Patents

Literature

69results about How to "Achieve electrical continuity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

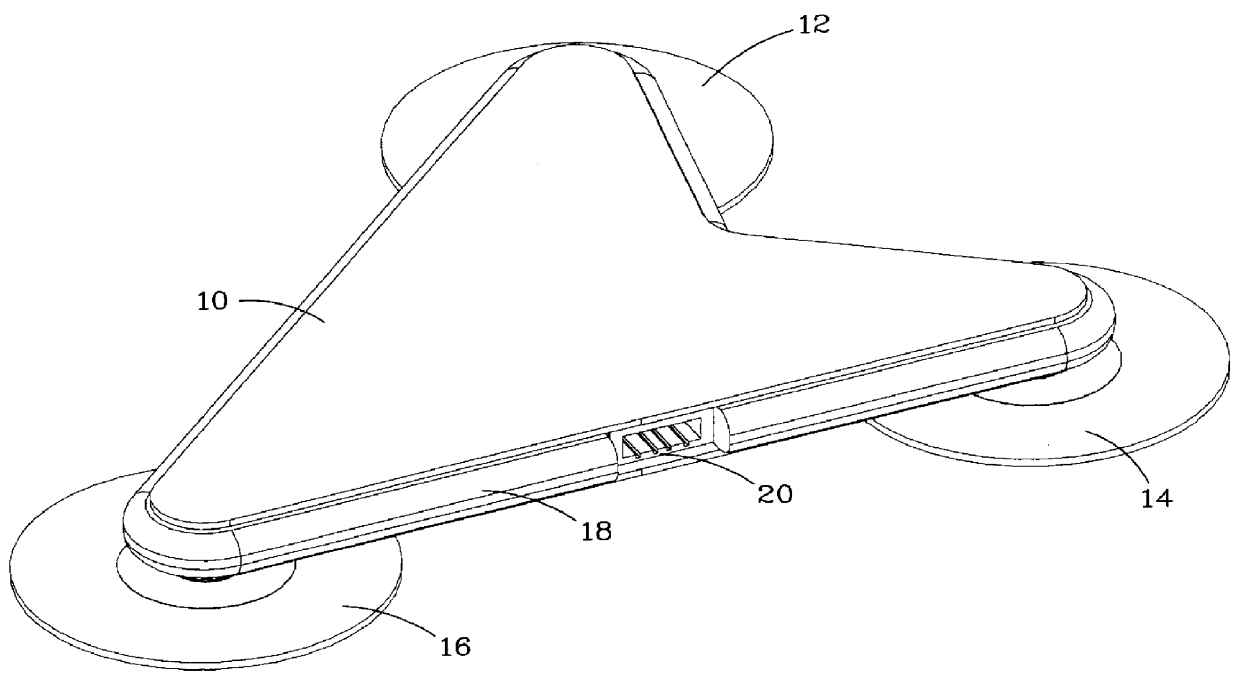

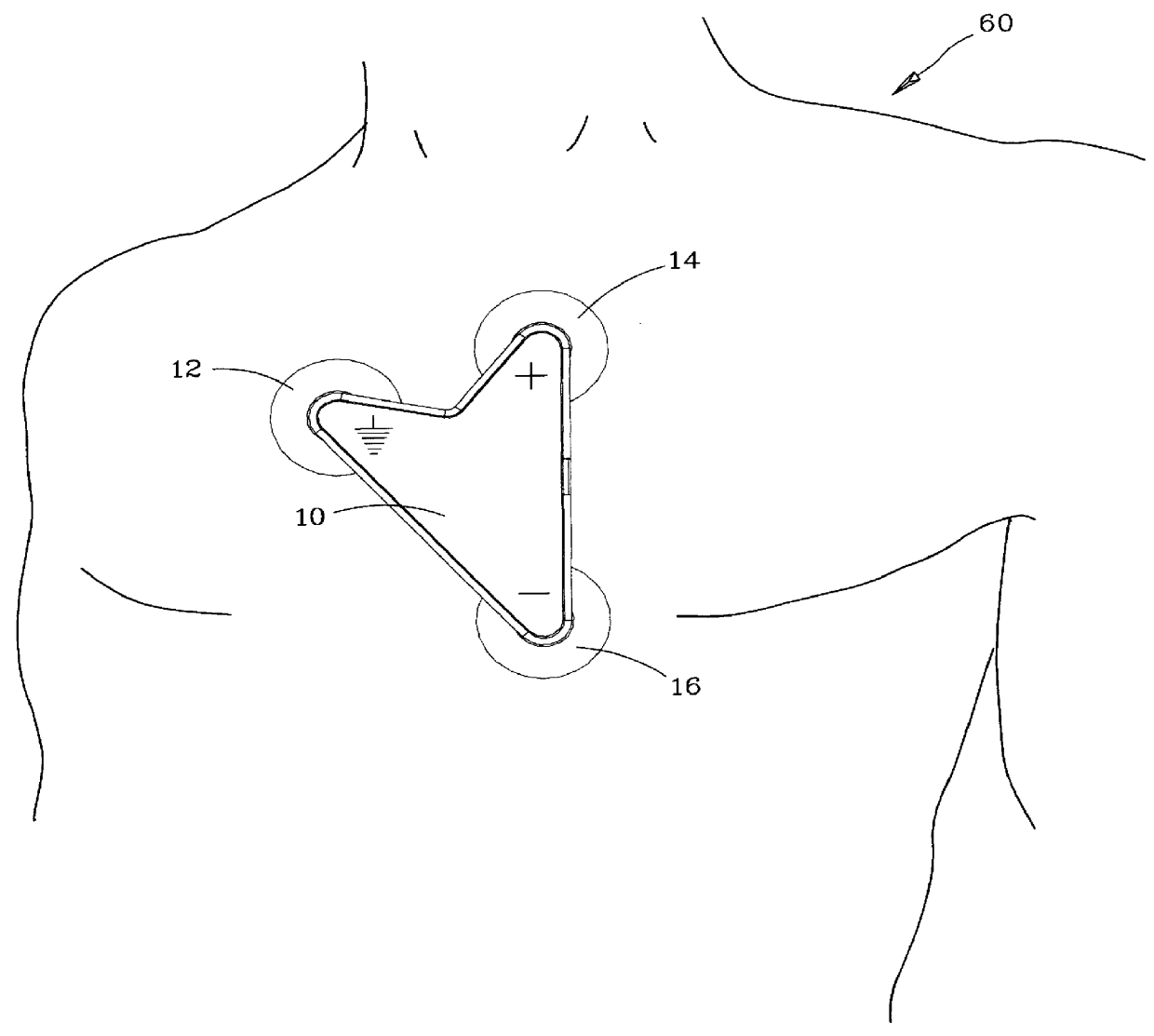

Long-term, ambulatory physiological recorder

InactiveUS6117077AComplete and reliableAchieve electrical continuityElectrocardiographySensorsTransducerEngineering

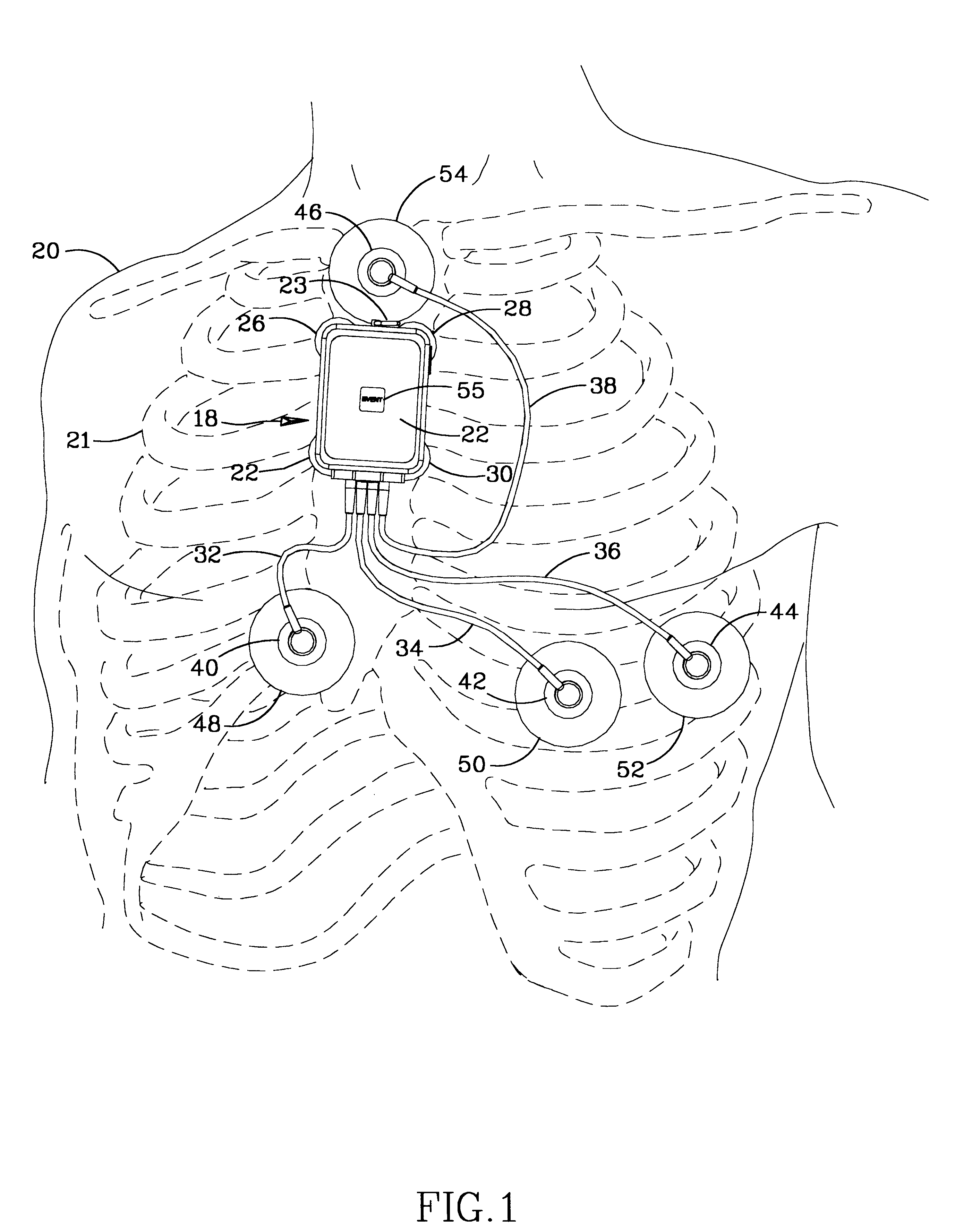

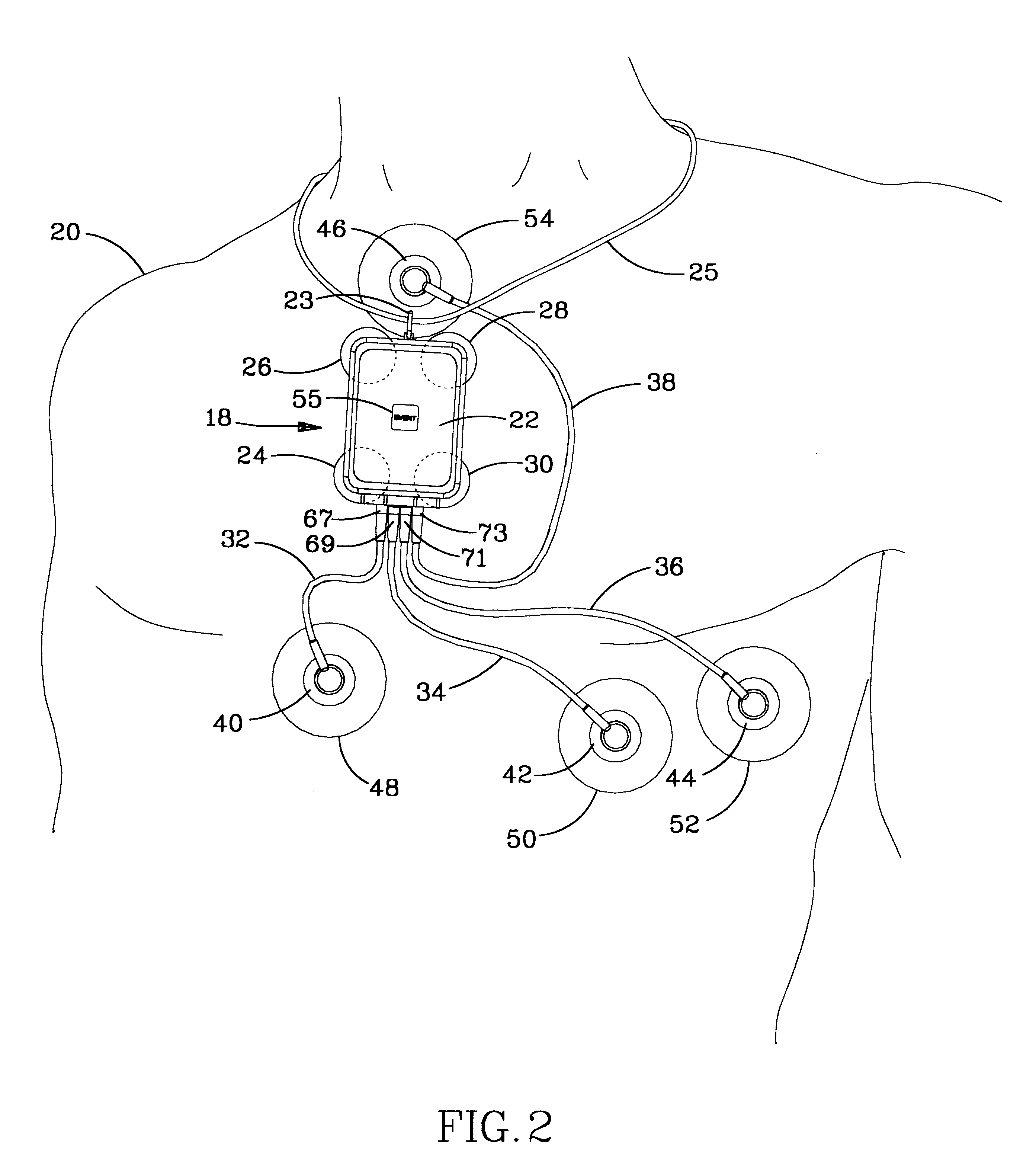

A self contained, compact, long term, ambulatory physiological recorder is designed for mounting directly to the body of a patient, immediately adjacent to the organ or system that is to be monitored, and is adhesively and covertly held there in place and comfortably under clothing by the very transducer, skin electrodes that detect the physiological information to be recorded, and thereby increasing continuity and decreasing artifact by obviating the need for numerous and cumbersome, hanging electrode leads as well as unsightly and cumbersome recorder pouches suspended from shoulder straps or belts.

Owner:SPACELABS HEALTHCARE LLC

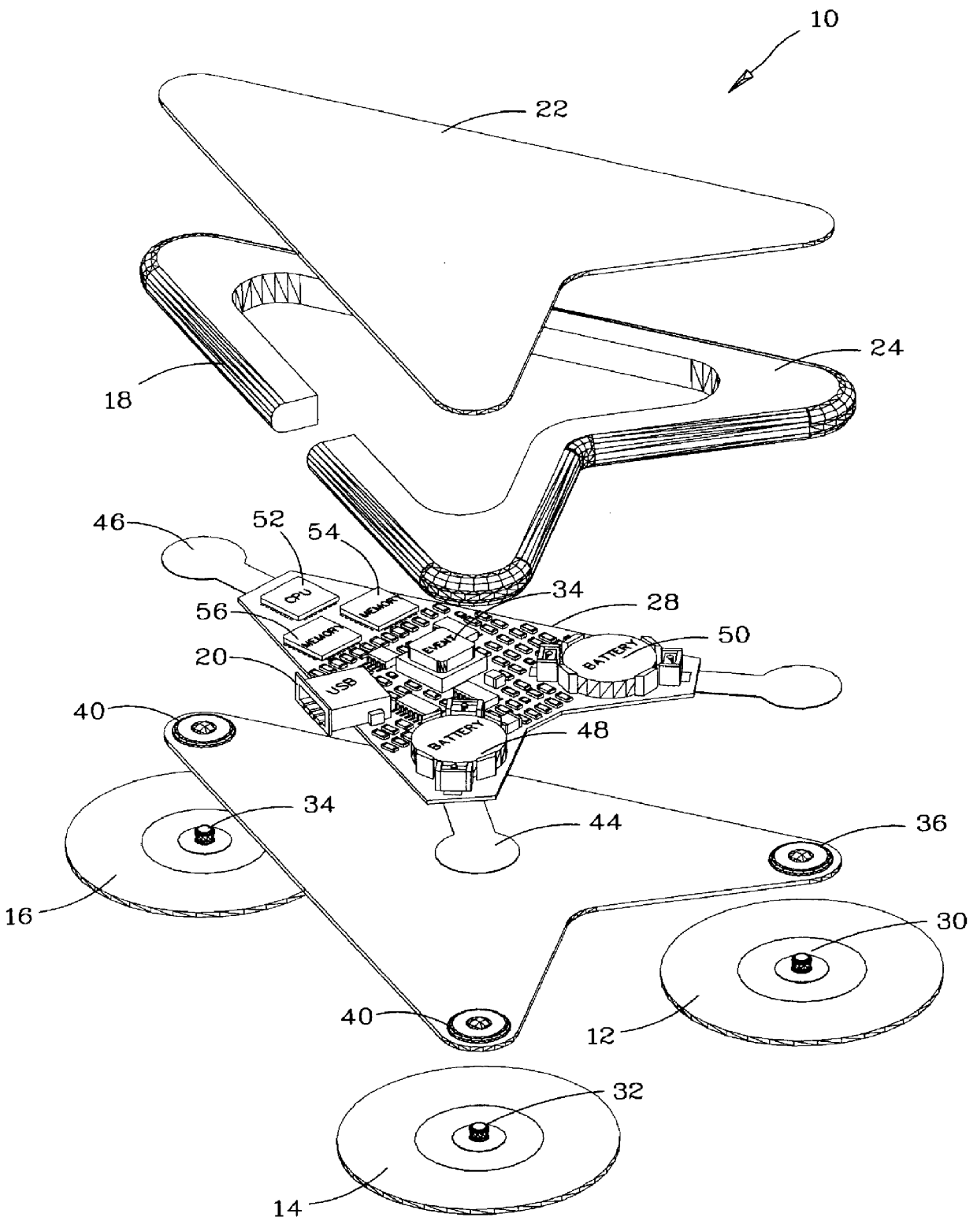

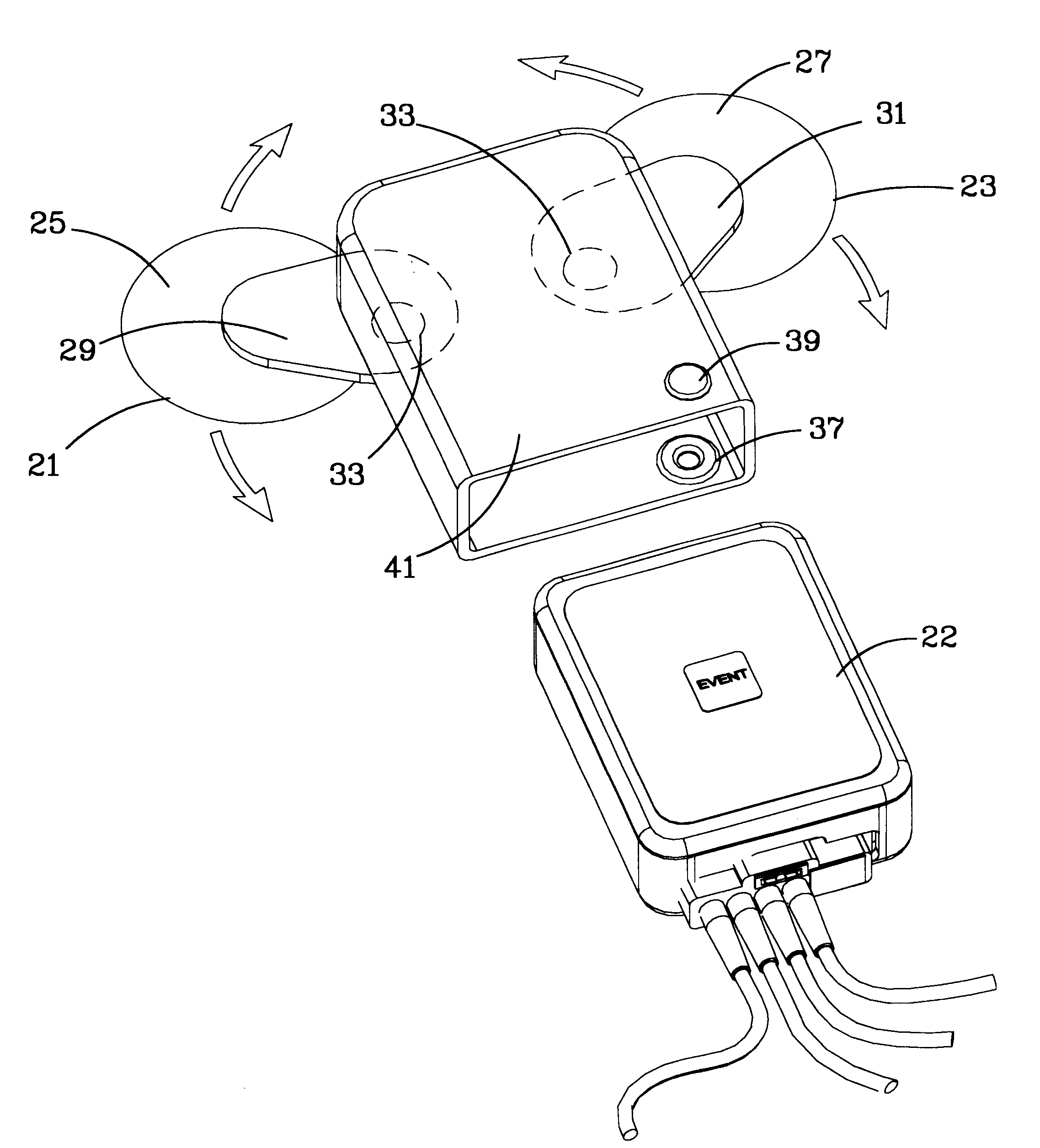

Ambulatory physio-kinetic monitor with envelope enclosure

InactiveUS6605046B1Complete and reliableShorten the lengthElectrocardiographySurgeryAmbulatoryAccelerometer

A water and moisture sealed, self contained, compact, long term, ambulatory physio-kinetic monitor is designed for mounting directly to the skin of an athlete or fitness performer, preferably immediately adjacent to the organ or system that is to be monitored, and is adhesively held there in place, covertly and comfortably, under clothing by disposable electrode, adhesive skin pads. At least three positive electrodes and a common negative electrode extend from the monitor and attach by similar disposable adhesive electrode pads to detect physiological, e.g. ECG data. Accelerometer means disposed within the monitor detects body movement and likewise stores that data on a third ECG data channel.

Owner:SPACELABS HEALTHCARE LLC

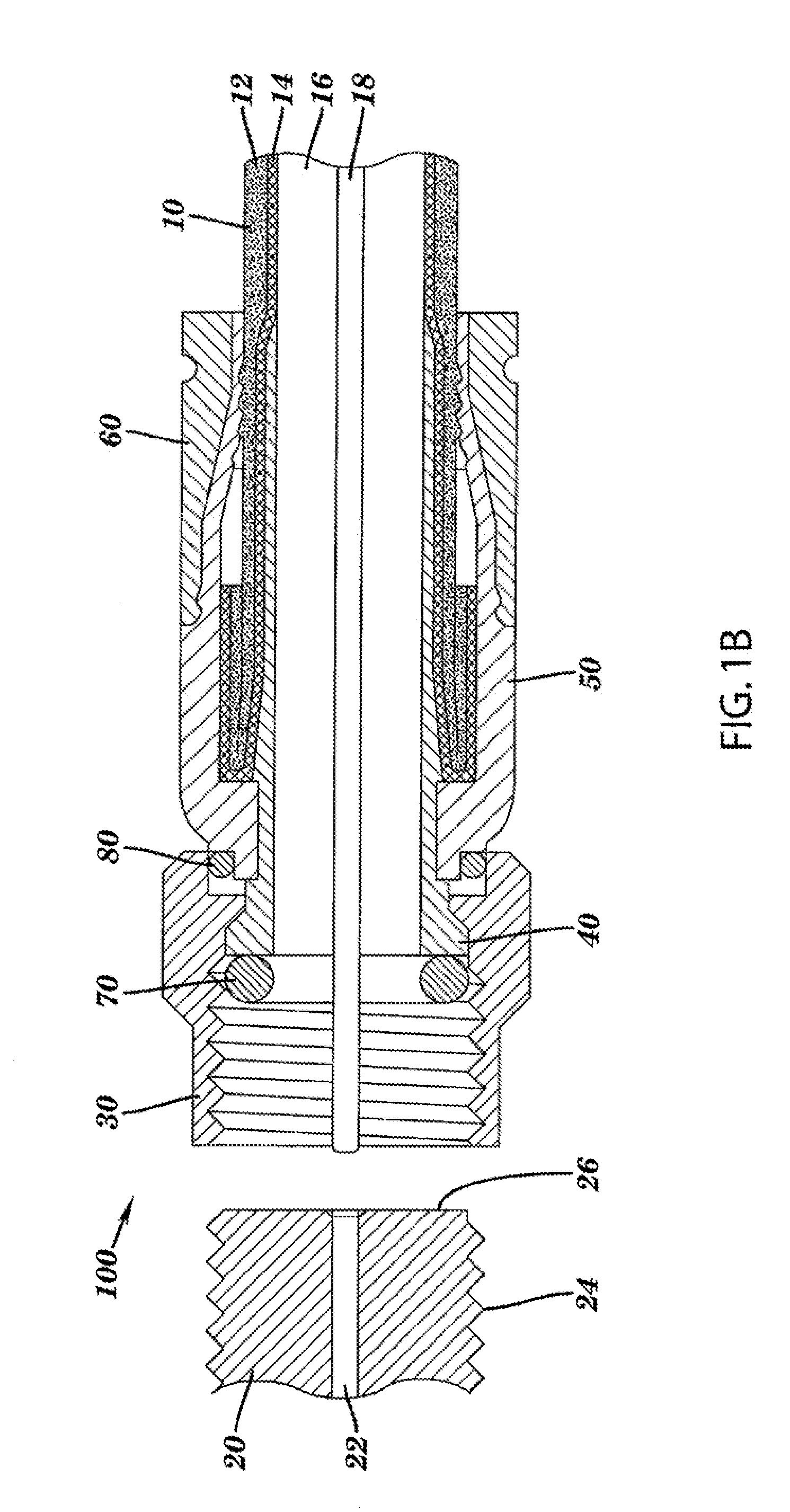

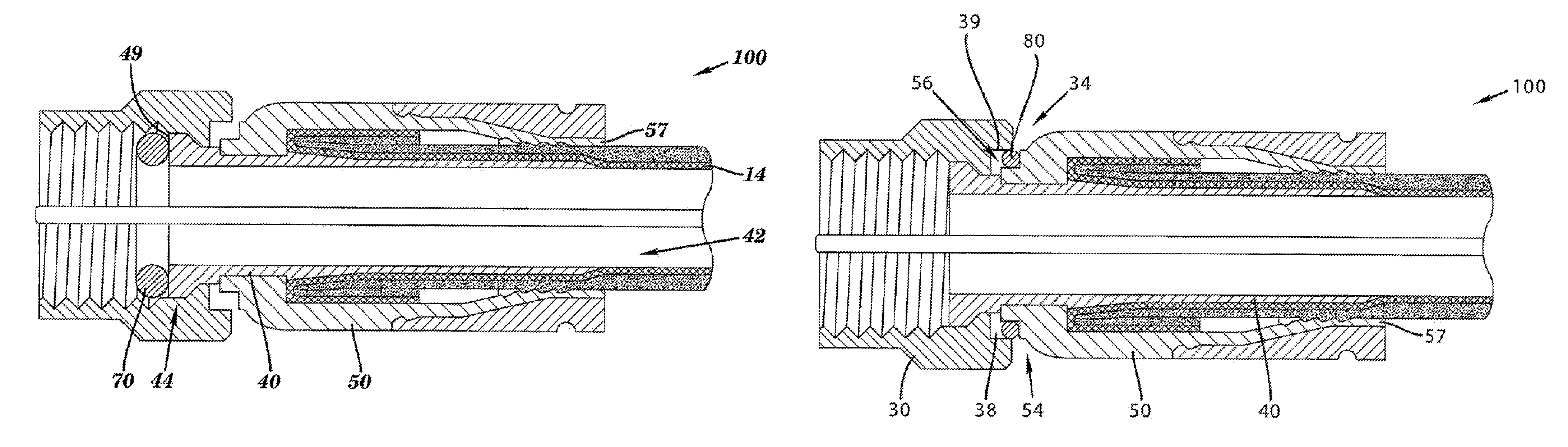

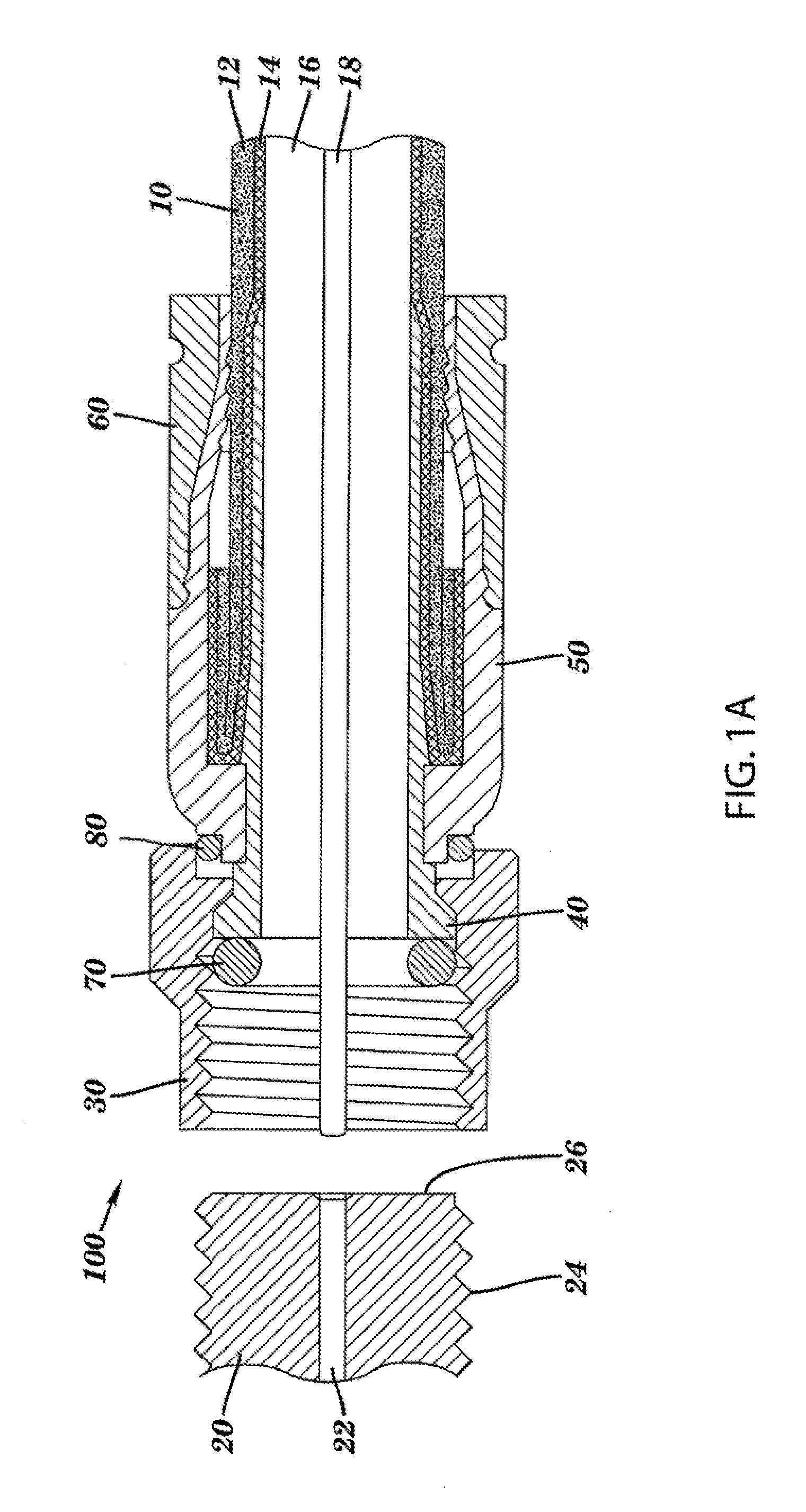

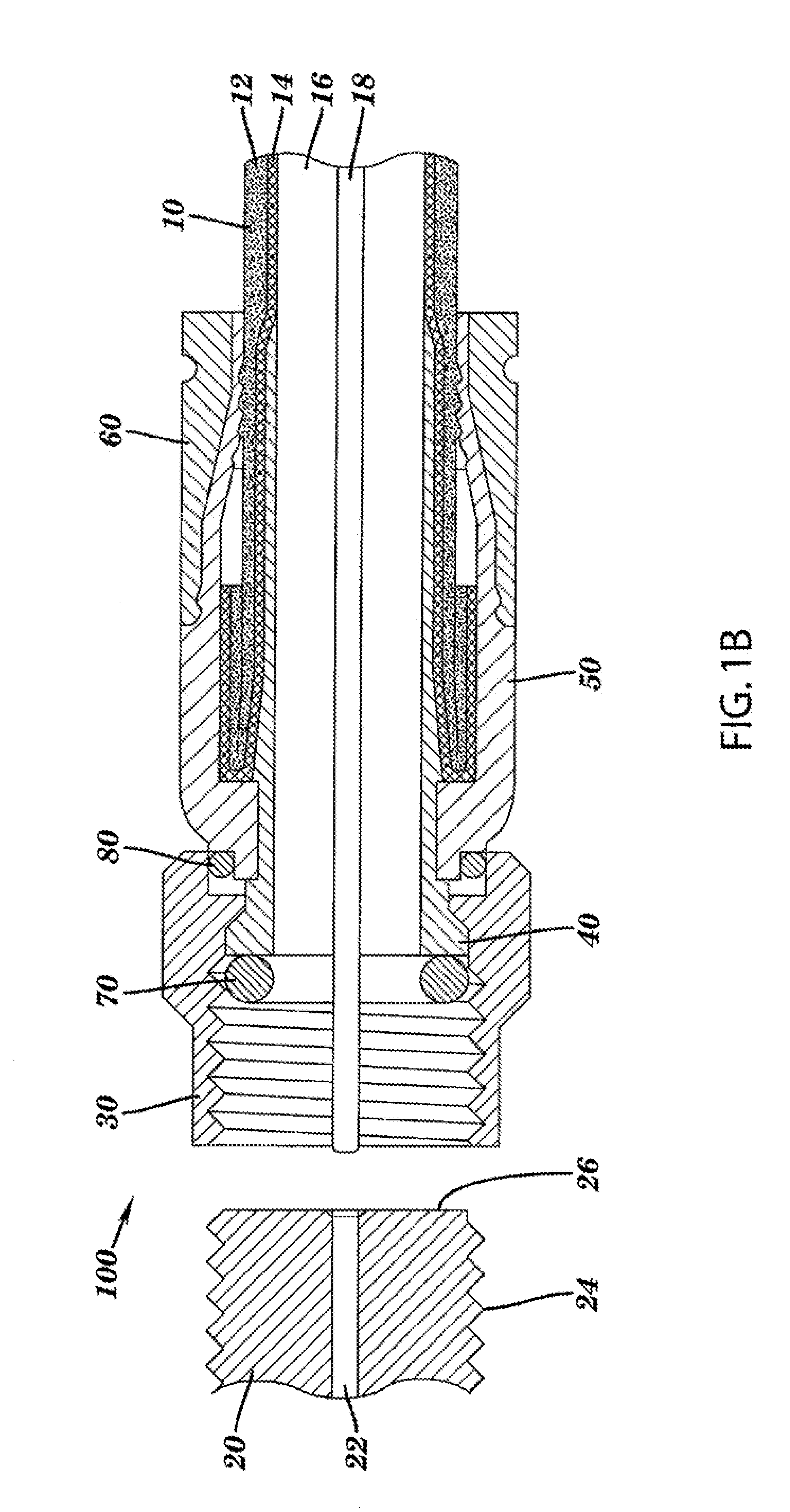

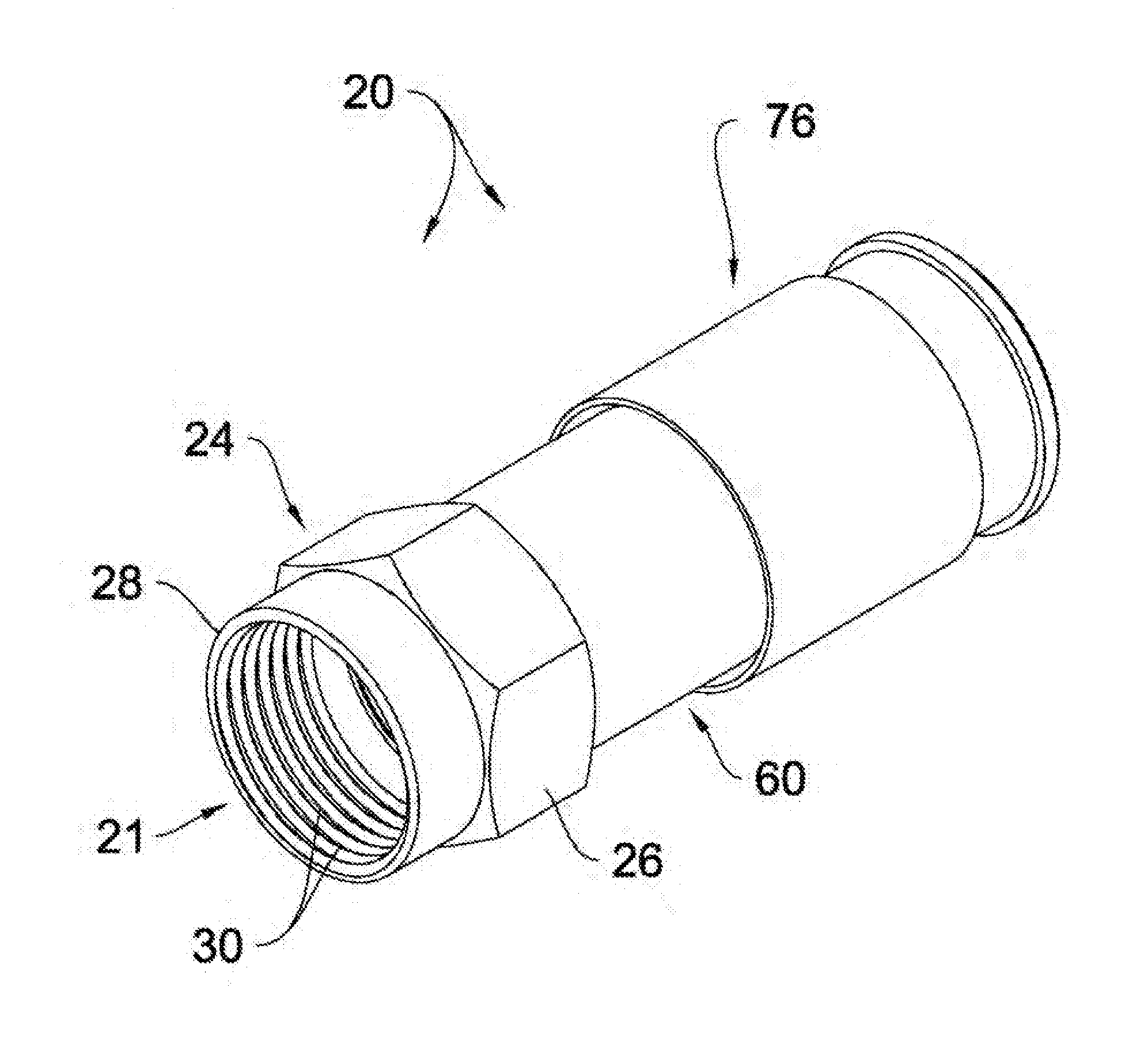

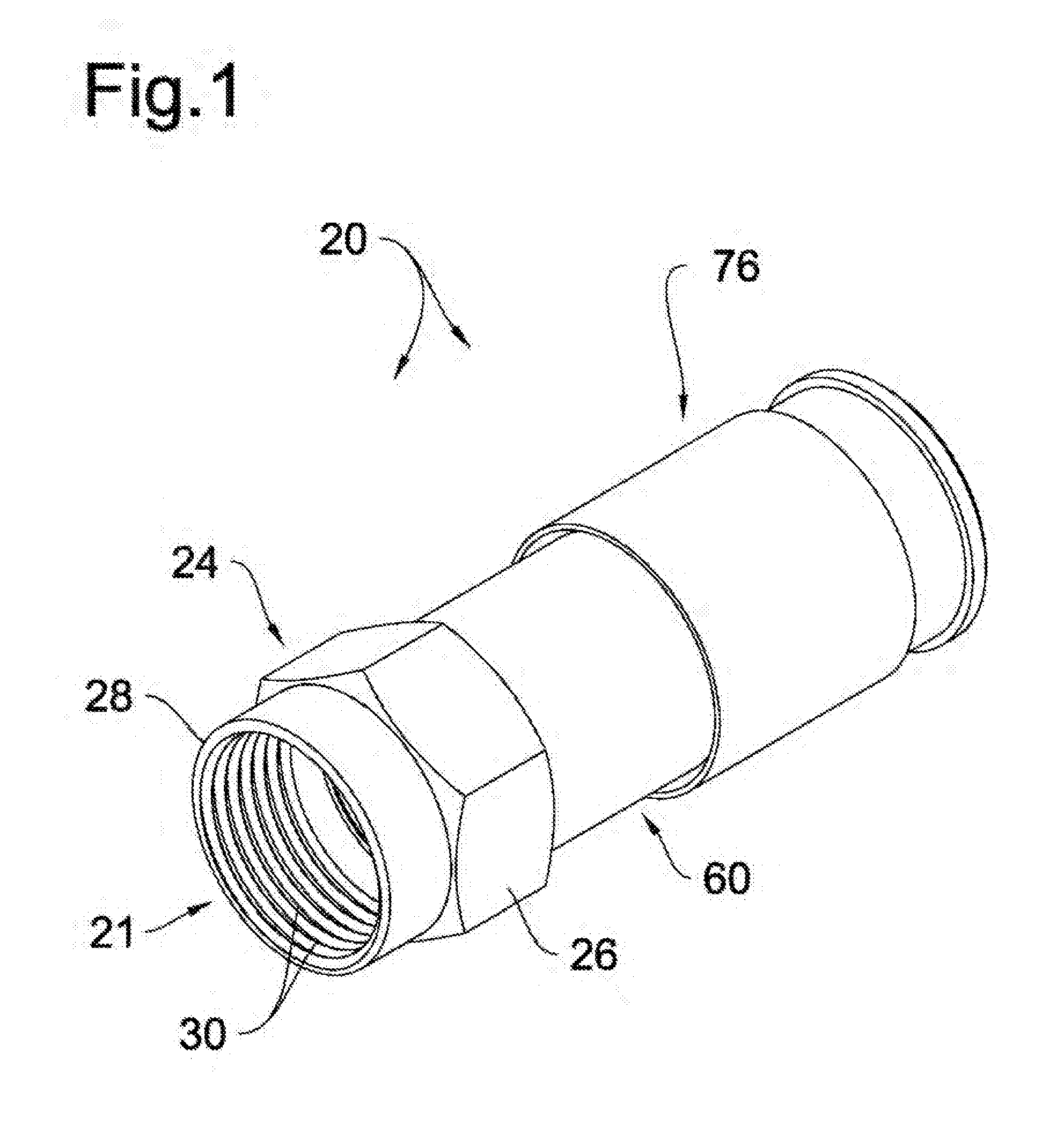

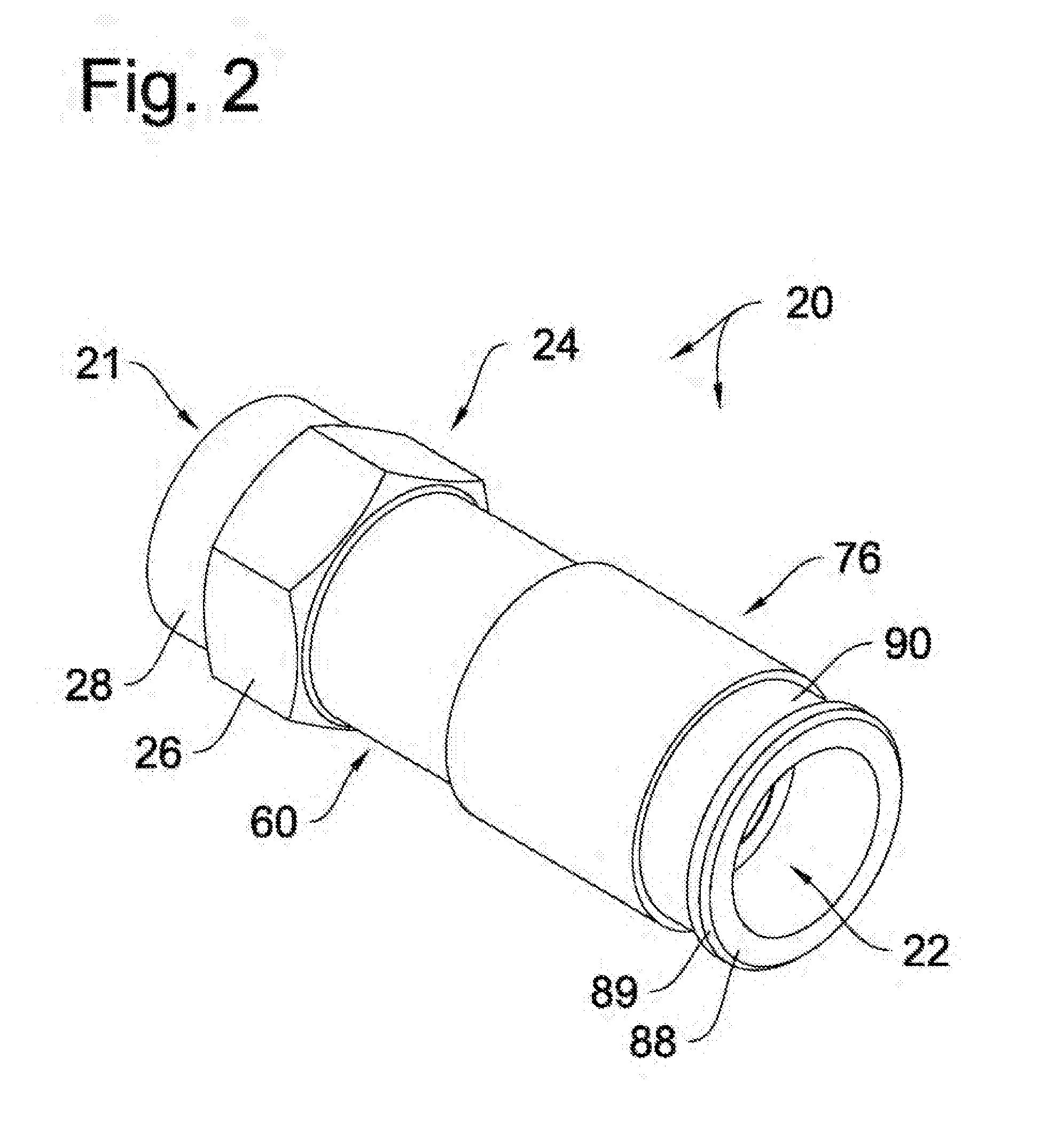

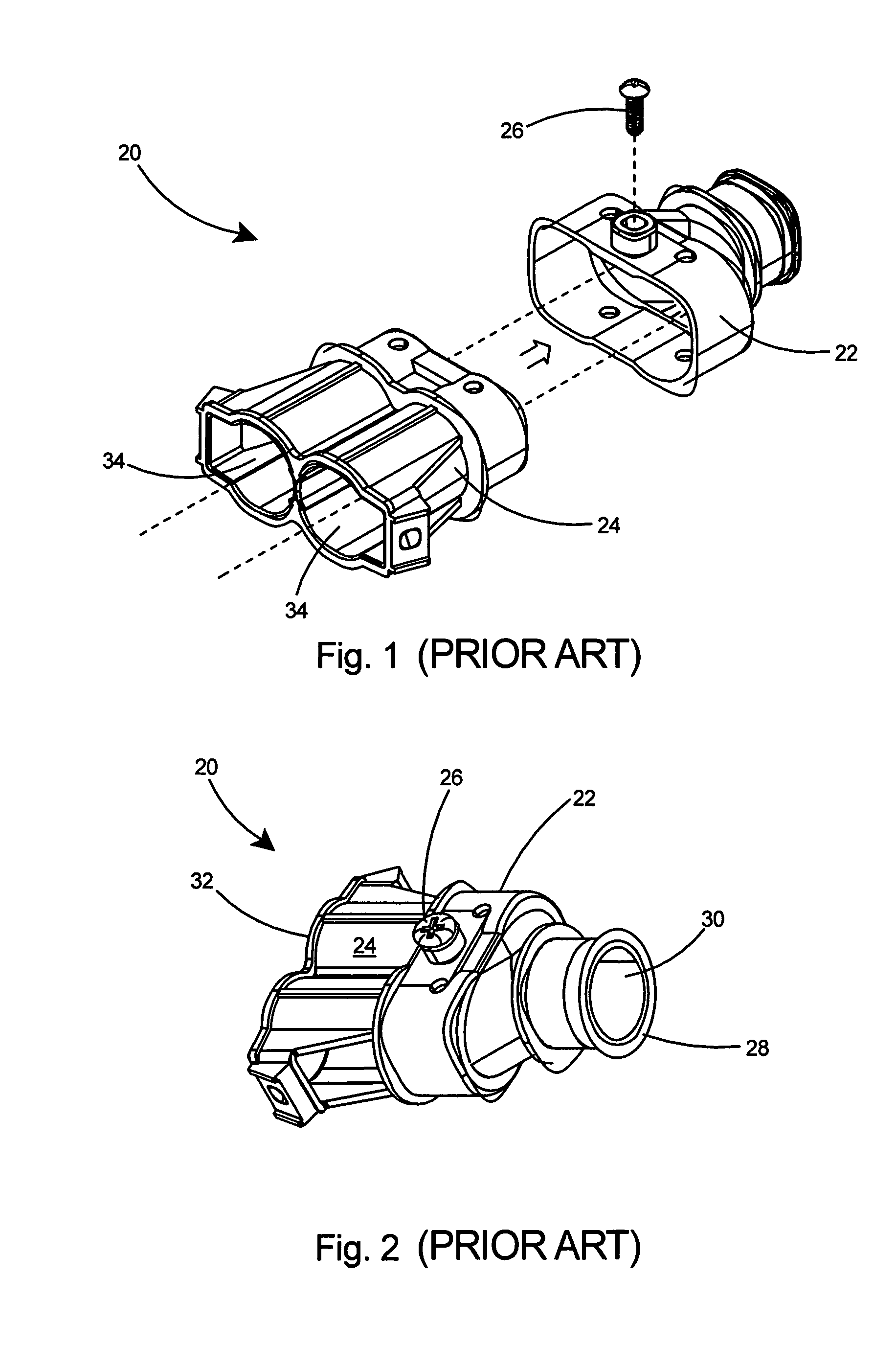

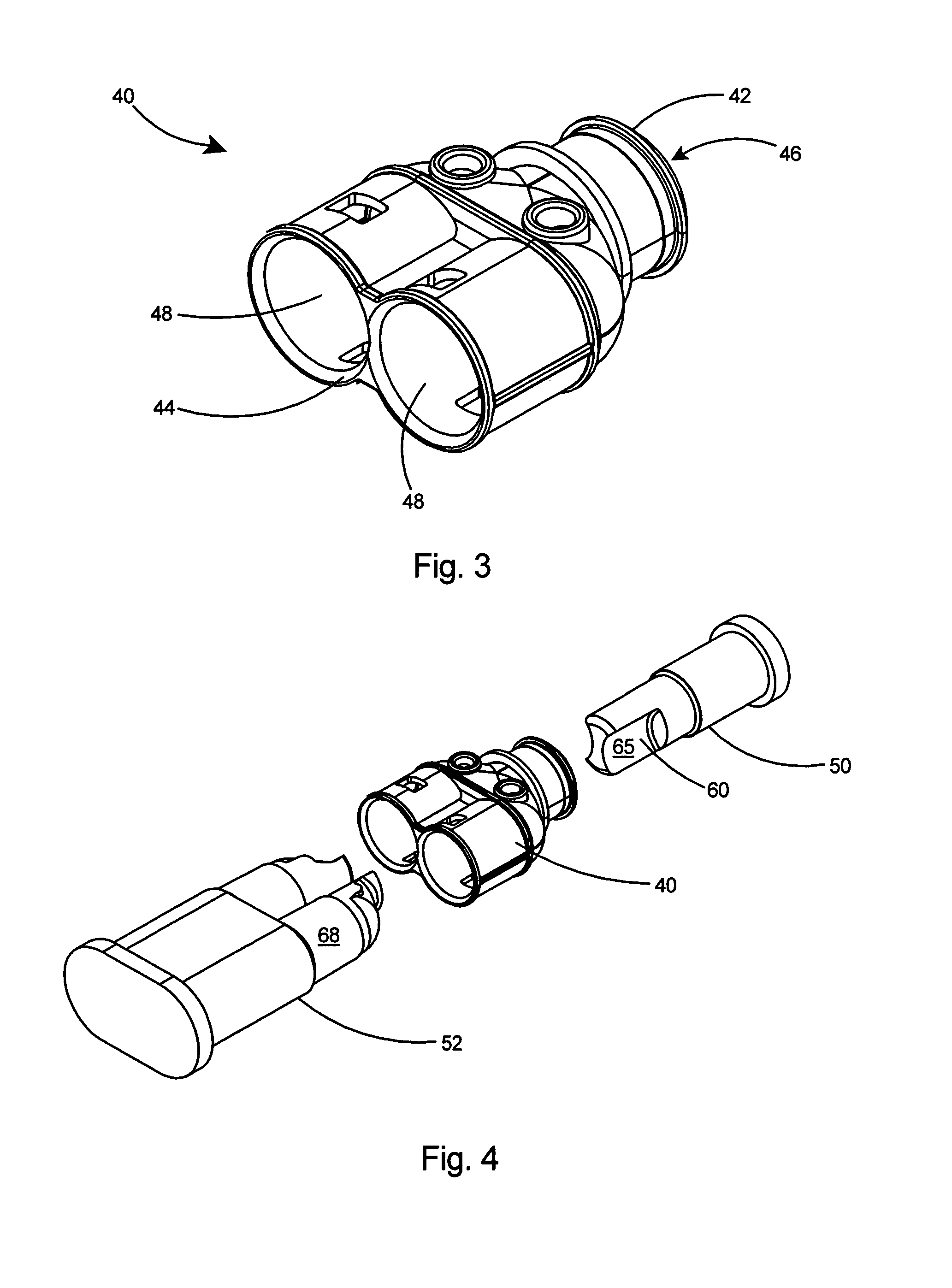

Connector having a conductively coated member and method of use thereof

ActiveUS20110230091A1Improve reliabilityEasy to GrindContact member manufacturingElectrically conductive connectionsEnvironmental noiseCoaxial cable

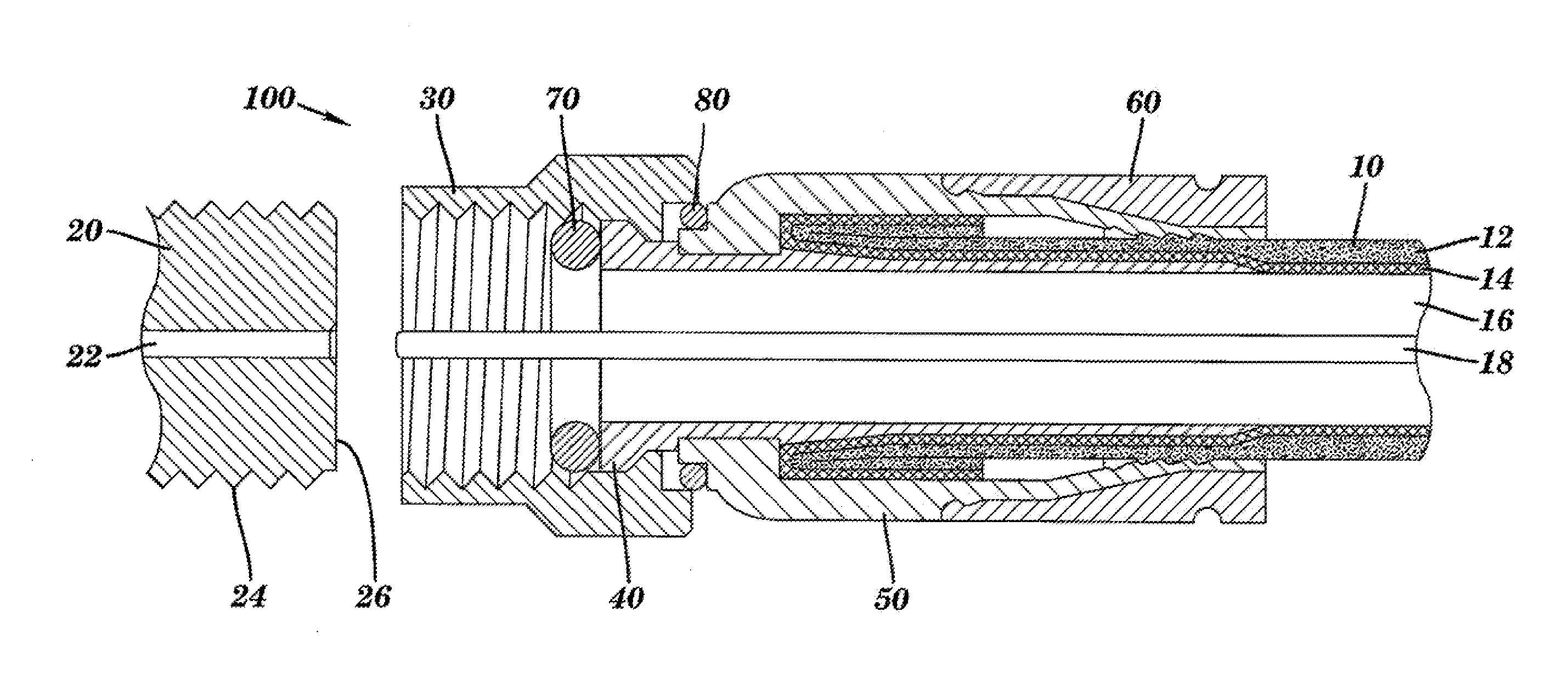

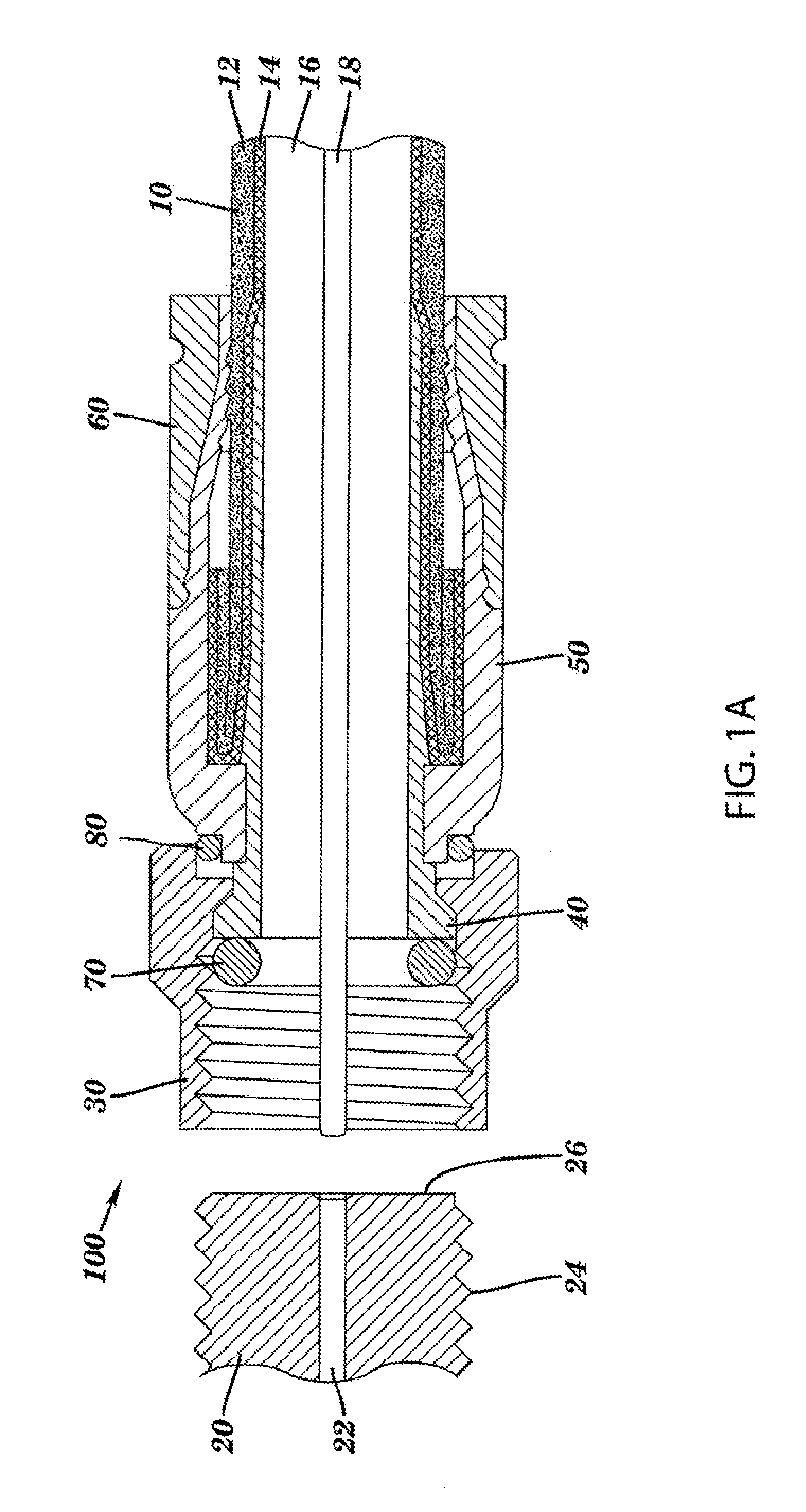

A connector having a conductively coated member is provided, wherein the connector comprises a connector body capable of sealing and securing a coaxial cable, and further wherein the conductively coated member, such as an O-ring, physically seals the connector, electrically couples the connector and the coaxial cable, facilitates grounding through the connector, and renders an electromagnetic shield preventing ingress of unwanted environmental noise.

Owner:PPC BROADBAND INC

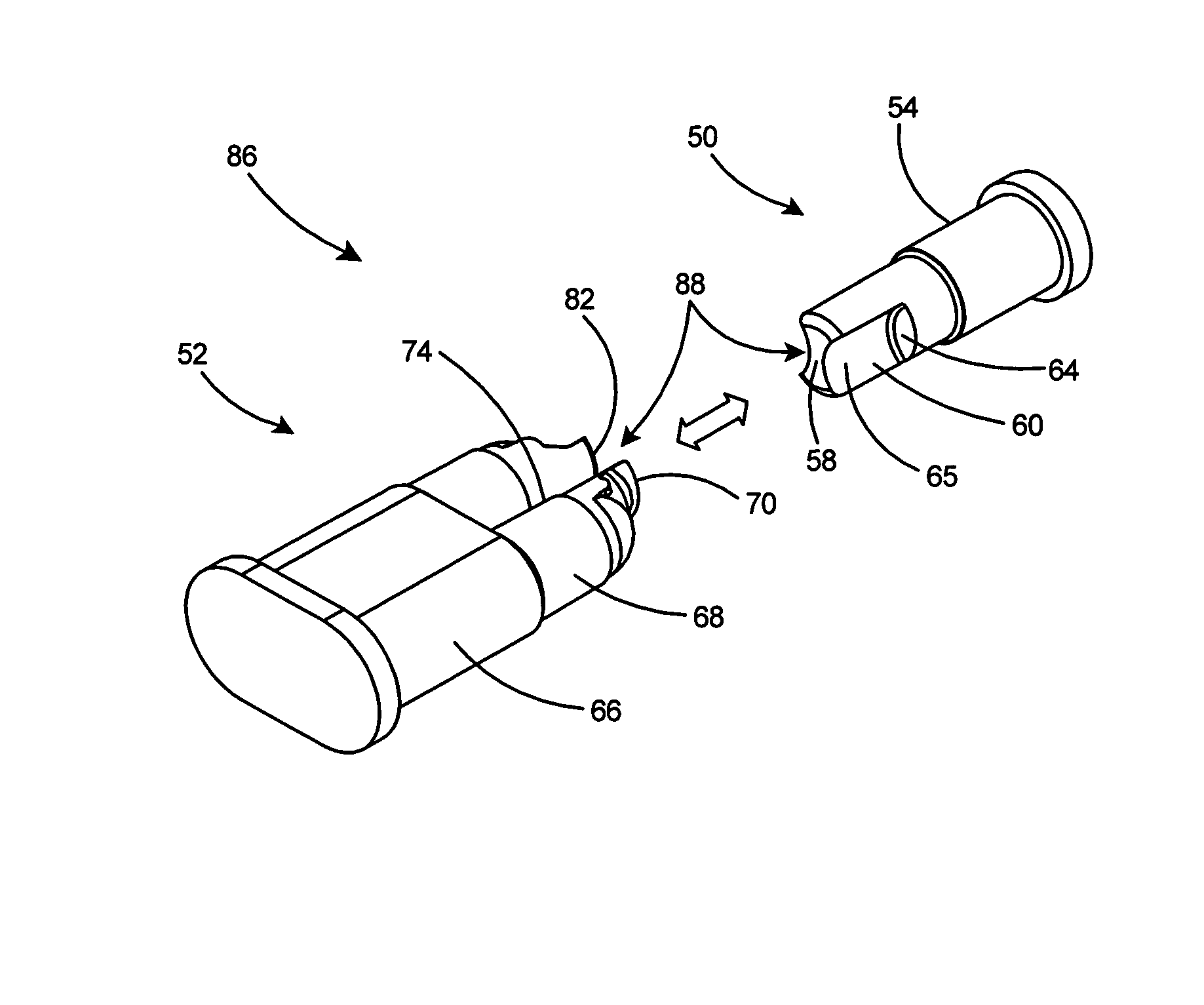

Connector having a conductively coated member and method of use thereof

ActiveUS8157589B2Improve reliabilityReliable electrical connectionElectrically conductive connectionsTwo pole connectionsCoaxial cableElectromagnetic shielding

A connector having a conductively coated member is provided, wherein the connector comprises a connector body capable of sealing and securing a coaxial cable, and further wherein the conductively coated member, such as an O-ring, physically seals the connector, electrically couples the connector and the coaxial cable, facilitates grounding through the connector, and renders an electromagnetic shield preventing ingress of unwanted environmental noise.

Owner:PPC BROADBAND INC

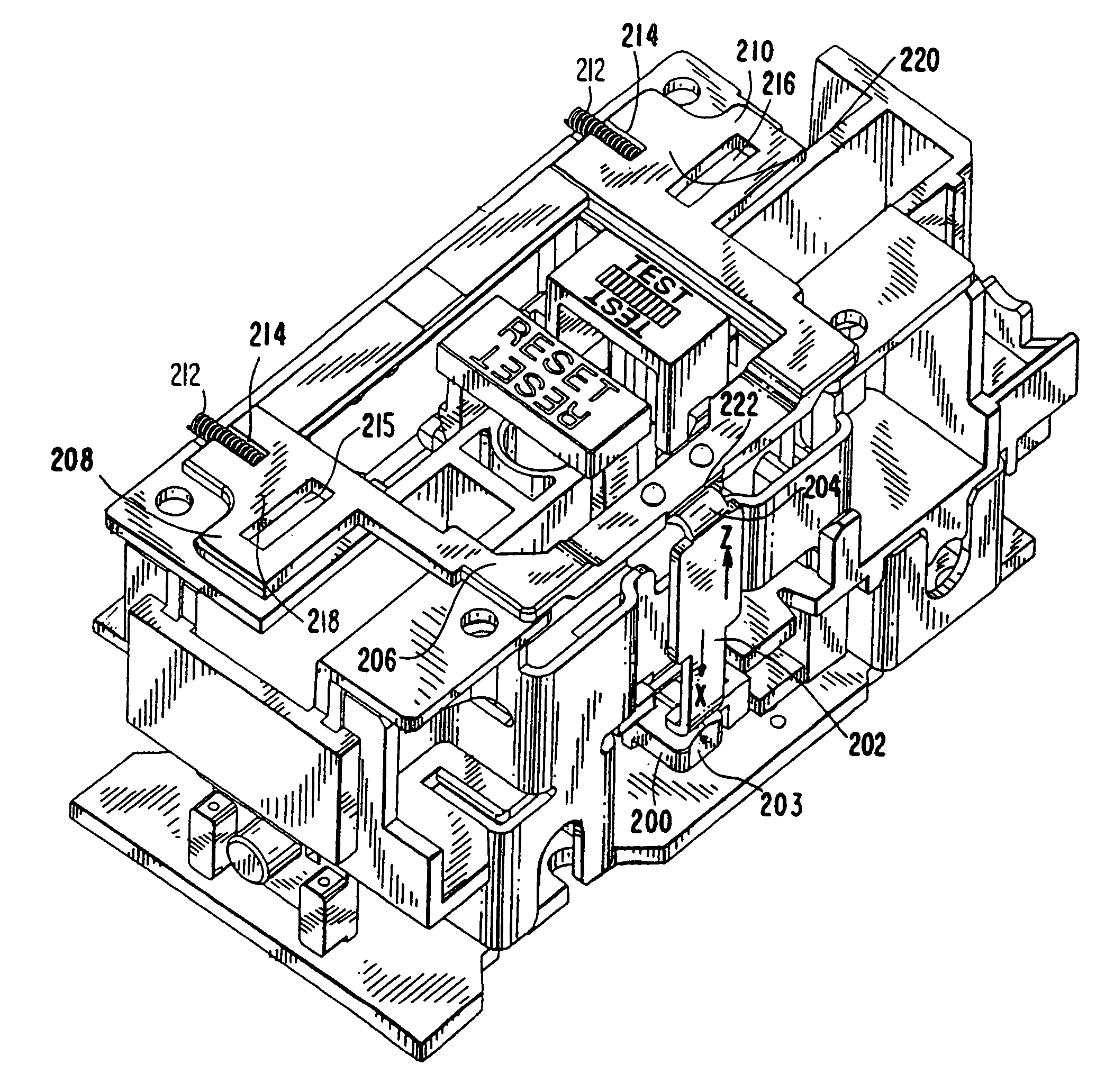

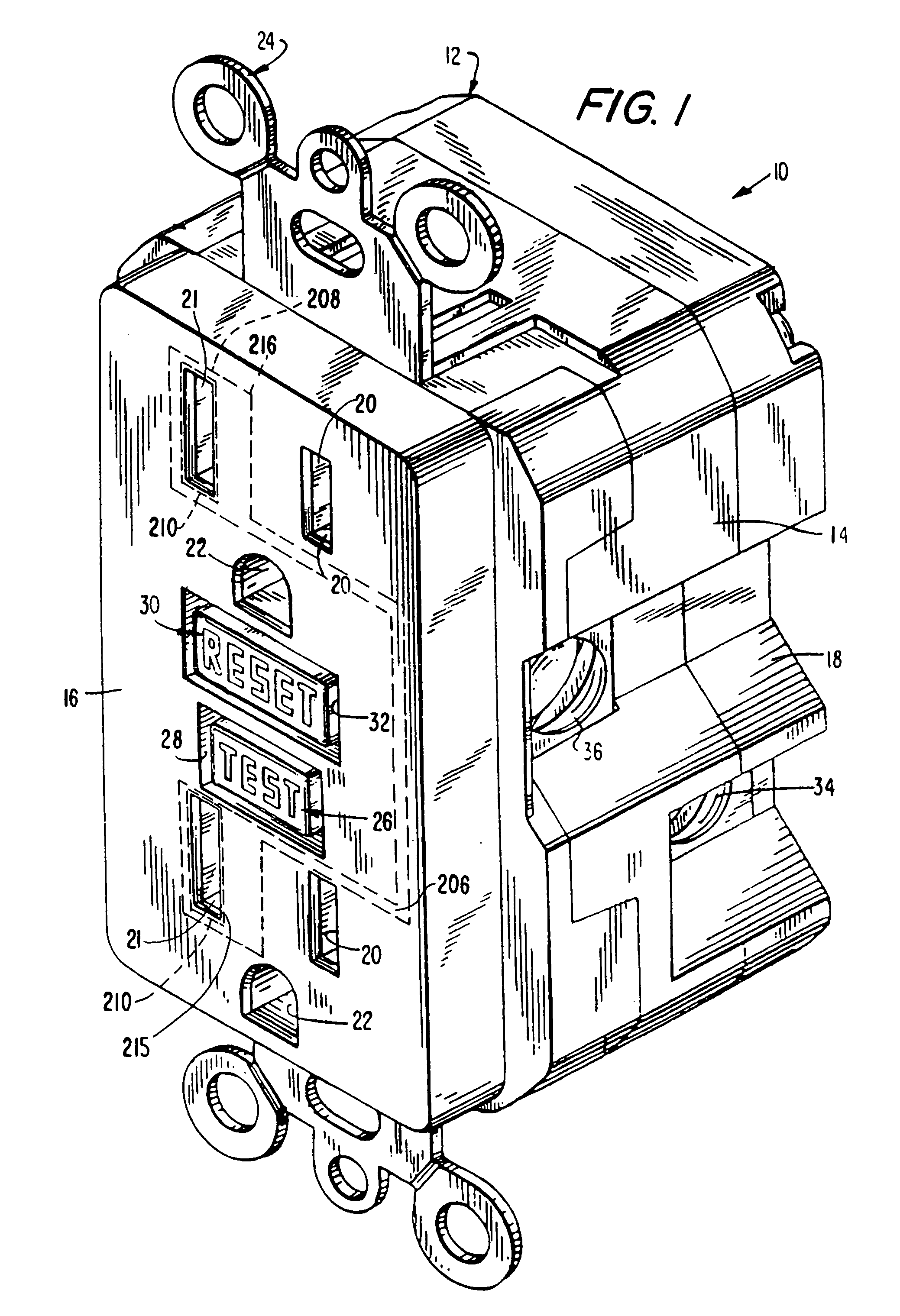

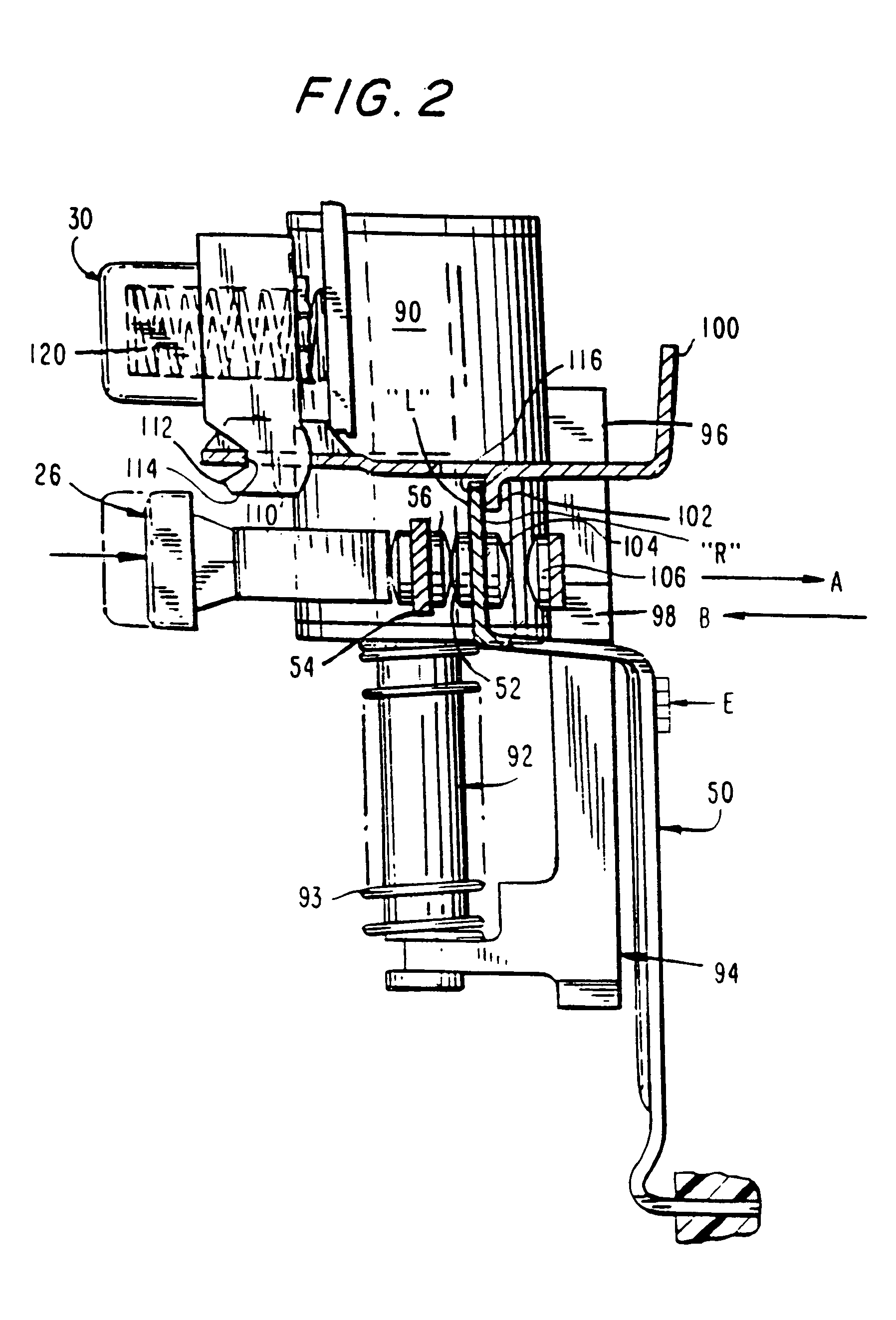

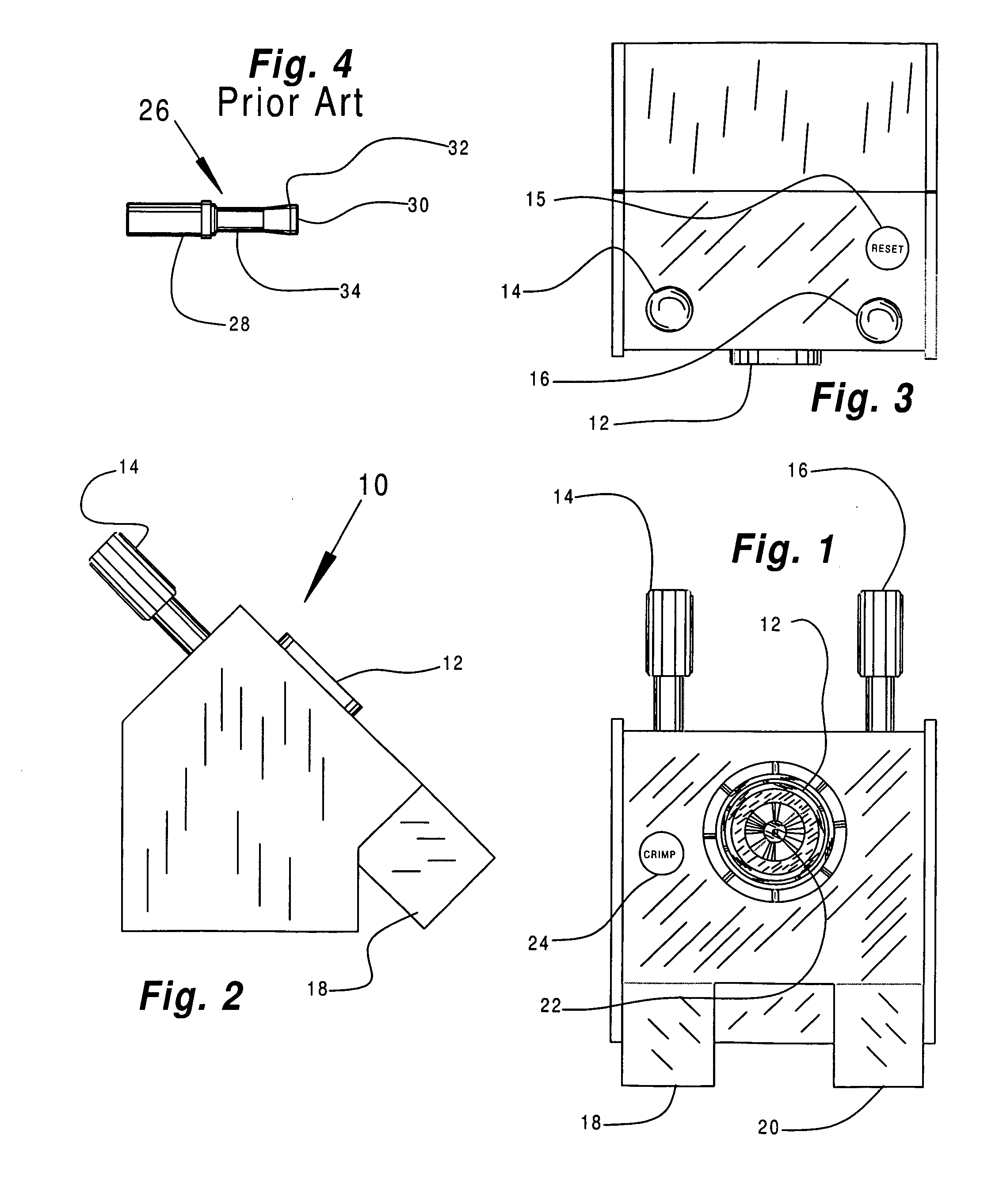

GFCI receptacle having plug blocking means

ActiveUS7026895B2Achieve electrical continuitySwitch operated by falling currentSwitch operated by earth fault currentsManufacturing cost reductionElectrical conductor

A shaped member having at least one window is located within a GFCI protected receptacle and is operated by movement of the contact arm of the GFCI to assume a first position to block at least one plug receiving opening in the receptacle and a second position which locates the window to allow the prong of a plug to freely enter the face of the receptacle. In operation, when the circuit interrupting device goes into a tripped state, the contact arm moves down to open the circuit. The downward movement of the contact arm, acting through a connecting linkage causes the shaped member to move to the first position, that of blocking at least one opening in the face of the receptacle. Resetting the circuit interrupting device by pressing in and then releasing the reset button of the GFCI causes the main contacts in the circuit interrupting device to close by the upward movement of the contact arm. As the contact arm moves up, it moves the connecting linkage to position the window of the shaped member to allow the prongs of a plug to freely enter the openings in the face of the receptacle. GFCI's normally have two separate sets of internally located contacts known as bridge contacts, one set for connecting a load to the source of electricity and a second set for connecting a user accessible load to the source of electricity. In the GFCI here disclosed the bridge contacts have been eliminated, thus reducing the cost of manufacture by coupling the conductors for both the load and the user accessible load to a single set of contacts.

Owner:LEVITON MFG

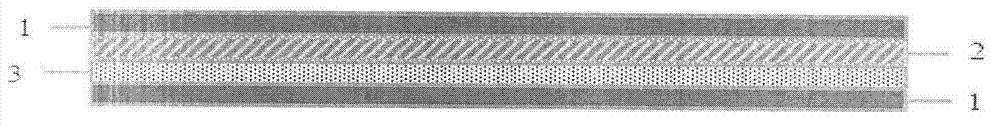

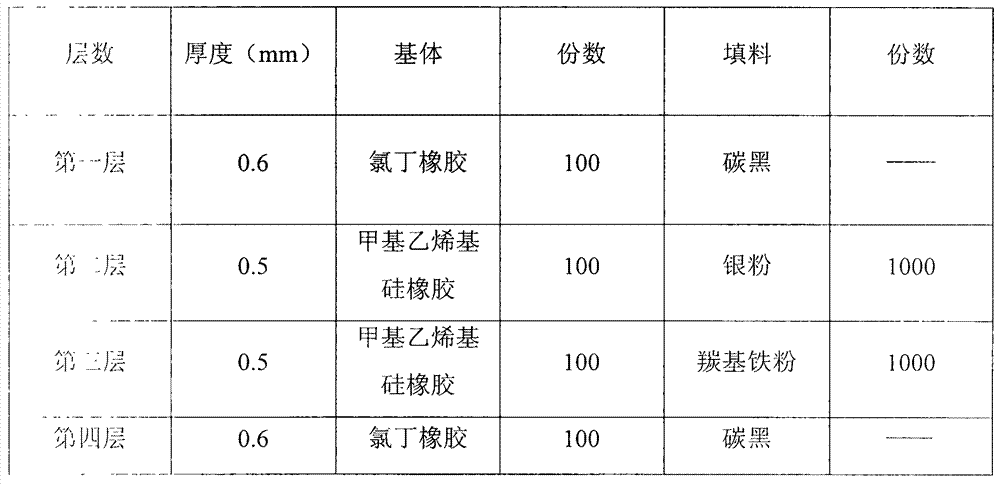

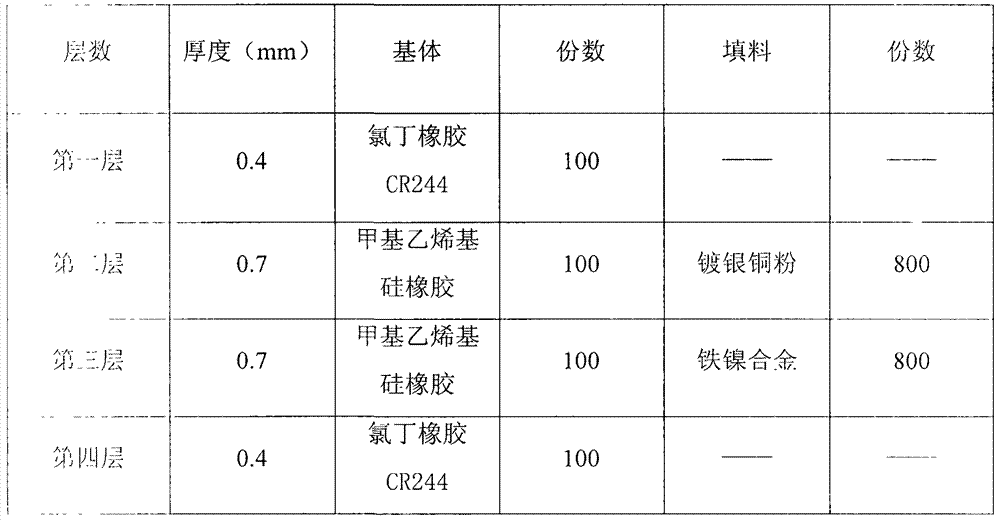

Electromagnetic shielding composite rubber material and preparation method thereof

ActiveCN104494241AAchieve electrical continuityImprove shielding effectLaminationLamination apparatusRubber materialBroadband

The invention provides an electromagnetic shielding composite rubber material, which is of a laminated structure, and comprises a shielding layer and a protective layer which are arranged from inside to outside, wherein the shielding layer comprises a conductive silicone rubber layer and a magnetic conductive silicone rubber layer, and the protective layer is a rubber layer. The shielding layer of the electromagnetic shielding composite rubber material comprises the conductive silicone rubber layer and the magnetic conductive silicone rubber layer, has an electromagnetic shielding performance in a broadband, wide shielding range and high shielding effectiveness, and can be widely used for electromagnetic shielding of electric power, electronics and other industries, and the protective layer selects rubber, and has excellent air tightness, and excellent watertight and mechanical properties, so that the overall strength of the composite material can be improved, the air is isolated, and the oxidation of the conductive filler is slowed, and thus the service life of the shielding material is prolonged, the service performances of the shielding material can be improved, and the shielding effectiveness of the material keeps stable as the service time increases.

Owner:STATE GRID CORP OF CHINA +2

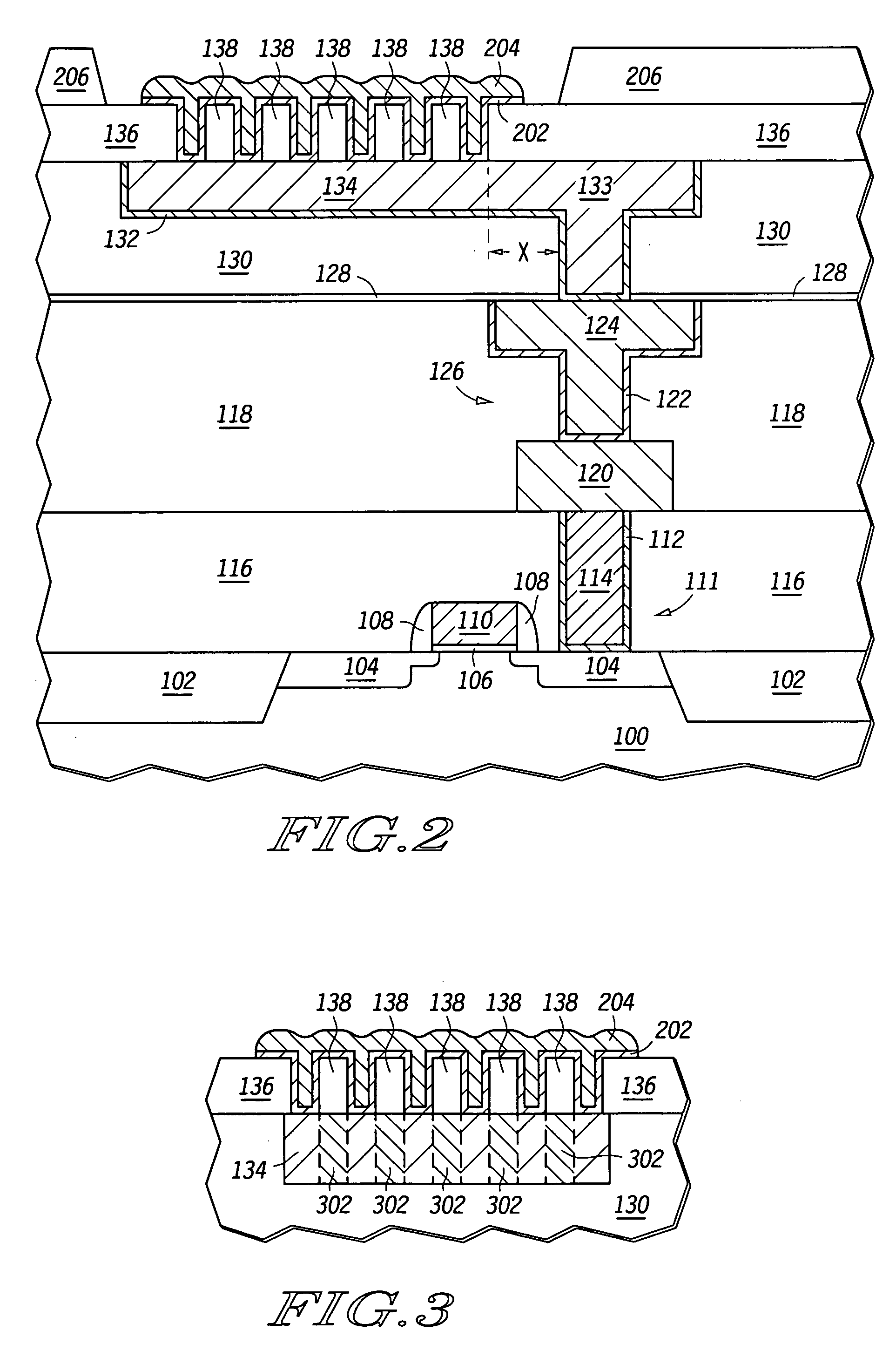

Method for forming a bond pad interface

InactiveUS20050014356A1Achieve electrical continuityReduced strengthSemiconductor/solid-state device detailsSolid-state devicesSemiconductorMaterials science

Owner:NXP USA INC

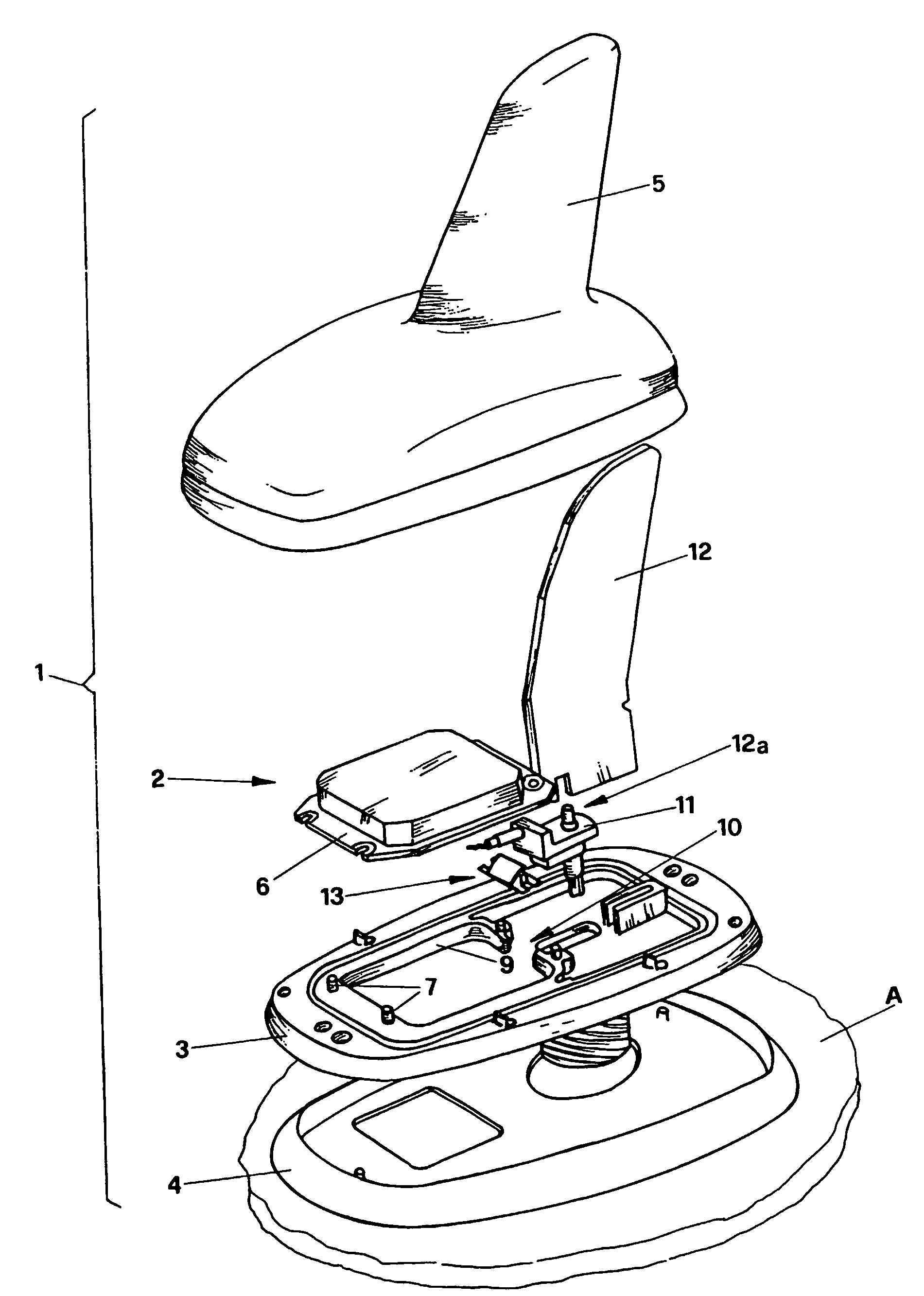

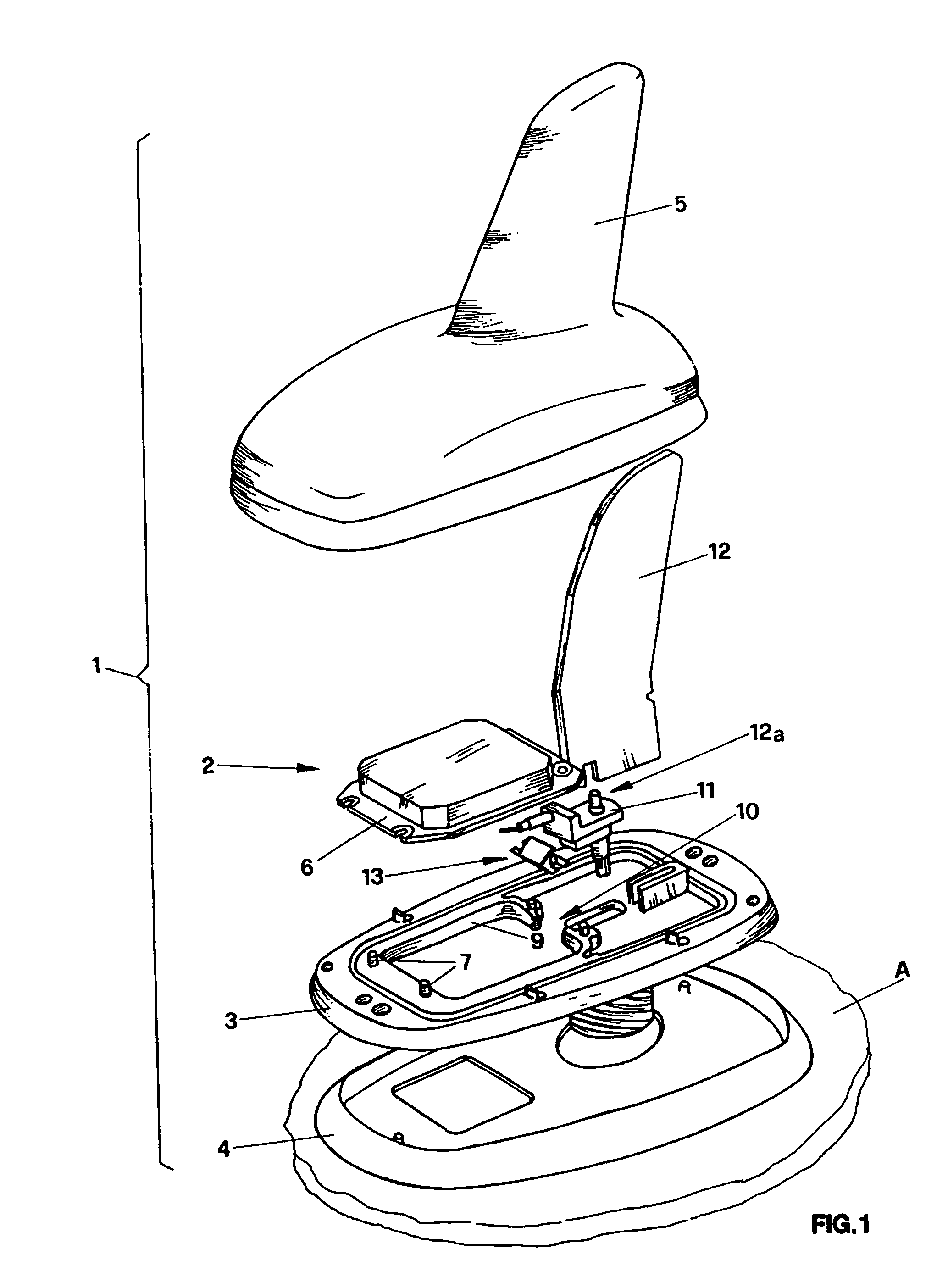

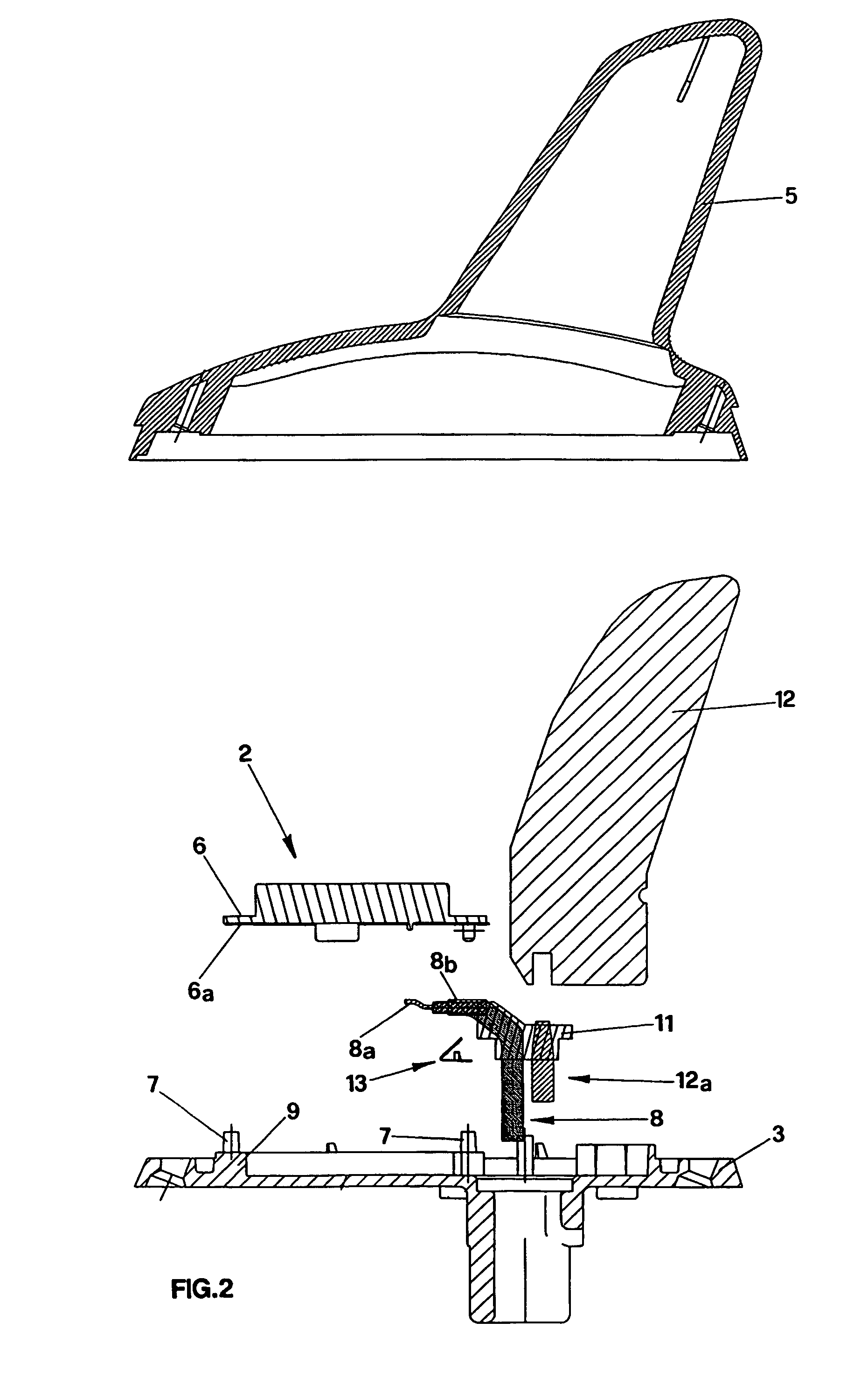

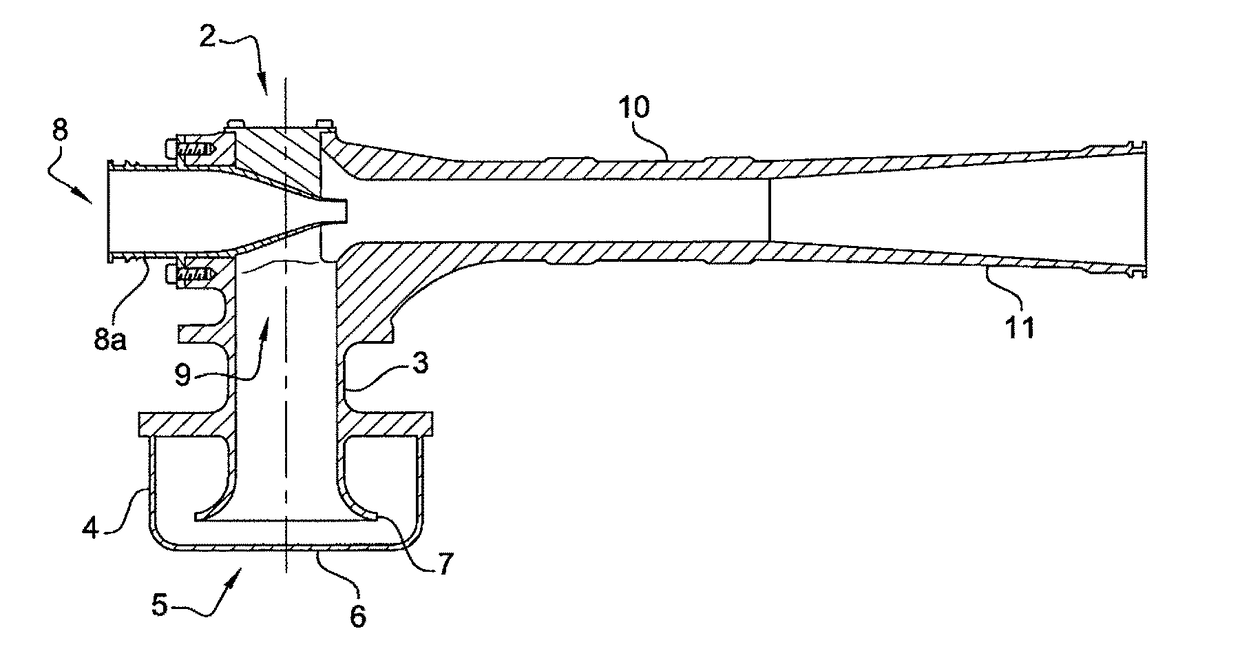

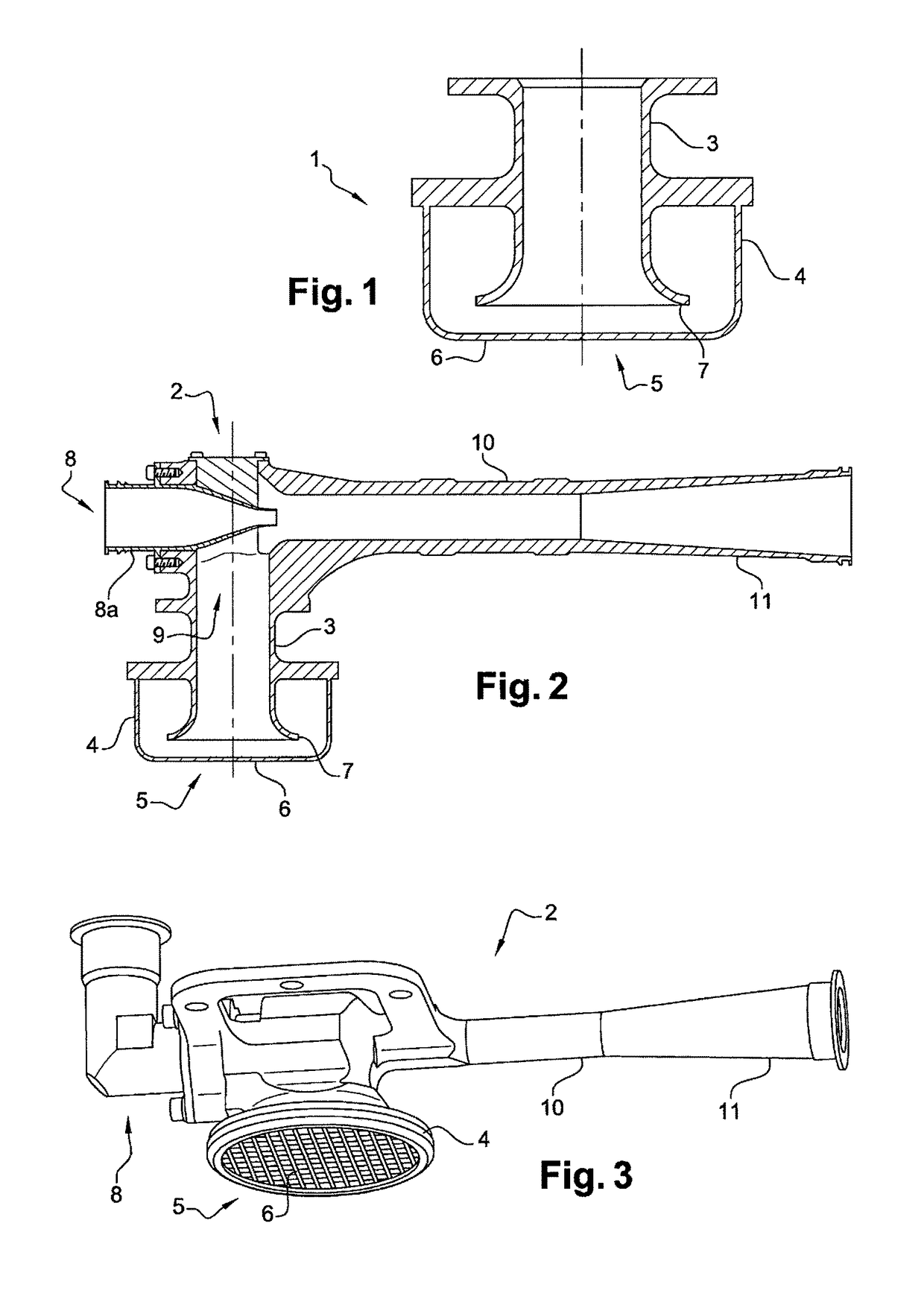

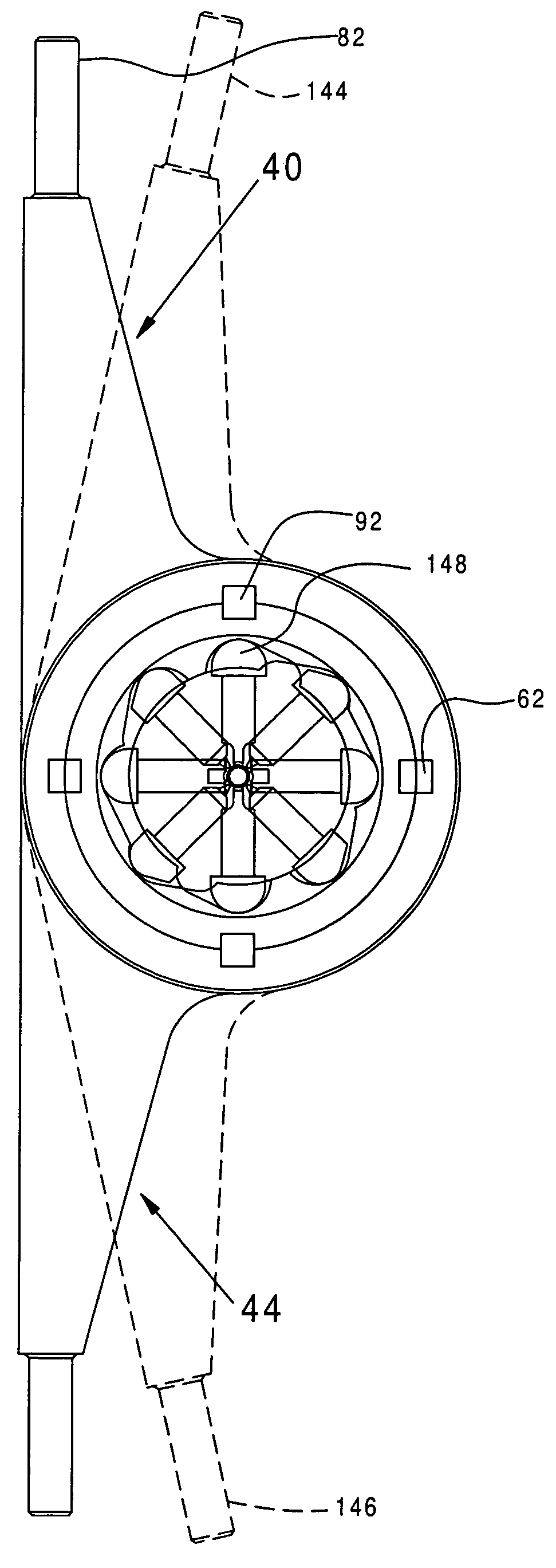

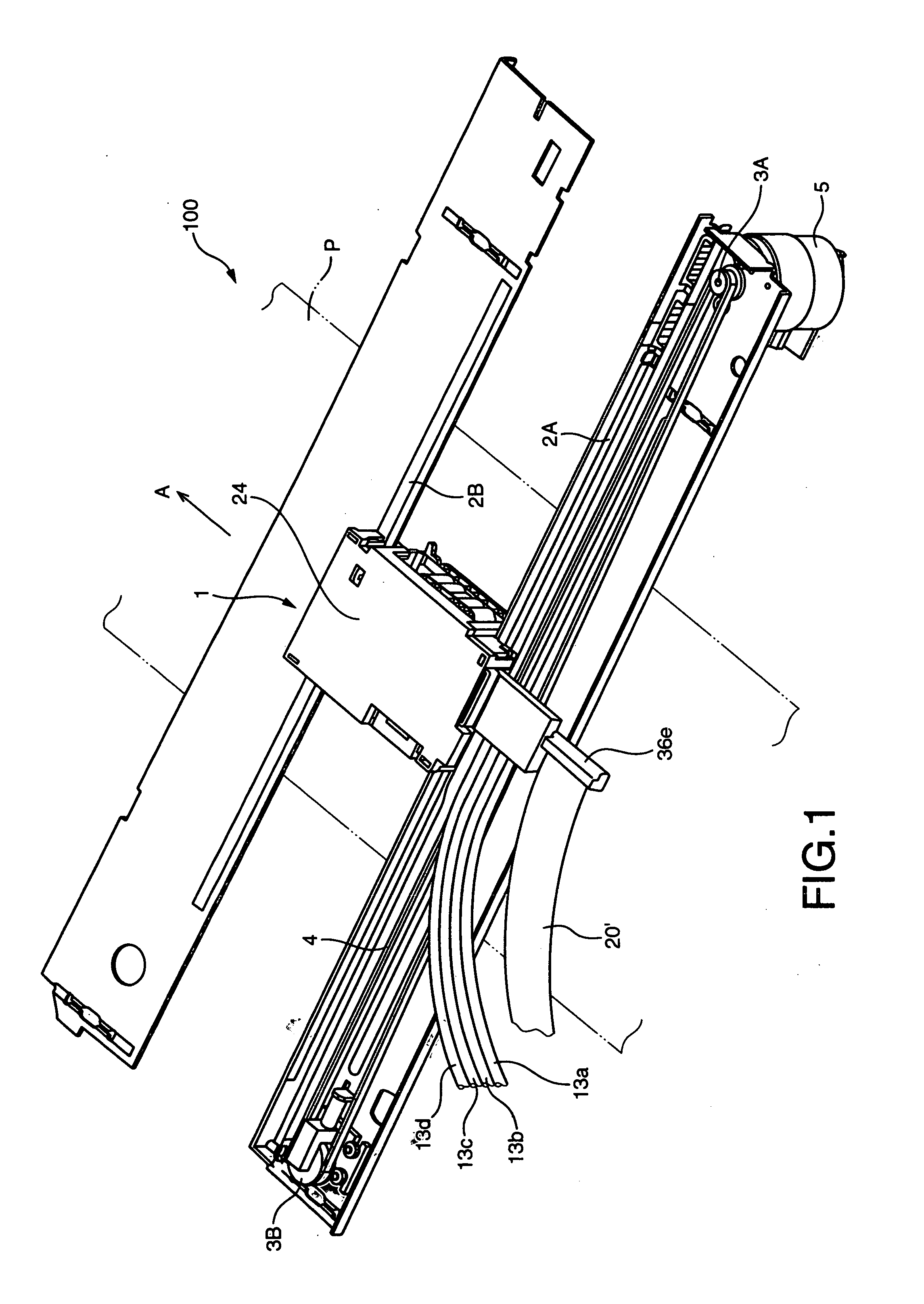

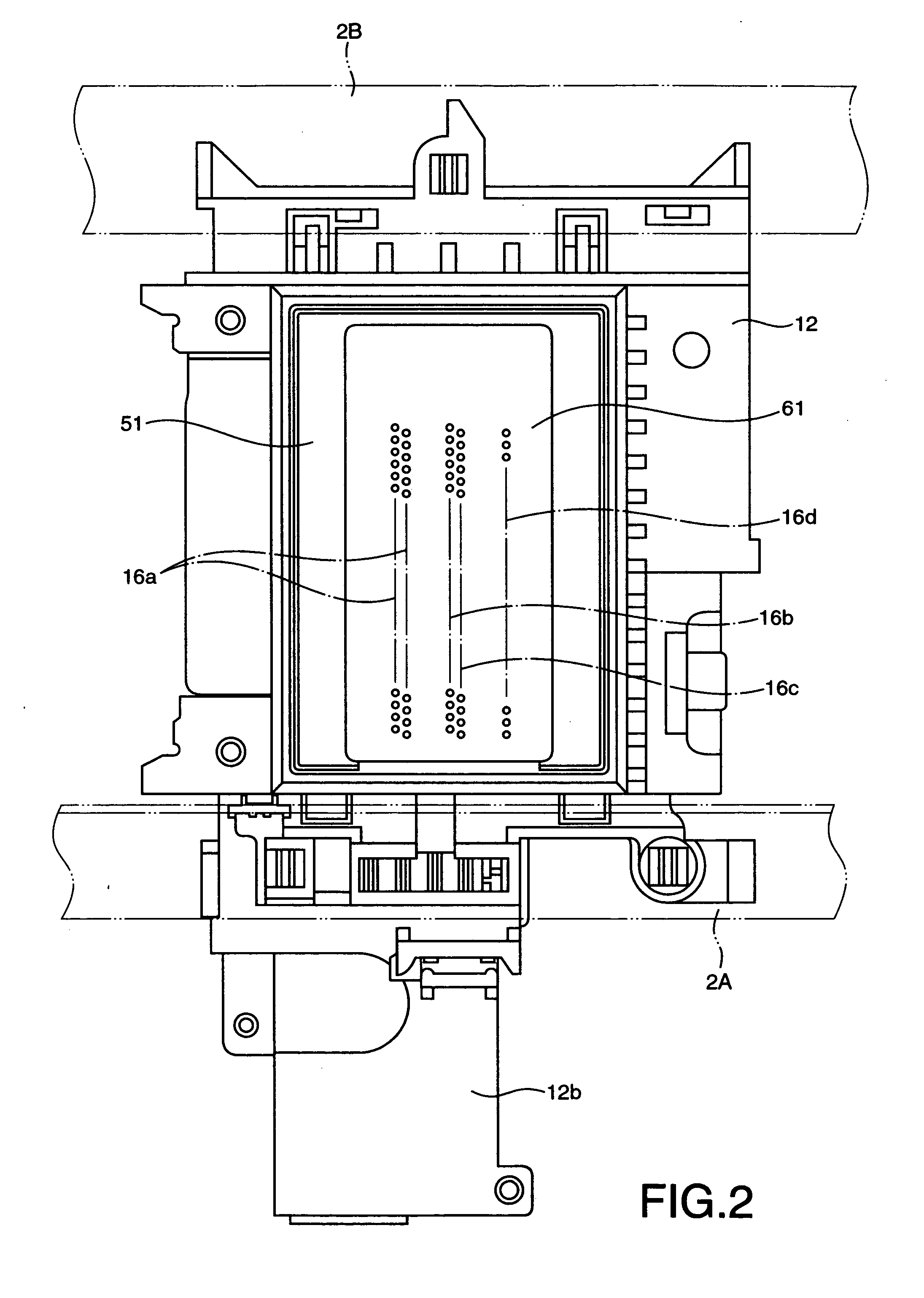

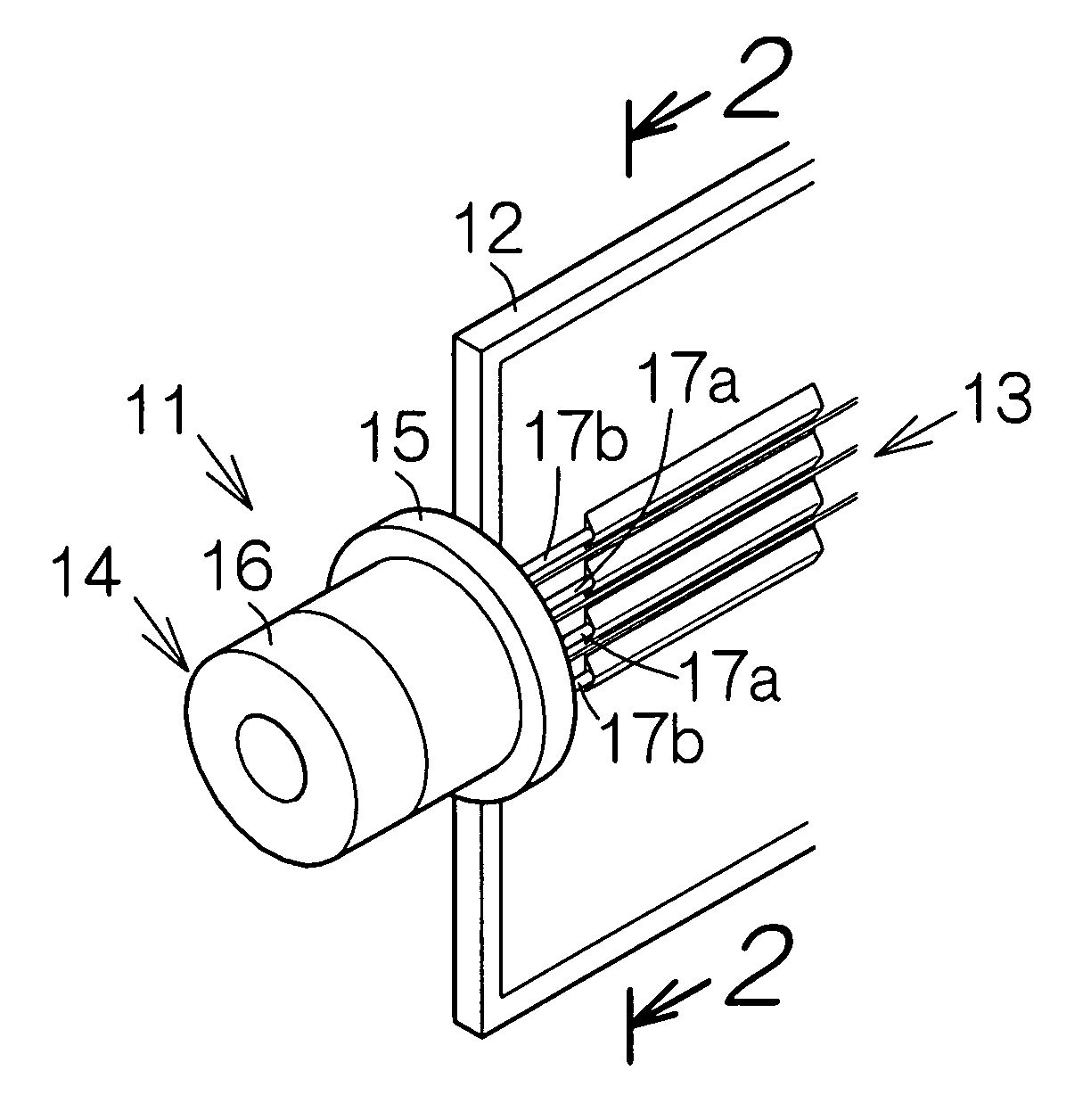

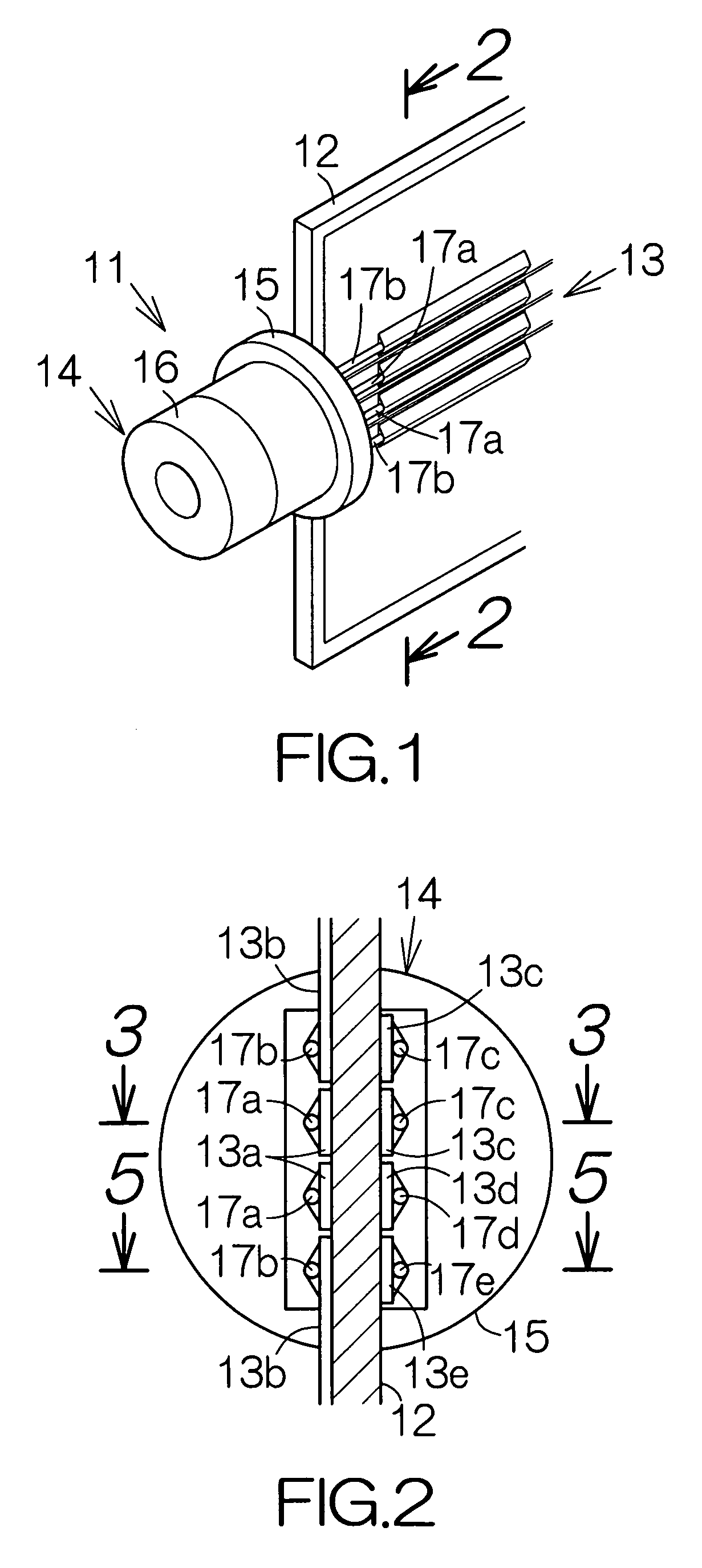

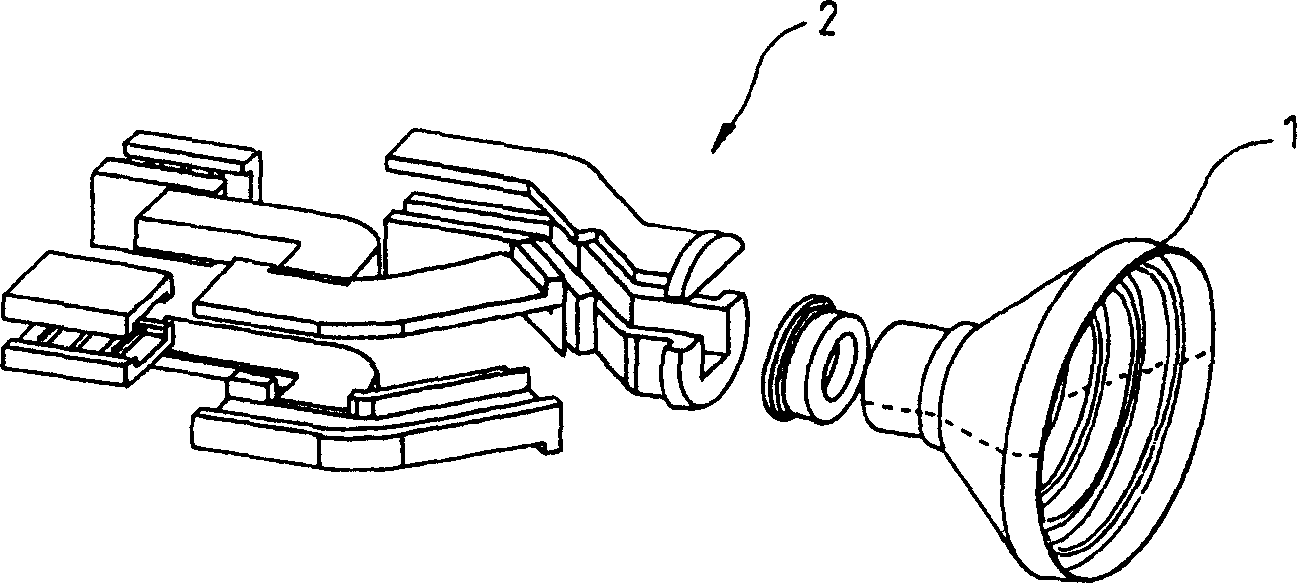

Vehicular antenna with improved screening

ActiveUS7091912B2Quicker and simpler and less-expensive to constructQuick filterAntenna supports/mountingsAntenna adaptation in movable bodiesCoaxial cableEngineering

vehicle antenna (1) comprising a satellite signal amplifier and / or receiver circuit (2) assembled on a board (6), an antenna base (3) for support of said board (6), applicable to the structure of a vehicle (A), connection means (7) to mechanically fix said board (6) to said antenna base (3), a coaxial cable (8) that connects the satellite signal amplifier and / or receiver circuit (2) to a receiving apparatus installed in the vehicle (A). Between the antenna base (3) and the board (6) electro-conductive elastic means (13) are interposed to achieve electricity continuity between the antenna base (3) and the metallic braiding (8b) of the coaxial cable (8) when the connection means (7) fix the board (6) to the antenna base (3).

Owner:CALEARO ANTENNE SRL

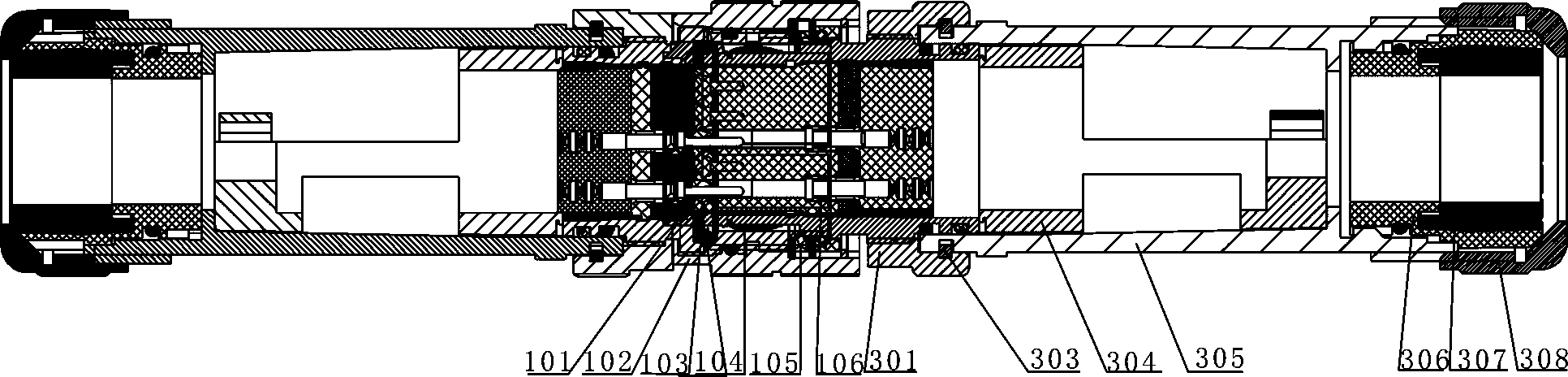

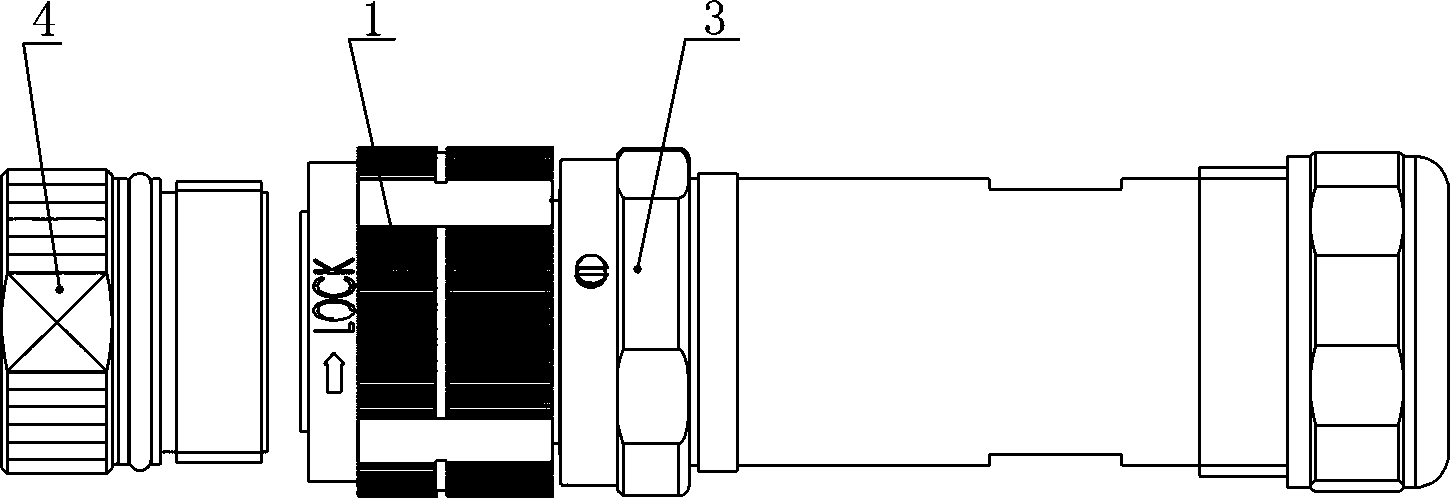

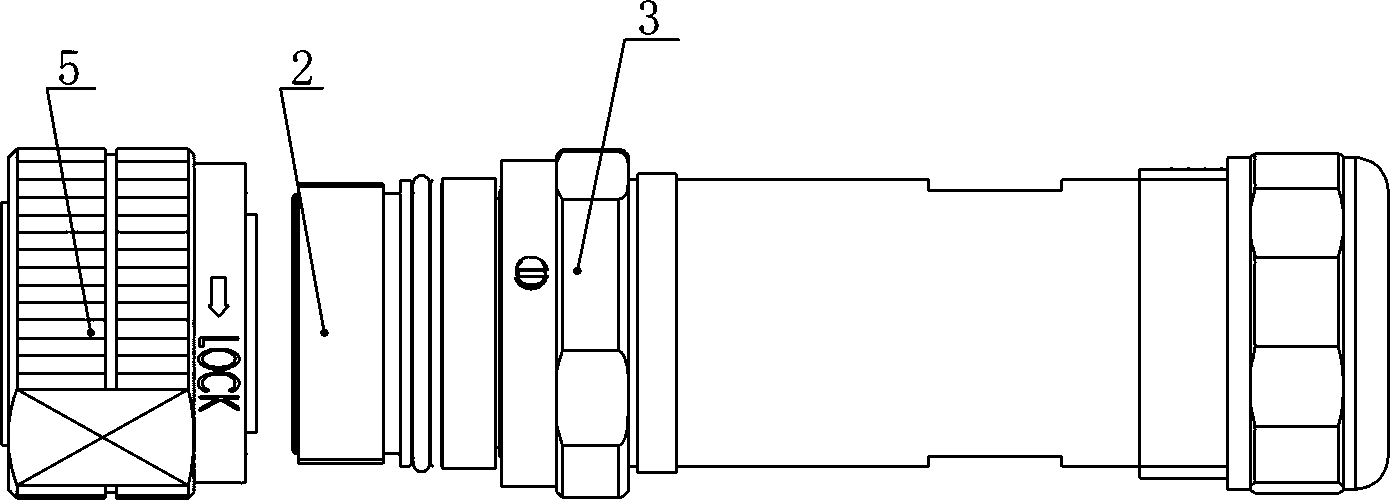

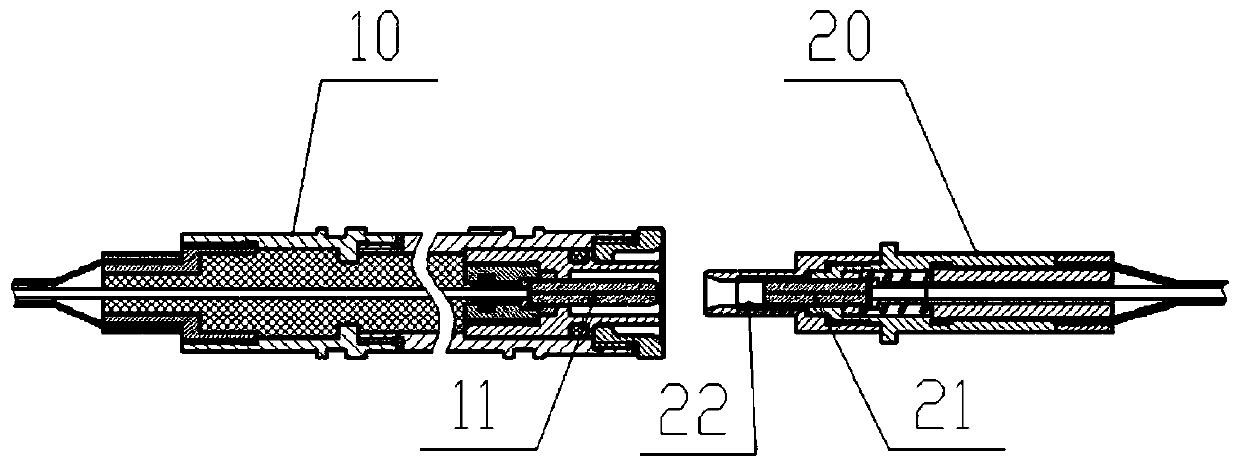

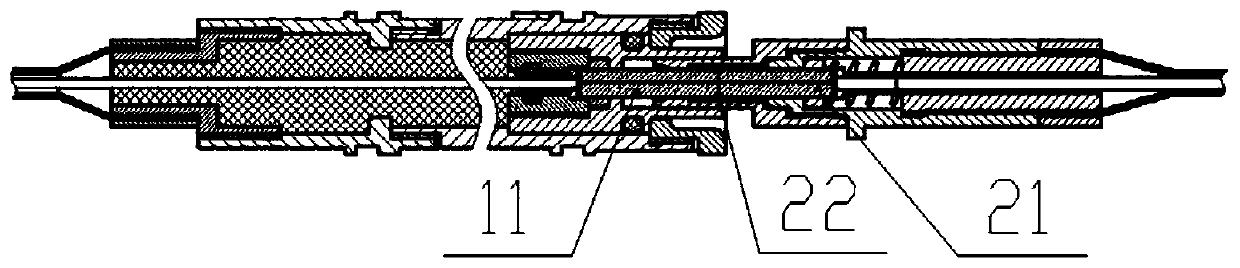

Shielded, sealed and anti-rotation circular connector

ActiveCN103682841ASealed cable rotationPrevents the cable from turningRelieving strain on wire connectionCouplings bases/casesEngineeringMechanical engineering

The invention discloses a shielded, sealed and anti-rotation circular connector which comprises a plug and a socket. The plug comprises a plug shell assembly and a tail assembly, and the socket comprises a socket shell assembly and a tail assembly; the plug shell assembly comprises components including a shell, a connecting ring, jacks, a shielding ring, a locking backstop mechanism, toothed sleeves, insulator assemblies and the like; the socket shell assembly comprises components including a socket shell, pins, a U-shaped sealing ring, a boundary sealing pad, insulator assemblies, toothed sleeves and the like; each tail assembly comprises a connecting nut, a sleeve, a cone-point set screw, elastic parts, a shielding bushing and the like. The shielded, sealed and anti-rotation circular connector has the advantages that after the plug is connected with the socket, a cable shielding layer without skin is directly clamped by the shielding bushings of the tail assemblies of the plug and the socket, so that the connector and a cable can be circularly shielded and can be prevented from being pulled by external force; the connecting nuts are fixedly connected with the sleeves by the elastic parts, and the sleeves are driven to axially move when internal threads on the connecting nuts are matched with external threads on the plug shell / the socket shell, so that the sleeves and the shells can be sealed.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

Method Of Manufacturing A Strainer, A Strainer, And An Ejector Comprising Such A Strainer

ActiveUS20170291714A1Simple designEasy to processAdditive manufacturing apparatusPower plant fuel tanksEngineeringGuide tube

Owner:SAFRAN AEROTECHNICS

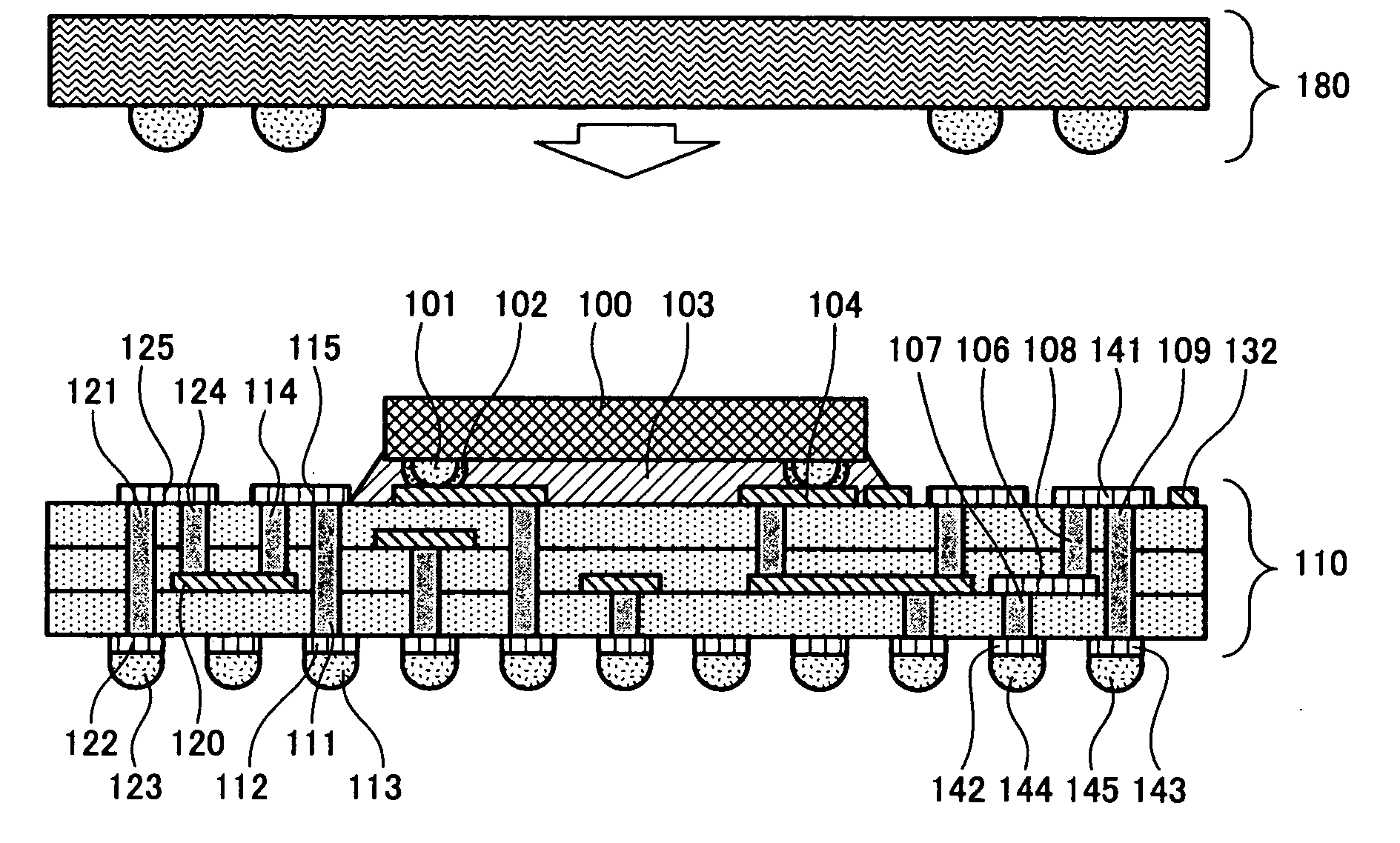

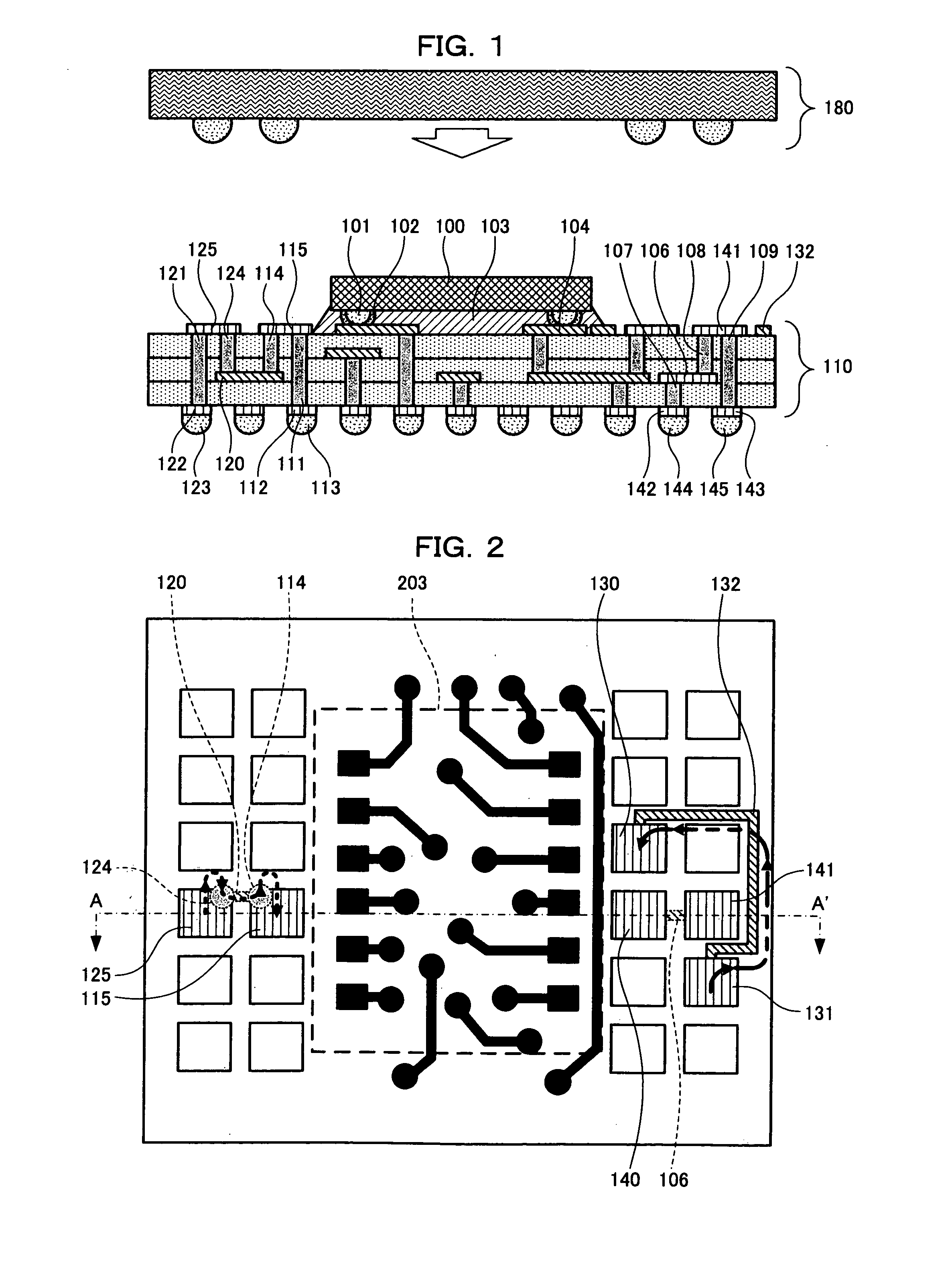

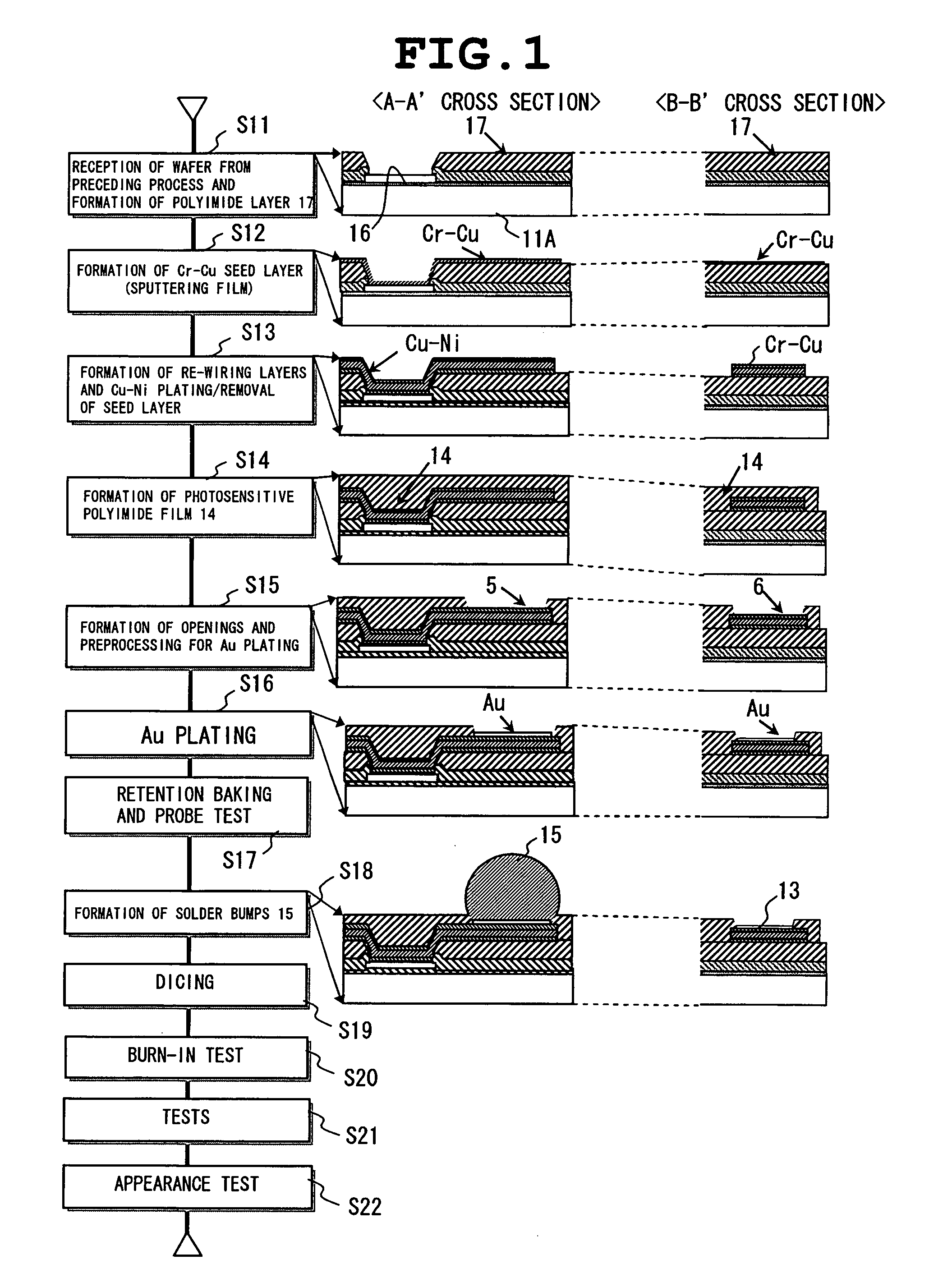

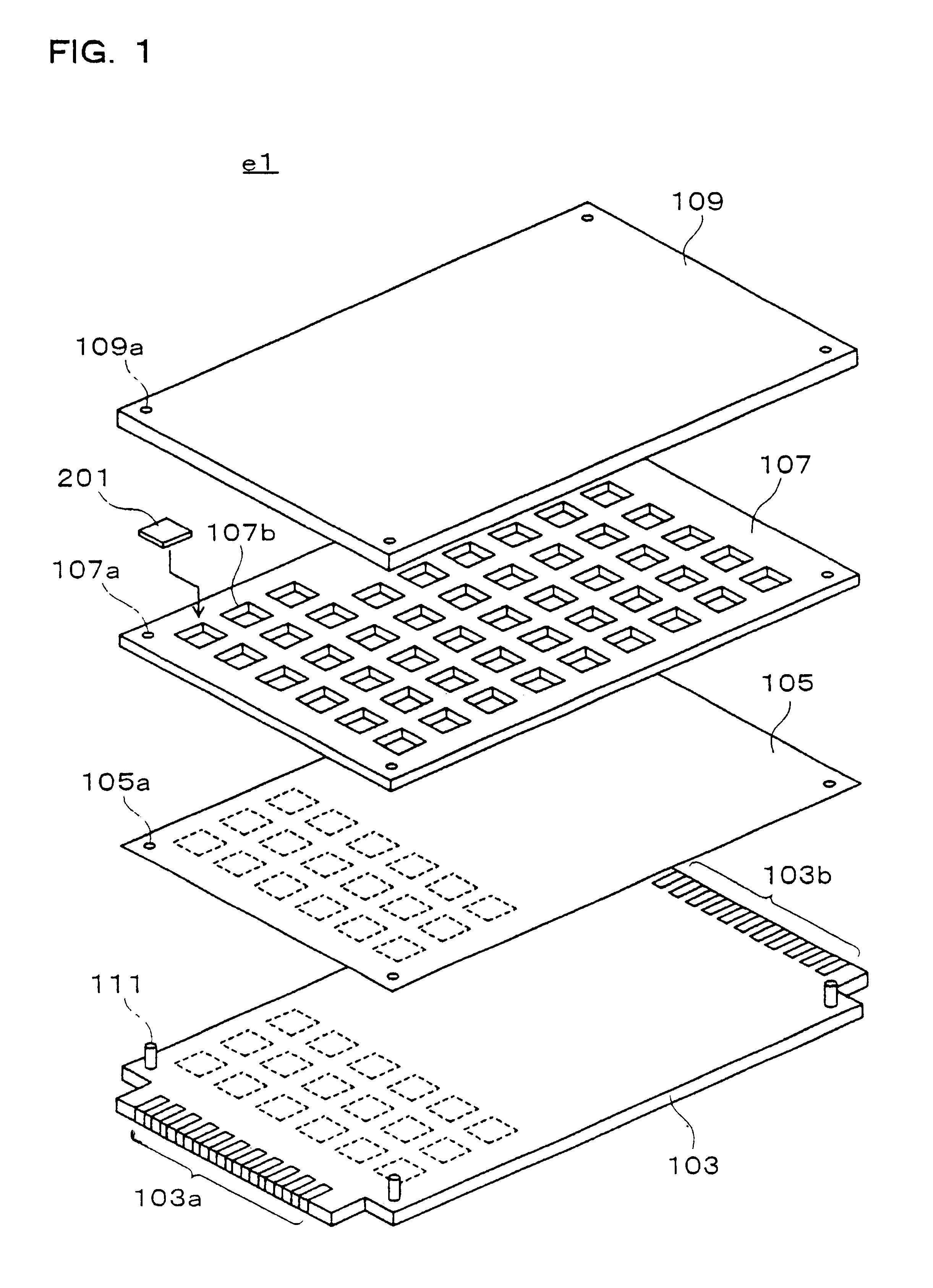

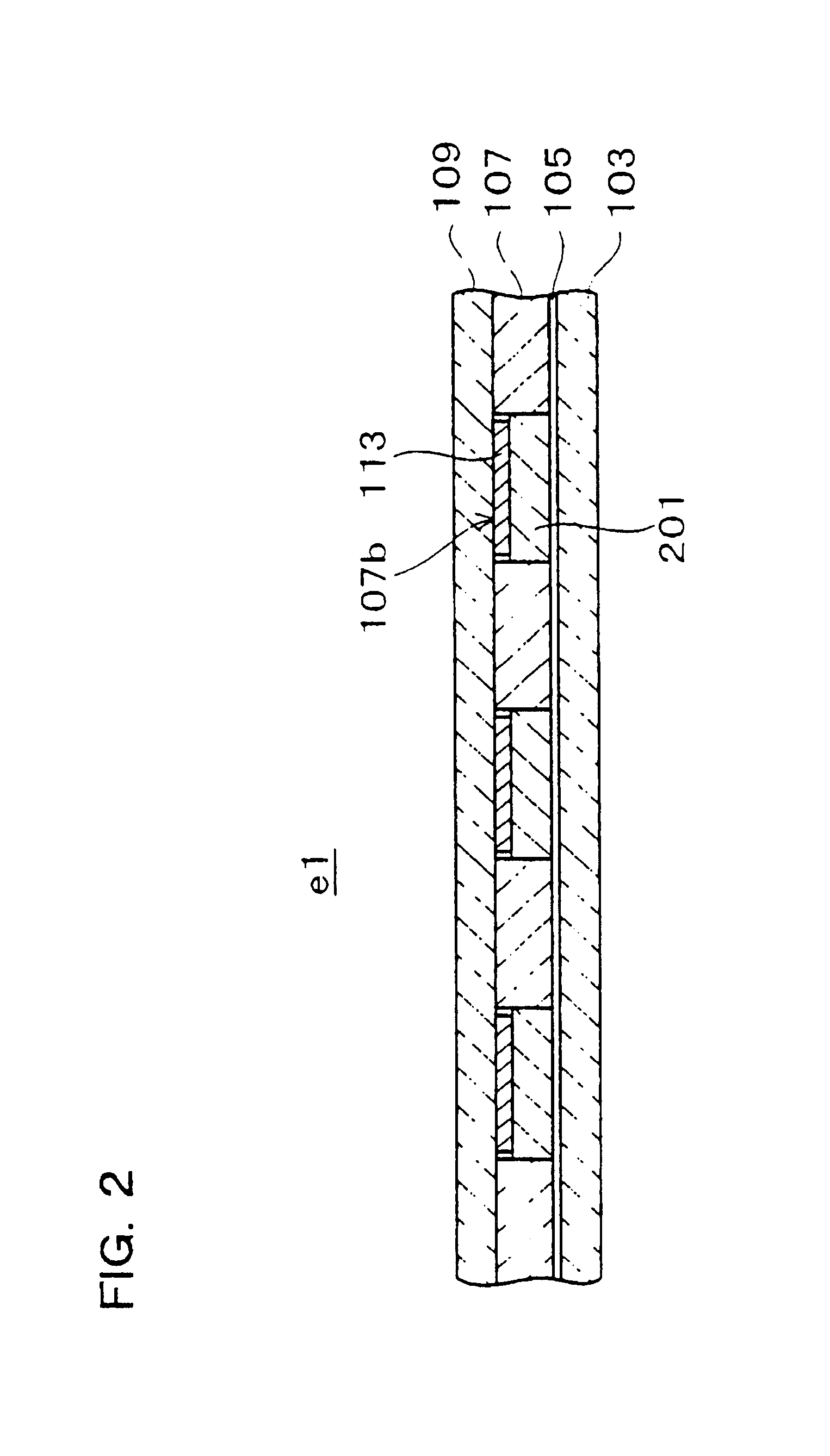

Semiconductor device, and inspection method thereof

ActiveUS20070138619A1Improve reliabilityAchieve electrical continuitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectrical conductorSemiconductor chip

In a substrate for a stacking-type semiconductor device including a connection terminal provided for a connection with a semiconductor chip to be stacked and an external terminal connected to the connection terminal through a conductor provided in a substrate, connection terminals of a power supply, a ground and the like, which terminals have an identical node, are electrically continuous with each other. Thus, it is possible to facilitate an inspection of electrical continuity between each connection terminal and an external terminal corresponding to each connection terminal by minimum addition of inspecting terminals. Further, it is possible to improve reliability of a stacking-type semiconductor module.

Owner:PANASONIC CORP

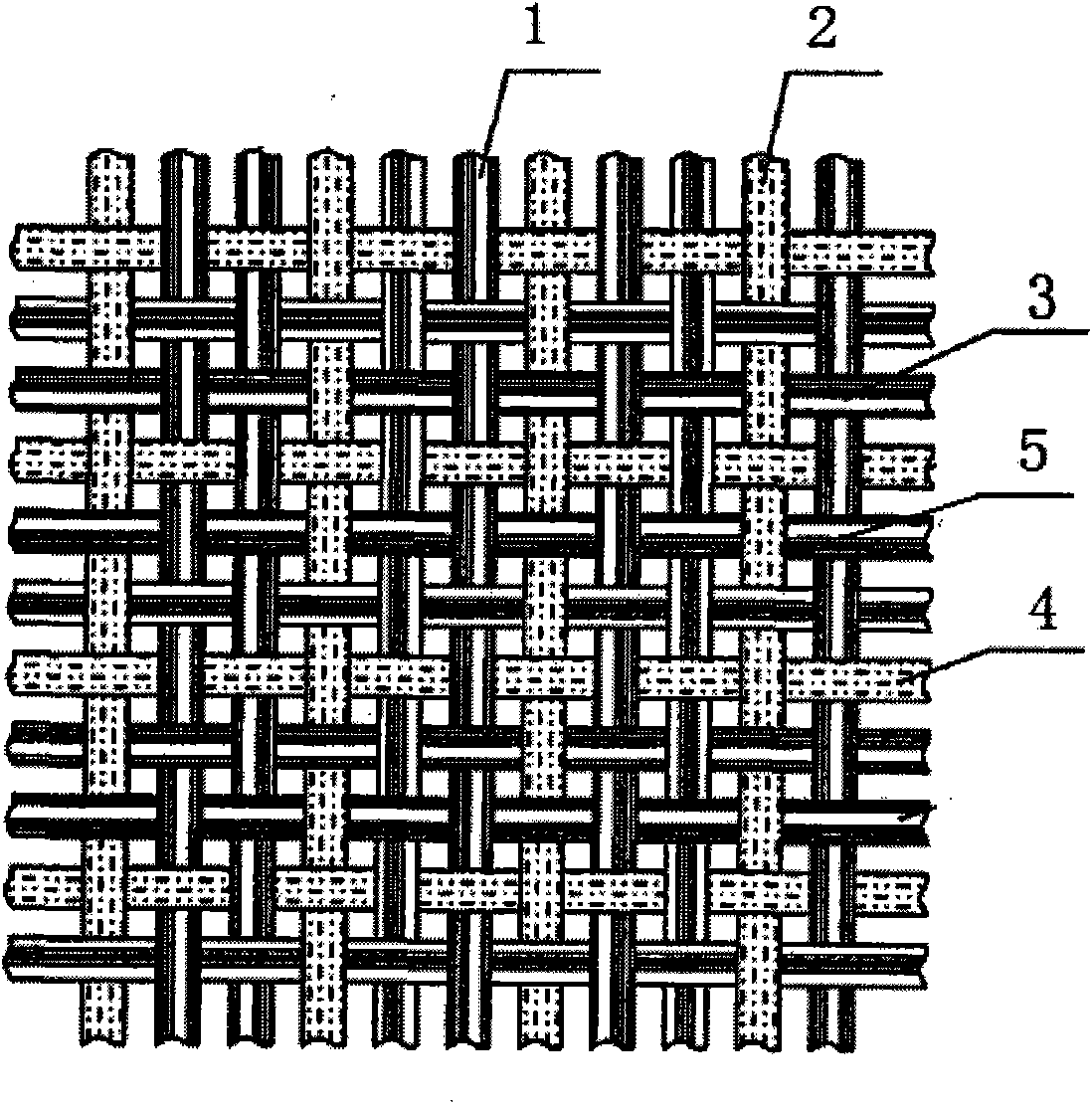

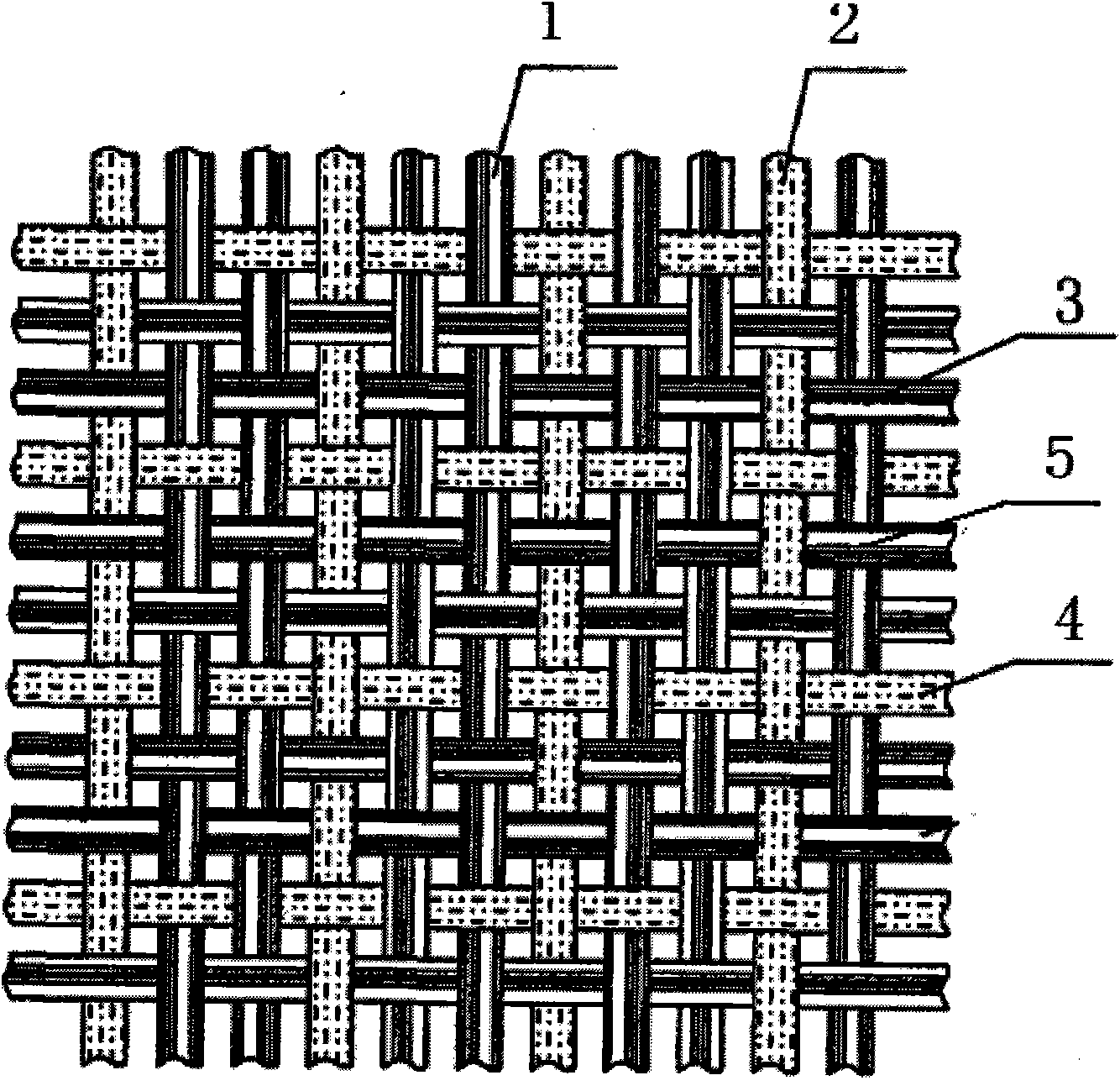

Woven high-shielding anti-radiation fabric

The invention discloses woven high-shielding anti-radiation fabric comprising warp and weft, wherein the first warp and the second warp are arranged in the proportion of 1: 1, the first weft and the second weft are arranged in the property of 1: 1, the warp and the weft are vertically interwoven, the warp is in contact and connection with the weft at intersection points, the first warp is woven yarn formed by mixed spinning of metallic fiber, multi-ion fiber and ordinary fiber, the first weft is woven yarn formed by mixed spinning of metallic fiber, multi-ion fiber and the ordinary fiber and second warp and particularly refers to 32S and 40S polyester cotton yarn. The second weft refers to one of 70D and 100D chinlon stretch yarn or 70D and 100D terylene low-elasticity interlaced yarn. The woven high-shielding anti-radiation fabric is soft in texture, good in hand feeling, washing-resistant, good in shielding performance and wide in range of applications, and the problems in the prior art can be solved.

Owner:江苏金纺针织有限公司

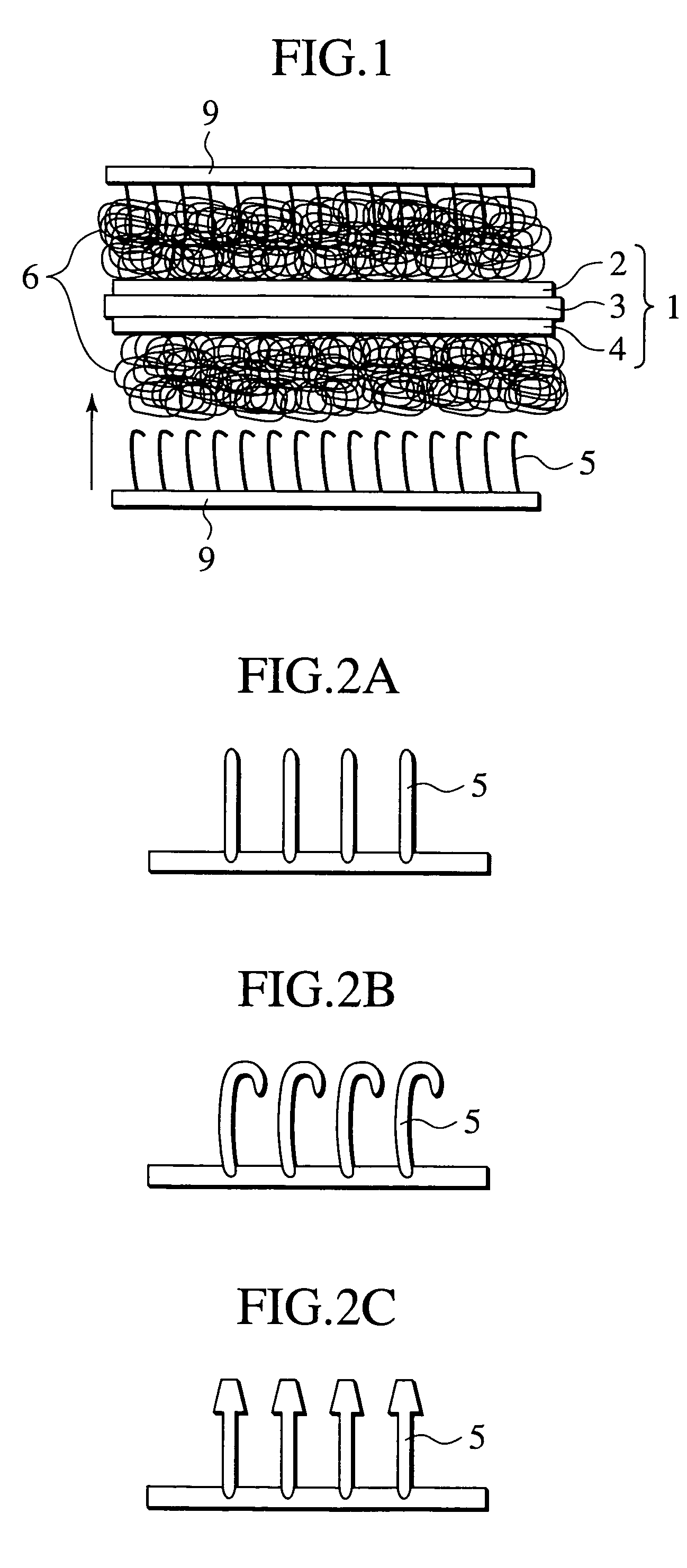

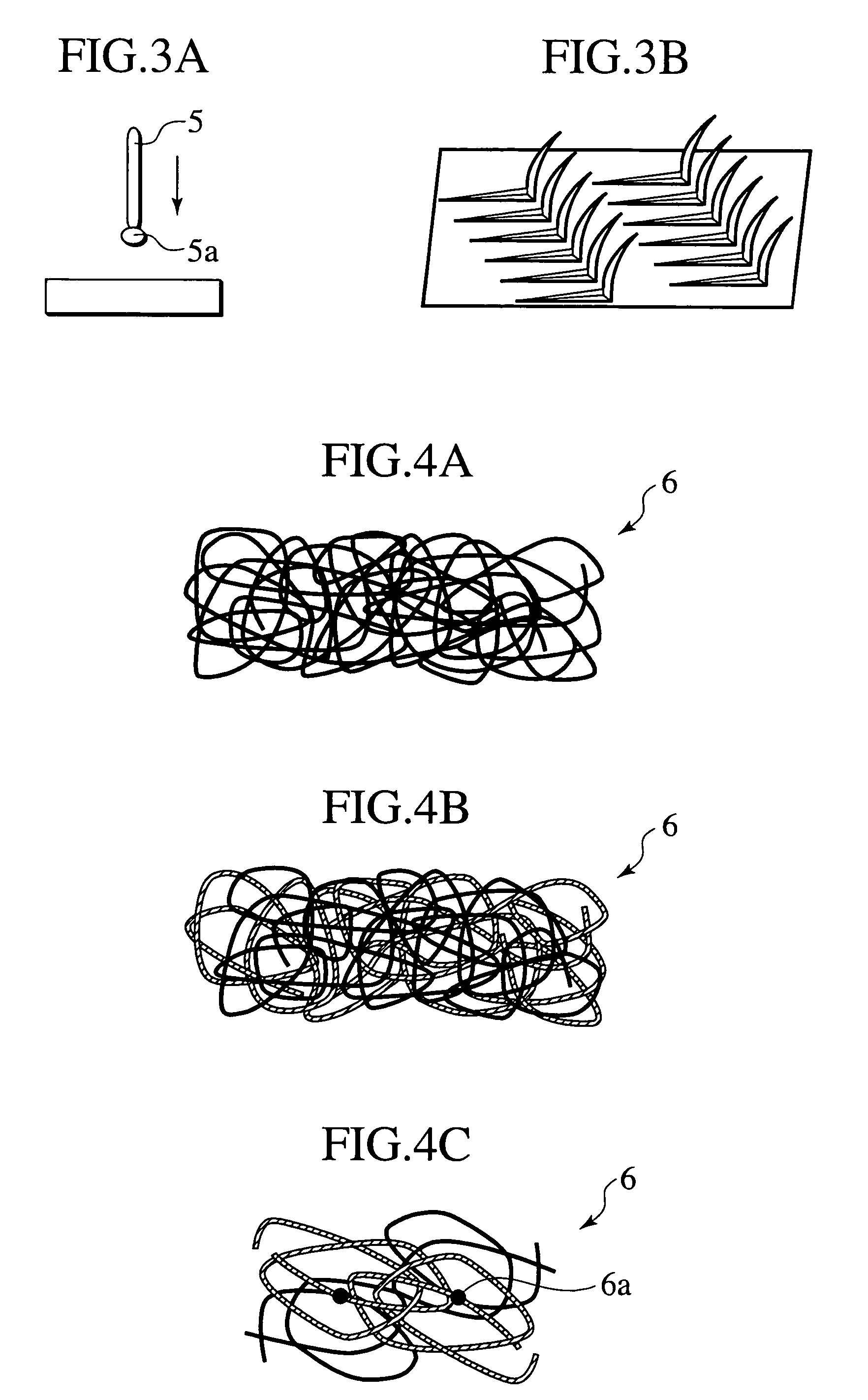

Fuel cell collector structure and solid oxide fuel cell stack using the same

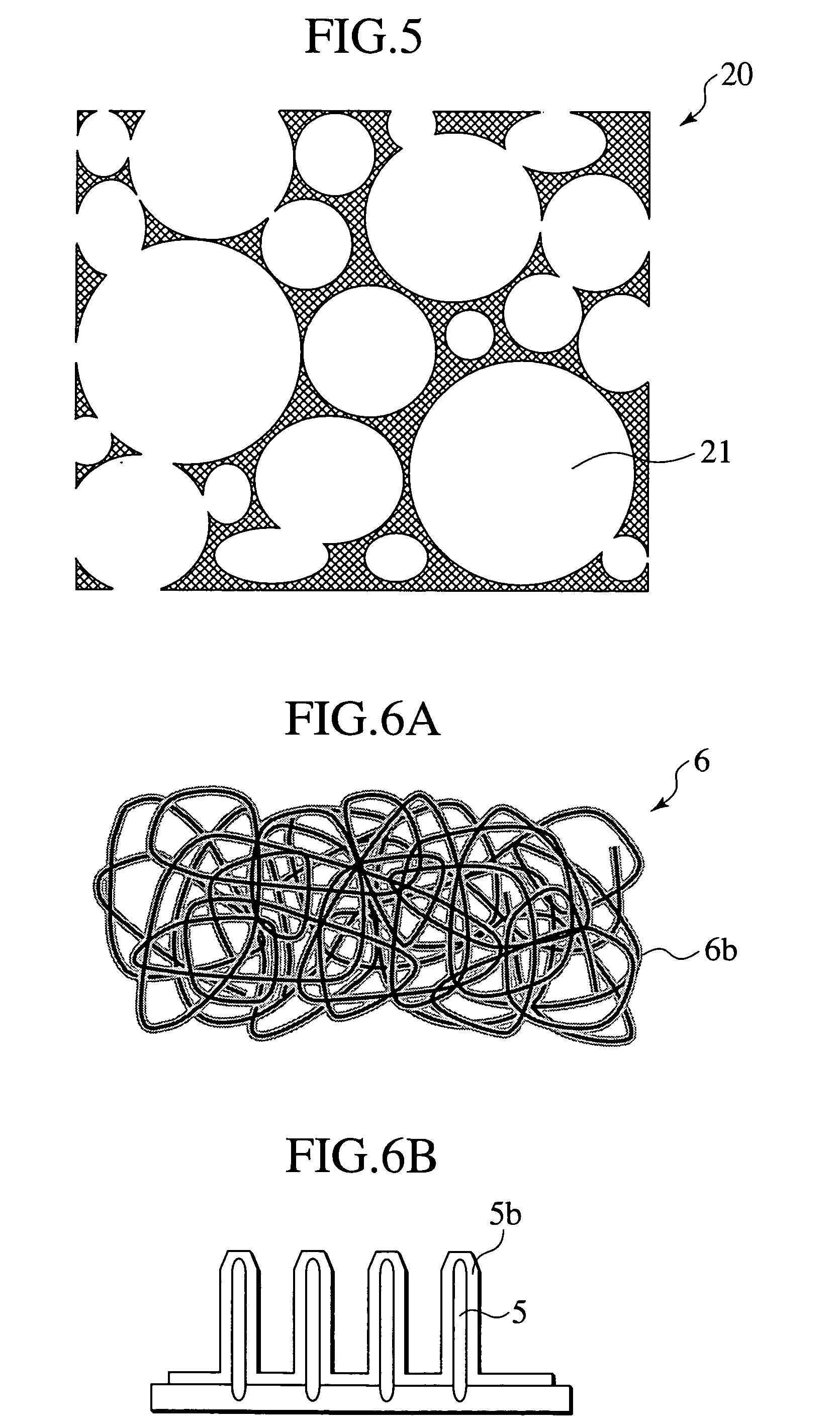

ActiveUS20050019642A1Achieve electrical continuityAvoid contact failureFuel cells groupingCell electrodesElectrically conductiveEngineering

A fuel cell collector structure of the present invention includes a single cell which is formed by sandwiching a plate-shaped solid electrolyte between a fuel electrode and an air electrode, a collector which is provided at a position adjacent to the single cell, and a separator which is provided at the position adjacent to the collector. In the fuel cell collector structure, the collector is made of a porous electric conductor having a plurality of apertures on a surface, the single cell and / or the separator has a plurality of electrically conductive projections on the surface, and the projections intrude into the apertures to come into contact with the collector.

Owner:NISSAN MOTOR CO LTD

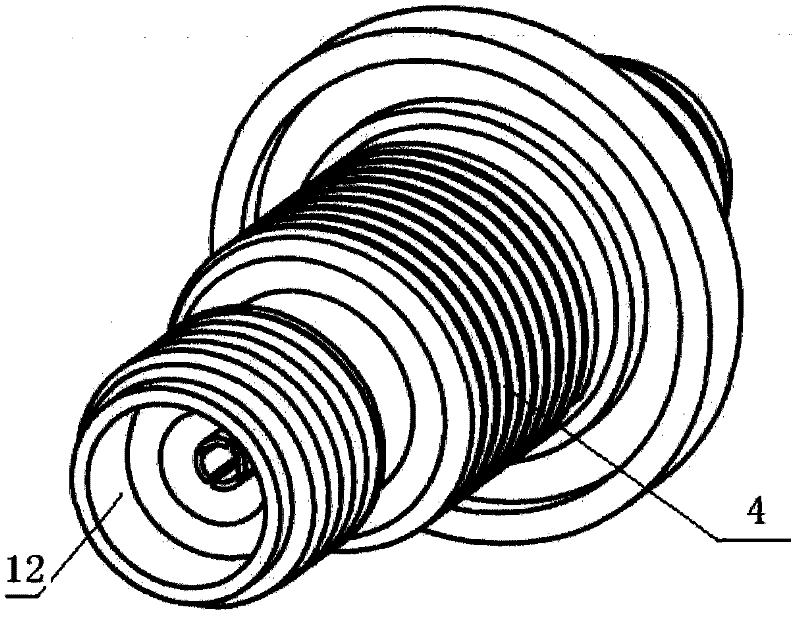

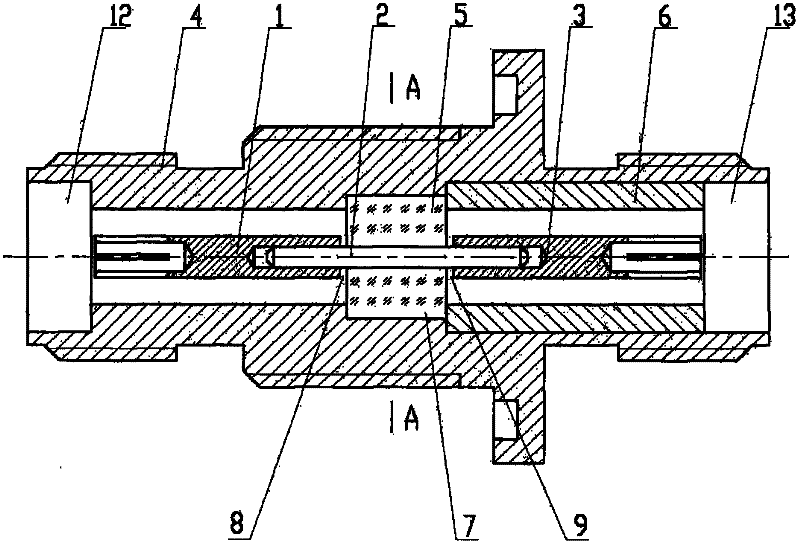

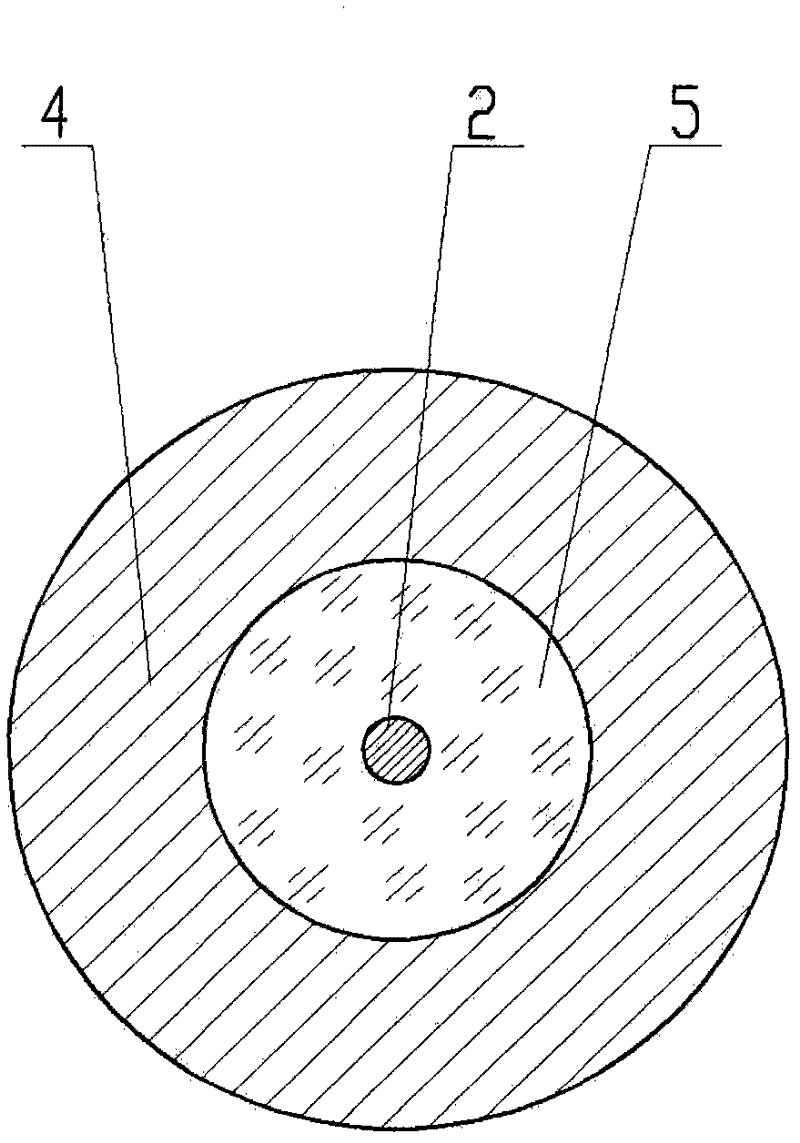

Air-tight-seal MMW (millimeter wave) coaxial connector and assembly method thereof

InactiveCN102176565ARealize the airtight functionMeet sealing application requirementsContact member assembly/disassemblySecuring/insulating coupling contact membersElectrical conductorWide band

The invention relates to an air-tight-seal MMW (millimeter wave) coaxial connector, comprising an inner conductor component, an outer conductor component, an intermediate insulator and two connecting termination points which are respectively arranged at two ends of the outer conductor, wherein the inner conductor component comprises an inner conductor contact pin and two inner conductor jacks; the outer conductor component comprises an outer conductor and an outer conductor pressing sleeve; step surfaces of the outer conductor and one end face of the outer conductor pressing sleeve form an outer conductor groove; the intermediate insulator is arranged in the outer conductor groove; the inner conductor contact pin passes through a though hole in the middle of the intermediate insulator, and two ends of the inner conductor contact pin are respectively inserted into the two inner conductor jacks; and two circular grooves are formed between two end faces of the intermediate insulator and end faces of the two inner conductor jacks respectively. The coaxial connector can realize wide-band microwave transmission, has good radio frequency performance in an MMW band, realizes an air-tight seal function of a wide-band radio frequency connector, meets air-tight application requirements in the environment of high air pressure difference, and greatly improves the vibration resistance performance and the impact resistance performance of a product.

Owner:CHINA AEROSPACE TIMES ELECTRONICS

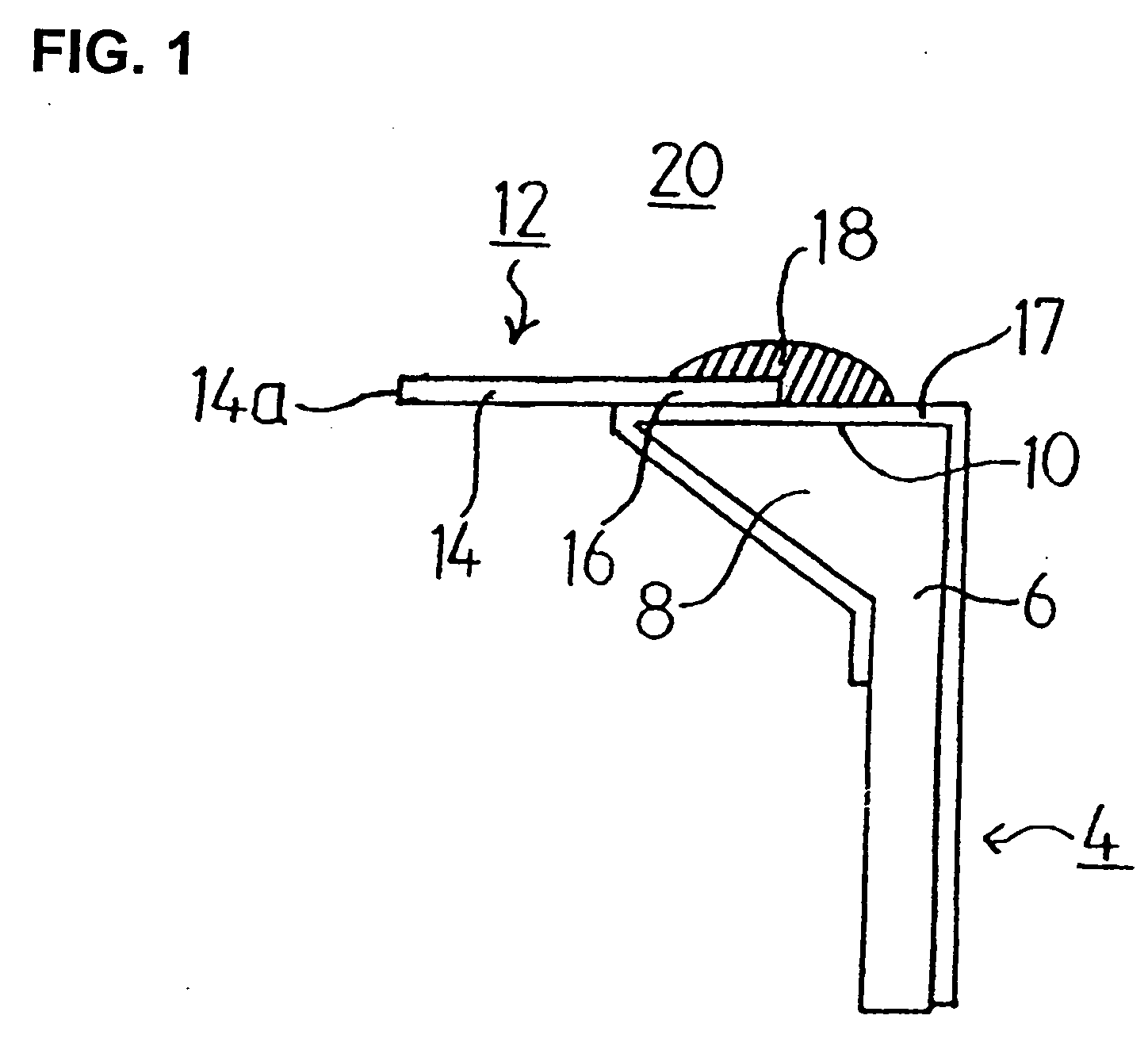

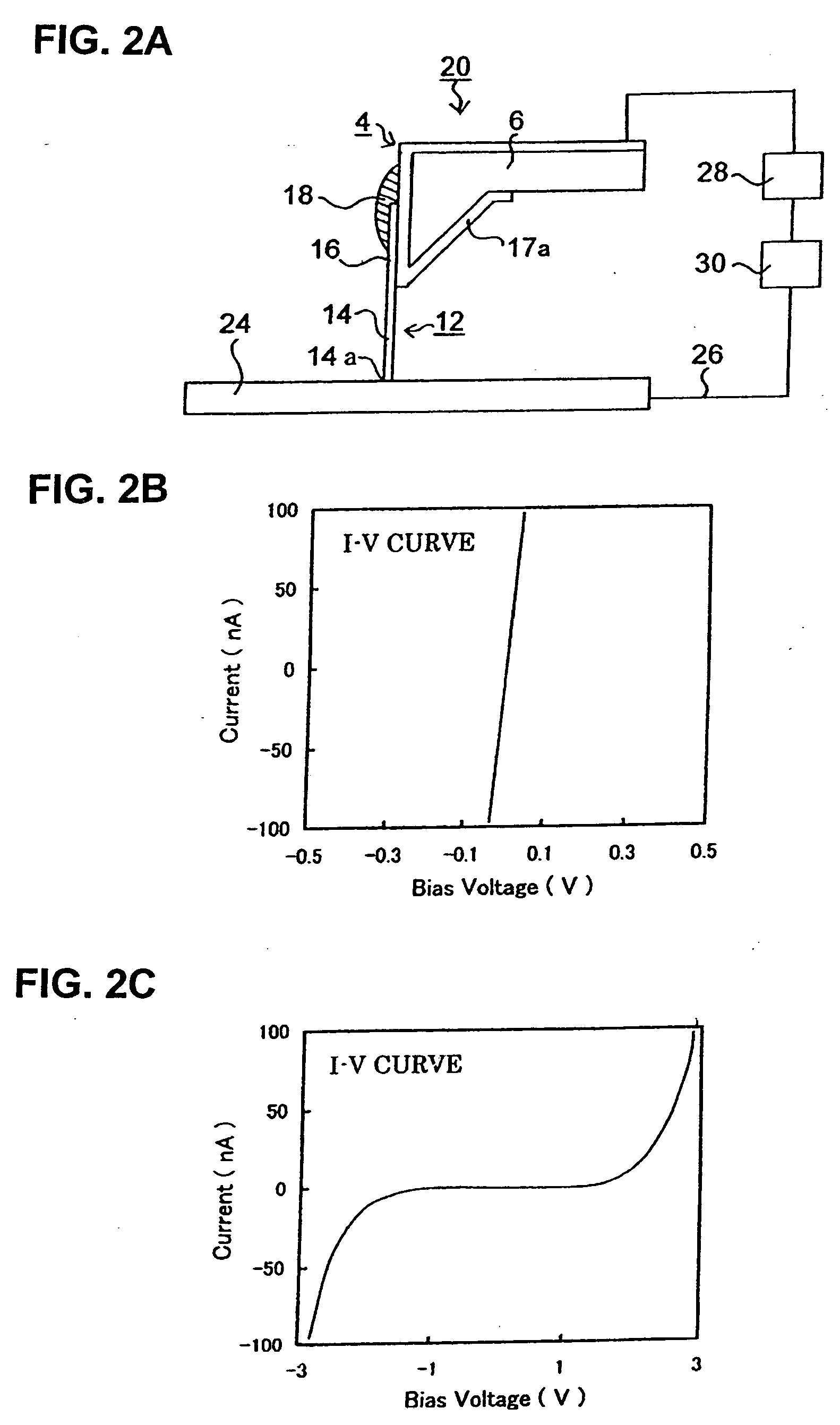

Probe for a scanning microscope

InactiveUS20060150720A1High sensitivityHigh-resolution magnetic imageNanosensorsScanning probe microscopyCantileverNanotube

A scanning microscope probe in which a palladium covering film is formed on the surface of the protruding portion of a cantilever, and the base end portion of a nanotube is disposed in contact with the palladium covering film with the tip end portion of the nanotube protruding to the outside, thus allowing the tip end to be used as a probe needle end for detecting signals. A coating film is formed to cover all or part of the surface of this base end portion, and the nanotube is thus firmly fastened to the cantilever. Since the base end portion adheres tightly to the palladium covering film, both of them are electrically continuous. This palladium covering film allows, as an electrode film, the application of a voltage to the nanotube or the passage of an electric current through the nanotube, showing also good adhesion to the nanotube and cantilever.

Owner:NAKAYAMA YOSHIKAZU +2

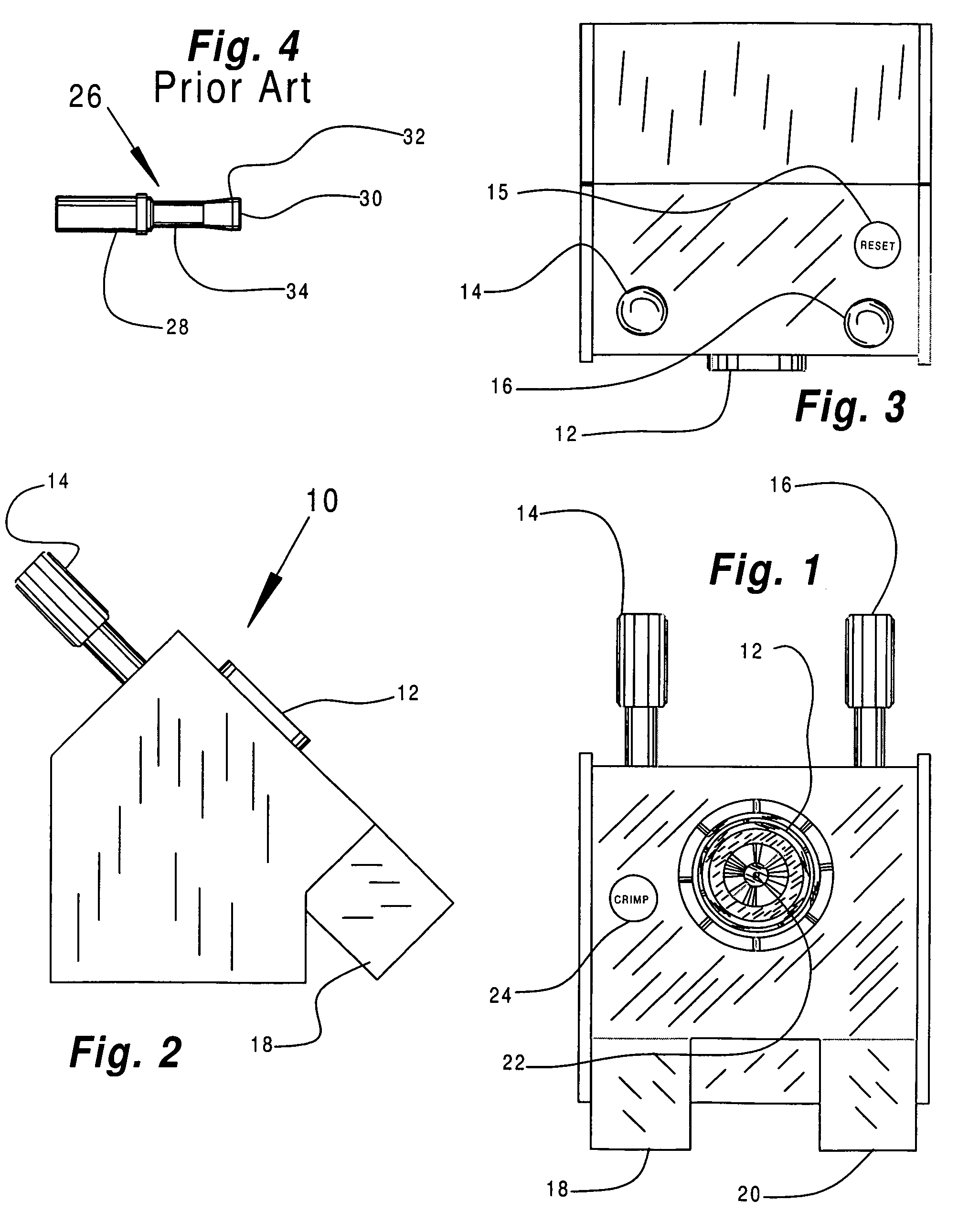

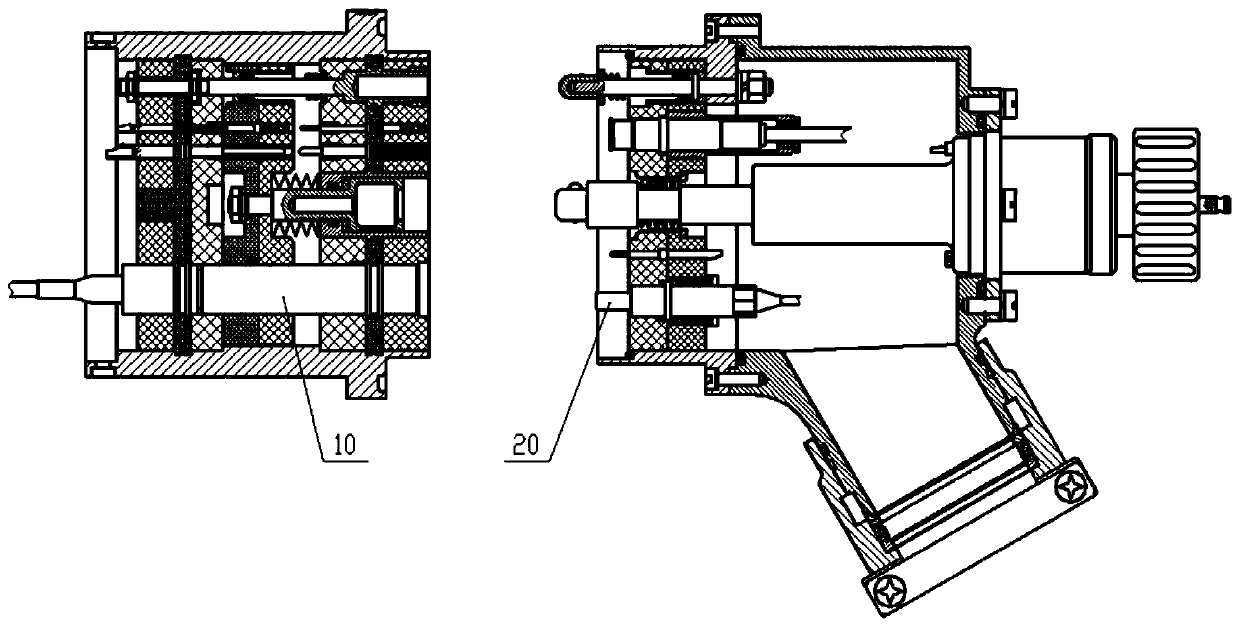

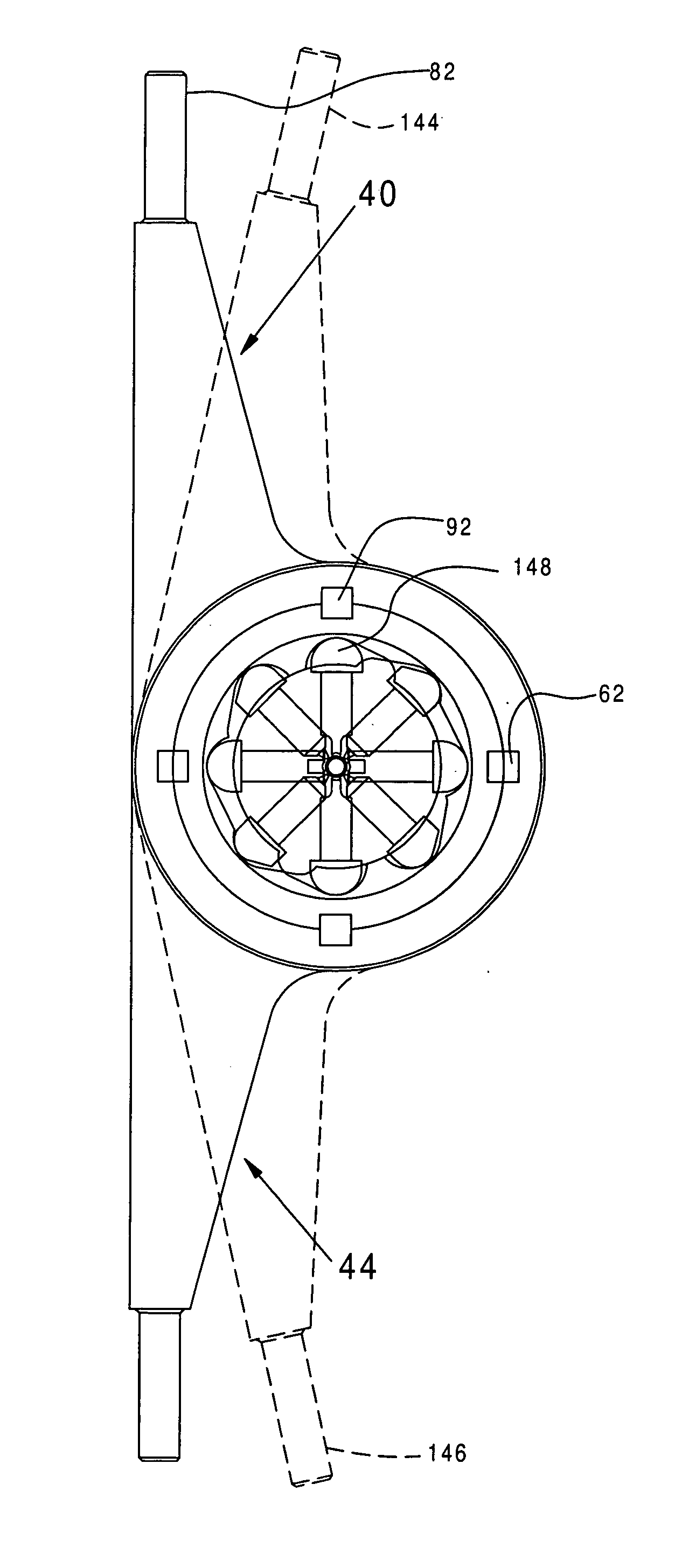

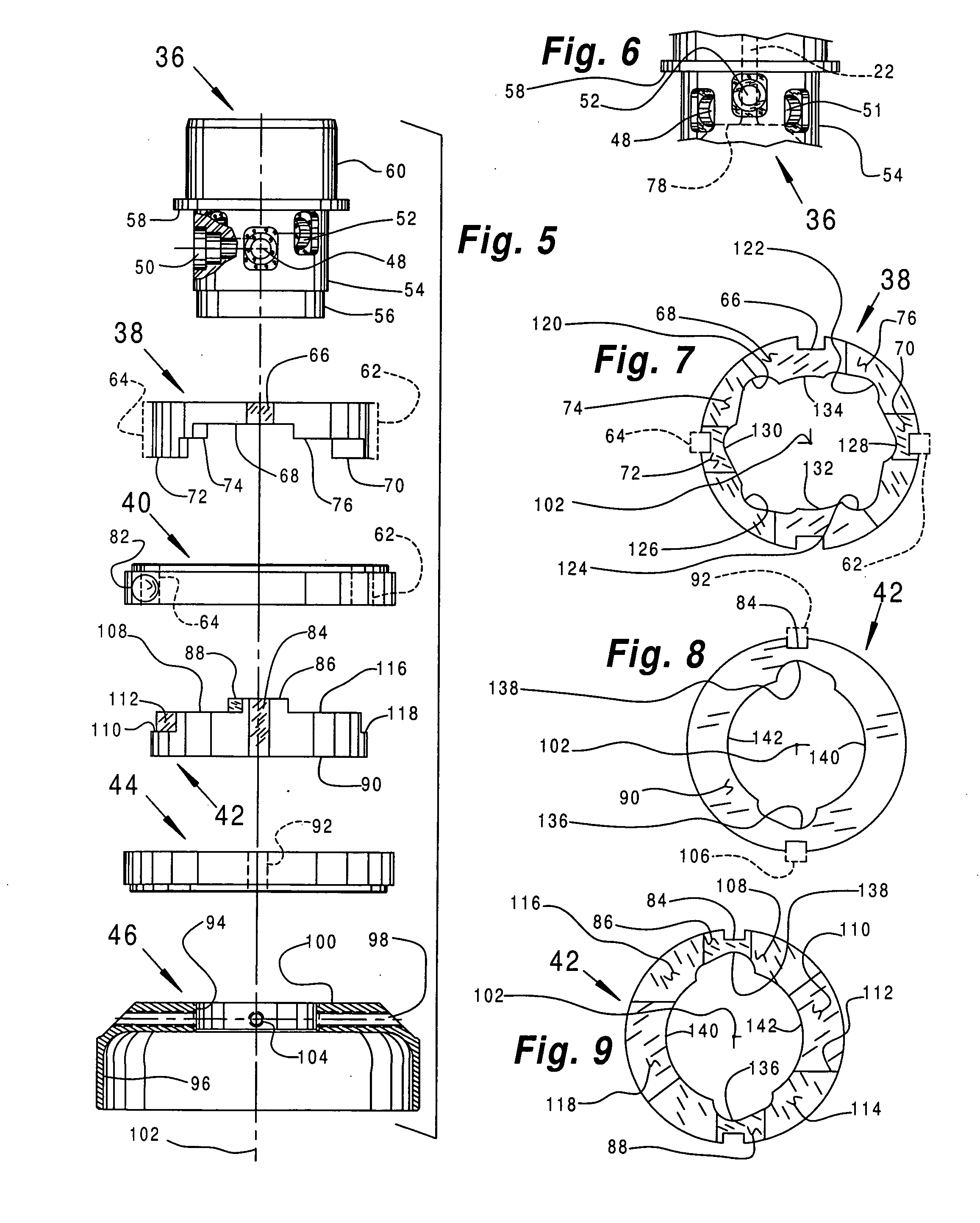

Crimping tool with quick-change crimp head for sealing and electrically crimping electrical contacts to insulated wire

InactiveUS7461448B2Easy and quick insertionAvoid performanceLine/current collector detailsForging hammersActuatorSensor system

A crimping tool with a quick-change crimp head for sealing and electrically crimping electrical contacts to insulated wires. The crimping tool includes a base unit with a receptacle that is configured to actuate and removably and replaceably receive the quick-change crimp head. A crimping die holder body includes a plurality of crimp-seal and continuity-crimping dies. These dies are mounted for movement in the crimping die holder body between an open configuration and a fully crimped configuration. The crimp-seal dies have arcuate die faces that define a substantially closed generally cylindrical form when the dies are in the fully crimped configuration. Actuators are mounted in the base unit. The actuators are adapted to cause the dies to move in the body. A sensor system is configured to prevent the crimping tool from unintentionally repeating a crimping operation on the electrical contact, and to verify continuity-crimp depth of indentation.

Owner:TRI STAR TECH

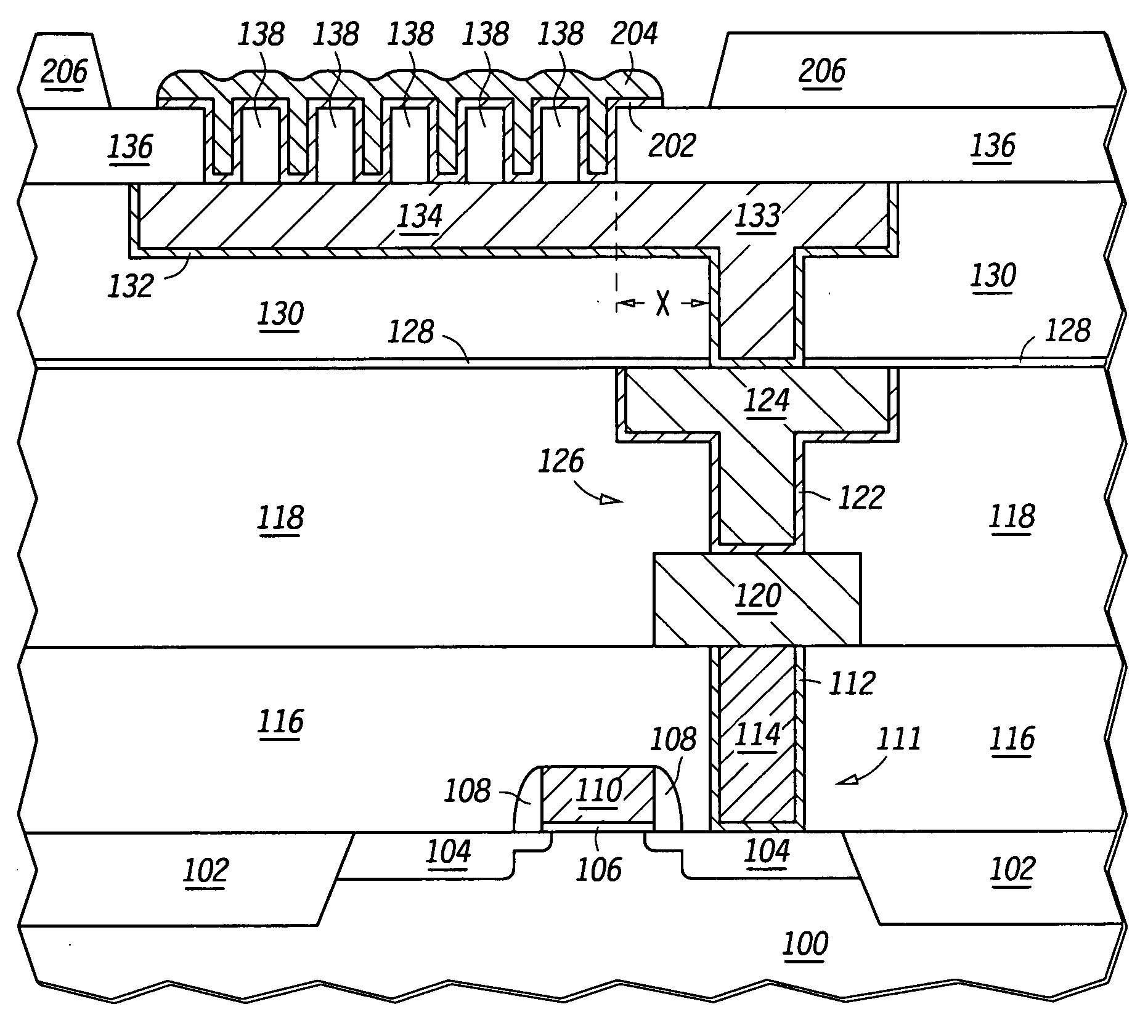

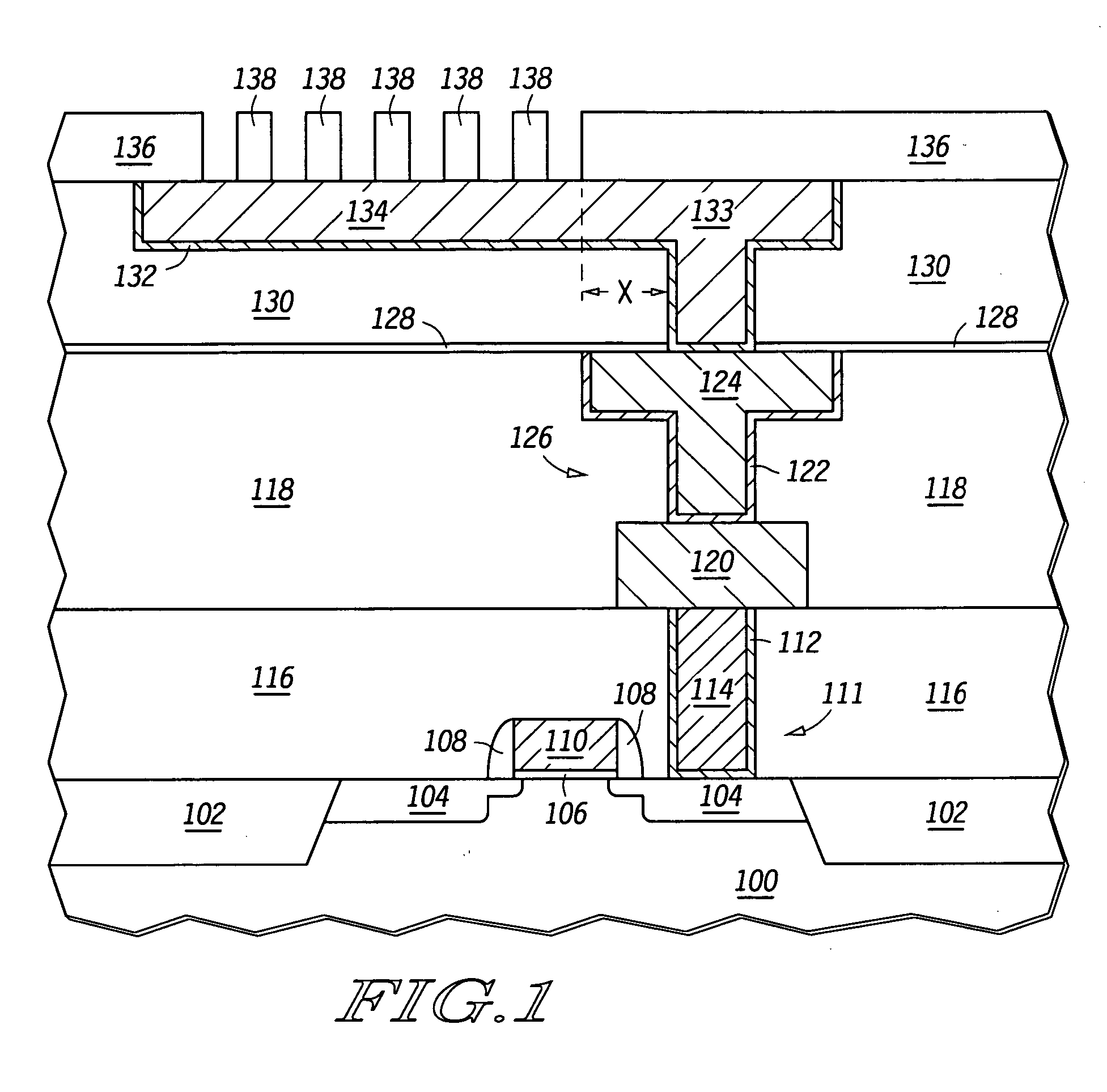

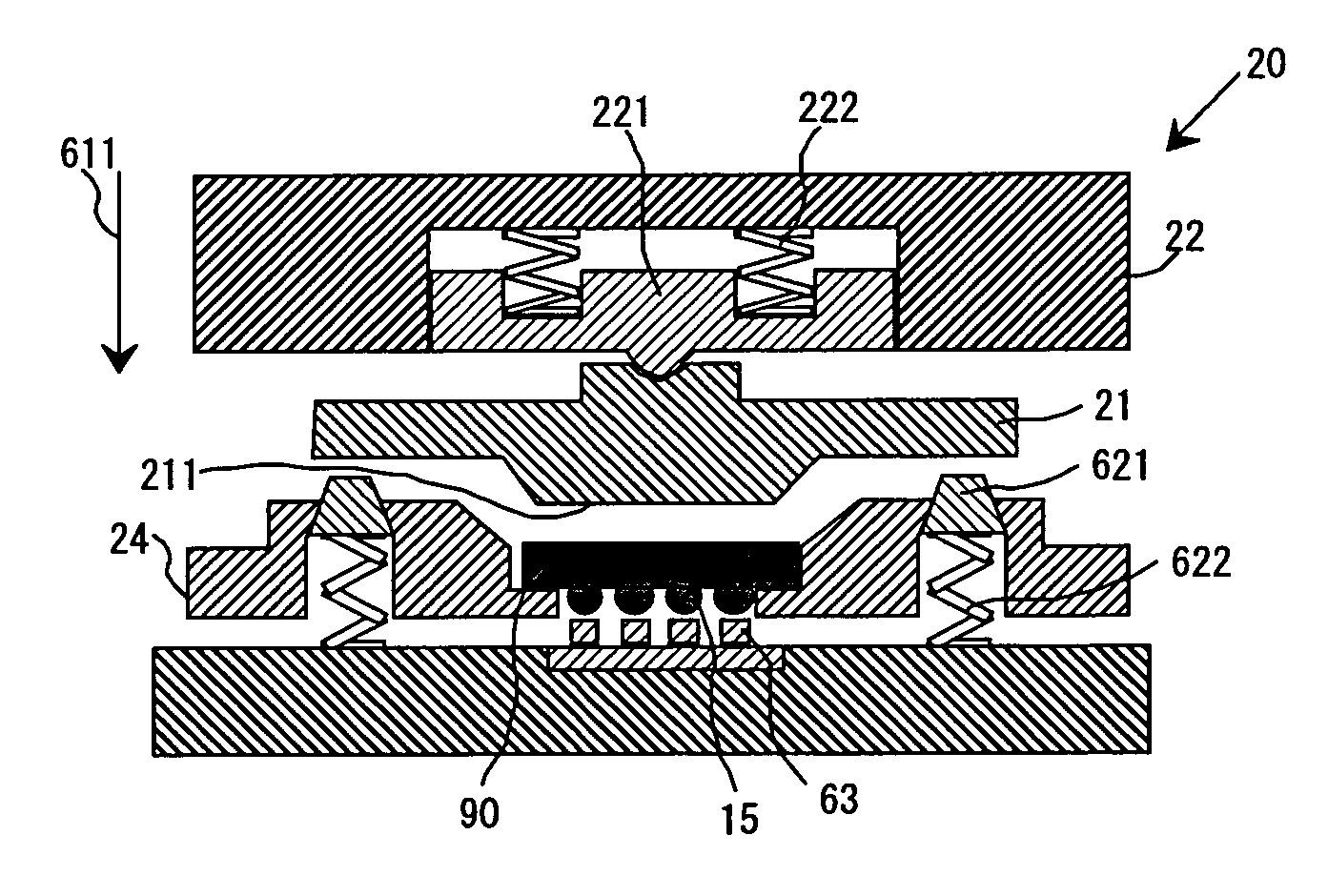

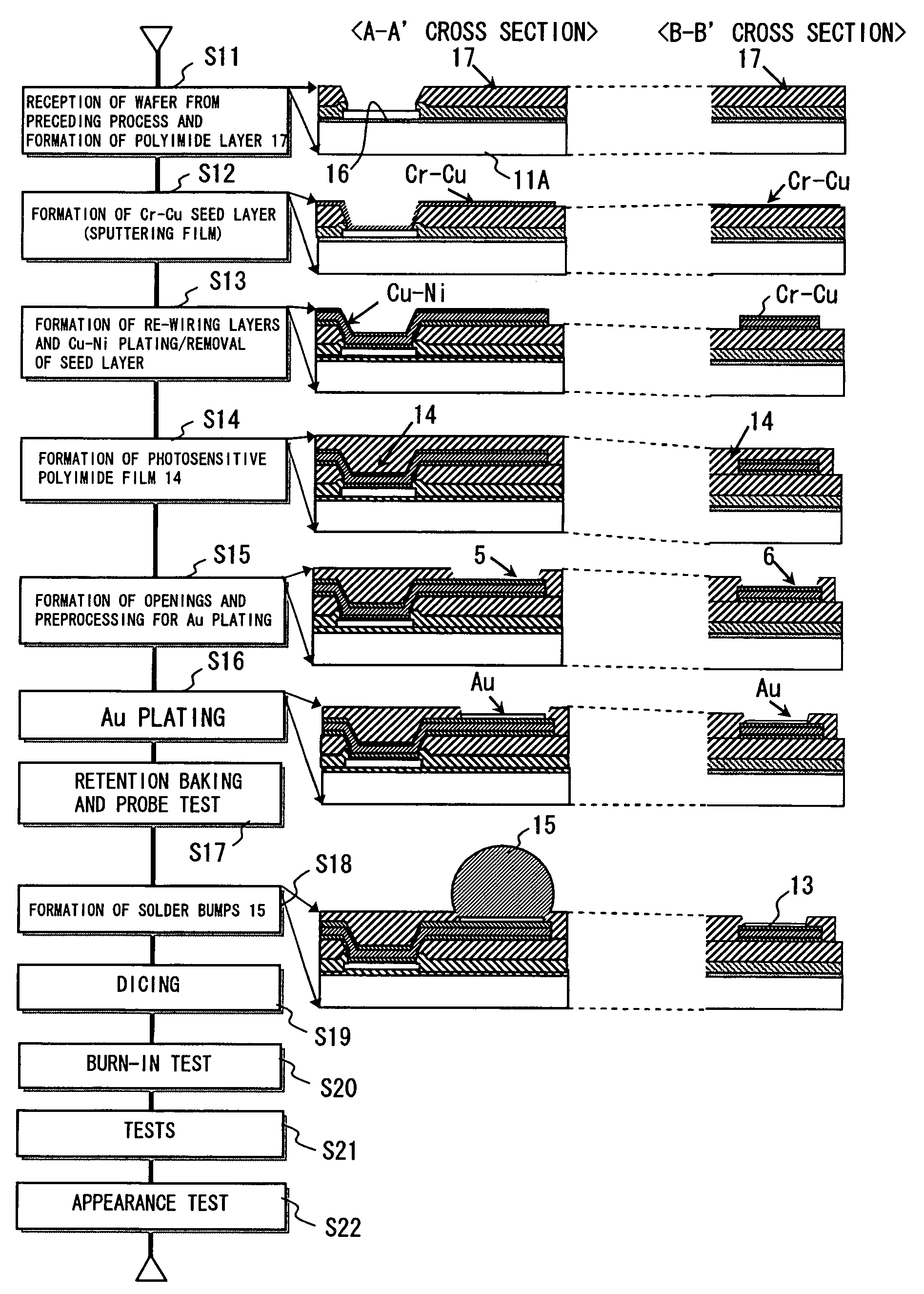

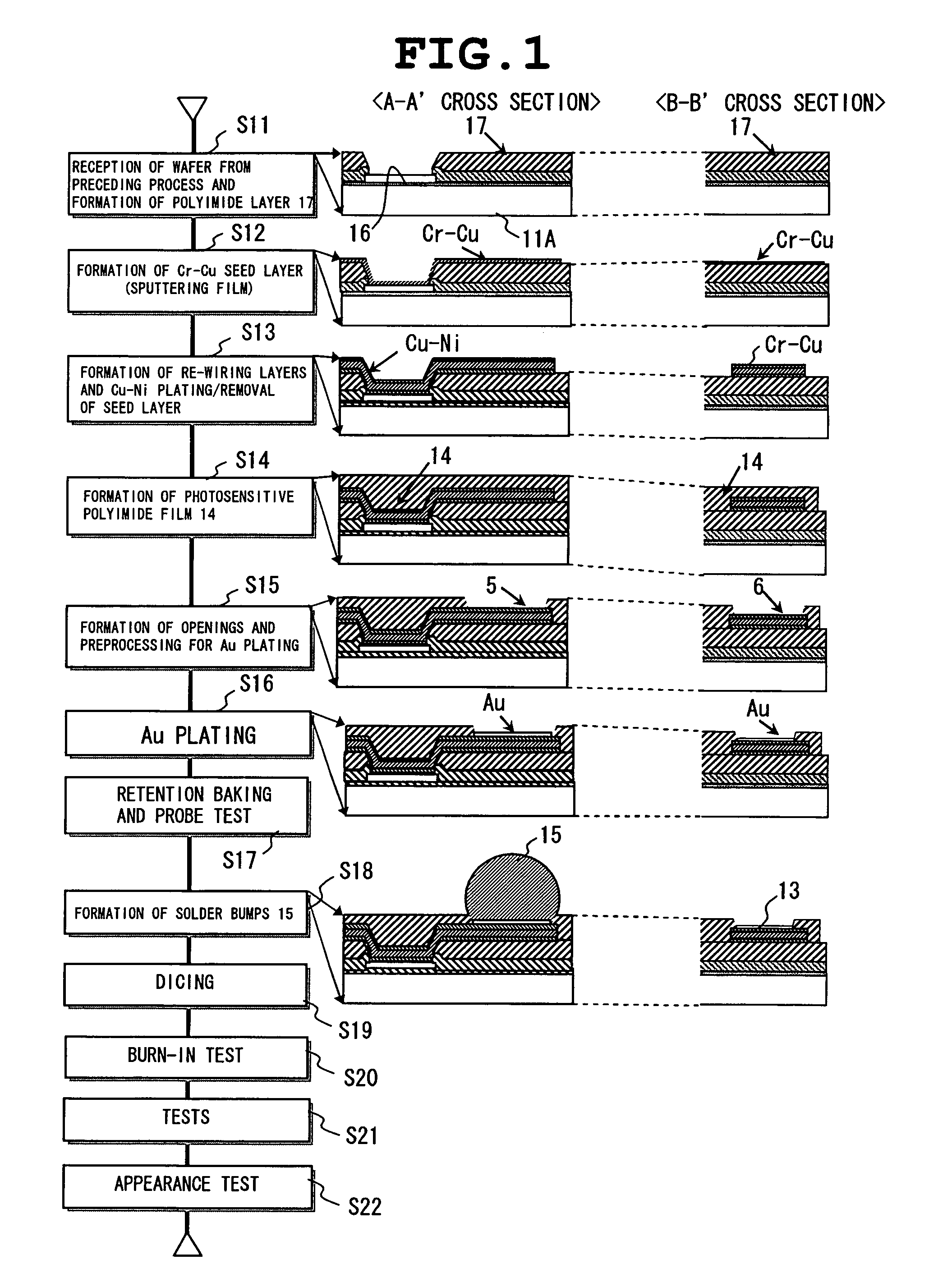

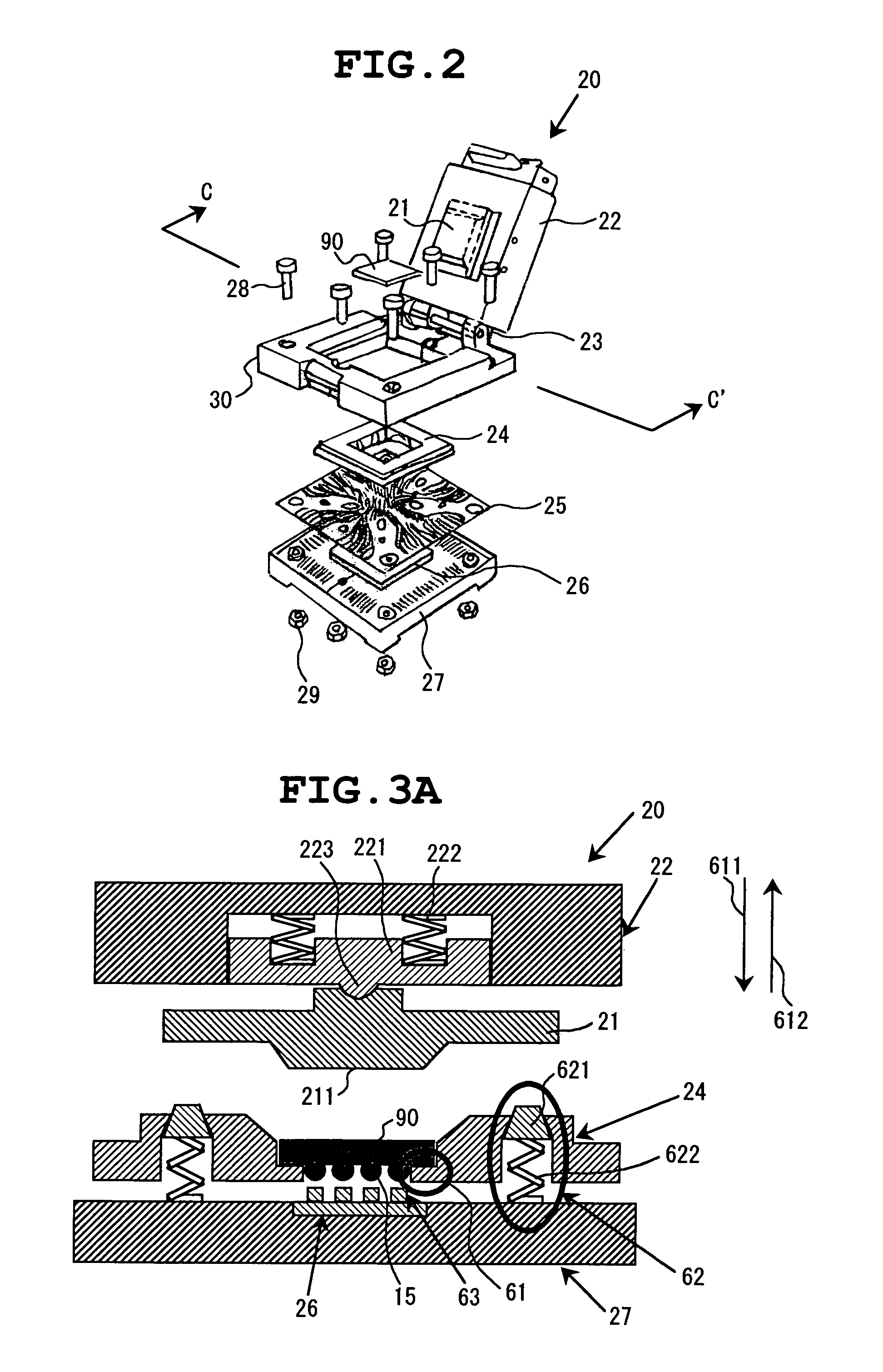

Method for Manufactuing a Semiconductor Integrated Circuit Device

InactiveUS20070287206A1Achieve electrical continuityHighly reliable semiconductor integrated circuit devicesSemiconductor/solid-state device testing/measurementElectronic circuit testingEngineeringSemiconductor

A burn-in process for a semiconductor integrated circuit device includes a first process of positioning bump electrodes of the semiconductor integrated circuit device with respect to pads of a socket having detachment mechanisms, a second process of pressing the bump electrodes against the pads by weighting the semiconductor integrated circuit device, and a third process of detaching the bump electrodes from the pads by exerting force on the semiconductor integrated circuit device in a direction opposite to a weighting direction of the second process. Automatic insertion and detachment of a semiconductor integrated circuit chip in a burn-in test is facilitated by detaching the bump electrodes from the pads by pushing up the semiconductor integrated circuit device.

Owner:RENESAS TECH CORP

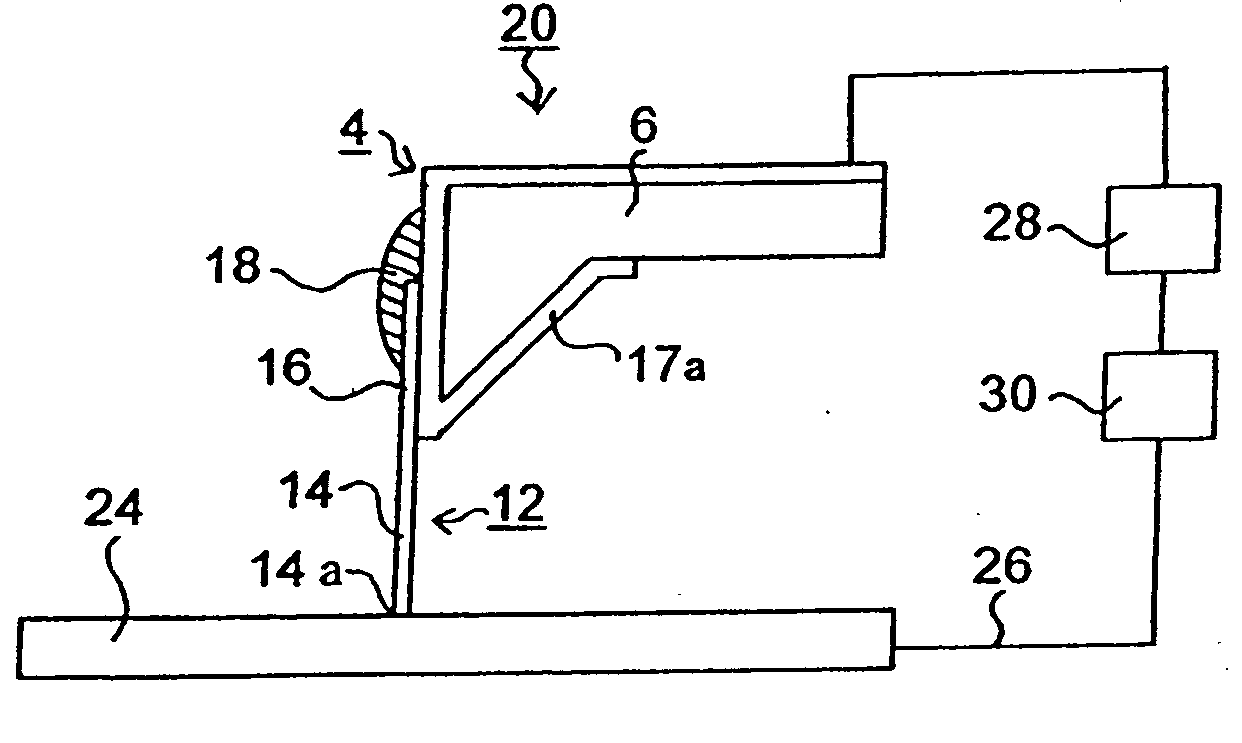

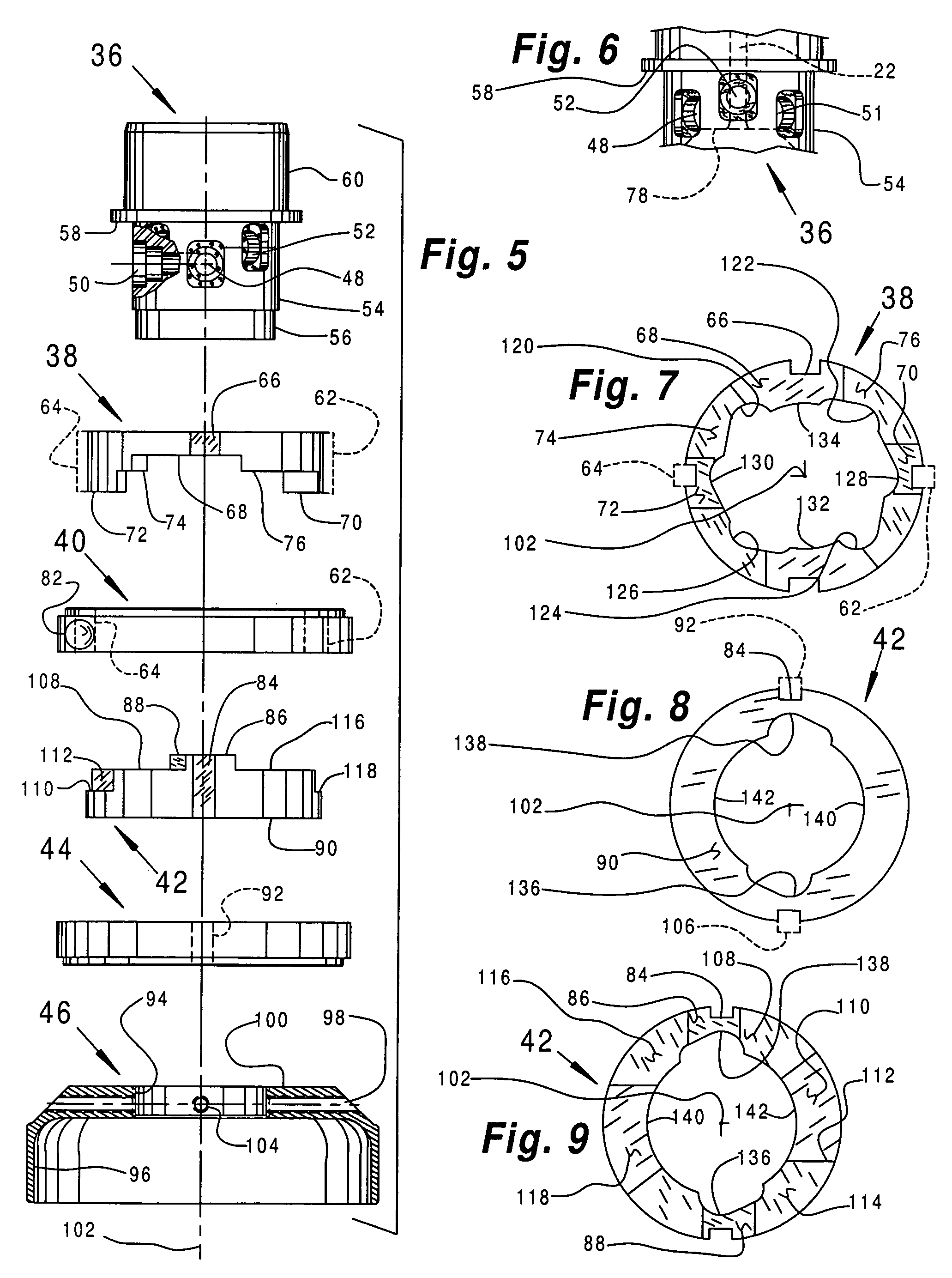

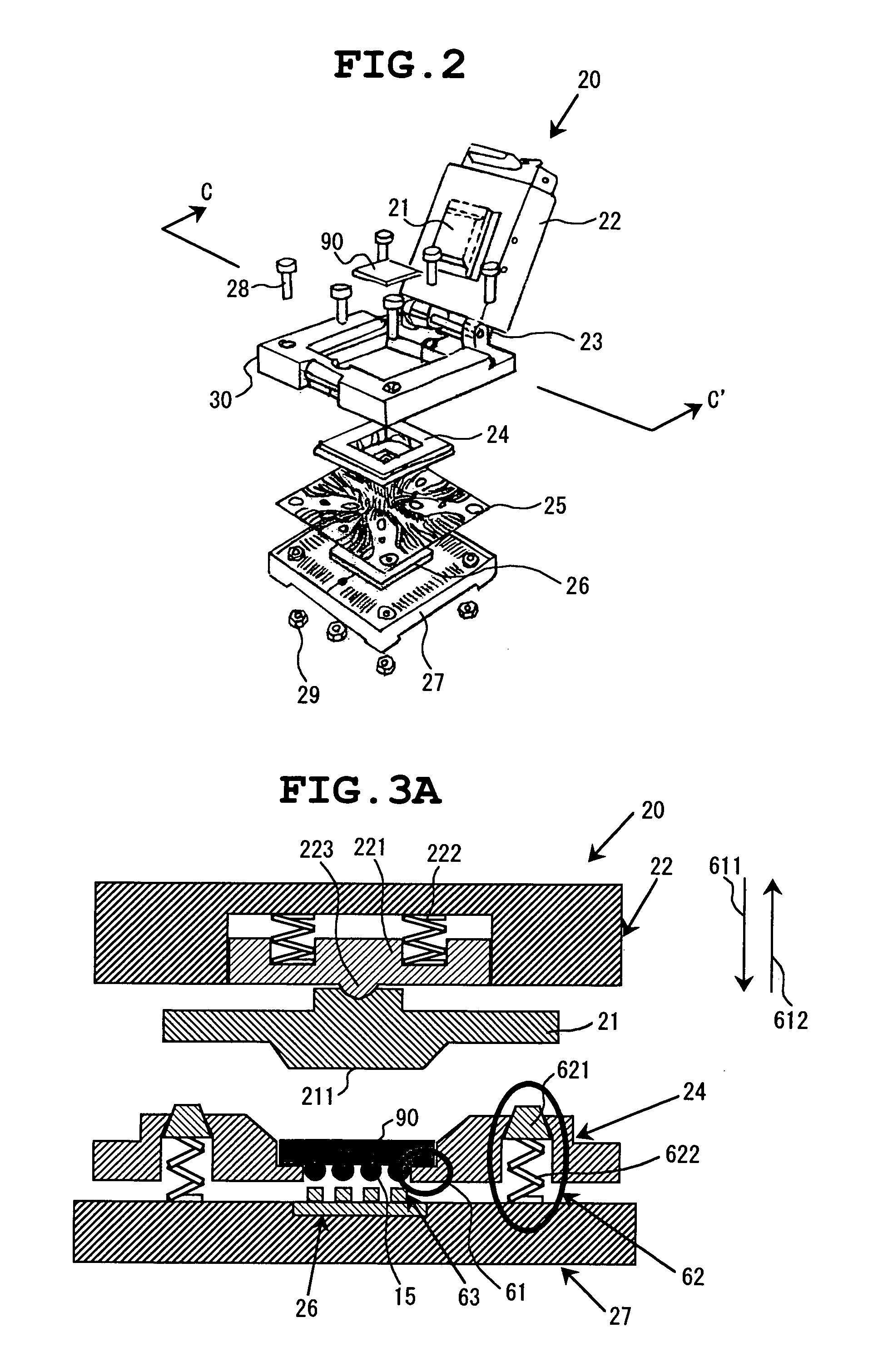

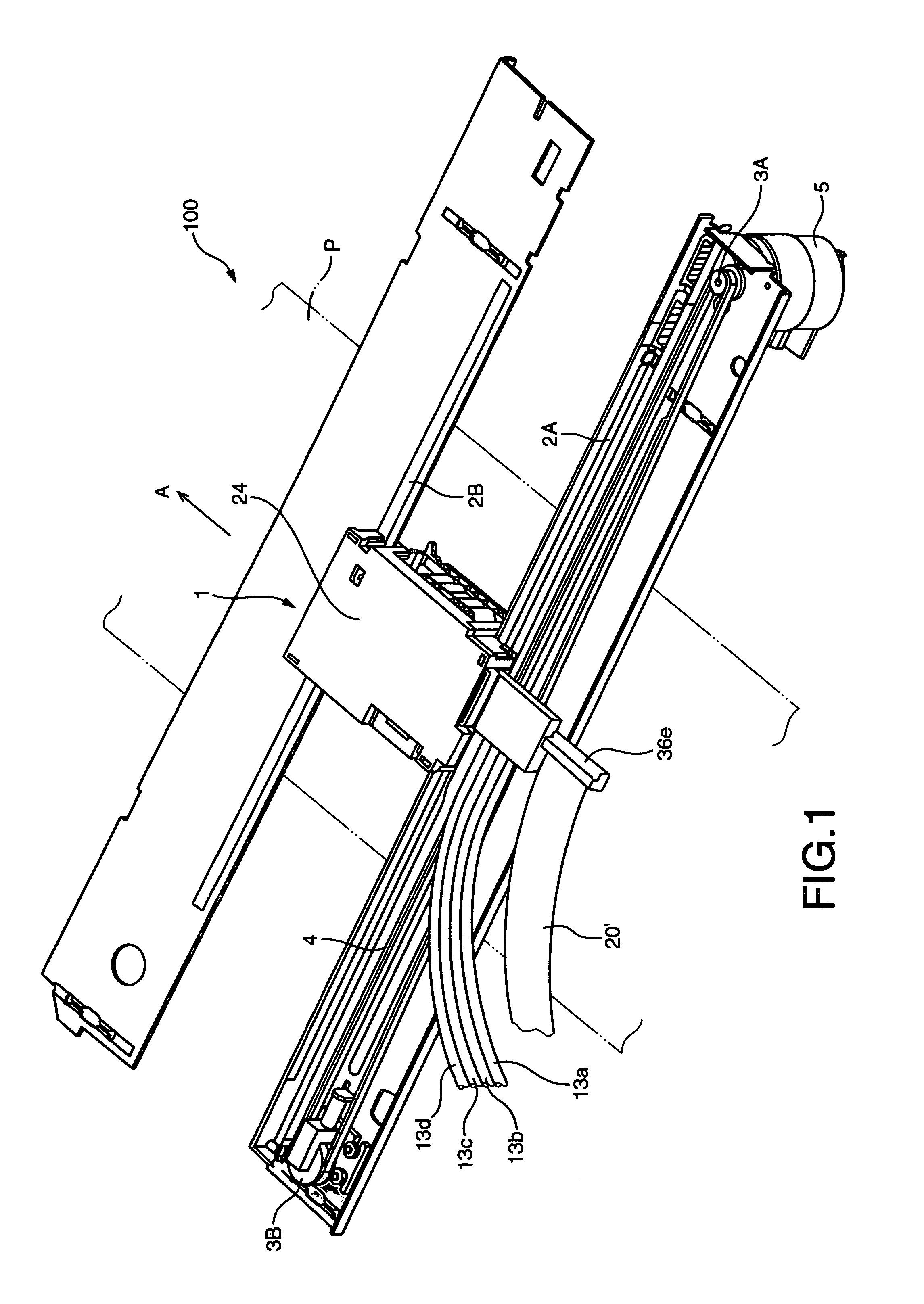

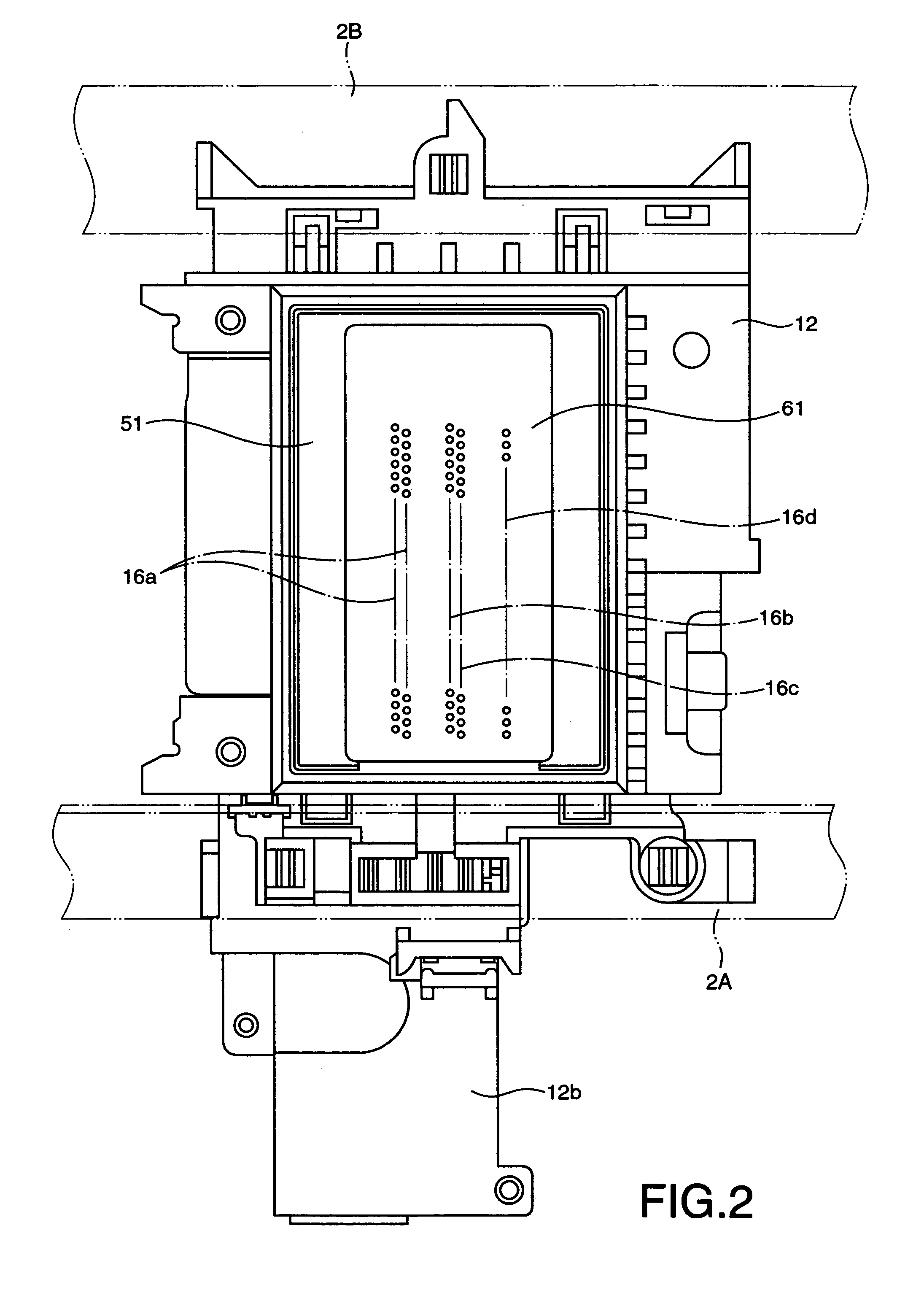

Inkjet head with conductive elastic member for electrical continuity between remote contacts in same

ActiveUS20060066675A1Simple circuit structureAchieve electrical continuityPrintingGround contactElectricity

An inkjet head for ejecting ink droplets is disclosed which includes: a nozzle unit having metal thin plates and a piezoelectric device, adapted to eject the ink droplets; a printed circuit board supplying to the piezoelectric device a drive signal for causing the nozzle unit to eject the ink droplets; a support supporting the nozzle unit and the printed circuit board in opposing relationship to each other; an earth contact disposed on the nozzle unit; a ground contact disposed on the printed circuit board, held at a reference potential; an electrically conductive elastic member disposed between the earth and ground contacts, such that portions of the elastic member are in electrical contact with the earth and ground contacts, respectively; and a movement limiter limiting movement of the elastic member to thereby prevent the elastic member from being disengaged from the earth and ground contacts.

Owner:BROTHER KOGYO KK

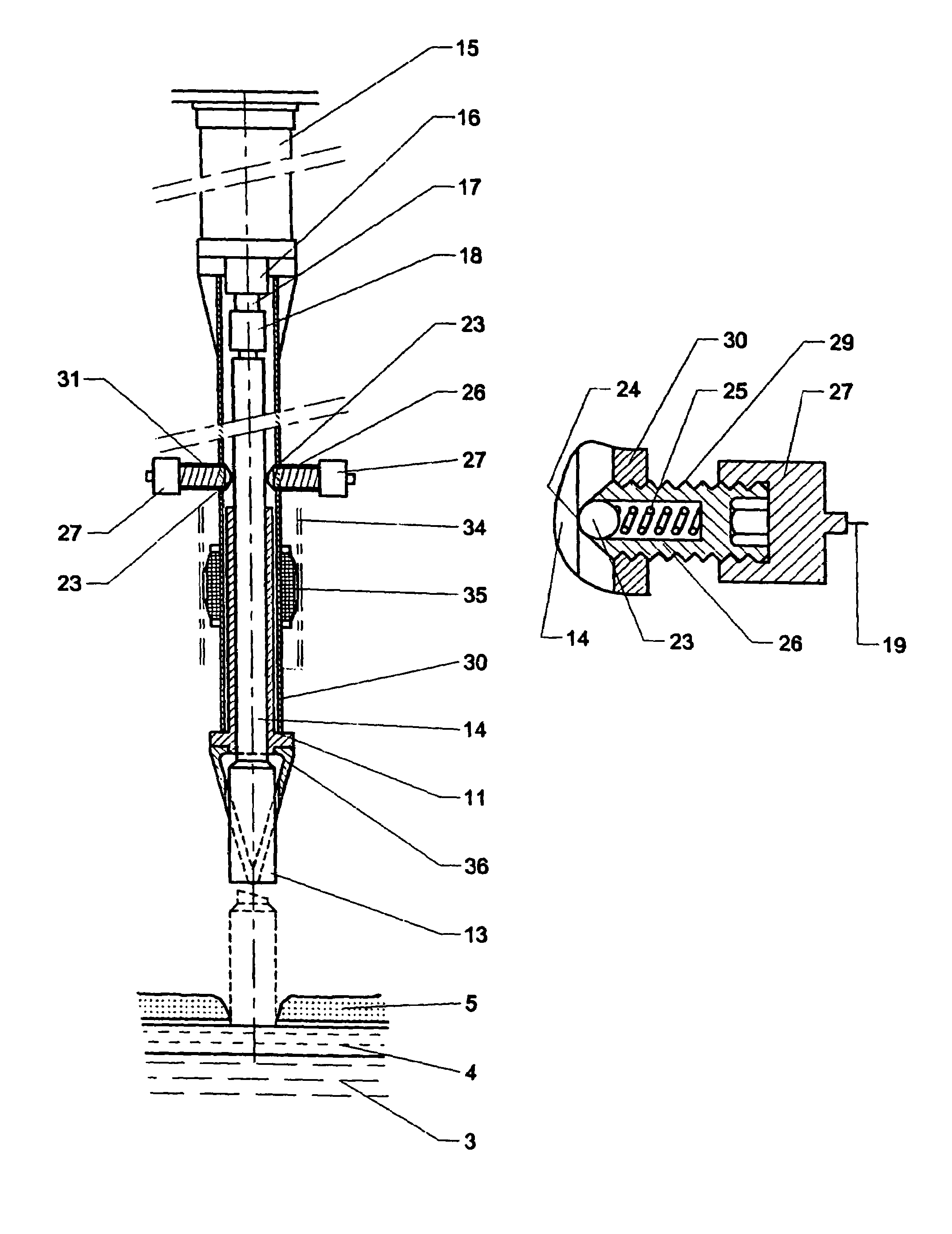

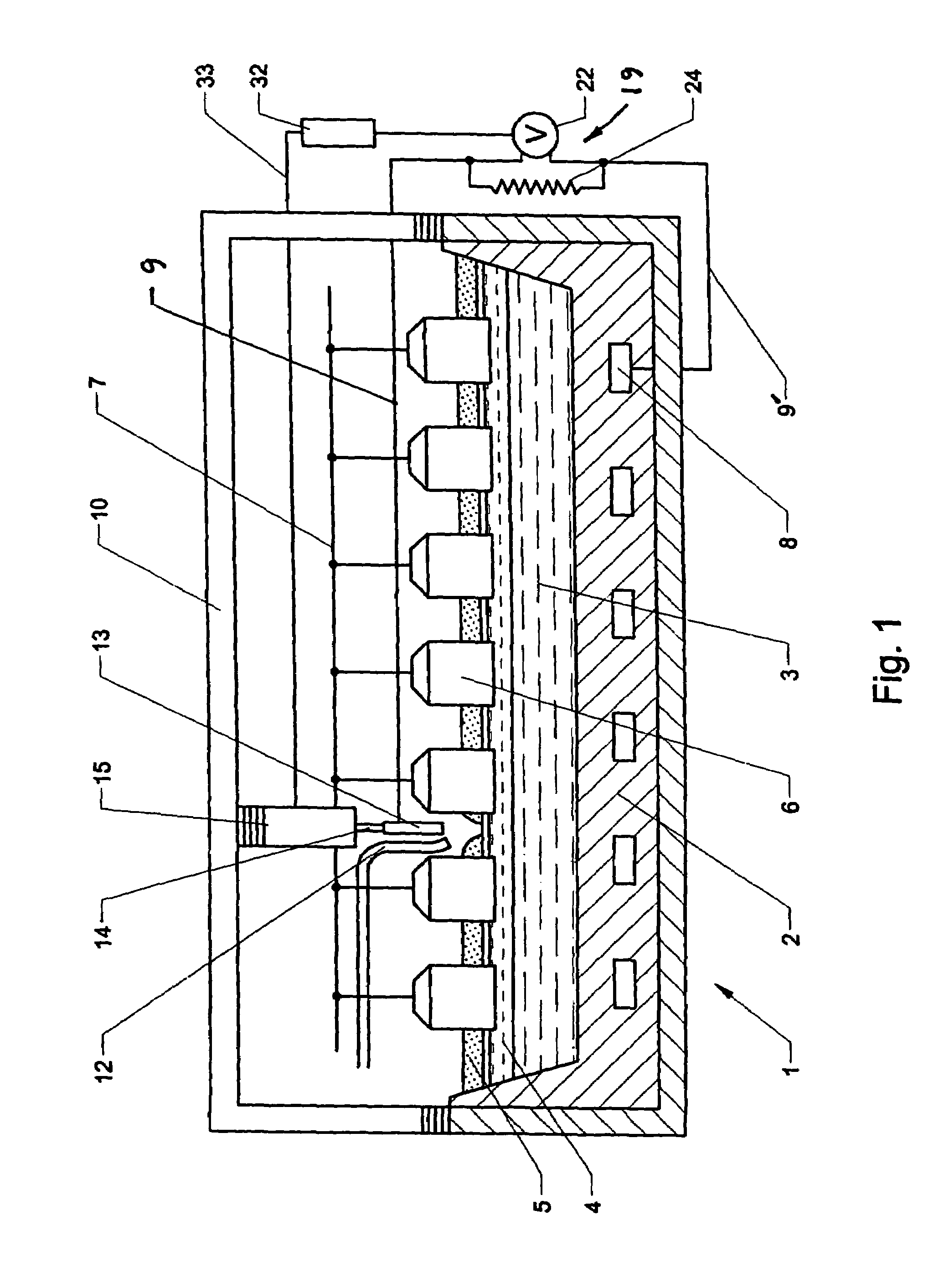

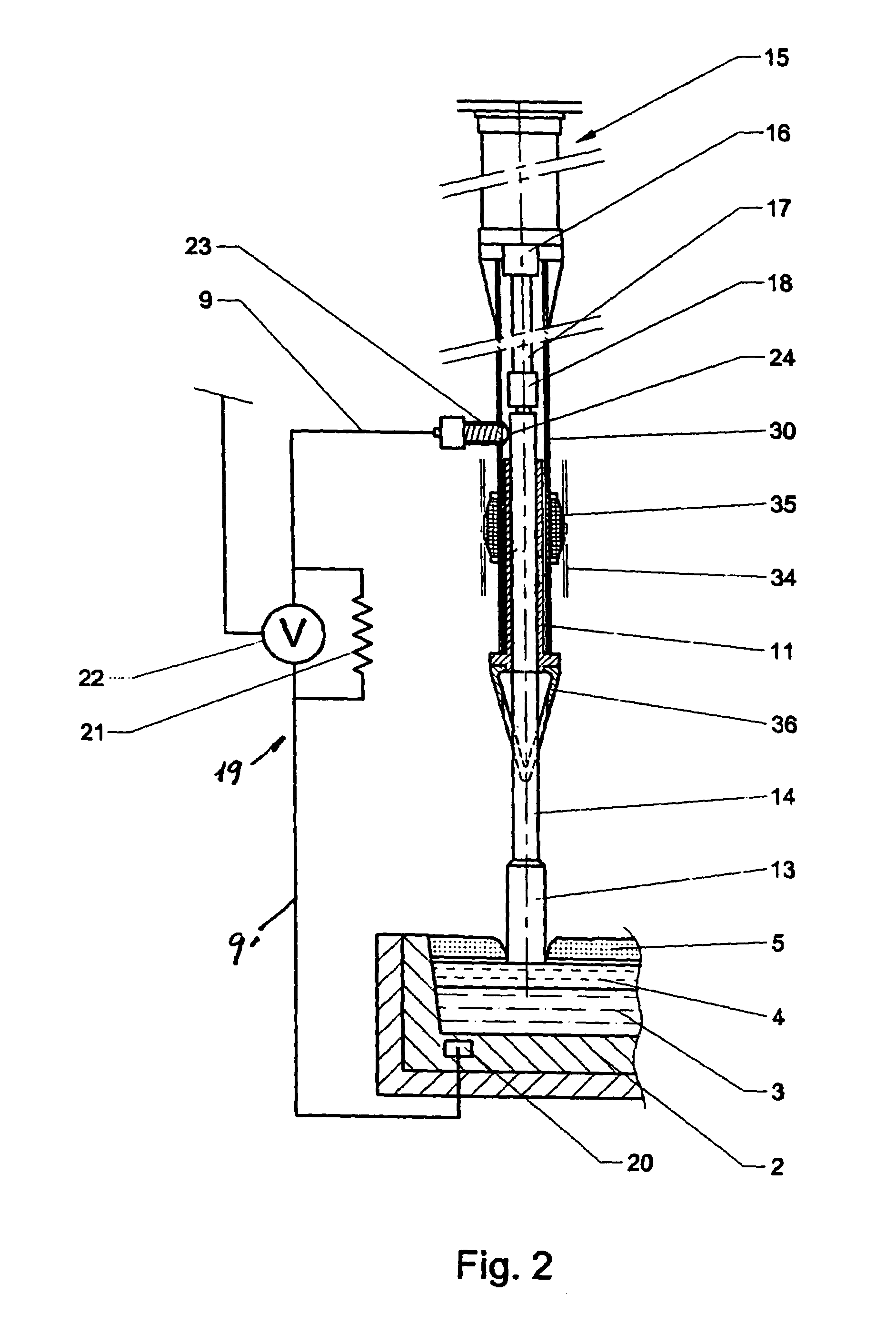

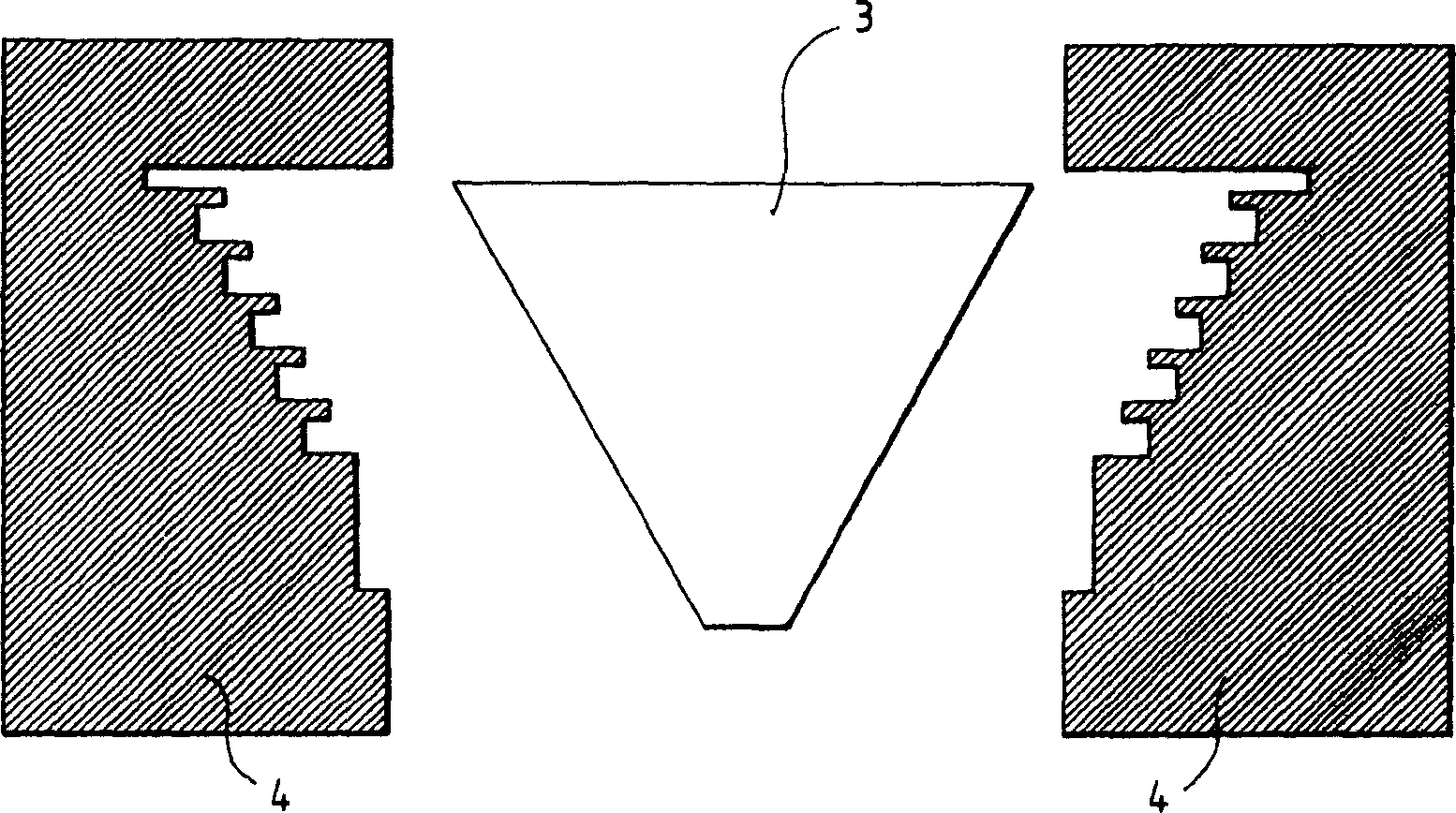

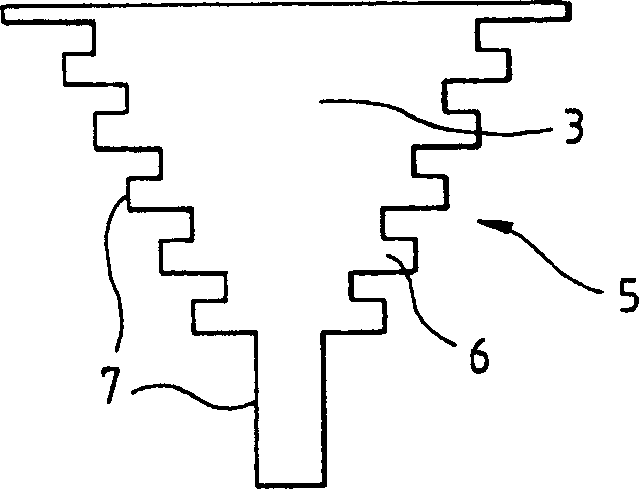

Device for controlling the travel distance of a chisel in a feeding system for an aluminium production electrolytic cell

InactiveUS7429314B2Easy to assembleEasy to replaceCellsElectric circuitsElectrical batteryEngineering

Device for equipment of a cell (1) comprising an electrolytic bath (4) covered with a crust (5), with a chisel (13) that can be moved vertically between a high position in which it is above the crust (5) and a low position in which the crust (5) is perforated and in which contact is made with the bath (4), the device (11) comprising means of detecting electrical contact between the chisel (13) and the bath (4), these means comprising an electrical circuit (19) capable of making an electrical measurement between the chisel (13) and a point (20) in the cell used as an electrical reference, and taking immediate action on the actuator to cause vertical upwards displacement of the chisel when a predetermined value of an electrical measurement is reached. The electrical circuit (19) is connected to the chisel (13), to the rod (14) of the chisel (13) or to the actuator rod (17) through connecting means capable of creating a point contact (24) at least one point between the circuit (19) and the chisel (13), the rod (14) of the chisel (13) or the actuator rod, these connecting means (23) being acted upon by elastic means (25) pushing them towards the chisel (13), the rod (14) of the chisel (13) or the actuator rod (17) respectively.

Owner:ALUMINUM PECHINEY

Separation and falling connector assembly with photoelectric conversion function

ActiveCN110265836AIncrease transfer rateAchieve conversionCouplings bases/casesTwo-part coupling devicesElectrical connectionEngineering

The invention proposes a separation and falling connector assembly with a photoelectric conversion function. A photoelectric conversion technology is employed, connection of optical signals of two ends of a separation and falling connector plug assembly and a separation and falling connector socket assembly is achieved, the optical signal of one end of the connector is converted to an electrical signal, the electrical signal passes through an insertion surface of the connector by a high-speed electrical contact piece, the electrical signal passing through the insertion surface is converted to an optical signal, and the optical signal is output. A ceramic contact piece can be prevented from being used, the problem that a fiber contact piece is easy to pollute and damage is prevented, daily application and operation specification of an electrical connector can be followed, high usability is achieved, special instrument equipment is not needed to check cleanness of an end surface of a connector ceramic insertion core and completeness of a ceramic sleeve, and the application is greatly facilitated.

Owner:杭州航天电子技术有限公司

Coaxial connector with grommet biasing for enhanced continuity

ActiveUS20140357120A1Improve continuityAchieve electrical continuityElectrically conductive connectionsCoupling protective earth/shielding arrangementsEngineeringInterconnection

A compressible, F-connector and method for interconnection with coaxial cable that includes a biasing grommet for promoting electrical continuity despite inadequate nut tightening. Each connector has a rigid nut, a post penetrating the nut, a tubular body, and an end cap. The conductive post coaxially extends through the connector, linking the nut and body. A post end penetrates the coaxial cable. Each connector body comprises a frontal ring groove in which is seated a biasing grommet with integral wings spiraling away from one or both grommet ends that bias the nut to insure mechanical and electrical contact with the post.

Owner:PERFECTVISION MFG

Dual crimping of single and multi-strand aluminum wire with quick-change crimp head

InactiveUS20070039168A1Easy and quick insertionEasy to removeLine/current collector detailsForging hammersEngineeringCam

A base unit for an insulated single and multi-strand aluminum wire crimping system includes a receptacle into which a quick-change crimp head may be slipped and locked. The crimp head includes a set of crimp-seal dies axially spaced from a set of continuity-crimping dies with both sets being mounted in a crimping die holder body. Both sets of dies perform crimping operations on the same contact-wire assembly. The crimp seal dies form the contact into a substantially smooth unbroken generally cylindrical wall hermetically sealed to the outside of the insulation on the core of the wire. The continuity-crimping dies crimp a wall of the contact into electrical contact with the core of the wire by indenting the wall into the wire. Ring cams drive the dies. These ring cams have internal cam profiles. The ring cams engage cam followers that are associated with the respective dies. The contact is received in the die holder body in a contact holder. The contact holder is quickly changeable. A sensor system prevents the crimping tool from unintentionally performing two crimping operations on the same contact-wire assembly, and detects non-compliant continuity-crimping.

Owner:TRI STAR TECH

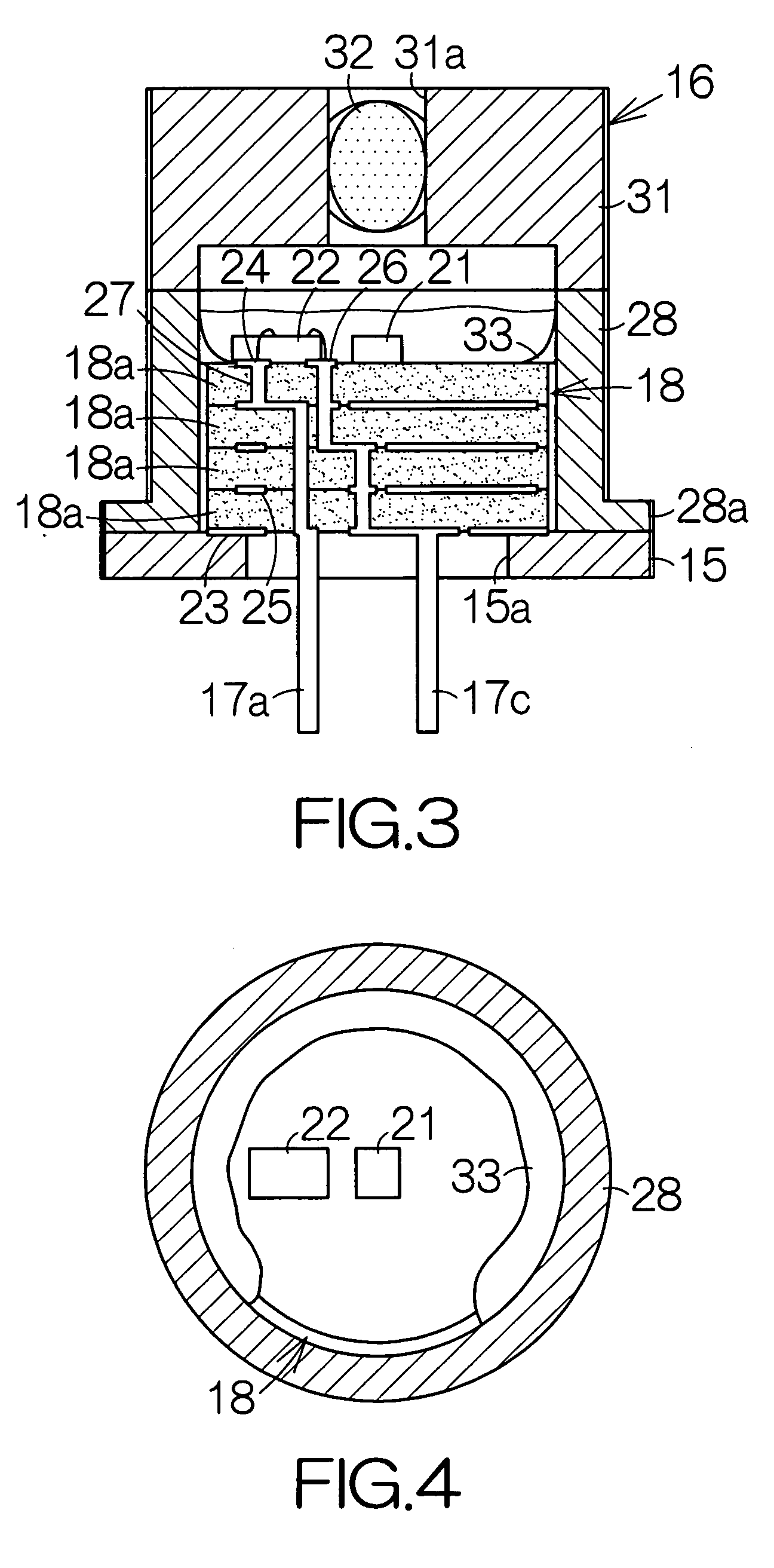

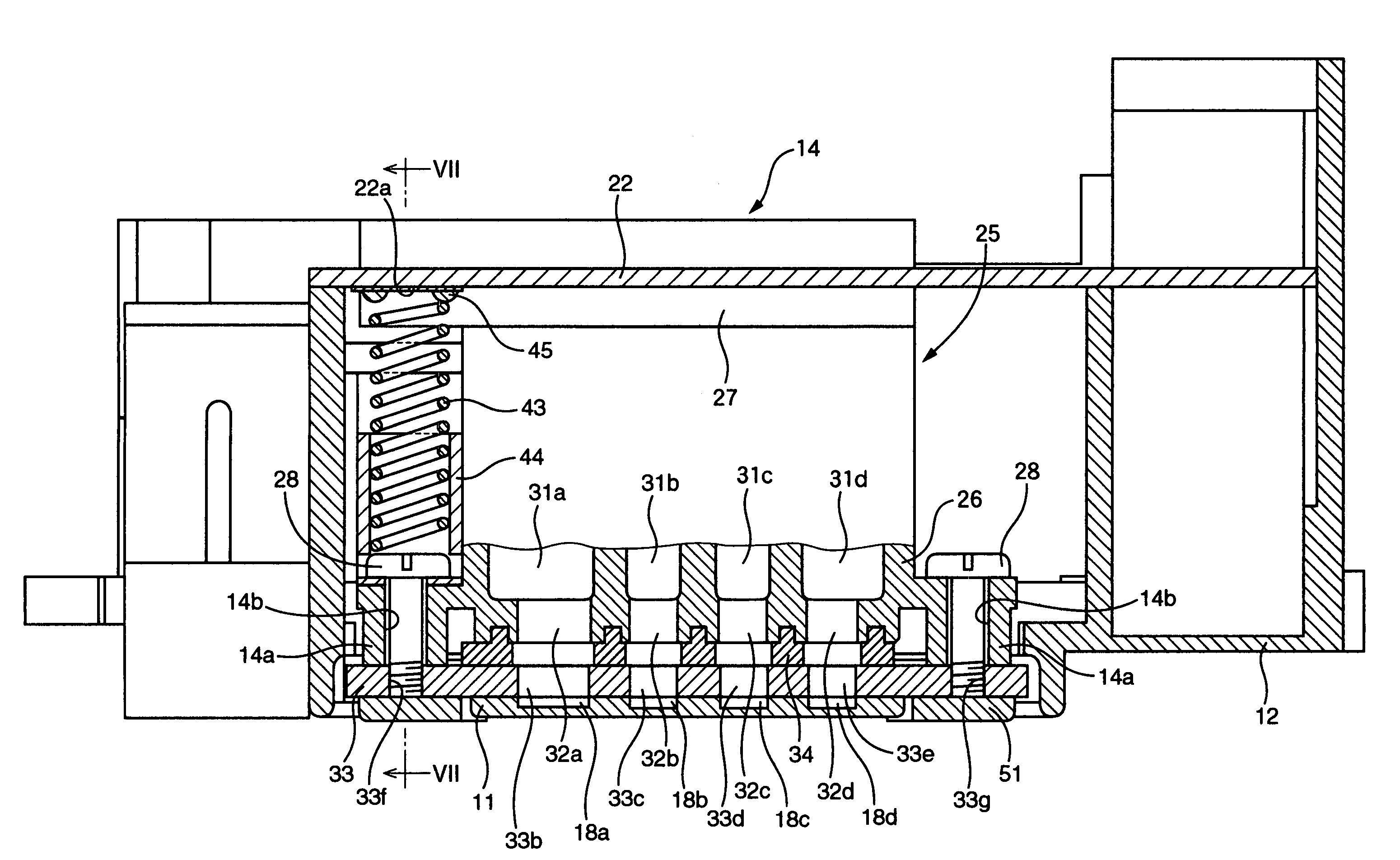

Receiver optical sub-assembly and optical receiver module

InactiveUS20090196626A1Achieve electrical continuityHigh densityRadiation pyrometryMaterial analysis by optical meansGround layerOptical receivers

A receiver optical sub-assembly includes a multilayered ceramic substrate mounted on an electrically conductive base. The multilayered ceramic substrate has a ground layer on the front surface. A light receiving element is mounted on the front surface of the multilayered ceramic substrate. A cap and the electrically conductive base enclose the multilayered ceramic substrate and the light receiving element. An electrically conductive body connects the ground layer to the electrically conductive base. Terminals are attached to the back surface of the multilayered ceramic substrate. The terminals project outside the electrically conductive base. A high frequency noise propagates from the ground layer to the base through the electrically conductive body. A sufficient amount of ground potential is obtained. Self-resonance is prevented. The multilayered ceramic substrate enables an enhanced density of the terminals based on a wiring pattern or patterns and a via or vias.

Owner:FUJITSU LTD

Inkjet head with conductive elastic member for electrical continuity between remote contacts in same

ActiveUS7578580B2Simple circuit structureAchieve electrical continuityPrintingGround contactElectricity

Owner:BROTHER KOGYO KK

Method for making a waveguide microwave antenna

InactiveCN1703804AReduce manufacturing costAchieve electrical continuityWaveguide hornsMicrowaveSynthetic materials

Owner:INTERDIGITAL CE PATENT HLDG

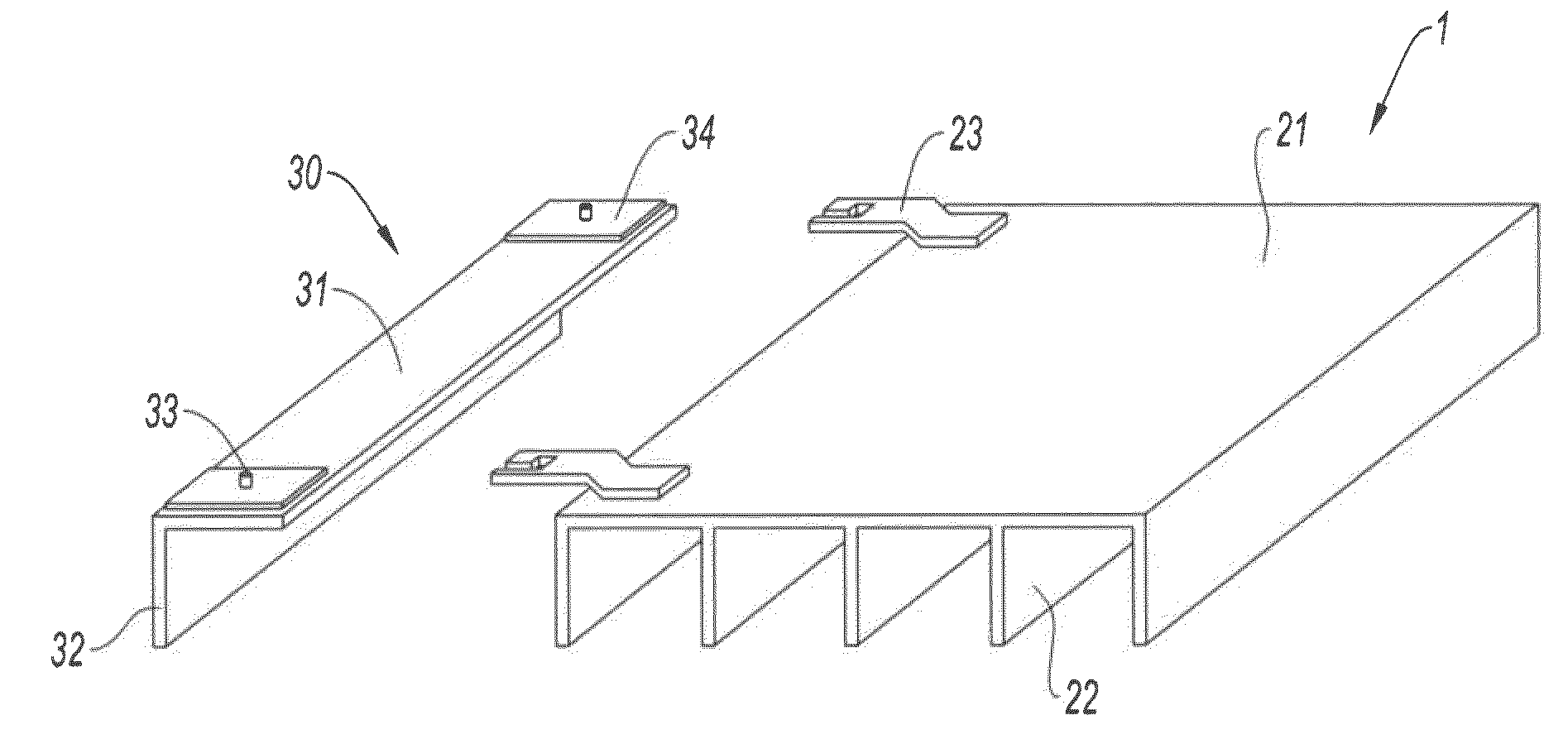

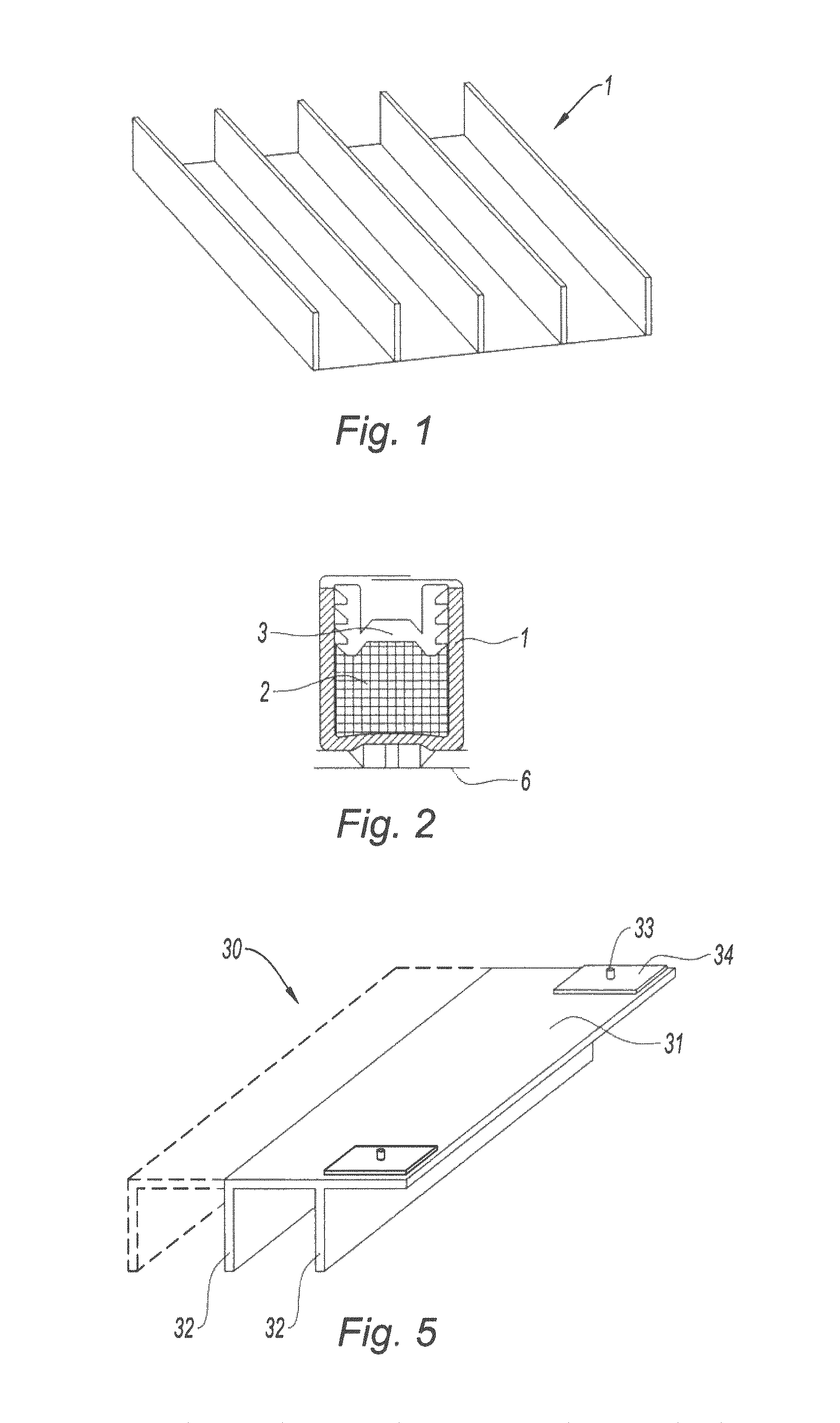

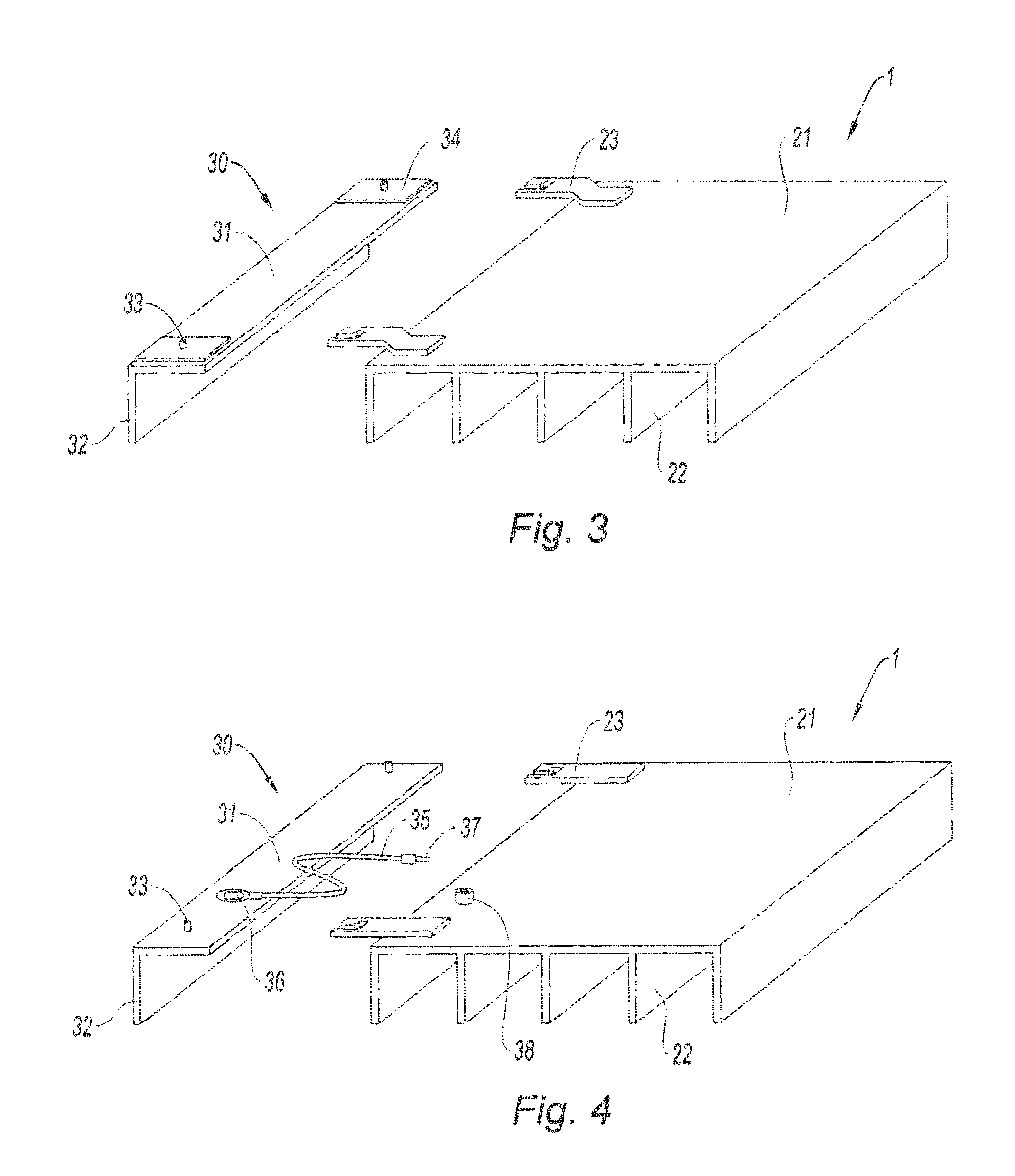

Expandable cableway for aircraft with a structure made of composite material

ActiveUS8436245B2Simply and quickly increaseIncrease volumePower cables with screens/conductive layersInsulated cablesTrunkingEngineering

Device for holding the cables of an aircraft onto the structure of the said aircraft, the said device having substantially the shape of a first trunking element, forming a basic trunking element, comprising means for coupling to the aircraft structure that are positioned on the side of its bottom and arranged to receive at least one cable running along the structure of the said aircraft and to provide an electrical continuity over the whole of its length, characterized in that the said basic trunking element comprises first attachment means capable of interacting with corresponding attachment means of a second trunking element, forming a lateral extension trunking element.

Owner:SAFRAN ELECTRICAL & POWER

Preparation method of anode of flexible OLED display panel and preparation method of display panel

PendingCN106783910AReduce breakageExtended service lifeFinal product manufactureSolid-state devicesSputteringFlexible display

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

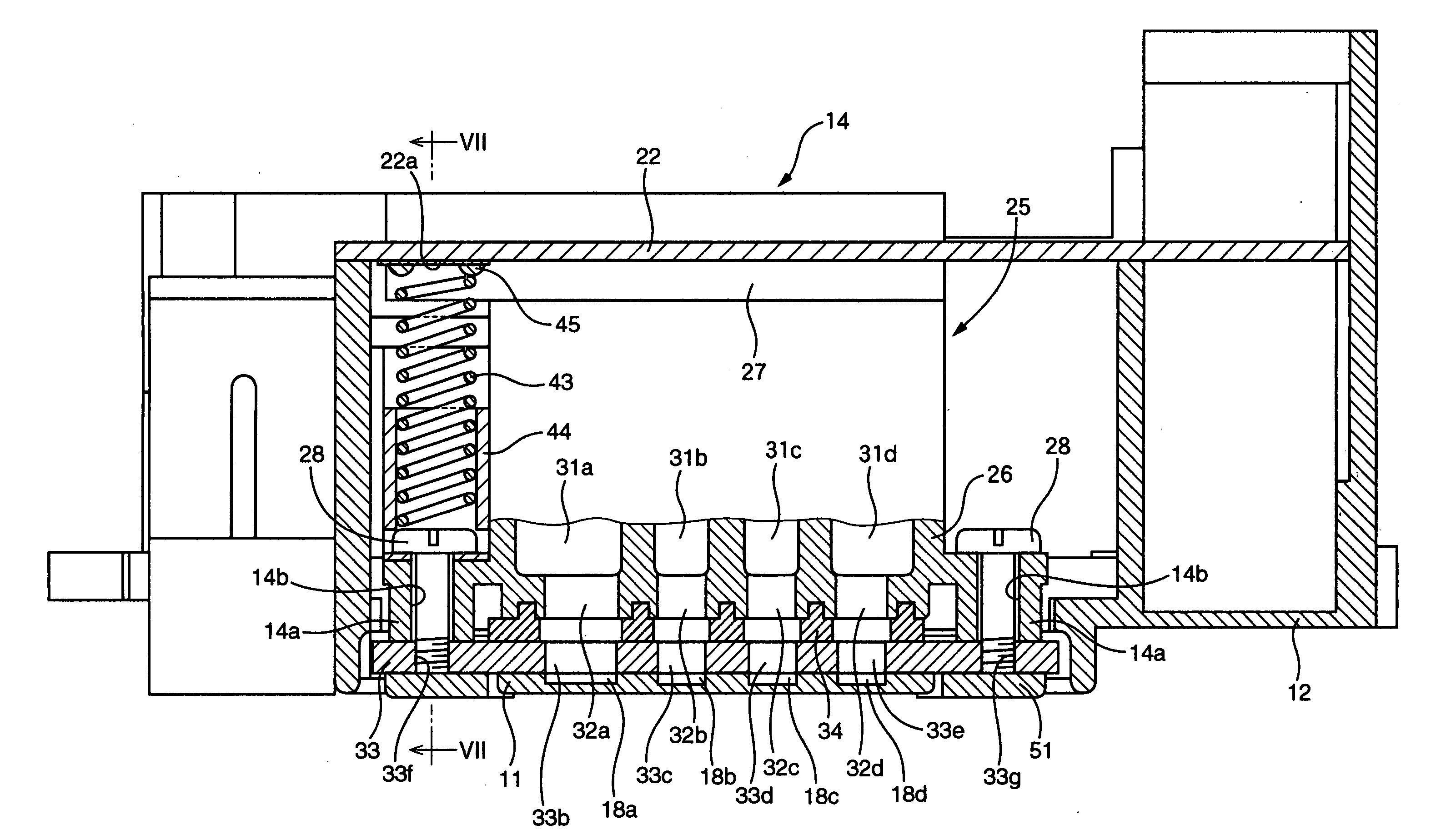

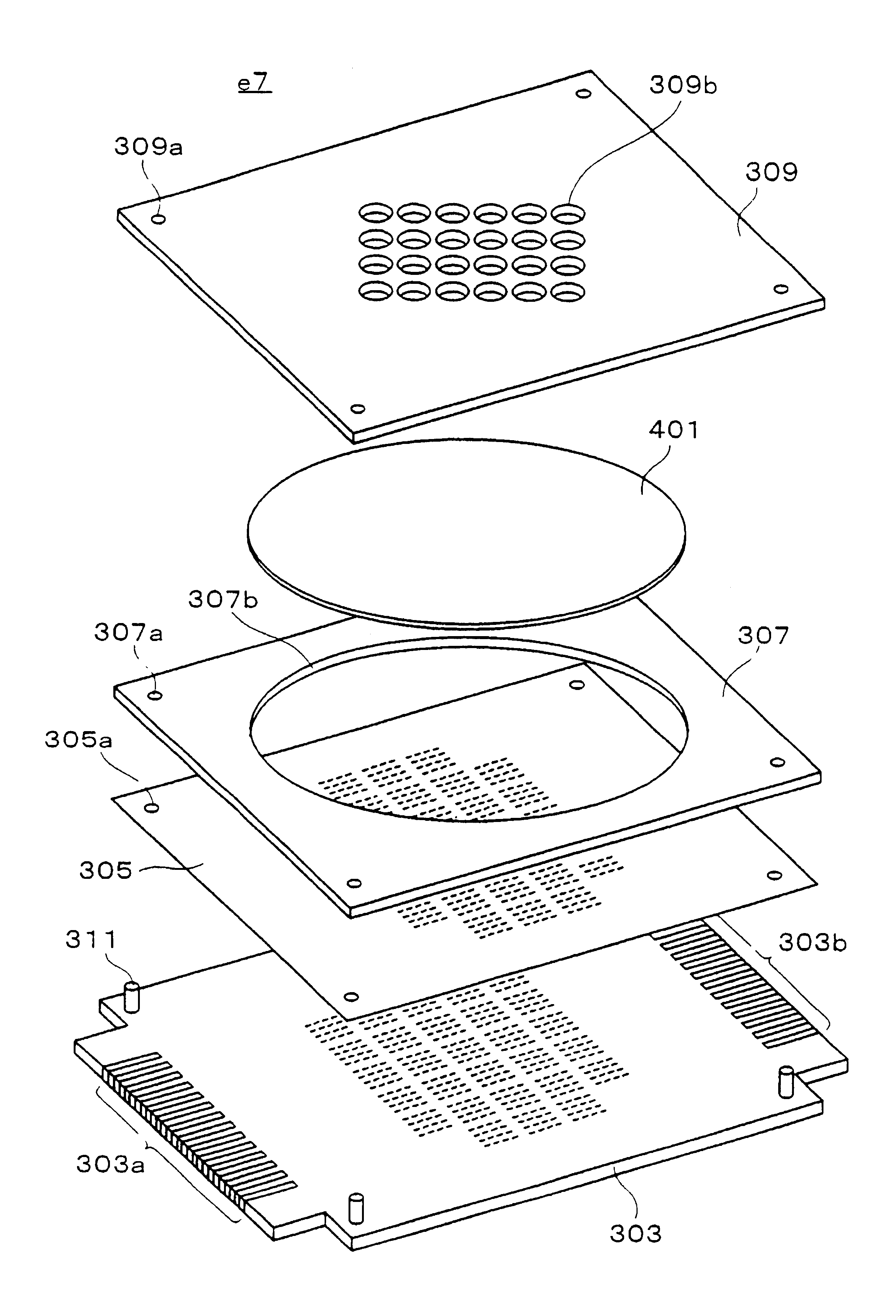

Method for manufacturing and batch testing semiconductor devices

InactiveUS6879169B2Increased durabilityAchieve electrical continuityThermometer detailsSemiconductor/solid-state device testing/measurementEngineeringSemiconductor

A semiconductor device test apparatus according to the present invention includes a circuit board 103 and a film 105. A plurality of electrodes 103c are formed at the circuit board 103 at positions that face opposite a plurality of electrodes 201a at a device to be measured 201, whereas bumps 105b are formed at the surface of the film 105 located toward the device to be measured 201, at positions that face opposite the plurality of electrodes 201a at the device to be measured 201 and electrodes 105c are formed at the surface of the film 105 located toward the circuit board 103 at positions that face opposite the plurality of electrodes 103c at the circuit board 103. The bumps 105b formed at one surface of the film 105 and the electrodes 105c formed at another surface of the film 105 are electrically connected with each other via through holes 105d to support semiconductor devices having electrodes provided at a fine pitch and to improve durability.

Owner:LAPIS SEMICON CO LTD

Method for manufactuing a semiconductor integrated circuit device

InactiveUS7524697B2Achieve electrical continuityHighly reliable semiconductor integrated circuit devicesSemiconductor/solid-state device testing/measurementElectronic circuit testingSemiconductorIntegrated circuit

Owner:RENESAS TECH CORP

Coring system and method for manufacturing a one-piece die cast electrical connector body

ActiveUS7882886B1Achieve electrical continuityElectrical apparatusFoundry mouldsElectricityDie casting

A coring system for producing a flash-free one-piece die-cast body for an electrical connector. The electrical connector of produced by the coring system of the present invention may be used for securing two electrical cables to an electrical panel or electrical box through a single knockout hole. The coring system includes a first core, a second core, and a connecting arrangement for connecting the first and second cores in such a manner that there are no gaps between the joined portions of the two cores. When the cores of the coring system are joined together by the connecting arrangement and placed in a mold, molten metal may be introduced to the mold at the joined area of the two core pieces to form a one-piece flash-free connector body according to the present invention.

Owner:ARLINGTON INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com