Patents

Literature

1887results about How to "Reduce environmental pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

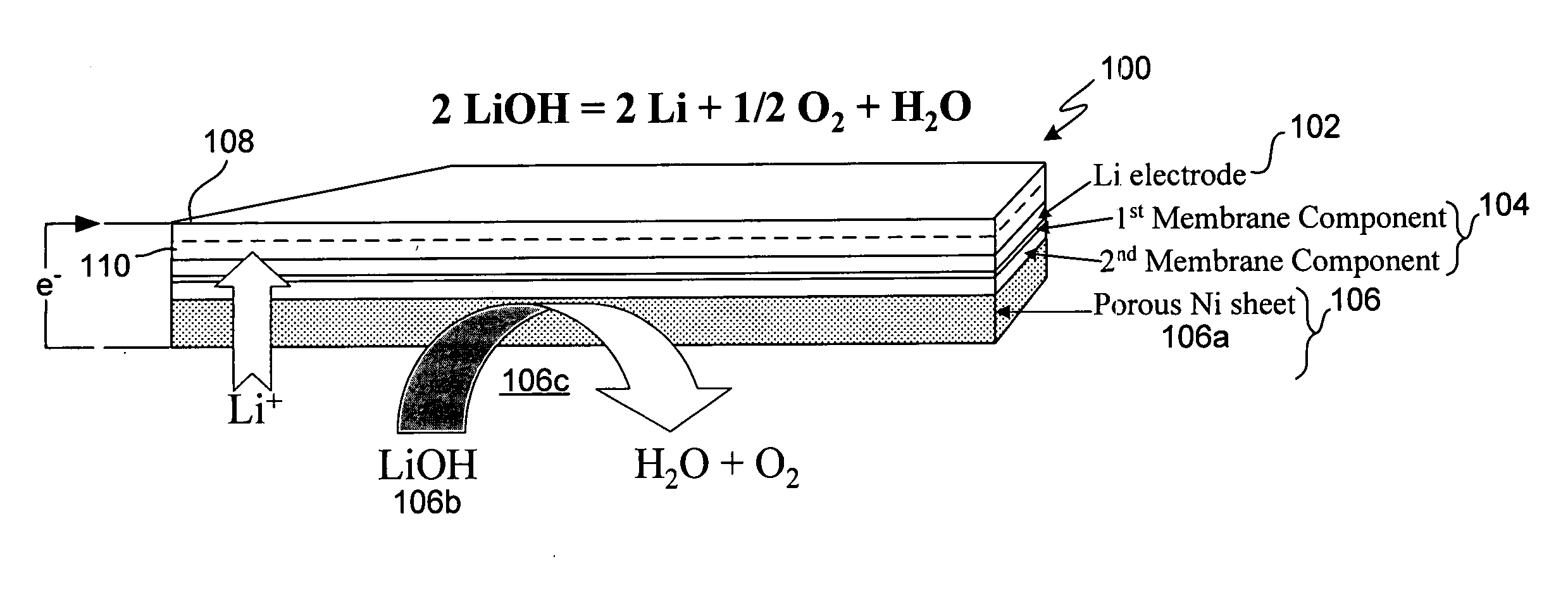

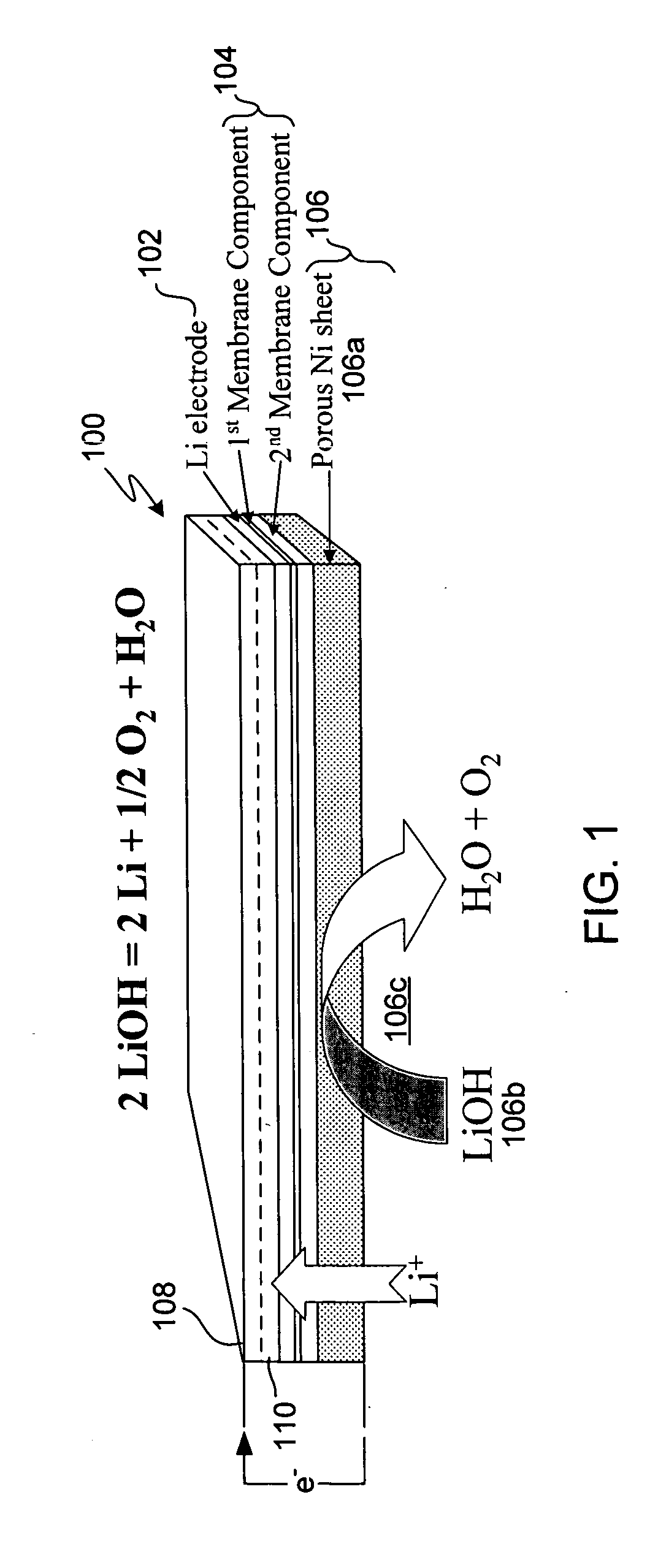

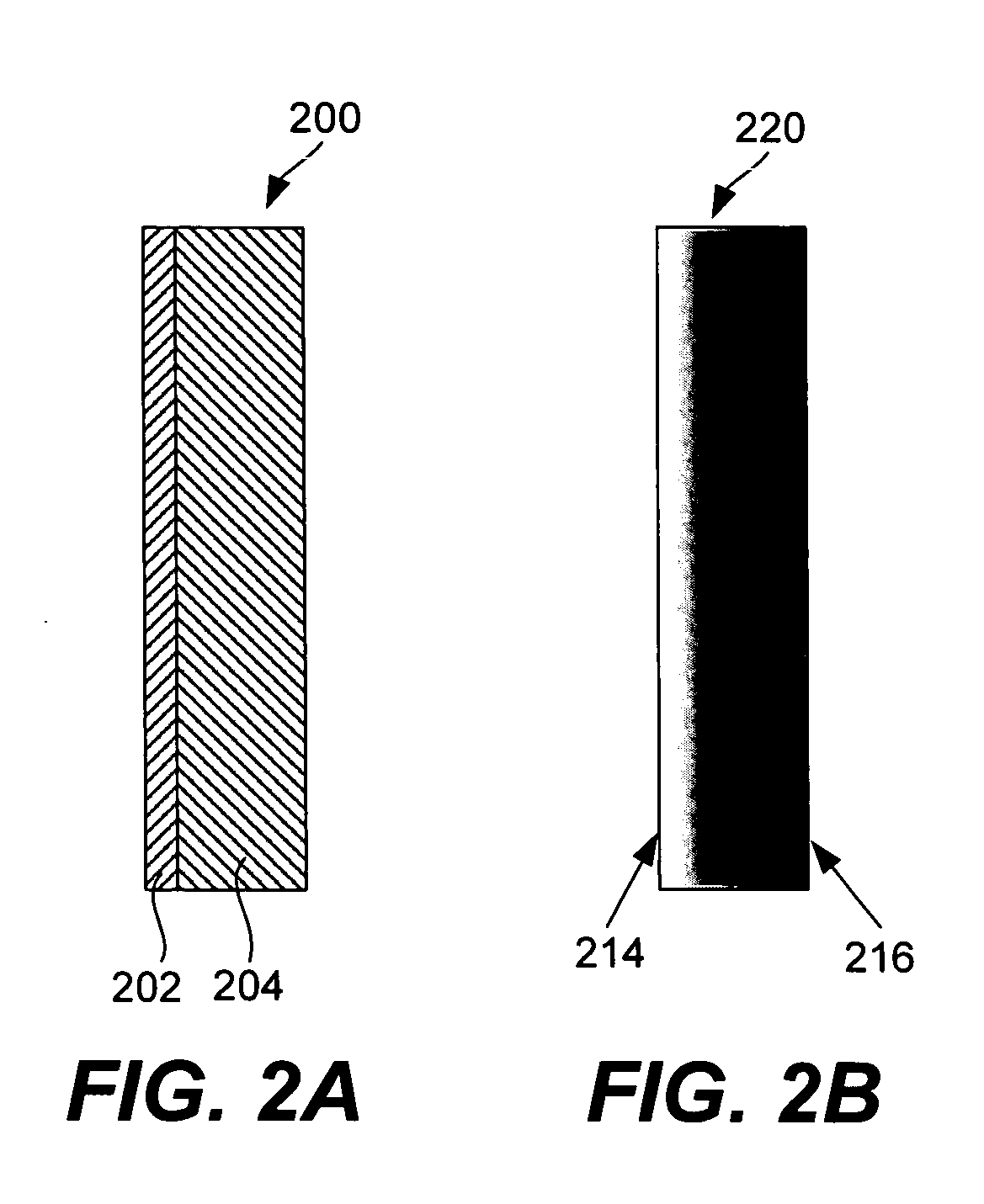

Active metal electrolyzer

InactiveUS20050100793A1Effective isolationReduce environmental pollutionPhotography auxillary processesElectrode manufacturing processesElectrolysisAqueous electrolyte

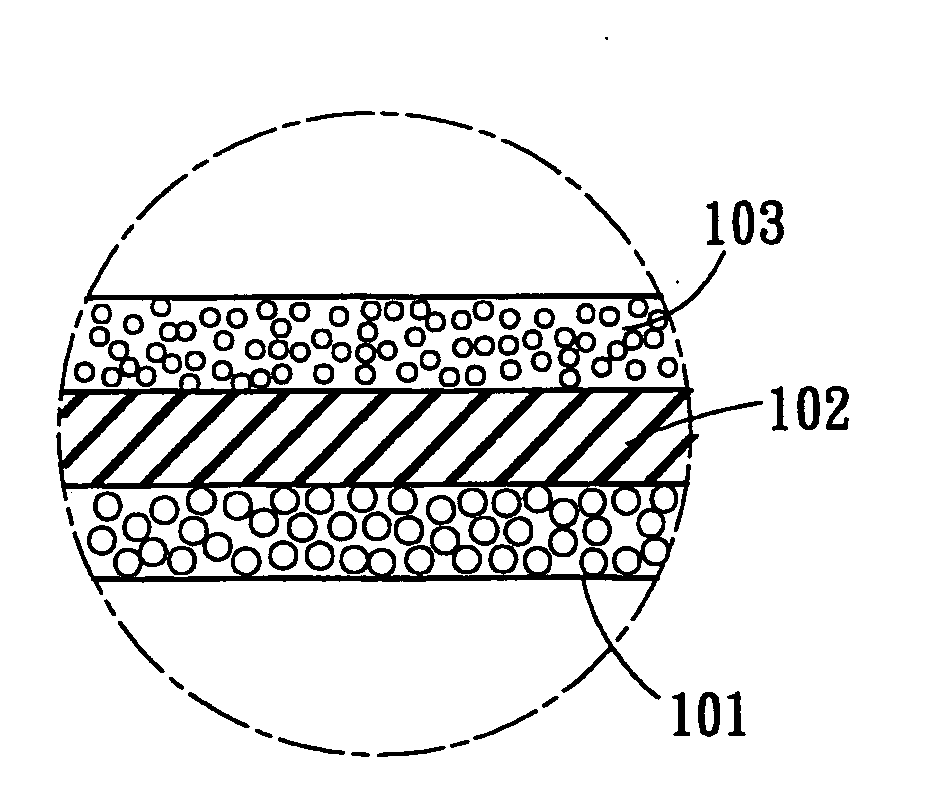

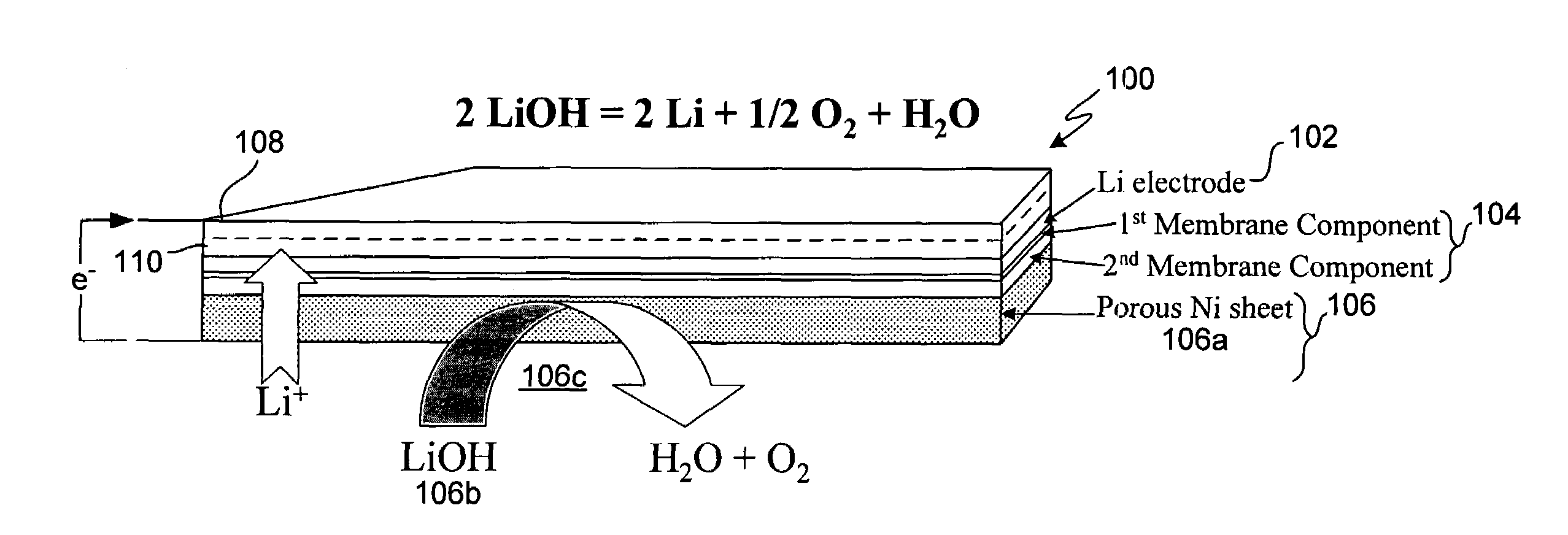

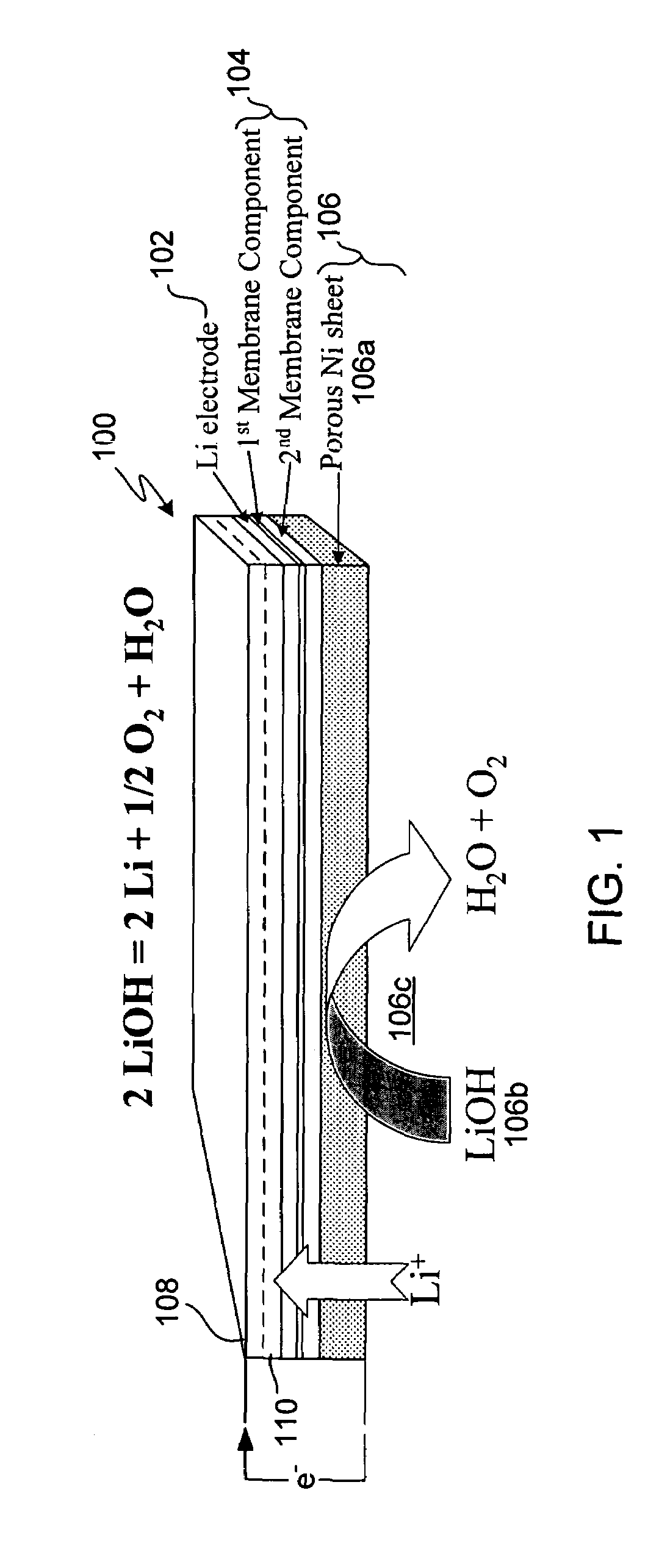

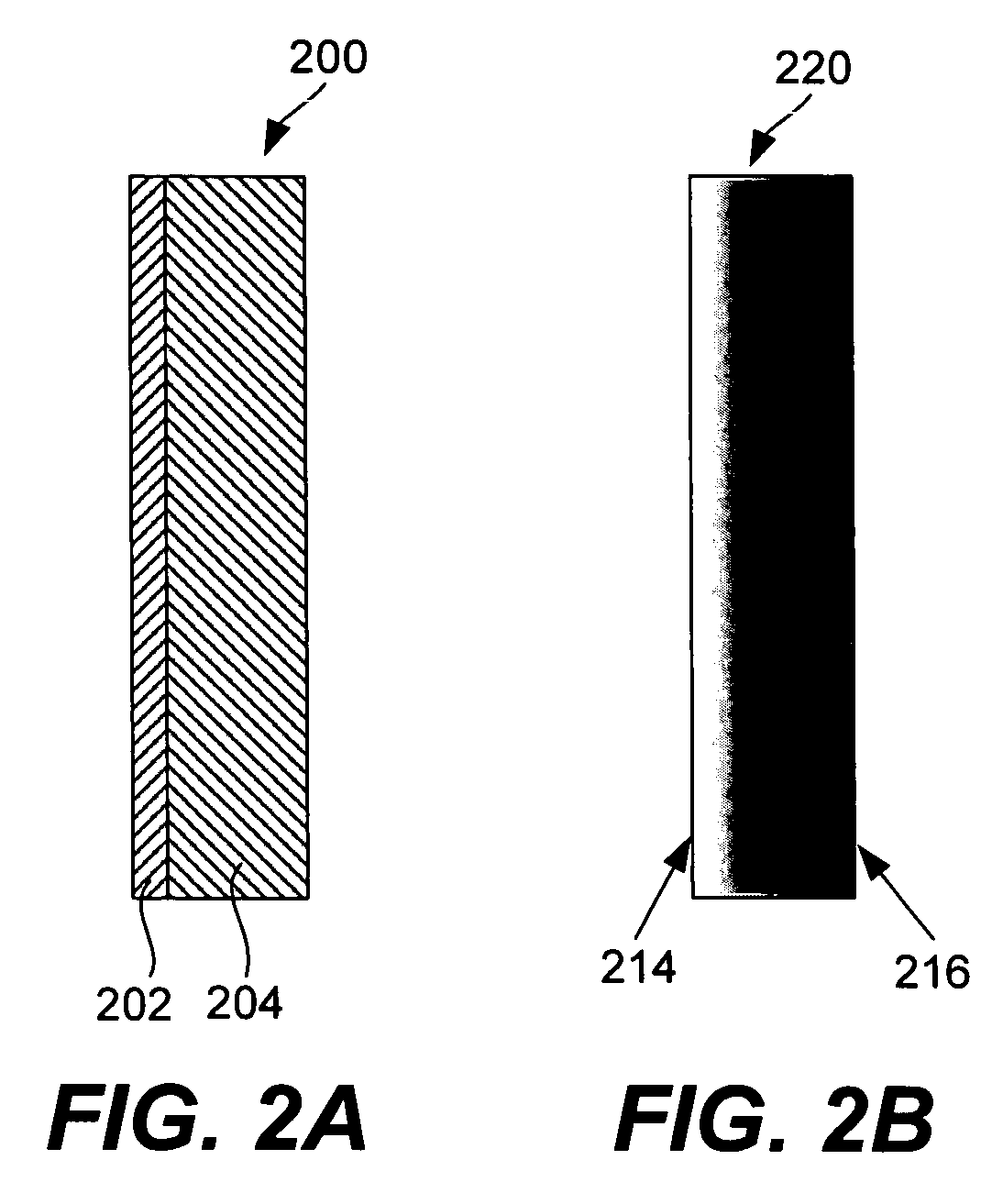

Electro-winning of active metal (e.g., lithium) ions from a variety of sources including industrial waste, and recycled lithium and lithium-ion batteries is accomplished with an electrolyzer having a protected cathode that is stable against aggressive solvents, including water, aqueous electrolytes, acid, base, and a broad range of protic and aprotic solvents. The electrolyzer has a highly ionically conductive protective membrane adjacent to the alkali metal cathode that effectively isolates (de-couples) the alkali metal electrode from solvent, electrolyte processing and / or cathode environments, and at the same time allows ion transport in and out of these environments. Isolation of the cathode from other components of a battery cell or other electrochemical cell in this way allows the use of virtually any solvent, electrolyte and / or anode material in conjunction with the cathode. The electrolyzer can be configured and operated to claim or reclaim lithium or other active metals from such sources.

Owner:POLYPLUS BATTERY CO INC

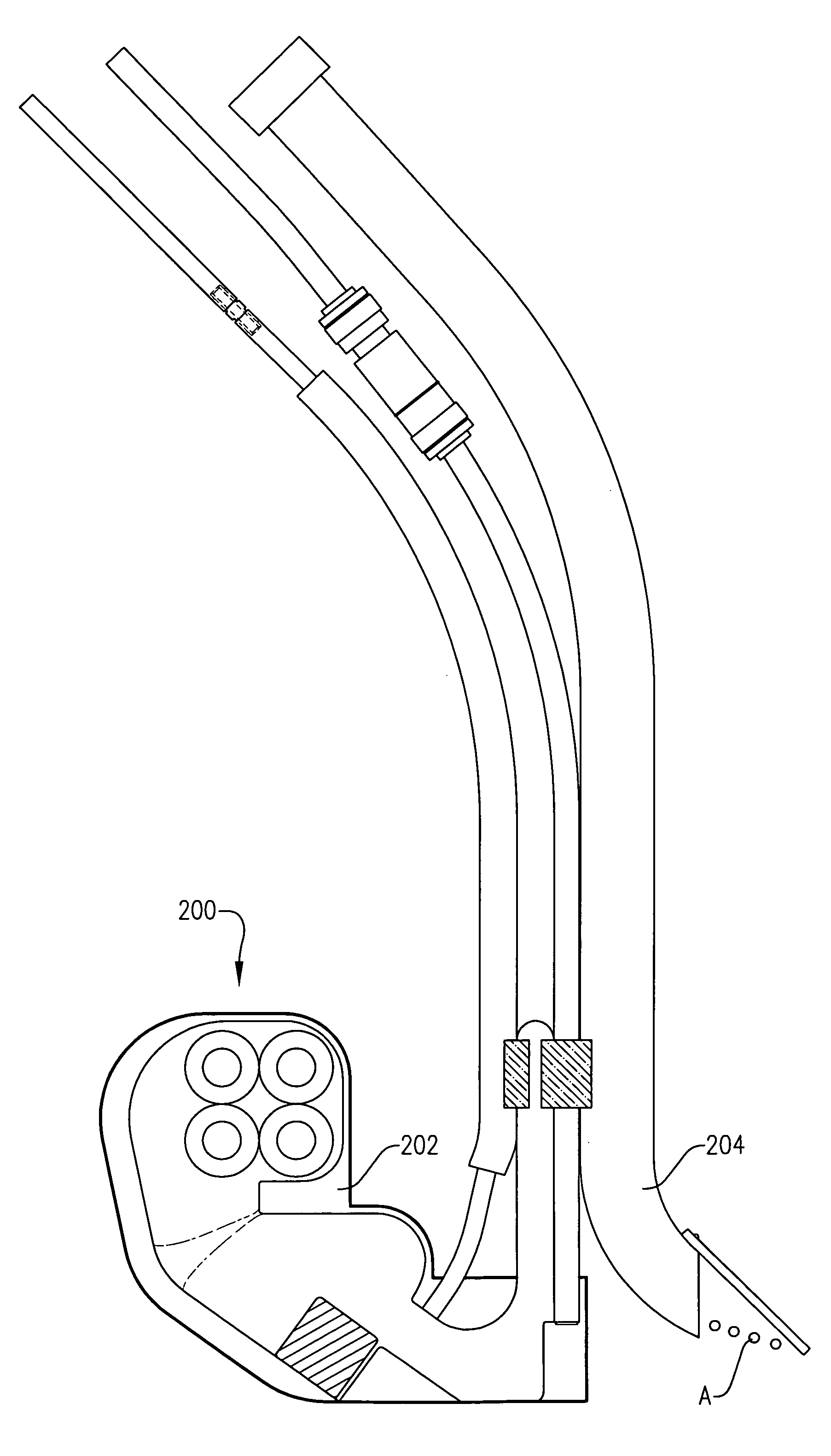

Multi-site body fluid sampling and analysis cartridge

ActiveUS20070179405A1Reduce environmental pollutionImmobilised enzymesBioreactor/fermenter combinationsMulti siteAnalyte

An arrangement includes a housing, a plurality of sampling and analysis sites contained within the housing, each of the sampling and analysis sites having a skin-penetration member having a first end configured to pierce the skin, and an inner lumen in communication with the first end, an actuator operatively associated with the skin-penetration member, and an analyte quantification member in fluid communication with the inner lumen of the skin-penetration member. Integrated devices including such arrangements are also described.

Owner:INTUITY MEDICAL INC

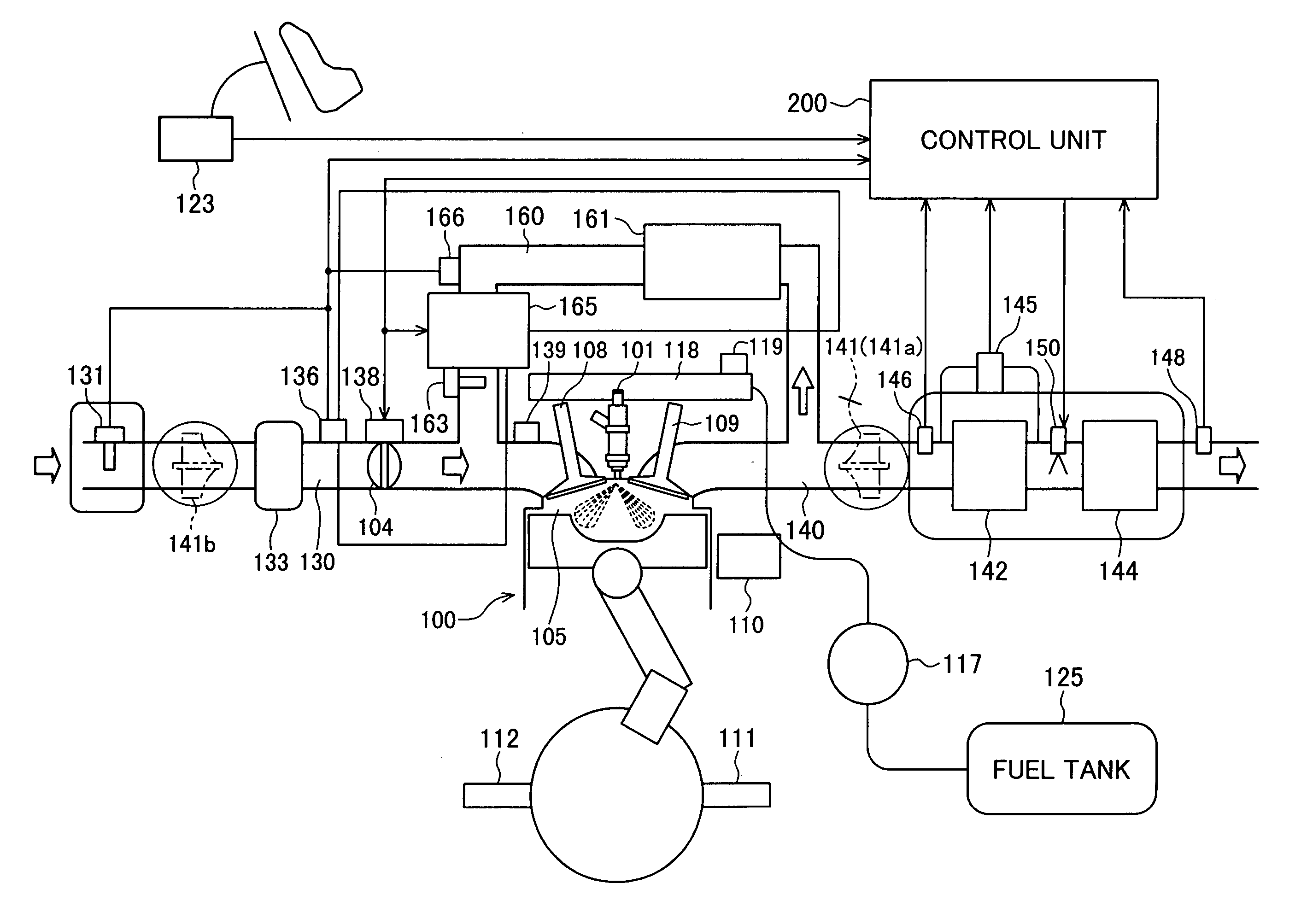

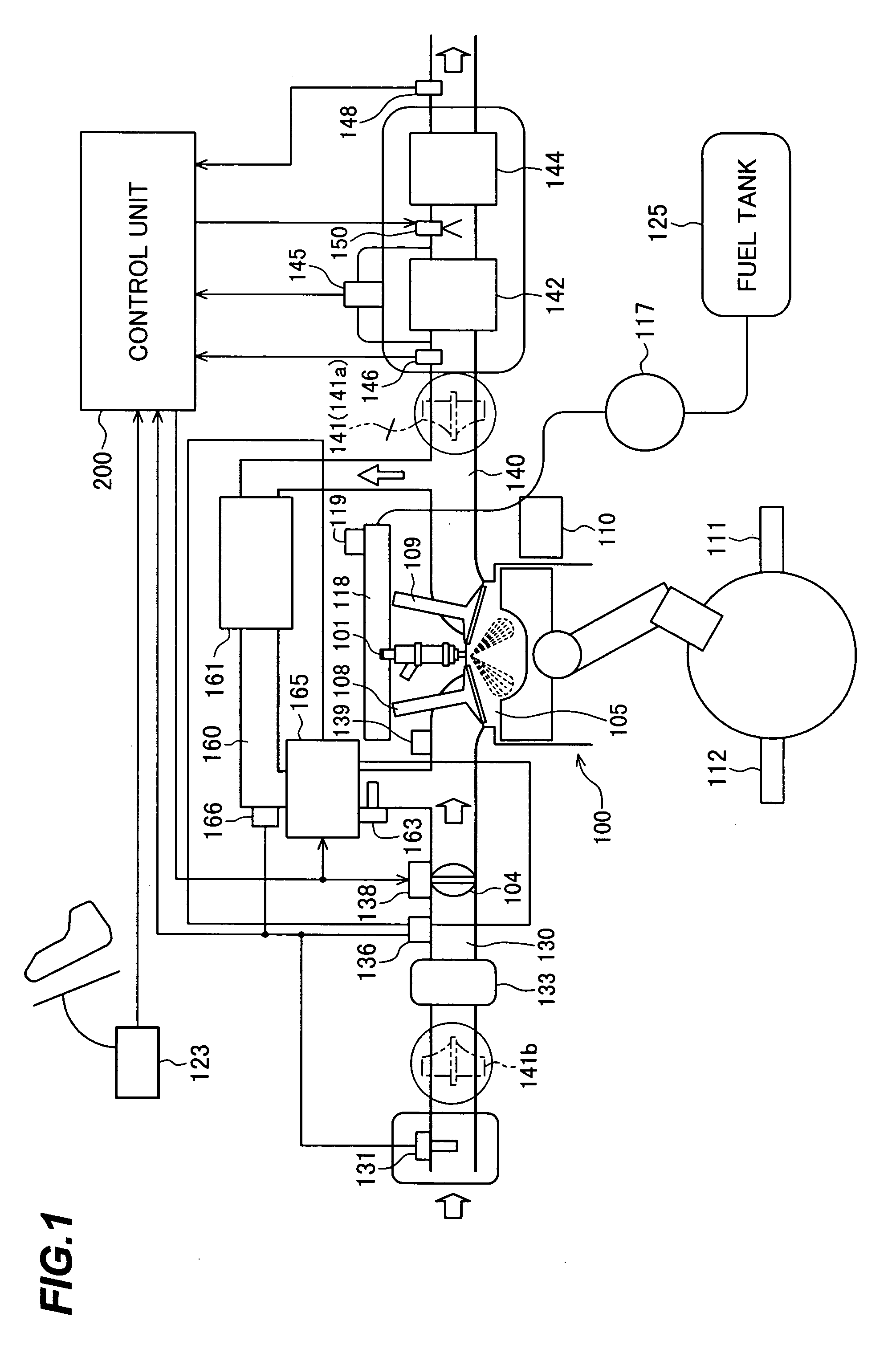

Engine exhaust gas cleaning method and system

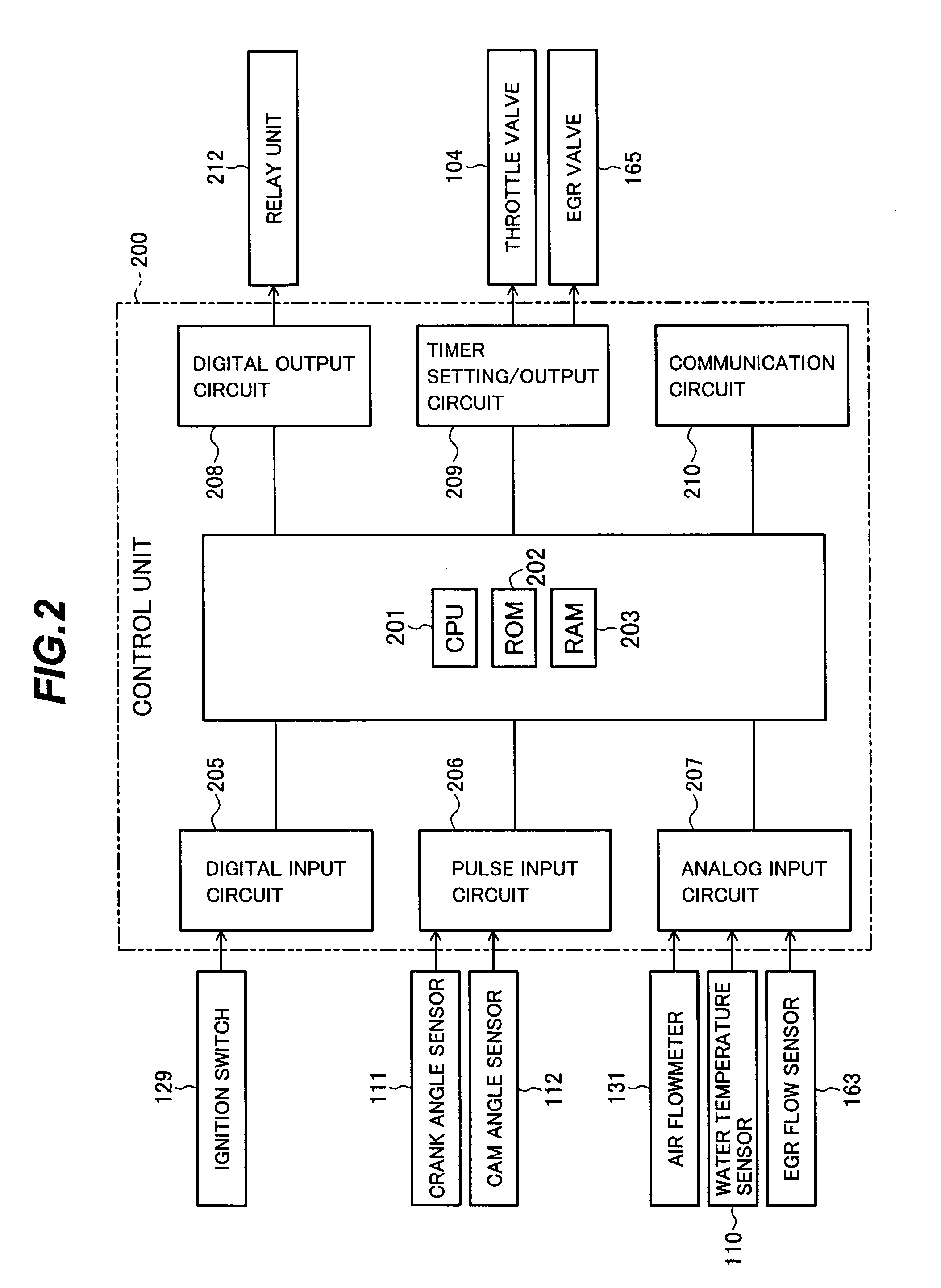

InactiveUS20060086080A1Emission reductionReduce cleaning rateElectrical controlNon-fuel substance addition to fuelExhaust fumesEnvironmental engineering

An engine exhaust gas cleaning method and system, which can effectively reduce emission amounts of particular components, such as NOx, contained in exhaust gas by adding an additive, such as urea water or light oil, into an exhaust passage, which is adaptable for a reduction of the cleaning rate caused by deterioration of a catalyst, which can always maintain a high cleaning rate during acceleration and deceleration as well, and which can minimize environmental pollution with use of the additive in the least necessary amount. The engine exhaust gas cleaning system comprises a catalyst for removing a particular component, represented by NOx, contained in exhaust gas of an engine, an additive adding unit for adding, to the exhaust gas, an additive for reducing the particular component represented by NOx, and an EGR amount adjusting unit for adjusting an EGR amount. An addition amount of the additive and the EGR amount are set depending on an operating state and deterioration of the catalyst with time. The catalyst is regenerated when a cleaning capability of the catalyst has reduced to a predetermined value or below.

Owner:HITACHI LTD

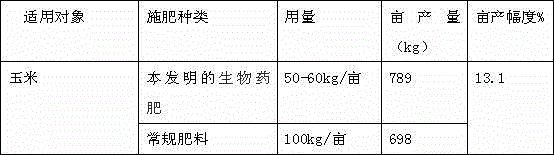

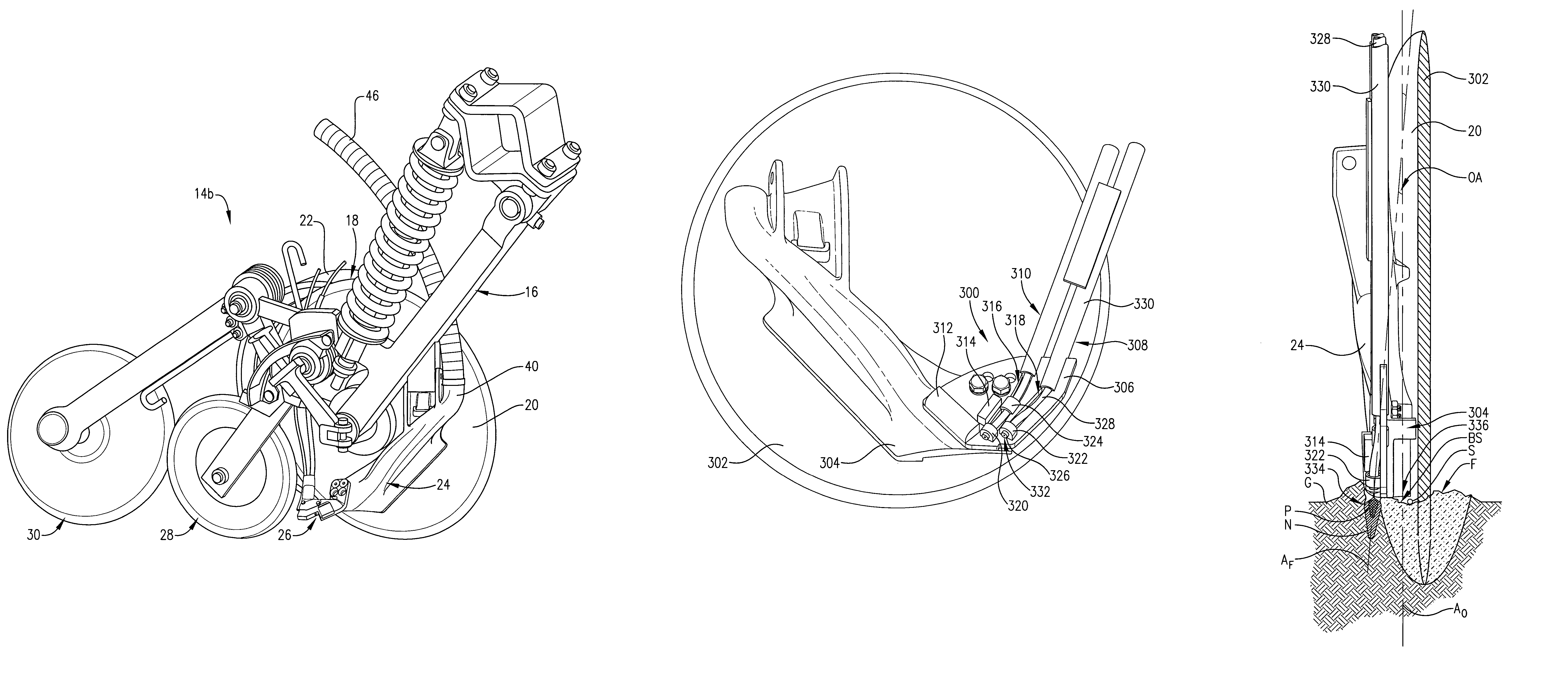

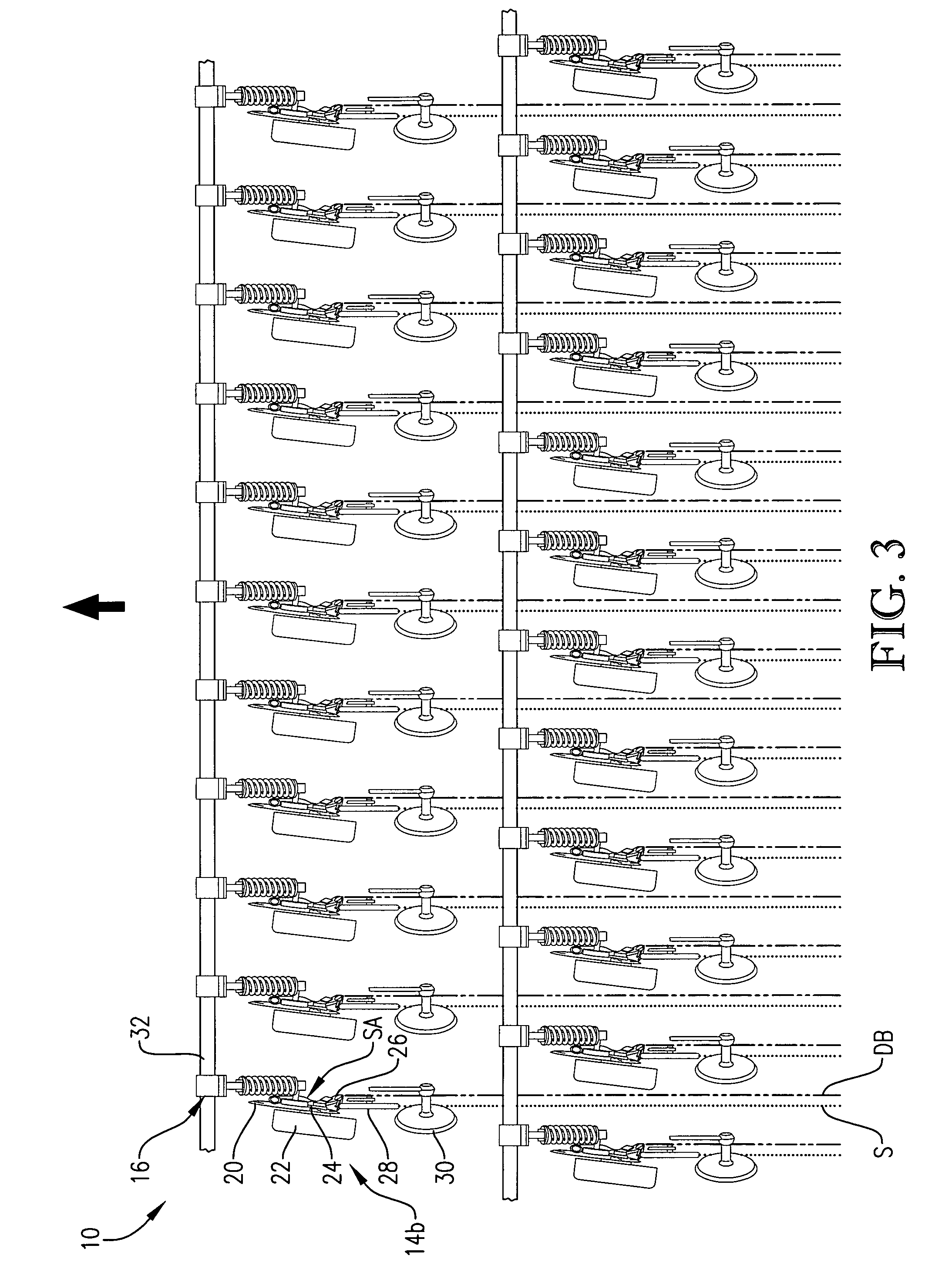

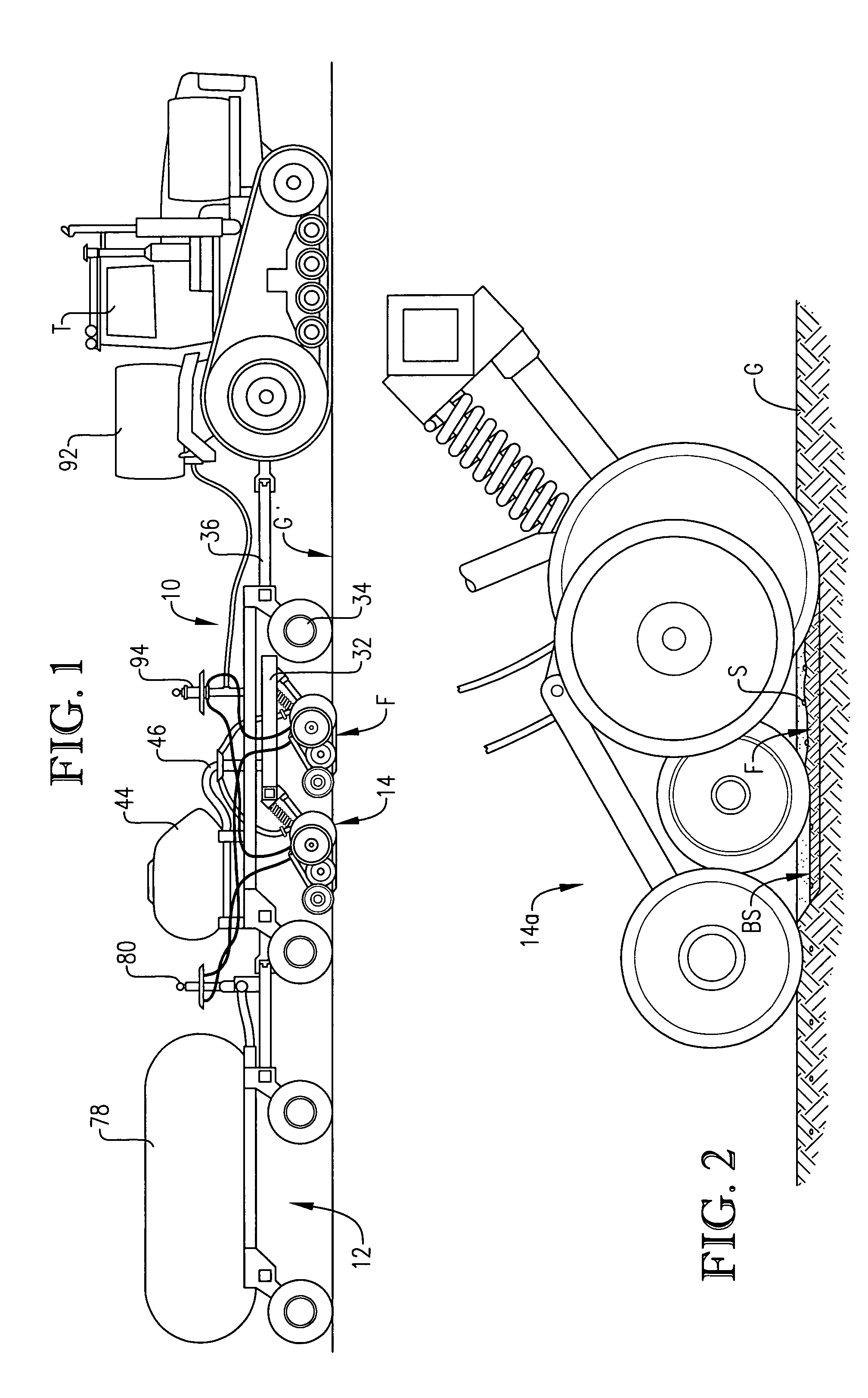

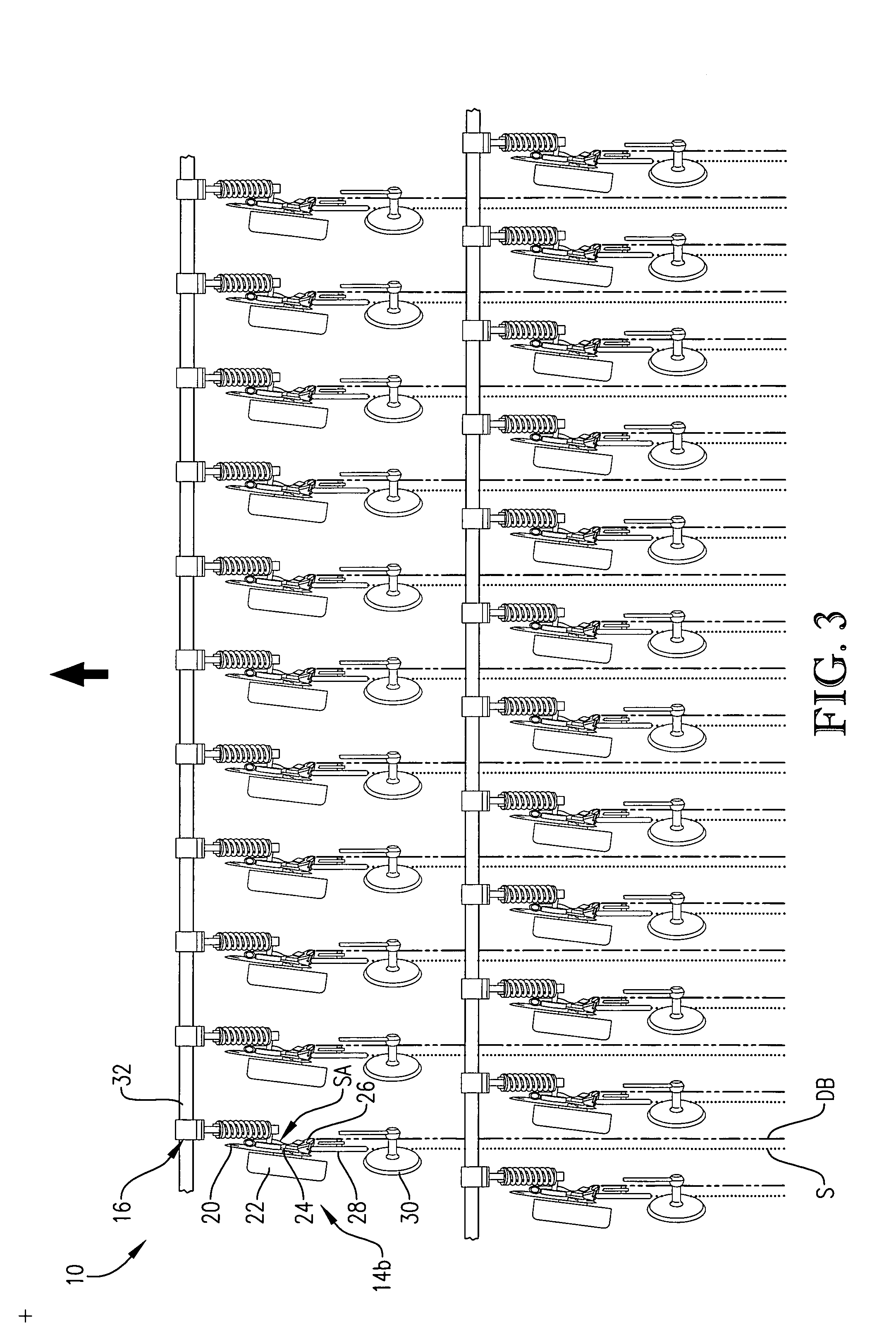

Fertilizer injector wing for disc openers

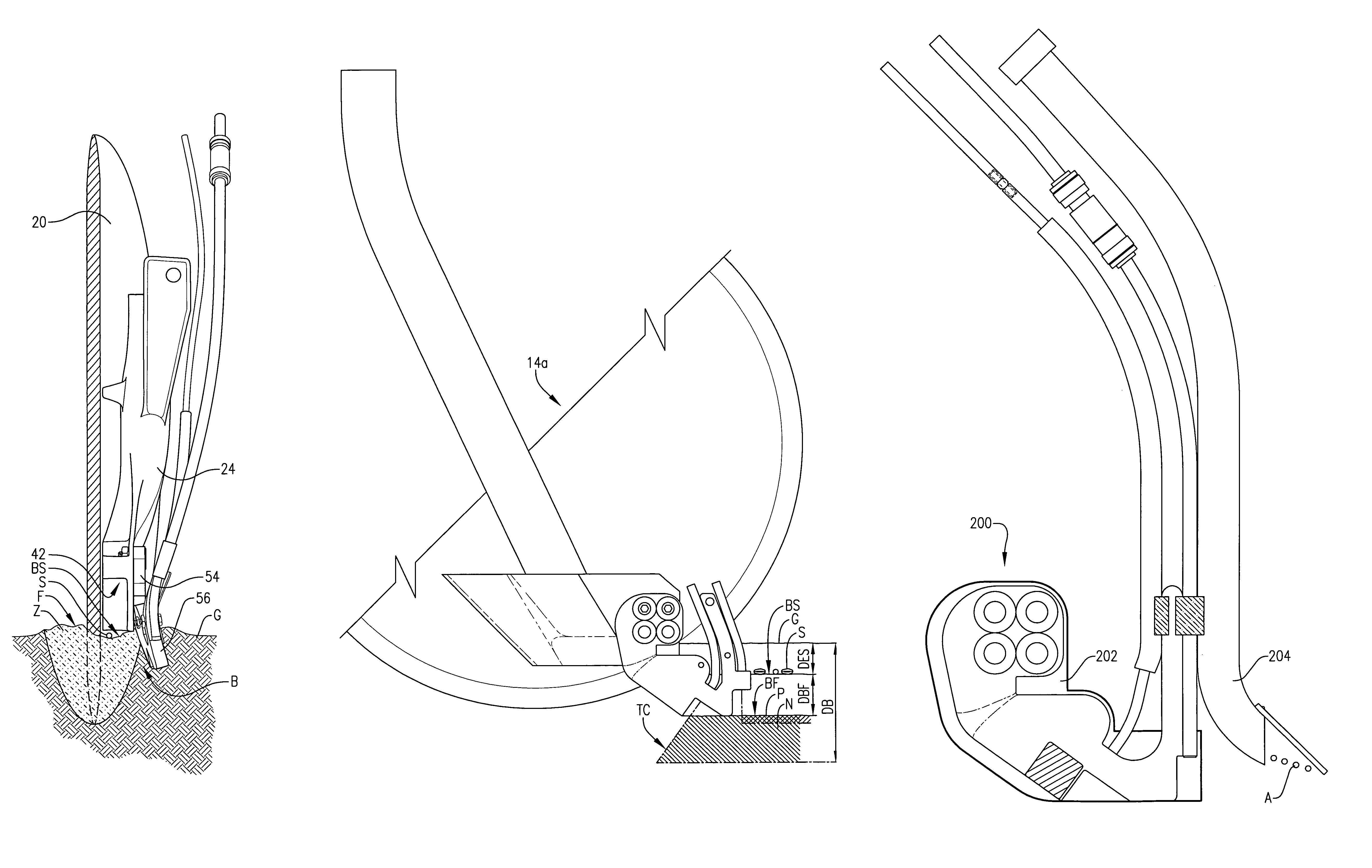

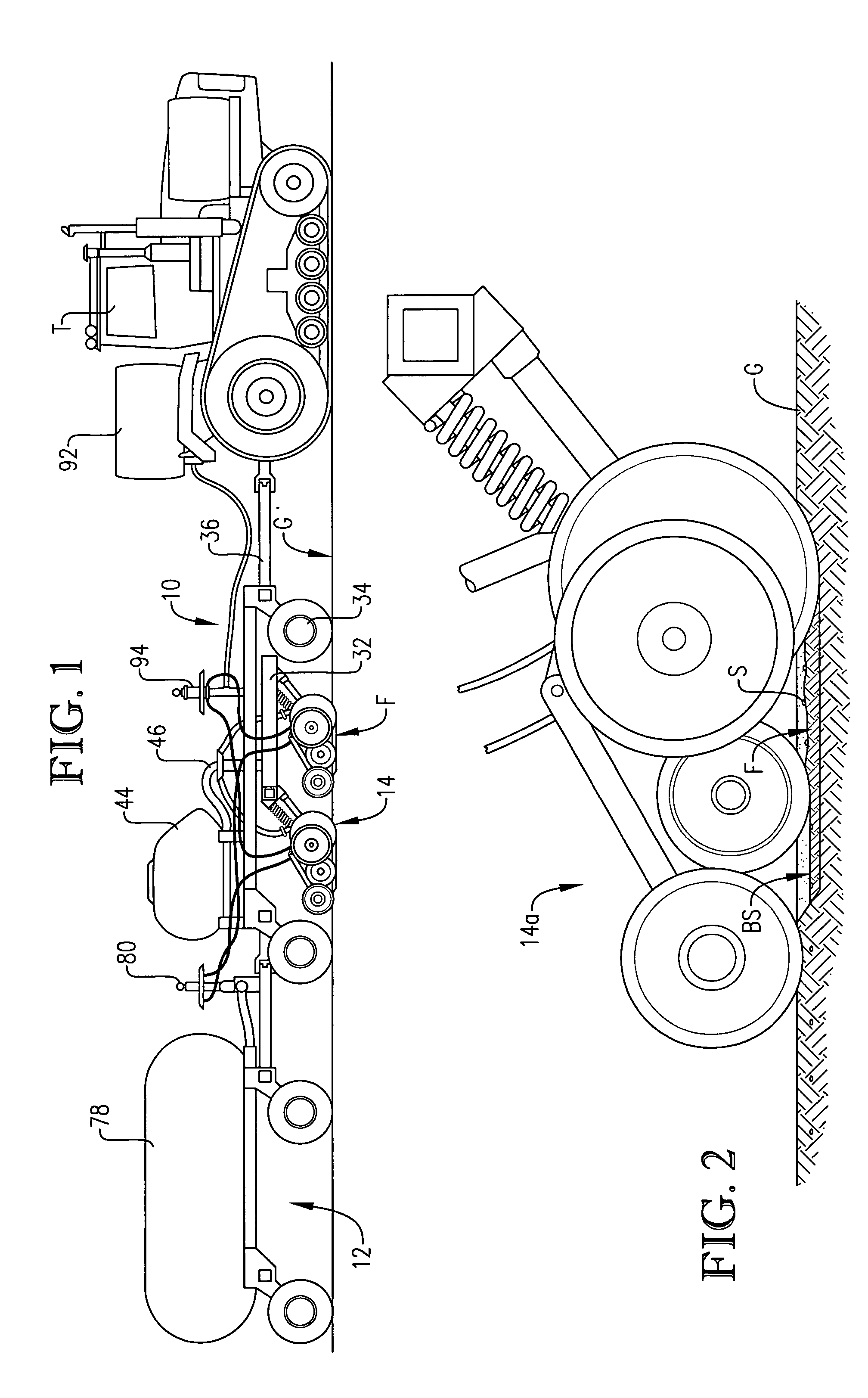

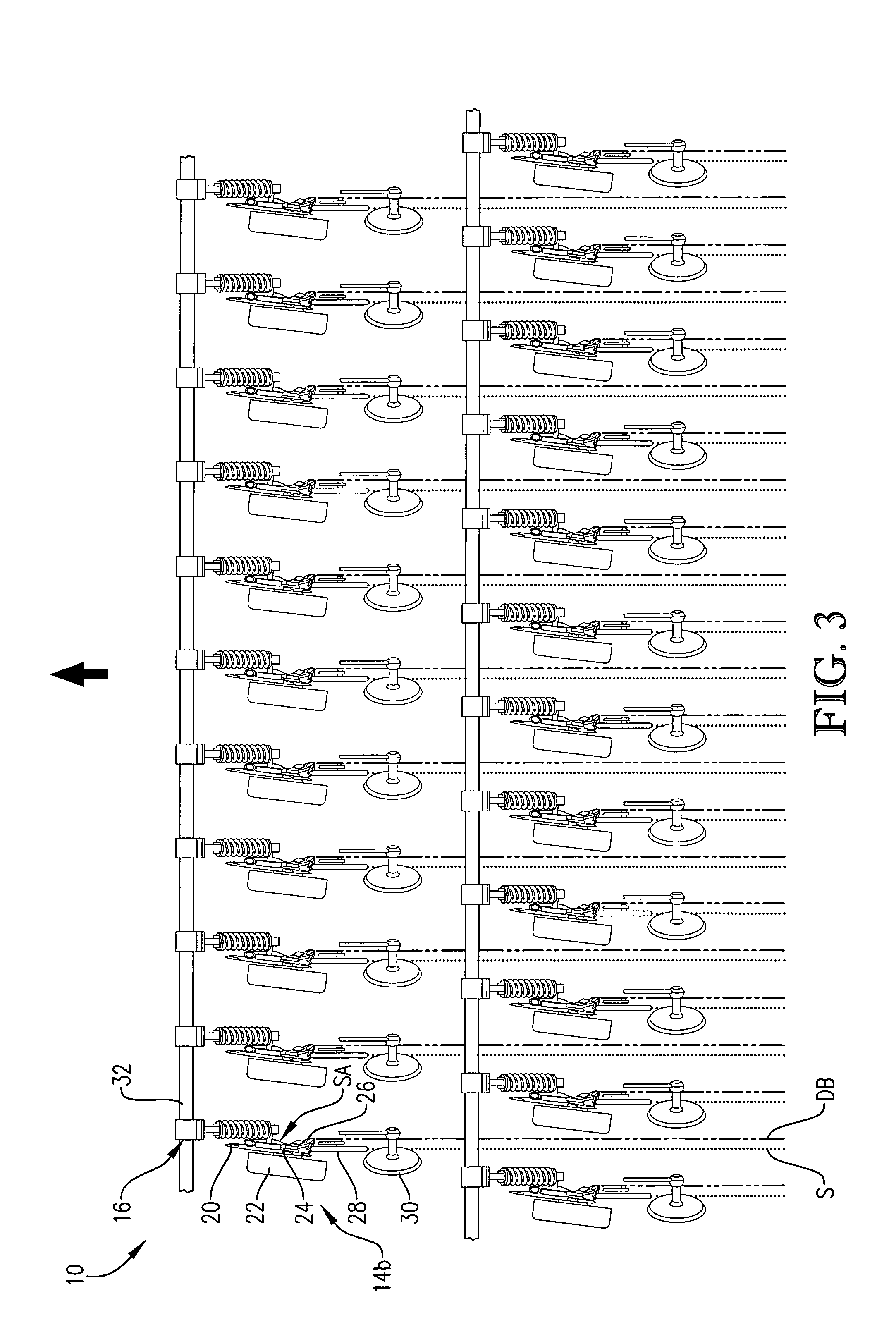

InactiveUS7004090B2High speed useReduce distractionsTill seedingDirect liquid fertiliser deliverySeederAgricultural engineering

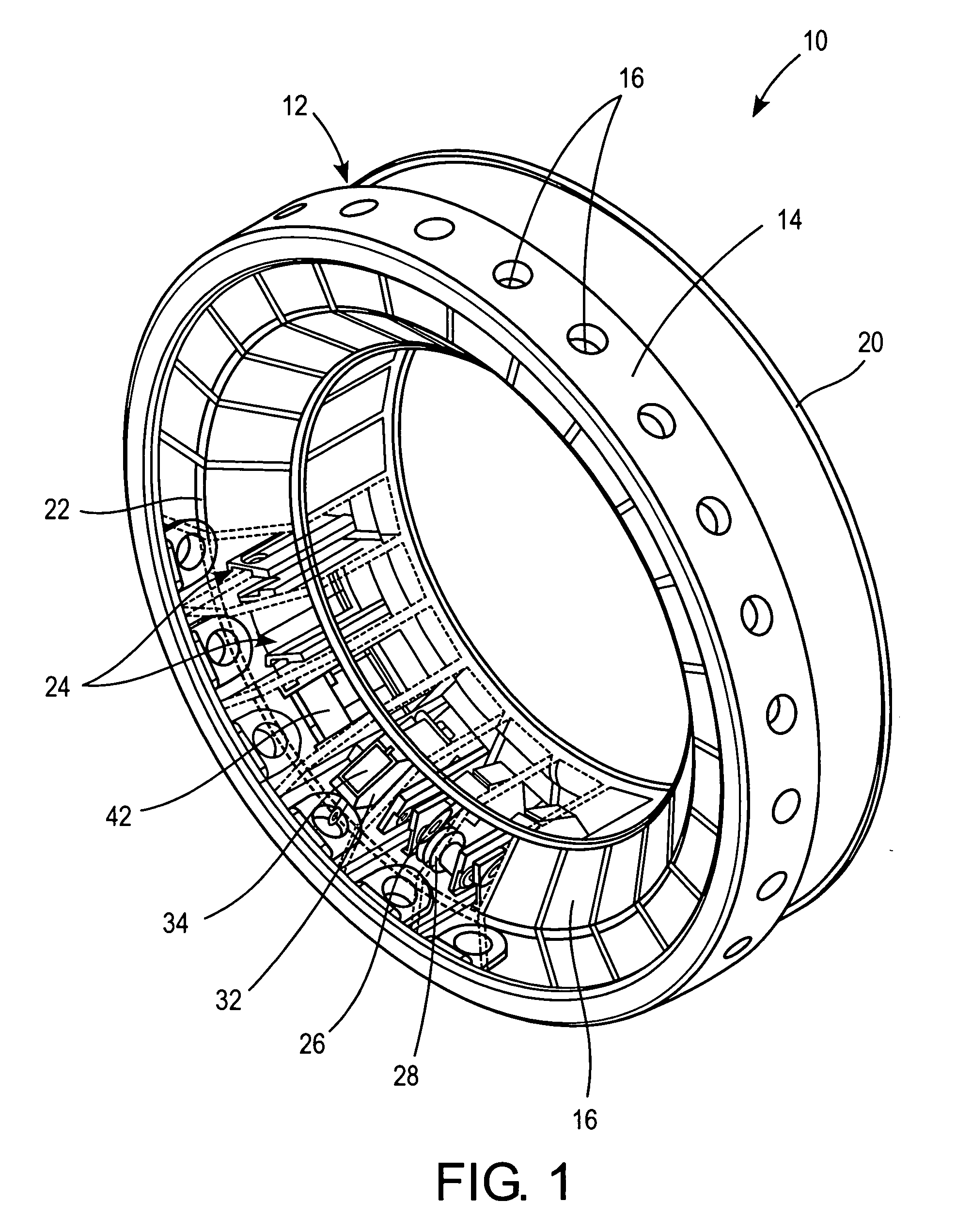

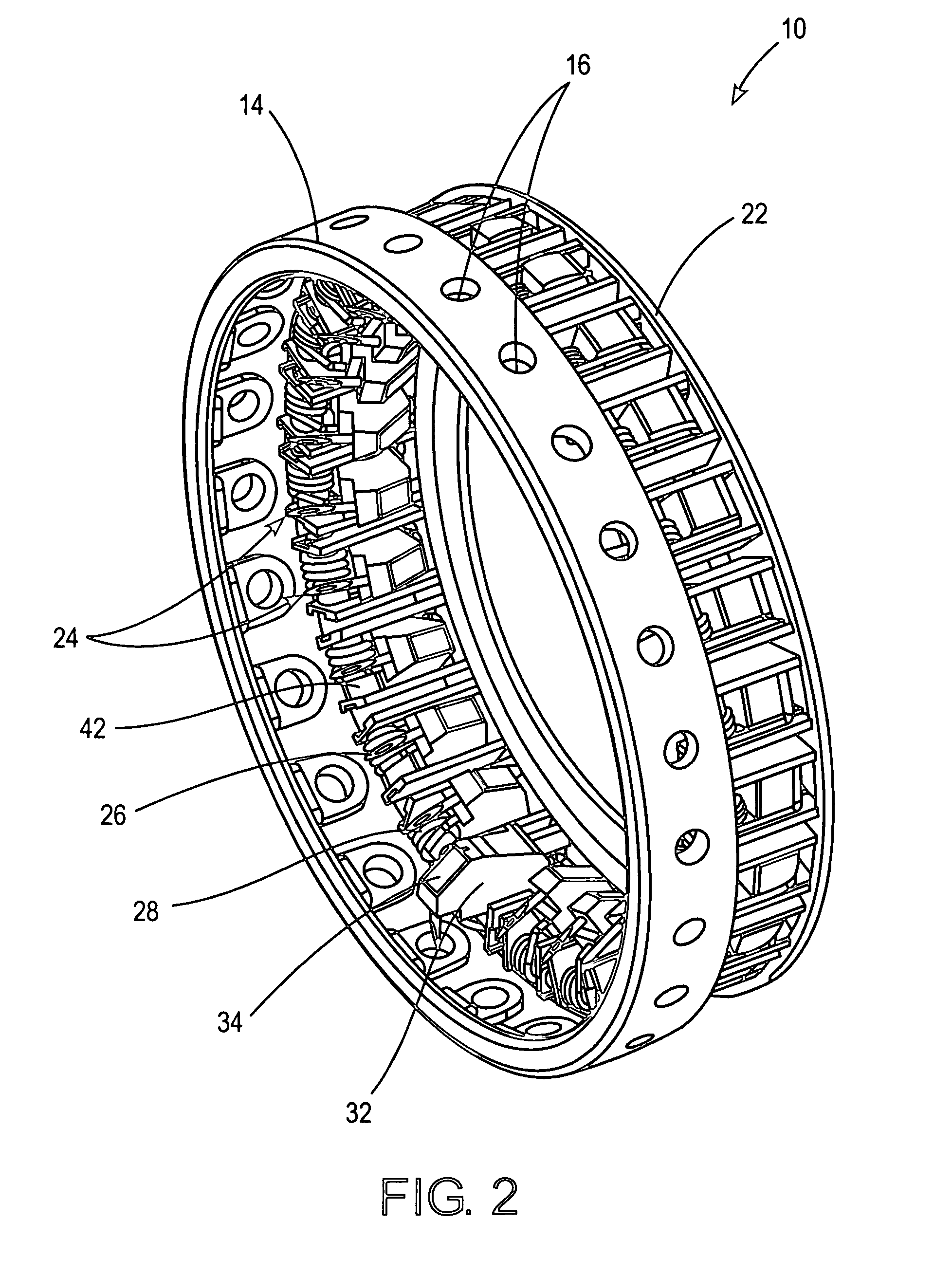

Disc openers (14) for use with an air seeder (10), are configured for seeding and fertilizing a field (G). The opener (14b) broadly includes a drawbar assembly (16), a disc assembly (18) including a coulter disc (20) and a gauge wheel (22), a seed boot (24), a fertilizer injector wing (26), a firming wheel assembly (28), and a closing wheel assembly (30). The fertilizer injector wing (26) is configured for fixed attachment to the seed boot (24) and broadly includes a body (48), including an angled outboard portion (56), a toxic fertilizer injector (50), and a non-toxic fertilizer injector (52). The opener (14b) with the fertilizer injector wing (26) is configured to place the seed row (S) and the dedicated fertilizer band (DB) at an optimum geometric positional alignment relative to the seed row (S), in a single, low soil disturbing planting pass without disrupting the seed bed (BS).

Owner:EXACTRIX

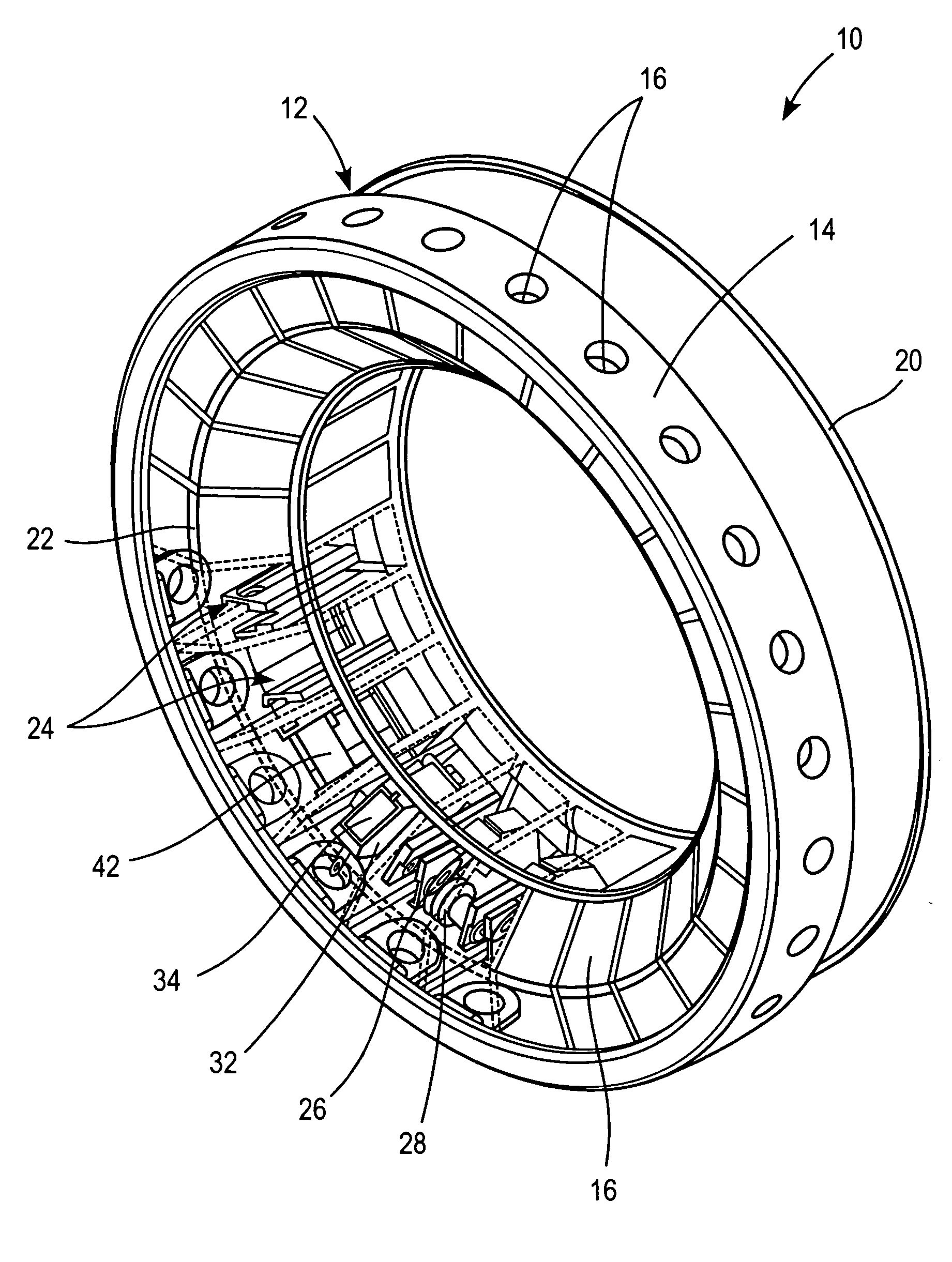

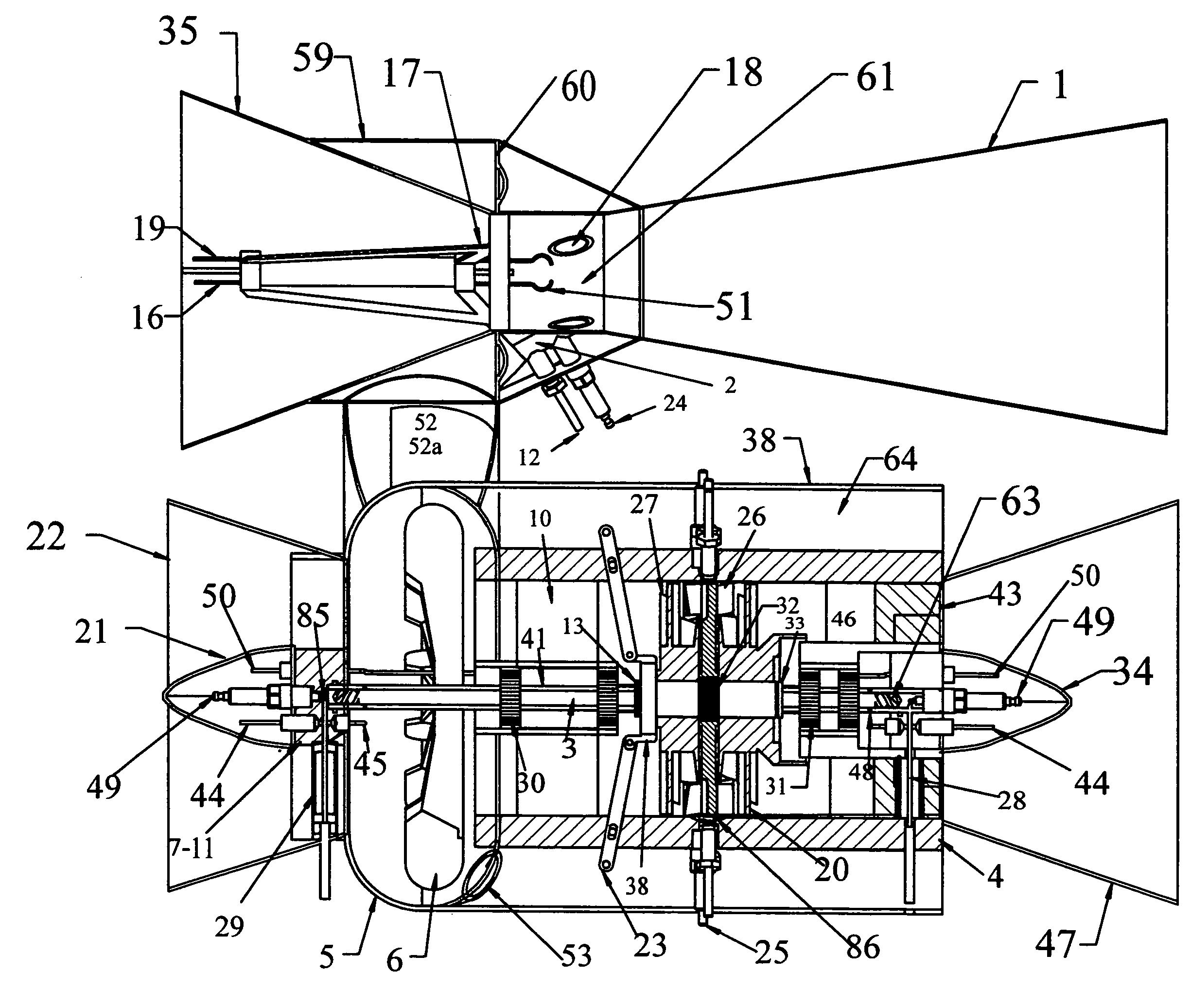

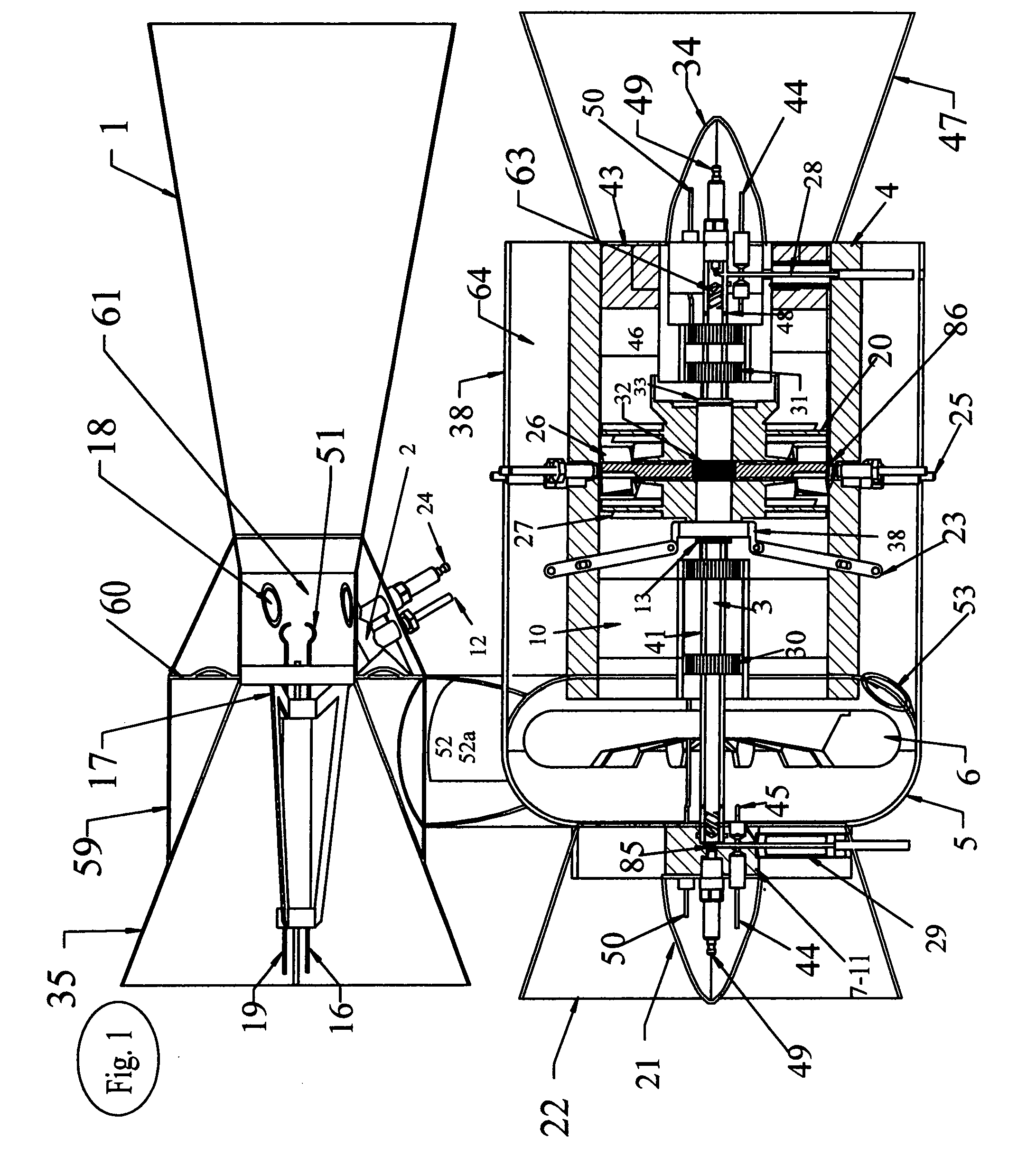

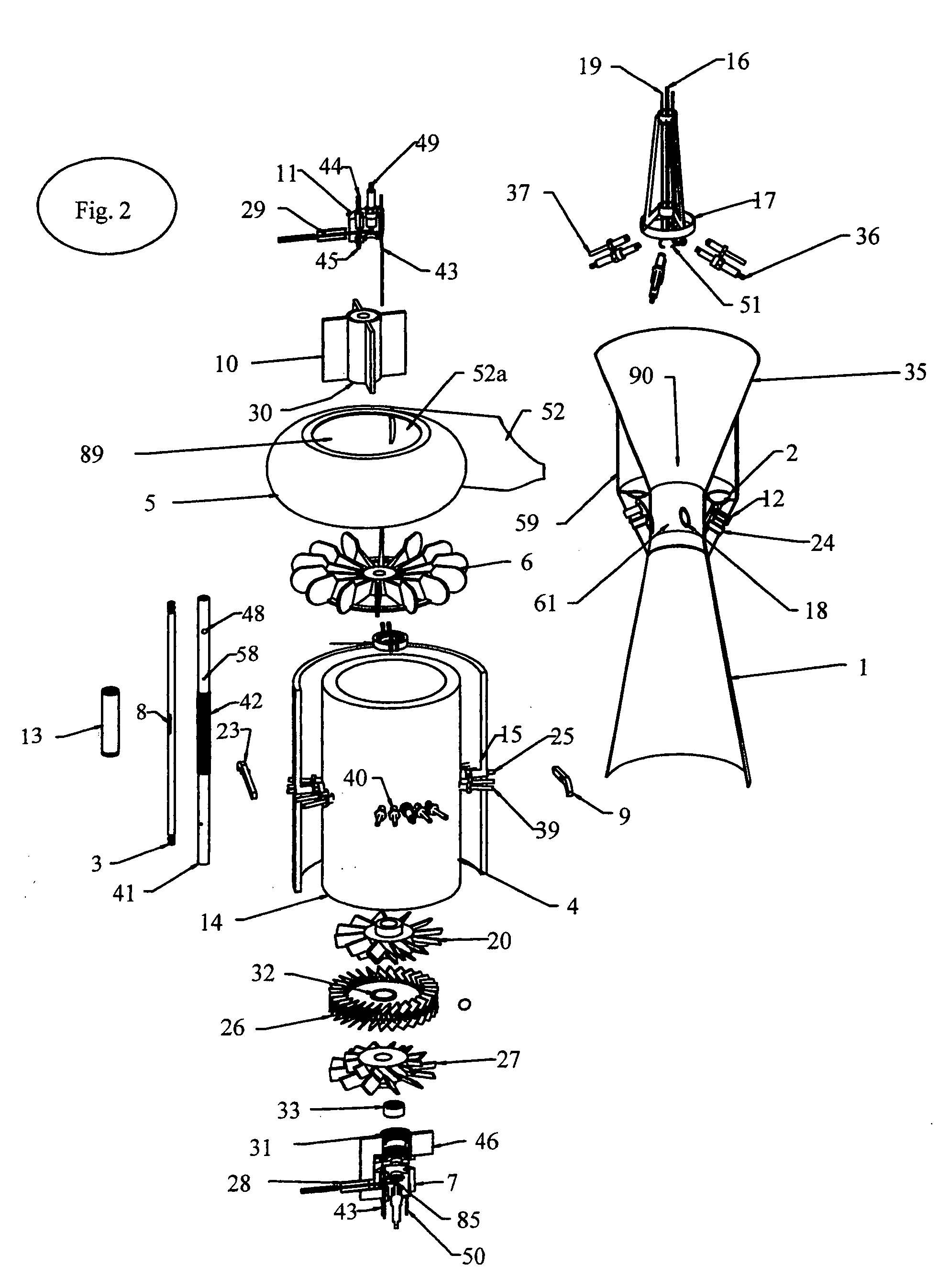

Methods of combining a series of more efficient aircraft engines into a unit, or modular units

InactiveUS20100251692A1More thermal capacityReduce environmental pollutionContinuous jet plantsRocket engine plantsRamjetFree-piston engine

The present invention generally relates to units of engines and more particularly to units containing a unique combined-cycle (combustion-detonation) “counter-rotation, anti-gyration, gyroscopic,” turbine fan-jet / free-piston engine configuration for induced air supercharging and boosting the performance of novel Ramjet engines or Ramjet engine configurations by improving internal air-stream dynamics. These dynamics are the result of co-operative air stream intermixing through convergent, supercharge-attenuated, inducted, compressed, tuned, pre-heated ambient air. Achieved through the varying of the geometric structural form and the utilization of unique engines and air induction and propulsion conformations, aided with supplemental air, fuel, oxygen and optiomal water and electrolyte charging.

Owner:KINDE SR RONALD AUGUST

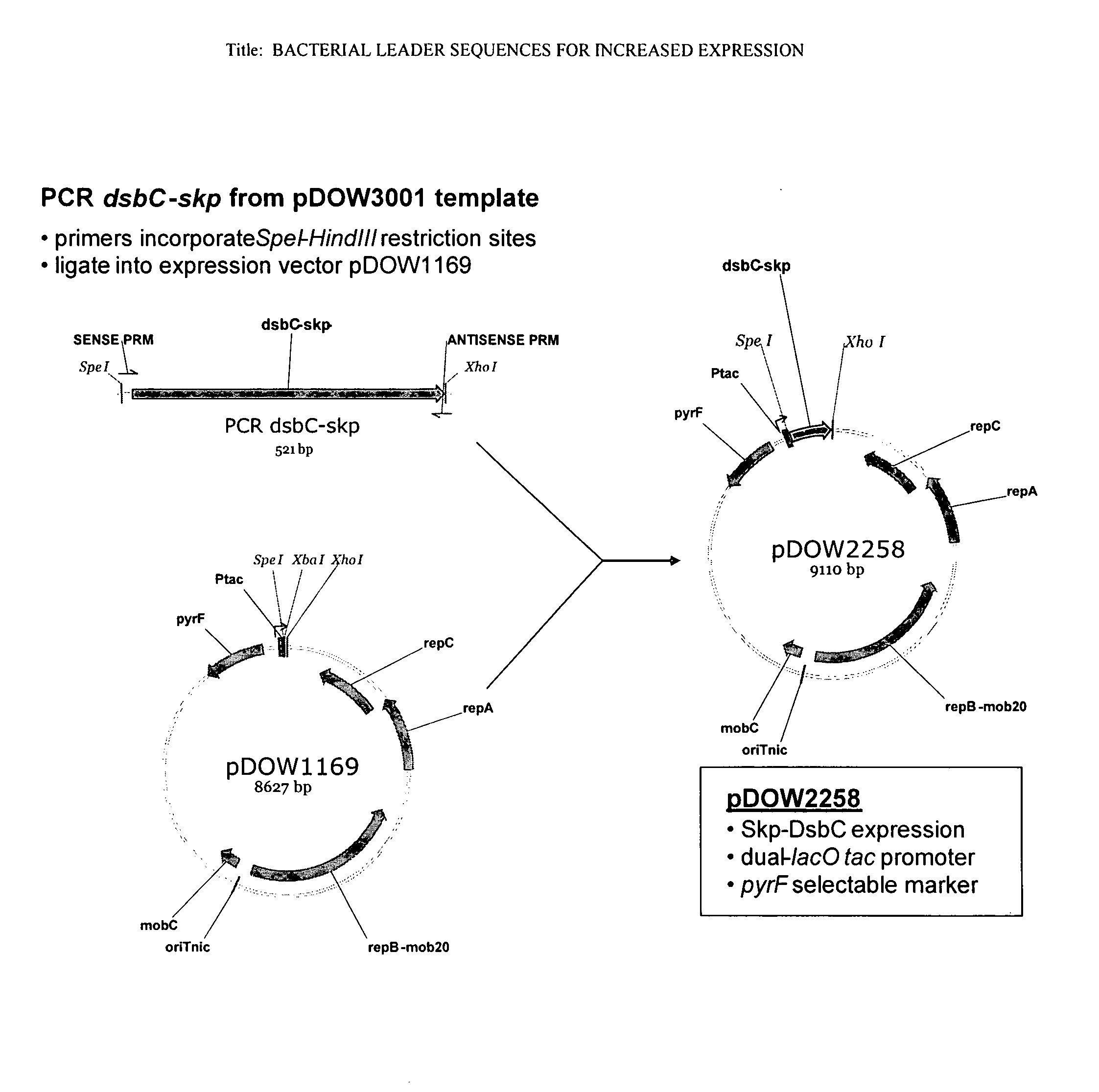

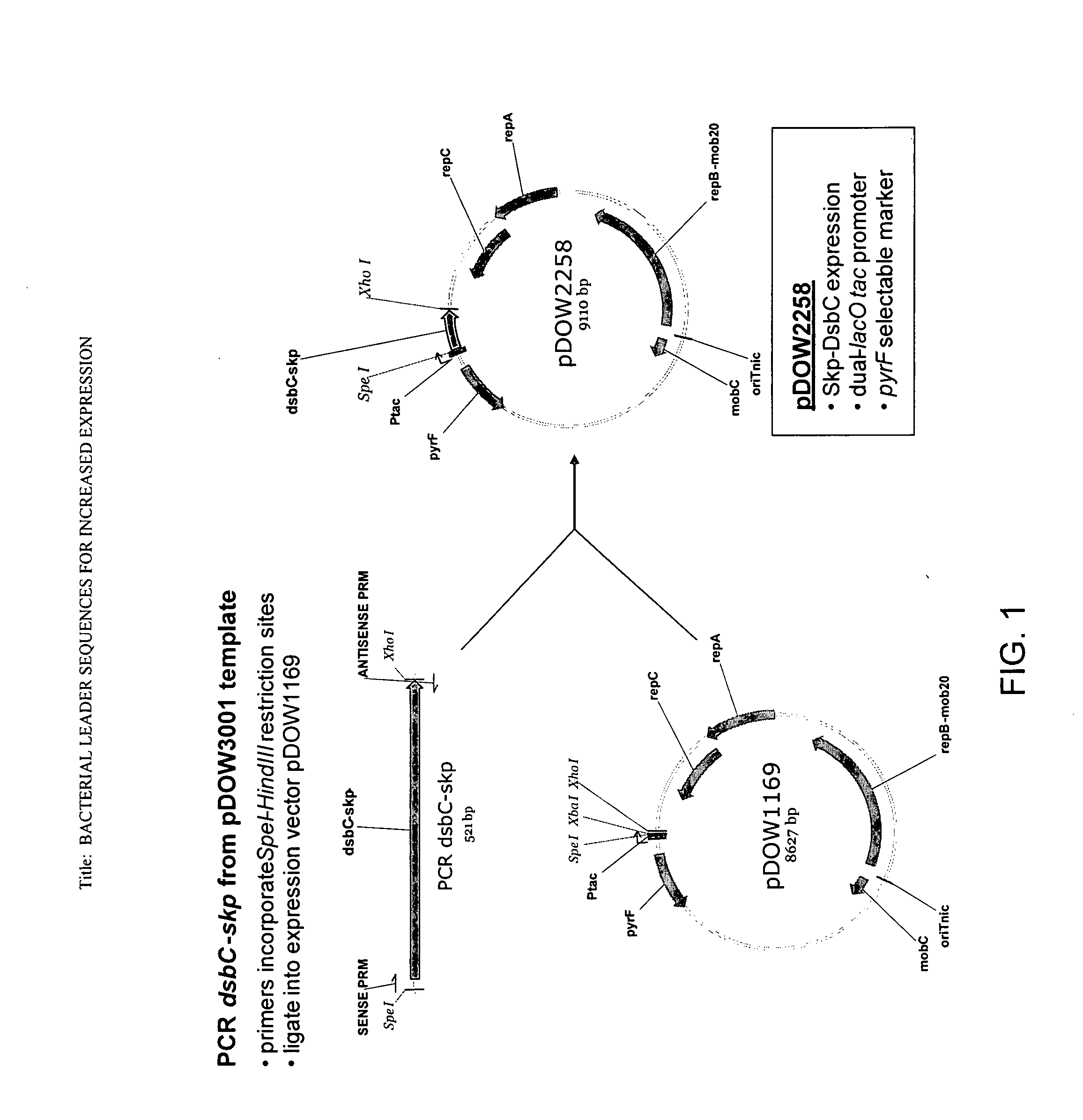

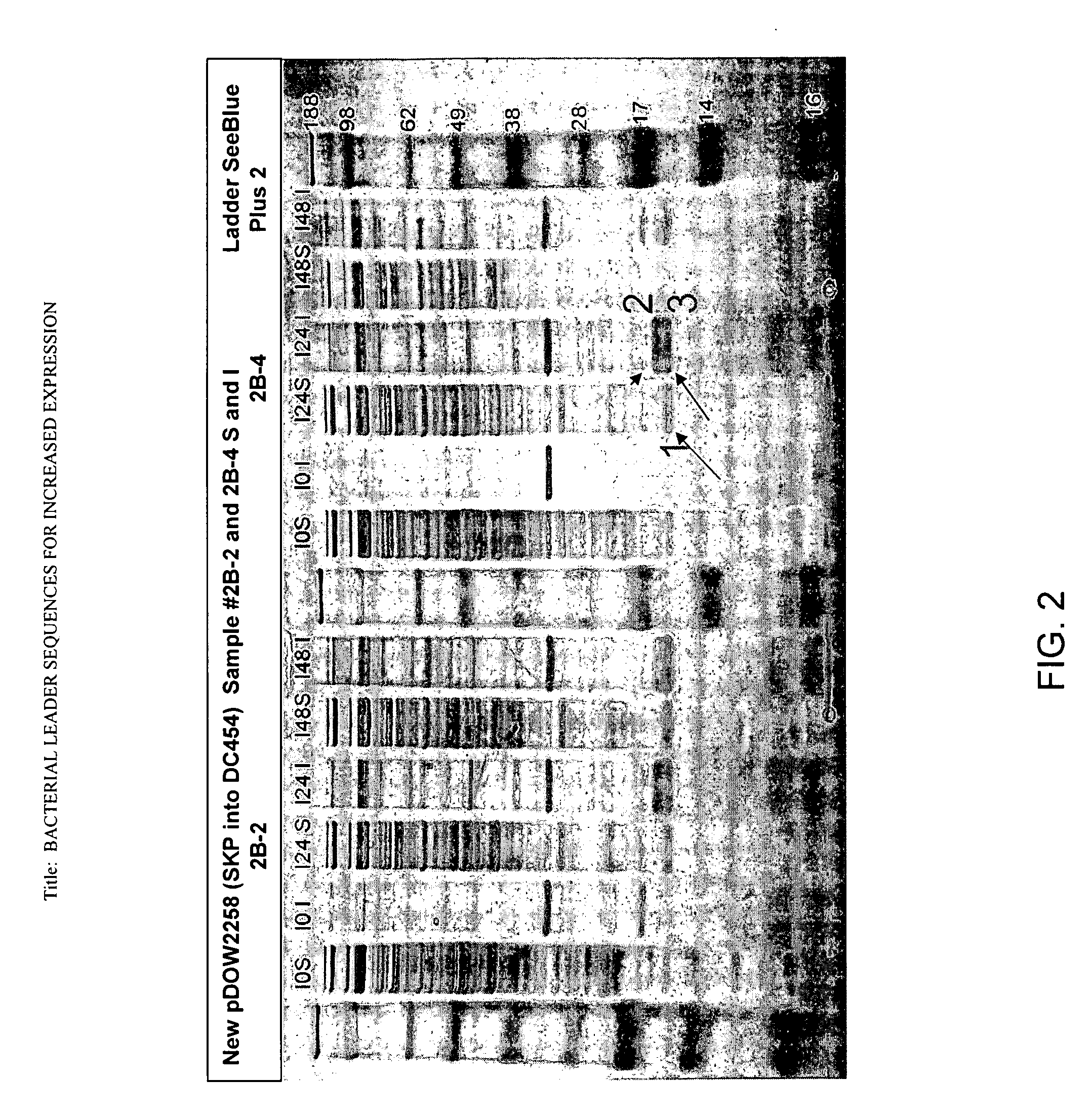

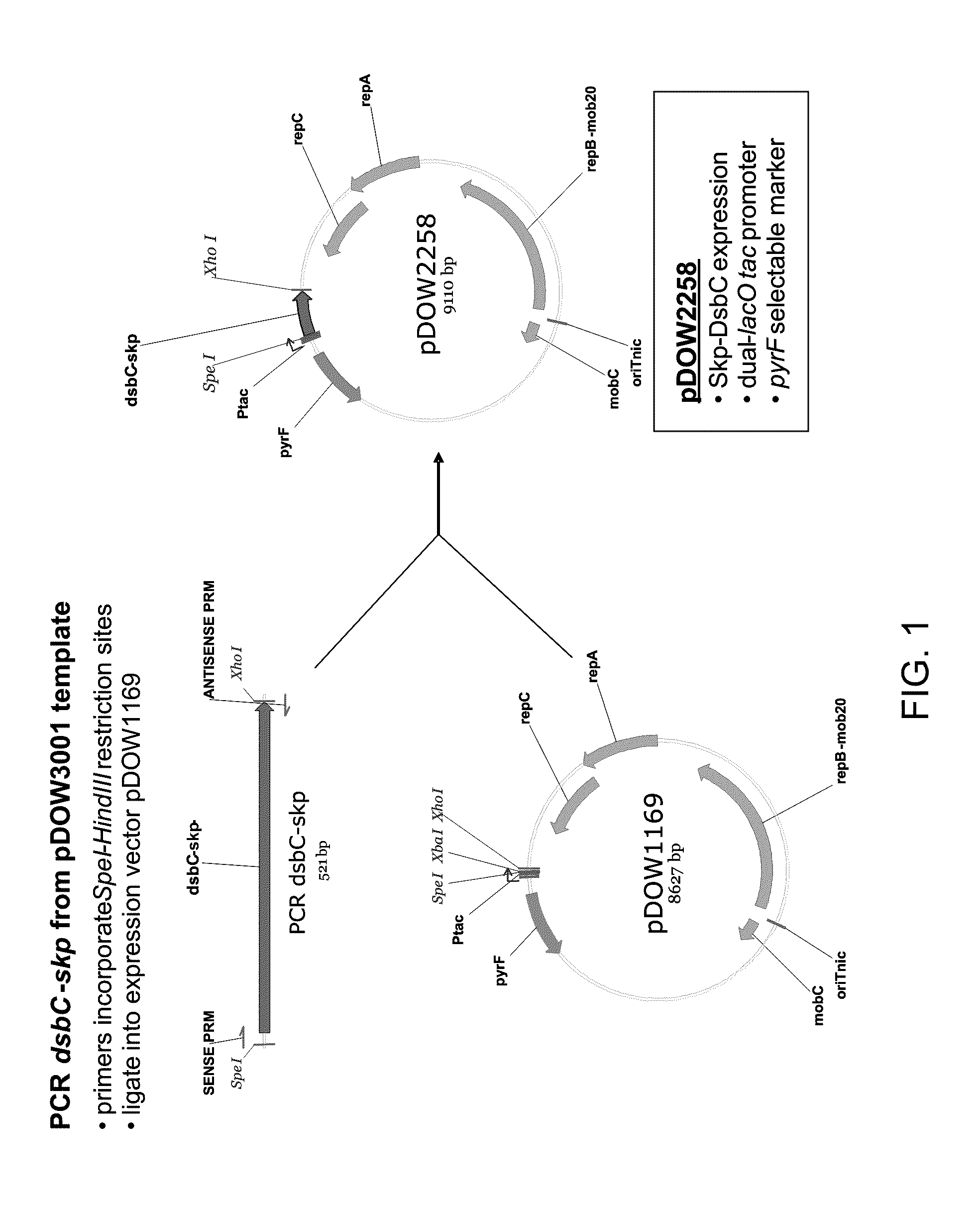

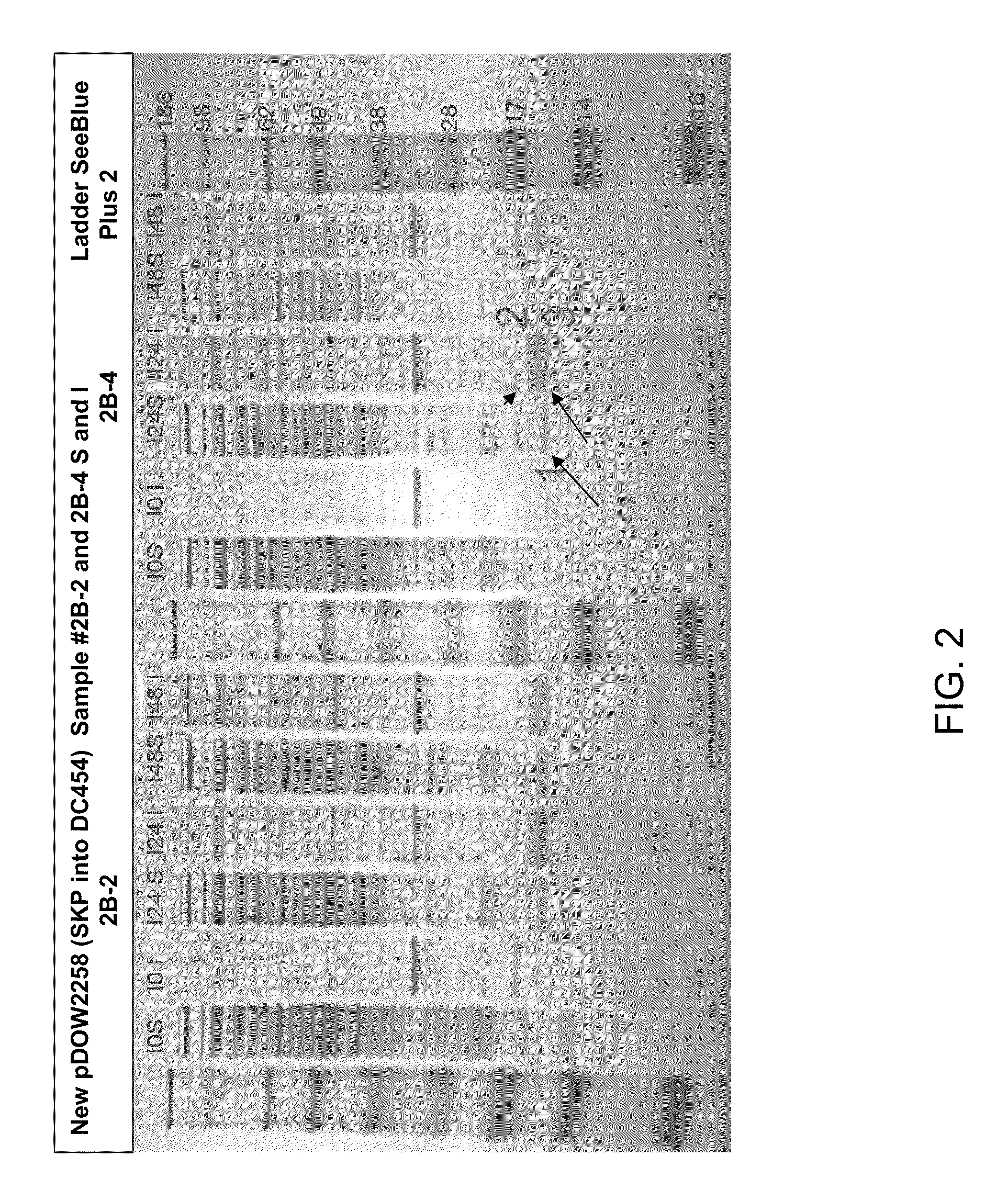

Bacterial leader sequences for increased expression

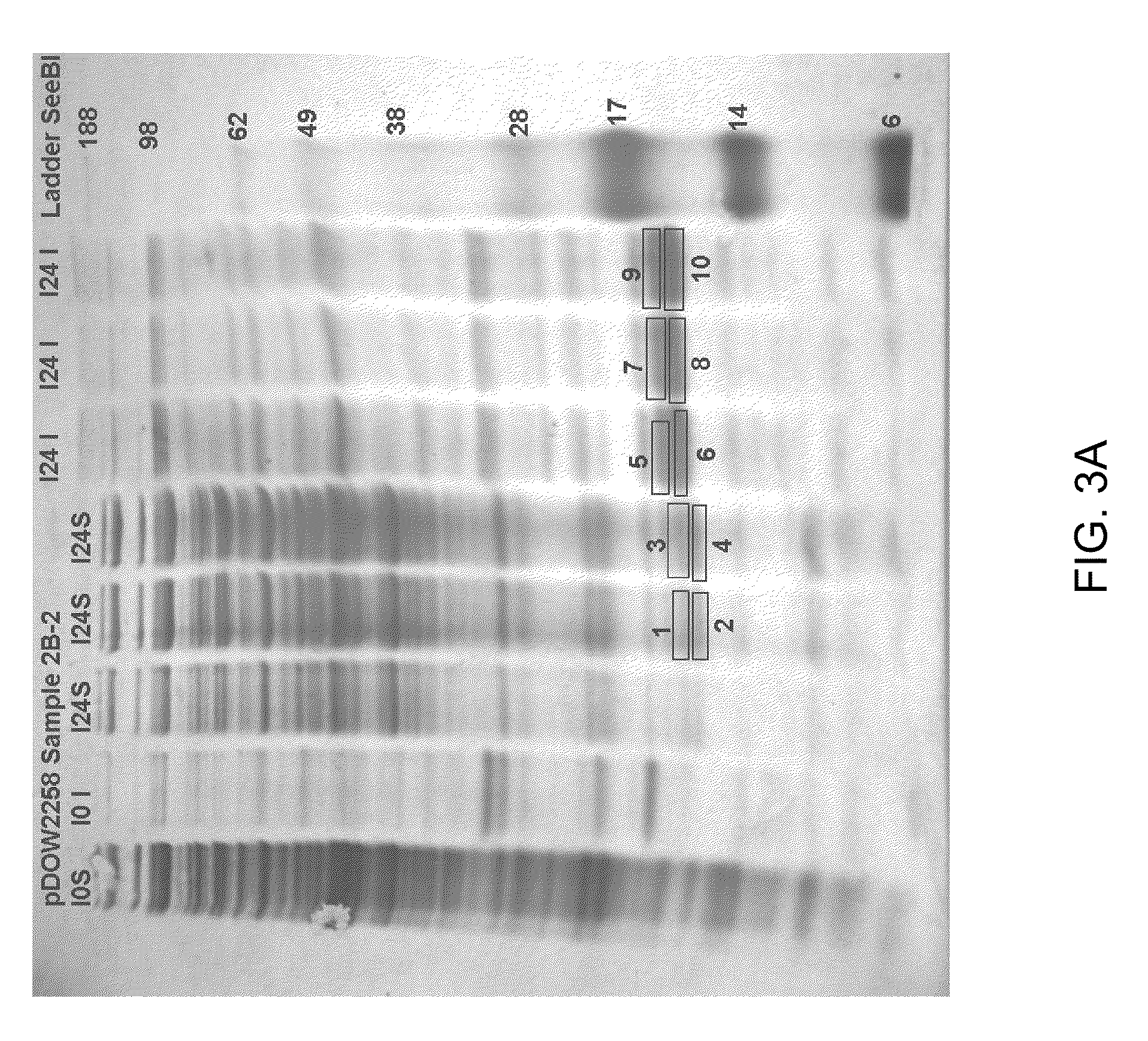

ActiveUS20080193974A1Promote targetingSimple compositionPolypeptide with localisation/targeting motifSugar derivativesNucleotideADAMTS Proteins

Compositions and methods for improving expression and / or secretion of protein or polypeptide of interest in a host cell are provided. Compositions comprising a coding sequence for a bacterial secretion signal peptide are provided. The coding sequences can be used in vector constructs or expression systems for transformation and expression of a protein or polypeptide of interest in a host cell. The compositions of the invention are useful for increasing accumulation of properly processed proteins in the periplasmic space of a host cell, or for increasing secretion of properly processed proteins from the host cell. In particular, isolated secretion signal peptide-encoding nucleic acid molecules are provided. Additionally, amino acid sequences corresponding to the nucleic acid molecules are encompassed. In particular, the present invention provides for isolated nucleic acid molecules comprising nucleotide sequences encoding the amino acid sequences shown in SEQ ID NO: 2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 22, and 24, and the nucleotide sequences set forth in SEQ ID NO: 1, 3, 5, 7, 9, 11, 13, 15, 17, 19, 21, and 23, as well as variants and fragments thereof.

Owner:PFENEX

Bacterial leader sequences for increased expression

ActiveUS7618799B2Reduce environmental pollutionHigh expressionBacteriaAntibody mimetics/scaffoldsADAMTS ProteinsAmino acid

Compositions and methods for improving expression and / or secretion of protein or polypeptide of interest in a host cell are provided. Compositions comprising a coding sequence for a bacterial secretion signal peptide are provided. The coding sequences can be used in vector constructs or expression systems for transformation and expression of a protein or polypeptide of interest in a host cell. The compositions of the invention are useful for increasing accumulation of properly processed proteins in the periplasmic space of a host cell, or for increasing secretion of properly processed proteins from the host cell. In particular, isolated secretion signal peptide-encoding nucleic acid molecules are provided. Additionally, amino acid sequences corresponding to the nucleic acid molecules are encompassed. In particular, the present invention provides for isolated nucleic acid molecules comprising nucleotide sequences encoding the amino acid sequences shown in SEQ ID NO: 2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 22, and 24, and the nucleotide sequences set forth in SEQ ID NO: 1, 3, 5, 7, 9, 11, 13, 15, 17, 19, 21, and 23, as well as variants and fragments thereof.

Owner:PELICAN TECH HLDG INC

Pressure-sensitive adhesive for optical films

ActiveUS20090305068A1High viscosityEasy to operateFilm/foil adhesivesSynthetic resin layered productsPolymer scienceHeat resistance

Pressure-sensitive adhesives for optical films exhibit high cohesion, excellent re-workability, adhesion properties, heat resistance and durability without chemical crosslinking.A pressure-sensitive adhesive contains an acrylic triblock copolymer (I) at not less than 60% by mass based on the total mass of all solids contained in the pressure-sensitive adhesive, the acrylic triblock copolymer being represented by the formula A1-B-A2 wherein: A1 and A2 are each independently an alkyl methacrylate polymer block having Tg of not less than 100° C. and B is an acryl acrylate polymer block having Tg of not more than −20° C.; the content of the polymer block B is 50 to 95% by mass; Mw is in the range of 50,000 to 300,000; and the molecular weight distribution is in the range of 1.0 to 1.5. In a preferred embodiment, the acrylic triblock copolymer (I) is a combination of an acrylic triblock copolymer (Ia) having Mw of 50,000 to less than 100,000 and an acrylic triblock copolymer (Ib) having Mw of 100,000 to 300,000, in a mass ratio (Ia):(Ib) of 45:55 to 75:25.

Owner:KURARAY CO LTD

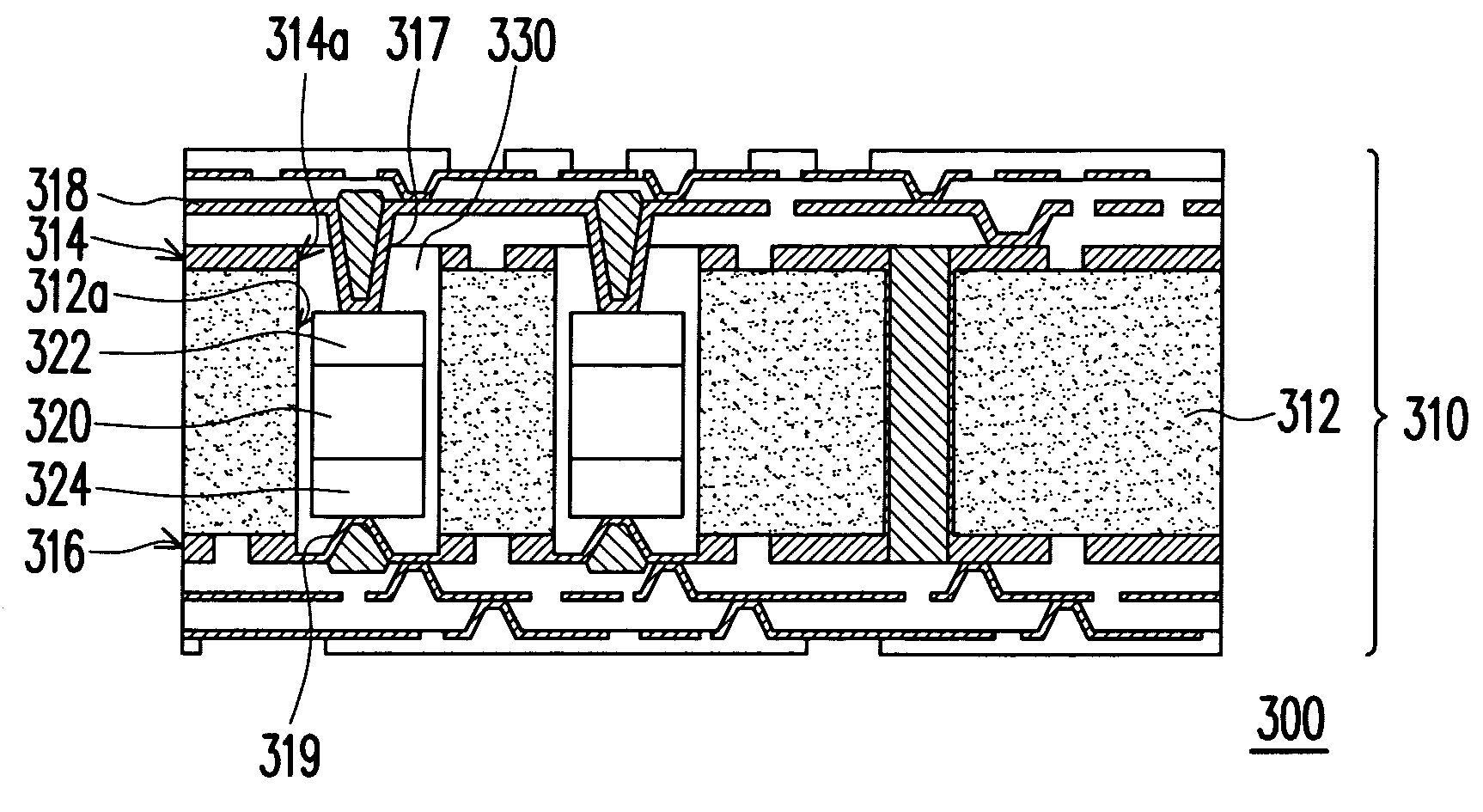

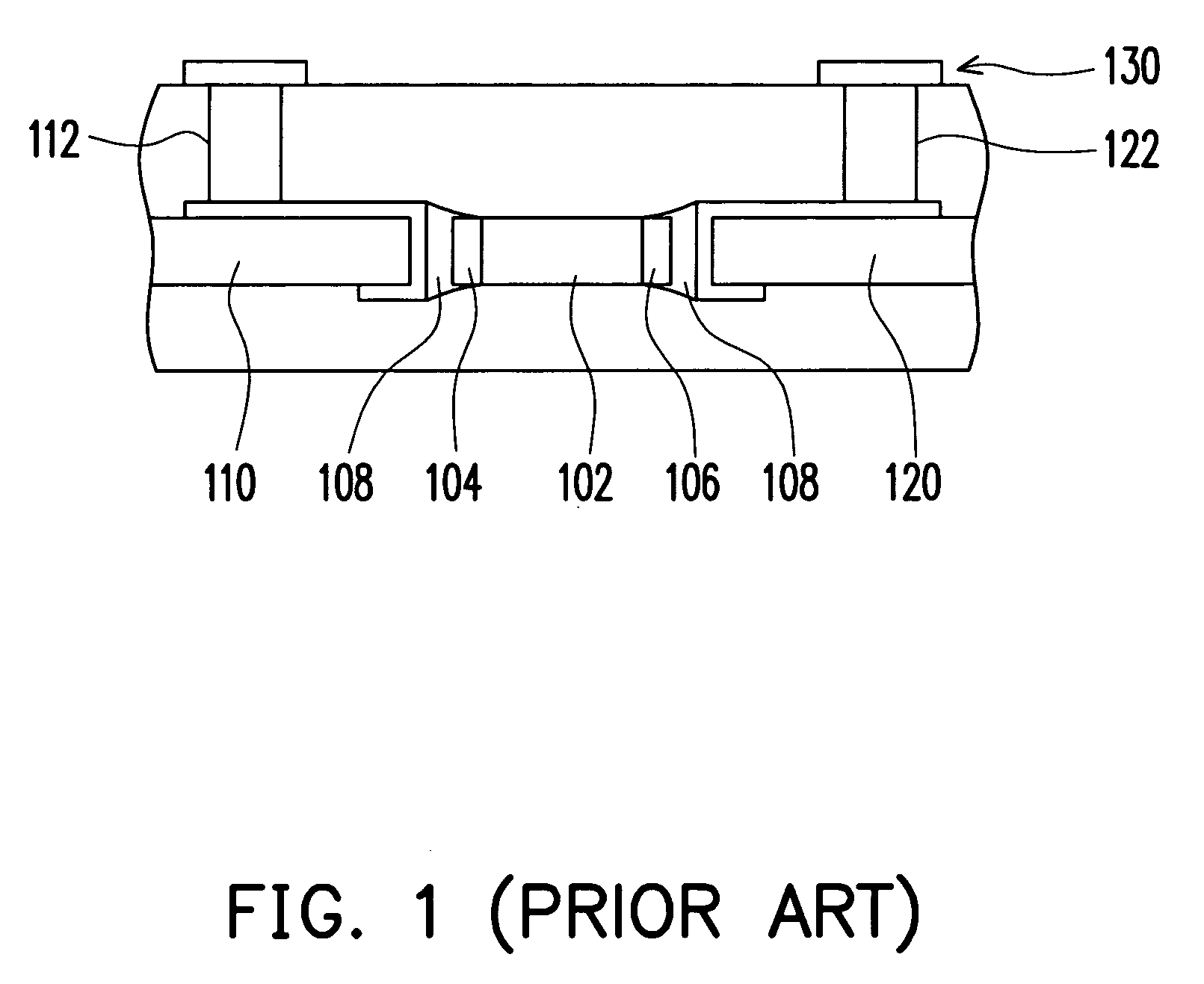

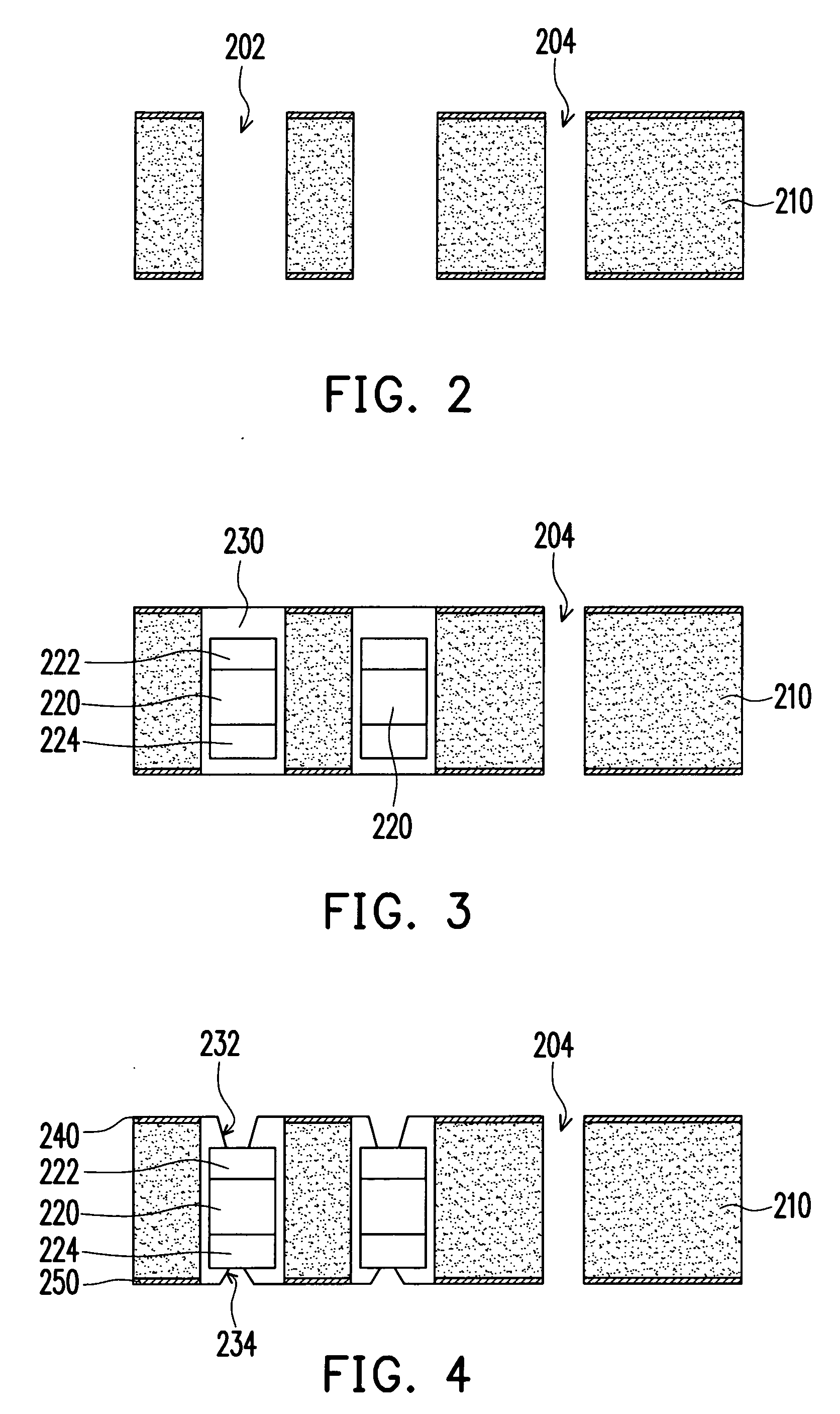

Assembly structure and method for embedded passive device

InactiveUS20060118931A1Improve convenienceImprove efficiencyFinal product manufactureSemiconductor/solid-state device detailsAssembly structureElectrical and Electronics engineering

An assembly structure for an embedded passive device is provided, including at least one passive device embedded in a through hole of a core layer in a circuit substrate. The embedded passive device comprises plural electrodes, which electrically connect through the top side and the bottom side of the core layer. Because the vertically embedded passive device does not occupy the layout area of internal circuit of the circuit substrate, the layout area of the circuit substrate can be increased, the signal transmission route can be reduced, and the performance of signal transmission can be enhanced.

Owner:VIA TECH INC

Electrophotographic photoconductor, preparation method thereof, electrophotographic apparatus and process cartridge

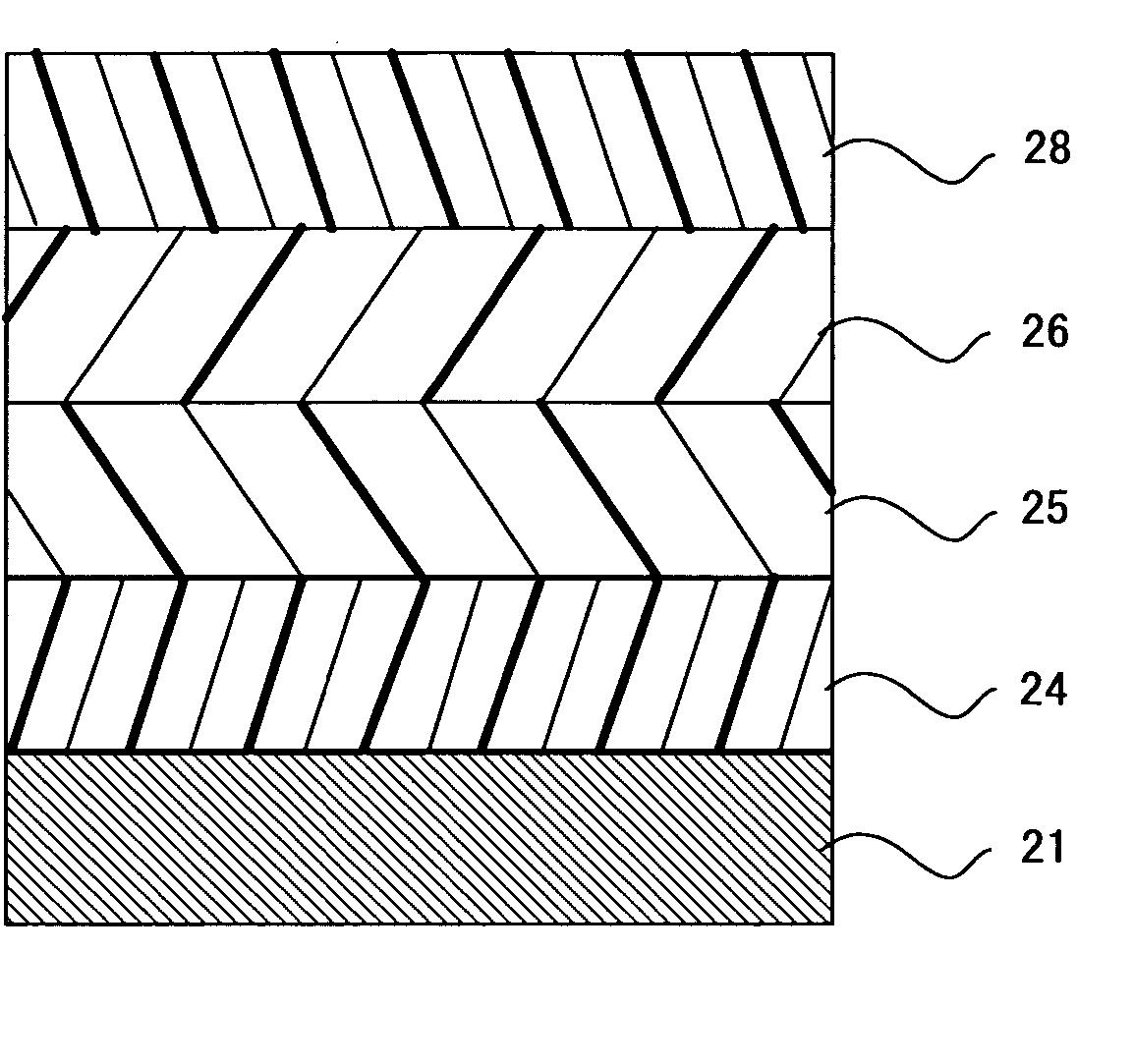

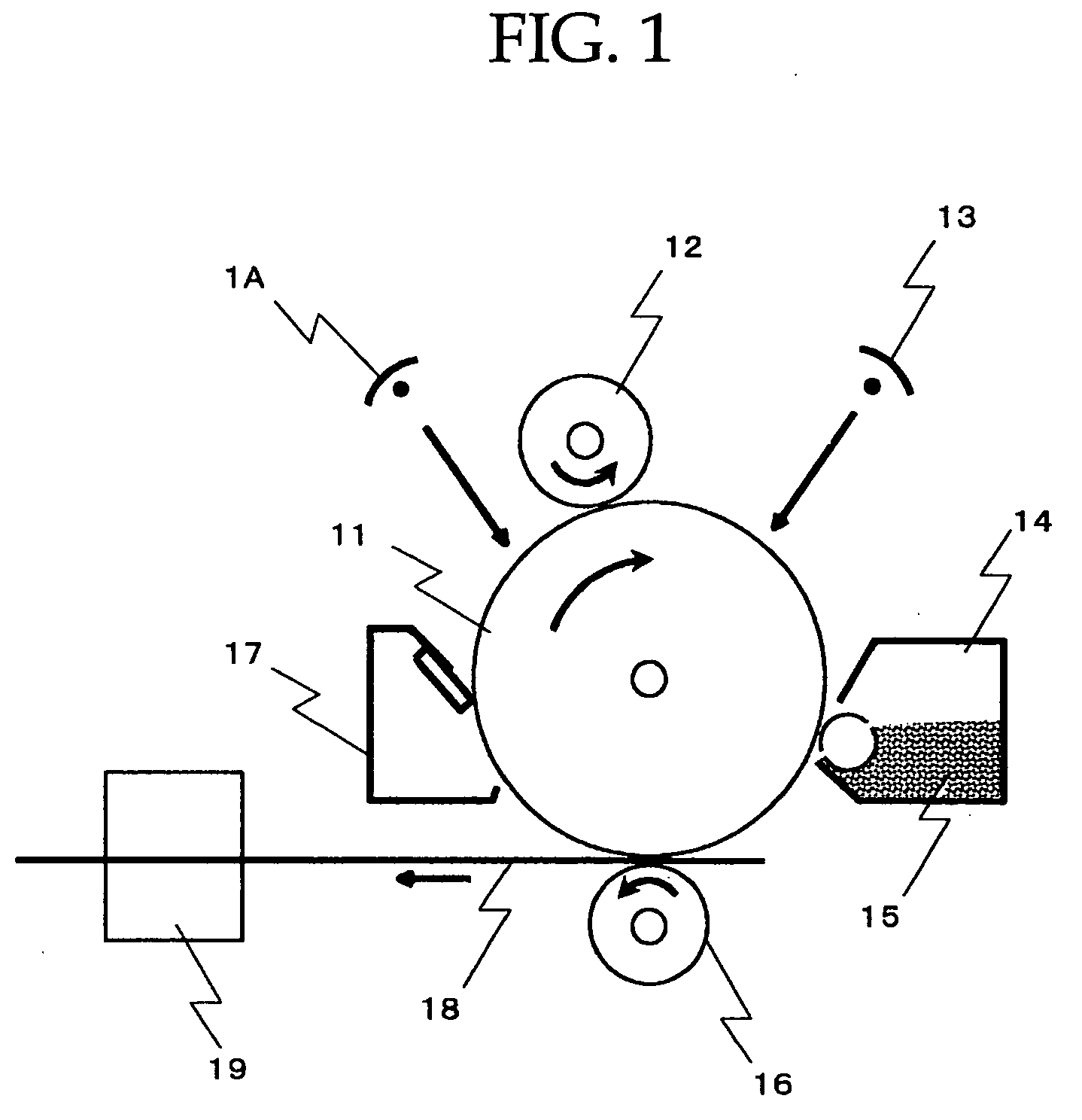

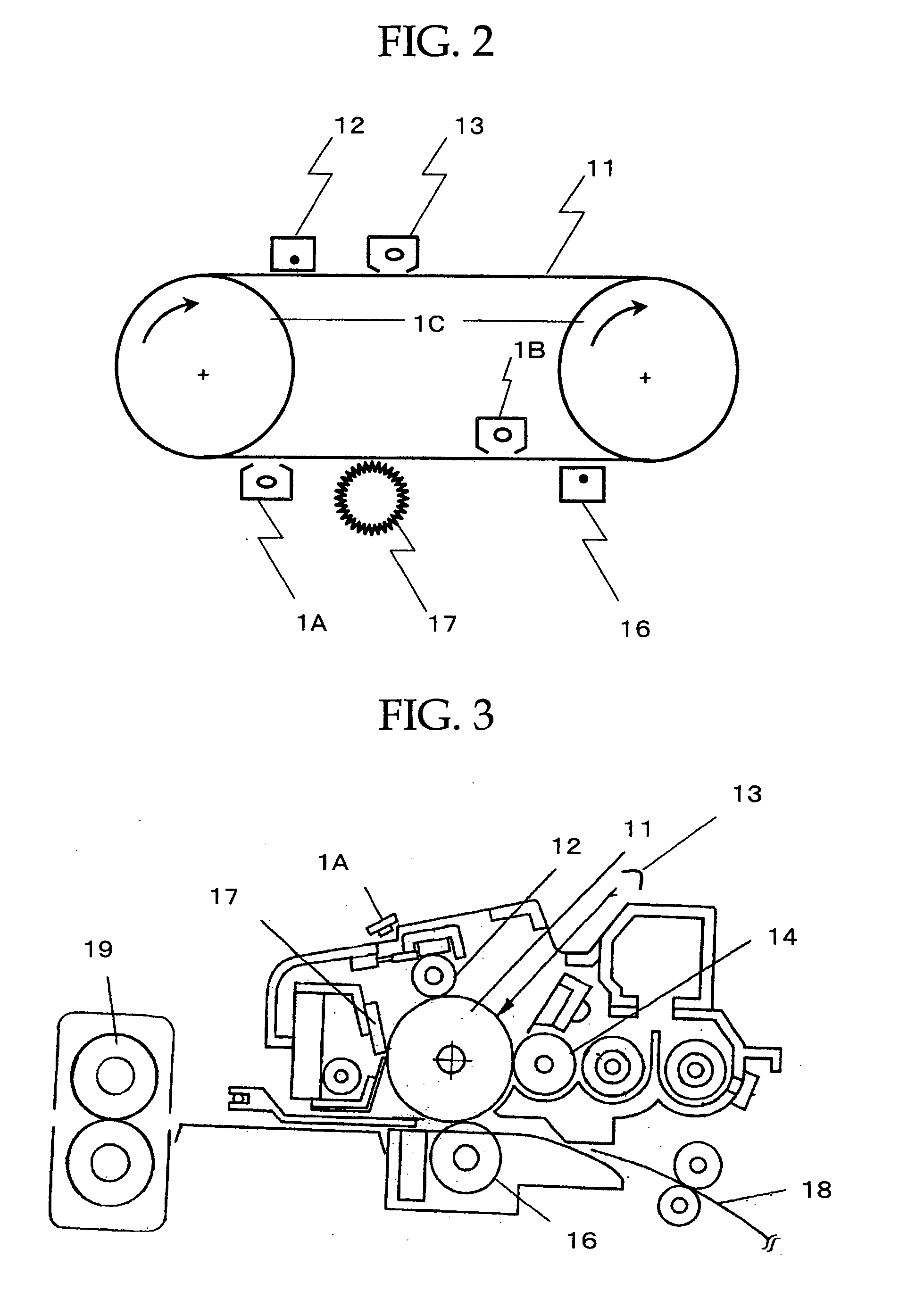

InactiveUS20050181291A1Satisfactory photosensitivity propertyHigh mechanical strengthElectrographic process apparatusCorona dischargeElectrical conductorTransport layer

An electrophotographic photoconductor includes an electroconductive substrate, a photoconductive layer arranged over the electroconductive layer with or without the interposition of an undercoat layer, and a surface top layer containing a crosslinkable resin arranged over the photoconductive layer, the photoconductive layer includes a charge generation layer containing a charge generating material, and a charge transport layer containing a charge transporting material, in which the surface top layer is substantially free from hydroxyl groups and residual uncured portions.

Owner:RICOH KK

Elastomeric foam article

InactiveUS20050221073A1Reduce wasteLow densityGlovesClothingsVolumetric Mass DensityPolymer chemistry

Owner:LIOU DER LIN

Active metal electrolyzer

InactiveUS7608178B2Effective isolationReduce environmental pollutionPhotography auxillary processesElectrode manufacturing processesElectrolysisAqueous electrolyte

Owner:POLYPLUS BATTERY CO INC

Integrated renewable energy system

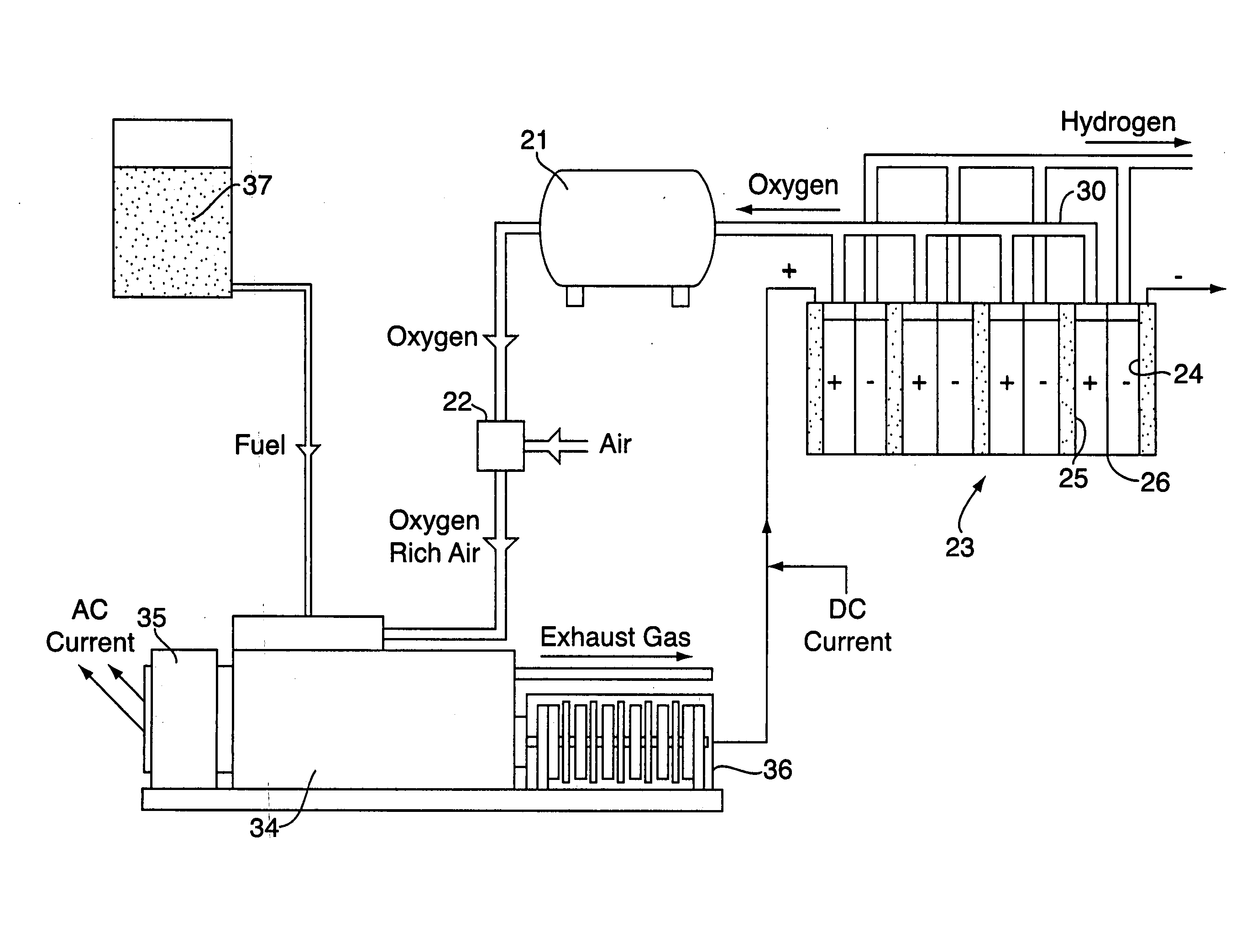

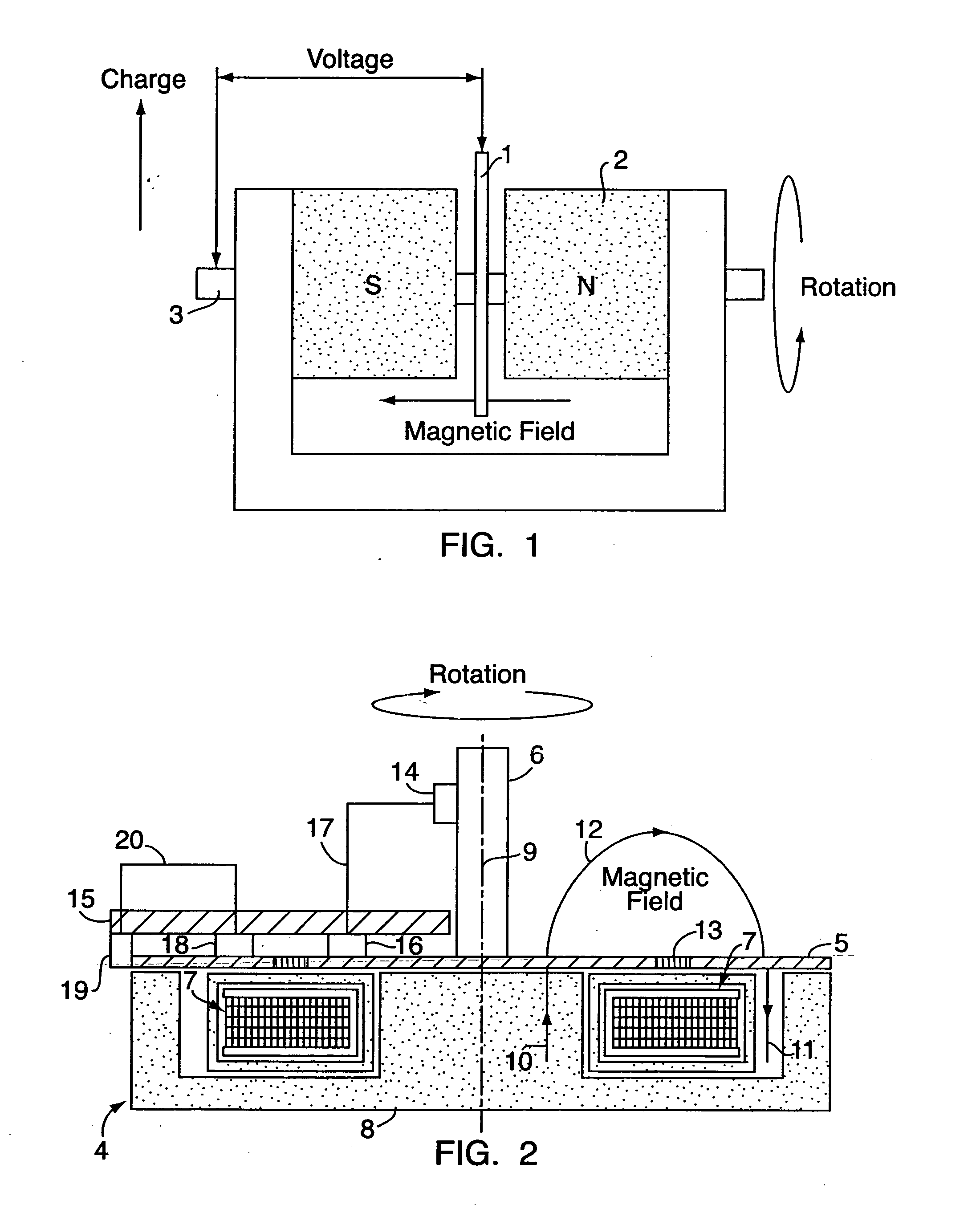

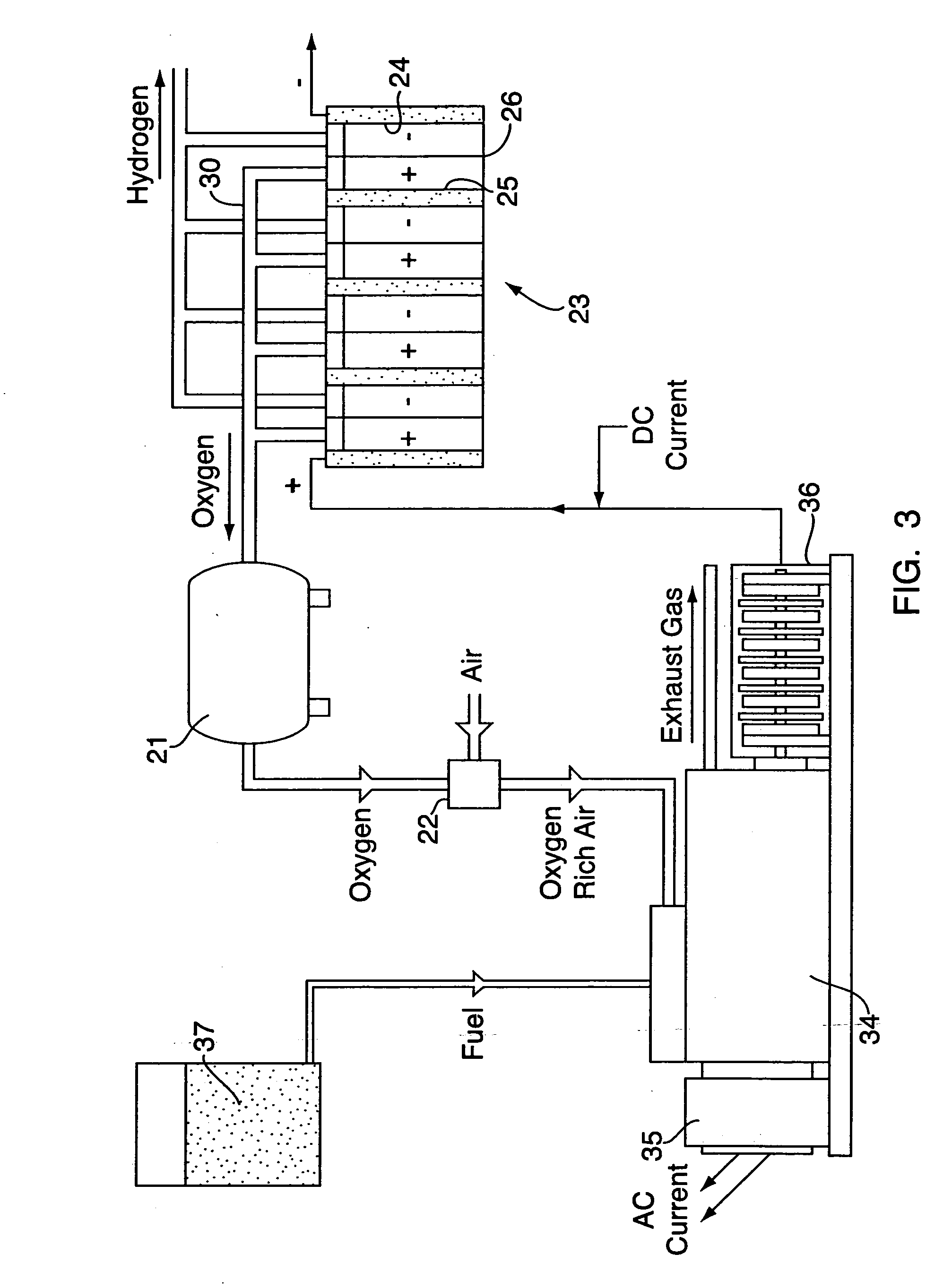

InactiveUS20070001462A1Reduce environmental pollutionFuel efficiencyElectrolysis componentsInternal combustion piston enginesElectrolysisOxygen

A system and method are disclosed comprising coupling a compression ignition engine (17) to an AC electrical generator (18) and / or a DC hompolar generator (19), wherein the homopolar generator (19) produces an electric current which is used to electrolyse water into hydrogen and oxygen. The hydrogen from the water electrolysis process may be used as a renewable fuel, either in the form of a gaseous fuel or a reactant in a fuel cell. The oxygen from the water electrolysis unit (23) may be used to produce an oxygen enriched combustion atmosphere in the engine (17). The oxygen may optionally be used as a reactant, along with the hydrogen, in a fuel cell.

Owner:H EMPOWER CORP

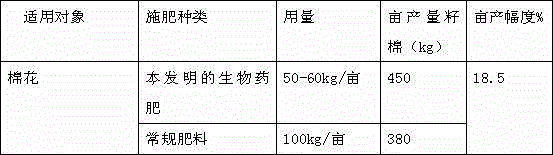

Specialized organic/inorganic composite biological medicine fertilizer for cotton, and preparation method thereof

InactiveCN102942407AReduce environmental pollutionFull of nutritionFertilizer mixturesHorticultureChemistry

The invention provides a specialized organic / inorganic composite biological medicine fertilizer for cotton, and a preparation method thereof. The weight parts of composition raw materials are as follows: 30-40 parts of household garbage, 20-30 parts of cotton straws, 10-15 parts of pig manure, 5-7 parts of plant ash, 10-12 parts of Chinese medicine residue, 20-24 parts of sodium humate, 15-18 parts of diammonium phosphate, 10-12 parts of potassium sulfate, 14-16 parts of urea, 12-14 parts of ammonium bicarbonate, 14-16 parts of fly ash, 8-10 parts of goose feather, 1-2 parts of an EM strain, 20-23 parts of modified attapulgite, 6-8 parts of granatum, 8-10 parts of neem, 5-7 parts of Lygodium japonicum root, 5-7 parts of pomegranate root, 0.8-1.3 parts of boric acid, 0.1-0.2 part of manganese sulfate, 3-4 parts of copper sulfate and 5-6 parts of cinnamon oil. A green organic fertilizer is obtained by mixing a plurality of organic wastes and fermenting the mixture, thereby reducing environment pollutions. The specialized organic / inorganic composite biological medicine fertilizer for the cotton has the advantages of comprehensive nutrition and enhanced sterilizing effects by mixing the fermented organic materials and inorganic fertilizer and adding medicine juice of the Chinese herbal medicine having insectidical functions. With the application of the fertilizer, cotton quality can be effectively increased; and the cotton has green leaves, white flower, prolonged flowering period and increased output.

Owner:合肥科友生物科技有限公司

Method of preparing thermal insulating mortar from solid waste

This invention relates to a method for preparing heat-preservation mortar utilizing solid castoffs, in which, the raw material is composed of two groups: group A includes the following components and weight percentage: slag powder 20-40%, powdered coal ash 20-30%, Portland cement 30-40%, Ca reinforcing agent 5-15%, abandon polystyrene foams 3-8%, PP fiber 0.05-0.15%, re-dispersible latex powder 1-3%, water preservation agent 0.2-0.6%, water reducer 0.1-0.5%, defoamer 0.05-0.10%, and quartz sand is the raw material of group B, and the weight ratio of group A and B is 1:1. Raw materials of group A are weighed and matched then to be put into a sterring mill and mixed uniformly and then quartz sand of equal volume is added in it to be mixed continuously to get the heat preservation mortar, which can be used by adding suitable volume of water.

Owner:SHANGHAI UNIV

Specialized organic/inorganic composite biological medicine fertilizer for corn, and preparation method thereof

InactiveCN102942408AReduce environmental pollutionFull of nutritionClimate change adaptationFertilizer mixturesNutritionZanthoxylum chalybeum

The invention provides a specialized organic / inorganic composite biological medicine fertilizer for corn, and a preparation method thereof. The weight parts of composition raw materials are as follows: 60-70 parts of corn straws, 15-20 parts of fruit residues, 3-5 parts of shrimp chaff, 10-15 parts of earthworm cast, 15-20 parts of potassium humate, 15-20 parts of cottonseed cakes, 10-12 parts of duck feather, 20-23 parts of sepiolite, 15-17 parts of urea, 12-14 parts of calcium superphosphate, 14-16 parts of calcium nitrate, 10-12 parts of potassium sulfate, 5-7 parts of areca-nut, 4-6 parts of pepper, 4-6 parts of coptidis rhizome, 4-6 parts of celastrus orbiculatus, 0.05-0.1 part of ammonium molybdate, 1.5-2.0 parts of copper sulfate, 0.7-1.0 part of manganese sulfate, 2-4 parts of ferrous sulfate, 2-3 parts of castor oil, 3-4 parts of EM strains and 3-5 parts of cinnamon oil. A green organic fertilizer is obtained by mixing a plurality of organic wastes and fermenting the mixture, thereby reducing environment pollutions. The specialized organic / inorganic composite biological medicine fertilizer for the corn has the advantages of comprehensive nutrition and enhanced sterilizing effects by mixing the fermented organic materials and inorganic fertilizer and adding medicine juice of the Chinese herbal medicine having insectidical functions. With the application of the fertilizer, corn quality can be effectively increased; and the corn has green leaves, white flower, prolonged flowering period and increased output.

Owner:合肥科友生物科技有限公司

Fertilizer injector wing for disc openers

InactiveUS7152539B2High speed useReduce distractionsTill seedingDirect liquid fertiliser deliverySeederEngineering

Disc openers (14) for use with an air seeder (10) are configured for seeding and fertilizing a field (G). The opener (14b) broadly includes a coulter disc (20), a seed boot (24), and a fertilizer injector wing (26). The fertilizer injector wing (26) is configured for fixed attachment to the seed boot (24) and broadly includes a body (48), including an angled outboard portion (56), a toxic fertilizer injector (50), and a non-toxic fertilizer injector (52). The opener (14b) with the fertilizer injector wing (26) is configured to place the seed row (S) and the dedicated fertilizer band (DB) at an optimum geometric positional alignment relative to the seed row (S), in a single, low soil disturbing planting pass without disrupting the seed bed (BS). In alternative wings (300 and 400), the sufficiently safe geometric positioning is accomplished by the force of delivery of the fertilizers (N and P) coupled with an offset angle (OA) defined between a fertilizer injection axis (AF) and a seed outlet axis (AO).

Owner:EXACTRIX

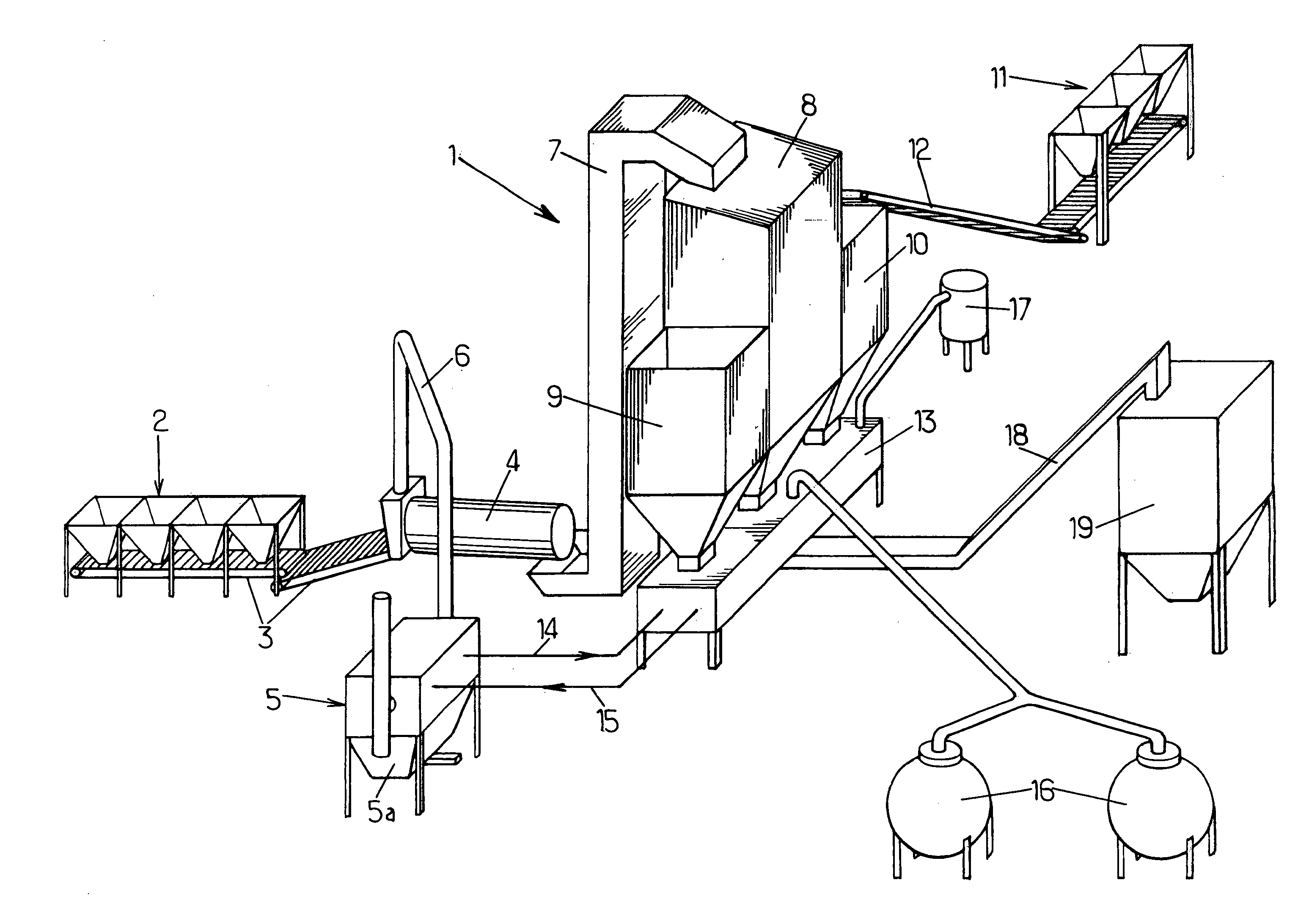

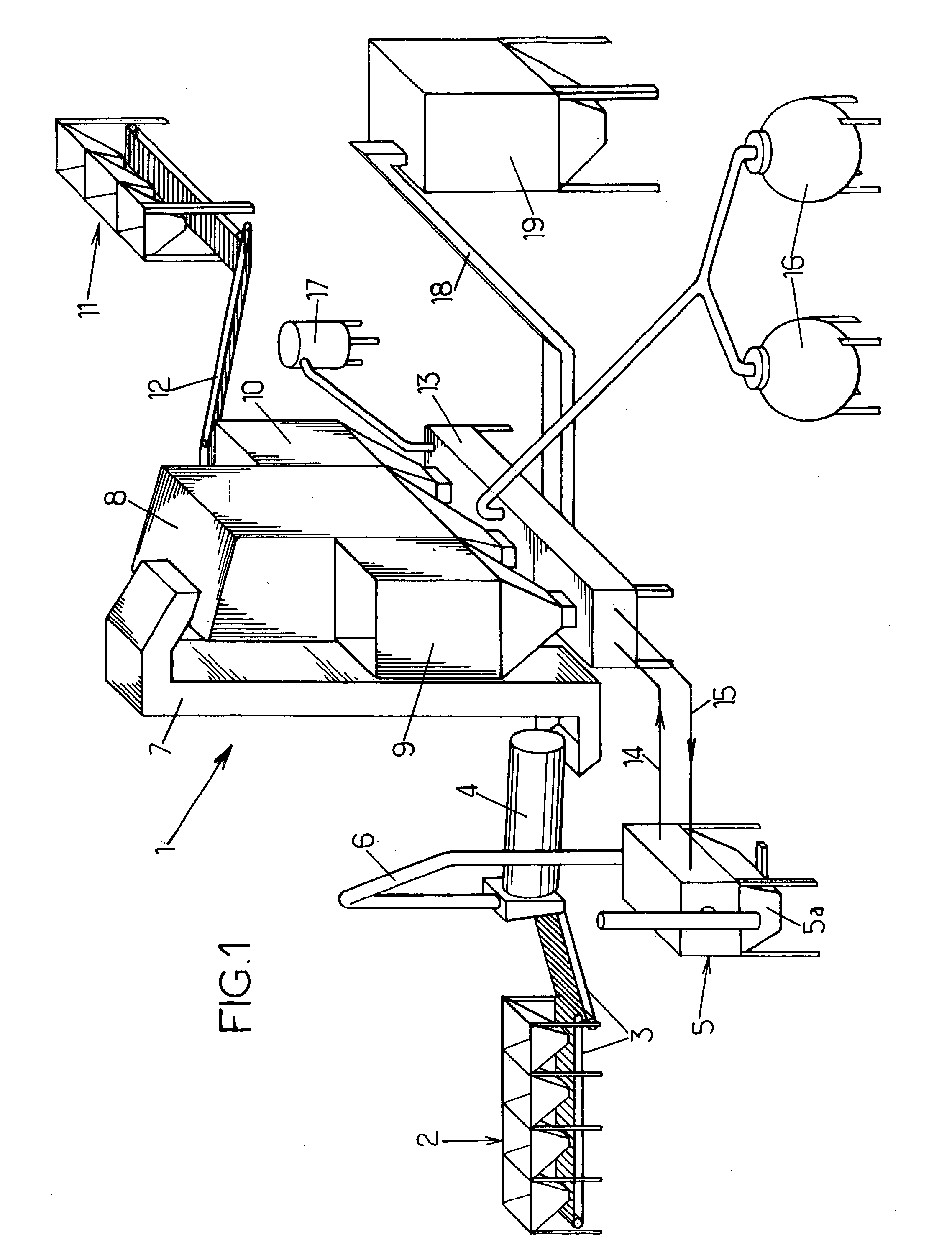

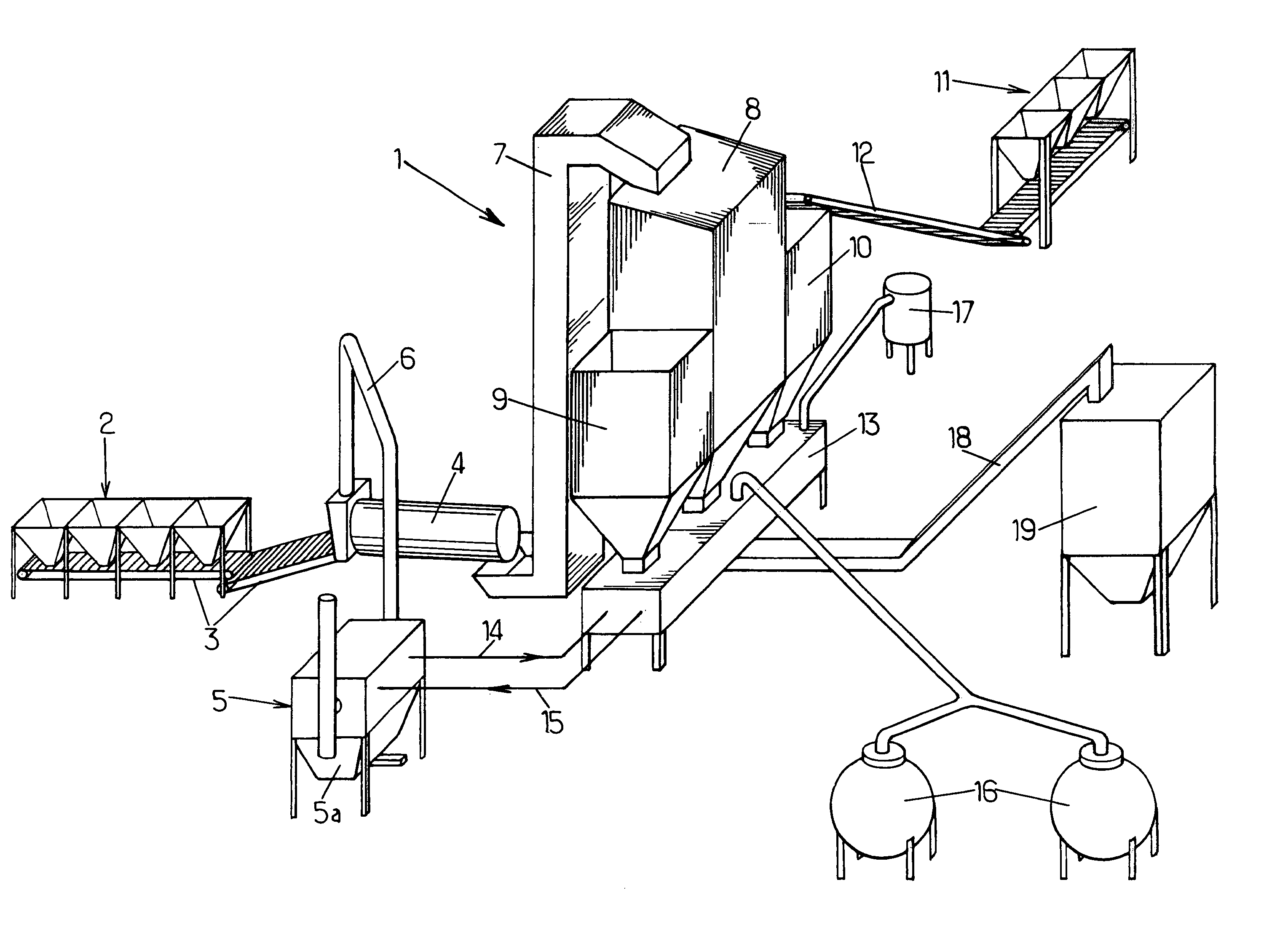

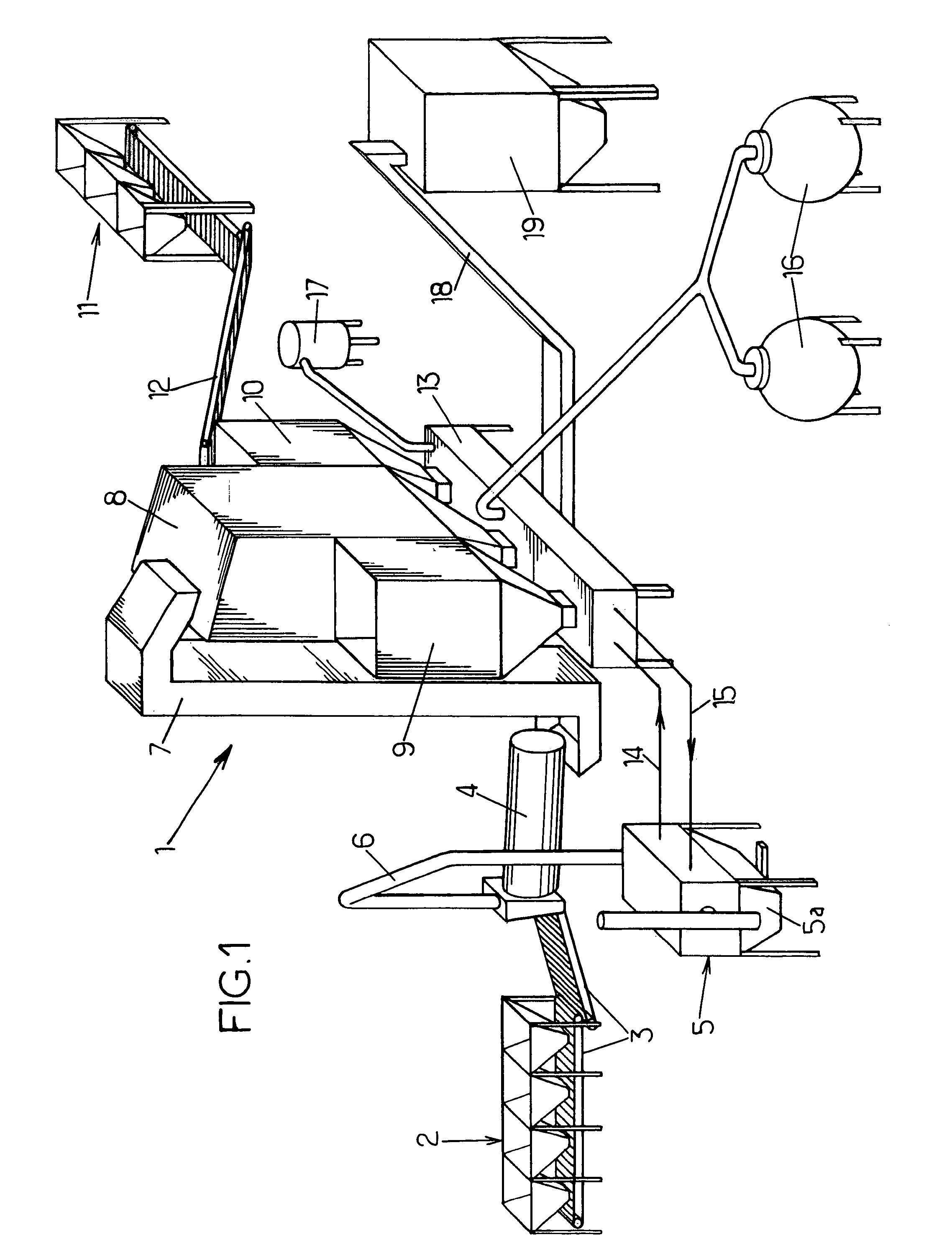

Method of manufacturing a bituminous coated aggregate mix

InactiveUS20050018530A1Keep dryGenerate much dustIn situ pavingsRoads maintainenceMetallurgyMaterials science

A method of manufacturing a bituminous coated aggregate mix, said method comprising at least the following steps: (a) chippings are dried by heating; (b) an intermediate mix is formed by coating the chippings with hot bitumen; and (c) wet sand is mixed with the intermediate mix obtained in step (b).

Owner:LEA INT

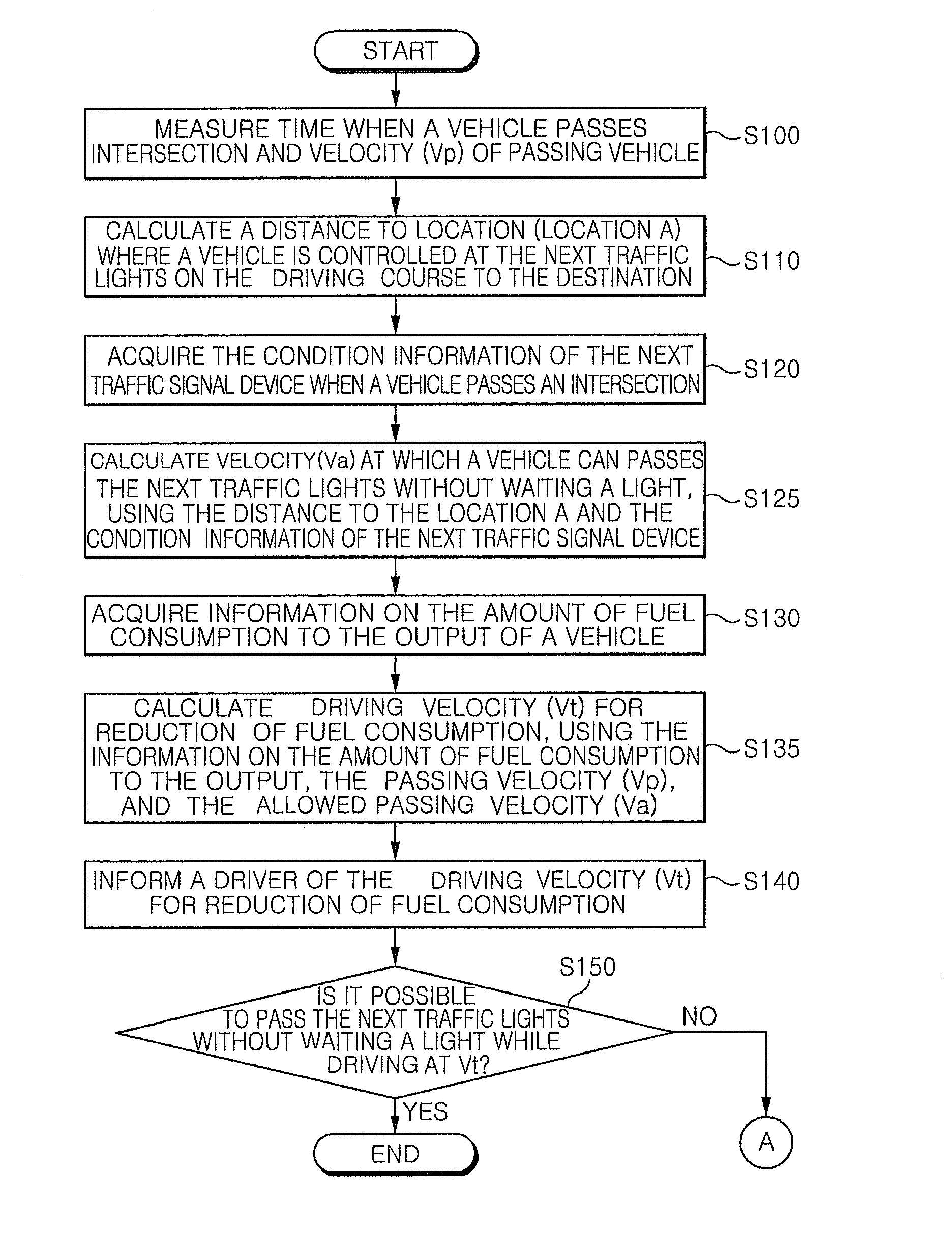

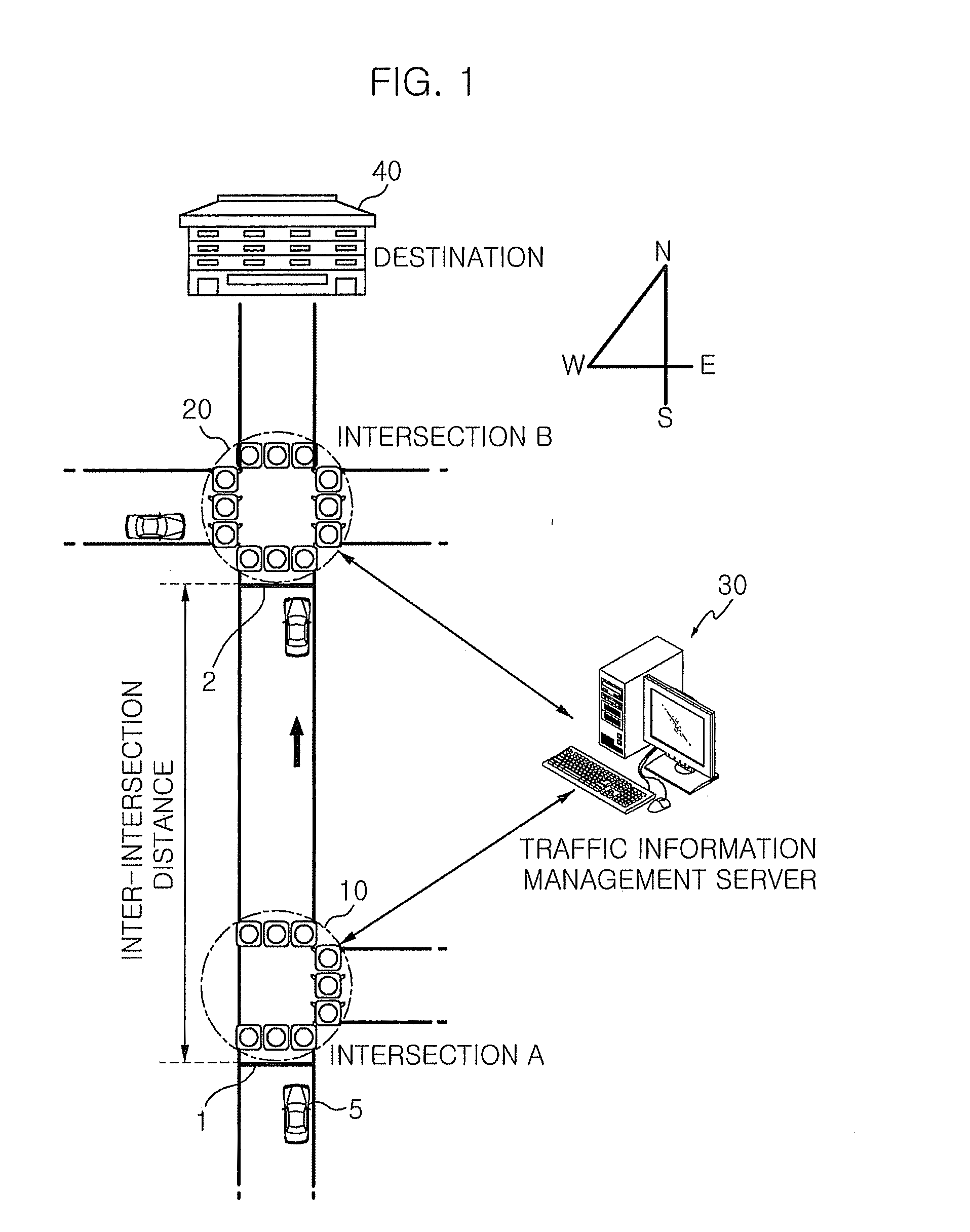

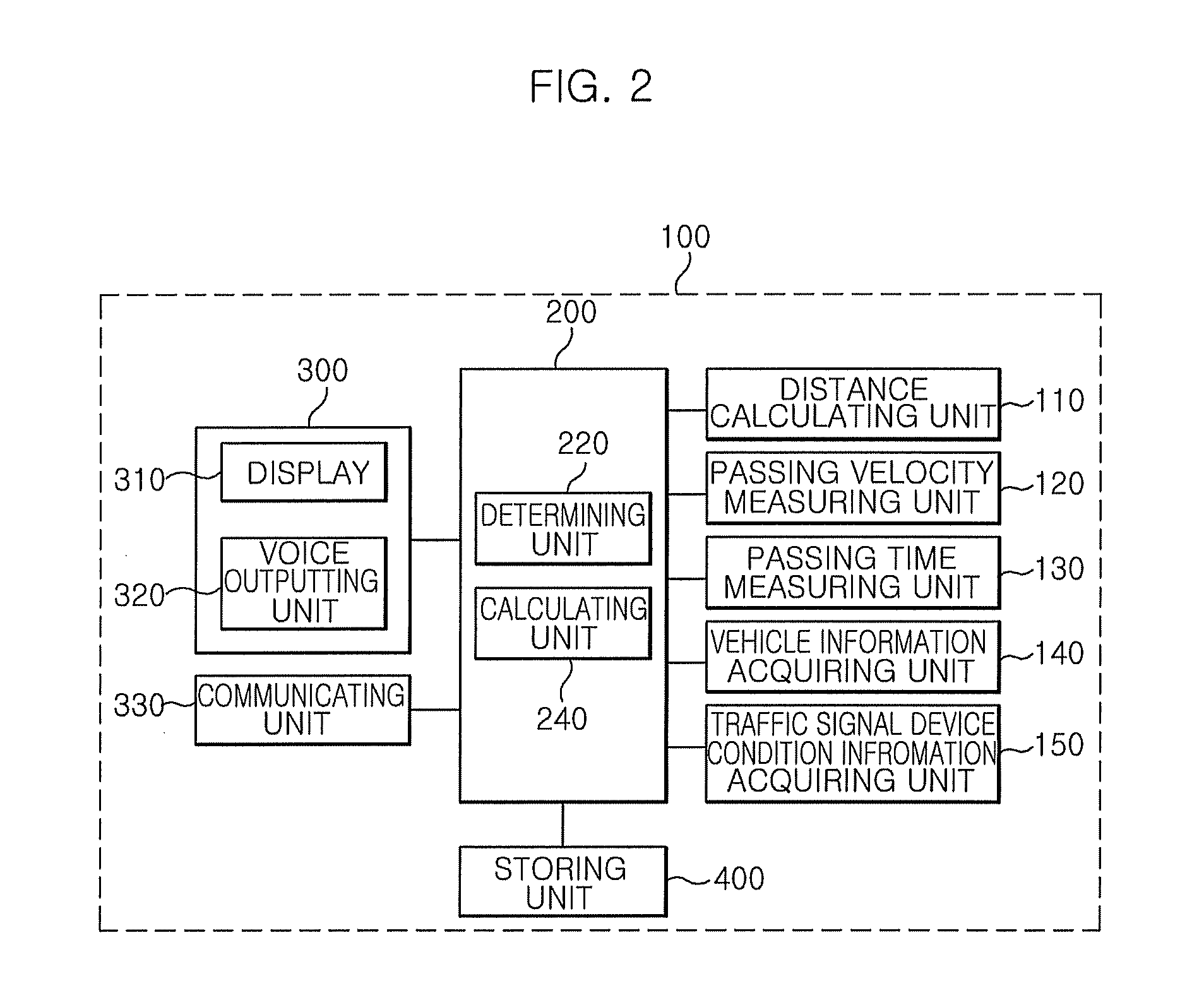

Apparatus for informing economical speed of vehicle and method thereof

ActiveUS20100145600A1Minimizing environmental pollutionMinimizing global warmingControlling traffic signalsAnalogue computers for vehiclesDriver/operatorExhaust fumes

Provided is directed to reduce unnecessary fuel consumption due to unnecessary rapid acceleration when a vehicle drives between intersections, and it is an object to allow for economical driving by reducing the fuel cost, and minimize environmental pollution by minimizing the exhaust gas of vehicle, by providing an economical speed for drivers such that vehicles that have passed through an intersection in accordance with the present traffic light economically drives to the next intersection.

Owner:ELECTRONICS & TELECOMM RES INST

Method of manufacturing a bituminous coated aggregate mix

InactiveUS7114843B2Keep dryGenerate much dustIn situ pavingsMixing operation control apparatusConstruction aggregateMaterials science

A method of manufacturing a bituminous coated aggregate mix, said method comprising at least the following steps:(a) course aggregate are dried by heating;(b) an intermediate mix is formed by coating the course aggregate with hot bitumen; and(c) wet sand is mixed with the intermediate mix obtained in step (b).

Owner:LEA INT

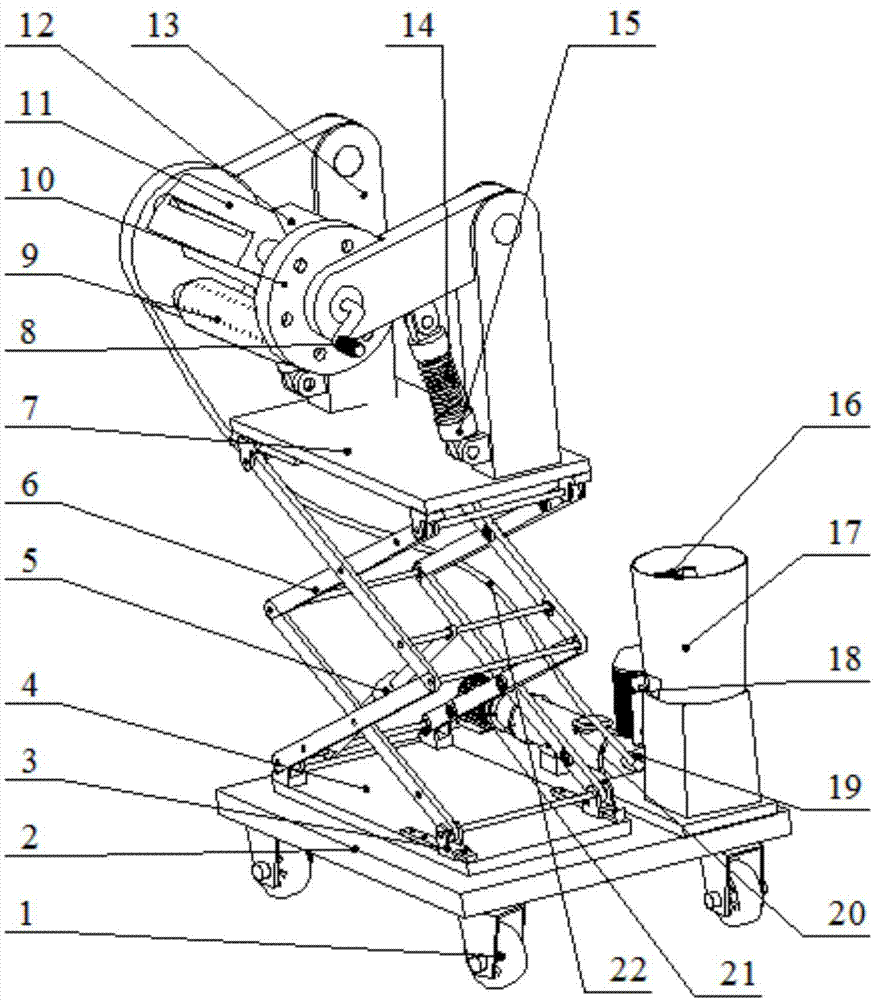

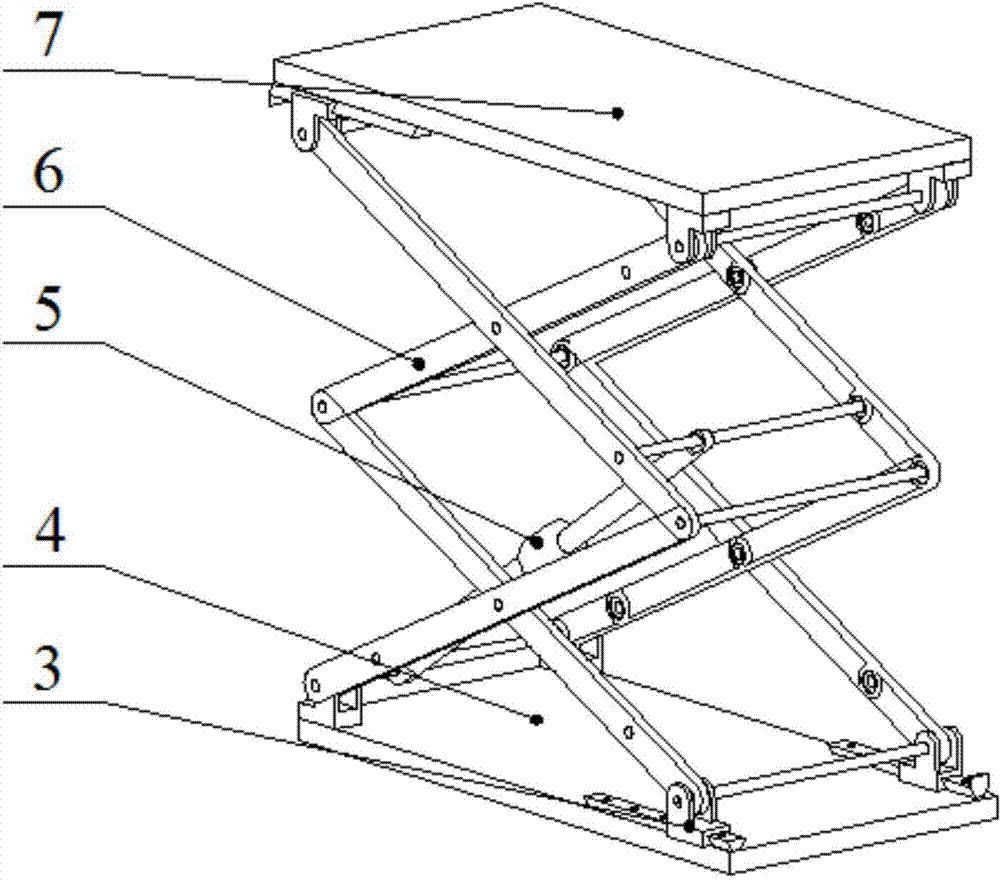

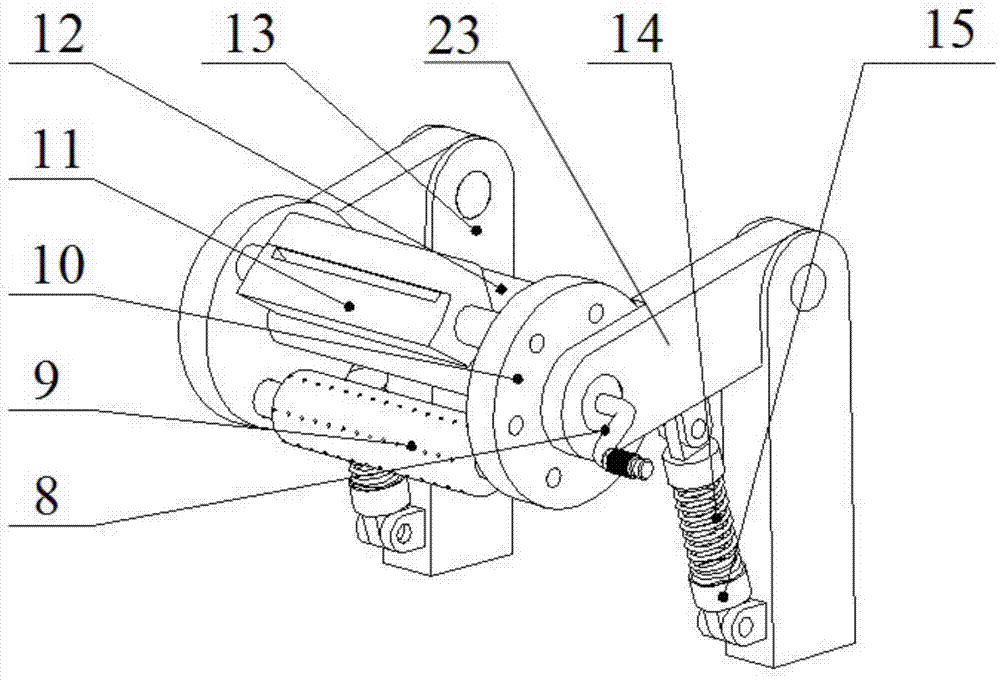

Multifunctional environment-friendly and coating-saving wall painting machine

InactiveCN104120863AGuarantee the quality of paintingAvoid harmBuilding constructionsUltimate tensile strengthMechanical engineering

The invention relates to a multifunctional environment-friendly and coating-saving wall painting machine. The multifunctional environment-friendly and coating-saving wall painting machine comprises a base, a movement module, a wall painting module, a feeding module and a stirring module. The movement module comprises a lifting mechanism installed on the base. The lifting mechanism drives the wall painting module to move vertically. The wall painting module comprises a roller brush, a puttying plate, a polishing plate and a rotary locating mechanism. The rotary locating mechanism comprises a rotary plate, a locating pin and a reset spring. A mechanical arm and a rotating arm are arranged above the lifting mechanism, the rotating arm is hinged to the mechanical arm, and a tension spring is arranged between the rotating arm and the mechanical arm. The multifunctional environment-friendly and coating-saving wall painting machine can achieve integration of automatic stirring, feeding, puttying, polishing and painting, guarantee accurate discharging, replace workers to complete complex wall painting work high in labor intensity, improve the work efficiency, guarantee the wall painting quality, liberate labor force, avoid injury to the human body, solve the problem of waste caused by leakage of coatings, lower the decoration cost and reduce the environmental pollution.

Owner:WUHAN UNIV OF TECH

Method for preparing furfuryl alcohol through furfural liquid-phase catalytic hydrogenation

ActiveCN102603681AReduce environmental pollutionGood hydrogenation activity at low temperatureOrganic chemistryRaney catalystsFurfuryl alcoholCopper

The invention discloses a method for preparing furfuryl alcohol through furfural liquid-phase catalytic hydrogenation, wherein Cr-free skeletal copper serves as a catalyst; right amount of Cr-free VIB or VIII group transition metal is contained in precursor copper aluminium alloy of the catalyst and used for increasing the activity and the selectivity of the skeletal copper catalyst; and the skeletal copper catalyst can be obtained through extracting and activating the copper aluminium alloy by utilizing an aqueous solution of caustic alkali or inorganic acid. According to the invention, right amount of skeletal copper catalyst and alkaline inorganic matter are added in a furfural liquid-phase hydrogenation system to serve as auxiliaries and the reaction is carried out at lower temperature and hydrogen pressure, therefore, excessive hydrogenation products i.e. 2- methyl furan and tetrahydrofurfuryl alcohol can be avoided from generating and the selectivity of the product furfuryl alcohol is increased. The method disclosed by the invention has the advantages of no chrome in the catalyst, low reaction and light-off temperatures, simpleness in process, high furfuryl alcohol yield and selectivity and capability of continuous indiscriminate application of the catalyst.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

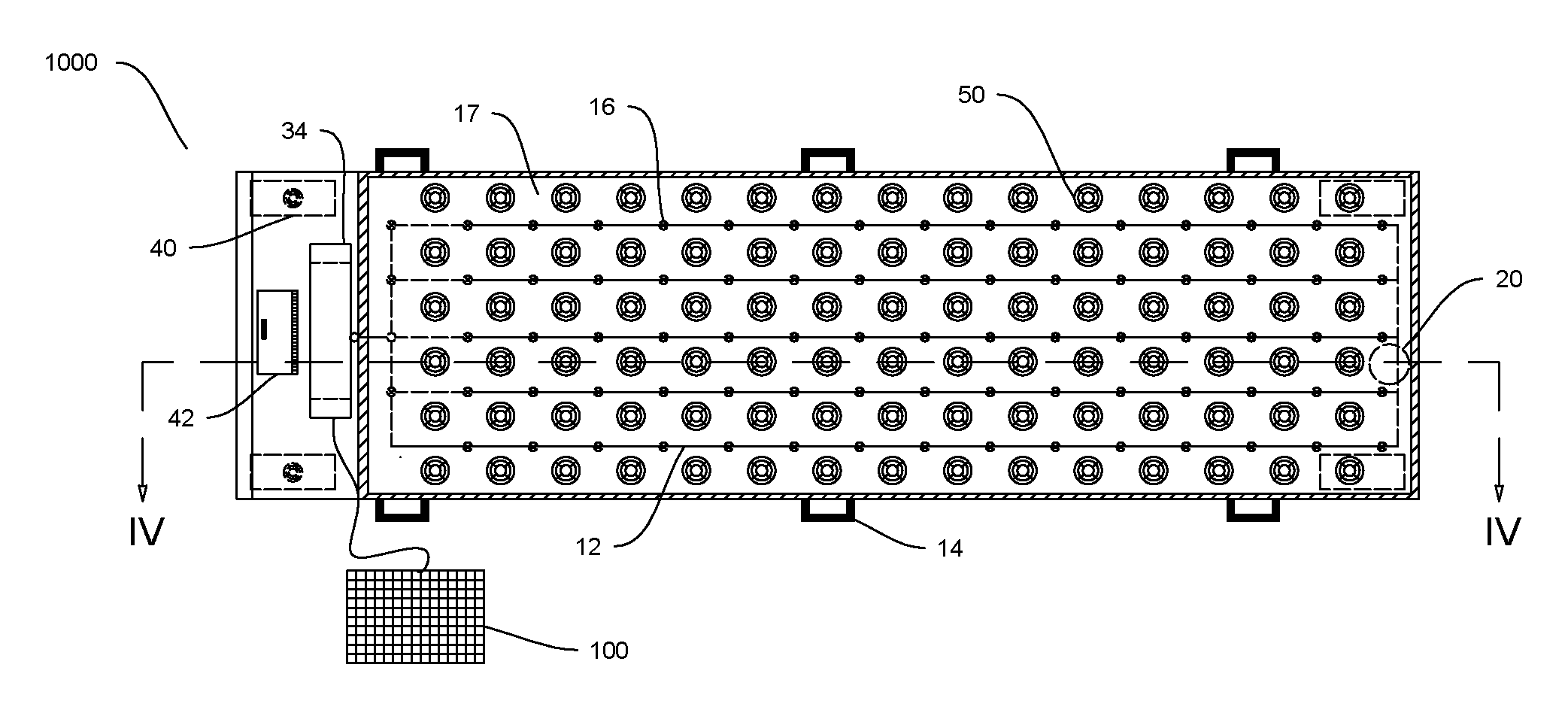

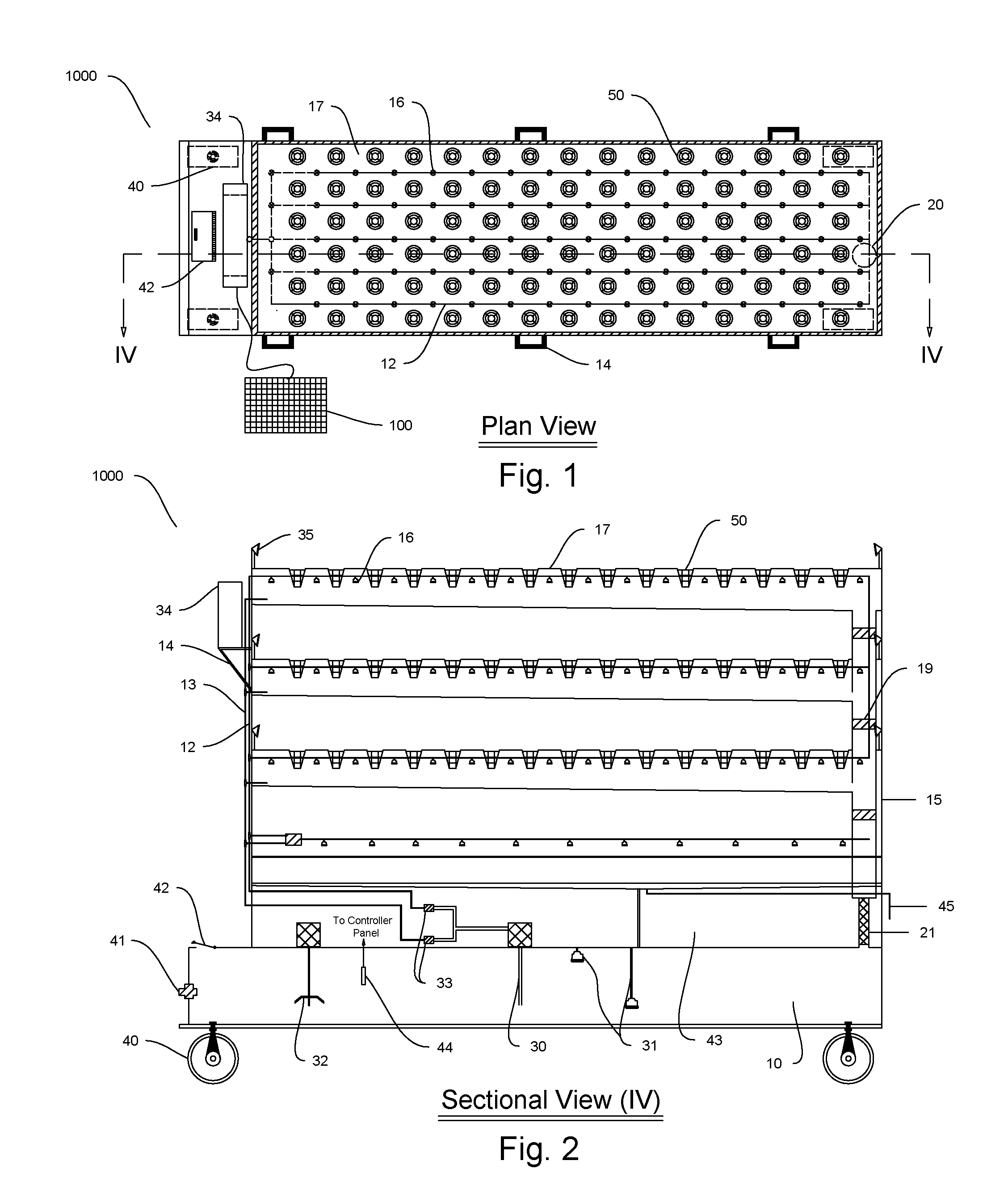

Mobile, Automatic Plant Growth System

InactiveUS20130019527A1Less spaceEasy to useAgriculture gas emission reductionCultivating equipmentsGrowth plantPlant nutrition

A flexible mobile or stationary automated plant growth and display system having a plurality of inter-connected removable or non-removable growing trays. It can be sized as needed and operates in a single or multiple modes using a pump, controller, and mixer that distribute plant nutrients via hydroponic and / or aeroponic water lines to grow chambers using one or more growth methods. It houses a storage area, dual hose bib for external use and a quick access door or lid for the addition of plant nutrients or servicing of pump if submerged. Fluid is recycled from the grow trays through a filter to the plant solution reservoir. The system is equipped with wheels for mobility and anchors for secure and safe operation. It can be mounted on, attached to vehicle or other device, or constructed as part of a vehicle or other device and operated indoors and outdoors.

Owner:HOWE SYLVAIN INGRID

Minimizing whisker growth in tin electrodeposits

InactiveUS6860981B2Reduce environmental pollutionInhibiting growth of tin whiskerLiquid surface applicatorsAnti-corrosive paintsCrystal orientationWhiskers

The present invention relates to a method for reducing tin whisker formation in tin deposits by plating on an underlying metal tin deposits which are predominantly in a predetermined crystal orientation that essentially matches that of the underlying metal in order to inhibit tin whisker growth. The most preferred crystal orientation is one that is the same as that of the underlying metal. The deposit preferably contains at least 95% tin and optionally at least one alloying element of silver, bismuth, copper or zinc in an amount of 5% or less. Advantageously, the tin deposits are provided during electroplating from a specially formulated plating solution.

Owner:TECHNIC INC

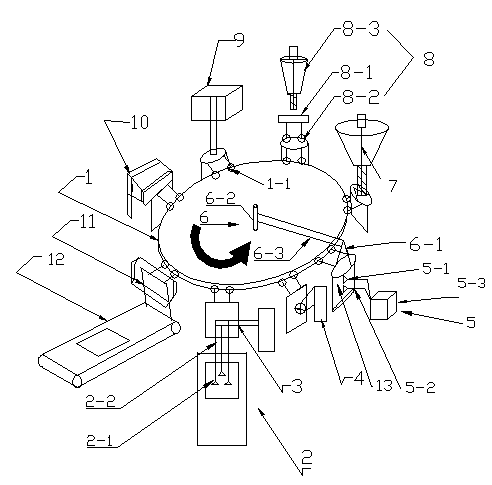

Automatic powder filling and packaging device and method

InactiveCN103523250AReduce intermediate linksReduce environmental pollutionSolid materialPackaging machinesVolume fillingAutomatic control

The invention relates to an automatic powder filling and packaging device and method. Eight sets of turntable mechanical clamps are arranged on the edge of a circular turntable. A bag fetching mechanical arm, an automatic ink-jet printer, a bag opening device, a volume filling device, a weighing filling device, a dust collector, a heat sealer and a knurling shaping device are independently arranged on fixing frames on the periphery of the circular turntable respectively. A rotating shaft of a bag supporting device is arranged in the center of the turntable and is controlled to be lifted through a cam at the lower end. A bag supporting clamp is connected to a rotating shaft through a rotating rod, the bag supporting clamp is controlled pneumatically and is capable of being opened and closed automatically, and a weighing device and a pair of weighing mechanical clamps are arranged on the outlet of a filling machine. A finished product conveying belt is arranged below the shaping device. The method comprises the steps of pretreatment of packaging bags, automatic bag feeding, code spraying of the packaging bags, opening of the packaging bags, fast filling, weighing filling, cleaning of openings of the bags, heat sealing of the openings of the bags, knurling and shaping, and manual casing. The whole process is automatically controlled, intermediate links and environment pollution are reduced, and damage to human bodies is avoided.

Owner:TIANJIN ZHONGHUAN TIANJIA ELECTRONICS

Fertilizer injector wing for disc openers

InactiveUS20050051068A1Eliminate needHigh speed useTill seedingDirect liquid fertiliser deliverySeederCircular disc

Disc openers (14) for use with an air seeder (10), or other no-till drill and the like, configured for seeding and fertilizing a field (G) for crop production are disclosed. The representative opener (14b) broadly includes a drawbar assembly (16), a disc assembly (18) including a coulter disc (20) and a gauge wheel (22), a seed boot (24), a fertilizer injector wing (26), a firming wheel assembly (28), and a closing wheel assembly (30). The inventive fertilizer injector wing (26) is configured for fixed attachment to the seed boot (24) and broadly includes a body (48), including an angled outboard portion (56), a toxic fertilizer injector (50), and a non-toxic fertilizer injector (52). The opener (14b) with the unique fertilizer injector wing (26) is configured to place the seed row (S) and the dedicated fertilizer band (DB) at an optimum geometric positional alignment relative to the seed row (S), in a single, low soil disturbing planting pass without disrupting the seed bed (BS). The inventive wing (26) enables a toxic charge (TC) of the fertilizer (N,P)—a charge containing the optimum nutrient package to sustain season long growth of the crop—to be placed sufficiently close to the seed (S) while minimizing soil disturbance so that weed growth and moisture loss are minimized and crop yield is maximized.

Owner:EXACTRIX

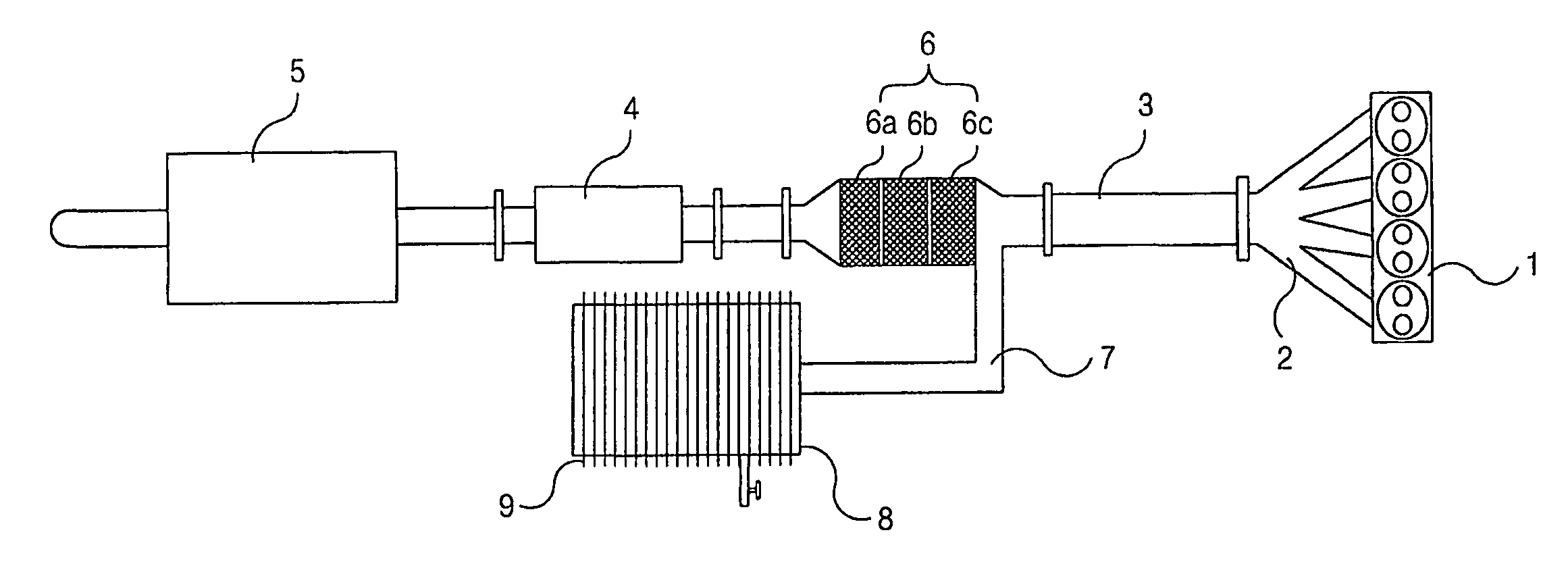

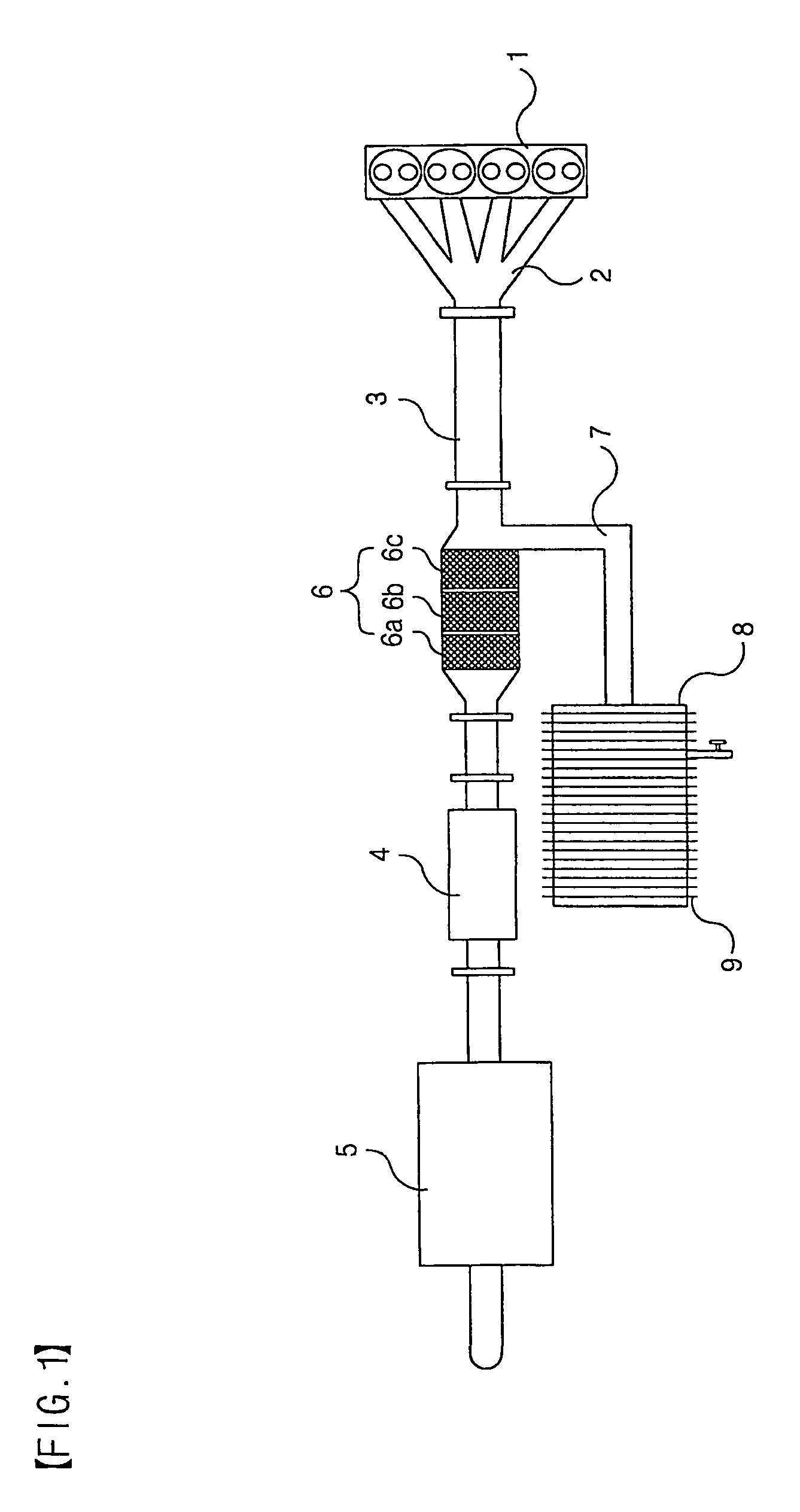

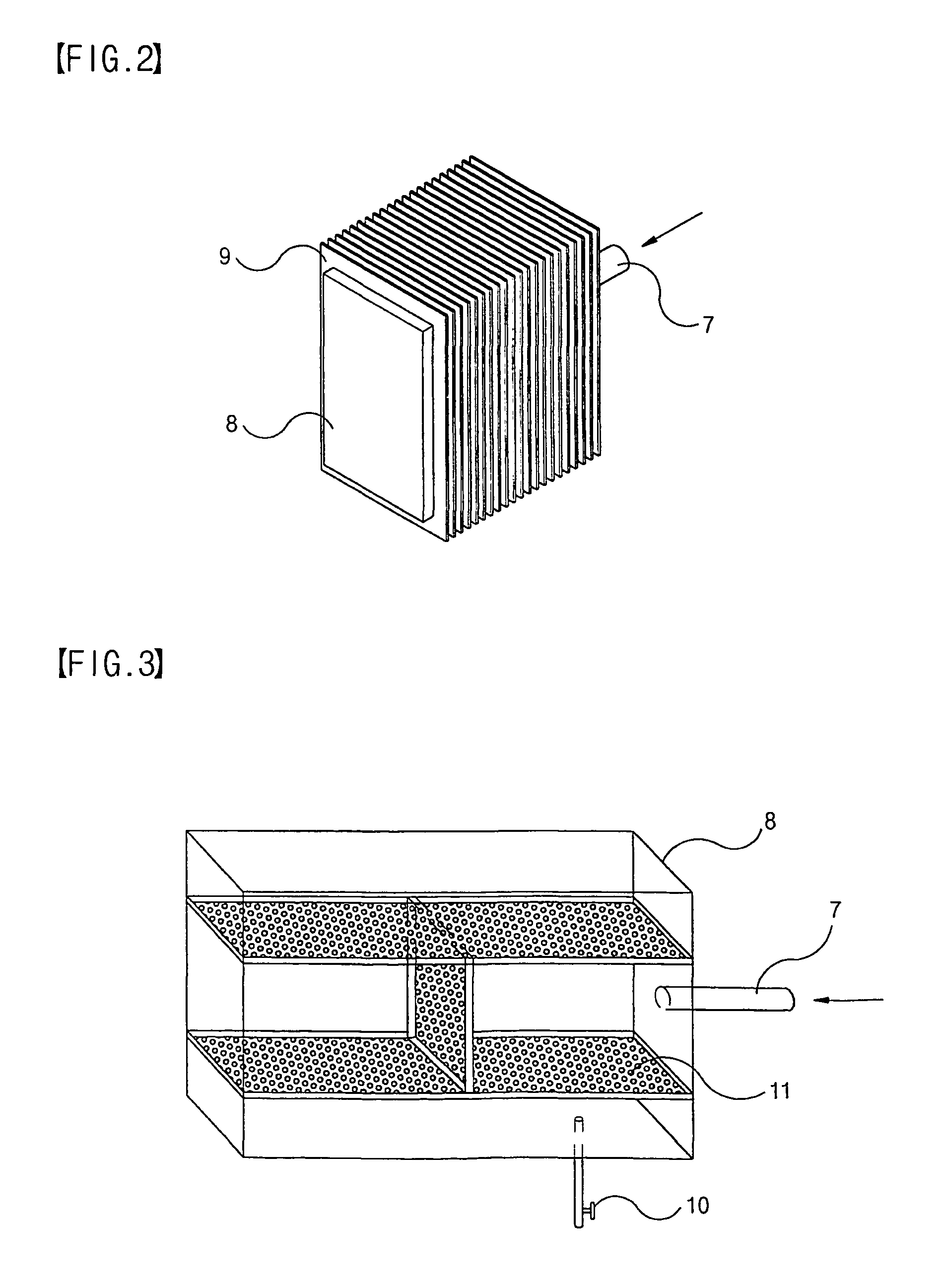

Exhaust gas control device for internal combustion engines

InactiveUS7007459B2Reduce environmental pollutionLower the volumeNon-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberHazardous substance

Disclosed herein is an exhaust gas control device for internal combustion engines. The exhaust gas control device has a main exhaust pipe (3) communicating with an exhaust manifold (2) used for guiding exhaust gas discharged from a combustion chamber (1) of an engine, a catalytic converter (6) arranged on a predetermined position of the main exhaust pipe (3) for purifying unburnt fuel discharged with the exhaust has and having a plurality of sequentially arranged catalyst units (6a, 6b, 6c), and an unburnt fuel collection tank (8) provided with a plurality of cooling fins (9) and connected to the catalytic converter (6) through a branch pipe (7). The collection tank (8) collects purified unburnt fuel after the unburnt fuel is treated by the catalytic converter (6) so as to remove noxious materials therefrom.

Owner:LEE JU CHEOL

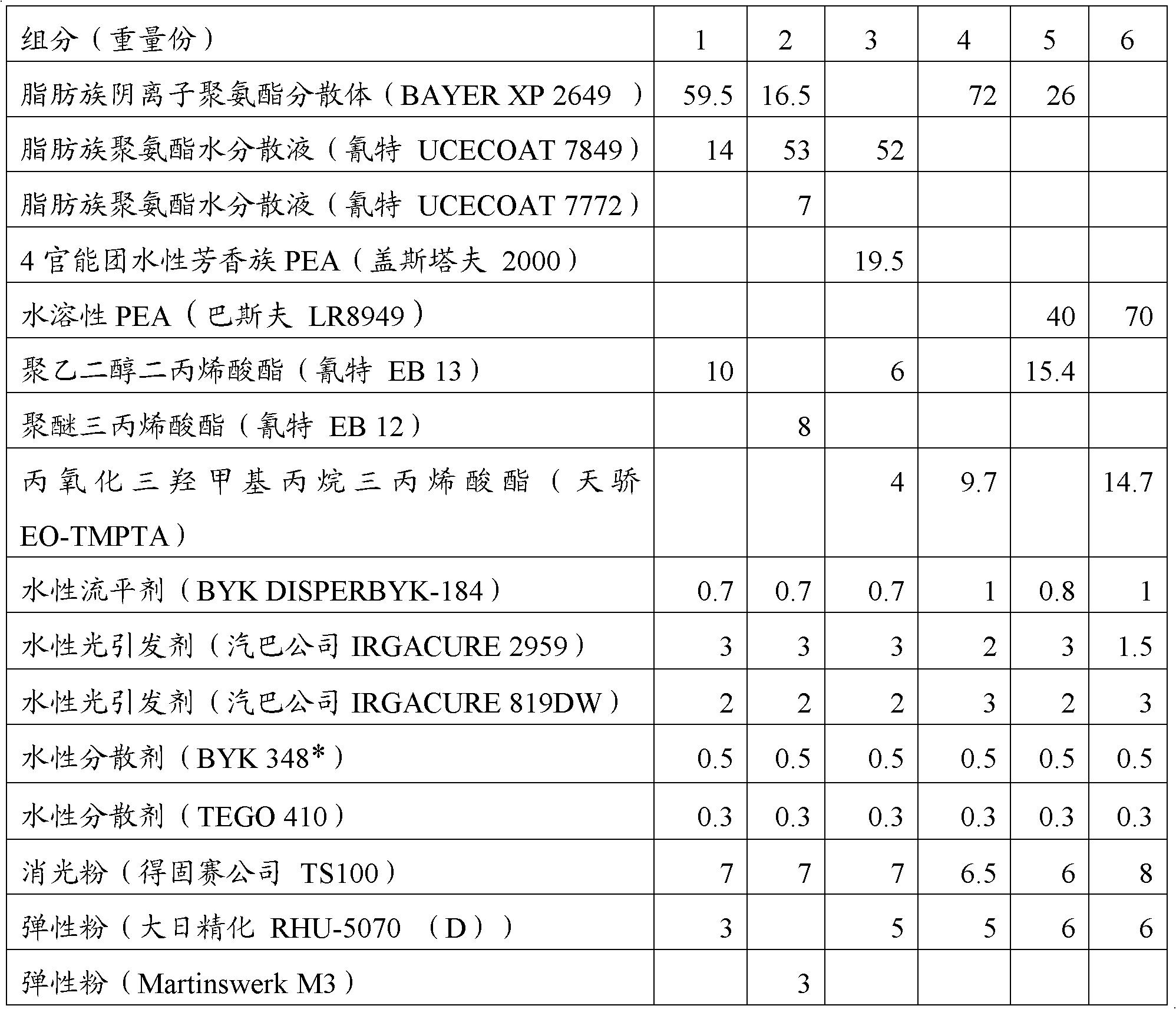

Water-based photo-cured elastomeric paint

InactiveCN102127362AImprove coating efficiencyReduce environmental pollutionPolyurea/polyurethane coatingsPolyether coatingsMonomerUltraviolet

The invention discloses a water-based photo-cured elastomeric paint, which consists of the following components in percentage by weight: 60-80 percent of water-based UV (Ultra Violet) elastic resin, 5-20 percent of water-based UV curing monomer, 1-8 percent of water-based initiator, 0.2-1 percent of water-based flatting agent, 0.2-1 percent of water-based dispersant, 3-9 percent of flatting silica and 1-10 percent of elastic powder. A coating is a water-based UV photo-cured elastomeric paint. Compared with a bi-component coating in the conventional elastic hand paint, the water-based photo-cured elastomeric paint has the advantages of fast curing, high coating efficiency and low environmental pollution.

Owner:ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

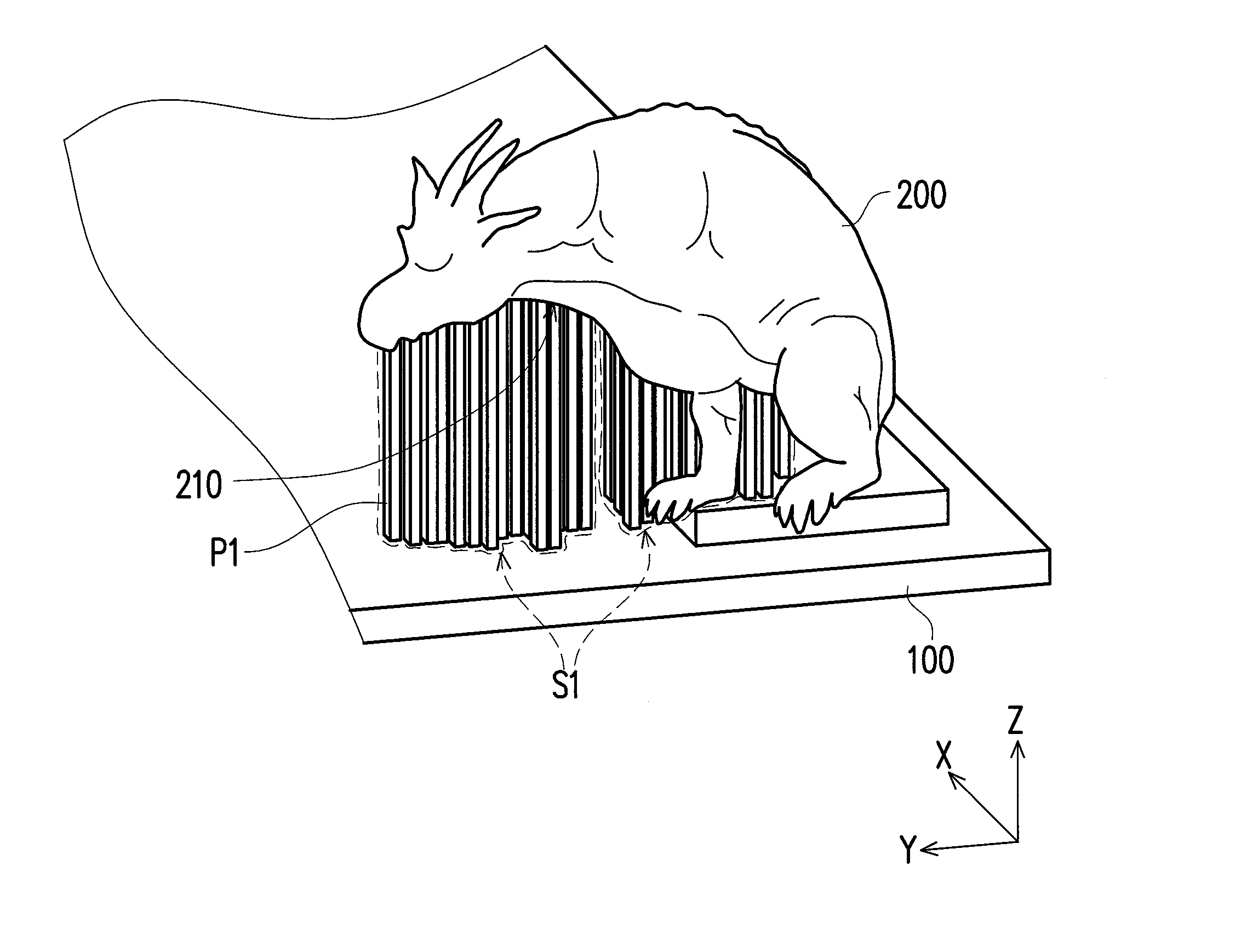

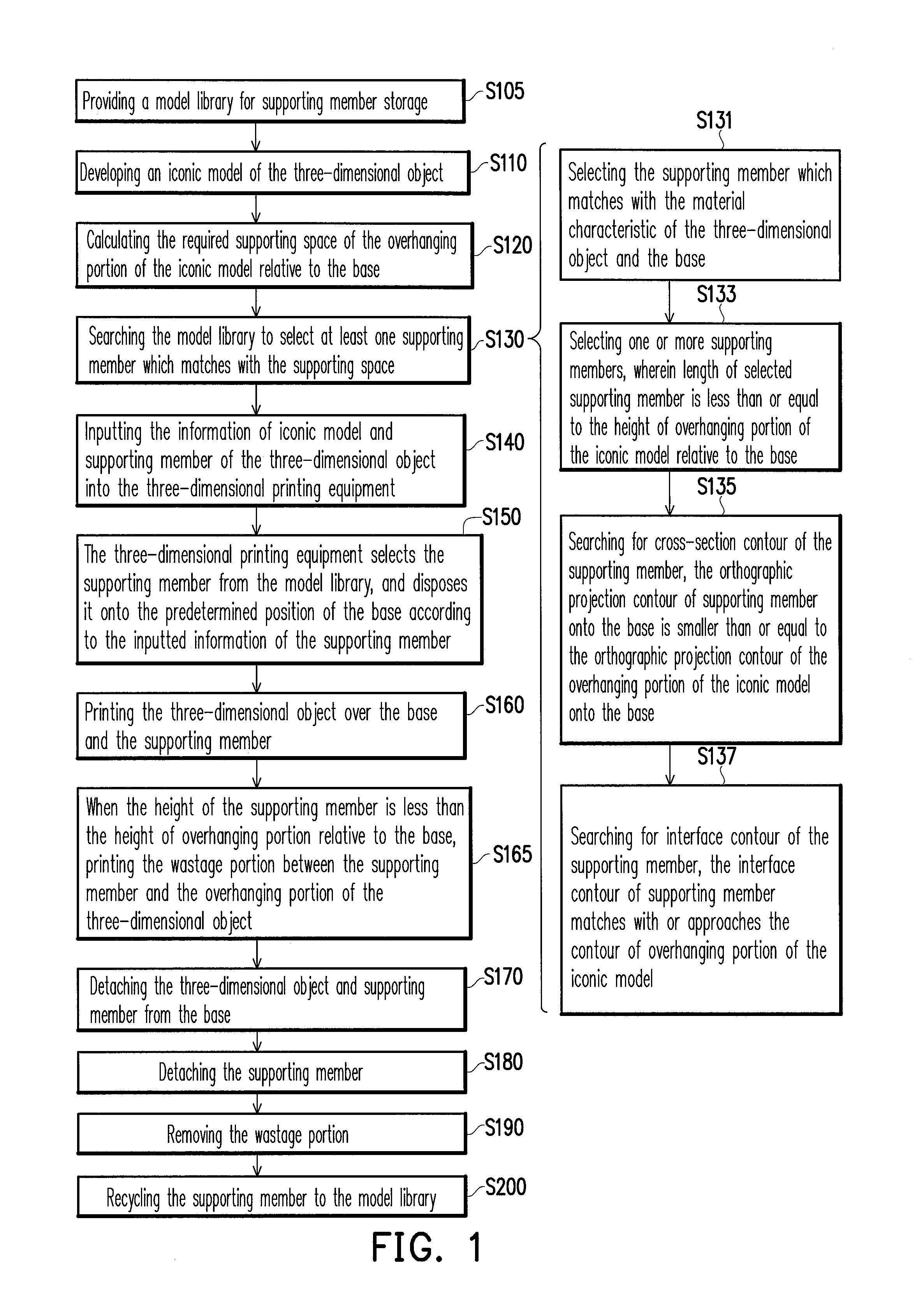

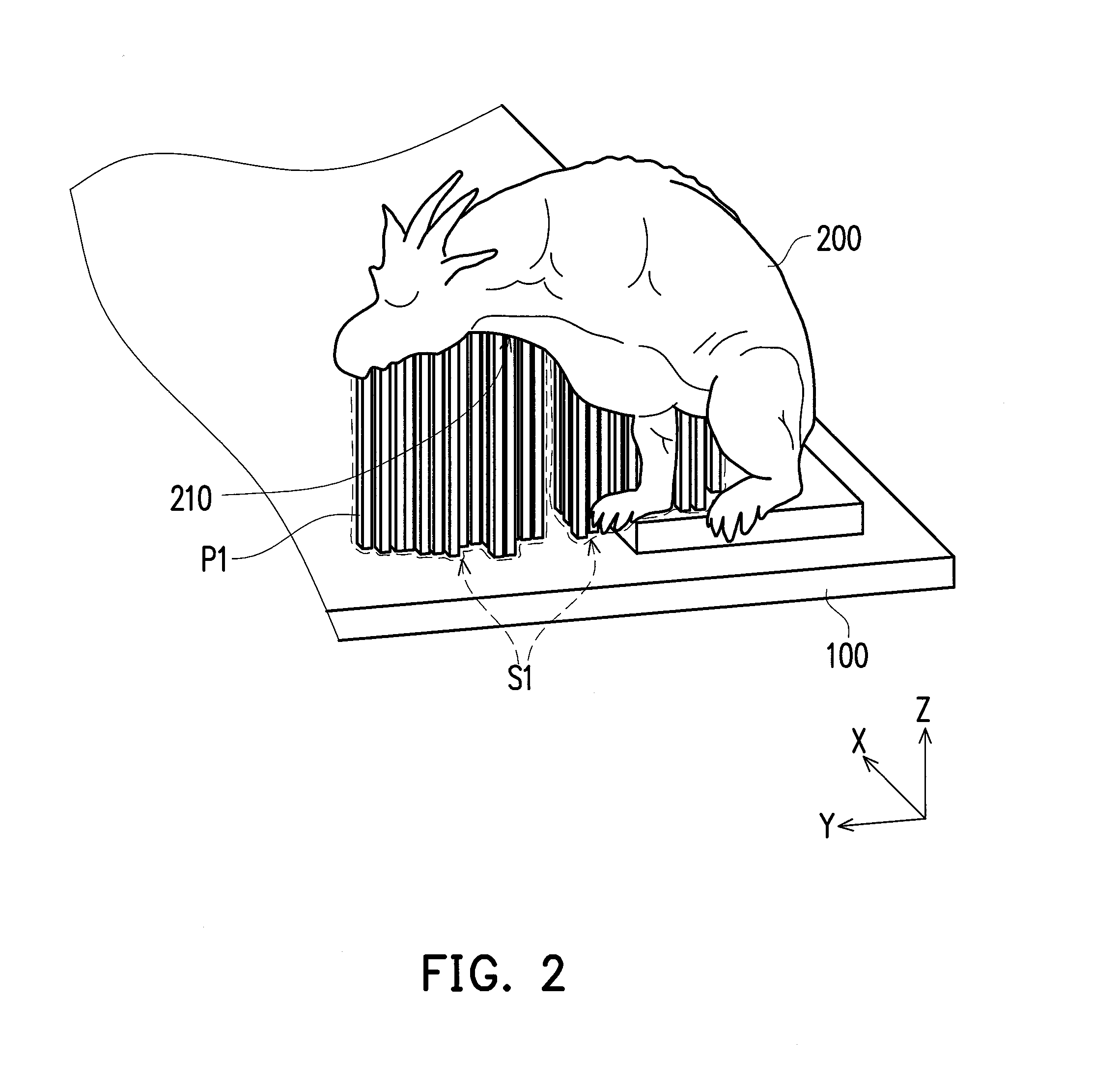

Three-dimensional printing method

ActiveUS20150137423A1Conserve costShorten production timeAdditive manufacturing apparatusCeramic shaping apparatusEngineering3 dimensional printing

A three-dimensional printing method for forming a three-dimensional object on a base is provided. The method comprises providing a model library comprising at least one supporting member, selecting the at least one supporting member from the model library and disposing the at least one supporting member onto the base. The three-dimensional object is printed over the base and the at the least supporting member, and the three-dimensional object has an overhanging portion relative to the base and the at least one supporting member is filled between the overhanging portion and the base.

Owner:XYZPRINTING +2

Method for preparing photocatalyst ecological bricks

InactiveCN102320791AEmission reductionReduce environmental pollutionSolid waste managementPhotocatalysisPerlite

The invention relates to a building material preparation process, in particular to a preparation process for brick substrates such as pervious bricks or floor bricks or concrete building blocks and the like. A method for preparing photocatalyst ecological bricks comprises the following steps that: A, waste ceramic impurities are crushed into crushed ceramic materials after being cleaned; B, wastefilter materials with main ingredients of diatomite and expanded perlite are dried, and then, rough filter material regenerated materials and fine filter material regenerated materials are sieved; C,the crushed ceramic materials and the rough filter material regenerated materials which are obtained in the steps A and B are mixed with ordinary portland cement and water and are stirred into dry concrete according to certain mass parts, the dry concrete is made into brick substrates, then, the fine filter regenerated materials, sand or stone dust, mineral pigment, white cement, nanometer titanium dioxide powder and water are mixed and stirred to be made into plus materials of the brick substrates, and the plus materials and the brick substrates are simultaneously pressed and formed; and D, the photocatalyst ecological bricks obtained in the step C are cured until the design strength is reached.

Owner:S_QBEE SHISHI ENVIRONMENTAL PROTECTIVE BUILDINGMATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com