Patents

Literature

6543 results about "Di-isocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fast curing compositions

Fast curing surgical adhesives and sealants contain an NCO-terminated hydrophilic urethane prepolymer derived from an aromatic diisocyanate and a polyol. Substantially all the aromatic diisocyanate used to prepare the NCO-terminated hydrophilic urethane prepolymer is in the para form. Optionally, the aromatic diisocyanate is substituted with at least one electron withdrawing group, such as, for example, a fluorine group.

Owner:TYCO HEALTHCARE GRP LP

Compositions with Improved Adhesion to Low Surface Energy Substrates

InactiveUS20080113094A1Excellent low surface energyImprove adhesionSynthetic resin layered productsOrganic dyesOligomerEnd-group

Acrylic-based pressure sensitive adhesives are modified with a telechelic hydrocarbon oligomer. The oligomer comprises a hydrocarbon polymer chain or backbone and a functional end group, e.g., an oligomer prepared from a mono hydroxyl polybutadiene polymer and toluene diisocyanate. The oligomer attaches to the acrylic backbone of the polymer as a pendant group and in a preferred embodiment, the oligomer is mixed with the PSA shortly before the PSA is coated.

Owner:BRADY WORLDWIDE INC

Electrophoretic media and displays with improved binder

An electrophoretic medium comprises discrete droplets of an electrophoretic internal phase comprising a fluid and carbon black particles in the fluid. The droplets are surrounded by a polyurethane binder formed by a diisocyanate and a polyether diol, at least 20 mole per cent of the diisocyanate being an aromatic diisocyanate.

Owner:E INK CORPORATION

Bioabsorbable and biocompatible polyurethanes and polyamides for medical devices

ActiveUS20060188547A1Low toxicitySuture equipmentsOrganic active ingredientsAbsorbable polymersPolyester

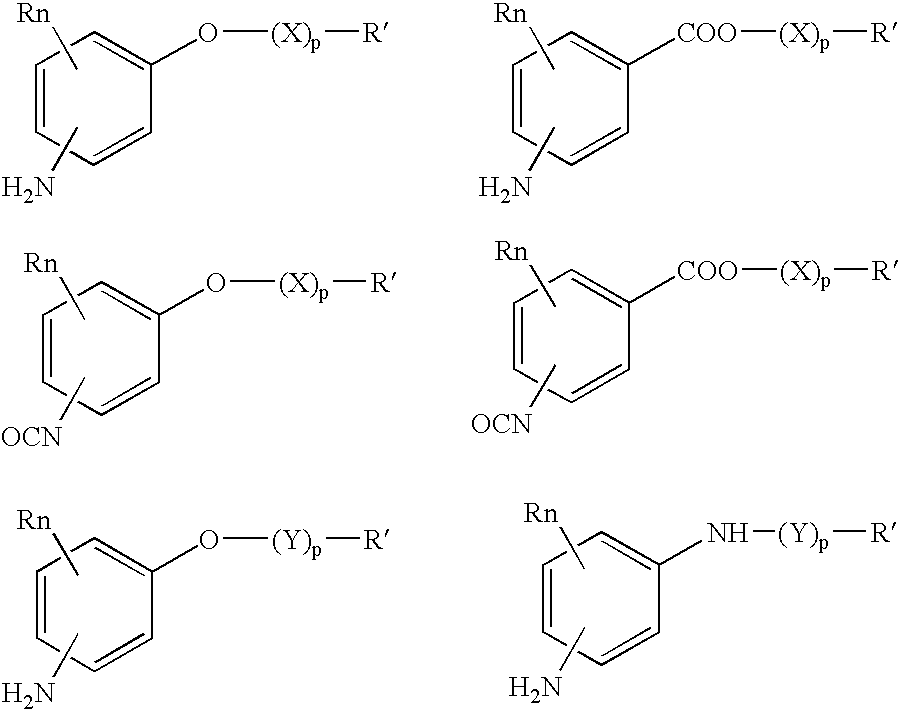

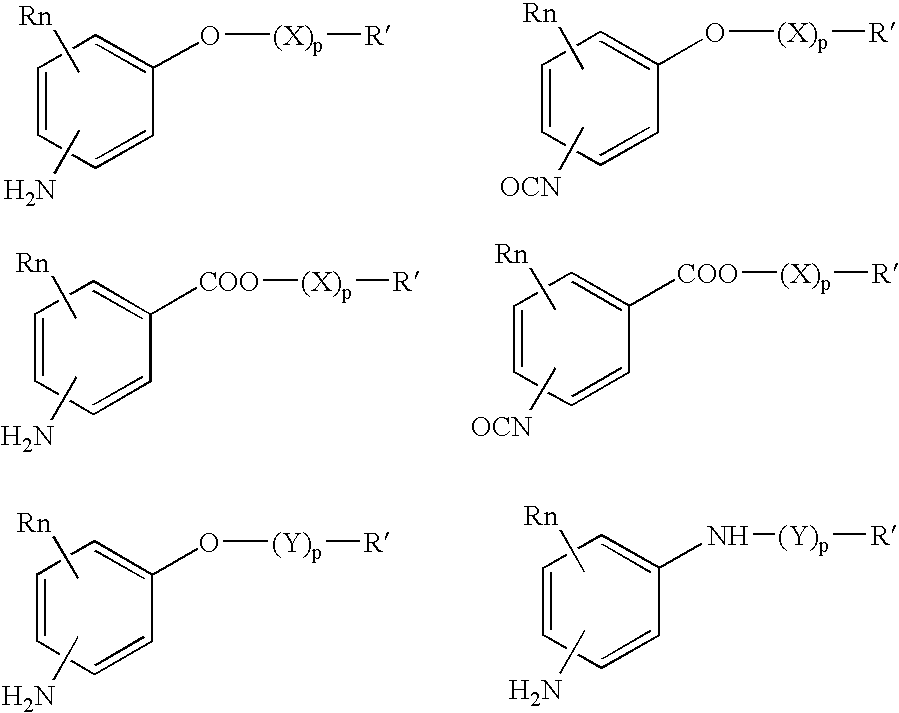

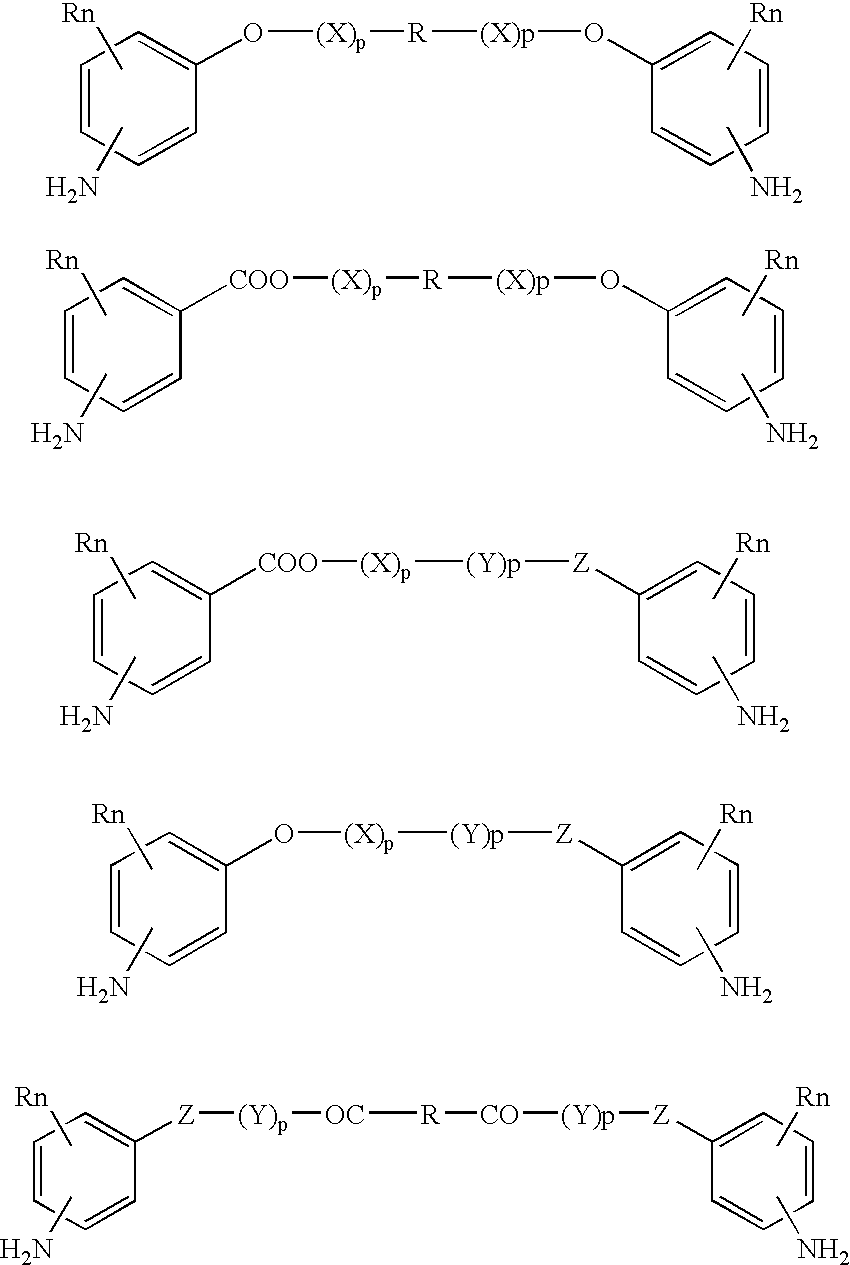

Absorbable polyurethanes, polyamides and polyester urethanes prepared from at least one compound selected from: or the diamines and diisocyanates thereof, wherein each X represents a member independently selected from —CH2COO— (glycolic acid moiety), —CH(CH3)COO— (lactic acid moiety), —CH2CH2OCH2COO— (dioxanone), —CH2CH2CH2CH2CH2COO— (caprolactone moiety), —(CH2)yCOO— where y is one of the numbers 2, 3, 4 or 6-24 inclusive, and —(CH2CH2O)z′CH2COO— where z′ is an integer between 2 and 24, inclusive; each Y represents a member independently selected from —COCH2O— (glycolic ester moiety), —COCH(CH3)O— (lactic ester moiety), —COCH2OCH2CH2O— (dioxanone ester), —COCH2CH2CH2CH2CH2O— (caprolactone ester), —CO(CH2)mO— where m is an integer between 2, 3, 4 or 6-24 inclusive, —COCH2O(CH2CH2O)n— where n is an integer between 2 and 24, inclusive; R′ is hydrogen, benzyl or an alkyl group, the alkyl group being either straight-chained or branched; p is an integer between 1 and 4, inclusive; and Rn represents one or more members selected from H, alkoxy, benzyloxy, aldehyde, halogen, carboxylic acid and —NO2, which is attached directly to an aromatic ring or attached through an aliphatic chain. Absorbable polymers prepared from these compounds are useful for drug delivery, tissue engineering, tissue adhesives, adhesion prevention and other implantable medical devices.

Owner:BEZWADA BIOMEDICAL LLC

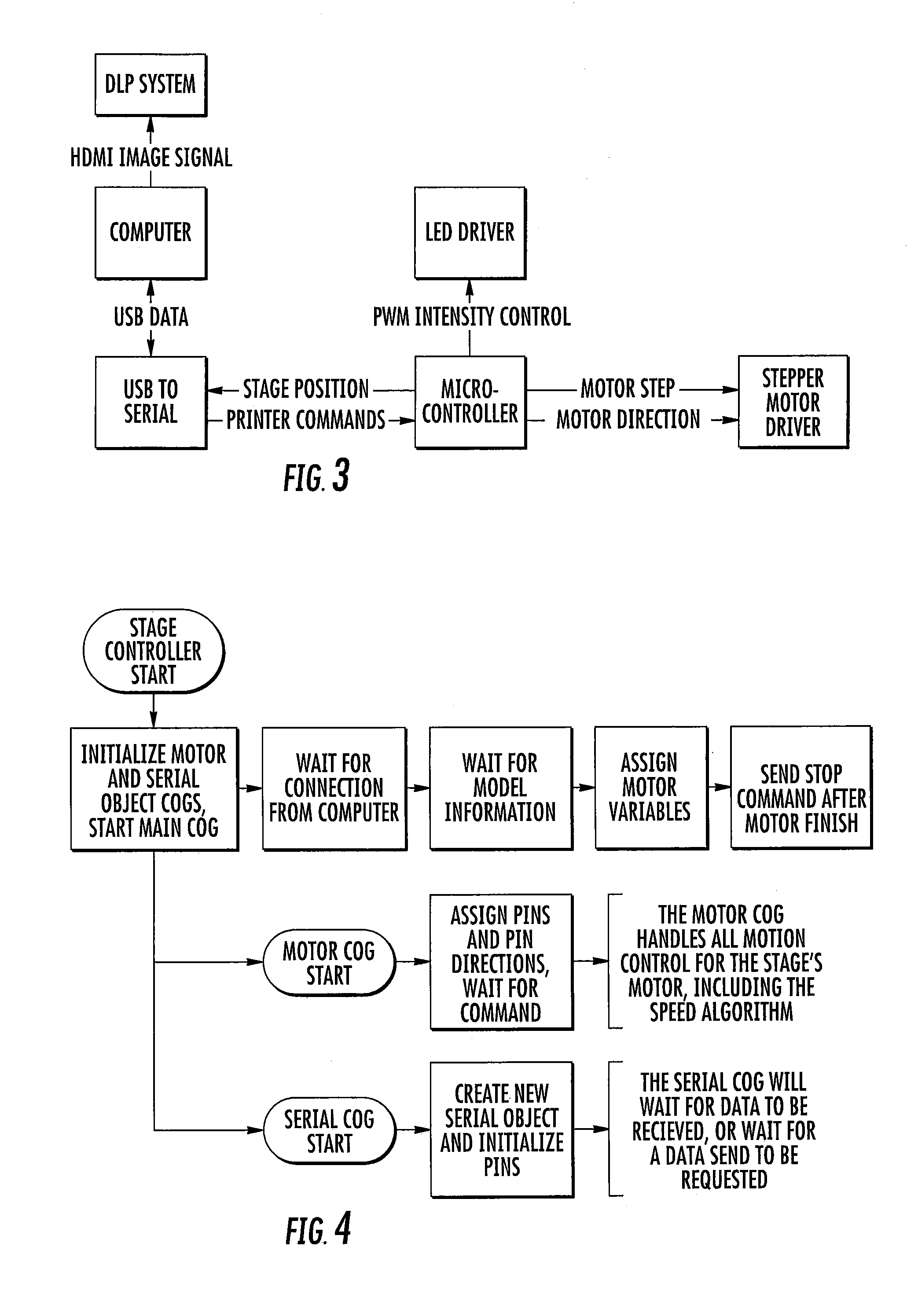

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

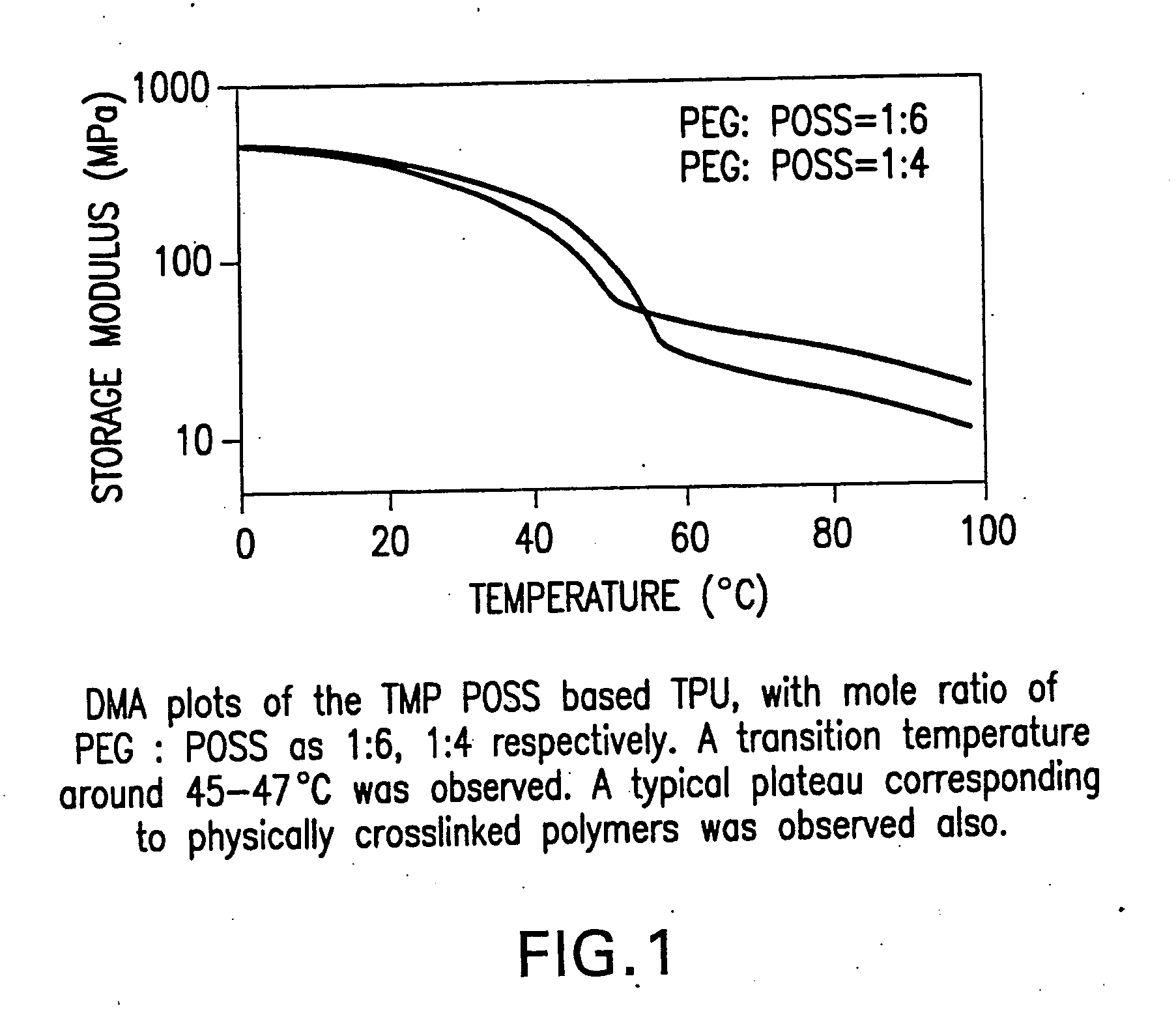

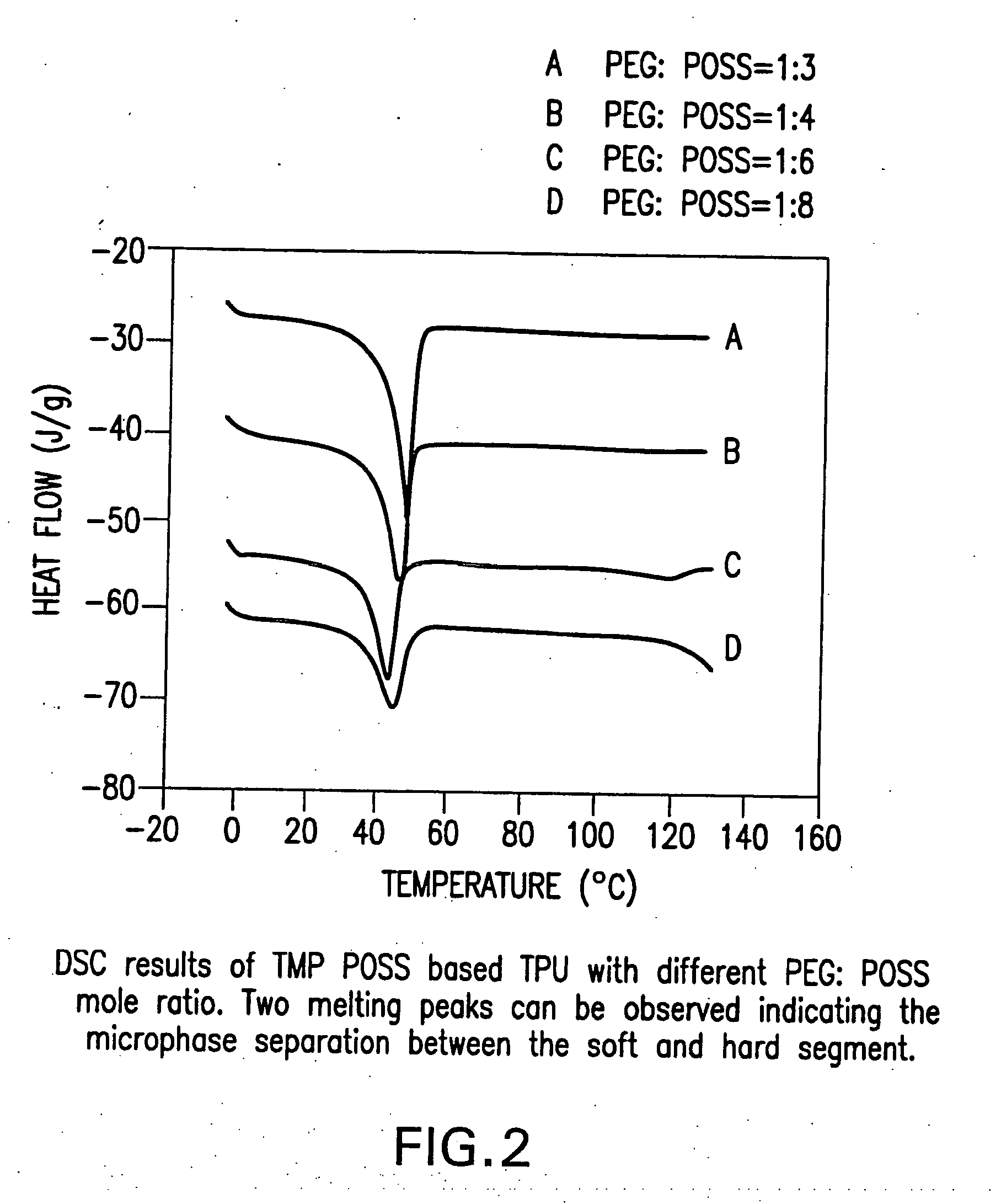

InactiveUS20050245719A1Sharp and tunable transition temperatureAbove melting pointPolymer scienceAdhesive

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligosilsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated polyhedral oligosilsesquioxane and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:UNIV OF CONNECTICUT

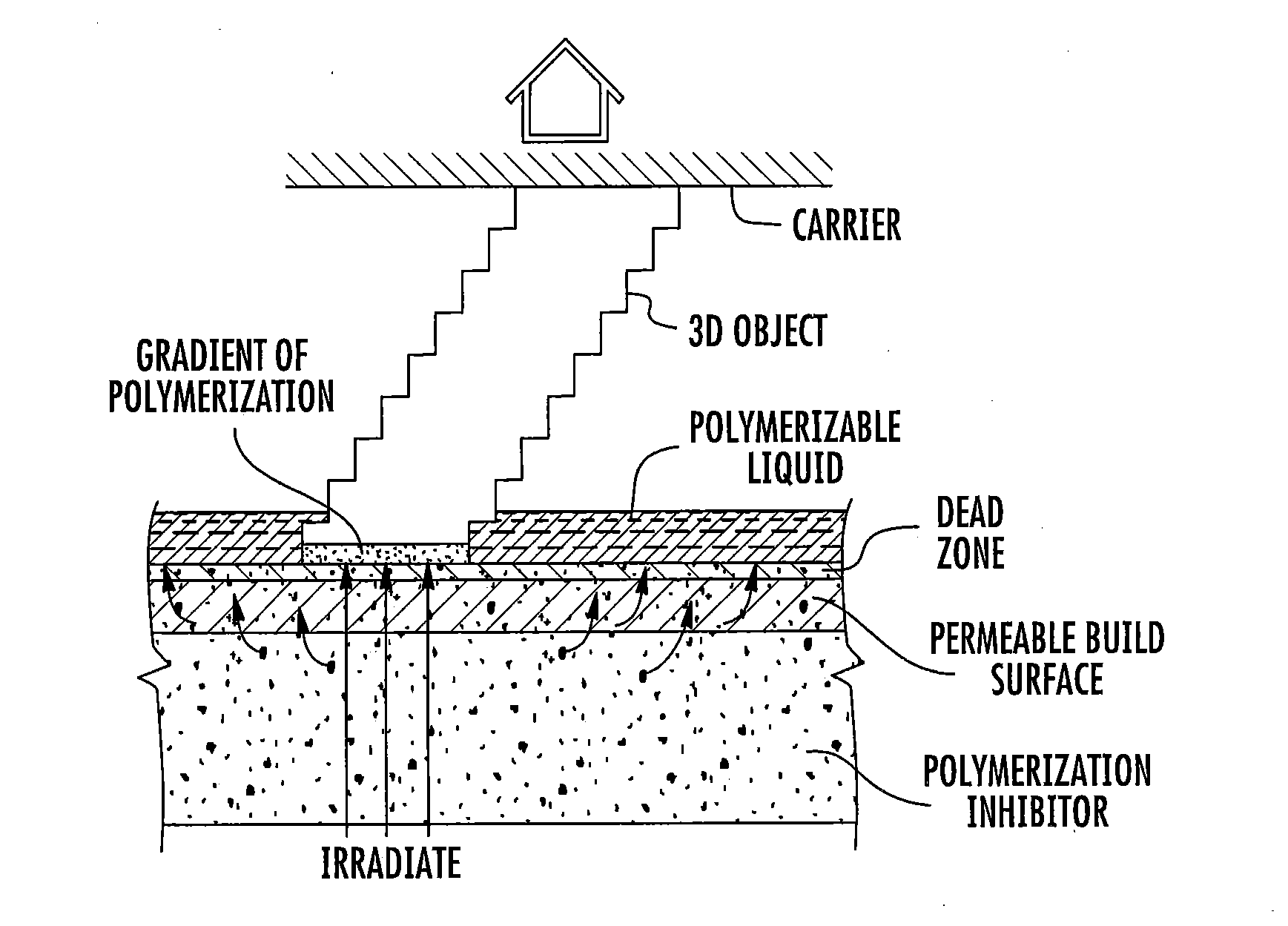

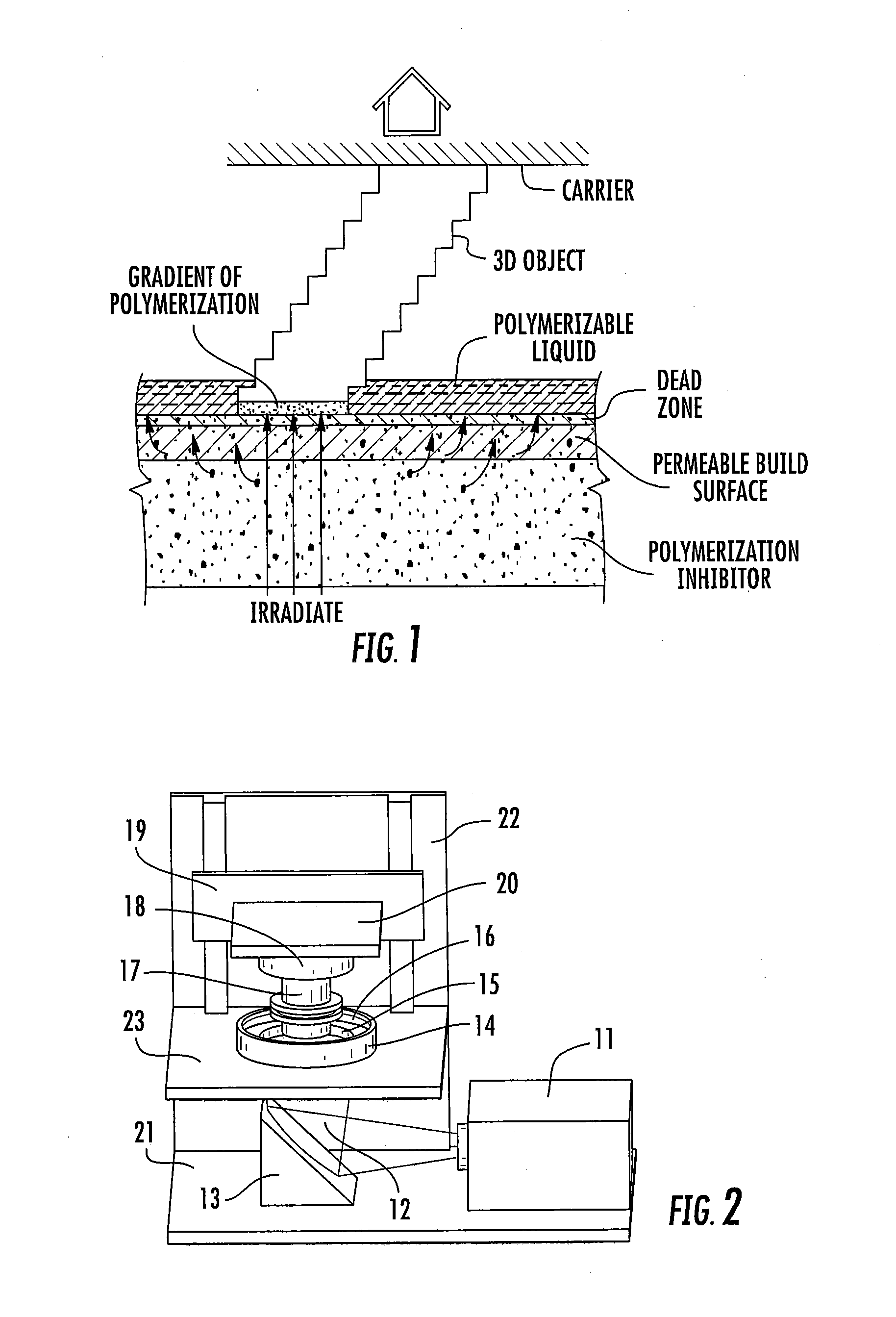

Polyurethane resins having multiple mechanisms of hardening for use in producing three-dimensional objects

ActiveUS20160137839A1Increased formationEnhance or speed the refilling of the build regionImpression capsManufacturing enclosuresEndcappingPolymer science

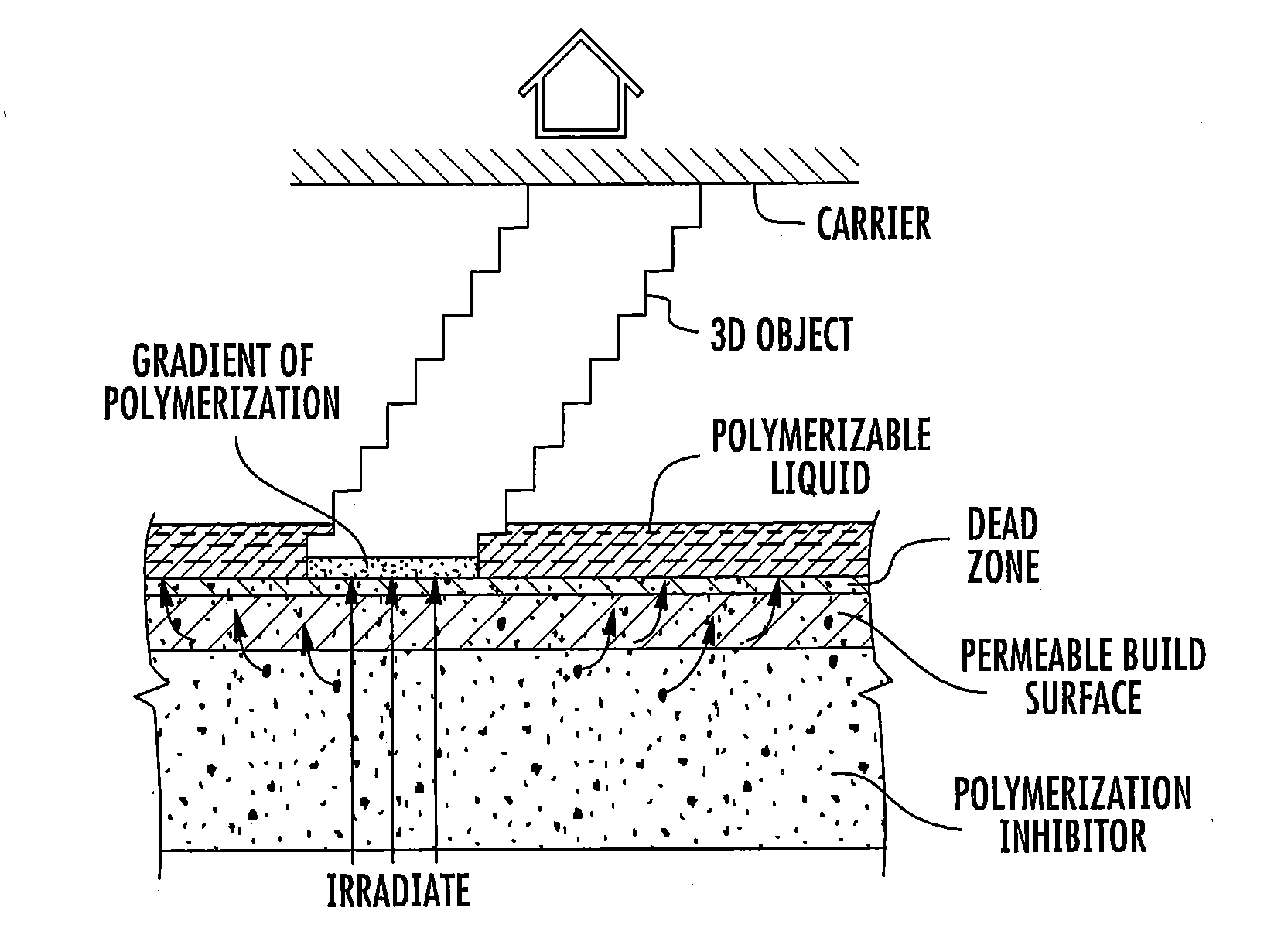

A polymerizable liquid, or resin, useful for the production by additive manufacturing of a three-dimensional object of polyurethane, polyurea, or a copolymer thereof, is described. The resin includes at least one of (i) a blocked or reactive blocked prepolymer, (ii) a blocked or reactive blocked diisocyanate, or (iii) a blocked or reactive blocked diisocyanate chain extender.

Owner:CARBON INC

Methods of producing polyurethane three-dimensional objects from materials having multiple mechanisms of hardening

ActiveUS20160137838A1Increased formationEnhance or speed the refilling of the build regionManufacturing enclosuresOptical articlesEndcappingPolymer science

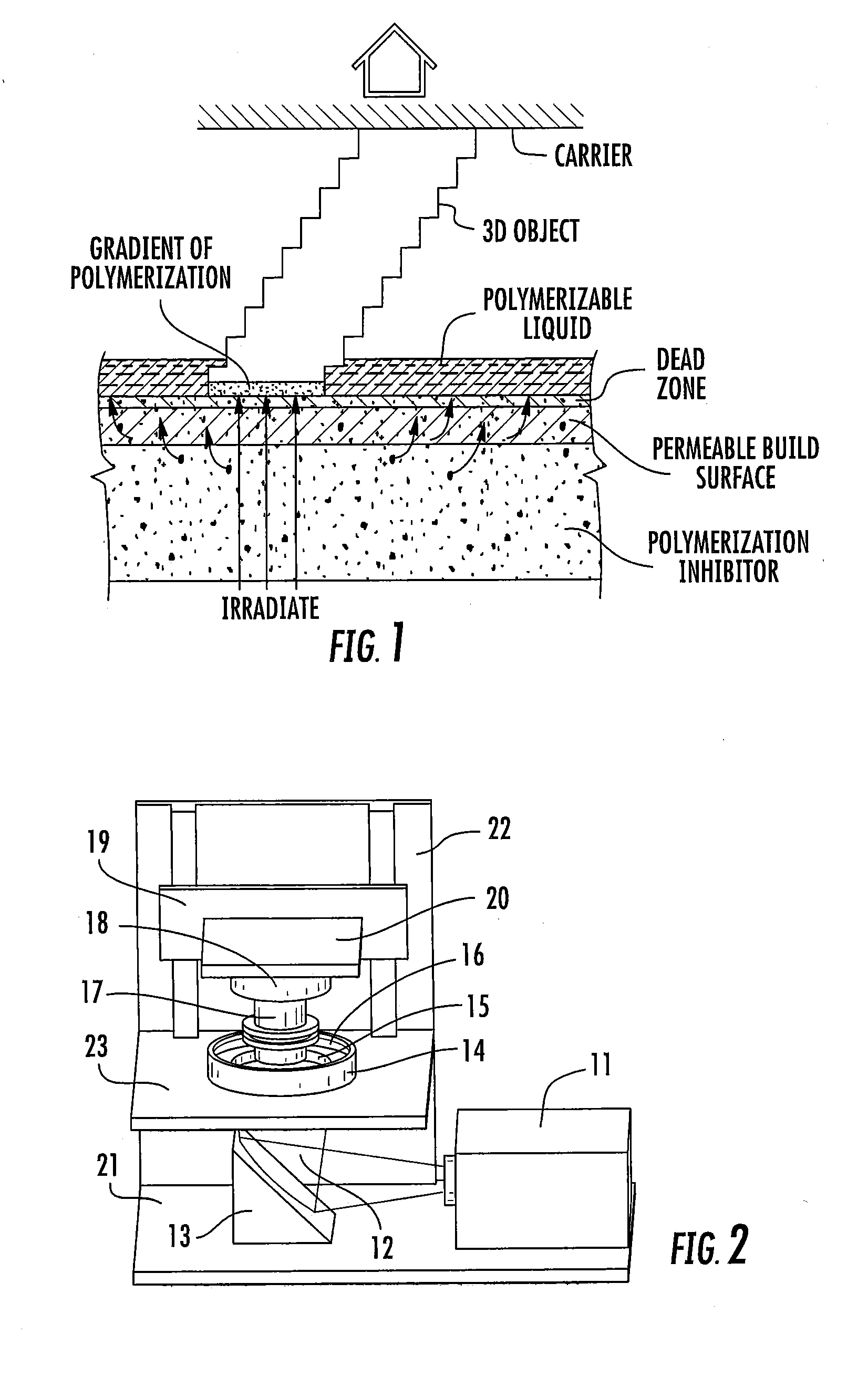

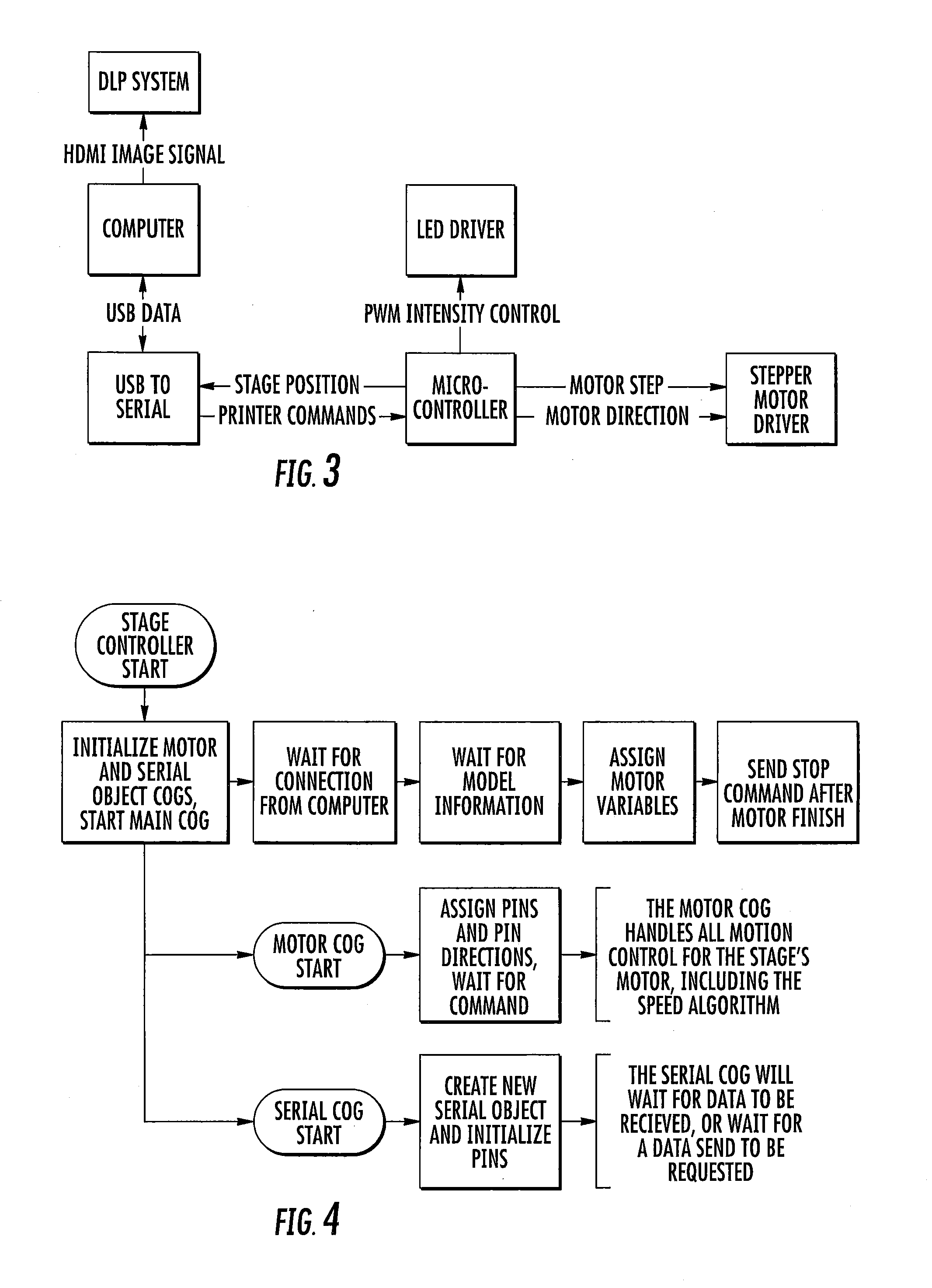

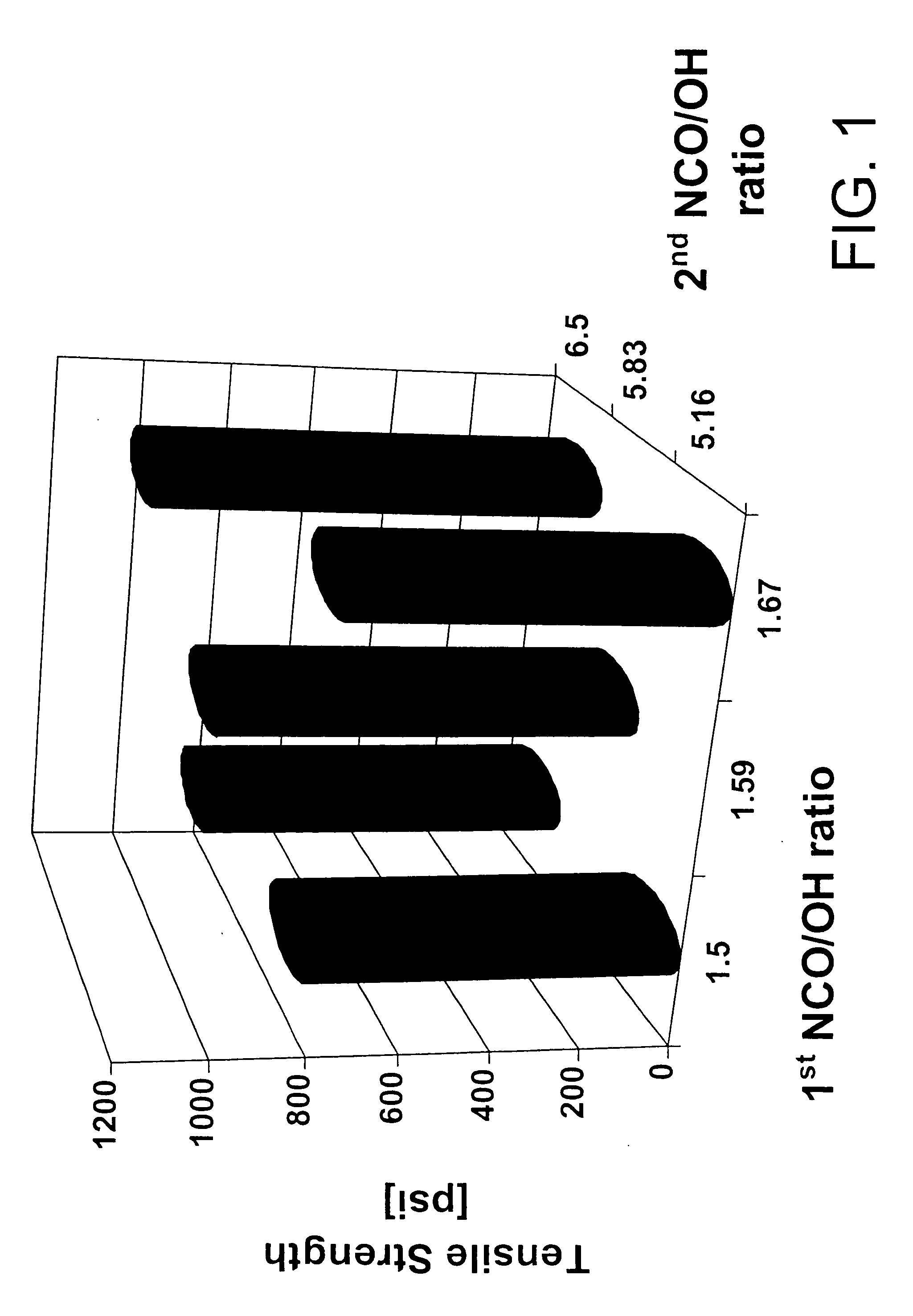

A method of forming a three-dimensional object of polyurethane, polyurea, or copolymer thereof is carried out by: (a) providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; (b) filling the build region with a polymerizable liquid, the polymerizable liquid including at least one of: (i) a blocked or reactive blocked prepolymer, (ii) a blocked or reactive blocked diisocyanate, or (iii) a blocked or reactive blocked diisocyanate chain extender; (c) irradiating the build region with light through the optically transparent member to form a solid blocked polymer scaffold and advancing the carrier away from the build surface to form a three-dimensional intermediate having the same shape as, or a shape to be imparted to, the three-dimensional object, with the intermediate containing the chain extender; and then (d) heating or microwave irradiating the three-dimensional intermediate sufficiently to form from the three-dimensional intermediate the three-dimensional object of polyurethane, polyurea, or copolymer thereof.

Owner:CARBON INC

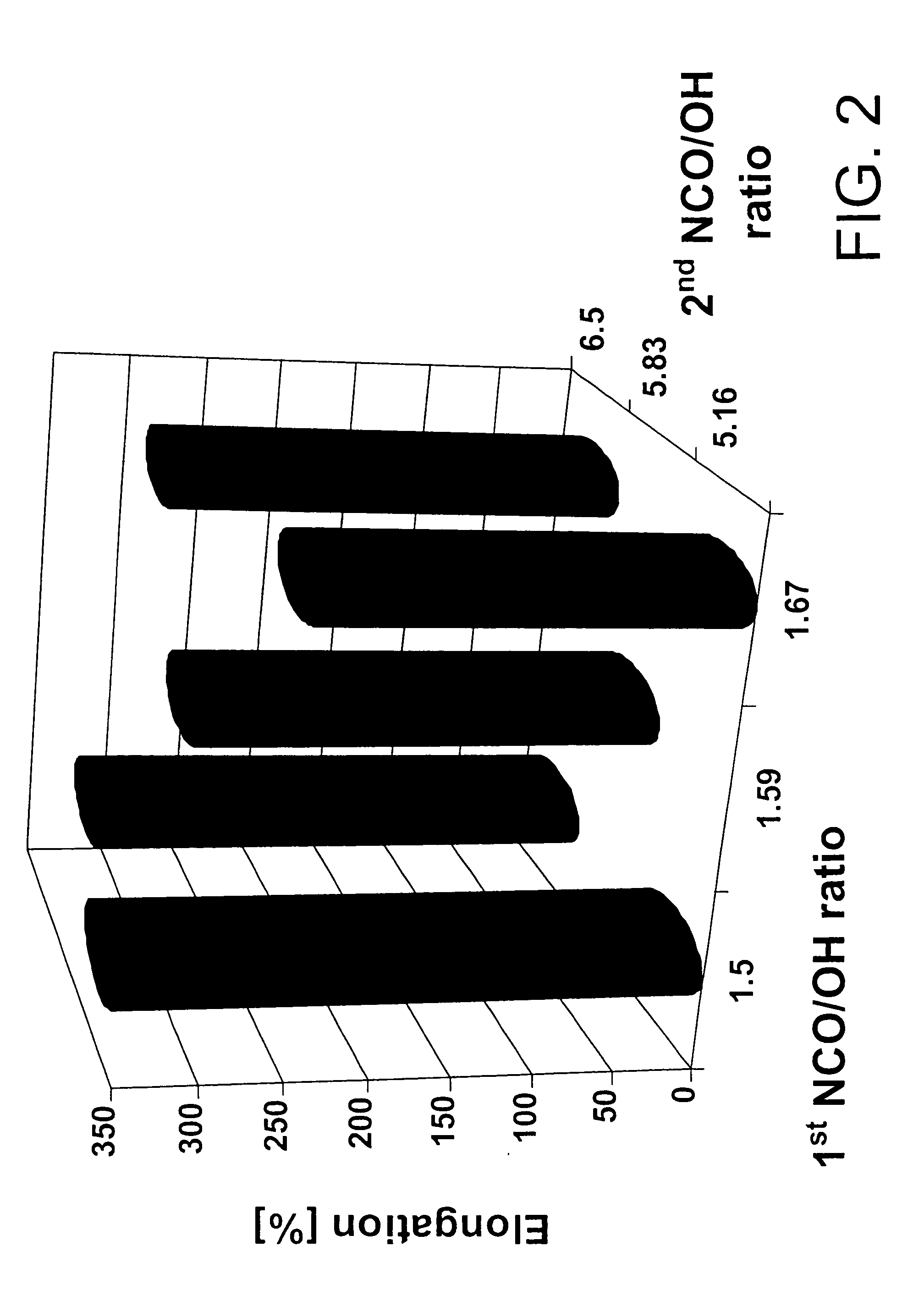

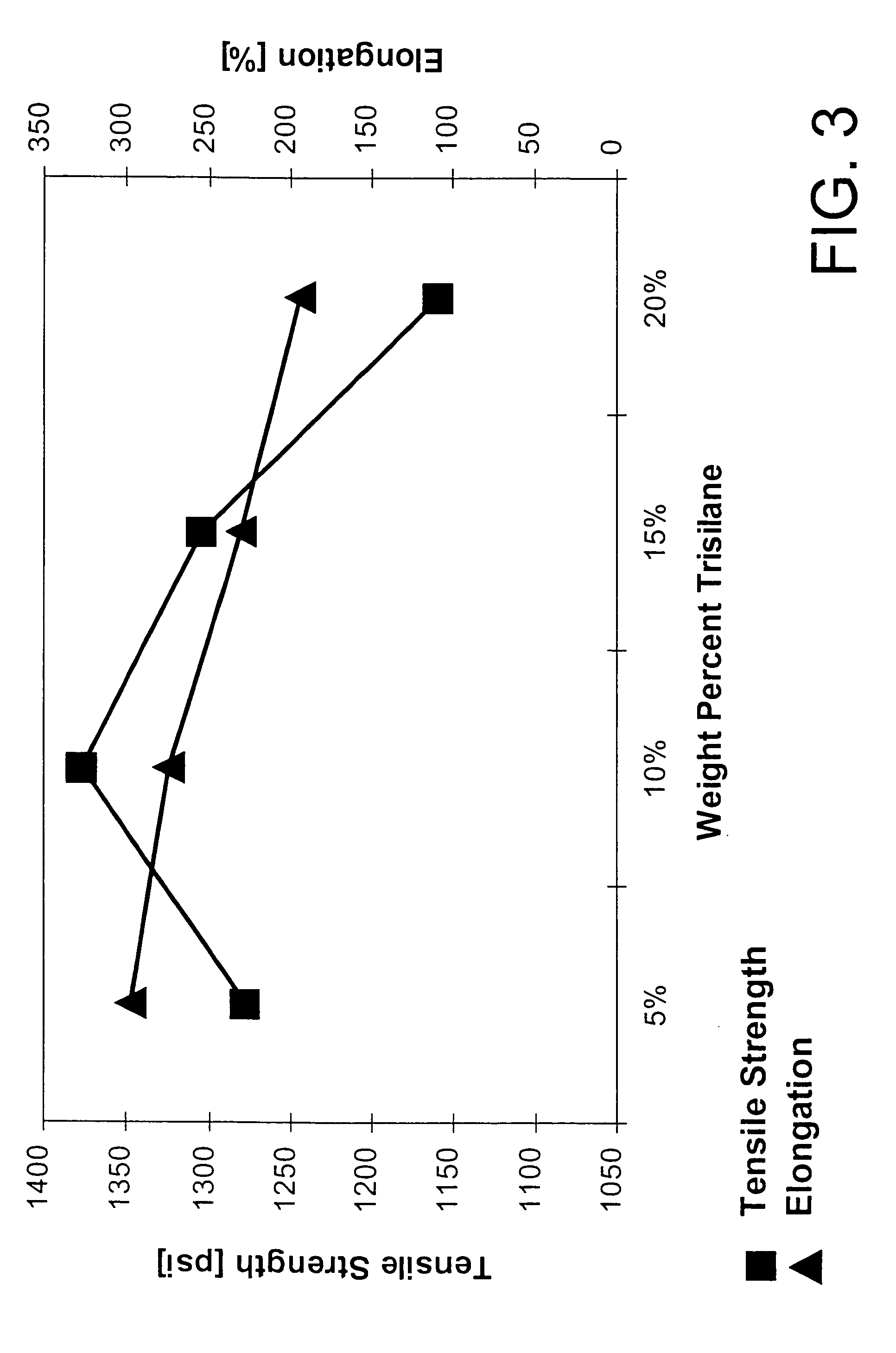

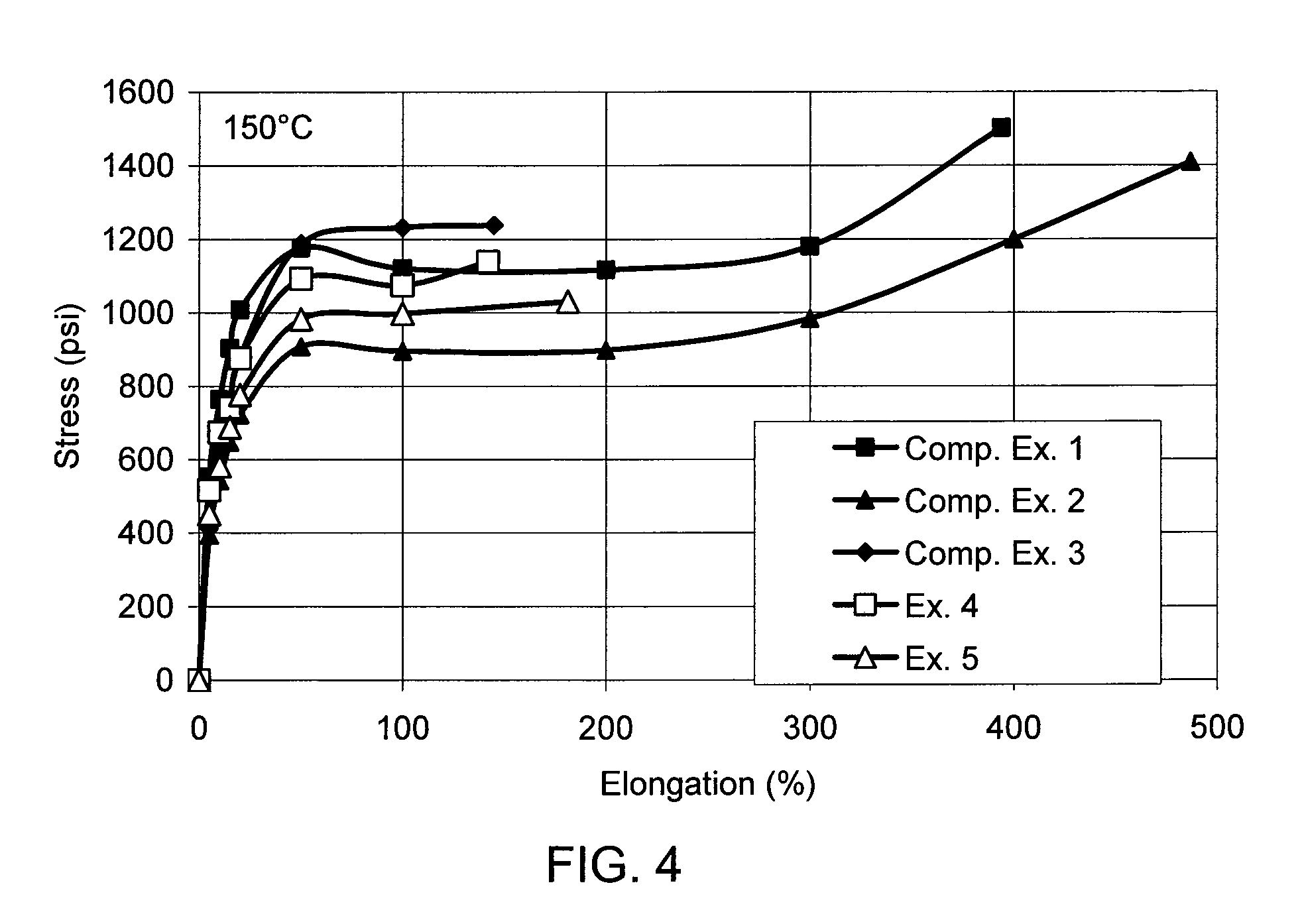

Silane-terminated polyurethanes with high strength and high elongation

A silane-terminated polyurethane composition is the reaction product of a silane-terminated polyurethane prepolymer component, a silane-terminated monomeric diisocyanate, and optionally at least one multifunctional trisilane or tetrasilane component. A method for making a composition includes (a) providing a silane-terminated polyurethane prepolymer component, a silane-terminated monomeric diisocyanate component, and optionally at least one multifunctional trisilane or tetrasilane component, and (b) combining the prepolymer component, monomeric component, and optional multifunctional silane component to form a silane-terminated polyurethane reaction product with a tensile strength of about 4 MPa or greater and an elongation of about 200% or greater.

Owner:CONSTR RES & TECH GMBH

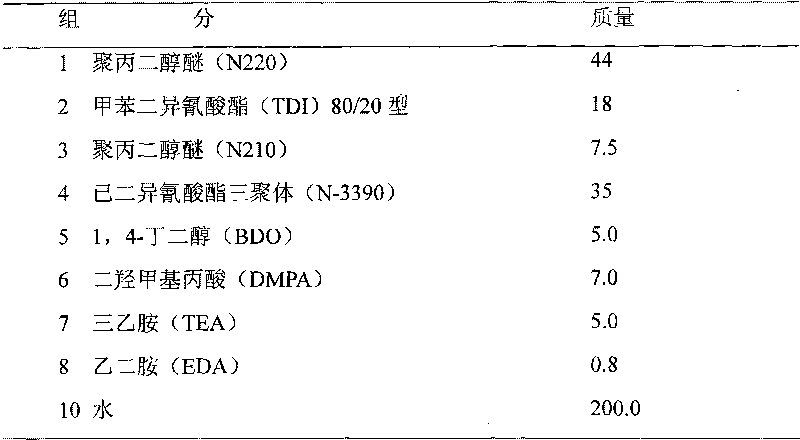

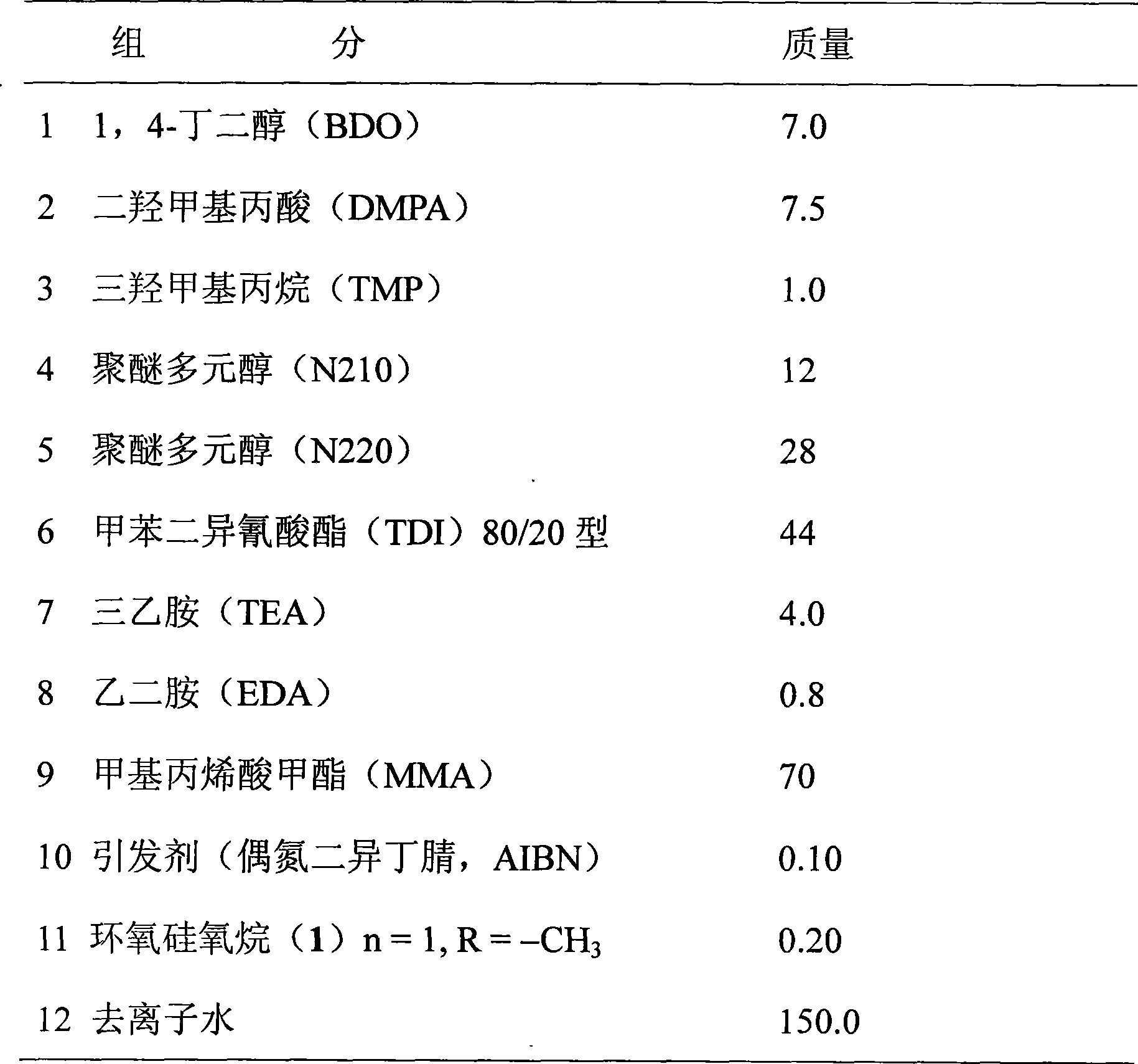

Organic silicon modified aqueous polyurethane

InactiveCN1854165AImprove water resistanceFeel goodFibre treatmentPolyureas/polyurethane adhesivesWater basedCross-link

An organic silicon modified water-based polyurethane and its production are disclosed.The polyurethane consists of low-polymer polybasic alcohol, vulcabond and chain extender. The production is carried out by dispersing pre-polymer in water, adding ammonia silane coupling agent into system, synthesizing pre-polymer, reacting amine base with residual vulcabond base, chain extending for pre-polymer while hydrolytic condensation polymerizing, cross-linked reacting and obtaining final product. It has better water resistance and handle, less surface performance and wider temperature range. It can be used for pigment, leather finishing agent and adhesive.

Owner:广州宏昌胶粘带厂

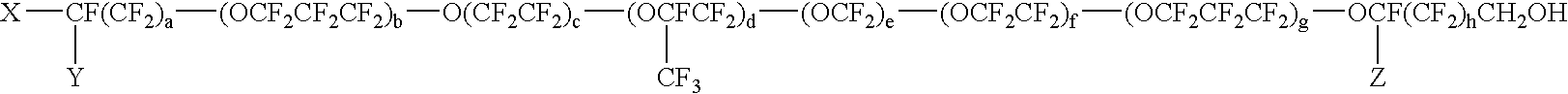

Surface-treating agent composition and process for producing the same

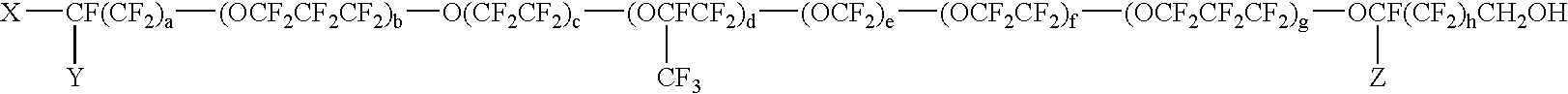

InactiveUS20040181008A1Fit closelySynthetic resin layered productsPolyurea/polyurethane coatingsPolymer sciencePerfluoropolyether

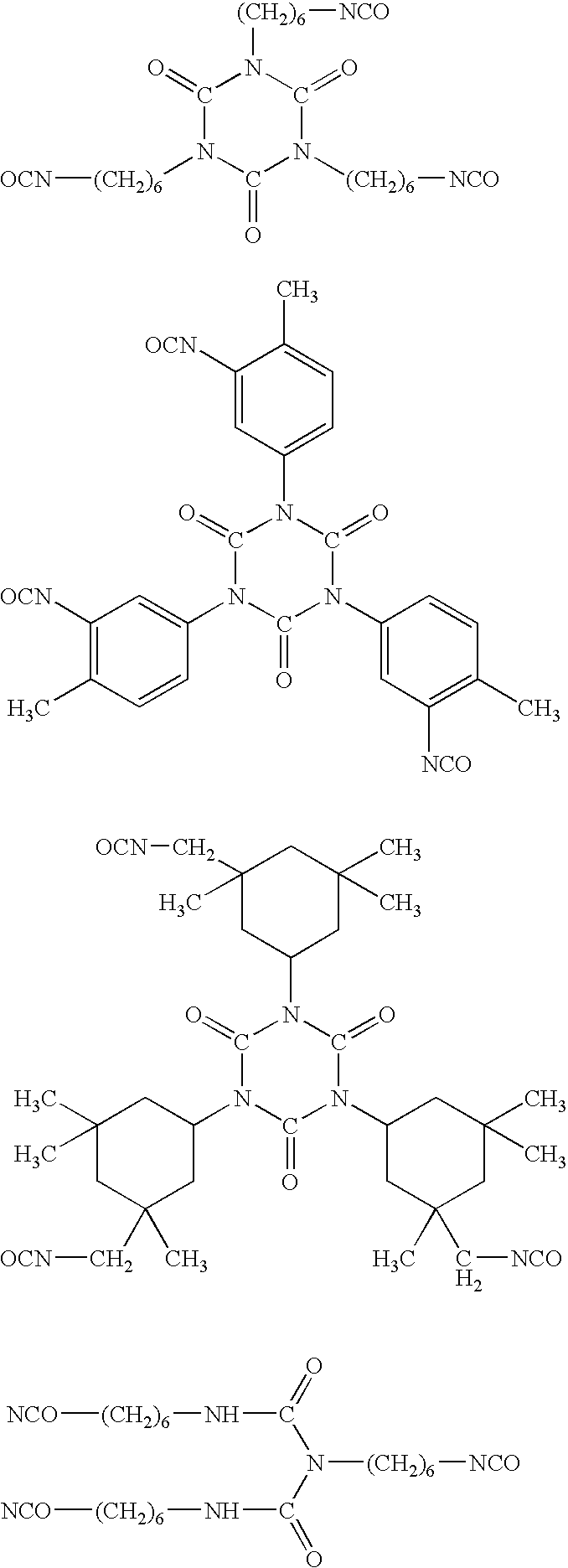

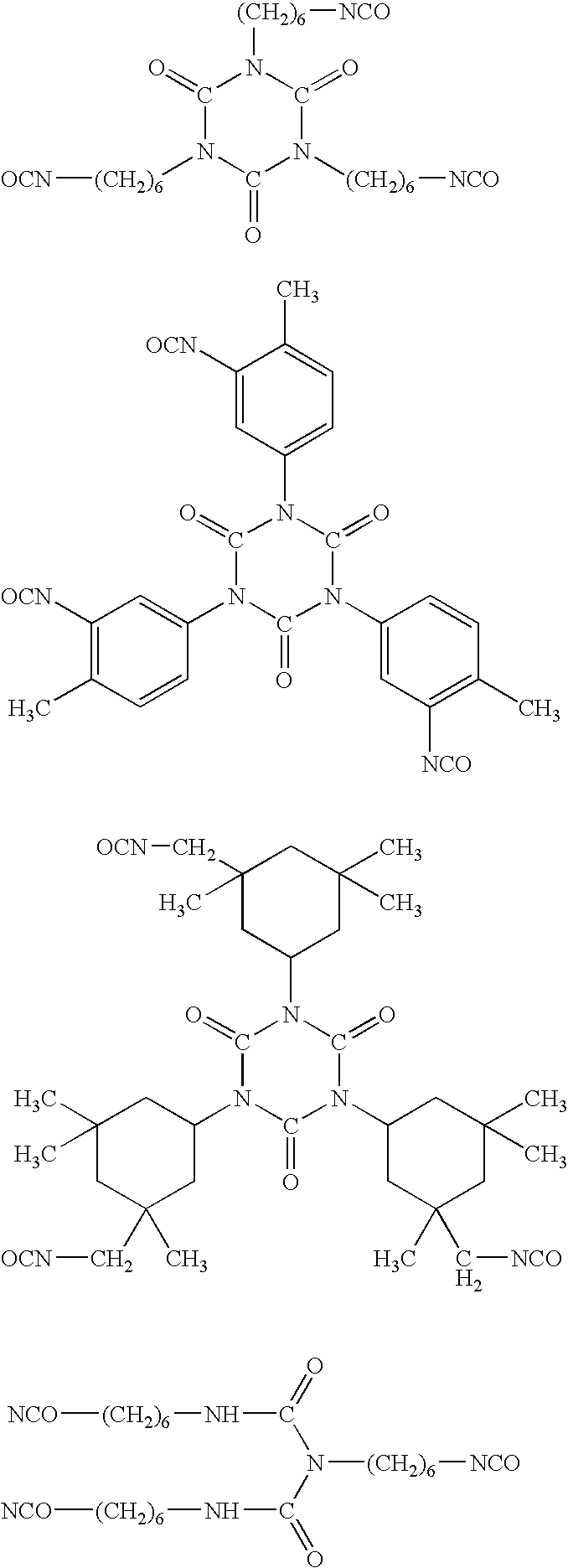

A perfluoropolyether-containing composition, which can easily conform to a fluorine-free substrate and can form a film on a surface of the substrate to fix the composition to the substrate surface, wherein the composition is a carbon-carbon double bond-containing composition comprising (A) a triisocyanate prepared by trimerizing a diisocyanate, and (B) a combination of at least two active hydrogen-containing compounds, and the component (B) comprises (B-1) a perfluoropolyether having at least one active hydrogen, and (B-2) a monomer having active hydrogen and a carbon-carbon double bond.

Owner:DAIKIN IND LTD

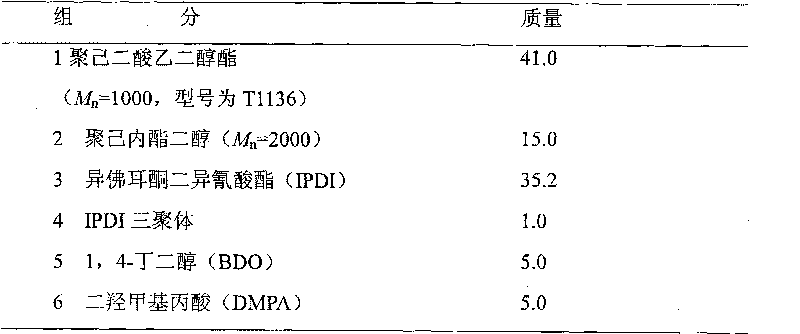

Preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents

InactiveCN101696262ASimple processEasy to operatePolyurea/polyurethane coatingsLeather surface finishingPolyesterSolvent

The invention discloses a preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents. The preparation method comprises the following steps of: carrying out prepolymerization reaction by using polyester polyol, vulcabond monomer and a polyisocyanate curing agent; reacting with a hydrophilic chain-extending agent and a micro-molecule chain-extending agent to obtain polyurethane prepolymer containing hydrophilic groups (carboxyl or sulfonic groups) and isocyanate(NCO)-terminated groups; neutralizing the polymer into salt, and then dispersing the salt into water; and preparing the modified polyurethane aqueous dispersions of the polyisocyanate curing agents by the chain extending of a polyamine chain-extending agent. The modified polyurethane aqueous dispersions of the polyisocyanate curing agents have self-crosslinking function at room temperature, and the self-crosslinking density is over 85%. Compared with non-modified polyurethane aqueous dispersions prepared under the same condition, the modified polyurethane aqueous dispersions have superior film forming property, water resistance, alcohol resistance, pollution resistance, cold resistance, dry / wet rubbing resistance and chemical solvent resistance; and coating films have especially high drying speed, high hardness increment speed and high final hardness.

Owner:SOUTH CHINA UNIV OF TECH

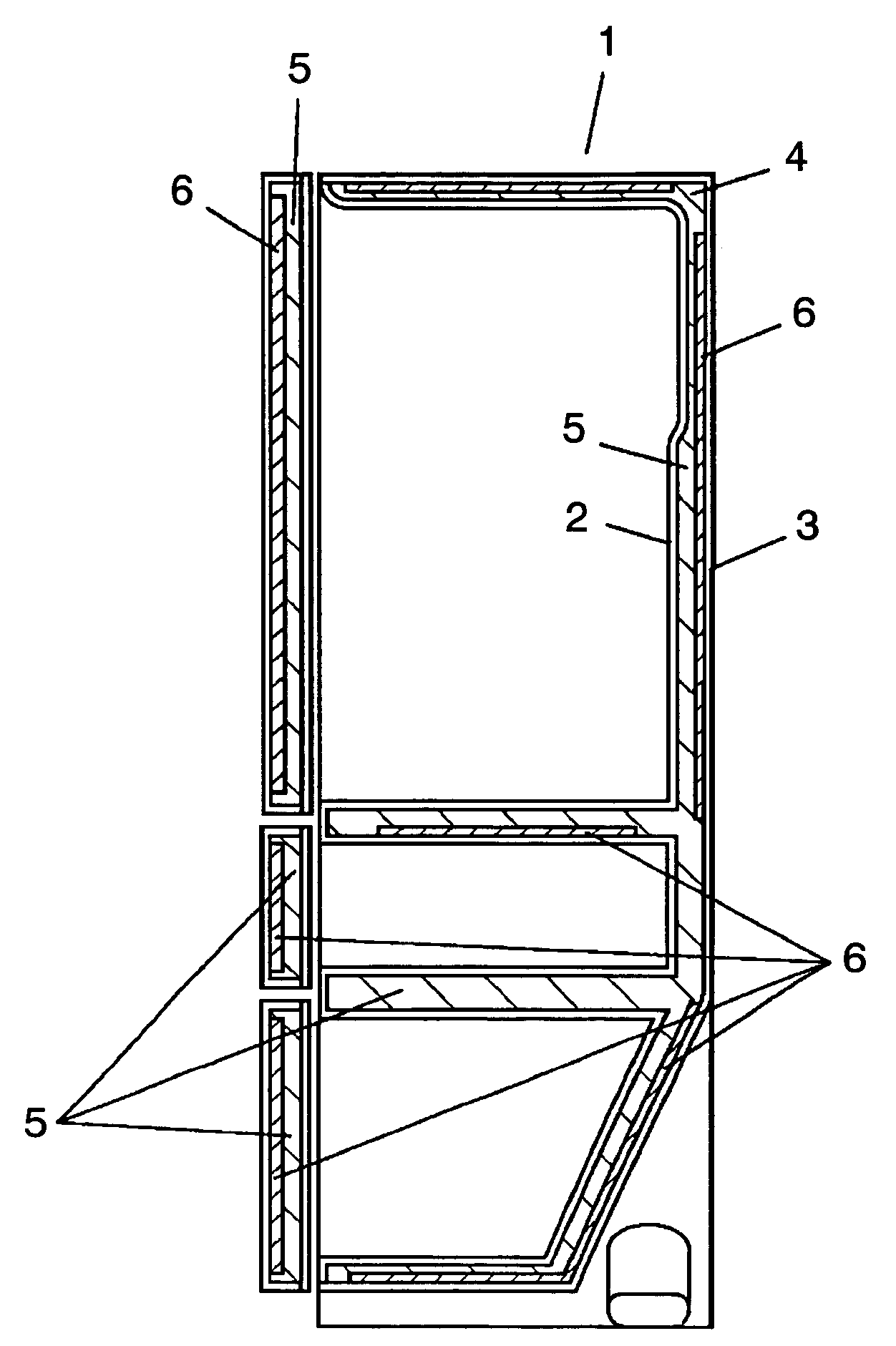

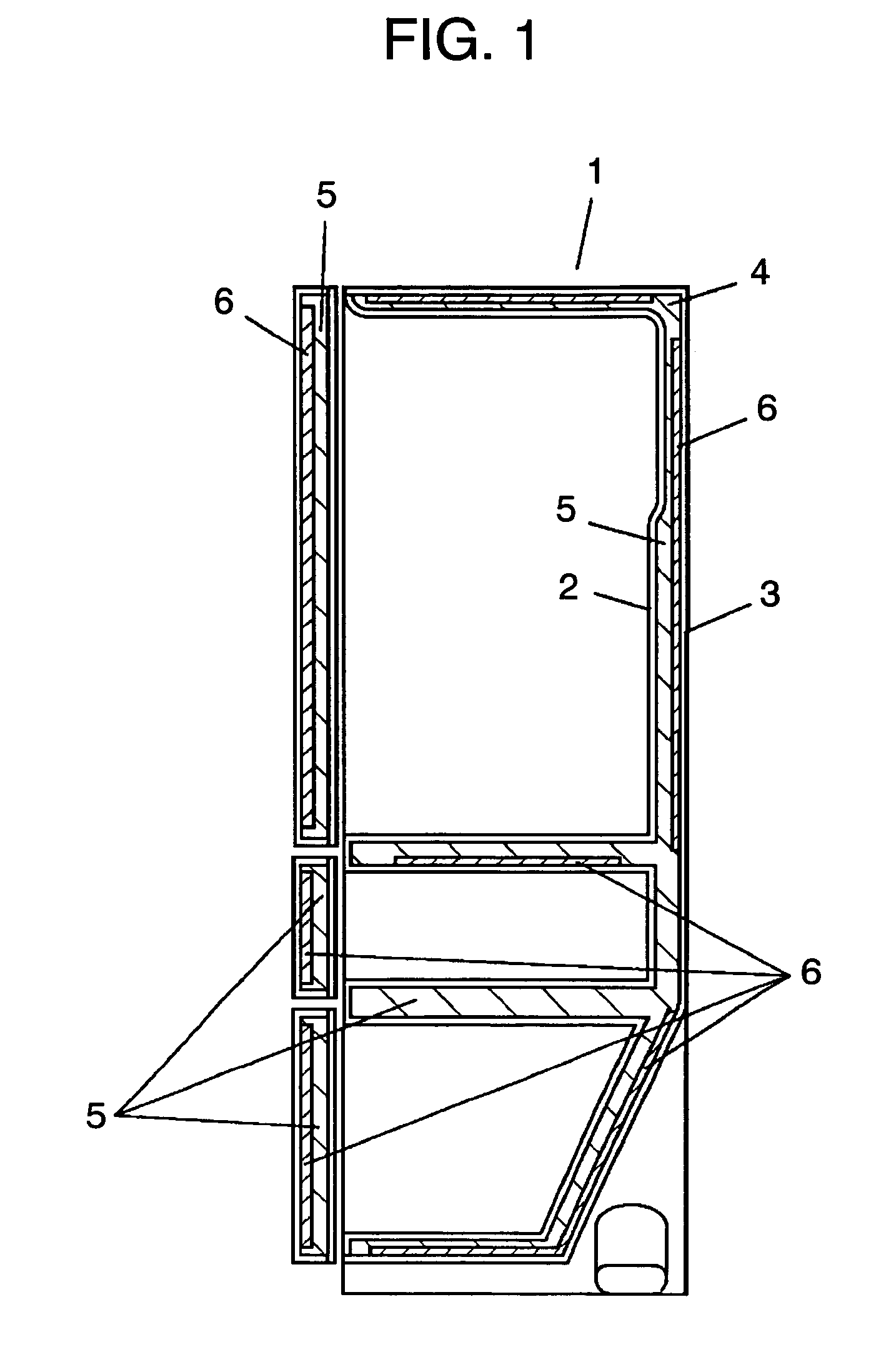

Insulated box body, refrigerator having the box body, and method of recycling materials for insulated box body

InactiveUS7316125B2Provide structural strengthImprove insulation efficiencyLighting and heating apparatusDomestic refrigeratorsVolumetric Mass DensityEngineering

An insulation box unit and a refrigerator of the present invention employs i) rigid urethane foam with a 8.0 MPa-or-greater bending modulus, and a 60 kg / m3-or-lower density, and ii) a vacuum insulation material. The proper bending modulus provides the insulation box unit with a substantial strength, even in the case that the coverage of the vacuum insulation material with respect to the surface of the outer box exceeds 40%. The proper density prevents the insulation box unit from poor insulation efficiency due to undesired solid thermal conductivity. Despite of an extended use of the vacuum insulation material, the insulation box unit offers an excellent insulation efficiency and therefore accelerates energy saving. According to the recycling method of the present invention, rigid urethane foam formed of tolylene di-isocyanate composition, which was separated from refrigerator wastes, is recycled as a material of rigid urethane foam.

Owner:PANASONIC CORP

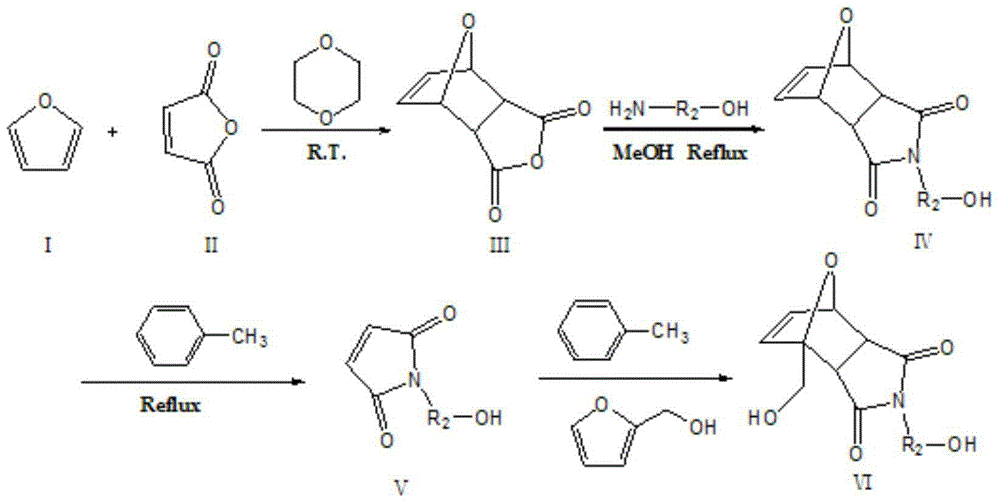

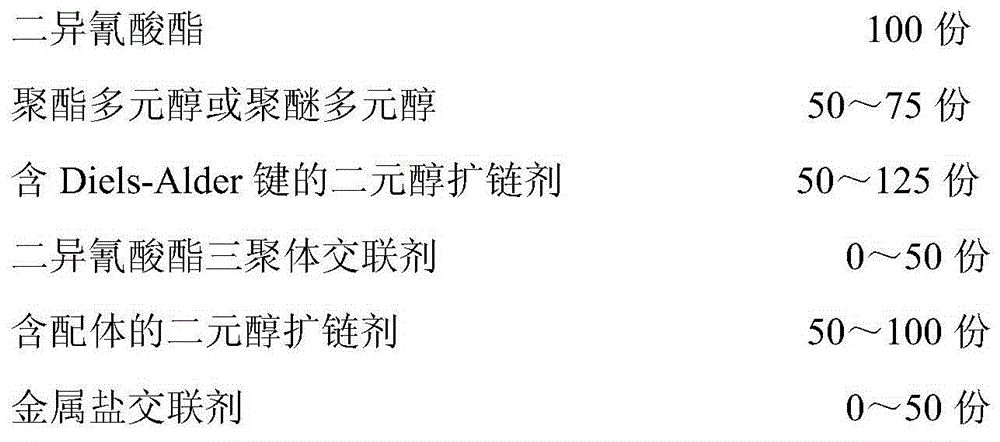

Dynamic bond-containing polyurethane material for 3D printing and its preparation method and use

ActiveCN104961881ALow viscosity3D printing process facilitatesAdditive manufacturing apparatusOrganic chemistryPolyesterAlcohol

Owner:SICHUAN UNIV

Surface treatment composition and preparation thereof

InactiveUS6906115B2Fit closelySynthetic resin layered productsPolyurea/polyurethane coatingsHydrogenPerfluoropolyether

Owner:DAIKIN IND LTD

Polyurethane PSA

ActiveUS7160976B2Polyureas/polyurethane adhesivesSynthetic resin layered productsPolymer sciencePolypropylene glycol

Pressure-sensitive adhesive based on polyurethane, characterized in that the polyurethane is composed of the following starting materials which are reacted with one another in the stated proportions:a) at least one aliphatic or alicyclic diisocyanate having in each case an asymmetrical molecular structure,b) a combination of at least one polypropylene glycol diol and at least one polypropylene glycol triol,the ratio of the number of hydroxyl groups in the diol component to the number of hydroxyl groups in the triol component being between 0.7 and 9.0, preferably between 1.5 and 2.5,additionally the ratio of the number of isocyanate groups to the total number of hydroxyl groups being between 0.9 and 1.1, preferably between 0.95 and 1.05, and the diols and triols alternatively being selected and combined in each case as follows:diols having a molecular weight of less than or equal to 1000 are combined with triols whose molecular weight is greater than 1000, preferably greater than or equal to 3000,diols having a molecular weight of greater than 1000 are combined with triols whose molecular weight is less than 1000.

Owner:TESA SE

Filled polymer composite and synthetic building material compositions

ActiveUS20050163969A1Improve mechanical propertiesLow costSolid waste managementLayered productsPolyesterFiber

The invention relates to composite compositions having a matrix of polymer networks and dispersed phases of particulate or fibrous materials. The polymer matrix contains a polyurethane network formed by the reaction of a poly- or di-isocyanate and one or more saturated polyether or polyester polyols, and an optional polyisocyanurate network formed by the reaction of optionally added water and isocyanate. The matrix is filled with a particulate phase, which can be selected from one or more of a variety of components, such as fly ash particles, axially oriented fibers, fabrics, chopped random fibers, mineral fibers, ground waste glass, granite dust, or other solid waste materials. The addition of water can also serve to provide a blowing agent to the reaction mixture, resulting in a foamed structure, if such is desired.

Owner:BORAL IP HLDG

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

InactiveUS7091297B2High modulusSufficient cross-linkingStentsOther chemical processesPolymer scienceAdhesive

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligomeric silsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated POSS and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:UNIV OF CONNECTICUT

Water-based intercoating composition and method of forming multilayered coating film

InactiveUS20060121204A1Improve propertiesGood lookingLiquid surface applicatorsPolyurea/polyurethane coatingsPolymer sciencePolyol

A water-based intermediate coating composition which contains a water-dispersible polyurethane composition is used. Here, the water-dispersible polyurethane composition is obtained from: a polyisocyanate component containing diisocyanate as an essential component; a polyol component containing polycarbonatediol with an average molecular weight of 500 to 5,000 and carboxyl group-containing diol as essential components; an amine component containing a monoamine compound as an essential component; a carboxyl group-neutralizing component; and water. A three-layered coating film including the water-based intermediate coating, a water-based base coating and a clear coating is formed through a wet-on-wet process on a material onto which an electrodeposited coating film is formed. Thereafter, the three coating films are baked and cured at the same time, thereby forming a multilayer coating film.

Owner:NIPPON PAINT CO LTD

Adhesive compositions containing blocked polyurethane prepolymers

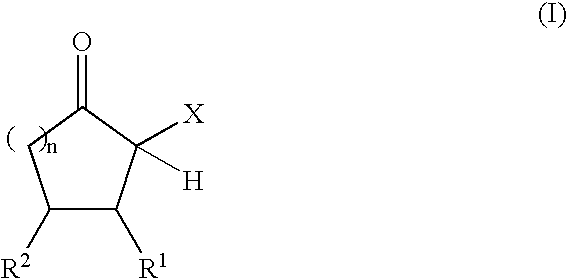

The present invention relates to reactive compositions containing A) one or more blocked polyurethane prepolymers which have a content of blocked isocyanate groups (calculated as NCO) of 0.1 to 20 wt. % and are prepared from i) at least one aromatic, aliphatic, araliphatic and / or cycloaliphatic diisocyanate having a content of free NCO groups of 5 to 60 wt. %, ii) a polyol component containing at least one polyester polyol, and / or at least one polyether polyol and / or at least one polycarbonate polyol, iii) CH-acidic cyclic ketones corresponding to formula (I) as blocking agents wherein X represents an electron-attracting group, R1 and R2 independently of one another represent the radicals H, C1-C20 (cyclo)alkyl, C6-C24 aryl, C1-C20 (cyclo)alkyl ester or amide, C6-C24 aryl ester or amide, mixed aliphatic / aromatic radicals with 1 to 24 carbon atoms that can also be part of a 4- to 8-membered ring, n is an integer from 0 to 5, and B) one or more OH-functional compounds in which the OH component undergoes activation by a deposition amine component. The present invention also relates to a composite system containing two adherends bonded together with the reactive composition according to the invention.

Owner:BAYER MATERIALSCIENCE AG

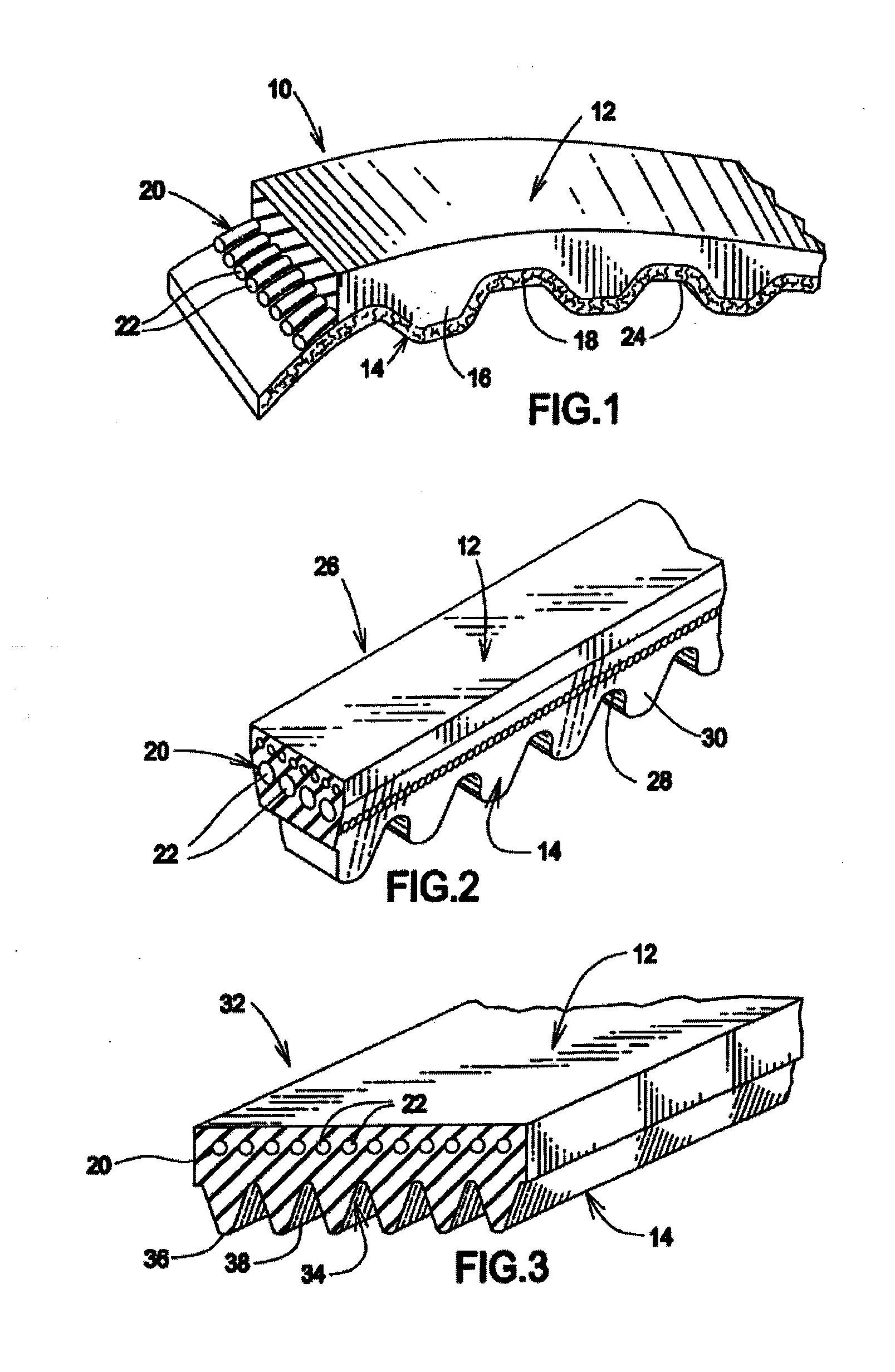

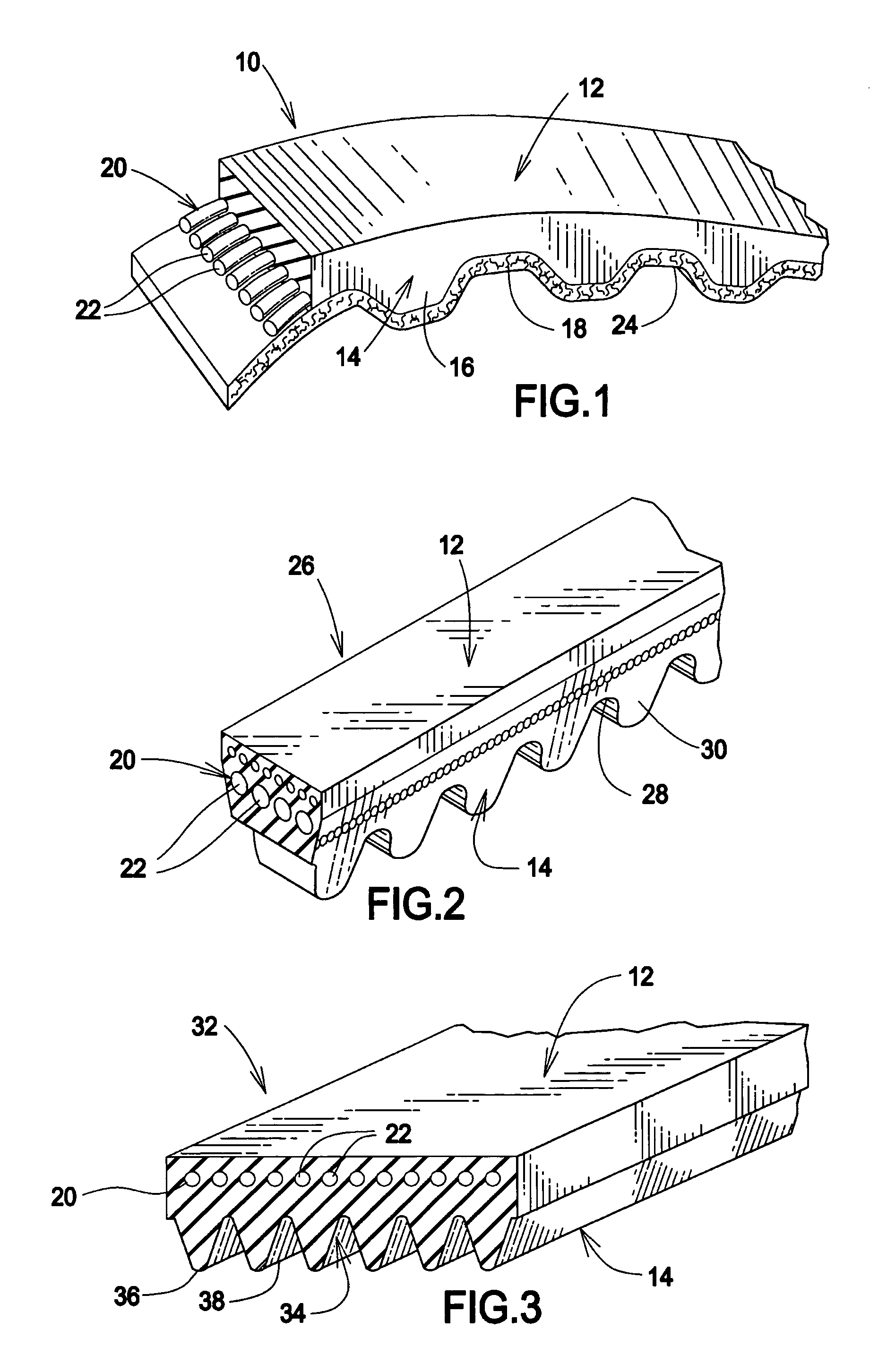

Polyurethane power transmission belt

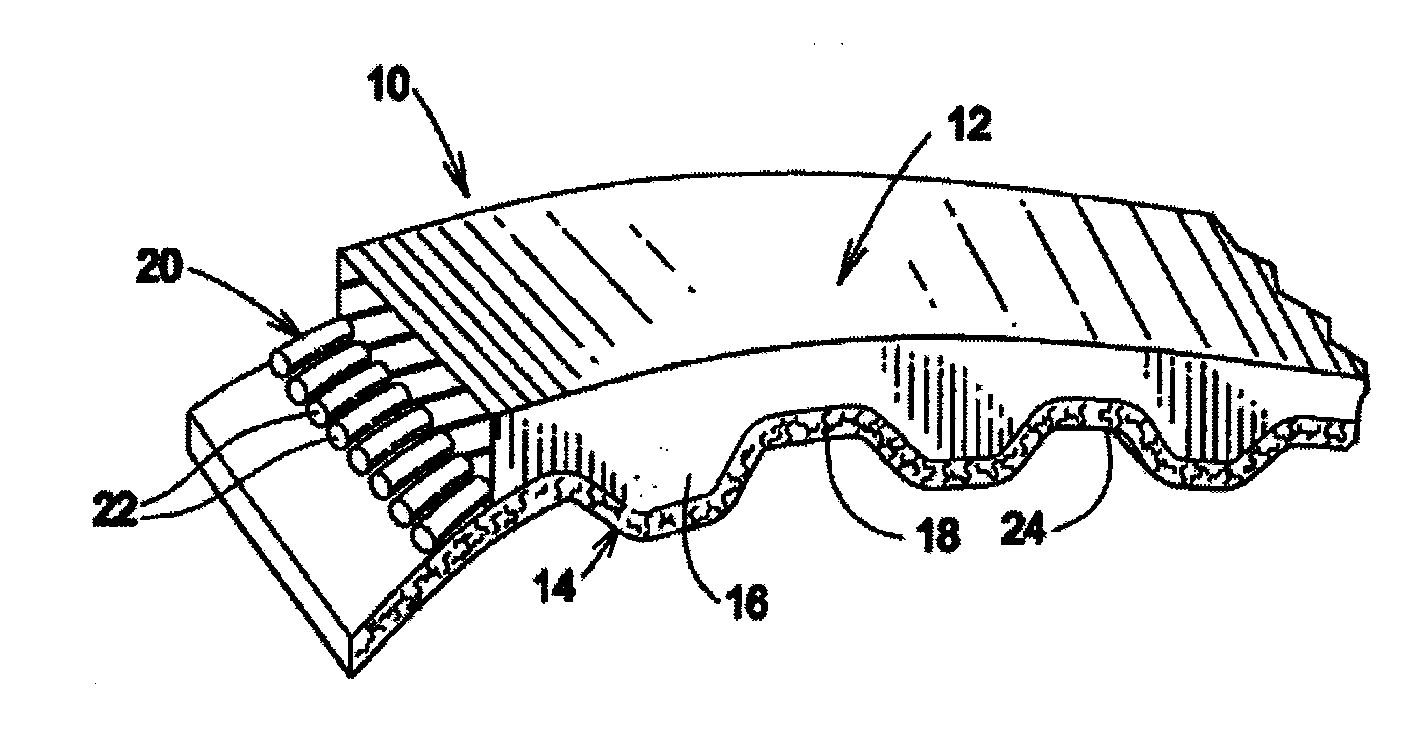

ActiveUS20090227406A1Increase load capacityIncrease resistanceV-beltsRopes and cables for vehicles/pulleyElastomerFiber

A power transmission belt having a main belt body portion of elastomeric material, a tensile reinforcement such as carbon fiber cord, disposed in said body portion, and a sheave contact portion integral with said main body portion. The elastomeric material includes the reaction product of a polyisocyanate prepolymer composition and a chain extender. The polyisocyanate prepolymer composition is prepared by reacting a diisocyanate and a polyol substantially free of moieties oxidative at less than about 150° C. and at least one triol crosslinker selected from the same group of polyols. Either before or after reacting the prepolymer, a plasticizer selected from the group consisting of alkyl-ether di-alkylesters such as polyethylene glycol di-alkylester is added thereto. The chain extender is an aromatic symmetric primary or secondary diamine chain extenders.

Owner:THE GATES CORP

Process for the manufacturing of an improved core for decorative laminates and a decorative laminate obtained by the process

InactiveUS6841023B2Improve brittlenessImprove the overall coefficientOrganic chemistryLamination ancillary operationsPolyesterFiber

A process for the manufacturing of a core forming a carrying structure for decorative laminates. The core comprises particles of cured, and optionally foamed, rigid, polyurethane, polyisocyanurate and / or phenolic resin. The particles are bonded to each other in a pressing procedure with a bonding agent comprising an adhesive such as a polymerizing monomer.i) The particles are achieved by grinding cured, and optionally foamed, rigid, polyurethane, polyisocyanurate and / or phenolic resin so that it passes through a 2 mm screen, preferably a 1 mm screen,ii) 100 parts per weight of particles is mixed with 1-100 parts per weight of fiber, the fiber additive having an average length in the range 1-15 mm.iii) The particle-fiber mixture is allowed to absorb a selected amount of water, the amount of water being in the range 1-15% by weight, The water is either added at any stage before the adding of bonding agent, and / or being used as a solvent in the bonding agent, and that,iv) 85 parts per weight of the particle mixture is mixed with 2-15 parts per weight of a bonding agent, the bonding agent selected from the group consisting of,a) A mixture of polyols, such as polyester or polyether, crude methylene diphenyl diisocyanate and possibly a small amount of blowing agent in a ratio forming a polymeric resin with a density in the range 600-1400 kg / m3.b) A formaldehyde based resin such as phenol-formaldehyde resin, urea-formaldehyde resin, melamine-urea-formaldehyde resin, melamine-urea-phenol-formaldehyde resin or phenol-resorcinol-formaldehyde resin, orc) Polyvinyl acetate resin.v)The mixture is applied between the belts of the continuos belt press or the press plates of a static press, optionally with at least one intermediate carrier web, the belts or press plates allowing a mainly uniform and specified material thickness to form. A slightly porous and preconditioned core with a selected water content in the range 0.8-12% is hereby achieved. The invention also relates to a decorative laminate achieved through the process.

Owner:PERGO

Coating compositions for glass substrates

InactiveUS20110045219A1Synthetic resin layered productsPolyurea/polyurethane coatingsPolyurethane dispersionPolyol

The present invention relates to an aqueous polyurethane coating composition comprising:1) 1 to 99 wt. % of the reaction product of:a) a polyol component, which is soluble or dispersible in water and is the reaction product of a polyisocyanate component containing 50 to 100 wt. % of an aliphatic diisocyanate, a polyol component containing one or more polyether polyols and having an OH number of 25 to 350 mg KOH / g solids and an isocyanate-reactive component containing at least one group capable of salt formation; andb) polyisocyanate component, which is soluble or dispersible in water, has blocked isocyanate groups and is the reaction product of one or more polyisocyanates having an isocyanurate group content of 2 to 30 wt. %, a reversible, monofunctional blocking agent for isocyanate groups, a nonionic hydrophilic component and a stabilizing component which has 1 to 2 hydrazide groups and a molecular weight of 70 to 300; and2) 1 to 99 wt. % of an aqueous polyurethane dispersion prepared from at least one polycarbonate polyol,wherein the total wt. % of components 1) and 2) add up to 100%.

Owner:COVESTRO LLC

Preparation method and application of graphene oxide-polyurethane foam material

InactiveCN103408718AImprove adsorption capacityGood removal effectOther chemical processesWater contaminantsMalachite greenPolymer science

The invention belongs to the field of high polymer material synthesis, and relates to preparation of a graphene oxide-polyurethane foam material, in particular to a preparation method and application of the graphene oxide-polyurethane foam material. The preparation method of the graphene oxide-polyurethane foam material comprises the following steps: firstly, preparing graphene oxide by adopting an improved Hummers method, then mixing and stirring graphene oxide, polyether glycol NJ-330, foaming agent, foam stabilizer and catalyst at room temperature, adding isophorone diisocyanate, and finally, foaming further to obtain the graphene oxide-polyurethane foam material. The graphene oxide-polyurethane foam material prepared through the method can be applied to absorption of coloring matters or heavy metal ions in waste water, and has better absorption and removal effects as shown in a test by taking a solution containing malachite green and Cd (II) as the absorption object. The application of the foam material to treatment of the coloring matters and the heavy metal ions in sewage has the characteristics of simplicity in operation and high absorption rate, and has a certain practical value.

Owner:JIANGSU UNIV

High solid content latent curing polyurethane acroleic acid hybrid emulsion

InactiveCN101481451AHigh solid contentHigh glossPolyurea/polyurethane coatingsPolyesterPolymer science

The invention relates to a method for preparing a high solid content latent cured polyurethane acrylic acid heterozygous latex and an application thereof. The preparation method comprises the following steps: pre-polymerizing polyester polyalcohol, hydrophilic chain extender and diisocyanate monomer to obtain the polyurethane prepolymer containing a hydrophilic group (carboxyl or sulfo group) and a terminal NCO group; then, neutralizing the polymer into salt and dispersing the salt in water to prepare the polyurethane water dispersoid; finally, using the dispersoid as macro molecular emulsifying agent and reactant to emulsify and disperse the acrylic ester monomer, initiating the polymerization by heating, dropping initiator to perform the latex polymerization, and regulating the pH of the latex by adding a latent curing agent to obtain the high solid content latent cured polyurethane acrylic acid heterozygous latex. The high solid content latent cured polyurethane acrylic acid heterozygous latex has a solid content of above 45%; the storage of the high solid content latent cured polyurethane acrylic acid heterozygous latex is stable; and high hardness film coating can be formed at the room temperature. Compared with acrylic acid latex and polyurethane latex, the high solid content latent cured polyurethane acrylic acid heterozygous latex has better film forming performance, water resistance, alcohol resistance, pollution resistance, dry / wet cleaning resistance and chemical solvent resistance, as well as high hardness.

Owner:SOUTH CHINA UNIV OF TECH

High temperature polyurethane/urea elastomers

InactiveUS6964626B1High and low temperature resistance propertiesHigh and low temperature resistance propertyV-beltsRopes and cables for vehicles/pulleyElastomerPolyester

The present invention relates to molded polyurethane / urea elastomers, and specifically to improved polyurethane / urea elastomers having high temperature stability to about 140–150° C. and low temperature flexibility at about −35–(−40)° C., for use in dynamic applications. These elastomers are particularly useful for application in belts, specifically in automotive timing or synchronous belts, V-belts, multi V-ribbed or micro-ribbed belts, flat belting and the like. The polyurethane / urea elastomers of the present invention are prepared by reacting polyisocyanate prepolymers with symmetric primary diamine chain extenders, mixtures of symmetric primary diamine chain extenders and secondary diamine chain extenders, or mixtures of symmetric primary diamine chain extenders and non-oxidative polyols, which are all chosen to eliminate the need for catalysts via standard molding processes, and to improve phase separation. The polyisocyanate prepolymers are reaction products of polyols which are nonoxidative at high temperatures, such as polycarbonate polyols, polyester polyols, or mixtures thereof, with organic polyisocyanates which are either compact, symmetric and aromatic, such as para-phenylene diisocyanate, 1,5-naphthalene diisocyanate, and 2,6-toluene diisocyanate, or are aliphatic and possess trans or trans,trans geometric structure, such as trans-1,4-cyclohexane diisocyanate and trans,trans-4,4′-dicyclohexylmethyl diisocyanate.

Owner:THE GATES CORP

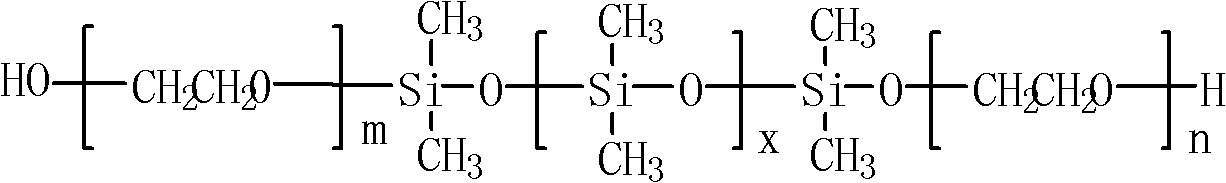

Organic silicon modified polyurethane resin for synthetic leather and preparation method thereof

The invention designs an organic silicon modified polyurethane resin for synthetic leather and a preparation method thereof, relating to the processing field of synthetic leather. The invention solves the technical problems of poor anti-sticking performance, poor water resistance, poor wear resistance and the like of the existing synthetic leather. The resin provided by the invention is characterized by comprising the following raw materials in mass percent: 2-30% of diisocyanate, 5-40% of polyester or polyether polyol, 0.5-20% of terminal hydroxyl organic silicon, 0-10% of small molecular polyol chain extender, 0-13% of small molecular polyamine chain extender, 0.01-1% of catalyst and the balance of solvent, wherein the terminal hydroxyl organic silicon adopts a polyether-polysiloxane copolymer of which the two ends are hydroxyl groups, and the polyether chain segment is polyoxyethylene or polyoxypropylene. The glossiness and transparency of the polyurethane resin modified by the invention can not be influenced by organic silicon, and simultaneously, the anti-sticking performance, surface smoothness, wear resistance and water resistance of the modified polyurethane resin can be obviously improved.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

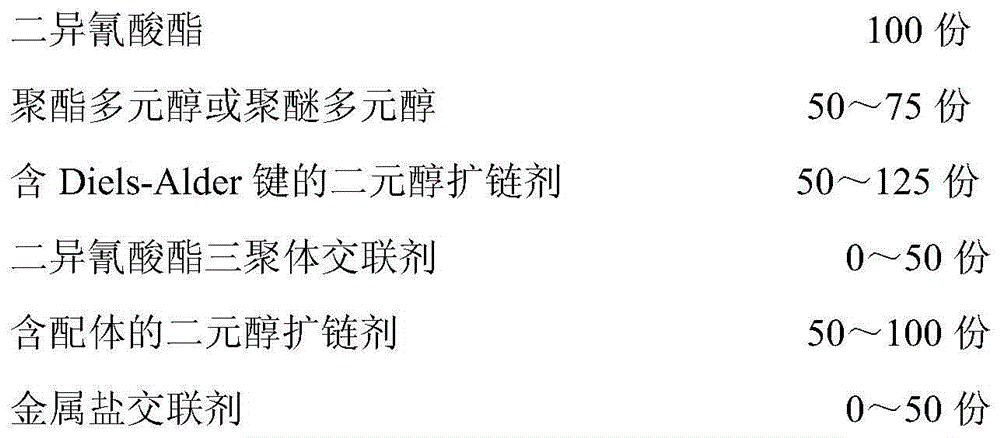

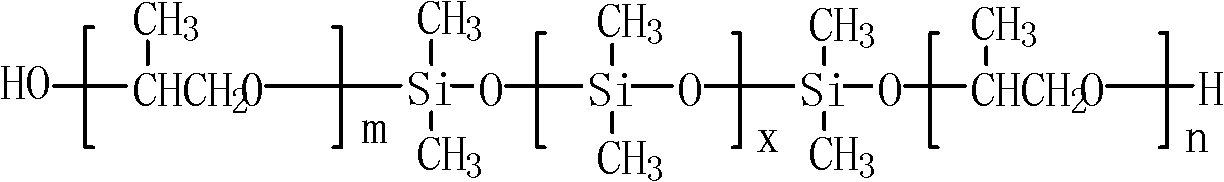

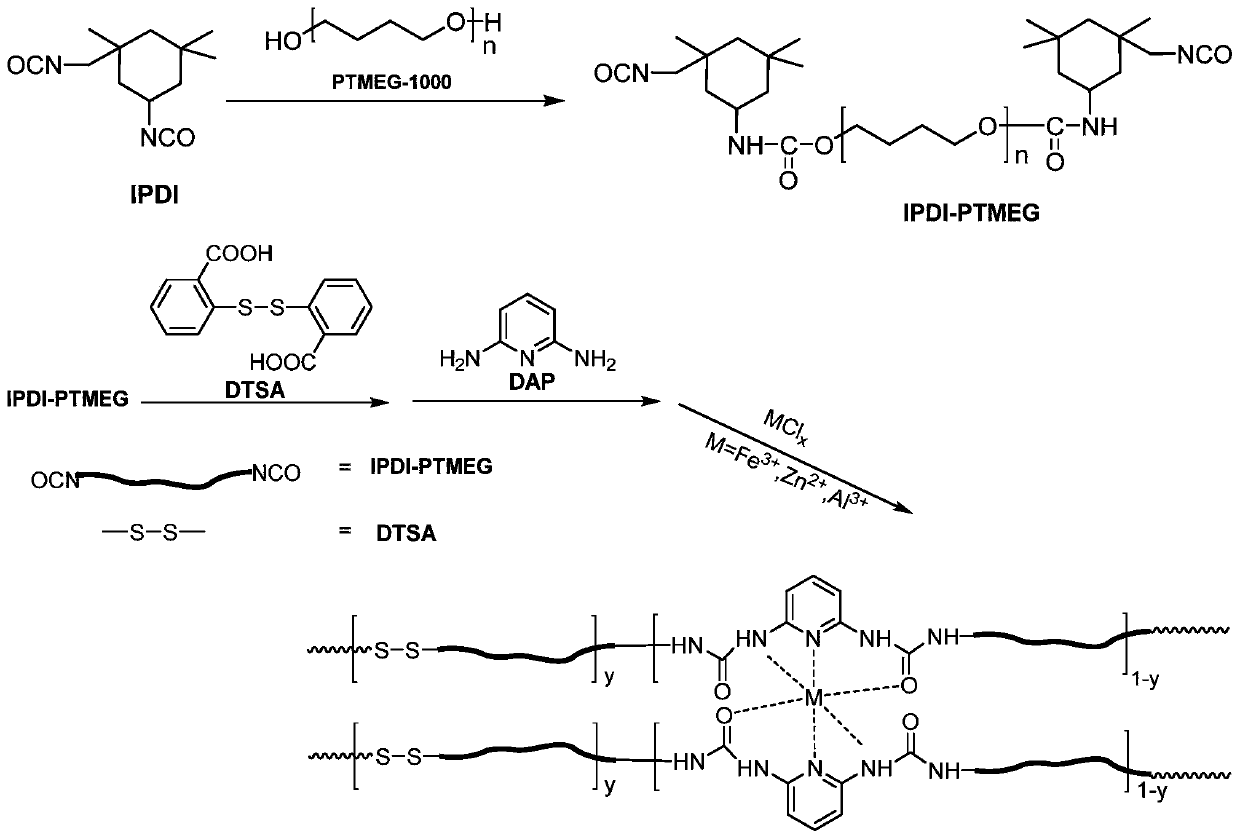

High-strength room-temperature self-repairing polyurethane elastomer based on multiple dynamic reversible effects as well as preparation and application of high-strength room-temperature self-repairing polyurethane elastomer

The invention belongs to the technical field of self-repairing elastomer materials, and discloses a high-strength room-temperature self-repairing polyurethane elastomer based on multiple dynamic reversible effects as well as preparation and application thereof. A preparation method comprises the following steps: 1) reacting a dihydric alcohol with a diisocyanate under the action of a catalyst to obtain a prepolymer; wherein the dihydric alcohol is a mixture of more than one from a polyether glycol and a polysiloxane glycol; 2) reacting a dicarboxylic acid chain extender with the prepolymer toobtain an oligomer; adding a diamine chain extender, continuously reacting, and carrying out subsequent treatment to obtain polyurethane; wherein the dicarboxylic acid chain extender and the diamine chain extender are collectively called as chain extenders, and the chain extenders contain disulfide bonds and pyridine groups; 3) in an organic solvent, reacting polyurethane with a metal salt cross-linking agent, and removing the solvent to obtain the high-strength room-temperature self-repairing polyurethane elastomer. The preparation method is simple and mild in condition, and the prepared polyurethane elastomer is excellent in mechanical property and high in self-repairing efficiency and is applied to a flexible substrate materials, wearable equipment and intelligent protective coating.

Owner:SOUTH CHINA UNIV OF TECH

Bioabsorbable surgical composition

Bioabsorbable macromer compositions are provided including a diisocyanate-functional bioabsorbable polymer. In some embodiments, the diisocyanate-functional bioabsorbable polymer can be combined with a functionalized polyol. The resulting bioabsorbable macromer composition can be employed as an adhesive or sealant for medical / surgical uses.

Owner:TYCO HEALTHCARE GRP LP

Dihydric alcohol containing acylhydrazone bond, dihydric alcohol containing acylhydrazone bond and disulfide bond, self-repairing polyurethane elastomer and preparation method thereof

ActiveCN106117486AAchieve self-healingGood physical and mechanical propertiesHydrazone preparationHydropoly/poly sulfide preparationPolyesterMechanical property

The invention provides dihydric alcohol containing an acylhydrazone bond, dihydric alcohol containing an acylhydrazone bond and a disulfide bond, a self-repairing polyurethane elastomer and a preparation method thereof. The polyurethane elastomer is prepared from the dihydric alcohol containing the acylhydrazone bond or the dihydric alcohol containing the acylhydrazone bond and the disulfide bond and a polyurethane prepolymer. The dihydric alcohol containing the acylhydrazone bond is prepared from a dihydrazide monomer and hydroxy aldehyde. The dihydric alcohol containing the acylhydrazone bond and the disulfide bond is prepared from a dithio lipid monomer, hydrazine hydrate and hydroxy aldehyde. The polyurethane prepolymer is prepared from a polyester or polyether polyol monomer and diisocyanate. After the self-repairing polyurethane elastomer is mechanically damaged, the acylhydrazone bond or the disulfide bond on a crosslinked polymer molecular chain achieves material self-repairing through dynamic exchange reaction. The self-repairing crosslinked polyurethane elastomer material is simple in preparation, can achieve self repairing at room temperature, is high in repairing capability, short in repairing time and capable achieving many times of self repairing and has better mechanical properties.

Owner:QINGDAO UNIV OF SCI & TECH +1

Method for improving water resistance of polyvinyl alcohol film by using poly(trimethylene carbonate) and poly(p-dioxanone)

The invention discloses a method for improving water resistance of a polyvinyl alcohol film by using poly(trimethylene carbonate) and poly(p-dioxanone). The method comprises the following steps of (1) adding poly(trimethylene carbonate), diisocyanate, a catalyst and a solvent into a drying reactor, and reacting while stirring at the temperature of 50-55 DEG C to obtain end-NCO group contained poly(trimethylene carbonate); (2) adding end-NCO group contained poly(trimethylene carbonate), polyvinyl alcohol, a solvent and a catalyst into the drying reactor, and reacting while stirring at the temperature of 50-55 DEG C to obtain a polyvinyl alcohol and poly(trimethylene carbonate) grafted copolymer; (3) adding the polyvinyl alcohol and poly(trimethylene carbonate) grafted copolymer, poly(p-dioxanone) and a solvent into the drying reactor, stirring and mixing at the temperature of 40-50 DEG C, filming by using a tape casting method and drying to obtain a target product required by the invention. The method is simple in preparation process and easy to master, and the water resistance of the obtained modified film is greatly improved.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com