Harvester with lifting lower header capable of crushing straws and preventing spatter of crushed straws

A harvester and header technology, applied in the direction of harvesters, headers, cutters, etc., can solve the problems of obstacles damaging machine equipment, affecting the driver's line of sight, affecting the threshing effect, etc., to achieve high cutting and crushing efficiency, straw Uniform pulverization and improved threshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

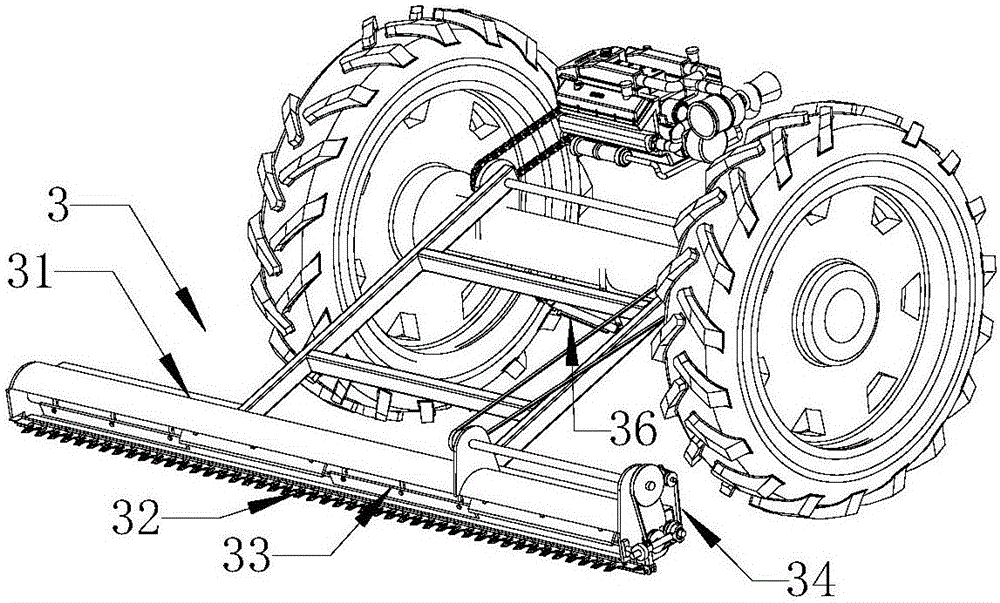

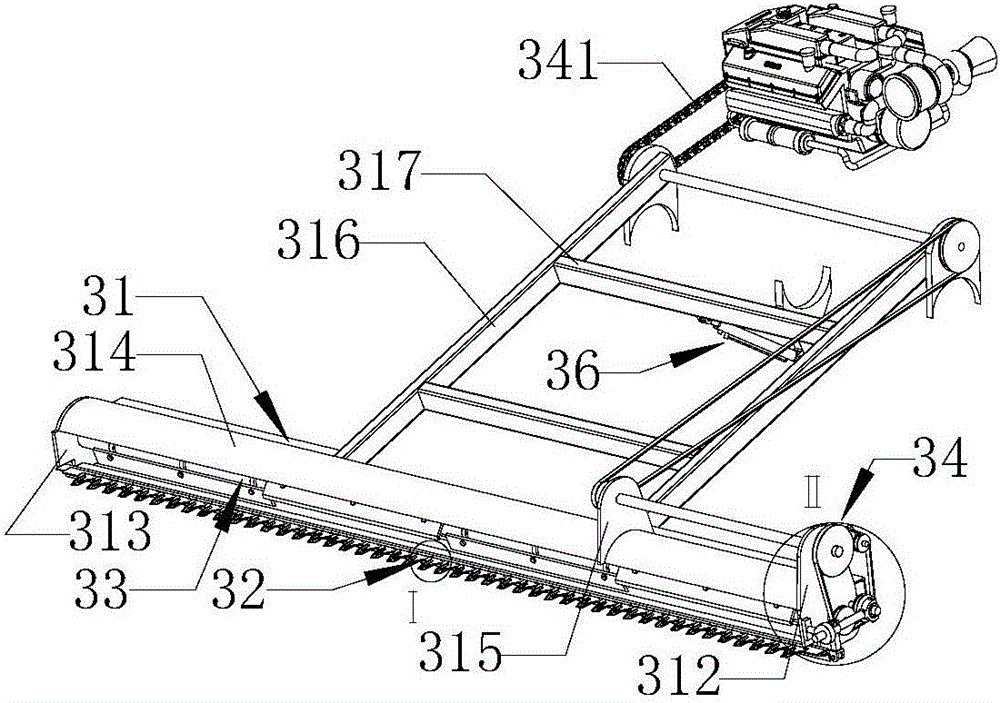

[0033] Such as figure 1 , 12 As shown, the harvester of the lift-type lower header that can crush straw and prevent the stalk from splashing includes a lower header 3, and the lower header 3 is hinged on the front axle of the harvester, including the lower header main frame 31, the lower header, and the lower header. Cutting mechanism 32, stalk crushing mechanism 33, transmission mechanism 34 and lower header lifting mechanism 36;

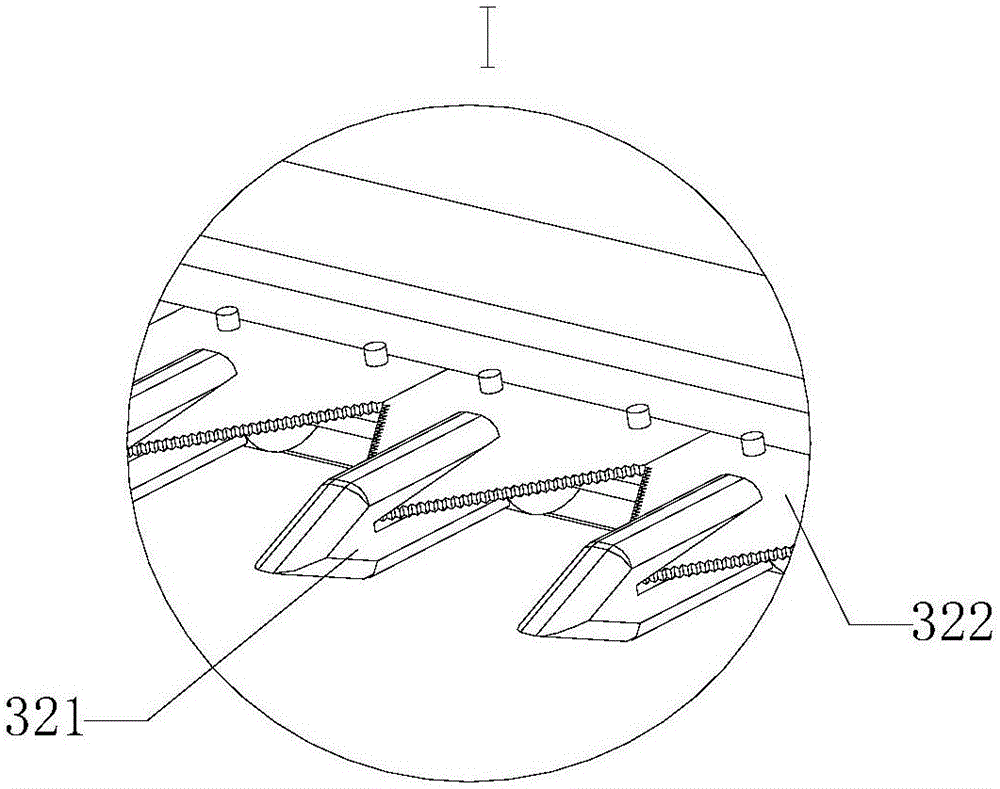

[0034] Such as figure 2 , 4, shown in 6 and 11, the bottom of the main frame 31 of the lower header is provided with a base 311, one end of the base 311 is fixed with a first sealing plate 312, and the other end is fixed with a second sealing plate 313, on the base 311 An arc-shaped baffle 314 is arranged above, and the first sealing plate 312 and the second sealing plate 313 are respectively fixed on both ends of the baffle 314, and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com