Patents

Literature

84results about How to "Good molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polyaramide resin modified by aromatic heterocycle and chloromonomer

InactiveCN101165078AGood molecular weightHigh molecular weightPolyamide coatingsMonocomponent polyamides artificial filamentTwo stepMonomer

The present invention discloses process of producing aromatic heterocycle and chlorated monomer modified polyaramide resin. Monomers including paraphthaloyl chloride and p-phenylene diamine in the calculated equivalents and 2-(4-aminophenyl)-5(6) aminophenyl benzimidazole in 20-80 % the calculated equivalent are synthesized inside NMP / CaCl2 solvent system into high molecular weight resin through one two-step process including the first reaction between partial paraphthaloyl chloride and all the p-phenylene diamine to form amido group terminated low molecular weight oligomer and the subsequent reaction between the rest paraphthaloyl chloride and the amido group terminated low molecular weight oligomer to form the high molecular weight resin. The aromatic heterocycle and chlorated monomer modified polyaramide resin has the advantages of high fireproof performance, high mechanical strength and low cost.

Owner:四川华通特种工程塑料研究中心有限公司

Hydrofining catalyst and preparation method thereof

InactiveCN101590417AImprove physical and chemical propertiesImprove adsorption capacityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsTitaniumBoron

The invention provides a hydrofining catalyst and a preparation method thereof. The catalyst comprises an aluminum oxide carrier which is modified by an assistant and VIII group and VIB group metal oxides which are loaded on the carrier, wherein, the assistant is at least one of boron, phosphorus, silicon and titanium compounds. The catalyst is prepared by an immersion method which is characterized in that an organic stabilizer is added into immersion fluid; the number of metal active centers of the catalyst is increased with the addition of the organic stabilizer; the physicochemical properties of the catalyst is improved by the way the aluminium oxide is modified by the assistant; therefore, the hydrofining catalyst prepared by the method in the invention has high desulfuration and denitrification activity, and is applicable to the hydrotreating process of various distillate oil, in particular to poor quality diesel oil.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

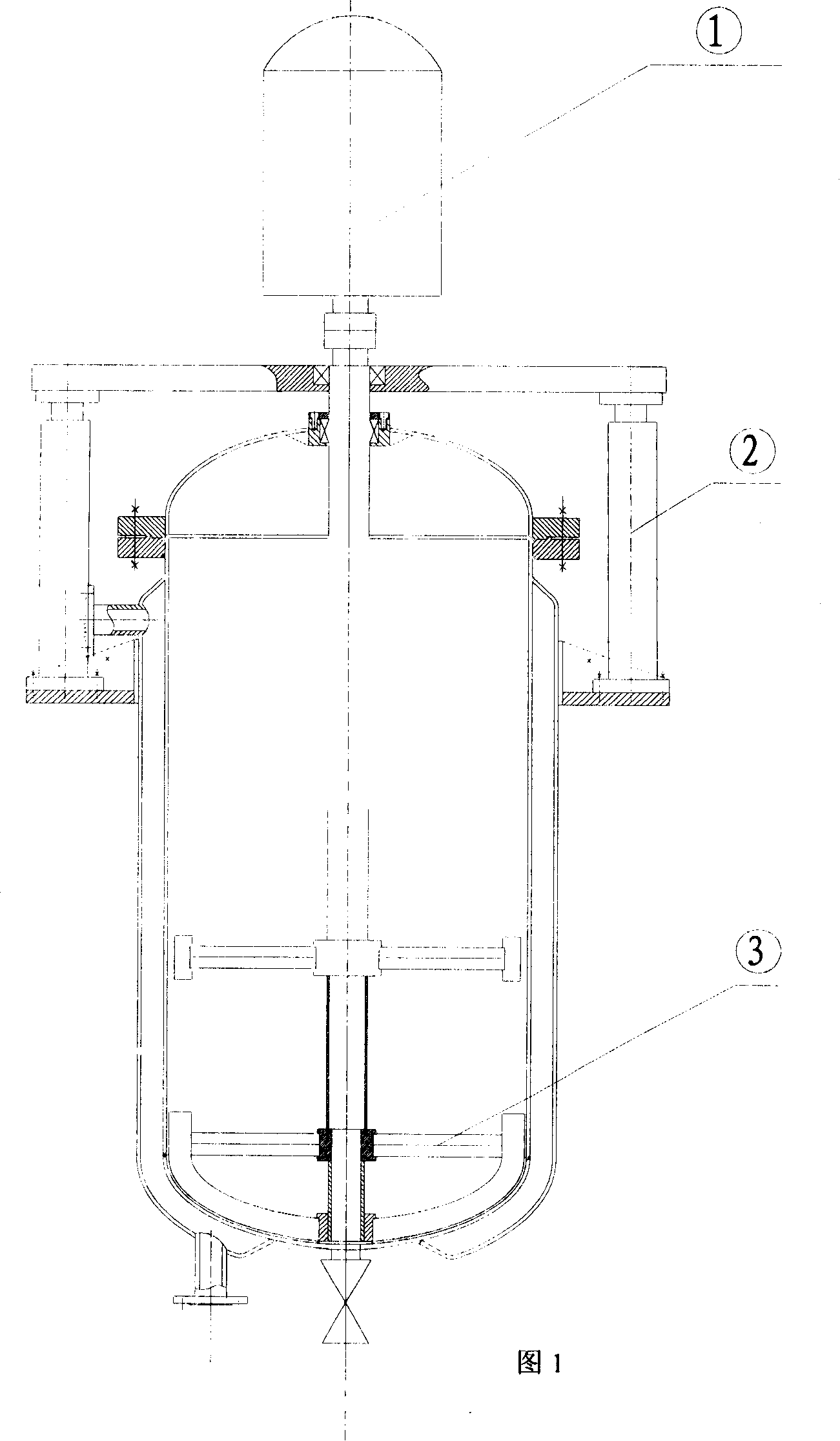

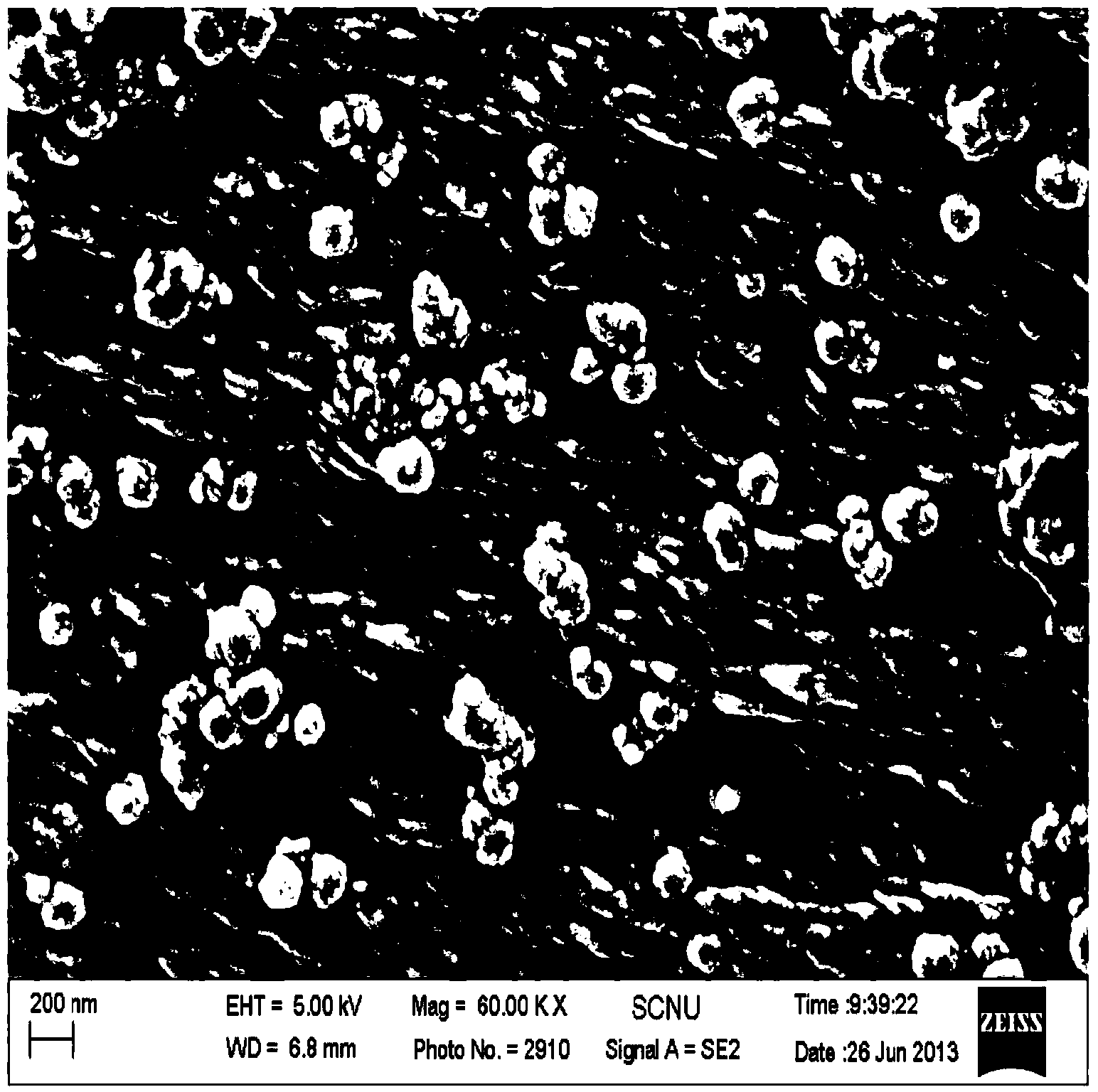

Preparation method of water-soluble polymer dispersion

The invention relates to a preparation method of a water-soluble polymer dispersion. The water-soluble monomer is dispersed in a solution polymerization system containing a dispersant, an initiator and a metal ion scavenger to perform polymerization and obtain the water-soluble polymer dispersion, wherein the dispersant is a composite dispersant system and contains at least one kind of water-insoluble inorganic macroparticles and at least one water-soluble polymer dispersant. The invention utilizes the composite dispersant system in which the water-insoluble inorganic macroparticles are matched with the polymer dispersant to form dispersion coating mechanism so as to reduce the concentration of high molecular polymer in continuous phase and ensure that the rolling friction and rigid impact are mainly adopted between the polymer molecule chain and the macroparticles. Therefore, the viscosity of the dispersion is effectively reduced while the molecular weight of polyacrylamide polymer in the dispersion is not reduced, and the water-soluble polymer dispersion with high concentration, good solubility, uniform dispersion, high efficiency and full water-solubility can be prepared.

Owner:JIANGSU FEYMER TECH

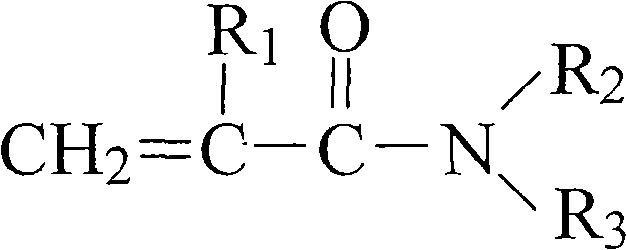

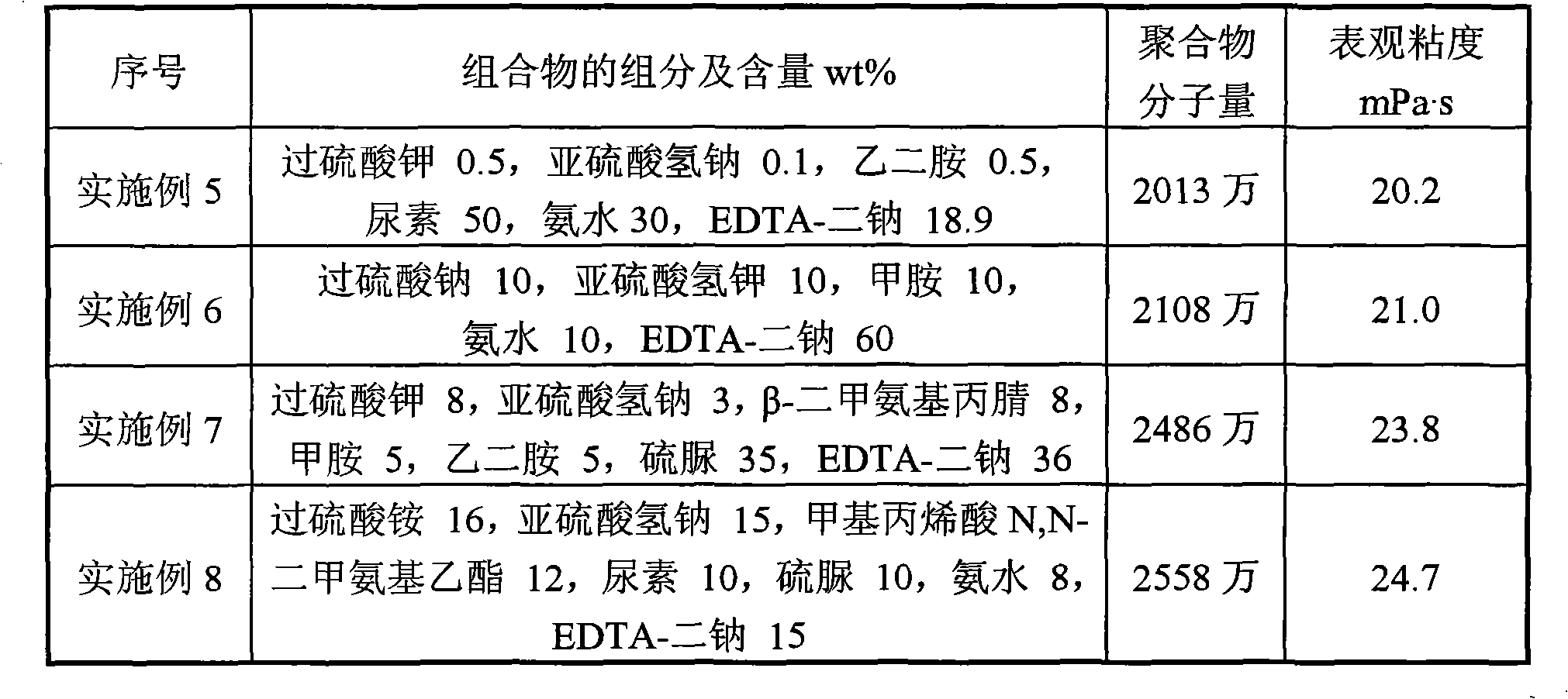

Initiator composition used for synthesizing polyacrylamide capable of displacing oil

ActiveCN102372806AImprove solubilityEven growthDrilling compositionEthylenediamineAmmonium compounds

The invention relates to an initiator composition used for synthesizing polyacrylamide capable of displacing oil, which mainly solves the problems of low polyacrylamide molecular weight, poor heat resistance and salt resistance performances and difficult satisfaction for technical requirement of tertiary oil extraction. The initiator composition used for synthesizing polyacrylamide capable of displacing oil comprises the following ingredients by weight percentage: (a) 0.5-20% of persulfate; (b) 0.1-40% of sulfite or acid sulfite; (c) 0.5-20% of NR1R2R3-represented trialkylamine compounds or N<+>R4R5R6R7-represented quaternary ammonium compounds or NH2R8-represented aliphatic amine compounds, wherein R1-R7 in the formula are selected from C1-C14 straight chain or branched chain alkyl or alkyl derivatives, R8 is selected from straight chain or branched chain alkyl or alkyl derivatives; (d) 10-80% of urea, thiourea or ammonia liquor; (e) 5-60% of ethylenediaminetetraacetic acid. The technical scheme of the invention better solves the problems and can be used in industrial production of oil displacement.

Owner:CHINA PETROLEUM & CHEM CORP +1

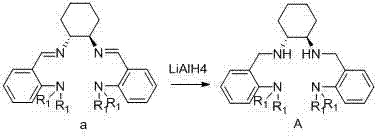

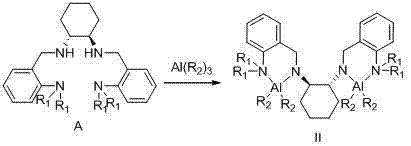

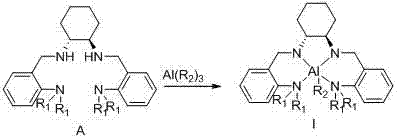

Chiral tetra-amino aniline ligand, aluminum compound thereof, preparation method and application

InactiveCN102924292AHigh catalytic activityWide molecular weight distributionOrganic compound preparationGroup 3/13 element organic compoundsLactideCombinatorial chemistry

The invention discloses a chiral tetra-amino aniline ligand, and a preparation method and application of an aluminum compound thereof. The structural formula of the ligand is represented as the formula (A), wherein R1 is alkyl in a C1-C4 straight chain branched chain structure. The aluminum coordination compound of the chiral tetra-amino aniline ligand can efficiently catalyze ring-opening polymerization reactions of lactide. The ligand and the aluminum compound of the ligand are simple to synthesize, high in product yield coefficient and stable in property, simultaneously catalyst activity is high, selectivity is good, the performance of an obtained polymer is good, and molecular weight and stereoselectivity of the polymer can be regulated by control of polymerization reaction conditions.

Owner:UNIV OF JINAN

Method for preparing biomedical polyether/polyester block copolymer

The invention belongs to the technical field of biological materials and particularly relates to a method for preparing a biomedical polyether / polyester block copolymer. In the method, the polyether / polyester block copolymer is prepared by triggering lactone to perform ring-opening polymerization under the vacuum condition by using fully dried polyether. The method comprises the following steps of: adding polyether, the lactone and a catalyst into a polymerization bottle; and heating and vacuumizing the polymerization bottle to remove moisture and solvent remained in a polymerization system to prepare the polyether / polyester block copolymer. The method is simple and practicable, the reaction conditions are easy to control, and a series of copolymers with different molecular weights can be obtained only by controlling the feed ratio of the polyether to the lactone; the reaction time can be shortened by a polymerization process so as to avoid side reaction, and the obtained copolymer has a stable structure, and high uniformity of molecular weight; and the content of the unreacted monomer and a heavy metal catalyst is extremely low, and the requirements of biomedical materials can be met.

Owner:上海谊众药业股份有限公司

Enzymatic preparation method of low molecular pectin

ActiveCN104419737ALow degree of esterificationReduce molecular weightFermentationPolymer scienceFiltration

The invention discloses an enzymatic preparation method of low molecular pectin. The method comprises the following steps: carrying out enzymolysis and de-esterification on high molecular high ester pectin by virtue of one or more of pectinase, cellulase, galacturonase and pectinesterase; and carrying out alkali liquor neutralization, filtration and drying and grinding on the product to obtain a pectin product with targeted molecular weight and degree of esterification. According to the method disclosed by the invention, the high molecular high ester pectin is hydrolyzed by adopting a multienzyme compound hydrolyzing technology so as to extract pectin with different molecular weights and degrees of esterification, high content of galacturonic acid and excellent taste from natural pectin. The low molecular pectin powder prepared by the preparation method meets the USP30 standard, various chance elements in the prior art are avoided, and the purity and success rate for extracting the low molecular pectin are improved. Meanwhile, the method is short in process flow, strong in capability of industrialization and suitable for being popularized on a large scale.

Owner:ZHEJIANG GUOYUAN KANGPIN BIOTECH CO LTD

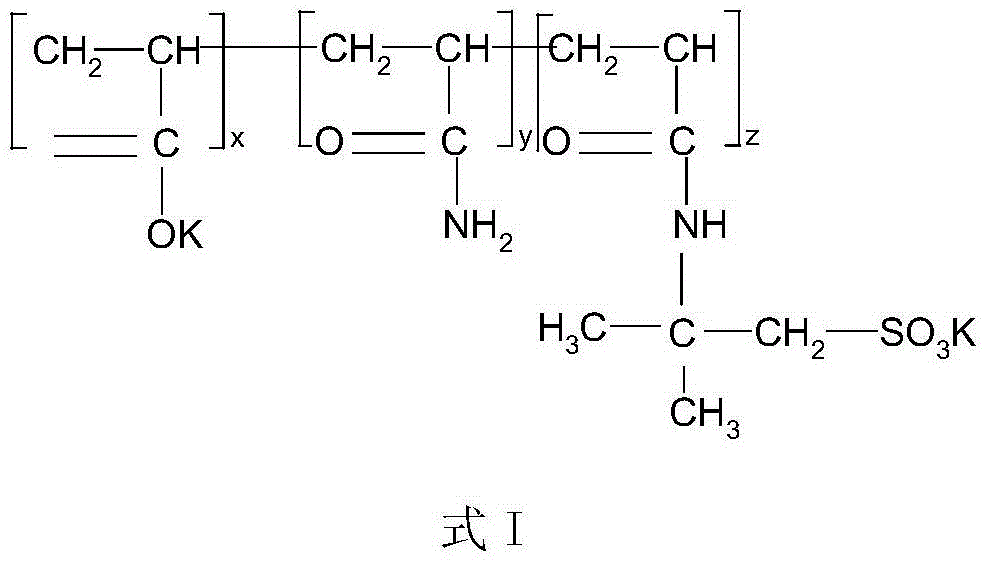

Synthetic method of lubricating fluid loss additive and application method thereof

InactiveCN104479070AGood molecular weightHigh molecular weightDrilling compositionWater soluble polymersChemistry

The invention relates to the technical field of oil-gas well engineering, specifically to a lubricating fluid loss additive and its synthetic process and application method. The technical scheme is as follows: the synthetic method of the lubricating fluid loss additive comprises the following steps: 1) preparing an aqueous phase solution; 2) preparing an oil phase solution; and 3) slowly adding the aqueous phase solution drop by drop into the oil phase solution for 10-20 min, introducing nitrogen, stirring, and polymerizing for 15min-1h by water bath of 40-65 DEG C after adding dropwise, so as to obtain the lubricating fluid loss additive. By the technical scheme, introduction of the oil phase endows the lubricating fluid loss additive water-soluble polymer with good lubricating property.

Owner:SINOPEC SSC +1

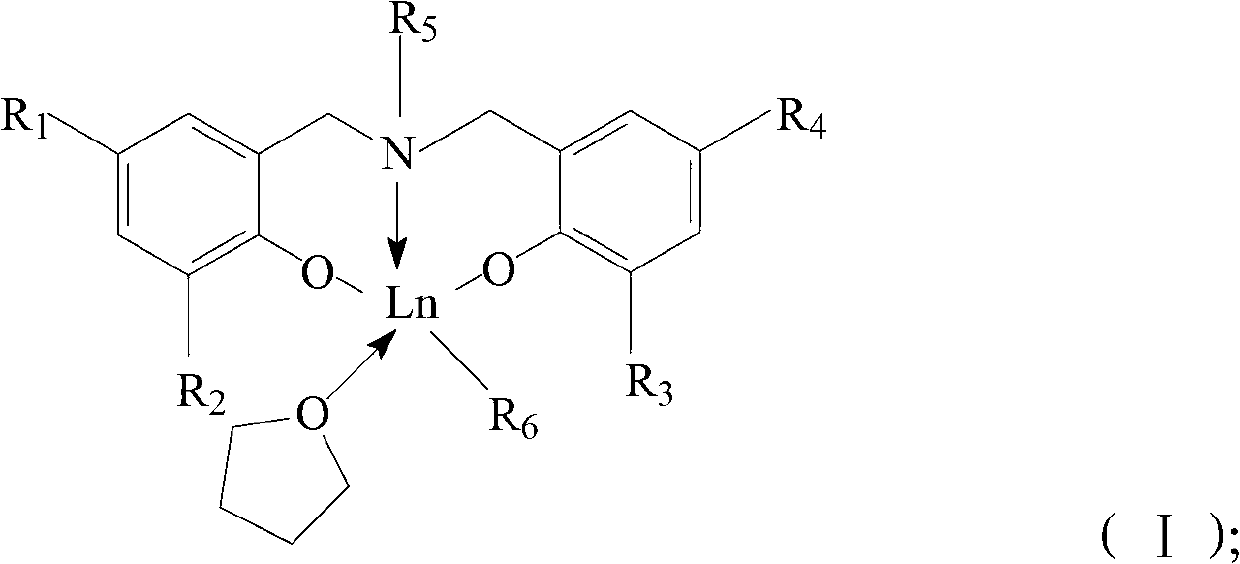

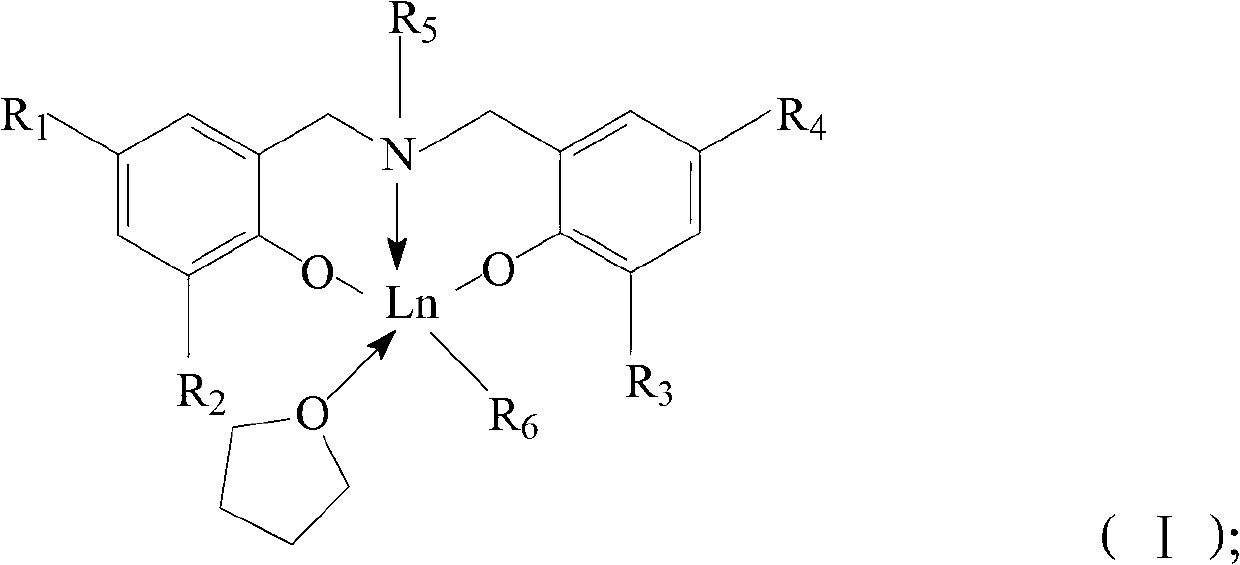

Catalyst composite and method for preparing polycarbonate

The invention provides a catalyst composite. The catalyst composite comprises a hydroxyl compound and a rare-earth metal complex having a structure of a formula (I), wherein the molar ratio of the rare-earth metal complex and the hydroxyl compound is 1:(1-500). The invention also provides a method for preparing polycarbonate. The method comprises the step of performing polymerization reaction on cyclic carbonate in an organic solvent in the presence of a catalyst composite to prepare polycarbonate. According to the invention, the rare-earth metal complex is matched with the hydroxyl compound, and polymerization reaction is carried out on cyclic carbonate by using the catalyst so that a small quantity of rear-earth metal complex is adopted in the composite to effectively catalyze the polymerization of cyclic carbonate; and the catalyst composite is high in catalysis efficiency and catalysis activity.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

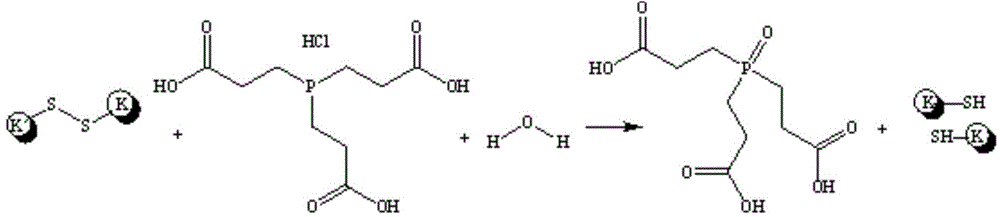

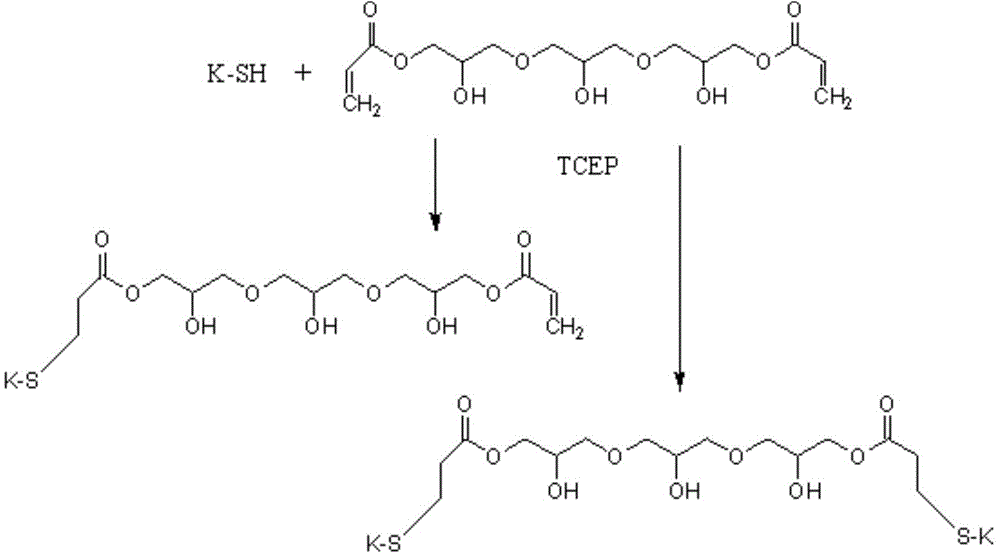

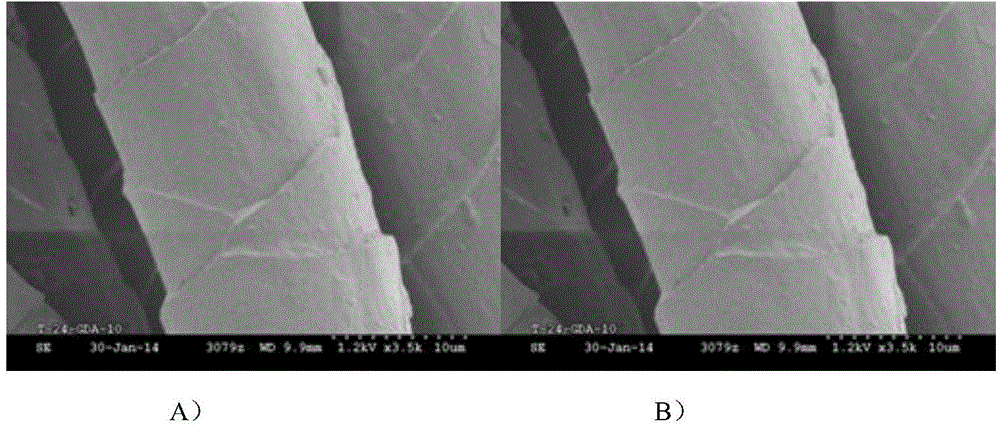

Method for providing anti-felting function for wool fabric

The invention relates to a method for providing an anti-felting function for a wool fabric. The method utilizes tris(2-carboxyethyl)phosphine (TCEP) to pre-treat a wool fabric so that disulfide bonds in wool fiber keratin are broken to form mercapto groups with high activity. 2-propenoic acid-(2-hydroxy-1,3-propanediyl)bis[oxy(2-hydroxy-3,1-propanediyl)]ester (GDA) and the wool fabric pre-treated by TCEP undergo a click chemical reaction, in other word, C-C double bonds and the mercapto groups undergo a reaction so that a molecular chain rich in hydroxyl is introduced into wool protein molecules by a medical bonding method. The treated product has an anti-felting function, realizes a certain degree of machine washing, has good size stability and has a certain durability by chemical treatment. The method has substantial effects, belongs to a chlorine-free treatment method and is safe and environmentally friendly.

Owner:DONGHUA UNIV

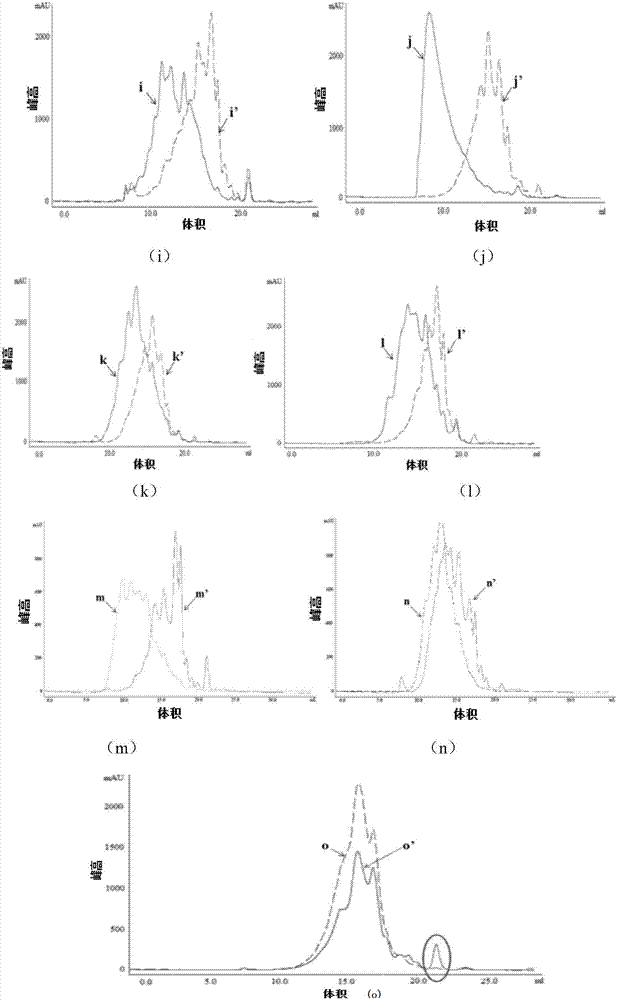

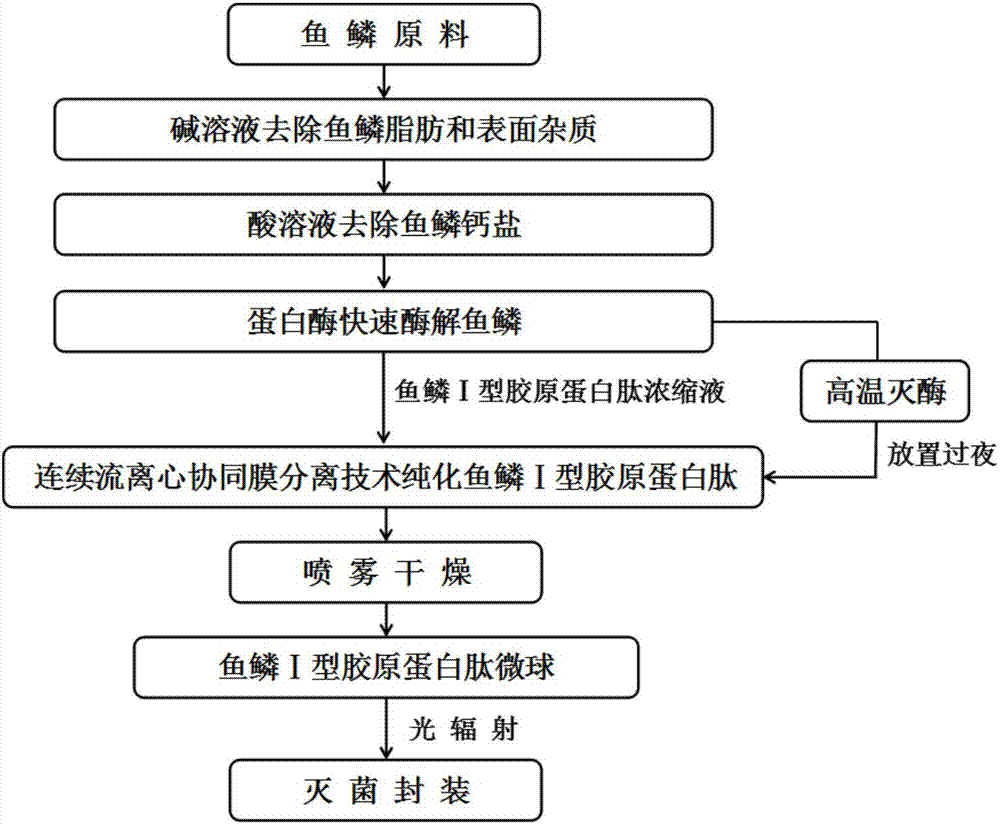

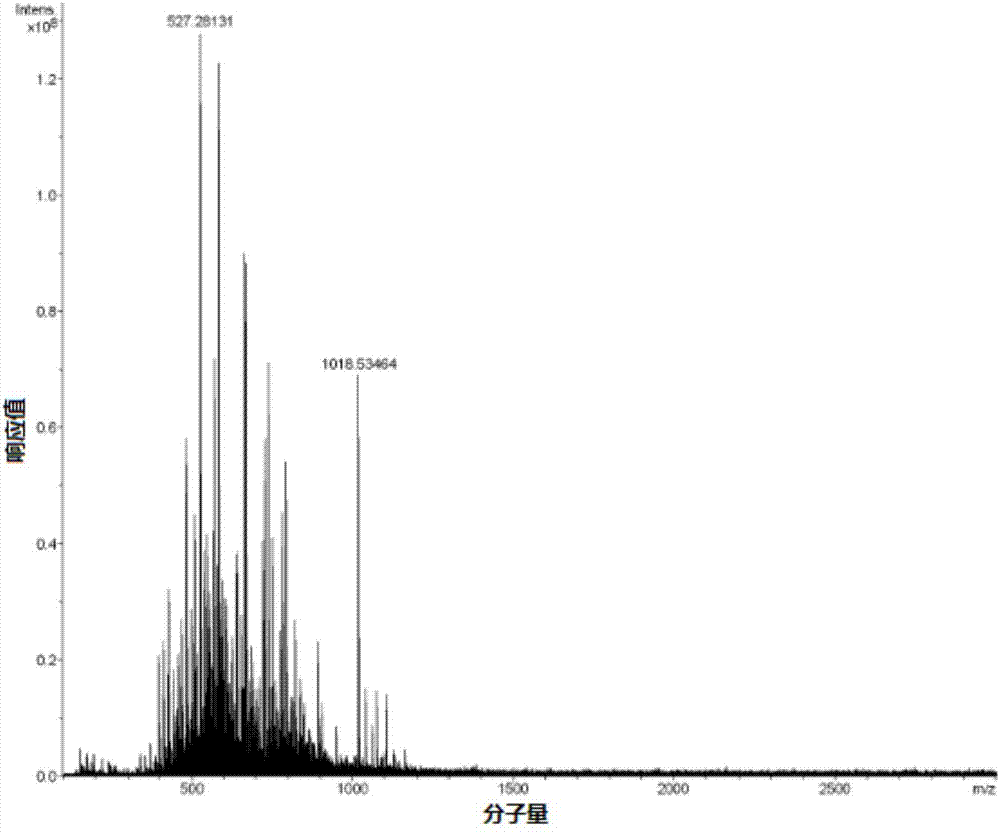

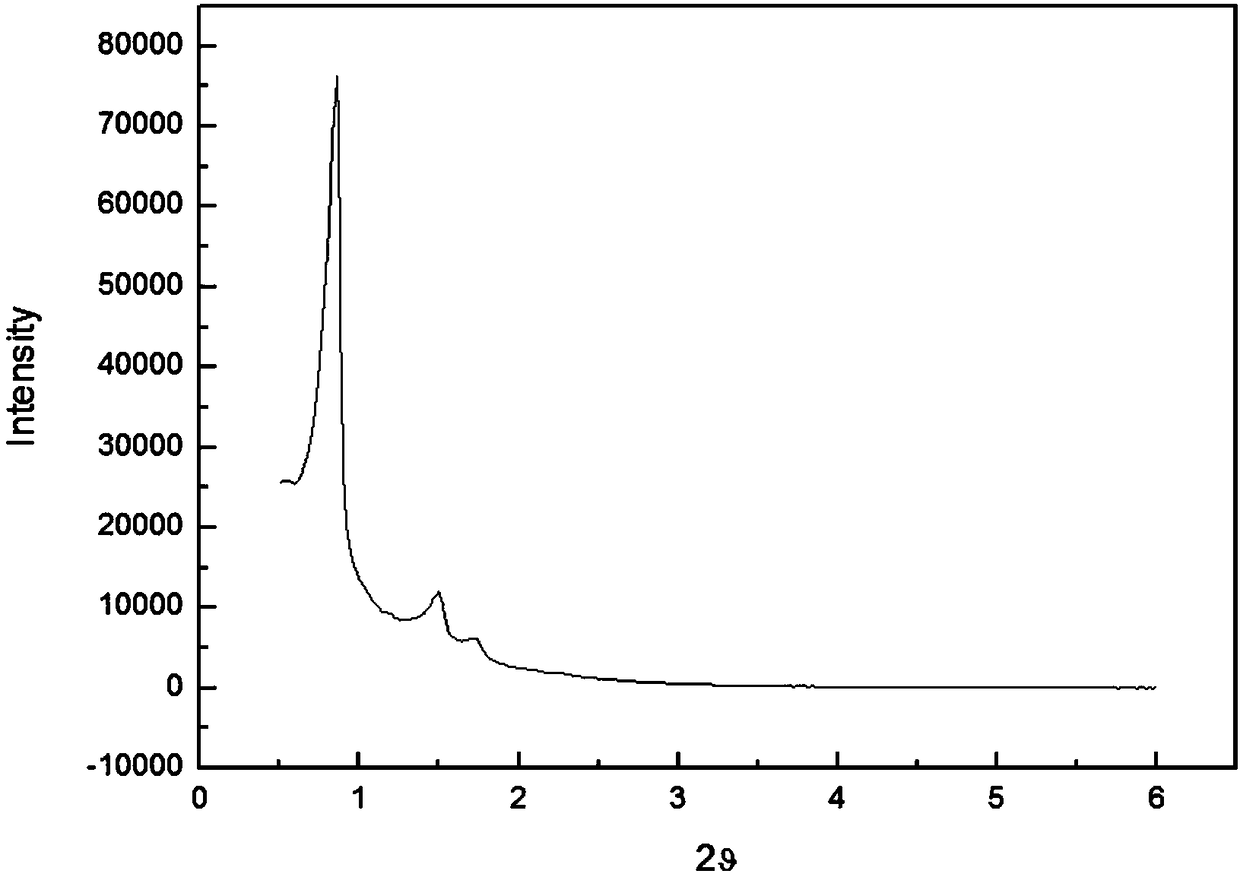

Large-scale preparation method of scale I-type collagen peptide applicable to cosmetics

InactiveCN107164439AClear configurationConcentrated and stable molecular weight distributionCosmetic preparationsConnective tissue peptidesMarine fishDegreasing

The invention relates to a large-scale preparation method of scale I-type collagen peptide applicable to cosmetics. The scales of marine fish or part of freshwater fish are adopted as a raw material; in pretreatment, an alkaline solution is adopted for fast degreasing, and an acid solution is adopted for fast decalcification; after that, a scale I-type collagen peptide solid obtained by the pretreatment is directly prepared into an I-type collagen peptide concentrated solution by a biological enzymolysis technology, and the extraction rate is higher than or equal to 97%; enzymatic hydrolysate is separated, purified and desalted at normal temperature by a continuous flow centrifugation collaborated membrane separation technology to obtain scale I-type collagen peptide liquid with the content of higher than or equal to 95%; finally, the scale I-type collagen peptide liquid is quickly dried by a spray drying technology to obtain scale I-type collagen peptide microspheres with a special hollow structure, and the scale I-type collagen peptide microspheres are quickly sterilized by an optical radiation technology, and are sealed and stored. According to the method provided by the invention, I-type collagen in the scales is almost completely turned into the I-type collagen peptide concentrated solution; the prepared scale I-type collagen peptide is of a microsphere shape, and the particle size is uniform and is mainly on a micron level of 1-10mu m.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

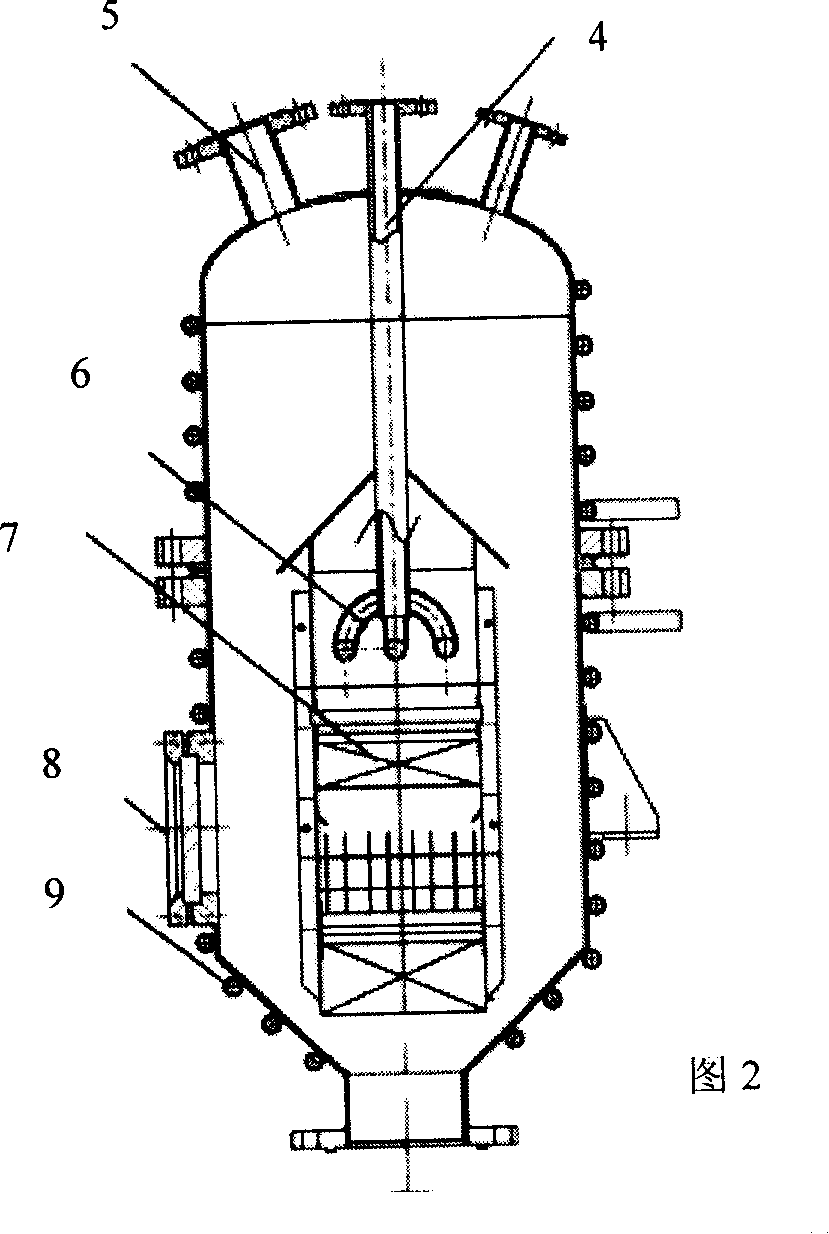

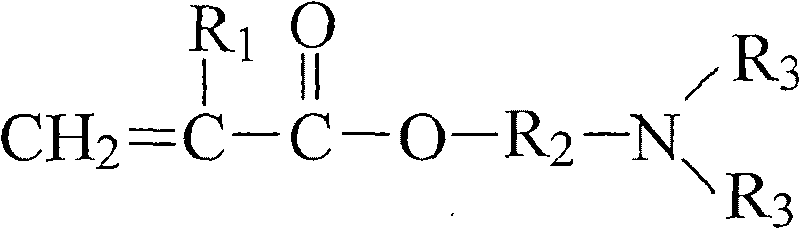

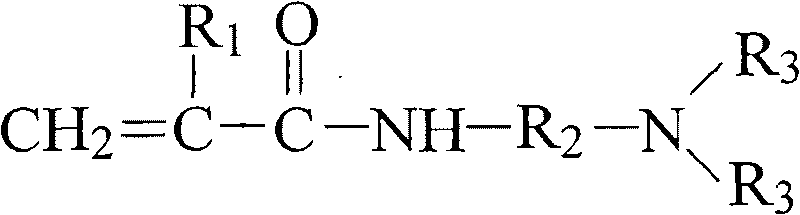

Terpolymer cationic polyacrylamide

ActiveCN104910321AWide pH range of useHigh molecular weightWater/sewage treatment by flocculation/precipitationFlocculationEngineering

The invention belongs to the technical field of flocculant in sewage treatment technology in environment engineering, and particularly relates to a terpolymer cationic polyacrylamide. The preparation method of the product comprises the following steps: preparation of a cationic monomer E-AM, preparation of a monomer water solution, terpolymerization of AM, E-AM and DAC, and the like. The terpolymer cationic polyacrylamide well embodies the high polymerization activity and favorable flocculation effect of the E-AM monomer and the characteristic that the DAC can be easily used for preparing high-molecular-weight copolymers. Compared with the existing common flocculant product, the terpolymer cationic polyacrylamide has the characteristics of high cation degree, high molecular weight and excellent flocculation property. The actual detection result indicates that the terpolymer cationic polyacrylamide also has the characteristic of high solubility, and thus, is suitable to be used as a flocculant in sewage treatment engineering.

Owner:HENAN HONGKANG ENVIRONMENTAL PROTECTION TECH

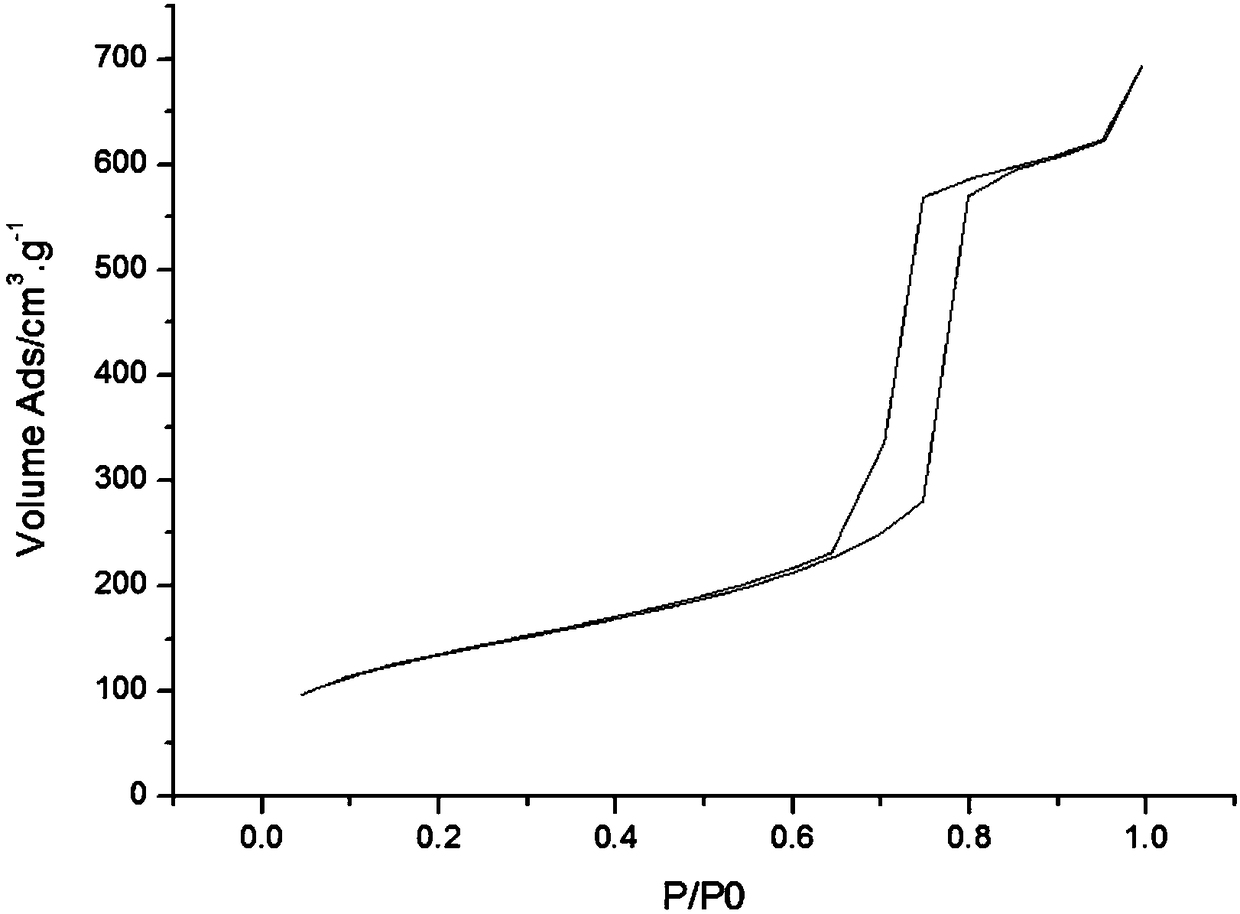

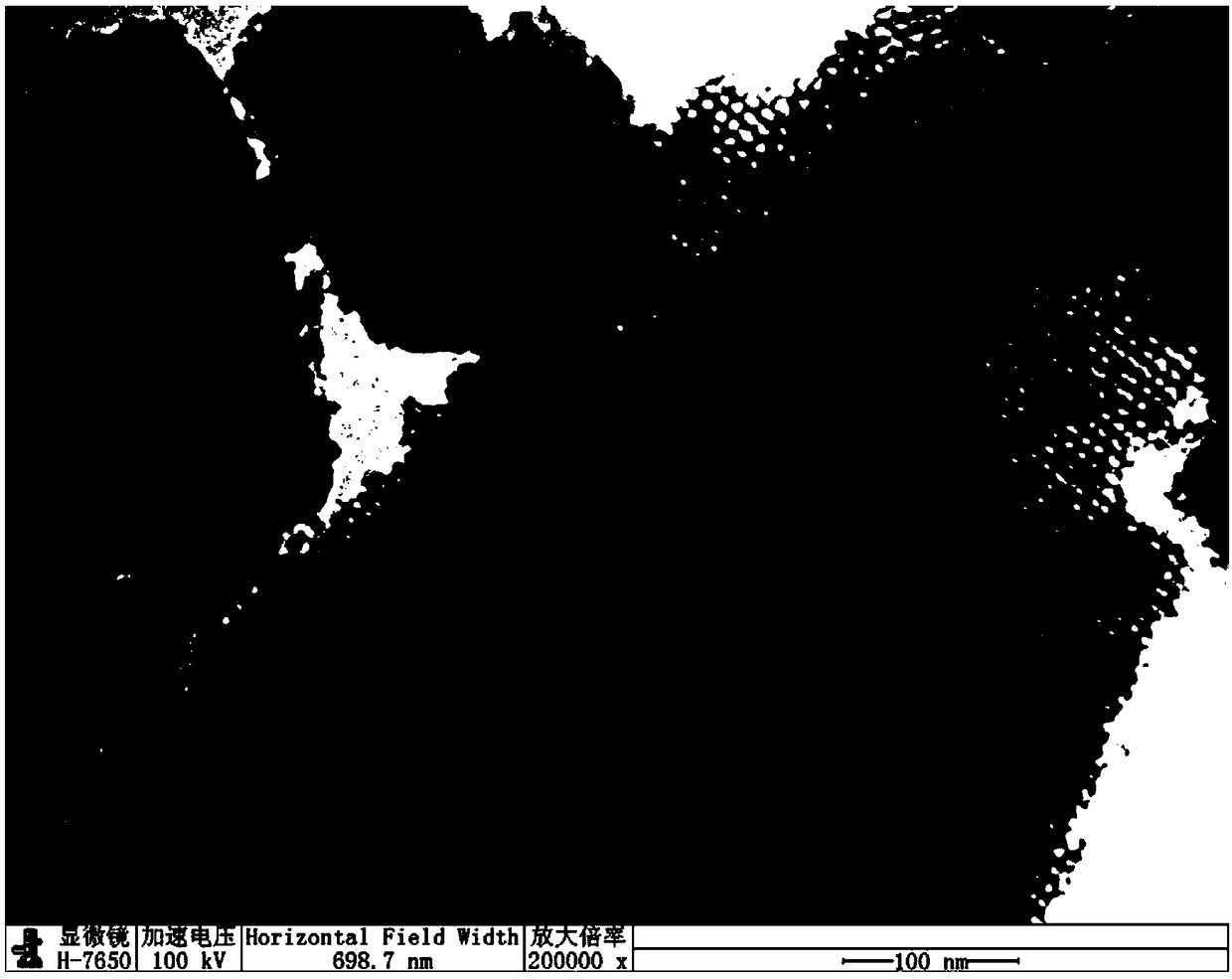

Preparation and application of Al-SBA-15 mesoporous molecular sieve and fatty alcohol ethoxylation reaction method

ActiveCN108187726ALarge specific surface areaOrdered microstructureMolecular sieve catalystsEther preparation from oxiranesMolecular sieveReaction temperature

The invention discloses a preparation method of an Al-SBA-15 mesoporous molecular sieve, application of the Al-SBA-15 mesoporous molecular sieve as a catalyst, and a method for catalyzing ethoxylationreactions of fatty alcohol. The fatty alcohol ethoxylation reaction method comprises the following steps: dispersing the Al-SBA-15 mesoporous molecular sieve into a certain amount of fatty alcohol, putting a dispersion liquid into a high-pressures kettle, performing nitrogen replacement, after the reaction temperature is 110-130 DEG C, adding ethylene oxide in batches, adding the ethylene oxide till the initial reaction pressure is 0.6-1.0 MPa each time, and cooling and discharging materials after reactions are completed. The Al-SBA-15 mesoporous molecular sieve catalyst prepared by using themethod has a relatively large specific surface area and an ordered microstructure, is good in catalysis activity, is narrow in catalyst product molecular weight distribution and can be repeatedly used.

Owner:JIANGSU SAILBOAT PETROCHEMICAL CO LTD +1

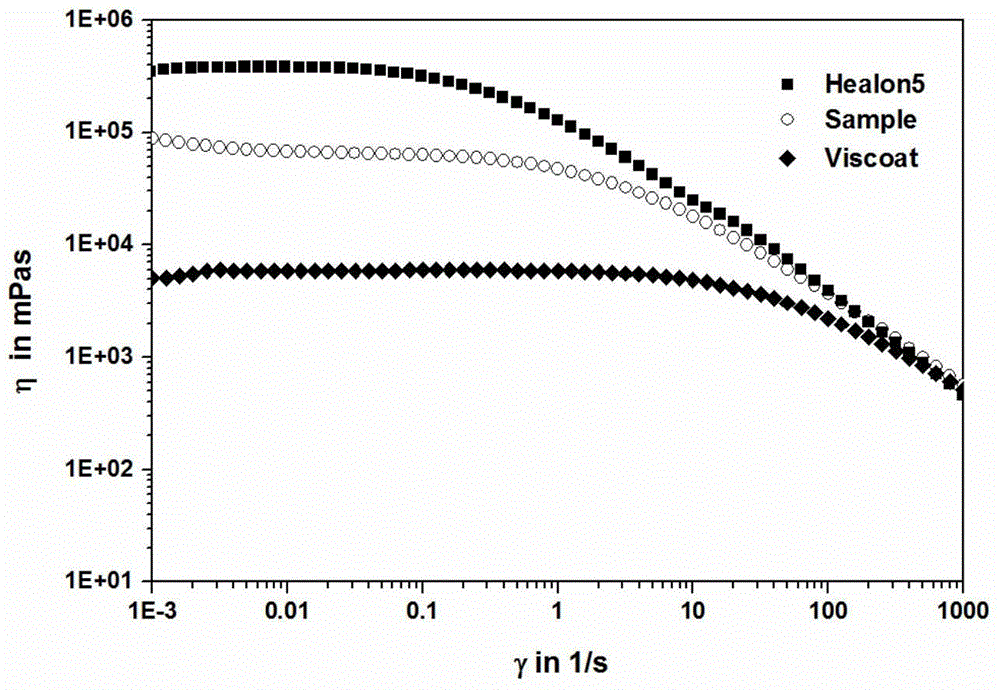

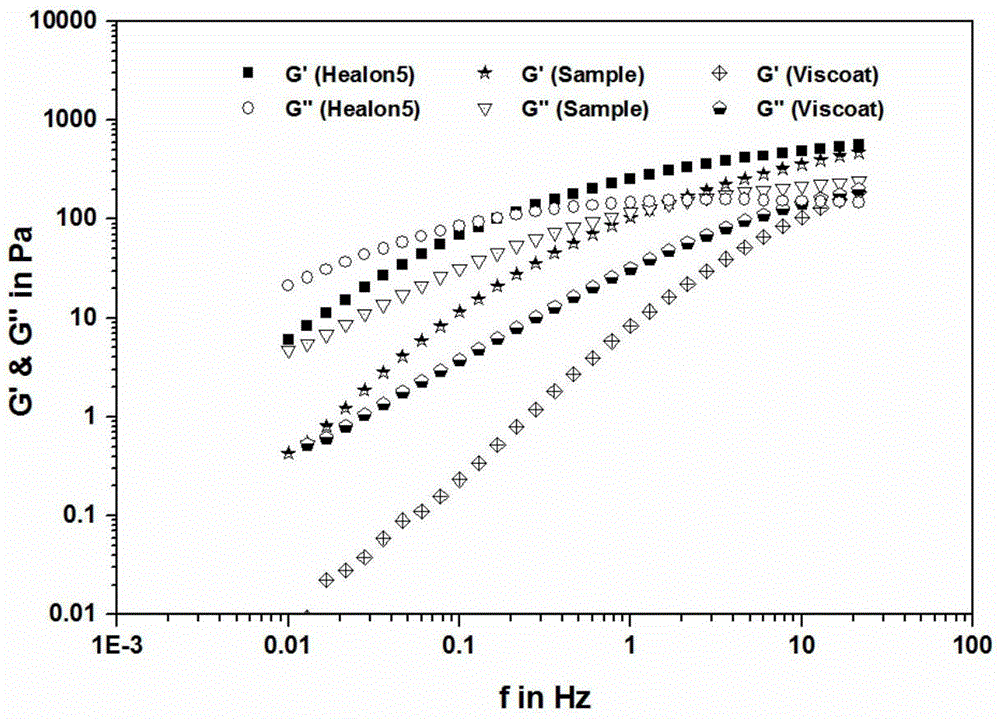

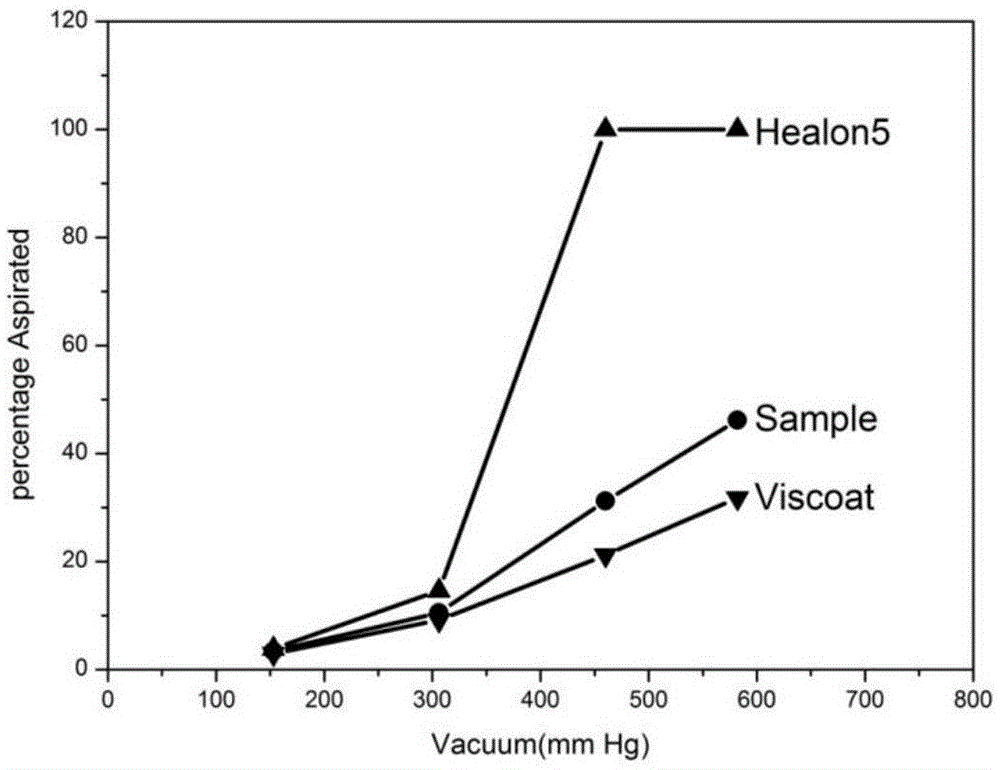

Preparation method of viscoelastic agent with cohesiveness and dispersivity

InactiveCN105903087AGood molecular weightSmall molecular weightSurgeryThermal instabilitySodium hyaluronate

Single cohesiveness or dispersivity cannot simultaneously satisfy different needs in the whole cataract surgery. Chitosan and sodium hyaluronate respectively belong to natural polycation and polyanion polysaccharides. Through charge interaction between chitosan and sodium hyaluronate, a polyelectrolyte complex is formed and the polyelectrolyte complex is processed to form the viscoelastic agent with cohesiveness and dispersivity. Medical chitosan gel has thermolability and after moist heat sterilization, the molecular weight of the chitosan gel is reduced and dispersivity is improved so that the chitosan gel can prevent corneal tissue mechanical damage. After positive and negative charge interaction, ionic crosslinked compound gel still has good cohesiveness, still has typical non-Newton rheological behavior and can be removed easily and reduce residual in eyes. Cohesiveness and dispersivity guarantees that a single product can satisfy demands in different stages in the whole cataract surgery and has a wide clinical application prospect.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

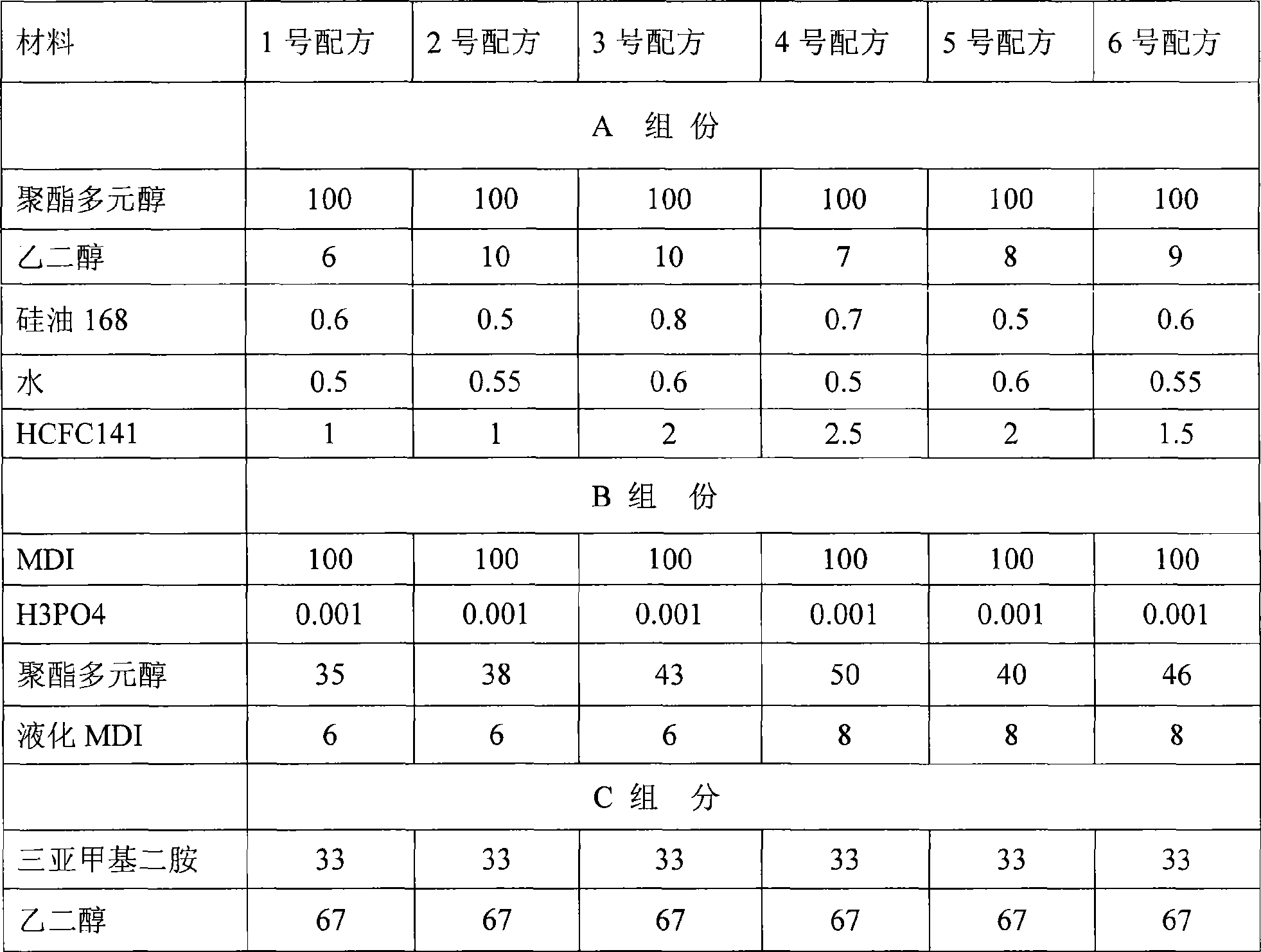

Resin for polyester type shoes

The invention belongs to a resin formula for shoes, and relates to three-component polyester polyurethane resin. Component A is a hydroxyl (OH) raw material and an active hydrogen-containing mixture, and mainly consists of a polymeric polyol with a long chain, a chain extender, a crosslinking agent, a surfactant, a foaming agent and other additives. Component B is an isocyanate (NCO) raw material, and mainly a 4,4-diphenyl diisocyanate (MDI) prepolymer modified by polyester. Component C is a catalyst and consists of glycol solution of triethylenediamine. In the formula, only one polyester polyol is adopted in the component A, which changes the original framework of two or more polyols, refines the formula, simplifies process flow and optimizes cost, thus being a major breakthrough in energy-saving and emission reduction and efficiency improvement.

Owner:无锡双象新材料有限公司

Method for preparing soybean protein

InactiveCN101779721AGood molecular weightHigh molecular weightProtein composition from vegetable seedsVegetable proteins working-up7s globulinSoybean protein

The invention relates to a method for preparing soybean protein, solving the problem of poor dispersibility and molecular structure integrity of the existing soybean protein. The method comprises the following steps: 1. preparing coarse 11S globulin; 2. preparing 7S globulin; 3. preparing mixed solution; 4. collecting a trapped part A; 5. collecting a trapped part B; and 6. carrying out spray drying to obtain soybean protein. The soybean protein prepared by the method of the invention has a dissolubility of more than 95% and features good dispersibility, a molecular weight of around 60 KD andgood molecular structure integrity.

Owner:HARBIN UNIV OF COMMERCE

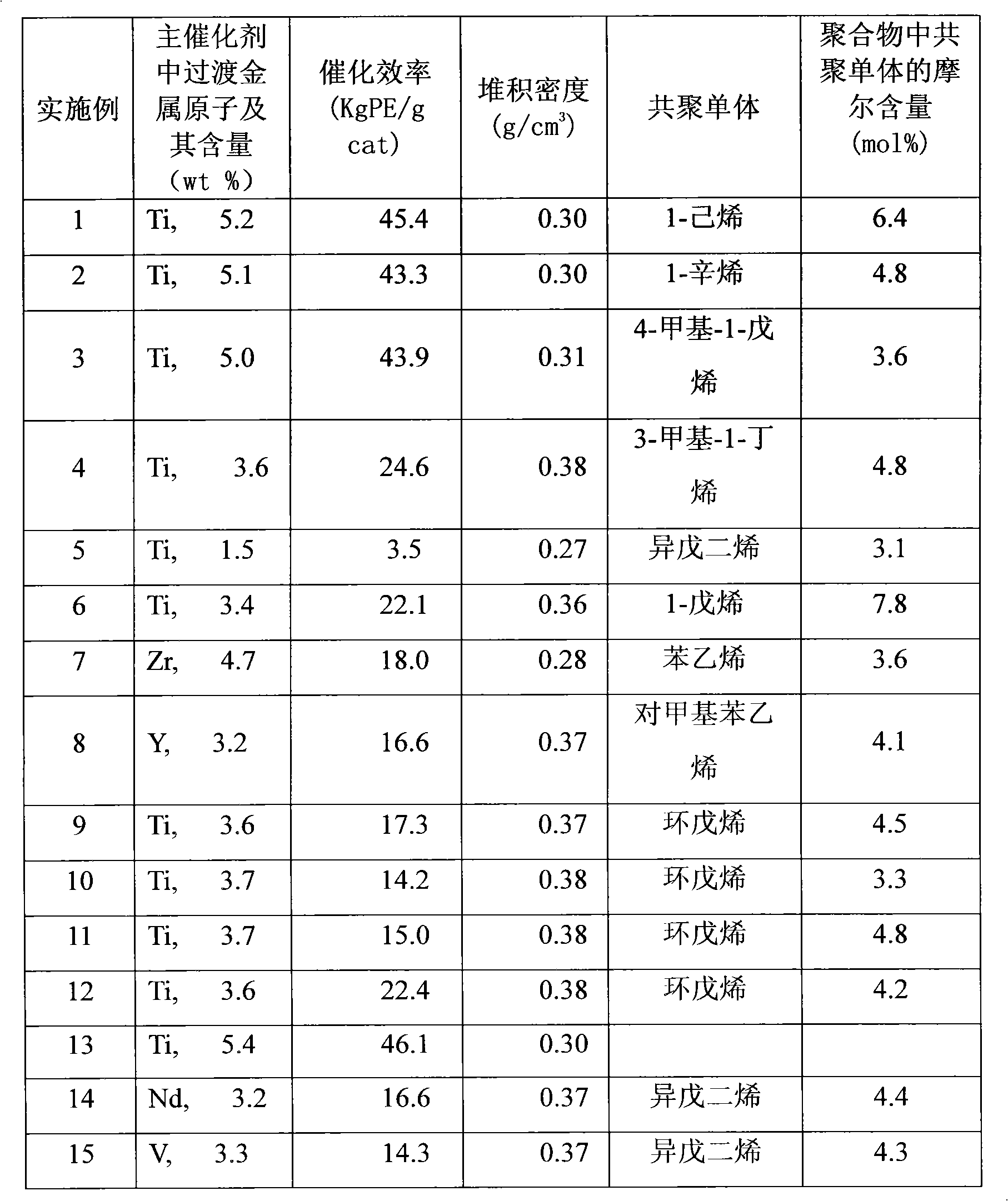

Ethylene polymerization catalyst, preparation and application thereof

The invention relates to an ethylene polymerization catalyst, preparation and application thereof. The catalyst consists of a carrier, transition metal halides, organic alcohol compounds, organic silicone compounds and an organic thiols in a molar ratio of 1:(0.01-20):(0.1-6):(0.01-5):(0.001-5). The organic thiols is one or a mixture of two or more of the compounds with a general formula of HS-R1, wherein the R1 is an alkyl group of which the carbon atom number is 1 to 20, a cycloalkyl group of which the carbon atom number is 3 to 20, an aryl group of which the carbon atom number is 6 to 30, an organic silyl group of which the carbon atom number is 1 to 30, an organic cycloalkyl group of which the carbon atom number is 3 to 30, an organic aryl group of which the carbon atom number is 6 to40 or an organic siloxy group of which the carbon atom number is 1 to 30. The catalyst has high activity; a polymer has high molecular weight and wide molecular weight distribution; and the preparation method has the characteristics of simple method, low requirement on equipment and low pollution to environment.

Owner:PETROCHINA CO LTD +1

Olefin polymerization catalyst and preparation method thereof

The invention relates to an olefin polymerization catalyst and a preparation method thereof. A main catalyst consists of a carrier, a transition metal halide, an organic alcohol compound, an organo-siloxane compound and organic silanol according to a molar ratio of 1:(0.01-20):(0.1-6):(0.01-5):(0.01-5). The molar ratio of the transition metal halide in the main catalyst to a cocatalyst is 1:(30-500); the organic silanol is one or a mixture of two or more of compounds with a general formula of HO-SiR1R2R3; and the carrier is an inorganic oxide carrier, a halide carrier or a polymer carrier. The catalyst has the advantages of good spherical grain shape, high activity, high polymer molecular weight, wide distribution of polymer molecular weight, and suitability for a slurry process, gas-phase polymerization technology or combined polymerization technology; and the preparation method has the advantages of simpleness, low equipment requirement and small environmental pollution.

Owner:PETROCHINA CO LTD

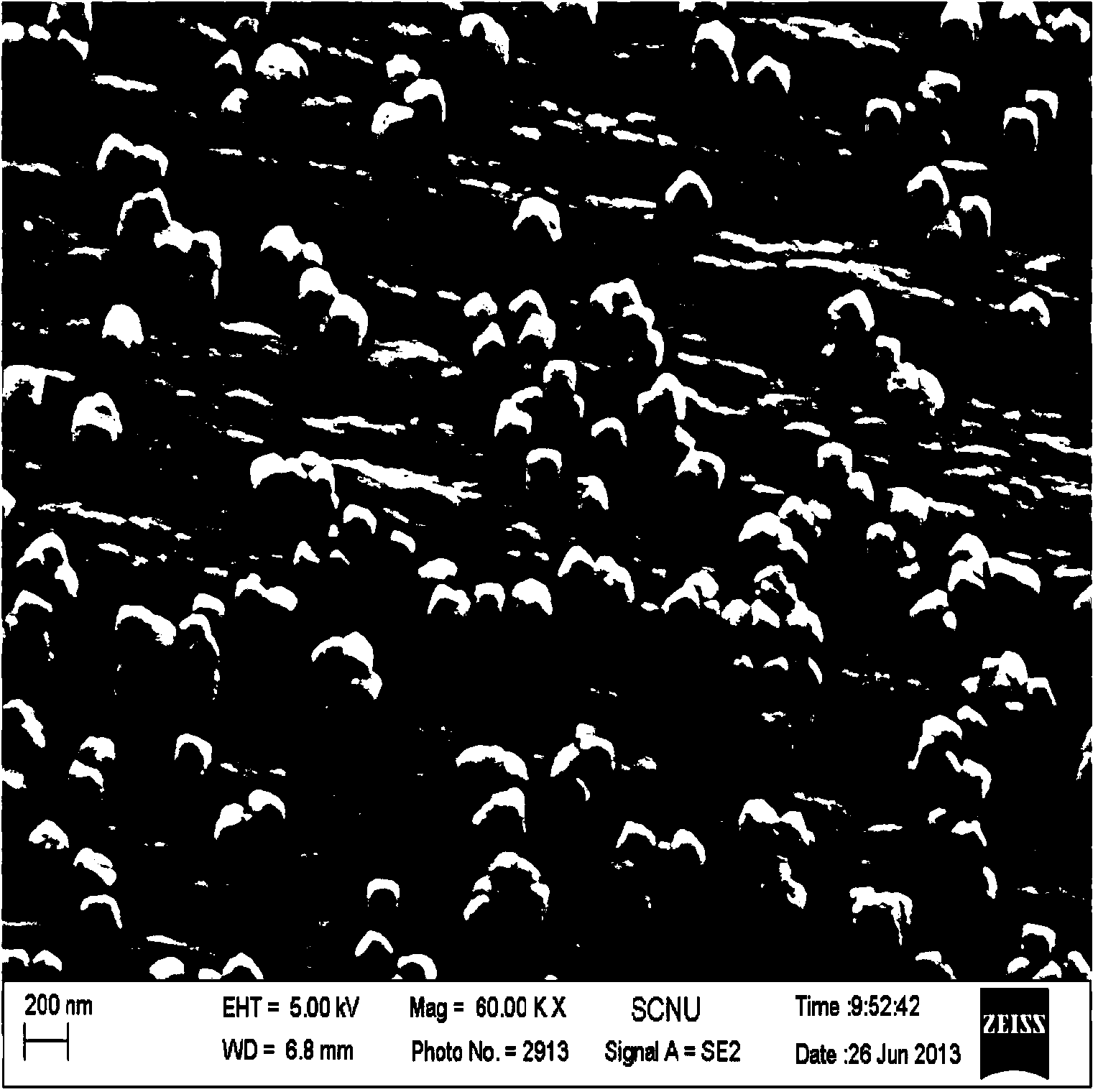

Method for preparing high-strength high-modulus organosilicone modified PI/SiO2 hybridization film

The invention discloses a method for preparing a high-strength high-modulus organosilicone modified PI / SiO2 hybridization film. The method includes the following steps that firstly, aminosilane coupling reagents are fully reacted with aromatic anhydride in a solvent; secondly, the aromatic anhydride is dissolved in the solvent and made into a solution, the system, the aromatic anhydride and tetraethyl orthosilicate in the first step are added into the solution, and a polymerization reaction is performed to obtain an organosilicone modified polyamide acid solution; the organosilicone modified polyamide acid solution obtained in the second step is diluted, arranged on a supporting body in a coating mode and roasted, and the film is obtained; fourthly, the film undergoes temperature rising, dehydration and crosslinking, and a product is obtained. According to the method for preparing the high-strength high-modulus organosilicone modified PI / SiO2 hybridization film, the prepared hybridization film is high in stretching strength and modulus of elasticity, and the defect that a large amount of water is brought to the system by conventionally adding sol-gel state silicon dioxide is overcome. The method for preparing the high-strength high-modulus organosilicone modified PI / SiO2 hybridization film can well control the reaction evenness and the reaction accuracy and is short in experimental period, simple in technology and suitable for industrial production.

Owner:SOUTH CHINA NORMAL UNIVERSITY

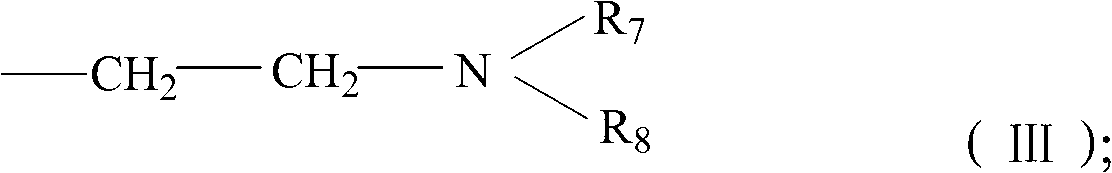

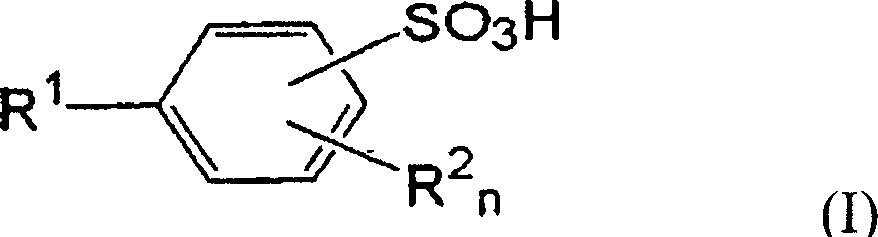

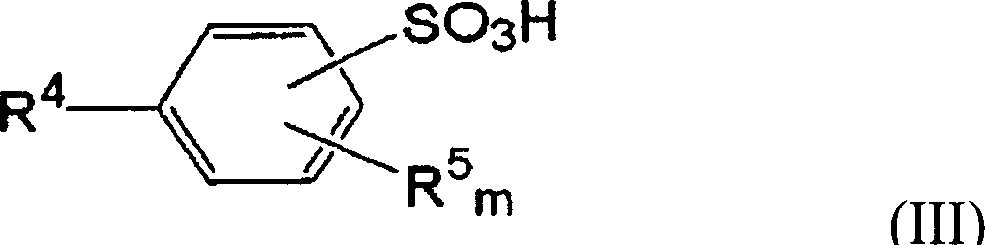

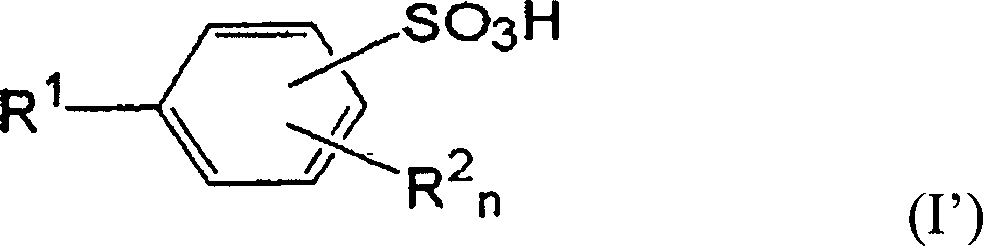

Method for producing binder resin, particulate resin dispersion, electrostatic image development toner, electrostatic image developer, and image forming method

InactiveCN1978484AGood dispersionGood molecular weightDevelopersElectrographic processes using charge patternParticulatesOrganic group

A method for producing a binder resin comprises polycondensing a polycondensable monomer by using a polycondensation catalyst that comprises: at least one of compounds of formula (I) or (II); and at least one of compounds represented of formula (III) or (IV), wherein weight ratio of total amount of the compounds of formula (I) or (II) to total amount of the compounds of formula (III) or (IV) is from 5:95 to 95:5, in (I) R1 represent C8-C20 straight chain alkyl, in (III) R2 represent univalence organic group, the number n of replace groupp R2 is integer from 0 to 4; in (II) R3 represent C8-C20 straight chain alkyl, in (III) R4 represent C8-C20 branch alkyl, R5 represent univalence organic group, the number m of replace groupp R5 is integer from 0 to 4, in (IV) R6 represent C8-C20 branch alkyl.

Owner:FUJIFILM BUSINESS INNOVATION CORP

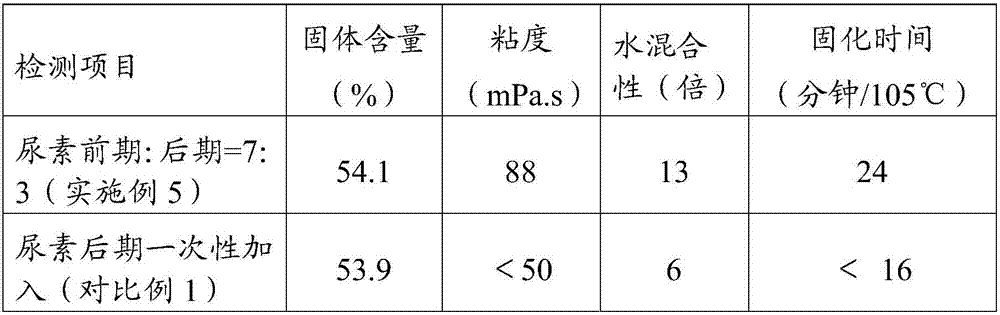

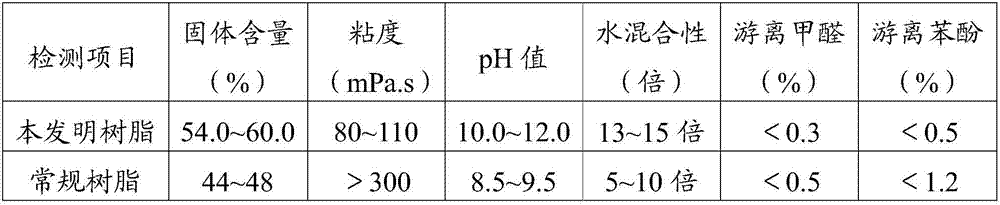

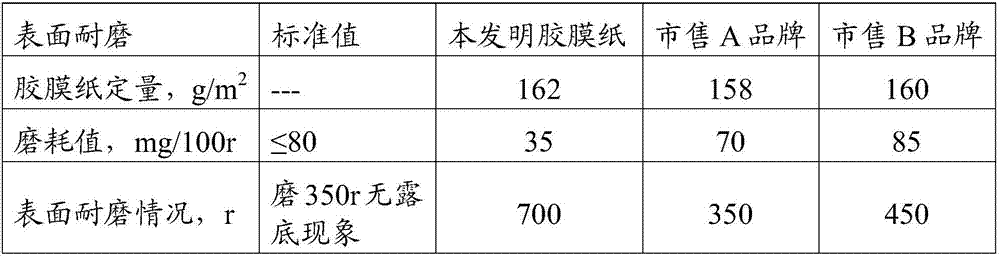

Impregnating phenolic resin and preparation method and application thereof

ActiveCN106866909AUniform and full colorHigh glossWax additionPaper/cardboardWear resistanceSolid content

The invention discloses impregnating phenolic resin with high solid content and low cost and a preparation method thereof, and also discloses a phenolic resin impregnation liquid containing the impregnating phenolic resin. The phenolic resin impregnation liquid is low in molecular weight and good in permeability and stability. The invention also discloses phenolic resin impregnated bond paper containing the phenolic resin impregnation liquid, and the phenolic resin impregnated bond paper is uniform and full in color, good in lustrousness, high in coverage rate and excellent in wear resistance. Besides, the invention discloses an impregnated bond paper veneer cement template containing the phenolic resin impregnated bond paper.

Owner:广州市长安粘胶制造有限公司

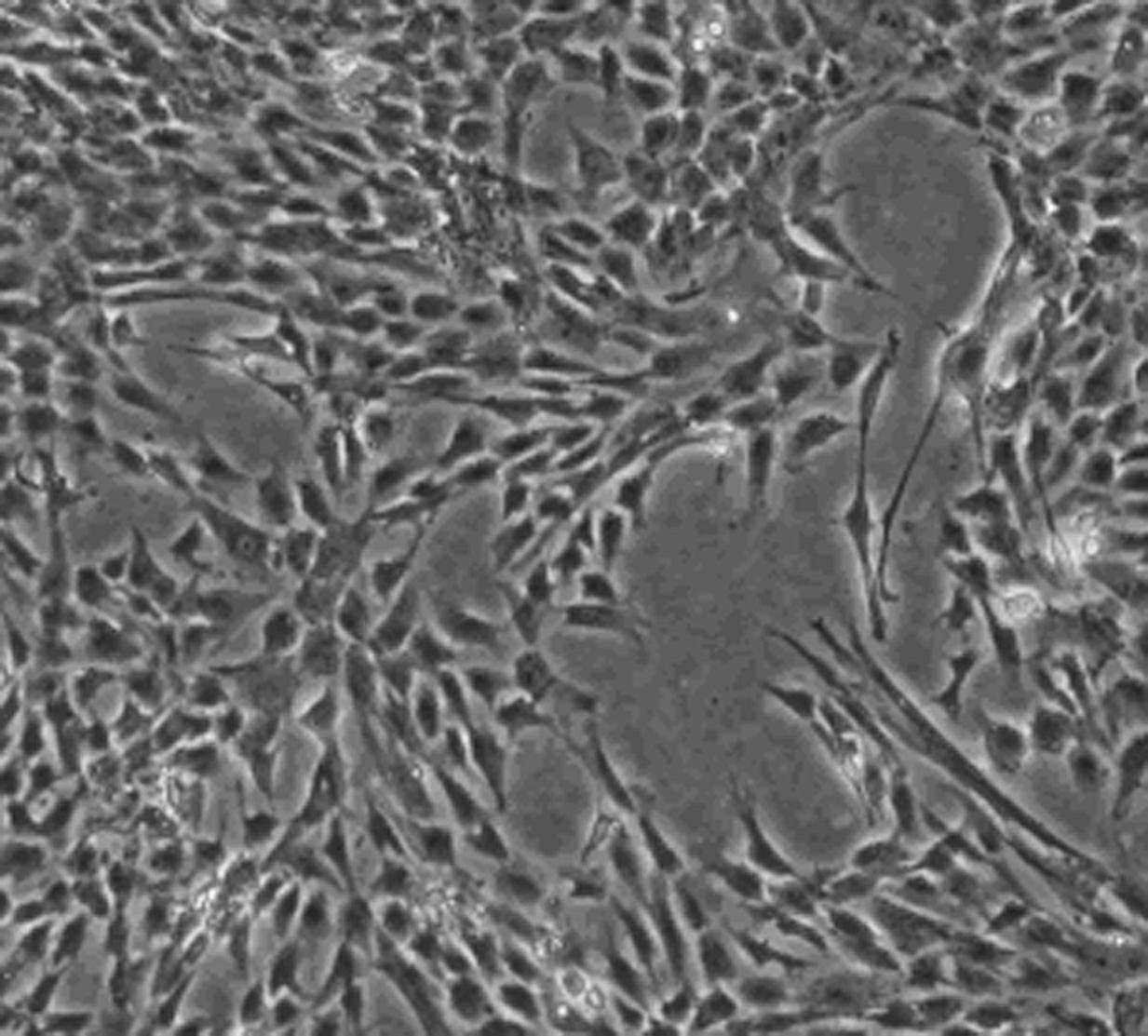

Cryogenic storing protection liquid for human umbilical cord Wharton's jelly tissue block

The invention discloses a cryogenic storing protection liquid for a human umbilical cord Wharton's jelly tissue block. One liter of cryogenic storing protection liquid comprises 1-1.4 mol of permeable cryoprotectant, 0.1-0.5 mol of impermeable cryoprotectant and the balance of base liquid. The cryogenic storing protection liquid provided by the invention contains the permeable cryoprotectant and the impermeable cryoprotectant at the same time, the concentration of the permeable cryoprotectant is low, so that good cryogenic storage effect can be achieved, and the toxicity of cells is also small. Meanwhile, the cryogenic storing protection liquid contains the base liquid, not only can nutrients be provided for the human umbilical cord Wharton's jelly tissue block, but also the toxicity of cryoprotectants on cells in the Wharton's jelly tissue block is lowered. The human umbilical cord Wharton's jelly tissue block cryogenically stored by the cryogenic storing protection liquid can be used for preparing high quality umbilical cord mesenchymal stem cells, few cells are damaged, and the cryogenic storing protection liquid has small residue, small toxic and side effects and no harm to human bodies in clinic use.

Owner:江苏省北科生物科技有限公司

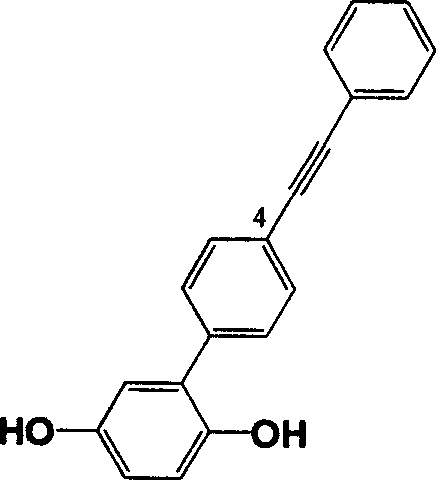

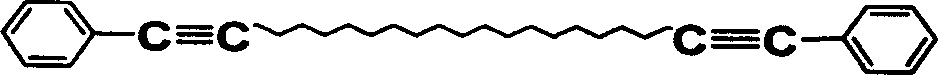

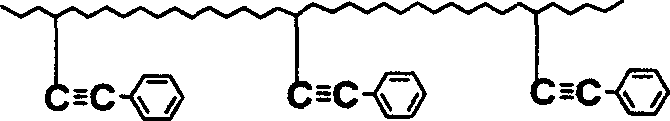

Preparation of monomer of dual functional groups containing lateral group phenylacetylene

InactiveCN1660757AImprove heat resistanceAdjustable molecular weightOrganic compound preparationCarbonyl compound preparationBromineBenzene

A dual-functional-group monomer containing phenylacetylene as side group is prepared from the Br contained intermediate through reacting on phenylacetylene in Pd(O) / Cu(I) catalyst system to obtain bifluorine and biphenol. It can take part in polycondensating reaction on other monomers to obtain the polyacryletherone or polyaryether containing phenylacetylene as side group.

Owner:JILIN UNIV

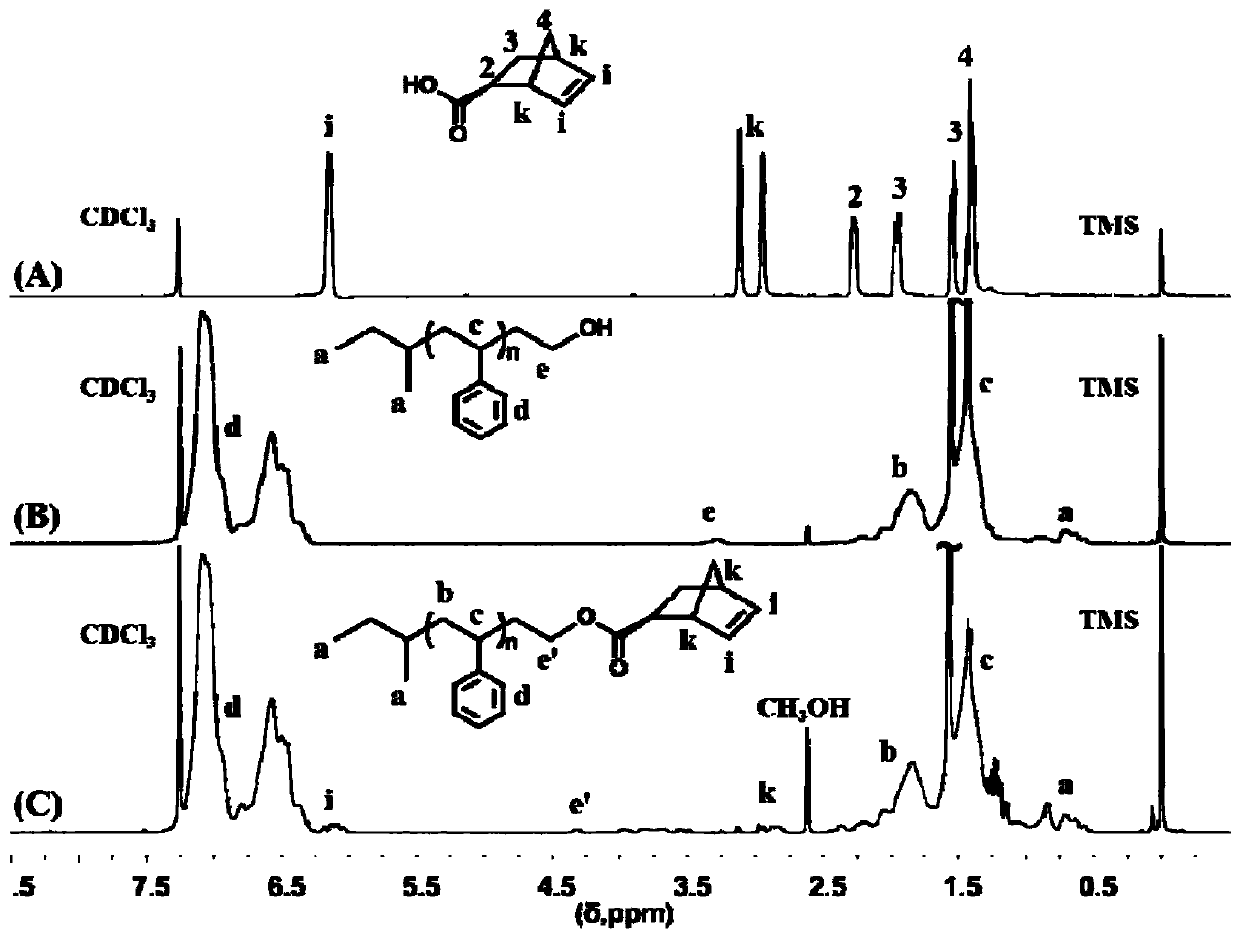

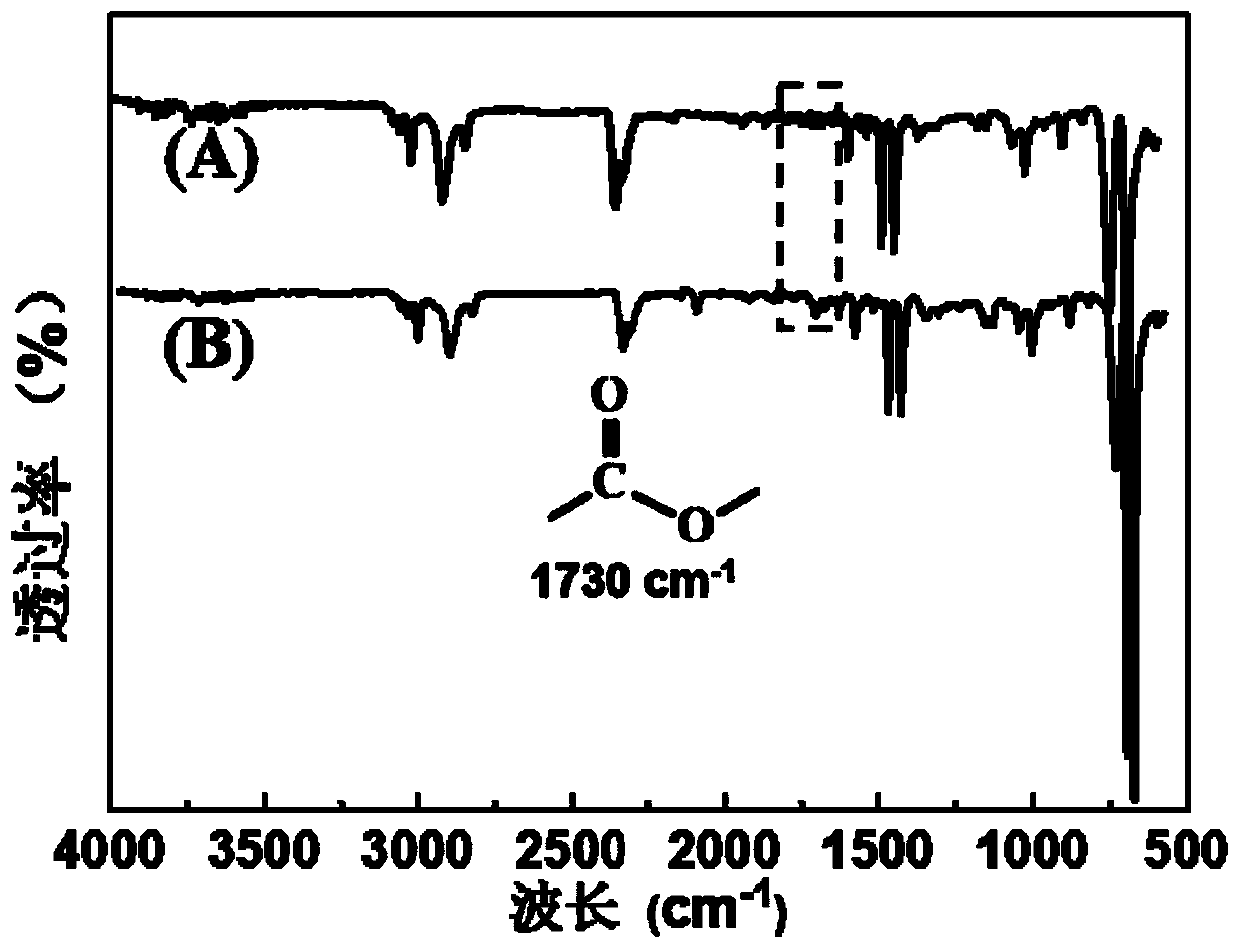

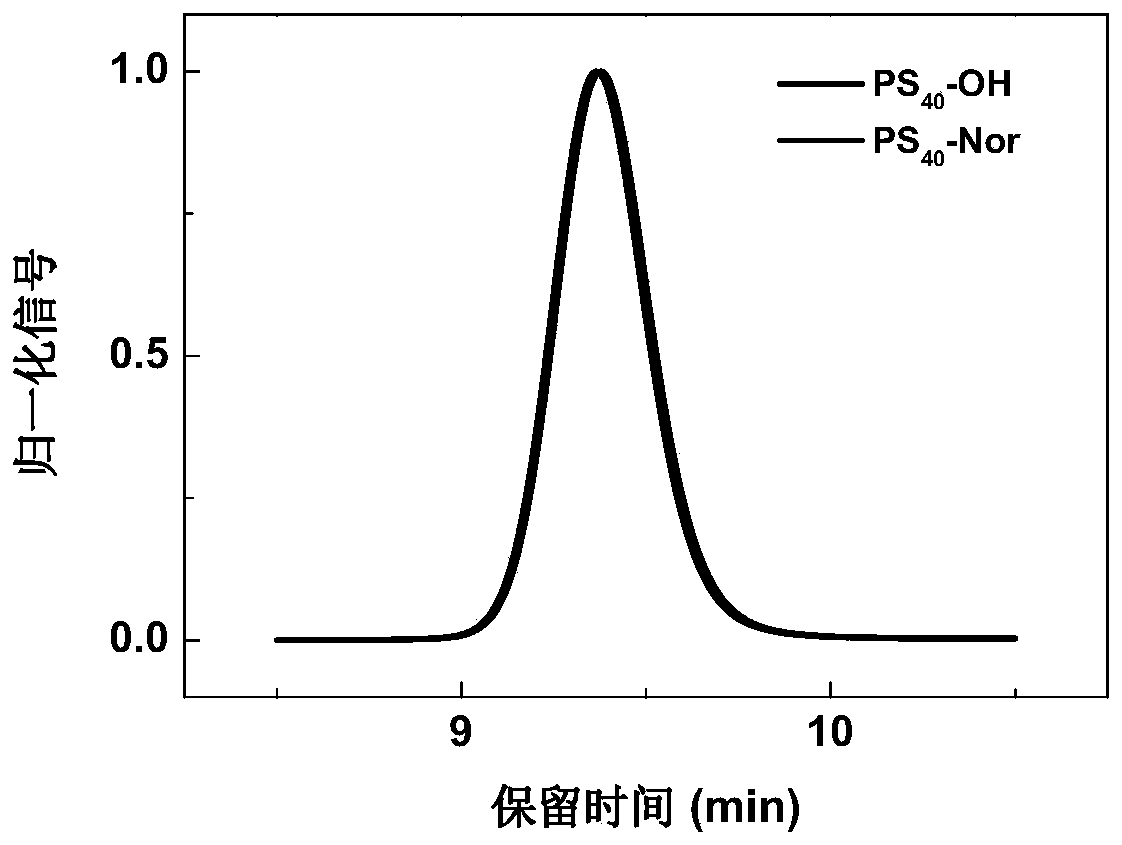

Brush copolymer and preparation method thereof

The invention discloses a brush copolymer and a preparation method thereof. The preparation method comprises the following steps: synthesizing hydroxyl-terminated polystyrene and polyisoprene througha reactive anion polymerization method, and then carrying out esterification reaction on the hydroxyl-terminated polystyrene and the polyisoprene or hydroxyl-terminated polyethylene glycol and exo-5-norbornene-2-carboxylic acid to synthesize norbornene-terminated polystyrene, polyisoprene and polyethylene glycol macromonomers; and changing the feeding ratio and the feeding mode of the macromonomers to carry out ring-opening metathesis polymerization so as to obtain a two-block brush copolymer and a random brush copolymer which have different side chain ratios and arrangement sequences. The method has the characteristics of high reaction efficiency, mild reaction conditions and few side reactions, and the brush copolymer prepared by the method is controllable in structure and molecular weight and narrow in molecular weight distribution.

Owner:SUZHOU UNIV

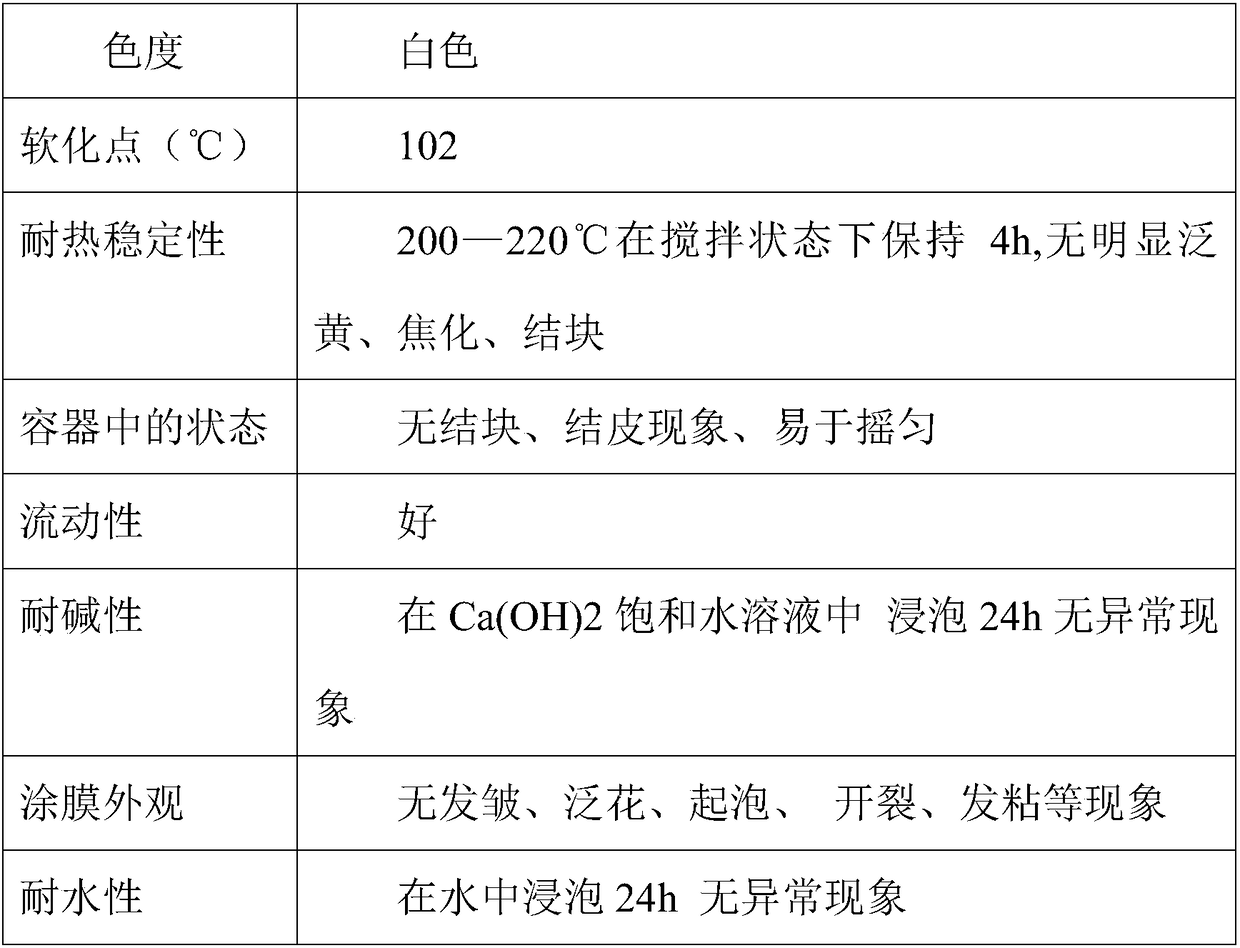

Heat molten pavement marking line paint

InactiveCN108795214AReduce environmental pollutionGood thermal stabilityFireproof paintsAntifouling/underwater paintsCorrosionPlasticizer

The invention belongs to the technical field of paint, and particularly relates to heat molten pavement marking line paint. The heat molten pavement marking line paint is mainly prepared from the following ingredients in percentage by weight: 12 to 25 percent of modified petroleum resin, 5 to 10 percent of color pigments, 45 to 60 percent of filling materials, 16 to 23 percent of reflecting materials and 1 to 5 percent of plasticizers. The pavement marking line paint provided by the invention has the advantages of environmental-friendly effects, light hue, good water-resistant and alkali-resistant corrosion performance, low fusion viscosity, good flowability, good heat resistant stability, good weathering resistance, longer service life and the like.

Owner:PUYANG RUISEN GASOLINEEUM RESINS +1

Preparation method of paclitaxel nano micelle

InactiveCN102423301AAvoid cyclizationRaise the polymerization temperaturePowder deliveryOrganic active ingredientsPolyesterEvaporation

The invention relates to a preparation method of paclitaxel nano micelle, which comprises the following steps of: taking a block copolymer of polyether and polyester as a medicine supplementary material and paclitaxel as a medicine; and preparing the paclitaxel nano micelle by rotating an evaporation solvent, wherein the medicine supplementary material is prepared through body ring-opening polymerization, and the terminal hydroxyl group of the copolymer is modified into carboxylate so as to increase the stability of the micelle. According to the micelle disclosed by the invention, during the preparation process, no stabilizing agent is added, and the obtained medicine-carrying micelle can stably exist for over 48h under the body fluid environment, is a paclitaxel nano sustained-release carrier with a good application prospect, and has the characteristics of stability and tumour targeted effect.

Owner:上海微丸医药开发有限公司

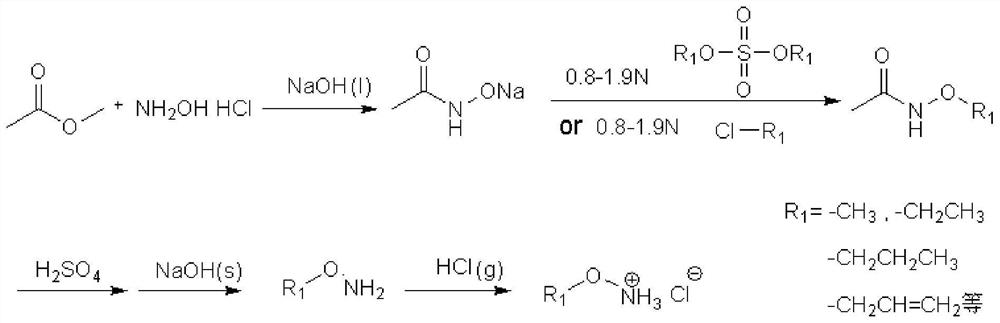

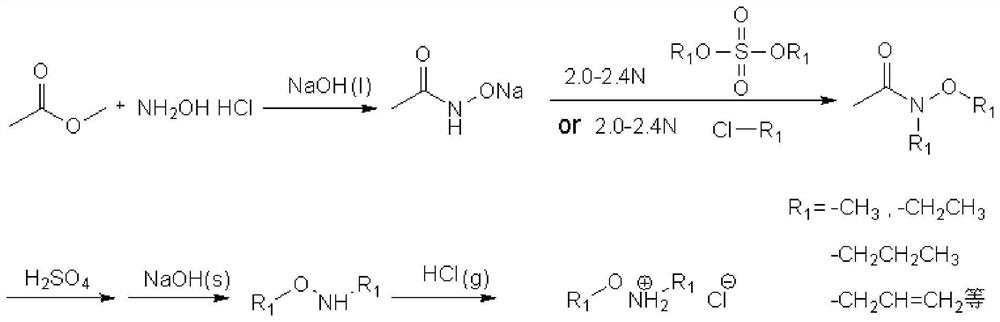

One-pot method for preparing O-alkyl hydroxylamine hydrochloride and N,O-dialkyl hydroxylamine hydrochloride

The invention relates to the field of organic synthesis, in particular to a one-pot method for preparing O-alkyl hydroxylamine hydrochloride and N,O-dialkyl hydroxylamine hydrochloride. The method comprises the following steps: S1, acetylation: mixing hydroxylamine hydrochloride with water and methyl acetate, and dropwise adding a sodium hydroxide solution while stirring at room temperature to obtain an intermediate acetyl hydroxylamine; S2, alkylation: dropwise adding an alkylation reagent into the reaction kettle at normal temperature, and then heating the reactants for reaction; S3, hydrolysis and purification: after the reaction is qualified, adding concentrated sulfuric acid, performing heating hydrolysis, after the reaction is qualified, adding caustic soda flakes or liquid caustic soda to adjust the pH value to 12, carrying out atmospheric distillation and hydrochloric acid acidification, cooling the product for crystallization, and centrifuging and drying the crystal to obtaina final product. According to the invention, methyl acetate is used as an acetyl protective agent, and compared with ethyl acetate, methyl acetate has the advantages of good water solubility, small reaction steric hindrance, sufficient protection, few impurities, low price and cost and the like; therefore, the method has the advantages of high product purity, simple process operation, accessible raw materials, simple wastewater components and environment friendliness, and is suitable for industrial production.

Owner:和德化学(苏州)有限公司

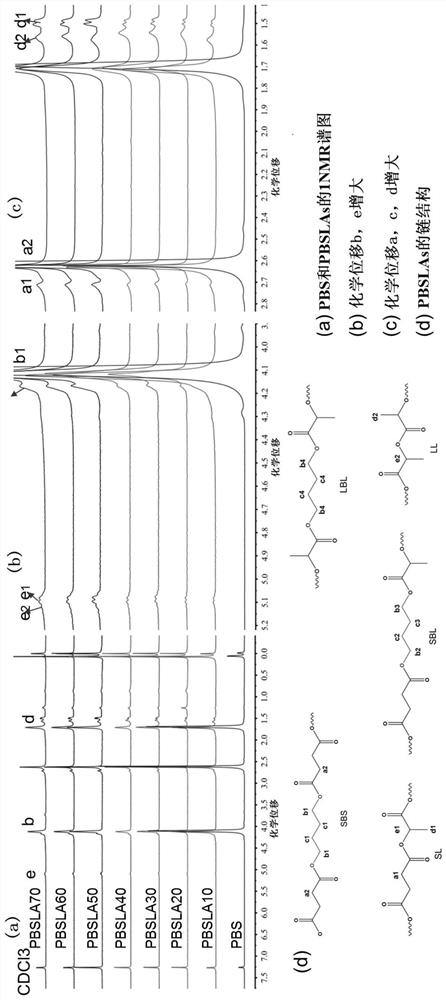

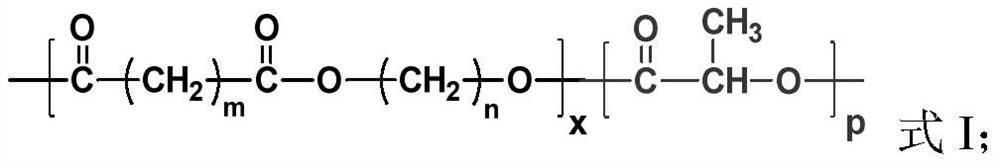

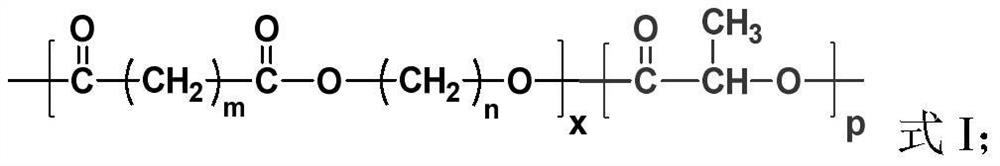

Degradable copolyester as well as preparation method and application thereof

ActiveCN113307957AImprove mechanical propertiesPromote degradationBio-packagingPolymer scienceCopolyester

The invention discloses a degradable copolyester which is a random copolymer or a double-block copolymer composed of difficult-to-hydrolyze polyester fragments and easy-to-hydrolyze fragments or sites, wherein the number-average molecular weight of the copolyester is 30000 g / moL to 500000 g / moL; and the easy-to-hydrolyze fragments or sites are selected from polylactic acid with different chain segment lengths. The copolyester is high in molecular weight, free of environment-unfriendly chain extenders, good in mechanical strength and toughness, resistant to heat and good in processability, and can be independently used as plastic. In various natural environments such as water, soil, compost and the like, the copolyester can be completely degraded in the natural environments to form environment-pollution-free carbon dioxide and water. The invention also discloses a preparation method and application of the degradable copolyester.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

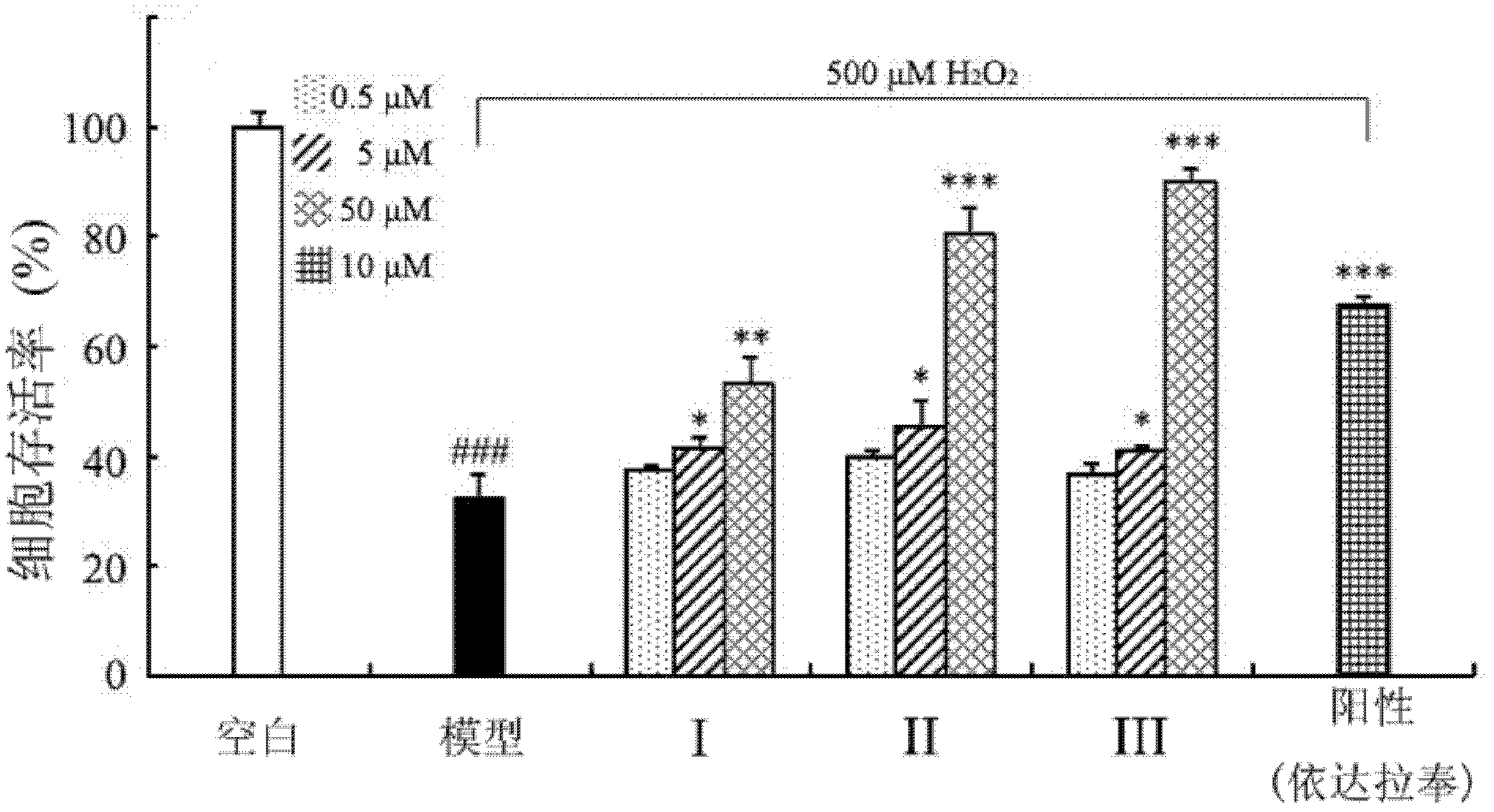

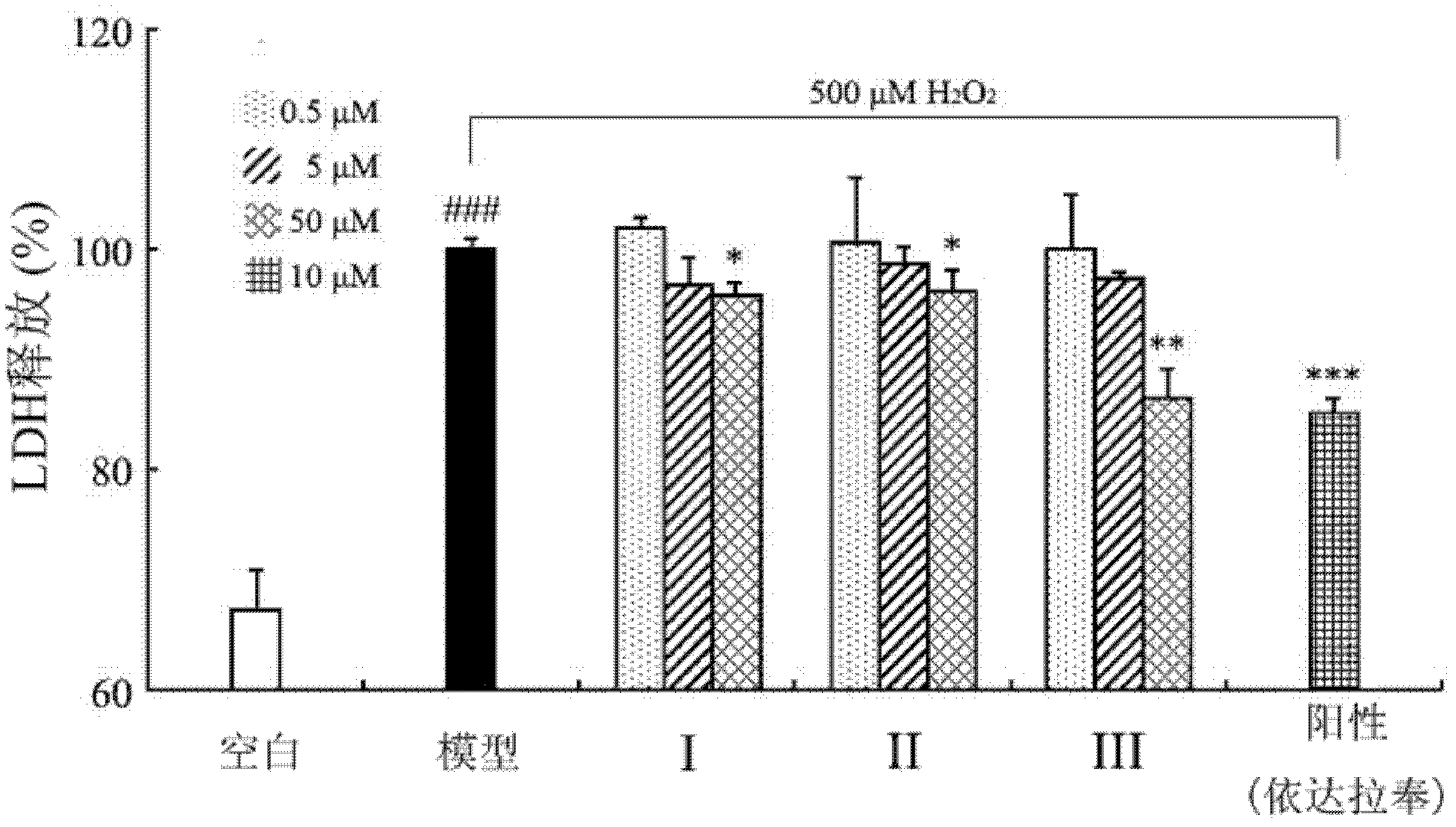

Horn polypeptide, and separation method and antioxidation application thereof

ActiveCN102304170AHas antioxidant activitySimple processPeptide/protein ingredientsAntinoxious agentsChemistrySeparation method

The invention relates to the technical field of medicines, particularly a horn polypeptide, and a separation method and application thereof. The horn polypeptide has the following sequence structure: Tyr-Glu-Asp-Cys-Thr-Asp-Cys-Gly-Asn. The polypeptide provided by the invention is extracted and separated from buffalo horns. The pharmacological test proves that the polypeptide provided by the invention has favorable antioxidation activity.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

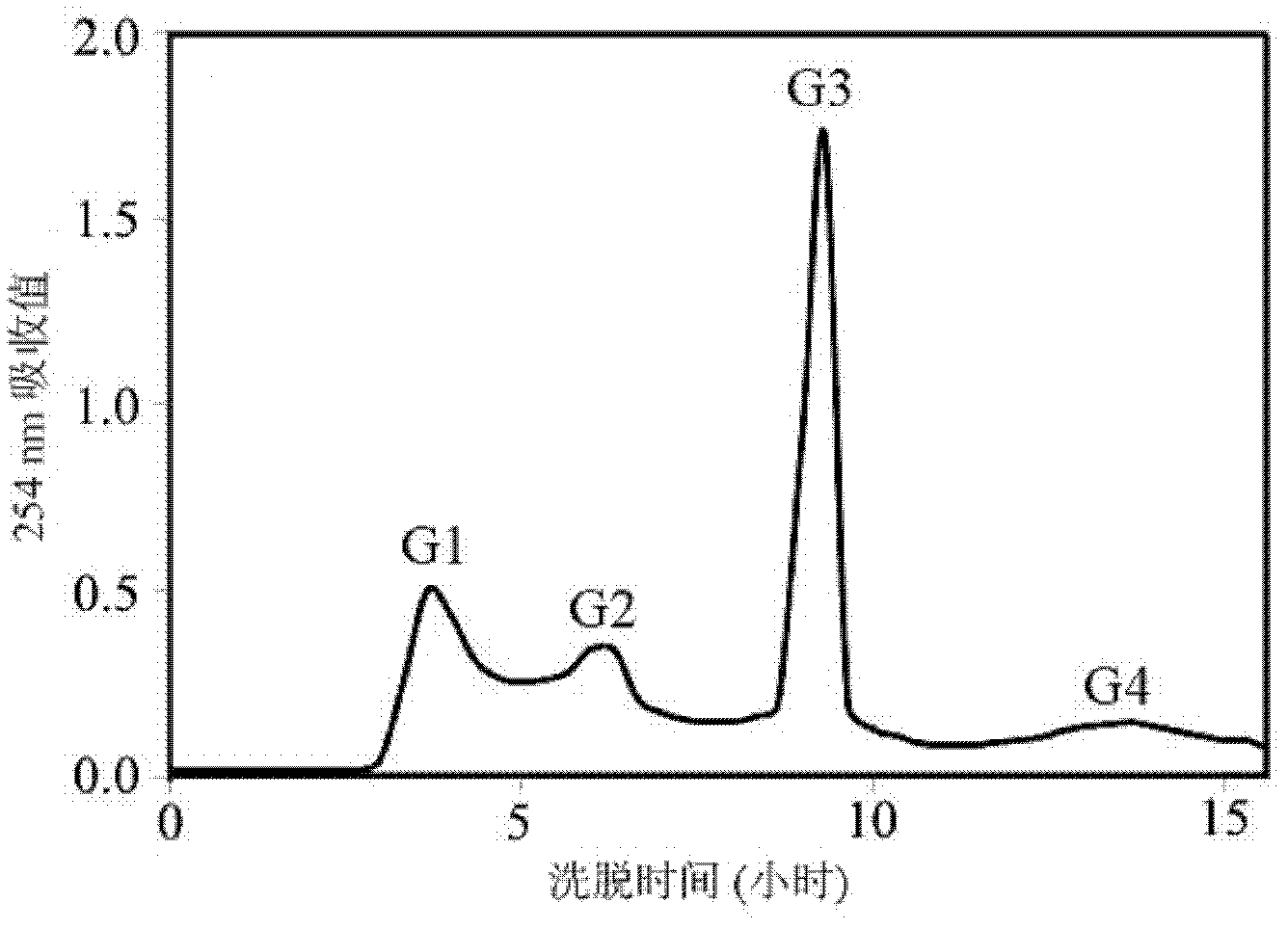

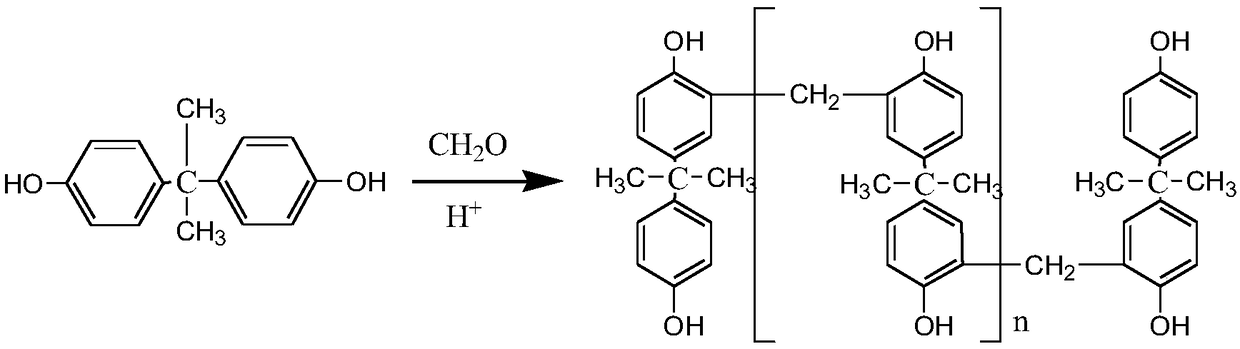

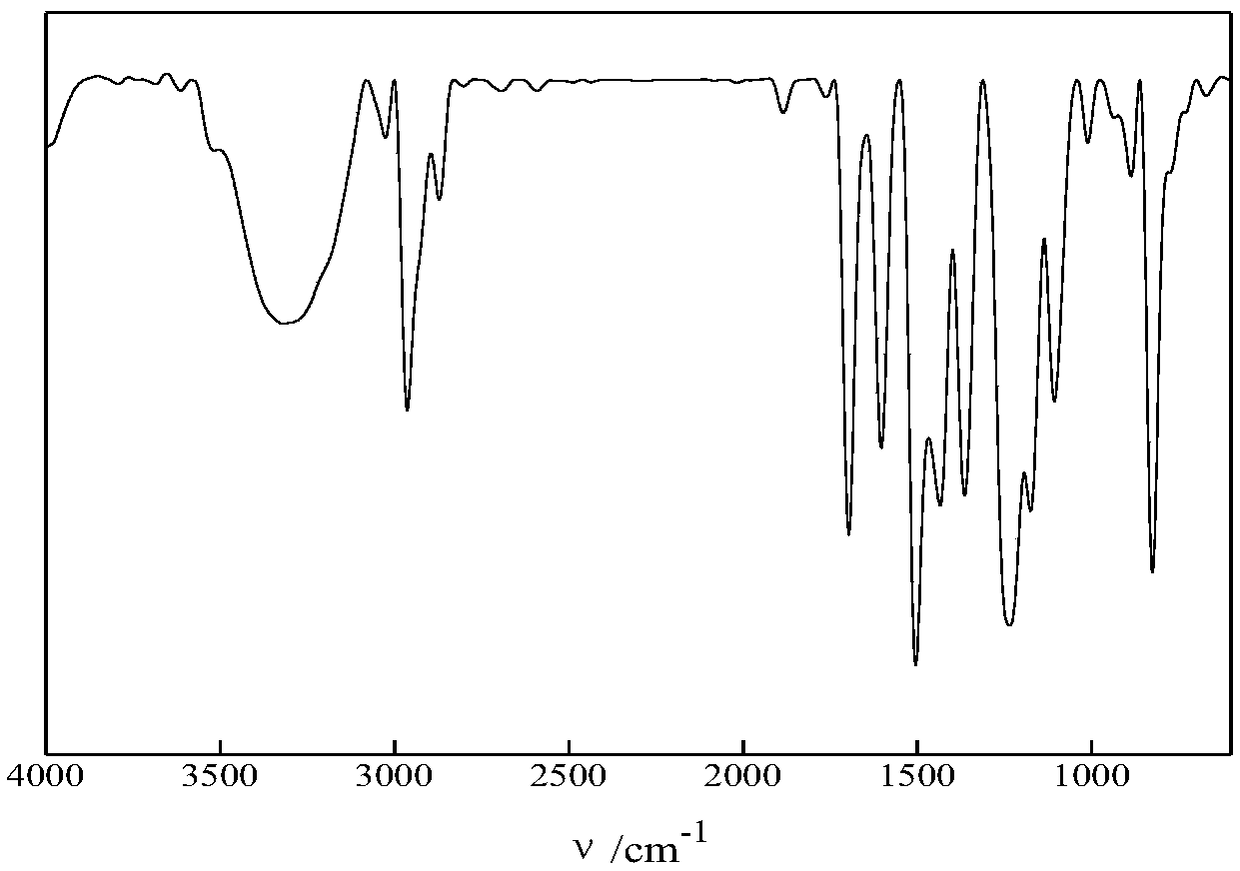

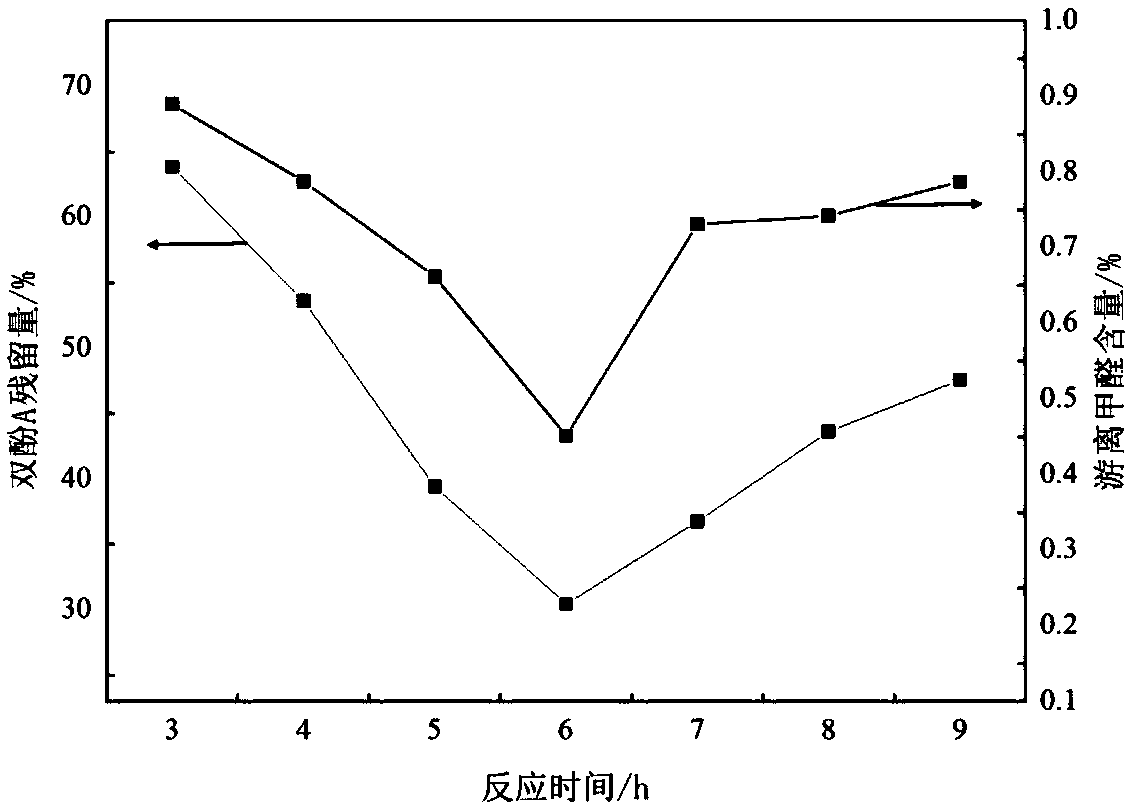

Bisphenol A formaldehyde phenolic resin and synthetic method thereof

InactiveCN108948299AImprove adhesionLow polarity of bonding surfaceAldehyde/ketone condensation polymer adhesivesBenzeneChemical reaction

The invention discloses bisphenol A formaldehyde phenolic resin and a synthetic method thereof. The molecular weight of the bisphenol A formaldehyde phenolic resin is 2000-3000, and the molecular weight is higher than that of existing bisphenol A formaldehyde phenolic resin. The bisphenol A formaldehyde phenolic resin is prepared from bisphenol A and formaldehyde free radicals which are polymerized by means of the method. The bisphenol A formaldehyde phenolic resin has excellent glueyness. On the one hand, original hydroxyl and benzene rings and active sites of bisphenol A are retained and themolecular weight of bisphenol A is also improved; on the other hand, as the polymer structure contains a great many of active sites, in the gluing process, chemical reactions happen or a curing agentis added to generate an undissolved polymer of a three-dimensional netty structure. Meanwhile, a condensation reaction is carried out on bisphenol A and formaldehyde to form methylene bridged bisphenol A. Therefore, the related molecular weight of the polymer is increased greatly, the polymer is then reacted with a bonding substrate, and can react through active groups, so that the bisphenol A formaldehyde phenolic resin is adhered quickly to achieve the adhering purpose.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com