Patents

Literature

3579 results about "Combine harvester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

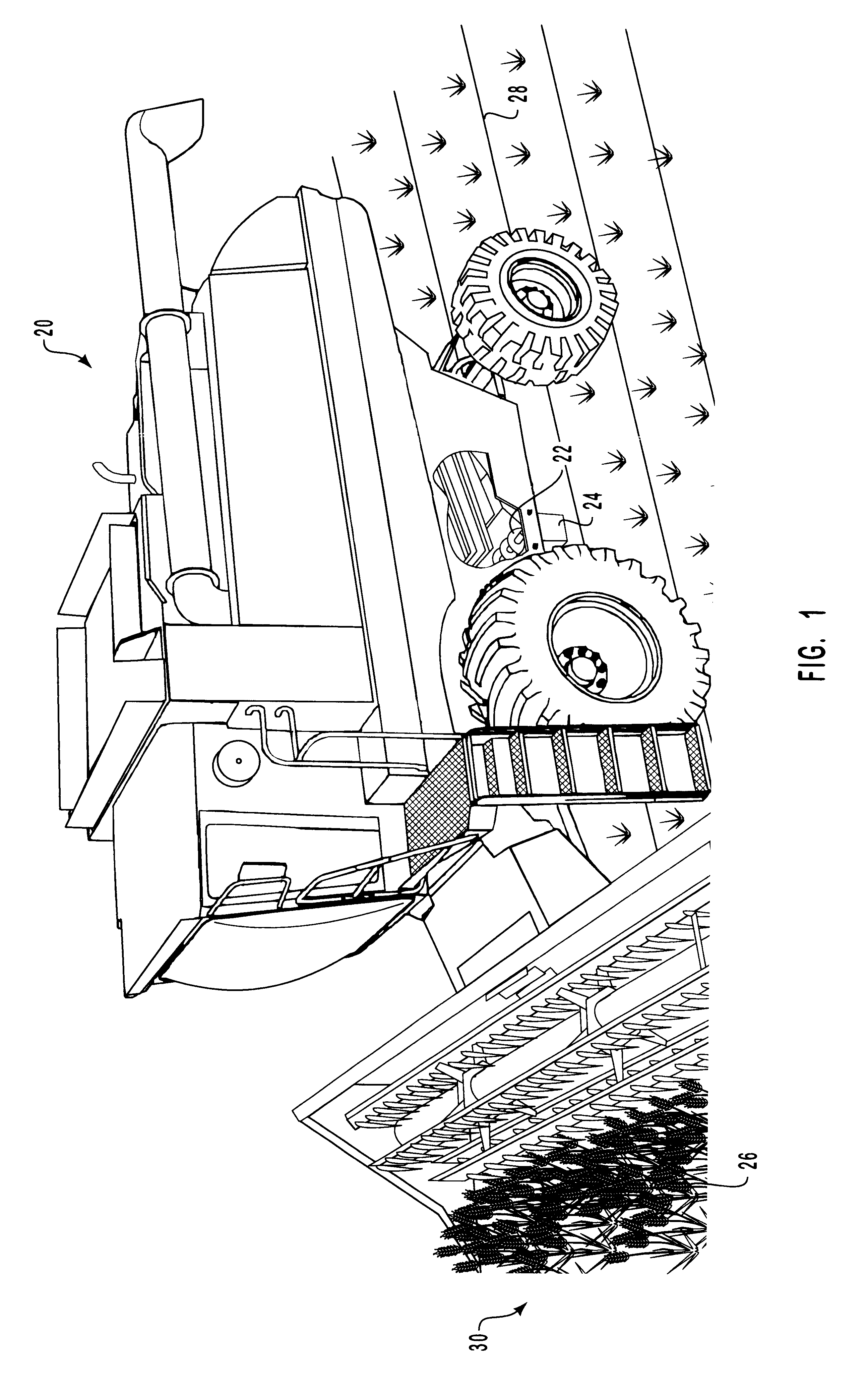

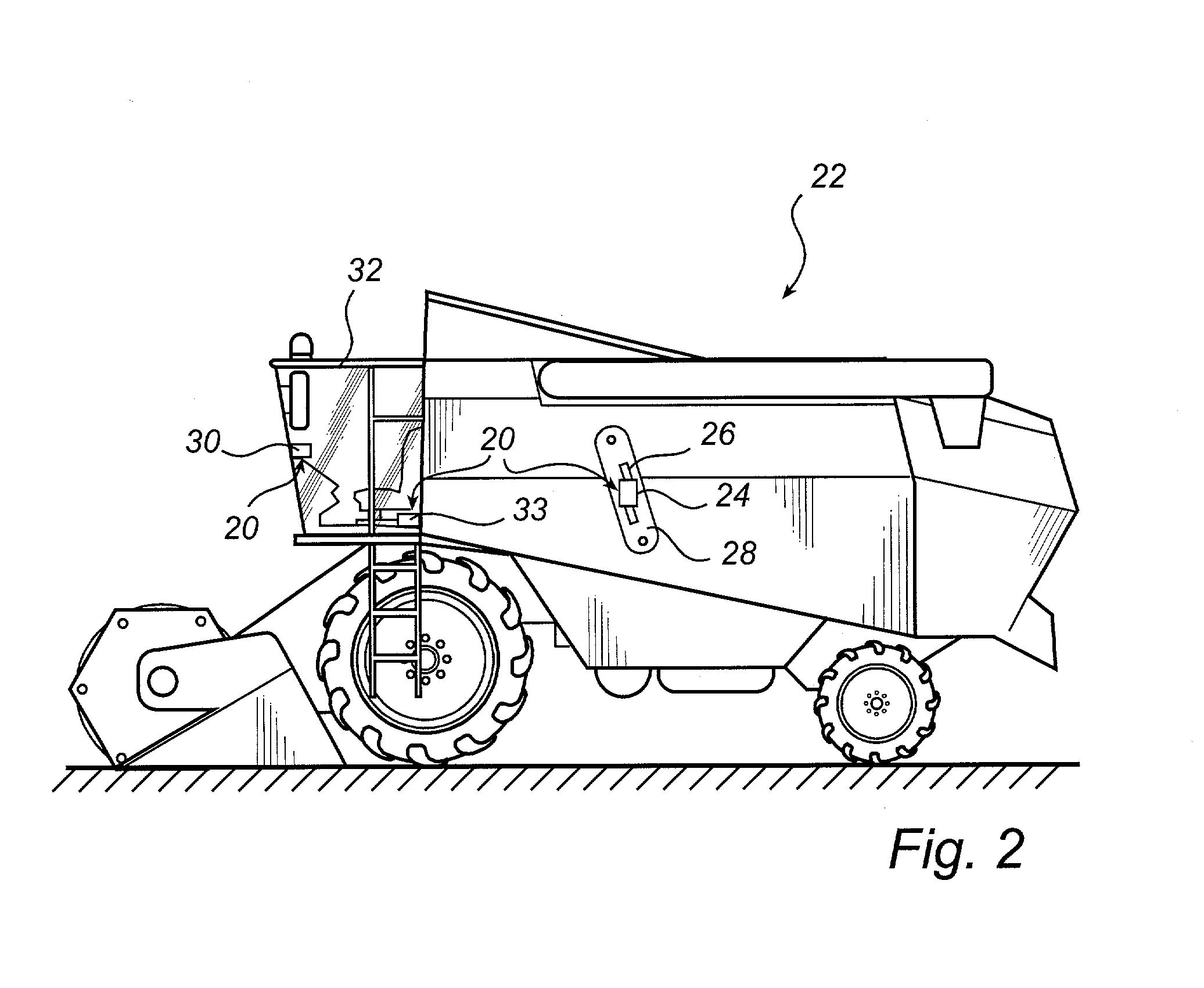

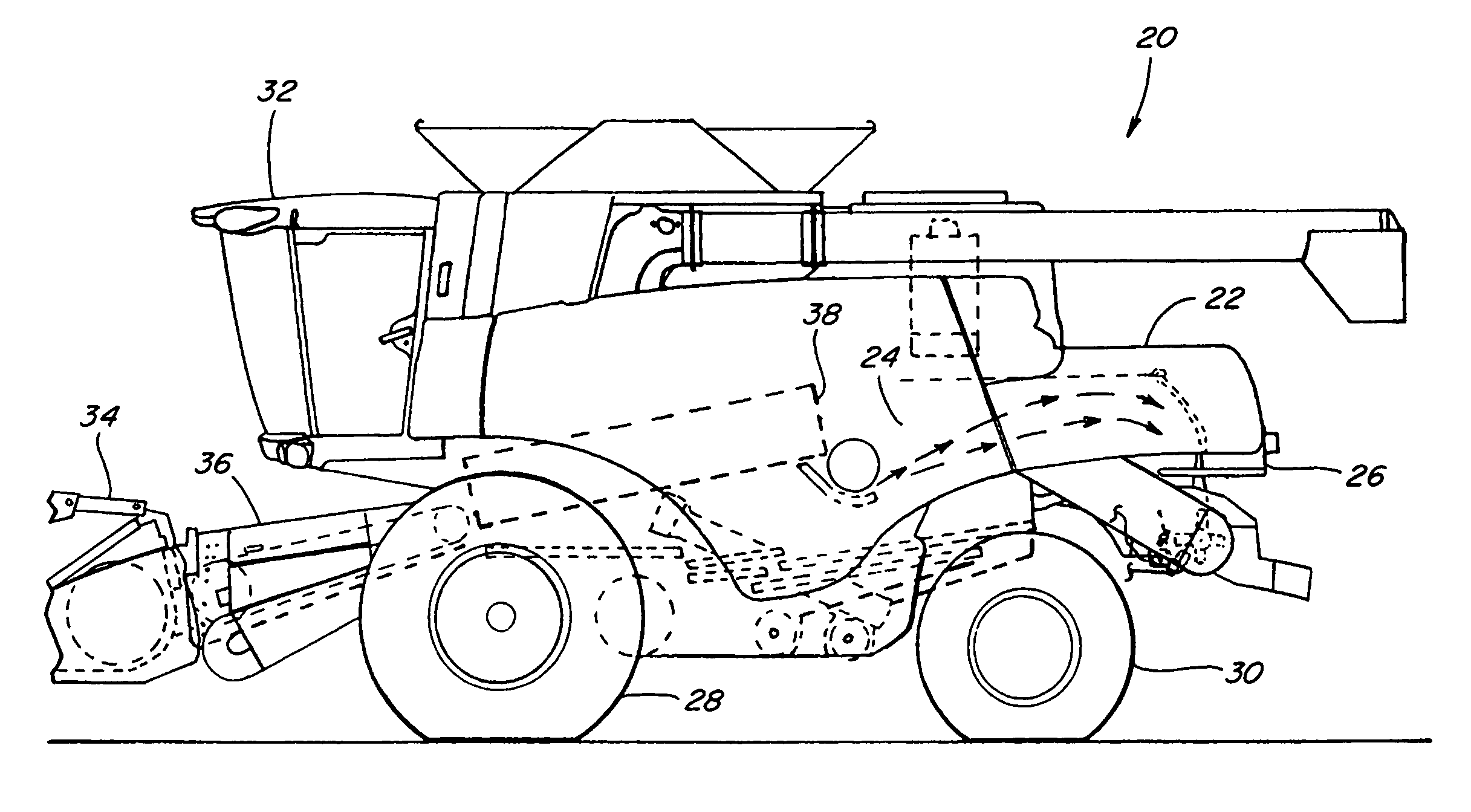

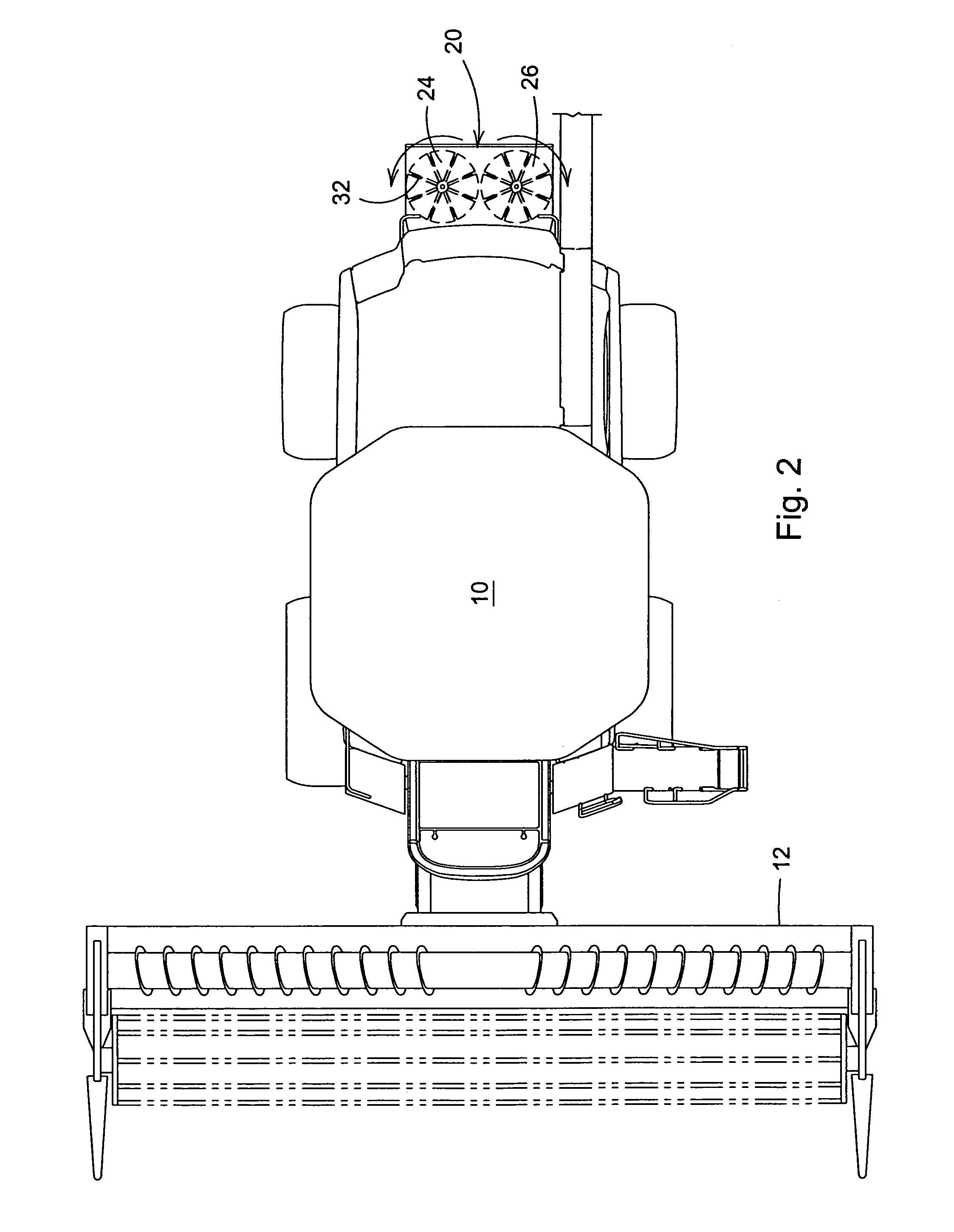

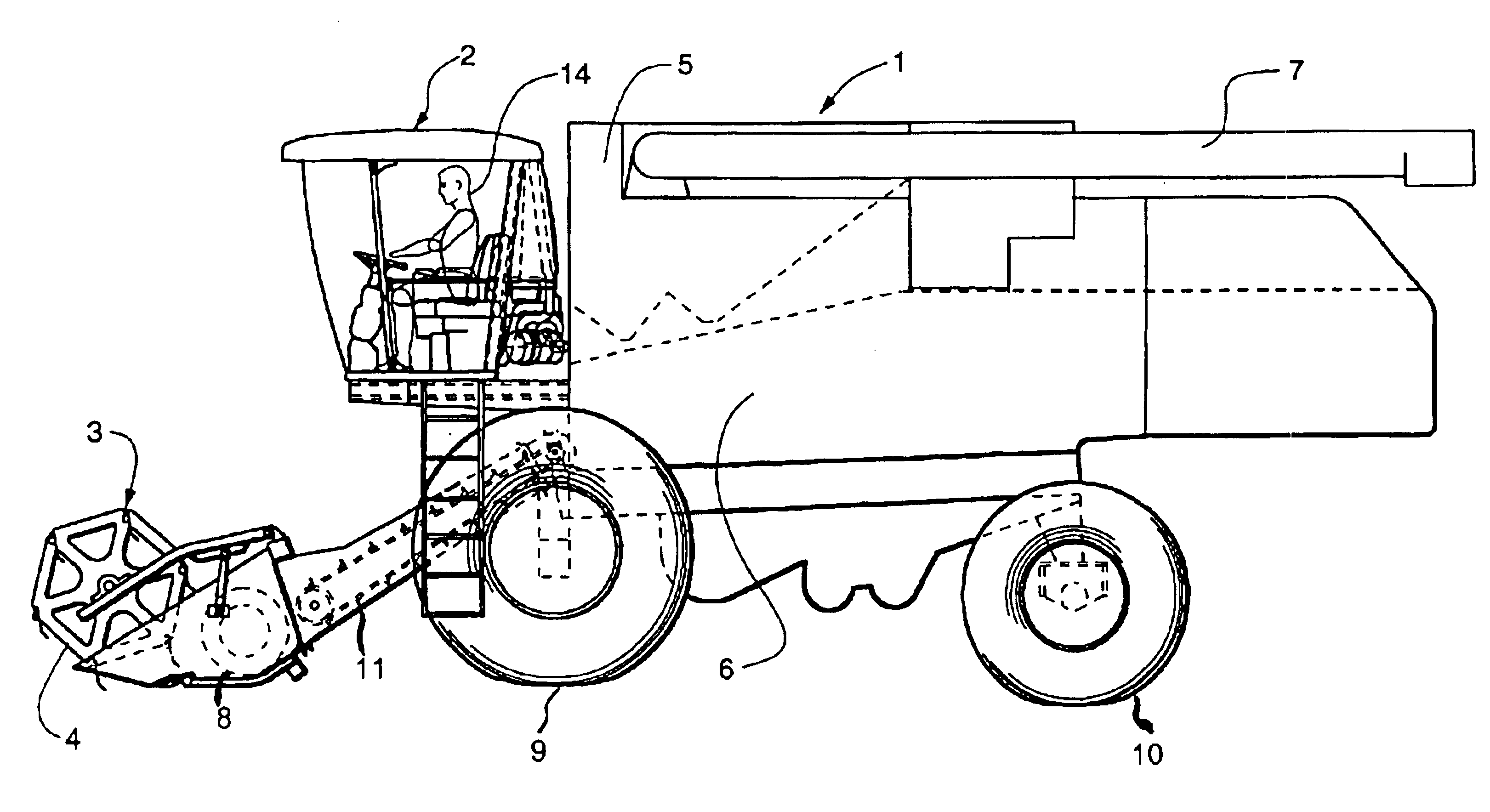

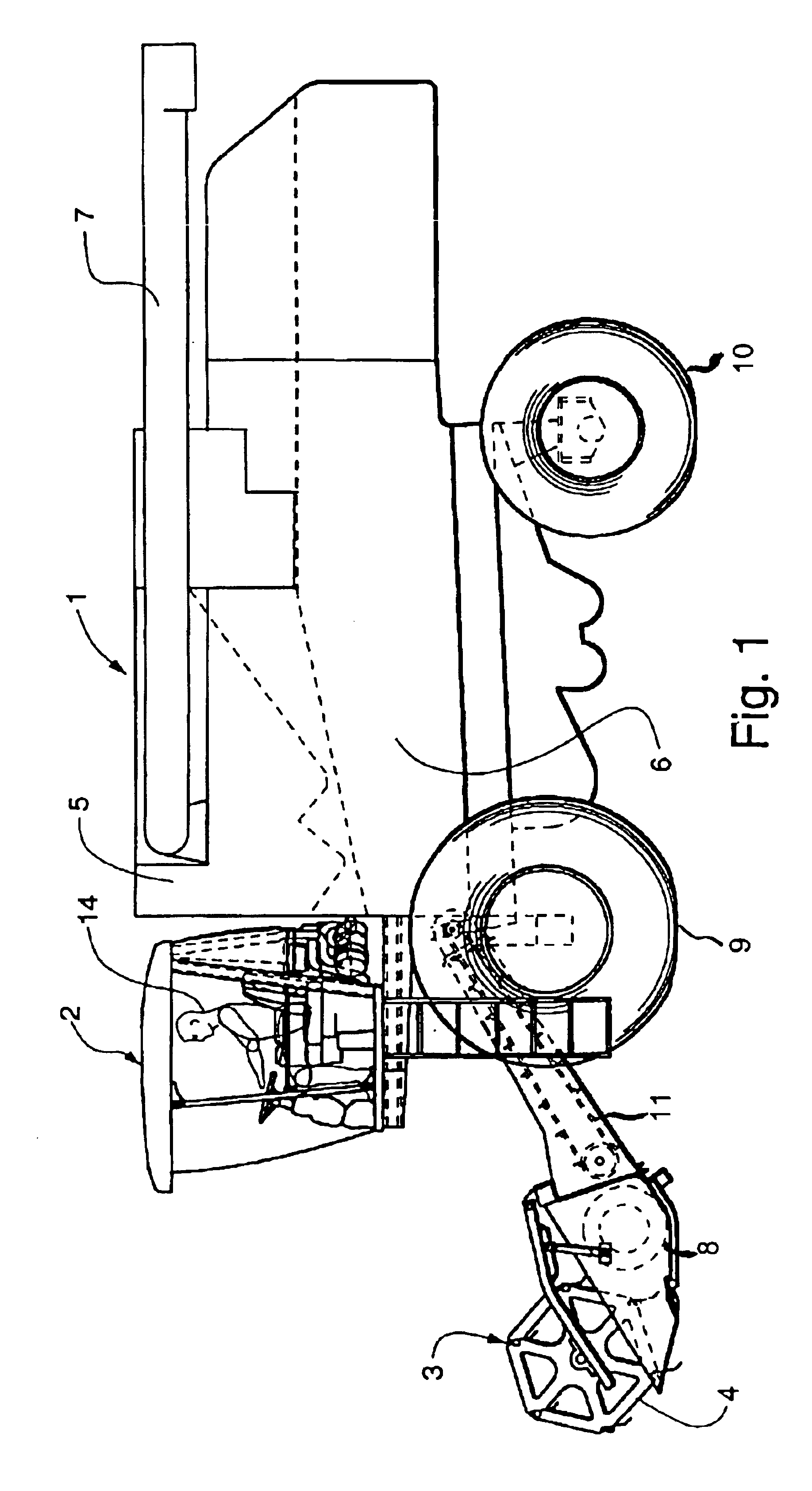

The modern combine harvester, or simply combine, is a versatile machine designed to efficiently harvest a variety of grain crops. The name derives from its combining three separate harvesting operations—reaping, threshing, and winnowing—into a single process. Among the crops harvested with a combine are wheat, oats, rye, barley, corn (maize), sorghum, soybeans, flax (linseed), sunflowers and canola. The separated straw, left lying on the field, comprises the stems and any remaining leaves of the crop with limited nutrients left in it: the straw is then either chopped, spread on the field and ploughed back in or baled for bedding and limited-feed for livestock.

Monitoring and control implement for crop improvement

ActiveUS20190150357A1Increase crop yieldPreserve landImage enhancementImage analysisReal time analysisEngineering

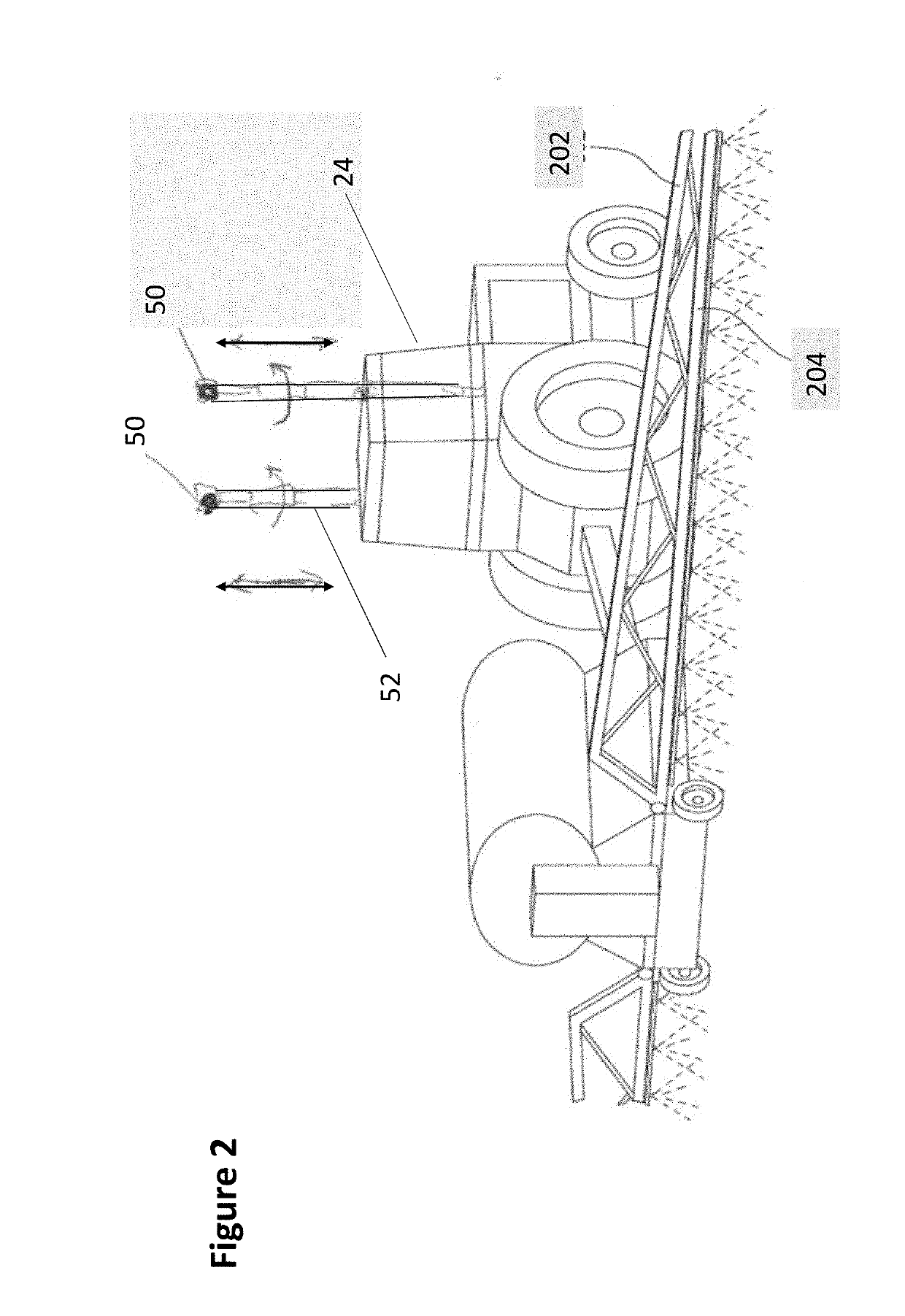

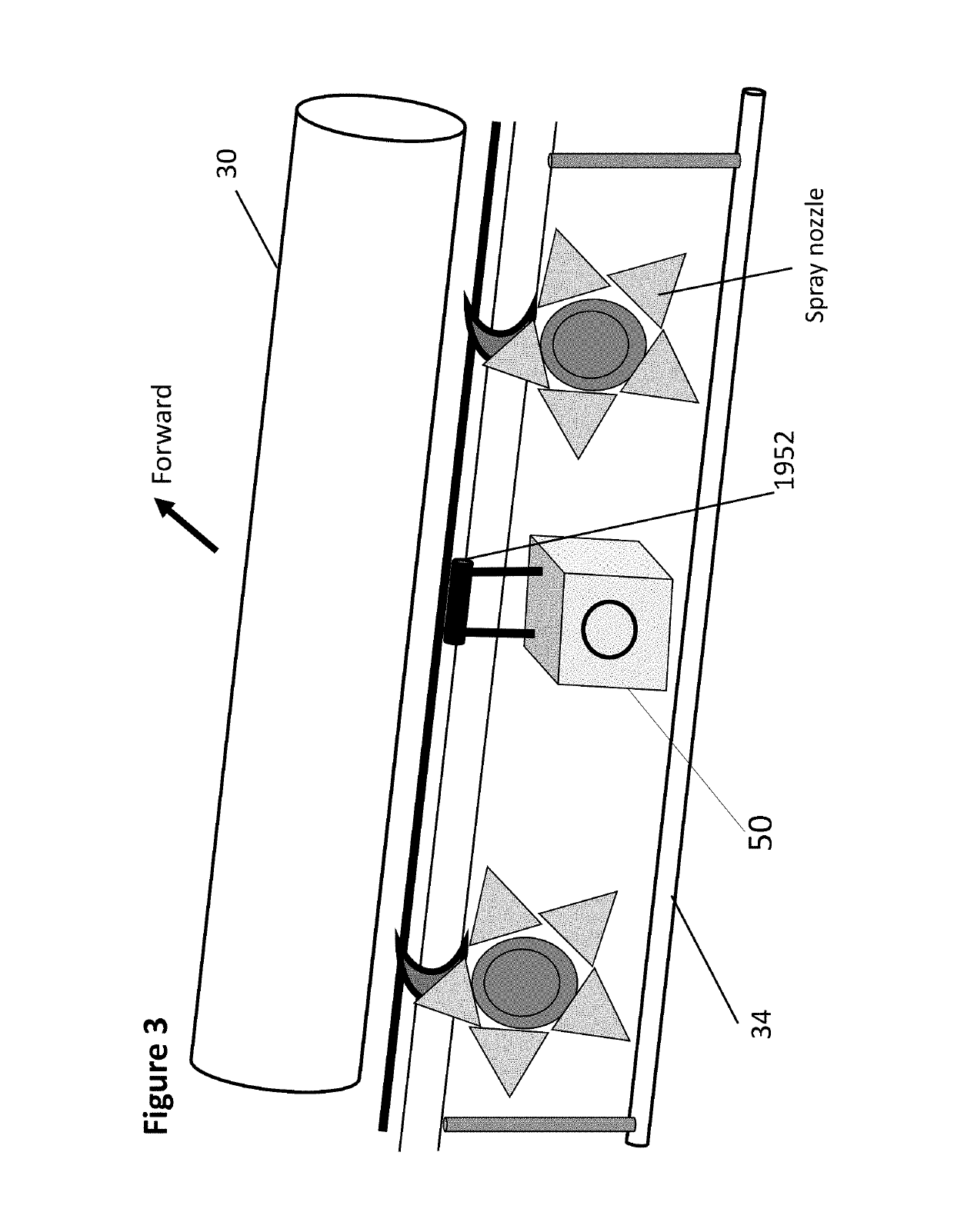

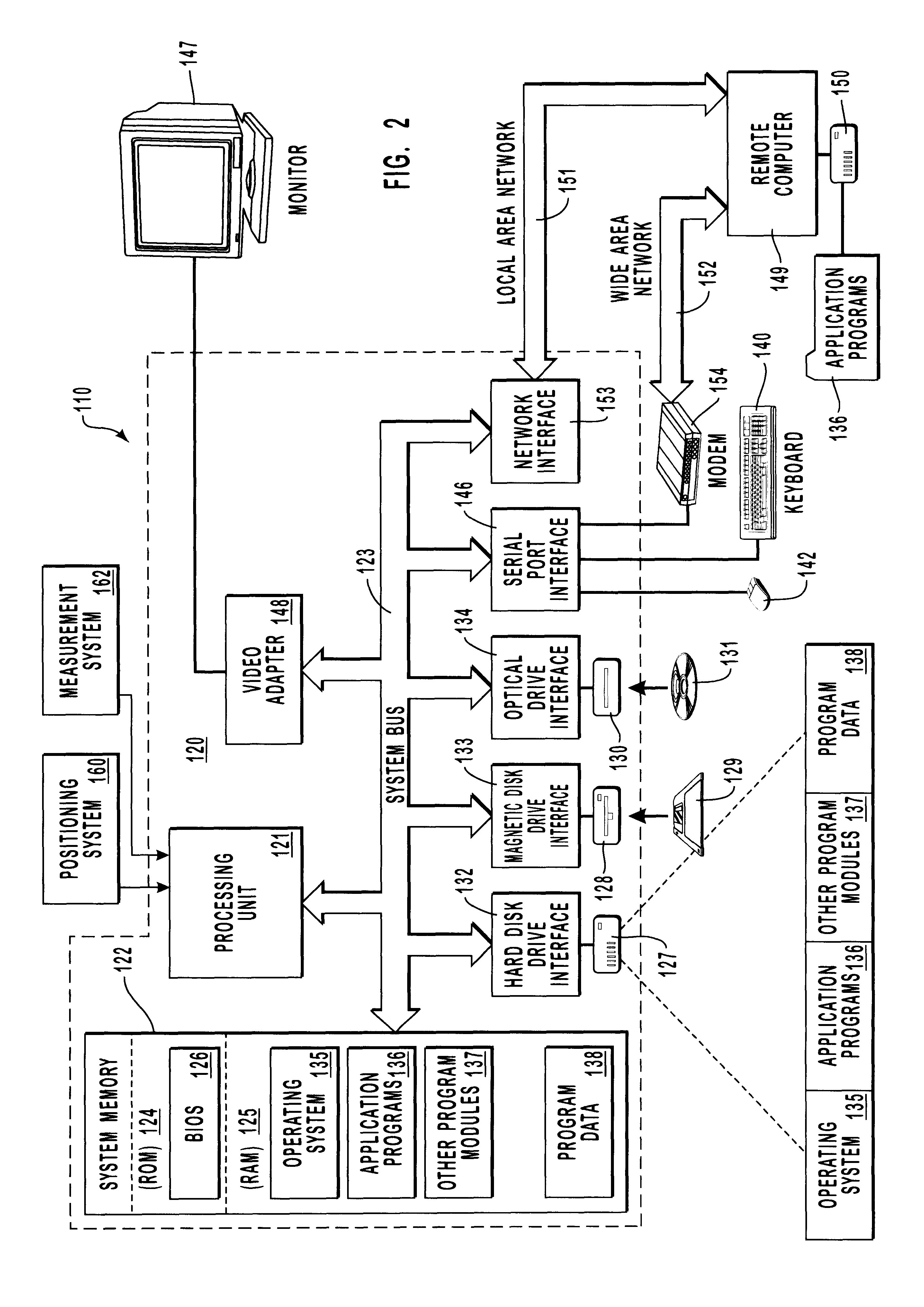

An example machinery includes an automated crop management motorized vehicle having an intelligent, modularized image sensor (e.g. camera or video) system that is portable to other crop management vehicles such as a combine, planter or a tillage machine. The image sensor system includes a framework having a bank of procedures for monitoring and control of navigation, spray application, weeding, seeding, machine configuration, in real time as the machines go through a crop field throughout a crop cycle. One example implementation includes electronic circuits, with more than one set mounted on a platform that facilitates moving the setup to other agricultural machines. The framework captures, preserves and corrects the captured images for real time analysis and response, and for spray management to improve crop yield that is correlated with the machine settings and crop management practices.

Owner:DOLLY Y WU PLLC

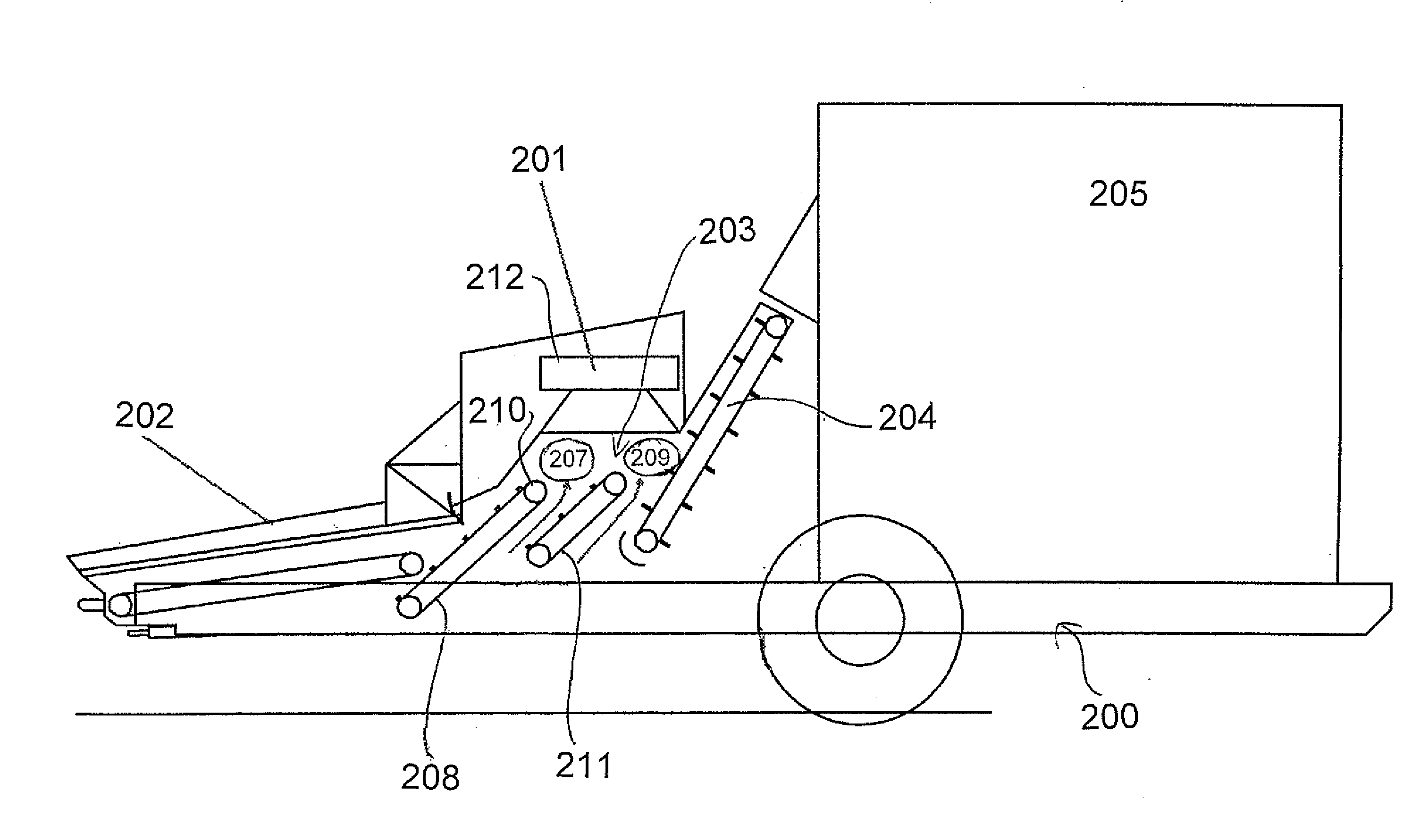

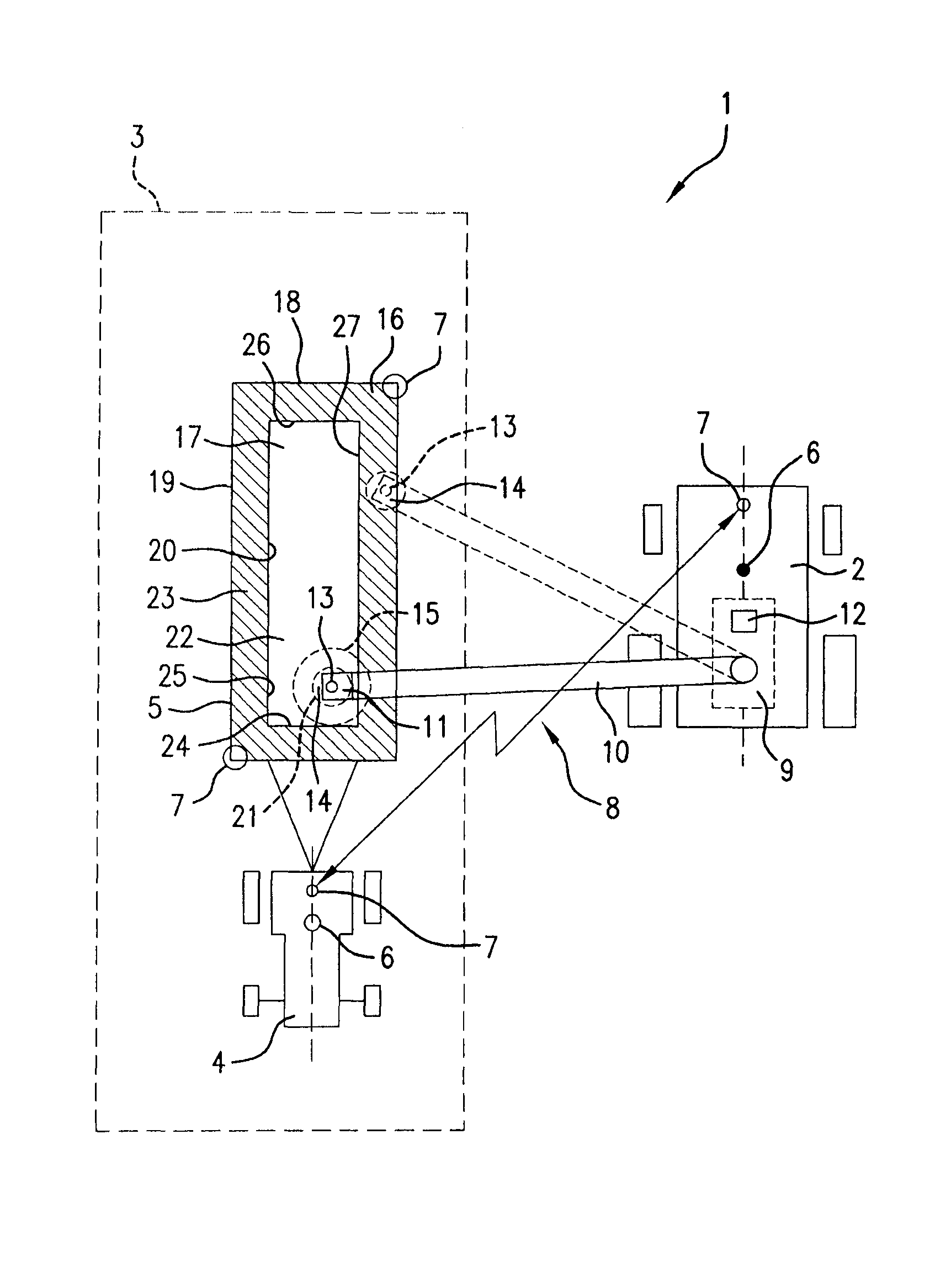

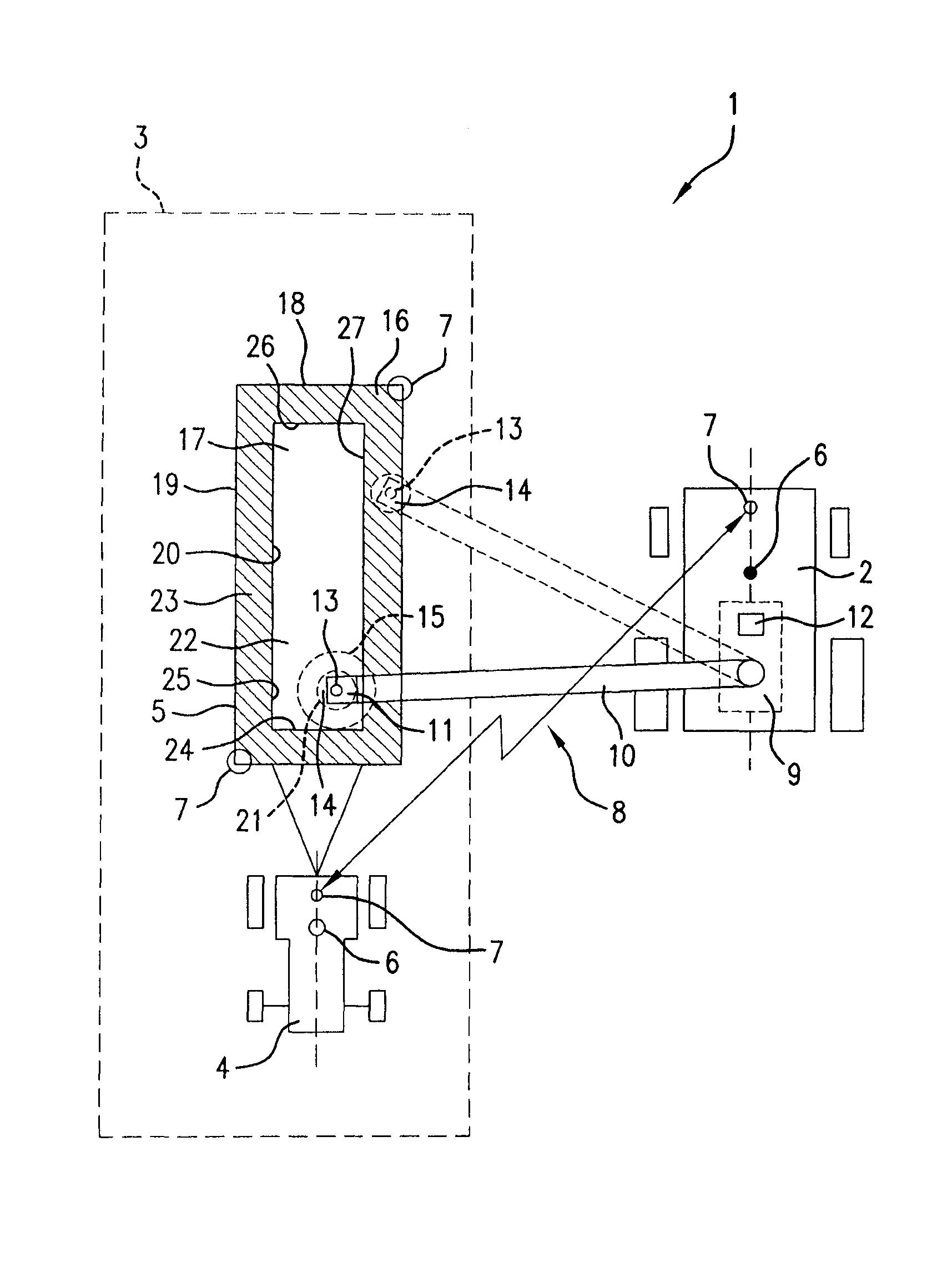

System and methods for real time linkage between harvest environment and marketplace

InactiveUS6327569B1Eliminate the problemImprovement of marketplaceFinanceClimate change adaptationTelecommunications linkEnvironment of Albania

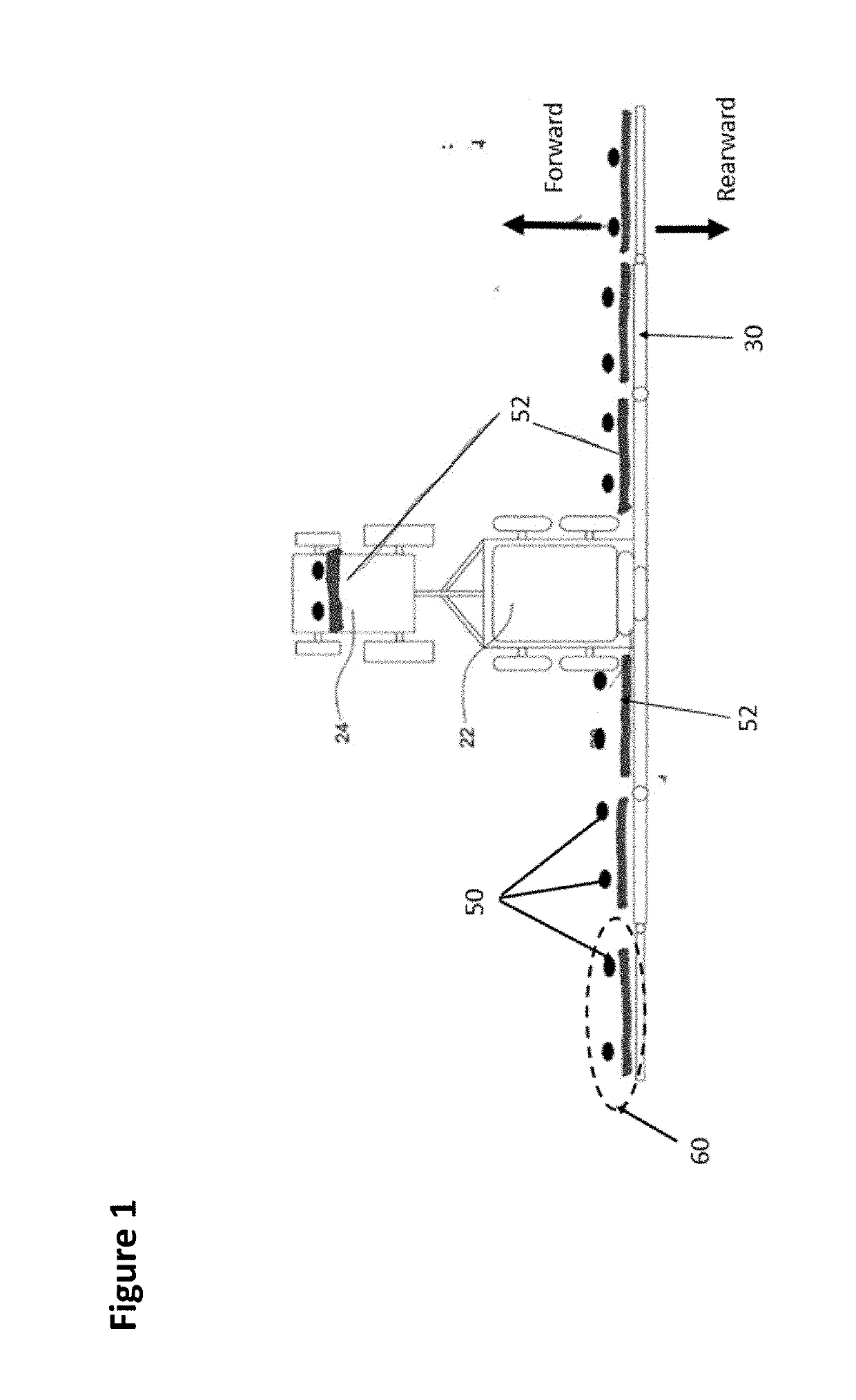

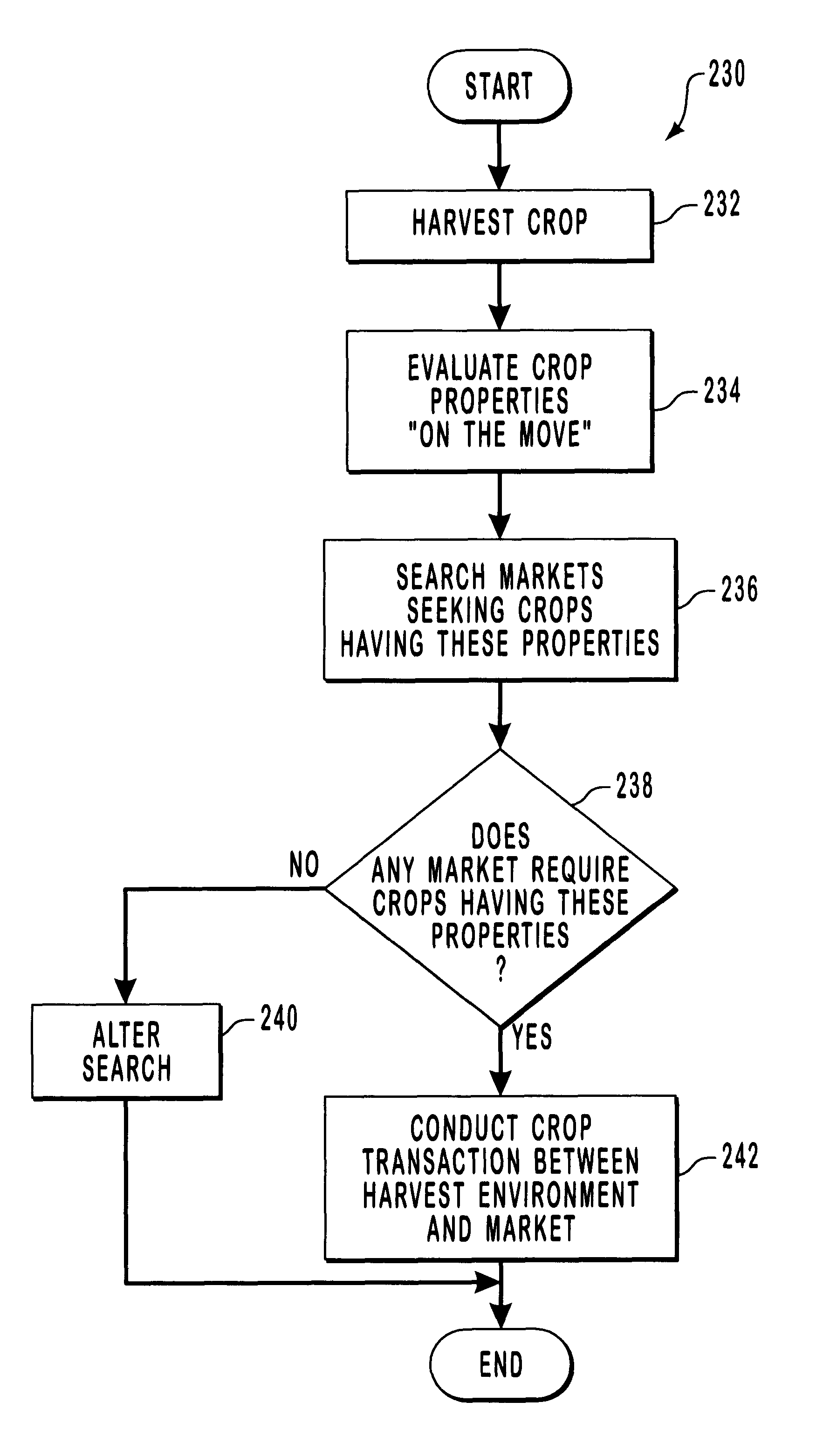

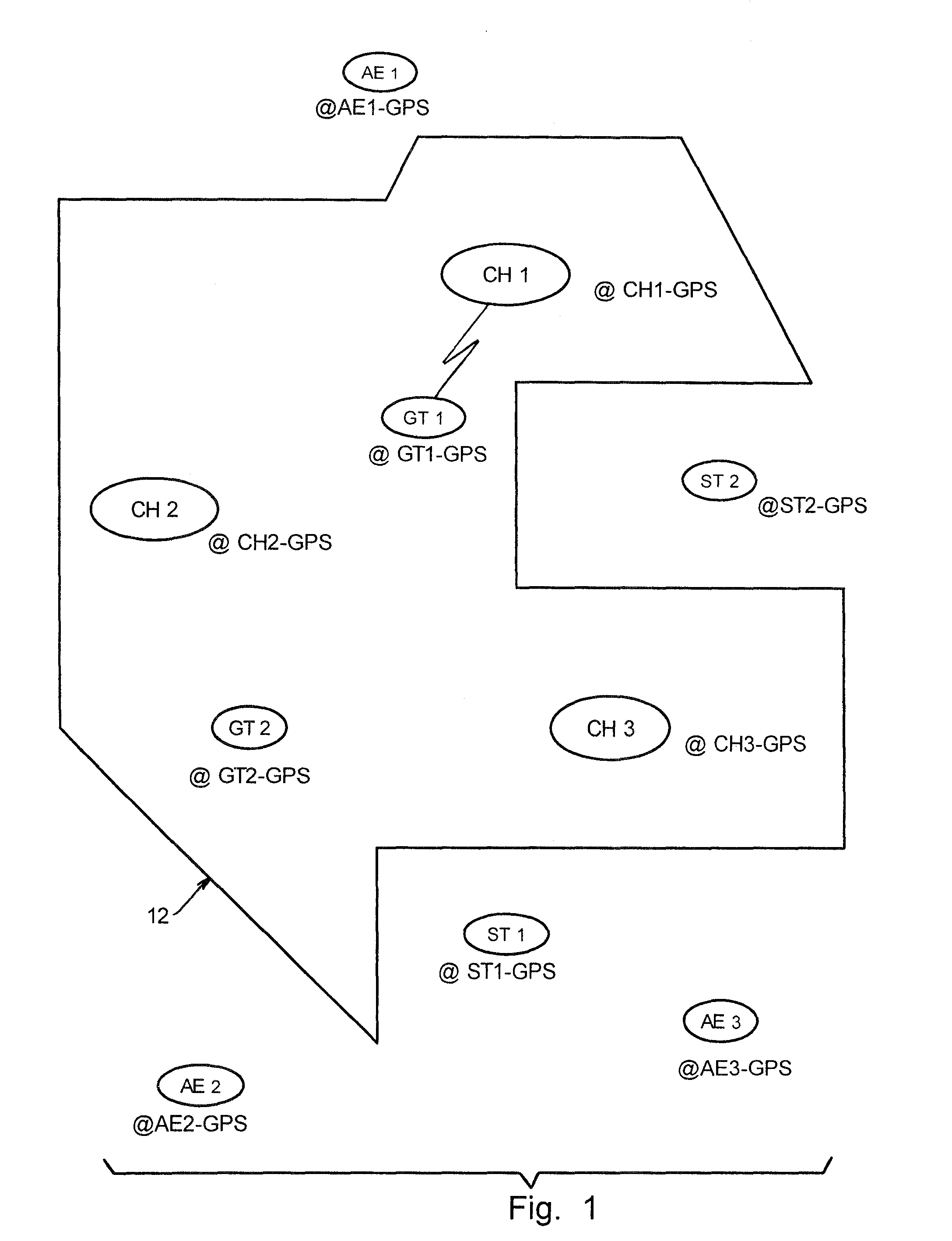

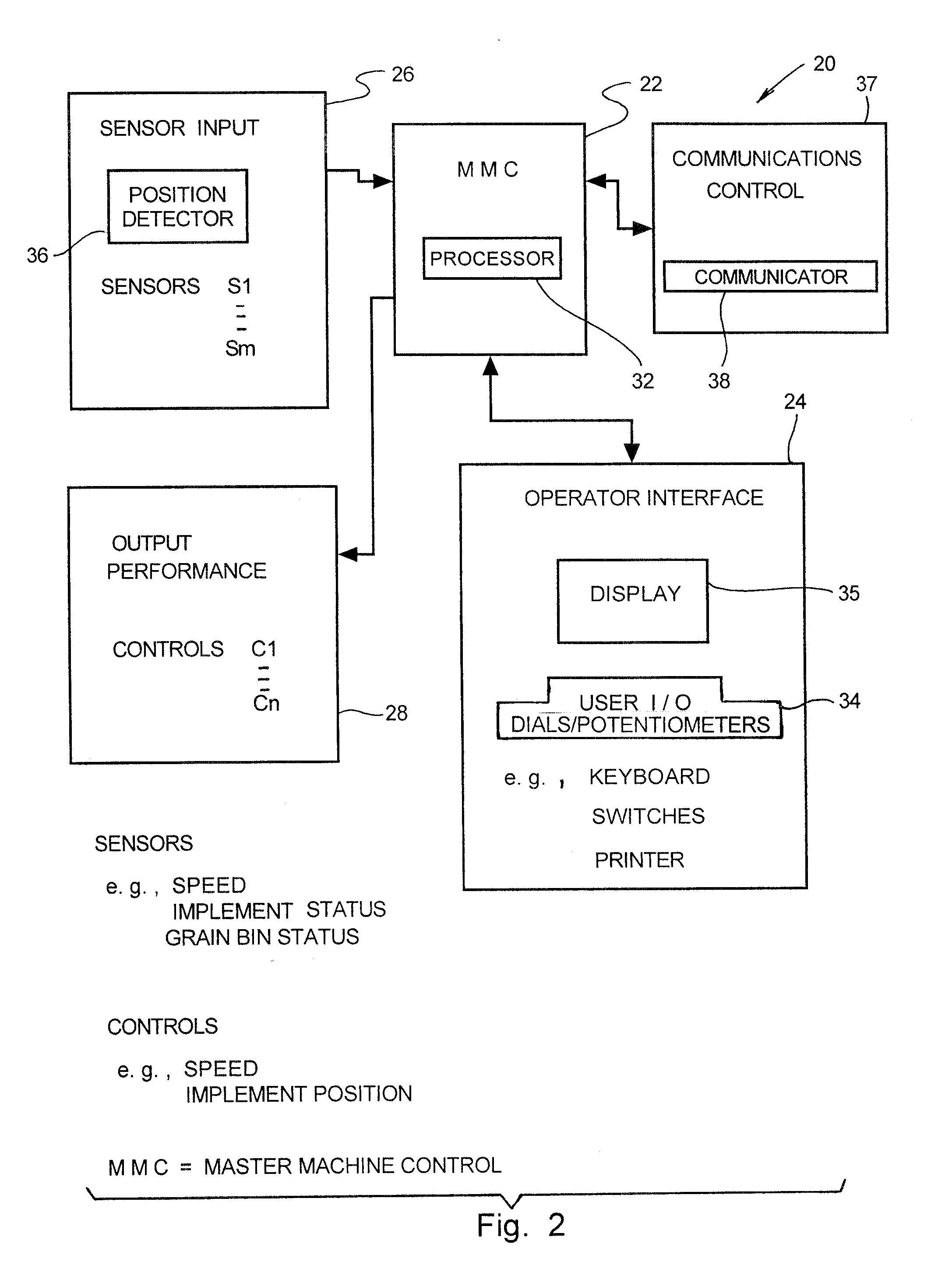

Systems and methods are provided for directly linking a harvest environment using precision farming techniques to the marketplace. It is a feature of this invention that properties of crops are evaluated "on-the-move," during the harvest thereof, and are made known to users in the harvest environment to enable the real-time transaction for the sale of these crops. In a preferred embodiment, crops are harvested from an agricultural field in the harvest environment with a combine having an auger section thereon. A plurality of properties of the crops are evaluated on-the-move by flowing the harvested crops through the auger section and over an optical device. The optical device utilizes light reflected from the crops to determine the properties. Thereafter, the marketplace is searched with a computing configuration aboard the combine for a market seeking the crop properties. If a market is found, a wireless communication link between the harvest environment and the market is used to transact for a sale of the crops. The properties of the crops are correlated to a location in the agricultural field to expand the knowledge base about the field to enhance future precision farming operations.

Owner:MILESTONE TECH

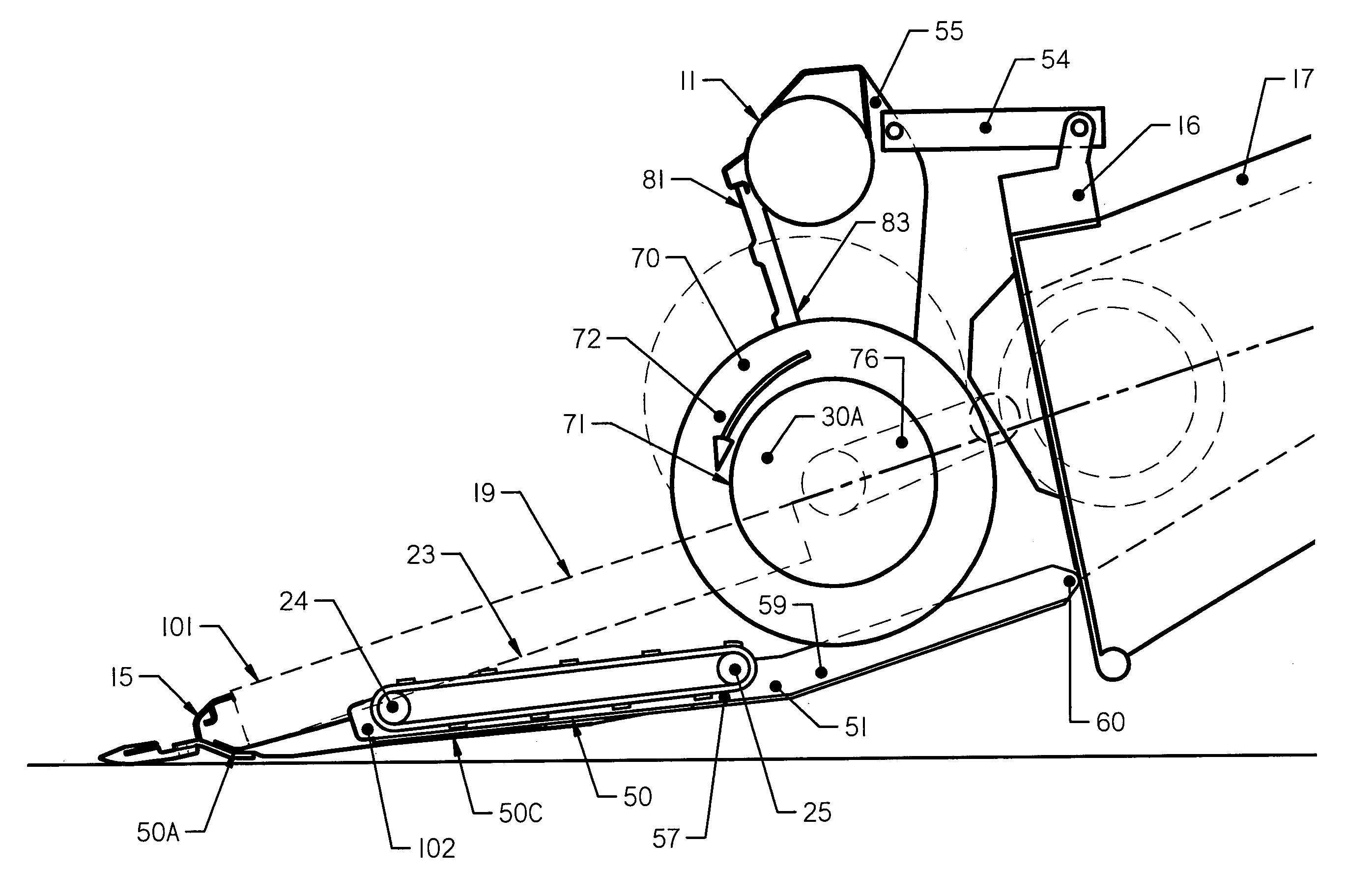

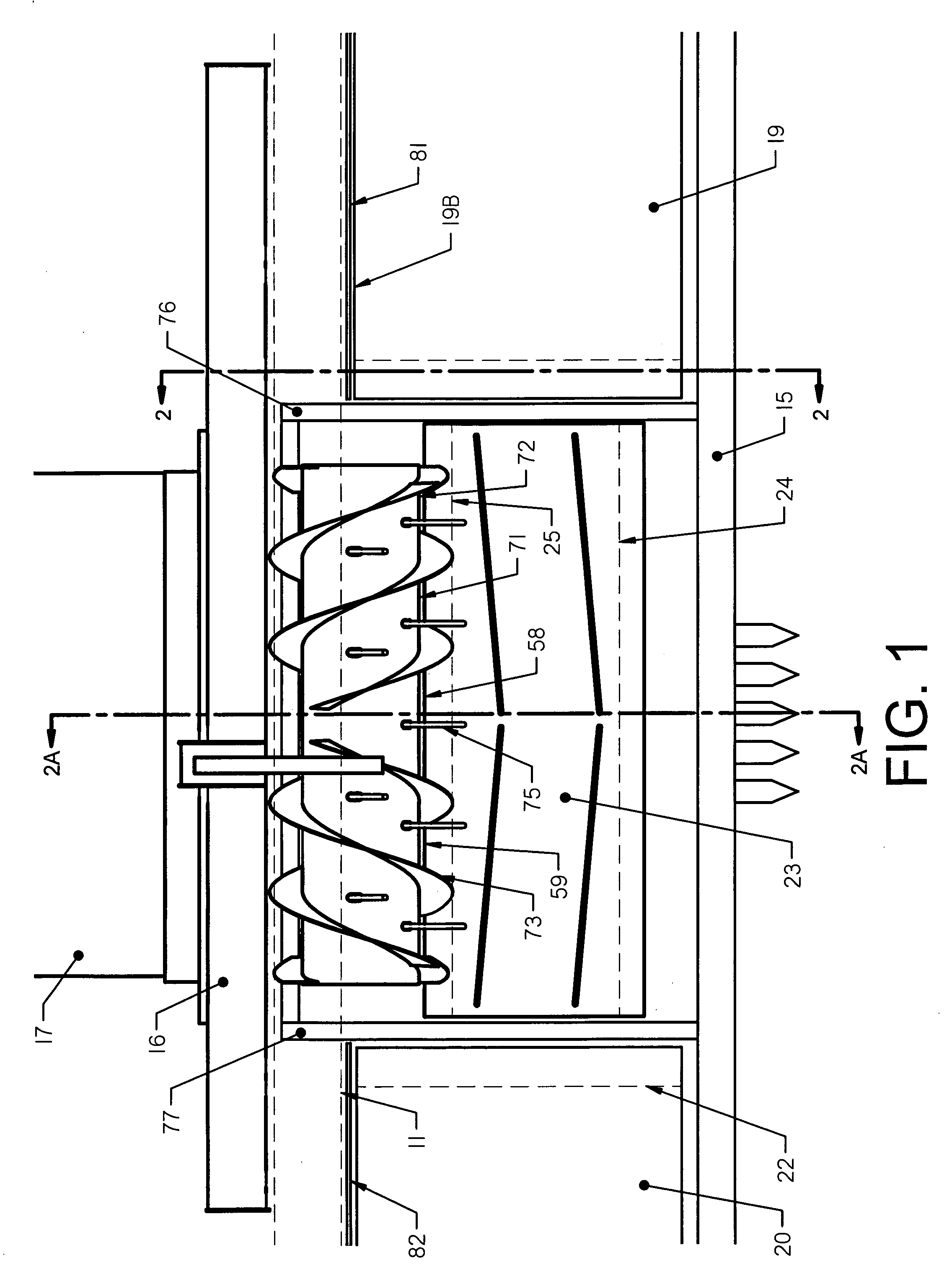

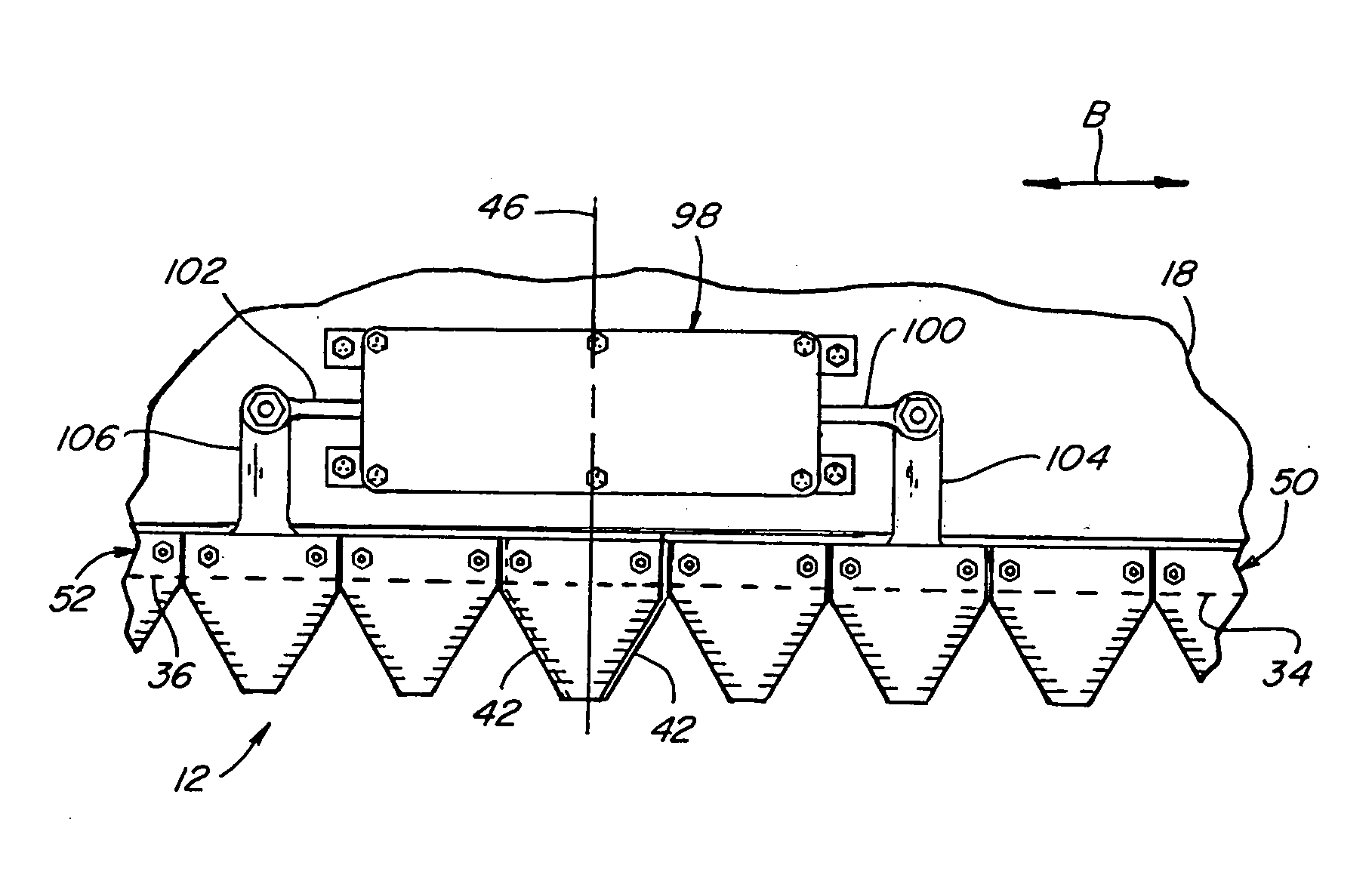

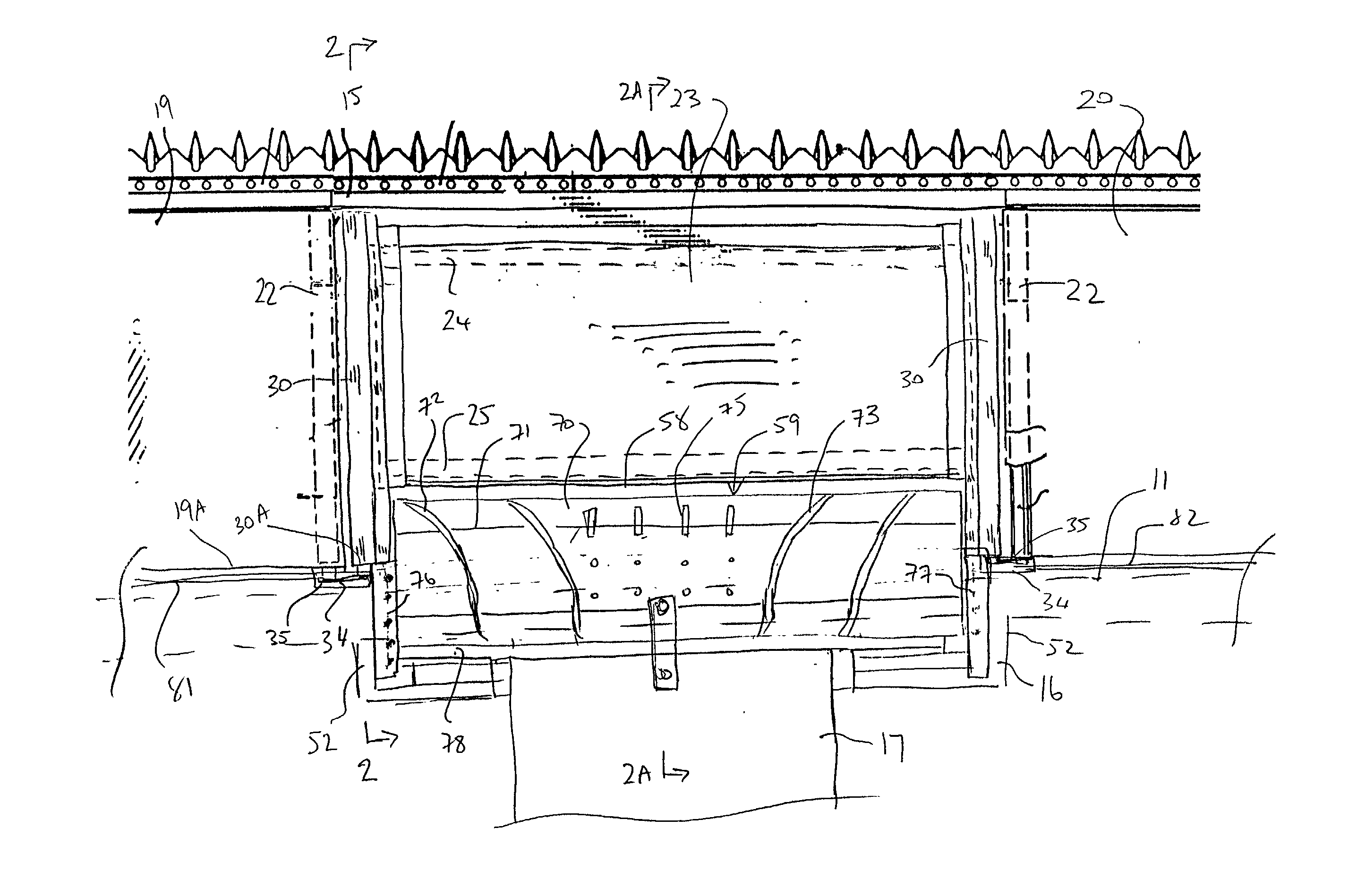

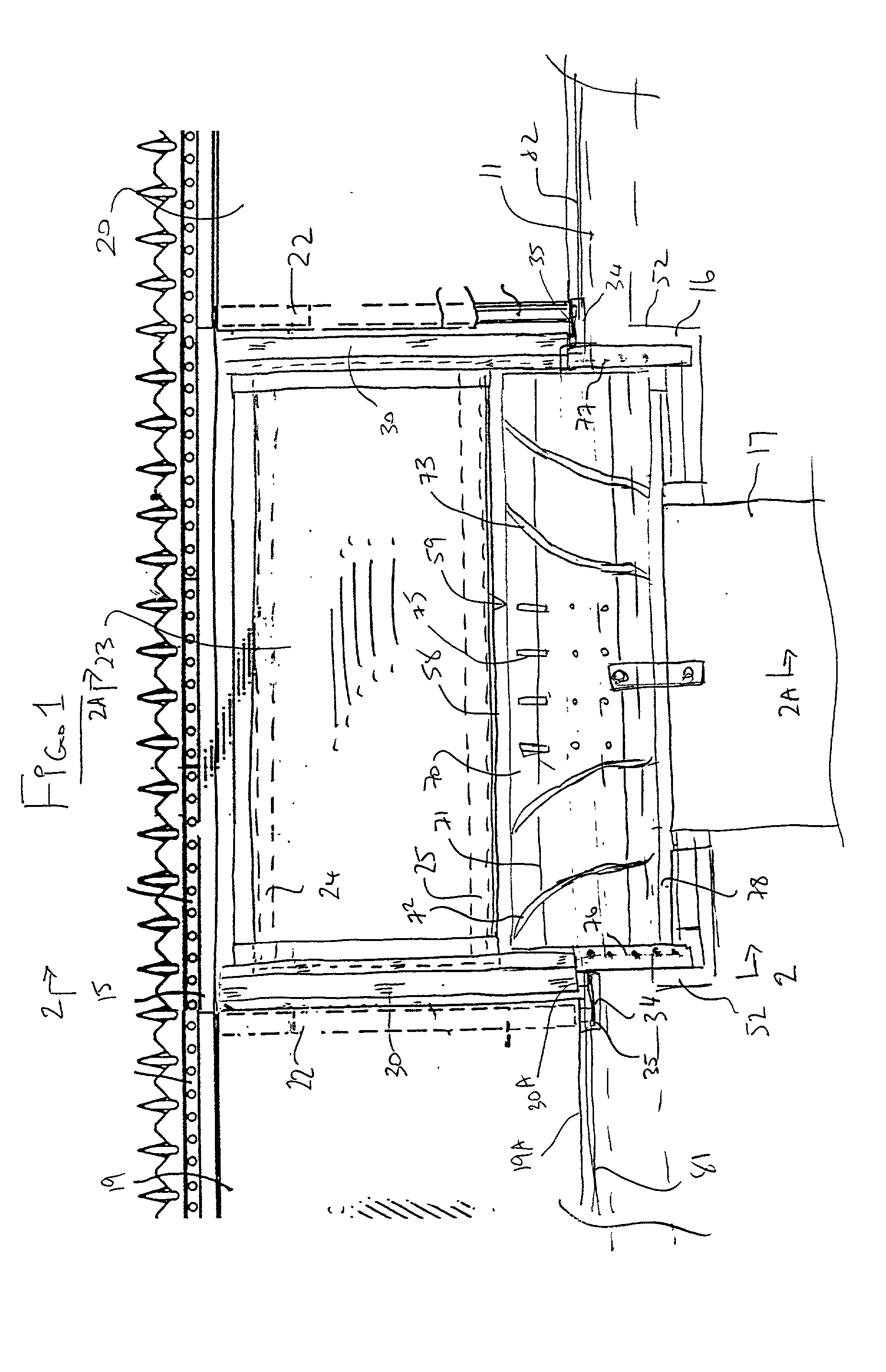

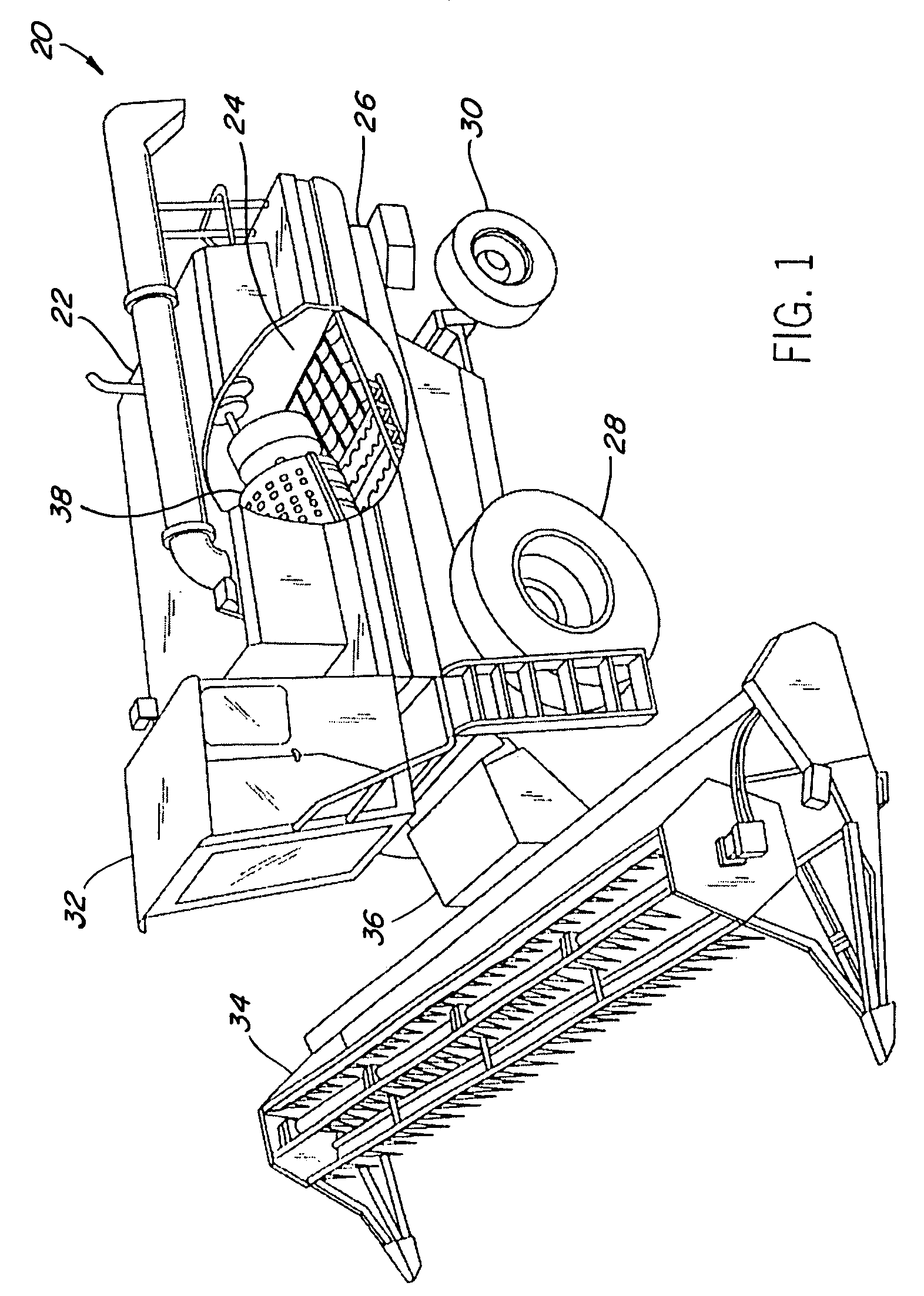

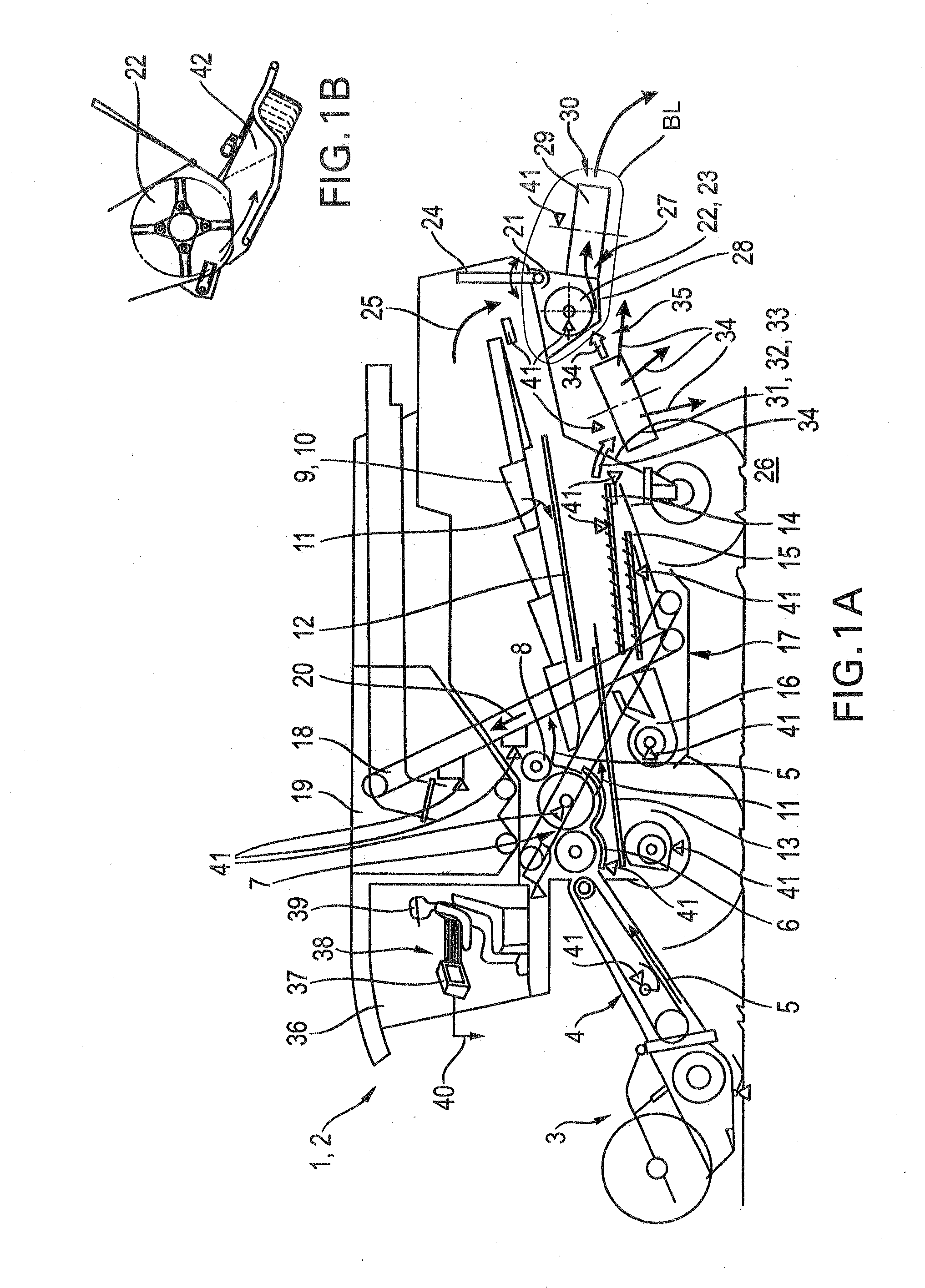

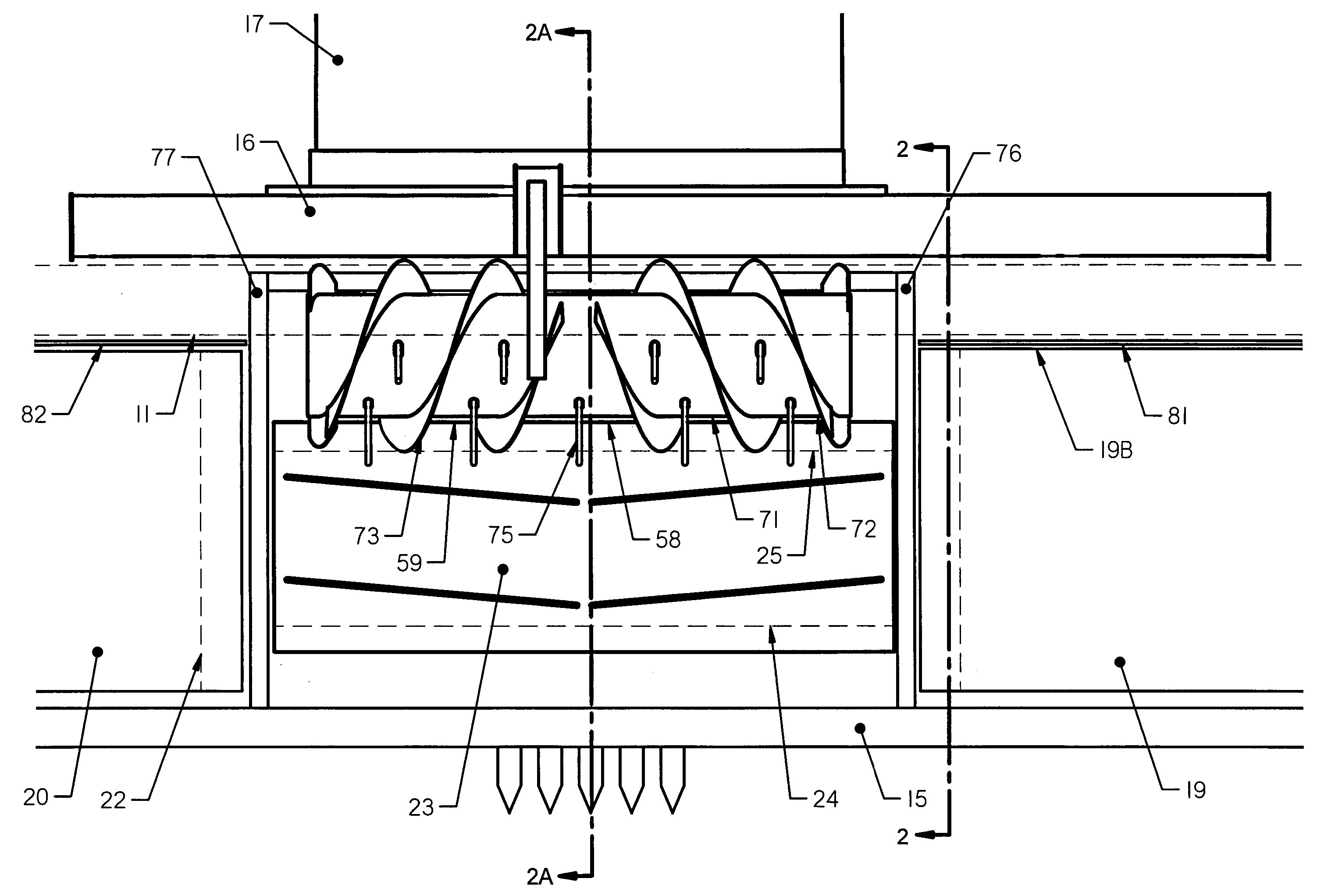

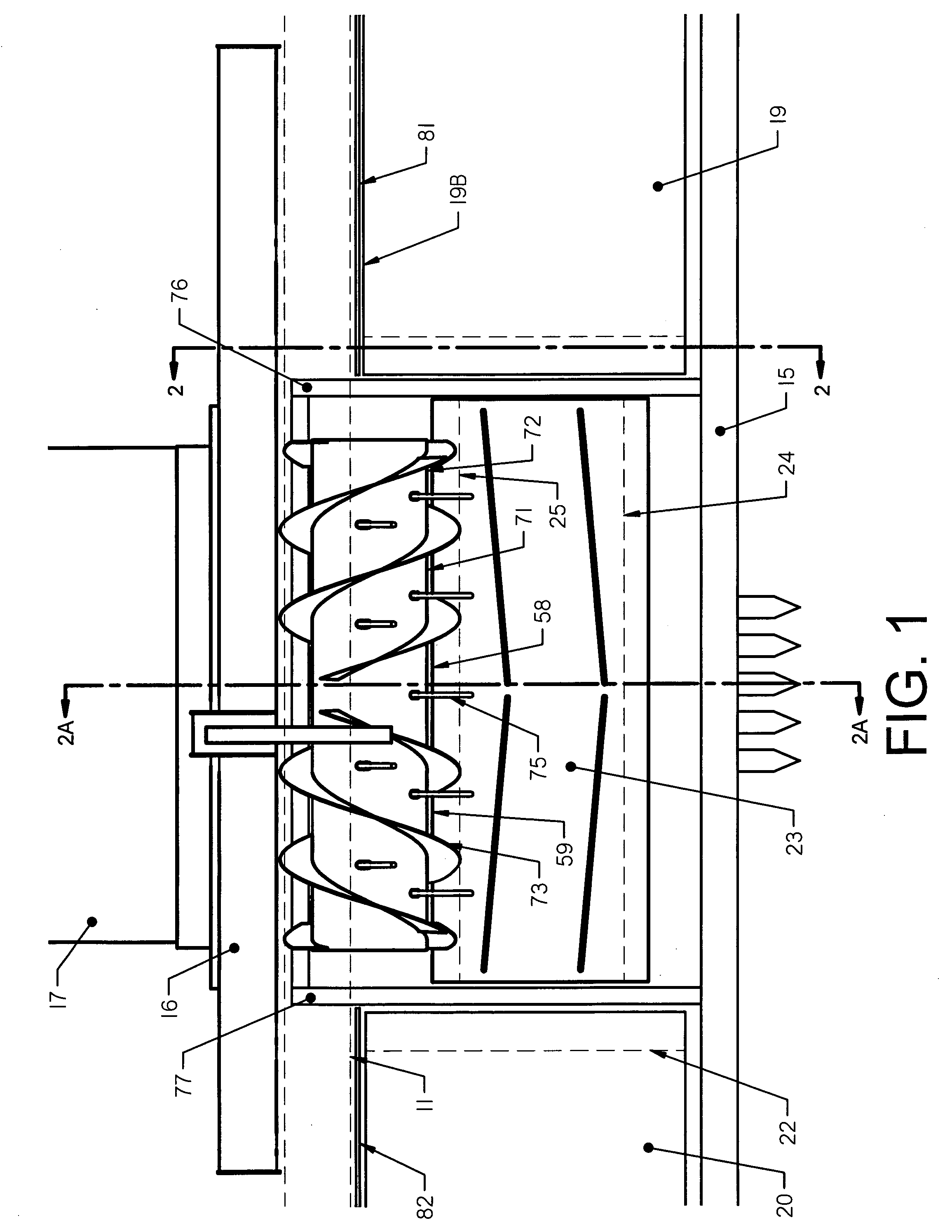

Crop feed arrangement for the header of a combine harvester

A draper header for a combine harvester includes two side drapers each running from an outer end guide roller at a first end of the header to an inner end guide roller adjacent the discharge location of the header and a central feed draper located at the discharge location and including a front guide roller just behind the cutter bar and running to a rear guide roller in front of the feeder house of the combine harvester. An auger is located between the discharge rollers with a front edge of the flight forward of the rear end of the discharge rollers to feed the material inwardly and underneath the auger to the inlet of the feeder house. A pan is located underneath the auger and is mounted on a common structure with the feed draper for common pivotal movement about a transverse horizontal axis.

Owner:MACDON INDS

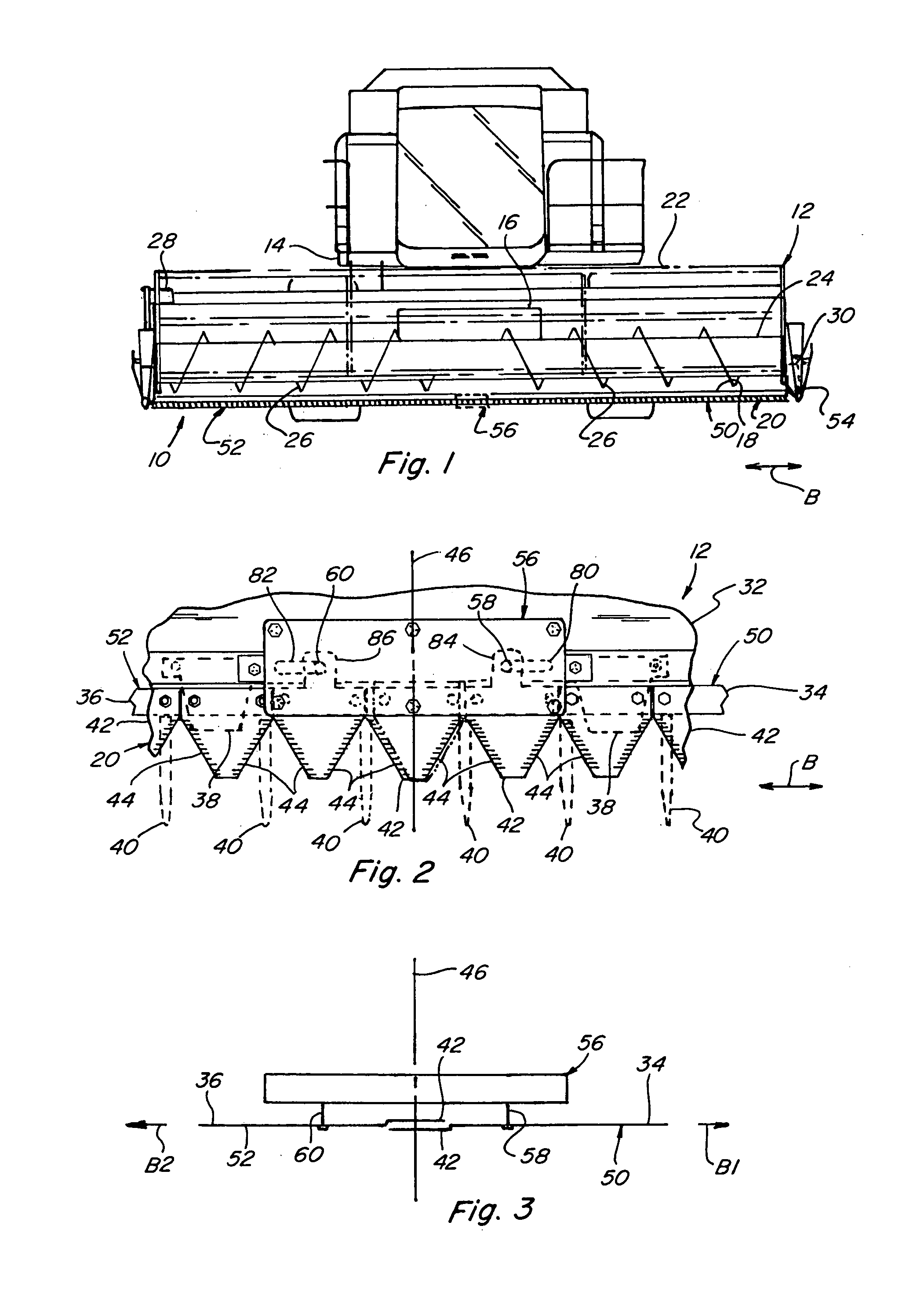

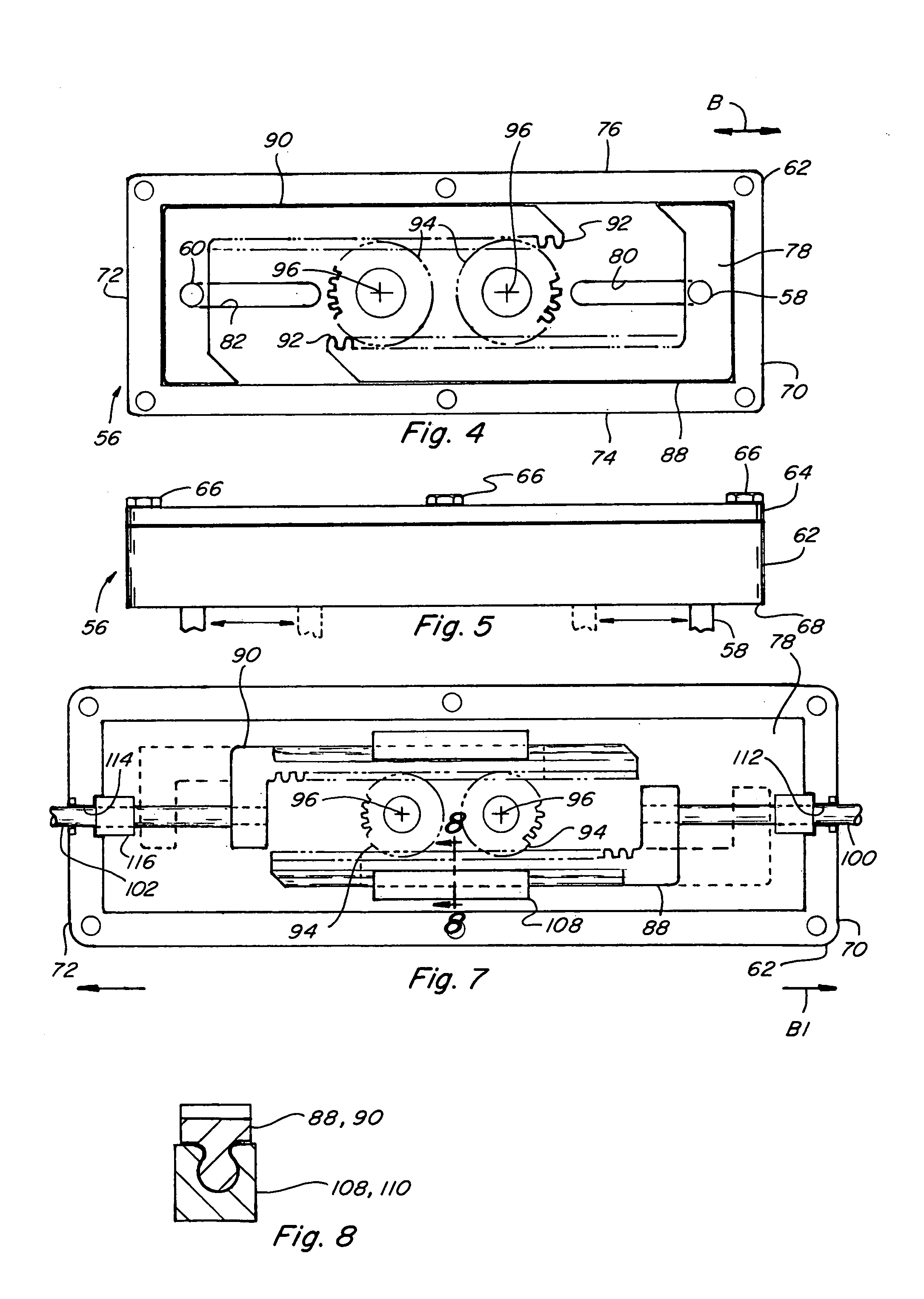

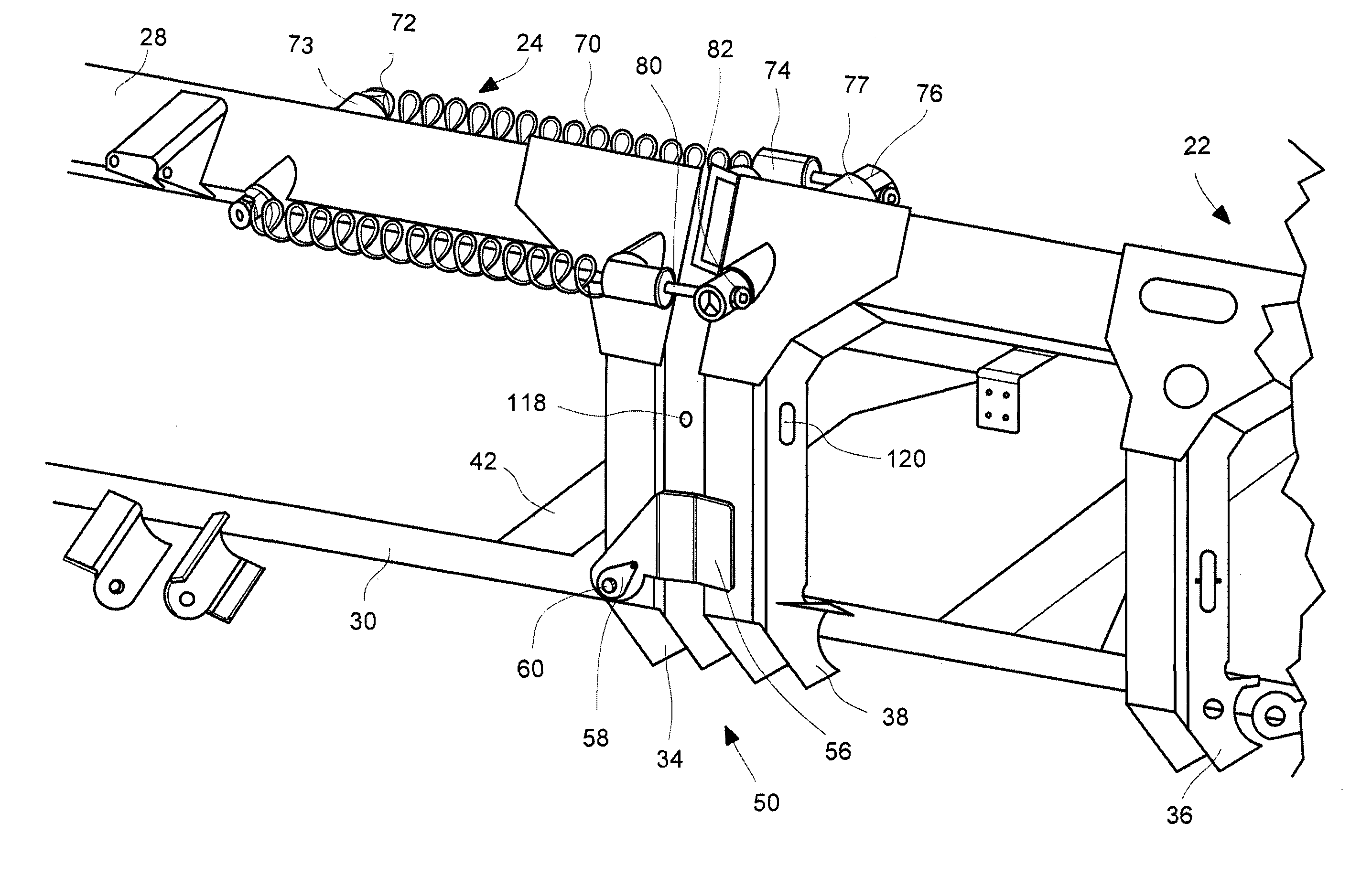

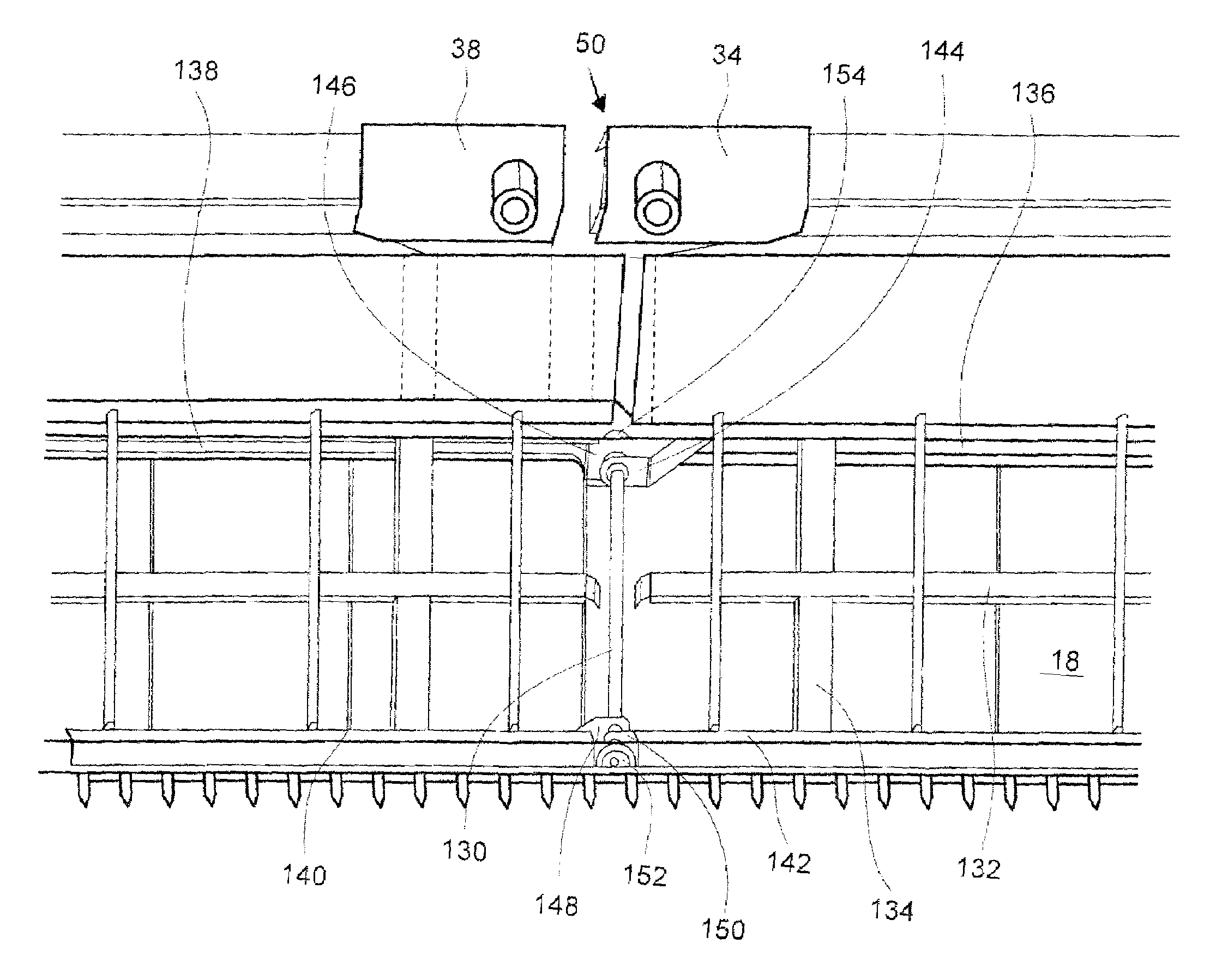

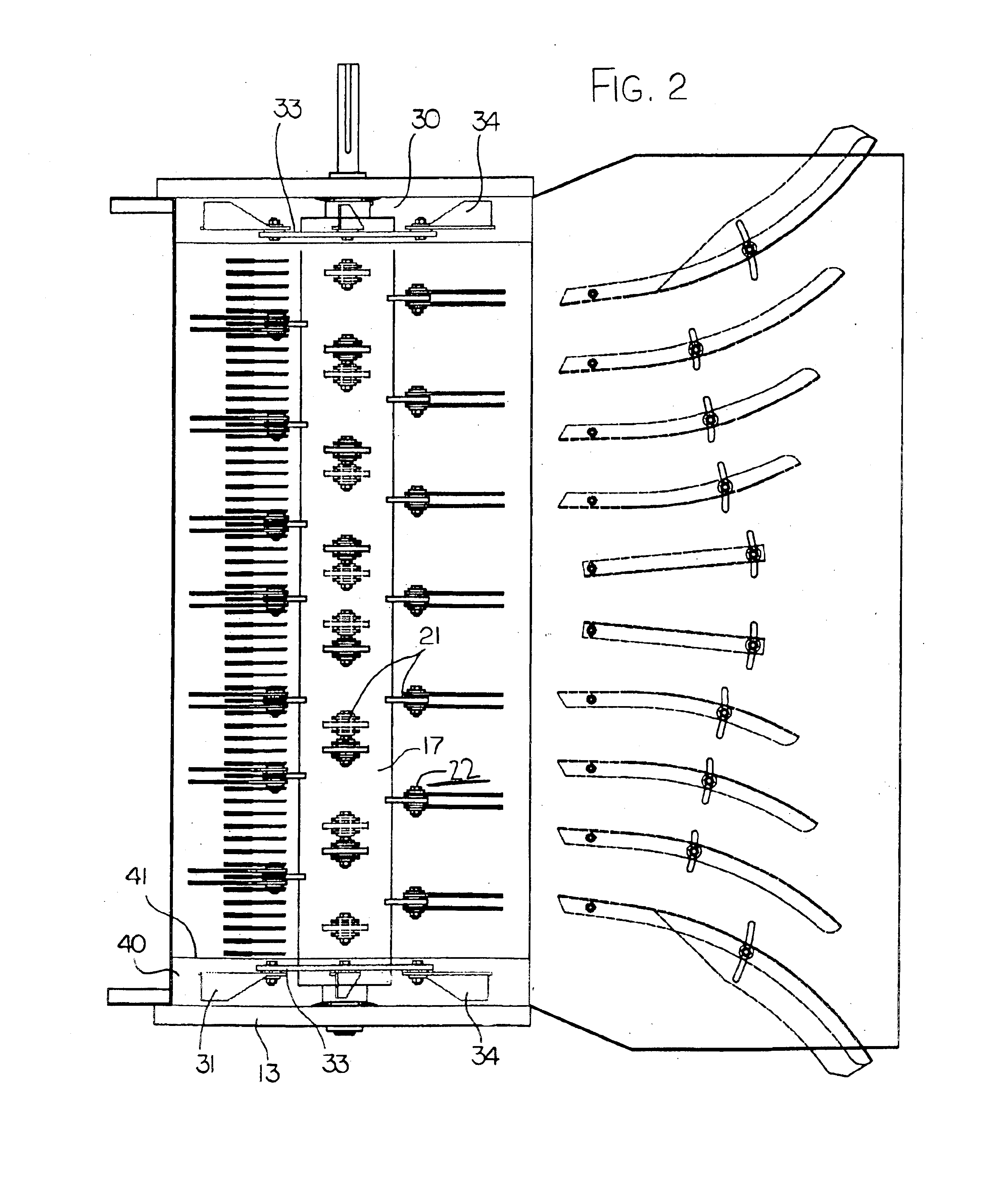

Reversing transfer drive for sickle cutting knives on a header of an agricultural combine

A drive for transferring sideward motion from a first or driving elongate sickle knife to a second or driven elongate sickle knife longitudinally aligned with the first sickle knife. A double rack and pinion arrangement is used including at least one pinion mounted at a fixed location, a first sidewardly extending rack is connected to the first sickle knife for sideward movement therewith and a second sidewardly extending rack is connected to the second sickle knife for sideward movement therewith, the racks both being enmeshed with the pinion such that sideward movement of the driving knife causes corresponding opposite sideward movement of the longitudinally aligned driven knife.

Owner:BLUE LEAF I P INC +1

Grain transfer control system and method

ActiveUS20100274452A1Evenly filledDigital data processing detailsRoad vehicles traffic controlAutomatic controlControl system

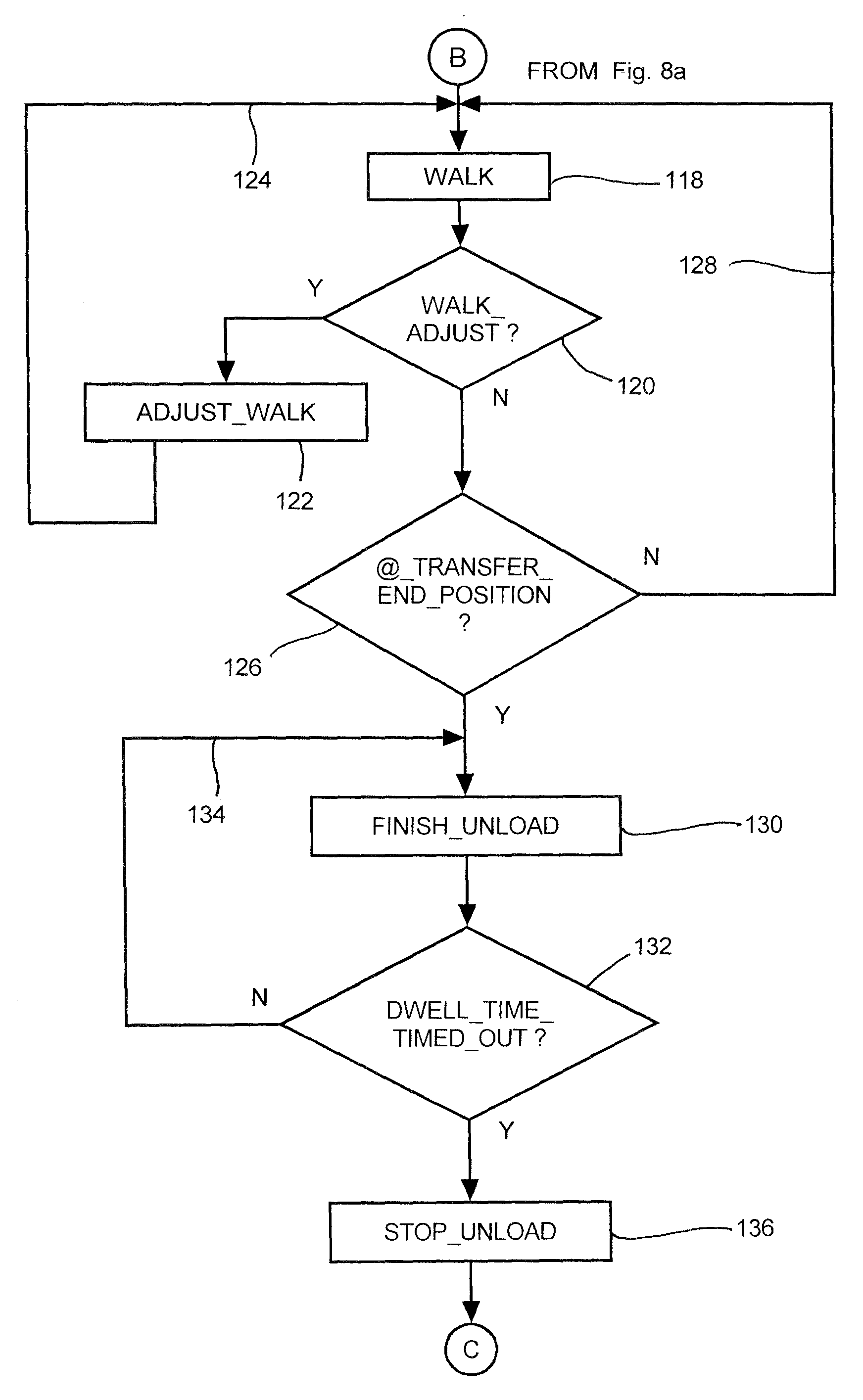

A grain transfer control system, and method of use thereof, for automatedly controlling the transfer of grain from a mobile transferor-type vehicle, such as a combine harvester, to a mobile transferee-type vehicle, such as a crop transport, by varying the position and speed of the transferor-type and transferee-type vehicles relative to one another during the transfer operation, especially by varying the position and rate of walk of the discharge spout along at least a portion of the length of a grain holding receptacle of the transferee-type vehicle, to effect a generally even fill of the grain holding receptacle of the transferee-type vehicle along the length of the grain holding receptacle.

Owner:BLUE LEAF I P INC

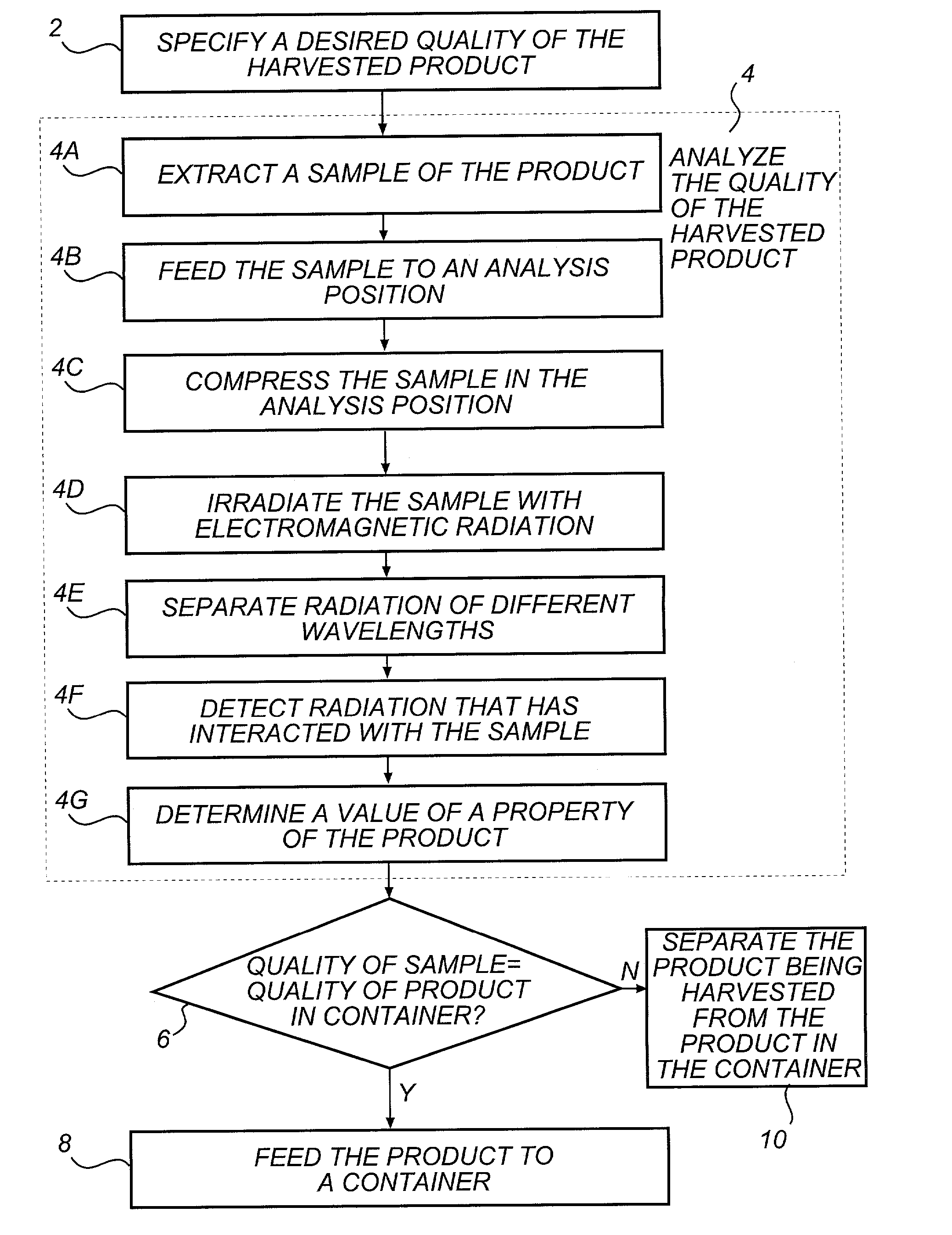

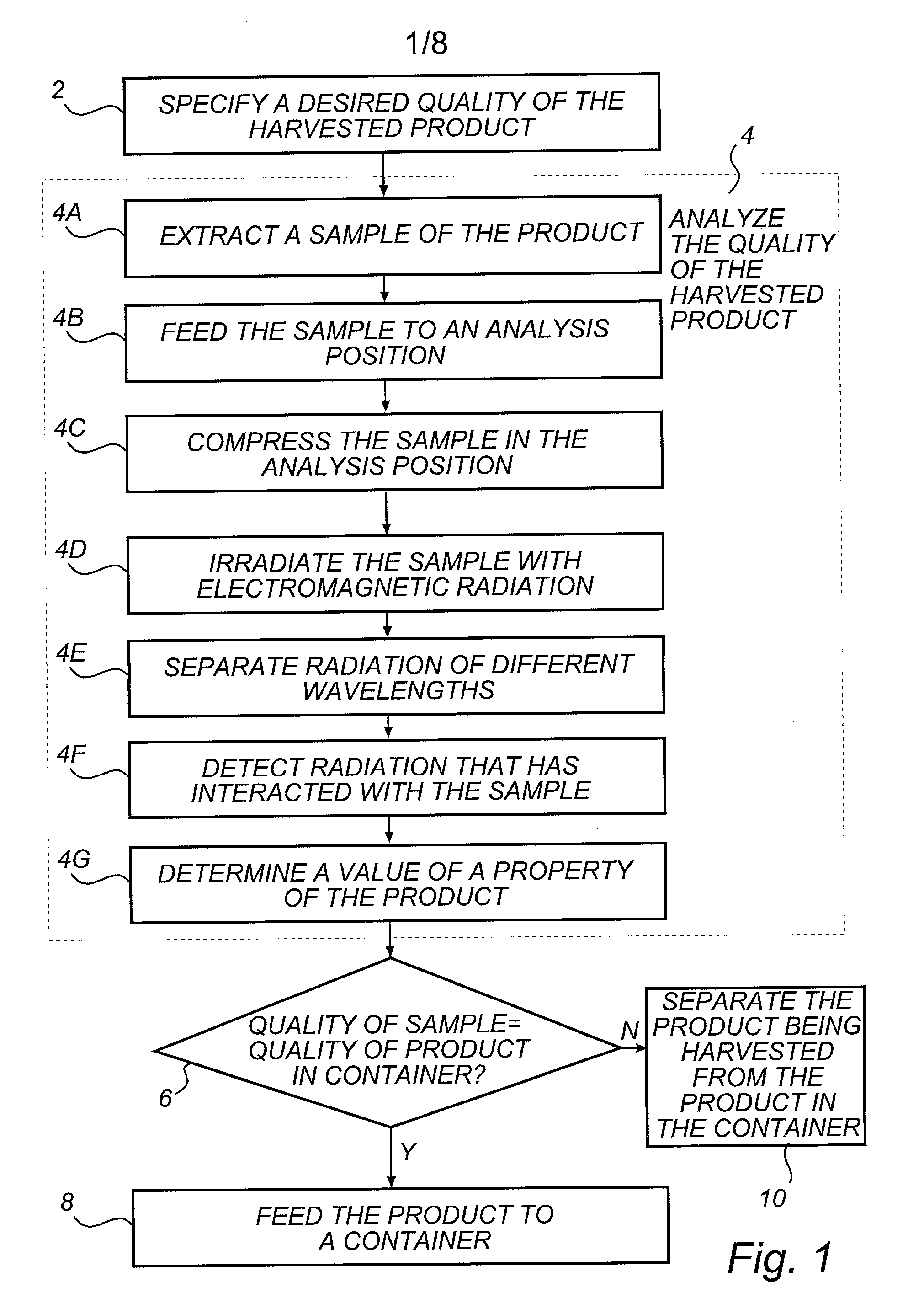

Sorting grain during harvesting

A method for segregating qualities of an agricultural product during processing of the product comprises the step of setting a desired range of a measurement value (2). The measurement value represents a property of the product and defines a first quality of the product for which the measurement value is inside the range and a second quality of the product for which the measurement value is outside the range. The method further comprises the step of analyzing (4) the quality of the product that is being processed. The step of analyzing comprises the steps of continuously extracting samples of the product (4a), irradiating each sample by electromagnetic radiation (4d), spatially separating electromagnetic radiation of different wavelengths (4e), and detecting electromagnetic radiation emitted from the sample (4f). The step of detecting produces intensity signals indicative of detected electromagnetic radiation of different wavelengths. The step of analyzing further comprises the steps of determining a sample value of said property of the product from the intensity signals, and determining a measurement value (4g) from at least one sample value. The method further comprises the step of separating the product of said first quality from the product of said second quality on the combine.

Owner:FOSS ANALYTICAL AB (SE)

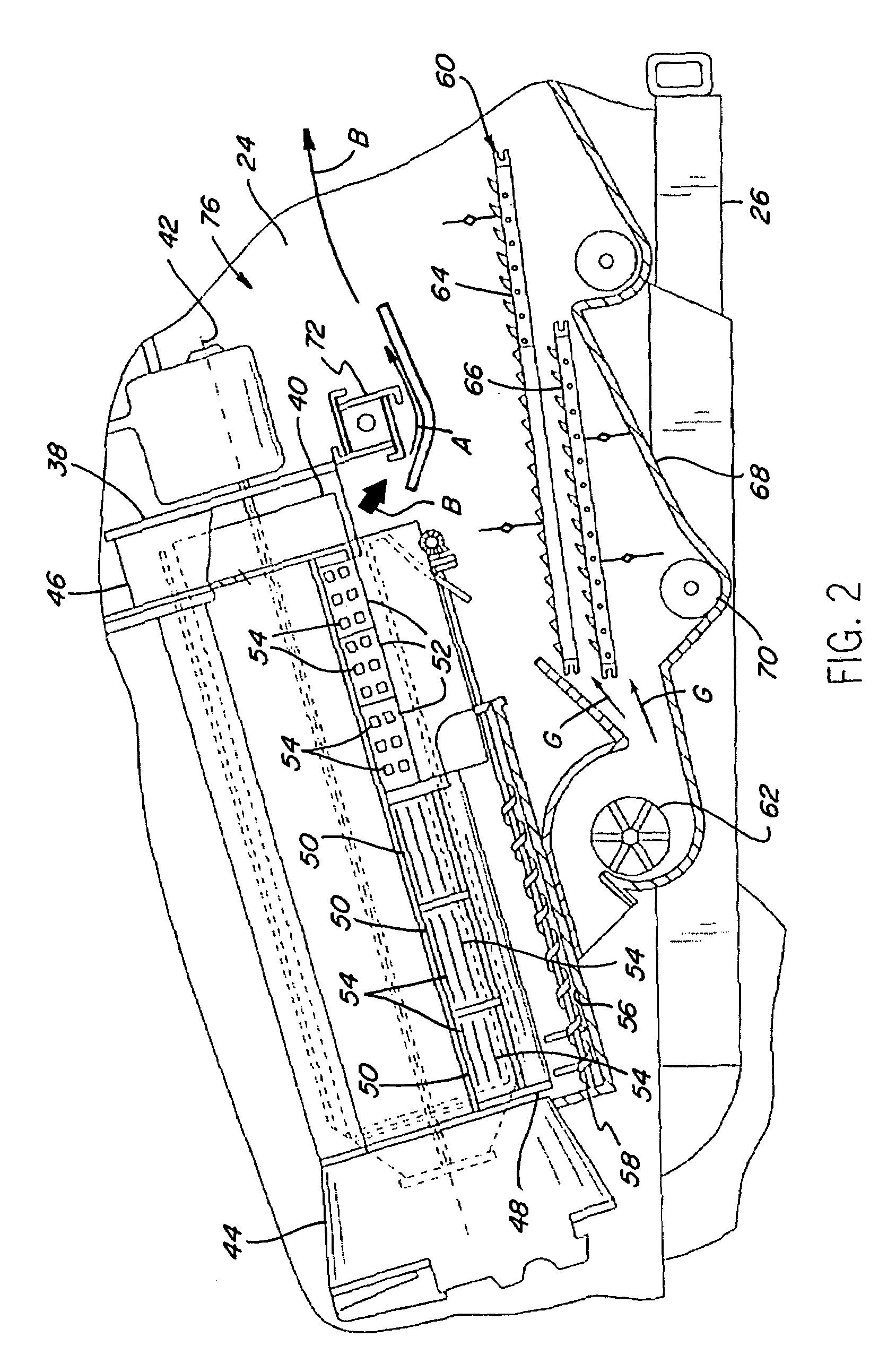

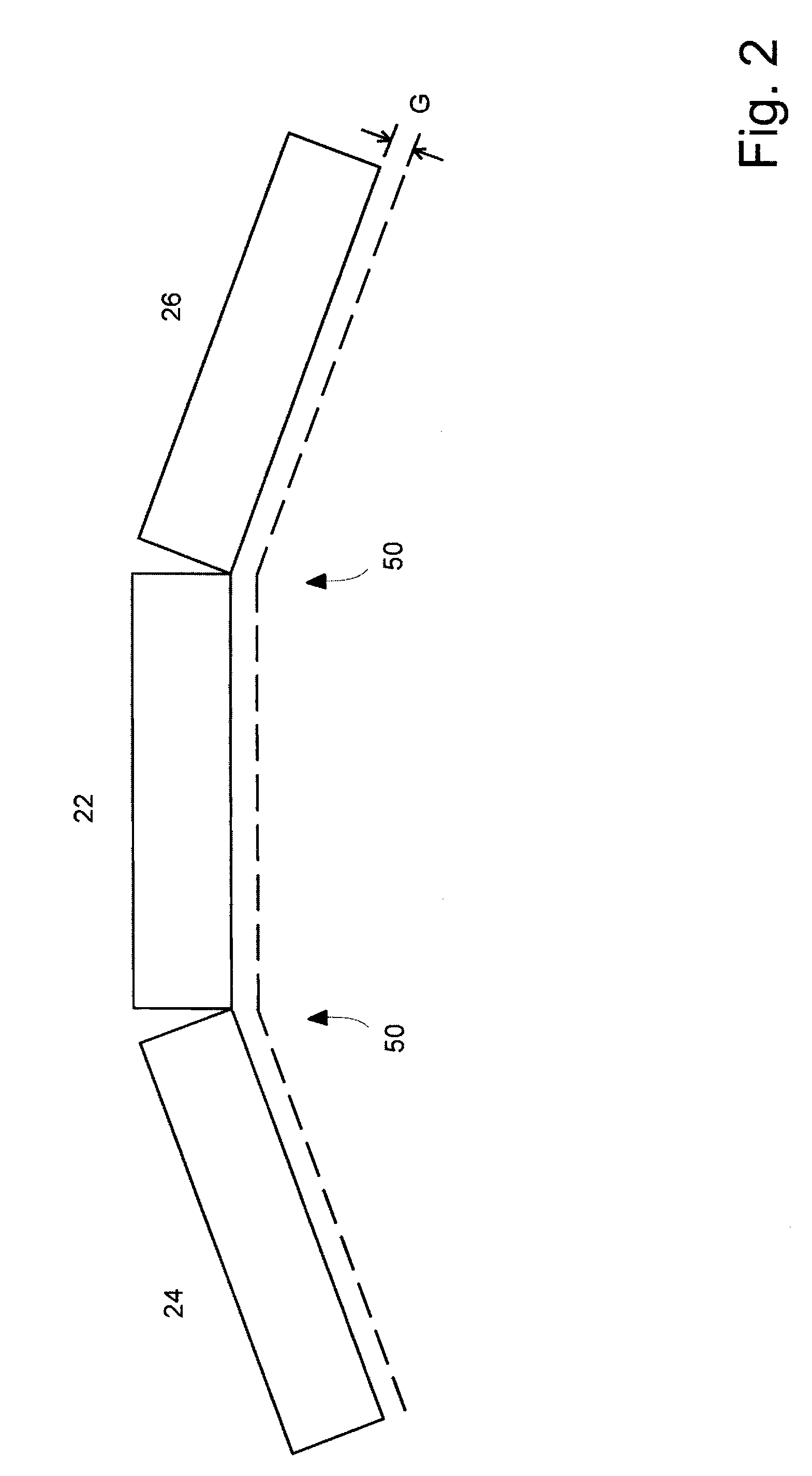

Crop stripper for the crop transport draper of a header

A draper header for a combine harvester includes two side drapers each running from an outer end guide roller at a first end of the header to an inner end guide roller adjacent the discharge location of the header and a central feed draper located at the discharge location and including a front guide roller just behind the cutter bar and running to a rear guide roller in front of the feeder house of the combine harvester. Each inner end guide roller is associated with a respective discharge roller immediately adjacent and parallel to it with a stripper blade in contact with the peripheral surface of the discharge roller so as to strip the crop from the peripheral surface along the full length of the roller. Each stripper blade is inclined downwardly and inwardly to a bottom edge closely adjacent the upper run of the feed draper. The stripper roller or in another arrangement the draper itself has rows of projections across the surface which pass through corresponding shaped recesses in the edge of the stripper blade so that the crop material is discharged onto the blade while the projections are shaped to prevent the crop from being driven into the recesses. An auger is located between the discharge rollers with a front edge of the flight forward of the rear end of the discharge rollers to feed the material inwardly and underneath the auger to the inlet of the feeder house.

Owner:MACDON INDS

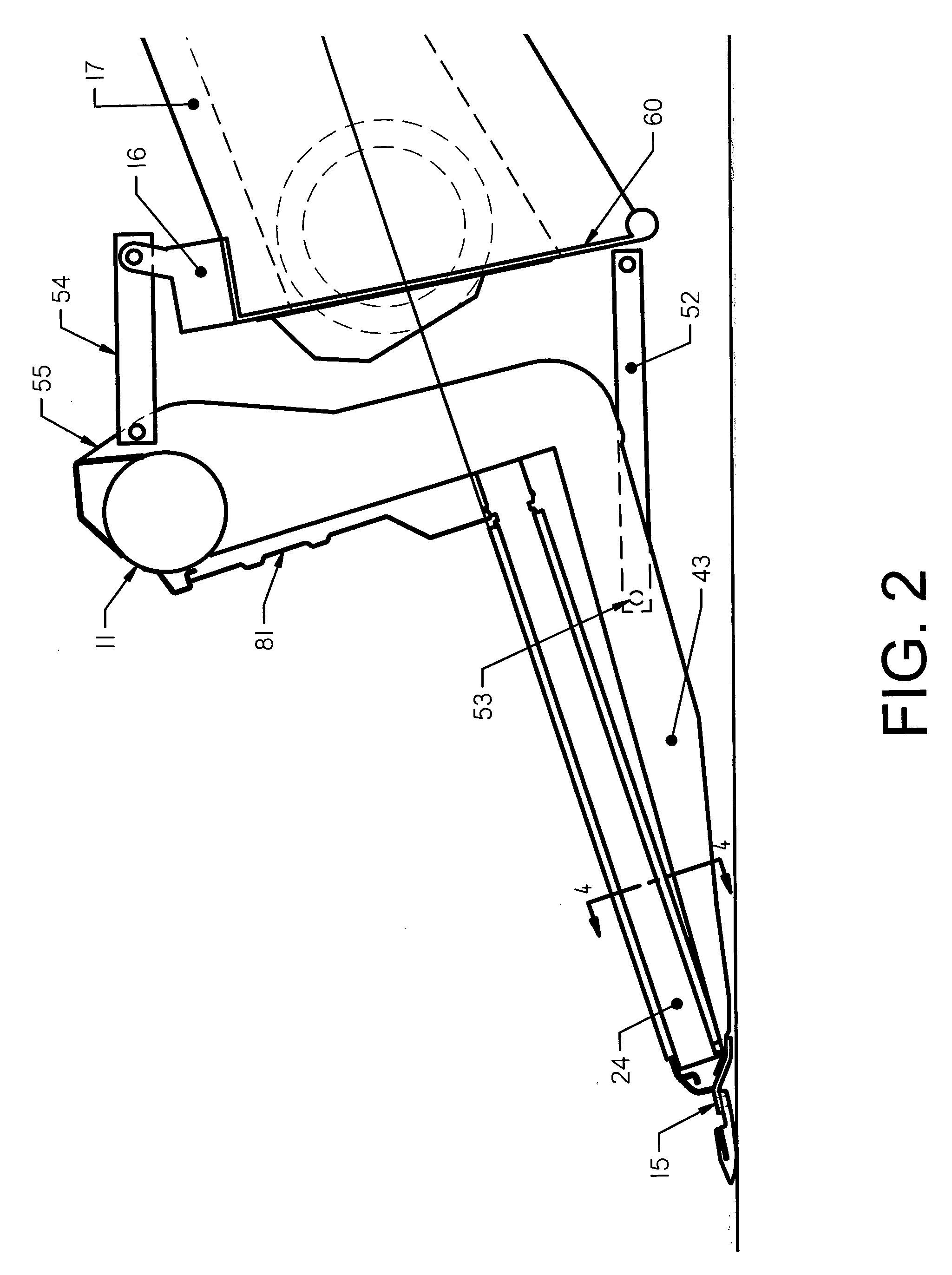

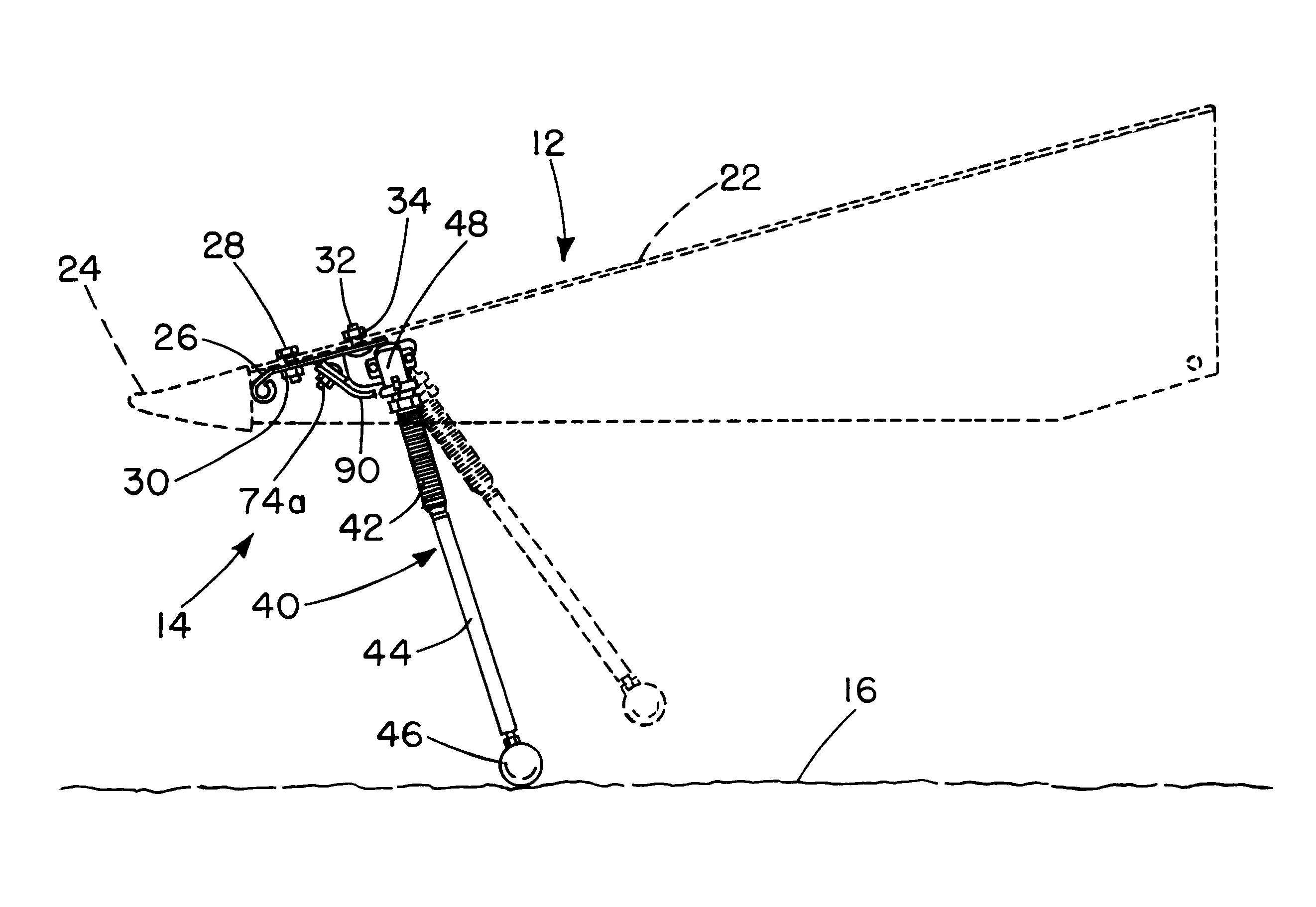

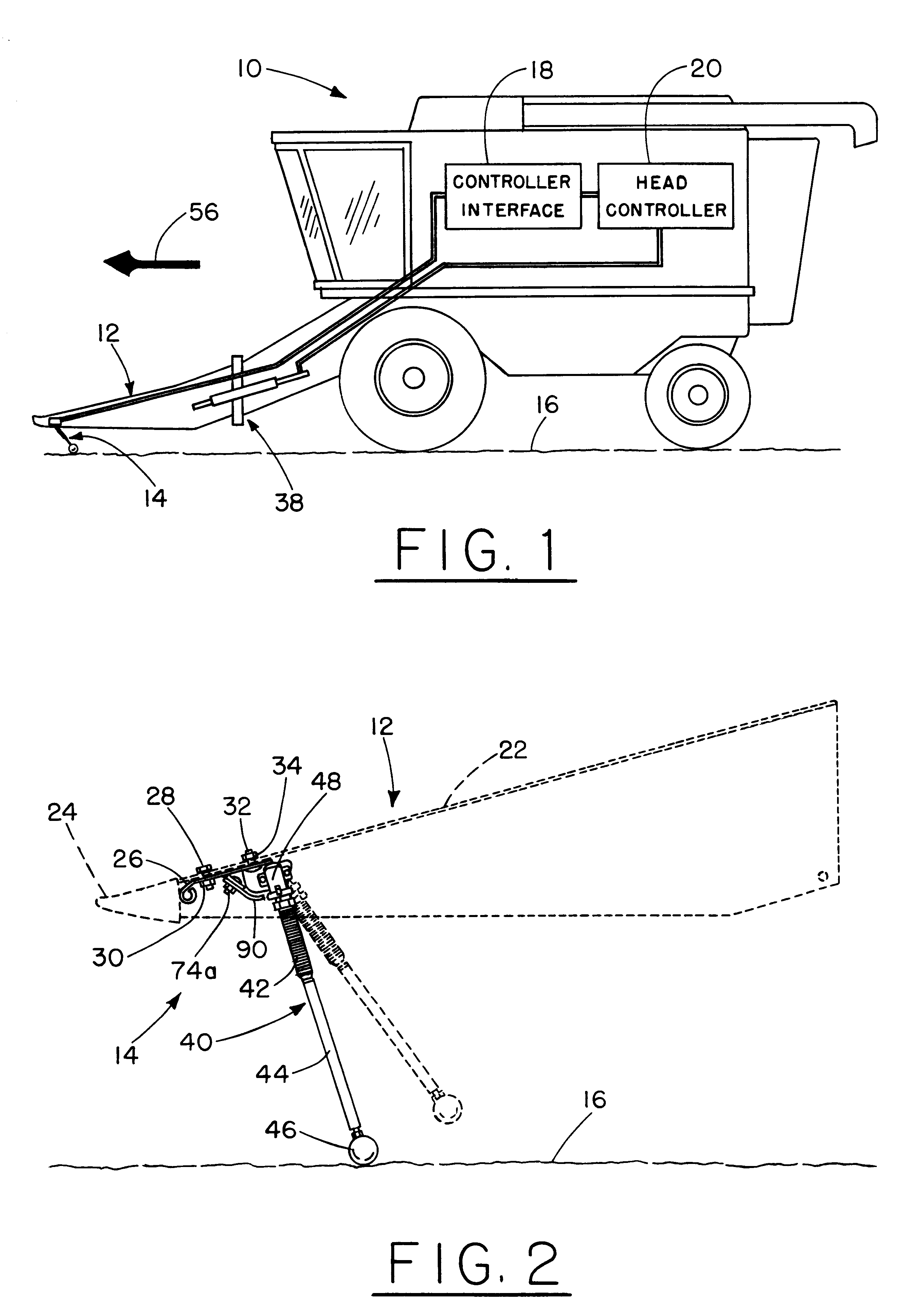

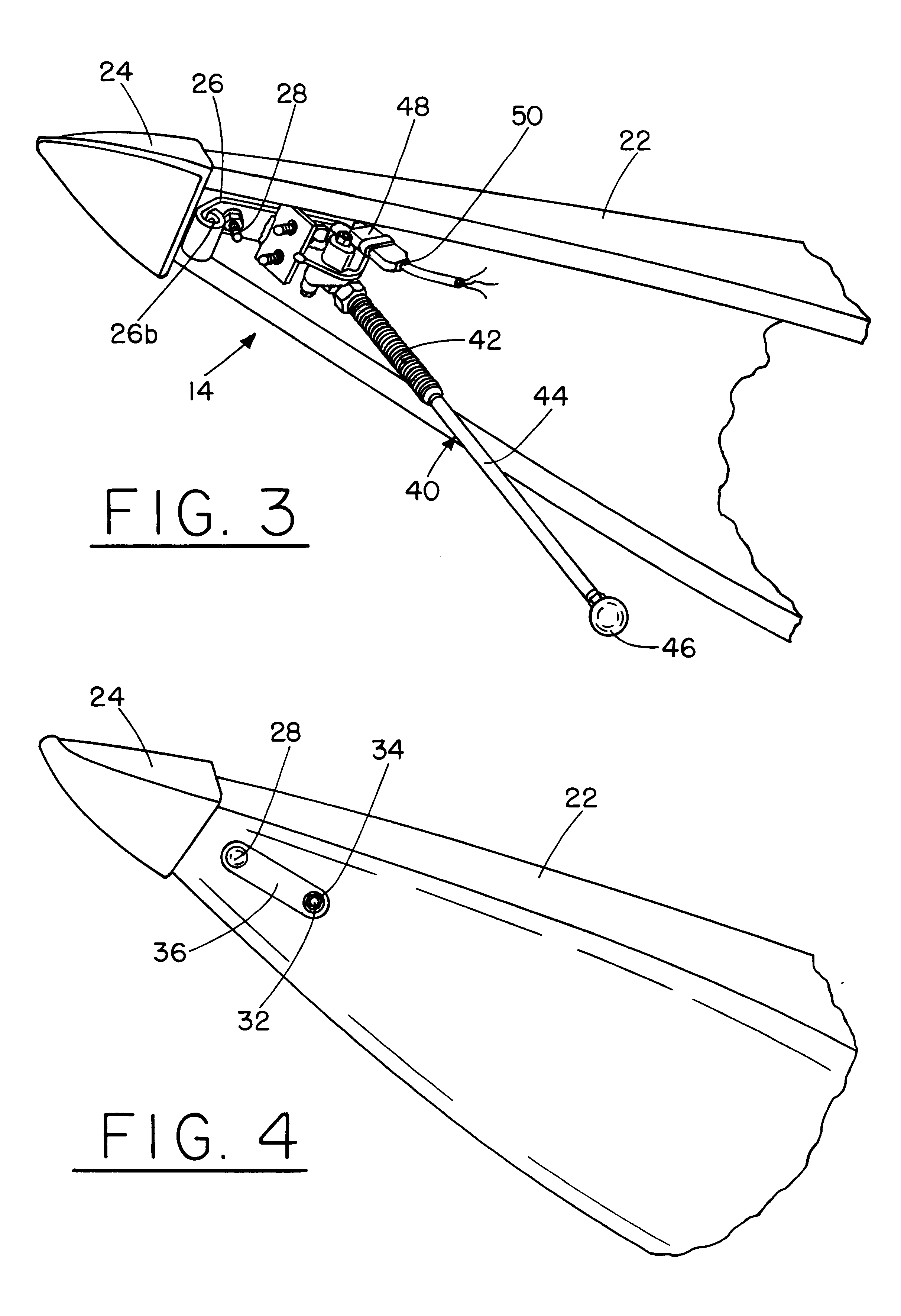

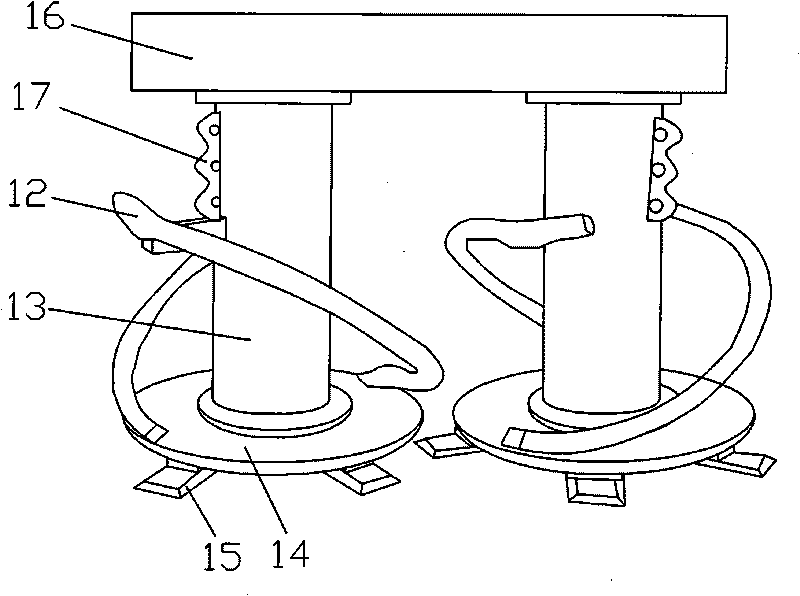

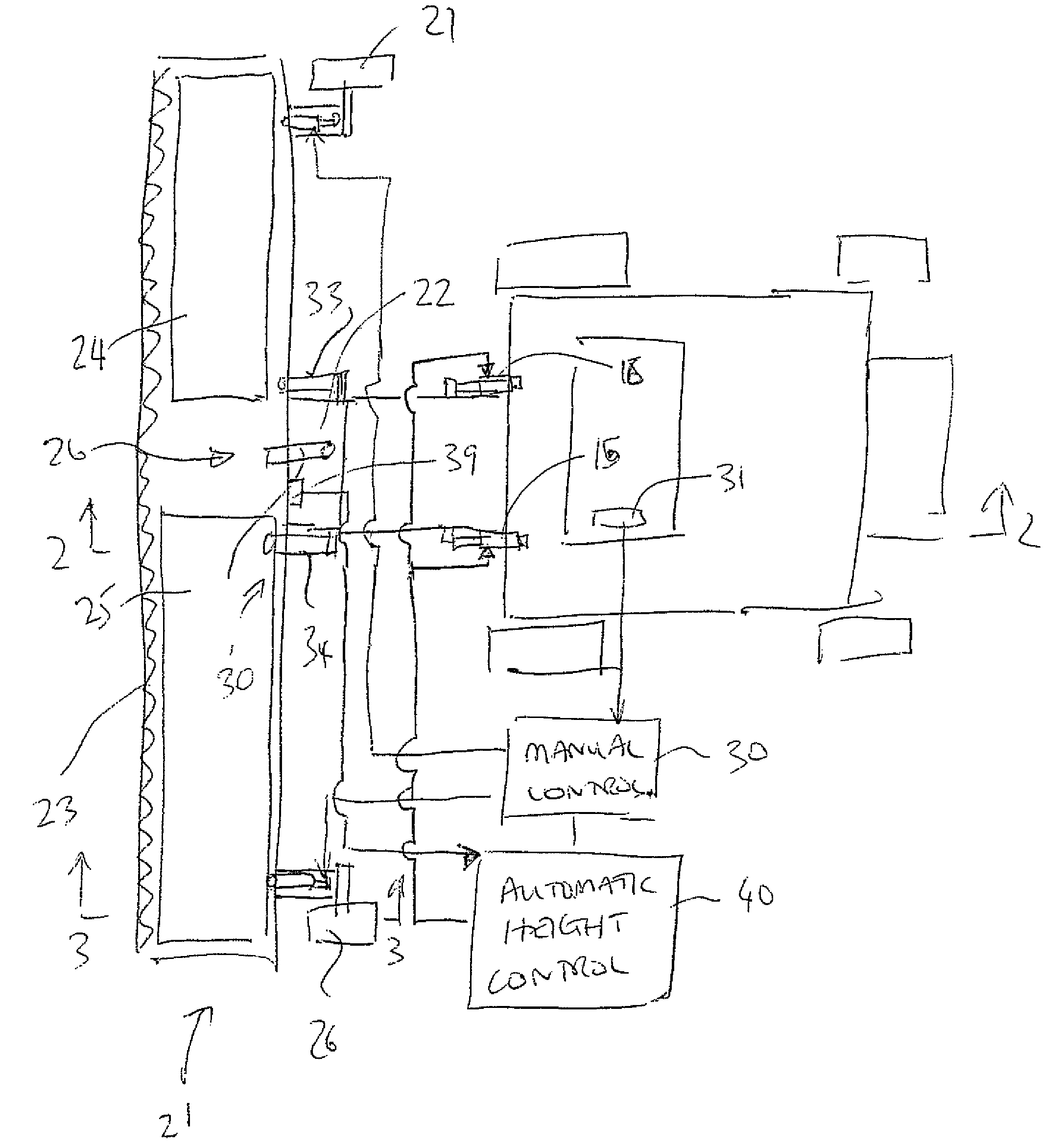

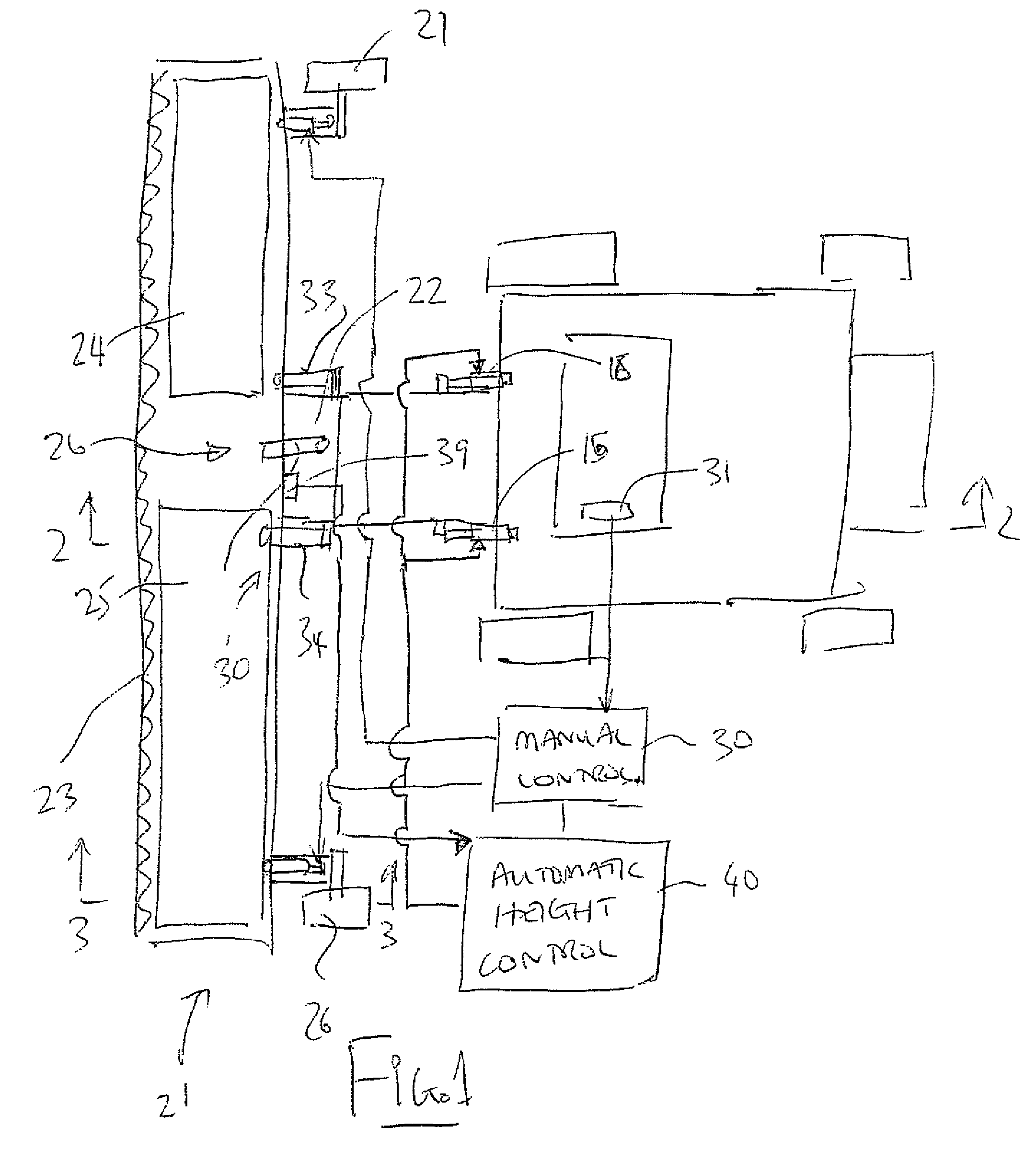

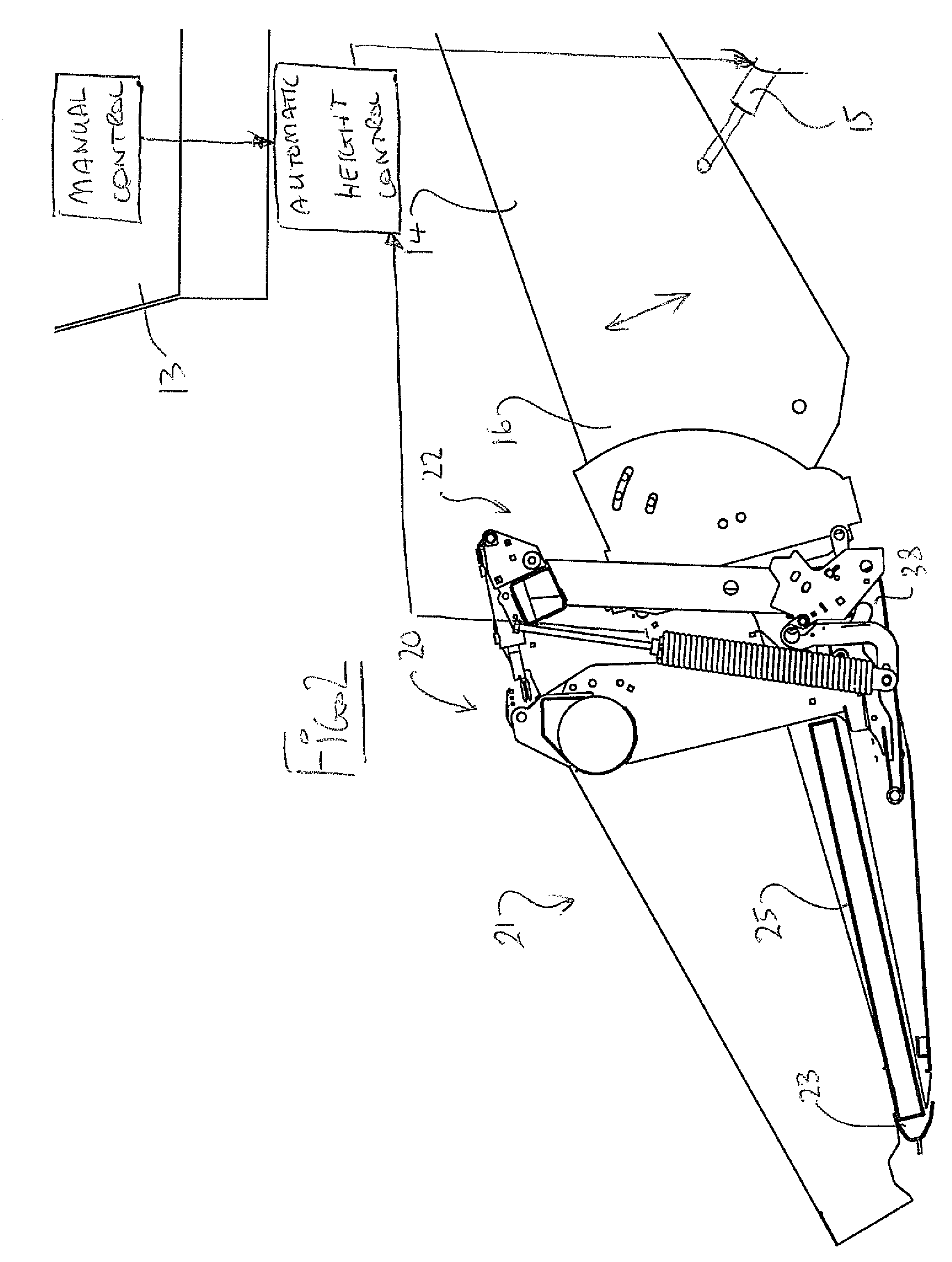

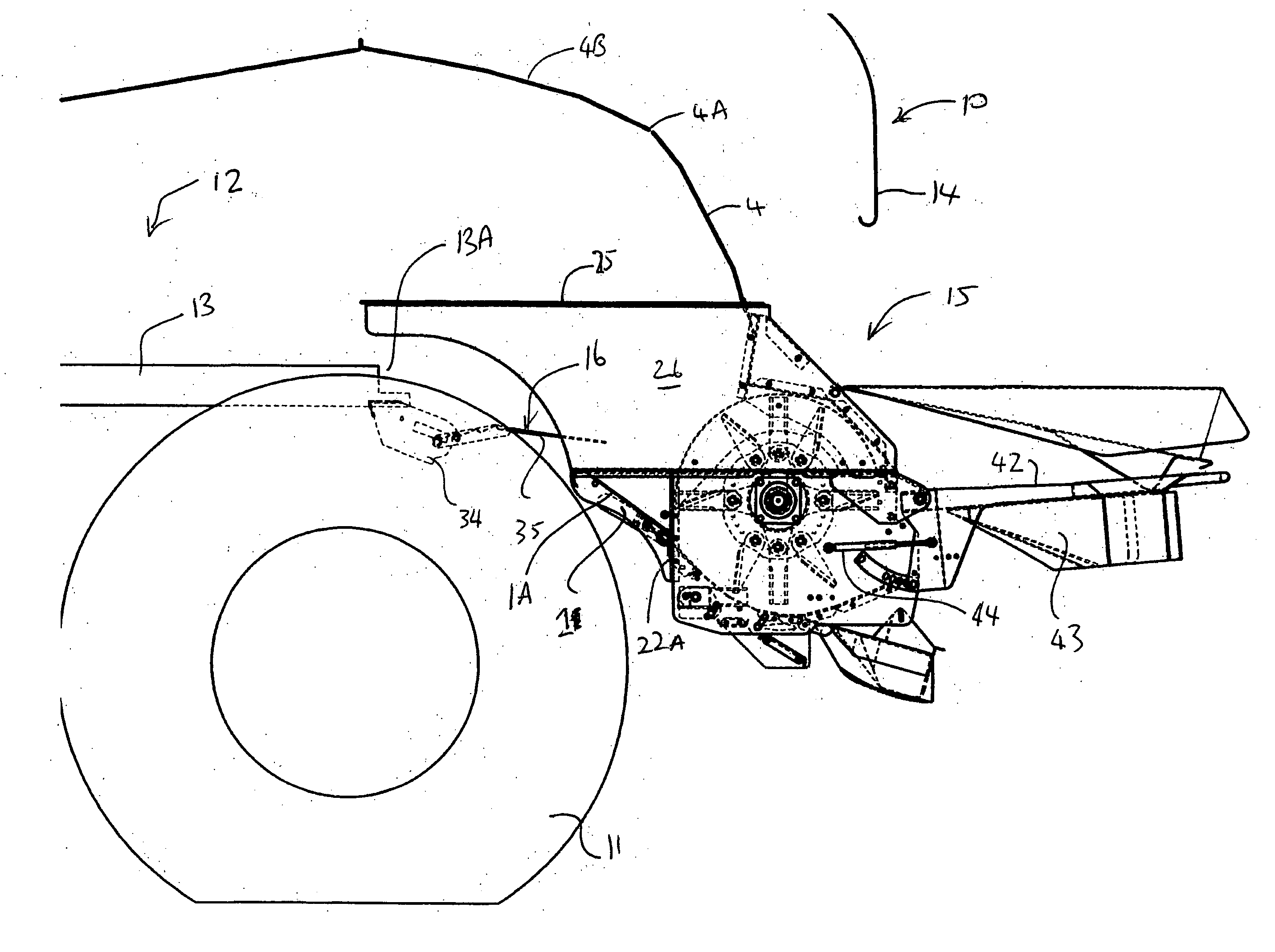

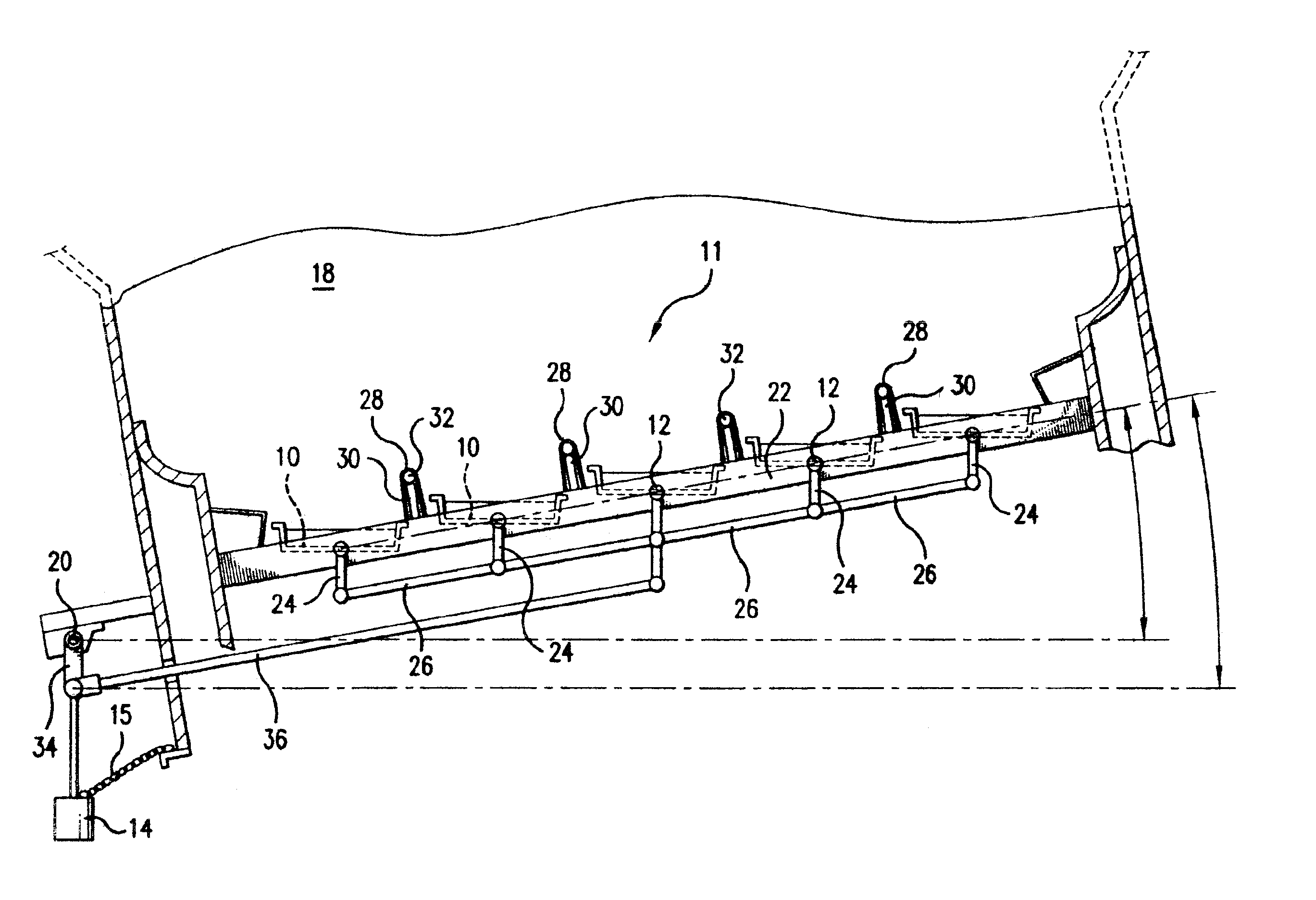

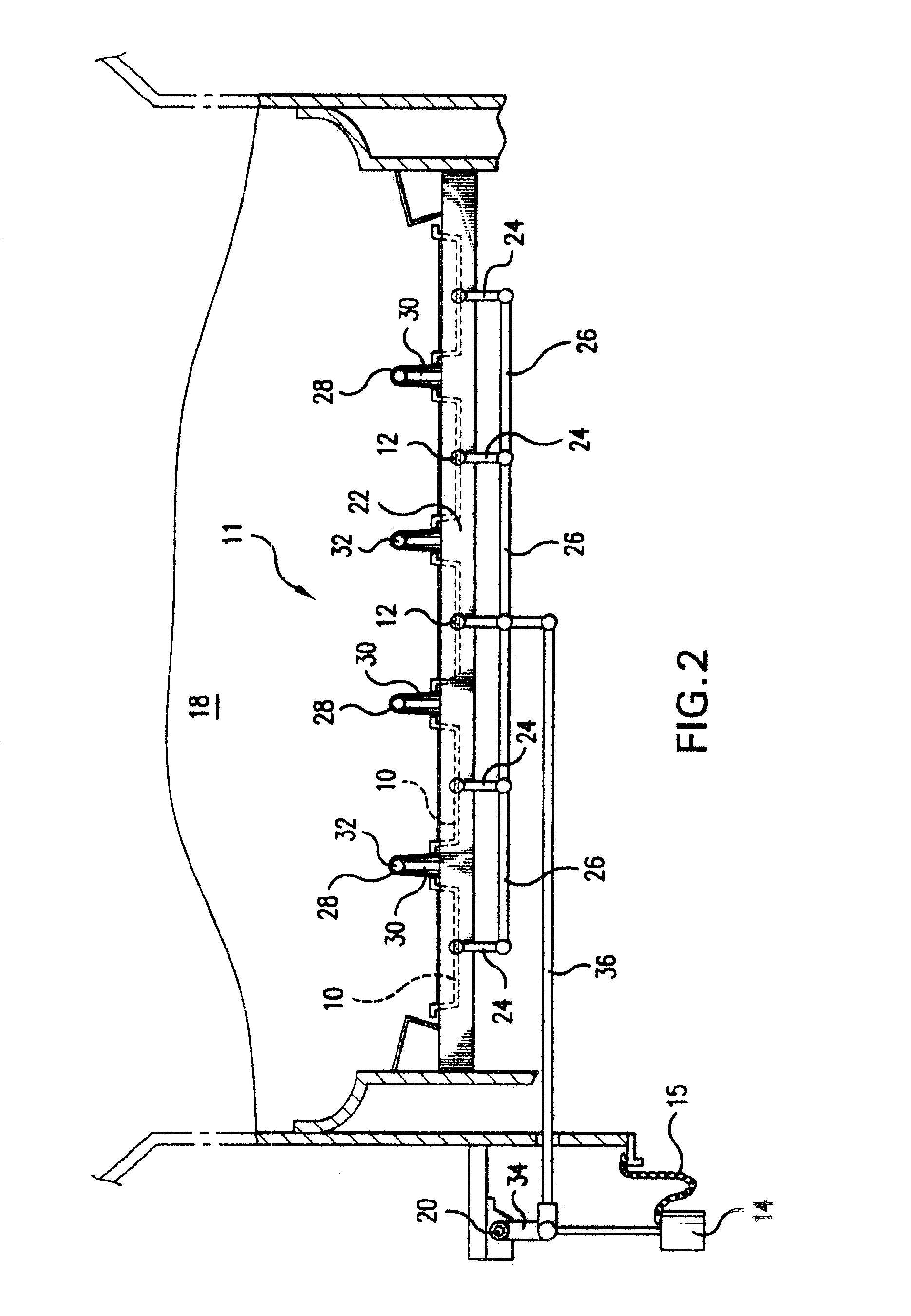

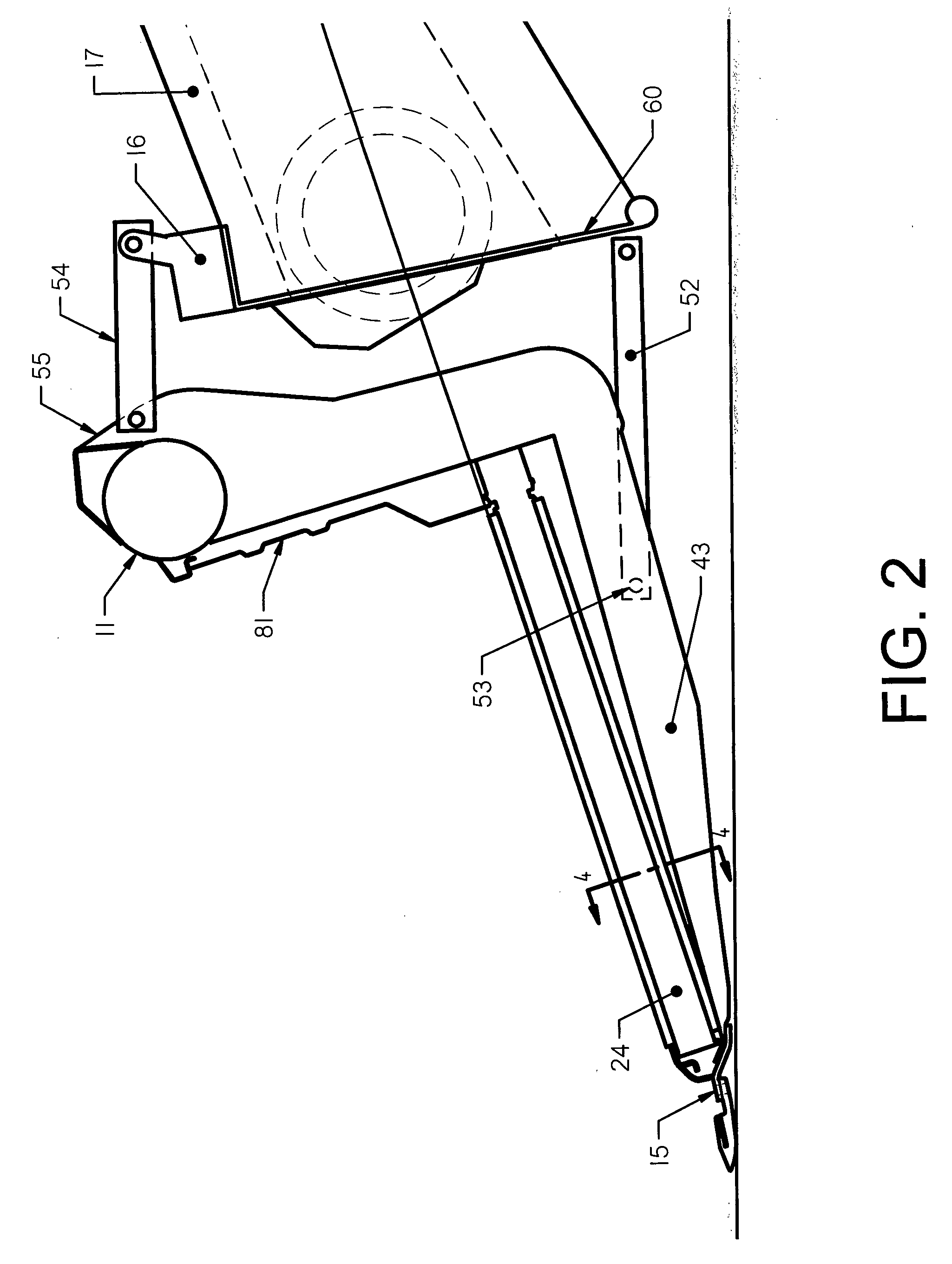

Combine header height control

InactiveUS6202395B1Accurate height positioningReduce combine ingestionAgricultural machinesMowersCoil springEngineering

An arrangement for controlling the height above or depth below an irregular surface of a body moving over or below the surface includes a rotation sensor coupled to a controller responsive to an angular deflection signal output by the rotation sensor. The rotation sensor and controller are mounted to a vehicle moving over the surface such as an agricultural vehicle traversing a field. A semi-rigid, flexible arm has a first end coupled to the rotation sensor with a ground engaging member attached to a second opposed end of the arm. In one embodiment, the flexible arm includes an elongated coil spring attached to a rigid shaft and the ground engaging member is a spherical ball attached to the shaft's distal end. The coil spring is pre-loaded to a selected bending or flexure force and permits the ground engaging member to impact obstructions in the field without damage to the rotation sensor. The coil spring also prevents damage to the rotation sensor when the vehicle is reversed in direction. The flexible arm may be urged downwardly to ensure that the ground engaging member contacts the soil and upward and downward rotation stops may be provided to limit rotation of the rotation sensor and flexible arm combination. When a plurality of rotation sensors and flexible arms are employed such as along the length of a combine header, each rotation sensor may be individually calibrated by rotating the sensor relative to the head unit to which it is mounted to permit all sensors to uniformly measure the height above or depth below the soil surface.

Owner:GRAMM RICHARD

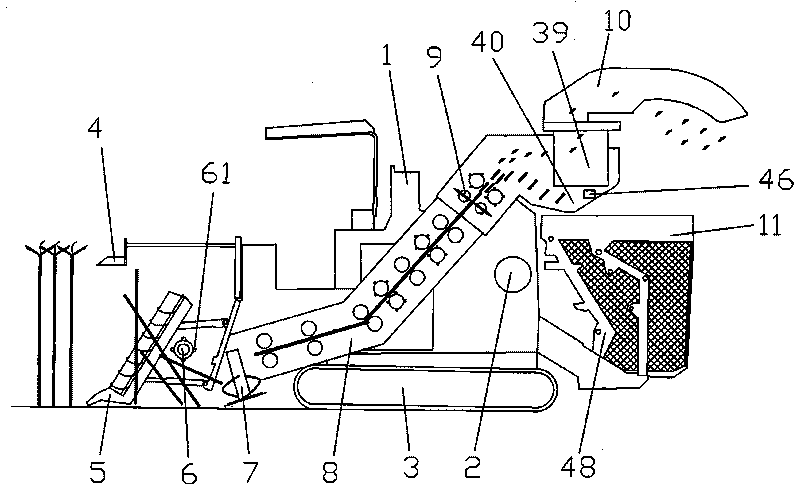

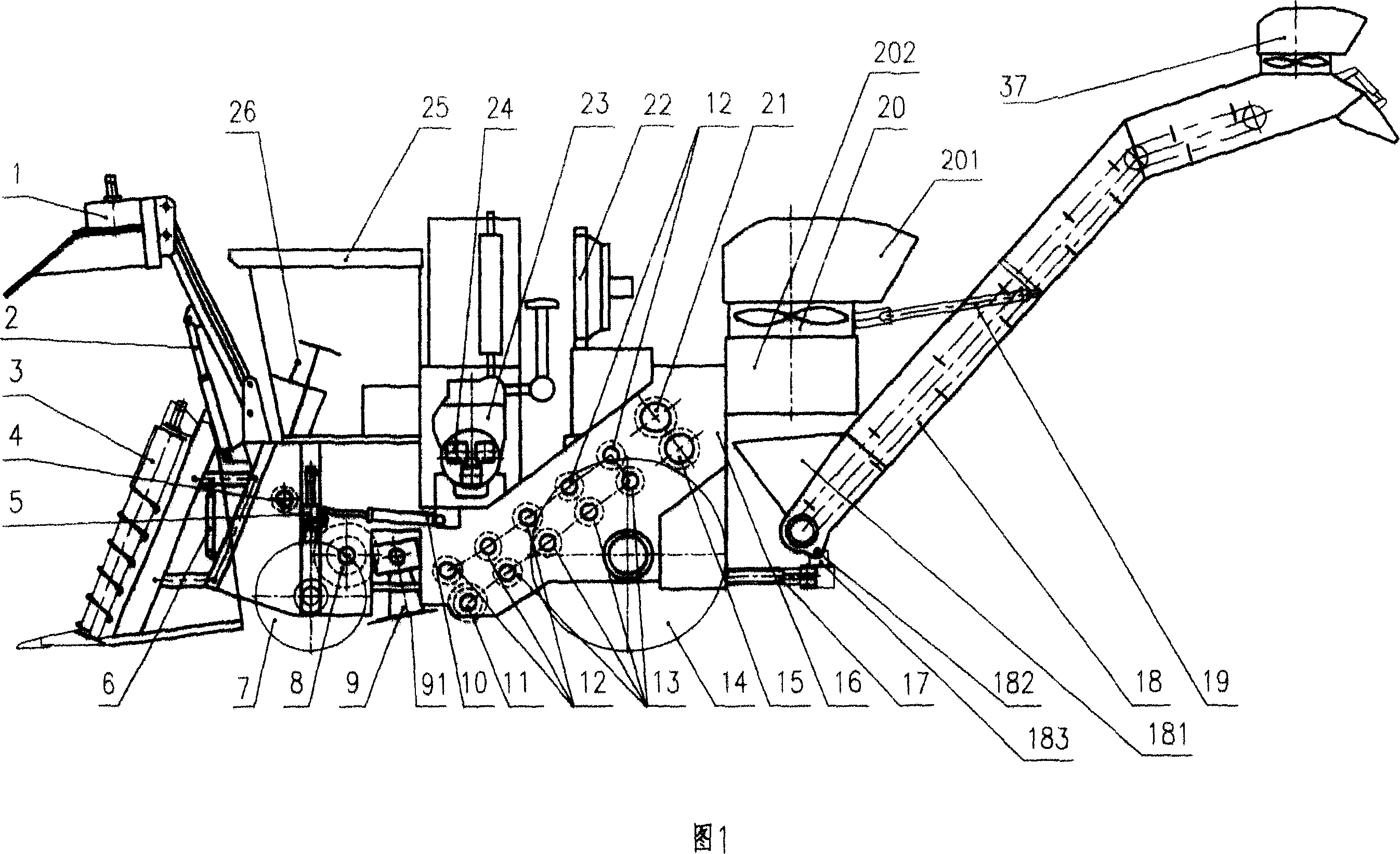

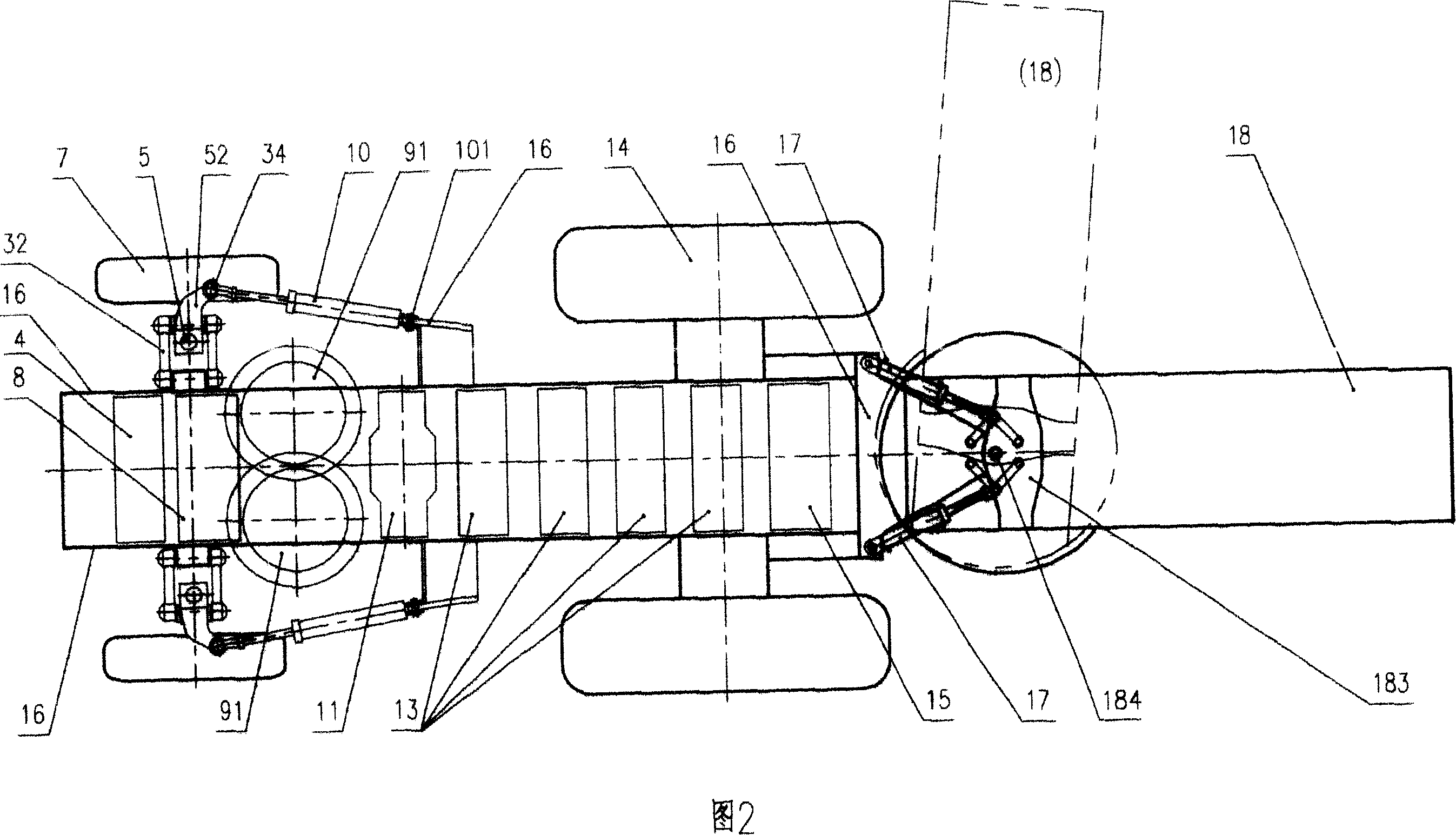

Segmenting type sugar cane combine harvester

InactiveCN101690449AAvoid cloggingReduce cloggingMowersAgricultural lifting devicesControl systemAgricultural engineering

The invention discloses a segmenting type sugar cane combine harvester, which comprises a machine frame, an engine, a crawler type traveling mechanism, a hydraulic power and control system, a sugar cane topper device, a sugar cane supporting device, a sugar cane pressing combing roller, a cutting device, a conveying leaf-removing device, a segmenting device, an impurity discharging device and a collecting device, wherein the cutting device comprises a left set of cutting component and a right set of cutting component, and each set of cutting component comprises a screw conveying rod, a rotary shaft sleeve, a cutter head and a plurality of blades; and the sugar cane supporting device comprises a left set of sugar cane supporting mechanism and a right set of sugar cane supporting mechanism, and each set of sugar cane supporting mechanism is controlled by an independent adjusting mechanism. The segmenting type sugar cane combine harvester has the advantages of having high capability of separating and harvesting sugar canes which are seriously flattened and / or intertwisted, lessening the choking phenomenon occurring in a process of harvesting sugar canes, improving fully removing rate of sugar cane leaves of the harvested sugar canes, reducing the impurity content in sugar cane segments, conveniently collecting sugar cane segments, avoiding the use of a following transport vehicle for collection and storage, along with compact structure, reasonable configuration, convenient travel and use in fields, good harvesting effect, high automation, low manufacturing cost and the like.

Owner:GUANGDONG KOLEA MODERN AGRI EQUIP

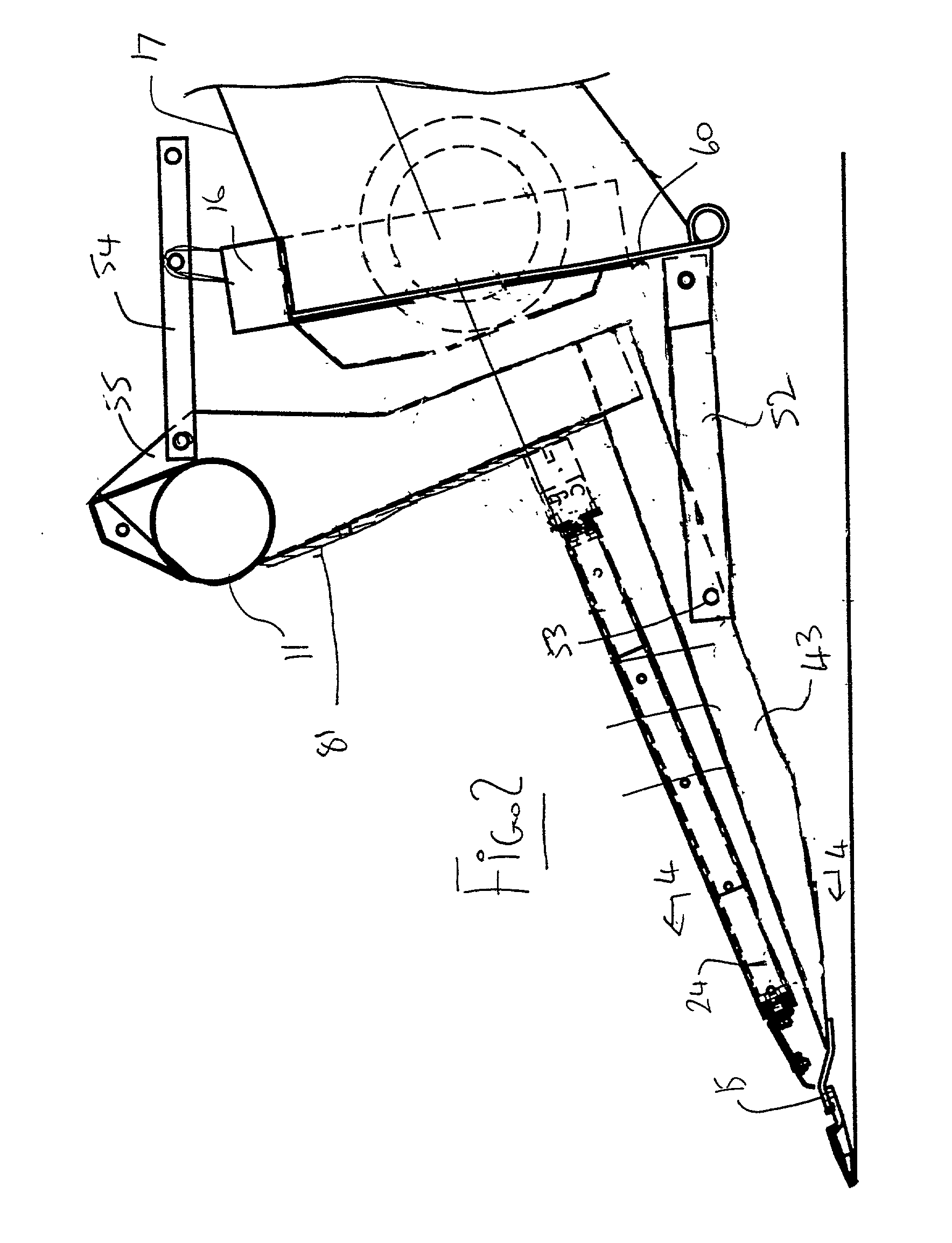

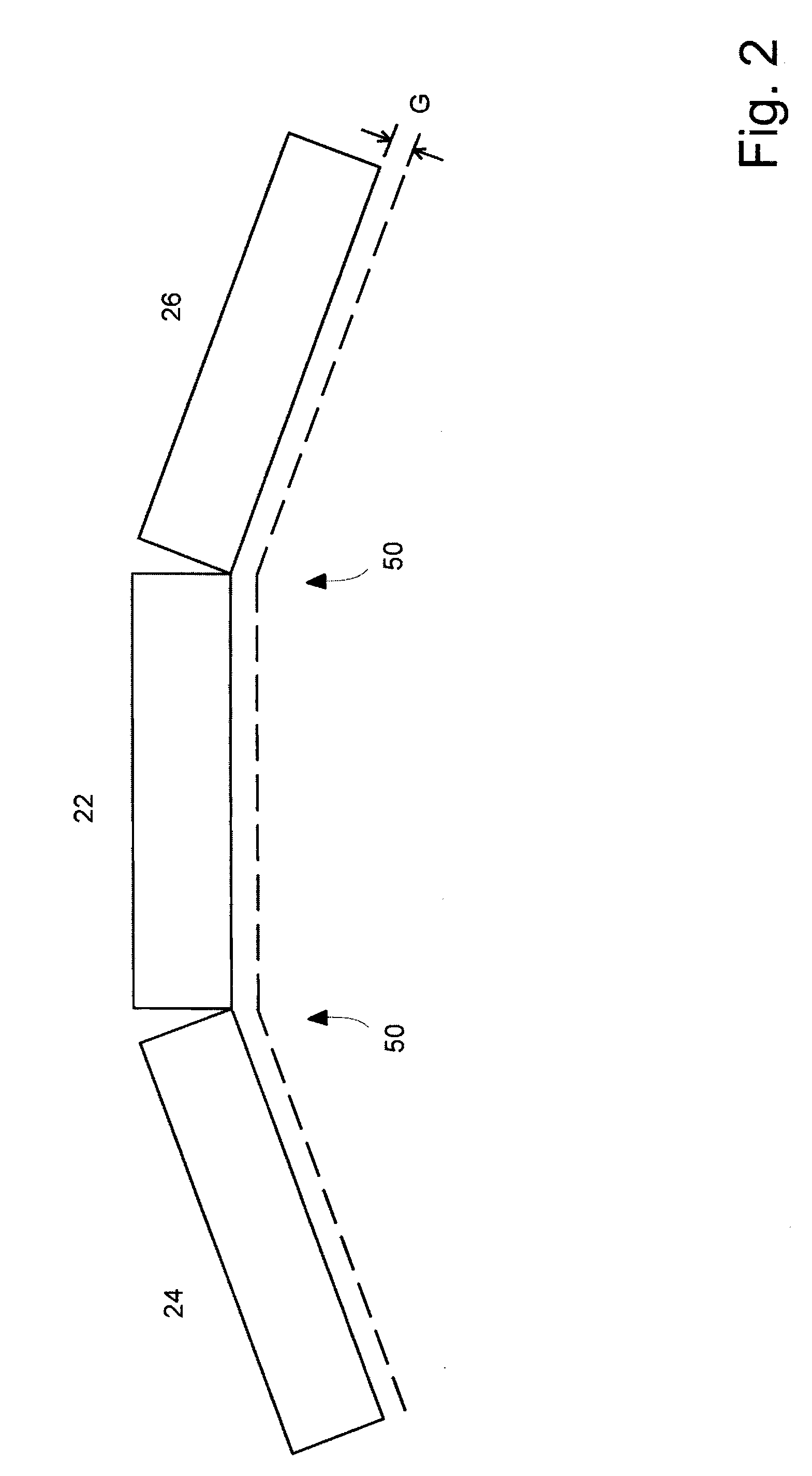

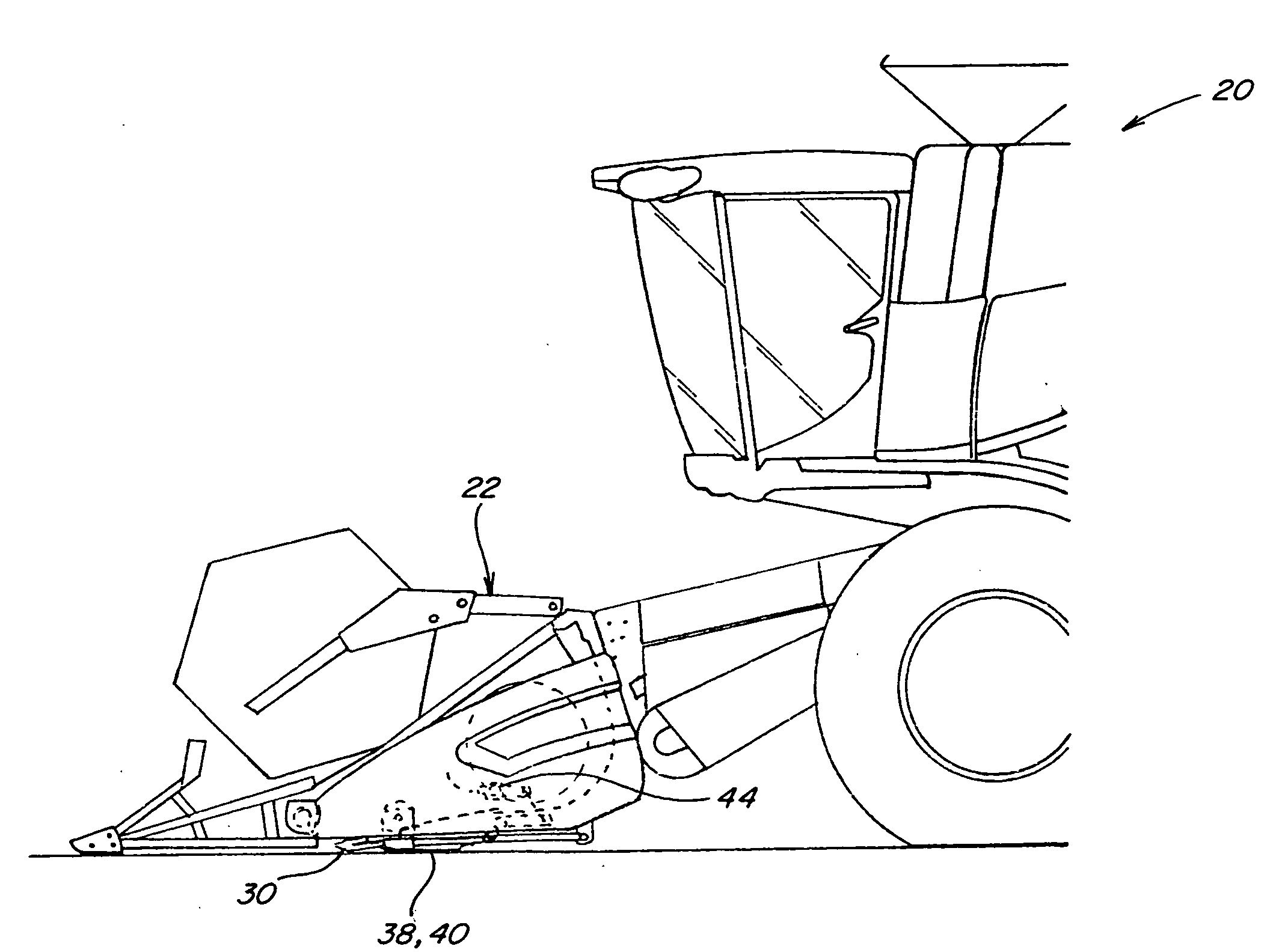

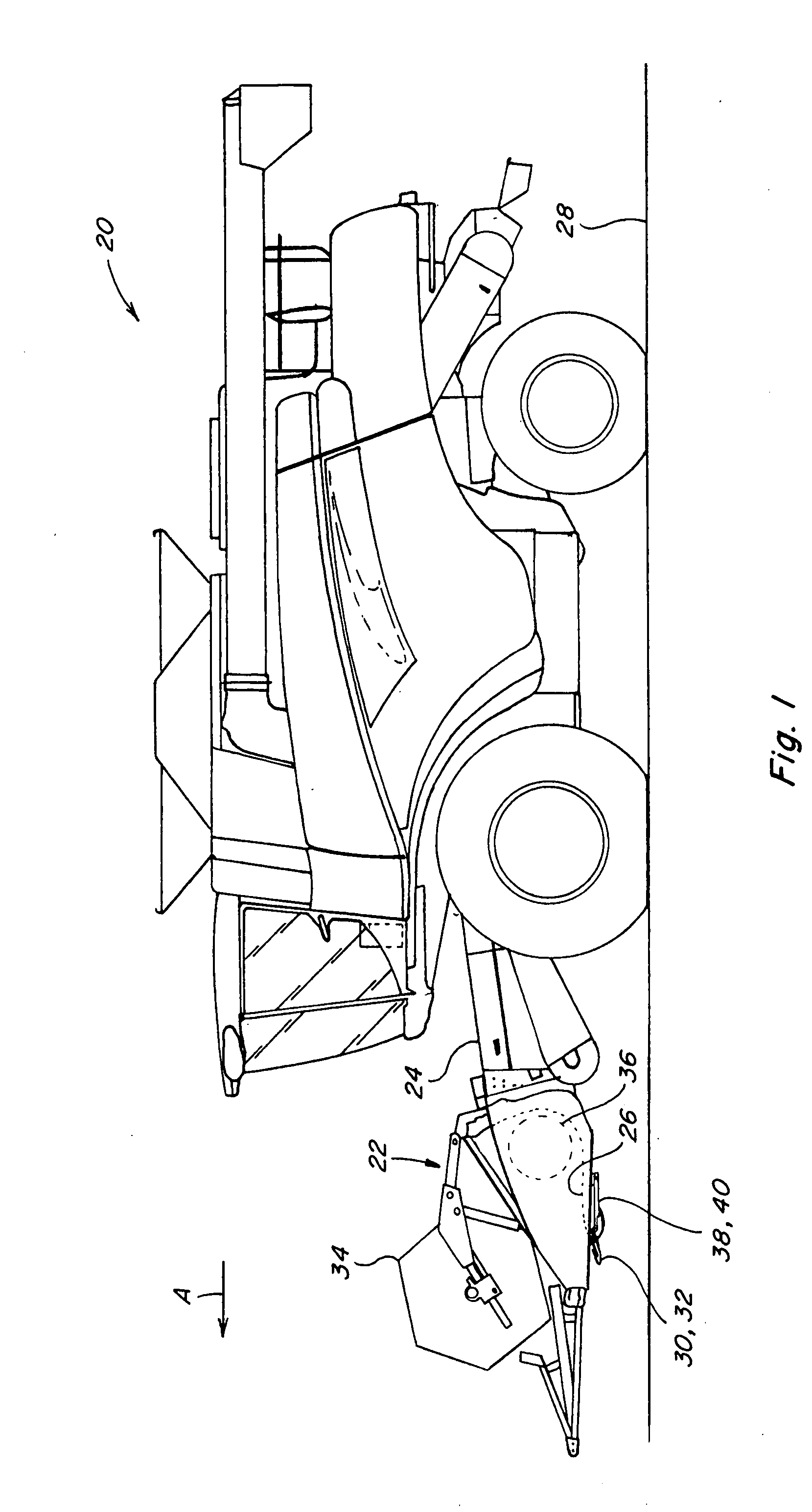

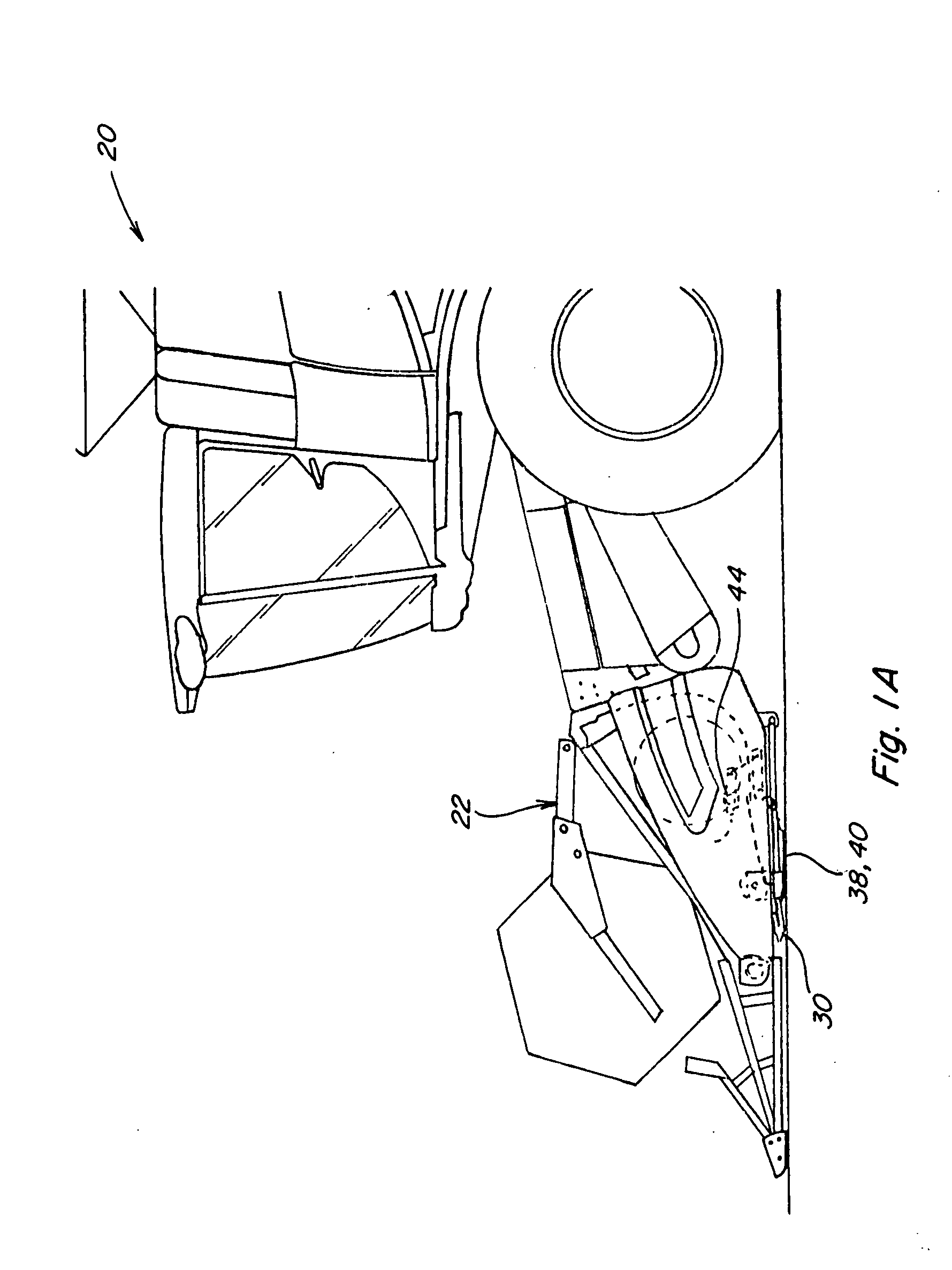

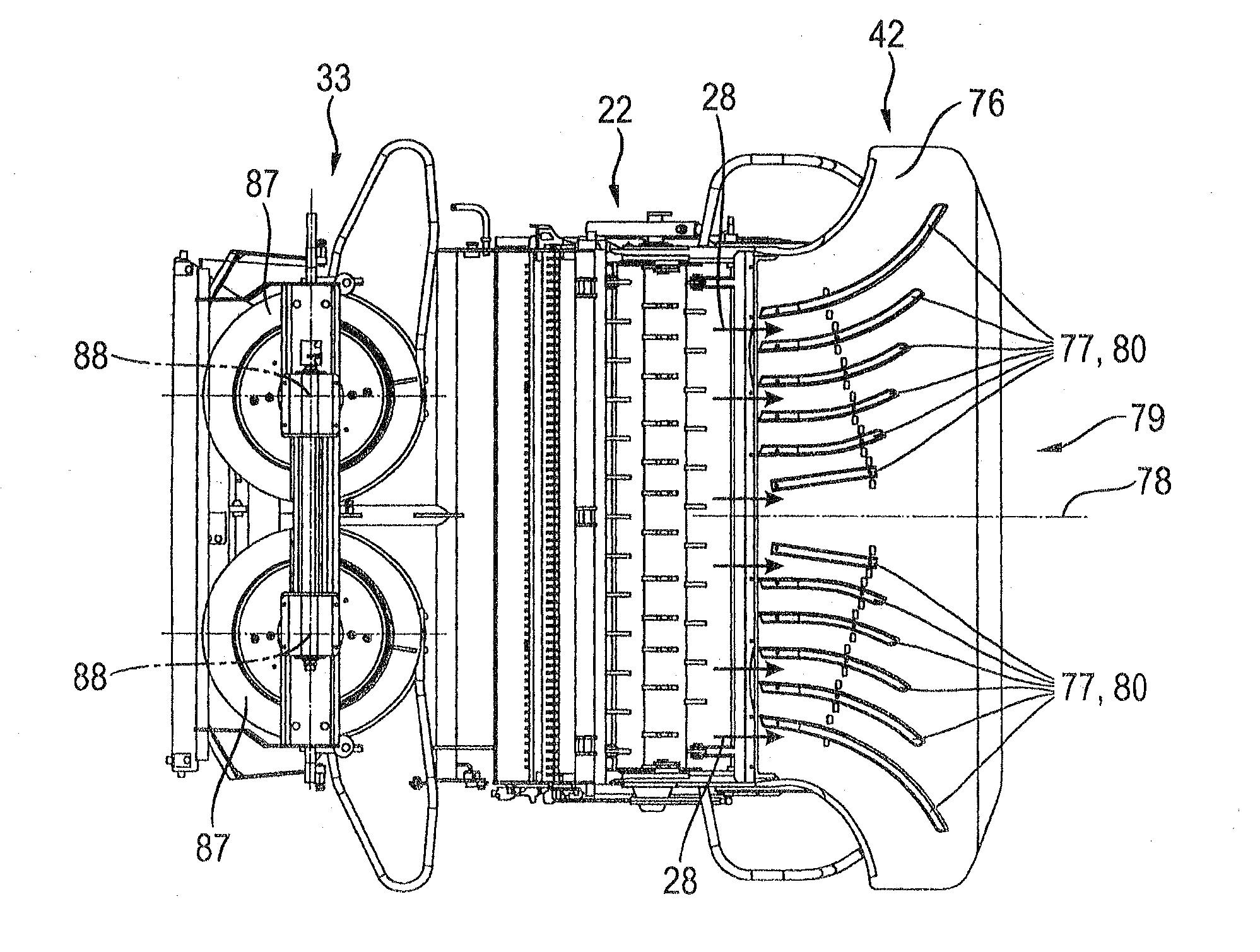

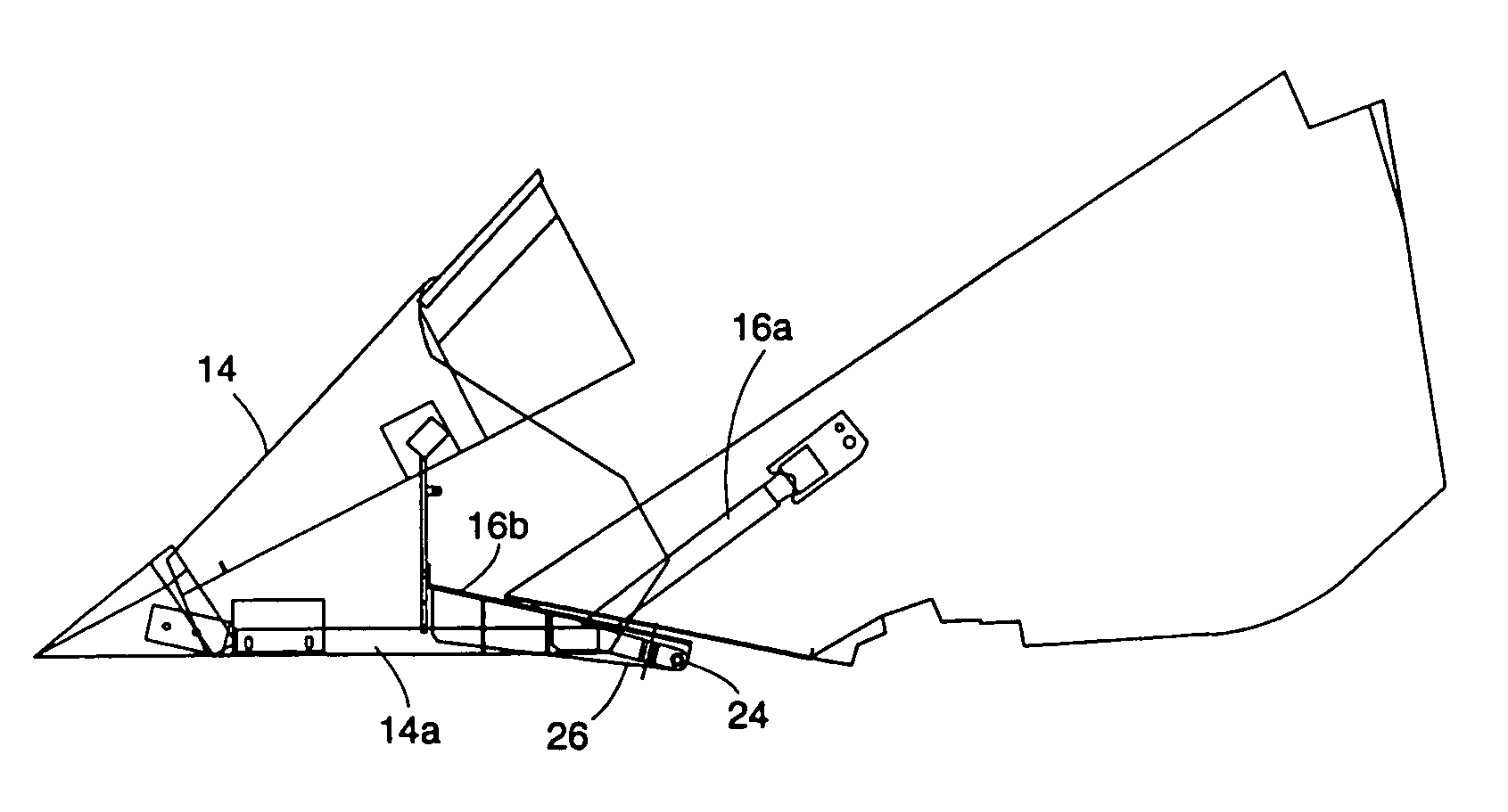

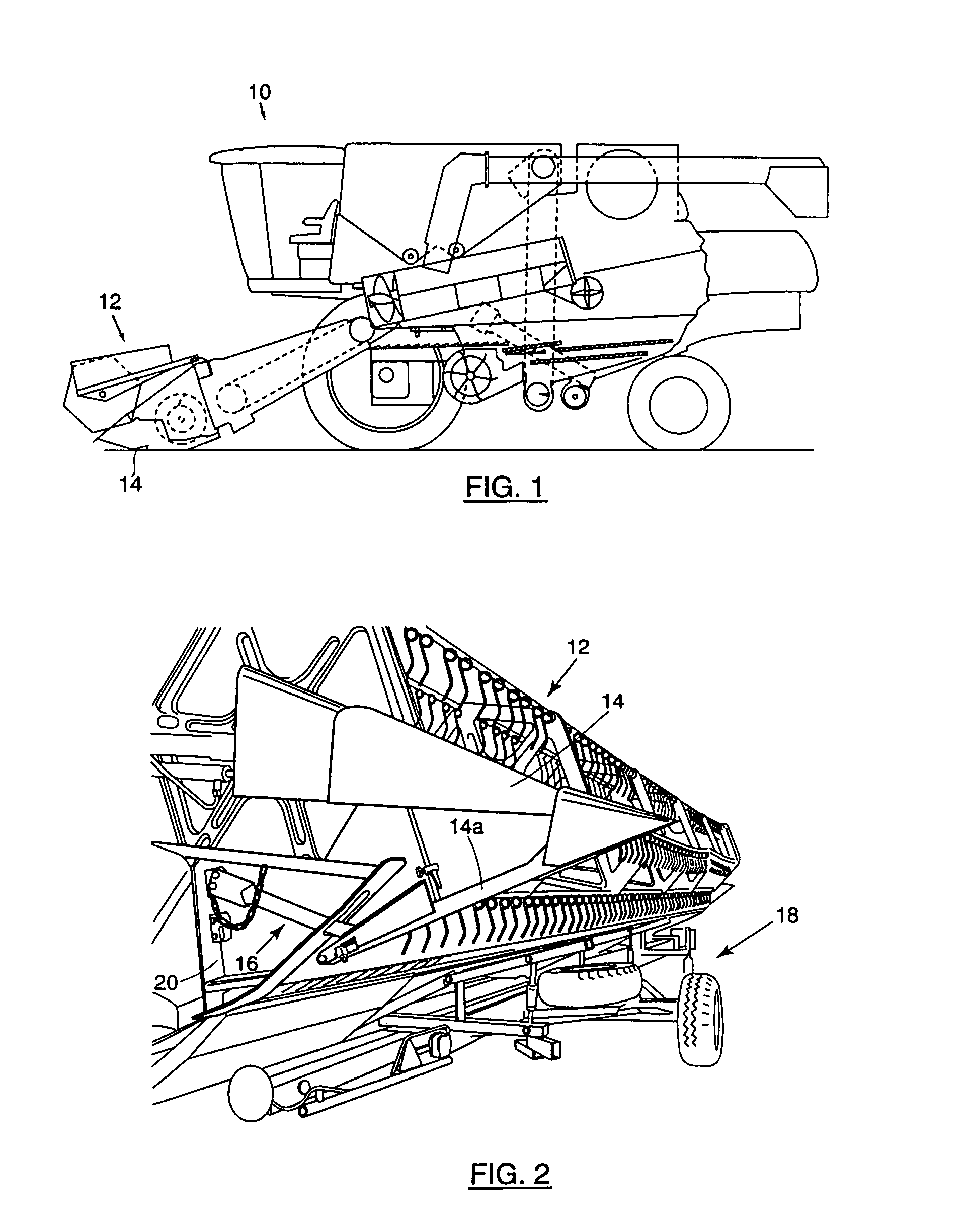

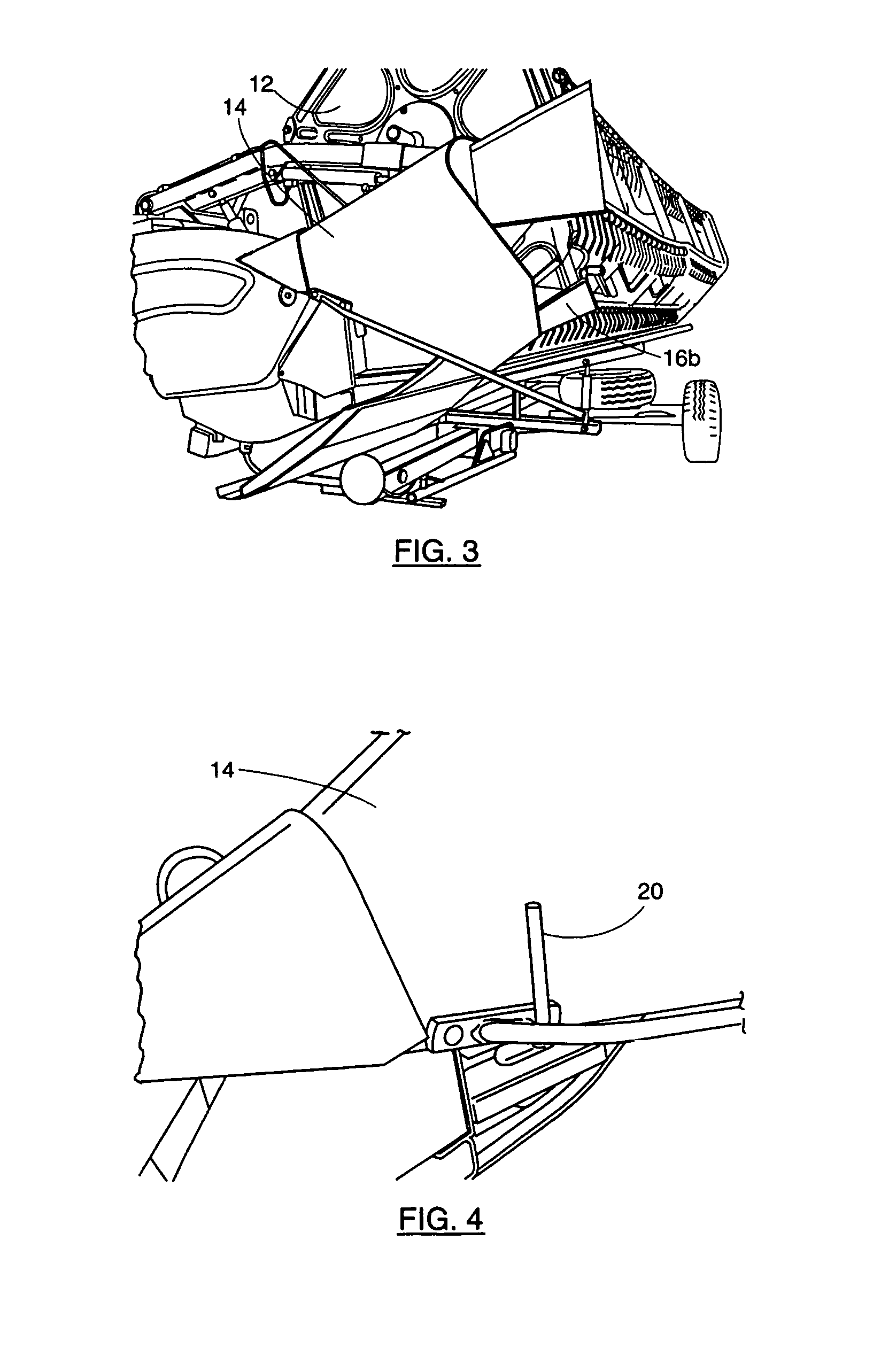

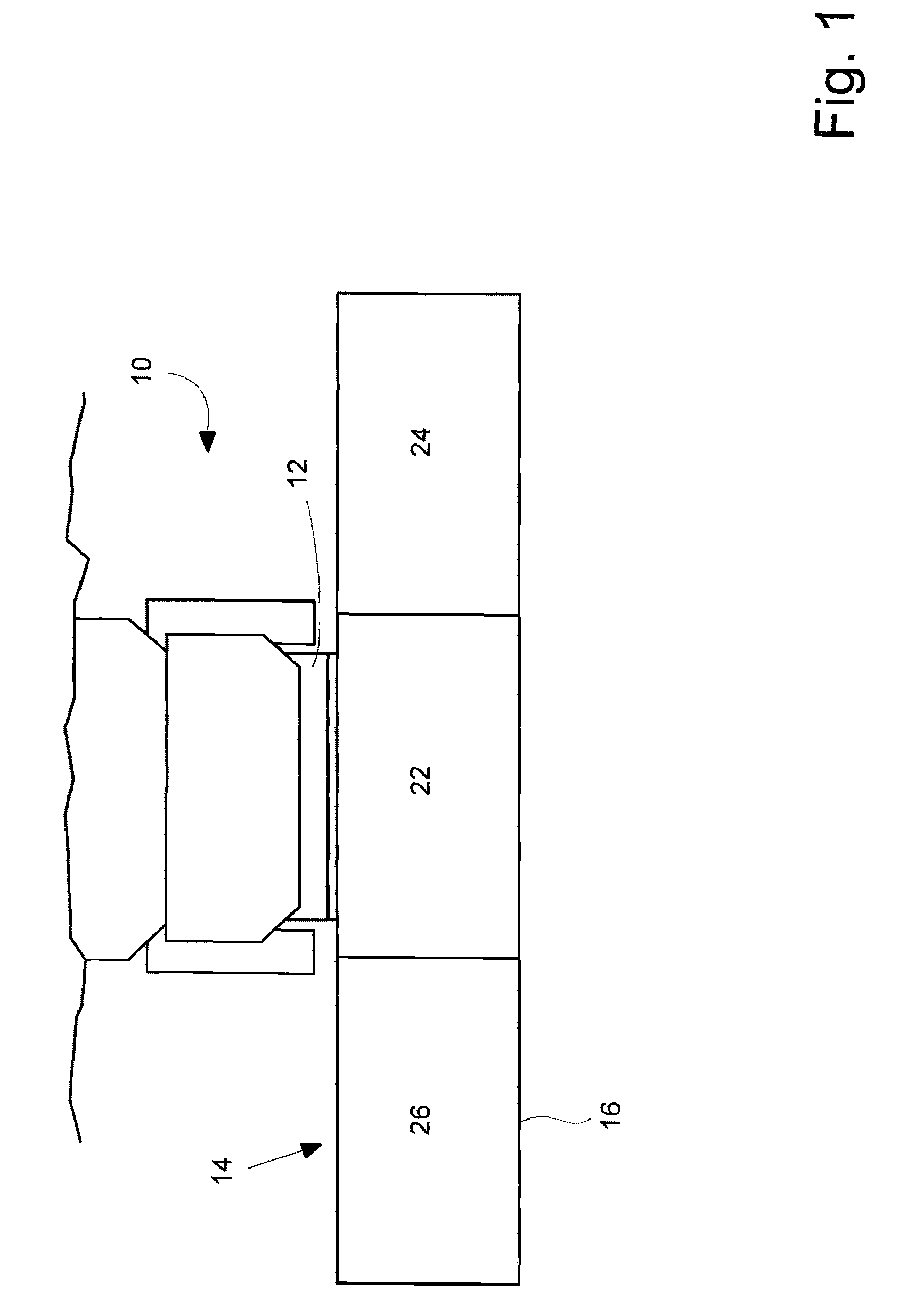

Winged header apparatus and method for a combine

A header for a combine or a harvester comprising a center portion of said header having a feeder house position disposed to direct cut crop from the center portion to a feeder house when the header is mounted on the feeder house. At least one lateral portion of the header is attached to the center portion by a frame hinge. A draper comprised of a frame and a belt disposed to rotate over the frame extends from the lateral portion to the center portion having a draper hinge. A cutter having a curving portion is disposed at a leading aspect of the header to cut crop. The frame hinge, draper hinge and curving portion along the same axis are parallel to a direction of travel of the combine or harvester. The lateral portion can raise and lower relative to the center portion by rotation around the axis.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

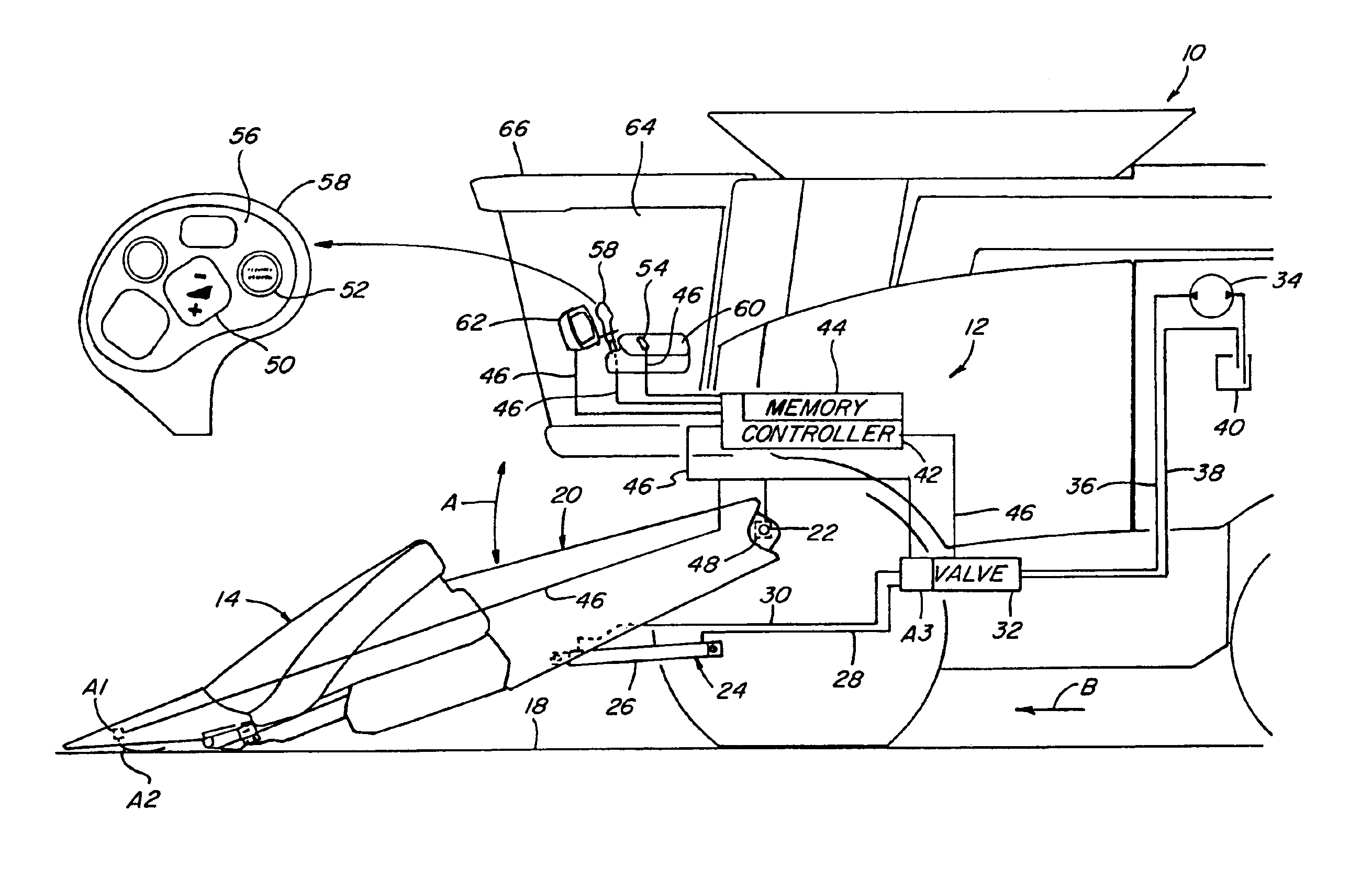

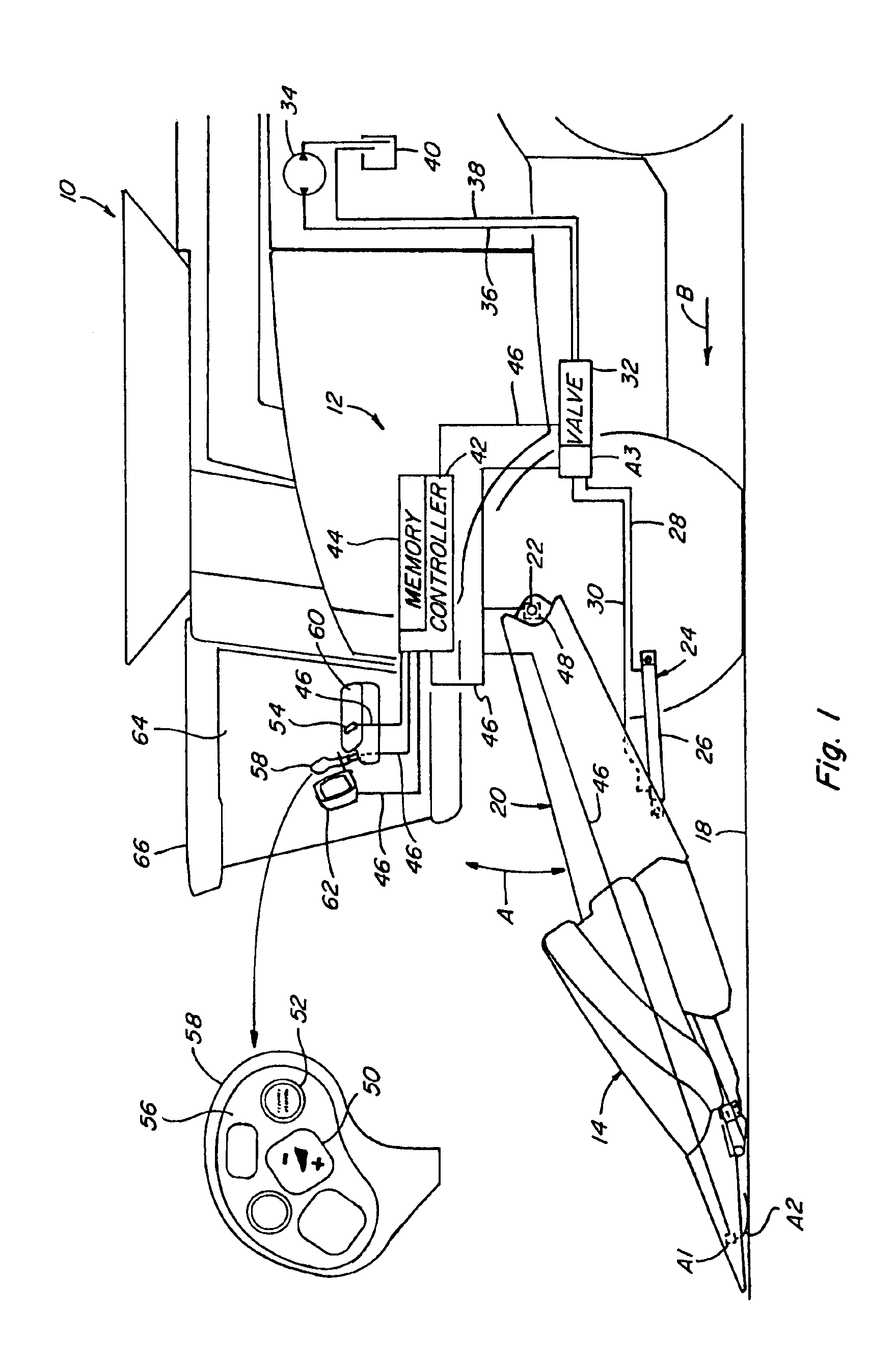

Header height resume

ActiveUS6871483B1Easy to operateOvercome problemsAnalogue computers for trafficMowersEngineeringCombine harvester

A control system for setting operation positions and operating modes for a combine header and automatically moving the header to those positions and modes. The system includes first and second operator inputs that can be located on a propulsion handle of the combine and can be actuated for inputting commands for causing manual and automatic movements, respectively. A third operator input is actuable for setting positions and modes to which the header is automatically movable and can be positioned at a different location. As a result, in operation, an operator can utilize the first input for manually controlling the header, and the second input for initiating automatic movements to at least two predetermined positions and modes, without removal or repositioning of his or her hand on the propulsion handle.

Owner:BLUE LEAF I P +1

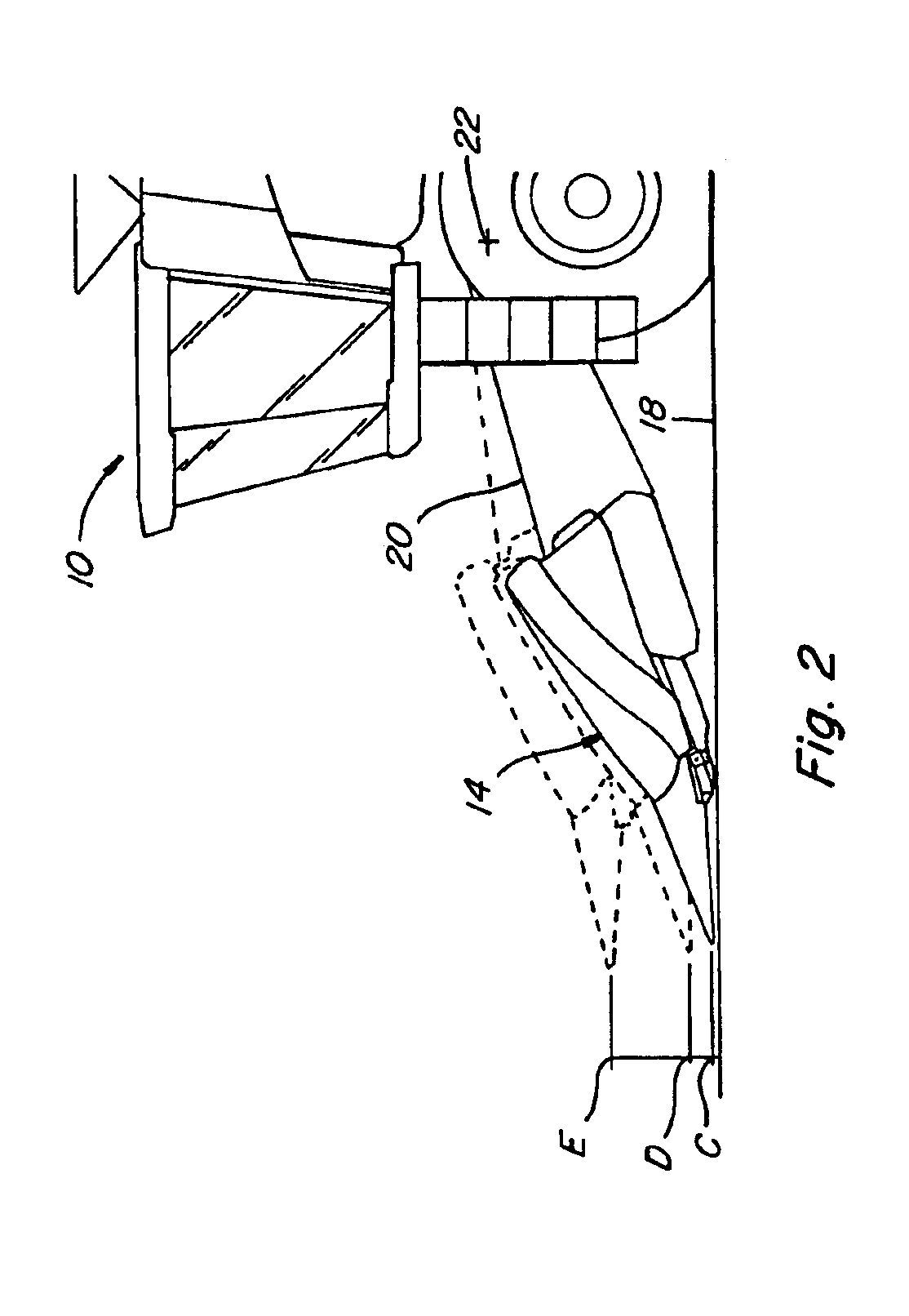

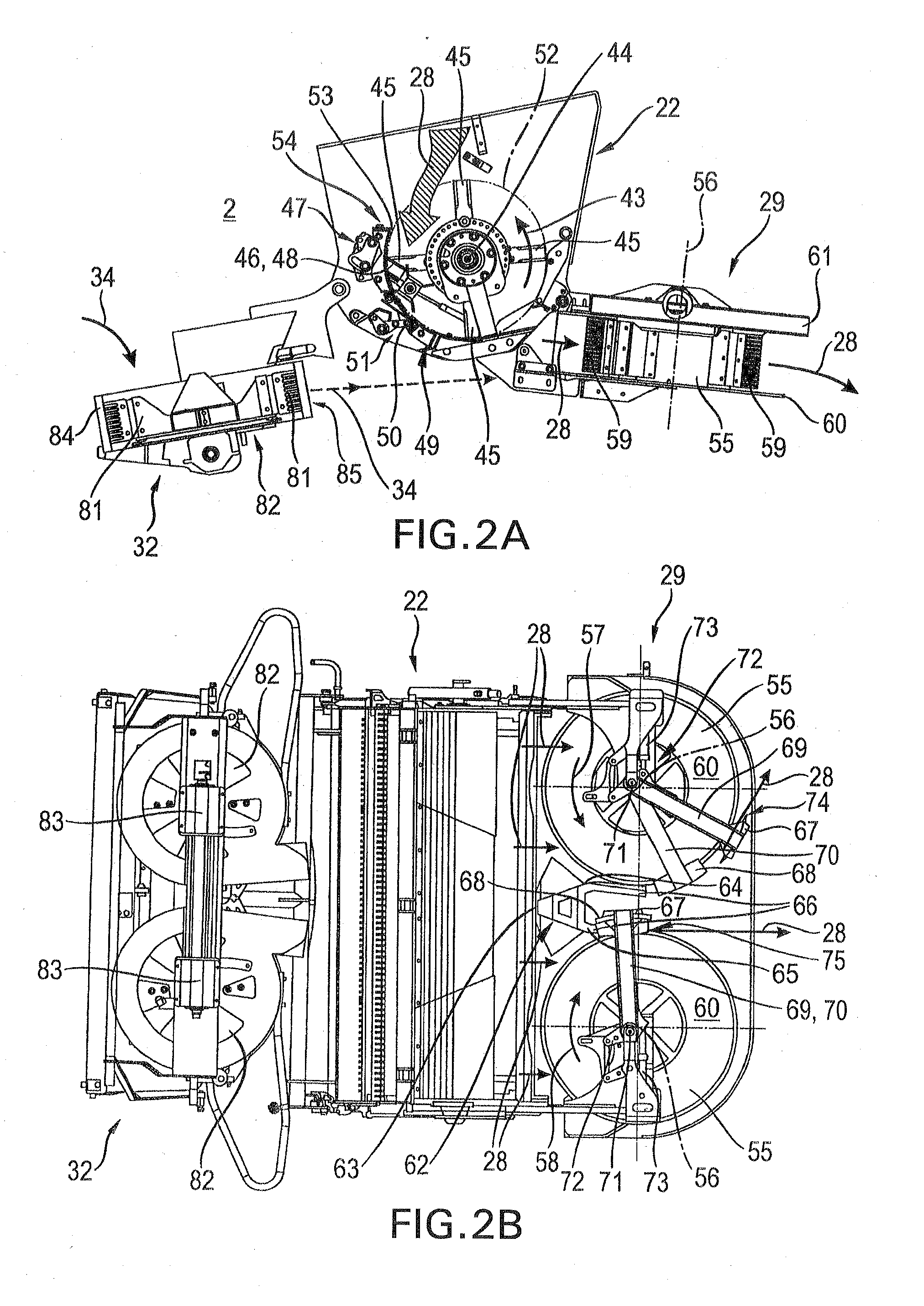

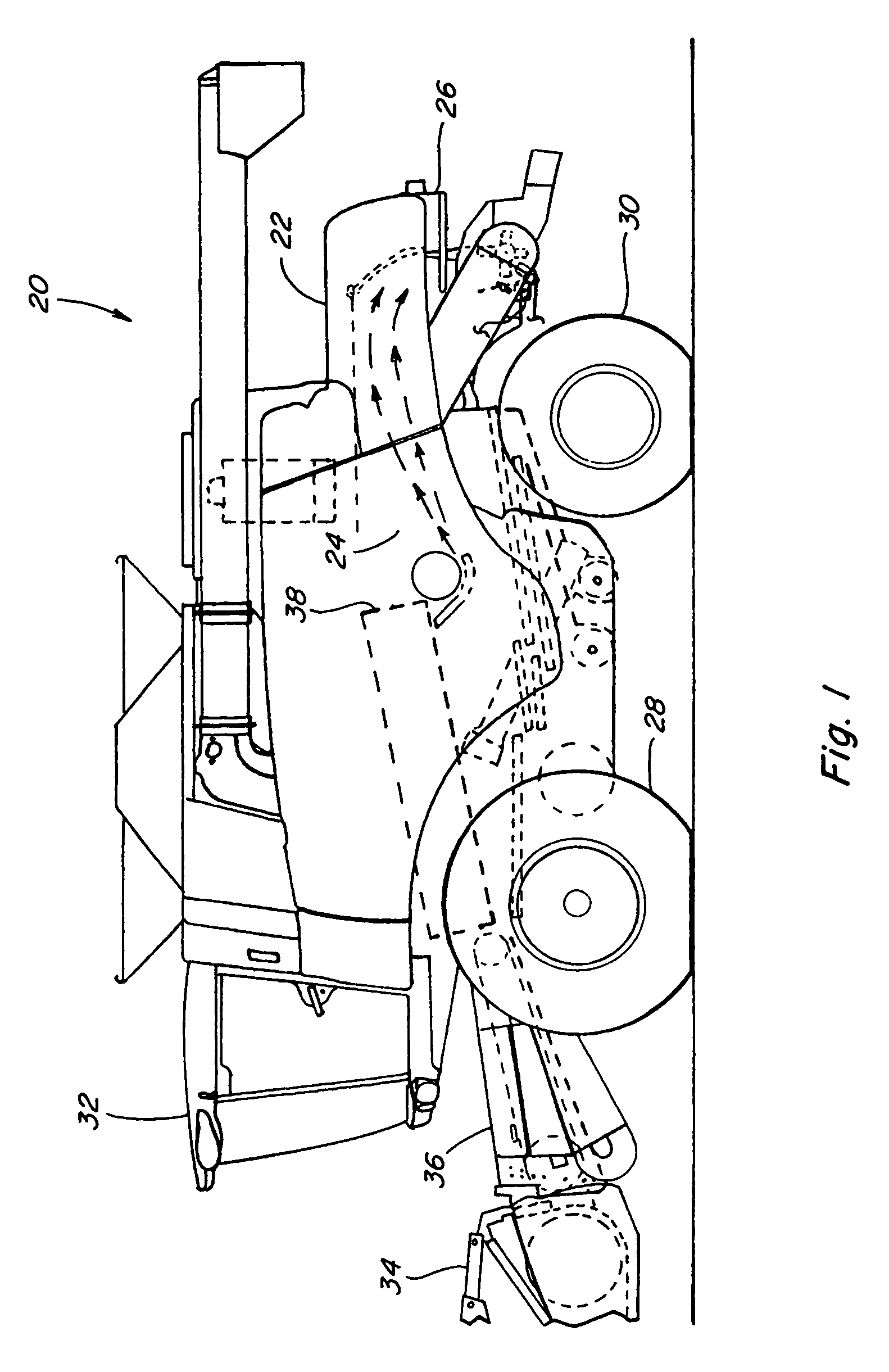

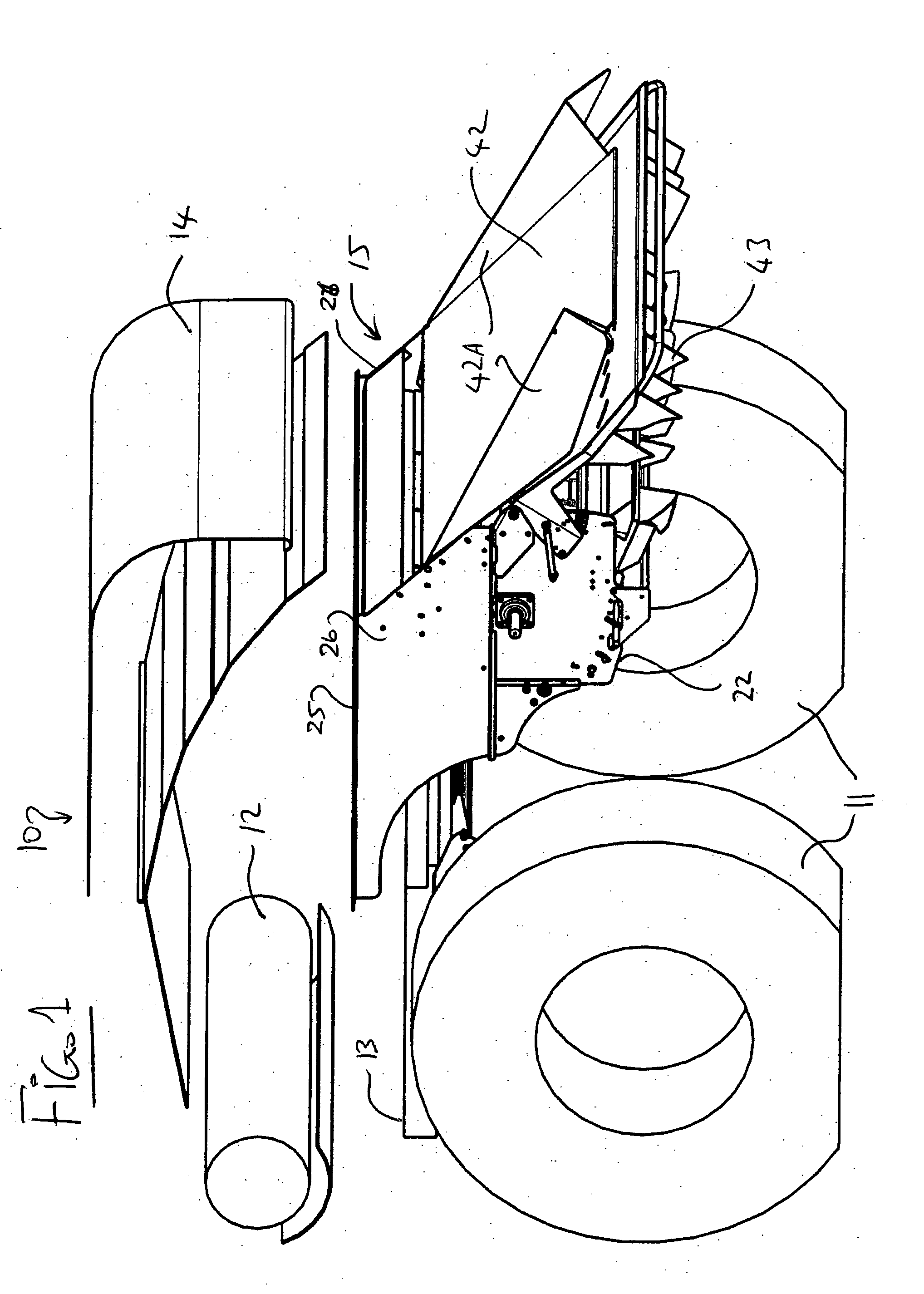

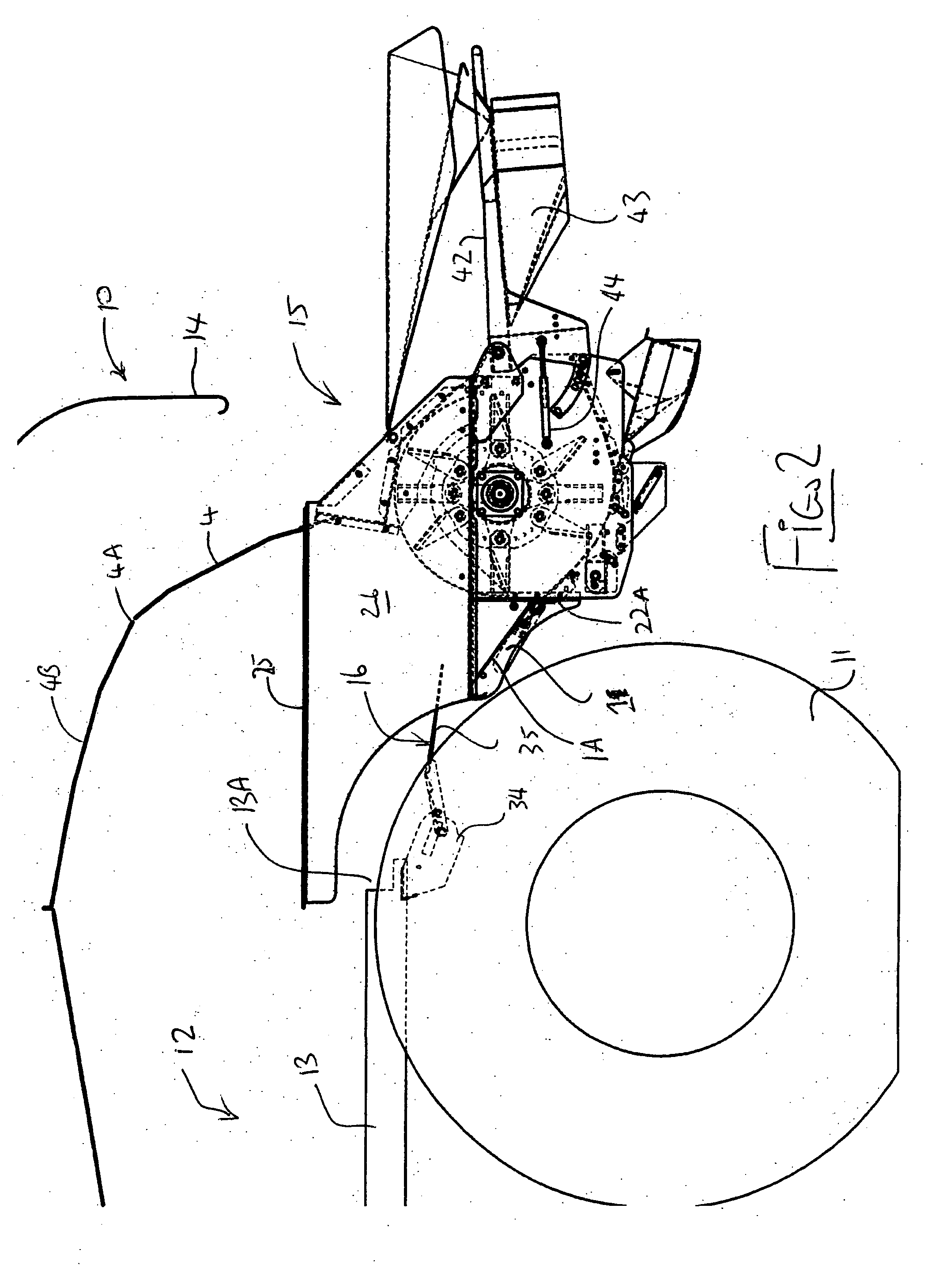

System and method for positively discharging crop residue from a combine

ActiveUS7066810B2Precise, efficient, and consistent crop residue dischargeDifferent typeMowersThreshersChaffEngineering

A system and method for positively discharging crop residue from a combine for precisely and consistently delivering crop residue from the threshing and separating area of a combine to the combine's residue handling system or outwardly from the rear of the combine and onto the harvested field below as a windrow. The present invention can include, or operate in cooperation with, a discharge mechanism, such as a conventional discharge beater, which delivers at least some of the crop residue to a conveying mechanism of the system. The system also includes a guide mechanism including a door arrangement configurable in several alternative configurations for receiving and merging and regulating crop residue flow from the discharge mechanism and the conveying mechanism, and directing the merged flow to a desired processing mechanism, such as, but not limited to, a chaff spreader, a straw chopper and / or spreader, etc.

Owner:BLUE LEAF I P INC

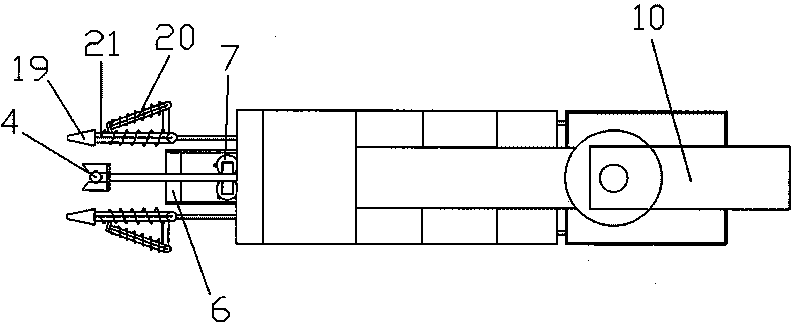

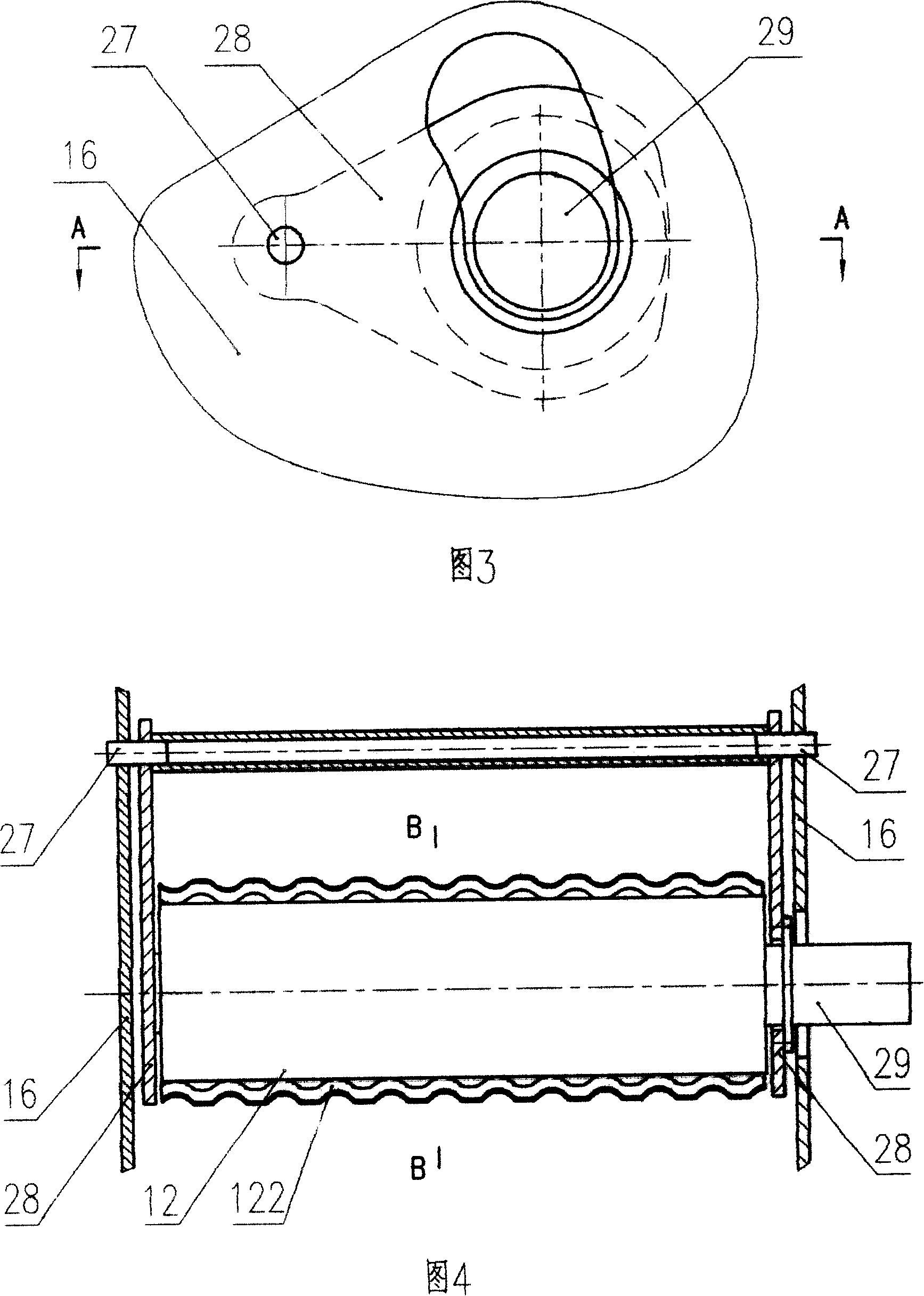

Sugarcane combine for cutting into pieces

The invention relates to a sectional sugar cane combine harvester, which belongs to the agricultural machine field and comprises a topper shear plate, a left holding device of the sugar cane, a right holding device of the sugar cane, a sugar cane pressing roller, a feeding roller, a cutter, a conveying roller, a plurality of upper conveying rollers, a plurality of down conveying rollers, a down cutting roller, an upper cutting roller, a frame, a lifter and a Level I trash separator. The utility model is characterized in that the sugar cane pressing roller, feeding roller and the cutter are arranged at both plates of the middle frame of the harvester from front to back and high to low; the back of the cutter is provided with the conveying roller, a plurality of the down conveying rollers and down cutting roller from front to back and low to high; a plurality of the upper conveying rollers are respectively arranged corresponding to a plurality of the down conveying rollers; the upper cutting rollers are arranged corresponding to the down cutting roller; the back of the upper and the down cutting rollers are provided with the lifters and the back up of the upper and down cutting rollers are provided with the Level I trash separator. The machine is used for the sugar cane harvest, can continuously finish lifting, topper cutting, feeding, conveying, cutting, trash separating, transportation and loading with high working efficiency.

Owner:广西农业机械研究院有限公司

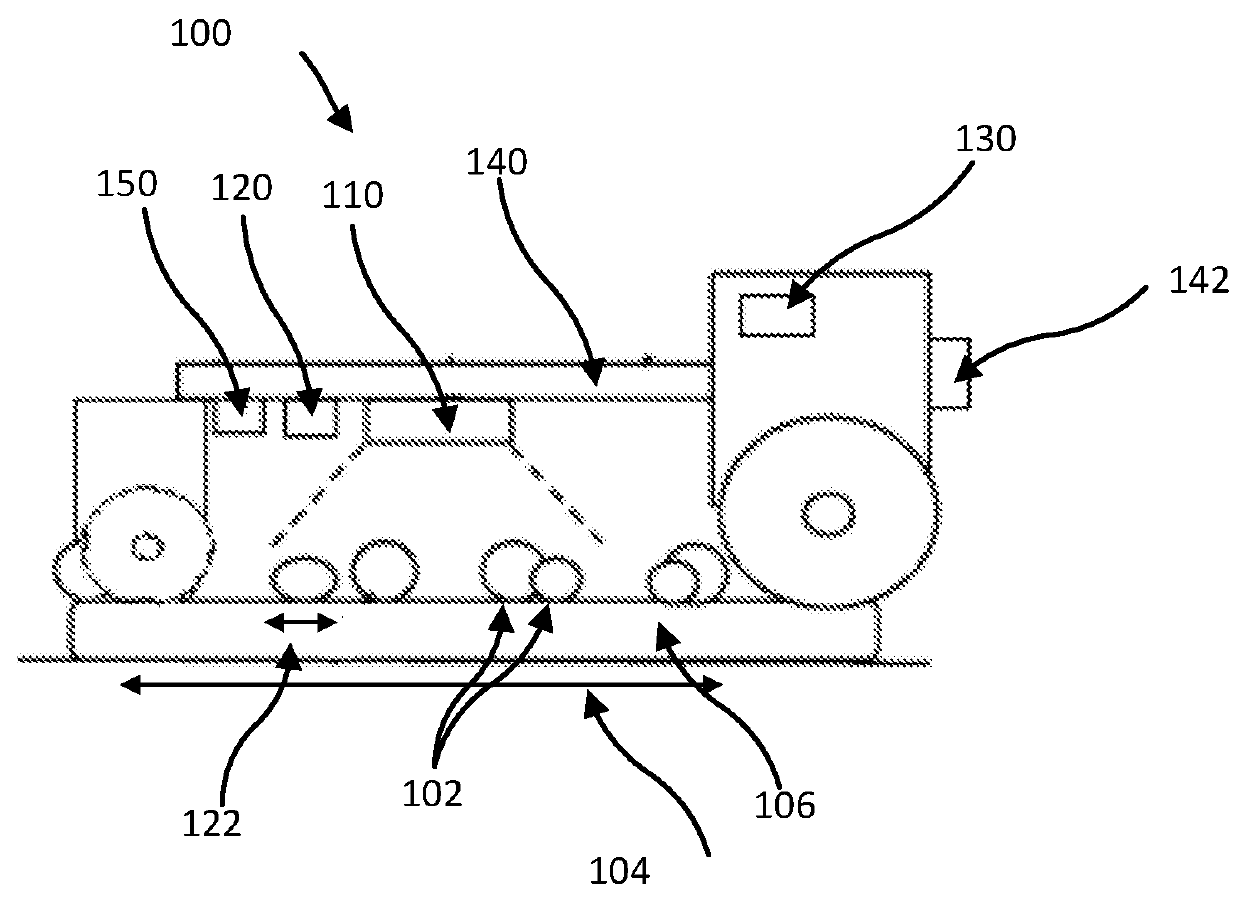

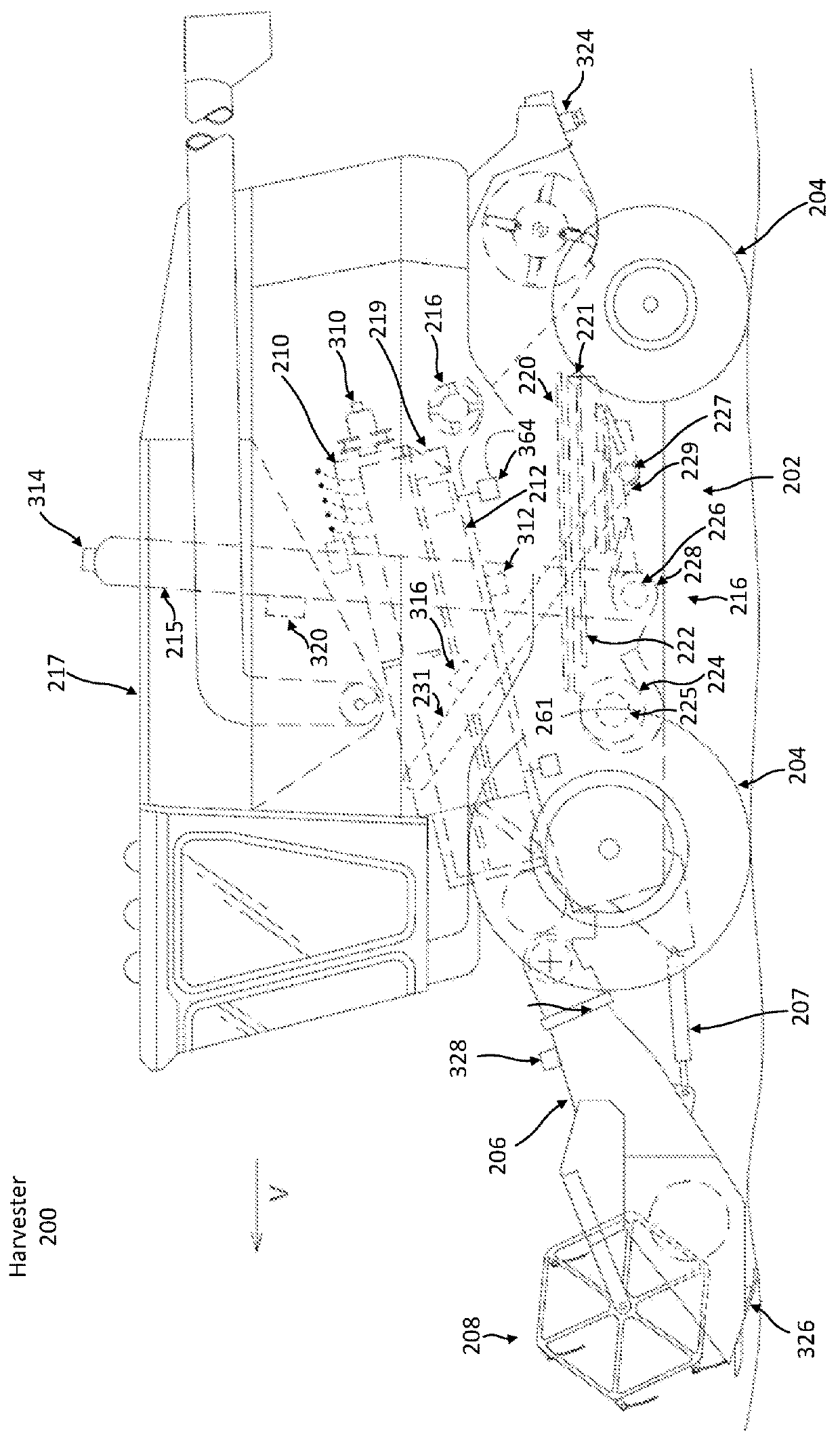

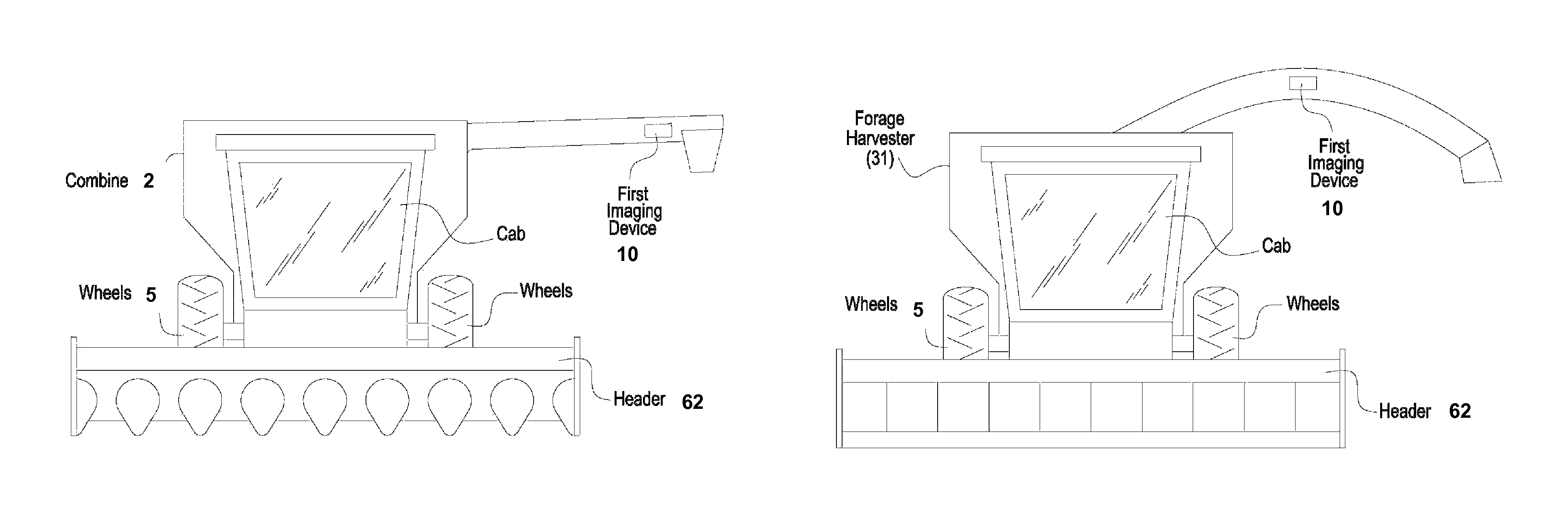

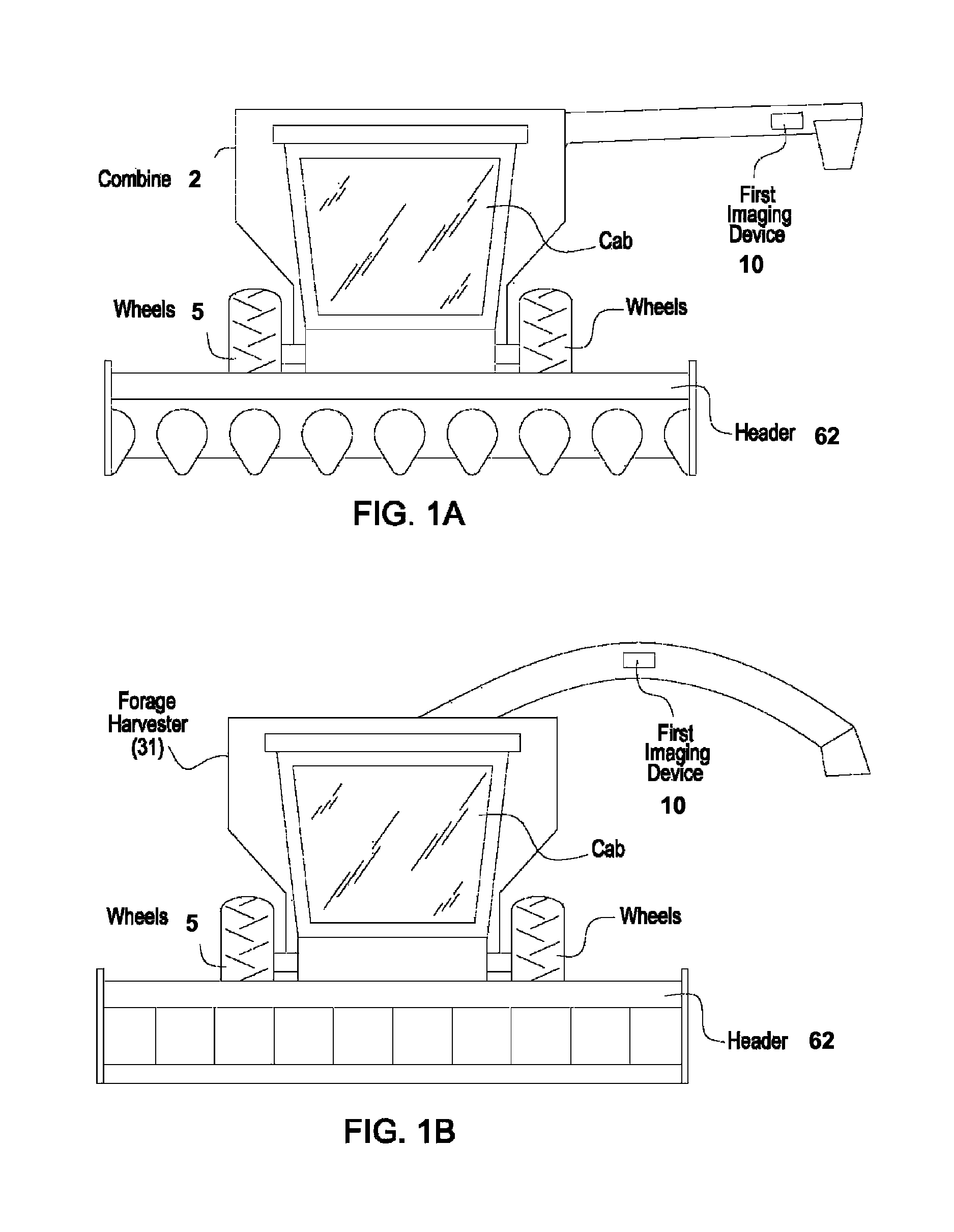

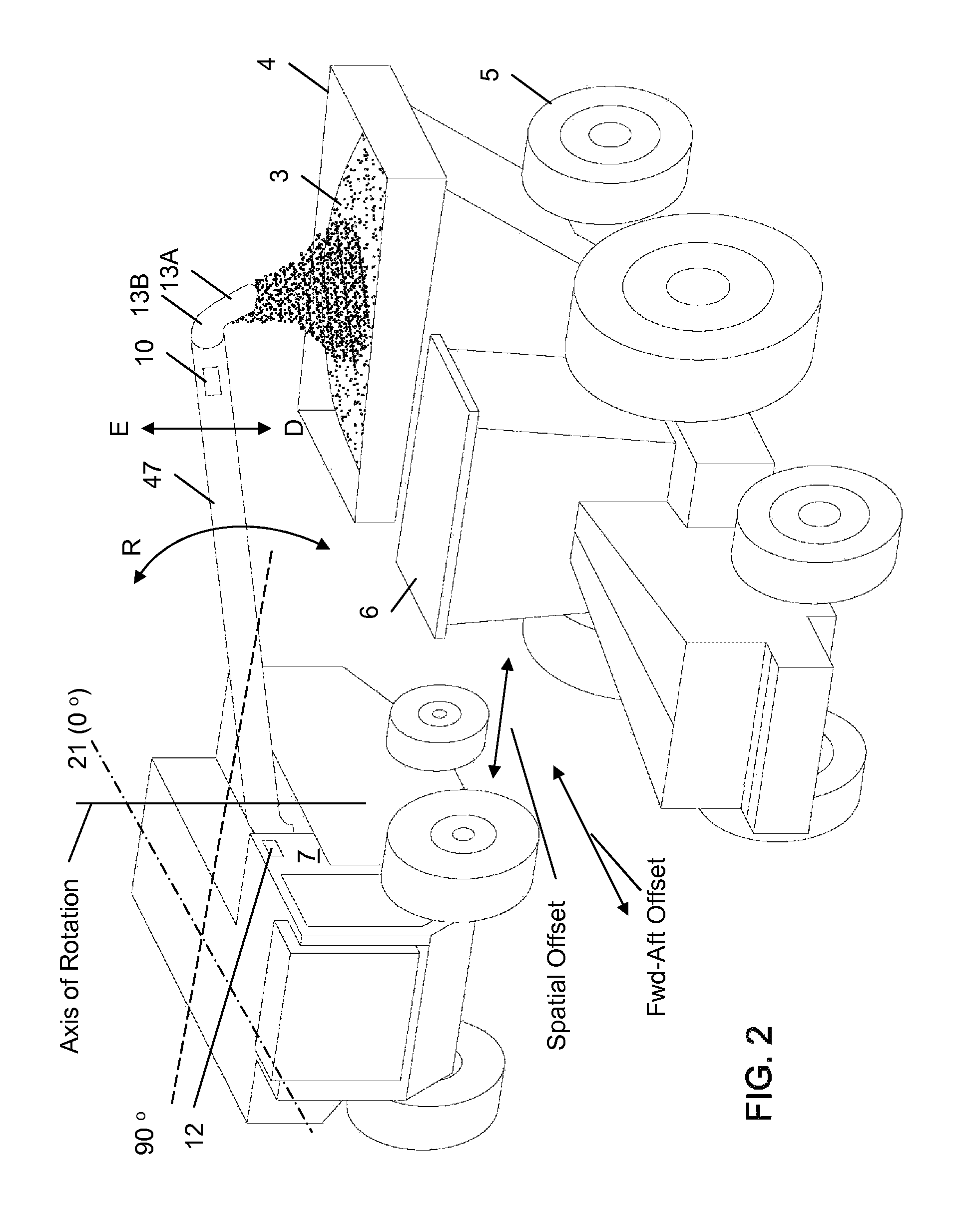

Combine Harvester Including Machine Feedback Control

InactiveUS20180271015A1Facilitate actionGood combination performanceMathematical modelsMowersControl systemEngineering

A combine harvester (combine) includes any number of components to harvest plants as the combine travels through a plant field. The components take actions to harvest plants or facilitate harvesting plants. The combine includes any number of sensors to measure the state of the combine as the combine harvests plants. The combine includes a control system to generate actions for the components to harvest plants in the field. The control system includes an agent executing a model that functions to improve the performance of the combine harvesting plants. Performance improvement can be measured by the sensors of the combine. The model is an artificial neural network that receives measurements as inputs and generates actions that improve performance as outputs. The artificial neural network is trained using actor-critic reinforcement learning techniques.

Owner:BLUE RIVER TECH

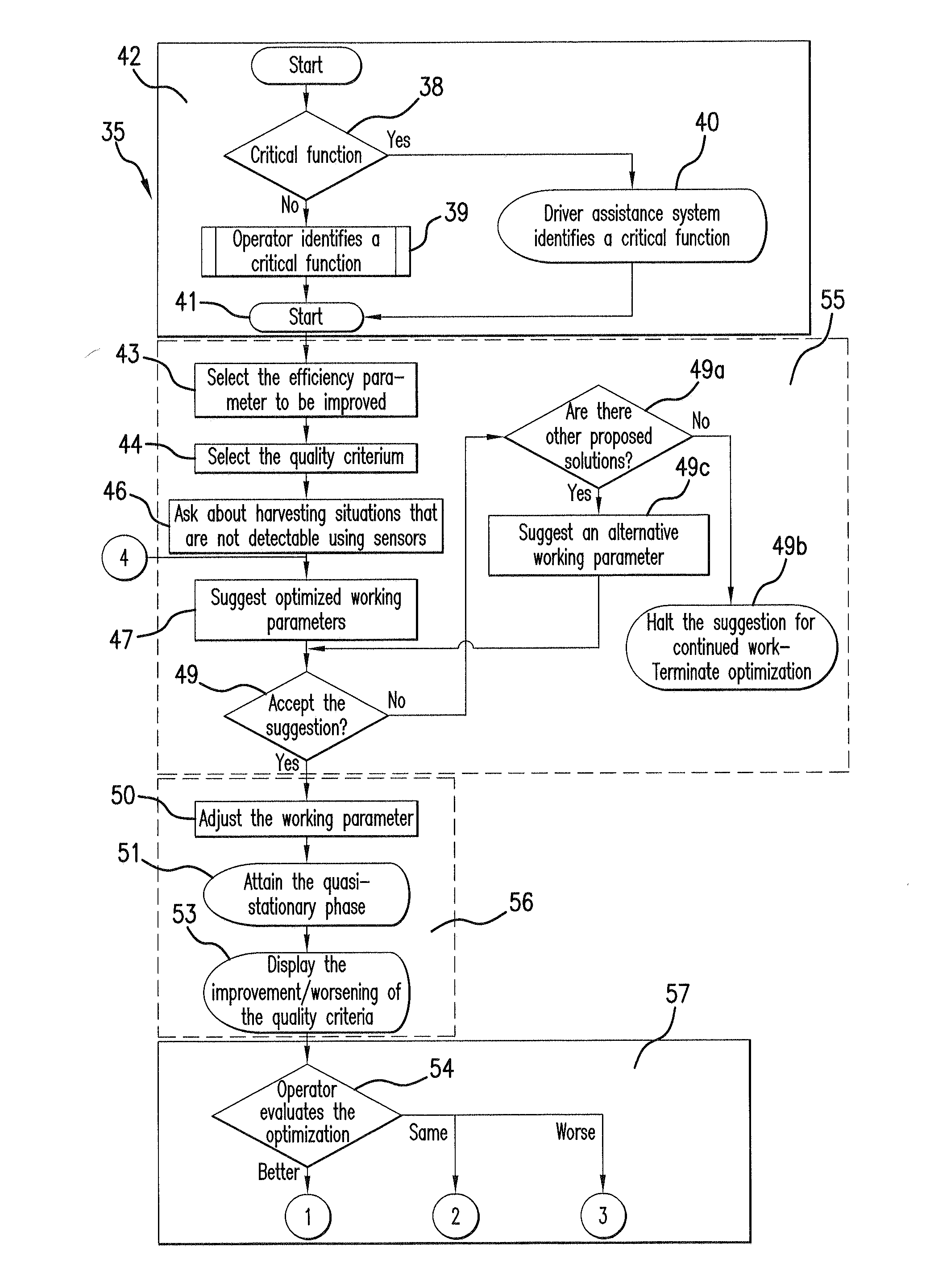

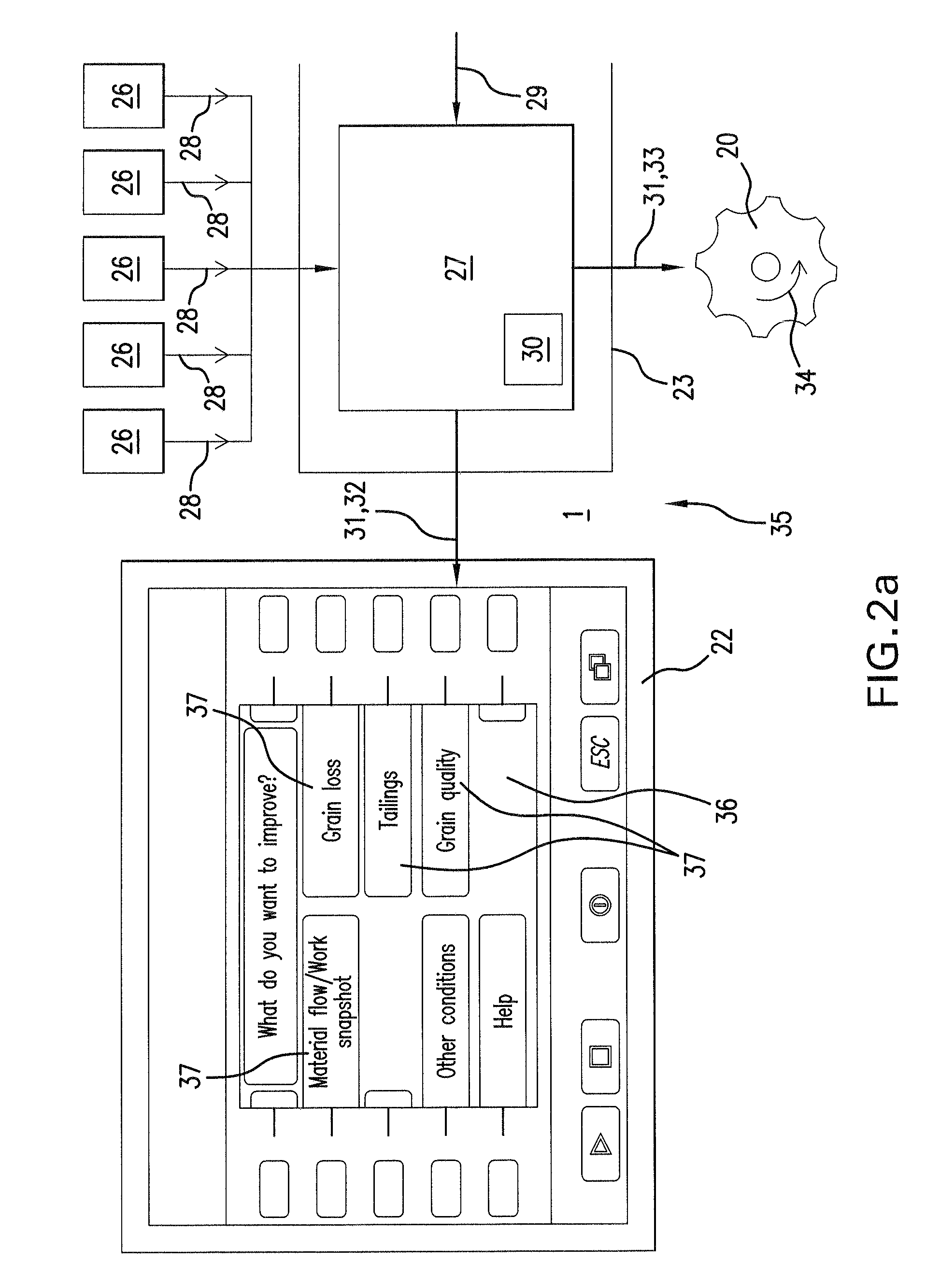

Driver assistance system for agricultural working machines

ActiveUS20100217474A1Improve efficiencyVehicle testingAnalogue computers for trafficArithmetic logic unitDriver/operator

A driver assistance system for an agricultural working machine, in particular a combine harvester has a large number of working mechanisms, an arithmetic logic unit, and at least one display unit, in which the arithmetic logic unit may process information generated by machine-internal sensor systems, external information, and information that is storable in the arithmetic logic unit, and in which the driver assistance system overcomes—with consideration for at least a selection of the available information—critical functions of the agricultural working machine in that efficiency parameters of the agricultural working machine are optimized via interactive, natural-language communication between the operator of the agricultural working machine and the driver assistance system.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Methods for improving the robustness of an automated unloading system

System utilizes stereo cameras to sense the position of a tractor-drawn grain cart relative to a combine during the unloading (on-the-go) process. The sensing system also detects the fill level of grain in the cart and adjusts the relative position of the tractor to the combine to achieve an even fill to the desired fill level.

Owner:DEERE & CO

Automatic control system for a header of an agricultural harvesting machine and method of operation of the same

A control system for a header for an agricultural harvesting machine such as a combine, providing features including an automatic reel position control operable to provide at least one selectable predetermined cutter bar and reel position combination, and which can also automatically control height and / or fore and aft positions of the reel responsive to cutter bar movements, as required, for purposes such as for maintaining and / or optimizing the reel / cutter bar relationship for a particular crop and / or condition, and for avoiding interference between the tines or fingers of the reel and the sickle of the cutter bar, and possible damage to the tines and / or sickles, and slippage of the reel and / or sickle drive, that can result.

Owner:CNH IND AMERICA LLC

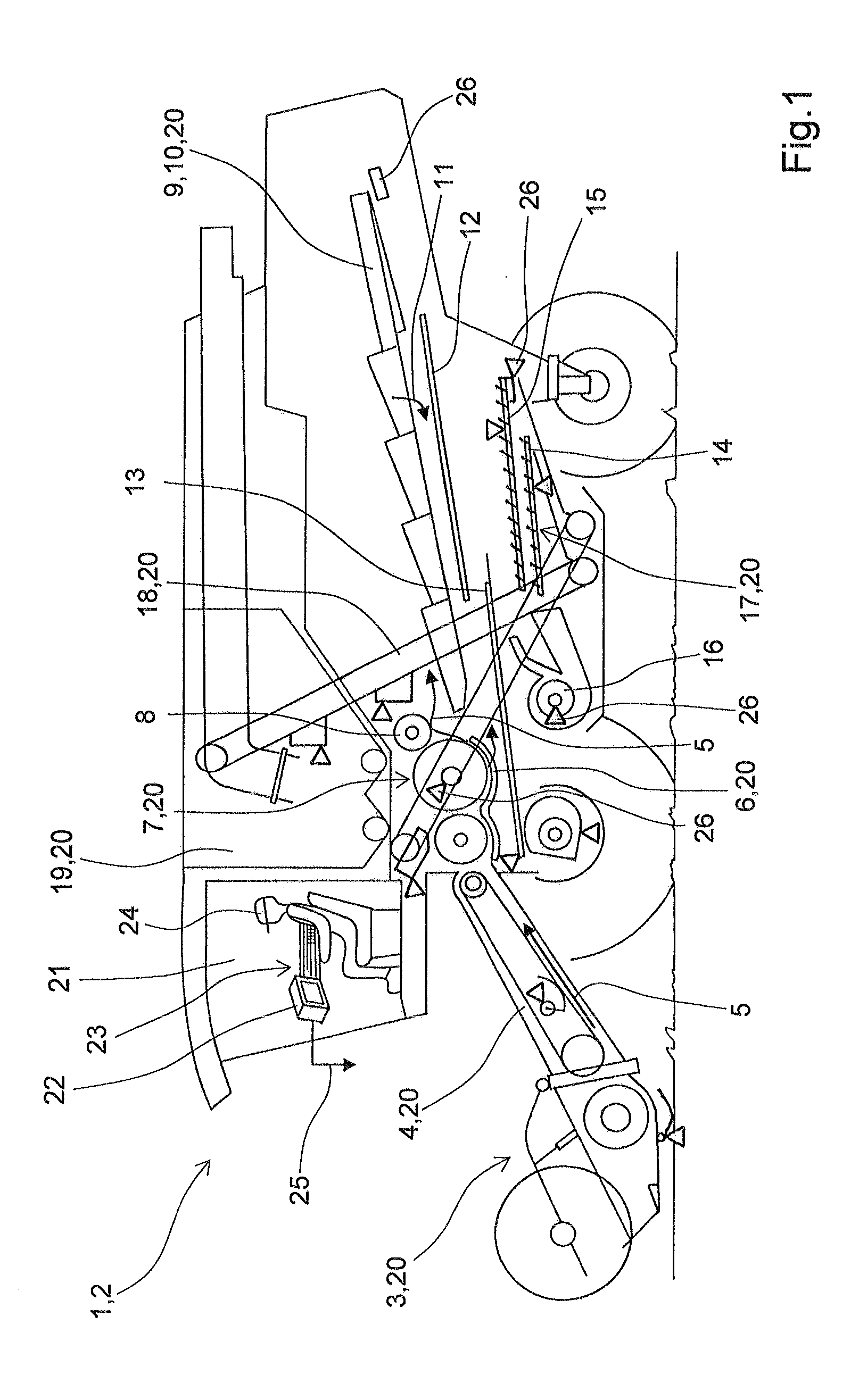

Combine harvester having a driver assistance system

ActiveUS20160088794A1Minimize energy demandConducive to decayMowersBalingCombine harvesterEmbedded system

A combine harvester includes a driver assistance system that regulates a spreading on the ground of a crop flow exiting the combine harvester. The driver assistance system includes spreading strategies that can be selected in order to regulate the spreading of the crop flow exiting the combine harvester.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Combine header with gauge wheels to control cut height

ActiveUS8245489B2Provide stabilityEasy to separateMowersAgricultural undercarriagesCouplingEngineering

Owner:MACDON INDS

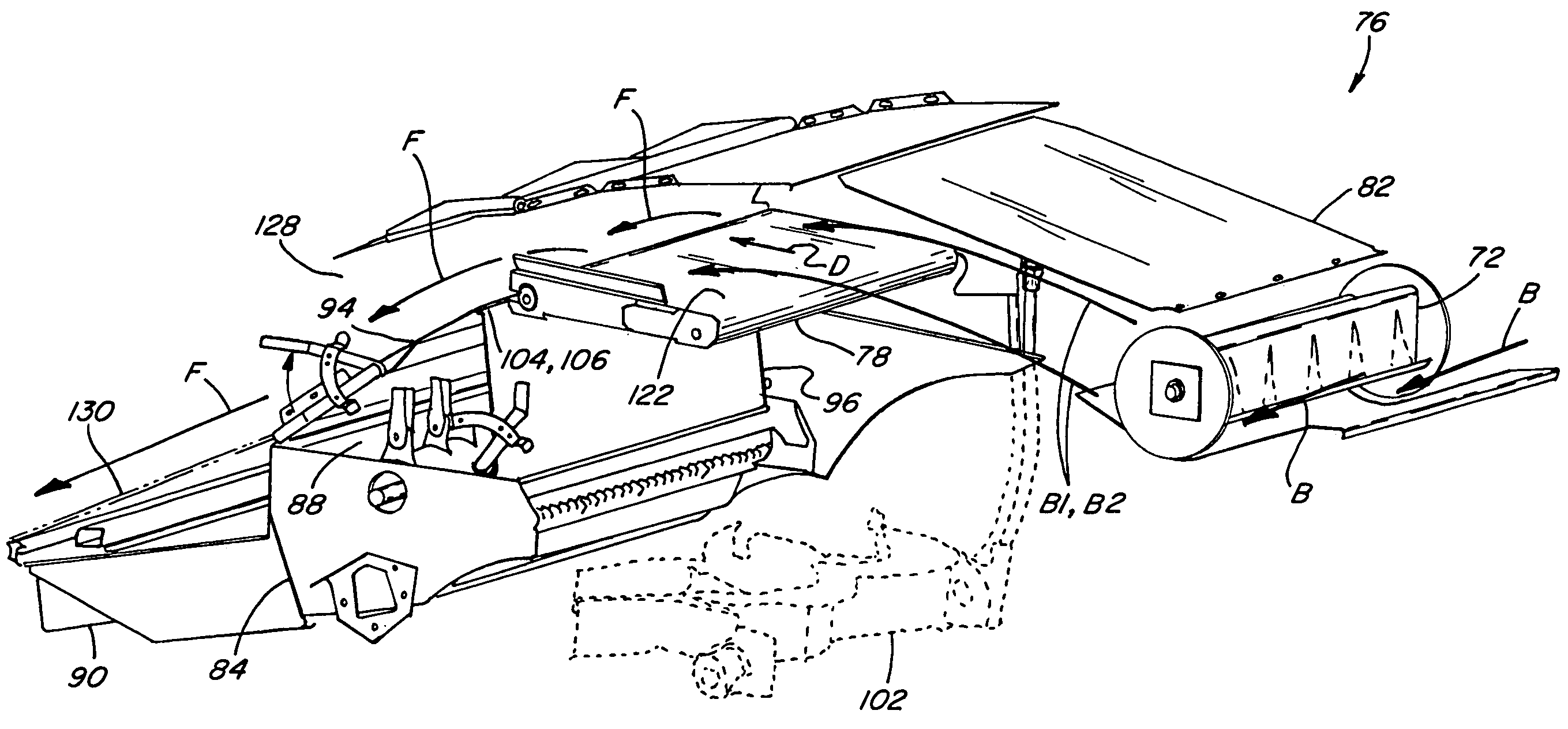

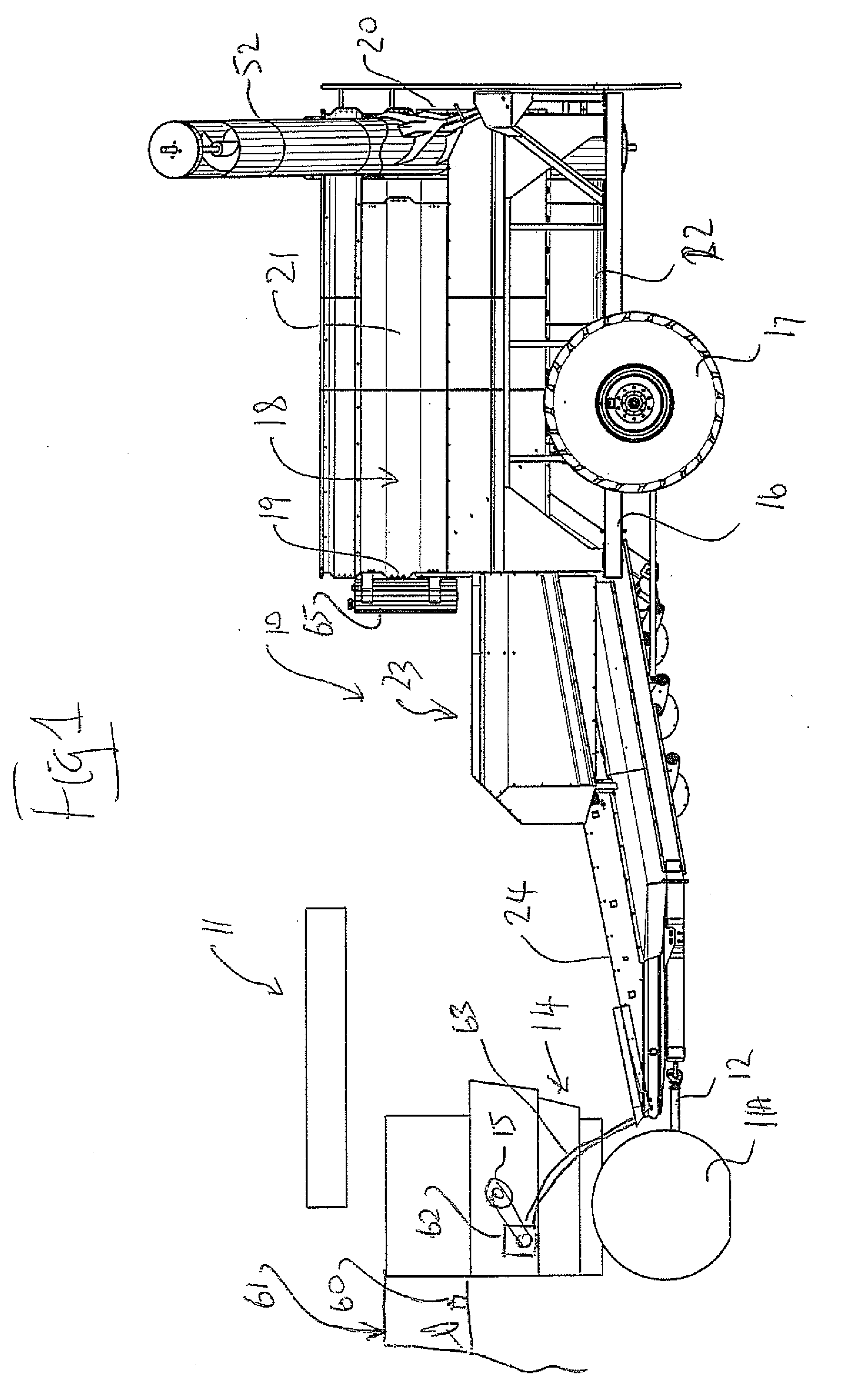

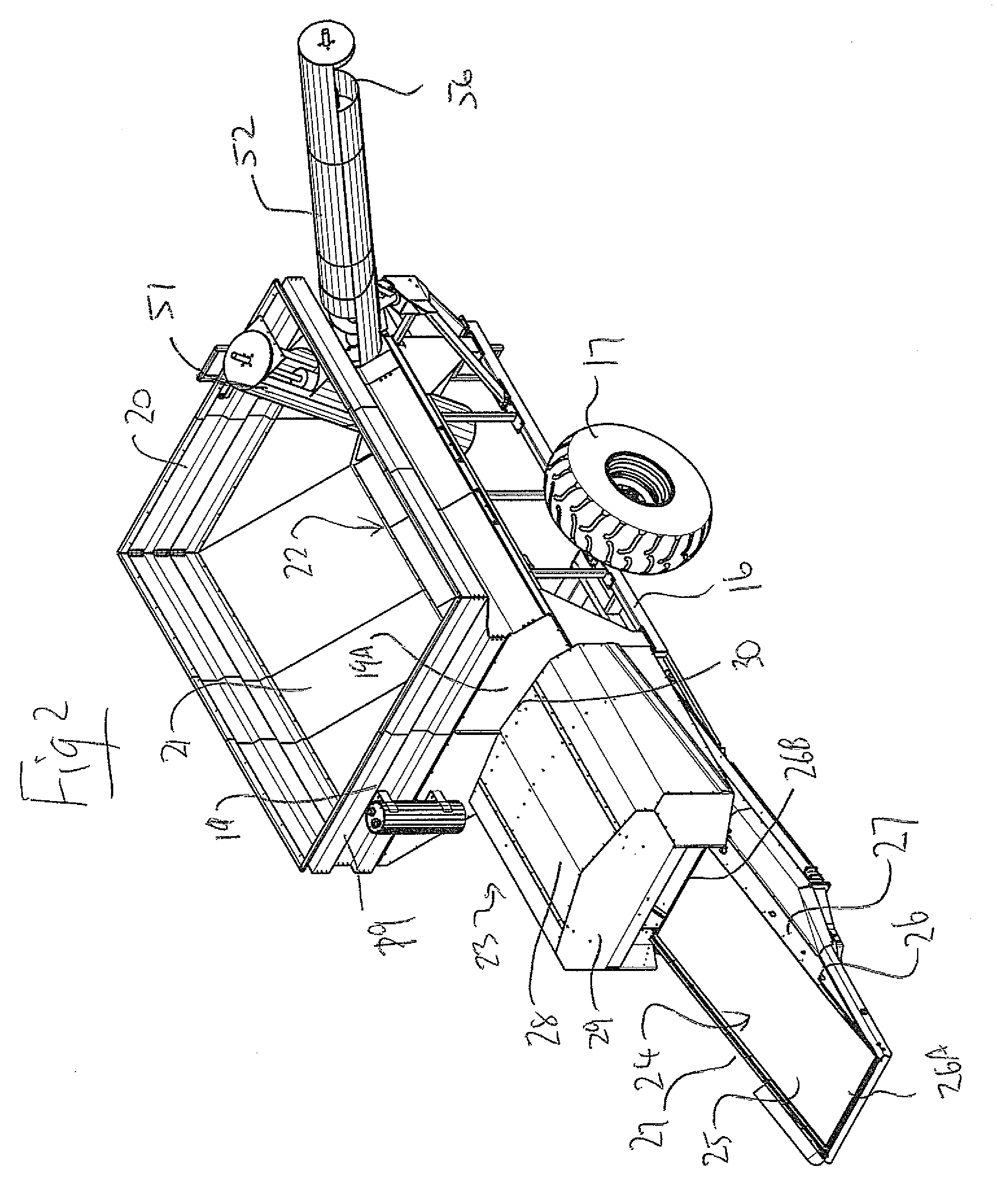

Harvesting corn cobs

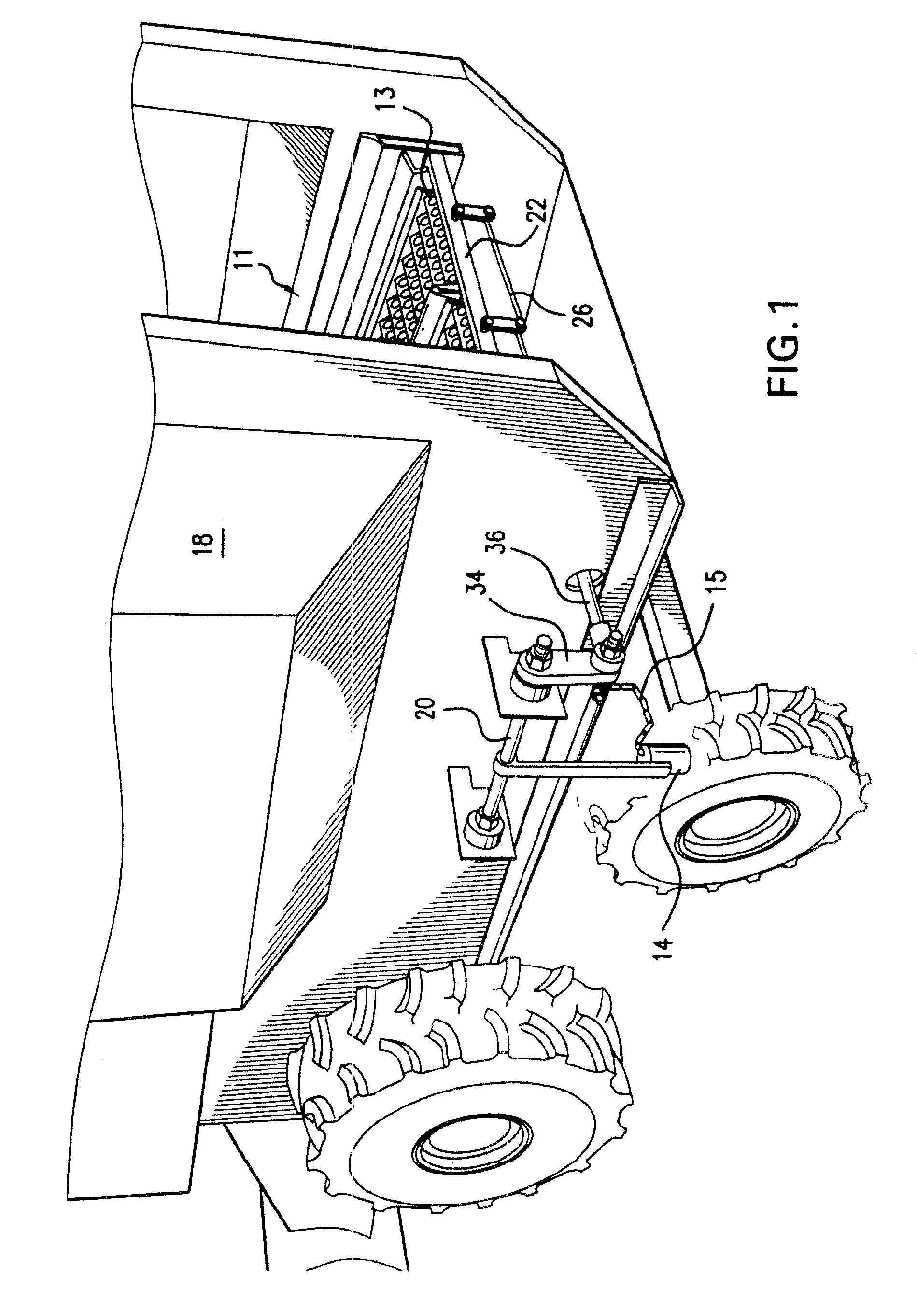

A cart is towed behind a combine harvester for collecting corn cobs and includes a conveyer belt feeding into a system for separating cobs from residue to be discharged and a tank for receiving and transporting the cobs. An unload auger is provided from the tank to one side of the cart while the cart moves forward. Power for driving the cart is obtained from a chopper drive of the combine harvester. The separating arrangement includes a suction fan or a single blower fan or a series of blower fans for blowing air through material from a conveyor and into a spreading guide which disperses the residue. The cobs are conveyed using a series of augers where the auger to flight distance is at least 2 inches and particularly a pair of augers feed the cobs through a front wall of the tank so as to push cobs upwardly into the tank.

Owner:REDEKOP ENTERPRISES

Combine harvester power management control

ActiveUS7648413B2Reduce total powerNeed for powerAnalogue computers for trafficMowersEngineeringCrop residue

A system and method of controlling maximum available engine power of a combine harvester wherein the engine drives the harvester and additionally powers a threshing mechanism for separating harvested crop into grain and crop residue and at least one further crop processing subsystem that may be selectively configured and disengaged, including a straw chopper engageable for chopping the crop residue and propelling the chopped residue from the harvester, structure configurable for directing the crop residue into the chopper or to bypass the chopper, utilizing a controller for automatically reducing the maximum available engine power as a function of the status of the engagement of the subsystems, particularly the chopper and the configuration of the associated structure.

Owner:BLUE LEAF I P INC

Combine harvester with ready adjustment of discharge positions of straw and chaff

A combine harvester has a straw chopper attached to a rear hood behind the rear edge of the sieve assembly with a chaff guide system to bypass the chaff in front of the chopper and a straw guide system to bypass the straw above the chopper and over the tailboard. The chopper has a housing with a feed opening into which straw and / or chaff can be fed depending upon the positions of the chaff guide system and the straw guide system. A chopping assembly mounted in the housing discharges through a discharge opening through onto the tailboard having a plurality of guide fins for spreading. The housing bottom wall has a pivotal adjustment portion to allow chaff entering the feed opening and engaging the chopping assembly to discharge from the housing at a discharge position different from the discharge opening for spreading onto a supplementary spreading device.

Owner:REDEKOP CHAFF SYST

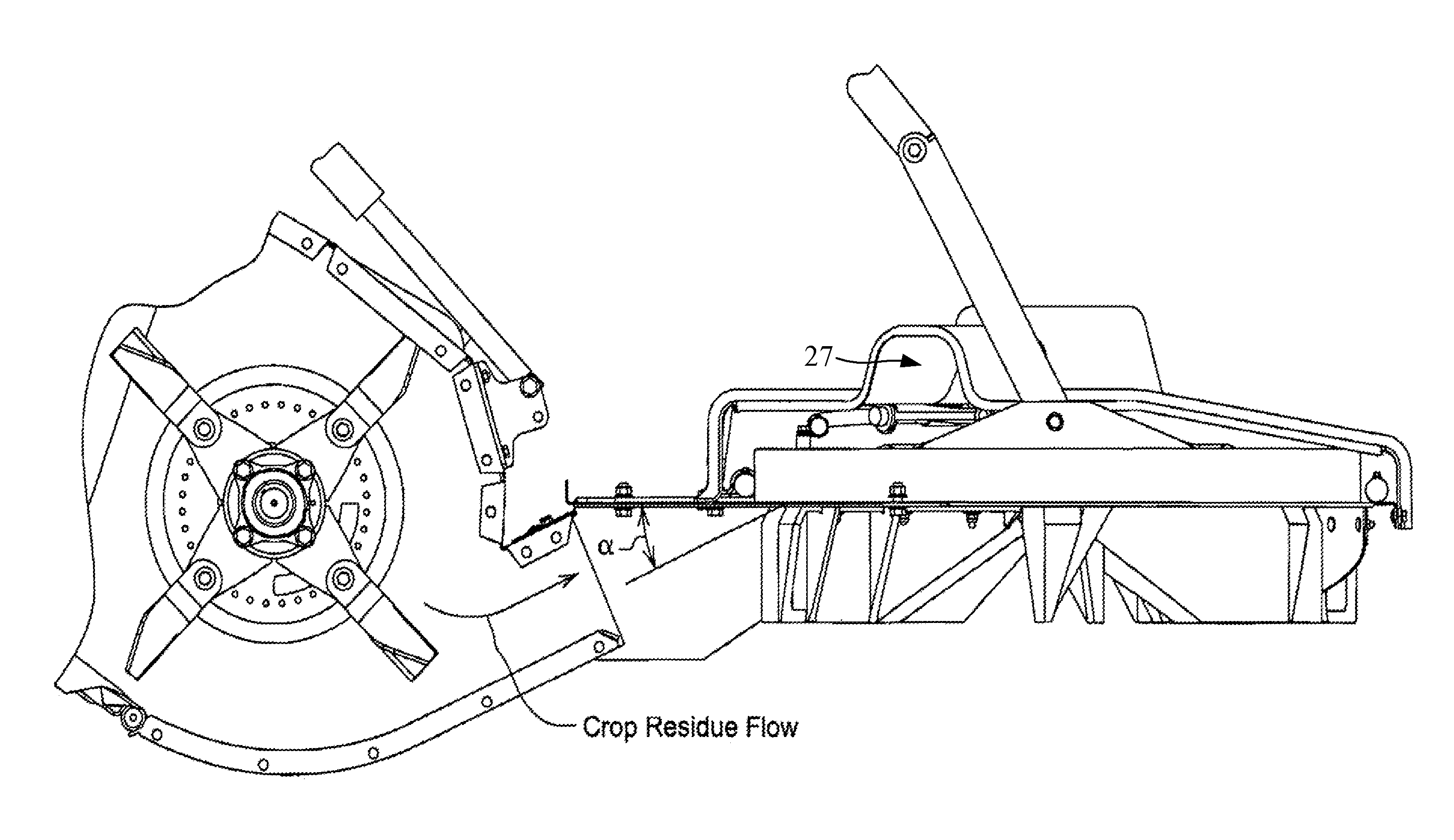

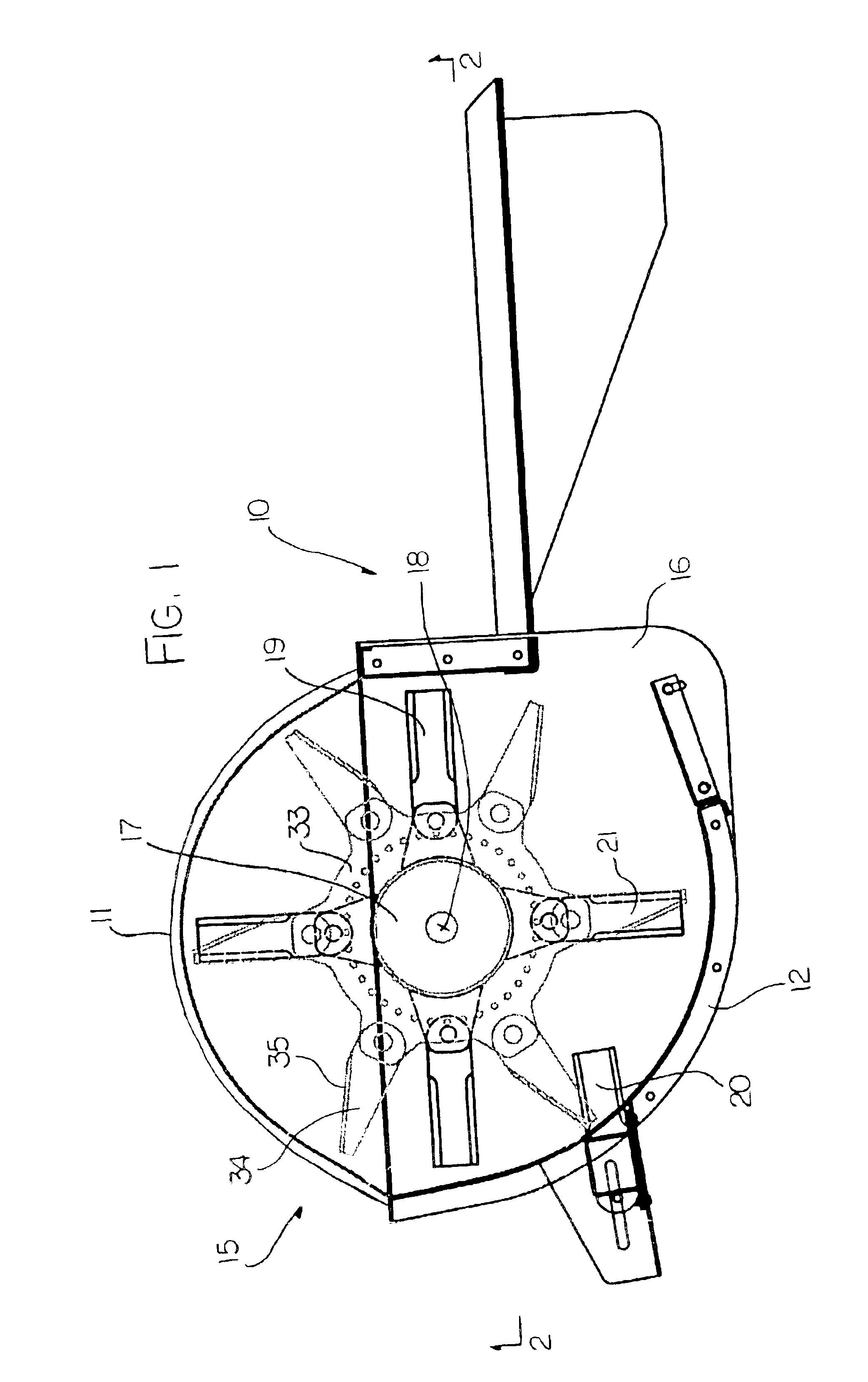

Wide-spread impeller spreader for harvesting combine

A chopper and wide-spread impeller spreader that feeds crop residue from the chopper into the spreader at a specific upward angle to more fully utilize the momentum the crop residue achieves in the chopper. The spreader incorporates air intake holes and air fins above the impellers to keep crop residue moving through the impellers without plugging of discharge material. The chopper propels the residue upwardly into the spreader resulting in a wide-spread broadcast, while preventing crop residue from plugging the spreader.

Owner:DEERE & CO

Cutting platform for a combine harvester

A cutting platform for a combine harvester is fitted with a crop divider that is pivotable relative to the cutting platform between a forwards projecting operating position and a retracted transport position. The divider is supported on a member that forms part of the cutting platform by means of a link which is secured at one end to the member in a manner to allow the link to pivot relative to the member about a first axis and which is secured at its other end to the divider in a manner to allow the divider to pivot relative to the link about a second axis which is inclined relative to the first axis.

Owner:BLUE LEAF I P INC

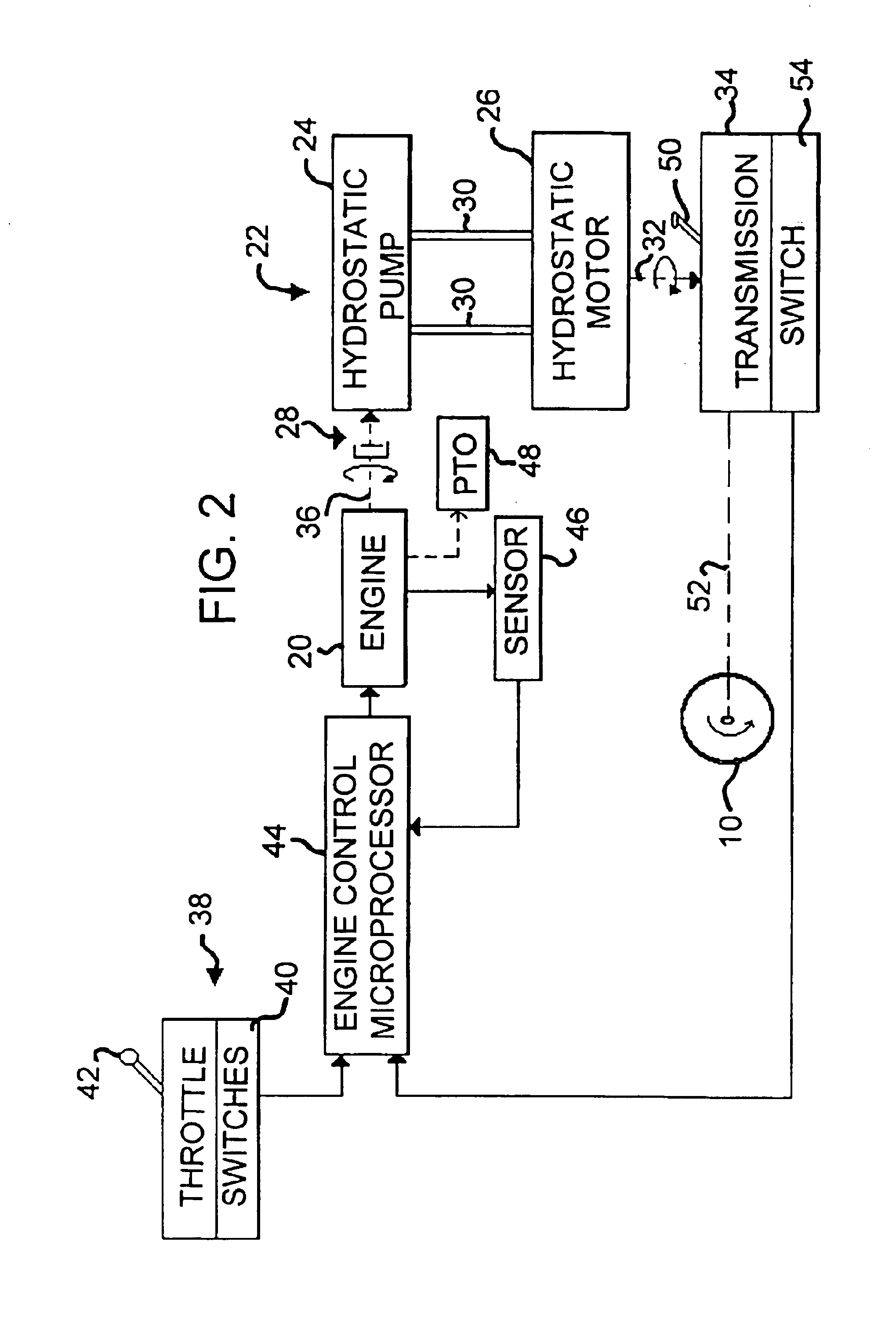

Combine power selection system

InactiveUS6865870B2Increase engine speedAvoid efficiencyAgricultural machinesVehicle fittingsThrottle controlRoad surface

A system for propelling a combine over the ground and driving other components of the combine includes an engine driving a transmission via a hydrostatic drive system. A microprocessor stores a work table and a road table for controlling engine speed. A gear selector operates a switch to select one of the tables and a throttle control operates switches to select a speed value from the selected table. When working a field, the work table is selected so that the engine runs at speeds in a range suitable for driving the other components. For transport of the combine the road table is selected so that the engine may run at a speed higher than speeds suitable for driving the other components. For a given setting of the throttle control, the engine is controlled to run at either a first or second speed depending on the setting of the gear select lever.

Owner:BLUE LEAF I P +1

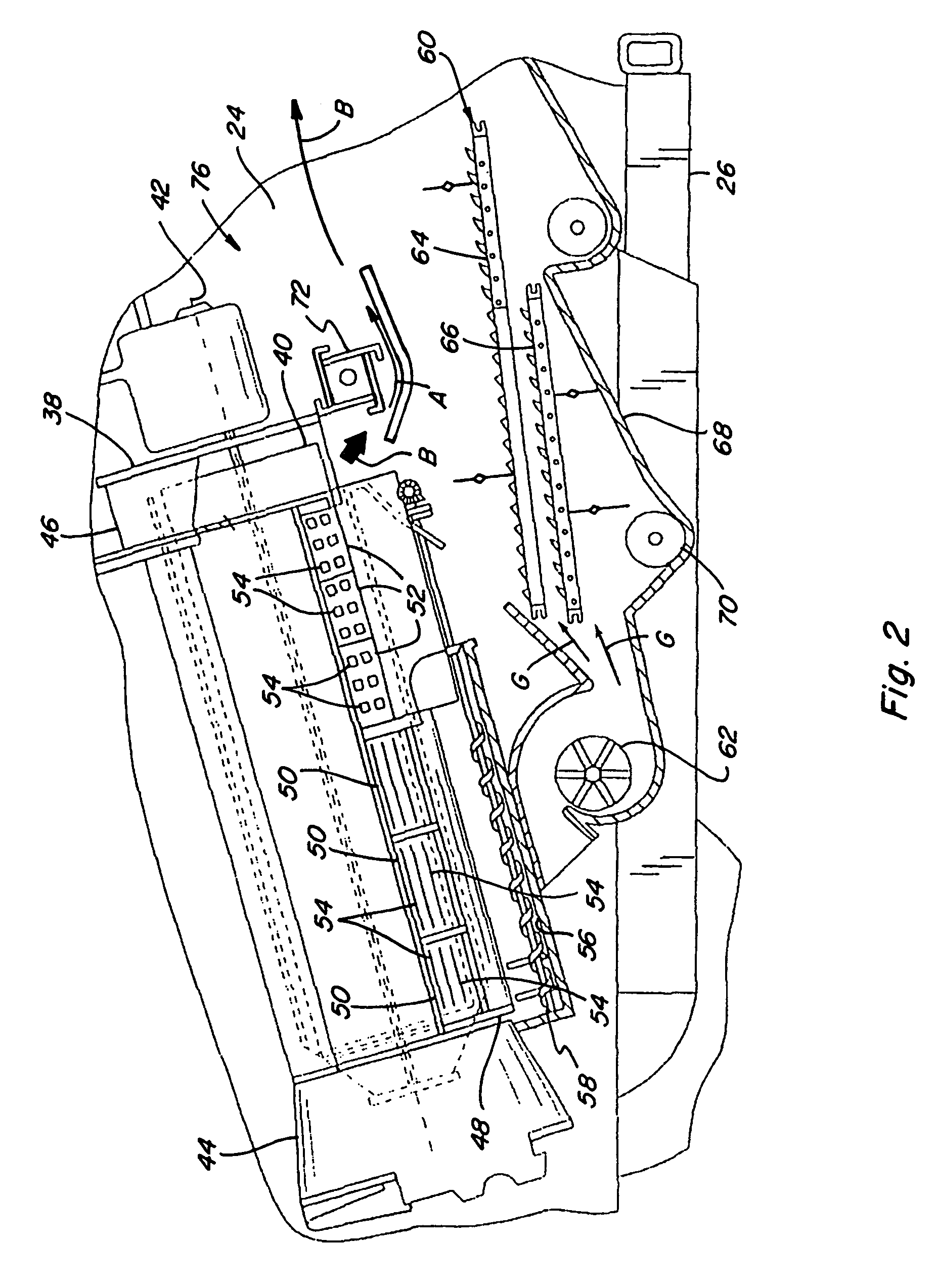

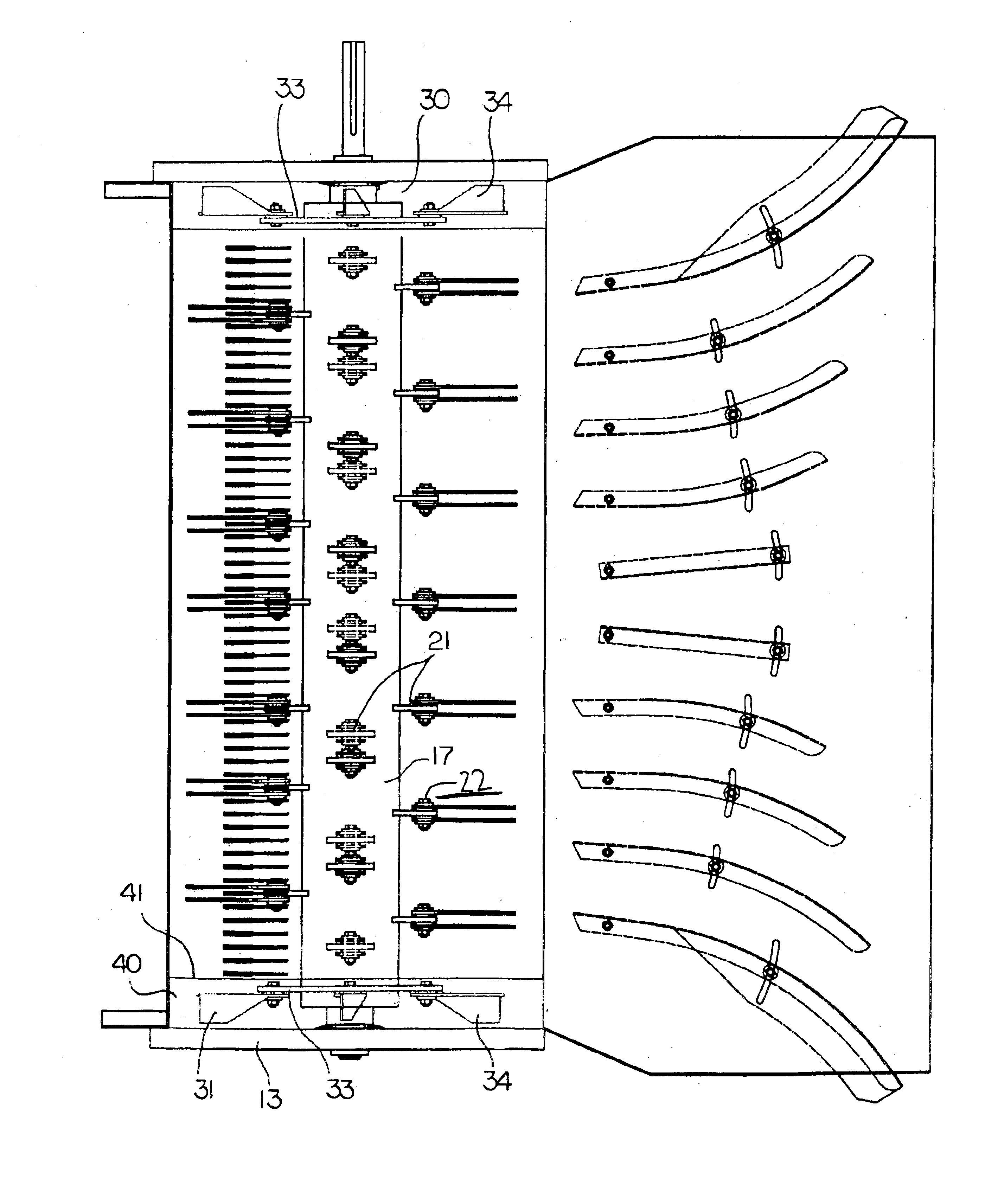

Floating combine sieve assembly

InactiveUS6843719B1Improve efficiencySeparation efficiency can be improvedSievingScreeningEngineeringCombine harvester

A sieve assembly for separating grain from chaff inside of a combine. The sieve assembly comprises a plurality of longitudinal sieve planks that pivot on their longitudinal axis. A hanging weighted member combined with the sieve planks regulates the angle of the sieve planks relative to the combine. As the combine becomes laterally inclined on a hillside, the weighted member changes its angular position relative to the combine. In doing so, the weighted member causes the sieve planks to pivot on their longitudinal axis so that the sieve planks remain level relative to the horizon. Dividers extend between each sieve plank.

Owner:SACQUITNE DAVID

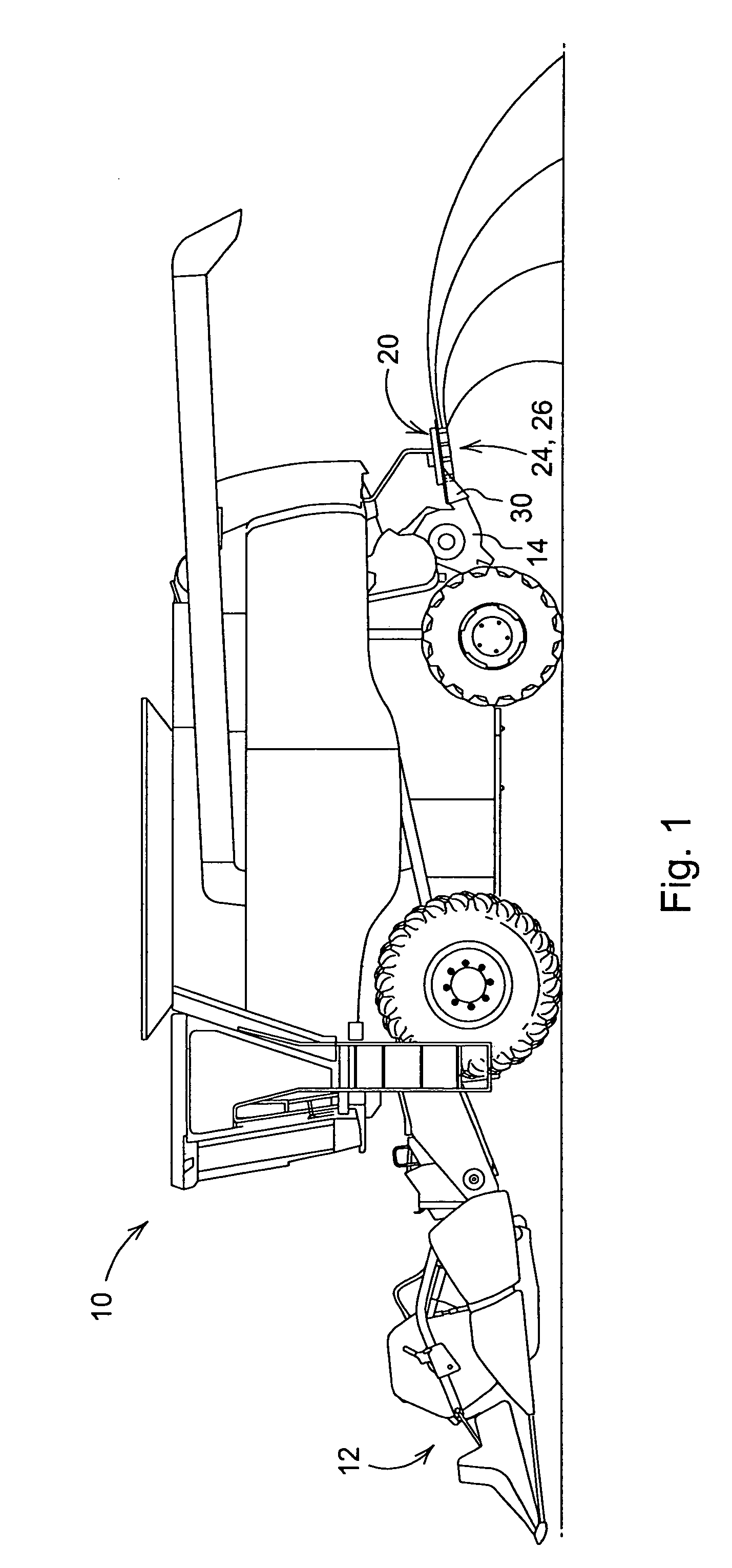

Self-propelled agricultural harvesting machine with controllable transfer device

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Crop feed arrangement for the header of a combine harvester

A draper header for a combine harvester includes two side drapers each running from an outer end guide roller at a first end of the header to an inner end guide roller adjacent the discharge location of the header and a central feed draper located at the discharge location and including a front guide roller just behind the cutter bar and running to a rear guide roller in front of the feeder house of the combine harvester. An auger is located between the discharge rollers with a front edge of the flight forward of the rear end of the discharge rollers to feed the material inwardly and underneath the auger to the inlet of the feeder house. A pan is located underneath the auger and is mounted on a common structure with the feed draper for common pivotal movement about a transverse horizontal axis.

Owner:MACDON INDS

Winged header apparatus and method for a combine

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Apparatus for chopping and discharging straw from a combine harvester

A chopper and discharge apparatus includes a stationary housing for attachment to the rear discharge of a combine harvester so that straw is fed from the combine into an inlet of the housing and is discharged from an outlet of the housing. Within the housing is mounted a hub for rotation about the horizontal axis with the hub carrying a plurality of lugs at angularly and axially spaced positions therearound, each lug carrying a pair of pivotal blade members which are rotated with the hub in the form of flails. Each lug is associated with a stationary blade on the inside of the housing so that the pair of blades carried on each lug sweep past the stationary blade each on a respective side of the stationary blade. The blade members include some flat cutting blades in a center section and only fan blades in end fan sections.

Owner:TRITANA HLDG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com