based on a block chain. The method comprises the following steps: constructing a block chain network through all accounting nodes and management servers, wherein the accounting nodes comprise a first accounting node and a second accounting node, the first accounting node comprises an application store server, and thesecond accounting node comprises a security supervision server; initiating, by the accounting nodes, an accounting request for accounting, and updating block chain account book information, wherein the initiating, by the accounting nodes, an accounting request comprises: issuing, by the first accounting node, an application, and discovering, by the second accounting node, application violation. According to the application distribution recording method and system, the block chain technology is applied to the application distribution recording, the application distribution is recorded through unified, distributed and arbitrarily falsifiable account information, the application distribution recording method and system have the advantages of having an retroactive effect, achieving effective supervision, and improving the efficiency and reliability of application distribution supervision.

Owner:NAT COMP NETWORK & INFORMATION SECURITY MANAGEMENT CENT

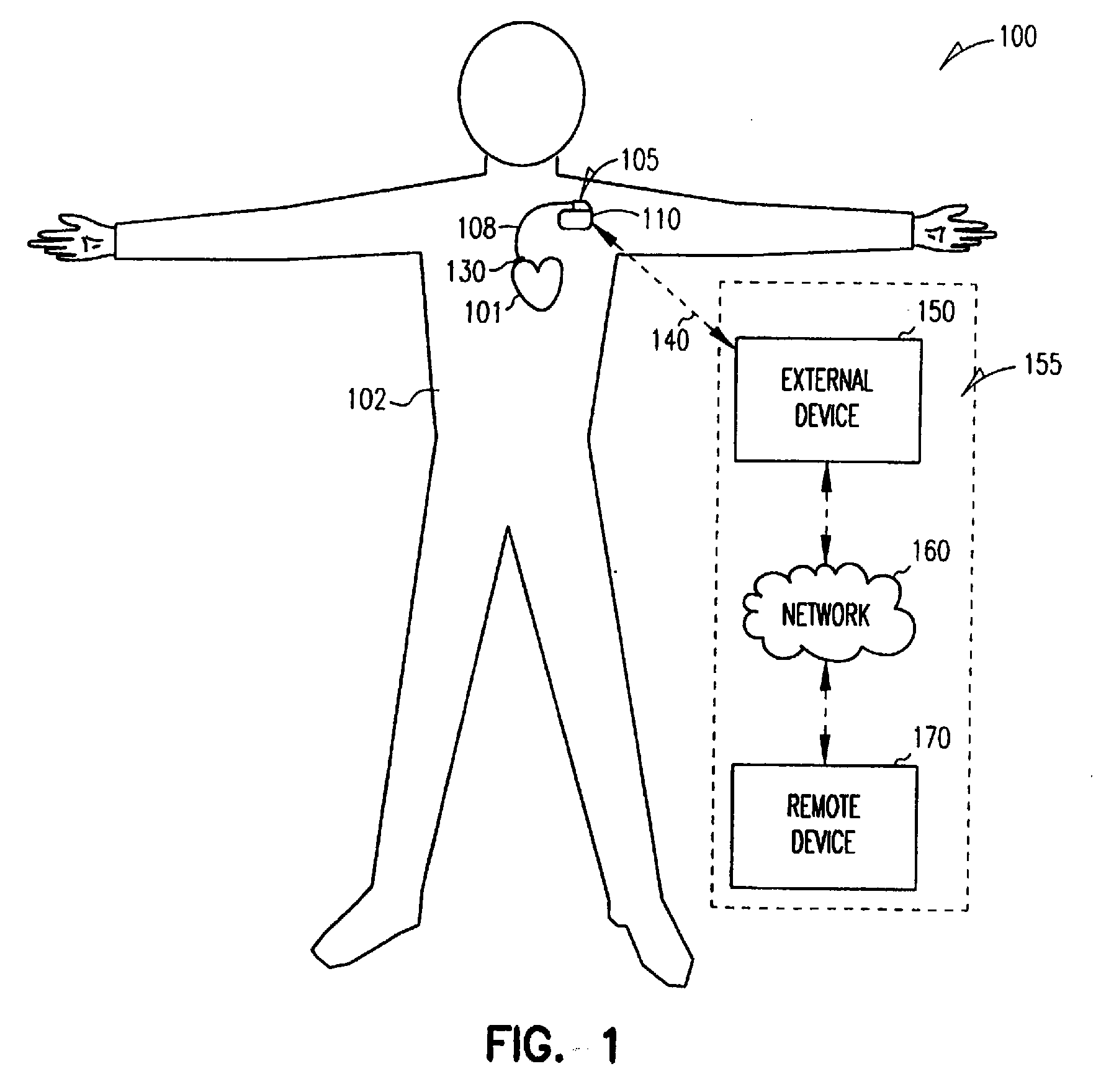

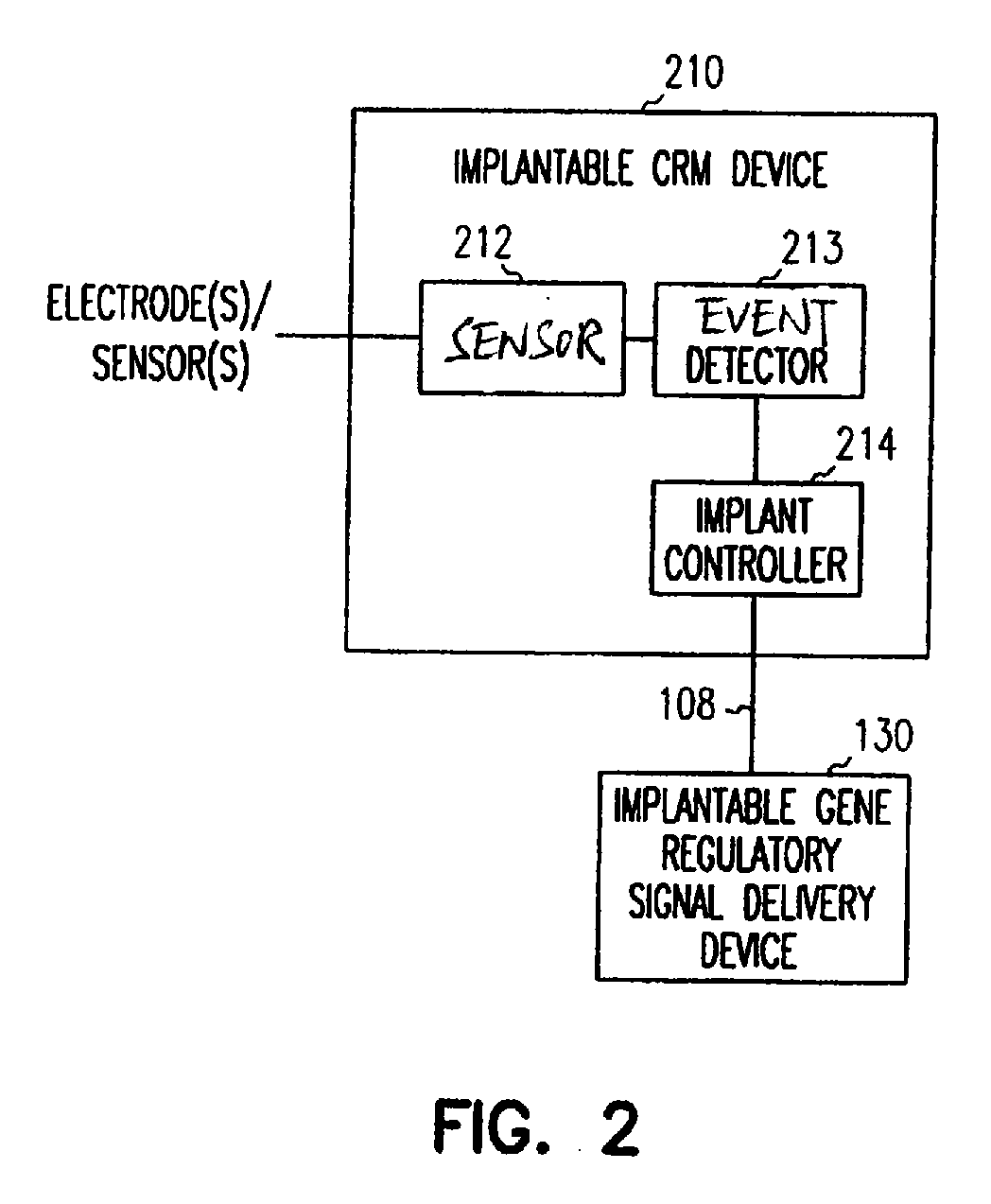

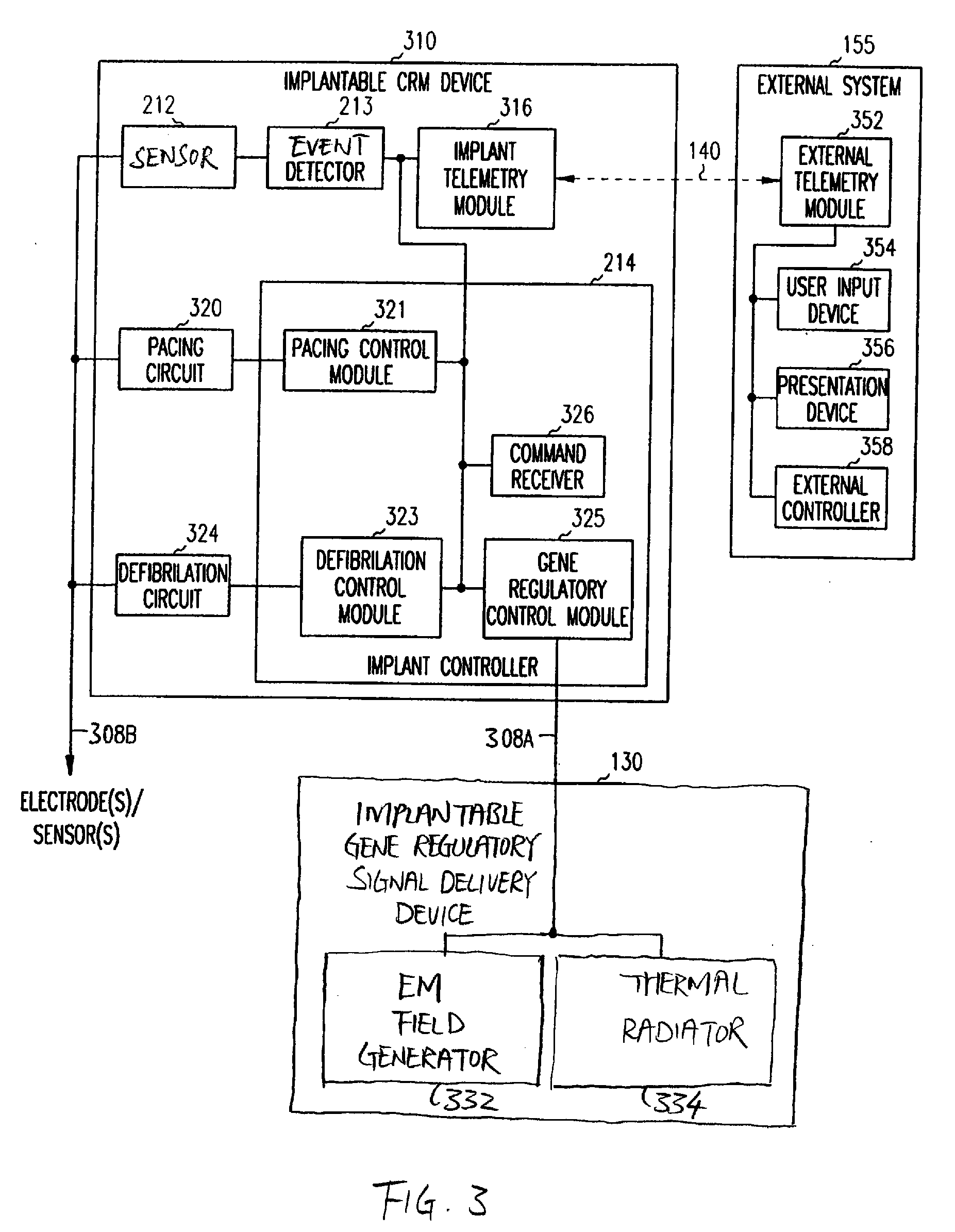

Method and apparatus for heat or electromagnetic control of gene expression

InactiveUS20070190028A1Increase expressionAltered propertyBiocideNervous disorderRegulator geneForms of energy

A gene regulatory system controls biomarker, gene therapy or endogenous gene expression by emitting one or more forms of energy that regulate gene expression. The system may include a sensor to sense a signal indicative of a need for therapy. The regulation of gene expression is controlled based on the sensed signal and / or a user command. In one embodiment, the system delivers one or more electrical therapies in conjunction with controlling gene therapy or endogenous gene expression.

Owner:CARDIAC PACEMAKERS INC

Unmanned aerial vehicle electric power circuit polling scheduling platform and method based on GIS (geographic information system)

ActiveCN103824233AReduce idle rateImplement configurationData processing applicationsLimited resourcesUncrewed vehicle

The invention discloses an unmanned aerial vehicle electric power circuit polling scheduling platform based on a GIS (geographic information system), which comprises a scheduling server, a human-computer interaction module, an RFID (radio frequency identification device) reader-writer, an identity card reader and a short message receiving-sending module; as an unmanned aerial vehicle electric power circuit polling scheduling method based on the GIS is matched for use, polling equipment, personnel, time and circuits are scheduled through a scheduling terminal in consideration of elements such as polling field state information, equipment information and personal information a plurality of polling tasks are finished as far as possible under a limited resource condition, the polling efficiency of the unmanned aerial vehicle is improved, the reliability and the security of the unmanned aerial vehicle polling are improved, and the unmanned aerial vehicle polling cost is lowered.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

Semiconductor Device and Method of Manufacturing the Same

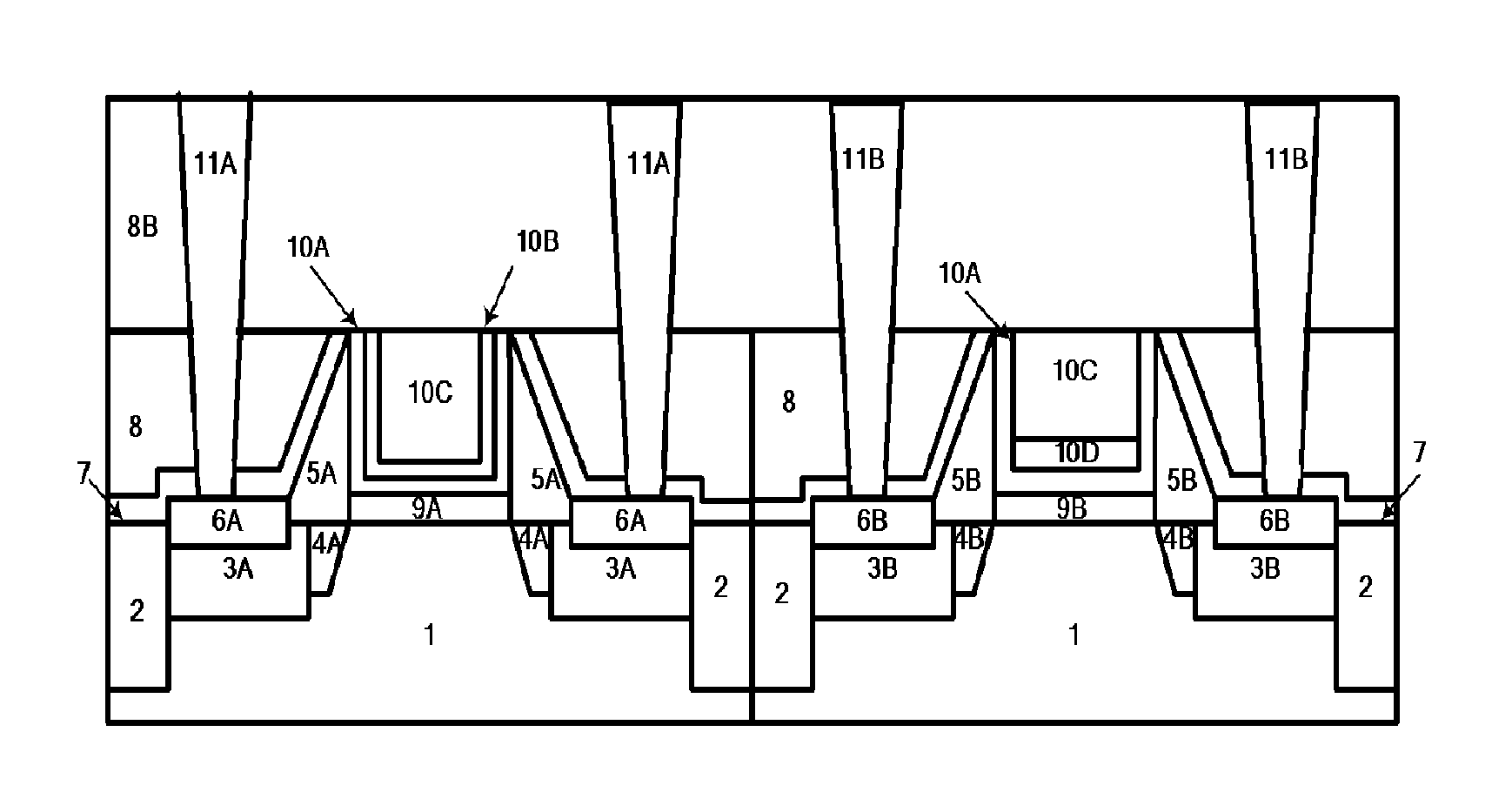

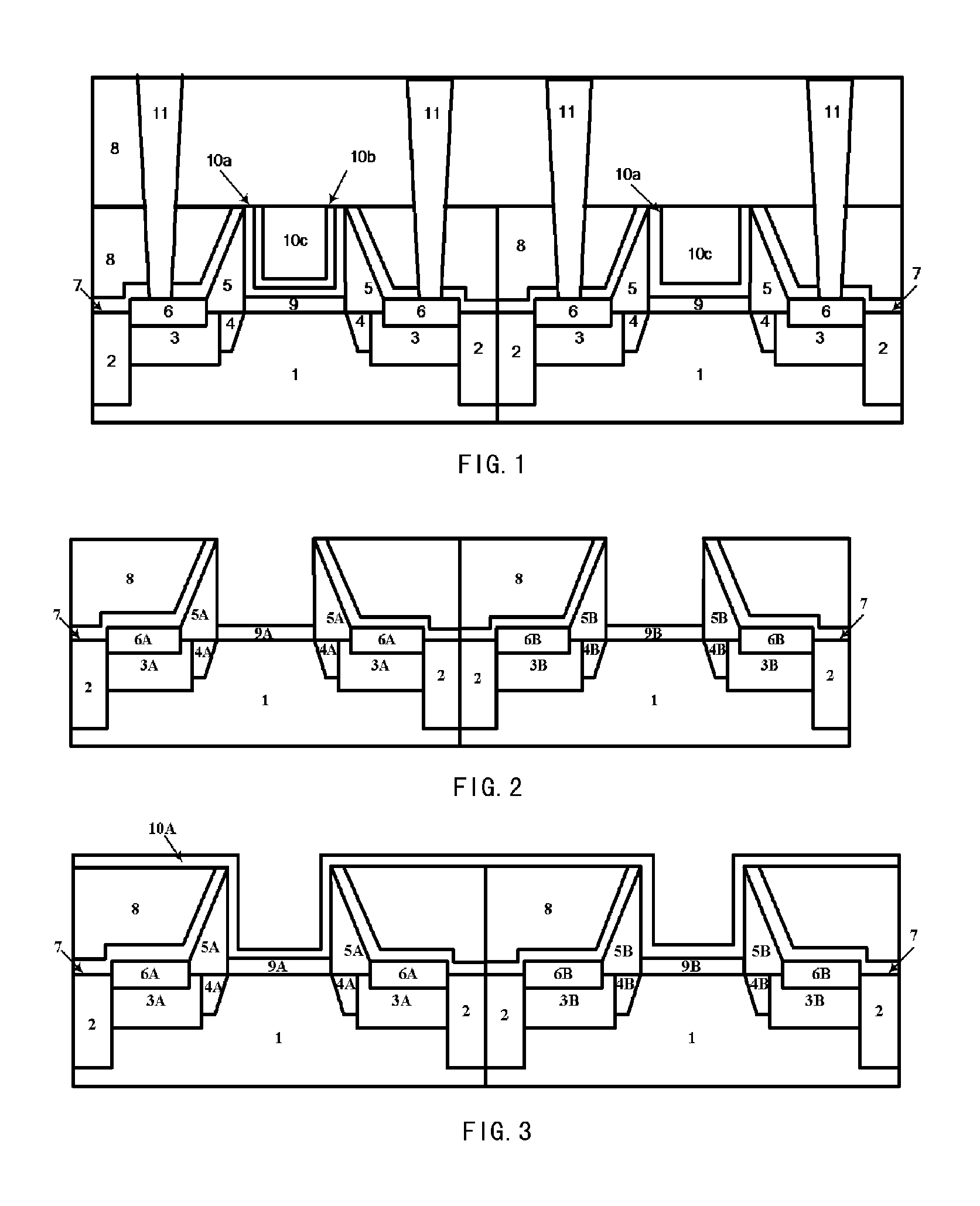

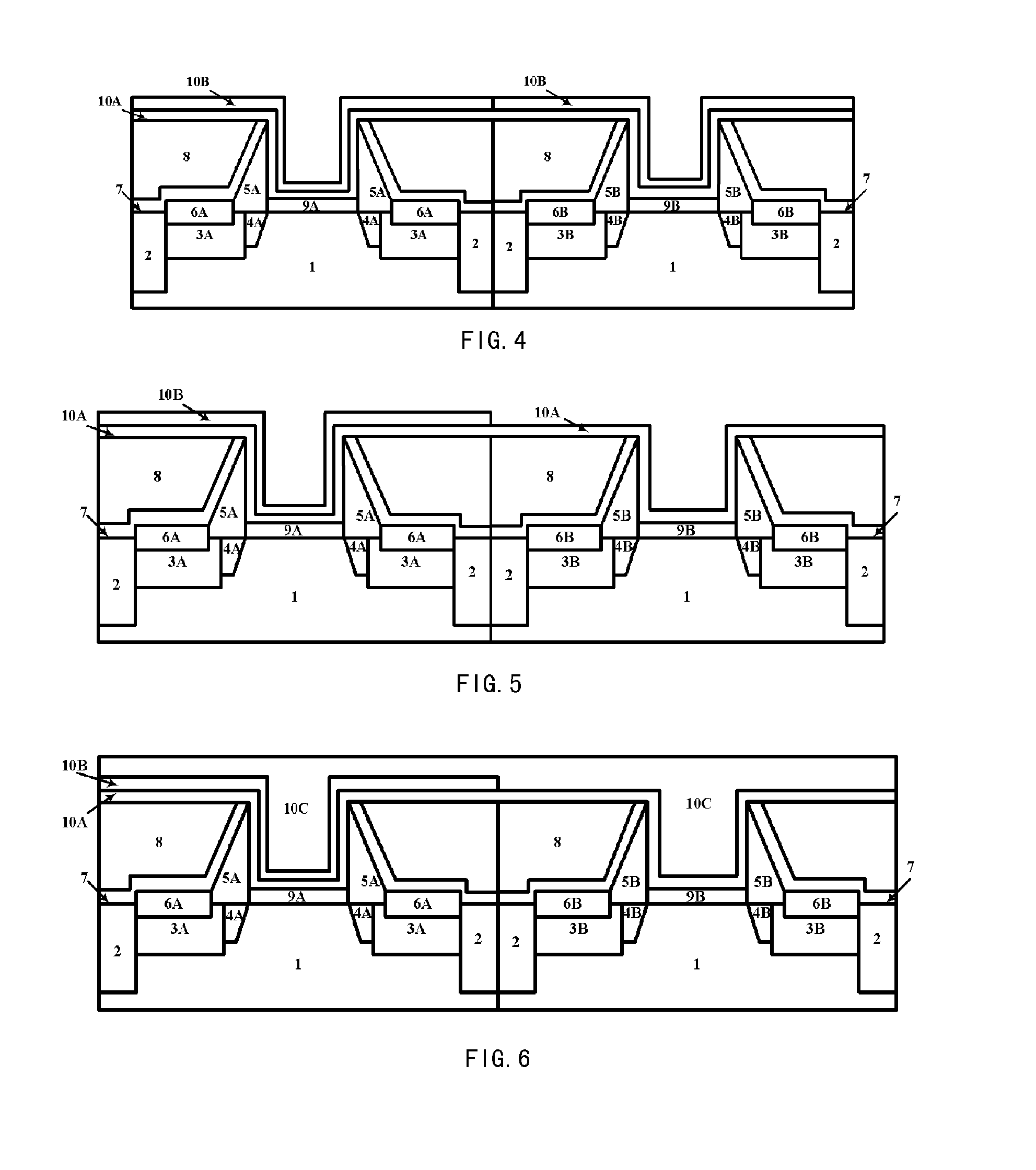

InactiveUS20130240996A1Enhance performanceEfficiently controlTransistorSemiconductor/solid-state device manufacturingWork functionBlocking layer

The present invention discloses a semiconductor device, comprising a substrate, a plurality of gate stack structures on the substrate, a plurality of gate spacer structures on both sides of each gate stack structure, a plurality of source and drain regions in the substrate on both sides of each gate spacer structure, the plurality of gate spacer structures comprising a plurality of first gate stack structures and a plurality of second gate stack structures, wherein each of the first gate stack structures comprises a first gate insulating layer, a first work function metal layer, a second work function metal diffusion blocking layer, and a gate filling layer, the work function is close to the valence band (conduction band) edge; each of the second gate stack structures comprises a second gate insulating layer, a modified first work function metal layer, a second work function metal layer, and a gate filling layer, characterized in that the second work function metal layer comprises implanted work function-regulating doped ions, which are simultaneously diffused to the first work function layer below to regulate the threshold such that the work function of the gate is close to the valence band (conduction band) edge and is opposite the original first work function, to thereby regulate the work function accurately.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

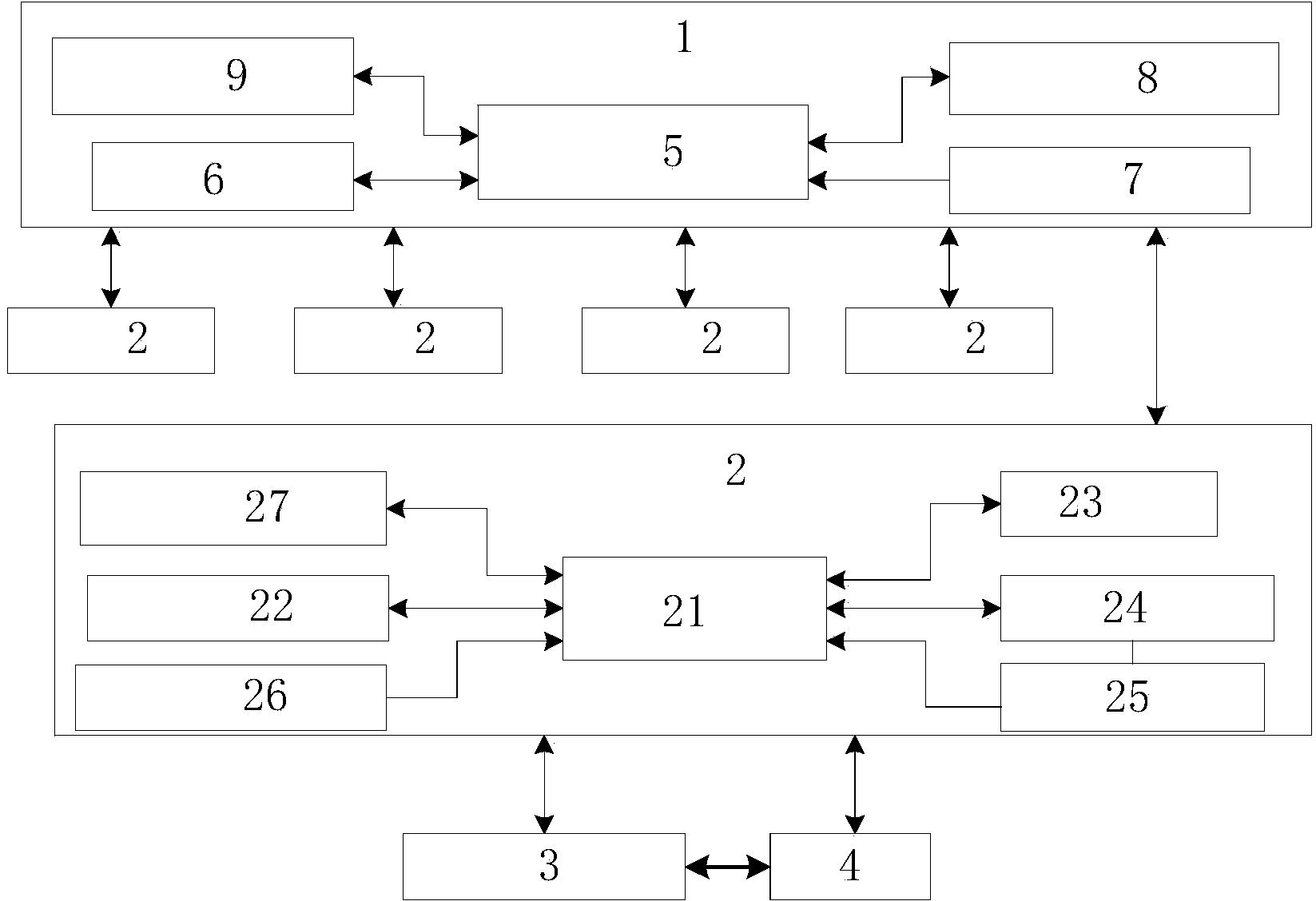

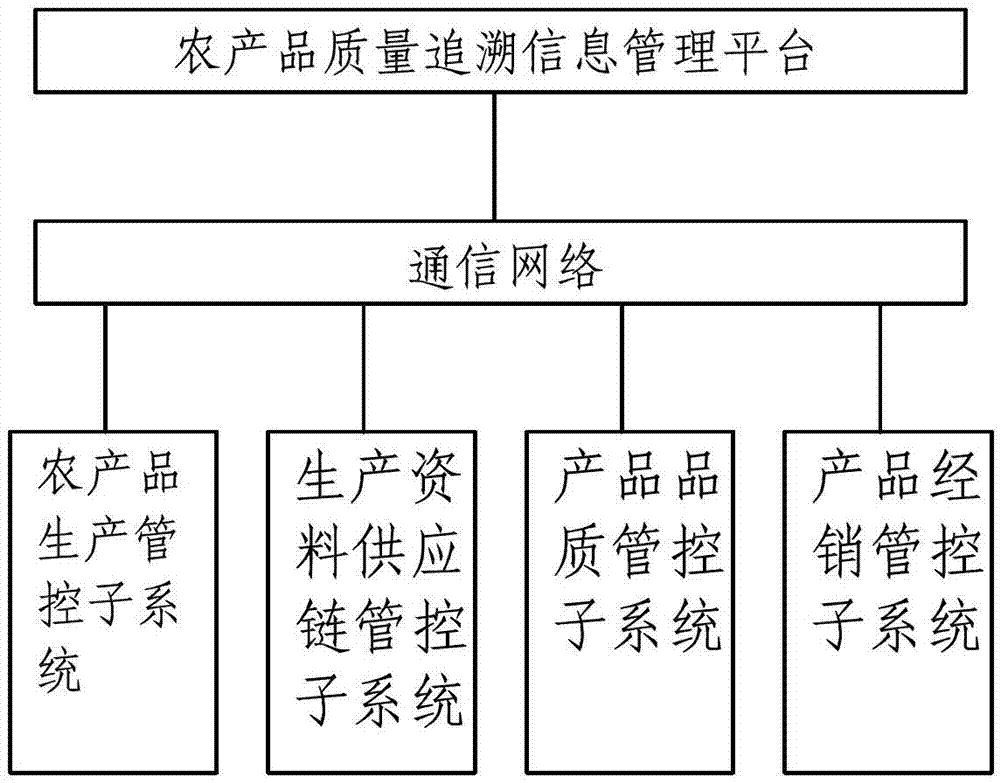

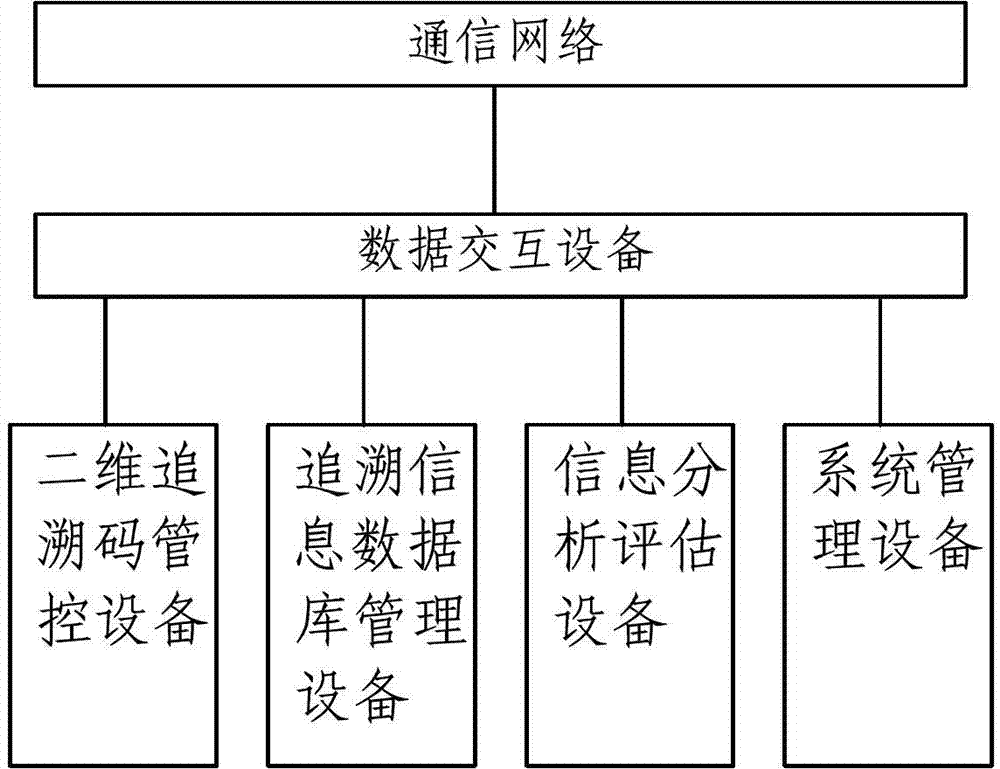

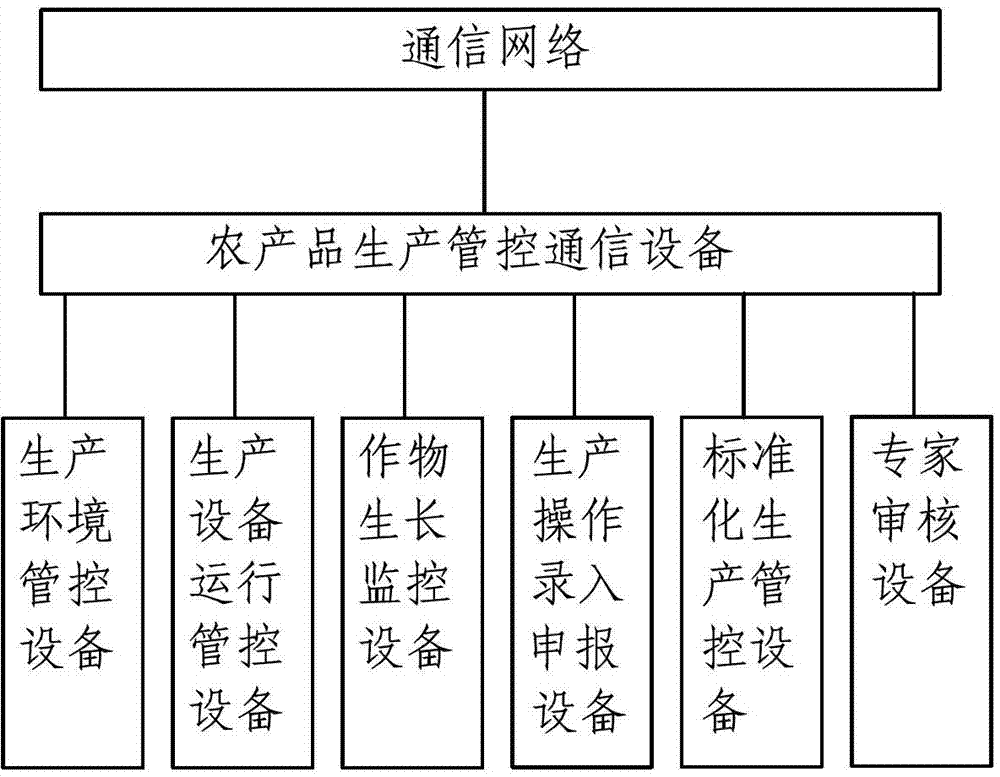

Agricultural product safe supply chain anti-fake management and control system

The invention provides an agricultural product safe supply chain anti-fake management and control system. The agricultural product safe supply chain anti-fake management and control system comprises an agricultural product quality tracing information management platform, an agricultural product production management and control system, a production material supply chain management and control subsystem, a product quality management and control subsystem, a product selling management and control subsystem and a communication network. The agricultural product quality tracing information management platform, the agricultural product production management and control system, the production material supply chain management and control subsystem, the product quality management and control subsystem and the product selling management and control subsystem are connected into the communication network. The agricultural product safe supply chain anti-fake management and control system takes the agricultural product quality tracing information management platform as the core, supports relevant equipment of other systems, receives, summarizes, analyzes and assesses information data of other subsystems, and build an agricultural product safe supply chain whole-process anti-fake management and control system. The agricultural product safe supply chain anti-fake management and control system forms effective supervision, control and supervision standardized production operation, and effectively ensures reality of information entry, thereby achieving safe supply of agricultural products.

Owner:QINGDAO ODO ENVIRONMENTAL TECH CO LTD

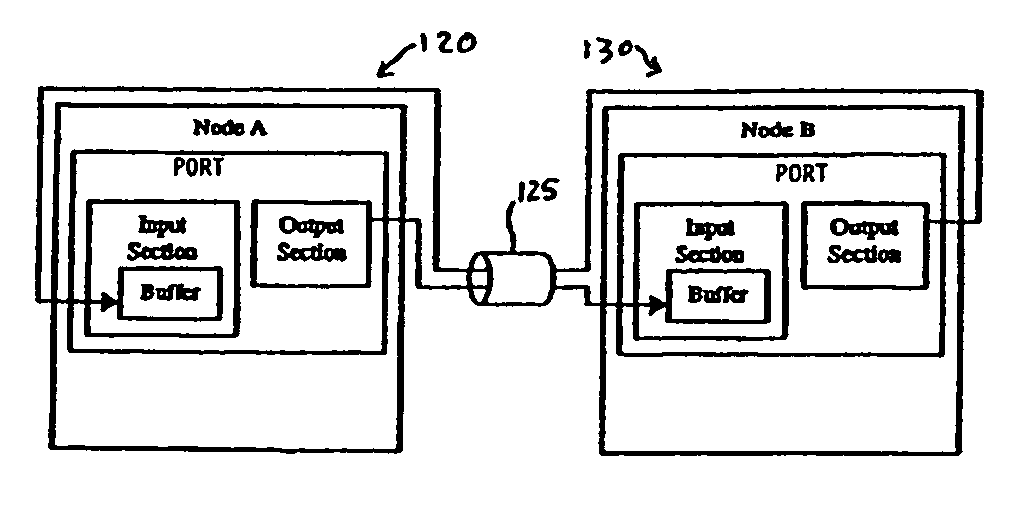

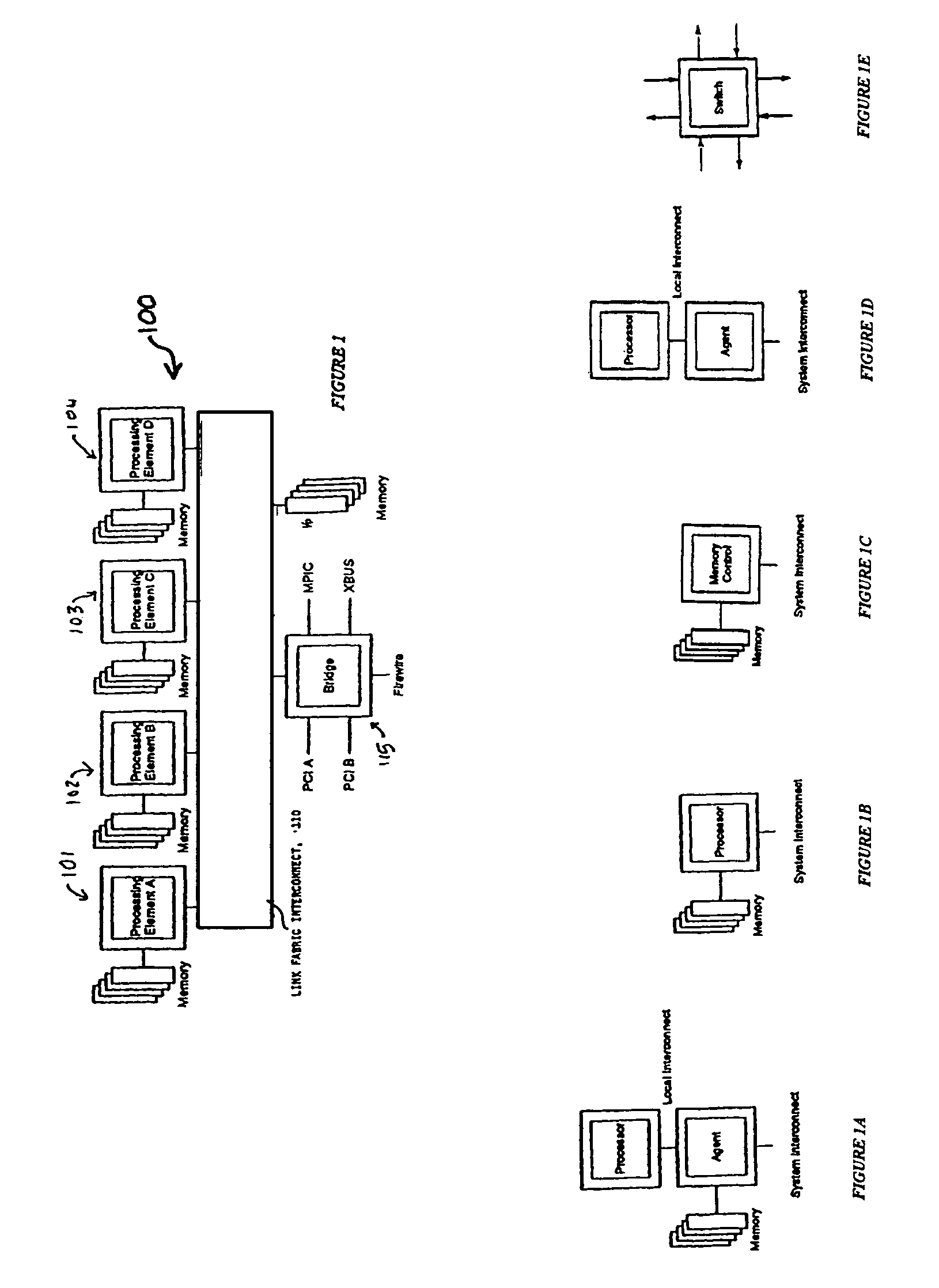

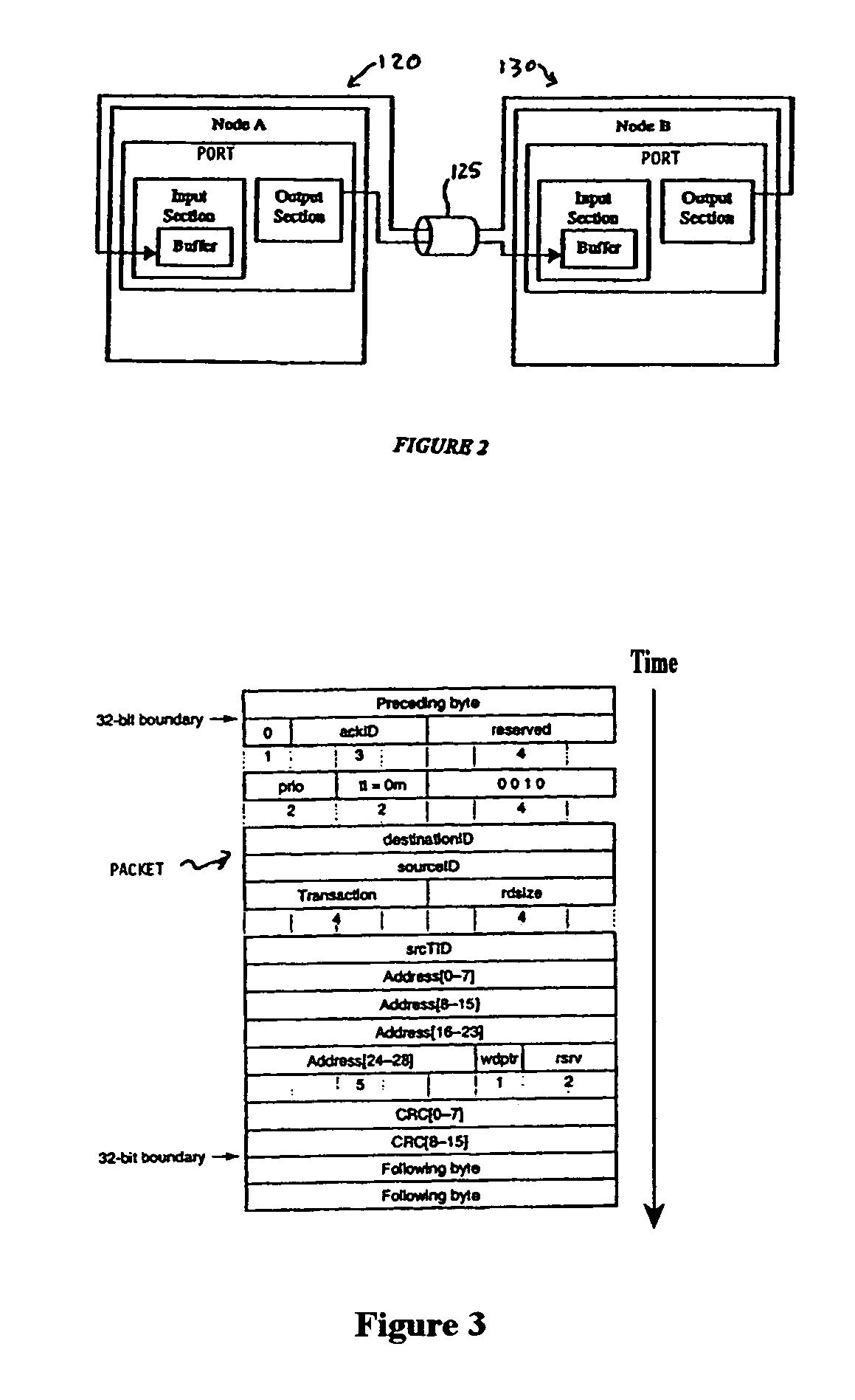

Method and system for link fabric error detection and message flow control

InactiveUS7106742B1Enhance accuracy and efficiencyRegulate transmission rateTransmission systemsFrequency-division multiplex detailsData transmissionDigital data

A digital data system employs multiple error protection mechanisms on messages that pass along a link interconnect fabric from one node or device to another node or device. The nodes may be end points (such as processor or storage units), or may be intermediate devices or branch points (such as routers or switches in the interconnect fabric). The interconnect fabric comprises a set of one or more routers, switches, electrical, optical, electroptical or other links along which messages are passed. Messages are packets having a defined format including, e.g., a header portion, typically with source and target addresses, and codes indicating message-type or other information, followed by one or more data or other fields. A first node (“sending” node) of a digital data system as described sends a data transmission comprising one or more message packets to a second node (“receiving” node) over a link of a fabric as described above. The receiving node returns a control symbol to the sending node for each packet received on the link. The sender uses information in that symbol to control the further transmission of message packets to receiver over the link.

Owner:NXP USA INC +1

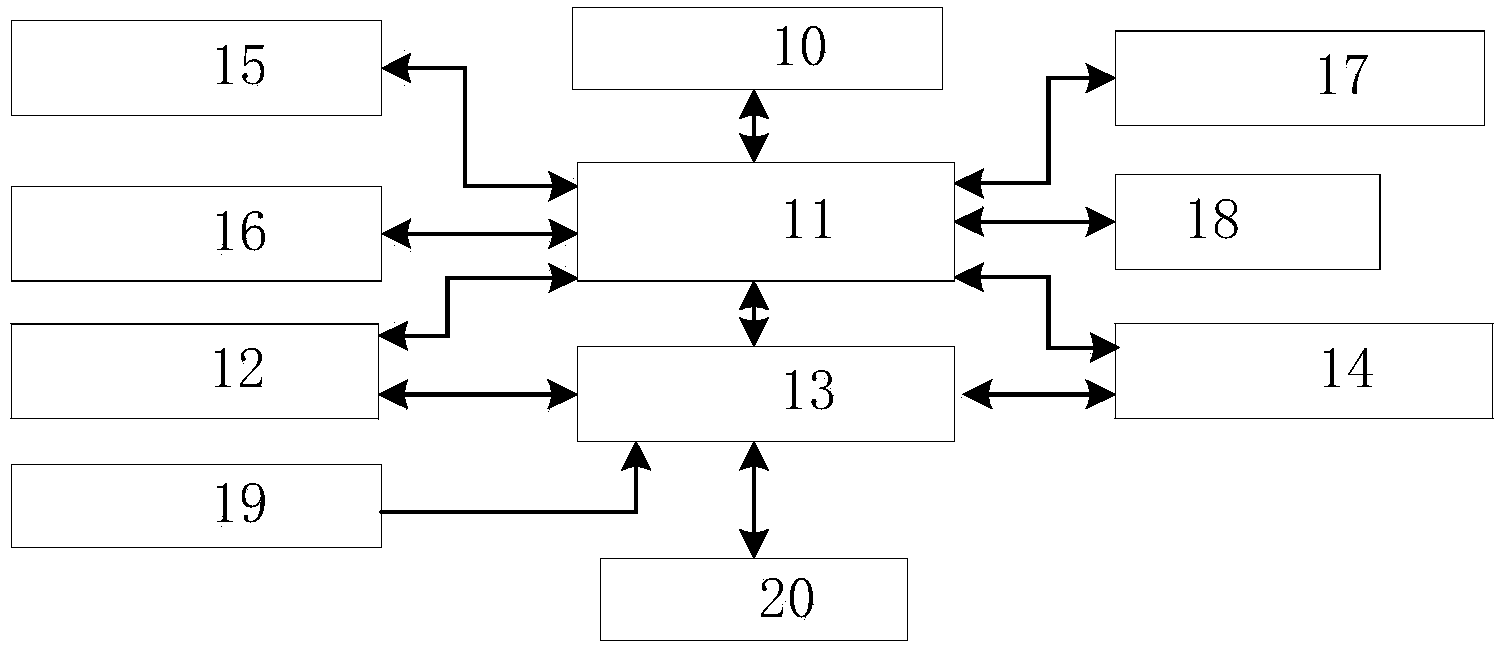

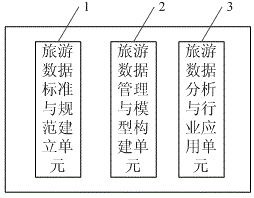

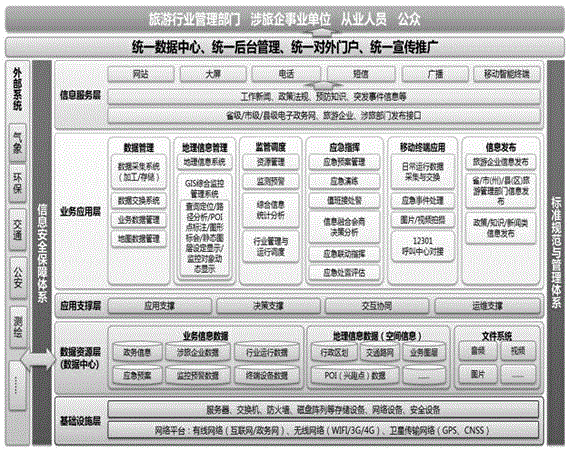

Tourism operation supervision and safety emergency management linkage command platform system

ActiveCN104835085AHighly integratedImprove overallData processing applicationsData informationAnalysis models

The invention discloses a tourism operation supervision and safety emergency management linkage command platform system. The system comprises a tourism data standard and specification establishing unit which is used for establishing tourism data catalog specifications, establishing tourism data acquisition rules and establishing tourism data exchanging and sharing standards, a tourism data management and model building unit which is used for storing and managing tourism data, building a tourism data analysis model and visually displaying tourism data, and a tourism data analysis and industry application unit which is used for monitoring the tourism industry, managing the tourism industry, making decision analysis, carrying out emergency command and providing public information service based on tourism data. Efficient, global and overall tourism industry supervision based on timely and highly-integrated information is realized, and emergency command scheduling can be supported with use of effective data information to achieve the technical effect of travel accident forecasting and warning.

Owner:成都中科大旗软件股份有限公司

Electrolytic pot for production of aluminum using the Hall-Héroult process comprising cooling means

InactiveUS6251237B1Improve cooling effectImprove cooling efficiencyCellsIsotope separationThermal energyHall–Héroult process

An electrolytic pot for the production of aluminum by the Hall-Héroult electrolysis process includes a cooling device for blowing air with localized jets, advantageously with variable flow, in order to evacuate and dissipate thermal energy from the pot. An aluminum production plant using the Hall-Héroult electrolysis process has at least some pots which, either individually or in common, include at least one cooling device.

Owner:ALUMINUM PECHINEY

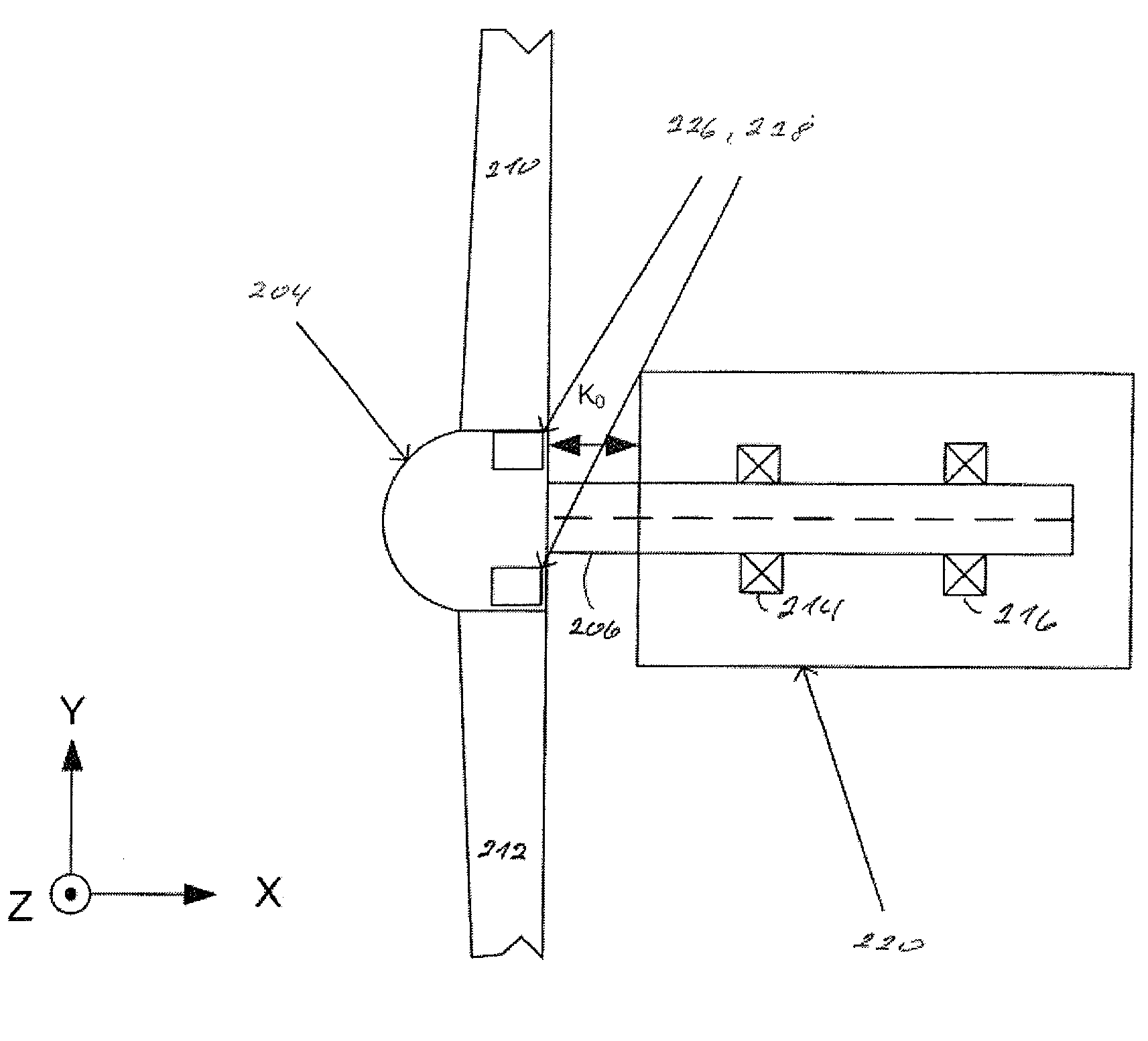

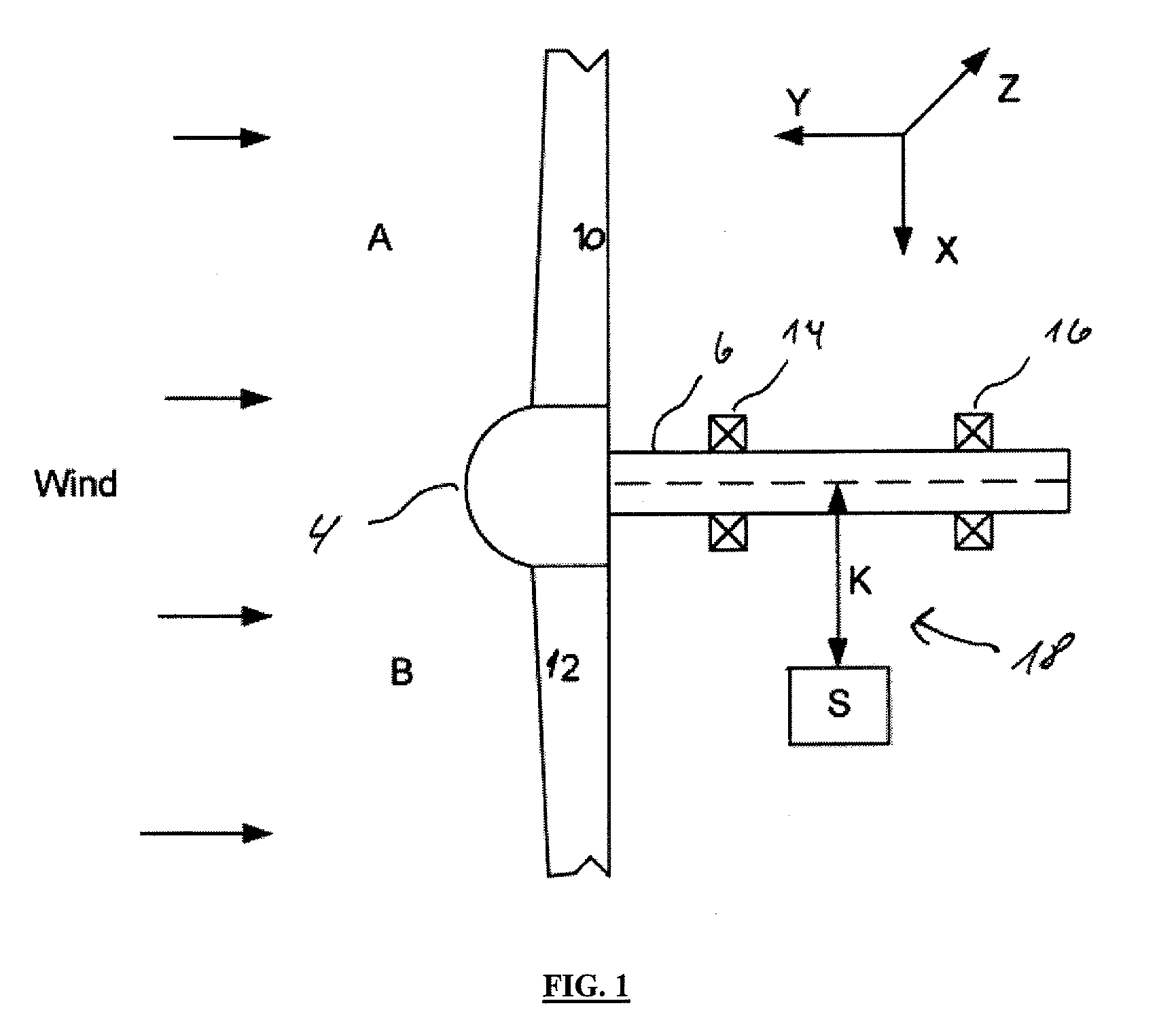

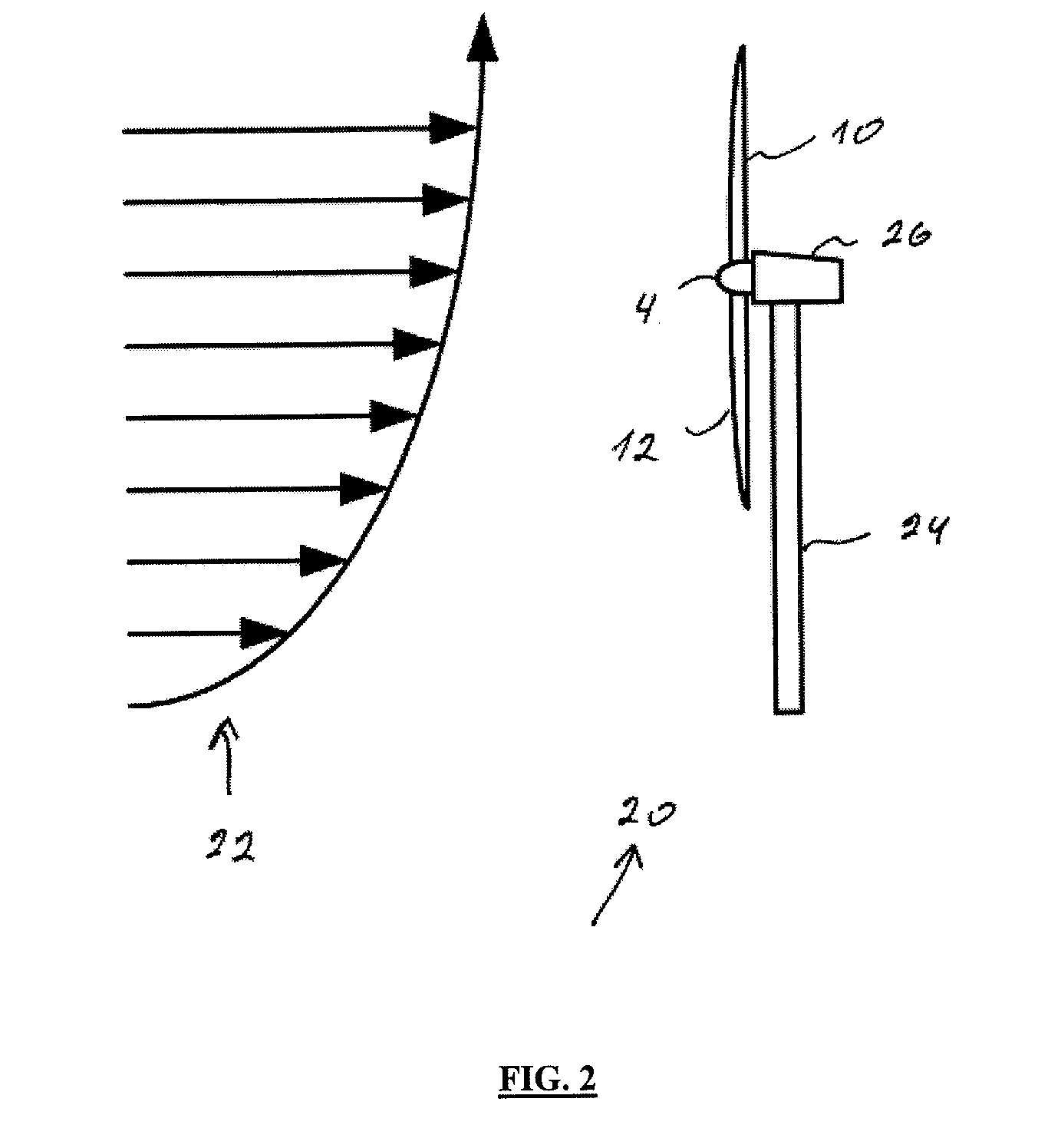

Method and system for operating a wind turbine

ActiveUS20090129924A1Increase power generationReduce wearPropellersPump componentsLoad regulationBlade pitch

The present invention relates to a method and a system for operating a Wind Turbine (WTG), which WTG comprises a rotor comprising at least two blades, which blades are pitch regulated, where the rotor is connected to a shaft, which shaft is supported by bearings, and which shaft drives at least one generator, where the WTG uses a load regulation system for regulating the individual pitch of at least two blades. The object of the invention is to compensate for asymmetric load on the rotor in a wind turbine, a second object is to reduce wearing at shaft bearings in the wind turbine, and a third object is to increase the power production of a wind turbine. This can be achieved if the load regulation system measures the actual rotor load by at least one displacement sensor, which displacement sensor is measuring the bending of the main shaft, where the load regulation system based on the shaft bending regulates the individual pitch of the blades for compensating asymmetric load at the rotor.

Owner:GAMESA INNOVATION & TECH SA

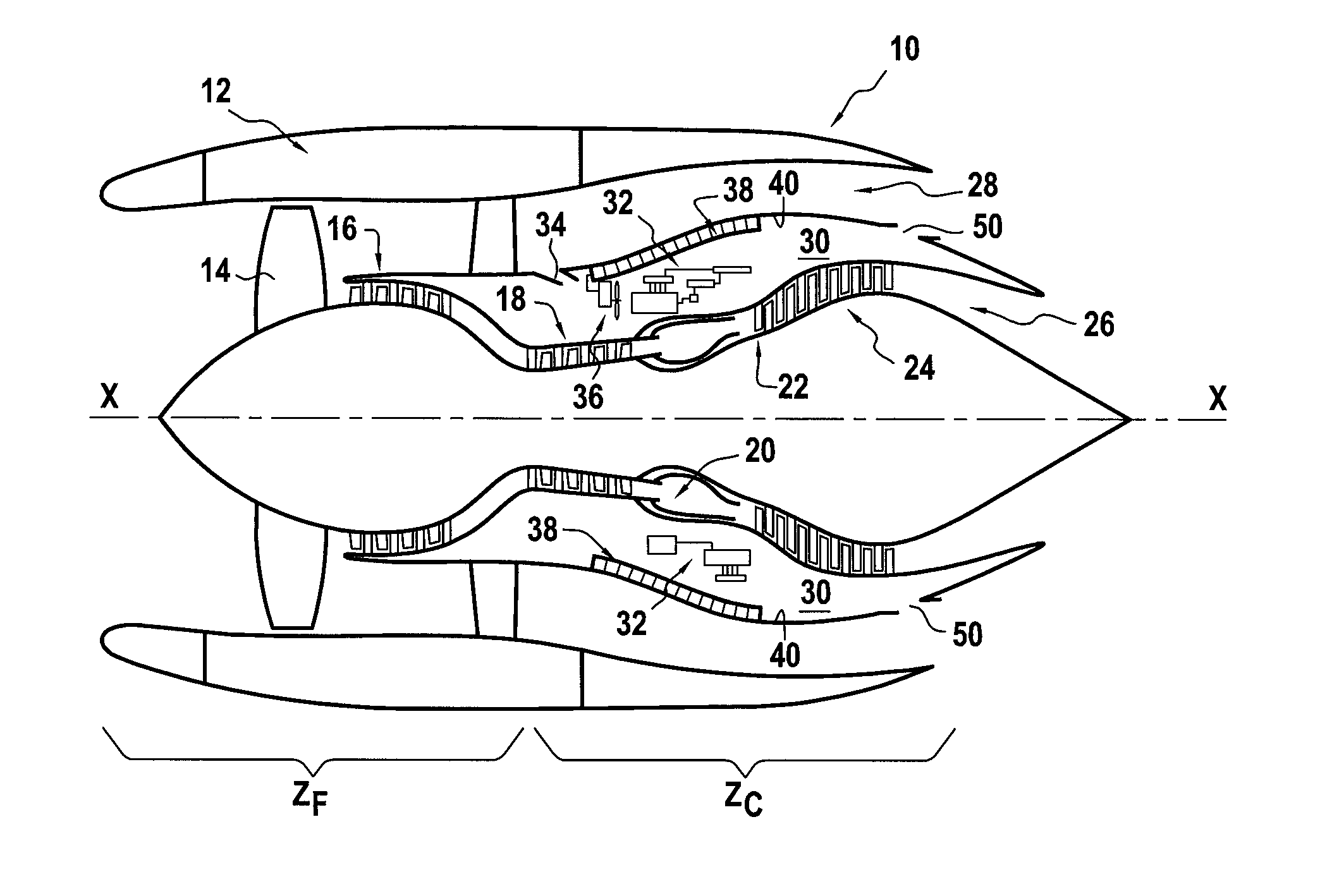

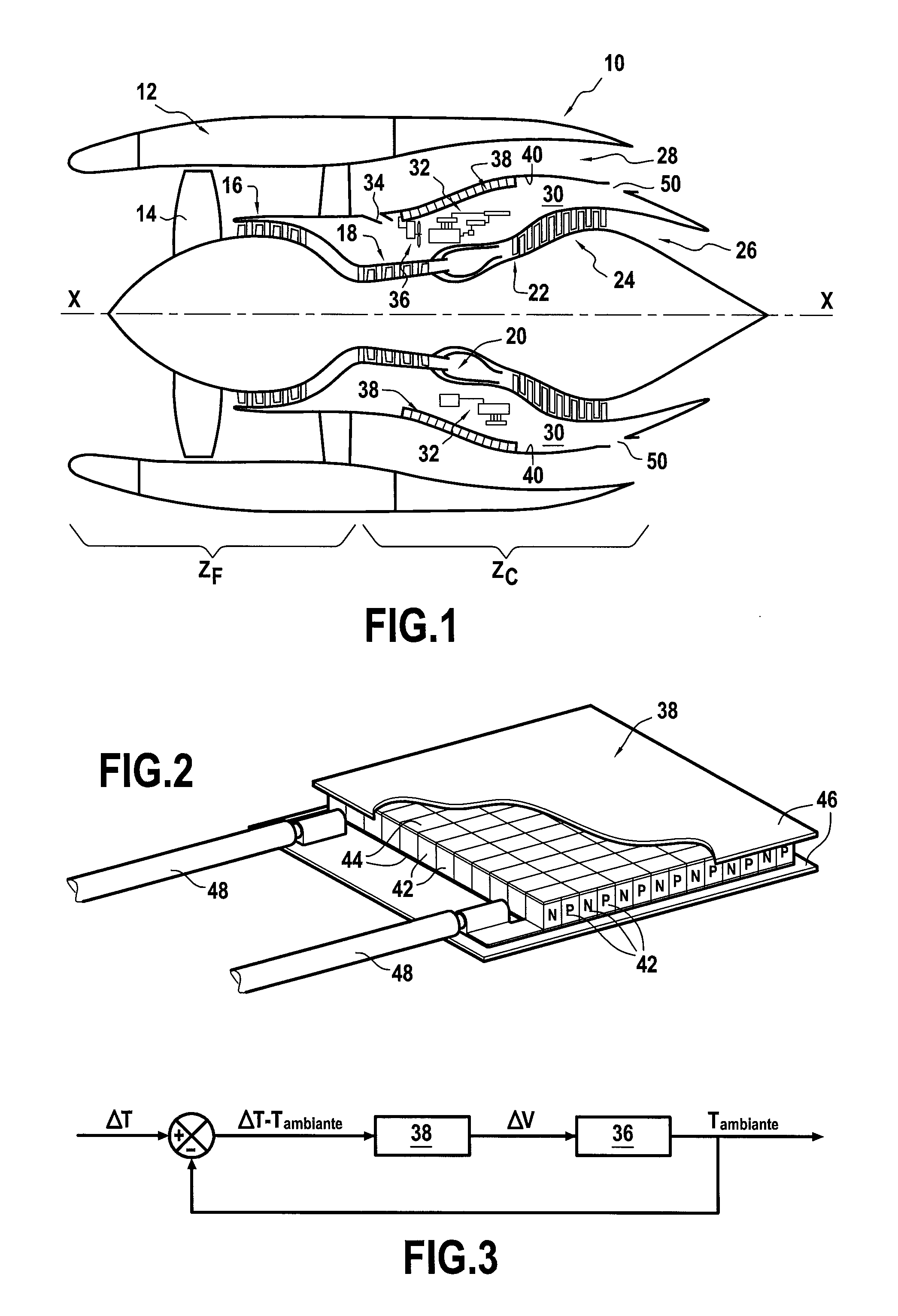

Method and a circuit for ventilating equipment of a turbojet by thermoelectricity

InactiveUS20160123185A1Limit overuseEffective supervisionPump componentsEngine fuctionsJet enginePotential difference

The invention provides a method of ventilating equipment of a turbojet, the turbojet (10) having a cold zone (ZF) including a fan (14) upstream from a hot zone (ZC), the turbojet equipment (32) for ventilating being arranged in a ventilation space (30) available around the hot zone between a primary air stream passage (26) and a secondary air stream passage (28) of the turbojet, the method comprising taking ventilation air from one of the air stream passages in order to convey it to the ventilation space, and providing forced flow of the ventilation air by means of at least one electric fan (36) positioned inside the ventilation space and powered electrically by at least one thermoelectric generator (38) suitable for inducing a potential difference (ΔV) and positioned in a wall (40) between the ventilation space and the secondary air stream passage.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

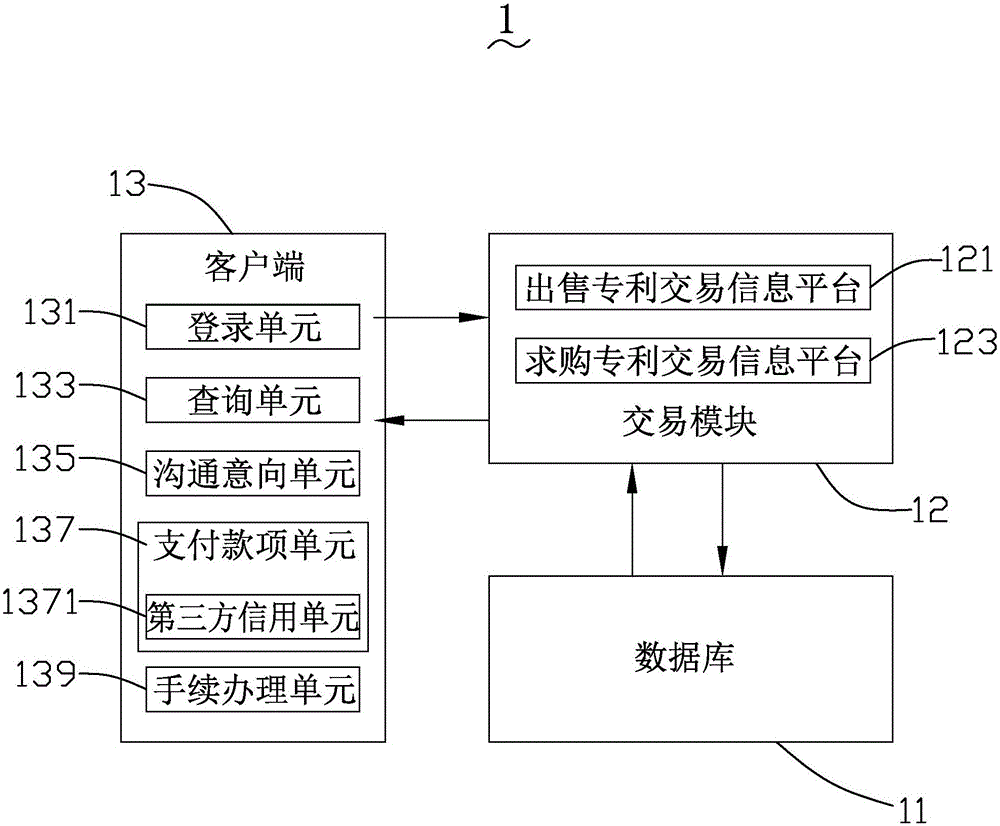

Patent transaction system

InactiveCN105160567AAccelerate circulation and useReduce transaction costsBuying/selling/leasing transactionsClient-sideDatabase

The present invention discloses a patent transaction system. The patent transaction system comprises a database, a transaction module and a client; modules are connected sequentially by means of a network and work collaboratively; the client is convenient for a user to input a service that needs to be queried and comprises a login unit, a query unit, a communicating intention unit, a payment unit and a procedure settlement unit; the database is used for storing patent big data and providing the data; the database is connected to the transaction module; and the transaction module is connected to the client. According to the patent transaction system disclosed by the present invention, patent transaction information is provided for the user, and a platform for ensuring a transaction procedure is provided for the user to make a patent transaction, so that a successful transaction between the users is facilitated.

Owner:CHANGSHA LUZHI INFORMATION TECH

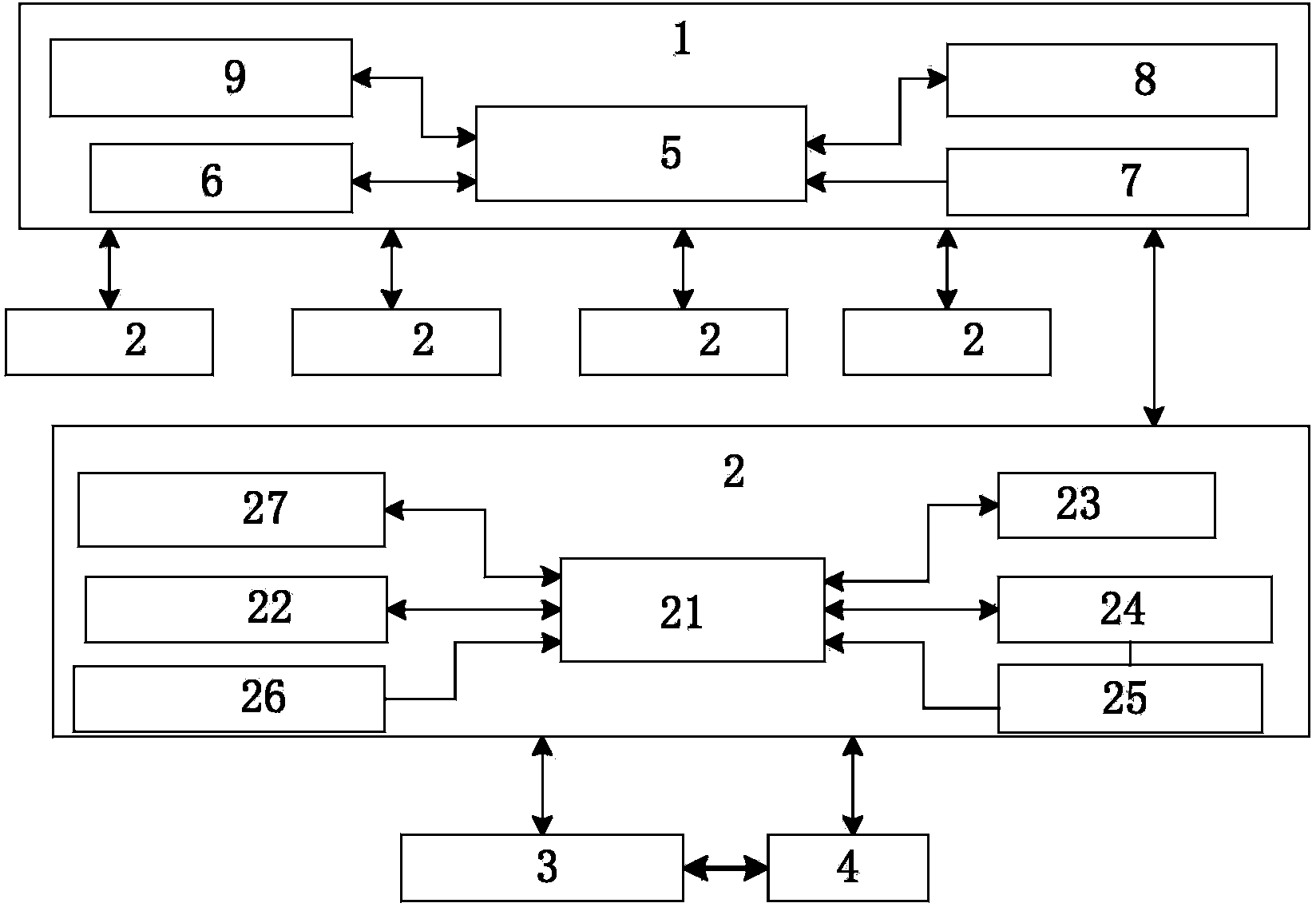

System and method for centralized dispatching of electric line patrol by unmanned aerial vehicle based on GIS

ActiveCN103823451AReduce idle rateImplement configurationTotal factory controlProgramme total factory controlUncrewed vehicleComputer science

The invention discloses a system and a method for centralized dispatching of electric line patrol by an unmanned aerial vehicle based on GIS. The system comprises a dispatching platform, a dispatching terminal, a ground monitoring station and an unmanned aerial vehicle, and according to the method for centralized dispatching of electric line patrol of an unmanned aerial vehicle, equipment, workers, time and line for patrol are dispatched through the dispatching terminal by considering the factors such as patrol field state information, equipment information and worker information to finish patrol tasks as many as possible under limited source conditions. Based on the system and the method, the patrol efficiency of the unmanned aerial vehicle is improved, the patrol reliability and safety of the unmanned aerial vehicle are improved, and the patrol cost of the unmanned aerial vehicle is reduced.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

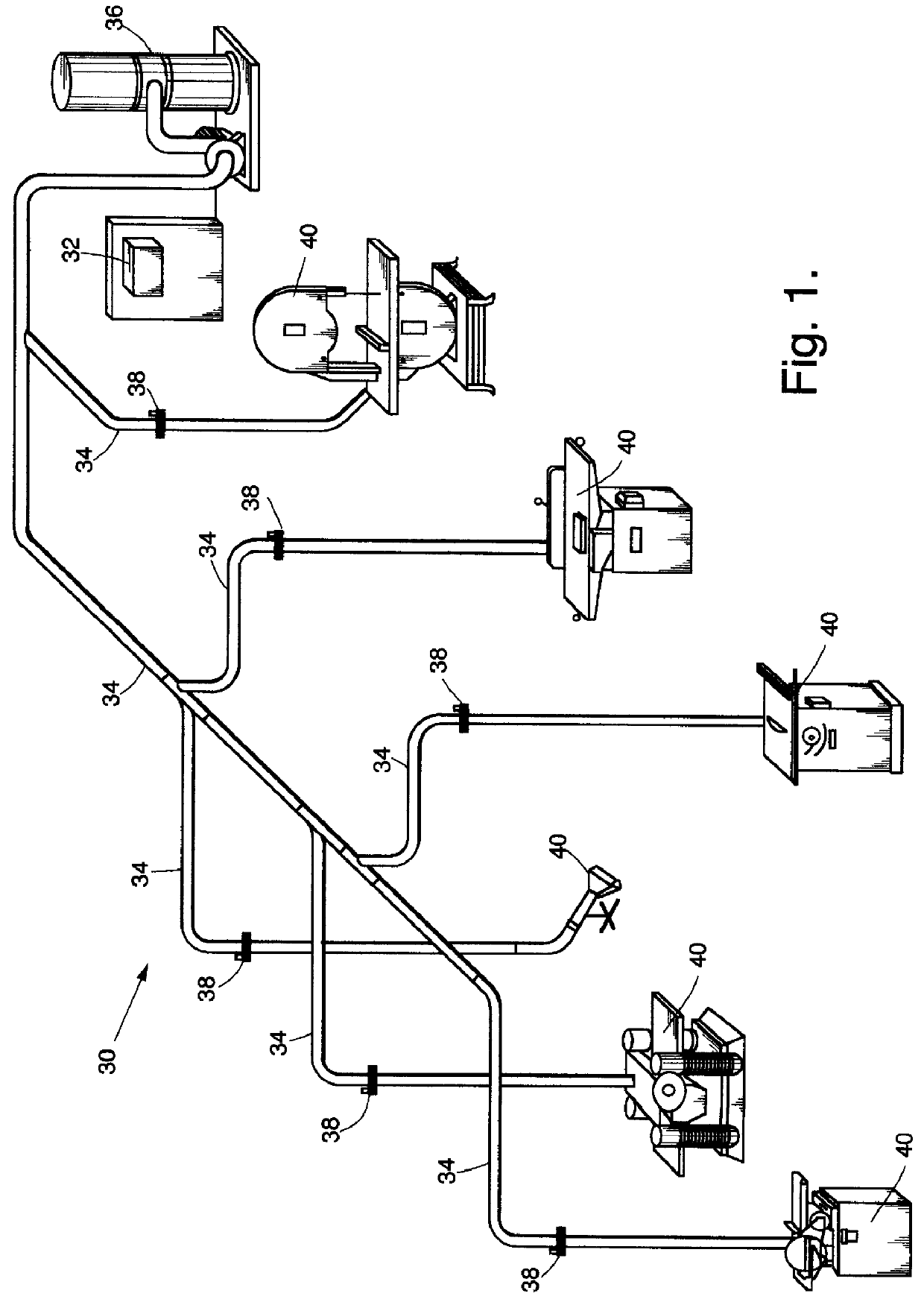

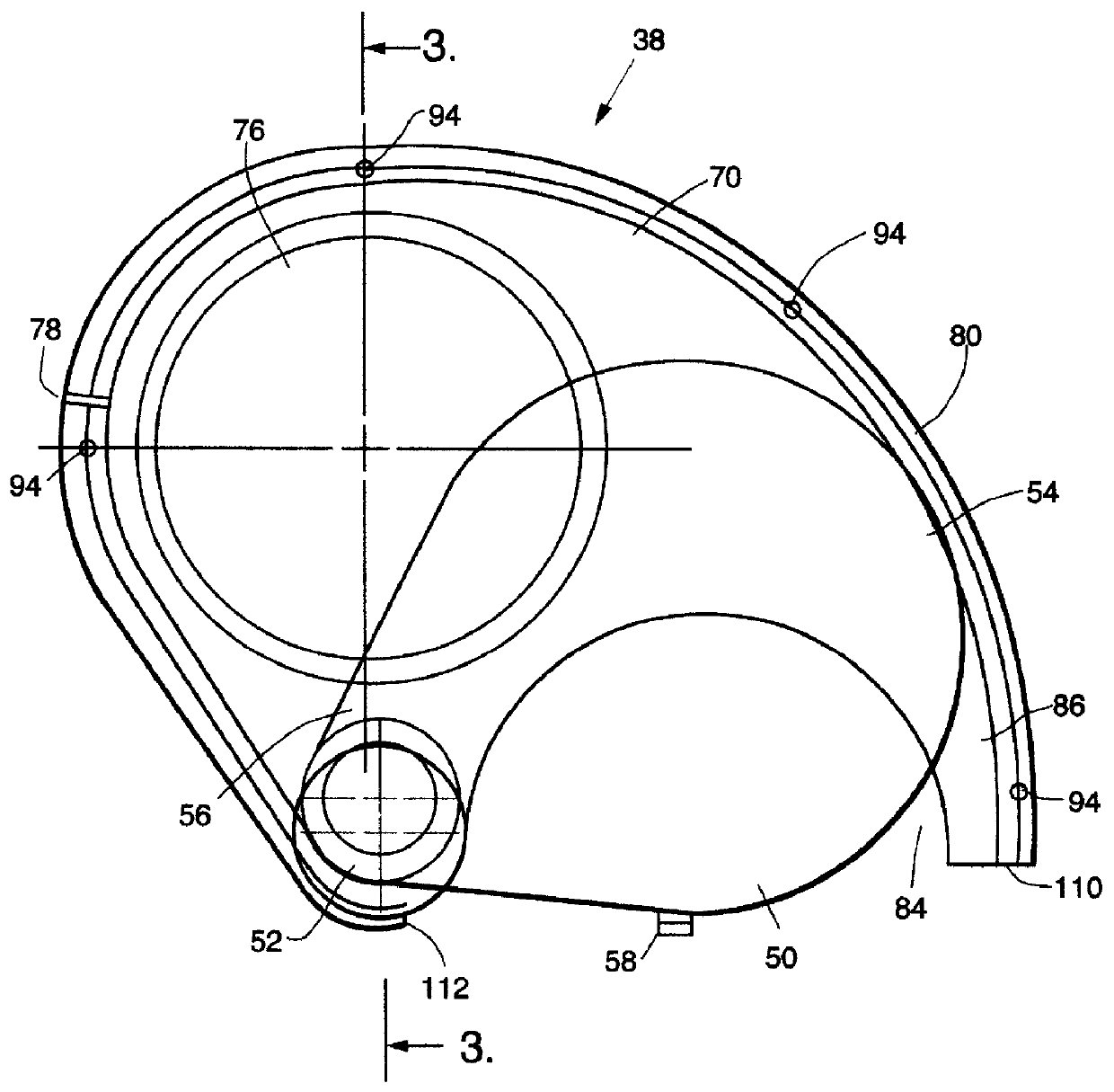

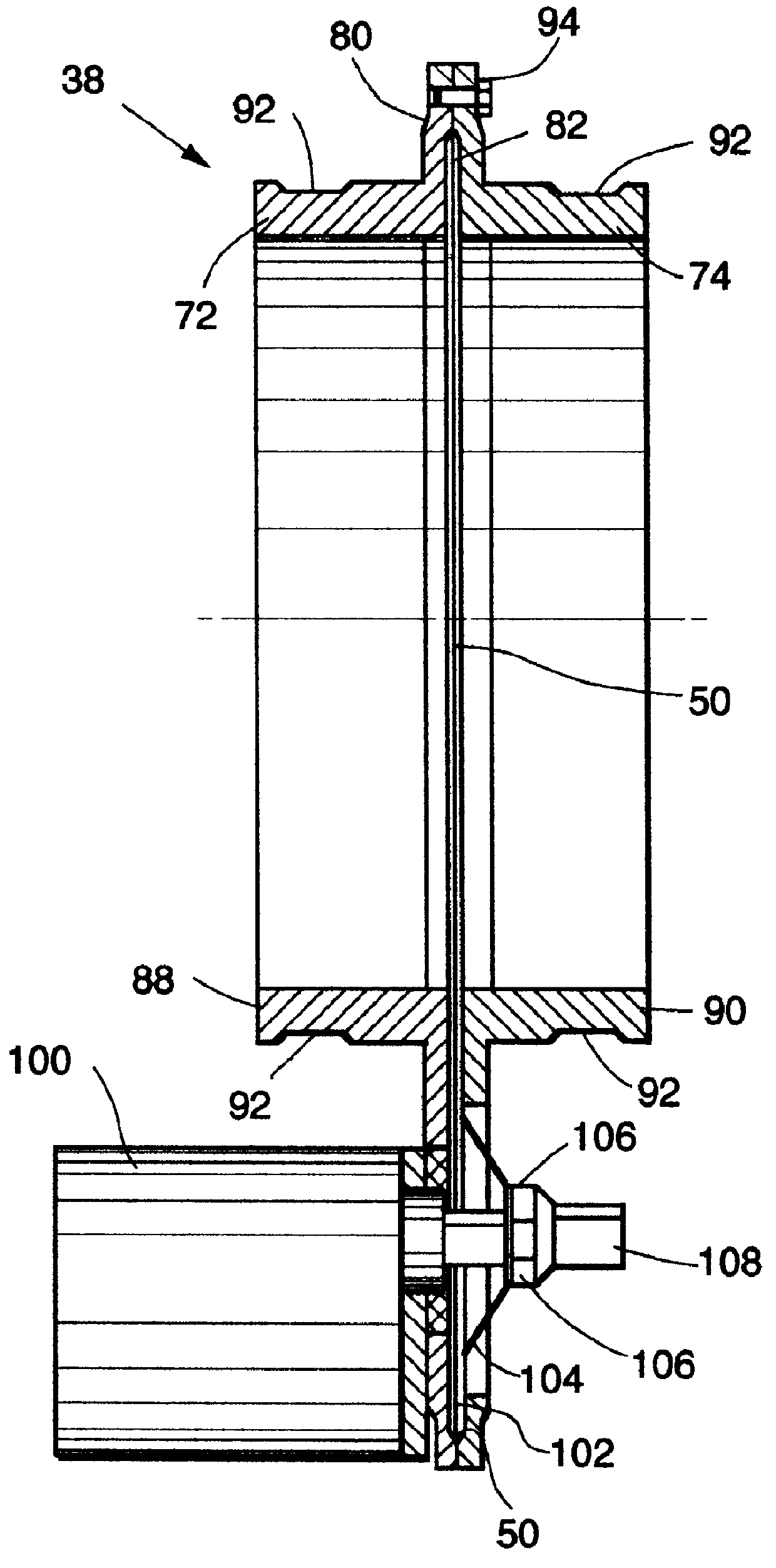

Refuse vacuum system for machine shops

InactiveUS6012199AInexpensiveEfficient mannerMetal sawing accessoriesLighting and heating apparatusParticulatesMachine shop

A vacuum system for machine shop dust, particulate matter, and the like. Blast gates control the flow of vacuum generated by a dust collector to individual machines that may or may not accommodate vacuum ductwork and the like. The blast gate has a rotating blade inside a chassis with a DC motor effectively using a slip clutch or an increased current feedback system to limit the rotation driving of the rotating blade. Importantly, a small aperture serves to allow air flow into the chassis gap through which the rotating blade rotates in order to ensure the particular matter does not lodge inside the chassis thereby preventing the proper operation of the rotating blade. A central controller having a microprocessor or the like may be programmed or programmable and serve to individually control a selected number of blast gates based upon a feedback mechanism. A piezoelectric sensor or the like senses the vibration arising from the turning on of the associated machinery, indicating the demand for vacuum power to collect particulate matter. In response to the piezoelectric sensor's signal, the blast gate is opened and the dust collector is either turned on or stepped up to accommodate the increase load upon the vacuum system. The reverse situation occurs when the machinery is turned off. The piezoelectric sensor ceases signalling the central controller of the machine "on" condition. The central controller then steps down the dust collector / vacuum system and closes the associated blast gate. Alternative embodiments are set forth whereby additional features provide for enhanced utility, including a computer operation, control, monitoring, and feedback.

Owner:LITOMISKY PETR +1

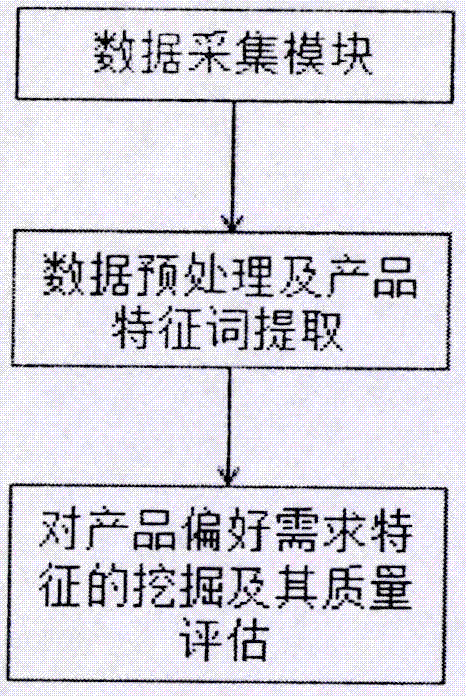

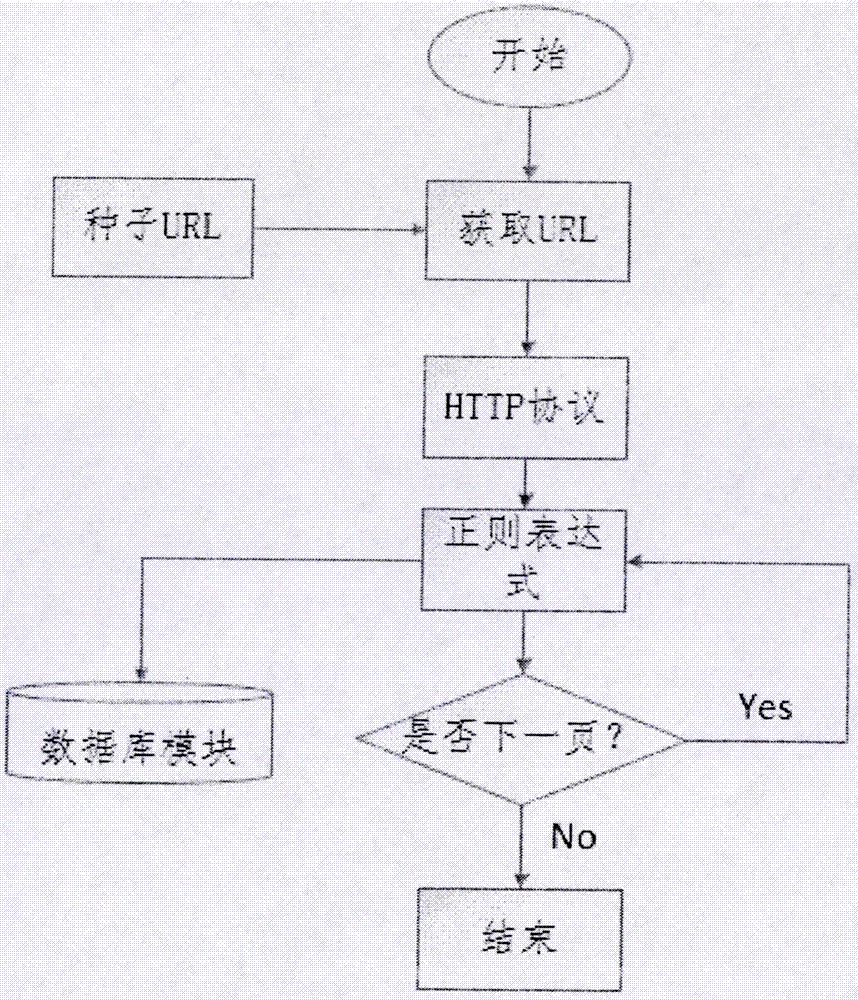

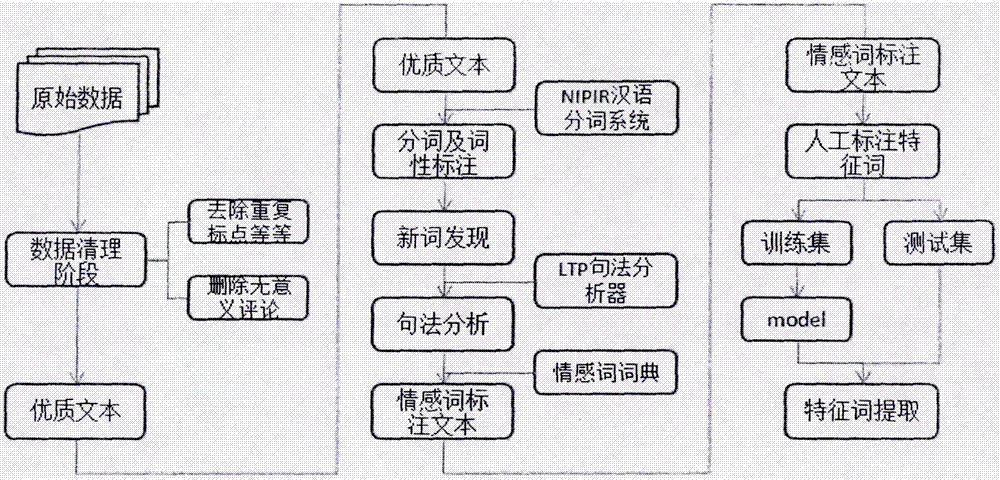

Product demand preference characteristic digging and quality evaluation method based on comment information

PendingCN107133214AEffective supervisionNatural language data processingData miningConditional random fieldDecision taking

The invention provides a product demand preference characteristic digging and quality evaluation method based on comment information. The method comprises the following steps: 1, crawling data, namely by using a network crawling technique, crawling product comment appointed information of an E-commerce platform and storing in a databank; 2, performing data preprocessing and product characteristic word extraction, namely performing data cleansing and preprocessing on acquired data, and further performing product characteristic extraction on preprocessed data by using a BiLSTM-CRF (Bidirectional Long Short-Term Memory-Conditional Random Field) model; and 3, performing product demand preference characteristic digging and quality evaluation. By adopting the method, quality problems of products can be rapidly understood according to feedback information of customers, demand preference characteristics of the customers can be understood, and thus companies can make relatively good decisions to meet the customers.

Owner:CHINA JILIANG UNIV

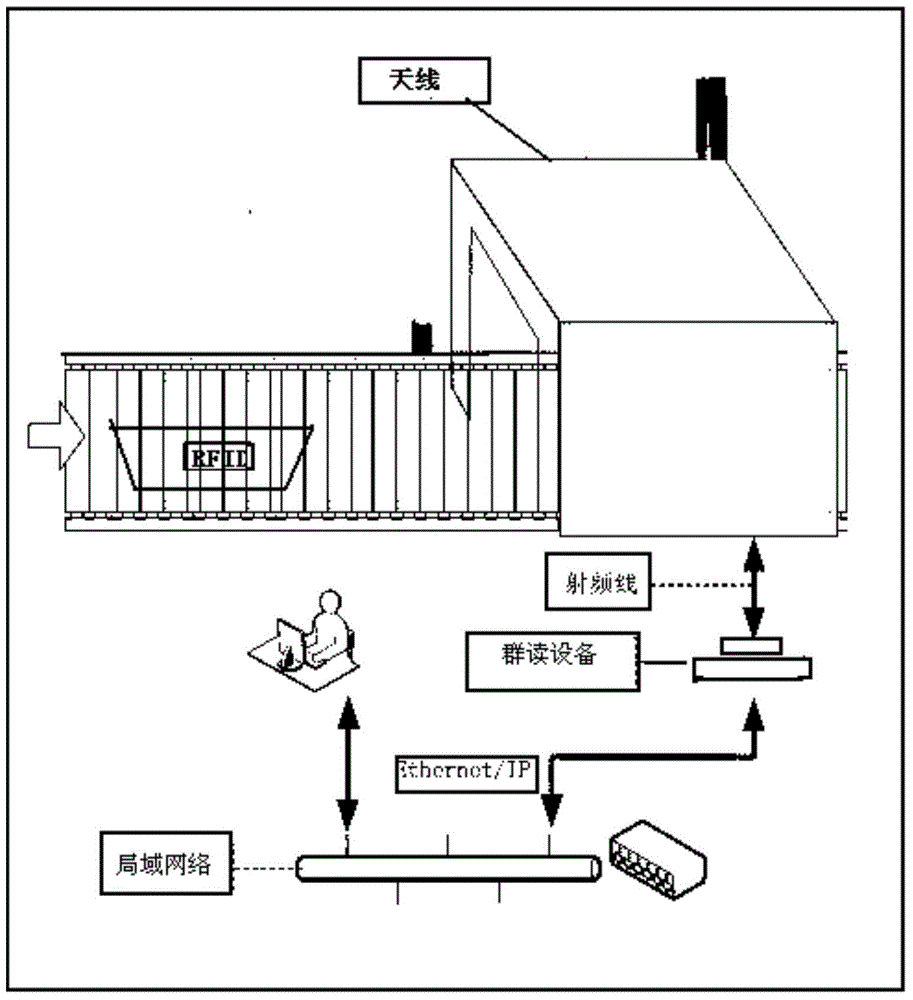

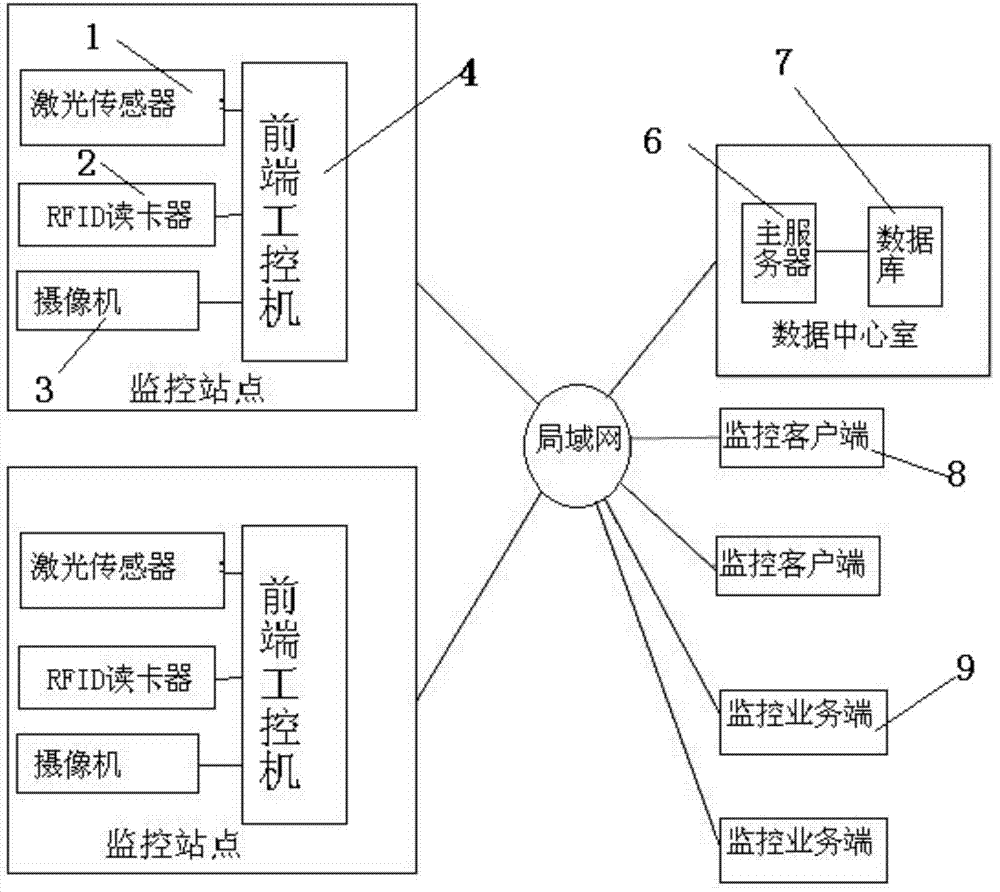

Automatic ship identification monitoring method fusing multiple data sources and supervisory system

ActiveCN103971543AGuarantee safety supervisionComprehensive supervisionCo-operative working arrangementsMarine craft traffic controlData centerData description

The invention relates to an automatic ship identification monitoring method fusing multiple data sources and a supervisory system. The method comprises the following steps: (1) performing laser scanning on a ship; (2) triggering a radio frequency identification (RFID) system to read radio frequency tag information of the ship and shoot a video image; (3) establishing a matching relation between a shore-based RFID reader and the ship; (4) acquiring the ship information through laser; (5) judging the data information of the detected ship, and counting the data; (6) performing manual intervention on the measurement result. The system comprises multiple monitoring sites, a data center room communicating with the multiple monitoring sites through a local area network, and a monitoring client and a service client. Three technical data sources from the RFID, the video image and the laser are fused, unique abstract data description is established for actual conditions such as identity, physical size, shipping conditions and cargo transport of the ship in inland waterways, the underway ship is comprehensively and effectively supervised by the channel and maritime affair department in real time, and a metadata support is provided for integrated management.

Owner:浙江省嘉兴市港航管理局 +1

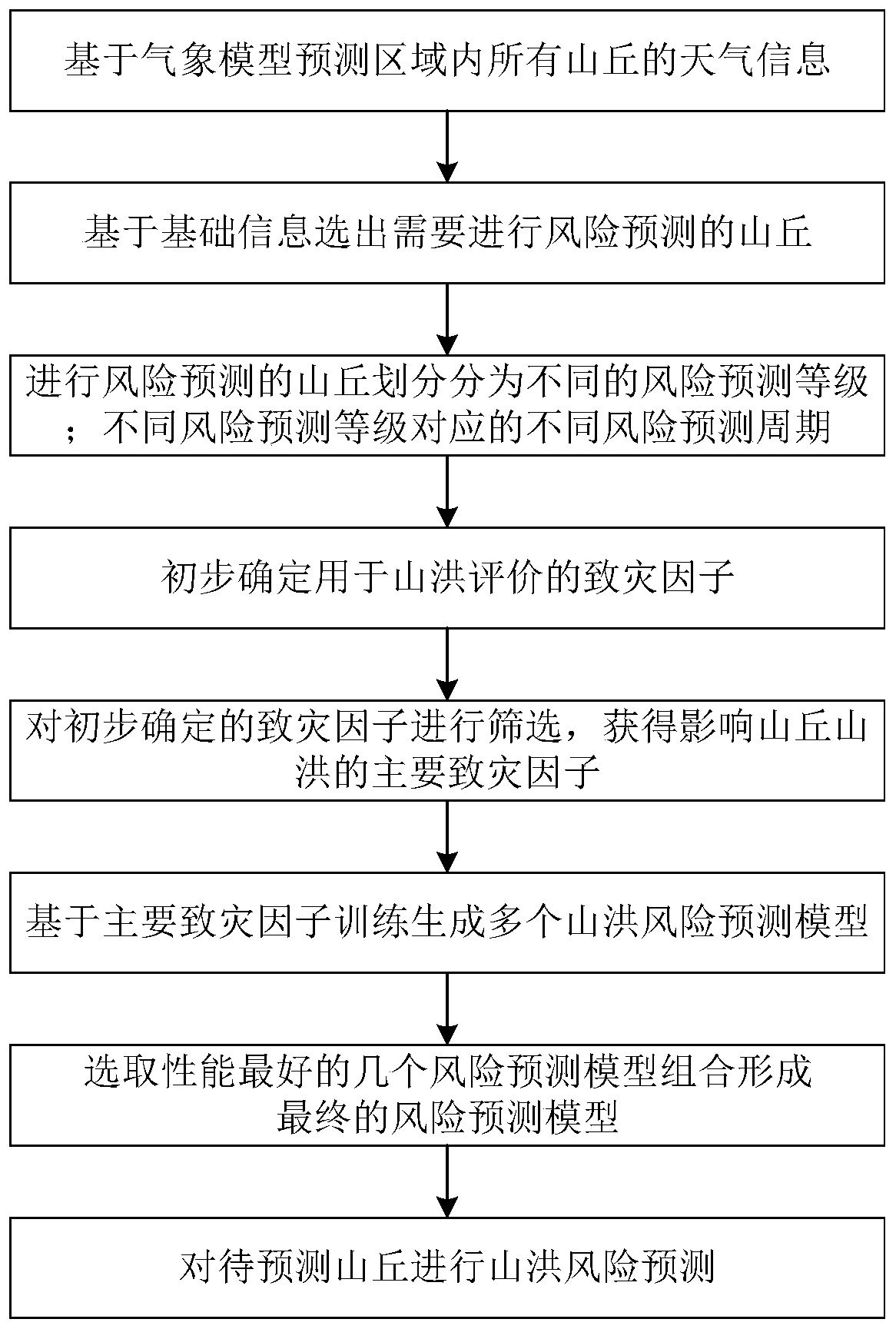

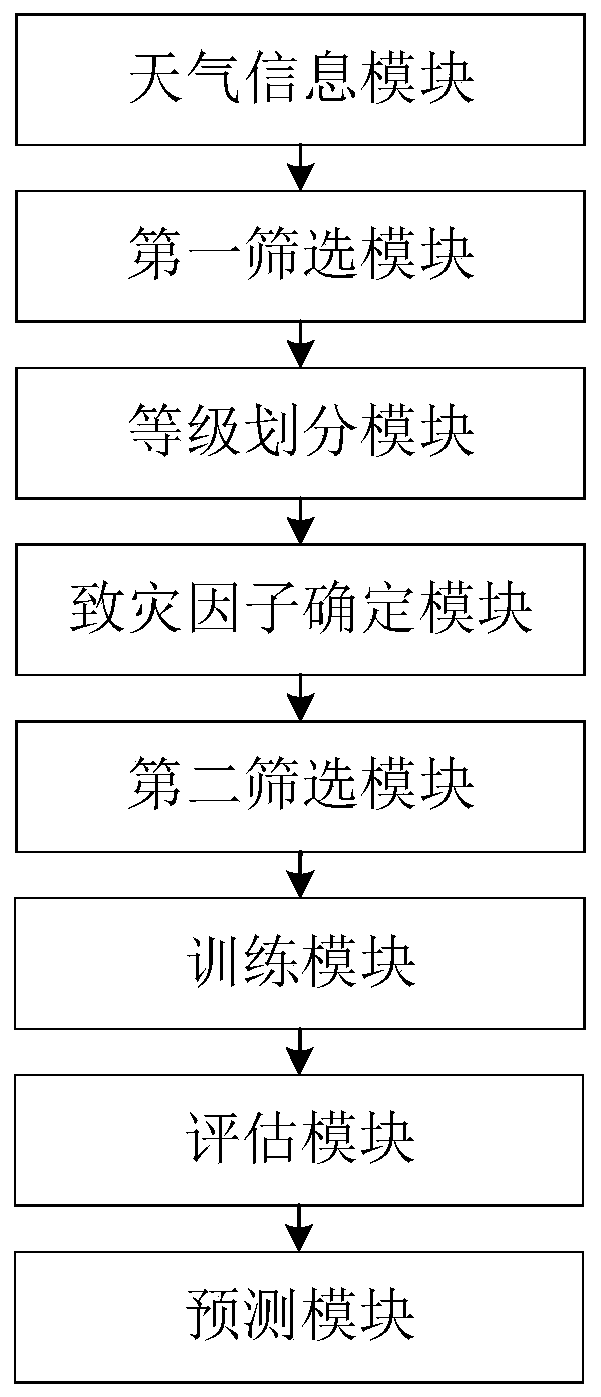

Regional mountain torrent risk prediction method and system

ActiveCN111047099APredicted Value at RiskAchieve forecastClimate change adaptationForecastingEngineeringAtmospheric sciences

The invention discloses a regional mountain torrent risk prediction method and system. The method comprises the steps: S1, predicting the weather information of all hills in a region based on a meteorological model; S2, screening out hills needing risk prediction based on the weather information; S3, dividing hills needing risk prediction into different risk prediction levels according to the basic information of the hills; wherein different risk prediction levels correspond to different risk prediction periods; S4, preliminarily determining disaster-causing factors for mountain torrent evaluation; S5, screening the preliminarily determined disaster-causing factors to obtain main disaster-causing factors influencing the mountain torrent; S6, training and generating a plurality of mountaintorrent risk prediction models based on the main disaster-causing factors; S7, several risk prediction models with the best performance are selected to be combined to form a final risk prediction model; and S8, performing mountain torrent risk prediction on the hill to be predicted. According to the method, the risk prediction of the regional hill is realized, the realization cost is low, the coverage is wide, the processing efficiency is high, and the safety of the hill is improved.

Owner:杭州鲁尔物联科技有限公司

Biologic device for regulation of gene expression and method therefor

InactiveUS20070036771A1Desirable effectAltered expressionBiocideInternal electrodesOpen reading frameRegulation of gene expression

A system and device are provided which include a gene regulatory system controlling expression of one or more expression cassettes present in or released by the device, by emitting one or more stimulations. An expression cassette includes a regulatable transcription control element that is responsive to the emitted stimulations linked to an open reading frame of interest. The system optionally includes a sensor to sense a parameter indicative of a need, a telemetry module to receive an external command, or a programmable device, for regulating gene expression of the open reading frame.

Owner:CARDIAC PACEMAKERS INC

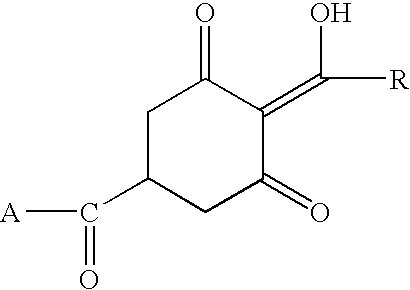

Plant growth regulation compositions and methods using gibberellin biosynthesis inhibitor combinations

ActiveUS20050032648A1Effective and efficient regulationEffective supervisionBiocideDead animal preservationGrowth plantGibberellic acid biosynthesis

Described are plant growth regulation compositions and methods utilizing combinations of Class A and Class B gibberellin biosynthesis inhibitors. Preferred methods and compositions involve the combination of trinexapac-ethyl with either or both of flurprimidol and paclobutrazol, in particular to provide a synergistic effect in the regulation of the growth of turfgrass.

Owner:SEPRO CORP

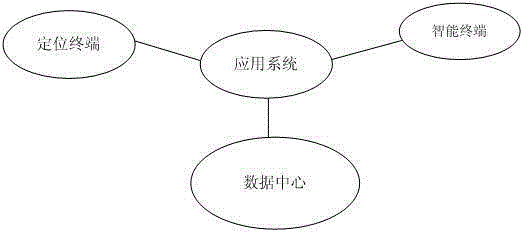

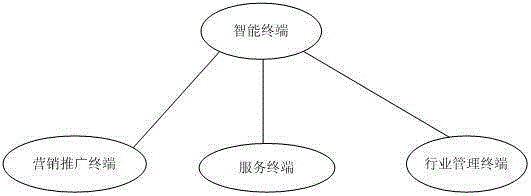

Comprehensive management system for scenic regions

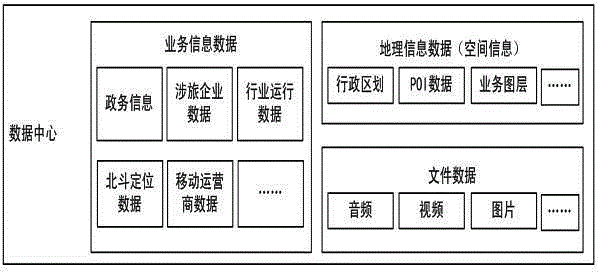

The invention discloses a comprehensive management system for scenic regions. The comprehensive management system comprises an intelligent terminal, at least one data center and at least one positioning terminal; the intelligent terminal comprises a marketing promotion terminal or / and a service terminal or / and an industrial management terminal; the positioning terminal is used for collecting static position data of scenic spots and facilities in scenic regions; the positioning terminal is further used for collecting dynamic position data of touring vehicles, tourists and team tourists; the data center is for obtaining business information data and geographic information data; the data center performs centralized database-establishment and management according to the business information data and the geographic information data; the data center is provided with corresponding an industrial management module, a service module and a marketing promotion module according to the business information data and the geographic information data; the marketing promotion terminal establishes marketing promoting activities with the data center through the marketing promotion module; the industrial management terminal establishes industrial management activities with the data center through the industrial management module; and the service terminal establishes service activities with the data center through the service module.

Owner:成都中科大旗软件股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com