Patents

Literature

121results about How to "Guarantee the quality of painting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

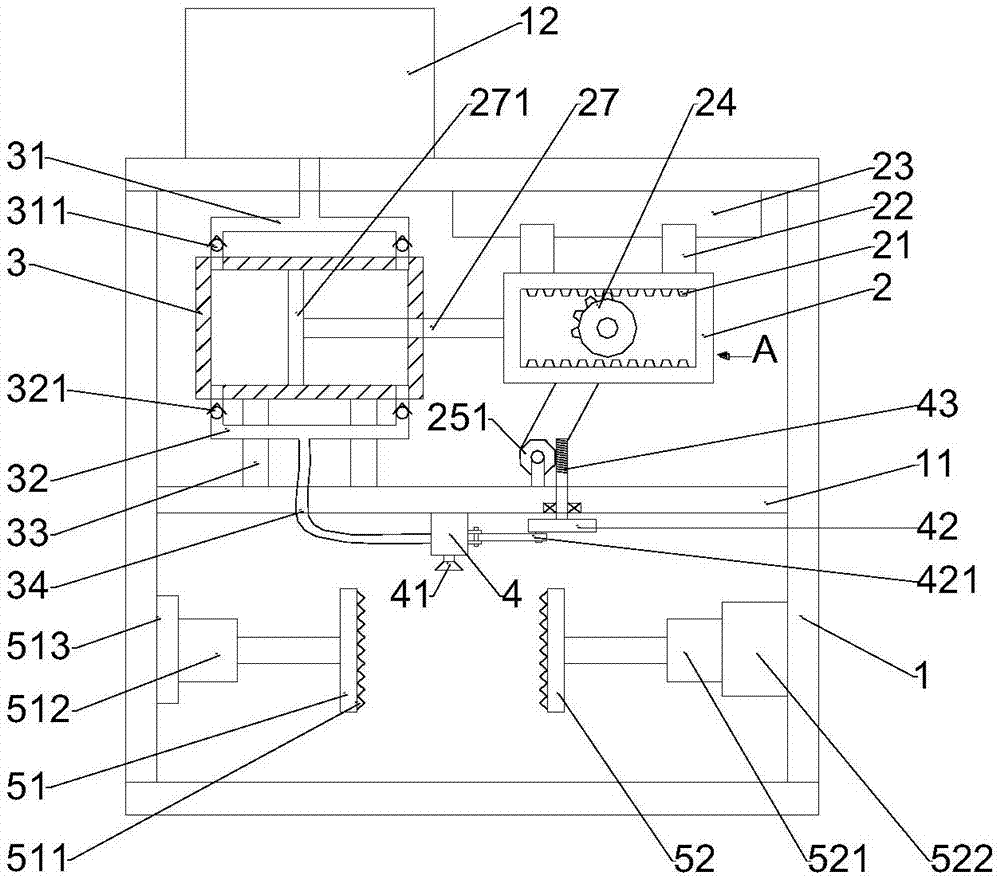

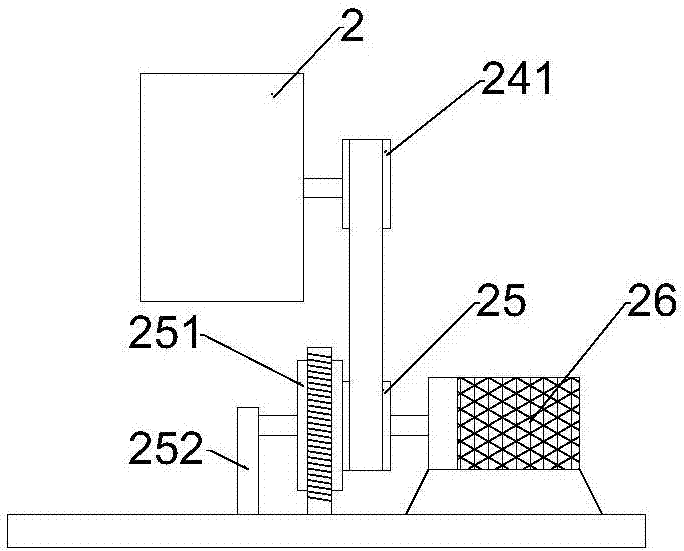

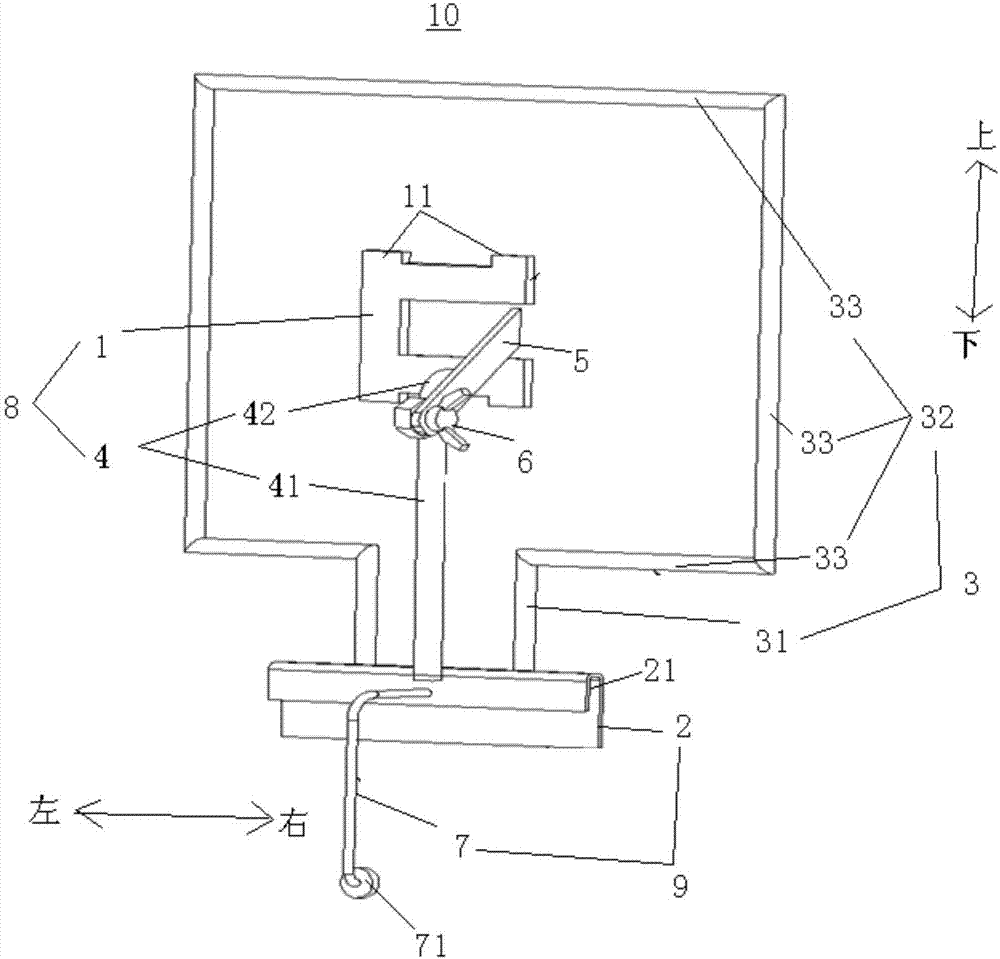

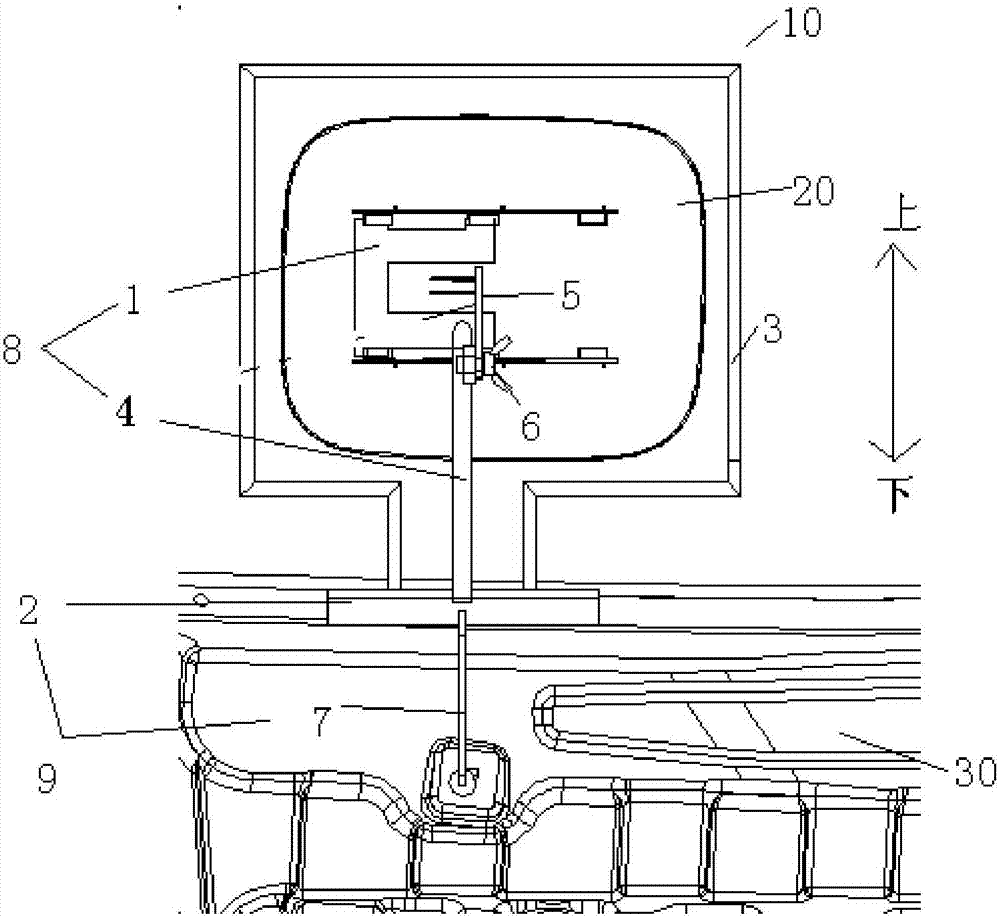

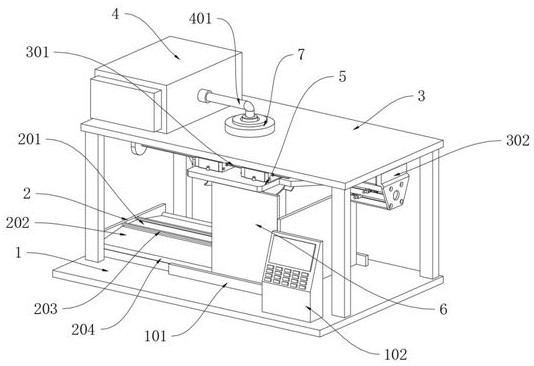

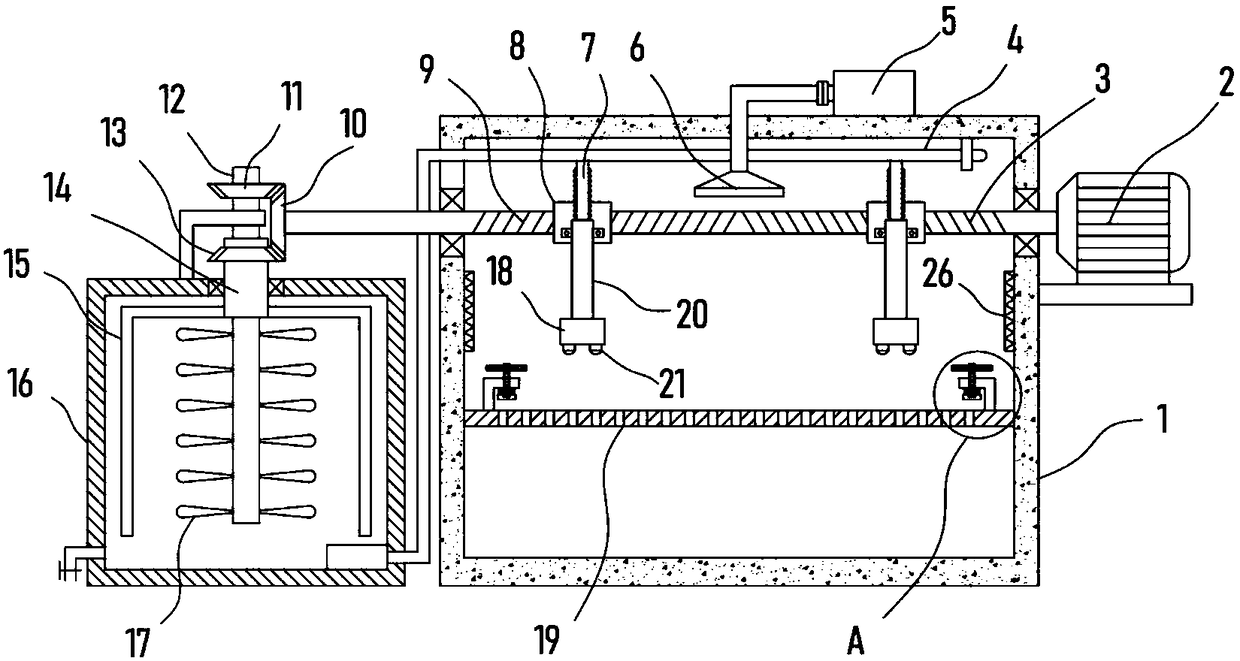

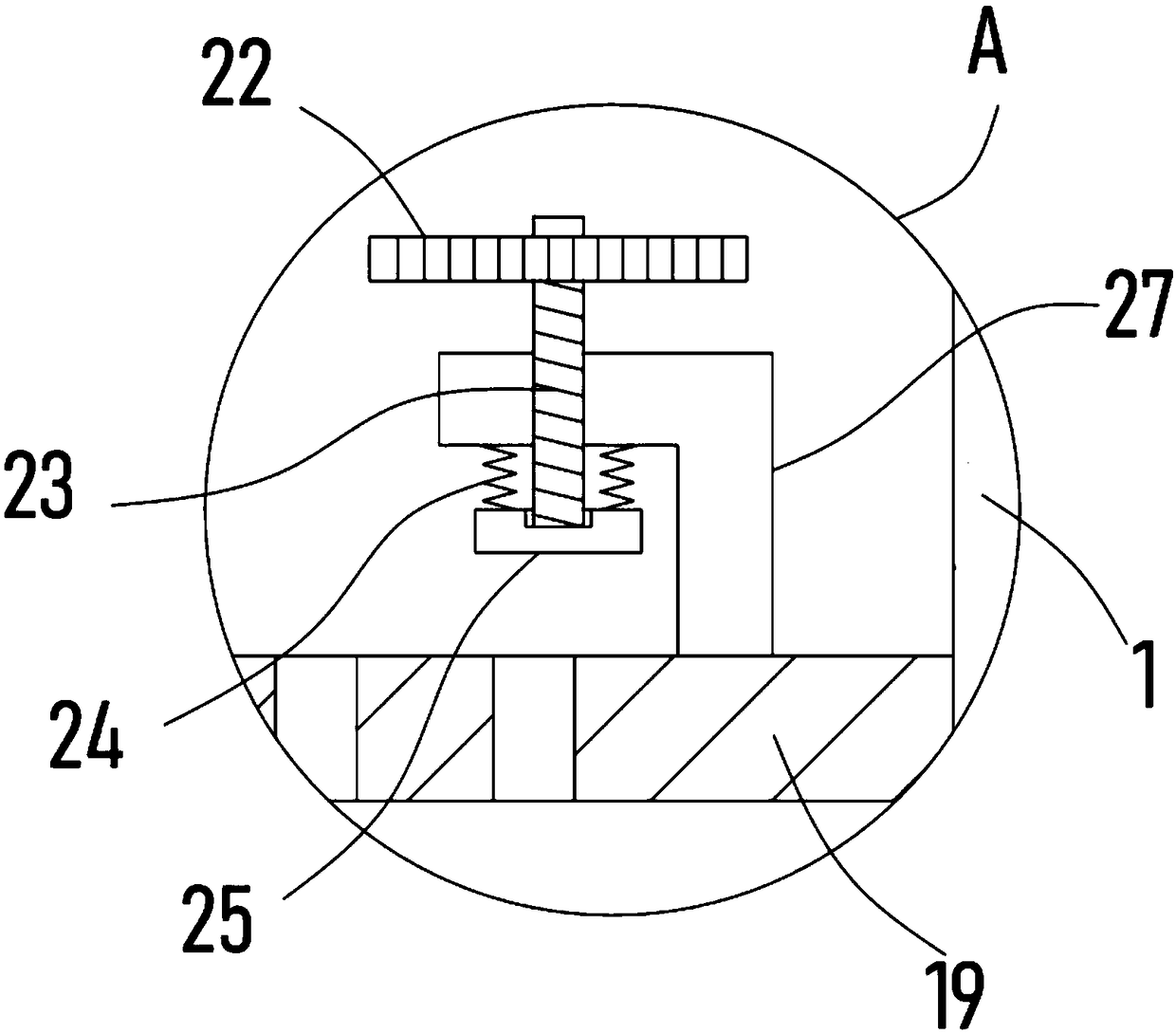

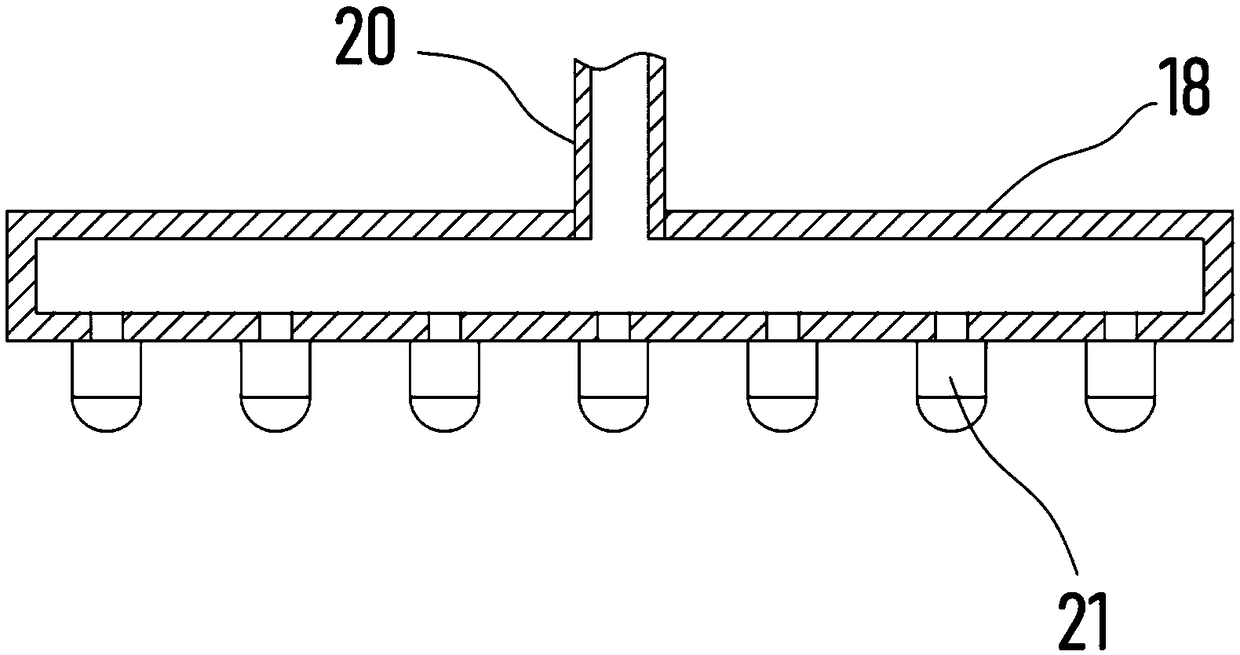

Multifunctional environment-friendly and coating-saving wall painting machine

InactiveCN104120863AGuarantee the quality of paintingAvoid harmBuilding constructionsUltimate tensile strengthMechanical engineering

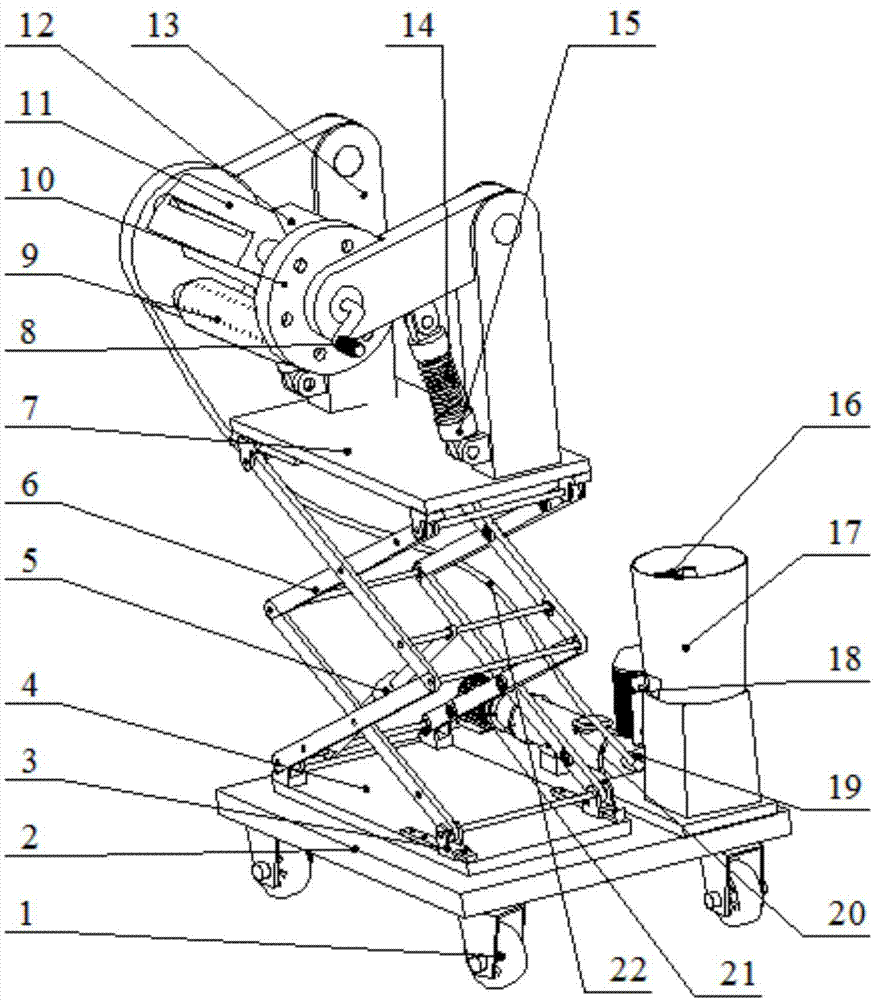

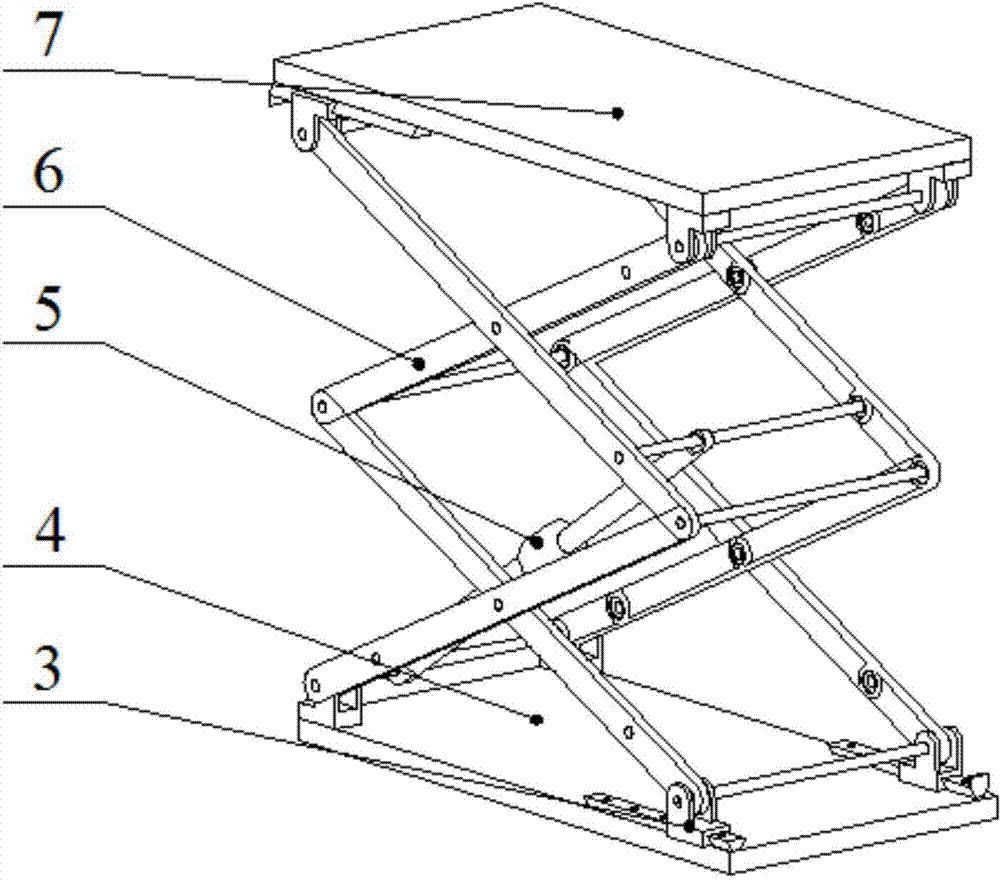

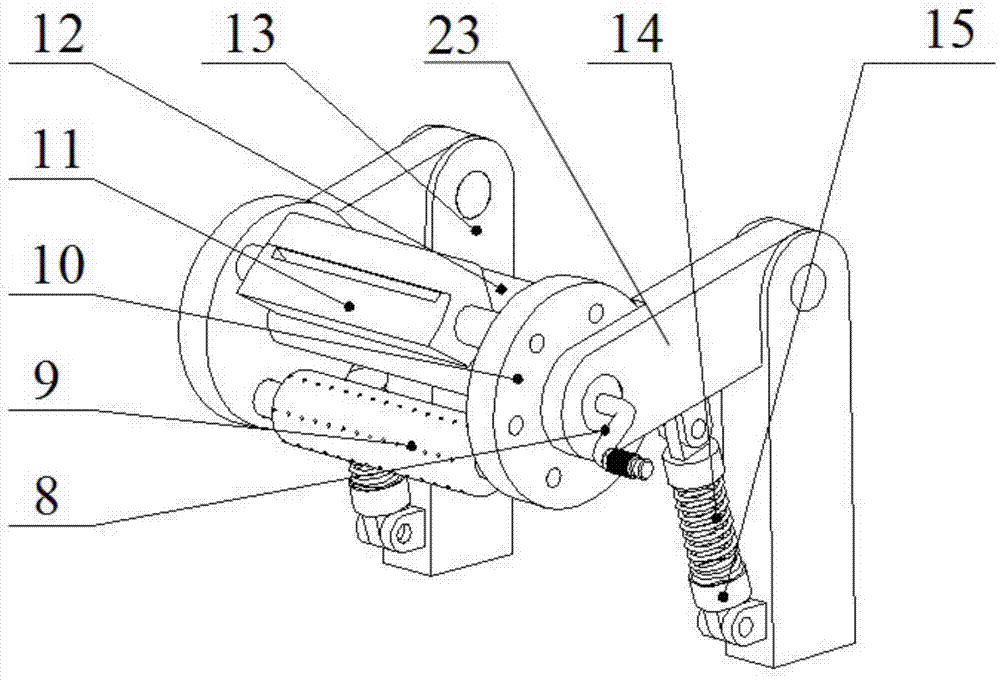

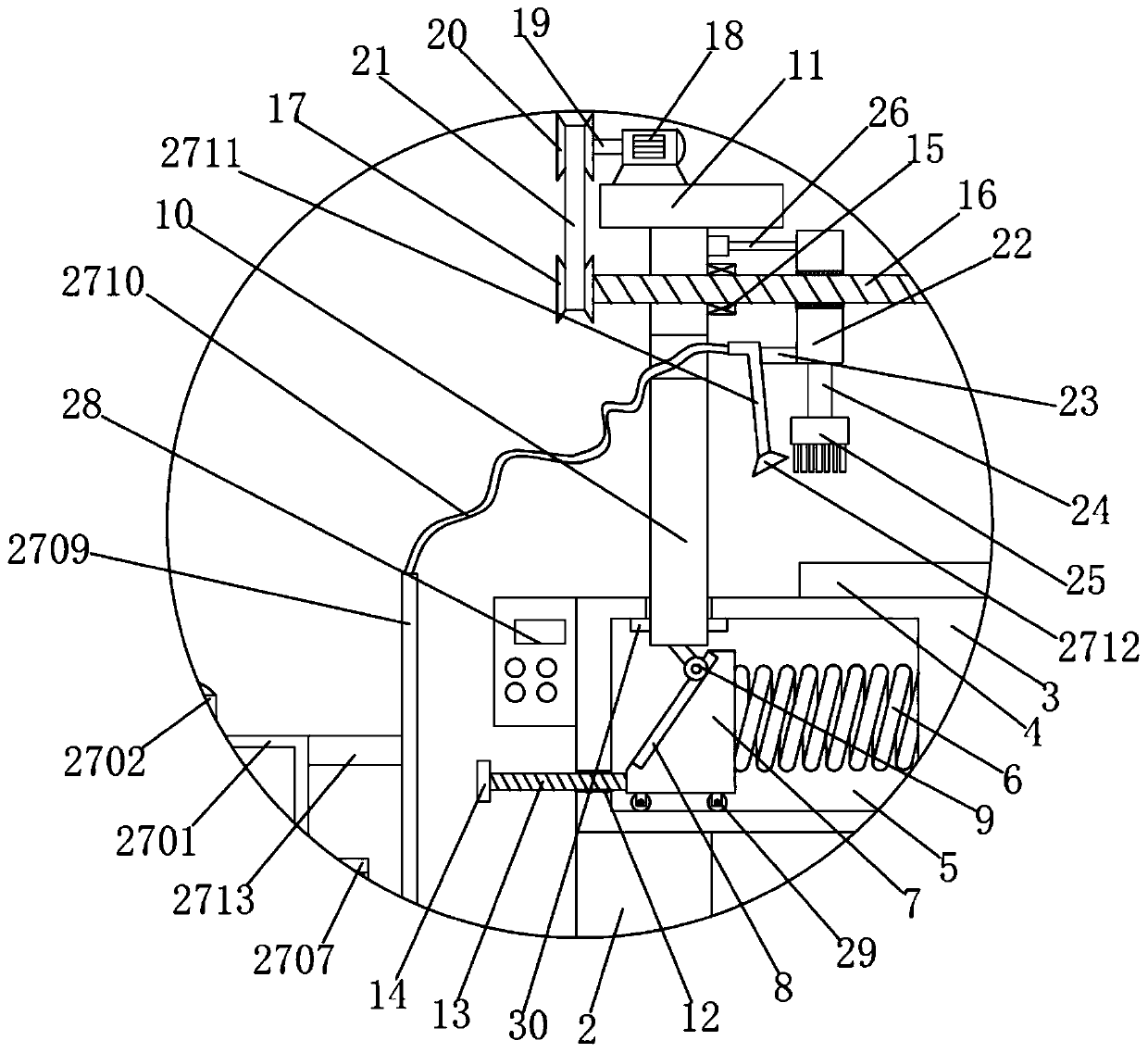

The invention relates to a multifunctional environment-friendly and coating-saving wall painting machine. The multifunctional environment-friendly and coating-saving wall painting machine comprises a base, a movement module, a wall painting module, a feeding module and a stirring module. The movement module comprises a lifting mechanism installed on the base. The lifting mechanism drives the wall painting module to move vertically. The wall painting module comprises a roller brush, a puttying plate, a polishing plate and a rotary locating mechanism. The rotary locating mechanism comprises a rotary plate, a locating pin and a reset spring. A mechanical arm and a rotating arm are arranged above the lifting mechanism, the rotating arm is hinged to the mechanical arm, and a tension spring is arranged between the rotating arm and the mechanical arm. The multifunctional environment-friendly and coating-saving wall painting machine can achieve integration of automatic stirring, feeding, puttying, polishing and painting, guarantee accurate discharging, replace workers to complete complex wall painting work high in labor intensity, improve the work efficiency, guarantee the wall painting quality, liberate labor force, avoid injury to the human body, solve the problem of waste caused by leakage of coatings, lower the decoration cost and reduce the environmental pollution.

Owner:WUHAN UNIV OF TECH

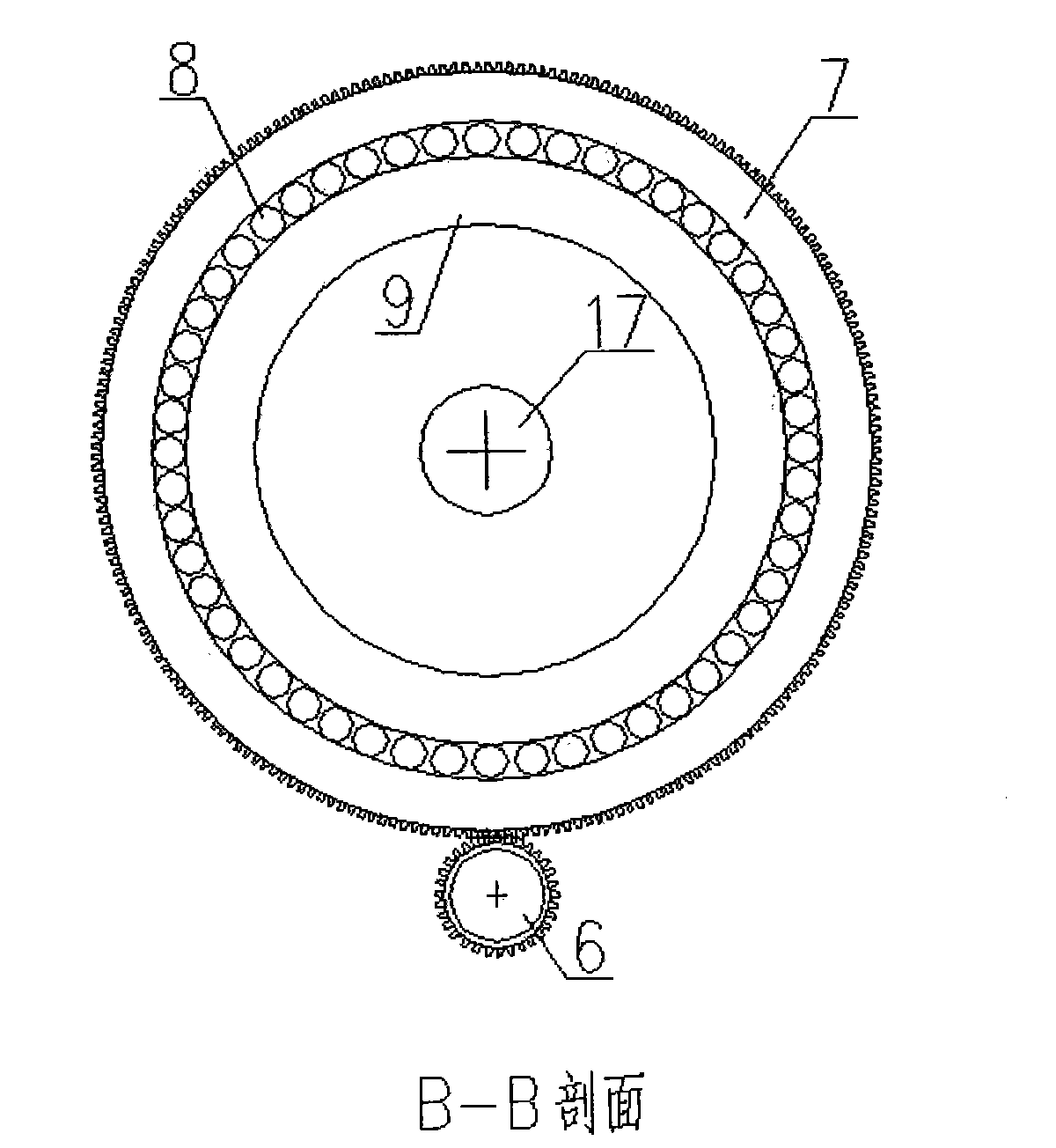

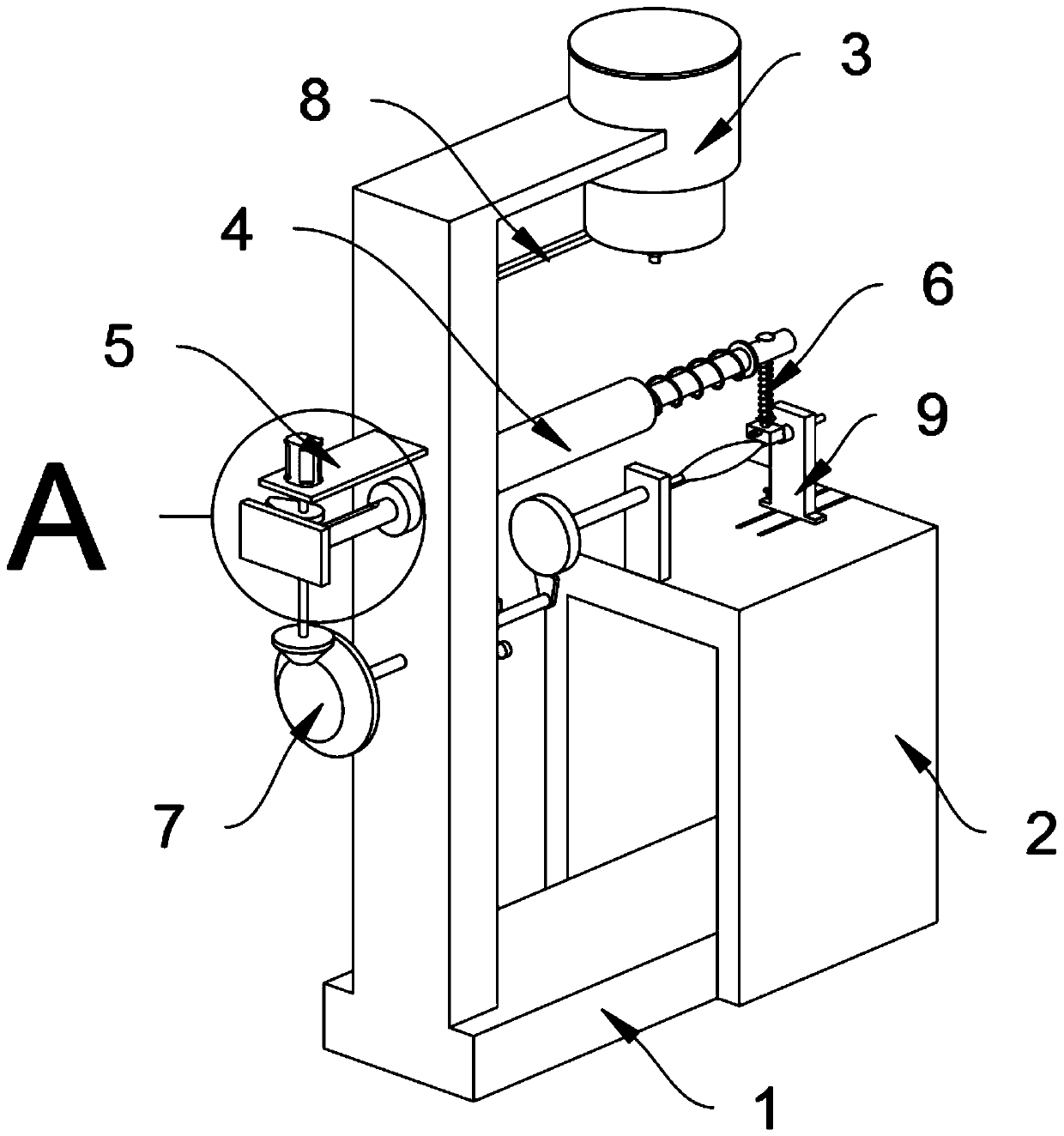

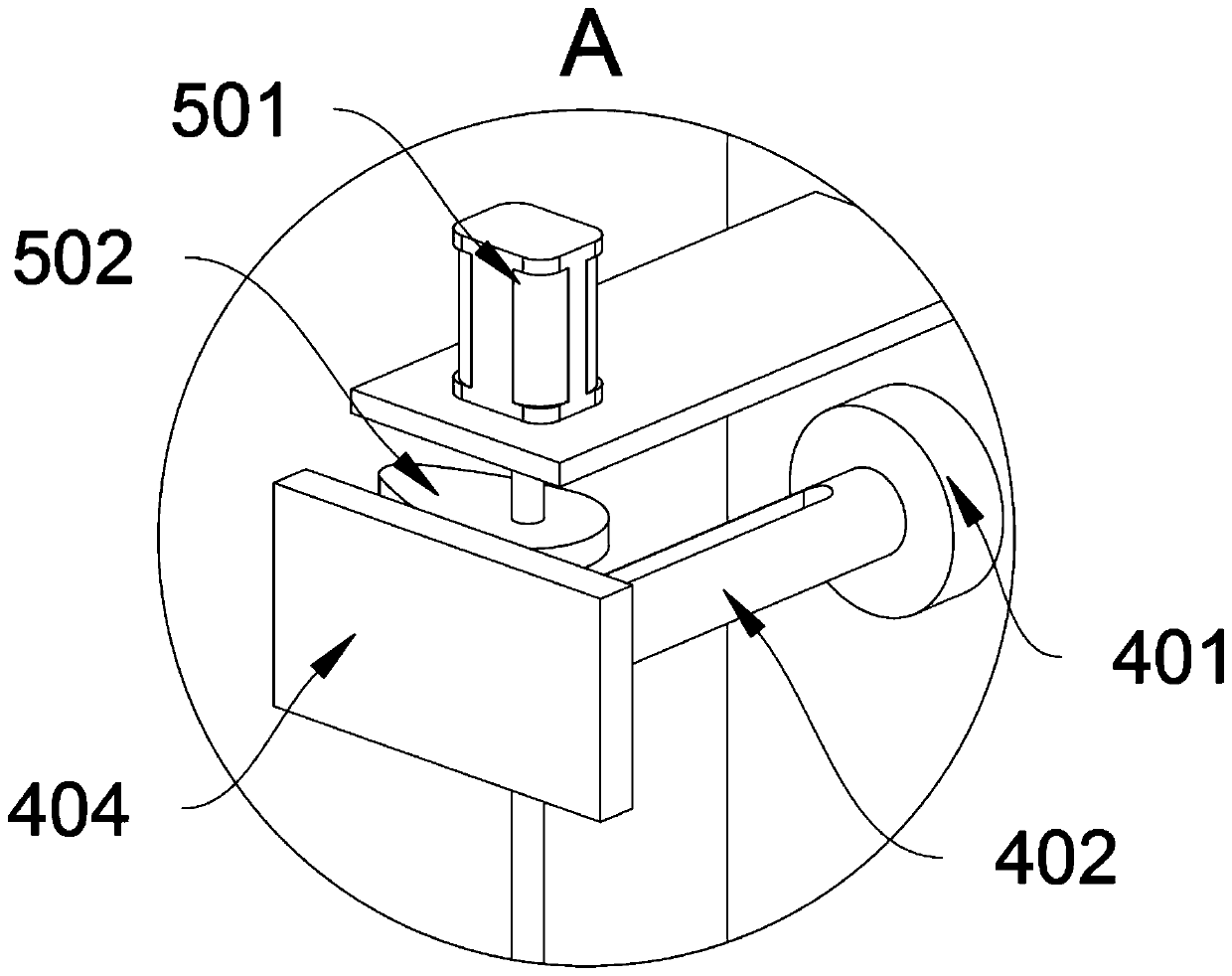

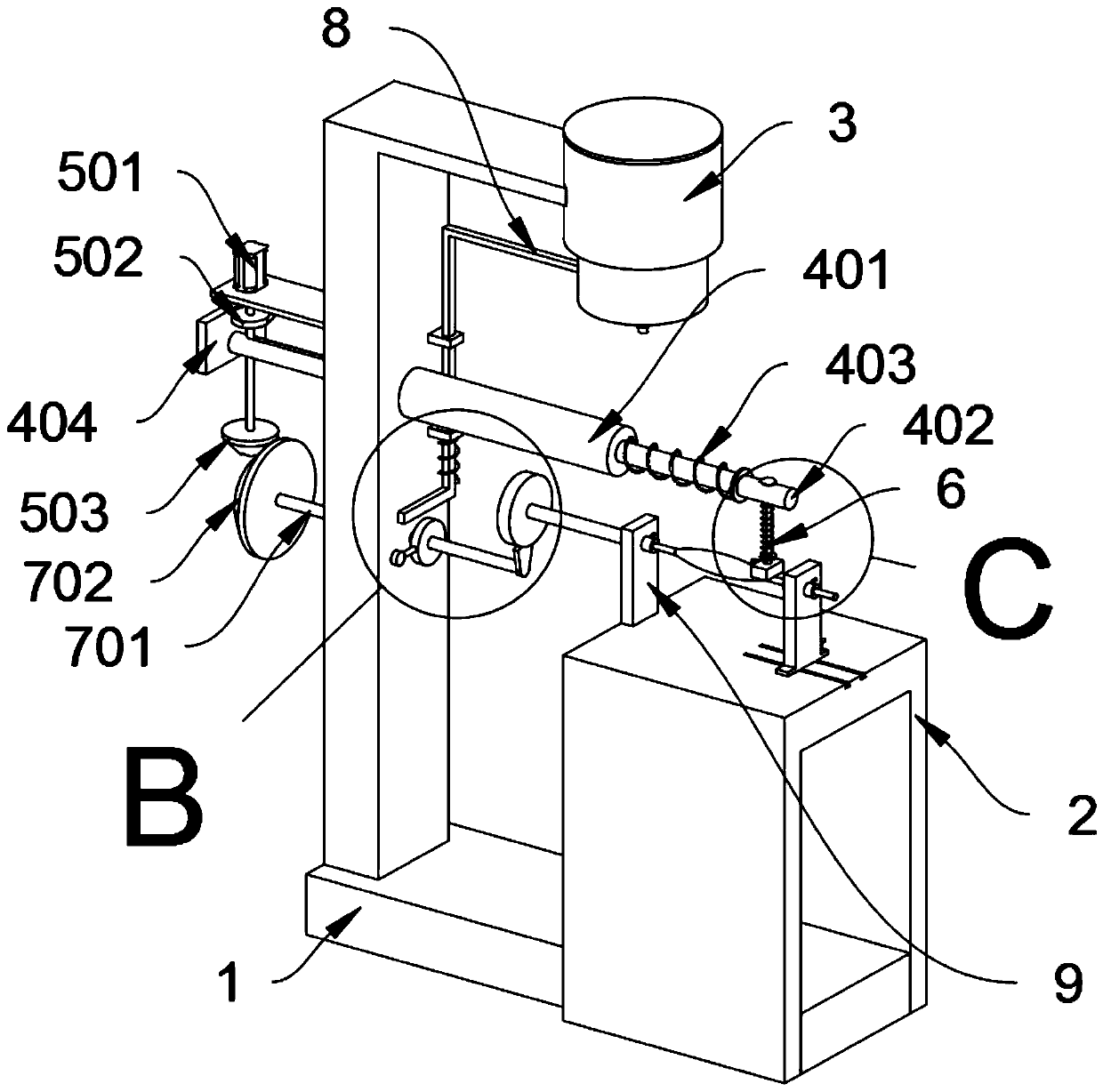

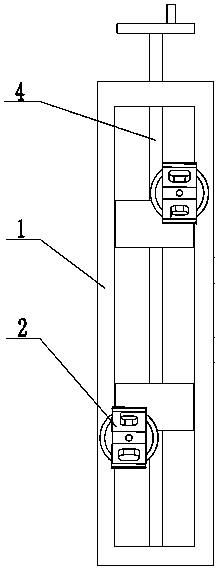

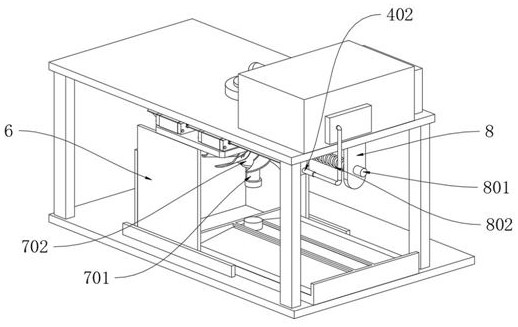

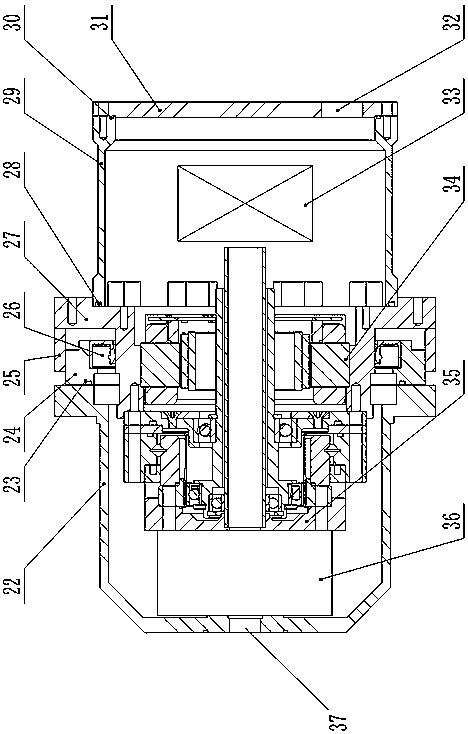

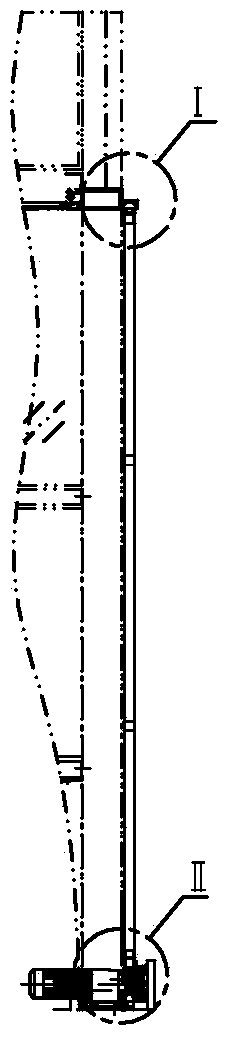

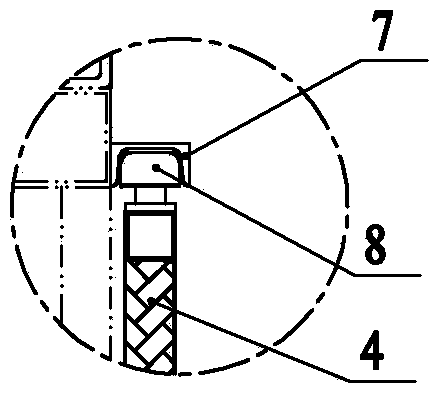

Semi-automatic derusting and paint spraying device for surface of metal tube and derusting and paint spraying method thereof

InactiveCN102151638AImprove work efficiencyGuaranteed cleanlinessCorrosion preventionPipe protection against corrosion/incrustationSemi automaticMetal

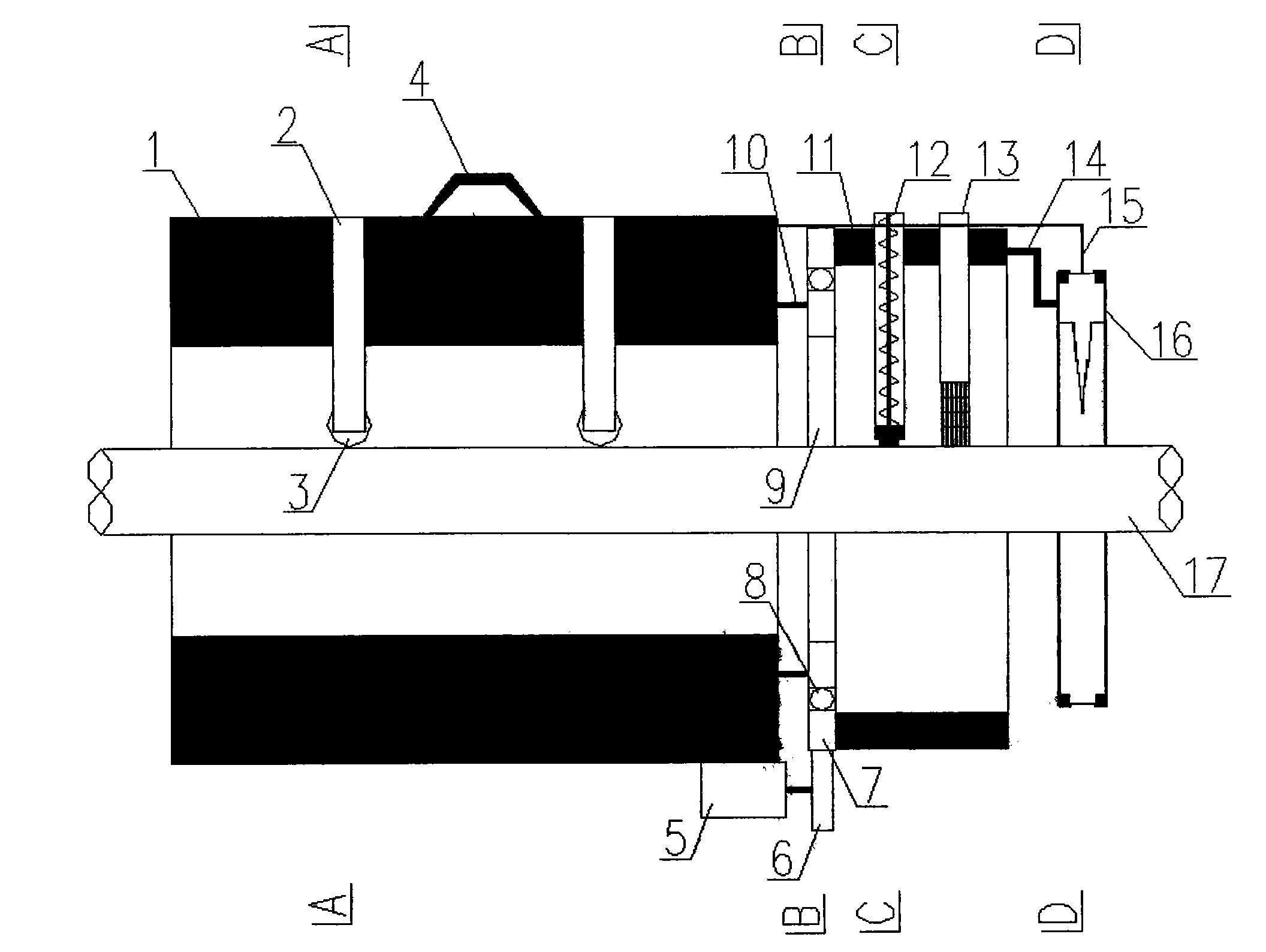

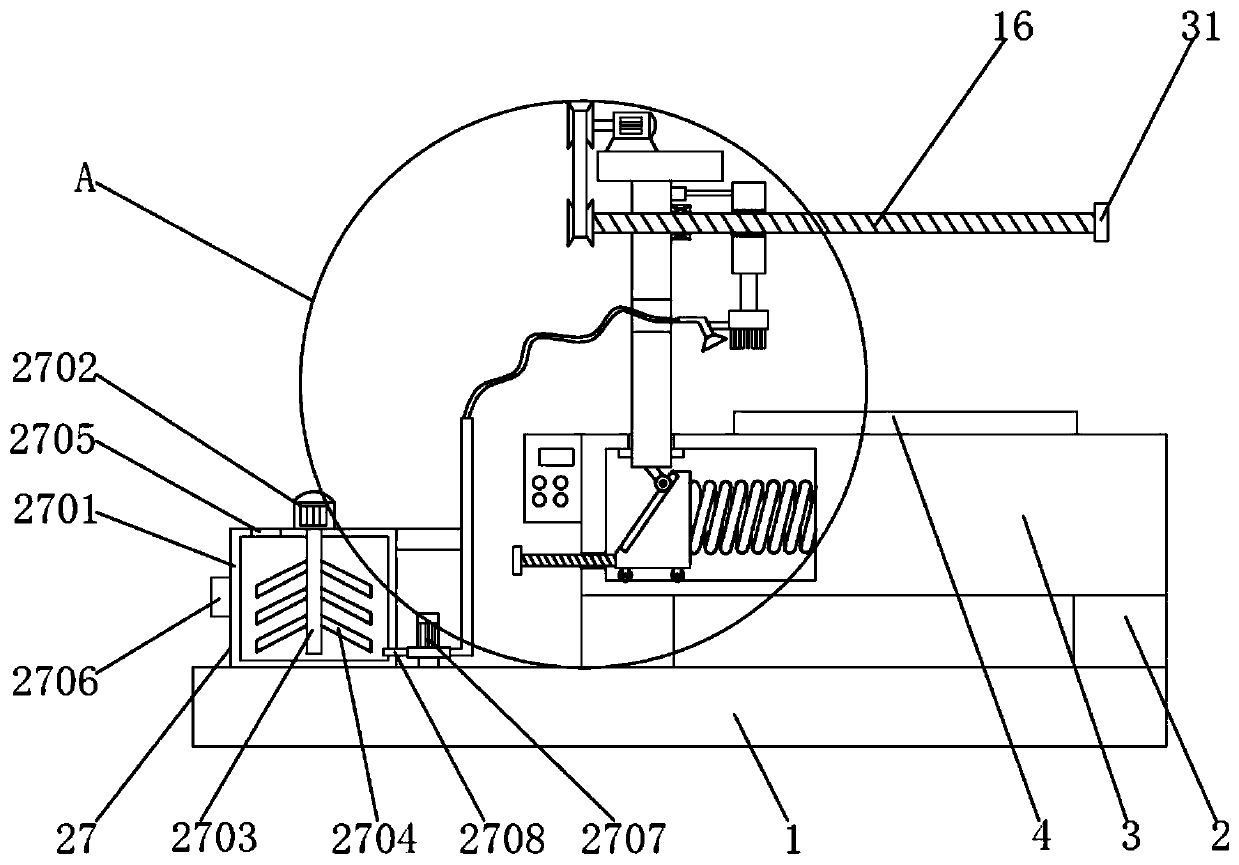

The invention relates to a semi-automatic portable derusting and paint spraying device for the surface of a metal tube, which comprises five parts, namely a movable hollow shaft system, a low-rotating speed transmission system, a derusting system, a cleaning system and a paint spraying system, wherein the movable hollow shaft system is used for fixing a metal tube on a central line of the movable hollow shaft system; the whole device moves forwards along a metal tube through the force applied on a handle; the circular motion of a motor self on the device is transferred to the derusting system, the cleaning system and the paint spraying system through the low-rotating speed transmission system, so that the derusting system, the cleaning system and the paint spraying system are driven to respectively carry out the circular motion around the metal tube, thereby performing procedures of derusting, cleaning and paint spraying on the metal tube; the whole device continuously moves forwards along the metal tube through the handle, and then the derusting and paint spraying work of the processed tube is finished.

Owner:贾韶强

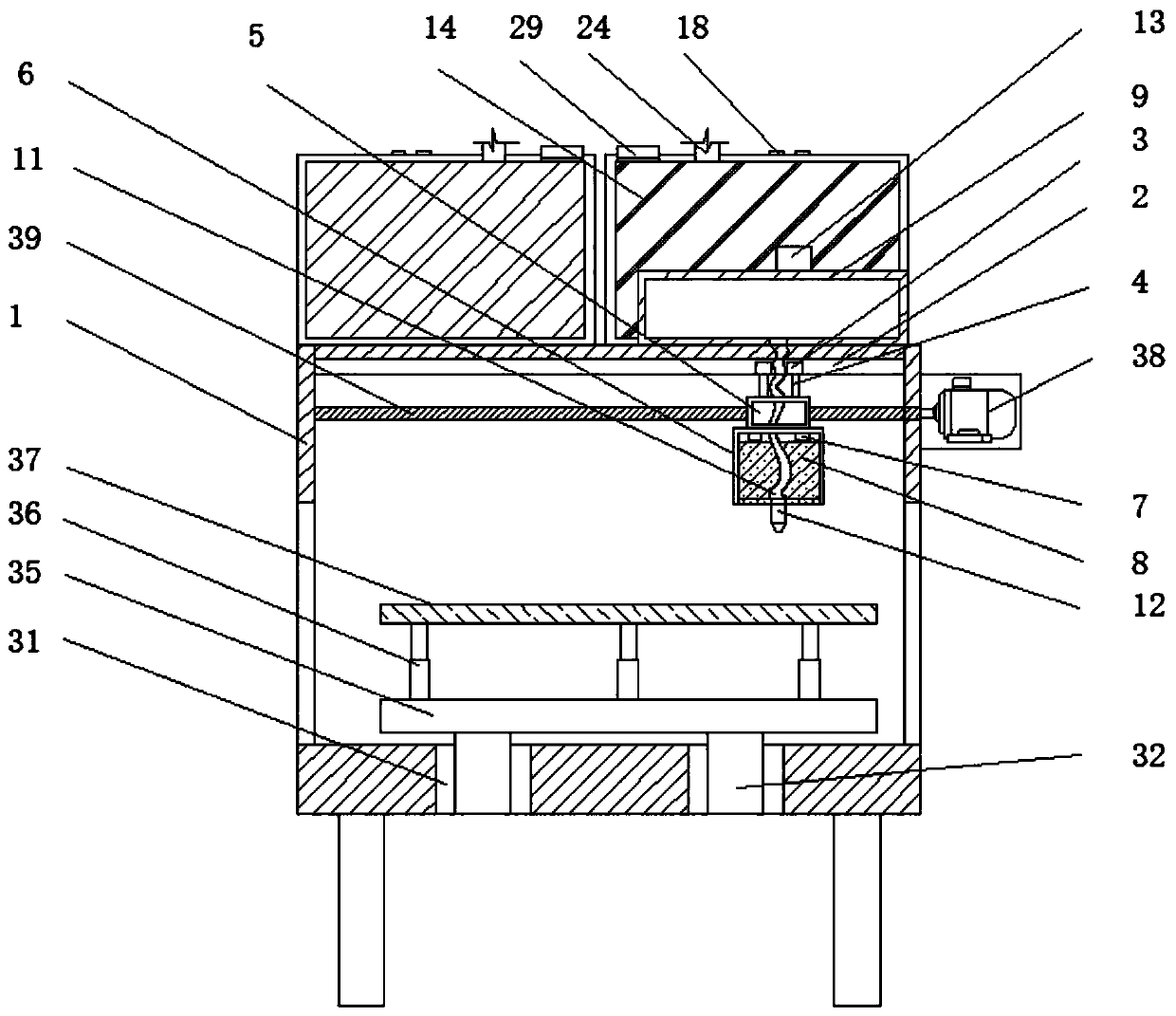

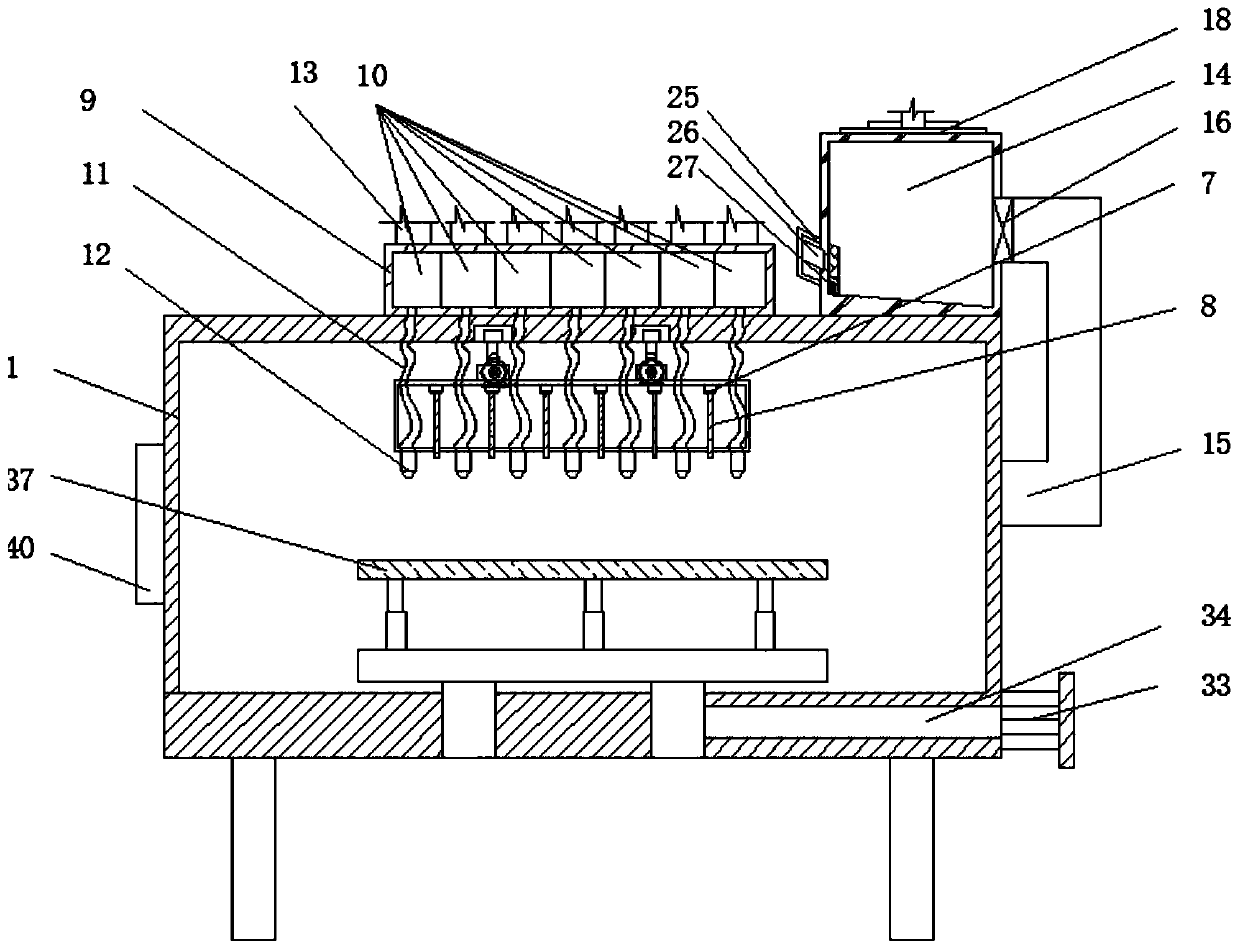

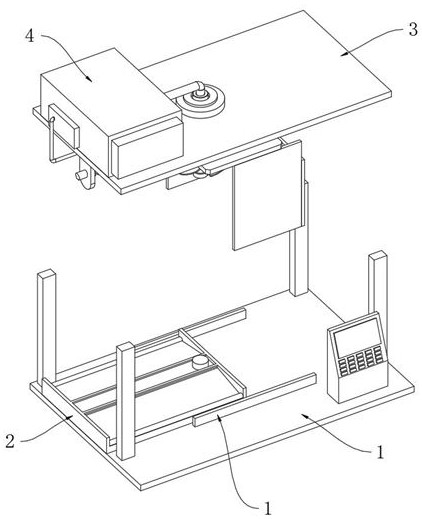

Efficient sheet metal paint spraying device

ActiveCN107159497ARealize all-round paintingGuaranteed continuitySpraying apparatusElectric machineryEngineering

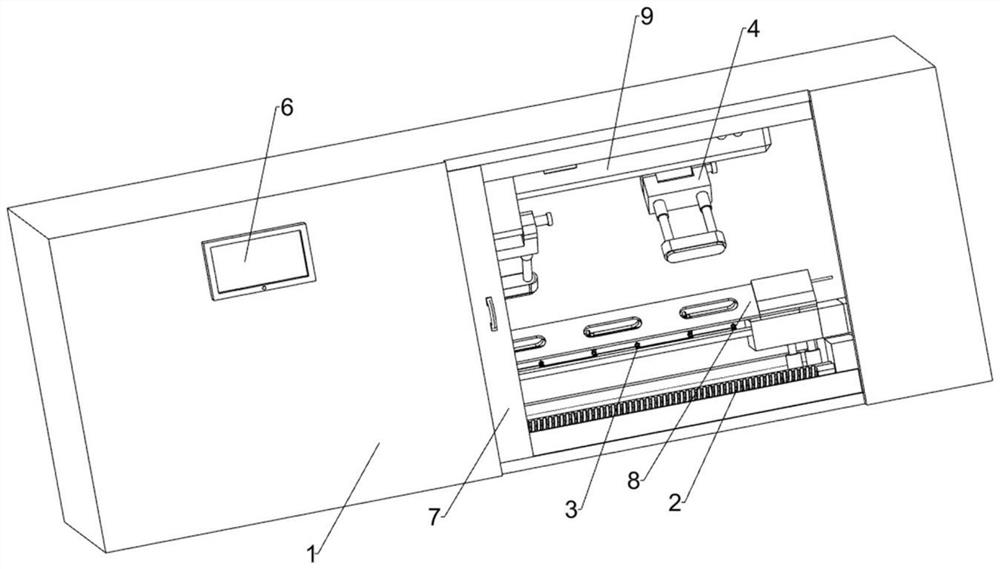

The invention discloses an efficient sheet metal paint spraying device. The efficient sheet metal paint spraying device comprises a frame body, a movable frame, a cylinder body, a movable block and a clamping device; a clapboard is arranged in the middle part of the inner cavity of the frame body, the movable frame and the cylinder body are located above the clapboard, sliding seats are symmetrically arranged on two sides of the top of the movable frame, and slidably fixed to a sliding rail which is fixed on the top of the inner cavity of the frame body in a clamped mode, and a drive motor which drives the motor to move back and forth is arranged on the movable frame; the left center of the movable frame is fixed with a piston rod which is matched with the cylinder body, and the cylinder body is provided with a two-channel design of a feeding pipe and a discharging pipe, and the discharging pipe is connected with a telescopic hose; a fluid passage is formed in the movable block, and the inlet end of the fluid passage is connected with the telescopic hose, and the outlet end of the fluid passage is connected with a nozzle; and the clamping device is located below the movable block, and provided with a rotating motor. According to efficient sheet metal paint spraying device, paint spraying work of the sheet metal parts can be efficiently completed, and meanwhile, the paint spraying effect is good, the operation is simple, and is worth popularizing and using.

Owner:JIANGSU NUOSHENG ENVIRONMENTAL PROTECTION TECH

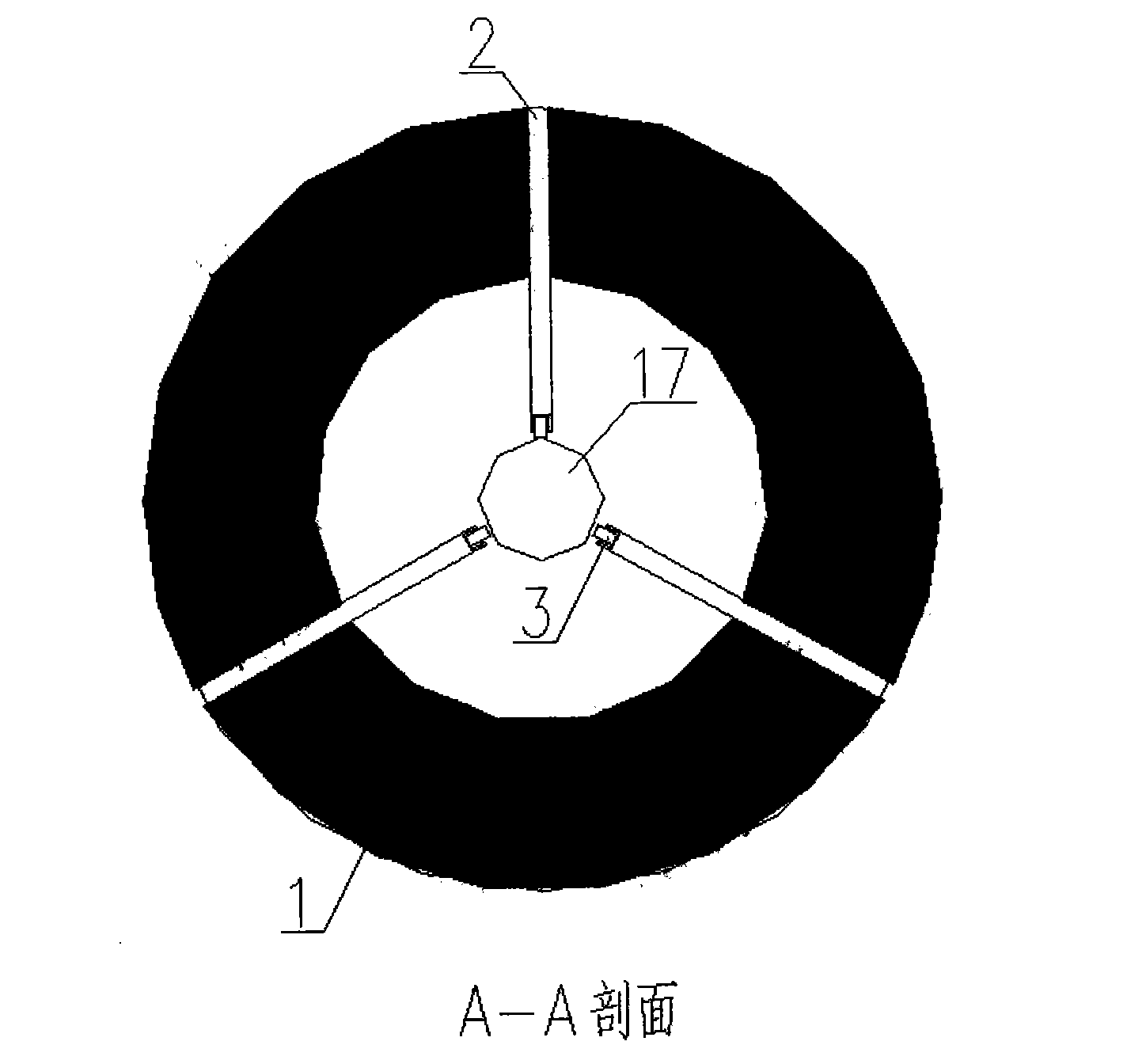

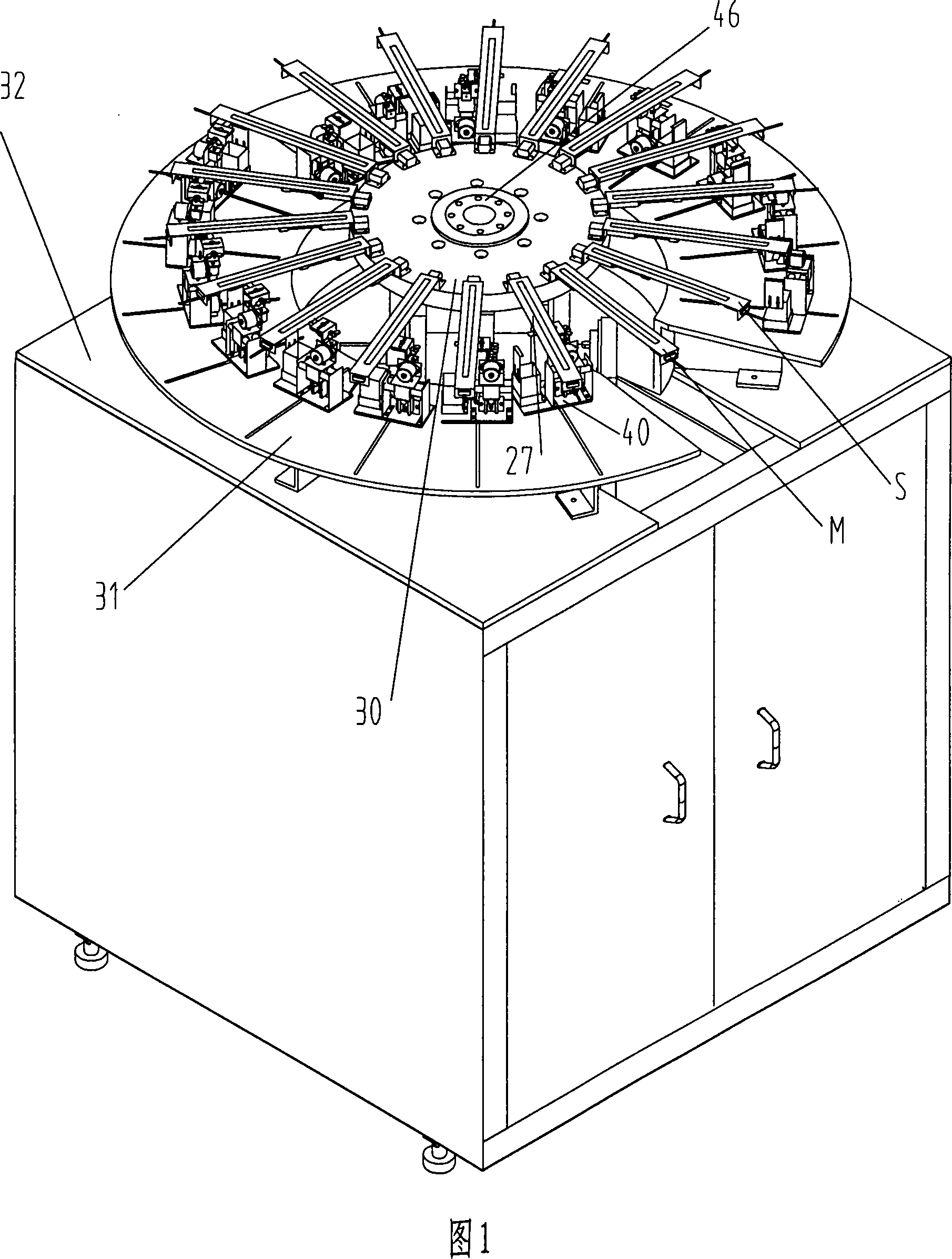

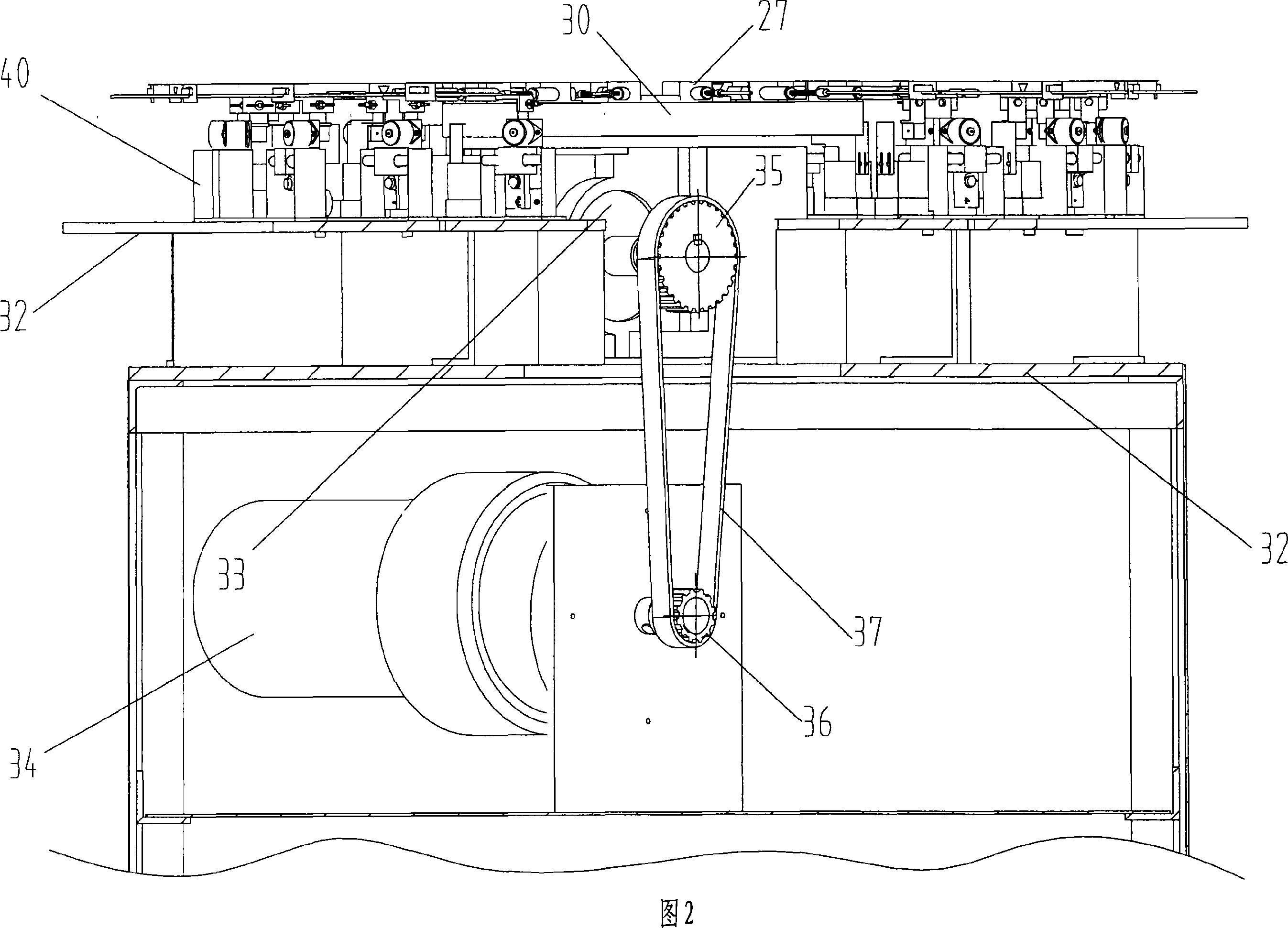

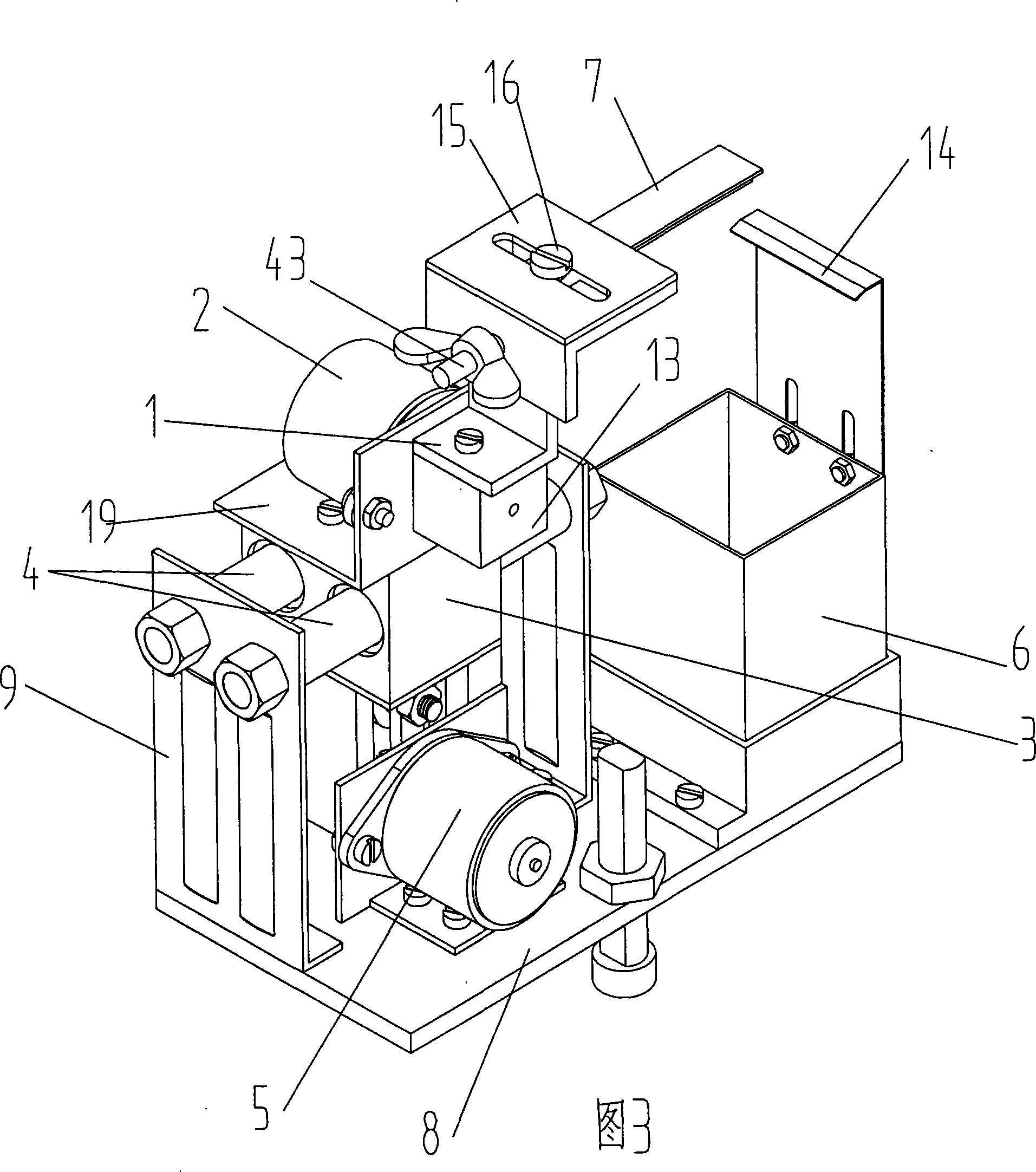

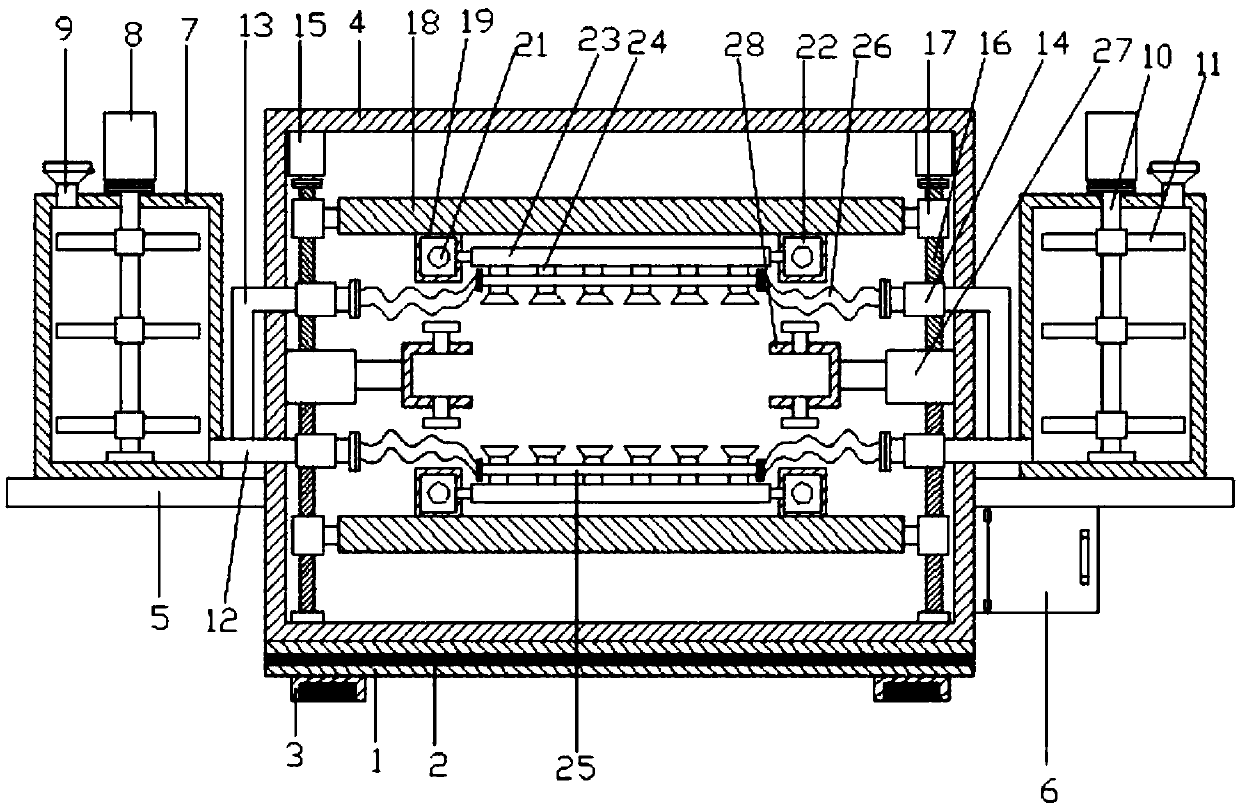

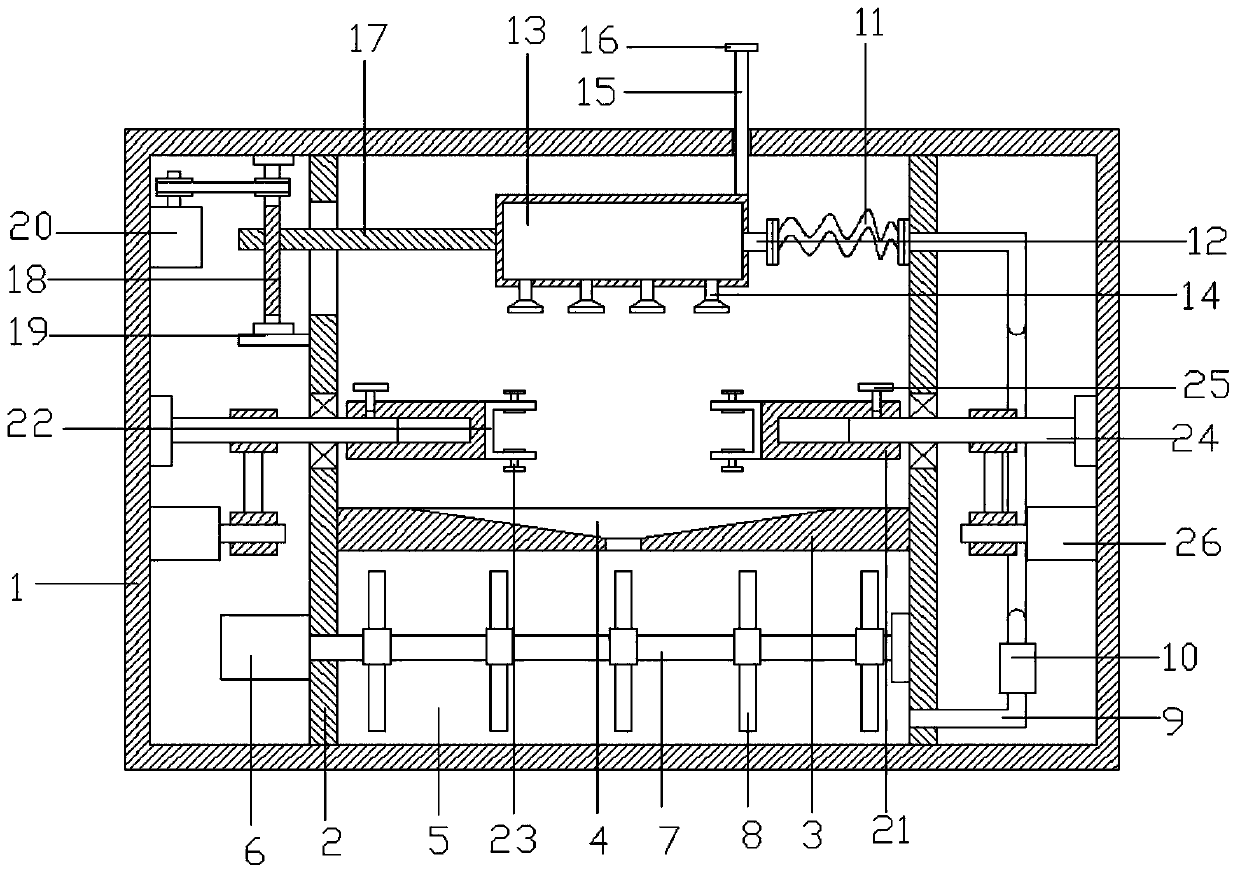

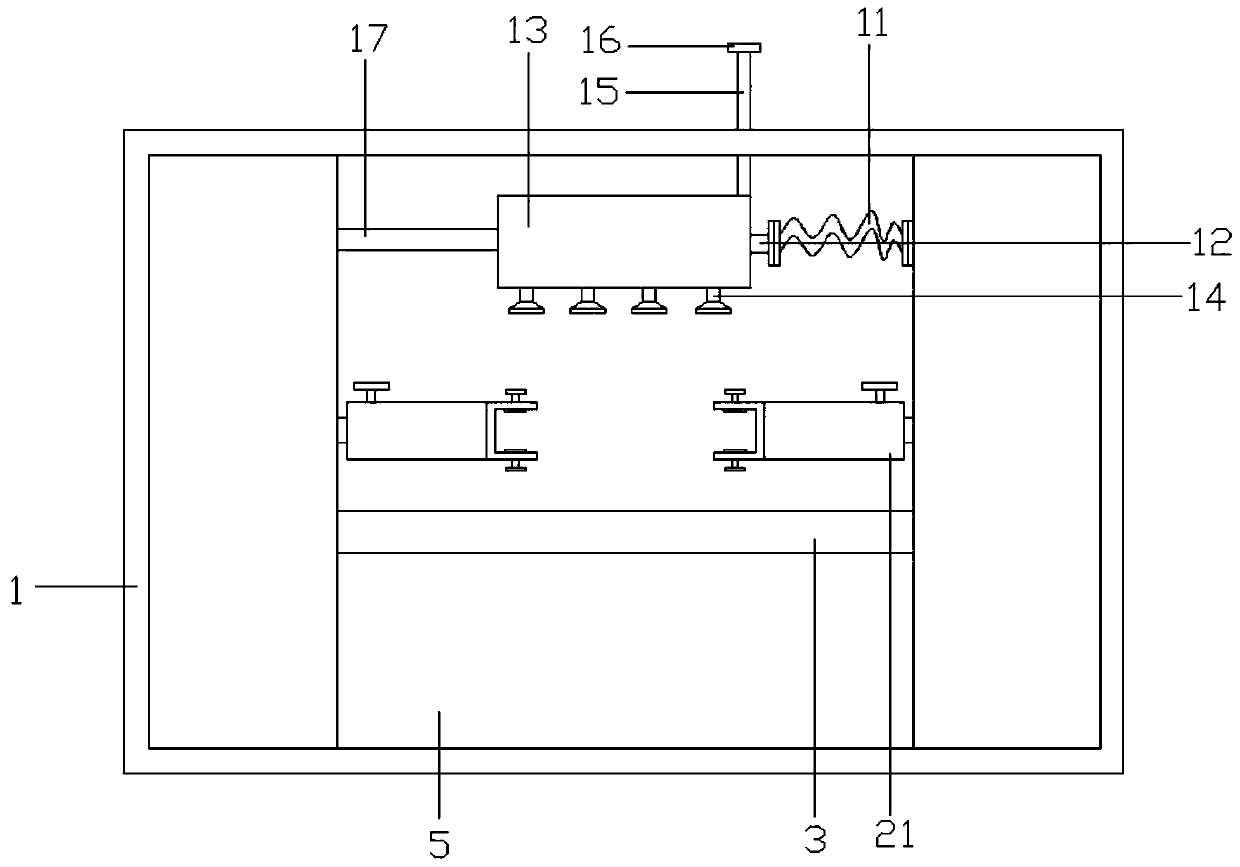

Thin plastic pipe machine for brushing

InactiveCN101041147AImprove efficiencyGood painting qualitySpecial surfacesCoatingsLacquerEngineering

The invention relates to a brushing machine of thin plastic pipe, belonging to the brushing mechanical technology field, for solving problems of low brushing efficiency in handwork, heavy labor intensity and no assurance for brushing quality. The invention comprises manipulator, clamping device and worktable. The manipulator can simulate human hand to dip lacquer, lift, brush and draw back. It can accomplish the brush of paint layer on the surface of thin plastic pipe mechanically and automatically. By adding intermittent rotator, the manipulator and the clamping device can be allocated according to the brushing work station to form the intermittent automatic brushing machine with multiple work stations. The brush to multiple thin and long plastic pipes with multiple purposes can be accomplished. It is provided with regular brushing work, even brushing layer, good brushing quality and high efficiency. It can be used as brushing equipments for thin plastic pipe, maw pipe and so on.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

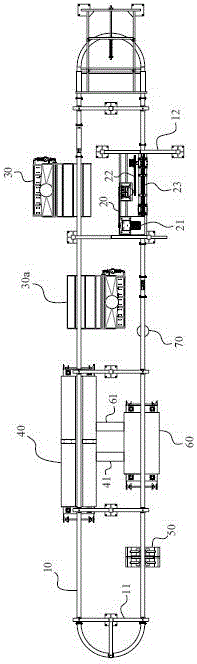

Energy-saving and environmental-protecting painting-drying-purification combination machine

InactiveCN106733371AGuarantee the quality of paintingGood technical effectLiquid surface applicatorsCleaning using toolsEngineeringMechanical engineering

The invention relates to an energy-saving and environmental-protecting painting-drying-purification combination machine, and belongs to the technical field of coating equipment. The machine comprises a suspension chain system; a lifting mechanism is hung below the suspension chain system; and the lifting mechanism circularly moves along the suspension chain system, and passes through a painting room, a paint film drying device, a suspension chain cleaning device and a suspension chain drying device in sequence. Through sequential design of the painting room, the paint film drying device, the suspension chain cleaning device and the suspension chain drying device, workpieces can be quickly dried after painting, and paint stained on the surface of the lifting mechanism can be cleaned through the suspension chain cleaning device; and through drying by the suspension chain drying device, the cleanness and the dryness of the lifting mechanism in one painting period can be guaranteed, the cleanness of a lifter before painting of the workpieces is guaranteed, the painting quality is guaranteed, and the beneficial technical effects and the prominent practical value are achieved.

Owner:安徽扬子弘福安防有限公司

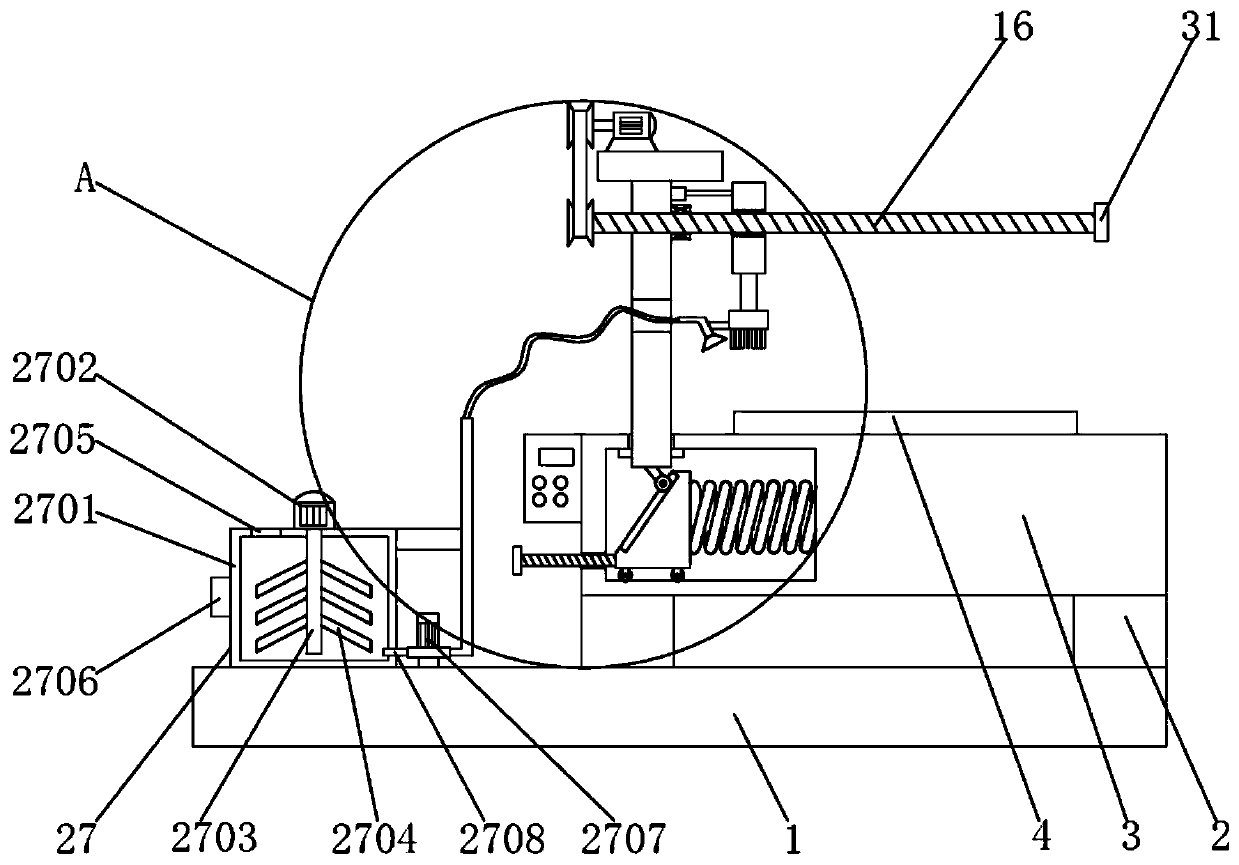

Special integrated production device for furniture parts

ActiveCN105057150AReduce transfer stepsSuitable for mechanized productionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

A special integrated production device for furniture parts comprises a machine frame and a feeding rack arranged on the machine frame. One end of the feeding rack is a feeding end, the other end of the feeding rack is a discharging end, and a first automatic dust removal device, a embellishing device, a drying device, a paint spraying device and an airing bin are arranged on the feeding rack sequentially from the feeding end to the discharging end at intervals. The embellishing device and the paint spraying device each comprises a paint spraying chamber with a paint spraying platform and two groups of spraying guns arranged in the paint spraying chamber, wherein each group comprises two spraying guns, a conveying belt is laid horizontally on the paint spraying platform, a transverse sliding rail is arranged above a feeding end and a discharging end of the conveying belt, and a movable seat is installed on the transverse sliding rail. The two spraying guns in each group are installed on the same movable seat and are arranged in the mode of inclining downwards towards the two outer sides of the corresponding paint spraying platform. The transverse sliding rails and the movable seats are arranged, uniform paint spraying on the furniture parts is realized through transverse and reciprocating swinging of the spraying guns. The special integrated production device is suitable for embellishing and paint spraying of various furniture parts, and improves the production and quality.

Owner:LIANYUNGANG MOBO HOUSEHOLD

Paint with low VOC (Volatile Organic Compound) for aircraft and preparation method thereof

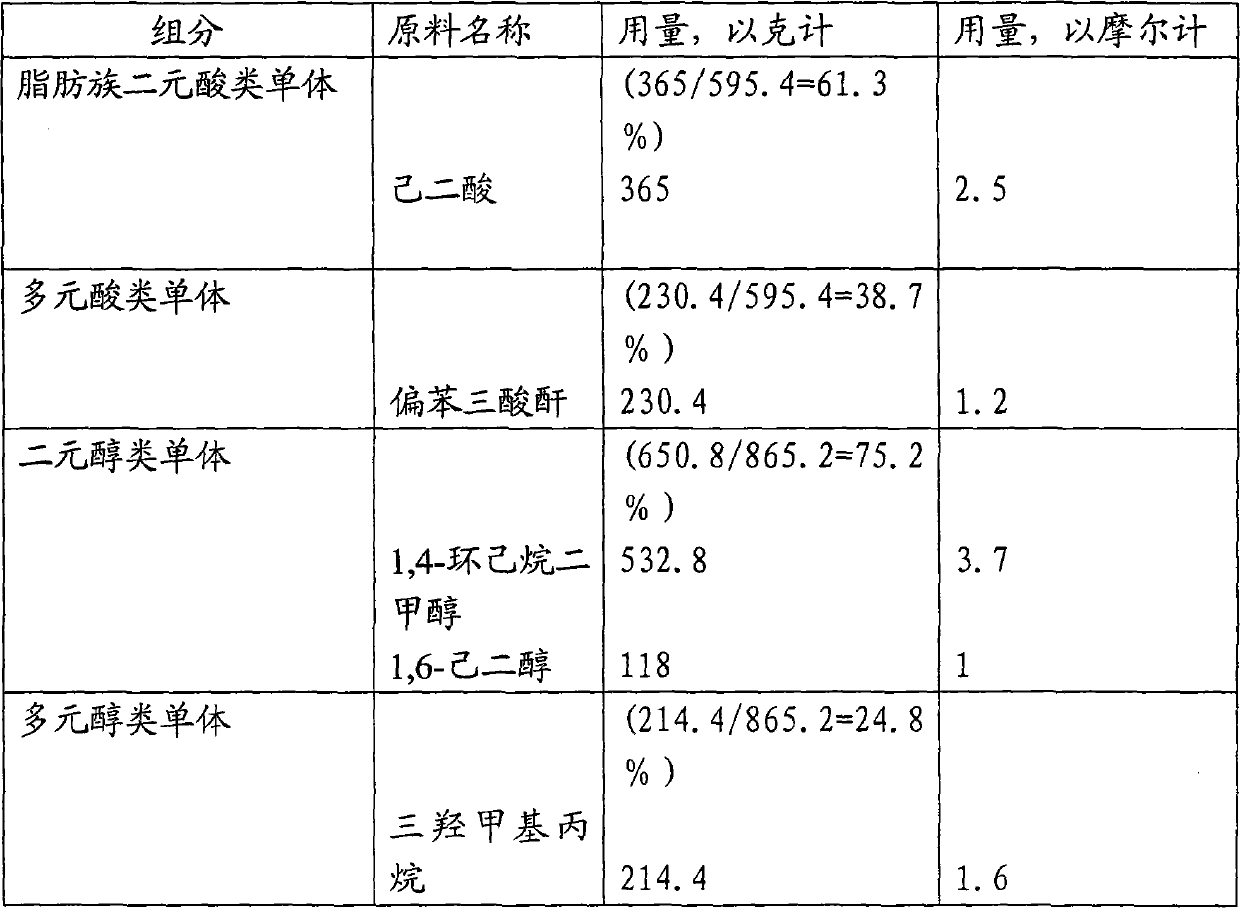

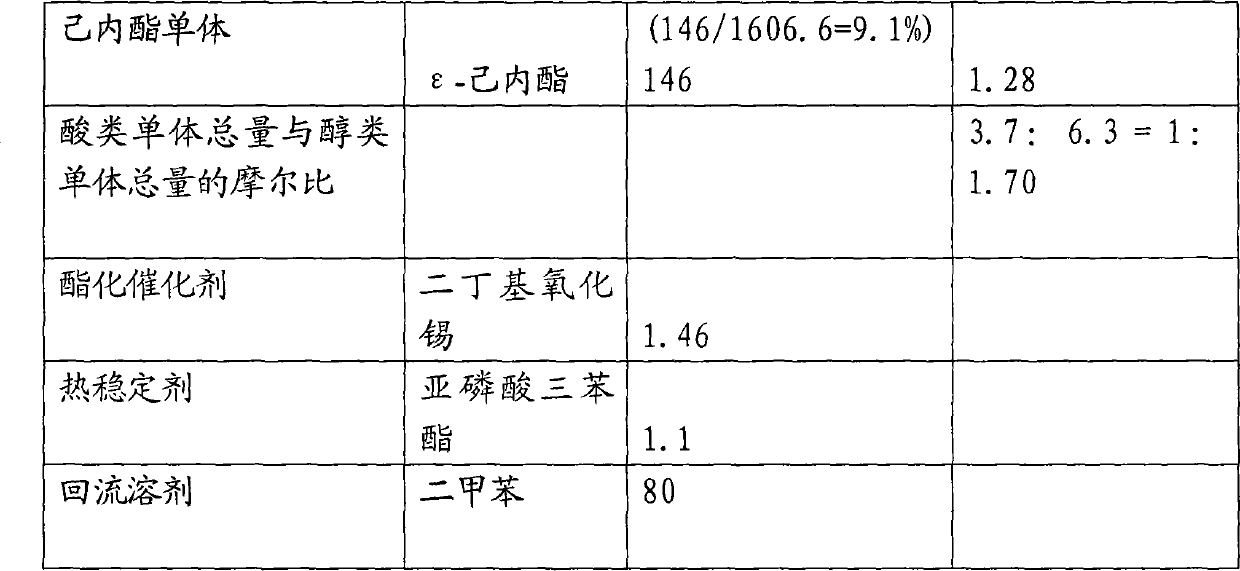

ActiveCN102174286AGuaranteed performanceReduce construction VOCPolyurea/polyurethane coatingsWaxPolyolefin

The invention relates to a paint with low VOC (Volatile Organic Compound) for an aircraft and a preparation method thereof. A component A of the paint is HDT-LV2 produced by the French Rhodia Company and has a nonvolatile matter content of 100 percent by weight; a component B of the paint consists of the following components in percentage by weight: 20-60 percent of caprolactone monomer modified hydroxyl polyester resin, 3-15 percent of polycaprolactone polyol resin, 5-50 percent of paint, 1-3 percent of dispersant, 0.1-1 percent of composite flatting agent, 0.05-0.15 percent of acetylacetonetype catalyst, 0.1-0.4 percent of hinderdeamine type light stabilizer, 0.2-0.6 percent of polyolefin wax type anti-settling auxiliary agent and the balance of mixed solvent; and the mixing ratio of the component A to the component B is (0.8-1.5):1 according to the molar ratio of NCO to OH. Comprehensive performance of the paint can meet requirements of aircraft industry and the paint has low construction VOC.

Owner:CHINA NAT OFFSHORE OIL CORP +2

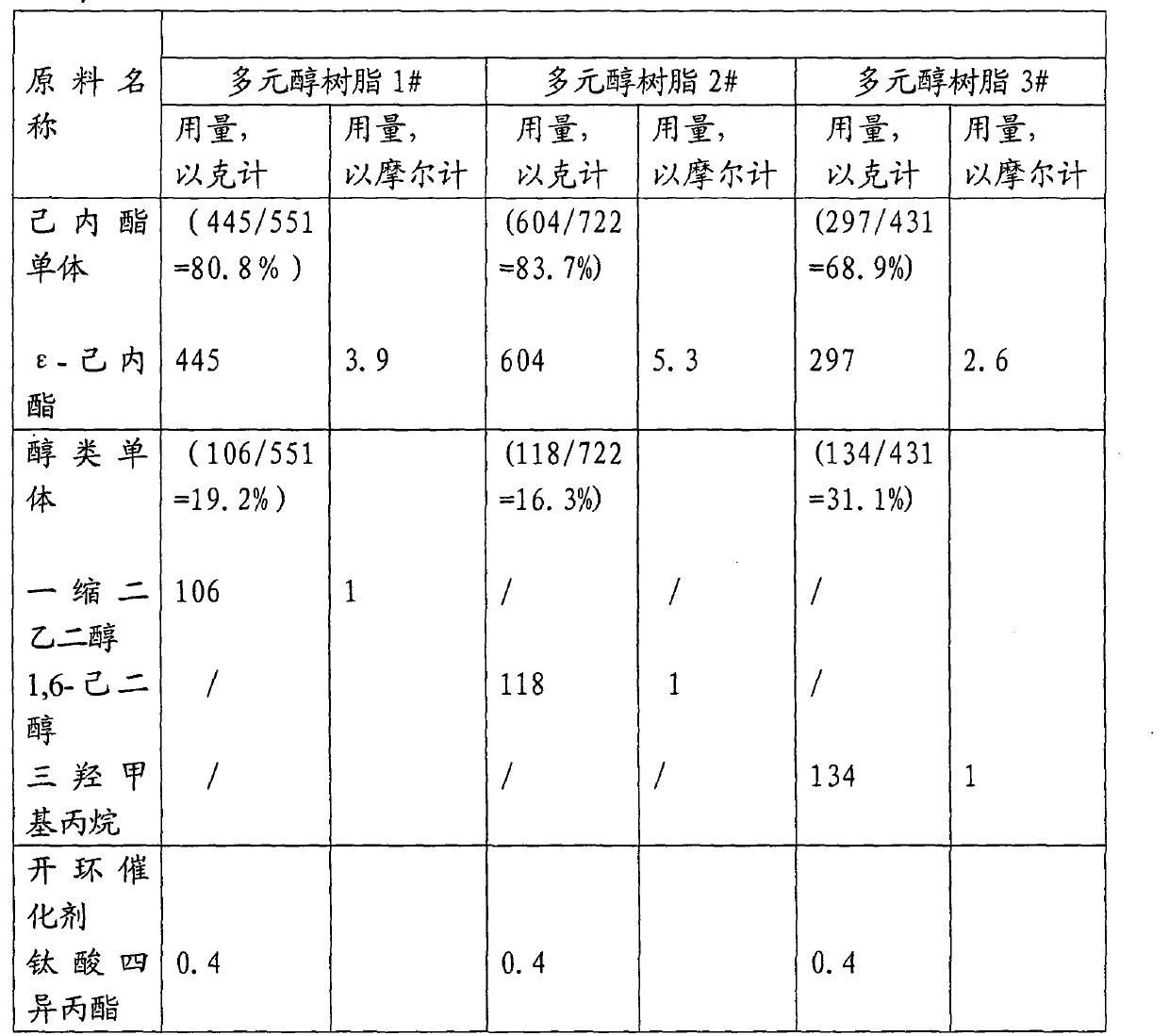

Integrated cabinet full-automatic production system based on smart home and production method thereof

InactiveCN112476691AAdjustable spacingImprove painting efficiencyPretreated surfacesCoatingsRubber matIndustrial engineering

The invention discloses an integrated cabinet full-automatic production system based on smart home and a production method thereof. The integrated cabinet full-automatic production system comprises aplate cutting and grinding mechanism, a plate edge sealing mechanism, a plate drilling mechanism, a plate paint spraying mechanism and a plate assembling mechanism. After being cut and ground by the plate cutting and grinding mechanism, integrated cabinet plates are conveyed to the plate edge sealing mechanism through a conveying belt to be subjected to edge sealing. The invention relates to the technical field of smart home. According to the integrated cabinet full-automatic production system based on smart home and the production method thereof, paint can be sprayed to the two faces of a plate at the same time, uniform drying is achieved after paint spraying, meanwhile, a clamping mechanism composed of a limiting block, a limiting groove, a first electric push rod and a rubber pad is rotated, the problem that the paint spraying effect is affected due to paint spraying dead corners can be prevented from happening to clamping parts of plates, the plates do not need to be turned over bypersonnel, through automatic drying of an electric heating pipe, the paint spraying efficiency of the plates can be improved, and the paint spraying quality is guaranteed.

Owner:浙江雷拓家居有限公司

Coating device for simultaneously spraying with different paints

InactiveCN110665718APlay the role of coveringImprove practicalitySpray boothsExhaust fumesProcess engineering

The invention discloses a coating device for simultaneously spraying with different paints. The coating device comprises a spraying chamber, a lead screw nut, a corrugated pipe and a first pipeline, wherein a first storage box is fixed to the lower side of the lead screw nut, a paint box shell and a waste gas treatment box shell are arranged on the upper side of the spraying chamber, paint storageboxes are arranged inside the paint box shell, a second slide way is fixed to the inside of the right side of the waste gas treatment box shell, one end of the first pipeline penetrates through the spraying chamber, the left side of a filter net is provided with a water tank, a second pipeline penetrates through the right side of the water tank, a third exhaust fan penetrates through the left side of the water tank, and a second storage box is arranged on the rear side of the water tank. According to the coating device for simultaneously spraying with different paints, the baffle and the paint box shell are arranged, seven paint storage boxes with seven colors are correspondingly stored paints with seven colors, so that the paints with different colors can simultaneously spray the platesthrough paint spraying heads, and the baffle plays a role in shielding when the plates are painted.

Owner:江苏纵湖涂装设备产业研究院有限公司

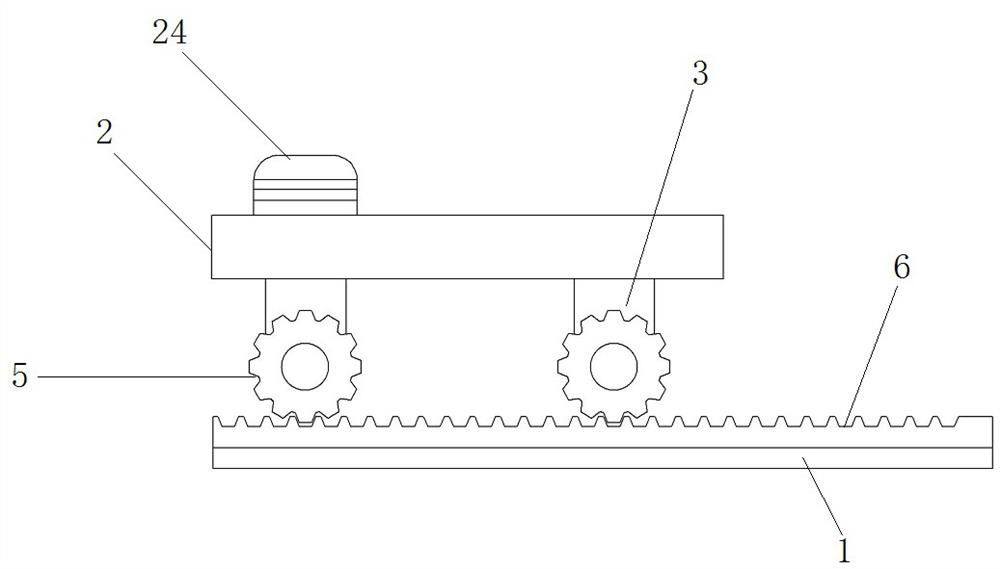

Buoy linkage paint brushing device

ActiveCN111318408AImplement auto-replenishmentSimple structureLiquid surface applicatorsCoatingsGear wheelElectric machinery

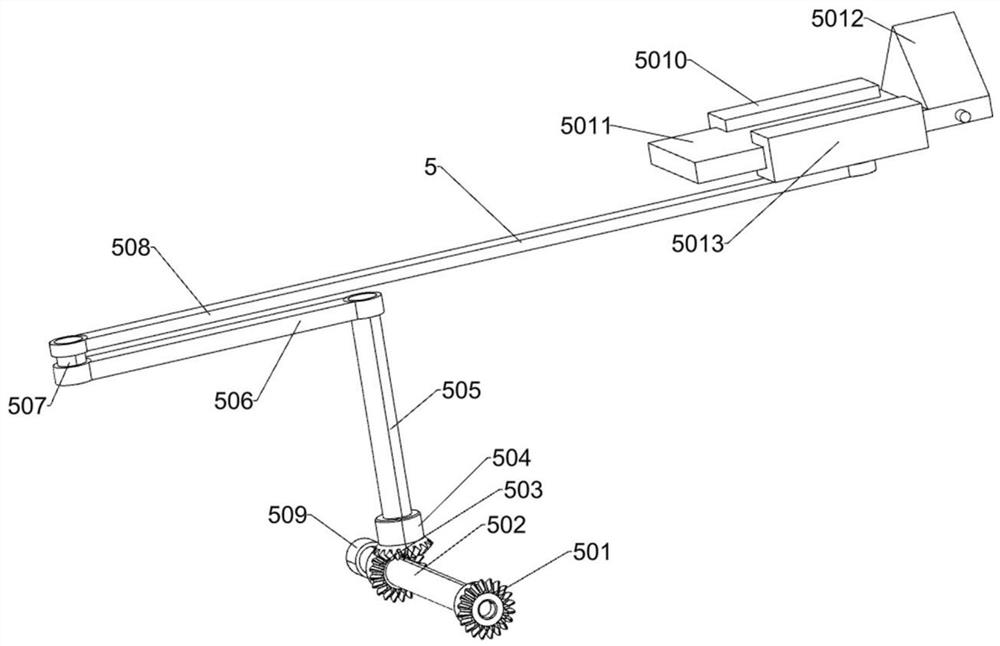

The invention provides a buoy linkage paint brushing device and relates to the field of brushing devices. The problems that during brushing, repeated dipping of pigment is needed mostly due to manualbrushing, a buoy needs to be constantly rotated, and the whole efficiency is low are solved. The buoy linkage paint brushing device comprises an installation frame, and a clamp seat is fixedly connected to the installation frame through bolts. According to the device, by means of a driving structure, a buoy rotation driving structure and a squeezing structure, as a bevel gear A and a bevel gear Bare engaged with each other, when a motor rotates, a rotating rod on the buoy rotation driving structure can be driven to rotate, at the moment, firstly, the rotating rod drives a poking head to rotate, the squeezing structure can be poked by rotation of the poking head to squeeze an elastic paint barrel, and supplement of the pigment of a brushing head is achieved; and secondly, the rotating roddrives an incomplete gear to rotate, the incomplete gear is engaged with the gears so that intermittent rotation of the buoy can be achieved through rotation of the motor.

Owner:陈依琳

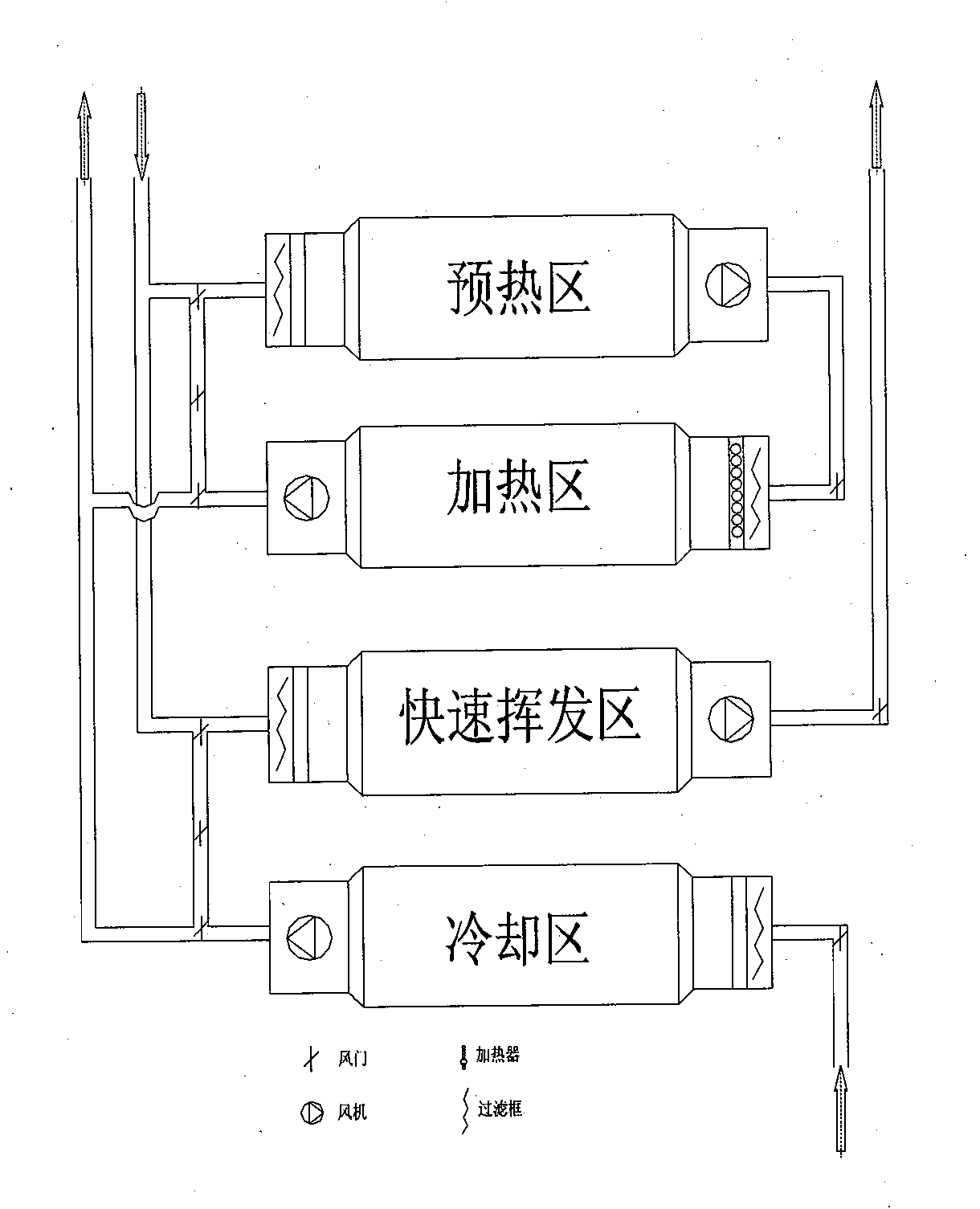

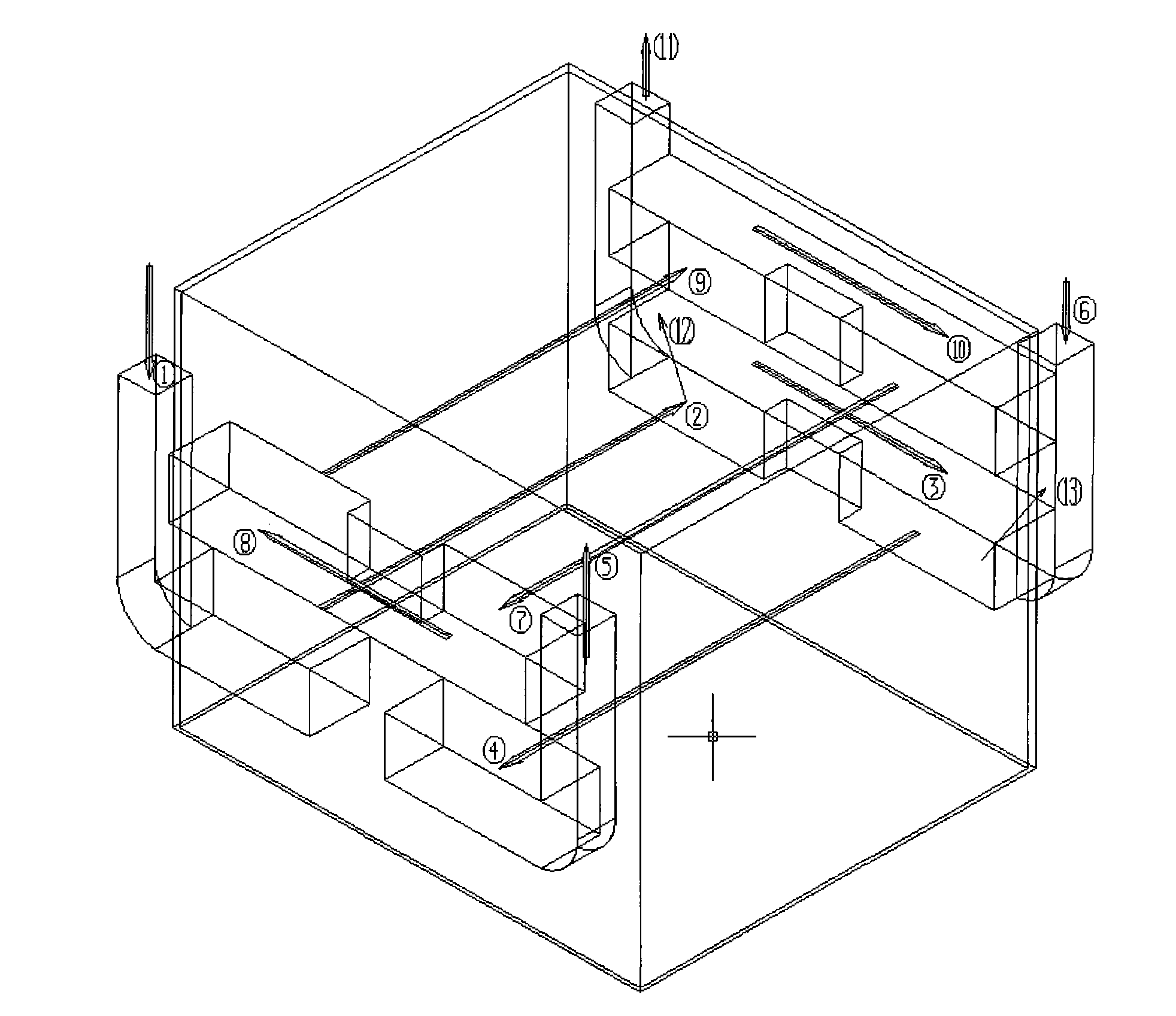

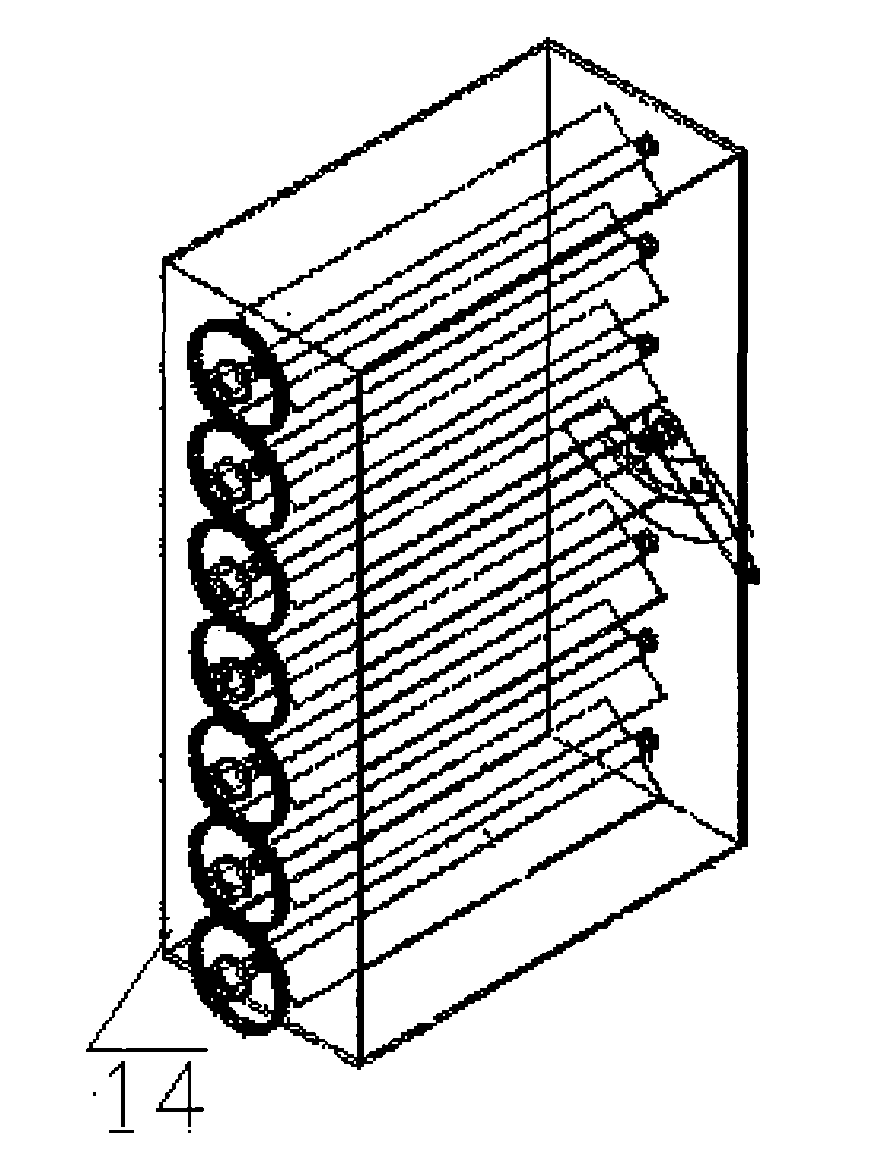

Vertical drying shed and drying method

InactiveCN101782313AEasy to dry in batchesImprove heat utilizationDrying solid materials with heatDrying gas arrangementsSolventAirflow

The invention relates to a vertical drying shed and a drying method. The wall body of the drying shed is spliced into a relatively closed space with doors at the four corners by polyurethane composite boards. The inside of the space is divided into a rapid volatilization area, a preheating area, a heating area and a cooling area. A heating fan and a cooling fan are arranged at one side of the wall body; the heating fan is located at the upper part of the cooling fan; a heating area air outlet is arranged at one side of the heating fan and a preheating area upper air port is arranged at the other side; the wall body opposite to the heating fan is provided with a heater and an air channel; a fan is arranged at one side of the heater; a volatilization fan is arranged at the lower part of the fan and is communicated with an air channel port; and a lower air port of the cooling area is connected with an air outlet of the heating area. The invention has the advantages that firstly, the closed drying space is convenient for batch drying, improves the heat utilization ratio and is convenient to collectively process air dust and volatilized paint solvent; secondly, ideal combination of a heat field and an air field and the adjustment of the airflow are realized; and thirdly, the paint quality of spraying workpieces is ensured, and the effective rate of energy is improved.

Owner:杭州景生木业机械有限公司

Fuel tank cap painting fixing device

InactiveCN107470058AImprove the effect of spray paintAnti-staticSpraying apparatusFuel tankStatic electricity

The invention discloses a fuel tank cap painting fixing device which comprises a fuel tank cap fixing assembly, a vehicle door supporting assembly and an antistatic ring, wherein the vehicle door supporting assembly is suitable for being detachably mounted on a vehicle door; the fuel tank cap fixing assembly is fixed on the vehicle door supporting assembly; and the antistatic ring surrounds the outer side of the fuel tank cap fixing assembly, and is fixed on the vehicle door supporting assembly. Therefore, the antistatic ring has a static electricity prevention effect, and can effectively adsorb and conduct electrostatic charges in a painting process, so that film defects, such as fat edge and sagging, on corners of a fuel tank cap due to charge accumulation can be effectively avoided, and the painting effect of the fuel tank cap can be effectively enhanced.

Owner:BEIQI FOTON MOTOR CO LTD

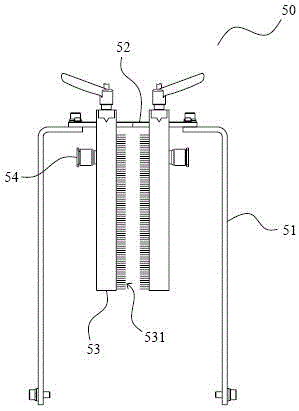

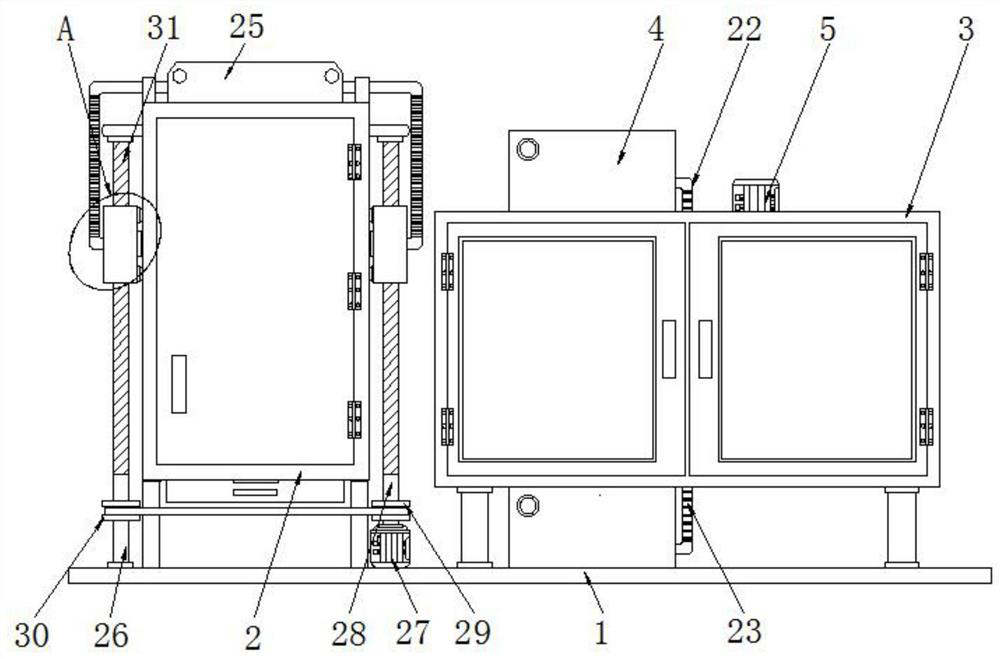

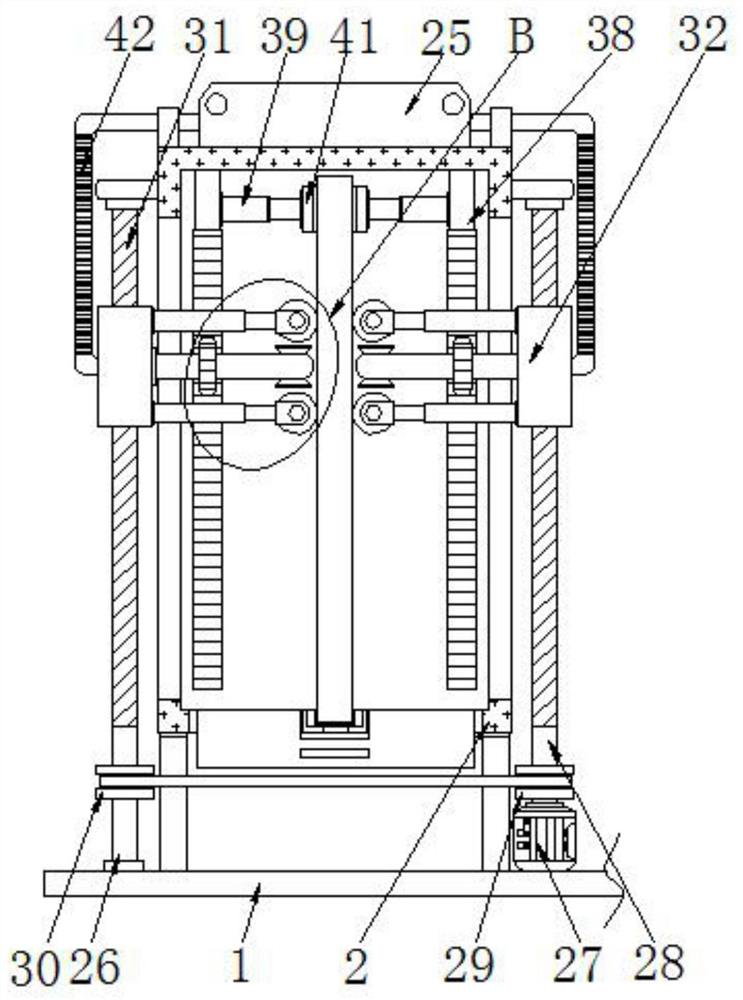

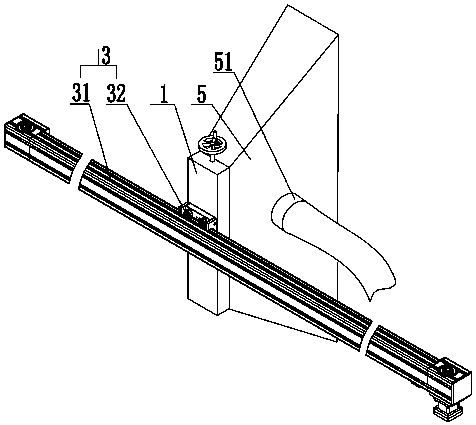

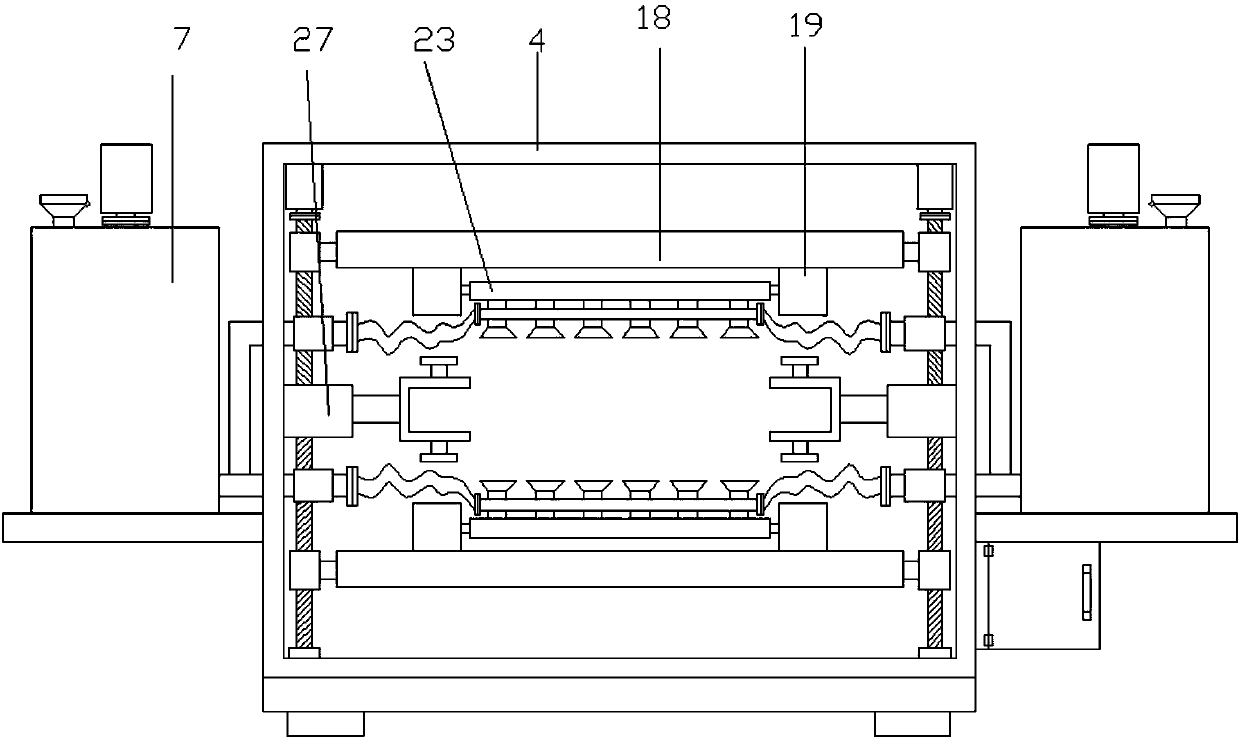

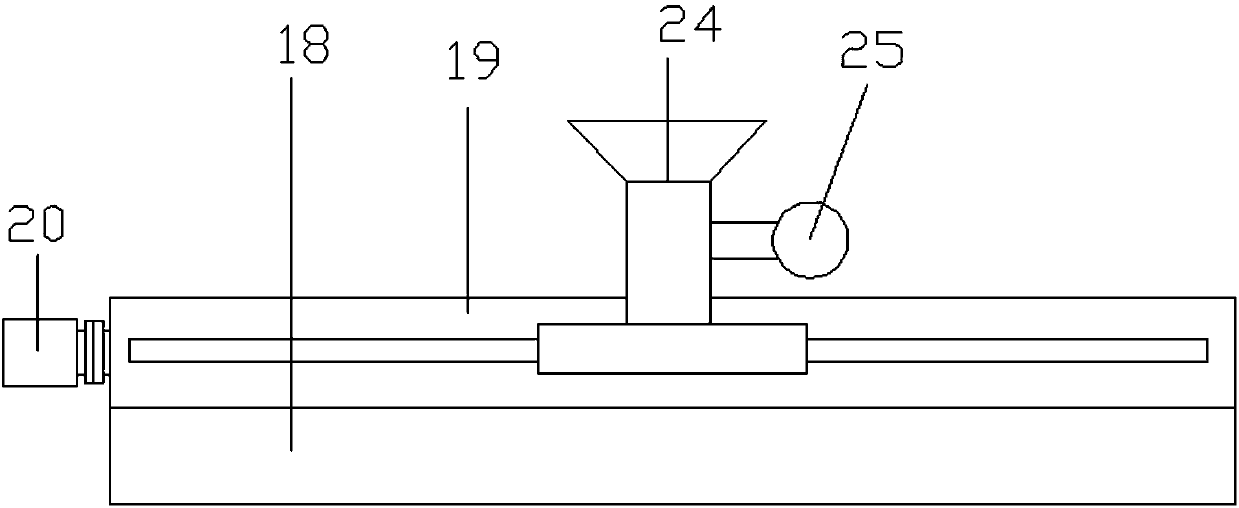

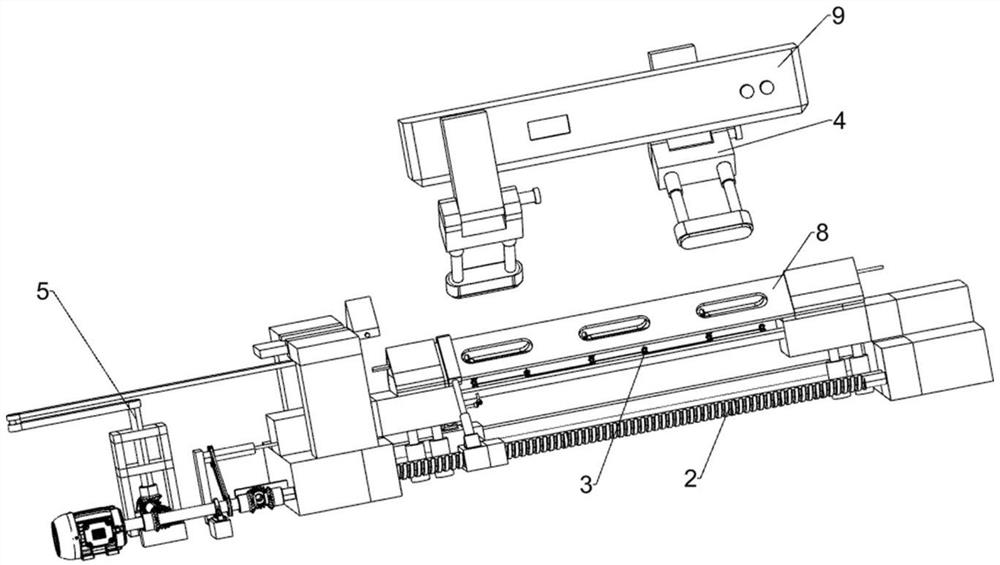

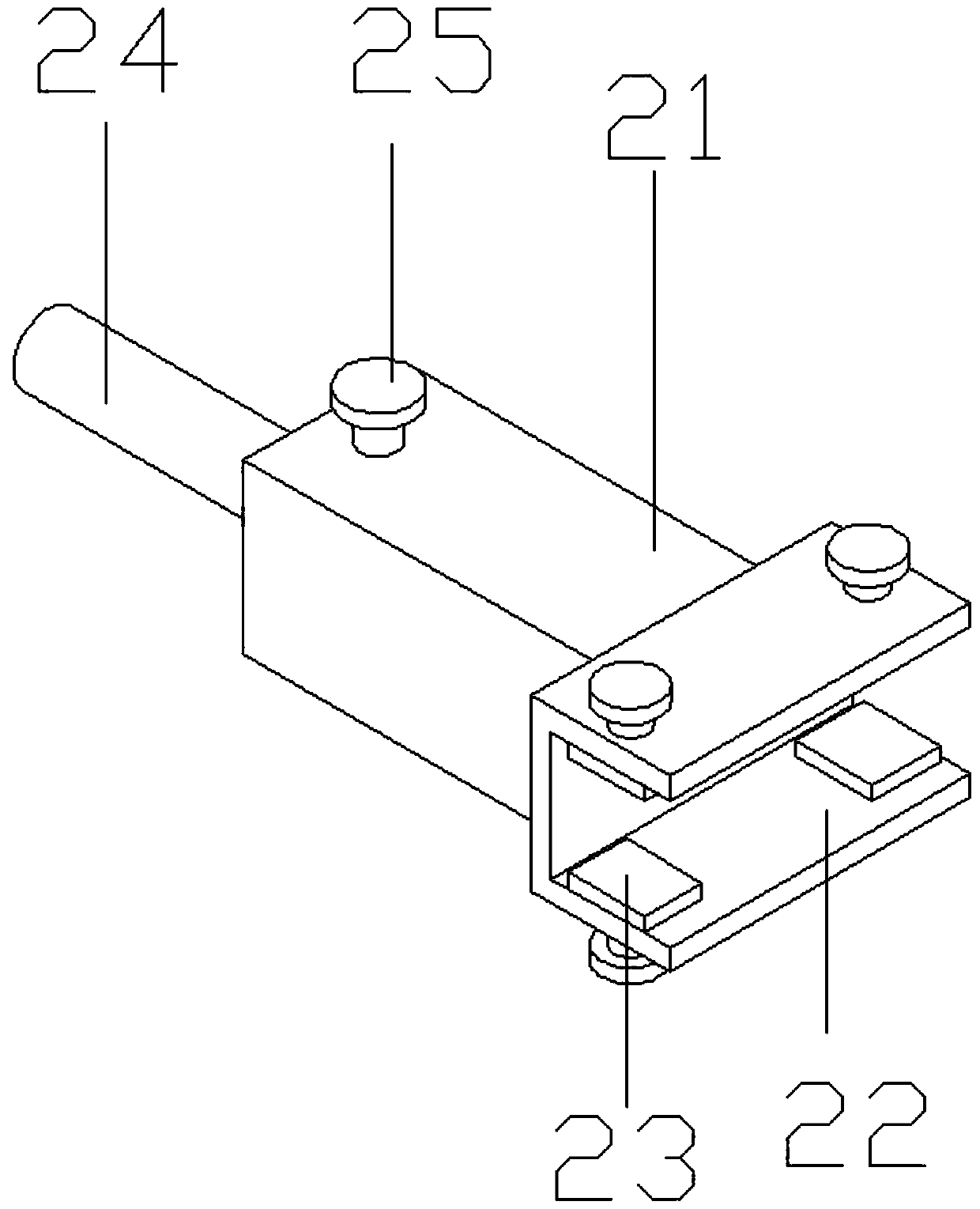

Spraying mechanism, semi-automatic spraying machine and a full-automatic spraying machine

PendingCN108452988AGuarantee the quality of paintingImprove painting efficiencySpraying apparatusSemi automaticCoating

The invention discloses a spraying mechanism, and aims at solving the problems of low coating quality and low working efficiency of a traditional spraying technology. The spraying mechanism comprisesa spraying gun rack on which at least one spraying gun is arranged, wherein the spraying gun rack is connected to a first sliding mechanism through which the spraying gun rack can horizontally reciprocate. According to the spraying mechanism, the spraying gun on the spraying gun rack can be driven by the first sliding mechanism to horizontally reciprocate to spray paint, thus the paint spraying quality in the horizontal position can be ensured, and the paint spraying efficiency is improved. Additionally, the invention also disclose a semi-automatic spraying machine and a full-automatic spraying machine which are on that basis of the abovementioned spraying mechanism.

Owner:ZHOUSHAN IMC YONGYUE SHIPYARD & ENG CO LTD

Automatic paint spraying device for hardware processing

ActiveCN111701778AImprove cleanlinessEasy accessPretreated surfacesCleaning using gasesEngineeringDust particles

The invention provides an automatic paint spraying device for hardware processing, relates to the technical field of automatic mechanical processing, so as to solve the problems that because a workpiece has small volume and high requirement for smoothness of the paint surface, during paint spraying, once dust particles carried in the air fall on the hardware workpiece, convex particles are prone to producing, the quality of a paint film is affected, moreover, the splashed paint liquid is prone to flying to surrounding operators, and the operators are adversely affected. The automatic paint spraying device comprises a base; and a paint spraying table is horizontally and fixedly installed at the part, close to the left, of the middle of the top plane of the base. According to the automatic paint spraying device, since horizontal clamping plates are correspondingly and fixedly installed at the front end edge and the rear end edge of the paint spraying table on the top plane of the base, arack is fixedly installed on a sliding table seat at the rear side of a travel hole, a protective cover can be driven to move through the movement of the sliding table seat, thus during paint spraying, the protective cover can cover the workpiece, when paint spraying is finished, the protective cover can move to the right end with the sliding table seat, and the workpiece is conveniently taken.

Owner:浙江华鑫拉链有限公司

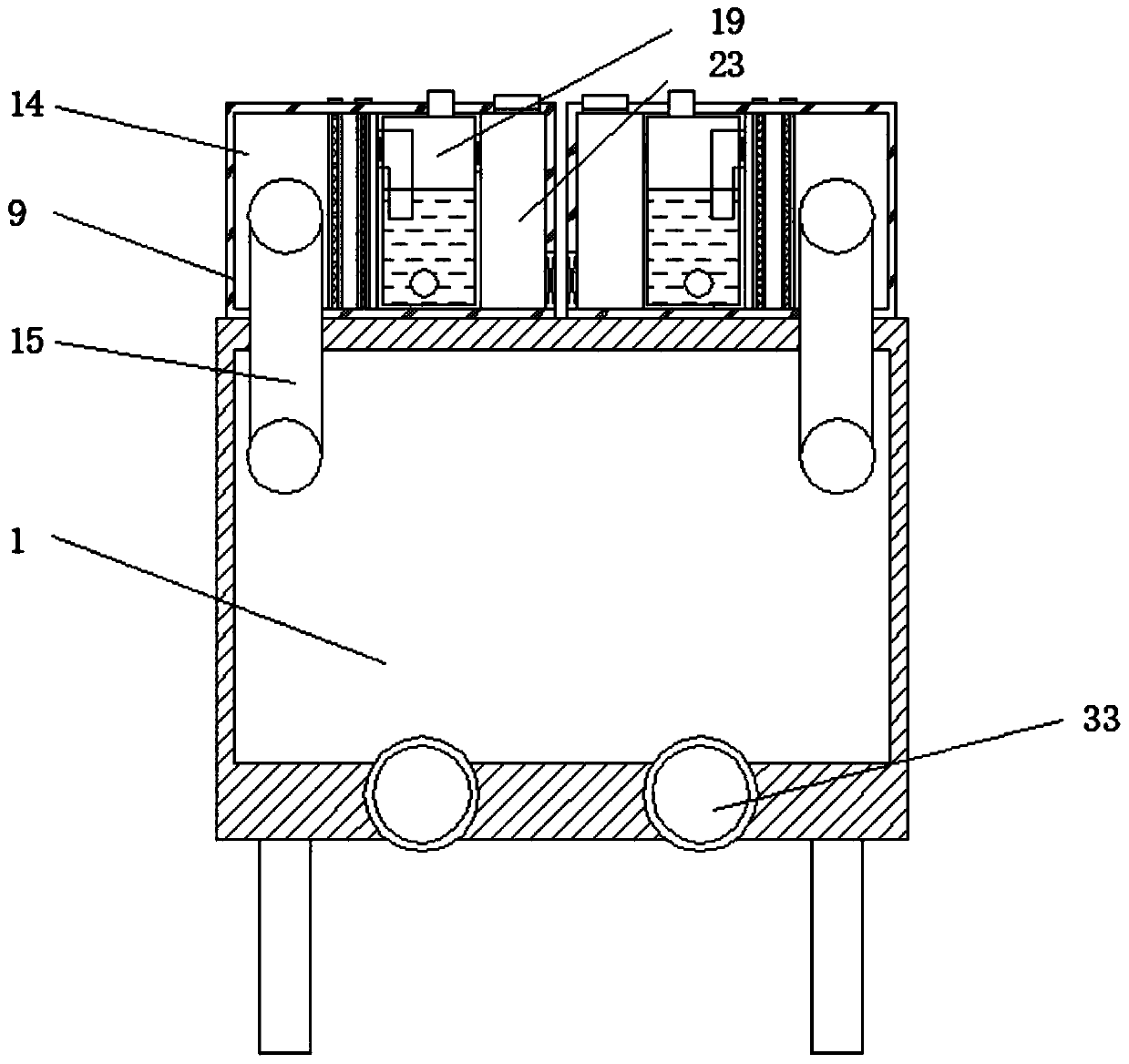

Bi-directional plank paint spraying equipment for building construction

The invention discloses bi-directional plank paint spraying equipment for building construction. The bi-directional plank paint spraying equipment comprises a bottom plate. The upper side of the bottom plate is provided with a connection frame. The lower ends of the left side and the right side of the connection frame are provided with supporting plates. The upper sides of the supporting plates are provided with stirring cavities. The inner sides of the stirring cavities are provided with liquid draining pipes, the upper sides of the liquid draining pipes are provided with first connection pipes, and telescopic rods are arranged between each liquid draining pipe and the corresponding first connection pipe. The inner side of each telescopic rod is provided with a clamping block. Second motors are arranged at four corners of the top end inside the connection frame. The lower sides of the second motors are provided with first lead screws. The upper end and the lower end of each first leadscrew are provided with first sliding blocks. Connection plates are arranged between the first sliding blocks. The left end and the right end of the inner side of each connection plate are provided with sliding grooves. A third motor is arranged on the rear side of each sliding groove. The front side of each third motor is provided with a second lead screw. Each second lead screw is provided witha second sliding block. Connection rods are arranged between the second sliding blocks. The inner sides of the connection rods are provided with spray heads. The front sides of the spray heads are provided with second connection pipes. The bi-directional plank paint spraying equipment for building construction can effectively and conveniently carry out rapid paint spraying, and in this way, the working efficiency of the equipment can be effectively improved.

Owner:THE ELEVENTH METALLURGICAL CONSTR GRP

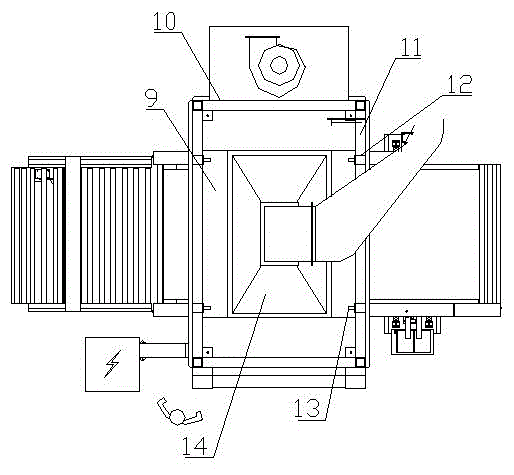

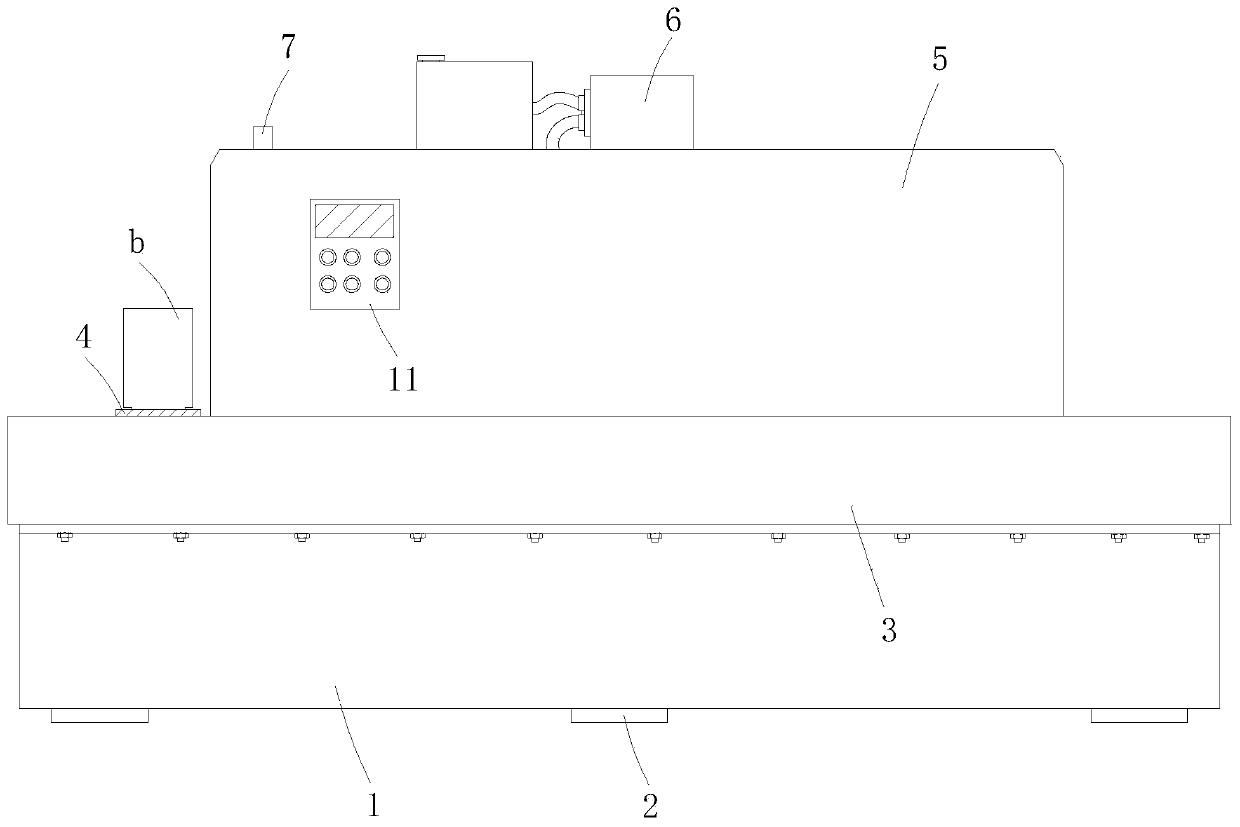

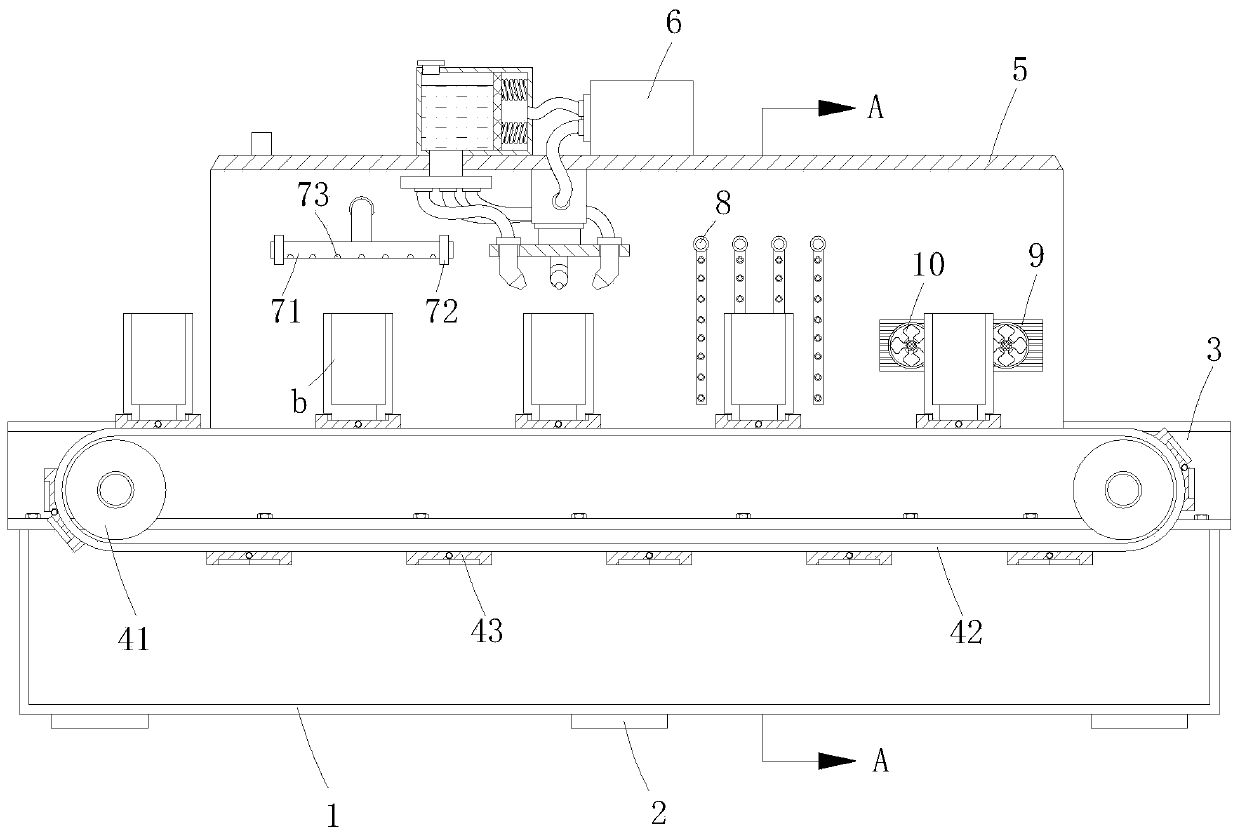

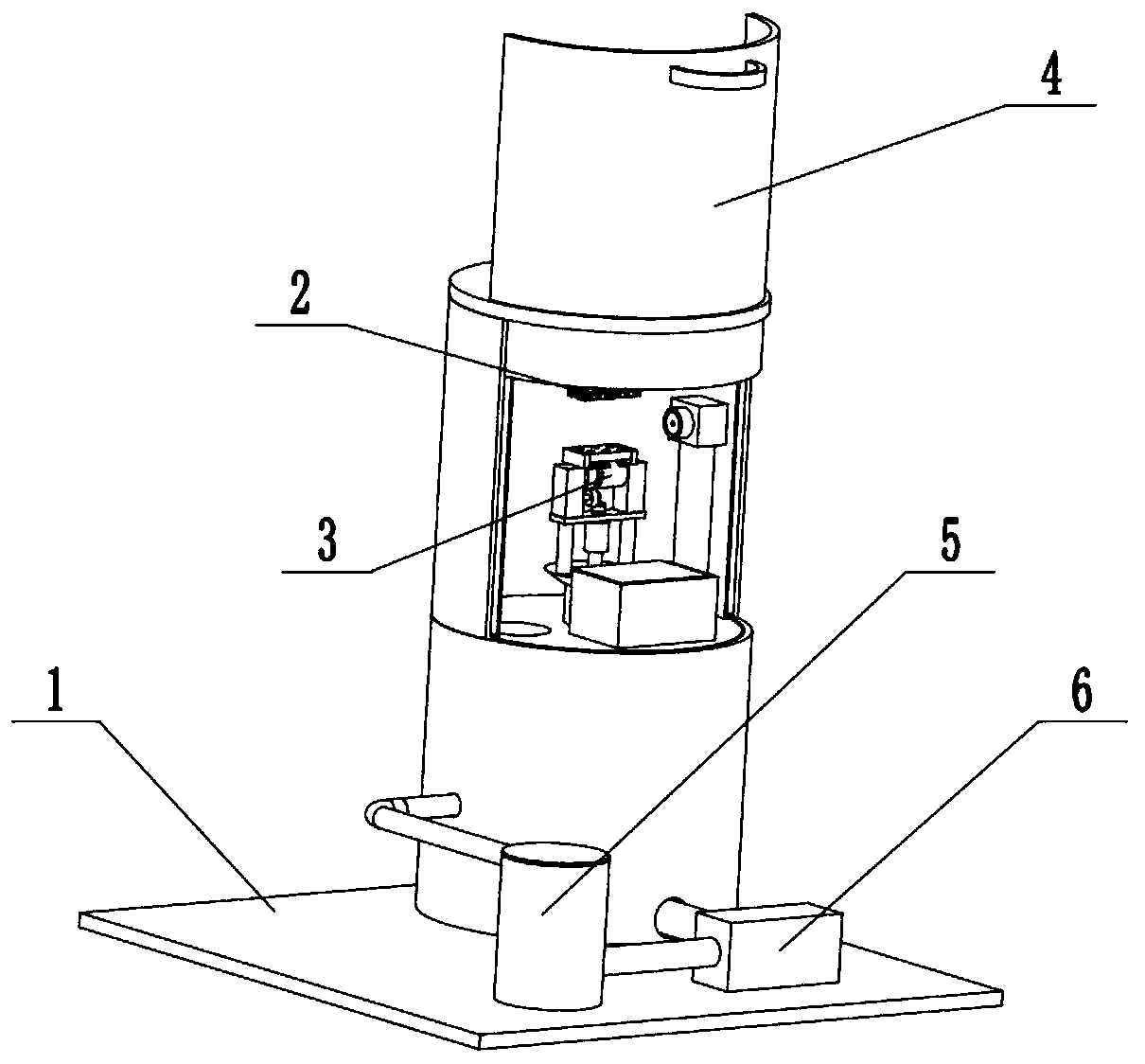

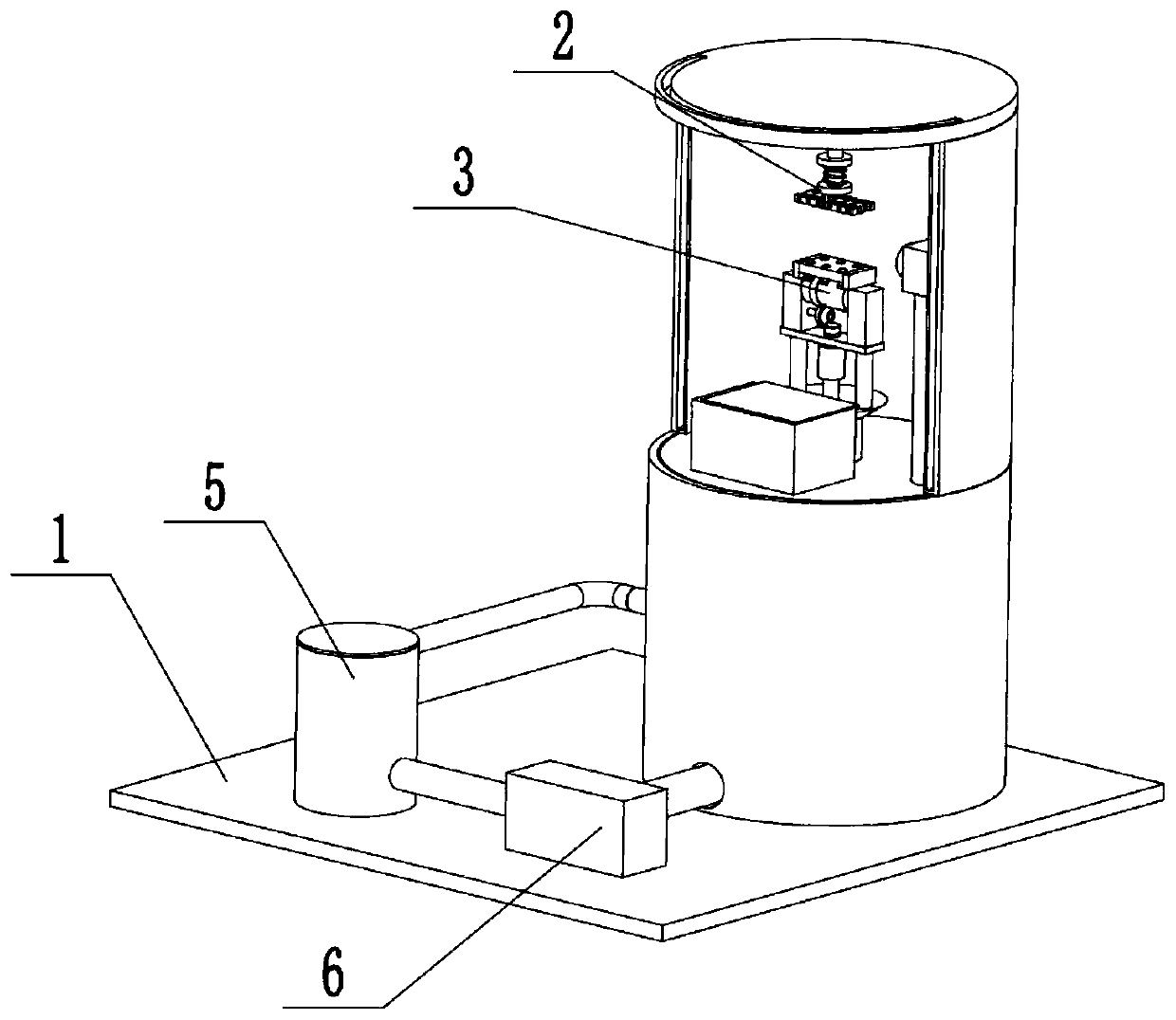

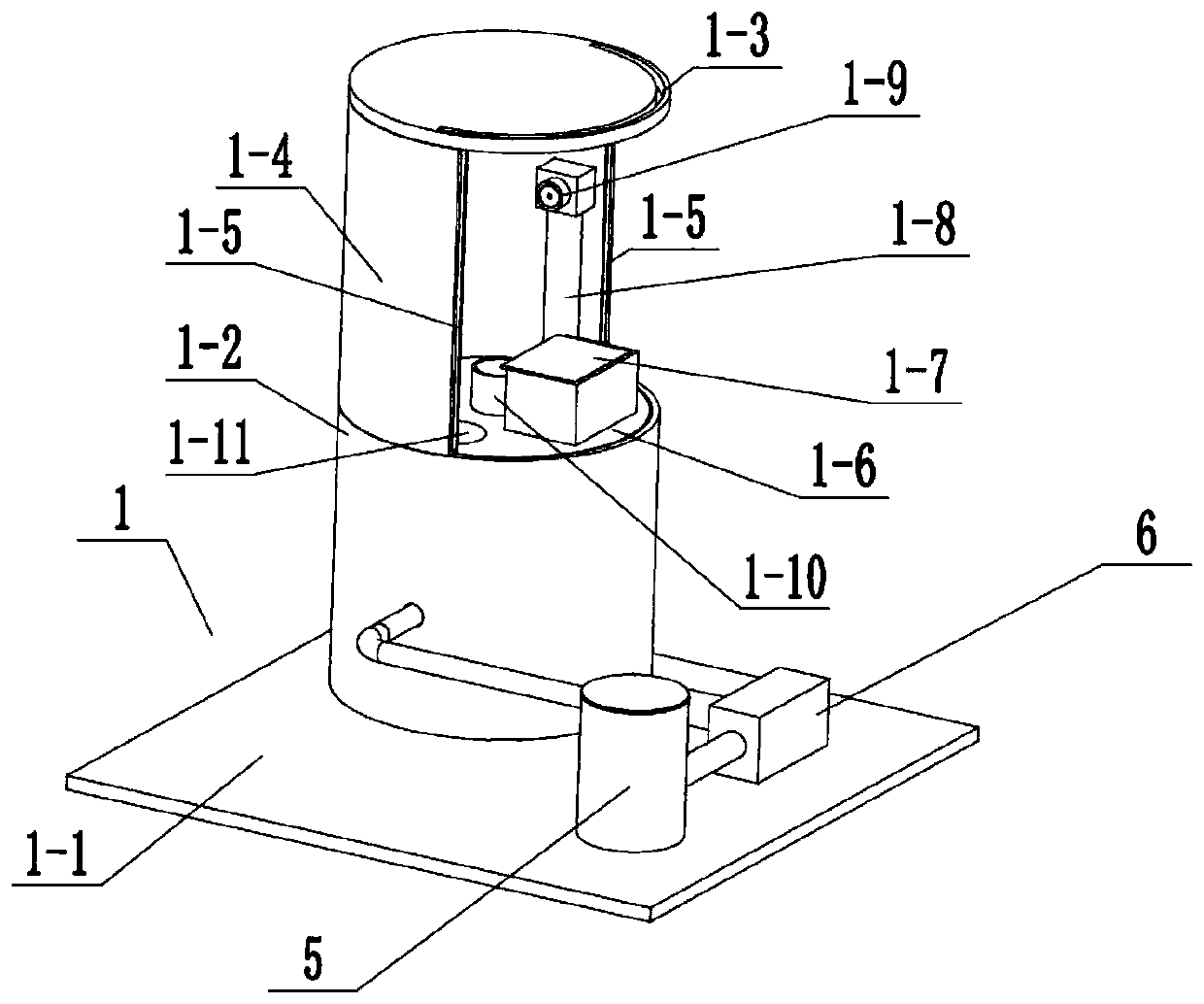

Surface paint spraying device for tubular connection part for architectural engineering

InactiveCN110624744AImprove painting efficiencyGuarantee the quality of paintingPretreated surfacesElectrostatic cleaningEngineeringTreatment time

The invention relates to the technical field of architectural engineering related equipment and provides a surface paint spraying device for a tubular connection part for architectural engineering. The surface paint spraying device aims to solve the problems that paint is sprayed manually during existing paint spraying work, certain harm is generated to human bodies, paint is liable to be sprayedunevenly on a workpiece, automatic paint spraying devices on the market are long in treatment time, equipment is complex, cost is high, clamping operation for pipe fittings is cumbersome, and production efficiency is lowered. The surface paint spraying device comprises a base box and a plurality of support legs installed at the lower end of the base box. Two C-shaped side edge plates are symmetrically installed on the two sides of the upper end of the base box through unit bolt nuts, and a paint spraying chamber is arranged at the upper ends of the two C-shaped side edge plates. A conveying mechanism is arranged between the two C-shaped side edge plates. An electrostatic dust collection mechanism, a paint spraying mechanism and a hot air drying mechanism are arranged sequentially from leftto right in an inner cavity of the paint spraying chamber in the movement direction of the conveying mechanism. The surface paint spraying device is especially suitable for spraying paint for the tubular connection part and has high social use value and application prospects.

Owner:戚崇圆

Paint spraying process for power distribution cabinet body plates

InactiveCN106903036ANot easy to blister and peel off paintThe painting process is simplePretreated surfacesCoatingsSurface cleaningFree cooling

The invention discloses a paint spraying process for power distribution cabinet body plates and relates to the field of power distribution cabinets. Through the process steps of cabinet body plate surface cleaning, acid pickling, phosphorization, blow-drying, putty brushing, drying, polishing, primer spraying, finish paint spraying, paint drying, forced cooling and natural cooling, the paint spraying effect and the paint spraying quality are guaranteed. The whole paint spraying process steps are controlled reasonably, so that the surfaces of power distribution cabinet bodies are not prone to blistering or depainting, and the service life is prolonged.

Owner:繁昌县易能科技有限责任公司

Aluminum alloy section paint spraying device

InactiveCN109465141AFull rotation stirringGuarantee the quality of paintingSpray boothsRotational axisAluminium alloy

The invention discloses an aluminum alloy section paint spraying device, and relates to the technical field of aluminum alloy paint spraying. The aluminum alloy section paint spraying device comprisesan operation frame and a paint box, a supporting net plate is horizontally and fixedly installed on the operation frame, an outer thread I and an outer thread II which are opposite in rotation direction are symmetrically tapped on a rotating shaft, threaded sleeve blocks sleeve and are fixed on the outer thread I and the outer thread II, paint spraying pipes are vertically fixed on the threaded sleeve blocks, and paint spraying discs with paint spraying heads are installed at the lower ends of the paint spraying pipes. According to the aluminum alloy section paint spraying device, the two threaded sleeve blocks on the rotating shaft can move towards or far away from each other through driving of a servo motor, then the paint spraying discs can move transversely and spray paint on an aluminum alloy section, the paint spraying efficiency is higher, a rotating frame and stirring blades which are opposite in rotation direction are arranged inside the paint box to rotate so as to fully rotate and stir the paint in the paint box, so that uniformity and refinement degree of the paint is effectively improved, the paint spraying quality on the surface of the aluminum alloy section is guaranteed, and the paint is more uniform and fine.

Owner:安徽太铝新材料科技有限公司

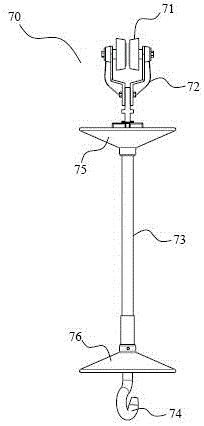

Wall surface rolling brushing type coating device

ActiveCN110565912AEasy to disassembleRealize automatic stirringBuilding constructionsEngineeringMechanical engineering

The invention discloses a wall surface rolling brushing type coating device, and relates to the technical field of construction machinery. The wall surface rolling brushing type coating device comprises a rolling brushing mechanism and a discharging mechanism; a fixed seat is arranged on the lower part of the rolling brushing mechanism, a groove is formed in the top of the fixed seat, a brushing roller is arranged inside the groove, and demounting mechanisms are arranged at the junctions of the two ends of the brushing roller and the fixed seat; and the discharging mechanism is arranged abovethe rolling brushing mechanism, side plates are arranged on the two sides of the discharging mechanism, a connecting seat is arranged between the two side plates, a linkage mechanism is arranged in the middle of the connecting seat, a material collecting groove is formed in the upper side of the connecting seat, a plurality of through holes are formed in the bottom of the material collecting grove, a coating box is arranged above the material collecting groove, a stirring mechanism is arranged inside the coating box, a transmission mechanism is arranged on one side of the coating box, and thetransmission mechanism is mechanically connected with the linkage mechanism. According to the wall surface rolling brushing type coating device, different brushing rollers can be demounted and replaced conveniently, automatic stirring and automatic sticking of coating can be achieved, the brushing quality is good, and the brushing efficiency is high.

Owner:唐山陶瓷集团设计研究有限公司

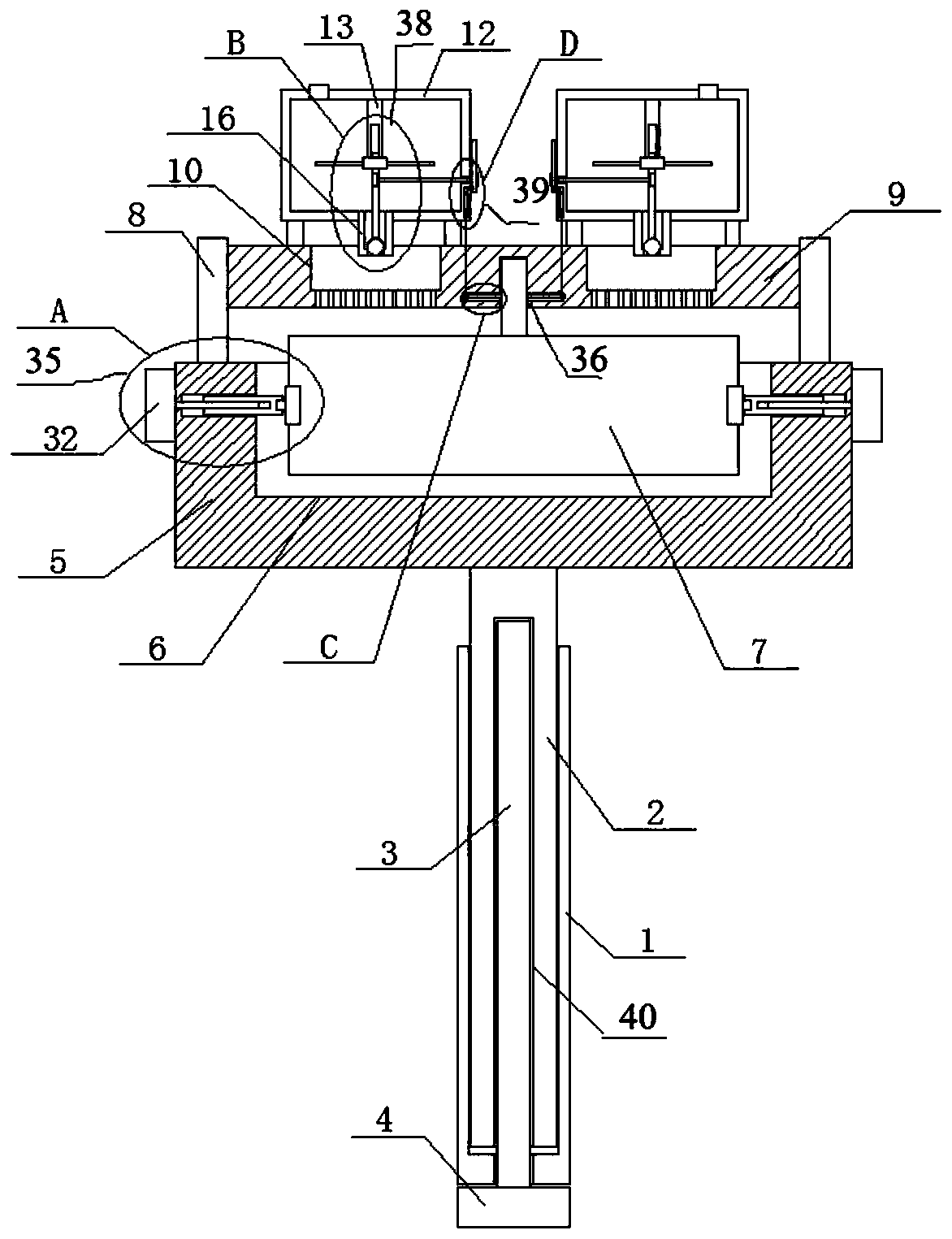

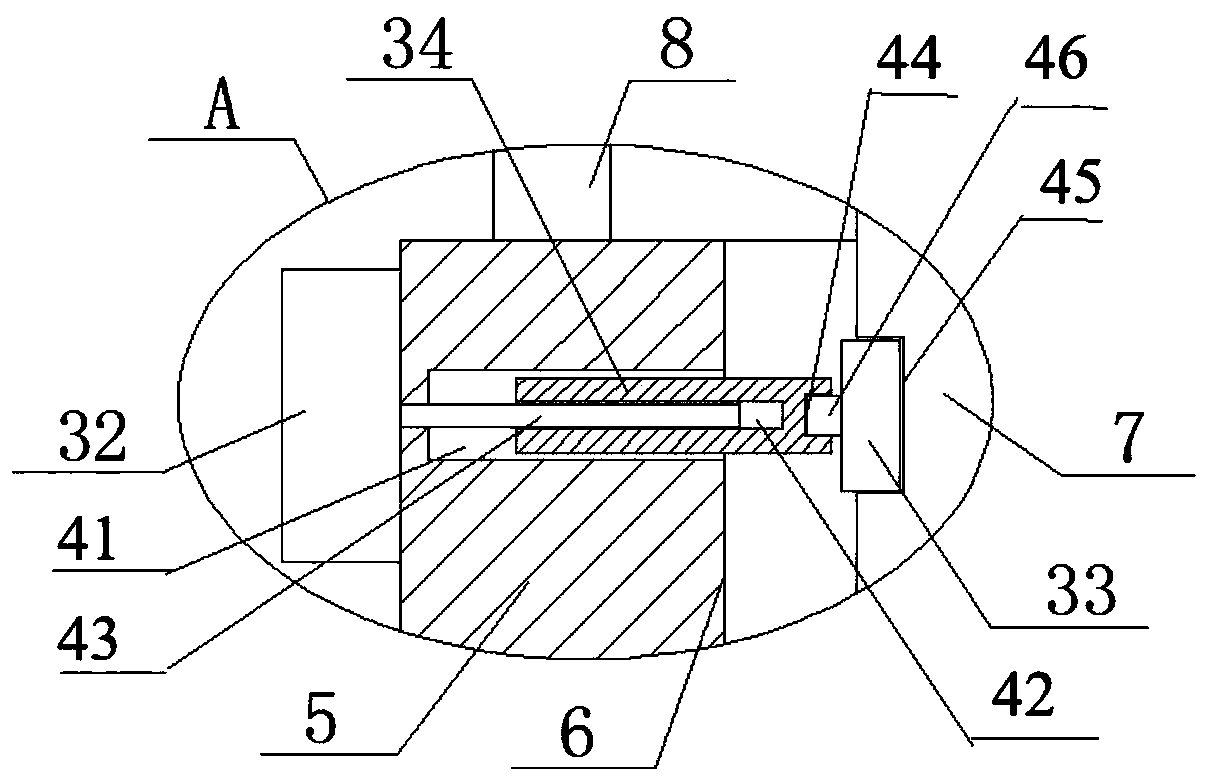

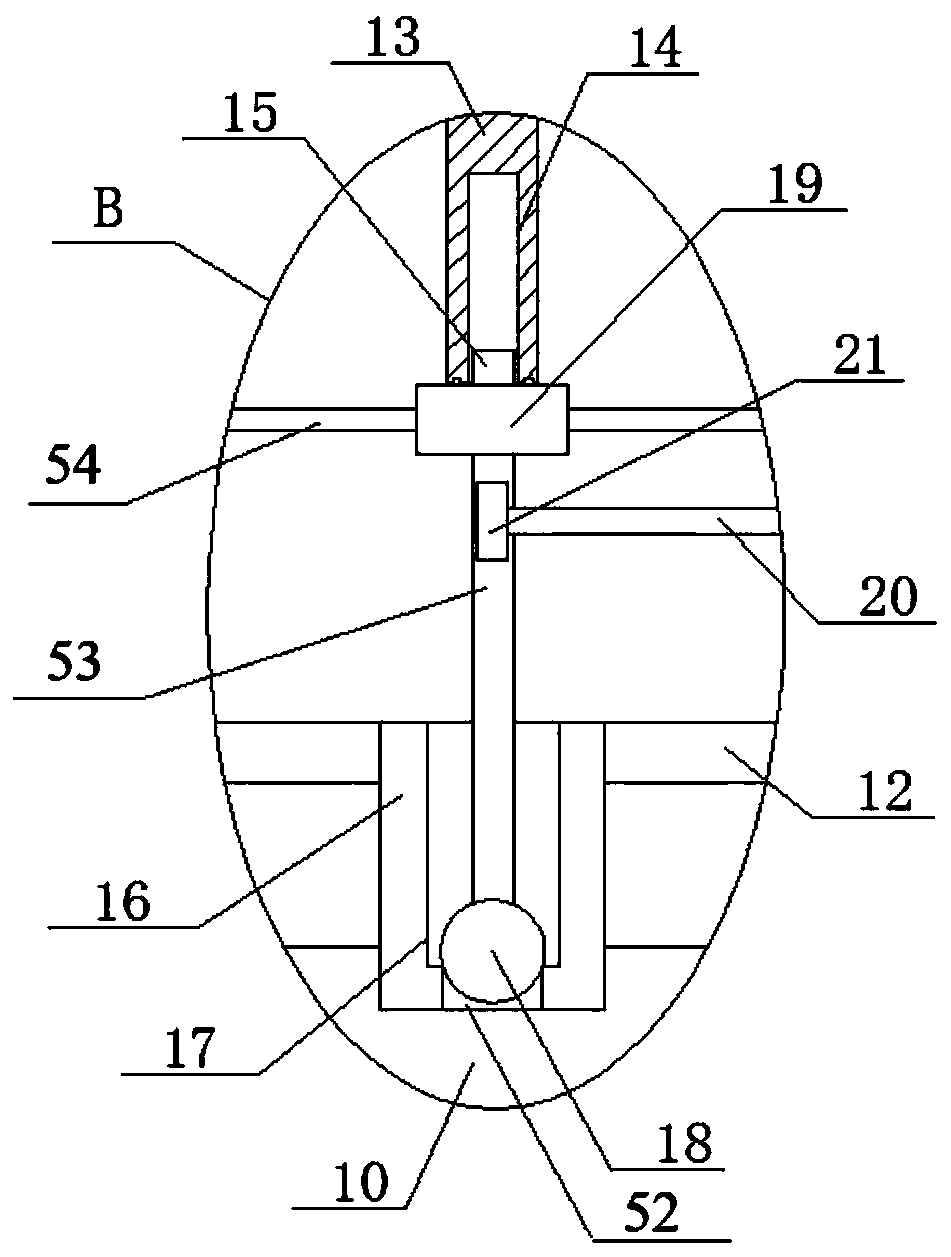

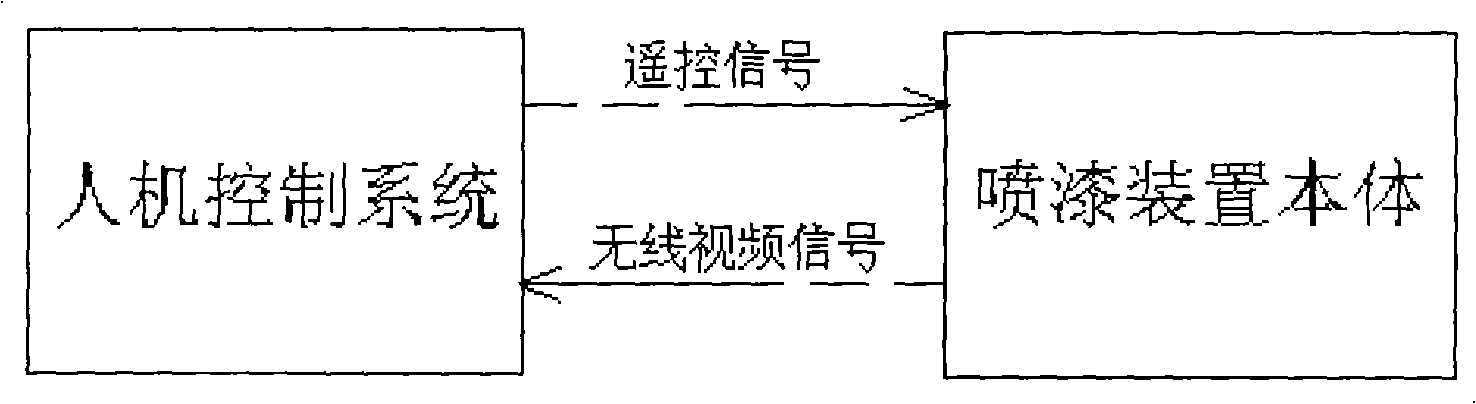

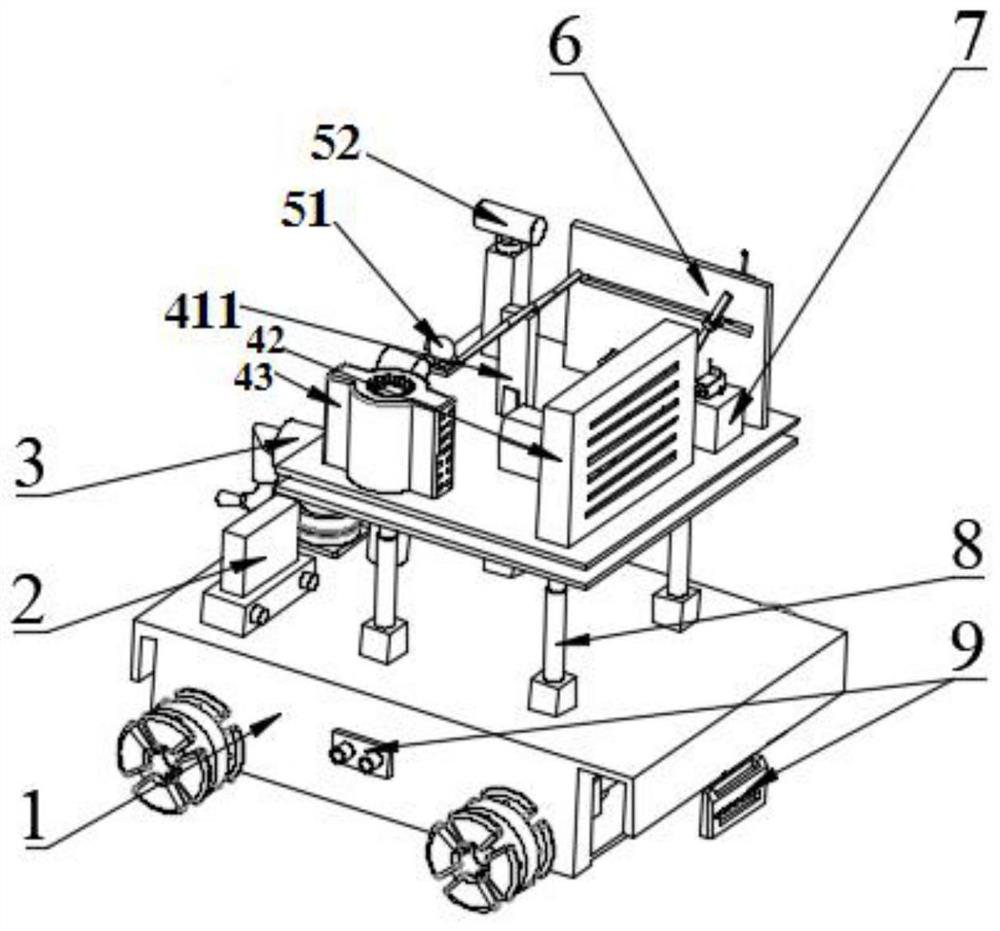

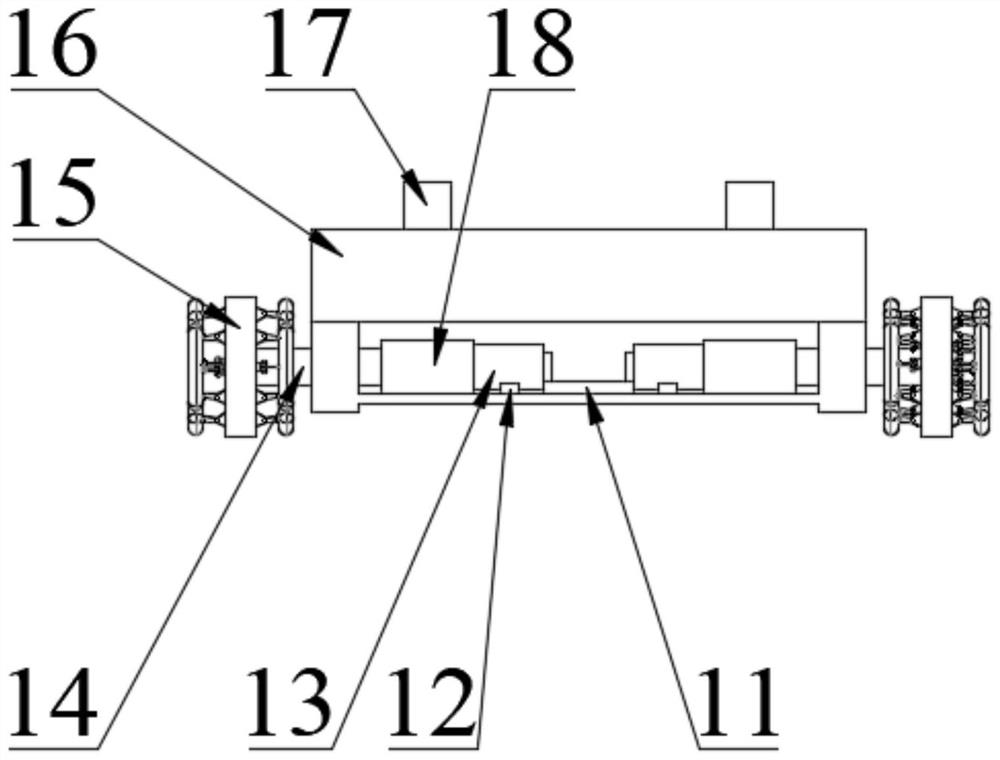

Intelligent type motorcar chassis lacquer spraying arrangement

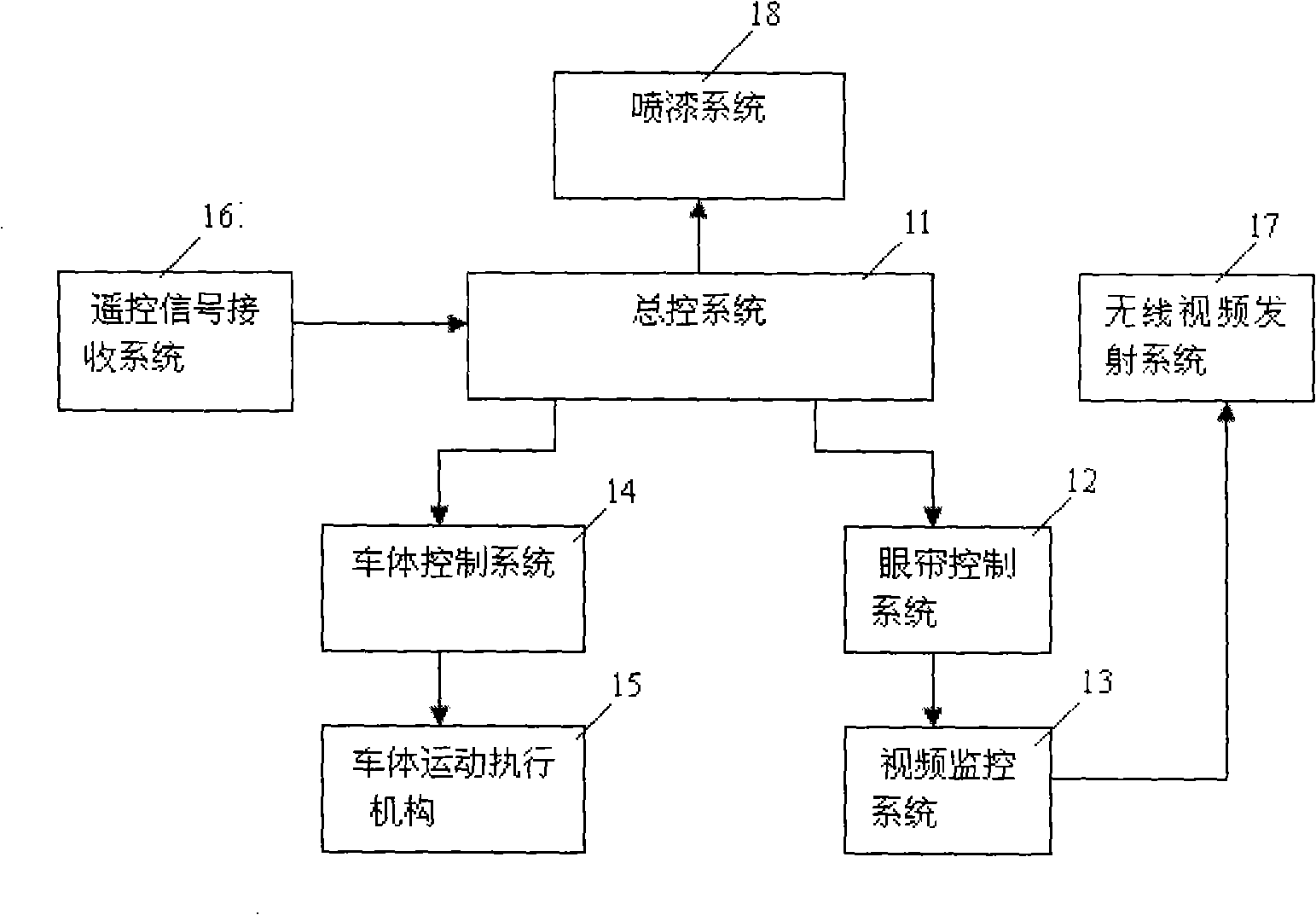

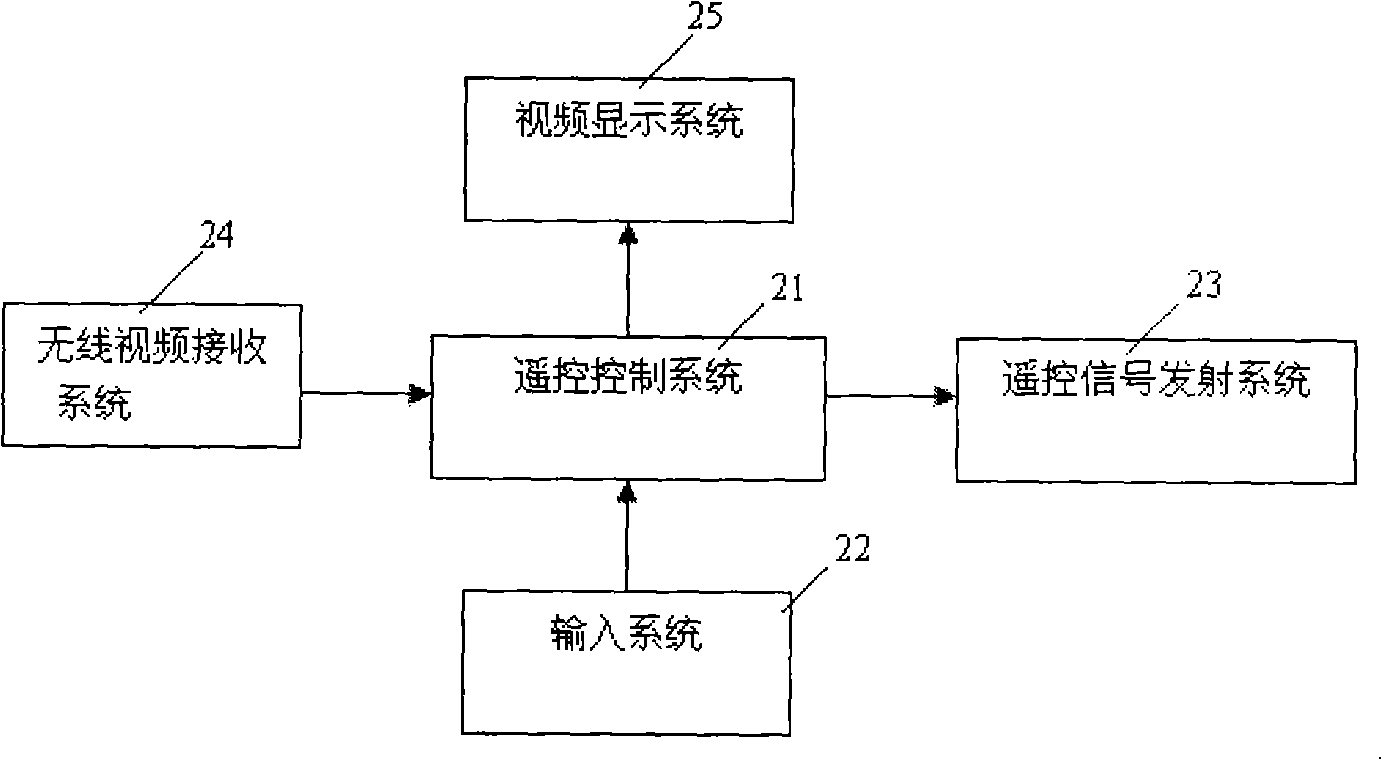

InactiveCN101284264ARealize automatic controlReduce labor intensityLiquid surface applicatorsCoatingsVideo monitoringComputer control system

The invention relates to a spray painting device. The invention discloses an intelligent automotive chassis spray painting device. The spray painting device comprises: a spray painting device body and a human-computer control system, wherein the human-computer control system communicates with the spray painting device by a remote control signal, and the spray painting device body is transferred to the human-computer control system by a wireless video signal. The spray painting device is used for the spray painting work of an automotive chassis, which can realize the automatic control and the automatic spray painting. When in spray painting, people do not need to enter the bottom part of an automobile, thus reducing the labor intensity and eliminating the unsafe hidden danger. At the same time, the spray painting device is provided with a video monitoring system, which can ensure the spray painting quality of the automotive chassis under the situation of automatic control.

Owner:刘雨盈

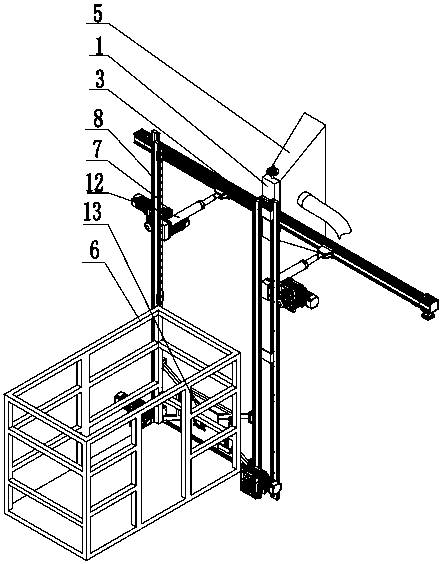

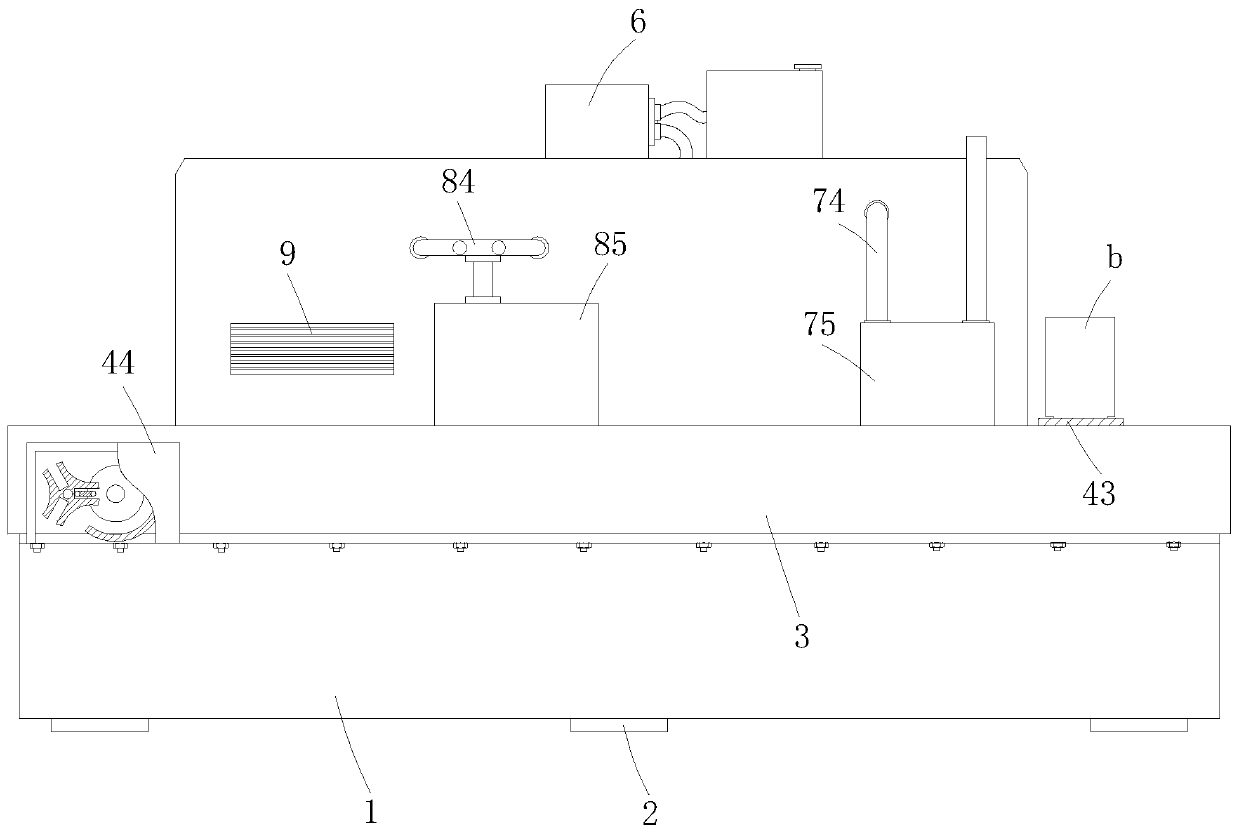

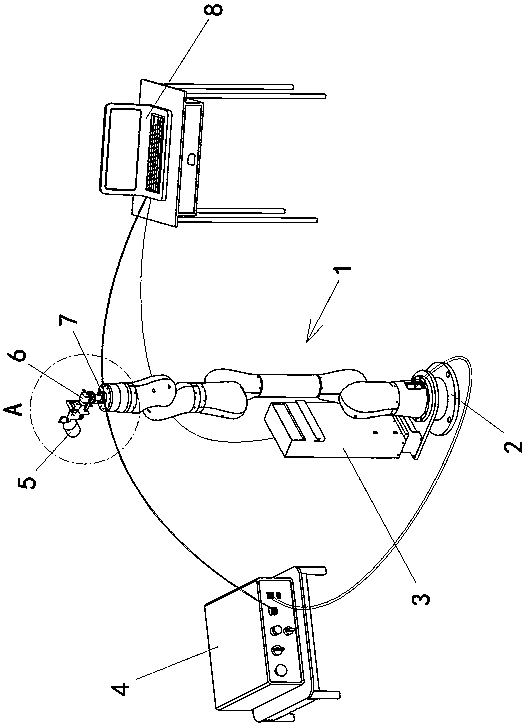

Automatic multifunctional wall painting machine and application

ActiveCN112523473AGuaranteed uptimeMake sure to jump over the obstaclesBuilding constructionsDrive shaftEngineering

The invention relates to an automatic multifunctional wall painting machine and application, and belongs to the technical field of building decoration equipment. The automatic multifunctional wall painting machine comprises a moving device, a lifting device, a working platform, a feeding device and a painting device, wherein the feeding device and the painting device are arranged on the working platform, the moving device comprises a vehicle body, four wheels are arranged on each of the two sides of the vehicle body, a controller is arranged in the vehicle body, the controller is connected with four direct-current motors, transmission shafts of the four direct-current motors are connected with the four wheels respectively and used for driving the wheels to rotate, the working platform comprises a main platform and an auxiliary platform, the feeding device and the painting device are located on the main platform, the lifting device is arranged between the vehicle body and the auxiliaryplatform, the auxiliary platform can move up and down relative to the vehicle body, the auxiliary platform and the main platform can rotate mutually, and the controller is connected with a driving structure of the lifting device and can control the lifting action of the lifting device. According to the automatic multifunctional wall painting machine and application, automatic wall painting is achieved, the working efficiency is high, and the adverse effect of manual wall painting on painting personnel is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

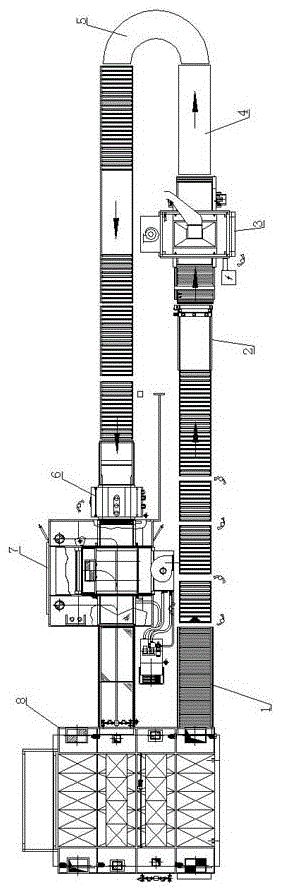

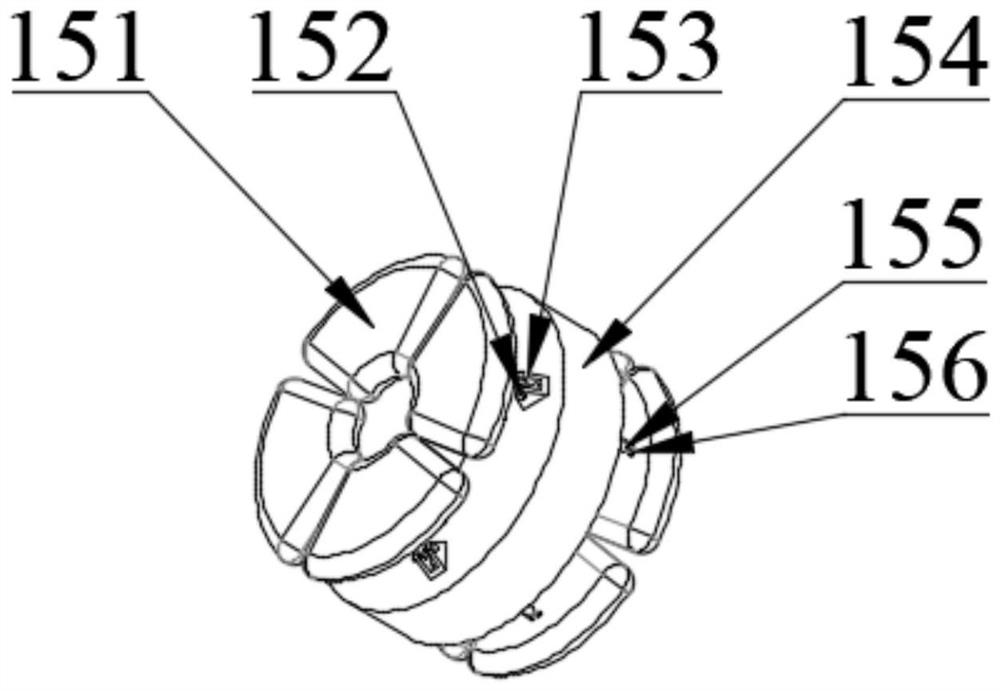

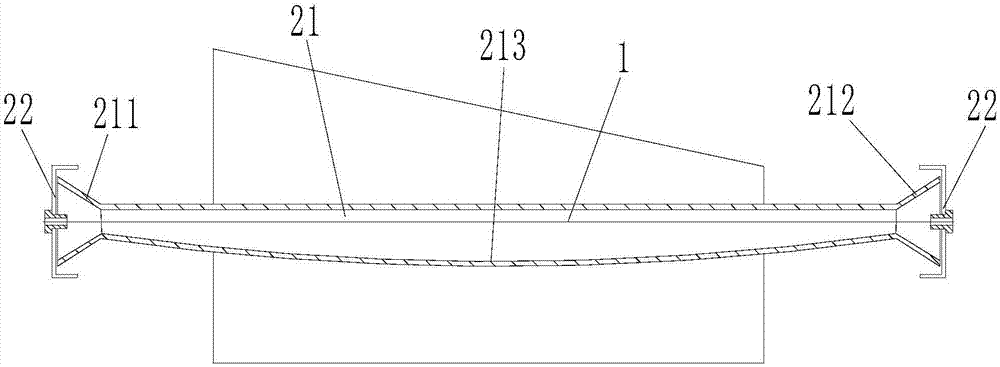

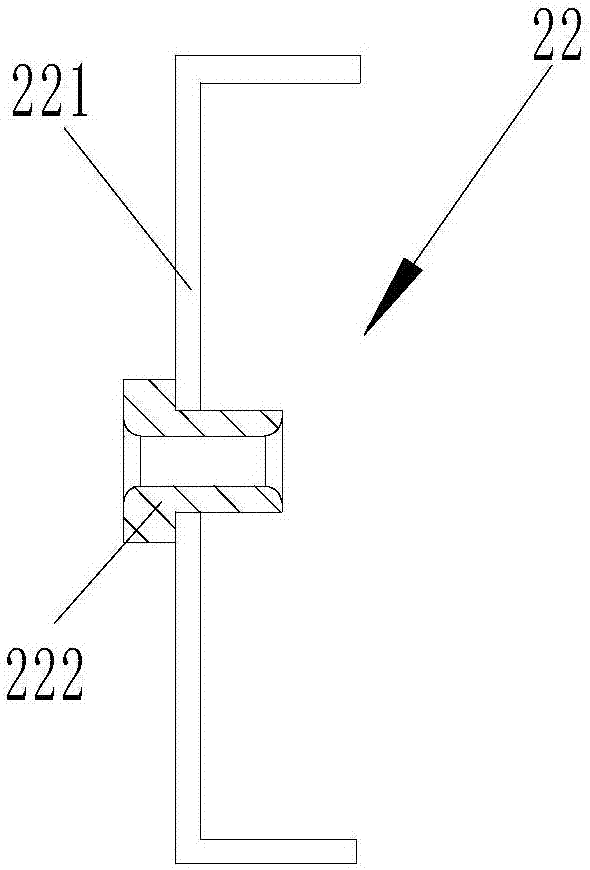

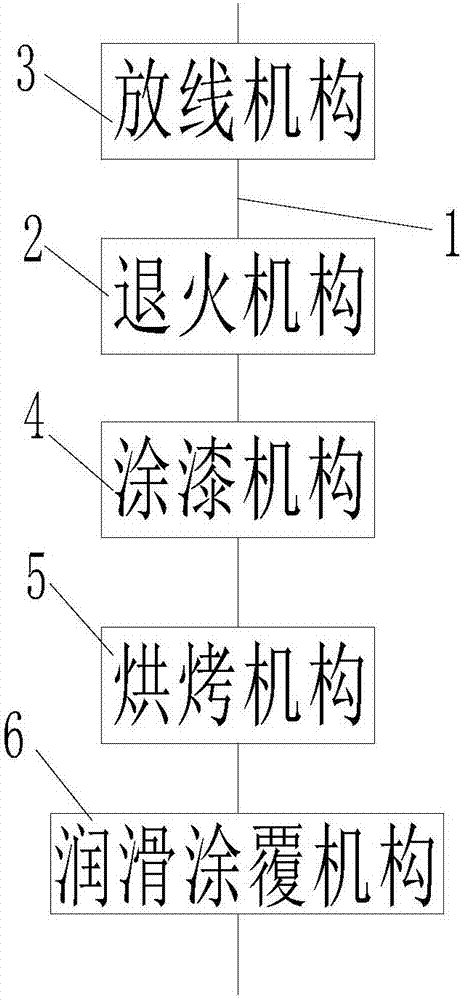

Annealing mechanism and enameled wire production system

ActiveCN106893854AAvoid bumpingGuarantee the quality of paintingFurnace typesHeat treatment furnacesMaterials science

The invention provides an annealing mechanism and an enameled wire production system. The annealing mechanism comprises an annealing pipe; two ends of the annealing pipe are respectively a wire inlet and a wire outlet; the bottom inner wall of the annealing pipe is a downwards recessed arc; and a wire body enters the annealing pipe from the wire inlet, and is discharged from the wire outlet after being heated by the annealing mechanism. The annealing mechanism has the advantages of capability of preventing the surface damage of the wire body in the annealing process and guarantee of the painting quality of the wire body.

Owner:格力电工(马鞍山)有限公司 +2

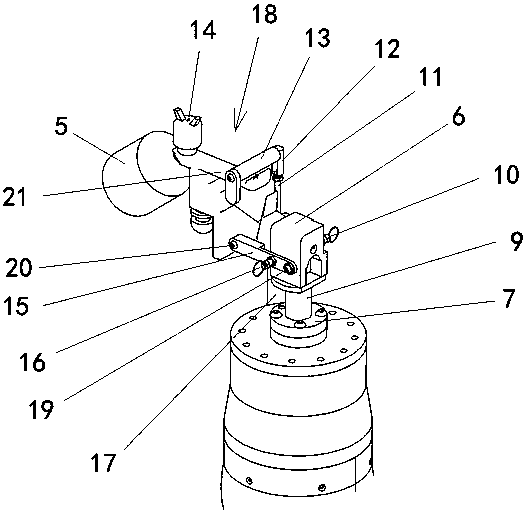

Intelligent paint spraying robot system

PendingCN108126850AMeet maintenance painting requirementsEnsure physical and mental healthImage enhancementProgramme-controlled manipulatorPaint robotAgricultural engineering

The invention provides an intelligent paint spraying robot system. A base is arranged at the lower end of a robot, the robot is connected with a controller, the controller is connected with a processor, the processor is connected with a depth camera, the upper end of the robot is connected with one end of a connecting shaft through a flange, and the other end of the connecting shaft is connected with a mounting base; a mounting shaft of a paint spraying device is inserted into a long hole formed in the vertical direction in the mounting base, and a first positioning bolt for positioning the mounting shaft of the paint spraying device is arranged on one side of the mounting base; the other side of the mounting base is rotationally connected with one end of a limiting arm through a hinge pin, the other end of the limiting arm is connected with a limiting shaft, and the limiting shaft is supported at the mounting shaft of the paint spraying device; a second positioning bolt is arranged between the middle of the limiting arm and the mounting base, and an air cylinder connected with a pneumatic device is fixedly arranged on the mounting base; the outer end of a piston rod matched with the air cylinder is connected with a poking rod through a connecting piece, and a stirring rod is matched with a trigger on the paint spraying device. The system has the advantages of being safe, reliable, capable of saving time, labor and energy, environmentally friendly and capable of reducing the production cost.

Owner:DALIAN NEWSTAR TOOL MFG

Workpiece painting device

InactiveCN111111978AReduce labor intensityImprove factory qualitySpraying apparatusDrive wheelRolling-element bearing

The invention discloses a workpiece painting device. The device comprises a bottom plate, and two supporting bases are fixedly connected to the right side of the top of the bottom plate. Through the cooperation among a cavity, a supporting spring, a trapezoidal block, a limiting sliding groove, a roller, a supporting column, a top plate, a threaded groove, a first threaded rod, a handle, a rollingbearing, a second threaded rod, a driven wheel, a forward and reverse motor, a forward and reverse rotating shaft, a driving wheel, a belt, a threaded sleeve, a fixing block, a connecting block, a brush, a telescopic rod, a paint spraying device, a stirring box, a stirring motor, a stirring rotating shaft, stirring blades, a heater, a conveying pump, a conveying hose, a paint spraying pipe and aspray head, the effect of high automation degree is achieved, manual painting is not needed, time and labor are saved, the labor intensity of workers is reduced, the painting quality is guaranteed, the situation of uneven painting is avoided, the ex-factory quality of workpieces is improved, and convenience is brought to manufacturers to sell, and great convenience is brought to manufacturers.

Owner:淮北德林机械设备有限公司

Angle steel painting device

ActiveCN111822272AImprove efficiencyGuarantee the quality of paintingLiquid surface applicatorsCoatingsPhysicsEngineering

The invention relates to the field of steel machining, and particularly relates to an angle steel painting device. The technical problem to be solved is to provide the angle steel painting device. Theangle steel painting device comprises a working chamber, an outer side smearing mechanism, a hole smearing mechanism, a lifting fixing mechanism, an inner side smearing mechanism, a control display screen, a working door, angle steel and a drying device; and the outer side smearing mechanism, the hole smearing mechanism and the lifting fixing mechanism are arranged inside the working chamber. According to the angle steel painting device, all holes of the angle steel are painted at the same time, the two sides of the outer surface of the angle steel are painted at the same time, then the interior of the angle steel is painted again through the drying device, it is guaranteed that all the positions of the angle steel can be painted, the painting efficiency is improved, and the painting quality of the angle steel is guaranteed.

Owner:胜利油田鸿胜石油工程有限责任公司

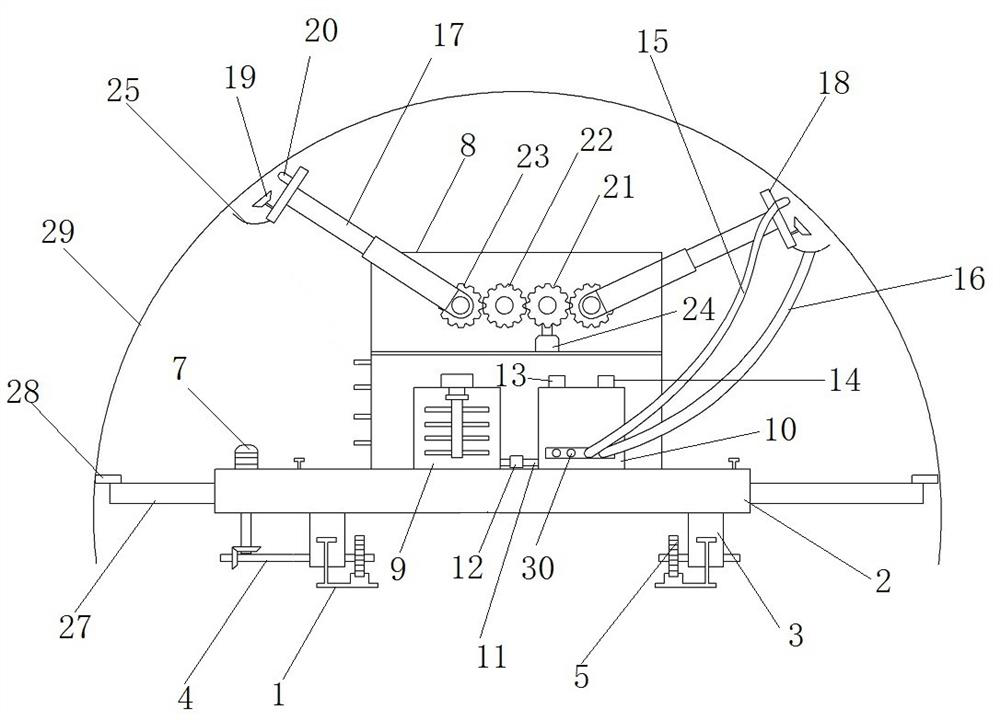

Automatic brushing device for waterproof coating on inner wall of tunnel

ActiveCN112718400AImprove brushing efficiencyReduce workloadLiquid surface applicatorsUnderground chambersGear driveSprayer

The invention relates to an automatic brushing device for a waterproof coating on the inner wall of a tunnel, and belongs to the technical field of tunnel waterproof construction. The automatic brushing device comprises a slide rail, a base movably assembled on the slide rail, a support frame, a waterproof coating brushing assembly and a material baffle plate, the base is provided with a waterproof coating stirring barrel and a material spraying barrel, and the support frame is provided with a gear transmission assembly and a gear driving motor; the waterproof coating brushing assembly comprises a hydraulic telescopic rod, a supporting plate connected to the driving end of the hydraulic telescopic rod, a coating brush installed on the supporting plate and a coating sprayer; the material baffle plate is arc-shaped and is provided with a containing groove, and power of the gear driving motor is transmitted to the hydraulic telescopic rod through the gear transmission assembly to drive the coating brush to brush the waterproof coating along the inner wall of the tunnel; and the splashed waterproof coating is blocked by the material baffle plate to enter the containing groove and flows into the material spraying barrel, so that waste is avoided. According to the automatic brushing device for the waterproof coating on the inner wall of the tunnel, automatic spraying and automatic brushing of the waterproof coating can be achieved, and the construction efficiency and the construction safety are improved.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

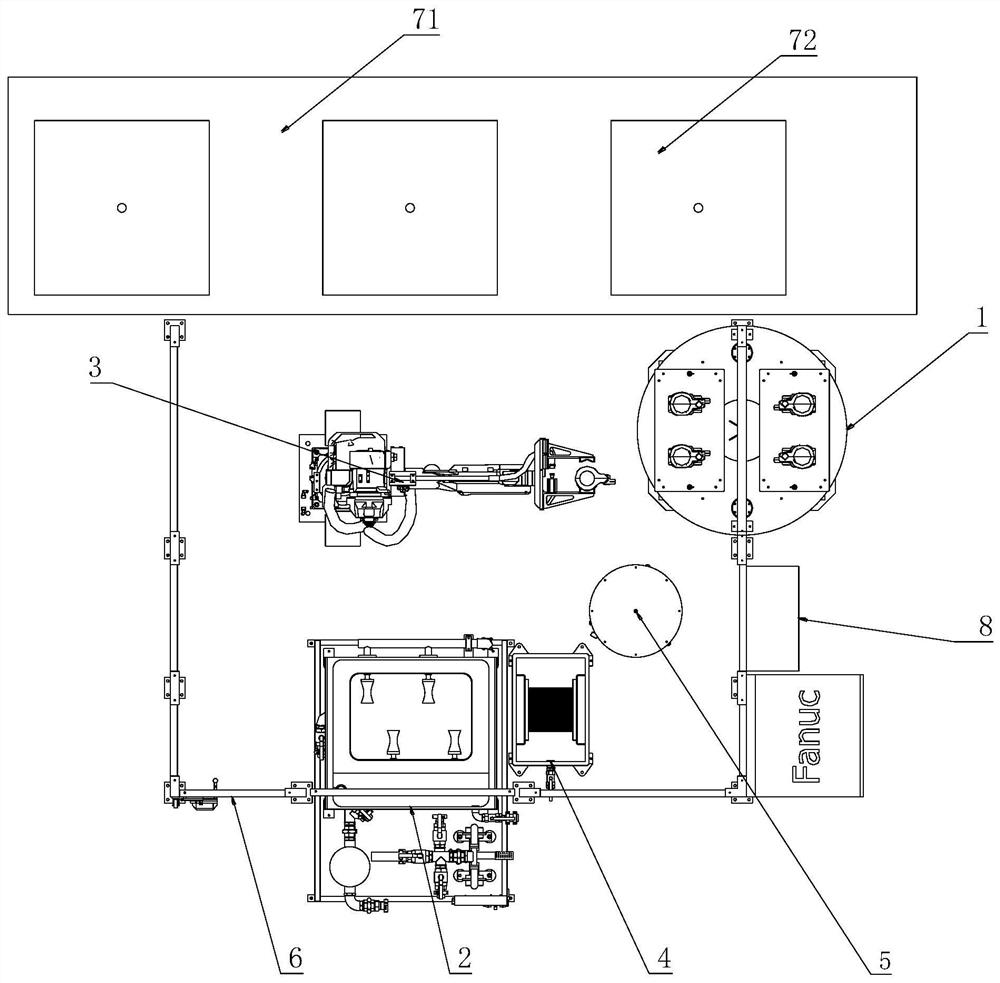

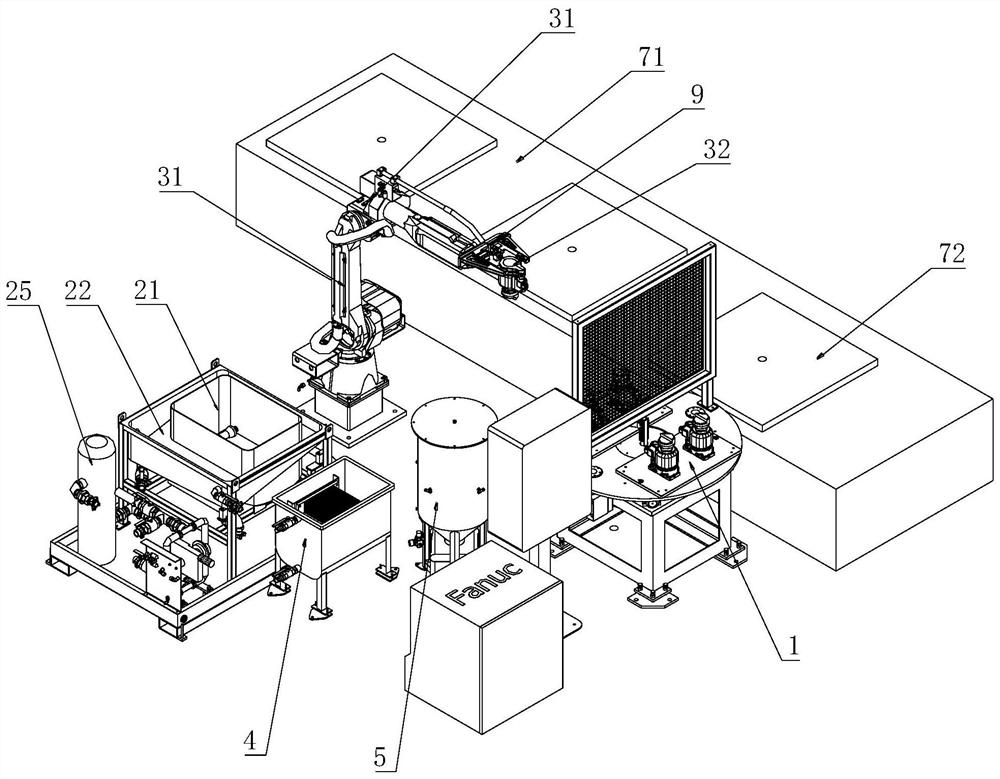

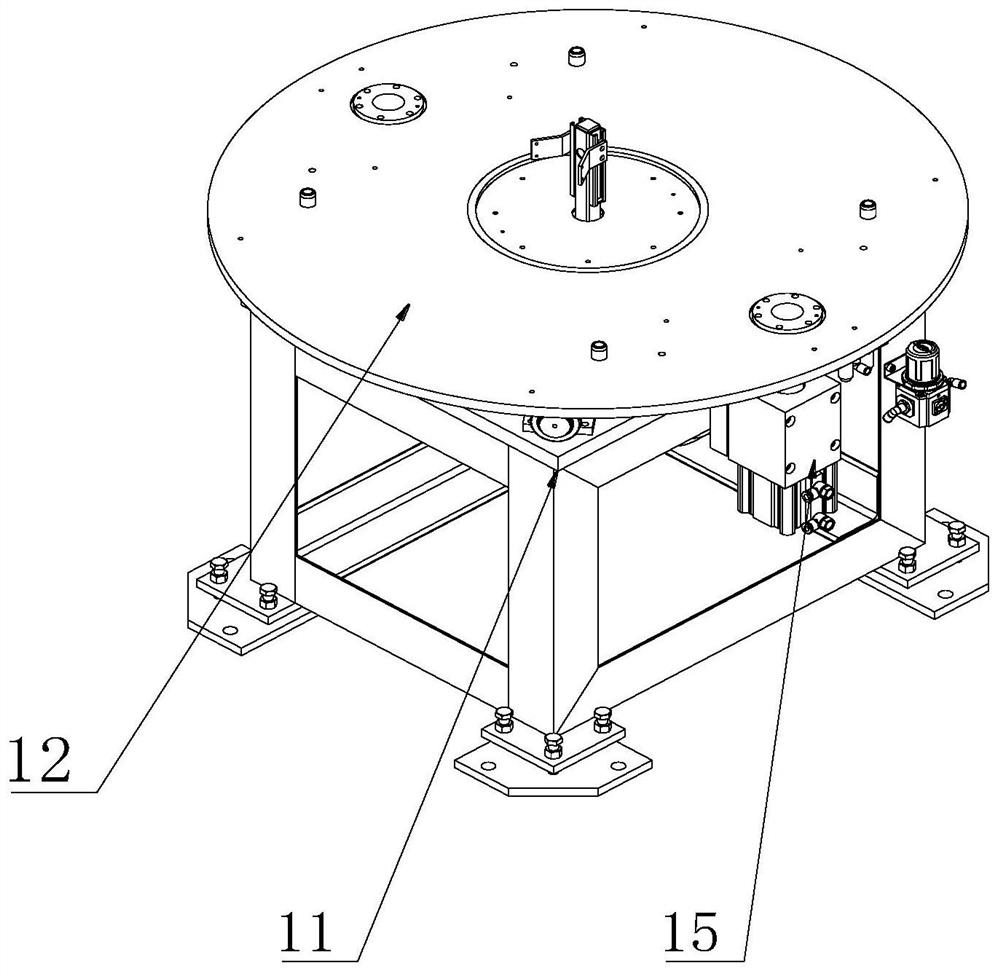

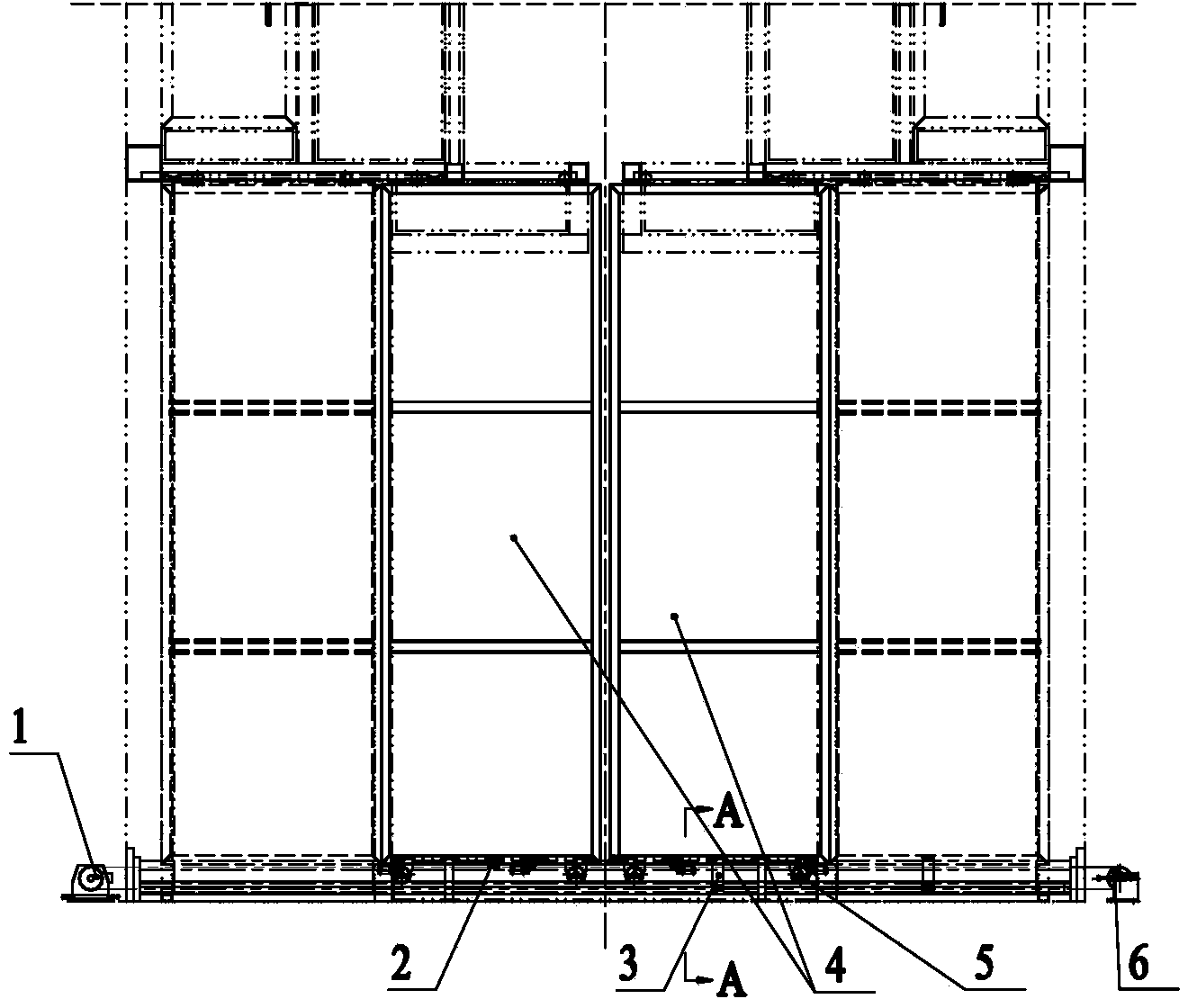

Full-automatic sand core dip-coating system and dip-coating method thereof

PendingCN112658218AIncrease productivityReduce labor costsMoulding toolsCoating systemControl system

The invention discloses a full-automatic sand core dip-coating system and a dip-coating method thereof. The full-automatic sand core dip-coating system comprises a feeding unit, a dip-coating unit, a clamping unit, a cleaning unit and a control system electrically connected with all the units. The feeding unit is used for providing a sand core blank; the clamping unit is used for clamping and transferring a sand core, and the dip-coating unit is used for dip-coating the sand core, and comprises a dip-coating module and a circulating module; and a cleaning device is used for cleaning a fixture. According to the dip-coating system, the integrated automatic process of sand core feeding, purging, dip-coating, conveying and fixture cleaning is achieved, not only is the labor cost greatly saved, but also the production efficiency and the casting quality are improved.

Owner:苏州艾励德智能装备有限公司

Electric oppositely-opening type door for prime paint spraying chamber body

InactiveCN104107775AImprove sealingIngenious structureLiquid surface applicatorsCoatingsStructural engineeringSpray painting

The invention relates to an electric oppositely-opening type door for a prime paint spraying chamber body. The electric oppositely-opening type door is characterized by comprising two door panels, an upper guide wheel, an upper guide channel steel, a lower support wheel, a lower guide rail assembly and an opening / closing drive mechanism, wherein the two door panels are arranged in an oppositely-opening manner, the upper guide wheel is arranged at the lower edges of the door panels, and is embedded in the upper guide channel steel, a guide channel is fixed on the outer wall of the chamber body, the lower support wheel is arranged at the lower edges of the door panels, the door panels are supported and arranged on the lower guide rail assembly through the lower support wheel, and the two door panels are driven by the opening / closing drive mechanism, and are capable of being synchronously oppositely close or reversely far away from each other. The electric oppositely-opening type door is ingenious in structure and reasonable to design, can be automatically opened or closed, is convenient to operate, facilitates the improvement of the sealing property of the chamber body and ensures the paint spraying quality of a product.

Owner:WUXI SUNDA INTELLIGENT AUTOMATION & ENG COMPANY

Paint spraying device for production of network filters

InactiveCN110813577AEasy to paintEasy to useLiquid spraying apparatusEngineeringStructural engineering

The invention relates to the field of production and machining of network filters, in particular to a paint spraying device for production of the network filters. The device comprises a supporting frame. First partitions are arranged at the left end and the right end of the supporting frame, a second partition is arranged at the lower end of the portion between the first partitions, a paint storage cavity is formed in the lower side of the second partition, a liquid suction pump is arranged on the right side of the paint storage cavity, the upper side of the liquid suction pipe is connected with a connecting hose through a connecting flange, the connecting hose is connected with a liquid adding pipe through a connecting flange, the liquid adding pipe is mounted on the right side of a connecting cavity, nozzles are arranged on the lower side of the connecting cavity, a connecting plate is arranged on the left side of the connecting cavity, a threaded rod is arranged on the portion, on the left side of the first partition located at the left end, of the connecting plate, the middles of the first partitions are connected with connecting rods through bearings, the portions, located onthe inner sides of the first partitions, of the connecting rods are connected with connecting pipes through fastening rotary knobs, and clamping grooves are fixedly mounted in the inner sides of the connecting pipes. Paint can be effectively and conveniently sprayed to the network filters, and the equipment is convenient to use.

Owner:LEIYANG YAXIANG ELECTRONICS TECH

Uniform dead angle-free paint spraying protection device

ActiveCN109731706AAvoid painting blind spotsGuarantee the quality of paintingLiquid spraying apparatusEngineeringMechanical engineering

The invention relates to the field of paint spraying, in particular to a uniform dead angle-free paint spraying protection device. The uniform dead angle-free paint spraying protection device comprises an operation base, an upper clamping block, a lower clamping block, a baffle, an oil paint recovery box and a feeding pump. The operation base comprises a bottom plate, a bottom frame, a baffle insertion groove, an upper frame, two sliding grooves, a center plate, a motor baffle, a feeding pipe, a spray gun, a sliding bottom frame, a recovery notch and a round feeding pipe fixing hole. The bottom frame is fixedly connected to the bottom plate. The upper frame is fixedly connected to the upper end of the bottom frame. The baffle insertion groove penetrates through the rear end of the upper frame up and down. The two sliding grooves are formed in the left side and the right side of the rear end of the upper frame correspondingly. The center plate is fixedly connected to the upper end of the inner wall of the bottom frame. The uniform dead angle-free paint spraying protection device has the beneficial effects that 360-degree dead-angle-free paint spraying can be carried out on an objectneeding paint spraying, a paint spraying blind area caused by clamping of a fixture is avoided, the paint spraying quality and the paint spraying effect are guaranteed, and meanwhile sprayed atomizedoil paint can be resisted and recovered.

Owner:ZHEJIANG DAFENGFAN FURNITURE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com