Heat molten pavement marking line paint

A road marking and hot melting technology, applied in the field of coatings, can solve the problems of poor weather resistance and thermal stability, poor compatibility of polar resins, poor thermal stability, etc., and achieve good thermal stability and fast heating and melting , Excellent anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

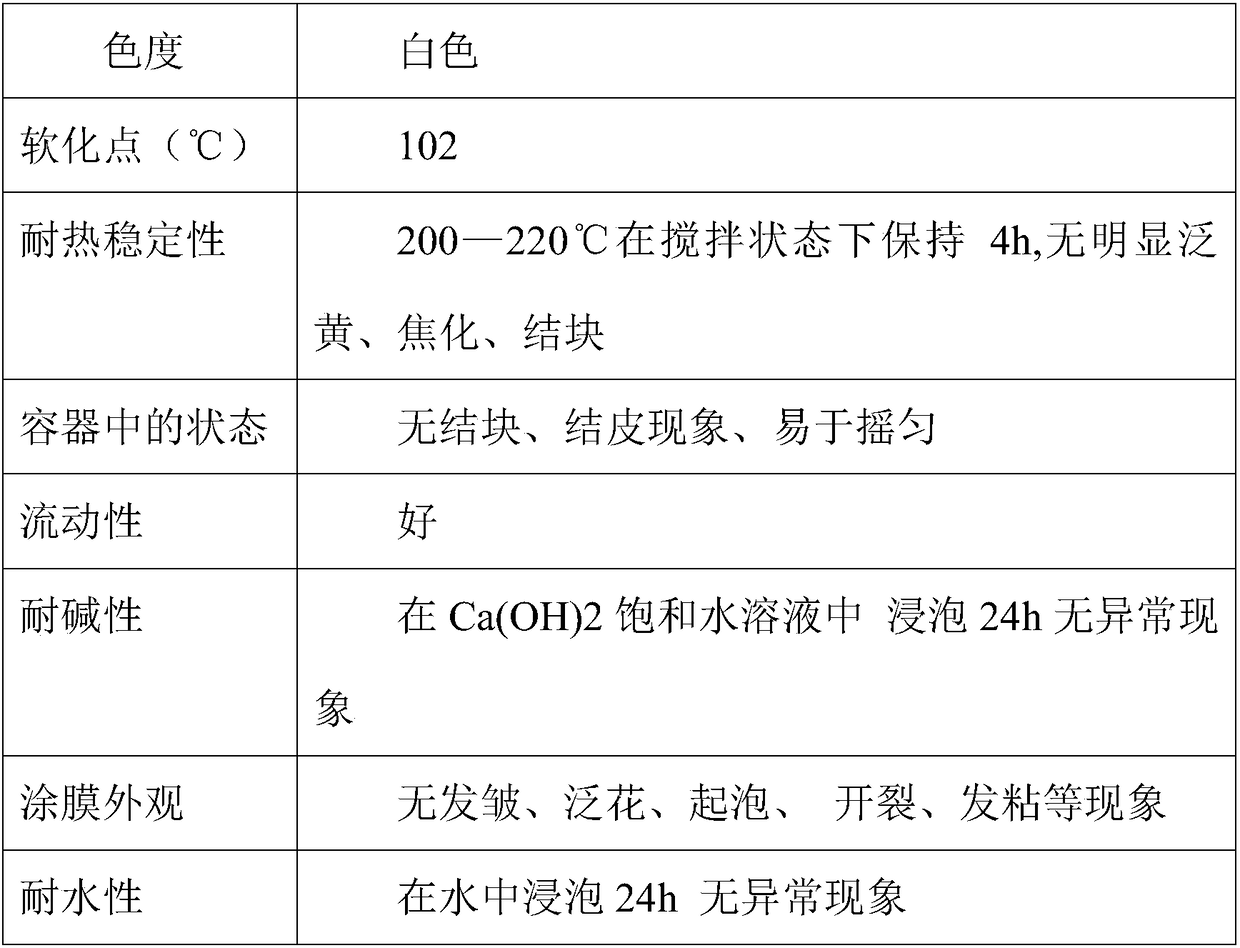

Embodiment 1

[0022] Mix 15 parts of modified petroleum resin, 30.1 parts of calcium carbonate, 30.1 parts of quartz, 5 parts of titanium dioxide, 18 parts of glass beads and 1.8 parts of soybean oil and soybean oil modified alkyd at 200 ° C In 15 minutes, the hot-melt type road marking paint material composition was obtained; wherein the modified petroleum resin was 1900g of crude dicyclopentadiene, 900g of C5 fraction and 1000g of toluene with a purity of 83%, and added to a high-pressure reactor with agitator Stir evenly in the medium, slowly raise the temperature to 260°C, and the reaction pressure is 2.0Mpa. After reacting at 260°C for 6 hours, the unpolymerized light components are first distilled out under normal pressure, and then the oligomers are distilled out under reduced pressure to obtain the basis of molten state. Petroleum resin 2000g; under the protection of nitrogen, add 26g of modifier maleic anhydride, raise the temperature to 200°C and keep it constant for 2 hours for ad...

Embodiment 2

[0024] Mix 18 parts of modified petroleum resin, 31.6 parts of calcium carbonate, 31.6 parts of quartz, 5 parts of titanium dioxide, 18 parts of glass beads and 1.8 parts of soybean oil and soybean oil modified alkyd at 200 ° C In 15 minutes, the hot-melt type road marking paint material composition was obtained; wherein the modified petroleum resin adopted a purity of 83% thick dicyclopentadiene 1900g, C5 fraction 900g and toluene 1000g, reacted at high pressure with agitator Stir evenly in the kettle, slowly heat up to 260°C, and the reaction pressure is 2.0Mpa. After reacting at 260°C for 6 hours, the unpolymerized light components are first distilled out under normal pressure, and then the oligomers are distilled out under reduced pressure to obtain molten 2000g of base petroleum resin; under the protection of nitrogen, add 26g of modifier maleic anhydride, raise the temperature to 200°C and keep it constant for 2 hours for addition reaction, the molten base petroleum resin...

Embodiment 3

[0026] Mix 20 parts of modified petroleum resin, 32.6 parts of calcium carbonate, 32.6 parts of quartz, 5 parts of titanium dioxide, 18 parts of glass beads and 1.8 parts of soybean oil and soybean oil modified alkyd at 200 ° C In 15 minutes, the hot-melt type road marking paint material composition was obtained; wherein the modified petroleum resin adopted was 1900g of crude dicyclopentadiene, 900g of C5 fraction and 1000g of toluene with a purity of 83%, and added it to a high-pressure reactor with agitator Stir evenly in medium, slowly raise the temperature to 260°C, and the reaction pressure is 2.0Mpa. After reacting at 260°C for 6 hours, the unpolymerized light components are first distilled out under normal pressure, and then the oligomers are distilled out under reduced pressure to obtain a resin in a molten state. 2000g; under the protection of nitrogen, add 26g of modifier maleic anhydride, raise the temperature to 200°C and keep it unchanged for 2 hours for addition r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com