Patents

Literature

576results about "Headers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

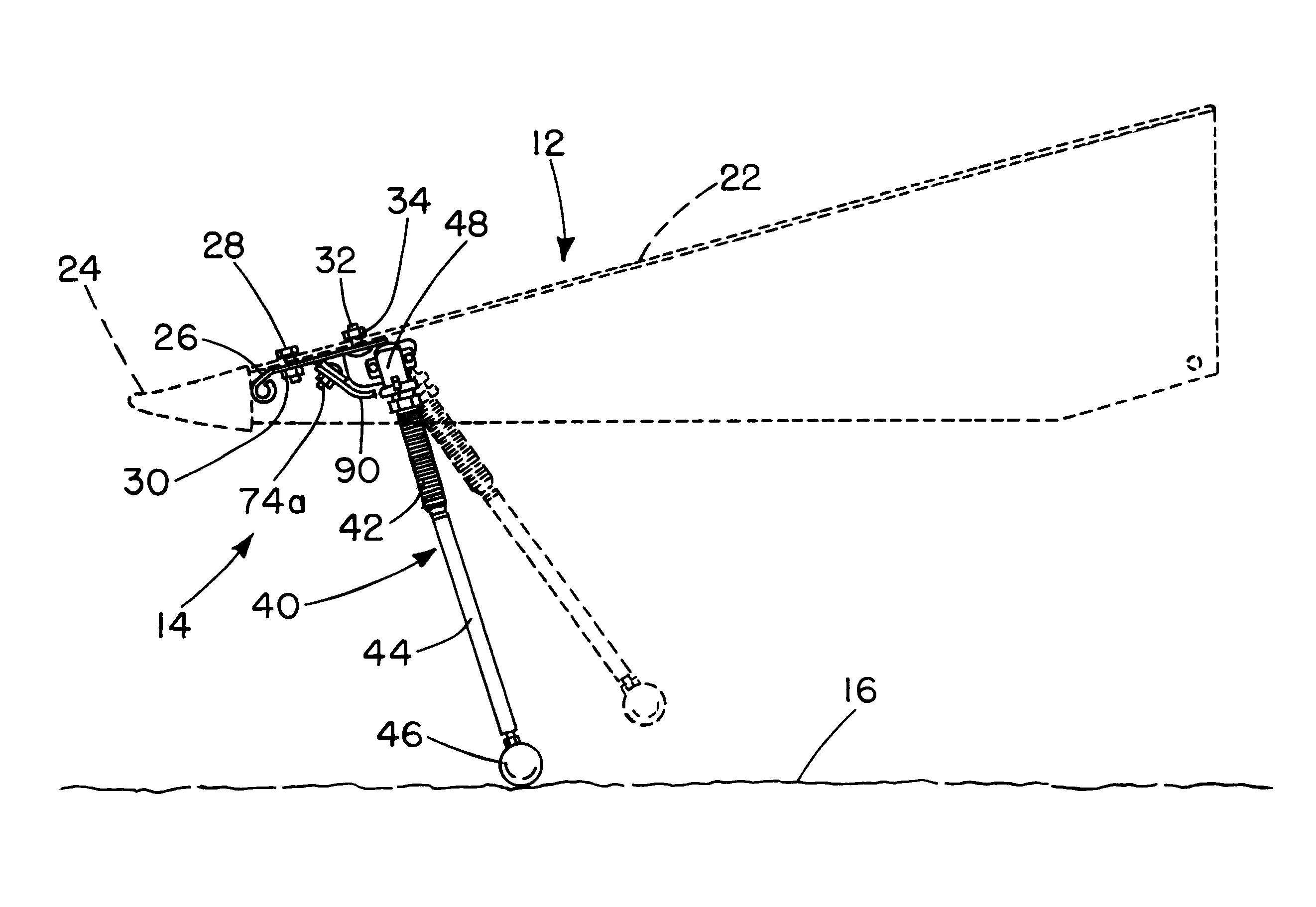

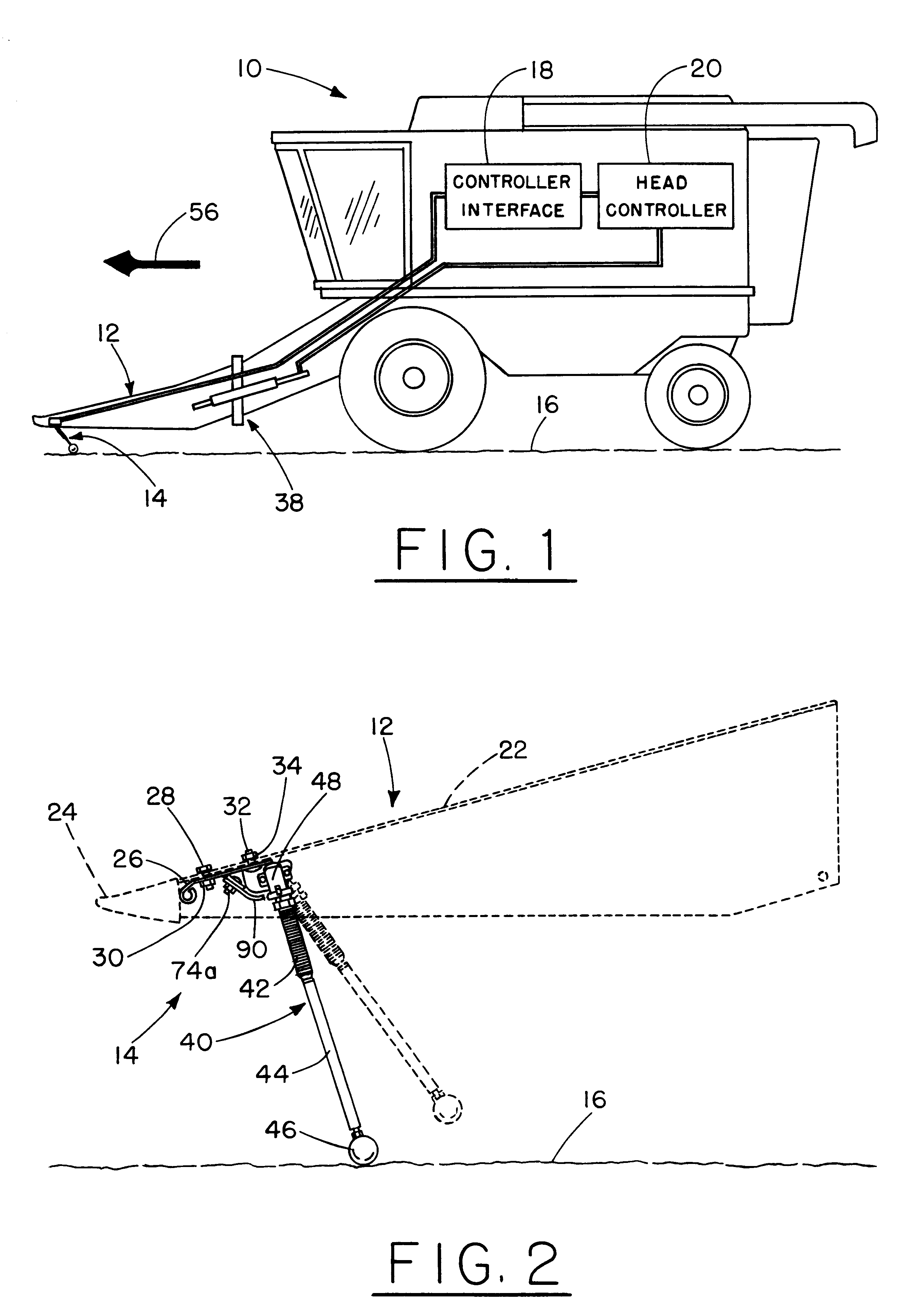

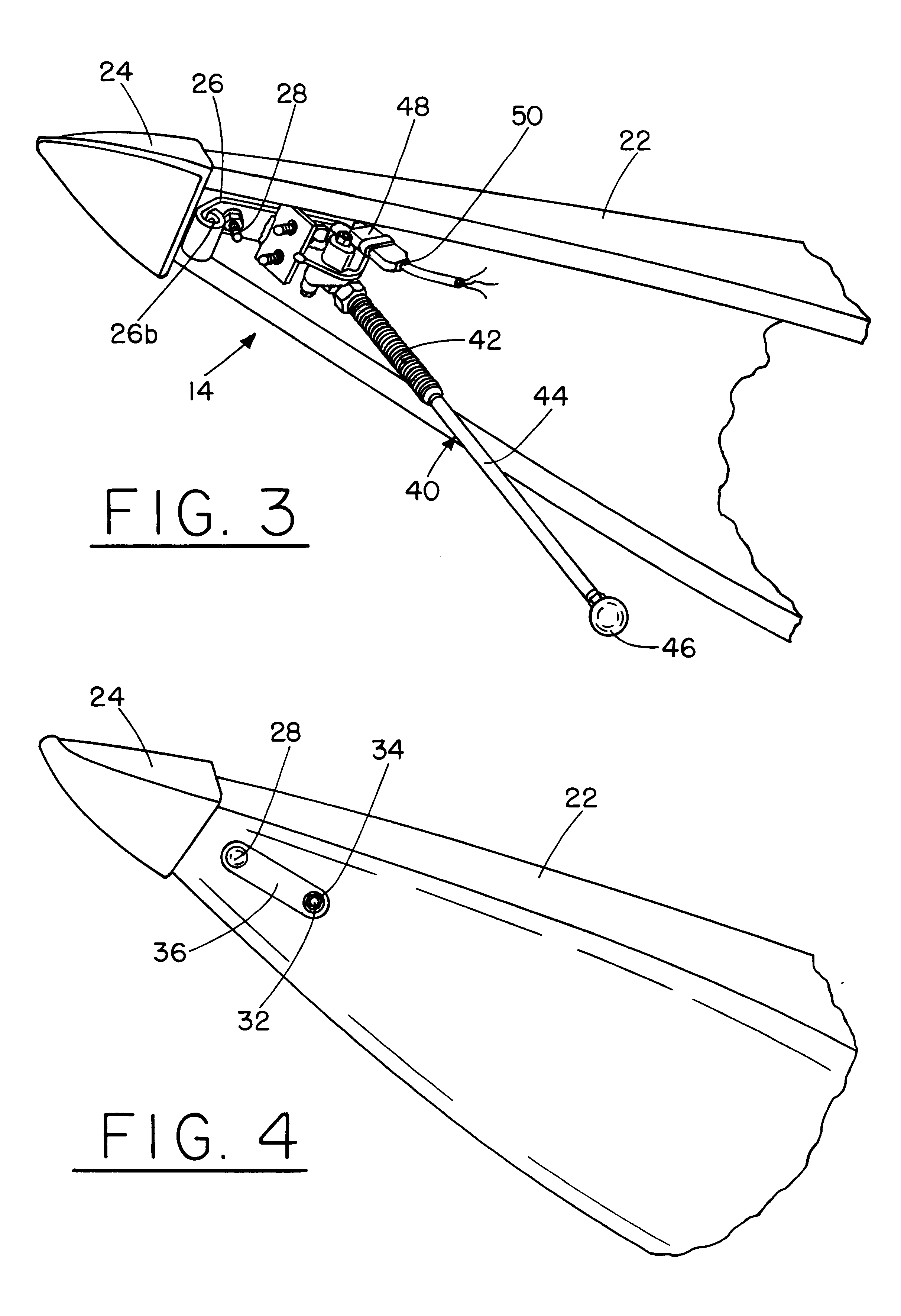

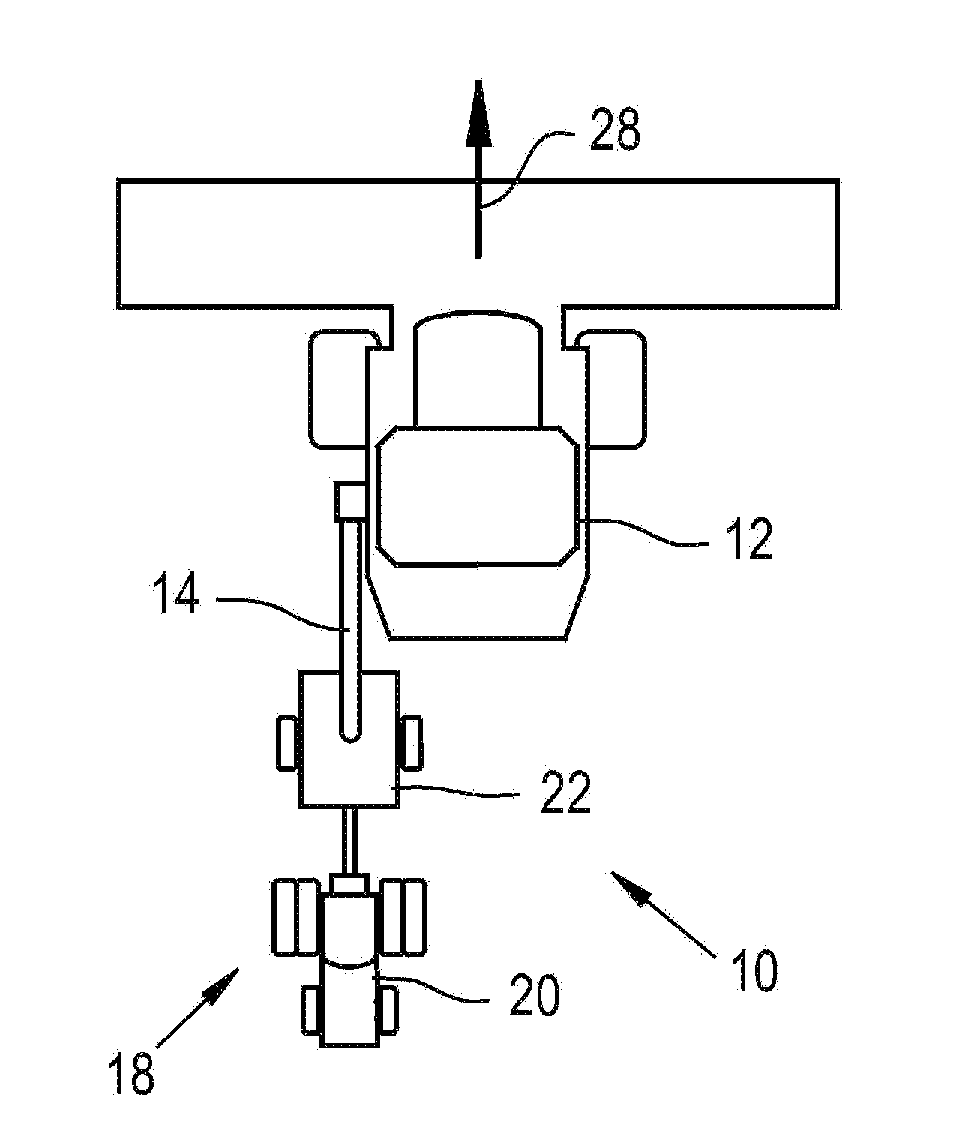

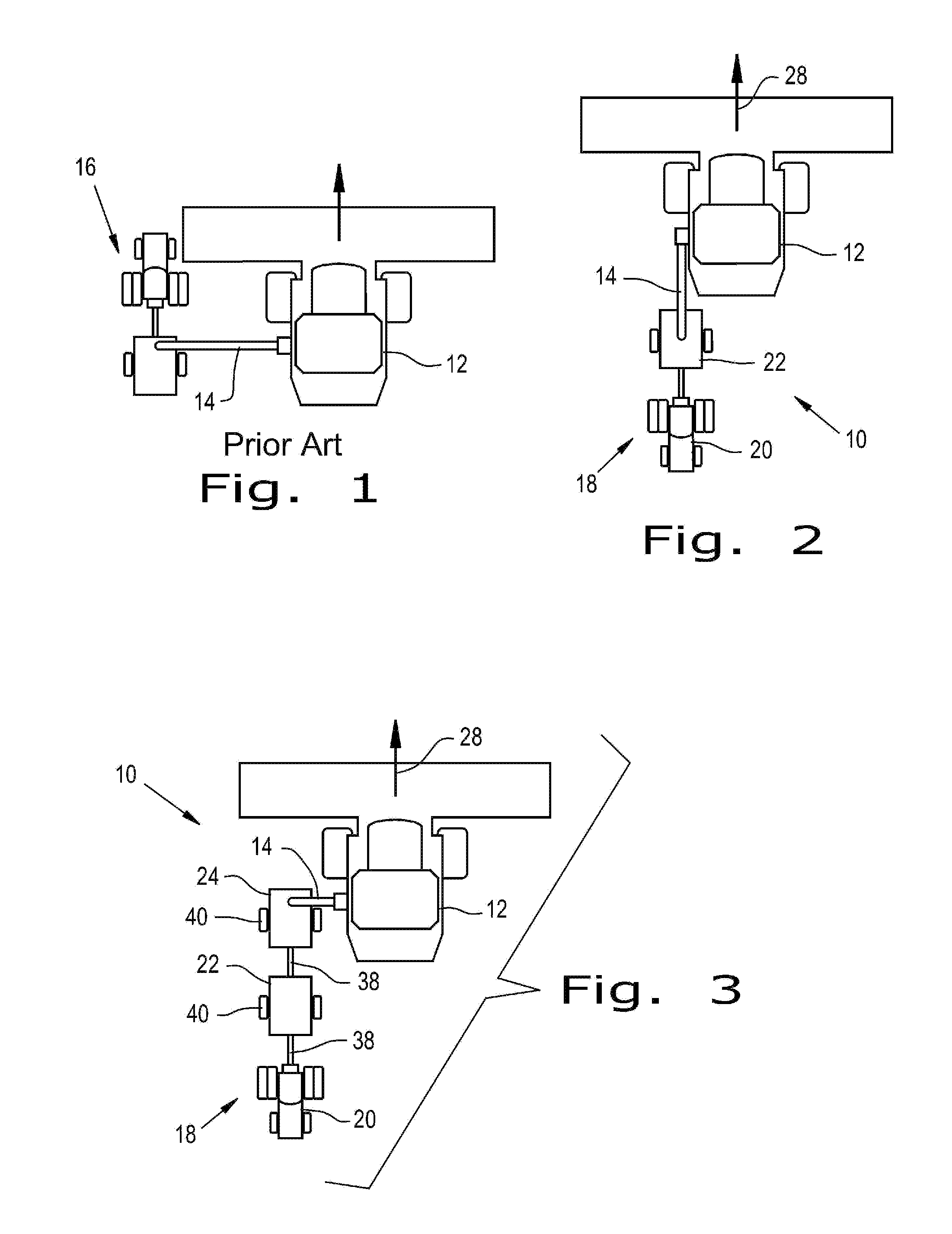

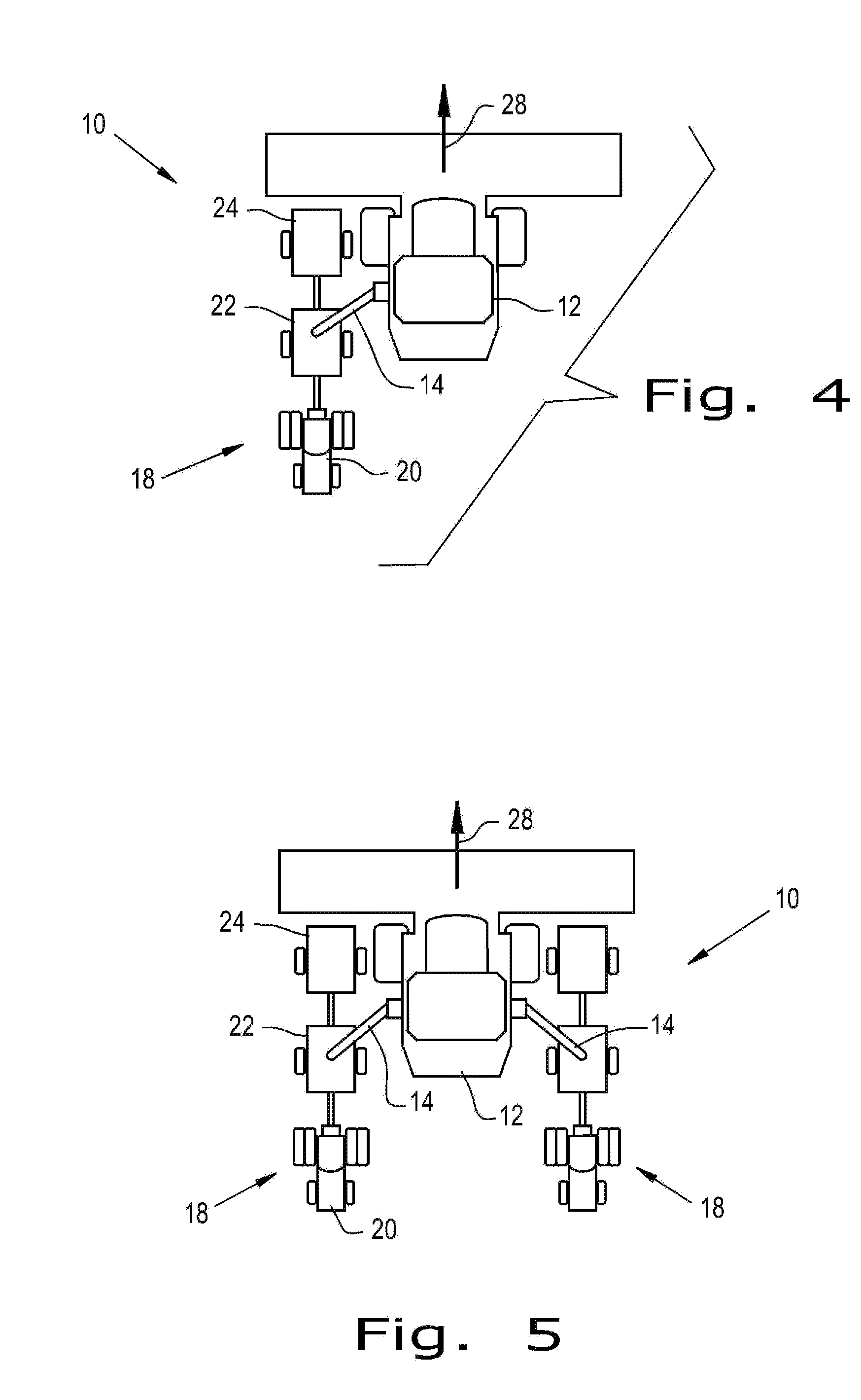

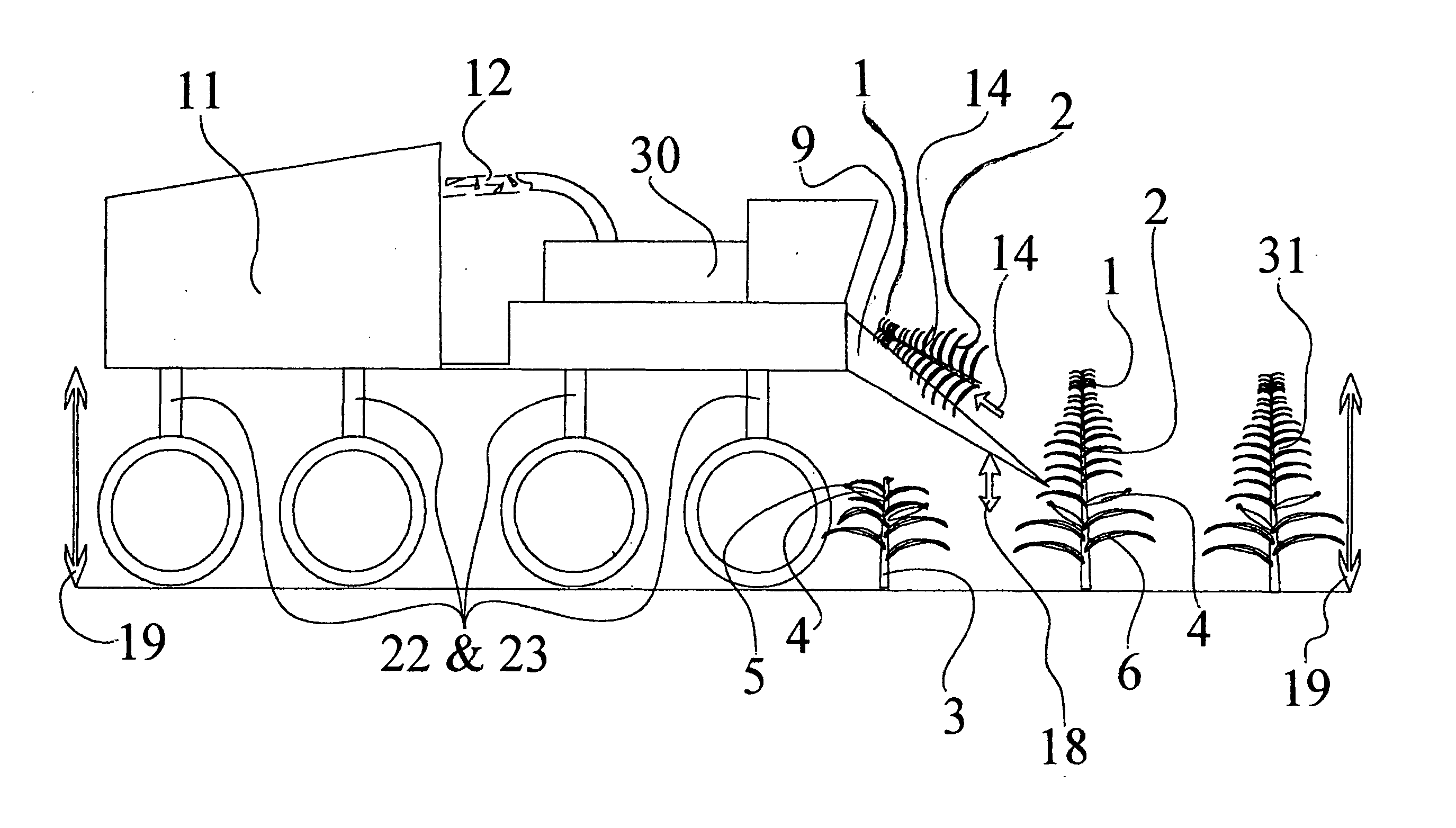

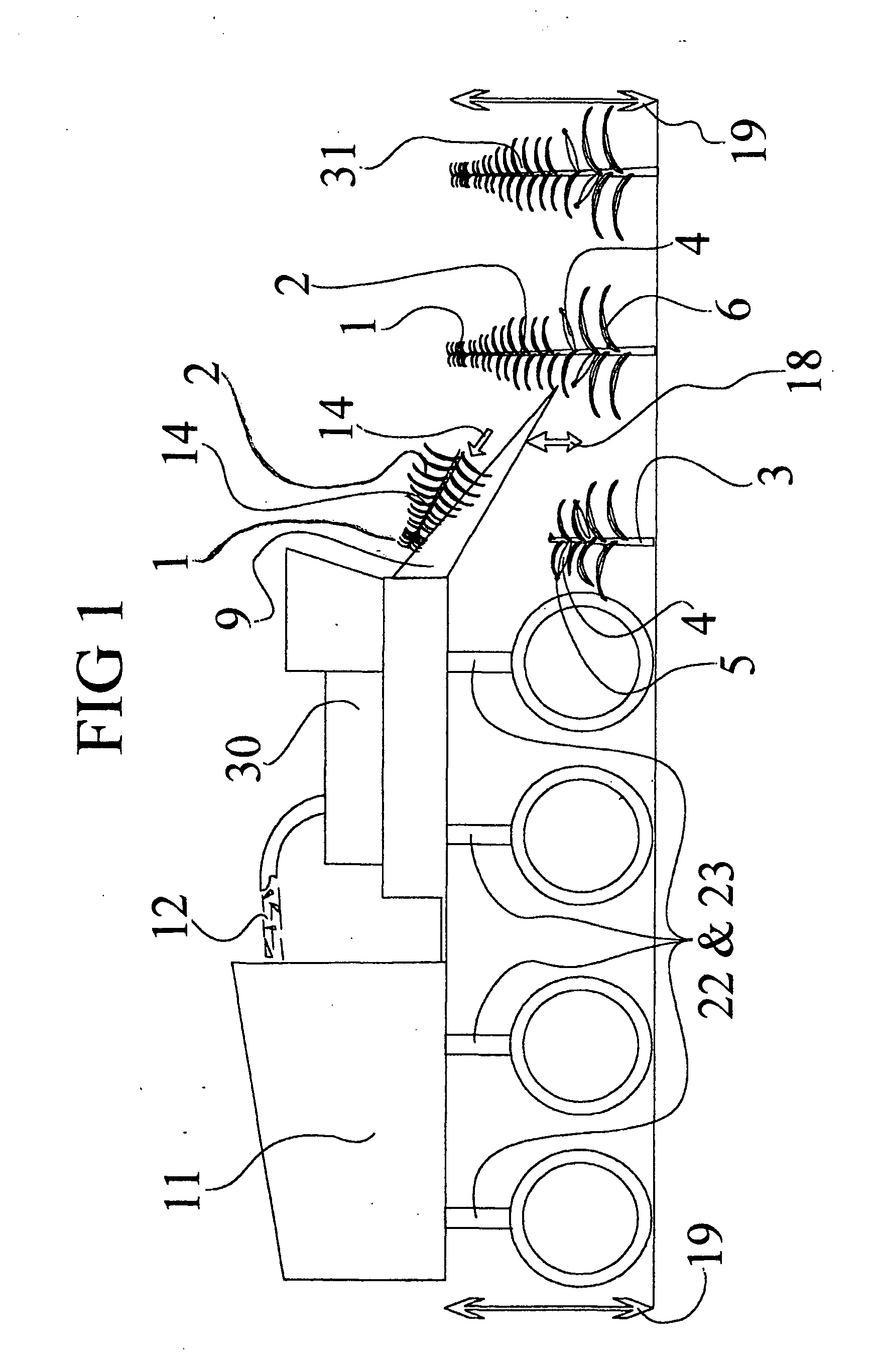

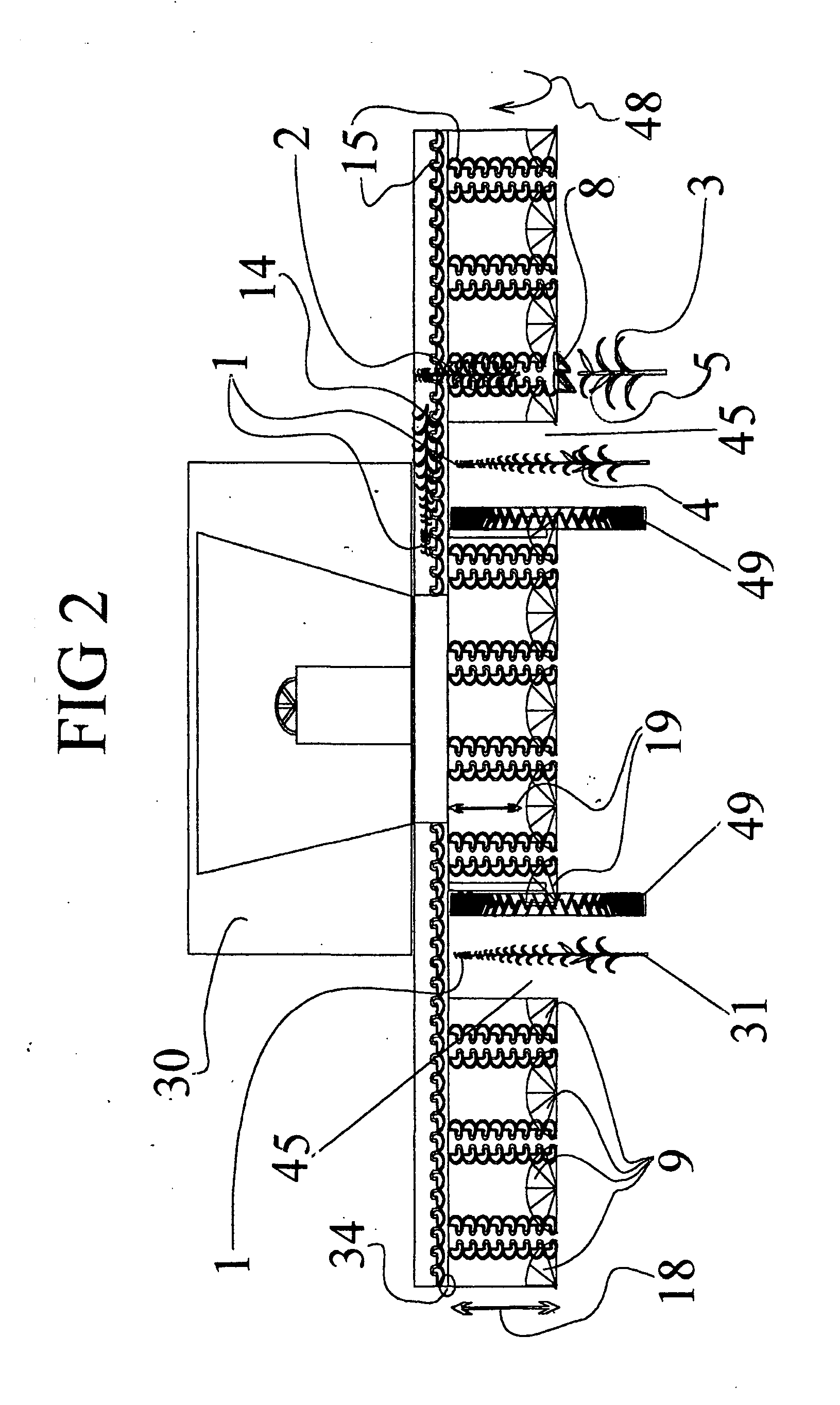

Combine header height control

InactiveUS6202395B1Accurate height positioningReduce combine ingestionAgricultural machinesMowersCoil springEngineering

An arrangement for controlling the height above or depth below an irregular surface of a body moving over or below the surface includes a rotation sensor coupled to a controller responsive to an angular deflection signal output by the rotation sensor. The rotation sensor and controller are mounted to a vehicle moving over the surface such as an agricultural vehicle traversing a field. A semi-rigid, flexible arm has a first end coupled to the rotation sensor with a ground engaging member attached to a second opposed end of the arm. In one embodiment, the flexible arm includes an elongated coil spring attached to a rigid shaft and the ground engaging member is a spherical ball attached to the shaft's distal end. The coil spring is pre-loaded to a selected bending or flexure force and permits the ground engaging member to impact obstructions in the field without damage to the rotation sensor. The coil spring also prevents damage to the rotation sensor when the vehicle is reversed in direction. The flexible arm may be urged downwardly to ensure that the ground engaging member contacts the soil and upward and downward rotation stops may be provided to limit rotation of the rotation sensor and flexible arm combination. When a plurality of rotation sensors and flexible arms are employed such as along the length of a combine header, each rotation sensor may be individually calibrated by rotating the sensor relative to the head unit to which it is mounted to permit all sensors to uniformly measure the height above or depth below the soil surface.

Owner:GRAMM RICHARD

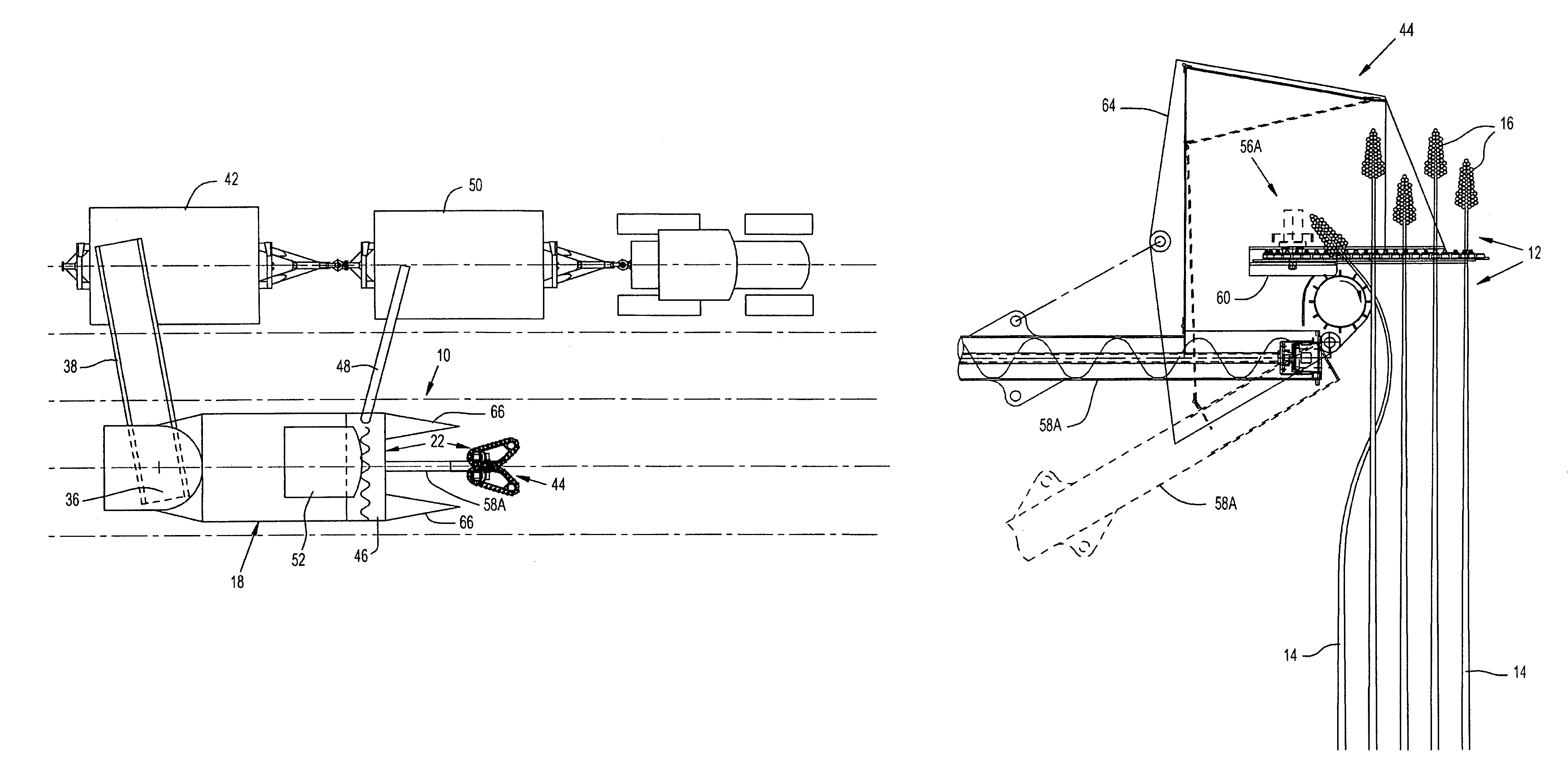

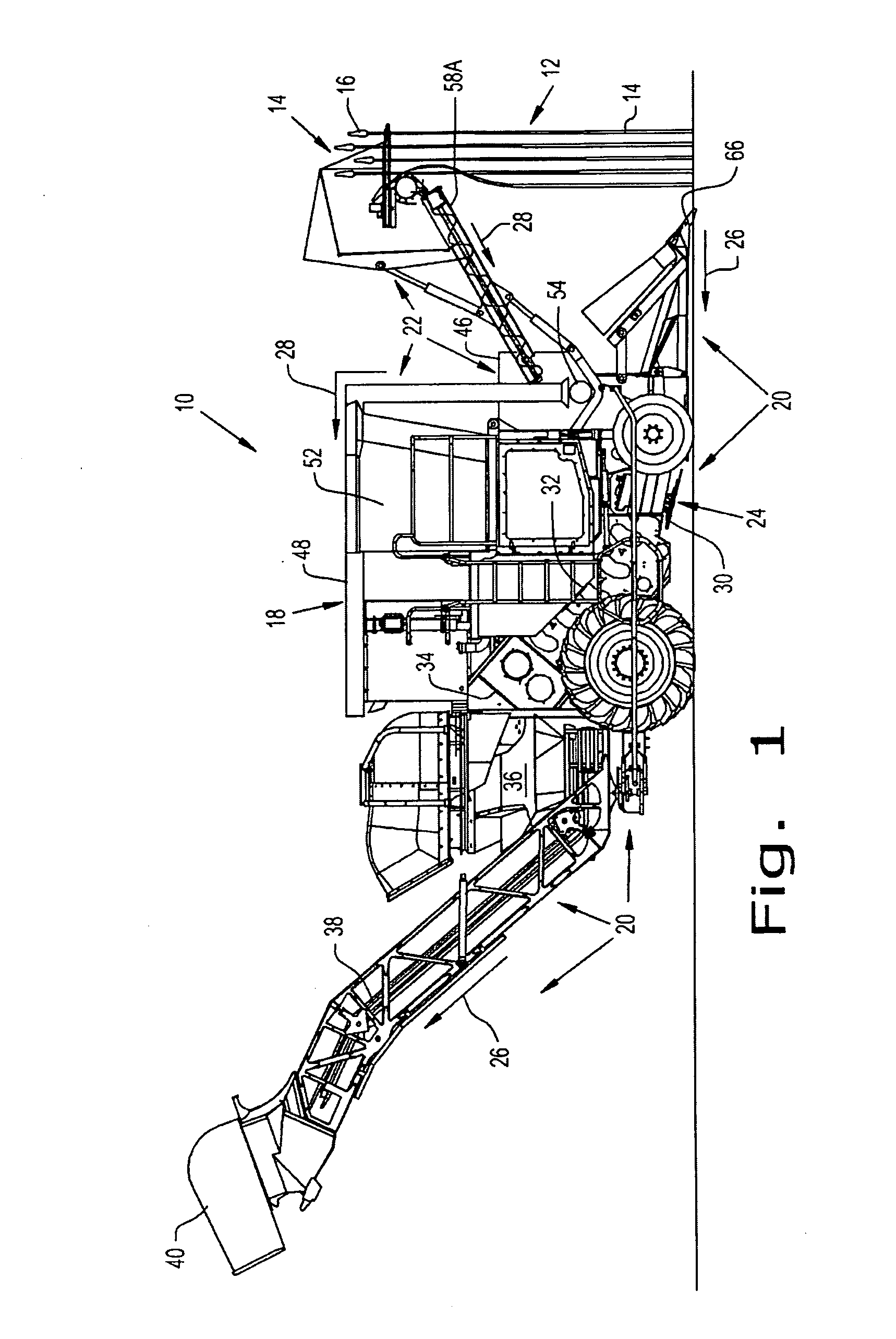

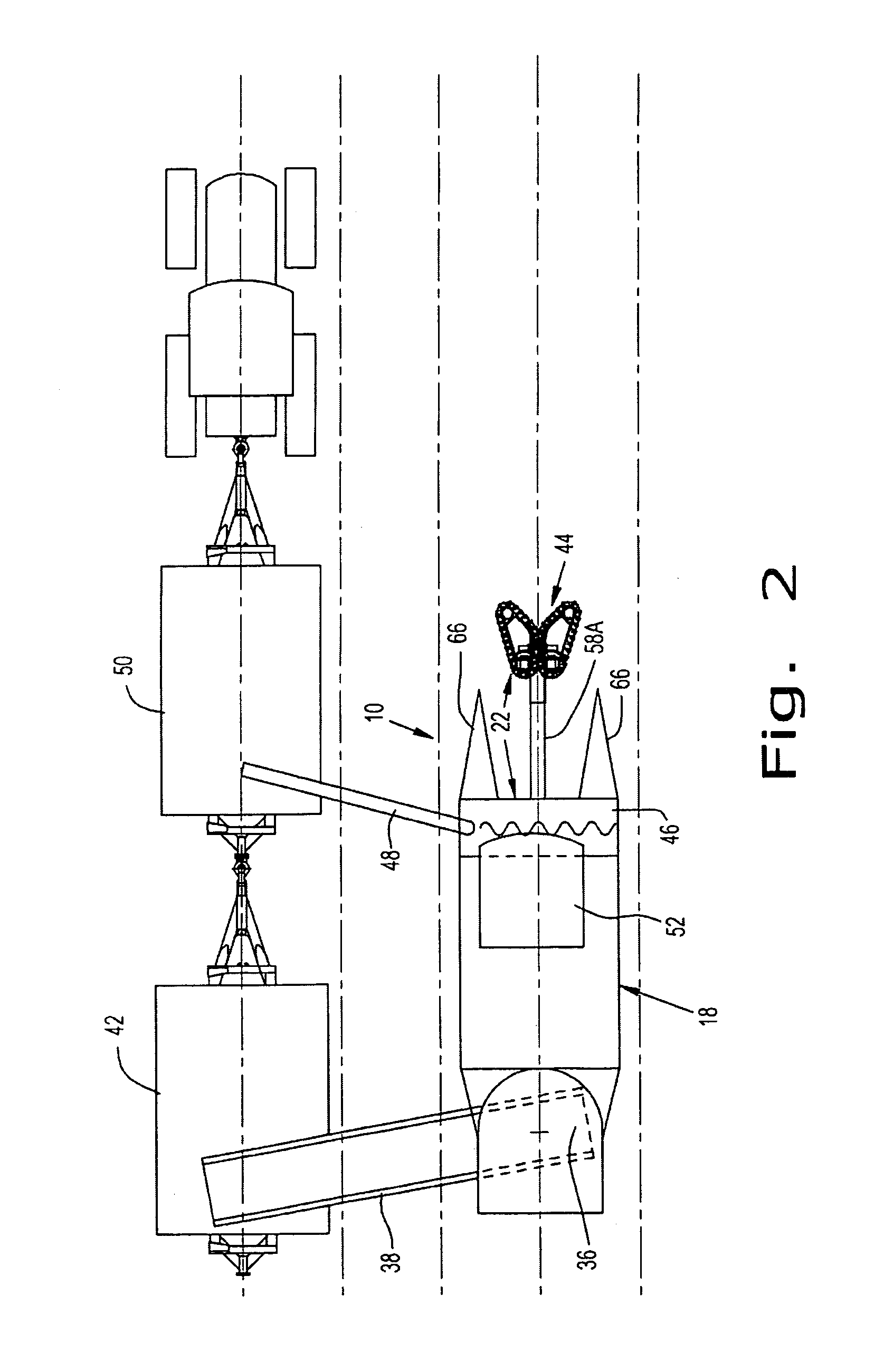

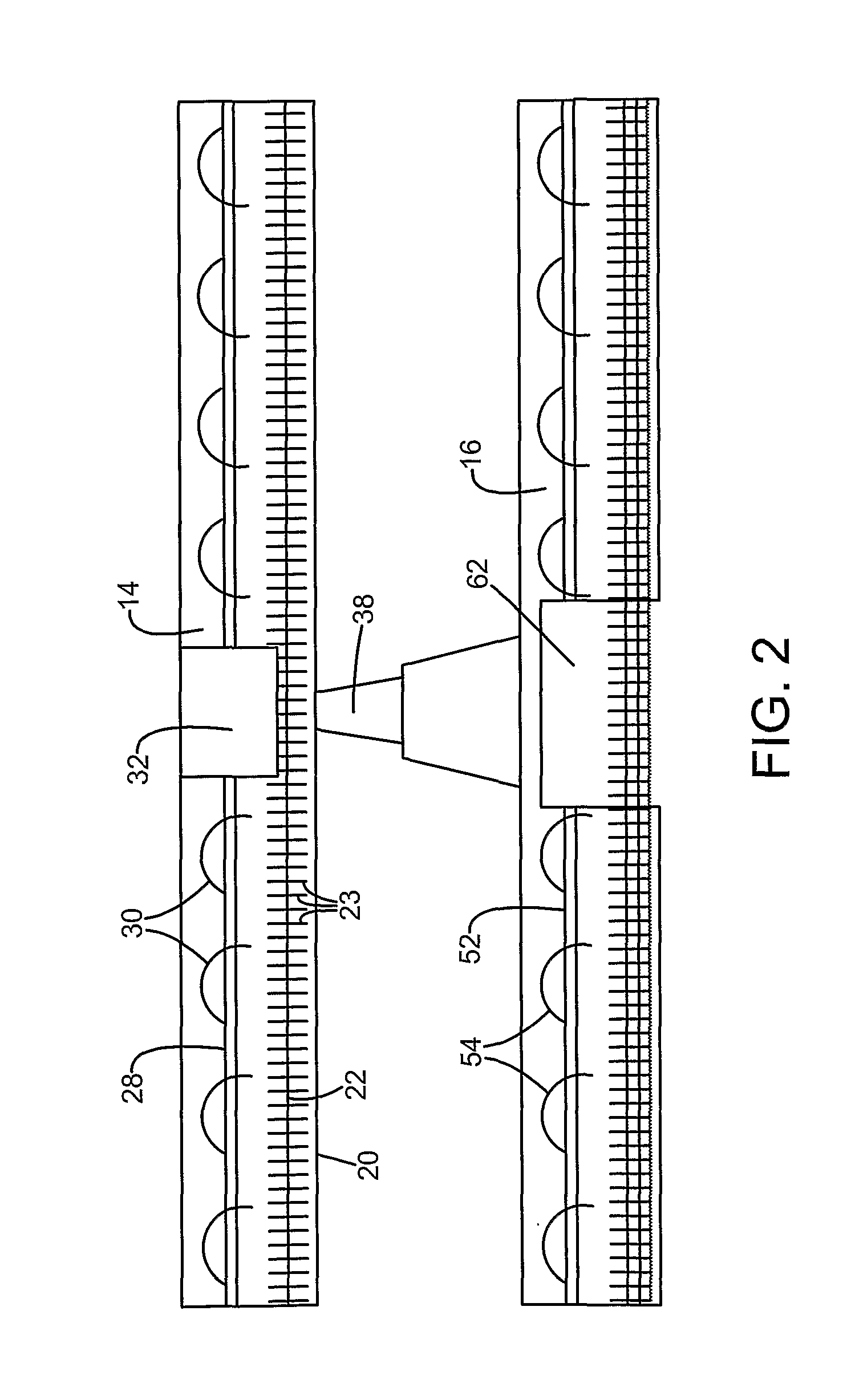

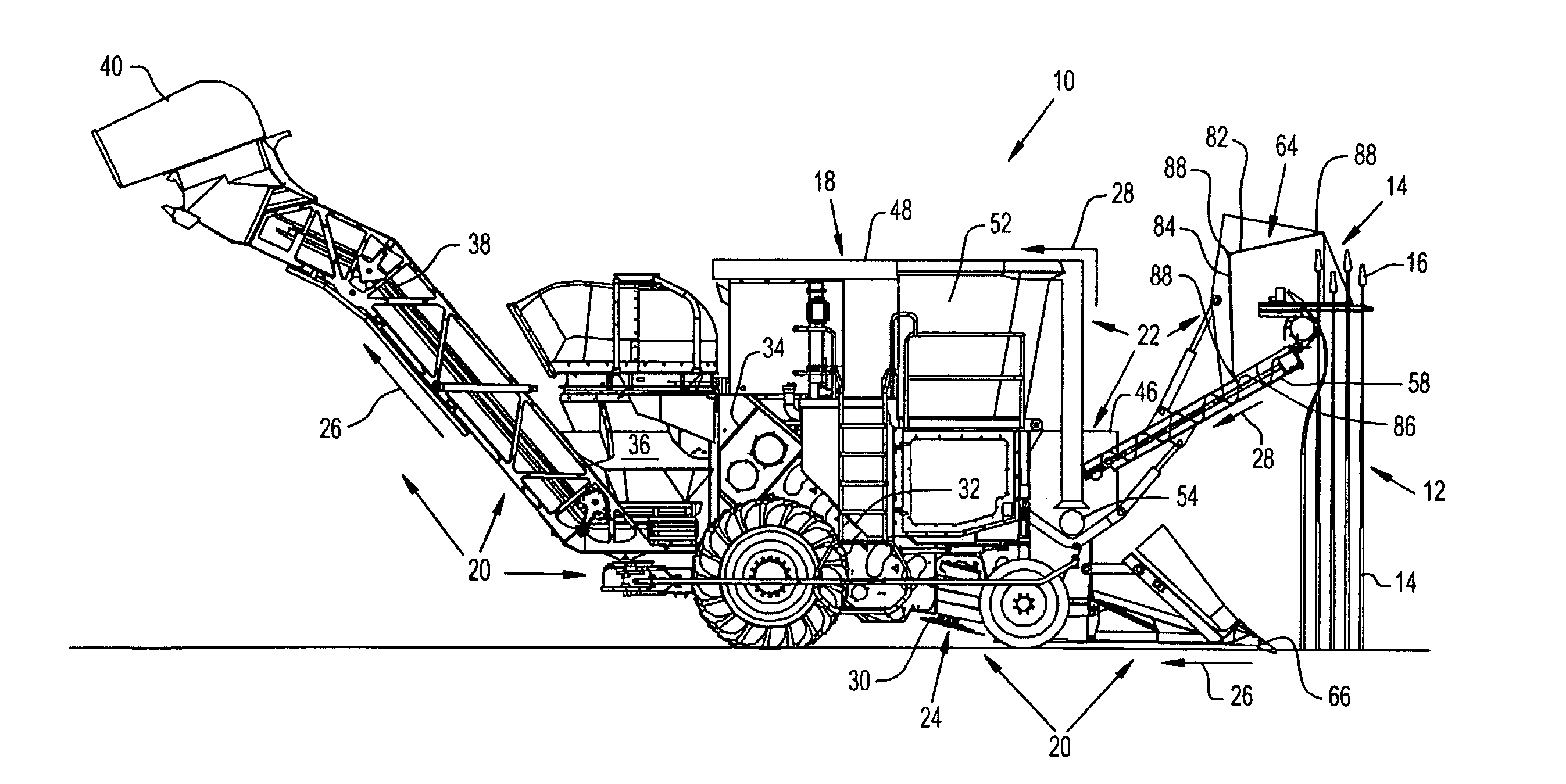

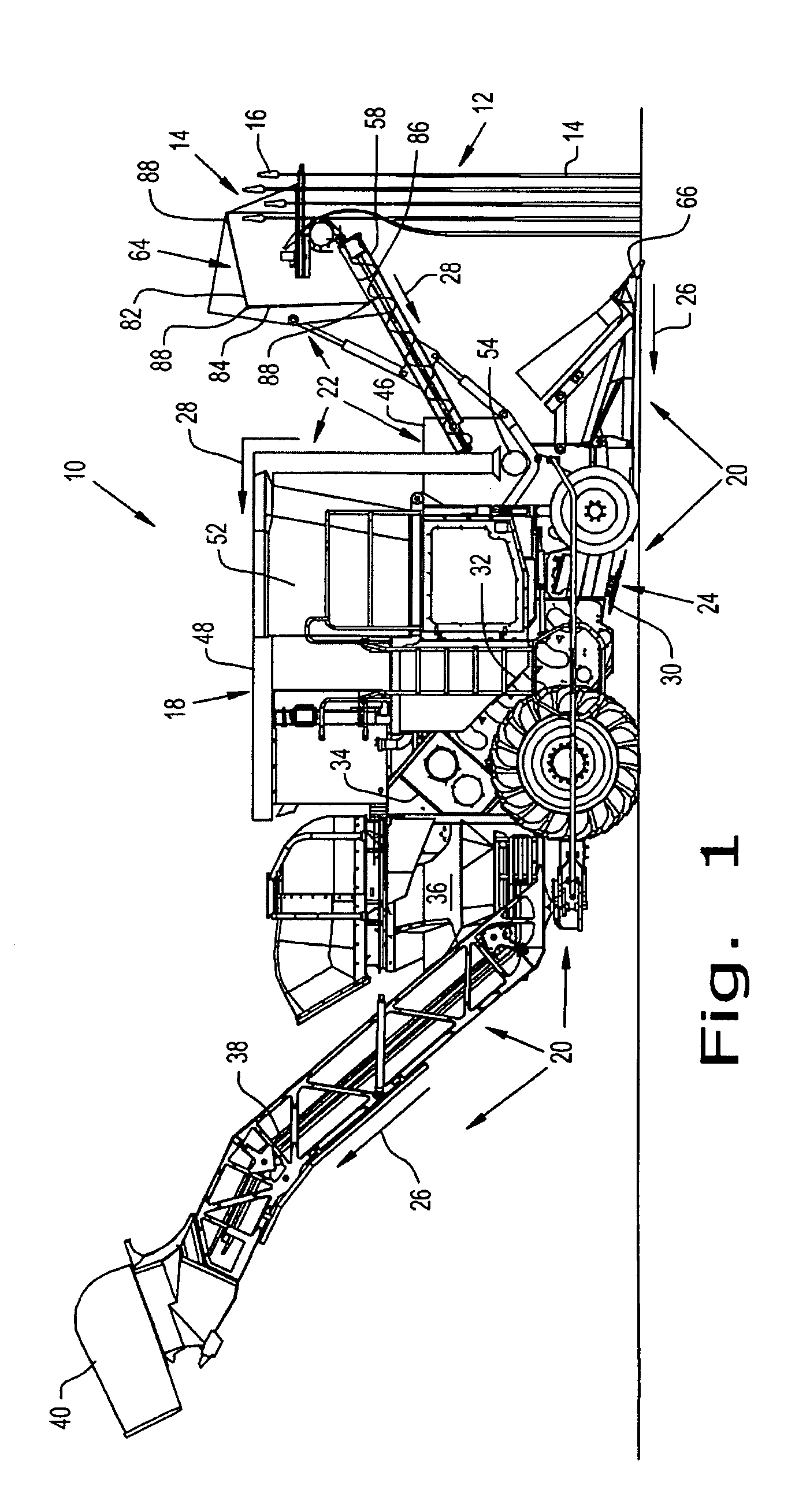

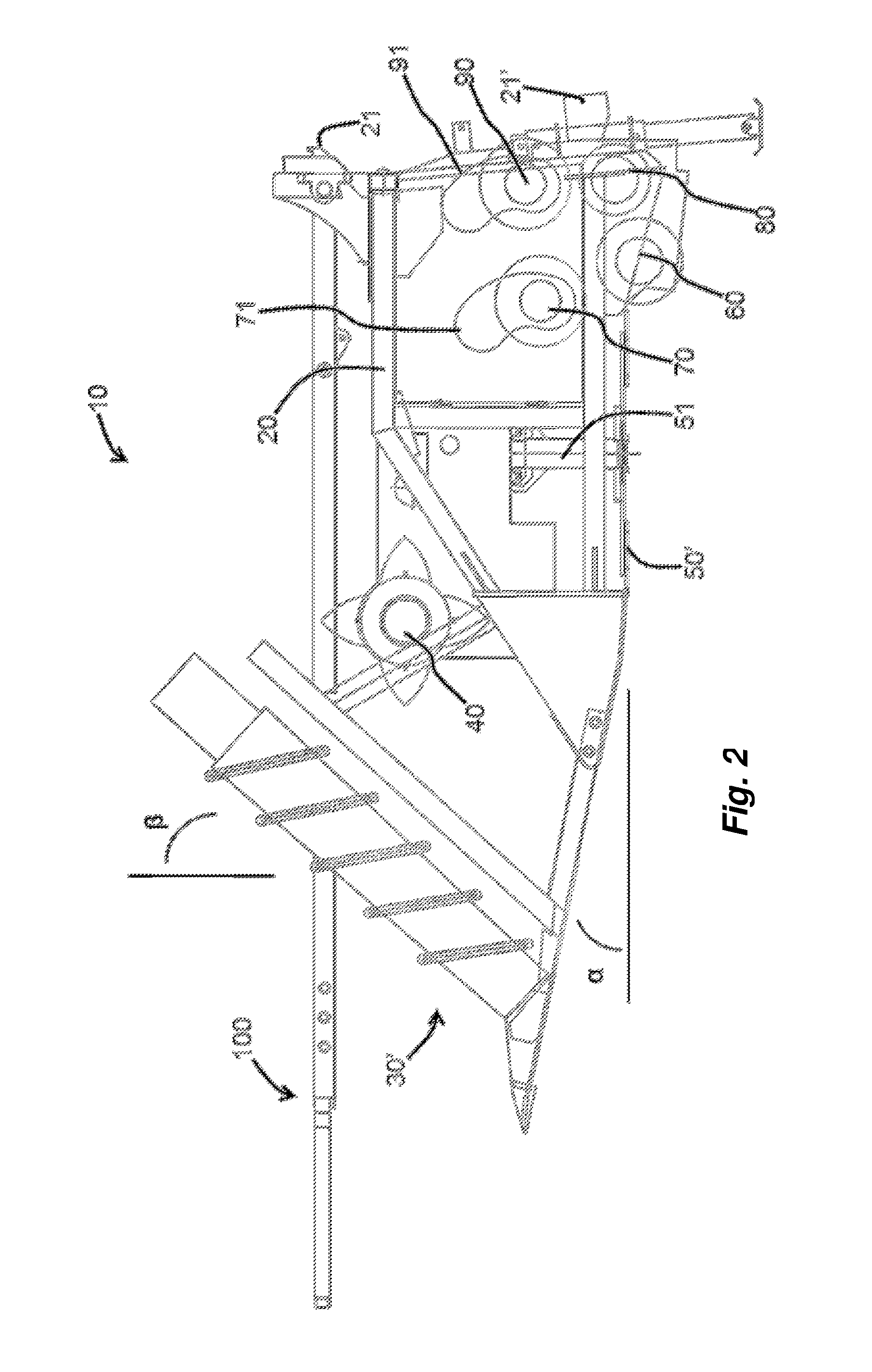

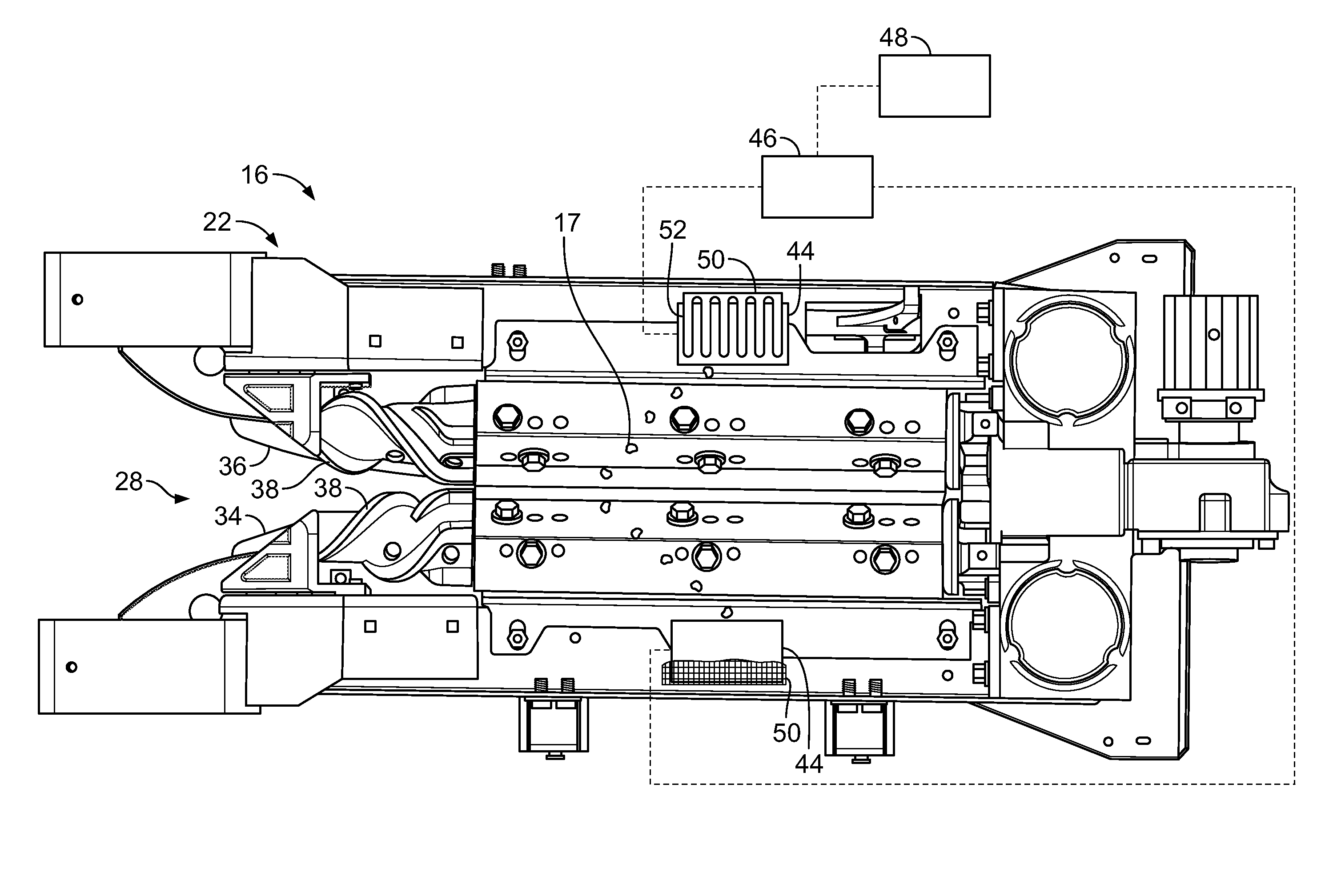

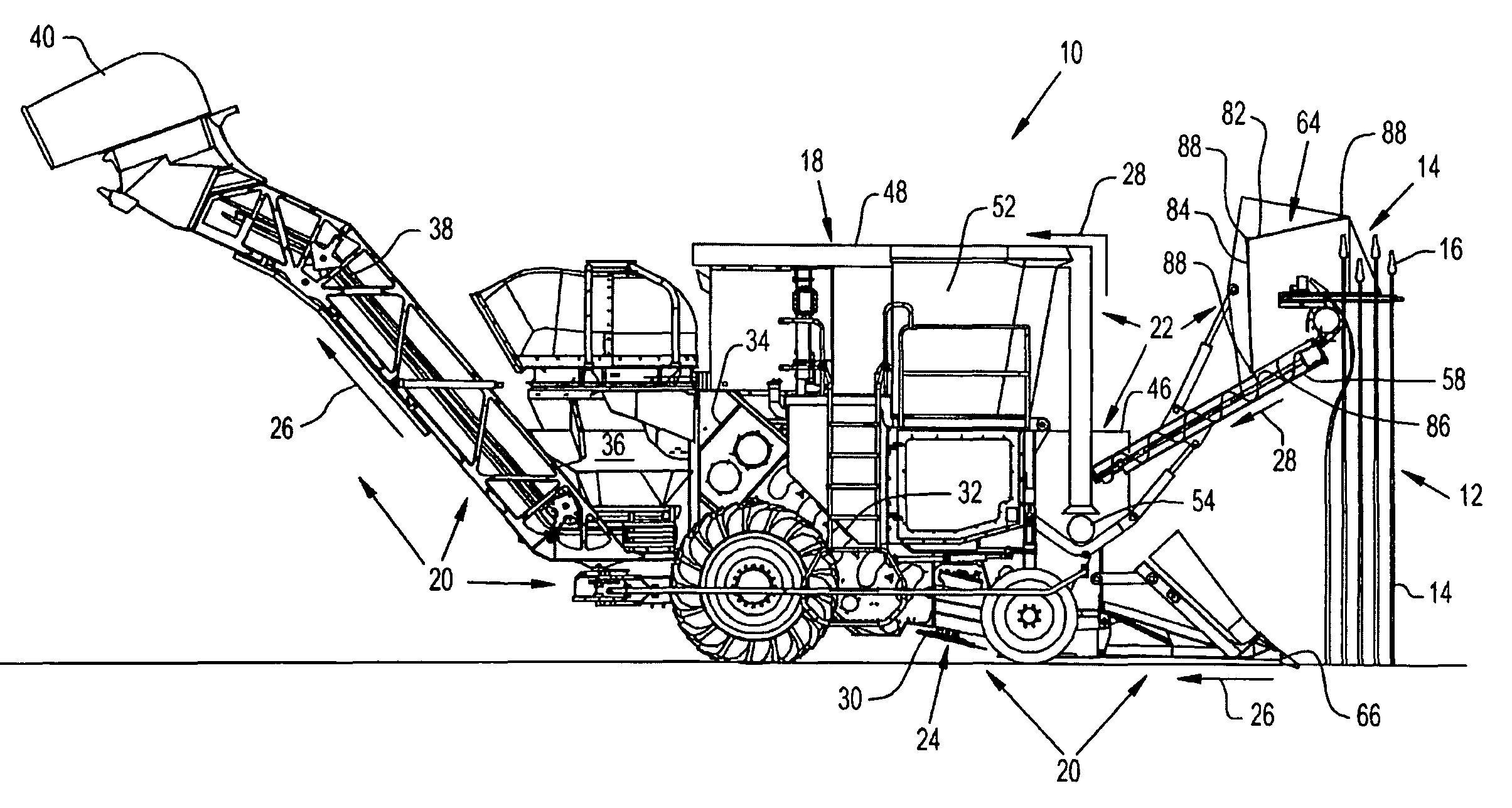

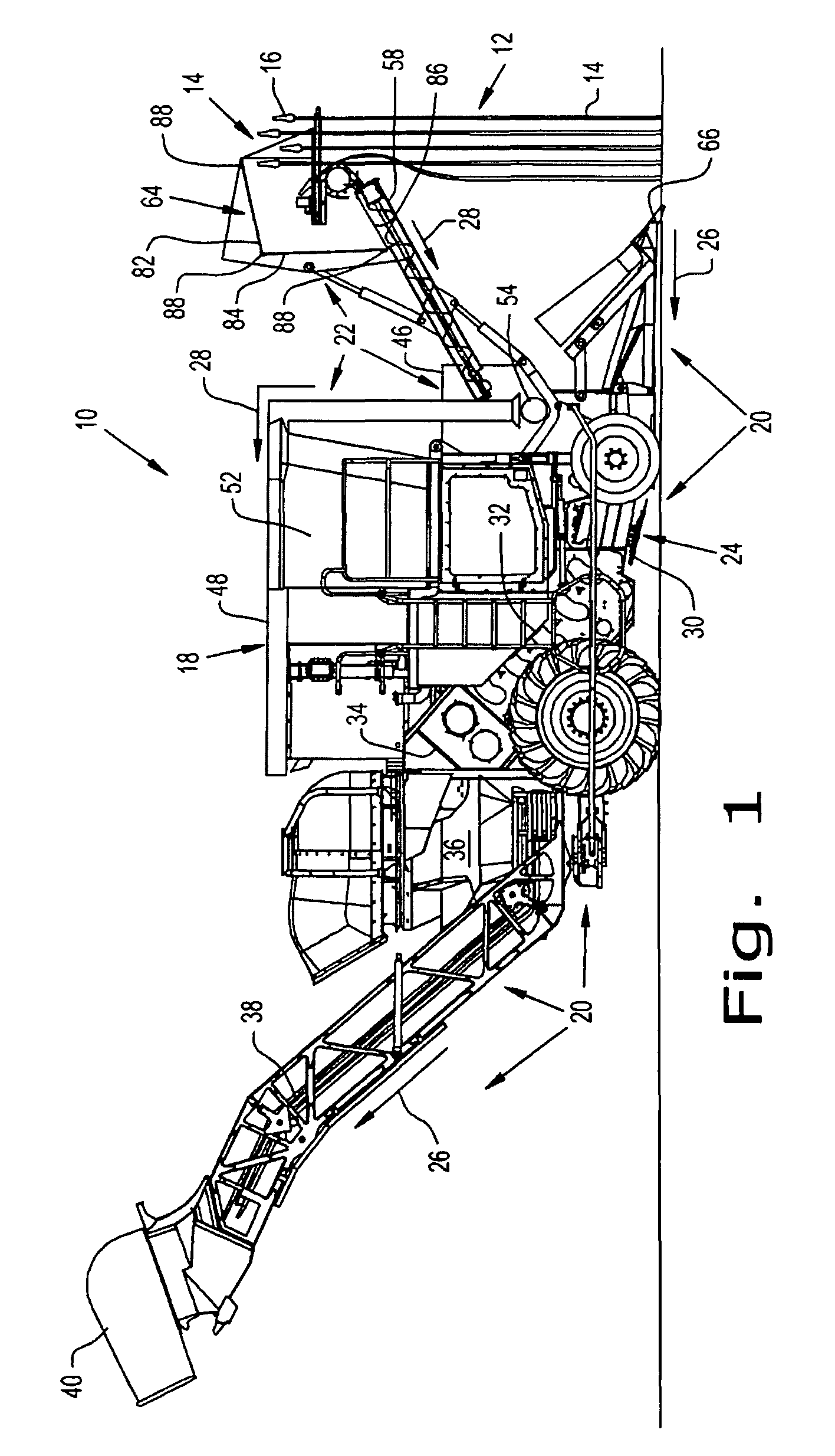

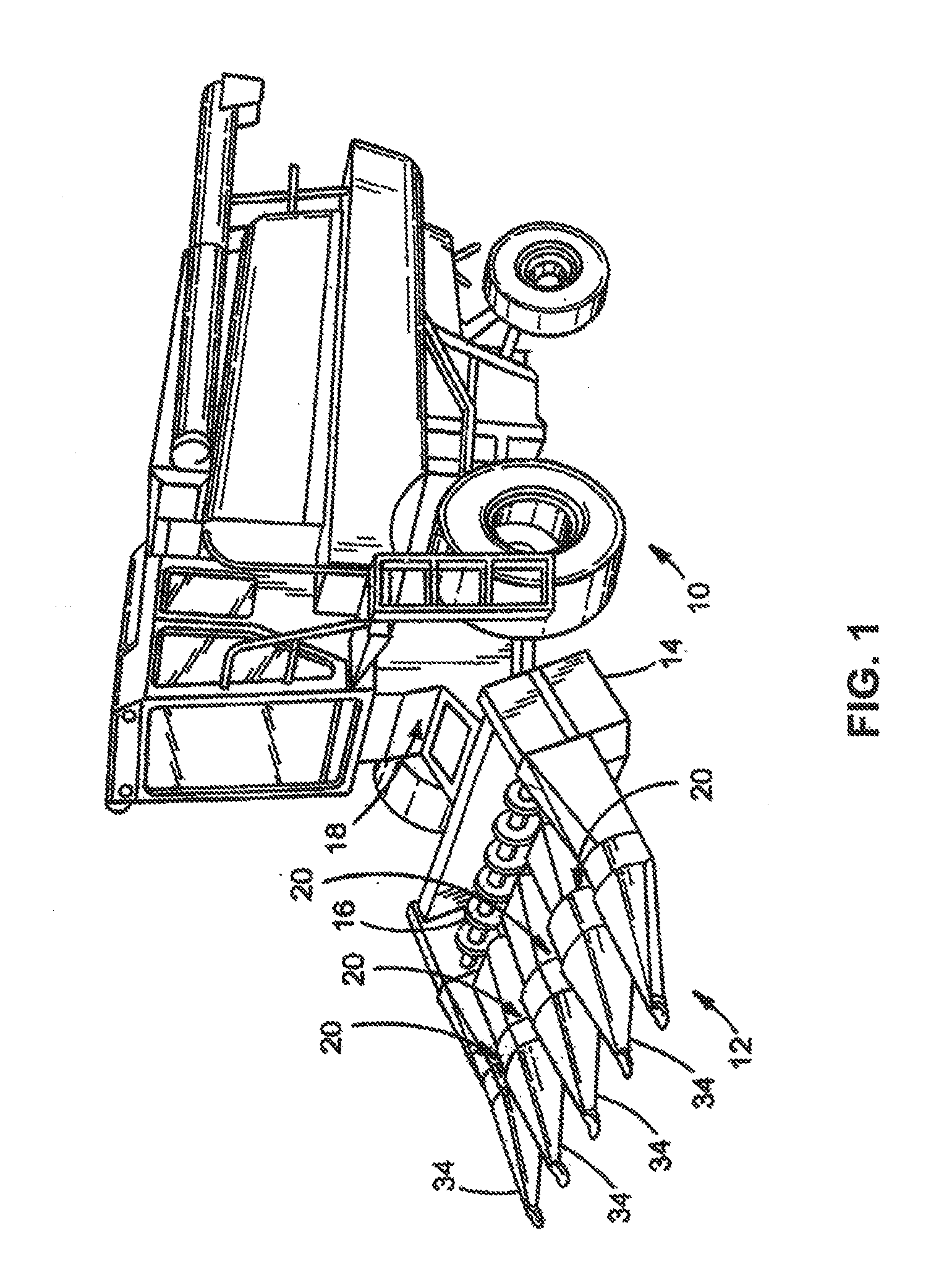

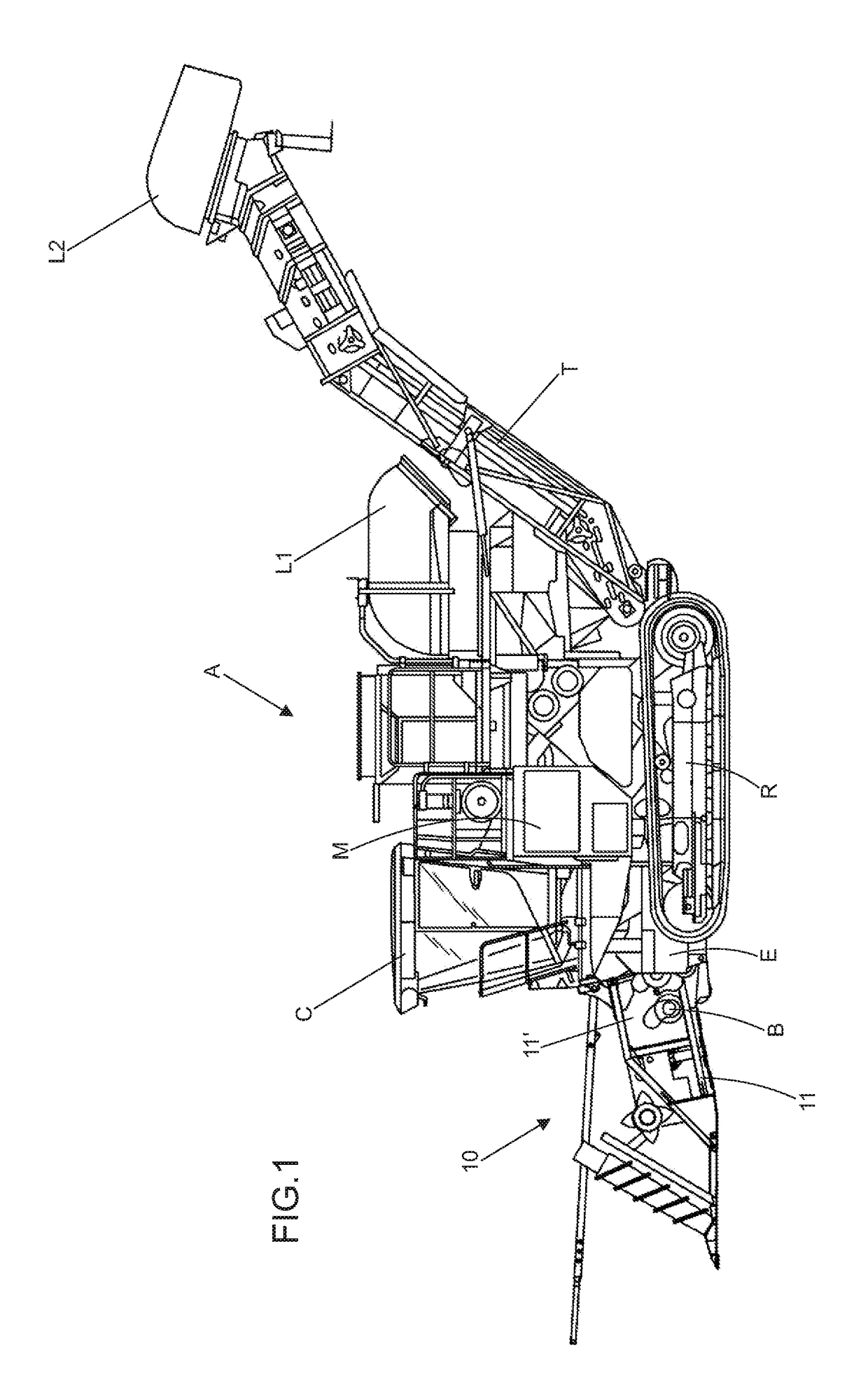

Agricultural harvester with simultaneous and independent seed and biomass processing

A harvester for crops including biomass crop material and seed heads. The harvester includes a base unit, a biomass harvester sub-system for harvesting the biomass crop material, and a seed harvester sub-system for harvesting the seed heads. The biomass harvester sub-system includes a biomass harvester carried by the base unit. The seed harvester sub-system is carried by the base unit and operable independent from the biomass harvester sub-system, whereby the biomass crop material and seed heads are processed independently from each other within the harvester.

Owner:DEERE & CO

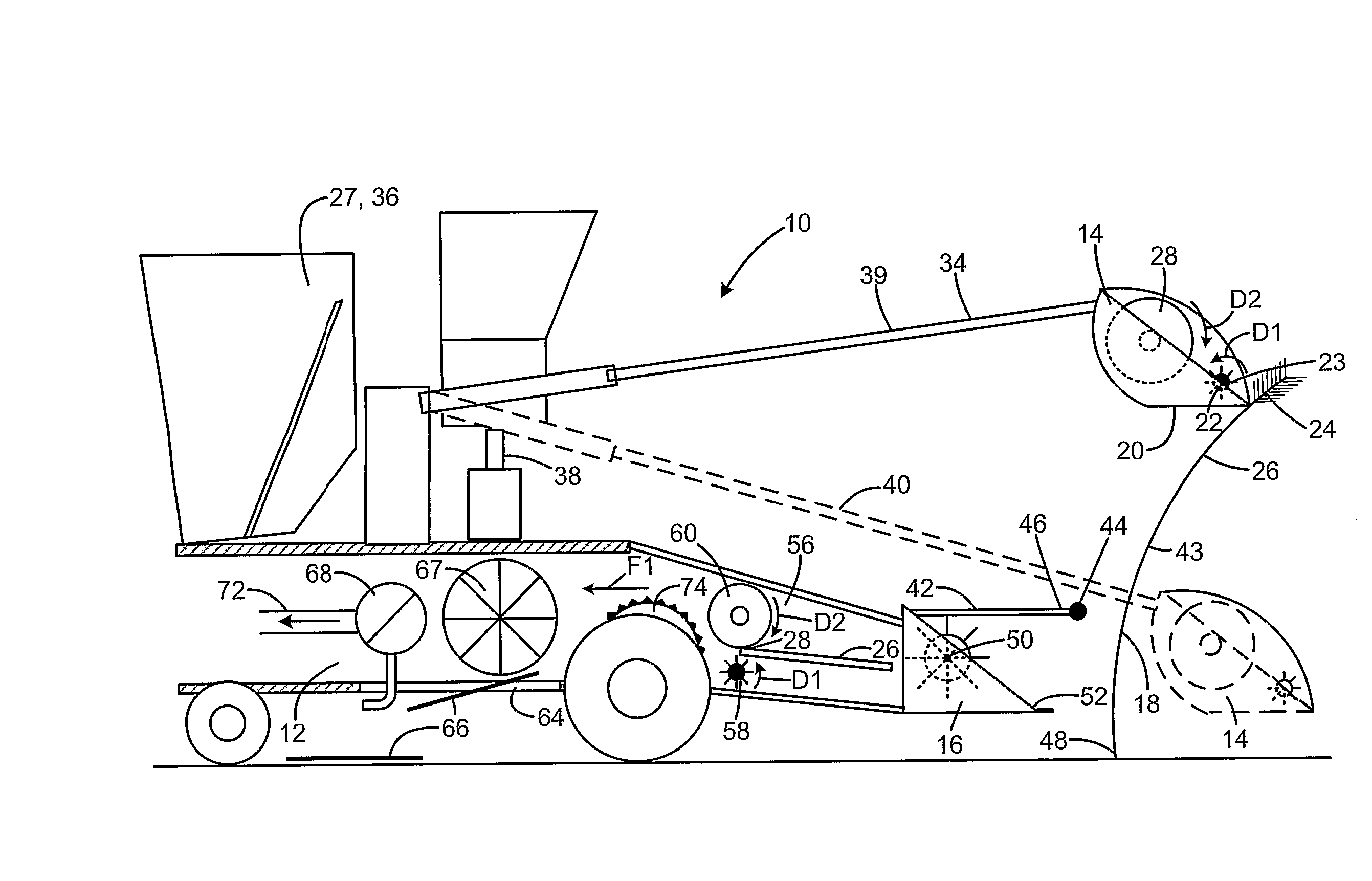

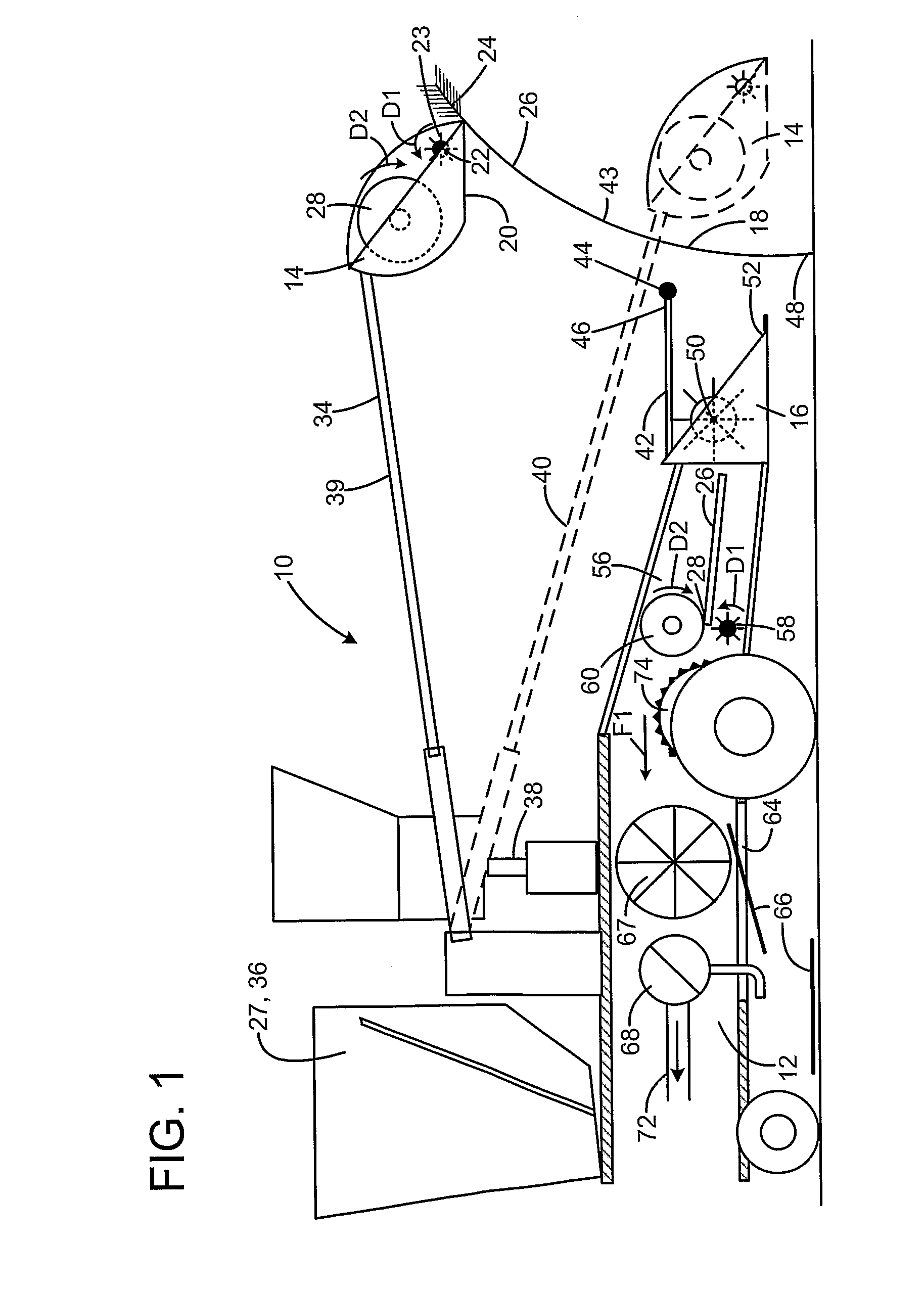

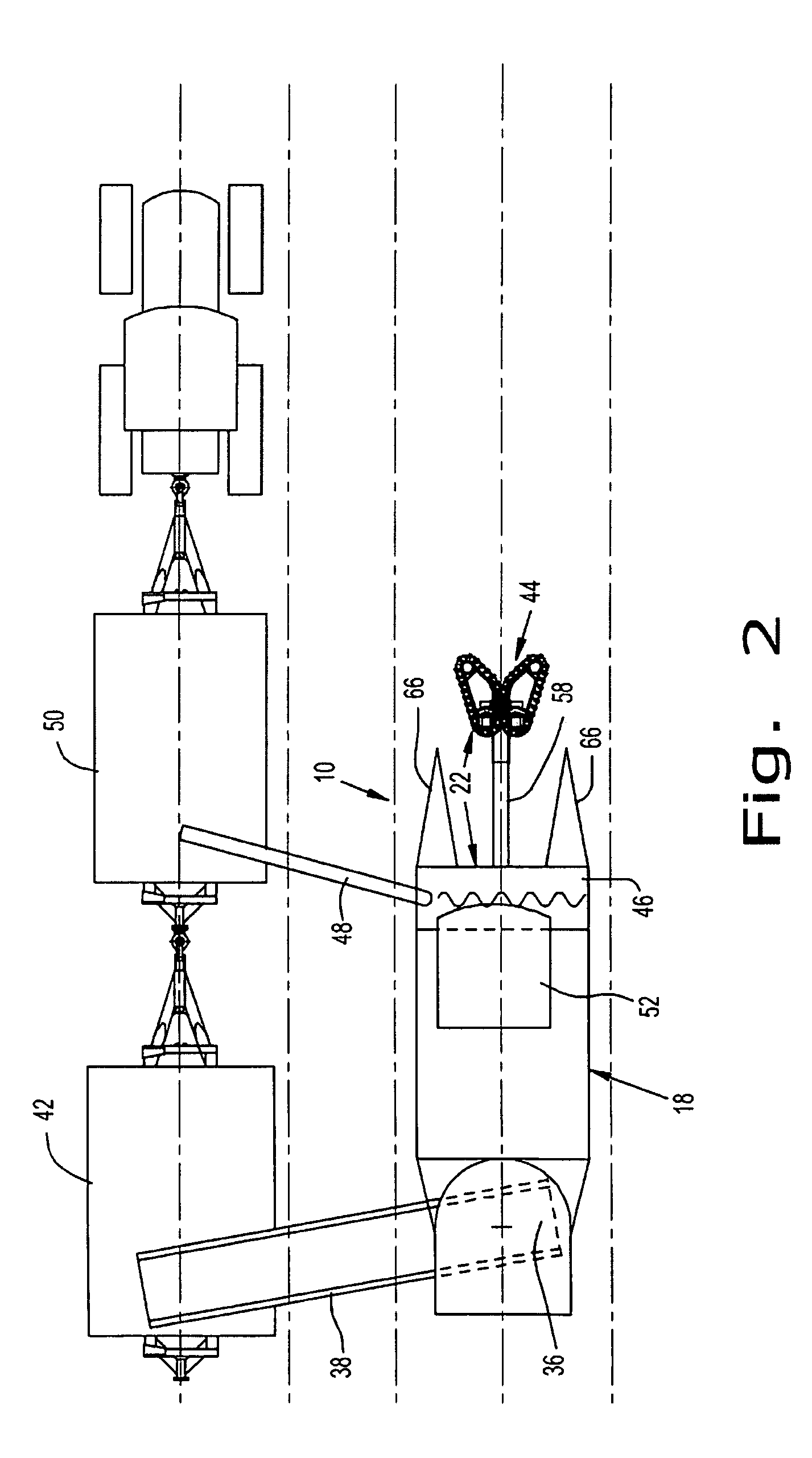

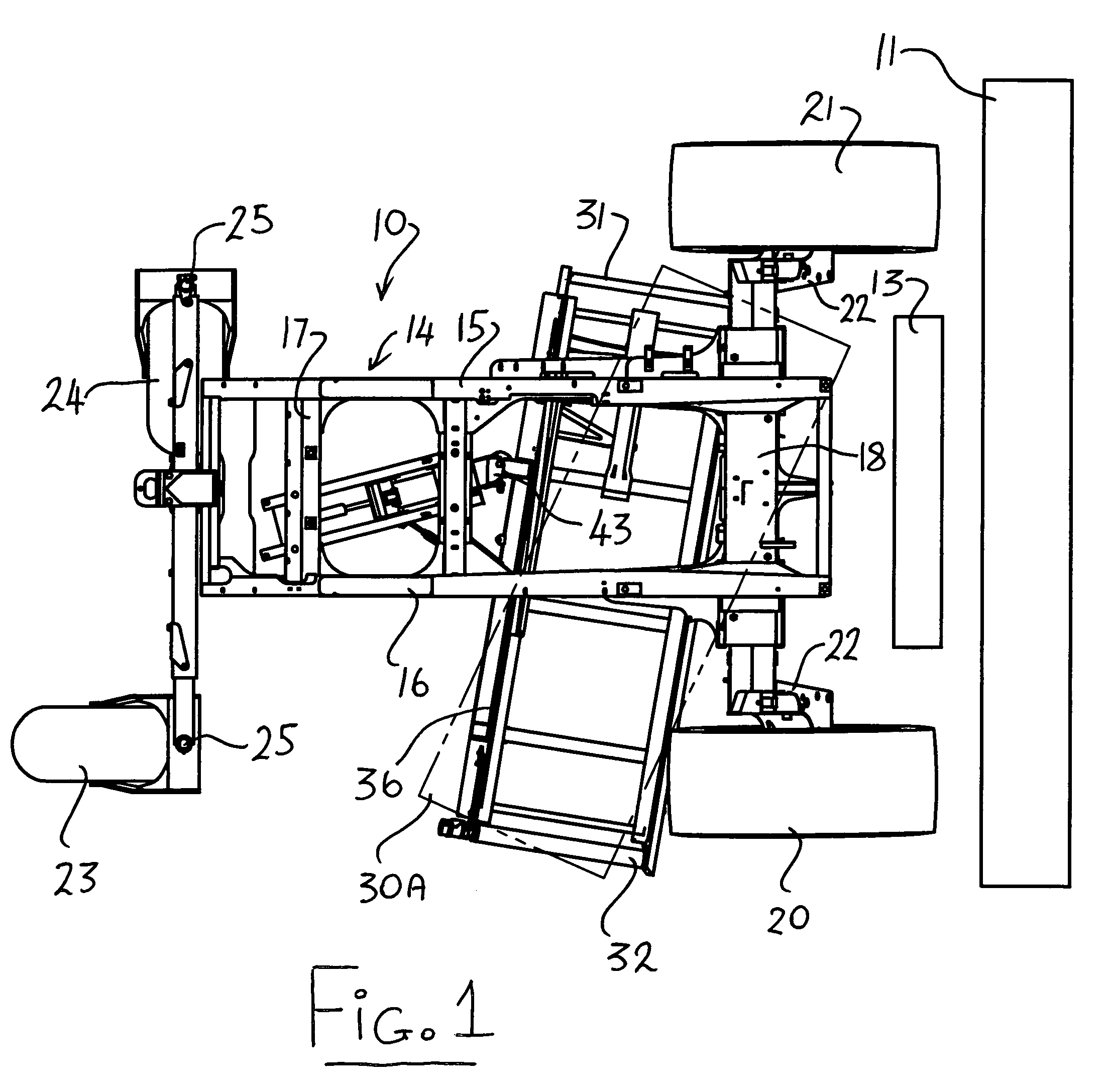

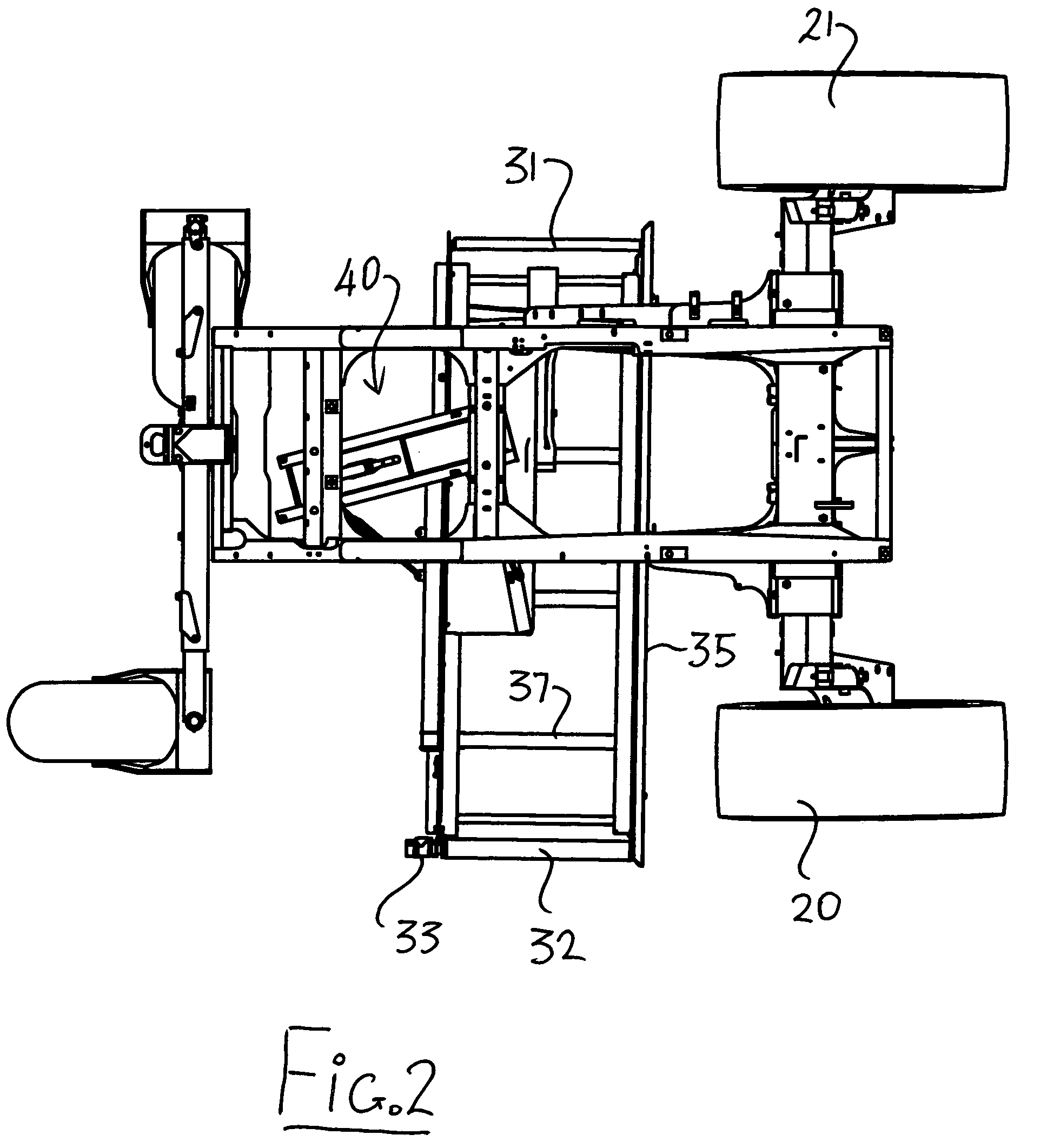

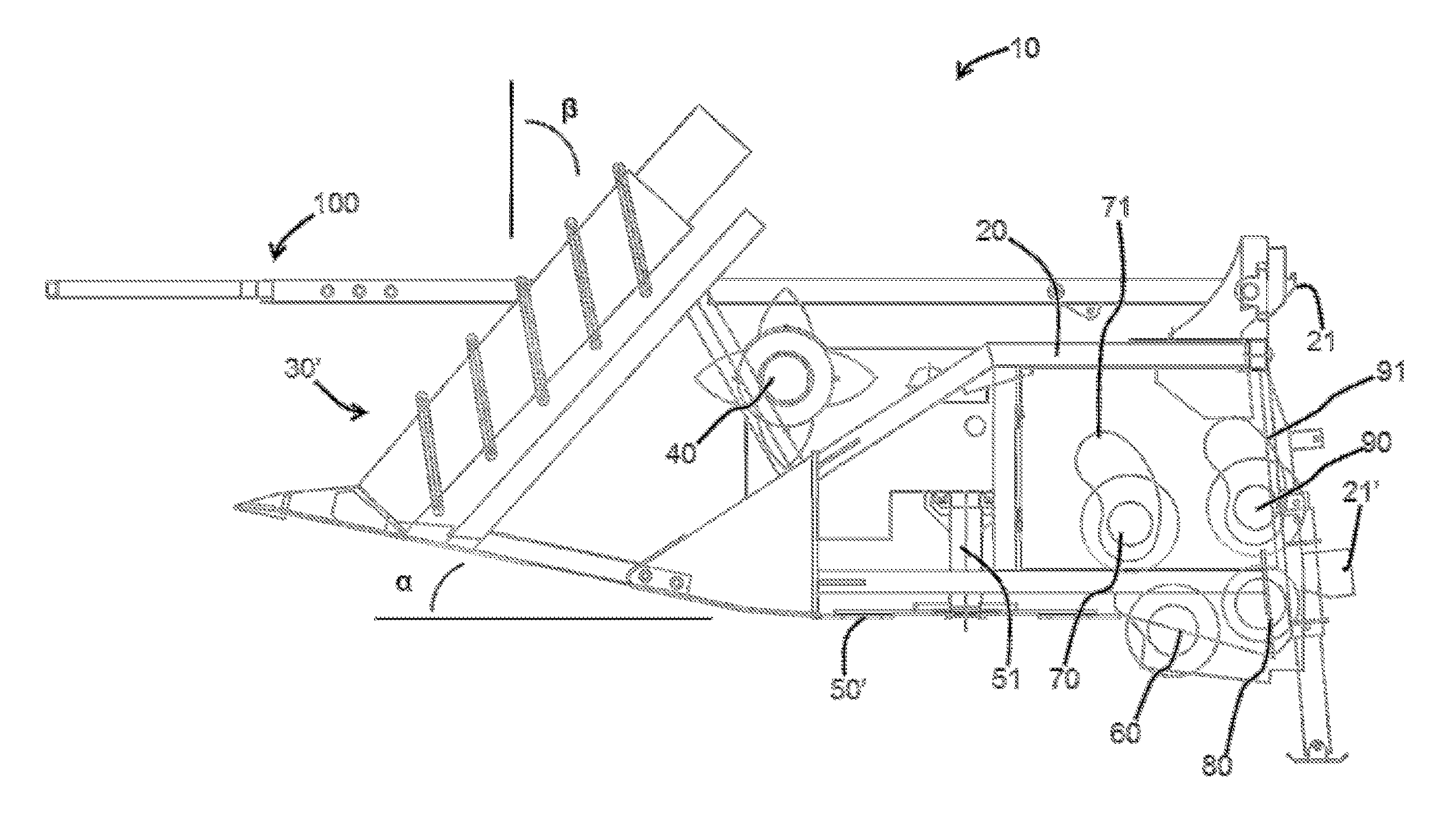

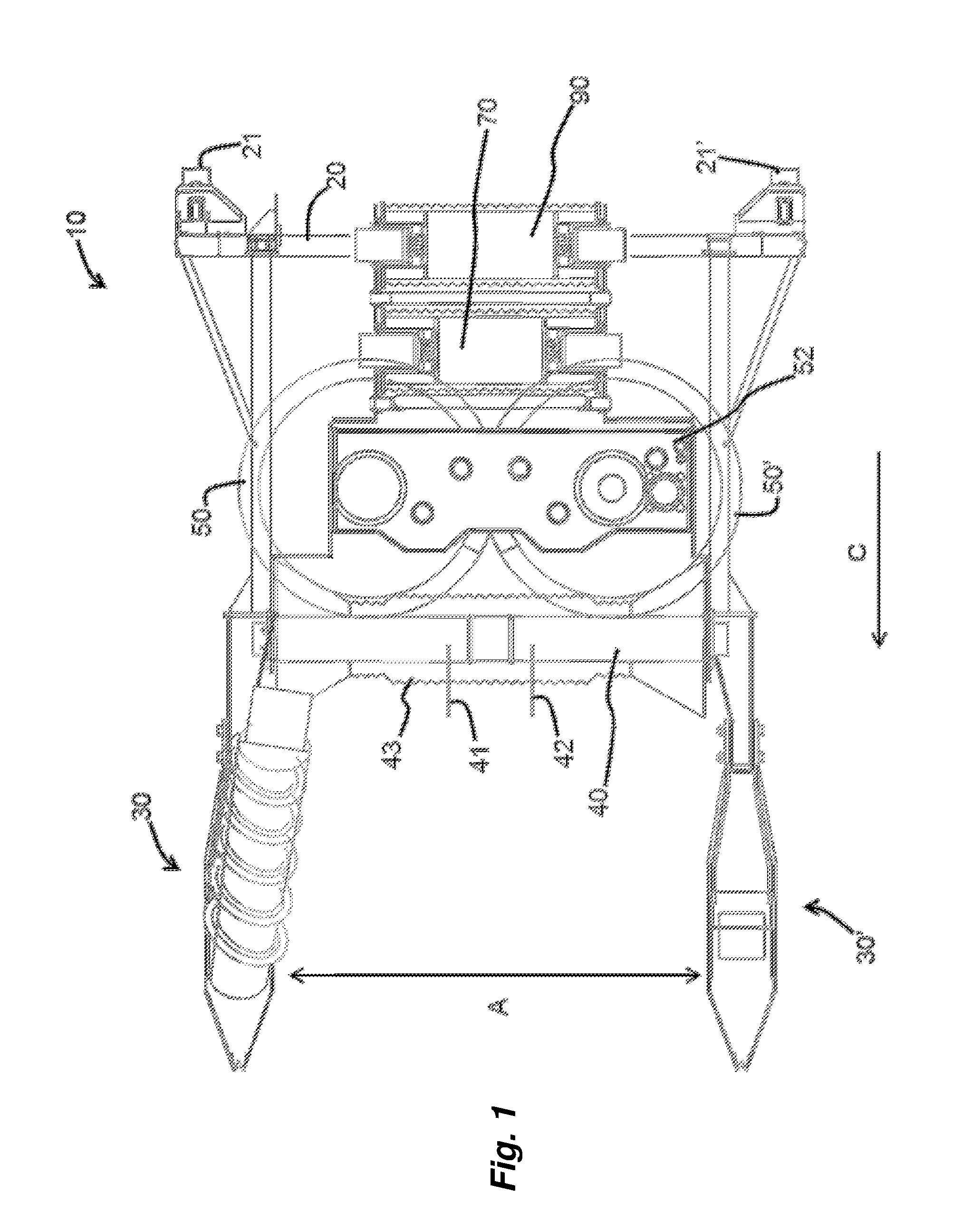

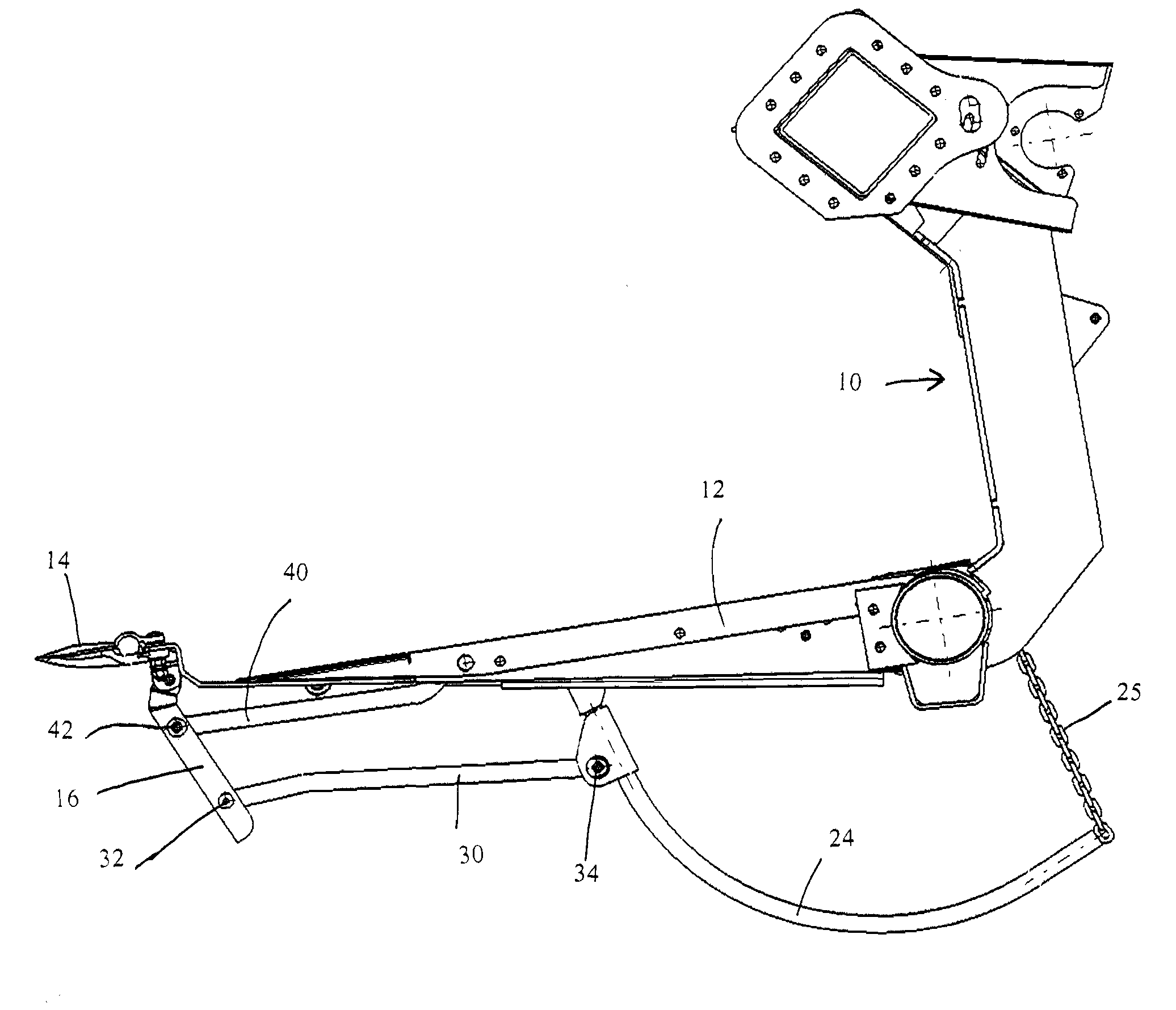

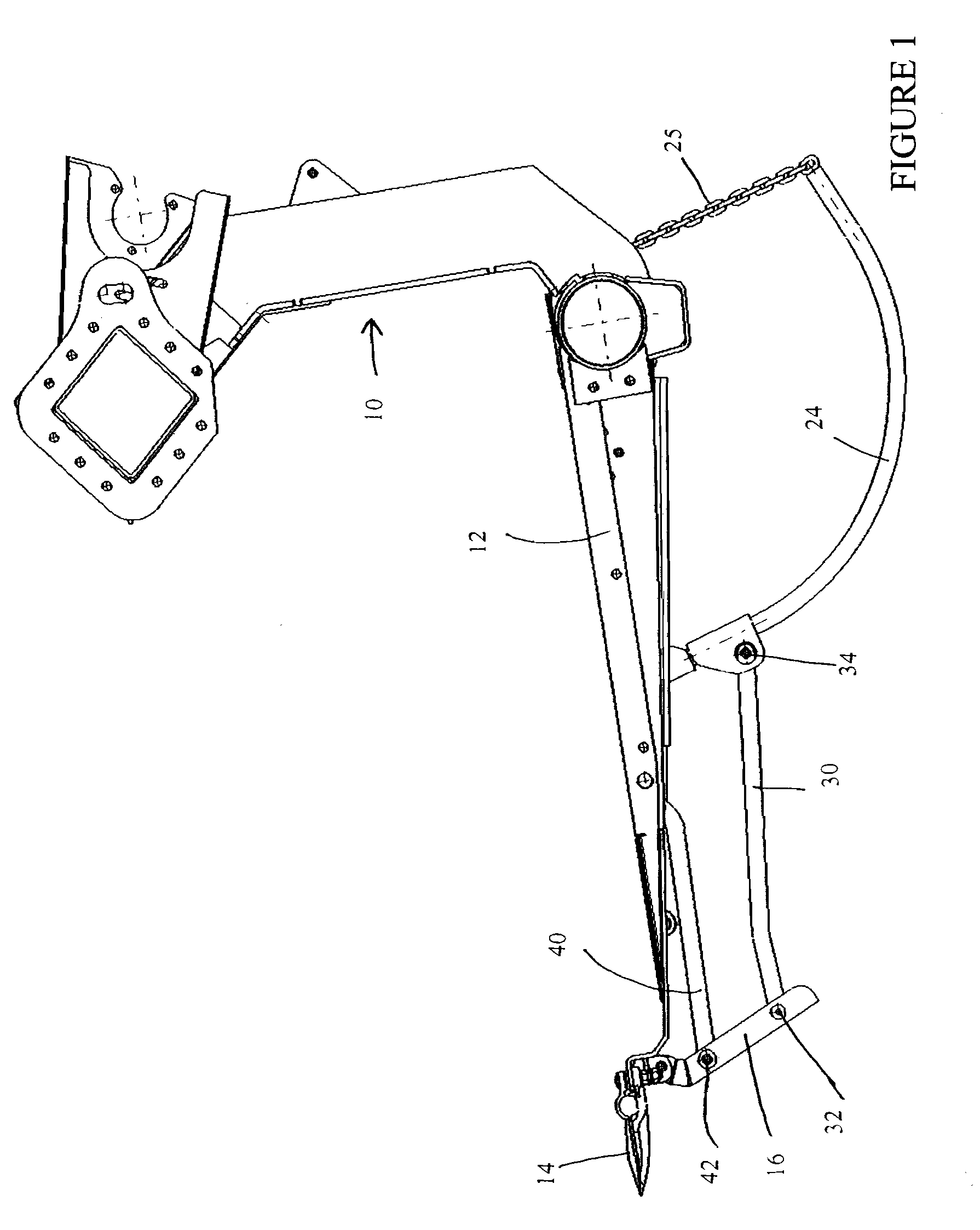

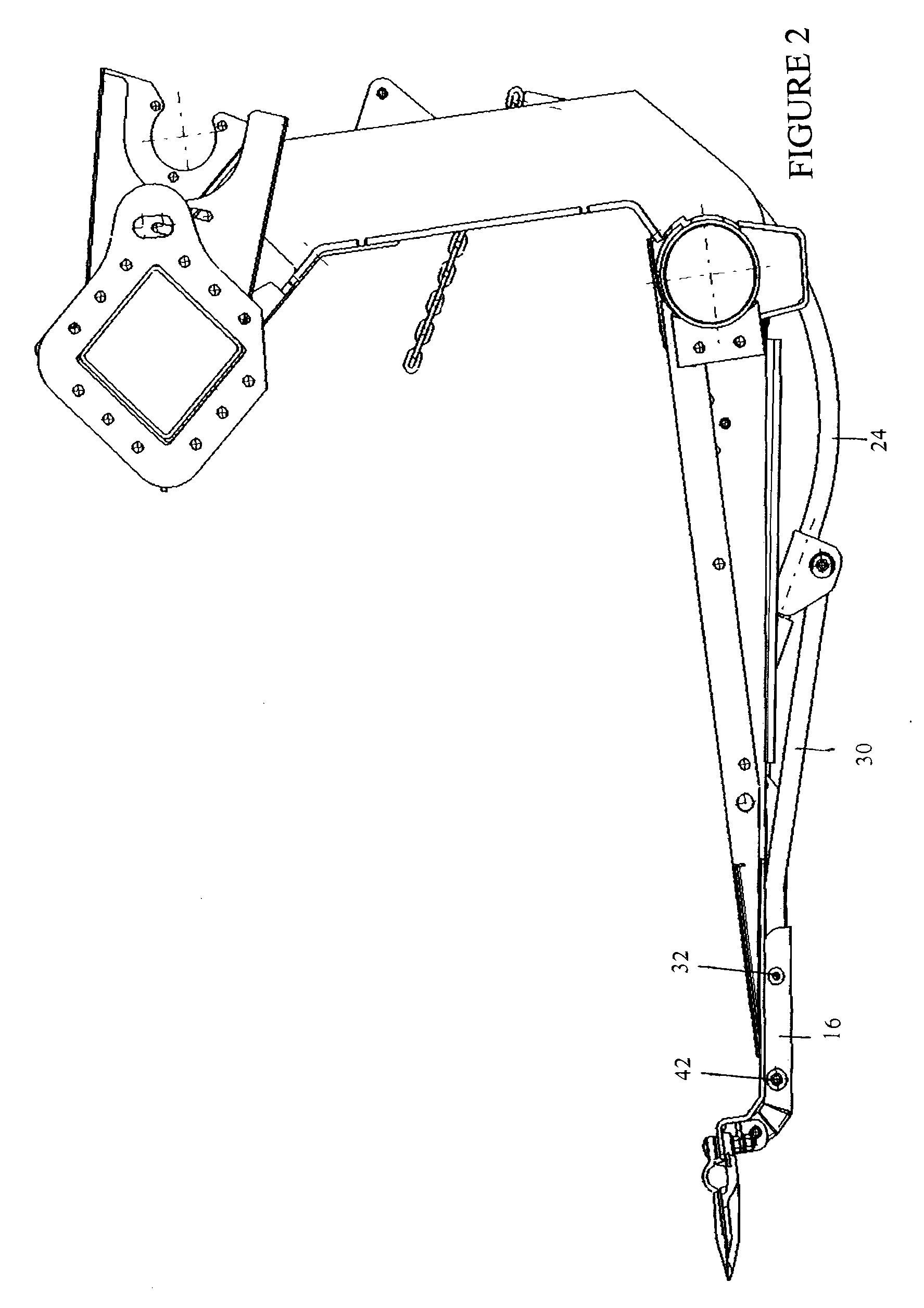

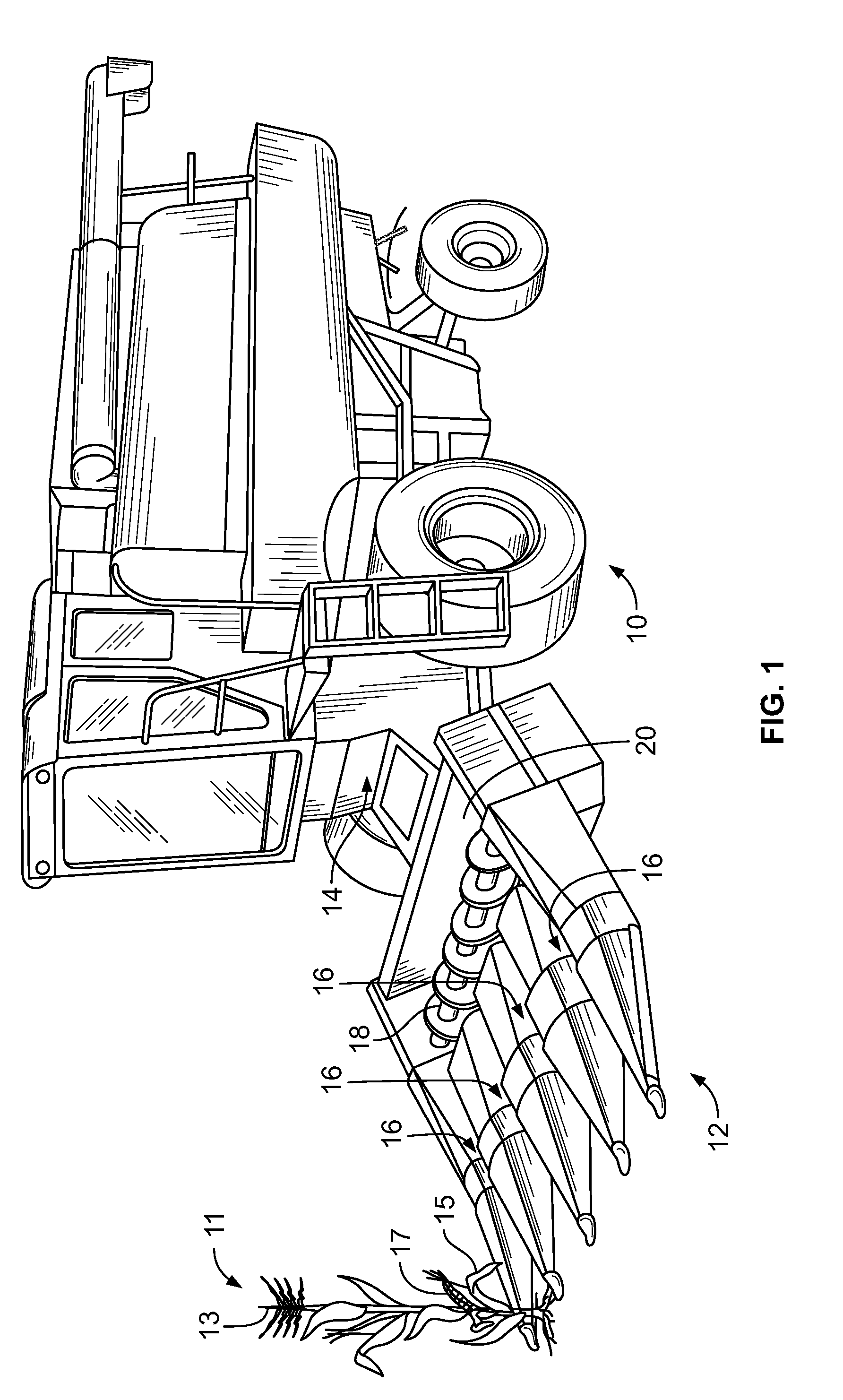

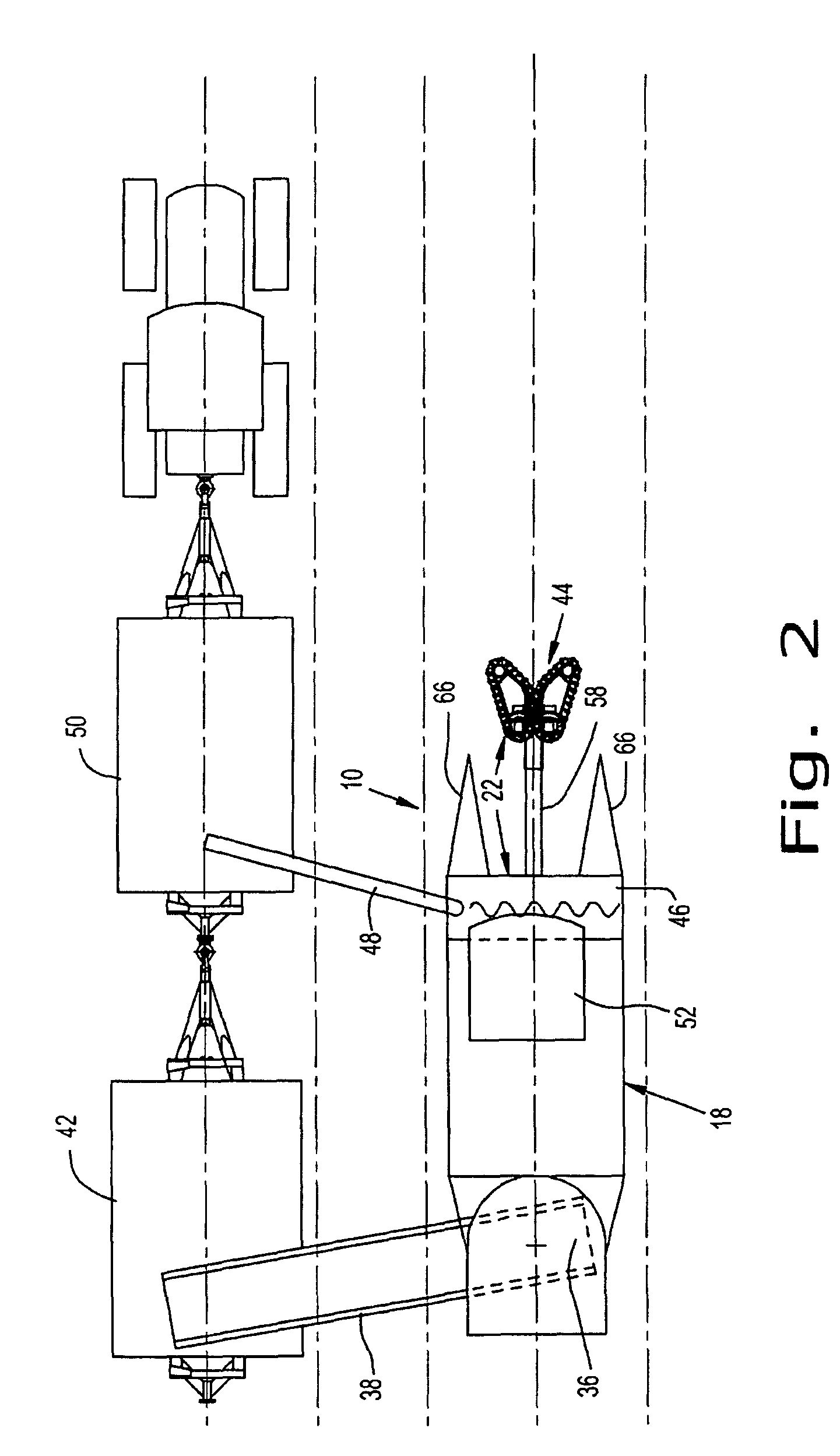

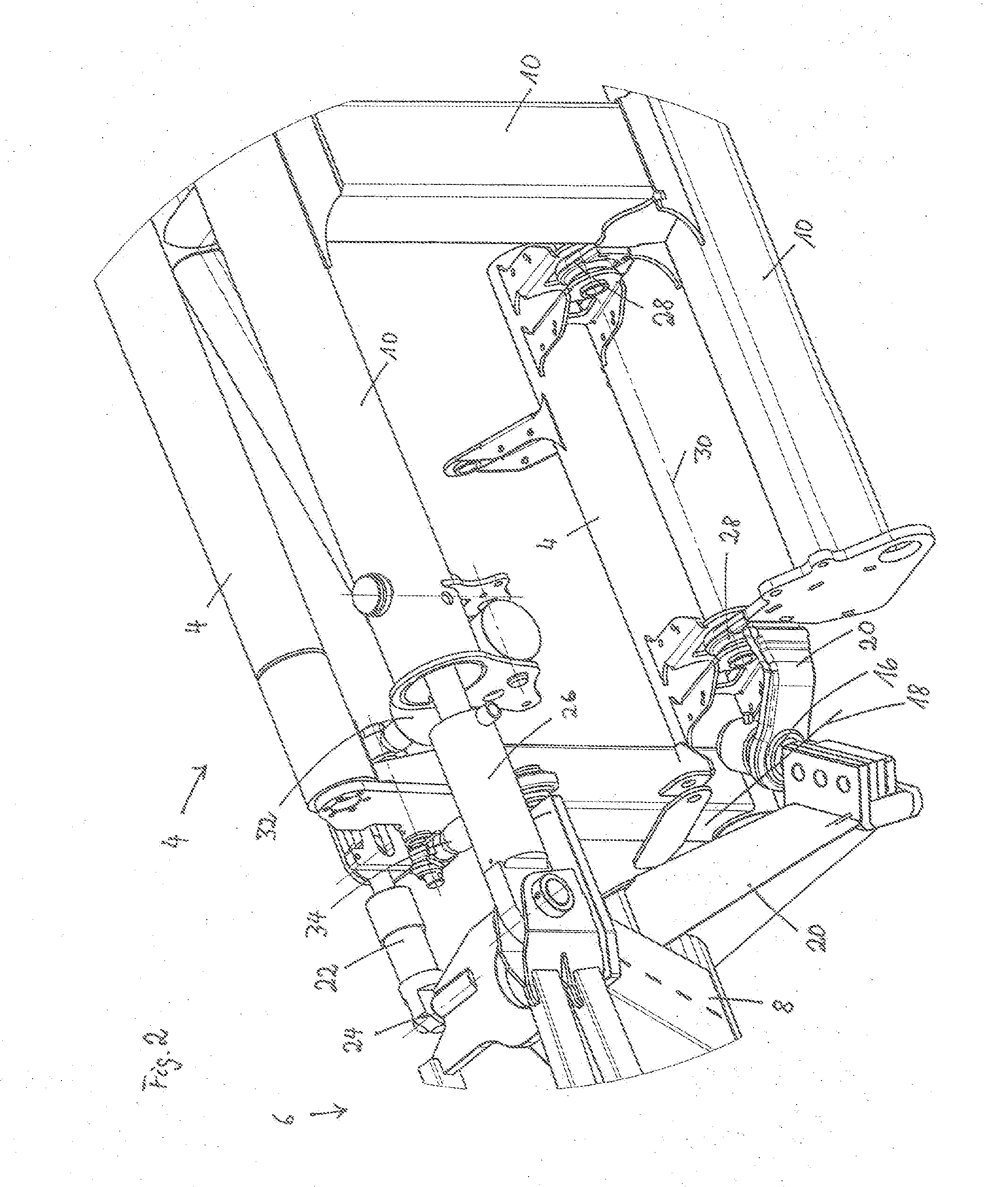

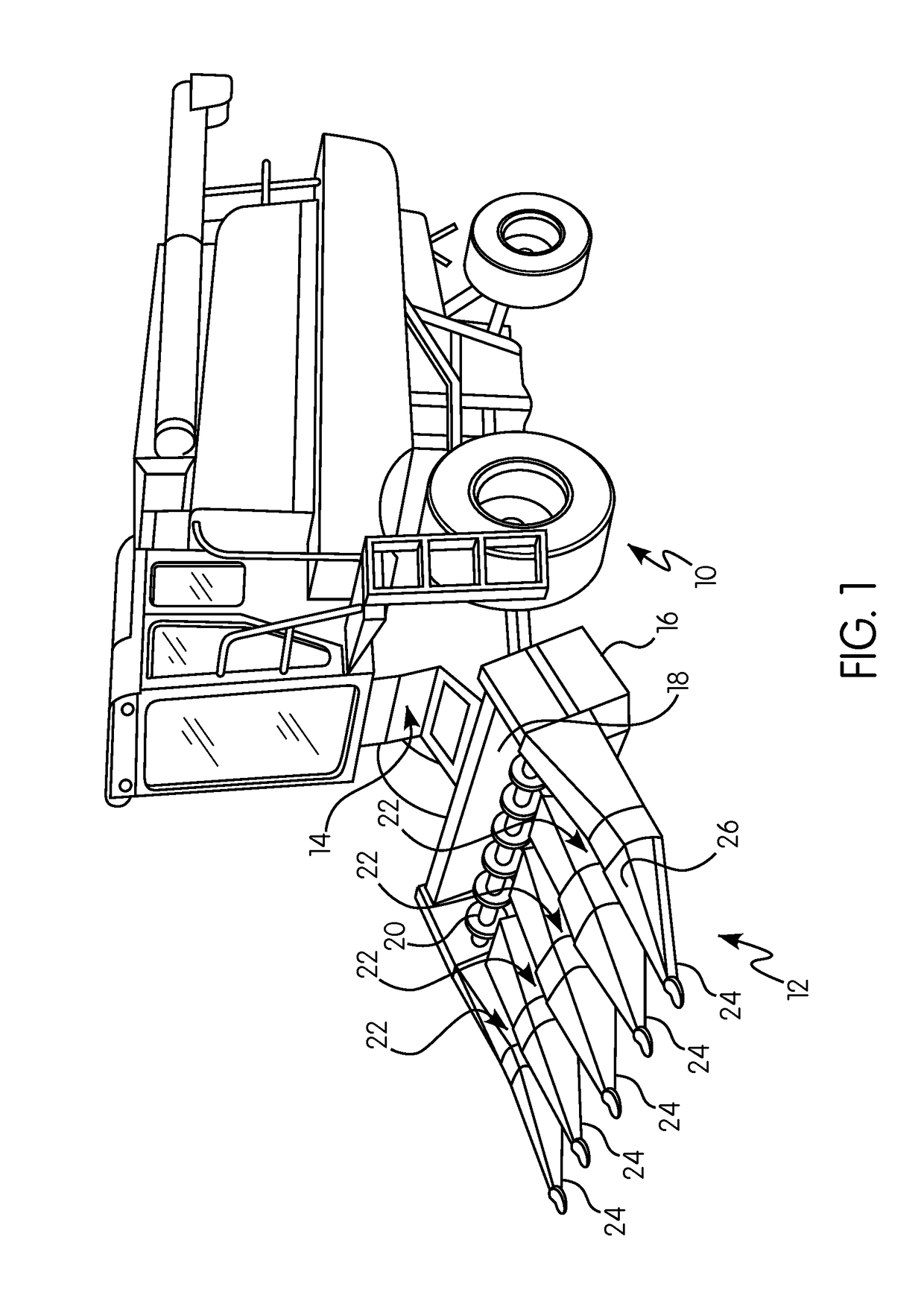

Harvesting device

The method is for harvesting a crop. A harvesting device (10) is provided that has an upper harvesting device (16) and a lower harvesting device (16). The upper harvesting device is in front of the lower harvesting device. The upper harvesting device detaches crop sections (24) of stalk sections (26) of crops (18). An intermediate engagement member (42) bends the stalk sections forwardly and the lower harvesting device cuts root sections (28) of the crops.

Owner:MALMROS DAN +3

Material transfer system

A material transfer system including a first vehicle, a second vehicle and at least one towed container. The first vehicle has a material discharge device. The second vehicle can move in a forward direction and a reverse direction. The at least one towed container includes a first towed container. The first towed container is coupled to the second vehicle such that the first towed container follows the second vehicle when the second vehicle moves in the forward direction. A control system is coupled to either the second vehicle or the at least one towed container. The control system coordinates the movement of the second vehicle and the towed container relative to the material discharge device as the first vehicle is moving and the second vehicle is moving in the reverse direction

Owner:DEERE & CO

Seed gathering device for use by an agricultural harvester

A work machine for harvesting a cane crop having a lower crop material gathering device. The work machine has a direction of travel and the work machine has a chassis and an upper crop material gathering device coupled to the chassis. The upper crop material gathering device includes at least one moving device and a stalk cutting device. The at least one moving device is configured to substantially surround a stalk of a cane crop plant as the at least one moving device moves. The at least one moving device is further configured to bend the head of the cane crop plant in a direction substantially opposite to the direction of travel. The stalk cutting device is positioned proximate to the at least one moving device. The stalk engaging device being configured to cut the peduncle of the cane crop plant.

Owner:DEERE & CO

Operating and storage positions of a swather conveyor

A self-propelled swather has a frame mounted on ground wheels with a header in front which discharges between the wheels. A swath conveyor belt is located underneath the frame and arranged to convey the cut crop across the frame to a first discharge side of the frame. A mounting assembly including a beam across the belt and a lift arm mounts the swath conveyor for movement between a raised storage position in which the belt is horizontal underneath the frame and a lowered operating position in which the belt is inclined forwardly and downwardly while at the same time causing the beam to twist to cause the inlet end of the belt to move forwardly further than the discharge end to a forwardly inclined position between the front wheels.

Owner:MACDON INDS

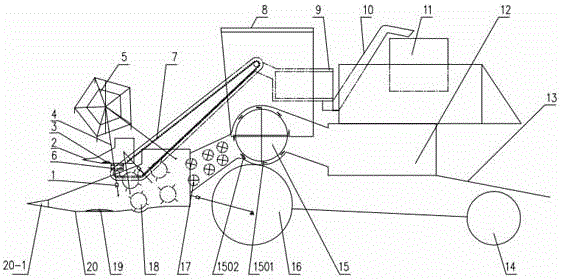

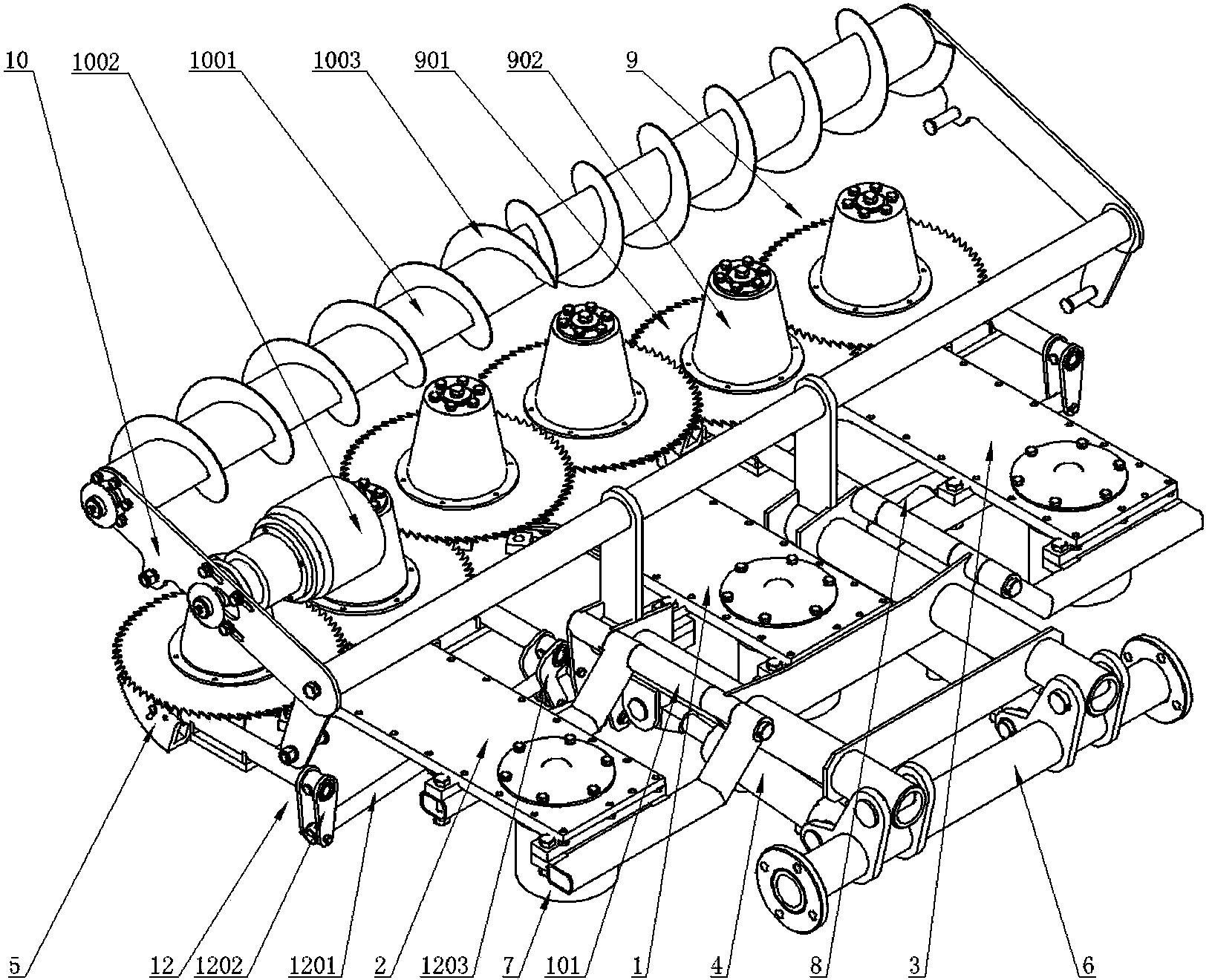

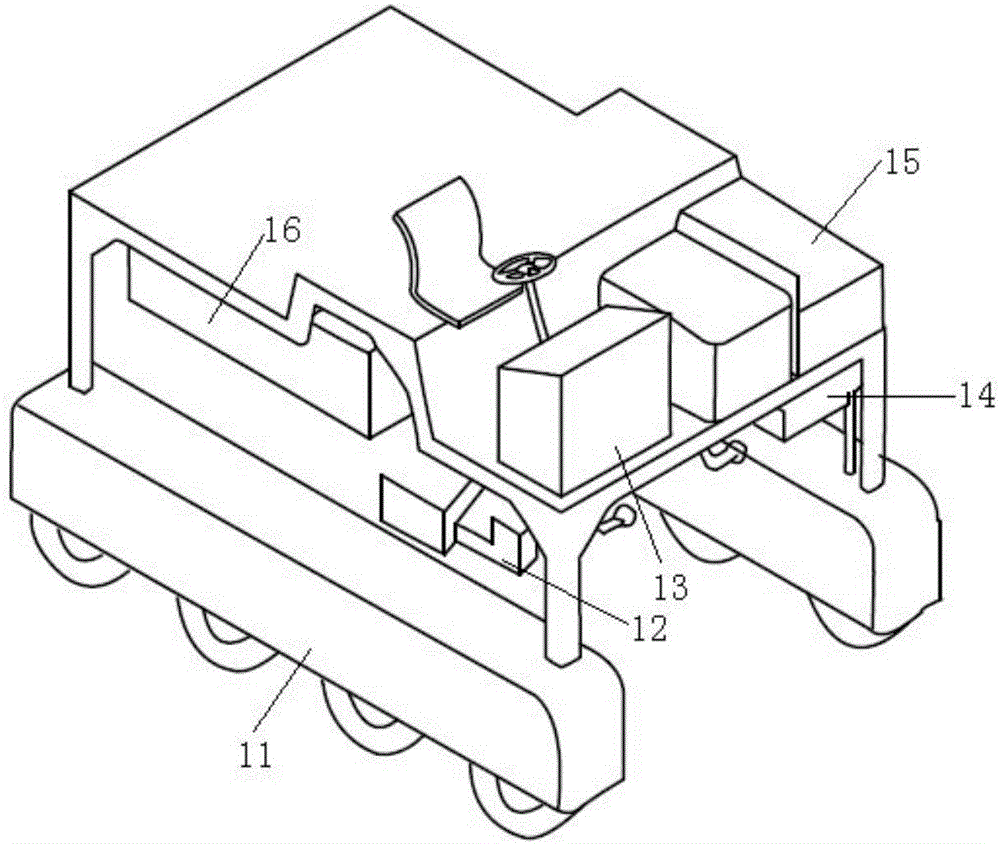

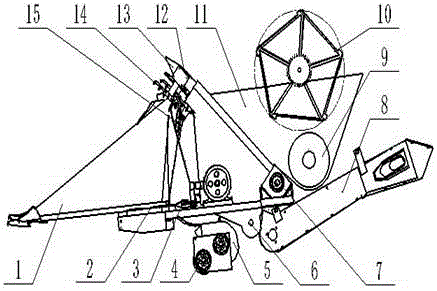

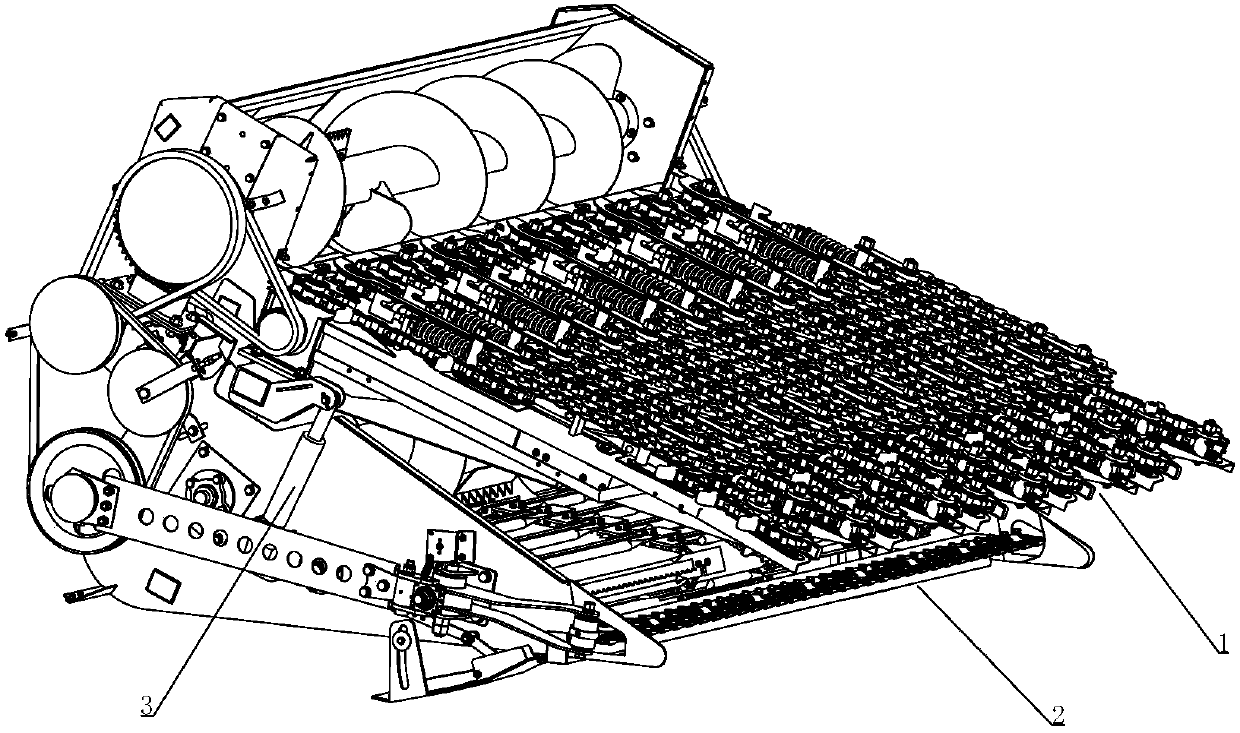

Millet combined harvester and system thereof

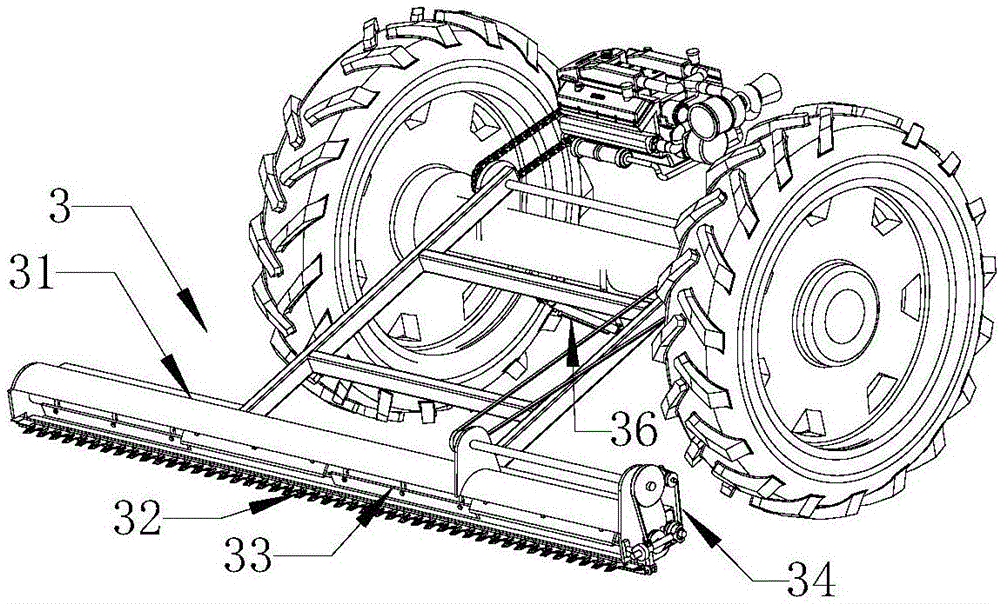

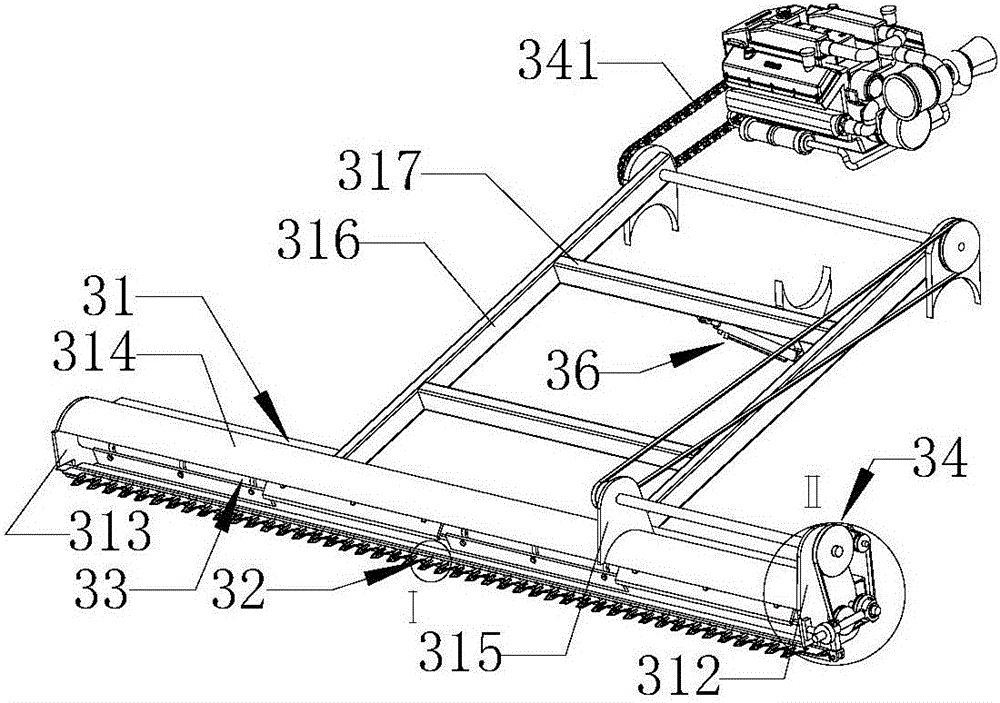

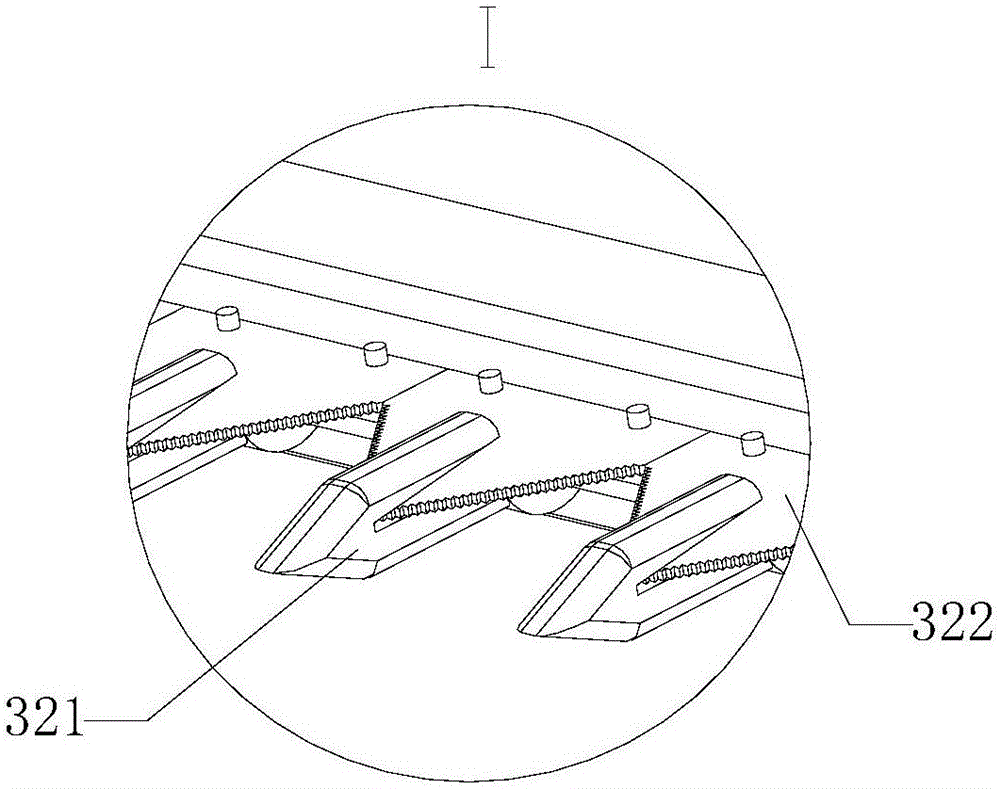

The invention discloses a millet combined harvester and a system thereof, and belongs to the technical field of crop combined harvest. The millet combined harvester comprises a header for combined harvest, a threshing separation part and a millet cleaning part. The header comprises a header frame, a reciprocating cutter, a left divider, a right divider, a header screw auger, a reel and a transmission mechanism, and the transmission mechanism is in transmission connection with the reciprocating cutter, the header screw auger and the reel. The threshing separation part comprises a threshing box, a front threshing cylinder, a rear threshing cylinder, a front separating screen, a rear separating screen, a transition separating screen, a front threshing top cover, a rear threshing top cover, and a power mechanism providing power for the front threshing cylinder and the rear threshing cylinder. The millet cleaning part comprises a cleaning frame, a front blower fan, a reciprocating vibration screen, and a vibration mechanism driving the reciprocating vibration screen to vibrate. The millet harvesting system comprises the millet combined harvester mentioned above and a controller. According to the invention, a header ear dropping phenomenon can be effectively controlled, rubbing and beating are integrally carried out, and the loss late, the broken rate and the impurity rate are low.

Owner:XINGGUANG AGRI MACHINERY

Corn Stalk Harvester

An apparatus for the harvesting and collecting of plant materials from the tops of the plants, such as a corn plant, or other types of crops, above the ear(s), either before, during or after pollination, sweet corn harvesting time or at the black layer, while the stalk is still alive, and has most of its moisture, or at any advantageous time in the growing cycle and collect such plant materials for livestock feed, fuels, sugars or other nutrients, and or for any other useful purpose.

Owner:DOERSCHER SR ARTHUR CHARLES

Header for a Harvesting Machine

A header for a harvesting machine. The header includes at least two row dividers spaced from one another in a transversal direction and at a predetermined distance, at least one roller, a driving for driving the roller comprising multiple projections, at least two base cutting discs, a driver for driving the at least two base cutting discs, one roller positioned behind the at least two base cutting discs to raise the cut plants, and at least one conveyor roller positioned above the said roller to raise plants, to transport the cut plants to the inside of a harvesting machine. The at least one roller includes multiple projections to collect and direct the plants downwards and towards the opening. The foregoing elements form an assembly mounted on a structure that may be connected to a harvesting machine

Owner:BLUE LEAF I P INC

Topper and shredder

An agricultural implement attached to a farm tractor by a three point hitch is used to cut the top of mature cotton stalks, or shred harvested crops or mow turn rows. Knives are mounted on the bottom of vertical shafts which are rotated by belt driven pulleys. The pulleys are driven from a right angle gear box which is driven from the power take off of the tractor. The knives are staggered along either side of a beam traverse to the direction of travel, so that the knives cannot strike other knives as they mow over-lapping swaths.

Owner:HEARD MARTIN PERRY

Harvester with protective ladder and lifting lower header capable of evenly chopping straws and preventing smashed straws from splashing

The invention discloses a harvester with a protective ladder and a lifting lower header capable of evenly chopping straws and preventing smashed straws from splashing. The harvester consists of a lower header and a protective ladder, wherein the lower header is hinged on the front bridge of the harvester and consists of a lower header main frame, a lower harvesting mechanism, a straw smashing mechanism, a transmission mechanism and a lower header lifting mechanism; a first right-angled side for stopping an angle iron is welded on the lower edge behind a blocking cover; and the lower header lifting mechanism consists of a lower header lifting oil cylinder, a lower header lifting oil cylinder upper seat and a lower header lifting oil cylinder lower seat. According to the harvester with the protective ladder and the lifting lower header capable of evenly chopping straws and preventing smashed straws from splashing, the remaining straw parts can be harvested and smashed after grains are harvested, and the feed-in quantity of the harvester can be lightened; cutting stubbles are low and flat, thus facilitating tillage; the cutting and smashing efficiency of straws are high, the straws are evenly smashed, and the smashed straws cannot splash; the lower header can be lifted up and down, thus controlling the height of the cutting stubbles and being capable of avoiding barriers and protecting the safety of equipment; and the arranged protective ladder not only can be used for safely and conveniently climbing, but also can be used as a safety guard.

Owner:纪小坤

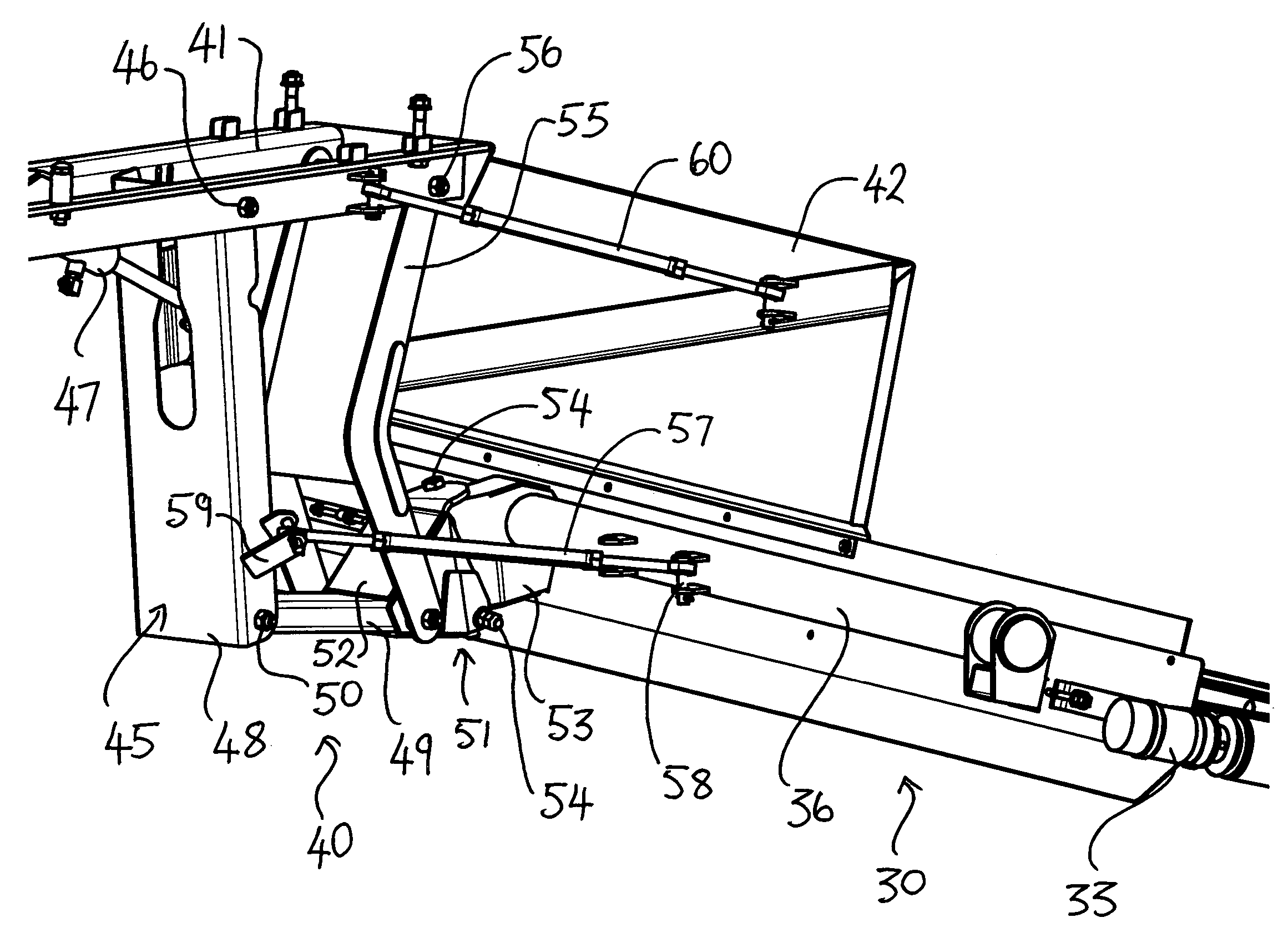

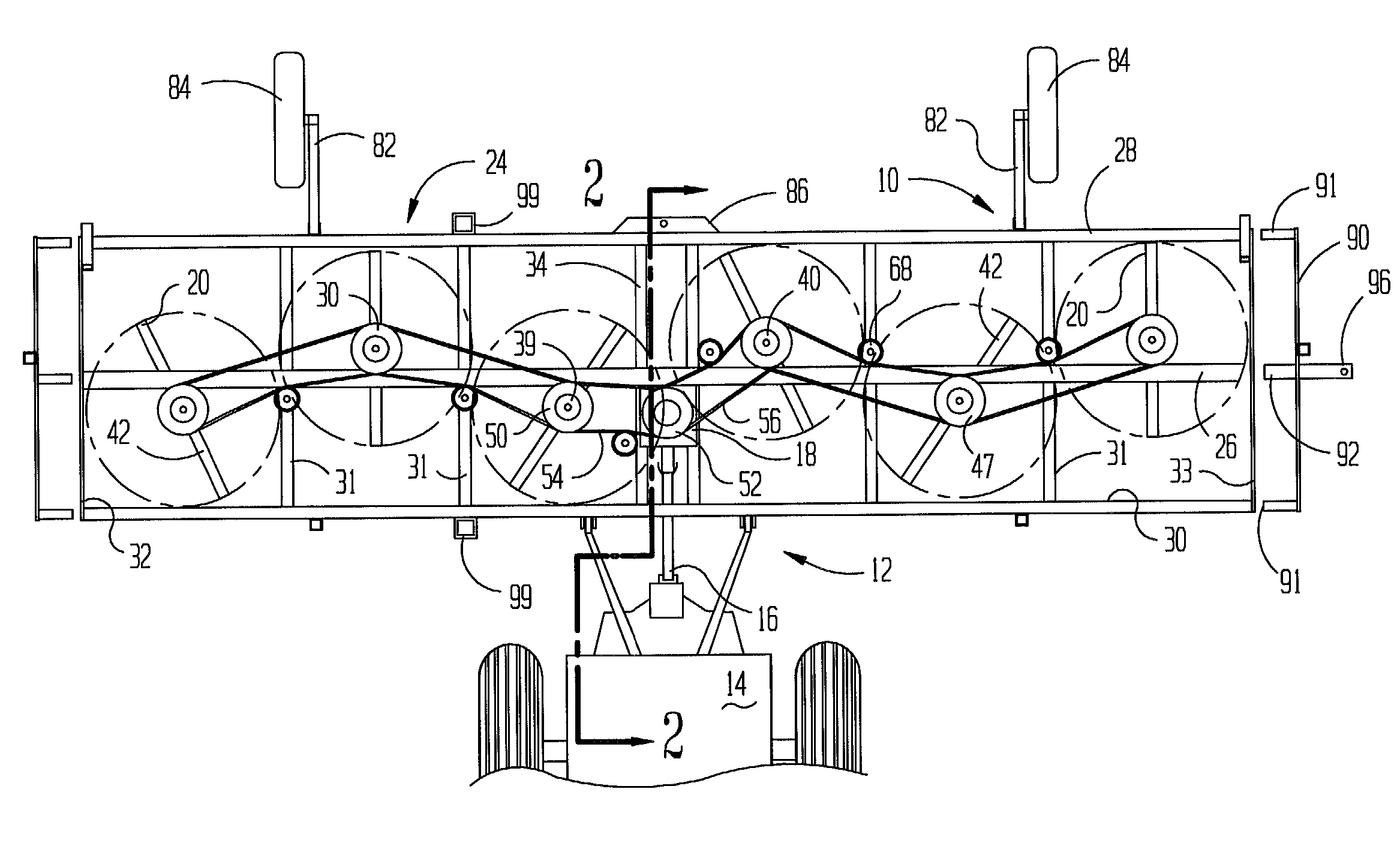

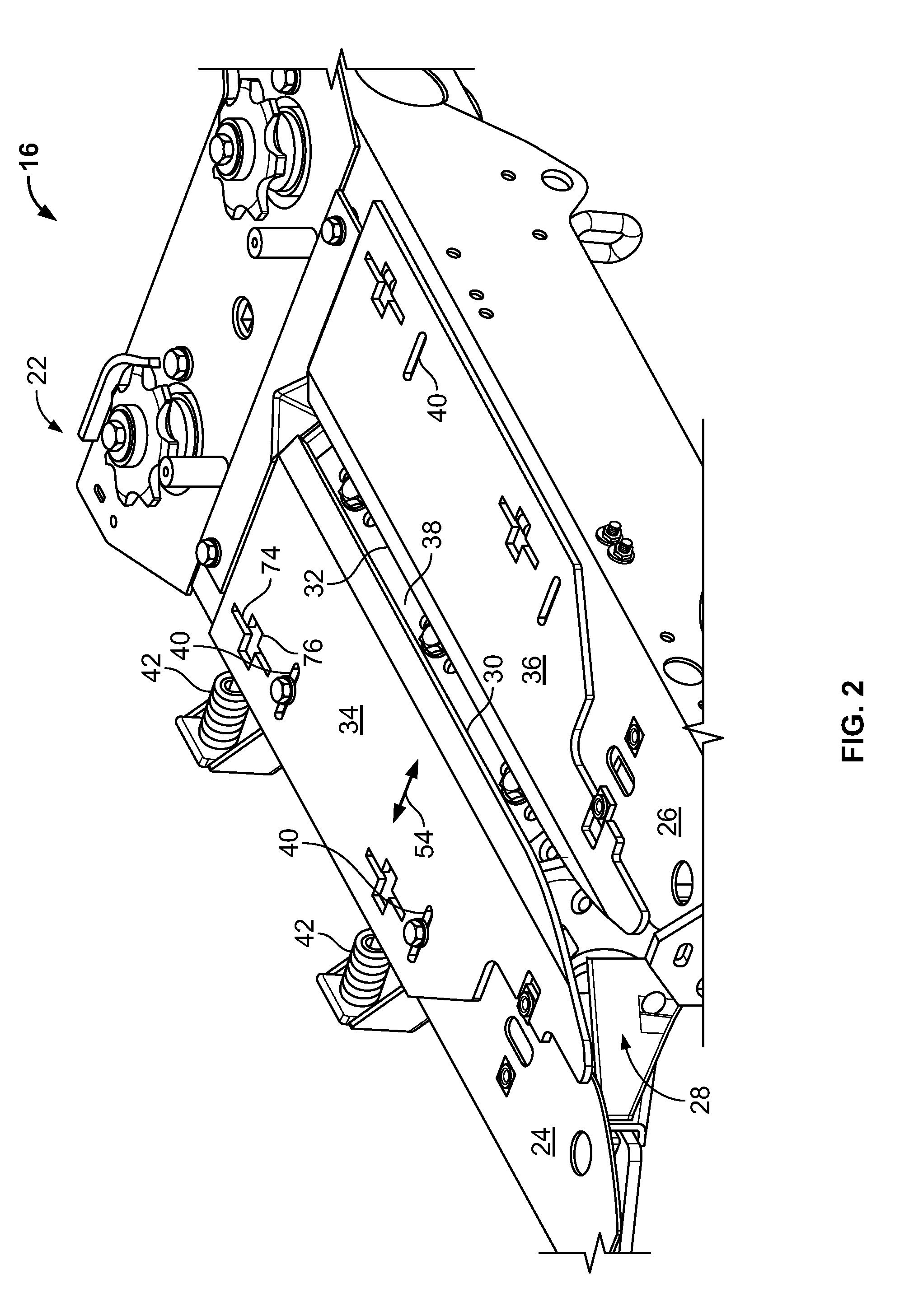

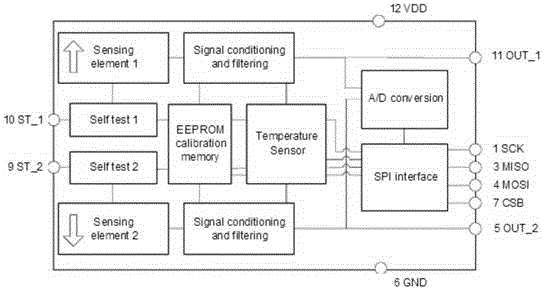

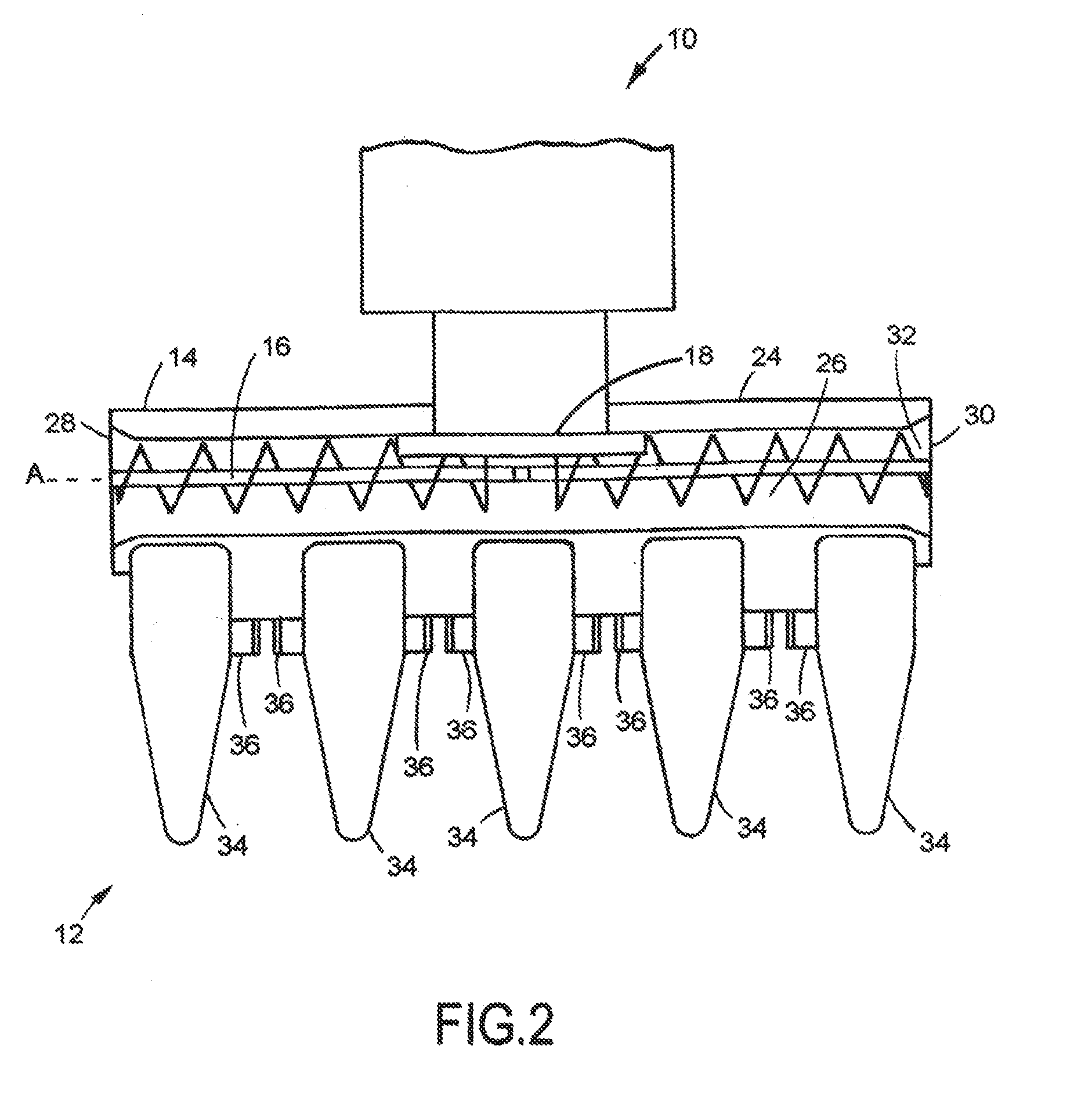

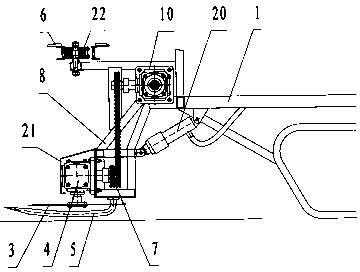

Header ground sensor

InactiveUS20100077712A1Reduce the possibility of damageMowersAgricultural undercarriagesEngineeringProtected area

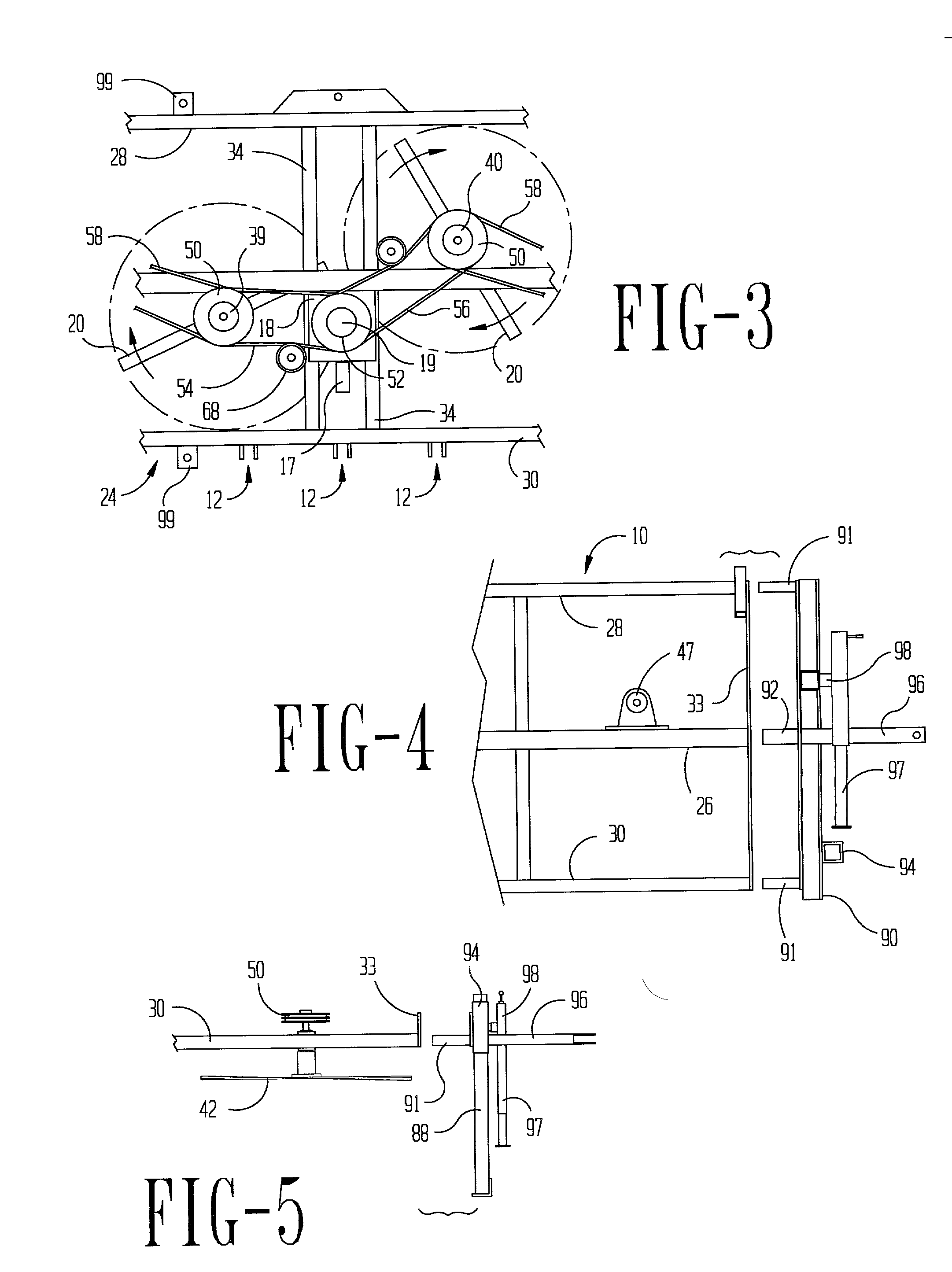

The invention is a combination of a short ground sensor arm mounted close to the cutter bar and a longer rod mounted towards the rear of the header. The short front sensor and long rear sensor are connected by a linkage which translates motions from either sensor to the other sensor. A second linkage translates the motions of both sensors rearward to a protected area under the header which contains the potentiometer. This configuration transmits useful ground position signals to the header height controller in both low and high cutting heights. The invention advantageously reduces the likelihood of damage to the short front sensor when the machine is reversed since the longer rear sensor arm pulls the shorter forward sensor arm up by means of the linkage to a position where damage is unlikely.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

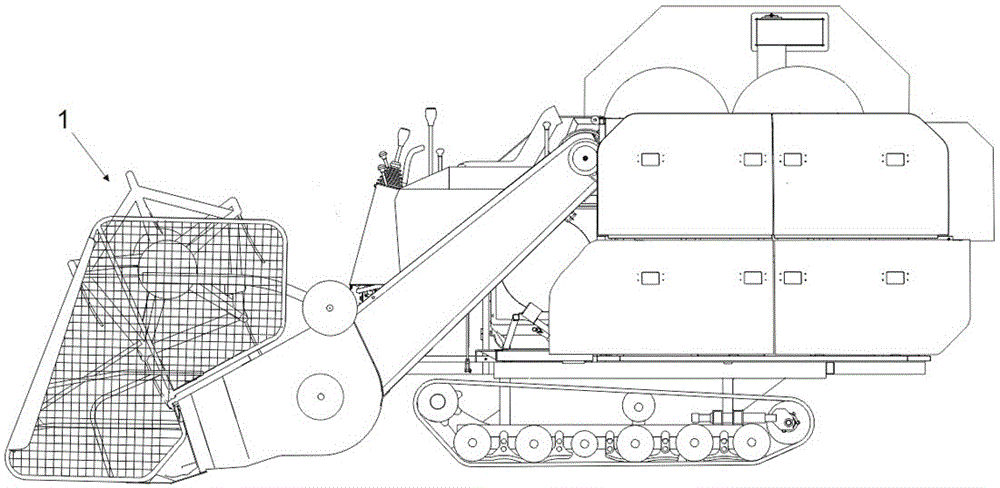

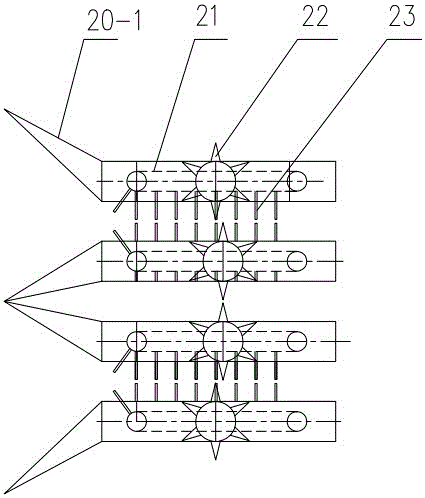

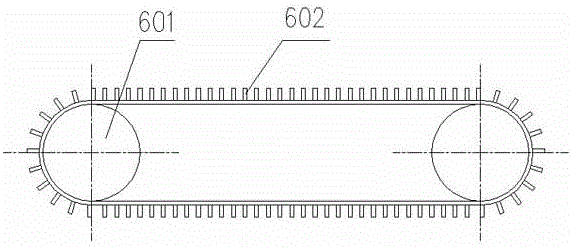

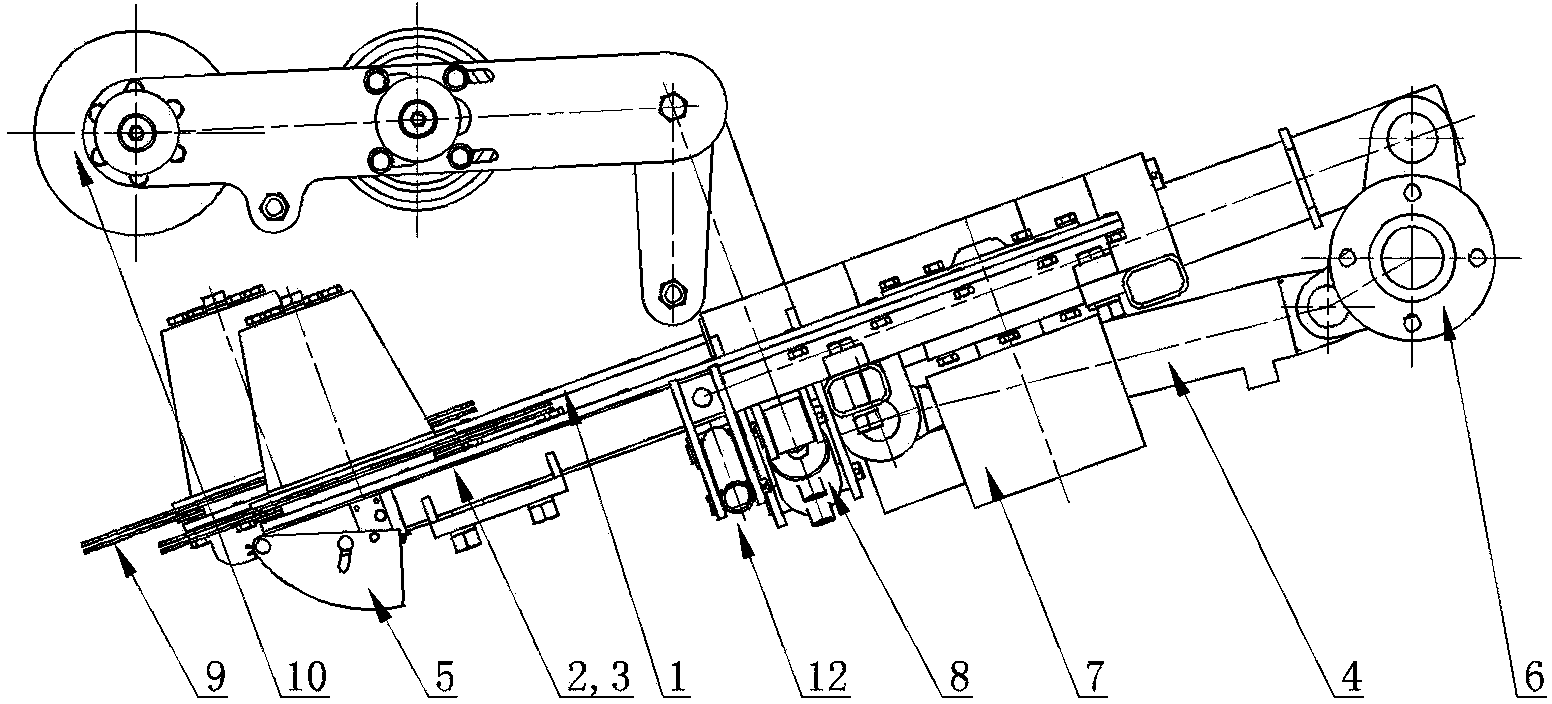

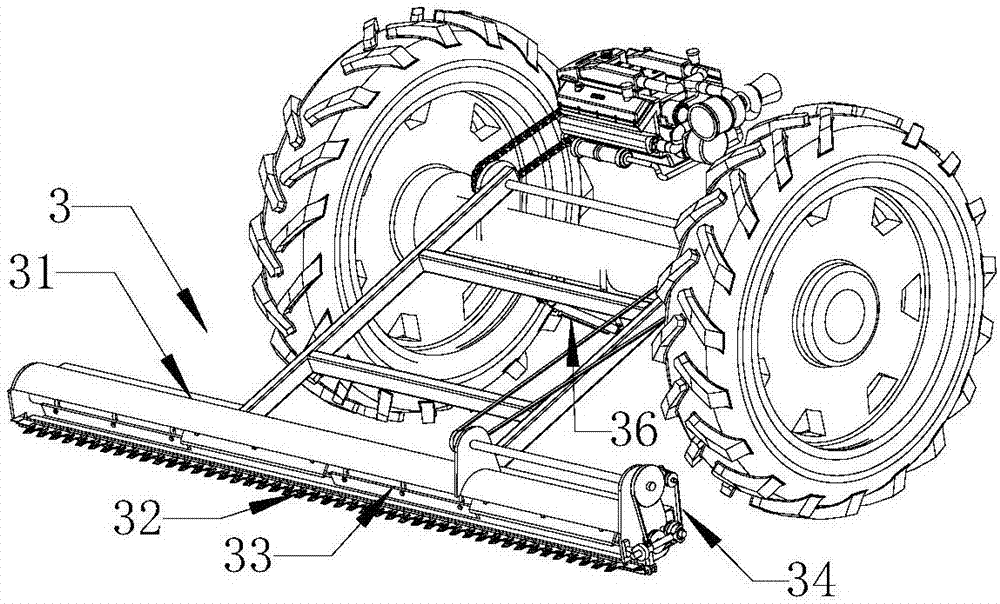

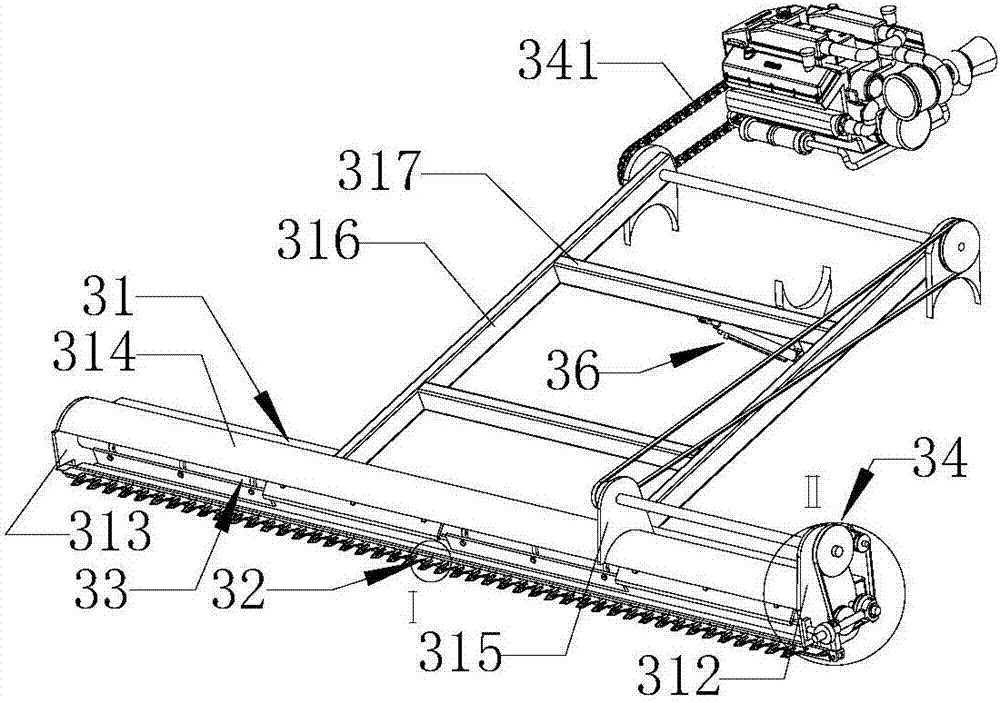

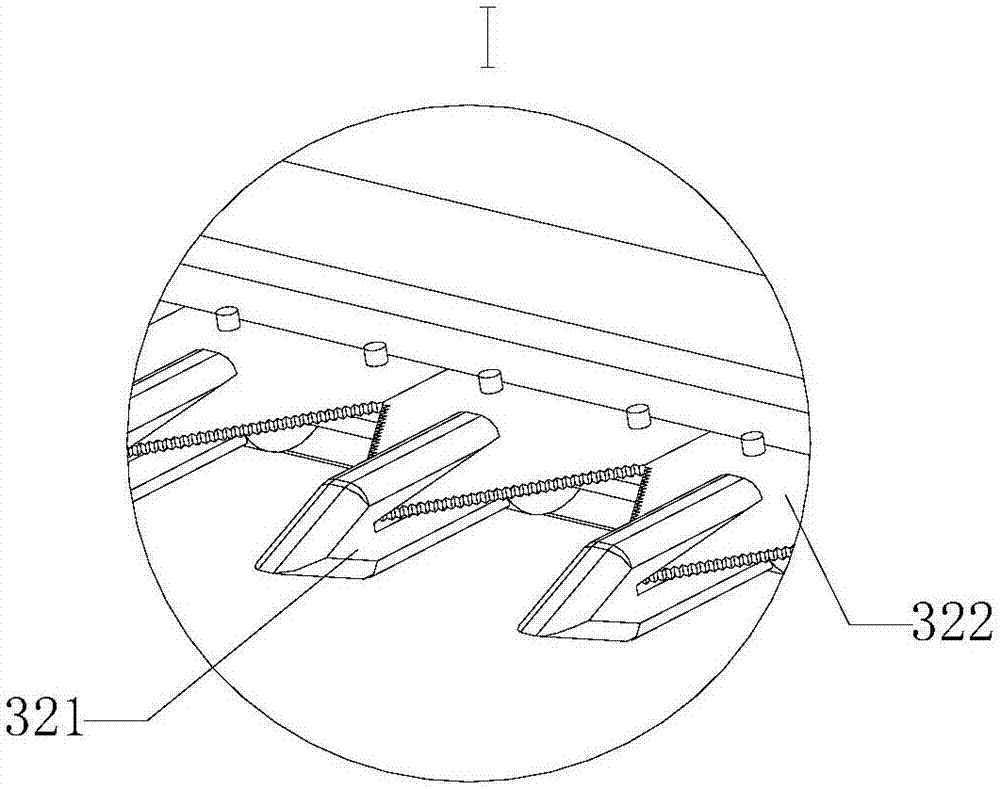

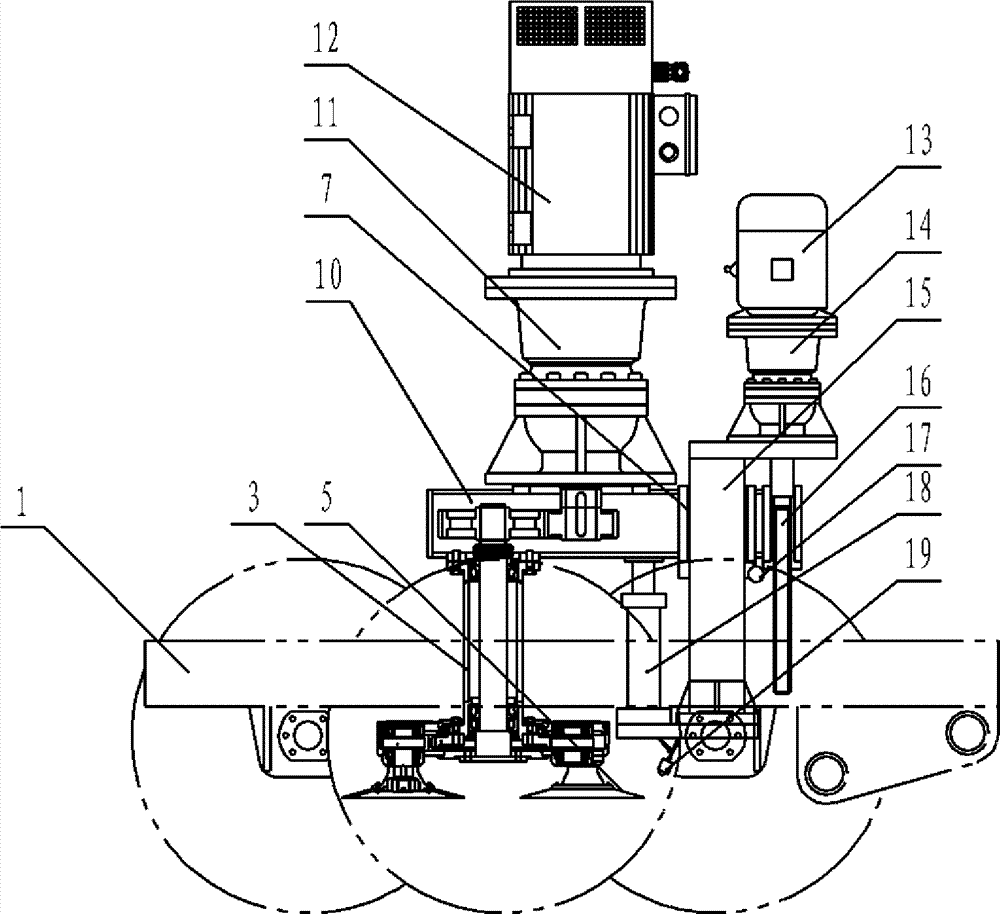

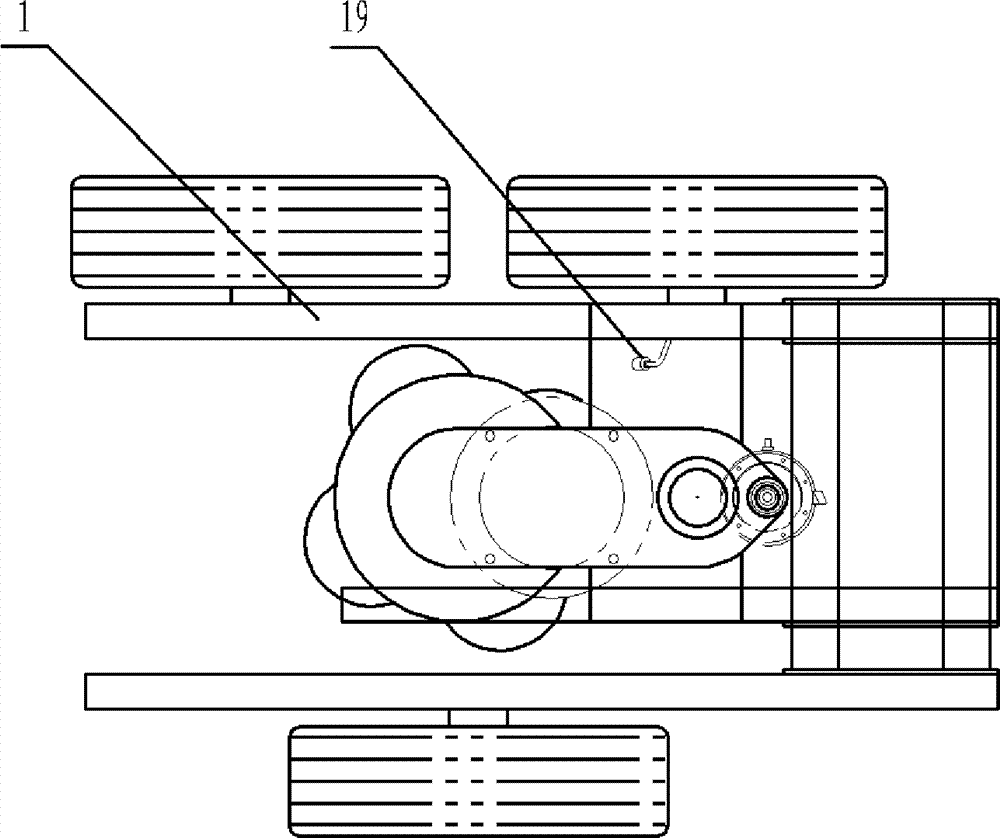

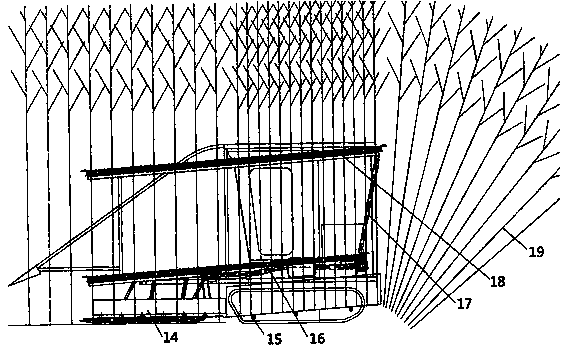

Shunting harvester of highland barley stalks and ears

ActiveCN106034554AIncrease profitSolve the problem of feeding valueMowersReaper-bindersEngineeringMechanical engineering

The invention discloses a shunting harvester of highland barley stalks and ears. The harvester comprises a rack and a walking mechanism, wherein a power system, an upper-layer cutting table, a lower-layer cutting table, a driving cab and a threshing device are disposed on the rack; multiple dividers are disposed on the lower-layer cutting table, and a clamping chain of which rotation is driven by a drive device is disposed on each divider; multiple poking fingers are uniformly disposed on the clamping chain; two seedling poking star wheels which are disposed correspondingly up and down and can conduct synchronous rotation are disposed on each divider; stalks are cut down by a cutting device under clamping and opposite-direction poking of the poking fingers as well as transmission of the clamping chains and are then conveyed to a first conveying roller through clamping and opposite-direction poking of the seedling poking star wheels and the poking fingers; the rear end of the first conveying roller is connected to a second conveying roller; the rear end of the second conveying roller is connected to a smashing device; and the rear end of the smashing device is connected to a bundling room. According to the invention, the harvesting mode comprises shunting harvesting of the stalks and ears and separate treatments of the stalks and ears; and the stalks are treated through one-time cutting, smashing and bundling, so that a utilization rate of the stalks is increased.

Owner:HENAN UNIV OF SCI & TECH

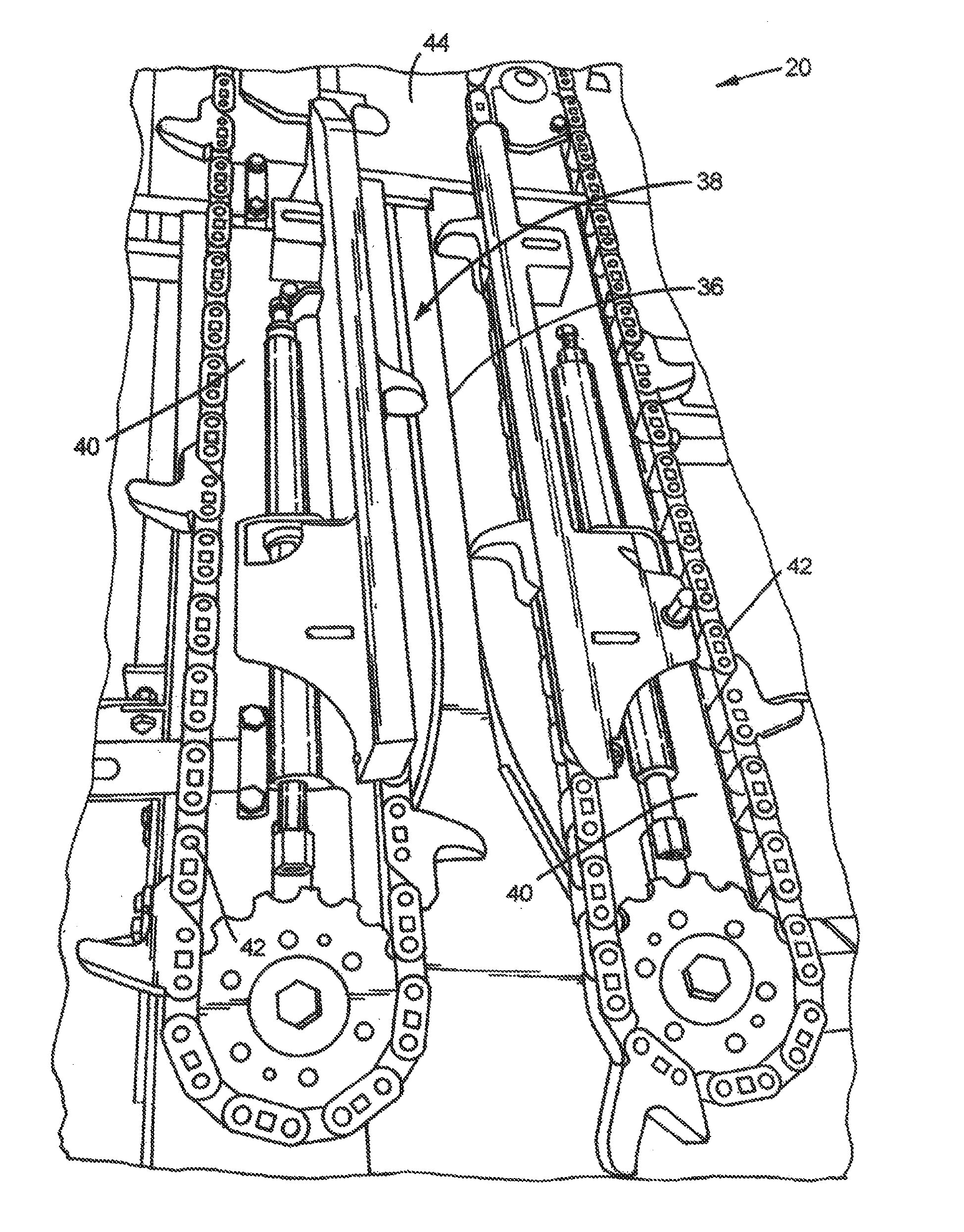

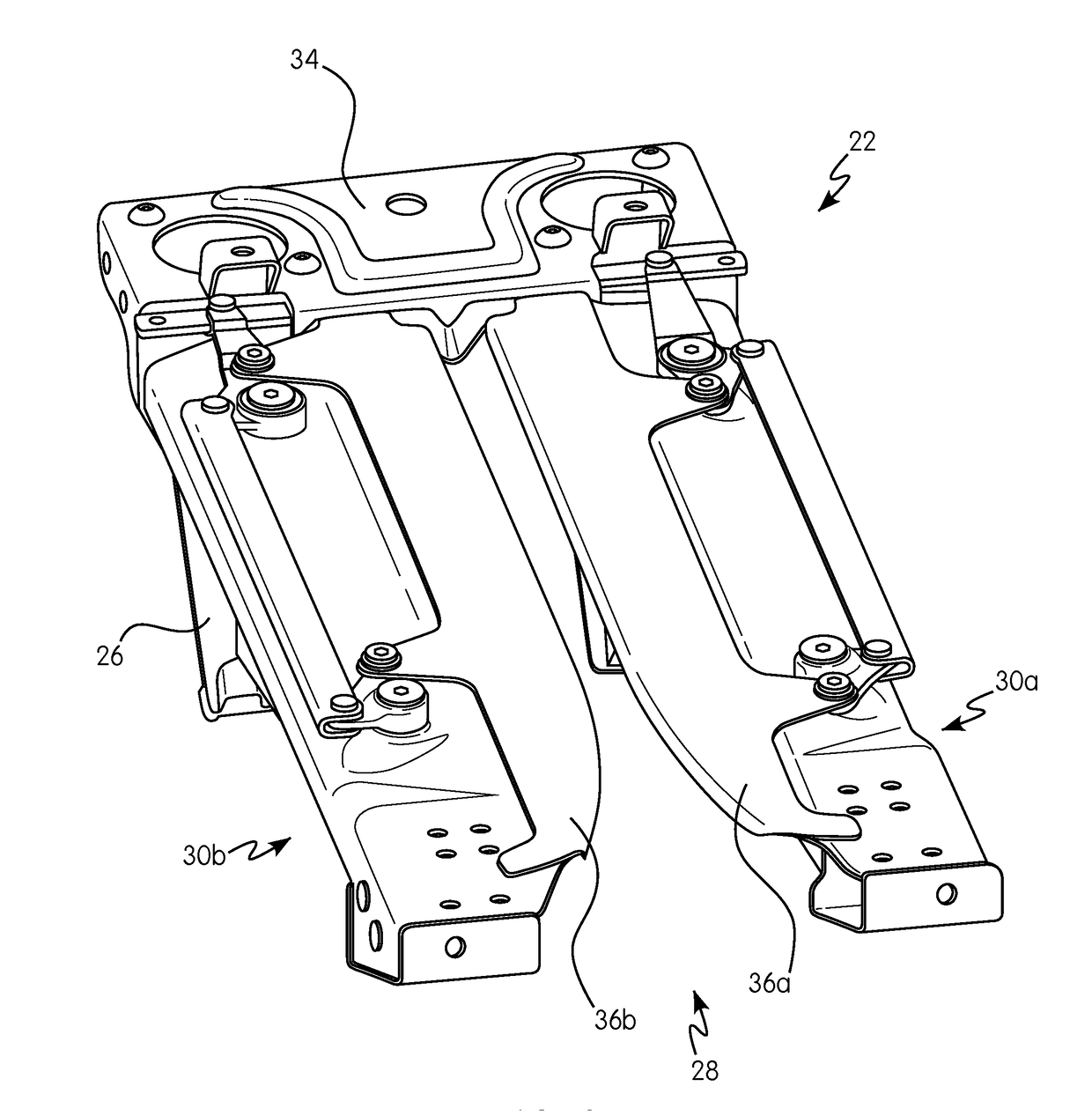

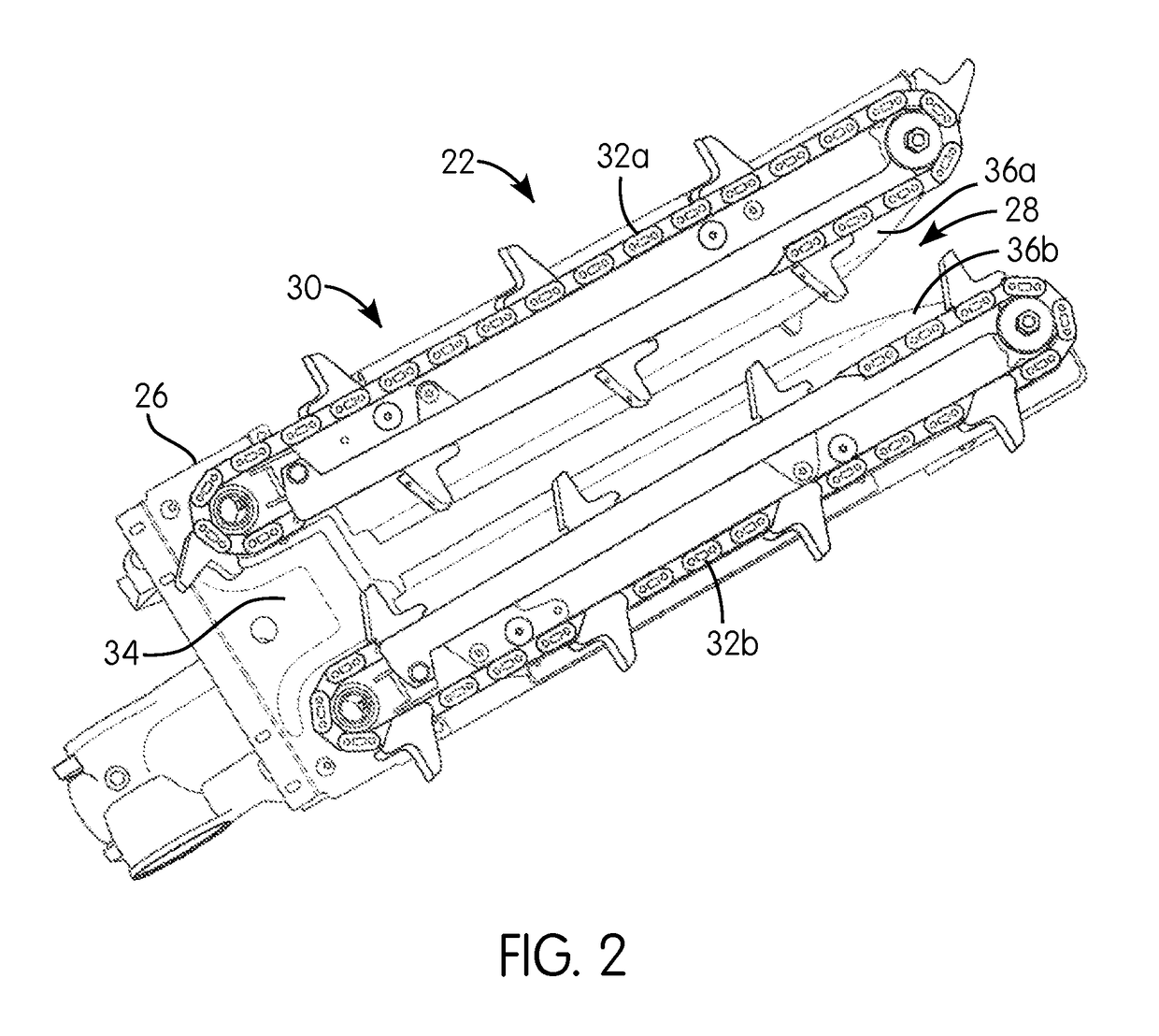

Cornhead row unit

Owner:BLUE LEAF I P INC

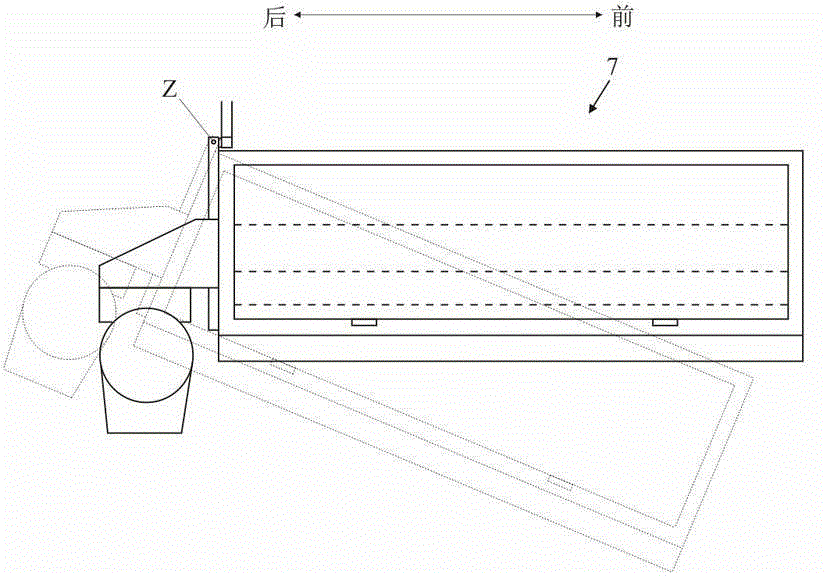

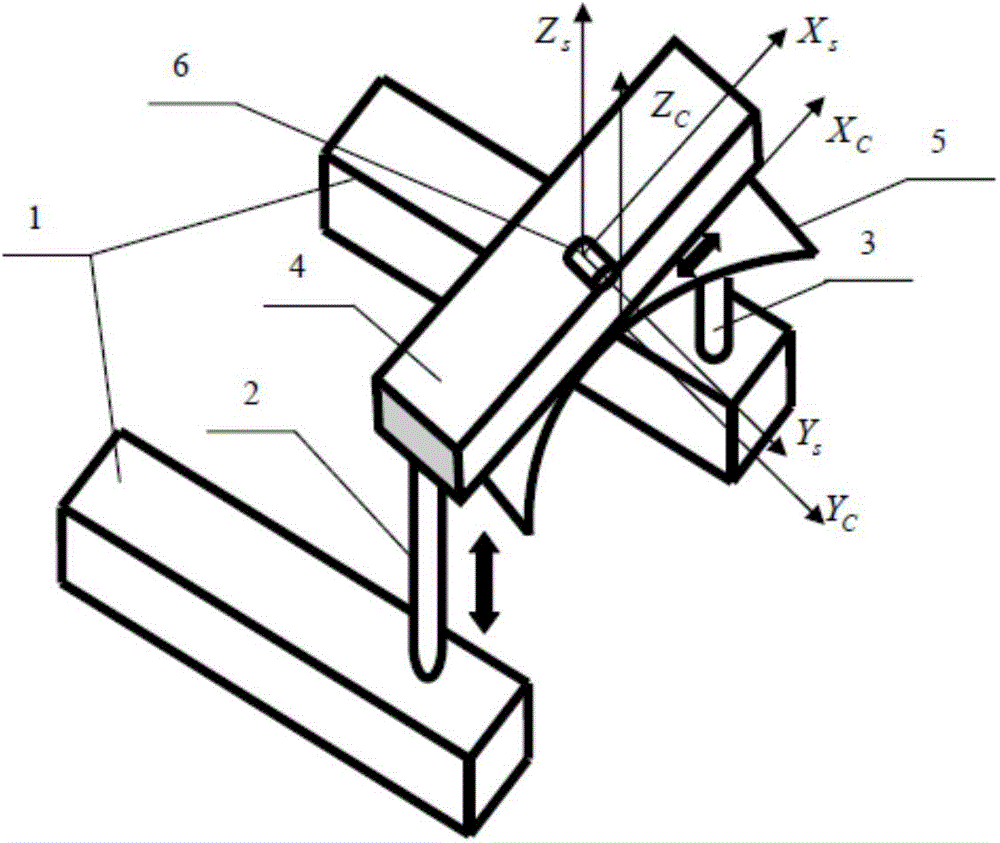

Omnidirectional profiling cutting table

ActiveCN104255175ARealize the pitching actionMeet the agricultural technical requirements for flat stubble harvestingMowersHeadersEarth surfaceDisc cutter

The invention discloses an omnidirectional profiling cutting table. A middle profiling assembly is hinged to a connecting frame, and the pitching action of the middle profiling assembly relative to the connecting frame and the longitudinal profiling action of the middle profiling assembly are controlled by use of a longitudinal profiling oil cylinder; a left profiling assembly and a right profiling assembly are hinged to the middle profiling assembly from the two sides, respectively, and the transverse profiling action of the left profiling assembly and the right profiling assembly controlled by use of a transverse profiling oil cylinder. A disc cutter is arranged on the front end of each profiling assembly; a profiling sensor is arranged under each profiling assembly to receive a surface height variation signal, and according to the surface height variation signals, the profiling oil cylinders are controlled to drive the profiling assemblies to act, and therefore, consistent cutting height, flat cutting and no ripping are guaranteed, and the agricultural technical requirements of stubble rejuvenation are met.

Owner:SHANXI AGRI UNIV

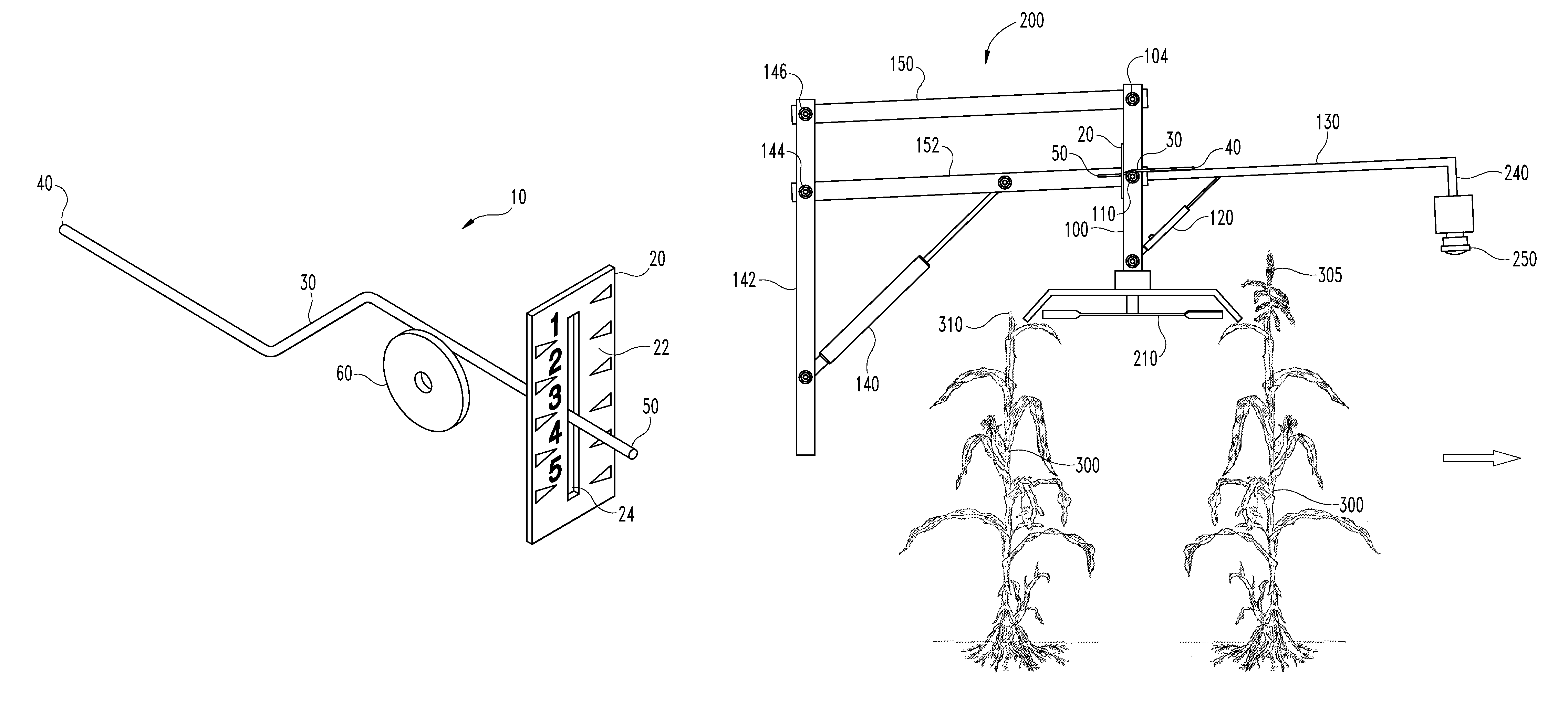

Automatic cutting type tea harvester cutting bench automatic levelling method and device

The invention discloses an automatic cutting type tea harvester cutting bench automatic levelling device used for improving tea new shoot picking integrity and consistency, and for improving tea leaf overall quality and picking efficiency. Through synchronously controlling the displacements of two support rods of a cutting bench, the height of the cutting bench from the ground is kept consistent, wherein the cutting bench is used for fixing a cutting blade. A tilt sensor is used for sensing the tilt state of the cutting bench, and a displacement difference of the two support rods of the cutting bench is adjusted, such that the shape of the cutting blade substantially matches the shape of a tea tree crown. Therefore, the automatic cutting type tea harvester can be well popularized in tea plantations at hilly areas. The invention also discloses an automatic cutting type tea harvester cutting bench automatic levelling method.

Owner:ZHEJIANG UNIV OF TECH

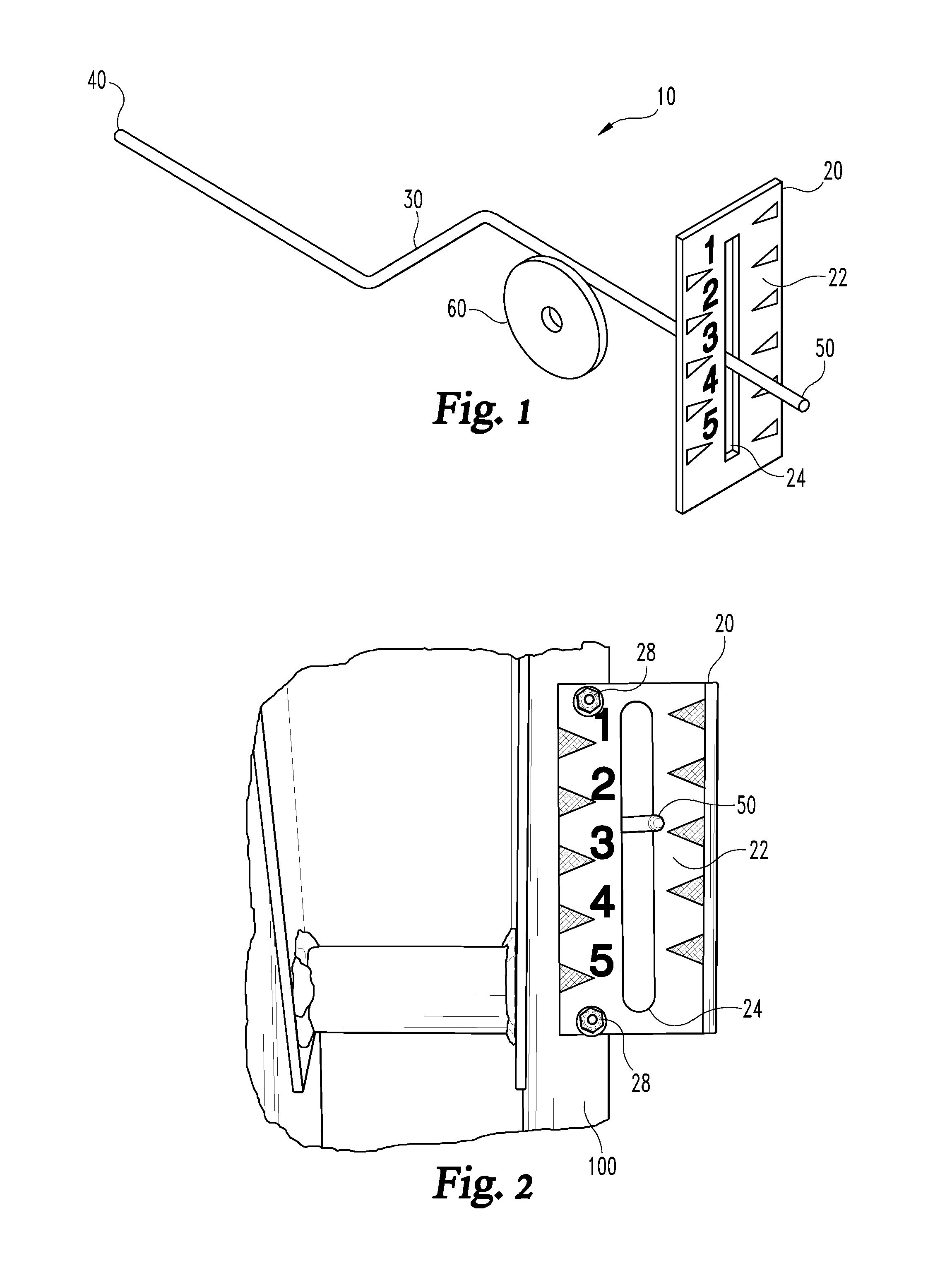

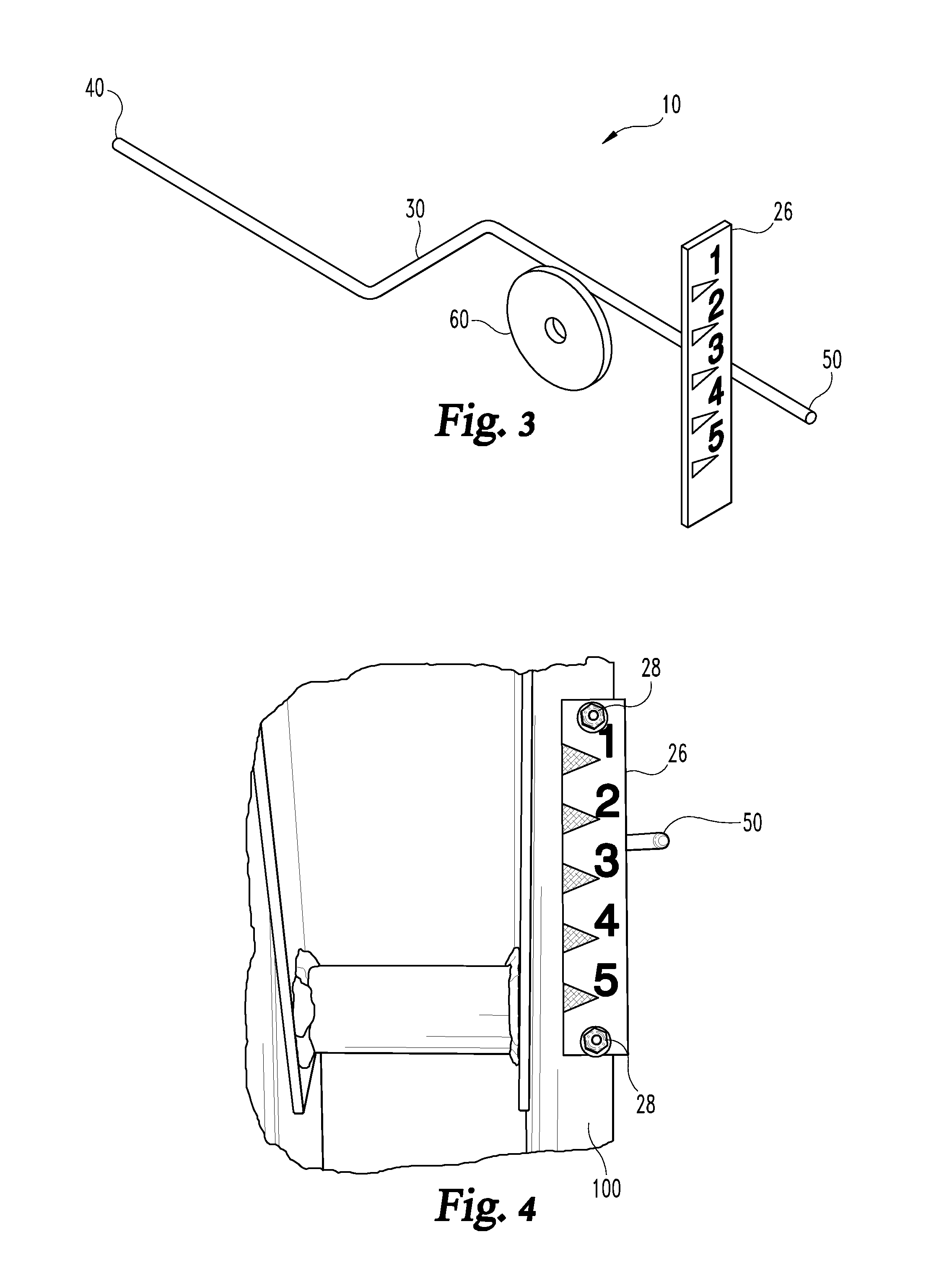

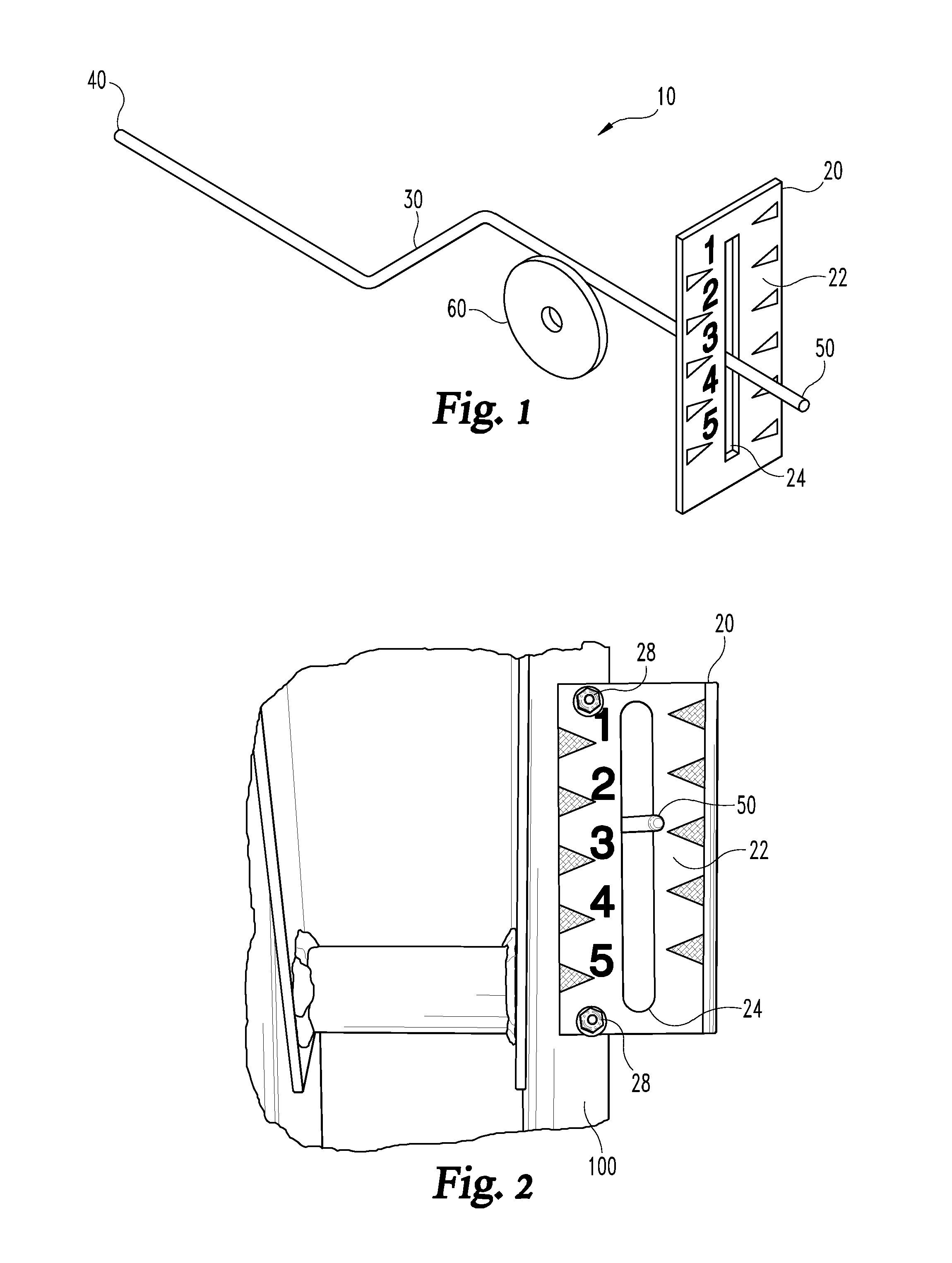

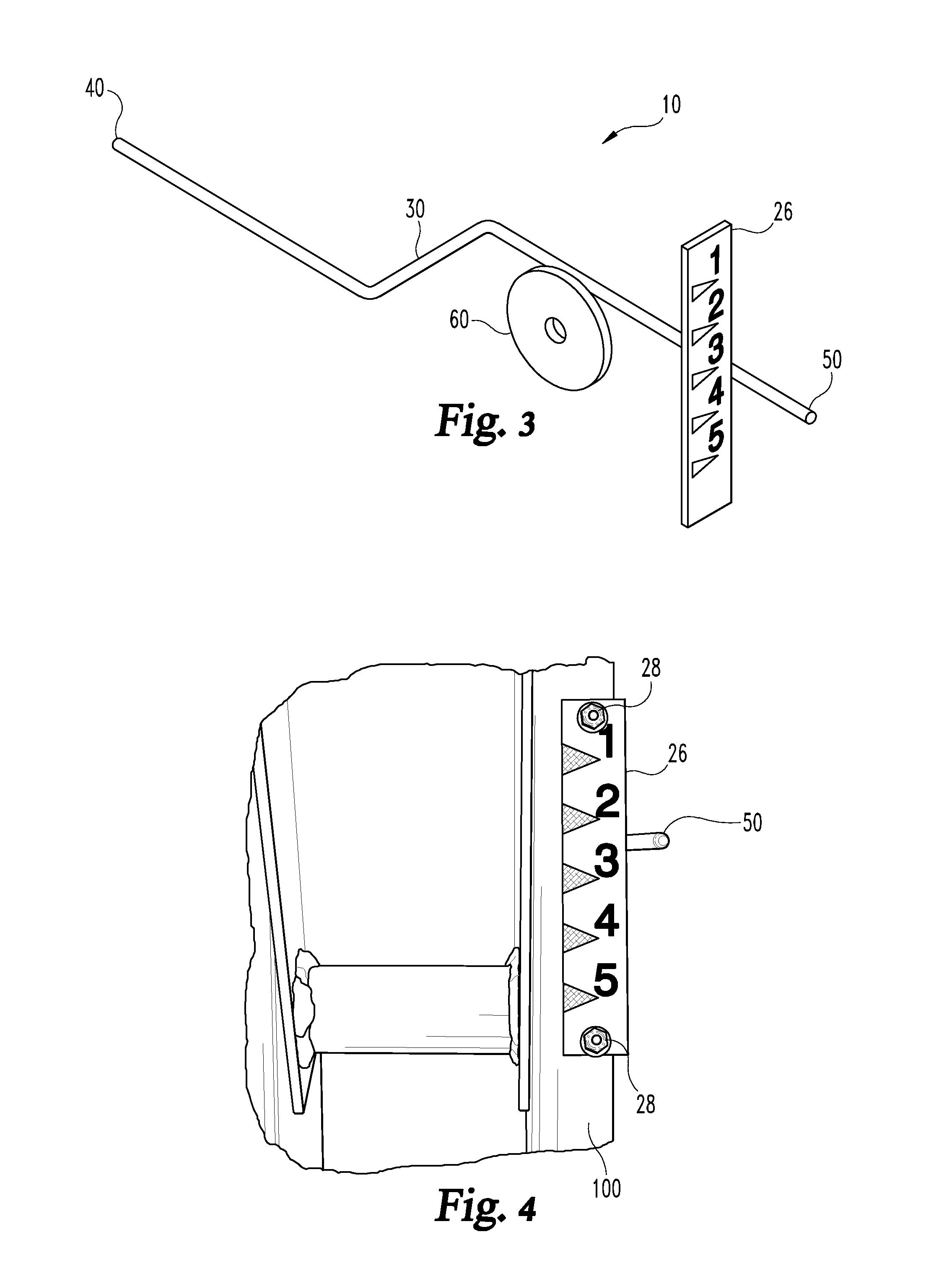

Cut sight gauge

A cut sight gauge for corn field production equipment used for detasseling operations where the cut sight gauge allows the operator to visually monitor the height of cutters and tassel pullers on corn crop cutting machines. The cut sight gauge ensures a uniform operating height of cut consistent with the optimum growing demands of the plants. The added safety advantage to the operator and the area supervisors who manage field operations are also a benefit for the field-specific set up applications as described herein.

Owner:DUNN WALTER

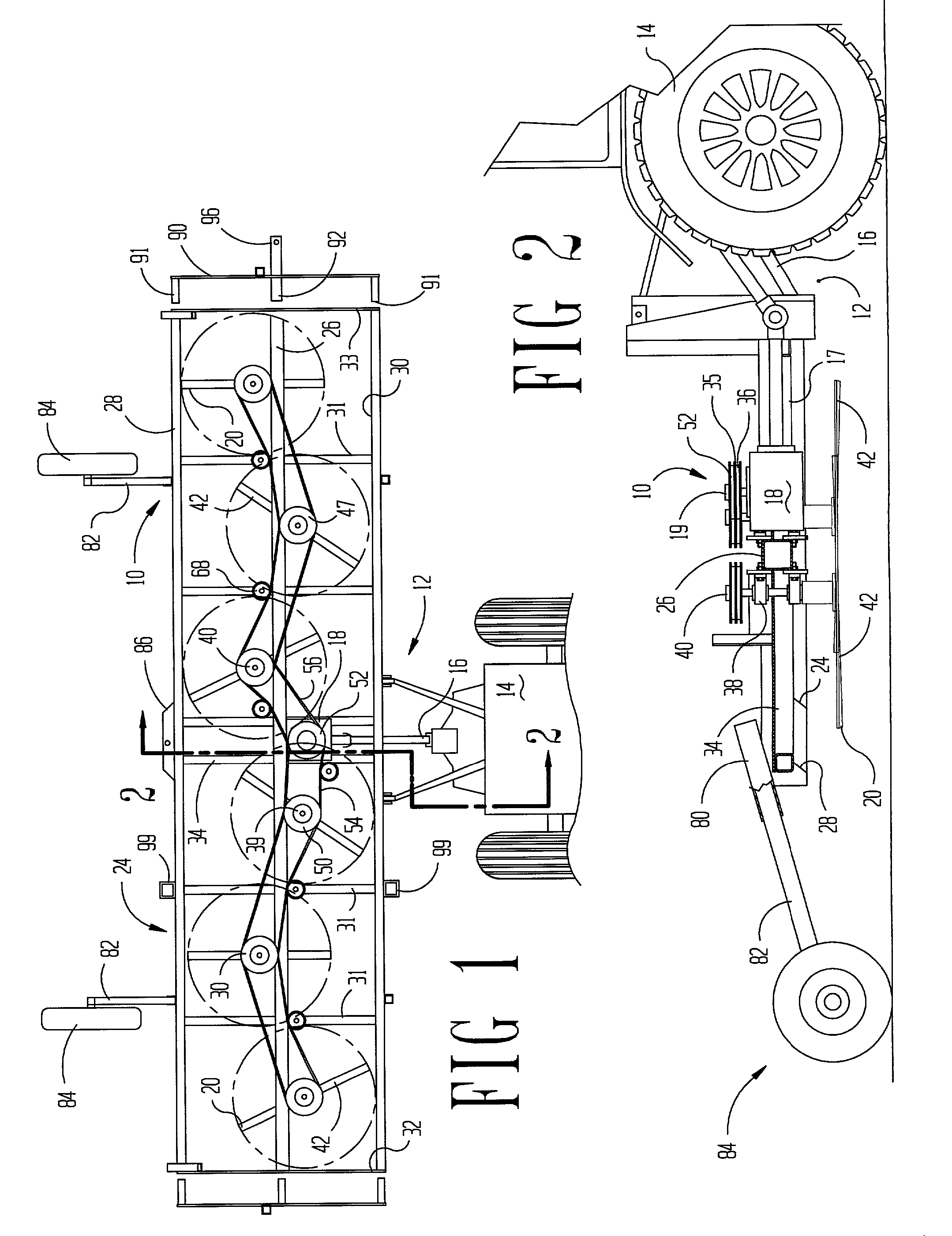

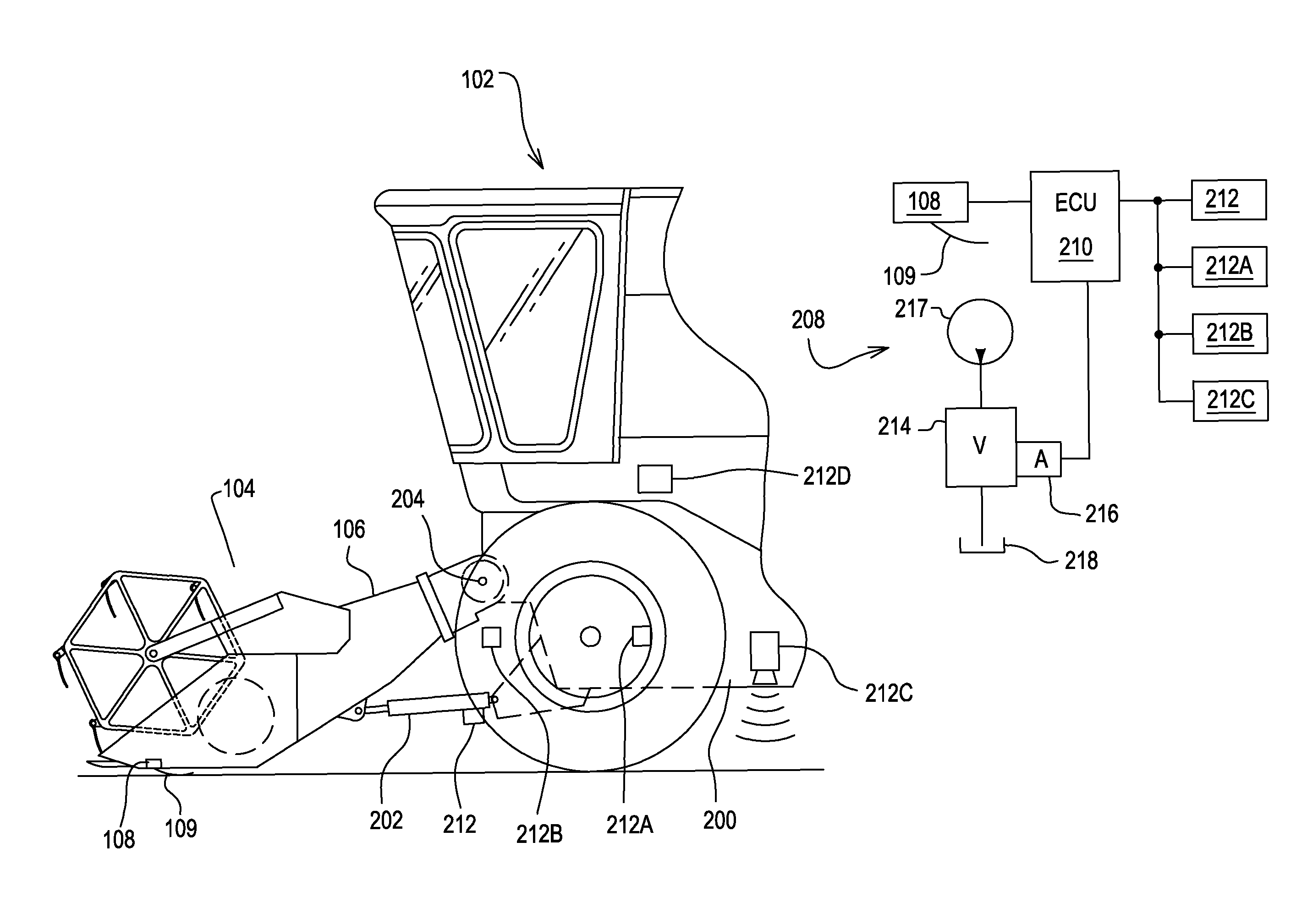

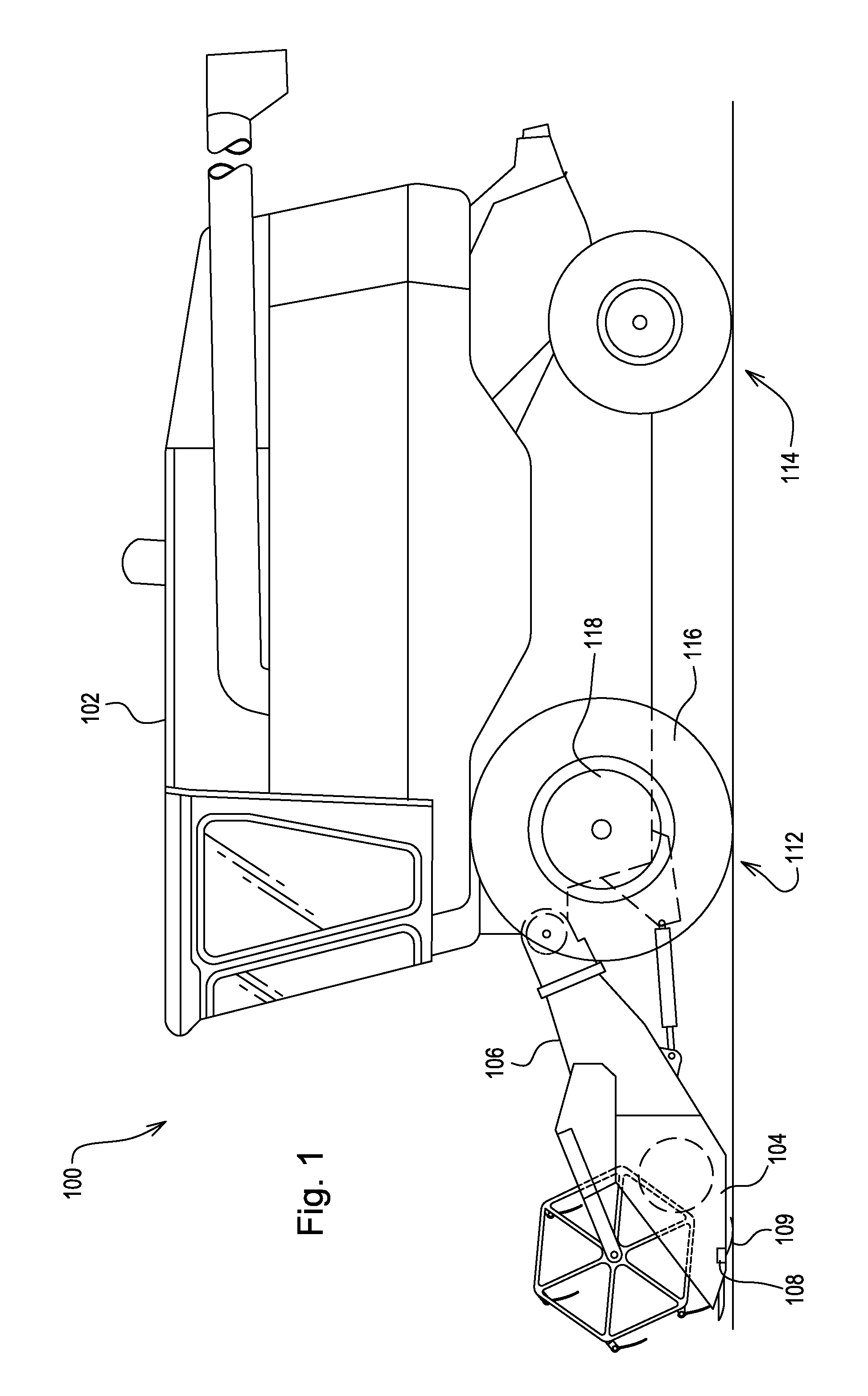

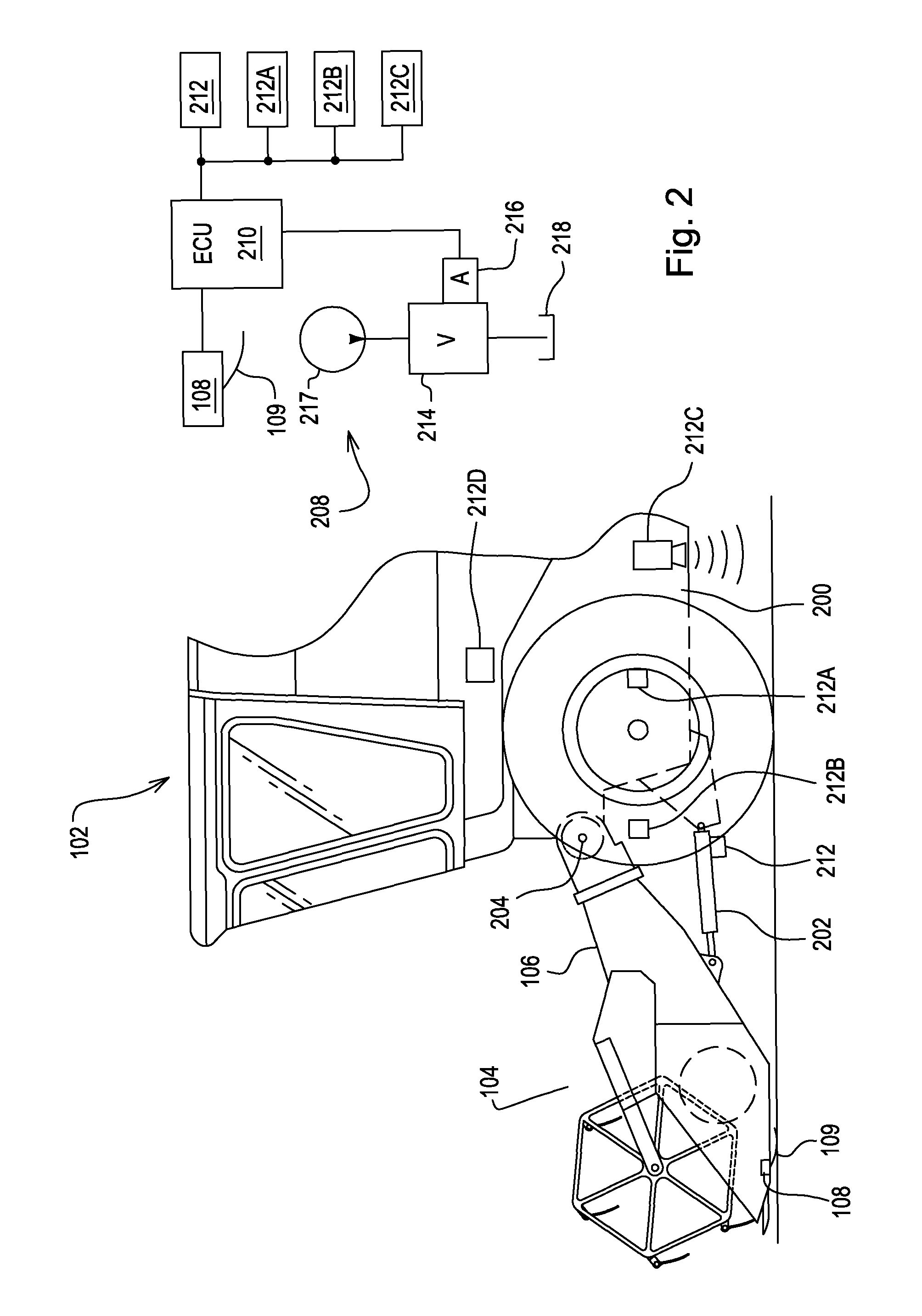

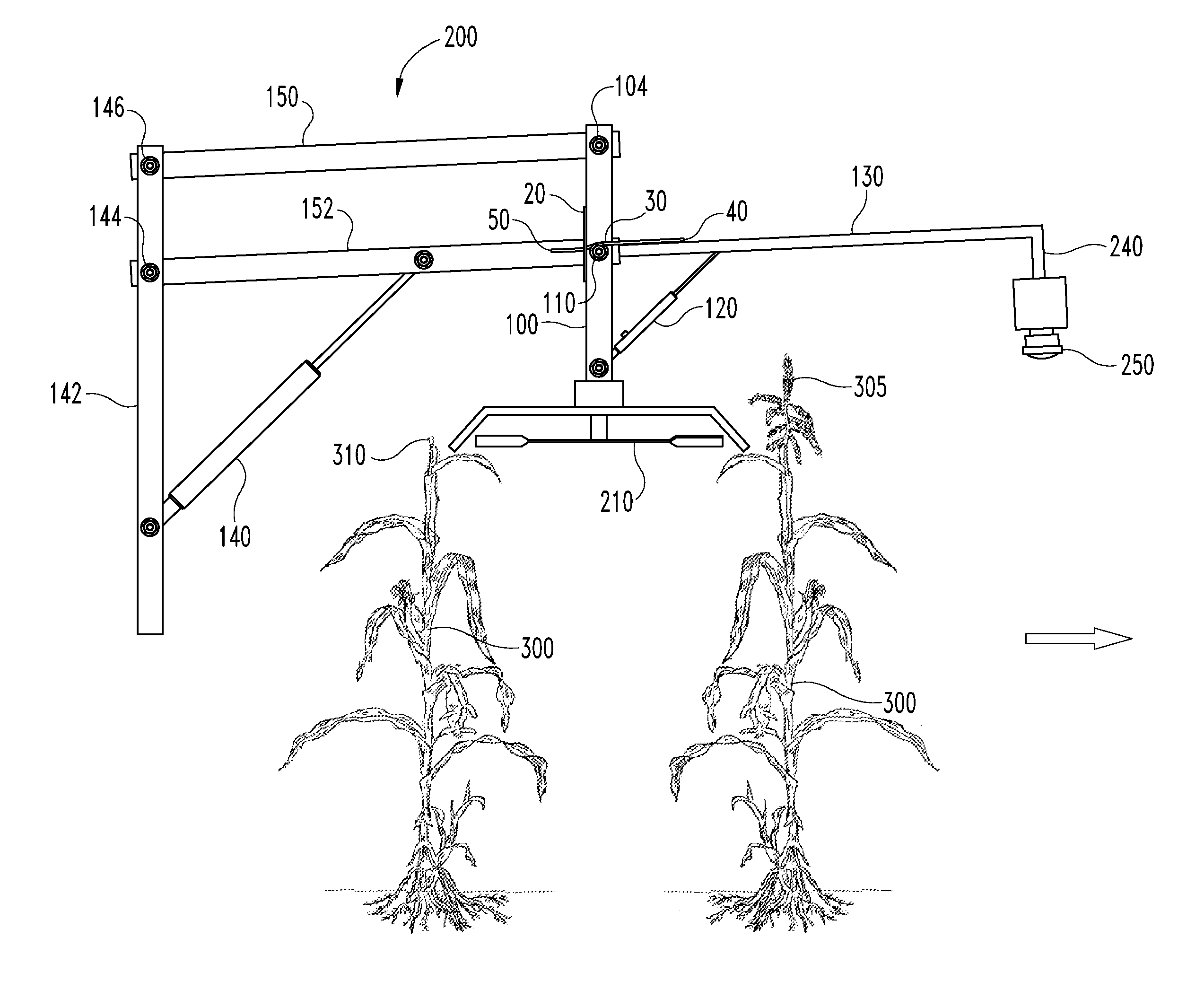

Header Height Control with Tire Flex Compensation

A header height control system (208) includes a header height sensor (108) and a tire compression sensor (212) coupled to an electronic control unit (210). The two signals are combined by the electronic control unit (210) to derive a compensated header height signal that compensates for the transient flexure of the pneumatic tires of the vehicle. This compensated header height signal is then used in a header height control algorithm executed by the electronic control unit (210) to control the height of the header (104).

Owner:DEERE & CO

Seed gathering device for use by an agricultural harvester

Owner:DEERE & CO

Cut Sight Gauge

The present invention relates to the field of corn field production equipment used for detasseling operations. More specifically, the present invention is a cut sight gauge for providing an integrated means of monitoring the height of cutters and tassel pullers on corn crop cutting machines. The cut sight gauge ensures a uniform operating height of cut consistent with the optimum growing demands of the plants. The added safety advantage to the operator and the area supervisors who manage field operations are also a benefit for the field-specific set up applications as described herein.

Owner:DUNN WALTER

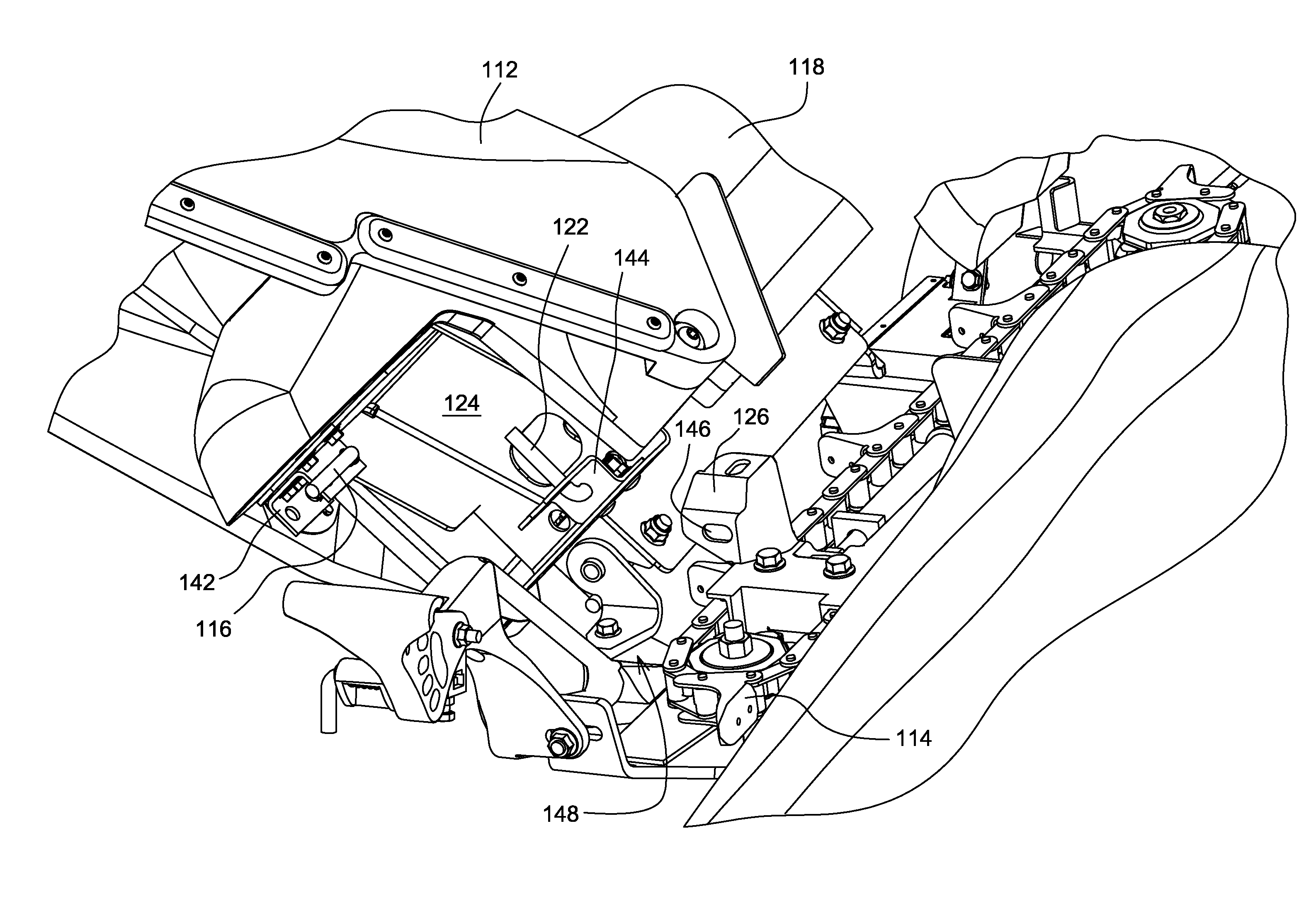

Adjustable row unit deck plate for a header of an agricultural harvester

ActiveUS20160174462A1Conducive to effective strippingAvoid easy cloggingMowersMetal working apparatusMarine engineering

An adjustable row unit for a header of an agricultural harvester is disclosed. The row unit includes a movable deck plate. The deck plate is connected to a row unit frame extending in a fore and aft direction of the header. A pivot shaft extends in the fore and aft direction and is pivotably connected to the row unit frame and the deck plate. A rocker assembly connects the deck plate to the pivot shaft for enabling selective positioning of the deck plate relative to the row unit frame in a direction substantially transverse to the fore and aft direction and whereby parallelism between the deck plate and an opposing deck plate is maintained throughout the crop harvesting process.

Owner:BLUE LEAF I P INC

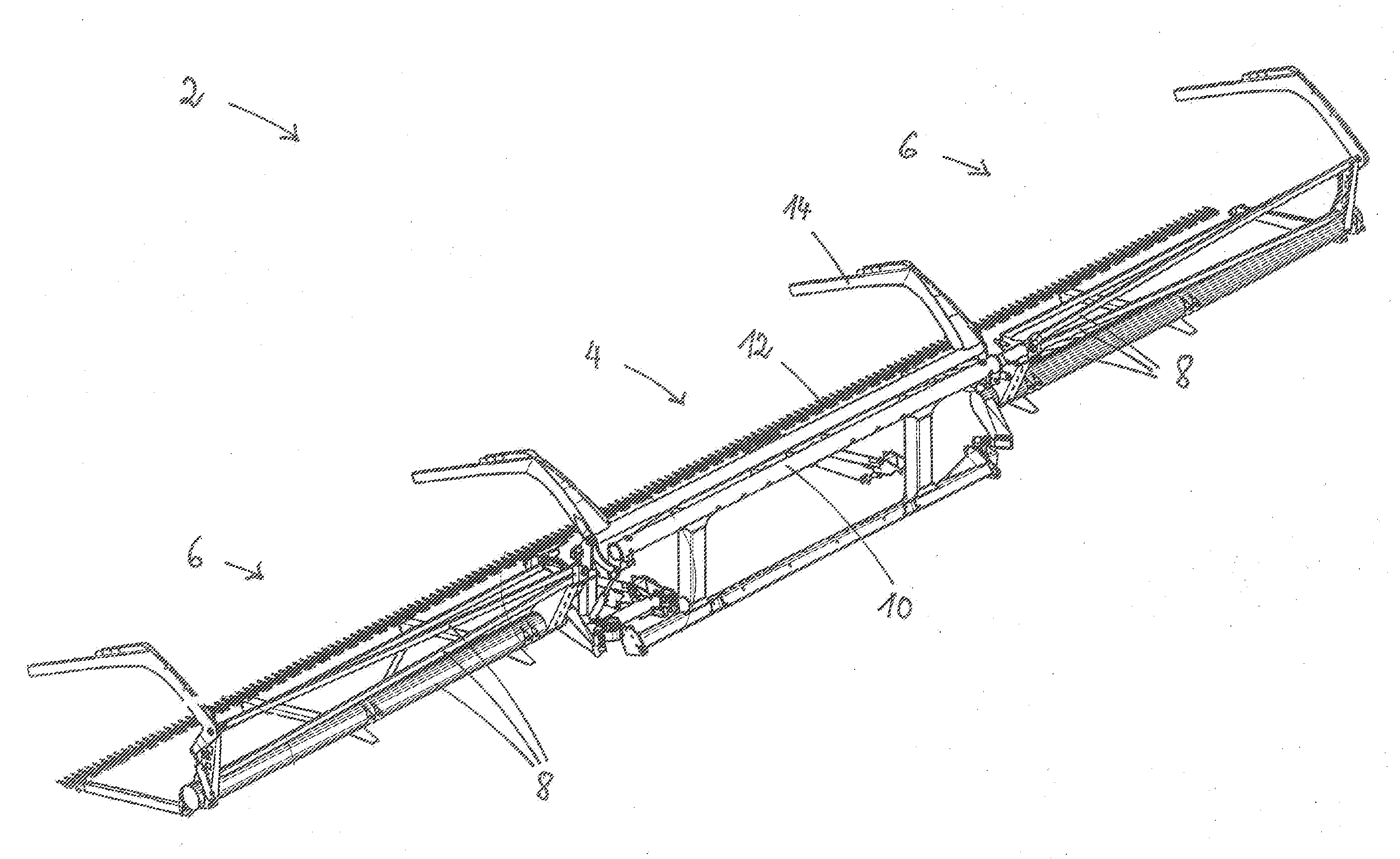

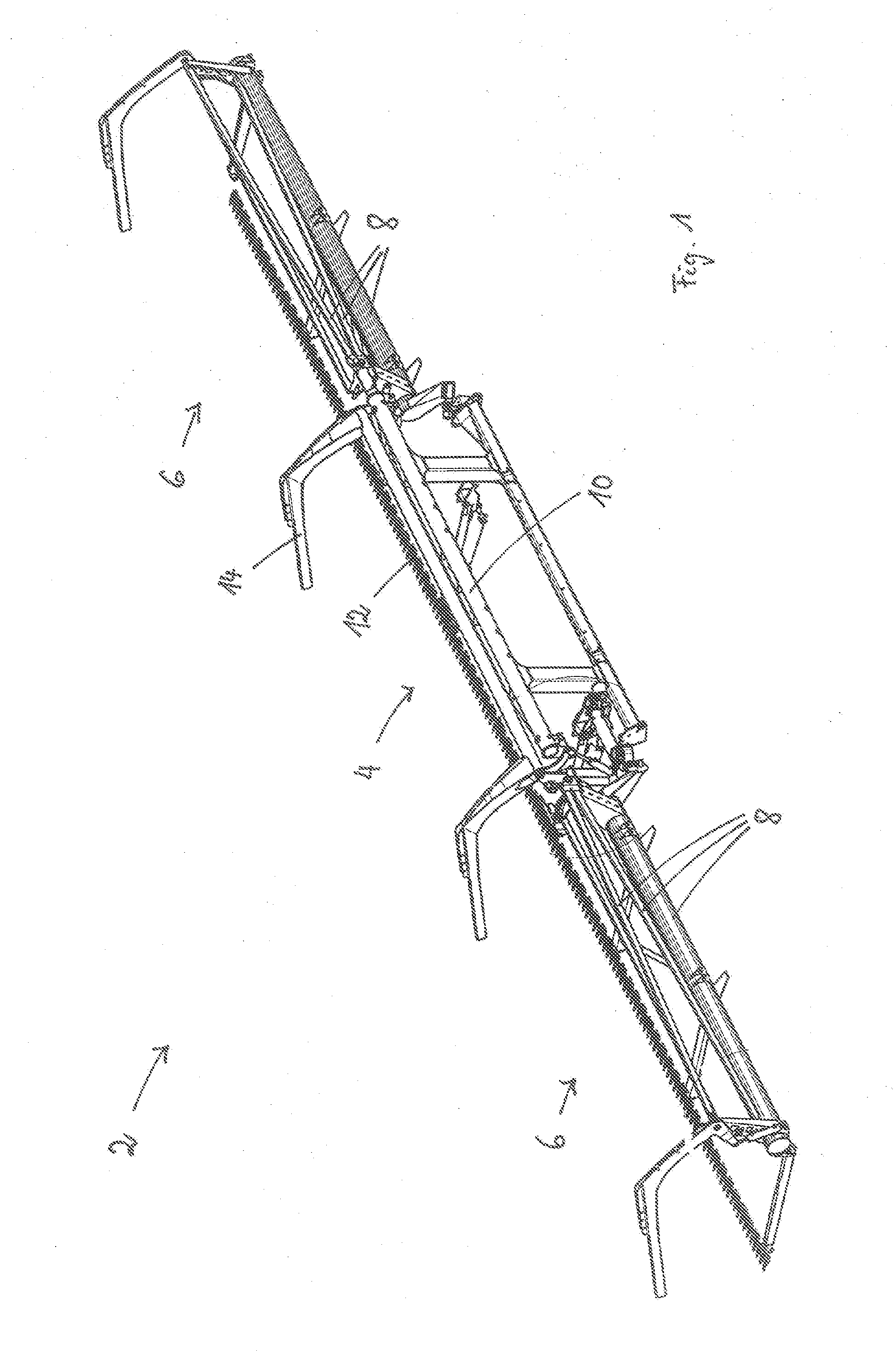

Header with center part and side parts adjustable relative to the center part

ActiveUS20150373907A1Realized faster and easyIncrease loadMowersAgricultural undercarriagesEngineeringBall joint

A header of a combine harvester has a center part connected by an attachment frame to the combine feed channel. A first side part with first lateral frame and a second side part with second lateral frame are adjustable for changing their position relative to the center part. The first and second lateral frames are connected by a first ball joint and a second ball joint to the attachment frame, respectively so that the weight of the first and second lateral frames is supported by the first and second ball joints on the attachment frame. The first and second ball joints form first and second pivot axes. An end of the first lateral frame facing away from the center part is pivotable about the first pivot axis. An end of the second lateral frame facing away from the center part is pivotable about the second pivot axis.

Owner:CARL GERINGHOFF GMBH & CO KG

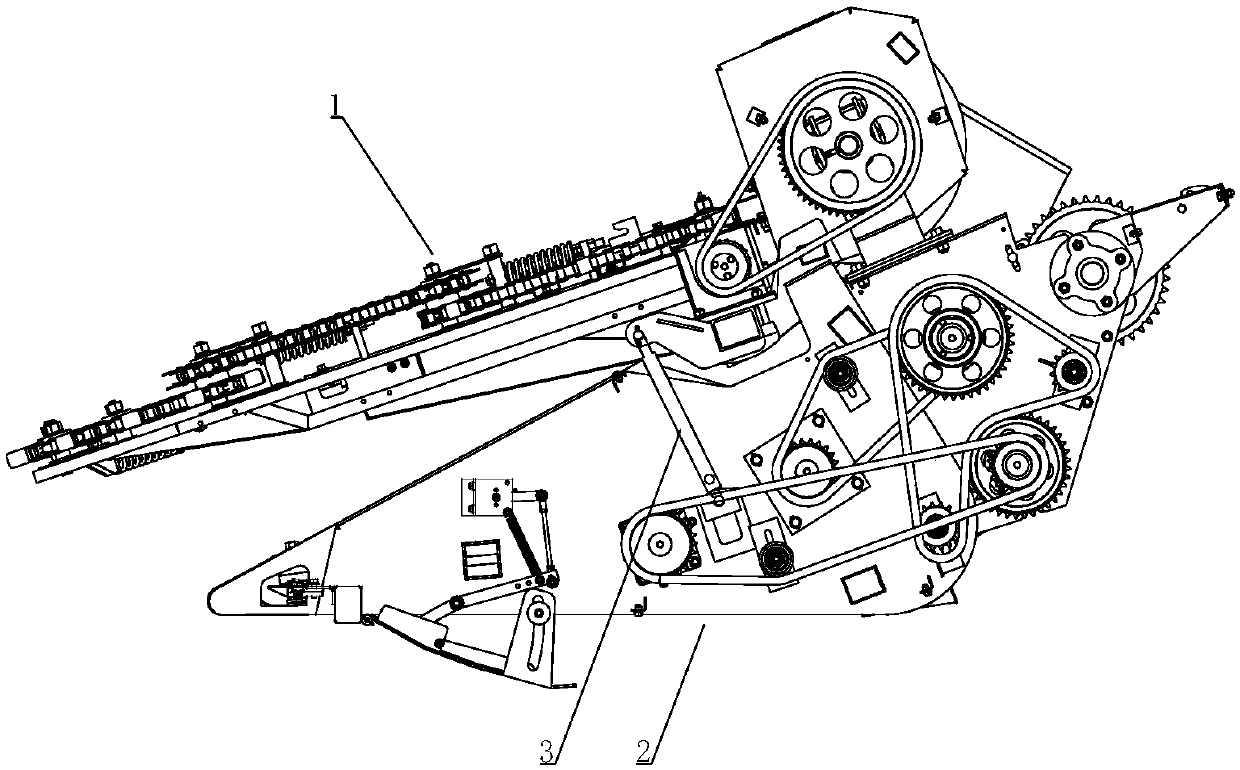

Harvester provided with protective ladder and lower lifting header and capable of smashing straw

The invention discloses a harvester provided with a protective ladder and a lower lifting header and capable of smashing straw. The harvester comprises the lower header and the protective ladder, wherein the lower header is hinged to a harvester front axle and comprises a lower header main frame, a lower cutting mechanism, a straw smashing mechanism, a driving mechanism and a lower header lifting mechanism. An included angle of cutting edges on two sides of a cutting blade is 60 angles. The lower header lifting mechanism comprises a lower header lifting oil cylinder, a lower header lifting oil cylinder upper seat and a lower header lifting oil cylinder lower seat wherein the lower header lifting oil cylinder is a single acting cylinder. The harvester provided with the protective ladder and the lower lifting header and capable of smashing straw can cut and smash grains and harvest residual straw portions, a threshing effect is improved, and cut stubbles are short and flat and facilitate land cultivation. The straw cutting and smashing efficiency is high, smashing is uniform, and the straw is used as a base fertilizer after being returned to fields. The lower header can lift so as to control the stubble cutting height and can avoid obstacles to ensure device safety. The arranged protective ladder can be used for safe and convenient climbing and can be also used as a safety fence.

Owner:见保林

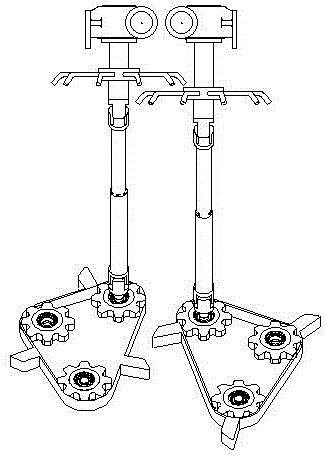

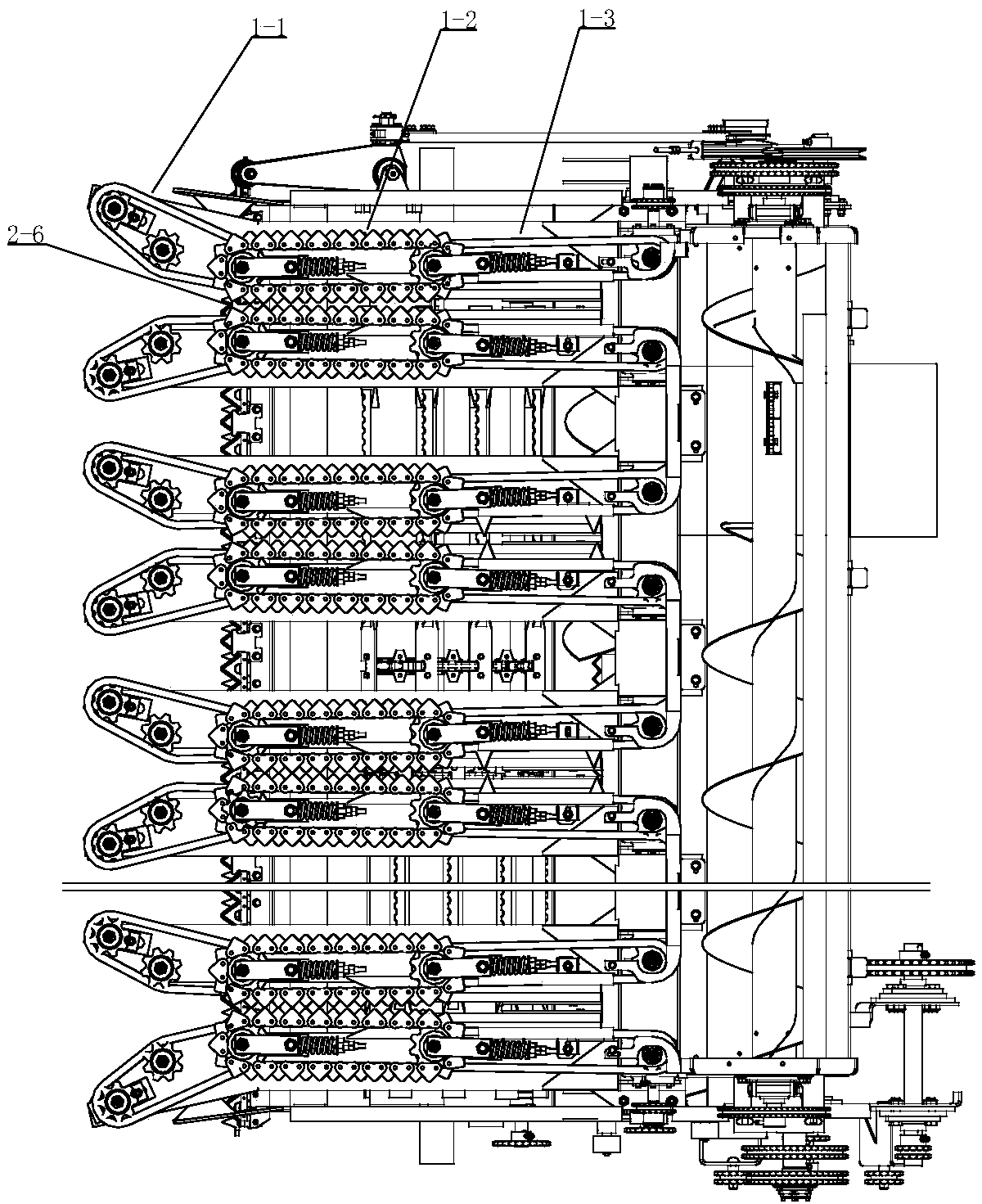

Standing grain pull chain type corncob-pickup straw-collecting stubble-cutting returning-type corncob and stem concurrent-harvesting header

The invention relates to a standing grain pull chain type corncob-pickup straw-collecting stubble-cutting returning-type corncob and stem concurrent-harvesting header and belongs to the technical field of corn harvesting machinery.The header comprises a standing-grain-pull stem-pull and corncob-pickup integrated device, a corncob collecting device, a straw-collecting recovery device, a stubble cutting and returning device and a rack, wherein the header is modularly designed, and each group serves as an independent individual and can form a series of corn harvesters different in harvesting line.The standing-grain-pull stem-pull and corncob-pickup integrated device is located in the forefront of the header and performs standing grain pull, feeding, cutting off, corncob pickup and other operations.The corncob collecting device is arranged under the standing-grain-pull stem-pull and corncob-pickup integrated device and facilitates corncob collection and conveying.The straw-collecting recovery device is installed above the back of the standing-grain-pull stem-pull and corncob-pickup integrated device and collects upper-portion corn straws.The stubble cutting and returning device is put under the back and used for cutting off corn root stubbles and returning lower-portion straws.

Owner:SHANDONG UNIV OF TECH

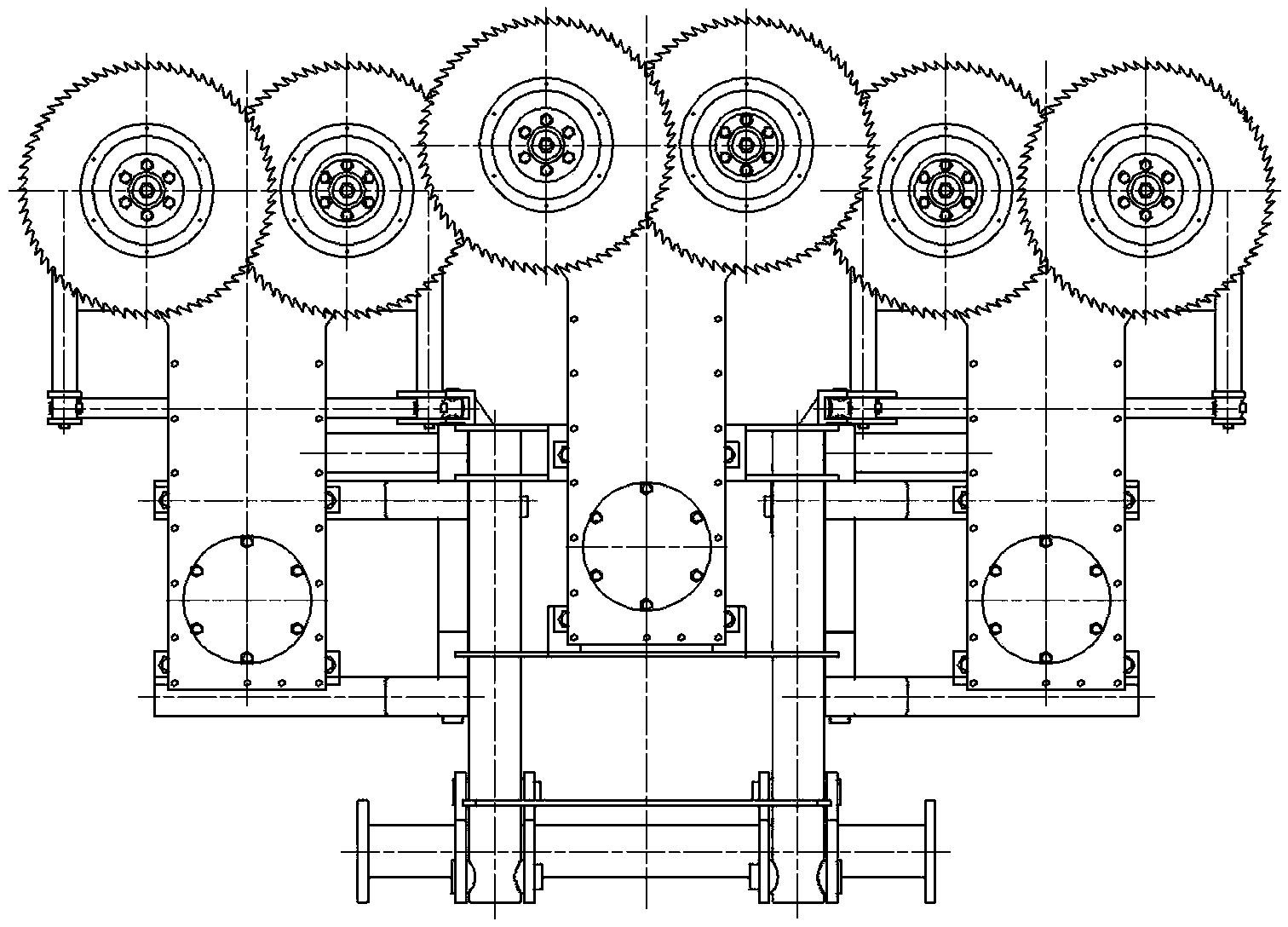

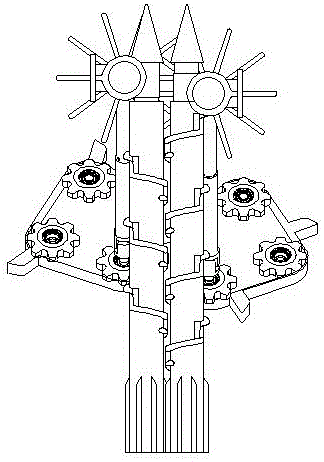

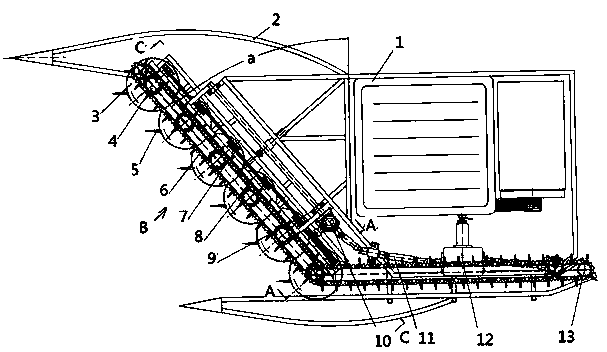

Corn ear and stalk header integrating ear picking and straw cutting recovery

The invention relates to a corn ear and stalk header integrating ear picking and straw cutting recovery. The corn ear and stalk header comprises an ear picking header located at the upper part and a straw cutting recovery header located at the lower part; the ear picking header includes an upper header support, one or more sets of ear picking operation units which are arranged side by side are arranged on the header support, each set of picking operation units comprises a forced feeding mechanism, a stalk clamping mechanism and an ear output mechanism which are successively connected, a left-and-right tool setting ear picking mechanism is arranged under the ear output mechanism; and the straw cutting recovery header includes a lower header support, a reciprocating cutter, a conveyor chainharrow structure and a conveyor auger which are successively connected are mounted in the lower header support, a feeding port is arranged in the rear baffle plate of the lower header support, and a movable cutter diving mechanism is arranged outside a sie plate at one side of the lower header support. The corn ear and stalk header realizes ear picking and stalk cutting recovery at a time to improve the harvesting speed and the harvesting efficiency; and the height of the harvesting header is adjustable, so the corn ear and stalk header is suitable for harvesting corn plants with different earheights.

Owner:YONGMENG MACHINERY CO LTD

Deckplate Auto Adjustment Mechanism for a Harvester Row Unit

A row unit for a header of an agricultural harvester is provided that includes a first longitudinally extending stripping plate and a second longitudinally extending stripping plate each mounted on a frame and each having opposed stripping edges which define a gap between the first stripping plate and the second stripping plate. The row unit includes both operator-selected macro adjustment of the gap and automatic micro adjustment of the gap. The micro adjustment occurs on both deck plates. The micro adjustment is achieved through resilient members positioned functionally between the deck plates and the row unit frame.

Owner:BLUE LEAF I P

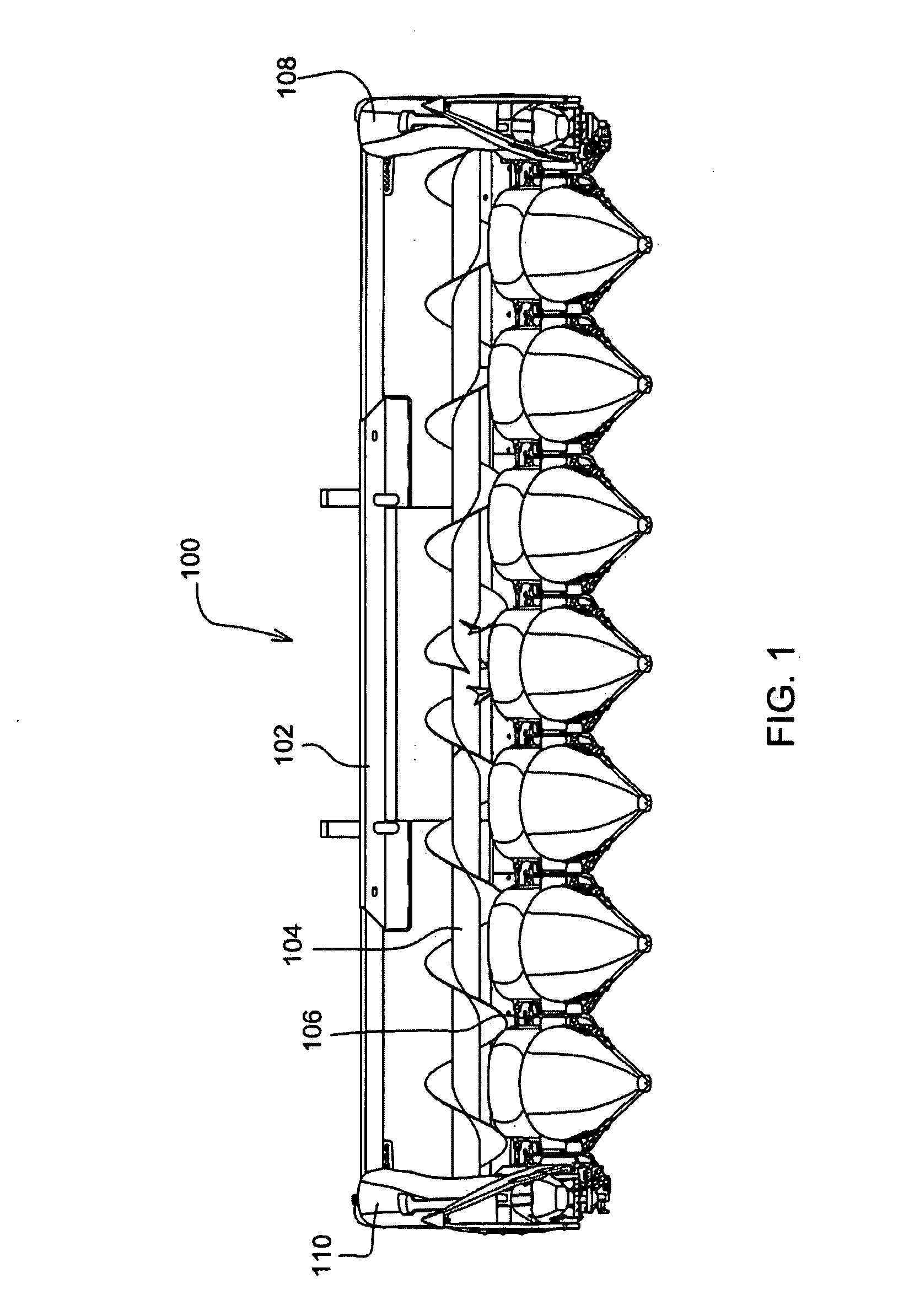

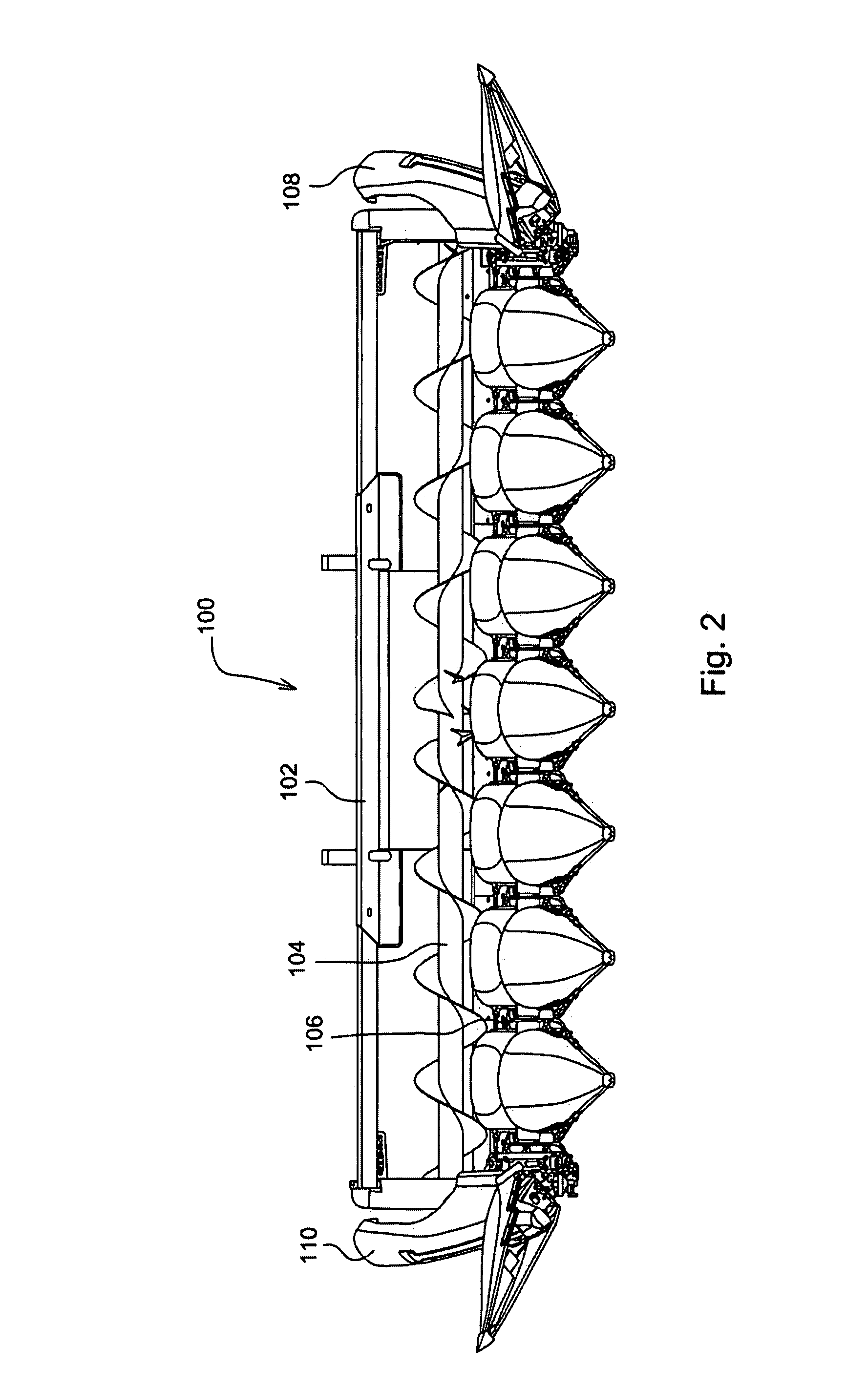

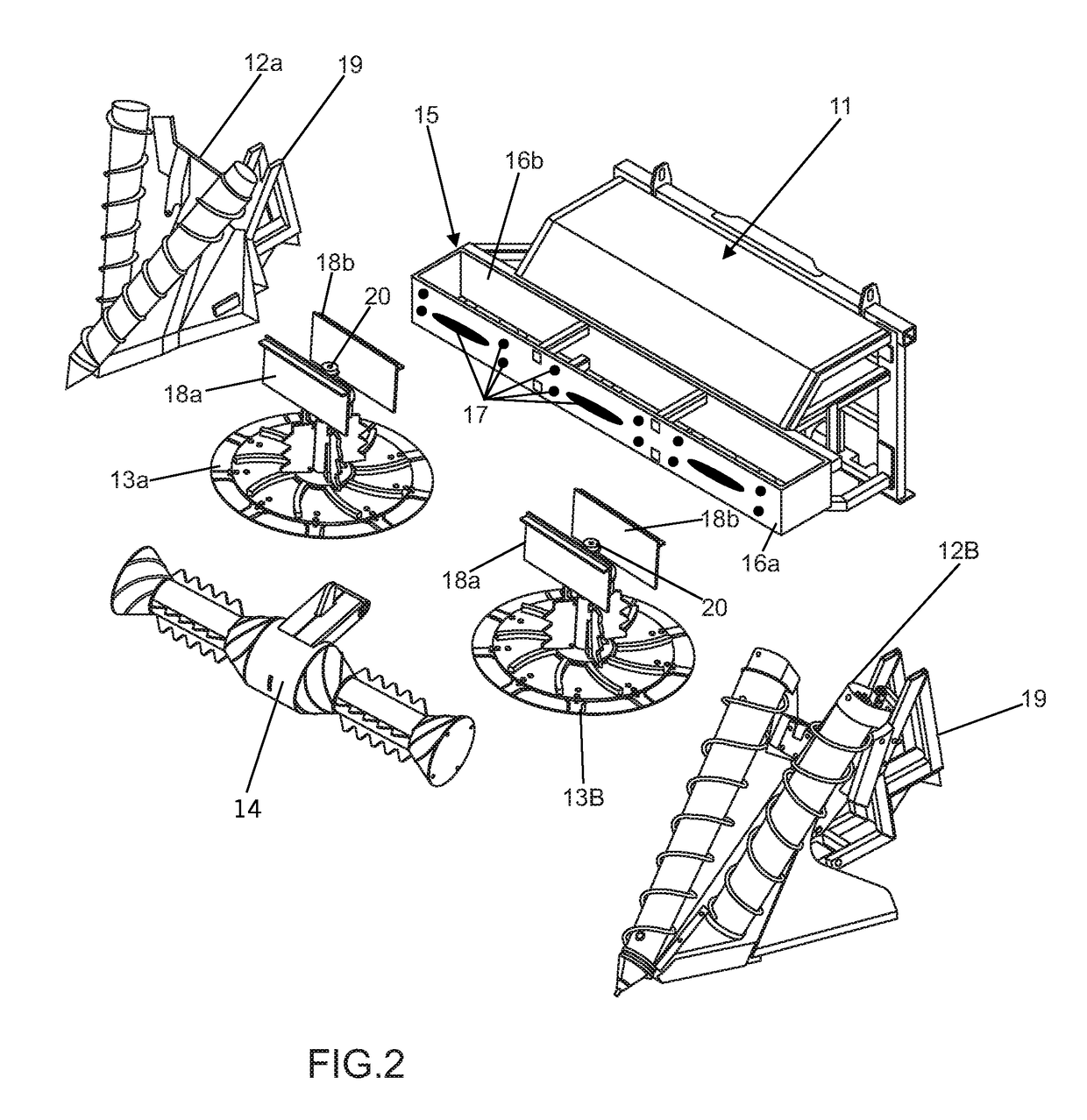

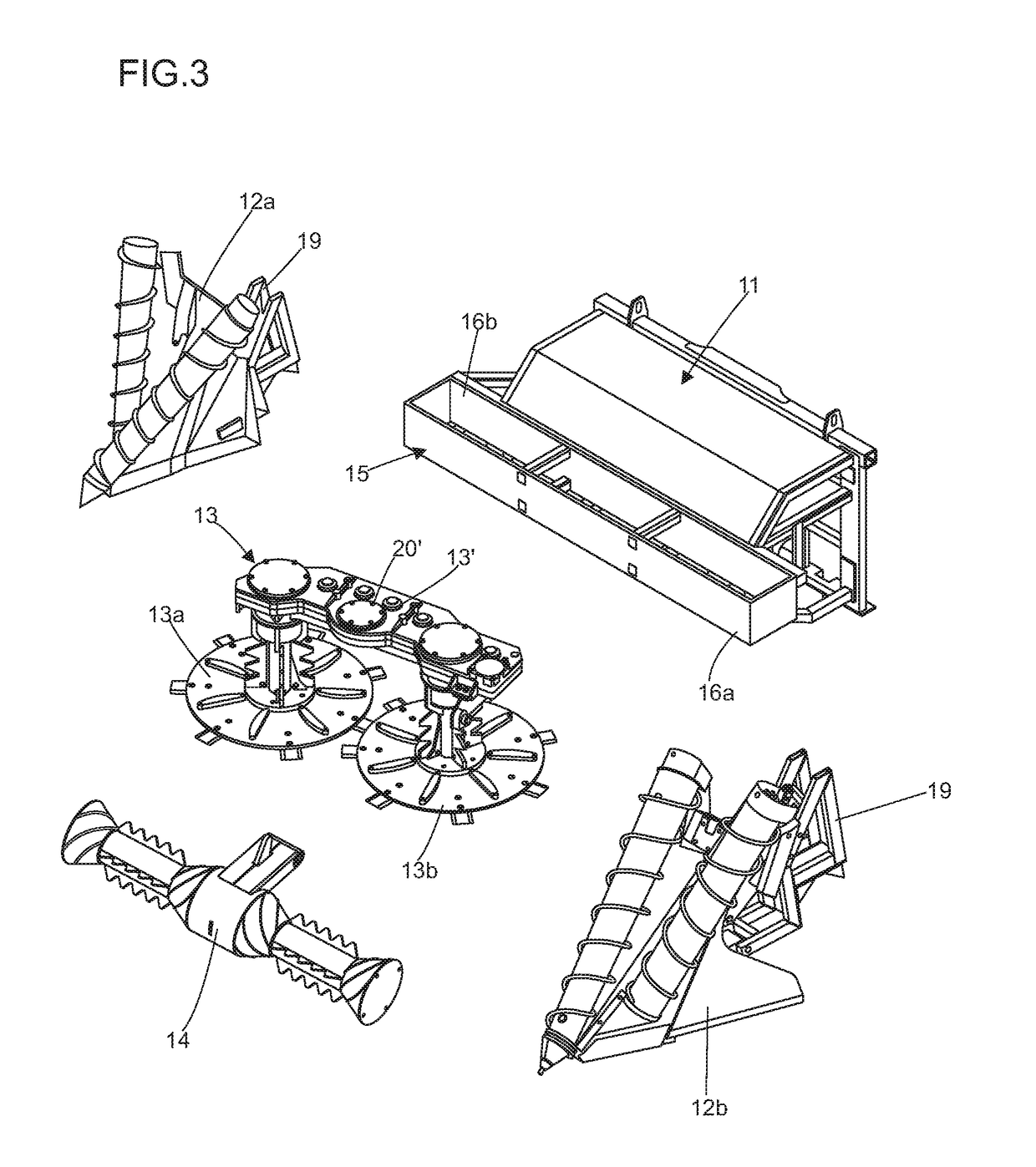

Adaptive Multi Row Header for Sugar Cane Harvester

An agricultural machine header which can be coupled to and uncoupled from a harvesting machine The header includes a frame having with a plurality of adjustable supports for coupling with at lest two row divider sets. The header further includes at least one pair of base cutting discs and at least one knock-down roller. The header supports the base cutting discs in an adjustable and flexible way that allows them to be adjusted according to conditions and characteristics of crop to be harvested.

Owner:BLUE LEAF I P INC

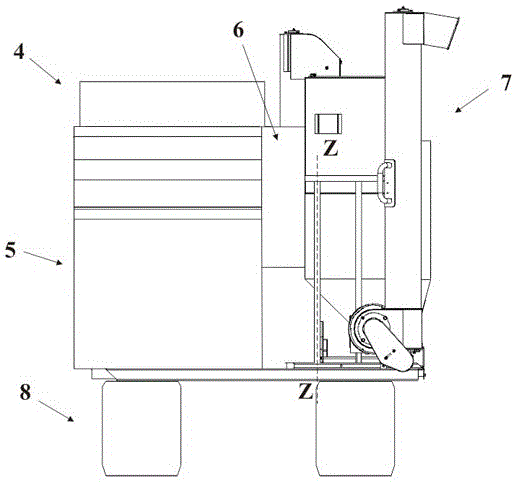

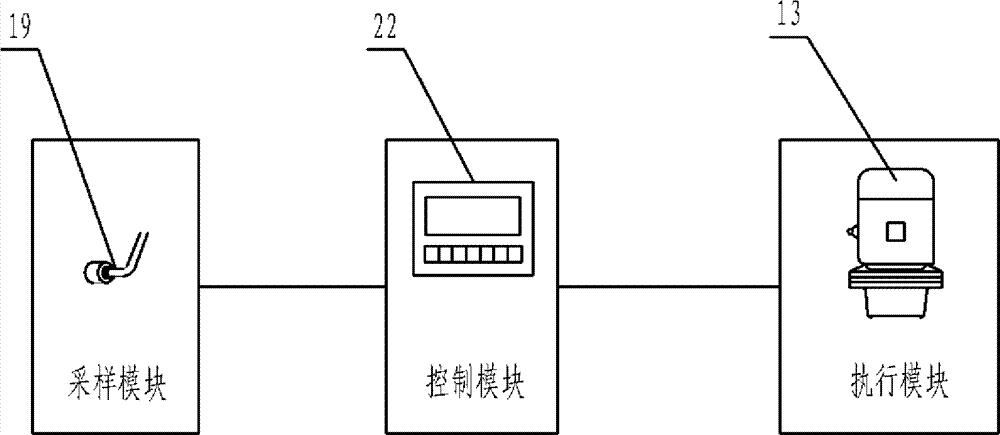

Header of cane harvester

The invention discloses a header of a cane harvester, which comprises a machine frame, an upright post mounted on the machine frame, and a lifting slider thereof, wherein an electric lifting mechanism is connected to one side of the lifting slider, the electric lifting mechanism is formed by a lead screw pair connected between the upright post and the lifting slider, and a lifting motor connected with the lead screw pair through a retarding mechanism. A cutter equipped with a main motor and a double rotation cutter blade plate is connected to the other side of the lifting slider, and a balance cylinder for balancing the weight is mounted between the machine frame and the cutter. A cutter lifting sensor is further mounted at the lower part of the machine frame, so as to form a cutter height automatic adjusting system comprising the cutter lifting sensor, a lifting controller, the electric lifting mechanism and the like. Therefore, the system can be used for adjusting the height of the cutter in real time according to the actual condition of harvest topography. Compared with the prior art, the header of the cane harvester, provided by the invention, solves the problems that the header of the conventional cane harvester is weak in topography adaptability, low in harvesting efficiency, and higher in harvesting cost.

Owner:朱季华

Harvester header device with multiple obliquely-arranged disc-shaped cutters and harvesting method

The invention discloses a harvester header device with multiple obliquely-arranged disc-shaped cutters and a harvesting method. The harvester header device comprises a header rack, the disc-shaped cutters, a transmission device and a conveying device. The header rack is installed on a harvester chassis, the disc-shaped cutters are installed on the header rack and driven by a power device on the harvester chassis through the transmission mechanism, the two or more disc-shaped cutters are combined into a disc-shaped cutter combination, all disc-shaped cutter devices of the disc-shaped cutter combination are transversely and obliquely arranged relative to a harvester, a conveying chain with shifting teeth is arranged on the cutters of the disc-shaped cutter combination, the front transverse conveying part of the conveying chain and the side backward conveying part of the conveying chain are combined into the whole chain, and the front transverse conveying part is arranged with the same oblique angle as the disc-shaped cutters. According to harvester header device with the multiple obliquely-arranged disc-shaped cutters, the multiple disc-shaped cutters are adopted, whole oblique conveying is achieved, intermediate connection between the two subsection conveying chains can be reduced, and conveying is smoother.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com