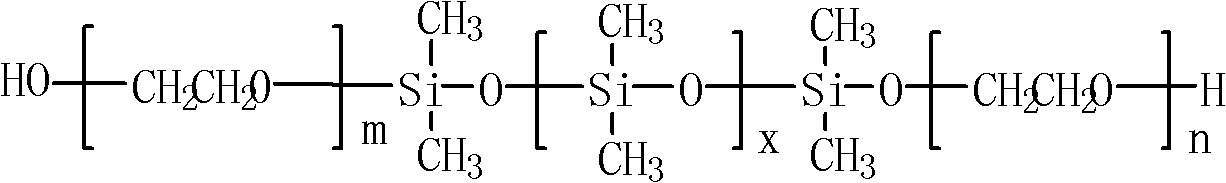

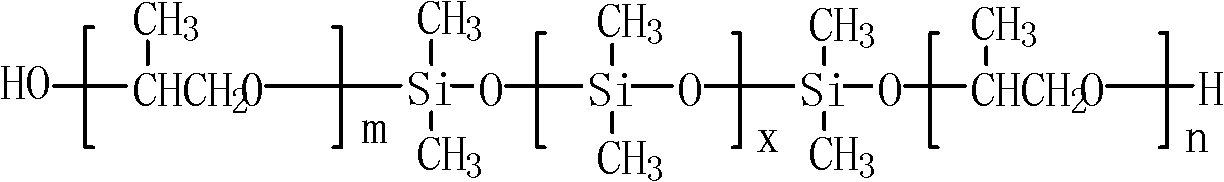

Organic silicon modified polyurethane resin for synthetic leather and preparation method thereof

A technology of polyurethane resin and silicone, which is applied in the direction of textiles and papermaking, can solve problems such as poor compatibility, obvious side effects, and affecting product appearance, and achieve the effect of improving water resistance and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] Heat 151 parts of polybutylene adipate diol (molecular weight 1000) to 100°C, vacuum dehydrate for about 1 hour, and cool down to 50°C; add 150 parts of toluene, 94 parts of IPDI, diethylene glycol 6 parts, 0.2 parts of dibutyltin dilaurate, stir evenly, raise the temperature to 90°C, and react for 2 hours; add 7 parts of 1,4-butanediol, 20 parts of polyether-polysiloxane, continue to react for 3 hours at 80°C; cool down To 50°C, add 50 parts of toluene, 300 parts of N, N-dimethylformamide, 200 parts of propylene glycol methyl ether and stir evenly, then slowly increase the viscosity with 21.8 parts of isophordione diamine, when the viscosity rises to 100000cps / At 25°C, stop adding isophordione diamine; continue to stir for 30 minutes, then cool to 30°C and discharge; the solid content is 30%, and the 100% modulus is about 40kgf / cm 2 Silicone modified polyurethane resin.

[0035] Compare the anti-adhesive properties, water resistance and abrasion resistance of silicon...

example 2

[0043]Heat 139.7 parts of polyoxypropylene glycol (molecular weight: 3000) to 100°C, vacuum dehydrate for about 1 hour, and cool down to 50°C; add 200 parts of DMF, 104 parts of IPDI, 48.4 parts of HDI, and 1 part of octanoic acid to the reaction kettle Stannous, stir evenly, heat up to 85°C, react for 3 hours; add 29 parts of neopentyl glycol, 5 parts of polyether-polysiloxane, continue to react for 3 hours at 80°C; cool down to 40°C, 200 parts of isopropanol, acetic acid After stirring 200 parts of ethyl ester evenly, use 72.8 parts of isophordione diamine to increase the viscosity. When the viscosity rises to 80000cps / 25°C, stop adding isophordione diamine; continue stirring for 30 minutes, then cool to 30°C , discharge; the obtained solid content is 40%, and the 100% modulus is about 180kgf / cm 2 Silicone modified polyurethane resin.

[0044] The modified polyurethane resin that example two obtains is compared with the polyether polyurethane resin that is not modified by s...

example 3

[0048] Heat 139.5 parts of polycarbonate diol (molecular weight 2000) to 100°C, vacuum dehydrate for about 1 hour, cool down to 50°C, add 400 parts of DMF, 30 parts of polyether-polysiloxane, 7.9 parts of 1 , 4-butanediol, 6.3 parts of ethylene glycol, stir evenly; add 21.2 parts of TDI, 35 parts of MDI, 0.5 parts of dibutyltin dilaurate and stir evenly, heat up to 75°C, react for 3.5h; add 250 1 part of TOL, keep the temperature at 75°C, use 9.6 parts of MDI to increase viscosity, feed once every 45 minutes, and feed 0.5-3 parts each time; after the viscosity reaches the predetermined value, cool down to 60°C, add 100 parts of methyl ethyl ketone and stir evenly , continue cooling to 30°C, and discharge. The solid content is 25%, the viscosity is 20000cps / 25℃, and the 100% modulus is 80kgf / cm 2 Silicone modified polyurethane resin.

[0049] The modified polyurethane resin obtained in Example 3 and the polyether polyurethane resin without silicone modification of similar for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| 100% modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| 100% modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com