Negative-pressure microwave uniform spraying and drying device and application

A negative pressure microwave and drying device technology, which is applied in the direction of drying solid materials, method combination to dry solid materials, drying, etc., can solve the problems of drying quality decline, high energy consumption, long drying time, etc., and achieve convenient use and operation, Low microwave absorption rate and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

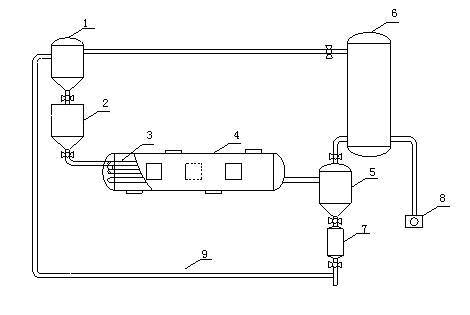

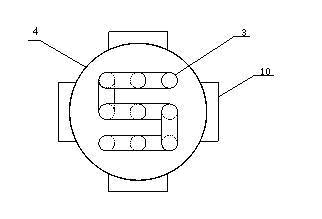

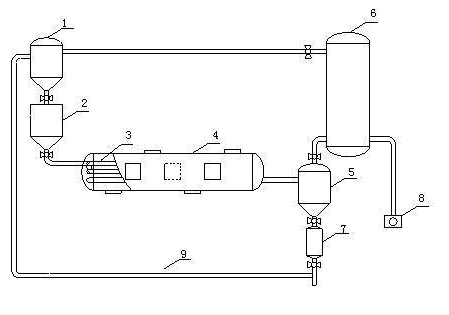

[0027] Example 1 A device for continuous negative pressure microwave spraying homogenization and drying of granular materials, such as figure 1 , figure 2 shown. Including circulation stocker 1 and feeder 2, also includes negative pressure spray pipe 3, microwave heating cavity 4, cyclone separator 5, vacuum storage tank 6, unloader 7, water ring vacuum pump 8, circulation pipe 9 and a microwave source 10 . The feeder 2 is a container for storing materials to be dried, and the amount of materials entering the negative pressure spray pipe 3 is controlled through flow regulation. The negative pressure spray pipe is installed in the microwave heating cavity 4, and the materials are flowed and dried in multiple processes. After the material is dried, it enters the cyclone separator 5, enters the unloader 7 through flow adjustment, and enters the circulation storage tank 1 through the circulation pipe 9 according to the moisture content of the material, or the drying ends. The...

Embodiment 2

[0029] Embodiment 2, carrot particle negative pressure microwave jetting homogenization drying method

[0030] Clean the fresh carrots, cut them into 5mm-10mm cubes, blanch them at 96-98°C for 2-3 minutes, take them out, add 1% glucose powder and mix them for 20 minutes, then use a centrifuge to remove the moisture attached to the surface. stand-by. Turn on the water ring vacuum pump 8 to make the vacuum degree of the vacuum storage tank reach 4000Pa, set the temperature value of the inlet, outlet, and middle three drying areas in the negative pressure tube every 1 minute within 1 hour, and the maximum temperature is 50°C, set for 1 hour Put the ready-to-use carrots into the feeder 2 every 1 minute at the vacuum degree value and the set value of the flow regulating valve, turn on the start switch, the valve connecting the vacuum storage tank and the cyclone separator 5 will automatically open, and the feeder 2 The regulating valve connected with the negative pressure spray pi...

Embodiment 3

[0031] Embodiment 3, negative pressure microwave jetting homogenization drying method of shallot section

[0032] Clean the new chives, cut them into 3-5mm sections, soak and blanch them in 2% sodium hypochlorite aqueous solution for 10-15 minutes, take them out and let them rest for 10 minutes, then use a centrifuge to remove the water attached to the surface and prepare for use. Turn on the water ring vacuum pump 8 to make the vacuum degree of the vacuum storage tank reach 5000Pa, set the temperature value of the inlet, outlet, and middle three drying areas in the negative pressure tube every 1 minute within 40 minutes, the maximum temperature is 60°C, set for 40 minutes Put the ready-to-use chives into the feeder 2 every 1 minute for the vacuum degree value and the set value of the flow regulating valve, turn on the start switch, the valve connecting the vacuum storage tank 6 and the cyclone separator 5 will automatically open, and the material will be fed. The regulator 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com