Patents

Literature

2294 results about "Discharger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A discharger in electronics is a device or circuit that releases stored energy or electric charge from a battery, capacitor or other source.

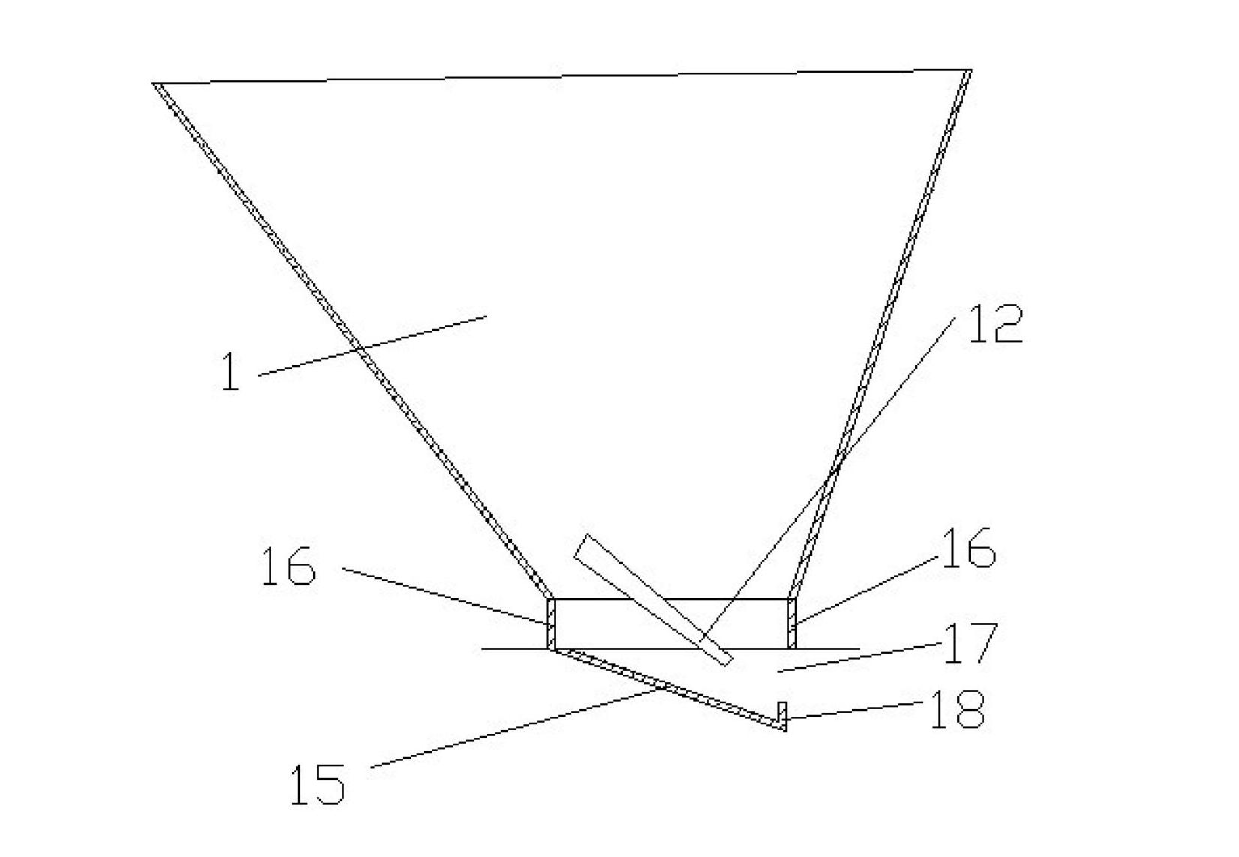

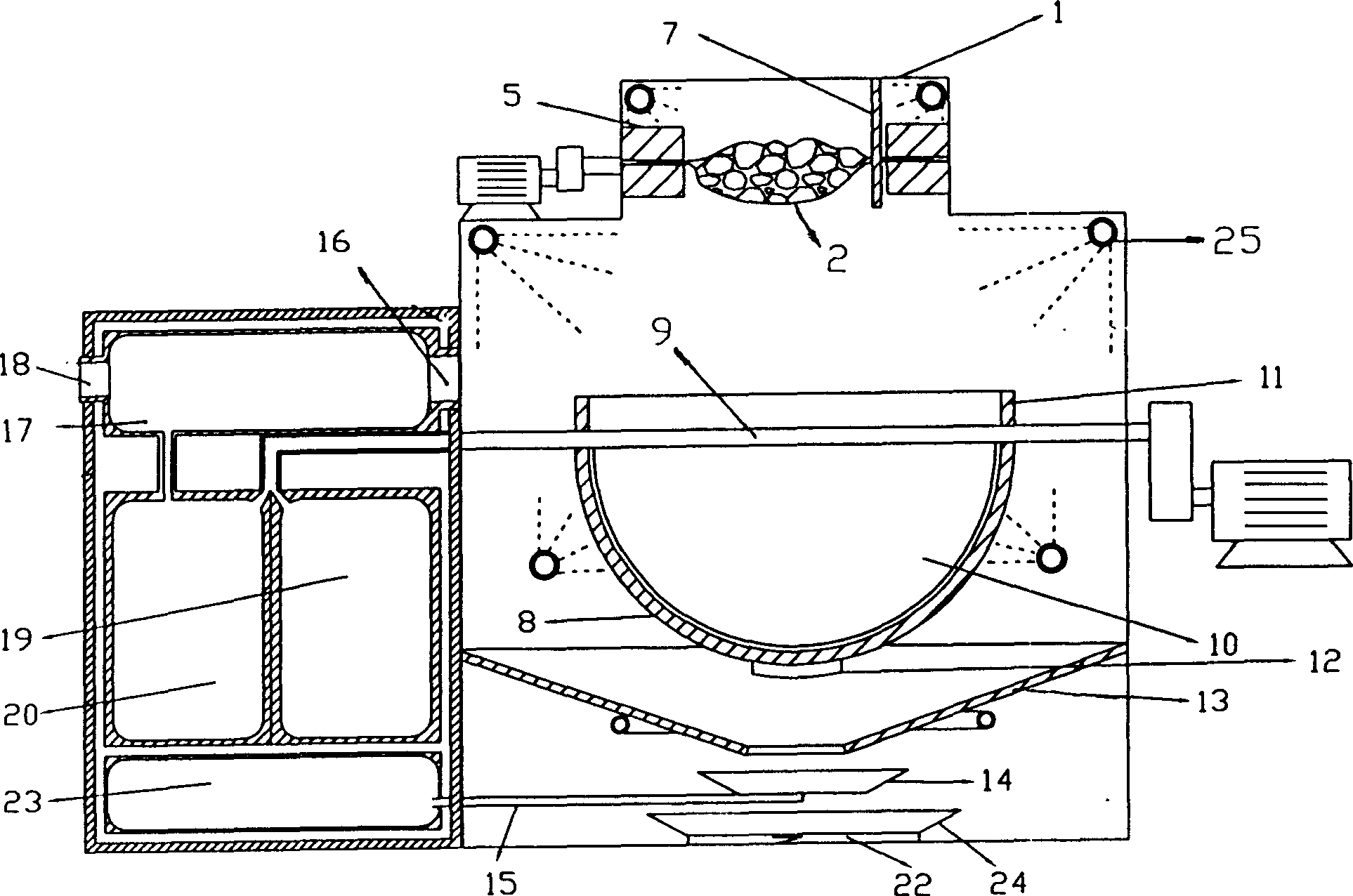

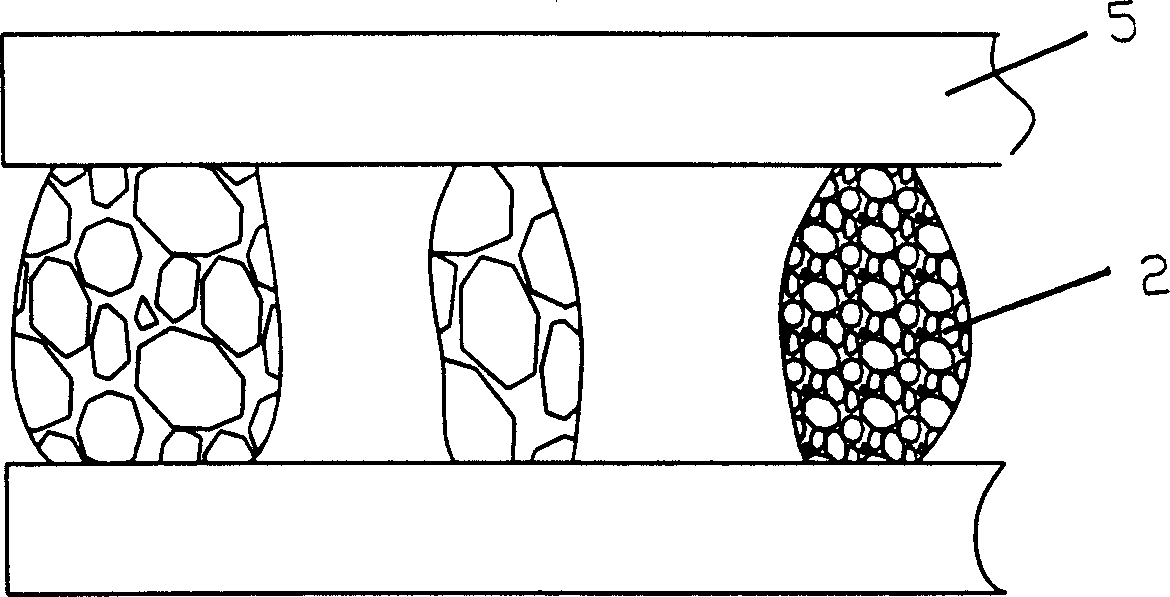

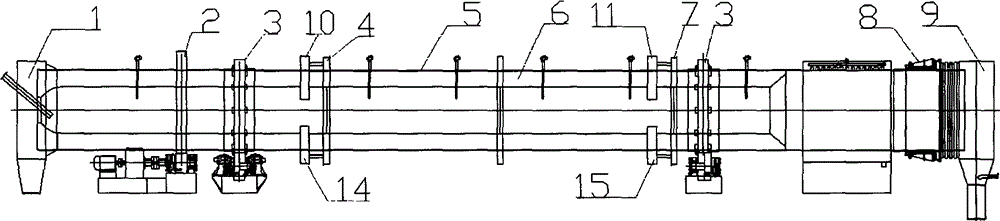

Equipment for conveying propping agents

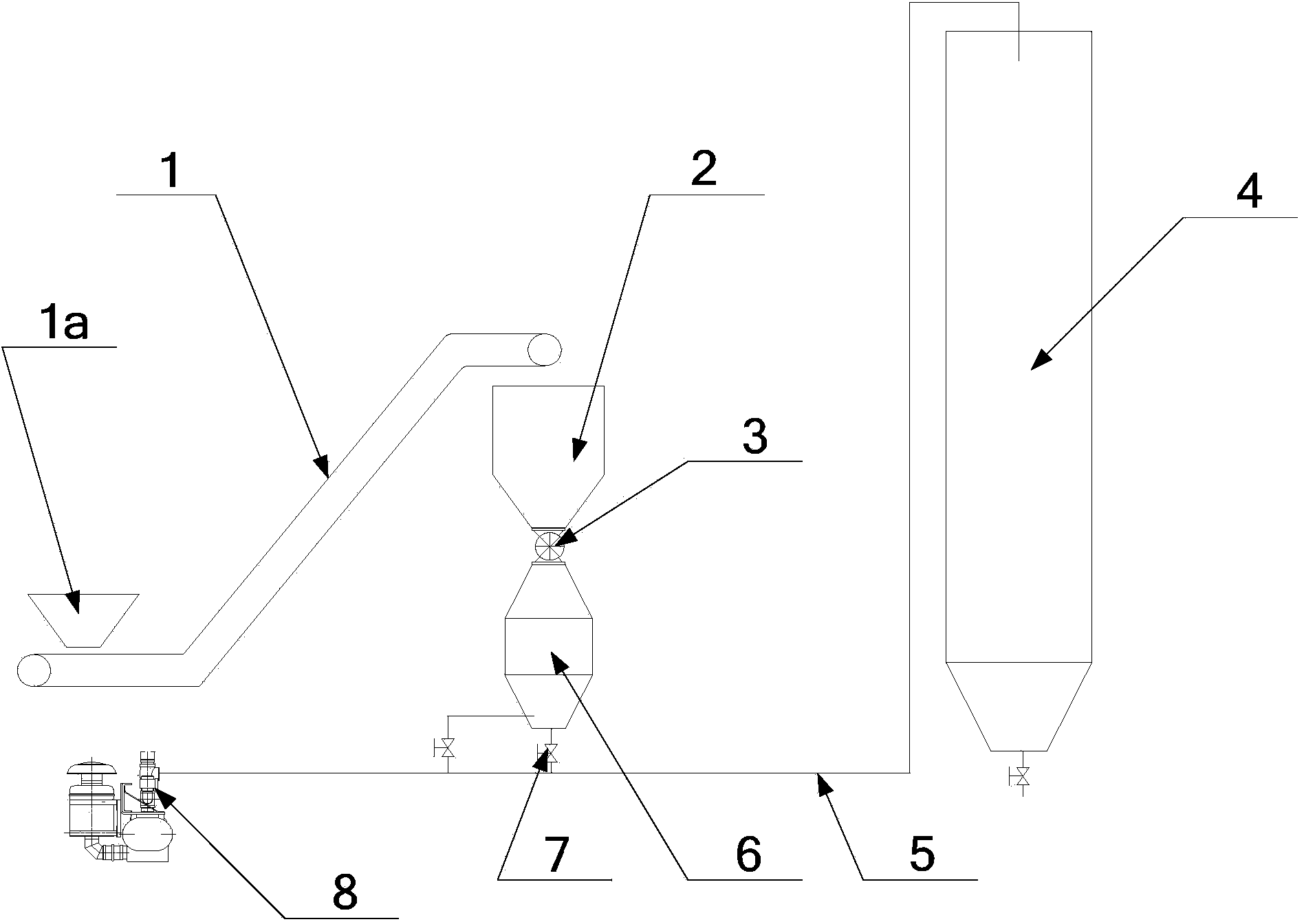

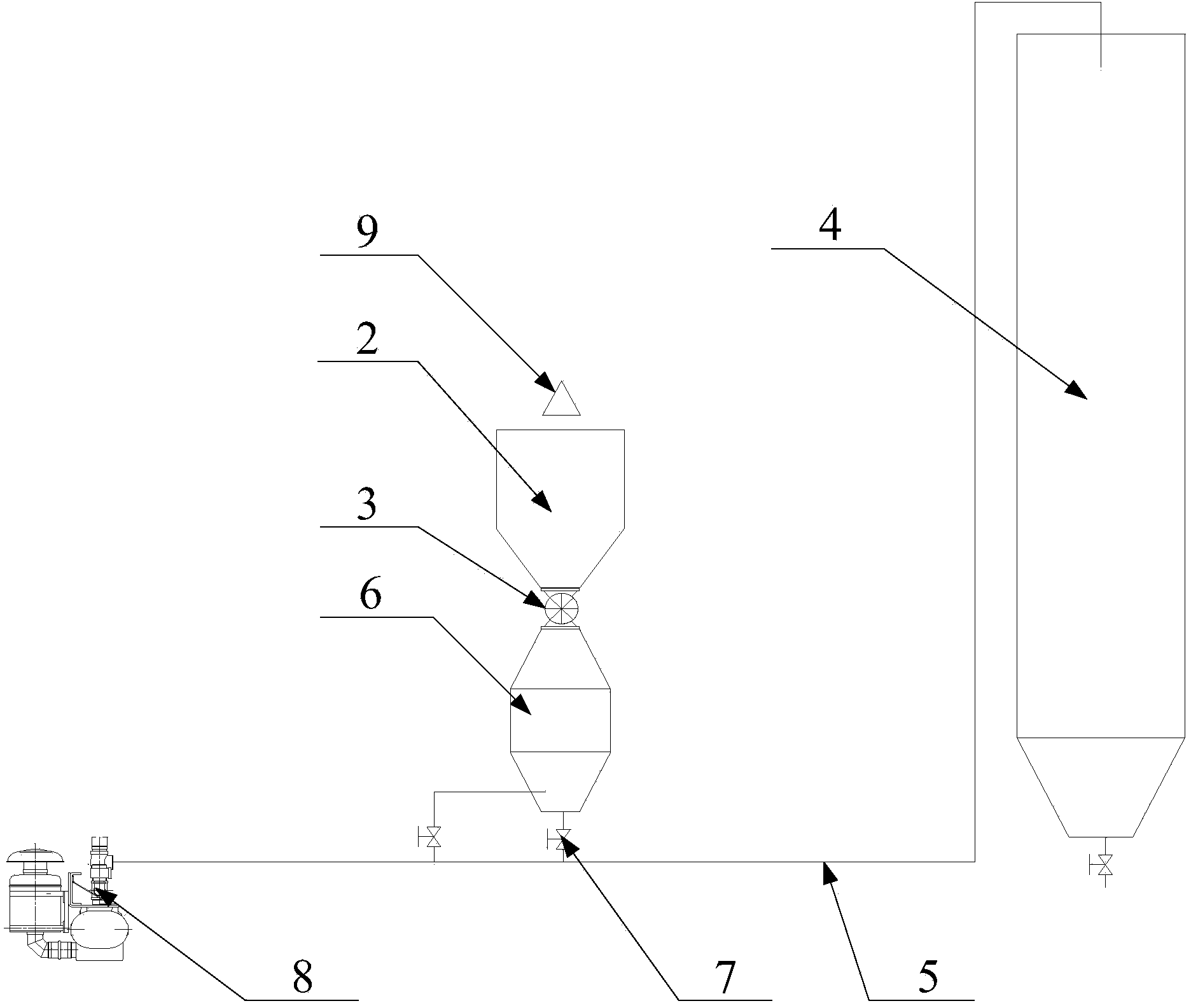

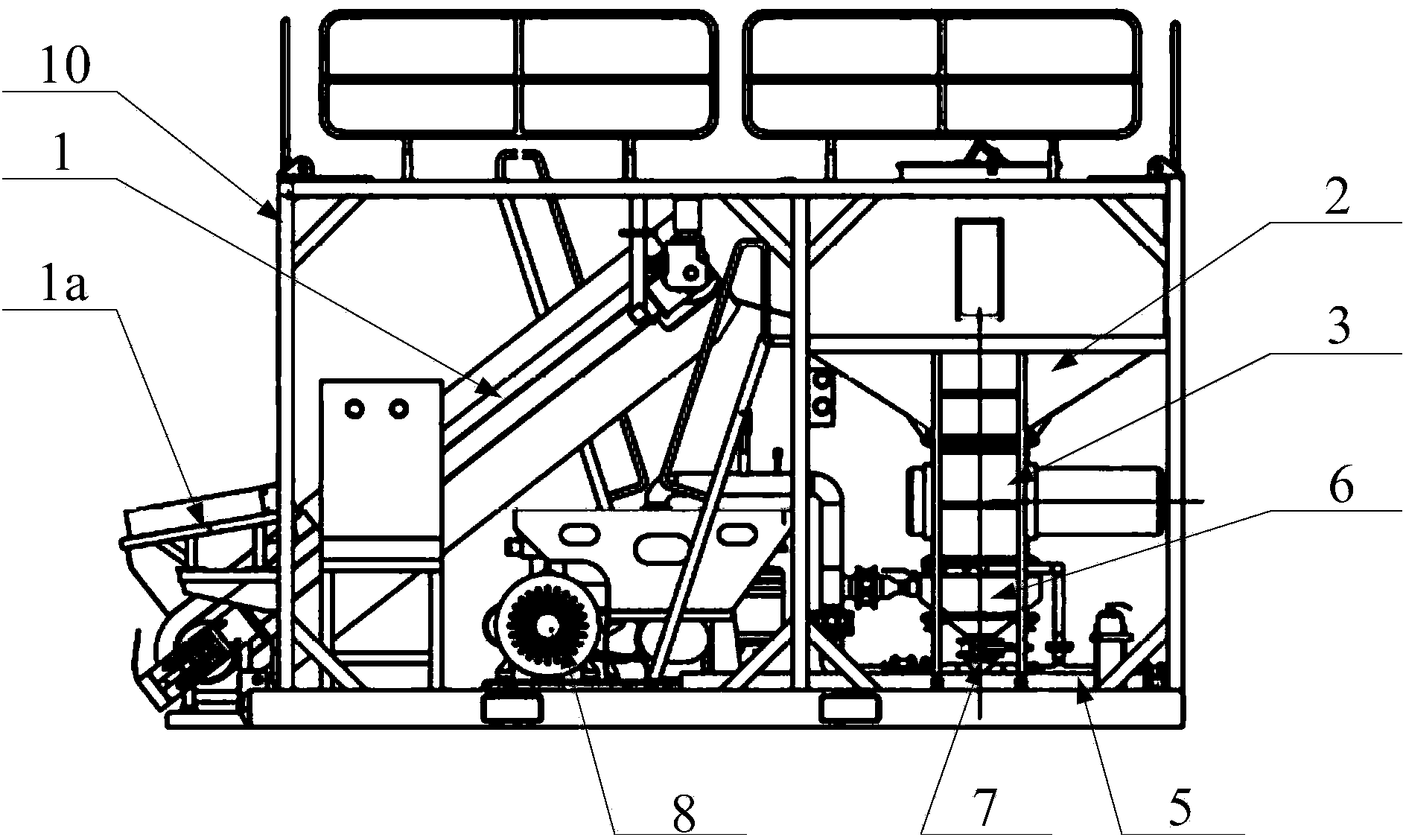

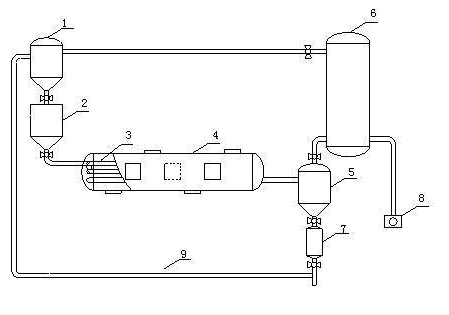

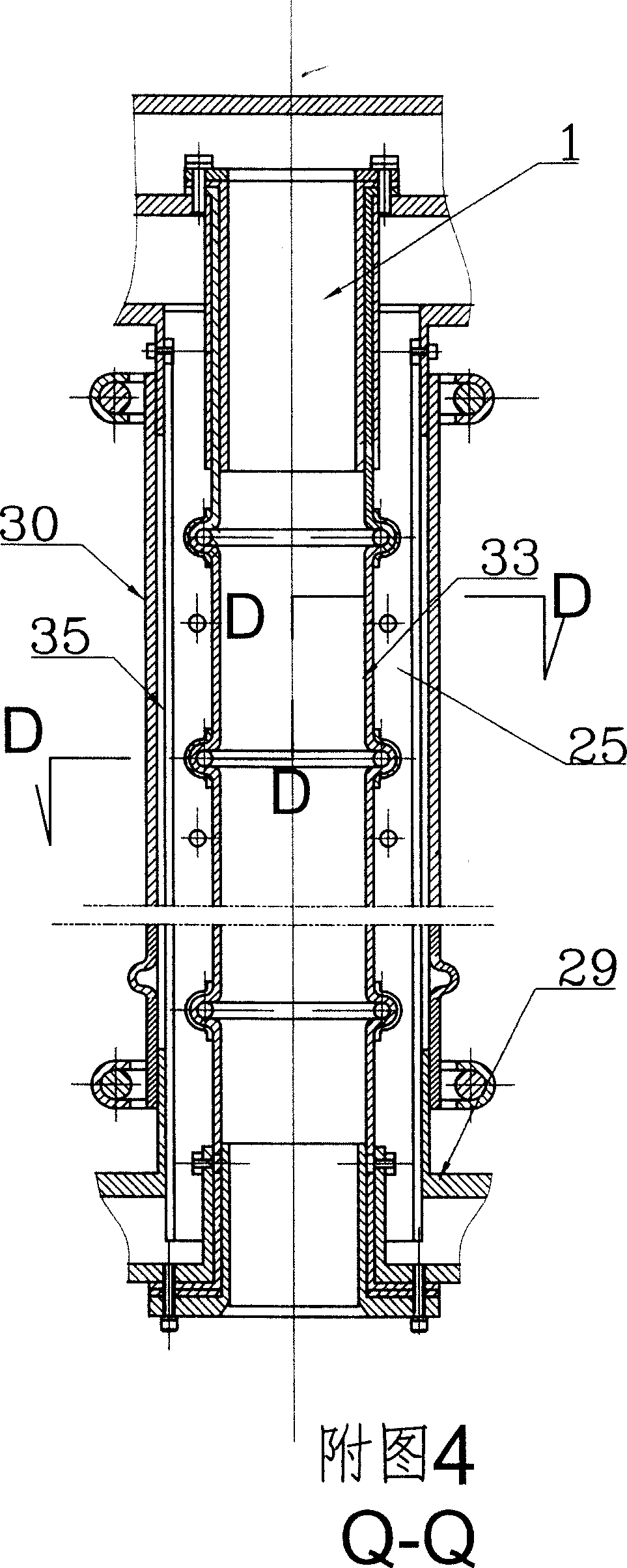

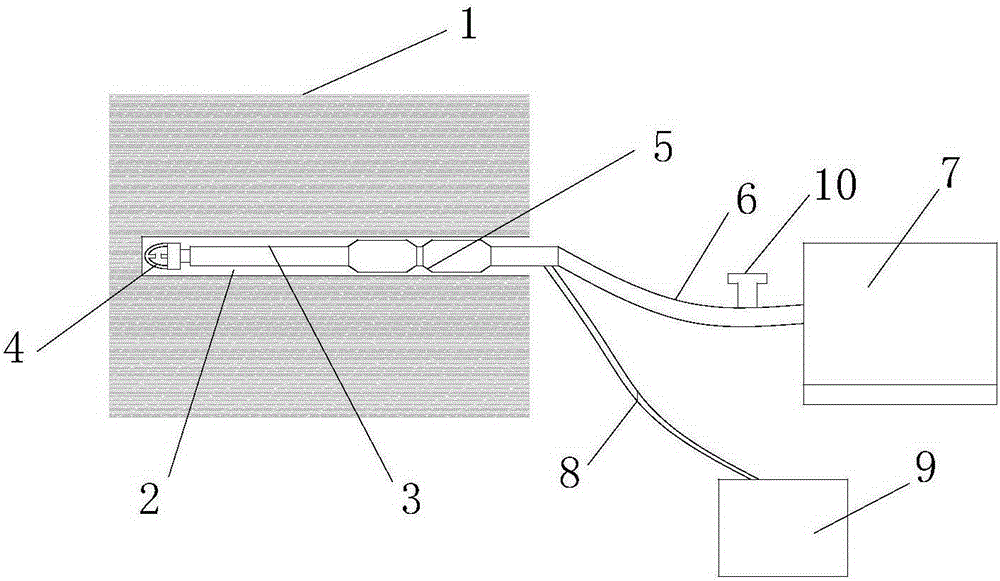

The invention discloses equipment for conveying propping agents. The equipment comprises a transition storage tank, a star discharger, a sending tank, a conveying pipeline, a fan and a first driving device, wherein the transition storage tank is provided with a feeding opening and a discharging opening; the star discharger is provided with a feeding opening and a discharging opening, and in addition, the feeding opening of the star discharger is communicated with the discharging opening of the transition storage tank; the sending tank is provided with a feeding opening and a discharging opening, and in addition, the feeding opening of the sending tank is communicated with the discharging opening of the star discharger; the inside of the conveying pipeline is communicated with the discharging opening of the sending tank through a connecting pipeline, and in addition, a discharging valve is connected in series onto the connecting pipeline; the fan is arranged at on end of the conveying pipeline; and the first driving device drives the fan to rotate. The equipment has the advantages that the propping agents are sent into a vertical sand tank with a certain height by using the flow rate and the pressure generated by the fan; the scheme of only communicating one end of the conveying pipeline with the vertical sand tank and setting the positions of the sending tank and the transition storage tank to be lower can be adopted, so the propping agents can be conveyed into the transition storage tank; and further, the propping agents can be conveniently conveyed into the vertical sand tank.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

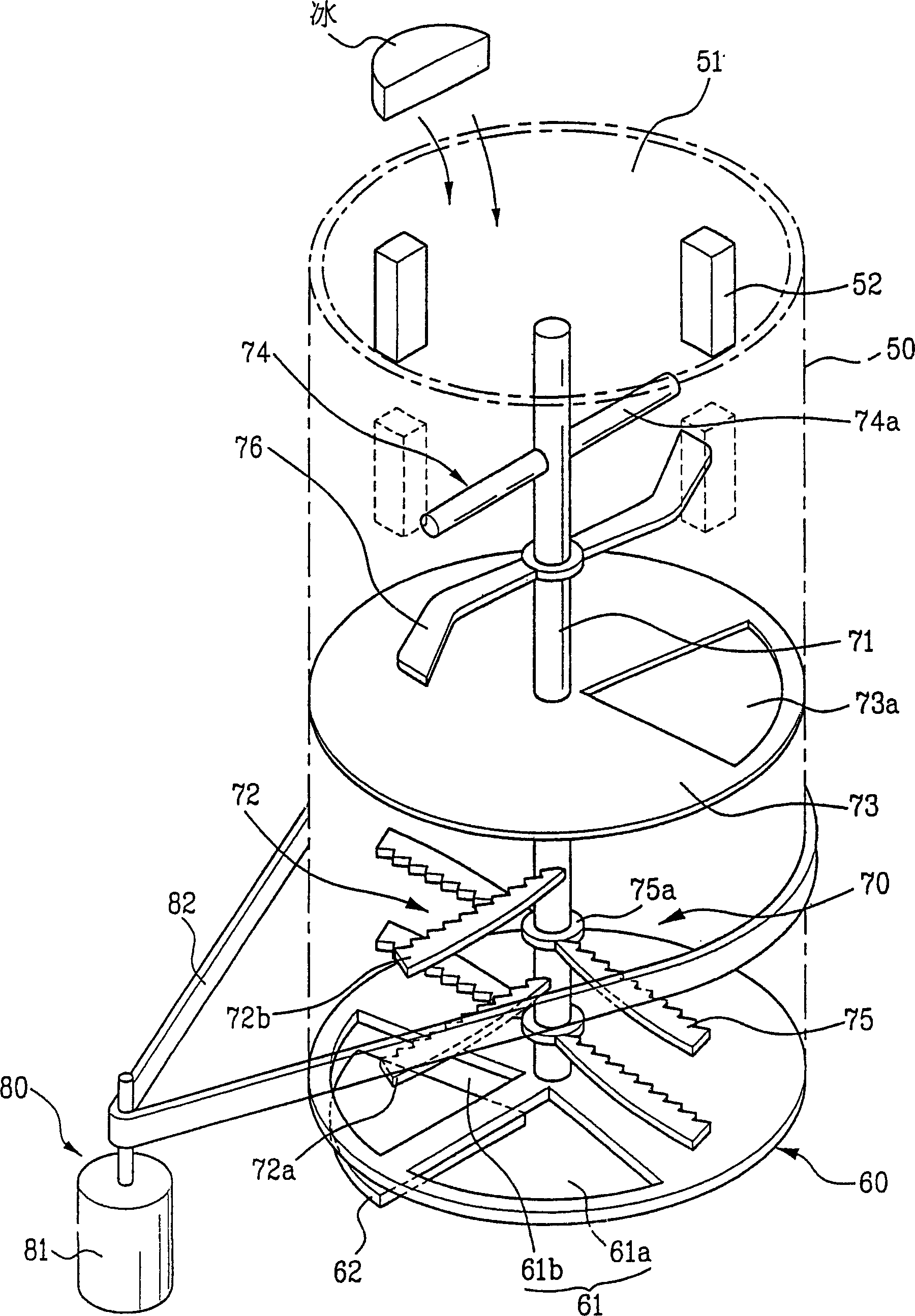

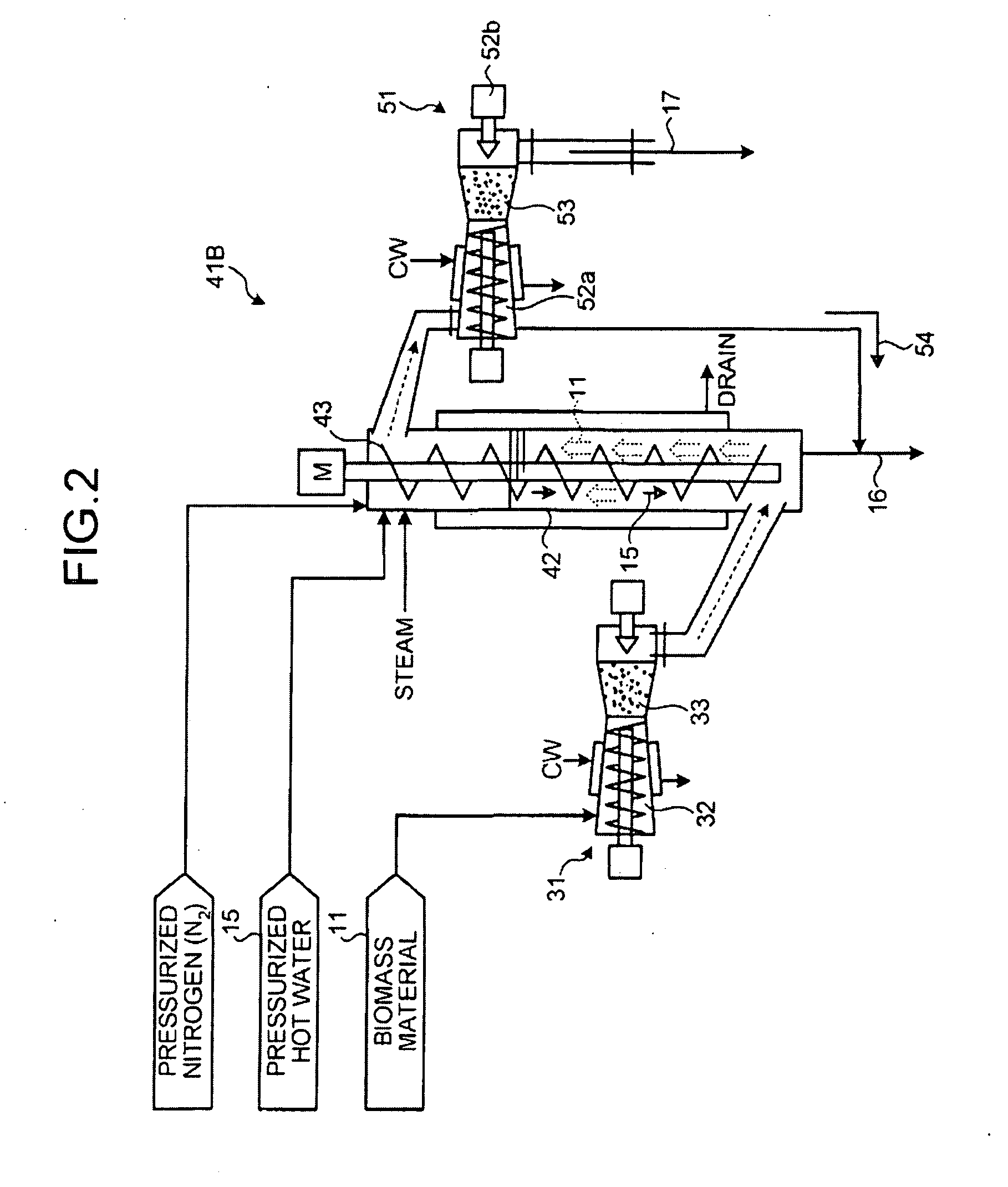

Biomass hydrothermal decomposition apparatus, method thereof, and organic material production system using biomass material

ActiveUS20100184176A1Efficiently saccharifyingEfficient productionBioreactor/fermenter combinationsBiological substance pretreatmentsDecompositionEngineering

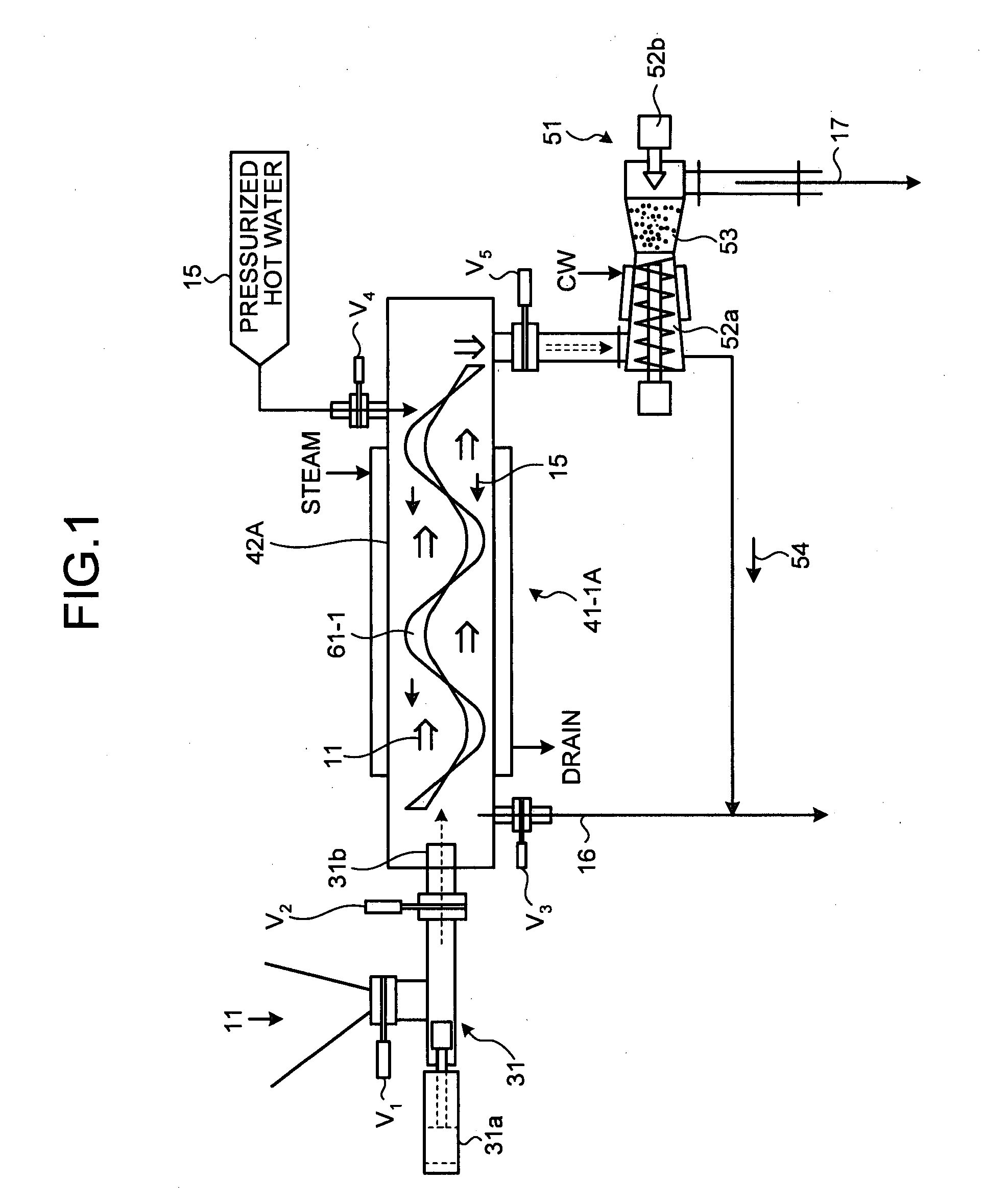

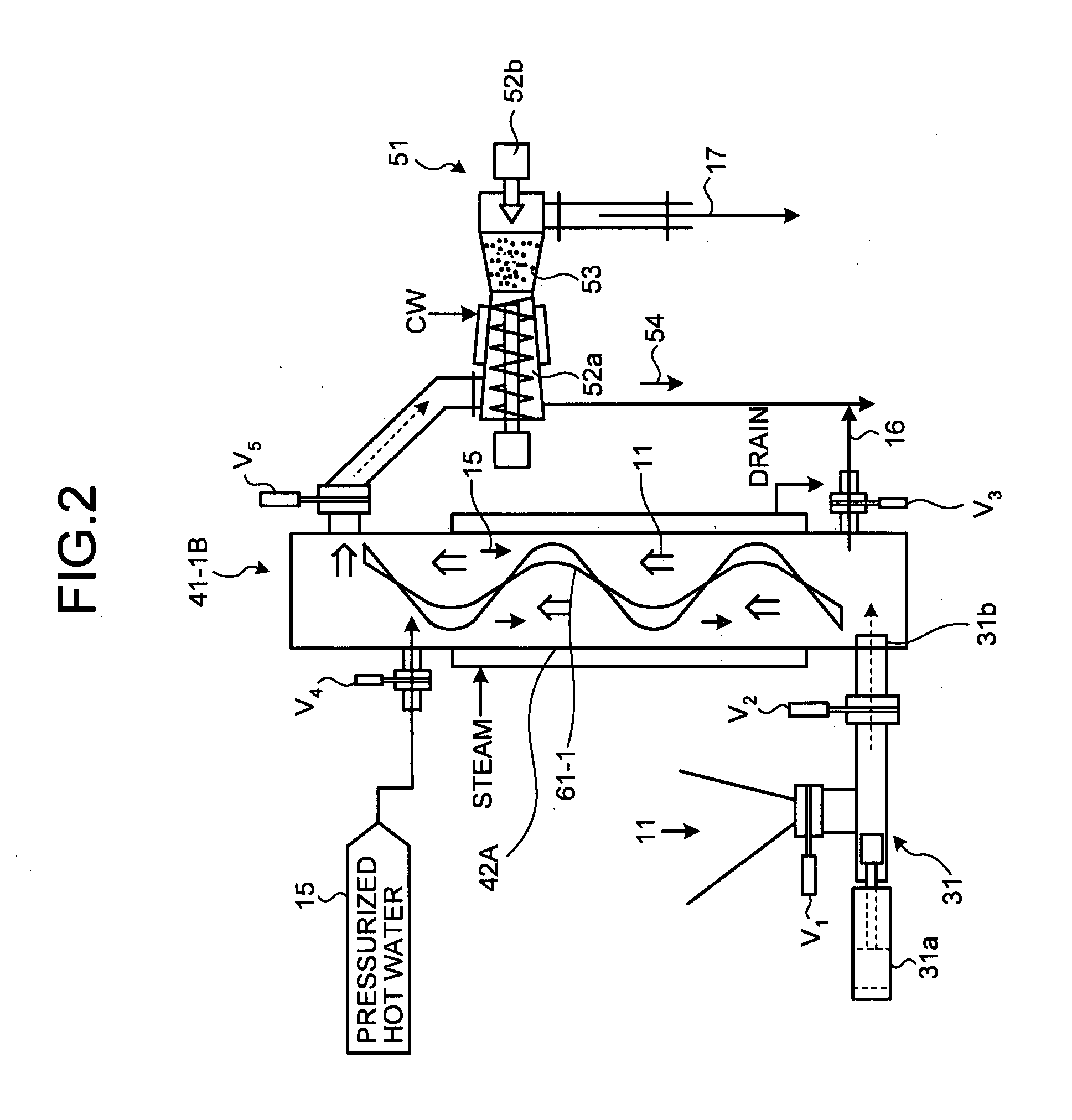

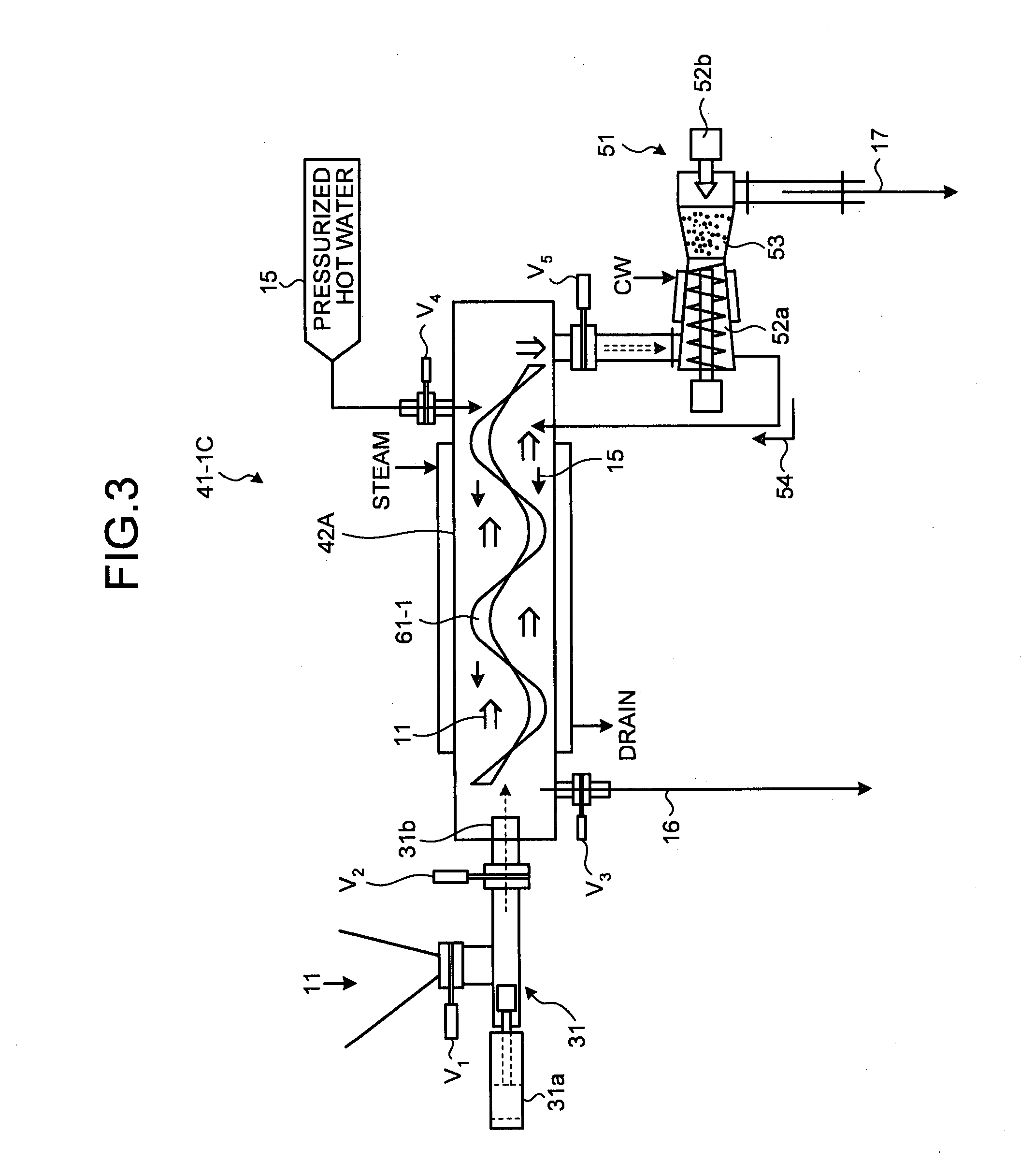

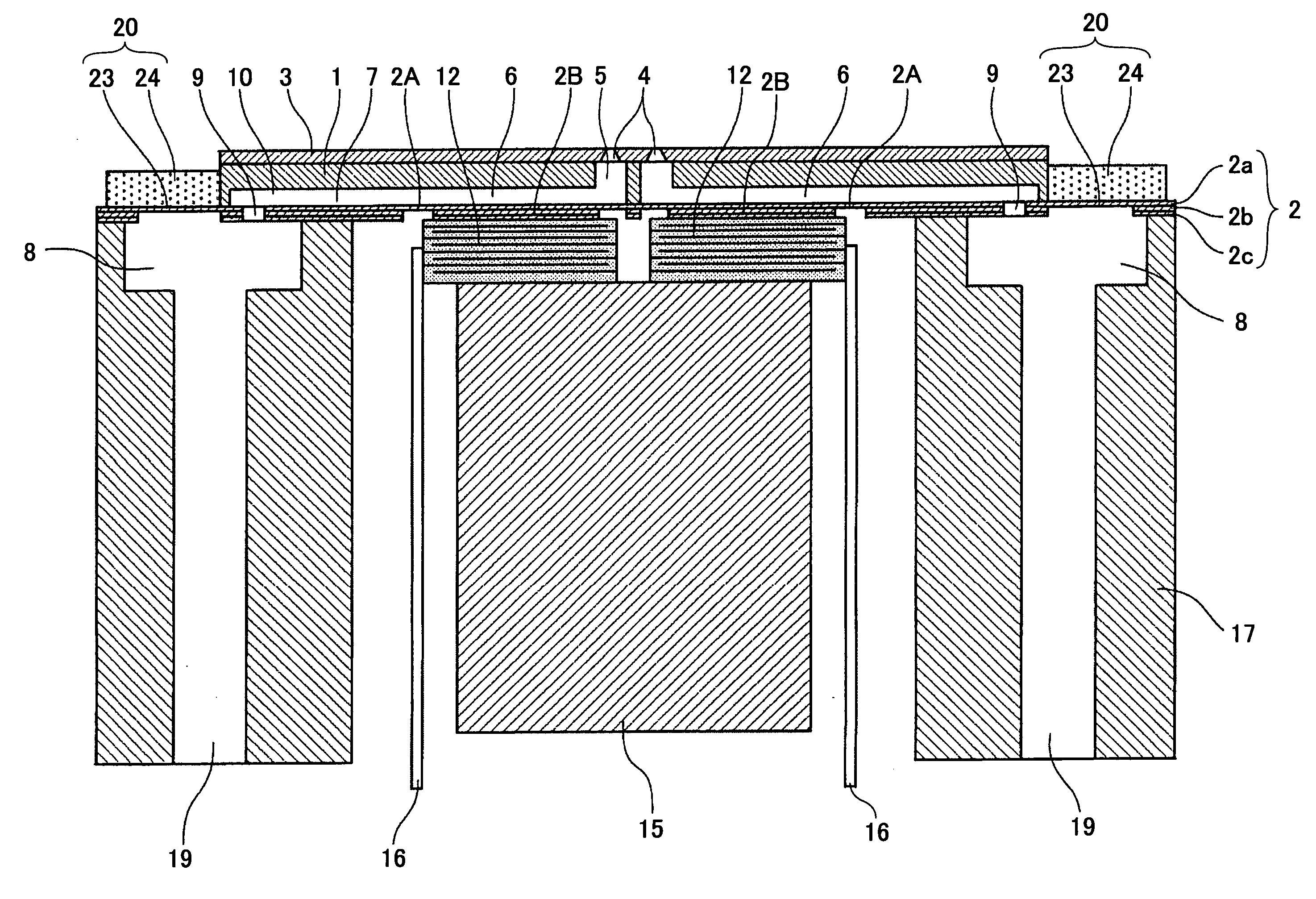

A biomass hydrothermal decomposition apparatus includes, a biomass feeder (31) that feeds biomass material (11) under normal pressure to under increased pressure, a hydrothermal decomposition device (42A) that allows the fed biomass material (11) to be gradually moved inside a device main body (42A) from either end thereof in a consolidated condition, and also allows hot compressed water (15) to be fed from an other end of a feed section for the biomass material into the main body (42A), so as to cause the biomass material (11) and the hot compressed water (15) to countercurrently contact with each other and undergo hydrothermal decomposition, and that elutes a lignin component and a hemicellulose component into the hot compressed water, so as to separate the lignin component and the hemicellulose component from the biomass material (11); and a biomass discharger (51) that discharges, from the side where the hot compressed water is fed into the device main body, a biomass solid residue (17) under increased pressure to under normal pressure.

Owner:MITSUBISHI HITACHI POWER SYSTEMS ENVIRONMENTAL SOLUTIONS LTD

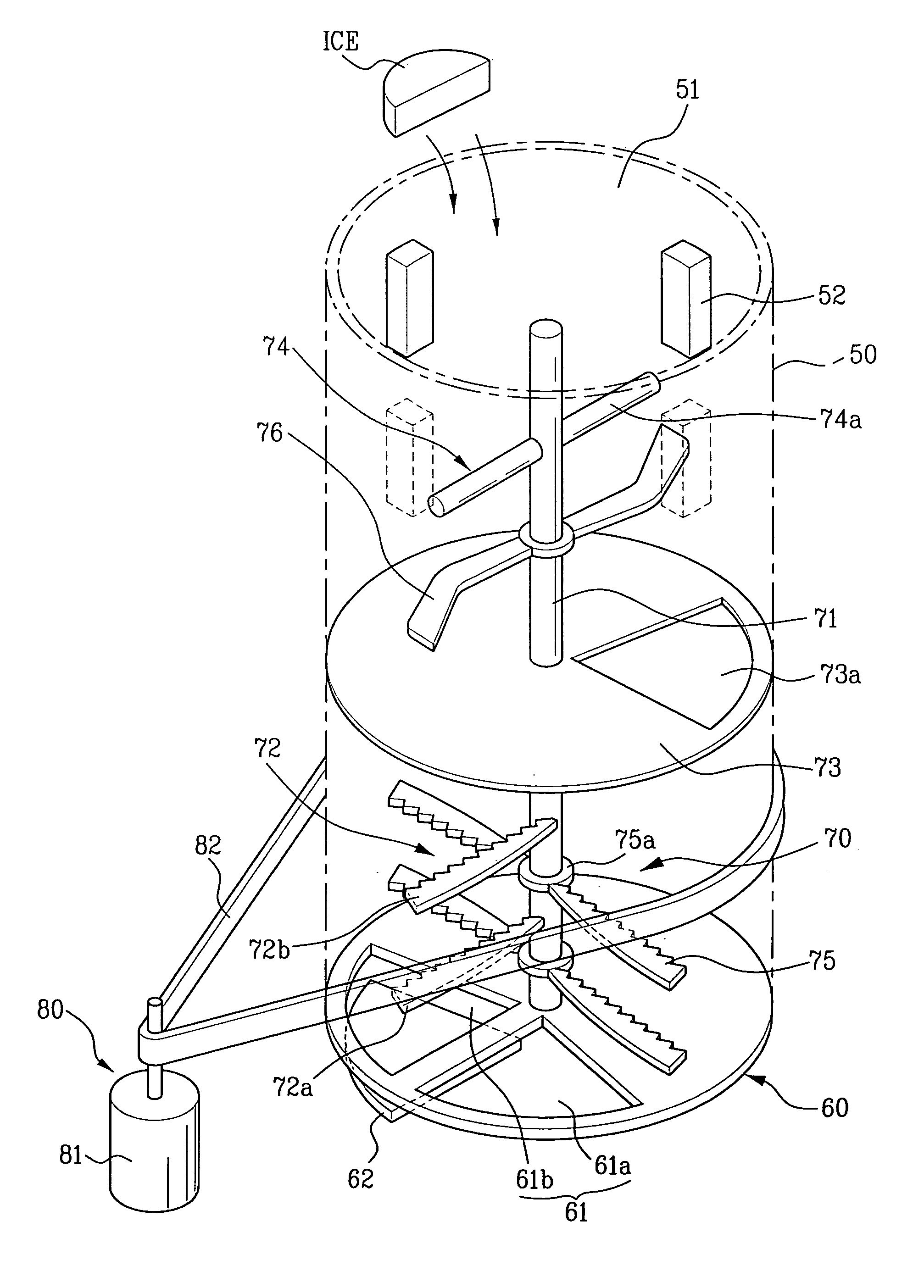

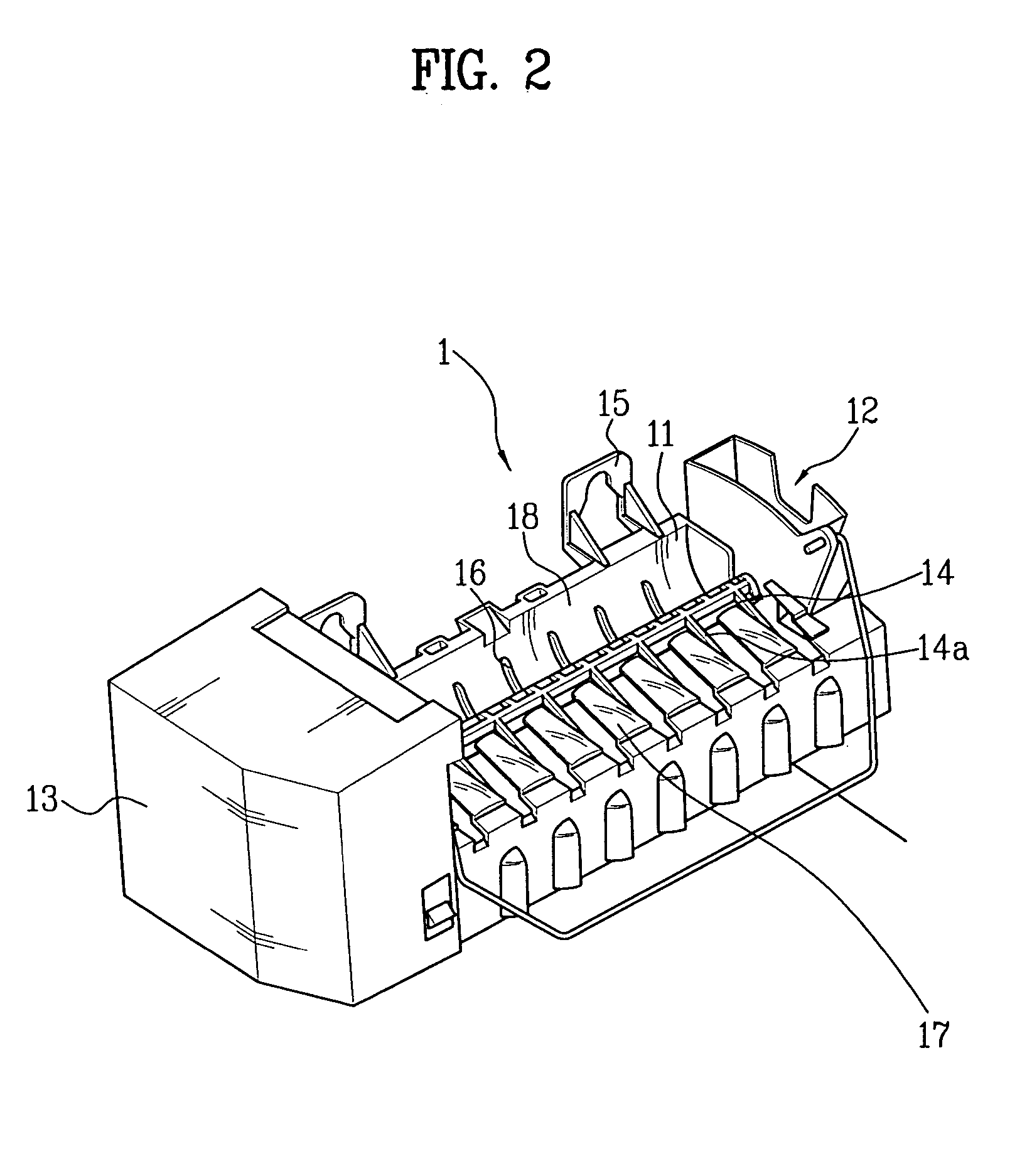

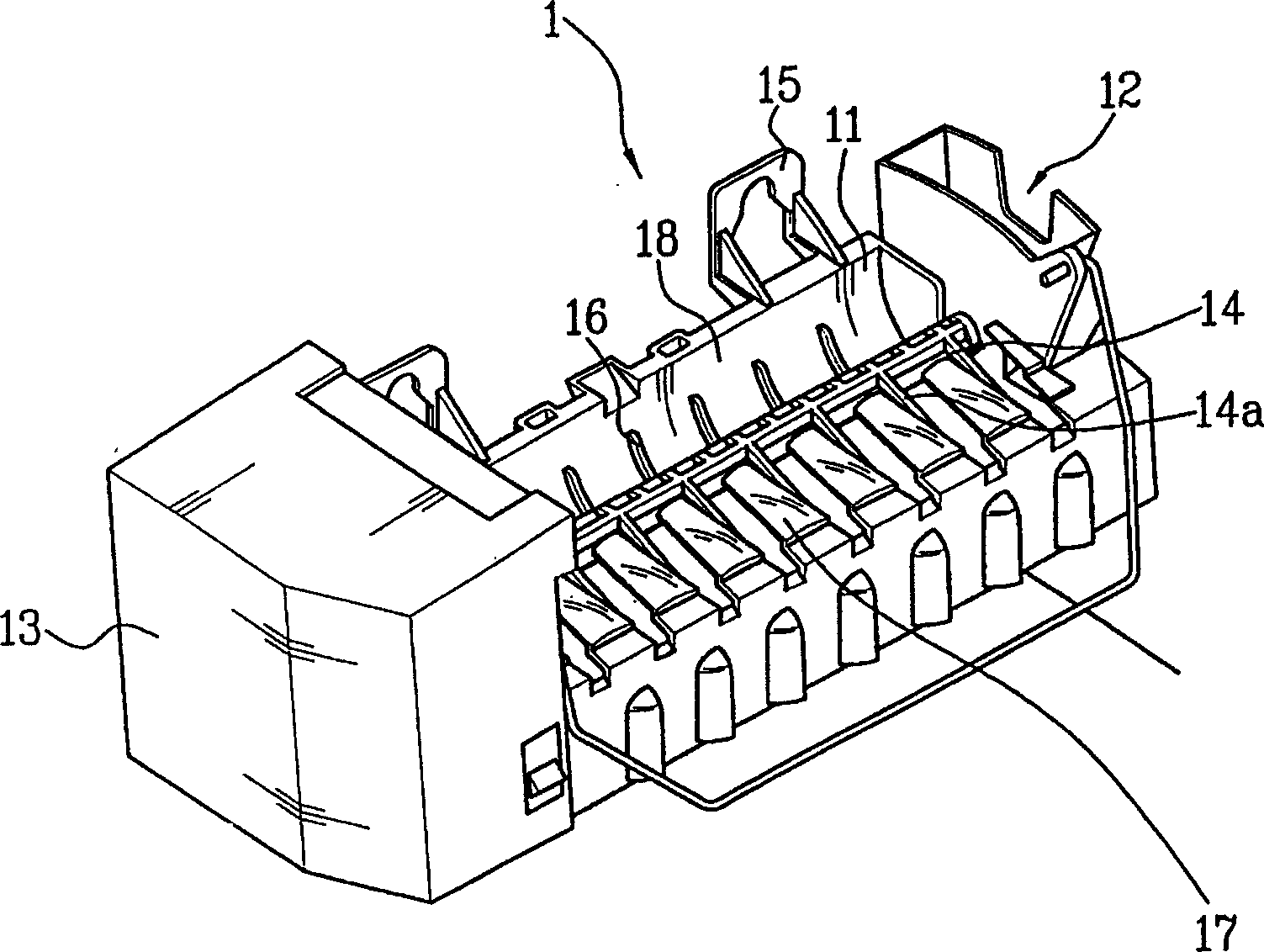

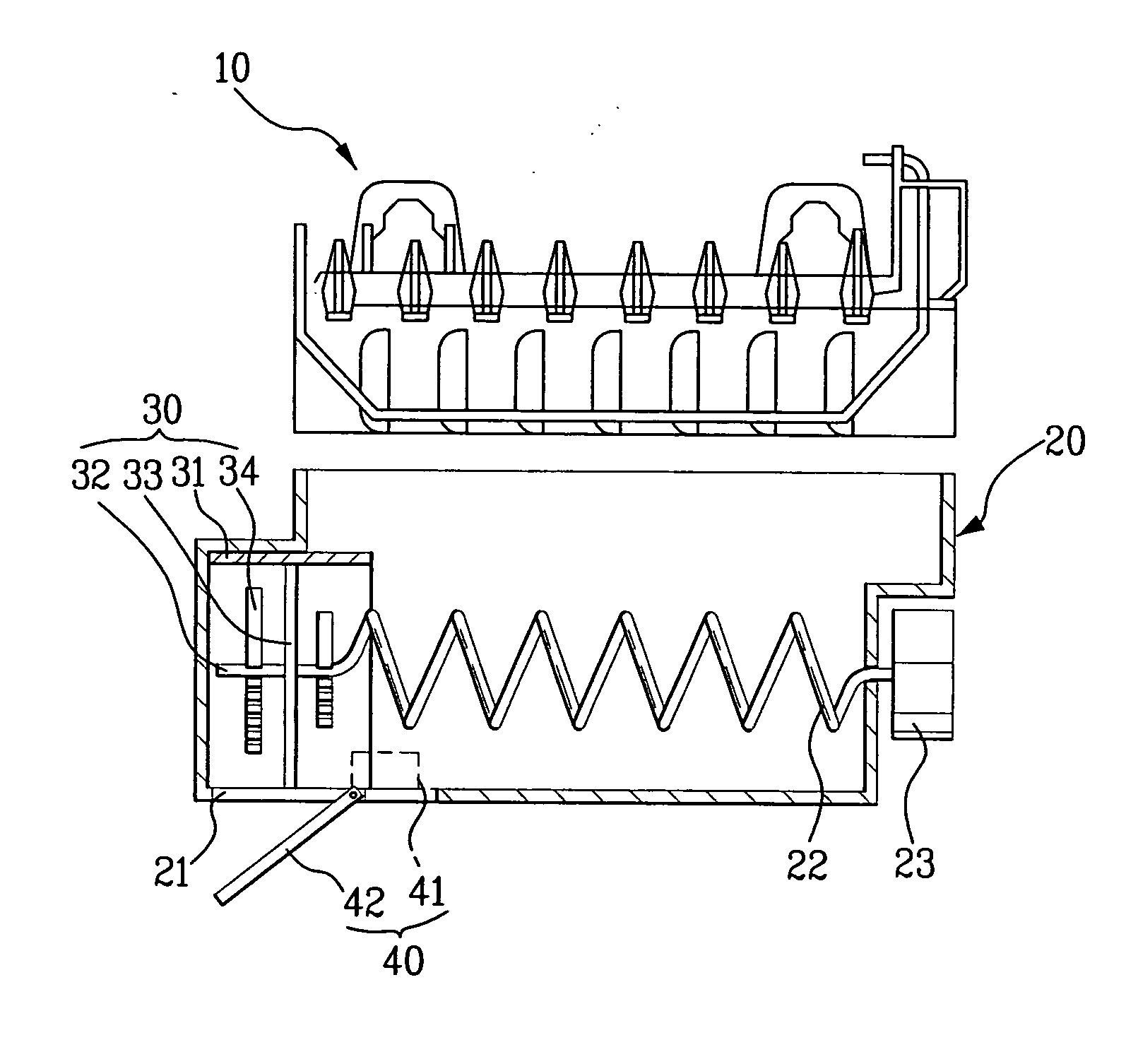

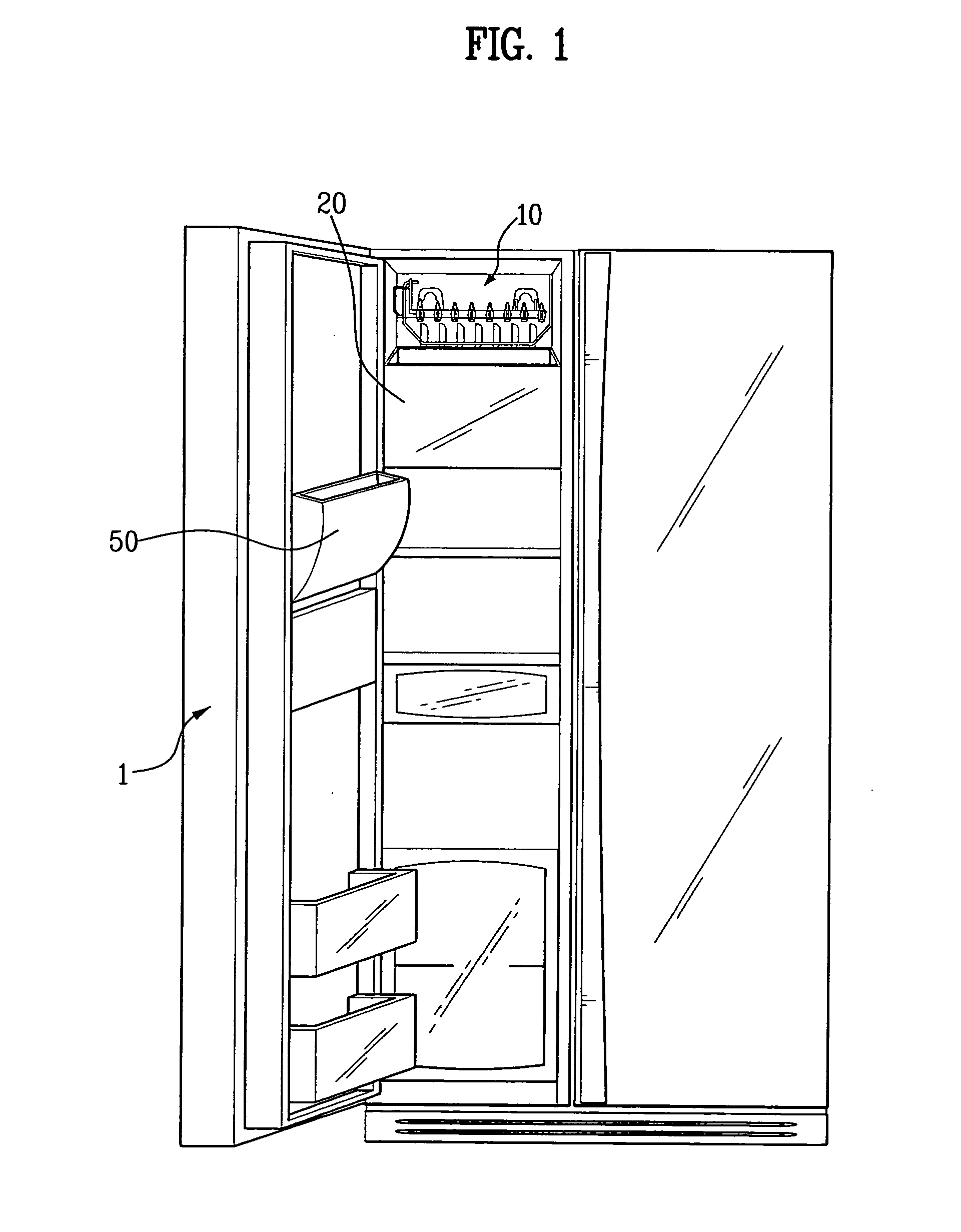

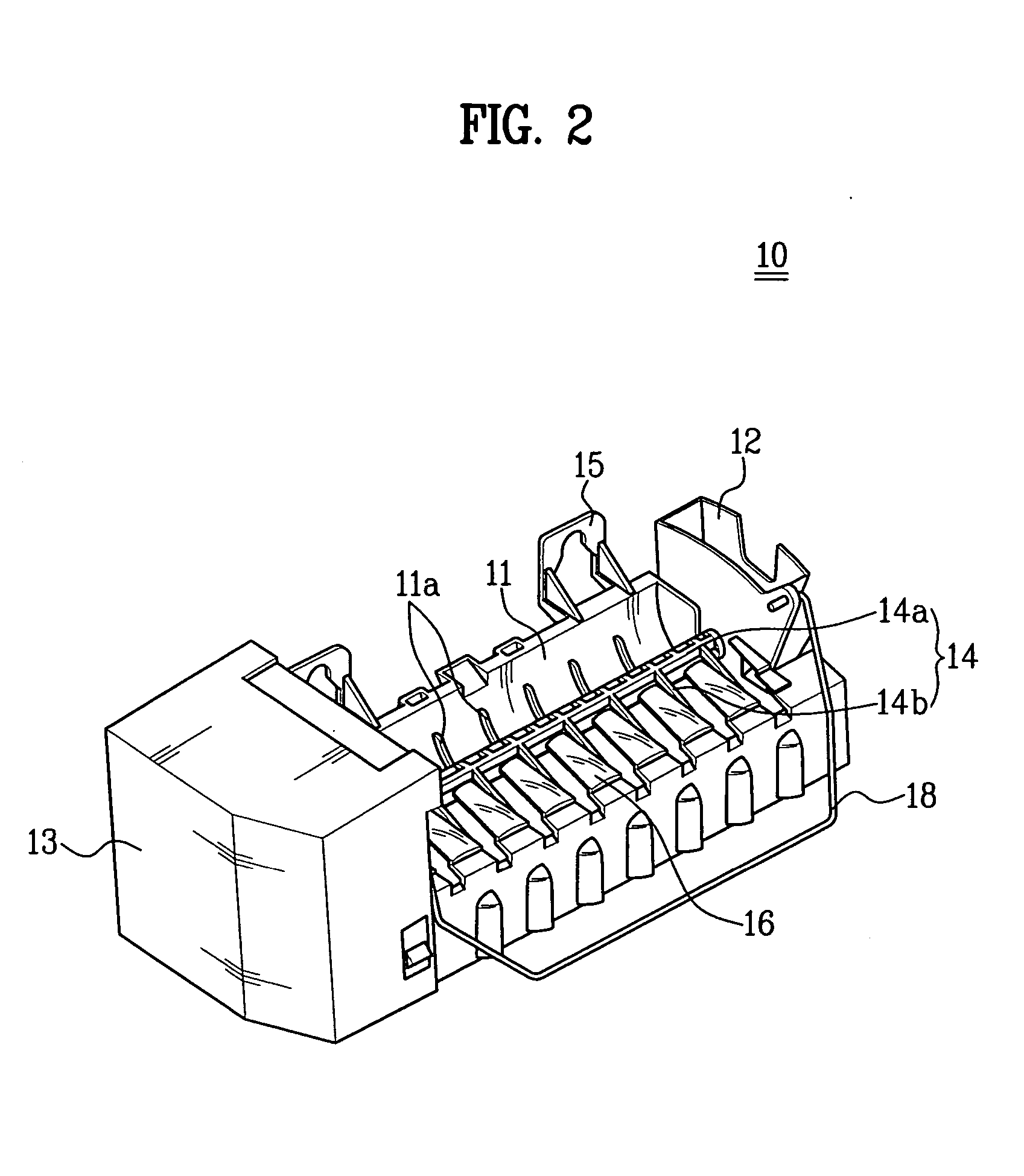

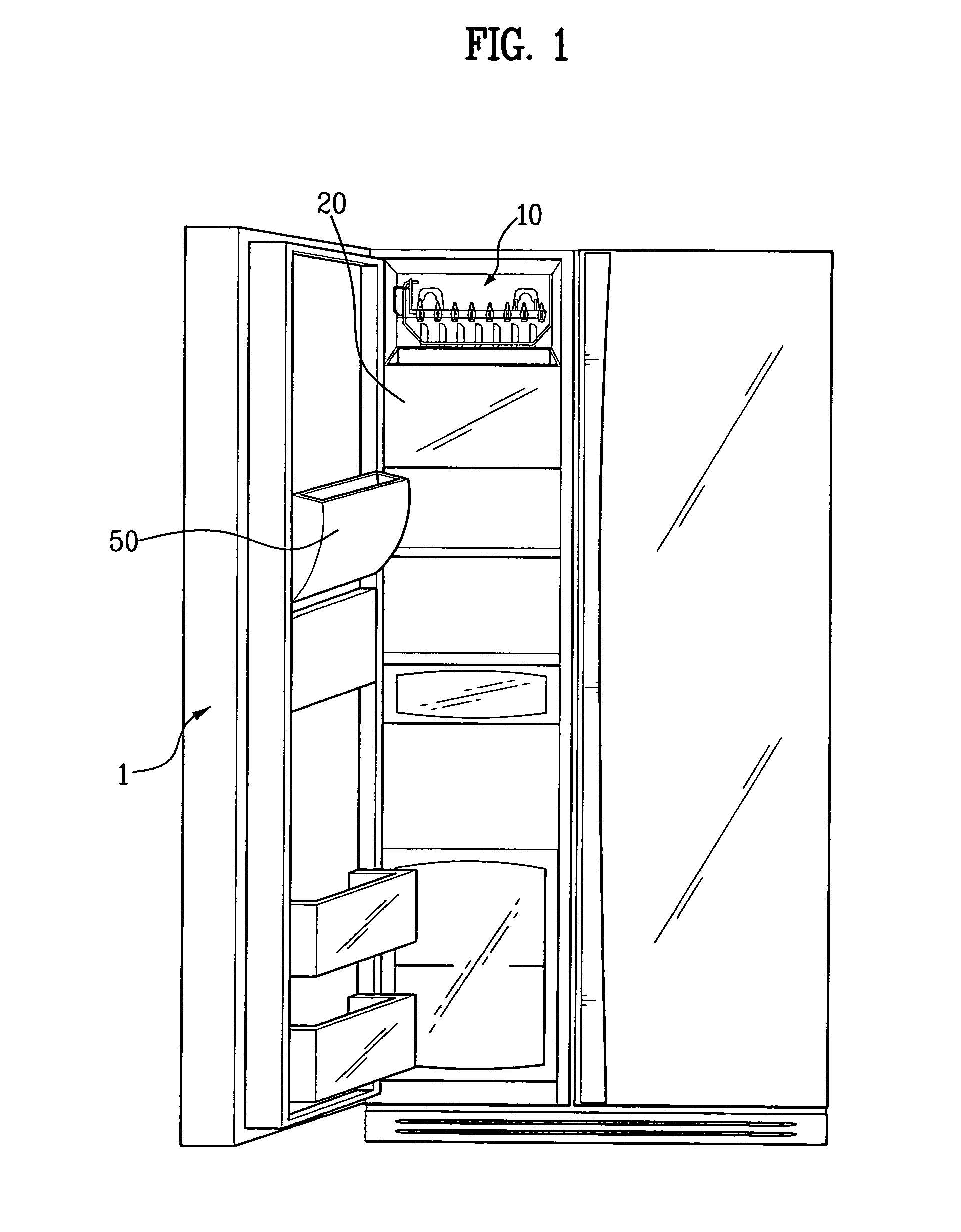

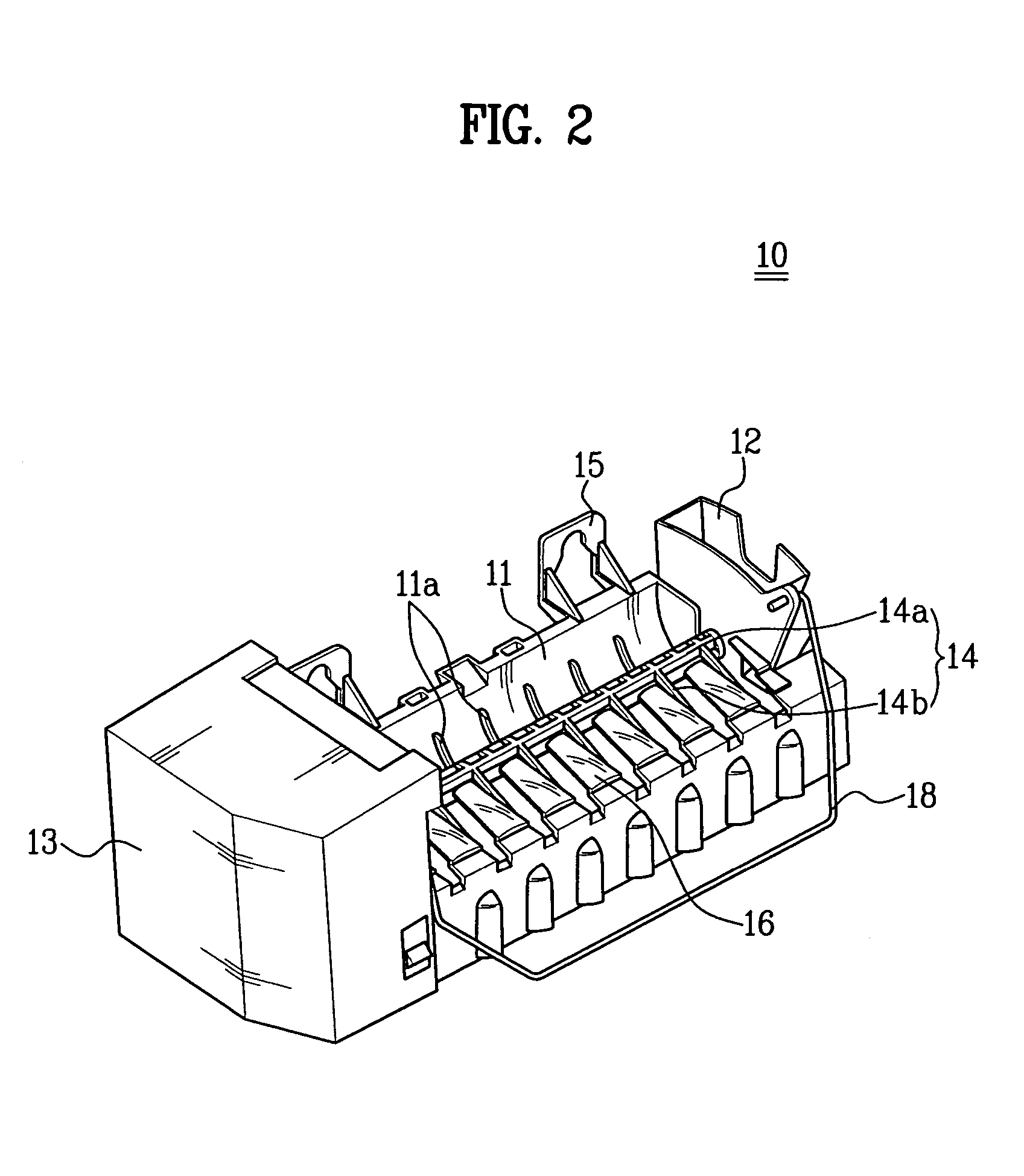

Ice bank of ice-making device for refrigerator

InactiveUS7111473B2Prevent fallingSmooth dischargeLighting and heating apparatusSolid waste disposalEngineeringCrusher

An ice bank of an ice-making device for a refrigerator is disclosed, for smooth crush and discharge of ice, which includes a housing for storing ice made in an icemaker, and provided rotatably to apply the power to the stored ice at a rotation direction; an ice discharger having at least one hole through which the ice is discharge to the external; a crusher provided in the inside of the housing, the crusher guiding the stored ice to the hole of the ice discharge and crushing the ice as a predetermined size before discharging the ice to the hole according to a user's select; and rotating means for rotating the housing. Also, the crusher includes fixed crushing means fixed to the inside of the housing, and rotation crushing means rotated for being synchronized with the housing so as to crush the ice before discharging the ice to the external according to a user's select.

Owner:LG ELECTRONICS INC

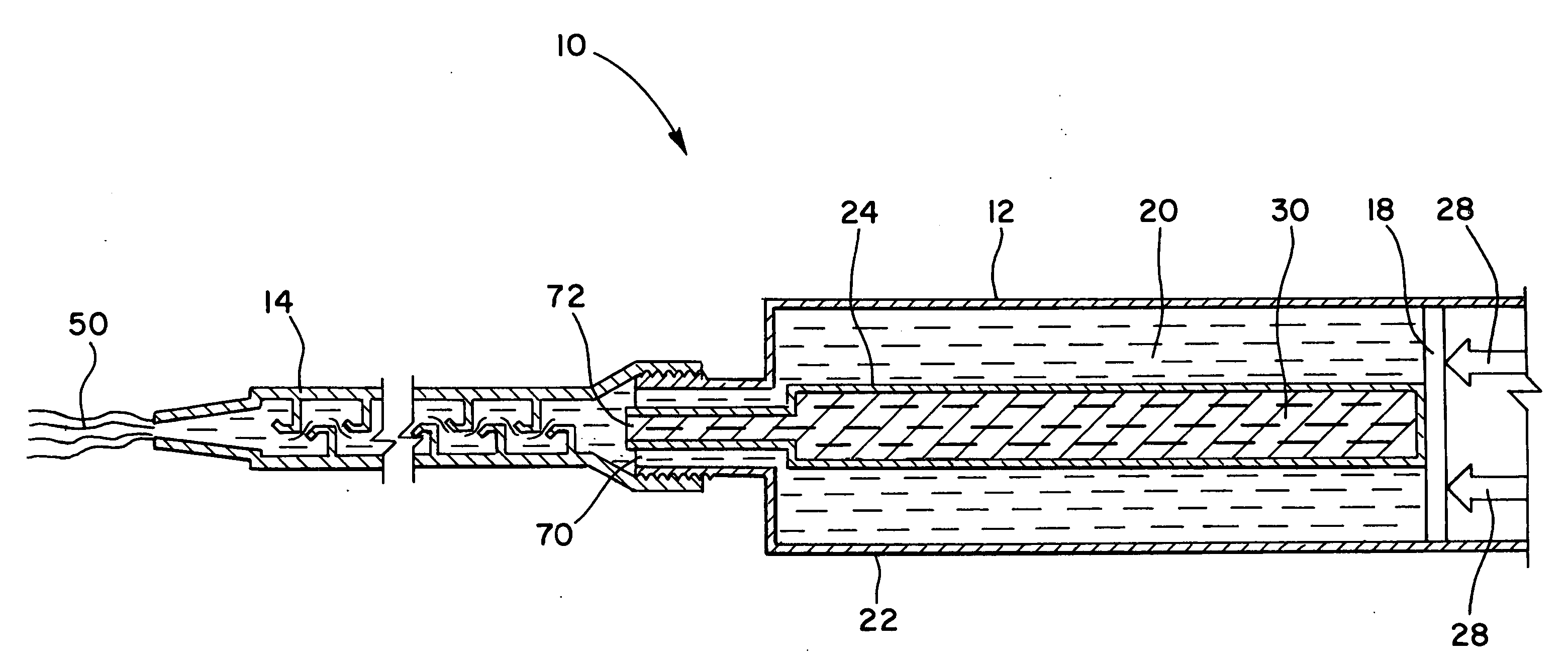

Apparatus and methods for mixing caulk and colorant

Apparatus for mixing caulk with colorant comprising a first compartment having a predetermined amount of caulk provided or placed therein; a second compartment having a predetermined amount of colorant provided or placed therein; a mixer in fluid communication with the two compartments; a discharger to discharge the caulk and the colorant from the compartments into the mixer, wherein the caulk and the colorant are mixed such that the colorant tints the caulk as it is dispensed. A method for mixing caulk with colorant comprising providing or placing a predetermined amount of caulk in a first compartment; providing or placing a predetermined amount of colorant in a second compartment; providing a mixer in fluid communication with the compartments; discharging the caulk and the colorant from the compartments into the mixer, and mixing the caulk and the colorant such that the colorant tints the caulk as it is dispensed.

Owner:TIKUSIS DANIEL J

Ice bank of ice-making device for refrigerator

InactiveCN1576760ASmooth dischargeLighting and heating apparatusSolid waste disposalEngineeringCrusher

Owner:LG ELECTRONICS INC

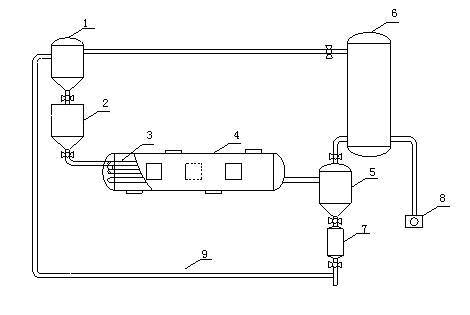

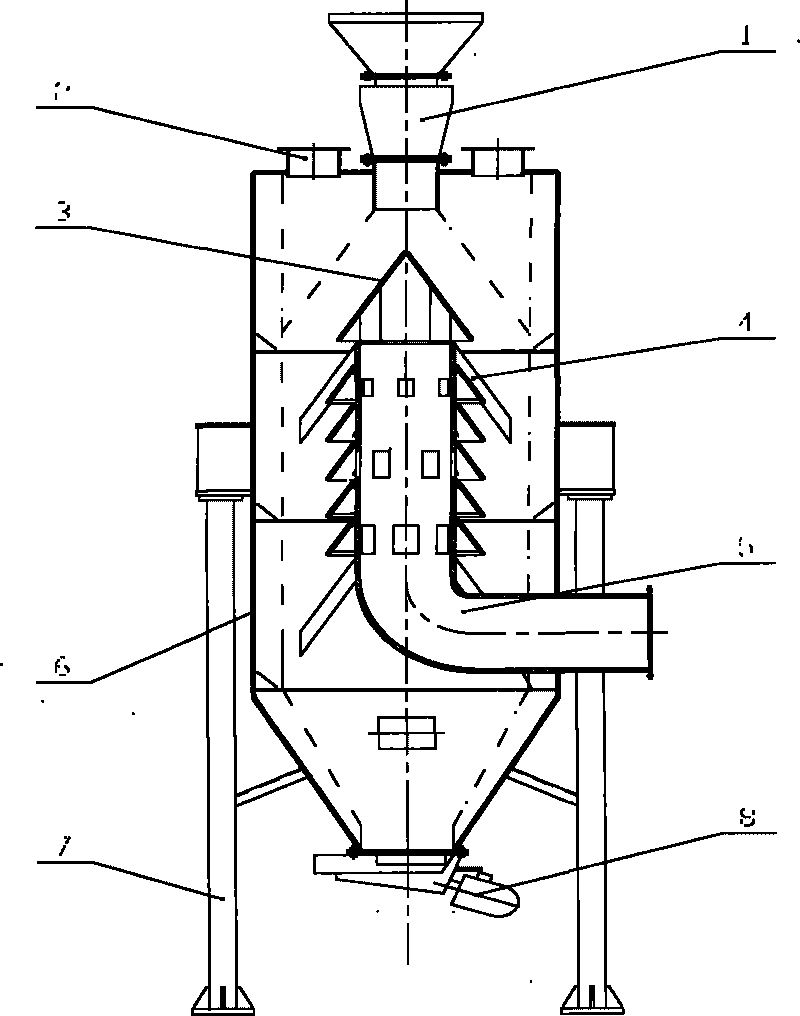

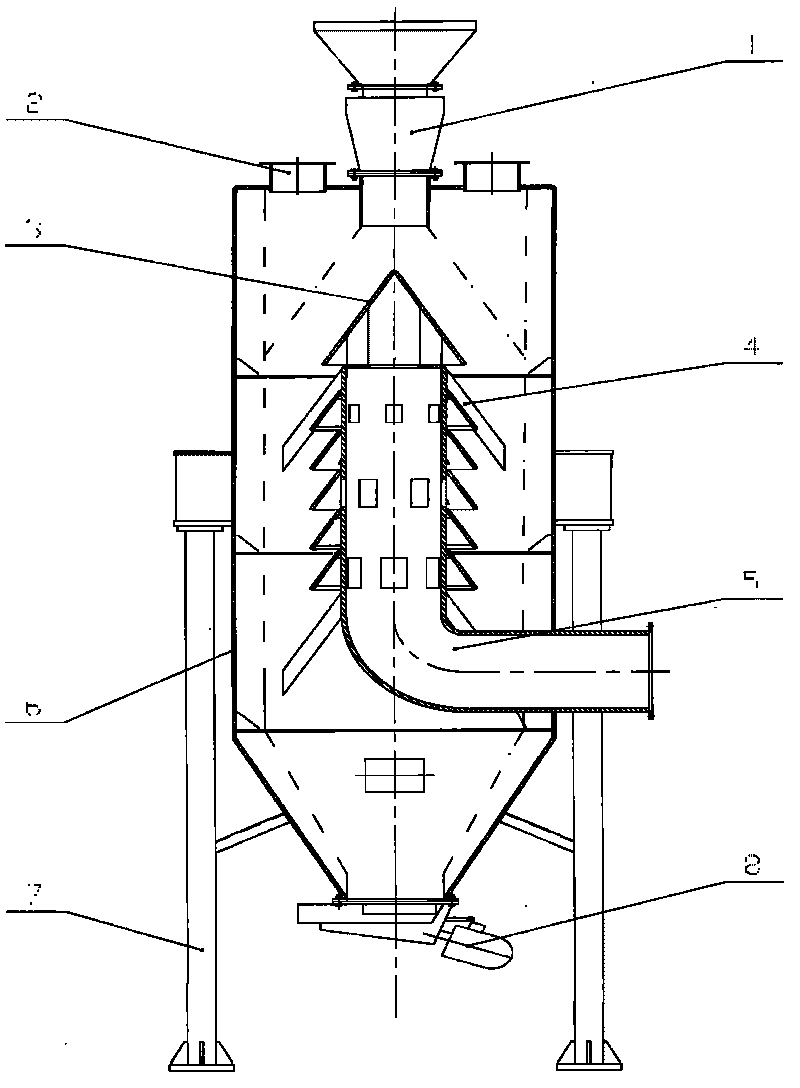

Negative-pressure microwave uniform spraying and drying device and application

ActiveCN102062525ADry evenlyAvoid uneven heatingDrying using combination processesDrying machinesMicrowaveDrying time

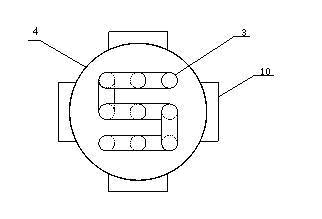

The invention discloses a negative-pressure microwave uniform spraying and drying device and application, belonging to the technical field of uniform drying devices. The negative-pressure microwave uniform spraying and drying device comprises a circulating material storage device, a feeder, a negative-pressure spraying pipe, a microwave heating cavity, a cyclone separator, a vacuum storage tank, a discharger, a water ring vacuum pump, a circulating pipe and microwave sources. The circulating material storage device is used for storing materials dried circularly, the feeder is used for feeding dry materials to the negative-pressure spraying pipe which is a channel for drying and circulating the materials, and the microwave sources are uniformly distributed inside the microwave heating cavity, two ends of which are sealed. The cyclone separator is connected with an outlet of the negative-pressure spraying pipe inside the microwave heating cavity and is connected with the vacuum storage tank and the discharger through a channel. The discharger is connected with the circulating material storage device through the circulating pipe. Because the materials can be sprayed under negative pressure, the device can be used for spraying, rotating and circulating the materials under a microwave vacuum drying condition so as to achieve the purpose of drying the materials efficiently and uniformly, meanwhile, is favorable for shortening the drying time by above 40% and reducing the cost of large-scale production.

Owner:JIANGNAN UNIV

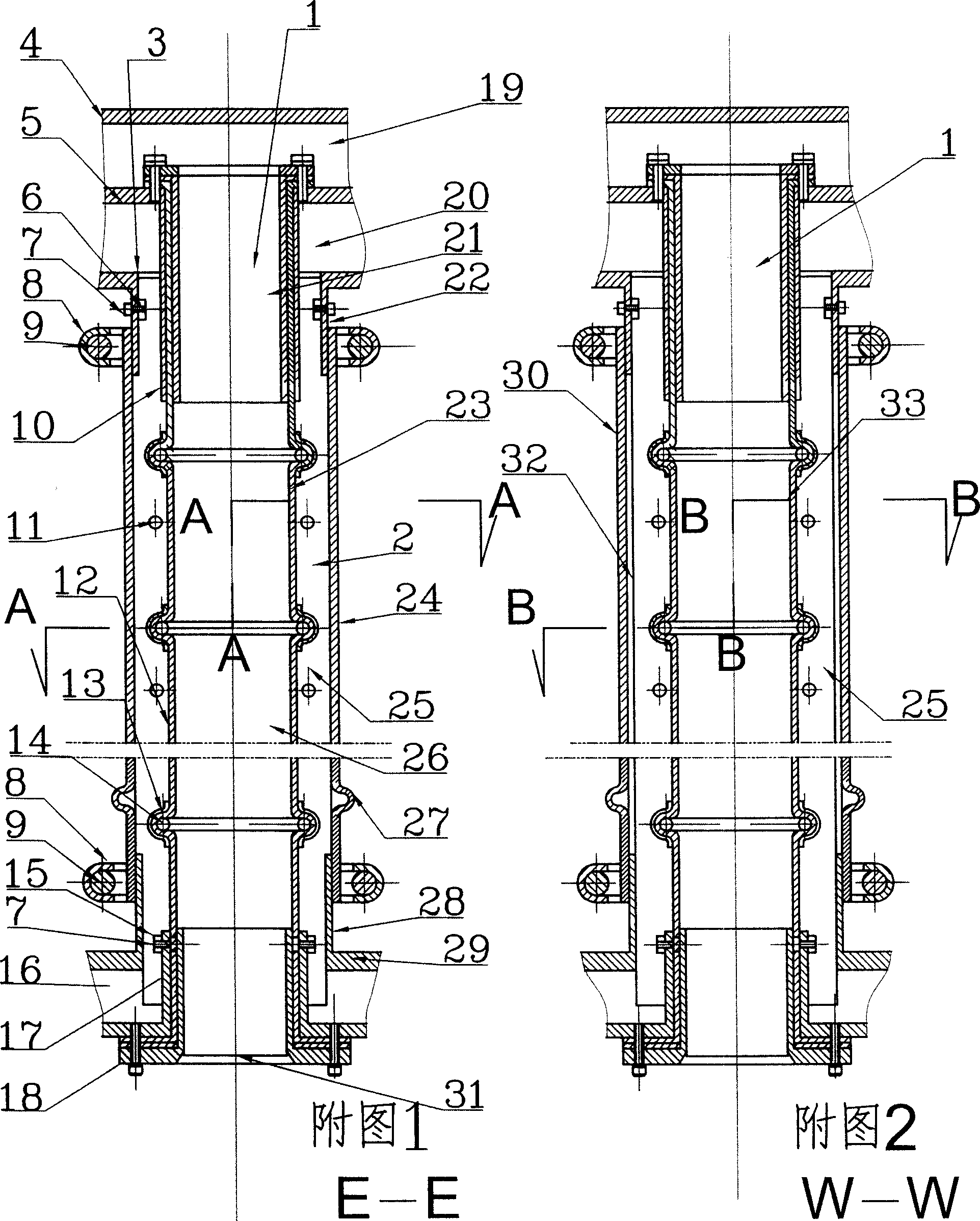

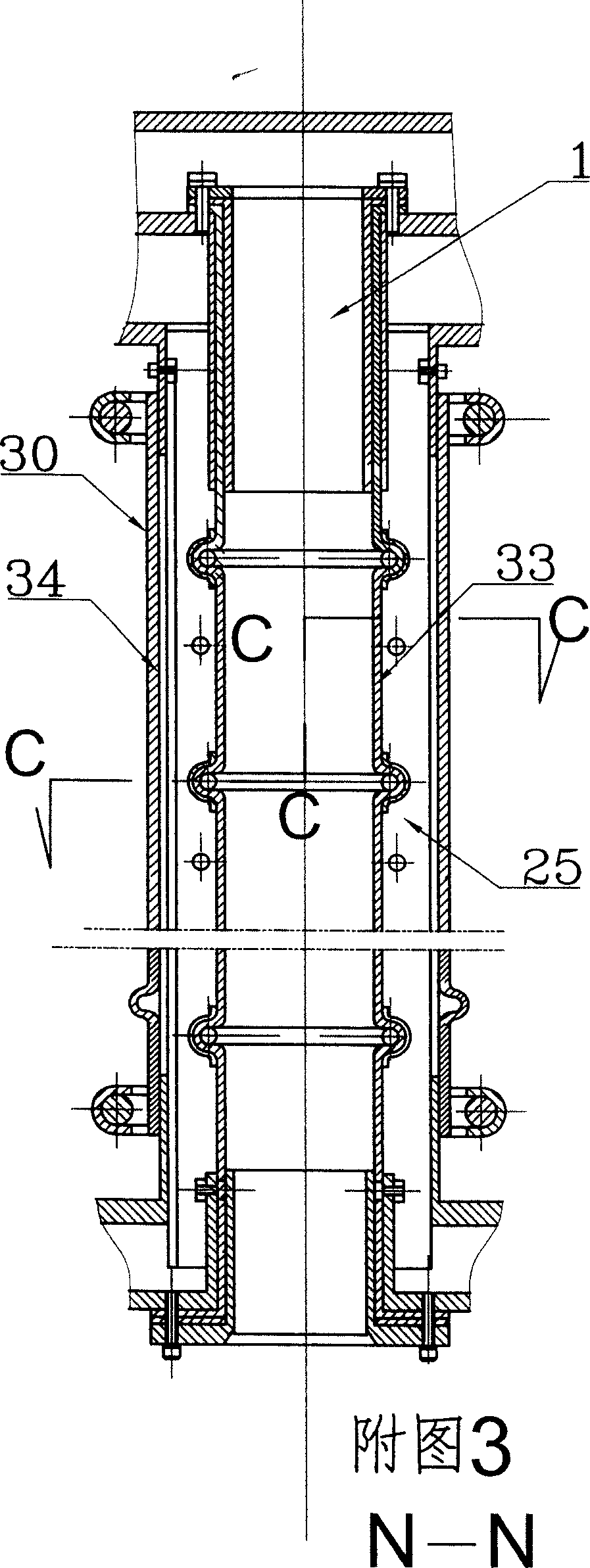

Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

InactiveCN1966129ALow costSimplify equipment componentsSemi-permeable membranesStationary filtering element filtersSlagEngineering

The invention relates to a flexible tubular solid liquid processor, with filter, heat exchange and thermal extraction functions, wherein the filter element at least comprises one flexible tubular membrane unit, upper flange room and lower flange room; the hydraulic extracting system comprises pressure container, extract pump and tubes; the material liquid of container can be filtered by the tubular filter membrane of membrane unit, and said material liquid can be used as work medium to extract the concentrated material liquid in the filter room of membrane unit and discharge filter slag; the pressure container or the filter room of membrane unit can be filled with medium to exchange heat, to realize thermal filter or extraction; the filter element is arranged on the bearing base inside the pressure container; the filter rotator can rotate the filter element to realize cross-flow filter; and the invention can be arranged with gas or water reverse tube and vacuum filter tube; the slag discharge system comprises slag discharger or tubular inner / outer membrane scraper, or vibration slag discharger, or compression slag discharger.

Owner:张民良

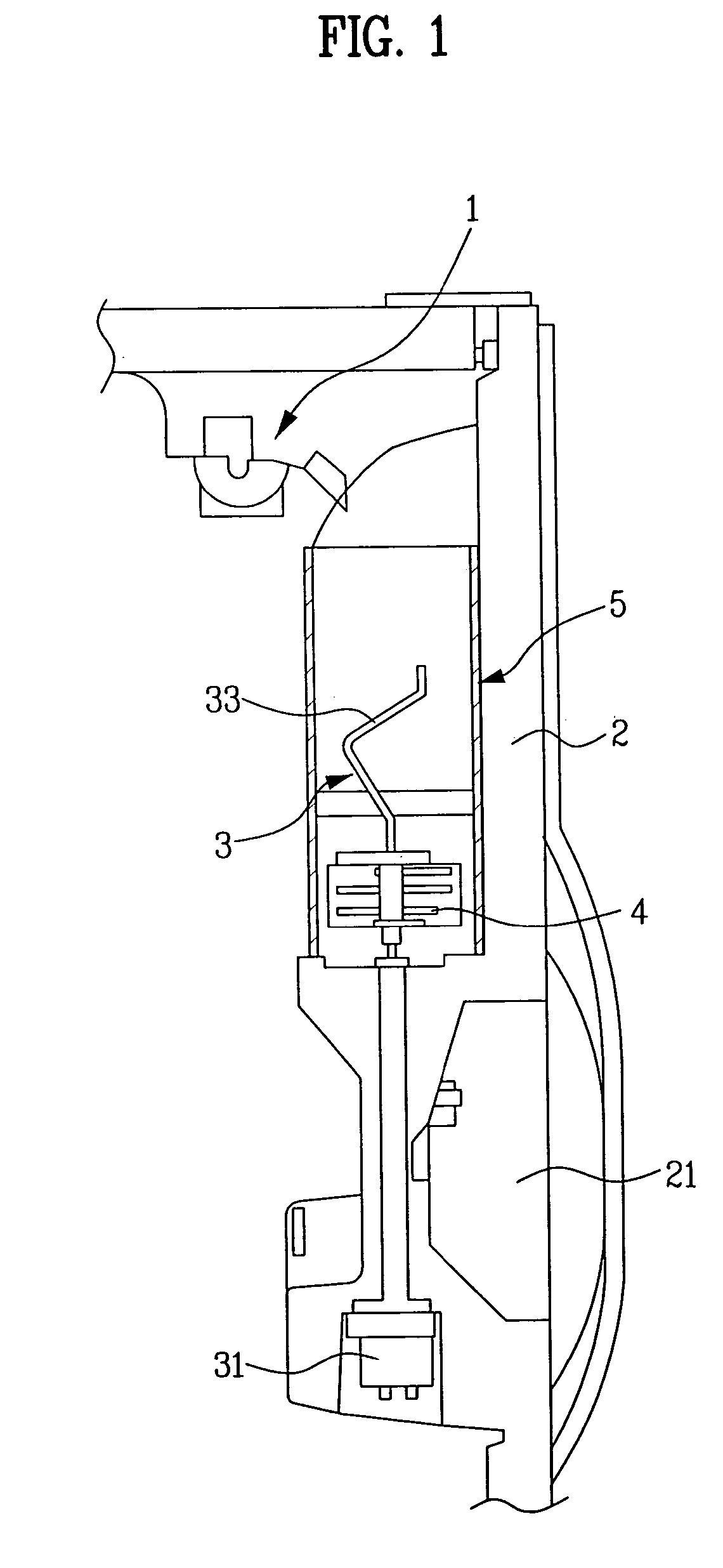

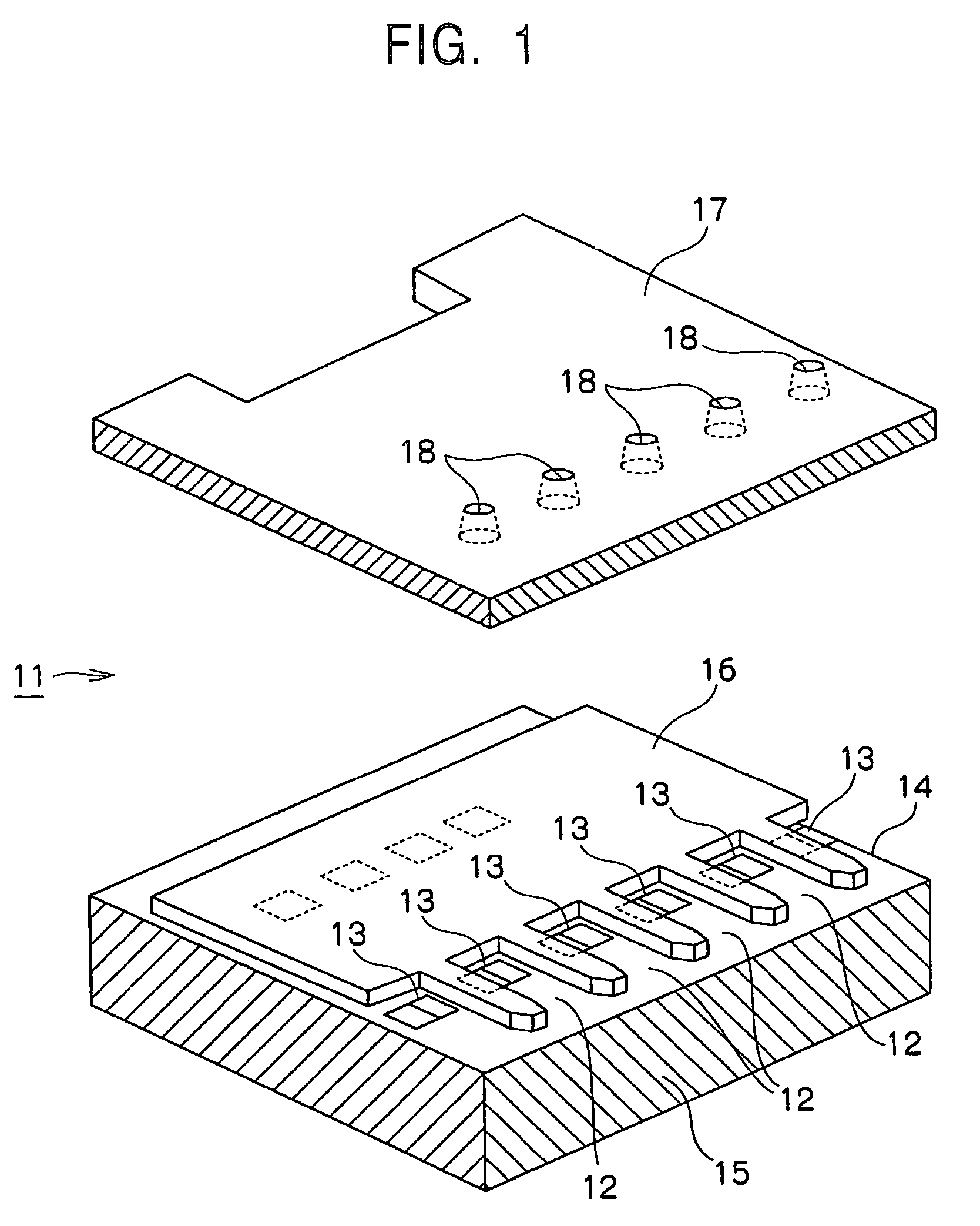

Image forming apparatus

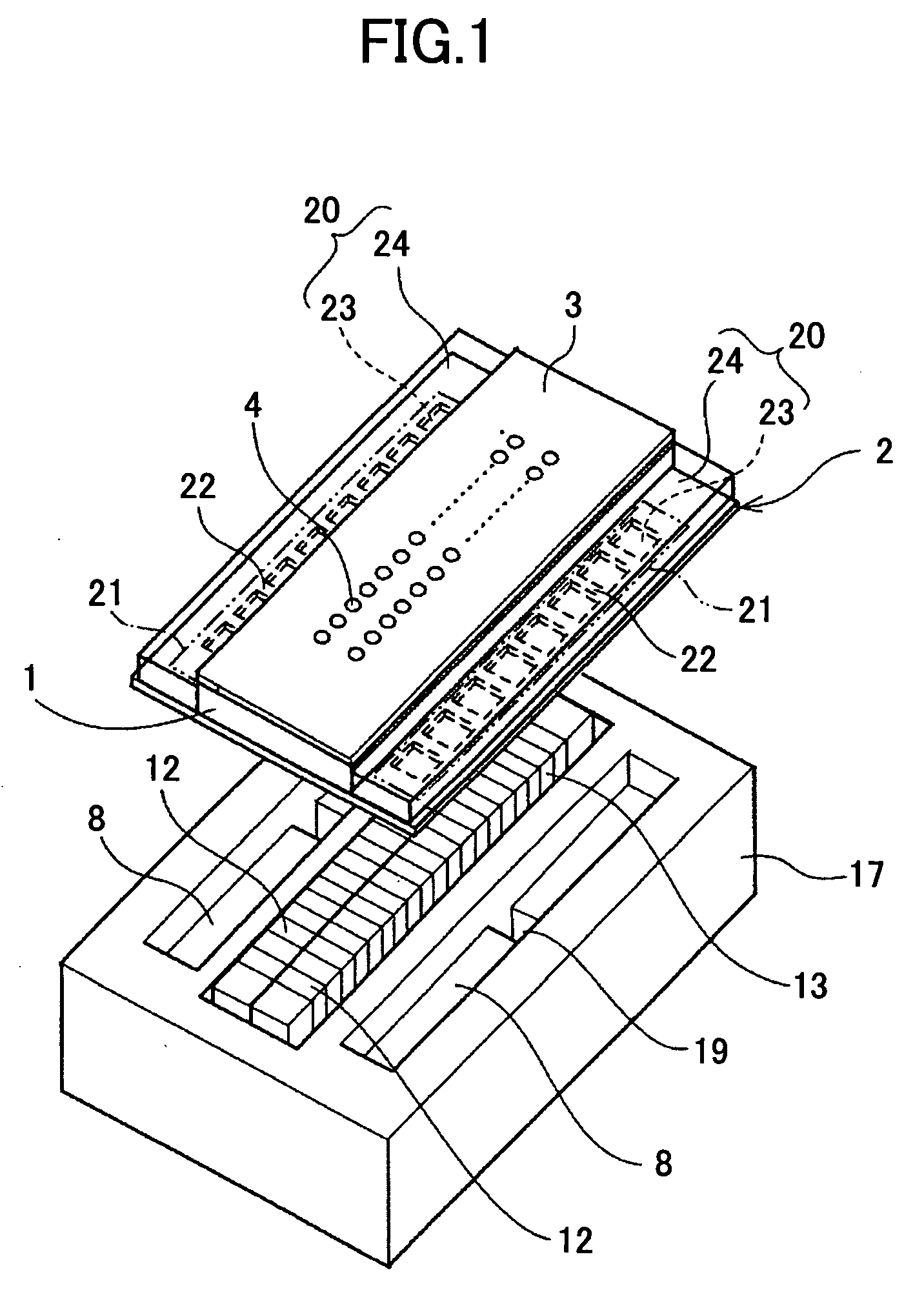

An image forming apparatus is disclosed that includes a liquid discharger including a liquid discharge head configured to discharge a droplet of liquid so as to form an image. The liquid discharge head includes multiple individual channels communicating with corresponding nozzles from which the liquid is discharged; a common channel configured to supply the liquid to the individual channels; a deformable member configured to form at least one wall face of the common channel; and a vibration damping member formed of a viscoelastic material, the vibration member being provided in contact with the deformable member.

Owner:RICOH KK

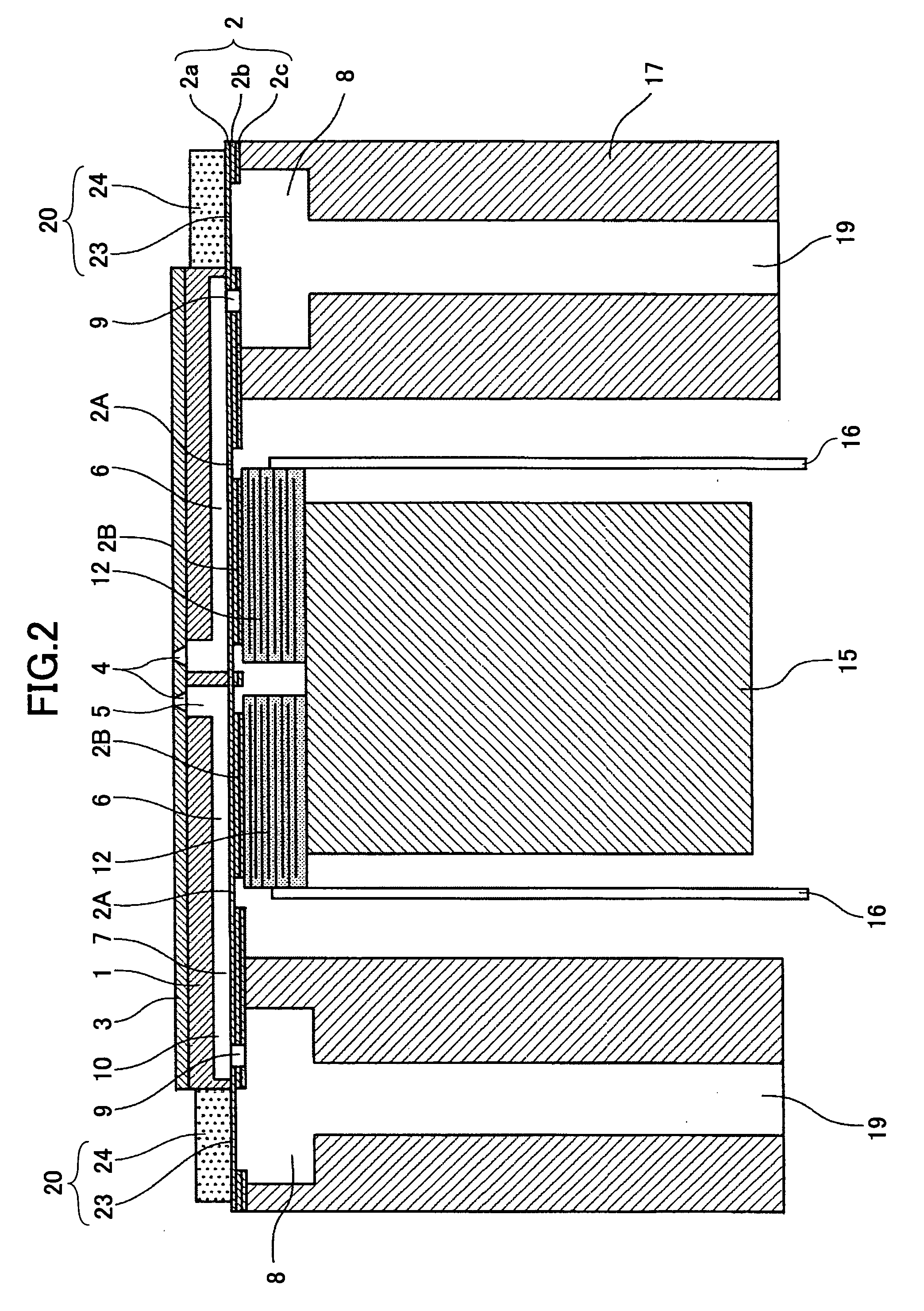

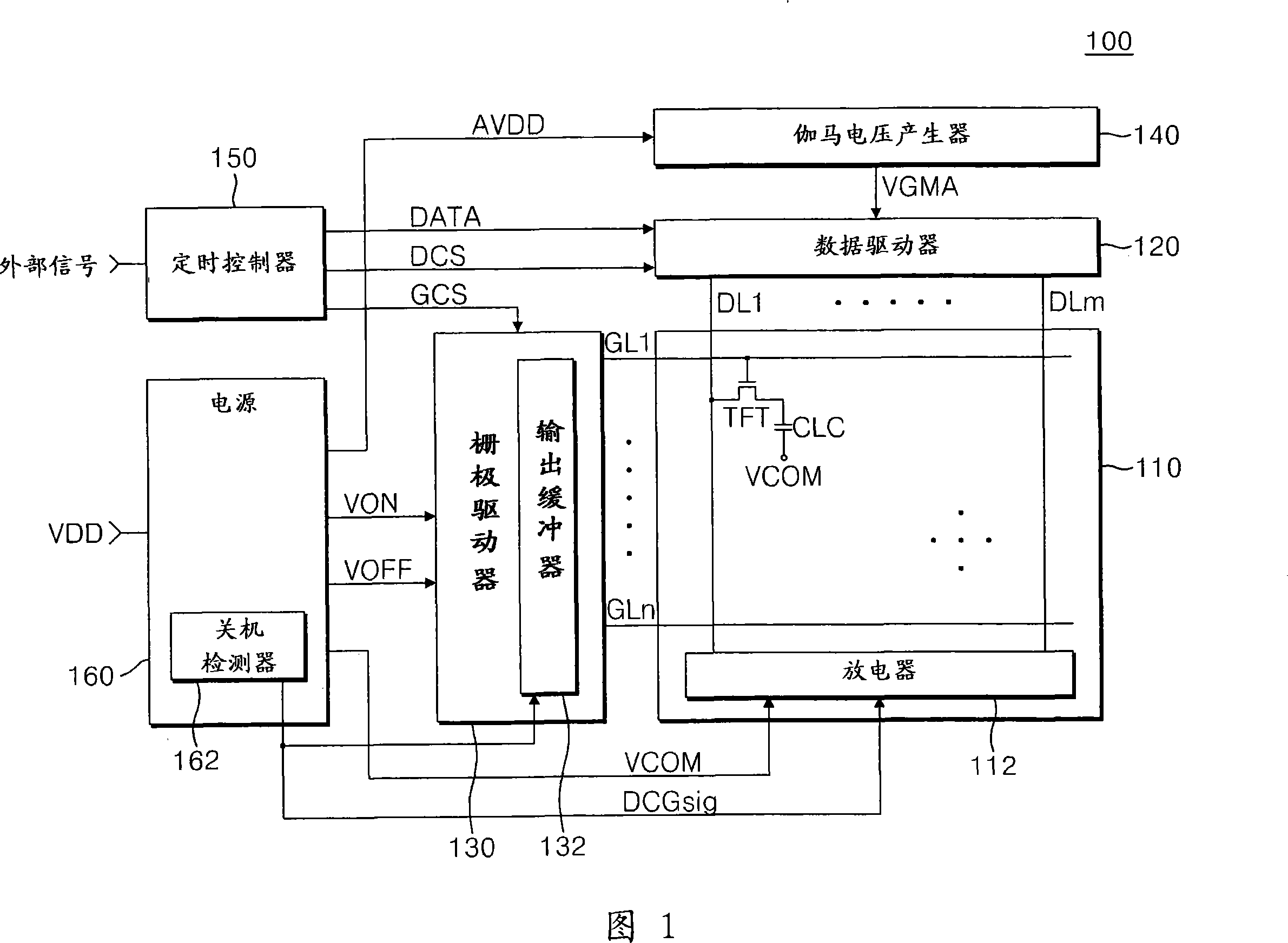

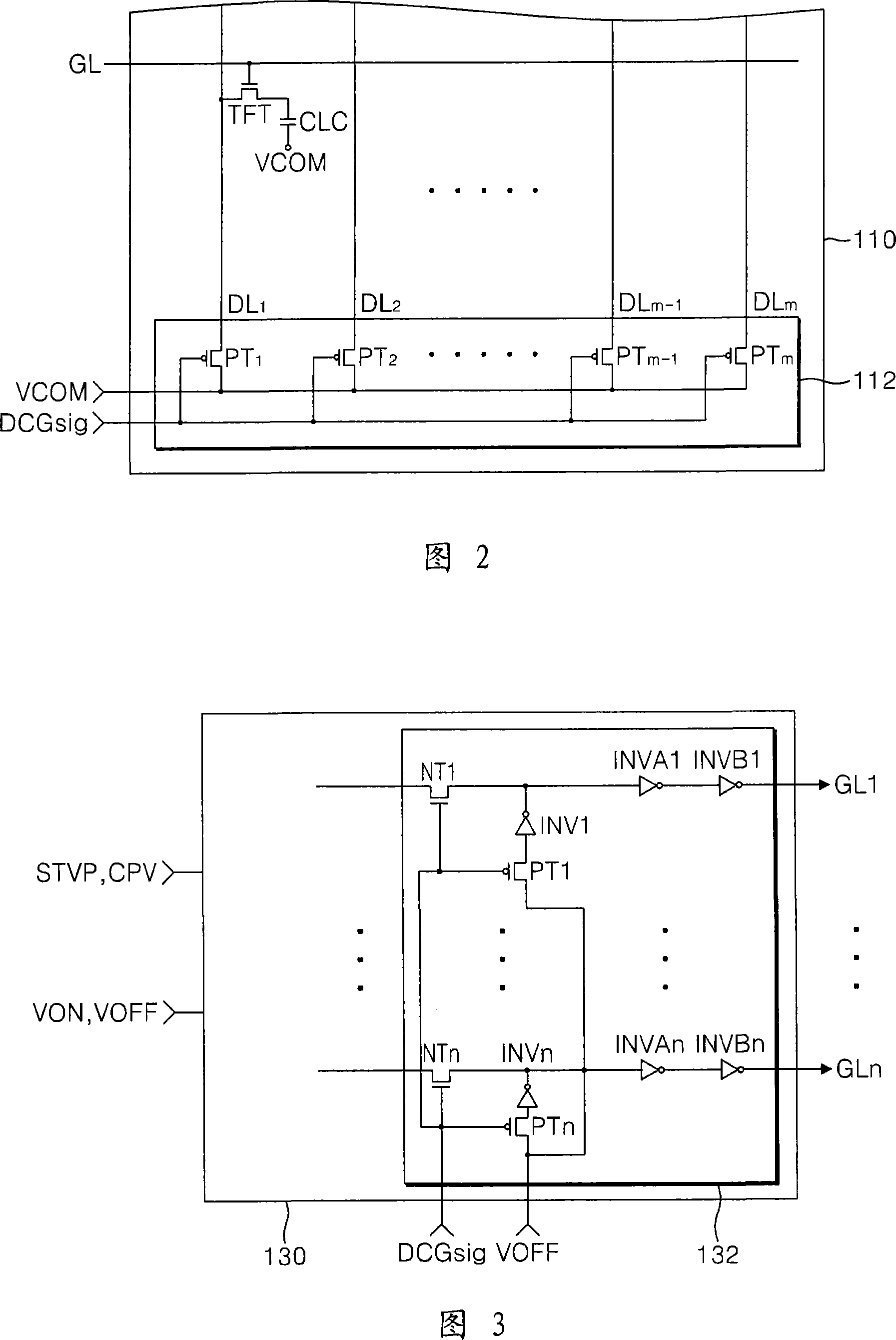

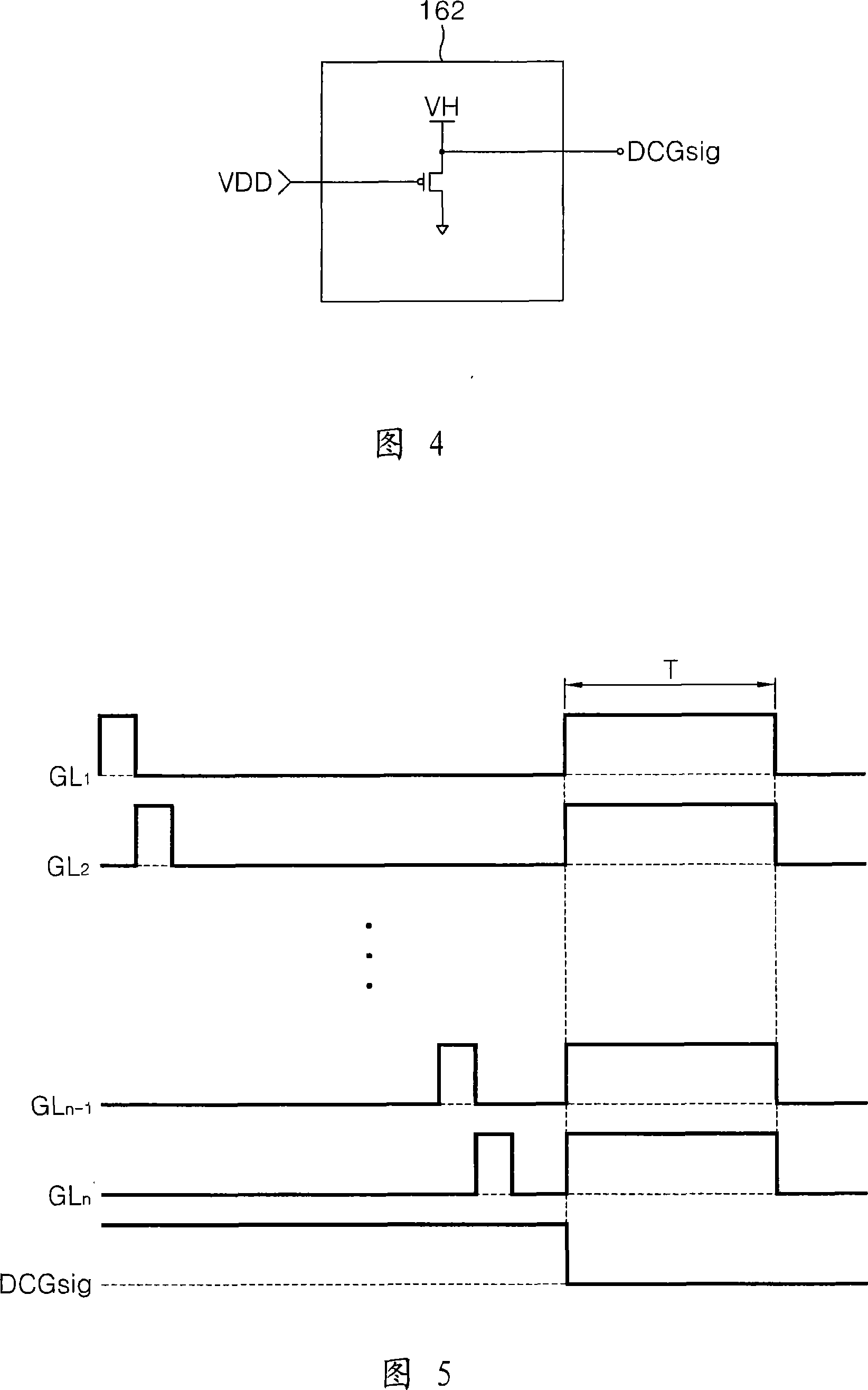

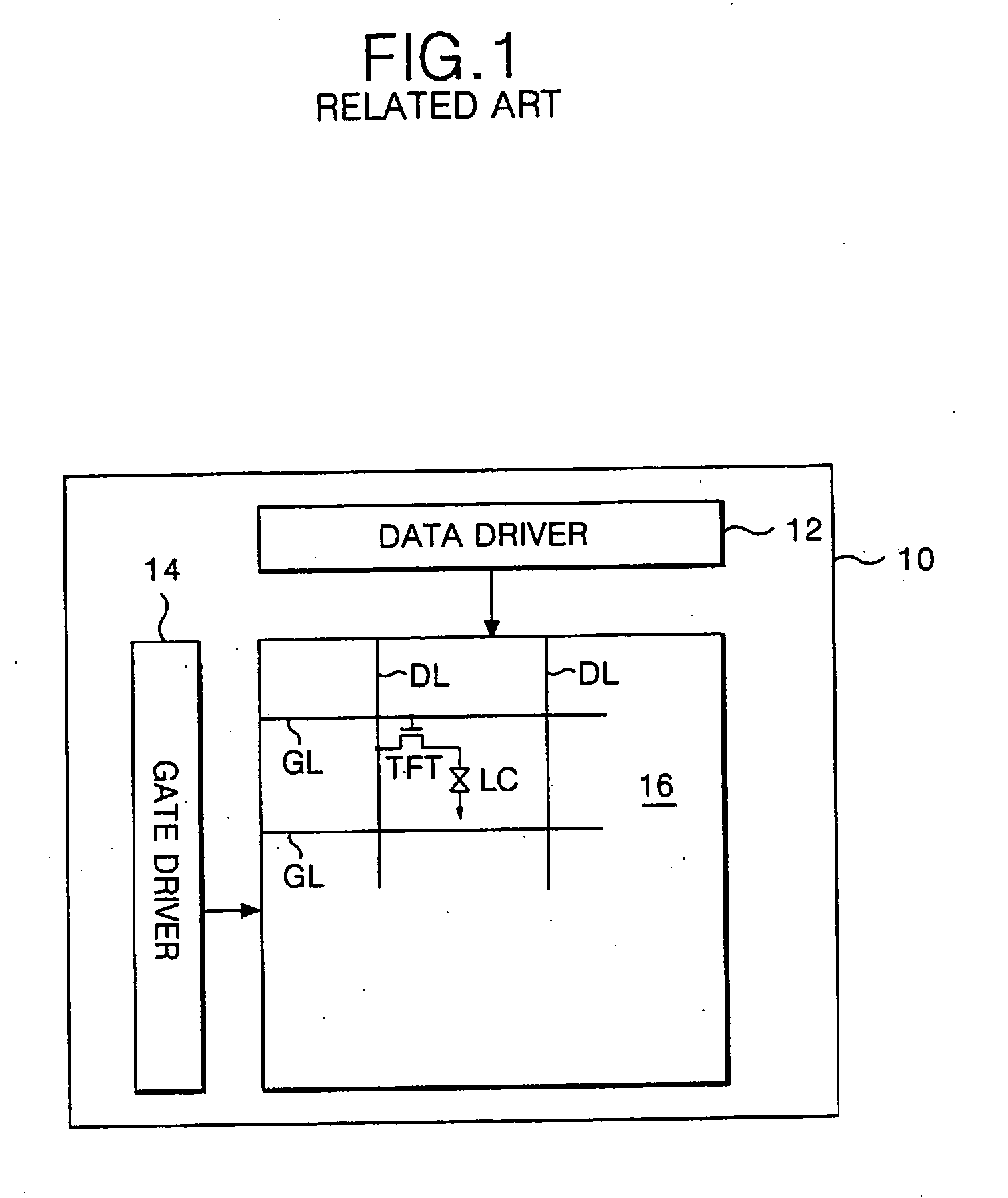

Liquid crystal display and method for eliminating afterimage thereof

A liquid crystal display ("LCD") for eliminating afterimages includes: a power supply, a gate driver, and a discharger. This power supply detects the interruption of the external supply voltage and provides a discharge signal. The gate driver provides gate driving signals to the plurality of gate lines simultaneously in response to the discharge signal, and the discharger provides a common voltage to the plurality of data lines in response to the discharge signal.

Owner:SAMSUNG DISPLAY CO LTD

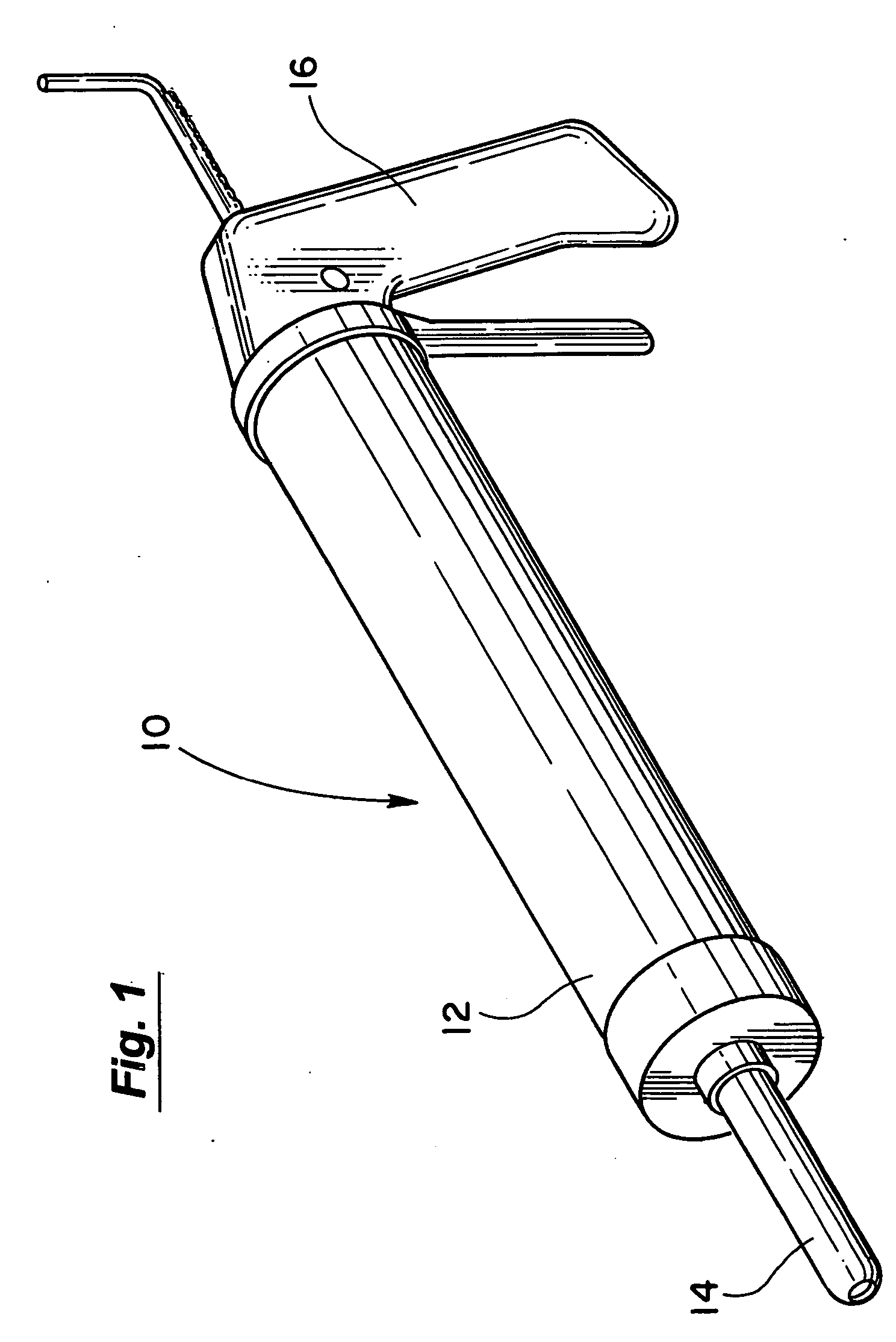

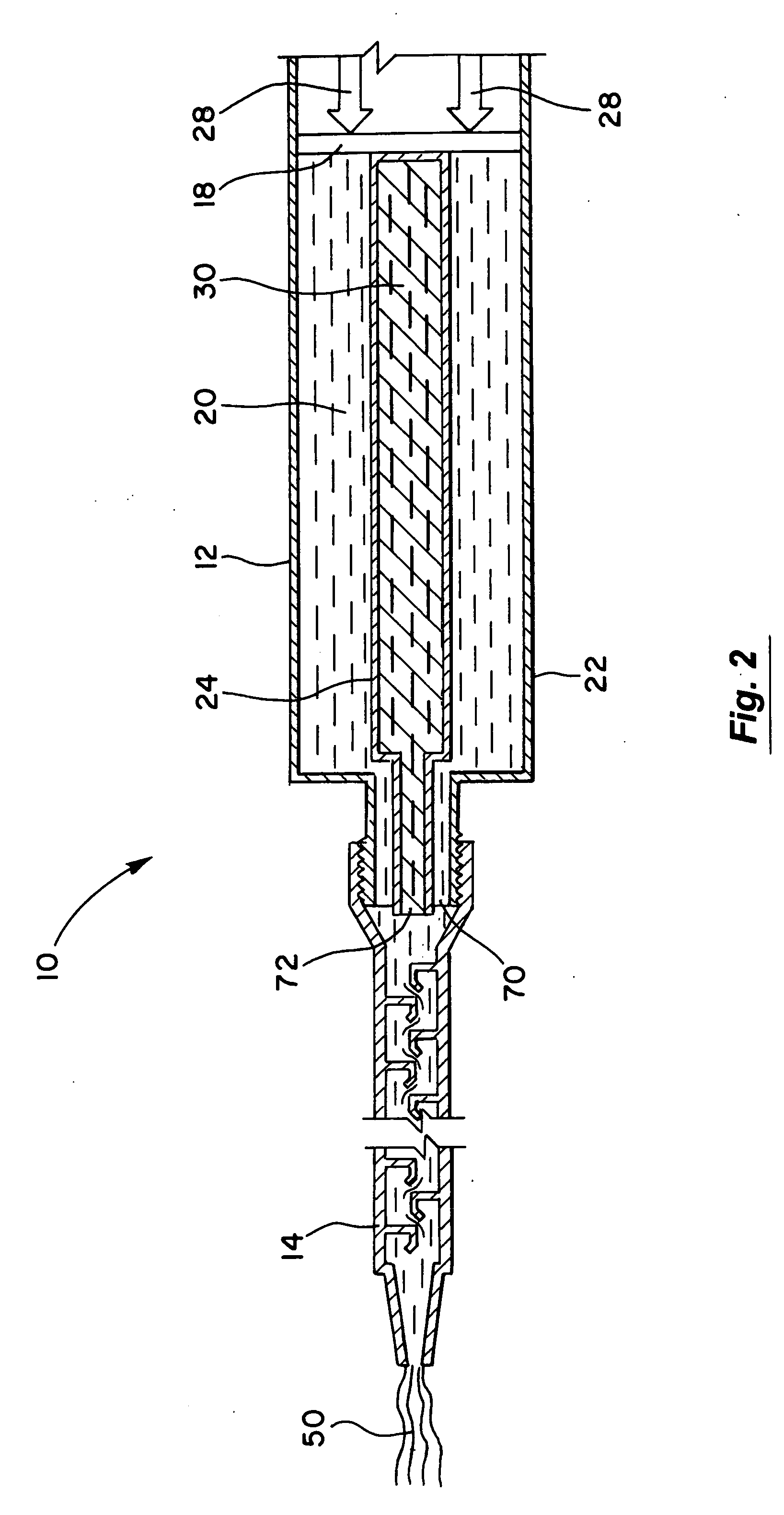

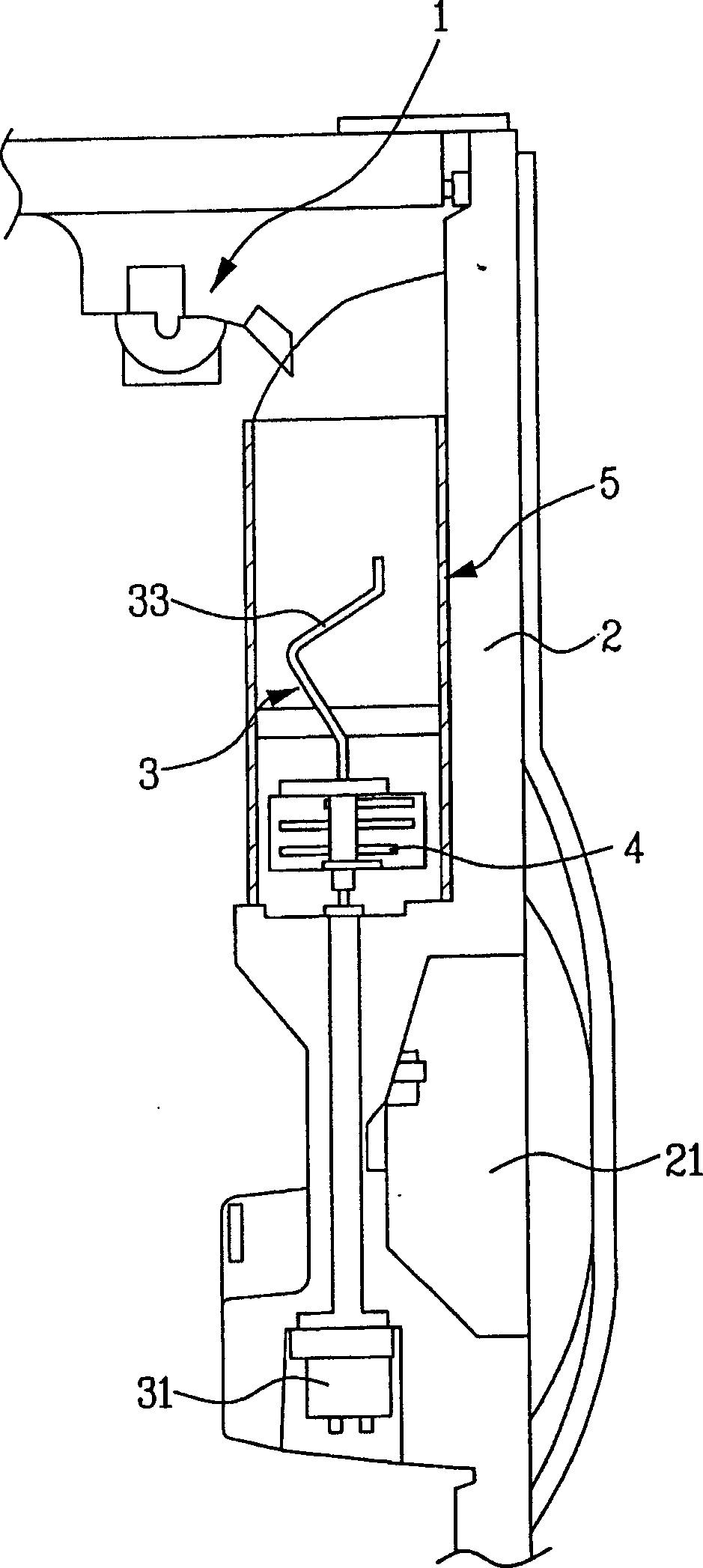

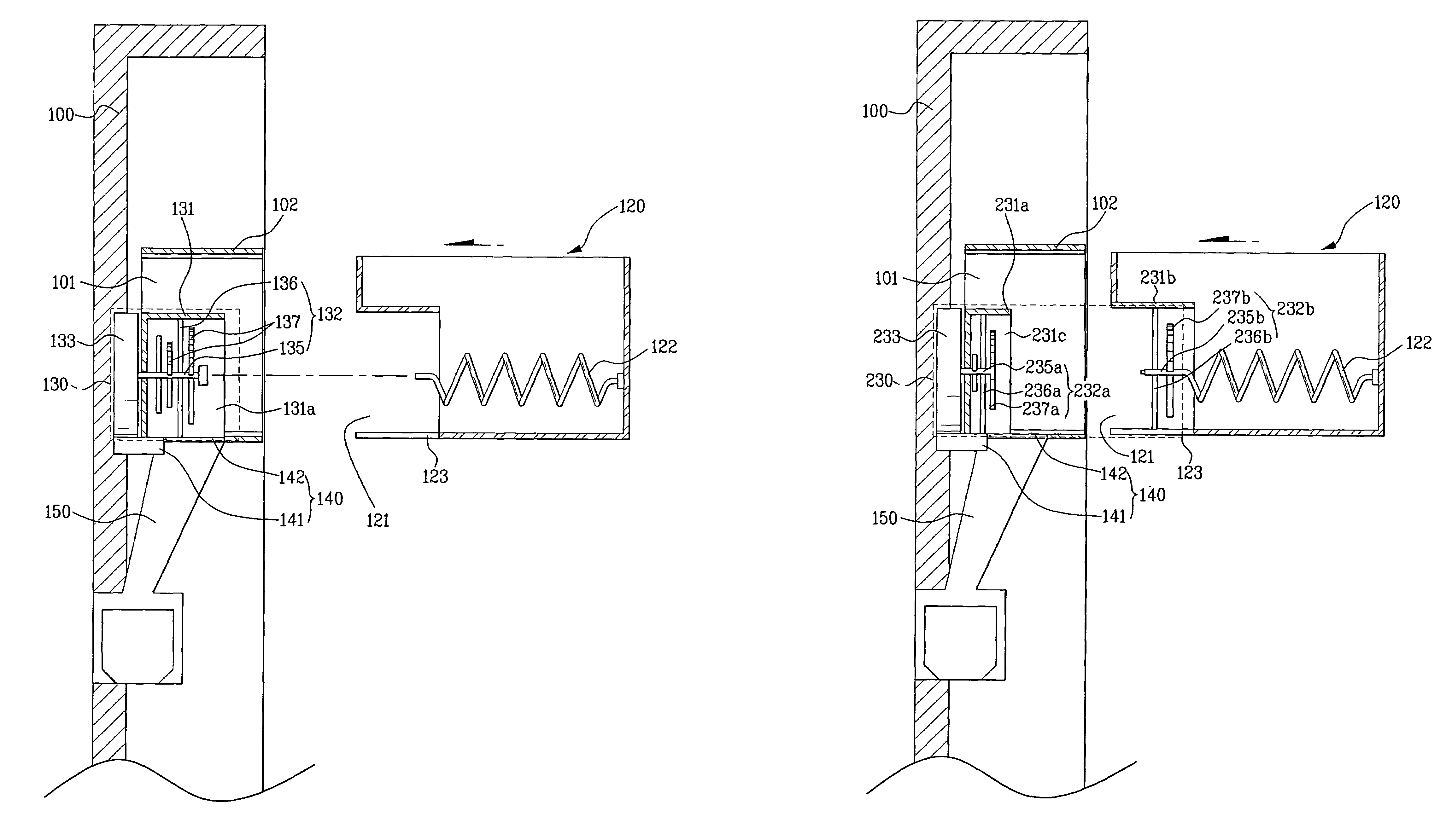

Ice supply system of refrigerator

ActiveUS20050044874A1Smooth slidingSimple structureLighting and heating apparatusIce productionMarine engineeringCrusher

Disclosed is an ice supply system provided at a door and freezer in a refrigerator. The ice supply system of the refrigerator of the present invention includes an icemaker, a container, a crusher and an ice discharger. The icemaker produces the ice by using cool air of the freezer and drops the ice to a lower part of thereof. The container is provided at a lower part of the icemaker, enabling to be inserted into and withdrawn from the door. In this case, the container includes an open top, a first opening provided at a side thereof, a transfer device rotating and transferring the ice to the first opening, and an outlet for discharging the ice. The crusher crushes the ice transferred by the transfer device and the ice discharger is provided for discharging the ice to an ice chute provided at the door by controlling an opening and closing amount of the outlet.

Owner:LG ELECTRONICS INC

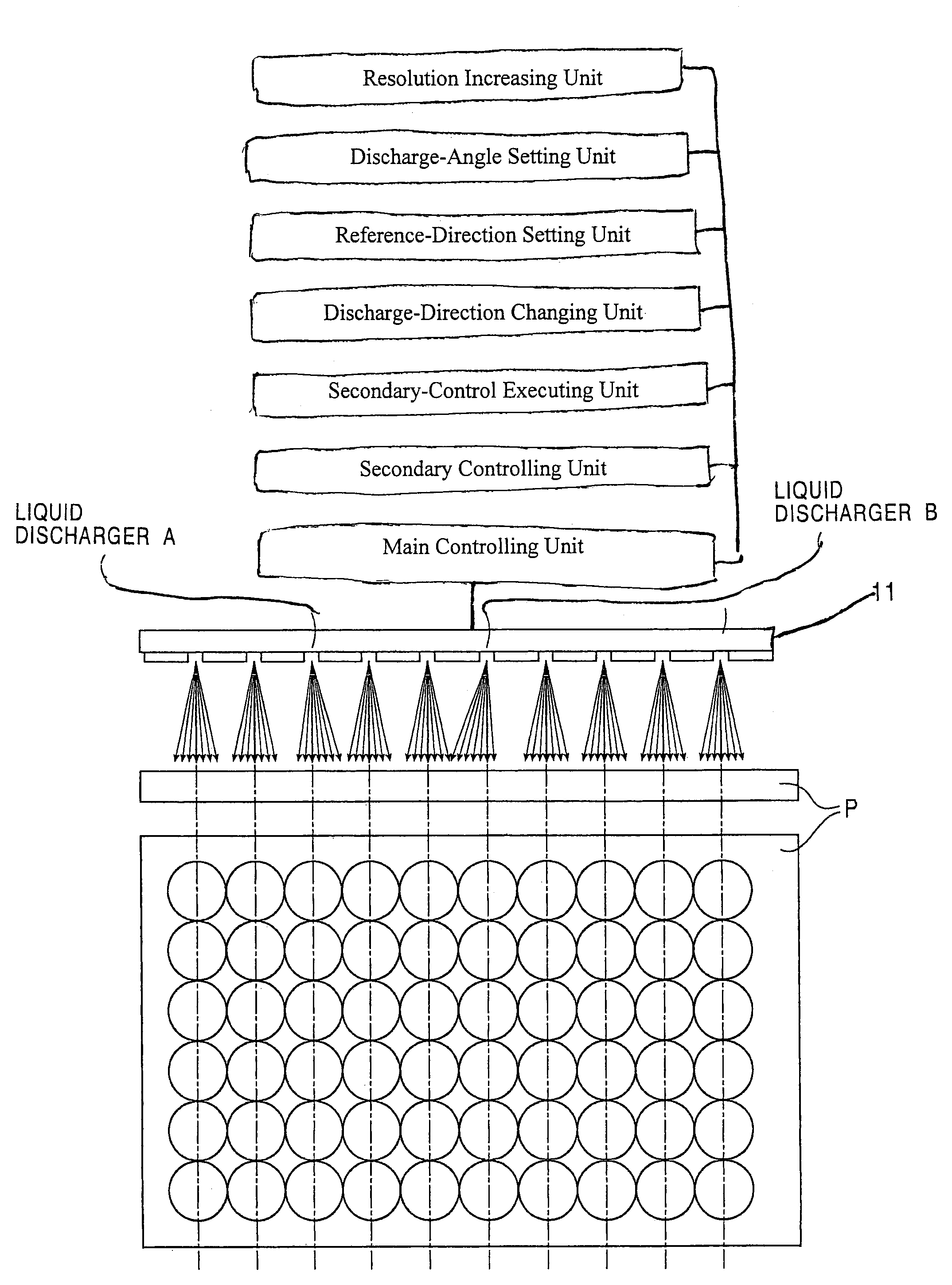

Liquid discharge apparatus and method for discharging liquid

InactiveUS7306309B2Reduce in quantityImprove printing qualityInking apparatusOther printing apparatusEngineeringDischarger

A liquid discharge apparatus having heads with liquid dischargers including nozzles aligned in parallel in a row. Each liquid discharger has a main controlling unit for discharging ink droplets from the nozzles of the liquid discharger, a secondary controlling unit for controlling the discharge of a droplet so that the droplet is discharged along at least one trajectory different from the trajectories of the droplets discharged from a liquid discharger controlled by the main controlling unit, and a secondary-control executing unit for individually setting whether or not the secondary controlling unit for each liquid discharger is operated. The liquid dischargers controlled by the secondary controlling unit discharge ink droplets along different trajectories compared to the ink droplets discharged by other liquid dischargers.

Owner:SONY CORP

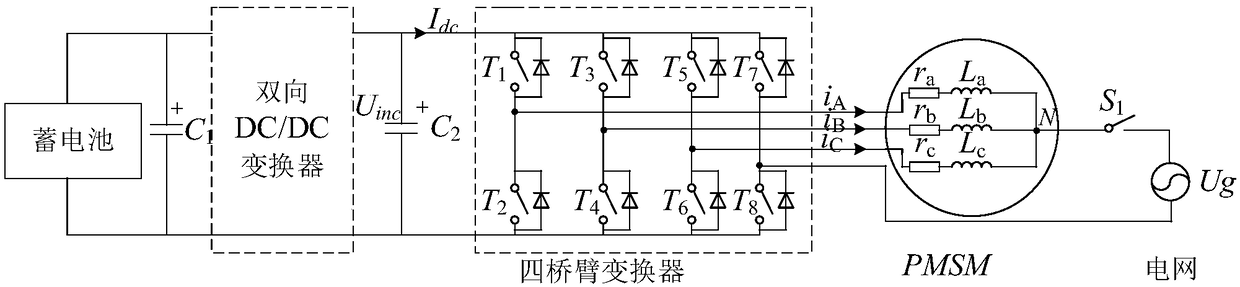

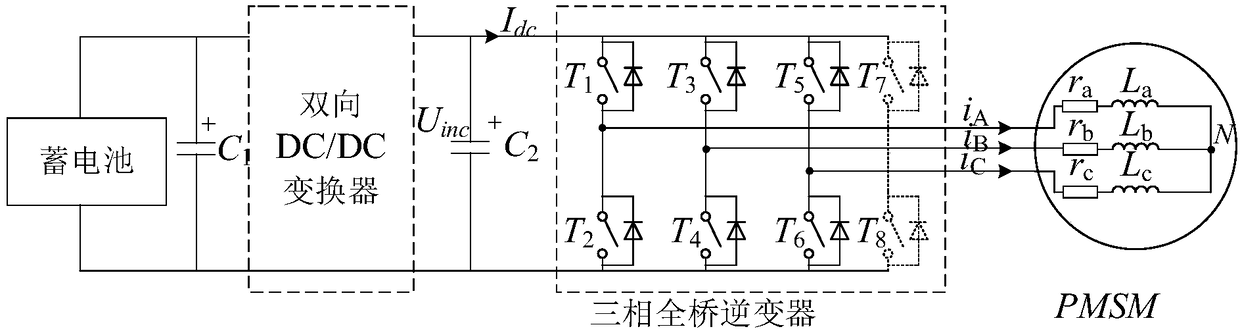

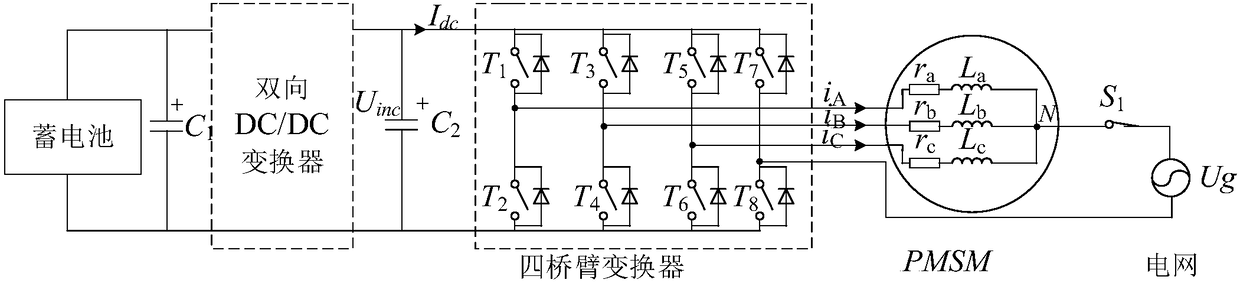

High-integration-degree motor driving and charger-and-discharger integrated topology

ActiveCN108123491AAchieving two-way flowGuaranteed stabilityBatteries circuit arrangementsSingle network parallel feeding arrangementsEngineeringError tolerance

The invention discloses a high-integration-degree motor driving and charger-and-discharger integrated topology, wherein the topology belongs to the field of power transmission technology. According tohigh-integration-degree motor driving and charger-and-discharger integrated topology, a front-stage bidirectional DC / DC converter and a back-stage four-leg bidirectional converter are used as the motor driving and charger-and-discharger integration topology; a four-leg bidirectional converter is used as a motor driving inverter and a charging-and-discharging converter which do not operate simultaneously; in realizing bidirectional energy flow of a storage battery and a power grid, a motor stator winding is used as a filtering inductor in power integration. According to the method, multiple functions which comprise a rectification function and a power integration inverting function in motor driving and charger-and-discharger technology can be realized through the integrated topology; the motor winding is used as the filtering inductor, thereby eliminating an additional filtering inductor, greatly saving use of a switch device and an energy storage element, improving system power density and effectively suppressing a power entering current harmonic wave; and furthermore a single-phase charging-and-discharging structure with three parallelly connected phases has certain error tolerance performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

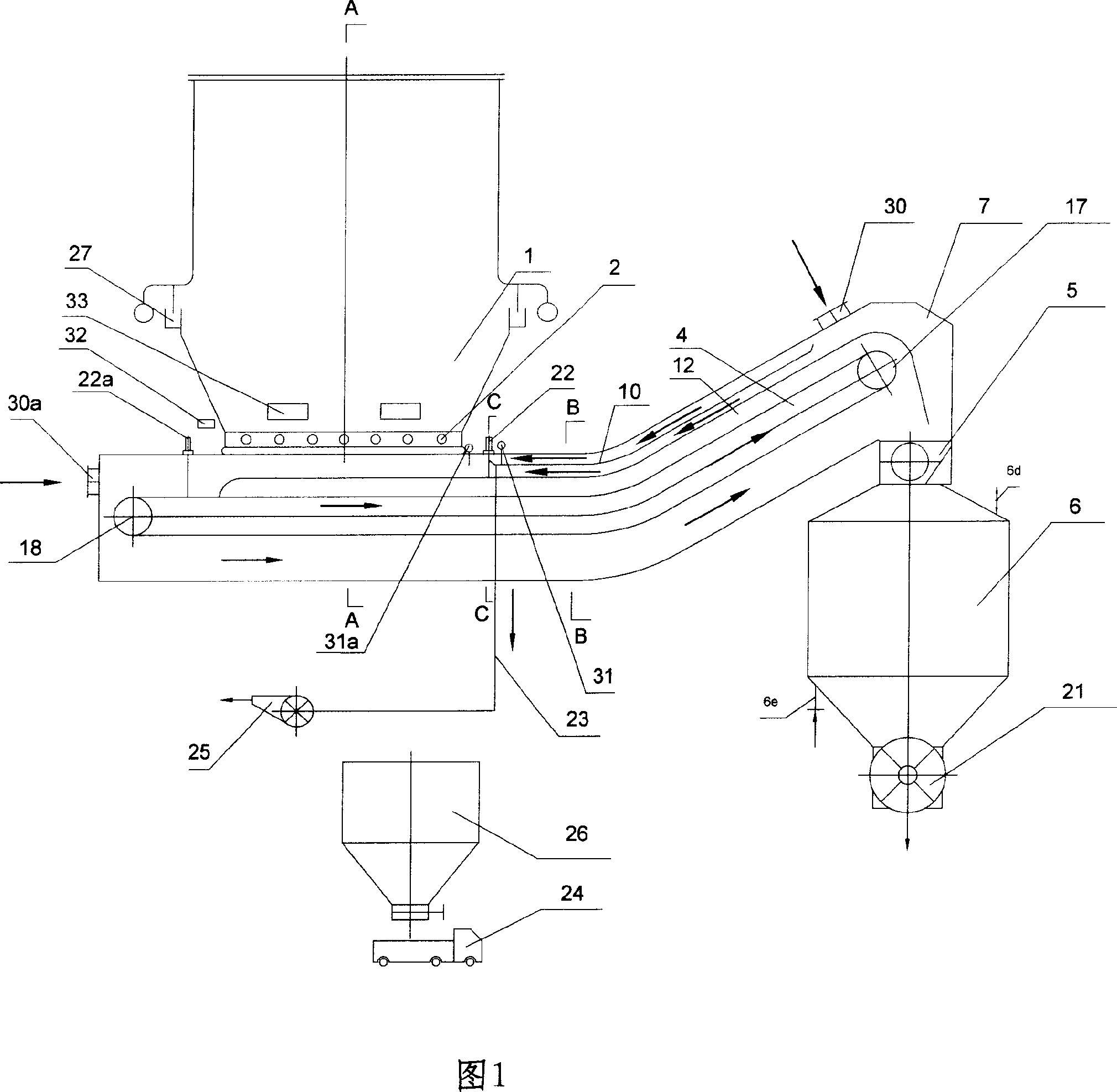

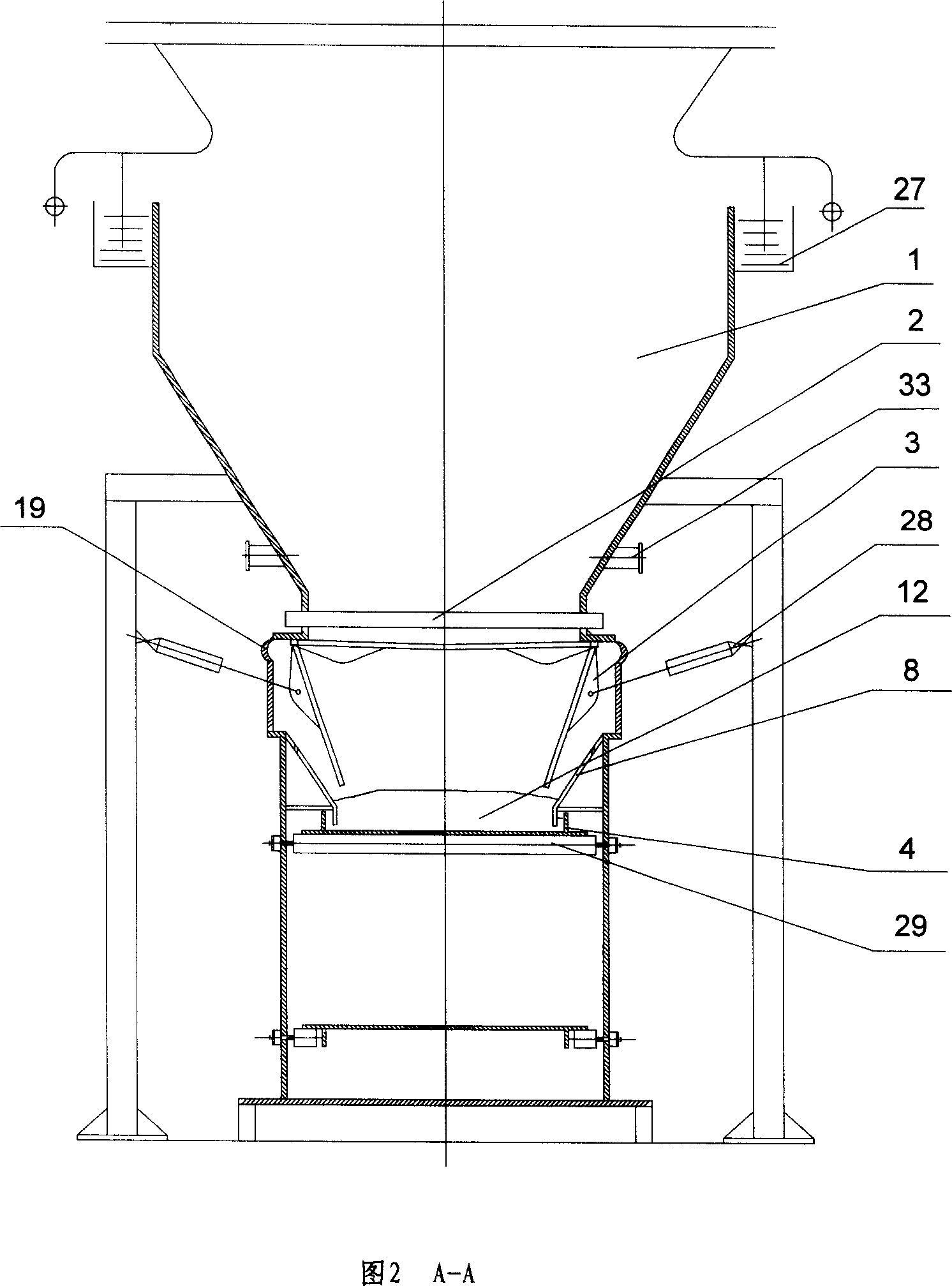

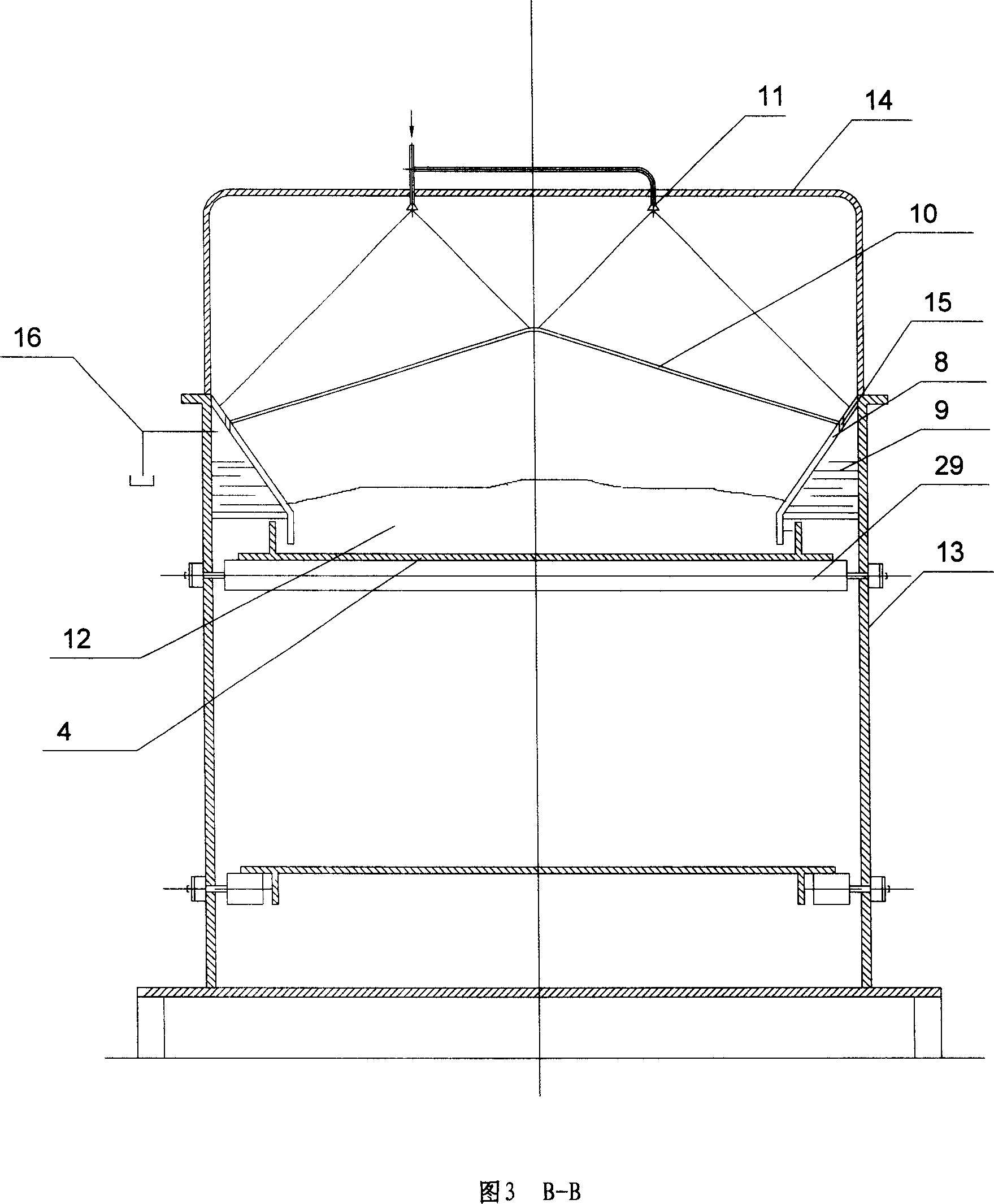

Dry slag-draining device of coal boiler

InactiveCN101008492AImprove cooling effectGuaranteed uptimeLighting and heating apparatusSlagEngineering

The invention discloses a coal boiler dry-type slag discharger, which comprises a seal box sealed and connected with the slag hopper of boiler. The seal box contains a high-temperature resistant transmission band; the descending part along the direction of transmission band between the seal box and the slag hopper is arranged with a wind inlet; the seal box is arranged with a wind valve for limiting the inlet cooling air into the slag hopper, while the wind valve is between the connection of seal box and slag hopper and the wind inlet; the seal box is also arranged with a wind outlet for outputting the hot air outside the seal box; along the direction of transmission band, and at the ascending part of the connection part between the seal box and the slag hopper, a baffle device is arranged for baffling the cooling air into the slag hopper. The invention can effectively improve the amount of cooling air to cool the slag and control the amount of cooling air at the bottom of boiler to operate the boiler normally.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

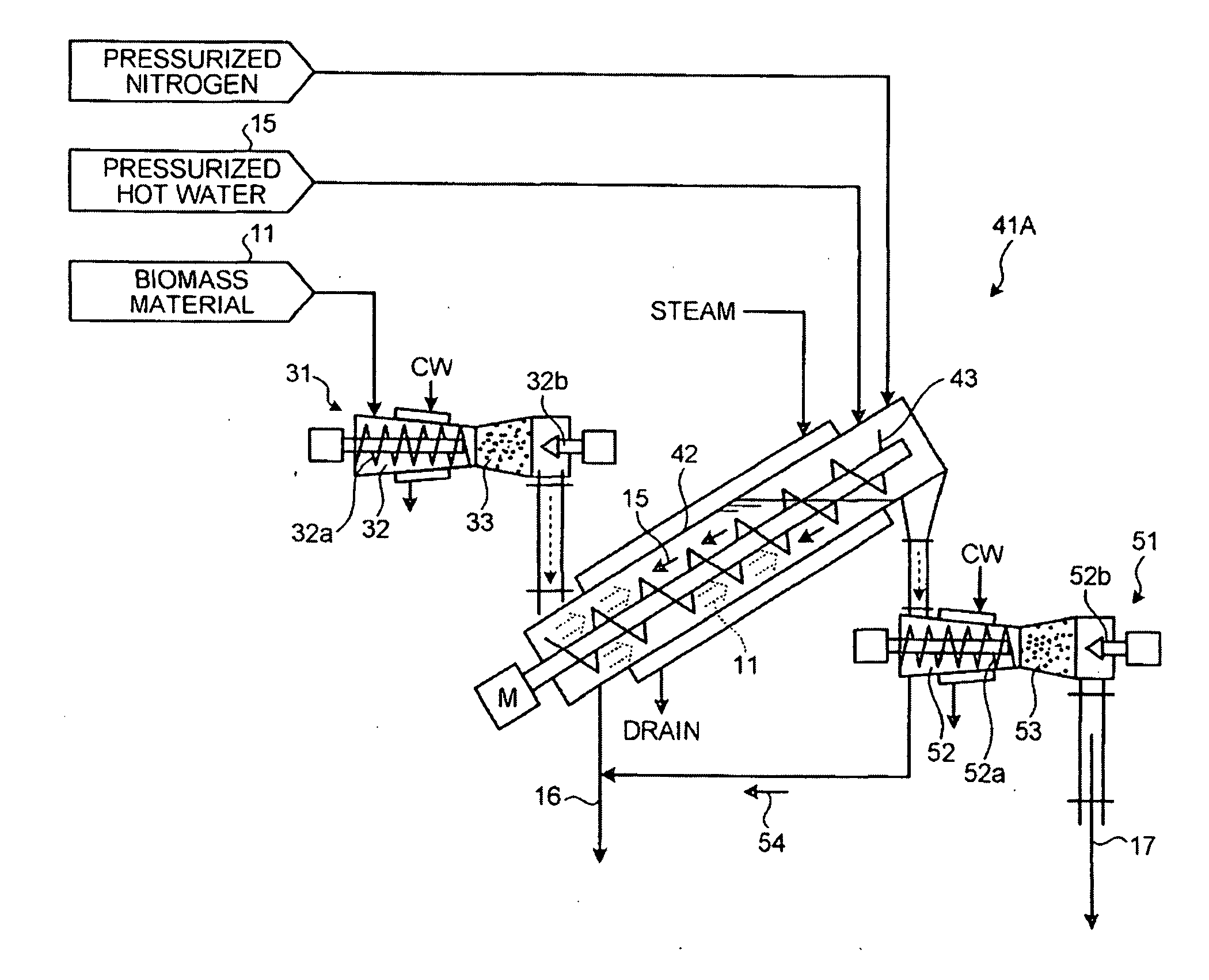

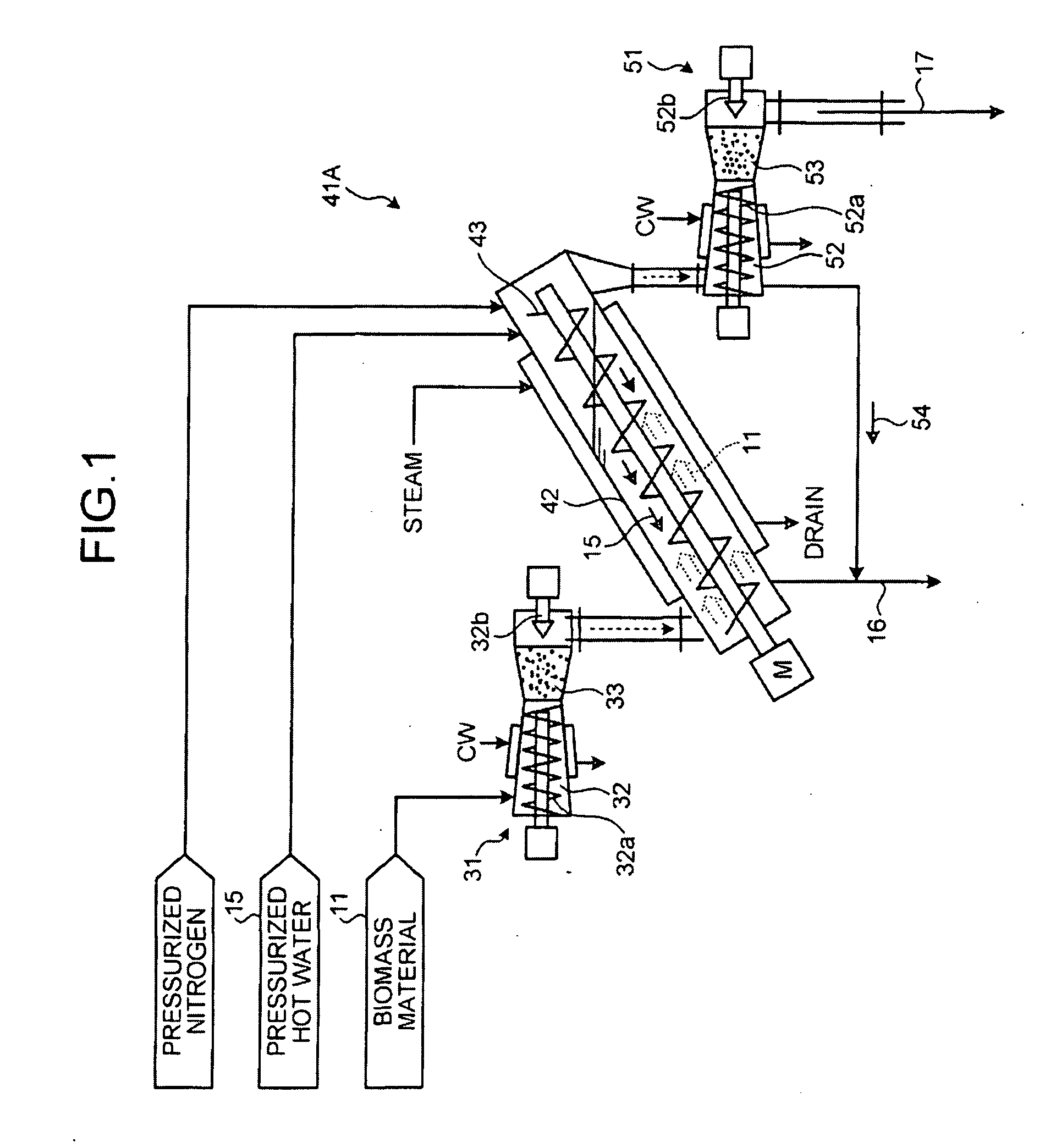

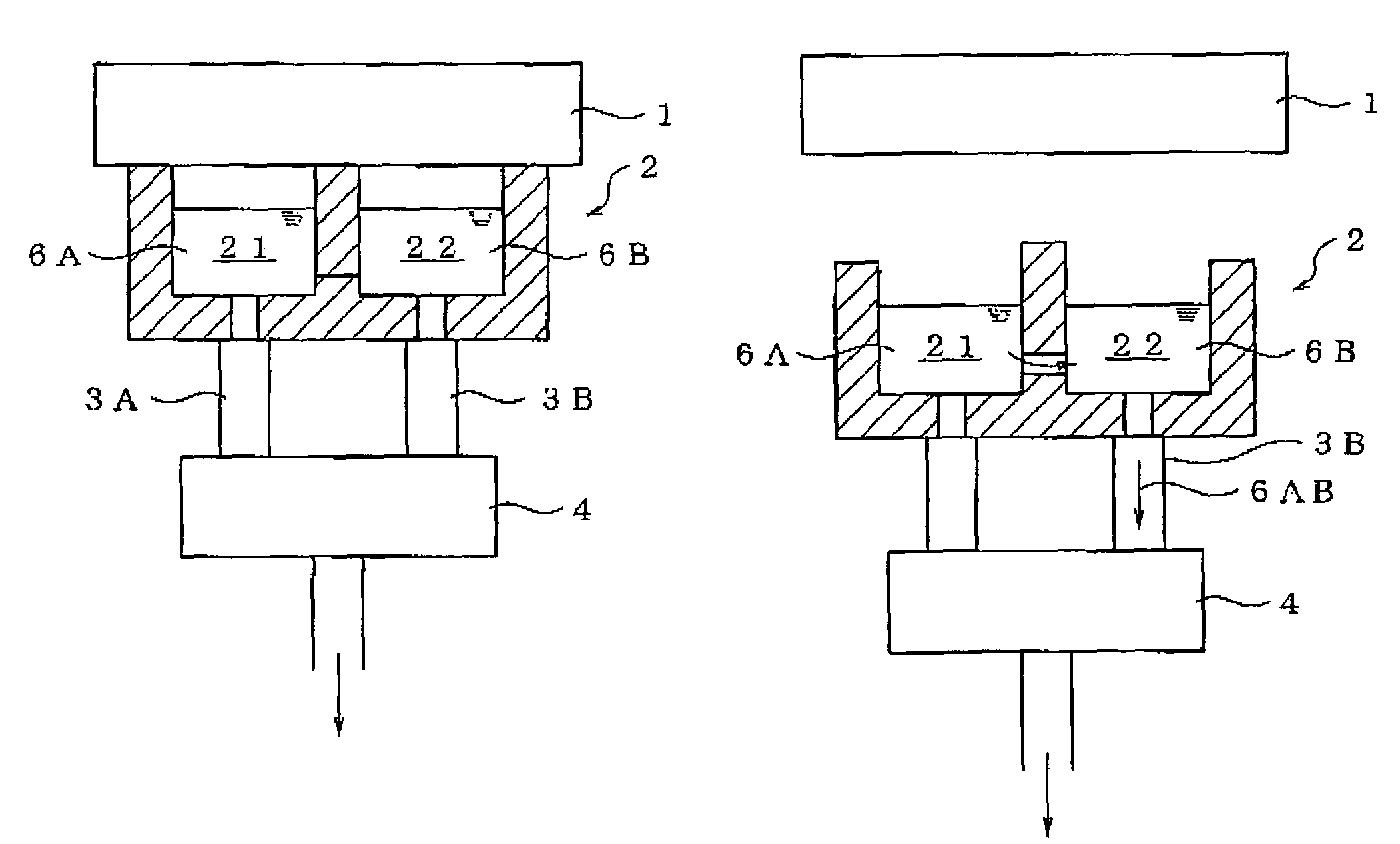

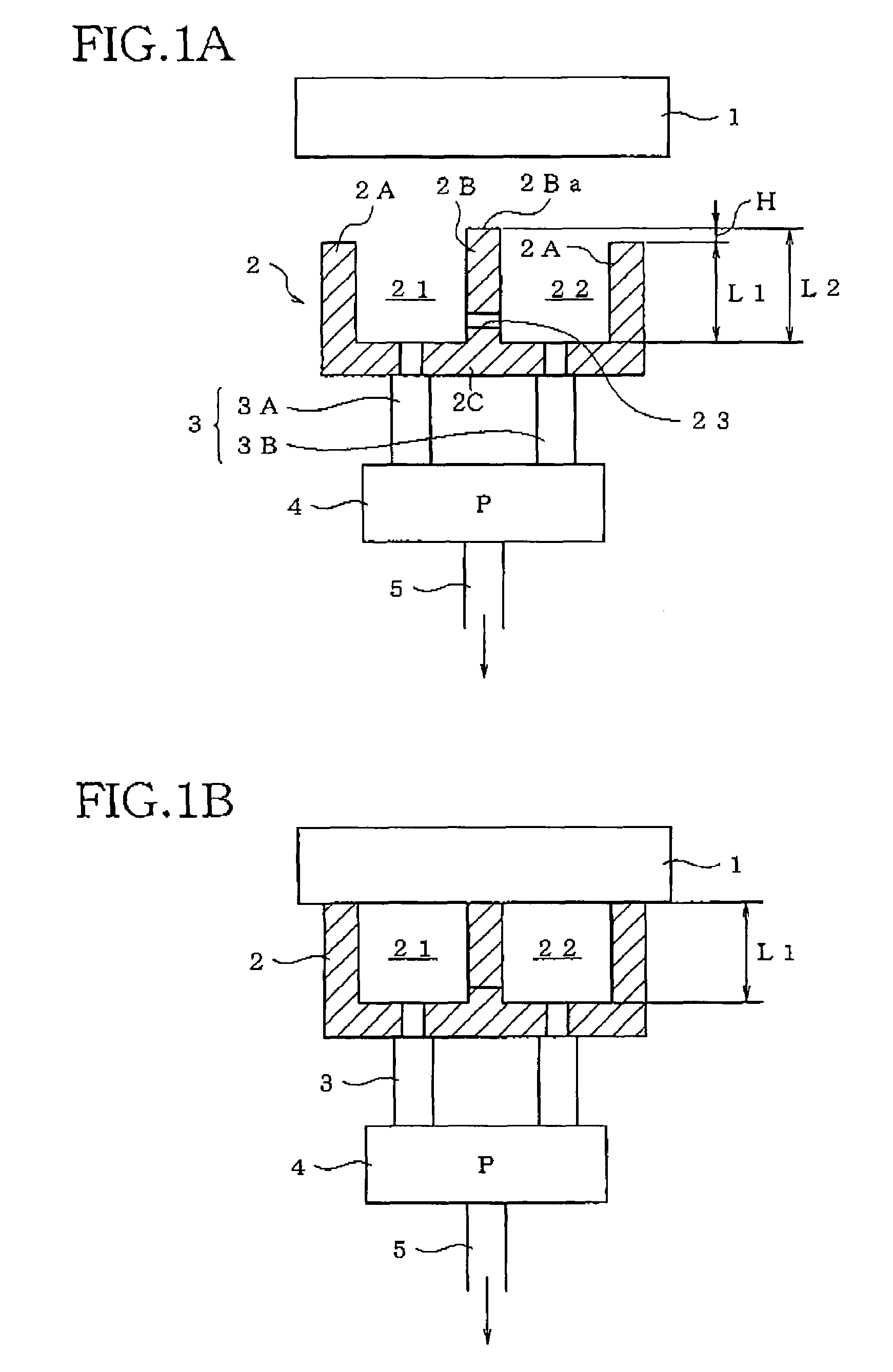

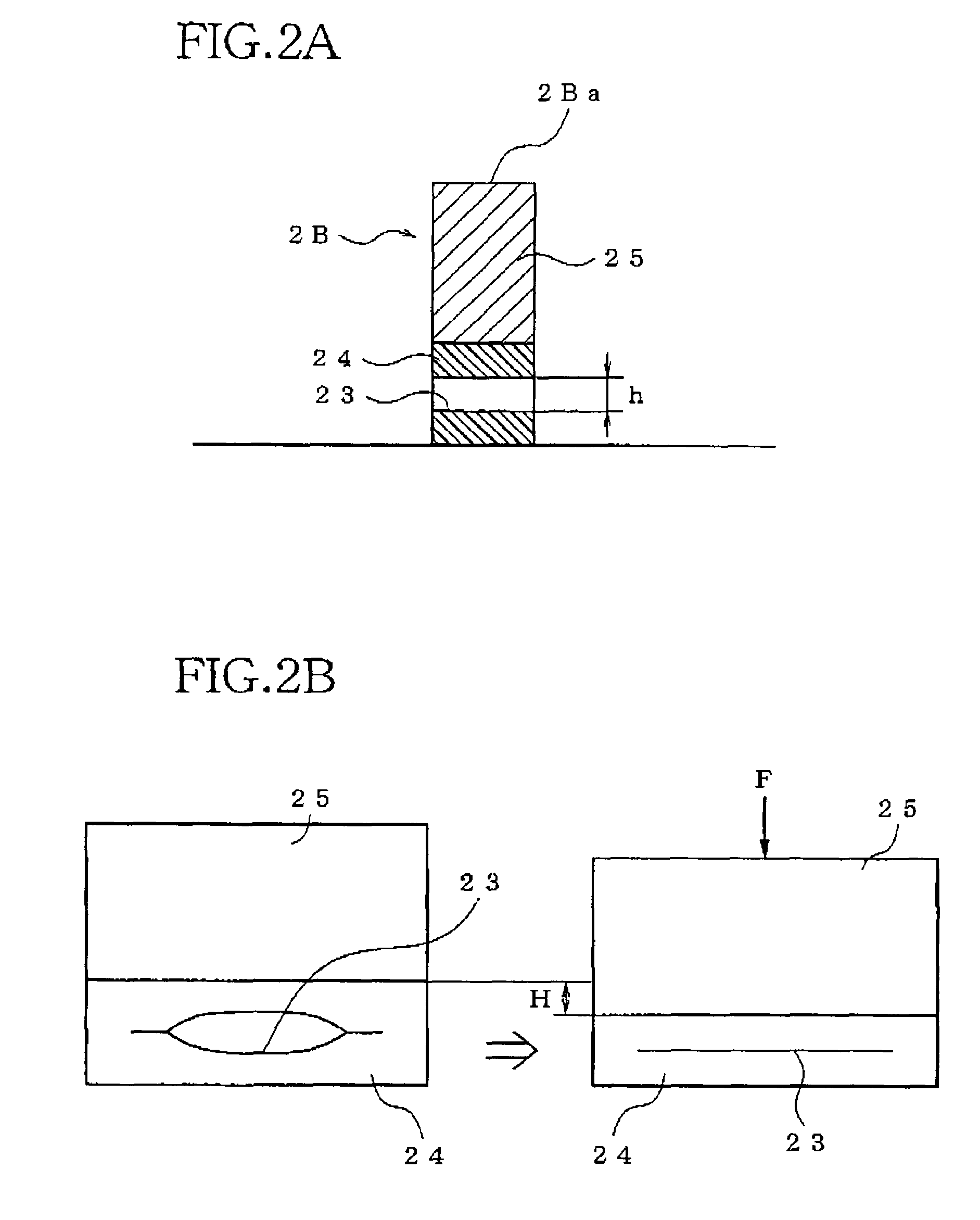

Biomass hydrothermal decomposition apparatus and method

ActiveUS20100285574A1Efficiently saccharifyingEfficient productionBioreactor/fermenter combinationsPressurized chemical processDecompositionHemicellulose

A biomass hydrothermal decomposition apparatus includes, a biomass feeder (31) that feeds biomass material (11) under normal pressure to under increased pressure, a hydrothermal decomposition device (41A) that allows the fed biomass material (11) to be gradually moved inside a gradient device main body (42) from a lower end thereof with a conveyor screw (43), and also allows hot compressed water (15) to be fed from an other end of a feed section (31) for the biomass material into the main body (42), so as to cause the biomass material (11) and the hot compressed water (15) to countercurrently contact with each other and undergo hydrothermal decomposition, and that transfers a lignin component and a hemicellulose component into the hot compressed water, so as to separate the lignin component and the hemicellulose component from the biomass material (11); and a biomass discharger (51) that discharges, from the upper end of the device main body (42), a biomass solid residue (17) under increased pressure to an under normal pressure.

Owner:MITSUBISHI HITACHI POWER SYSTEMS ENVIRONMENTAL SOLUTIONS LTD

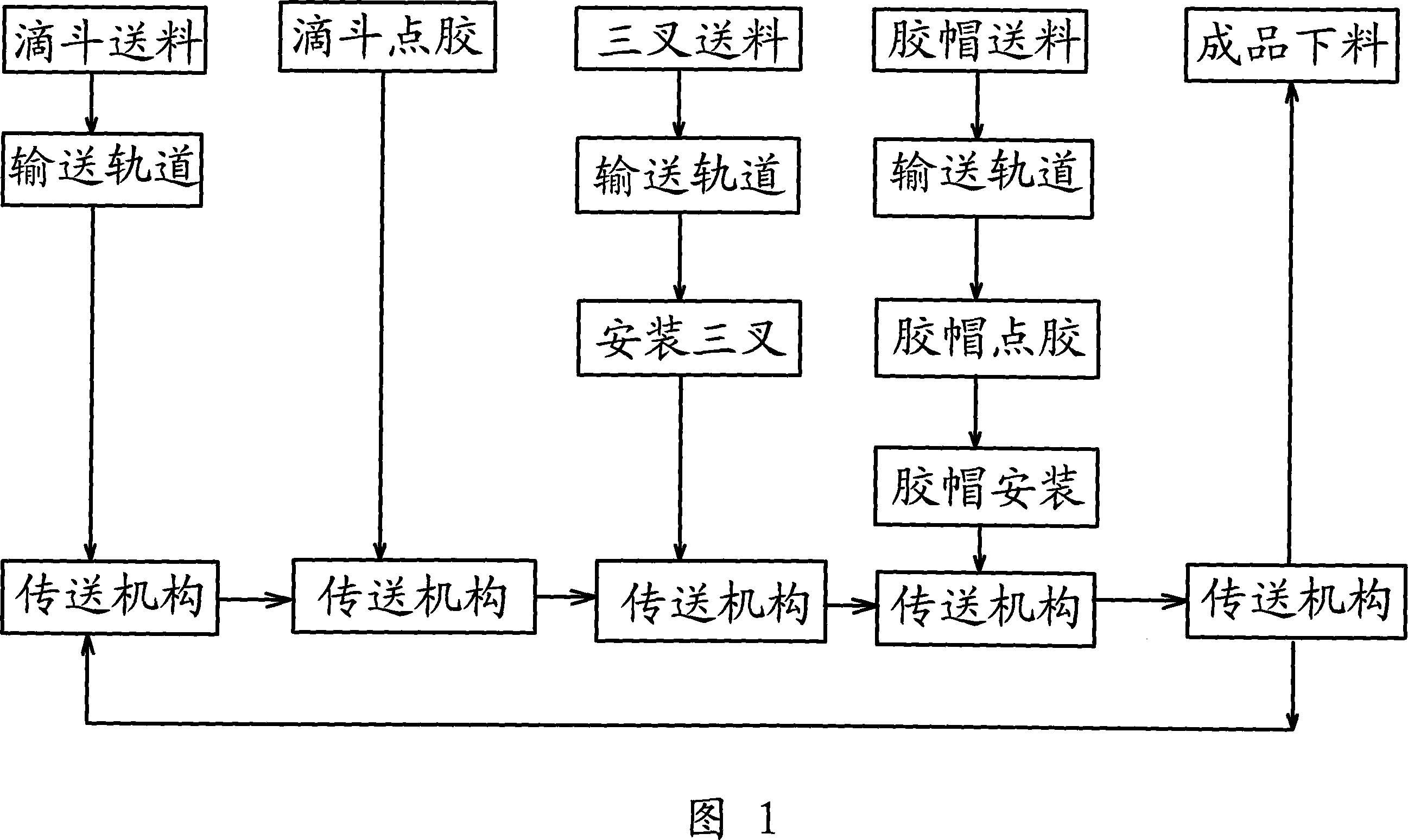

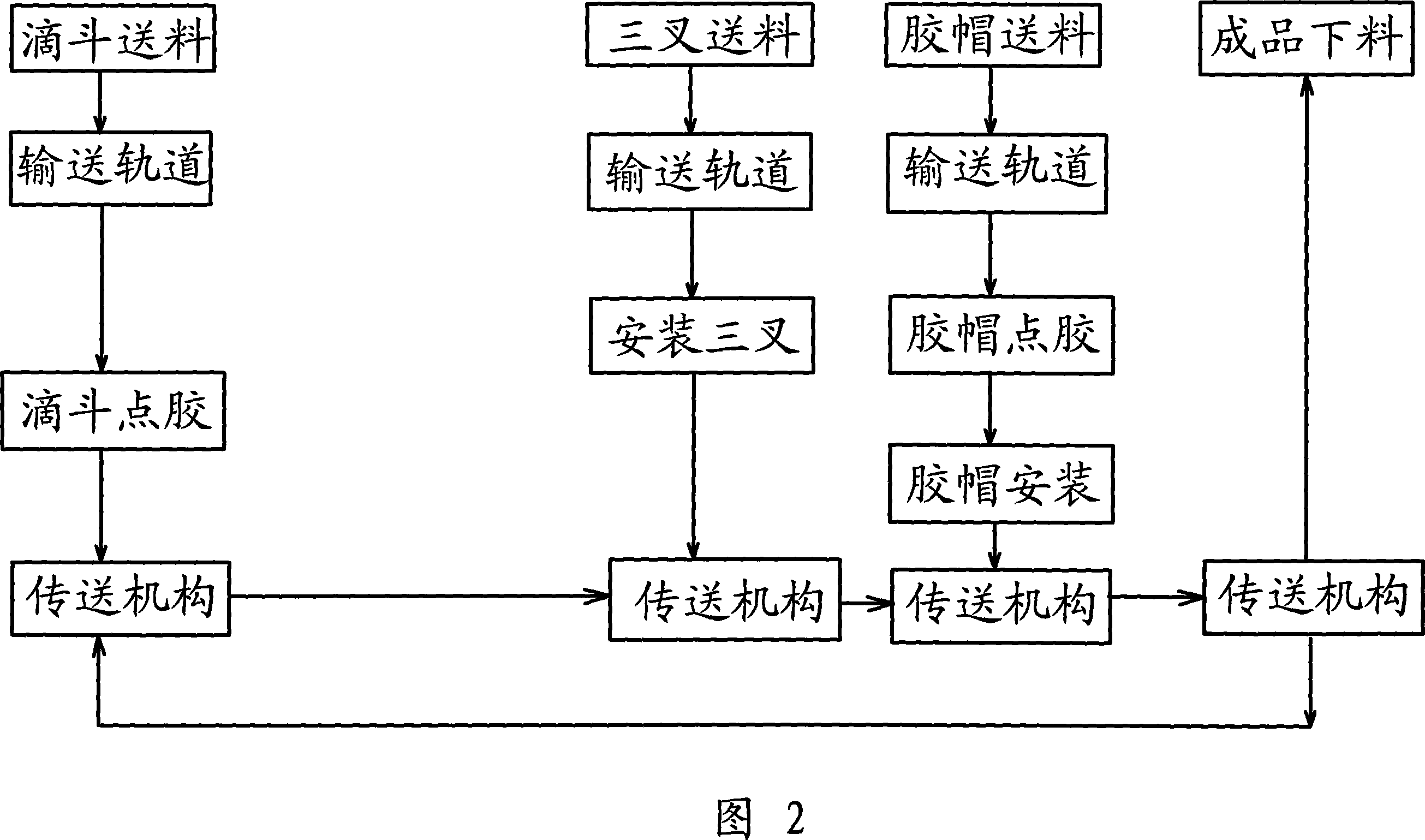

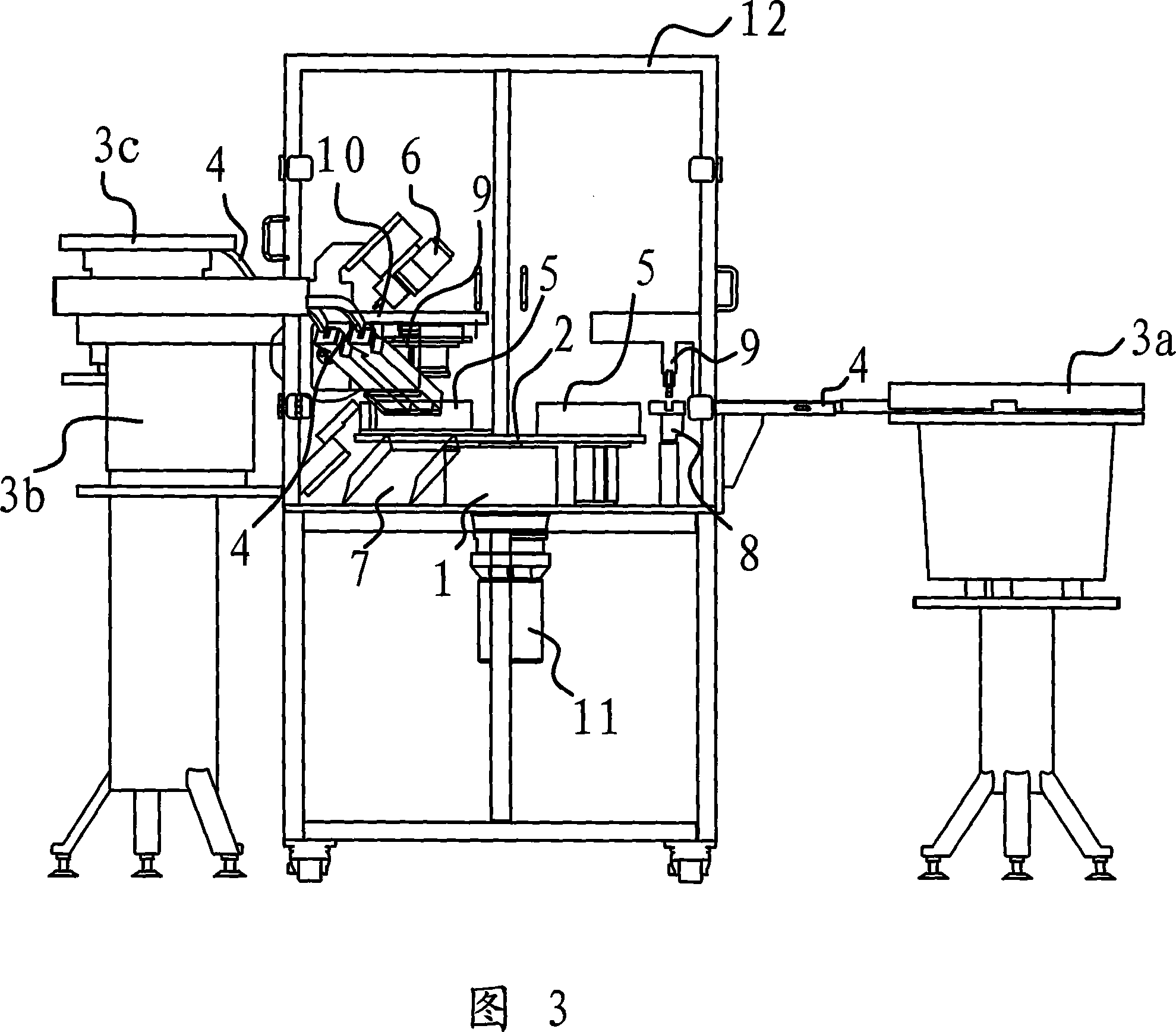

Process and apparatus for assembling infusion unit titrimeter assembly

A technology for automatically assembling the dripping hopper module of perfusion device includes such steps as putting the dripping hoppers, three-way tubes and rubber caps in feeders, arranging them on respective conveying tracks, conveying the dripping hopper in transfer mechanism, fixing, transferring to next workstation, coating adhesive, inserting a three-way tube in it, continuous transferring, installing rubber cap, and releasing the module. Its apparatus is composed of rotary axle, rotary table fixed to said rotary axle, feeders, adhesive applying mechanism and discharger.

Owner:MAIDER MEDICAL IND EQUIP

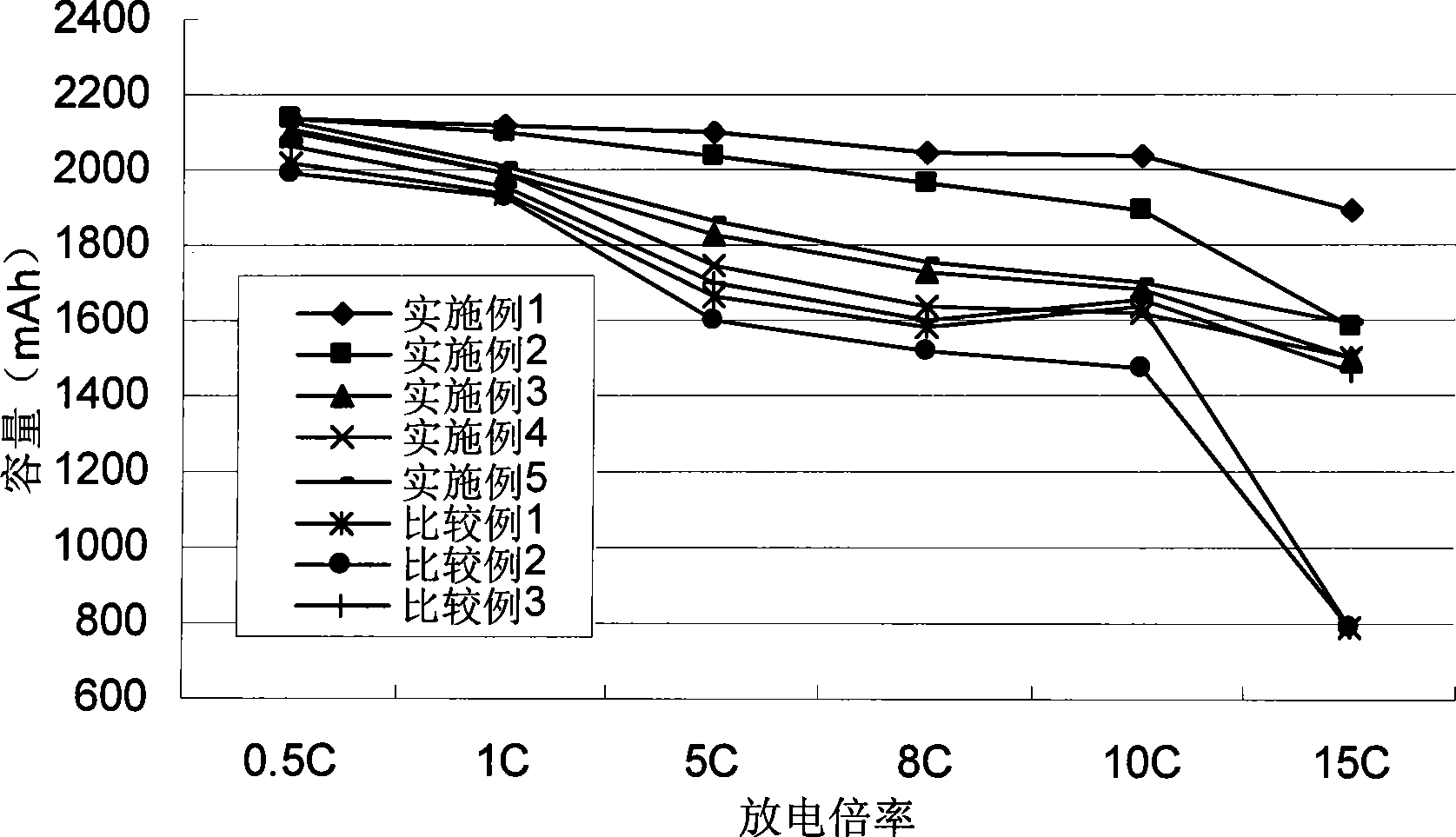

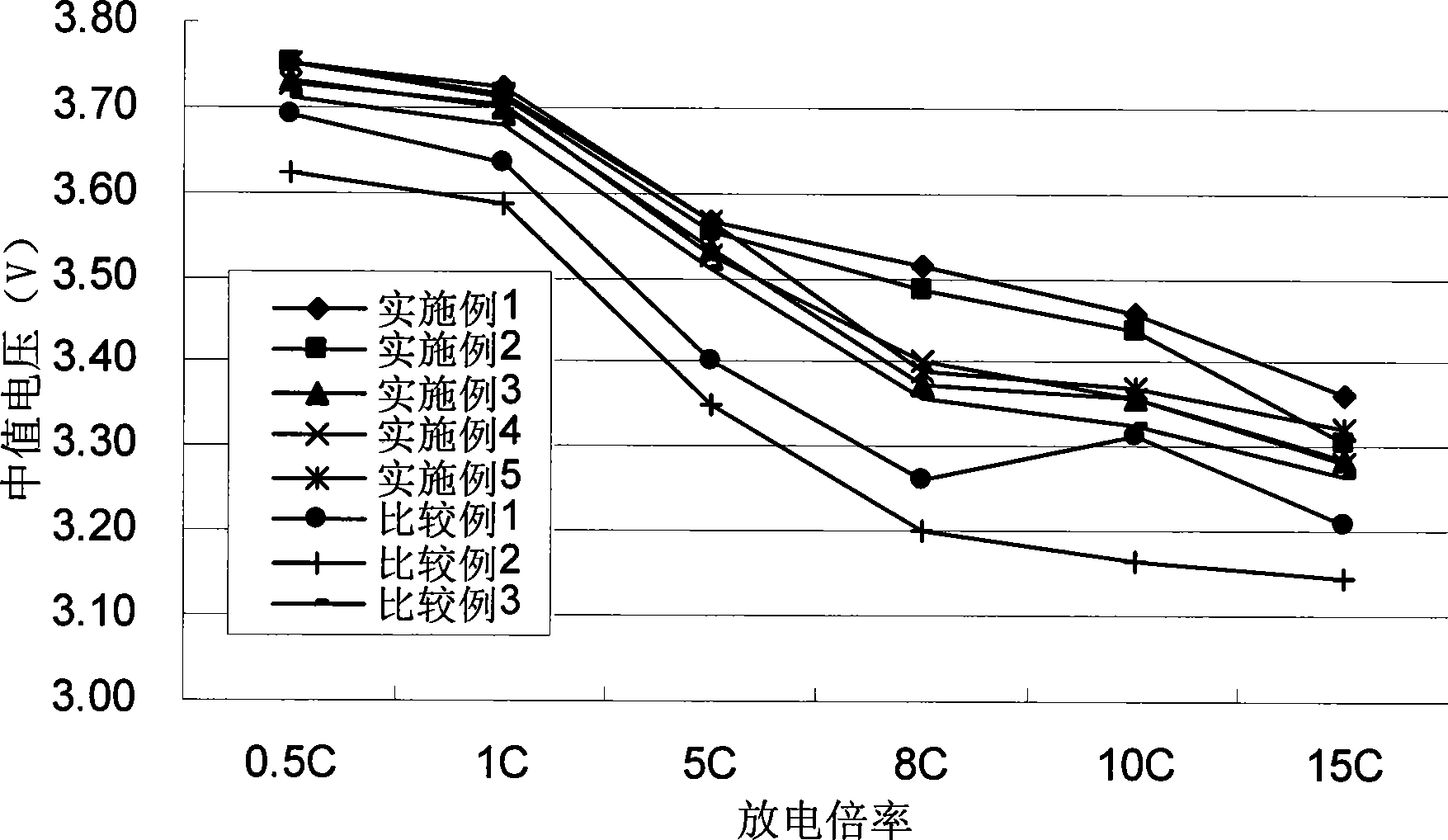

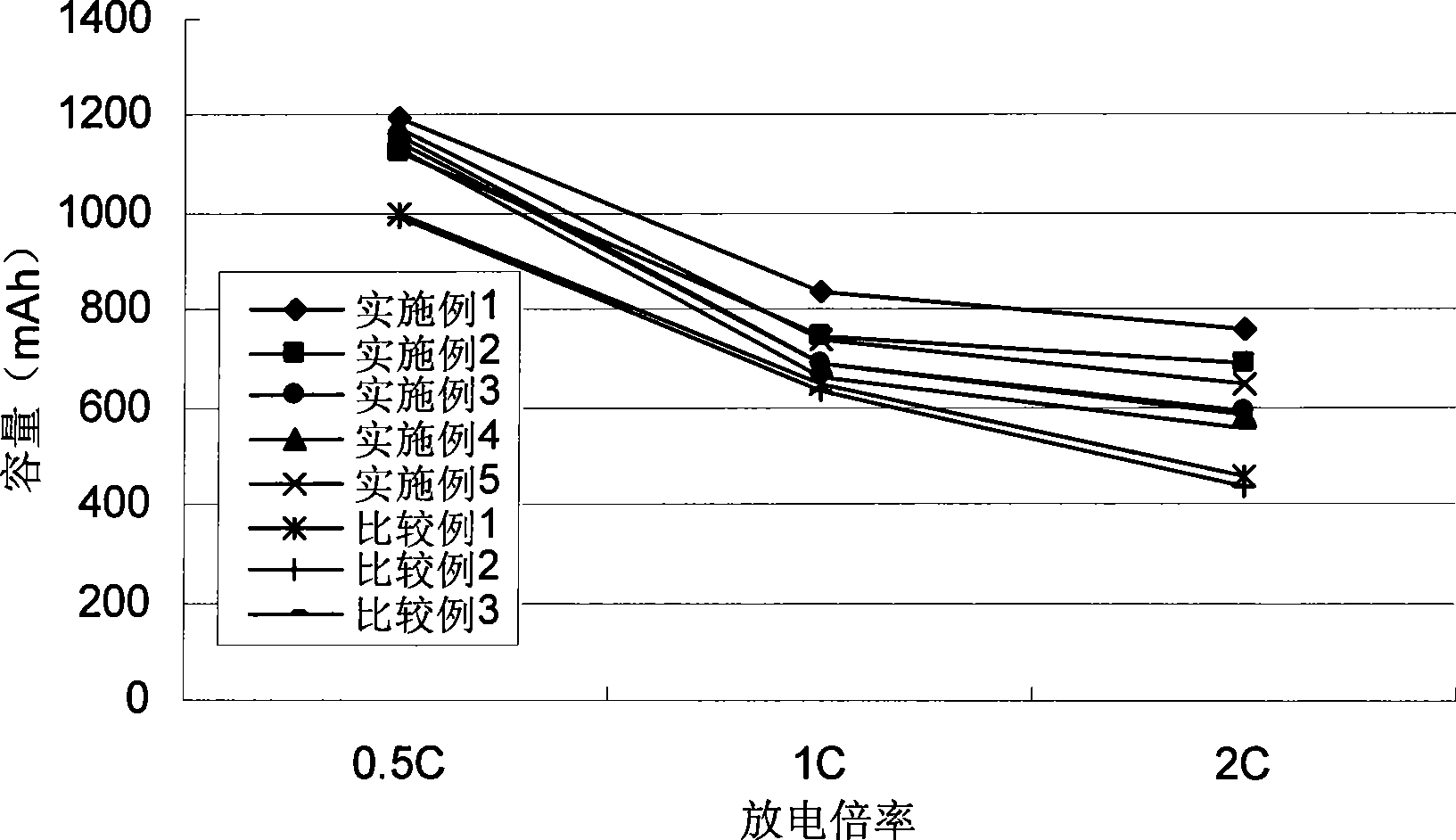

Diaphragm and preparation method thereof as well as lithium ion battery

InactiveCN101471432AMeet the requirements of high rate batteryGood discharge performance at low temperatureSecondary cellsCell component detailsPore distributionHigh rate

A diaphragm is selected from a composite membrane containing polyethylene terephthalate membrane as the base material. The composite membrane contains at least one organic polymer membrane consisting of polymer film-forming materials with a thermal resistant temperature of 170 DEG C to 500 DEG C and heat shrinkage of 0% to 5%. Preferably, a plasticizer is added during solution preparation to achieve more uniform pore distribution so as to obtain the composite membrane with excellent performance. The diaphragm has high temperature resistance and high safety when used for battery diaphragm. In addition, the diaphragm has good solution adsorption performance, so that the diaphragm can adsorb the electrolyte to improve the circle performance of the battery. The invention also provides the diaphragm preparation method, which is simple and convenient. Compared with the conventional battery and the battery using PET composite diaphragm with inorganic coating, the battery using the diaphragm has higher capacity, better high-rate discharge characteristics and low-temperature discharger performance, no flame and liquid leakage during high-temperature test, and excellent high-temperature safety performance.

Owner:BYD CO LTD

Inkjet printer including discharger with cap

An inkjet printer includes: (a) a head unit having ejecting portions and operable to eject a plurality of kinds of inks through the ejecting portions; (b) a discharger for discharging the inks through the ejecting portions; and (c) a communication controller. The discharger includes: (b-1) a cap selectively placeable in a contact state in which the cap is held in contact with the head unit, and in a separate state in which the cap is separated from the head unit; (b-2) a suction pump; and (b-3) a connector connecting the cap and the suction pump. The cap defines therein ink storage chambers in which the respective kinds of inks are to be stored. The connector includes passage definers defining respective discharge passages each communicating the corresponding ink storage chamber and a chamber of the suction pump. The communication controller allows communication between at least two of the ink storage chambers when the cap is placed in the separate state, and inhibits the communication between the at least two ink storage chambers when the cap is placed in the contact state.

Owner:BROTHER KOGYO KK

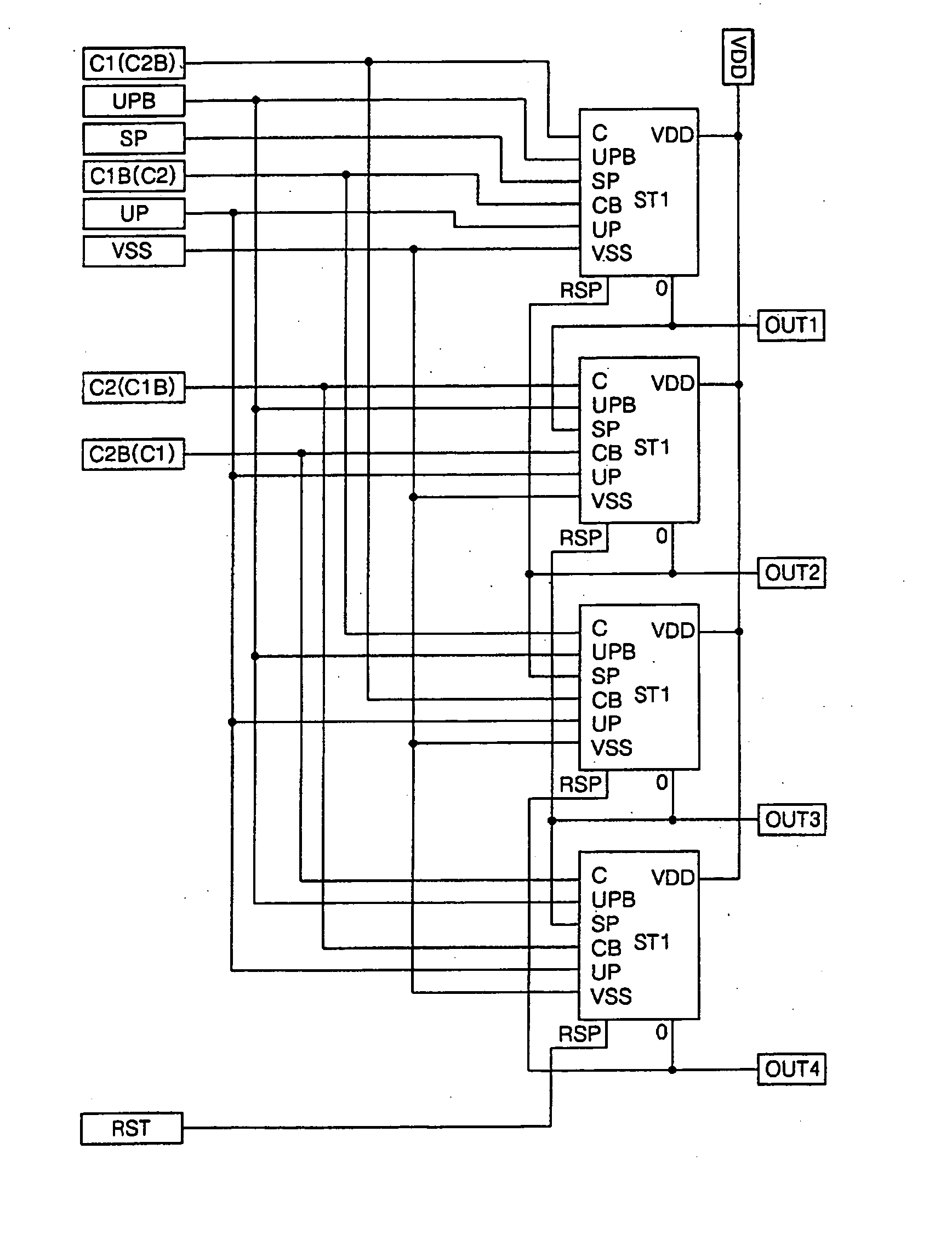

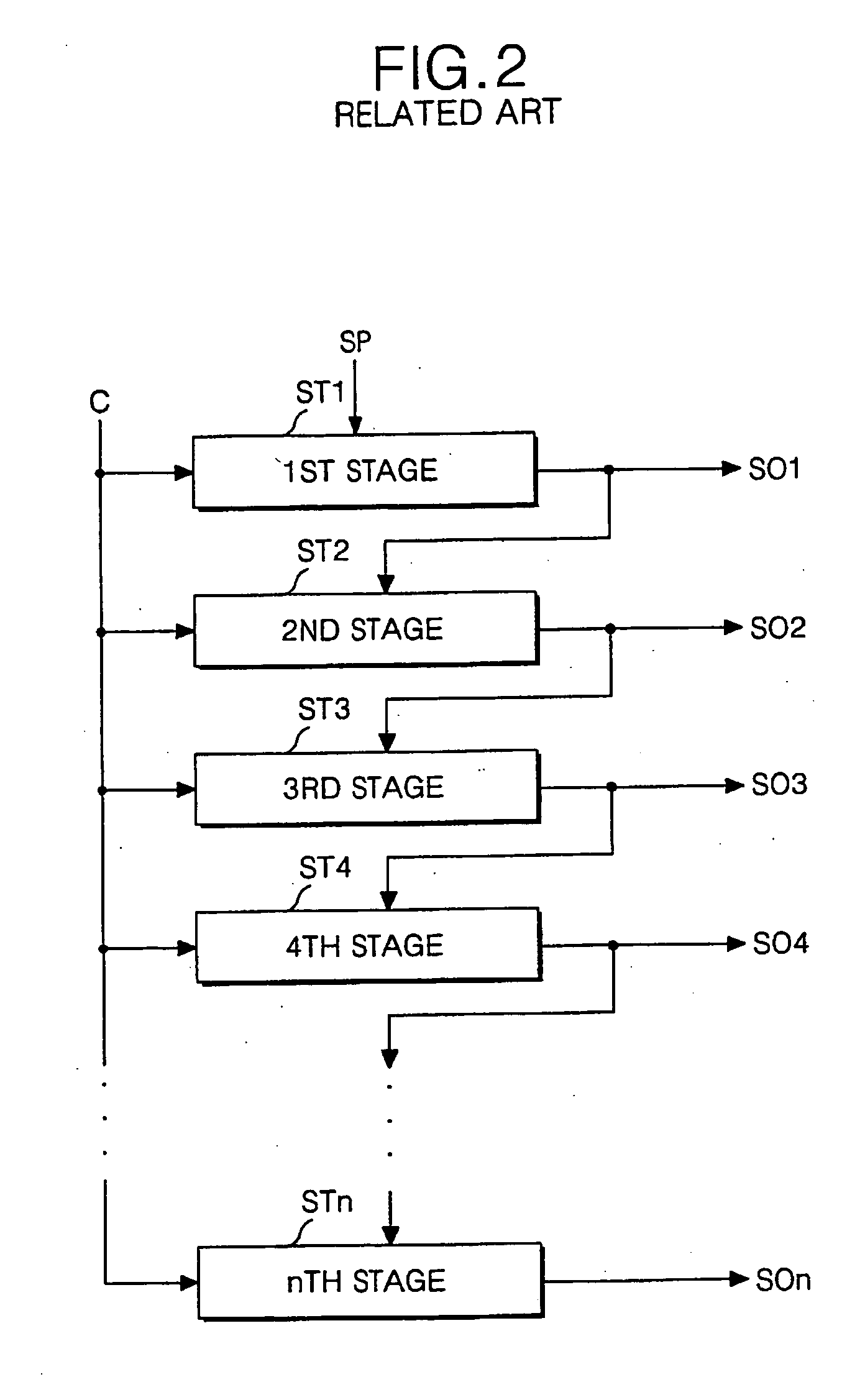

Shift register

InactiveUS20050018807A1Simple configurationImprove responseStatic indicating devicesDigital storageShift registerControl signal

A shift register having a simple configuration and improved response and power consumption is disclosed. In the shift register, a plurality of stages are connected to each other in cascade and scanned in a bilateral direction. In the stages, a charger charges a first supply voltage into a first node in response to a clock signal. A discharger discharges the first node in response to a first start pulse or a second start pulse. A scan direction controller is connected between the charger and the discharger to discharge the first node into a different path in response to a scan direction control signal. An output part outputs any one of said first and second supply voltages as an output signal in response to a voltage at the first node. A latch part latches said output signal using said output signal and a clock signal inverted from said clock signal to feed back the latched output signal to the first node.

Owner:LG DISPLAY CO LTD

Rejection type intelligent capsule inspection machine

ActiveCN102680491AImprove efficiencySimple mechanical structureMaterial analysis by optical meansSortingControl systemEngineering

The invention relates to a machine, in particular to an electromechanical rejection type intelligent capsule inspection machine. The rejection type intelligent capsule inspection machine comprises a feeding mechanism, an electronic detection system, a conveying mechanism, a rejector, a discharger, a blowing and suction mechanism and a master control system, the master control system is electrically connected with the feeding mechanism, the electronic detection system, the conveying mechanism, the rejector, the discharger and the blowing and suction mechanism, the feeding mechanism is arranged at the initial end of the conveying mechanism, and the discharger is arranged at the tail end of the conveying mechanism. A feeding outlet, a sidewall, a blowing nozzle and a sensing probe of the rejection type intelligent capsule inspection machine can cooperate to control the discharge speed in order to prevent an excessive quantity of materials from being stored in a storage box to affect feeding; a plurality of cameras jointly work to shoot the different parts of each capsule, thus preventing the phenomenon of missing and increasing the accuracy of detection; an air nozzle of the rejector can blow rejects out of a conveyer belt, the structure is simple, the speed is high, and the rejector is convenient and cannot damage capsules.

Owner:XINCHANG HANGDA MACHINERY MFG

Ice supply system of refrigerator

ActiveUS7017363B2Simple structureEasy to installLighting and heating apparatusIce productionMarine engineeringCrusher

An ice supply system of a refrigerator is provided. The ice supply system of the refrigerator includes an icemaker, a container, a crusher and an ice discharger. The icemaker produces the ice by using cool air of the freezer and drops the ice to a lower part of thereof. The container is provided at a lower part of the icemaker. The container is insertable into and detachable from the door of the refrigerator. The container includes an open top, a first opening at a side thereof, a transfer device rotating and transferring the ice of the first opening, and an outlet for discharging the ice. The crusher crushes the ice transferred by the transfer device and the ice discharger is provided for discharging the ice to an ice chute at the door by controlling a size of an opening of the outlet.

Owner:LG ELECTRONICS INC

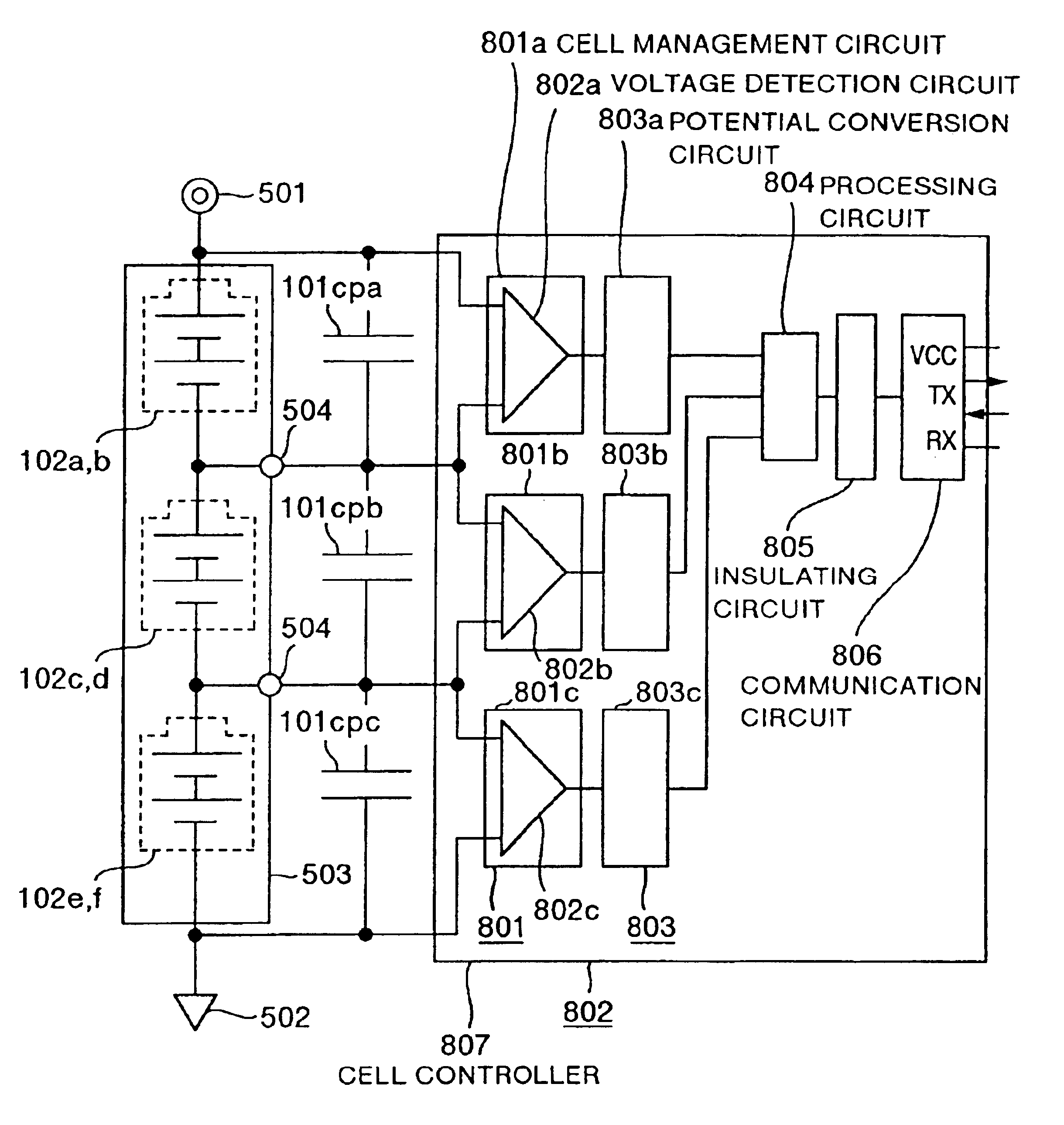

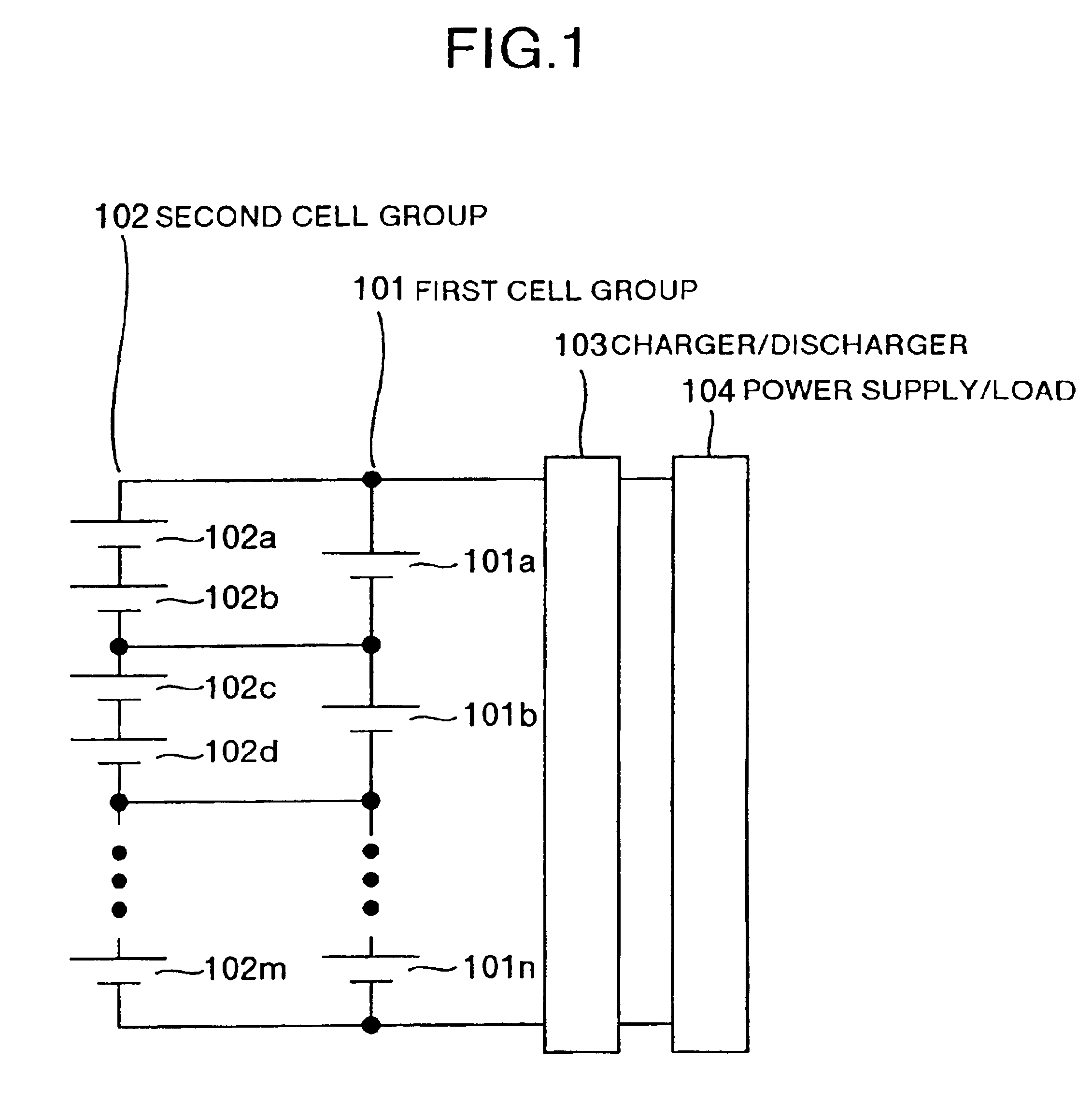

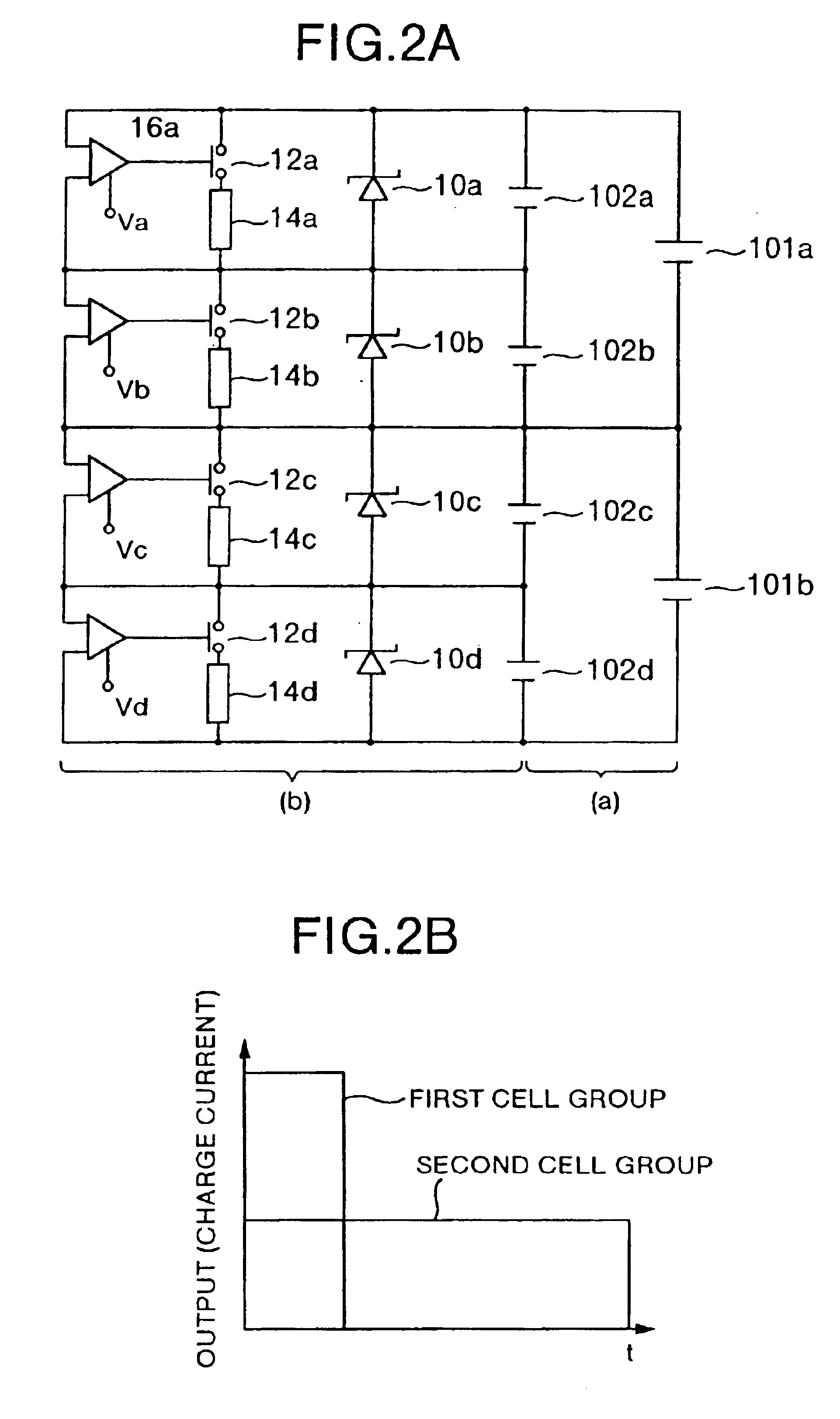

Power supply unit, distributed power supply system and electric vehicle loaded therewith

InactiveUS6917181B2Prevent overcurrentReduce in quantityFuel and primary cellsCharge equalisation circuitElectrolysisElectrical battery

A power supply unit with improved charge / discharge operation for use in distributed power supply system or electric vehicles. The power supply unit includes a storage battery comprising a plurality of circuits connected in series. Each of the plurality of circuits includes a first cell group and a second cell group connected in parallel. The first cell group includes lithium secondary cells or electrical double layer capacitors. The second cell group utilizes an electrolyzable electrolytic solution, or is capable of generating recombinable gas. The second cell group may include lead cells, nickel hydrogen cells, nickel cadmium cells and / or fuel cells. A charger / discharger is provided for controlling charge / discharge of the storage battery adapted to charge the storage battery up to a voltage at which the electrolytic solution of the second cell group is electrolyzed, or to a voltage at which the generated gas is recombined.

Owner:HITACHI LTD

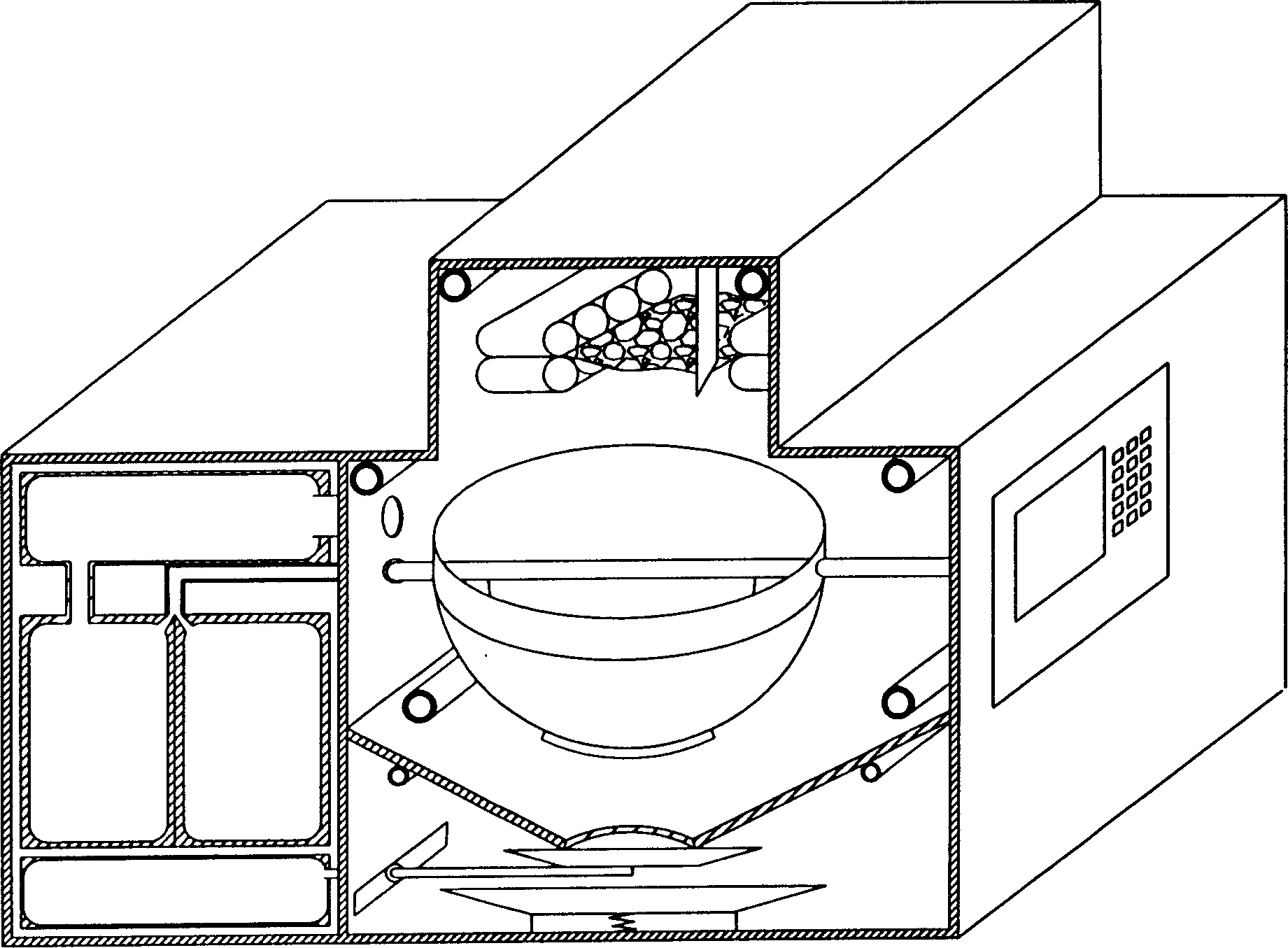

Automatic cooker

InactiveCN1552265ARealize industrializationAchieve standardizationCooking vesselsProcess engineeringCooking process

An automatic cooking machine is composed of a casing able to be enclosed, a controller for controlling cooking process according to chosen cooking program, a feeder for feeding the raw materials, a cooking unit for performing said cooking process, a dish discharger, and a cleaning unit for exhausting oil soot and cleaning all units.

Owner:罗毅

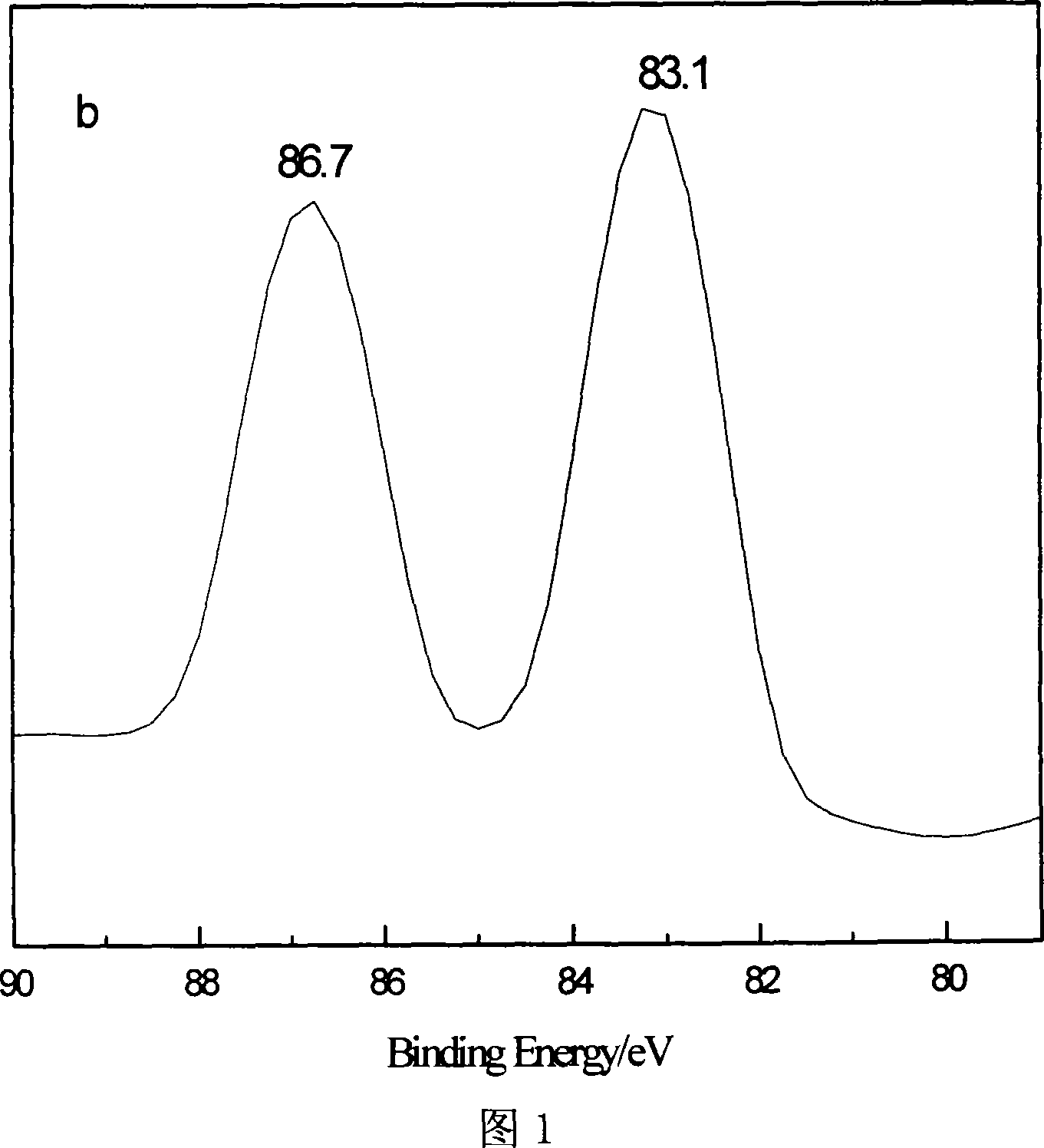

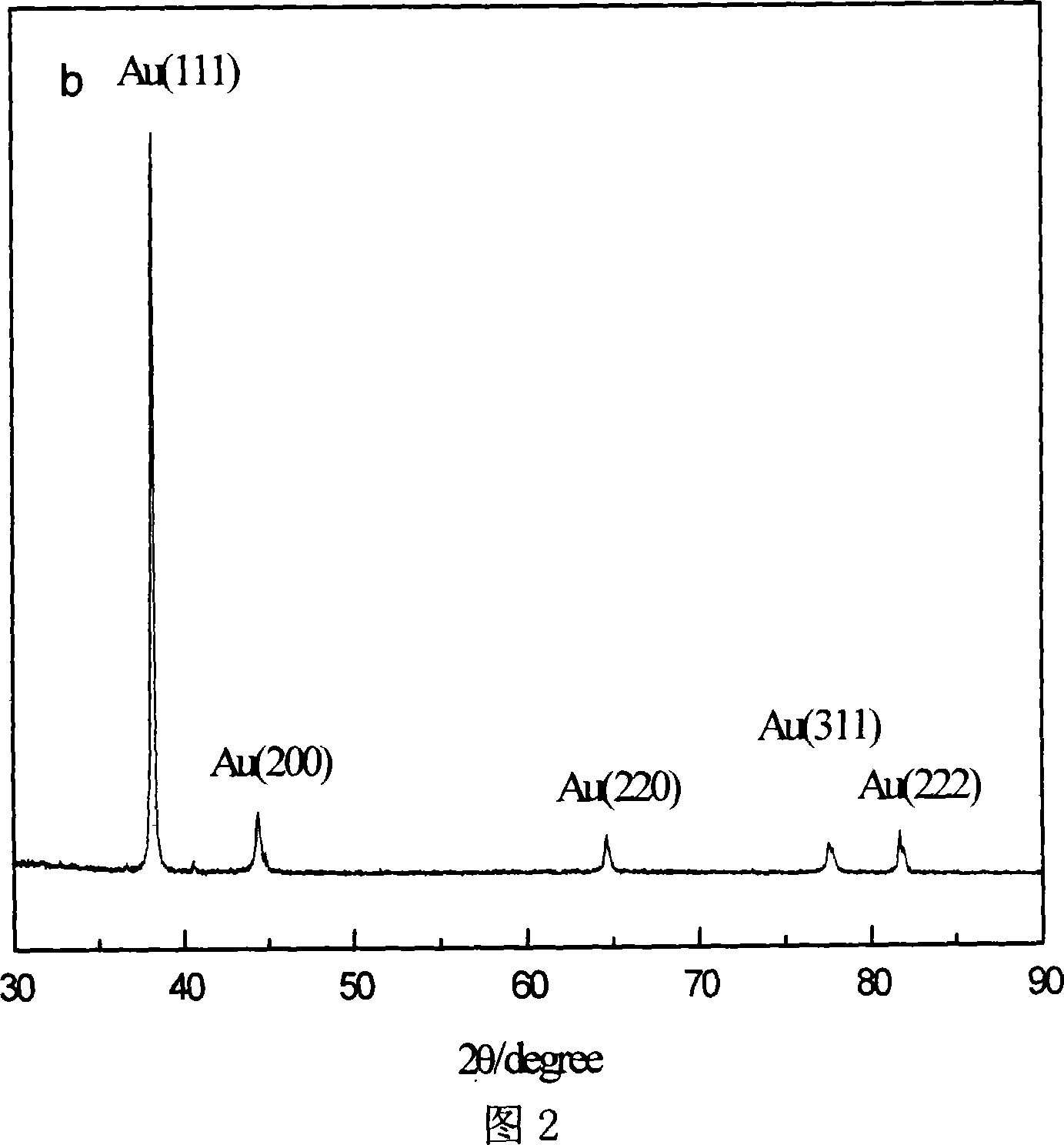

Method for producing nanometer metal by plasma deoxidization in low termprature

The present invention relates to material technology, and is low temperature plasma reduction process for preparing nanometer metal. The production process includes: filling metal salt into vacuum chamber of plasma discharger, vacuumizing the vacuum chamber, introducing plasma discharge gas to pressure of 30-200 Pa, and applying DC or AC voltage of 200-5,000 V with a high voltage power source to discharge the gas and to form plasma reducing the metal salt for 5-120min, so as to prepare nanometer metal particle. The production process has simple equipment, easy operation, low power consumption, great metal treating amount and environment friendship; and the prepared nanometer metal particle has high purity, small size, narrow size distribution, high dispersivity, excellent performance and unique compounding performance with other material, and may find wide application foreground in molecular device, chemical / biological sensor and other fields.

Owner:TIANJIN UNIV

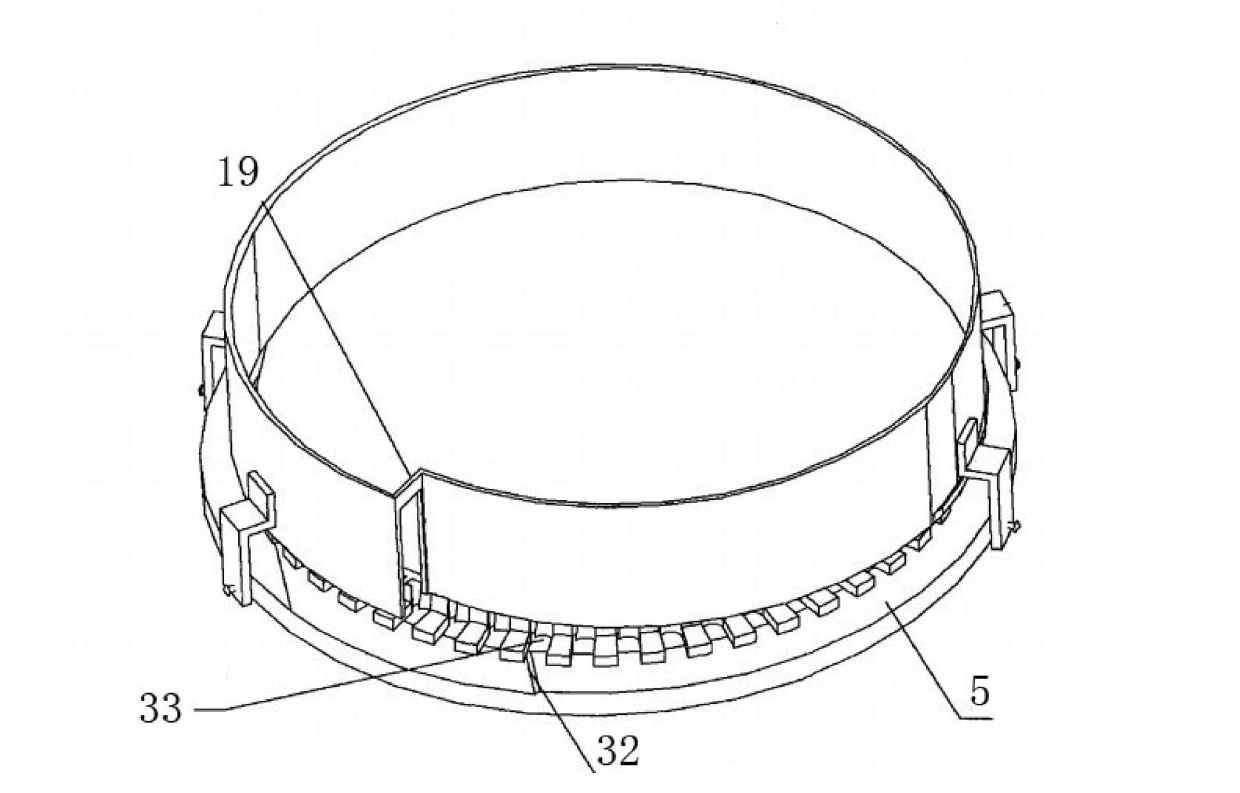

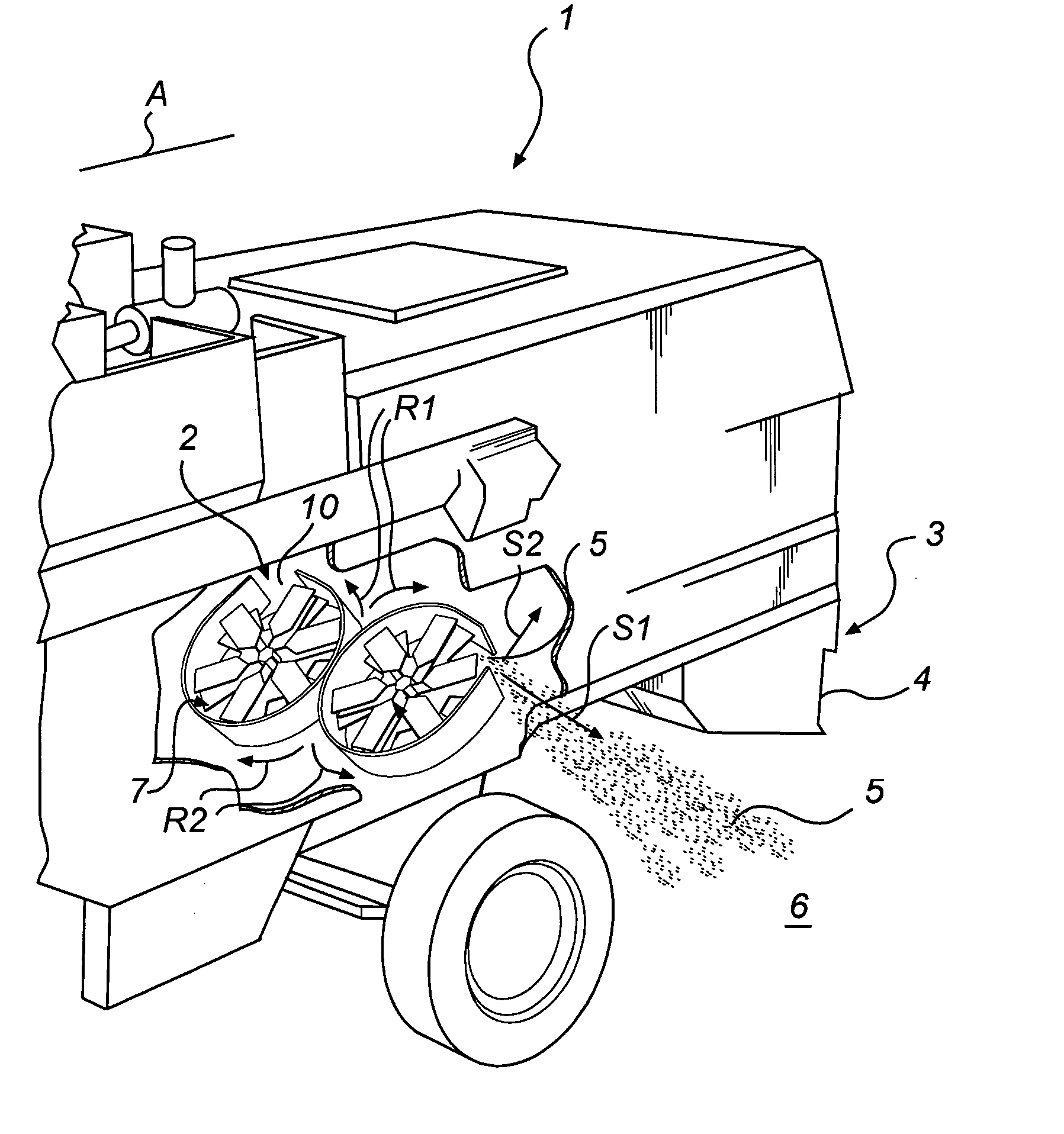

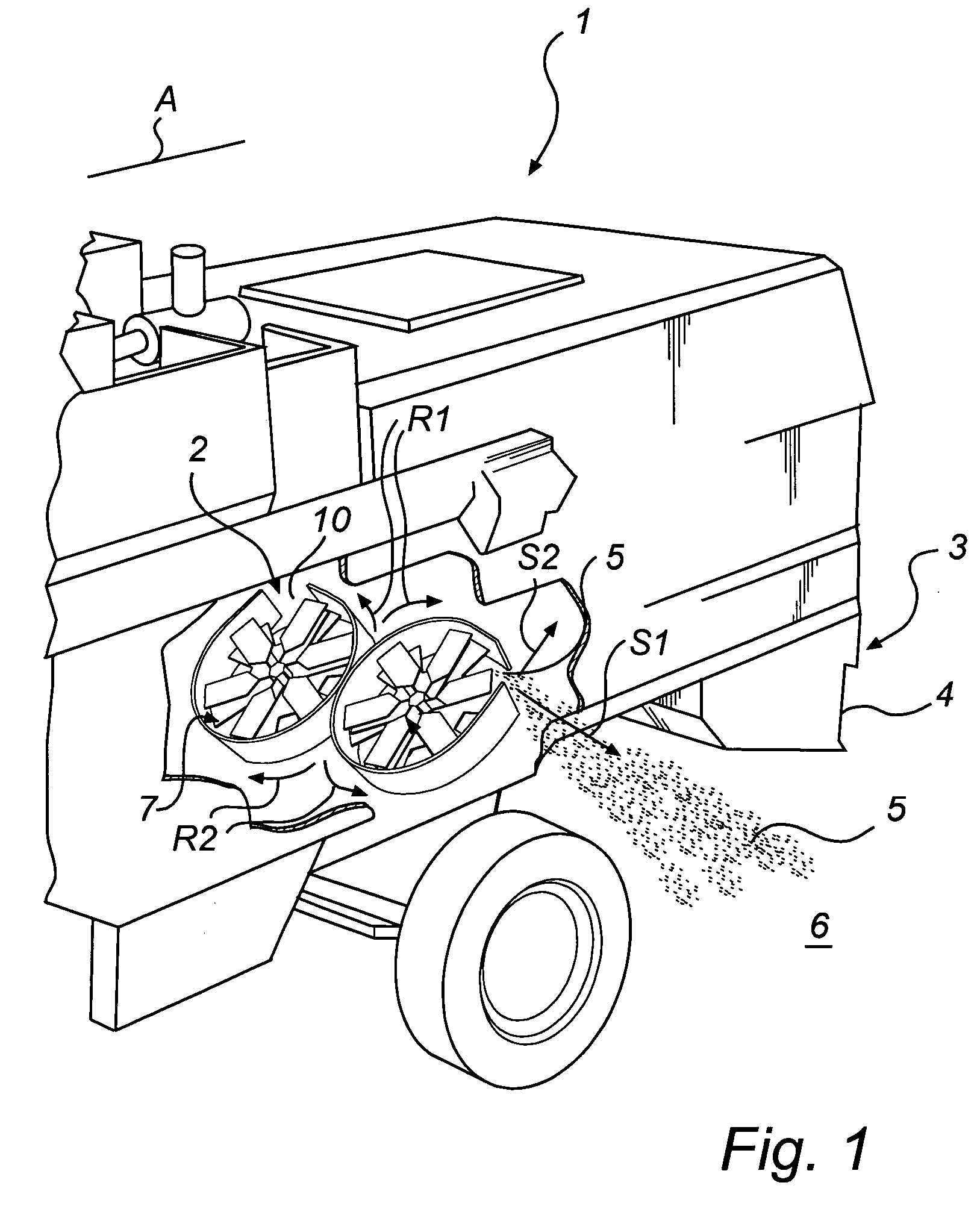

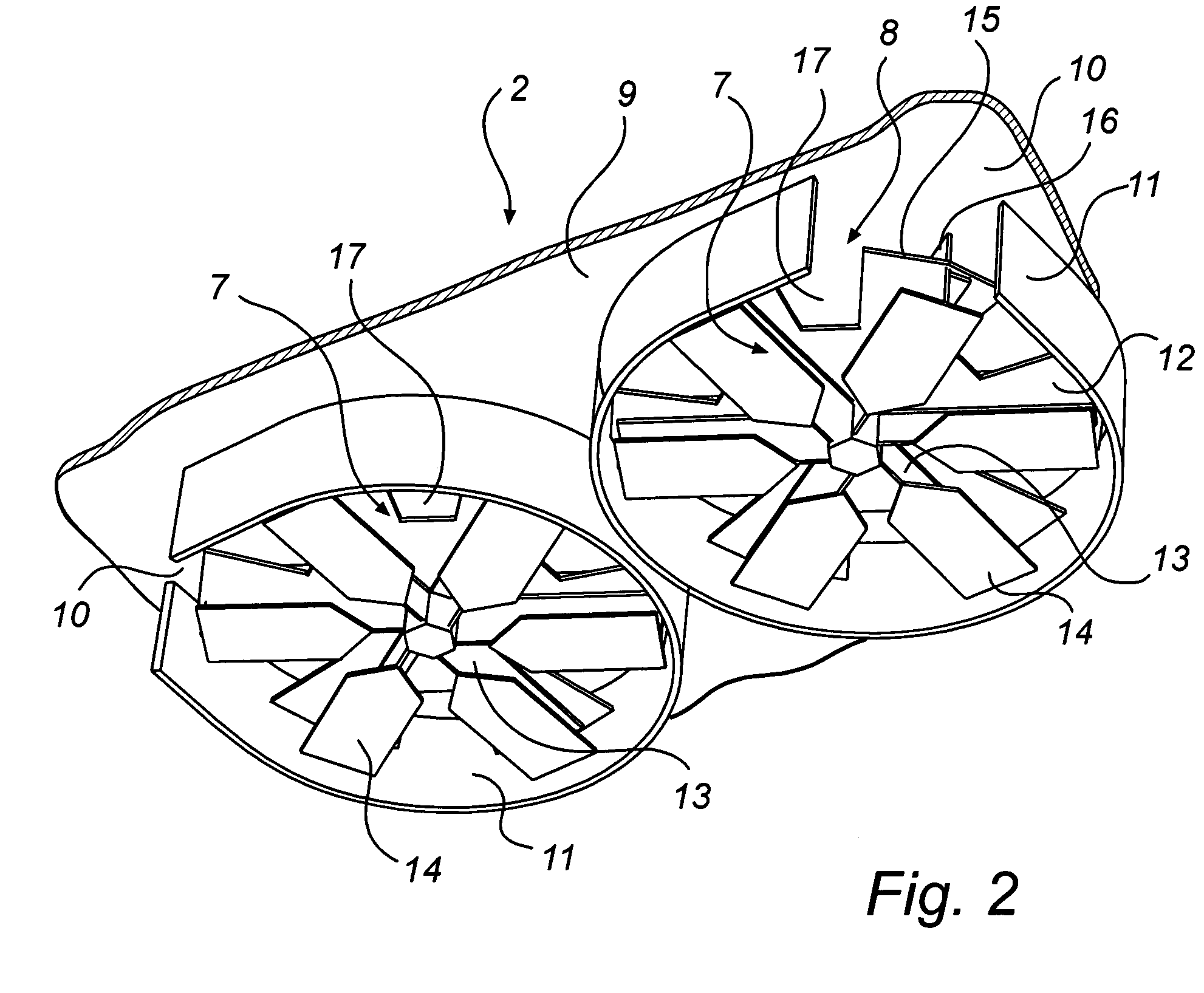

Combine chaff discharger

A chaff discharger (2) intended for a combine harvester (1) for discharge of chaff (5) from a sieving on the combine, is positioned downstream of the sieving unit and has least one radial fan wheel (7), which is rotationally mounted in a fan housing (8), said housing having an end wall (9), which is turned away from the sieving unit, and an peripheral wall (11), in which is formed at least one chaff discharge opening (10). The direction of rotation (R1, R2) of the fan wheel is reversible so as to permit discharge of the chaff (5) in different directions (S1, S2) via the associated chaff discharge opening (10), depending on the fan wheel direction of rotation.

Owner:REKORDVERKEN SWEDEN

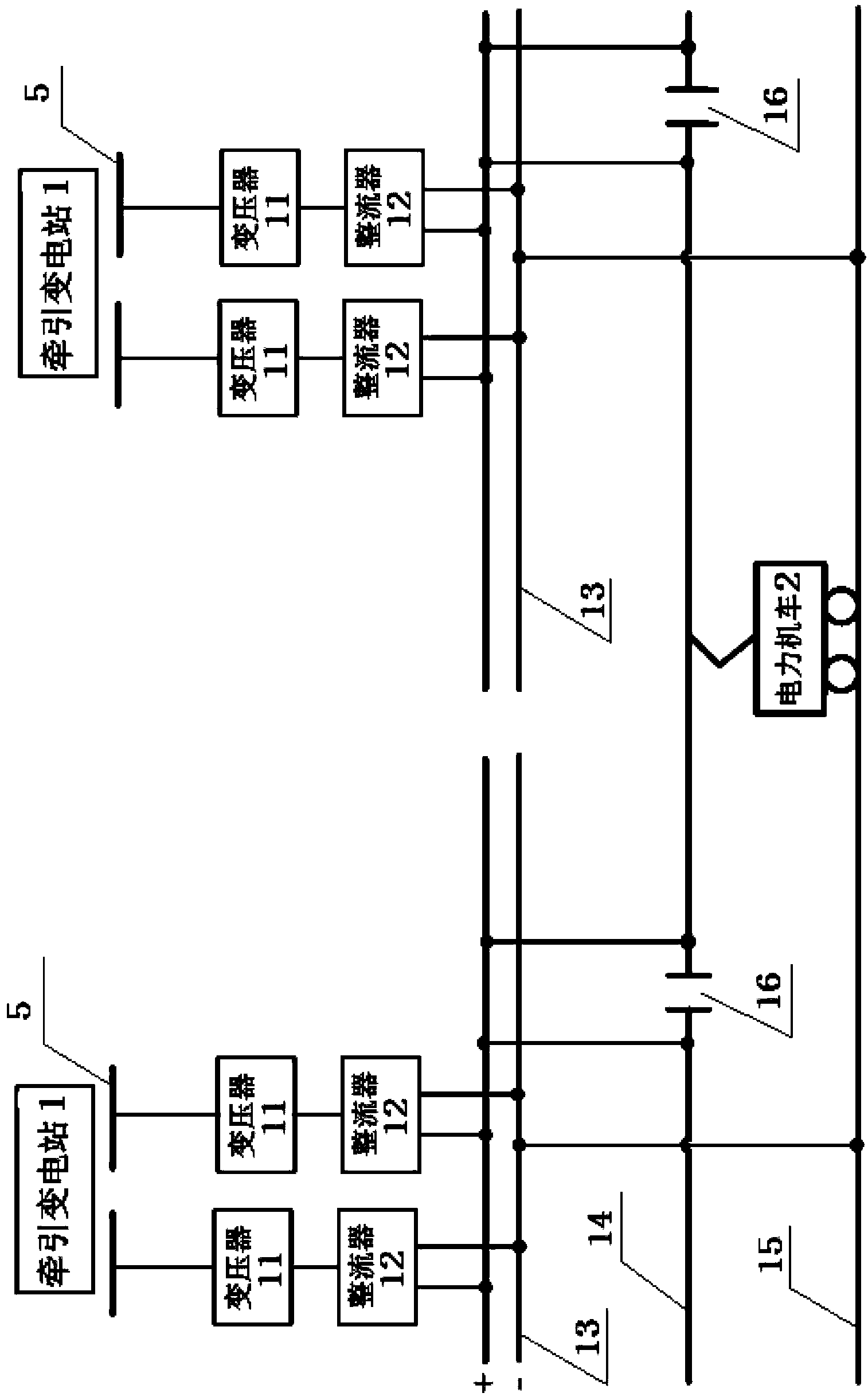

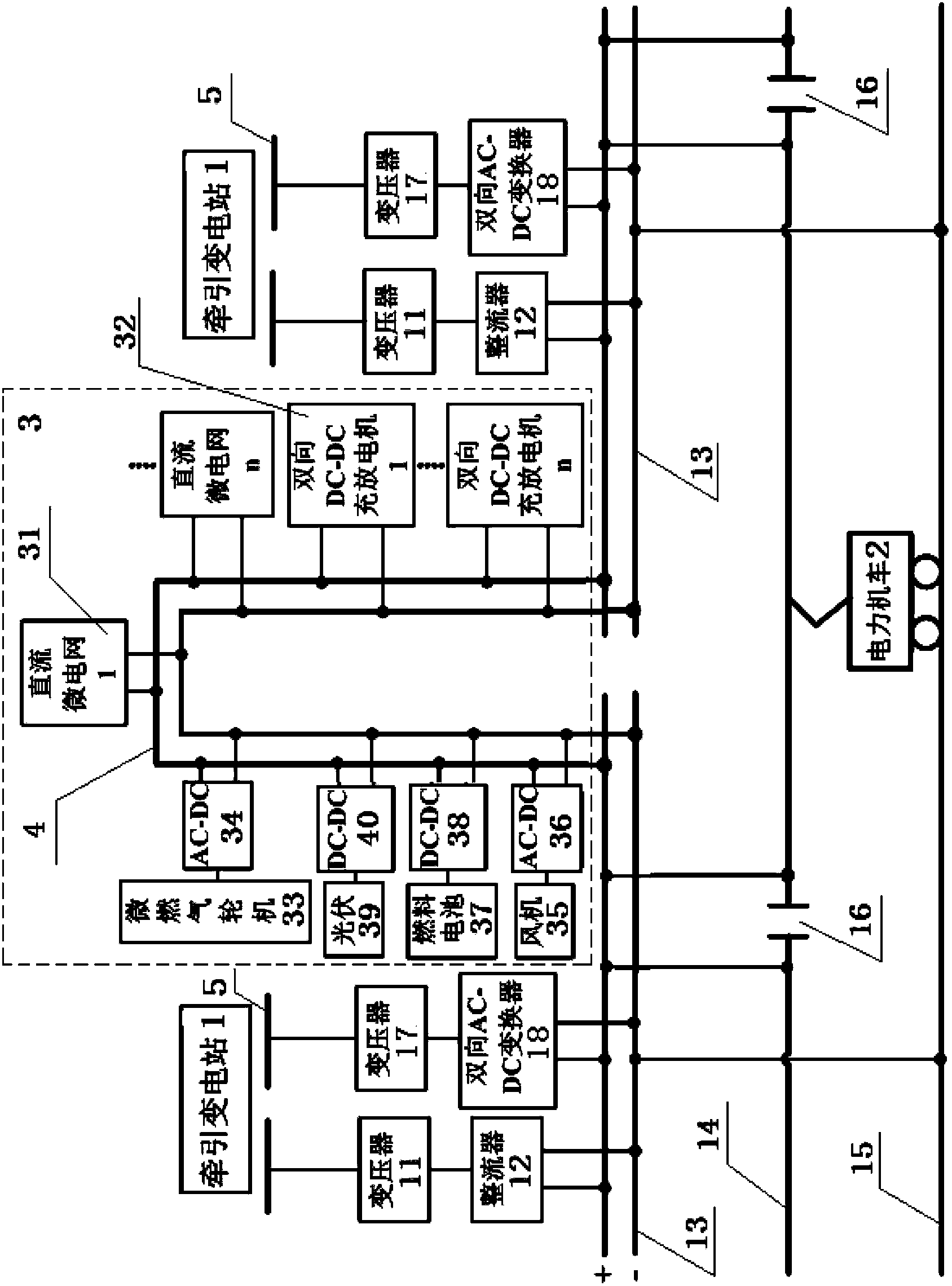

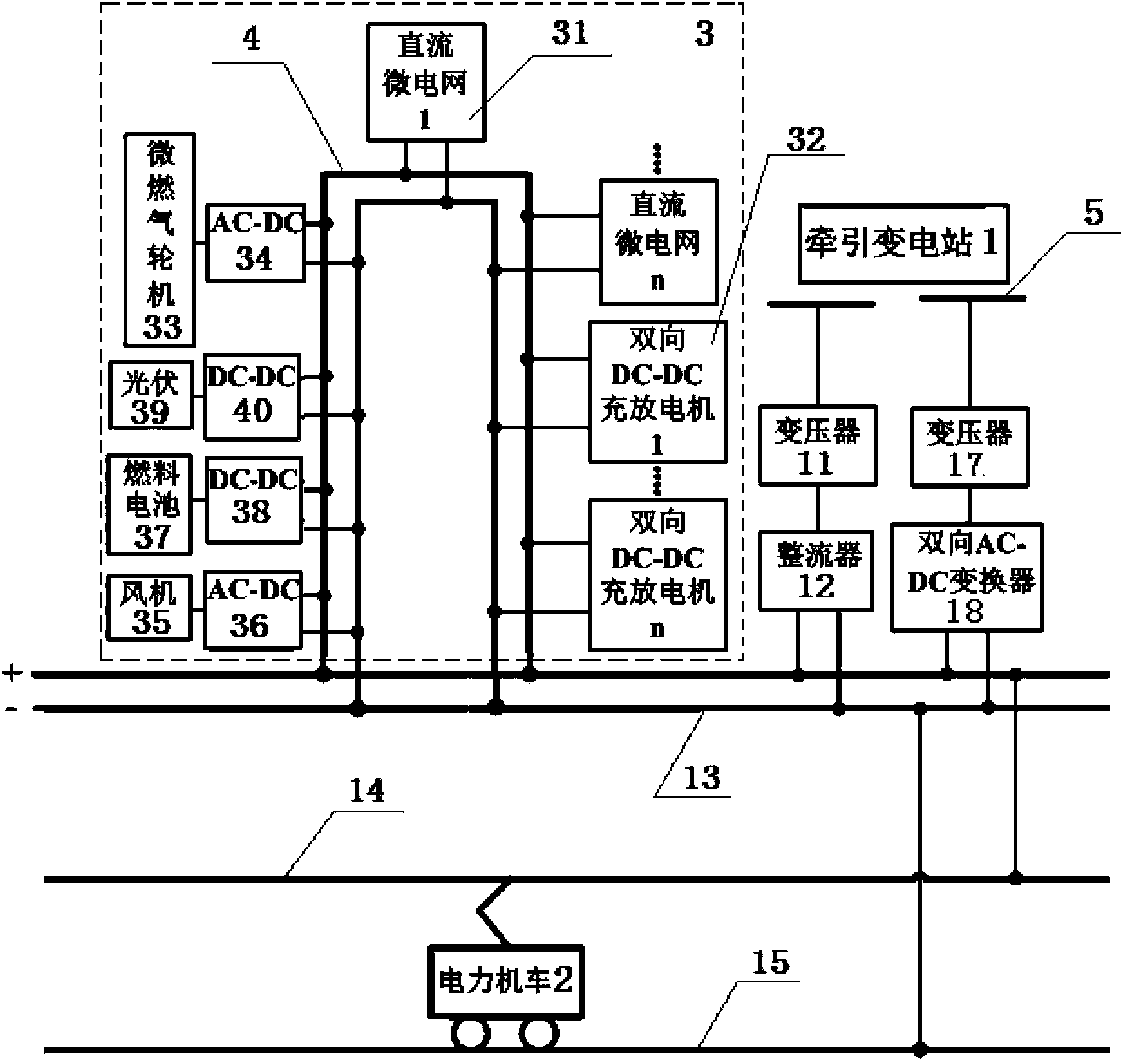

New energy-based hybrid bidirectional interactive direct-current traction power supply system

InactiveCN103434421AImprove power supply reliabilitySmall fluctuationBatteries circuit arrangementsPower supply linesLow voltageNew energy

A new energy-based hybrid bidirectional interactive direct-current traction power supply system is provided with two traction substations, and each traction substation comprises transformers, rectifiers, bidirectional alternating current-direct current (AC-DC) converters, a direct-current bus, a contact system, rails and a section post. A direct-current new energy system which comprises an electric automobile charging and discharging system, a distributed power supply and more than one low-voltage direct-current micro-grid is arranged on the direct-current bus between the two neighboring traction substations, and is connected with the direct-current buses of the two neighboring traction substations through a high-voltage direct-current bus, so that a direct-current loop micro-grid is formed in a power supply section, wherein the electric automobile charging and discharging system comprises more than one bidirectional direct current-direct current charger-discharger which is used for connection with the power cells of electric automobiles. The new energy-based hybrid bidirectional interactive direct-current traction power supply system realizes the effective utilization of distributed new energy and the recovery of the braking energy of electric locomotives; the fluctuation of the voltage of the direct-current bus is reduced, and thereby the reliability of the power supply of the direct-current traction power supply system is enhanced.

Owner:NORTH CHINA ELECTRIC POWER UNIV +2

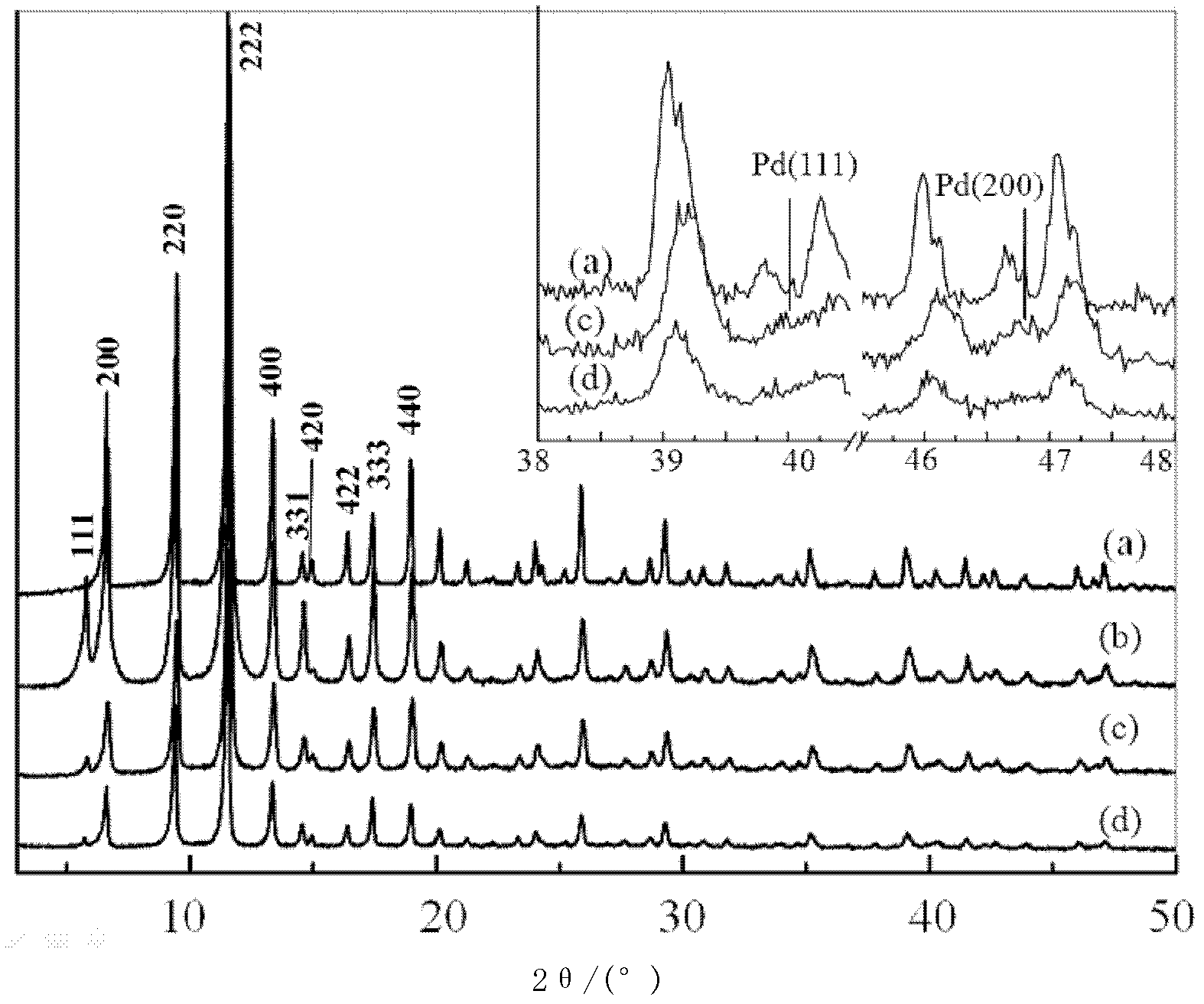

Method for preparing catalyst with thermal-instability material carrier by using low-temperature plasma and application of catalyst

InactiveCN102151586AIncrease productionHigh catalytic activityCarbon compoundsOrganic-compounds/hydrides/coordination-complexes catalystsThermal instabilityActive component

The invention relates to a method for preparing a catalyst with thermal-instability material carrier by using low-temperature plasma and an application of the catalyst, and the method comprises the following steps: impregnating thermal-instability material with metal salt; directly loading the thermal-instability material carrying the metal salt into a plasma discharger; vacuumizing the interior of the plasma discharger, then introducing plasma discharge gas, maintaining the pressure of the gas at 30-200Pa, utilizing a high-voltage power supply to apply 200-5000V direct current or alternatingcurrent to two ends of an electrode for enabling the discharge gas to discharge, and reducing or decomposing the metal salt with the formed plasma for 5-120 minutes without damaging the structure of the thermal-instability material so as to obtain the required catalyst finally. The catalyst with a thermal-instability material carrier, which is prepared from plasma, has the advantages of large output, good catalytic activity and the like, and the particle size of active components can be controlled easily. The adverse thermal effect and the series damages to the structure of the material with the thermal instability under high temperature can be avoided, so that the active components are fine and small in particles, uniform in distribution, high in purity and good in dispersivity.

Owner:TIANJIN UNIV

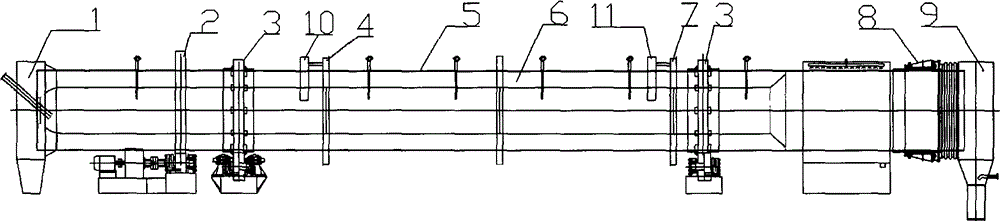

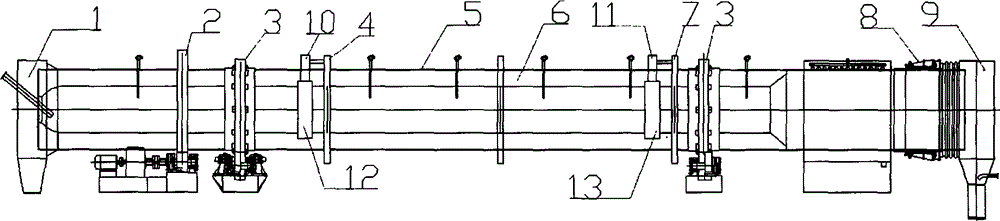

Electric heating rotary kiln

ActiveCN103335513AEliminate heat transfer processImprove thermal efficiencyRotary drum furnacesEngineeringAlternating current

An electric heating rotary kiln comprises a rotary pipe, a heat-insulating part, a belt pulley, bearing wheels, a heating system, a head feeder, a tail discharger and other parts, and is characterized in that: the part of the inner wall of the rotary pipe or the heat-insulating part, which is in contact with material, is insulating material; the heating system at least comprises two electrodes or two groups of electrodes, one electrode or one group of electrodes are the anode, the other electrode or the other group of electrodes are the cathode, alternating-current or direct-current voltage is applied on the two electrodes or two groups of electrodes, the electrodes run through the rotary pipe to get into the rotary kiln and touch heated material, current gets to the material and then the cathode via the anode, so that the material heats as a resistor, and thereby the material is heated. Compared with other electric heating rotary kilns, the electric heating rotary kiln has the advantages that: the electric heating rotary kiln can be produced into an internal electric heating rotary kiln, the material can be uniformly heated for the material heats, the electric heating efficiency is high, energy consumption is low, and the heating and insulating measure is simple and convenient.

Owner:冯良荣

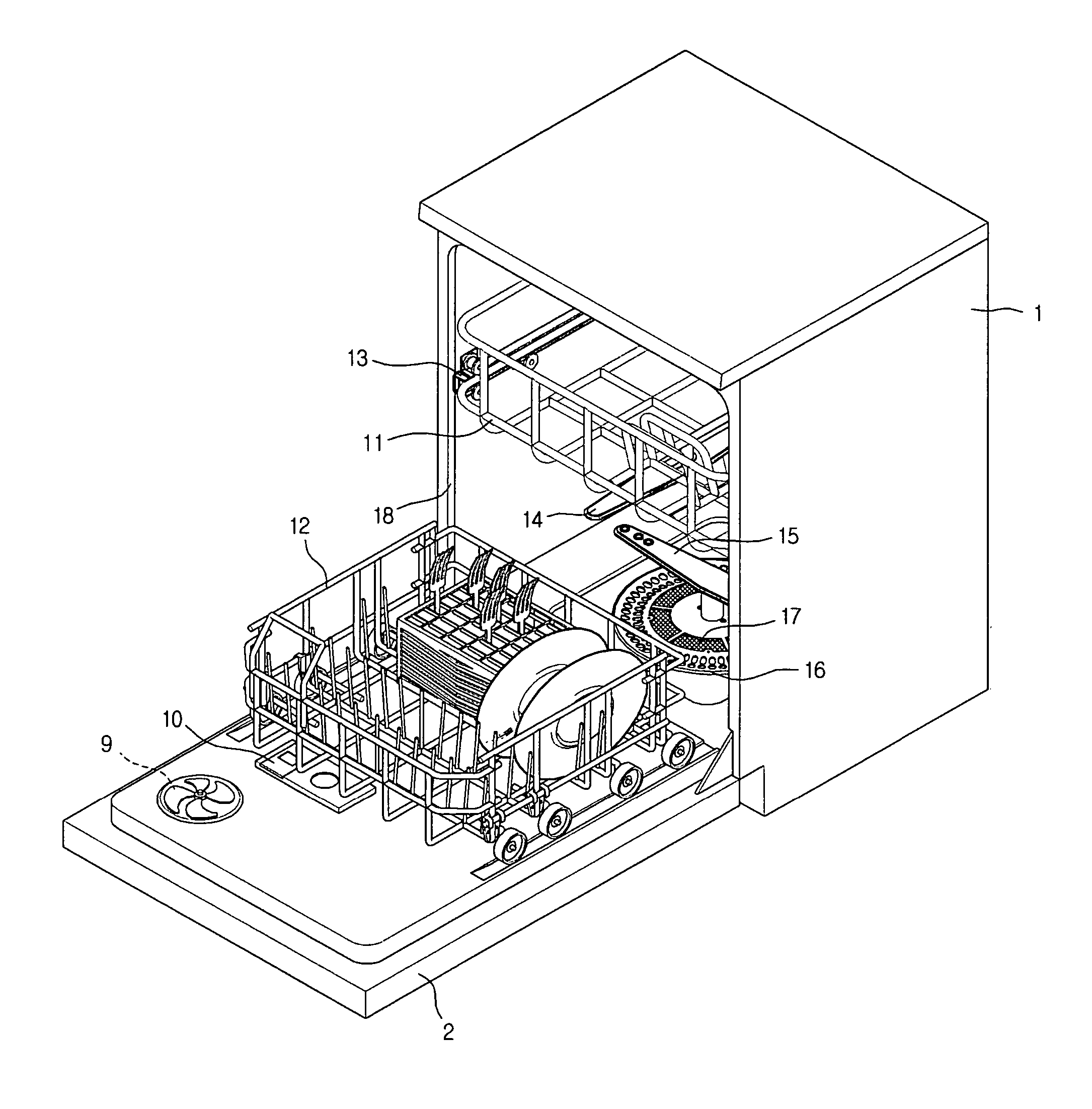

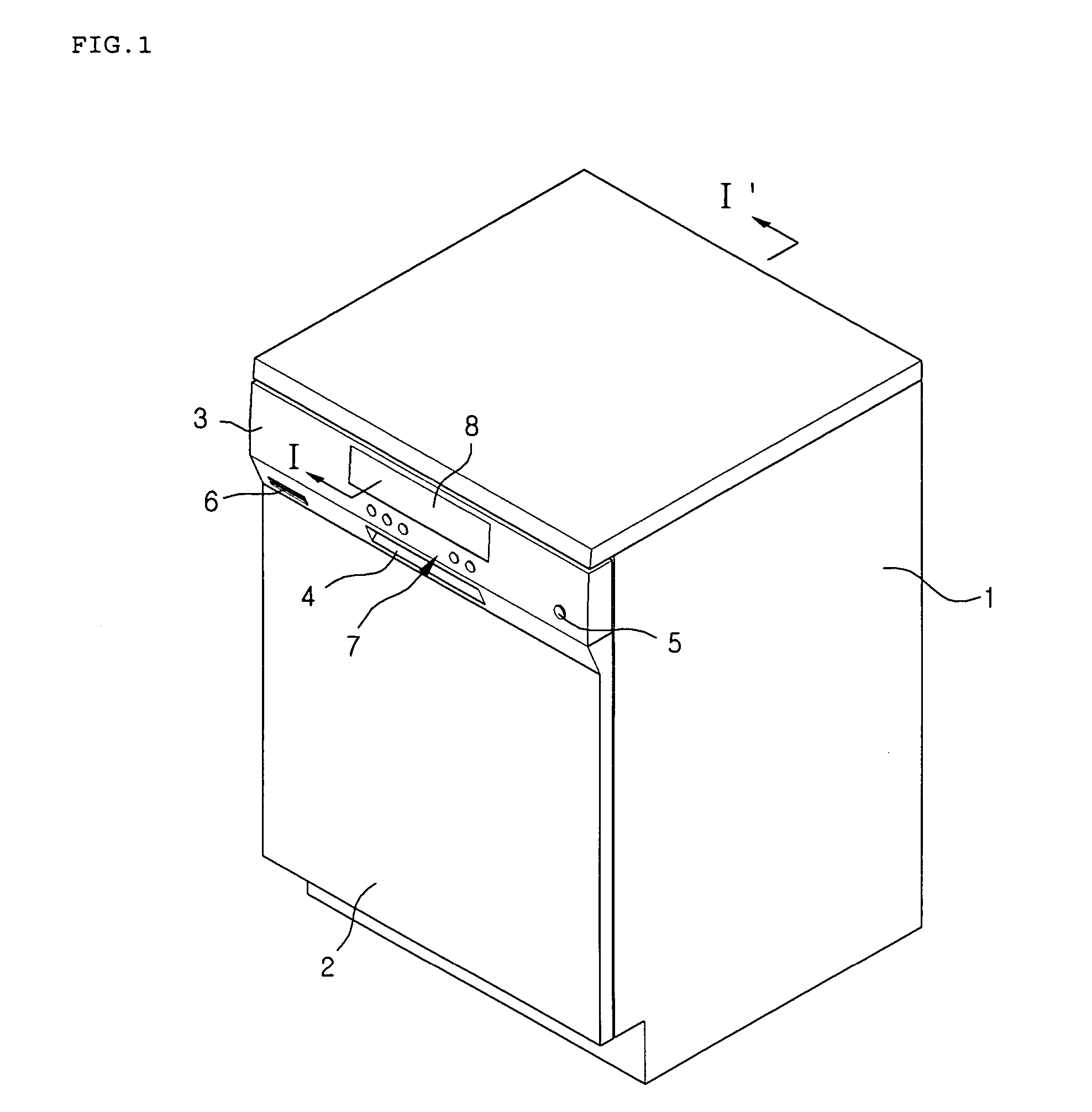

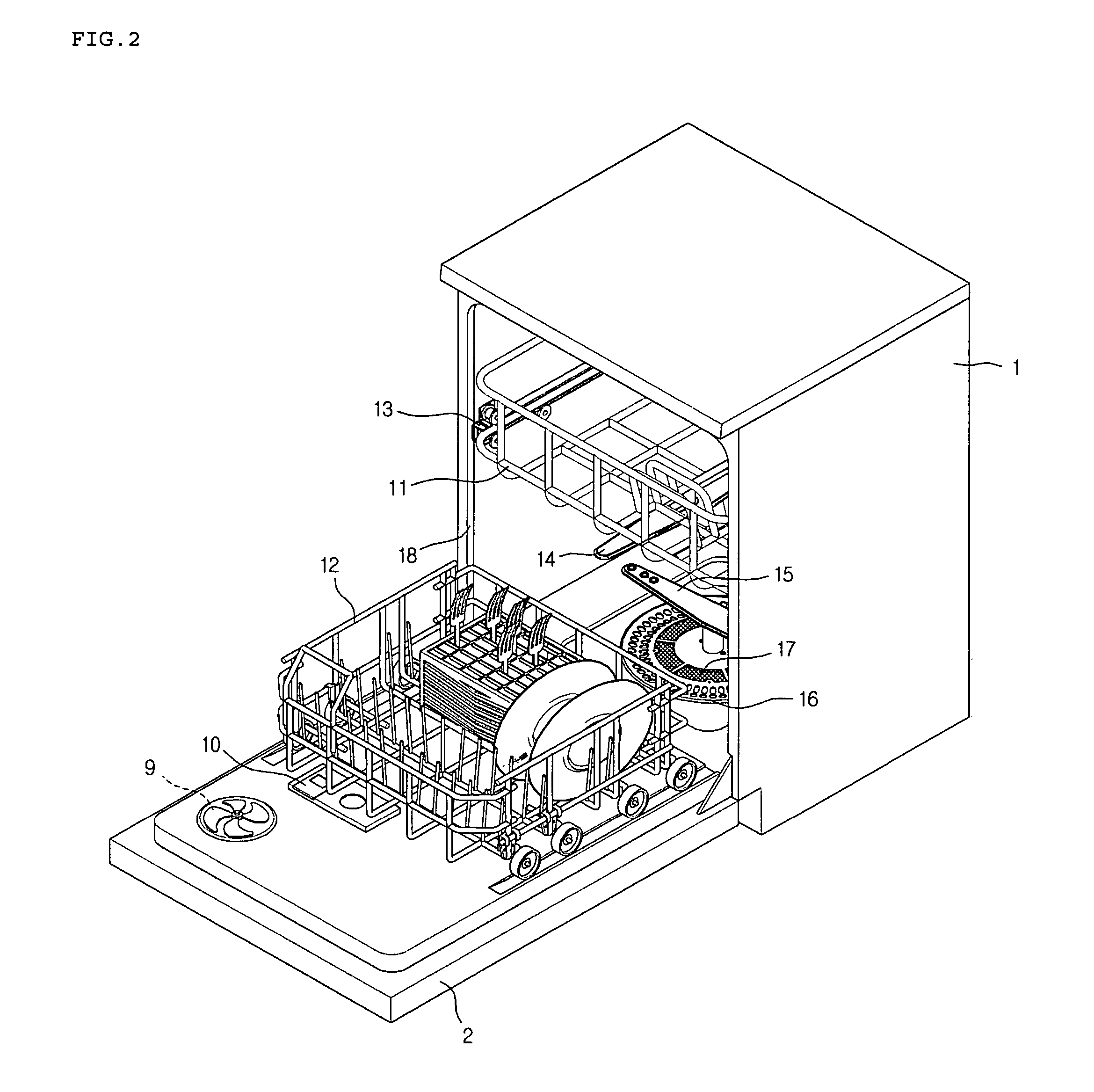

Dishwasher and controlling method thereof

ActiveUS20070102025A1Easy to useSatisfy cleanlinessWashing processesHollow article cleaningEngineeringHolding room

A dishwasher and a controlling method thereof are provided. The dishwasher includes a tub, a door, a steam generator, and a dish storage. The tub holds dishes and is opened at one end. The door selectively seals the opened end of the tub. The steam generator is provided outside the tub to generate steam. The steam discharger discharges the steam generated by the steam generator into the tub. The dish storage stores dishes to be sterilized by the steam discharged from the steam discharger.

Owner:LG ELECTRONICS INC

Coal mine underground high-power electric knock assisted hydraulic fracturing permeability enhancement method

ActiveCN105275443AIncrease the number of cracksIncrease the lengthFluid removalGas removalShock waveHigh energy

The invention relates to a coal mine underground high-power electric knock assisted hydraulic fracturing permeability enhancement method suitable for increasing extraction radius and total extraction amount of gas extraction drilling. The method comprises the following steps that: a borehole extends from one side of a laneway to a coal seam is constructed; a high-voltage pulse discharger which is installed at the front end of a fracturing steel pipe is sent to the bottom of the borehole; a hole packer, which is separated from the orifice of the borehole by 2 to 3m, is installed on the borehole; the outer end of the fracturing steel pipe is connected with a high-pressure pump station through a high-pressure rubber hose; and the high-voltage pulse discharger is connected with a high-voltage electric pulse generator through a cable; after water with a certain pressure is injected into the borehole, the high-voltage electric pulse generator is started so as to apply high-power electric knock assisted hydraulic fracturing to the coal seam; after the high-power electric knock assisted hydraulic fracturing, the high-voltage pulse discharger and the fracturing steel pipe are quitted; and a gas extraction pipeline is connected into the borehole. According to the method of the invention, high energy released by high-voltage electric pulses is utilized to form shock waves in the water, and therefore, a large number of cracks can be formed in the coal seam, and primary cracks are extended. With the method adopted, the permeability coefficient of a coal body can be increased by 100 to 300 times, and single-hole gas extraction efficiency can be effectively improved.

Owner:CHINA UNIV OF MINING & TECH

Incineration treatment method for domestic refuse

ActiveCN101761928AReduce dosageAchieve recyclingCement productionIncinerator apparatusSlagCalcination

The invention provides an incineration treatment method for domestic refuse. The method comprises: having an incinerator arranged between a rotary kiln and a decomposing furnace; introducing tertiary hot air into a wind tower of the incinerator and baking an incinerator body; crushing domestic refuse with the water content less than 20 percent into refuse material 50 to 80 millimeters in particle size and guiding the refuse material into the incinerator body through an electronic control feeder of the incinerator; allowing a material level meter to send a feedback signal to stop adding the refuse material when a refuse material layer is 50 millimeters away from a material separation body; drying the refuse material; burning, decomposing and gasifying organic substances in the refuse material through the tertiary hot air out of a multi-layer air outlet of a central air pipe; ensuring that the temperature in the incinerator body is above 850 DEG C; discharging produced flue gas to the decomposing furnace through a smoke outlet; ensuring that the decomposing furnace reaches a temperature of above 900 DEG C and is in an alkaline atmosphere; and further neutralizing acidic flue gas. Refuse ash-slag is discharged through an electrical vibrating material discharger, sent into the rotary kiln, and is taken as raw material burden for cement production to participate in calcination, so that the aim of treating domestic refuse in a 'harmless, amount-reducing and resource-recovering' way is achieved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com