Patents

Literature

1079 results about "Resin modified" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Toughened epoxy adhesive composition

ActiveUS20050209401A1High impact strengthImprove crash resistanceMacromolecular adhesive additivesEpoxy resin adhesivesAcrylonitrileEpoxy adhesive

The invention relates to an epoxy adhesive composition comprising a) a first epoxy resin, b) a second epoxy resin modified with an acrylonitrile-butadiene rubber, the latter comprising on average less than about 25 weight percent acrylonitrile, and c) a toughener. The total amount of component b) and component c) is higher than about 30 percent based on the total weight of the composition, and the weight ratio of component c) to component b) is greater than about 1:1. The invention further relates to the use of said epoxy adhesive composition for the assembly of parts of a vehicle. It also relates to a vehicle, parts of which are assembled by said epoxy adhesive composition.

Owner:DOW GLOBAL TECH LLC

Urea-formaldehyde binder composition and process

An aqueous binder composition containing a urea-formaldehyde resin modified with a protein, preferably with a source of soy protein and the use of the binder for preparing fiber mats, especially glass fiber mats.

Owner:GEORGIA PACIFIC CHEM LLC

Coating composition and article coated therewith

InactiveUS20050215670A1Improve corrosion resistancePlastic/resin/waxes insulatorsAnti-corrosive paintsEpoxyTriazole antifungals

A coating composition used for coating of a steel material and / or aluminum material comprises a corrosion inhibitor, a base resin and a curing agent. The corrosion inhibitor may be selected from cerium compounds, lanthanum compounds, molybdate salt compounds, gluconic acid derivative salts, porous base materials, triazole compounds, thiazole compounds, tetracyclines, and metal phosphate salt compounds of ascorbic acid. The base resin may include a xylene-formaldehyde-resin-modified amino-containing epoxy resins obtained by reacting an epoxy resin having an epoxy equivalent of from 180 to 2500 with a xylene formaldehyde resin and an amino-containing compound. The curing agent may be a blocked polyisocyanate compound obtained by blocking an isocyanate group of a polyisocyanate compound with a blocking agent.

Owner:KANSAI PAINT CO LTD

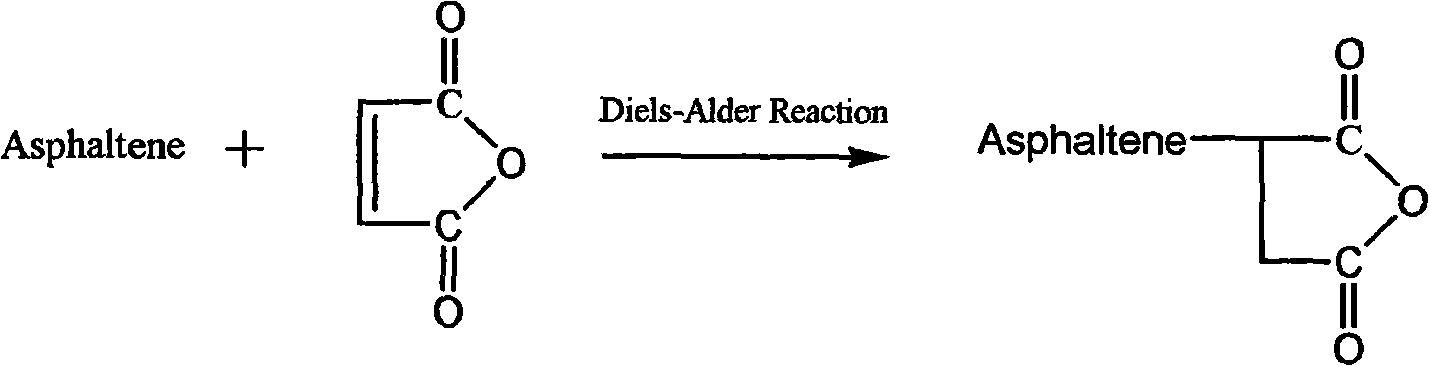

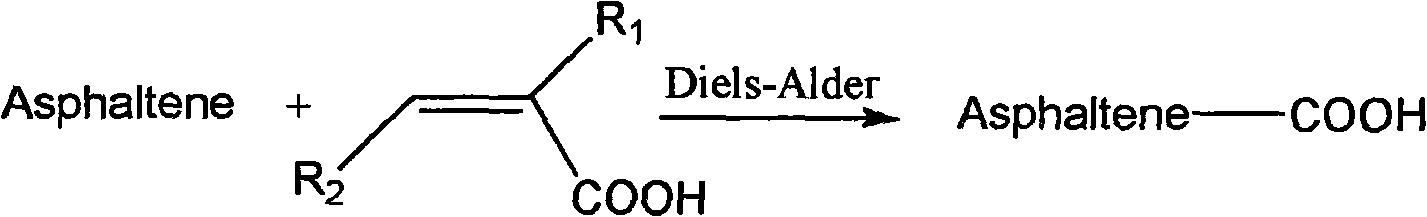

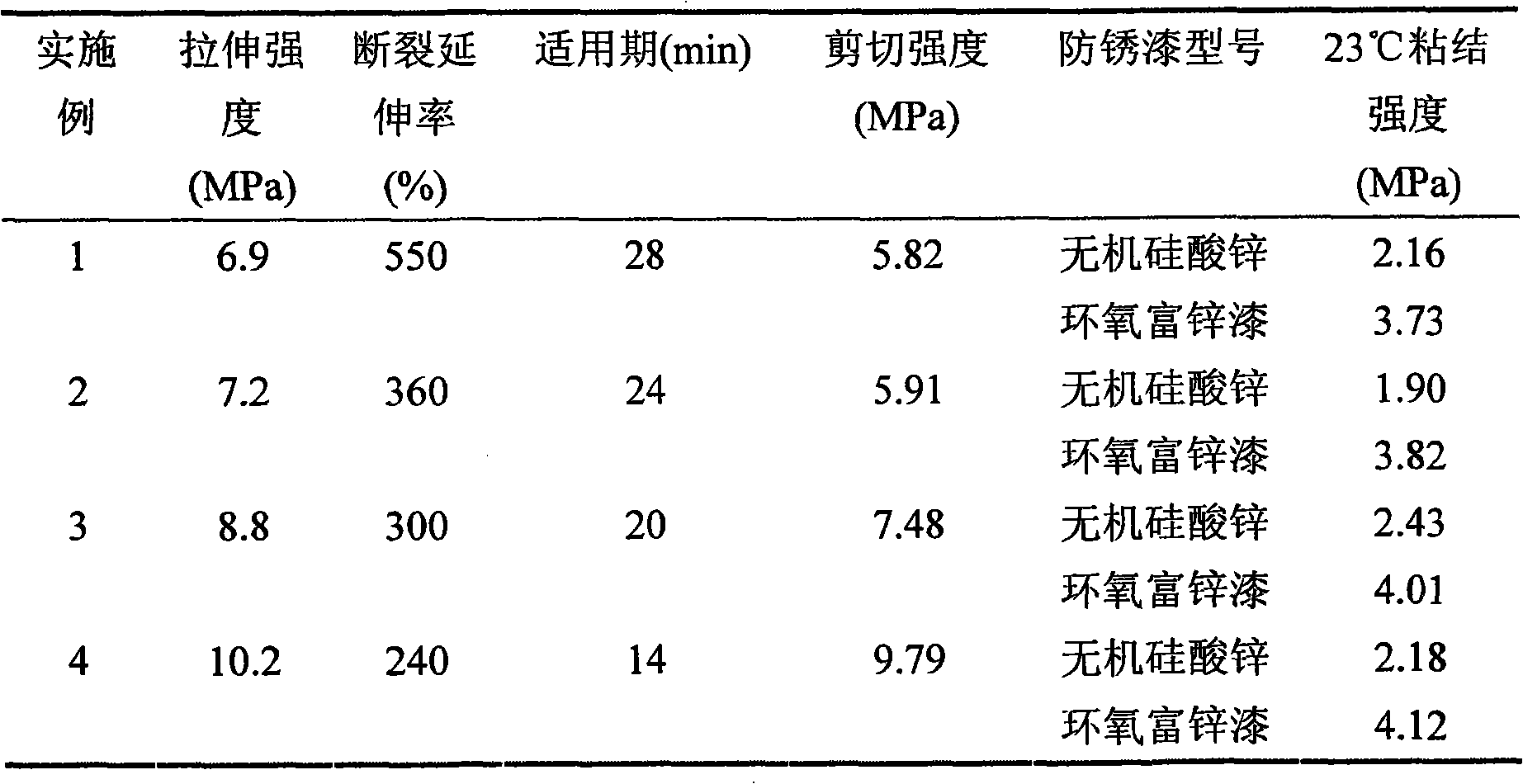

Epoxy asphalt material for road-bridge and environment-friendly preparation method thereof

The invention provides an epoxy asphalt material for bridge and green preparation method, comprising A part and B part, wherein the weight constitute of the A part is: modified asphaltum with carboxyl or anhydride group 60-76 parts, monohydric alcohol or polyhydric alcohol 2-20 parts, aliphatic diprotic acid, dimer acid or alkyd resin 11-25 parts, fatty acid anhydride 10-25 parts, solidified promoter 0.05-0.65 parts; and the constitute of the B part is epoxy resin. The mass ratio of A and B part is 2.2:1-10:1. The epoxy resin modified asphalt material has excellent property with high intensity and good flexibility; provides corresponding operation time according to different requirement and adjust the operation time to satisfy the different performance requirement at will with good storage stability. The corresponding epoxy asphalt concrete has excellent high, low temperature performance and fatigue endurance, and the environment is friendly, suitable for occasion with higher requirement such as autoroute and bridge, and arterial street, bus stop and airfield path. The invention also provides a preparation method thereof.

Owner:SOUTHEAST UNIV

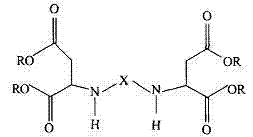

Thick paste quick-drying type weather-resistant and wear-resistant coating for wind turbine blades and preparation method thereof

ActiveCN102391771AFast dryingNot easy to foamAnti-corrosive paintsPolyurea/polyurethane coatingsWear resistantAgricultural engineering

The invention discloses a thick paste quick-drying type weather-resistant and wear-resistant coating for wind turbine blades and a preparation method thereof, the coating takes poly-asparaginic acid ester and elastic resin-modified aliphatic isocyanate as base materials, a nano-material is adopted for being effectively bonded with a resin matrix, and appropriate auxiliaries and additives for enhancing the performances of the coating. The thickness of a film which is formed by the coating for the wind turbine blades once can achieve 300 mu m; furthermore, the drying speed is fast and the coating is less prone to bubbling; the weather resistance is excellent, and the coating has higher tensile strength and elongation at break, and prominent wear resistance and impact resistance; the performances of water resistance, chemical product resistance, wet heat resistance, salt mist resistance and high and low temperature resistance are excellent; and the coating has certain anti-pollution and anti-icing properties. The construction efficiency of the coating is high, the performances of the coating are particularly suitable for wind field environments in China, the service life of a unit can be prolonged and the maintenance cost can be reduced.

Owner:洛阳双瑞防腐工程技术有限公司

Protein-modified isocyanate-functional adhesive binder for cellulosic composite materials

InactiveUS20060231968A1Polyureas/polyurethane adhesivesWood working apparatusMaterials scienceResin modified

An adhesive binder composition containing an isocyanate-functional resin modified with a protein, preferably with a source of soy protein, and the use of the binder for preparing wood composites, especially OSB.

Owner:GEORGIA PACIFIC CHEM LLC

Waterborne epoxy modified emulsified asphalt concrete for steel bridge surface and preparation method thereof

ActiveCN102173663AReduce energy consumptionSolve the problem of energy consumptionEnvironmental resistanceEpoxy

The invention provides a waterborne epoxy modified emulsified asphalt concrete for a steel bridge surface and a preparation method thereof. The waterborne epoxy modified emulsified asphalt concrete for the steel bridge surface is prepared by the following steps of: adding waterborne epoxy resin, a curing agent, and a stabilizing agent into modified emulsified asphalt, continuously stirring until the mixture is uniform, and shearing to obtain waterborne epoxy resin modified emulsified asphalt emulsion; and stirring coarse aggregate and fine aggregate in a container, adding the waterborne epoxyresin modified emulsified asphalt and then stirring, adding a filler and then mixing and stirring, and adding cement and stirring to obtain the waterborne epoxy modified emulsified asphalt concrete. A paving material prepared by the method has the characteristics of environment-friendliness, low volatile organic compound (VOC), low energy consumption, high bonding strength with a steel plate, high cryogenic stabilization, excellent water stability performance, high tenacity, and high fatigue resistance performance.

Owner:WUHAN UNIV OF TECH

Method for preparing polyaramide resin modified by aromatic heterocycle and chloromonomer

InactiveCN101165078AGood molecular weightHigh molecular weightPolyamide coatingsMonocomponent polyamides artificial filamentTwo stepMonomer

The present invention discloses process of producing aromatic heterocycle and chlorated monomer modified polyaramide resin. Monomers including paraphthaloyl chloride and p-phenylene diamine in the calculated equivalents and 2-(4-aminophenyl)-5(6) aminophenyl benzimidazole in 20-80 % the calculated equivalent are synthesized inside NMP / CaCl2 solvent system into high molecular weight resin through one two-step process including the first reaction between partial paraphthaloyl chloride and all the p-phenylene diamine to form amido group terminated low molecular weight oligomer and the subsequent reaction between the rest paraphthaloyl chloride and the amido group terminated low molecular weight oligomer to form the high molecular weight resin. The aromatic heterocycle and chlorated monomer modified polyaramide resin has the advantages of high fireproof performance, high mechanical strength and low cost.

Owner:四川华通特种工程塑料研究中心有限公司

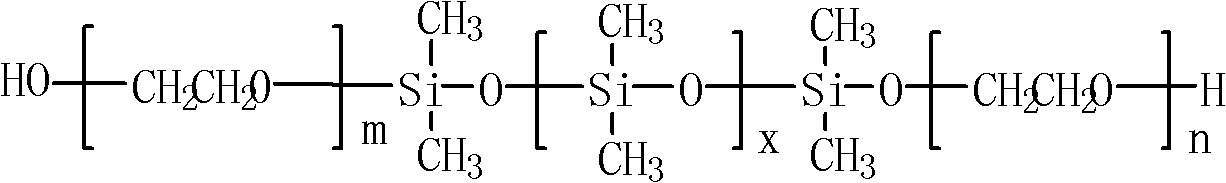

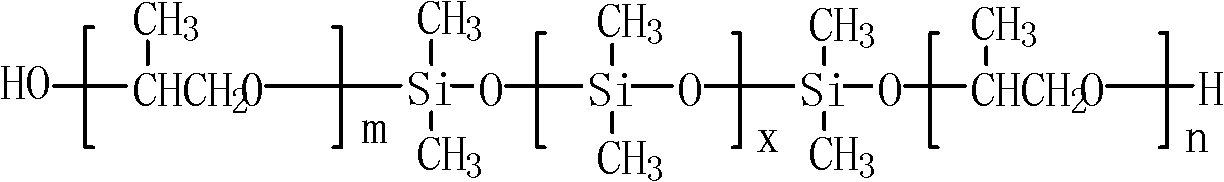

Organic silicon modified polyurethane resin for synthetic leather and preparation method thereof

The invention designs an organic silicon modified polyurethane resin for synthetic leather and a preparation method thereof, relating to the processing field of synthetic leather. The invention solves the technical problems of poor anti-sticking performance, poor water resistance, poor wear resistance and the like of the existing synthetic leather. The resin provided by the invention is characterized by comprising the following raw materials in mass percent: 2-30% of diisocyanate, 5-40% of polyester or polyether polyol, 0.5-20% of terminal hydroxyl organic silicon, 0-10% of small molecular polyol chain extender, 0-13% of small molecular polyamine chain extender, 0.01-1% of catalyst and the balance of solvent, wherein the terminal hydroxyl organic silicon adopts a polyether-polysiloxane copolymer of which the two ends are hydroxyl groups, and the polyether chain segment is polyoxyethylene or polyoxypropylene. The glossiness and transparency of the polyurethane resin modified by the invention can not be influenced by organic silicon, and simultaneously, the anti-sticking performance, surface smoothness, wear resistance and water resistance of the modified polyurethane resin can be obviously improved.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

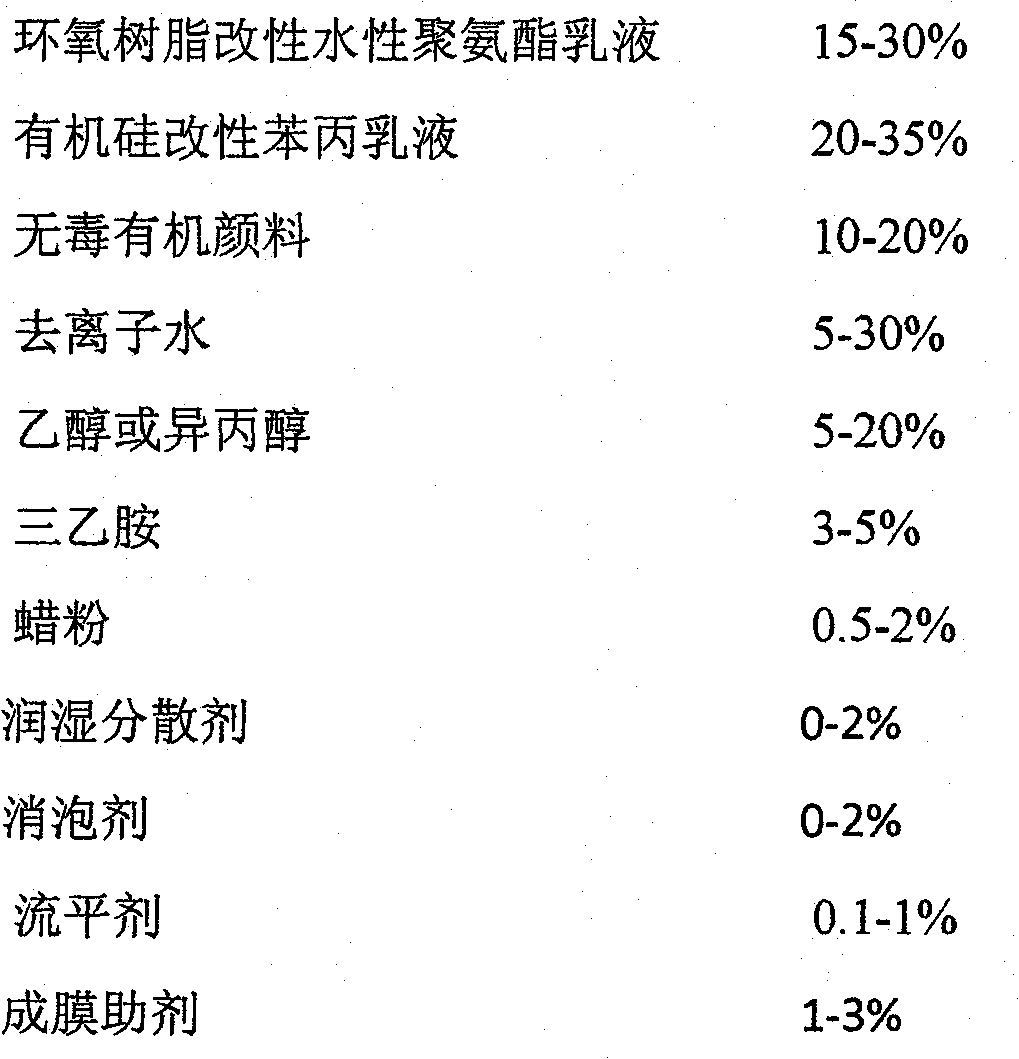

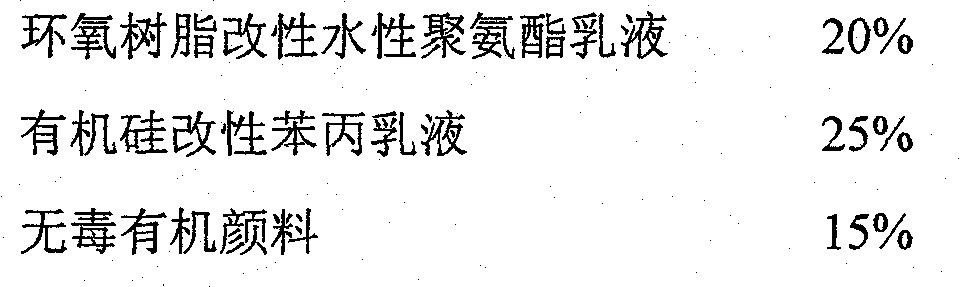

Water-based ink for plastic printing and preparation method thereof

The invention discloses a water-based ink for plastic printing and a preparation method thereof. The water-based ink is prepared by using epoxy resin modified water-based polyurethane emulsion and organic silicon modified styrene-acrylic emulsion as base materials and using deionized water and alcohol as solvents. The water-based ink comprises the following components by weight percent: 15-30% of epoxy resin modified water-based polyurethane emulsion, 20-35% of organic silicon modified styrene-acrylic emulsion, 10-20% of non-toxic organic pigment, 5-30% of deionized water, 5-20% of ethanol or isopropanol, 3-5% of triethylamine and 1.6-10% of additive. The water-based ink does not contain the volatile organic solvent, is incombustible, nonexplosible and non-toxic and has high attachment fastness on the plastic film and good printing effect; the ink has high chemical resistance, acid resistance and alkali resistance; and the ink has good water resistance, heat resistance, freezing resistance and oil resistance. The ink can be widely used in the packaging and printing of the industries such as grain, vegetables, alcohol and tobacco, and food; and the safety and non-toxicity of the ink can be ensured, and the ink is a green and environmentally-friendly product and has considerable market potential.

Owner:哈尔滨绿科科技有限公司

Preparation and application of latent nonionic self-emulsifying epoxy curing agent

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

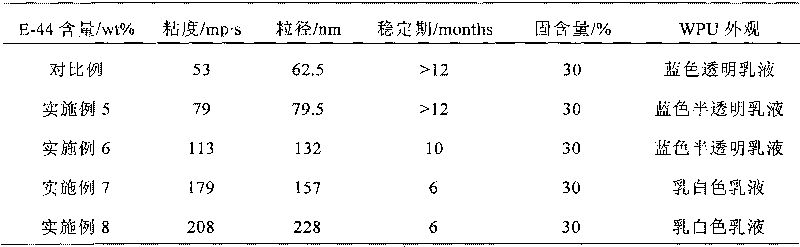

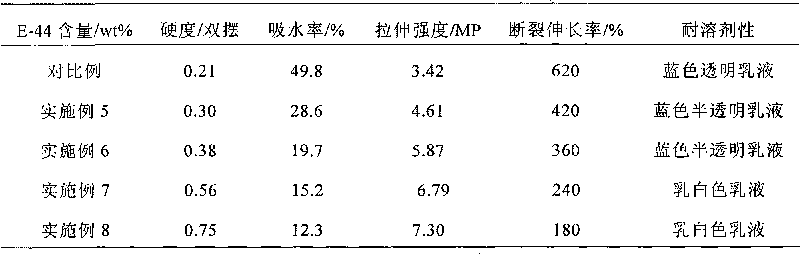

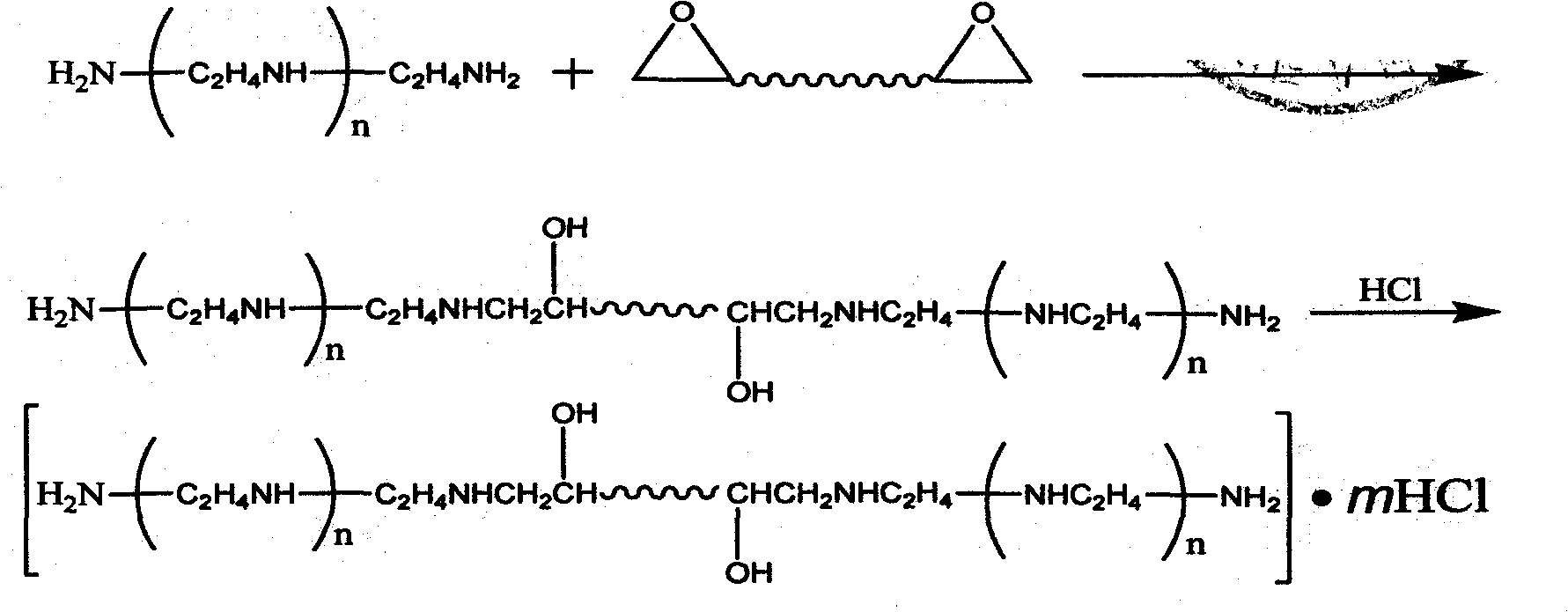

Epoxy resin modified water-based polyurethane emulsion and preparation method thereof

InactiveCN101717488AHigh molecular weightImprove cohesive energyPolyurea/polyurethane coatingsPolyesterWater based

The invention relates to an epoxy resin modified water-based polyurethane emulsion and a preparation method thereof. The emulsion comprises the following components in percentage by weight: 20 to 40 percent of isophorone diisocyanate, 20 to 40 percent of polyester, 5 to 10 percent of hydrophilic chain extender, 2 to 10 percent of chain extender, 1 to 3 percent of crosslinker, 3 to 10 percent of neutralizing agent, 2 to 10 percent of epoxy resin and 10 to 20 percent of acetone. The preparation method comprises the steps of feed preparation, polyester dehydration, the synthesis and neutralization of prepolymer, and chain extension and emulsification. Compared with the prior art, the epoxy resin modified water-based polyurethane emulsion has the advantages of high hardness of film, good water resistance and solvent resistance and the like, and is widely applied in the field of packaging coatings.

Owner:SHANGHAI WEIKAI CHEM

Wood composites bonded with protein-modified urea-formaldehyde resin adhesive

InactiveUS20050070635A1Aldehyde/ketone condensation polymer adhesivesResin adhesiveUrea-formaldehyde

An adhesive binder composition containing a urea-formaldehyde resin modified with a protein, preferably with a source of soy protein and the use of the binder for preparing wood composites, especially particleboard.

Owner:GEORGIA PACIFIC RESINS INC

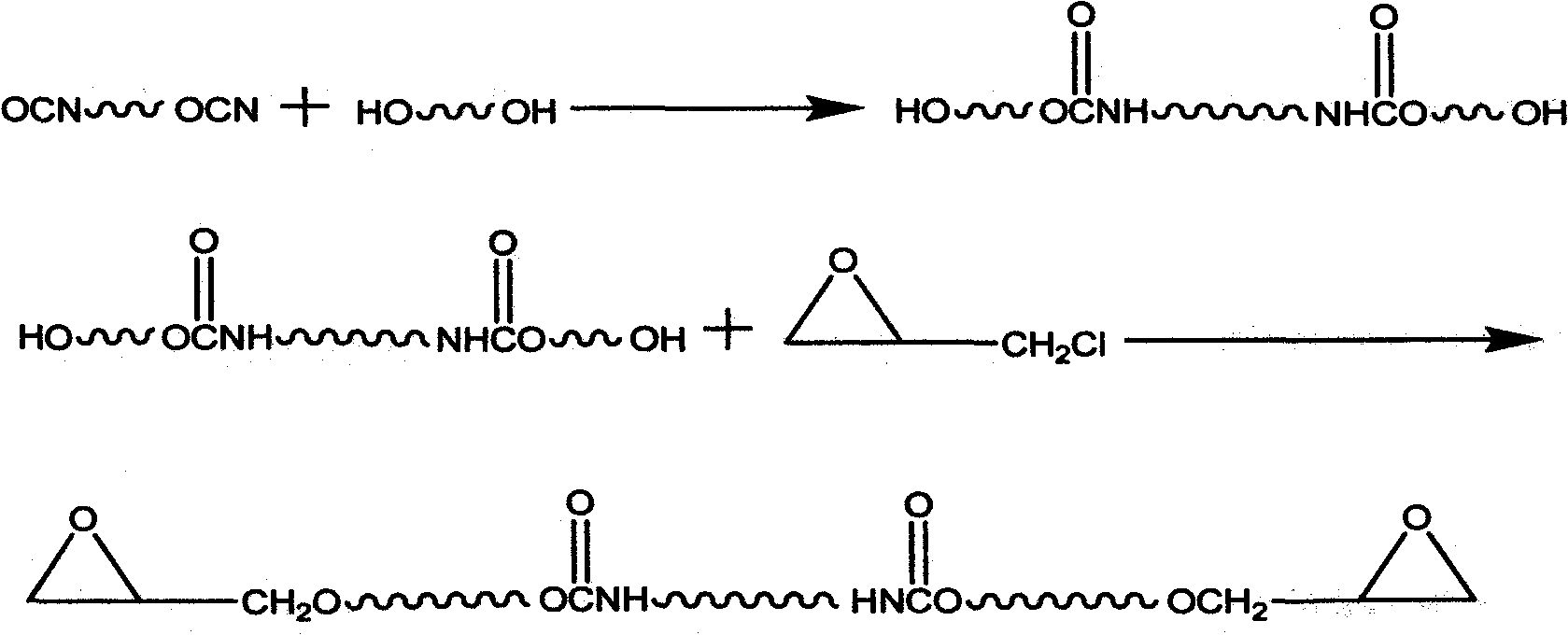

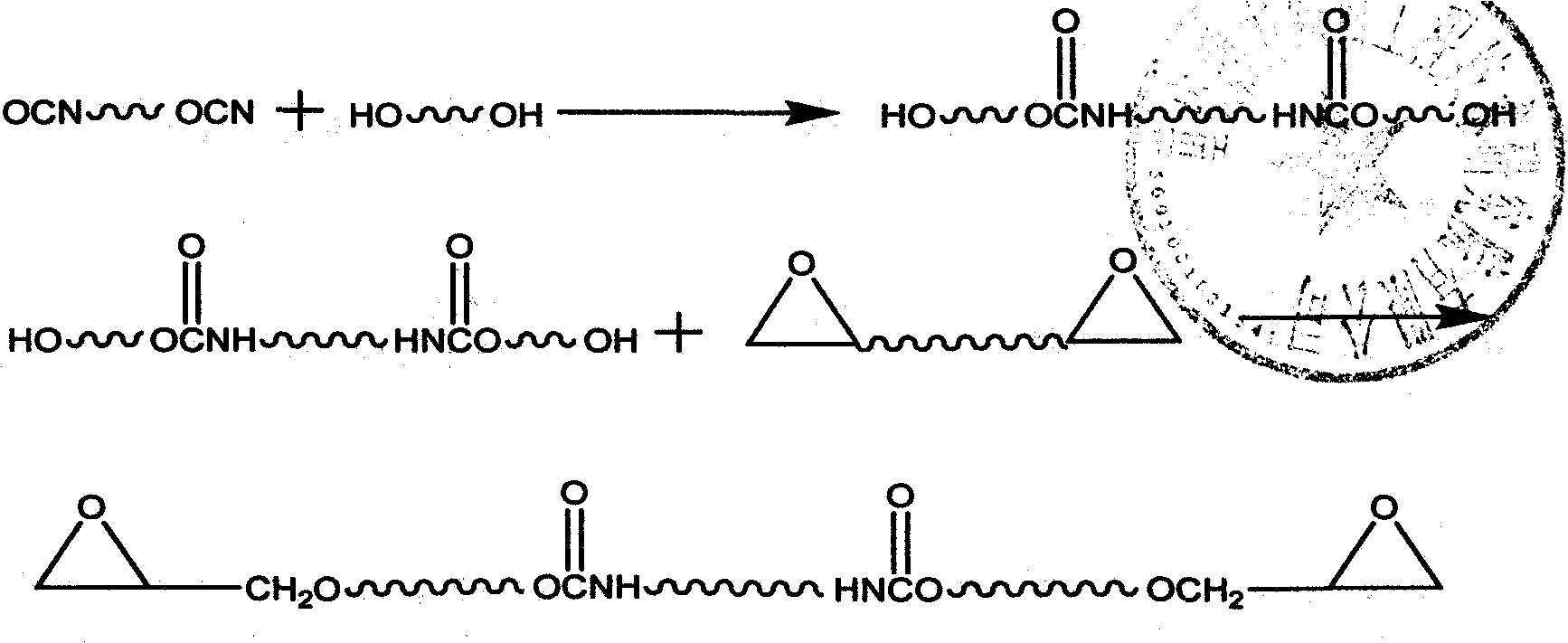

Epoxy resin modified organosilicon fire-resistant anticorrosion paint

The present invention relates to one kind of epoxy resin modified heat resistant anticorrosive organosilicon paint, which consists of two components, including one component A comprising epoxy resin modified organosilicon 30-40 wt%, pigment, stuffing and assistant 20-35 wt%, and solvent 25-50 wt%; and one component B of liquid polyamide resin in the amount of 7-20 wt% of the component A. Of the paint, the epoxy resin modified organosilicon is prepared with organosilicon pre-polymer and through modification with epoxy resin. The heating cured coating formed with the paint has excellent performances, including high structural stability, high heat resistance, high water tolerance, high organic solvent tolerance, high acid and alkali resistance, high weather resistance, etc. and is suitable for industrial application.

Owner:BEIJING UNIV OF CHEM TECH +1

Waterborne polyurethane epoxy resin modified emulsified asphalt

ActiveCN102321372AImprove adhesionGood flexibilityIn situ pavingsBuilding insulationsEpoxyPavement maintenance

The invention relates to waterborne polyurethane epoxy resin modified emulsified asphalt, which comprises an ingredient A and an ingredient B, wherein the ingredient A is modified alicyclic amine epoxy resin curing agent aqueous solution, the ingredient B consists of the following ingredients in mass parts: 5 to 40 parts of waterborne polyurethane epoxy resin and 60 to 95 parts of emulsified asphalt, and the mass percent ratio of the ingredient A to an ingredient B is 1 / 10 to 1 / 30. During application, the ingredient A and the ingredient B are proportionably and uniformly mixed, and the waterborne polyurethane epoxy resin modified emulsified asphalt is obtained. Various indexes of the modified emulsified asphalt are all superior to those of the modified emulsified asphalt in common use in markets, good low-temperature flexibitity and high-temperature stability are realized, the brittle rupture is not easily caused under the loading effect, the adhesivity with stone materials and pavements is good, the binding force is strong, and the waterborne polyurethane epoxy resin modified emulsified asphalt can be used for pavement maintenance or can be used as cementing materials of preventive maintenance and pot hole repair materials.

Owner:CHONGQING SPECIAL ENG TECH

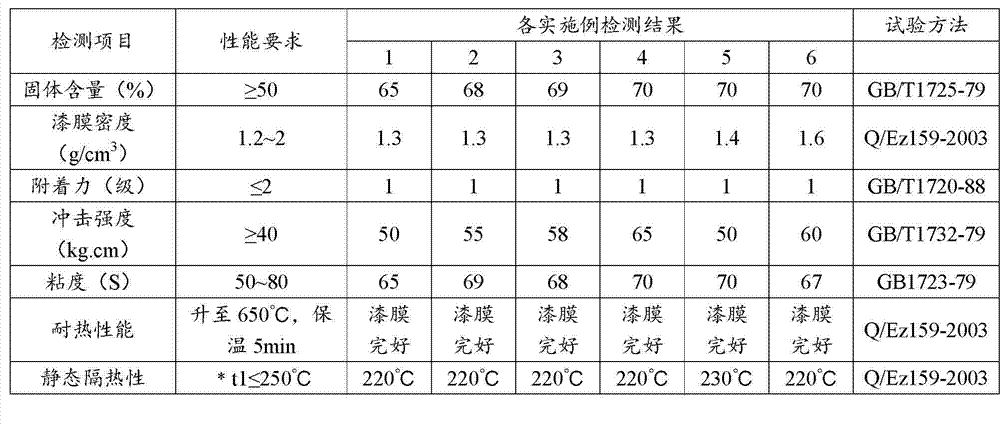

High-temperature-resistant heat-insulation paint and preparation method thereof

The invention relates to high-temperature-resistant heat-insulation paint and a preparation method thereof and belongs to the technical field of materials. The paint is used for heat-insulation protection of spacecrafts. The paint comprises, by weight, 25-35 parts of epoxide resin modified organic silicon resin containing nano particles, 10-20 parts of polybenzimidazole, 5-10 parts of high-temperature-resistant inorganic nonmetal compounds, 20-30 parts of high-temperature-resistant fillers, 1-3 parts of curing agents and 5-27 parts of solvents. The paint is high-temperature resistant, low in thermal conduction, high in shock resistance, low in density, good in bonding capacity, good in comprehensive performance index and capable of guaranteeing strength and rigidity of structural materials under the high temperature condition and meeting harsh requirements of aviation and space fields.

Owner:SHANDONG LIAOCHENG QILU SPECIAL PAINT

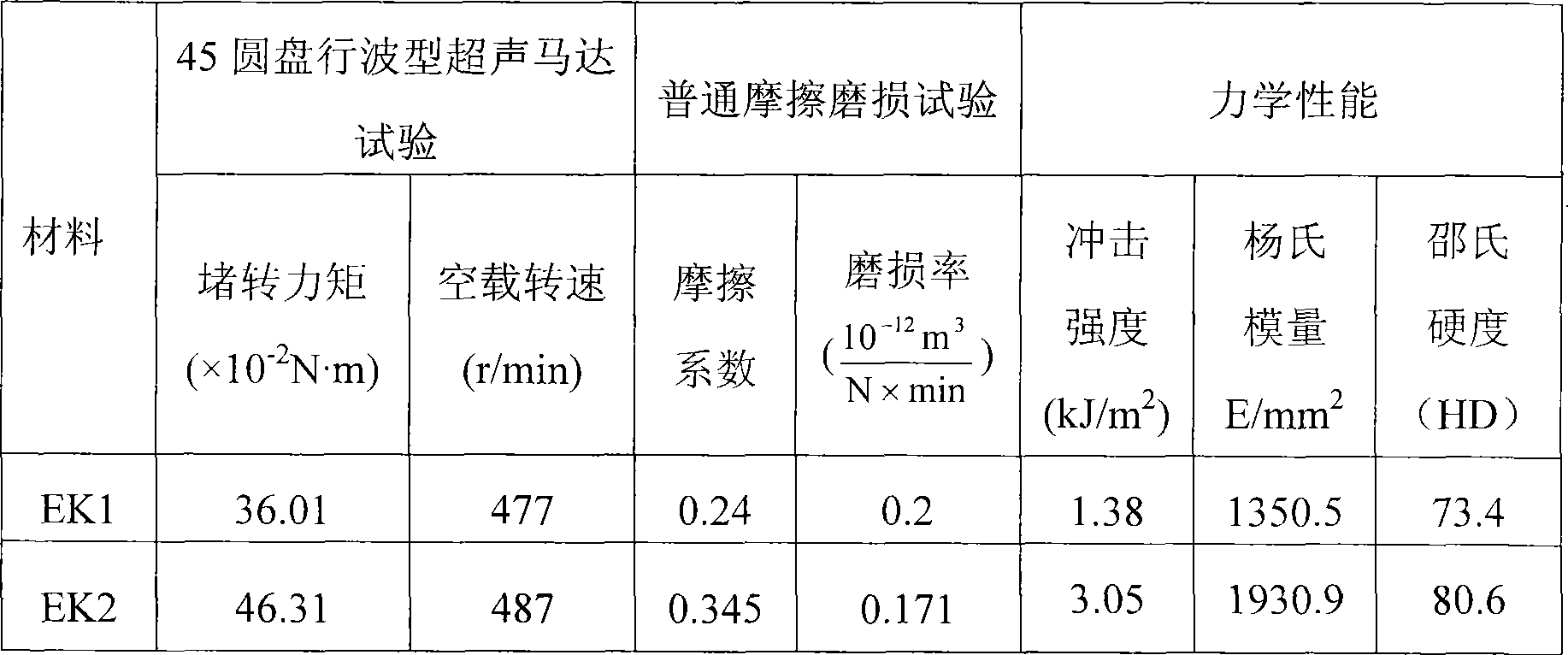

Temperature-resistant resin modified polyphenyl ester ternary alloy ultrasonic motor friction material

The invention discloses a ternary alloy hyperacoustic motor frictional material of the fire resistance resin modified polyphenyl ester, which solves the low friction coefficient problem, the low impact strength problem, the low abradability problem and the bad processability problem of the prior hyperacoustic motor. The invention is made by 5-25% politef, 5-20% fire resistant resin and the rest polyphenyl, which can also add one or a plurality of 10-35% fortifying fiber, 1-15% metal powder and 1-15% ceramic powder. The invention keeps all the advantages of the present polyphenyl ester plastic alloy hyperacoustic motor frictional material, which is provided with the high friction coefficient, the good abradability, the low noise, the high hardness and the high impact strength.

Owner:HARBIN INST OF TECH

Binder composition and process

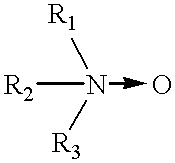

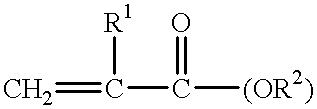

The specification discloses a binder composition comprising a urea formaldehyde resin modified with a water soluble non-ionic amine oxide and optionally further modified with an anionic acrylic latex and / or a water soluble polymer comprising 40-100% by weight, based on polymer weight, of a polymerized ethylenically unsaturated carboxylic acid monomer, the polymer having a weight average molecular weight from 100,000 to 2,000,000. Glass fiber mats bonded with the binder composition as well as roofing products, e.g., shingles, prepared from the glass mats bonded with the binder composition of this invention are also disclosed. The binder composition containing the amine oxide provides superior tear strength to glass fiber mats and with the use of the latex and / or water soluble polymer an improved tensile strength of the mats, as well as to asphalt roofing and other products made therefrom while maintaining the high tear strength. The specification also discloses processes for making: the binder; the bonded glass fiber mats; and the roofing products. The disclosure also provides a process for choosing a glass fiber mat or a specific formulation of the binder for use with each other which provides a desirable tensile and tear strength to the mat.

Owner:HEXION INC

High-bonding-strength and high-temperature-resisting phenolic resin modified polyurethane adhesive and preparation method thereof

The invention discloses a high-bonding-strength and high-temperature-resisting phenolic resin modified polyurethane adhesive and a preparation method thereof. The preparation method comprises the following steps of: synthesizing modified phenolic resin, preparing polyurethane prepolymer, synthesizing modified polyurethane prepolymer, and synthesizing the modified polyurethane adhesive, wherein the step of synthesizing the modified phenolic resin is carried out by adding methoxyl dimethylbenzene monomer and phenols in phenolic resin to react under the effect of an acid catalyst, cooling the mixture, and then adding a basic catalyst, solvent and formaldehyde in the mixture for dehydration reaction under vacuum until the mixture is transparent, thus obtaining the modified phenolic resin; the step of preparing the polyurethane prepolymer is carried out by adding polyisocyanates and polyester polyol in the modified phenolic resin for reacting; the step of synthesizing the modified polyurethane prepolymer is carried out by modifying the polyurethane prepolymer through the modified phenolic resin to obtain the modified polyurethane prepolymer; and the step of synthesizing the modified polyurethane adhesive is carried out by adding water to the modified polyurethane prepolymer, and dispersing the modified polyurethane prepolymer through dispersing agent, and finally adding neutralizing agent, cross-linking agent and chain extender into the dispersed modified polyurethane prepolymer to obtain the modified aqueous polyurethane adhesive. The preparation method disclosed by the invention is simple, and improves the bonding strength and high temperature resistance of the polyurethane adhesive.

Owner:高金技术产业集团有限公司

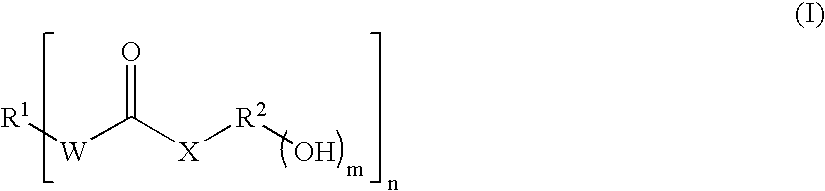

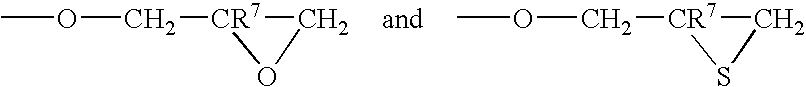

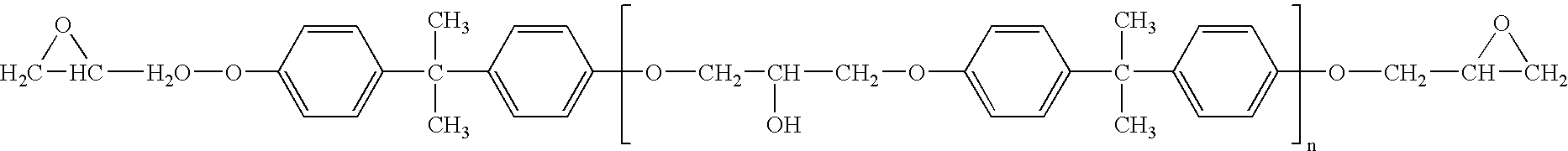

Modified epoxy resins comprising the reaction product of a biomass derived compound and an epoxy resin, and aqueous dispersions and coatings comprising such resins

Modified epoxy resins comprising the reaction product of a cycloaliphatic, polycyclic and / or aromatic biomass derived compound and an epoxy resin are disclosed. Aqueous dispersions and coatings comprising these reaction products are also disclosed.

Owner:PPG IND OHIO INC

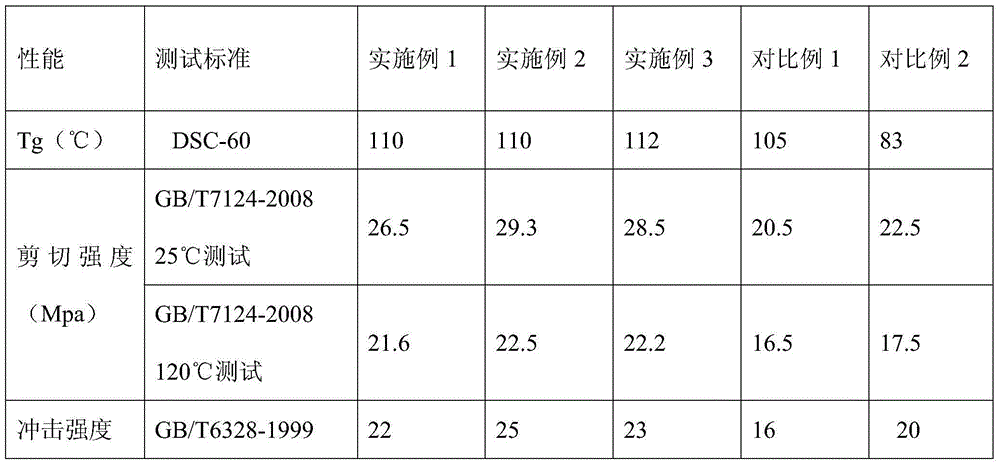

Room temperature curing high-temperature-resistant high-tenacity epoxy adhesive and preparation method thereof

ActiveCN104804691AEasy accessIncreased shear strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyamideFatty amine

The invention discloses a room temperature curing high-temperature-resistant high-tenacity epoxy adhesive and a preparation method thereof. The room temperature curing high-temperature-resistant high-tenacity epoxy adhesive is prepared from raw materials comprising a component A and a component B based on weight percent, wherein the component A comprises the following raw materials in weight percent: epoxy resin, a flexibilizer, a thinner, a coupling agent, fumed silica, a packing and a defoaming agent; the component B comprises the following raw materials in weight percent: alicyclic amine, polyamide, modified fatty amine, a coupling agent, fumed silica, a packing and a defoaming agent; the flexibilizer in the component A adopts epoxy resin modified by nanometer core-shell particles. According to the room temperature curing high-temperature-resistant high-tenacity epoxy adhesive disclosed by the invention, the excellent tenacity is achieved by using the common epoxy resin, the epoxy flexibilizer modified by the nanometer core-shell particles and the polyamide curing agent; the epoxy resin is cheap in price, accessible and capable of retaining higher shear strength at the high temperature; when alicyclic amine and modified fatty amine are selected and used as curing agents, the Tg can be higher, and the shear strength at the high temperature can be kept excellent.

Owner:上海都昱新材料科技有限公司

Stress/Thermal Cracking Resistant Cable Sheath Material

InactiveUS20100101822A1Improve the immunityPlastic/resin/waxes insulatorsInsulated cablesCrazingEthyl acetate

A composition useful as a wire or cable insulation or sheathing layer, the composition comprising (i) an inorganic flame retardant, e.g., aluminum trihydroxide (ATH), (ii) ethylene ethyl acetate (EEA) or ethylene butyl acrylate (EBA), (iii) a homogeneous polyethylene, (iv) an ethylenic resin modified with an organo-functional group, e.g., maleic anhydride (MAH) grafted polyethylene, (v) a silicone polymer, and optionally, (vi) a smoke suppressant. The insulation or sheathing layer comprising the composition of this invention exhibits good resistance to stress and / or thermal cracking.

Owner:DOW GLOBAL TECH LLC

Acrylate solvent-based pressure sensitive adhersive and product thereof

InactiveCN102226067AMeet performance needsSimple structureFilm/foil adhesivesEster polymer adhesivesCross-linkSolvent based

The invention discloses an acrylate solvent-based pressure sensitive adhersive. The acrylate solvent-based pressure sensitive adhersive comprises, by weight, 100 parts of a tackifying resin modified acrylate prepolymer, 0.5-3 parts of a catalyst and 0.1-2 parts of a cross linking agent. The invention further discloses adhesive products prepared from the acrylate solvent-based pressure sensitive adhersive. The acrylate solvent-based pressure sensitive adhersive is characterized by: adopting the tackifying resin modified acrylate prepolymer as a main component, adding proper catalyst and proper cross linking agent according to different use requirements before being coated to adjust performance of the adhersive so as to satisfy performance requirements of a plurality of products, optimize product structures, raise production efficiency and facilitate product development and product transformation.

Owner:永一胶粘(中山)有限公司

Adhesive of epoxy resin, diene copolymer-modified epoxy resin, phenolic-terminated elastomeric toughener and polyester segment polymer

ActiveUS7615595B2Improve corrosion resistanceImprove crash resistanceEpoxy resin adhesivesPolyesterElastomer

The present invention relates to an epoxy adhesive composition comprisinga) a first epoxy resin,b) a second epoxy resin modified with a copolymer based on a 1,3-diene and a polar, ethylenically unsaturated comonomer,c) a toughener andd) a polymer comprising a polyester segment, said polymer being at least partially crystalline at room temperature and having a softening temperature in the range of 40° to 125° C.The invention further relates to the use of such an epoxy adhesive composition for bonding parts of a vehicle without prehardening of the epoxy adhesive composition and to a vehicle, parts of which are bonded by the epoxy adhesive composition.

Owner:DOW GLOBAL TECH LLC

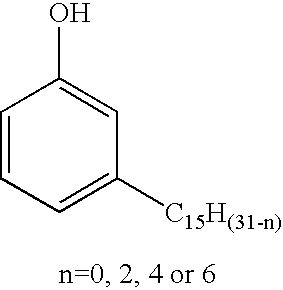

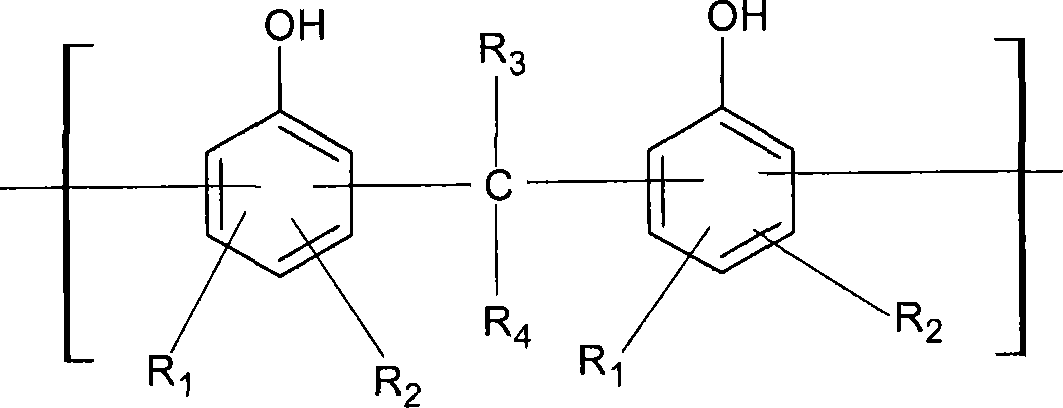

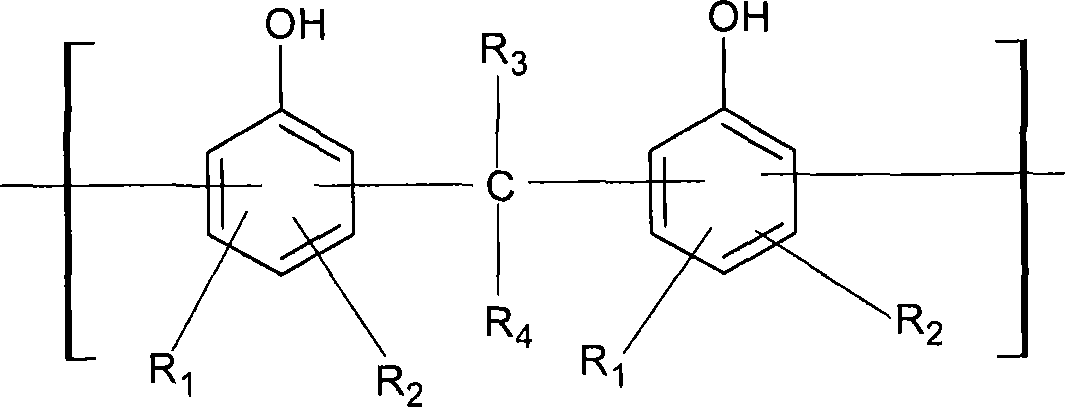

Resorcin phenolic resin modified rubber composition

The invention relates to a modified cured rubber compound which comprises (i) the rubber components of natural rubber or synthetic rubber, (ii) methano donator, (iii) aralkyl substituted phenol resin as the methano acceptor, wherein the aralkyl substituted phenol (resorcin) methano donator resin can be prepared by reacting the substituted or non-substituted phenol compound, vinyl aromatic compound and aldehyde and / or ketone in the presence of organic metal phosphate or phosphite ester catalyst. The inventive methano acceptor has lower smoke degree than R-80 (resorcin-80). And in the tension strength and dynamic mechanical property test, the aralkyl substituted resorcin phenol resin has better performance than R-80 and resorcin-formaldehyde (RF) resin.

Owner:SINO LEGEND CHINA CHEM

One-component polyurethane adhesive from epoxy resin modification and preparation method thereof

InactiveCN101358122AHigh bonding strengthImprove toughnessPolyureas/polyurethane adhesivesEpoxyPolyurethane adhesive

The present invention relates to an epoxide-resin-modified single-ingredient polyurethane adhesive and a preparation method thereof. In the preparation method, the hydroxy group of polyalcohol compound is placed in catalyst and under a high-temperature condition of more than 100 DEG C, so that the ring of the epoxy group is opened, as a result, epoxide-resin-modified polyalcohol is produced, and then, the epoxide-resin-modified polyalcohol is reacted with isocyanate, so that the modified single-ingredient polyurethane adhesive, which can be cured without curing agent, is prepared.

Owner:HUNAN SHENLI IND

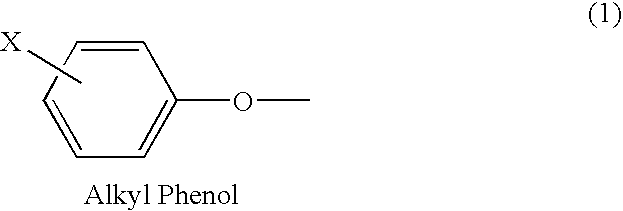

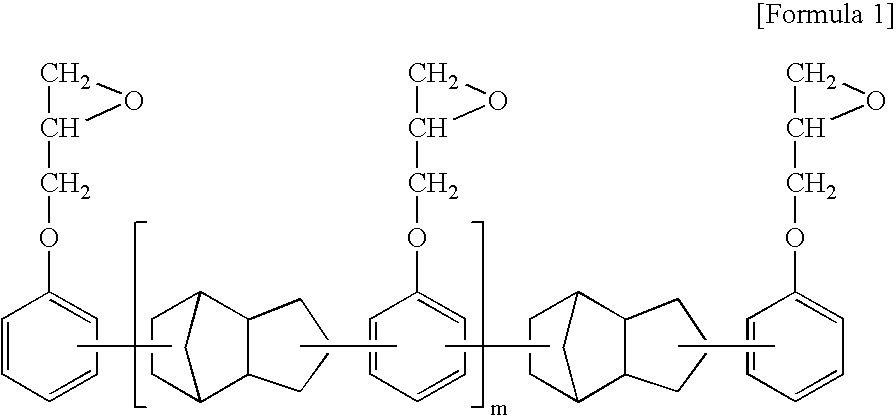

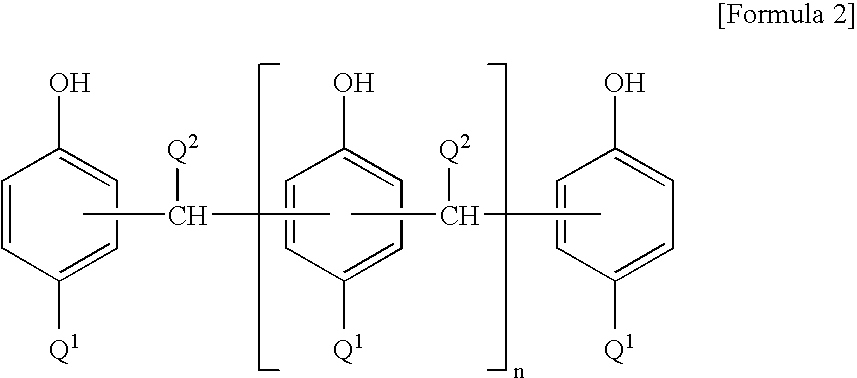

Resine Composition For Printed Circuit Board And Composite Substrate And Copper Laminates Using The Same

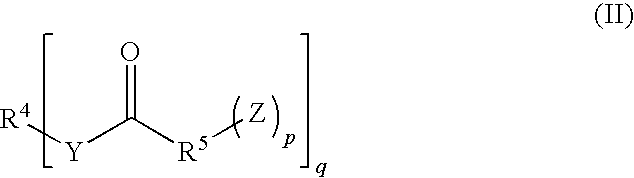

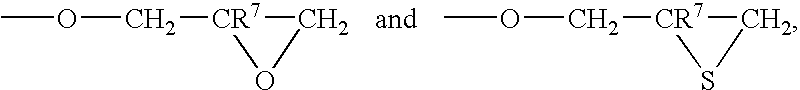

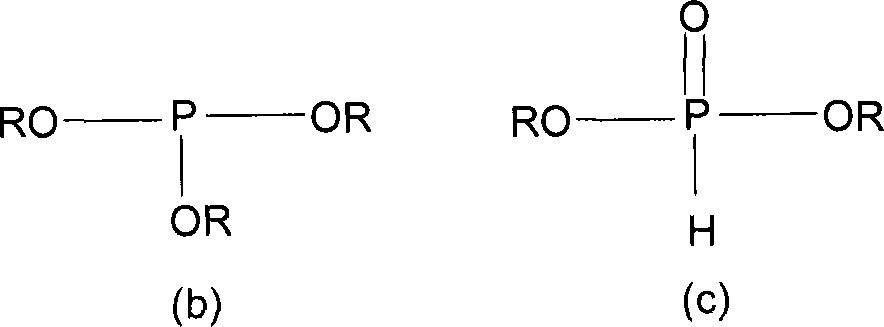

InactiveUS20090004484A1Desirable formabilityDesirable processibilitySynthetic resin layered productsElectrical equipmentEpoxyComposite substrate

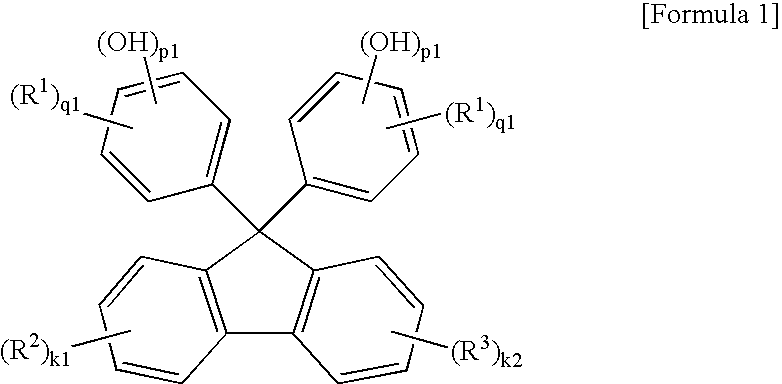

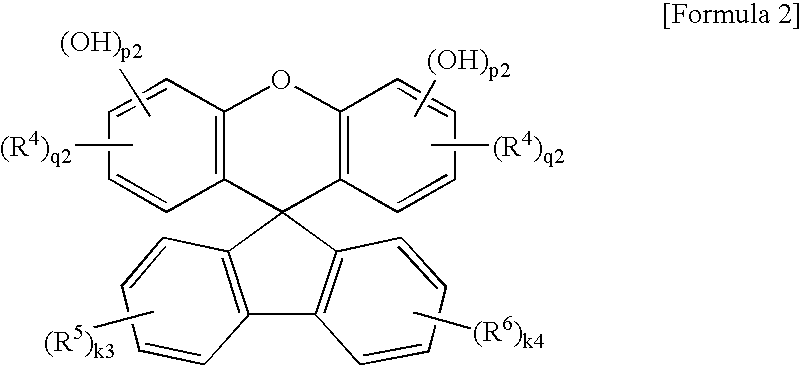

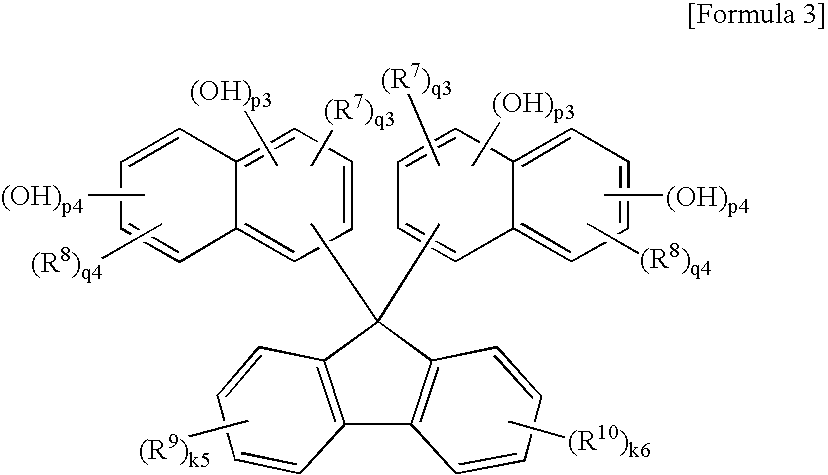

Disclosed is a resin composition for a PCB, the composition including: (a) a polyphenylene ether resin modified via a redistribution reaction of polyphenylene ether in the presence of 9,9-bis(hydroxyaryl)fluorene or 9,10-dihydro-9-oxa-10-(dihydroxyaryl)-10-phosphaphenanthrene 10-oxide; (b) a dicyclopentadiene epoxy resin represented by Formula 1; and (c) an alkylphenol aldehyde novolak curing agent represented by Formula 2, wherein, when the polyphenylene ether resin is modified via a redistribution reaction of the polyphenylene ether in the presence of 9,9-bis(hydroxyaryl)fluorene, the composition further includes (d) a brominated epoxy resin. Also, a composite substrate and a copper laminate using the same are disclosed.

Owner:DOOSAN CORP

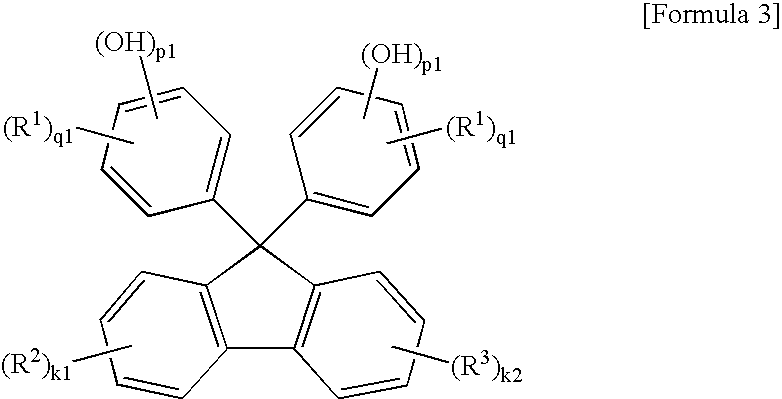

Resine Composition For Printed Circuit Board and Composite Substrate And Copper Laminates Using The Same

InactiveUS20090004488A1Desirable formabilityDesirable processibilityPrinted circuitsThin material handlingComposite substrateCyanate compound

Disclosed is a resin composition for a PCB, the composition including: (a) a polyphenylene ether resin modified via a redistribution reaction of polyphenylene ether in the presence of 9,9-bis(hydroxyaryl)fluorene or 9,10-dihydro-9-oxa-10-(dihydroxyaryl)-10-phosphaphenanthrene 10-oxide; (b) a polymer binder; and (c) cyanate ester or a prepolymer of the cyanate ester, wherein, when the polyphenylene ether resin is modified via a redistribution reaction of the polyphenylene ether in the presence of 9,9-bis(hydroxyaryl)fluorene, the composition further includes (d) a flame retardant. Also, a composite substrate and a copper laminate using the same are disclosed.

Owner:DOOSAN CORP

Wood composites bonded with soy protein-modified urea-formaldehyde resin adhesive binder

InactiveUS20060234077A1Synthetic resin layered productsWood working apparatusResin adhesiveUrea-formaldehyde

An adhesive binder composition containing a urea-formaldehyde resin modified with a modified soy protein, and the use of the binder for preparing wood composites, especially particleboard.

Owner:GEORGIA PACIFIC CHEM LLC +1

Method for preparing modified urea-formaldehyde resin powder material

InactiveCN101200549ALow free formaldehyde contentReduce formaldehyde emissionUrea-formaldehydeResin modified

The present invention provides a preparation method of modified urea formaldehyde resin powder material. The method firstly mixes the product obtained in the reaction between formaldehyde and urea and the urea formaldehyde resin modified agent, and then powderizes the liquid of modified urea formaldehyde resin; wherein, the urea formaldehyde resin modified agent should be added at least for two times. The content of dissociating formaldehyde of the urea formaldehyde resin obtained from the preparation method of modified urea formaldehyde resin provided by the present invention is quite low, thus greatly reducing the formaldehyde burst size of artificial board products in timber manufacturing process. For example, the content of dissociating formaldehyde of the modified urea formaldehyde resin provided by the present invention can be reduced to no more than 0.20 percent, so the veneer prepared by the modified urea formaldehyde resin can meet E1(is less than or equal to 1.5mg / L) stipulated in the international standard. In addition, the modified urea formaldehyde resin powder material provided by the present invention is powder, which is conducive to storage and transport.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com