Cloth stamping powder-dusting device

A powder spreading machine and printing technology, applied in printing, printing process, gold powder printing, etc., can solve the problems of high labor intensity, low productivity, low labor intensity and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

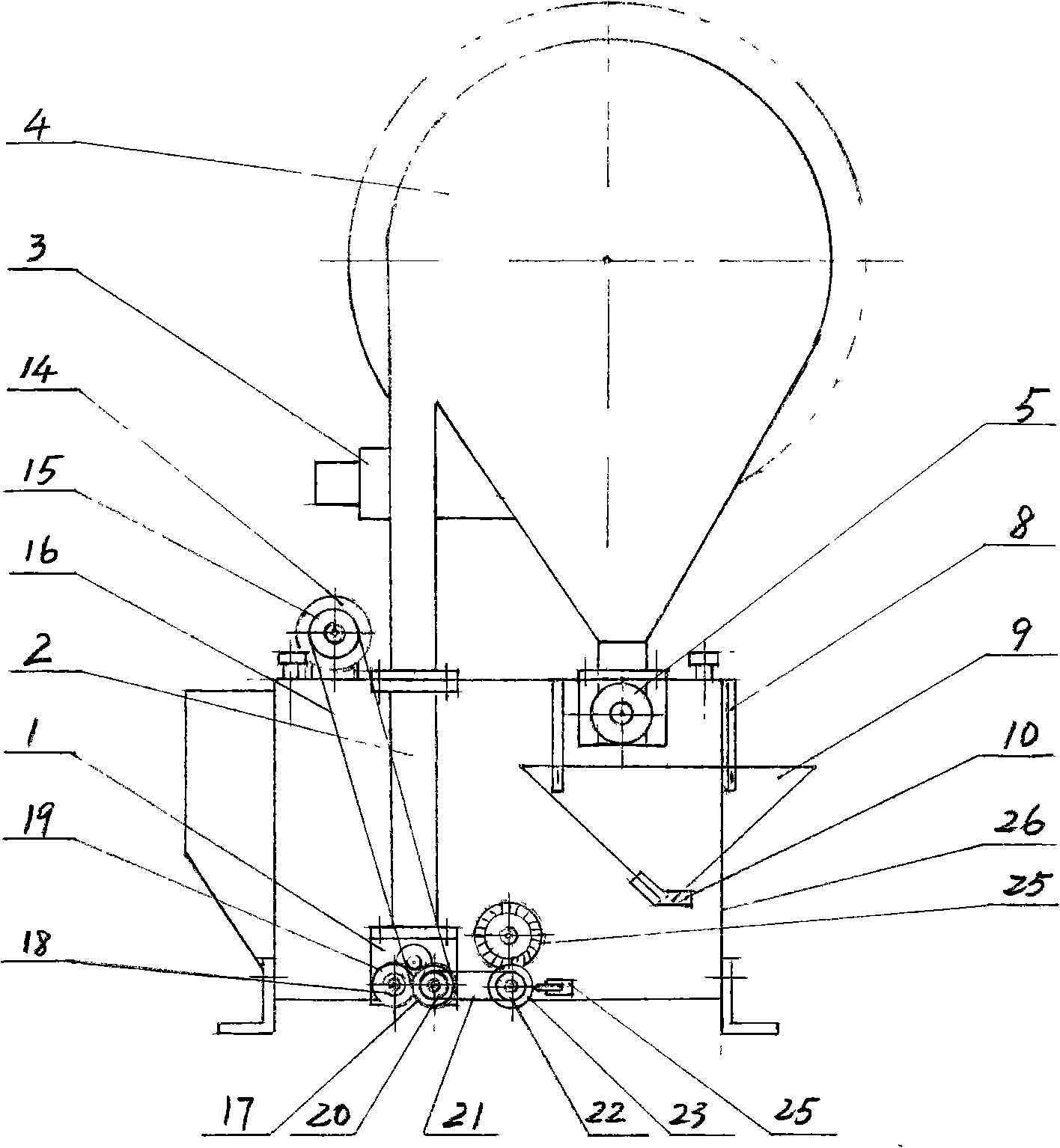

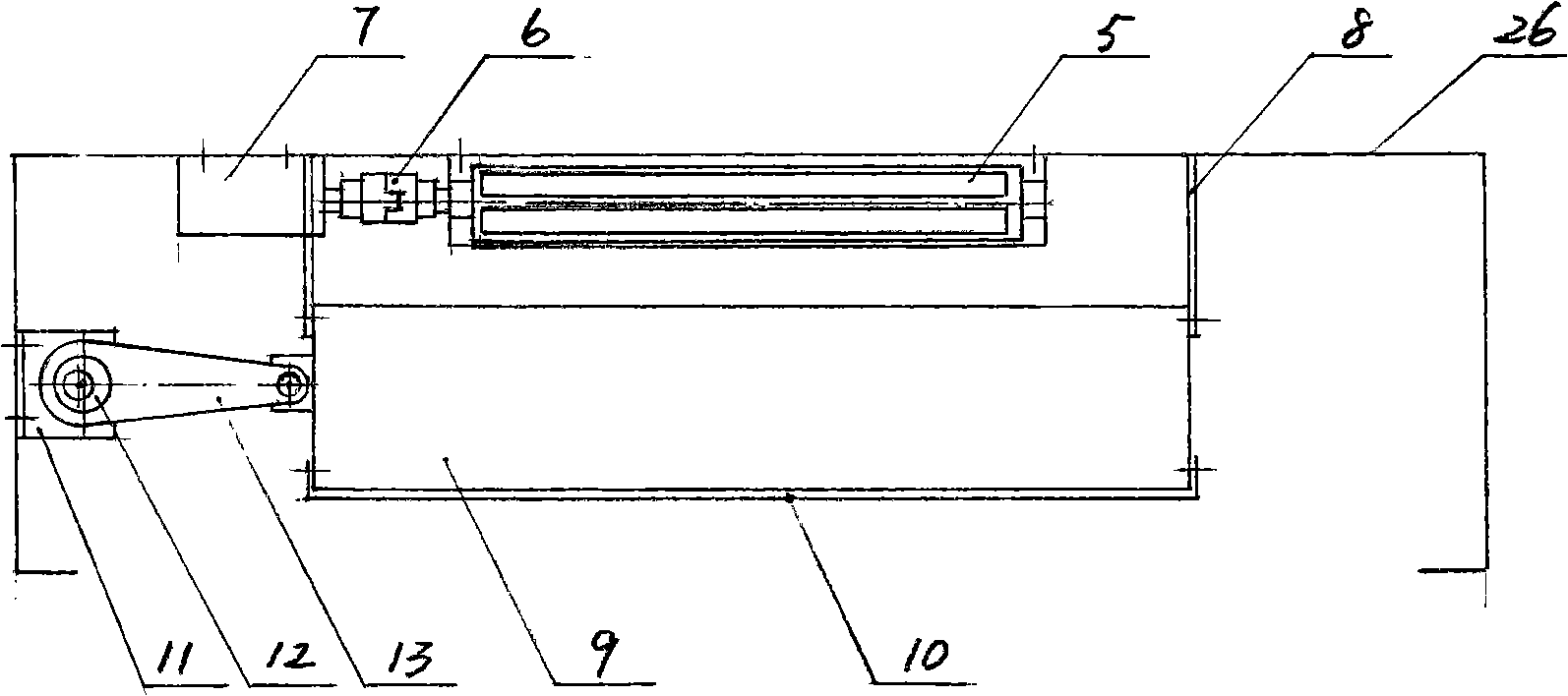

[0008] Below in conjunction with accompanying drawing, cloth printing duster of the present invention is described in further detail:

[0009] (1) Installation process: first the frame 26 is placed on the platform, the wind powder separator 4 is installed on the frame 26, the blower fan 3 is connected and fixed on the frame 26 with the wind powder separator, and the powder suction pipe 2 is connected with the wind powder separator. The powder separator 4 bottom surface is fixed on the frame 26, and the powder unloader 5 is fixed on the frame 26, and the cloth pressing wheel 19, the gear 18, the sprocket wheel 17, the sprocket wheel 20, the cloth pressing wheel shaft and the shaft seat form the powder suction port 1. Connect with the lower opening of the powder suction pipe, the pressure roller 23, the sprocket 22 and the shaft seat are assembled and connected to the powder suction port 1 shaft seat, the brush roller 25 and the shaft seat are installed on the pressure roller sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com