Integrated equipment for treating and shaping of medicinal materials

A technology for equipment and medicinal materials, which is applied in the field of integrated equipment for medicinal materials processing and molding, can solve the problems of wasting manpower, affecting medicinal efficacy, and inability to pulverize medicinal materials, and achieves the effects of reducing friction damage, strengthening the rotation effect, and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

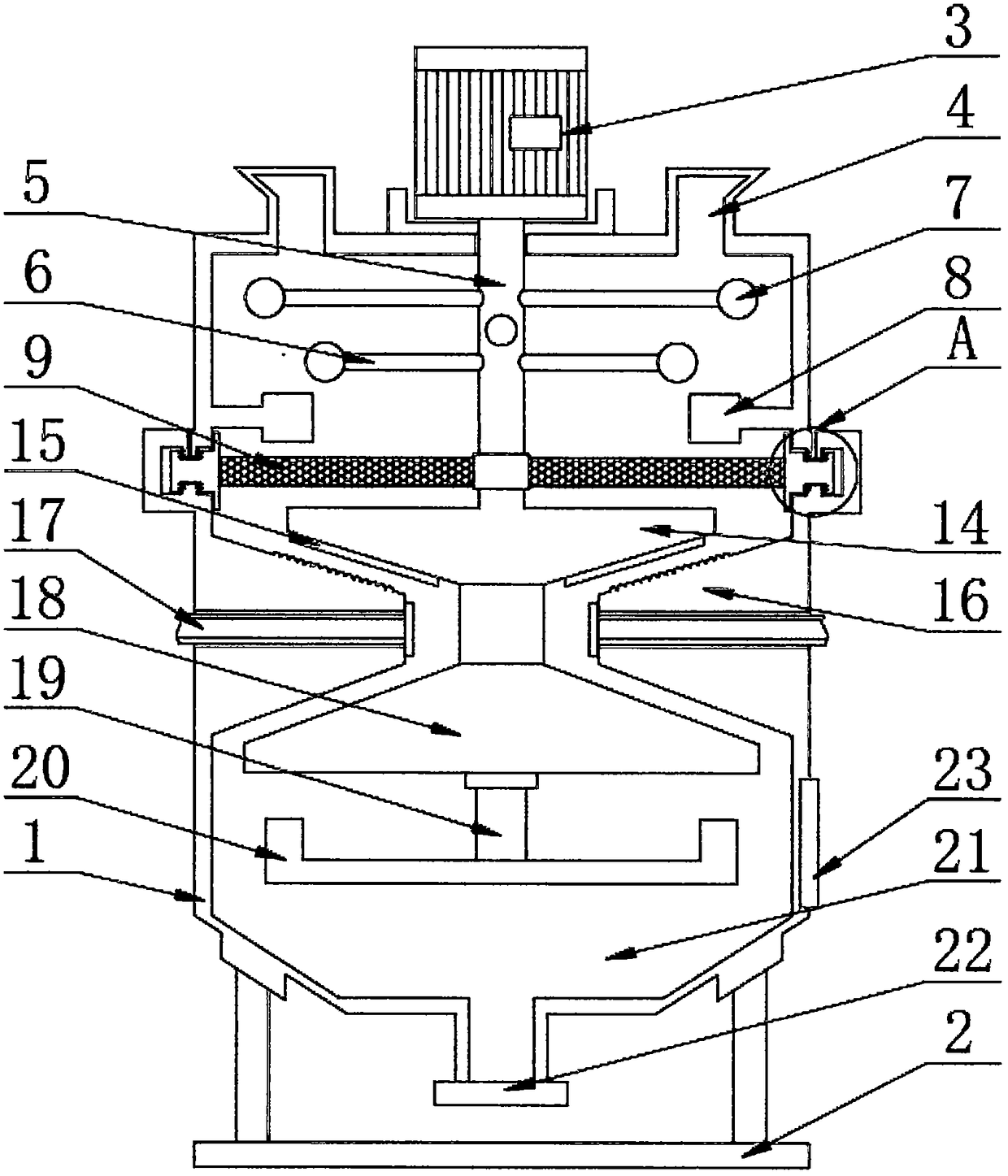

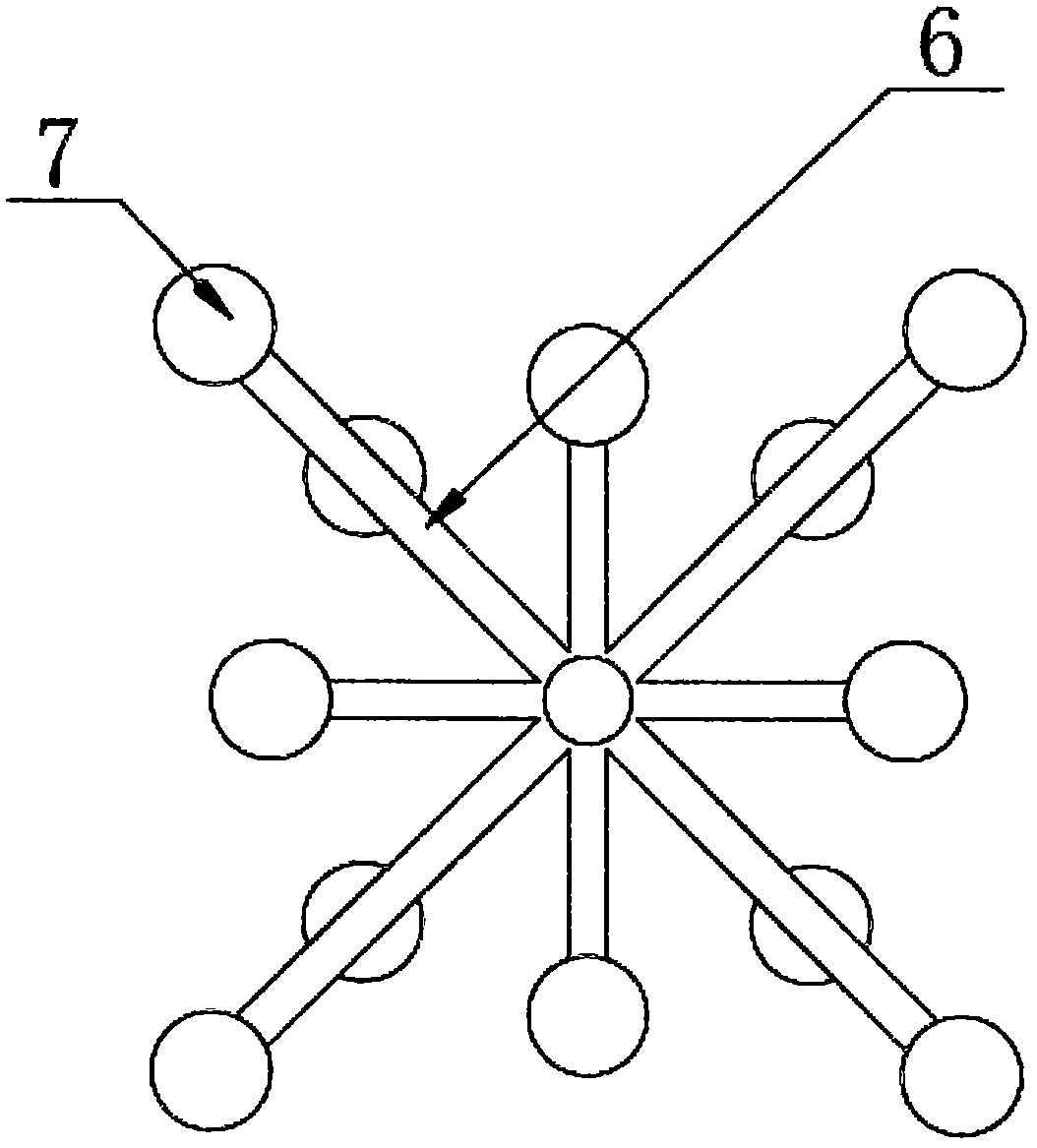

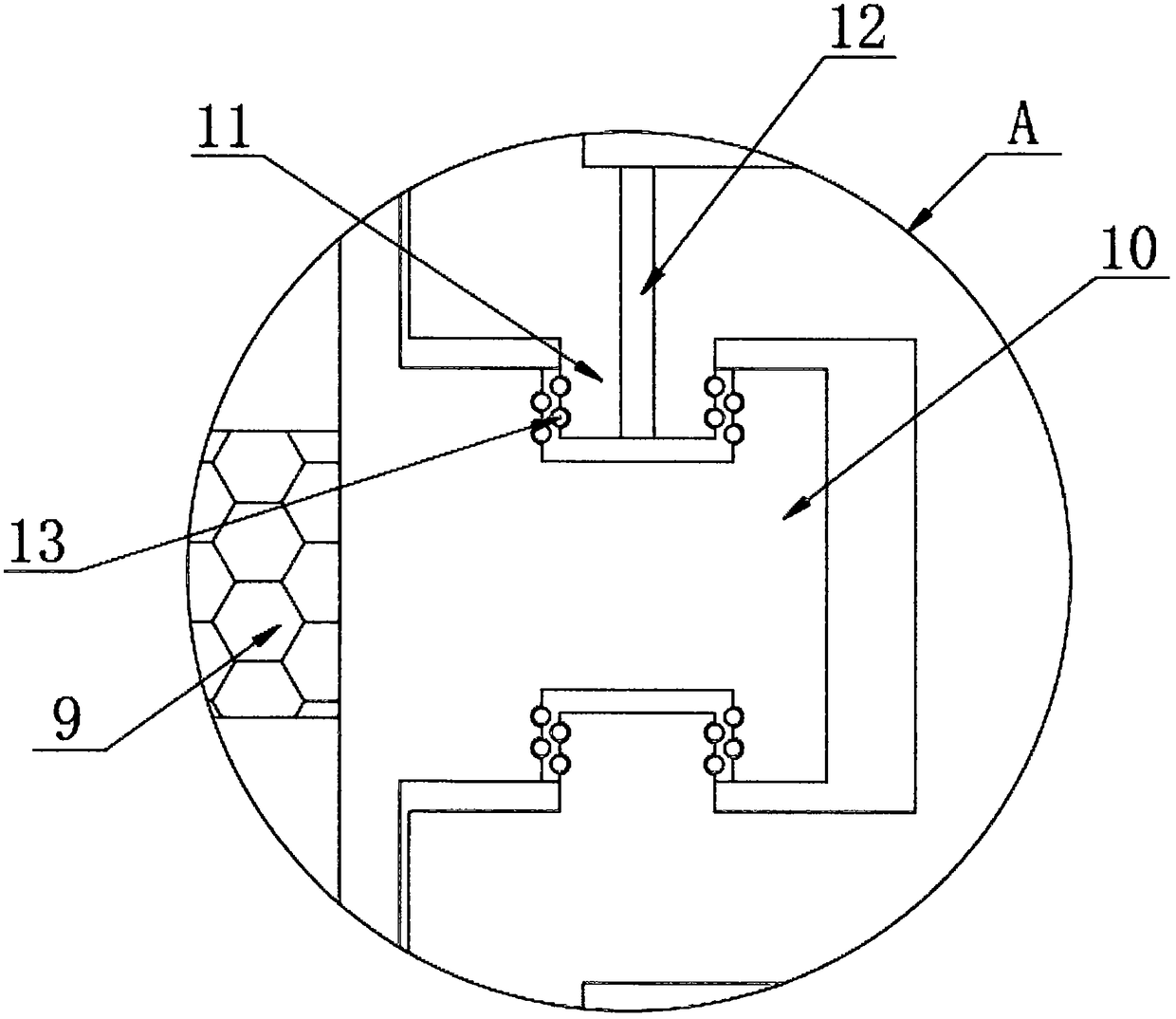

[0023] The present invention provides Figure 1-3 The shown integrated equipment for processing and molding medicinal materials includes a housing 1, a bracket 2 is provided at the bottom of the housing 1, a motor 3 is provided on the top of the housing 1, and both sides of the motor 3 are provided The feed port 4 is provided with a rotating rod 5 inside the housing 1, a connecting rod 6 is provided on the outside of the rotating rod 5, an impact ball 7 is provided at one end of the connecting rod 6, and a dial is provided at the bottom of the connecting rod 6 The material rod 8, the bottom of the shift rod 8 is provided with a sieve plate 9, the outer side of the sieve plate 9 is provided with a sliding block 10, the outer side of the sliding block 10 is provided with a limiting block 11, and the top of the limiting block 11 is provided with Oil hole 12, the surface of the limit block 11 is provided with balls 13, the bottom of the sieve plate 9 is provided with a first grindin...

Embodiment 2

[0026] The surface of the fixed ring block 16 is provided with a grinding layer, and the first grinding block 14 and the second grinding block 18 are matched with the fixed ring block 16, which facilitates the use of the first grinding block 14 and the second grinding block 18 Double grinding treatment increases the crushing effect of medicinal materials.

[0027] The shape of the first grinding block 14 and the second grinding block 18 are both set in the shape of a truncated cone. Both the first grinding block 14 and the second grinding block 18 are fixedly connected to the rotating rod 5 by a center line, which is convenient for the first grinding block 14 And the second grinding block 18 smoothly rotates inside the housing 1 without shaking inside the housing 1, thereby reducing damage to the housing 1. The rotating rod 5 is fixedly connected to the output end of the motor 3.

[0028] The inner wall of the housing 1 is provided with a sliding groove, the sliding groove is match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com