Pipeline paint spraying equipment for architectural decoration engineering

A technology of architectural decoration engineering and painting equipment, which is applied in the field of architectural decoration engineering, and can solve problems such as environmental pollution, paint falling, and affecting the effect of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

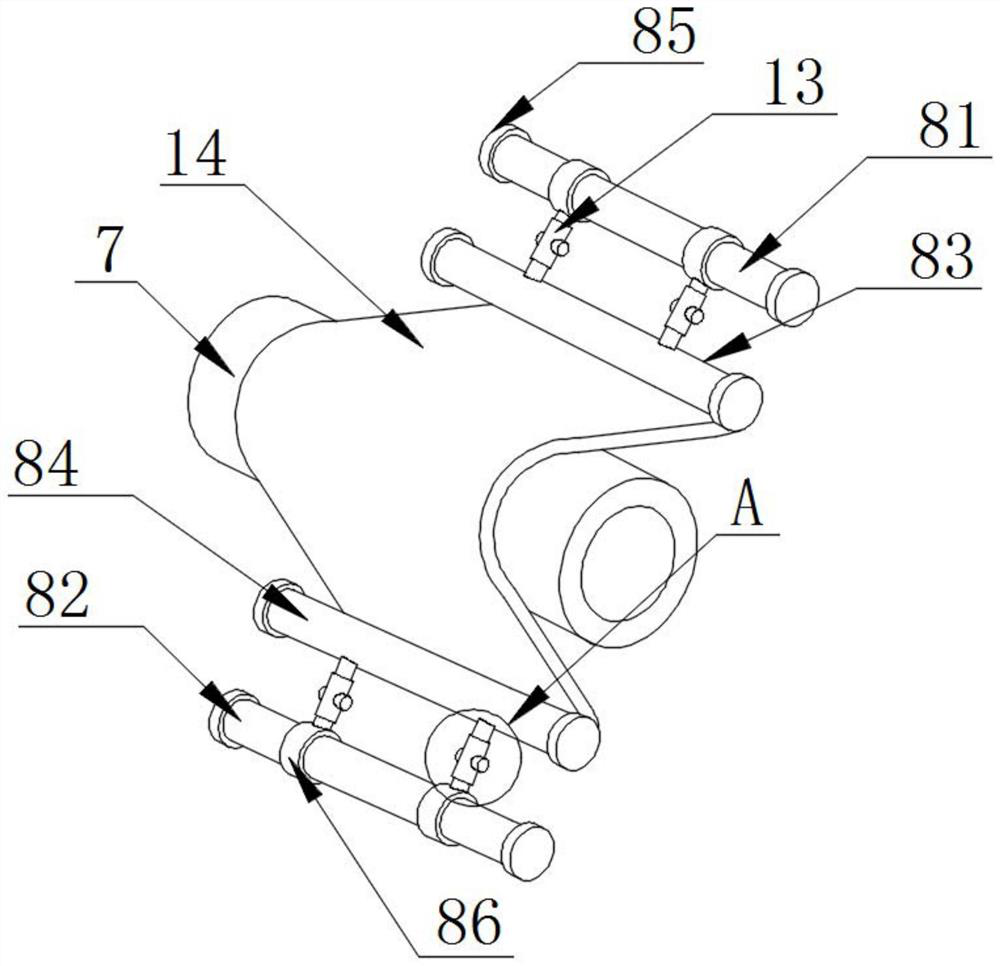

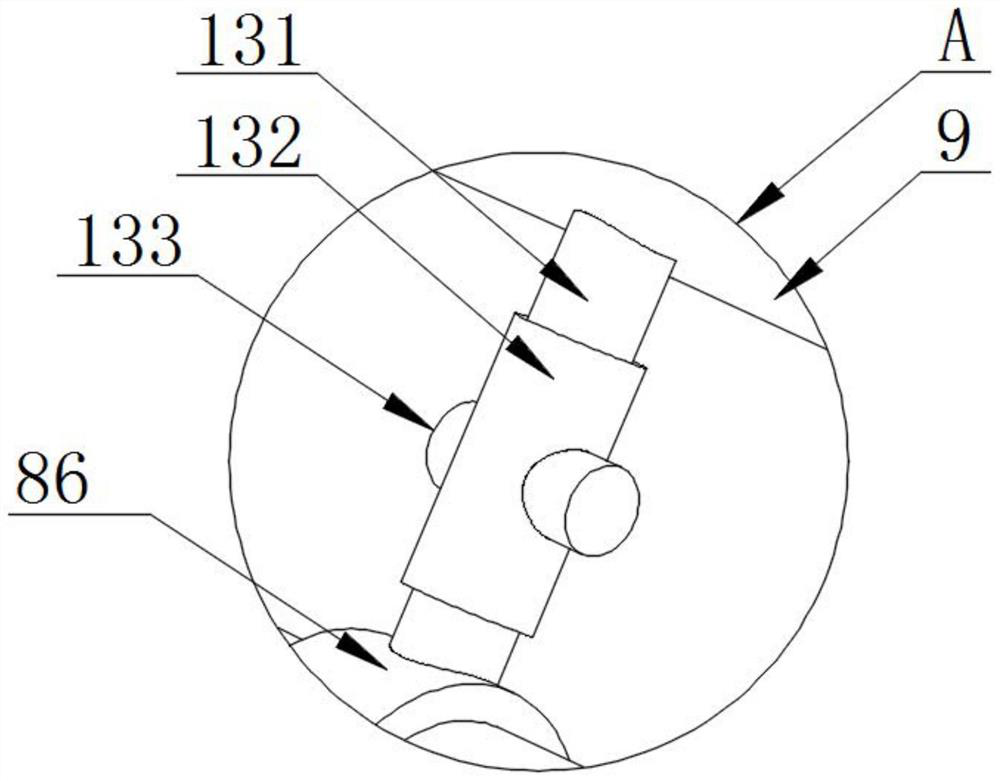

[0034] The embodiment is specifically: the fixed push rod 132 on the surface of the top installation pipe 81 and the bottom installation pipe 82 and the corresponding movable push rod 131 on the surface of the cloth top pipe 83 and the cloth bottom pipe 84 perform back and forth adaptive movement to react the pipe The active force produced on the surface of the material 7 makes the even paint cloth 14 in a stretched state, so as to paint evenly.

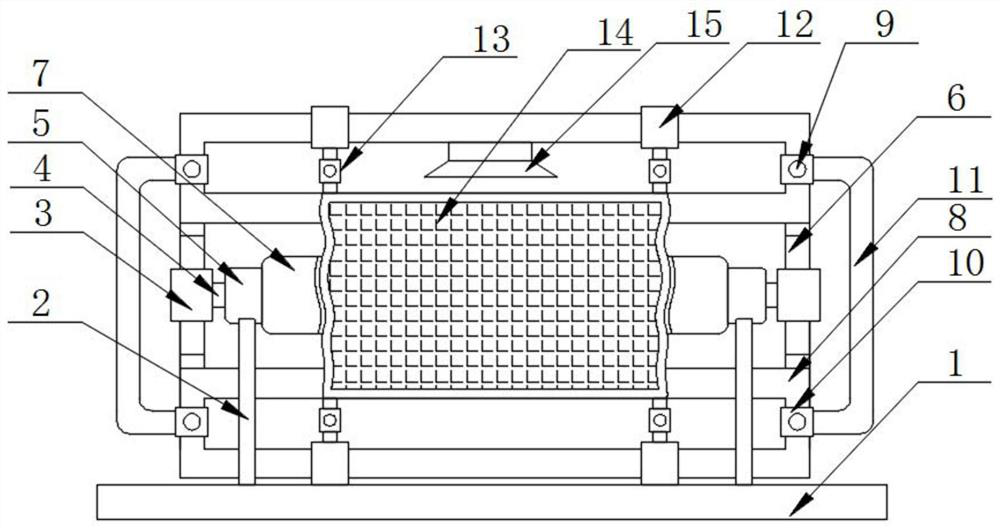

[0035] Working principle: Put the pipe that needs to be painted on the surface of the pipe on the surface of the pipe casing 5. At this time, turn on the paint gun 15 to spray paint on the pipe material 7 on the surface of the pipe casing 5, turn on the motor 3, and the motor 3 drives the rotating shaft 4 to rotate, because the rotating shaft 4 is linked with the pipe sleeve 5, the pipe sleeve 5 drives the pipeline material 7 to rotate at a uniform speed, so that the surface of the pipeline is evenly painted, and the pipeline material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com