Patents

Literature

448results about How to "Reduce friction damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-scratch-resistance abrasion-resistant coating material and preparation method thereof

InactiveCN106752923AIncrease elasticityAvoid scratch damageFireproof paintsAnti-corrosive paintsDispersityMechanical property

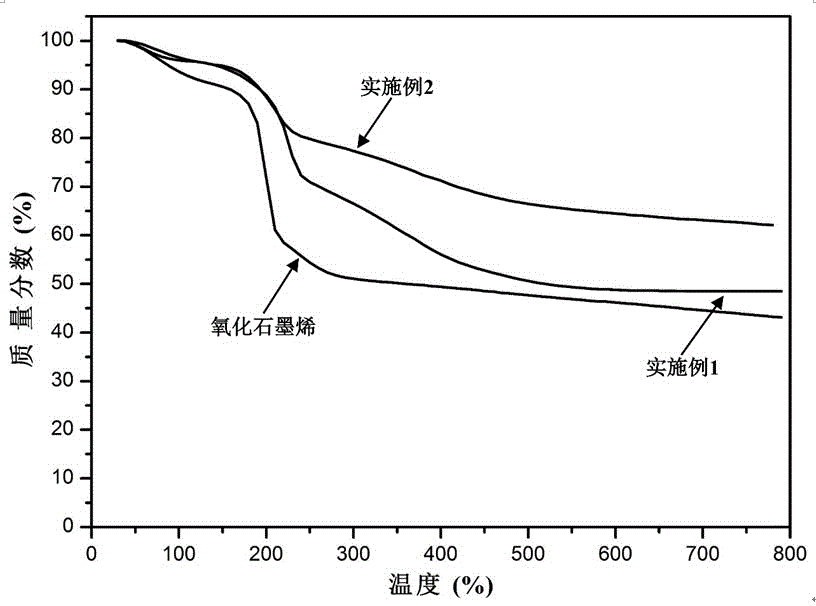

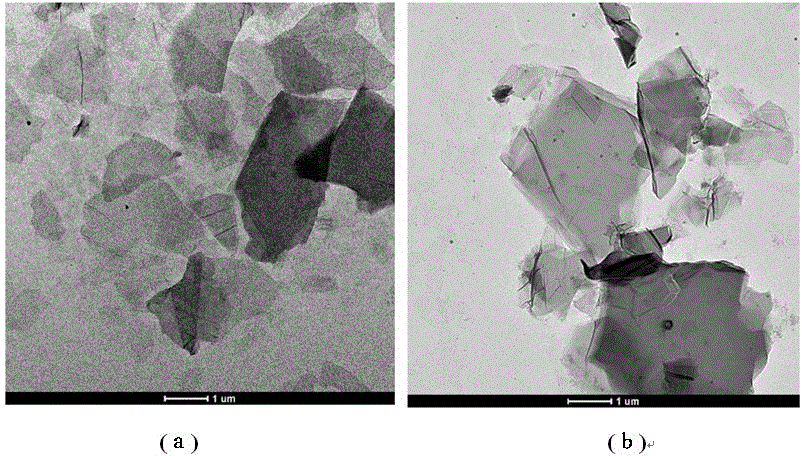

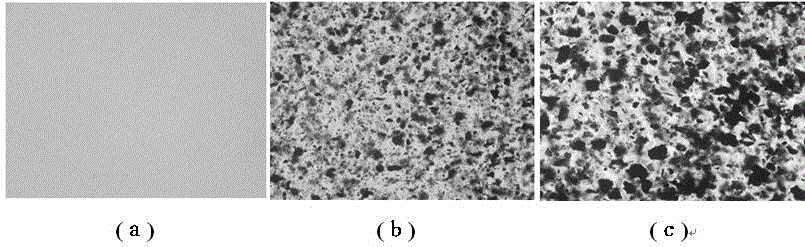

The invention provides a high-scratch-resistance abrasion-resistant coating material and a preparation method thereof. The preparation method comprises the following steps: modifying the graphene surface by using active groups by a chemical modification technique to obtain modified graphene, and blending the modified graphene with polysiloxane to obtain the high-scratch-resistance abrasion-resistant nano composite coating material. The surface modification is carried out to enhance the dispersity of the graphene and the interactions between the graphene and polysiloxane matrix, thereby enhancing the mechanical properties of the coating. No pigment or filler is added. The scratch resistance of the transparent graphene / polysiloxane composite coating is enhanced by 140% or above, and the abrasion loss is reduced by 60% or above. The transparent graphene / polysiloxane composite coating has excellent adhesion, heat resistance, weather resistance, flame retardancy and corrosion resistance. The graphene / polysiloxane composite coating can be used for surface protection and shielding of various metals, plastics, wood, concrete, glass and other substrates, and is applicable to the fields of automobile paints, photoelectric materials, precision instruments, marine heavy-corrosion protection, buildings and the like.

Owner:FUDAN UNIV

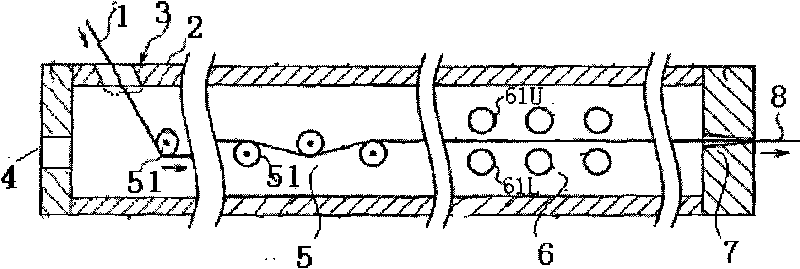

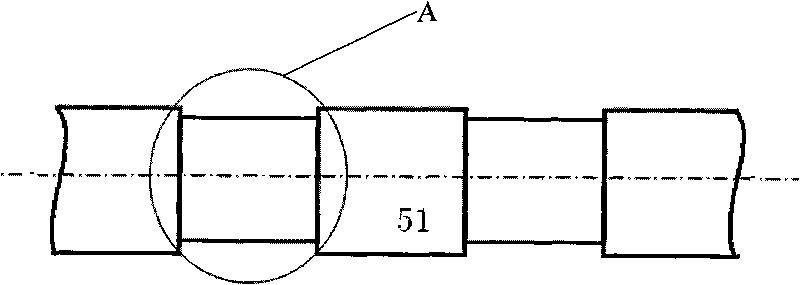

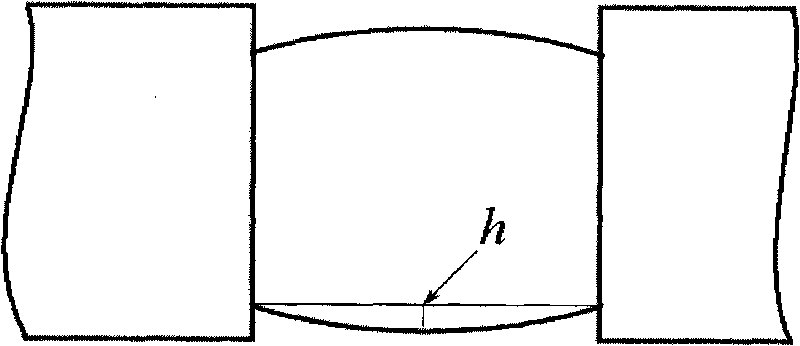

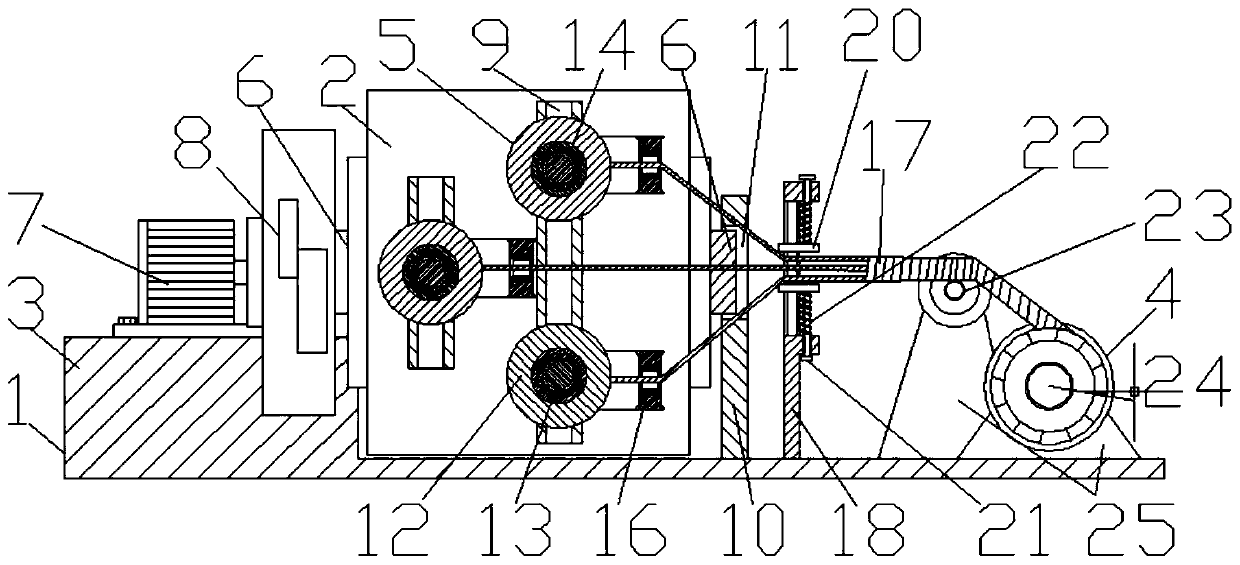

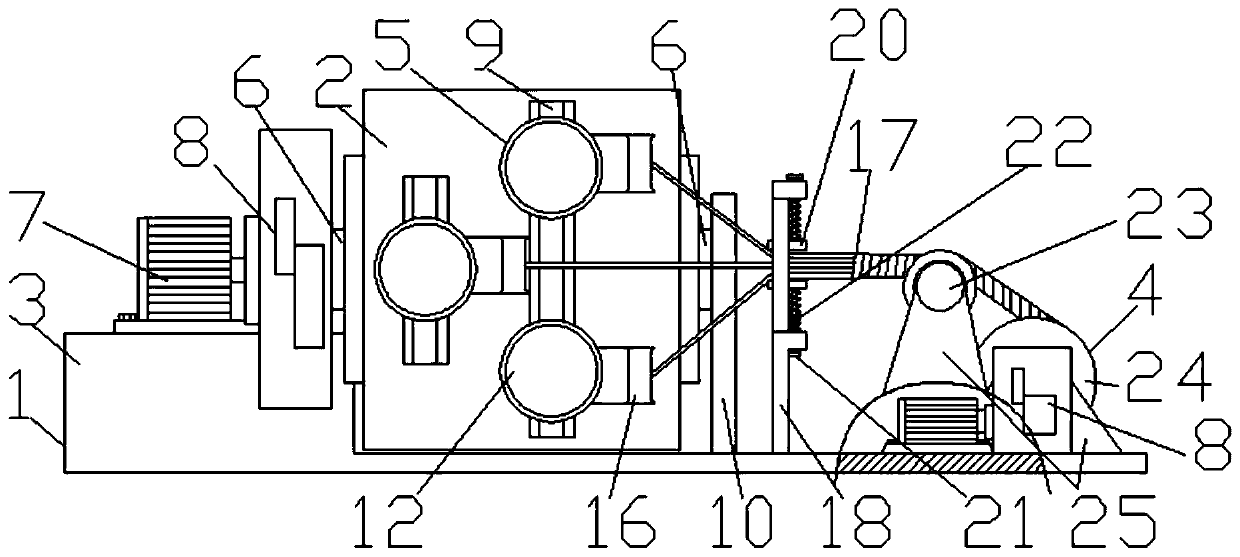

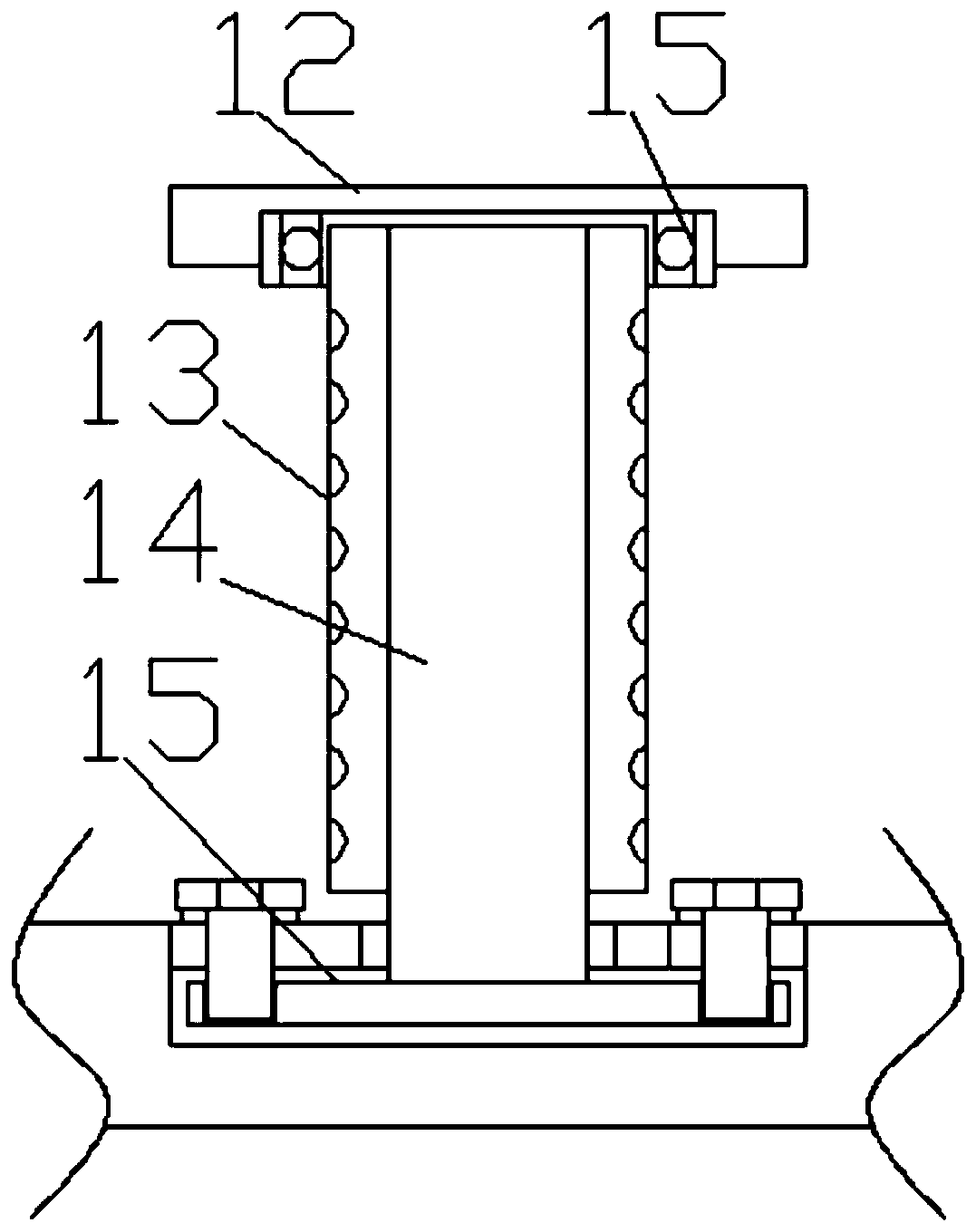

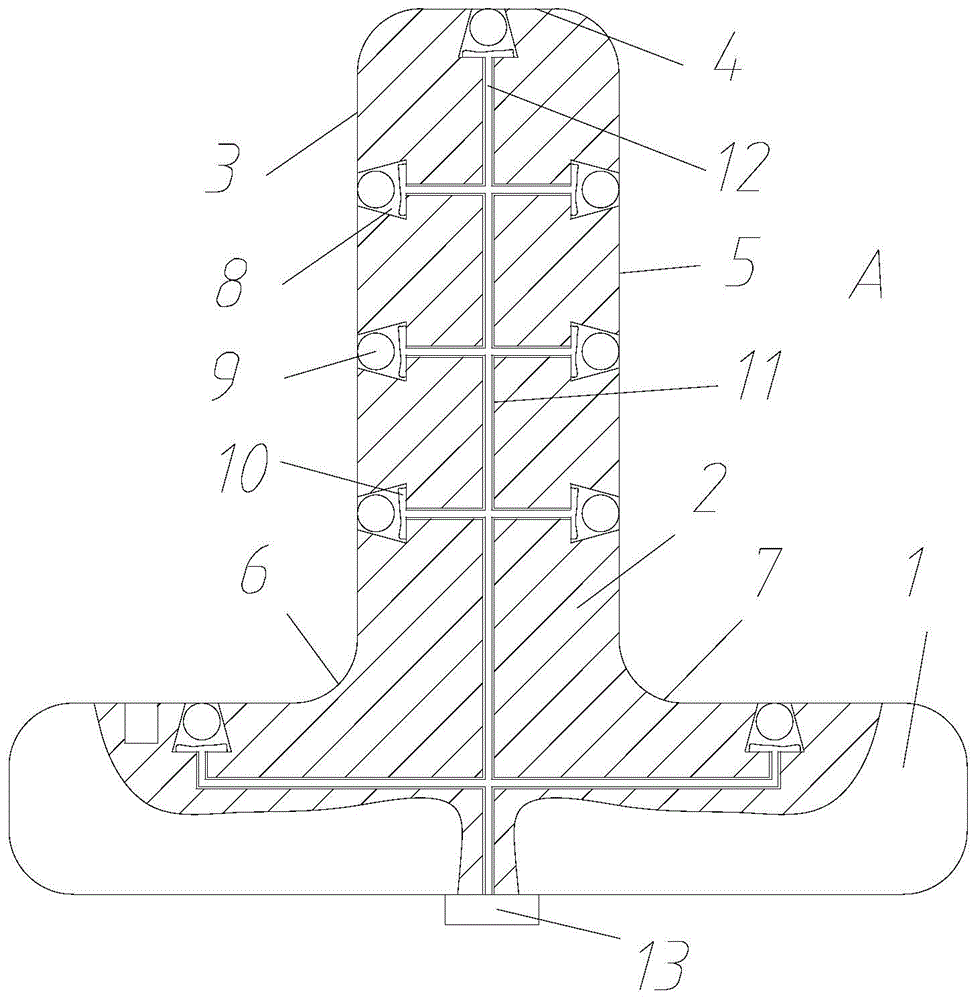

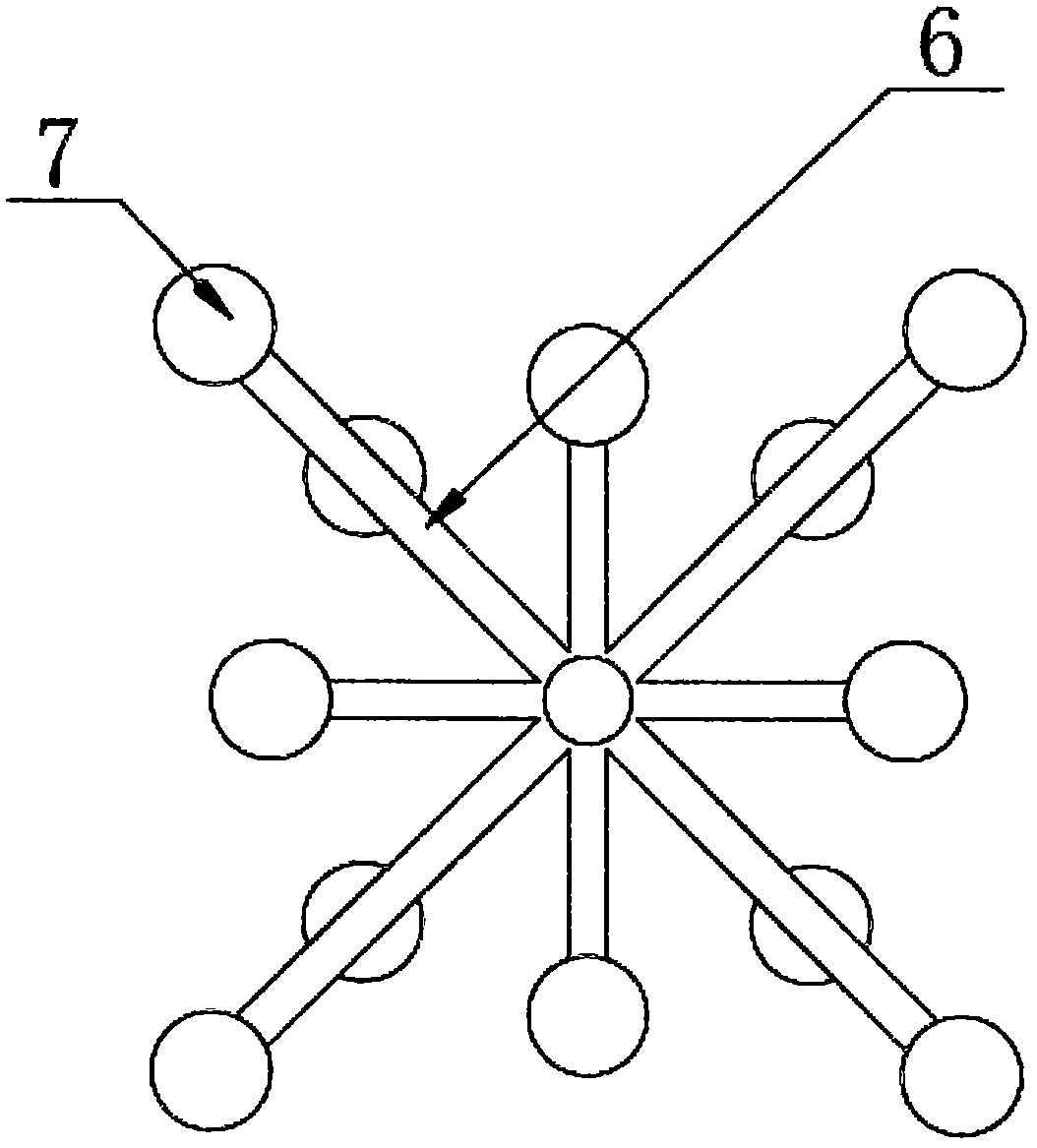

Fiber bundle fuse dipping die head for producing long fiber reinforced plastic and dipping method

ActiveCN101695873AReduce frictional damageImprove impregnation efficiencyLong-fiber-reinforced thermoplasticFiber bundle

The invention discloses a fiber bundle fuse dipping die head for producing long fiber reinforced plastic and a dipping method. The fiber bundle fuse dipping die head comprises a die head shell, a contact fiber guiding roll and a non-contact fiber guiding roll pair which are arranged in the die head shell. The contact fiber guiding roll includes a coaxial drum body; the non-contact fiber guiding roll pair is a fixing roll or an automatic driving roll and has a round, polygon or multi-edge transverses section surface. The dipping method comprises the following steps: in a die cavity full of fusant, a fiber bundle alternately winds the drum body of the contact fiber guiding roll under the tension traction and penetrates through a gap between the non-contact fiber guiding roll pair, and the dipped fiber bundle is exported from a derivative channel. The invention can reduce the friction consumption of the single fiber, ensure that the fuse and the dipping of the continuous fiber bundle operate stably at high dipping line speed, improve the dipping efficiency and reduce the production cost of long fiber reinforced thermoplastic plastics.

Owner:GUANGZHOU KEYUAN INNOVATIVE MATERIALS

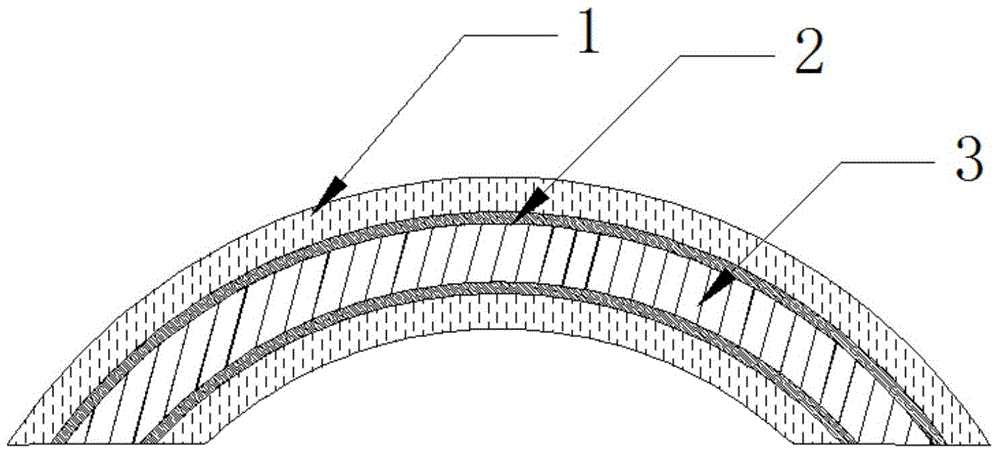

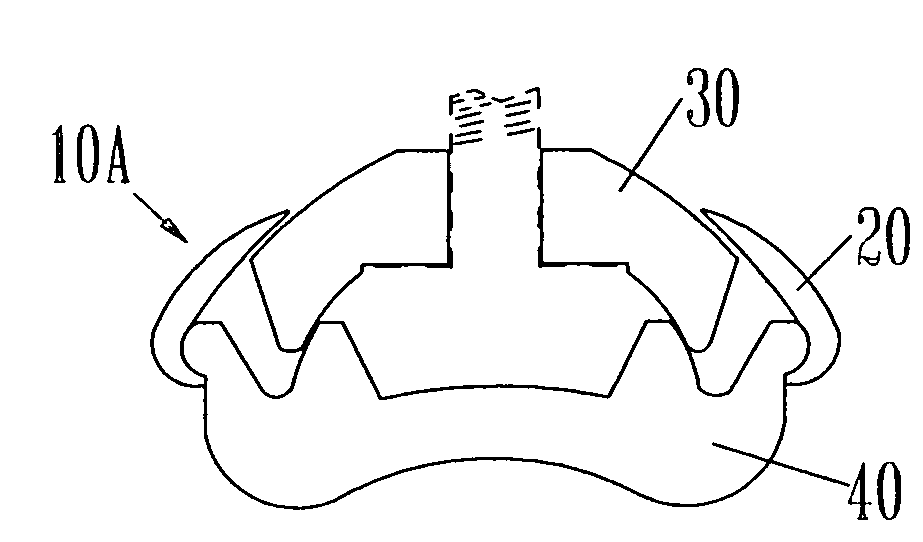

Cranioplasty prosthesis with biological activity and preparation method of cranioplasty prosthesis

InactiveCN104667345AFast productionSmall sizeAdditive manufacturing apparatusCoatingsBiocompatibility TestingDrug biological activity

The invention relates to cranioplasty prosthesis with biological activity and a preparation method of the cranioplasty prosthesis. The cranioplasty prosthesis with biological activity sequentially comprises an unmodified cranioplasty prosthesis layer, a modified cranioplasty prosthesis layer and a nanofiber membrane layer from inside to outside. The invention further provides a preparation method of the cranioplasty prosthesis. By virtue of a three-layer structure and polyaryletherketone materials which are equivalent to a bone of a human body in hardness, strength and weight, are good in biocompatibility, and a 3D printing technology, a cranioplasty prosthesis implant has reliably safety and effectivity and high matching degree. The cranioplasty prosthesis provided by the invention is capable of loading a plurality of bionic scaffolds and bioactive substances, and promoting exchange of nutrient substances inside and outside the prosthesis, and is beneficial to growth of tissues.

Owner:MEDPRINSHENZHEN REGENERATIVEA MEDICAL TECH CO LTD

Buried and embedded copper block PCB manufacturing method

InactiveCN104853523AReduce offsetReduce friction damageMultilayer circuit manufacturePrinted circuit non-printed electric components associationMetallurgyEngineering

The invention discloses a buried and embedded copper block PCB manufacturing method, which comprises steps of laminating treatment of a buried copper block, groove milling, gold immersion, laminating treatment of an embedded copper block and the like. The step of lamination of the buried copper block comprises a buried copper block lamination pre-treatment process. The buried copper block lamination pre-treatment process comprises groove treatment on the edge of the bottom part of the copper block, round corner treatment on the edge of the copper block, and chamfer treatment on the edge corner of the copper block. The step of lamination of the embedded copper block comprises an embedded copper block lamination pre-treatment process, which comprises groove treatment on the edge of the bottom part of a groove hole into which the copper block needs to be embedded, round corner treatment on the edge of the groove hole into which the copper block needs to be embedded and chamfer treatment on the edge corner of the groove hole into which the copper block needs to be embedded. The buried and embedded copper block PCB manufacturing method has the advantages of high product yield, high production efficiency, good quality consistency and simple operation.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

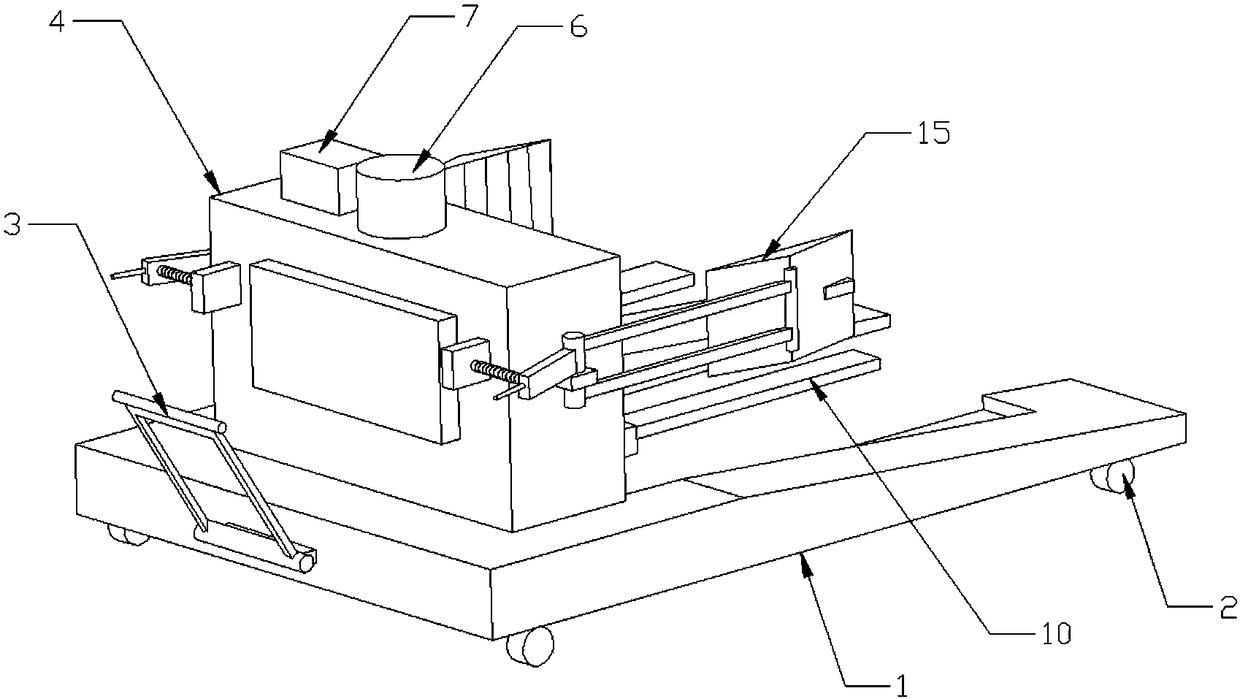

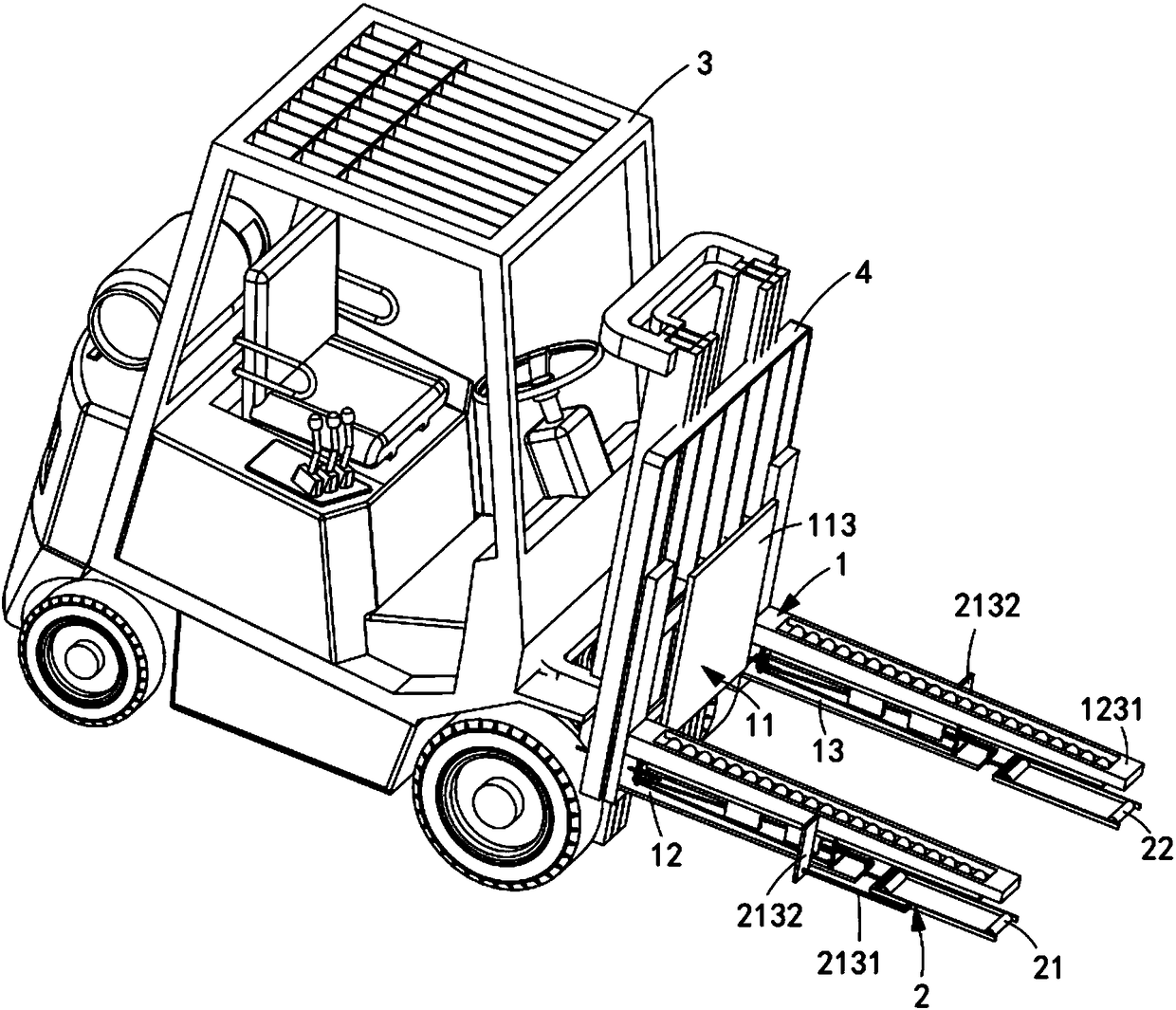

Electric forklift facilitating loading and unloading of goods

PendingCN108502807AReduce friction damageEasy loading and unloadingLifting devicesHydraulic cylinderDrive motor

The invention discloses an electric forklift facilitating loading and unloading of goods. The electric forklift comprises a base. A driving box is connected to the left side of the top of the base. Alifting mechanism is arranged on an inner cavity of the driving box. A driving motor is connected to the center of the top of the driving box. A storage battery is arranged on the top of the driving box. Lifting ports are symmetrically formed in the right side wall of the driving box. An adjusting seat is arranged on the right side walls of the lifting ports. Fork claws are symmetrically connectedto the front side and the rear side of the right side wall of the adjusting seat. A hydraulic cylinder is arranged on the top of the adjusting seat. A hydraulic telescopic rod is connected to the right side of the hydraulic cylinder. A push plate is connected to the right end of the hydraulic telescopic rod. Clamping mechanisms are symmetrically connected to the front side and the rear side of the driving box. The electric forklift is reasonable in structural design, and the fork claws can be quickly placed at the bottom of the goods through the material guide inclined plane at the right endof the base, so that the friction damage of the fork claws is reduced, the fork claws are driven to ascend and descend through the lifting mechanism, the unloading operation is assisted through the push plate, and the loading, unloading and transportation of goods are facilitated.

Owner:张青美

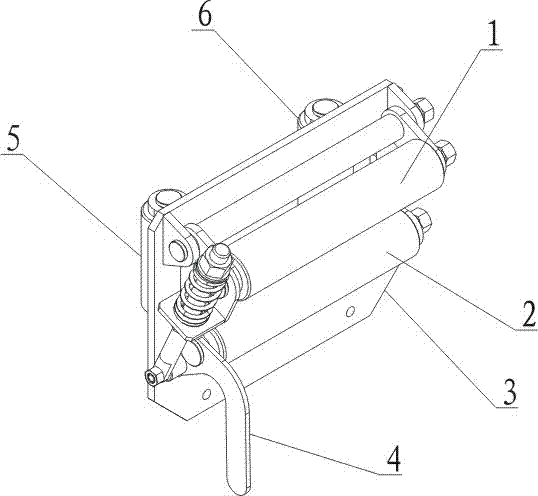

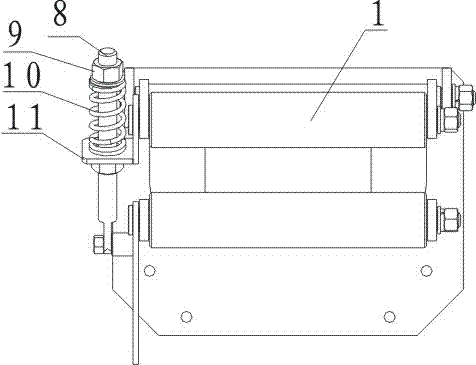

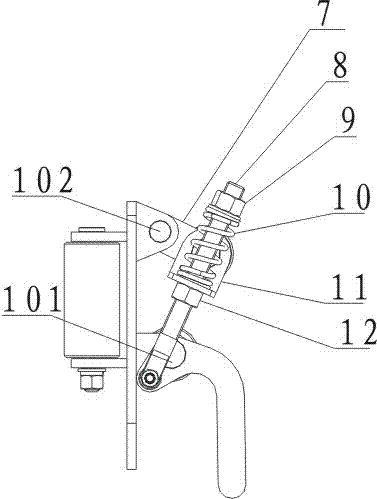

Adjustable tensioning guide device for retracting hose cable

The invention discloses an adjustable tensioning guide device for retracting a hose cable, and the device comprises a mounting base plate, a driving pinch roller, a lower pressure-bearing wheel, a handle, a rocker arm, a screw rod, a pressure regulating nut, a pressure spring, a rotary connecting seat and a lower check nut, wherein the driving pinch roller and the lower pressure-bearing wheel are arranged at the frontage of the mounting base plate; the lower pressure-bearing wheel is positioned below the driving pinch roller; one end of the rocker arm is connected with the upper part of the mounting base plate, and the other end of the rocker arm is connected with the end part of the driving pinch roller by virtue of a pin shaft; one end of the rotary connecting seat is sheathed on the pin shaft positioned at the outer side of the driving pinch roller, and the other end of the rotary connecting seat is sheathed on the screw rod; the spring is sheathed on the screw rod arranged above the rotary connecting seat; the pressure regulating nut is sheathed at the end part of the screw rod; the lower check nut is sheathed on the screw rod arranged below the rotary connecting seat; the bottom end of the screw rod is connected with the lower pressure-bearing wheel by a pin shaft; and the handle is arranged on the pin shaft. The adjustable tensioning guide device can be used for changing the tensile force and the pressure gap by virtue of simple adjustment, thus adapting to different cables.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

Wear-resisting foil type dynamic pressure thrust gas bearing and manufacturing method

ActiveCN104214205AReduce friction damageImprove the lubrication effectMolten spray coatingSliding contact bearingsStart stopMicrometer

The invention relates to a wear-resisting foil type dynamic pressure thrust gas bearing and a manufacturing method. The gas bearing is composed of bottom plates, wave foil and top fold, and the top foil is made of nickel-base superalloy. The top foil is coated with a nickel package graphite micro particle lubricating coating, the thickness of the coating is 0.050 mm to 0.055 mm, the mass fraction of nickel and graphite in nickel package graphite micro particles is 5 to 8:5 to 2, and the granularity of the nickel package graphite micro particles is 60 micrometers to 80 micrometers. The spraying process of the nickel package graphite micro particle lubricating coating of the top foil comprises the steps that (1) particles in the nickel package graphite micro particles are put into an oven to be dried for two hours to four hours at the temperature of 150 DEG C; (2) the top foil is put into an ultrasonic cleaning machine to be cleaned for 5 minutes to 20 minutes, and is preheated to 150 DEG C to 180 DEG C; (3) the nickel package graphite micro particles are sprayed on the upper surface of the top foil through an oxygen-acetylene flame powder spraying method. The nickel package graphite micro particle lubricating coating is sprayed on the surface of the top foil, and the start-stop service life of the foil type gas bearing is prolonged. The oxygen-acetylene flame powder spraying method is utilized for spraying, and the wear-resisting foil gas bearing meeting the quality requirement can be manufactured.

Owner:SHIJIAZHUANG KINGSTON BEARING TECH

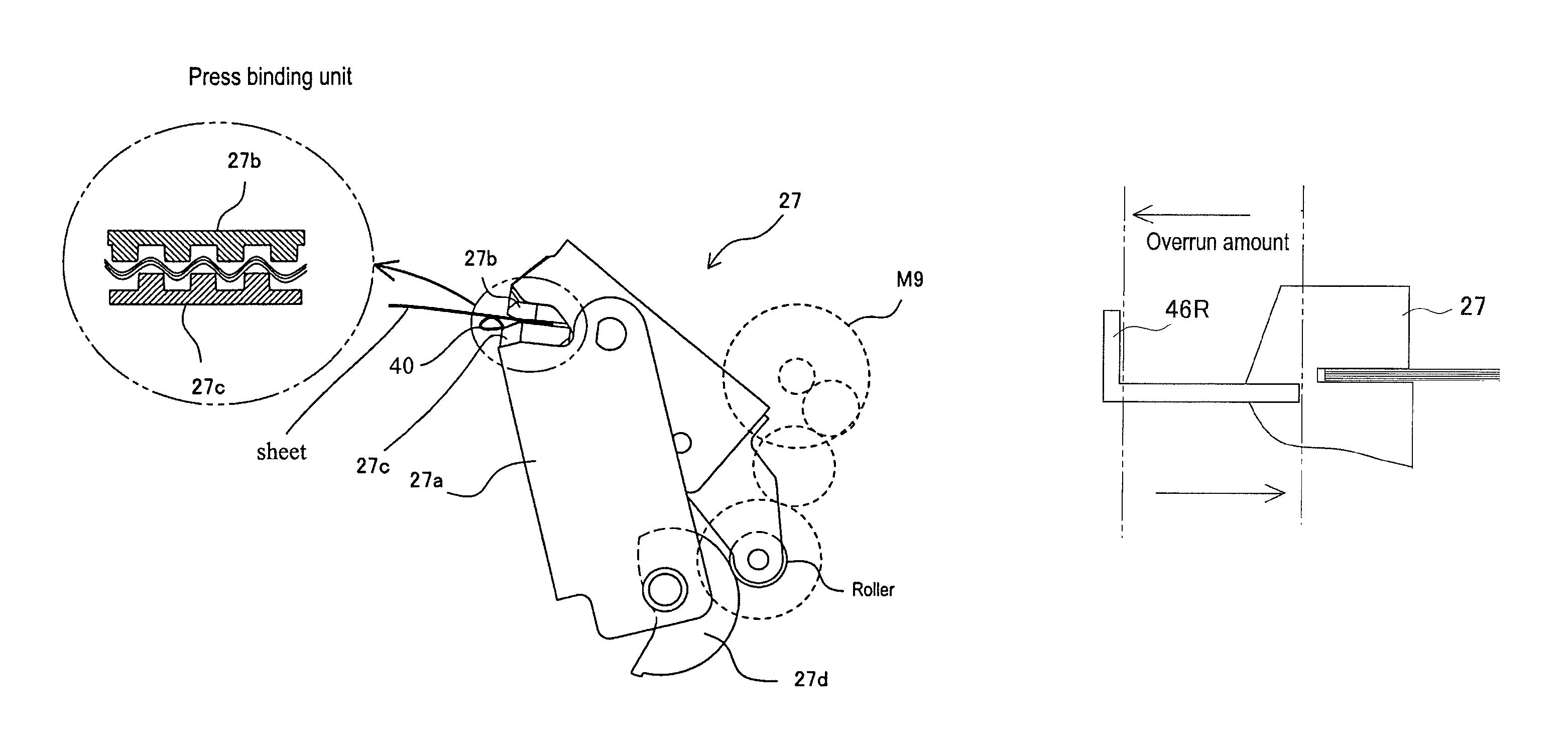

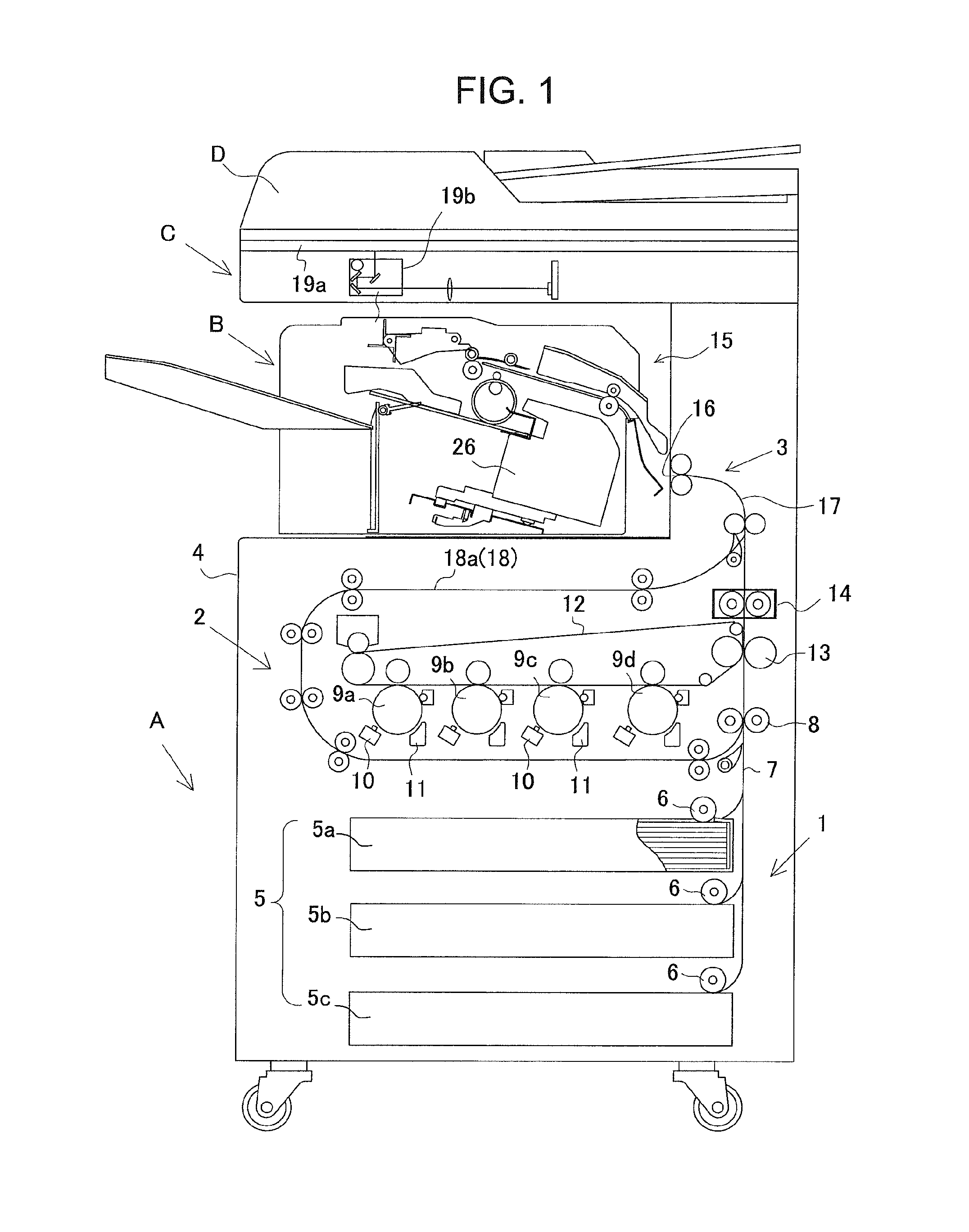

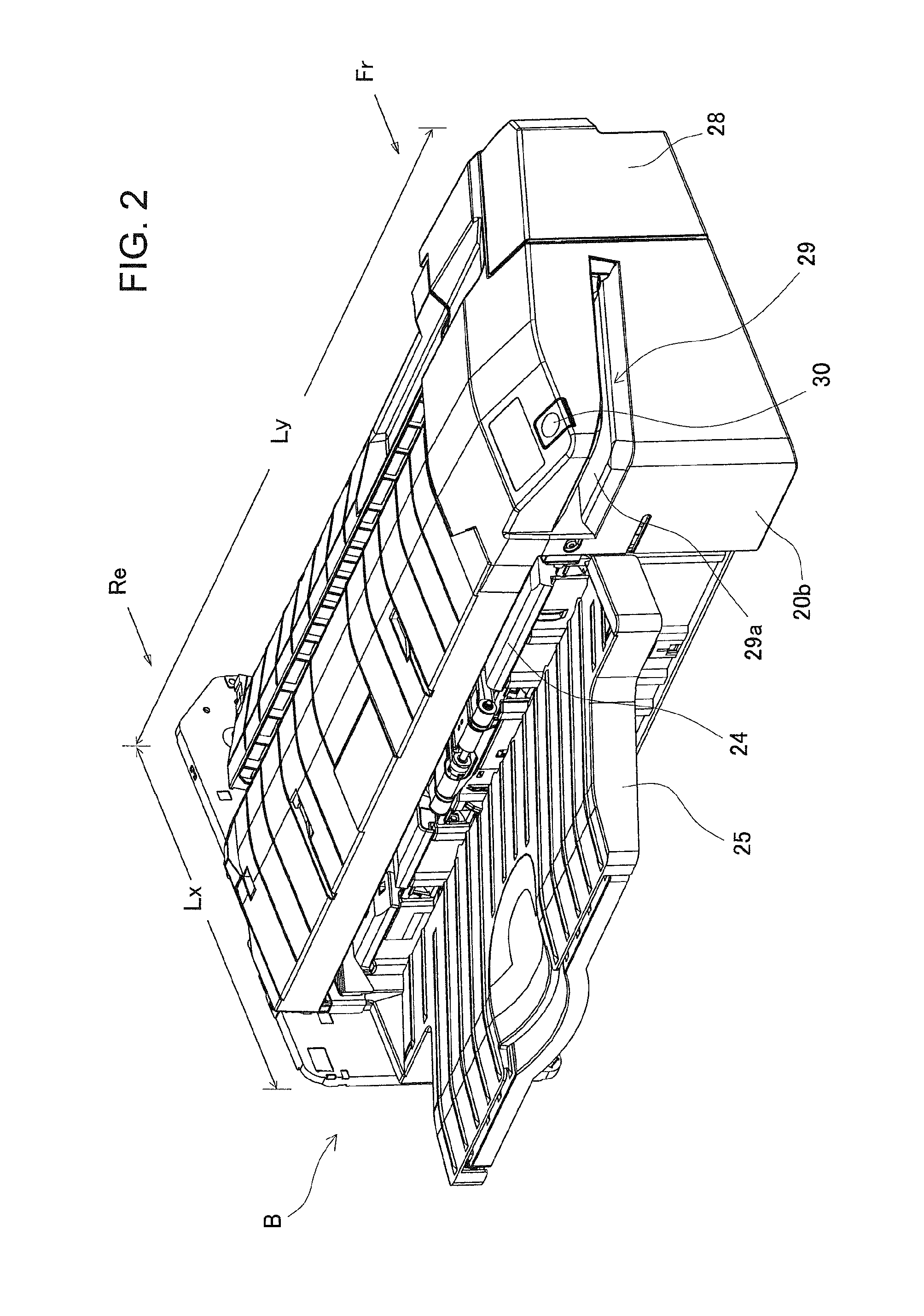

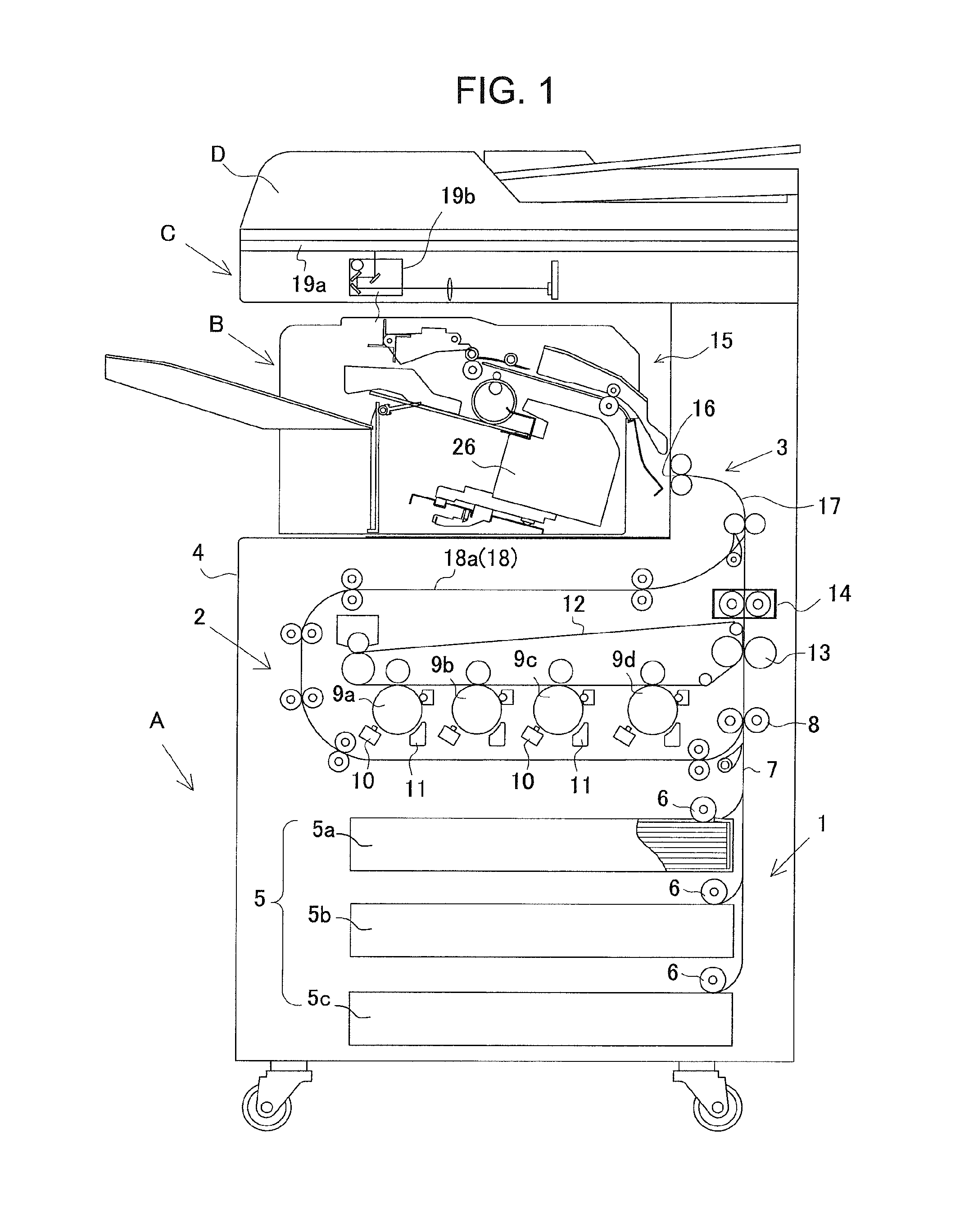

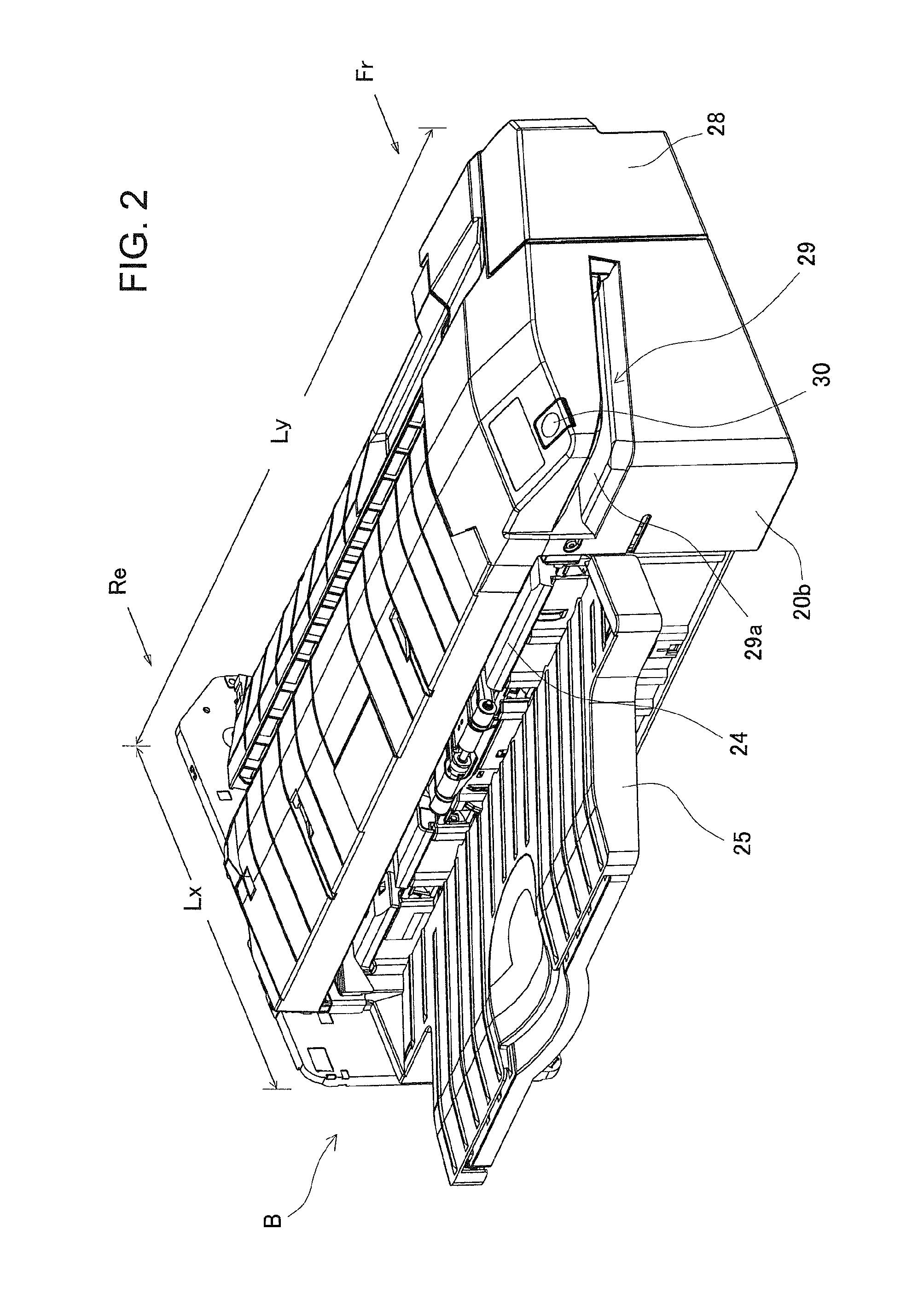

Sheet bundle binding processing apparatus and image forming system having the same

ActiveUS9409740B2Good adhesionReduce friction damageMechanical working/deformationElectrographic process apparatusEngineeringMechanical engineering

Owner:COPYER +1

Parallel gripper

InactiveCN103786041ASimple structureImprove reliabilityGripping headsPositioning apparatusSlider crankGrippers

A parallel gripper comprises a base, connecting ports arranged on the base, a pair of gripping beams, at least two rotating wheels respectively mounted on the two gripping beams, connecting blocks, a cylinder base fixed on the gripper base, a cylinder mounted on the cylinder base, a floating connector and a centrosymmetric slider crank mechanism mounted on the gripper base. The two gripping beams are connected to two ends of the centrosymmetric slider crank mechanism through the connecting blocks respectively, and the end portion of the cylinder is connected with the floating connector through the connecting blocks. The parallel gripper is simple in structure, high in reliability and low in cost, actions of gripping and loosening are completed by the aid of action of the centrosymmetric slider crank mechanism, and hubs can be gripped efficiently.

Owner:苏州久工自动化科技有限公司

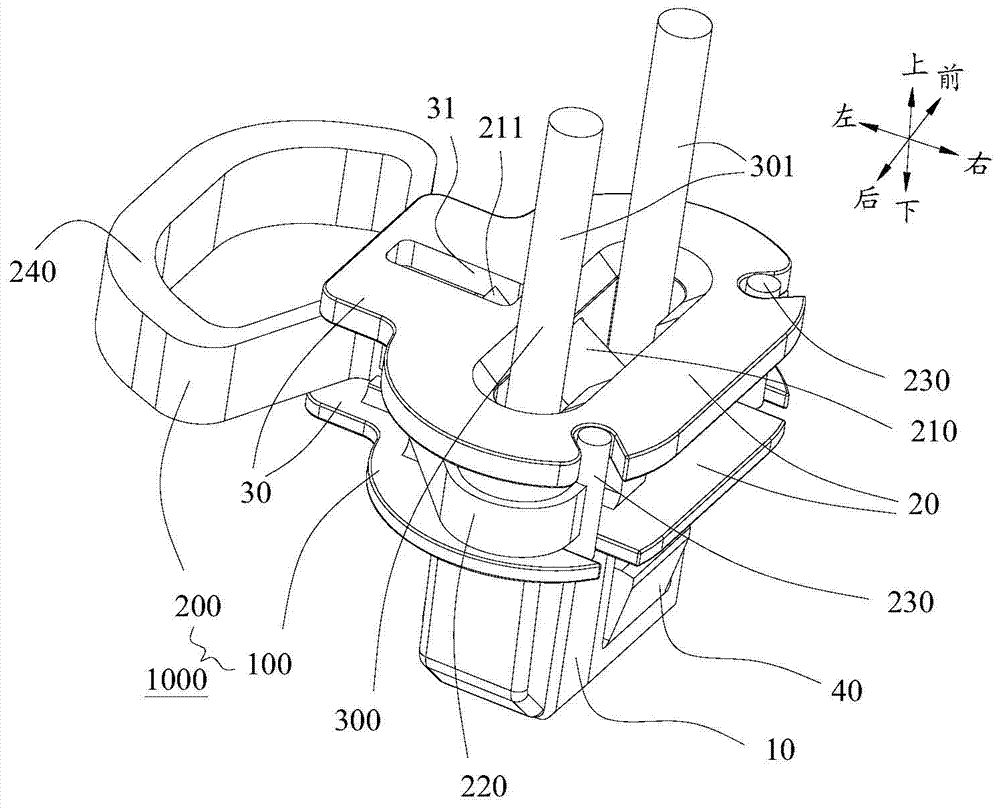

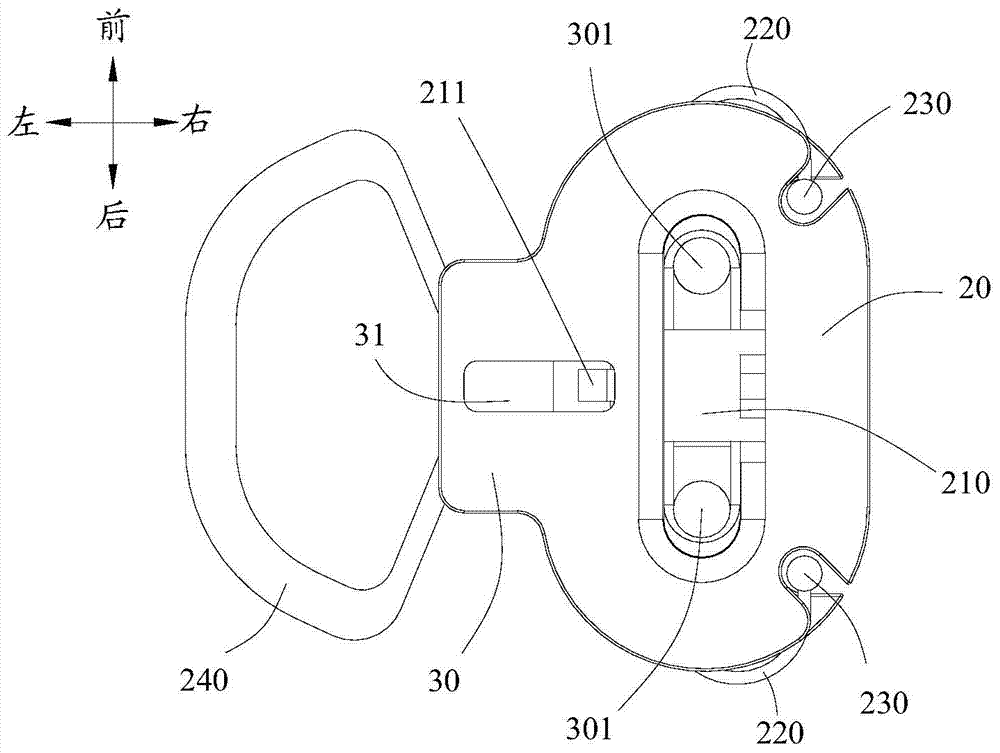

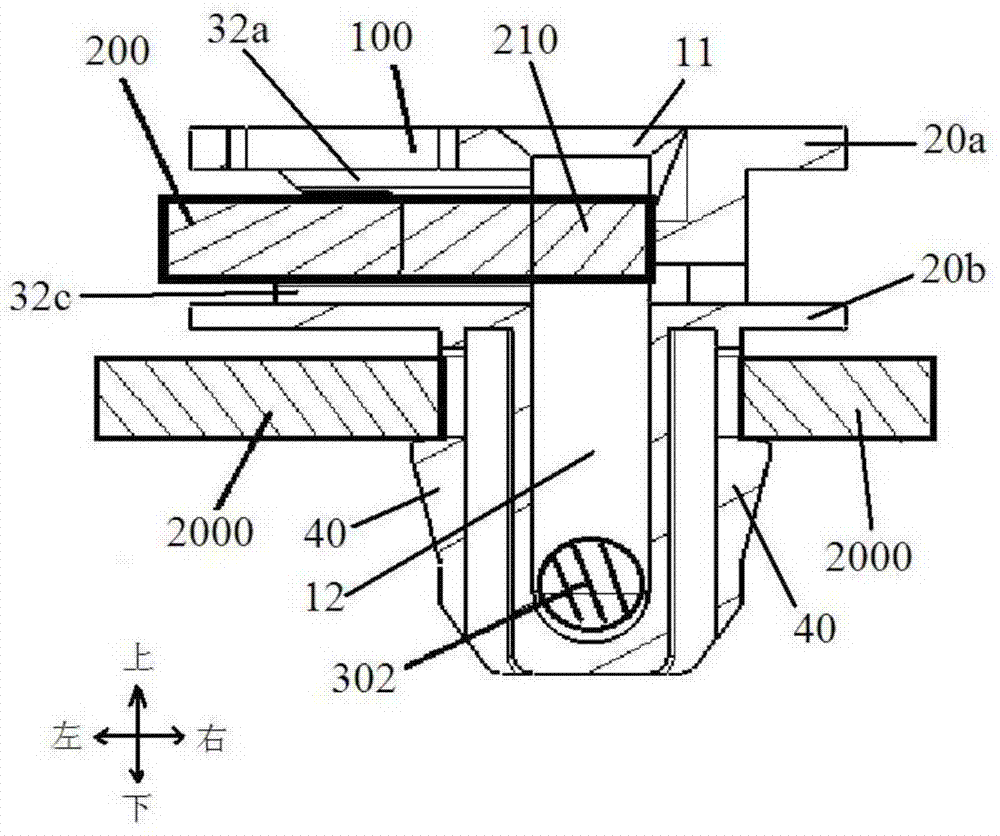

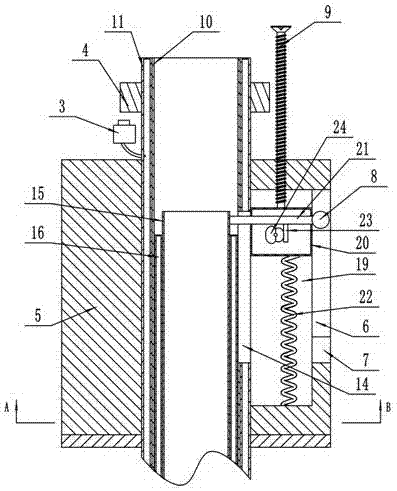

Cushion locking device and vehicle with cushion locking device

ActiveCN104512280AReasonable structureEasy to operateVehicle seatsRopes and cables for vehicles/pulleyInterference fitCushion

The invention discloses a cushion locking device and a vehicle with the cushion locking device, wherein the cushion locking device comprises a deck and a fastener; the deck is internally provided with an accommodation cavity with a slot in the top; a pin hole communicated with the accommodation cavity is formed in the side wall of the deck. The fastener comprises a pin and two grabs which are arranged on the opposite side walls of the pin and are symmetrical relative to the pin; one end of the pin is inserted into the accommodation cavity through the pin hole; the two grabs are arranged on the peripheral wall of the deck in a matching manner, so that the fastener is enabled to be arranged on the deck. According to the cushion locking device, by arranging the fastener on the deck, the cushion locking device is reasonable in structure, and convenient to operate, and a cushion and a car body can be connected firmly and reliably. Meanwhile, the cushion locking device does not adopt a steel wire, so that interference fit between the steel wire and the deck is avoided, the friction damage and the plastic deformation of the deck are decreased, and the deck can also be used even after the cushion is disassembled and assembled for multiple times, so that the use cost is lowered.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

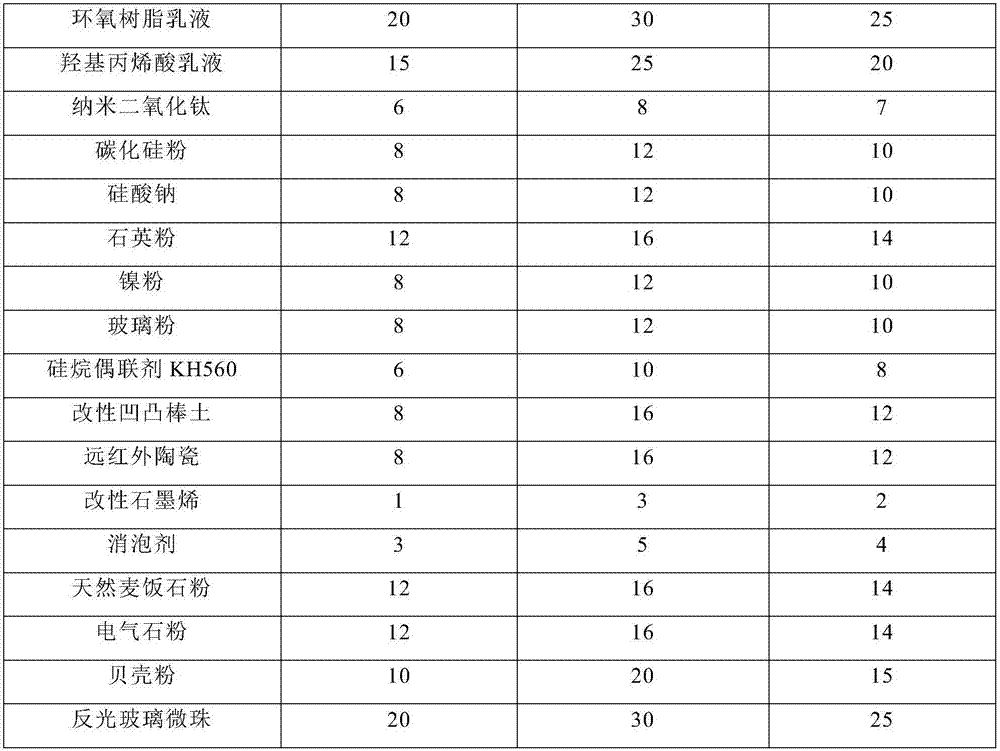

Wear-resistant and corrosion-resistant waterproof coating for environmental protection equipment

InactiveCN107573811AImprove compactnessHigh strengthAnti-corrosive paintsEpoxy resin coatingsWear resistantFar infrared

The invention relates to a wear-resistant and corrosion-resistant waterproof coating for environmental protection equipment. The wear-resistant and corrosion-resistant waterproof coating has the advantages of having good acid and alkali corrosion resistance, oil and water resistance, scratch resistance and wear resistance, effectively avoiding the corrosion damage on the outer surface of the equipment, reducing the frictional damage, and prolonging the service life of the equipment; modified graphene has the advantages of having better dispersibility, increasing the density and strength of thecoating, and effectively improving the waterproof performance of the coating and the permeability of a solvent; modified attapulgite has the advantages of having better viscosity, dispersibility andcompatibility, improving the adhesion between various components, and increasing the adhesion and anti-stripping performance of a paint; tourmaline powder, medical stone, far-infrared ceramics and other functional accessories are added to enhance the functionality of the coating, and benefit the human health; reflective glass beads are used to enhance the recognition capability of operators; a preparation method is simple in process, and low in energy consumption and cost.

Owner:SUZHOU TIANJIANHENG ELECTRONICS INFORMATION TECH CO LTD

Metal spinning powder and preparation method thereof

ActiveCN104388155AEasy to cleanReduce friction damageLubricant compositionPotassium hydroxideHigh pressure

The invention discloses metal spinning powder and a preparation method thereof. The metal spinning powder is characterized by being prepared from the following raw materials in parts by weight: 100-300 parts of sodium carbonate or potassium carbonate, 1-5 parts of sodium benzoate, 300-600 parts of water, 10-60 parts of sulfonated castor oil, 5-30 parts of chlorcosane, 5-30 parts of tall oil, 2-15 parts of powdery sodium hydroxide or potassium hydroxide, and 5-30 parts of white carbon black. The invention also discloses the preparation method of the metal spinning powder. The metal spinning powder disclosed by the invention has the advantages of favourable lubricating property, corrosion resistance, high temperature resistance, high pressure resistance, lower cost and easy storage.

Owner:HENAN NORMAL UNIV

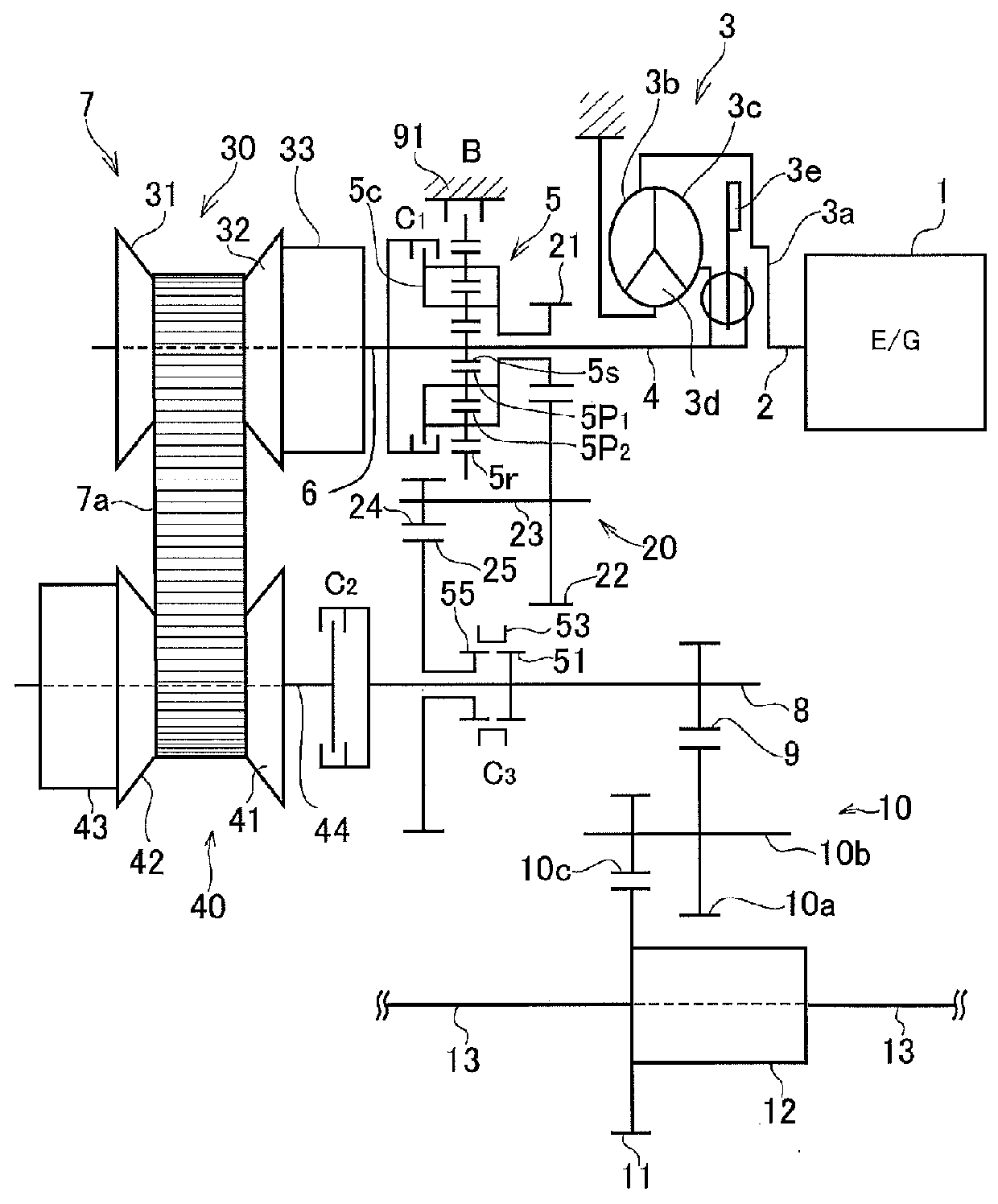

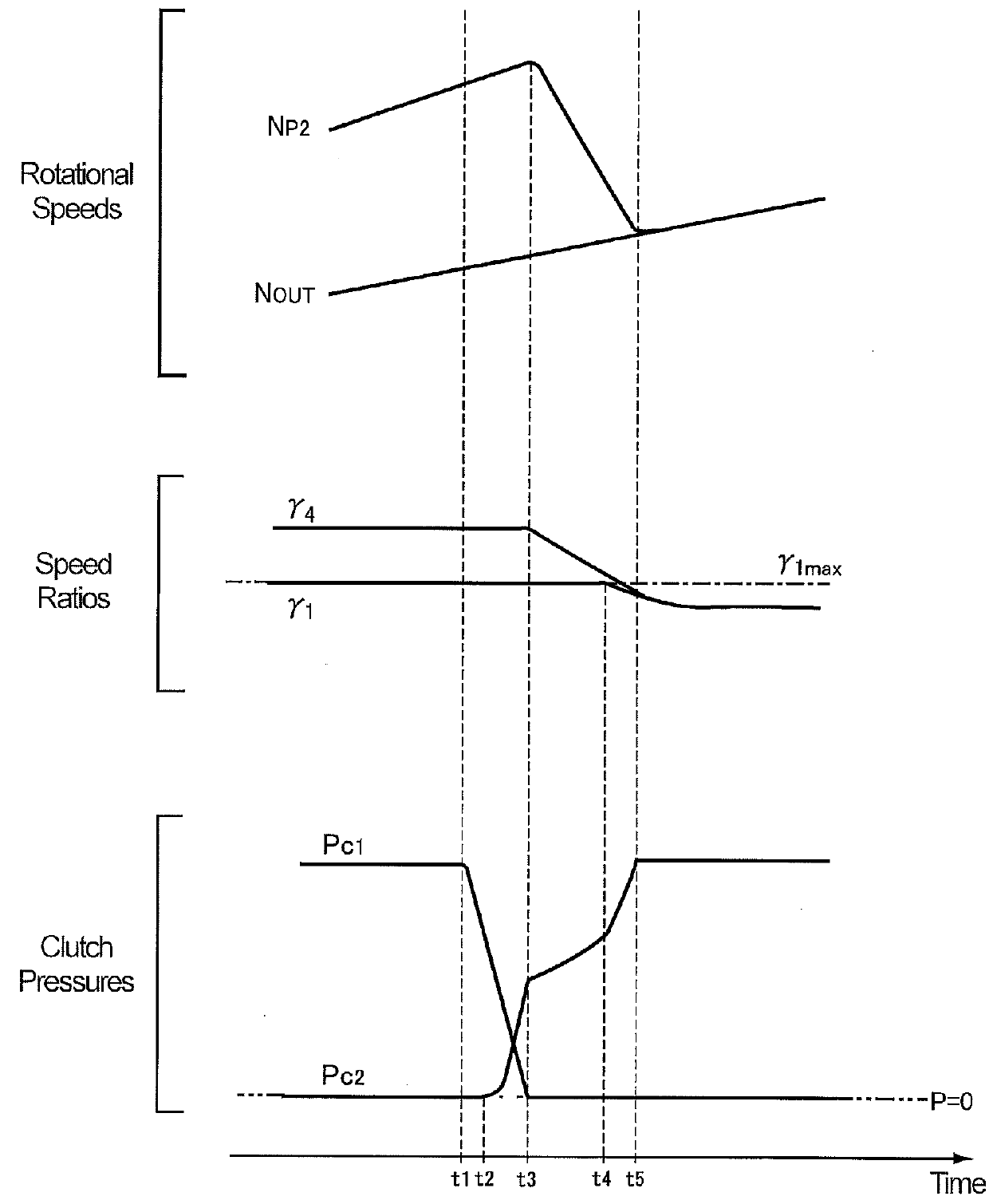

Vehicle control system and vehicle control method

ActiveUS20160052522A1Reduce shift shockLess discomfortGearingPortable liftingControl systemTorque transmission

Vehicle control system and method provided to change speed ratio smoothly when switching a power transmission route from a route including a geared transmission to a route including a continuously variable transmission. Vehicle control system applied to a vehicle comprising: continuously variable transmission for changing speed ratio continuously is disposed between input shaft and output shaft; geared transmission is disposed parallel to the continuously variable transmission, and is adapted to establish speed ratio that cannot be established by continuously variable transmission; and friction clutch is brought into engagement to switch torque transmission route from a route including the geared transmission to a route including the continuously variable transmission. Vehicle control system configured to start speed change operation of continuously variable transmission before the friction clutch is brought into engagement completely when switching torque transmission route from the route including the geared transmission to the route including the continuously variable transmission.

Owner:TOYOTA JIDOSHA KK

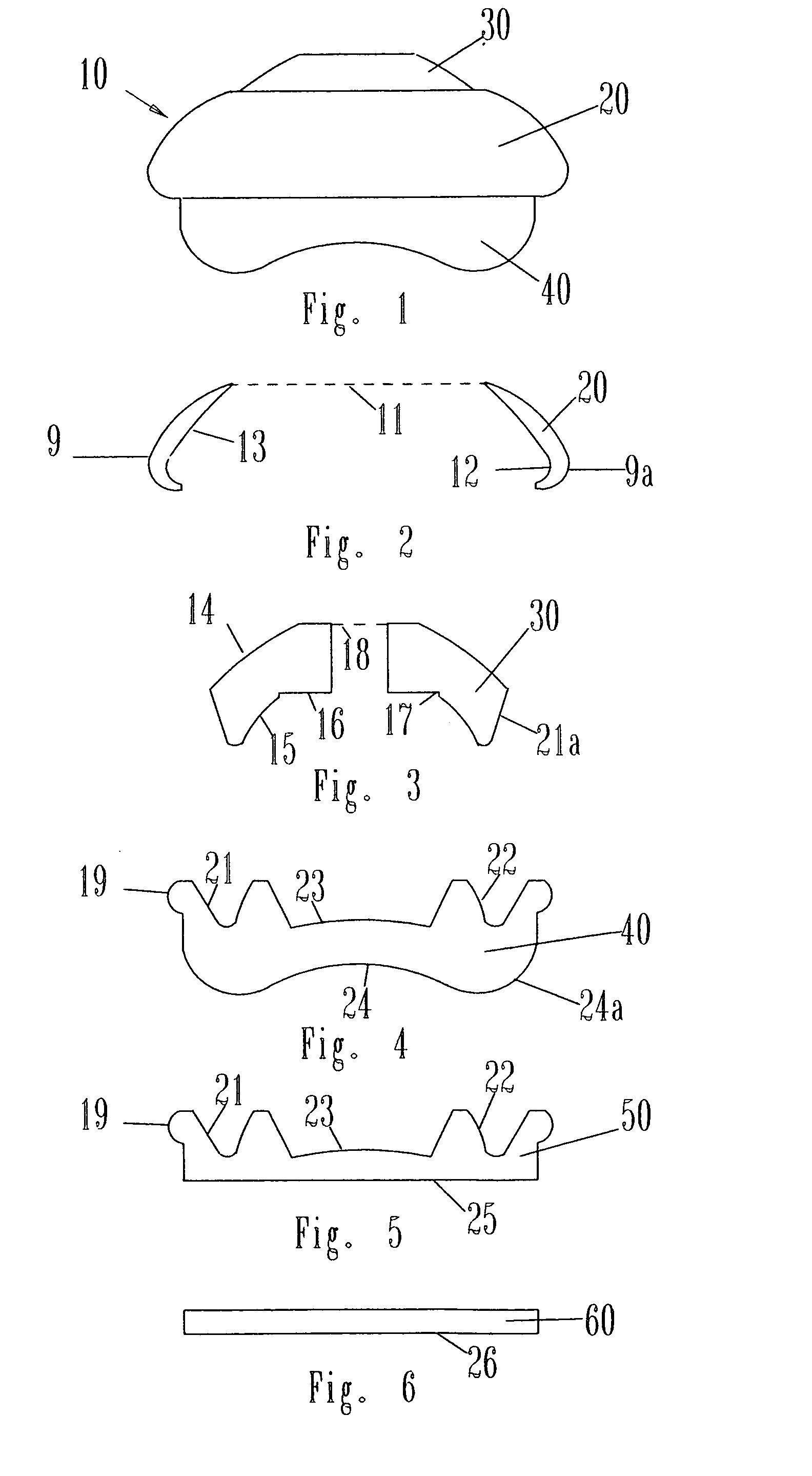

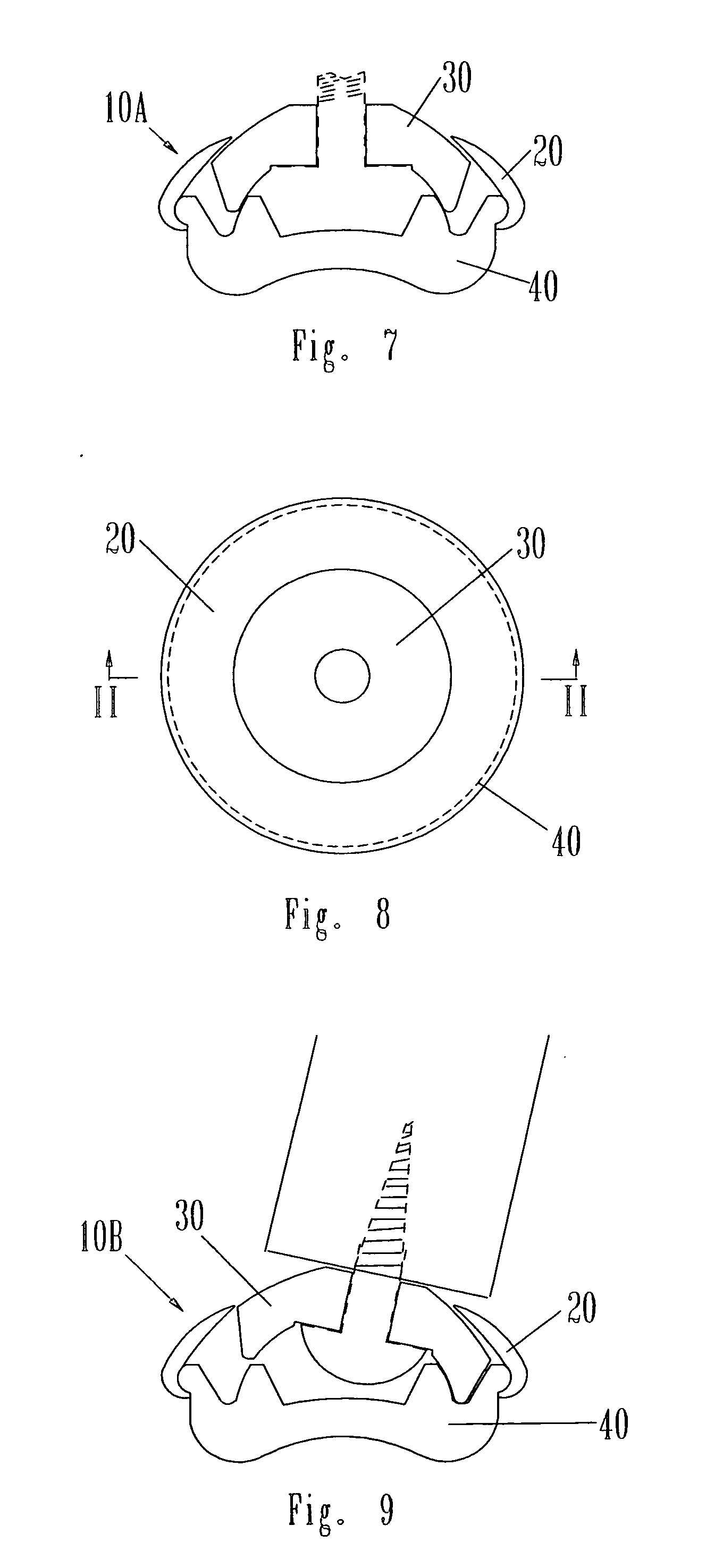

Fungible furniture glide

A three component swiveling and rolling glide device, of which two components comprise the mounting assembly and one is an exchangeable base. The mounting assembly is designed to accept multiple attachment means, such as screws, bolts, nails etc. The glide base is removable by finger pressure only without the need for tools enabling the easy interchangeability of the glide base and the attachment means, as desired. This glide also has a tandem swiveling and rolling capability and will also adapt to a singular rolling function, if required, in deep carpets or whenever the glide is at maximum tilt. The hard base, of my invention, has a unique base design to encourage the swiveling and rolling action of the glide. The soft base can accept different materials for the specific need, such as, felt to protect hardwood or tile flooring or rubber for a non-skid function. This glide is designed to combine all the above functions, allowing it to adapt to multiple furniture styles and numerous uses.

Owner:VORPAHL STEVEN A

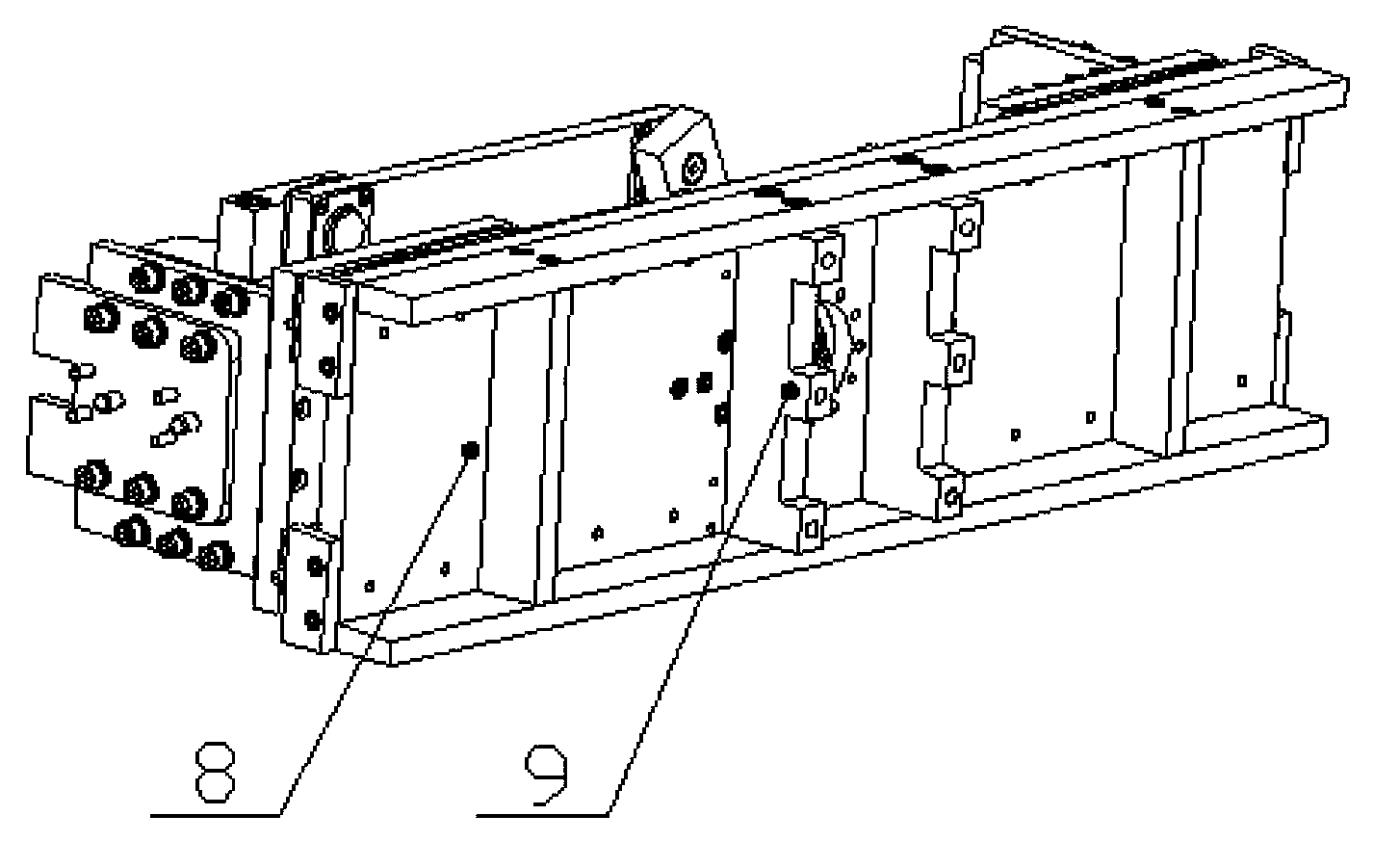

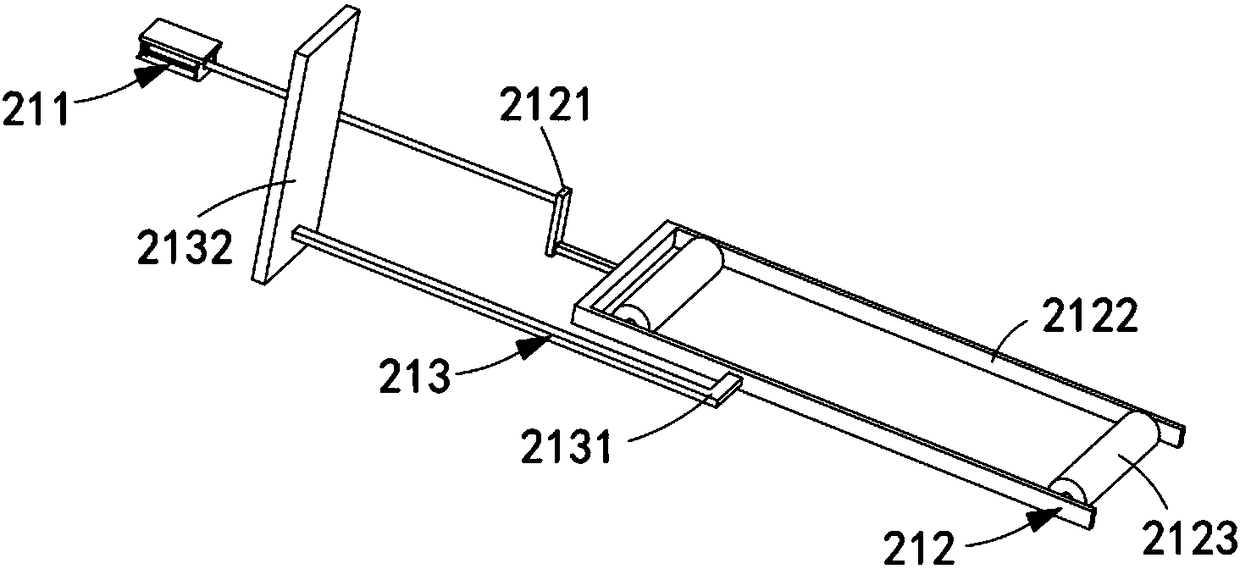

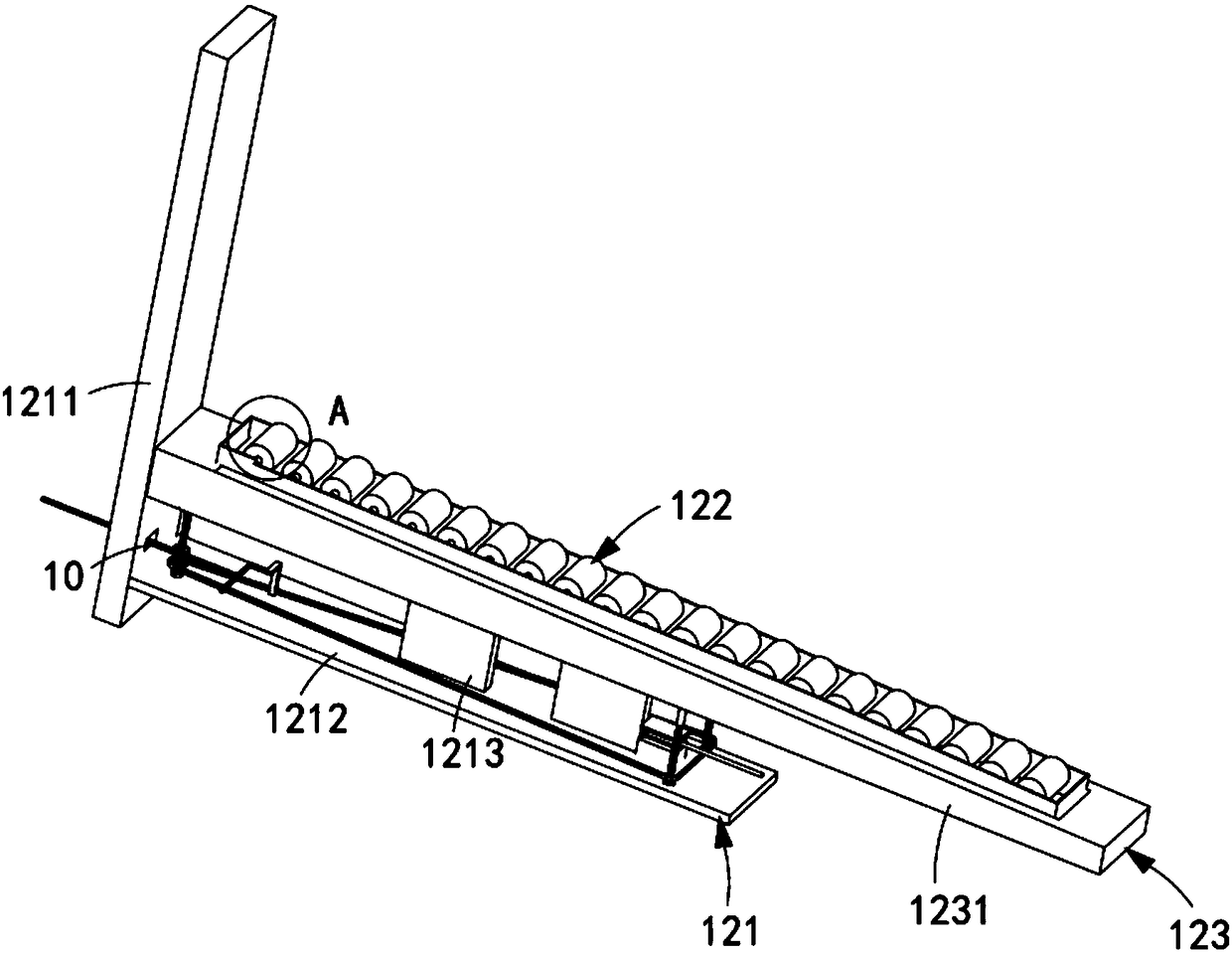

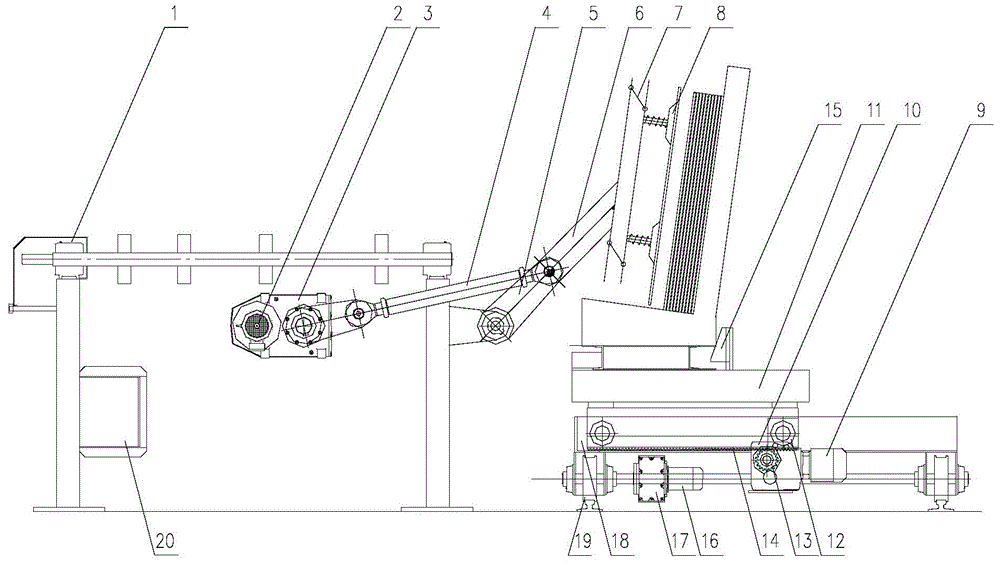

Smooth feeding door frame assembly for forklift and forklift applying smooth feeding door frame assembly

The invention relates to a smooth feeding door frame assembly for a forklift and a forklift applying the smooth feeding door frame assembly. The assembly comprises a primary material discharging mechanism and a secondary material discharging mechanism, wherein the primary material discharging mechanism comprises a driving component, a first pushing component and a second pushing component, whereinthe driving component is fixedly arranged at the middle position of a lifting frame, the first pushing component and the second pushing component are symmetrically arranged on the two sides of the driving component and are arranged on the lifting frame in a sliding mode, and the driving component cooperates with the first pushing component and the second pushing component to carry out primary unloading; the secondary material discharging mechanism comprises a first feeding component and a second feeding component, wherein the first feeding component is arranged at the lower part of the firstpushing component and is located at the rear half part of a cargo material conveying direction, and the second pushing component is arranged at the lower part of the second pushing component and is located at the rear half part of the cargo material conveying direction; and the first feeding component and the second feeding component are both arranged in a telescopic mode along the horizontal conveying direction of a cargo material. According to the assembly, the problem that the bottom surface of a panel is obliquely arranged, when the cargo is slid and sent to a destination, the cargo with heavier weight can be overturned due to the fact that the ground is firstly contacted with one side of the bottom surface of the cargo is solved.

Owner:ZHEJIANG SHANGJIA MACHINERY

Bactericidal and antiallergic non-woven fabric

InactiveCN102704188AImprove breathabilityGood instant water absorptionNon-woven fabricsPolymer scienceNonwoven fabric

The invention relates to a non-woven textile made from fibers, and especially to a non-woven fabric for sanitary towel fabrics, protection pad fabrics or paper diapers, in particular to a bactericidal and antiallergic non-woven fabric. The non-woven fabric is prepared by bamboo fibers, base fibers and silk cotton according to the following parts by weight and steps: (1) proportions: 15-30 parts of bamboo fibers, 40-60 parts of base fibers and 10-20 parts of silk cotton; (2) steps: step 1. performing at least two-time cotton blending and at least two-time loosening operations on the bamboo fibers, base fibers and silk cotton; step 2. paving the bamboo fibers, base fibers and silk cotton treated by the cotton blending and loosening operations in step 1 to a net through a lapping machine and combing the bamboo fibers, base fibers and silk cotton through a combing machine; and step 3. carrying out hot rolling on the bamboo fibers, base fibers and silk cotton through a hot rolling mill. The bamboo fibers and the silk cotton are added in the non-woven fabric, so that the non-woven fabric is smoother, bactericidal and bacteriostatic and has the faint scent of bamboo.

Owner:重庆百亚卫生用品股份有限公司

Multifunctional anti-loosening bolt nut

The invention relates to the technical field of machine parts, in particular to a multifunctional anti-loosening bolt nut. The multifunctional anti-loosening bolt nut comprises a bolt jointed rod piece, a fastening nut and a locking nut, wherein a main body of the bolt jointed rod piece is provided with a fastening bolt jointed part; at least one end of the bolt jointed rod piece is provided witha locking bolt jointed part; the fastening bolt jointed part is provided with an external thread structure; the locking bolt jointed part is provided with an external thread structure or an inner bolthole structure; the screwing direction of the fastening bolt jointed part is opposite to the screwing direction of the locking bolt jointed part; a first inner hole and a second inner hole are formedin the locking nut; when the fastening bolt jointed part is of an external thread structure, the second inner hole is provided with an inner bolt hole structure; and when the locking bolt jointed part is of an inner bolt hole structure, the second inner hole is provided with an external thread structure. The self-loosening phenomenon of the bolt nut can be prevented from occurring and developing,thus preventing potential safety hazards even accidents from occurring. The multifunctional anti-loosening bolt nut has the functions of thread water prevention and dust prevention.

Owner:青海左丌右电气技术服务有限公司

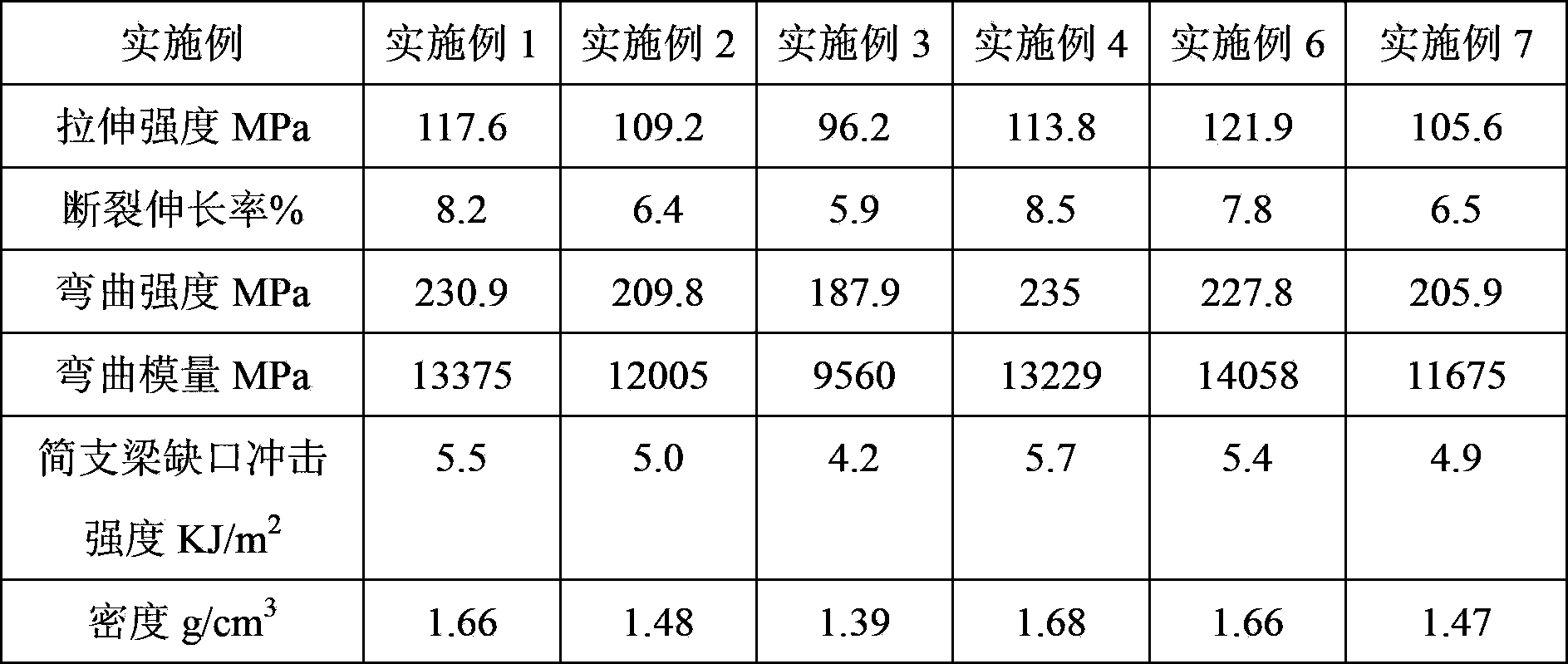

Wear-resistant self-lubricating modified polyphenylene sulfide material and preparation method thereof

The invention belongs to the technical field of polymer materials, and relates to a polyphenylene sulfide material and a preparation method thereof. The composite material is composed of the following raw materials in parts by weight: 45 to 55 parts of polyphenylene sulfide, 5 to 10 parts of anti-wear agent, 0.5 to 1 part of lubricant, 0.2 to 0.4 part of antioxidant, 0.6 to 1 part of coupling agent, and 35 to 45 parts of glass fiber. The preparation method comprises the following steps: adding 45 to 55 parts of polyphenylene sulfide, 5 to 10 parts of anti-wear agent, 0.5 to 1 part of lubricant, 0.2 to 0.4 part of antioxidant, 0.6 to 1 part of coupling agent, and 35 to 45 parts of glass fiber into a high-speed mixer, evenly mixing the materials in a high speed in the high-speed mixer, then pouring the mixture into a screw extruder, extruding the mixture strips, and cutting the strips into granules so as to obtain the finished product. The material has the advantages of high strength, self-lubricating, and wear resistance, and can be made into gears, bearings, and the like.

Owner:HEFEI GENIUS NEW MATERIALS

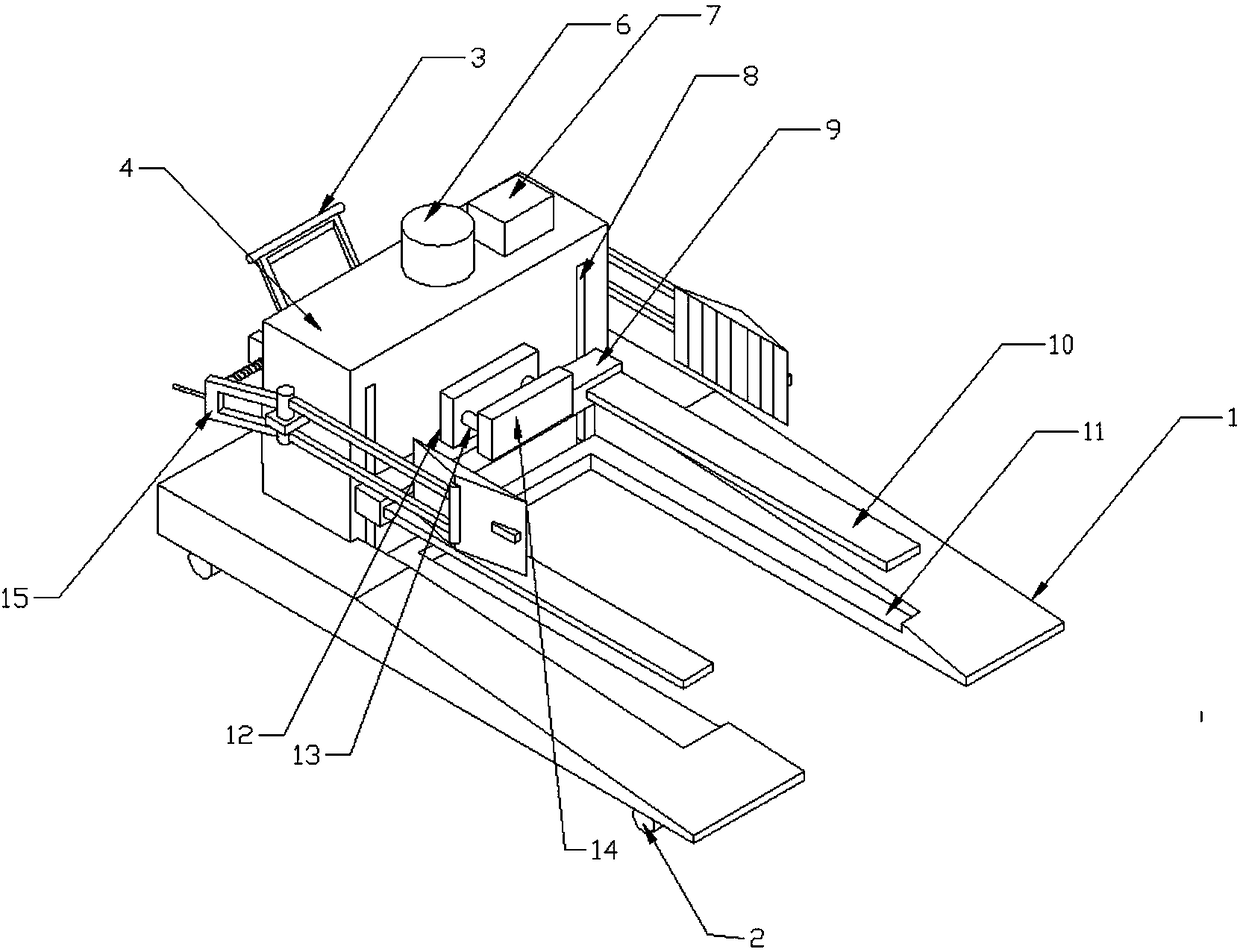

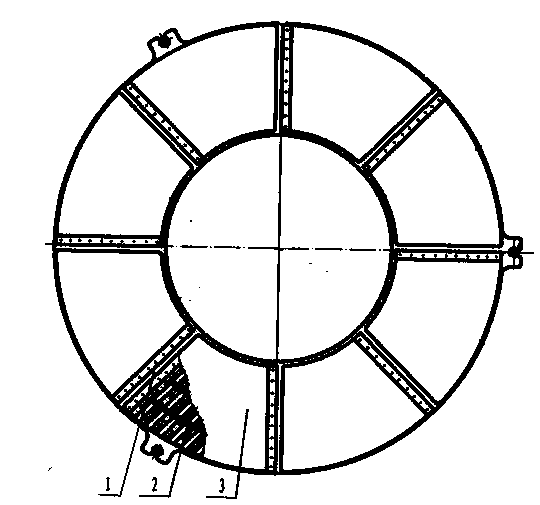

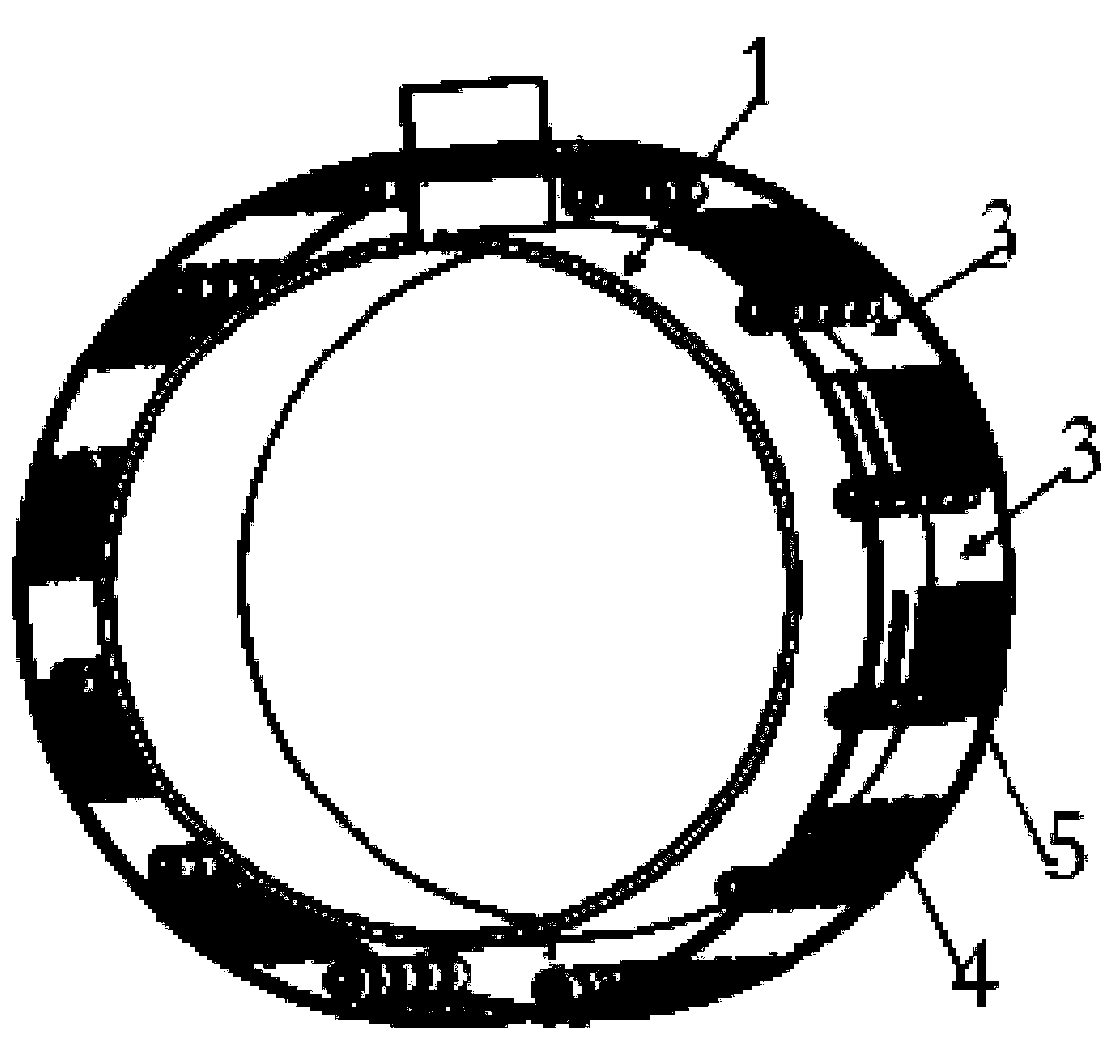

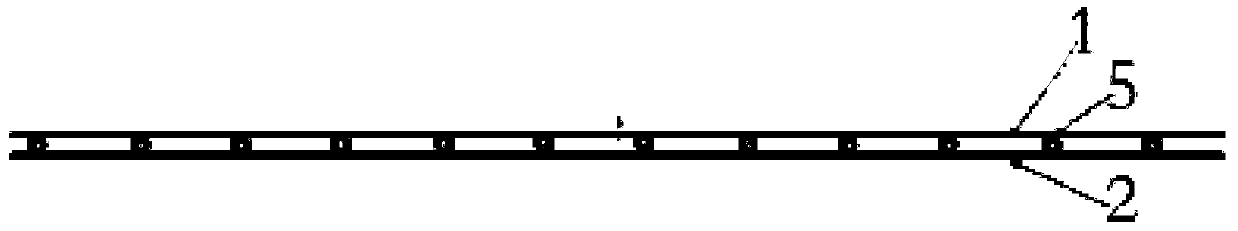

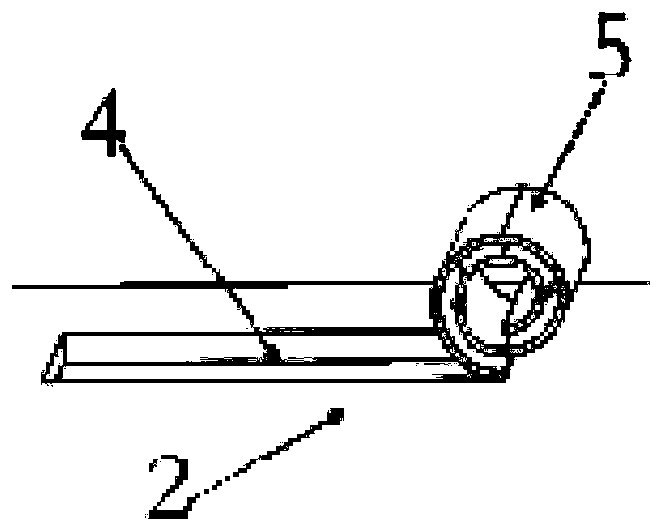

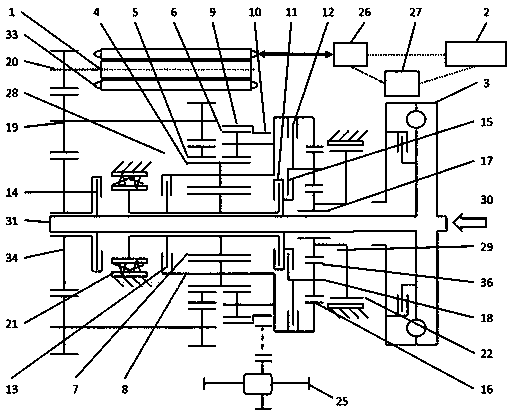

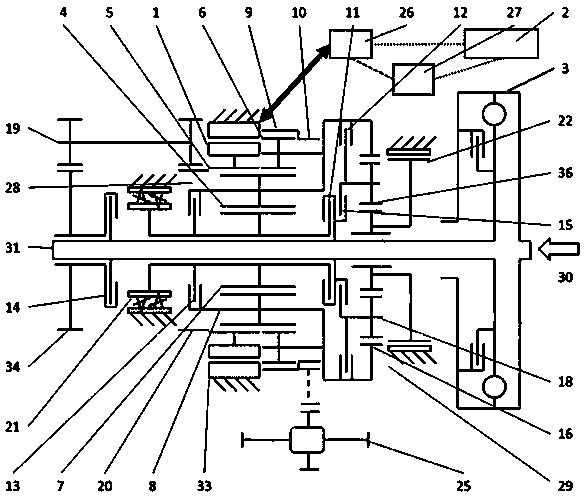

Polyvinyl chloride insulation fireproof power cable cabling stranding machine

InactiveCN110660534ARealize the adjustment functionImprove adaptabilityCable/conductor manufactureRotational axisPower cable

The invention discloses a polyvinyl chloride insulation fireproof power cable cabling stranding machine, which comprises a mounting base, a rotary stranding frame, a take-up device and pay-off devices, wherein the rotary stranding frame is arranged in the middle of the top end surface of the mounting base, the left side of the top end surface of the mounting base is fixedly provided with a boss, the take-up device is arranged on the right side of the top end surface of the mounting base, a plurality of pay-off devices are fixedly arranged on the front and rear end surfaces of the rotary stranding frame, and the left and right end surfaces of the rotary stranding frame are fixedly provided with rotating shafts. According to the invention, the rotary stranding frame is matched with the plurality of pay-off devices to form an integrated automatic stranding structure, and the function of adjusting the stranding position is realized by sliding a fixed rod, so that the adaptability to different stranding strength of different single-stranded cables is facilitated. In addition, a wire guide plate and a collecting device are arranged, so that the single-stranded cable is enabled to have directional output, the friction damage in the stranding process can be well reduced, and the stranding quality is improved. The stranding speed is greatly improved through a wire lapping wheel and a take-up wheel.

Owner:安徽华上电缆科技有限公司

Safe and reliable elevator guide rail

The invention relates to a safe and reliable elevator guide rail. The safe and reliable elevator guide rail comprises a rail bottom, and a rail body which is arranged vertical to the rail bottom; the rail bottom and the rail body are connected to form a reversed T shaped structure; a plurality of groups of ball grooves are uniformly formed in the left surface, the top surface and the right surface of the rail body, and the top left surface and the top right surface of the rail bottom; balls are mounted in the ball grooves, and air bags are arranged in the bottoms of the ball grooves; and an automatic air inflation device for inflating air into the air bags is arranged at the bottom part of the rail bottom. The safe and reliable elevator guide rail adopting the scheme above has the advantages that the frictional force between an elevator guide shoe and the guide rail can be reduced through the balls when an elevator runs normally and thus the friction-cased damage on the guide rail can be reduced; in case of overspeed of the elevator, the air is inflated into the air bags, some balls are propped out from the ball grooves under the extruding effects of the ball grooves and the air bags, the propped-out balls are limited to roll to decelerate the elevator under overspeed, so as to lower down the speed of the elevator under overspeed, and as a result, the overspeed-cased damage can be reduced.

Owner:常州市晨光汽车消声器厂

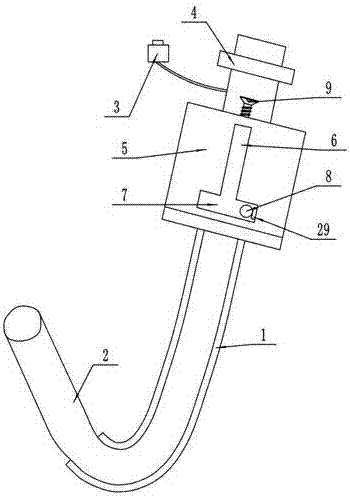

Ventilation apparatus for general anesthesia

PendingCN107376082AEasy to insertAchieve fixationTracheal tubesMedical devicesTracheal tubeLaryngeal Masks

The invention belongs to the field of medicines, and particularly discloses a ventilation apparatus for general anesthesia. A tracheal catheter comprises a tracheal inner layer and a tracheal bladder arranged outside the tracheal inner layer. A control unit comprises a rotary sleeve which is in rotary connection with a laryngeal mask catheter, guide slots are formed in the outer side of the rotary sleeve, and the top of the rotary sleeve is connected with a bolt. A sliding cavity and an air supply assembly are arranged in the rotary sleeve; the air supply assembly is used for supplying and feeding air for the tracheal bladder; a slider is in sliding connection in the sliding cavity; a connecting rod penetrates the inside of the slider and is provided with a stop plate; one end of the connecting rod runs through a third communicating port and is connected with the tracheal inner layer; the other end of the connecting rod is connected with an indicating ball which is in sliding connection in the guide slots. A cam mechanism is also arranged in the slider and abutted against the tracheal catheter. According to the technical scheme, hurt to the patient's body caused by rubbing generated in the process of inserting the laryngeal mask catheter and the tracheal catheter can be reduced, insertion of the tracheal catheter is facilitated, the state of the tracheal catheter can be switched conveniently, and thus, work efficiency of medical staff is improved.

Owner:蔡容

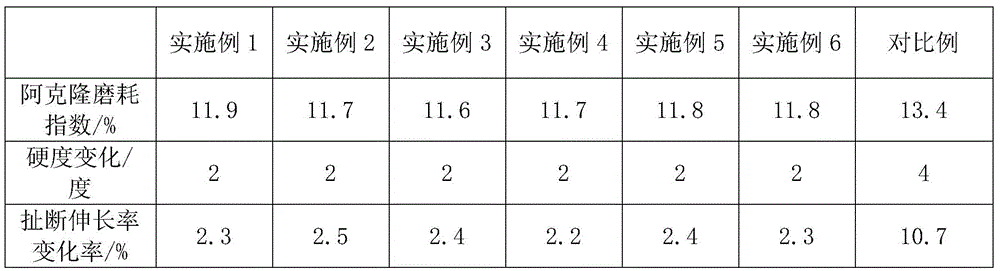

Wear-resistant and heat-resistant EPDM (ethylene-propylene-diene monomer) sole material and preparation method thereof

The invention provides a wear-resistant and heat-resistant EPDM (ethylene-propylene-diene monomer) sole material, which is prepared from the following ingredients in parts by weight: 56 to 66 parts of EPDM, 8 to 10 parts of EVA (ethyleno vinyl acetale), 1 to 2 parts of cross-linking agents, 5 to 12 parts of filling materials, 3 to 5 parts of foaming agents, 2 to 3 parts of dispersion agents, 0.5 to 1 parts of antioxidants, 4 to 9 parts of softening oil, 2 to 3 parts of accelerating agents, 4 to 5 parts of tackifiers, 4 parts of zinc oxide, 3 parts of zinc stearate and 5 to 6 parts of modified aluminum oxide. The invention also provides a preparation method of the wear-resistant and heat-resistant EPDM sole material. The EPDM sole material provided by the invention has the advantages of good wear-resistant performance and good heat-resistant and aging-resistant performance.

Owner:SUZHOU JINGRO TECH

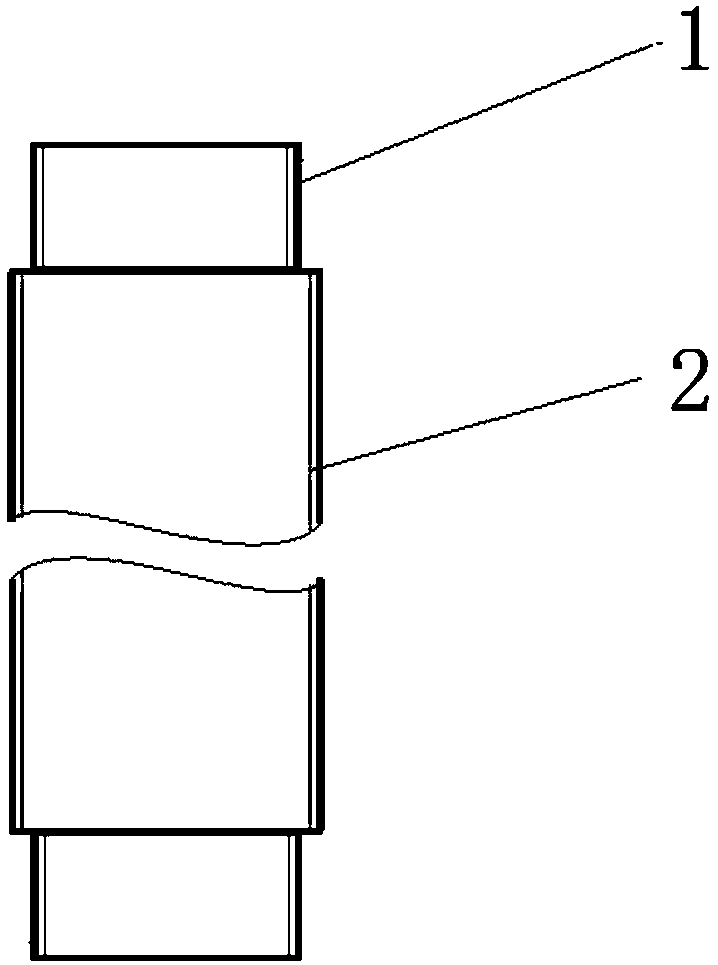

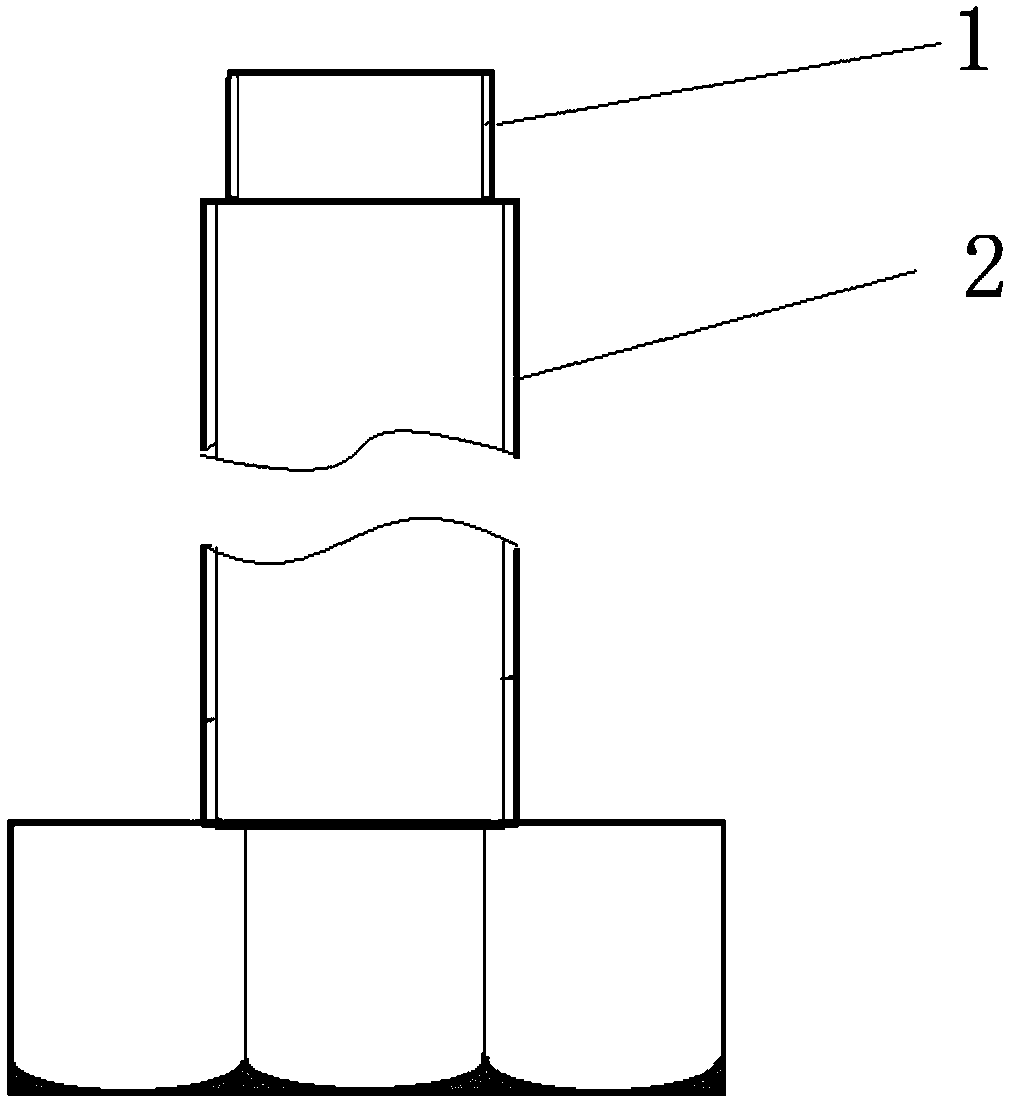

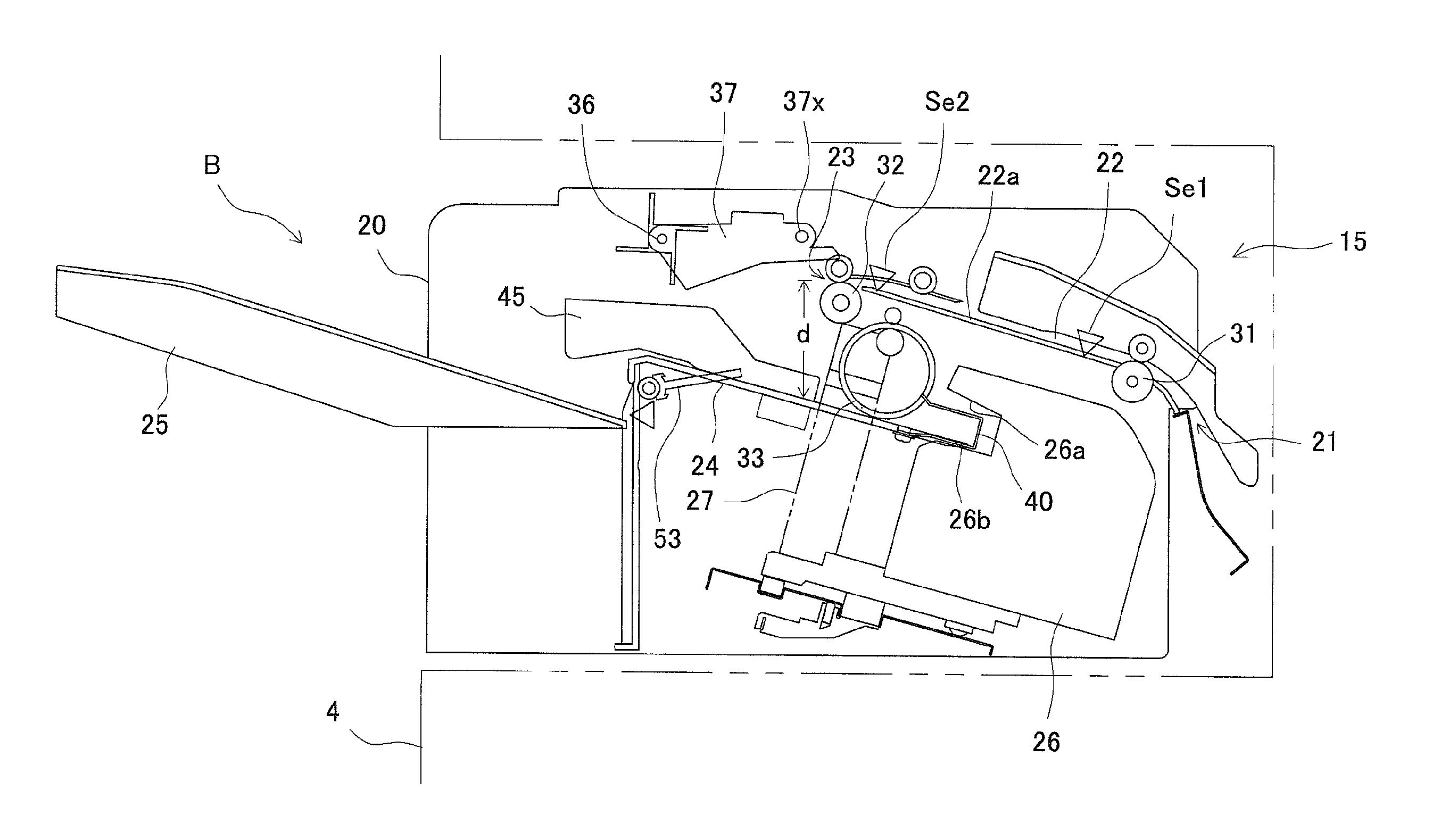

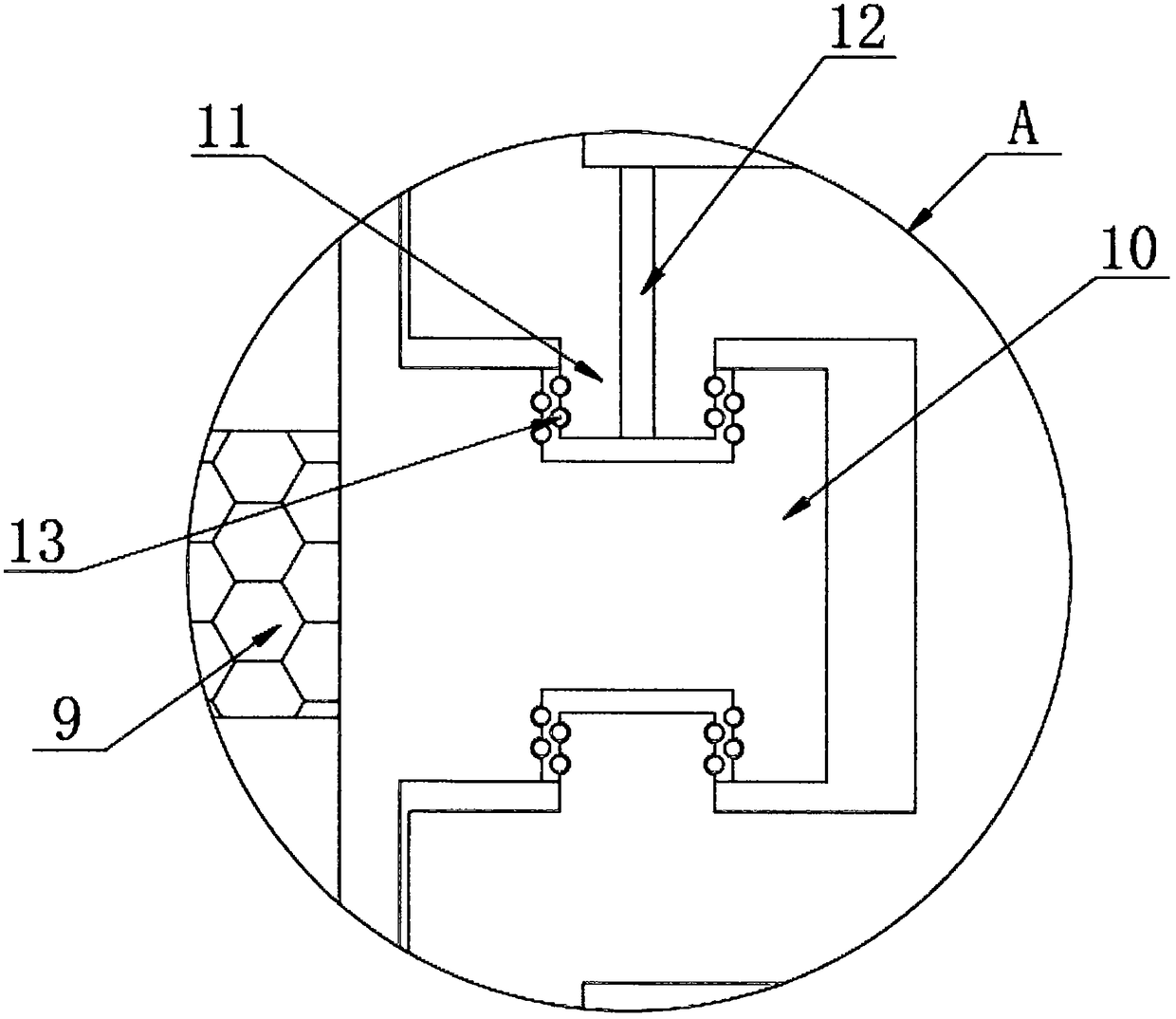

Sheet bundle binding processing apparatus and image forming system having the same

ActiveUS20150021844A1Incomplete separationReduce frictionMechanical working/deformationElectrographic process apparatusMechanical engineering

The purpose of the present invention is to provide a sheet bundle binding processing apparatus capable of providing relatively strong bonding when a plurality of sheets are bound by corrugation-shaped pressurizing faces with nip-pressure deformation and causing less frictional damage on a sheet face when a sheet bundle is introduced to and discharged from the binding unit. The present invention comprises a sheet bundle binding processing apparatus including a processing tray which includes a sheet placement face on which sheets are stacked, a press binding device which bonds mutually overlapped sheets stacked on the processing tray with pressure-bonding deformation, a taking-off device which applies a taking-off force to sheets bound by the press binding device along the sheet placement face for taking off the sheets from the press binding device, and a sheet bundle discharging device by which the sheets taken off from the press binding device by the taking-off device is discharged from the processing tray.

Owner:COPYER +1

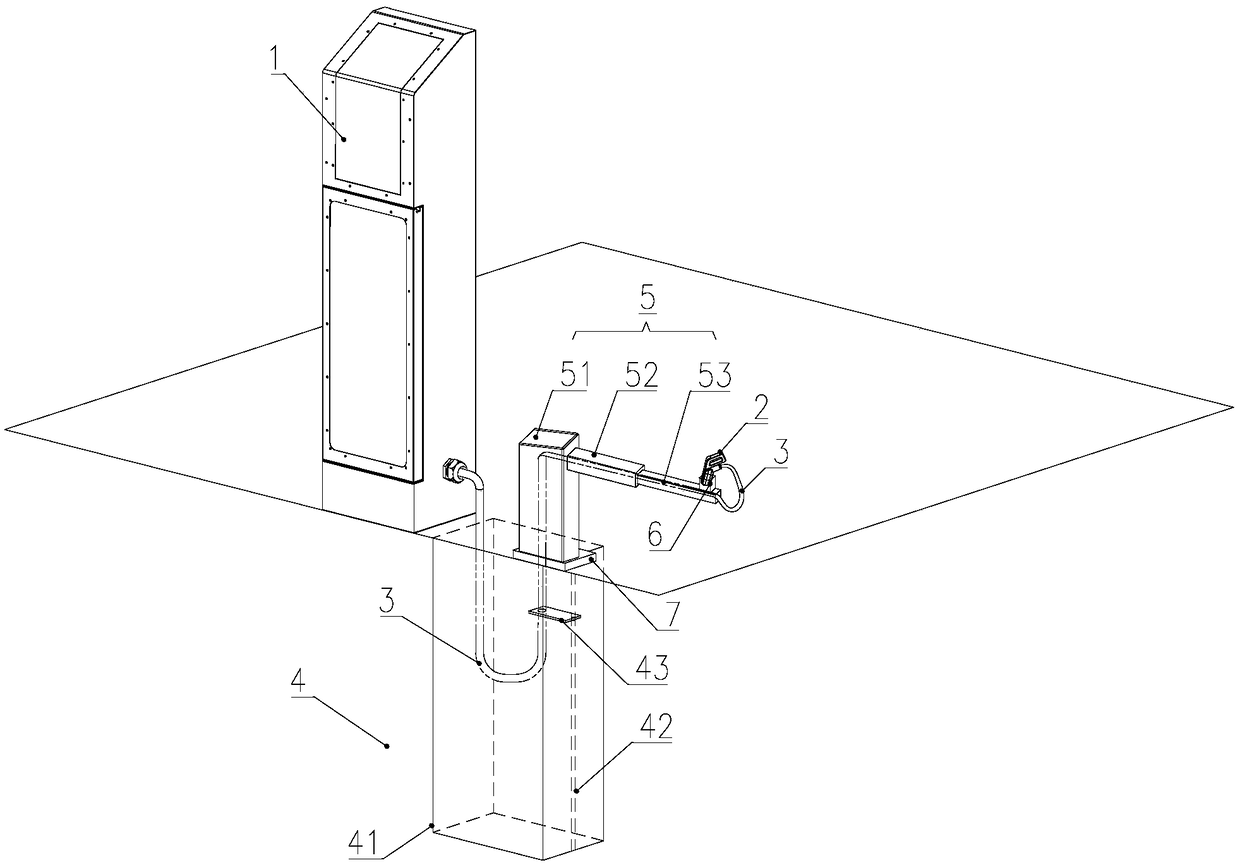

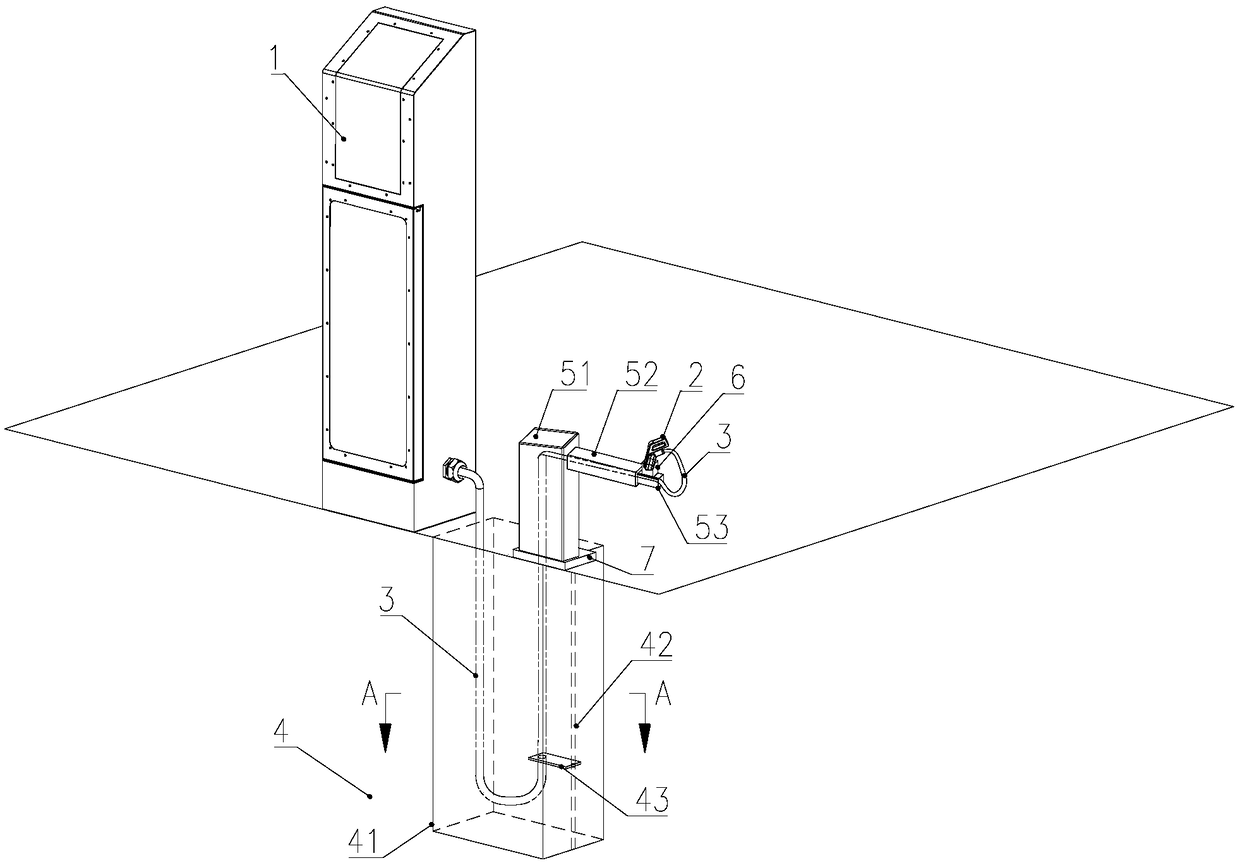

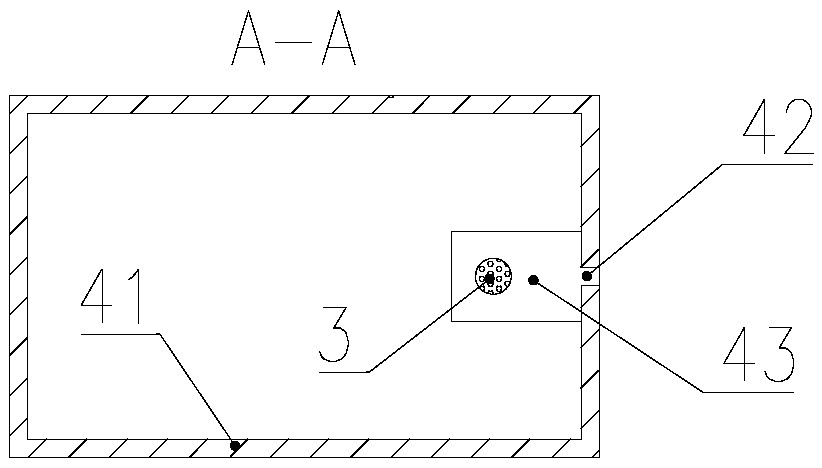

Charging pile

ActiveCN109050280AReduce the chance of theftReduce friction damageElectric propulsionElectrical and Electronics engineeringEngineering

The invention relates to the field of charging piles, in particular to a charging pile, comprising a charging pile, a charging gun and a gun wire, wherein one end of the gun wire is connected with thecharging pile and the other end is connected with the charging gun, and the charging pile further comprises a gun wire retracting and placing device and a bracket; Wherein the sliding device is provided with a control device; A sensing device is arranged on the charging gun, and the sensing device is linked with a control device; The gun wire receiving and releasing device is buried under the ground for storing or releasing the gun wire; The bracket is arranged on the ground for supporting the gun wire; The gun thread receiving and placing device of the invention is buried under the ground, and the bracket is seamless all-metal structure, so that it is difficult for the thief to dismantle the gun thread, and the stolen probability is reduced; By means of the control device and the induction device, the automatic retracting and placing of the gun wires is realized, the process of the user dragging the gun wires is avoided, the damage of the gun wires due to friction is reduced, or theforce at the interface between the charging gun and the gun wires due to the dragging is increased, and the service life of the charging gun and the gun wires is prolonged.

Owner:正星科技股份有限公司

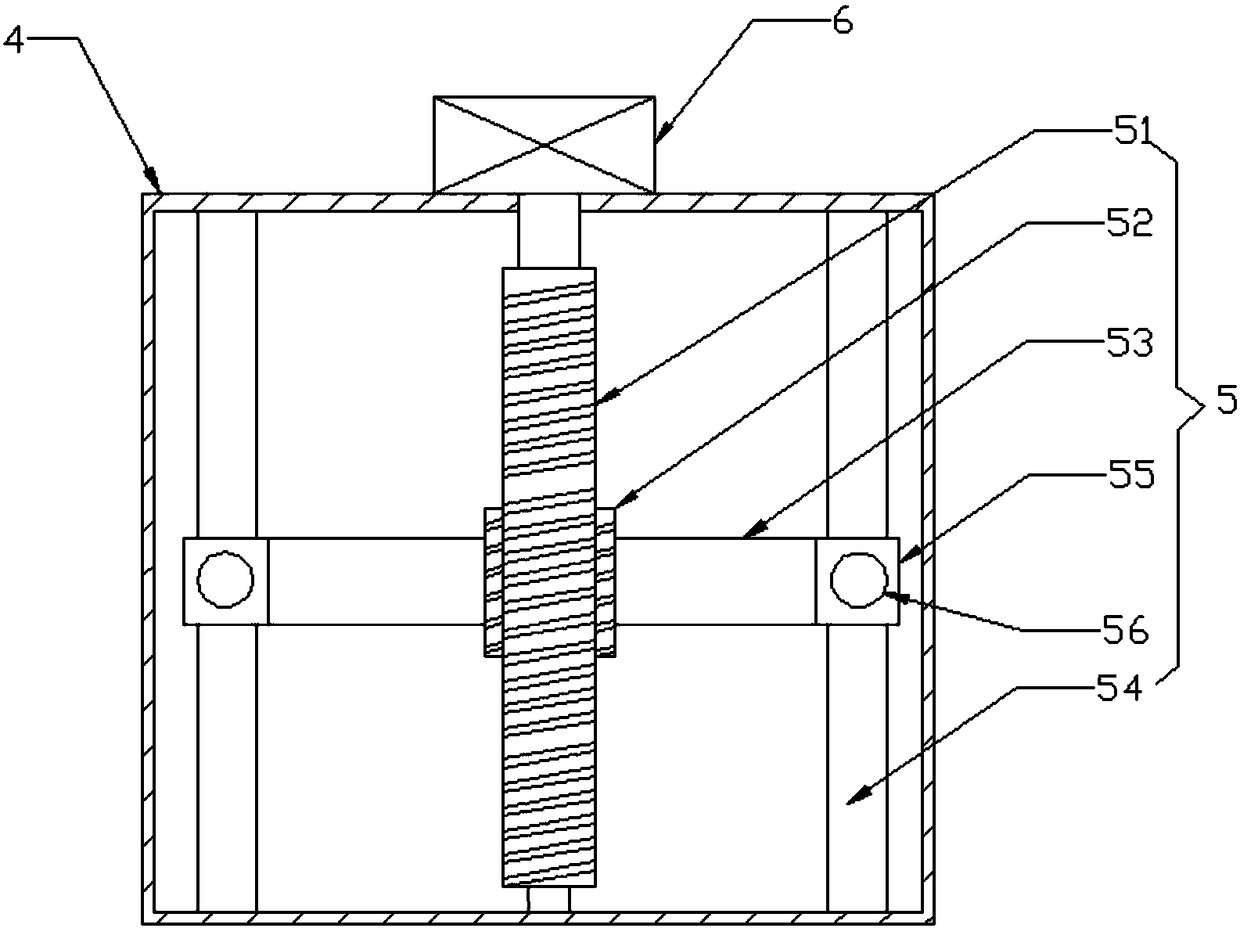

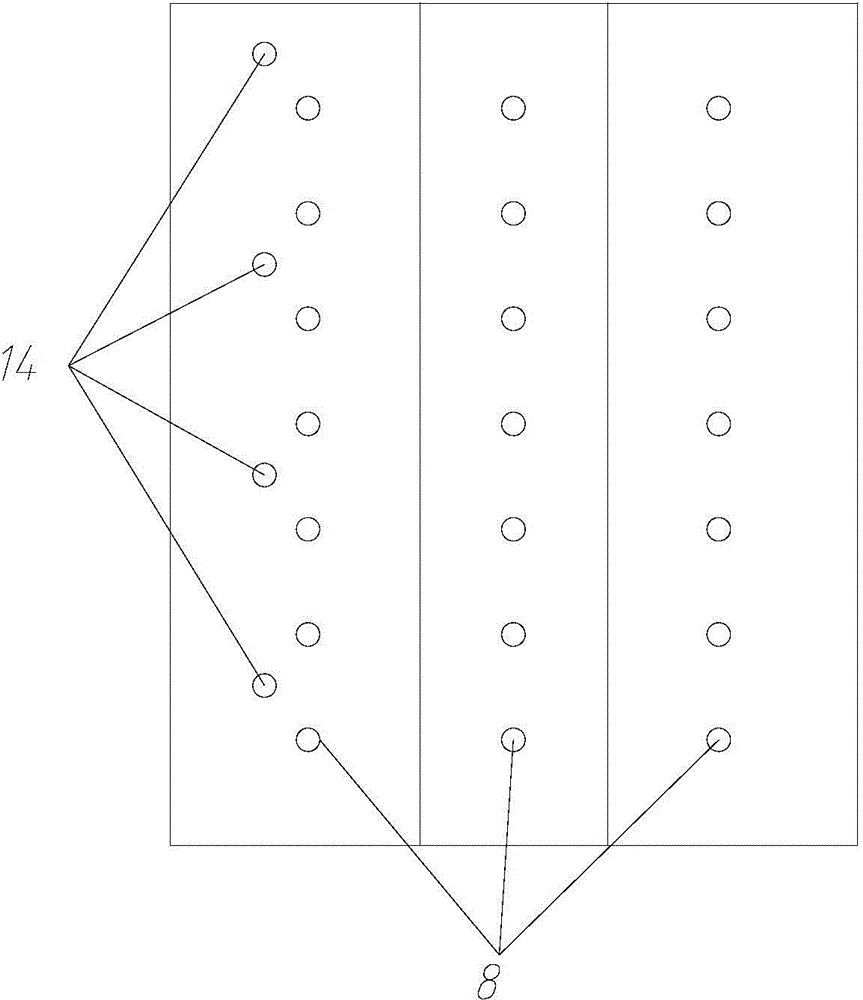

Multi-stage elastic supporting assembly and dynamic pressure gas radial bearing

PendingCN109915477AReduce starting friction torqueReduce friction damageSliding contact bearingsBearing coolingEngineeringMechanical engineering

The invention belongs to the technical field of mechanical equipment, and particularly relates to a multi-stage elastic supporting assembly and a dynamic pressure gas radial bearing. A supporting foilsheet of an existing bulled radial dynamic pressure gas bearing comprises an elastic foil sheet with bubbles and a flat foil; the bubble type elastic foil sheet has the advantages of being high in rigidity and damping performance, high in vibration absorbing capacity, and high in stability; the bubbles are small in size, and the supporting stiffness is limited, and frictional damage and undetermined impact are easily caused during starting, stopping and operating. The multi-stage elastic supporting assembly comprises a flat coil and an elastic barrel foil sheet which are sequentially arranged, wherein the elastic barrel foil sheet comprises an elastic barrel surface; a plurality of through holes are formed in the surface of an elastic barrel and are connected to one side of a bending coiling part; and the bending coiling part is protruded and is in a multi-layer bending coiling form. According to the multi-stage elastic supporting assembly, the stiffness and the load are borne by stages; the flow around the multi-stage elastic supporting assembly is increased, so that the heat exchanging area is increased, heat can be conveniently dissipated after bearing for a long time, and as aresult, the operation performance is further improved.

Owner:XI AN JIAOTONG UNIV

Electric drive and hybrid power transmission device based on composite planetary gear train

PendingCN111546871AImprove powerReduce noiseHybrid vehiclesGas pressure propulsion mountingGear wheelElectrical battery

The invention discloses an electric drive and hybrid power transmission device based on a composite planetary gear train. The hybrid power system comprises the composite planetary gear train with twogear rings, a simple planetary gear train transmission mechanism, a generator, a driving motor, a plurality of clutches, direction-selectable clutches, a controller, a motor inverter, an external battery pack and external power such as an engine. A small gear ring of the composite gear train is connected with the motor through a fixed speed ratio, and a large gear ring is connected with the outputshaft through a fixed speed ratio. The composite planet carrier is connected with a gear ring of the simple gear train. An external power input shaft can be connected with a simple planet carrier, acomposite gear train sun gear and a motor connecting gear through a clutch. The device can provide a hybrid power working mode with three electric drive speed ratio gears, one series connection, threecontinuous speed changes and nine fixed speed ratios. The electric drive and hybrid power transmission device is suitable for electric drive and hybrid power coupling transmission of electric and hybrid power vehicles, including ships and amphibious vehicles, aircrafts, and engineering machinery.

Owner:嵘波科技有限公司

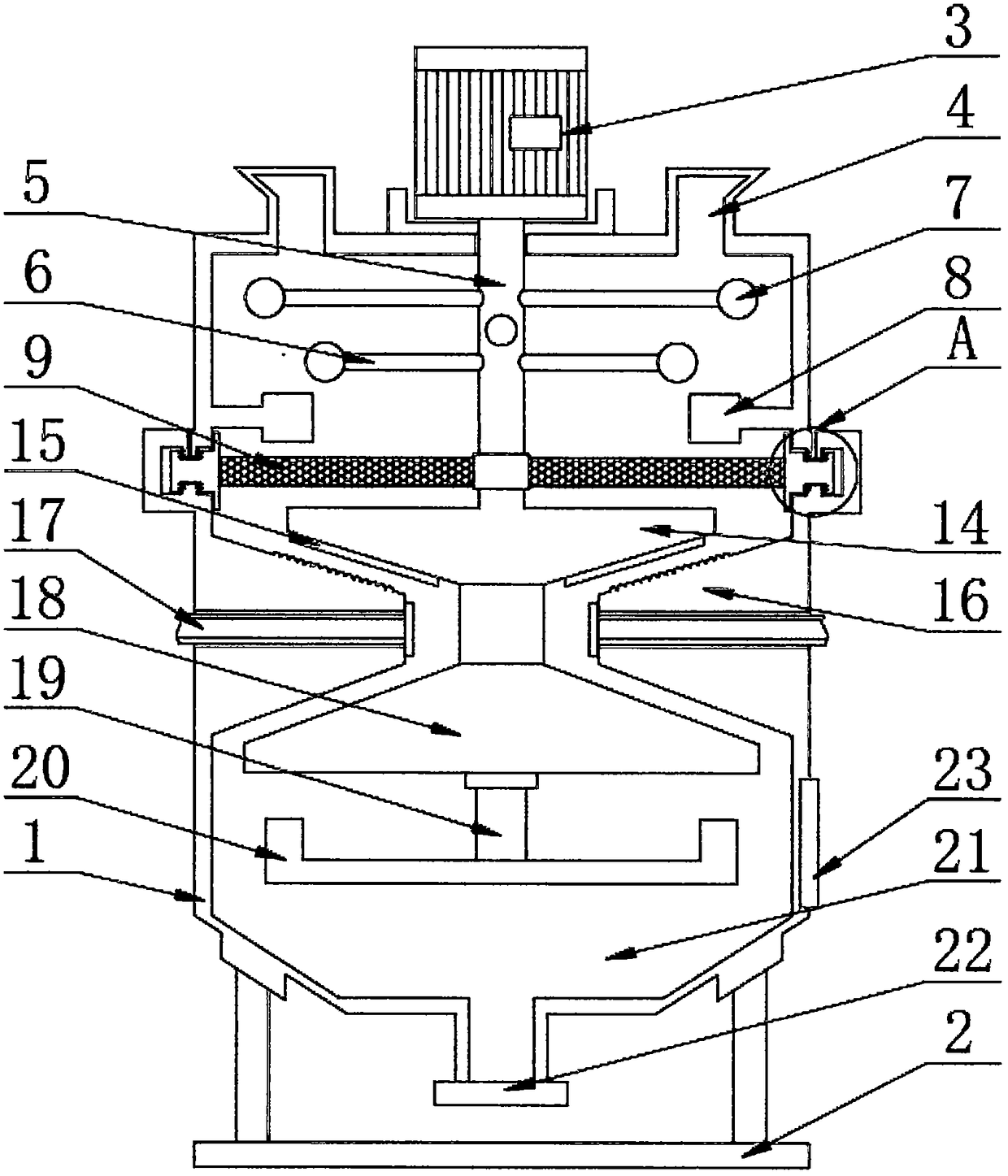

Integrated equipment for treating and shaping of medicinal materials

InactiveCN109225489AEasy to handleAvoid passingRotary stirring mixersTransportation and packagingEngineeringSieve

The invention discloses integrated equipment for treating and shaping of medicinal materials. The integrated equipment comprises a housing, wherein a bracket is arranged at the bottom of the housing;an electric motor is arranged at the top of the housing; feeding openings are respectively formed in two sides of the electric motor; a rotating rod is arranged in the housing; connecting rods are arranged on the outer side of the rotating rod; an impact ball is arranged at one end of each connecting rod; and a material toggling rod is arranged at the bottom of each connecting rod. According to the integrated equipment disclosed by the invention, a sieve plate is arranged, so that treating on medicinal materials on the top surface of the sieve plate is facilitated, and the situation that large-scale medicinal material blocks pass through is avoided; traditional Chinese medicine materials required to be decocted are put in the housing through the feeding openings, and the feeding openings are sealed, so that the situation that minces generated by crushing of the medicinal materials are leaked is avoided; the connecting rods rotate to drive the impact balls to rotate, and large-scale crushed medicinal material blocks are blocked by the sieve plate; the material toggling rods are used for rotatably shoveling up the medicinal materials accumulated on the outer side of the top surface of the sieve plate; and through the rotation of the connecting rods and the rotation of the impact balls, the medicinal materials are beaten, so that the medicinal materials are converted into small granules to enter two sides of a first grinding block through the sieve plate.

Owner:宁夏爱打听科技有限公司

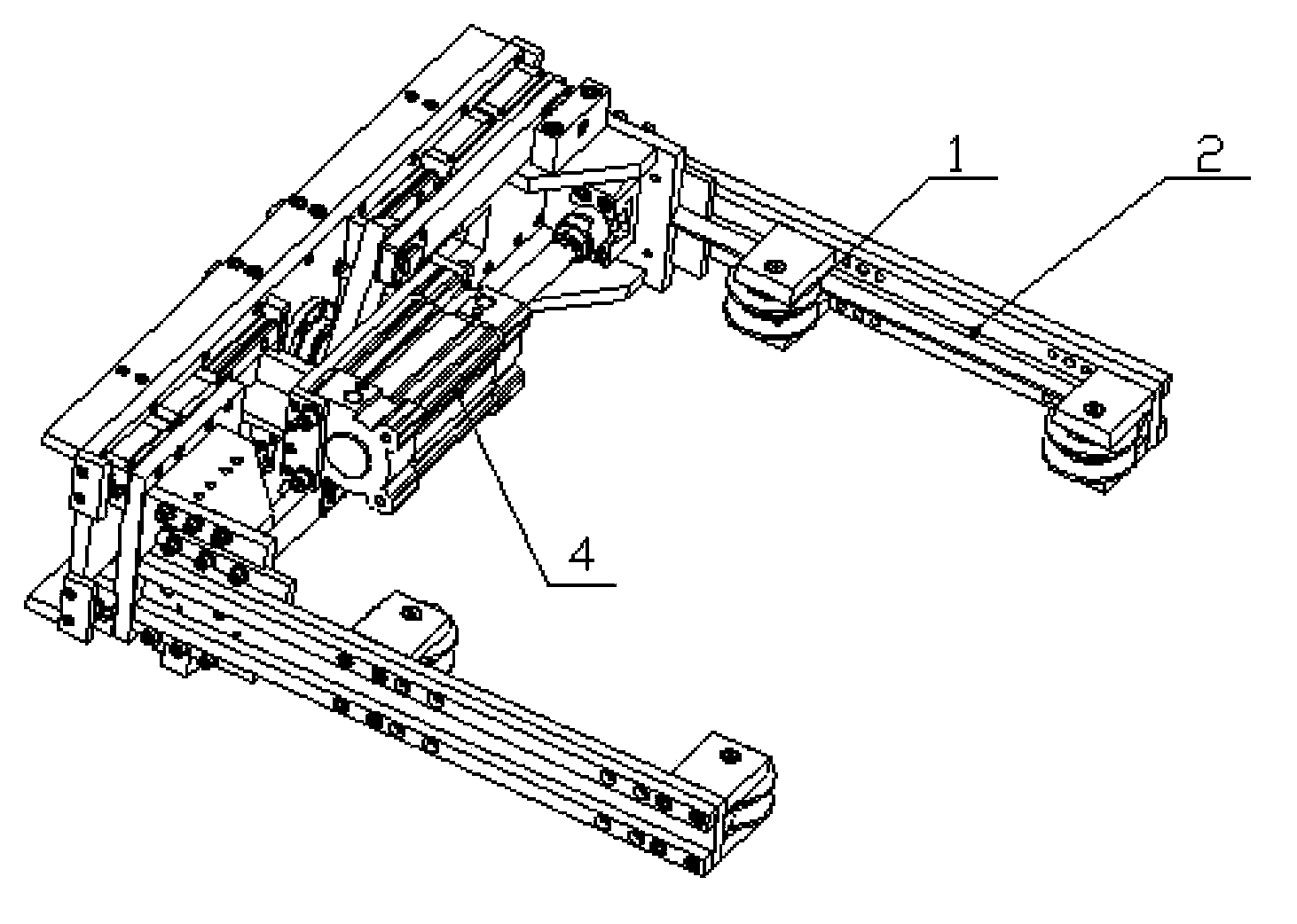

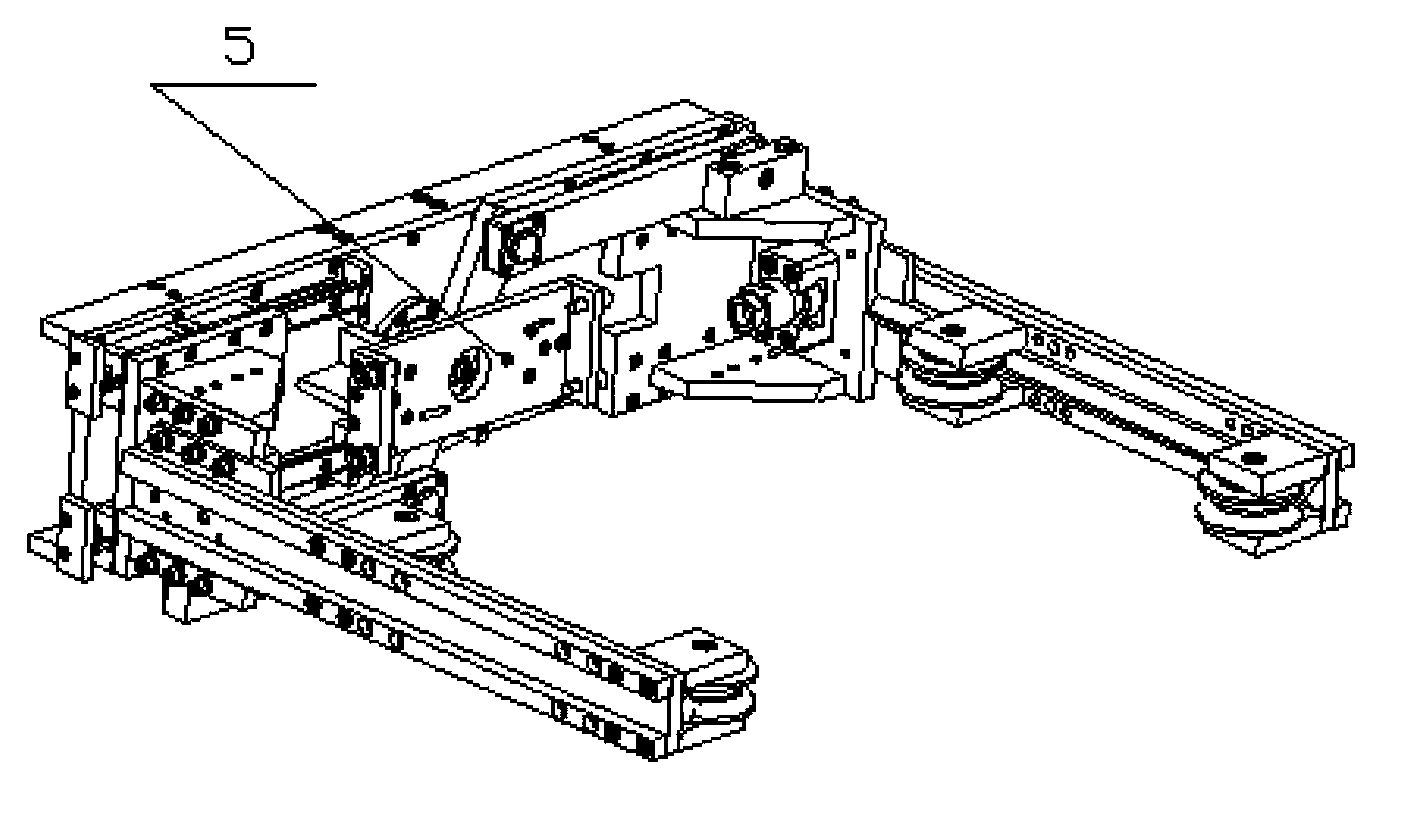

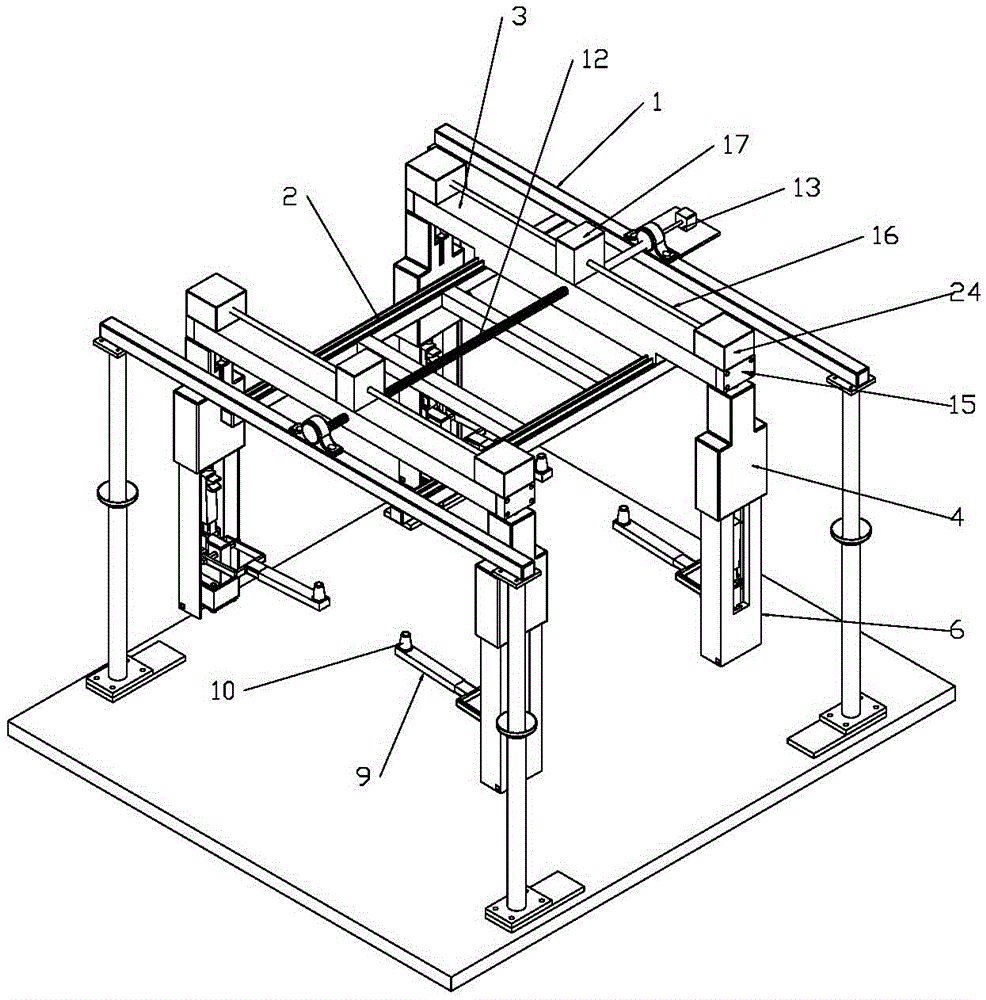

Flexible clamp apparatus for automobile assembly parts conveying system

The invention discloses a flexible clamp apparatus for an automobile assembly parts conveying system, comprising two bearing beams parallel to each other; a slide rail is provided between the two bearing beams, at least two clamp units are disposed on the slide rail, a spacing adjustment is arranged between the two bearing beams, each clamp unit comprises a support frame slidably and fitly mounted on the slide rail, two ends of the support frame are provided with clamp mechanisms respectively, each clamp mechanism comprises a connecting sleeve, the upper end of each connecting sleeve is provided with a connecting shaft that is rotationally fitly connected with the corresponding support frame, a rotational drive mechanism is arranged on each support frame, the lower end of each connecting sleeve is provided with a clamp support that is provided with a switching support mechanism, each switching support mechanism comprises two rotary shafts arranged horizontally and parallel to each other with the two rotary shafts being rotationally fitly mounted to the corresponding clamp supports respectively, a connecting fork is connected to each rotary shaft, a support rod is releasably mounted on each connecting fork, each support rod is provided with a positioning pin or a V-shaped block, and each clamp support is provided with a switching drive mechanism.

Owner:CHONGQING UNIV

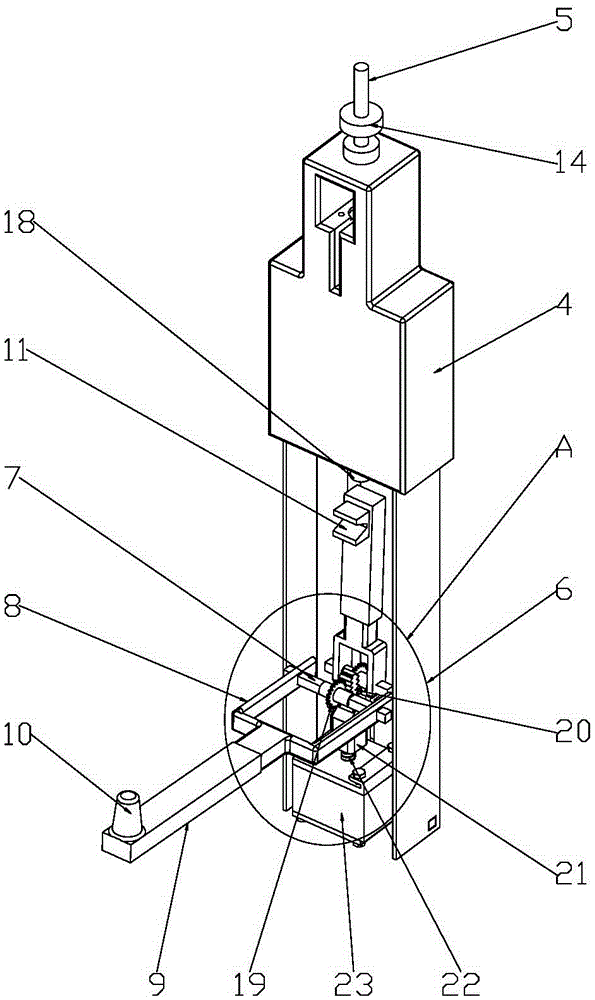

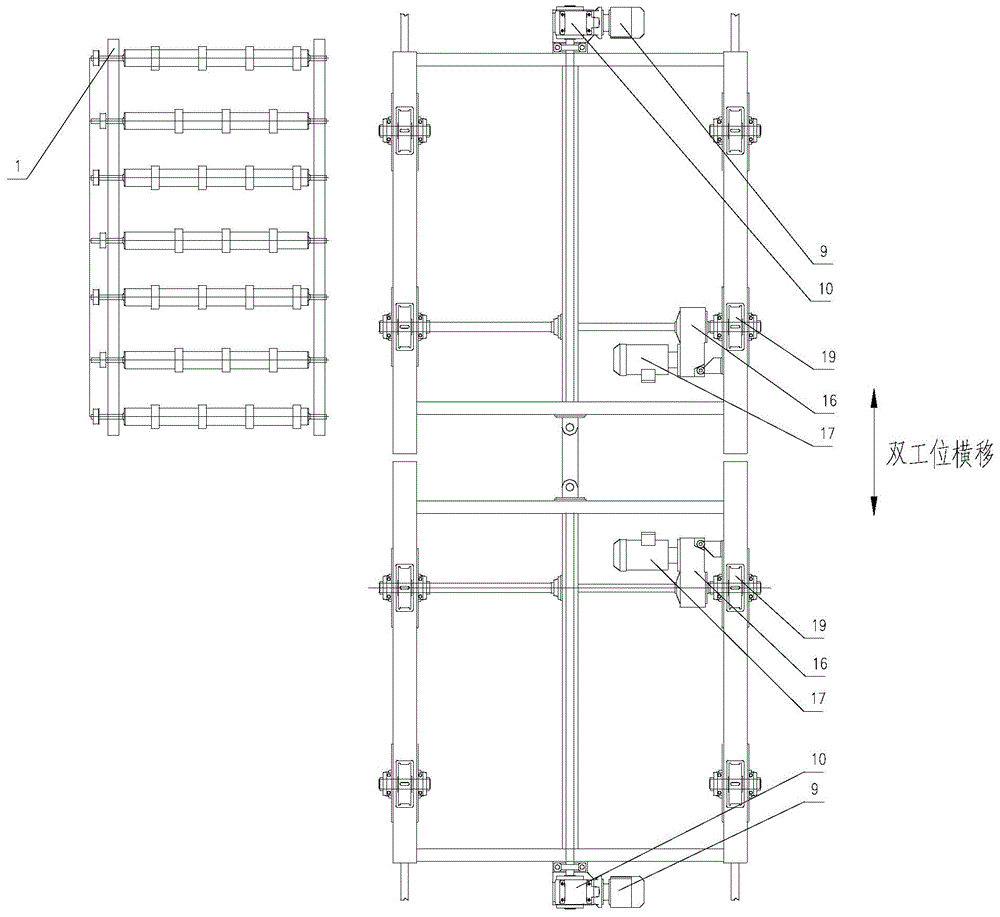

Online lower taking vertical stacking system of float glass

PendingCN104960964ASimple structureReduce friction damageConveyor partsArticle deliveryMarine engineeringReducer

The invention discloses an online lower taking vertical stacking system of float glass. The system comprises a turnover platform and a double-station stepper car, wherein the turnover platform consists of a sucker lifting mechanism, a fixed roller way, a pneumatic system, a four-rod mechanism, a sucker bracket, a sucker lifting mechanism, a vacuum system, a motor and a speed reducer; and the double-station stepper car consists of a stepper platform, a transposition platform, a positioning device, a gear, a rack, a wheel set, a motor and a speed reducer. According to the online lower taking vertical stacking system of the float glass, a sucker grabs a glass plate from a tin surface to keep a non-tin surface natural and smooth. The stepper mechanism is mounted on the double-station stepper car, so that the structure of the turnover platform is simplified, stacking actions are decomposed, the system stability is improved, and the movement speed of single action is quickened.

Owner:CHINA TRIUMPH INT ENG

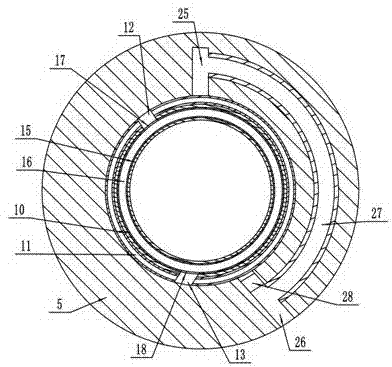

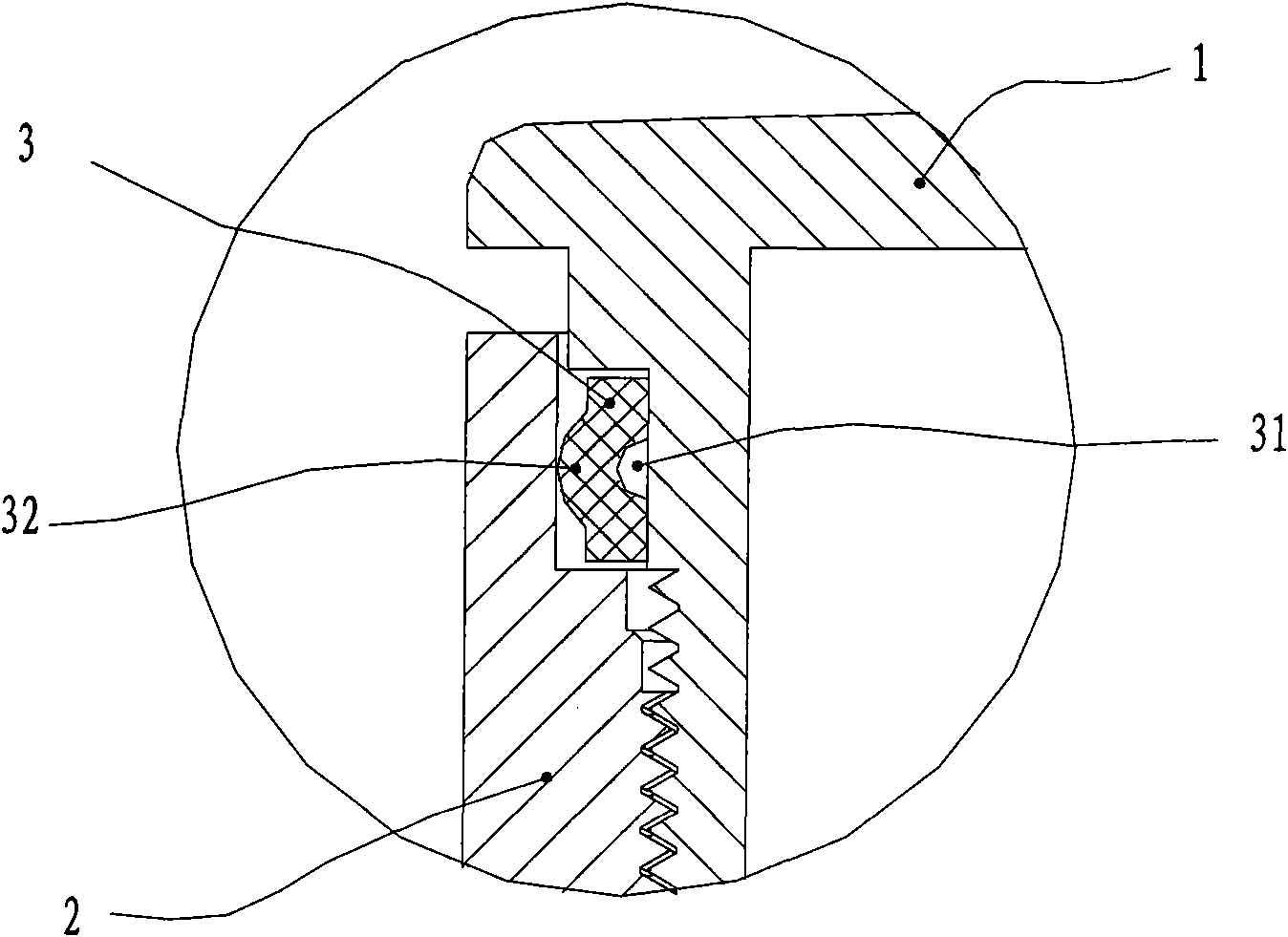

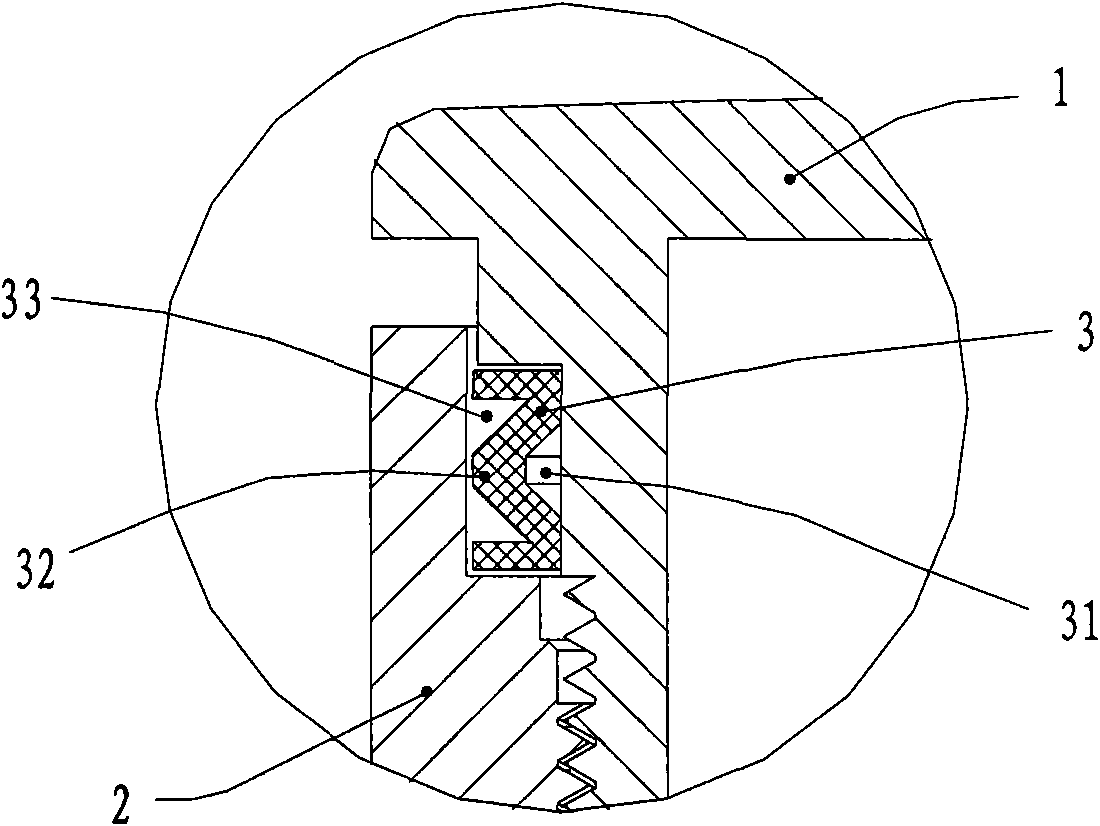

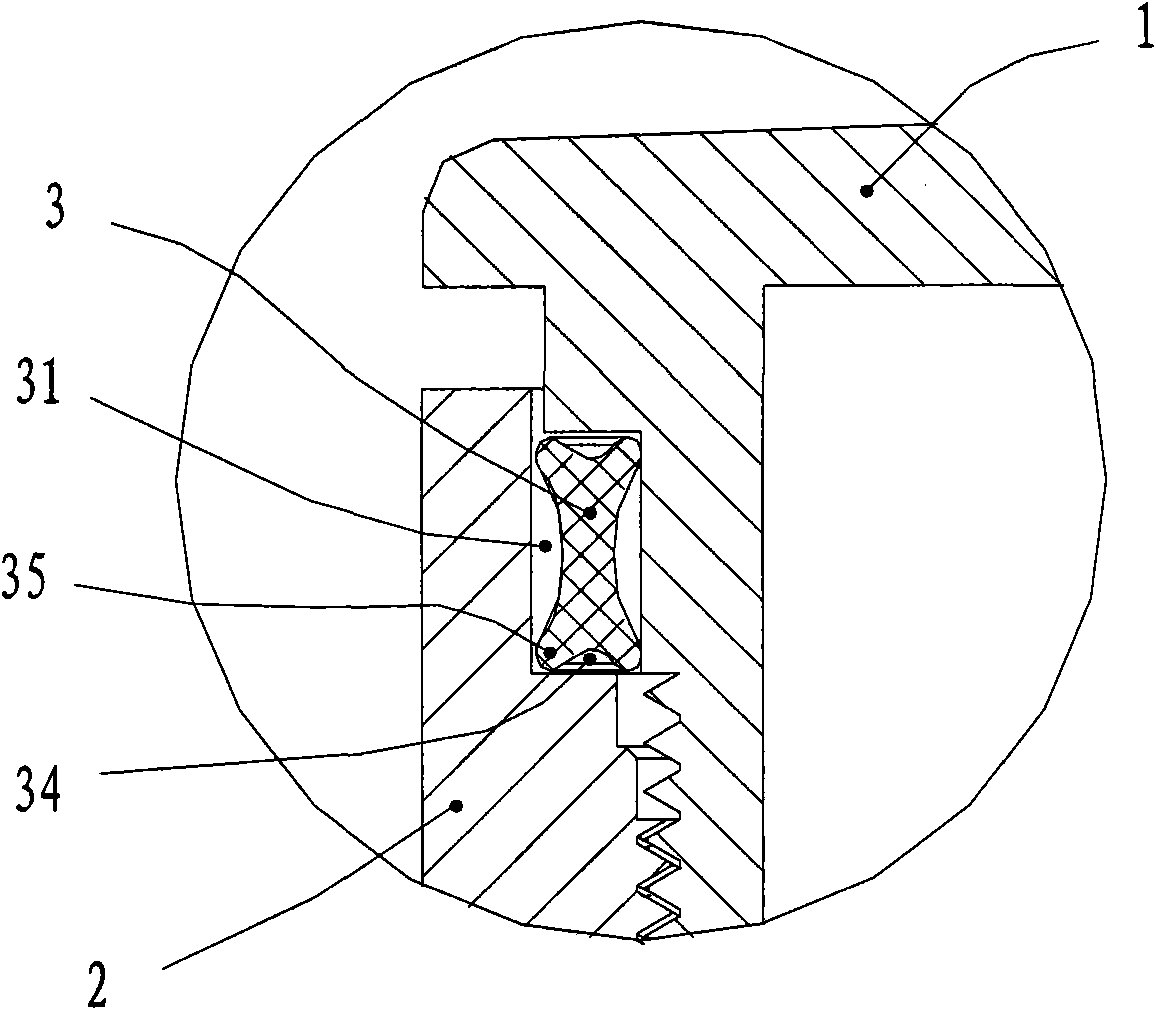

Fixed radial sealing piece

InactiveCN101922697ALarge deformationReduce friction damageGas-tight/water-tight arrangementsInterference fitMachining

The invention discloses a fixed radial sealing piece. The fixed radial sealing piece is arranged between an upper shell and a lower shell which are correspondingly matched and connected with each other, comprises a body made of a flexible material, and is characterized in that: at least one first groove capable of tolerating the body to be deformed by force in the axial direction is formed on the body; and the section of the first groove can be a concave arc, a triangle, a trapezoid, a wooden club, a square or a rectangle. By using the structural design of the sealing piece of the invention, relatively large axial deformation can be tolerated, so that relatively large clearance fit between the upper shell and the lower shell is not needed, assembly is convenient, meanwhile, the machining precision of the fitting surfaces of the upper and lower shells can be reduced, and the machining cost can be saved; and the abrasive damage of the sealing piece in the rotational locking process of the upper and lower shells is relatively small, so that sealing reliability is further improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com