Uniform dead angle-free paint spraying protection device

A protection device and no dead angle technology, applied in the field of painting, can solve the problems of painting blind spots, etc., to achieve the effect of guaranteeing the effect of painting, ensuring the quality of painting, and avoiding the effects of painting blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

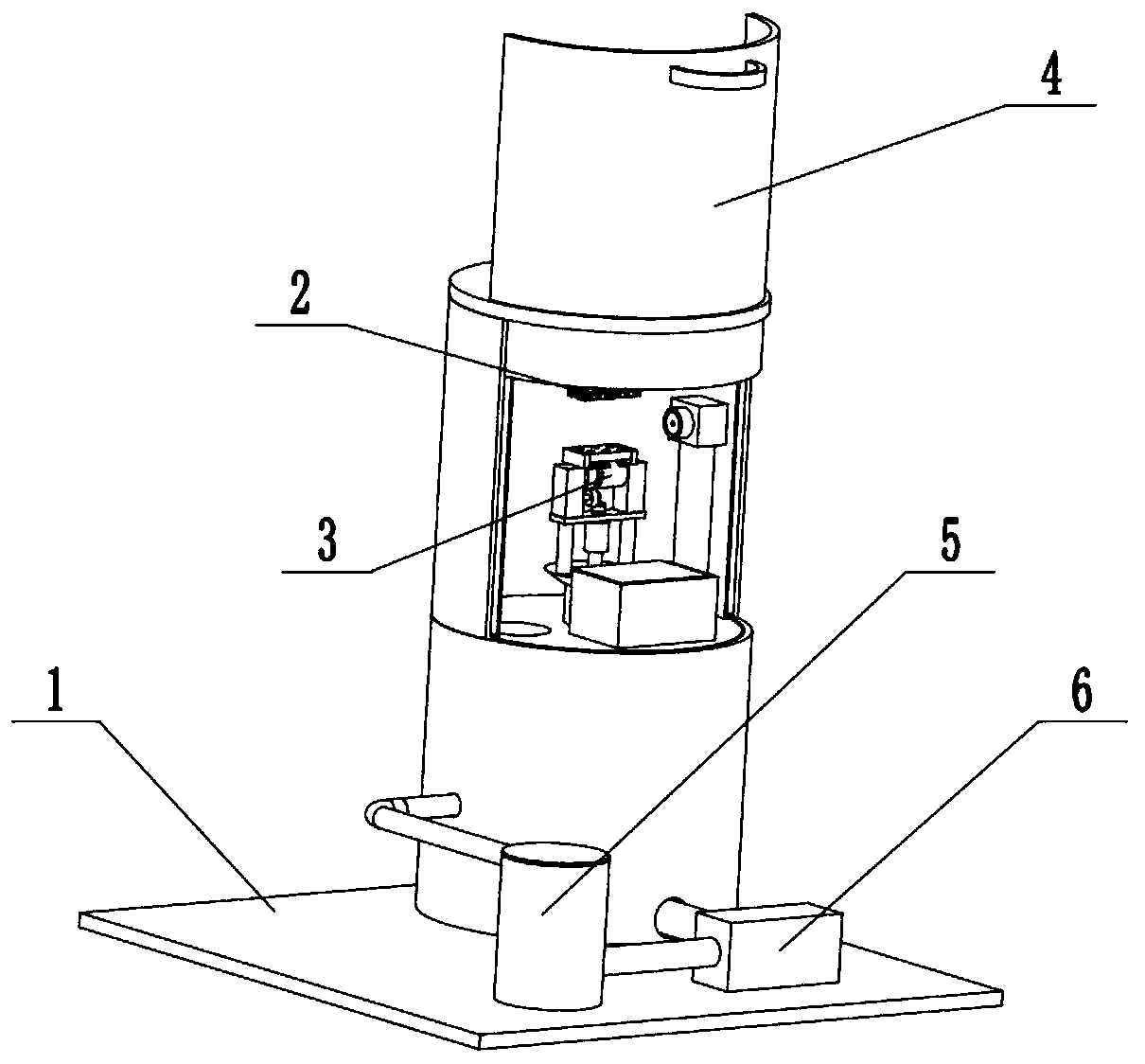

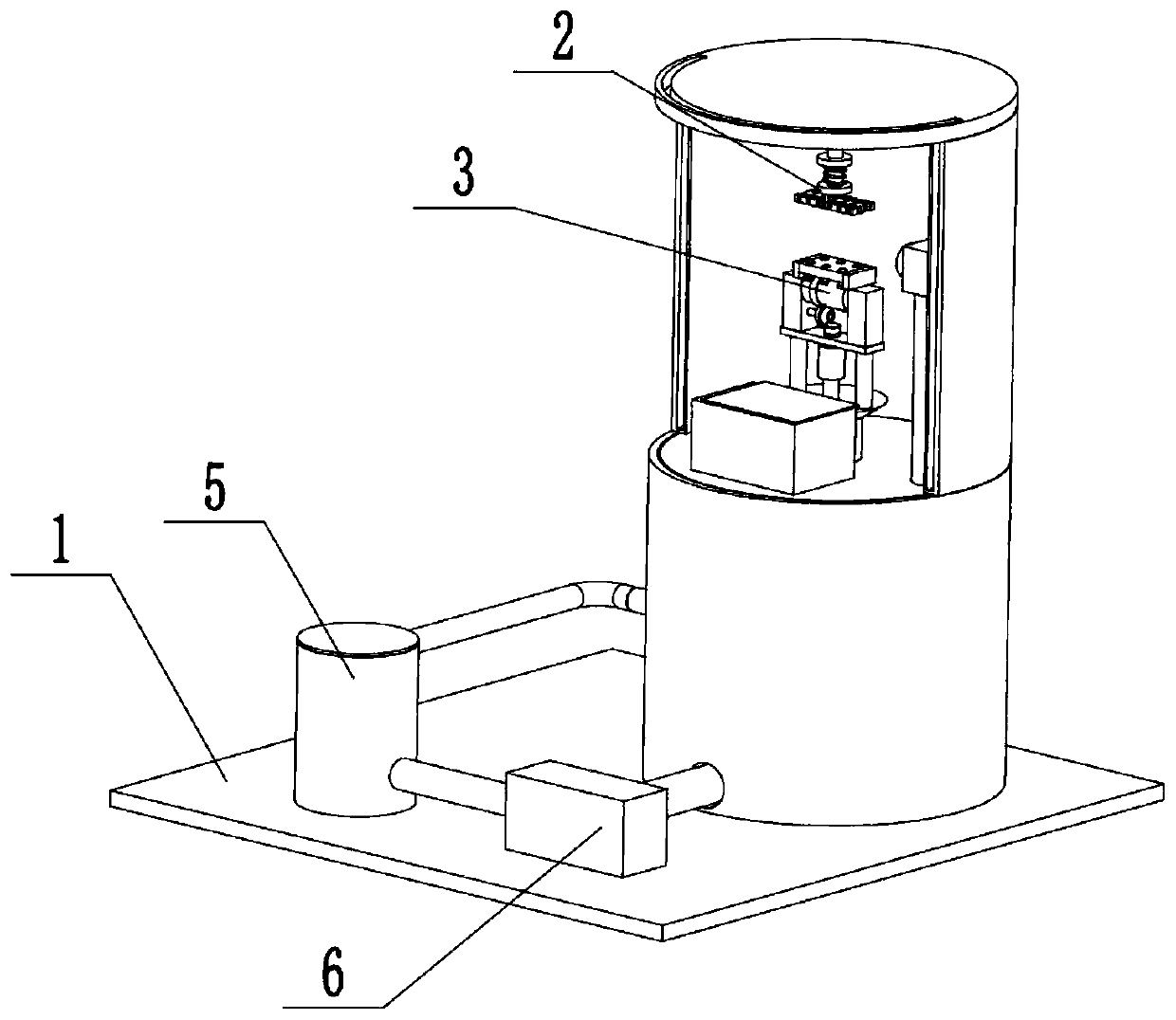

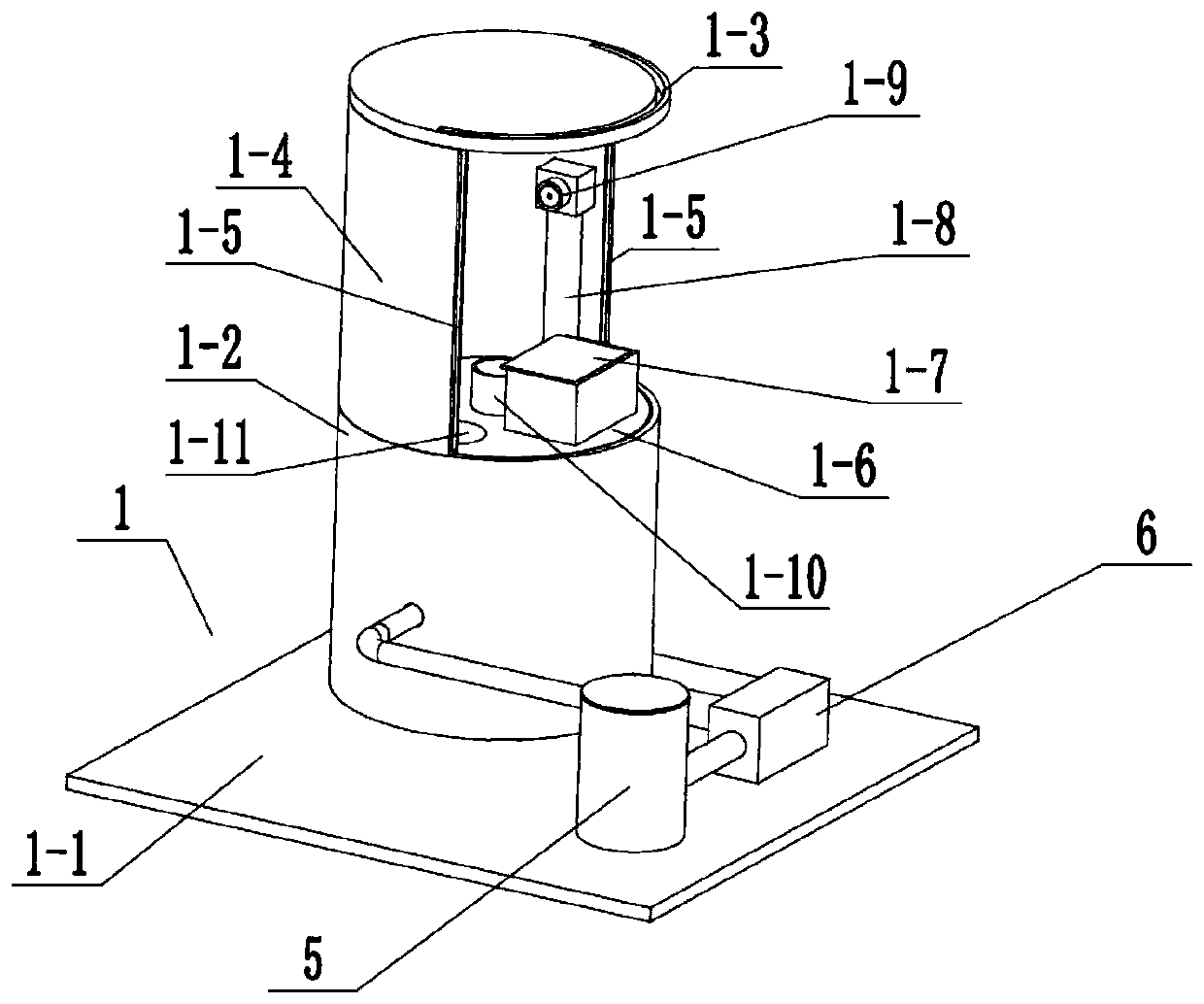

[0033] Such as Figure 1 to Figure 11As shown, a uniform paint protection device without dead ends includes an operating base 1, an upper clamping block 2, a lower clamping block 3, a baffle plate 4, a paint recovery box 5 and a feeding pump 6, and the operating base 1 includes a bottom plate 1 -1, bottom frame 1-2, baffle slot 1-3, upper frame 1-4, two chute 1-5, center plate 1-6, motor baffle 1-7, feeding tube 1-8 , spray gun 1-9, sliding bottom frame 1-10, recovery notch 1-11 and feeding tube fixing round hole 1-12, described bottom frame 1-2 is fixedly connected on the bottom plate 1-1, and upper frame 1 -4 is fixedly connected to the upper end of the bottom frame 1-2, the baffle slot 1-3 runs through the rear end of the upper frame 1-4 up and down, and the two slide grooves 1-5 are respectively arranged on the left and right of the rear end of the upper frame 1-4 On both sides, the center plate 1-6 is fixedly connected to the upper end of the inner wall of the bottom fra...

specific Embodiment approach 2

[0037] Such as Figure 1 to Figure 11 As shown, this embodiment will further explain Embodiment 1, the baffle plate 4 is clearance fit in the baffle plate slot 1-3, and the left and right ends of the baffle plate 4 are respectively slidably connected in the two chute 1-5 . Make the baffle plate 4 stop the mist spray paint with all one's heart, avoid polluting others, realize the recovery of paint simultaneously, avoid waste.

specific Embodiment approach 3

[0038] Such as Figure 1 to Figure 11 As shown, this embodiment further describes the first embodiment. The paint recovery box 5 is connected to the recovery notch 1-11 through the recovery pipe 5-1, and the paint recovery box 5 is fixedly connected to the bottom plate 1-1. Achieve paint recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com