Intelligentized static microwave vacuum drying machine

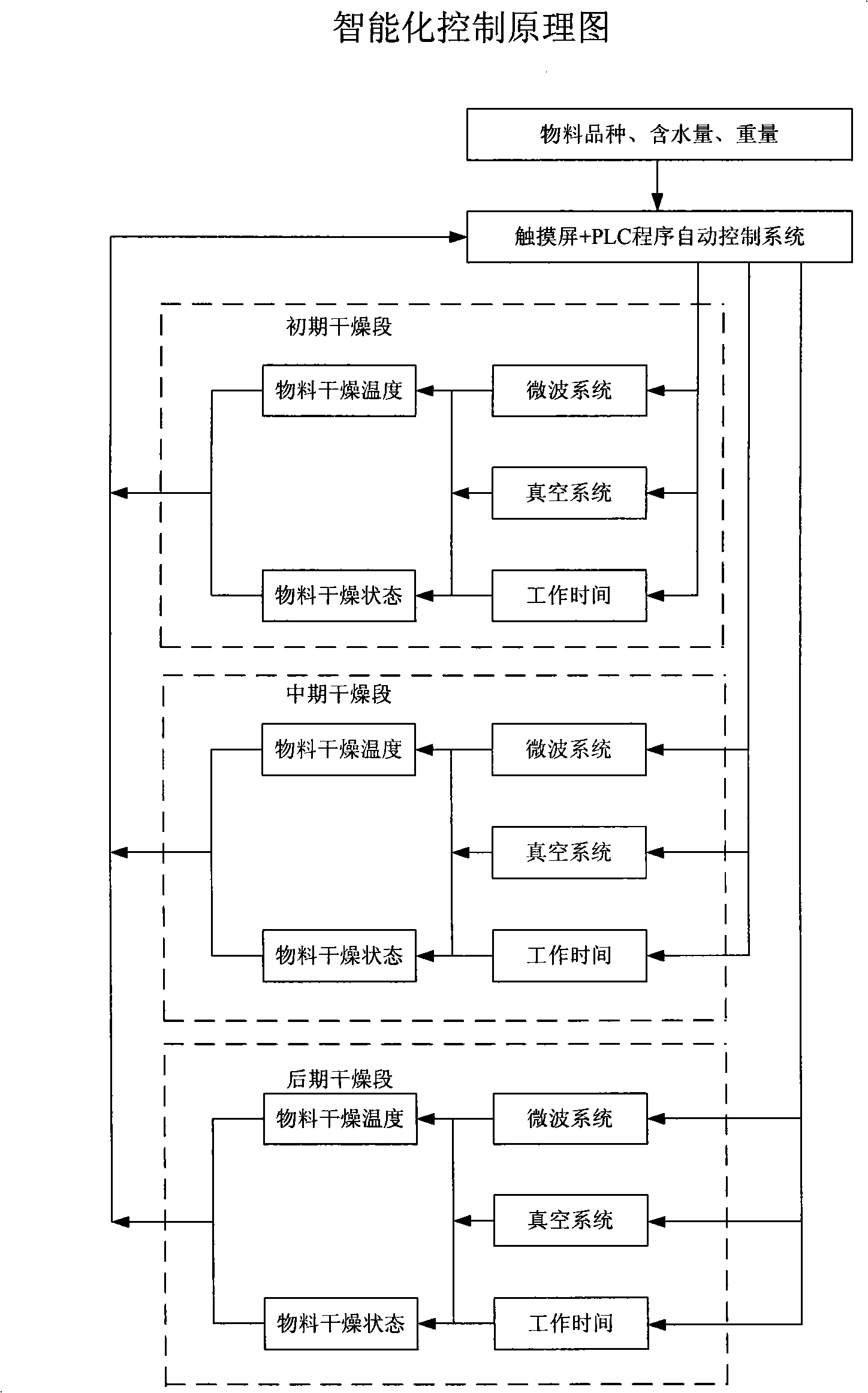

A microwave vacuum drying and static technology, which is used in dryers for static materials, local stirring dryers, dryers, etc., can solve the problems of long cycle, large investment, and unstable equipment operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

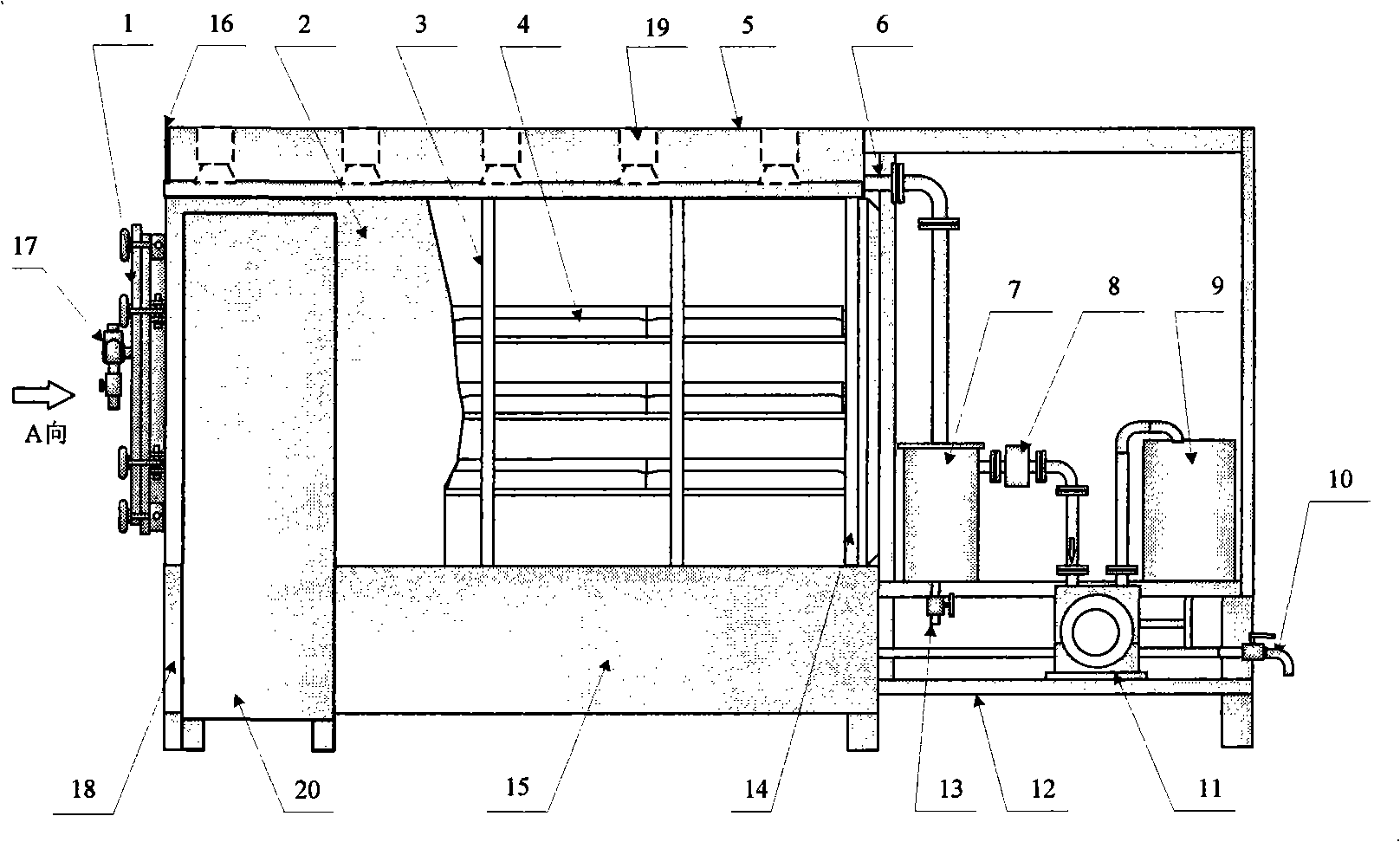

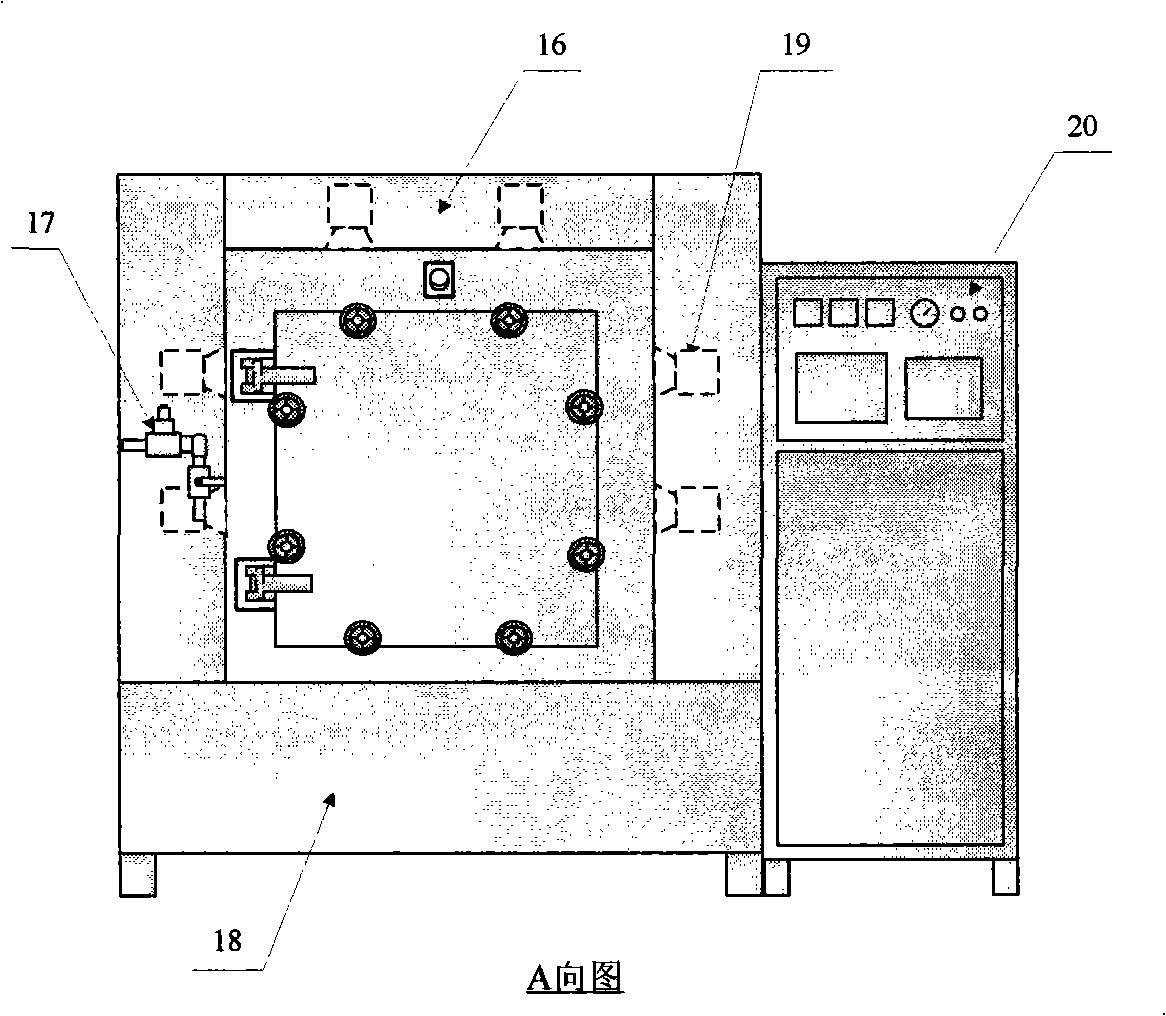

[0007] In the figure: the equipment door (1) is composed of metal plate, compression handwheel, hinge, door switch; the heater shield (2) is made of metal sheet; the inner bracket (3) is processed by polypropylene or polyethylene plate The charging box (4) is made of plastic; the outer top cover (5) is made of sheet metal; the steam extraction pipe (6) is made of metal pipes and flanges; the buffer tank (7) is made of metal tank and inlet The exhaust port is composed of a one-way valve (8) consisting of a one-way valve body and a flange; the steam-water separator (9) is composed of a metal tank, a water inlet, an overflow pipe and a water level detector; the drain pipe (10) is composed of a metal The vacuum pump (11) is an outsourced vacuum pump; the equipment chassis (12) is connected by metal parts; the buffer tank drain valve (13) is composed of valves and pipe fittings; the heater box (14) is composed of metal plates The welded rectangular box has a square hole at one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com