Patents

Literature

200results about "Outside dividers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

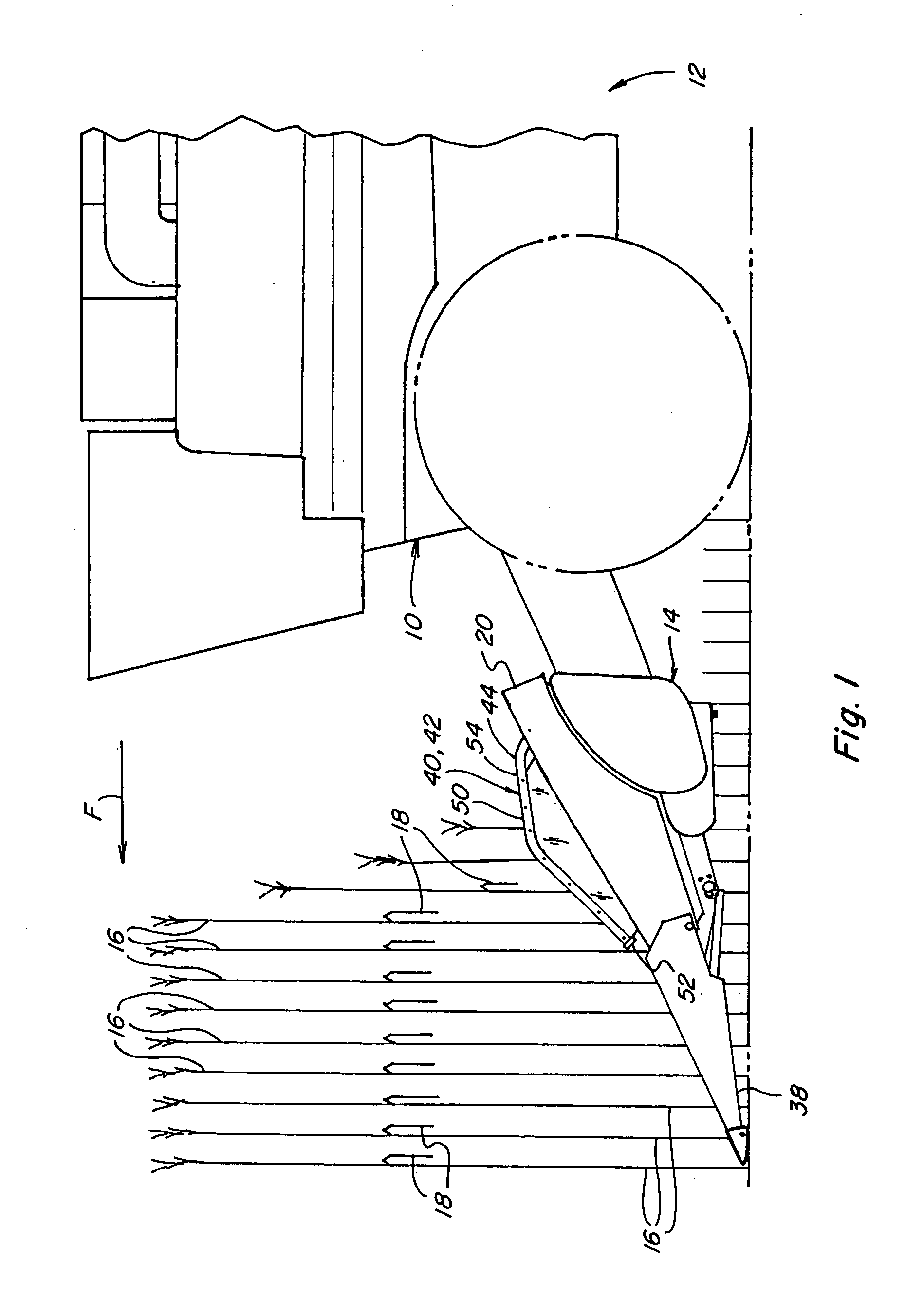

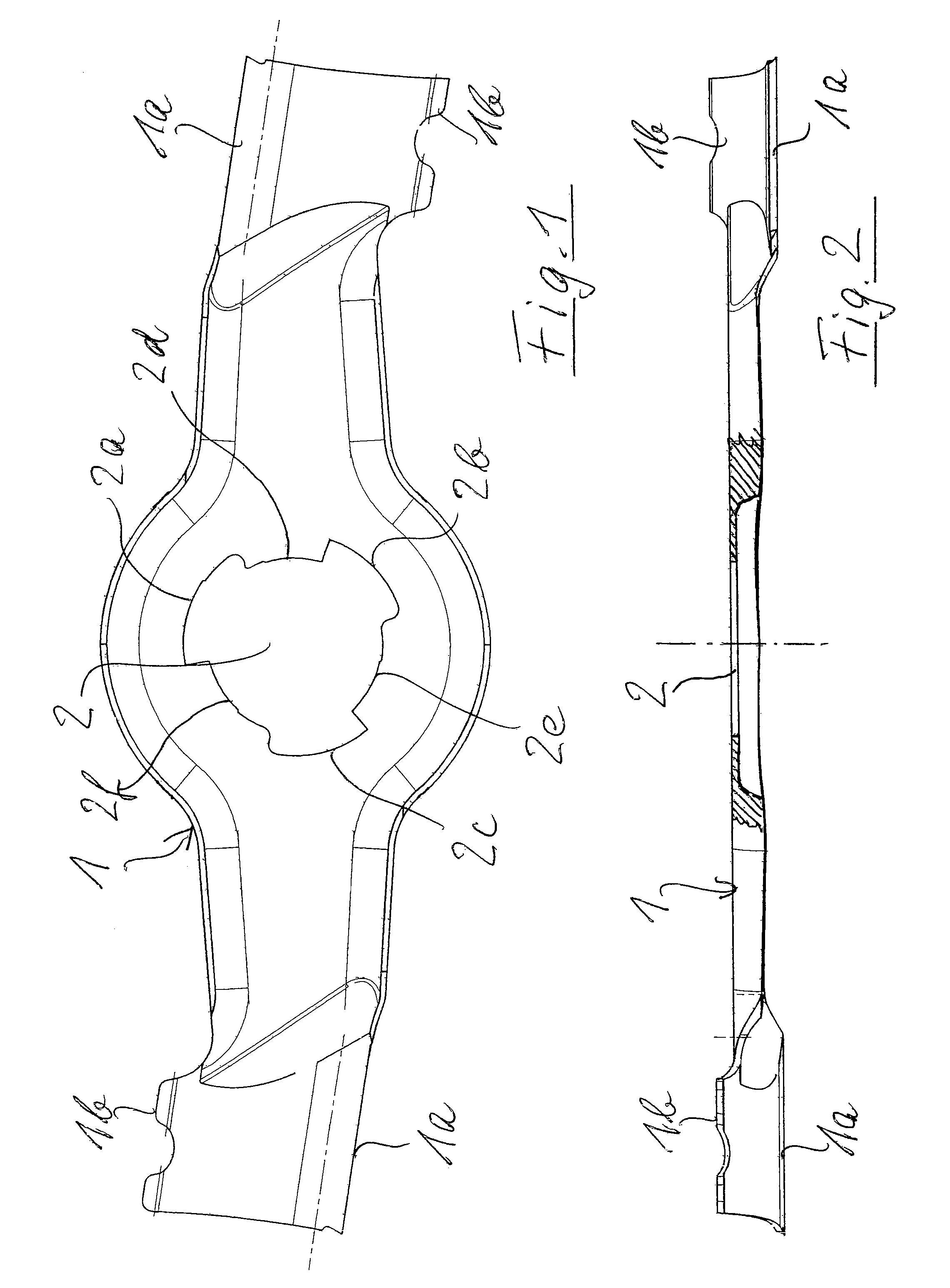

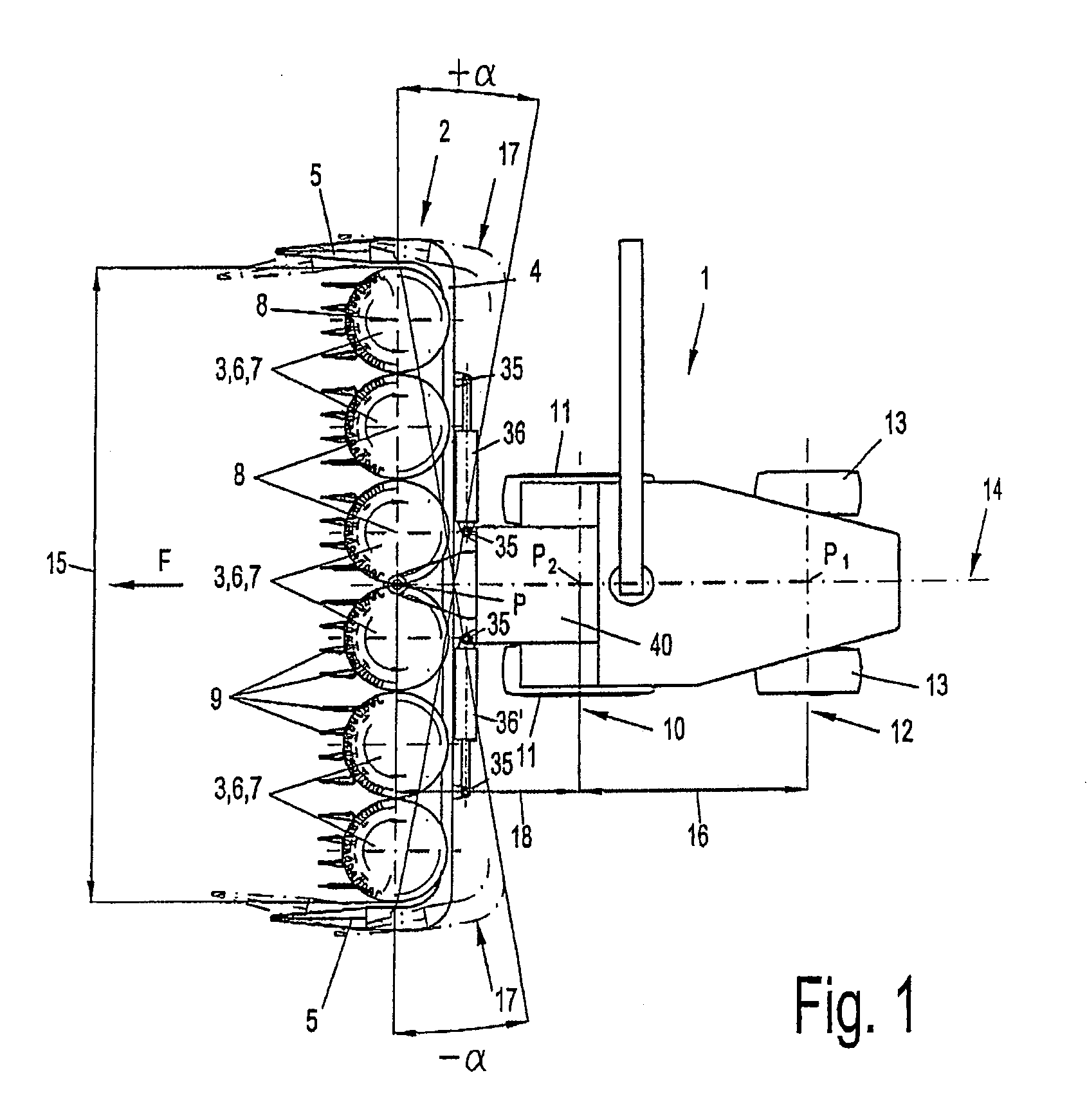

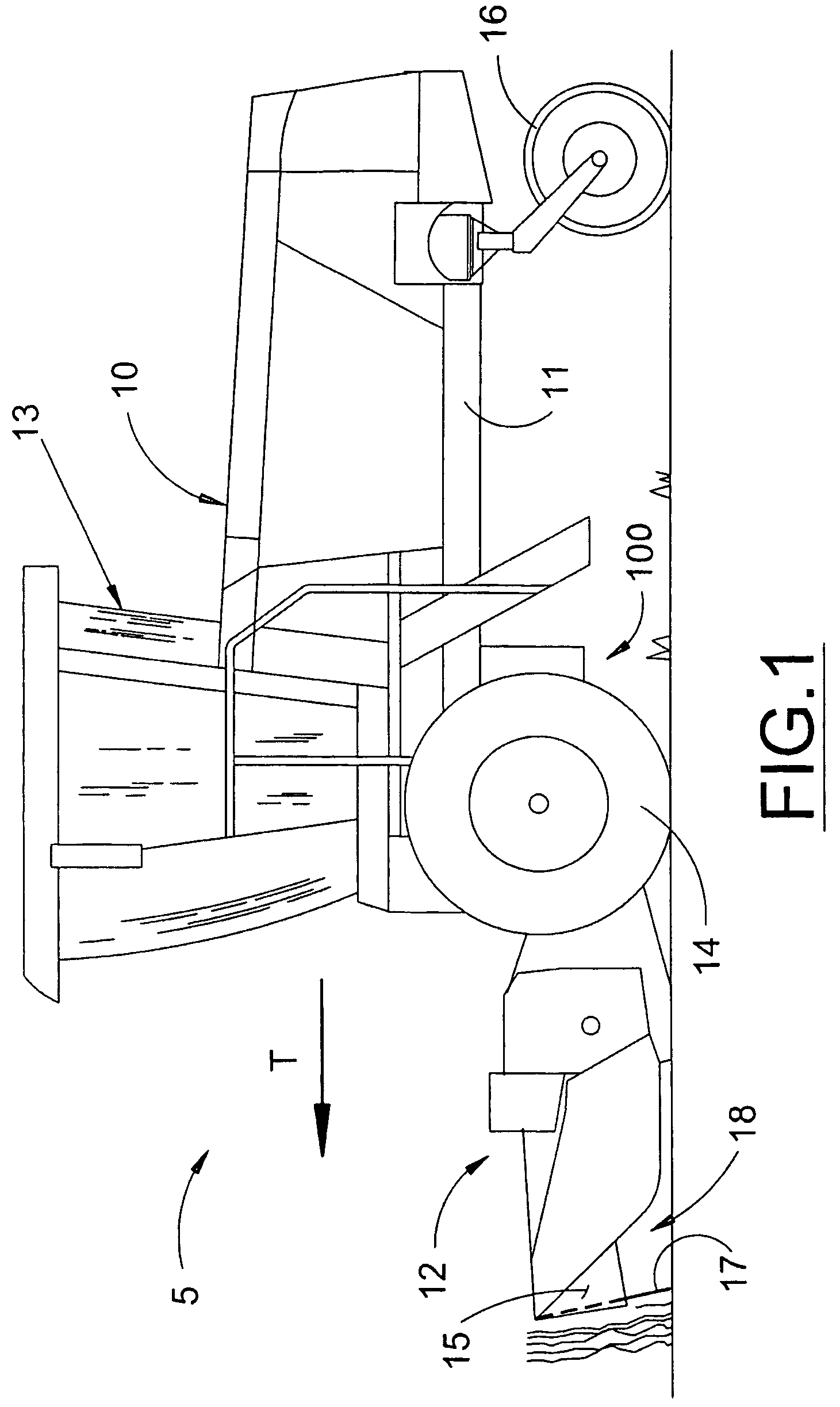

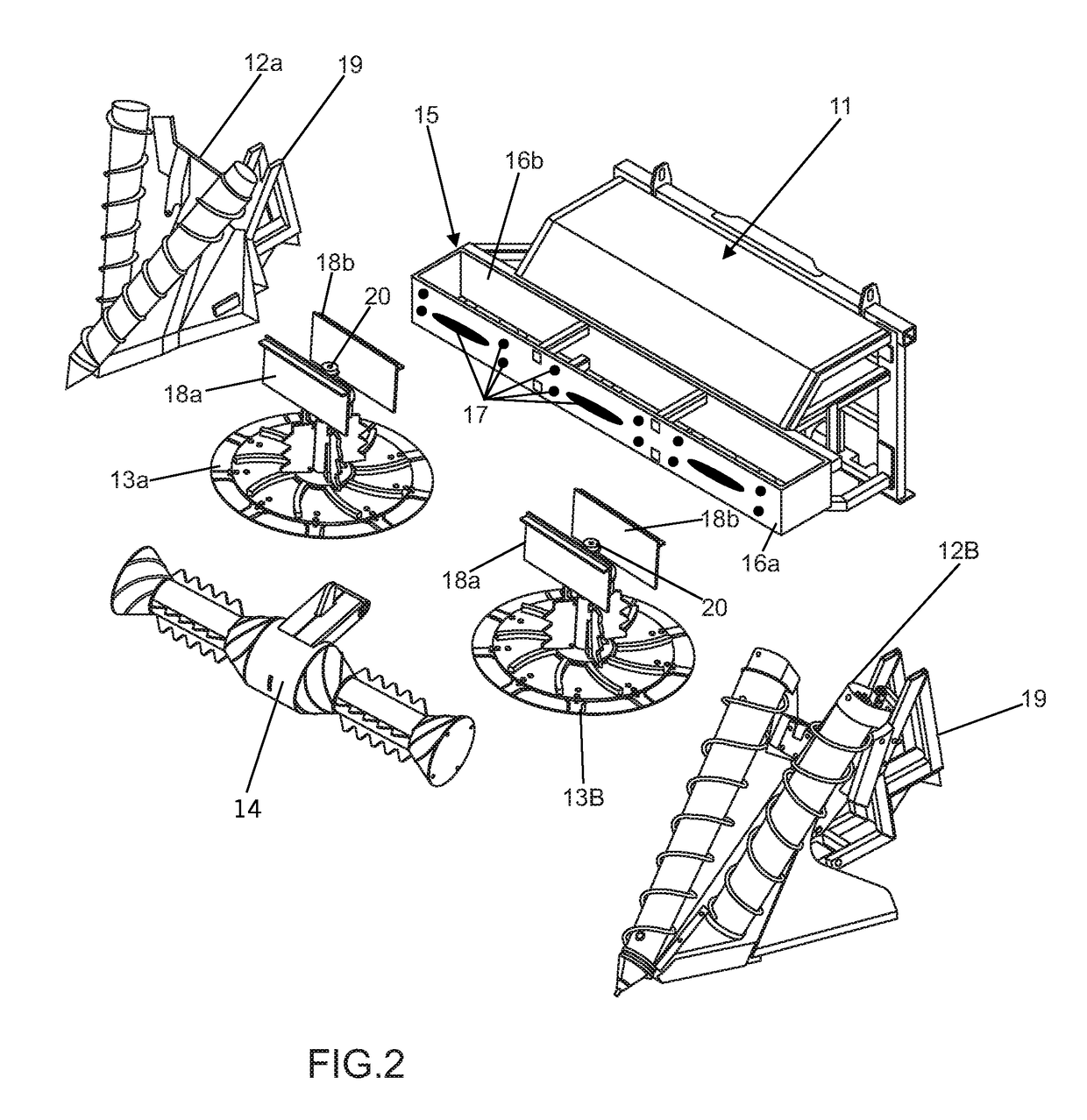

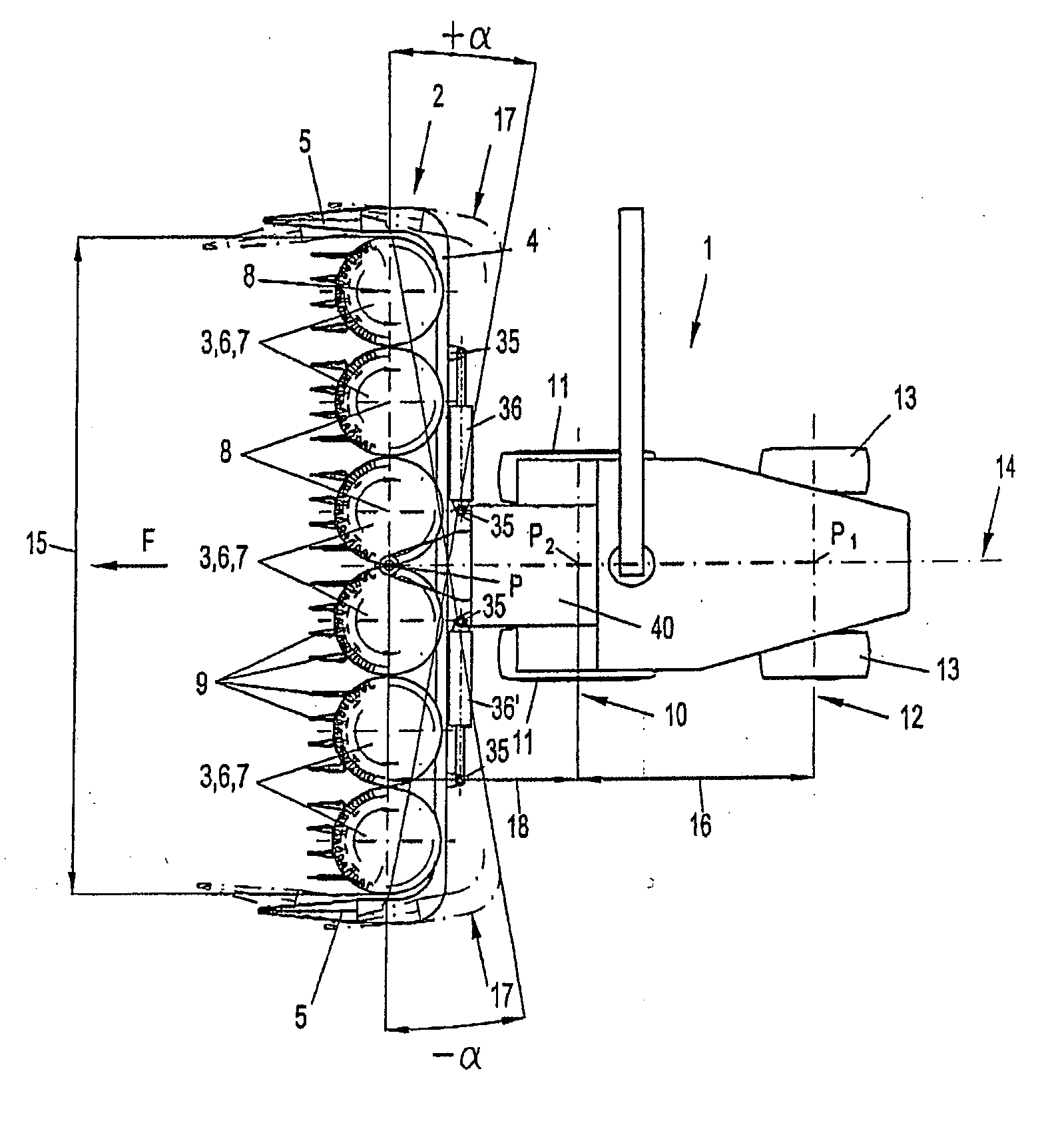

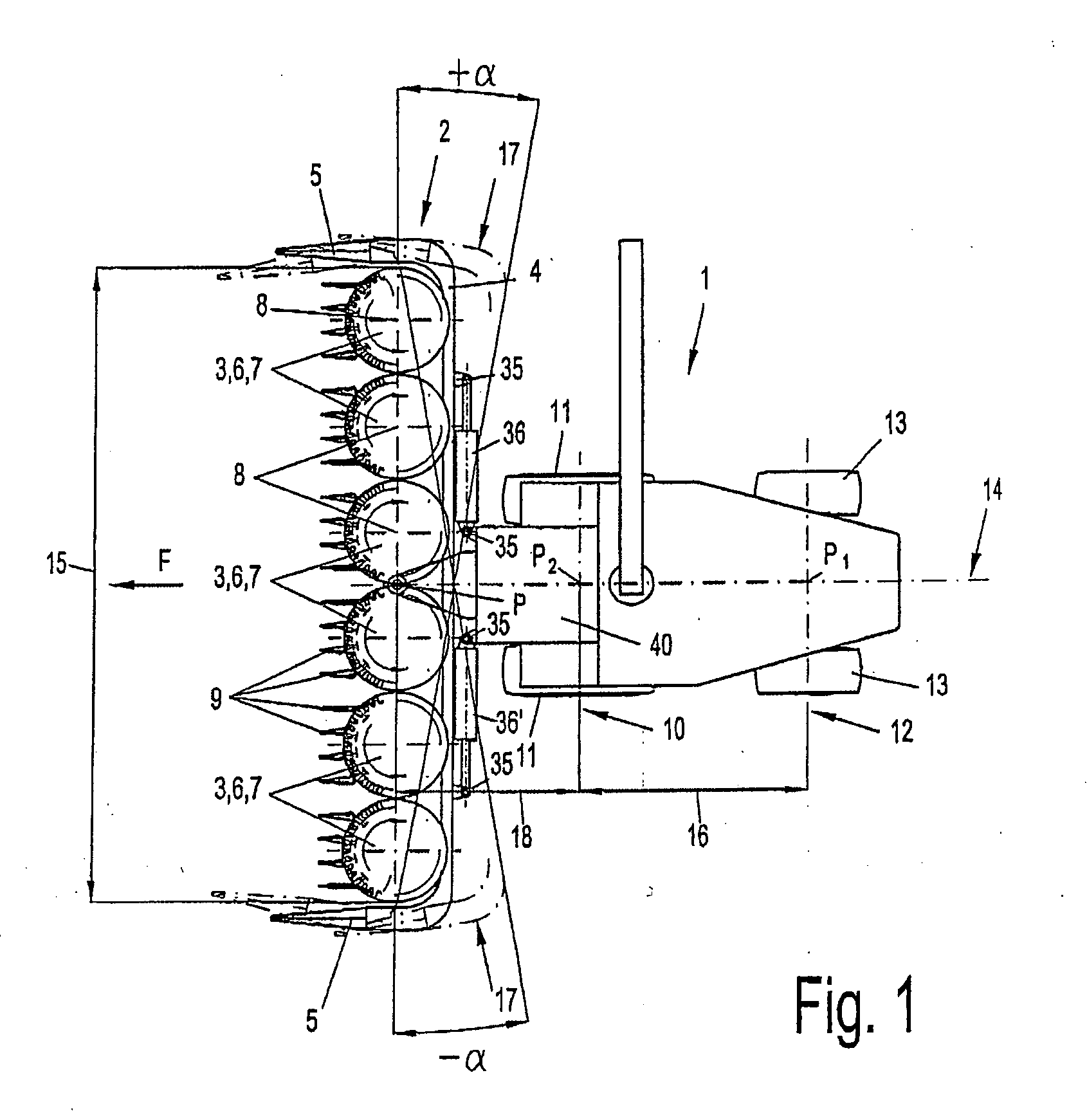

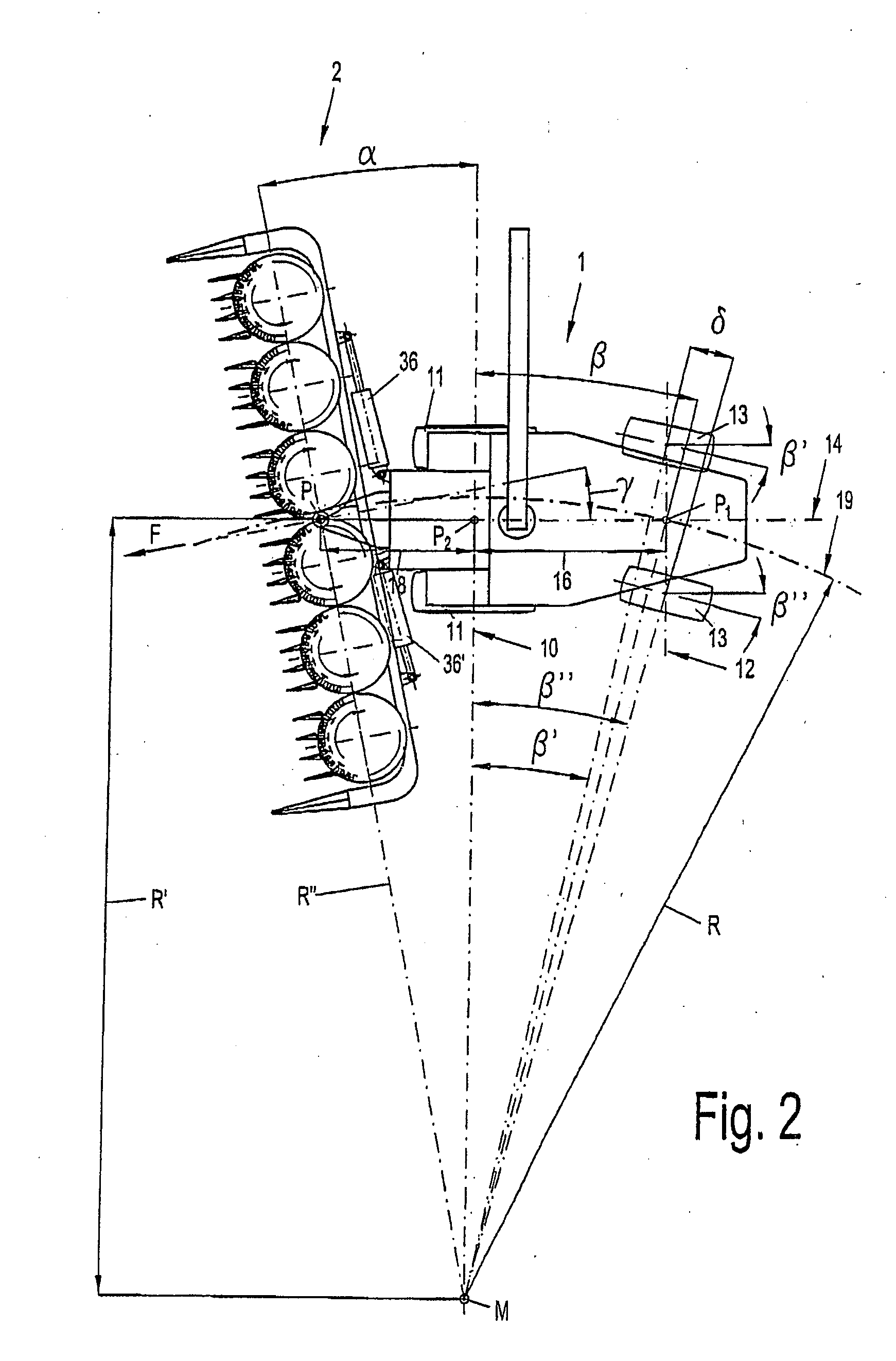

Harvesting implement for harvesting stalk-like plants

A harvesting implement for the harvesting of stalk-like plants comprising an intake arrangement for taking up plants located on a field and a stalk divider arranged ahead of the intake arrangement in the forward direction. The crop divider is supported in bearings so that it is free to move relative to the intake arrangement when it is in its harvesting position. The stalk divider is free to move in the sideways direction, that extends transverse to the forward direction.

Owner:MASCHFAB KEMPER

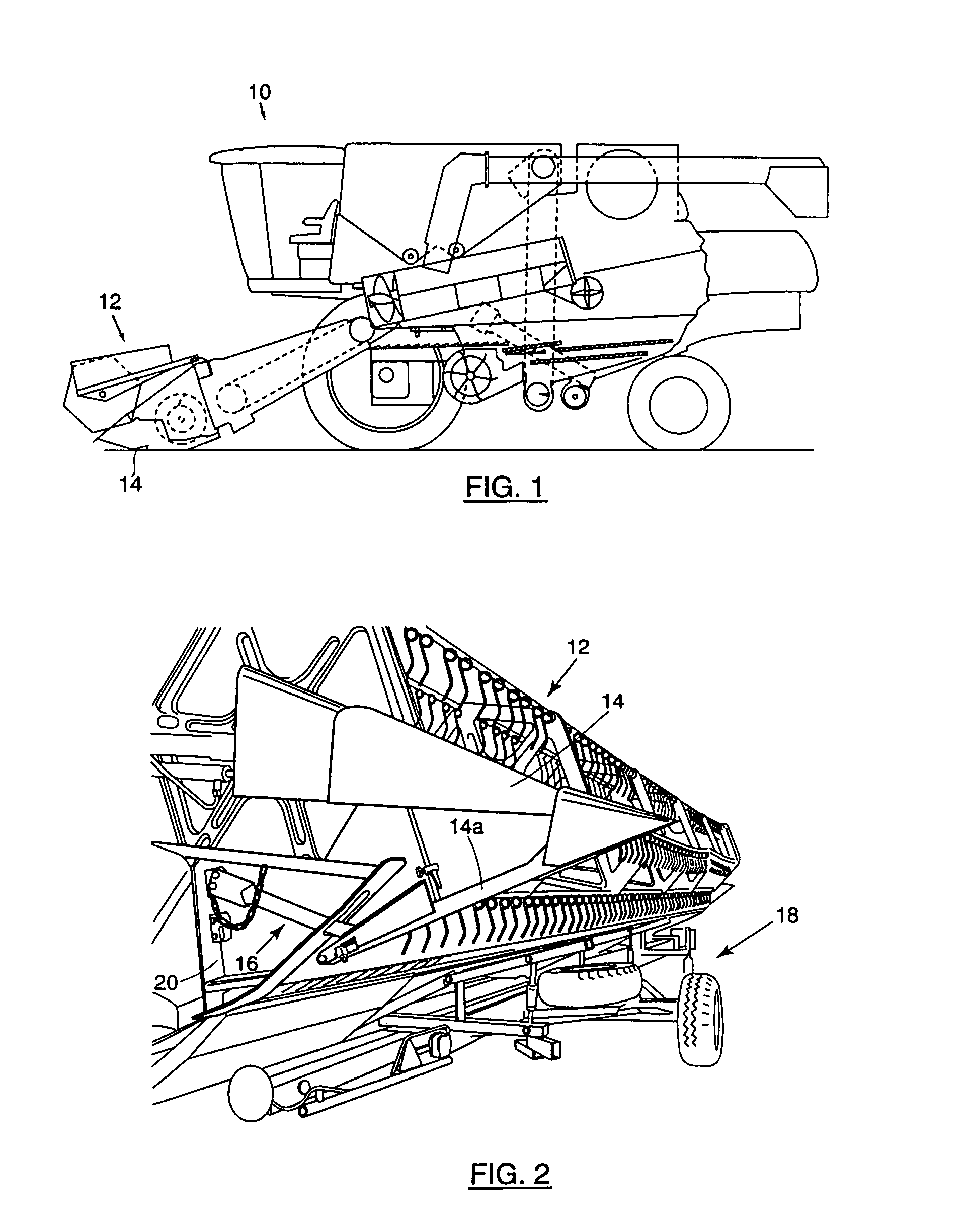

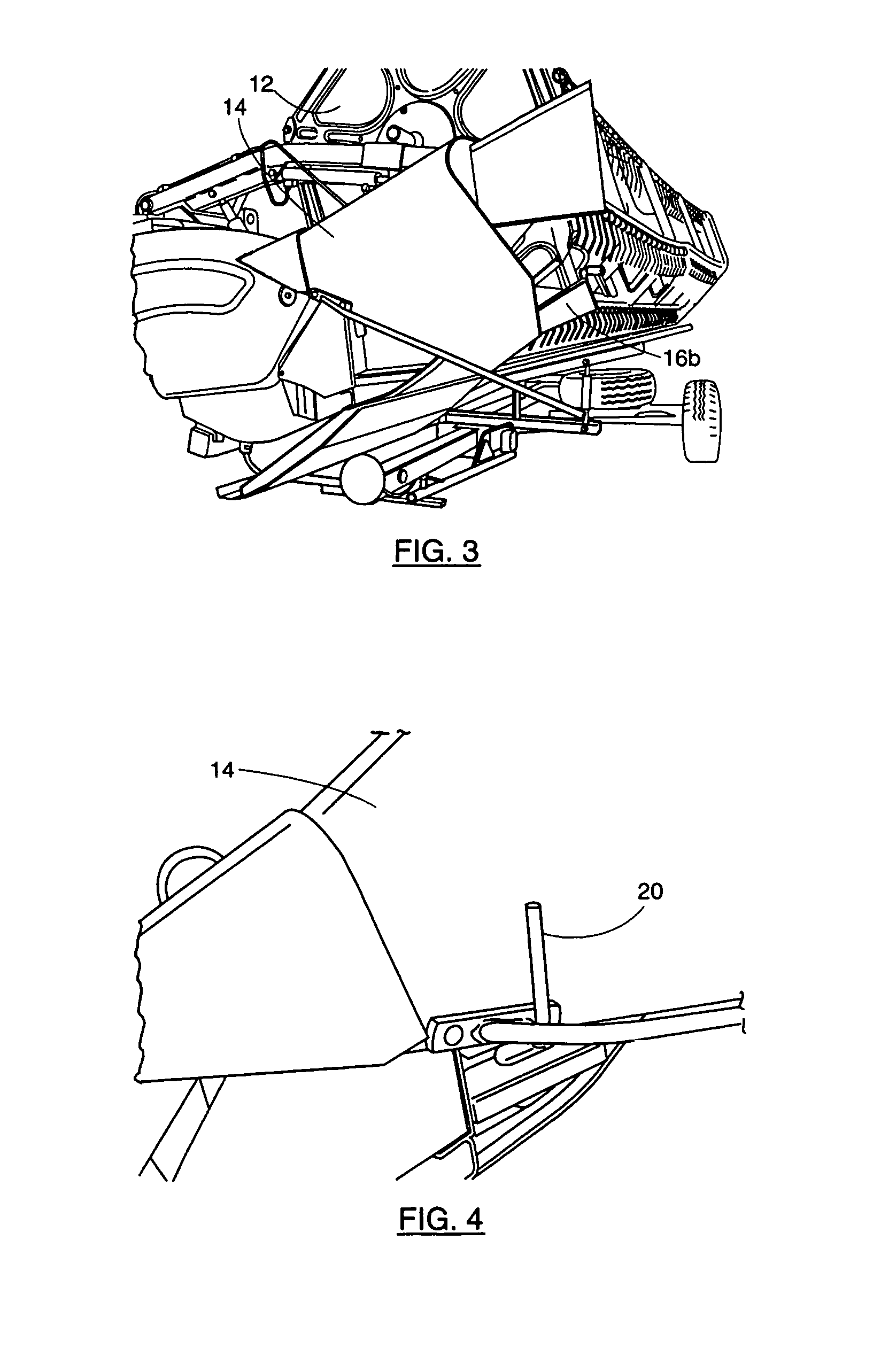

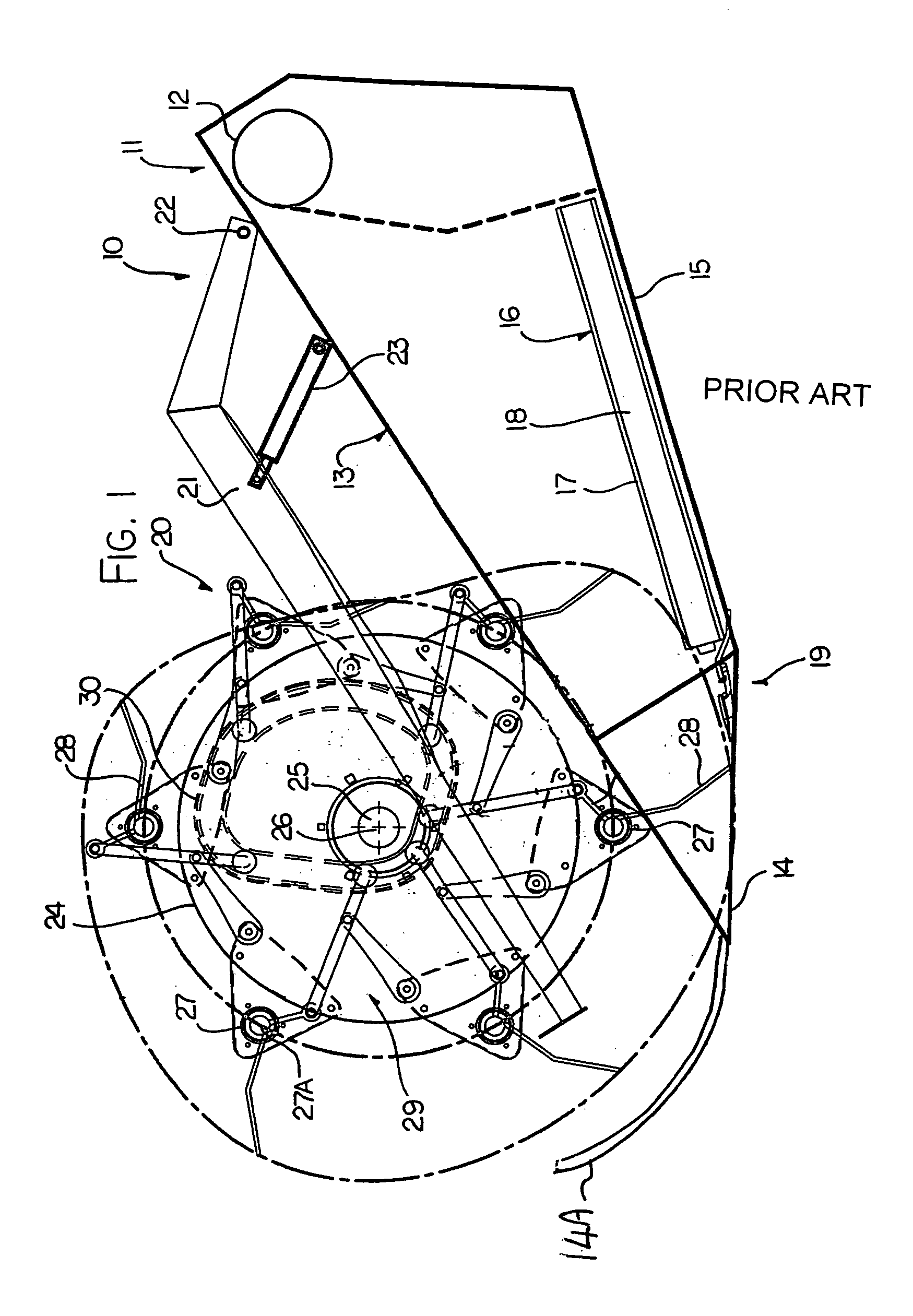

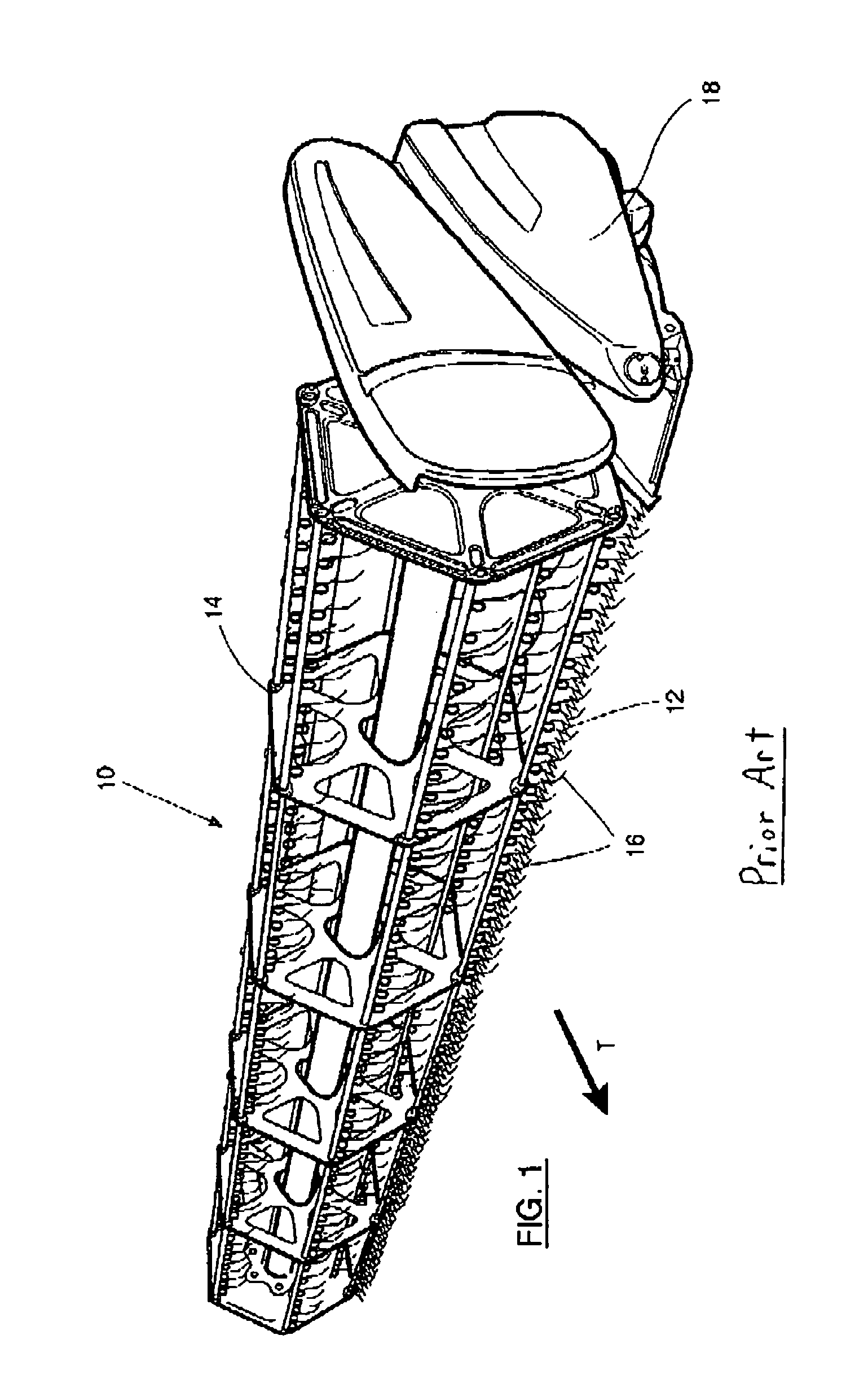

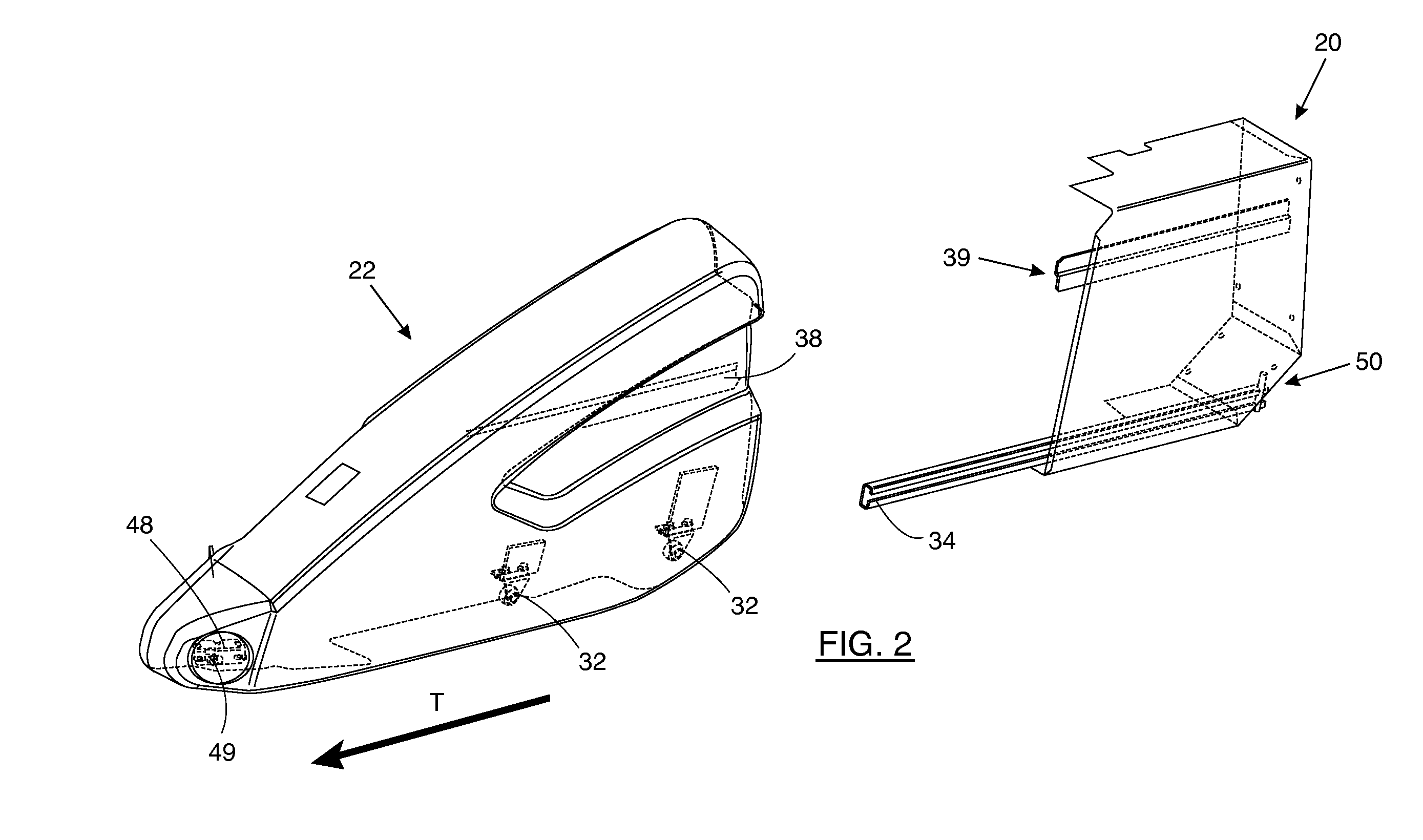

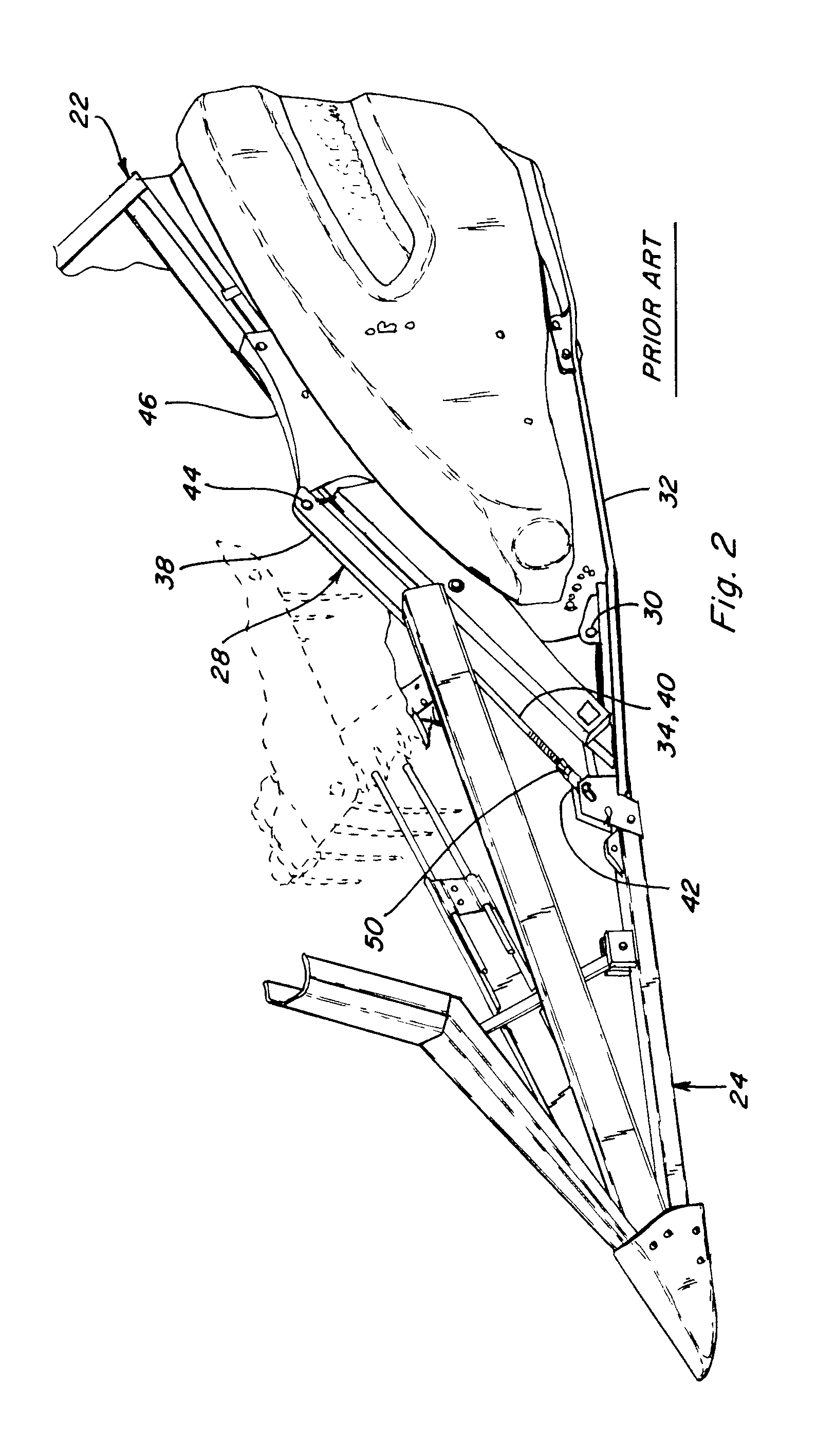

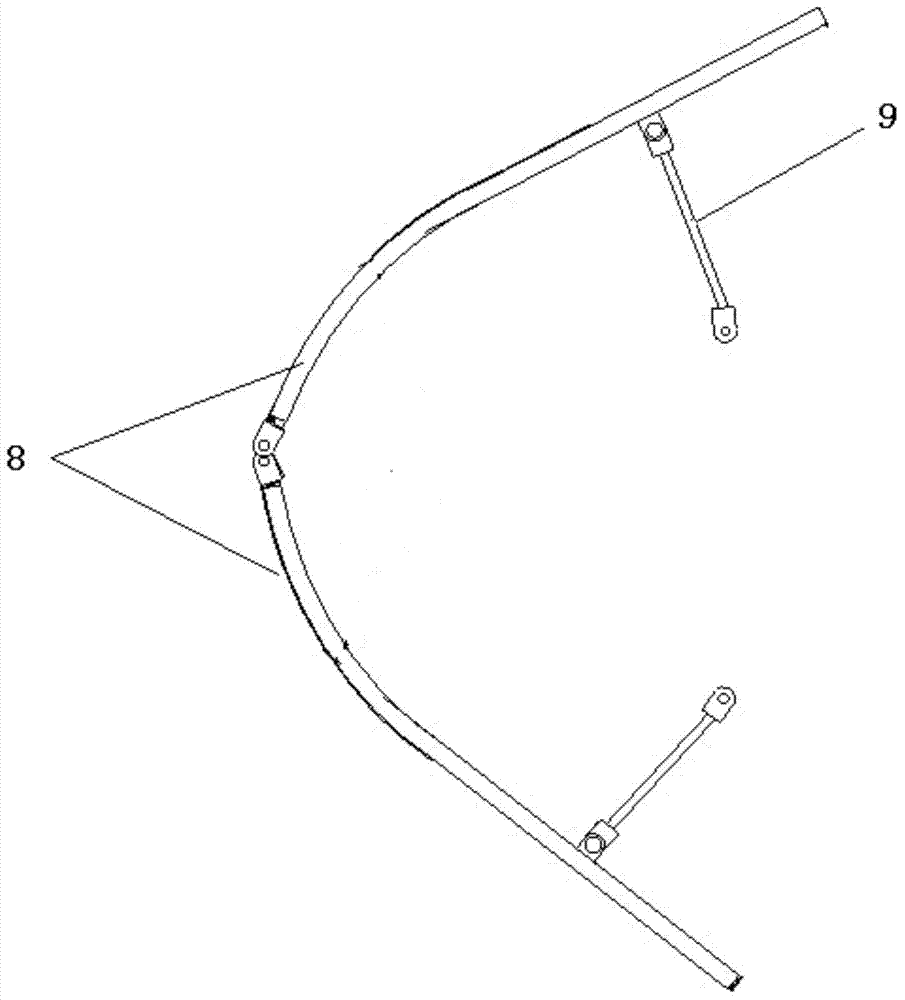

Cutting platform for a combine harvester

A cutting platform for a combine harvester is fitted with a crop divider that is pivotable relative to the cutting platform between a forwards projecting operating position and a retracted transport position. The divider is supported on a member that forms part of the cutting platform by means of a link which is secured at one end to the member in a manner to allow the link to pivot relative to the member about a first axis and which is secured at its other end to the divider in a manner to allow the divider to pivot relative to the link about a second axis which is inclined relative to the first axis.

Owner:BLUE LEAF I P INC

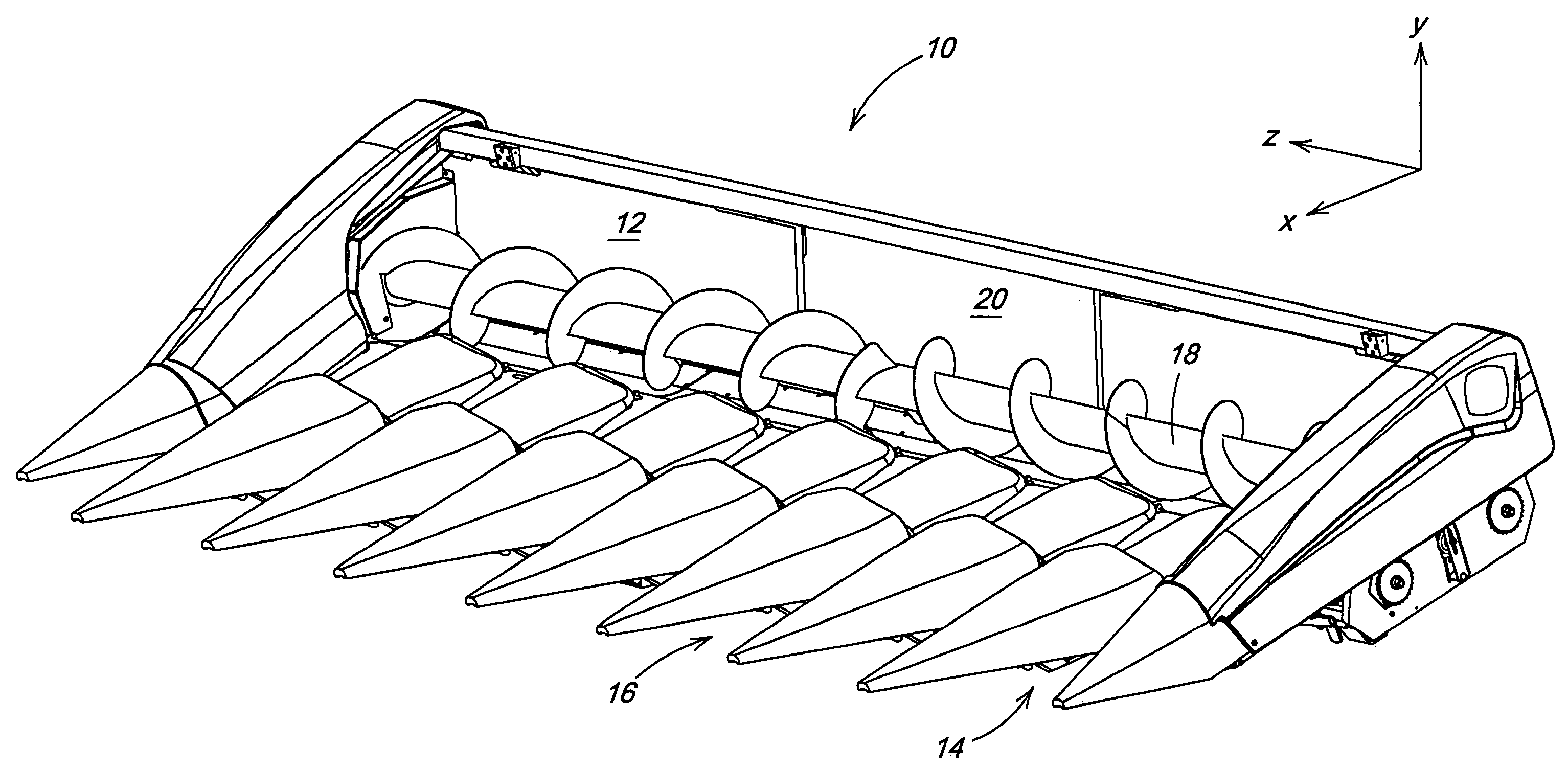

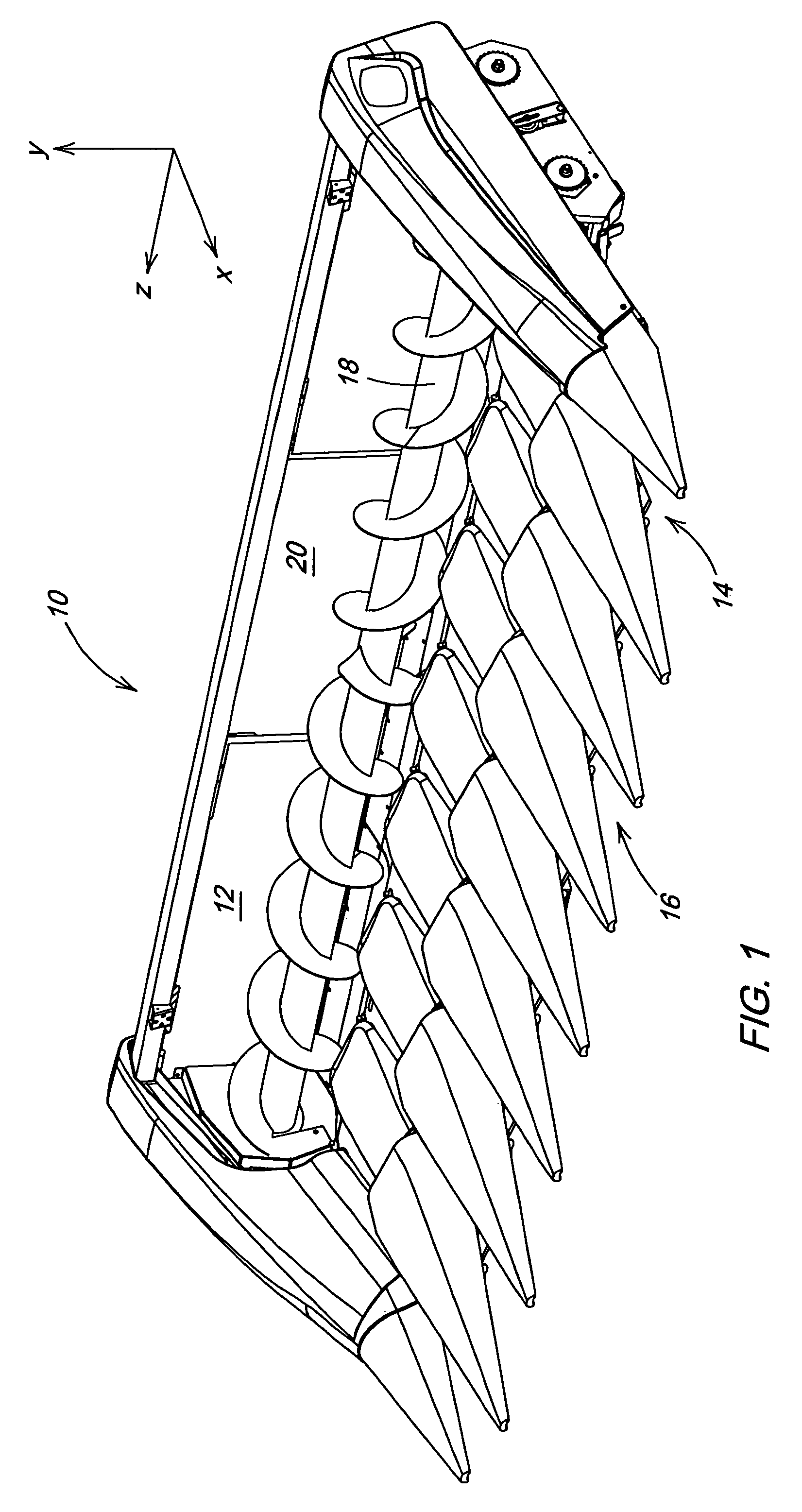

Crop harvesting header with crop divider members carried on the reel

Owner:MACDON INDS

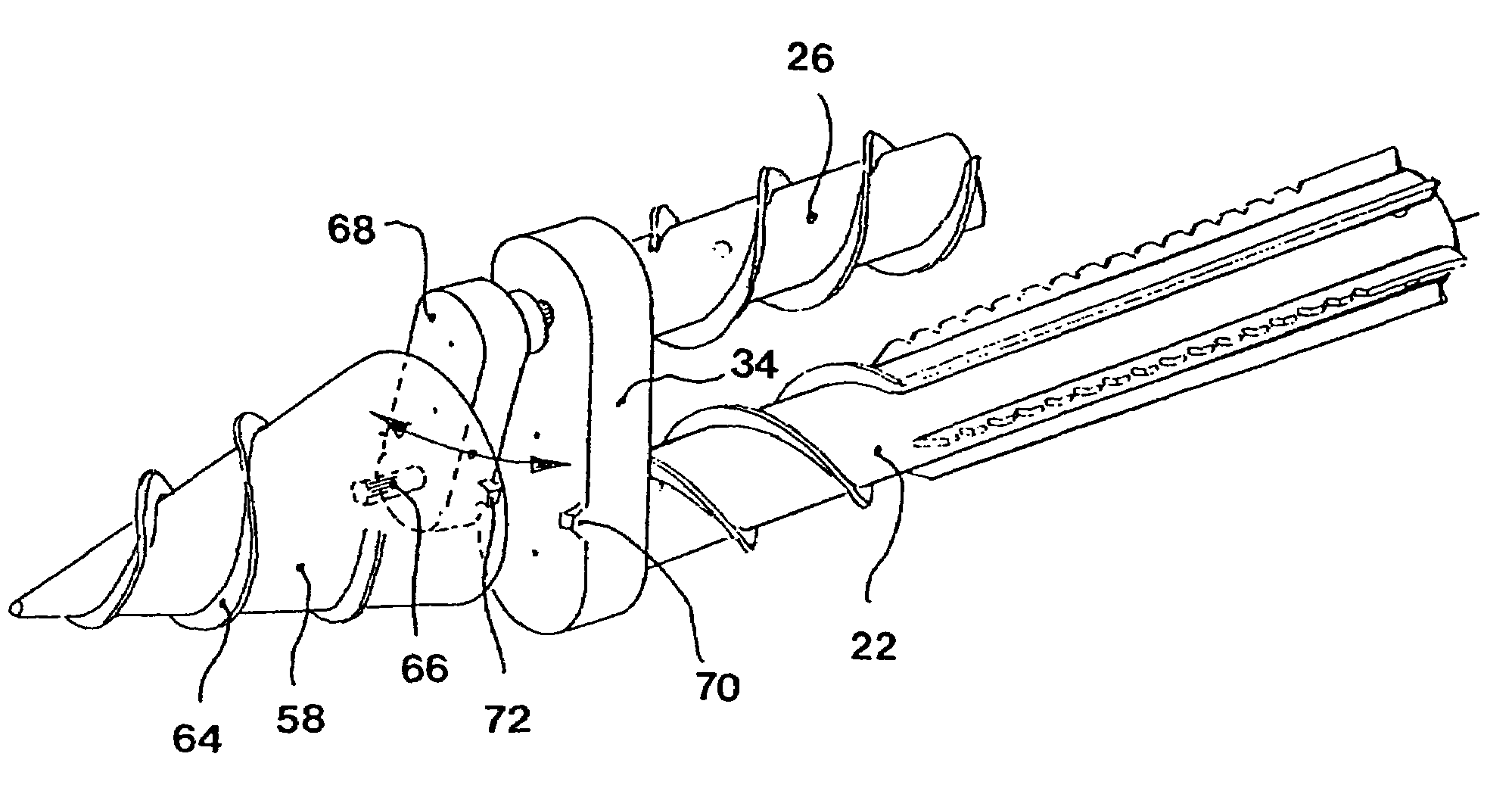

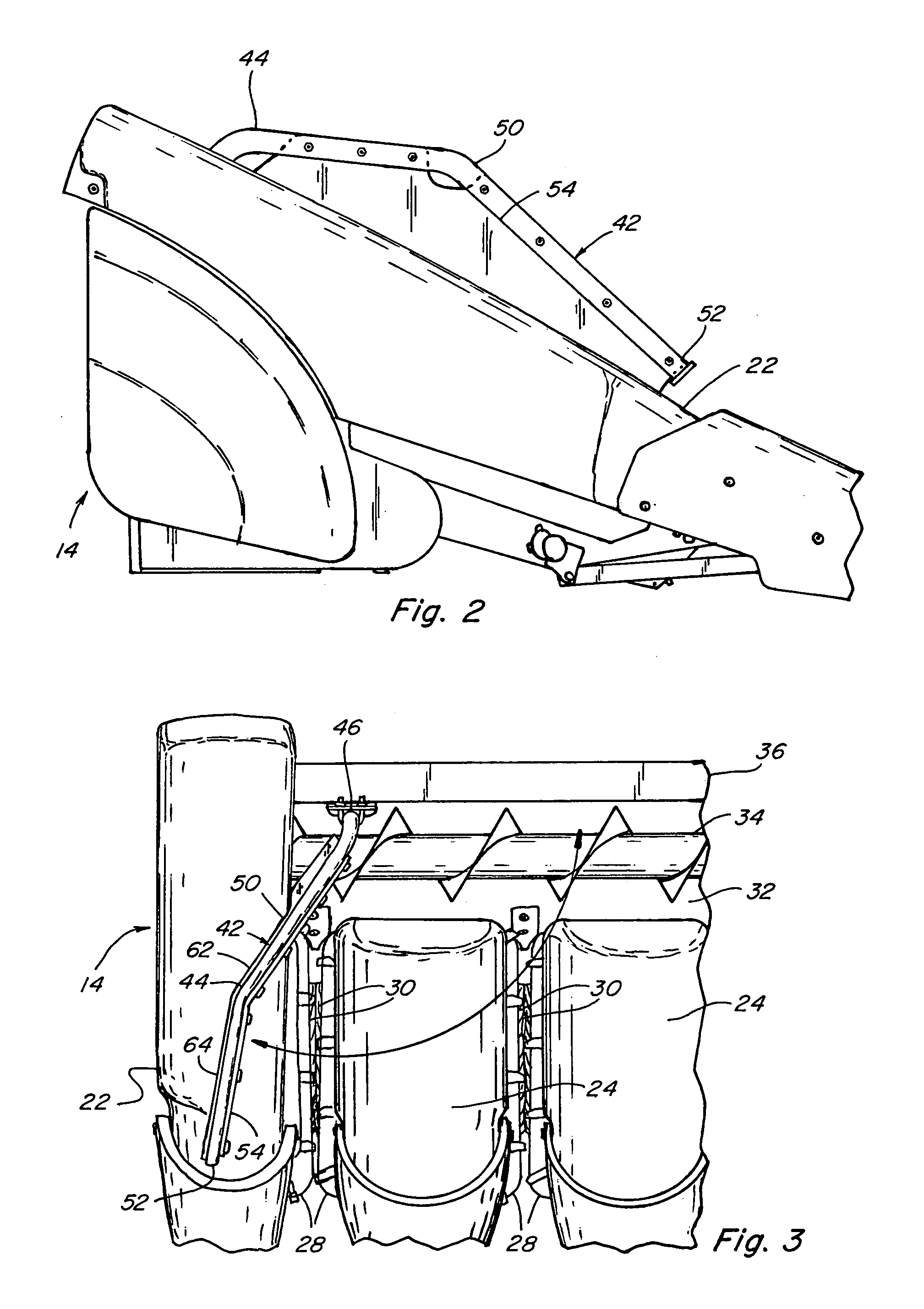

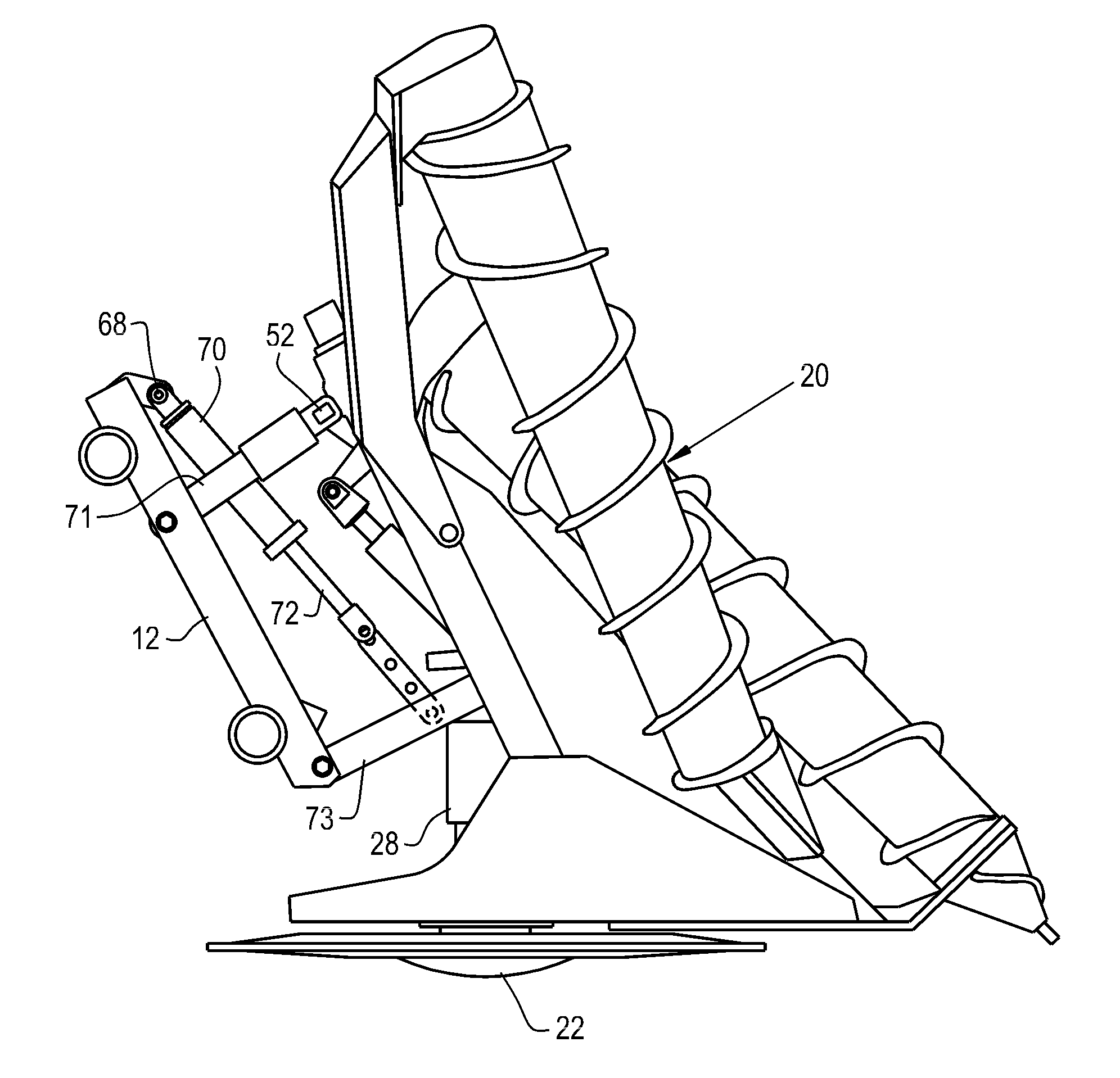

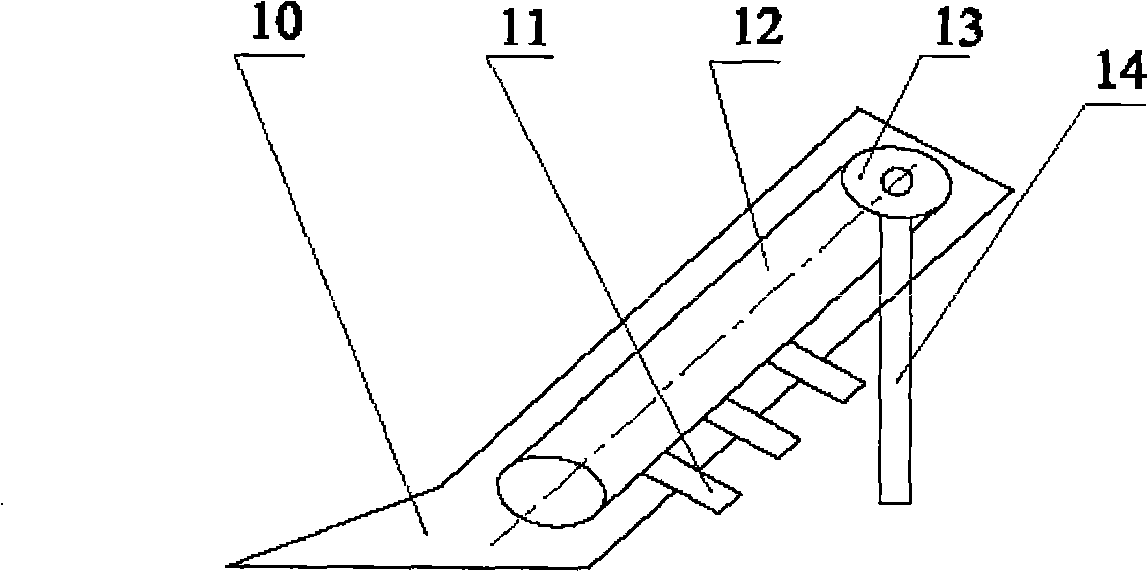

Row divider having a variable-height ear saver

For a row crop header, a row divider having a variable-height ear saver feature. The row divider comprises a point, a cover, and a partition. The point has a trailing edge vertically moveable relative to the cover. The partition fills a resultant gap between the point and the cover, forming a variable-height ear saver feature. A crankshaft functions to articulate the trailing edge relative to the cover, and to move the partition vertically with the trailing edge. A support functions to support the point at a midpoint. A guide constrains the partition within the gap.

Owner:DEERE & CO

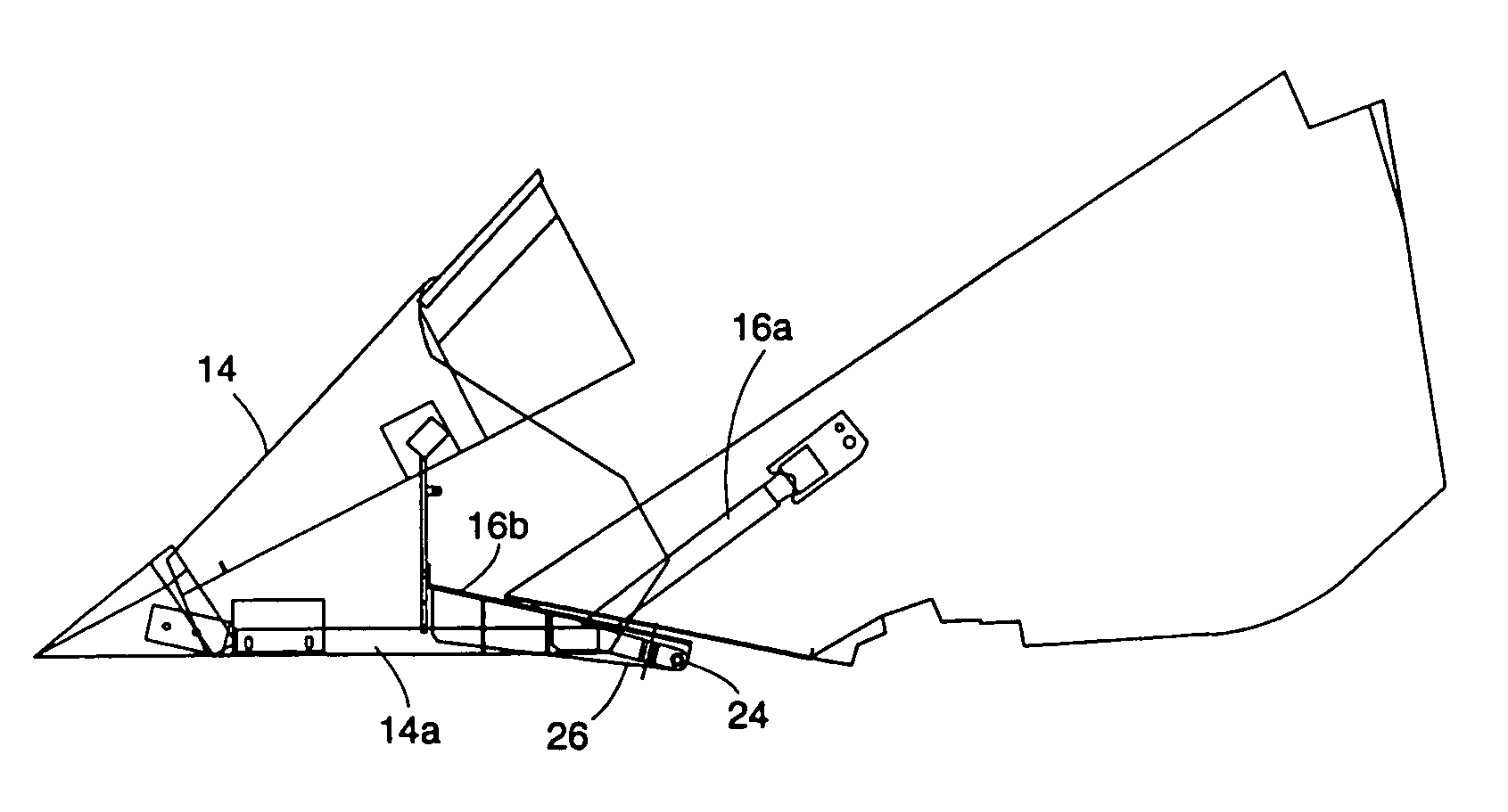

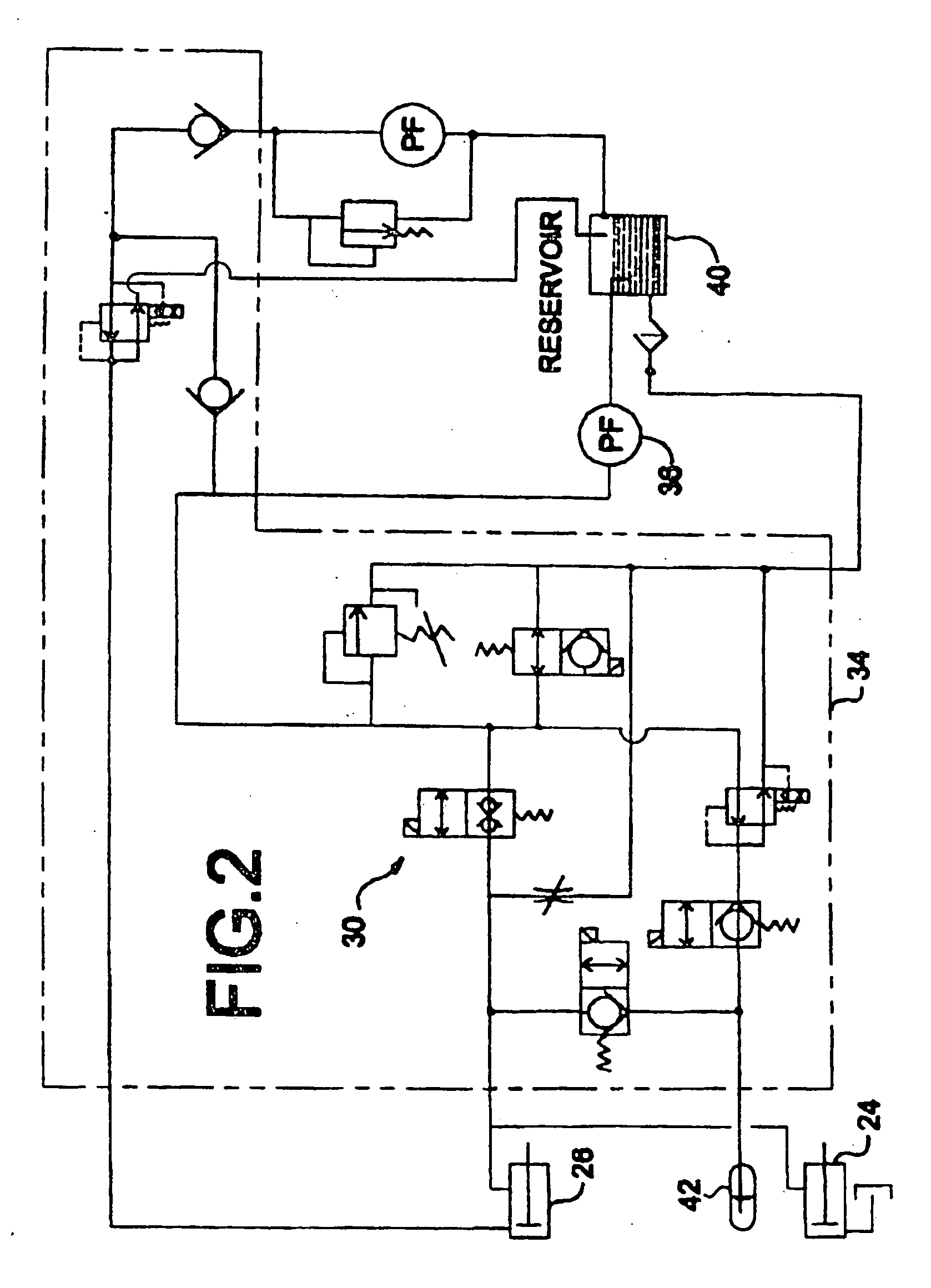

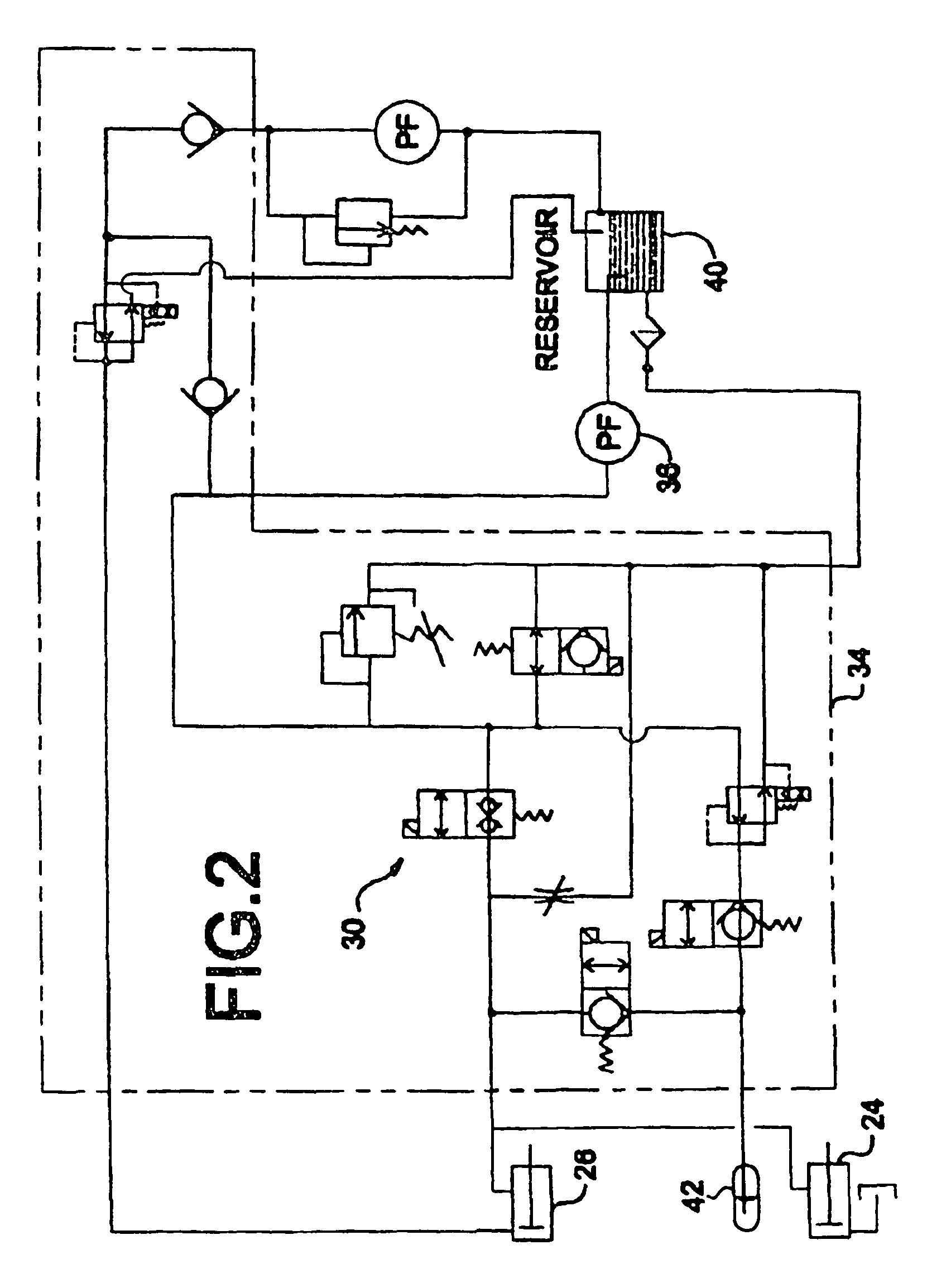

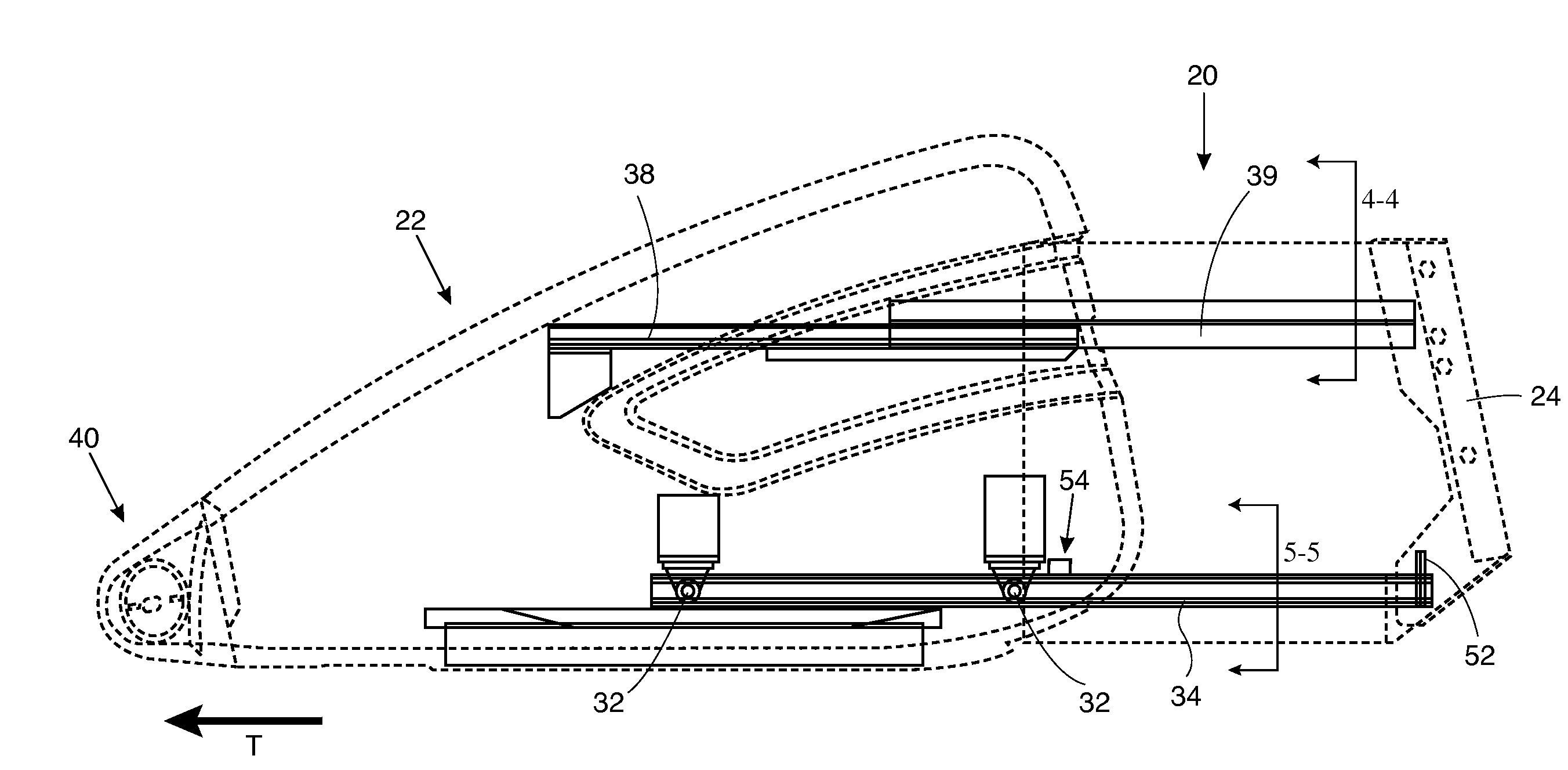

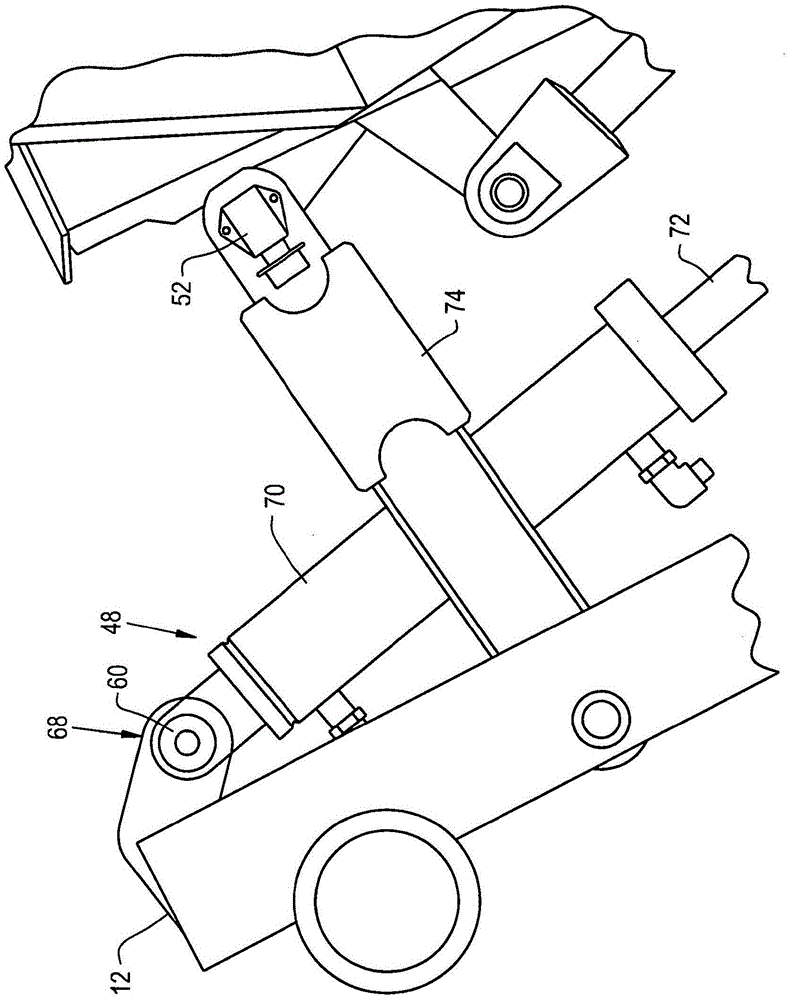

Method and apparatus to put a windrower header in the transport mode under specified conditions

ActiveUS20060248868A1Reduces hydraulicReduces mechanical shock loadingAnalogue computers for vehiclesAnalogue computers for trafficAutomatic controlNormal mode

A method and apparatus for automatically controlling a header lift system of an agricultural harvesting machine, particularly a windrower, to put a header of the machine into a transport mode wherein the header is raised to an elevated transport position, under certain specific conditions. Such conditions can include, but are not limited to, the machine operating in a high-speed range, the header not operating, the speed of the machine being above a predetermined level, and the last inputted control command being a header raise command. When in the transport mode, the lift system can also be operated in a float mode. Further, the header lift system can be returned to a normal mode when certain criteria are present for doing so.

Owner:BLUE LEAF I P

End hood extension for a corn header

ActiveUS6901730B1Simply and easily pivotedImprove effectivenessAgricultural lifting devicesOutside dividersEngineeringExtremity Part

The extension includes a support member including a mounting end mountable to a corn header adjacent to a rear end thereof for pivotable movement about a generally upwardly to downwardly extending pivotal axis between at least one forwardly extending position spaced above the end hood, and a second or stored position at angle to the forwardly extending position or positions. The support member has a free end extending upwardly and outwardly from the mounting end to a terminal end portion, and supports a sheet along substantially the length thereof to serve as a barrier to the passage of corn between the support member and the end hood and to deflect ears that strike it into an adjacent crop gathering channel. When it is not desired or required to use the extension it can be quickly and easily pivoted to the stored position, out of the way.

Owner:BLUE LEAF I P INC +1

Method and apparatus to put a windrower header in the transport mode under specified conditions

ActiveUS7869922B2Good flexibilityFew pointAnalogue computers for vehiclesAnalogue computers for trafficAutomatic controlNormal mode

A method and apparatus for automatically controlling a header lift system of an agricultural harvesting machine, particularly a windrower, to put a header of the machine into a transport mode wherein the header is raised to an elevated transport position, under certain specific conditions. Such conditions can include, but are not limited to, the machine operating in a high-speed range, the header not operating, the speed of the machine being above a predetermined level, and the last inputted control command being a header raise command. When in the transport mode, the lift system can also be operated in a float mode. Further, the header lift system can be returned to a normal mode when certain criteria are present for doing so.

Owner:BLUE LEAF I P INC

Guard for a header of a harvester

ActiveUS7380392B2Avoid separationLess expensiveMowersAgricultural lifting devicesEngineeringMechanical engineering

Owner:BLUE LEAF I P INC

Modular platform for cutting sugar cane

An agricultural harvesting machine for harvesting sugar cane, with means for working coupled to a tractor or any self-propelling machine, by using mechanic power (TDP) converted into hydraulic power (pump) to activate different devices of a set, so that it may form a wire cutting front for lanes of plants which are cut and thrown behind over the soil and organized in rows for later collecting and processing.

Owner:IND REUNIDAS COLOMBO LTD

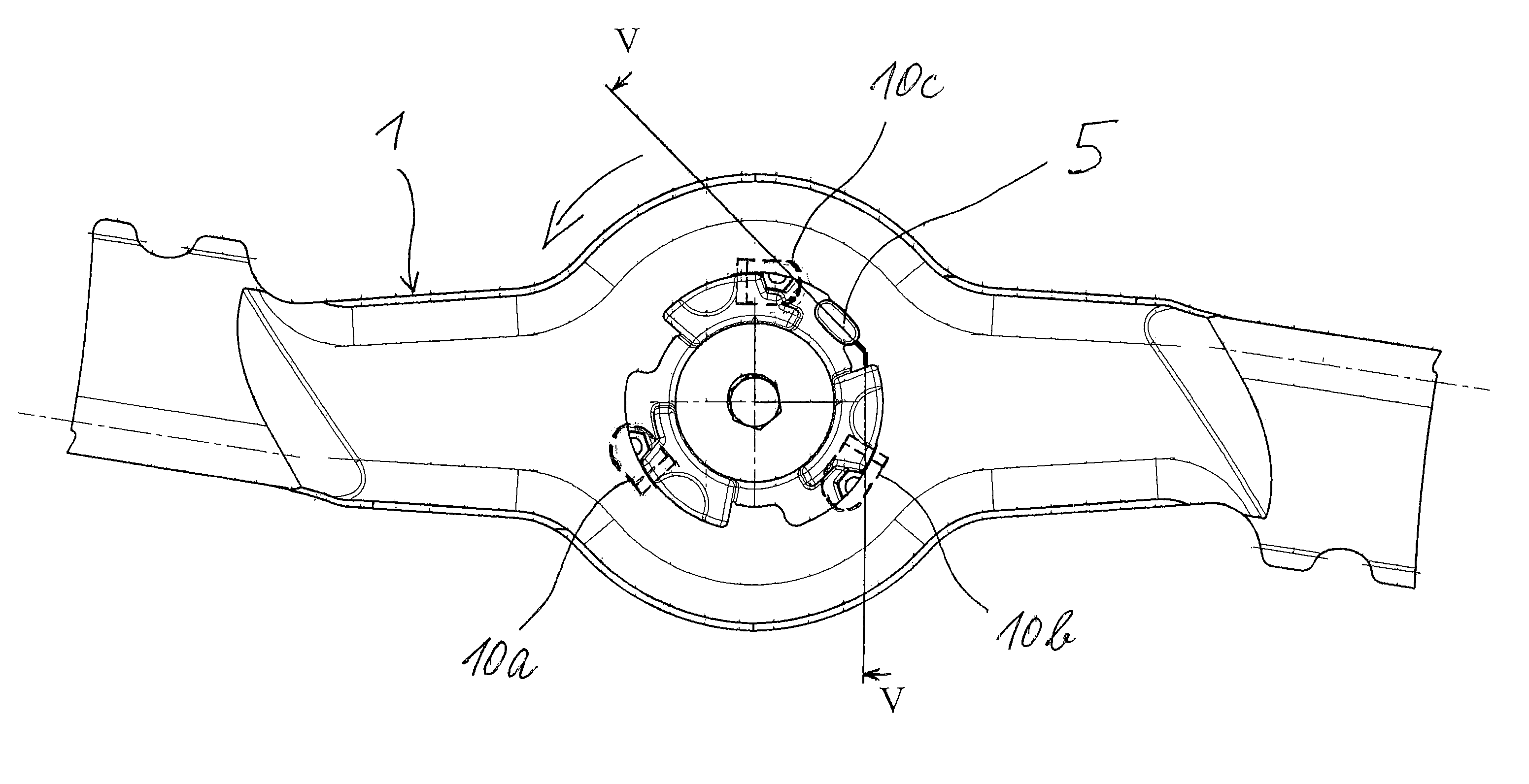

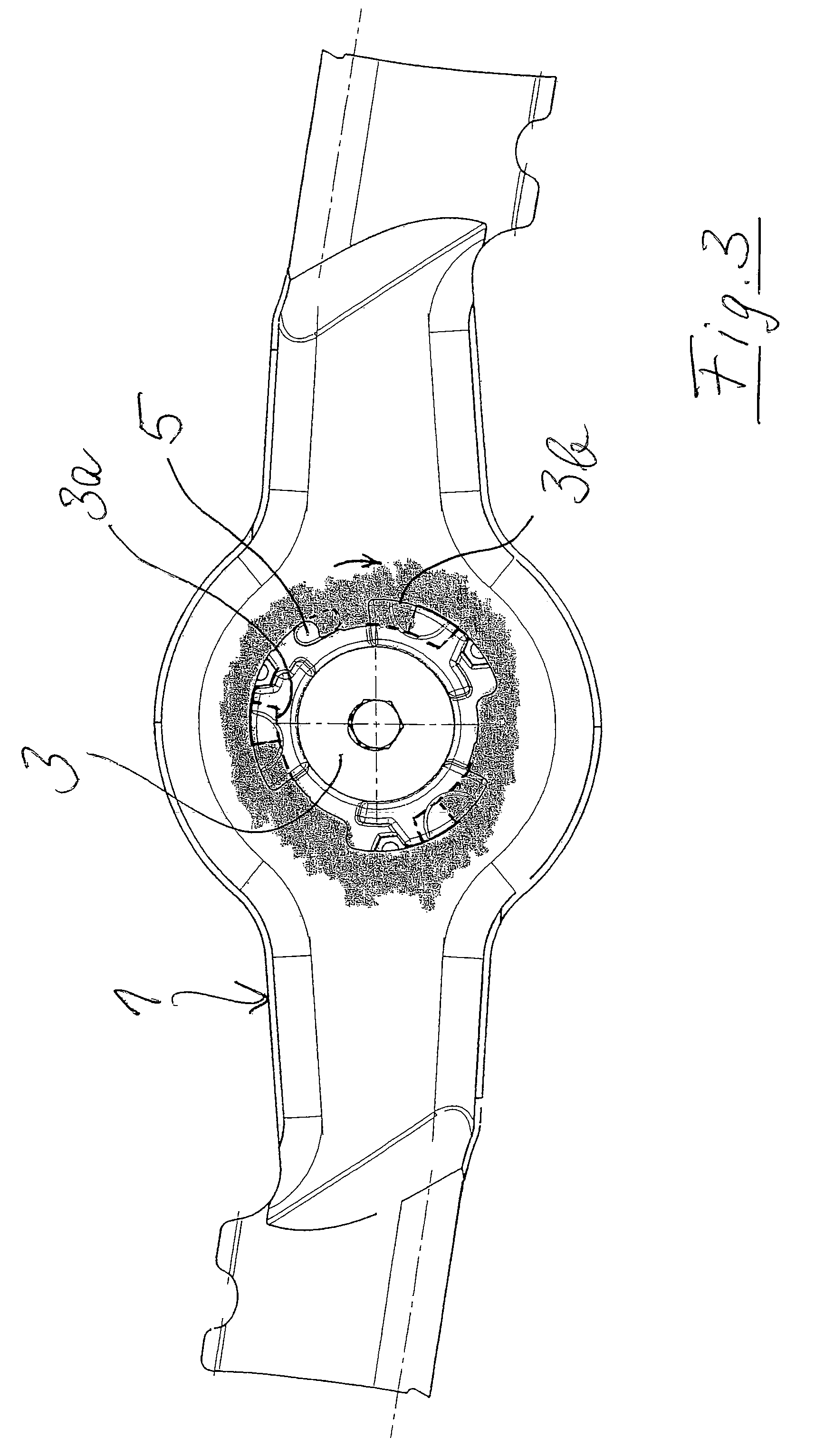

Cutting device, particularly a lawn mower

A cutting device, particularly a lawn mower, has at least one rotating knife mounted on a rotating, motor-driven knife carrier by a screwless, detachable connection. This connection is detachable by a relative rotation between the knife and the knife carrier. It is essential that the connection between the knife and its knife carrier be made by a centrally arranged bayonet lock and that this bayonet lock be locked in the closed position by an additional locking element.

Owner:WOLF OUTILS

Row divider having a variable-height ear saver

For a row crop header, a row divider having a variable-height ear saver feature. The row divider comprises a point, a cover, and a partition. The point has a trailing edge vertically moveable relative to the cover. The partition fills a resultant gap between the point and the cover, forming a variable-height ear saver feature. A crankshaft functions to articulate the trailing edge relative to the cover, and to move the partition vertically with the trailing edge. A support functions to support the point at a midpoint. A guide constrains the partition within the gap.

Owner:DEERE & CO

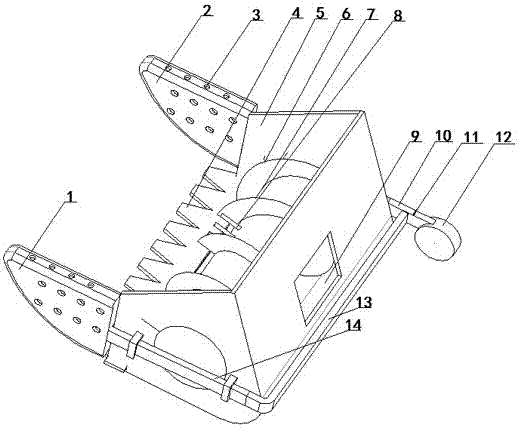

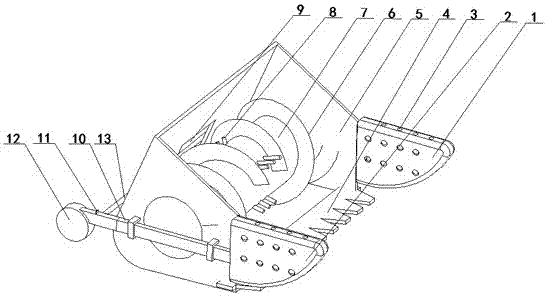

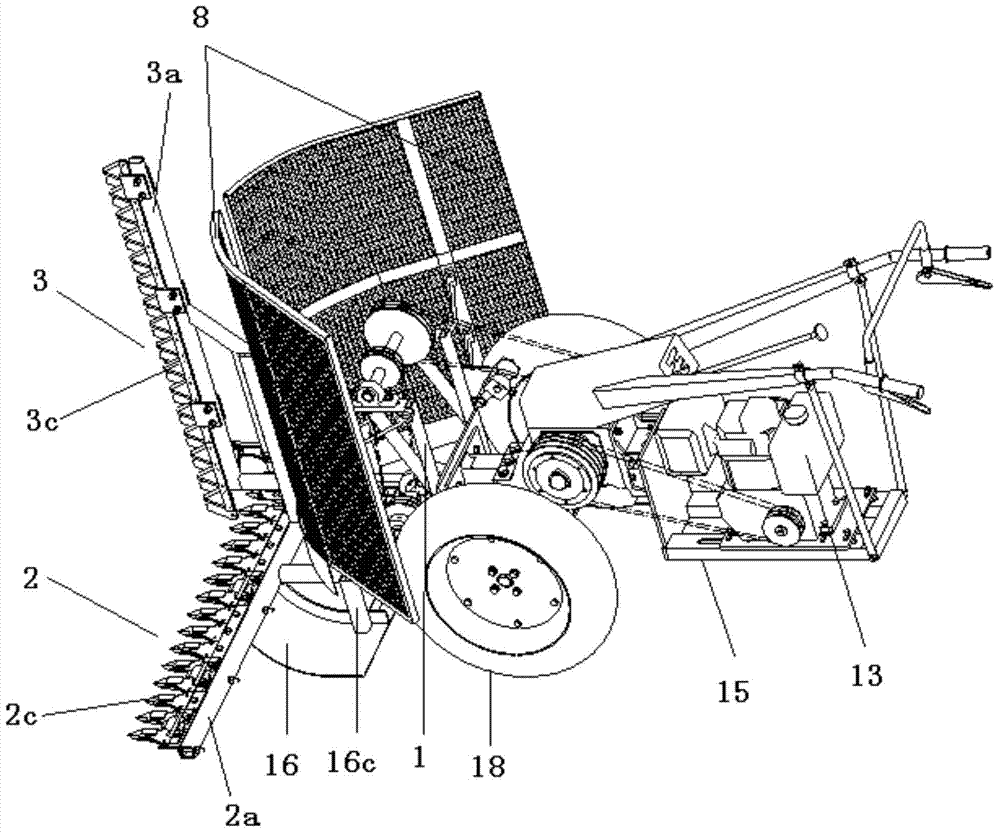

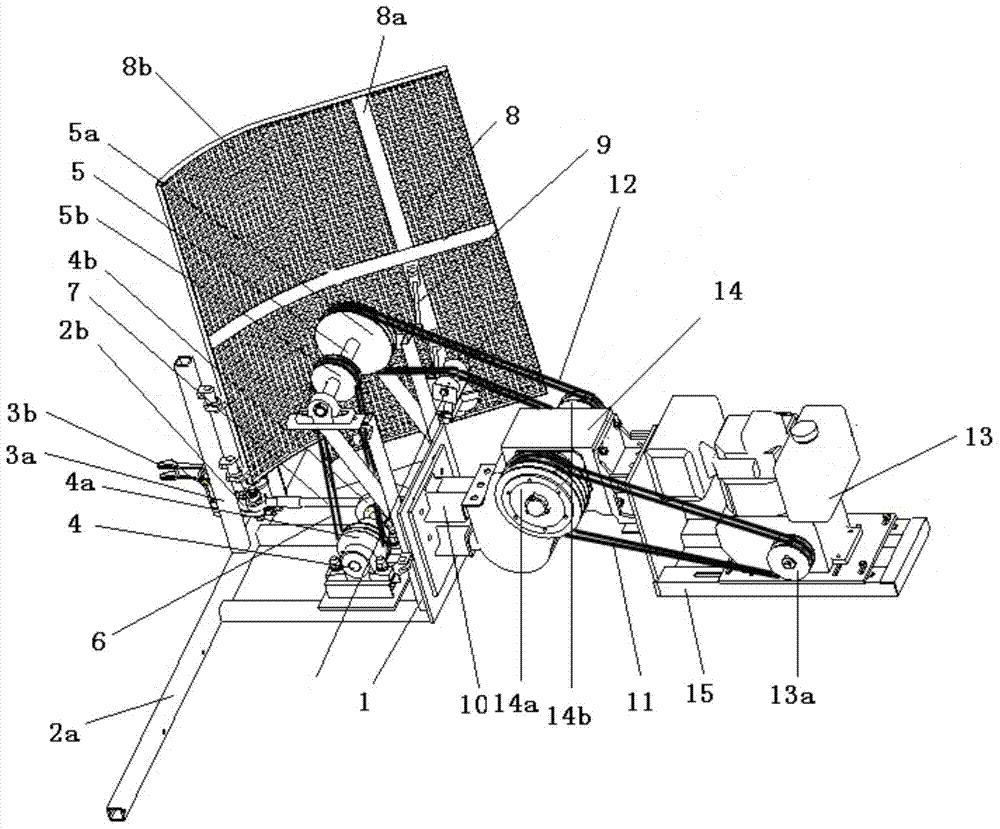

Millet combined harvester and system thereof

The invention discloses a millet combined harvester and a system thereof, and belongs to the technical field of crop combined harvest. The millet combined harvester comprises a header for combined harvest, a threshing separation part and a millet cleaning part. The header comprises a header frame, a reciprocating cutter, a left divider, a right divider, a header screw auger, a reel and a transmission mechanism, and the transmission mechanism is in transmission connection with the reciprocating cutter, the header screw auger and the reel. The threshing separation part comprises a threshing box, a front threshing cylinder, a rear threshing cylinder, a front separating screen, a rear separating screen, a transition separating screen, a front threshing top cover, a rear threshing top cover, and a power mechanism providing power for the front threshing cylinder and the rear threshing cylinder. The millet cleaning part comprises a cleaning frame, a front blower fan, a reciprocating vibration screen, and a vibration mechanism driving the reciprocating vibration screen to vibrate. The millet harvesting system comprises the millet combined harvester mentioned above and a controller. According to the invention, a header ear dropping phenomenon can be effectively controlled, rubbing and beating are integrally carried out, and the loss late, the broken rate and the impurity rate are low.

Owner:XINGGUANG AGRI MACHINERY

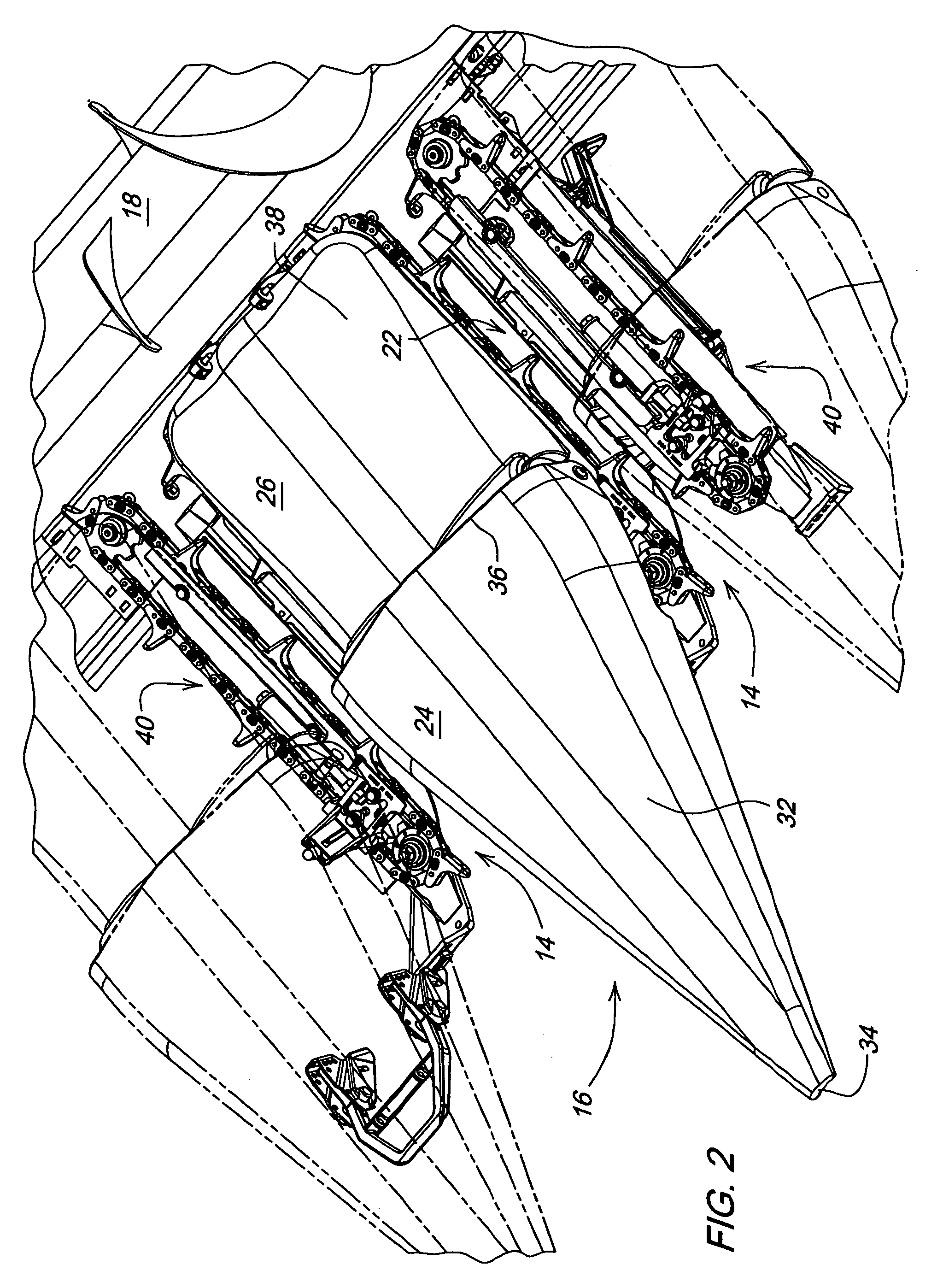

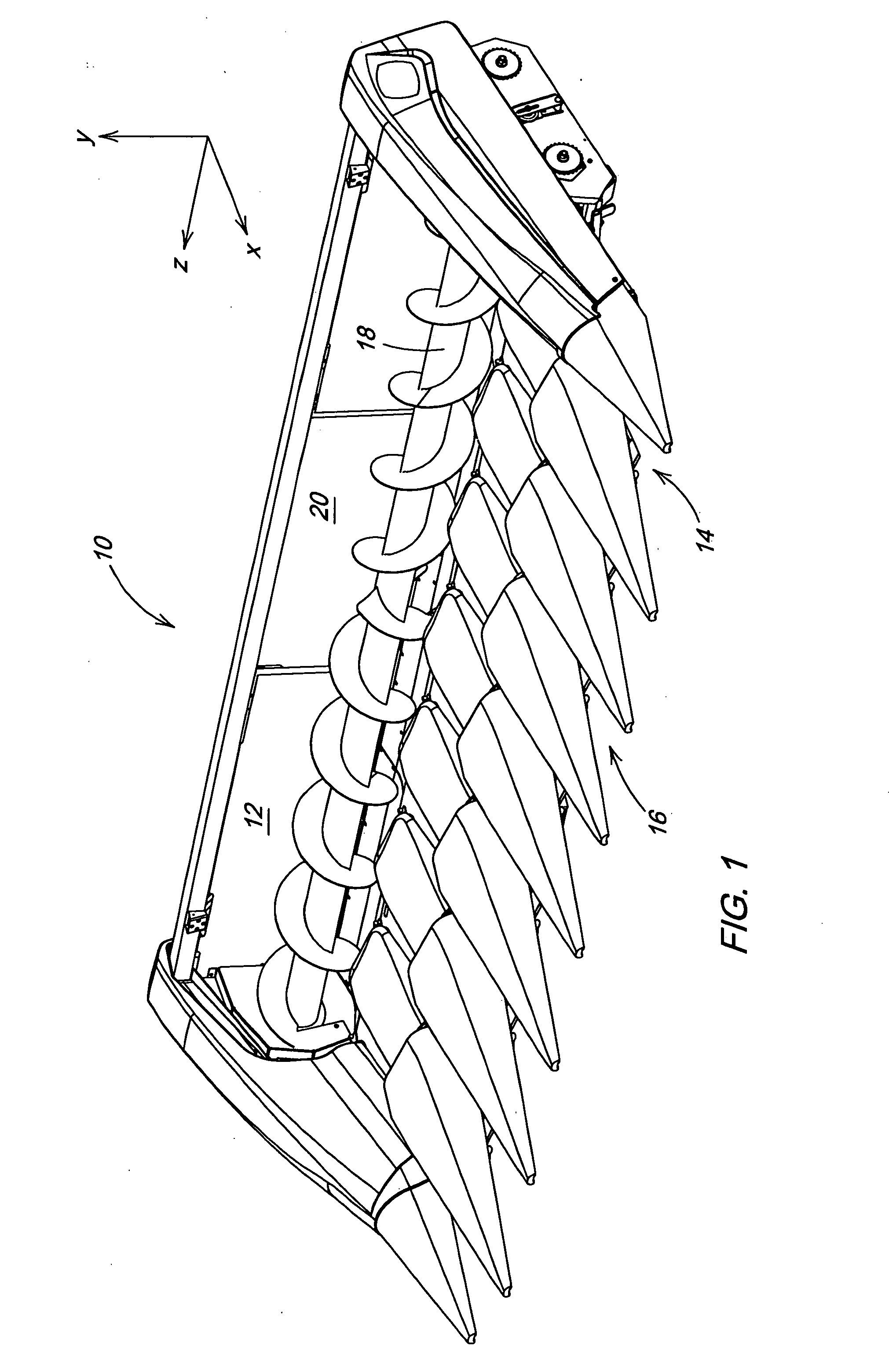

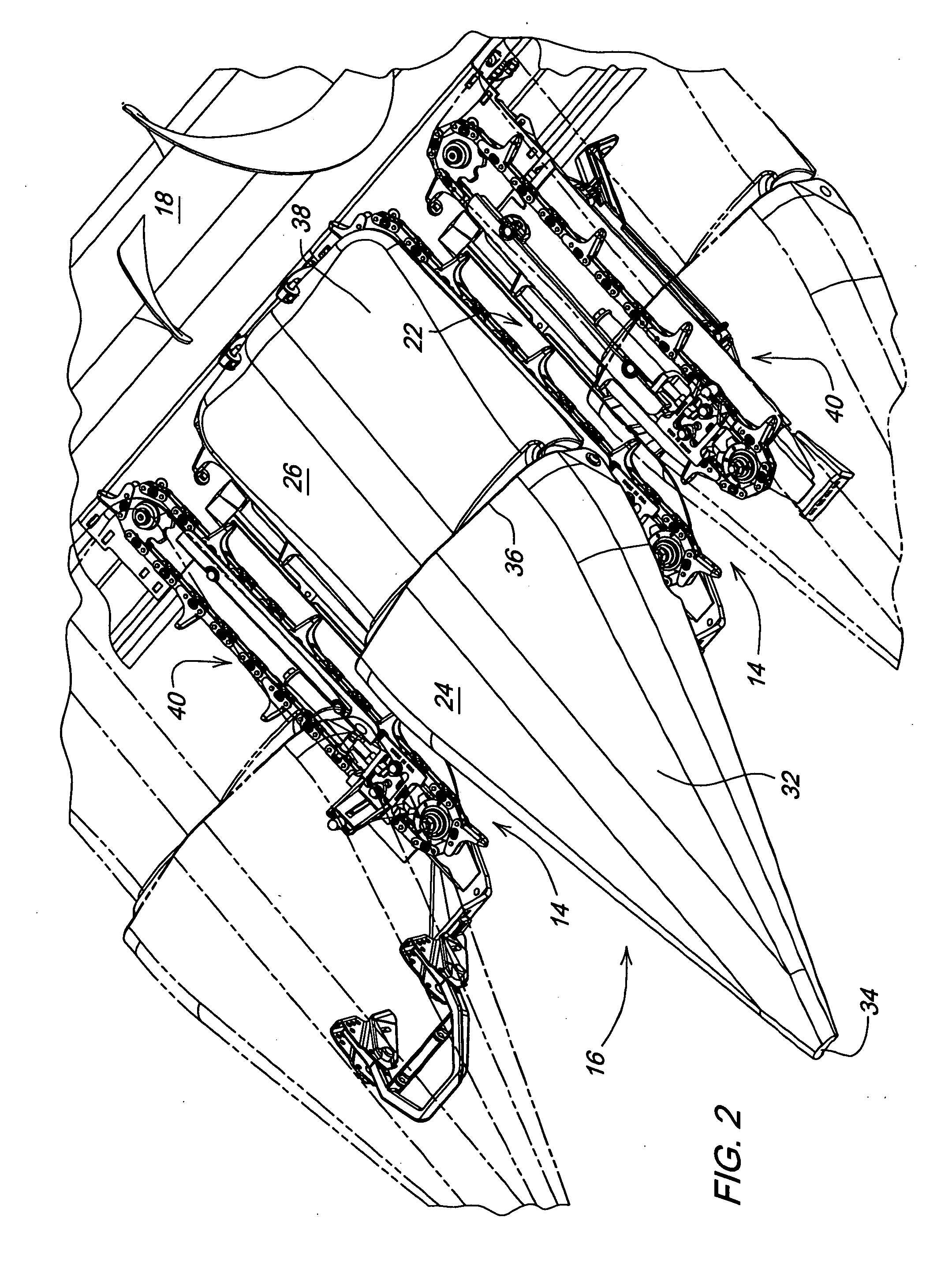

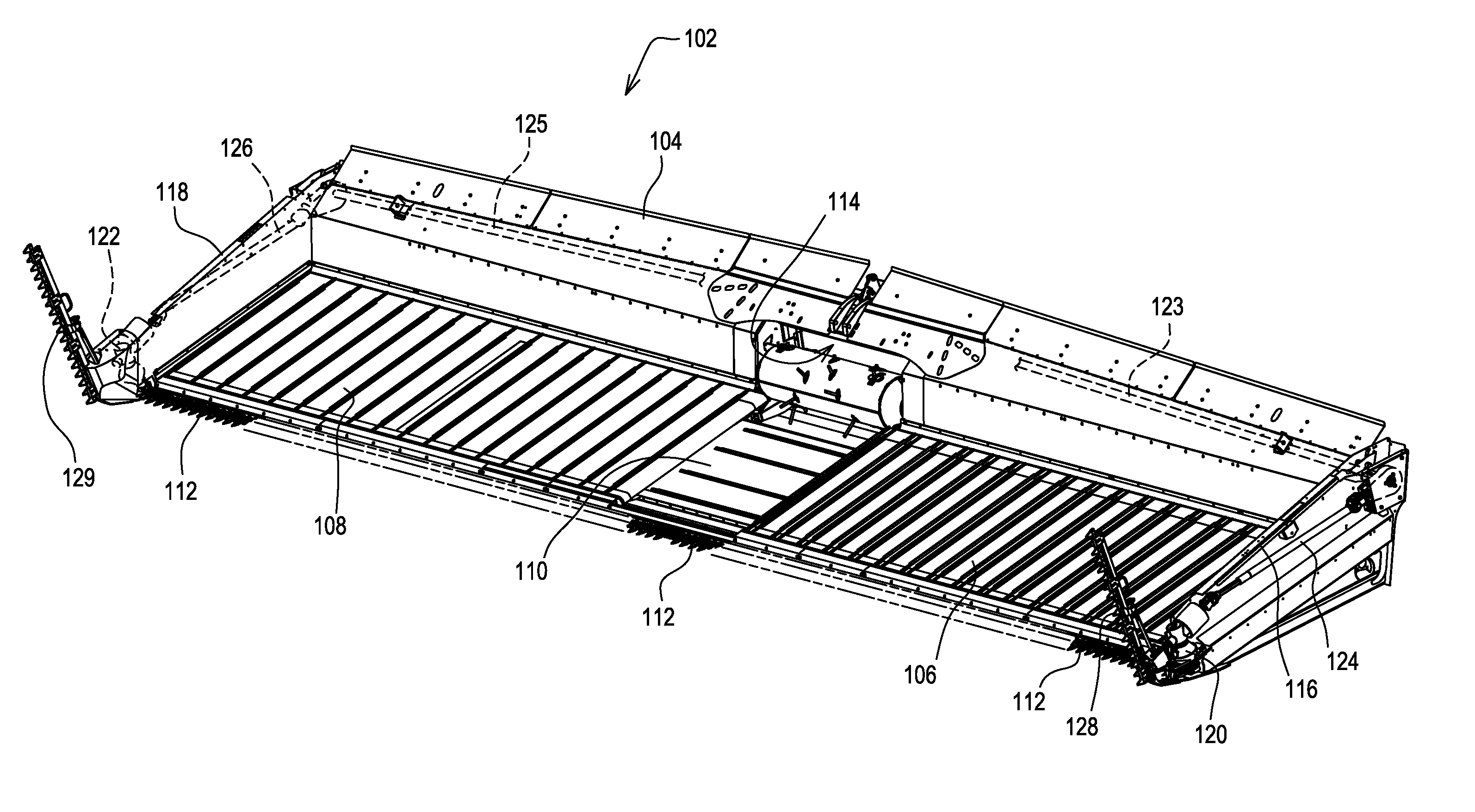

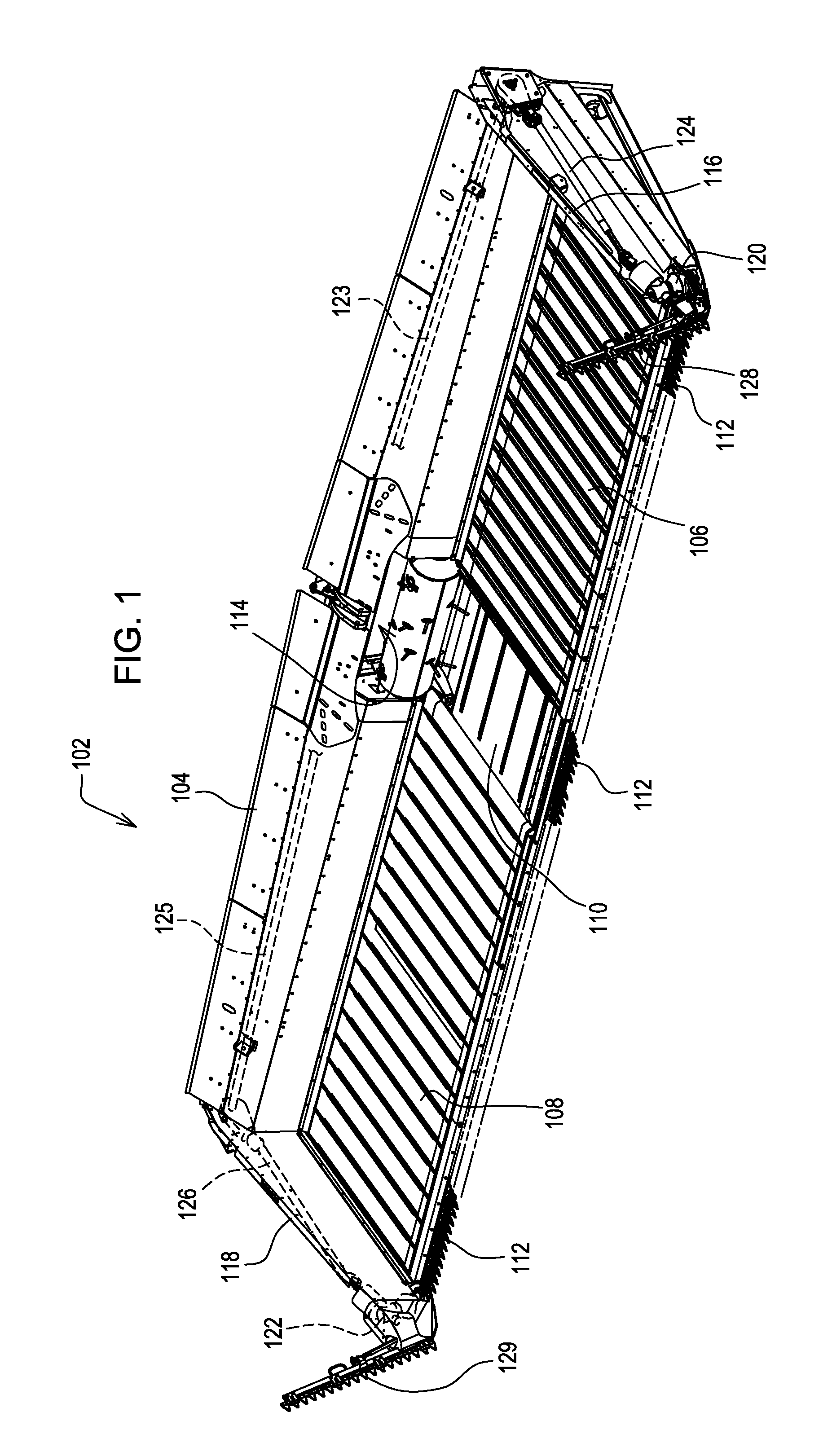

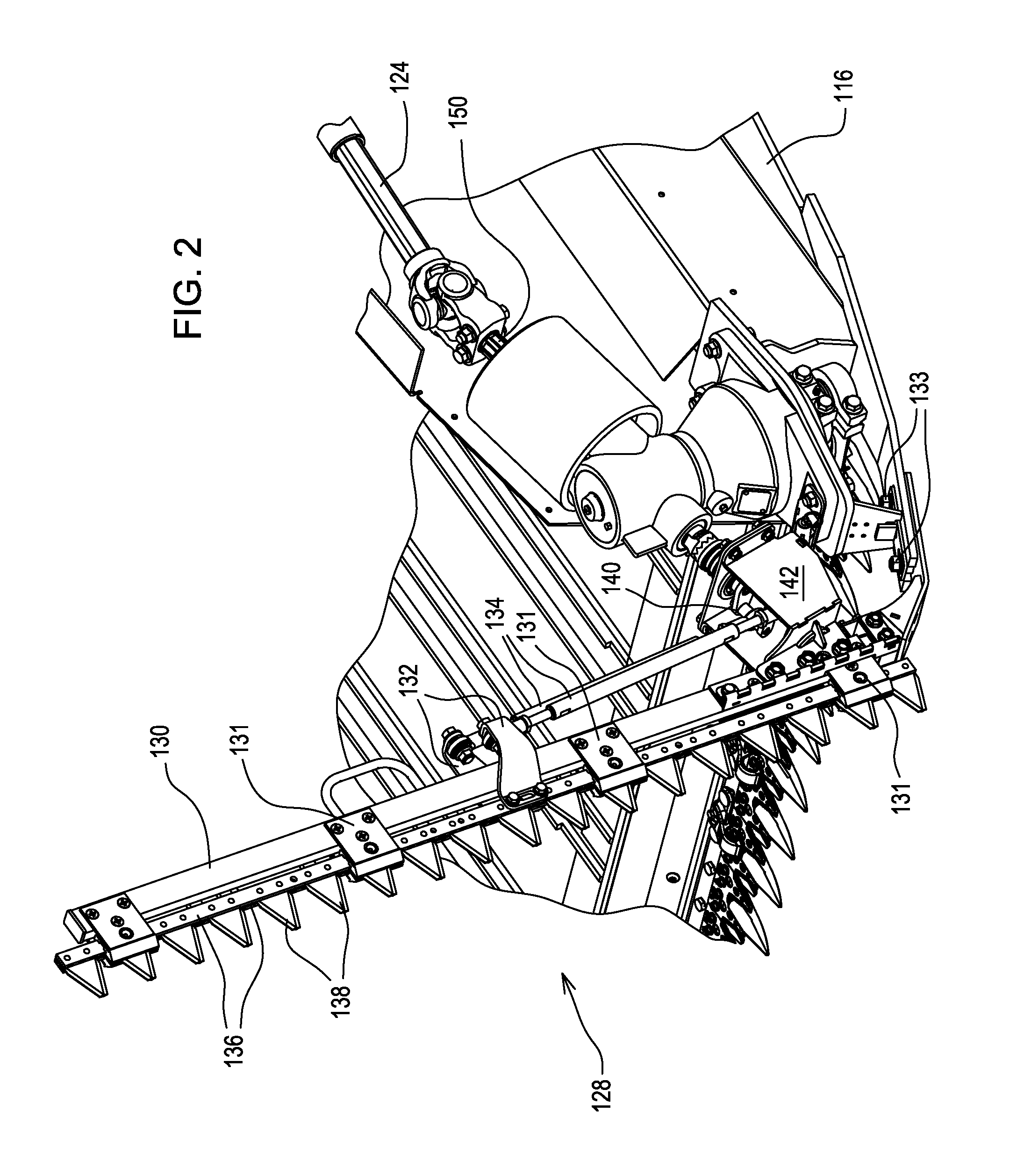

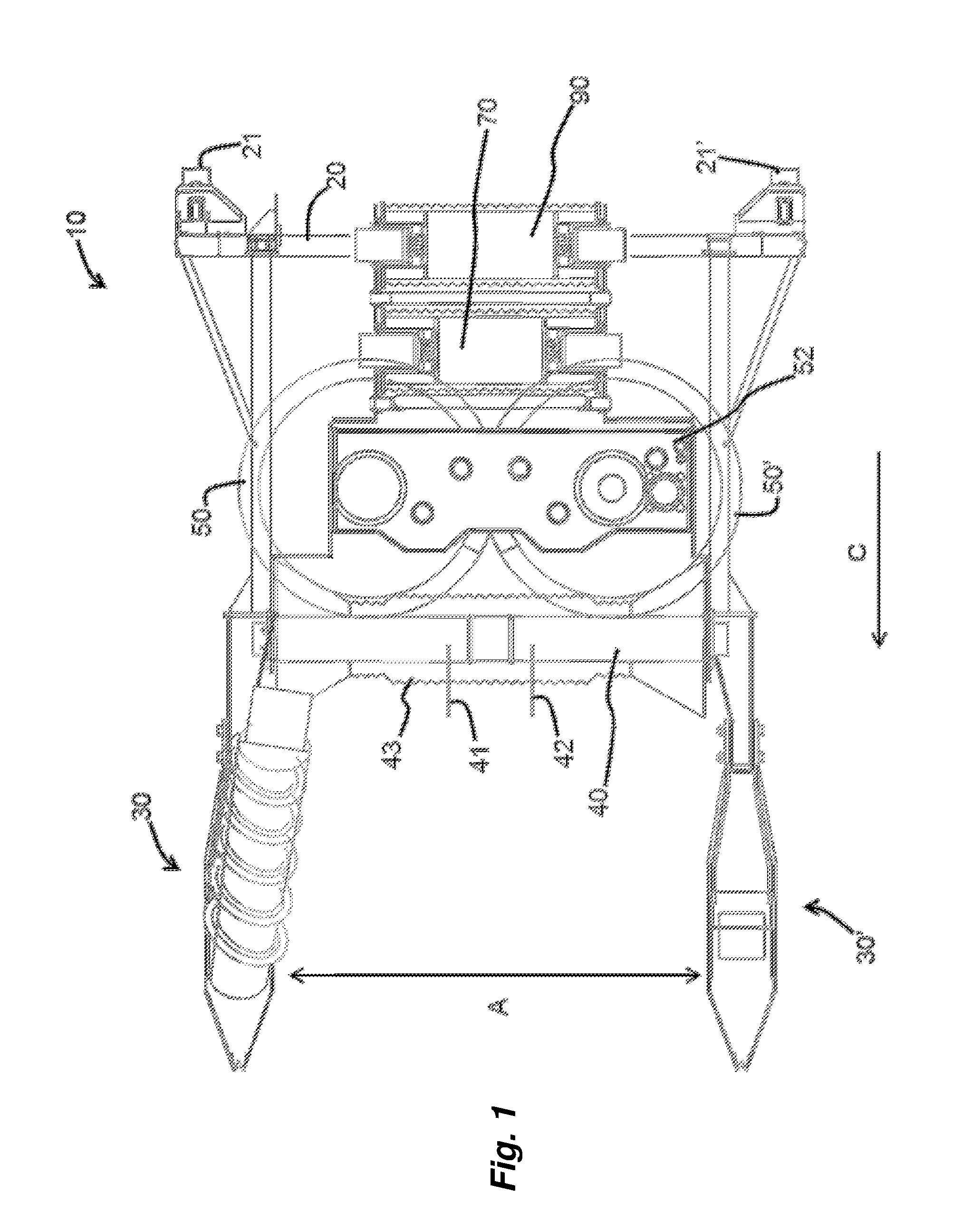

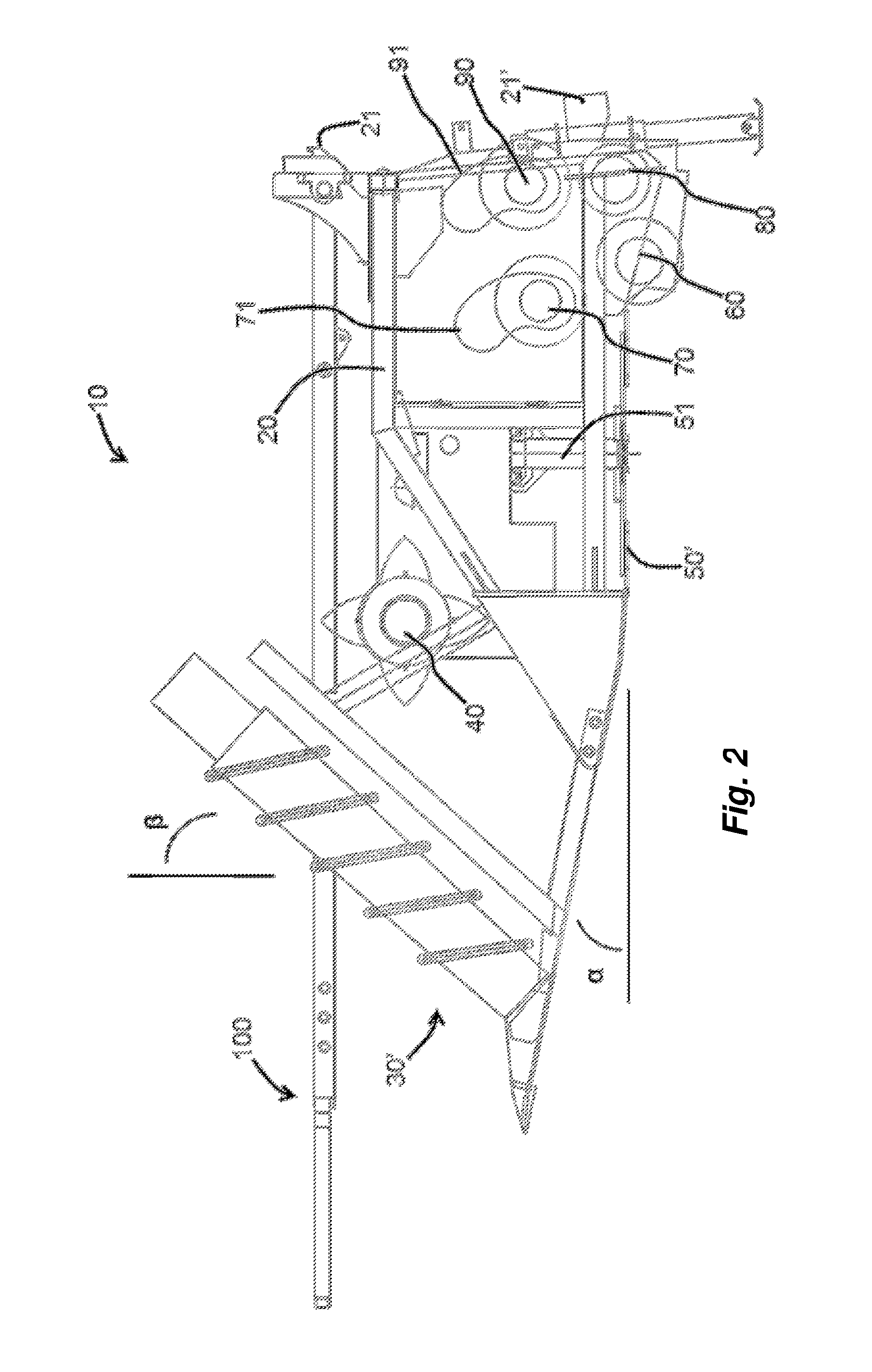

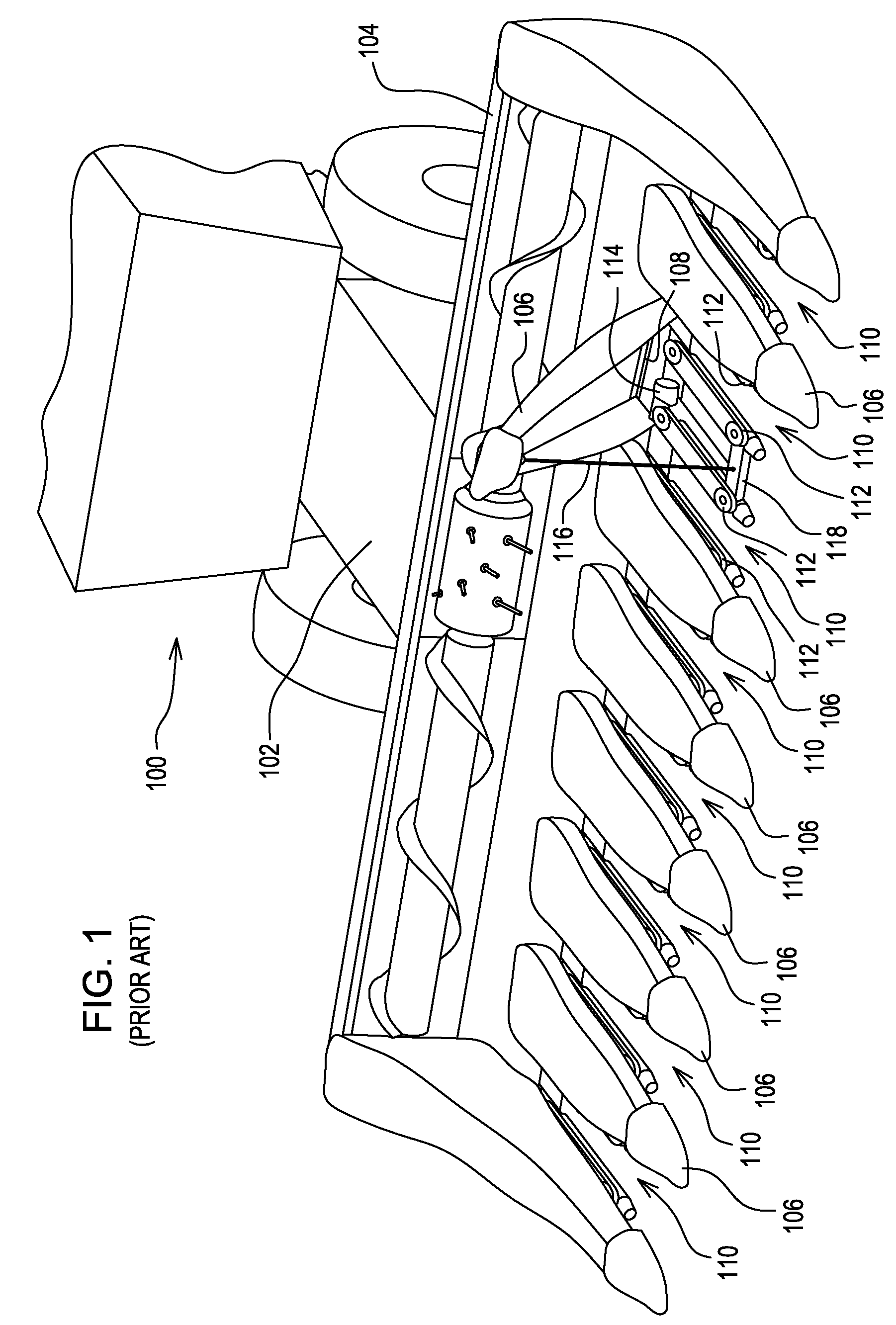

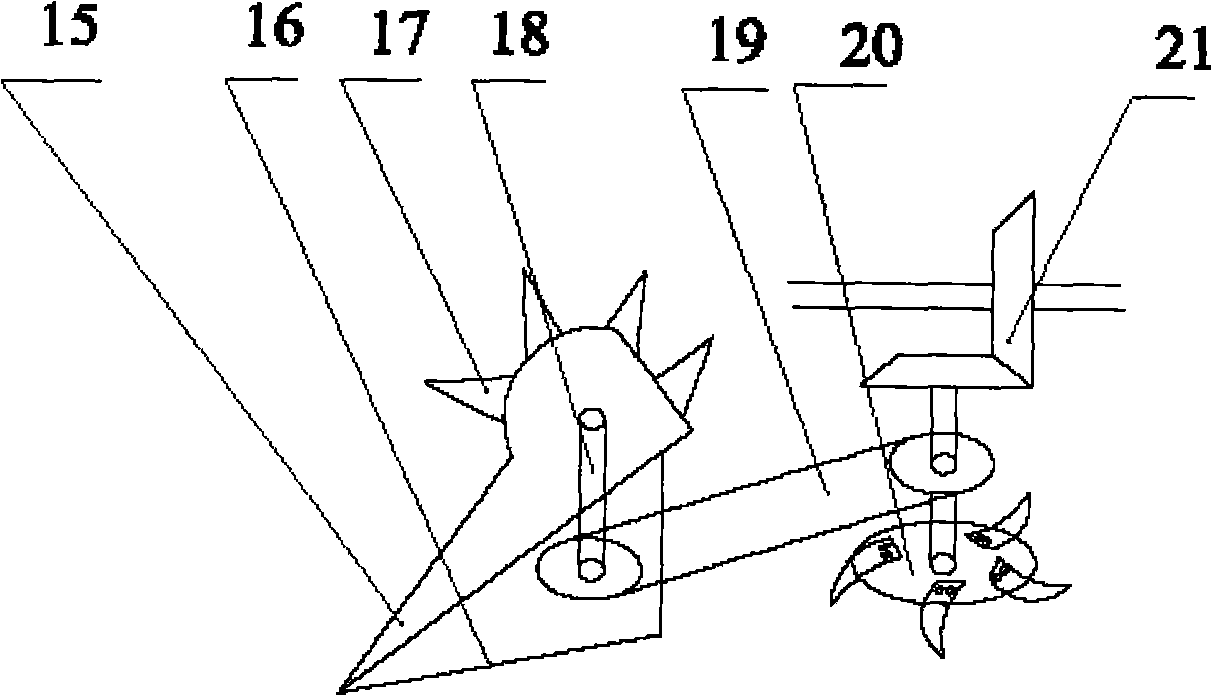

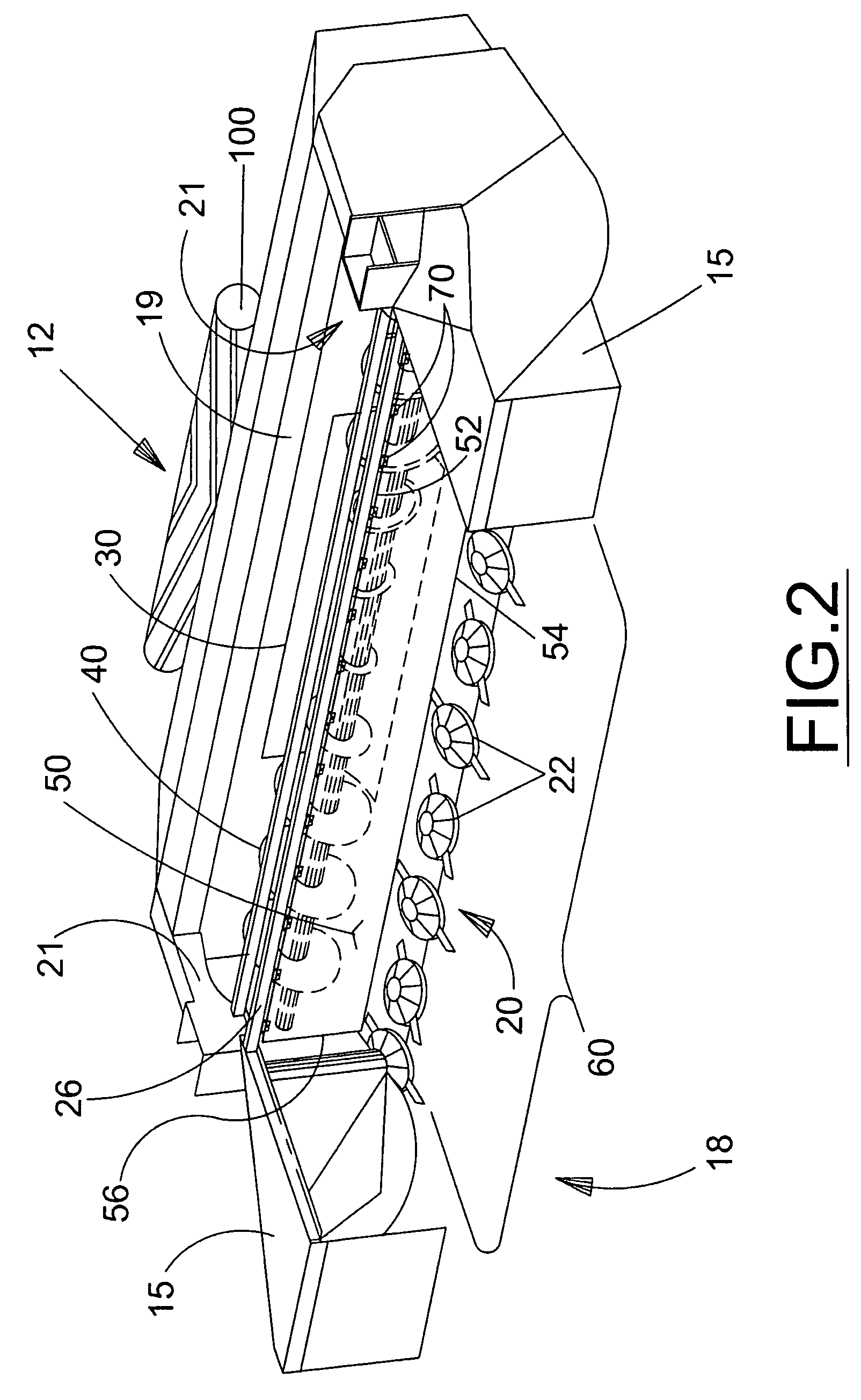

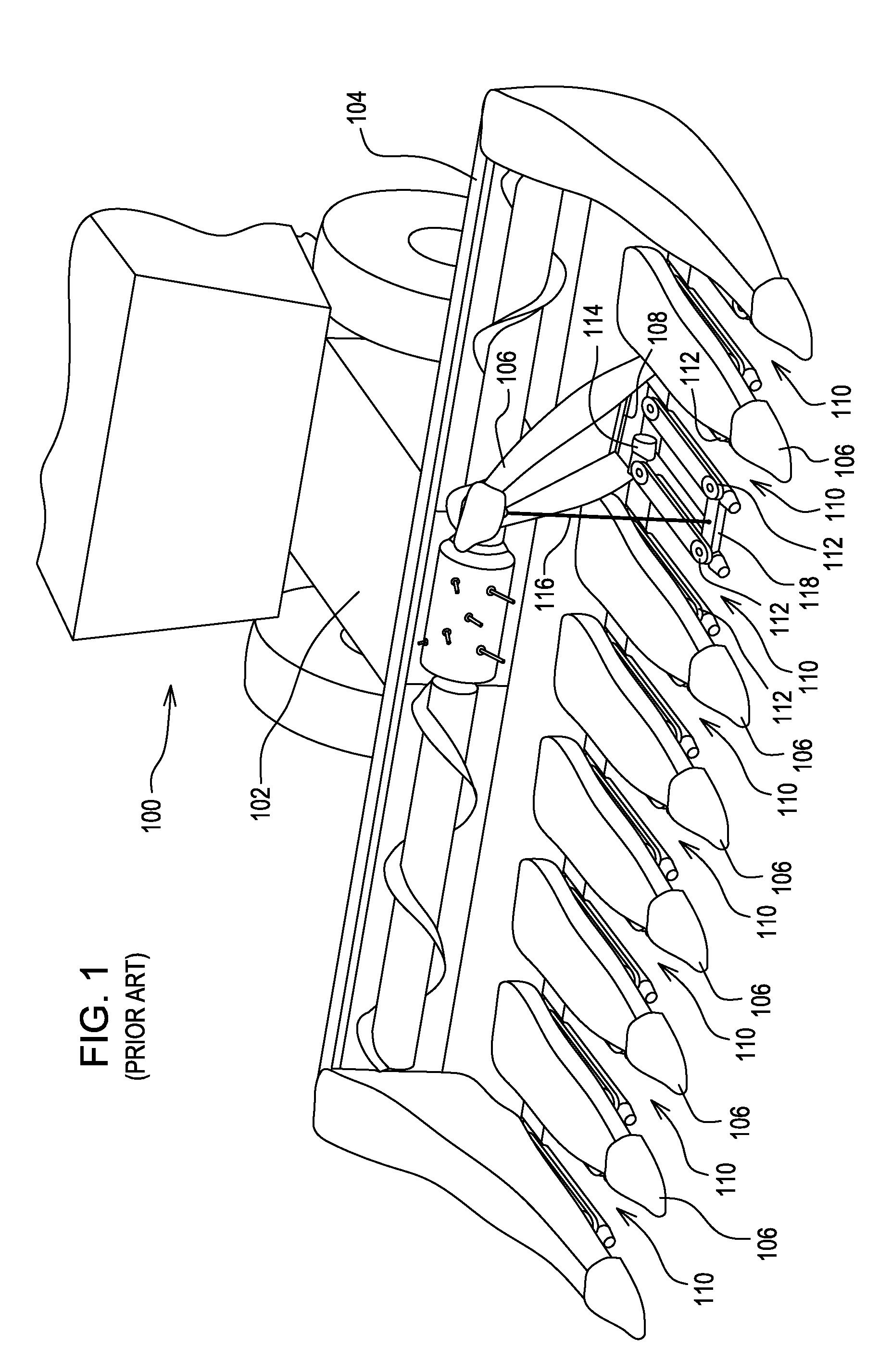

Draper header and crop divider knife

A draper header (102) is provided having the elongate laterally extending frame (104) and two forwardly extending crop dividers (116, 118) at each end. A gear box (120, 122) is mounted on the front of each crop divider (116, 118). The gearbox (120, 122) has two output shafts (148, 152), a first shaft (148) that is coupled to and drives an elongate reciprocating knife (112) extending across the leading edge of the draper header (102) and a second shaft (152) that is coupled to and drives a crop divider knife (128, 129). The crop divider knife (128, 129) includes a quick coupling (144) that engages a quick coupling (154) mounted on the second shaft (152).

Owner:DEERE & CO

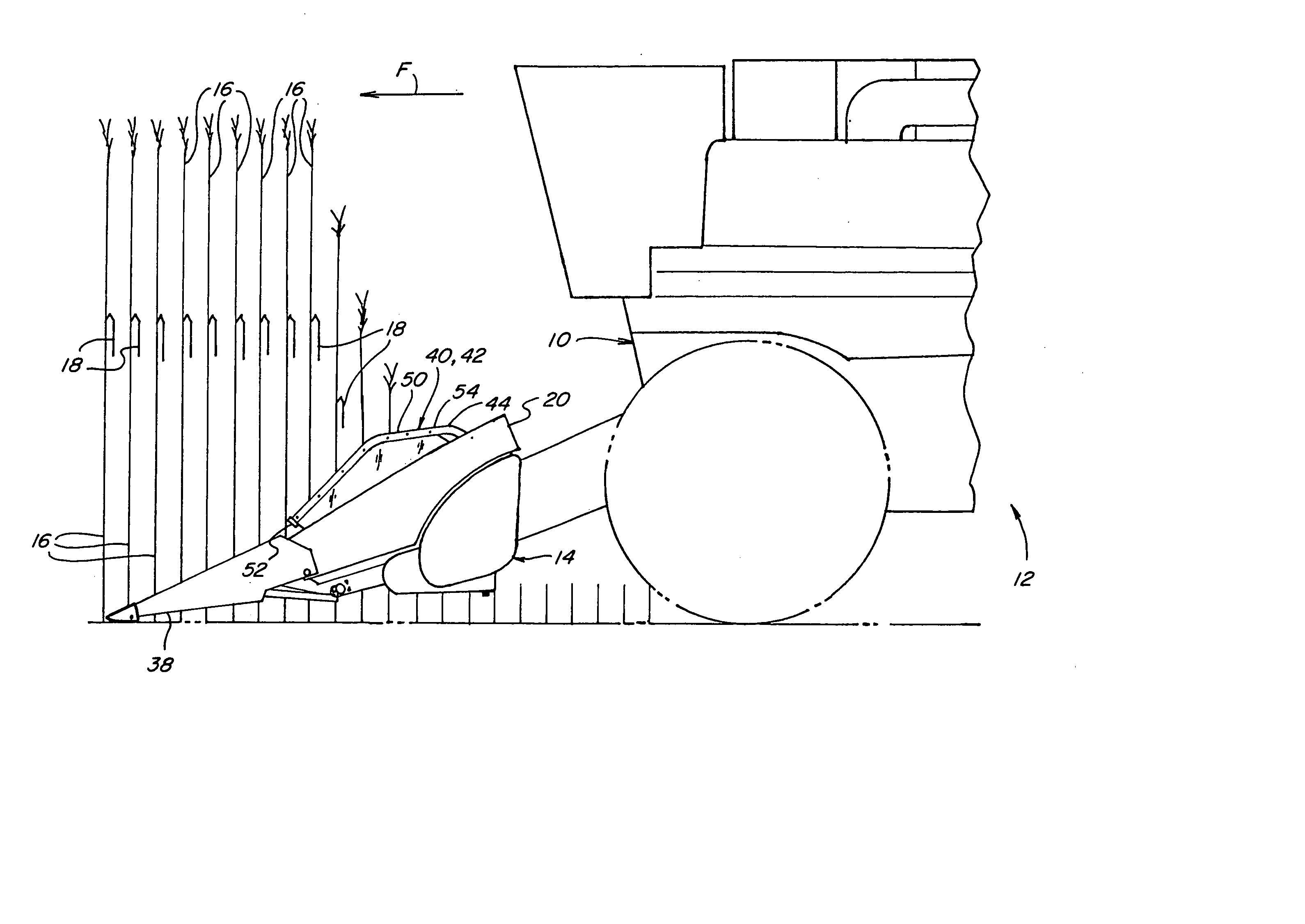

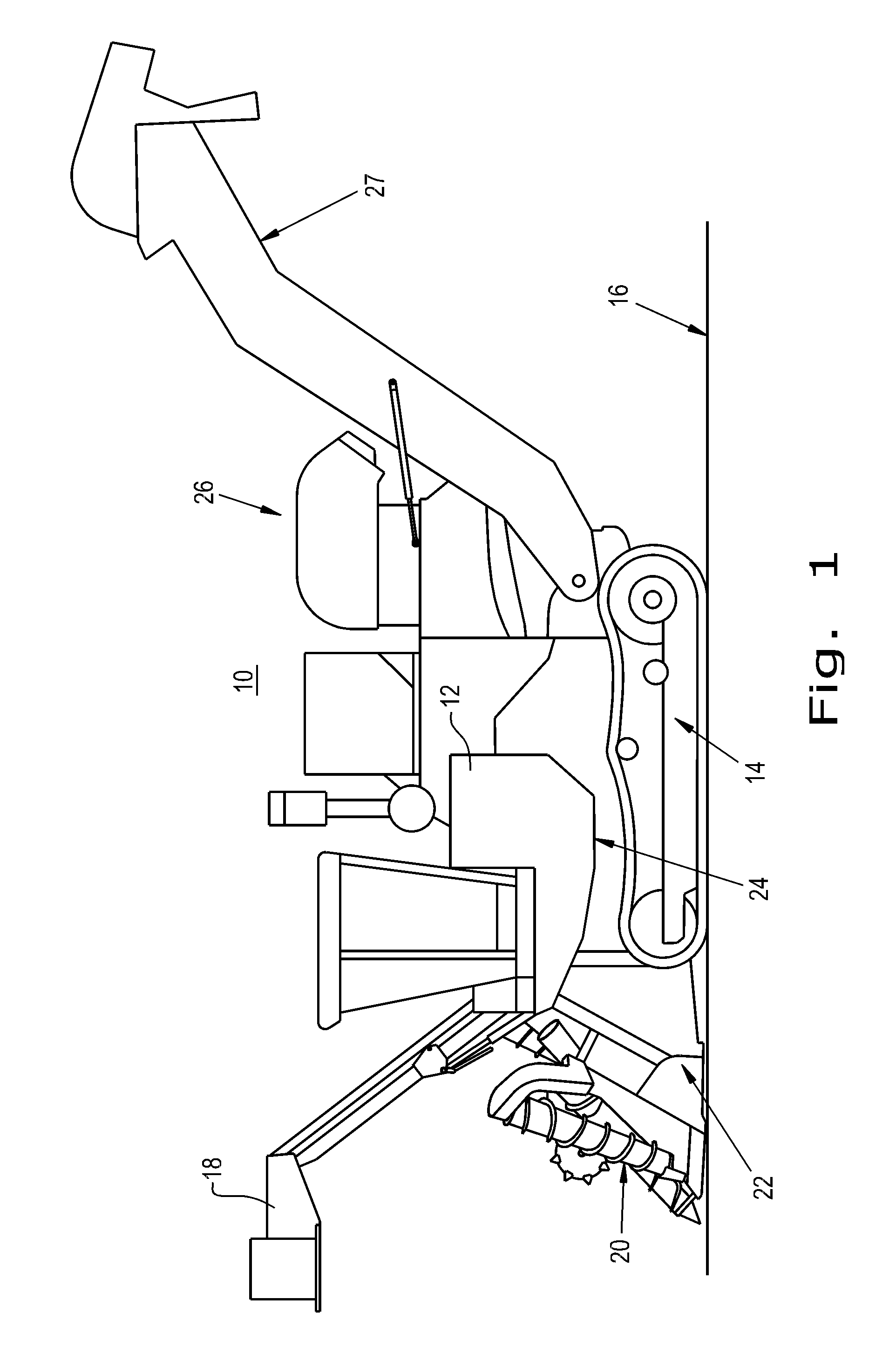

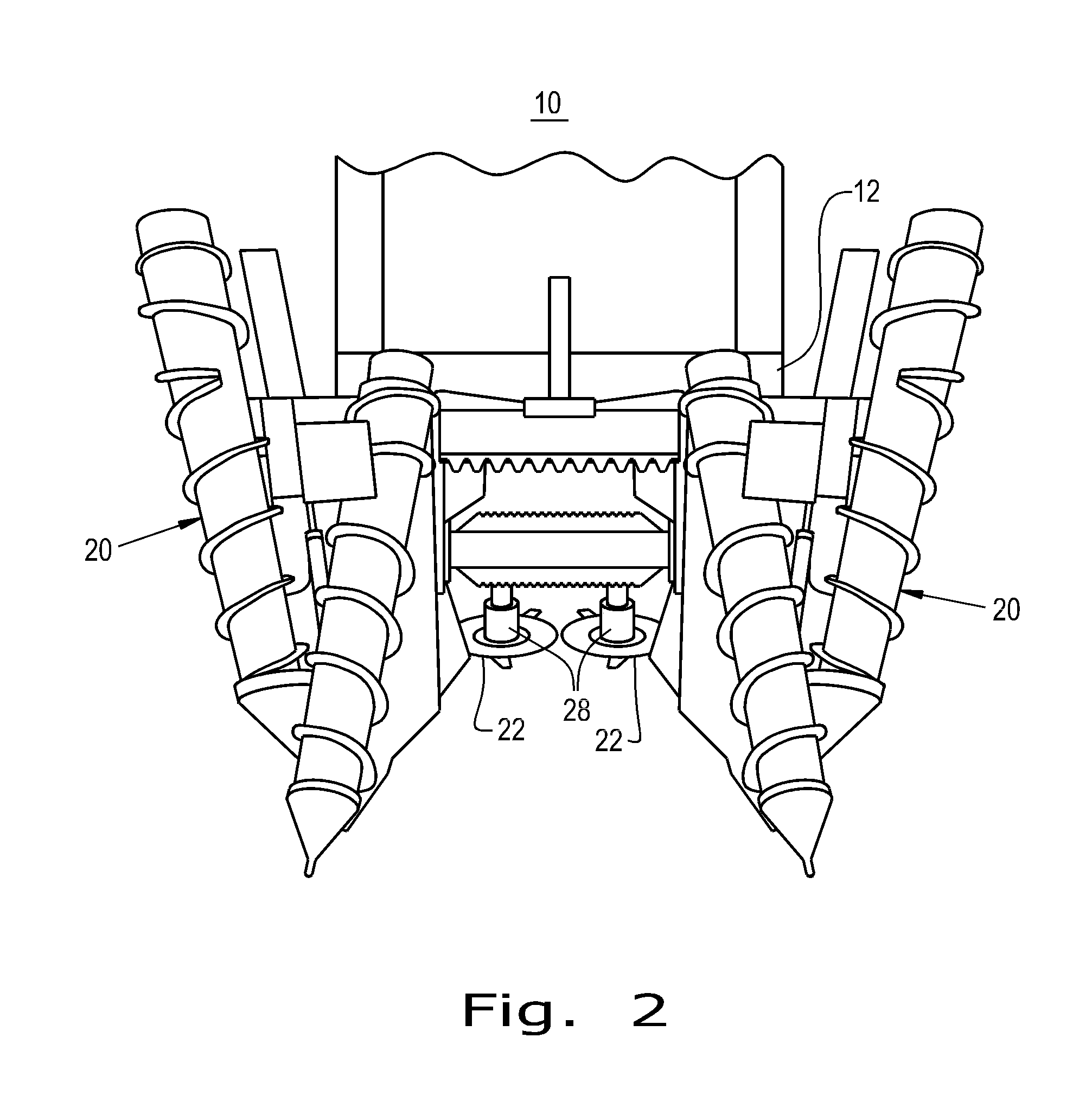

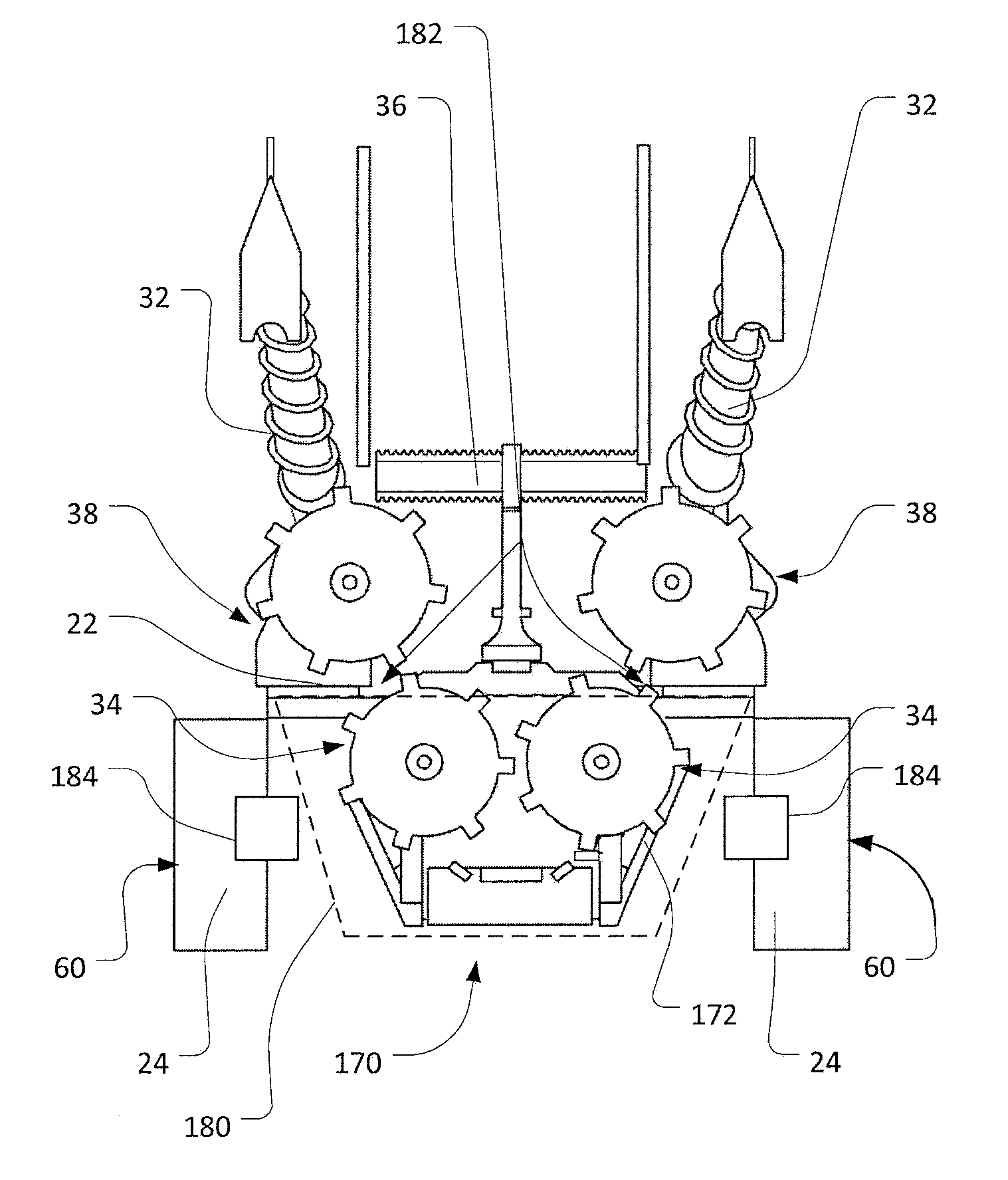

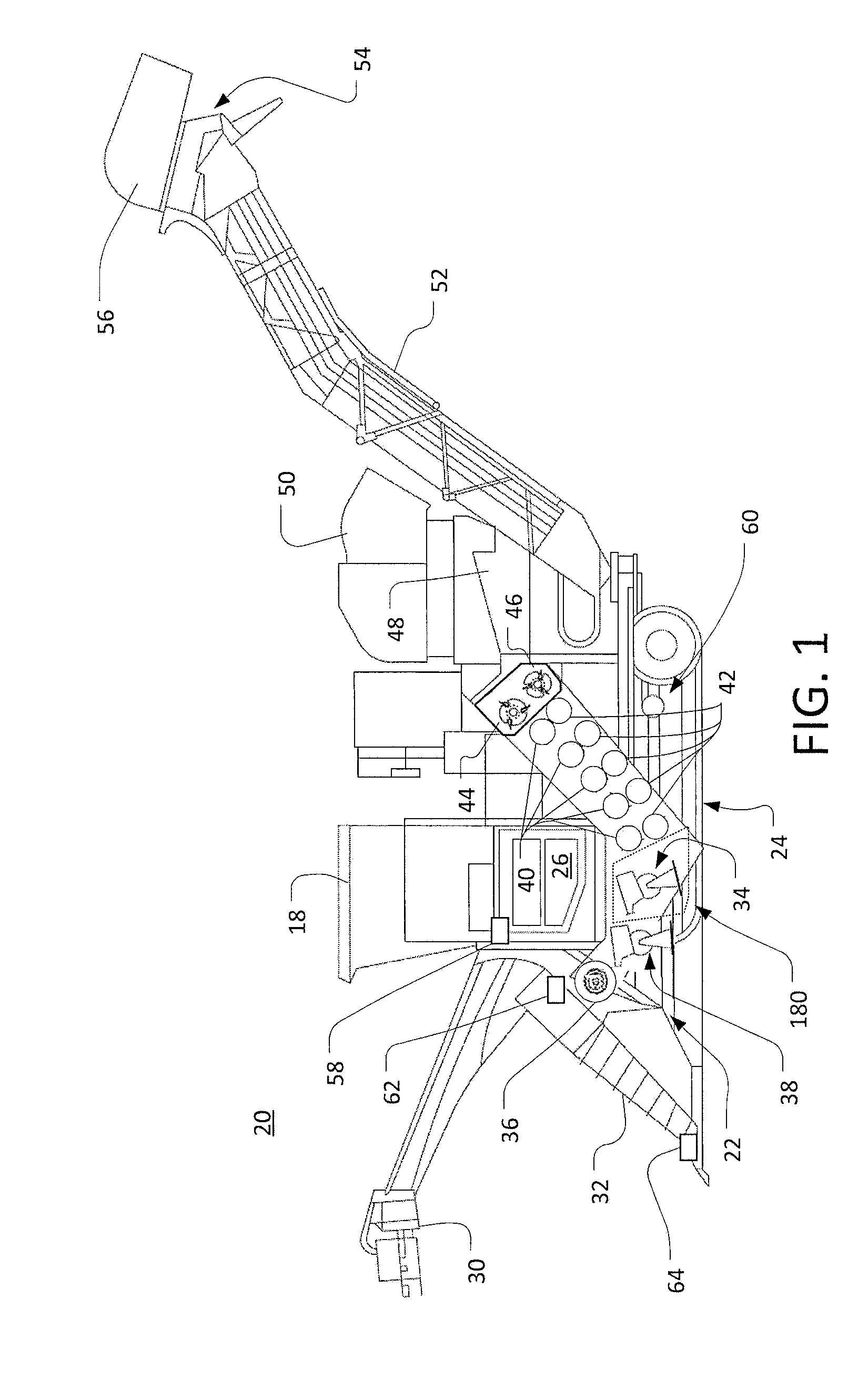

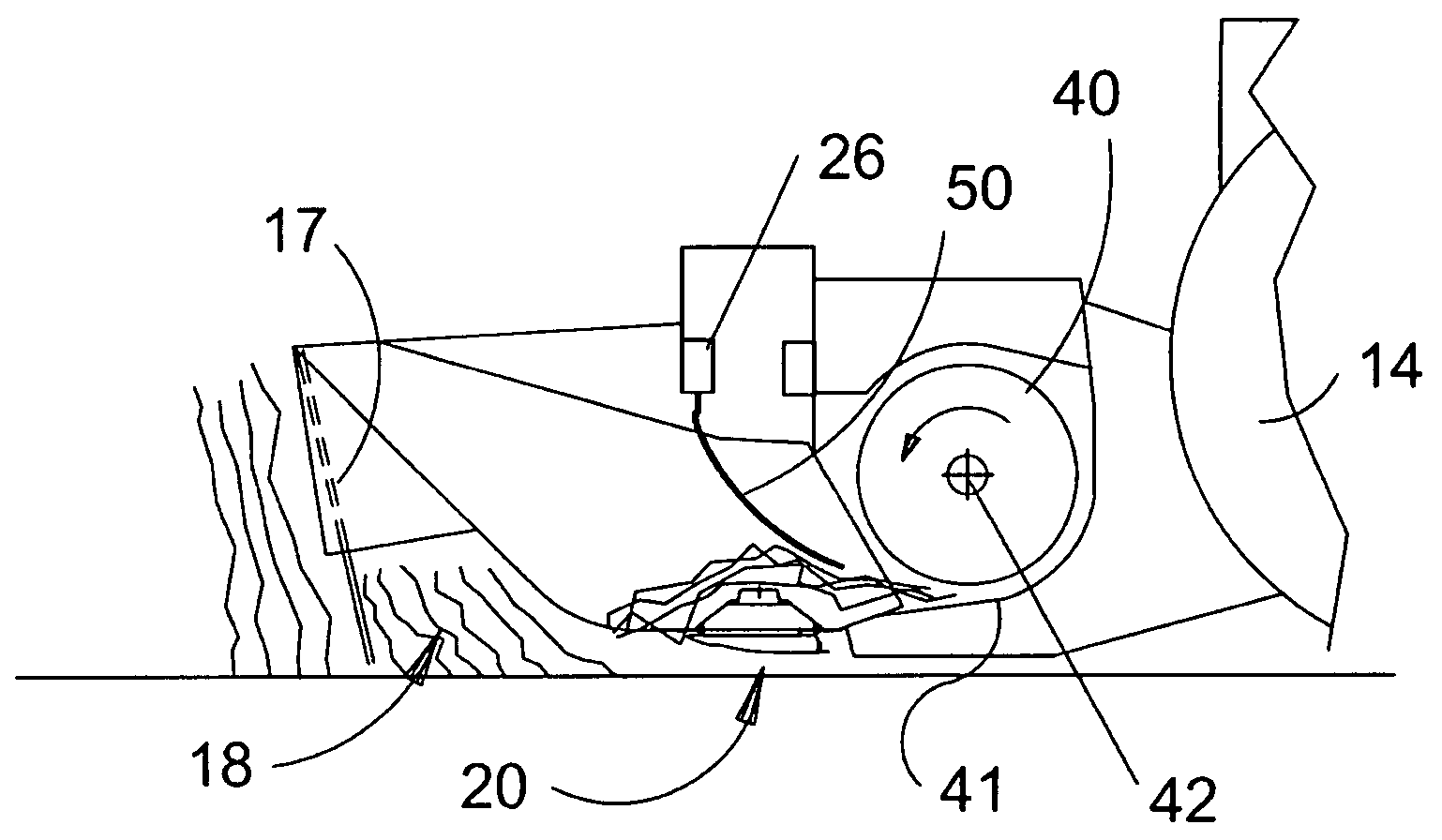

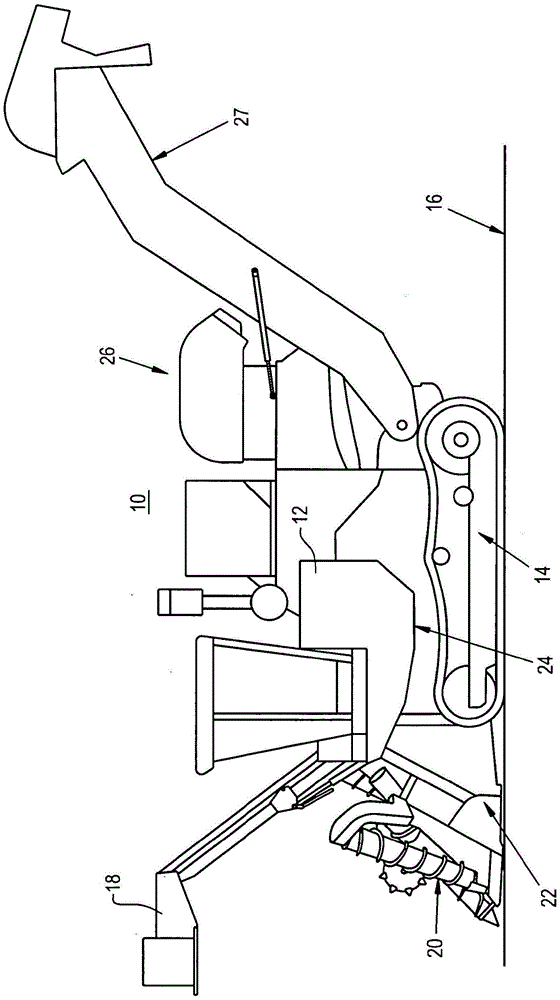

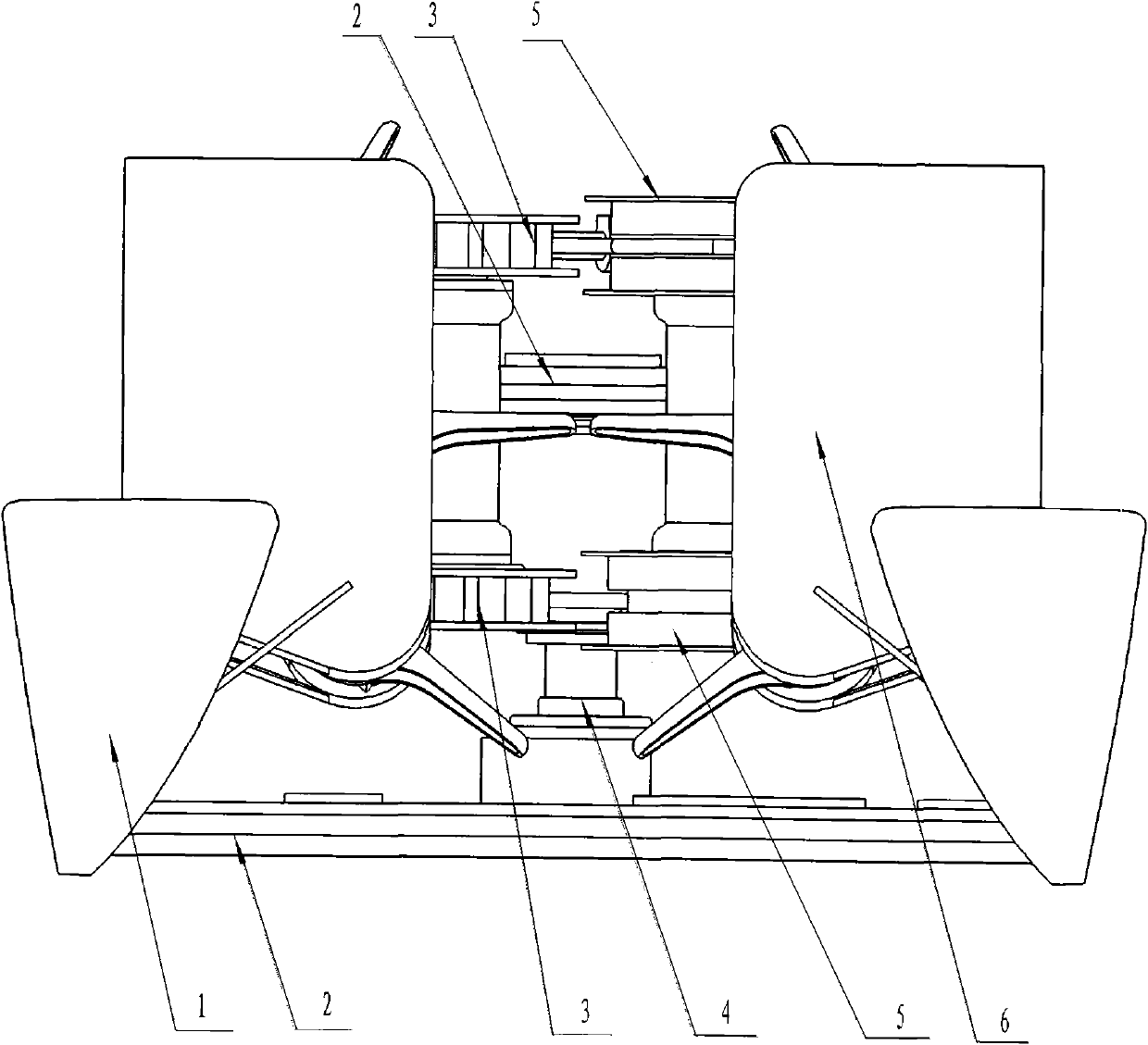

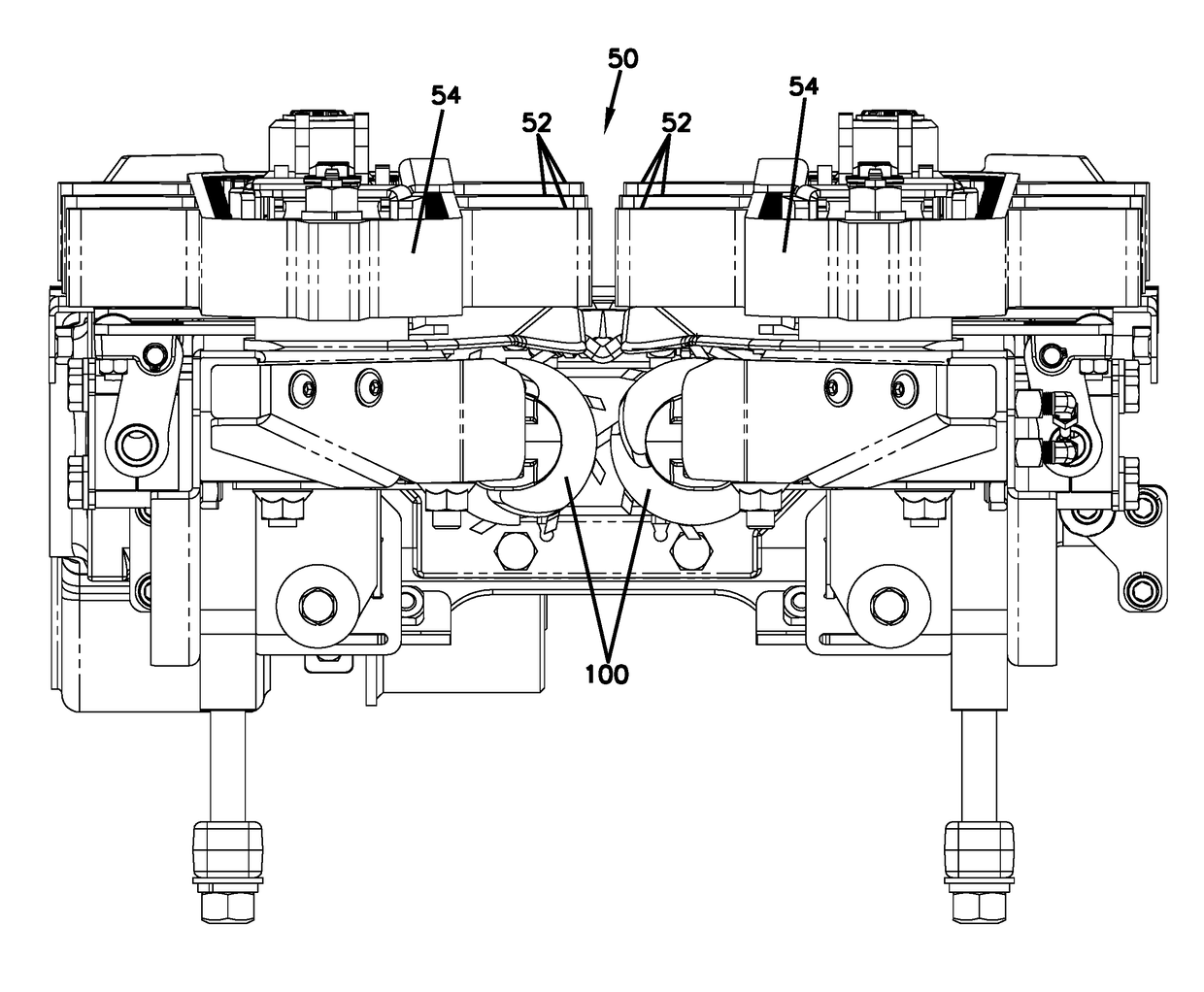

Method and Apparatus for Control of Base Cutter Height for Multiple Row Sugar Cane Harvesters

A multiple row sugar cane harvester having automatic and independent control of multiple base cutters utilized to severe sugar cane stalks in adjacent rows. Position sensors sense the height of the base cutters relative to the chassis of the sugar cane harvester and feed the signals to a controller for adjusting the height to a preselected level. The base cutters are individually driven by hydraulic motors through individual hydraulic circuits and the operating pressure is sensed and fed to the controller for determining whether a choke condition exists. A load sensor is incorporated between the linkage and the sugar cane harvester chassis for determining whether the base cutters have ground contact to elevate the base cutters.

Owner:BLUE LEAF I P

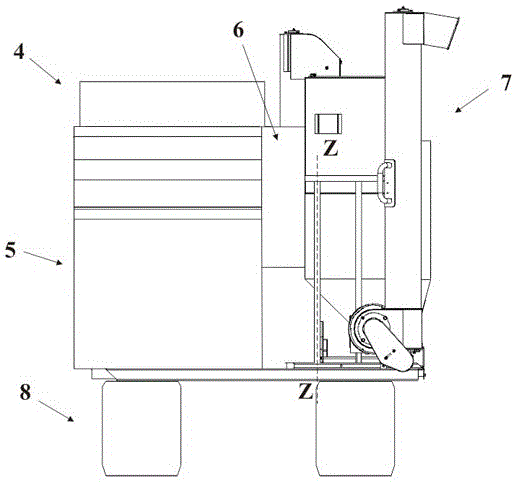

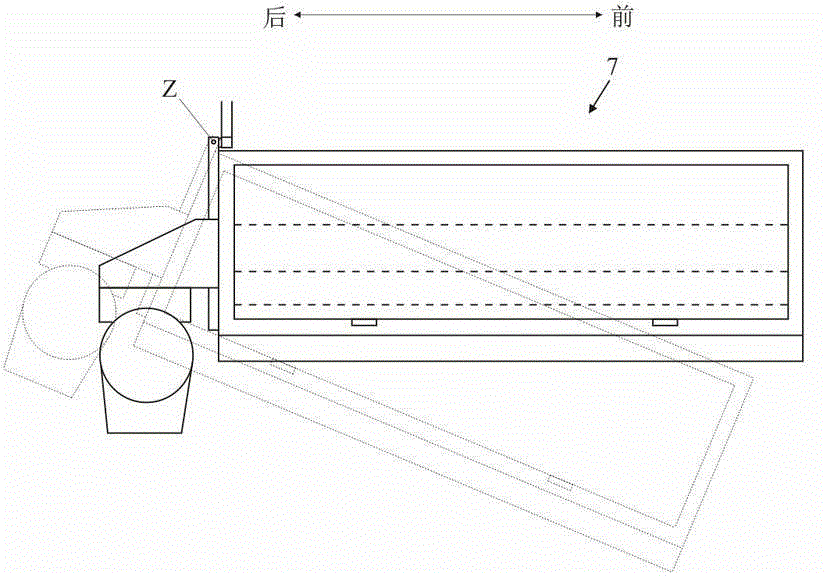

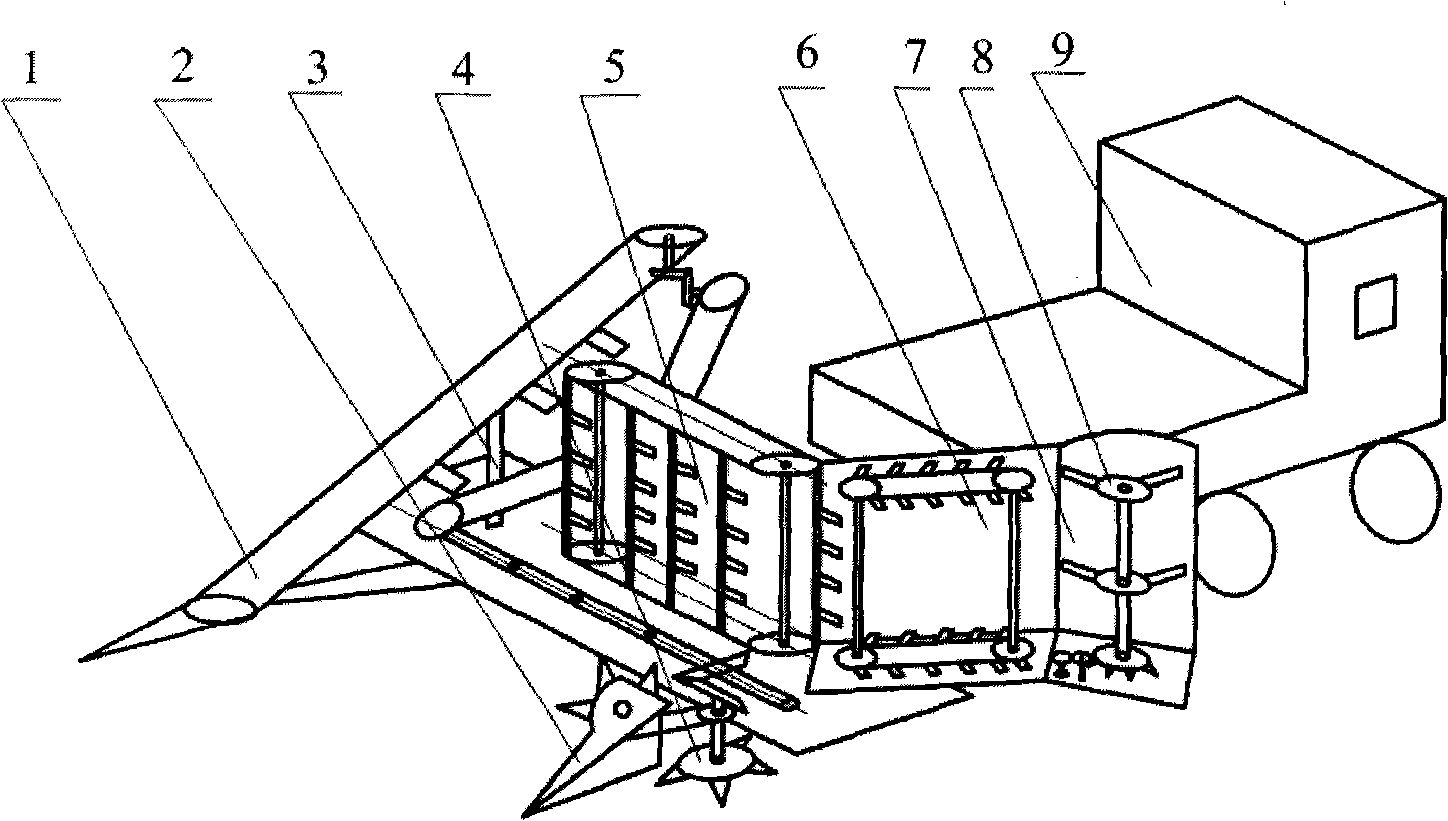

Rape windrower

InactiveCN102484962AEfficient cuttingEffective conveying and layingMowersAgricultural lifting devicesHarvest timeAgricultural engineering

The invention relates to the technical field of harvesters in agricultural machinery, in particular to a rape windrower. The rape windrower mainly comprises a rack, dividers, a grain lifter, cutting devices, a conveying system, transmission devices and a suspension device and is characterized in that the windrower is hung at the rear to realize middle windrowing of the rapes. The rape windrower has the following beneficial effects: the rape windrower is suitable for transplanting and directly seeding the rapes and can realize effective cutting of the rape stems and effective conveying and windrowing after cutting; windrowing channels are not needed to be opened up manually in advance; a hydraulic device freely controls the stubble height; the rape windrower avoids blockage and has wide cutting range, high efficiency and low power consumption; by adopting the way of staged harvesting, the harvest time of the rapes is prolonged and the loss rates of the rapes are reduced; a practical machine tool is provided for mechanically harvesting the rapes; and the rape windrower can harvest soybeans, corn stalks, grass and the like through technical parameter adjustment.

Owner:HUAZHONG AGRI UNIV

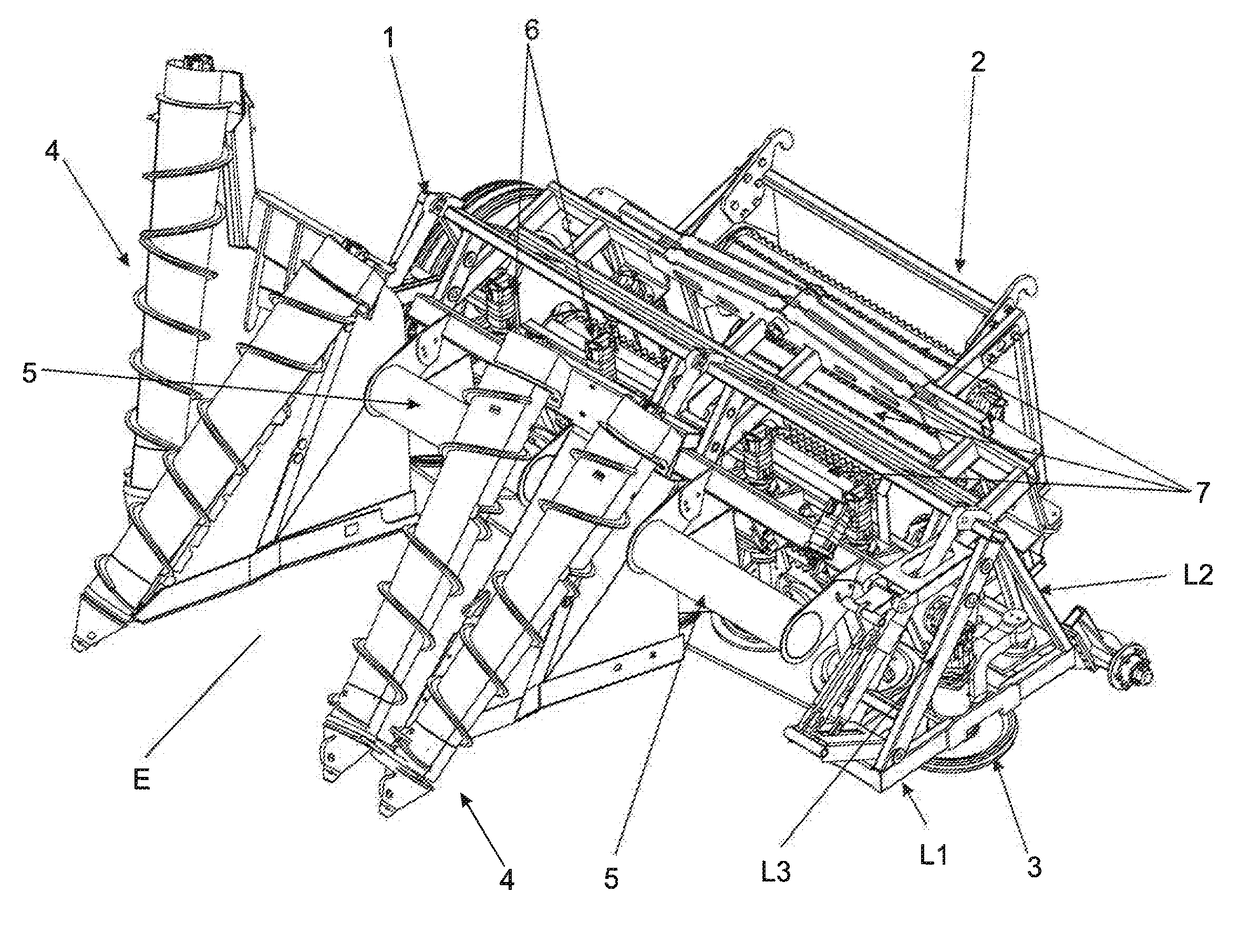

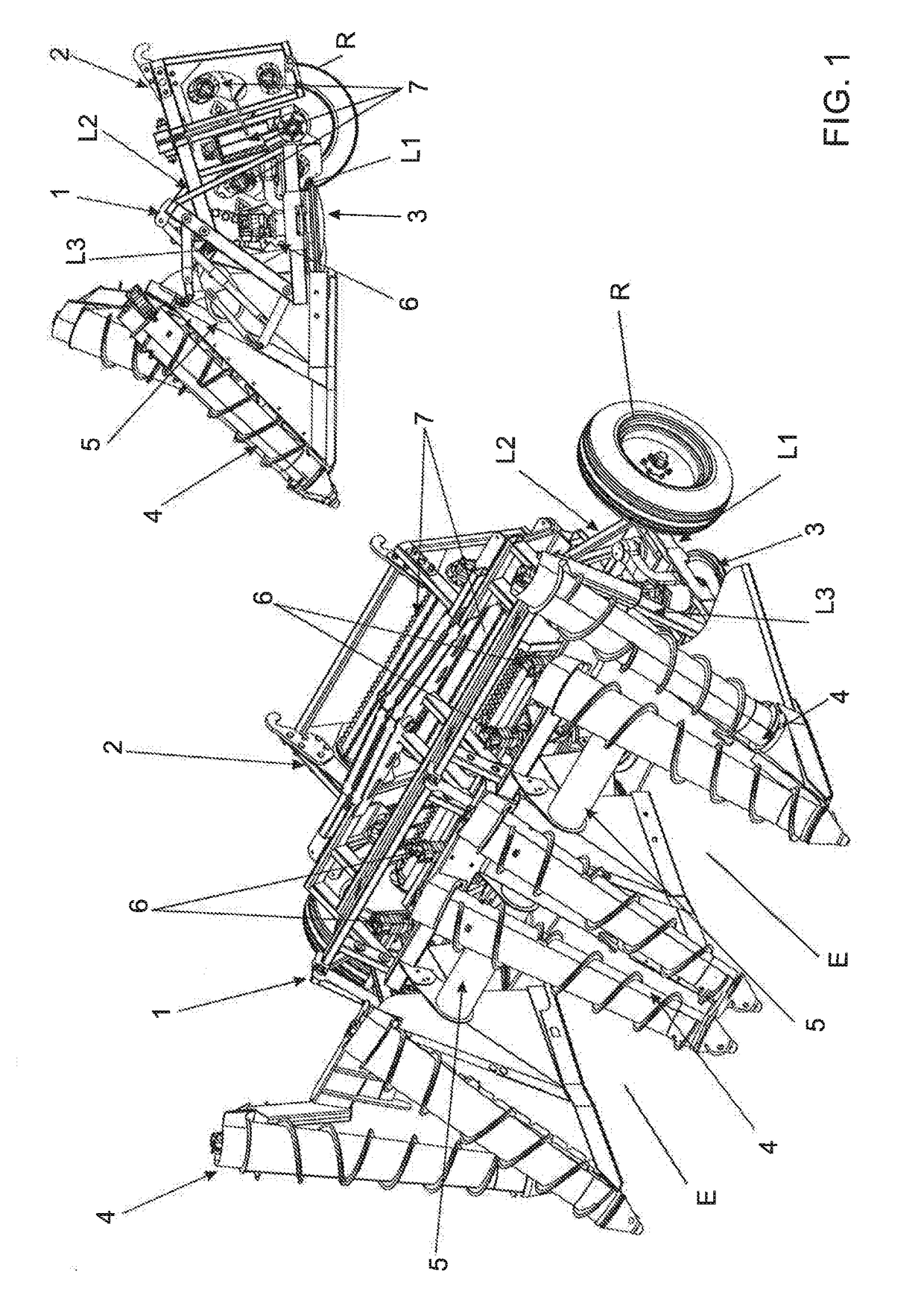

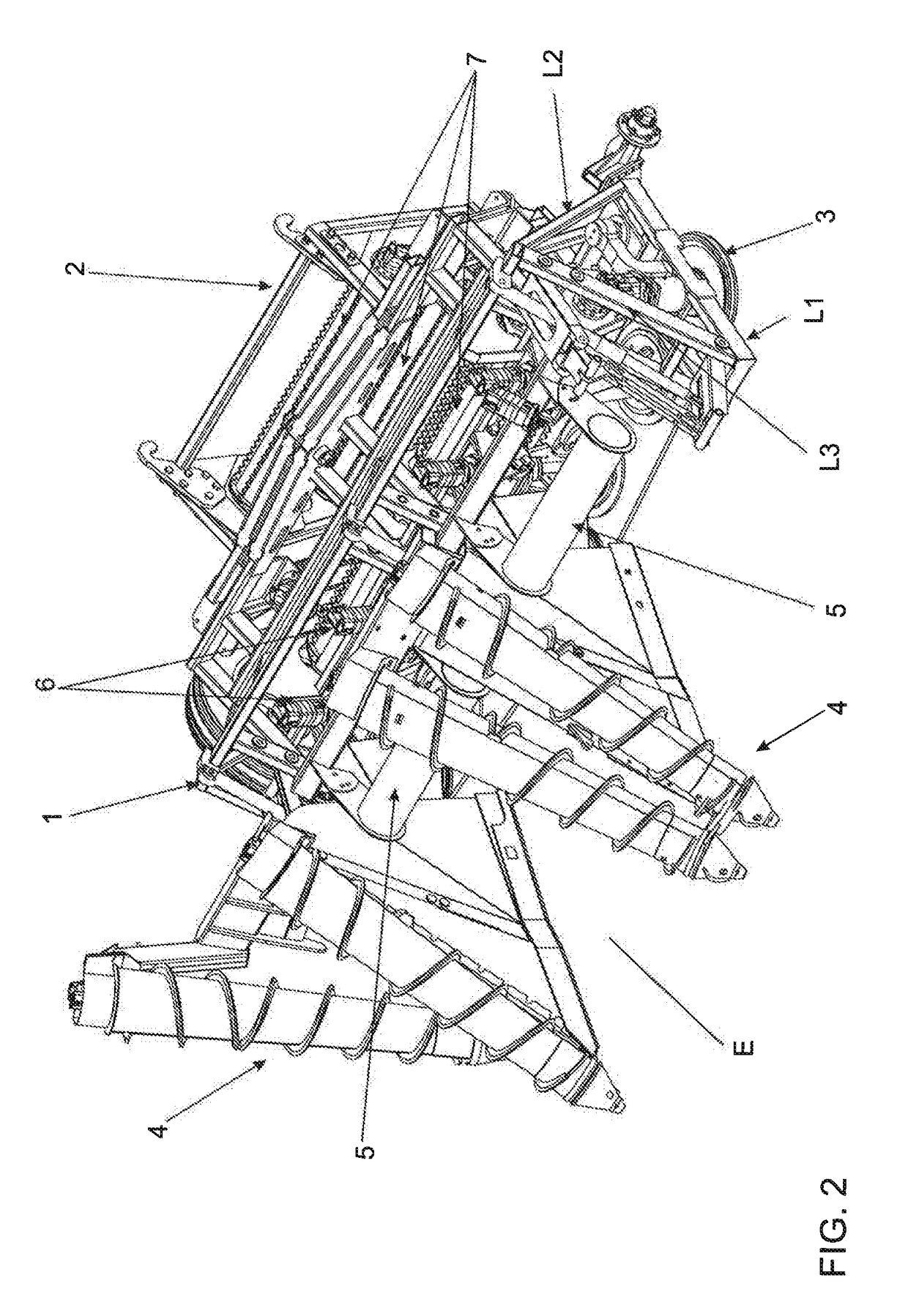

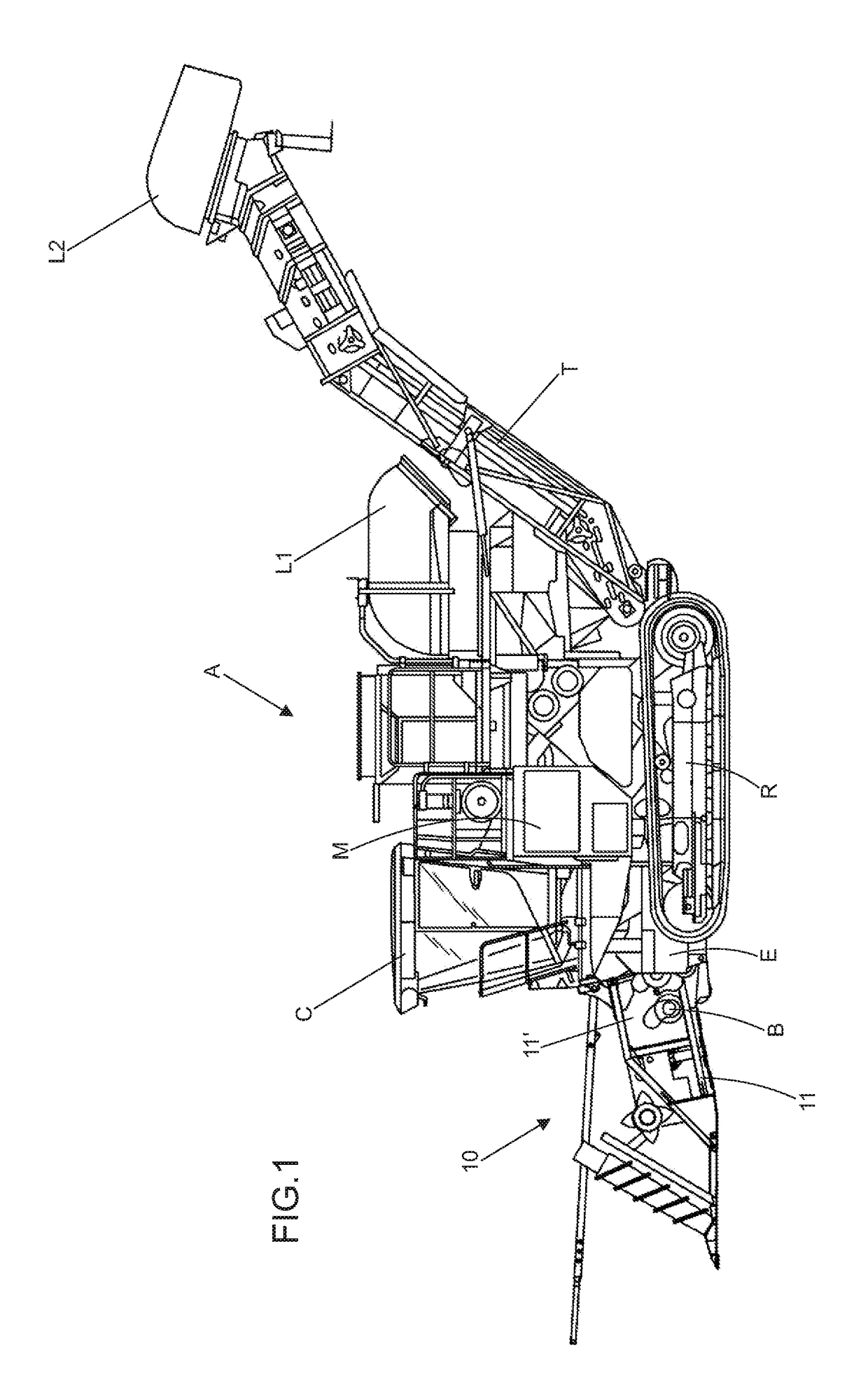

Header for a Harvesting Machine

A header for a harvesting machine. The header includes at least two row dividers spaced from one another in a transversal direction and at a predetermined distance, at least one roller, a driving for driving the roller comprising multiple projections, at least two base cutting discs, a driver for driving the at least two base cutting discs, one roller positioned behind the at least two base cutting discs to raise the cut plants, and at least one conveyor roller positioned above the said roller to raise plants, to transport the cut plants to the inside of a harvesting machine. The at least one roller includes multiple projections to collect and direct the plants downwards and towards the opening. The foregoing elements form an assembly mounted on a structure that may be connected to a harvesting machine

Owner:BLUE LEAF I P INC

Steering lock of a steering wheel activating an angle of inclination of an attachment

Owner:CLAAS SAULGAU

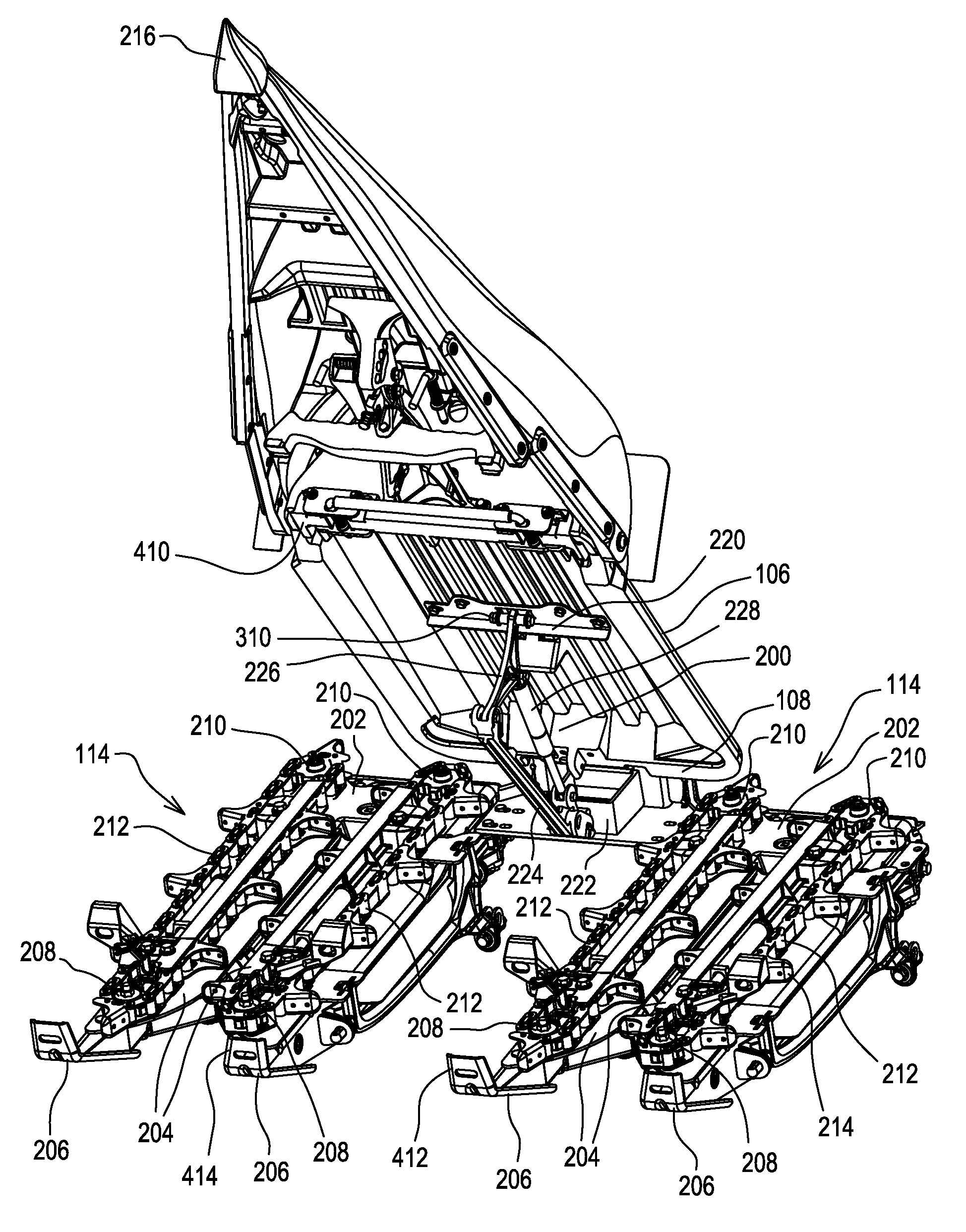

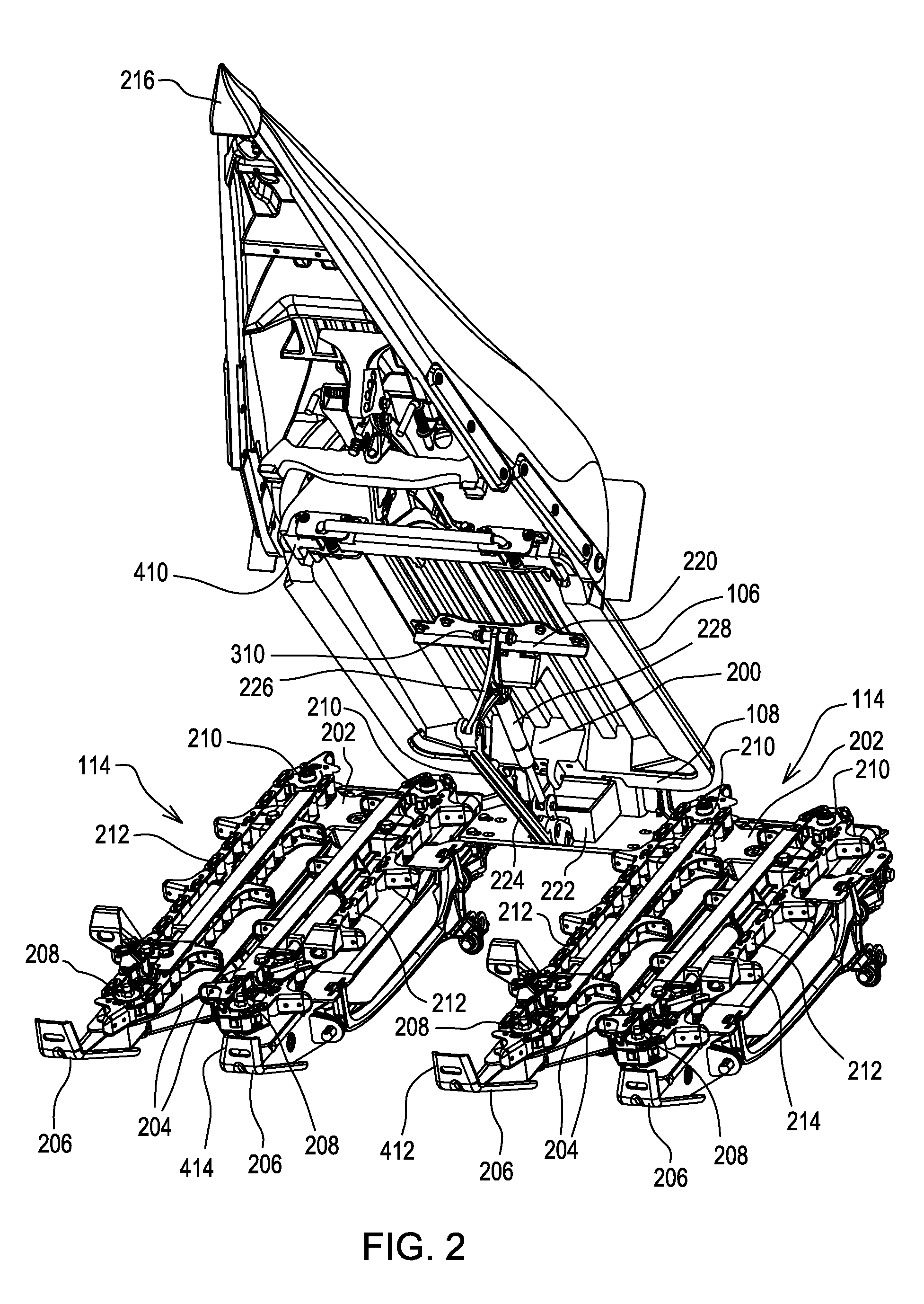

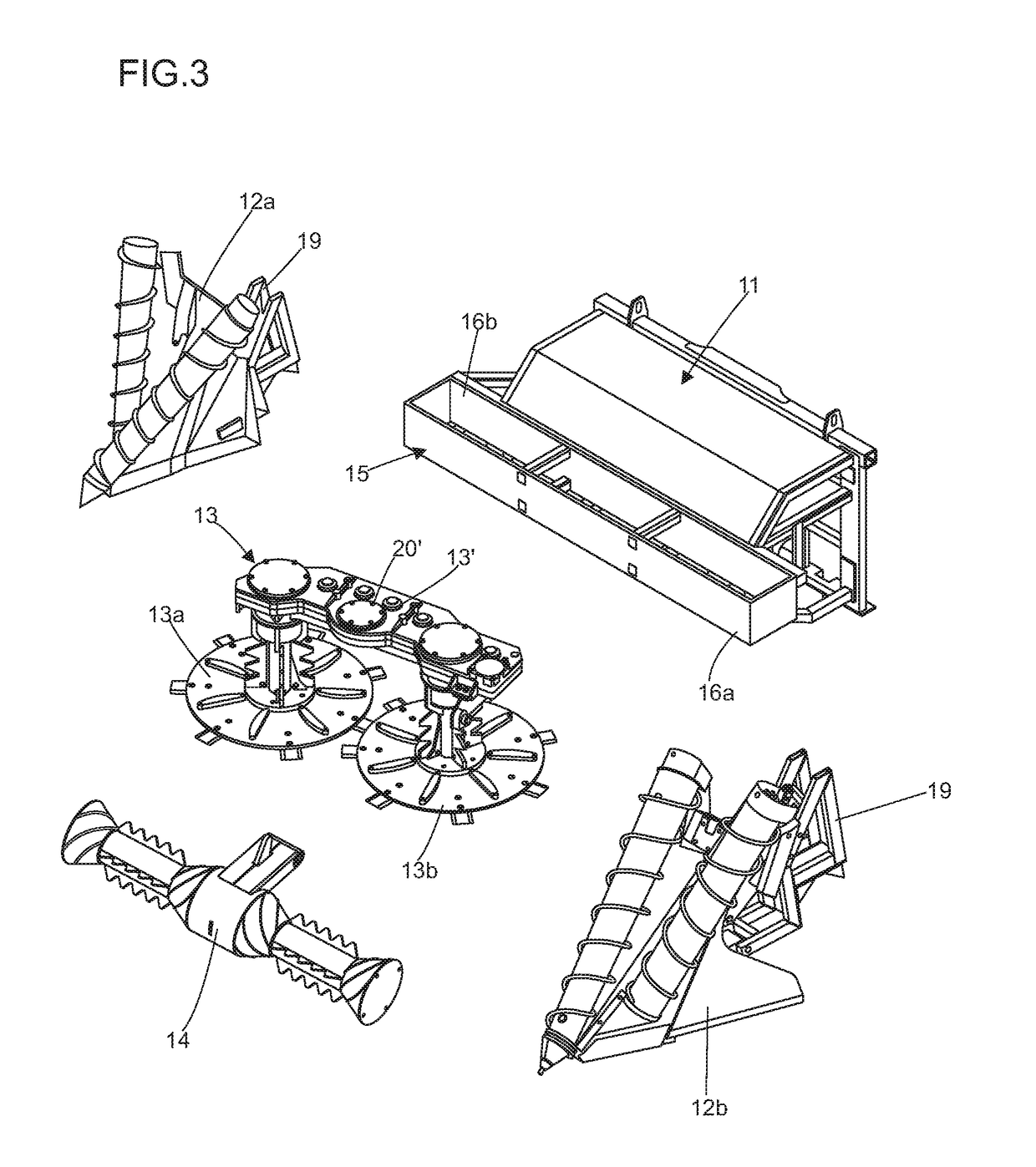

Modular assembly for sugarcane harvesters

A modular assembly for a sugarcane harvester is disclosed. A sugarcane harvester may include a chassis with various discreet and laterally separated mounting locations. Crop divider support modules may be configured to separately and fixedly attach to the chassis at various of the mounting locations, in order to support respective crop dividers in a variety of discreet and laterally separated orientations.

Owner:DEERE & CO

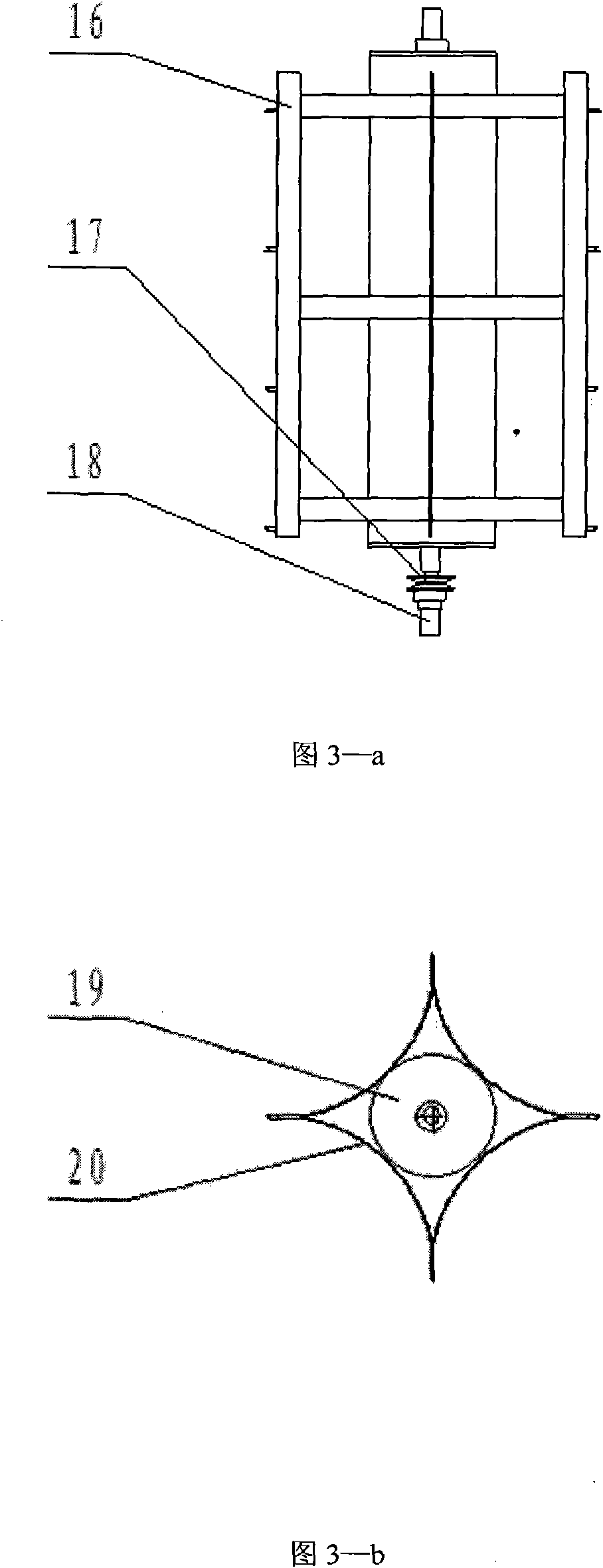

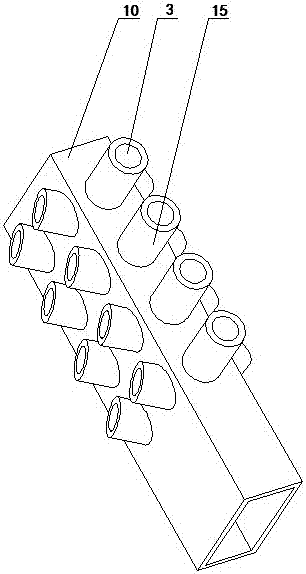

Combine harvester gas blowing type divider suitable for coarse grain harvesting

The invention relates to a combine harvester gas blowing type divider suitable for coarse grain harvesting. A gas blowing type dividing mechanism comprises a fan, an gas flow pipe I, an gas flow pipe II, an gas flow pipe III, a left divider sleeve and a right divider sleeve; the left divider sleeve and the right divider sleeve are mounted on a cutting table frame; a plurality of gas guide pipes are arranged at one end, extending into the left divider sleeve, of the gas flow pipe III as well as at one end, extending into the right divider sleeve, of the gas flow pipe I; gas holes which are identical with the gas guide pipes in quantity and are matched with the gas guide pipes in position are formed in each of the left divider sleeve and the right divider sleeve. The divider provided by the invention has the benefits that in the driving process, to-be-harvested and unharvested crops are better divided through the inner gas holes and the outer gas holes; the gas holes above the divider can effectively blow open the intertwined crops; through gas blown in three directions, the purpose of dividing the intertwined crops can be better realized.

Owner:HENAN UNIV OF SCI & TECH

Divider support apparatus with integral adjustable torsional preload mechanism and vibration damper

InactiveUS8141331B2Easy to adjustSufficient vibration damping propertyMowersAgricultural lifting devicesMechanical engineeringVibration damper

Owner:BLUE LEAF I P INC

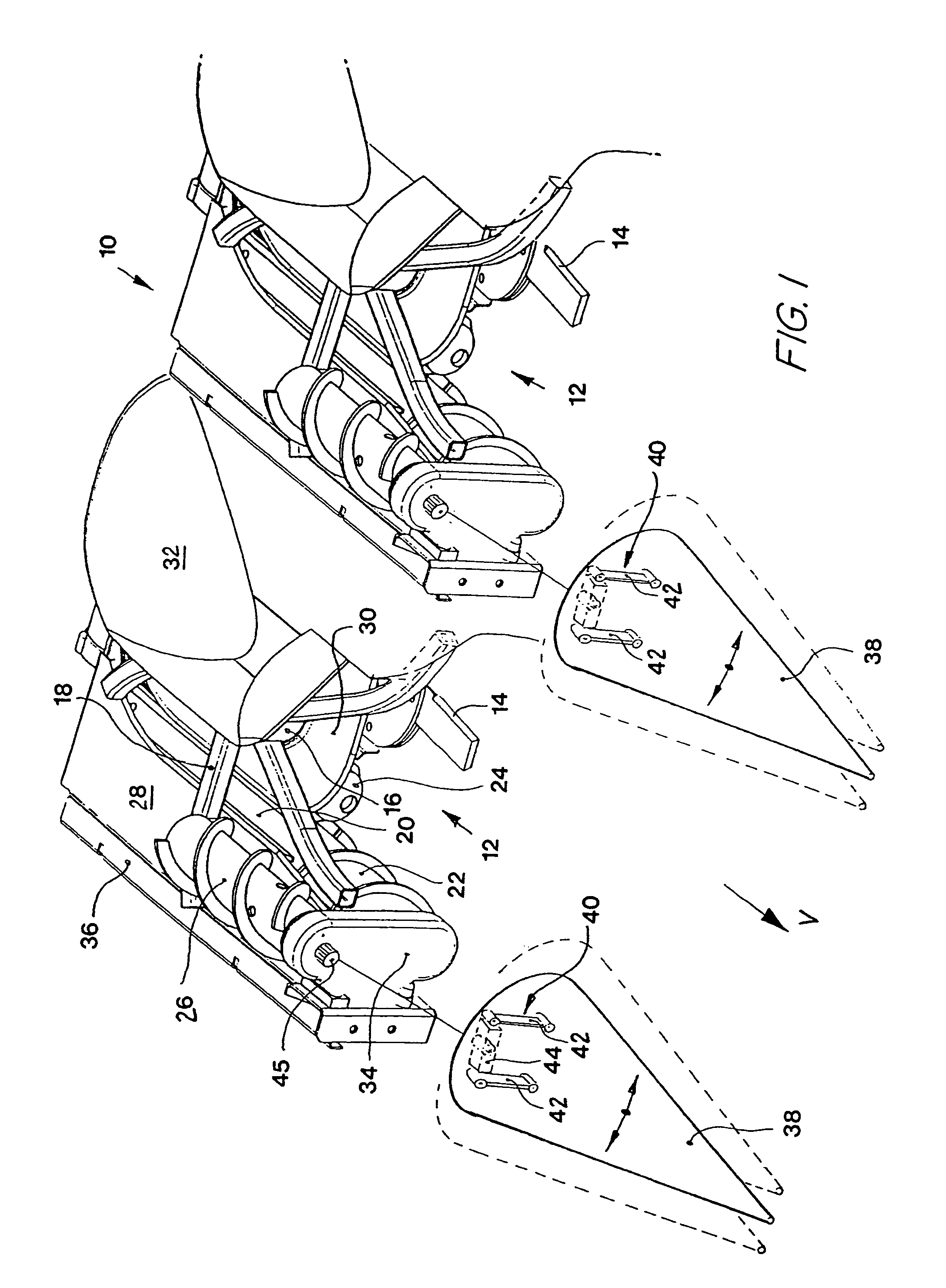

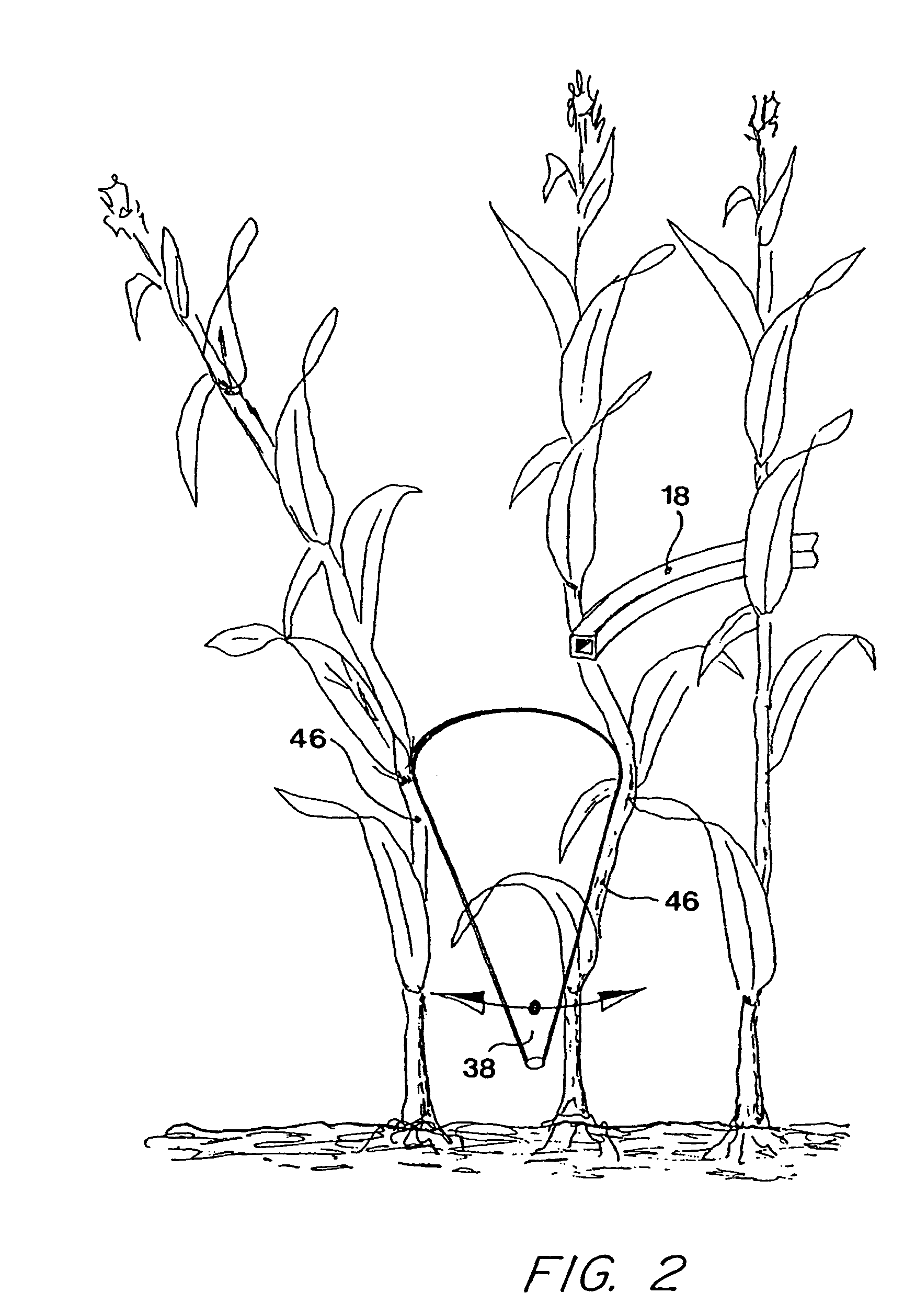

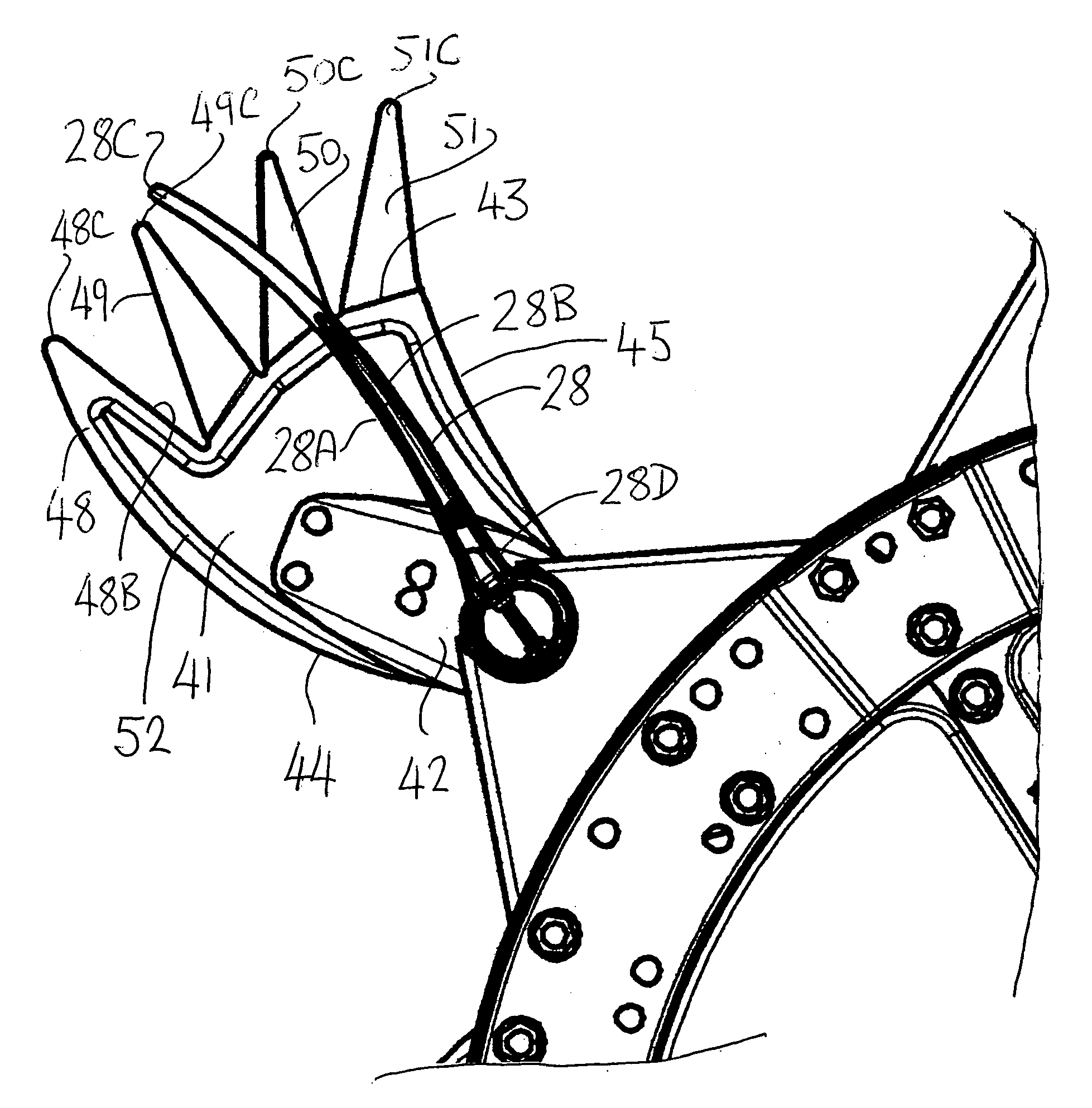

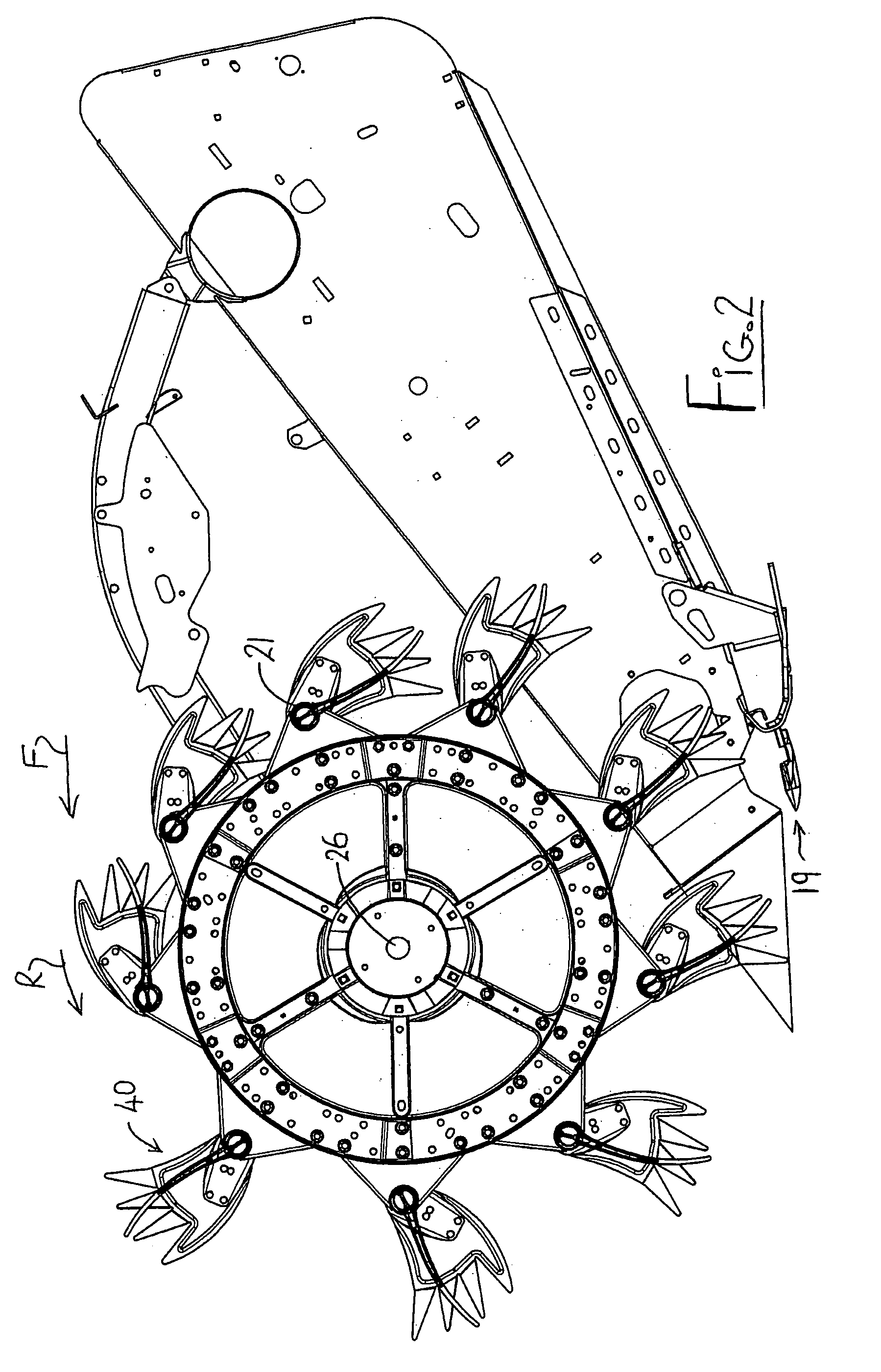

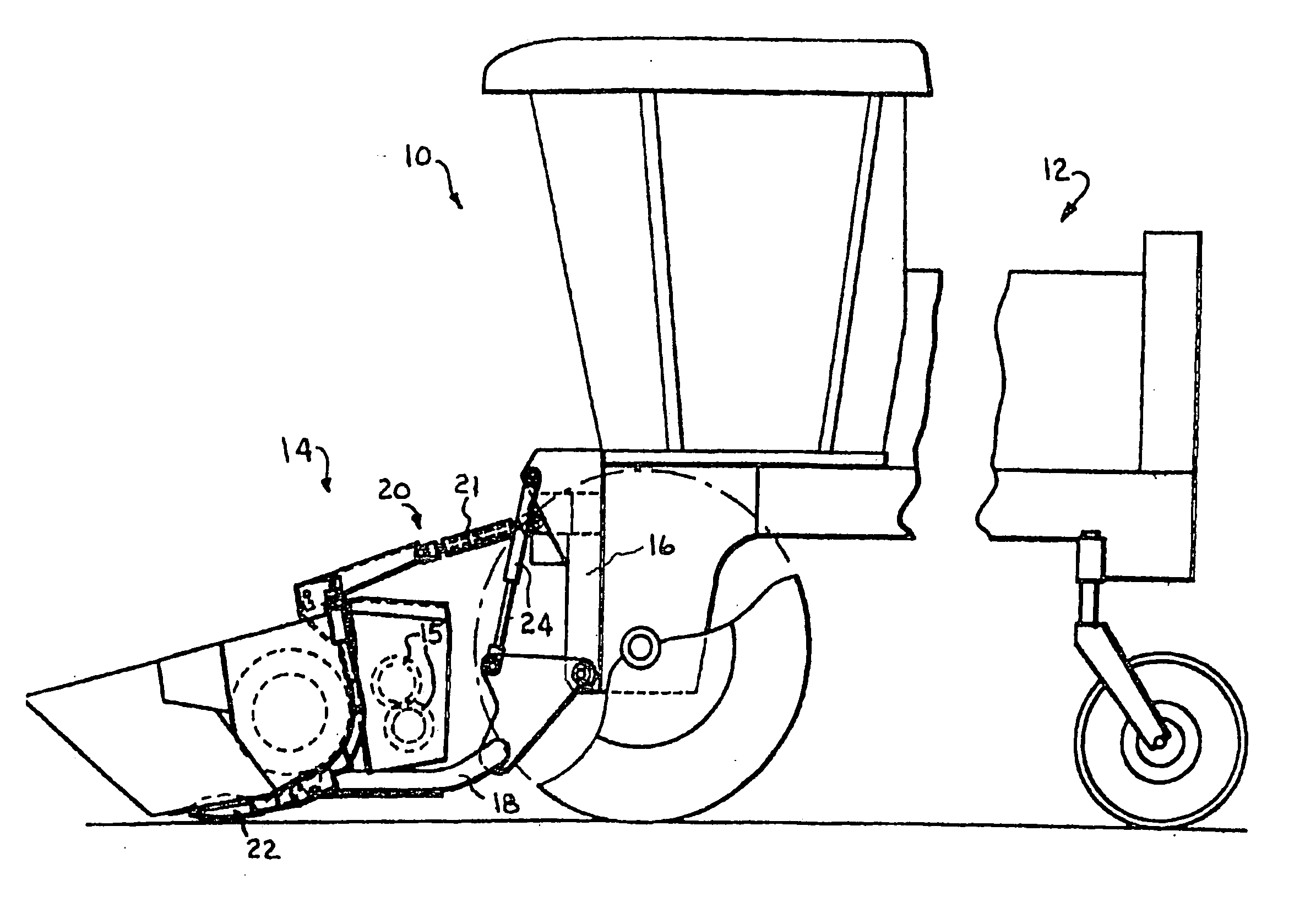

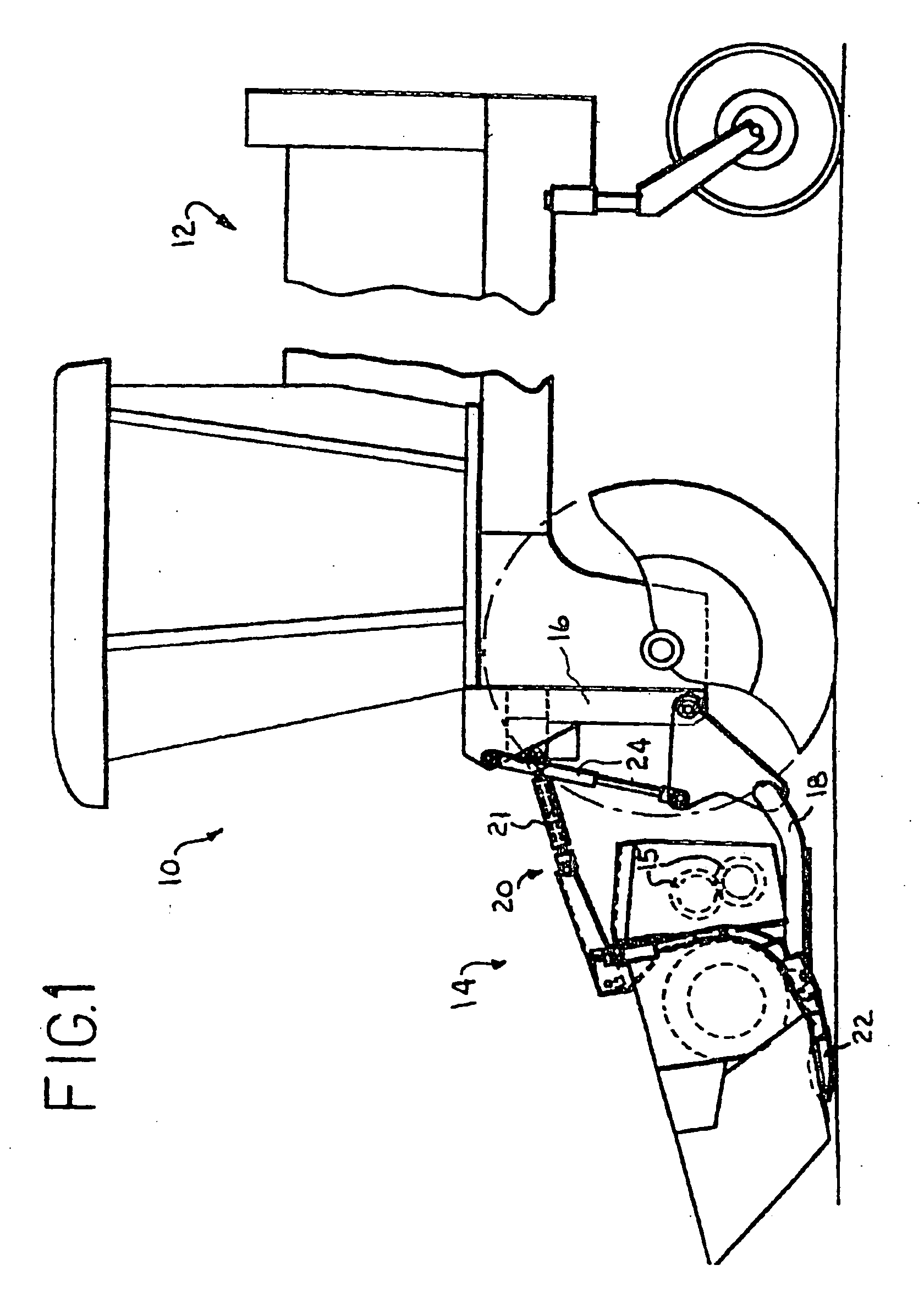

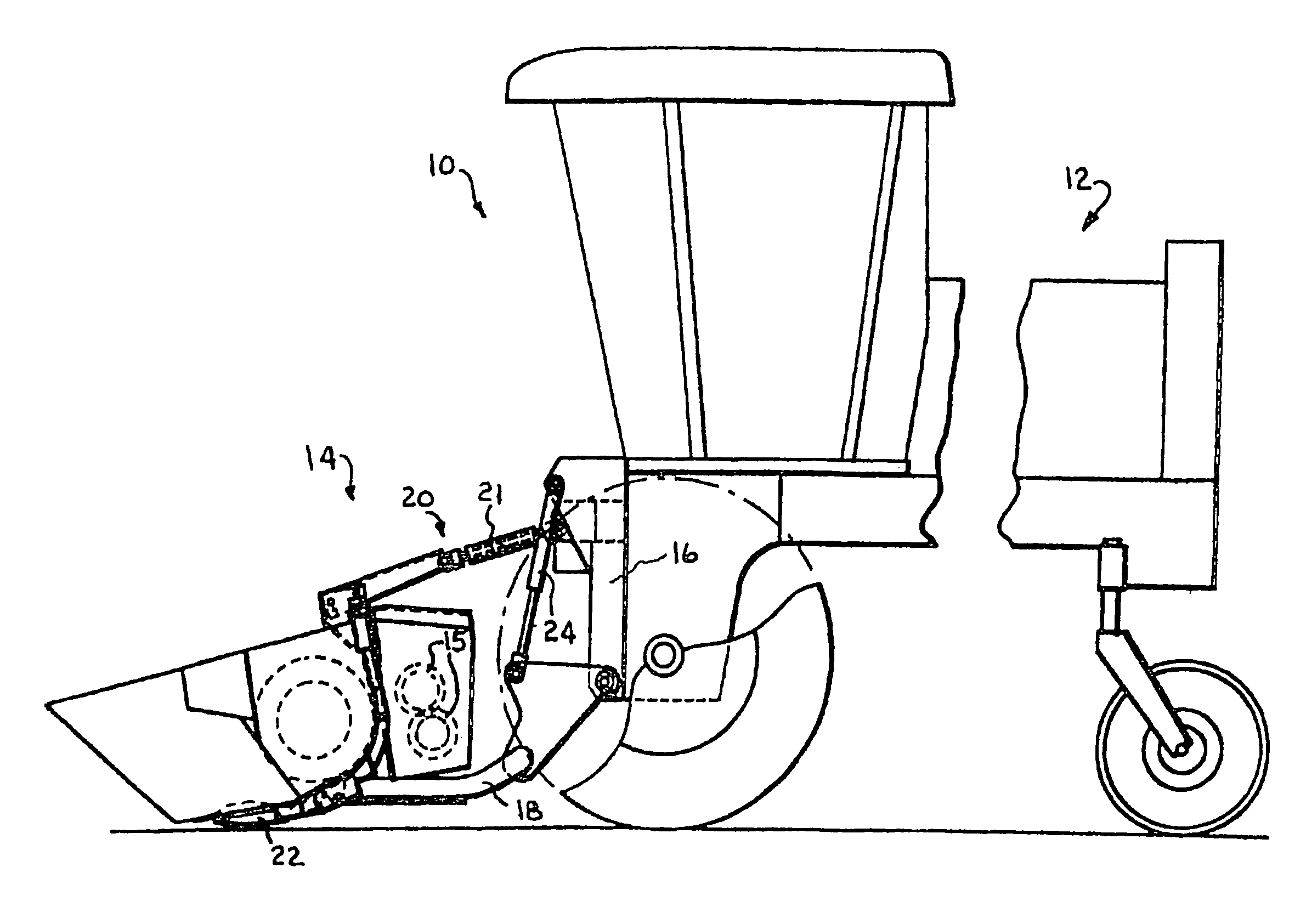

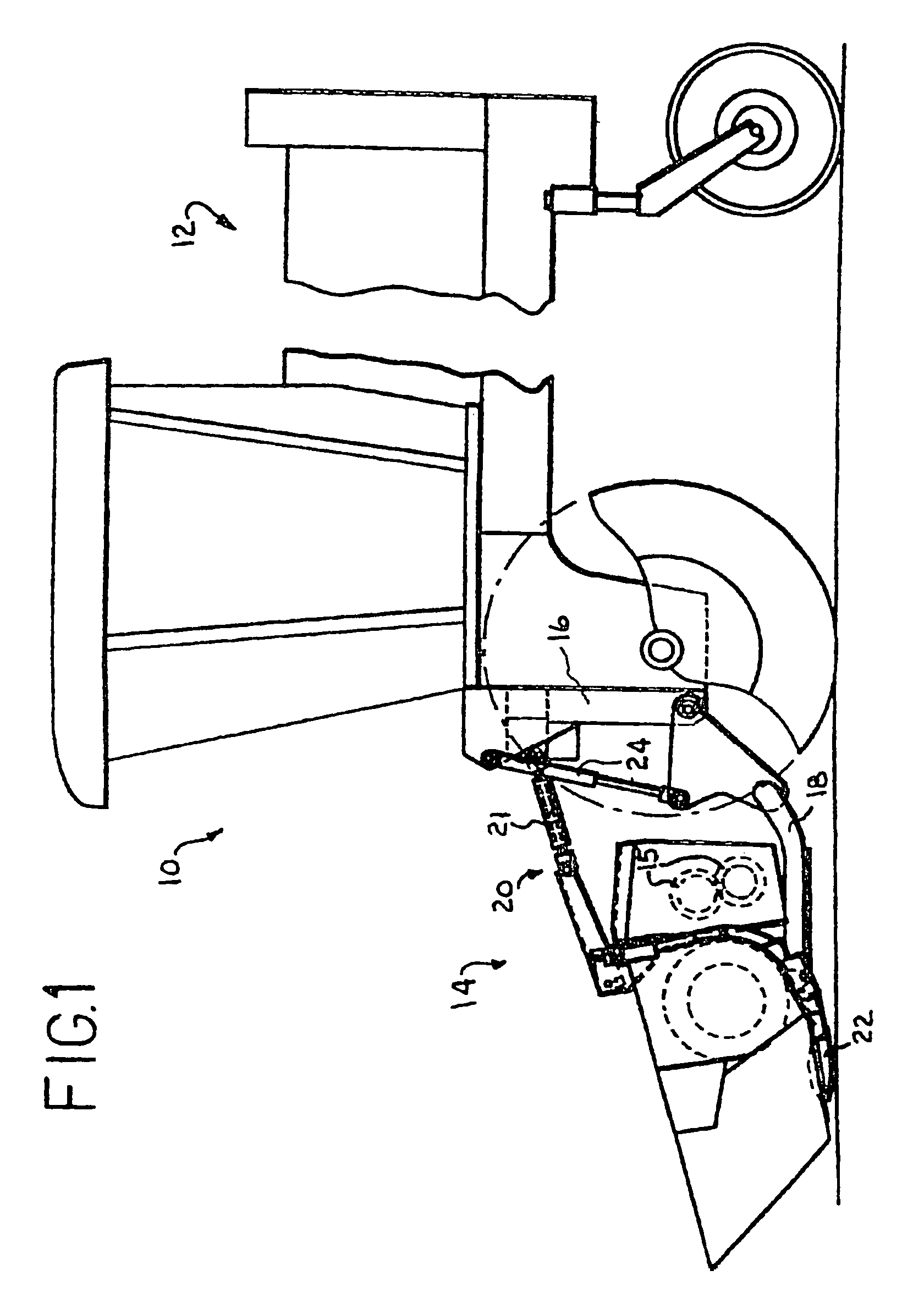

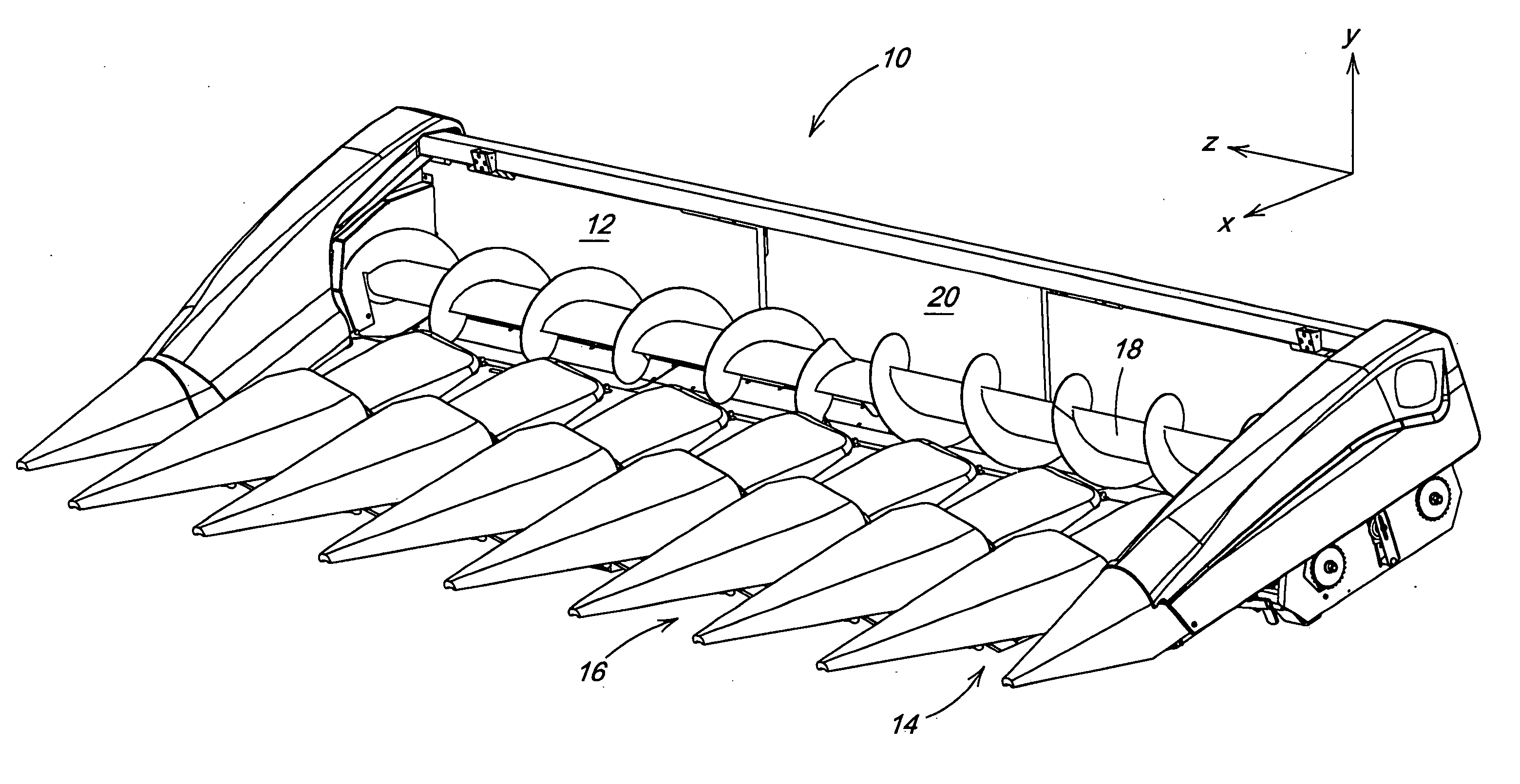

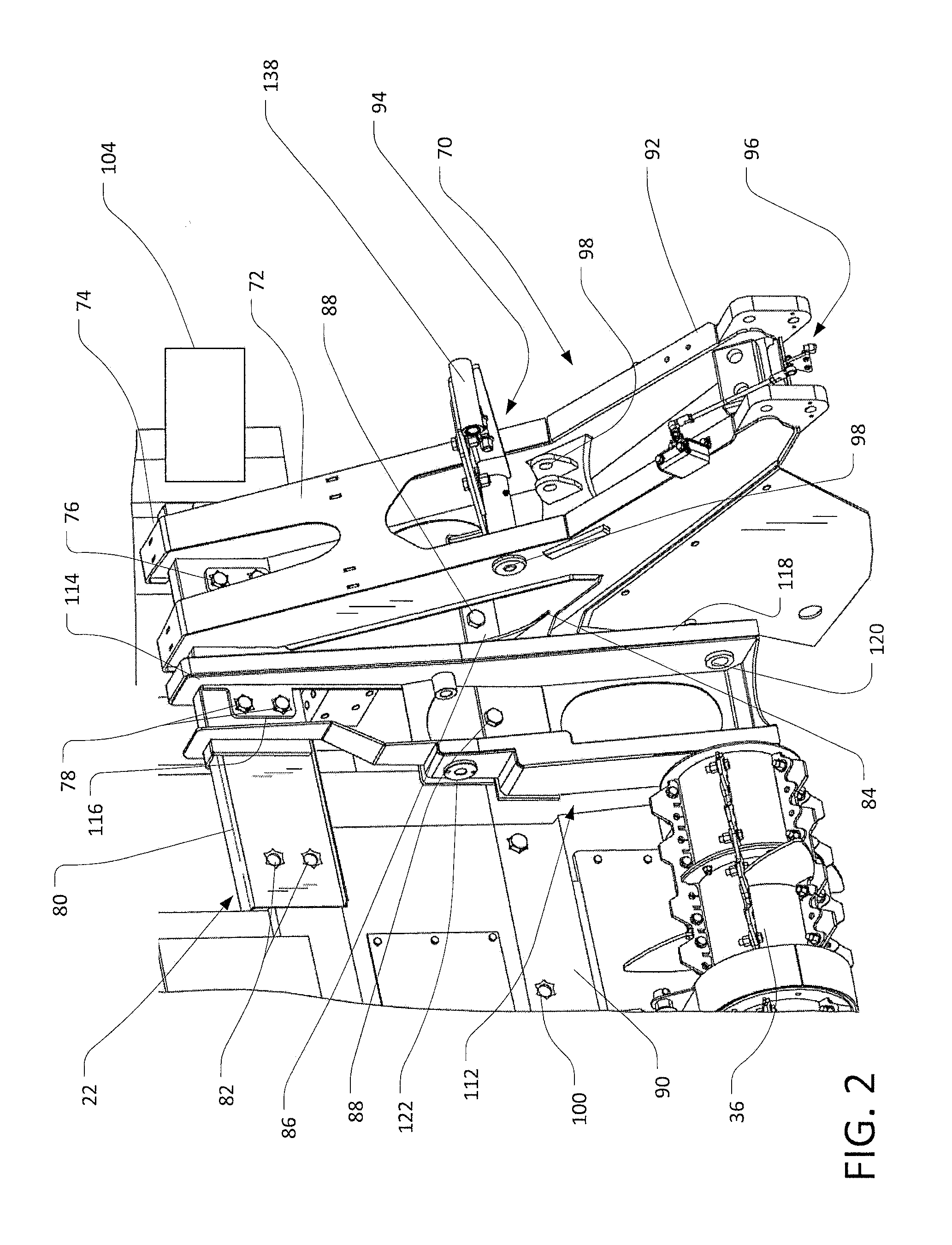

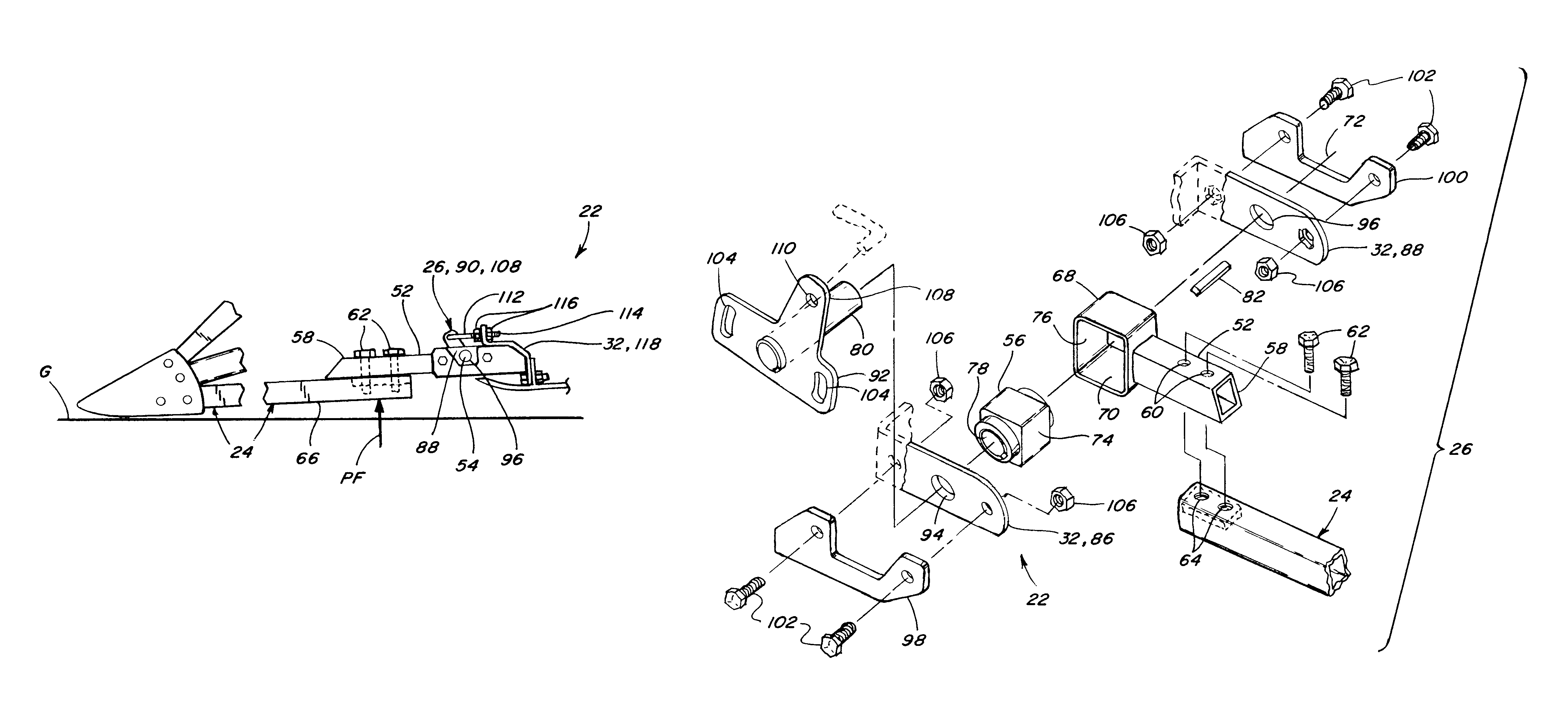

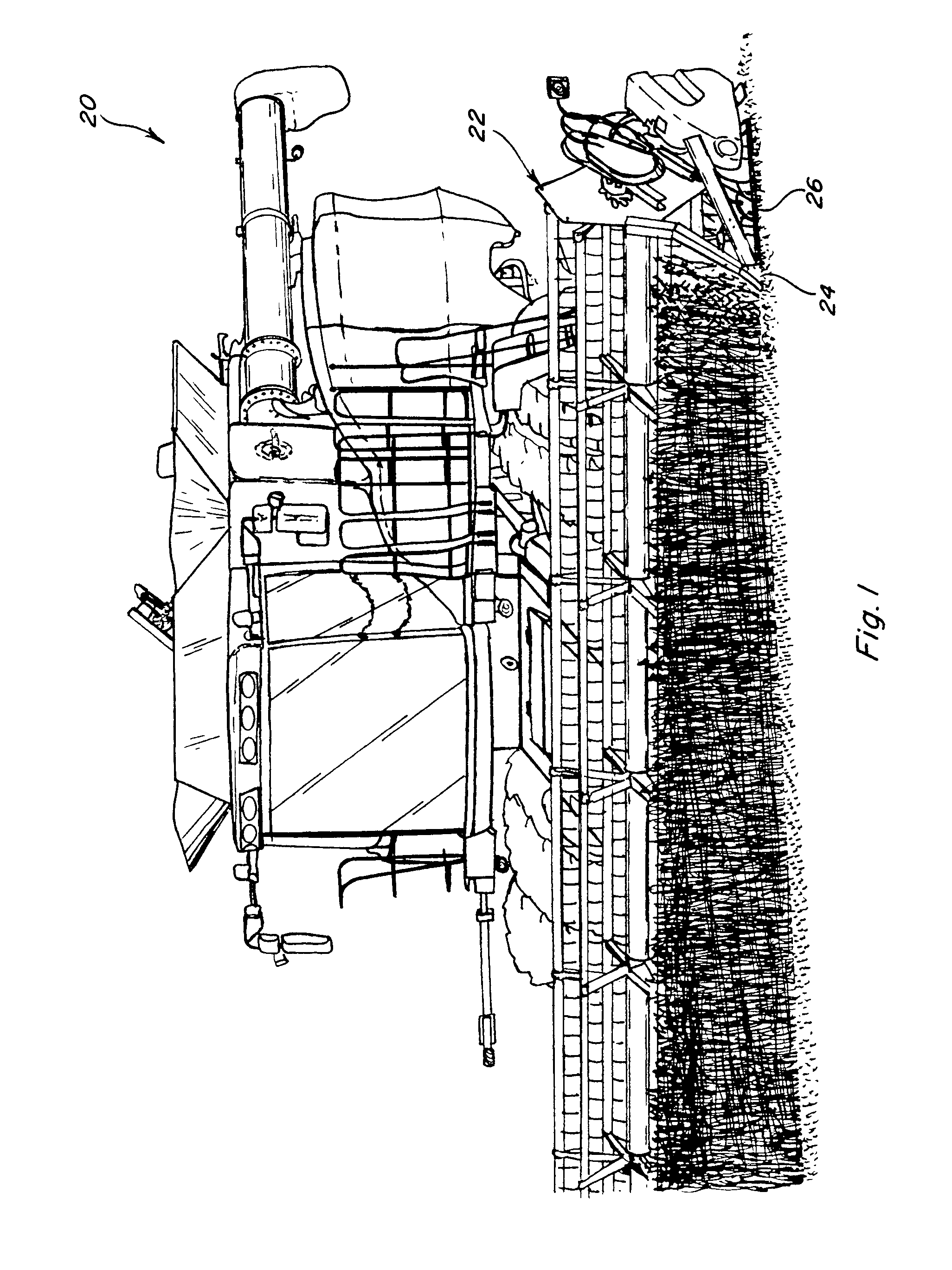

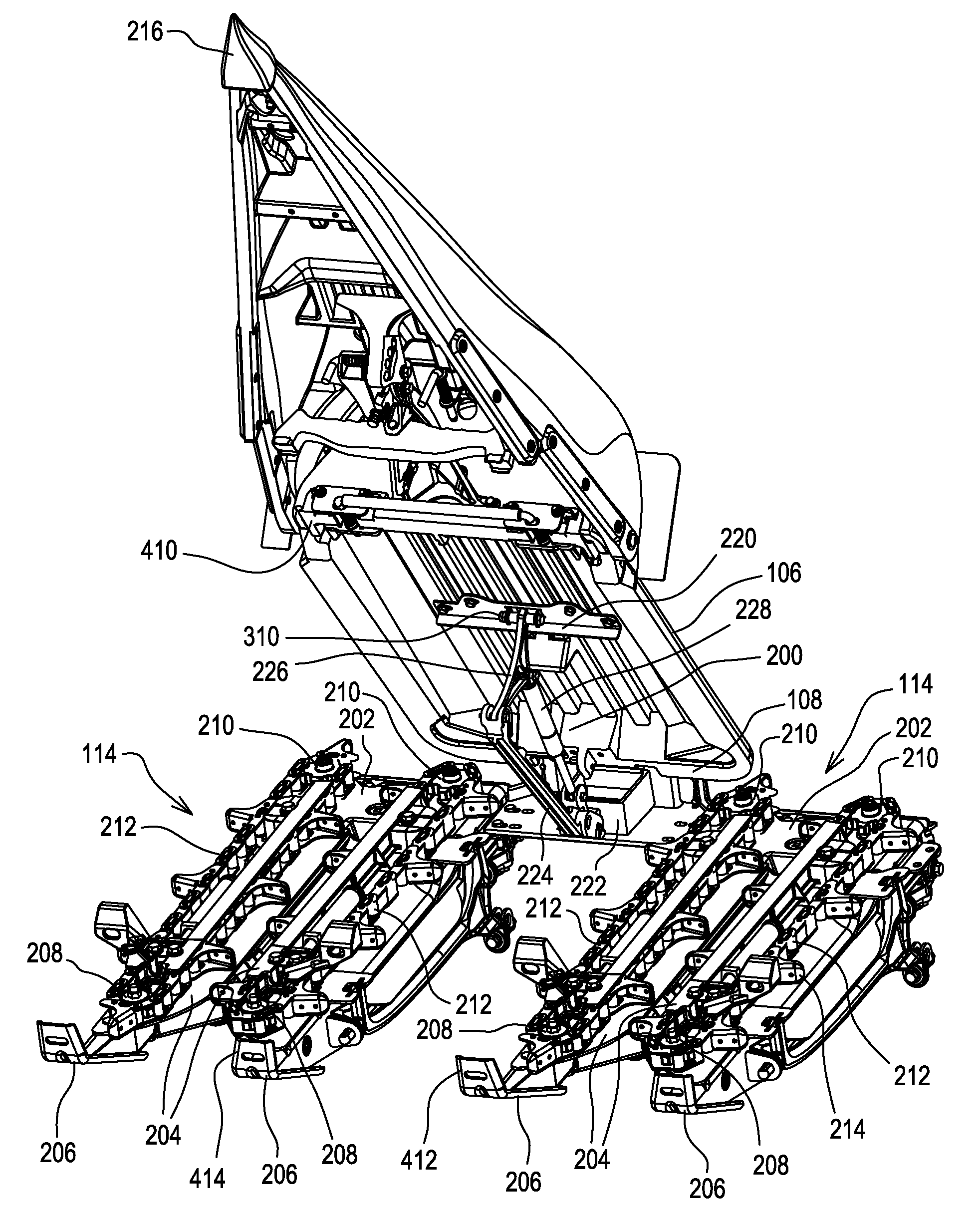

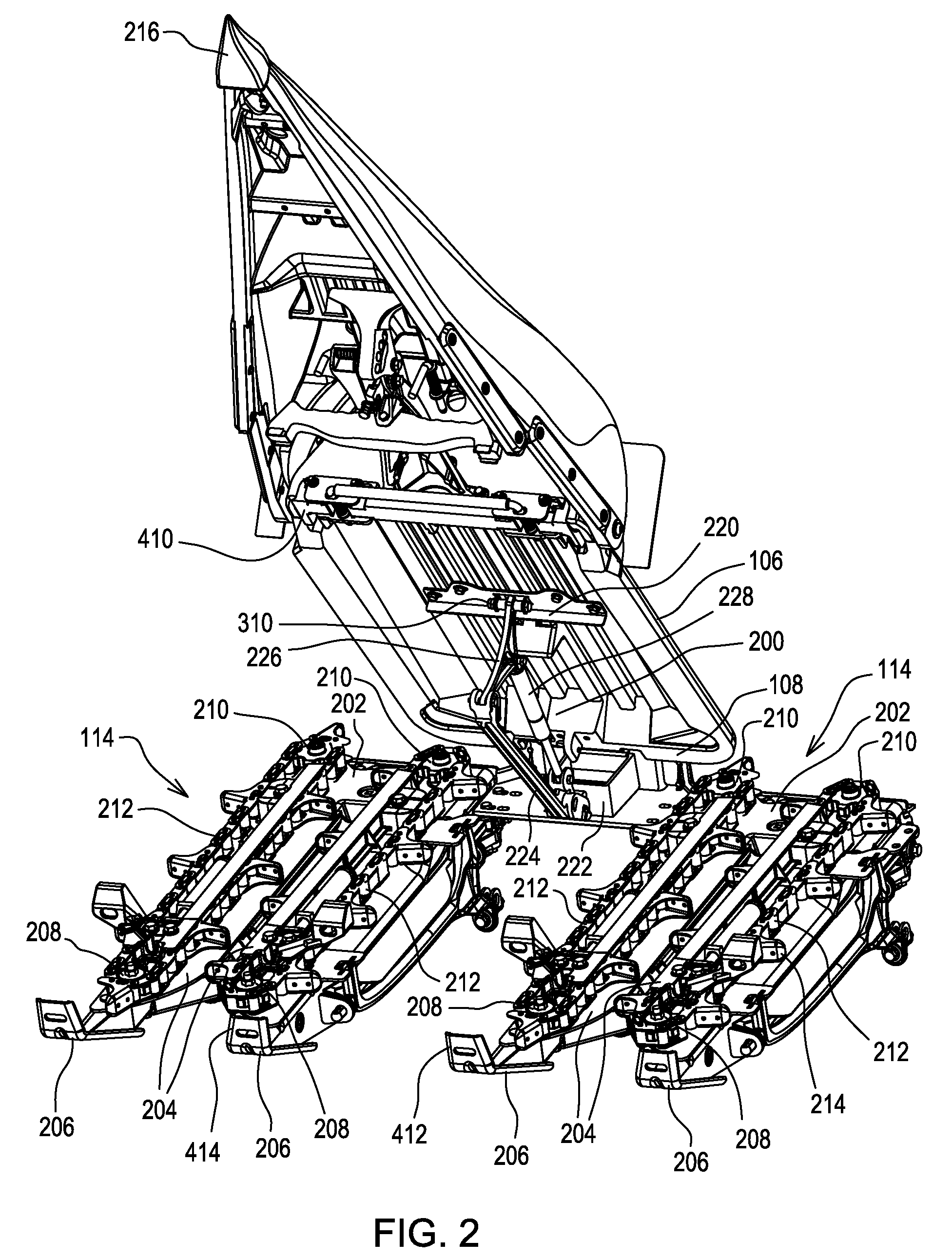

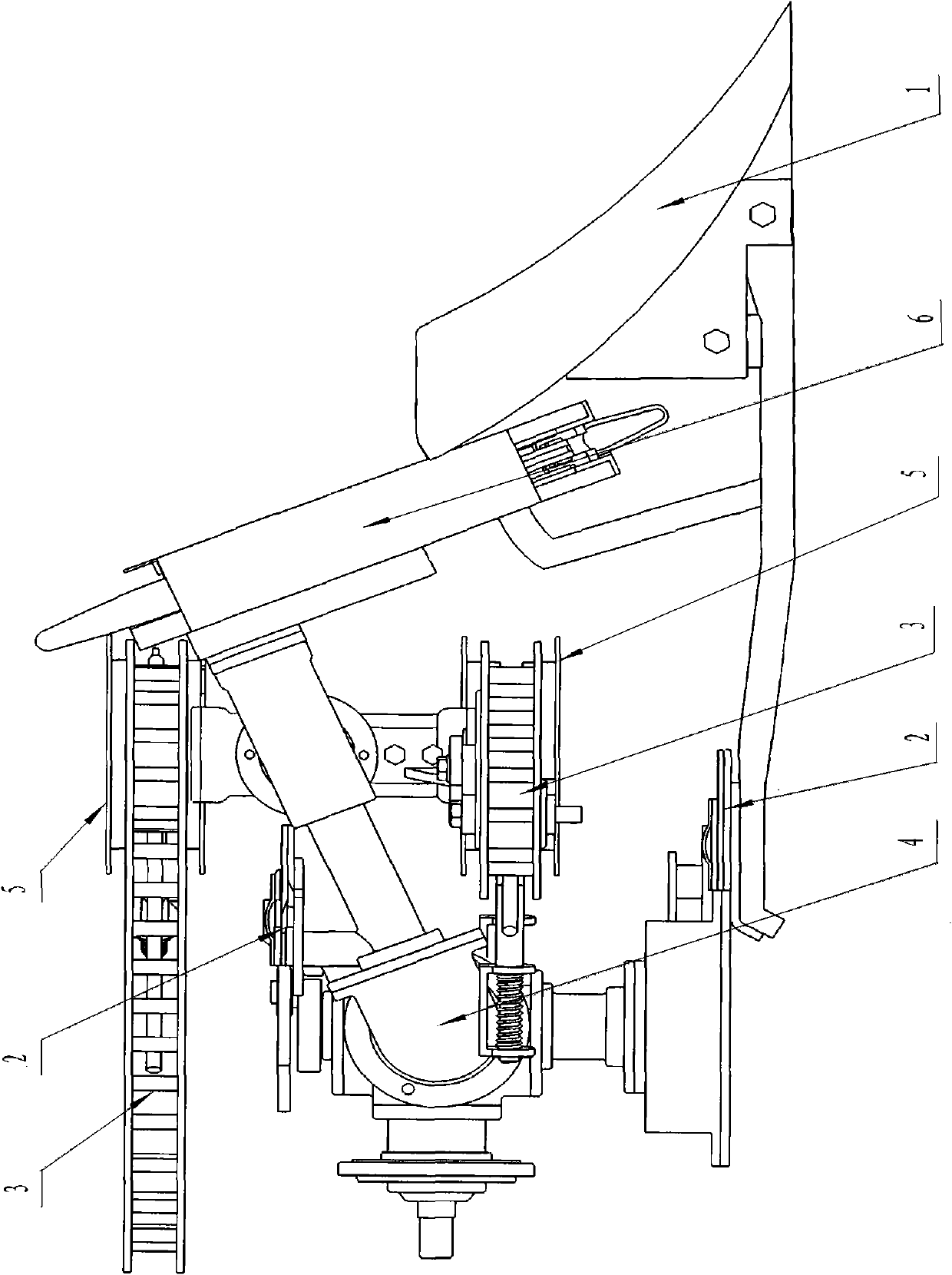

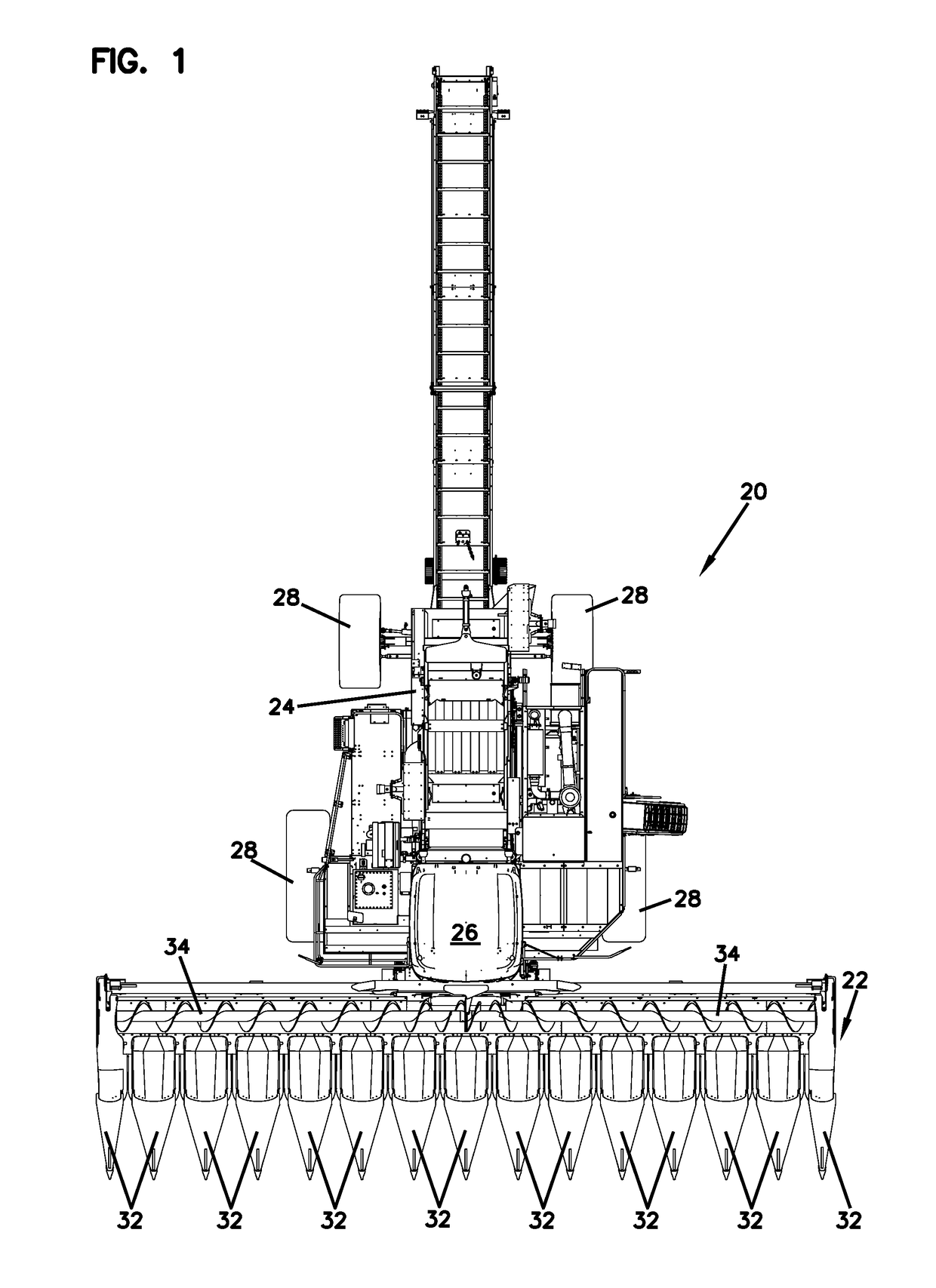

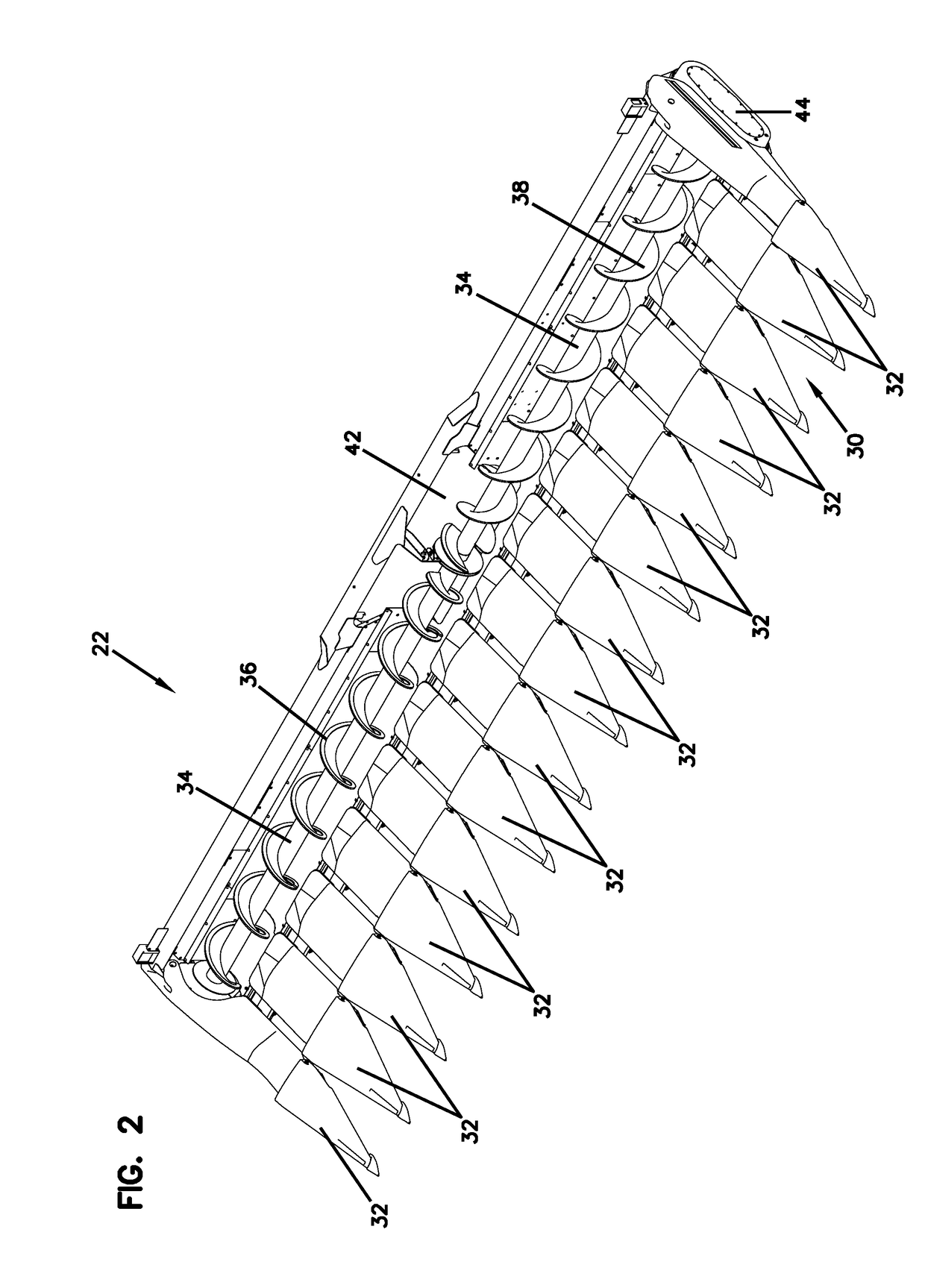

Cornhead divider lift assist linkage

ActiveUS8387352B2Maintaining compressionAgricultural lifting devicesOutside dividersMechanical engineering

A corn head divider lift assist linkage comprises two members and a spring pivotally coupled together, wherein one of the two members is pivotally coupled to a row crop divider and another of the two members is pivotally coupled to a bracket that is fixed at the rear of two adjacent row units.

Owner:DEERE & CO

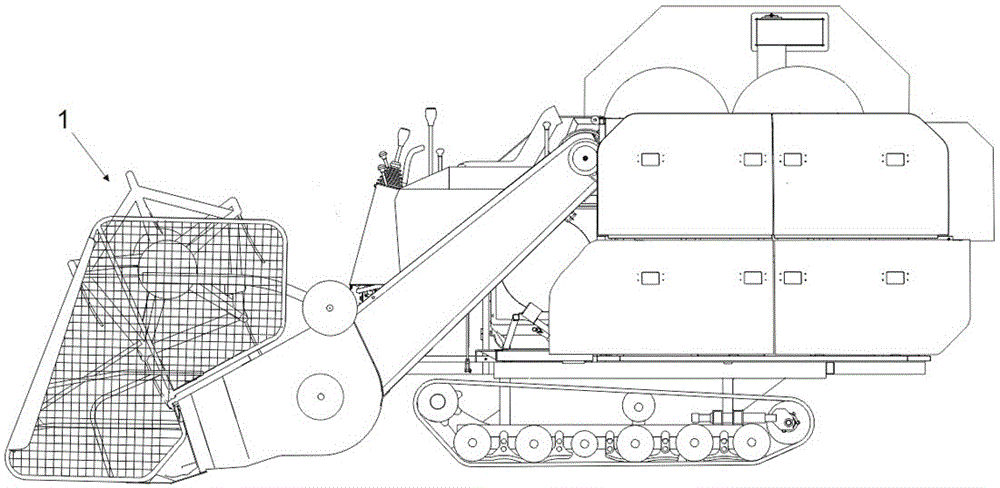

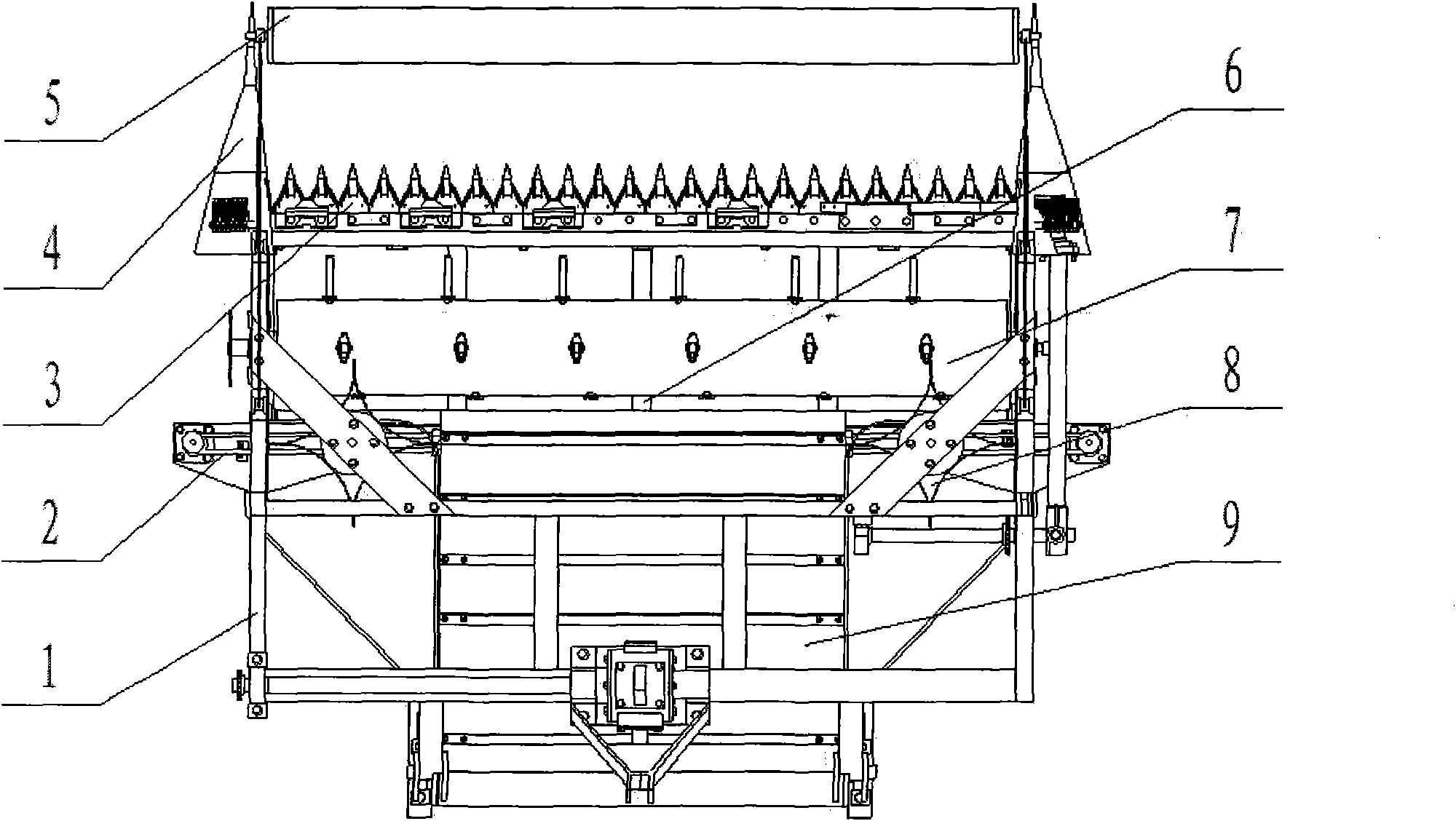

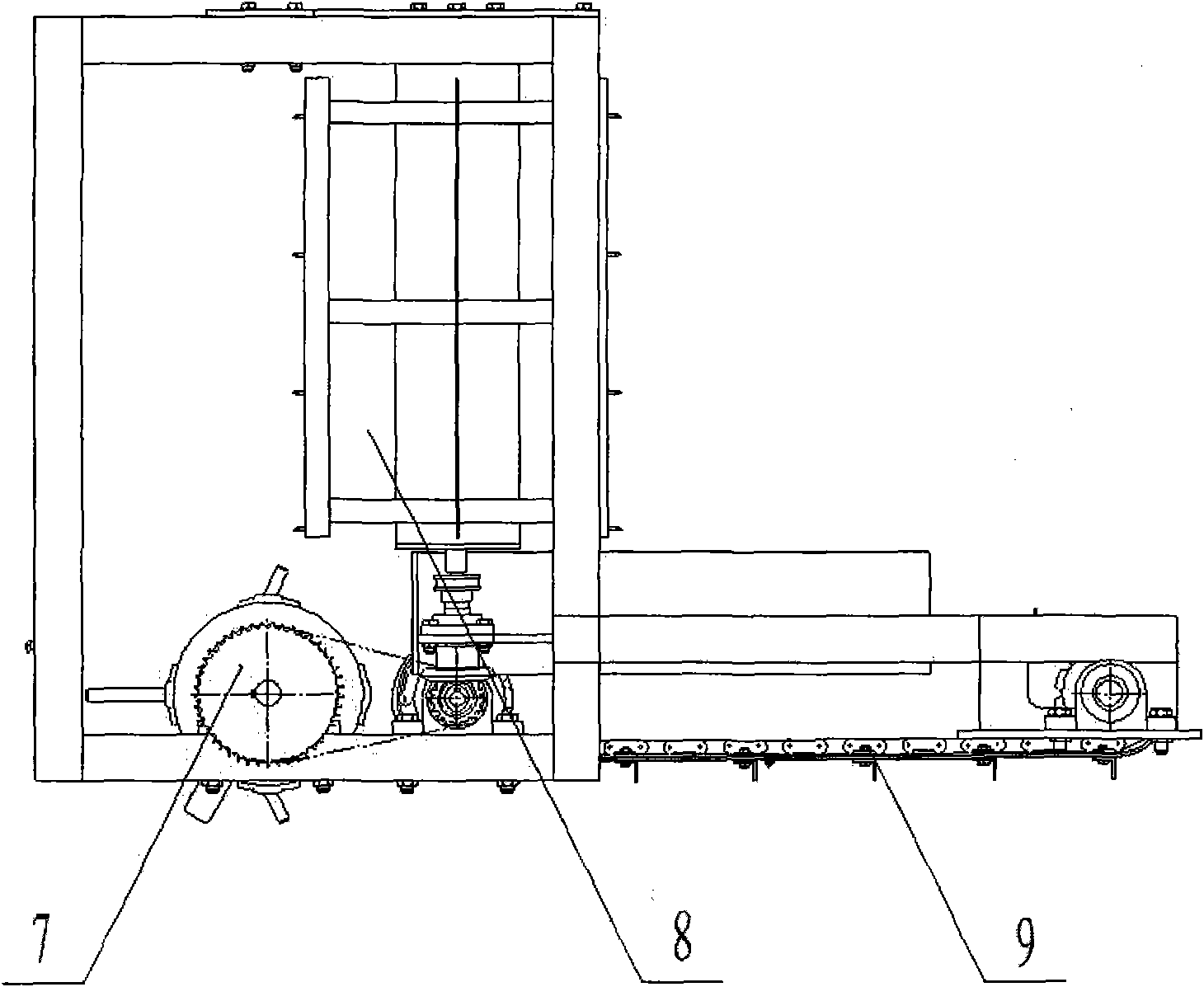

Ramie combine harvester

InactiveCN101491181AImprove performance qualityImprove fiber qualityOutside dividersEngineeringCombine harvester

The invention relates to a ramie combined harvester, which belongs to agricultural machinery, and mainly solves the harvest problem of ramie. The ramie combined harvester comprises a stander, a ramie supporting unit, a ramie supporting and cutting unit, a conveying unit, a stacking and laying unit and a traveling unit, wherein the ramie supporting unit, the ramie supporting and cutting unit, the conveying unit and the stacking and laying unit are fixedly connected with the stander to form a cutting table according to the pushing and supporting, cutting, conveying, stacking and laying procedures; and the traveling unit is connected with the cutting table to complete the traveling and cutting combined operation. The ramie combined harvester adopts a subsection harvest machinery proposal, completes the procedures of the supporting, the cutting, cutting for spreading and stacking for once, has light load, high efficiency and strong adaptability, and is widely suitable for cutting long-stalked plants such as ramie, jute, hemp, and the like.

Owner:WUHAN TEXTILE UNIV

Curtain to direct crop in a header

A curtain for directing severed crop movement in a cutting header in an agricultural harvester. The curtain optimizes crop movement between a cutterbar to a crop conveying auger for lateral movement of the crop material from outboard ends of the cutting header toward an interior discharge zone for formation of a windrow. The curtain also reduces the tendency for clogging that occurs when crop approaches conveying augers on both sides of an axial centerline by directing all crop material toward the trailing side of the rotating auger and by preventing airflow generated by the auger from disrupting crop approaching the auger. Crop smoothing by the curtain also reduces disturbances to the crop material during movement within the header which reduces seed loss in seed-bearing specialty crops.

Owner:BLUE LEAF I P INC

Method and apparatus for control of base cutter height for multiple row sugar cane harvesters

A multiple row sugar cane harvester having automatic and independent control of multiple base cutters utilized to severe sugar cane stalks in adjacent rows. Position sensors sense the height of the base cutters relative to the chassis of the sugar cane harvester and feed the signals to a controller for adjusting the height to a preselected level. The base cutters are individually driven by hydraulic motors through individual hydraulic circuits and the operating pressure is sensed and fed to the controller for determining whether a choke condition exists. A load sensor is incorporated between the linkage and the sugar cane harvester chassis for determining whether the base cutters have ground contact to elevate the base cutters.

Owner:CNH IND MASCH (HARBIN) CO LTD

Cornhead divider lift assist linkage

ActiveUS20120291410A1Relieve stressTension is releasedAgricultural lifting devicesOutside dividersEngineeringMechanical engineering

A corn head divider lift assist linkage comprises two members and a spring pivotally coupled together, wherein one of the two members is pivotally coupled to a row crop divider and another of the two members is pivotally coupled to a bracket that is fixed at the rear of two adjacent row units.

Owner:DEERE & CO

Header

InactiveCN102084757ASimple structureAvoid premature threshingMowersAgricultural lifting devicesEngineeringCombine harvester

The invention provides a header which comprises two or a plurality of nearside dividers, two or a plurality of holding-straight devices, two or a plurality of holding devices, two or a plurality of including discs, two cutters and a transmission device, wherein the nearside dividers are positioned at the front end of the header; the two including discs positioned on a same vertical shaft are arranged at the rear of the nearside dividers, the holding devices are arranged at the sides of the including discs, and the including discs and the holding devices are on the same horizontal surface; the two cutters are respectively positioned below the two including discs and the holding devices, and the two cutters are parallel to each other and are arranged vertical to the side of a combine harvester; and the two holding devices and the cutters are respectively connected with the transmission device. The header provided by the invention can harvest lodged grain, reduce the harvesting attrition rate, optimize the mechanical structure, and improve the reliability and the working efficiency.

Owner:广西汽牛农业机械有限公司

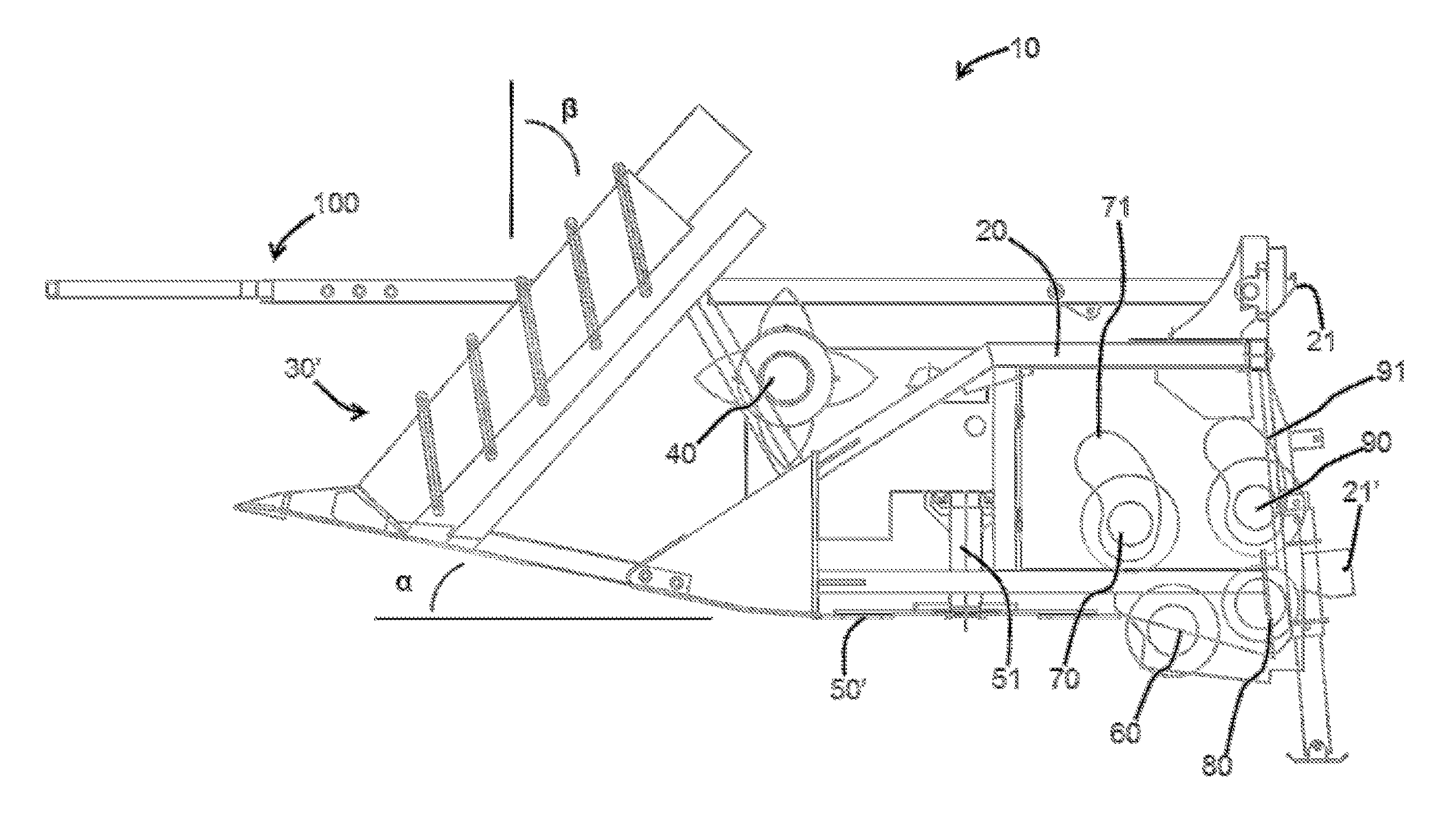

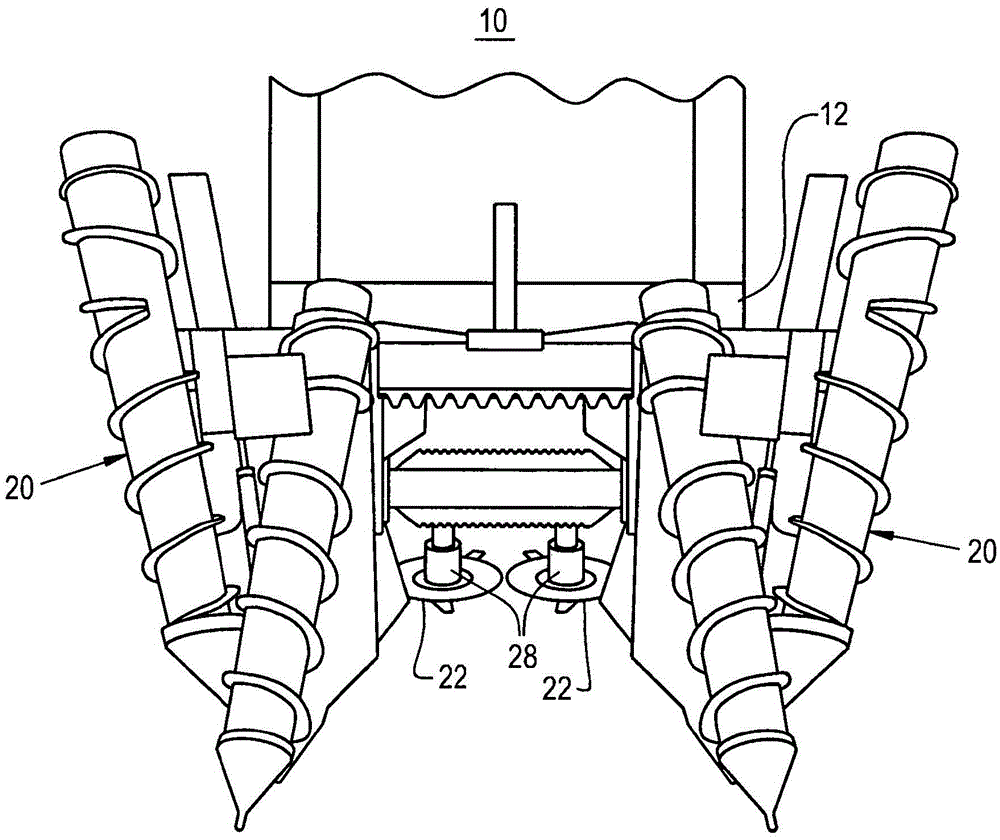

Adaptive Multi Row Header for Sugar Cane Harvester

An agricultural machine header which can be coupled to and uncoupled from a harvesting machine The header includes a frame having with a plurality of adjustable supports for coupling with at lest two row divider sets. The header further includes at least one pair of base cutting discs and at least one knock-down roller. The header supports the base cutting discs in an adjustable and flexible way that allows them to be adjusted according to conditions and characteristics of crop to be harvested.

Owner:BLUE LEAF I P INC

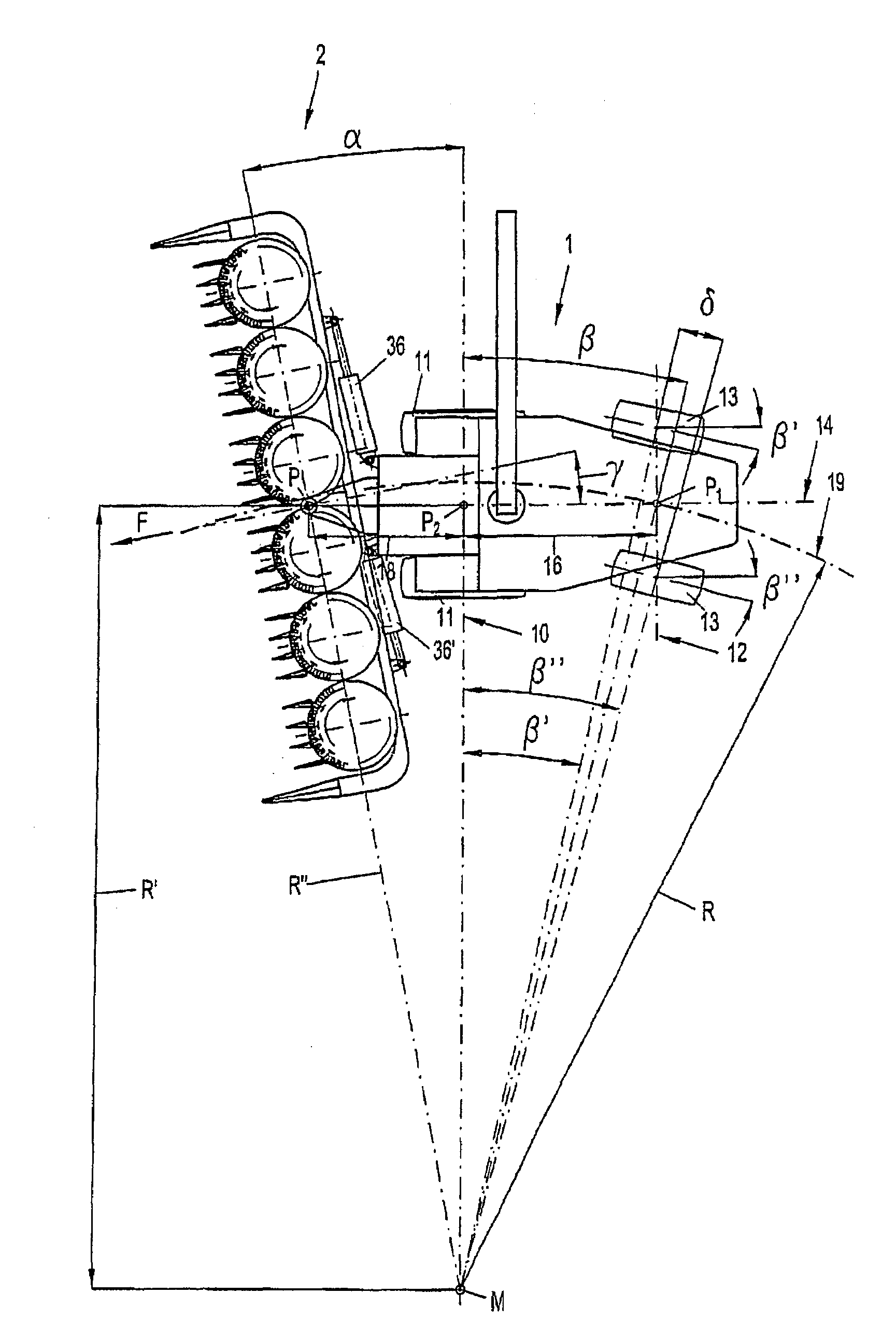

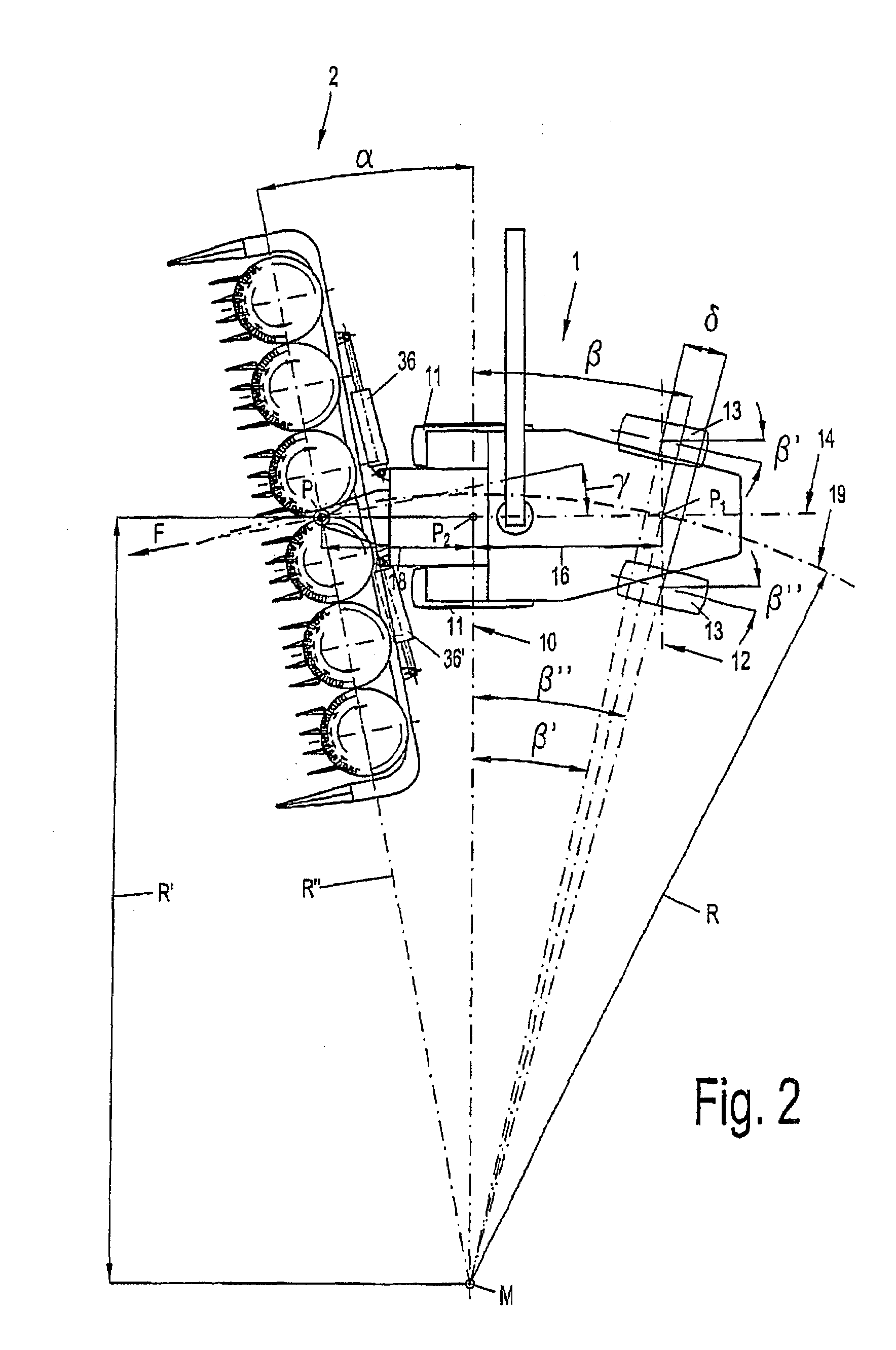

Method and device for operating an attachment for harvesting stalk-like crops

InactiveUS20060277885A1Promote resultsMowersOutside dividersAgricultural scienceAgricultural engineering

Owner:CLAAS SAULGAU

Walking oilseed rape cutting and drying machine

ActiveCN103583150ARetrofitting workload is smallEasy to transformOutside dividersDesign guideEngineering

The invention discloses a walking oilseed cutting and drying machine which comprises a header rack, a horizontal cutting device, a vertical cutting device, a main shaft, a middle transition shaft, a first belt, a crank connecting rod, oilseed rape separating plates, a power mechanism and the like, wherein one end of the crank connecting rod is arranged on a crank base. An existing walking tractor commonly used in China is adopted for the power mechanism, the using range is wide, the amount of modification work performed on the walking tractor is small, modification is convenient, only cutting and walking actions are finished by the power mechanism, and power of an active guiding laying device is saved. The round hole hollowed plates are adopted for the designed guiding laying device, so that the operation visual field is guaranteed, and under the action of forwarding speed and oilseed rape stalk inertia, oilseed rape stalks are guided to the left side and the right side to be laid. The designed oilseed rape separating plates are located in the middle of the front of a machine set, active oilseed rape separating is adopted for distinguishing an oilseed rape harvesting area into a left area to be cut and a right area to be cut, and after cutting, the oilseed rape stalks are laid on the two sides under the action of the guiding laying device.

Owner:HUAZHONG AGRI UNIV

Knife rolls with differing lengths

Stalk rolls are used for a corn harvester or combine having a chassis, an engine, a cab mounted to the chassis with a head mounted at the front of the body. The head includes an auger, row separators, corn stalk gathering assemblies between the row separators and ear removal assemblies. Each ear removal device includes a pair of stalk rolls. Each stalk roll has a core and longitudinally extending flutes about a periphery of the corn extending along the core. Each stalk roll has a straight first section and a tapered second section. The flutes on each stalk roll have different lengths and end at different locations at the front of the stalk roll. The flutes of the stalk roll may also have notches and different shaped leading edges.

Owner:OXBO INT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com