Patents

Literature

2350results about How to "Easy to Grind" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

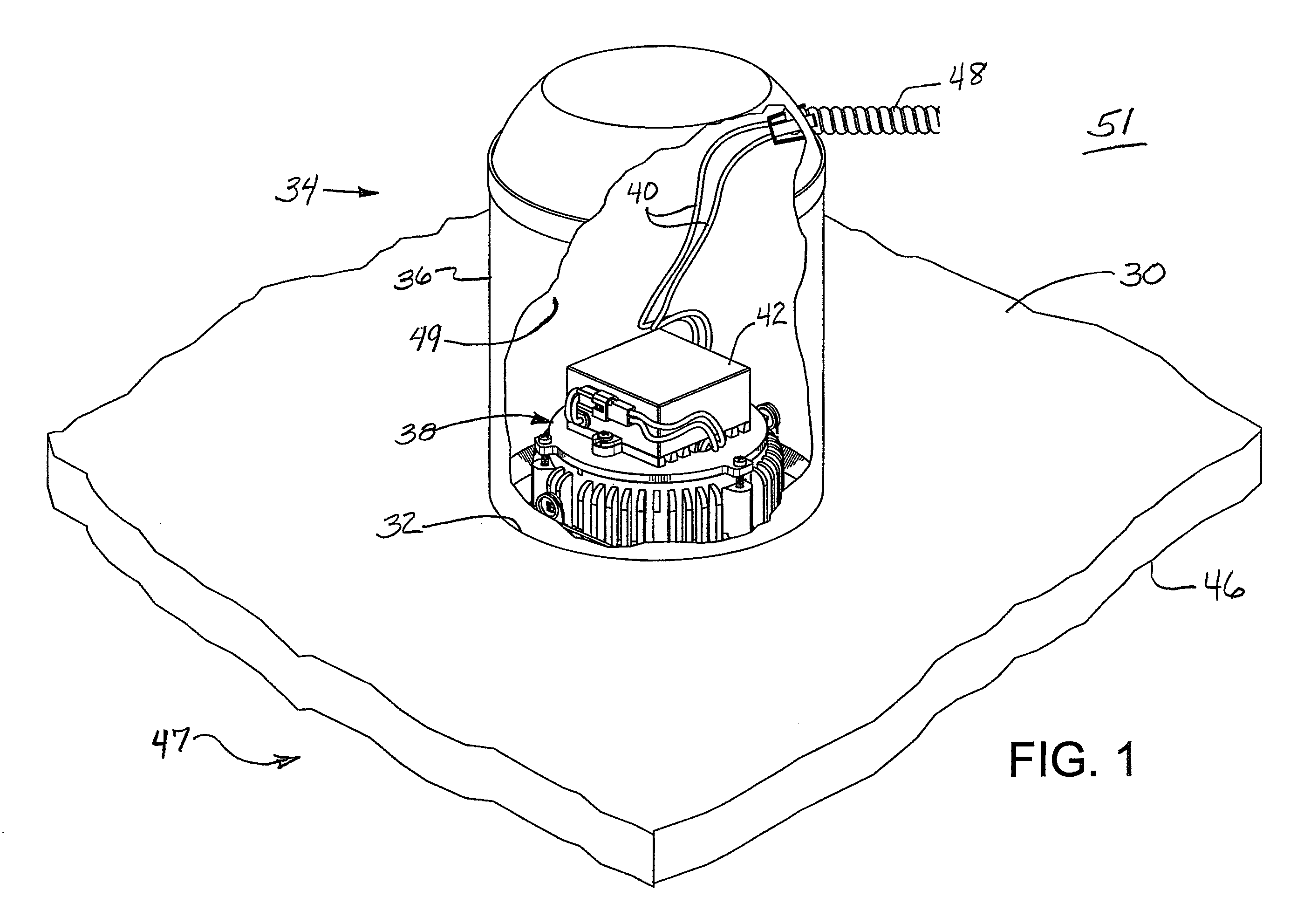

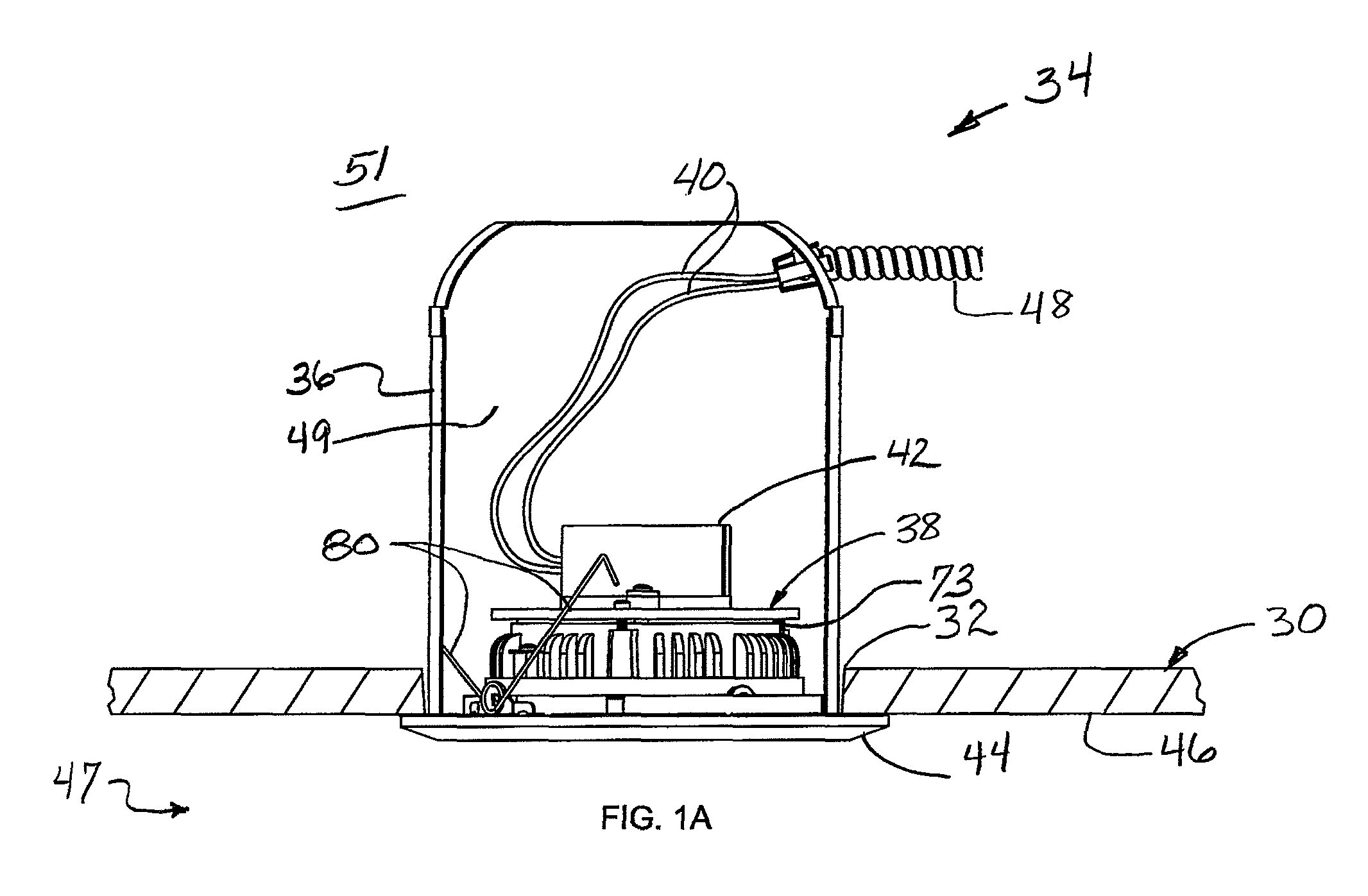

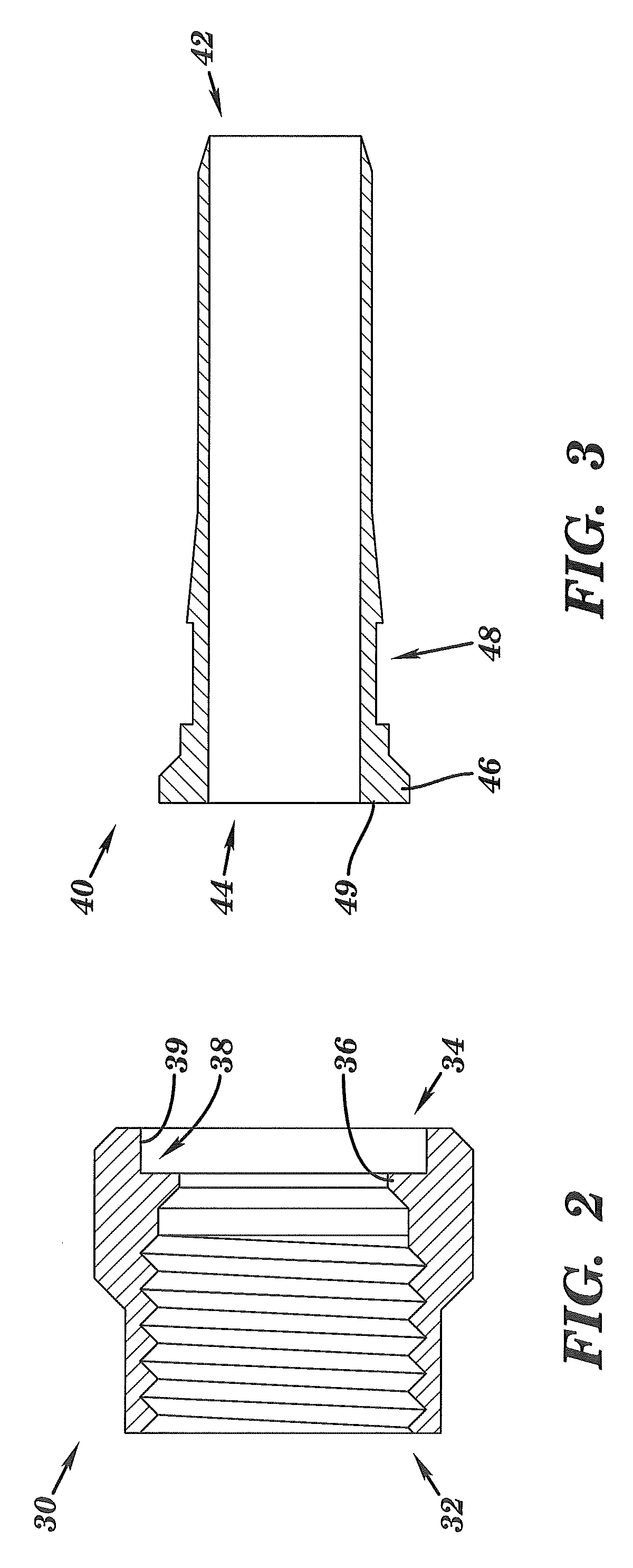

Lighting fixture with recessed baffle trim unit

InactiveUS7722227B2Easy to GrindGood thermal controlLighting support devicesPoint-like light sourceEffect lightEngineering

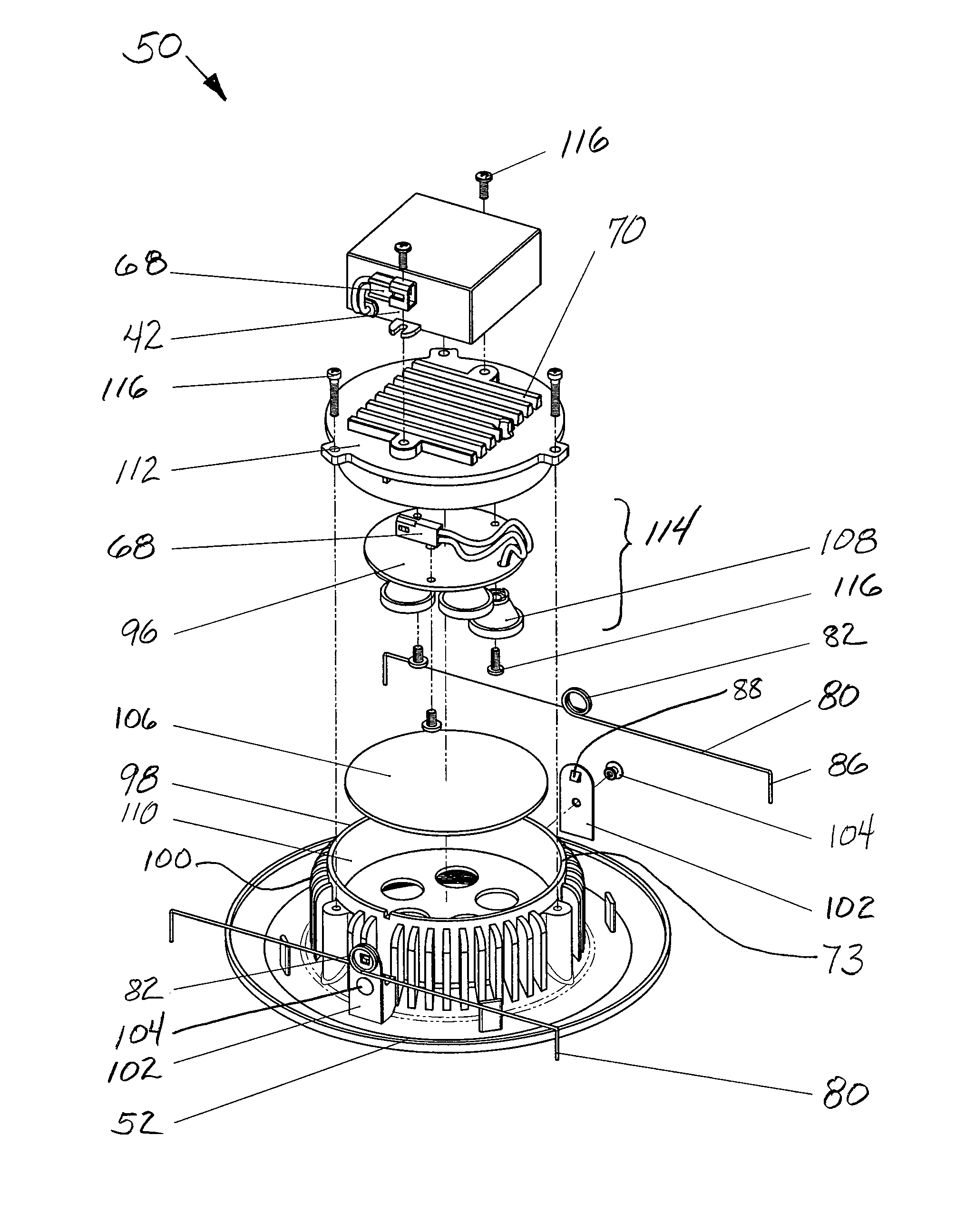

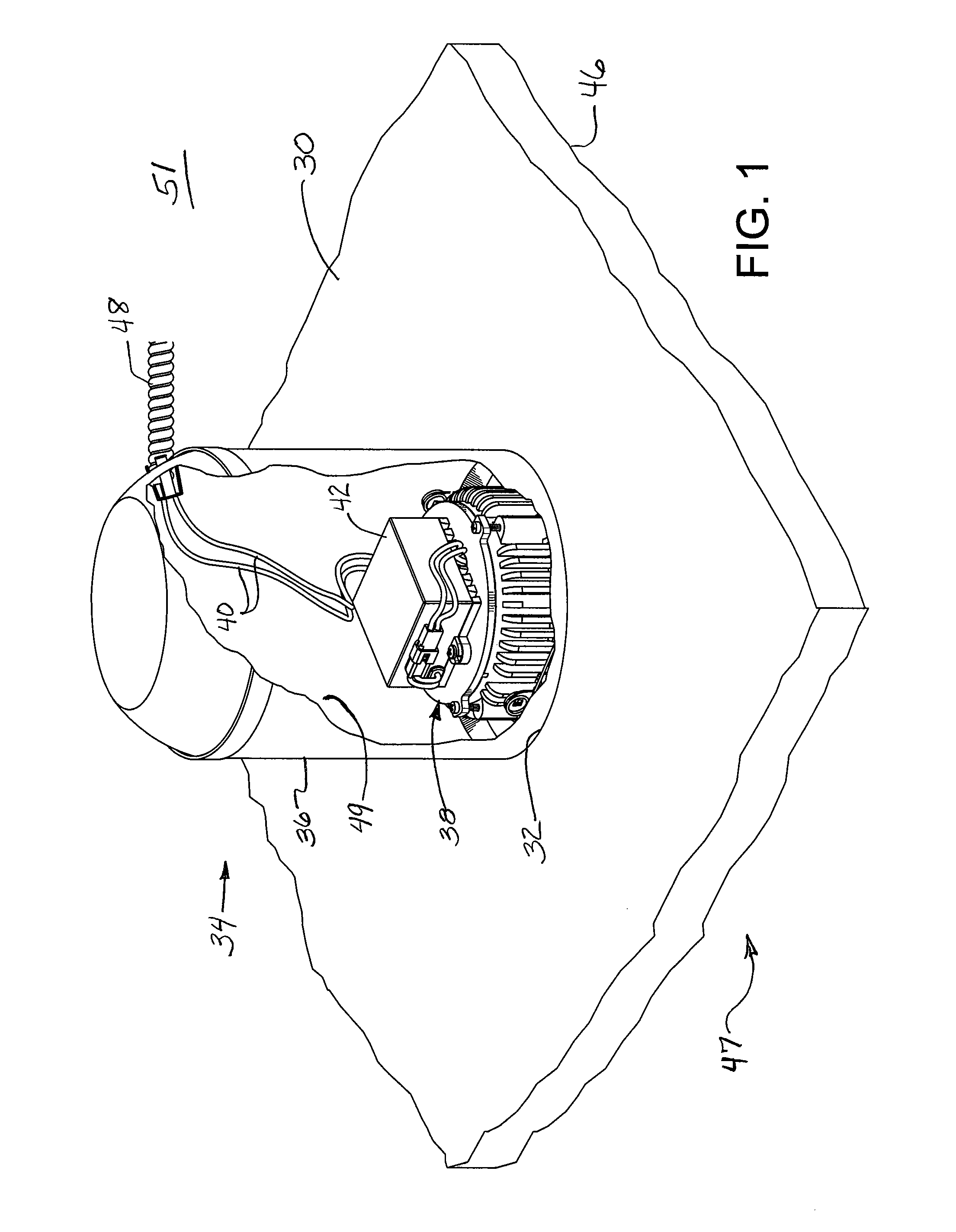

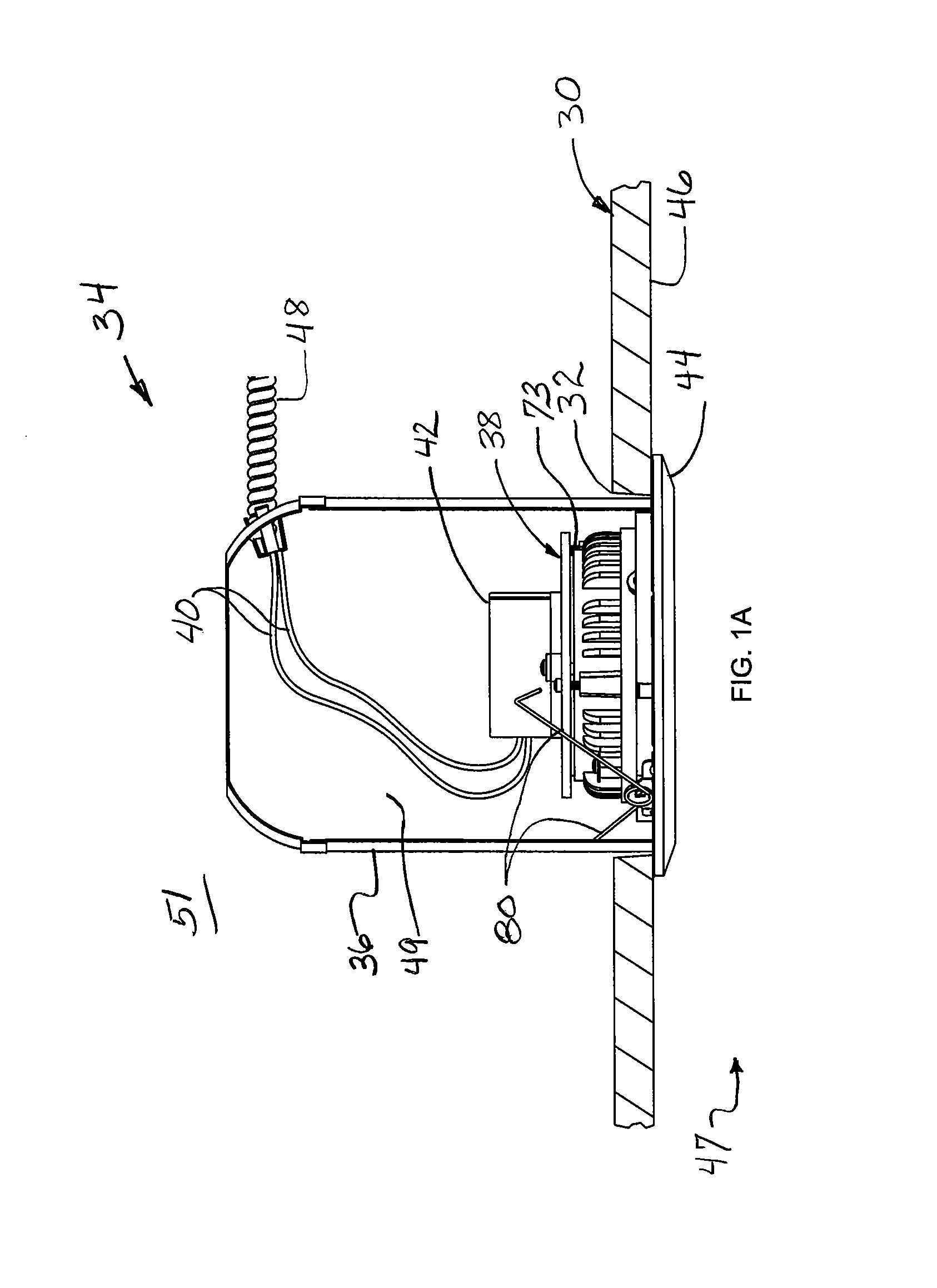

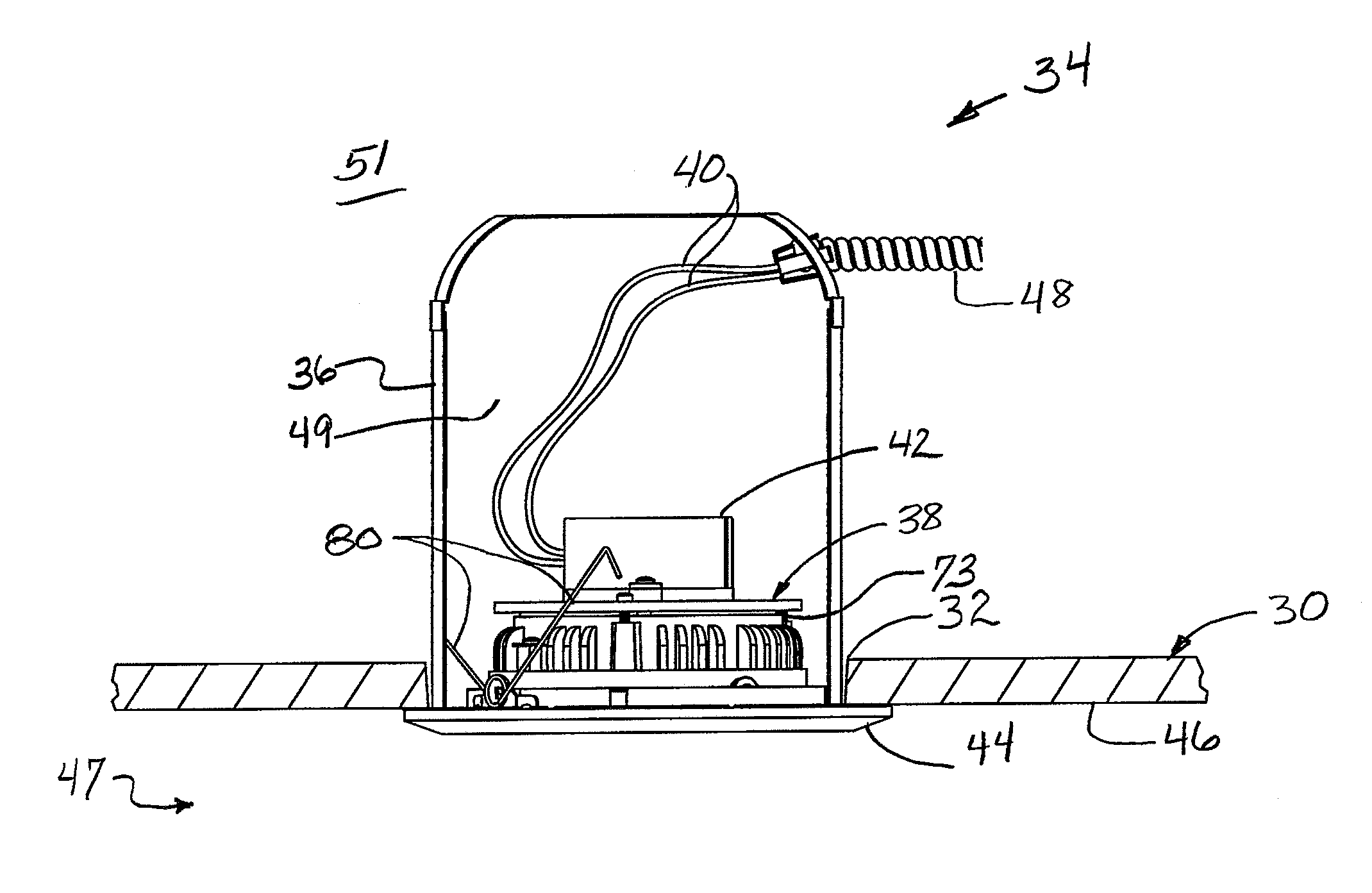

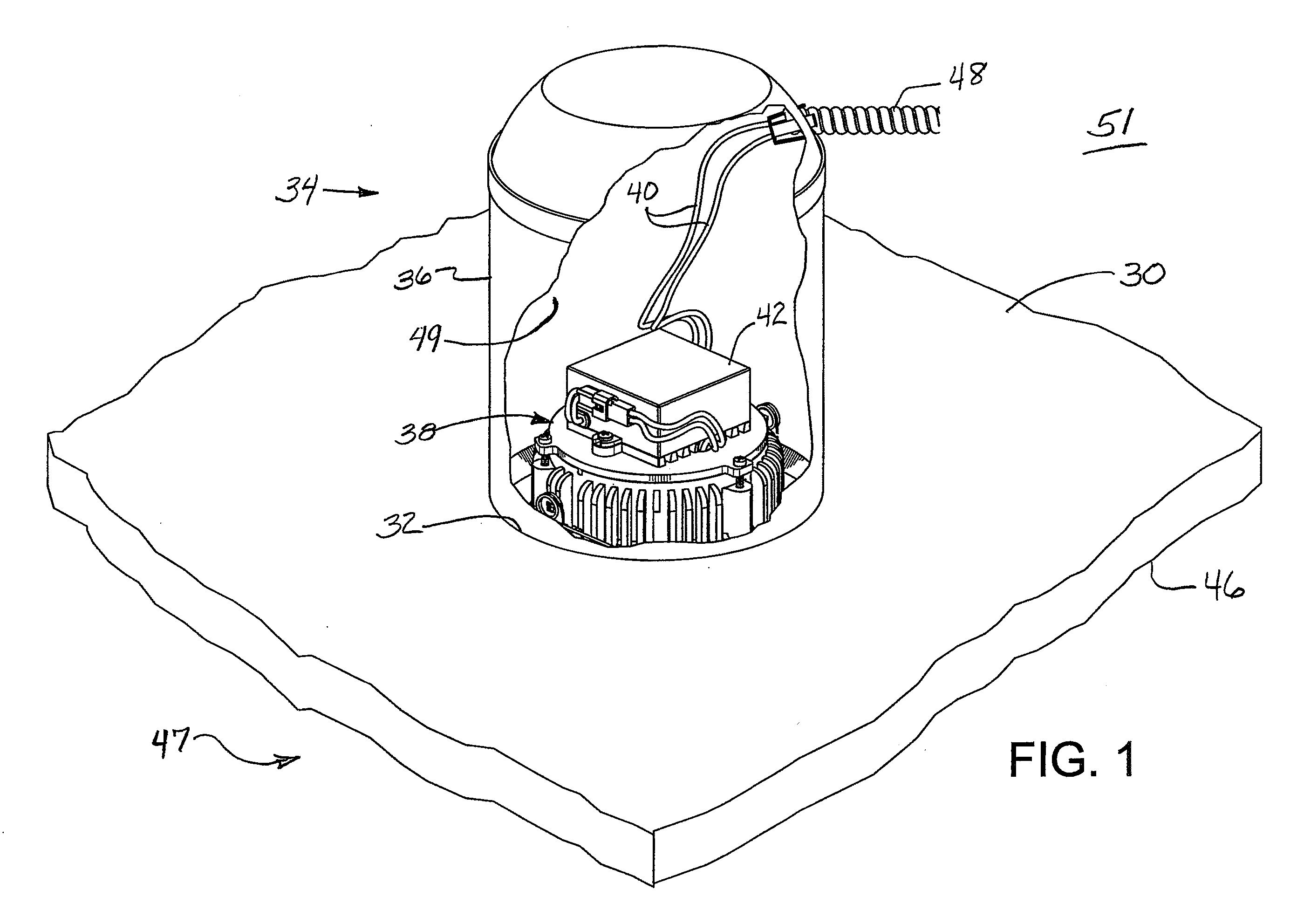

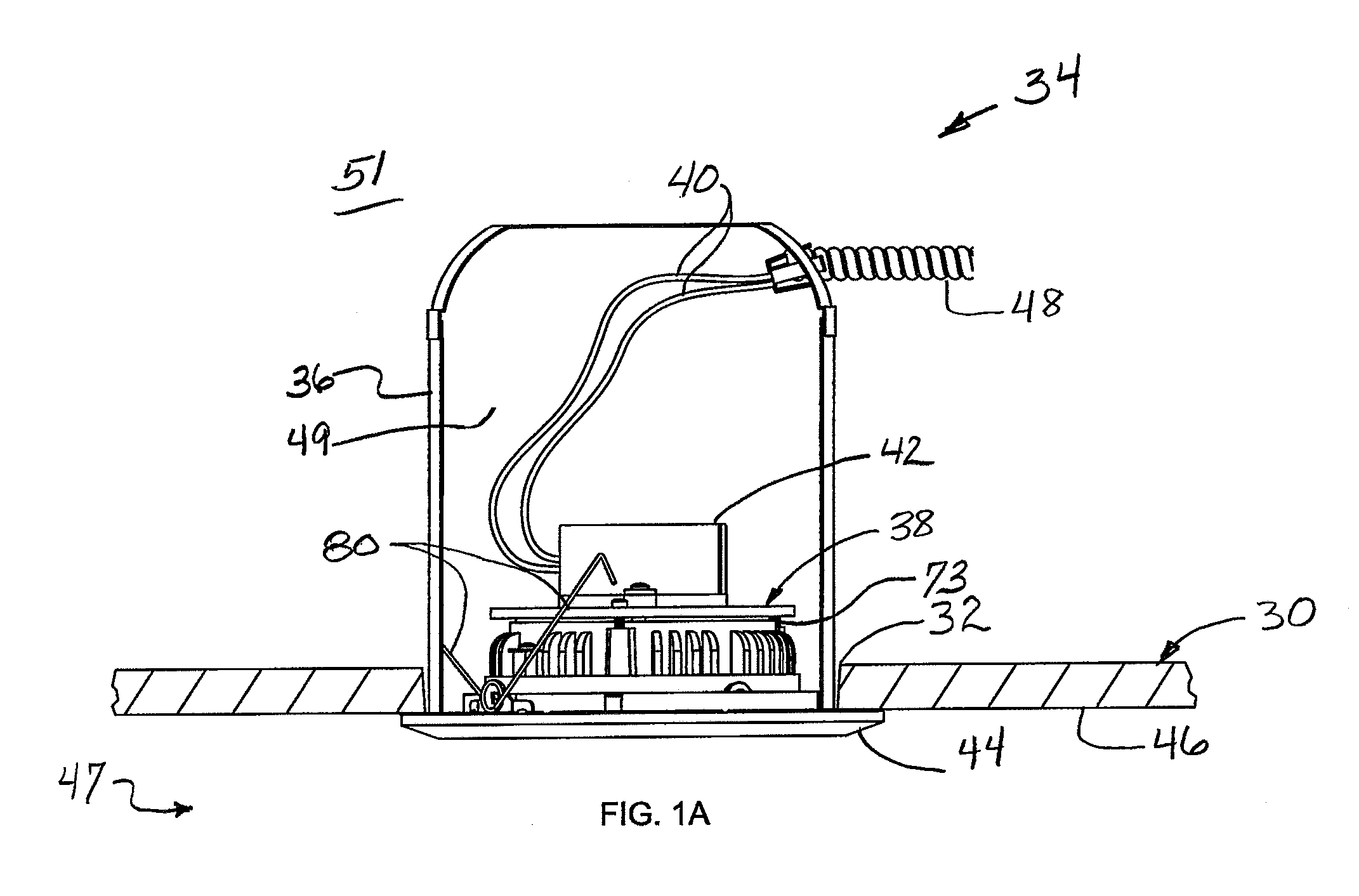

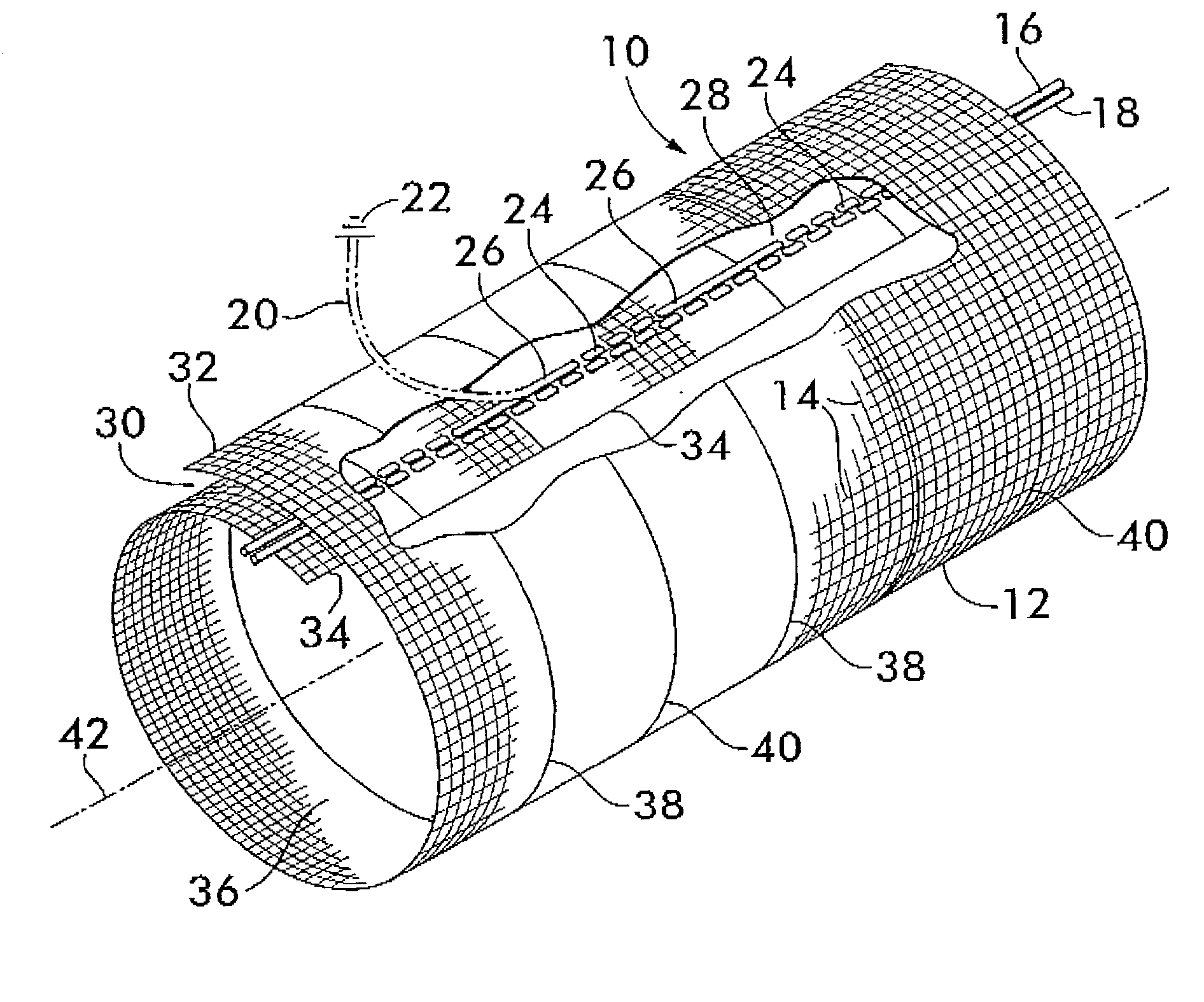

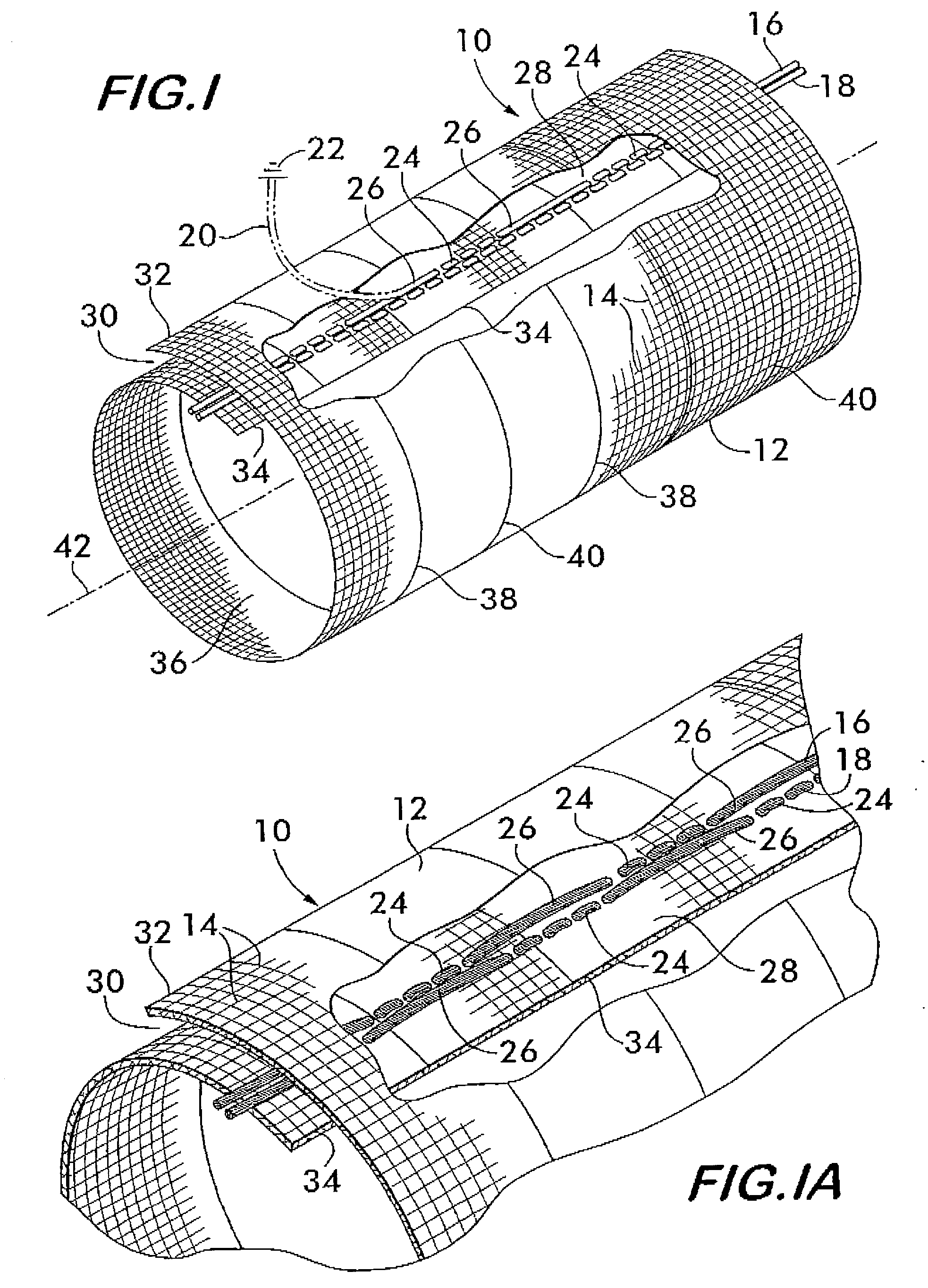

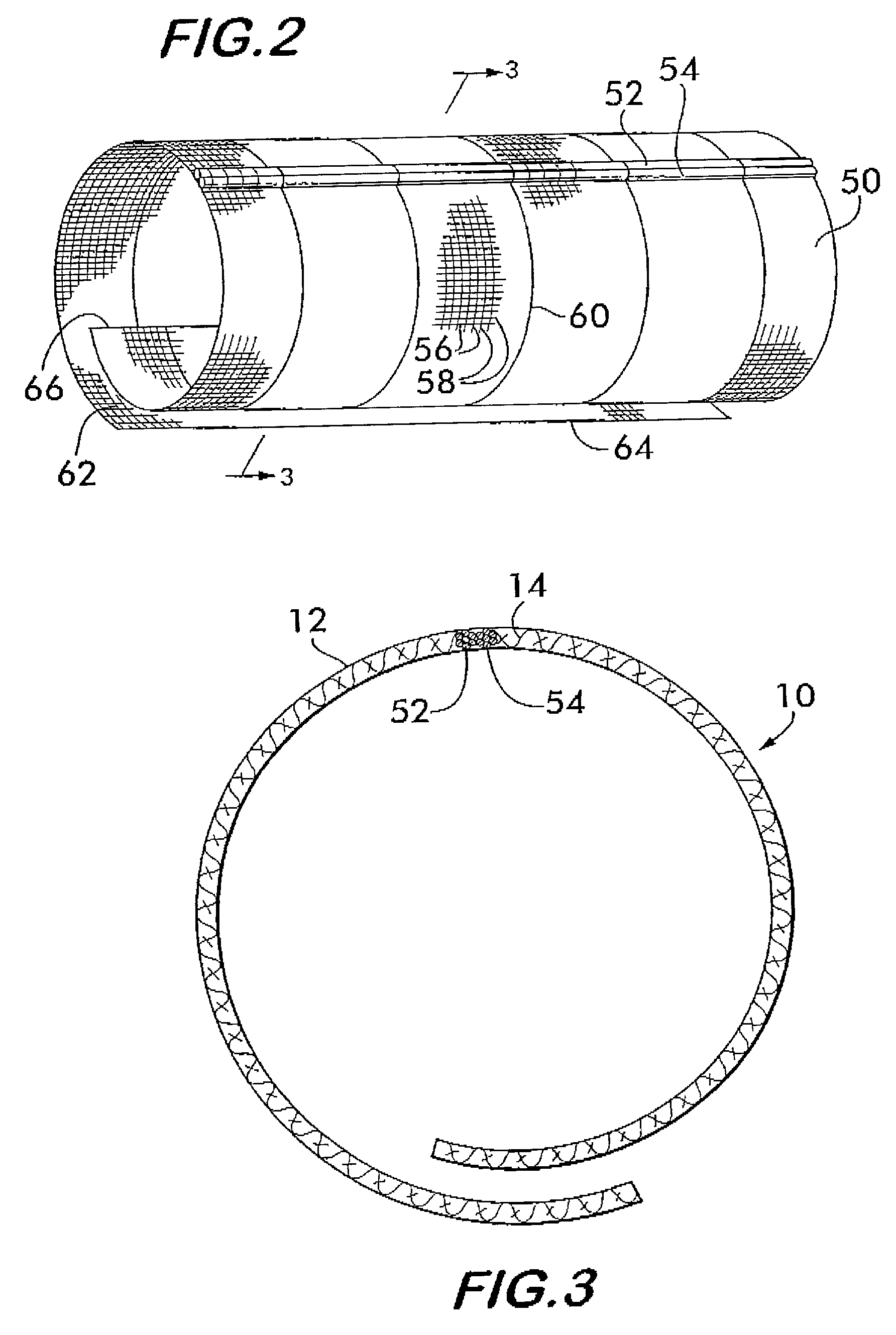

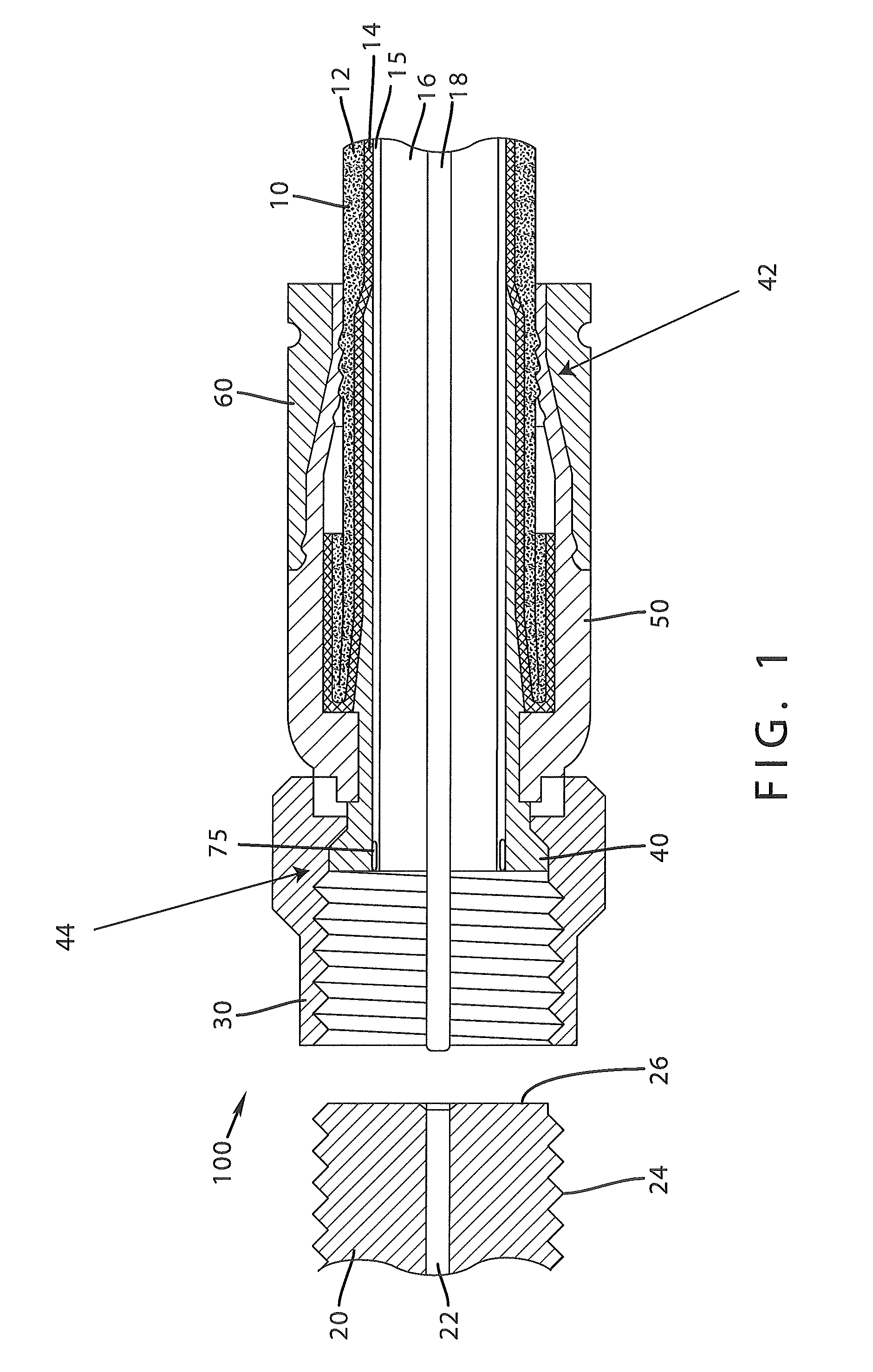

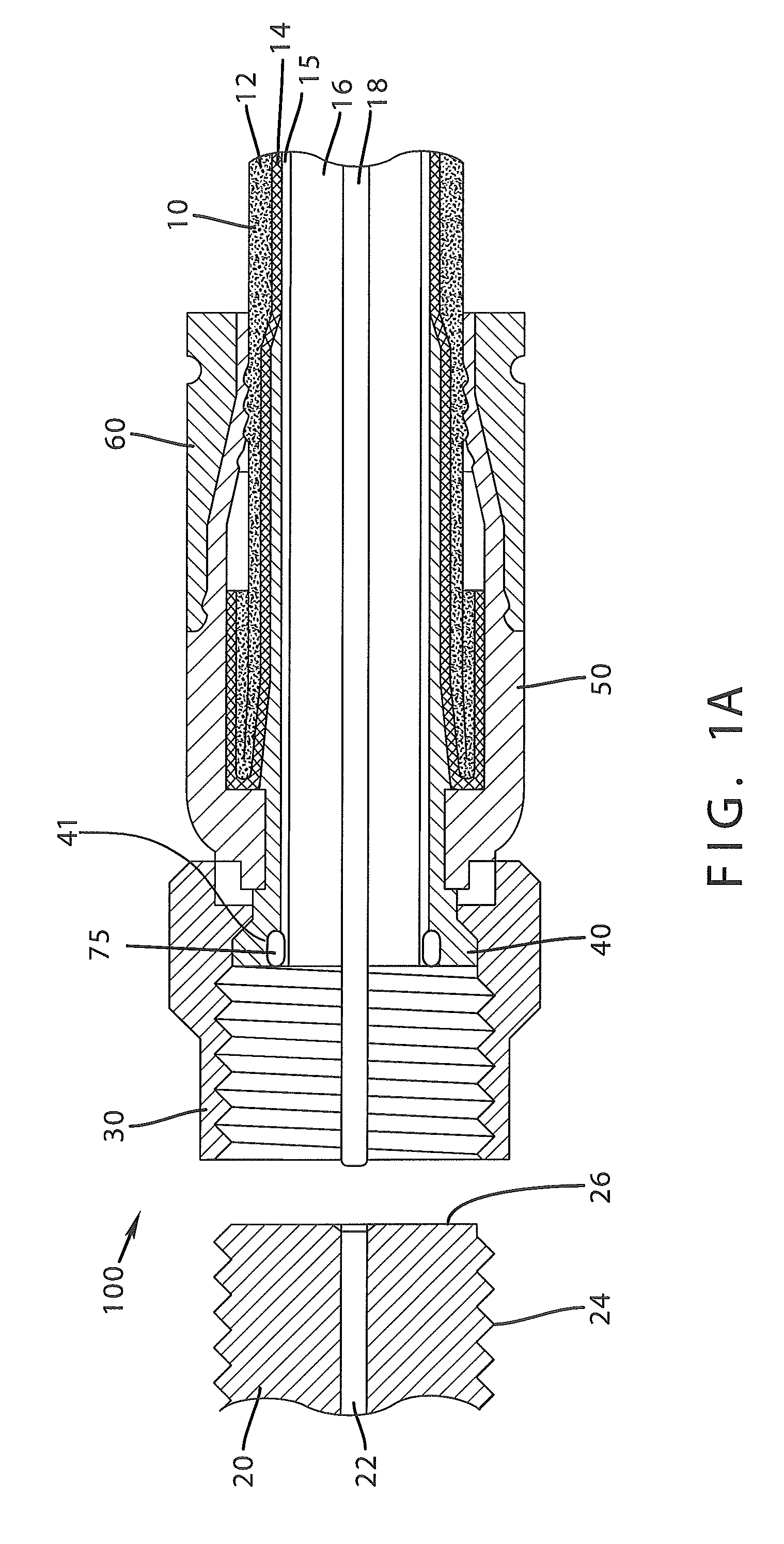

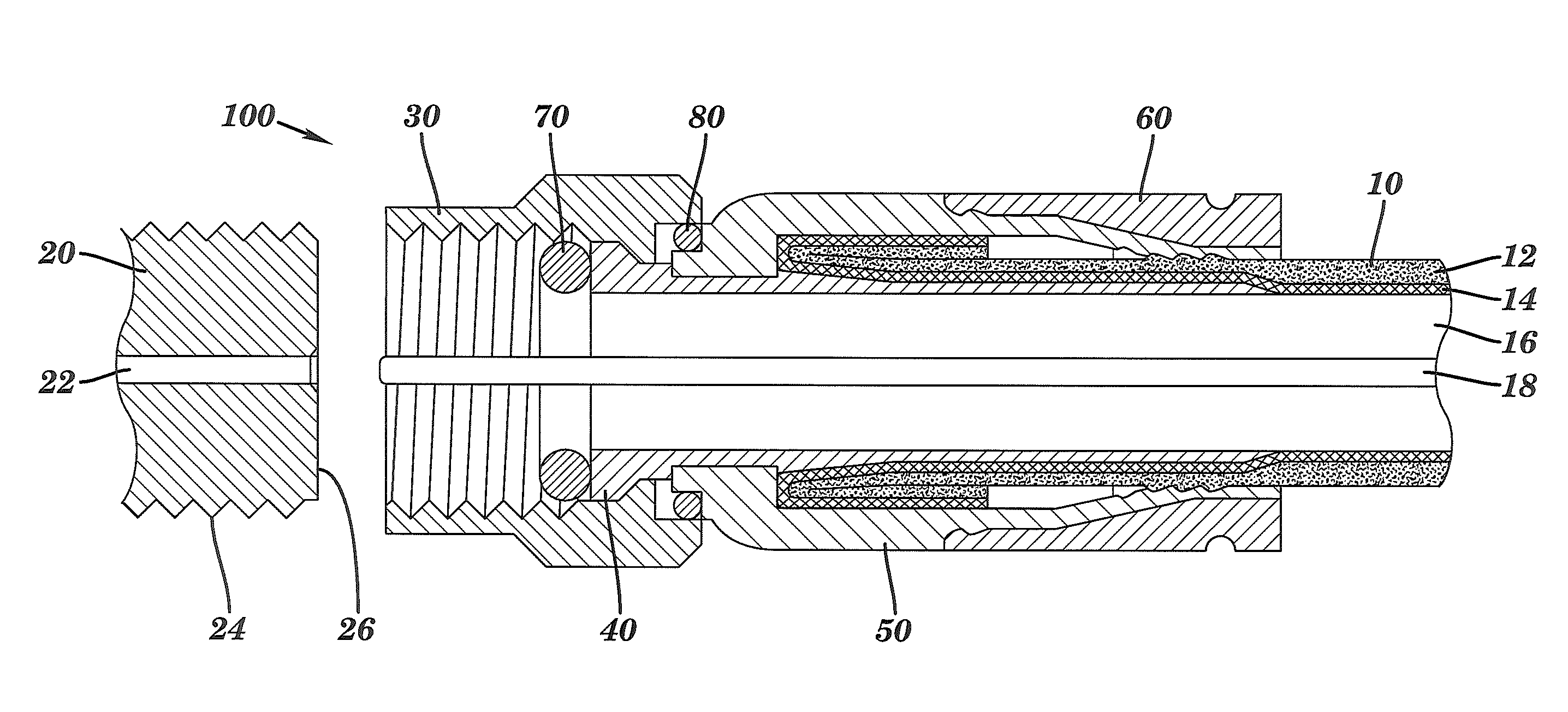

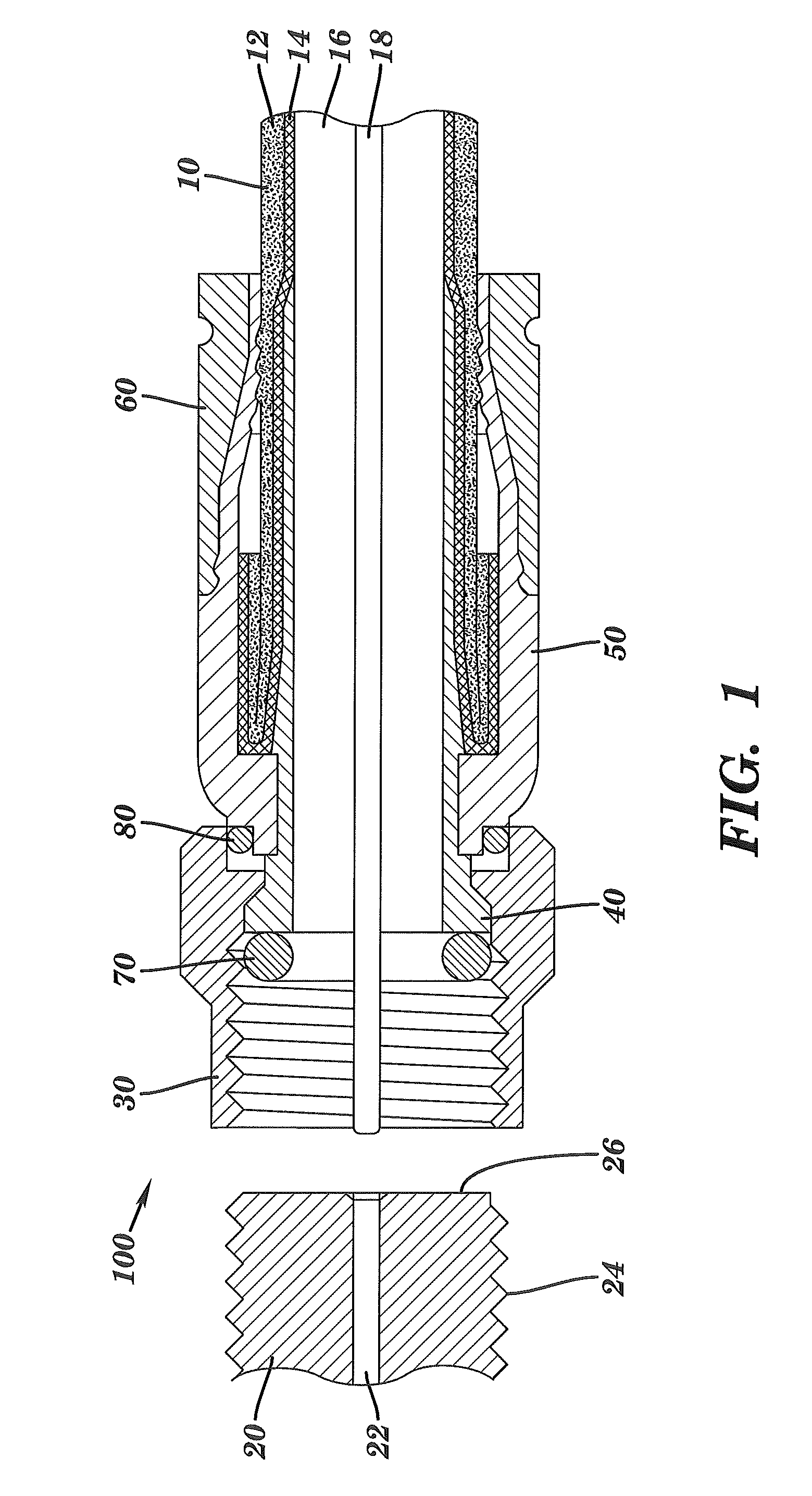

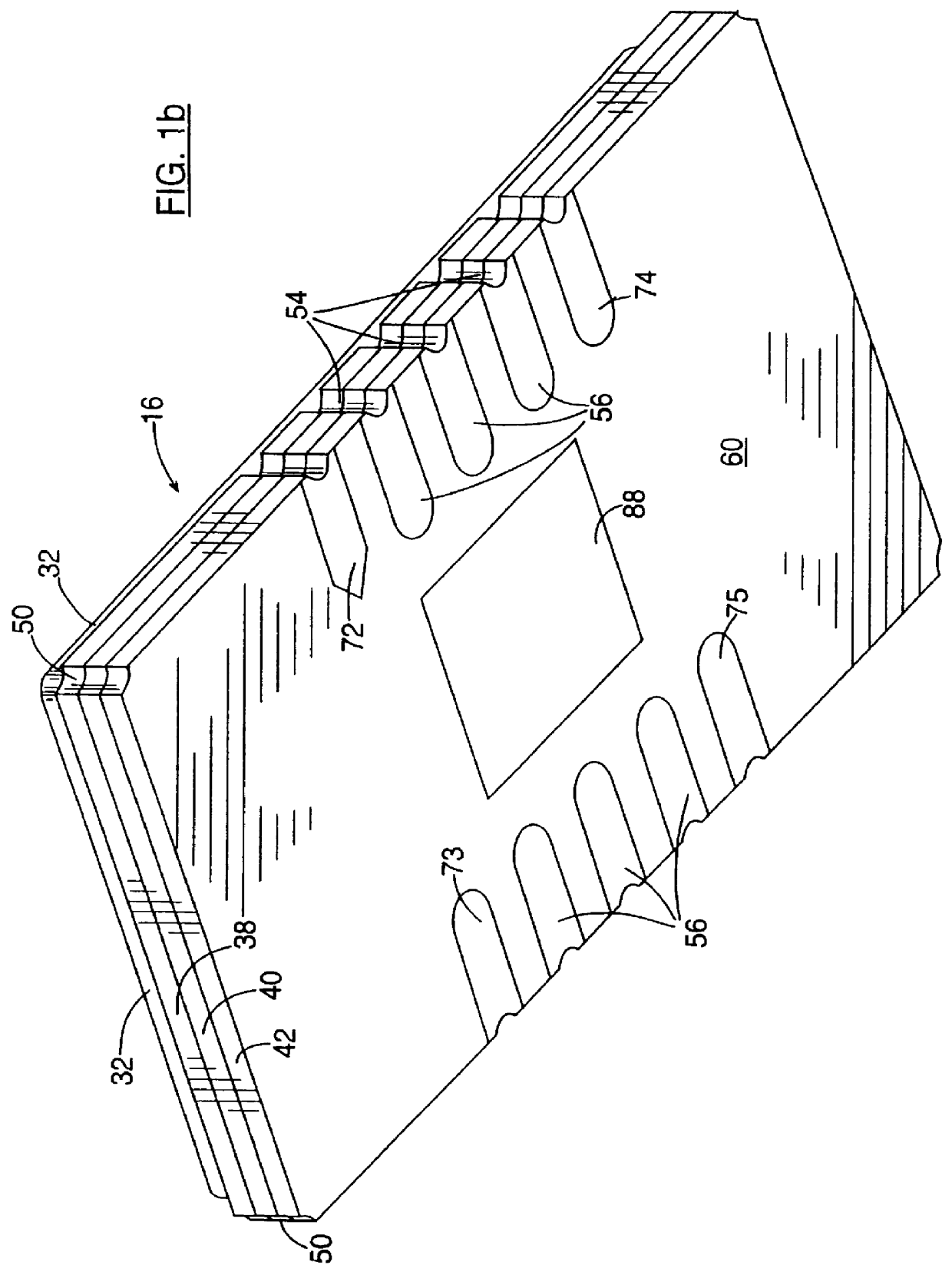

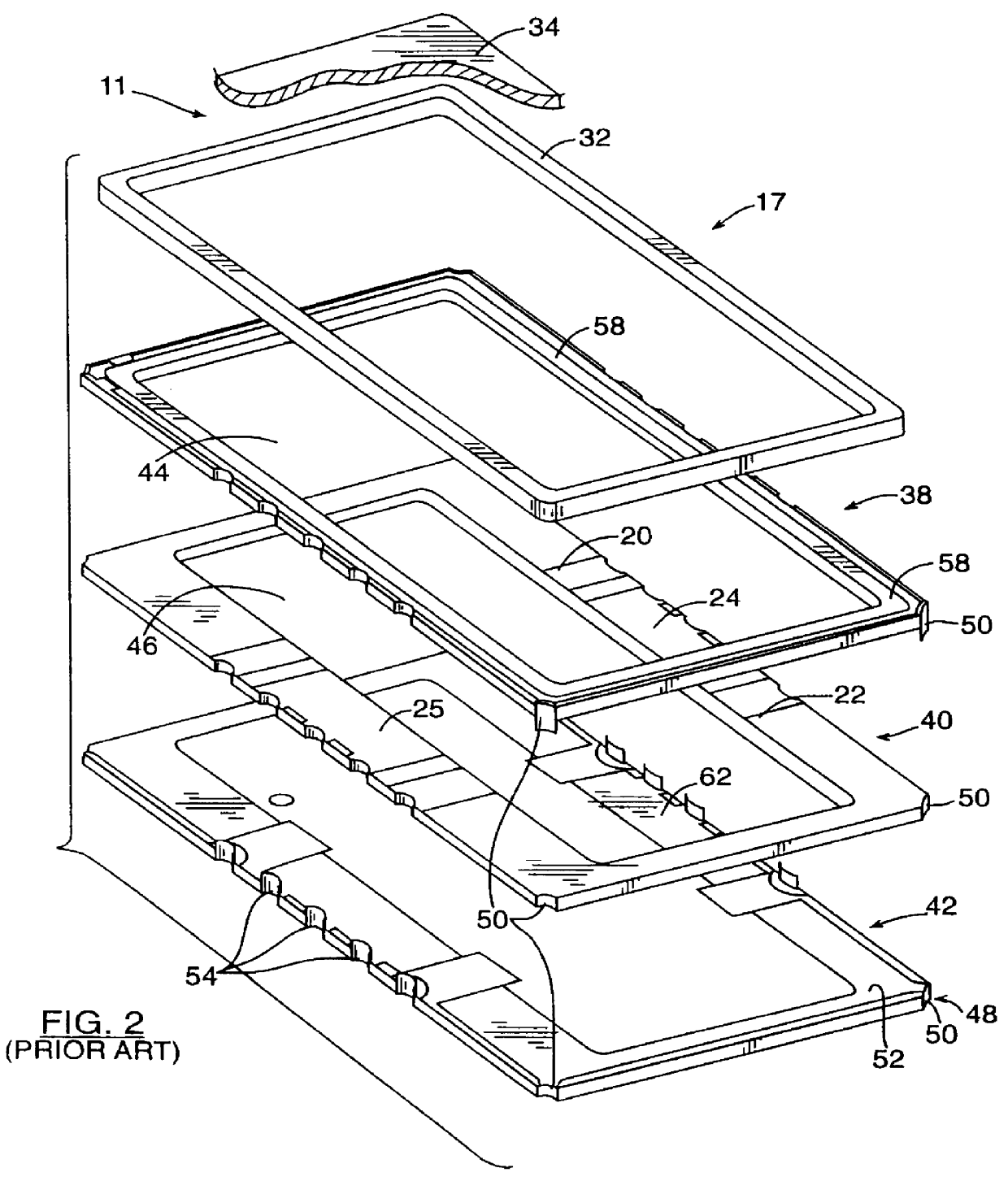

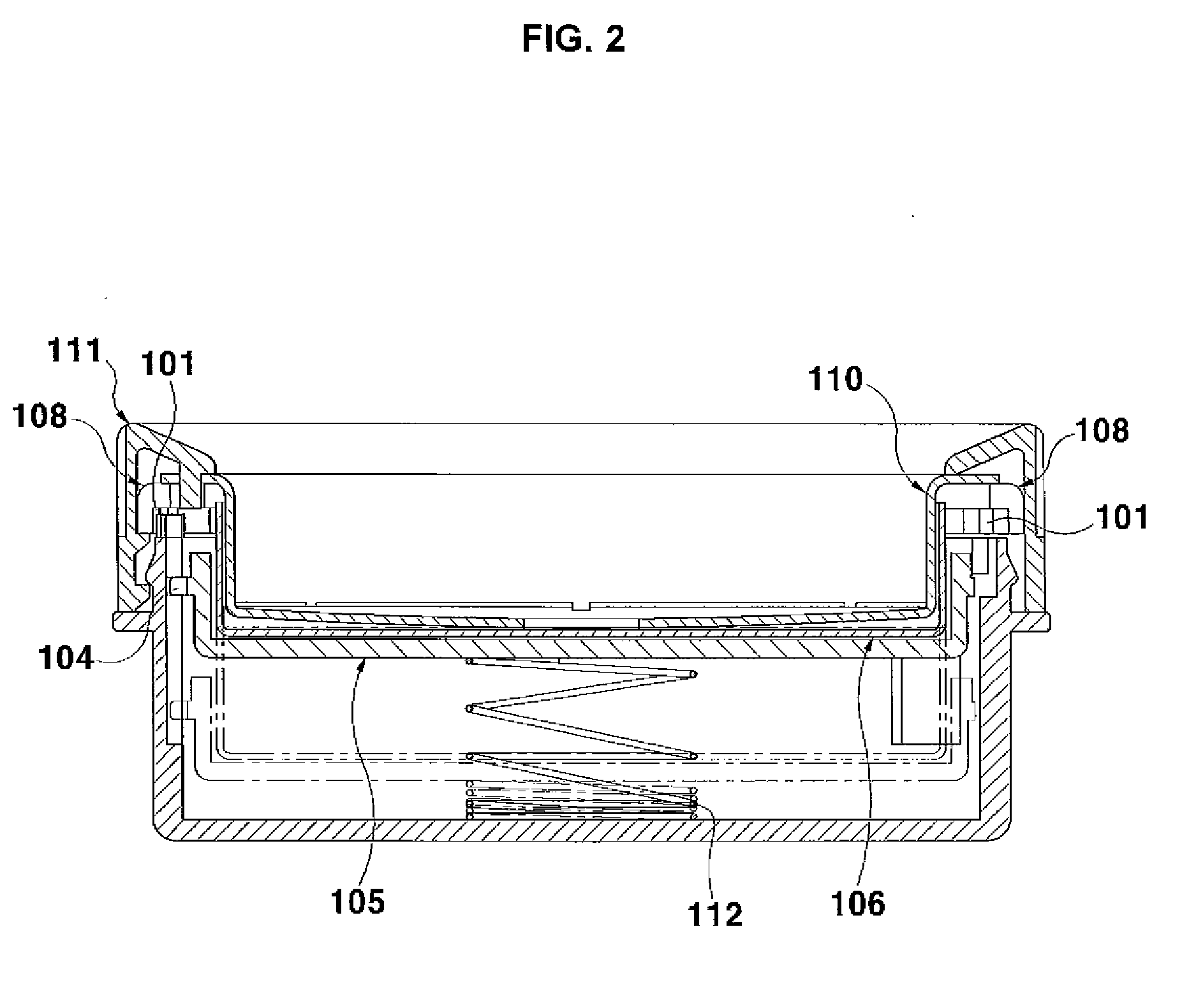

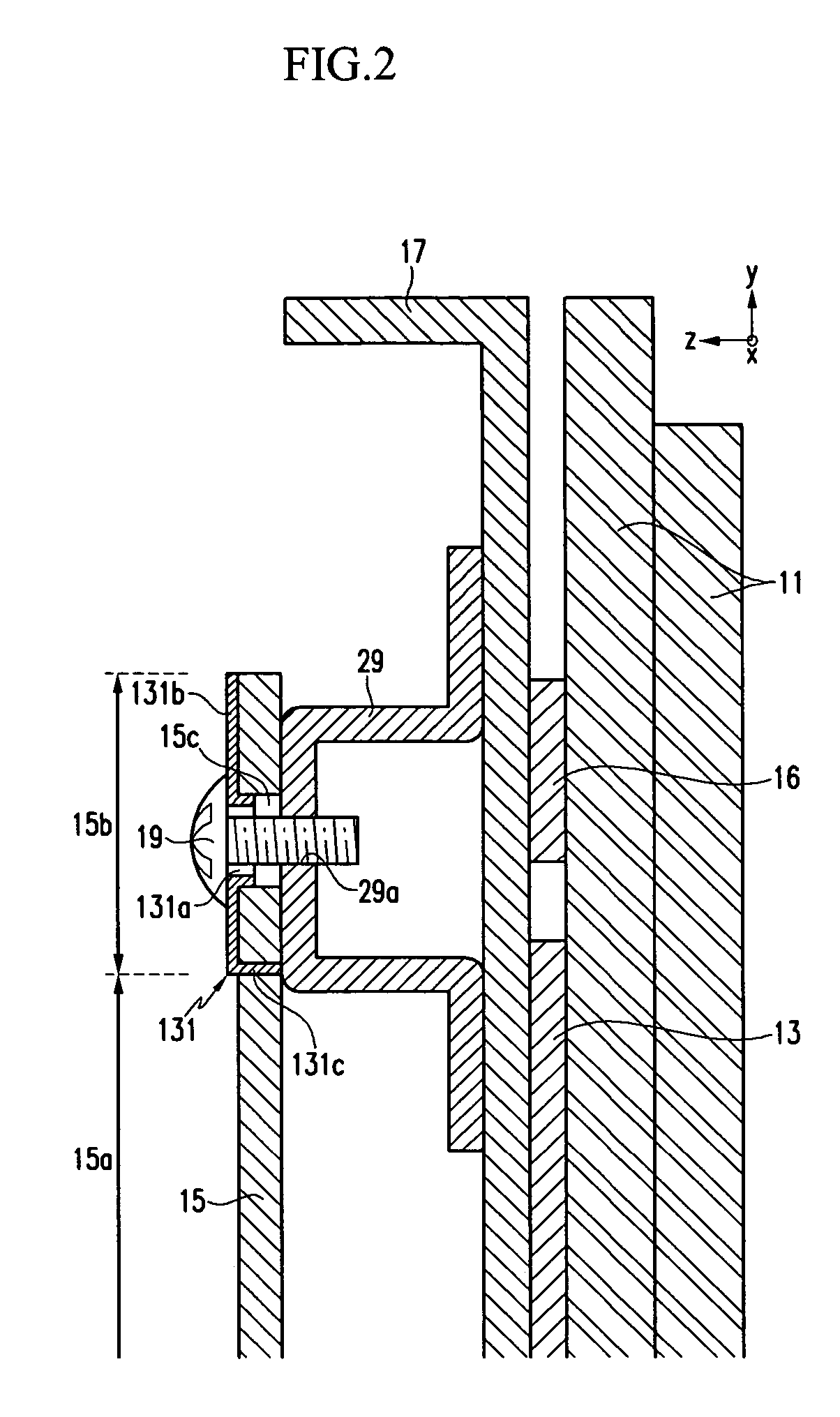

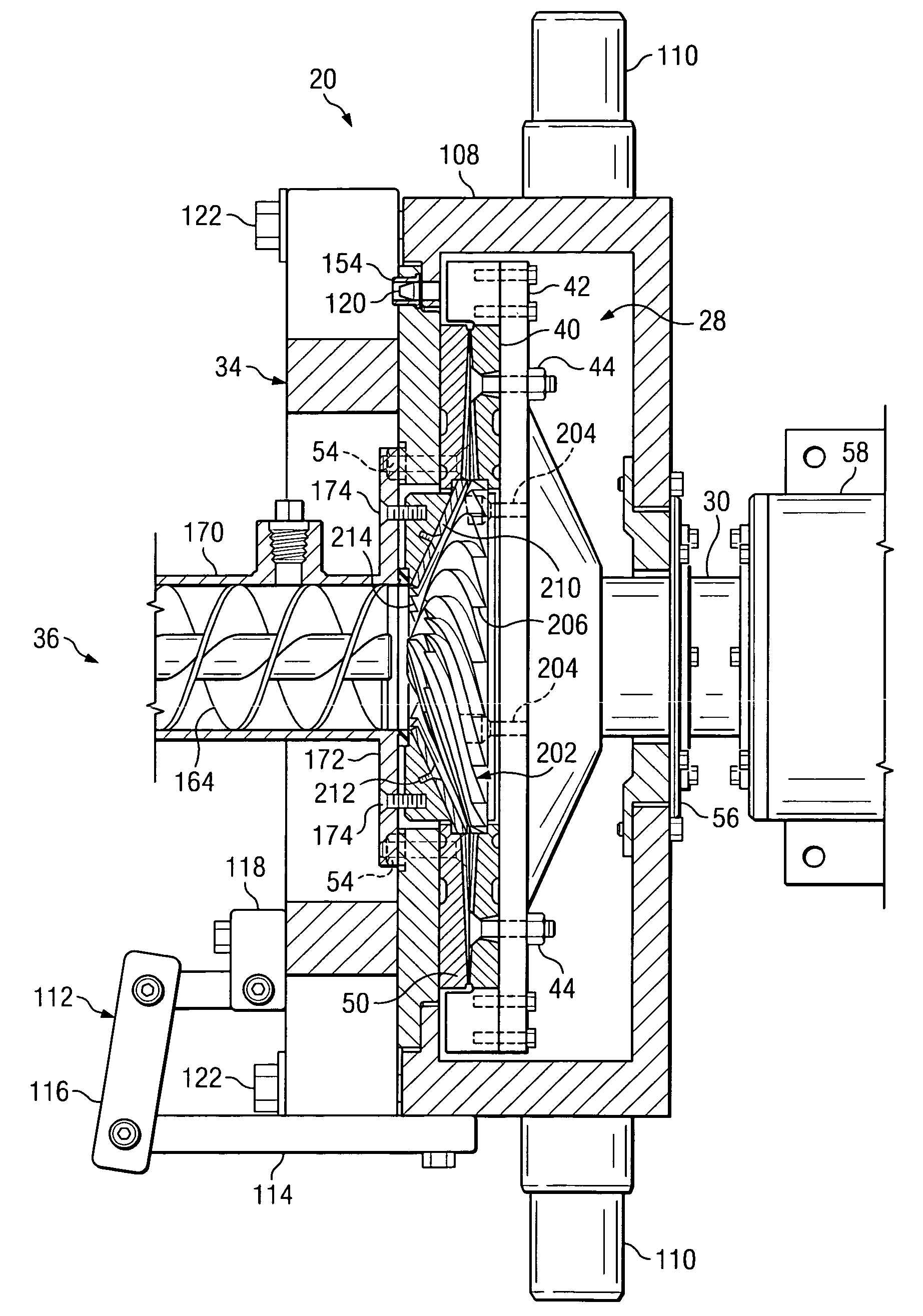

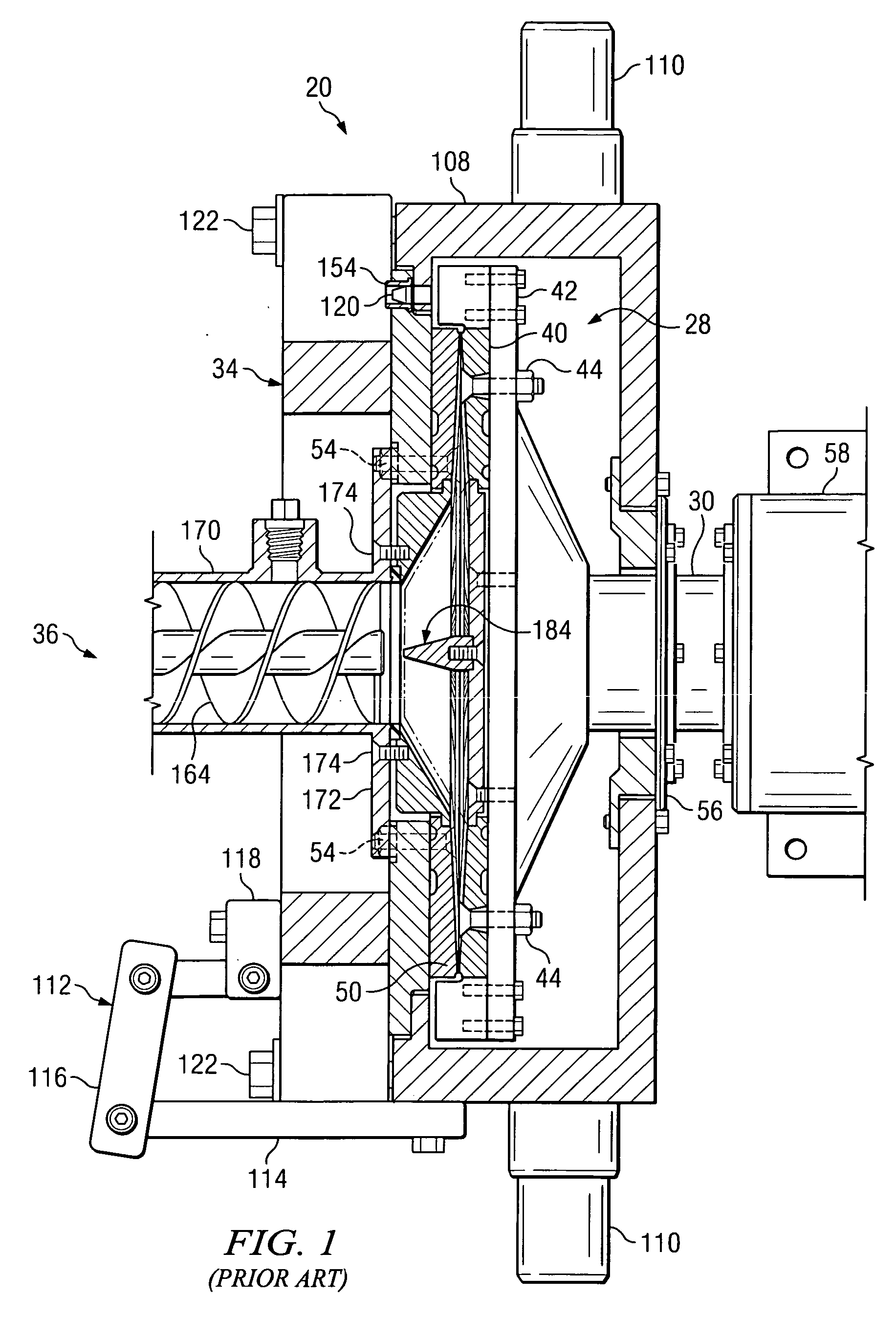

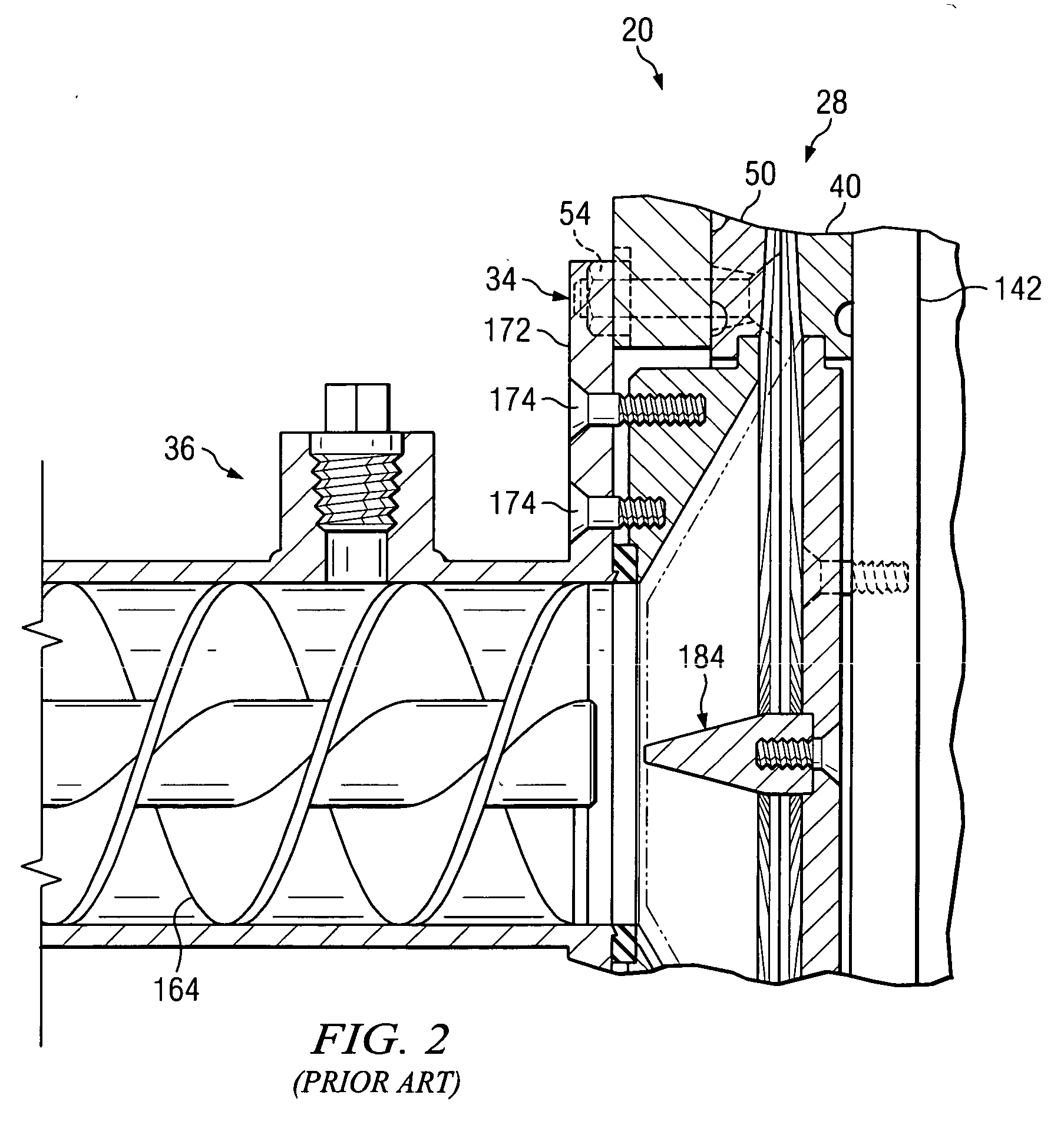

A recessed lighting fixture providing illumination from a light source comprising a plurality of light emitting diodes (LEDs) placed within a cavity of a planar surface, such as a ceiling, wall, or shower. The fixture comprises a baffle integrated with a low profile heat sink that is used to draw heat out of the fixture and communicate that heat to a trim ring of the fixture for dissipation of the heat in the room so that higher intensity light sources can be used. Improved grounding of the recessed trim unit to the recessed housing is provided with combination support and grounding springs. One embodiment of the light source is fixed in position while a second embodiment is gimbal mounted for aiming the light produced by the fixture.

Owner:CORDELIA LIGHTING

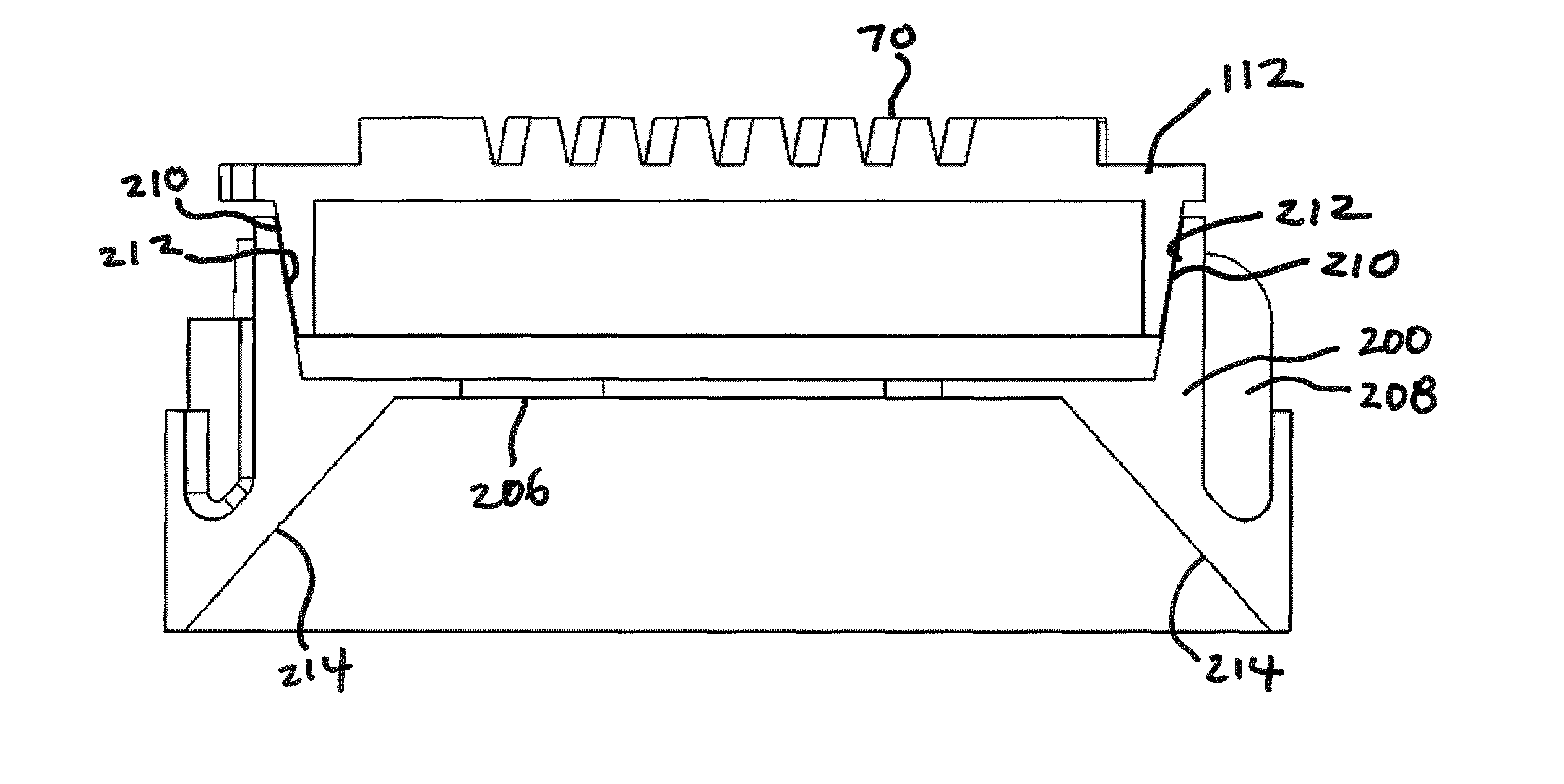

Lighting fixture with recessed baffle trim unit

InactiveUS20100061108A1Easy to GrindGood thermal controlLighting support devicesElectric circuit arrangementsEffect lightEngineering

A recessed lighting fixture providing illumination from a light source including a plurality of light emitting diodes (LEDs) placed within a cavity of a planar surface, such as a ceiling, wall, or shower. The fixture comprises a baffle integrated with a low profile heat sink that is used to draw heat out of the fixture and communicate that heat to a trim ring of the fixture for dissipation of the heat in the room so that higher intensity light sources can be used. Improved grounding of the recessed trim unit to the recessed housing is provided with combination support and grounding springs. One embodiment of the light source is fixed in position while a second embodiment is gimbal mounted for aiming the light produced by the fixture.

Owner:CORDELIA LIGHTING

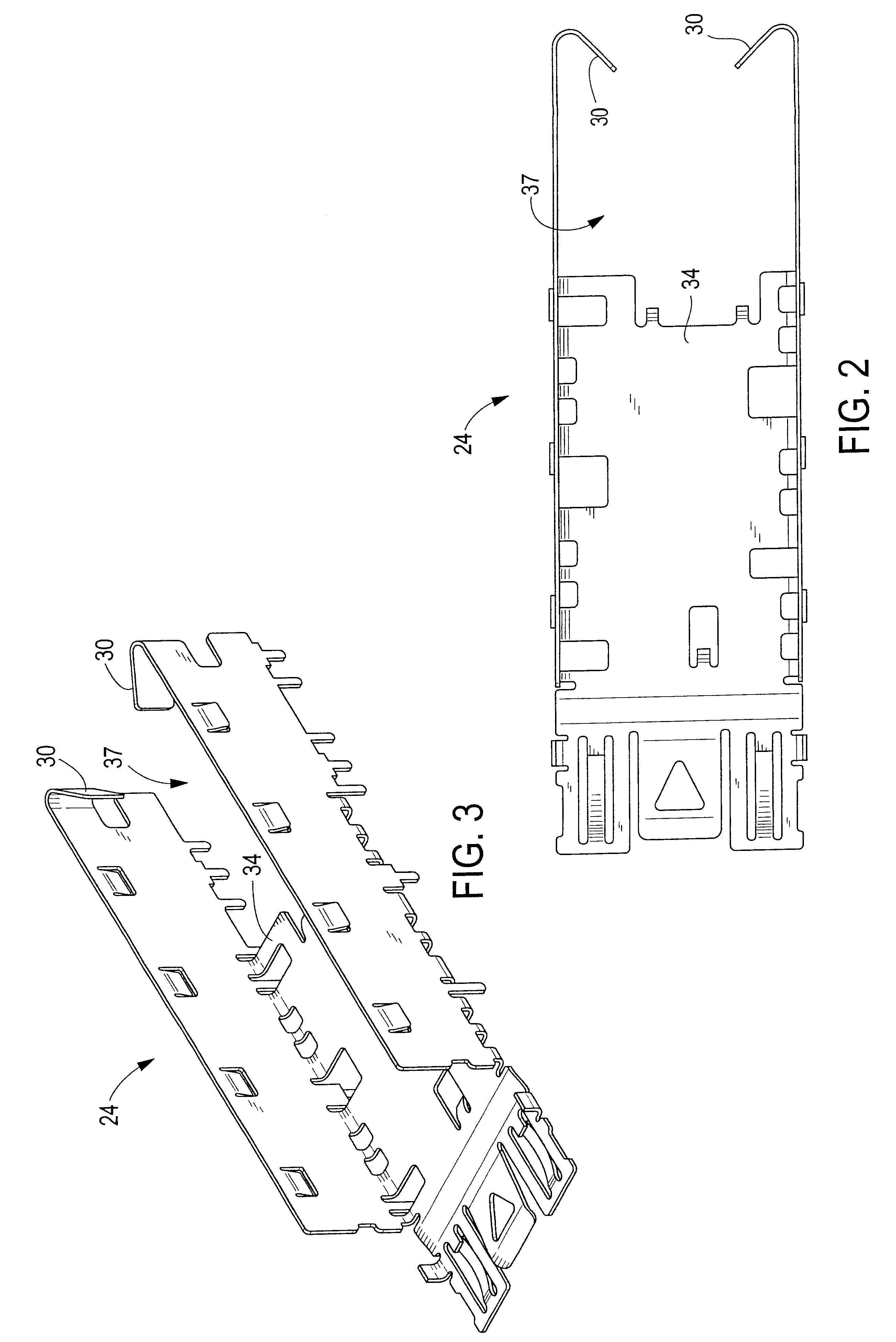

Pluggable module and receptacle

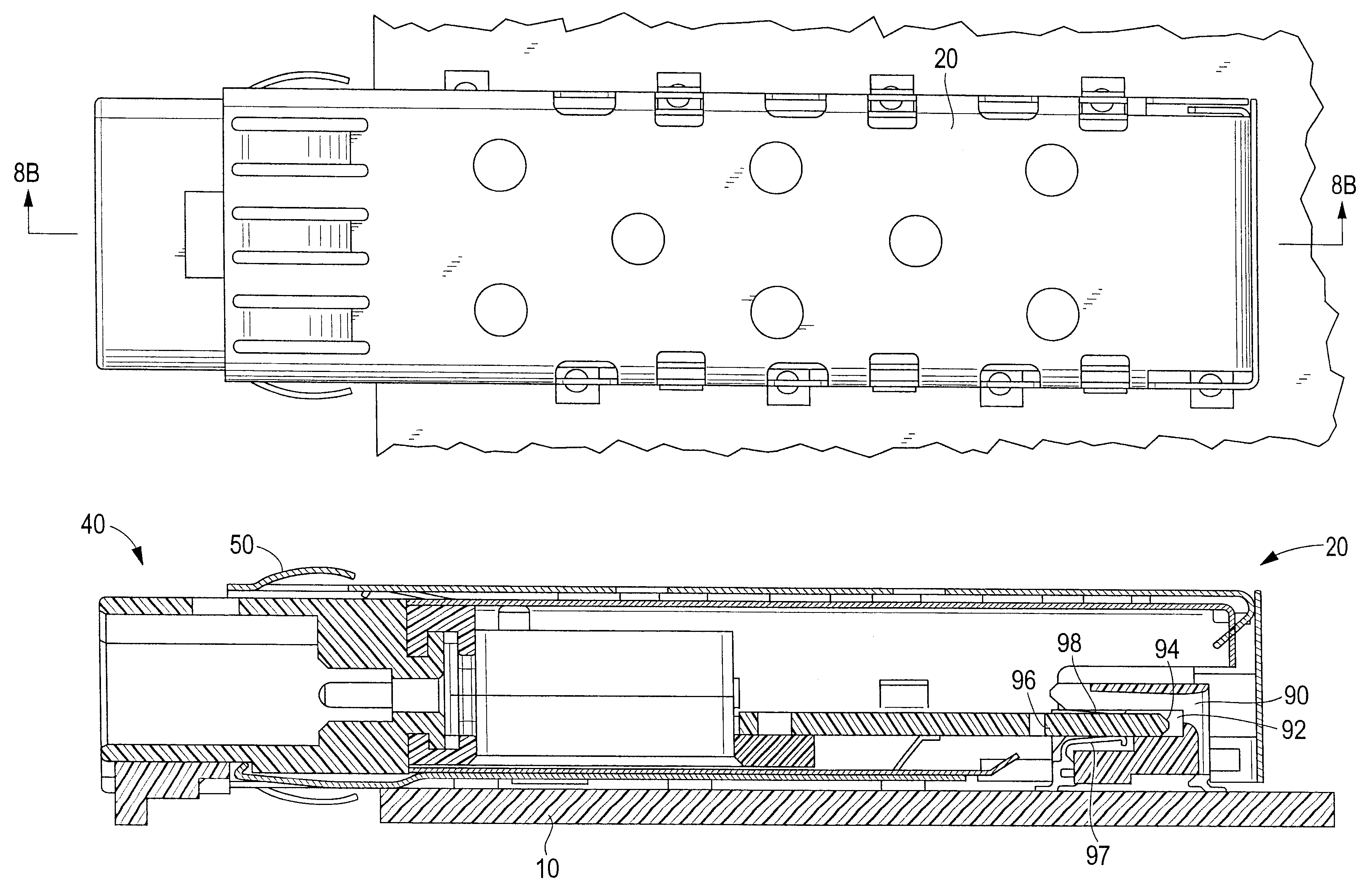

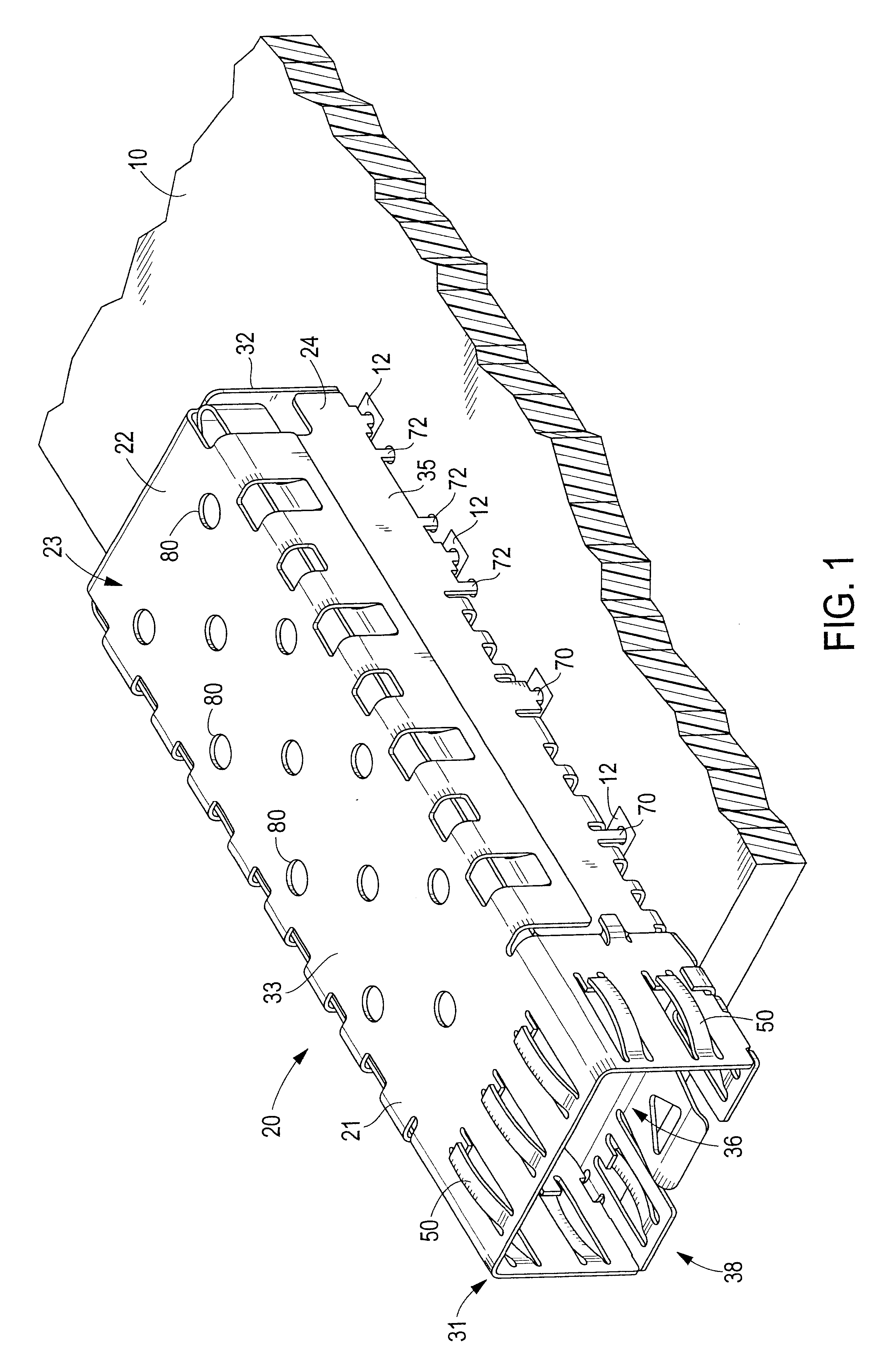

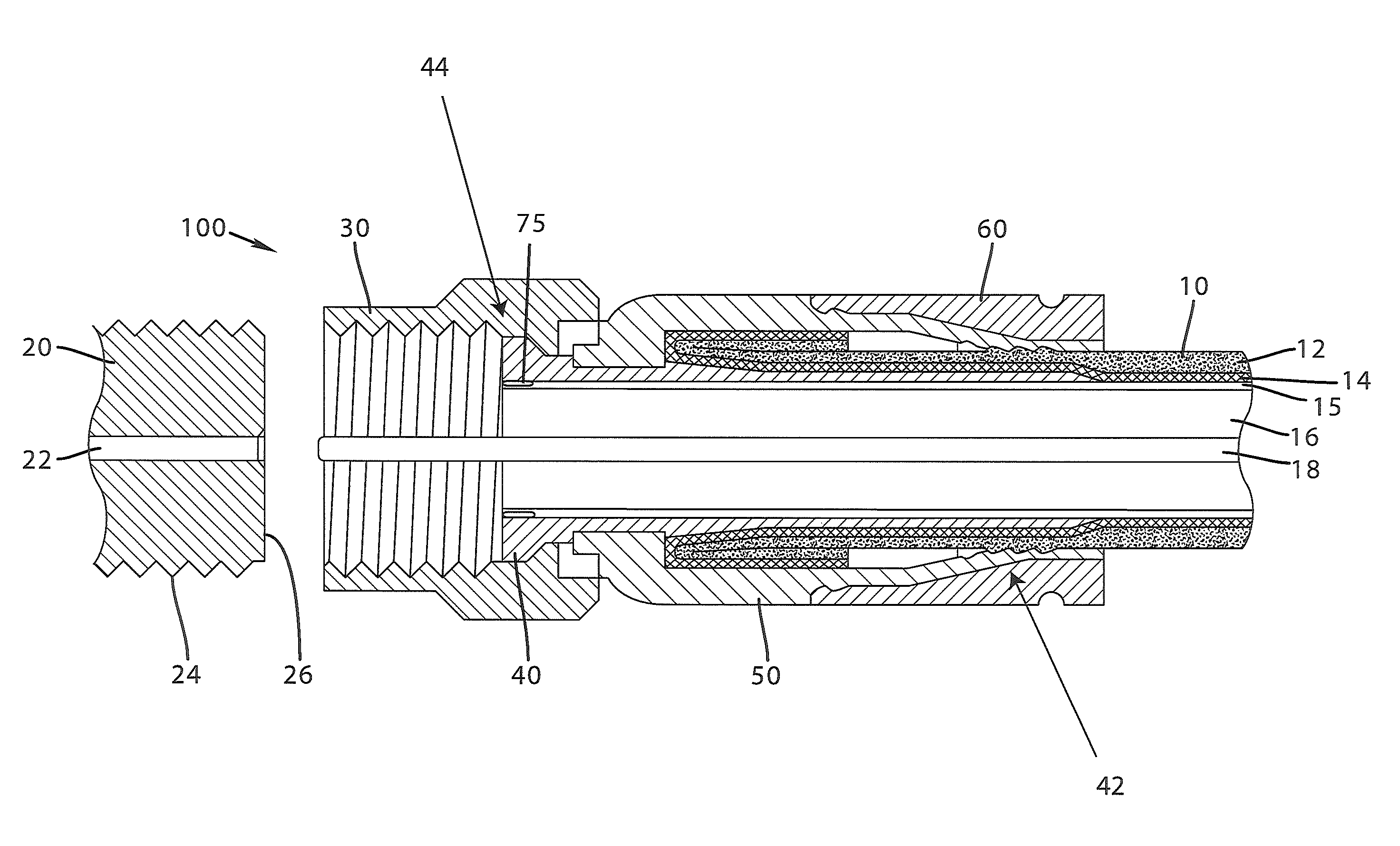

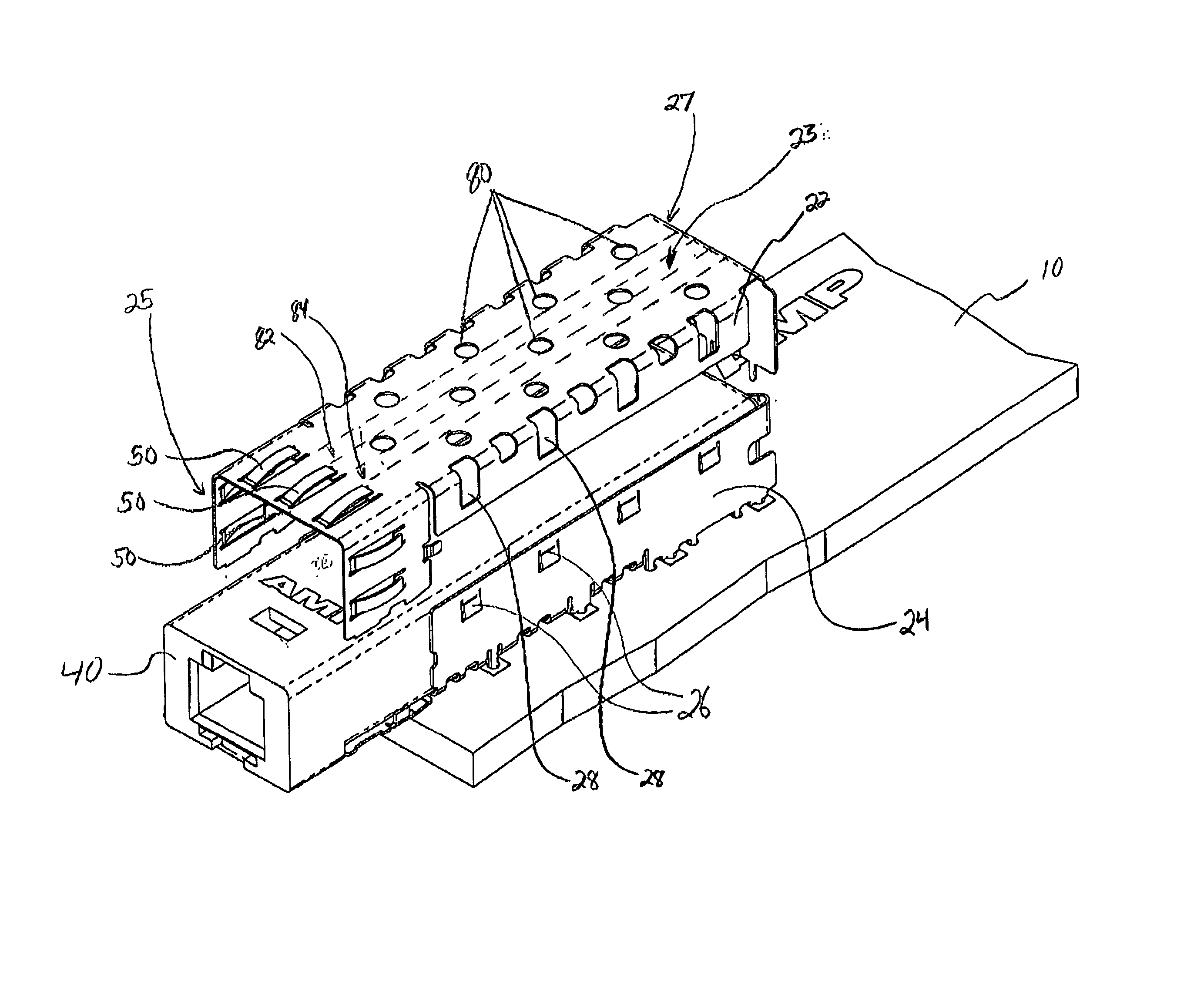

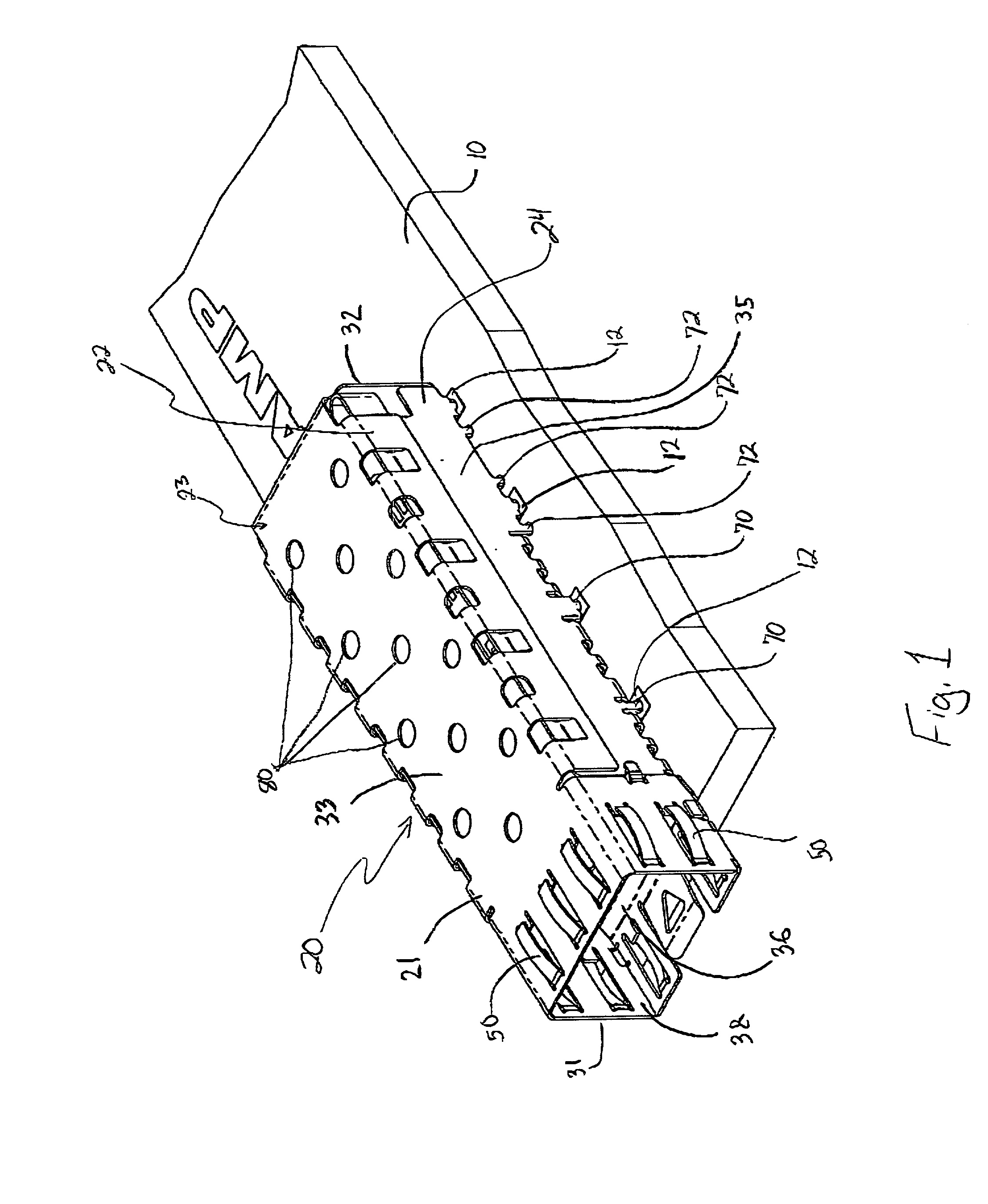

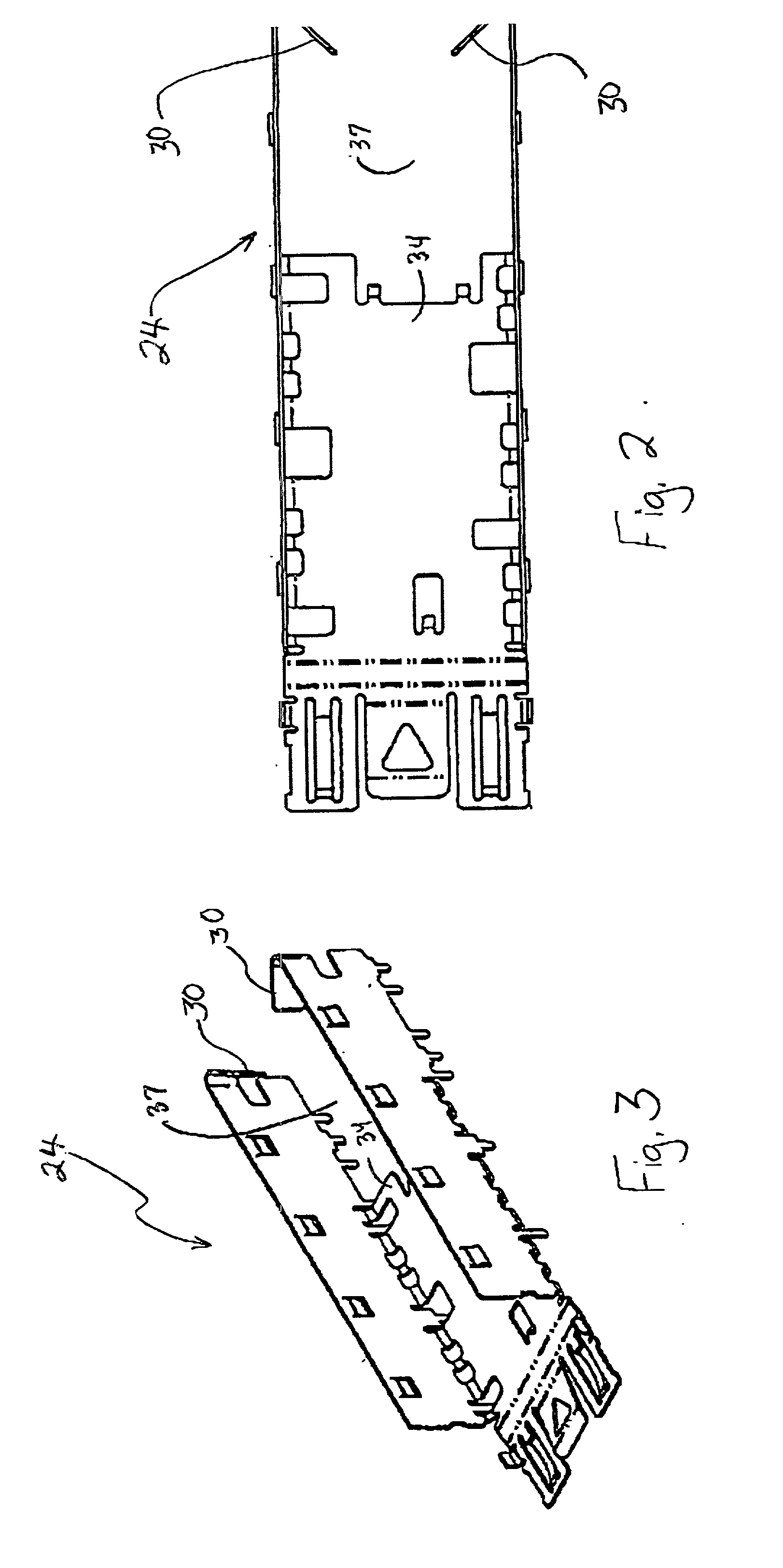

InactiveUS6517382B2High frequencyHighly miniaturizedMagnetic/electric field screeningContact members penetrating/cutting insulation/cable strandsElectrical connectionConductive materials

A receptacle for a pluggable module includes a housing having a front, a back wall, a top wall, a bottom wall, and side walls and defining a cavity for receiving a module. The bottom wall has a bottom opening to receive a receptacle connector, and the front has a front opening to receive the module. The walls of the housing are made from a conductive material. A plurality of elongated members extend down from the housing past the bottom wall. The elongated members are adapted for electrical connection to a host circuit board such that the walls of the housing are electrically connected to the host circuit board.

Owner:TE CONNECTIVITY CORP

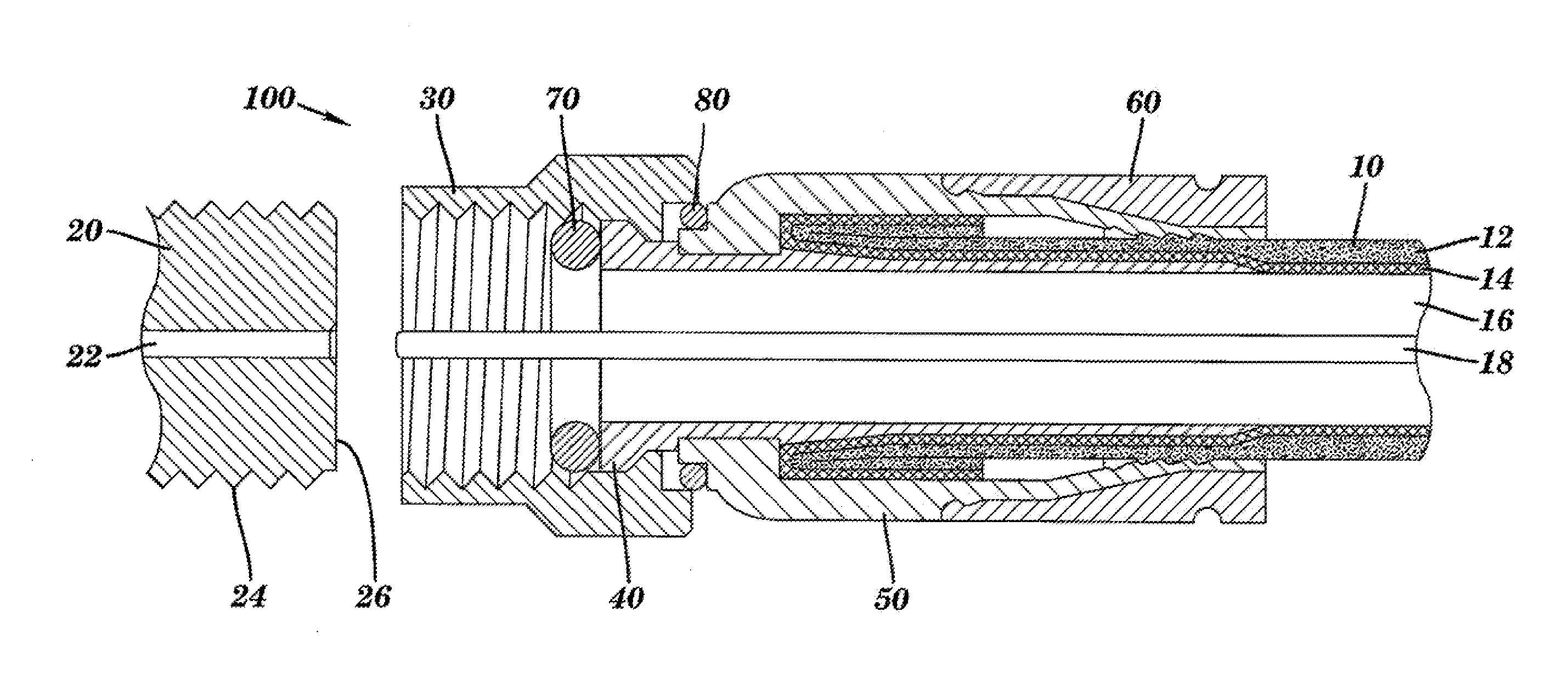

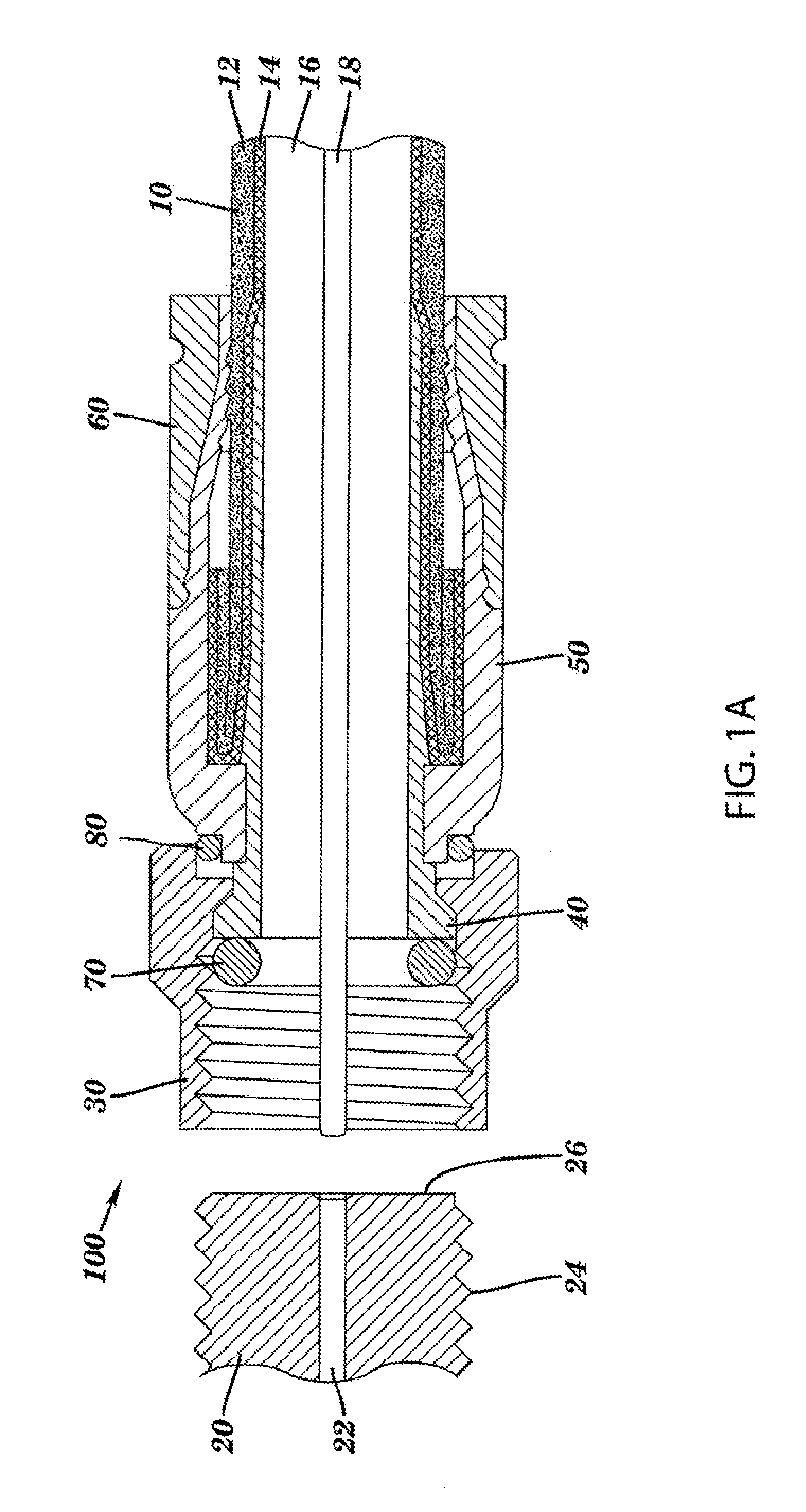

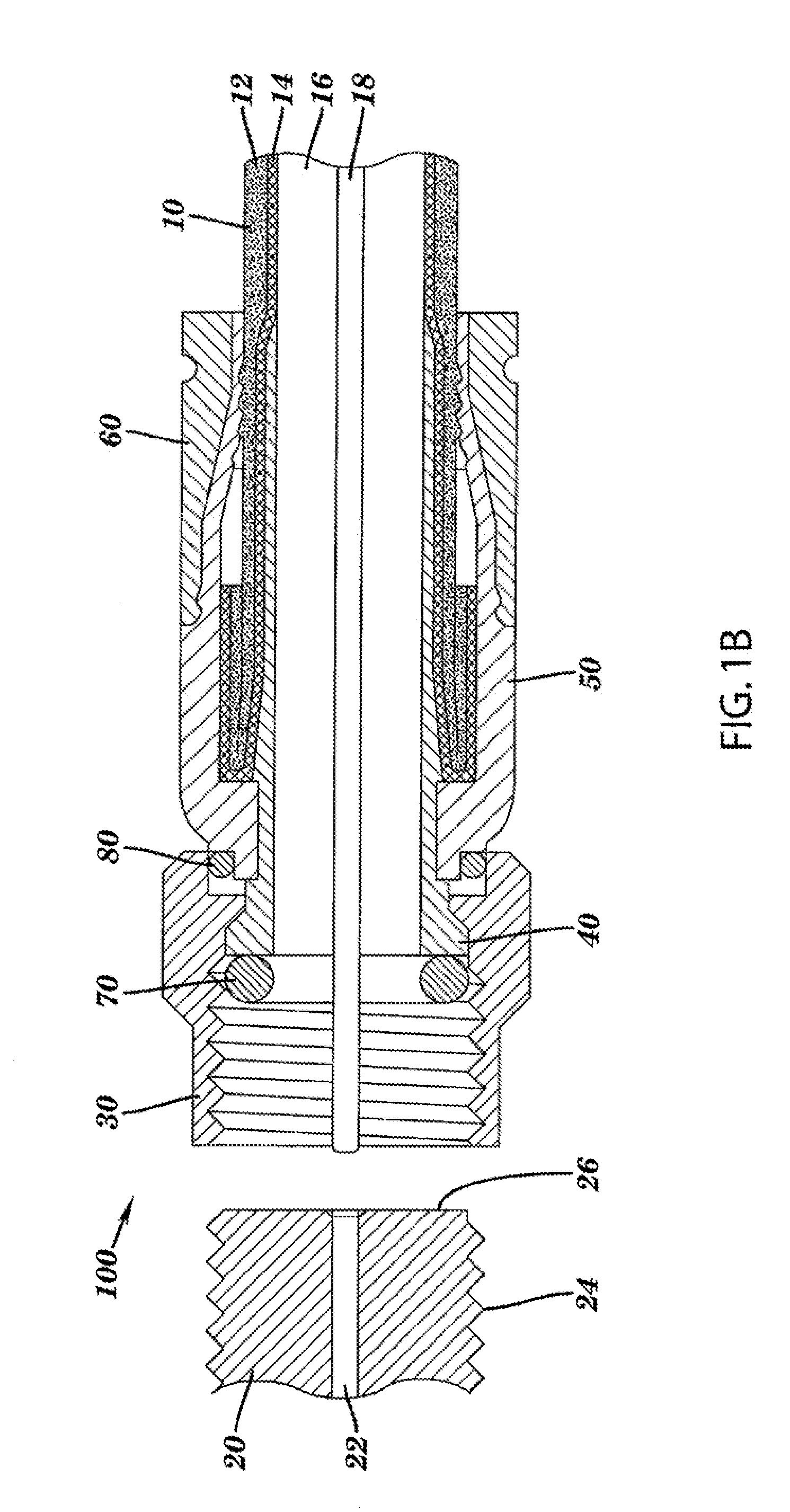

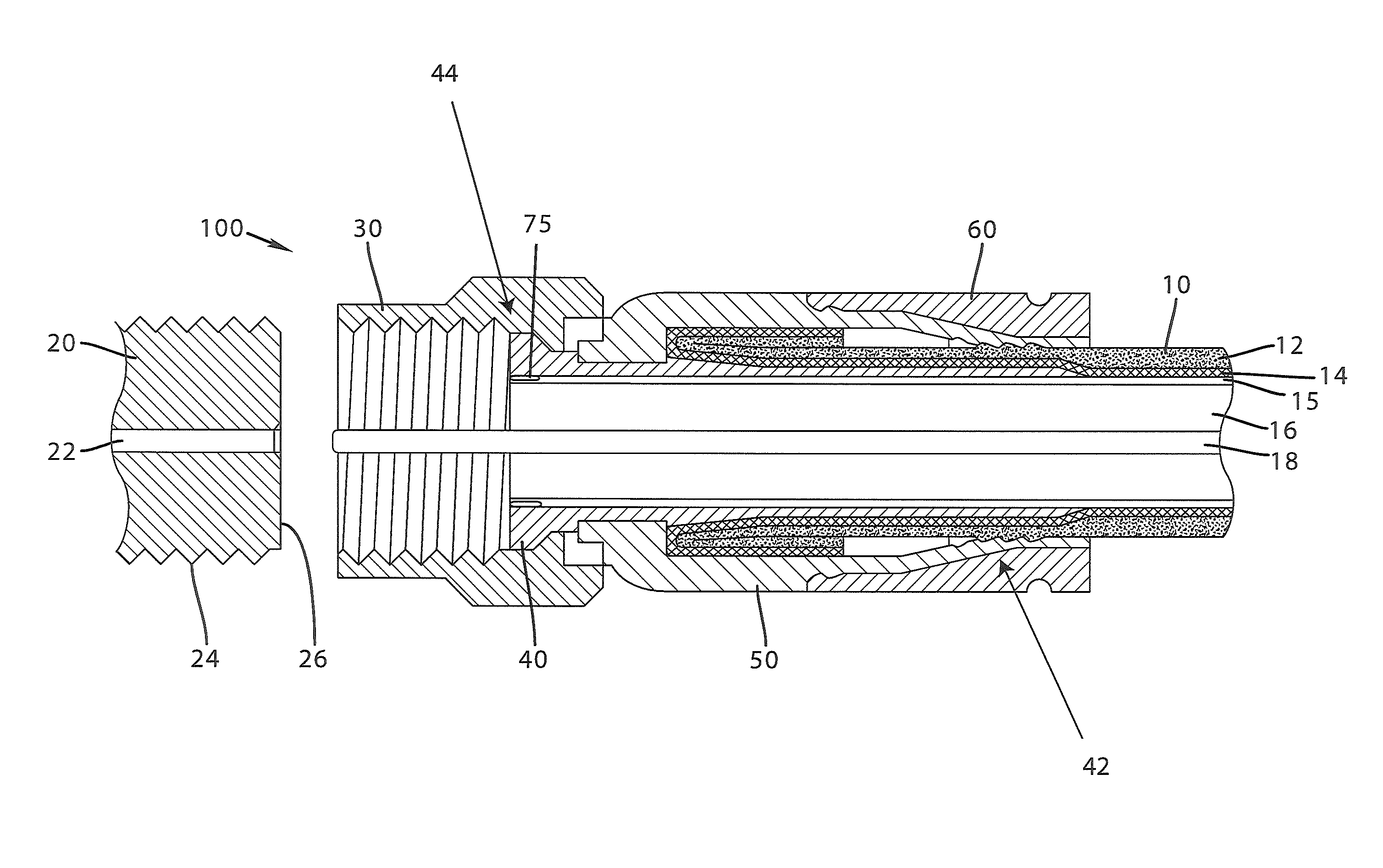

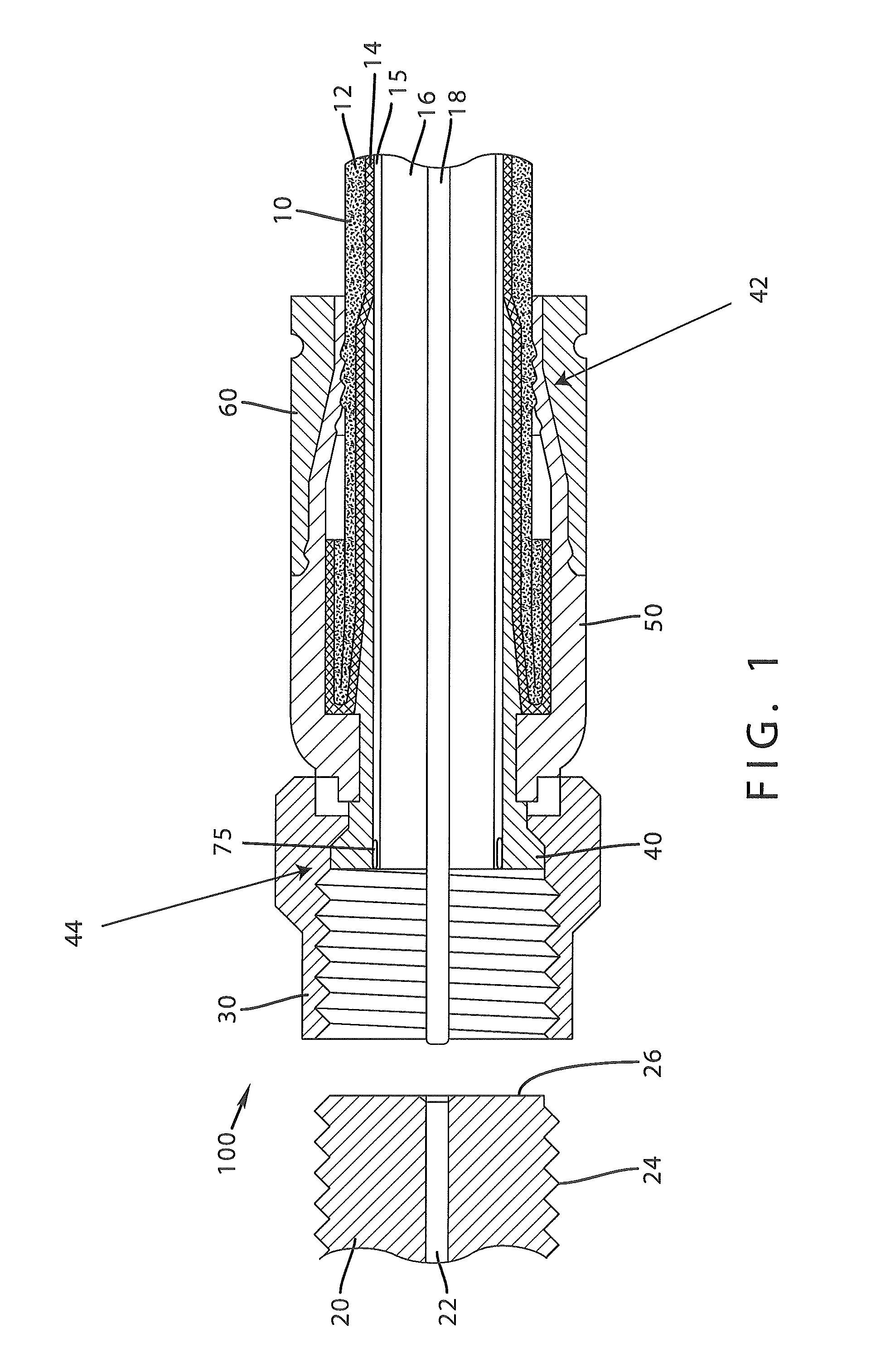

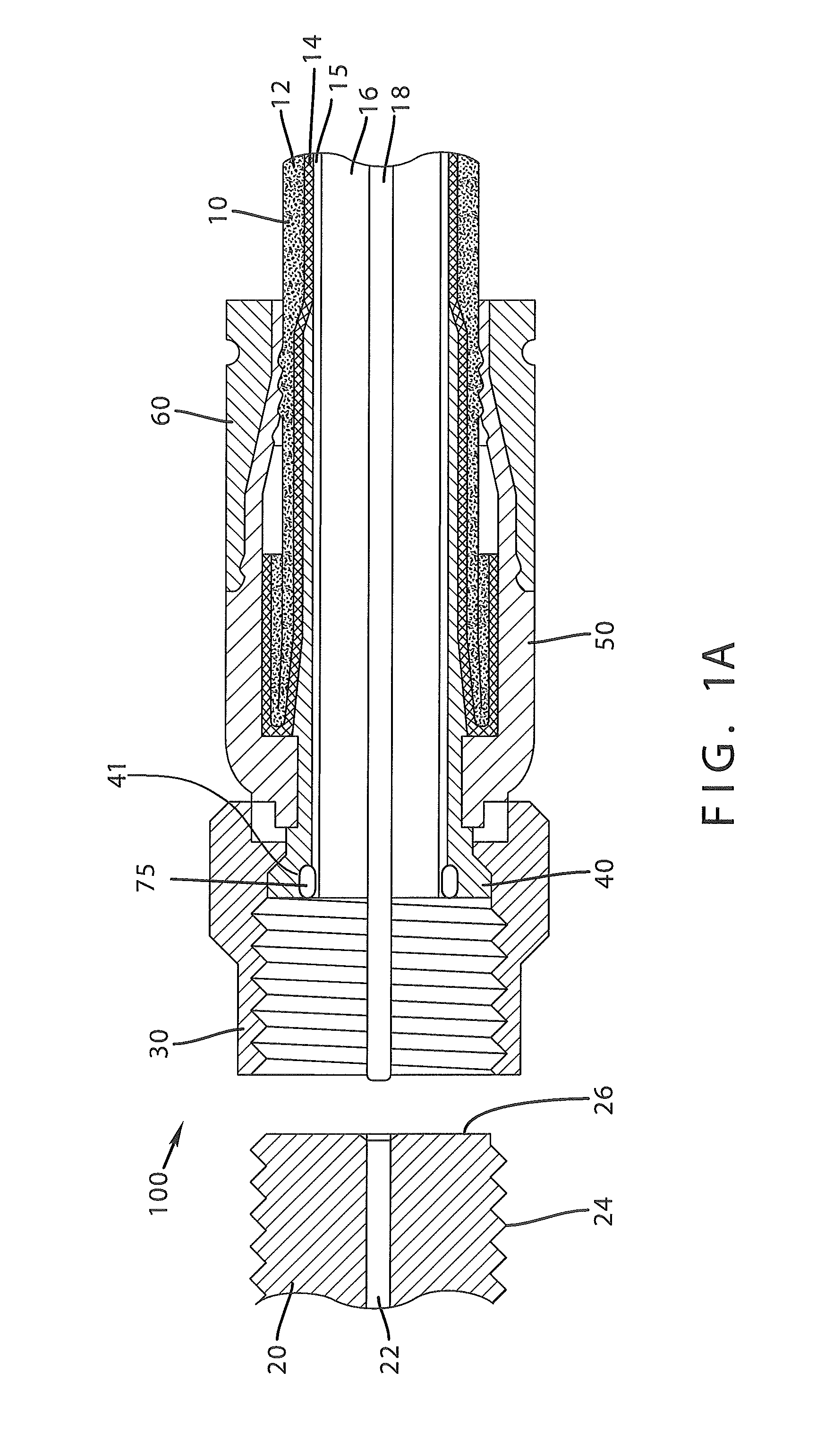

Connector having a conductively coated member and method of use thereof

ActiveUS20110230091A1Improve reliabilityEasy to GrindContact member manufacturingElectrically conductive connectionsEnvironmental noiseCoaxial cable

A connector having a conductively coated member is provided, wherein the connector comprises a connector body capable of sealing and securing a coaxial cable, and further wherein the conductively coated member, such as an O-ring, physically seals the connector, electrically couples the connector and the coaxial cable, facilitates grounding through the connector, and renders an electromagnetic shield preventing ingress of unwanted environmental noise.

Owner:PPC BROADBAND INC

Dielectric sealing member and method of use thereof

InactiveUS8167635B1Improve reliabilityAvoid enteringElectrically conductive connectionsCouplings bases/casesDielectricEngineering

A connector having a sealing member is provided, wherein the sealing member prevents environmental elements, such as rainwater from entering the connector. Furthermore, a sealing member placed on the inner surface of a post forming a barrier against moisture and other contaminants proximate the second end of the post is also provided.

Owner:PPC BROADBAND INC

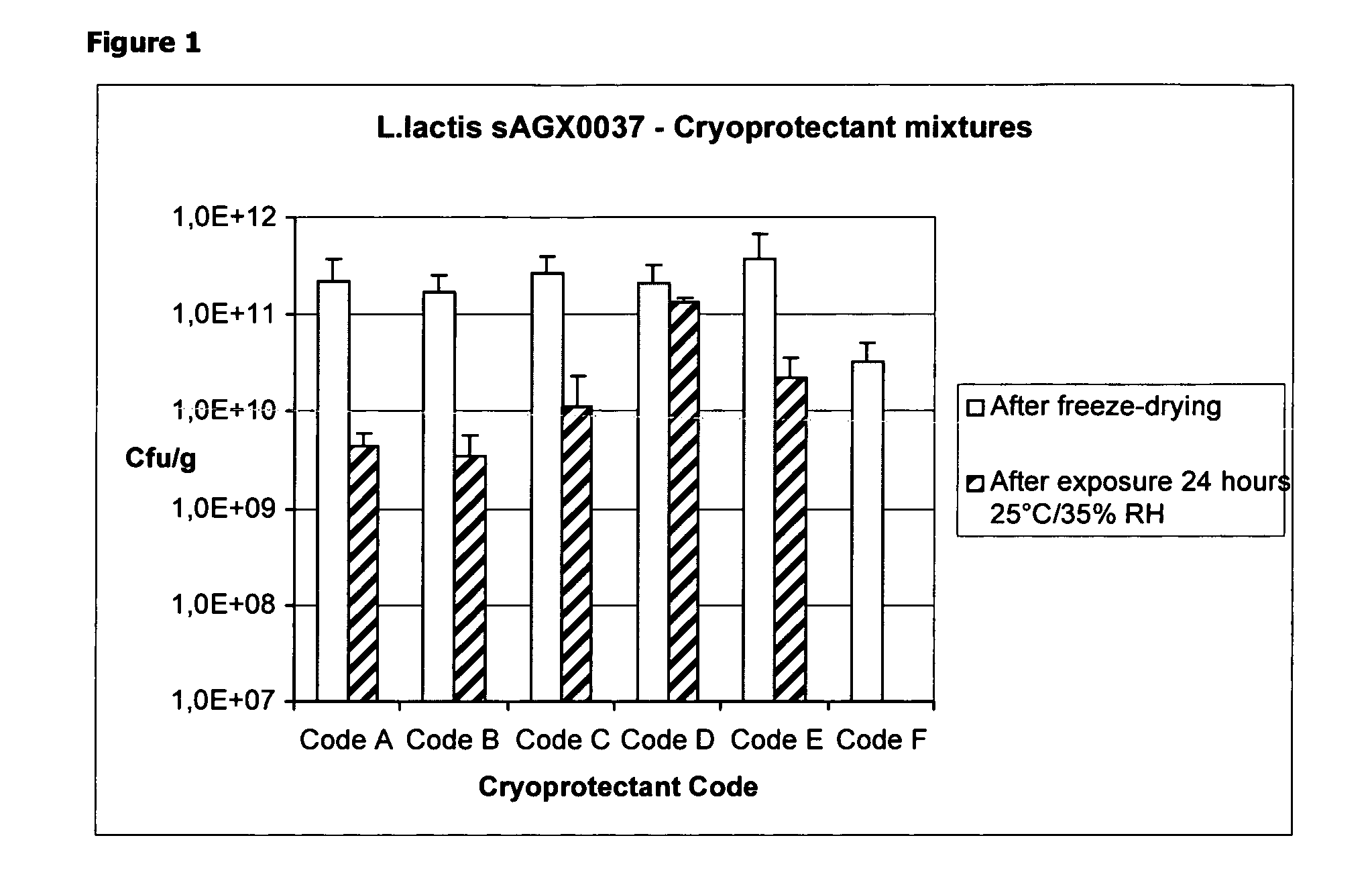

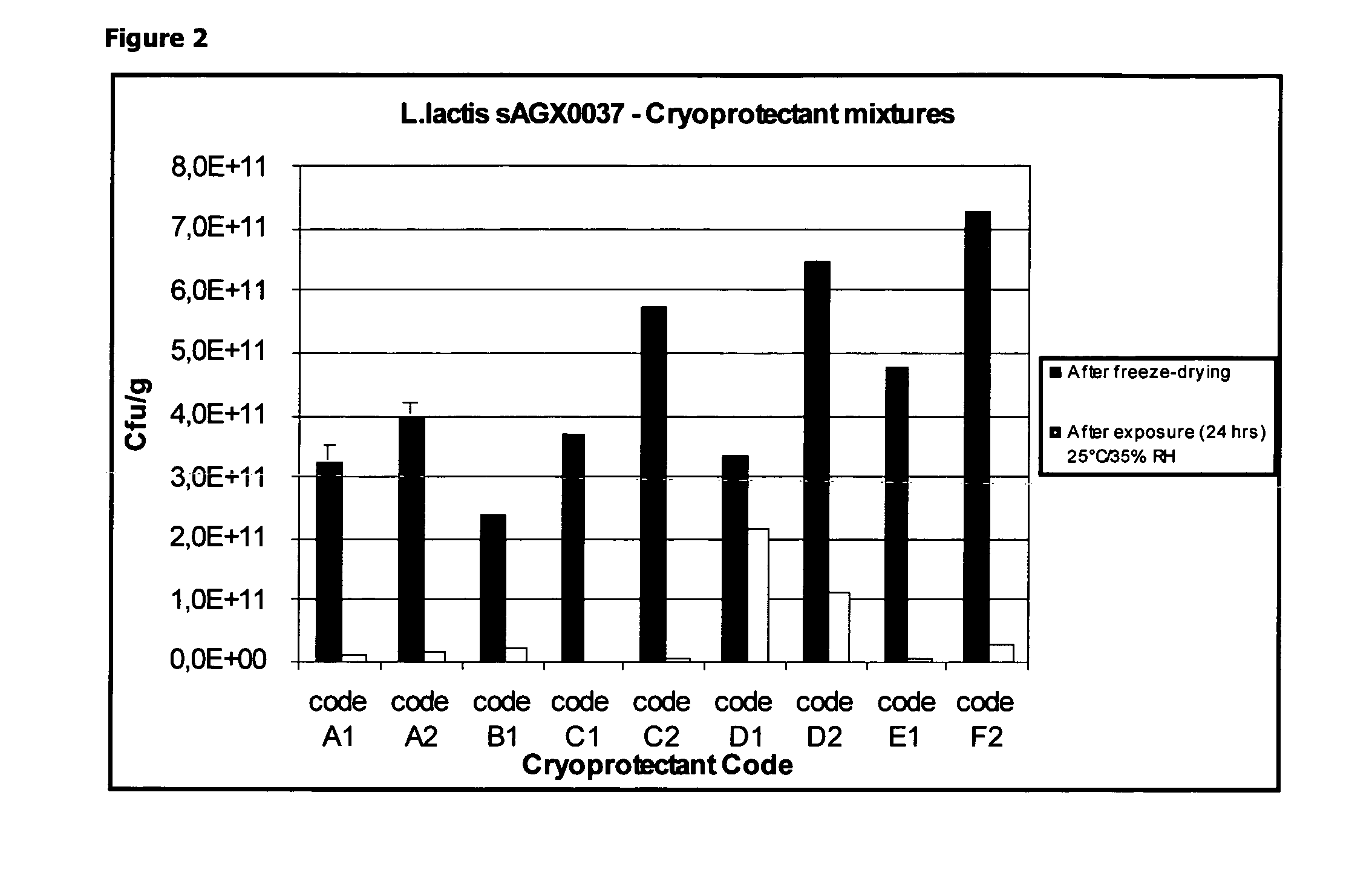

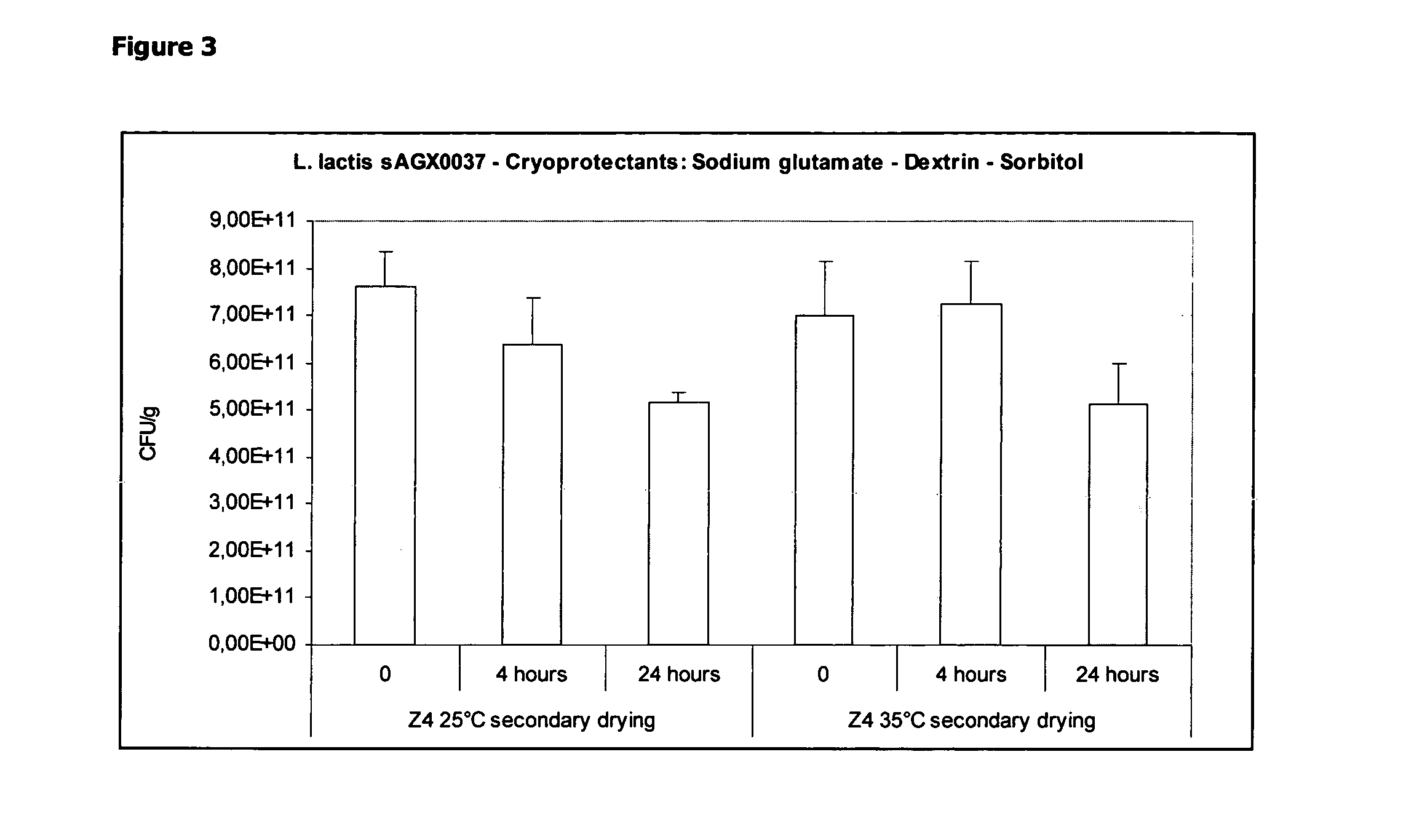

Cryoprotectants for freeze drying of lactic acid bacteria

ActiveUS20120039853A1Improve survivabilityImprove textureBiocideMilk preparationBacteroidesVaccination

The present invention comprises the discovery and development of an effective cryoprotectant composition, without containing skim milk or any other animal-derived compounds, to achieve long-term stability of freeze-dried lactic acid bacteria (LAB), at different temperatures, whereby the retention of viability of the freeze-dried LAB after 6 months of storage, preferably after 9 months of storage, more preferably after 12 months of storage is more than 50%. The invention is in the field of producing freeze dried bacteria, in particular Lactic acid bacteria. More in particular, the invention relates to the use of a novel combination of cryoprotectants for increasing the viability of bacteria after freeze drying, improving the texture of the lyofilized cake for easy grinding and improving the long term stability of the freeze dried bacteria at different temperature conditions. The invention further relates to such freeze dried bacteria for use in food industry or in human or animal health applications. More in particular, the invention relates to the increased viability and long-term storage of recombinant bacteria capable of expressing heterologous proteins or peptides and administered to humans or animals for therapeutic or vaccination purposes.

Owner:INTREXON ACTOBIOTICS NV

Lighting fixture with recessed baffle trim unit

InactiveUS8182116B2Easy to GrindGood thermal controlLighting support devicesElectric circuit arrangementsEffect lightEngineering

A recessed lighting fixture providing illumination from a light source including a plurality of light emitting diodes (LEDs) placed within a cavity of a planar surface, such as a ceiling, wall, or shower. The fixture comprises a baffle integrated with a low profile heat sink that is used to draw heat out of the fixture and communicate that heat to a trim ring of the fixture for dissipation of the heat in the room so that higher intensity light sources can be used. Improved grounding of the recessed trim unit to the recessed housing is provided with combination support and grounding springs. One embodiment of the light source is fixed in position while a second embodiment is gimbal mounted for aiming the light produced by the fixture.

Owner:CORDELIA LIGHTING

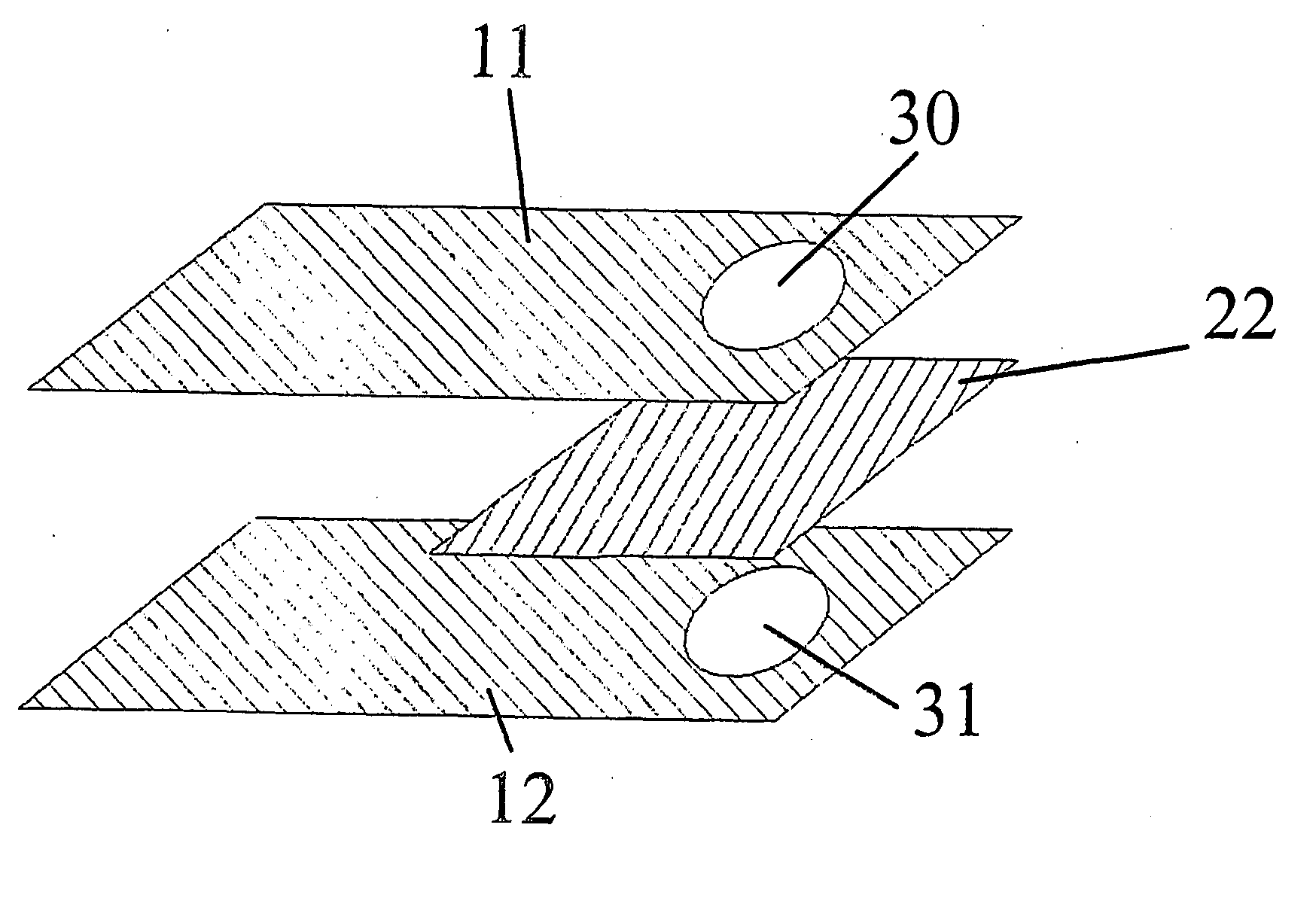

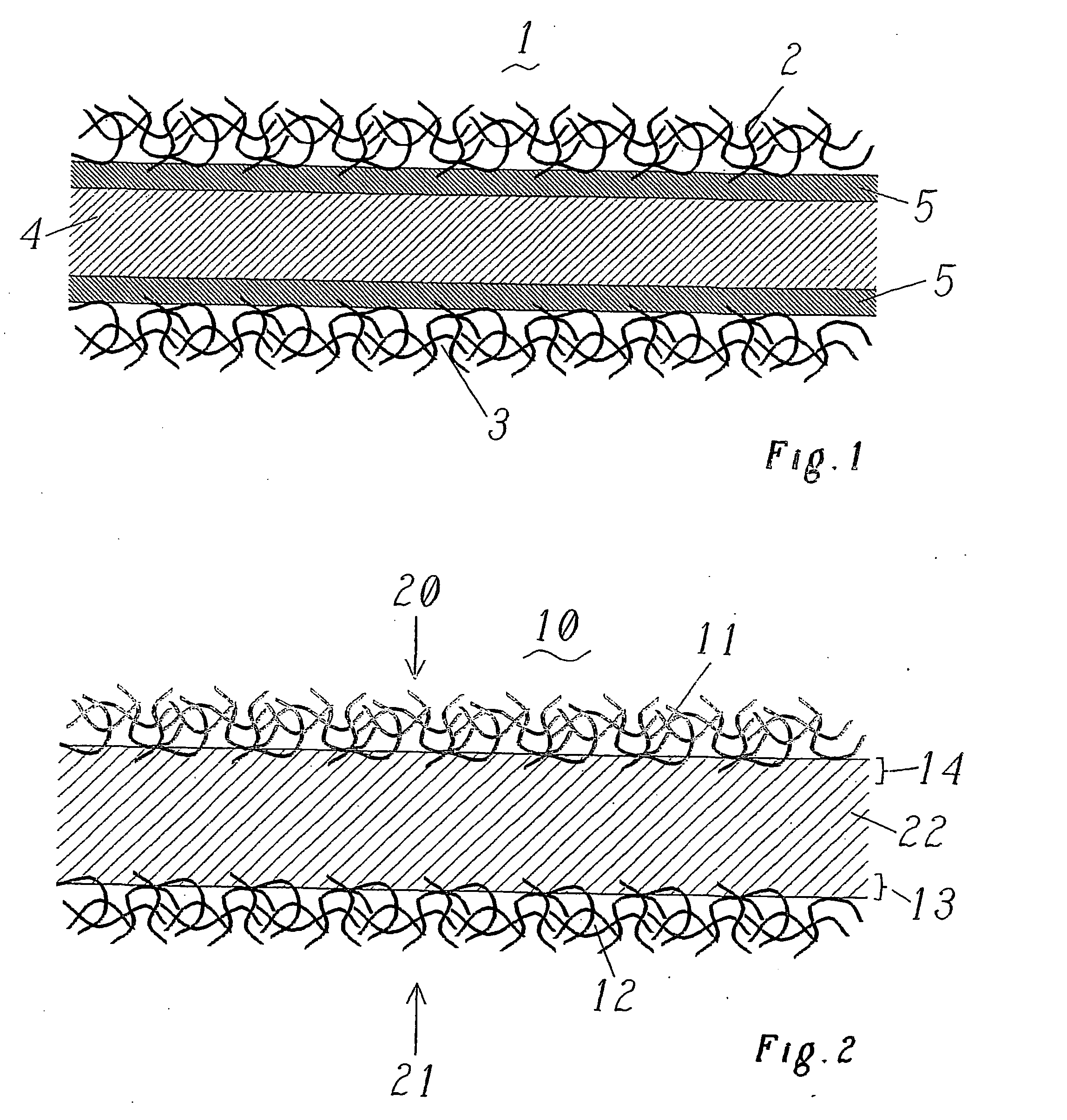

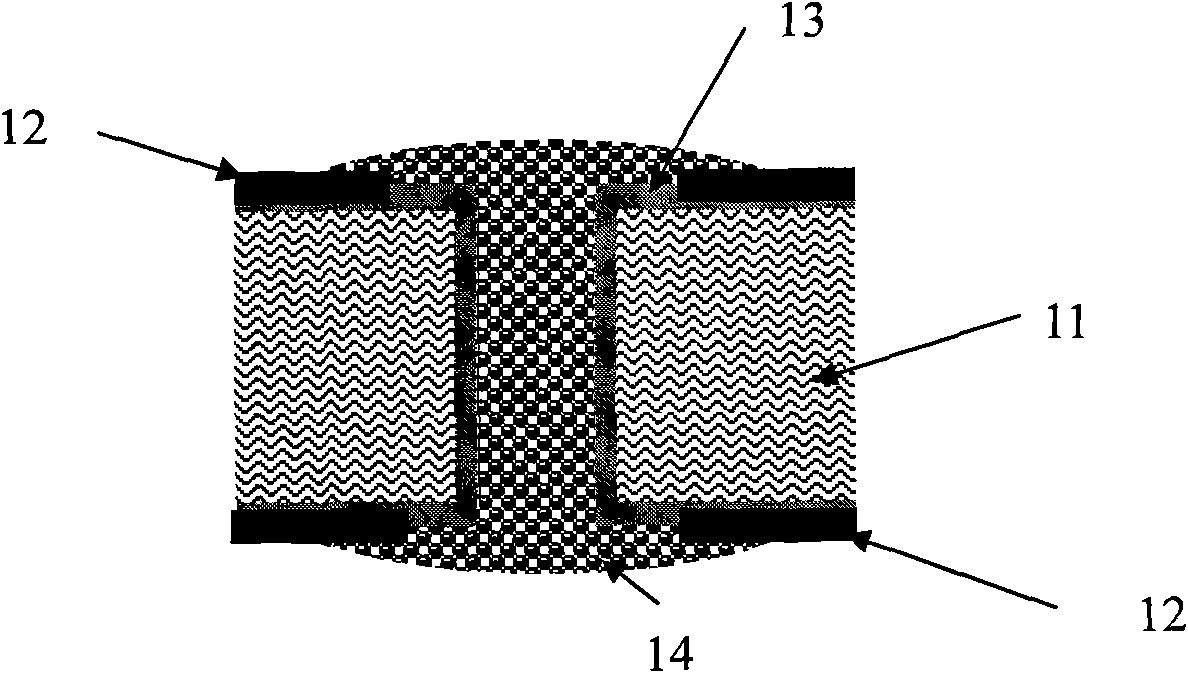

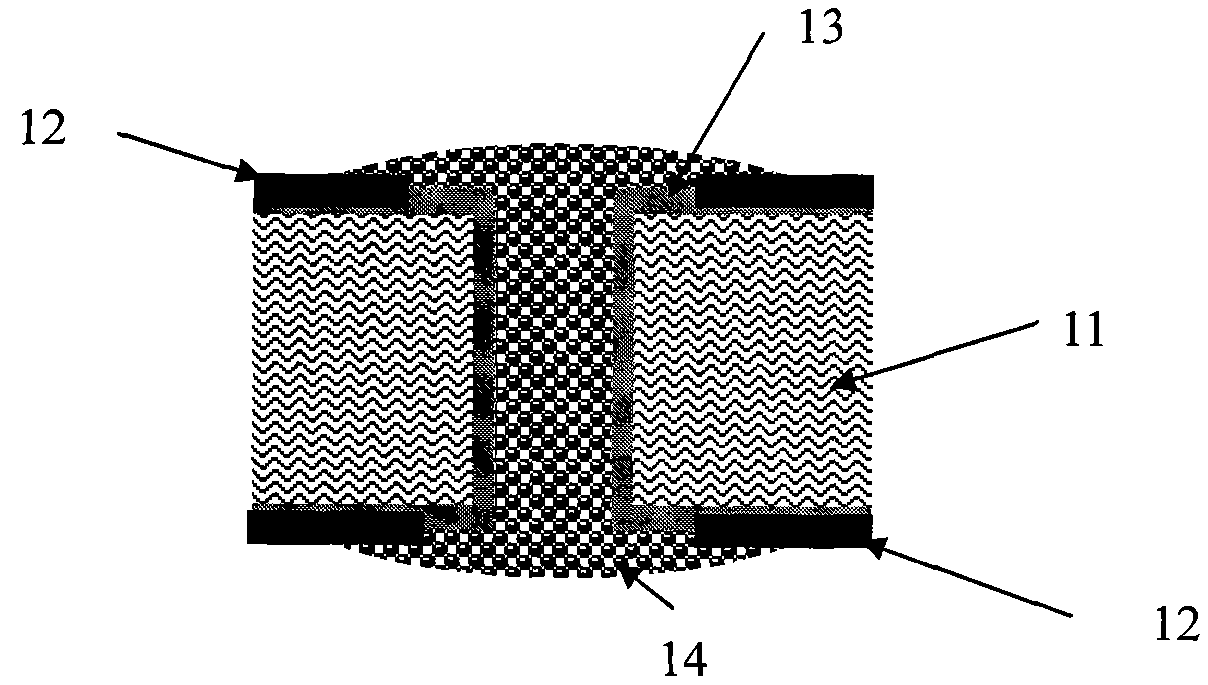

Multiple layer laminate

InactiveUS20060198987A1Stable and intimate bondComplicate adhesion of ink and inkSpecial paperSynthetic resin layered productsFiberMultiple layer

The invention relates to a multiple layer laminate such as a printing carrier, especially in the form of antifalsification paper such as bank notes. Said multiple layer laminate or more precisely the printing carrier comprises at least one plastic layer (22) having an upper side (20) and a lower side (21), an upper paper layer (11) which is connected to the upper side (20) of the plastic layer (22), and optionally a lower paper layer (12) which is connected to the lower side (21) of the plastic layer (22). The aim of the invention is to achieve an especially intimate connection between the individual layers, with simultaneously good printability and with similar haptic characteristics such as those of pure paper carriers. To this end, a thermoplastic polymer material is used as the plastic layer (22), and the connection between the paper layers (11, 12) and the plastic layer (22) is ensured, essentially without additional bonding agents, by means of penetration regions (13, 14) in which parts of the plastic layer (22) are melted with the mass of fibre composite of the paper layers (11, 12). To this end, the penetration regions (13, 14) essentially do not extend to the surfaces of the paper layers opposing the plastic layer (22).

Owner:LANDQUART +1

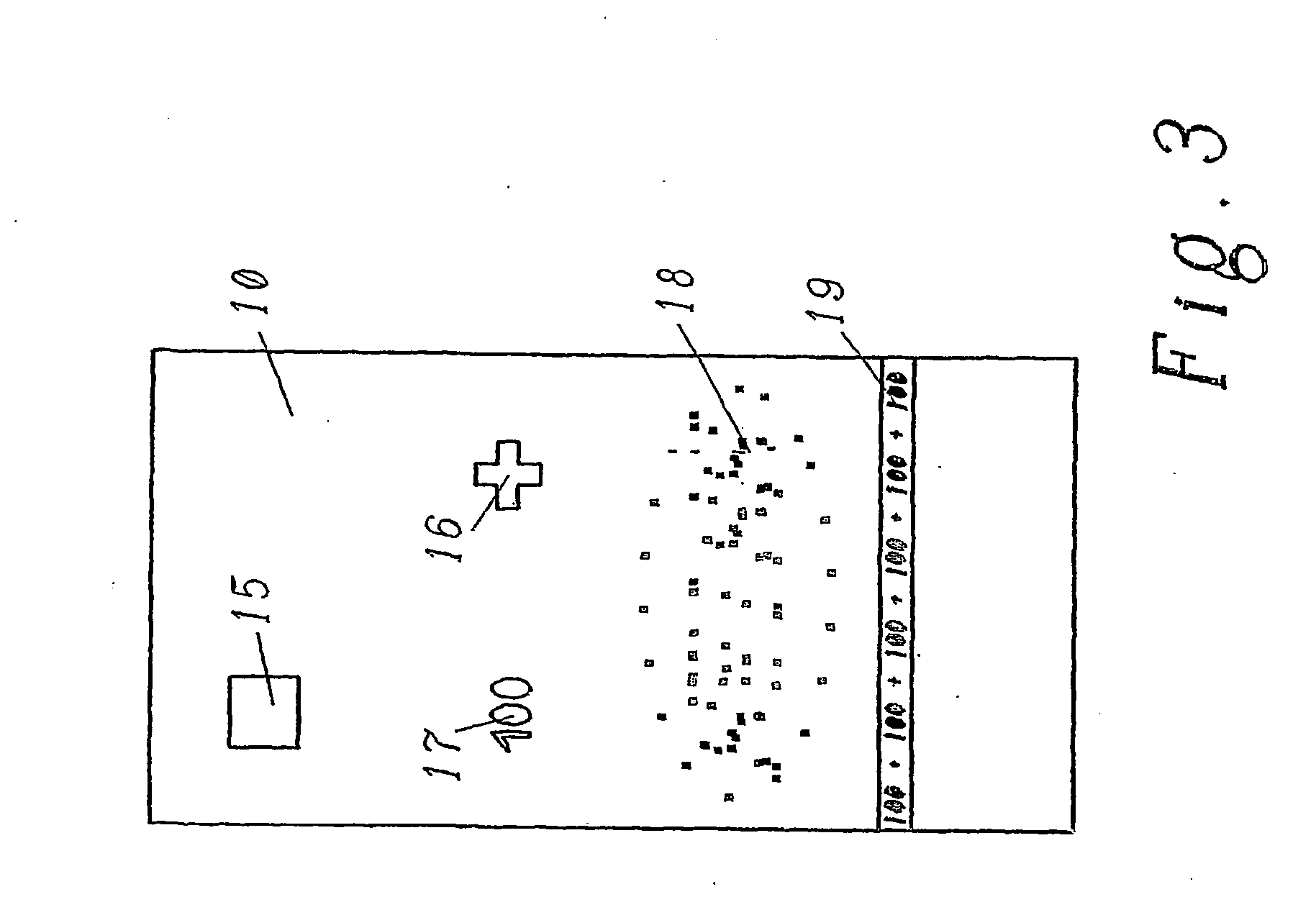

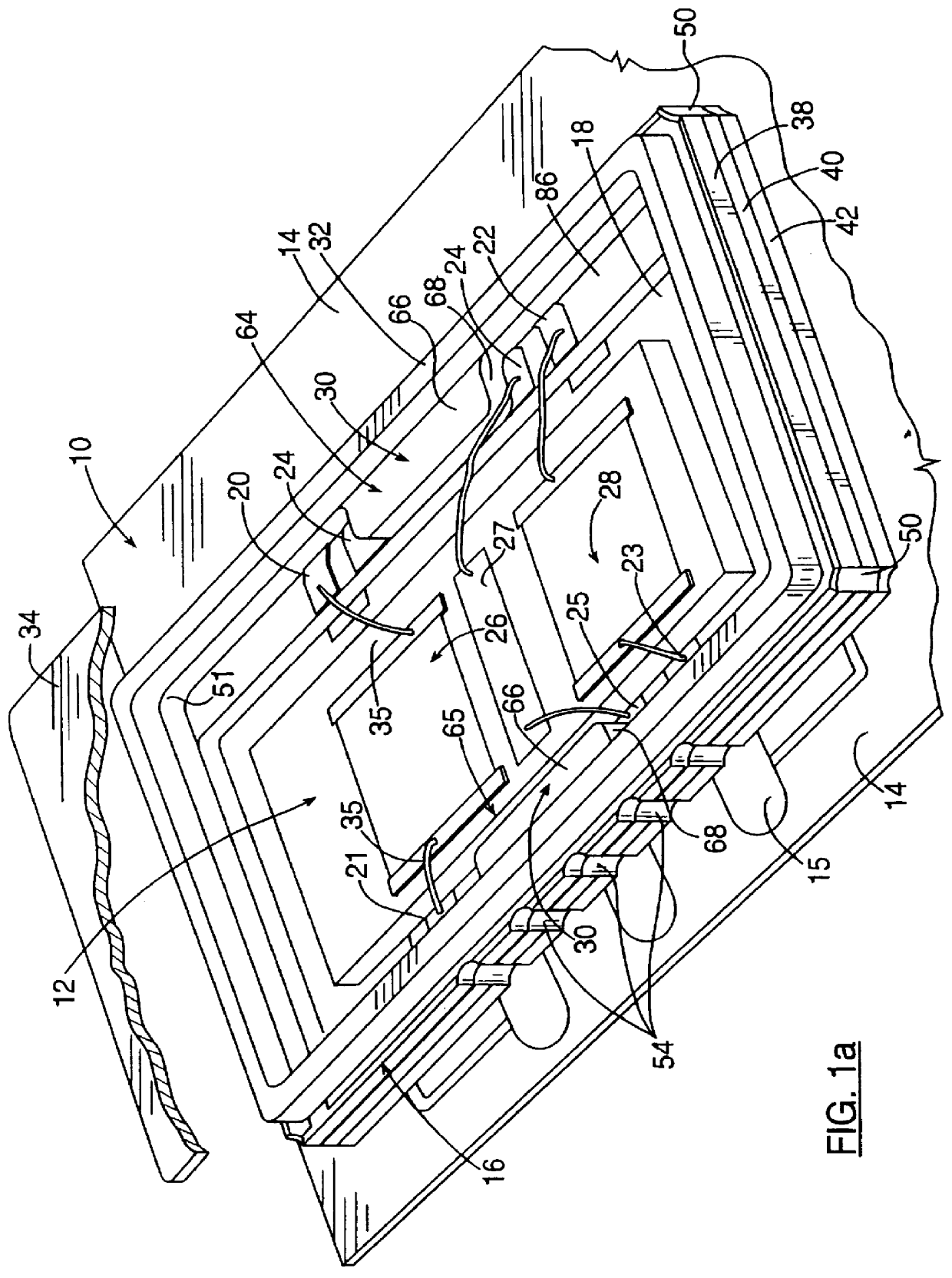

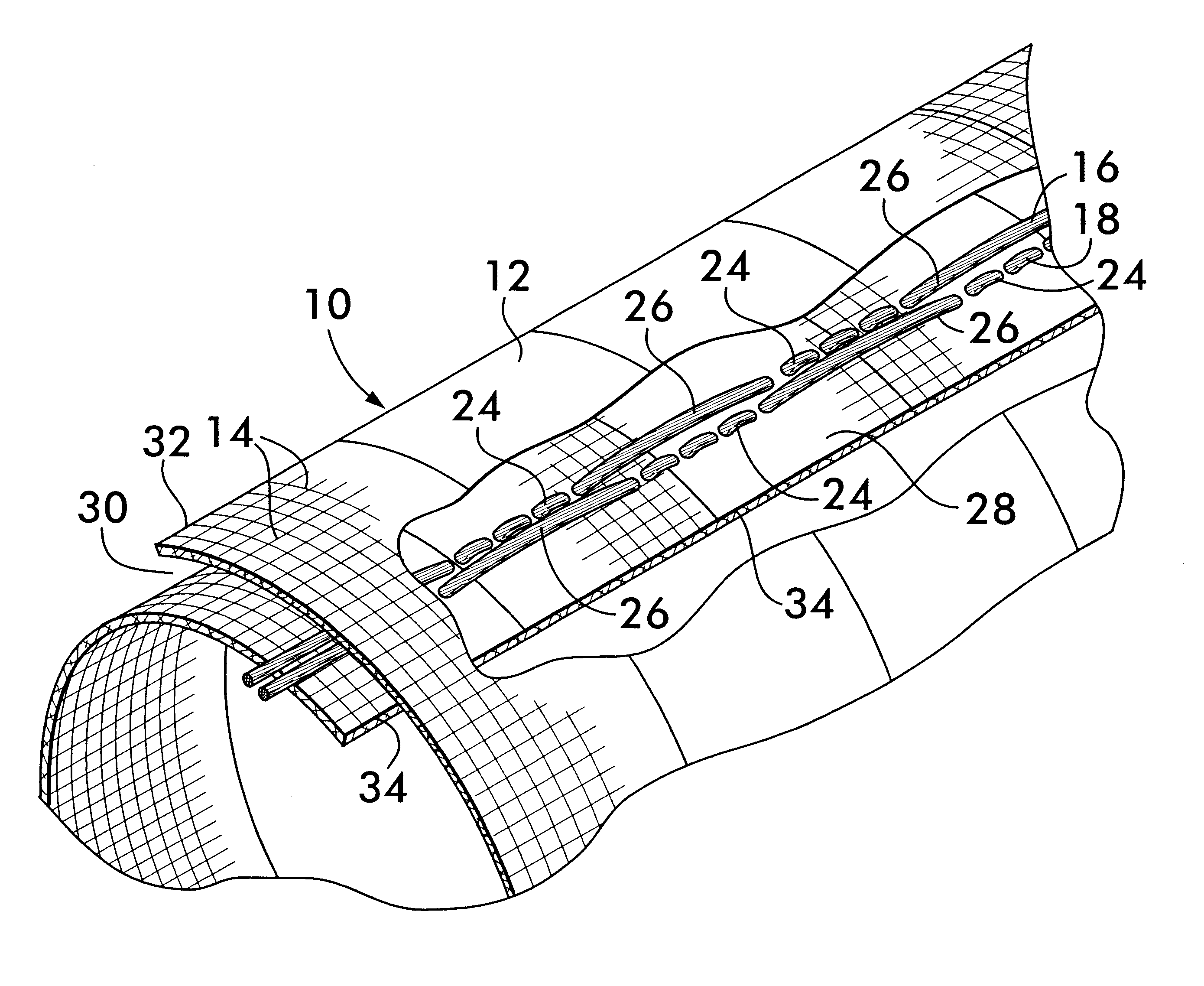

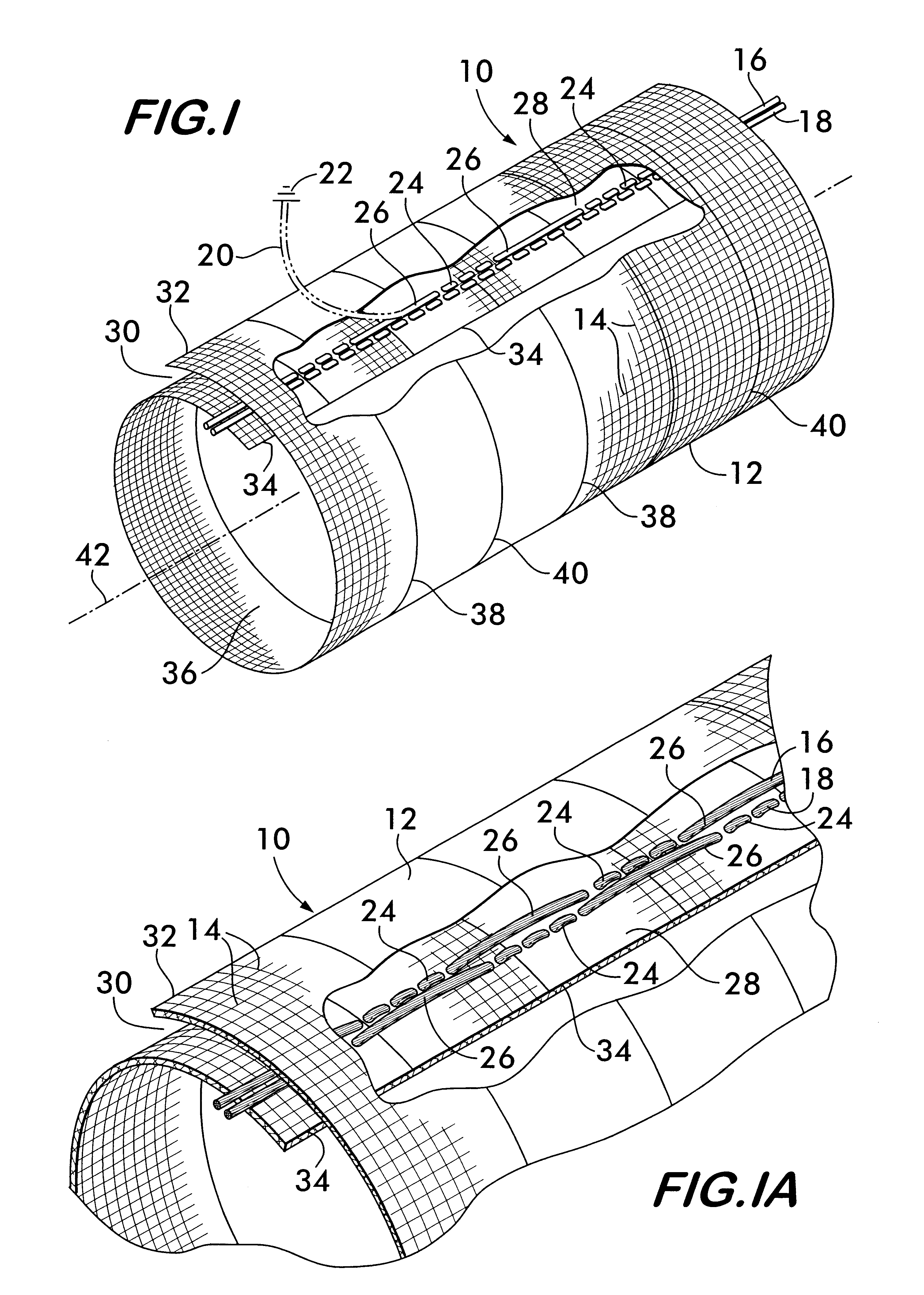

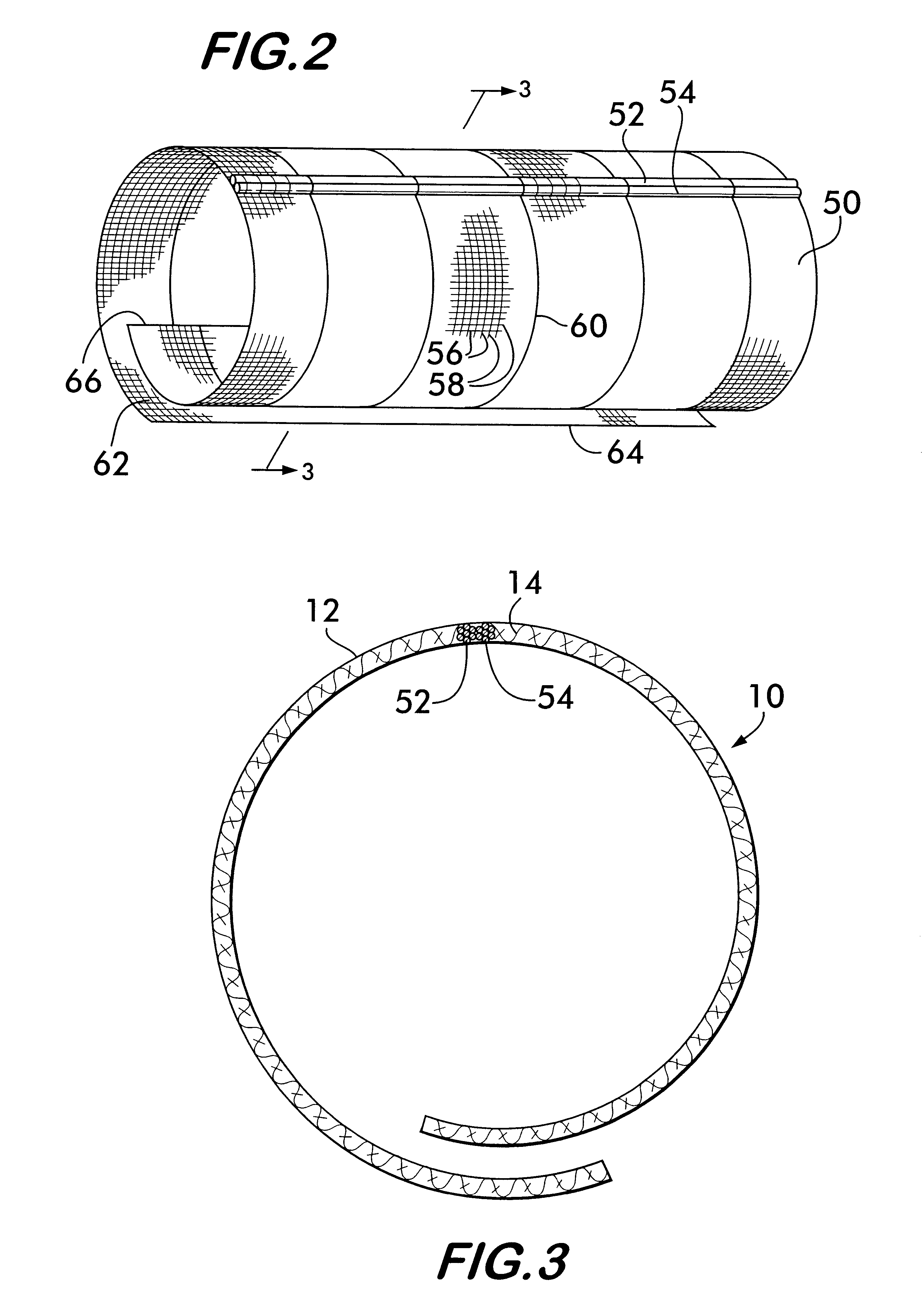

Extendible drain members for grounding RFI/EMI shielding

InactiveUS20020195260A1Easily groundableEasy to GrindElectrically conductive connectionsOrnamental textile articlesEngineeringMechanical engineering

Owner:FEDERAL MOGUL SYST PROTECTION GRP INC

Connector having electrical continuity about an inner dielectric and method of use thereof

InactiveUS8167646B1Improve reliabilityEasy to completeLine/current collector detailsElectrically conductive connectionsElectricityDielectric

A connector having a conductive member is provided, wherein the conductive member electrically couples a dielectric and a post, thereby establishing electrical continuity about an inner dielectric throughout the connector. Furthermore, the conductive member facilitates grounding through the connector, and renders an electromagnetic shield preventing ingress of unwanted environmental noise.

Owner:PPC BROADBAND INC

Connector having conductive member and method of use thereof

ActiveUS20090176396A1Improve reliabilityEasy to GrindElectrically conductive connectionsCouplings bases/casesEnvironmental noiseCoaxial cable

A connector having a conductive member is provided, wherein the connector comprises a connector body capable of sealing and securing a coaxial cable, and further wherein the conductive member, such as an O-ring, physically seals the connector, electrically couples the connector and the coaxial cable, facilitates grounding through the connector, and renders an electromagnetic shield preventing ingress of unwanted environmental noise.

Owner:PPC BROADBAND INC

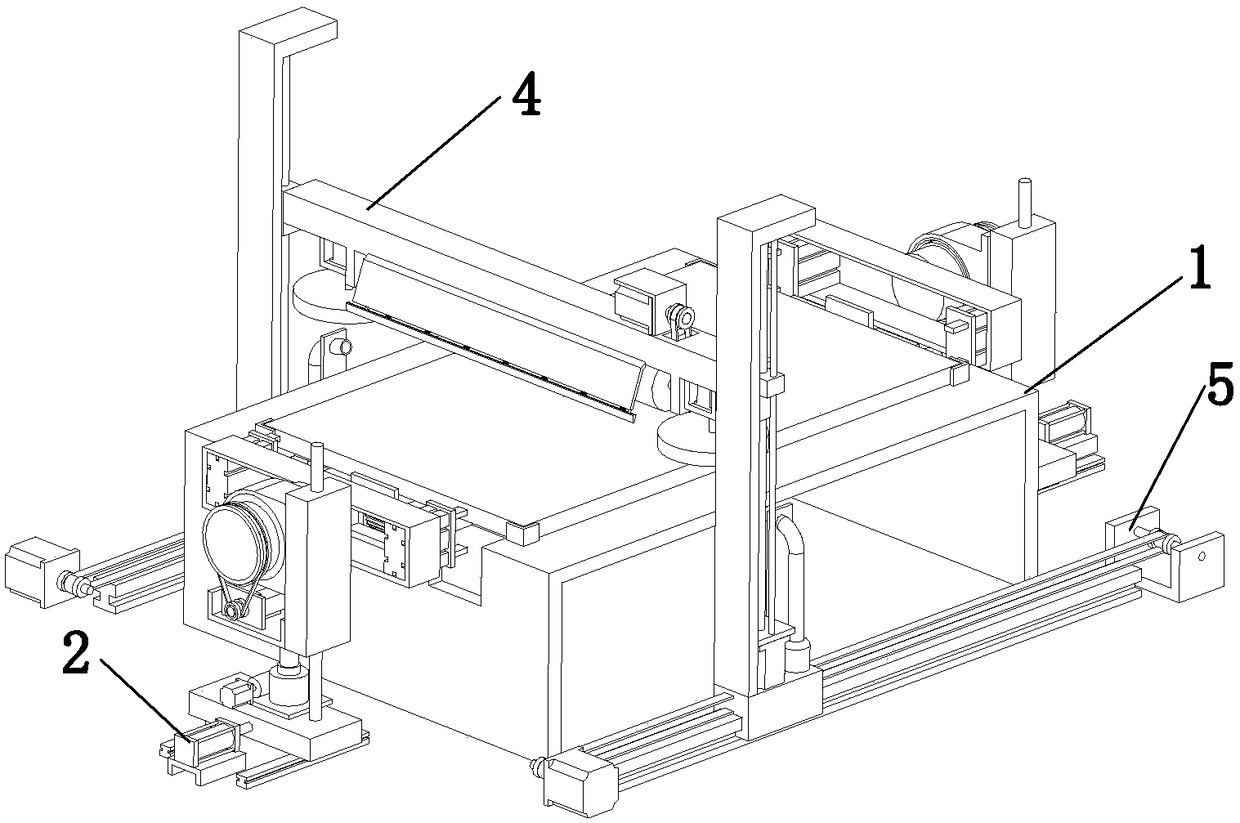

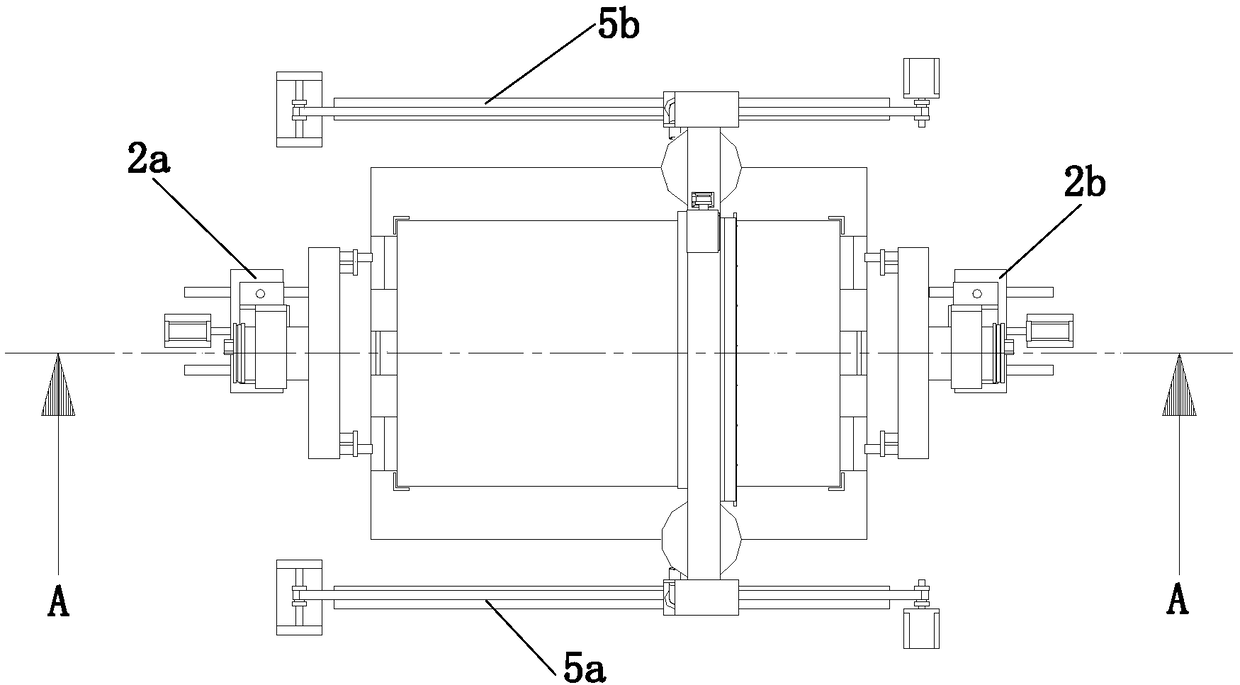

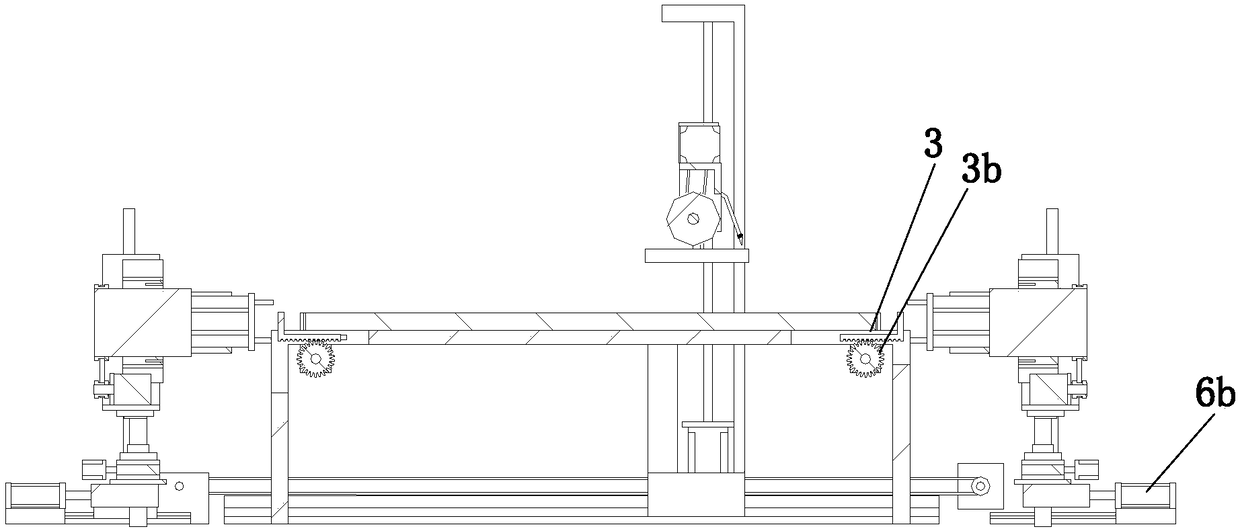

Grinding device for wooden door manufacturing

InactiveCN108581773AReduce labor intensityAvoid scrappingEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

The invention provides a grinding device for wooden door manufacturing. The grinding device for wooden door manufacturing comprises a bracket, an overturning assembly, a limiting assembly, a grindingassembly and a material moving assembly used for driving the grinding assembly to move horizontally. The bracket comprises a left side plate, a right side plate and a top plate of a cuboid structure.The material moving assembly comprises a first feed assembly and a second feed assembly. The overturning assembly comprises a first material overturning assembly and a second material overturning assembly. The first material overturning assembly and the second material overturning assembly are of the same structure and each comprise a rotary tube, a clamping assembly located the end, close to thetop plate, of the rotary tube and a rotating assembly used for driving the rotary tube to rotate in the axial direction of the rotary tube. The grinding device has the beneficial effects that workpieces can be turned over through the overturning assembly and can be limited through the limiting assembly, and the situation that the workpieces are scrapped due to not being limited; the surface and the two sides of each workpiece can be ground through the grinding assembly, and the grinding device can also conduct processing on wood bits produced during grinding.

Owner:SHENZHEN DAVINCI INNOVATION TECH CO LTD

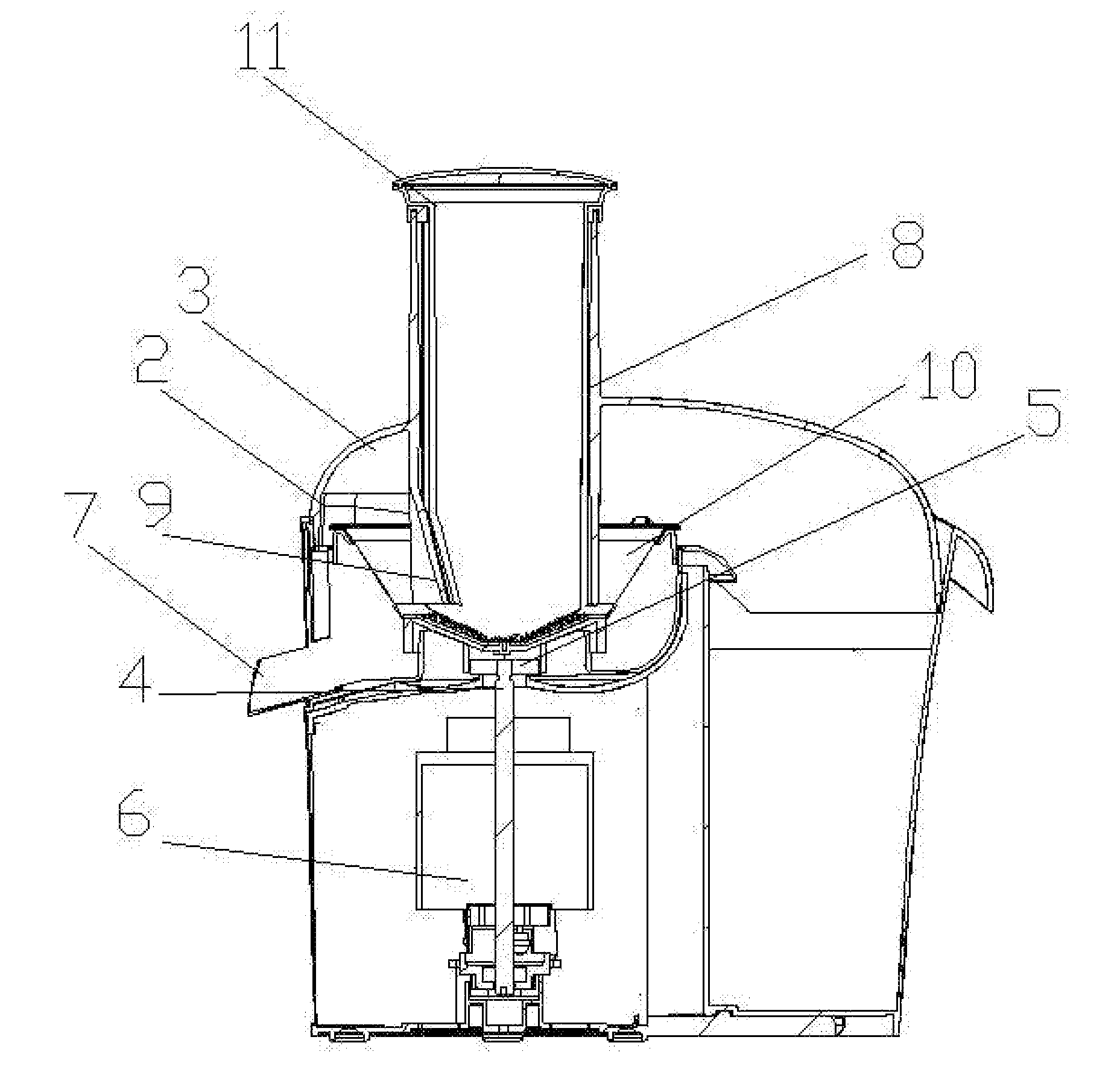

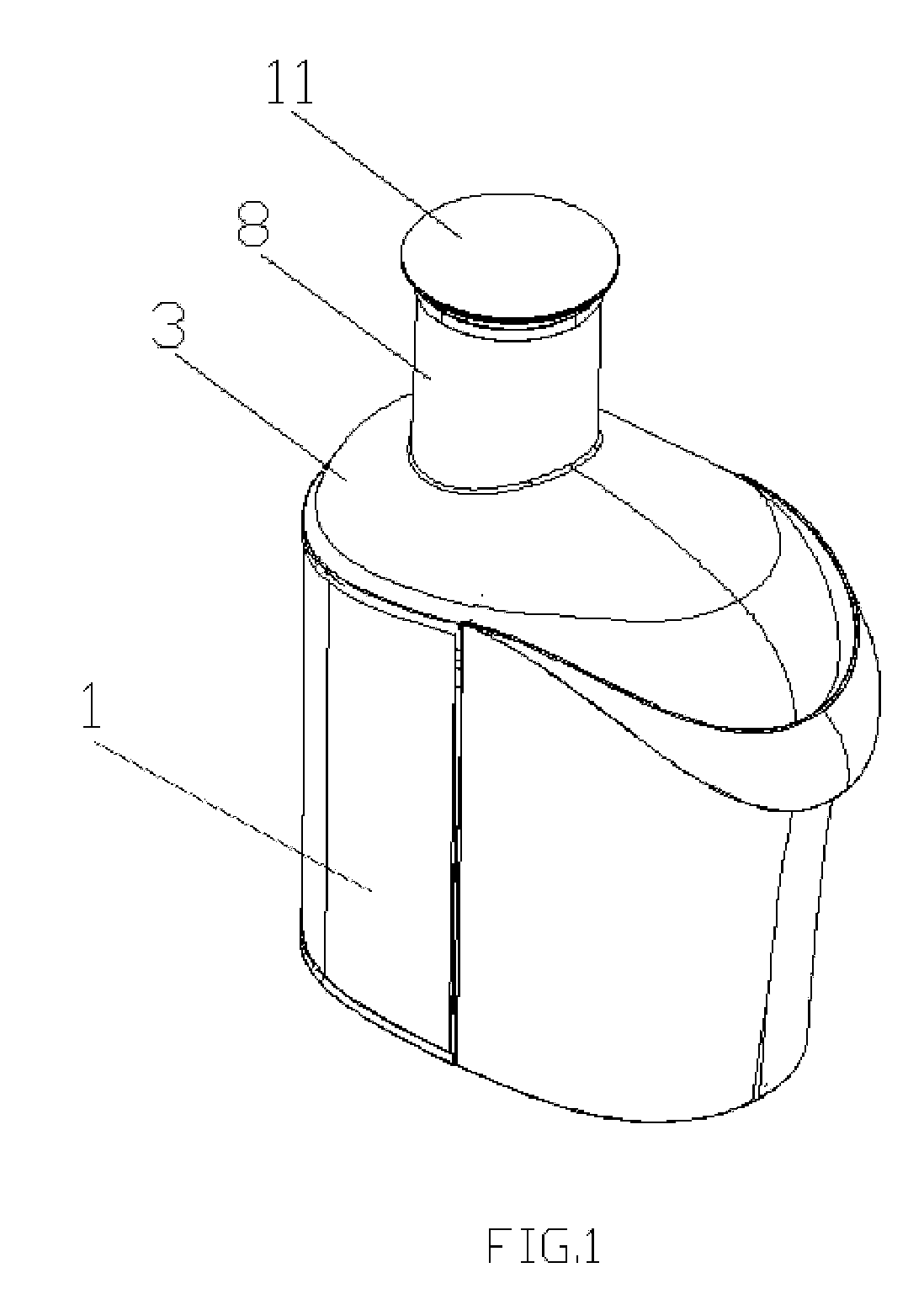

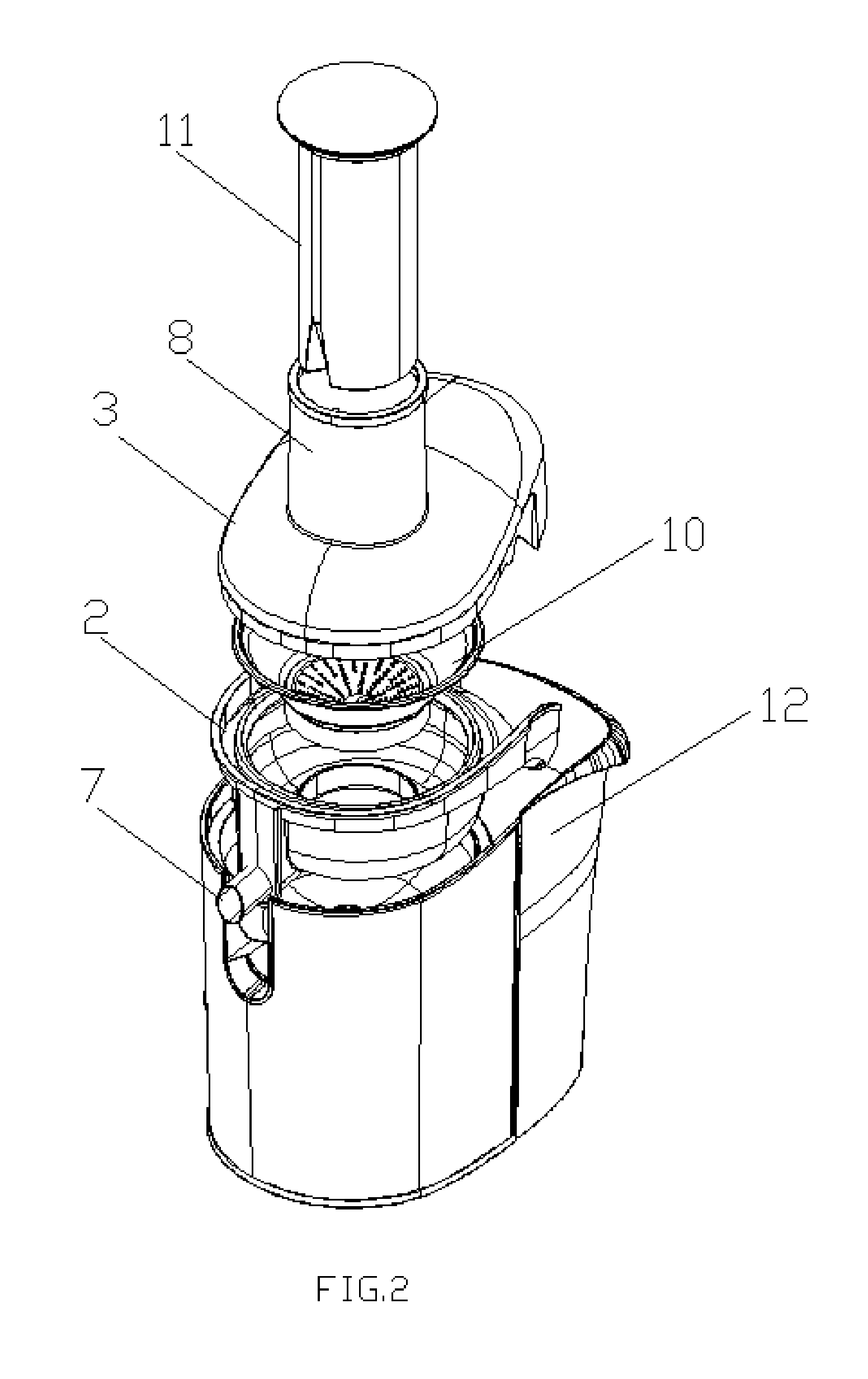

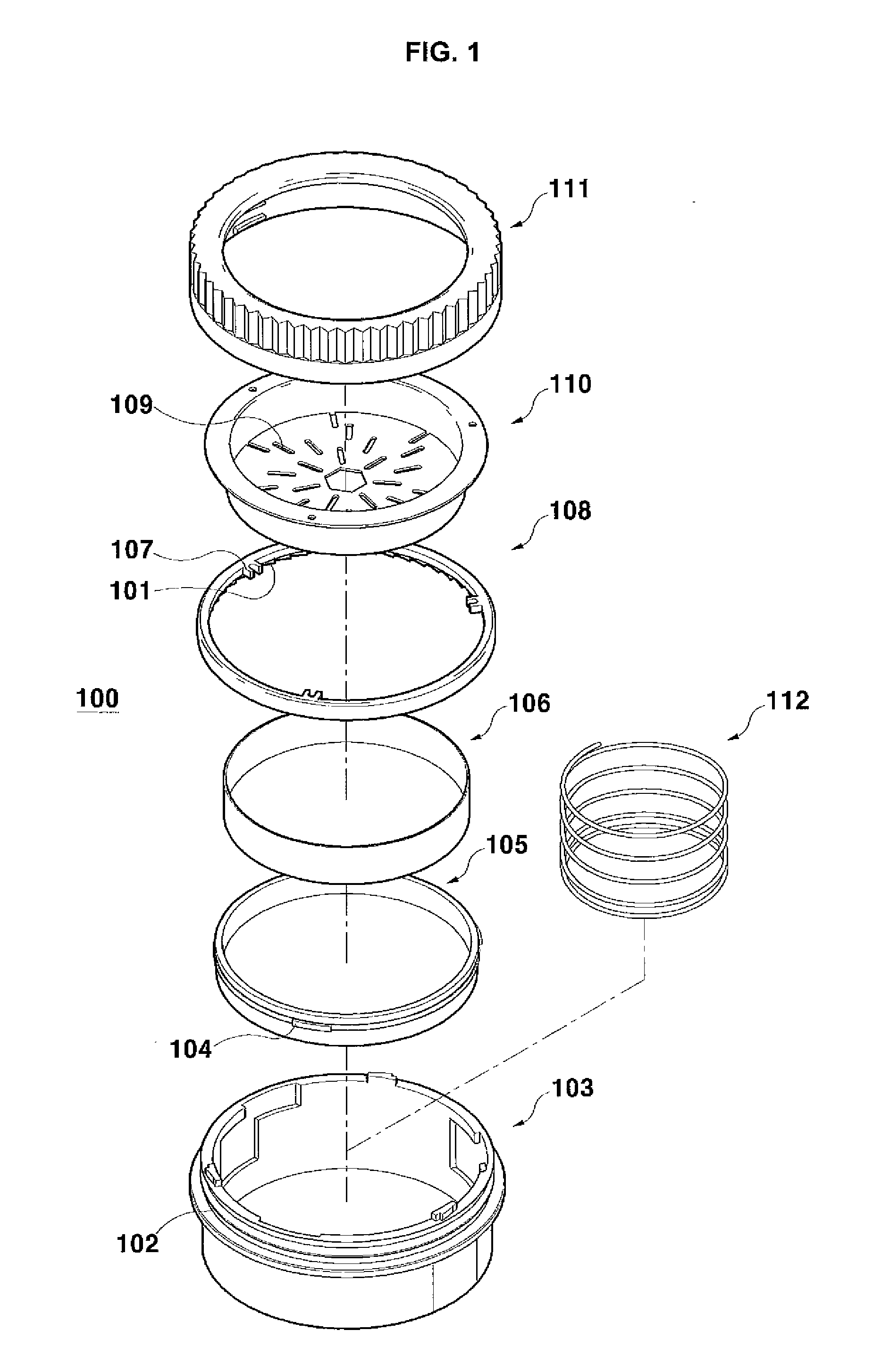

Juicer

ActiveUS20090272280A1Excessive noiseExcessive vibrationJuice extractionCentrifugesGastric tube feedingFeeding tube

There is provided a juicer for extracting juice from fruits and vegetables comprising a lower base, an upper base, a top cover with a hollow cylindrical feeding tube, a grating-disk and mesh filter assembly, a pulp collector, and a pusher. The upper base is mounted on a lower base and receives the grating-disk and mesh filter assembly. The grating disk is a concave shape and tooth-like cutters are arranged into rows on an inclined surface of the grating disk. The top cover is fitted on the upper base and houses a hollow cylindrical feeding tube. Inside the feeding tube is an anti-rotation protrusion, located at the bottom of the feeding tube made an integral part of the feeding tube to prevent the food from spinning inside the tube. The pusher is inserted into the feeding tube and contains a opening that matches the anti-rotation protrusion and into which rests the anti-rotation protrusion. The bottom of the pusher is convex-shaped and matches the concave grating disk. The pusher forces the fruit or vegetable through the bore of the feeding tube onto the grating disk.

Owner:HUIYANG ALLAN PLASTIC & ELECTRIC INDS

Leadless ceramic chip carrier crosstalk suppression method

InactiveUS6105226AReduce electromagnetic signal effectReduce crosstalkPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblySurface mountingElectrical connection

A leadless ceramic chip carrier useful in surface mounting of SAW devices includes electrically conductive vias and metalization between input and output bond pads for improved crosstalk suppression between input and output device connections. A protrusion extending from a top layer of a multilayer ceramic carrier provides additional electrical contact to a package seal brazed thereto. The vias are positioned between input and output bond pads and connect the metalized protrusion to package ground pads through contact with multiple metalized layers of the package for enhancing the electrical connection between the package Kovar seal ring and customer accessed ground pads. For further suppression of crosstalk, bond pads within the package for connection to the SAW device are spaced at a greater distance from each other than their corresponding pads on the package bottom surface thus maintaining an optimum spacing for package connection to printed circuit board pads for minimizing thermal mismatch effects.

Owner:TRIQUINT

Process for biomass conversion

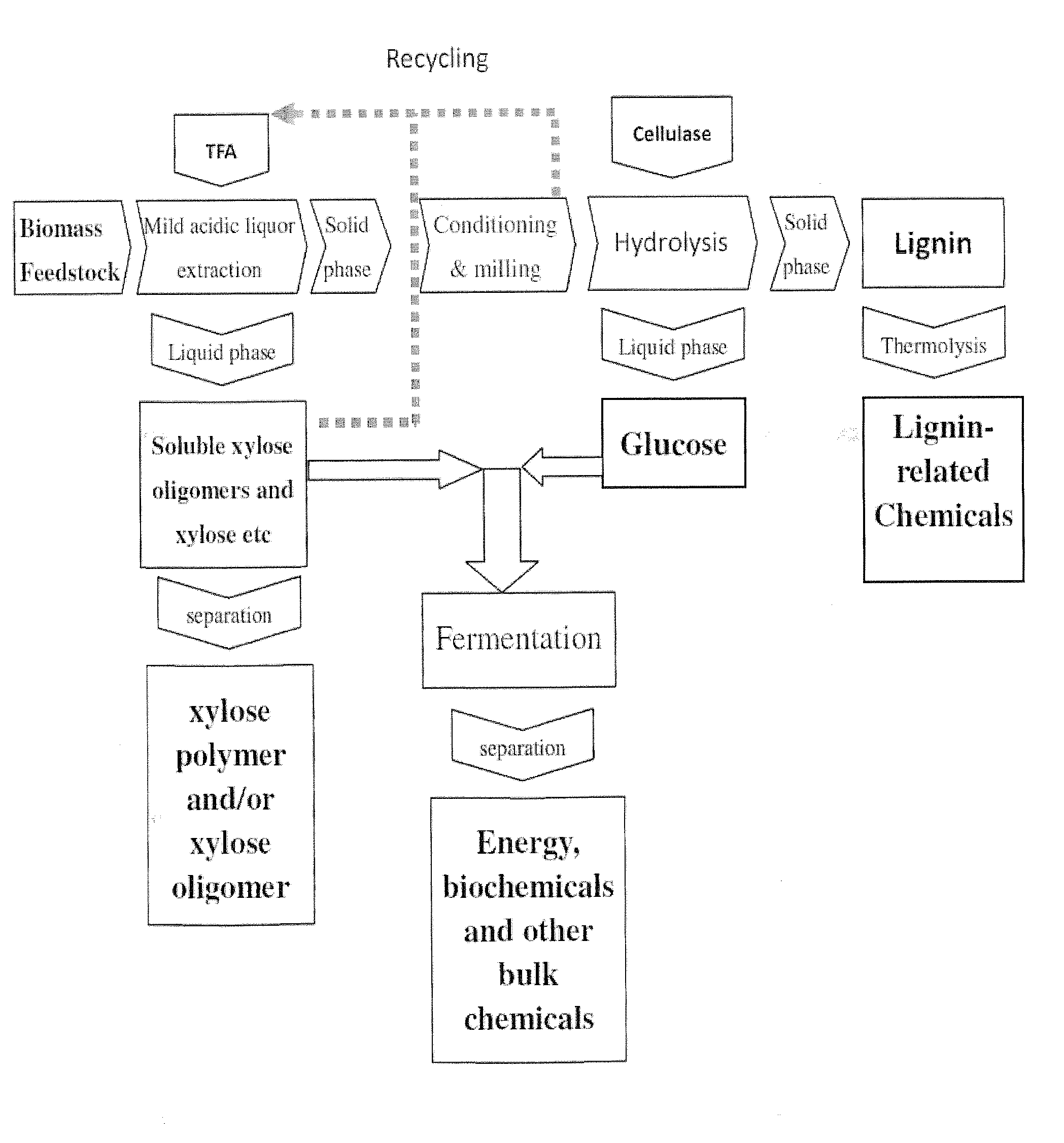

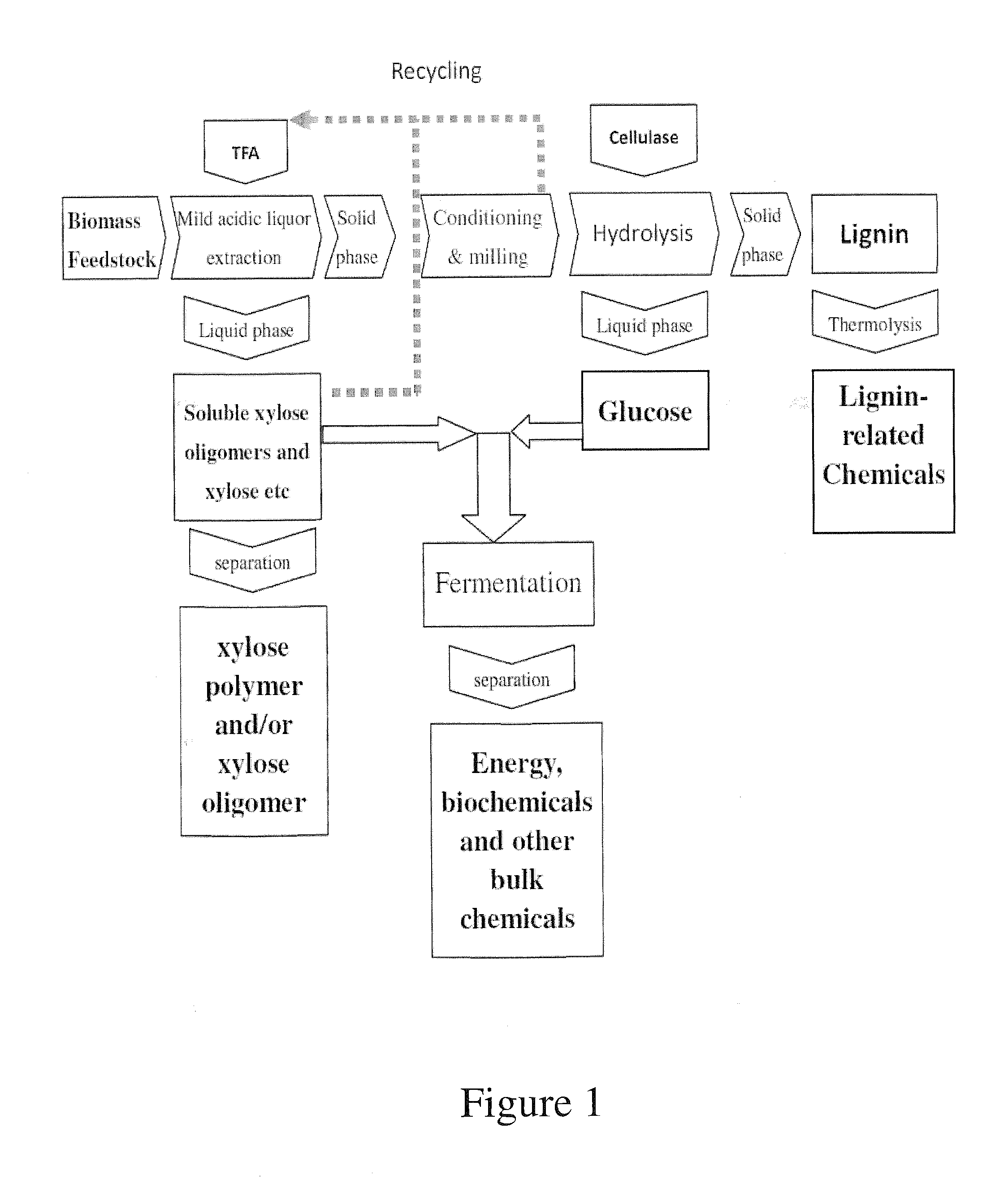

InactiveUS20100297704A1Easy to GrindIncrease ratingsSugar productsPretreatment with acid reacting compoundsPolymer scienceEnergy products

The present invention relates to a clean process of preparing high grade biomass products, and their use in the production of health care products, bio-energy products, biochemicals, bio-originated chemicals and biodegradable plastics.

Owner:LI RONGXIU

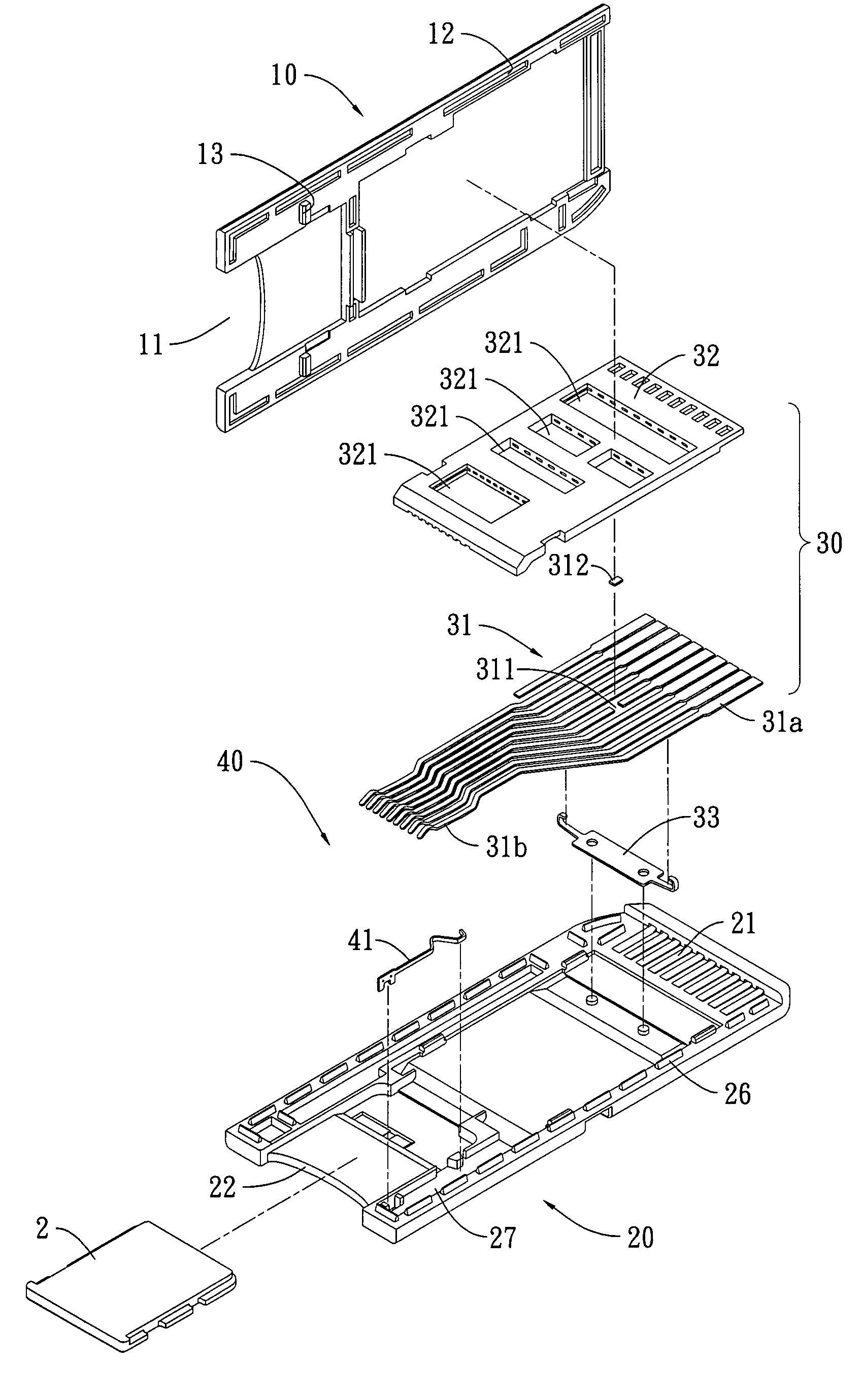

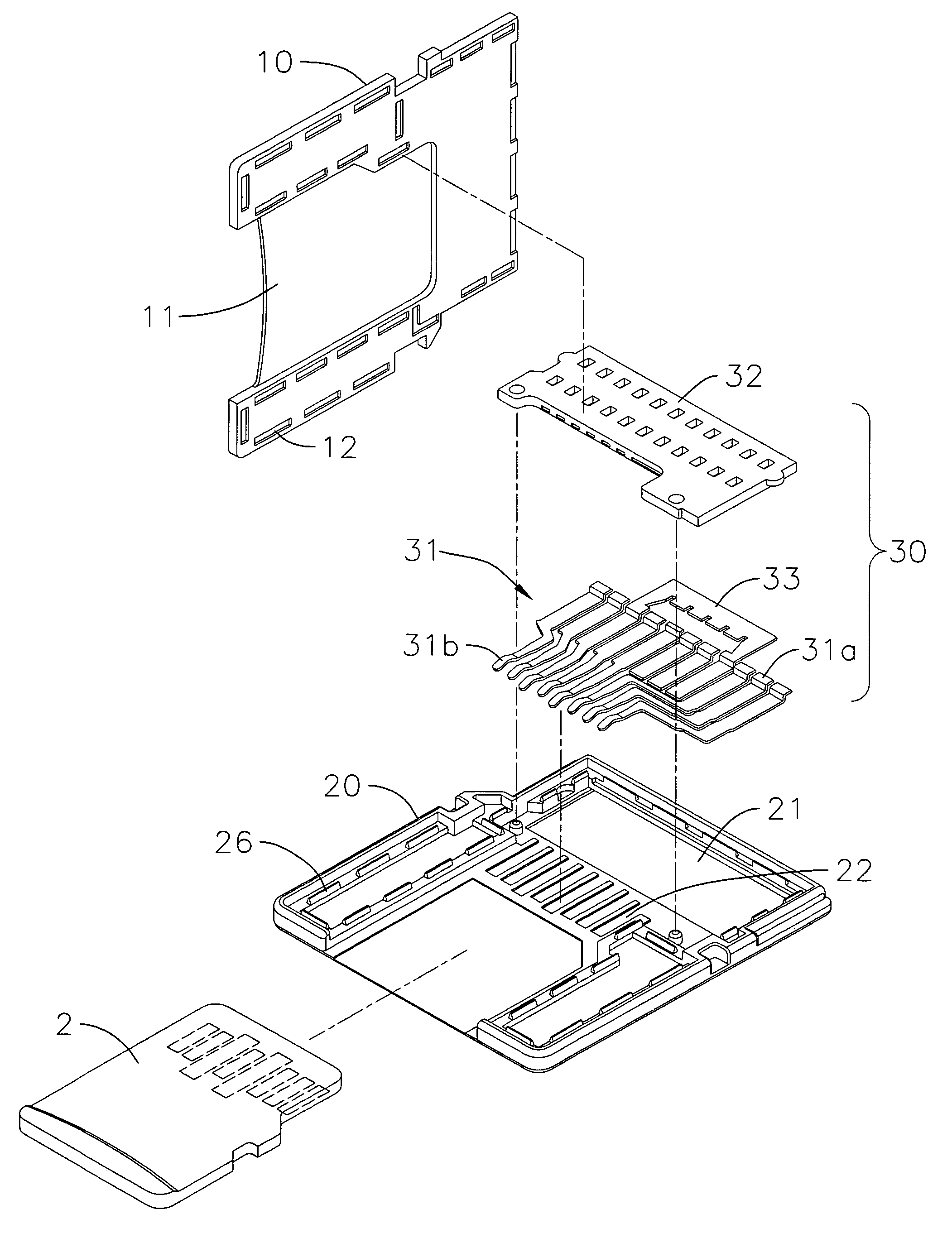

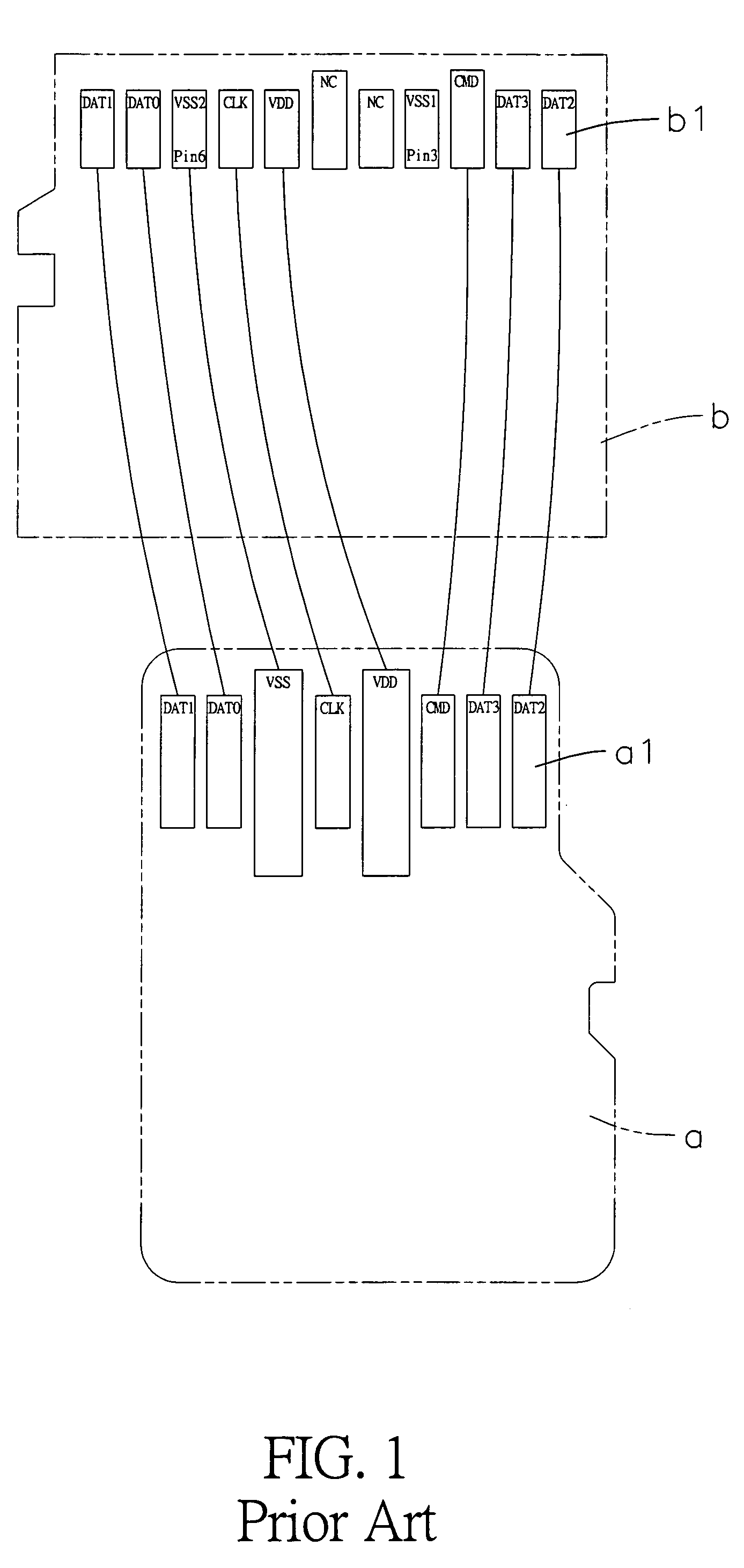

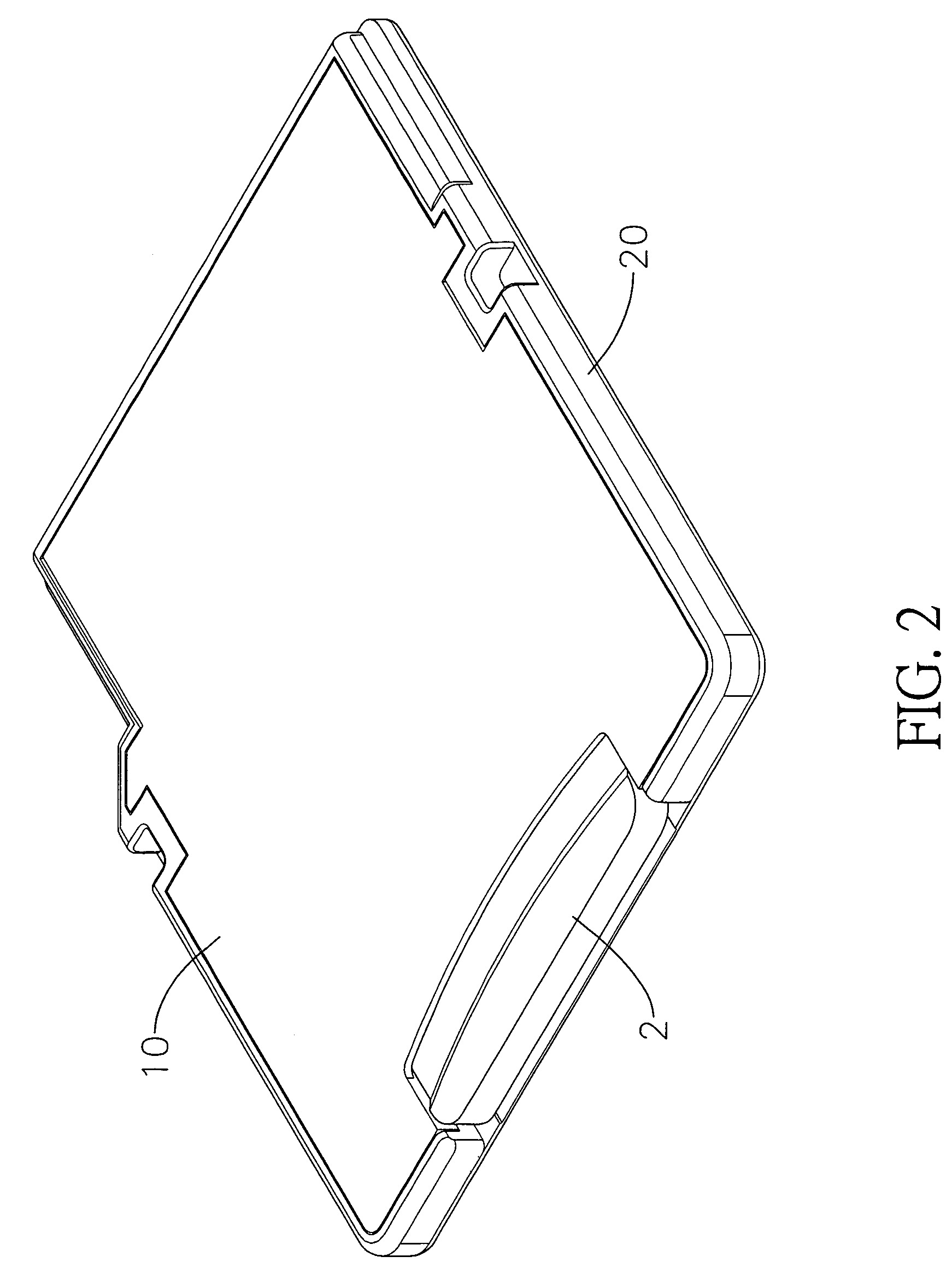

Card adapter structure

InactiveUS7326086B1Increasing practicability and convenienceSimple structureTwo-part coupling devicesRecord carriers used with machinesElectrical resistance and conductanceEngineering

The present invention provides an improved card adapter structure that includes an upper cover, a lower cover, a converter terminal set and a positioning elastic strip set. The upper cover has a structure designed to conform to short memory card (MS) specifications, wherein an insertion slot is defined at the rear of the upper cover corresponding to the shape of a micro memory card (M2). The lower cover has a fixing portions and a positioning structure corresponding to those of the upper cover. Moreover, at least one terminal of the No. four, six, seven and eight terminals of the converter terminal set is configured with a gap that is joined to an electric resistance. The positioning elastic strip set is correspondingly located between both covers. Accordingly, the present invention is able to convert a micro memory card into a short memory card of relatively larger size.

Owner:LEE YUN HSIU

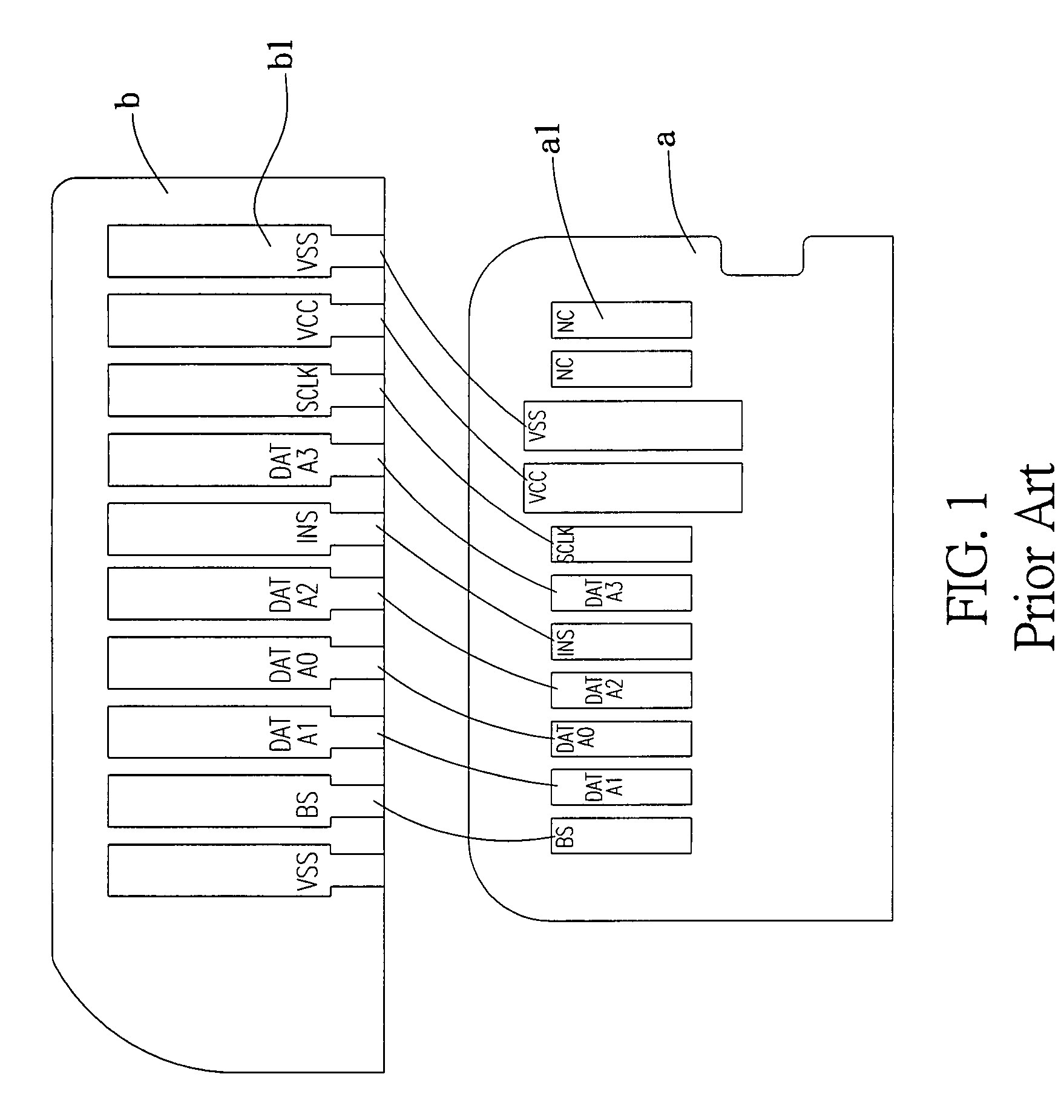

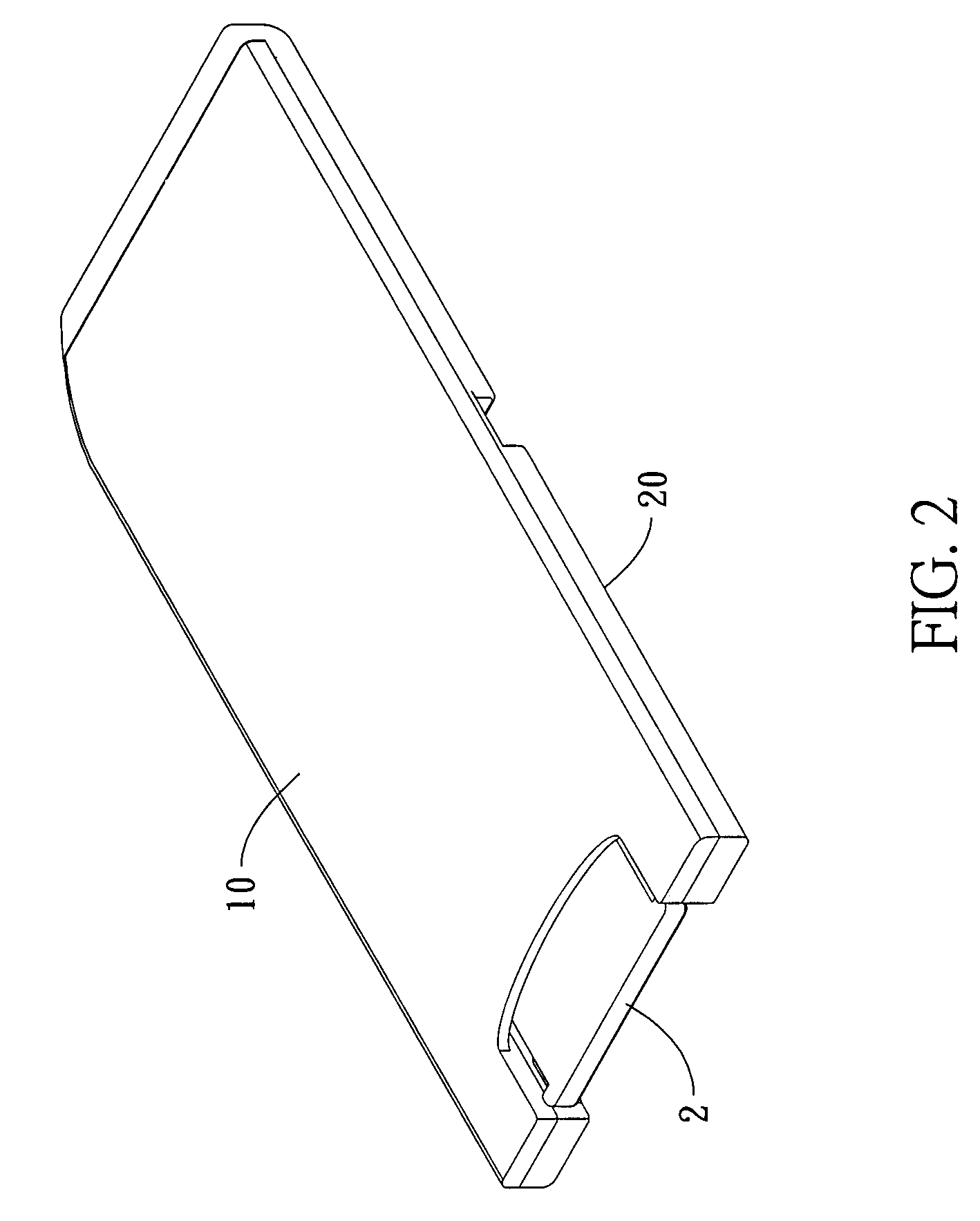

Card adapter structure

InactiveUS7371119B1Large and stable grounding areaAvoid signalingTwo-part coupling devicesSensing record carriersEngineeringMemory cards

The present invention provides an improved card adapter structure which includes an upper cover, a lower cover and a converter terminal set. The upper cover is designed to conform to short memory card specifications, wherein an insertion slot is defined at the rear of the upper cover corresponding to the shape of a micro memory card. A port is configured in a central portion of the lower cover to accommodate a micro memory card. The converter terminal set is configured with eleven terminals, wherein an injection molded fixing mount fixedly covers each pin of the converter terminal set, and eleven pins extend outward towards a short memory card opening. Pin three and pin six are jointly configured with a large grounding area, and eight pins extend outward towards the micro memory card port. Accordingly, the adapter structure conveniently converts a micro memory card into a short memory card.

Owner:LEE YUN HSIU

Manufacturing process for plugging conductive holes of circuit board with resin

InactiveCN101854778AImprove efficiencyLow costPrinted element electric connection formationEngineeringElectroplating

The invention discloses a manufacturing process for plugging conductive holes of a circuit board with resin, which comprises the following steps: A) carrying out plated through hole and electroplating treatment on a circuit board substrate which is provided with conductive holes; B) carrying out windowing treatment on conductive holes of the circuit board substrate which is electroplated, and adhering a dry film to transfer the printed picture; C) electroplating the conductive holes of the circuit board which is provided with the dry film; D) filling resin into the conductive holes so as to plug the conductive holes, and baking the circuit board at low temperature after the conductive holes are plugged; E) removing the remained resin through polishing way; F) removing the film of the circuit board after being polished; and G) and baking the circuit board at high temperature after the film is removed. The process not only can solve the problem that the air bubbles are easy to produce by directly filling ink or other anti-corrosion materials, but also greatly reduces the polishing difficulty; and during the hole plugging process of the conductive holes of the circuit board, the circuit board is only required to be polished for one time, so not only the efficiency is improved, but also the cost is reduced.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

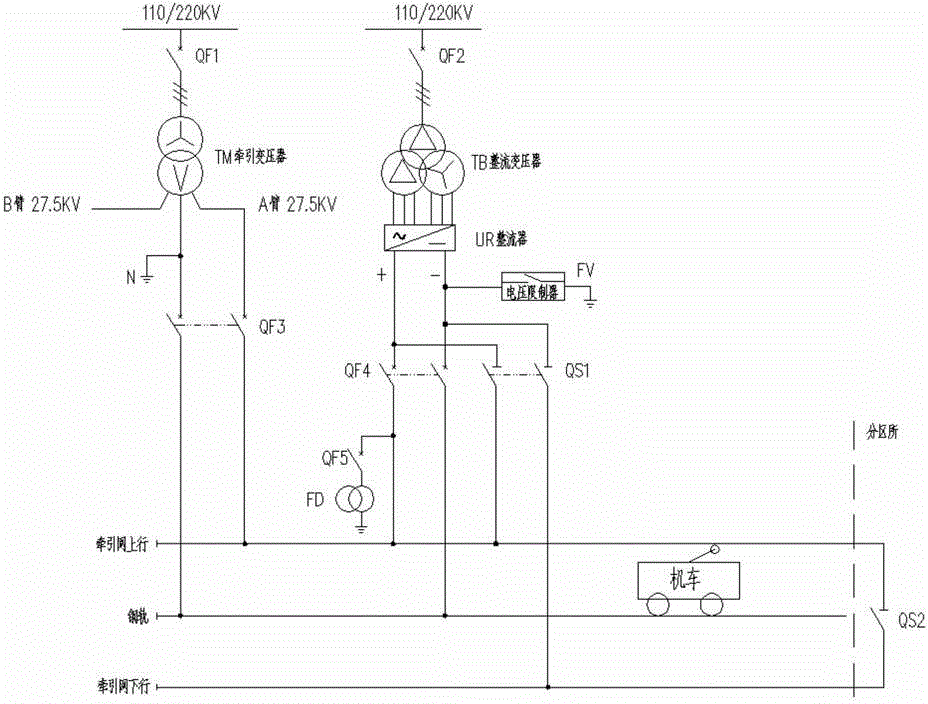

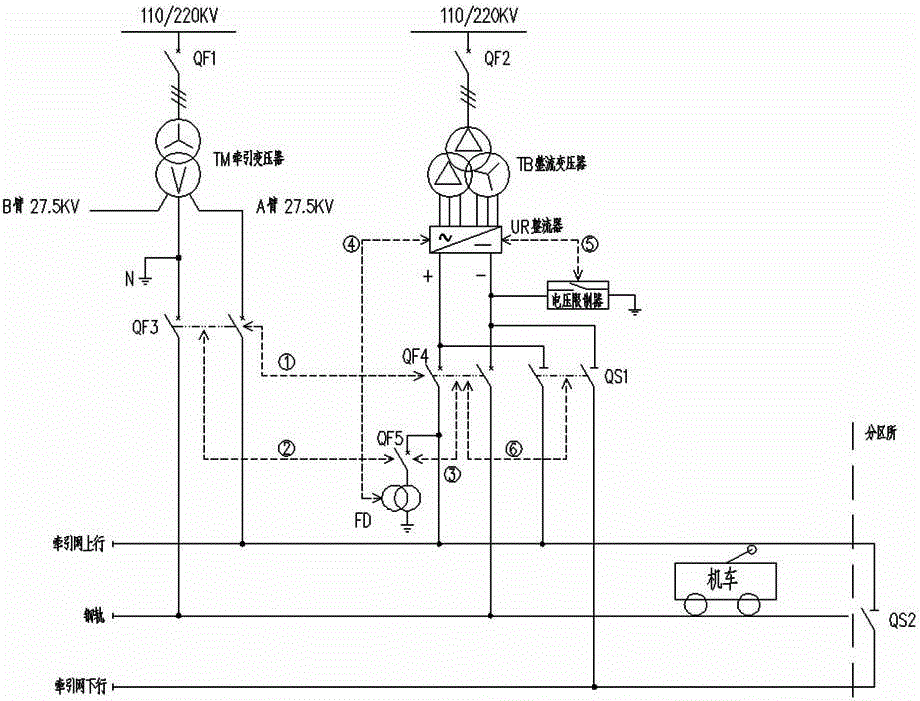

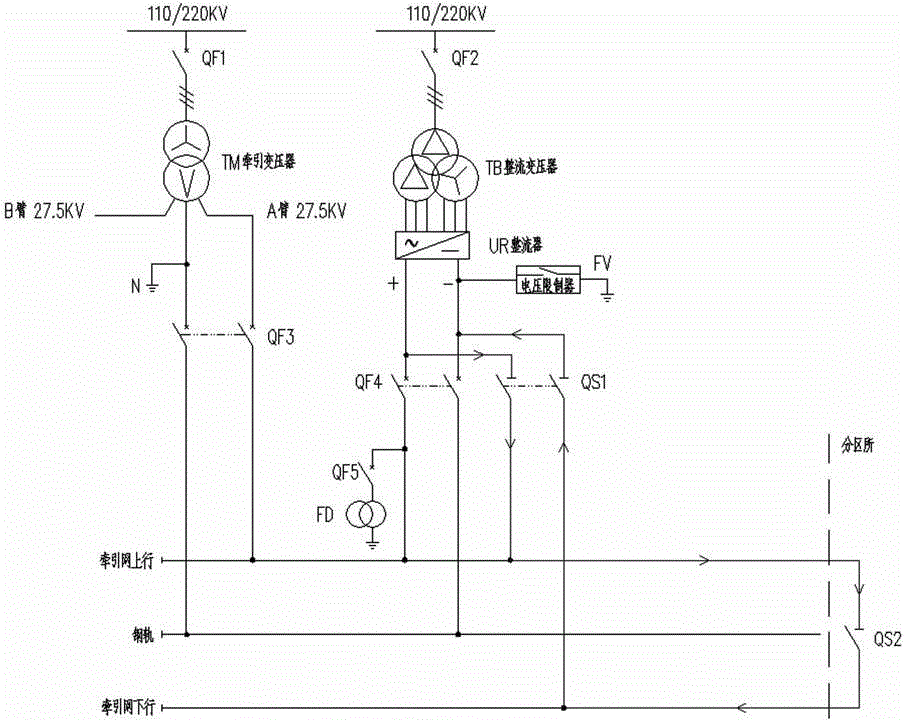

Alternating current and direct current mixed traction power supply system with ice melting function

ActiveCN103950394AWill not interfere with each otherSwitching is clear and easyOverhead installationThyristorAC - Alternating currentEngineering

The invention relates to an alternating current and direct current mixed traction power supply system with an ice melting function. The alternating current and direct current mixed traction power supply system comprises an alternating current power supply assembly, a direct current power supply assembly and a discharging coil, wherein the alternating current power supply assembly is used for realizing alternating current power supply, a traction transformer of the alternating current power supply assembly is connected into a traction power supply net through a first circuit breaker, the traction transformer outputs alternating current after the voltage reduction and is connected with the traction net through an alternating current feeder switch, the direct current power supply assembly is used for realizing direct current power supply, a rectifying transformer of the direct current power supply assembly is connected into a traction power supply net through a second circuit breaker, the rectifying transformer is subjected to voltage reduction and outputs direct current after being rectified via a rectifier, one path is connected with the traction net through the direct current feeder switch, the other path is connected with the traction net through a double-electrode high-voltage isolation switch, in addition, a high-voltage isolation switch used for realizing short circuit on a traction net uplink and a traction net downlink is arranged at the tail end of a section post line, and the traction net uplink and the traction net downlink form a ice melting loop; the discharging coil is arranged at the positive bus end of the output side of the direct current feeder switch and is provided with a high-voltage switch. The alternating current and direct current mixed traction power supply system has the advantages that the principles are simple, the function integrality is high, the operation is safe and reliable, and the like.

Owner:ZHUZHOU NAT ENG RES CENT OF CONVERTERS

Clamp for grinding spherical pad

InactiveCN101391391AImprove efficiencyReduce processing costsSpherical surface grinding machinesBiomedical engineeringSurface smoothness

The invention discloses a fixture which is used for grinding a spherical gasket and is characterized in that the fixture comprises a flange and a clamp head which are fixedly connected; the clamp head has a same spherical arc surface as the spherical gasket, and the inside of the clamp head is provided with an electromagnetic coil. The fixture can fast clamp and fix a plurality of spherical gaskets, and is convenient for the processing device to finely process the spherical gasket with high efficiency. The accuracy and the surface smoothness of the spherical gasket are greatly increased without greatly increasing the processing cost..

Owner:RUIAN VEHICLE FITTING FACTORY

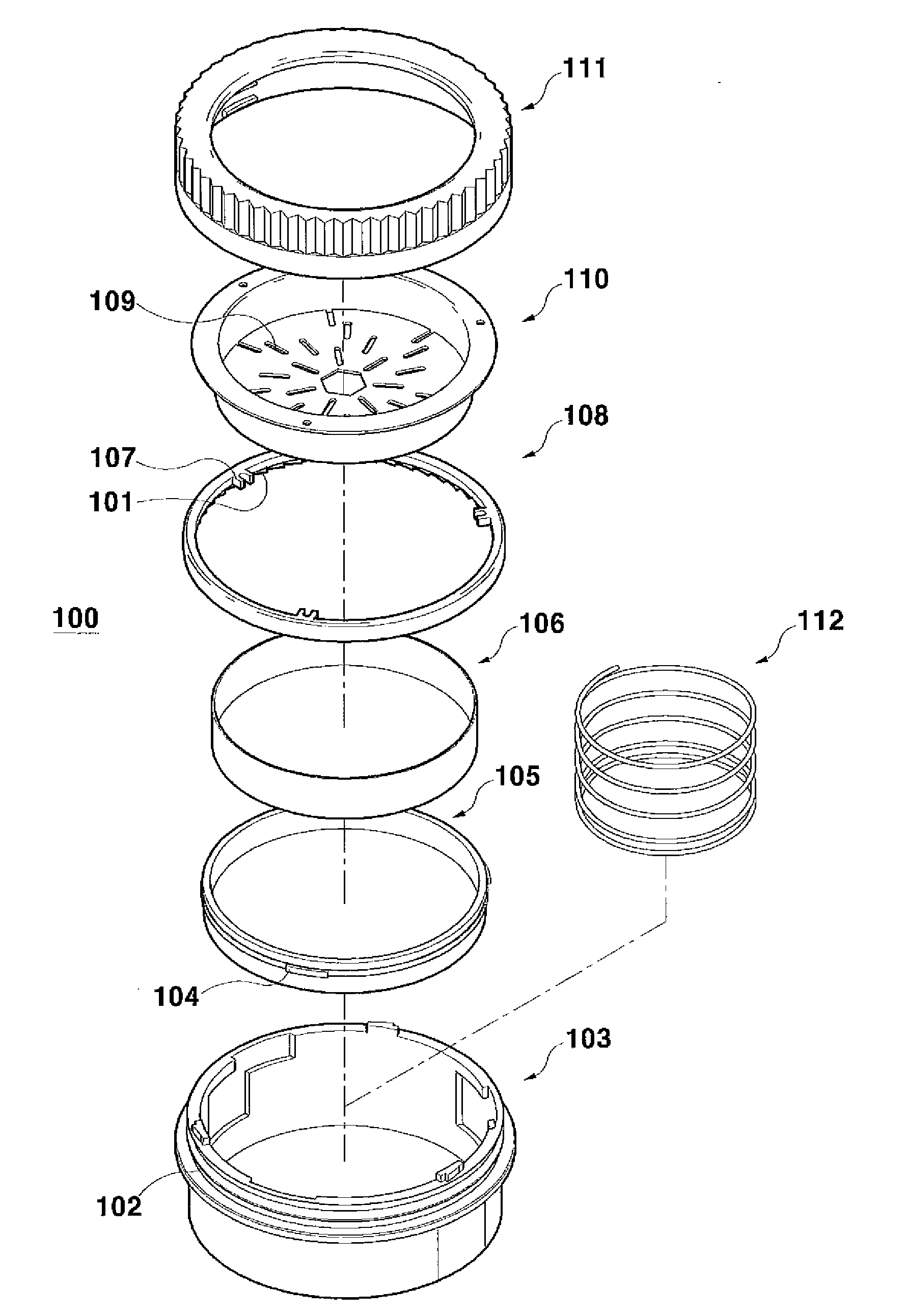

Cosmetics case

ActiveUS20080276956A1Avoid dischargeEasy to GrindPackaging toiletriesPackaging cosmeticsCouplingEngineering

The present invention relates to a cosmetics case including a cover having a lock protrusion and a hinge protrusion; a base case to which the cover is pivotally connected; an intermediate case installed in the base case and in which a button and a spring are installed; a powder case receiving solid powder therein, installed in the intermediate case and supported by the spring; and a grinding member rotatably installed in a coupling groove of the intermediate case to grind the surface of the solid powder received in the powder case. The present invention provides the cosmetics case capable of rotating in both directions, in which rotation in one direction permits grinding of the solid powder and rotation in the other direction permits pressing down of the surface of the solid powder, thereby preventing the ground powder from being discharged outwards, and after use, the cover is closed to prevent impurities from being put into the solid powder.

Owner:CHO KYU SUK

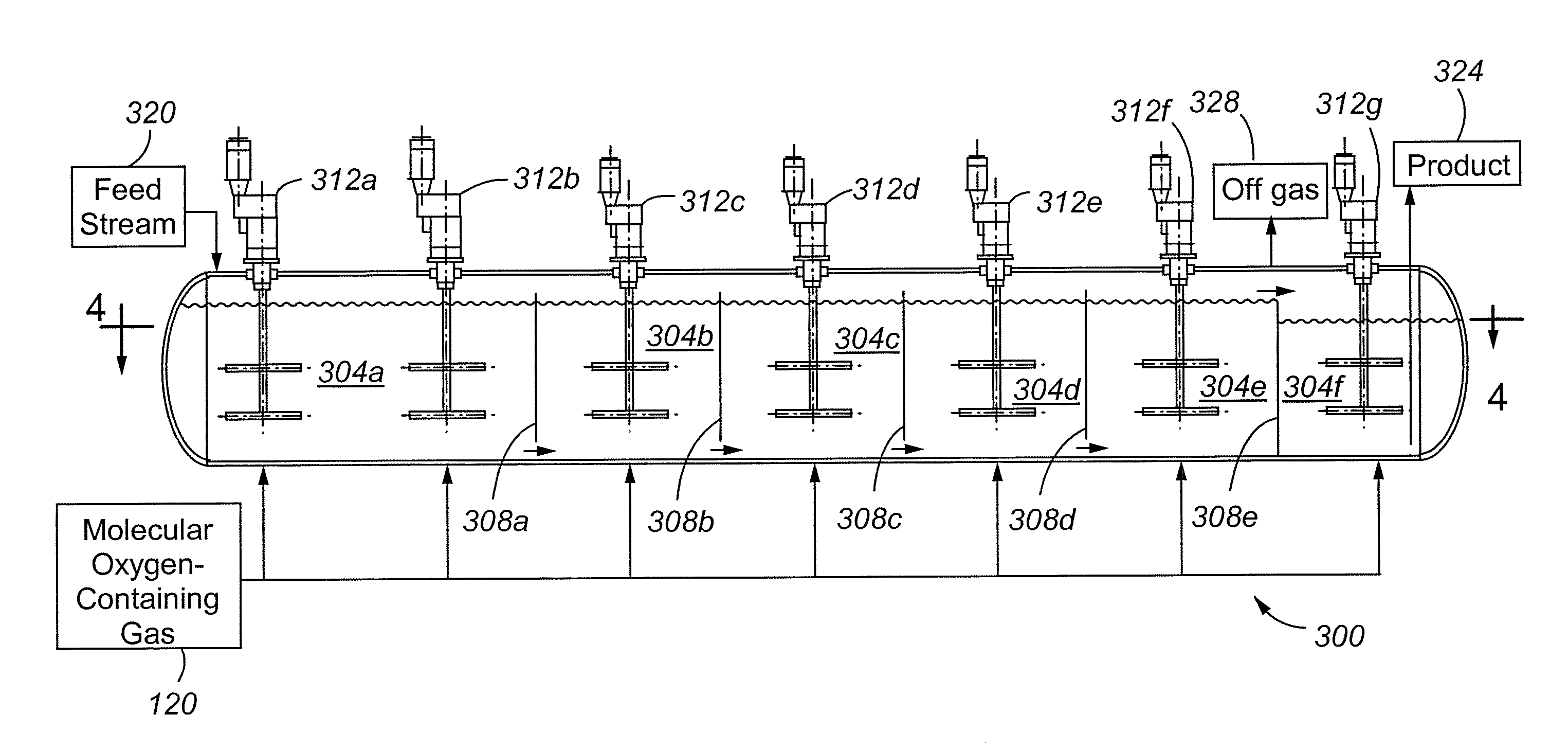

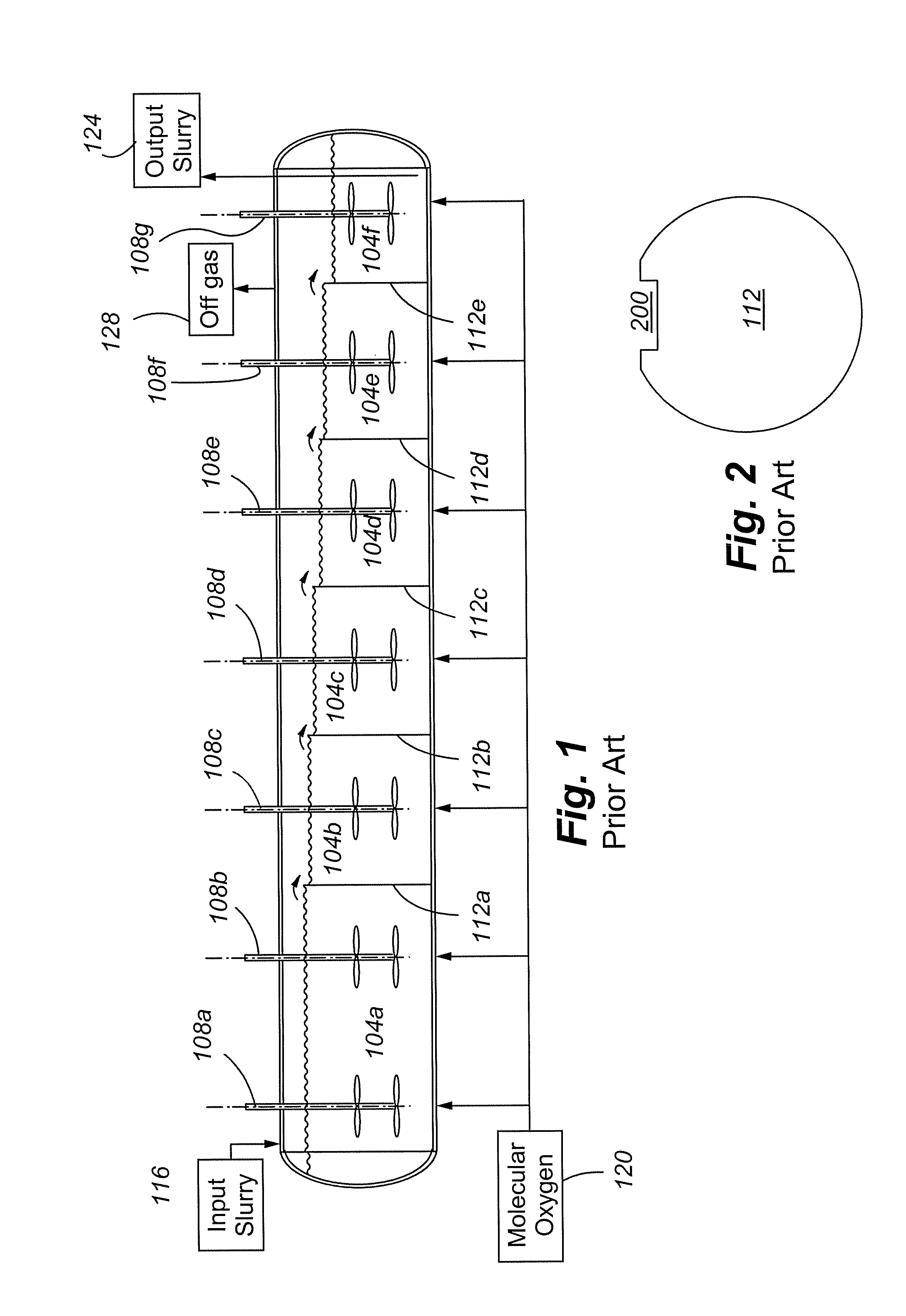

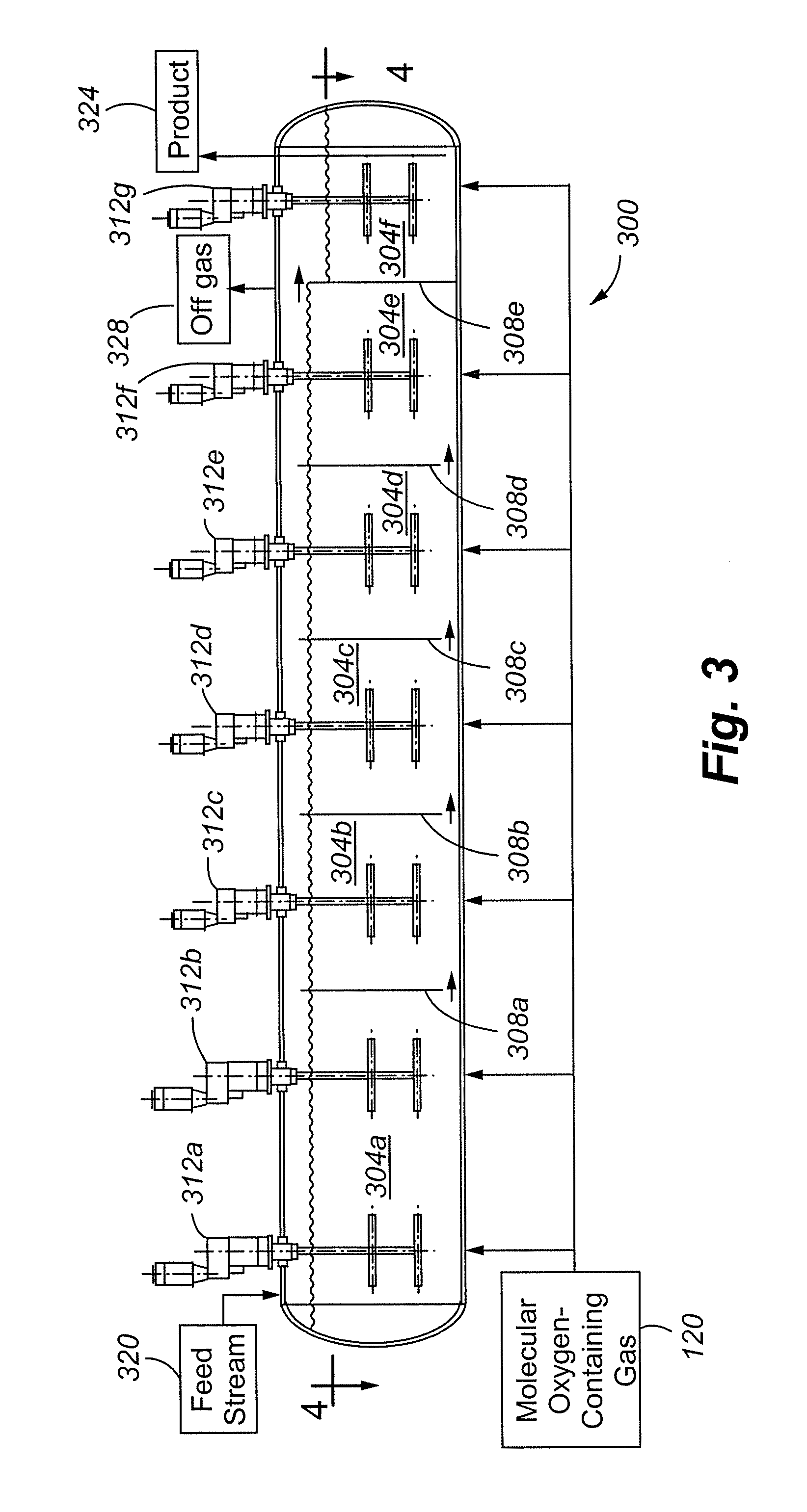

Autoclave with underflow dividers

InactiveUS20070217285A1Lower Level RequirementsEasy constructionSolvent extractionRotary stirring mixersEngineeringAutoclave

Owner:BARRICK GOLD

Extendible drain members for grounding RFI/EMI shielding

InactiveUS6639148B2Easy to GrindElectrically conductive connectionsOrnamental textile articlesEngineeringFree edge

Owner:FEDERAL MOGUL SYST PROTECTION GRP INC

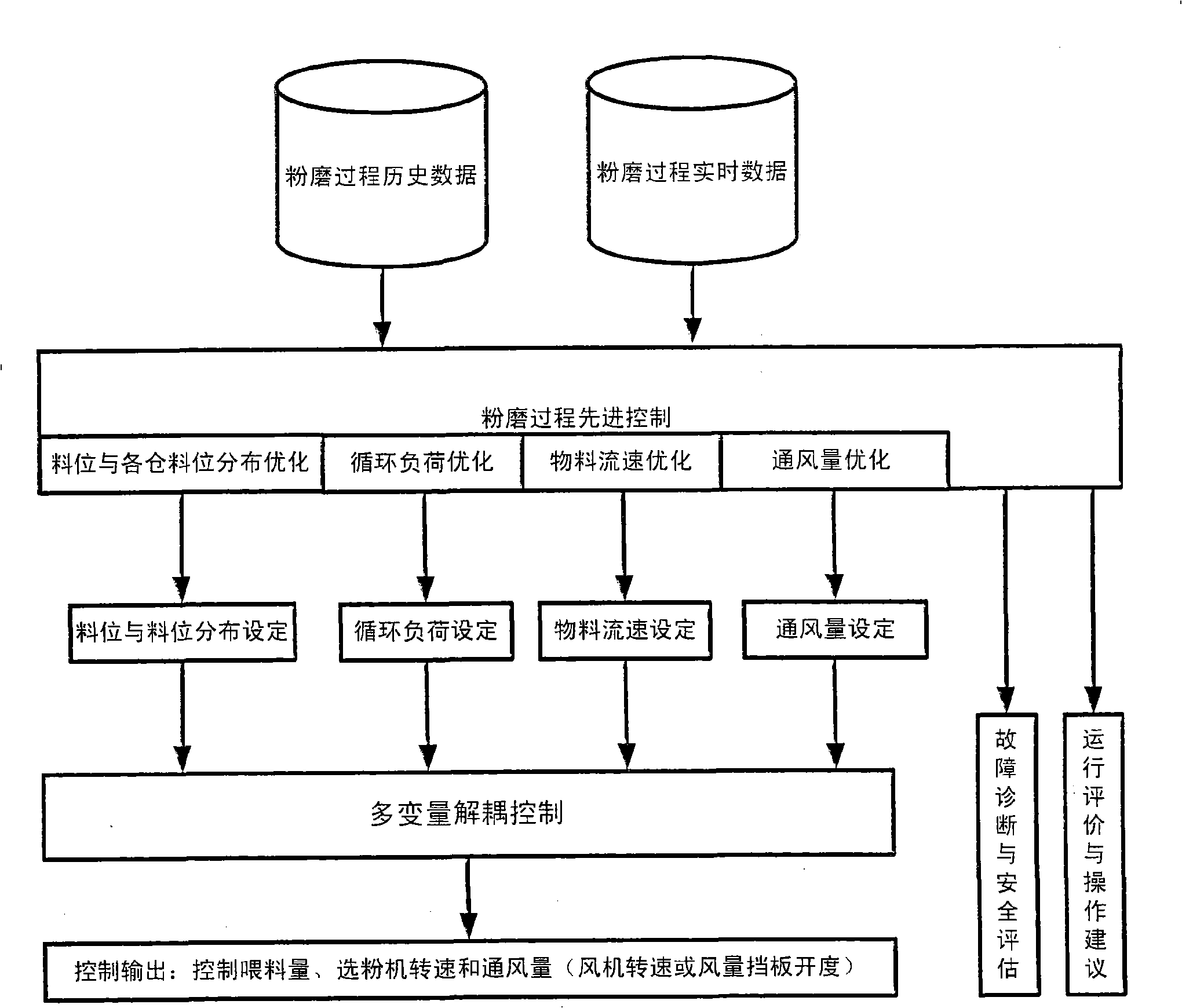

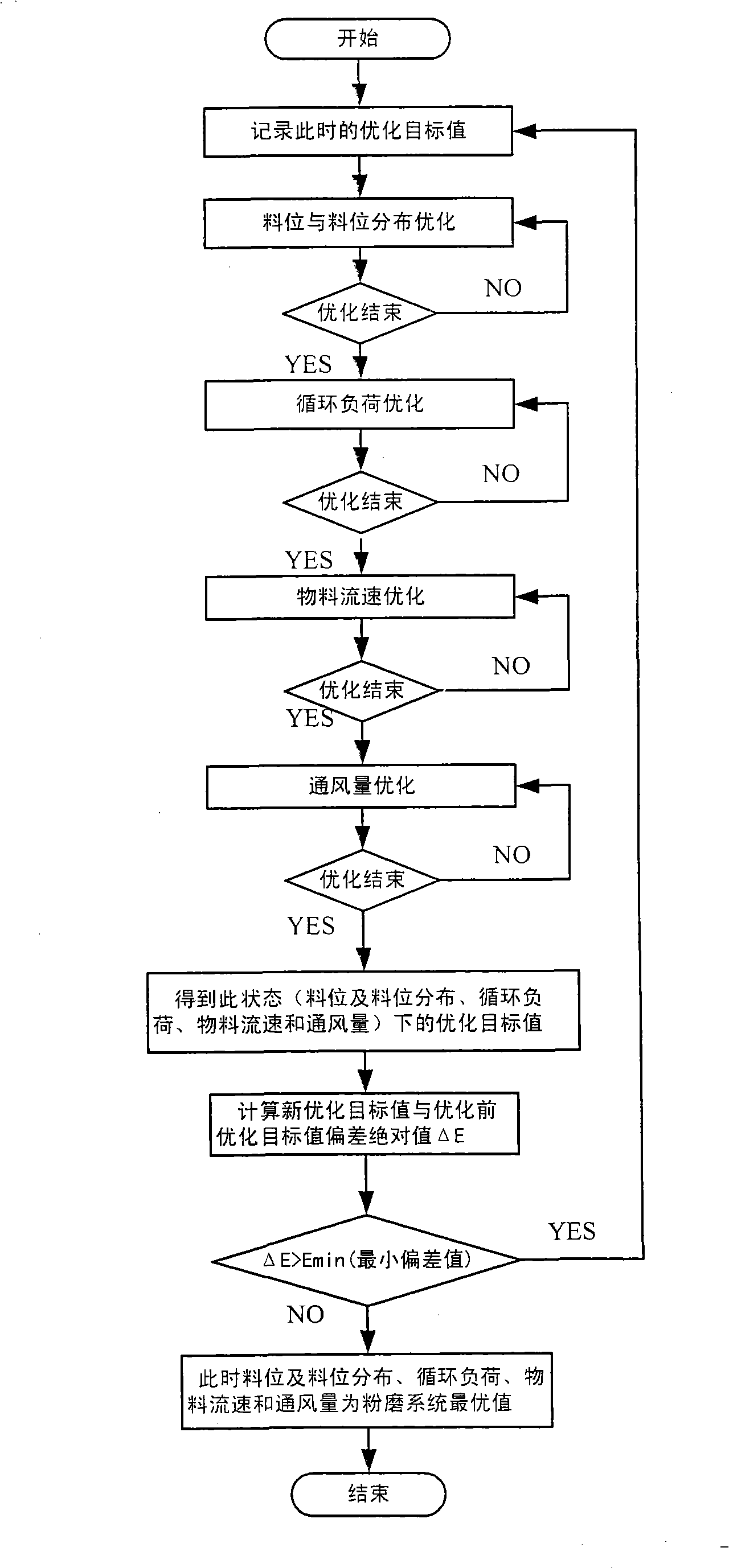

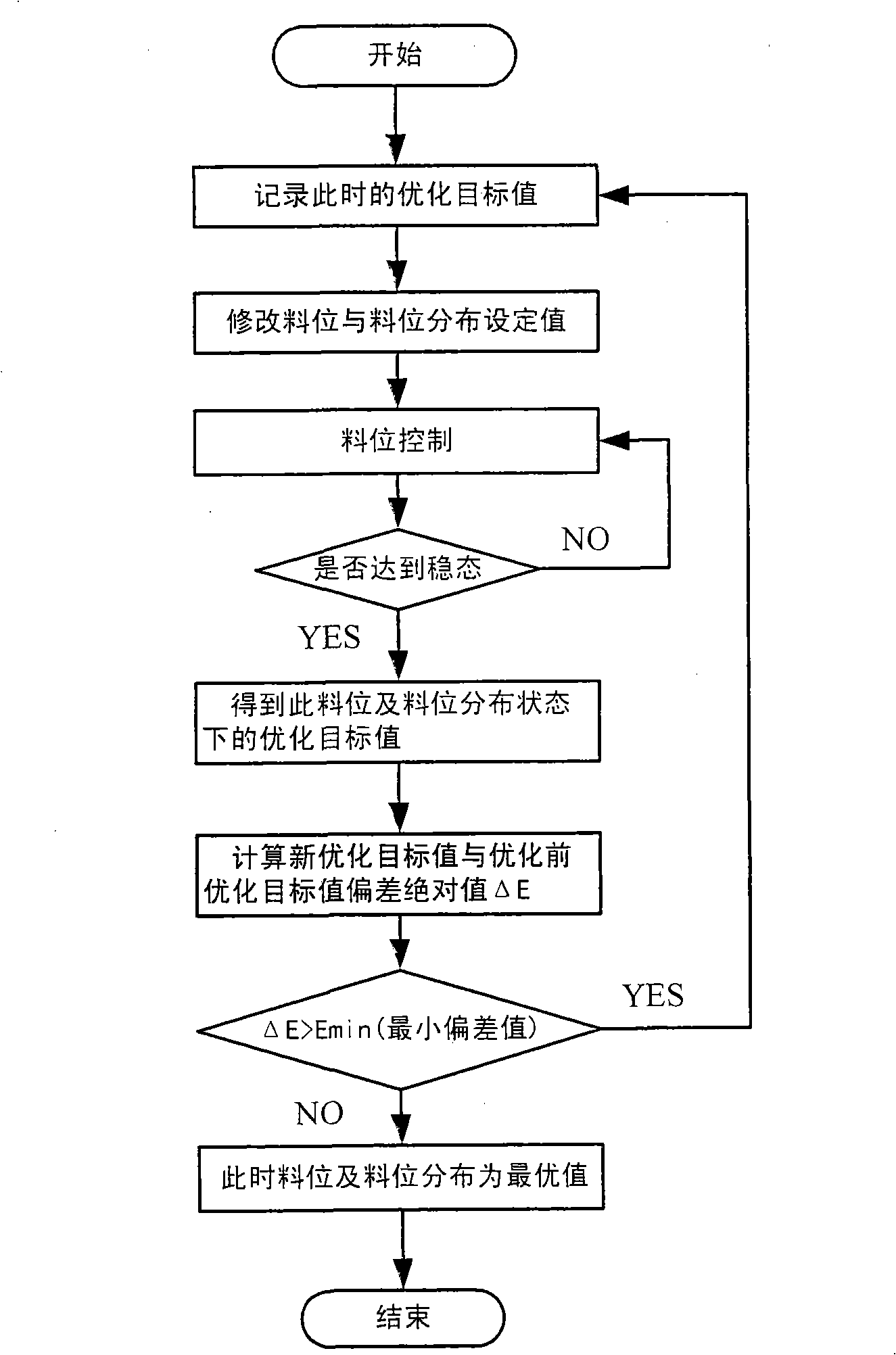

Control method for grinding process optimization of cement factory

InactiveCN101318158AStable finenessImprove uniformityElectric testing/monitoringCement productionAutomatic controlCement factory

The invention discloses an optimal control method for a grinding process in a cement plant. By collecting grinding process signals and taking the advanced control as the core, the method realizes automatic control of material level and material level distribution, automatic control of circulating load and ventilation and also realizes optimization of material level of every bin in the mill, optimization of material velocity, optimization of circulating load and ventilation and also realizes output control of feed quantity, rotational speed of a powder-choosing machine and the rotational speed of a fan. The method optimizes the whole grinding process and realizes maximum time-production operation of the grinding process and minimum grinding unit consumption. At the same time, the failure of the grinding process is diagnosed, the safety of the grinding process is estimated, the grinding process is evaluated and analyzed, and the reasonable suggestion is given to the operation of the grinding process, thus assuring a continual, stable, safe and economical operation of the grinding process. The method can be widely used in the grinding process in the cement plant or in similar grinding processes in other fields.

Owner:XIAN IBL TECH DEV

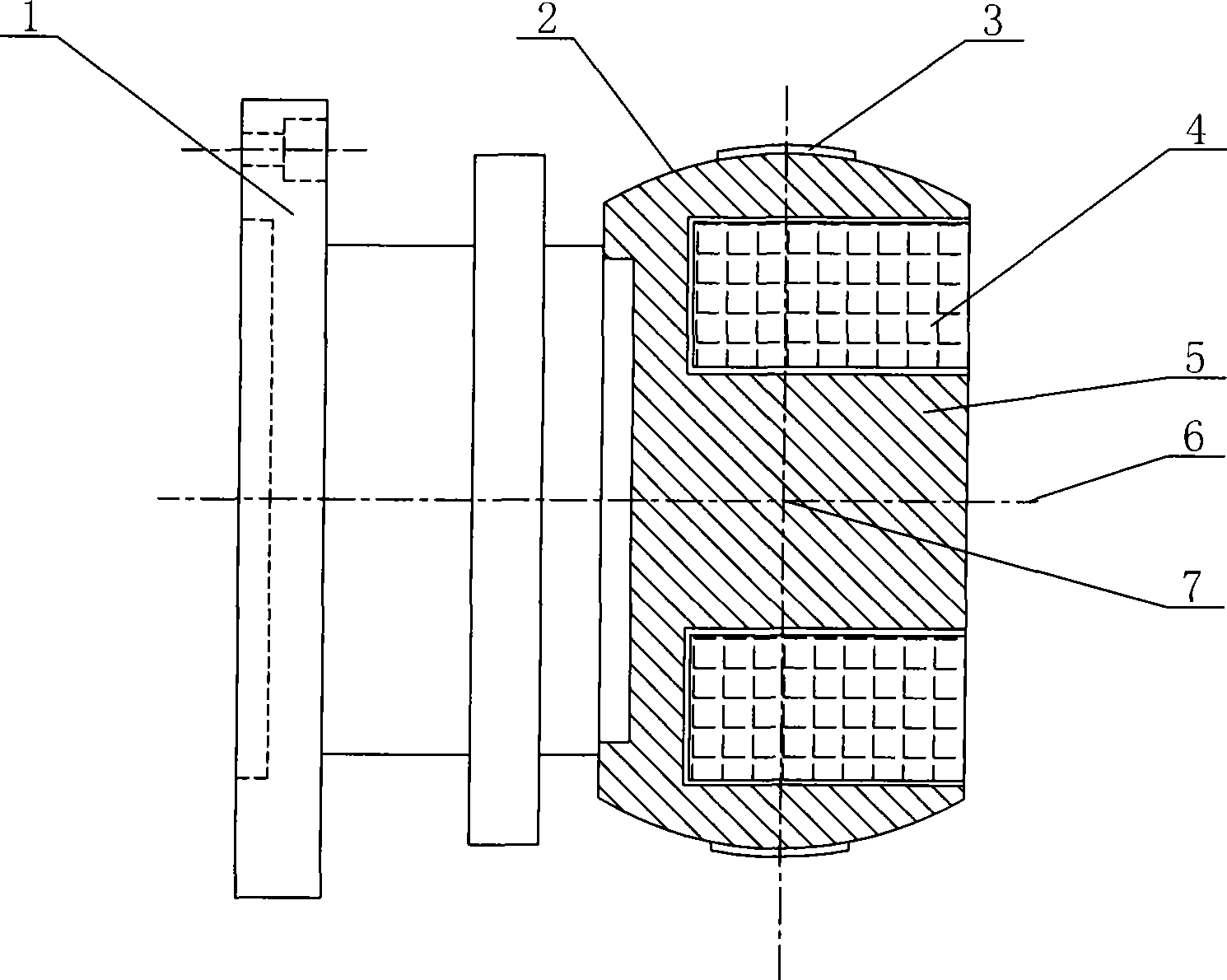

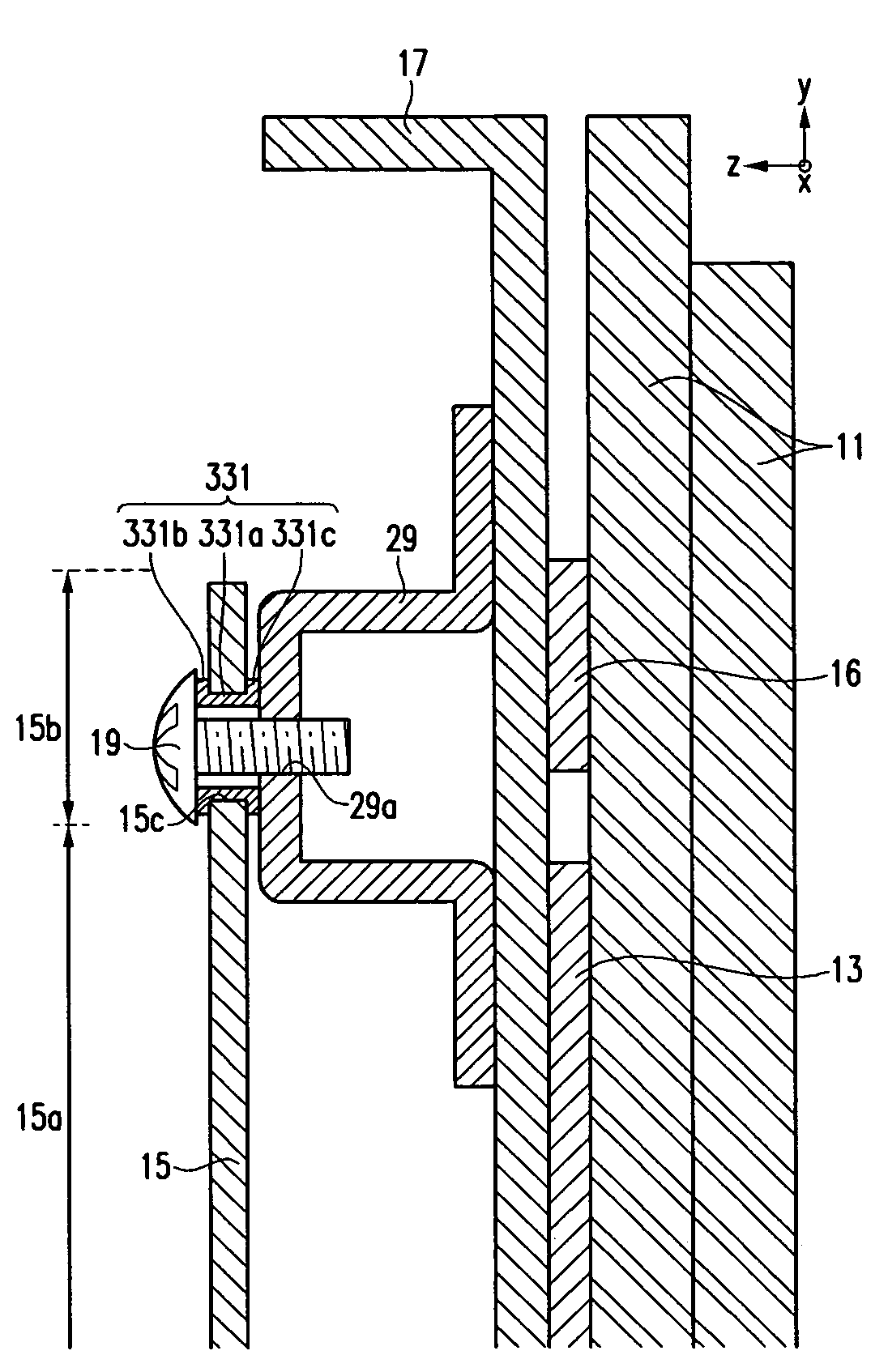

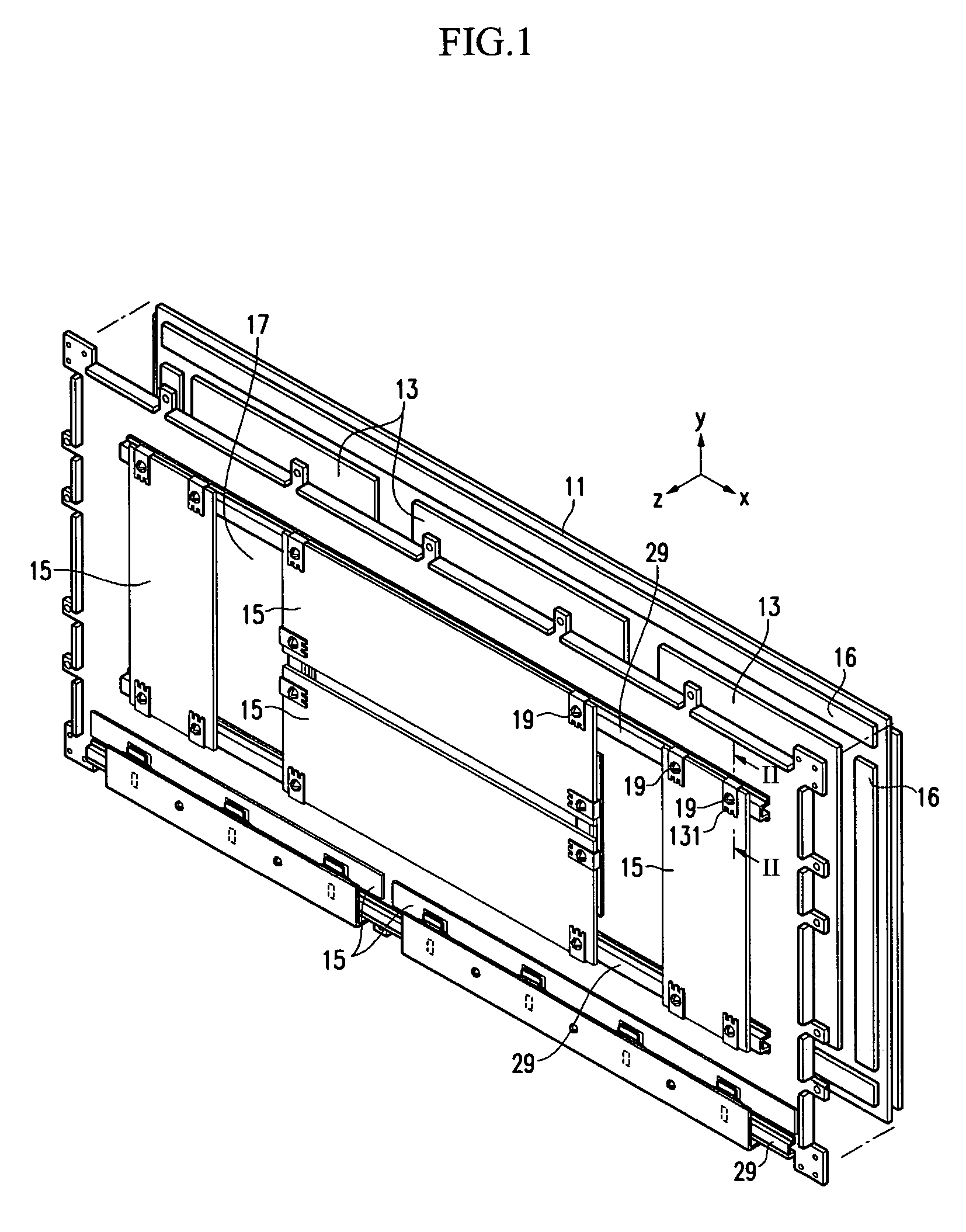

Plasma display device with grounding module

InactiveUS7357645B2Simplified chassis base structureEasy to GrindMagnetic/electric field screeningGas discharge vessels/containersComputer moduleDisplay device

A plasma display device includes a plasma display panel mounted on a first side of a chassis base, a mount on a second side of the chassis base, the mount being electrically connected to the chassis base, a printed circuit board including an electrical grounding section and having an opening in the electrical grounding section, the printed circuit board mounted on the mount by an electrically conductive fastener passing through the opening in the electrical grounding section, and a grounding module positioned in the opening so as to be between the electrical grounding section and the electrically conductive fastener and electrically connecting the electrical grounding section to the mount.

Owner:SAMSUNG SDI CO LTD

Pluggable module and receptacle

InactiveUS20020068481A1High frequencyHighly miniaturizedMagnetic/electric field screeningContact members penetrating/cutting insulation/cable strandsElectrical connectionConductive materials

A receptacle for a pluggable module includes a housing having a front, a back wall, a top wall, a bottom wall, and side walls and defining a cavity for receiving a module. The bottom wall has a bottom opening to receive a receptacle connector, and the front has a front opening to receive the module. The walls of the housing are made from a conductive material. A plurality of elongated members extend down from the housing past the bottom wall. The elongated members are adapted for electrical connection to a host circuit board such that the walls of the housing are electrically connected to the host circuit board.

Owner:TE CONNECTIVITY CORP

Methods of producing meat and egg products with enhanced nutritional quality

InactiveUS6103276AImprove abilitiesReduce productionAnimal feeding stuffAccessory food factorsAnimal scienceNutritional quality

The invention relates to livestock feed compositions and methods for producing food products of improved nutritional quality from the livestock. Specifically, in one embodiment, feed compositions comprising whole flaxseed and dietary grit, and further comprising menhaden oil, soybean oil, and vitamin E, can be used to produce chicken eggs with improved essential fatty acid and vitamin E contents. The eggs so produced score favorably when compared to control eggs in taste tests. Furthermore, there is no reduction in egg production from the chickens fed a diet of the compositions disclosed.

Owner:PILGRIMS PRIDE CORP

Cup and cone feed distributor

InactiveUS20060175447A1Reduces downtimeFacilitate distributionCocoaGrain treatmentsEngineeringDistributor

A cup and cone feed distributor enables a finer grind of the foodstuffs ground within a grinding chamber, and more efficiently distributes the foodstuffs for engagement with grinding members, preventing accumulation of the foodstuffs at the bottom of the grinding members.

Owner:DALLAS A C HORN

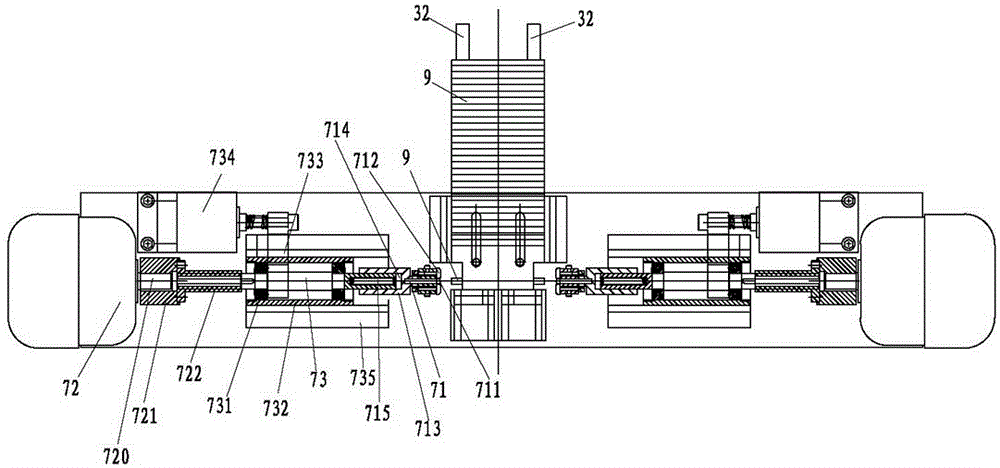

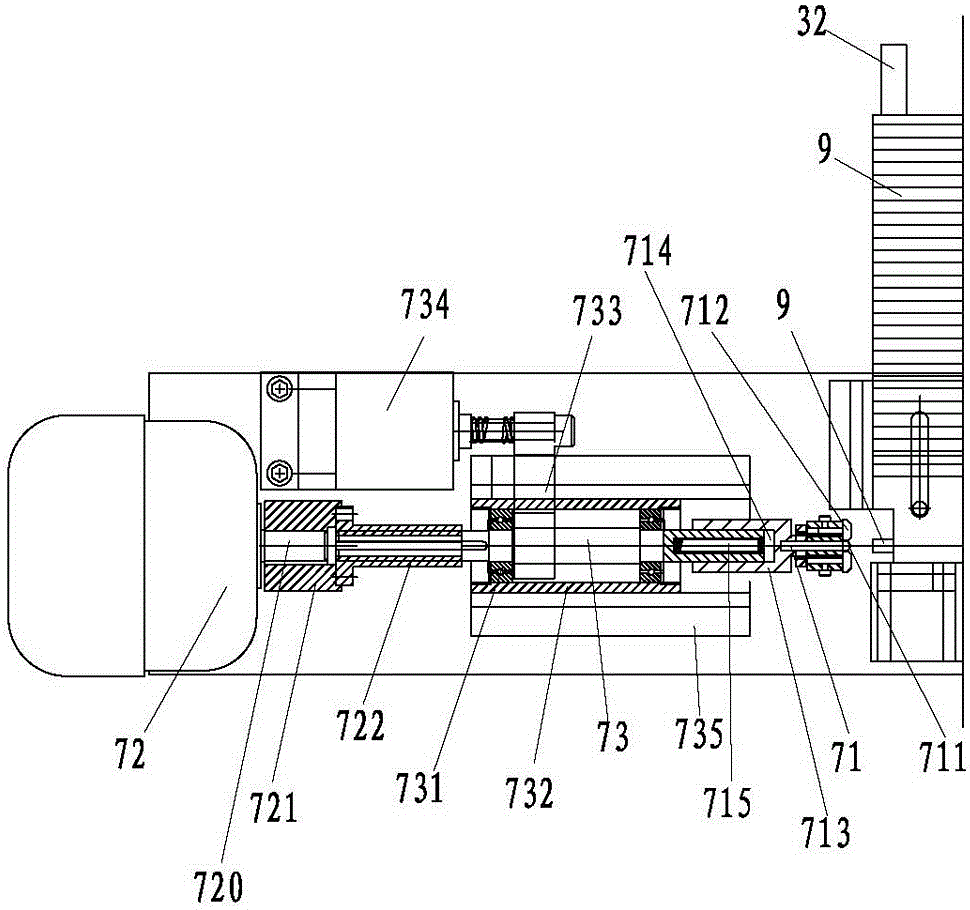

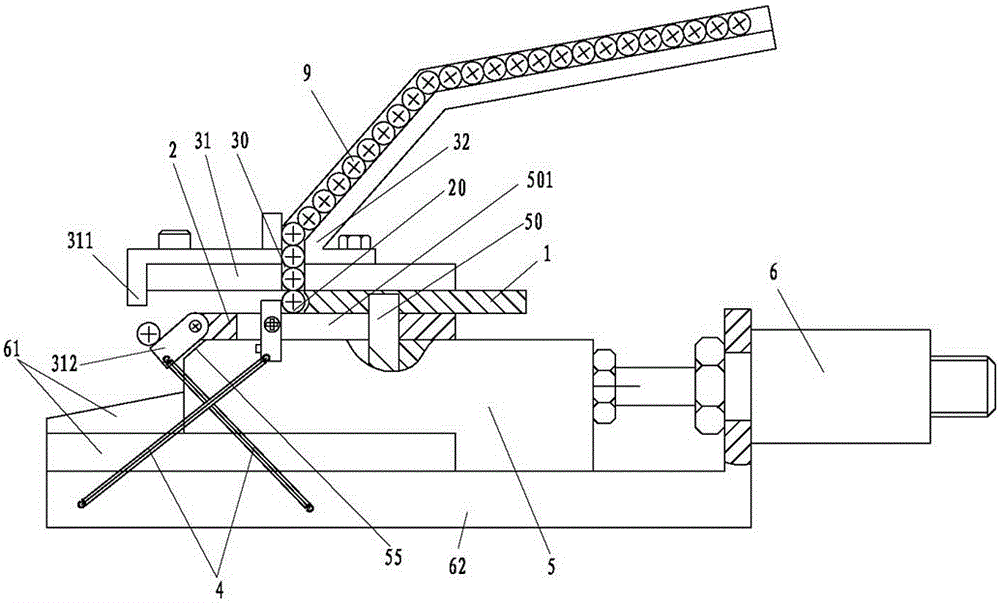

Pipe double-end internal and external chamfering processing apparatus

InactiveCN105108601AImprove mobilityIncrease linkageEdge grinding machinesGrinding feedersElectric machineryEngineering

The invention relates to the technical field of pipe processing equipment, and specifically discloses a pipe double-end internal and external chamfering processing apparatus. The apparatus comprises a feeding mechanism and a pipe double-end internal and external chamfering processing mechanism. The feeding mechanism comprises two feeding devices oppositely arranged on the left and right sides. Each feeding device comprises a feeding plate and a bearing platform, and the bearing platform is provided with an initial falling point from which place the pipe falls. At an initial state, the portion, acting on the pipe, at the front end of each feeding plate is located behind the initial falling point. A front limiting top plate limiting the front part of the pipe is arranged at the position close to the front end of each bearing platform. A discharging plate through which the pipe is supported and discharged is arranged at the front end of each bearing platform. The pipe double-end internal and external chamfering processing mechanism comprises two internal and external chamfering processing devices which are oppositely arranged. Each internal and external chamfering processing device comprises a polishing means including an inner polishing head and an outer polishing head. A motor is arranged on the side, opposite to the pipe, of each polishing means. The pipe double-end internal and external chamfering processing apparatus is safe and stable in operation, high in efficiency and high in fluency, and has good positioning and processing effects.

Owner:ZHEJIANG TENGYUN REFRIGENRATION TECH

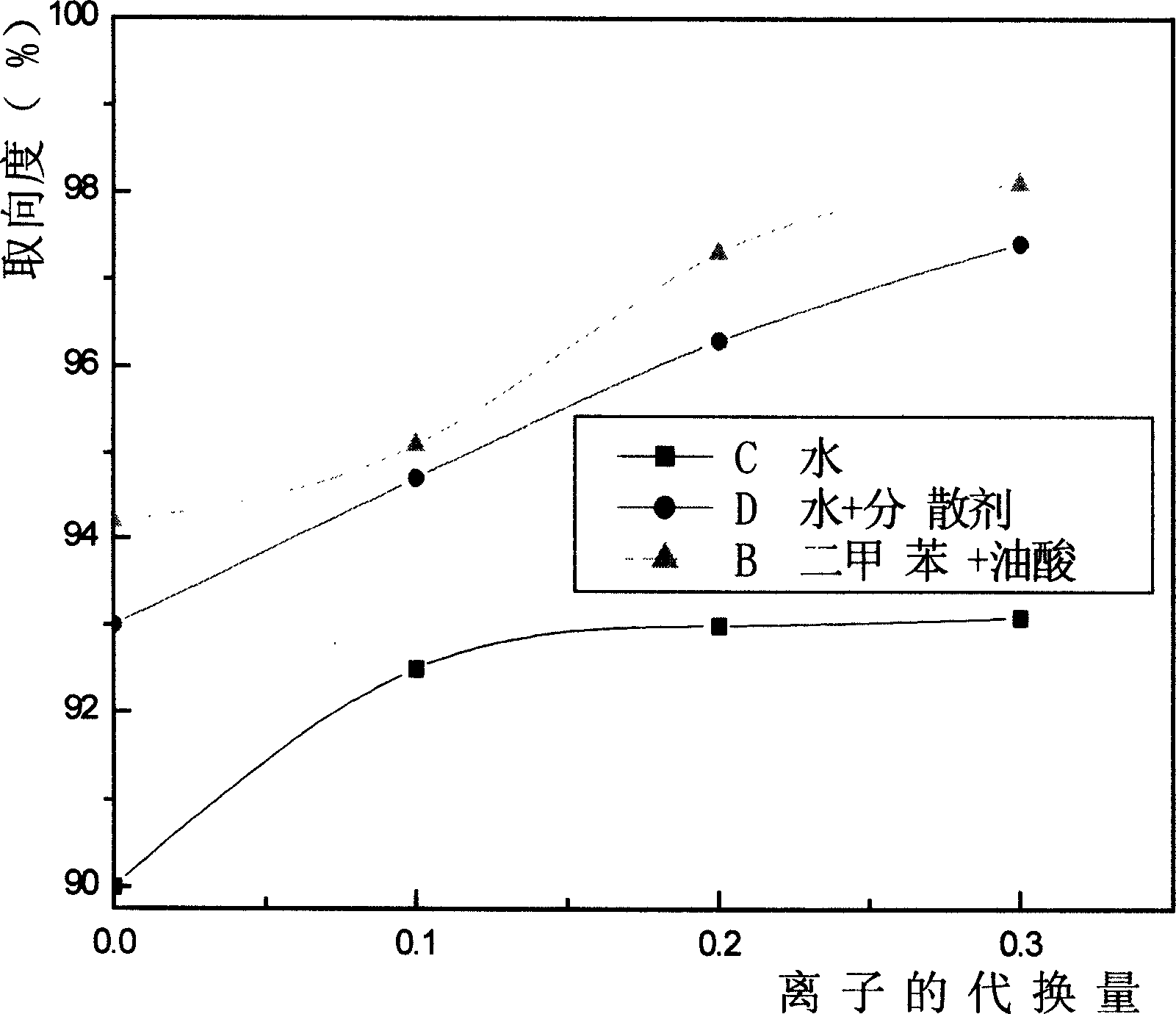

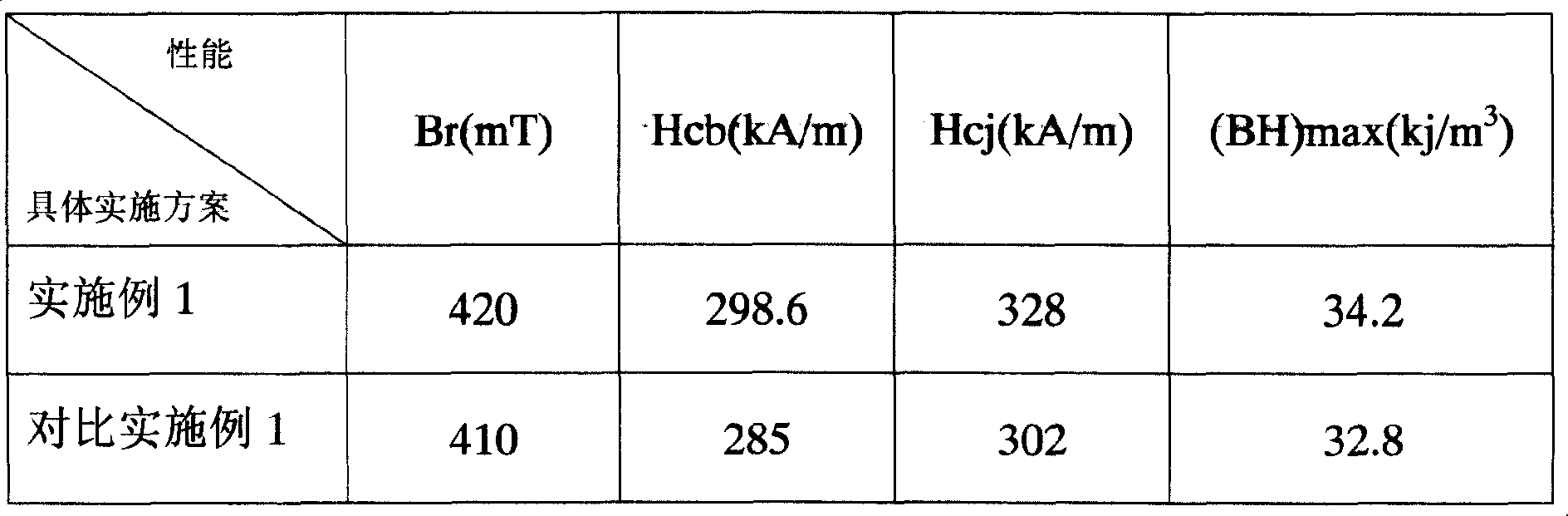

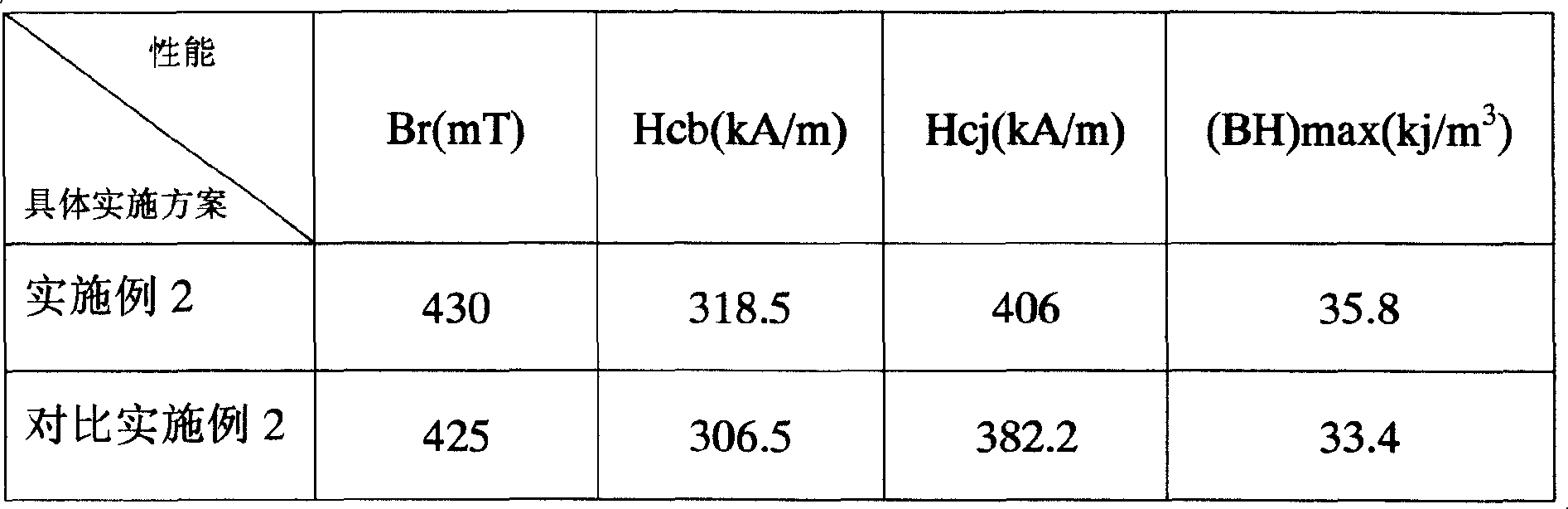

Process for preparing magnetic powder and sintered magnet and product produced thereby

ActiveCN1655295AIncrease the anisotropy constantImprove intrinsic coercive forceInorganic material magnetismInductances/transformers/magnets manufactureMetallurgyFerrite powder

This invention relates to magnetic material field and especially to a process method improvement and its formula to hexagonal magnetic lead ferrite powder and sinter magnetism, wherein the said magnetism or magnetic powder has one-Curie temperature with A,R, B and Fe hexagonal ferrite main phase and the following molecular formula: A1-XRx[(Fe3+aFe2+b)12-yBy]zO19, through adding positive three Co and optimizing the formula and improving the magnetism crystal aeolotropism constant K1.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com