Patents

Literature

123results about How to "Powder evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

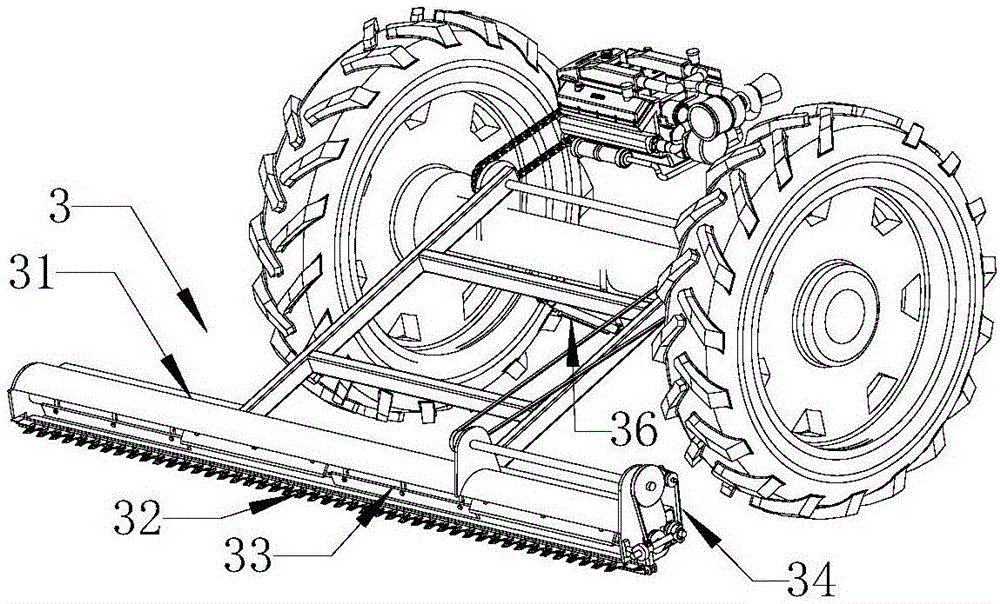

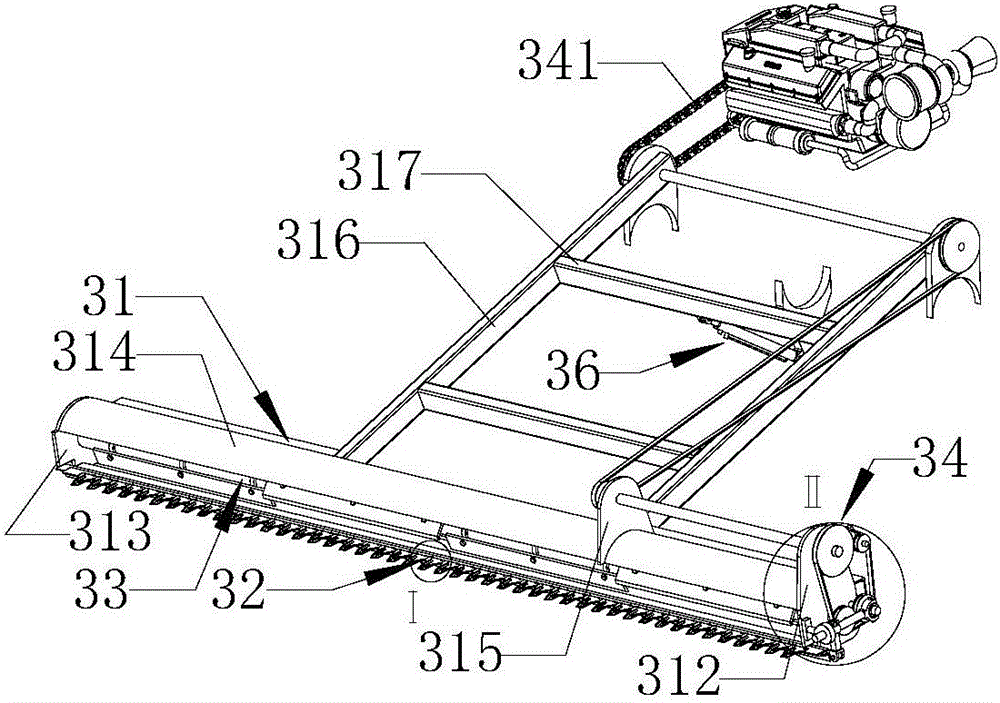

Harvester provided with protective ladder and lifting type lower header capable of smashing straw and preventing smashed straw from splashing

The invention discloses a harvester provided with a protective ladder and a lifting type lower header capable of smashing straw and preventing the smashed straw from splashing. The harvester comprises the lower header and the protective ladder, and the lower header is hinged to a front axle of the harvester. The lower header comprises a lower header main frame, a lower cutting mechanism, a straw smashing mechanism, a transmission mechanism and a lower header lifting mechanism. Blocking angle iron is further fixedly connected with the rear portion of a shield of the lower header main frame. The lower header lifting mechanism comprises a lower header lifting oil cylinder, a lower header lifting oil cylinder upper base and a lower header lifting oil cylinder lower base. The harvester provided with the protective ladder and the lifting type lower header capable of smashing straw and preventing the smashed straw from splashing can cut and smash straw left after grain harvesting, and the feed quantity of the harvester is reduced. Cutting stubbles are short and flat so that tillage can be convenient. The straw cutting and smashing efficiency is high, smashing is uniform, and the smashed straw cannot splash. The lower header can ascend and descend so as to control the height of the cutting stubbles and avoid obstacles to protect equipment safety. The arranged protective ladder makes people climb safely and conveniently, and can also be used as a safety guardrail.

Owner:纪小坤

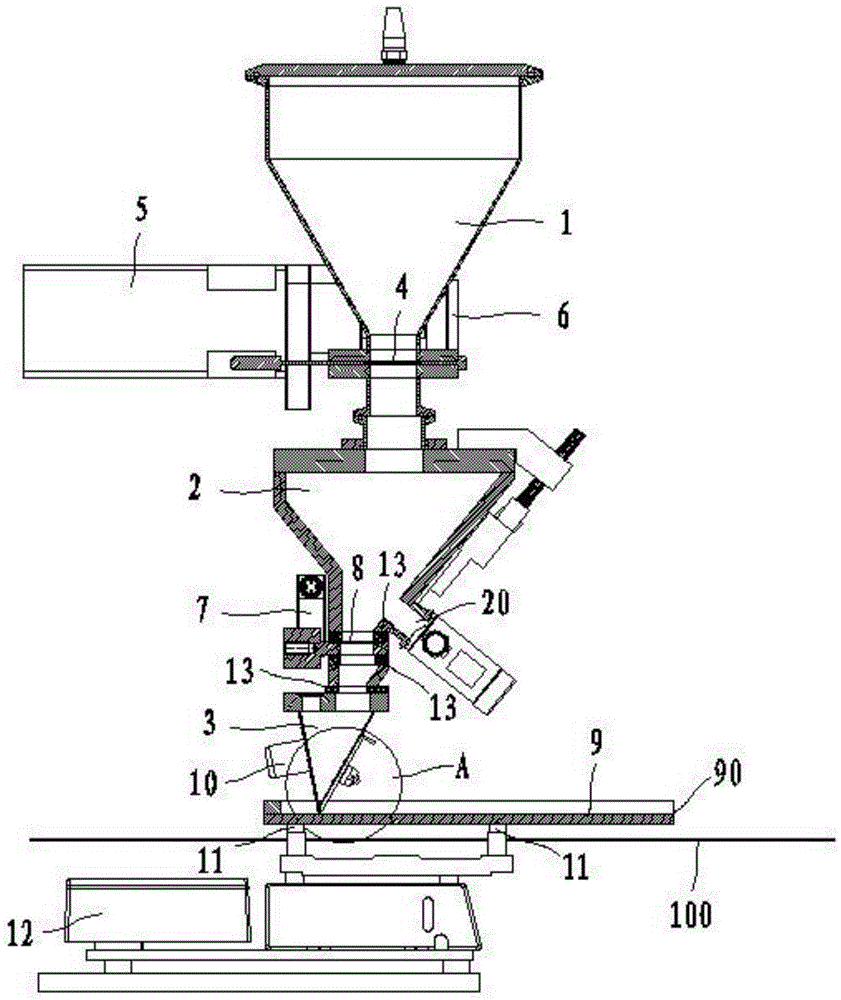

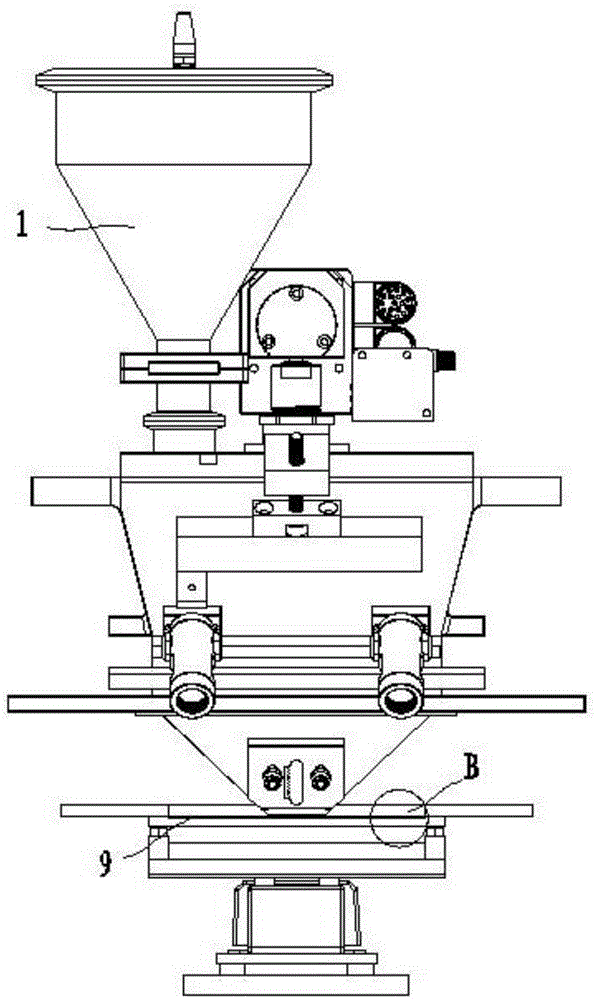

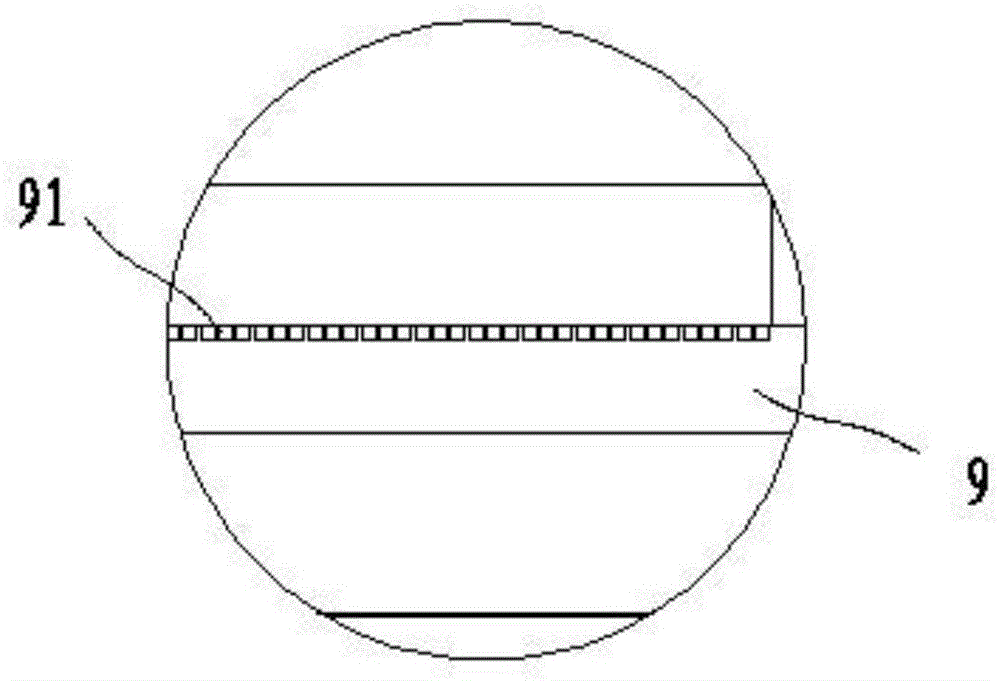

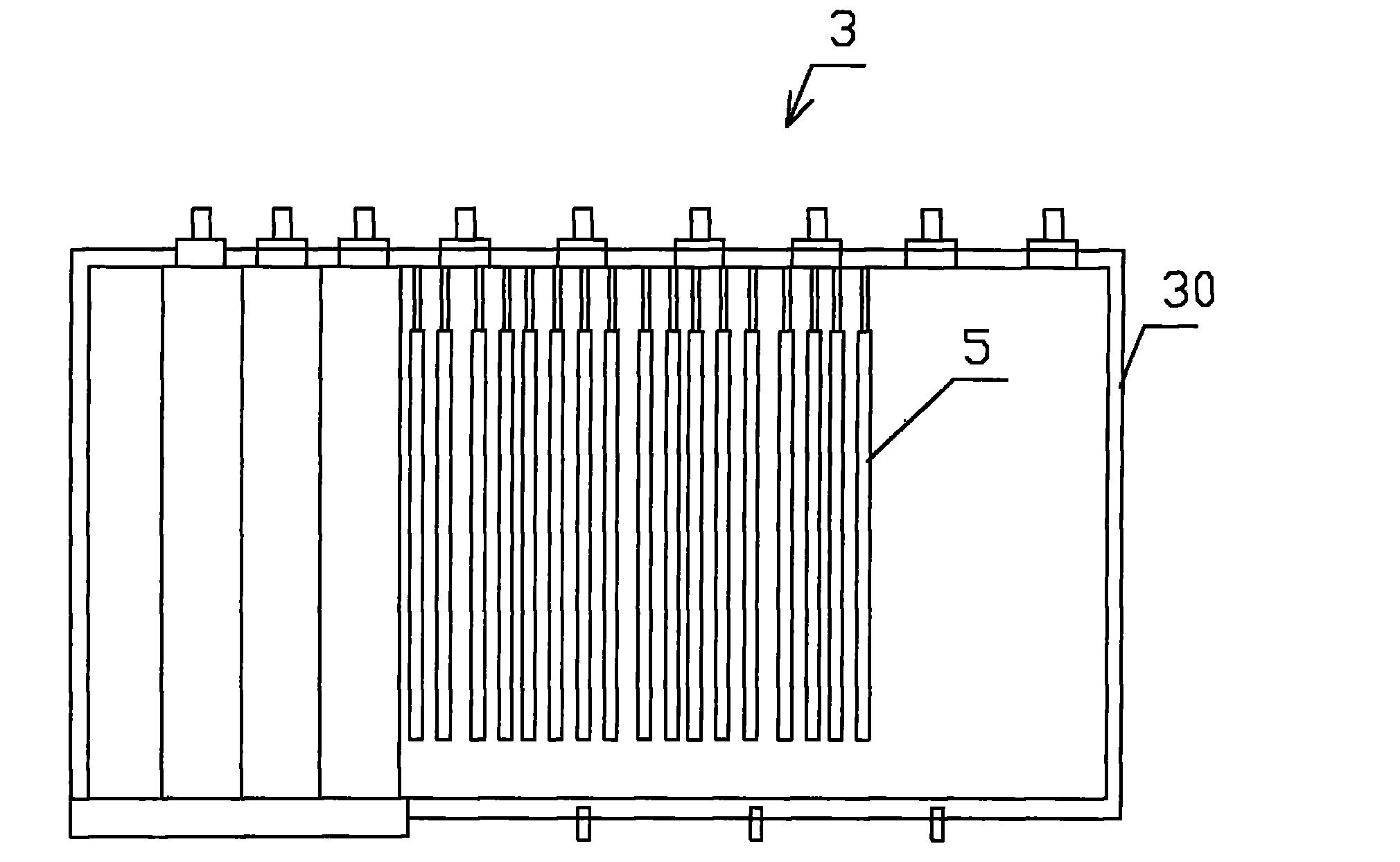

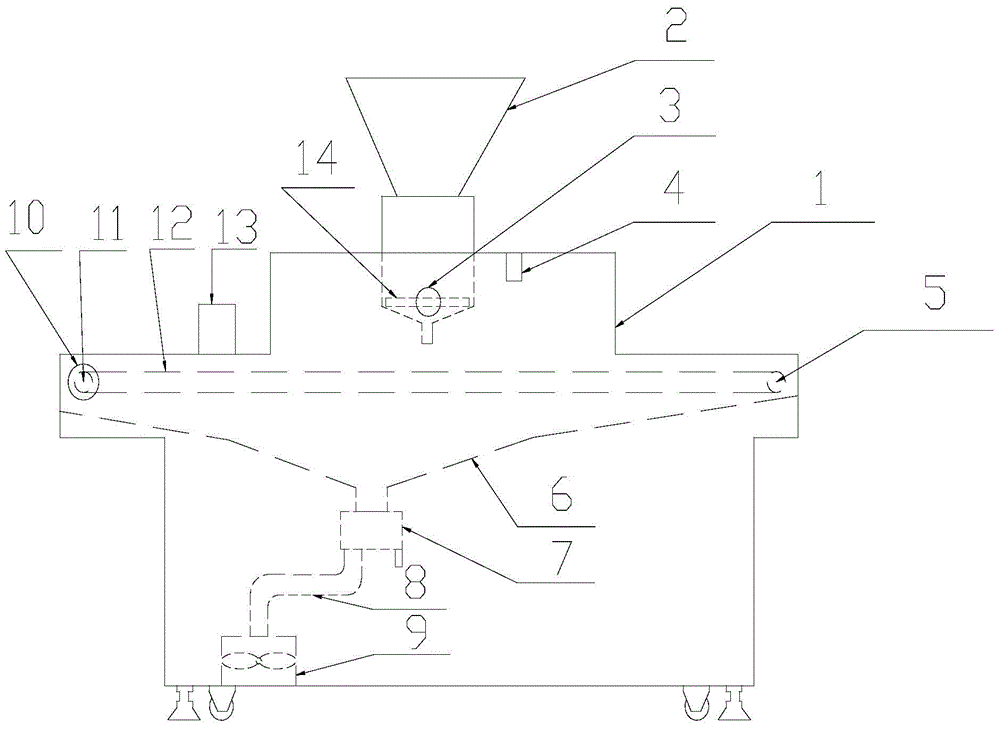

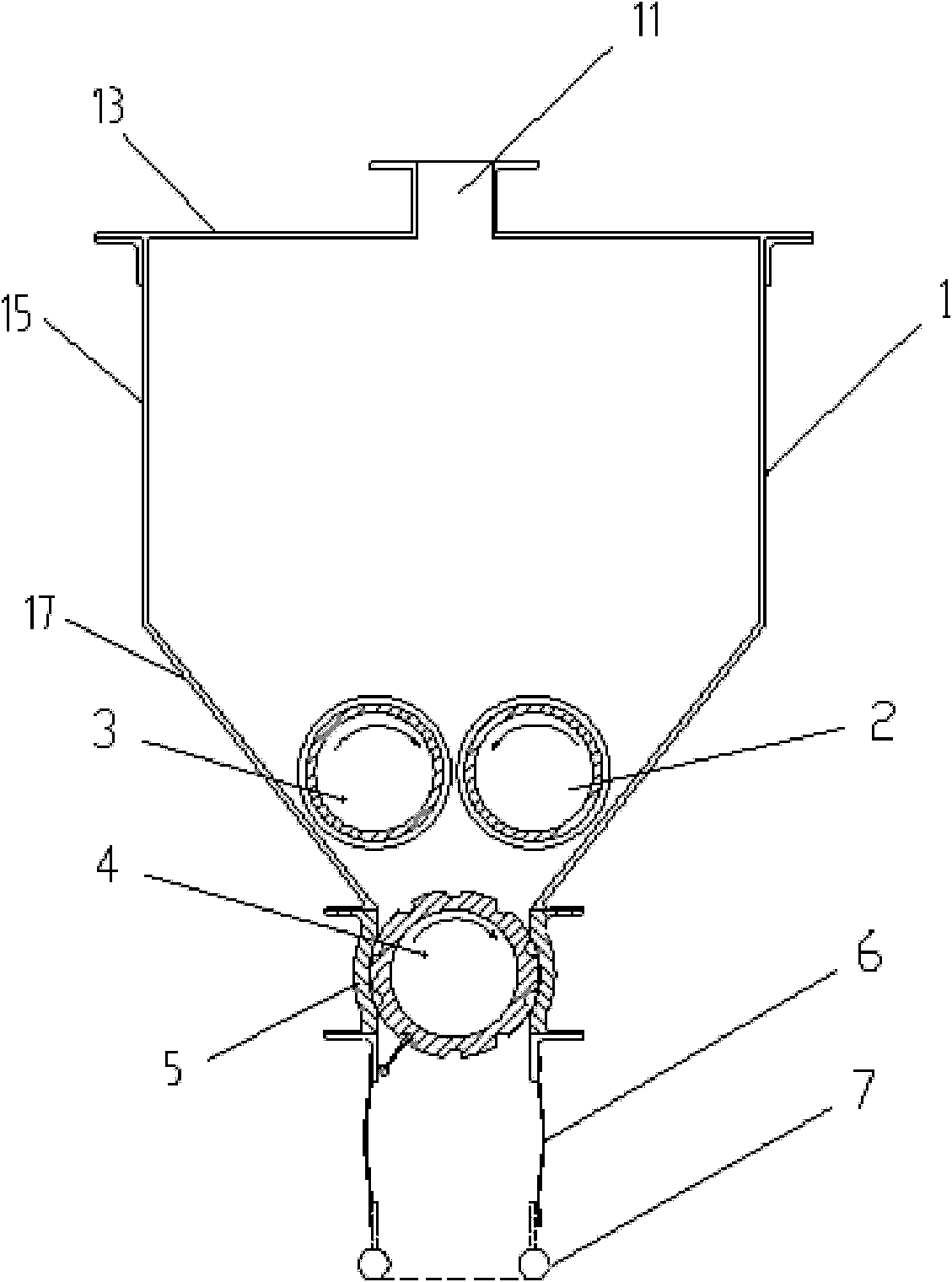

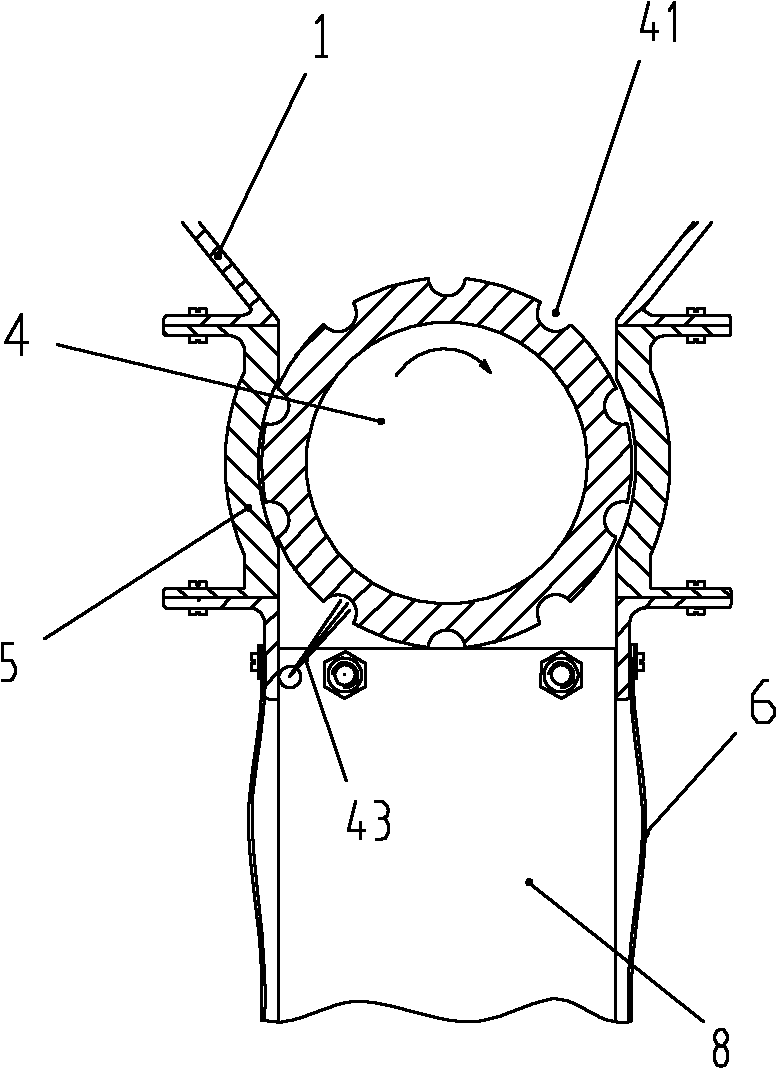

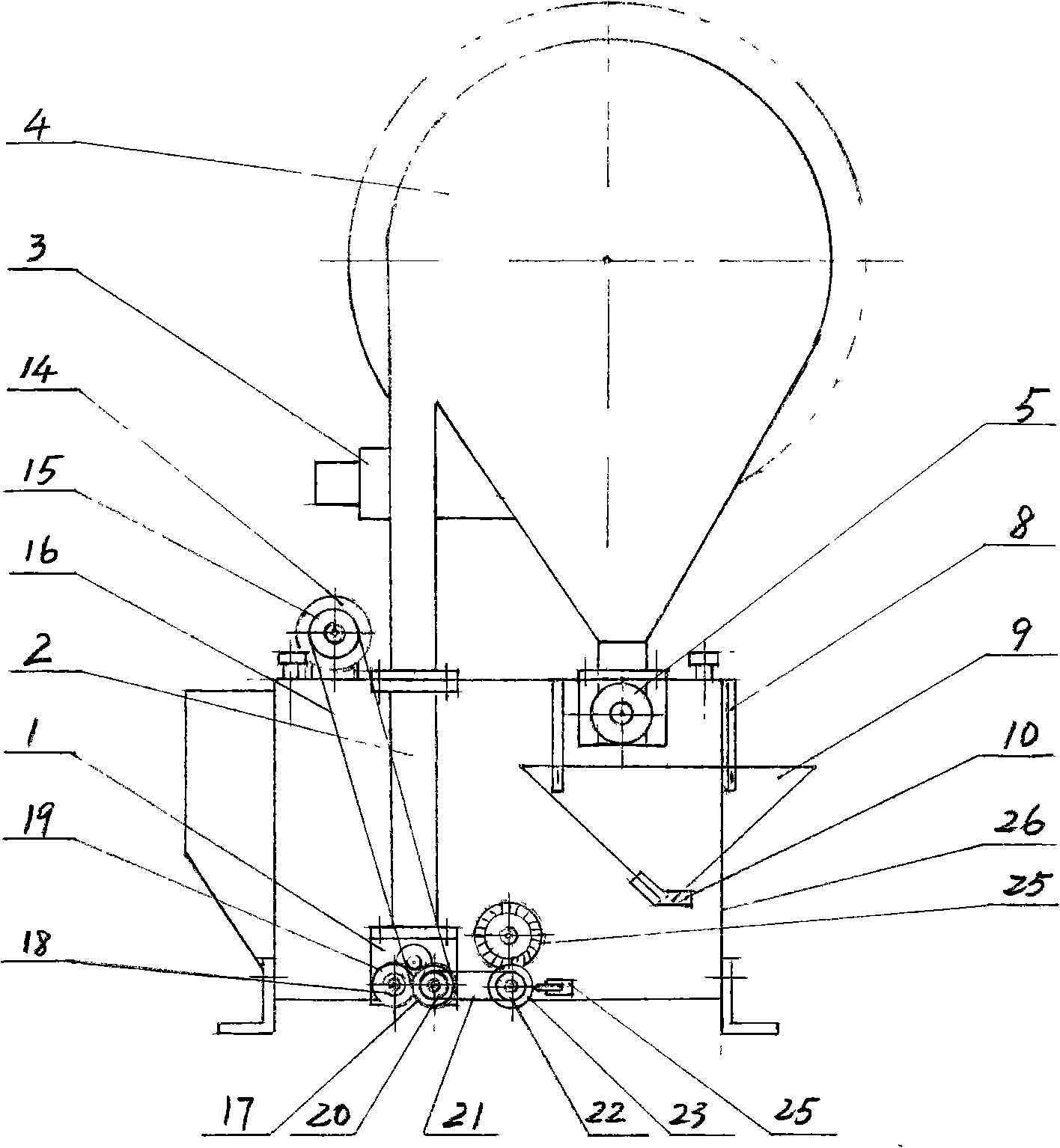

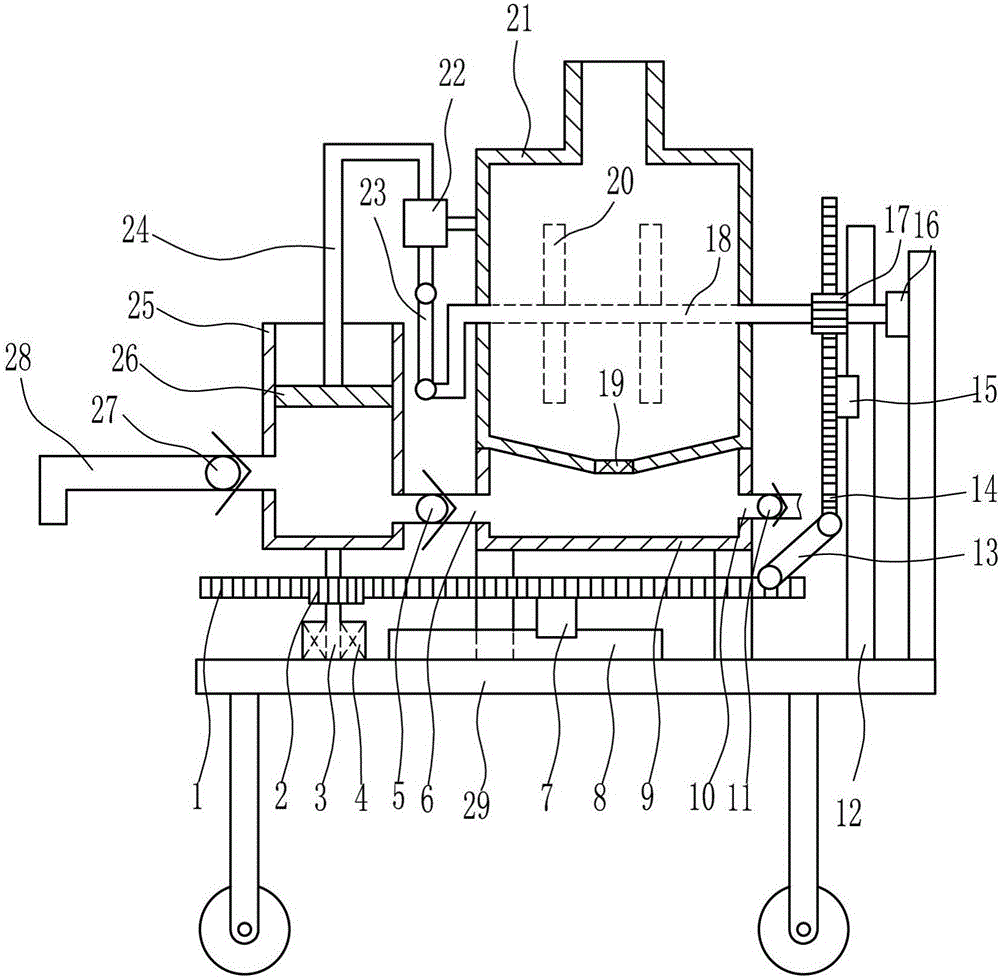

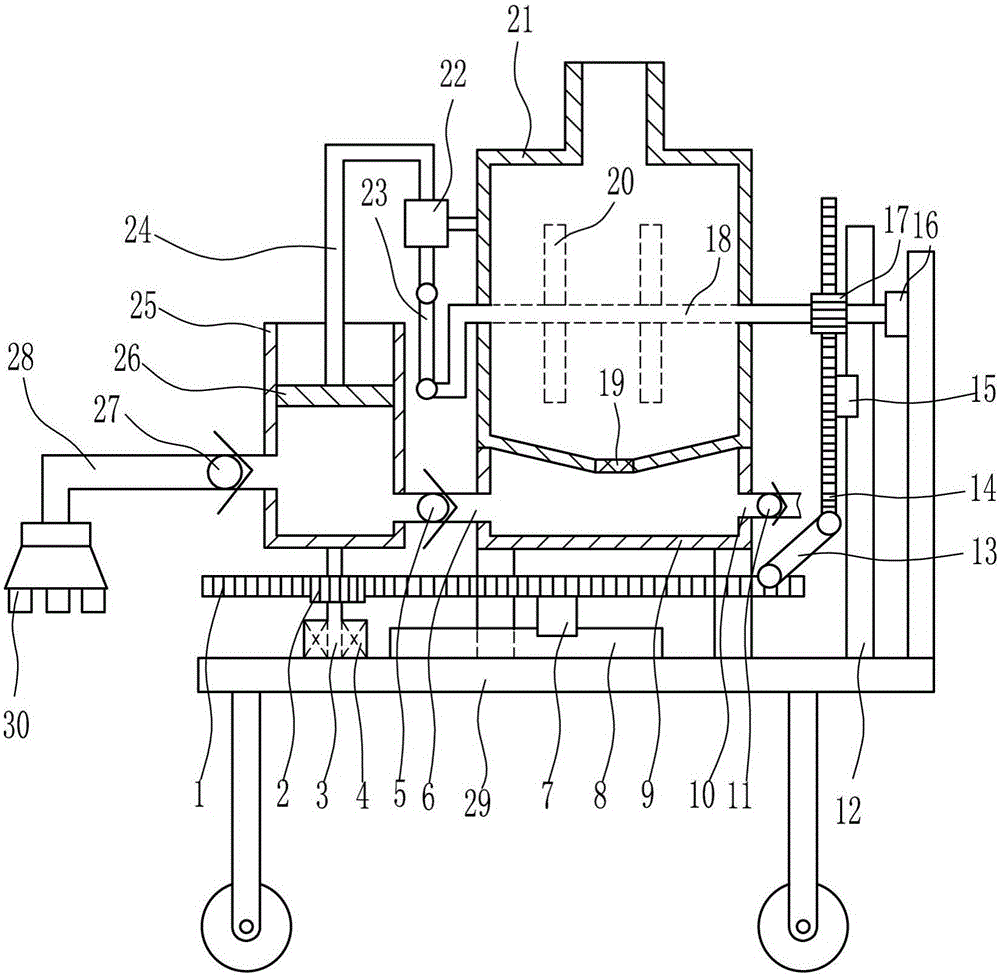

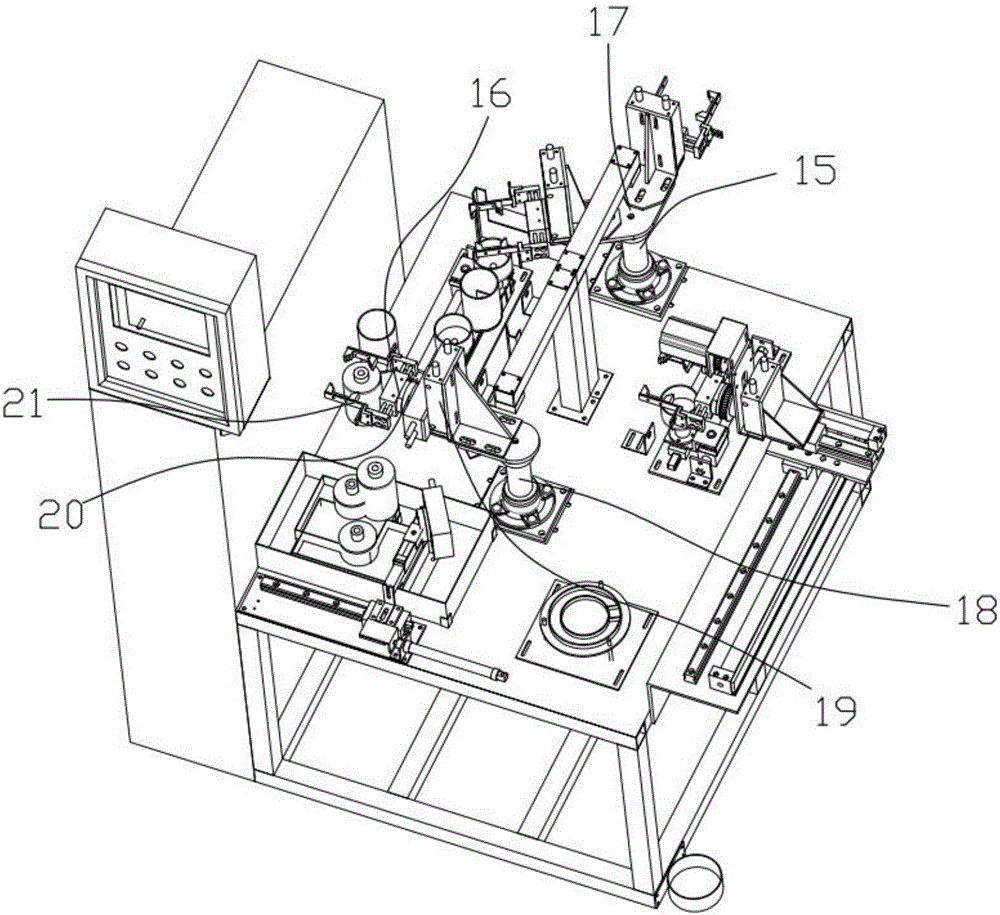

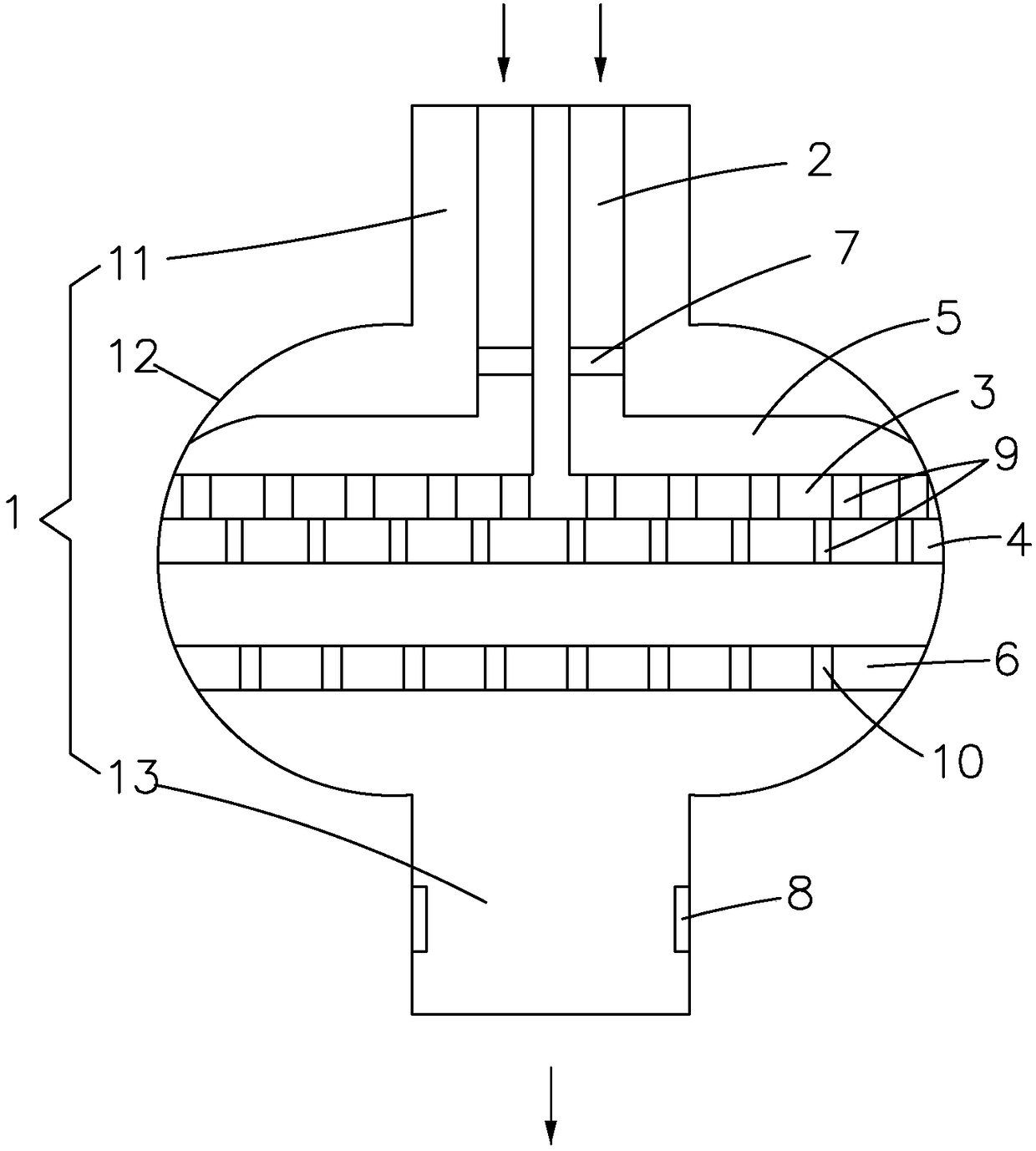

Powder scattering device

ActiveCN105600501AAccurately control inventoryConstant speed movementLoading/unloadingLaser sensorAcoustics

The invention discloses a powder scattering device which comprises a hopper, a primary bin, a secondary bin and a material plate. A screen is arranged between the hopper and the primary bin, a vibration motor is connected to the screen, and a first laser sensor for detecting the material level of the primary bin is arranged above the primary bin. An ultrasonic screen is arranged between the primary bin and the secondary bin, and a second laser sensor for detecting the material level of the secondary bin is arranged above the secondary bin. The material plate is located under the secondary bin, an electromagnetic oscillator and at least one pressure sensor for sensing the powder amount on the material plate are connected to the material plate, and a system adjusts the working frequency of a vibrator according to signals of the pressure sensors so as to adjust the inventory of the powder fed to the material plate. The powder scattering device has the advantages of achieving final, uniform and equal-amount powder scattering through multi-point control, equal-amount control and constant speed control.

Owner:CONTEMPORARY AMPEREX TECH CO

Silicon-titanium alloy film coat of air preheater tube and electrostatic spraying process thereof

InactiveCN101792262AHigh densityUniform coatingLiquid spraying plantsSteel tubeTemperature resistance

The invention relates to a silicon-titanium alloy film coat of an air preheater tube and an electrostatic spraying process thereof, and belongs to the electrostatic spraying technology of an environment-friendly, energy-saving and efficient silicon-titanium alloy film air preheater tube. Main components of the coat comprise SiO2, NiO, B2O3, TiO2, Pb2O3, NaO2 and K2O. A preparation method for the coat comprises the following steps: mixing and crushing common silicon-titanium alloy power and K2O to charge the powder, spraying the mixture to an air preheater steel tube under the high pressure of 30 to 120KV by using a positioning gun, heating and cooling the steel tube, and cushioning a high-temperature pad to obtain the coat. The process can realize automatic powder spraying, does not need manpower, obtains workpieces with unlimited lengths, and has the characteristics of environmental protection, energy conservation and high efficiency; due to the addition of K2O, the atomization is stable, the film is coated uniformly, the mass density is high and the thickness is controllable; the manpower and spraying cost are saved, and the service life is prolonged; and the prepared coat is superior to that in a common enamel process and a plastic powder electrostatic spraying process on the aspects of mechanical strength, adhesive force, high temperature resistance, abrasion resistance, acid and alkali corrosion resistance, ageing resistance and the like.

Owner:济南屹林科技有限公司

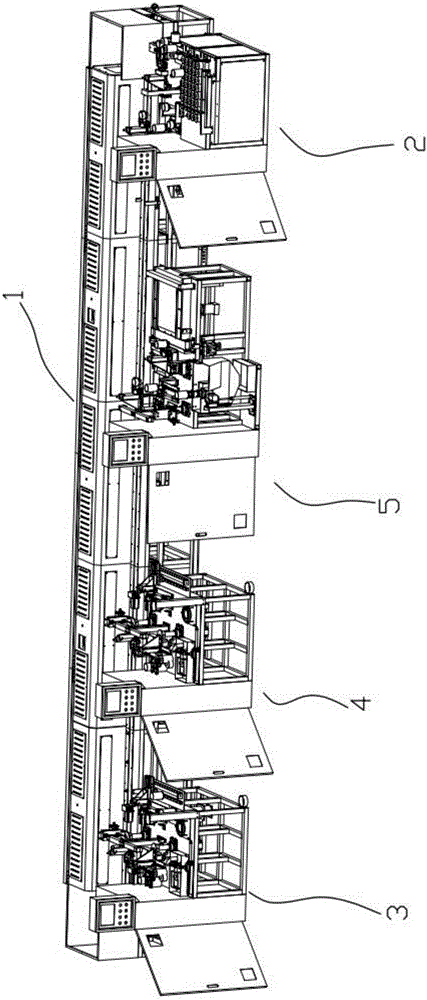

Vertical automatic coating production line of aluminum profile

InactiveCN102161022APowder evenlyGood running stabilityLiquid spraying plantsPretreated surfacesPre treatmentEngineering

The invention discloses a vertical automatic coating production line of an aluminum profile. The production line comprises pre-treatment equipment, coating equipment and drying equipment, wherein both of the pre-treatment equipment and the drying equipment are connected through a conveyer belt; a drying passage shell of the drying equipment consists of a gum sealed plate layer, an inner rock cotton layer, an air heat-isolating layer and an outer rock cotton heat-preserving layer from inside to outside; and a workpiece is vertically hung in the coating equipment and the drying equipment. Through the production line, the aluminum profile is automatically coated without human labor and is uniformly powdered; rotation is not required in work; the stability is high; and the surface layer temperature of the equipment is at most 5 DEG C more than the environment temperature.

Owner:ZHEJIANG MINGQUAN INDAL COATING

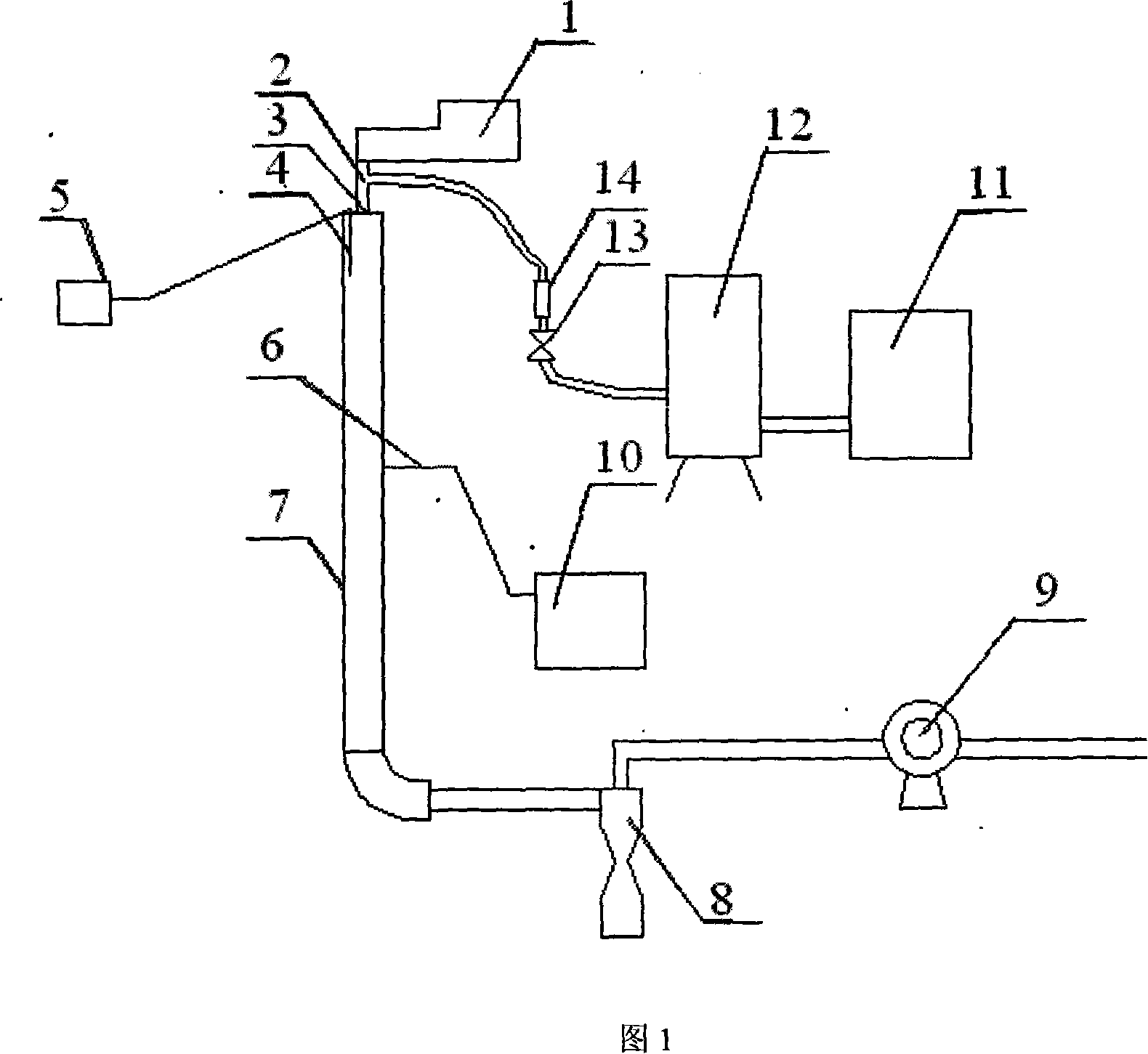

Device for calcining aluminum oxide clinker by directly utilizing coal powder and method thereof

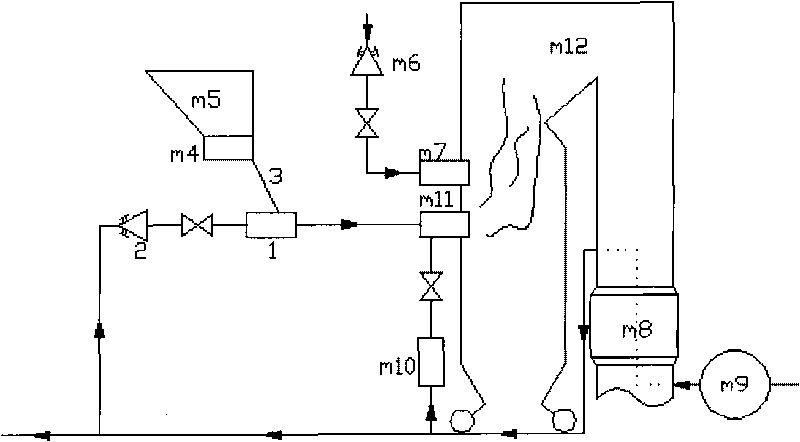

InactiveCN101148262AAdjustable feedAchieve recyclingAluminium oxide/hydroxide preparationThermal energyHearth

The apparatus for calcining alumina clinker with coal powder includes one hearth with one temperature measuring thermocouple connected to the first temperature controlling instrument to measure the temperature in the upper part of the hearth and one temperature controlling thermocouple connected to the second temperature controlling instrument to control the temperature rise in the hearth, one coal feeder in the inlet of the hearth, one coal powder mixer with burner connected to the coal feeder, one cyclonic separator and one induced draft fan connected to the outlet of the hearth, one flowmeter and one air flow rate regulating valve connected between the coal powder mixer and one air tank, and one air compressor connected to the air tank. During calcining alumina clinker proper amount of calcium containing material is added into high aluminum coal powder, and the present invention has low power consumption for extracting alumina from coal powder.

Owner:XI AN JIAOTONG UNIV

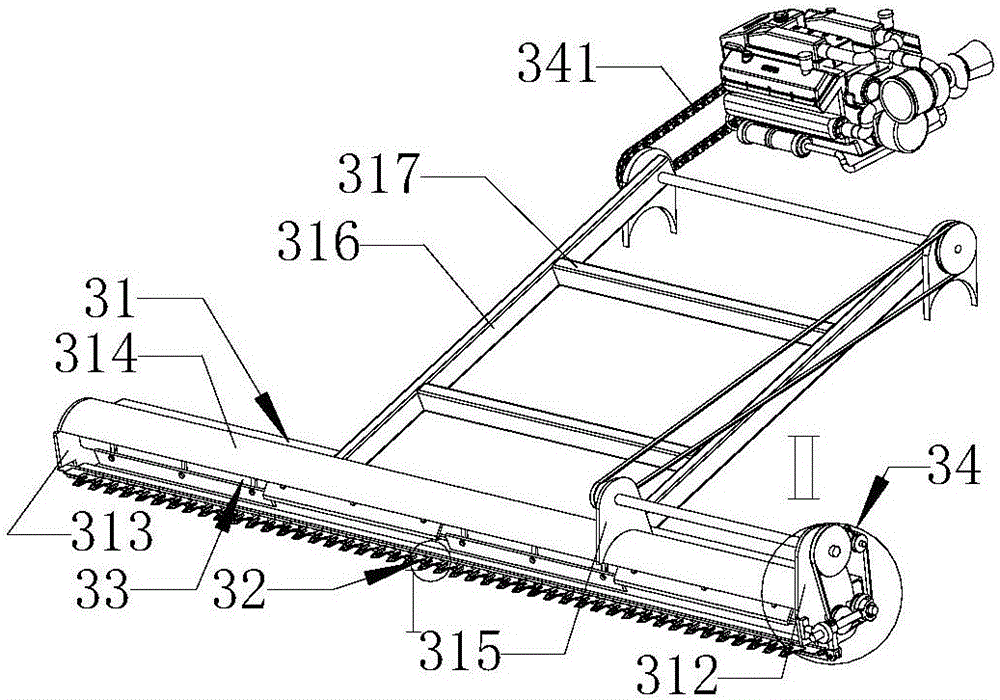

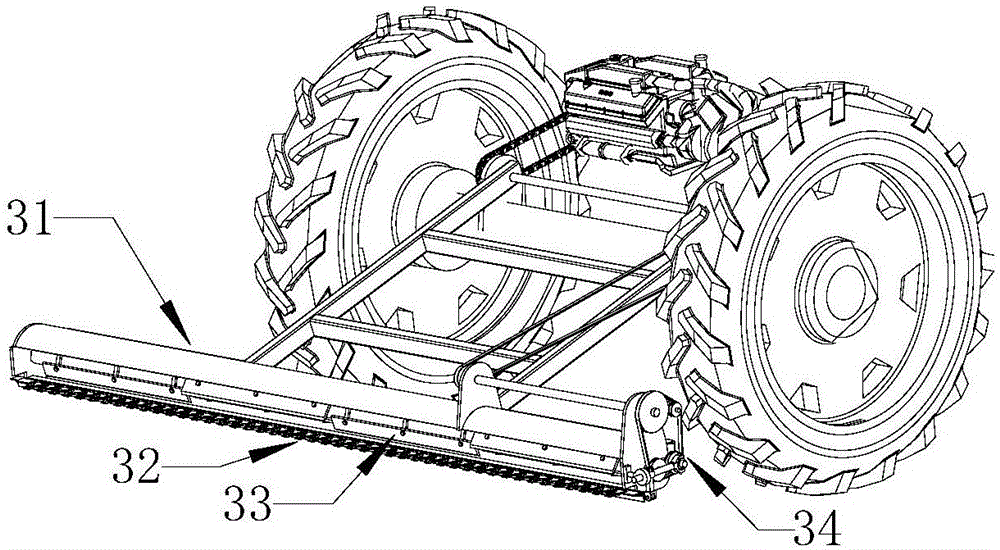

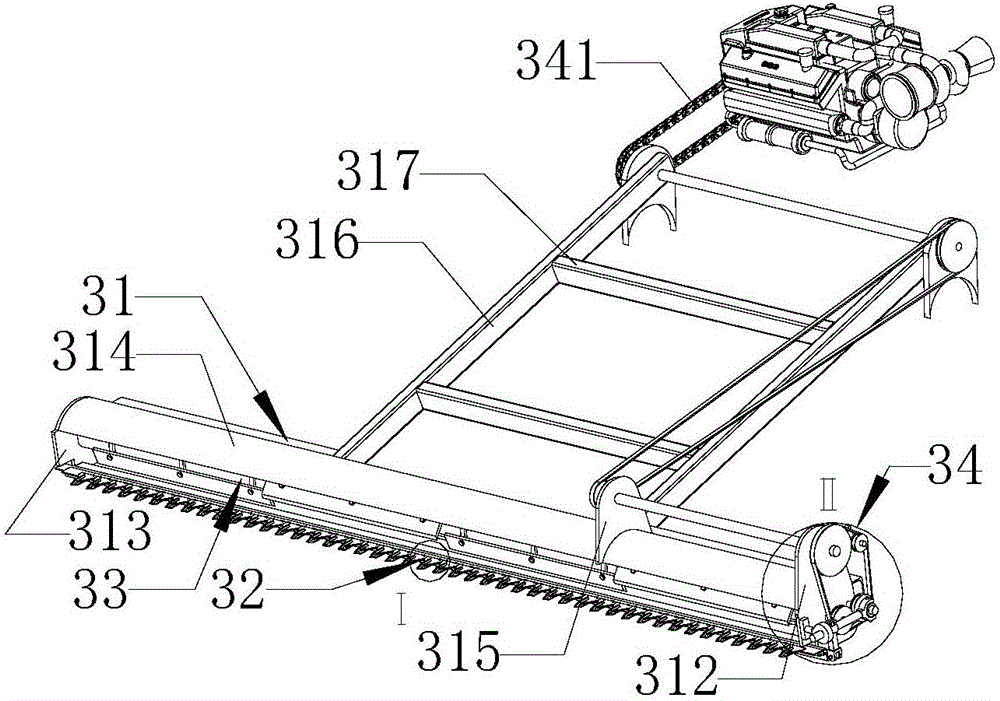

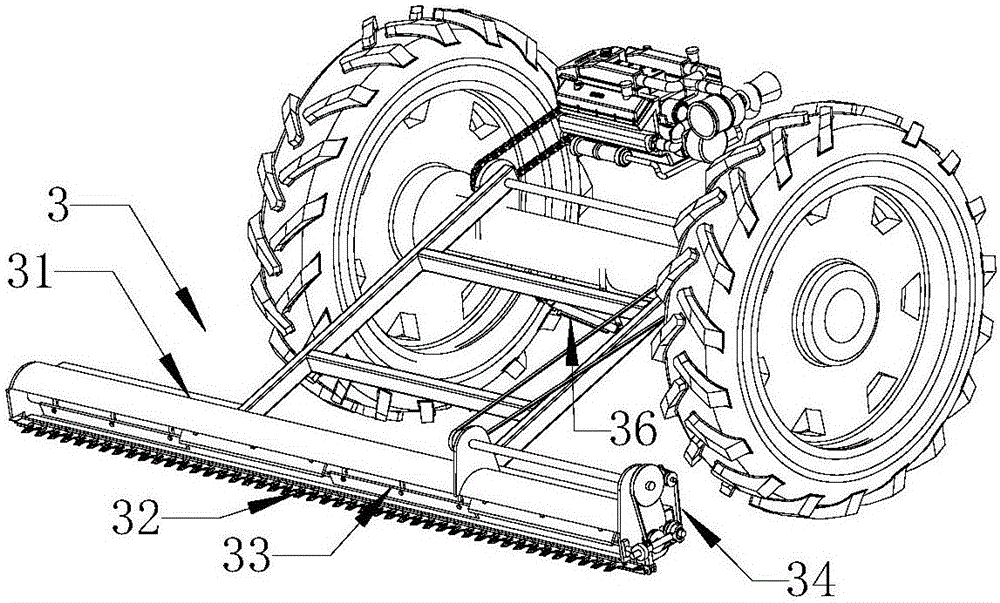

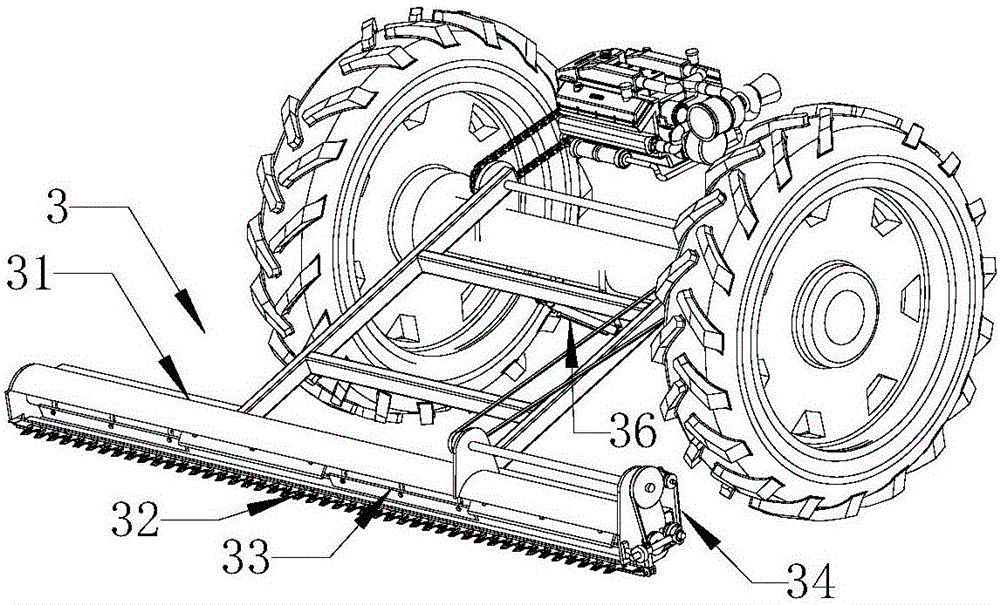

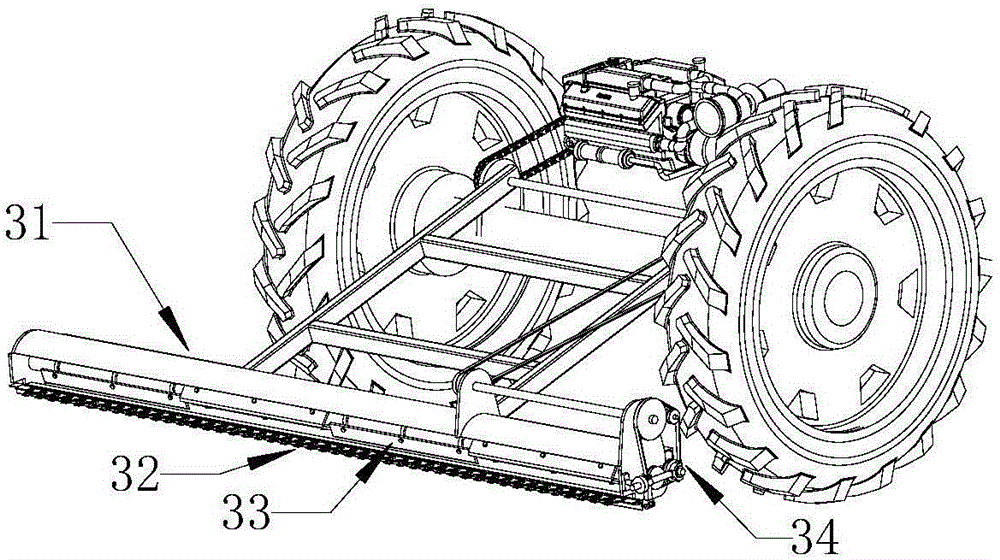

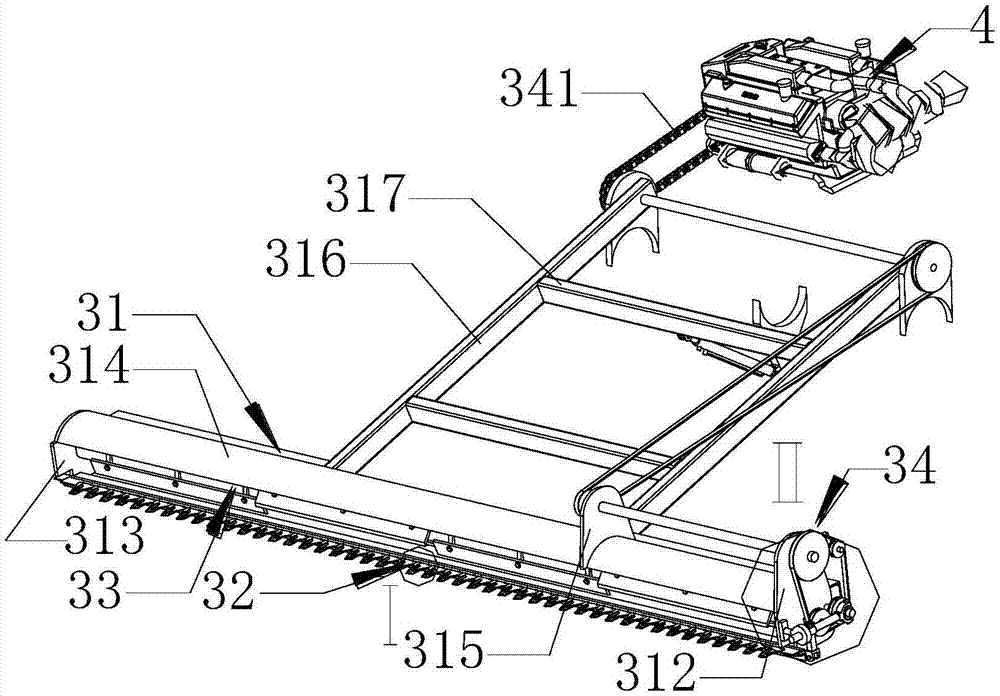

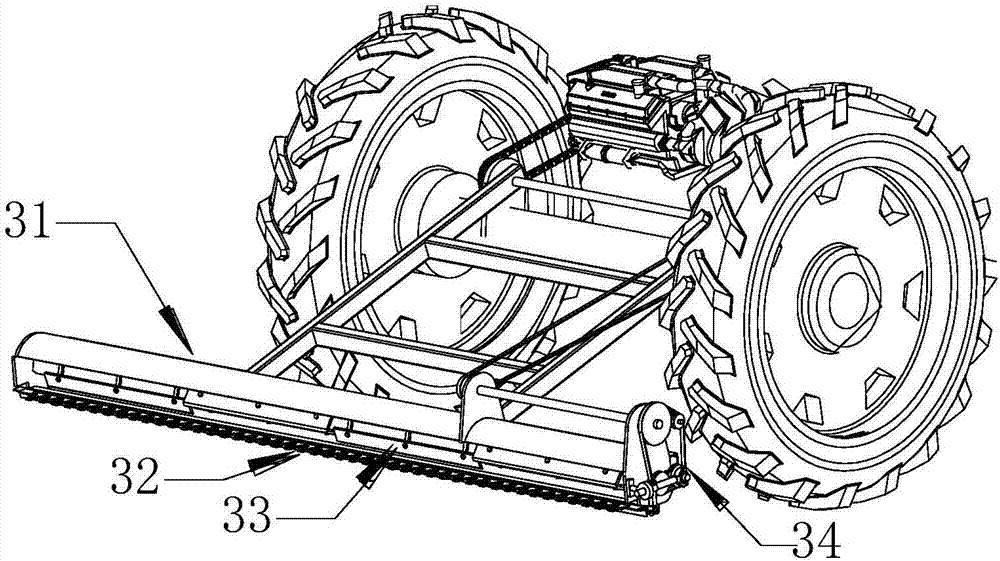

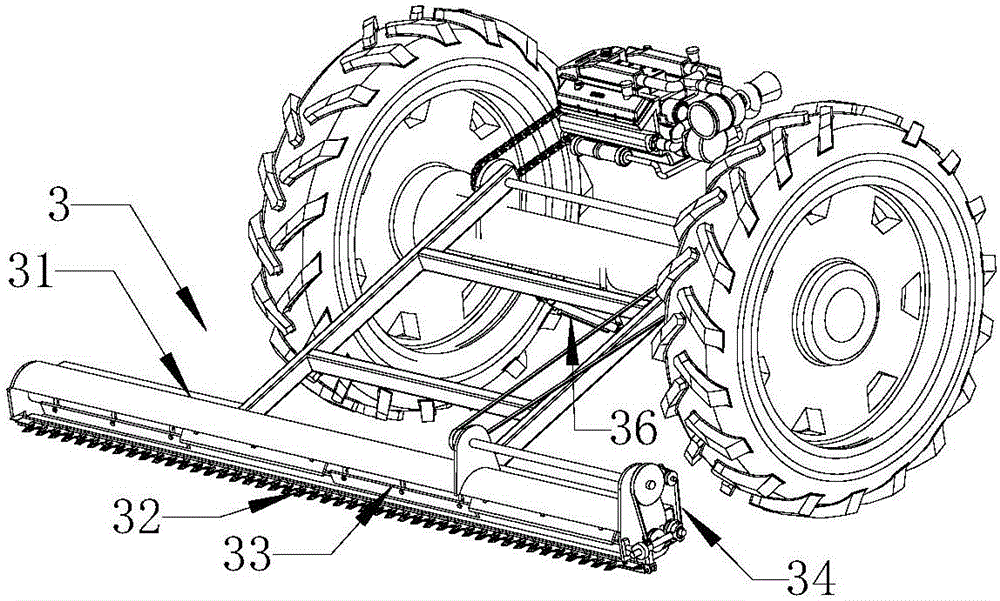

Harvester of fixed lower header capable of preventing splashing of broken straws

The invention discloses a harvester of a fixed lower header capable of preventing splashing of broken straws. The harvester comprises the lower header, wherein the lower header is firmly welded on a front axle of the harvester and comprises a lower header main frame, a lower cutting mechanism, a straw breaking mechanism and a transmission mechanism. The harvester also comprises a fixation rod and blocking angle iron, wherein a first right angle edge of the blocking angle iron is welded on the lower edge of the rear part of a blocking cover; and a second right angle edge is located under the first right angle edge and perpendicular to the horizontal ground. Each cutting blade is parallel to the horizontal ground. The transmission mechanism comprises a chain, a driven chain wheel, a first transmission shaft, a first pulley, a first belt, a second pulley, a second transmission shaft, a third pulley, a third belt, a tensioning pulley and a tensioning pulley installation shaft. The harvester of the fixed lower header capable of preventing the splashing of the broken straws disclosed by the invention has the advantages that straw parts left after cereal reaping can be cut and smashed, so a feeding amount of the harvester can be reduced, and machine losses and threshing loads can be reduced; stubble cutting is low and smooth, so ploughing becomes easier; and straw smashing efficiency is high, and the broken straws will not be splashed.

Owner:纪小坤

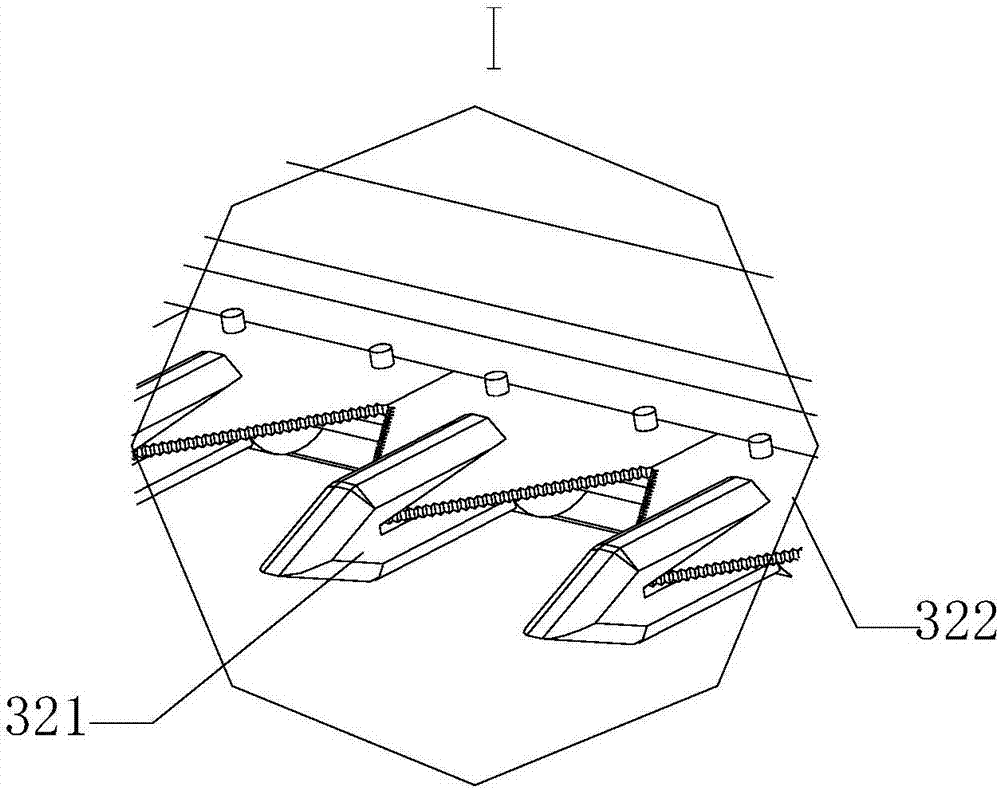

Harvester capable of chopping straw and provided with fixed lower cutting table

The invention discloses a harvester capable of chopping straw and provided with a fixed lower cutting table. The harvester comprises the lower cutting table. The lower cutting talbe is fixedly welded on a front axle of the harvester, and comprises a lower cutting table main frame, a lower cutting mechanism, a straw chopping mechanism and a transmission mechanism. One end of each of lower cutting table connecting rods is fixedly welded on the front axle. The lower cutting mechanism comprises a plurality of fixed tool bits which are arranged in a straight line and fixedly arranged on a base. Each cutting blade is parallel to the horizontal ground. The straw chopping mechanism is mounted in an accommodating space defined by the base, a covering shelter, a first sealing plate and a second sealing plate. The harvester has the advantages that the straw parts left after harvesting of crops can be cut and chopped, the feeding quantity of the harvester is reduced, the machine loss and the threshing load are reduced, the threshing effect is improved, the cut stubble heights are consistent, low and level and convenient for ploughing, the cutting and chopping efficiency of the straw is high, the chopped straw can be directly plough down in the soil in ploughing, and the straw is used as a base fertilizer after returning to the field.

Owner:纪小坤

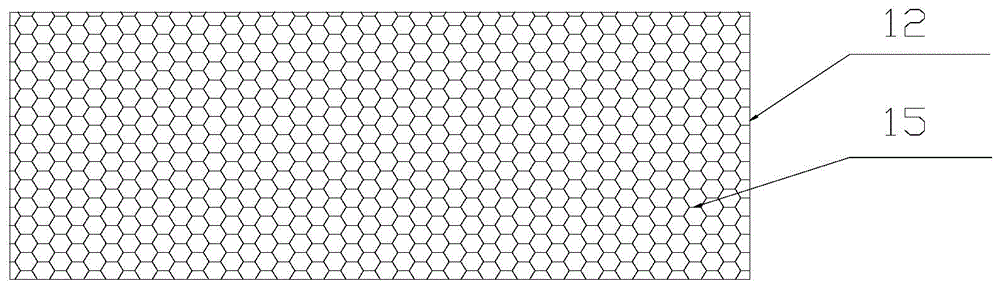

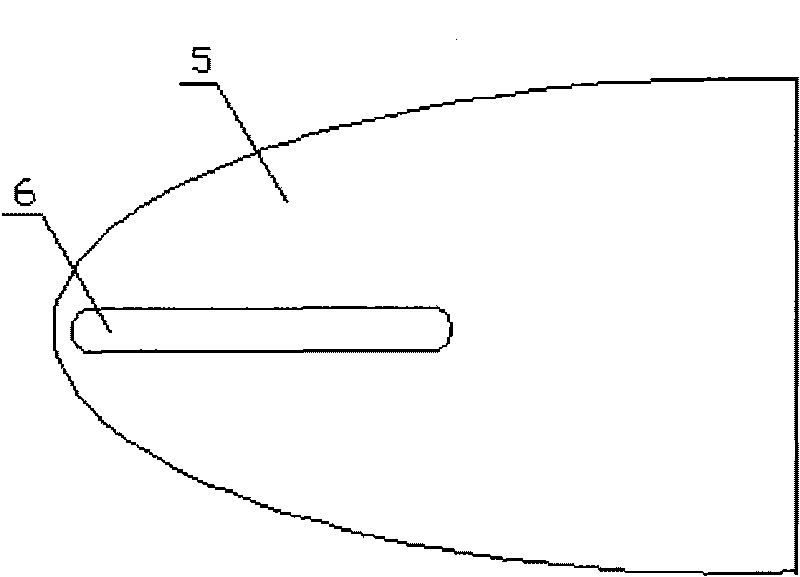

Hot-melt adhesive powder distributing mechanism

The invention discloses a hot-melt adhesive powder distributing mechanism. The mechanism comprises a rack, a hopper, a vibrating screen motor, an infrared sensing device, a driven rotating shaft, a hot-melt adhesive powder recovering bucket, a wind-driven powder separator, a blast pipe, a negative pressure fan, a rotating shaft motor, a drive rotating shaft, a conveyor belt, a control device, a vibrating screen and air holes. According to the hot-melt adhesive powder distributing mechanism, the conveyor belt of the traditional hot-melt adhesive powder distributing machine is replaced by the conveyor belt with a plurality of air holes, and the hot-melt adhesive powder recovering bucket and the negative pressure fan are arranged below the conveyor belt, so that a coiled fabric material can be flattened on the surface of the conveyor belt through the negative pressure fan and the conveyor belt with the plurality of air holes, and as a result, the hot-melt adhesive powder can be uniformly distributed; in addition, a screening structure of the vibrating screen is added to the hopper of the traditional hot-molt machine, and thus the phenomenon that the hopper is blocked by the hot-melt adhesive powder can be avoided.

Owner:TAICANG TAIBANG ELECTRONICS TECH

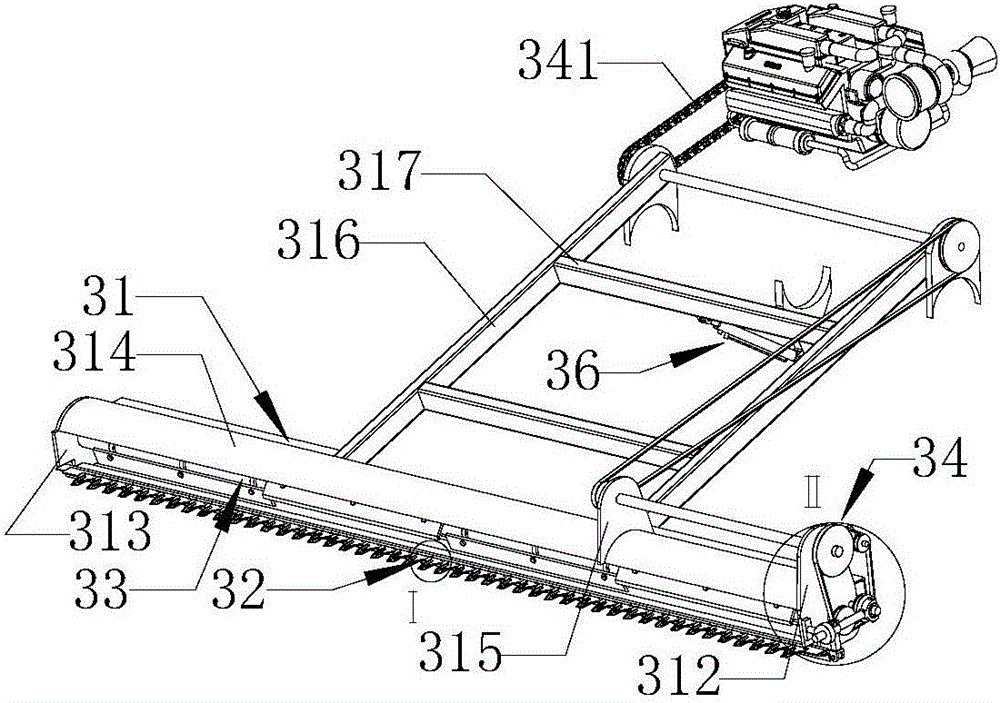

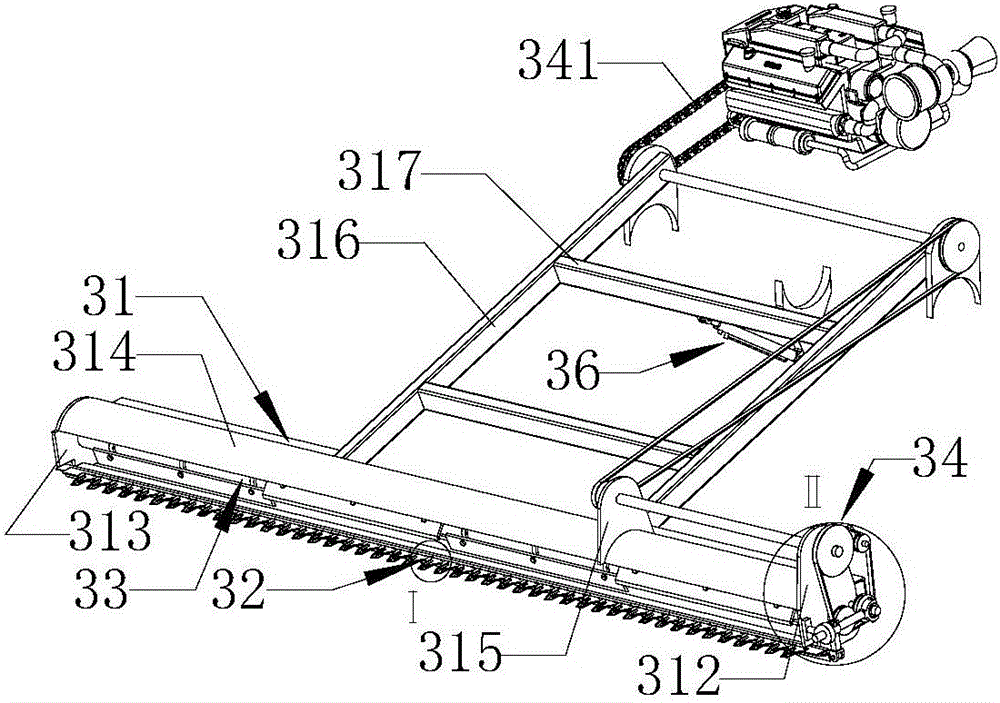

Harvester with lifting lower header capable of crushing straws and preventing spatter of crushed straws

The invention discloses a harvester with a lifting lower header capable of crushing straws and preventing spatter of the crushed straws. The harvester comprises the lower header, the lower header is hinged on a front axle of the harvester and comprises a lower header main frame, a lower cutting mechanism, a straw crushing mechanism, a driving mechanism and a lower header lifting mechanism, a blocking angle iron preventing spatter of the crushed straws is fixedly connected with the rear of a retaining cover of the lower header main frame, and the lower header lifting mechanism comprises a lower header lifting cylinder, a lower header lifting cylinder upper seat and a lower header lifting cylinder lower seat. According to the harvester with the lifting lower header capable of crushing the straws and preventing spatter of the crushed straws, straws remained after harvest of grains can be cut and crushed, feed quantity of the harvester is relieved, machine loss and threshing load are reduced, threshing effect is improved, cutting stubble is low and flat, lands are conveniently cultivated, cutting and crushing efficiency of the straws is high, crushed straws cannot spatter, the lower header can rise and fall, the height of the cutting stubble is controlled, barriers can be avoided, and device safety is protected.

Owner:纪小坤

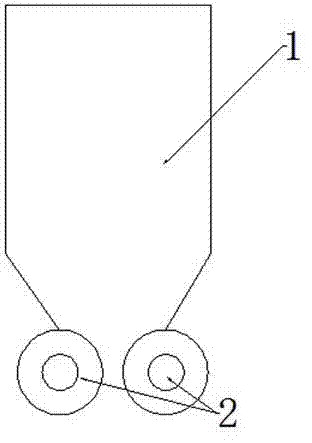

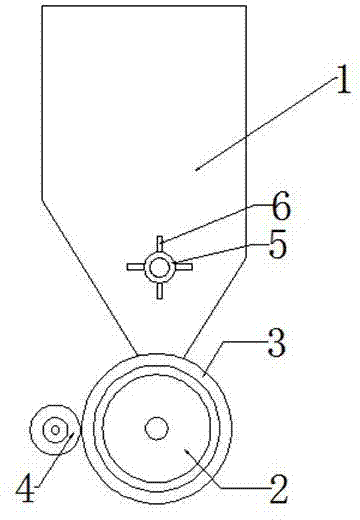

Powder sprinkling device

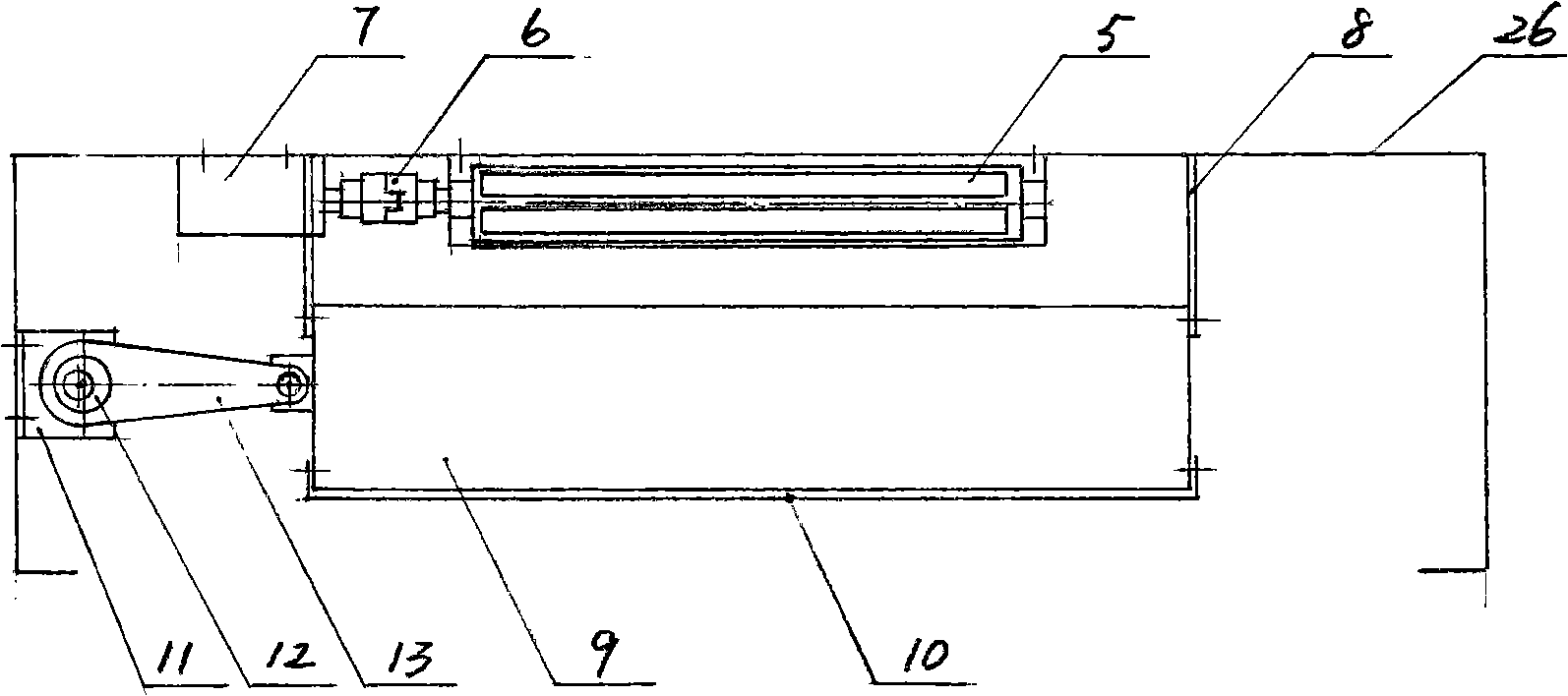

The invention provides a powder sprinkling device which comprises a powder bucket (1), a shell (5), a metering roller (4), a connecting passage (6) and a vibrating screen (7), wherein the shell (5) is connected with one end of the powder bucket; the metering roller (4) is arranged in the shell and is in contact with the inner surface of the shell; the connecting passage (6) is arranged below the shell and is connected with the shell; the vibrating screen (7) is connected with the connecting passage and is arranged below the metering roller; and the metering roller is driven by a first driving device. Because the metering roller is driven by the first driving device, the powder sprinkling quantity can be set by setting the rotation speed of the first driving device.

Owner:SHAANXI UNIV OF SCI & TECH

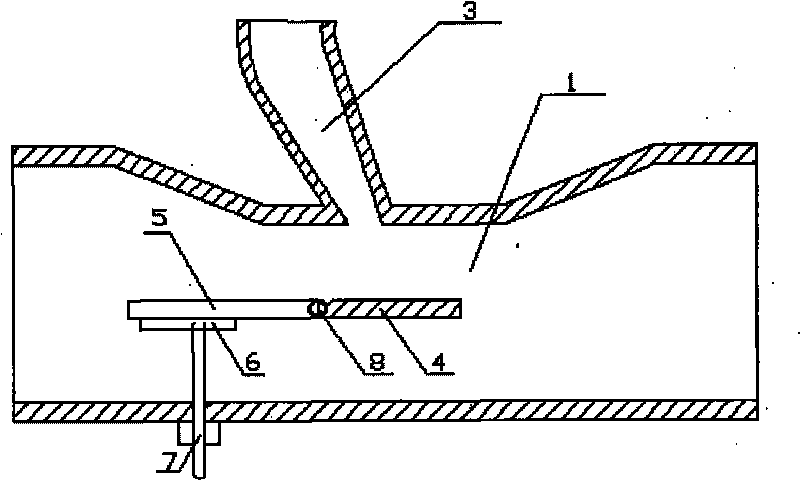

Adjustable air and powder mixer

InactiveCN101701718AChange the effective cross-sectional areaUnobstructed powderLump/pulverulent fuel preparationAir volumeEngineering

The invention relates to a preparation method of massive or powdery fuel used for fuel-burning equipment, in particular to an adjustable air and powder mixer which is structurally characterized by also comprising an adjustable baffle and an operating member, wherein one end part of the adjusting baffle is hinged with one end part of a fixed baffle, the other end part of the adjusting baffle is a movable end connected with the operating member. The invention has the advantages that the adjustable air and powder mixer is provided with the adjustable baffle, and the adjusting baffle swings up and down through operating the operating member of the adjustable baffle by taking a hinged end as a fulcrum, thereby changing the effective section area for the flow of the air flow of an air box, and further controlling the air pressure of the air box to a mixed cavity to match with the powder feeding pressure of a powder feeding tube so as to ensure that the pressure from bottom to top inside the powder feeding tube and the pressure from top to bottom inside the powder feeding tube are in needed balance to achieve the technical aim of smooth and uniform powder feeding of the powder feeding tube.

Owner:FUJIAN ELECTRIC POWER TEST & RES INST +2

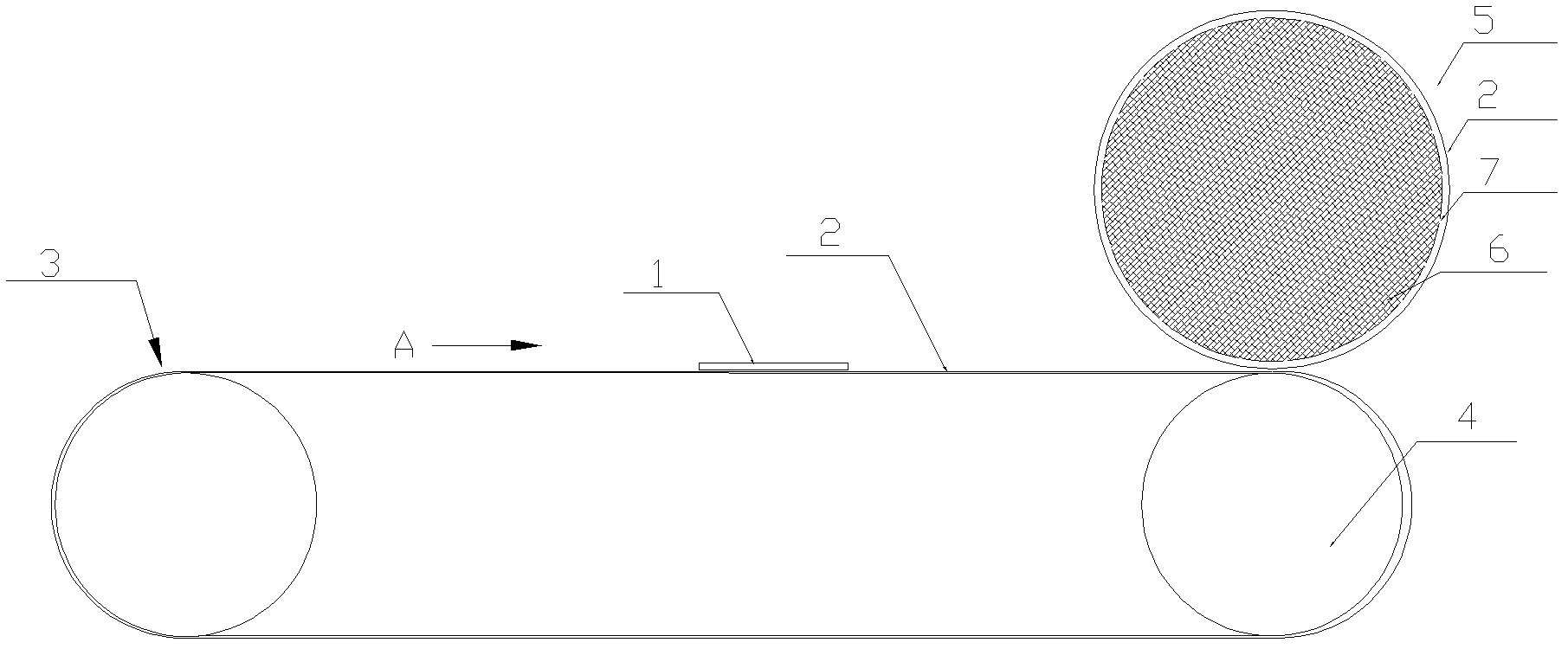

Production technology of steel wire ring for tires

The invention discloses a production technology of a steel wire ring for tires. The technology includes the steps of: steel wire unwinding, straightening, wiping cleaning, electric preheating, extrusion and rubber coating, cooling, coil forming, cutting, and isolation powder coating. During isolation powder coating, the surface of a shaped steel wire ring is coated with isolation powder through a coating powder conveyor so as to prevent sticking of the rubber coated shaped steel wire ring. The coating powder conveyor comprises a conveyer belt with a flannelette surface, and a roller above the conveyer belt. The isolation powder is disposed in the roller, the surface of which is provided with uniformly distributed holes and is wrapped by flannelette. The new technological method provided in the invention for a steel wire ring production process improves the steel wire ring sticking problem in current steel wire ring production. The employment of the flannelette equipped conveyer belt and the roller that make movement in opposite directions to coat the steel wire ring for tires with powder uniformly, and the efficiency is improved.

Owner:SICHUAN YUANXING RUBBER

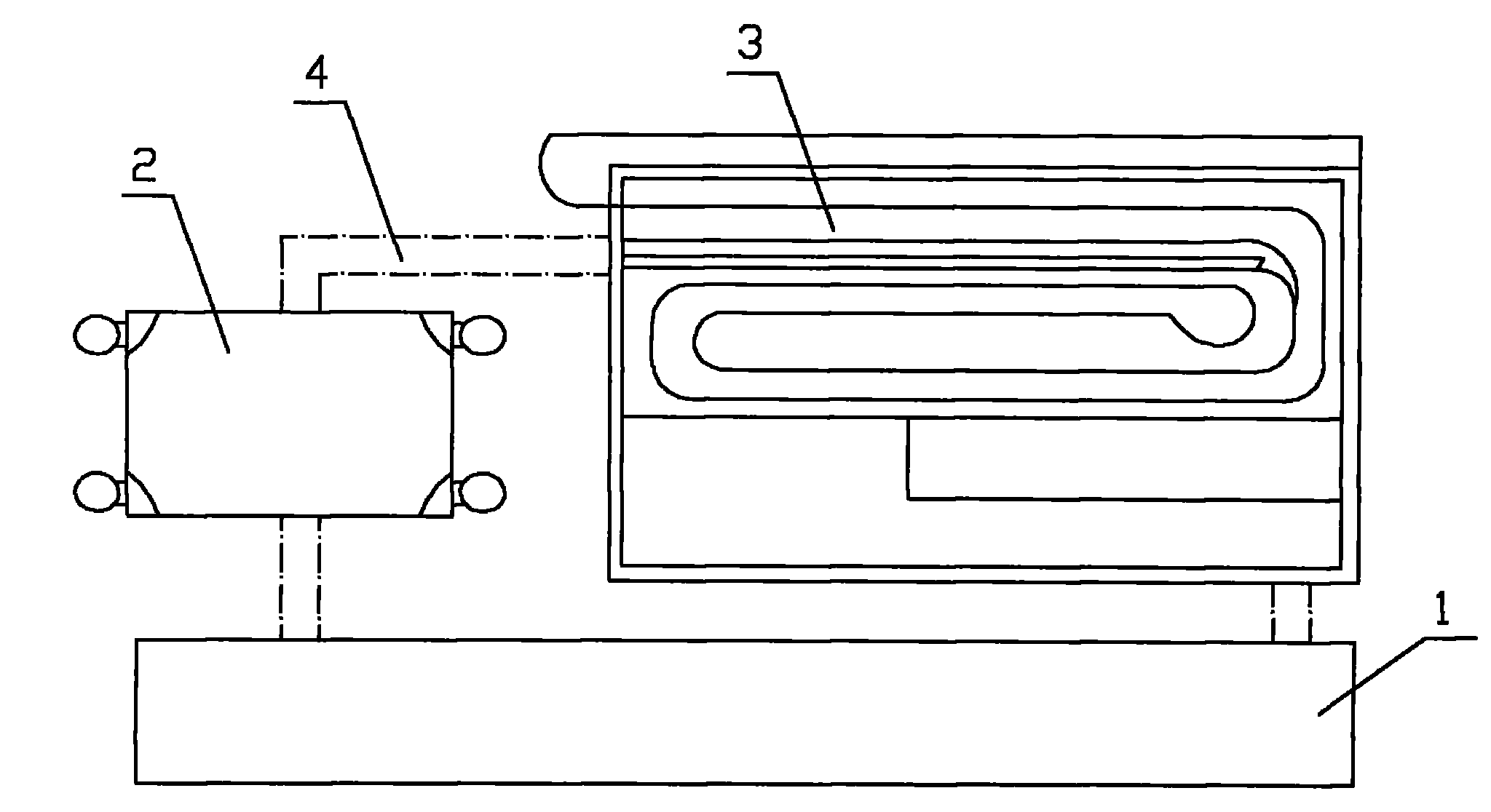

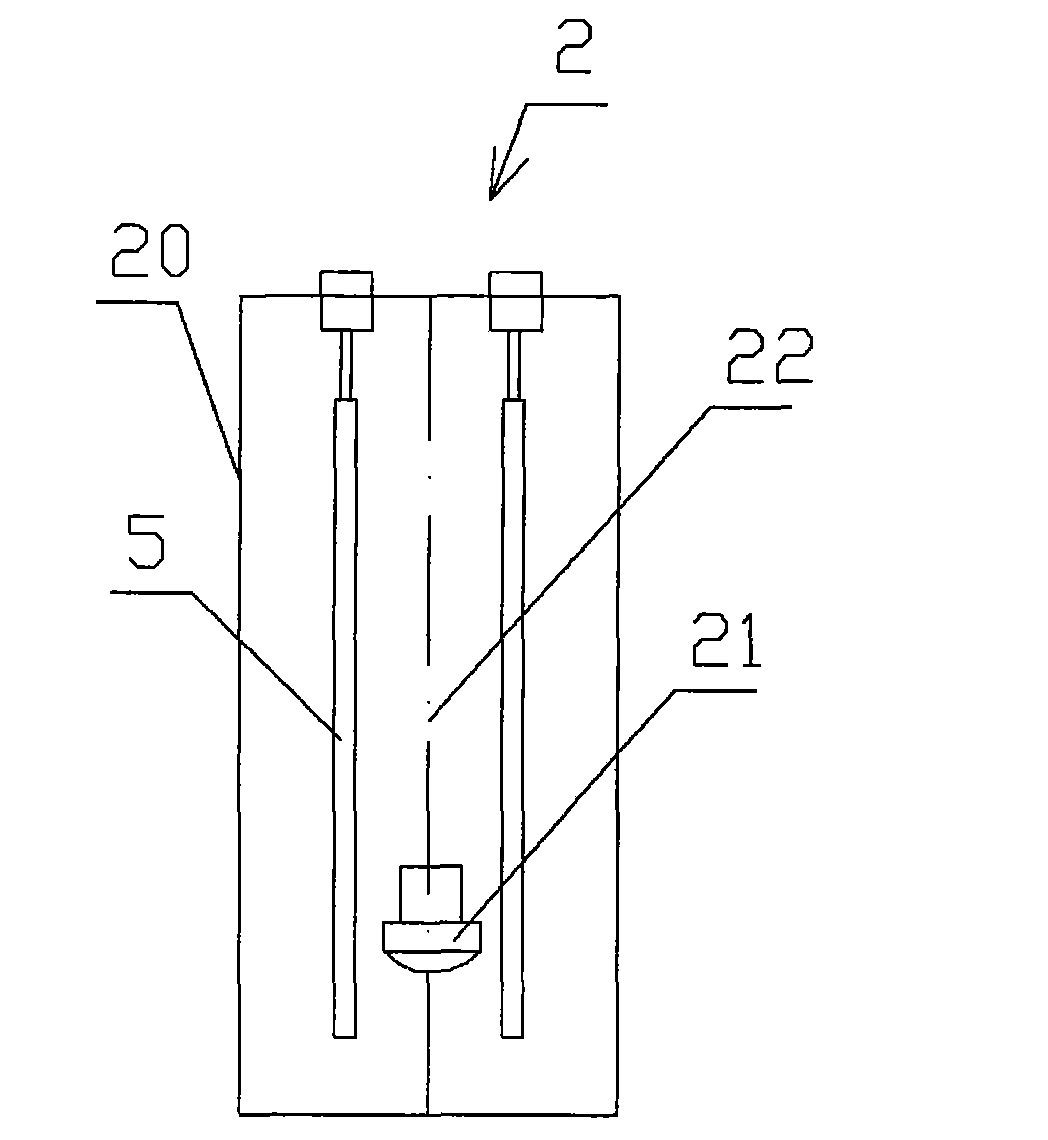

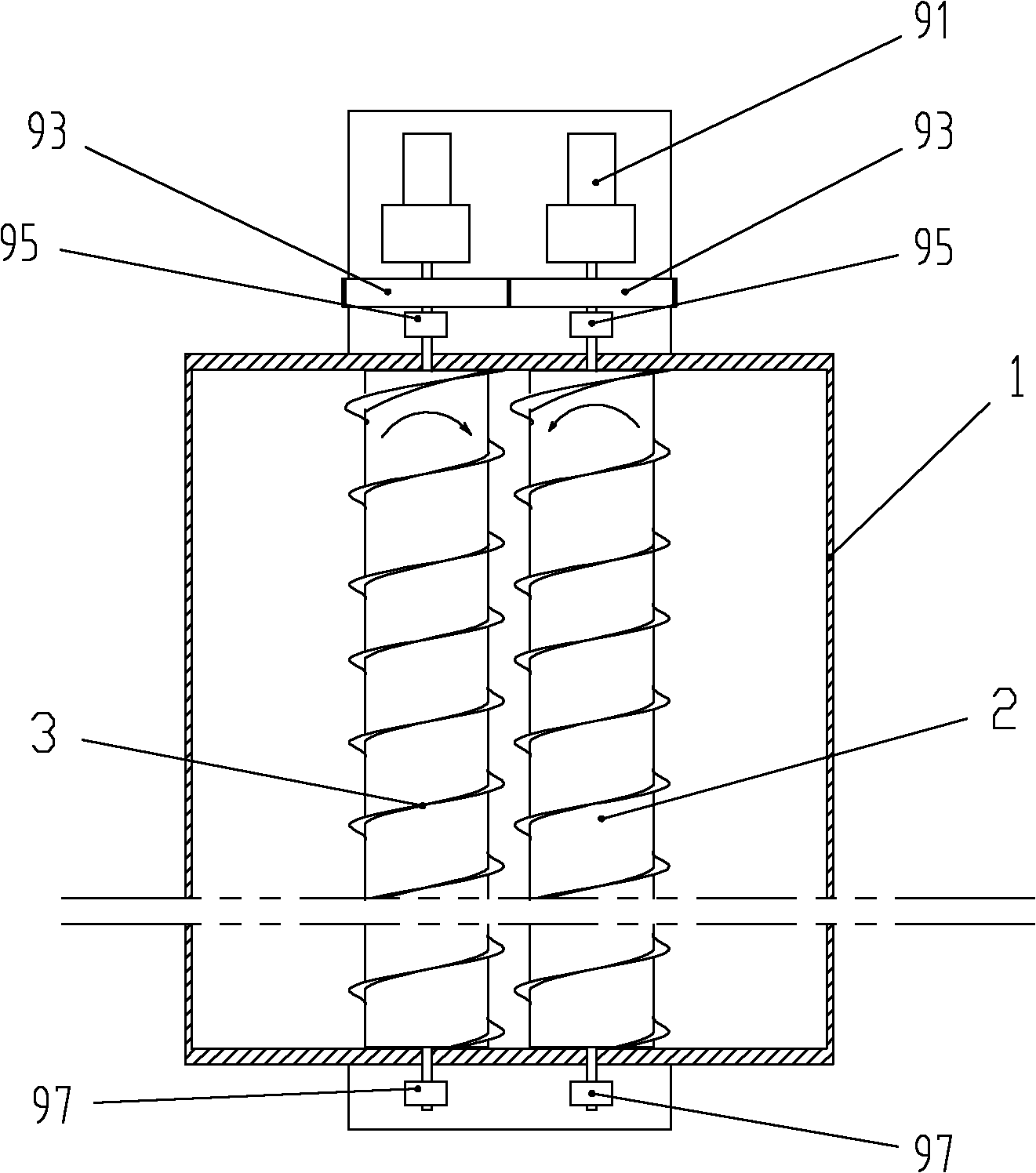

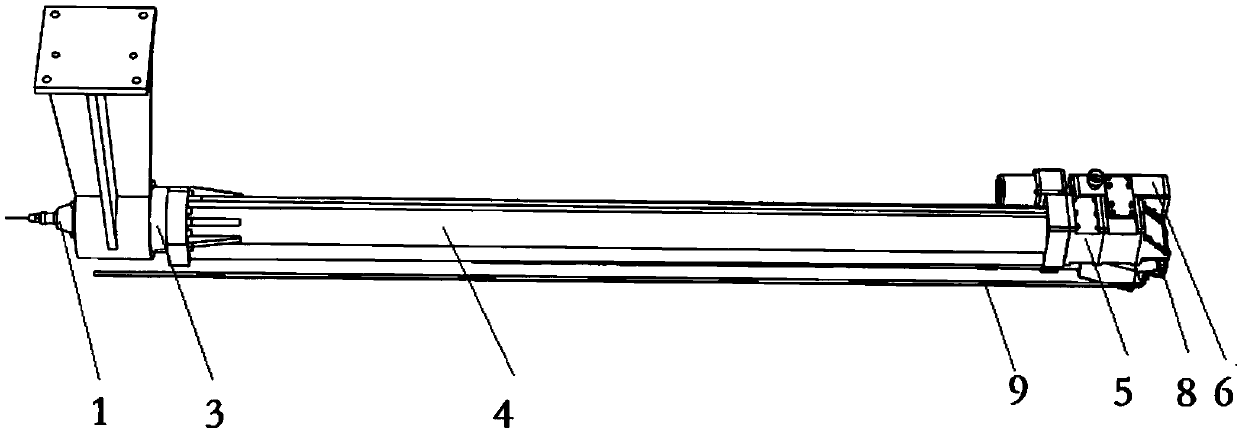

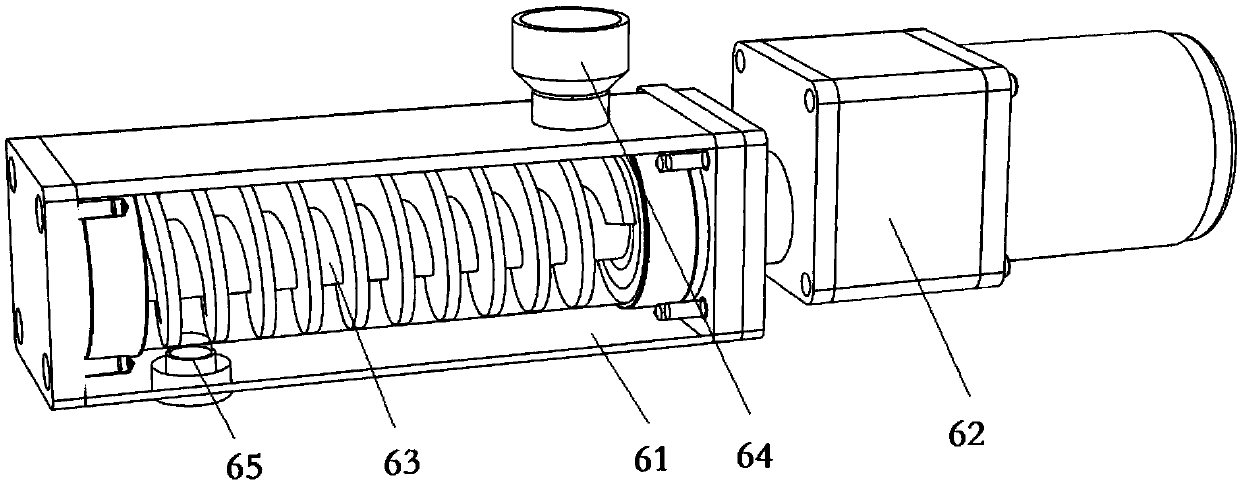

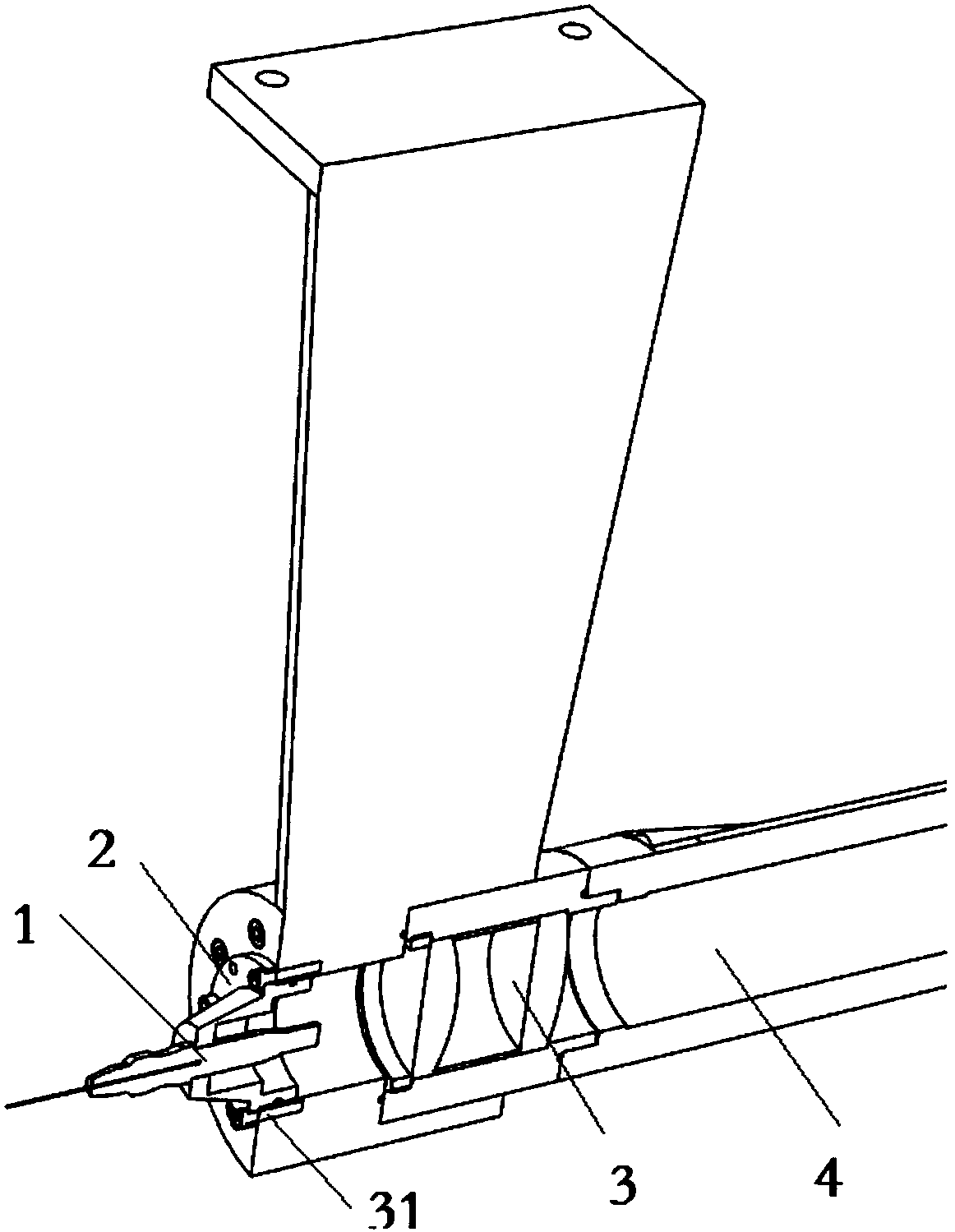

Laser inner hole cladding equipment and gravity powder feeder

PendingCN109576699AIncrease profitPowder evenlyMetallic material coating processesLaser lightMaterials science

The invention relates to laser inner hole cladding equipment and a gravity powder feeder. According to the laser inner hole cladding equipment and the gravity powder feeder, the problems that in the case of existing laser inner hole cladding equipment, the powder feeding process is not uniform, the powder feeding stability is relatively poor, and the residual dust influences the laser light path and the cladding effect are solved. The laser inner hole cladding equipment comprises an optical fiber head, a rear-end lens set, an intermediate connecting piece, a front-end lens set and a powder feeding assembly arranged on one side of the front-end lens set, wherein the optical fiber head, the rear-end lens set, the intermediate connecting piece, the front-end lens set and the powder feeding assembly are sequentially arranged, the front-end lens set comprises a front-end lens and a front-end lens shell, the powder feeding assembly comprises the gravity powder feeder and a powder feeding nozzle, powder is fed into the powder feeding nozzle through the gravity powder feeder, the gravity powder feeder comprises a powder feeder shell, a driving device and a screw rod, the screw rod is arranged in the powder feeder shell, and is driven by the driving device, and a feeding hole and a discharging hole are formed in the powder feeder shell.

Owner:XIAN BESAME LASER TECH CO LTD

Cloth stamping powder-dusting device

The invention relates to a cloth printing duster matched with a cloth printing machine, which mainly comprises a dusting device, a transmission mechanism and a surplus powder recovering device. The cloth printing duster is characterized in that the transmission mechanism is connected with the surplus powder recovering device through a powder suction port and a powder suction pipe; the dusting device is arranged below a powder discharger of the surplus powder recovering device; the dusting device is hung on a machine frame through a powder shaking bucket by a spring sheet, and is connected with a connecting rod, a motor and an eccentric wheel; the bottom of the powder shaking bucket is connected with a powder shaking adjustor, and the motor rotates to drive the powder shaking bucket to shake so as to achieve a dusting process; an air and powder separator provided with a blower is arranged above the machine frame, and the bottom of the air and powder separator is connected with the powder discharger and the powder suction pipe respectively; the powder suction pipe is connected with the powder suction port, and an air discharge device is connected with a union joint provided with the motor; and surplus golden and silver powder on the cloth enters the air and powder separator through the powder suction port and the powder suction pipe, and is sent into the powder shaking bucket through the powder discharger so as to achieve the aim of recovering the surplus powder. The cloth printing duster has the advantages of uniform dusting, recycle of the surplus powder on the cloth, labor intensity reduction, environmental pollution reduction, and the like.

Owner:蔡梦炎

Method for making roasted-wing-flavor crispy leisure dry noodles

The invention discloses a method for making roasted-wing-flavor crispy leisure dry noodles. A noodle cake is made from, by weight, 68-72 parts of wheat flour, 18-22 parts of vegetable oil, 0.8-1.2 parts of starch, 0.1-0.15 part of aginomoto, 1.5-2.5 parts of salt, 0.1-0.2 part of sodium bicarbonate, 2-4 parts of crisping powder, 0.01-0.02 part of acidity regulator, 0.1-0.2 part of guar gum, 0.5-1.5 parts of hydrolyzed vegetable protein and 18-22 parts of water. Seasoning powder is made from, by weight, 30-35 parts of salt, 20-25 parts of fine sugar, 15-20 parts of dry-cured spice, 15-20 parts of aginomoto, 0.2-0.4 part of composite flavor enhancer and 0.3-0.5 part of chicken oil-shaped essence. The method for making the roasted-wing-flavor crispy leisure dry noodles is disclosed, the raw materials are selected, the special crispy raw materials and making process are selected, and the crispy degree of the leisure dry noodles is greatly improved. The specific flavor of the dry noodles is embodied more directly and uniformly, and the original specific flavor of the dry noodles can be guaranteed to the largest degree.

Owner:HUAIBEI SHUNFA FOOD

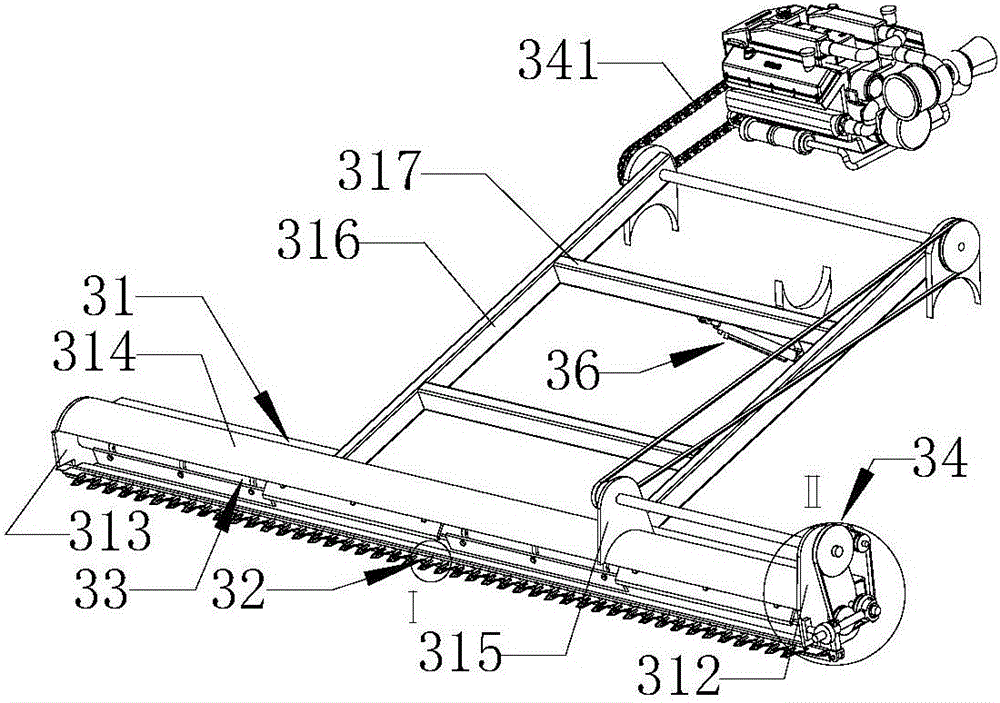

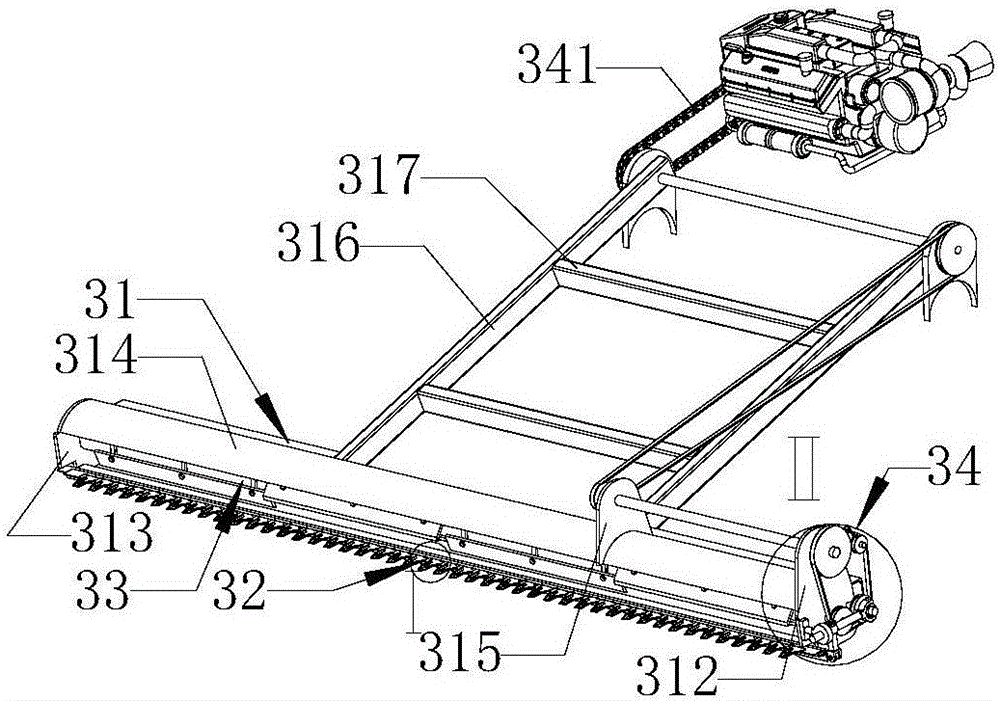

Lifting type lower cutting table capable of smashing straw and preventing smashed straw from splashing

The invention discloses a lifting type lower cutting table capable of smashing straw and preventing smashed straw from splashing. The lifting type lower cutting table is hinged to a front axle of a harvester and comprises a lower cutting table main frame, a lower cutting mechanism, a straw smashing mechanism, a transmission mechanism and a lower cutting table lifting mechanism; blocking angle iron used for preventing the smashed straw from splashing is fixedly connected to the back portion of a blocking cover of the lower cutting table main frame; the lower cutting table lifting mechanism comprises a lower cutting table lifting oil cylinder, a lower cutting table lifting oil cylinder upper base and a lower cutting table lifting oil cylinder lower base. According to the lifting type lower cutting table capable of smashing the straw and preventing the smashed straw from splashing, straw portions retained after grain harvesting can be cut and smashed, the feeding amount of the harvester is decreased, the machine loss and the threshing load are reduced, and the threshing effect is improved; cut stubbles are low and flat, and therefore ploughing is convenient; the straw cutting and smashing efficiency is high, and the smashed straw cannot splash; meanwhile, lifting can be achieved, therefore, the cut stubble height can be controlled, and the cutting table can keep away from obstacles, so that equipment safety is guaranteed.

Owner:见保林

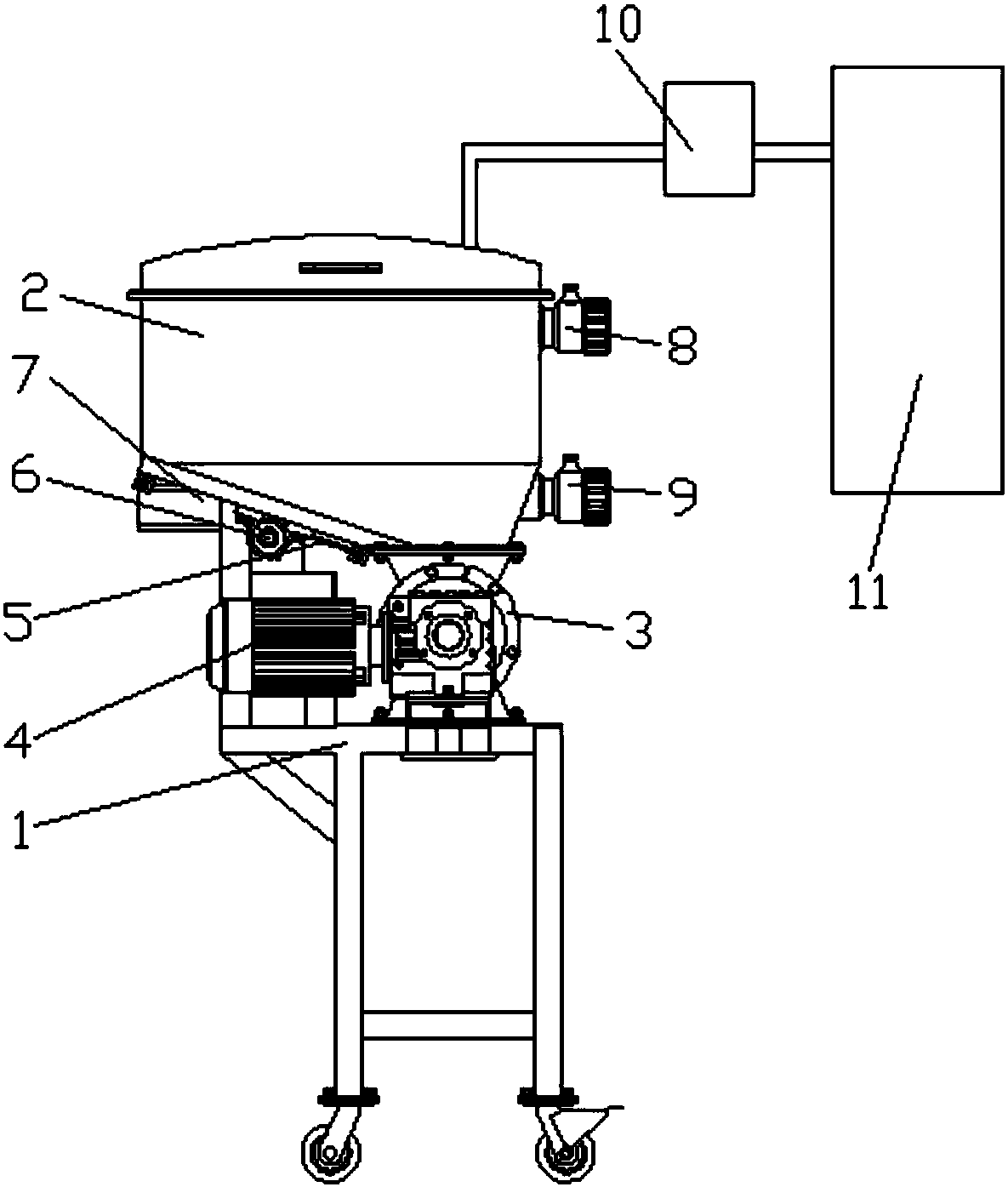

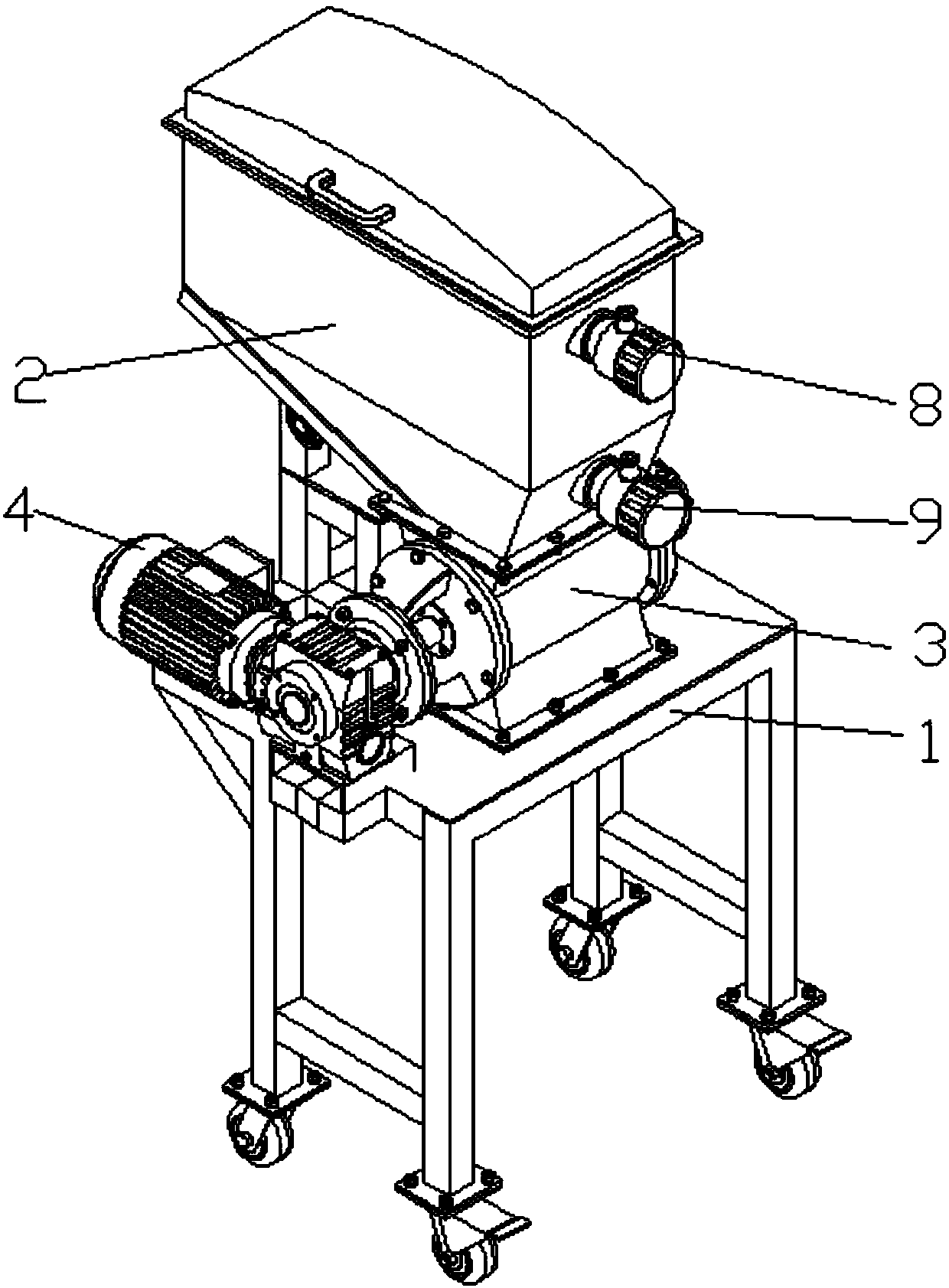

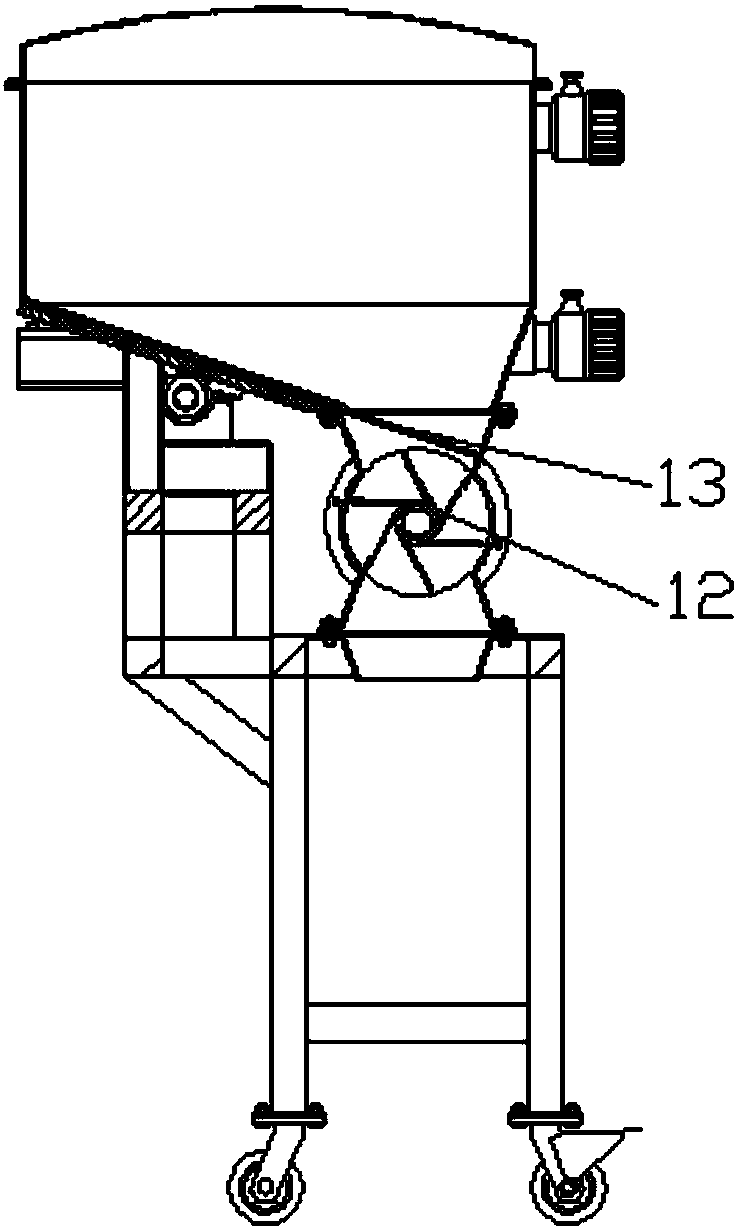

Fully-automatic powder spreading device

The invention discloses a fully-automatic powder spreading device. The fully-automatic powder spreading device comprises a machine frame, a material bin, an impeller feeding machine, a powder conveying pump and a powder bin, wherein the material bin is arranged on the machine frame; the impeller feeding machine is arranged at a bottom material outlet of the material bin; an impeller rotary shaft of the impeller feeding machine is connected with an output shaft of a first deceleration motor; an adjustable gate plate valve device is arranged at the material outlet of the material bin, and comprises a gate plate, a gear and a gear rack; the gate plate is arranged in the material bin, and is fixedly connected with the external gear rack; the gate plate and the gear rack can be slide at the material outlet, and the gear rack is engaged with the gear; the gear is connected with an output shaft of a second deceleration motor through a rotary shaft; an upper limiting material level controllerand a lower limiting material level controller are respectively arranged at the upper part and lower part of the material bin, and the top part of the material bin is connected with the powder bin through the powder conveying pump. The automatic powder spreading device has the advantages that the powder feeding speed is adjusted by a frequency-variable speed governing technique; more convenience in use is realized, the powder spreading is uniform, quantitative and accurate, the labor is saved, and the efficiency is improved.

Owner:SHANGHAI BEYOND MACHINERY

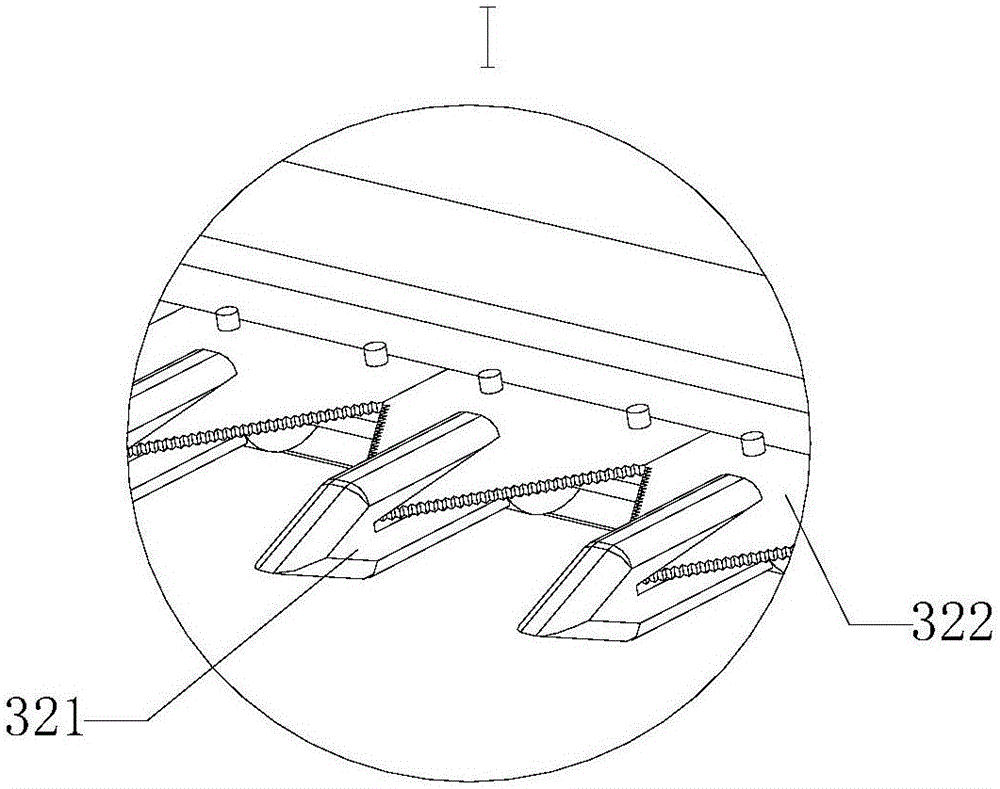

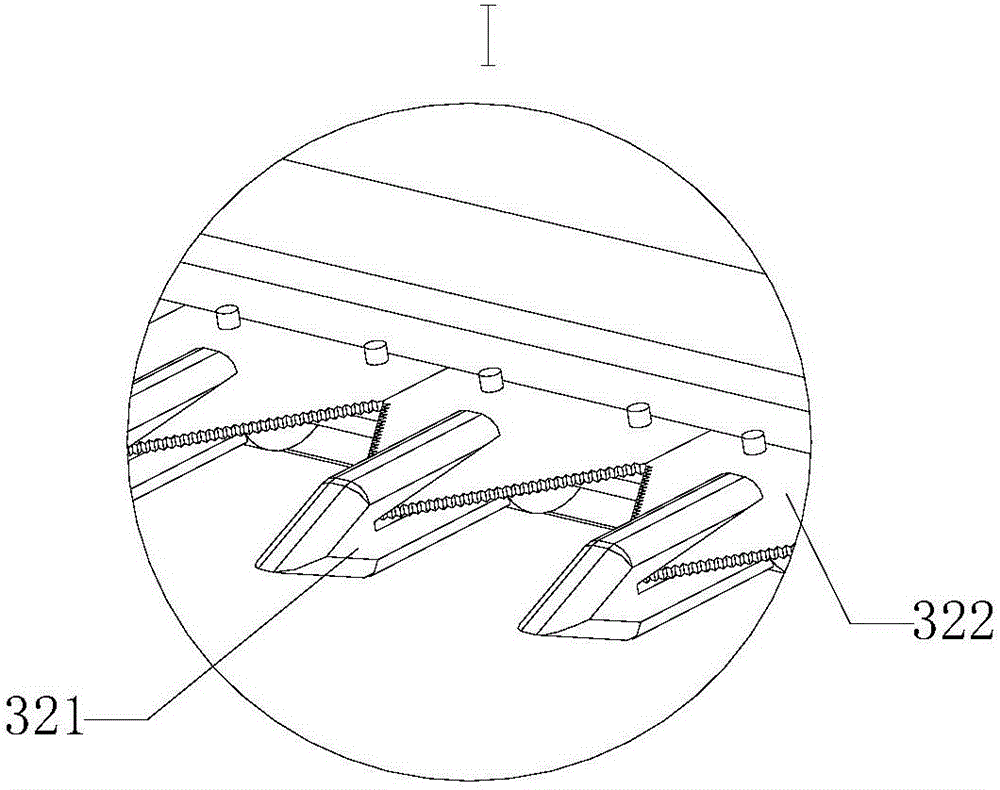

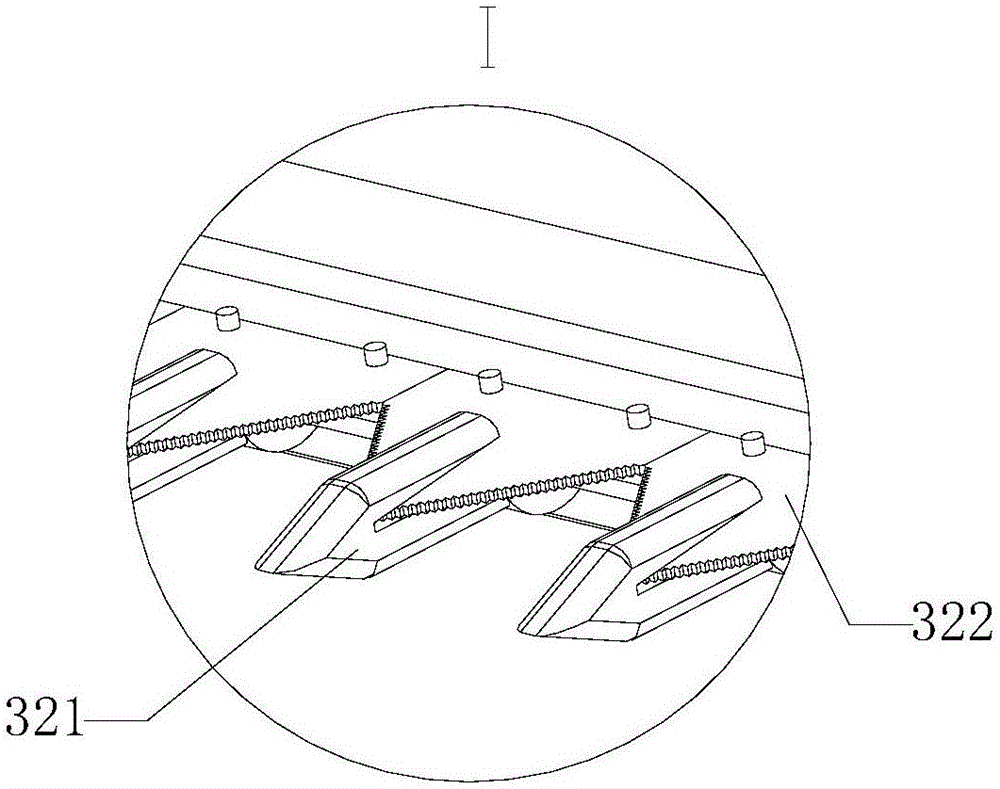

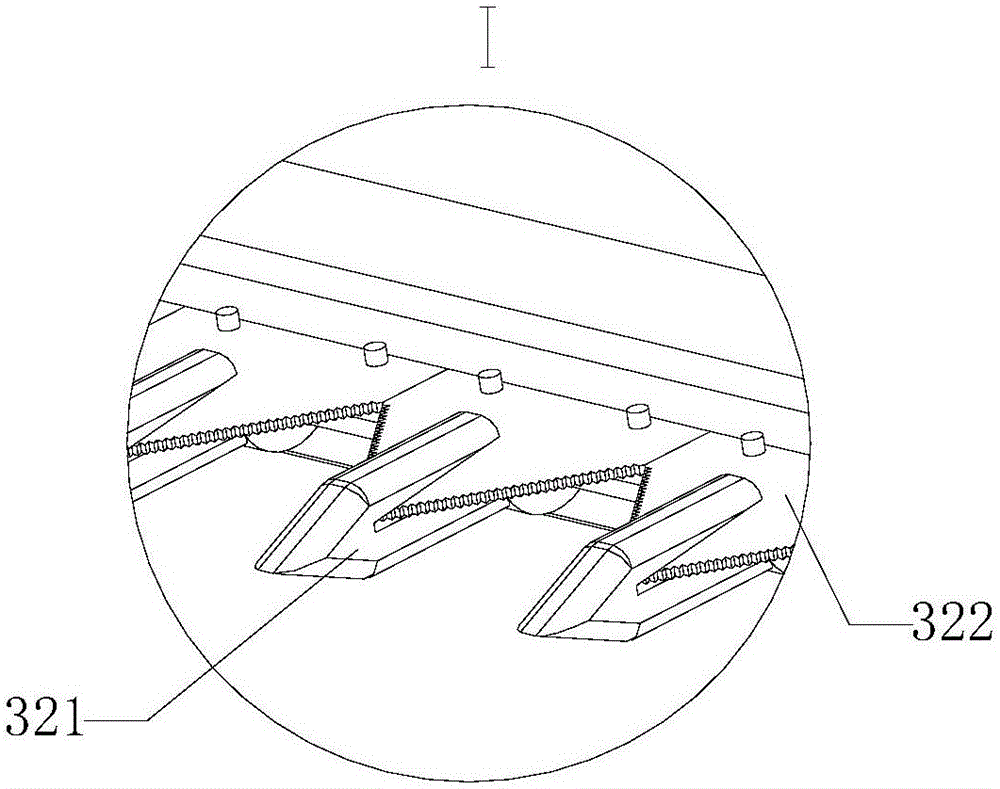

Harvester with fixed type lower header and capable of uniformly crushing straws and preventing crushed straws from spattering

The invention discloses a harvester with a fixed type lower header and capable of uniformly crushing straws and preventing crushed straws from spattering. The harvester comprises the lower header, wherein the lower header is hinged to a front axle of the harvester; the lower header comprises a lower header main frame, a lower cutting mechanism, a straw crushing mechanism and a transmission mechanism; stopping angle iron capable of preventing the crushed straws from spattering is further fixedly connected with the rear part of a stopping cover of the lower header main frame; the included angle of cutting blades on two sides of a cutting blade is 60 degrees and saw teeth are arranged on the cutting blade on each side; the straw crushing mechanism is mounted in a containing space formed by a base, the stopping cover, a first sealing plate and a second sealing plate; an adjusting gap is formed in the top of a swinging arm. The harvester with the fixed type lower header and capable of uniformly crushing the straws and preventing the crushed straws from spattering, disclosed by the invention, can be used for cutting and crushing straw parts remained after cereals are harvested; the feeding amount of the harvester is alleviated, and the loss and threshing load of a machine are reduced; cutting stubbles are low and flat, so that a land is easy to plough; positions of the cutting blades can be easily and conveniently adjusted; high efficiency of cutting the straws is guaranteed and the crushing is uniform; meanwhile, the crushed straws do not spatter.

Owner:纪小坤

Special-shaped glass powder feeding device

ActiveCN108031622AAvoid the problem of accumulation on the concave surface of special-shaped glassPowder evenlyLiquid surface applicatorsCoatingsReciprocating motionEngineering

The invention relates to the technical field of surface coating devices, and particularly discloses a special-shaped glass powder feeding device. The device comprises a box body, a vacuum pump, a power mechanism, a working mechanism and a transmission mechanism; the power mechanism comprises a motor, a first gear and a first rack meshed with the first gear, and the middle section of the first rackis provided with a paw for fixing special-shaped glass; the transmission mechanism comprises an L-shaped handle arranged on the first rack and a cylinder body, wherein a first piston is arranged inside the cylinder body in a sliding fit mode, and the free end of the handle is fixedly connected with the first piston; the working mechanism comprises a groove body communicating with the cylinder body and a bearing groove arranged above the groove body, the size of the bearing groove is larger than the size of the special-shaped glass, and the groove body is arranged at the bottom of the box body; and a second piston is arranged in the groove body in a sliding fit mode, and the second piston is fixedly connected with a crank sliding block mechanism for driving horizontal reciprocating motionof the bearing placing groove. According to the technical scheme, the surface of the special-shaped glass can be uniformly coated with powder, and therefore, the device can be widely applied to the powder feeding of the special-shaped glass.

Owner:CHONGQING HECHUAN JINXING GLASS PROD CO LTD

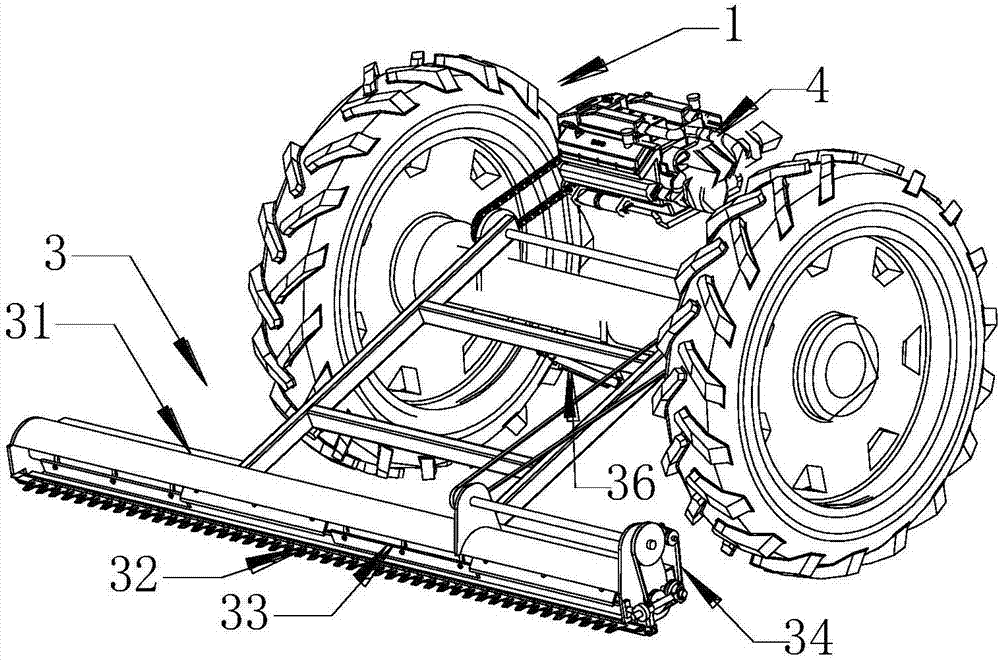

Uniform straw smashing and smashed straw splattering prevention type double header linkage harvester with ladder stand

The invention discloses a uniform straw smashing and smashed straw splattering prevention type double header linkage harvester with a ladder stand. The harvester comprises an upper header, a lower header, a linkage rod and the ladder stand. The upper header is hinged to a front axle, and the lower header is hinged to the front axle and positioned below the upper header. The upper header comprises an upper header main frame, an upper cutting mechanism, a screw, a reel and an upper header lifting mechanism. The lower header comprises a lower header main frame, a lower cutting mechanism, a straw smashing mechanism and a transmission mechanism, and a first right-angle side of a retaining angle iron is welded to the rear lower edge of a shield. The harvester has advantages that straws remained after grain harvesting can be cut and smashed, threshing load is relieved, cutting blade position can be adjusted easily and conveniently to guarantee high straw cutting efficiency and smashing uniformity, and smashed straws are prevented from splattering; the lower header is in lifting linkage with the upper header, and accordingly stubble height can be controlled while obstacles can be avoided so as to protect equipment safety, and energy saving and consumption reduction are realized; the ladder stand can be used for climbing safely and conveniently and can also serve as a safety fence.

Owner:界首市民强农业发展有限公司

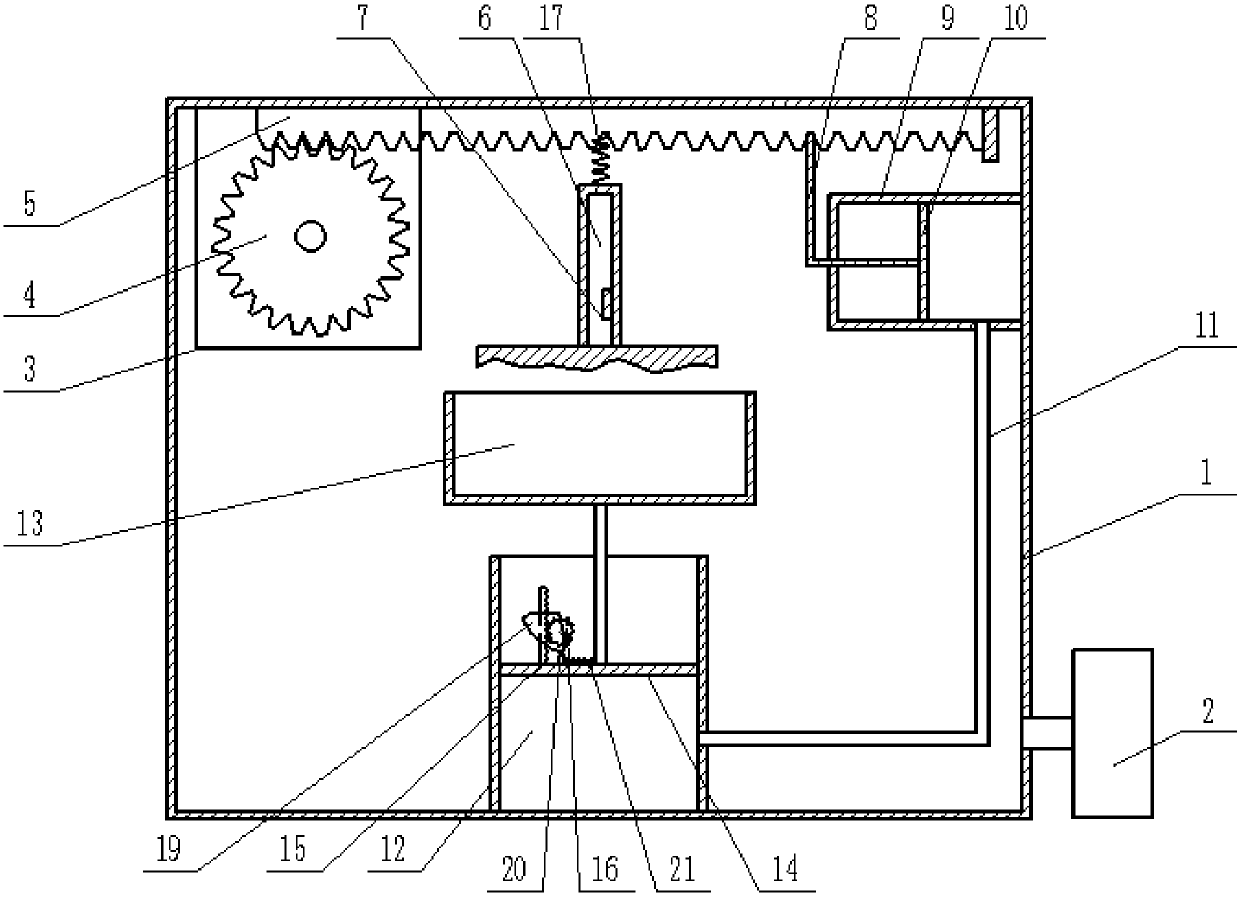

Agricultural high-reliability powder spraying machine

InactiveCN106670015ASpeed up the rate of dustingThe dusting operation is smoothMovable spraying apparatusLiquid spraying apparatusGear wheelPowder Spray

The invention relates to a powder spraying machine, in particular to an agricultural high-reliability powder spraying machine. The agricultural high-reliability powder spraying machine is uniform in powder output, controllable in powder spraying amount and not easy to block. To achieve the technical aims, the agricultural high-reliability powder spraying machine is provided. The agricultural high-reliability powder spraying machine comprises a first rack, a first gear, a first rotary shaft, a first bearing seat, a first one-way valve, a connecting pipe, a first sliding block, a first sliding rail, a channel, an air inlet pipe and the like. The first bearing seat, the channel, the first sliding rail and a second sliding rail are sequentially arranged on the top of a cart from left to right. The first rotary shaft is arranged on the first bearing seat. The first gear and a cylinder body are sequentially arranged on the first rotary from bottom to top. The agricultural high-reliability powder spraying machine has the beneficial effects of being uniform in powder output, controllable in powder spraying amount and not easy to block, so that powder spraying operation can be better conducted in the agricultural production process, the powder spraying amount is stable, and the powder spraying speed is increased.

Owner:湖州浩森科技股份有限公司

Papermaking and composite processing technology for composite liquid absorbing material and equipment thereof

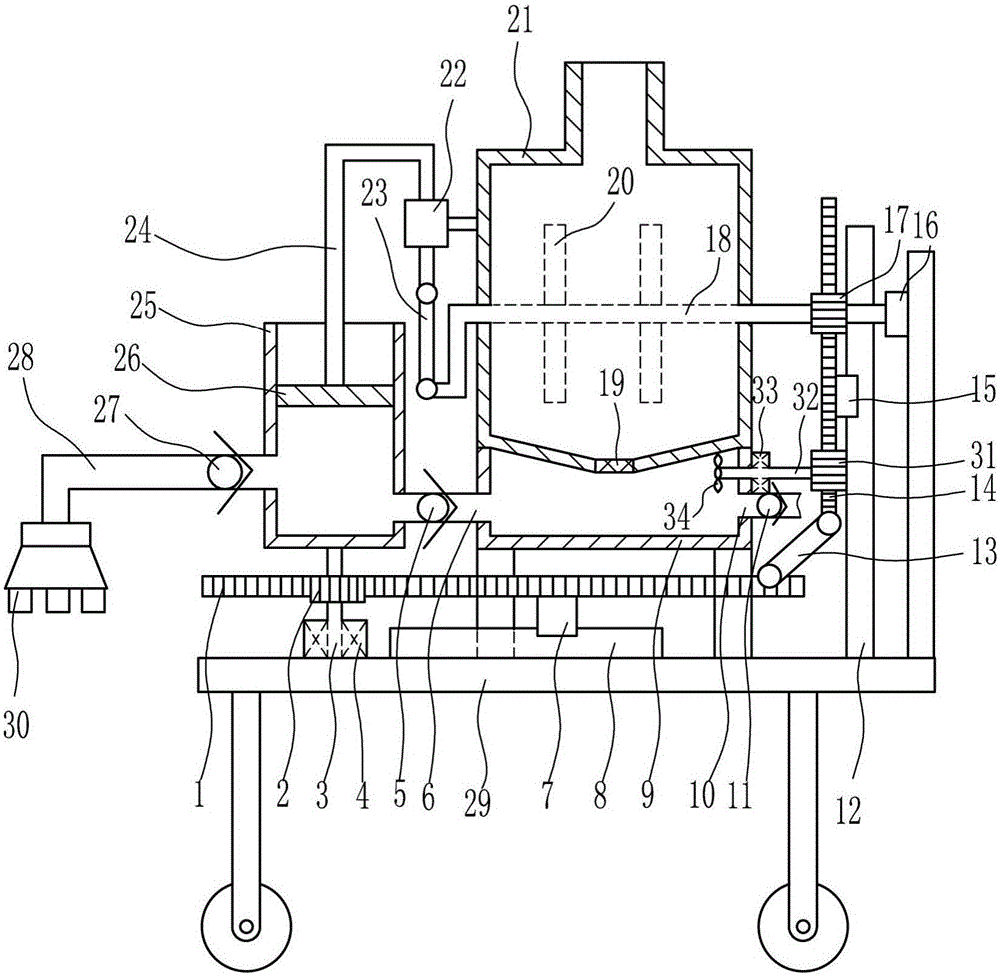

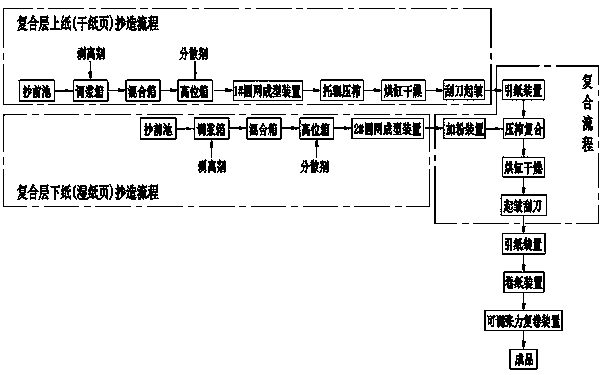

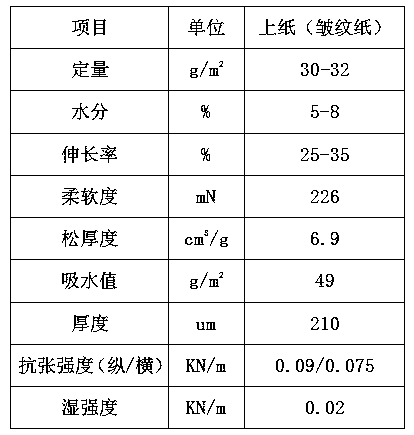

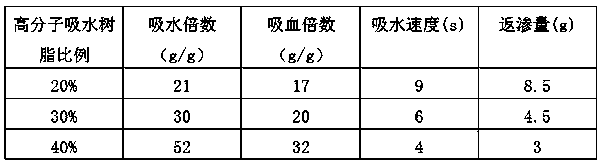

ActiveCN111379188AThe total amount is easy to controlEasy to operatePaper-making machinesArticle deliveryMolding machinePapermaking

The invention discloses a papermaking and composite processing technology of a composite liquid absorbing material. The technology comprises the steps of composite layer upper paper papermaking, composite layer lower paper papermaking, compounding and rewinding processing. The invention further discloses papermaking and composite processing equipment for the composite liquid absorbing material, the papermaking and composite processing equipment comprises a first rotary screen forming mechanism, a second rotary screen forming mechanism, a drying cylinder drying mechanism, a composite drying cylinder drying mechanism and a novel adjustable tension rewinding mechanism, and the first rotary screen forming mechanism and the second rotary screen forming mechanism are symmetrically arranged and are opposite in rotating direction; a squeezing composite mechanism is installed under the composite drying cylinder drying mechanism, and a powder scattering mechanism is installed under the squeezingcomposite mechanism; the process for adding the high-molecular water-absorbent resin is simple and convenient to operate, and the total adding amount is easy to control; the water absorption speed, the water locking performance and the comfort level of the liquid absorption material are improved; the water absorption rate is increased to 50 times or above, and the diffusion and permeation width can be adjusted as required; continuous production is realized; and powder spraying process is uniform.

Owner:潍坊杰高非织材料科技有限公司

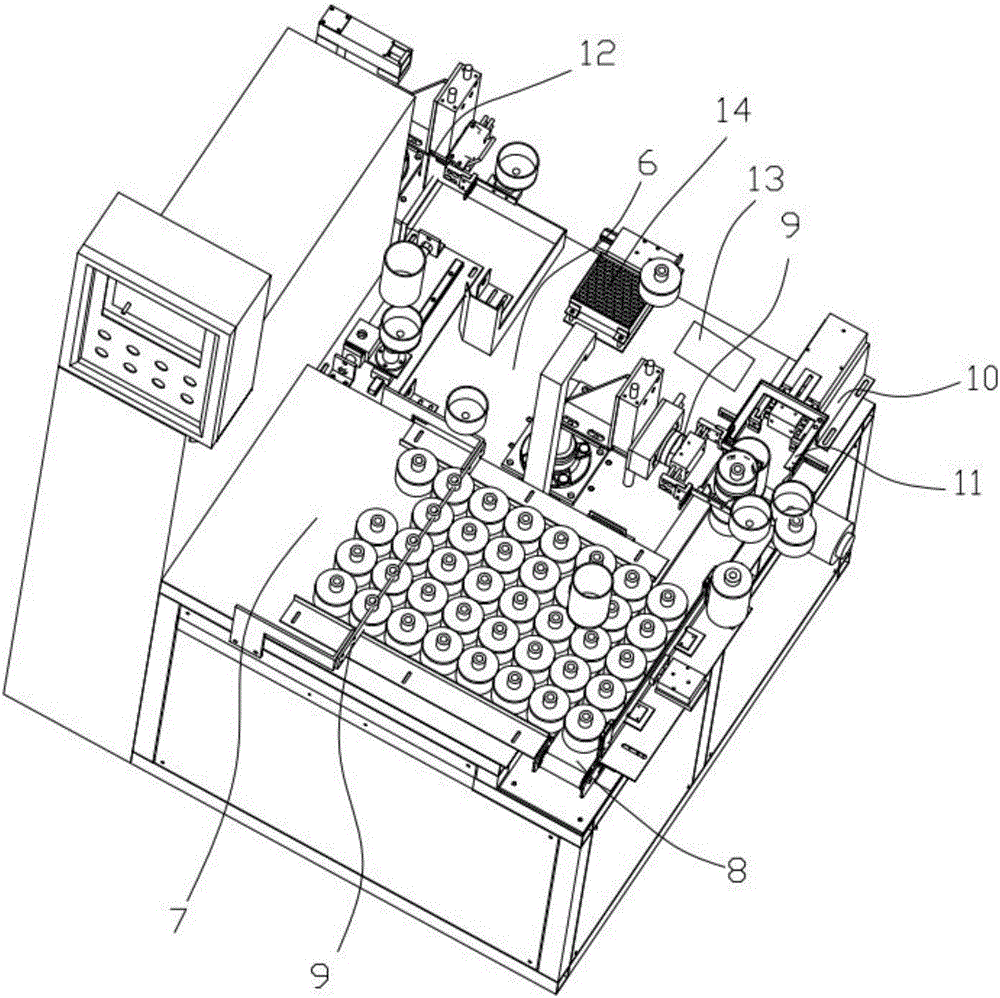

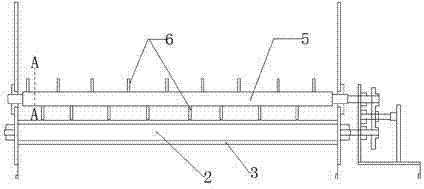

Diamond drill bit braze welding production line

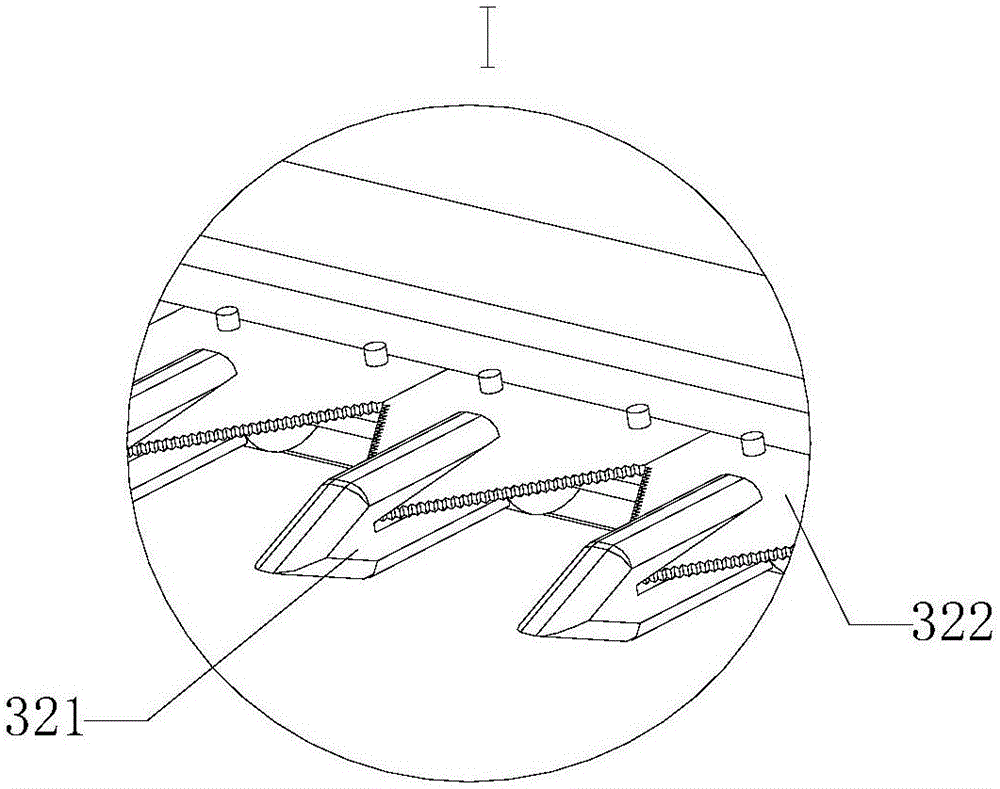

ActiveCN106270894APowder evenlyHigh degree of automationMetal working apparatusSolder feeding devicesPower stationEngineering

The invention provides a diamond drill bit braze welding production line which comprises a baking transmission mechanism, a first work station, a second work station, a third work station and a fourth work station, wherein the first work station, the second work station, the third work station and the fourth work station are positioned on the side of the baking transmission mechanism. The first work station and the second work station are positioned at two ends of the baking transmission mechanism respectively, and the third work station and the fourth work station are positioned between the first work station and the second work station. The production line feeds, discharges, automatically feeds gum and automatically and uniformly coats with diamond powder through an automation device and is high in automation degree, labor consumption is greatly reduced, and working efficiency is improved.

Owner:昆山迈通自动化设备有限公司

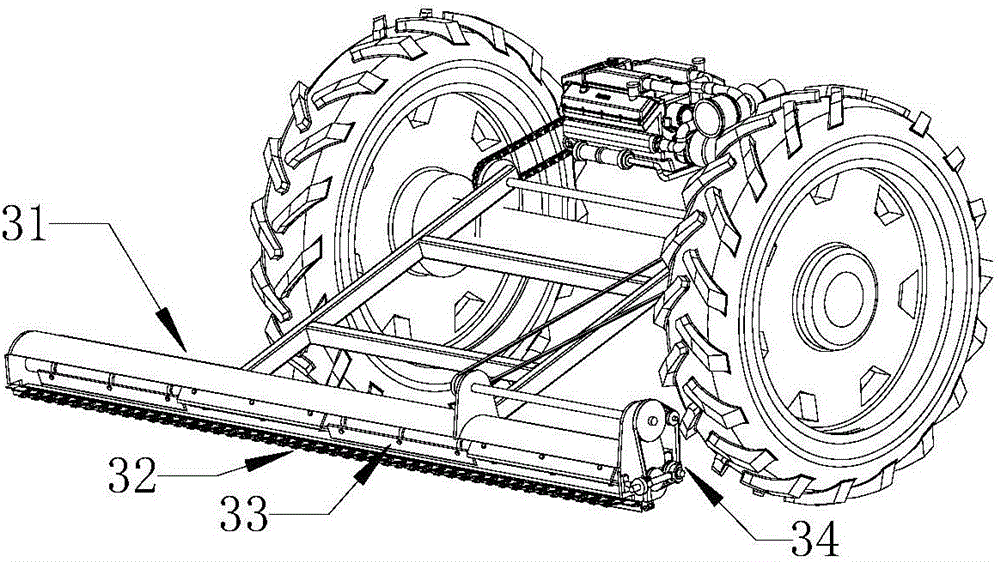

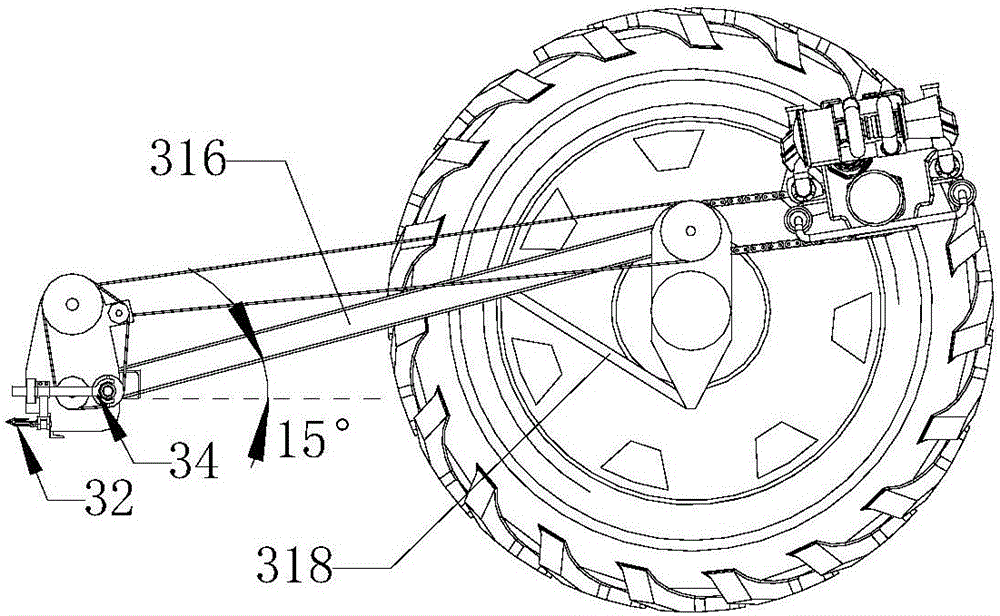

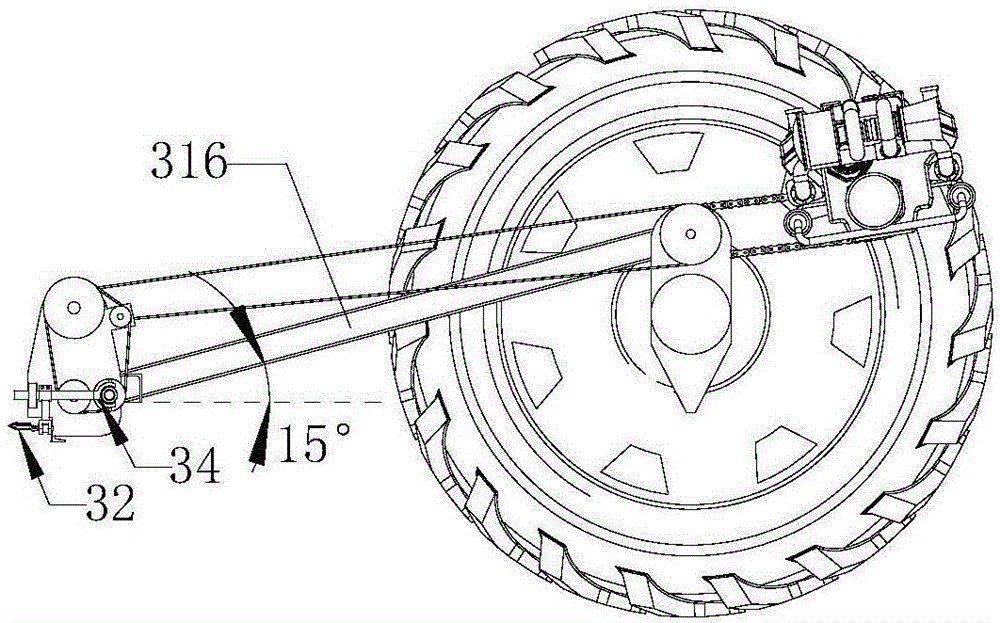

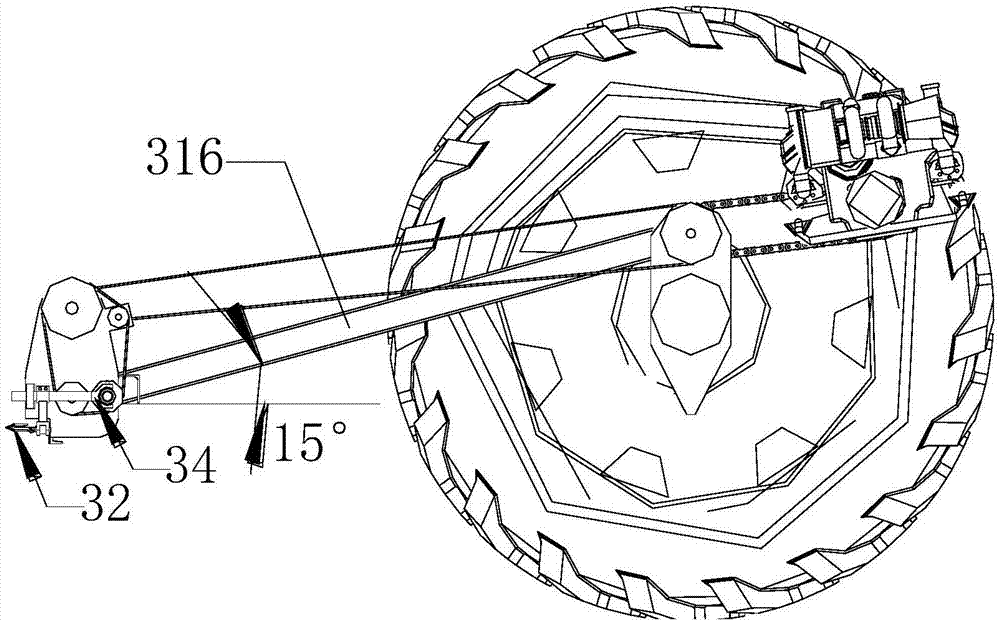

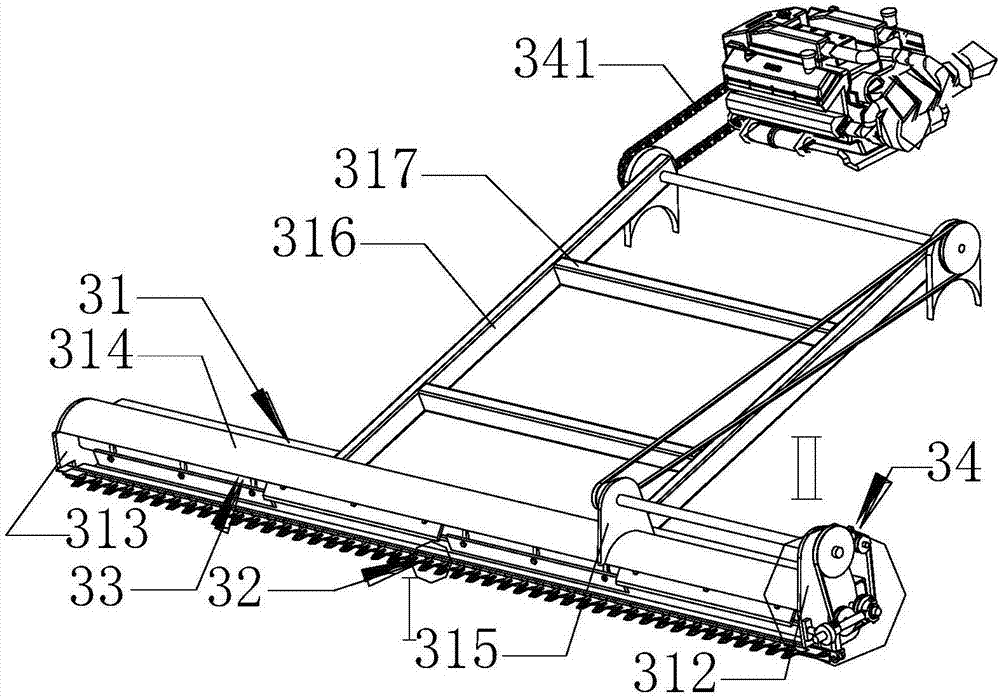

Harvester with ladder, adjustable cutting blades and fixed lower cutting table

The invention discloses a harvester with a ladder, adjustable cutting blades and a fixed lower cutting table. The harvester comprises a lower cutting table and a ladder; the lower cutting table is fixedly welded on a front axle of the harvester, and comprises a lower cutting table main frame, a lower cutting mechanism, a crushing mechanism and a transmission mechanism; the included angle between a connecting rod of the lower cutting table and the horizontal ground is 15 degrees; the included angle between the blades on both sides of the cutting blade is 60 degrees; an L-shape hinge rod is fixed on a movable cutter seat; a straight corner edge of the hinge rod is welded to the movable cutter seat; the other corner edge is hinged to an end of a swing arm connecting joint; and the top of the swing arm is provided with an adjusting gap. The harvester with the ladder, the adjustable cutting blades and the fixed lower cutting table provided by the invention can cut and crush remaining straw parts after grains are harvested, so the feeding amount of the harvester is reduced and the threshing effect is improved. The stubble is low and flat and is convenient for field ploughing; the position of the cutting blades can be easily and conveniently adjusted, so that high efficiency of cutting and crushing the straw is ensured; and the arranged ladder not only can be used for safely and conveniently climbing, but also can be used as a safety barrier.

Owner:界首市民强农业发展有限公司

Multi-station powder coating machine for inner wall of spiral lamp tube

InactiveCN103077871AAdjust the blowing angleAchieve powder coatingLuminescent coatings applicationMechanical engineeringPowder coating

The invention discloses a multi-station powder coating machine for the inner wall of a spiral lamp tube. The multi-station powder coating machine comprises a turntable and a drying channel which are along the circumference; a plurality of station devices are uniformly distributed on the turntable; the multi-station powder coating machine is characterized in that air collection boxes are arranged on the station devices; the air collection boxes are connected with air inlet pipes; a row of corrugated pipes are arranged on the air collection boxes; a rotating shaft is arranged on each station device; a workpiece seat is arranged on each rotating shaft; and each workpiece seat is aligned with the outlet of each corrugated pipe. By the multi-station powder coating machine, air can be blown to a spiral lamp tube workpiece which is subjected to powder coating by the corrugated pipes which can be bent at random angles; powder is coated on the inner wall of the lamp tube uniformly without accumulated powder or flow mark; the powder coating quality of the inner wall of the lamp tube and the light efficiency of the lamp tube are improved; and the continuous automatic operation of powder coating and drying of the spiral lamp tube can be realized.

Owner:浙江力胜电子科技有限公司

Manufacturing technology of electrodeless lamp

InactiveCN102760624AFirmly connectedEasy to operateLuminescent coatings applicationCold cathode manufactureManufacturing technologyStress relieving

The invention mainly discloses a manufacturing technology of an electrodeless lamp. The manufacturing technology comprises the following steps: lamp tube cleaning, lamp tube drying, bepowdering of the inner wall of the lamp tube, seal abutting, stress relieving annealing, exhausting and amalgam baking. The operation is convenient and simple, uniform bepowdering is realized, the connection of the abutting parts is convenient, and the finally obtained products are high in quality and yield.

Owner:SHAOXING UNIVERSITY

Grinding-assisted laser cladding powder feeder

InactiveCN108359980AKeep drySolve the problem of clumpingMetallic material coating processesMetallurgyLaser

The invention provides a grinding-assisted laser cladding powder feeder. The powder feeder comprises a box, a powder feeding pipe, an upper rotary disc and a lower grinding disc. The box is provided with an upper opening, a middle section and a lower opening. The powder feeding pipe is arranged inside the upper opening and the upper portion of the middle section. The upper rotary disc and the lower grinding disc are arranged in the middle section, and the lower grinding disc is fixedly connected with the inner wall of the middle section. The upper rotary disc acts on the lower grinding disc. Aplurality of through holes are formed in each of the upper rotary disc and the lower grinding disc. The powder feeder has the advantages that firstly, by grinding composite powder, the problems thatthe composite powder is not uniformly mixed and cakes are solved; secondly, an induction heating coil is additionally arranged, the dryness of the mixed powder is improved, and the problem of powder caking can be solved easily; and thirdly, an oscillator is additionally arranged, the ground mixed powder is subjected to oscillation mixing and screening again, and meanwhile, the ground powder is more uniform when being discharged.

Owner:FUJIAN UNIV OF TECH

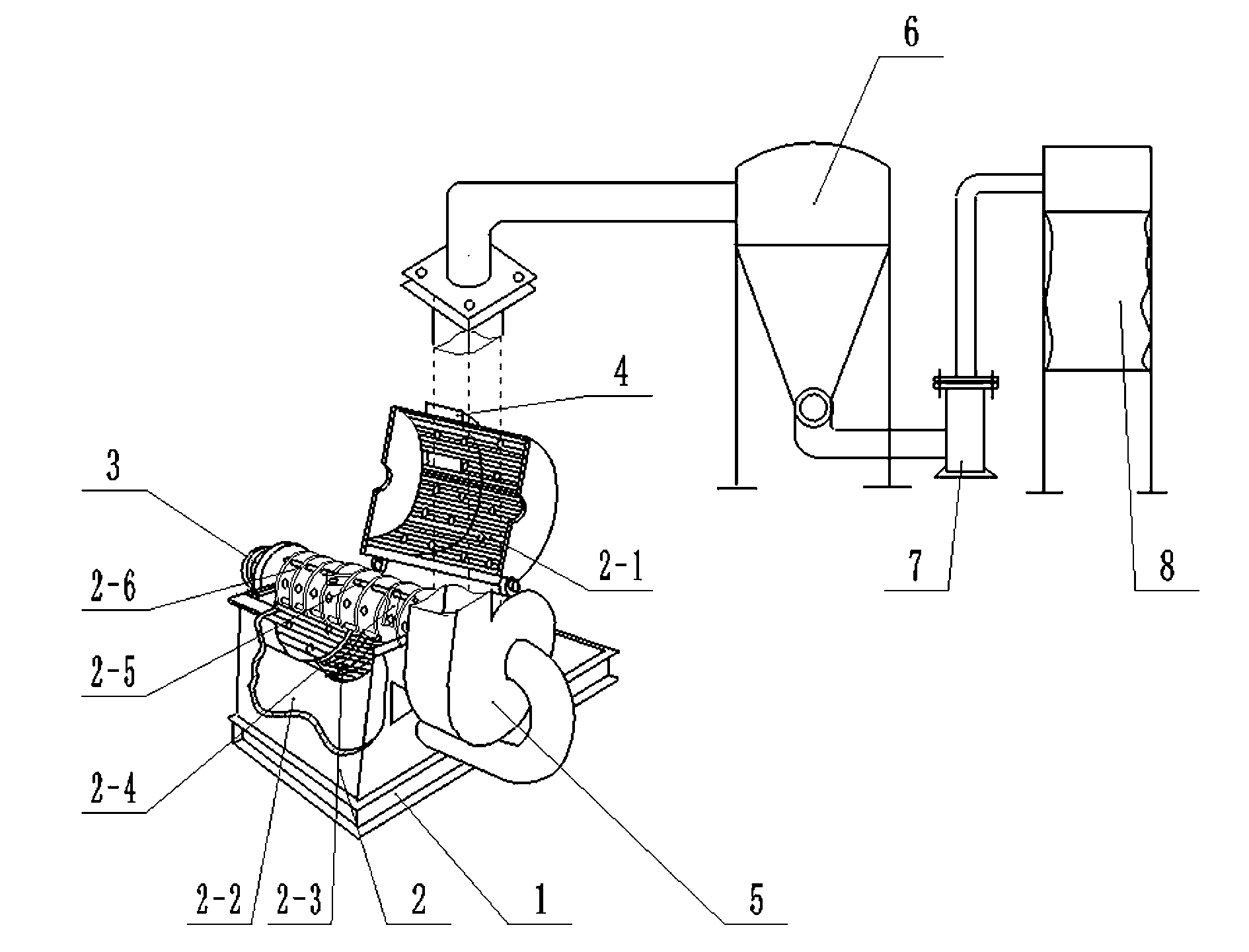

Environmentally-friendly old circuit board grinding machine

The invention discloses an environmentally-friendly old circuit board grinding machine which is characterized by comprising a machine seat, a grinding box on the machine seat, a belt wheel, a motor connected with the belt wheel, a lifting fan connected with a material outlet of the grinding box, a helical recycling hopper connected with the lifting fan, a vibration sieve connected with the helical recycling hopper, and a bag-type dust remover. The environmentally-friendly old circuit board grinding machine has the beneficial effects that hammers are wear-resisting and saved, energy is saved, the yield is high and triples that of other grinding machines, environment pollution is avoided, and a good foundation is laid for next selection; and furthermore, rough grinding is not needed, and large sheets can be directly ground.

Owner:梁刚

Harvester with hoisting type lower header and capable of crushing straws

The invention discloses a harvester with a hoisting type lower header and capable of crushing straws. The harvester comprises the lower header, wherein the lower header is hinged to a front axle of the harvester; the lower header comprises a lower header main frame, a lower cutting mechanism, a straw crushing mechanism, a transmission mechanism and a lower header hoisting mechanism; the included angle of cutting blades on two sides of a cutting blade is 60 degrees; the lower header hoisting mechanism comprises a lower header hoisting oil cylinder, a lower header hoisting oil cylinder upper seat and a lower header hoisting oil cylinder lower seat; the lower header hoisting oil cylinder is a single acting cylinder. The harvester with the hoisting type lower header and capable of crushing the straws, disclosed by the invention, can be used for cutting and crushing straw parts remained after cereals are harvested; the feeding amount of the harvester is alleviated, the loss and threshing load of a machine are reduced and the threshing effect is improved; cutting stubbles are low and flat, so that a land is easy to plough; the cutting and crushing efficiency of the straws is high and the crushed straws can be directly overturned and pressed into soil in a ploughing process; the straws can also be used as a basic fertilizer after being returned to the field; the lower header can be hoisted so that the height of the cutting stubbles is controlled, obstacles can be avoided and the equipment safety can be protected.

Owner:纪小坤

Powder spreading device

The invention discloses a powder spreading device which comprises a powder containing box, a powder spreading roller arranged at an outlet of the lower end of the powder containing box, a powder clamping piece arranged on the outer side of the powder spreading roller and used for bearing powder, and a sweeping piece which is relative to the powder spreading roller and is used for sweeping off powder on the surface of the powder spreading roller. The powder spreading device is even in powder spreading, incapable of making redundant powder to be left on the powder spreading roller, is high in powder spreading efficiency, saves cost, and is stable in operation.

Owner:镇江立达纤维工业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com