Patents

Literature

138results about How to "Feed less" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

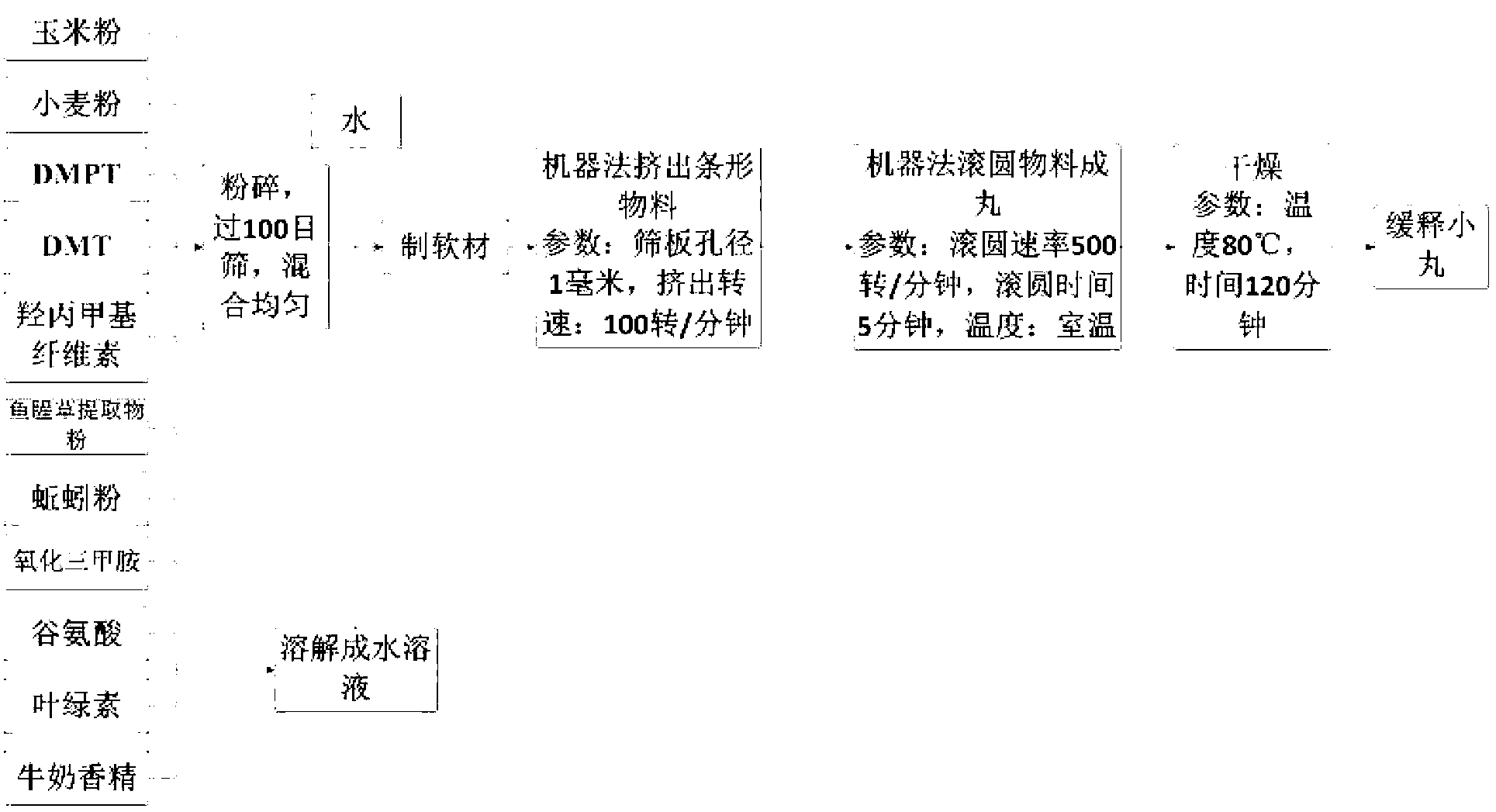

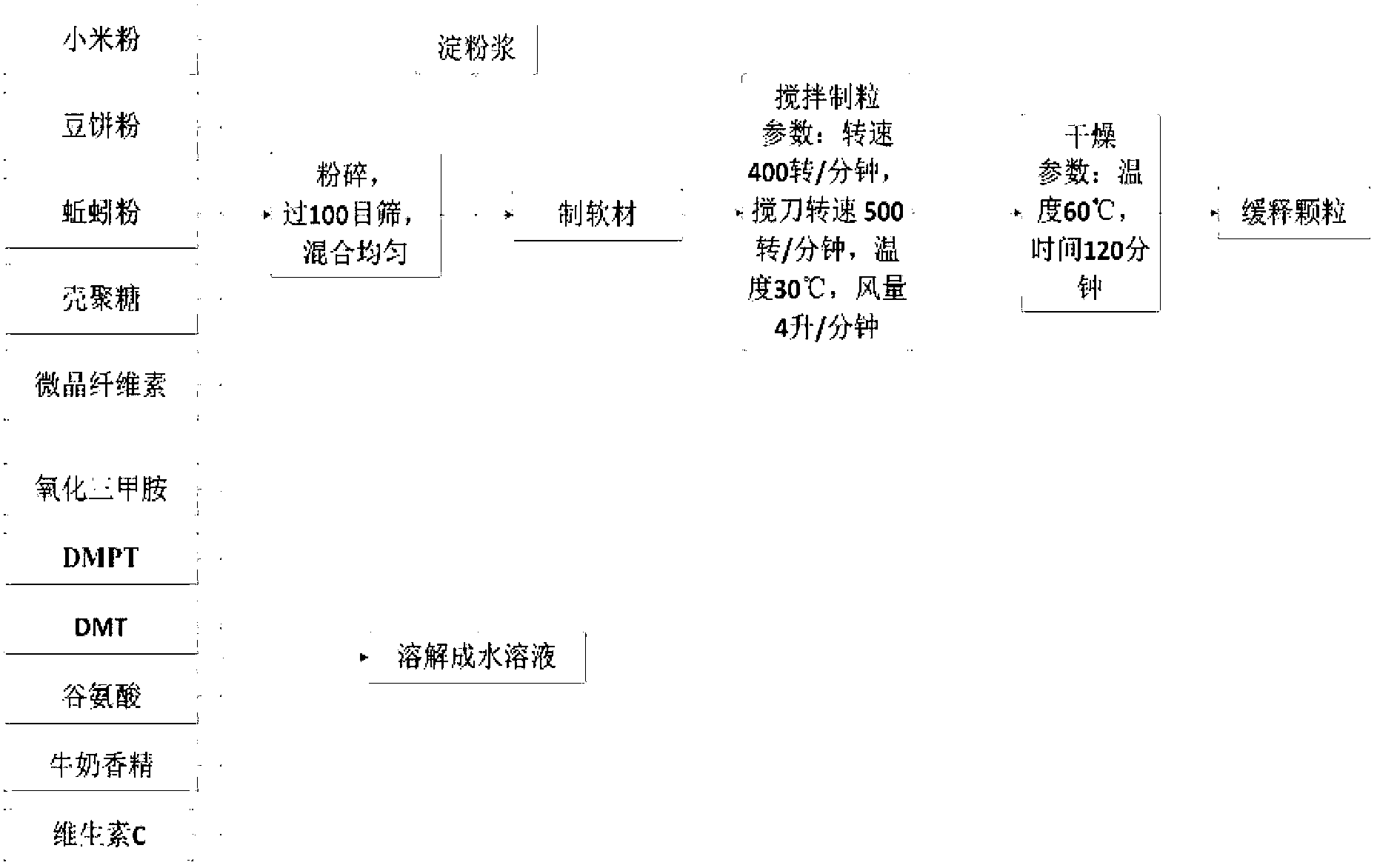

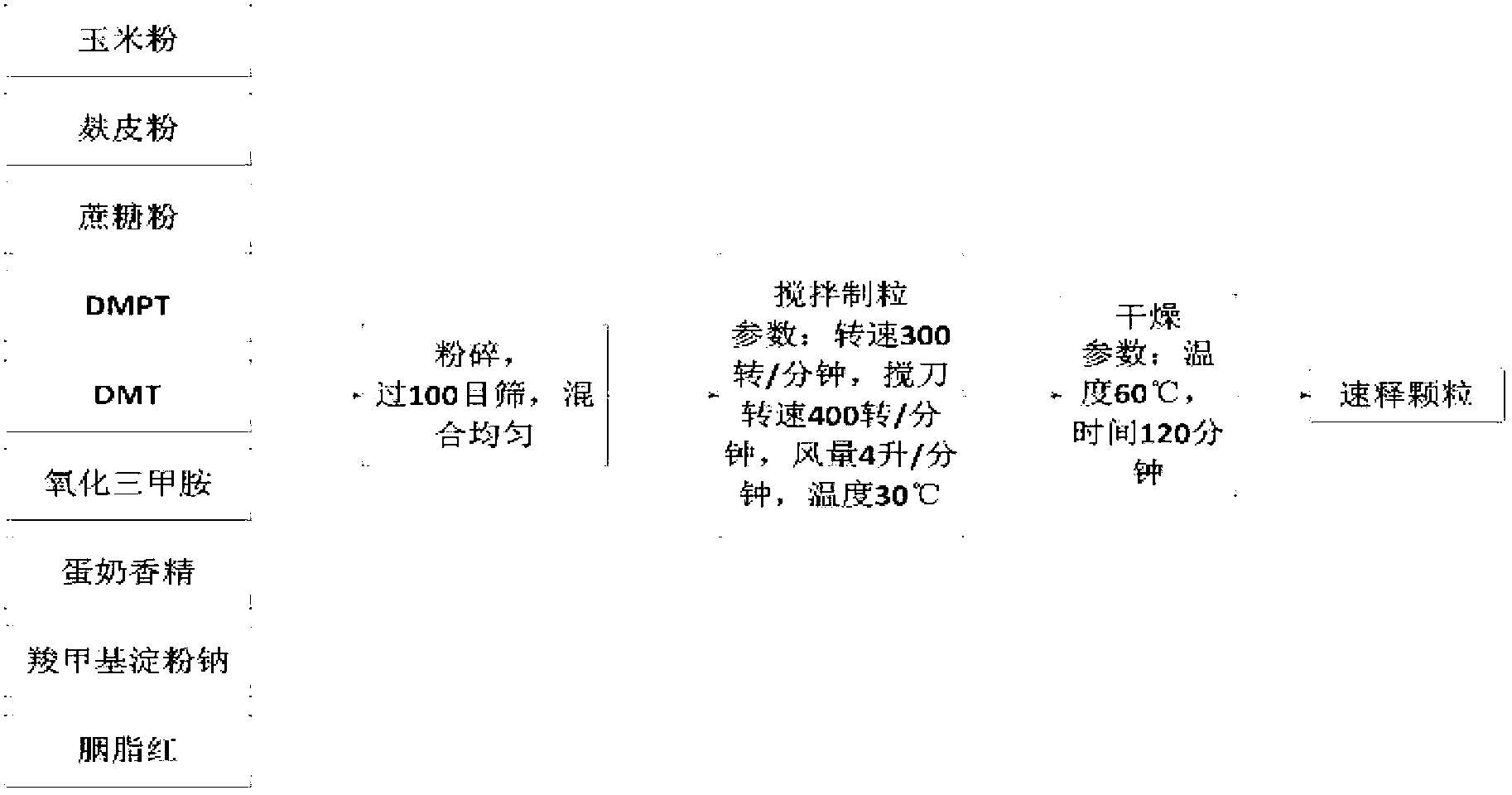

Controlled release bait material and preparation method thereof

InactiveCN103004717AQuick and long-lasting releaseFast and long-lasting effectOther angling devicesWater insolubleMicrosphere

The invention relates to a controlled release bait material and a preparation method thereof. The controlled release bait material refers to small pills, micro-pills, microcapsules, microspheres, particles or sticks prepared from raw materials including a basic material, a feed attractant, a bonding agent, a hydrophilic high-polymer material, a water-insoluble high-polymer material, a quick-release material, a filler, a colorant, a flavoring agent and the like through a preparation means; and the controlled release bait material can be coated for improving the controlled release effect. The invention further discloses a preparation method of the bait material. The controlled release material has rapid and lasting attracting force on fishes, the fish attracting time can be adjusted according to the habit of a fisherman and the habits of fishes, the food ration and frequency of fishes are increased, the fishing success rate can be increased, the food intake of fishes in cultivation of fishes can be increased, the corrosion ratios of remnant feeds and feeds in water bodies are reduced, the utilization ratios of feeds is increased, and the water body environmental pollution is lowered. The preparation method provided by the invention is suitable for industrial production.

Owner:李群益 +2

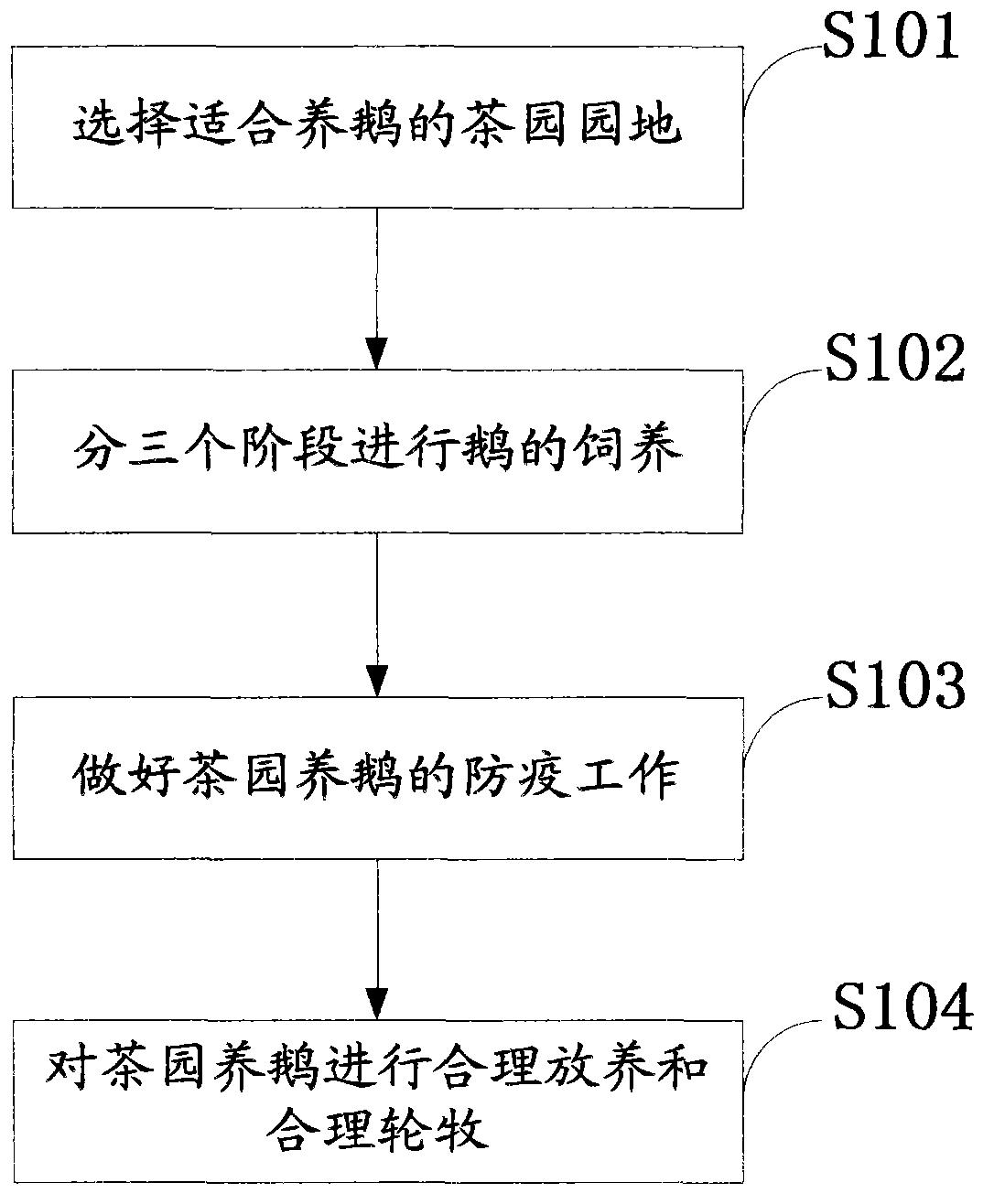

Tea-garden-type goose raising method

The invention discloses a tea-garden-type goose raising method. The tea-garden-type goose raising method comprises the steps that a plot of land, suitable for raising gooses, in a tea garden is chosen; the gooses are raised according to the three phases that epidemic prevention work for the gooses raised in the tea garden is well prepared, and reasonable putting and raising are conducted on the gooses raised in the tea garden, and reasonable rotation grazing is conducted on the gooses raised in the tea garden. Being raised in the tea garden, the gooses do activities in the garden, ventilating conducted among plants is enhanced, and the gooses peck weeds in the garden to reduce feeding amount and help tea trees to remove insect attack, and increase organic fertilizers. When a group of gooses is put and raised in a field in a group mode, because activity ranges are enlarged and activity intensity is increased, the resistance of the goose group is improved, epidemic diseases are reduced, and meat quality and economic benefits are better. Because the goose group is grazed in the tea garden, all kinds of resources are effectively used, the purposes that the allocation of the resources is optimized and the resources are efficiently used are achieved, and the mutually-beneficial and mutual-promoting healthy cultivation model with the coordination of farming and animal husbandry and the matching of planting and breeding is achieved.

Owner:SICHUAN AGRI UNIV

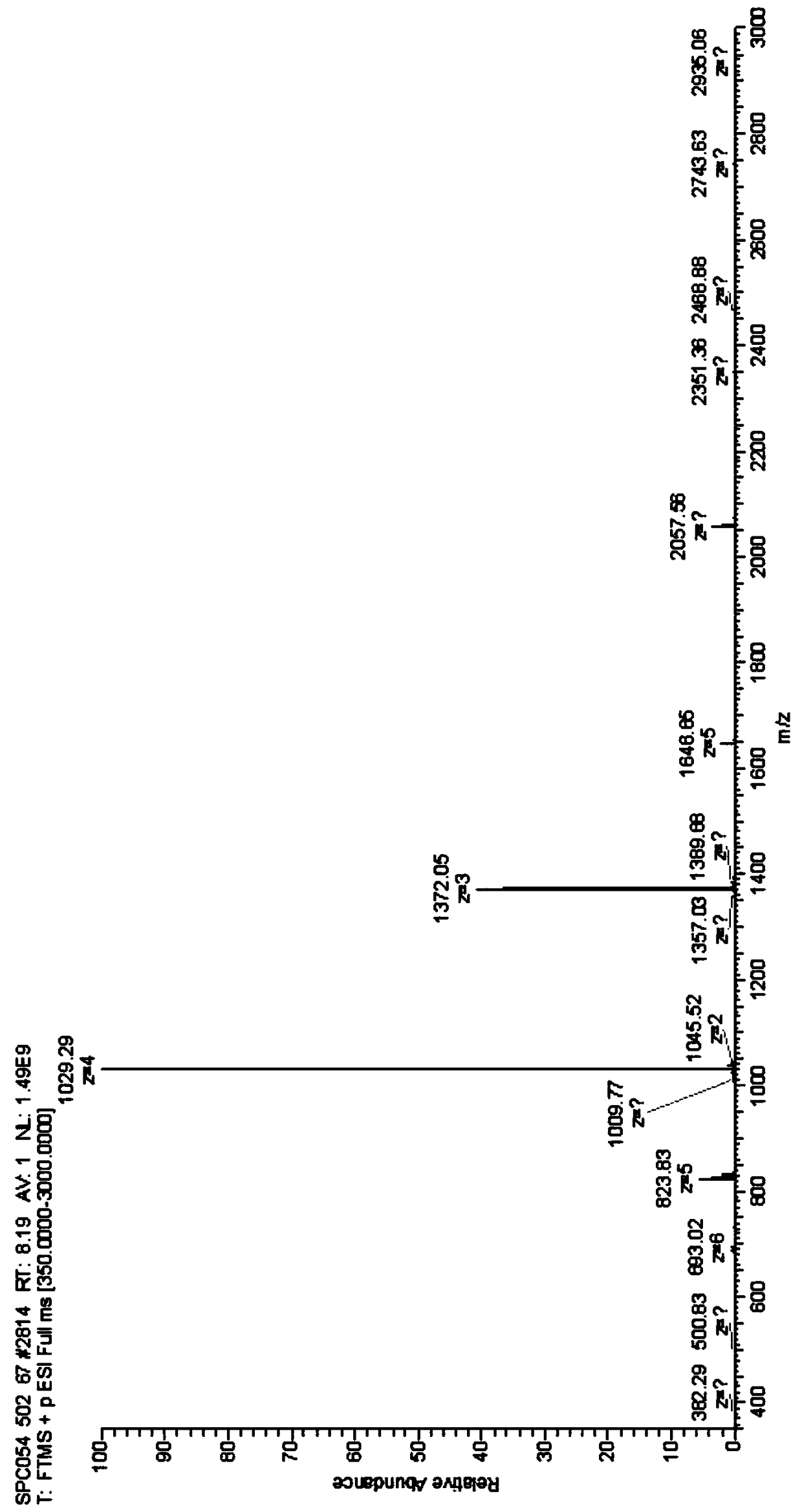

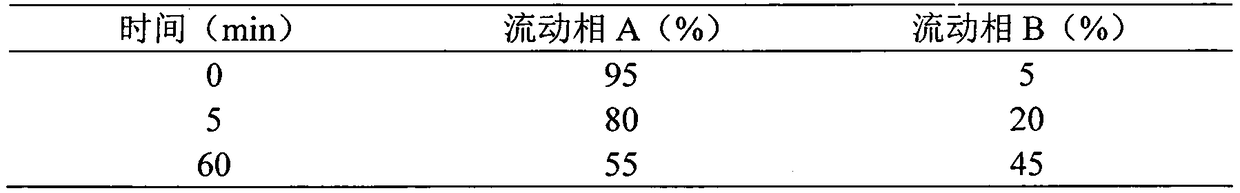

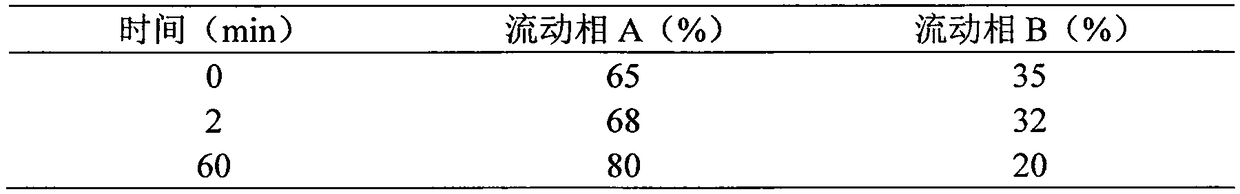

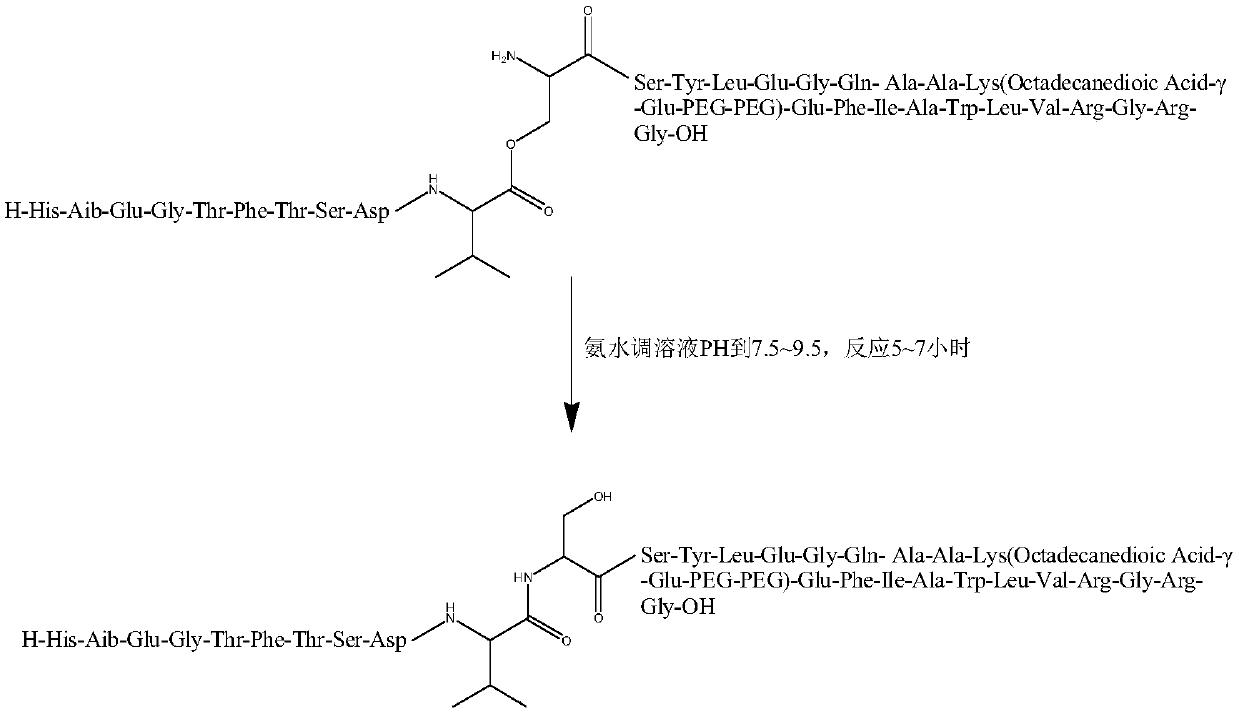

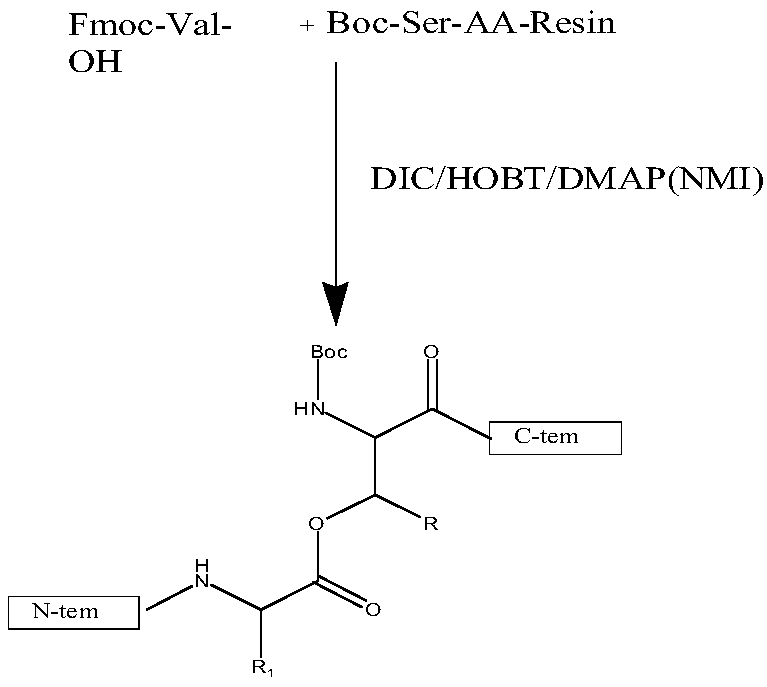

Synthetic method for semaglutide

PendingCN109456402ADestroy secondary structureTroubleshoot compositingPeptide preparation methodsBulk chemical productionSide chainCombinatorial chemistry

The invention discloses a synthetic method for semaglutide and belongs to the field of polypeptide synthesis. In the method, amino acids at 1-30 positions of a main sequence of the semaglutide is obtained by adopting solid phase synthesis, Val at 10 position and Ser at 11 position adopt Fmoc-Val10-Ser11 (Psi(Me, Me) pro)-OH; and an Lys side chain at 20 position adopts Fmoc-Lys(X)-OH. The method comprises the following steps of performing cracking precipitation to obtain a semaglutide crude peptide; and performing purification to obtain the semaglutide. In the method, by introducing the Fmoc-Val10-Ser11 (Psi(Me, Me) pro)-OH to solve the problem of difficult sequence synthesis of the semaglutide, difficult sequence synthesis becomes simple and easy; and meanwhile, the yield is greatly increased, the purity of the crude peptide is greatly improved, the production cost is greatly lowered, and industrial amplification production is facilitated.

Owner:SINOPEP ALLSINO BIOPHARMACEUTICAL CO LTD

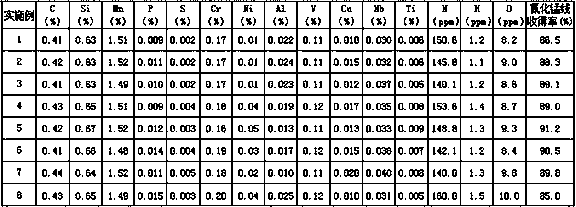

Smelting method of non-quenched and tempered steel

ActiveCN110055450AImprove purityReduced activityManufacturing convertersProcess efficiency improvementSmelting processCalcium cyanamide

The invention discloses a smelting method of non-quenched and tempered steel. The smelting method comprises the working procedures of converter smelting, LF refining, VD vacuum treatment and continuous casting, and comprises the specific technological steps that (1) nitrogen is blown at the bottom in the whole converter smelting process, and converter high-carbon drawing and tapping is carried out; (2) diffusion deoxidation is carried out in the LF refining process, good deoxidation and desulfurization effects are guaranteed, and the N content of molten steel after LF finishing is 75-90ppm; (3) VD vacuum treatment is carried out, wherein the content of N in the molten steel after hollow breaking is 50-60 ppm, after hollow breaking, soft blowing time is larger than or equal to 30 min, and argon flow is smaller than or equal to 25 L / min; and (4) continuous casting adopts crystallizer stirring and tail-end stirring, medium-high carbon tundish covering agent and medium-carbon crystallizercovering slag are used, and continuous casting billets are cooled slowly in an off-line mode. According to the smelting method of the non-quenched and tempered steel, the nitrogen content yield is stable, the performance of the non-quenched and tempered steel is good, calcium cyanamide (CaCN2) is not adopted, environmental pollution is small, the feeding amount of the manganese nitride wire is small, and the production cost is low.

Owner:石钢京诚装备技术有限公司

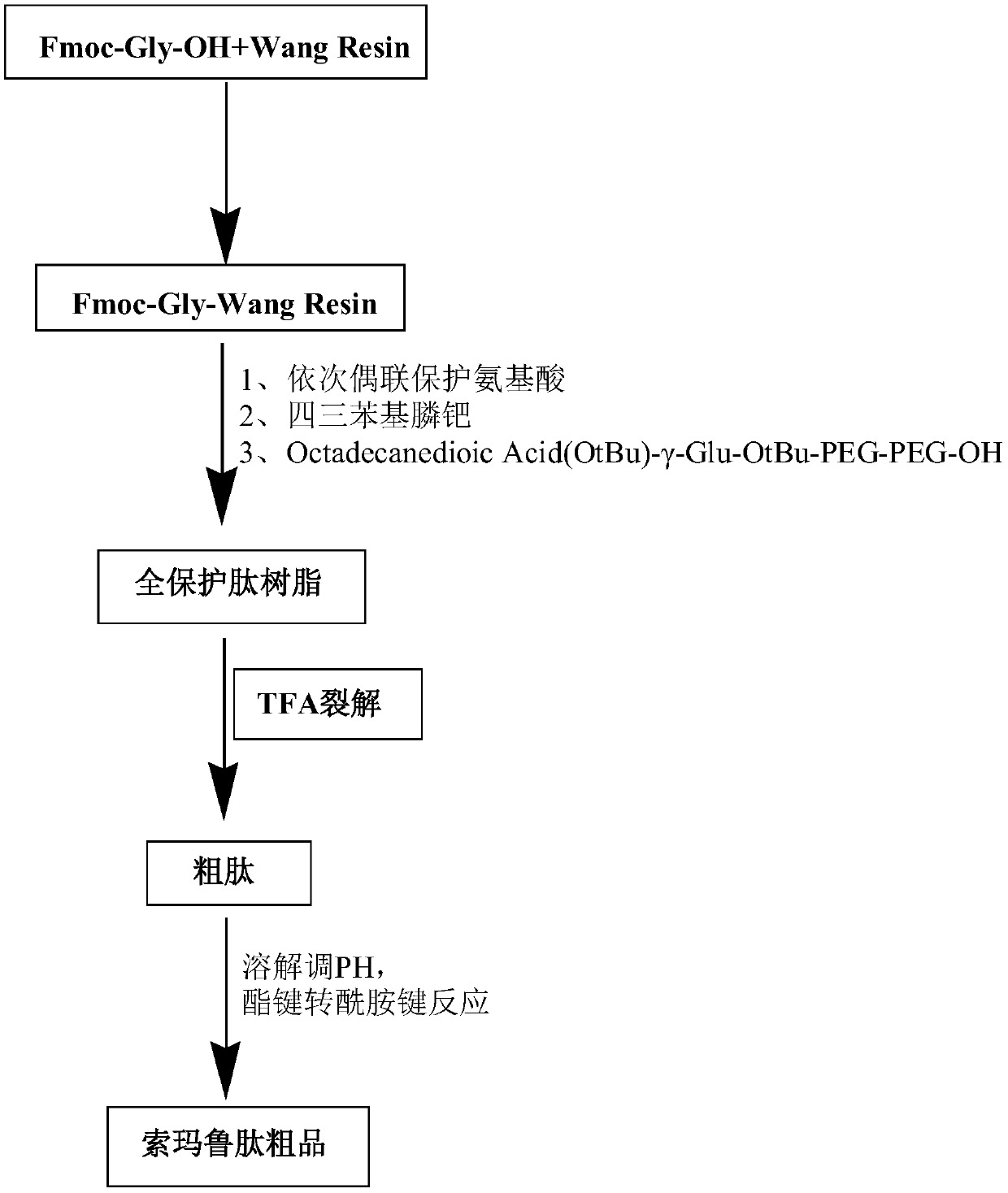

Synthesizing method of sermaglutide

ActiveCN108676087ASolve coupling difficultiesFeed lessPeptide preparation methodsGlucagonsPeptideAmino acid

The invention discloses a synthesizing method of sermaglutide. The synthesizing method comprises the following steps of step 1, preparing Fmoc-Gly-Wang resin; step 2, using the Fmoc-Gly-Wang resin, protective amino acids, and octadecandioic acid (OtBu)-gamma-Glu-OtBu-PEG-PEG-OH as the raw materials to prepare full-protective peptide resin which contains Depsipeptide Units; step 3, performing TFA (trifluoroacetic acid) cracking on the peptide resin, so as to obtain crude peptide; step 4, dissolving the crude peptide obtained in step 3, adjusting the pH (potential of hydrogen) value, and converting ester bonds into amide bonds to react, so as to obtain a crude product of the sermaglutide. The synthesizing method has the advantages that by introducing the Depsipeptide Units, the problem of difficulty in sequential synthesizing of the sermaglutide is solved, and the target product is obtained by the reaction of converting the ester bonds into the amide bonds; the purity and yield of the crude peptide are improved, and the synthesizing method is suitable for downstream purifying, and is suitable for industrialized production.

Owner:SINOPEP ALLSINO BIOPHARMACEUTICAL CO LTD +1

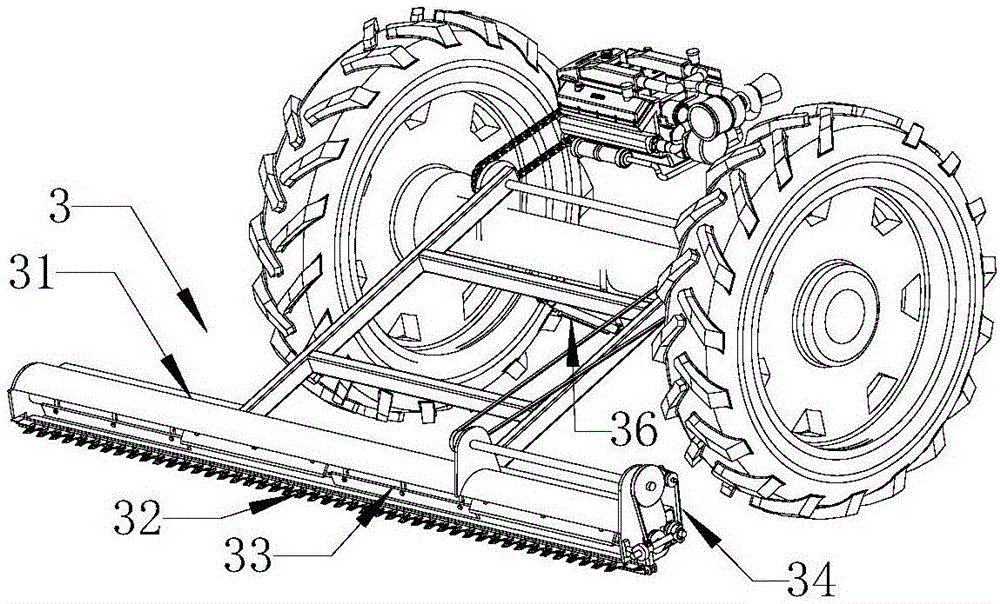

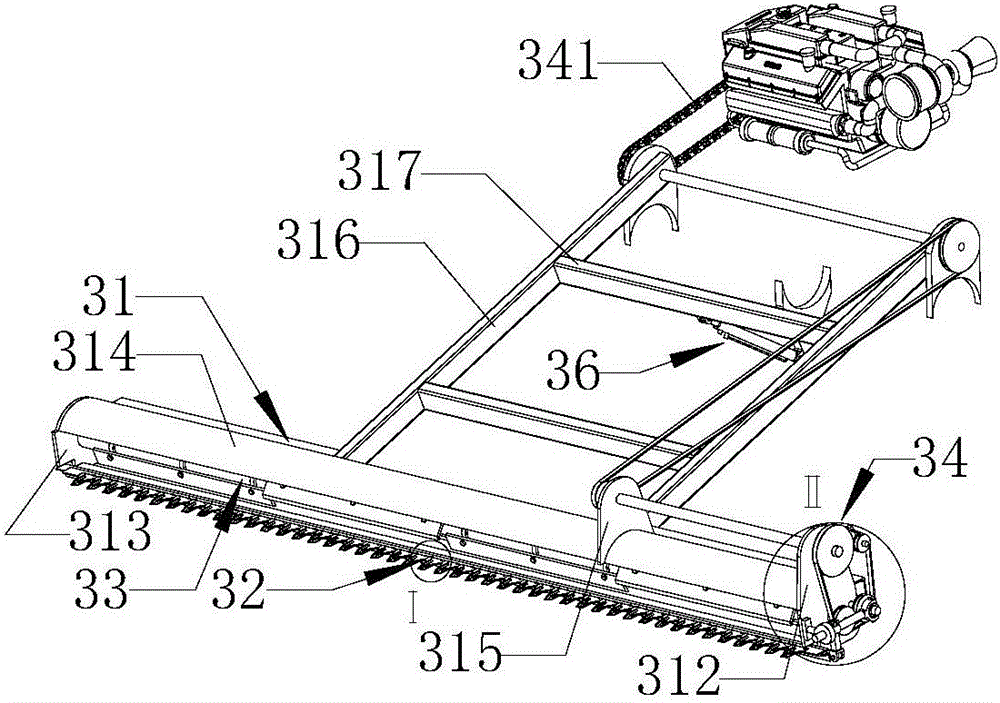

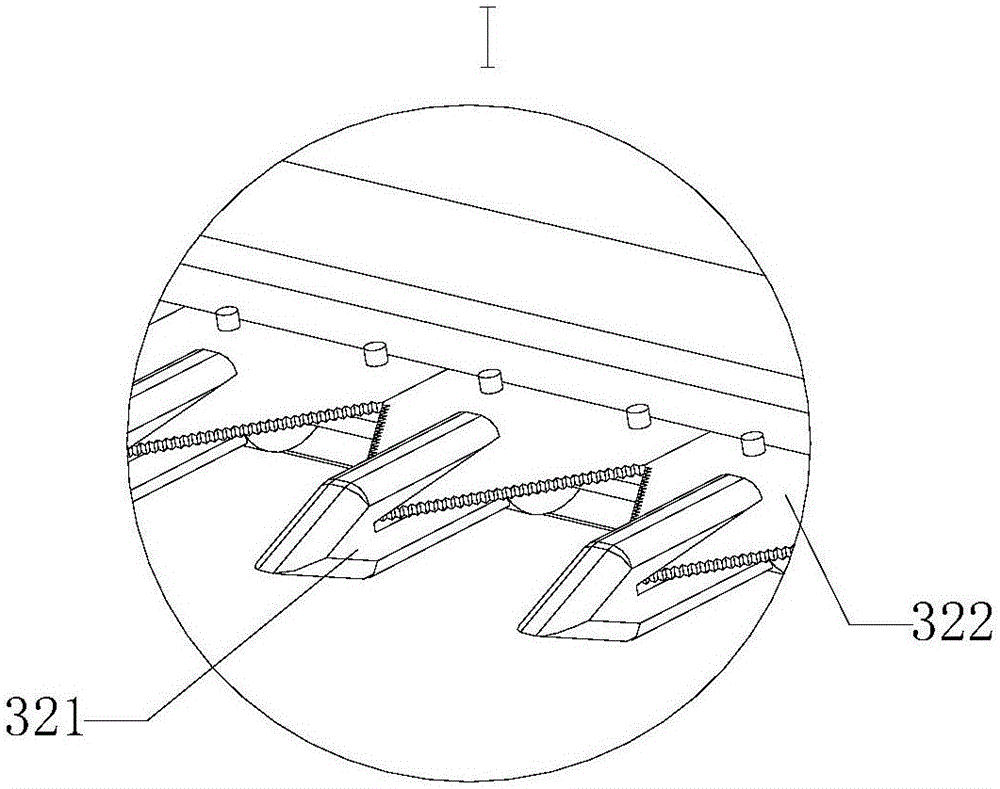

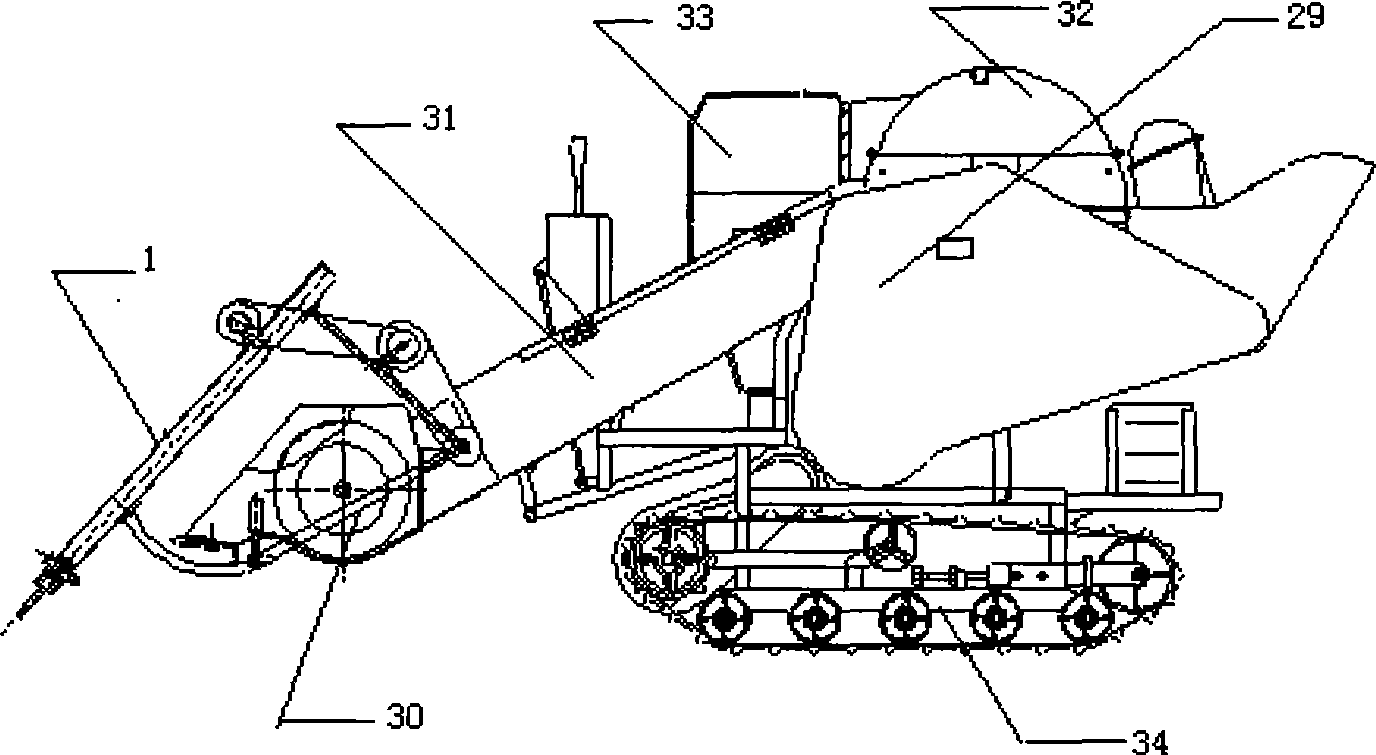

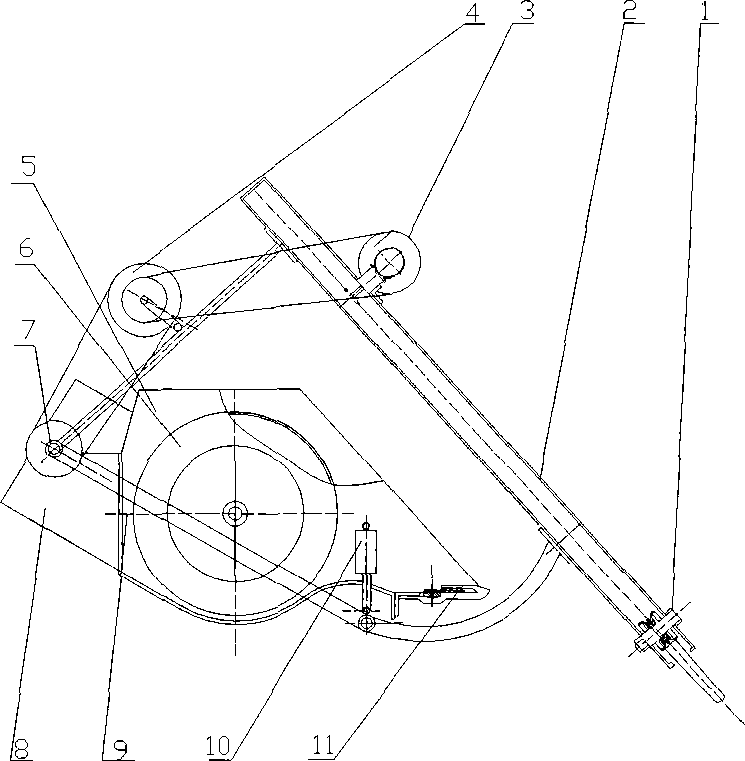

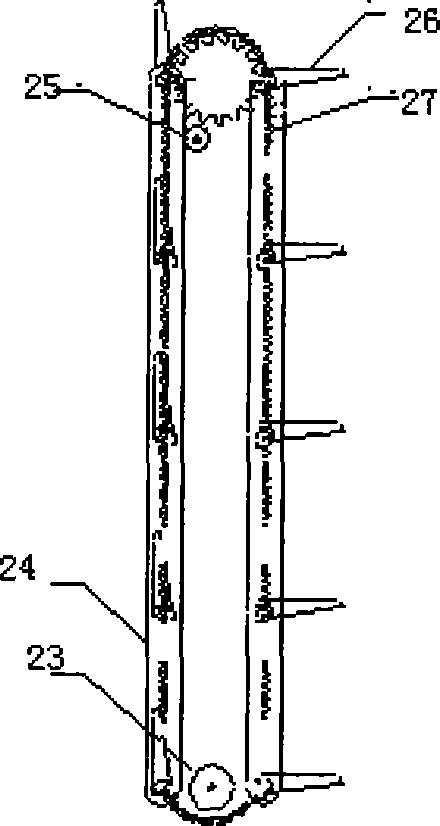

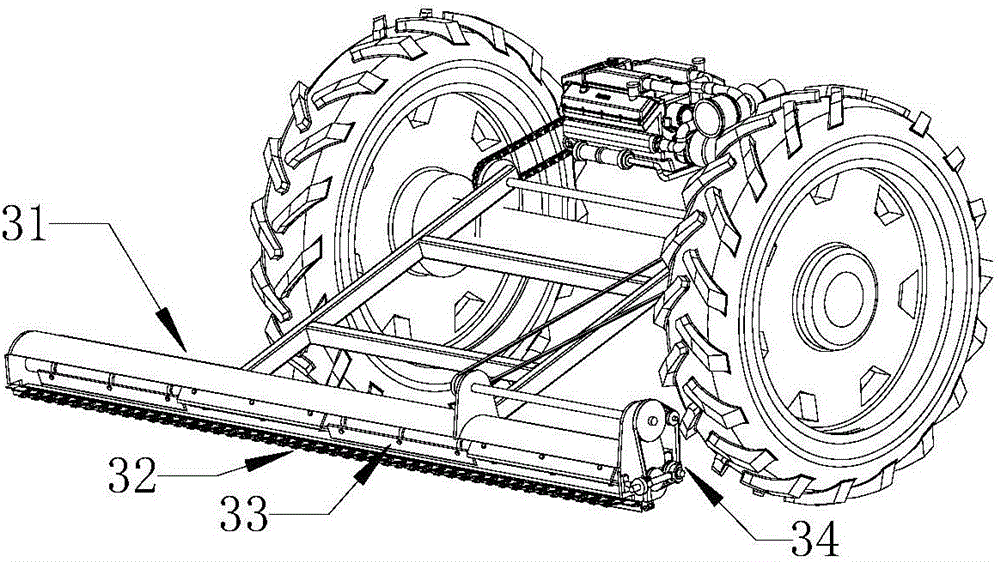

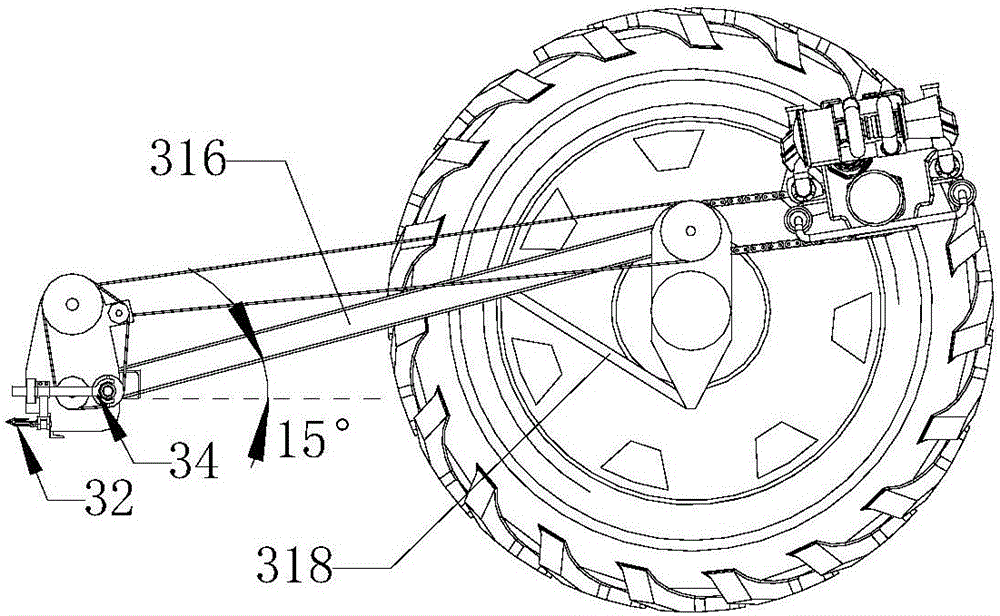

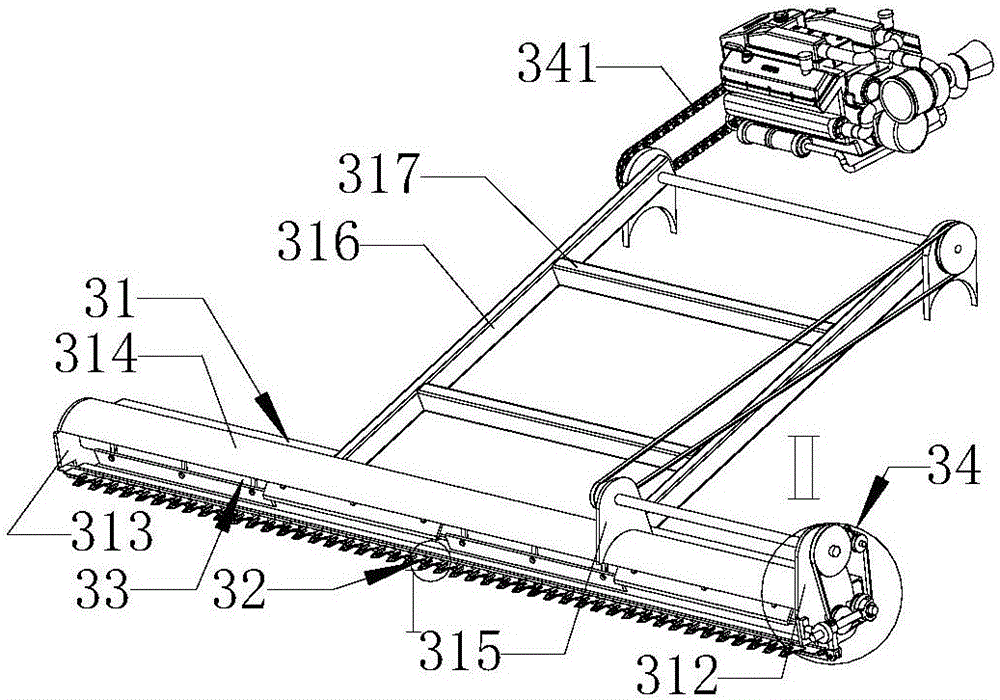

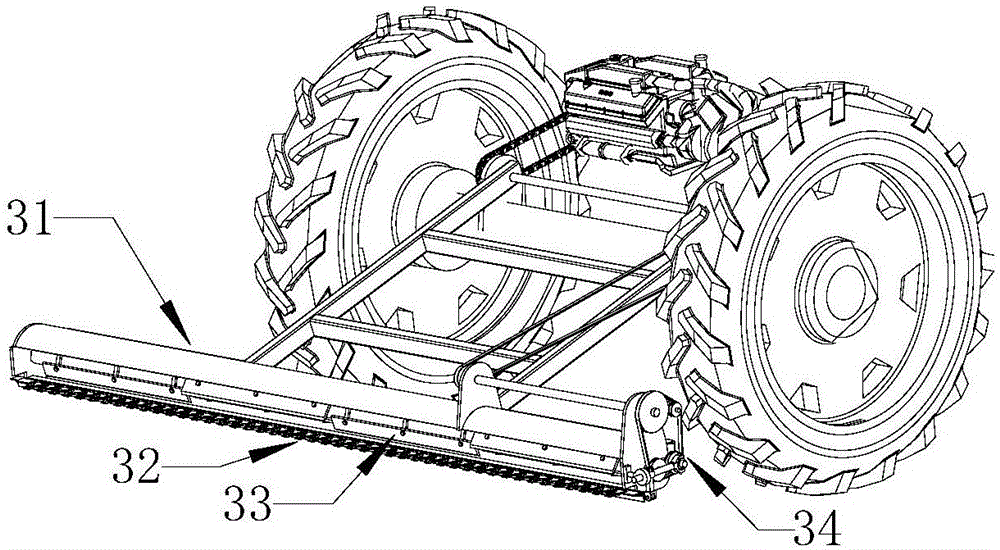

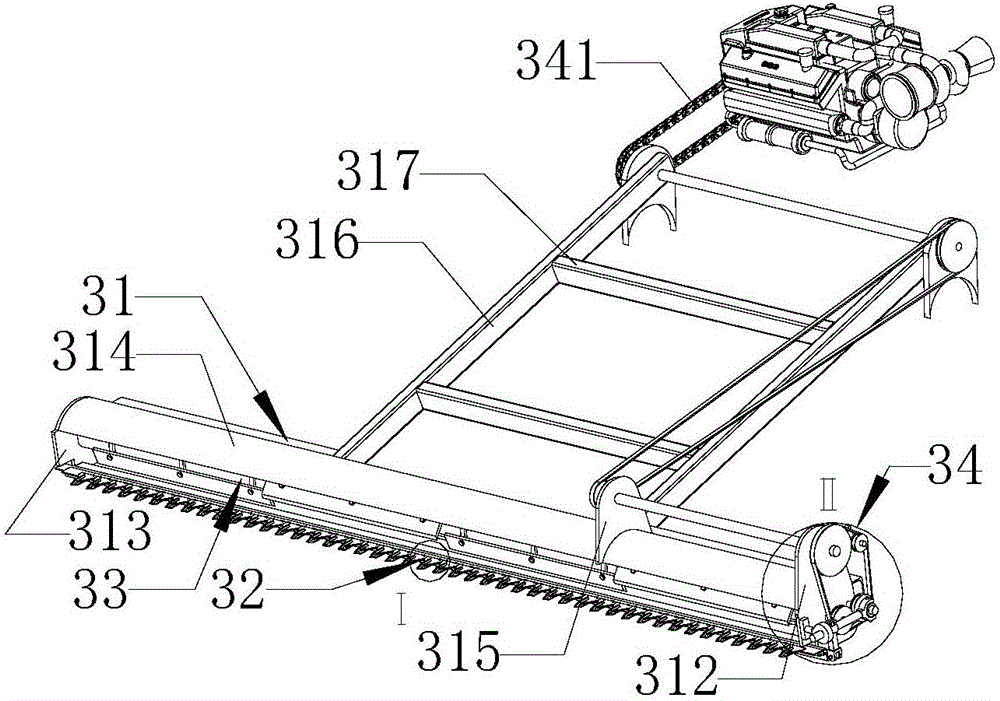

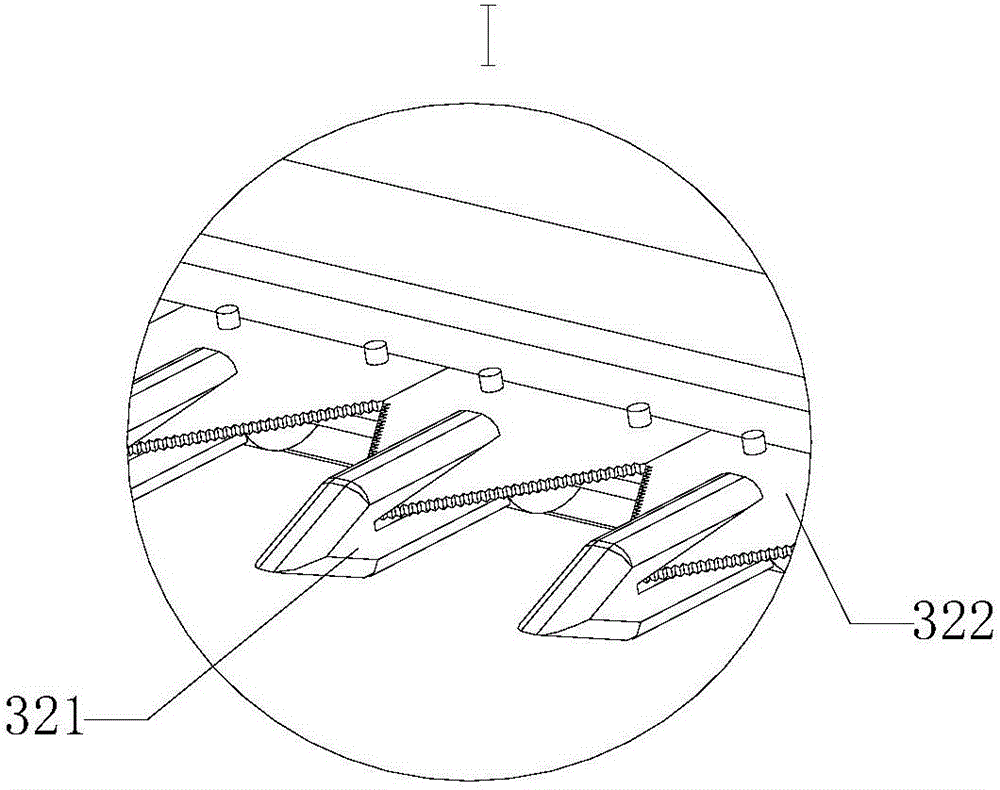

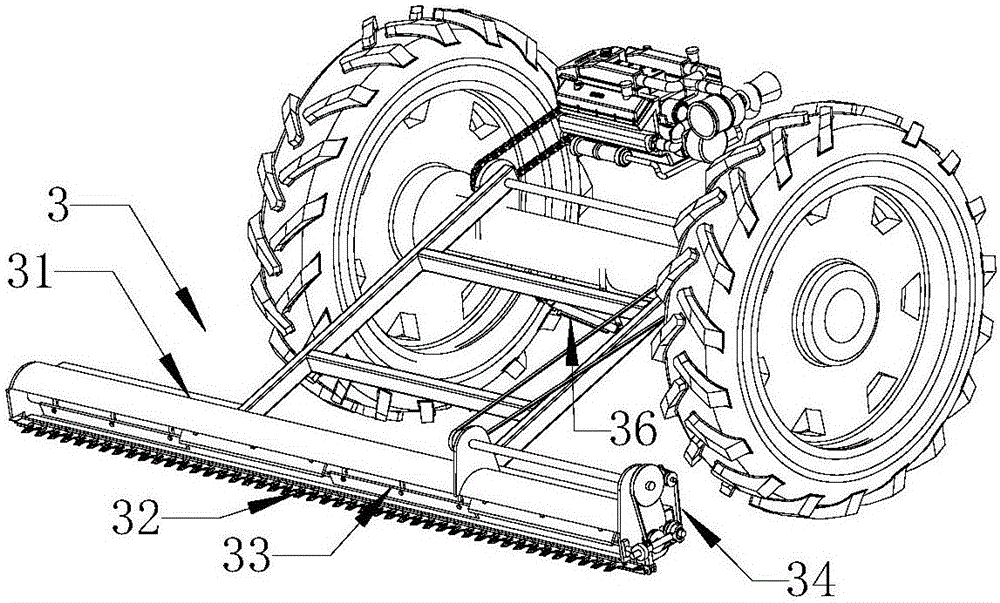

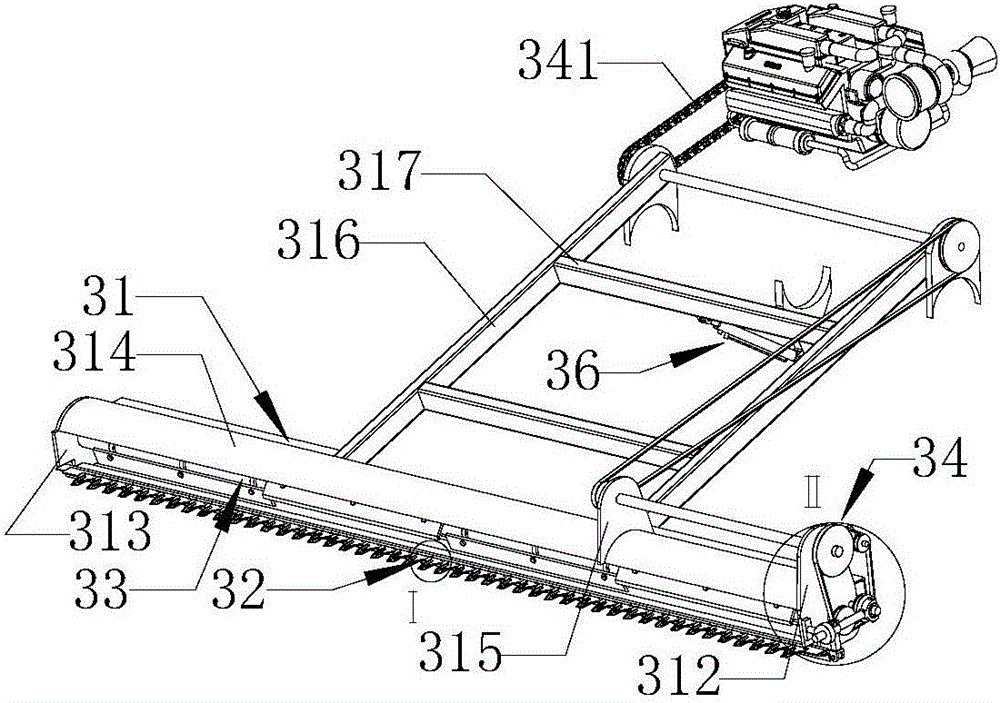

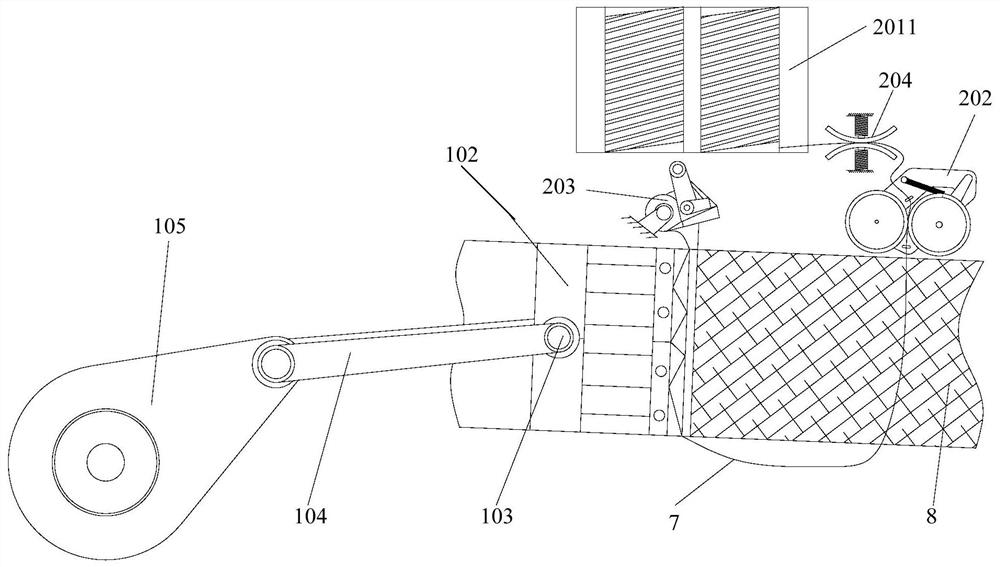

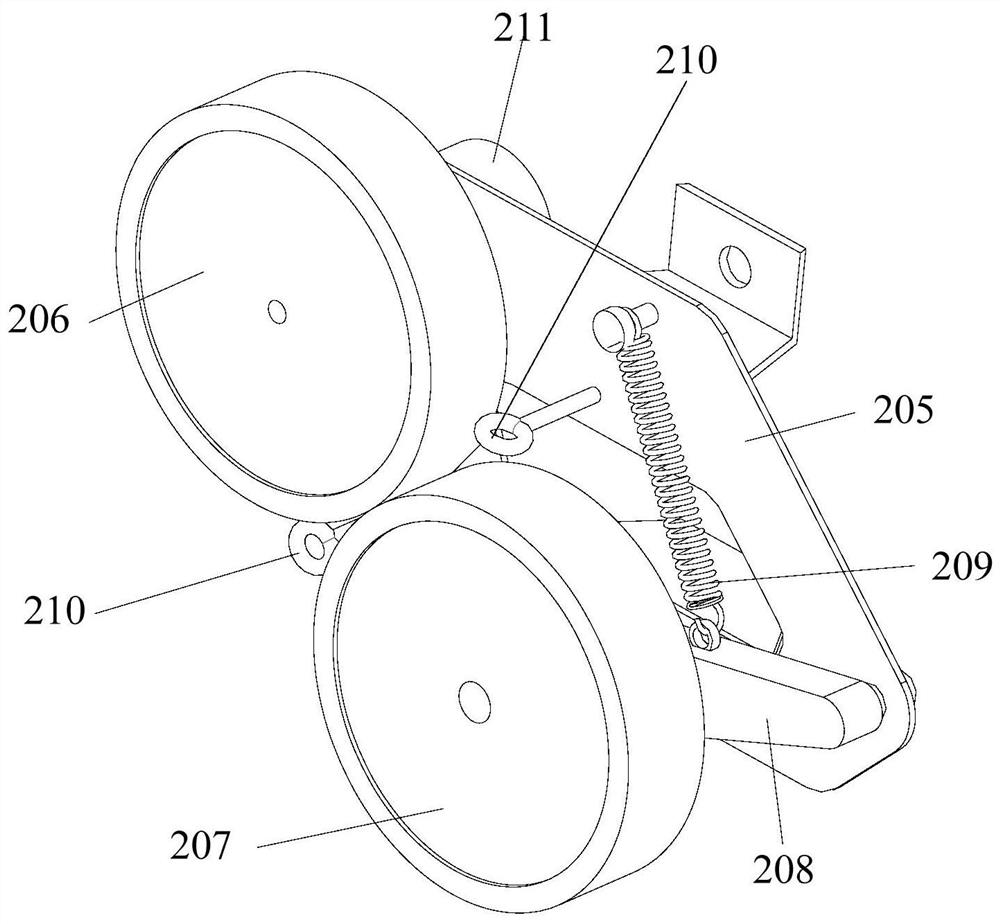

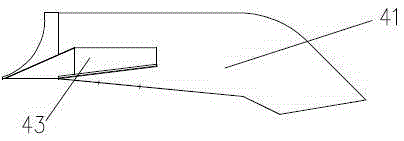

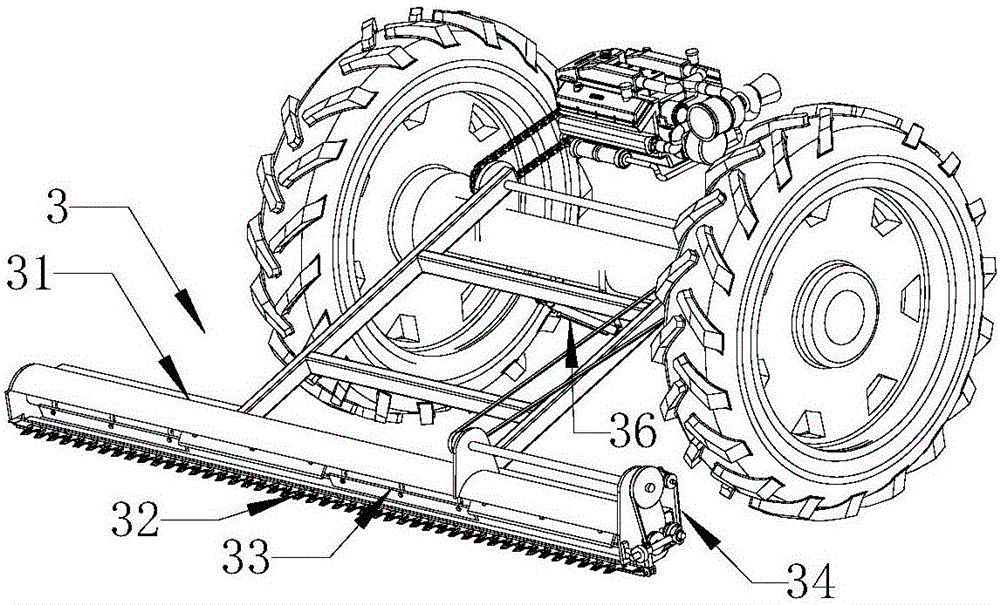

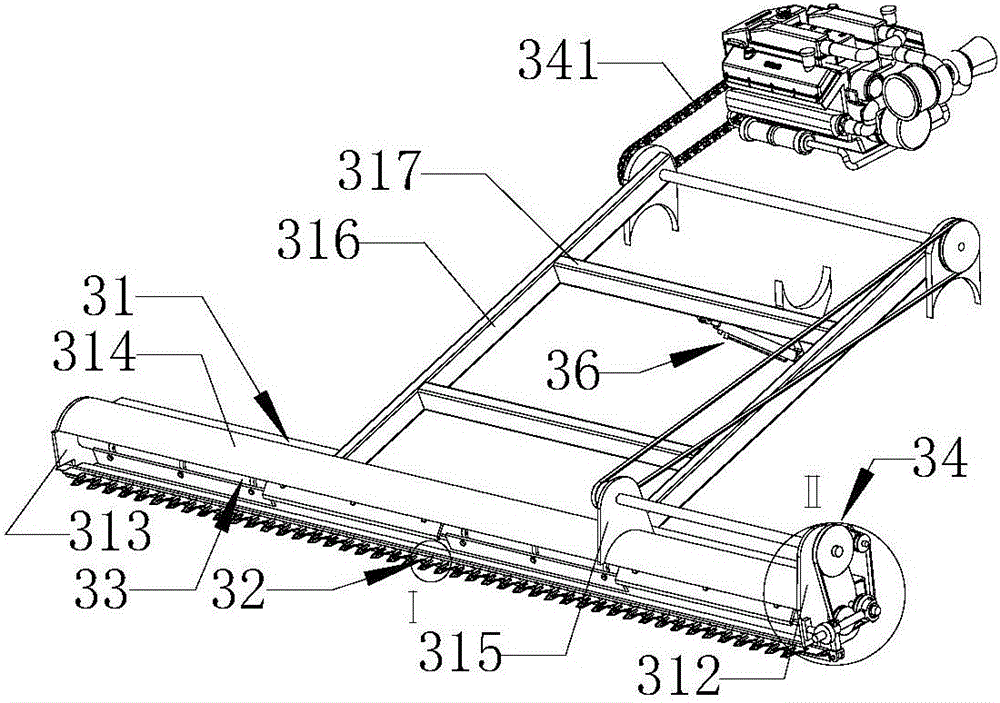

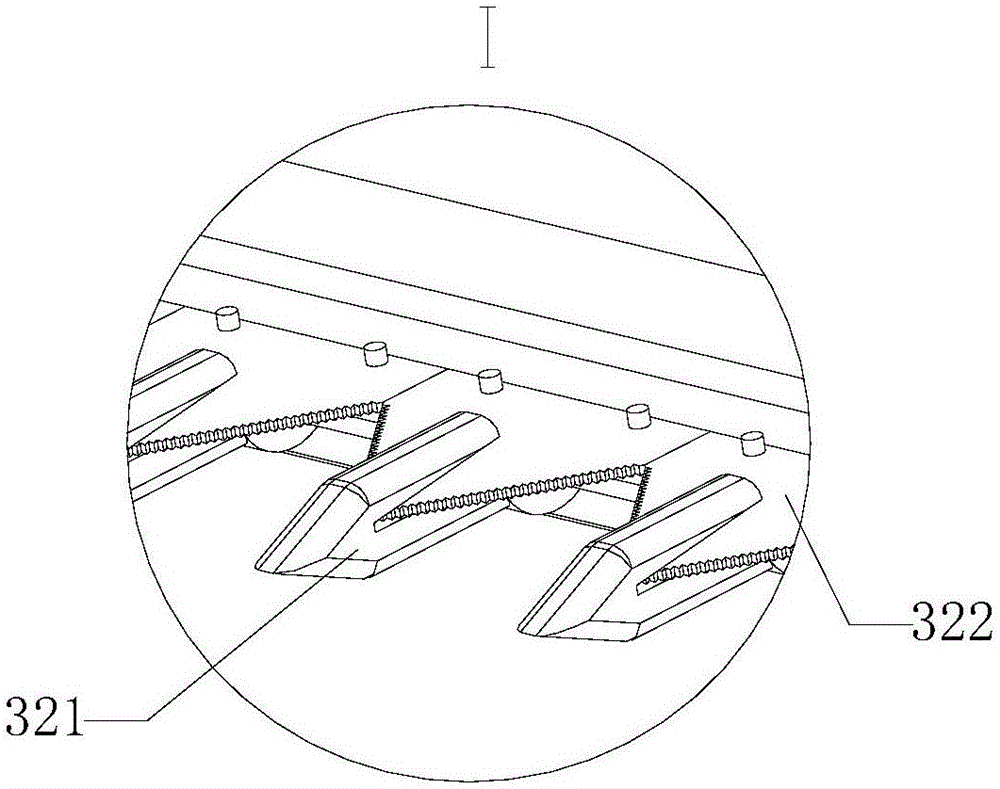

Harvester provided with protective ladder and lifting type lower header capable of smashing straw and preventing smashed straw from splashing

The invention discloses a harvester provided with a protective ladder and a lifting type lower header capable of smashing straw and preventing the smashed straw from splashing. The harvester comprises the lower header and the protective ladder, and the lower header is hinged to a front axle of the harvester. The lower header comprises a lower header main frame, a lower cutting mechanism, a straw smashing mechanism, a transmission mechanism and a lower header lifting mechanism. Blocking angle iron is further fixedly connected with the rear portion of a shield of the lower header main frame. The lower header lifting mechanism comprises a lower header lifting oil cylinder, a lower header lifting oil cylinder upper base and a lower header lifting oil cylinder lower base. The harvester provided with the protective ladder and the lifting type lower header capable of smashing straw and preventing the smashed straw from splashing can cut and smash straw left after grain harvesting, and the feed quantity of the harvester is reduced. Cutting stubbles are short and flat so that tillage can be convenient. The straw cutting and smashing efficiency is high, smashing is uniform, and the smashed straw cannot splash. The lower header can ascend and descend so as to control the height of the cutting stubbles and avoid obstacles to protect equipment safety. The arranged protective ladder makes people climb safely and conveniently, and can also be used as a safety guardrail.

Owner:纪小坤

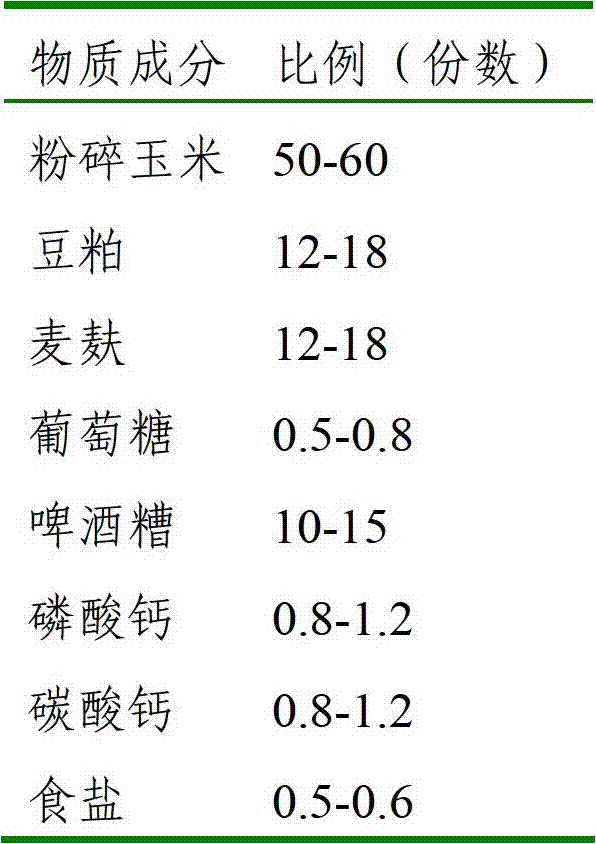

Forage composition containing whole soyabean and steaming tabletted corn for calf and preparation thereof

InactiveCN1817177AImprove digestibilityHigh speedFood processingAnimal feeding stuffAlcoholCornflakes

A composite feed for calf is proportionally prepared from steam pressed corn flakes, steam pressed soybean flakes, soybean peel, cotton seed dregs, distilled corn generated by preparing alcohol, distilled grains generated by preparing beer, and edible salt through mixing, pulverizing and packing.

Owner:KAITE FORAGE GROUP HEBEI

Production method of high-cleanliness sulfur-containing and aluminum-containing steel

ActiveCN111235341ARaise the initial sulfur contentReduce production process costsManufacturing convertersProcess efficiency improvementSlagMolten steel

The invention discloses a production method of high-cleanliness sulfur-containing and aluminum-containing steel. The production method comprises the following steps: a top-bottom blowing combined converter is used for blowing, and molten steel is subjected to composite deoxidation, alloying and slagging in the tapping process; heating in the LF refining process, diffusing and deoxidizing of a slagsurface, and precipitating and deoxidizing of molten steel are performed, desulfurizing is not deliberate, the flow of ladle bottom blowing and stirring argon in the whole refining process is controlled, and calcium treatment and soft blowing are performed on the molten steel before the refining is finished; the molten steel is transferred to an RH station, a sulfur line is fed according to the residual sulfur content of the molten steel to a resulfurization target value of the molten steel, vacuum treatment is performed, and micro-calcium treatment denaturation is performed again after the molten steel is broken; and standing and soft blowing are performed on the molten steel; and an arc continuous casting machine performs protective casting. According to the method, the original sulfurcontent of the molten steel is improved, the refining process is not supplemented with slag materials for deliberate desulfurization, only molten steel diffusion and precipitation deoxidation are adopted, weak bottom blowing stirring and calcium treatment are adopted to promote inclusion removal, the sulfur line is fed before the molten steel enters the RH station, so that no component adjustmentis needed after the molten steel RH circulation, secondary pollution of the molten steel is avoided, and high cleanliness control of the molten steel is realized.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

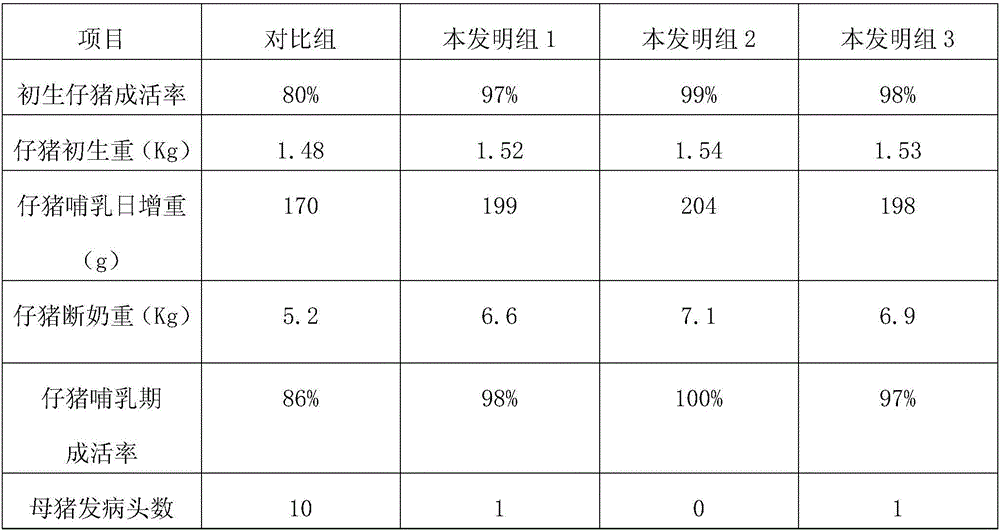

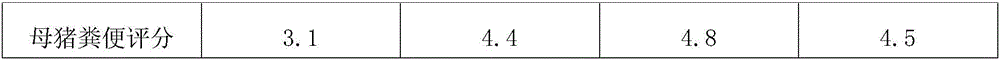

Feed for sows and breeding method of sows

The invention provides feed for sows and a breeding method of sows, and relates to the technical field of breeding. The feed for the sows is prepared from feed for pre-pregnant sows, feed for pregnant sows and feed for lactating sows. The invention also provides the breeding method of the sows. The breeding method comprises the steps of (1) pig house management, (2) feeding management and (3) stocking management. The feed for the sows is reasonable in proportion of the three groups of feed, green and safe, and simple in preparation process; in a breeding process, by means of differential feeding in a targeted way in different stages, the different nutritional requirements of the sows at the different stages can be met, the health of the sows is guaranteed, the farrowing survival rate of the pregnant sows is improved, the probability of abortion, stillbirth and mummy fetuses is reduced, and the lactating sows are smooth in circulation of qi and blood, healthy in fur and smooth in milk secretion. After the feed for the sows and the breeding method of the sows are adopted, the sows are fed in a targeted way, so that the breeding benefit is maximized, the aims of saving cost and improving feed utilization rate are achieved, and the feed and the breeding method are worth of being generalized.

Owner:陆川县横山伟旺猪场

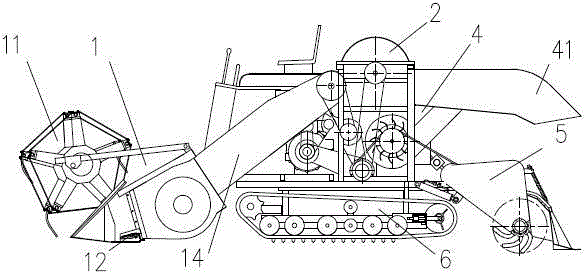

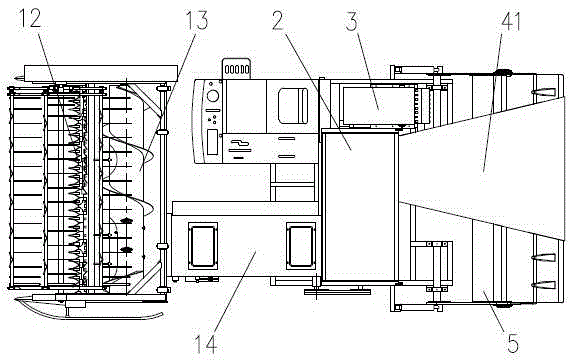

Whole-feeding combine harvester equipped with lifting device

The invention relates to a combine harvester. The combine harvester is a full-feed harvester with a lifting device and is designed to combine the advantages of full-feed harvesters and semi-feed harvesters. The combine harvester is formed by restructuring a full-feed harvester consisting of a machine frame, a header, an ear conveying device, a threshing device, a storage device, a power device and a traveling device, that is, by mounting a crop lifting device in front of a hopper of the header to form the header with the hopper, a screw feeder, a cutter, a transmission mechanism and the lifting device. The combine harvester can be used to harvest laid crops, improve working efficiency, reduce loss during harvest, effectively reduce feed quantity, reduce machine load, faults and costs, is high in efficiency and easy to popularize, and overcomes drawbacks that the full-feed harvesters can not effectively harvest laid crops .

Owner:方友祥

Composition for promoting estrus of sows as well as feed and application thereof

The invention provides a composition for promoting estrus of sows as well as a feed and application thereof. The composition consists of the following components in parts by weight: 5 to 10 parts of Chinese angelica, 8 to 15 parts of root of rehmannia, 2 to 7 parts of white peony root, 2 to 6 parts of Szechuan lovage rhizome, 2 to 6 parts of corydalis tuber, 8 to 15 parts of nutgrass galingale rhizome, 8 to 15 parts of hawthorn, 8 to 15 parts of medicated leaven and 5 to 10 parts of motherwort. The composition is reasonable in formula; by fully considering the compatible regulation and stimulating the hypophysis cerebri of the sows, secretion of in-vivo reproductive hormone is regulated, the disordered reproductive cycle of the sows is regulated, the estrus of the sows is promoted, and the yearly litter size of the sows is improved; and the composition does not have side effect, and can be used for estrus promotion of postpartum sows or adaptive sows.

Owner:CHONGQING KAIZHOU JIUDING ANIMAL HUSBANDRY SCI & TECH DEV

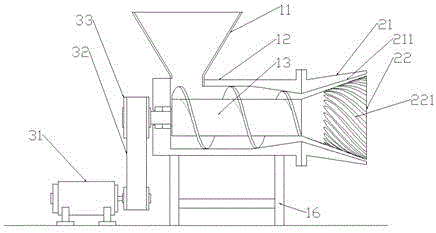

Biomass fuel block production method and equipment

ActiveCN105597862AImprove textureUniform textureBiofuelsSolid fuelsMolding machineProcess engineering

The invention discloses a biomass fuel block production method and equipment. Straw is cut into blocks, rubbed in a straw rubbing machine, extruded in a biomass fuel movable mold forming machine at certain temperature to fill up a movable mold, placed in a heat insulation bin for 2-5 min at the temperature of 190 DEG C or above for shaping and then subjected to demolding. According to the straw rubbing machine, an auger and a rubbing head are matched to carry out rubbing, the fiber structure of the straw is compressed, the size is reduced, density is increased, and therefore the material feeding quantity in the forming machine is increased. According to the biomass fuel movable mold forming machine, the movable mold is adopted, a movable mold track and the heat insulation bin are additionally arranged, a choke pipe in an extruding machine is omitted, a shaping pipeline in a shape keeping area is shortened, frictional force between materials and the mold and loss of the mold are reduced, cost is lowered, and energy consumption is saved; the mold is automatically transferred into a heat insulation device after being filled, the extruding machine continues to operate, production time for a single fuel block is shortened, shape keeping time is prolonged, and the produced biomass fuel blocks are good in shape, high in density, uniform in texture and consistent in specification.

Owner:丁启航

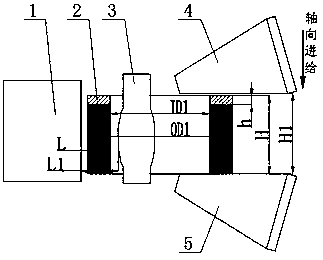

Large SRB wind power main bearing outer ring profiling rolling method

The invention discloses a large SRB wind power main bearing outer ring profiling rolling method. The method comprises the following steps that S1, in the blank manufacturing preparing stage, a blank (2) with the assigned process size is obtained, OD is the assigned forge piece outer diameter size, ID is the assigned forge piece inner diameter size, and H is the assigned forge piece height size; and S2, the blank size is input into a horizontal grinding replacing machine, OD1 is the blank outer diameter and is equal to the sum of OD and x, x is larger than 0, ID1 is the blank inner diameter andis equal to the difference of ID and y, y is larger than 0, H1 is the blank height and is the sum of H and z, and z is larger than 0. According to the large SRB wind power main bearing outer ring profiling rolling method, due to the high conical roller pressure, material gathering on the two end faces is achieved, near-net forming rolling of a large-wall-thickness-difference SRB bearing ring canbe achieved, the work face fit degree is high, metal flow line cutting-off is reduced, enhancing of the integral product performance is facilitated, and the product fatigue life is long. Through the high conical roller pressure, material gathering on the two end faces is achieved, the production process is stable, product consistency is good, and few quality problems exist; and through the high conical roller pressure, material gathering on the two end faces is achieved, the production efficiency is high, charging is little, cost is low, the material utilization rate is high, and enhancing ofthe market occupancy is facilitated.

Owner:江苏翔能科技发展有限公司

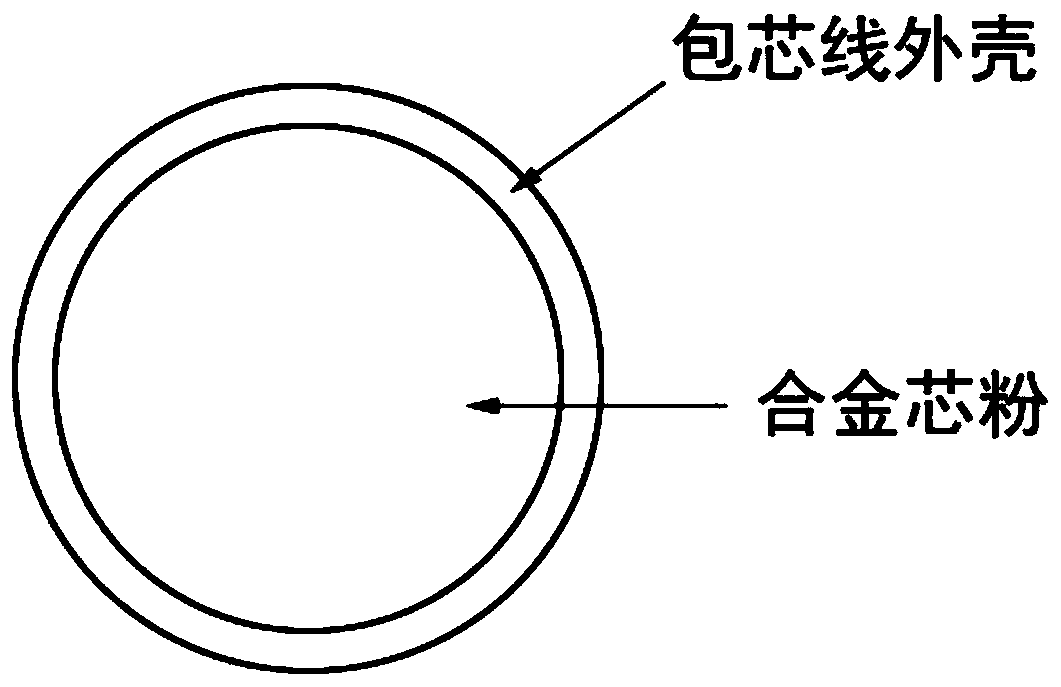

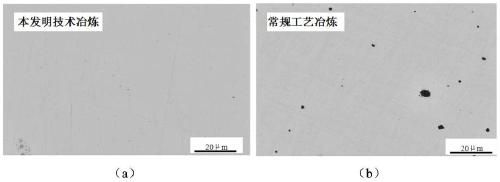

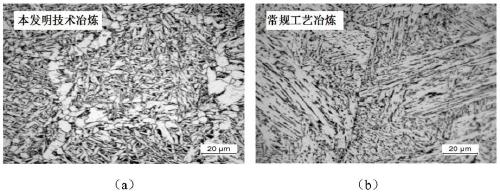

Composite core-spun yarn and large-line-energy welding steel preparing method

The invention discloses a composite core-spun yarn and a large-line-energy welding steel preparing method, and belongs to the technical field of steel metallurgy. Based on the oxide metallurgy basic principle, multiple alloy composite adding modes are selected in the core-spun yarn, and through reasonable core powder chemical component design, the functions of deep deoxygenation, deep desulfuration and inclusion harmless control in the steel smelting process are fused, the metallurgy process chemical reaction is sufficiently utilized, and fine, spheroidization, dispersion and composite controlof inclusions in the steel is achieved. According to a 60 mm EH36 ship making steel plate manufactured through the core-spun yarn, after EGW is conducted when the line energy is 460 kJ / cm, the -40 DEG C ballistic work value of the welding heat affected zone is larger than or equal to 170 J. After the core-spun yarn is used for replacing a Ni-Mg alloy commonly used during current large-line-energywelding steel production, the ton-steel alloy cost can be reduced to be smaller than or equal to 100 yuan from the cost higher than 300 yuan in the original technology, economic and social benefits are obvious, and very good popularization and application prospects are achieved.

Owner:李素坤

Pond three-dimensional breeding method

InactiveCN104904631AHigh economic valueExcellent output qualityClimate change adaptationAgricultural fishingShrimp aquacultureZoology

The invention relates to a pond three-dimensional breeding method. The method comprises the steps that a pond is built, aquatic plants are planted, freshwater shrimps are bred, snakehead is bred, green ducks are bred in pens, and ducks are bred in the pond. By means of the method, the snakehead output quality and the duck egg output quality are good, fed fodder is little, ecological benefits are good, and the economic value is high.

Owner:秦峰

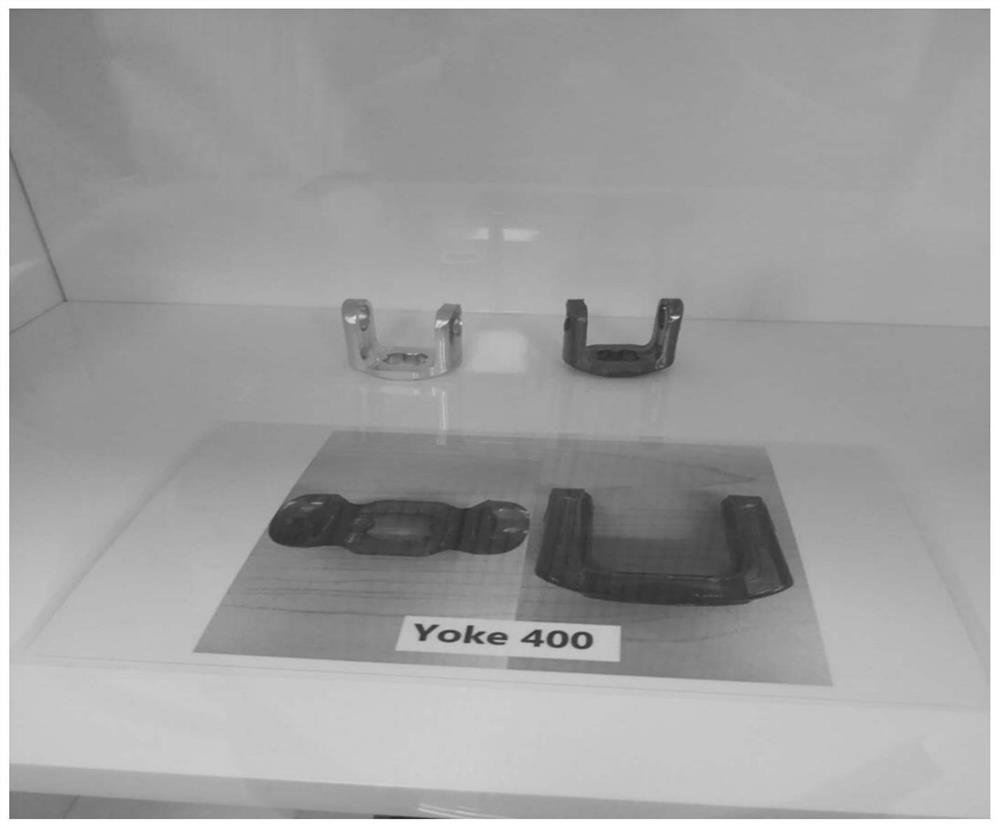

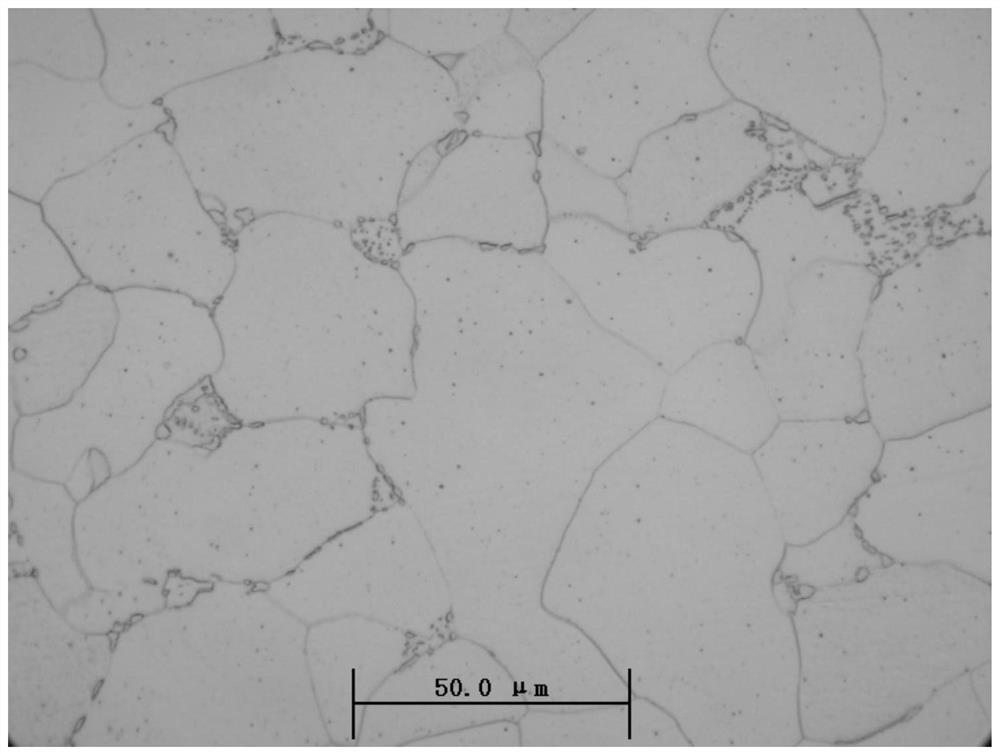

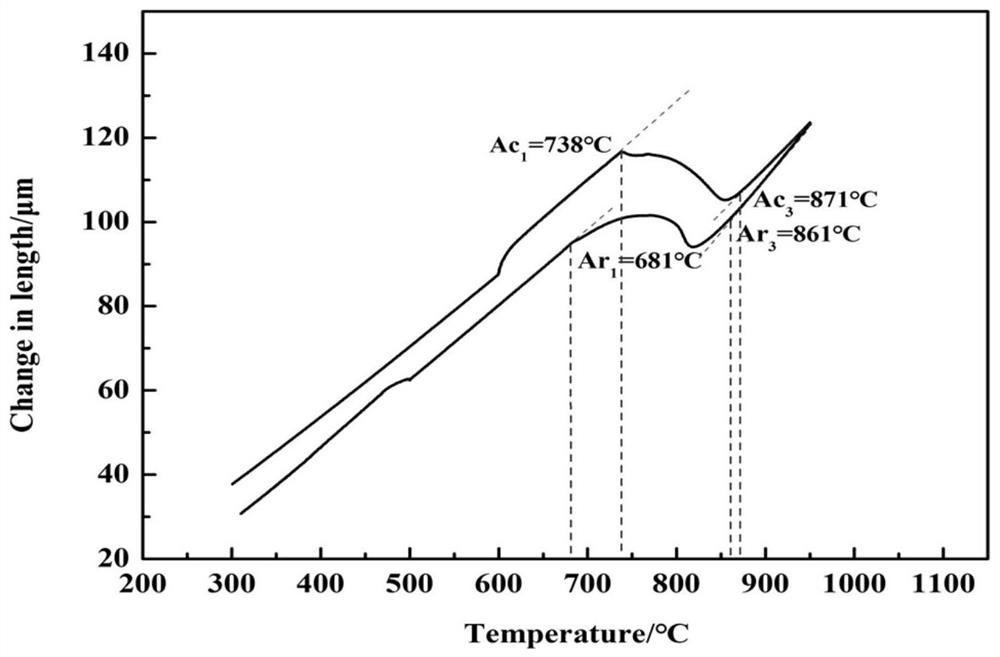

Steel for cold forging of universal joint fork of passenger car and manufacturing method of steel

The invention relates to steel for cold forging of a universal joint fork of a passenger car and a manufacturing method of the steel. The steel comprises the following chemical components in percentage by mass: 0.04 to 0.10 percent of C, 0.01 to 0.12 percent of Si, 0.40 to 0.60 percent of Mn, less than or equal to 0.015 percent of P, 0.020 to 0.035 percent of S, less than or equal to 0.10 percent of Cr, less than or equal to 0.10 percent of Ni, less than or equal to 0.10 percent of Cu, less than or equal to 0.02 percent of Mo, 0.020 to 0.050 percent of Al, 0.007 to 0.009 percent of N and the balance of Fe and inevitable impurity elements. The texture of the steel is ferrite and pearlite, and the spheroidization rate of the pearlite is larger than or equal to 85%. The production process route comprises the steps of molten iron pretreatment, primary smelting in a converter, refining, continuous casting, continuous casting billet cooling, continuous casting billet heating, rolling, cooling, spheroidizing annealing and lathing. Taking a bar with the diameter phi of 20-40 mm as an example, the surface hardness is smaller than or equal to 110 HV30; Rp0.2 is smaller than or equal to 280 MPa, Rm is smaller than or equal to 360 MPa, the ductility A5 is larger than or equal to 40%, the percentage reduction of area Z is larger than or equal to 75%, and a product has excellent plasticity and low deformation resistance and is steel for cold forging with ideal performance.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Harvester of fixed lower header capable of preventing splashing of broken straws

The invention discloses a harvester of a fixed lower header capable of preventing splashing of broken straws. The harvester comprises the lower header, wherein the lower header is firmly welded on a front axle of the harvester and comprises a lower header main frame, a lower cutting mechanism, a straw breaking mechanism and a transmission mechanism. The harvester also comprises a fixation rod and blocking angle iron, wherein a first right angle edge of the blocking angle iron is welded on the lower edge of the rear part of a blocking cover; and a second right angle edge is located under the first right angle edge and perpendicular to the horizontal ground. Each cutting blade is parallel to the horizontal ground. The transmission mechanism comprises a chain, a driven chain wheel, a first transmission shaft, a first pulley, a first belt, a second pulley, a second transmission shaft, a third pulley, a third belt, a tensioning pulley and a tensioning pulley installation shaft. The harvester of the fixed lower header capable of preventing the splashing of the broken straws disclosed by the invention has the advantages that straw parts left after cereal reaping can be cut and smashed, so a feeding amount of the harvester can be reduced, and machine losses and threshing loads can be reduced; stubble cutting is low and smooth, so ploughing becomes easier; and straw smashing efficiency is high, and the broken straws will not be splashed.

Owner:纪小坤

Harvester capable of chopping straw and provided with fixed lower cutting table

The invention discloses a harvester capable of chopping straw and provided with a fixed lower cutting table. The harvester comprises the lower cutting table. The lower cutting talbe is fixedly welded on a front axle of the harvester, and comprises a lower cutting table main frame, a lower cutting mechanism, a straw chopping mechanism and a transmission mechanism. One end of each of lower cutting table connecting rods is fixedly welded on the front axle. The lower cutting mechanism comprises a plurality of fixed tool bits which are arranged in a straight line and fixedly arranged on a base. Each cutting blade is parallel to the horizontal ground. The straw chopping mechanism is mounted in an accommodating space defined by the base, a covering shelter, a first sealing plate and a second sealing plate. The harvester has the advantages that the straw parts left after harvesting of crops can be cut and chopped, the feeding quantity of the harvester is reduced, the machine loss and the threshing load are reduced, the threshing effect is improved, the cut stubble heights are consistent, low and level and convenient for ploughing, the cutting and chopping efficiency of the straw is high, the chopped straw can be directly plough down in the soil in ploughing, and the straw is used as a base fertilizer after returning to the field.

Owner:纪小坤

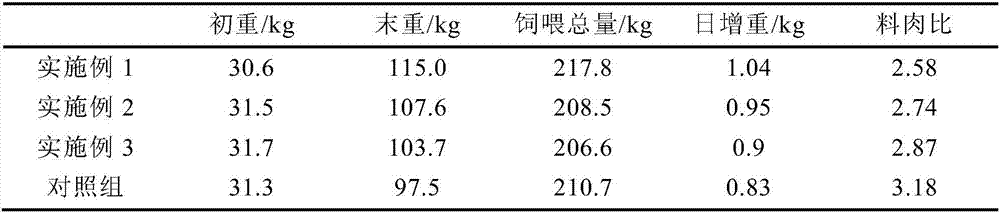

Premix for growth fattening pigs and preparation method of premix

InactiveCN107136330AHigh antibacterial activityImprove surface activityAnimal feeding stuffAccessory food factorsORIGANUM OILTrace element

The invention provides a premix for growth fattening pigs. The premix for the growth fattening pigs mainly comprises the following components in parts by mass: 0.4-0.5 part of composite vitamins, 1.3-1.6 parts of composite trace elements, 0.3-0.5 part of a composite phagostimulant, 14.0-17.0 parts of stone powder, 7.0-9.0 parts of dicalcium phosphate, 3.7-3.9 parts of sodium chloride, 6.0-10.0 parts of composite amino acids, 1.2-1.8 parts of complex enzymes, 0.5-0.6 part of choline, 0.4-0.5 part of an antioxidant, 0.25-0.50 part of cretian origanum oil and 56.0-65.0 parts of a carrier. The premix for the growth fattening pigs can effectively improve the digestion and the absorption of feeds by the fattening pigs, and reduce the raising cost. Besides, the invention further provides a preparation method of the premix for the growth fattening pigs. The method is simple and easy to operate, and the premix can be in mass production.

Owner:河南农科牧业有限公司

Harvester with lifting lower header capable of crushing straws and preventing spatter of crushed straws

The invention discloses a harvester with a lifting lower header capable of crushing straws and preventing spatter of the crushed straws. The harvester comprises the lower header, the lower header is hinged on a front axle of the harvester and comprises a lower header main frame, a lower cutting mechanism, a straw crushing mechanism, a driving mechanism and a lower header lifting mechanism, a blocking angle iron preventing spatter of the crushed straws is fixedly connected with the rear of a retaining cover of the lower header main frame, and the lower header lifting mechanism comprises a lower header lifting cylinder, a lower header lifting cylinder upper seat and a lower header lifting cylinder lower seat. According to the harvester with the lifting lower header capable of crushing the straws and preventing spatter of the crushed straws, straws remained after harvest of grains can be cut and crushed, feed quantity of the harvester is relieved, machine loss and threshing load are reduced, threshing effect is improved, cutting stubble is low and flat, lands are conveniently cultivated, cutting and crushing efficiency of the straws is high, crushed straws cannot spatter, the lower header can rise and fall, the height of the cutting stubble is controlled, barriers can be avoided, and device safety is protected.

Owner:纪小坤

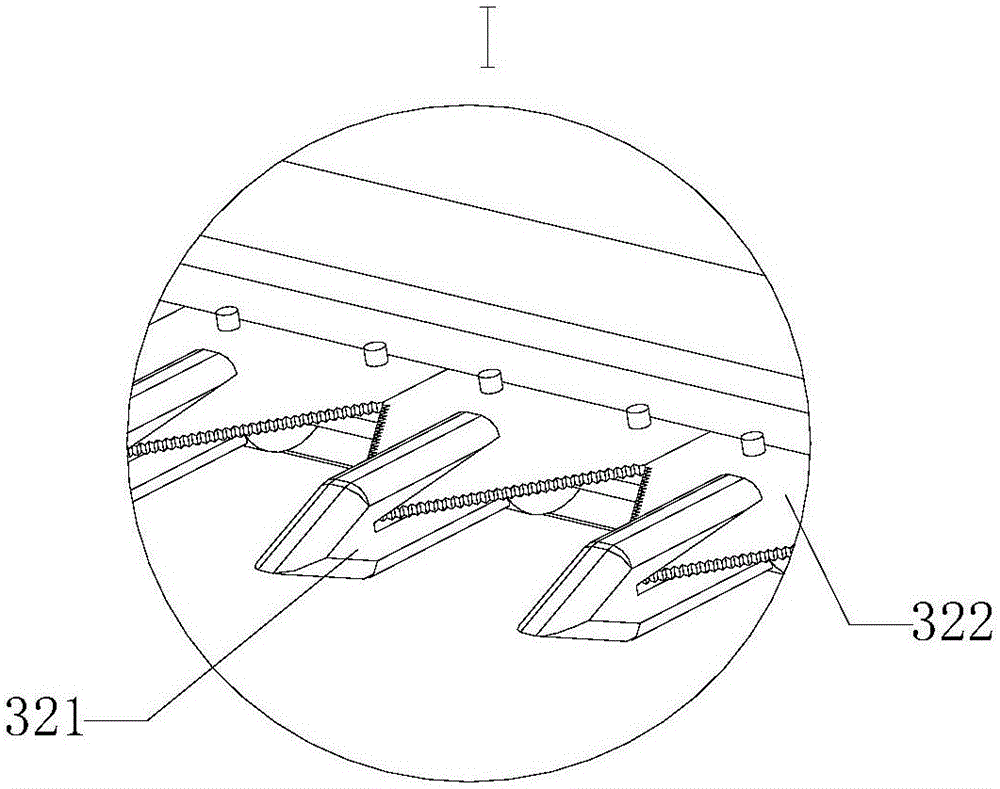

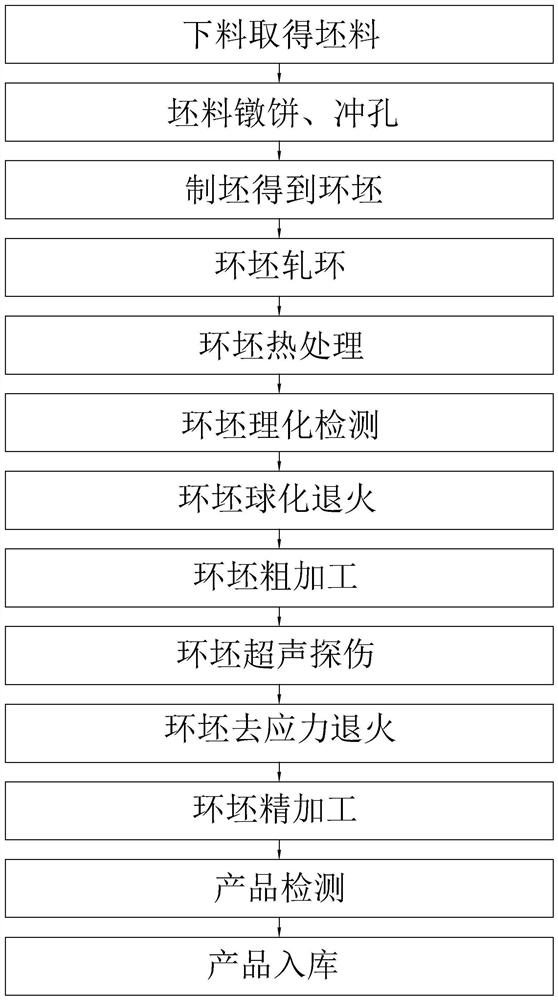

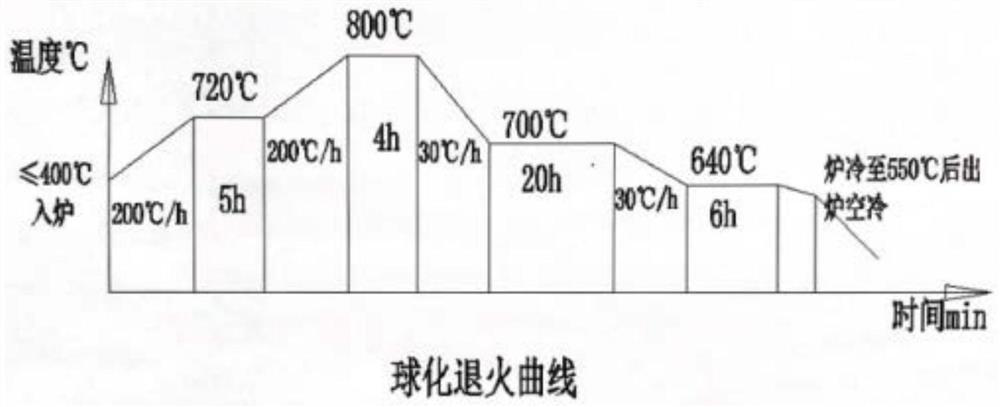

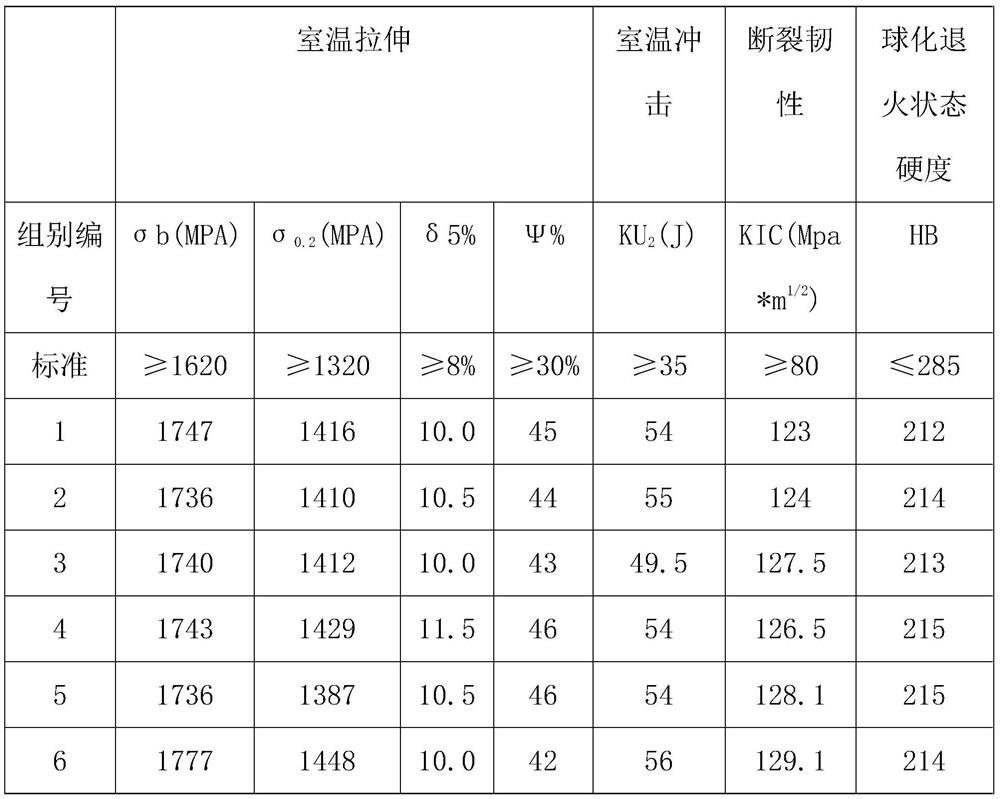

Forming method of large-diameter thin-wall high-barrel type ultrahigh-strength steel D406A ring forging

PendingCN112853079AImprove deformation abilityHigh precisionFurnace typesHeat treatment furnacesPunchingStress relief

The invention discloses a forming method of a large-diameter thin-wall high-barrel type ultrahigh-strength steel D406A ring forging, and belongs to the technical field of high-strength steel forming. According to the technical scheme, the method is characterized by comprising the following steps that S1, blanking is performed, and a blank is obtained; S2, the blank is upset into a cake, and punching is performed; S3, a ring blank is obtained through blank making; S4, the ring blank is rolled into a ring; S5, heat treatment is performed on the ring blank; S6, physical and chemical detection is performed on the ring blank; S7, spheroidizing annealing is performed on the ring blank; S8, rough machining is performed on the ring blank; S9, ultrasonic flaw detection is performed on the ring blank; S10, stress relief annealing is performed on the ring blank; S11, finish machining is performed on the ring blank. The method has the advantage that the accuracy, the quality stability and the reliability of the ring forging are improved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

Conservation method for piglets of Ziyun flower pigs

InactiveCN106614321AIncrease stressFeed lessFood processingAnimal feeding stuffDiseaseAnimal science

The invention relates to the technical field of piglet cultivation, in particular to a conservation method for piglets of Ziyun flower pigs. The method comprises the following steps of (1) after delivery of sows and in the feeding process, performing manual intervention and weaning the piglets when the weight of each piglet is above 4.5 kg; and (2) putting the piglets weaned in the step (1) into conservation rings according to the specification of 10 piglets per ring, paving on the lowest layer in the ring with a bedding material, covering with a mulching film and paving the upper layer with cotton after disinfecting the upper layer. According to the method, the newly born piglets are fed with pig milk and artificial milk alternately, so the stress resistance of the piglets is improved, the conditions of diarrhea and cold of the piglets caused by weaning at later period are avoided, the survival rate is increased, the growth of the piglets is effectively promoted, the development of organs is promoted and the immunity is improved; besides, scientific and reasonable vaccine injection is conducted in the conservation stage, so diseases are effectively avoided, the survival rate is increased, the slaughtering rate is guaranteed, and a guarantee is provided for huge requirements of the current market on the Ziyun flower pigs.

Owner:紫云自治县板当镇语馨生态养殖场

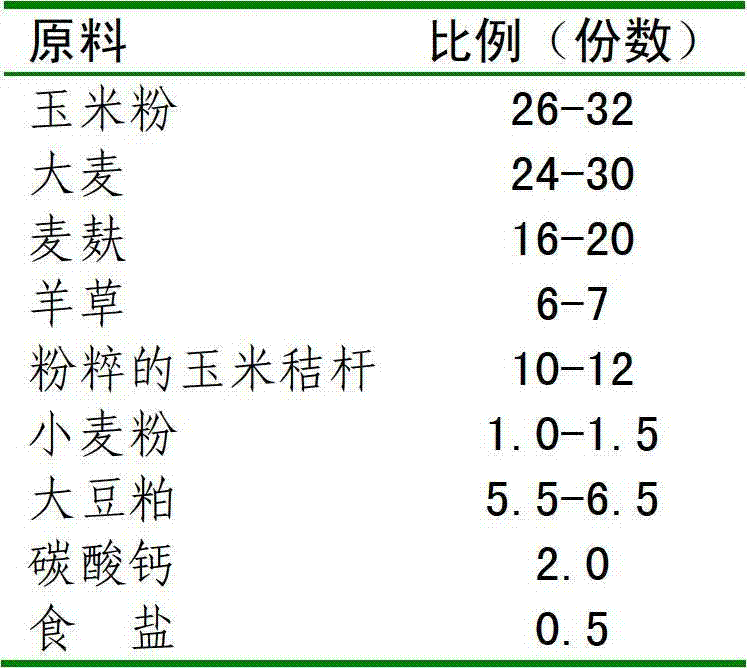

Feeding method for hybridization wagy rich in snowflake marbling meat

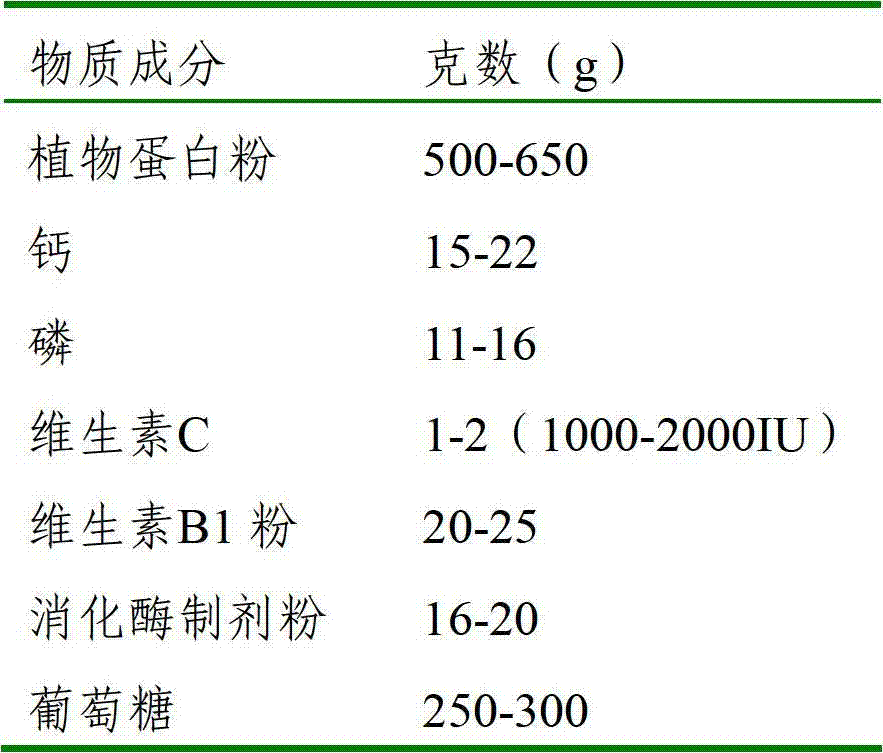

ActiveCN103181366BImprove qualityIncrease nutritional contentAnimal feeding stuffMilk substitutesBiotechnologyNutrition

The invention provides a breeding method for hybrid Wagyu cattle rich in snowflake marble pattern meat, comprising: feeding the calf with milk substitute; feeding hay and formula feed for young cattle starting from the age of 3 months; feeding roughage and concentrated feed in combination from the age of 9 months Feed and supplement vitamin A; 15-22 months old control blood vitamin A content at 35-45IU / 100ml blood. Through this method, the bred hybrid Wagyu cattle weigh more than 800 kg, have an average marbling grade of 4-5, and a comprehensive meat quality grade of B4. The feeding method provided by the invention is simple, easy to operate and easy to control, and the output beef has good quality, high nutritional content and high economic value.

Owner:AIDE INSPECTION TECH

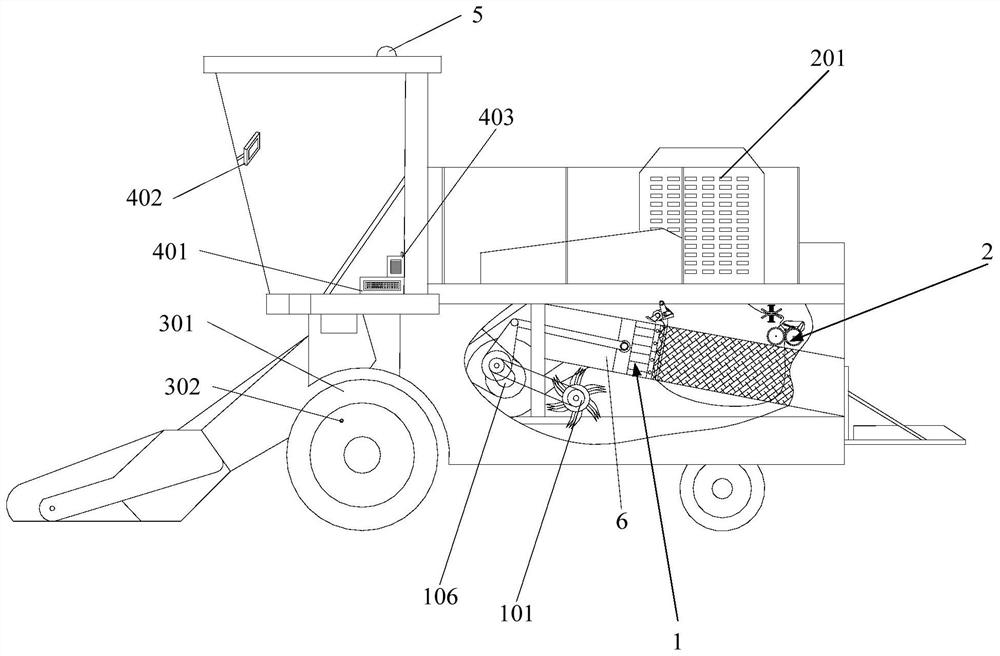

Bundling machine feeding amount monitoring system and bundling machine

PendingCN112243707AReal-time monitoring of feeding amountEasy to adjustBalingDriver/operatorControl engineering

The invention relates to the technical field of mechanical equipment, in particular to a bundling machine feeding amount monitoring system and a bundling machine. The bundling machine feeding amount monitoring system comprises a compression mechanism, a bundling mechanism, a walking mechanism and a control device which are arranged at intervals, and the compression mechanism, the bundling mechanism, the walking mechanism and the control device are all arranged on the bundling machine; and the bundling machine feeding amount monitoring system synchronously works along with the bundling machine,the compression mechanism is provided with a first detection device, the bundling mechanism is provided with a second detection device, the walking mechanism is provided with a third detection device, and the first detection device, the second detection device and the third detection device are connected with the control device. According to the bundling machine feeding amount monitoring system,the feeding amount of the bundling machine can be monitored in real time, a driver can adjust the feeding amount conveniently in time, and the situation that the feeding amount is too high or too low,blockage is caused or the bundling size is too small, and the bundling efficiency is affected is avoided.

Owner:XINJIANG XINYANMUSHEN TECH CO LTD

Synbiotic feed additive for pregnancy sows as well as preparation method and application

InactiveCN108338258AGood for healthPrevent proliferationAnimal feeding stuffAccessory food factorsMiscarriageIsomaltooligosaccharide

The invention discloses a synbiotic feed additive for pregnancy sows. The synbiotic feed additive is prepared from a composite probiotic agent, maltodextrin, isomaltooligosacharide, glucose, citric acid, complex vitamins, radix astragali, honeysuckle flowers, bighead atractylodes rhizomes, rhizoma atractylodis, cortex magnoliae officinalis, katsumada galangal seeds, Chinese mugwort, semen cuscutae, Chinese taxillus herb and crispateleaf ardisia roots, wherein the composite probiotic agent is a mixture of enterococcus faecium, microzymes, bacillus subtilis and bacillus coagulans. The inventionfurther provides an application method of the additive. During period of pregnancy of sows, the feed additive is added to feeds according to the addition quantity that the added feed additive is 0.3-5% of the weight of the pregnancy sows for feeding. The feed additive has the efficacy of preventing miscarriage, promoting delivery, nourishing the liver, supplementing qi, resisting bacteria, diminishing inflammation, being nutritive and health-care and the like, is free from toxic and side effects, and can be used as a feed additive to be added to a feed for the pregnancy sows for feeding. The feed additive can improve the constitutions of the pregnancy sows in essence, the immunity and the stress resistance of the pregnancy sows can be improved, the spontaneous delivery rate of the sows canbe greatly increased, and improving of quality of piglets produced by the sows can be facilitated.

Owner:广西青又青生物肥业有限公司

Rice straw returning seeder and rice straw returning seeding method

ActiveCN105379457AGood job qualityReduce power consumptionSpadesCrop conditionersRice strawAgricultural engineering

The invention relates to a rice straw returning seeder and a corresponding rice straw returning seeding method, and belongs to the technical field of agriculture. The seeder is mainly composed of a walking chassis, a straw cutting and conveying device, a straw shredding device, a seeding device and a smashed straw spraying device. Straw picking, cutting, conveying, shredding, seeding and smashed straw covering operation can be completed at a time. The corresponding method comprises the steps that long straw stubble and threshing discharge obtained after rice harvesting are cut and collected, and the smashed straw with the length not larger than 8 cm is obtained through cutting; then, crop seeds are sown on an inasaka stubble field in rows, and then the field surface is evenly covered with shredded straw. According to the rice straw returning seeder and the corresponding rice straw returning seeding method, the full quantity of rice straw can be returned to the field, so that environmental protection is facilitated, the seeding quality of afterreap crop (rice, oilseed rape and the like) can be improved, the yield is improved, and therefore good social and economic benefits can be obtained through usage and popularization of the rice straw returning seeder and the corresponding rice straw returning seeding method.

Owner:CHANGZHOU CHANGFA AGRI EQUIP ENG TECH RES +1

Lifting type lower cutting table capable of smashing straw and preventing smashed straw from splashing

The invention discloses a lifting type lower cutting table capable of smashing straw and preventing smashed straw from splashing. The lifting type lower cutting table is hinged to a front axle of a harvester and comprises a lower cutting table main frame, a lower cutting mechanism, a straw smashing mechanism, a transmission mechanism and a lower cutting table lifting mechanism; blocking angle iron used for preventing the smashed straw from splashing is fixedly connected to the back portion of a blocking cover of the lower cutting table main frame; the lower cutting table lifting mechanism comprises a lower cutting table lifting oil cylinder, a lower cutting table lifting oil cylinder upper base and a lower cutting table lifting oil cylinder lower base. According to the lifting type lower cutting table capable of smashing the straw and preventing the smashed straw from splashing, straw portions retained after grain harvesting can be cut and smashed, the feeding amount of the harvester is decreased, the machine loss and the threshing load are reduced, and the threshing effect is improved; cut stubbles are low and flat, and therefore ploughing is convenient; the straw cutting and smashing efficiency is high, and the smashed straw cannot splash; meanwhile, lifting can be achieved, therefore, the cut stubble height can be controlled, and the cutting table can keep away from obstacles, so that equipment safety is guaranteed.

Owner:见保林

Fully-cooked granulated feed for greenhouse breeding of soft-shelled turtles and preparation method of feed

InactiveCN105746955AIncrease contentFeed lessClimate change adaptationAnimal feeding stuffDiseaseBetaine

The invention discloses fully-cooked granulated feed for greenhouse breeding of soft-shelled turtles and a preparation method of the feed. The feed is prepared from raw materials in parts by weight as follows: fish meal, fermented soybean meal, fermented sunflower seed meal, extruded soybeans, blue-green algae, glycine betaine, beta-glucan, pawpaws, vital gluten, fish oil, monocalcium phosphate, methionine, composite vitamins, composite minerals and a traditional Chinese medicine preparation. Compared with the prior art, the feed has the advantages as follows: the matching ratio of amino acid to protein raw materials is balanced, the content of crude protein in the feed is increased, the crude protein and other raw materials in the feed are matched and have a synergistic function, the feed amount of nitrogen and phosphorus is reduced, and accordingly, loss of nitrogen and phosphorus is reduced; livers of the bred soft-shelled turtles are small and bear little load, the disease resistance is higher, antibiotics are avoided, the breeding cost is saved, and the body immunity is activated by generating non-specific immunoregulation factors.

Owner:JINMAOYUAN BRANCH OF WUHE JINTANG AQUACULTURE CO LTD

Tor-brevifilis and spinibarbus-hollandi pond micro flowing water aquaculture method

InactiveCN104719221AReduce generationReduce the risk of diseaseClimate change adaptationAnimal feeding stuffDiseaseWater flow

The invention discloses a tor-brevifilis and spinibarbus-hollandi pond micro flowing water aquaculture method. The tor-brevifilis and spinibarbus-hollandi pond micro flowing water aquaculture method includes the following steps: A, repairing and maintaining a pond; B, breeding fries, wherein in the beginning of March, 790 to 810 young spinibarbus hollandis with the sizes ranging from 50 g to 100 g are bred in every 667 square meters, in mid-April, and 780 to 820 tor brevifilises with the body lengths ranging from 1.5 cm to 2.5 cm and 18 to 20 water-quality-adjusting fishes with the sizes ranging from 1.8 kg to 2.1 kg are bred in every 667 square meters; C, managing feeding, wherein before taming feeding is carried out, minced fillets are fed once every day, and the everyday feeding amount is 1% of the weight of all the fishes; after taming feeding is carried out, when the water temperature is lower than 28 DEG C, the everyday feeding amount is 3% to 4% of the weight of all the fishes, and when the water temperature is higher than or equal to 28 DEG C, the everyday feeding amount is 2% to 3% of the weight of all the fishes; D, managing the water quality, wherein water in the pond is kept in the flowing state, and the water flowing speed ranges from 19 cm / s to 22 cm / s; E, carrying out daily management; F, preventing fish diseases.

Owner:安徽铜草花现代农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com