Patents

Literature

6760results about "Fuel cells grouping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

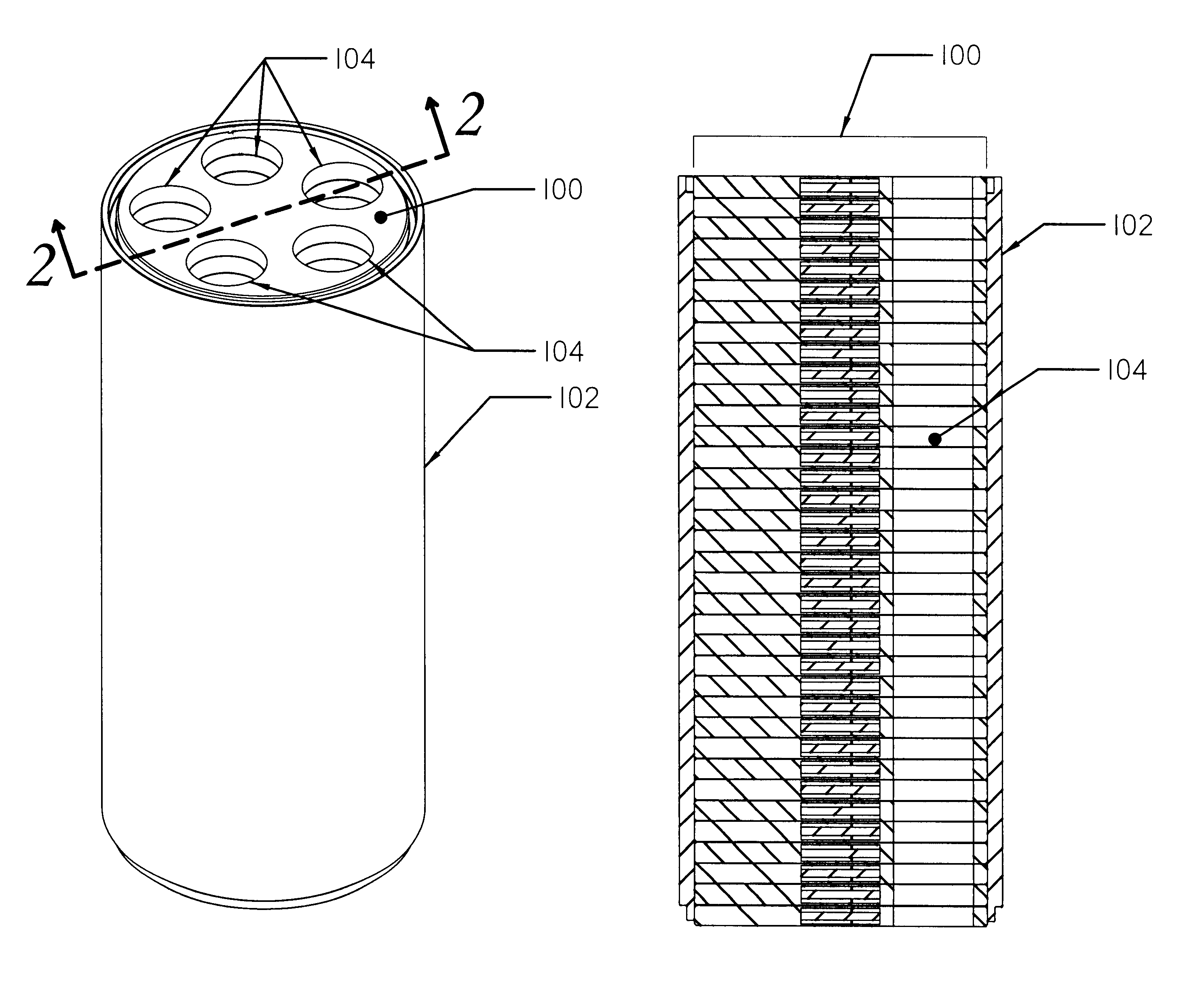

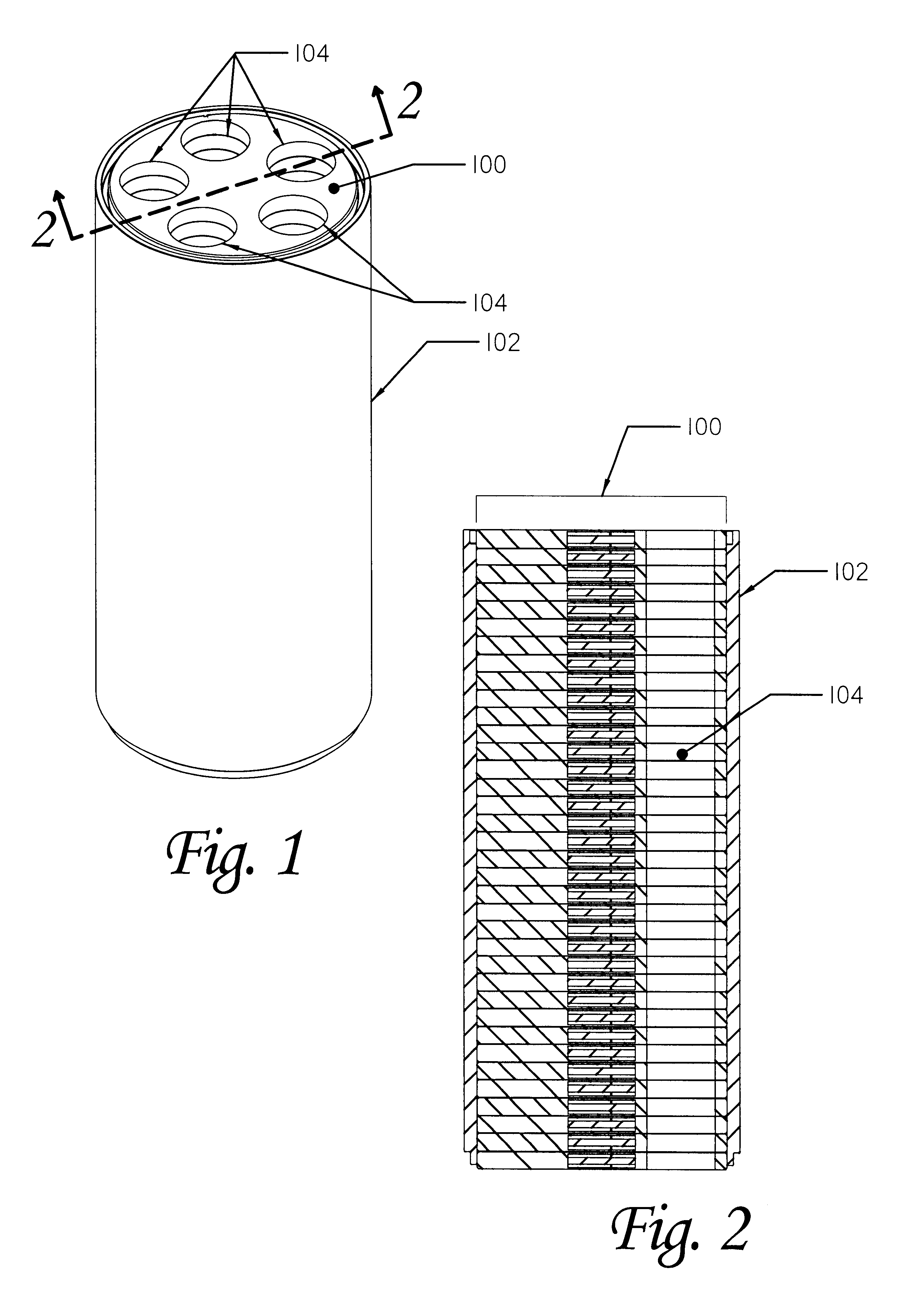

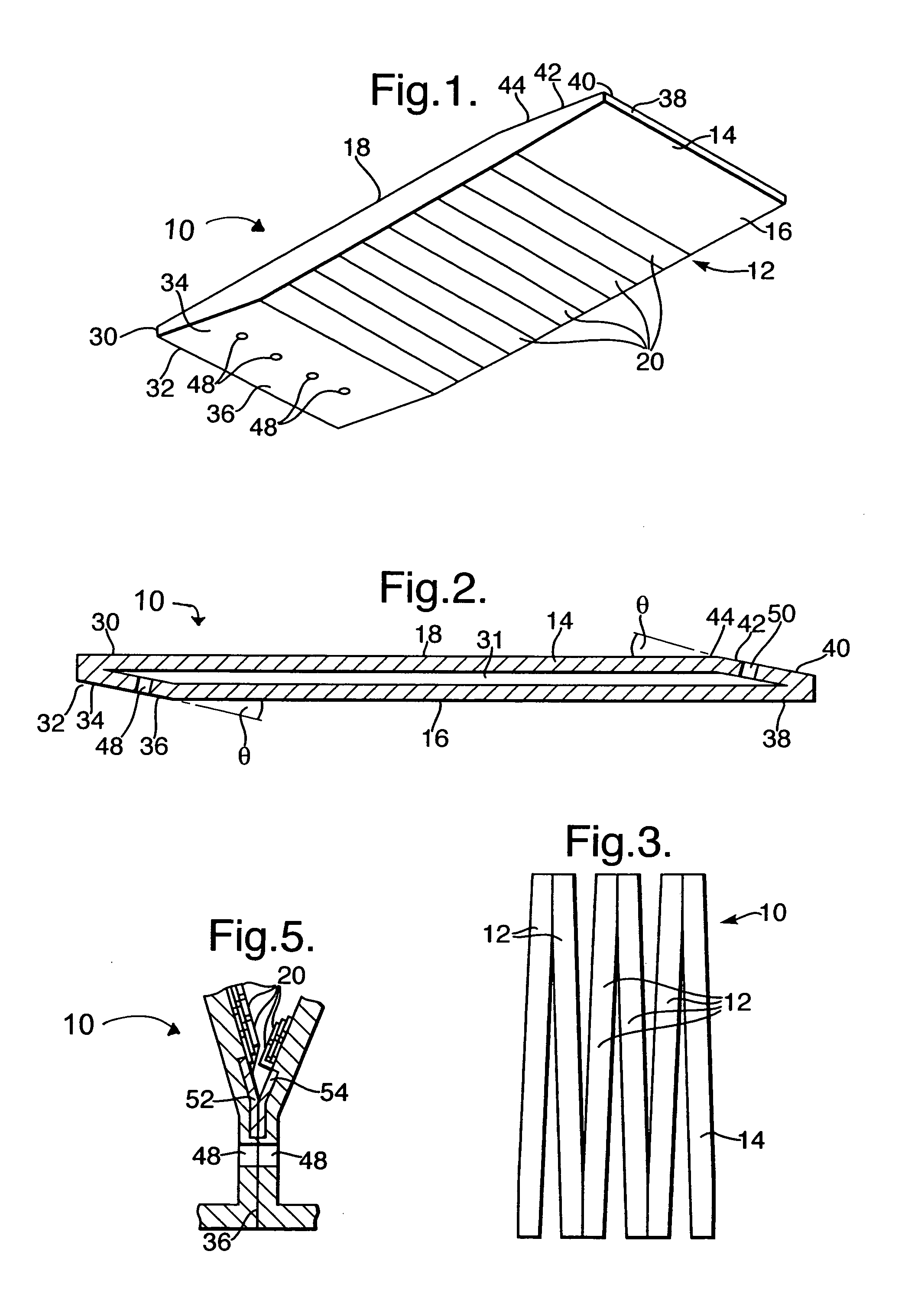

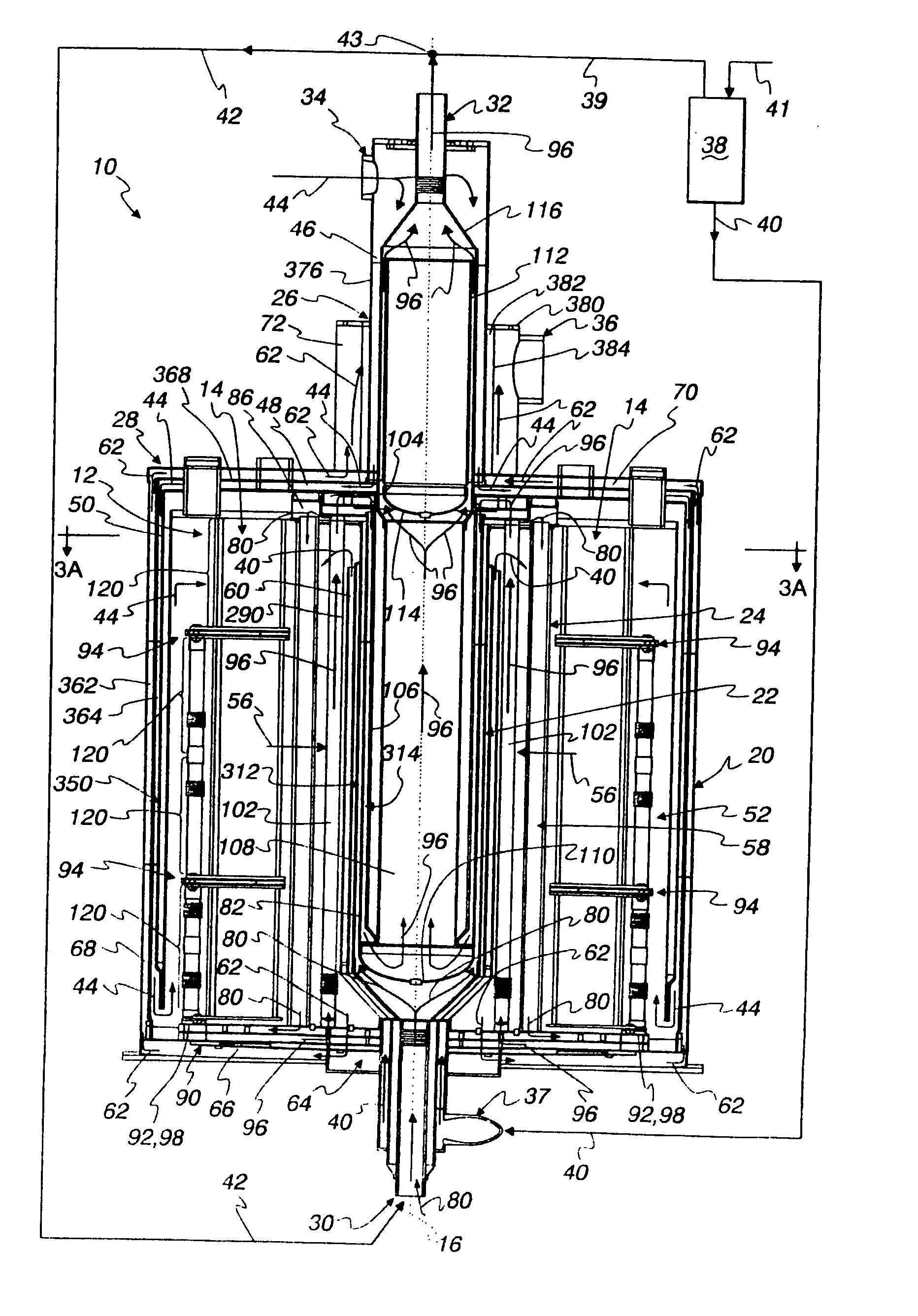

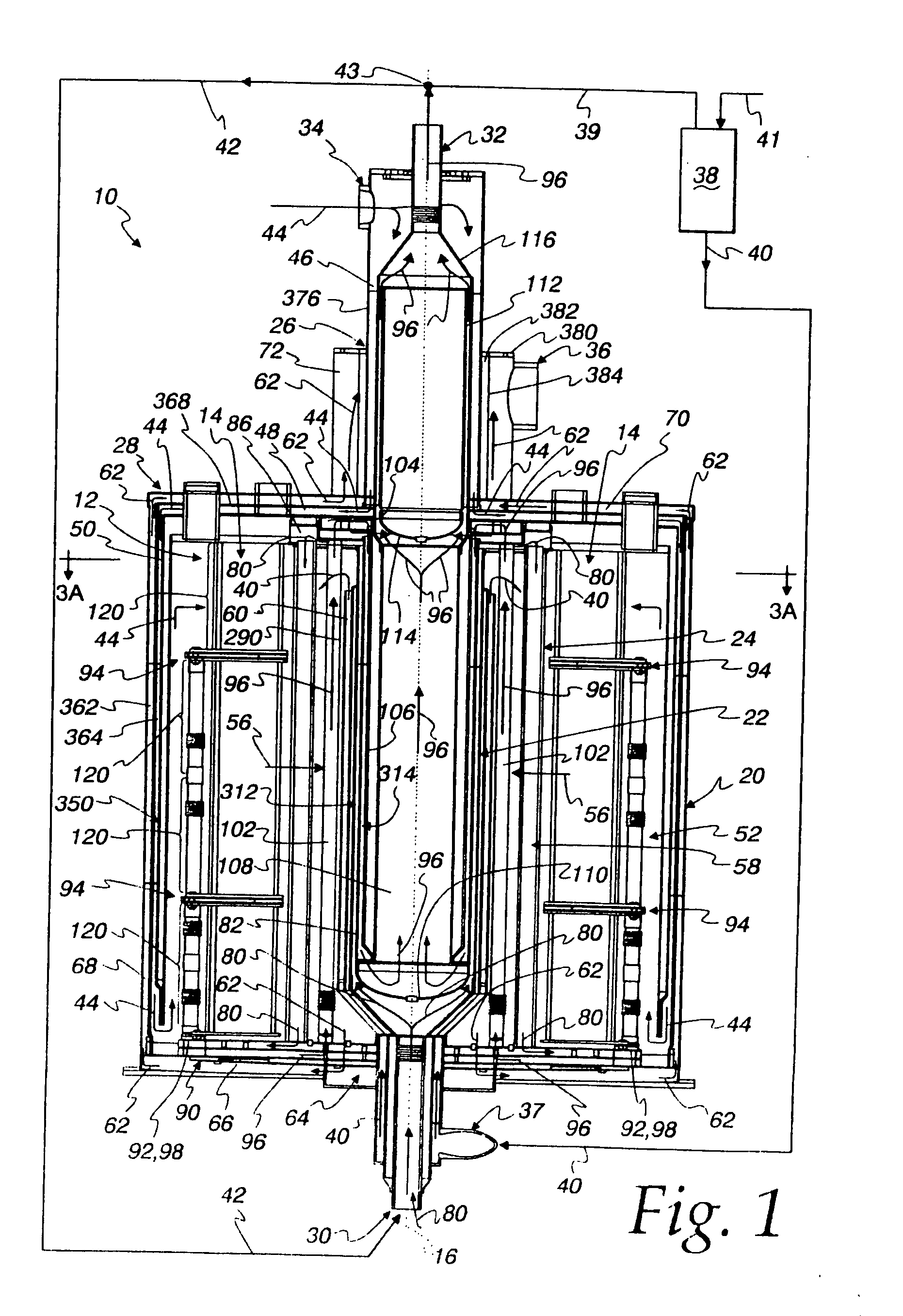

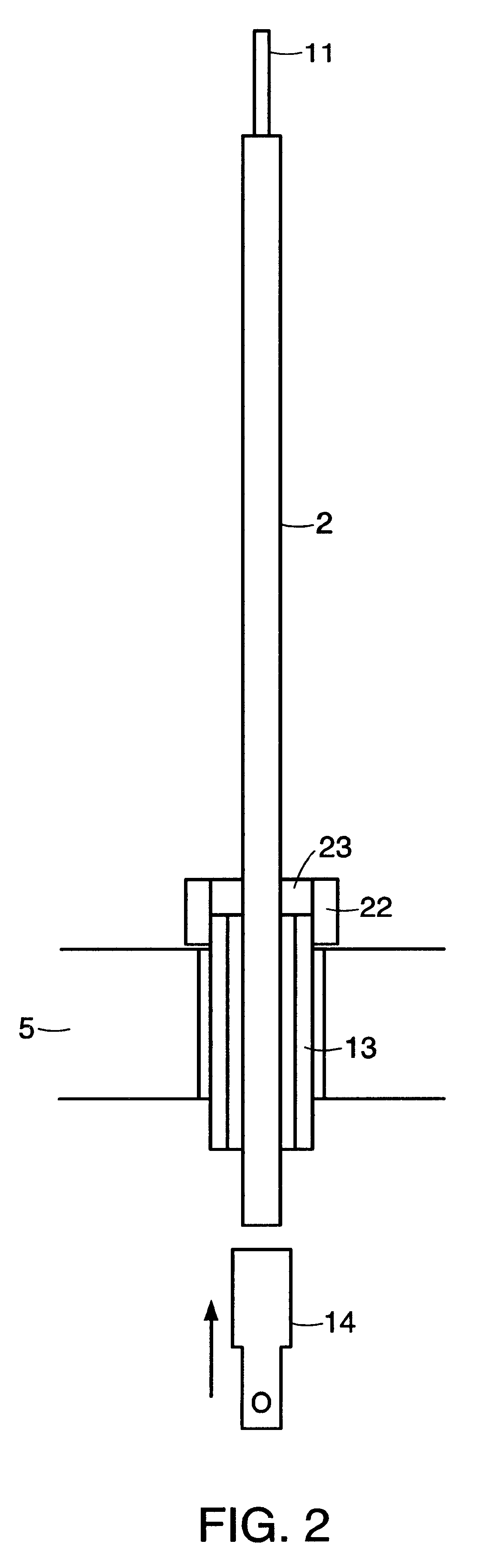

Apparatus and method for heating subterranean formations using fuel cells

InactiveUS6684948B1Eliminate needAvoid inefficiencyFuel cell heat exchangeFuel cells groupingElectricityFuel cells

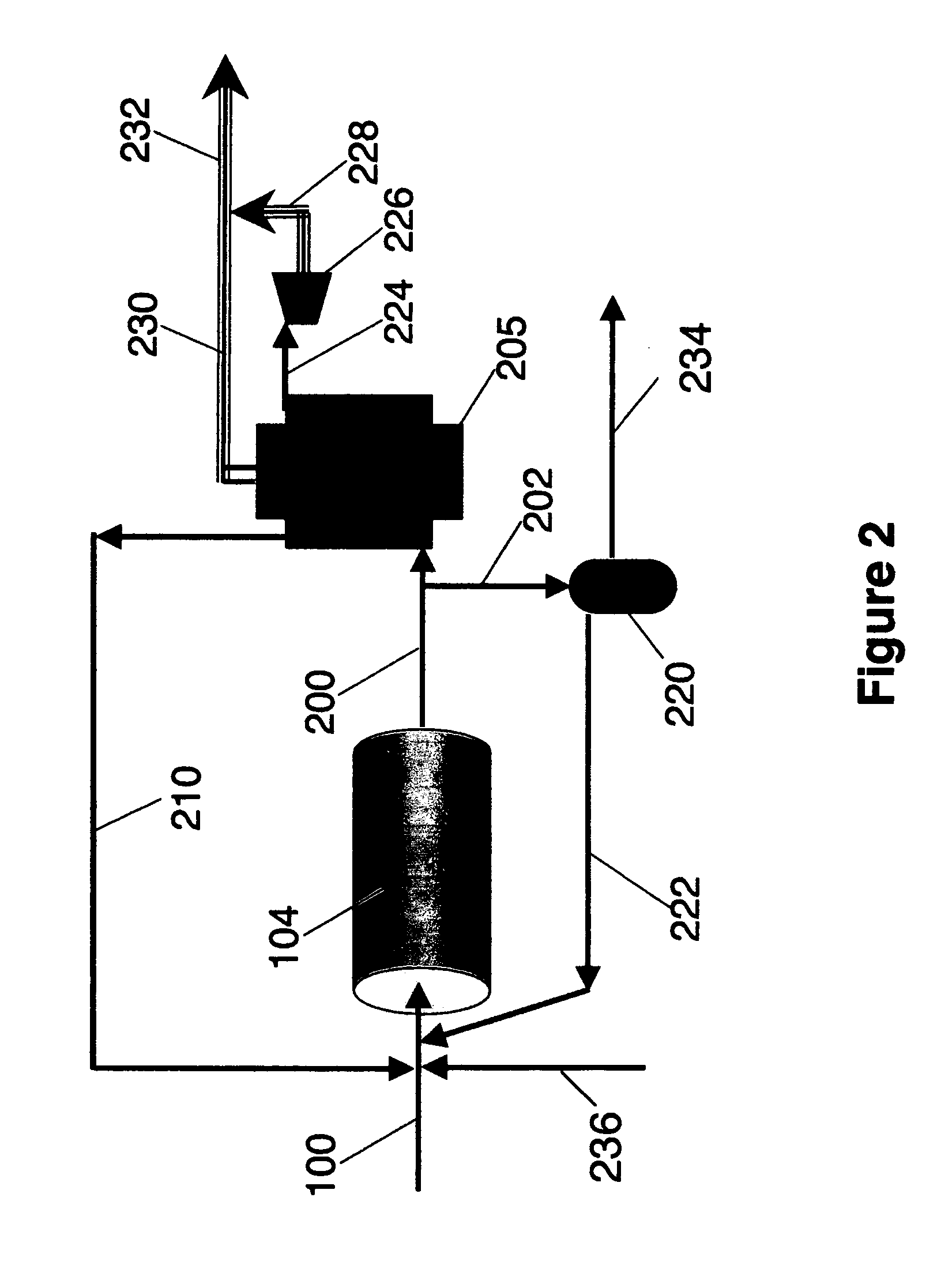

A fuel cell based subterranean heater for mineral extraction, in situ decontamination, or other applications. The fuel cells are preferably stacked within a casing which is then inserted into a hole bored, or otherwise formed, into the formation to be heated. Conduits within the casing, and preferably formed by adjacent, aligned holes formed through the plates of the individual fuel cells supply fuel and air and extract exhaust gases. An optional manifold is used to span the overburden without applying heat to it directly. The manifold may also function as a heat exchanger between incoming and exhaust gases. Preferably the fuel cell is fueled by gases produced by the formation and also generates electricity which is available for use or export.

Owner:IEP TECH INC

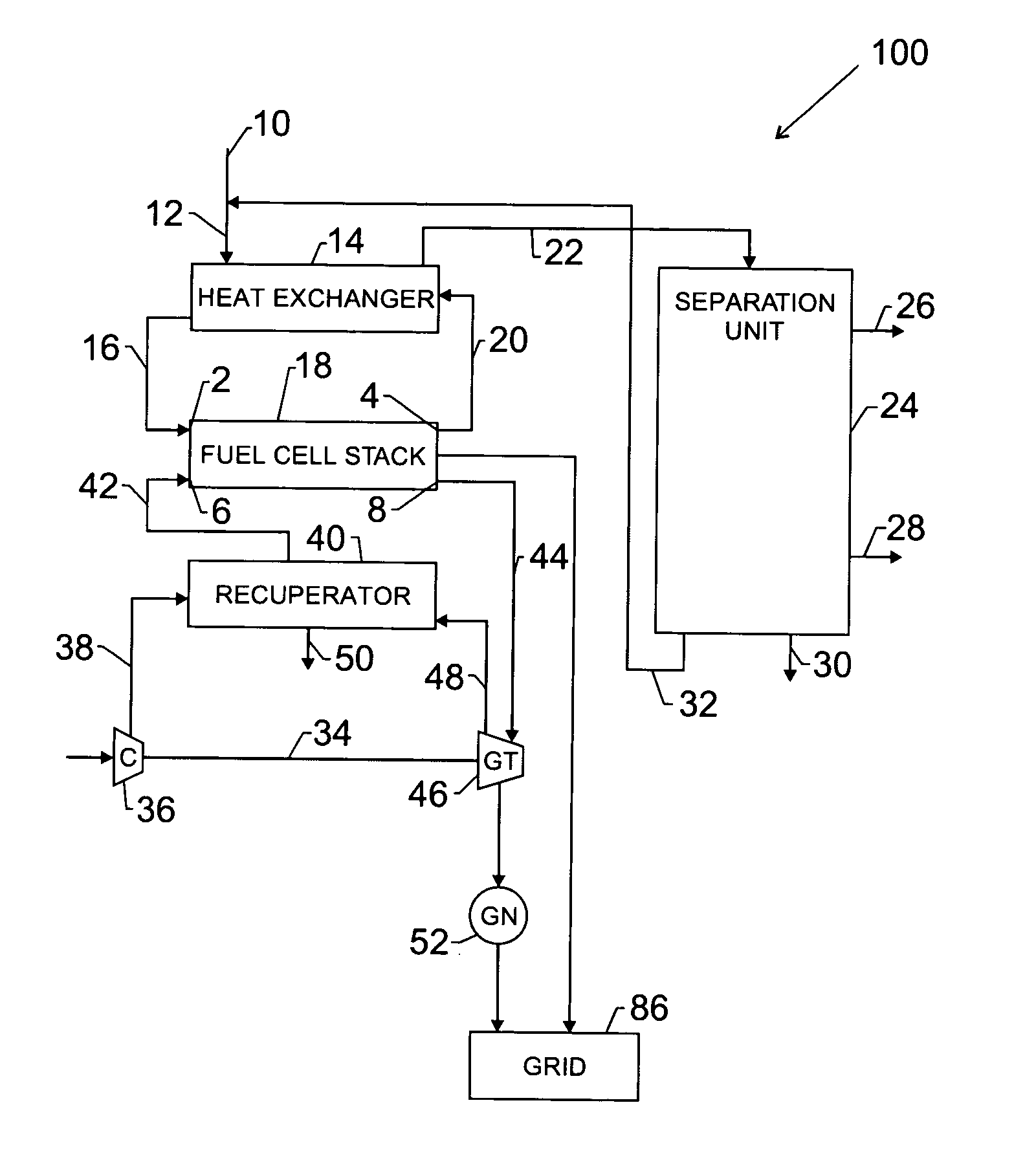

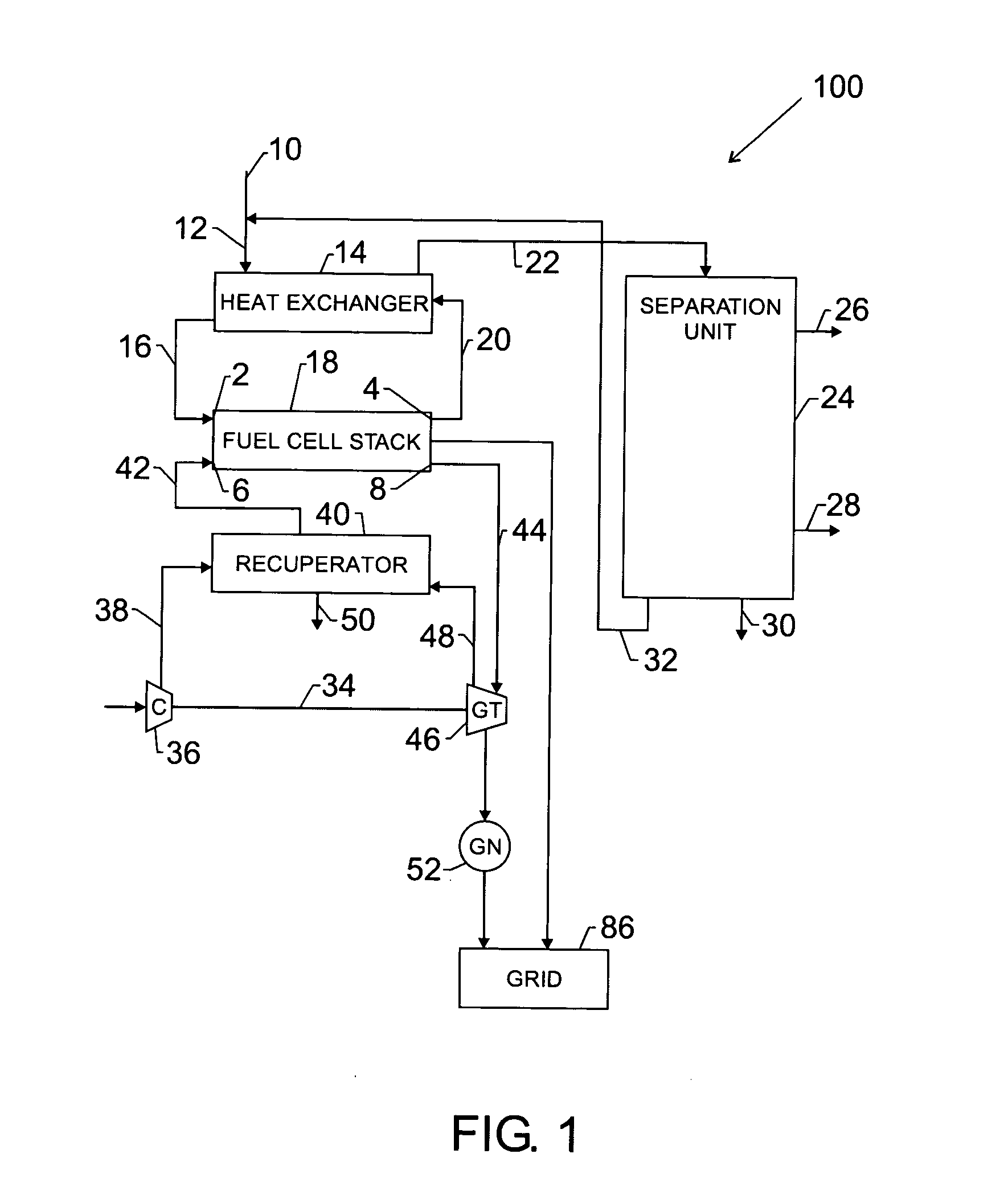

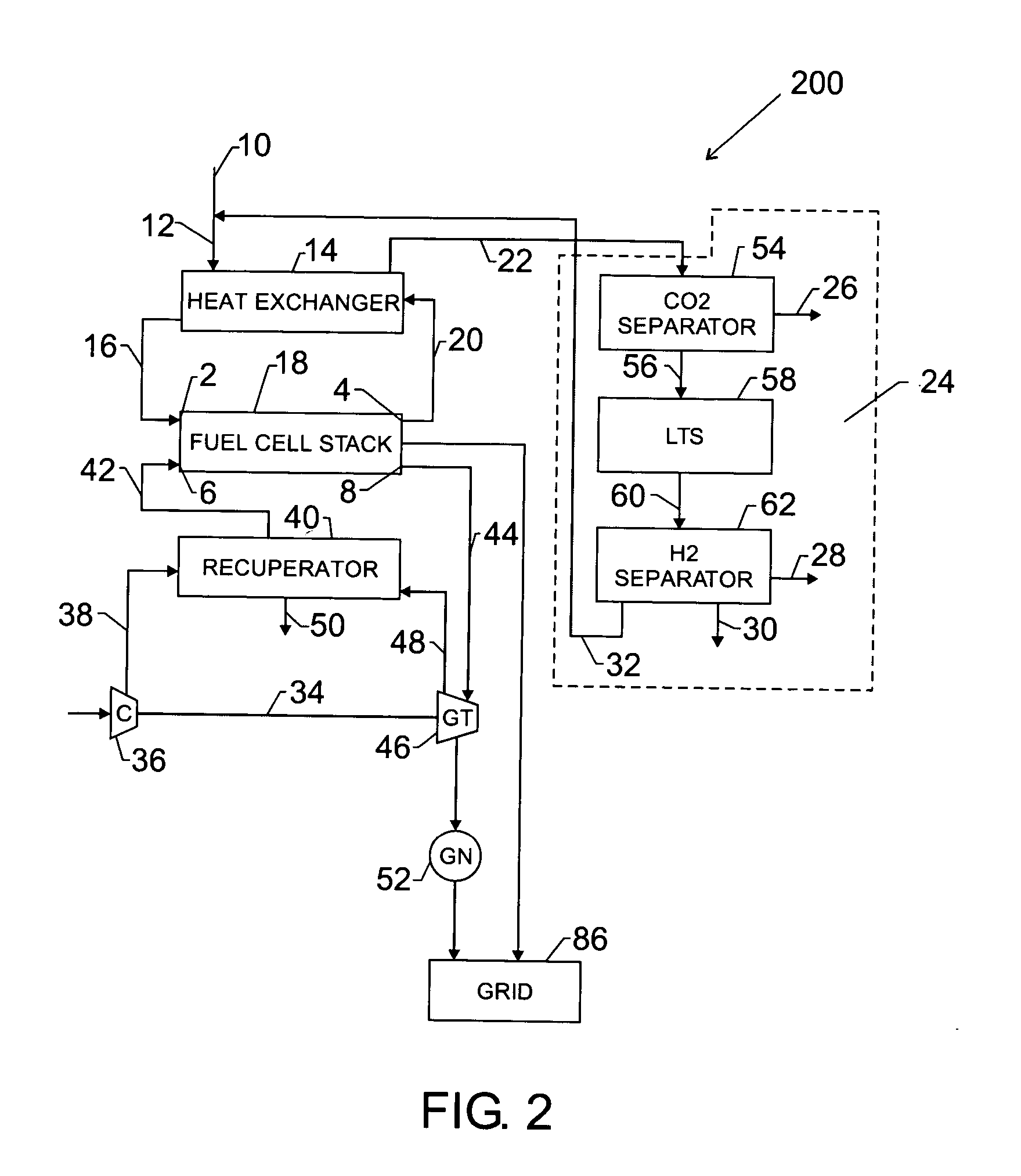

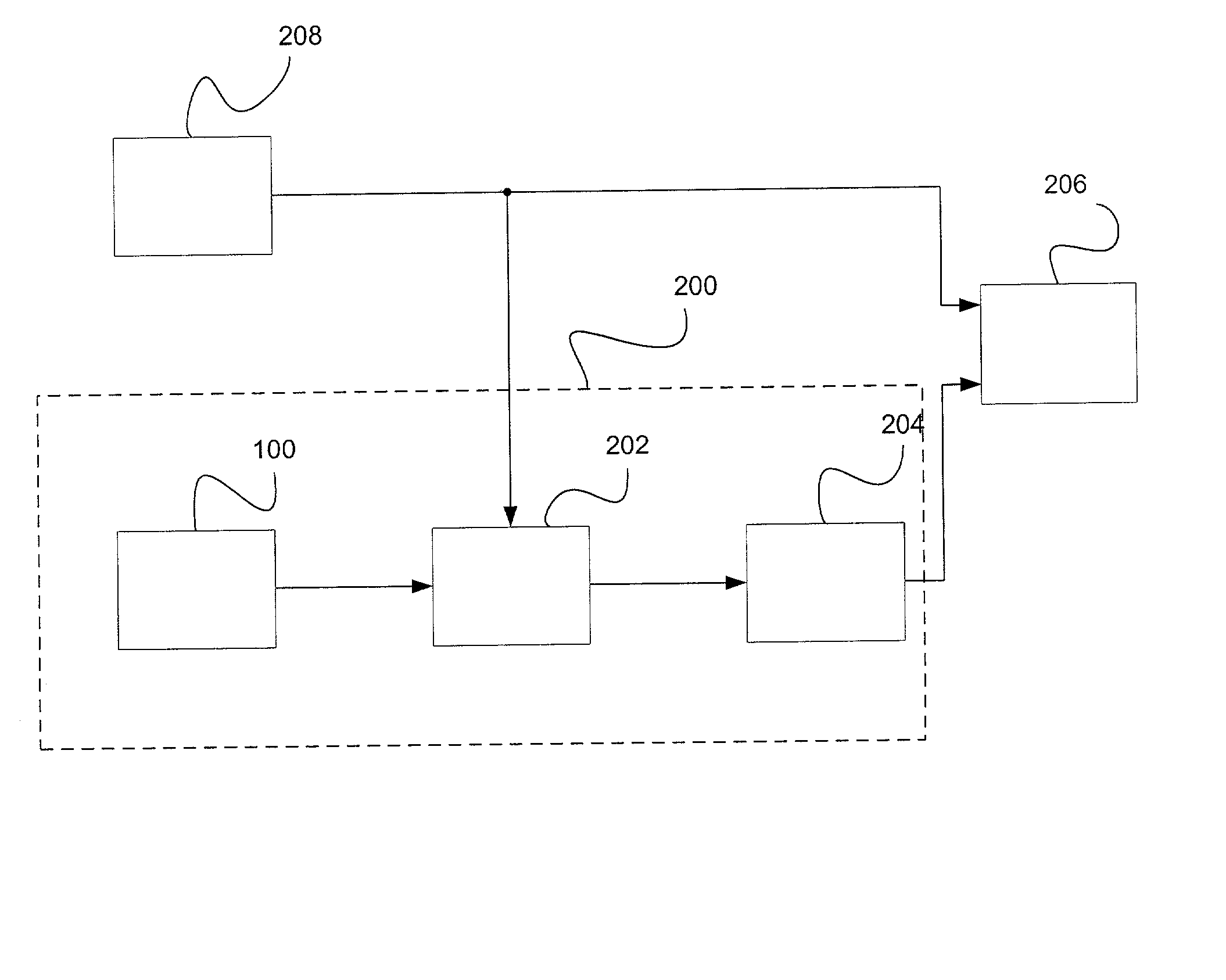

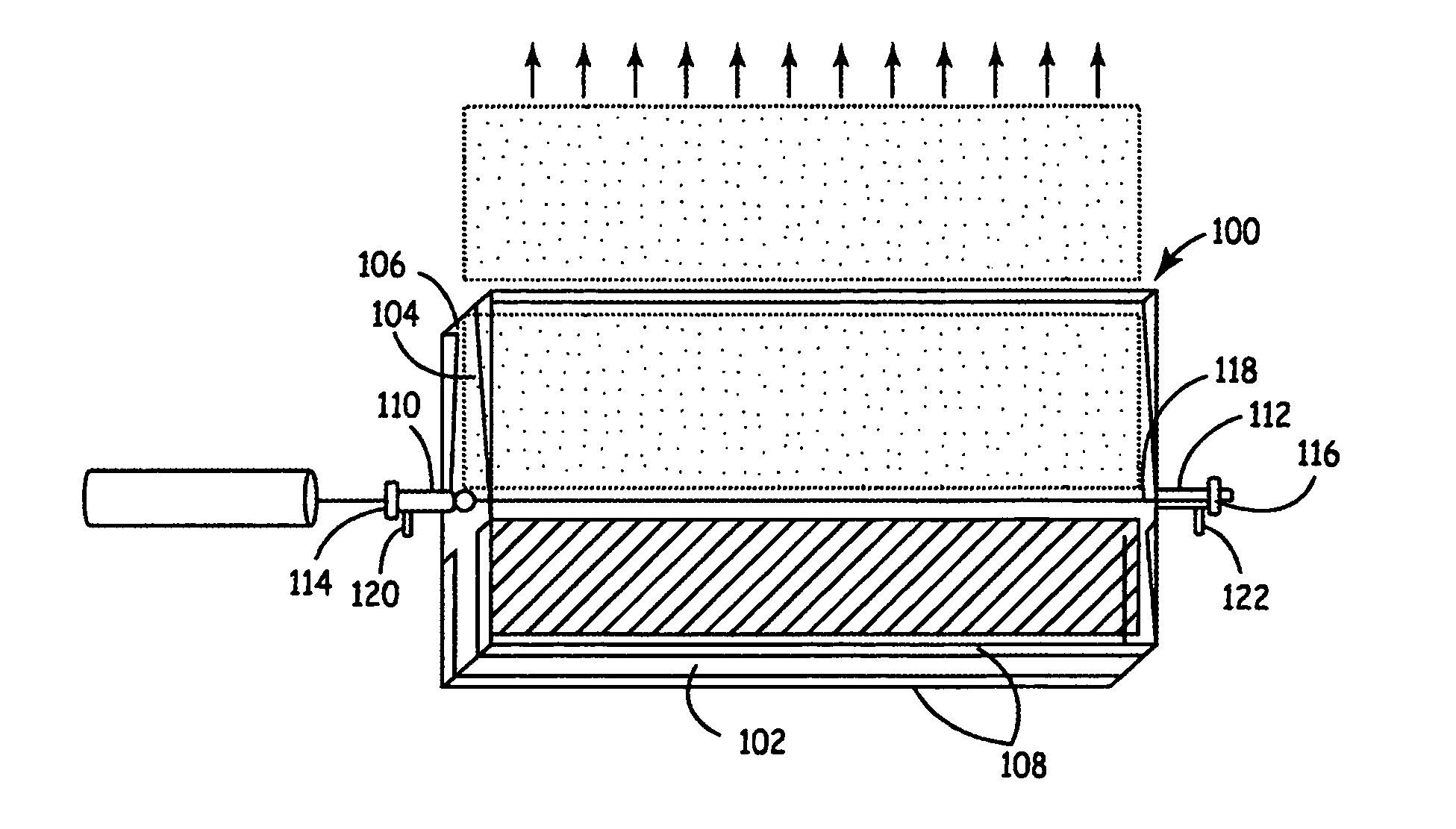

System and method for co-production of hydrogen and electrical energy

InactiveUS20050123810A1Fuel cell combinationsHydrogen separation at low temperatureHydrogenFuel cells

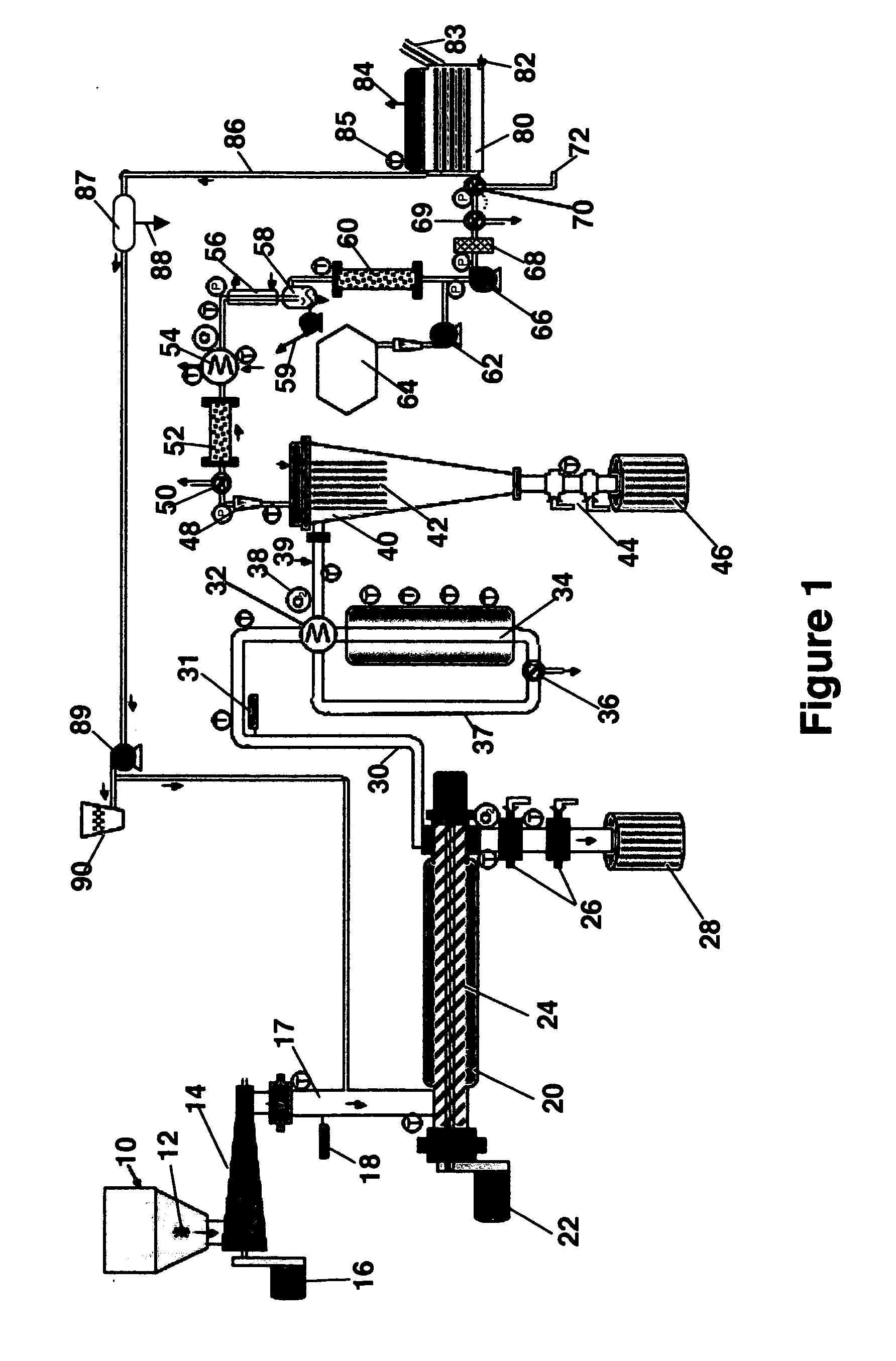

A system and method for co-production of hydrogen and electrical energy. The system comprises a fuel cell assembly comprising a plurality of fuel cells. The fuel cells further comprise a cathode inlet for receiving a compressed oxidant, an anode inlet for receiving a fuel feed stream, an anode outlet in fluid communication with an anode exhaust stream and a cathode outlet in fluid communication with a cathode exhaust stream. At least a portion of the fuel feed stream reacts with the oxidant to produce electrical power. The anode exhaust stream comprises hydrogen. The co-production system further comprises a separation unit in fluid communication with the fuel cell assembly. The separation unit is configured to receive the anode exhaust stream from the fuel cell assembly to separate hydrogen from the anode exhaust stream.

Owner:GENERAL ELECTRIC CO

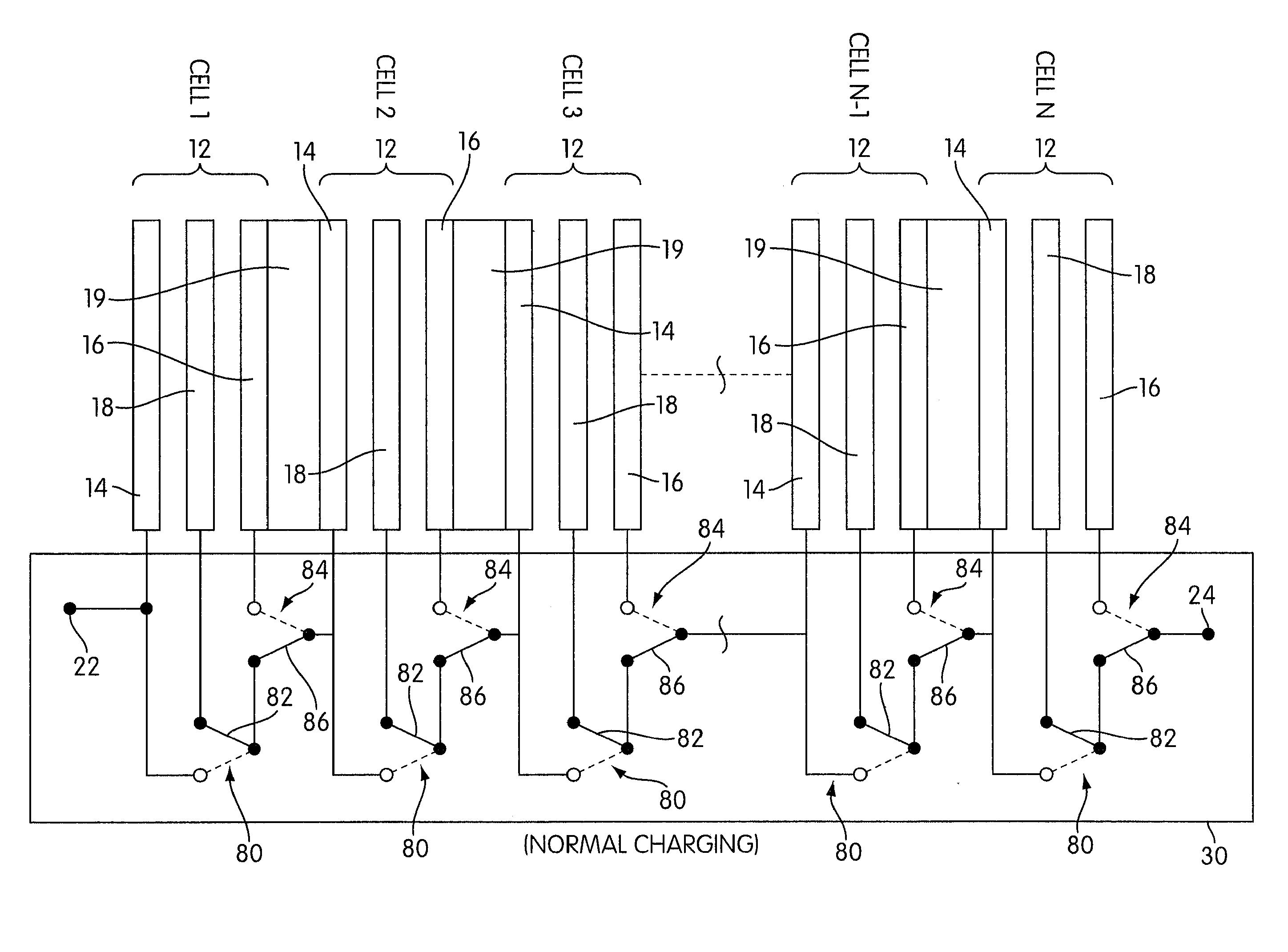

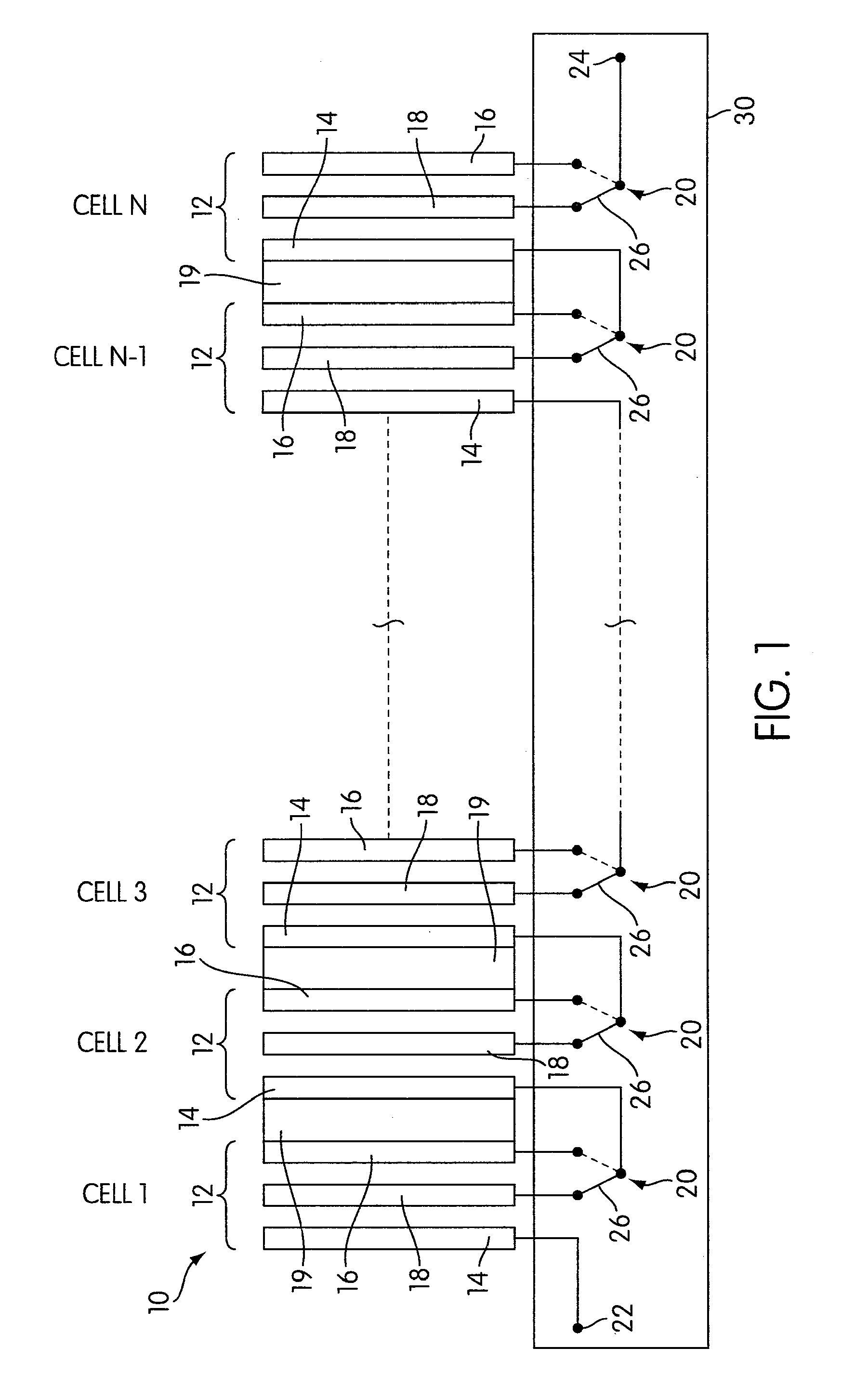

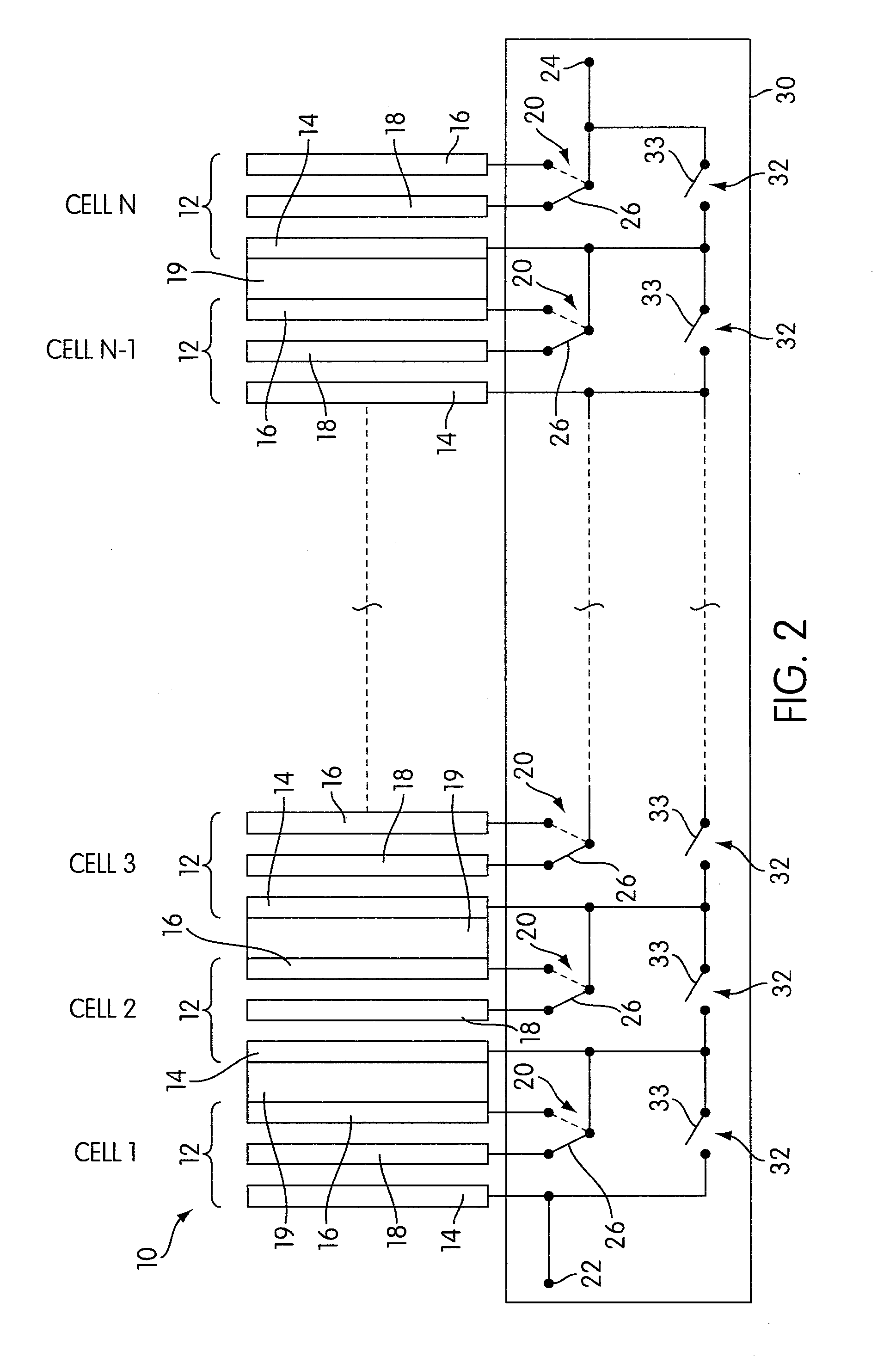

Rechargeable electrochemical cell system with a charging electrode charge/discharge mode switching in the cells

One aspect of the present invention provides a rechargeable electrochemical cell system for generating electrical current using a fuel and an oxidant. The cell system comprises N electrochemical cells each comprising a fuel electrode, an oxidant electrode, a charging electrode, and an ionically conductive medium communicating the electrodes, wherein N is an integer greater than or equal to two. Any number of cells may be used. The cell system includes a plurality of switches that are switcheable to a discharge mode coupling the oxidant electrode of each cell to the fuel electrode of the subsequent cell, a charge mode coupling the charging electrode of each cell to the fuel electrode of the subsequent cell, and a bypass mode coupling charging electrode or the oxidant electrode of a previous cell to the fuel electrode of a subsequent cell.

Owner:FLUIDIC

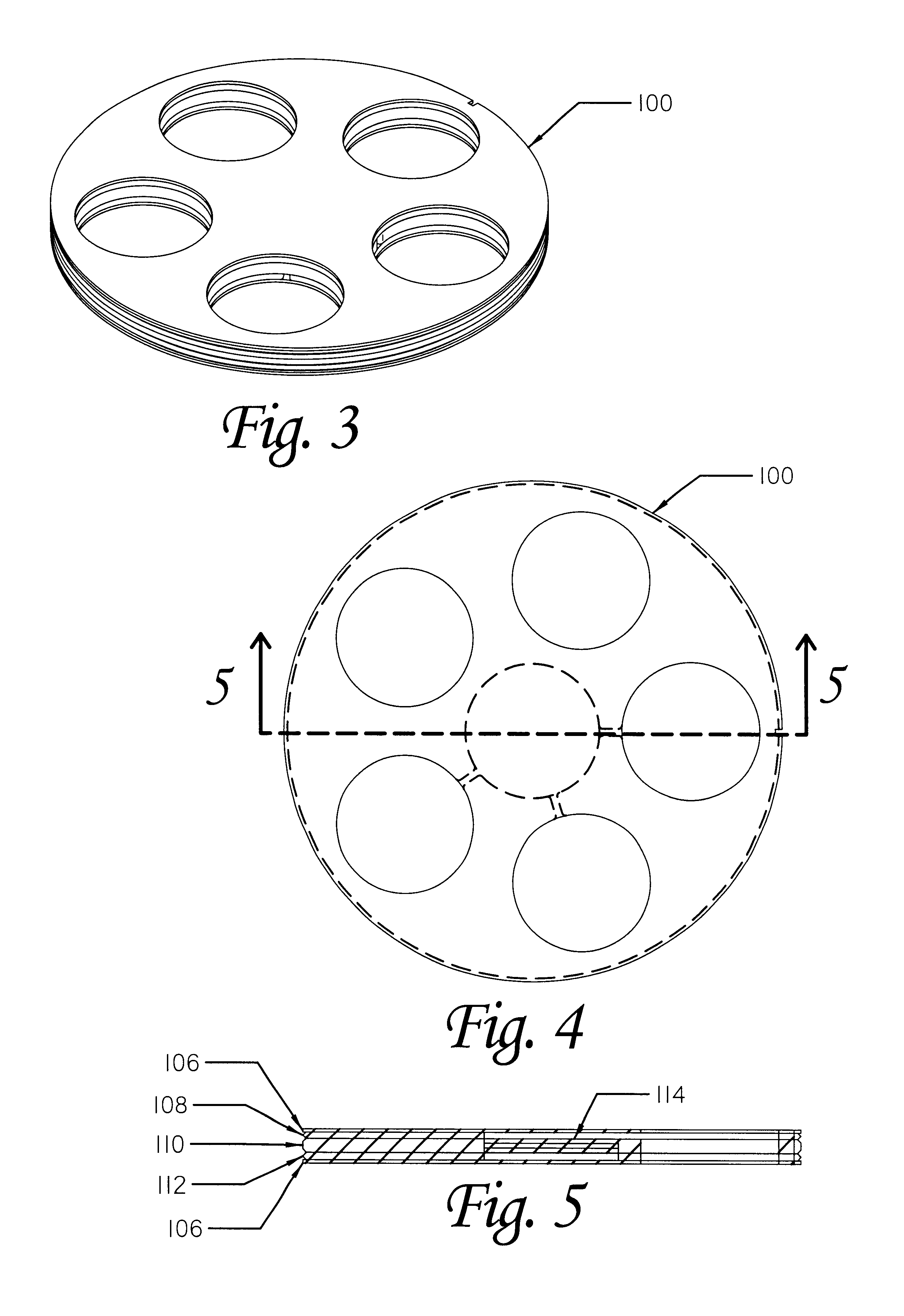

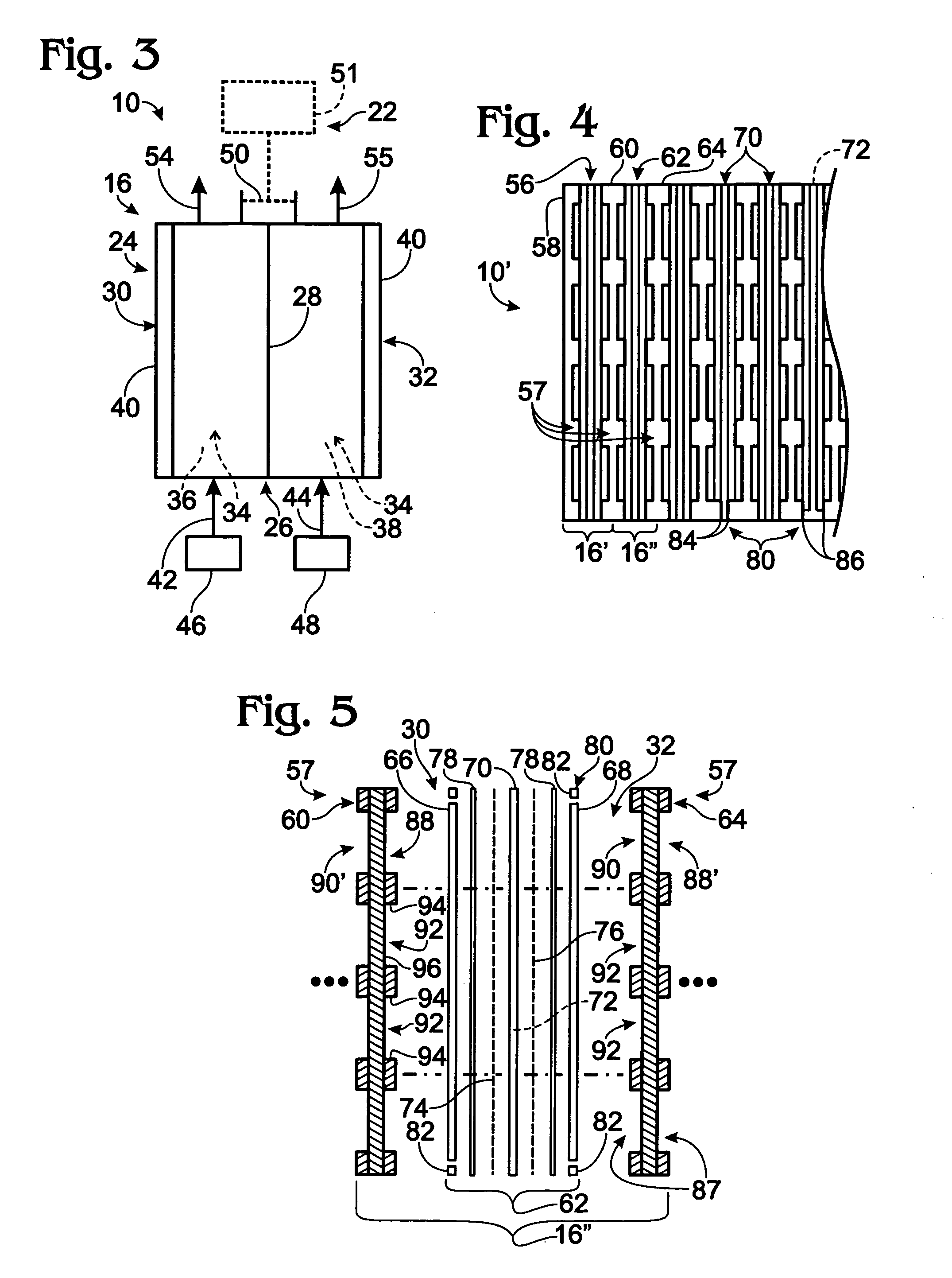

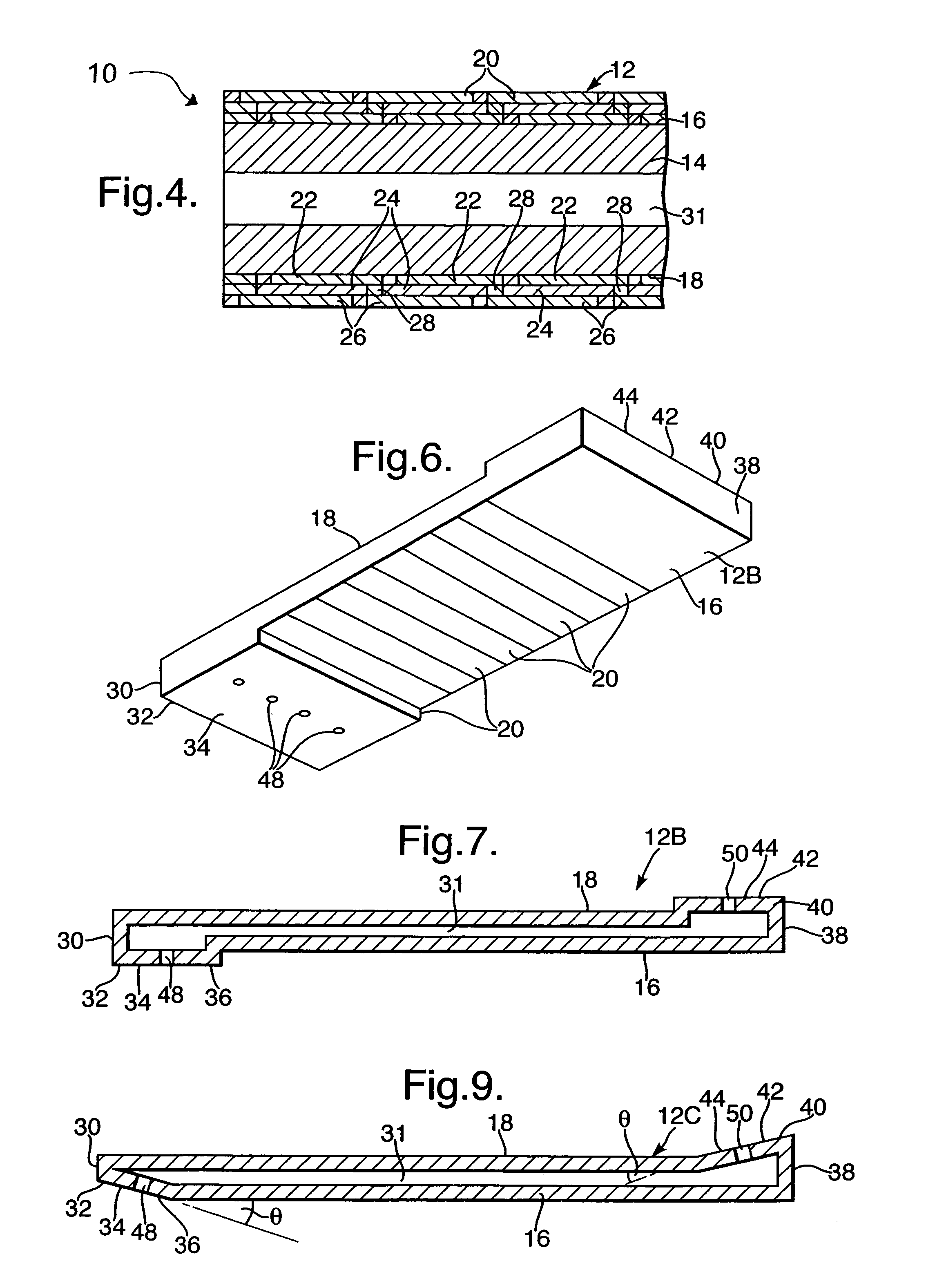

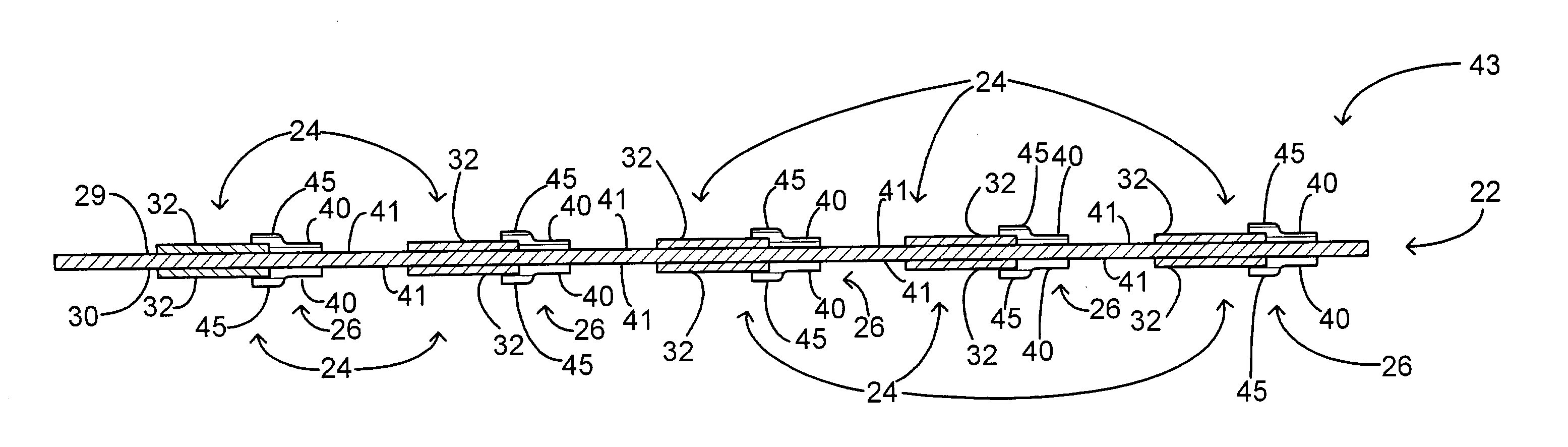

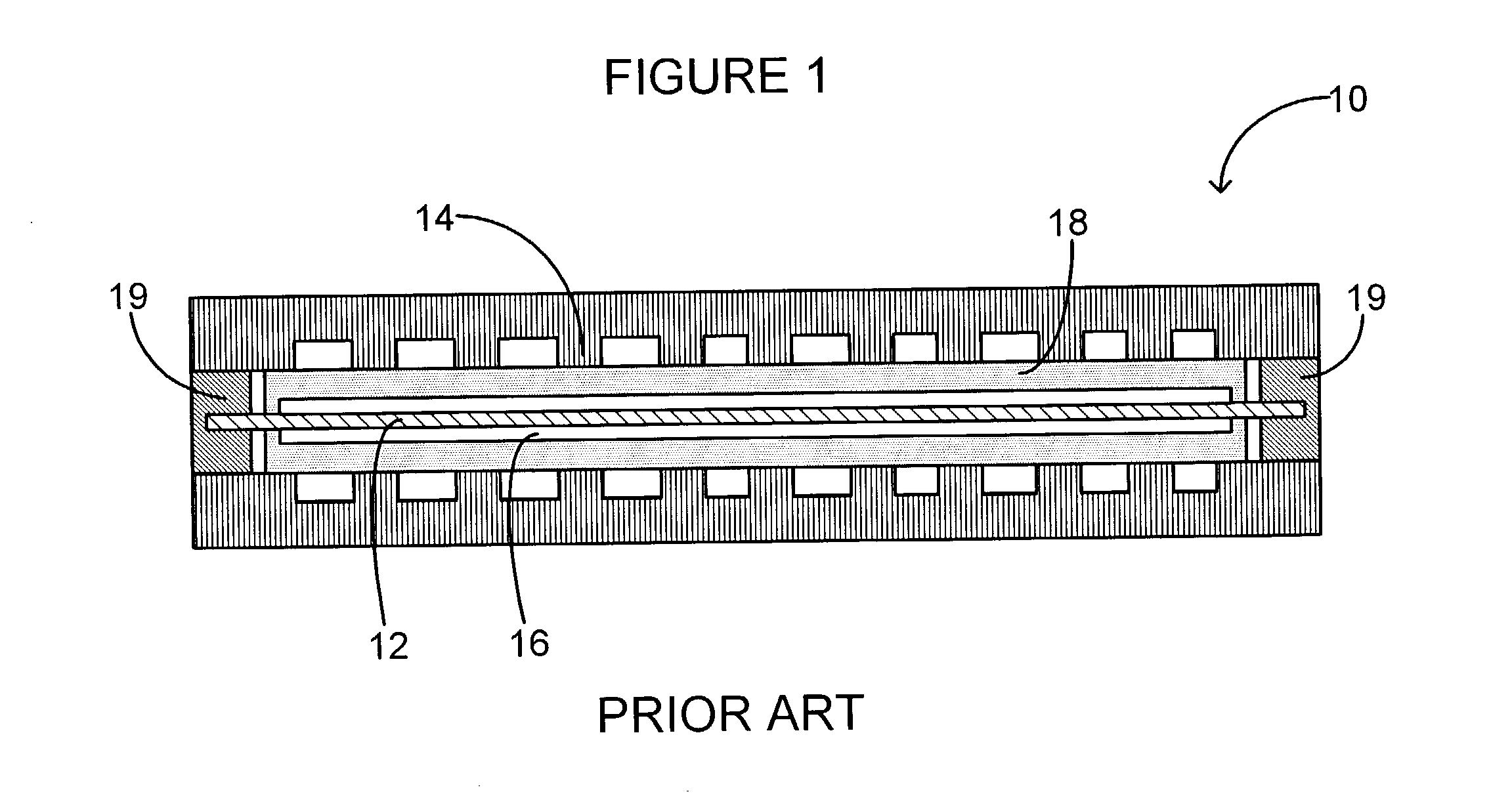

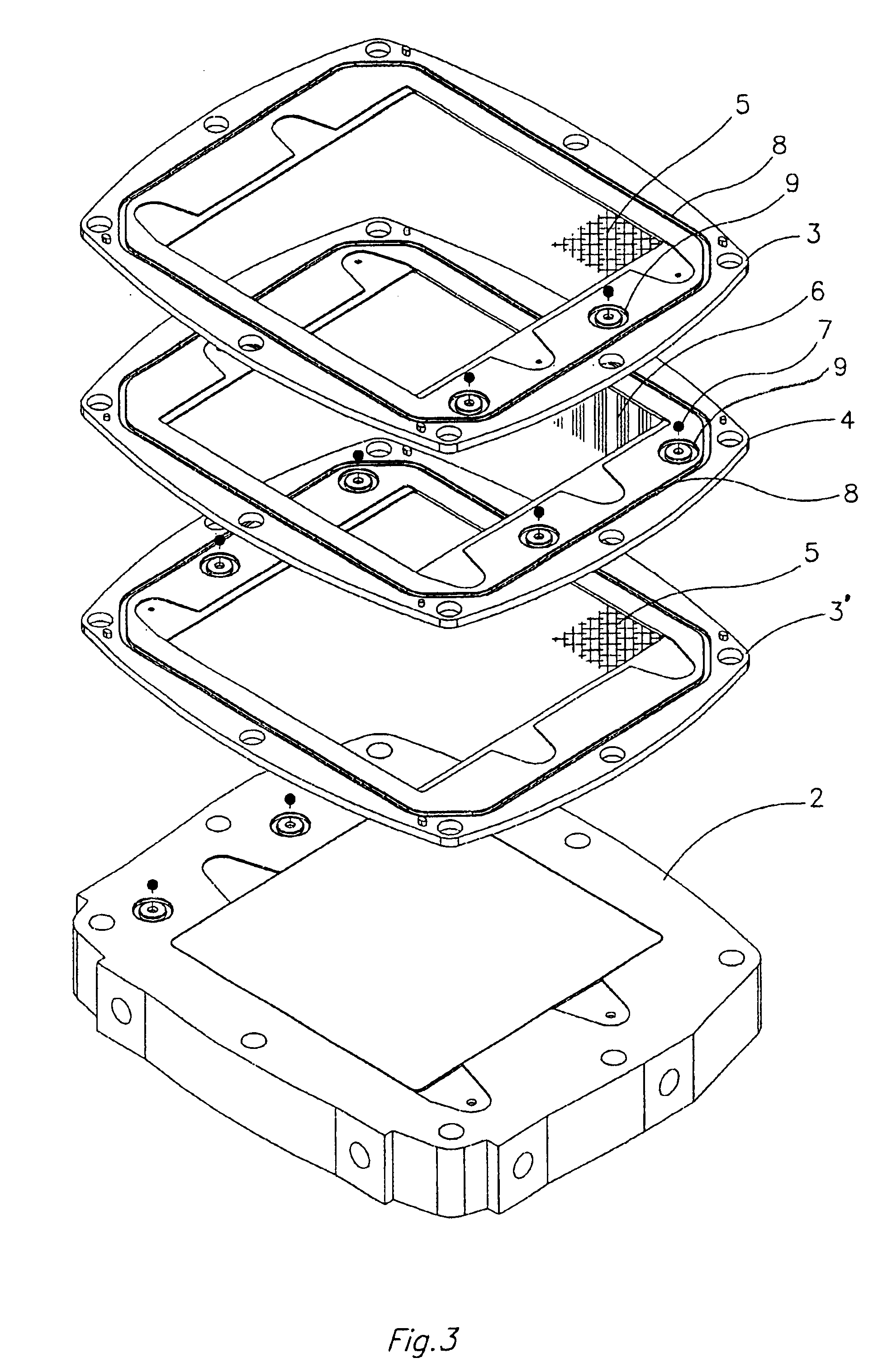

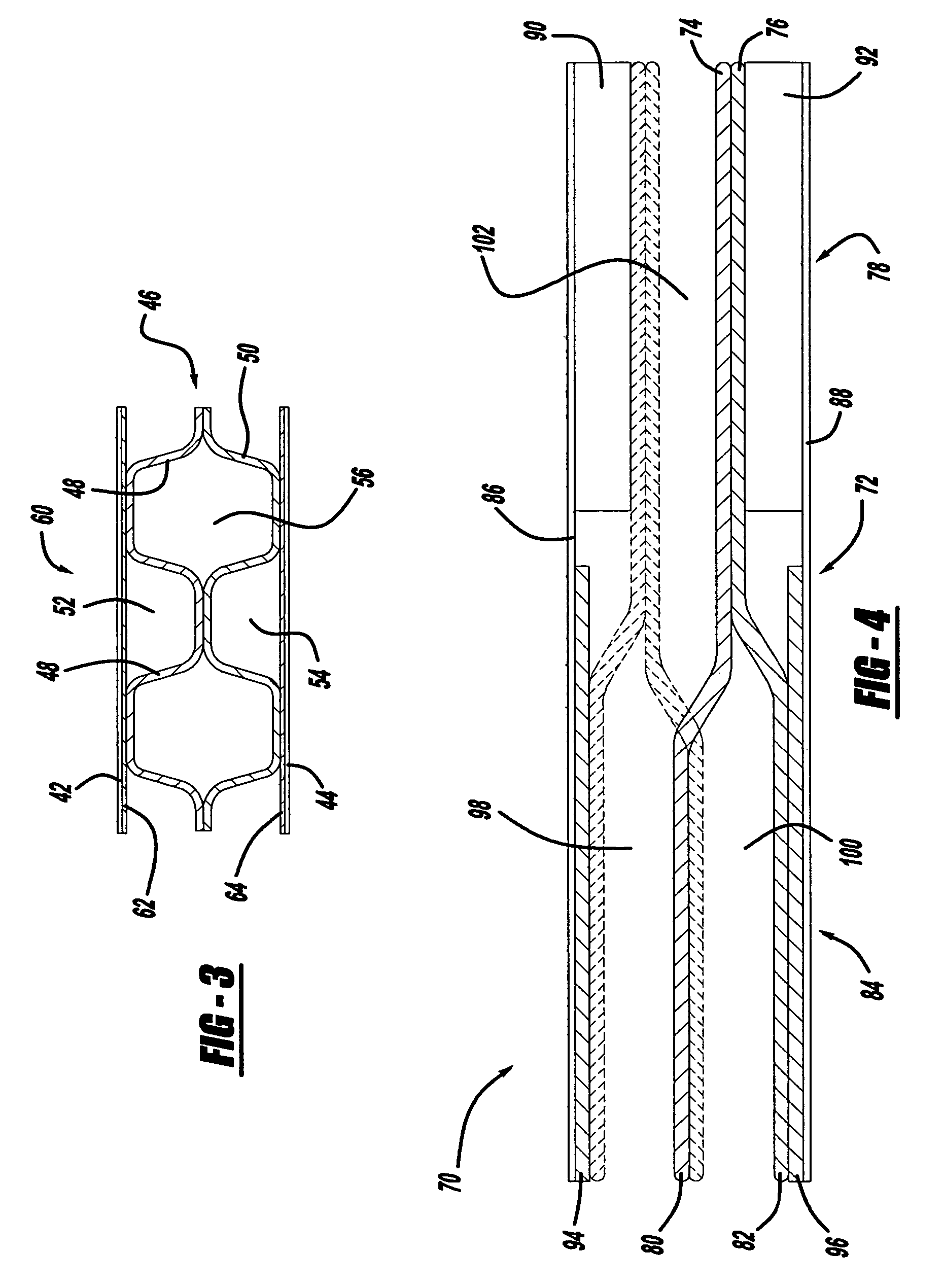

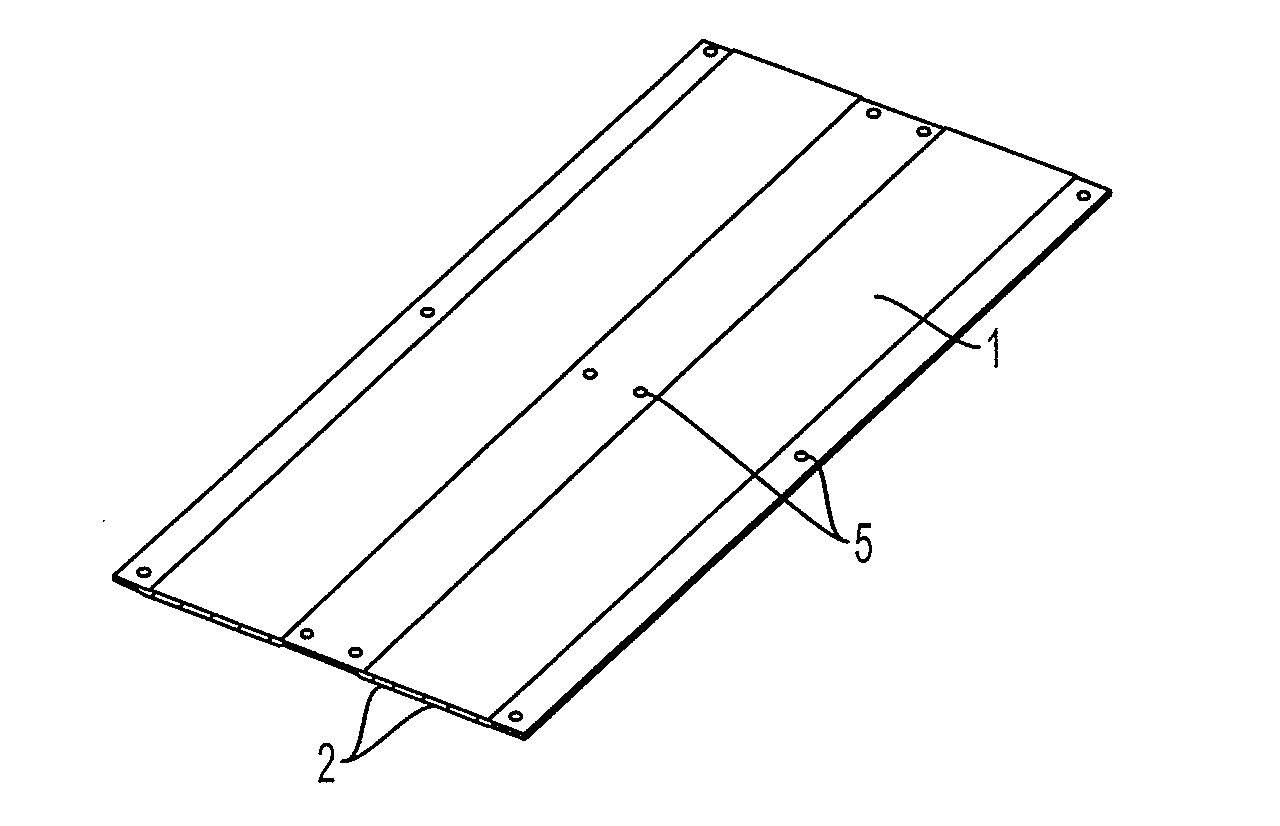

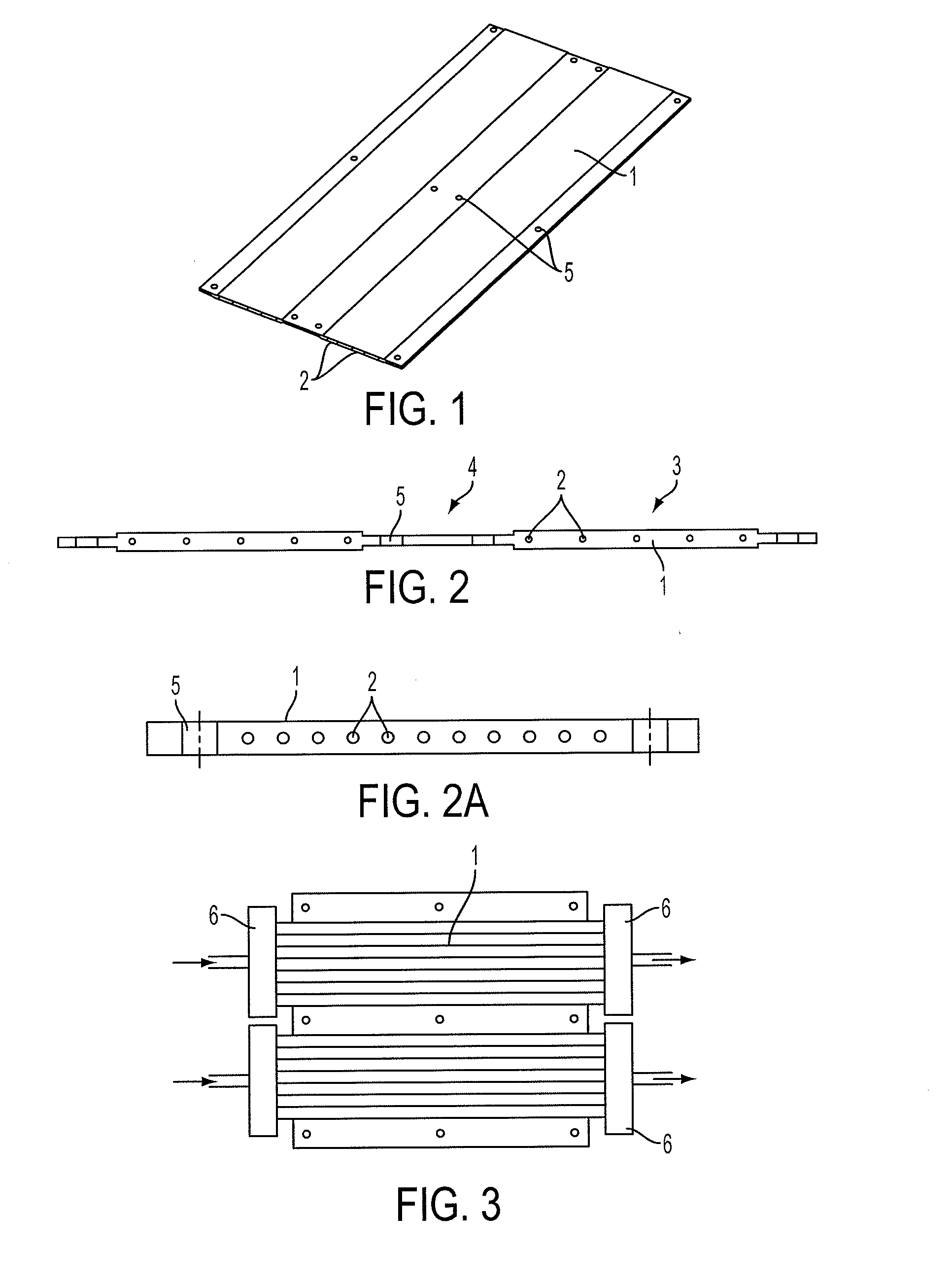

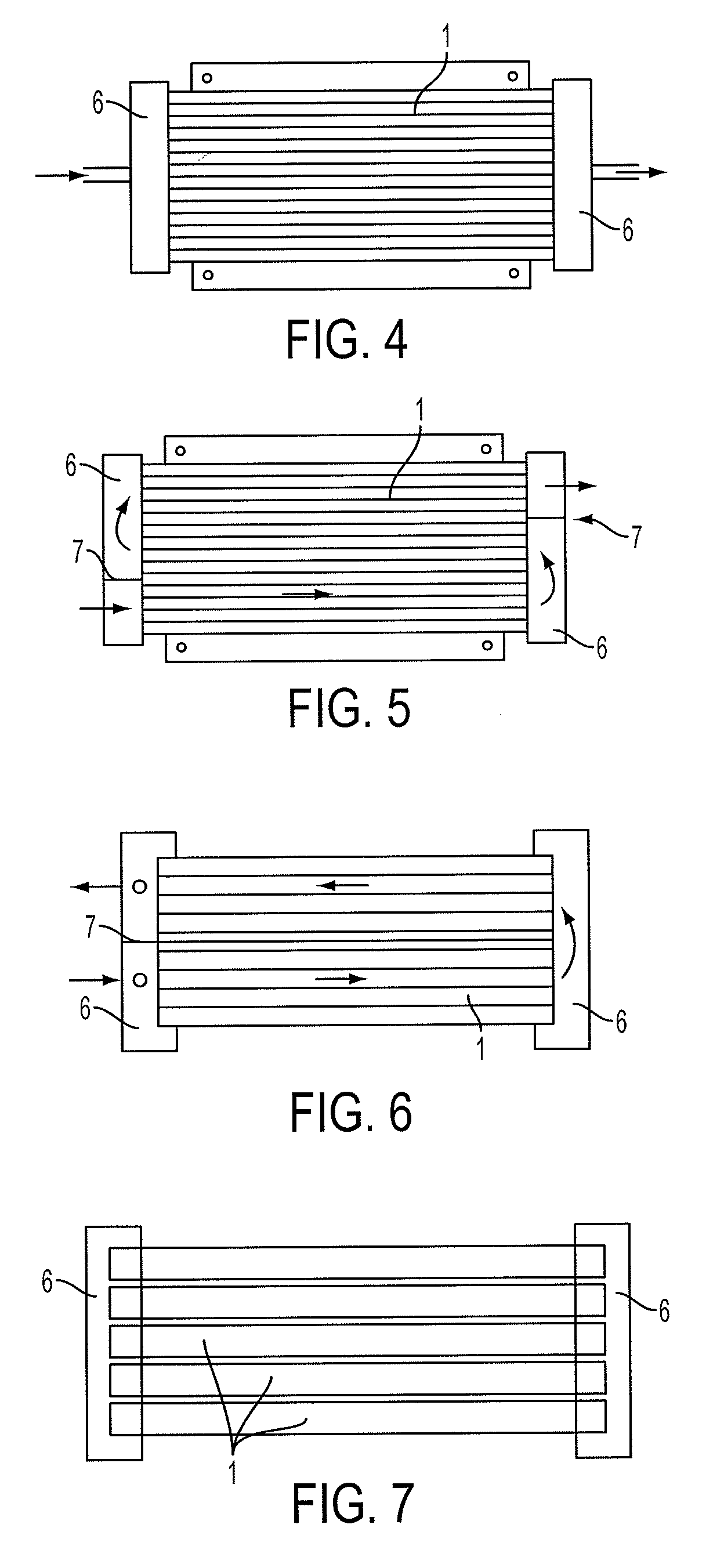

Fuel cell platelet separators having coordinate features

InactiveUS6051331ASimple designEvenly distributedSolid electrolytesFuel cells groupingLaser etchingFuel cells

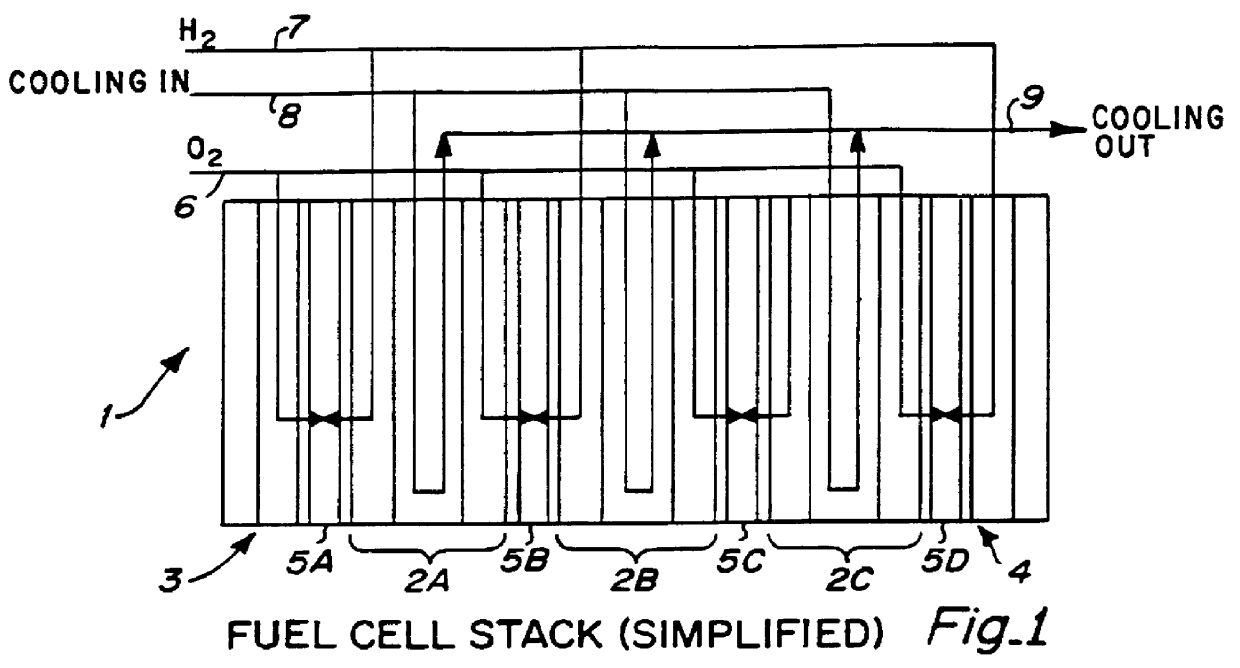

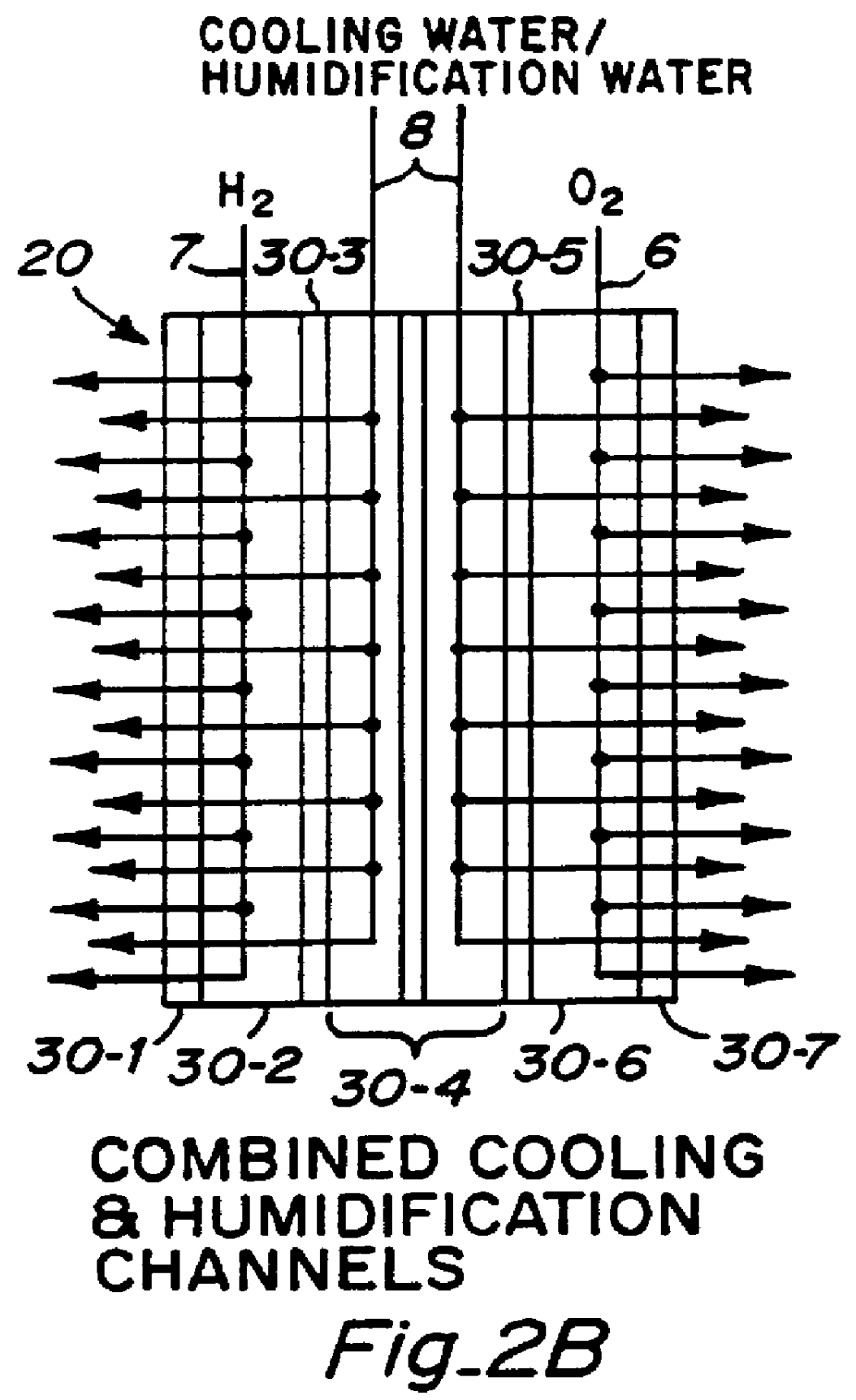

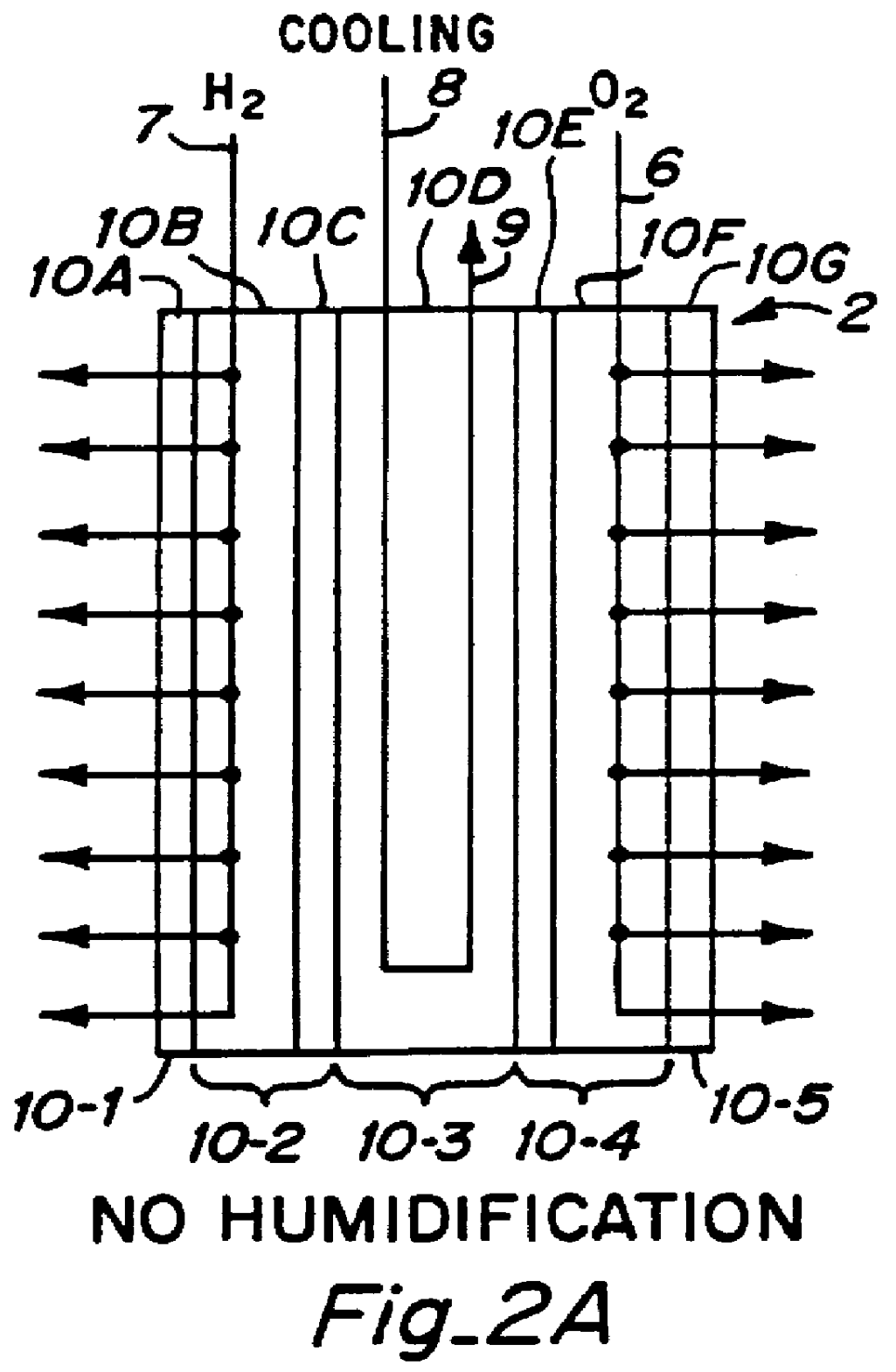

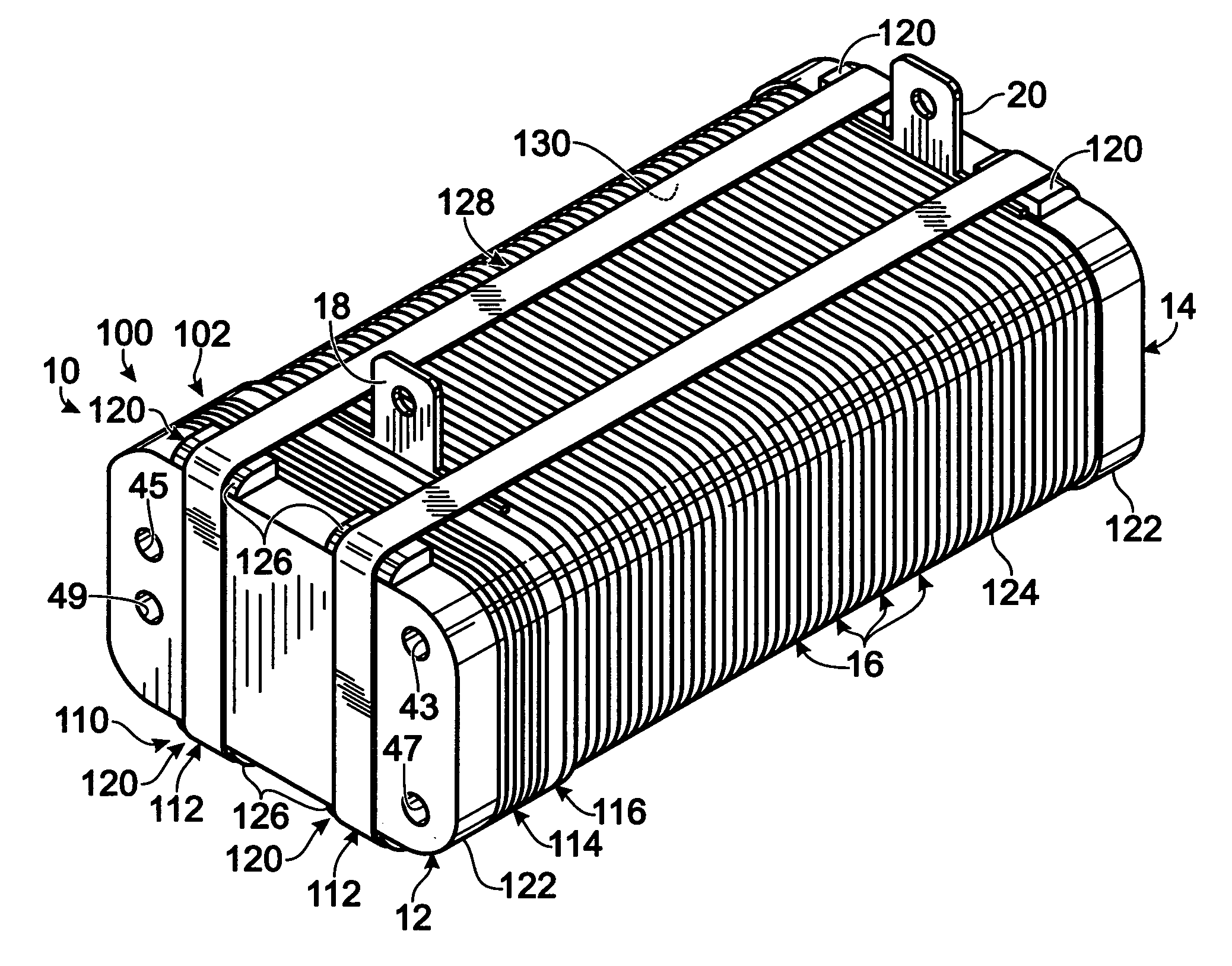

PCT No. PCT / US95 / 13325 Sec. 371 Date Sep. 28, 1997 Sec. 102(e) Date Sep. 28, 1997 PCT Filed Oct. 10, 1995 PCT Pub. No. WO96 / 12316 PCT Pub. Date Apr. 25, 1996Fuel cell stacks comprising stacked separator / membrane electrode assembly fuel cells in which the separators comprise a series of thin sheet platelets, having individually configured serpentine micro-channel reactant gas humidification active areas and cooling fields therein. The individual platelets are stacked with coordinate features aligned in contact with adjacent platelets and bonded to form a monolithic separator. Post-bonding processing includes passivation, such as nitriding. Preferred platelet material is 4-25 mil Ti, in which the features, serpentine channels, tabs, lands, vias, manifolds and holes, are formed by chemical and laser etching, cutting, pressing or embossing, with combinations of depth and through etching preferred. The platelet manufacturing process is continuous and fast. By employing CAD based platelet design and photolithography, rapid change in feature design can accommodate a wide range of thermal management and humidification techniques. One hundred H2-O2 / PEM fuel cell stacks of this IFMT platelet design will exhibit outputs on the order of 0.75 kW / kg, some 3-6 times greater than the current graphite plate PEM stacks.

Owner:H POWER

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

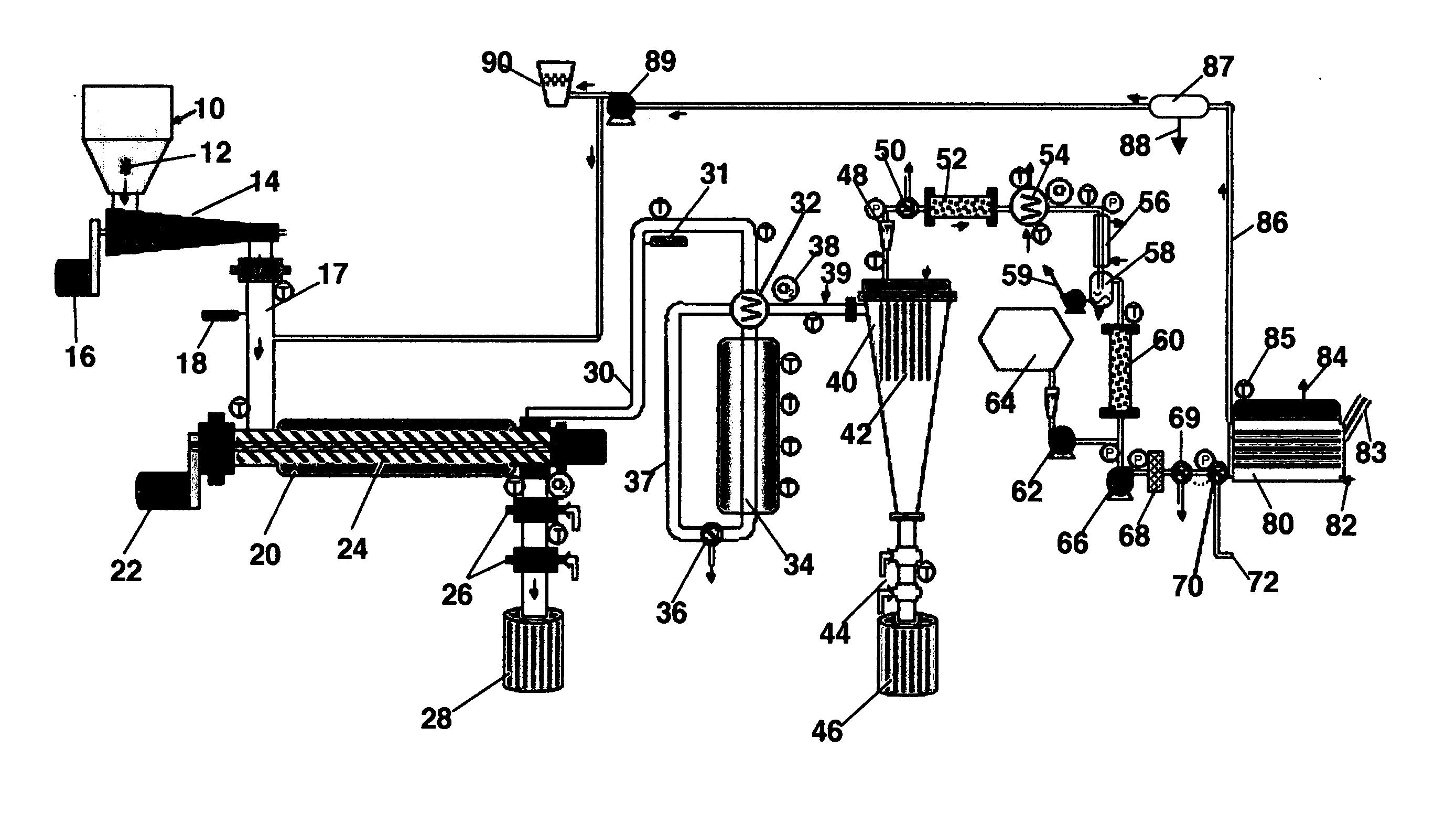

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

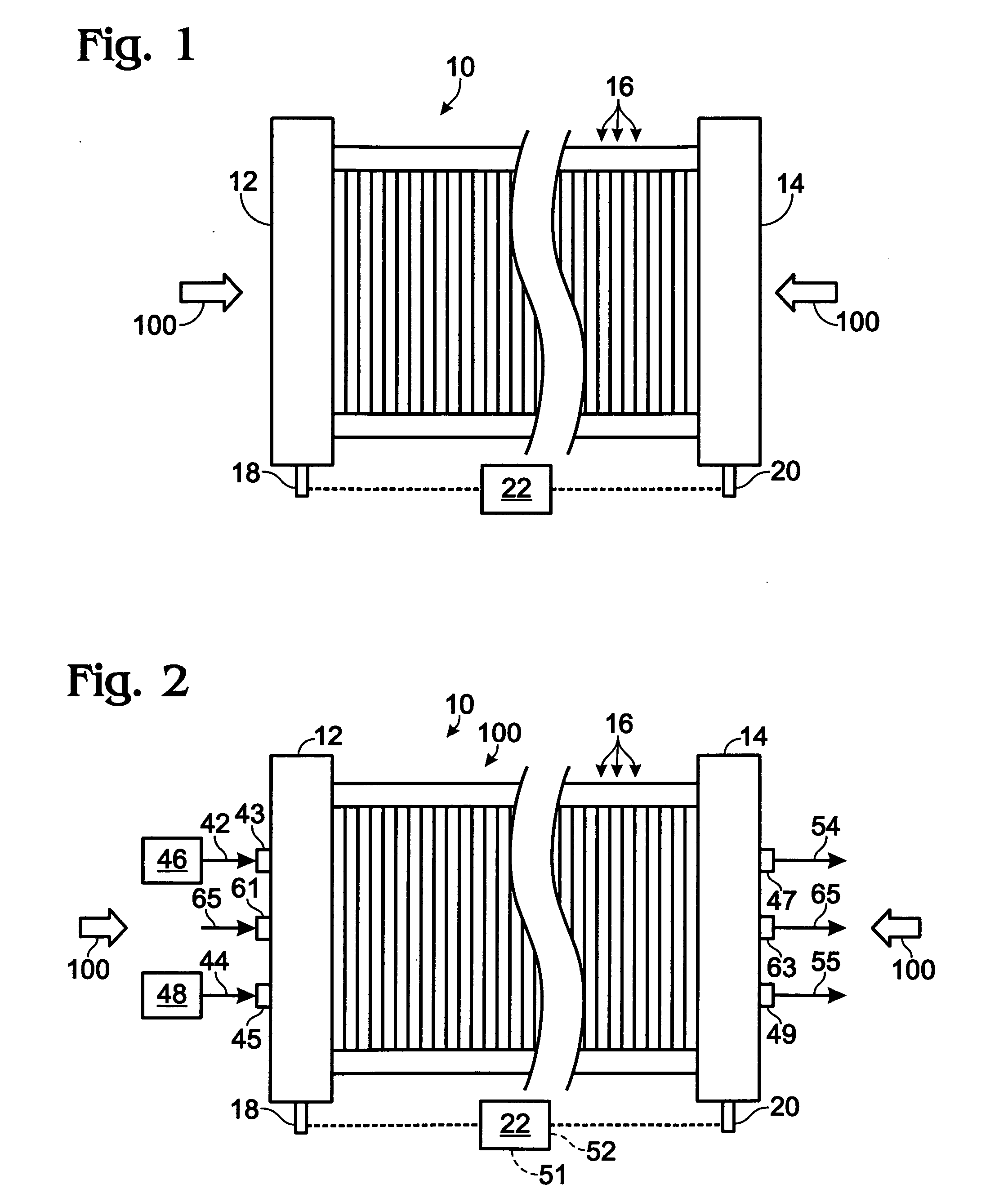

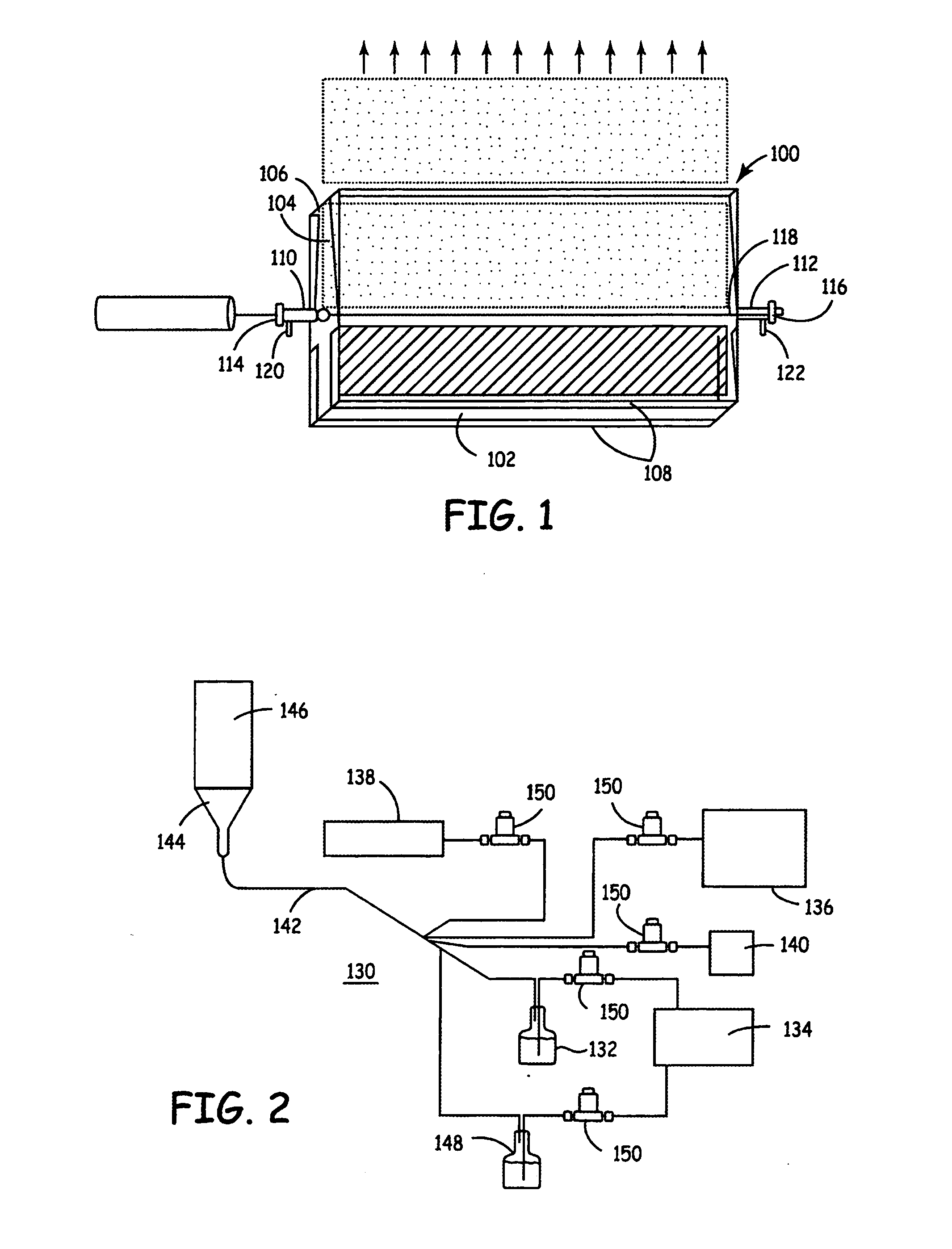

Fuel cell stack compression systems, and fuel cell stacks and fuel cell systems incorporating the same

Fuel cell stack compression systems, and fuel cell stacks and fuel cell systems containing the same. The compression systems include banded, framed, and / or segmented compression systems. In some embodiments, the compression systems include at least one compressive band that extends around the end plates and fuel cells, such as in a closed loop. In some embodiments, the banded compression systems include a force-directing structure, compressive inserts, and / or band positioning mechanisms. In some embodiments, the compression systems include a frame into which the stacks' end plates and cells are positioned and with which at least one end plate may be integrated. The frame includes a compression mechanism, which may be an adjustable compression mechanism and / or include one or more jacking members and / or a compression plate. In some embodiments the compression systems include toothed, or striated, segments that interconnect the end plates and retain the plates in compression with ratcheting lock assemblies.

Owner:IDATECH LLC

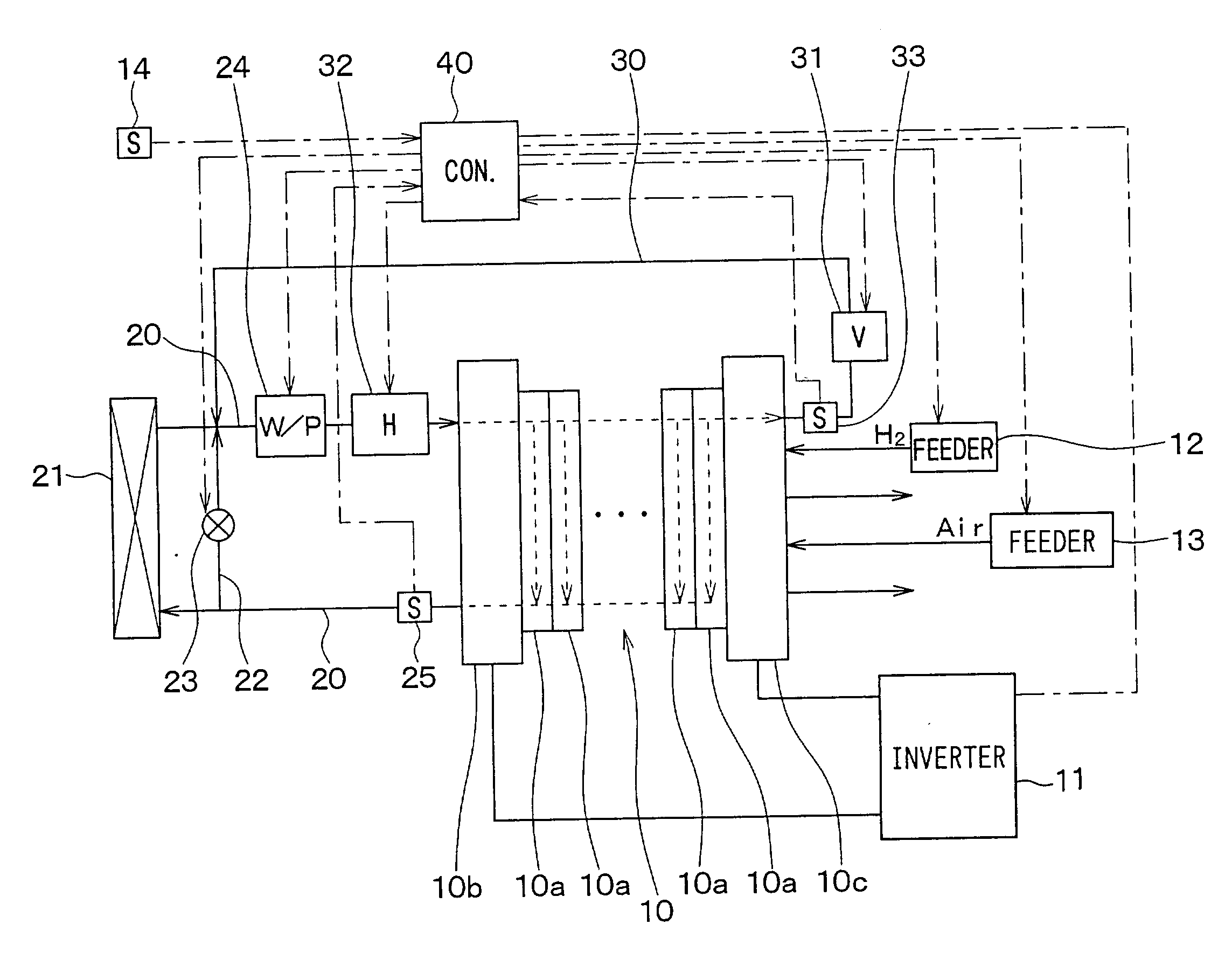

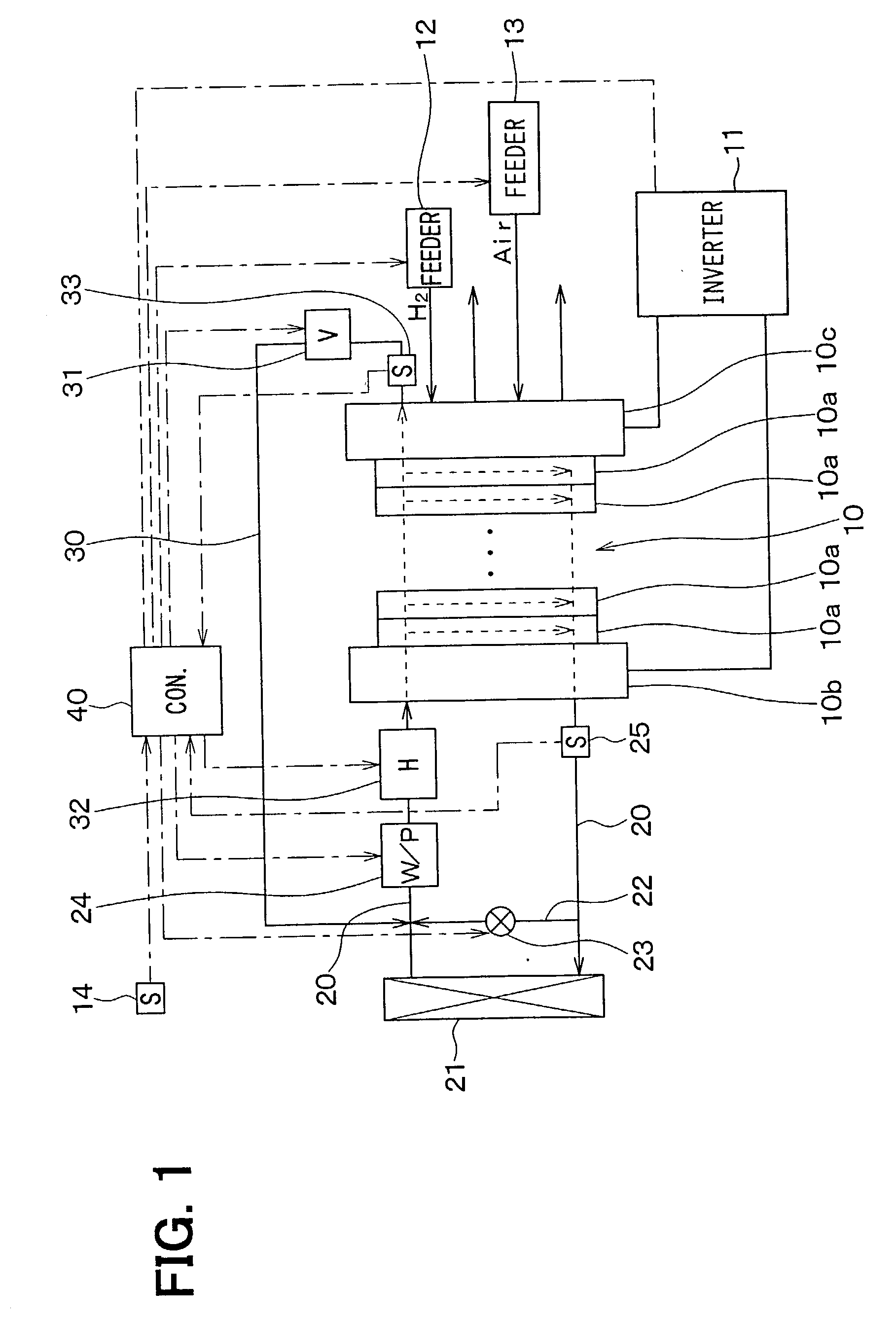

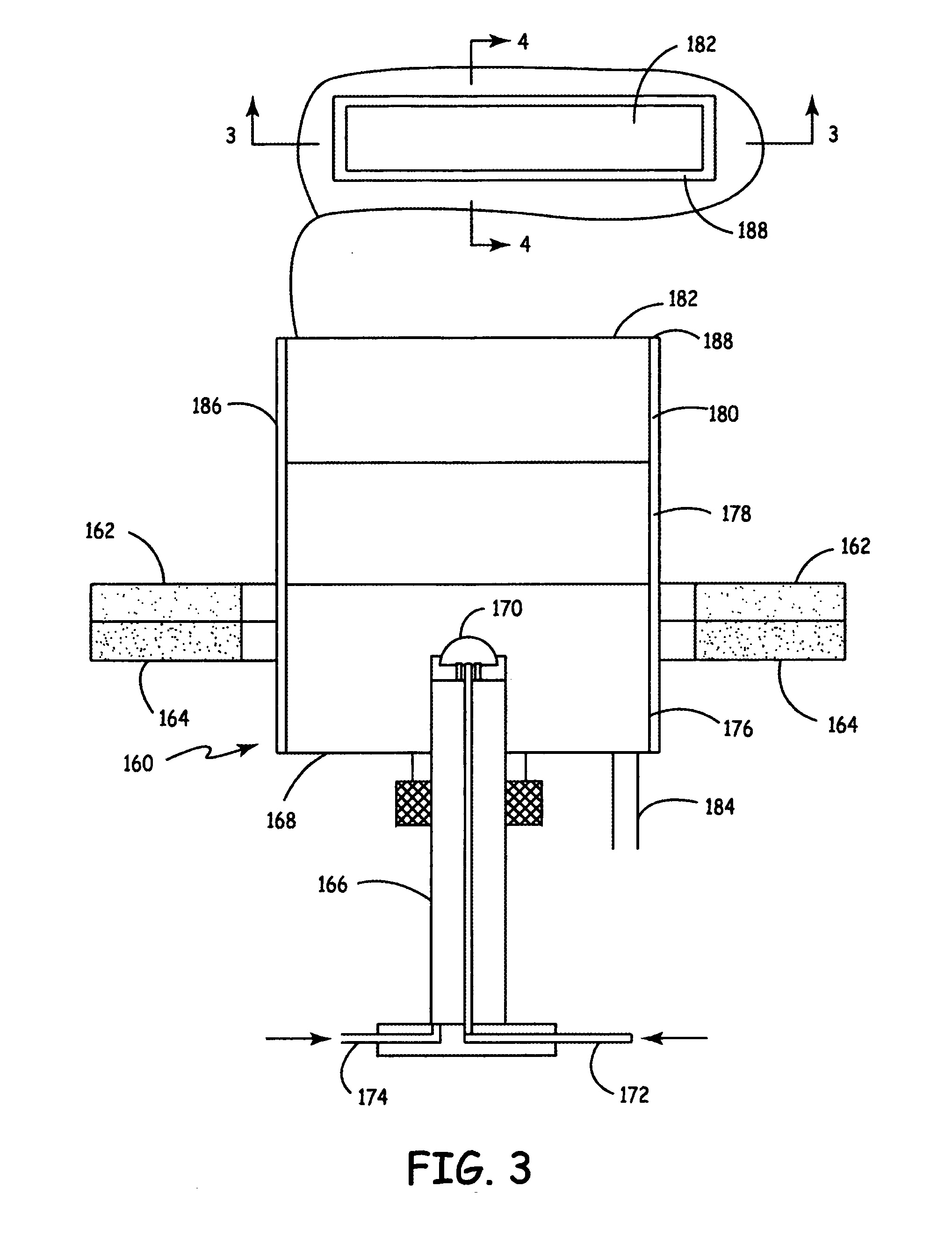

Fuel cell system

InactiveUS20030031905A1Small sizeHeating up fastFuel cell heat exchangeFuel cells groupingFuel cellsEngineering

A fuel cell system includes a fuel cell constructed by plural stacked cells, a circulation path through which a thermal medium is circulated into each cell, a heater for heating the thermal medium, a bypass path through which the thermal medium is circulated into a part of each cell while bypassing the other part thereof, and a flow control valve for controlling a flow amount of the thermal medium circulated in the bypass path. The thermal medium can be circulated into only the part of each cell in a warm-up operation, so that the part of each cell is collectively heated. An amount of the thermal medium circulated into the other part of each cell is controlled, so that all of each cell is finally warmed up in the warm-up operation.

Owner:DENSO CORP

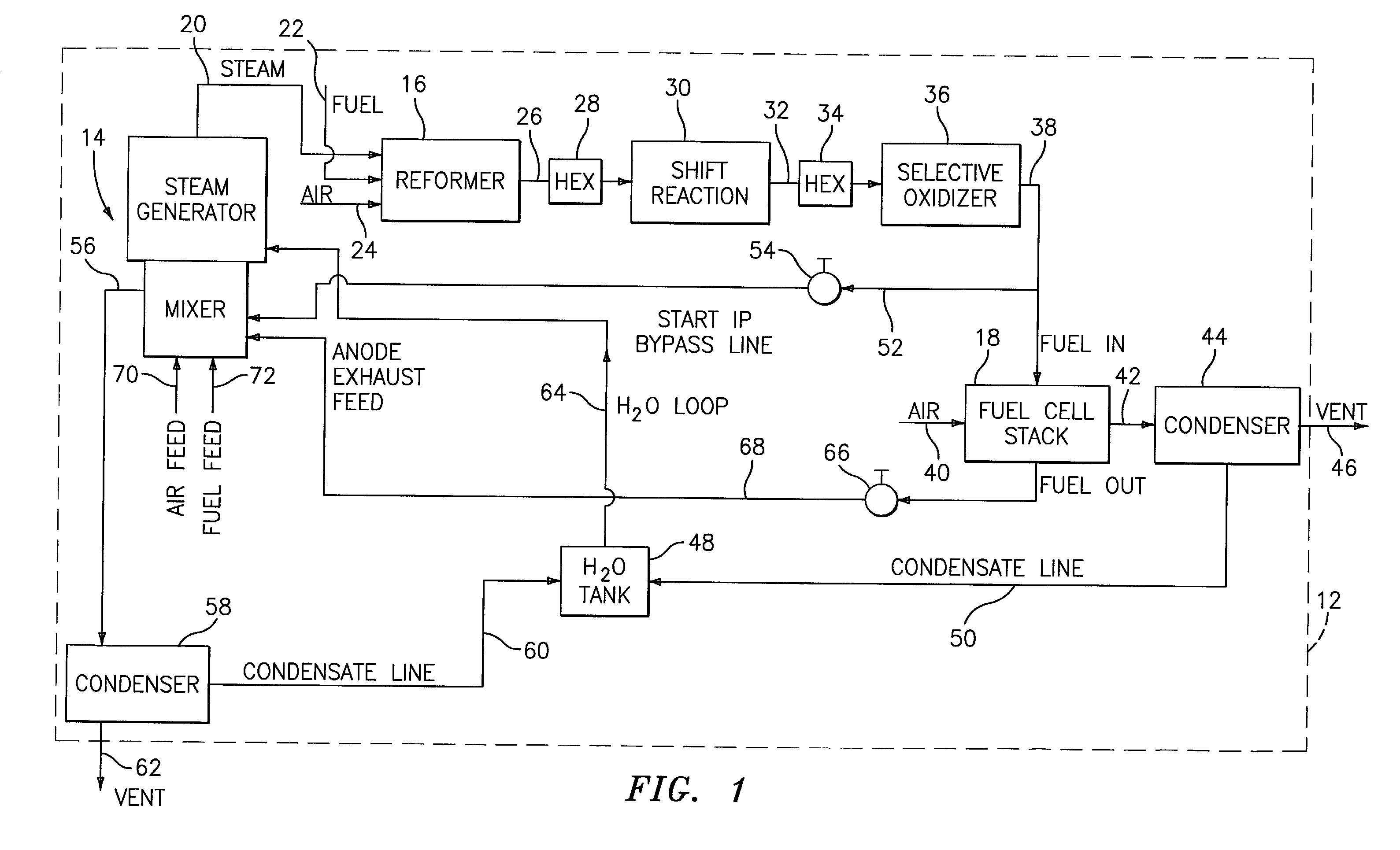

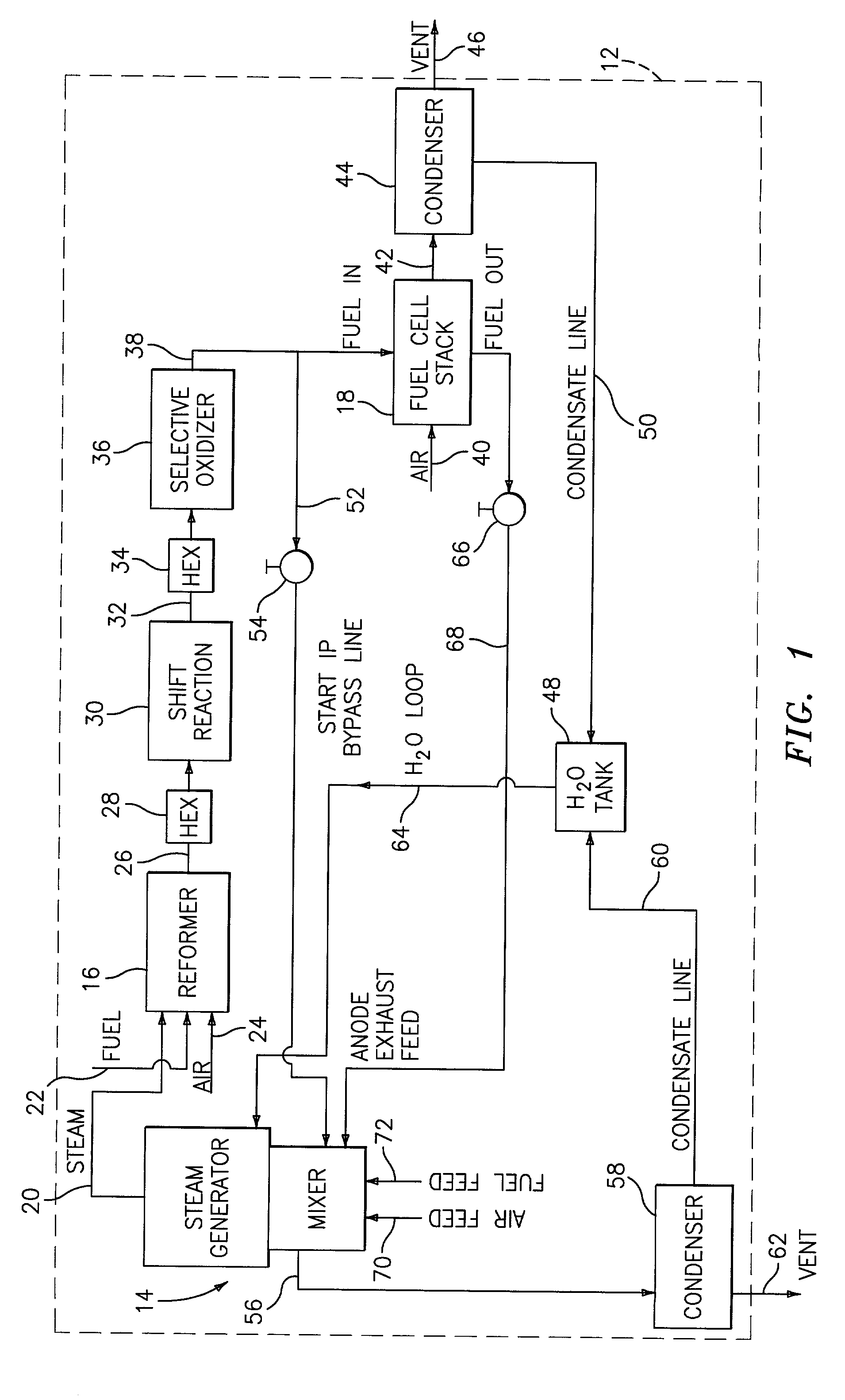

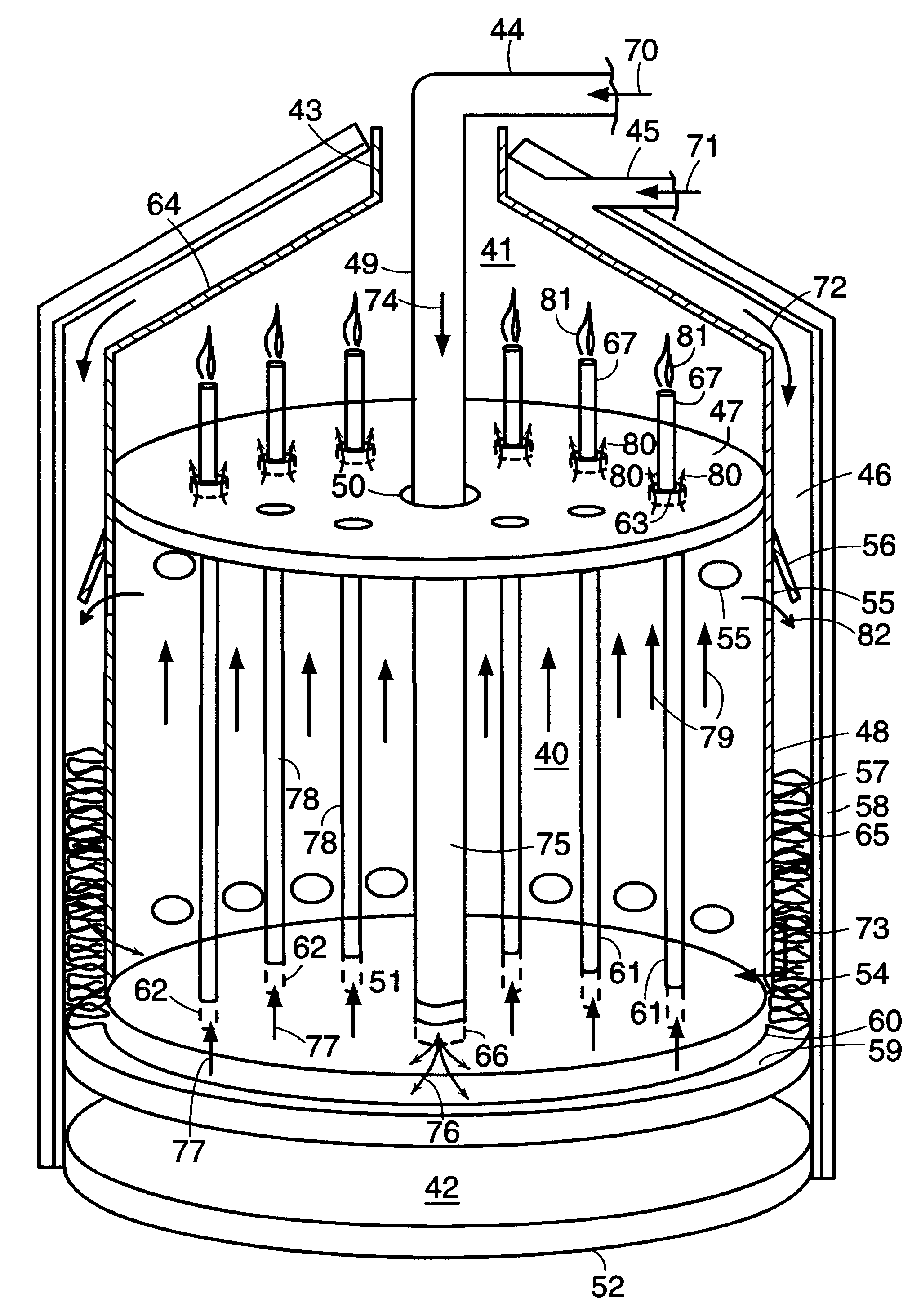

Steam generator for a PEM fuel cell power plant

A burner assembly includes a catalyzed burner for combusting an anode exhaust stream from a polymer electrolyte membrane (PEM) fuel cell power plant. The catalysts coated onto the burner can be platinum, rhodium, or mixtures thereof. The burner includes open cells which are formed by a lattice, which cells communicate with each other throughout the entire catalyzed burner. Heat produced by combustion of hydrogen in the anode exhaust stream is used to produce steam for use in a steam reformer in the PEM fuel cell assembly. The catalyzed burner has a high surface area wherein about 70-90% of the volume of the burner is preferably open cells, and the burner has a low pressure drop of about two to three inches water from the anode exhaust stream inlet to the anode exhaust stream outlet . The burner assembly operates at essentially ambient pressure and at a temperature of up to about 1,700° F. (646° C.). The burner assembly can combust anode exhaust during normal operation of the fuel cell assembly. The burner assembly also includes an adjunct burner which can combust gasoline or anode bypass gas (the latter of which is a reformed fuel gas which is tapped off of the fuel cell stack fuel inlet line) during startup of the fuel cell power plant. Once start up of the fuel cell power plant is achieved, the burner assembly will need only combustion of the anode exhaust by the catalytic burner to produce steam for the reformer.

Owner:BALLARD POWER SYSTEMS

Sheet metal bipolar plate design for polymer electrolyte membrane fuel cells

InactiveUS6261710B1Compact designIncrease the number ofSolid electrolytesFuel cells groupingPolymer electrolytesFuel cells

A separator plate for a polymer electrolyte membrane fuel cell stack constructed of at least two coextensive sheet metal elements shaped to promote the distribution of reactant gases to the electrodes of the fuel cell units of the fuel cell stack. The coextensive sheet metal elements are nestled together and form a coolant flow space therebetween.

Owner:INST OF GAS TECH

Solid oxide fuel cell stack

A fuel cell stack comprises a plurality of modules and each module comprises an elongate hollow member and one passage extending through the hollow member for the flow of a reactant. Each hollow member has a first flat surface and a second flat surface. At least one of the modules includes a plurality of fuel cells arranged on at least one of the first and second flat surfaces. Each module has a first and second integral feature to provide a spacer and a connection with its adjacent modules. The first integral feature comprises a third flat surface and the second integral feature comprises a fourth flat surface. The third flat surface is arranged at an intersecting angle to the first flat surface and the fourth flat surface is arranged at an intersecting angle to the second flat surface.

Owner:LG FUEL CELL SYST

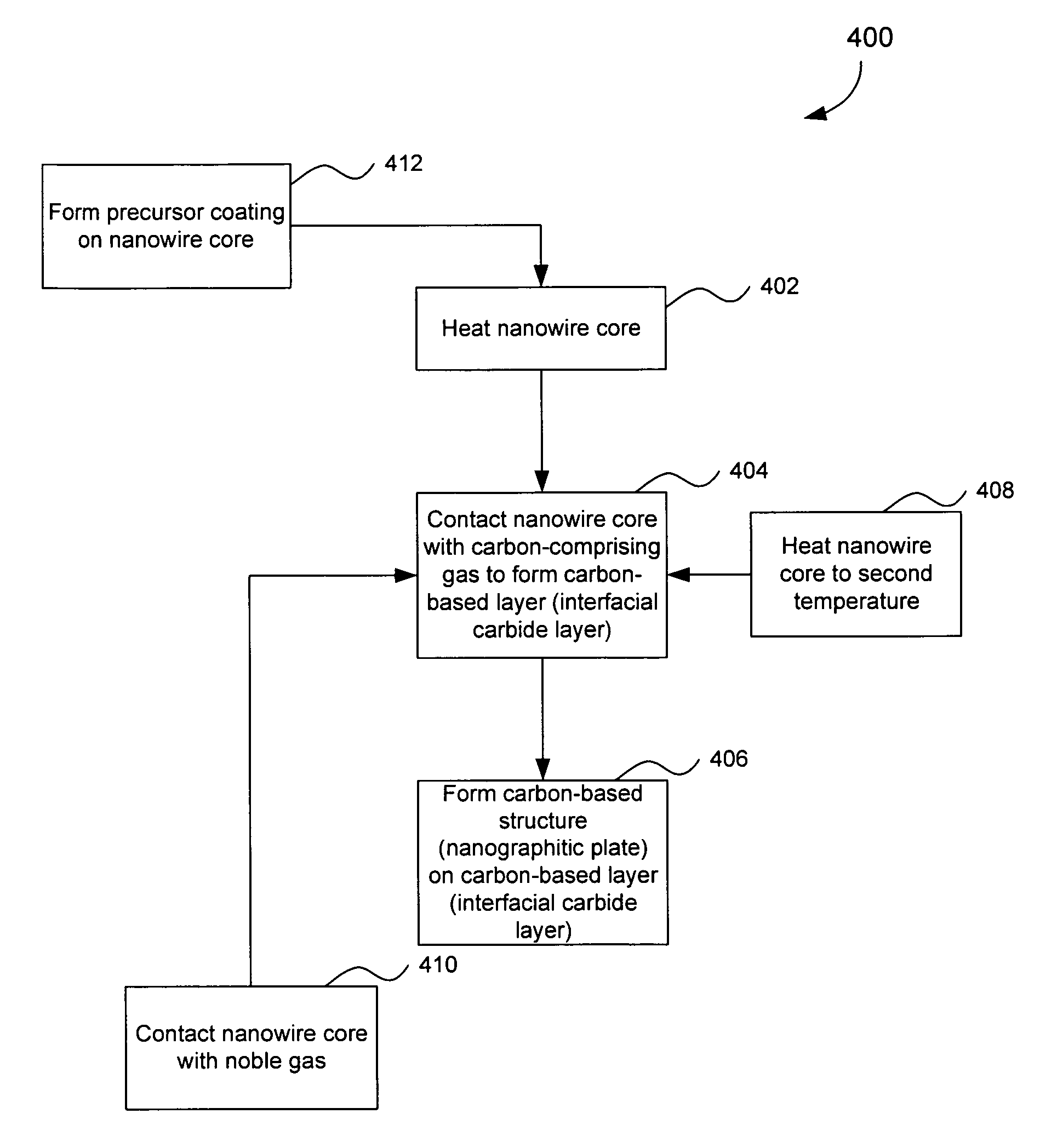

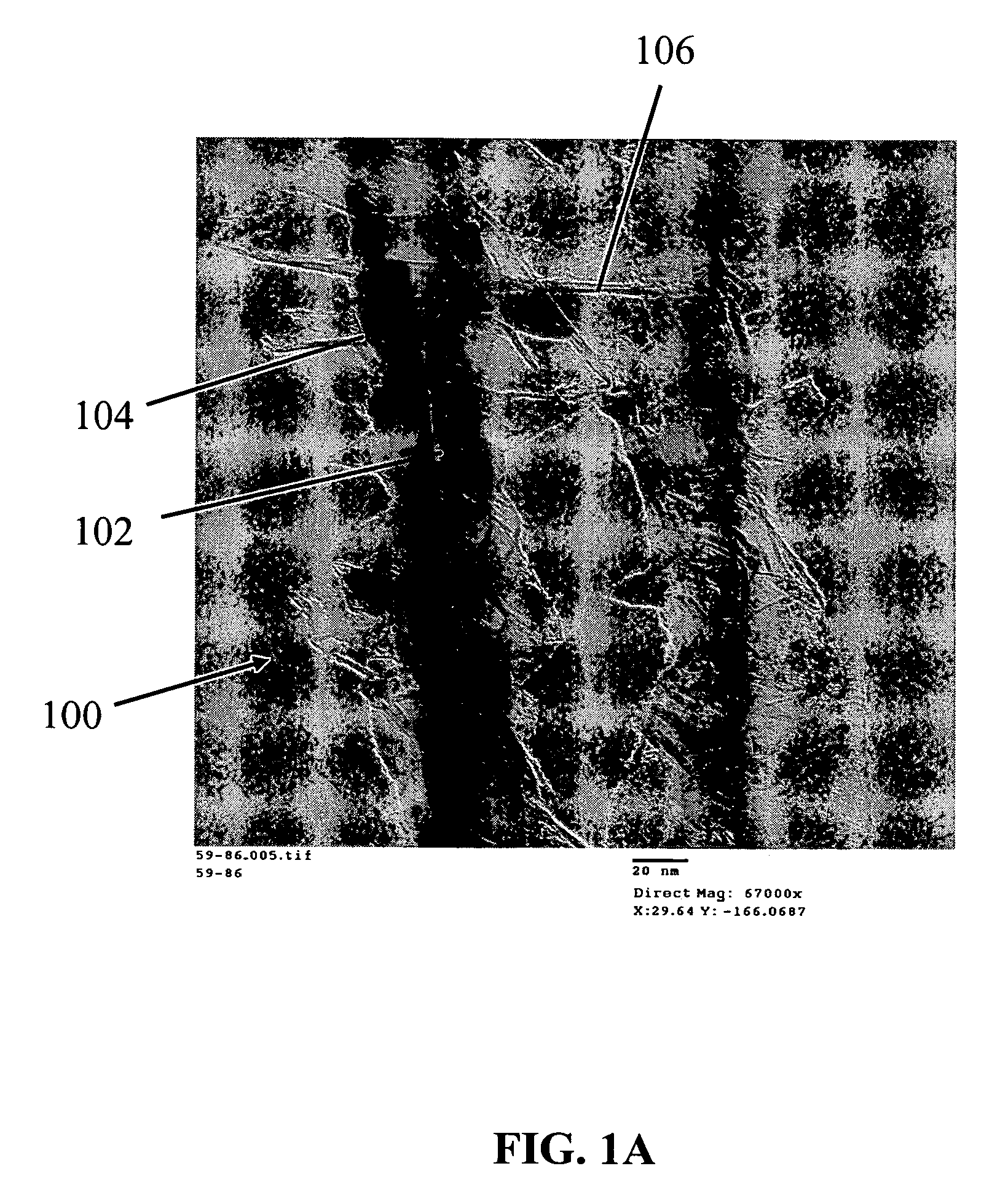

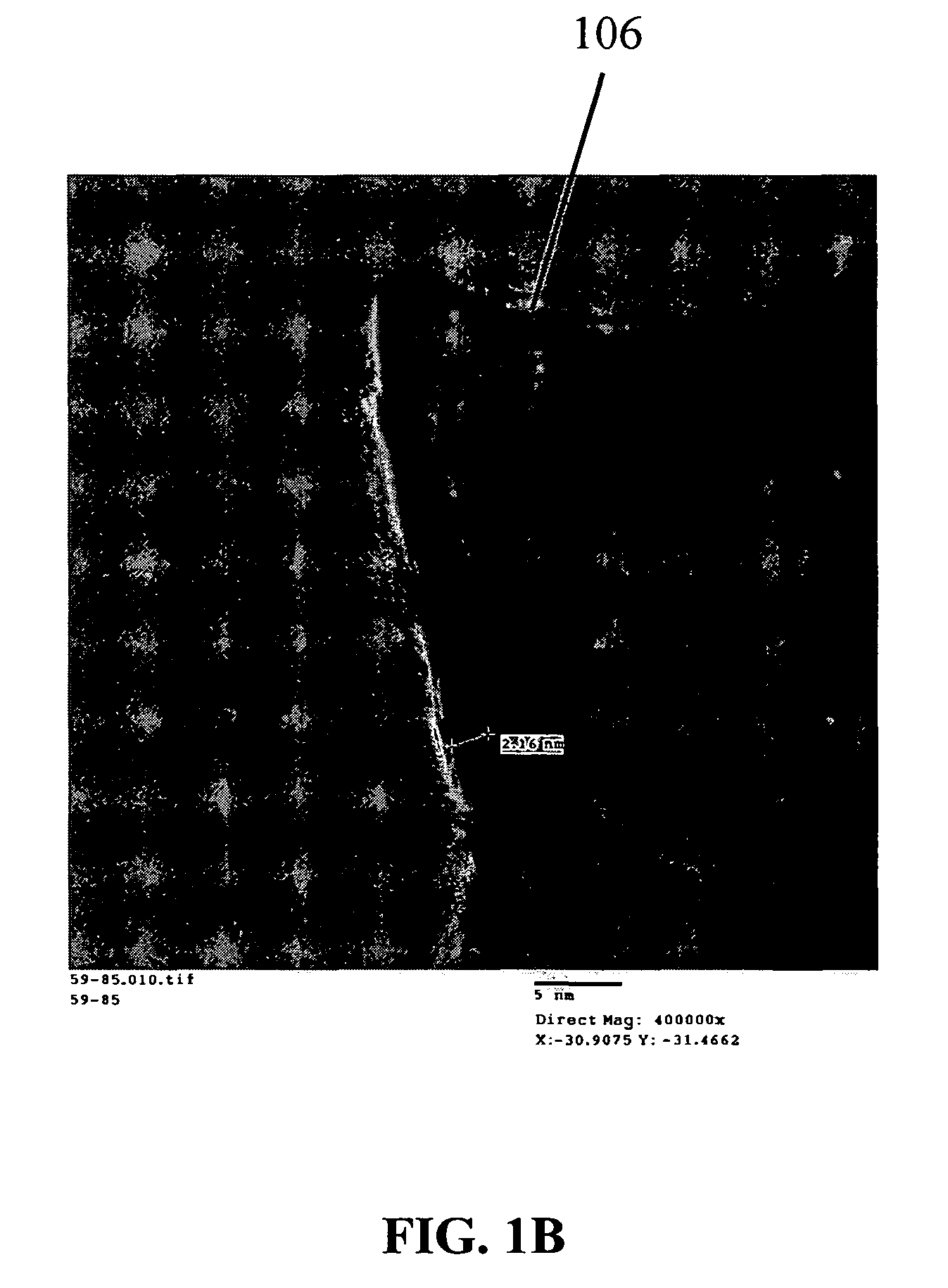

Nanowire structures comprising carbon

ActiveUS7939218B2High rateLow costElectric discharge heatingFuel cells groupingField emission deviceNanowire

The present invention is directed to nanowire structures and interconnected nanowire networks comprising such structures, as well as methods for their production. The nanowire structures comprise a nanowire core, a carbon-based layer, and in additional embodiments, carbon-based structures such as nanographitic plates consisting of graphenes formed on the nanowire cores, interconnecting the nanowire structures in the networks. The networks are porous structures that can be formed into membranes or particles. The nanowire structures and the networks formed using them are useful in catalyst and electrode applications, including fuel cells, as well as field emission devices, support substrates and chromatographic applications.

Owner:ONED MATERIAL INC

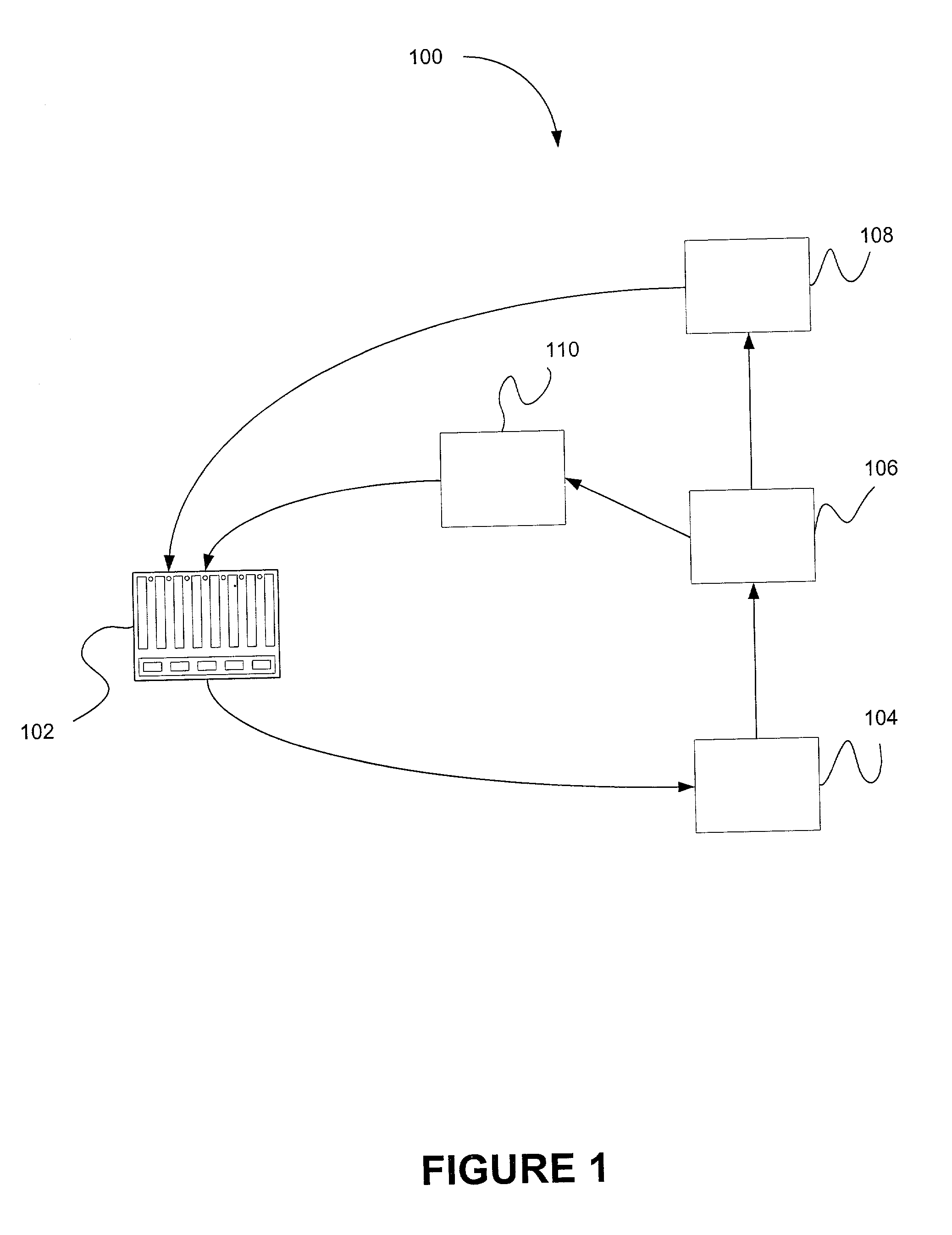

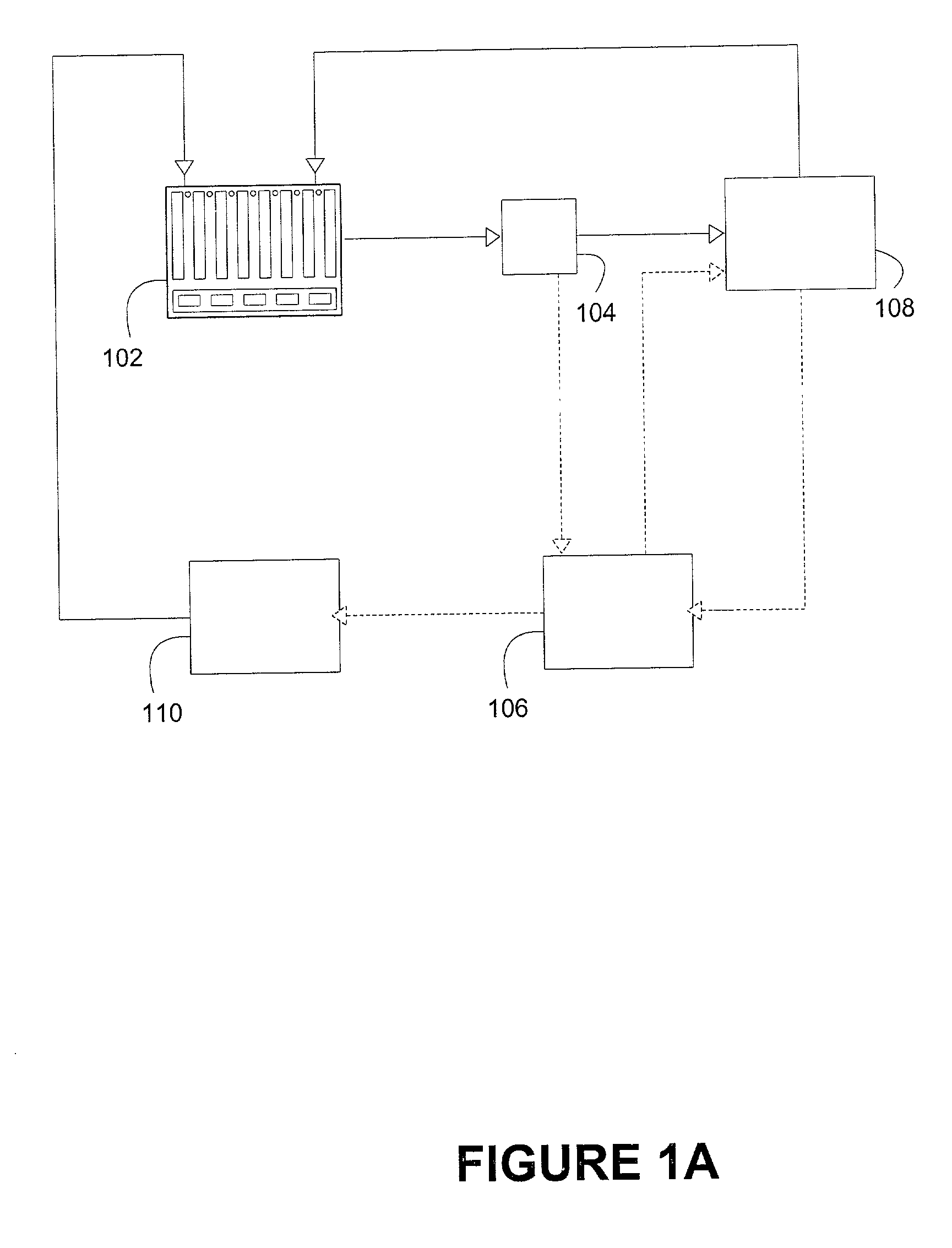

Methods of using fuel cell system configured to provide power to one or more loads

A fuel cell system is described for providing primary and / or auxiliary / backup power to one or more loads selected from the group comprising: lawn & garden equipment; radios; telephone; targeting equipment; battery rechargers; laptops; communications devices; sensors; night vision equipment; camping equipment; stoves; lanterns; lights; vehicles; cars; recreational vehicles; trucks; boats; ferries; motorcycles; motorized scooters; forklifts; golf carts; lawnmowers; industrial carts; passenger carts (airport); luggage handling equipment (airports); airplanes; lighter than air crafts; blimps; dirigibles; hovercrafts; trains; locomotives; submarines (manned and unmanned); torpedoes; security systems; electrical energy storage devices for solar-based, tidal-based, hydro-based, wind-based, and other renewable energy source; equipment for which a primary and / or backup power source is necessary or desirable to enable the equipment to function for its intended purpose, military-usable variants of above, and suitable combinations of any two or more thereof. The system provides power to the one or more loads upon the occurrence of a power outage condition, which includes a disruption or discontinuation in the delivery of primary power (i.e., power from a system-external primary source, namely, a source other than the fuel cell system) to, or power demand condition by, the one or more loads. A controller senses outage of primary power to, or demand for primary power by, the one or more loads, and, responsive thereto, operatively engages one or more fuel cells to provide power to the one or more loads.

Owner:METALLIC POWER INC

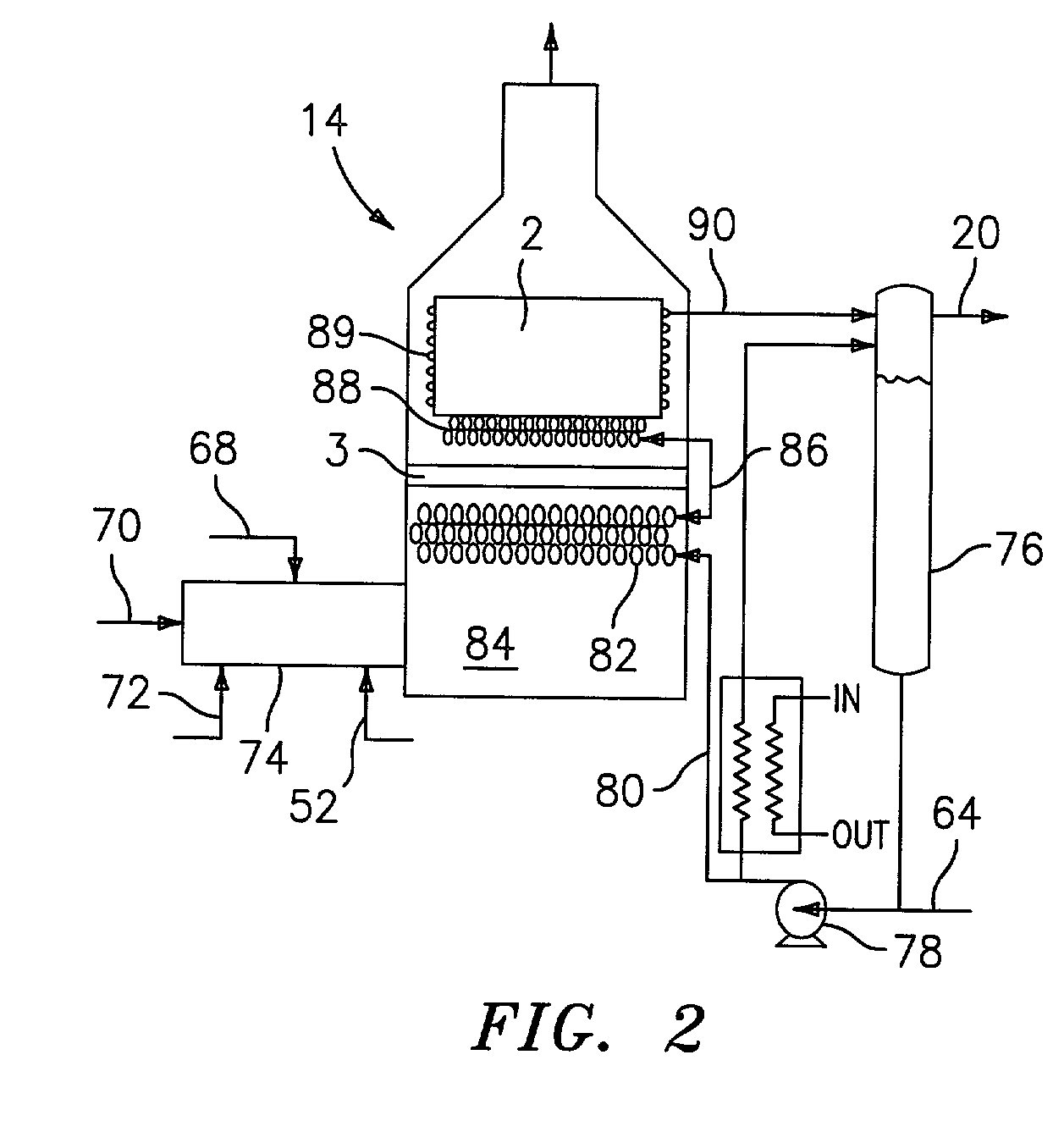

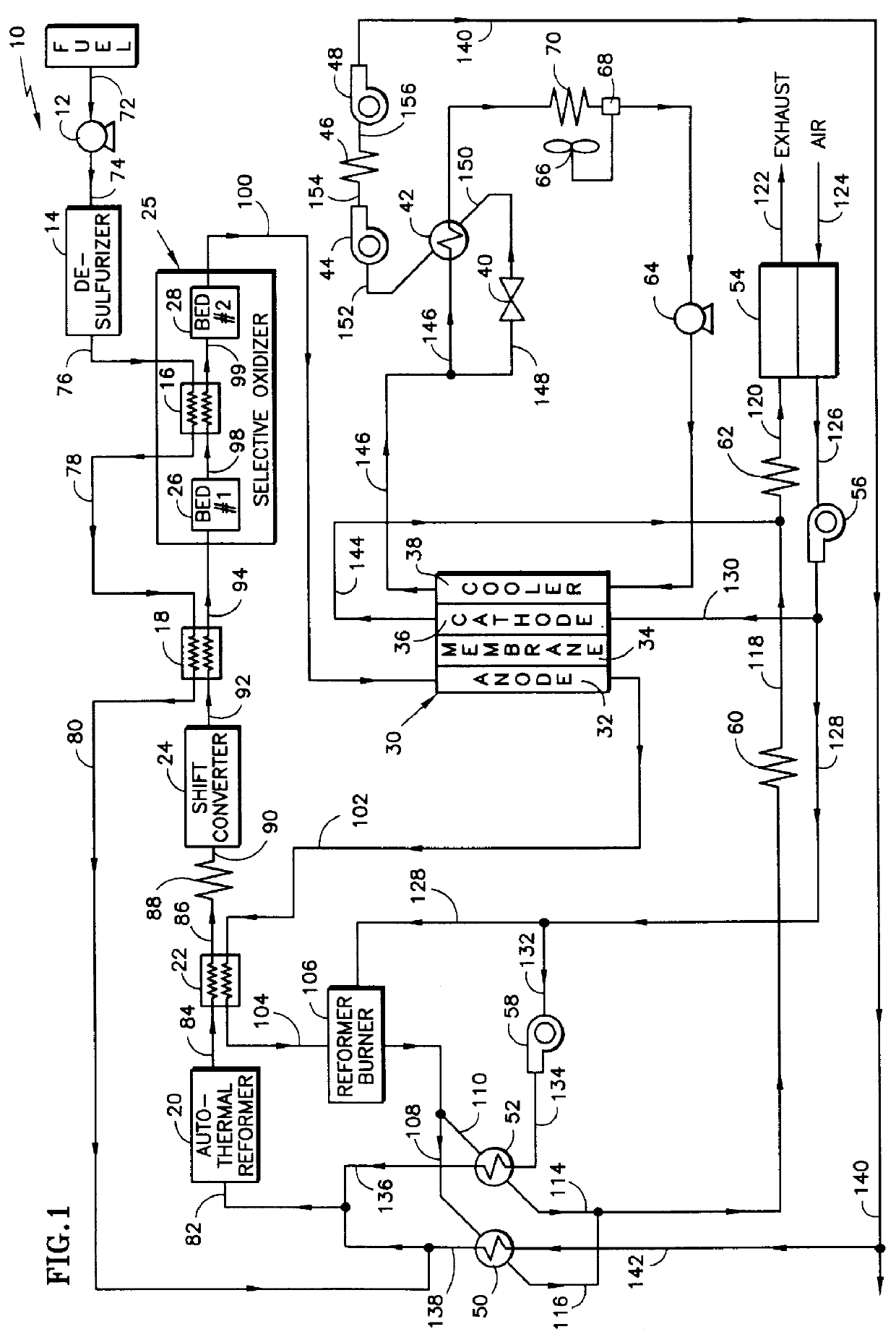

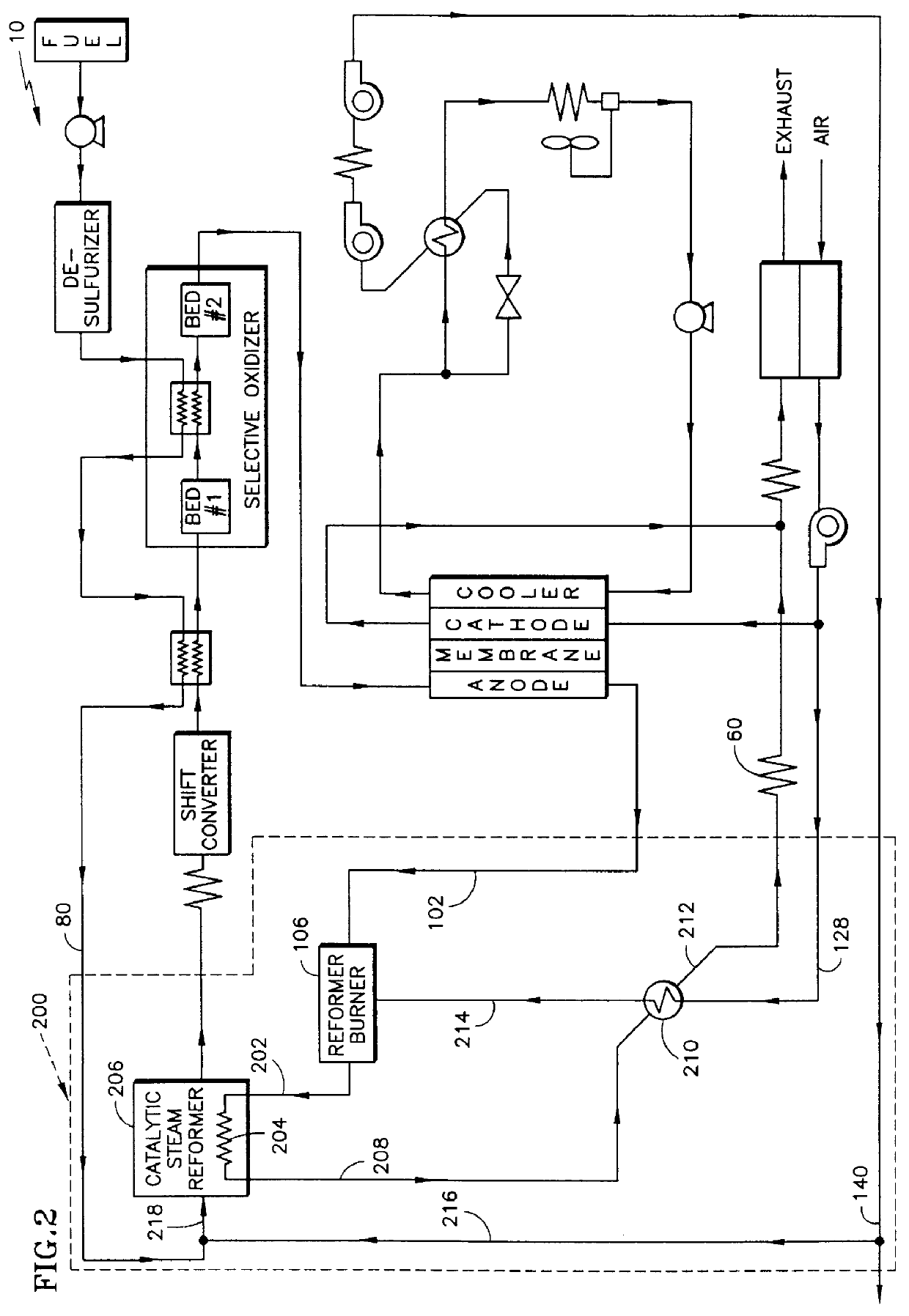

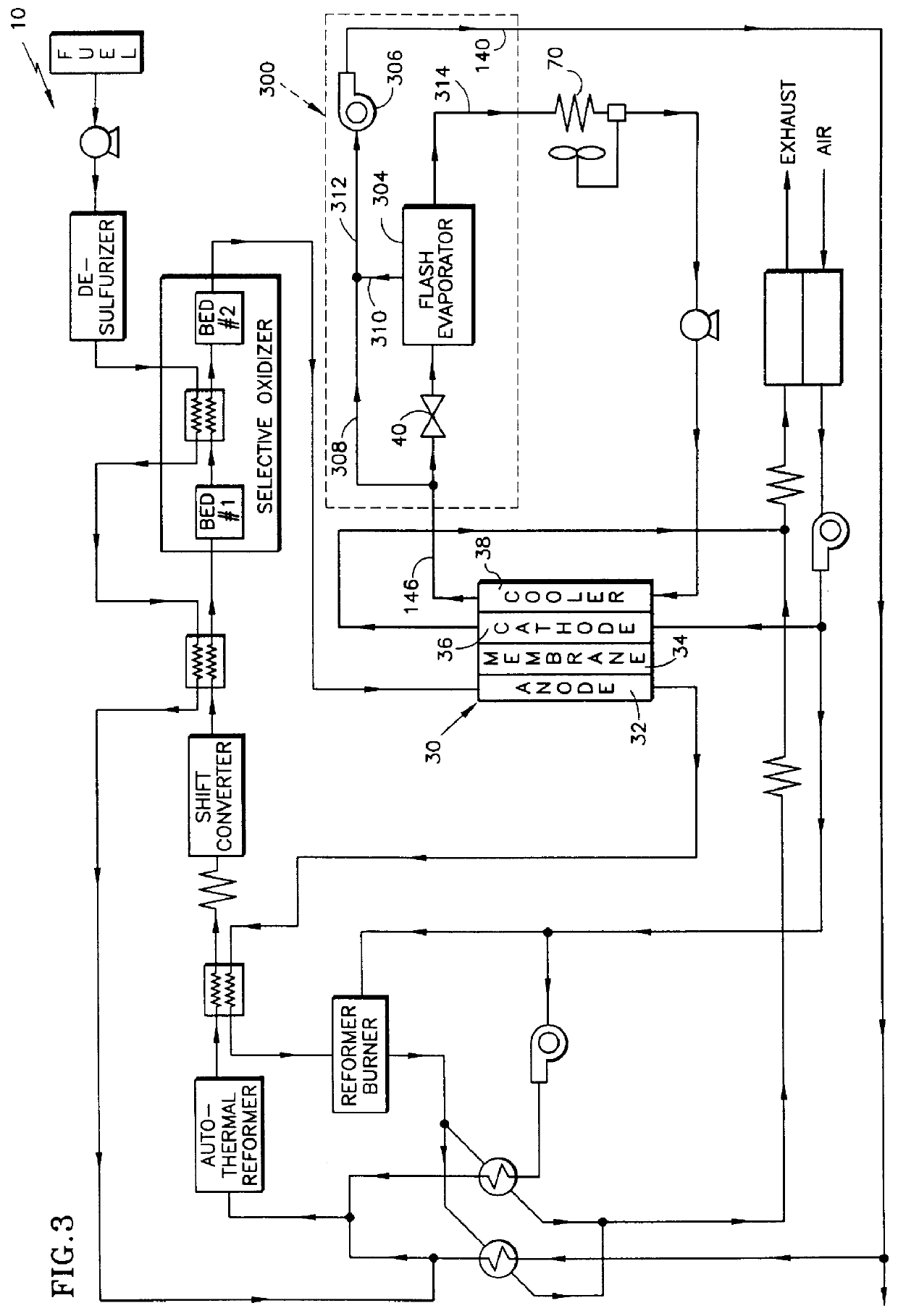

Steam producing hydrocarbon fueled power plant employing a PEM fuel cell

InactiveUS6120923AReduce pressureIncrease steam temperatureHydrogenSolid electrolytesFuel cellsPower station

The present invention relates to a method and apparatus for creating steam from the cooling stream of a proton exchange membrane (PEM) fuel cell. As the cooling stream exits the PEM fuel cell, a portion of the cooling fluid is extracted from the circulating cooling stream, thereby creating a secondary stream of cooling fluid. This secondary stream passes through a restriction, which decreases the pressure of the secondary stream to its saturation pressure, such that when the secondary stream enters a flash evaporator it transforms into steam. Creating steam from the cooling stream of a PEM fuel cell power plant provides the fuel processor with a co-generated source of steam without adding a significant amount of auxiliary equipment to the power plant.

Owner:INT FUEL CELLS

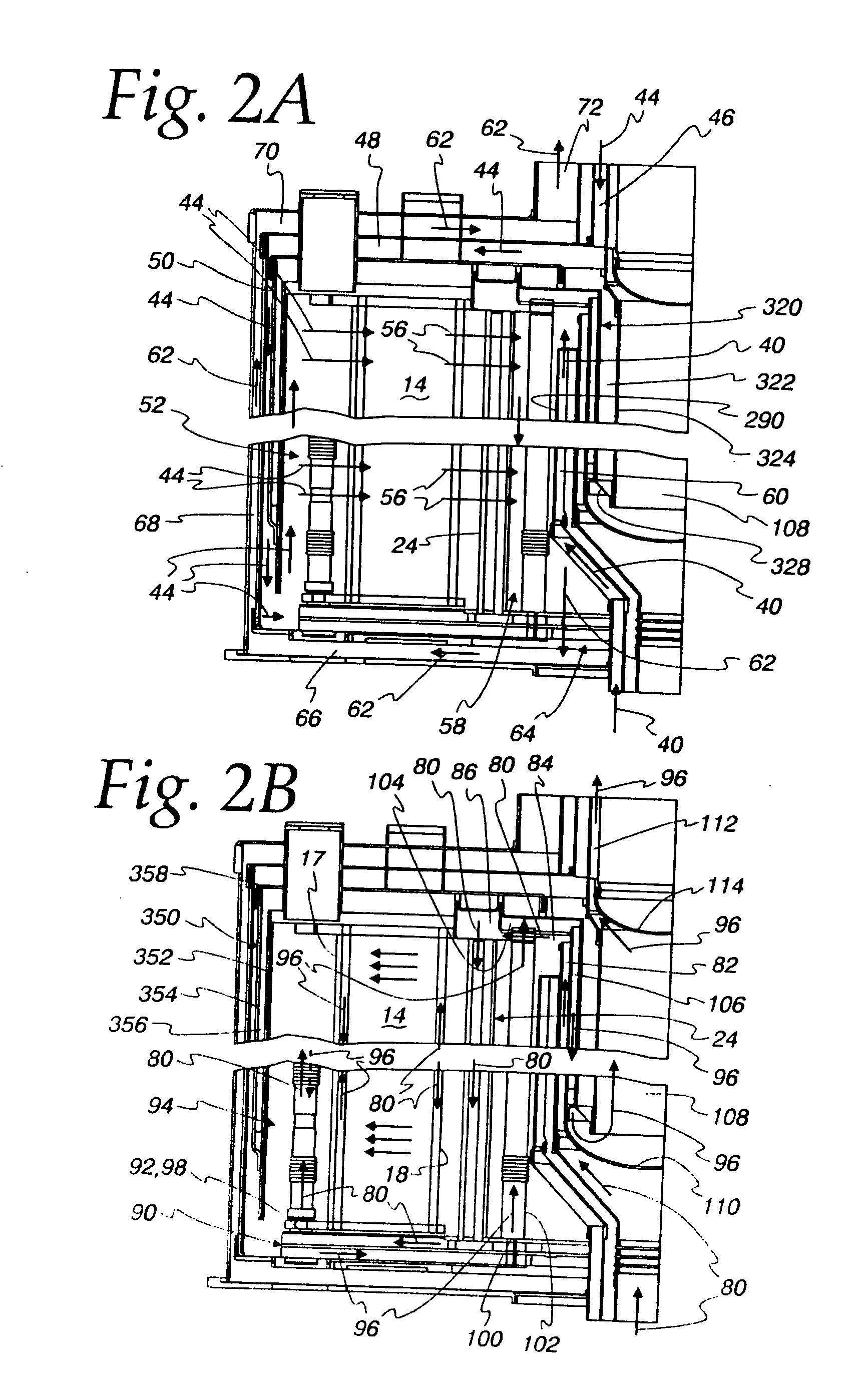

Intergrated solid oxide fuel cell and fuel processor

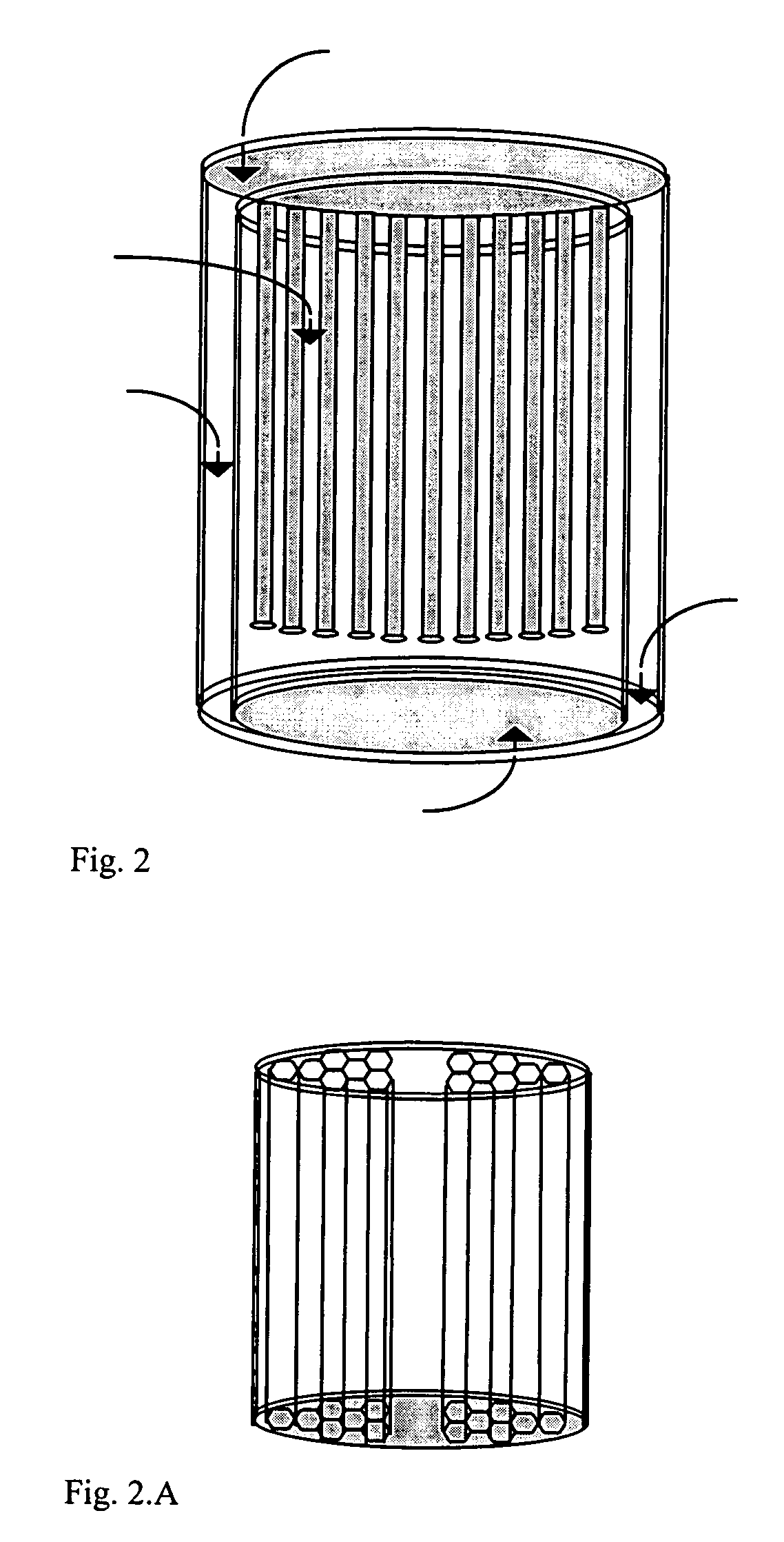

An integrated fuel cell unit (10) includes an annular array (12) of fuel cell stacks (14), an annular cathode recuperator (20), an annular anode recuperator (22), a reformer (24), and an anode exhaust cooler (26), all integrated within a common housing structure (28).

Owner:BLOOM ENERGY CORP

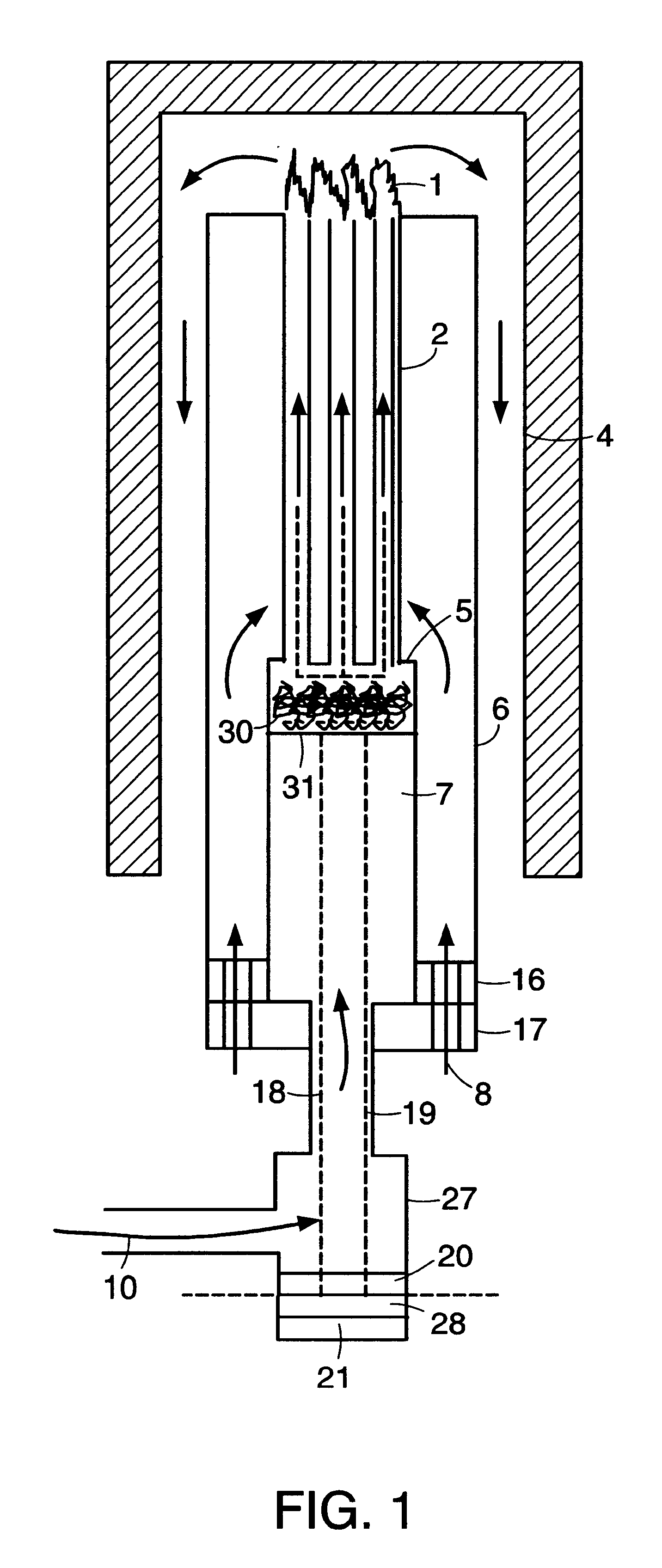

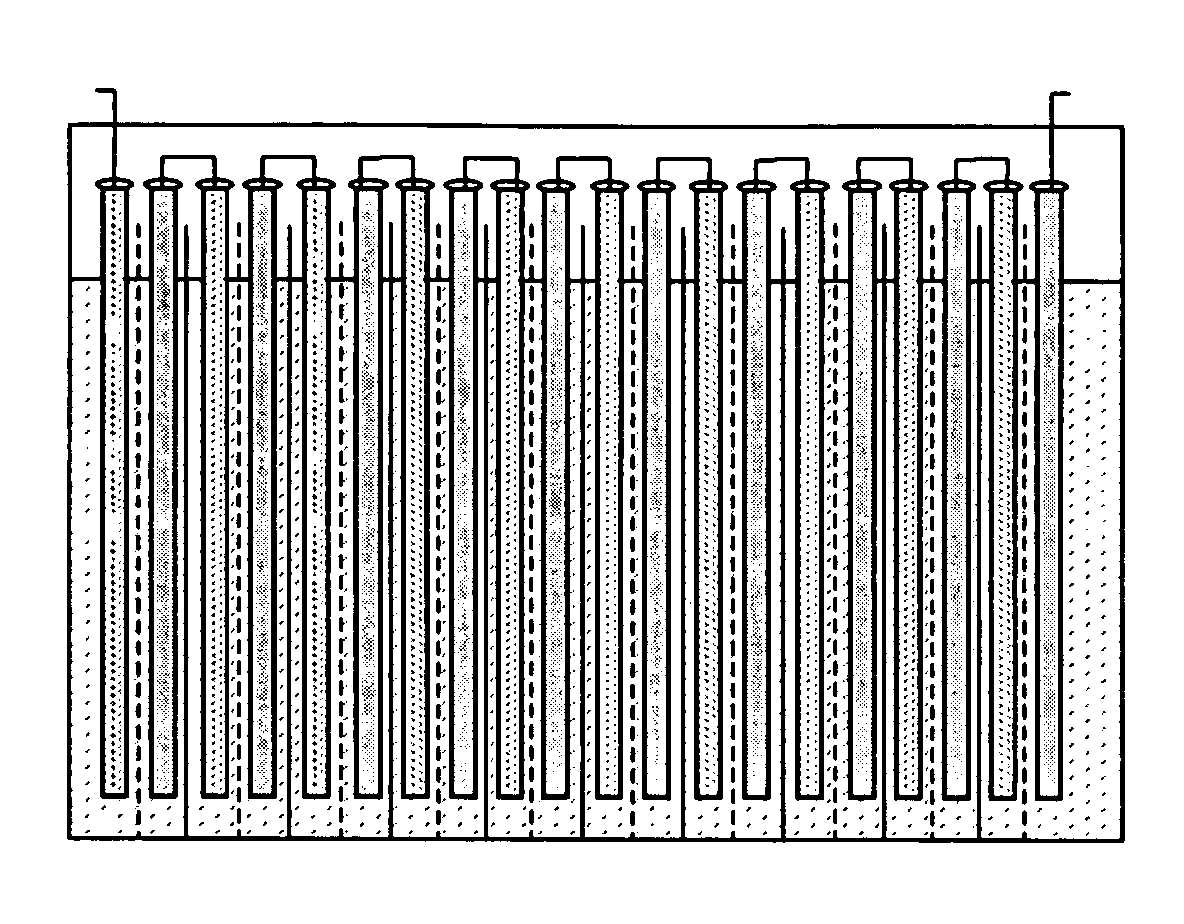

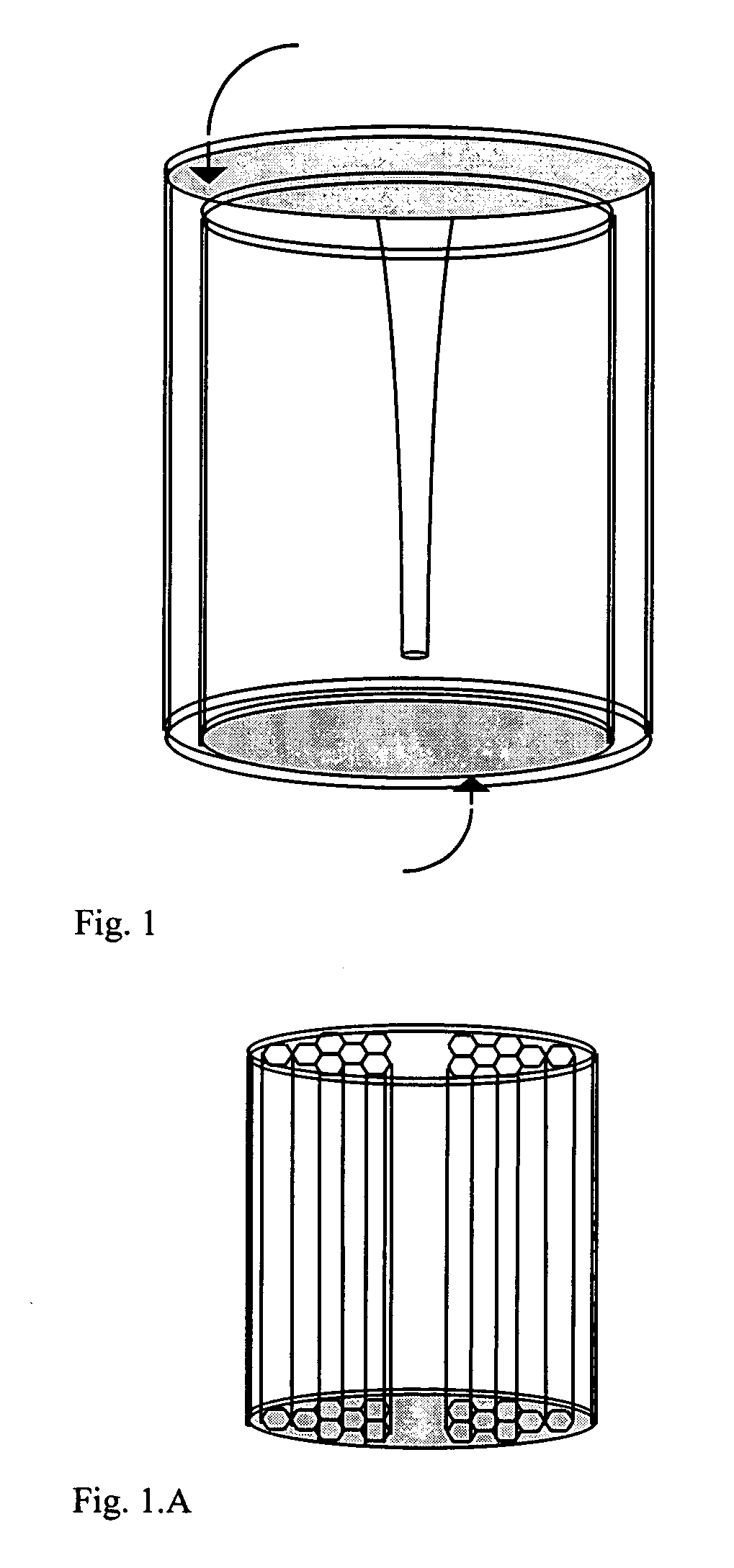

Integrated solid oxide fuel cell and reformer

A disclosed apparatus for generating electrical power has, according to one embodiment of the invention, a plurality of tubular solid oxide fuel cells contained in a reaction chamber. The fuel cells are secured at one end thereof in a manifold block, the other ends thereof passing freely through apertures in a baffle plate to reside in a combustion chamber. Reaction gases are supplied to the insides of the tubular fuel cells from a plenum chamber below the manifold block and to the reaction chamber surrounding the outsides of the fuel cells through an annular inlet path, which may include a reformation catalyst. The gases inlet path to the plenum chamber, and the annular inlet path surround the reaction chamber, are both in heat conductive relation with the reaction chamber and the combustion chamber, and raise the gases to formation and reaction temperatures as appropriate.

Owner:ACUMENTRICS

Reactive deposition for electrochemical cell production

Light reactive deposition can be adapted effectively for the deposition of one or more electrochemical cell components. In particular, electrodes, electrolytes, electrical interconnects can be deposited form a reactive flow. In some embodiments, the reactive flow comprises a reactant stream that intersects a light beam to drive a reaction within a light reactive zone to produce product that is deposited on a substrate. The approach is extremely versatile for the production of a range of compositions that are useful in electrochemical cells and fuel cell, in particular. The properties of the materials, including the density and porosity can be adjusted based on the deposition properties and any subsequent processing including, for example, heat treatments.

Owner:NANOGRAM

Planar solid oxide fuel cell stack with metallic foil interconnect

A solid oxide fuel cell stack having a plurality of integral component fuel cell units, each integral component fuel cell unit having a porous anode layer, a porous cathode layer, and a dense electrolyte layer disposed between the porous anode layer and the porous cathode layer. The porous anode layer forms a plurality of substantially parallel fuel gas channels on its surface facing away from the dense electrolyte layer and extending from one side to the opposite side of the anode layer, and the porous cathode layer forms a plurality of substantially parallel oxidant gas channels on its surface facing away from the dense electrolyte layer and extending from one side to the opposite side of the cathode. A flexible metallic foil interconnect is provided between the porous anode and porous cathode of adjacent integral component fuel cell units.

Owner:VERSA POWER SYST

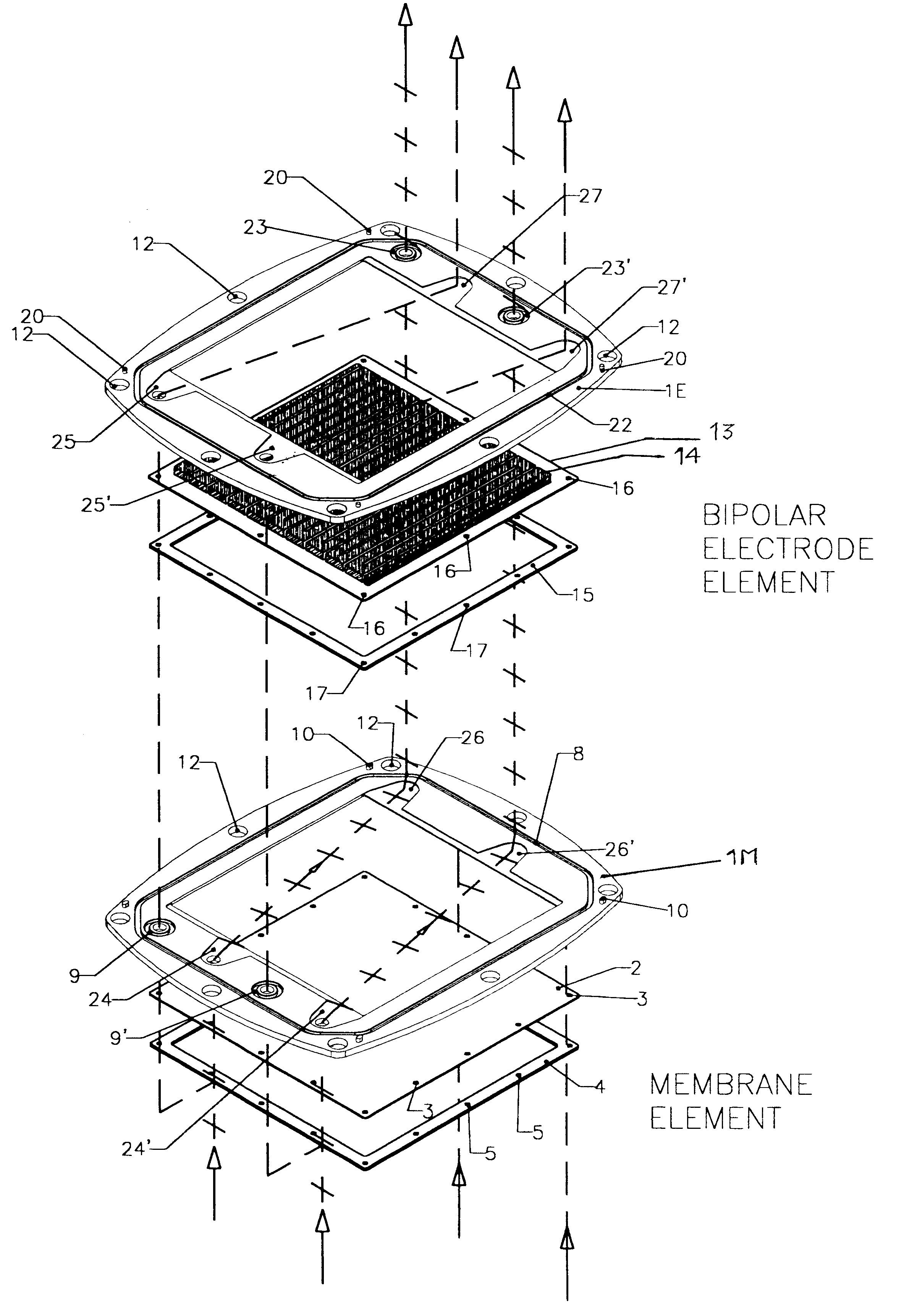

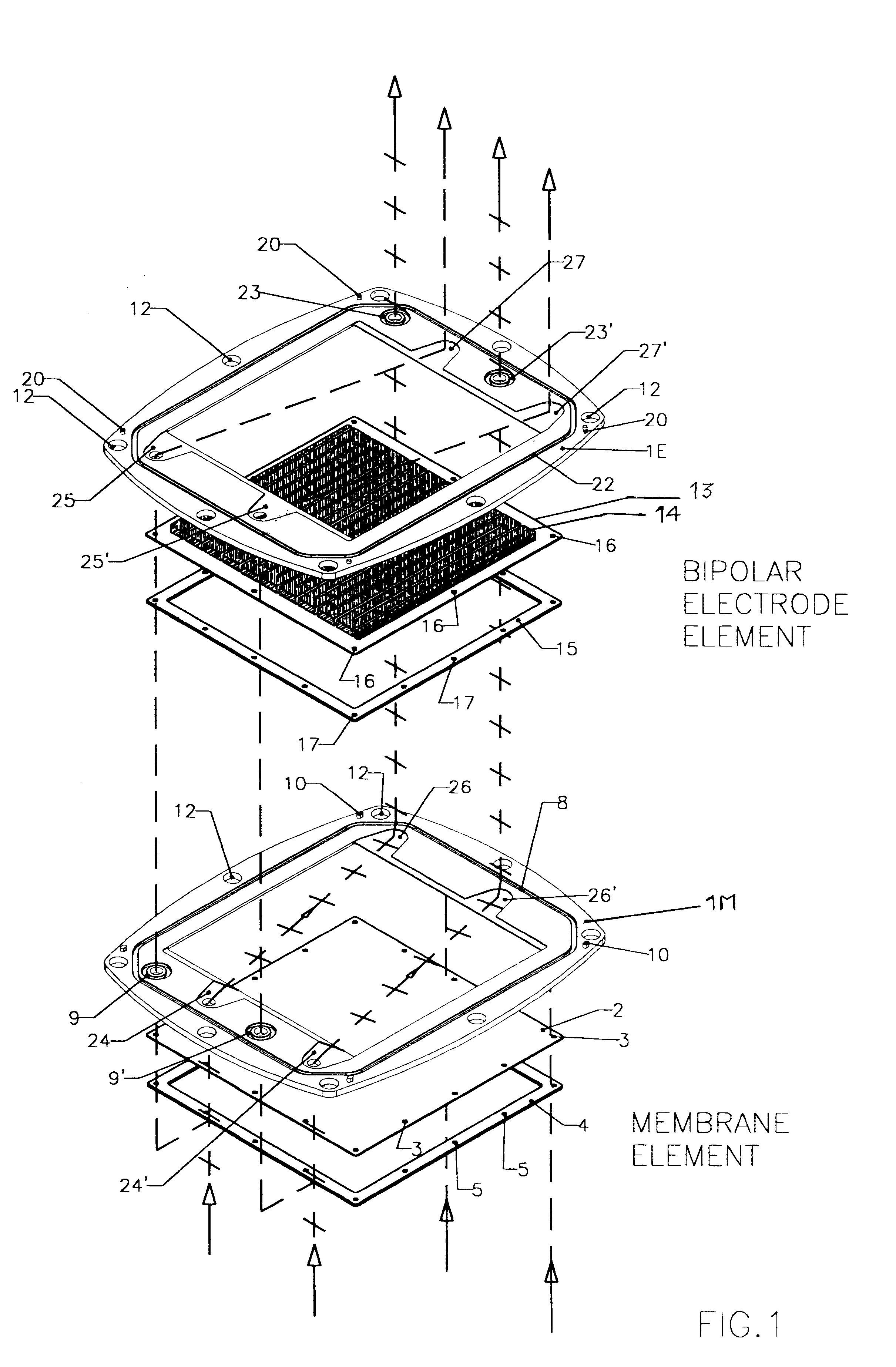

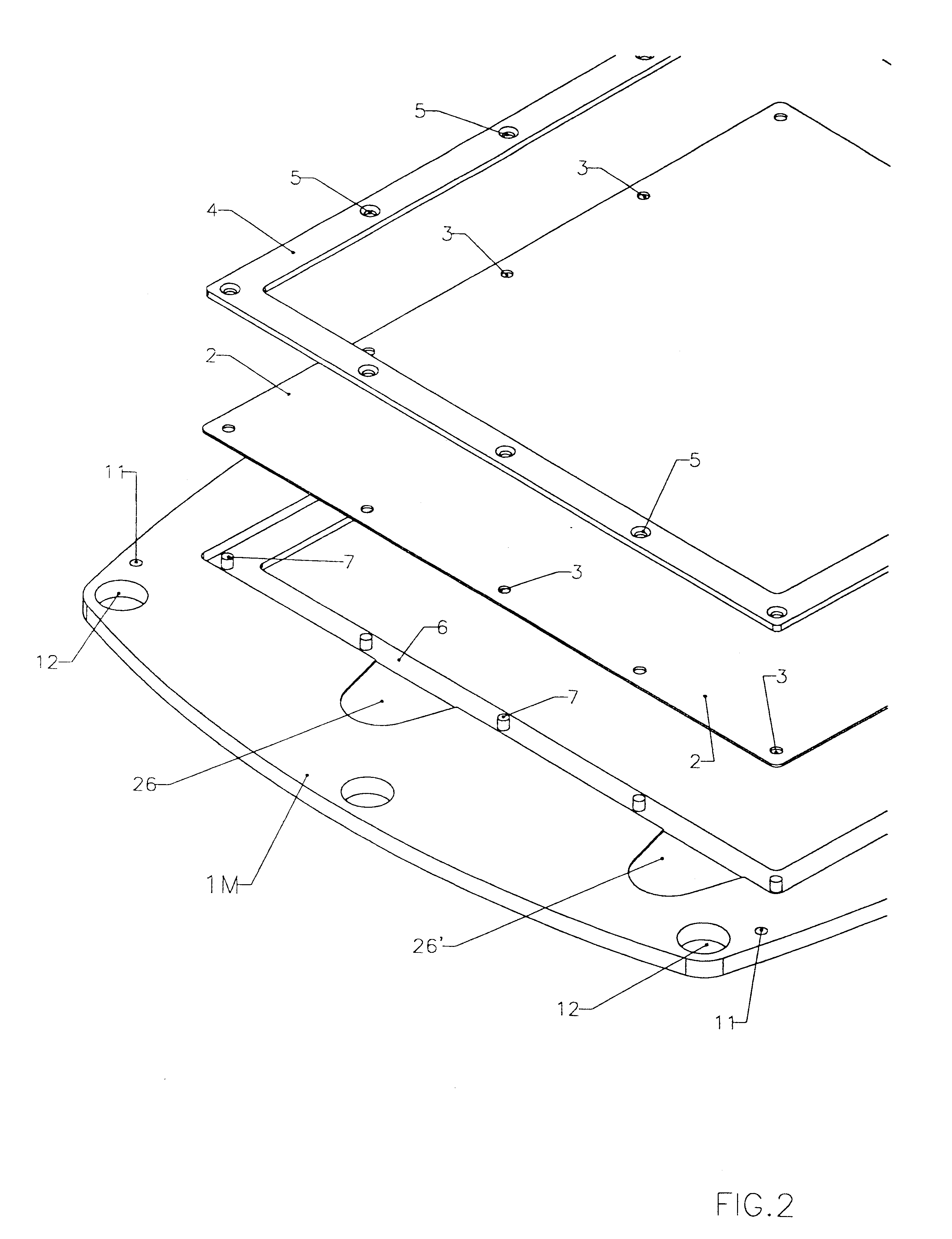

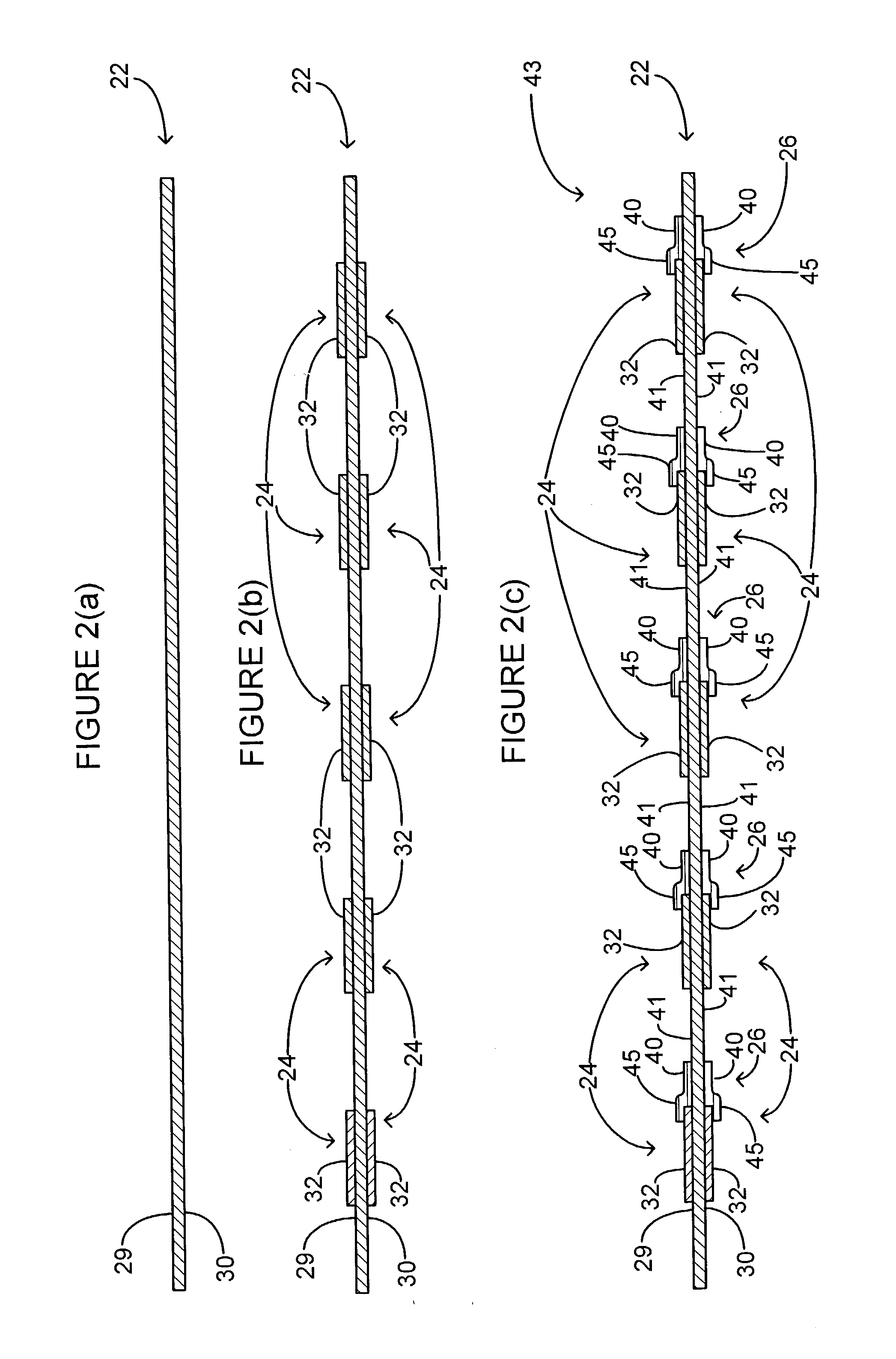

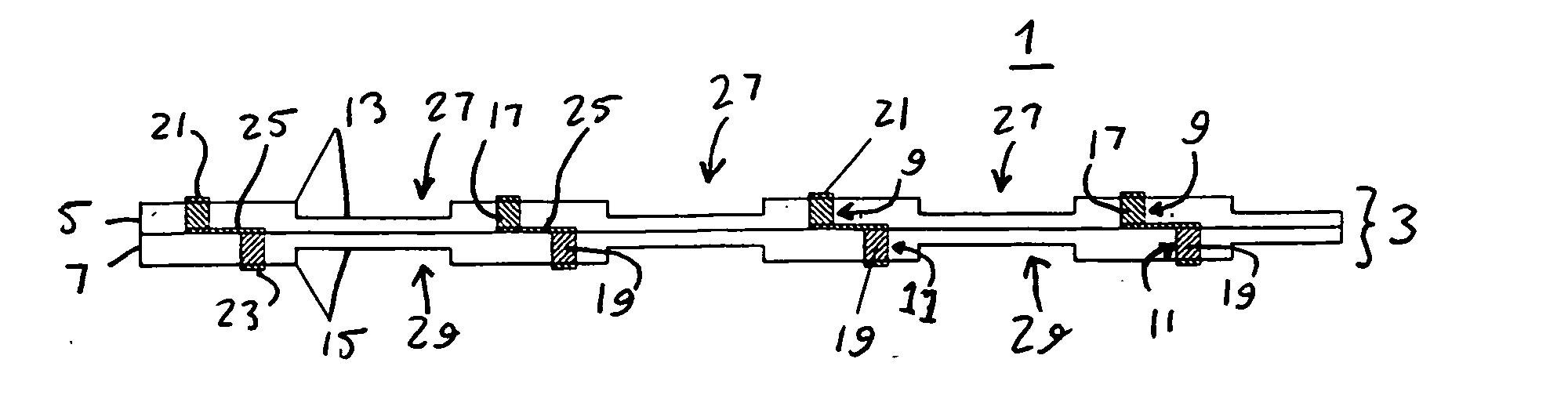

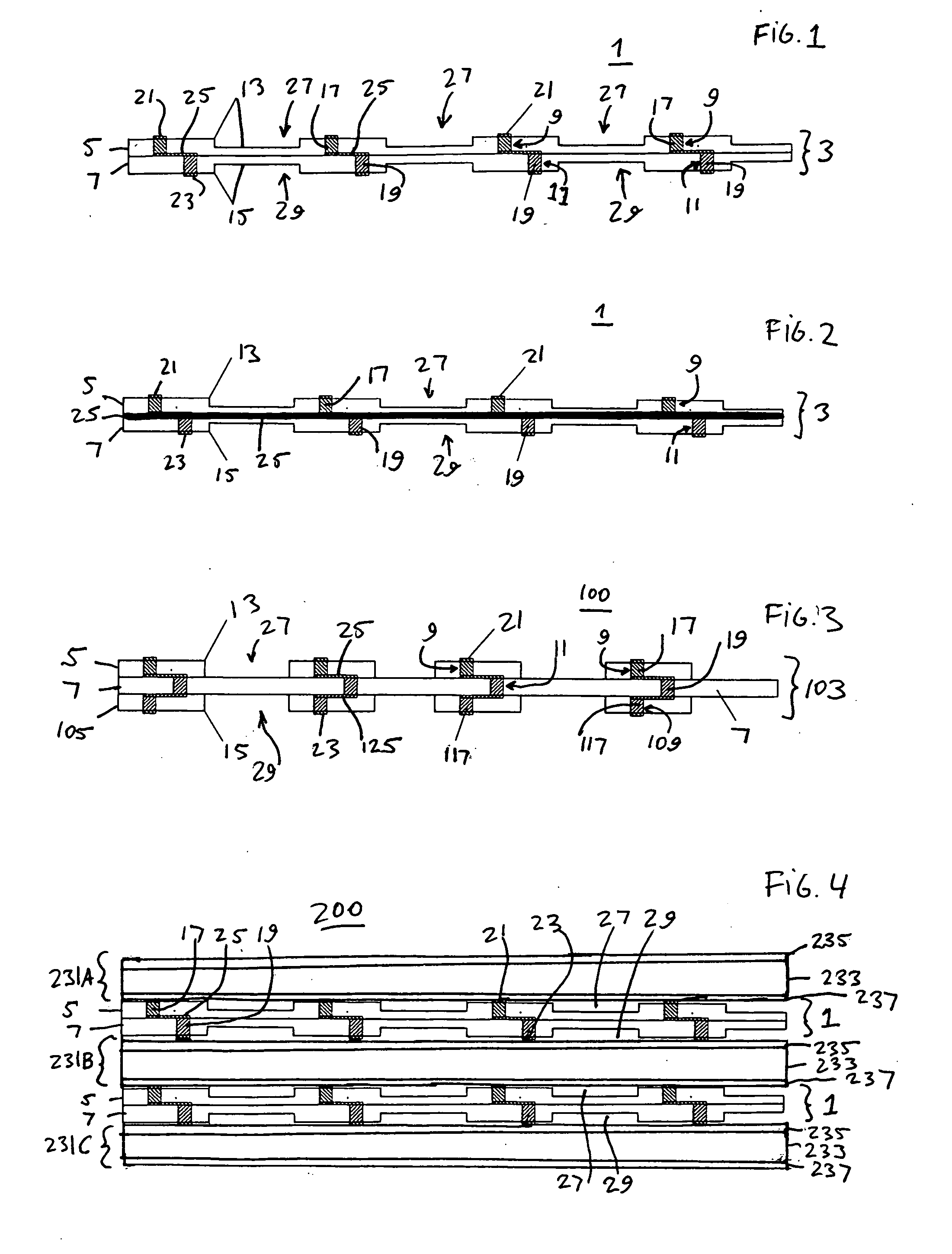

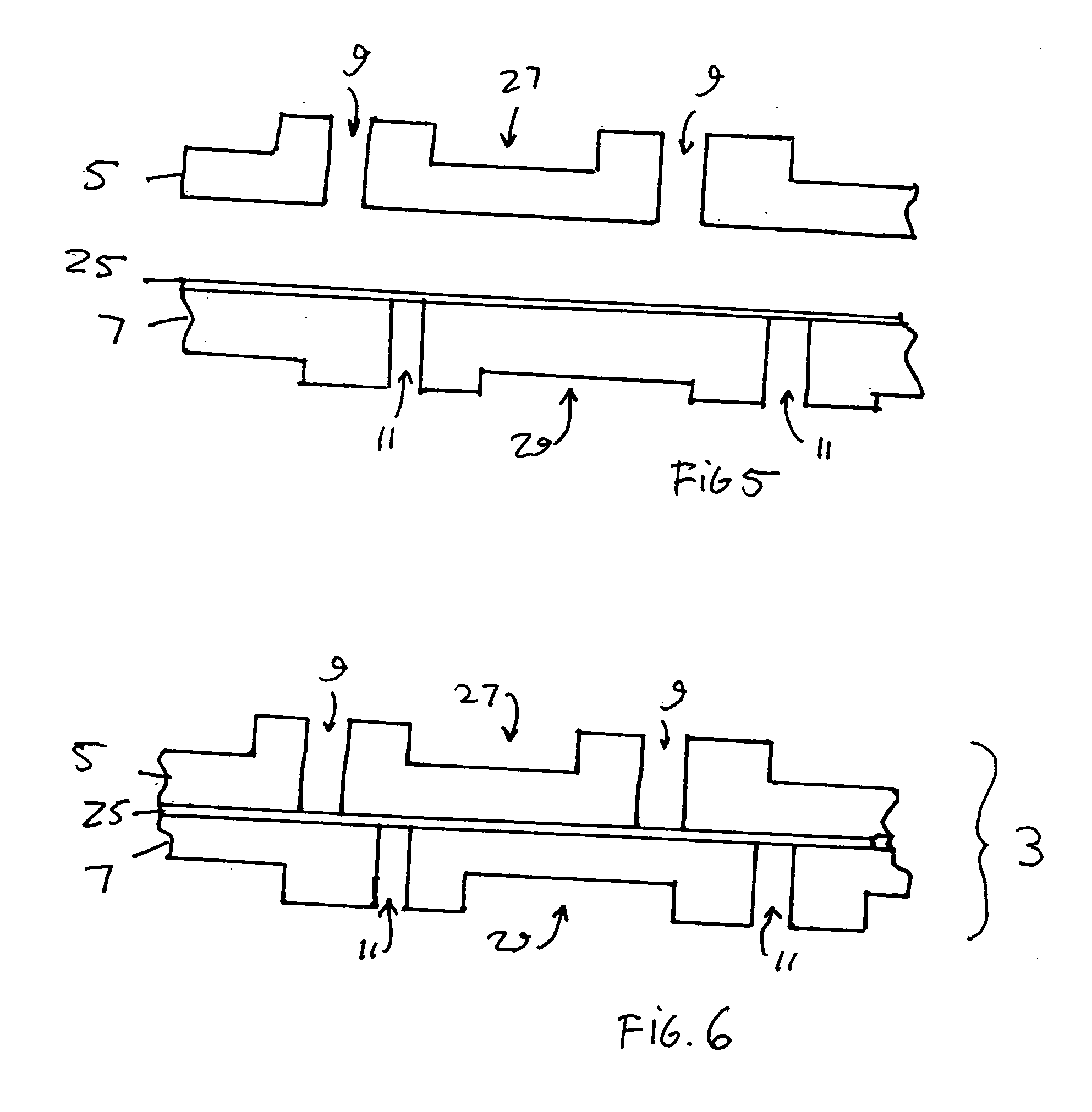

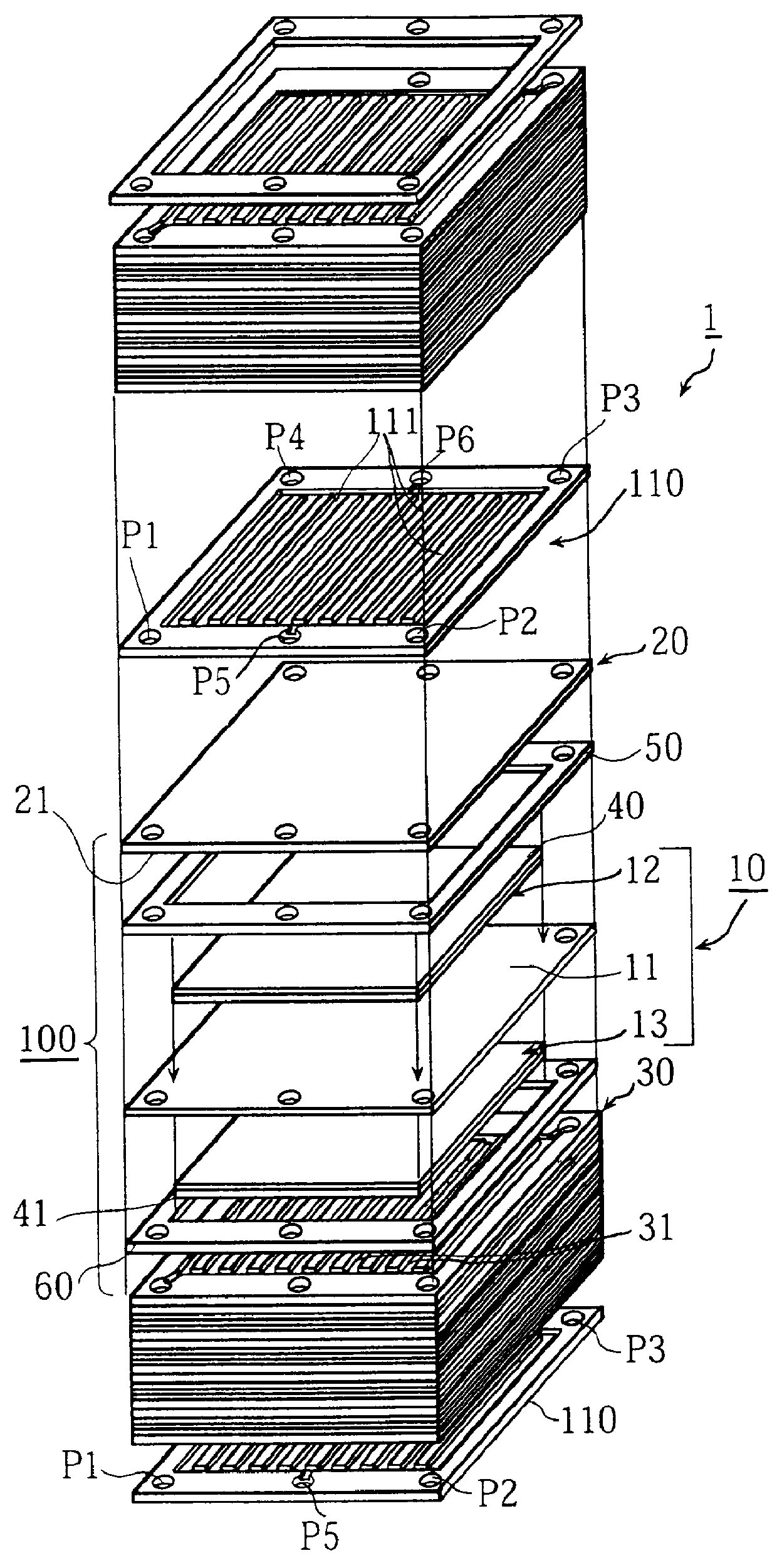

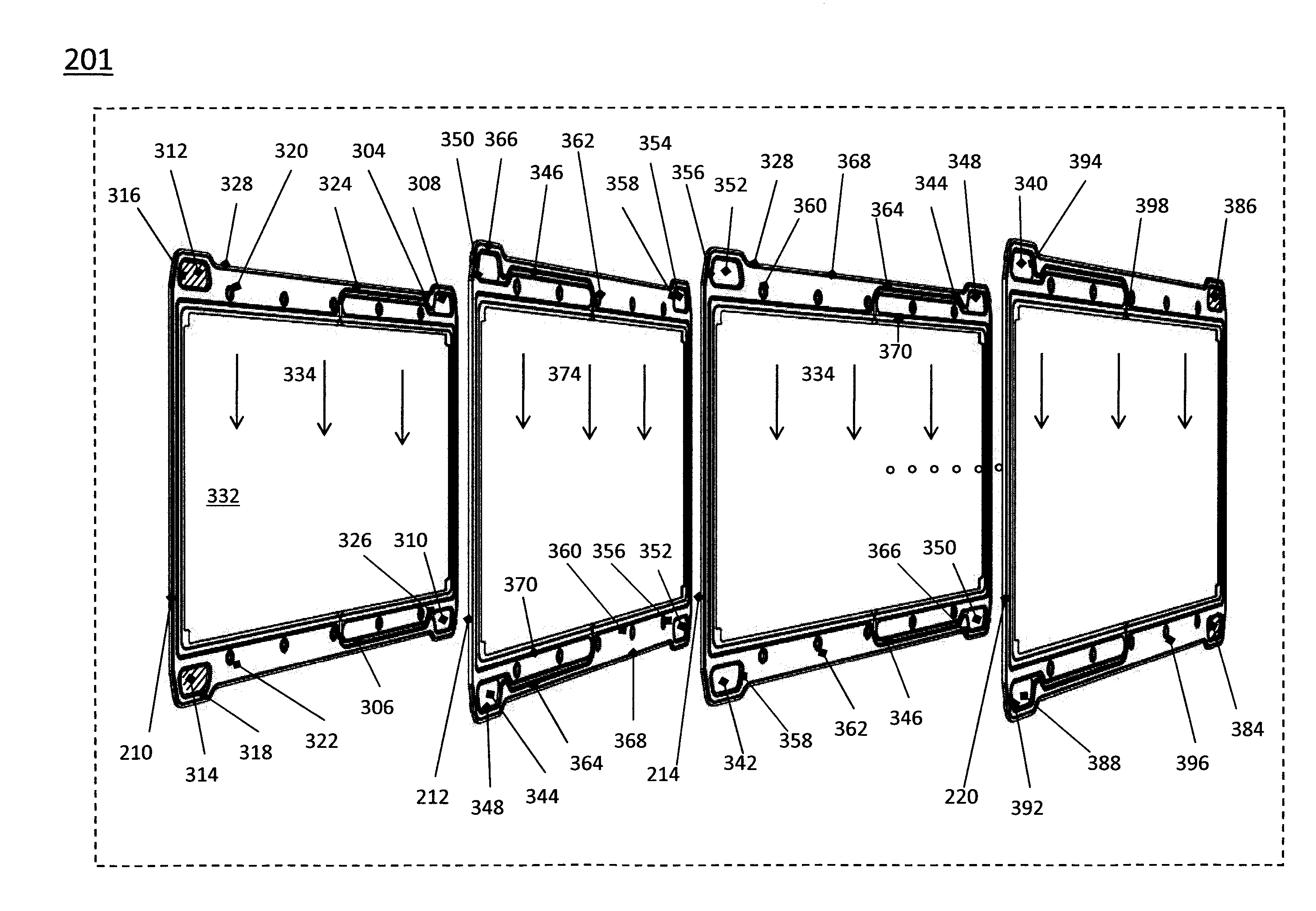

Membrane-separated, bipolar multicell electrochemical reactor

InactiveUS6555267B1Improve electrochemical performanceLower overall pressure dropFuel cells groupingFuel cell auxillariesPlastic materialsIon-exchange membranes

A multicell assembly is constituted by alternately stacking two types of pre-assembled elements: a bipolar electrode holding subassembly and a membrane holding subassembly. The alternate stack of elements is piled over a bottom end element and the stack is terminated by placing over the last membrane holding element a top end electrode element. Each bipolar plate electrode holding element and each ion exchange membrane separator holding element includes a substantially similar rectangular frame piece, made of an electrically nonconductive and chemically resistant material, typically of molded plastic material, having on its upper (assembly) face grooves for receiving O-ring type gasket means, and having through holes and recesses in coordinated locations disposed along two opposite sides of the rectangular frame forming, upon completion of the assembling, ducts for the separate circulation of the negative electrolyte and of the positive electrolyte through all the negative electrolyte flow chambers and all positive electrolyte flow chambers, respectively, in cascade.

Owner:SQUIRREL HLDG

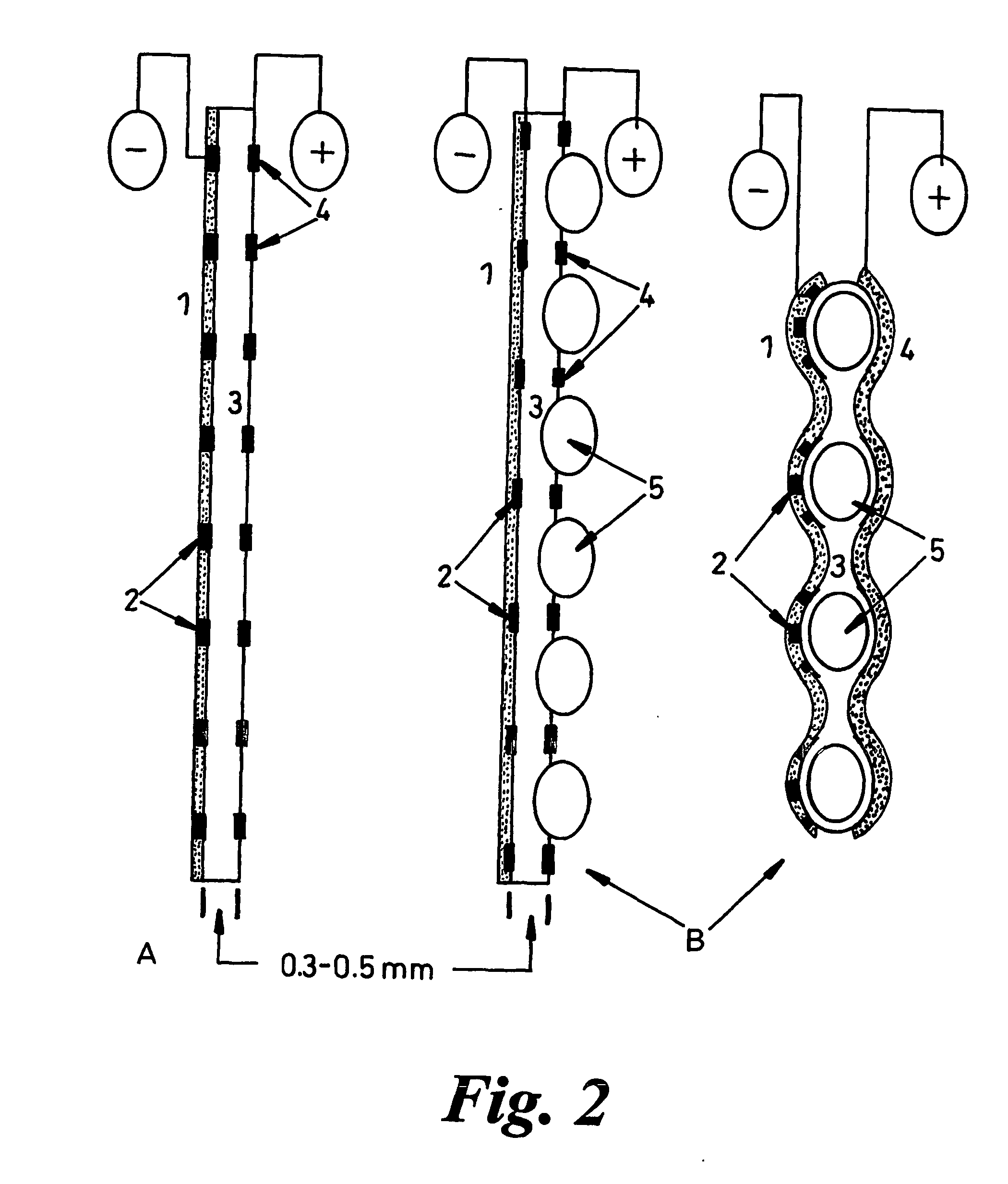

Method of fabricating fuel cells and membrane electrode assemblies

InactiveUS20040053100A1Low production costOvercome limitationsFuel cells groupingCell electrodesElectrical resistance and conductancePower battery

The application relates to a method of fabricating micro fuel cells and membrane electrode assemblies by thin film deposition techniques using a dimensionally stable proton exchange membrane as a substrate. The application also relates to membrane electrode assemblies and fuel cells fabricated in accordance with the method. The method includes the steps of successively depositing catalyst, current collector and flow management layers on the membrane substrate in predetermined patterns. Since the fuel cell is formed layer by layer, the need for assembly and sealing of discrete components is avoided. The method improves the contact resistance between the current collectors and catalyst layers and reduce ohmic losses, thereby avoiding the need for end plates or other compressive elements. This in turn reduces the overall thickness of the manufactured fuel cell. Since the fuel cell layers are optionally flexible, the devices may be fabricated using a continuous roller process or other automated means. The method minimizes production costs and costs of non-essential materials and is particularly suitable for low power battery replacement applications.

Owner:NAT RES COUNCIL OF CANADA

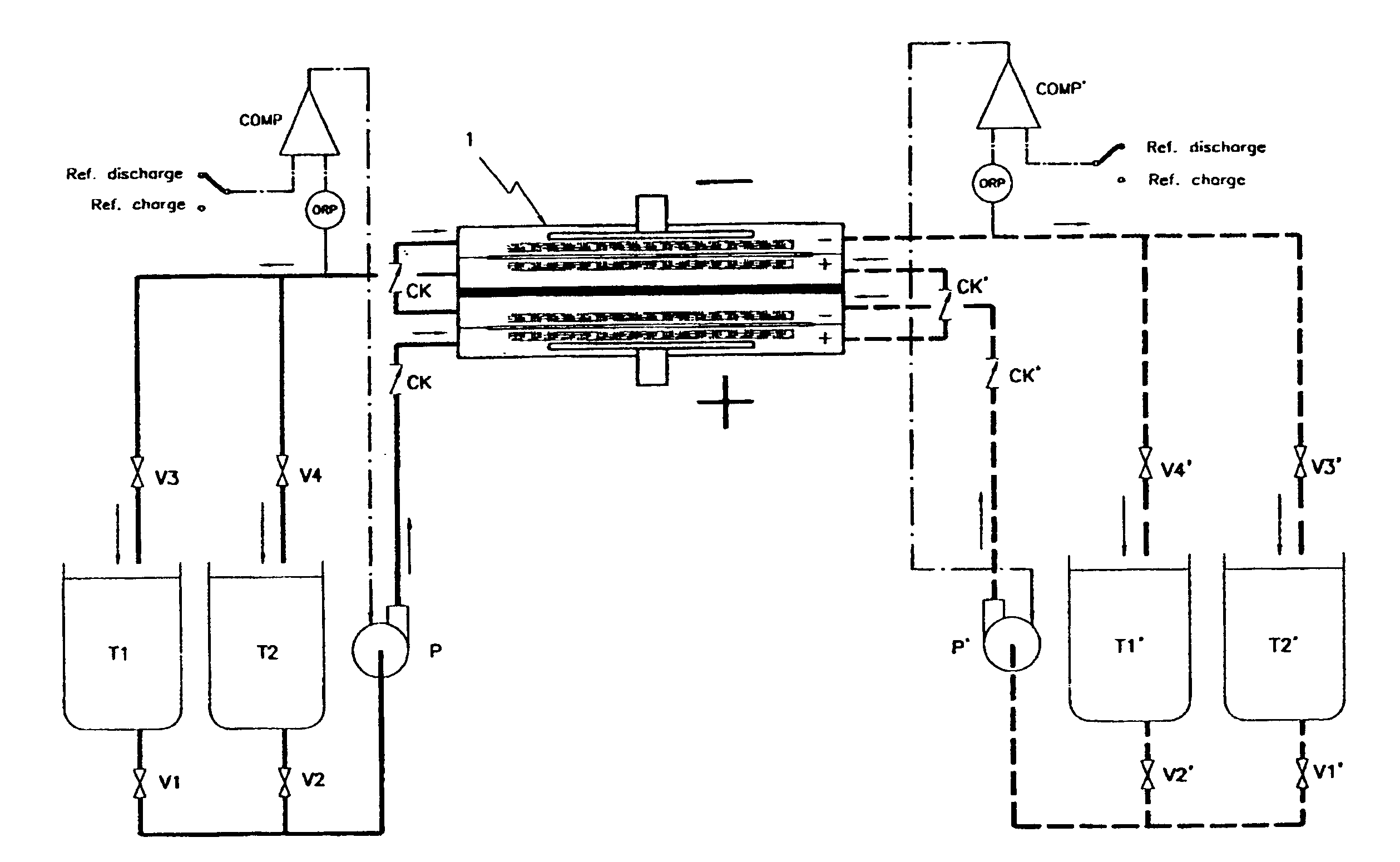

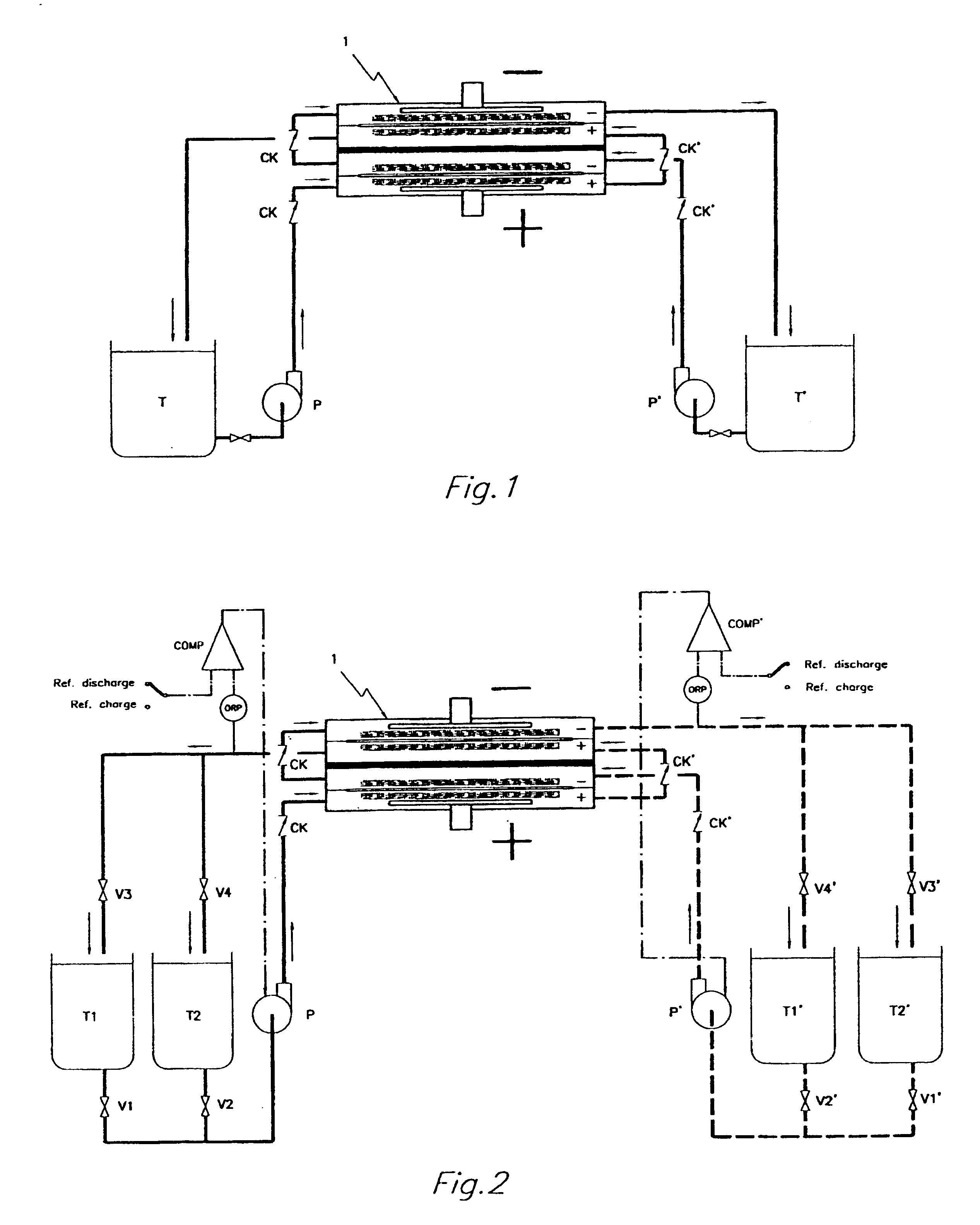

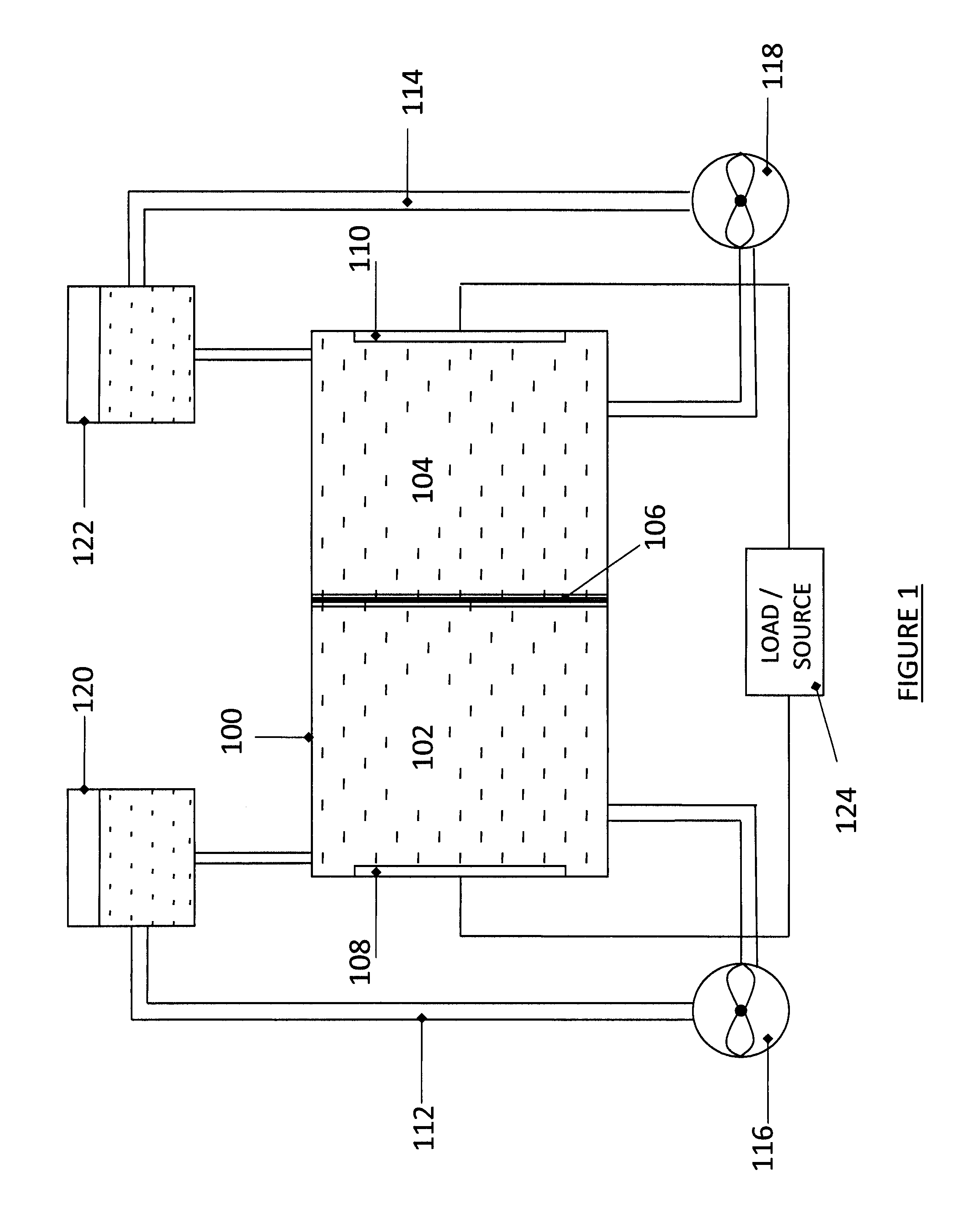

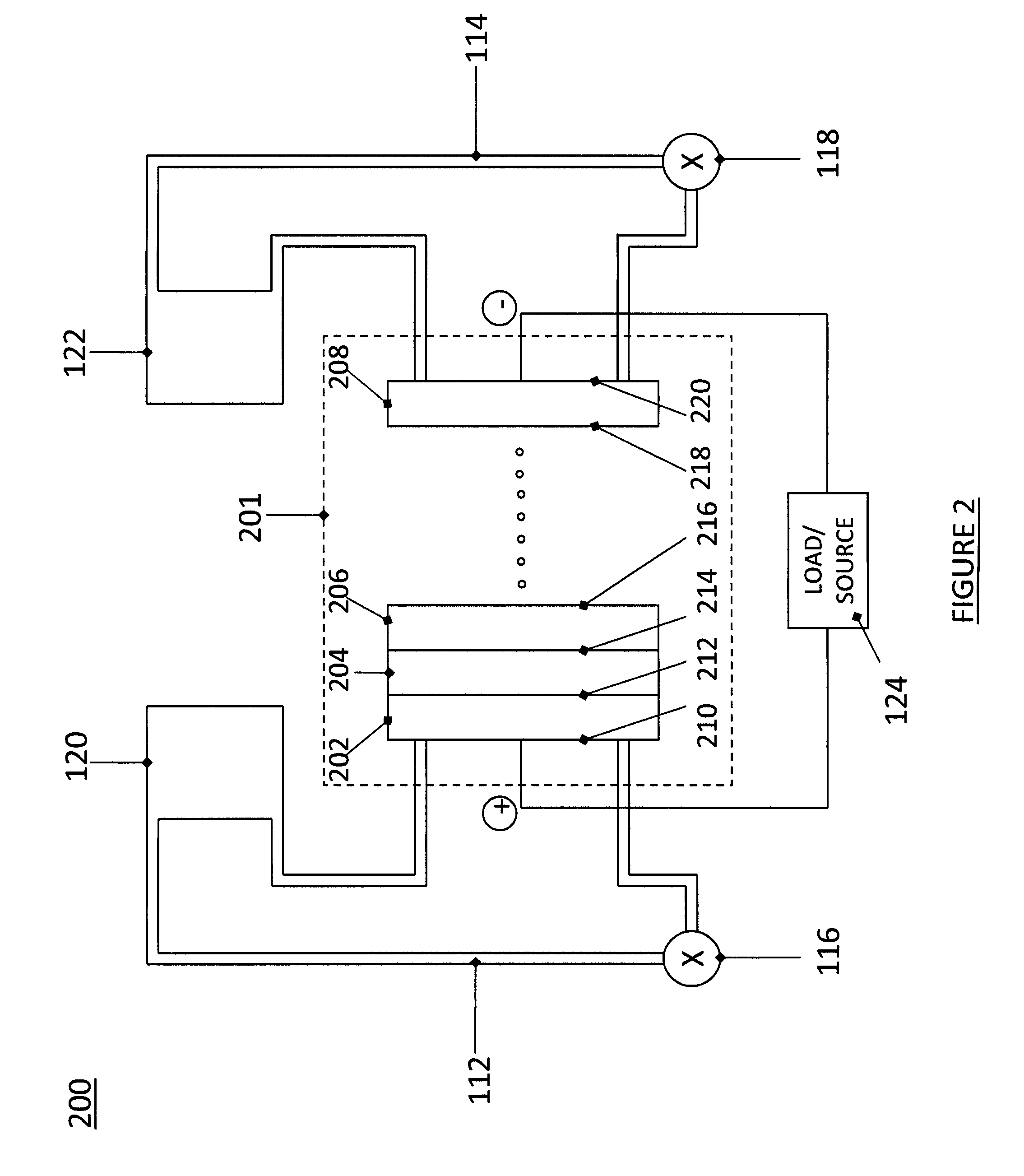

Redox flow battery and method of operating it

InactiveUS6692862B1Easy dischargeImprove efficiencyElectrolyte moving arrangementsFuel cells groupingWork cycleRedox

By realizing or installing check valve liquid vein interrupters in each compartment of the battery the phenomenon of slow discharge of the retained volumes of electrolytes during long periods of inactivity of a redox flow battery, with the electrolyte pumps stopped altogether, can be practically eliminated with the effect that the battery is perfectly ready to deliver electric power immediately upon request even after prolonged periods of inactivity. Moreover, the presence of liquid vein interrupters on each compartment in either an outlet or an inlet port substantially preventing by-pass current during a not pumping phase, permits to increase the by pumping the electrolytes through the compartments of a battery stack intermittently, in other words in a pulsed manner, with a certain duty-cycle. Relatively brief pumping phases at relatively high flow rate alternated to phases of not pumping provide for a volumetrically adequate refreshing of the electrolytes present in the battery compartments and contrast the formation of gradients in the bodies of electrolyte.

Owner:SQUIRREL HLDG

Offset interconnect for a solid oxide fuel cell and method of making same

InactiveUS20050227134A1Fuel cells groupingFinal product manufactureFuel cellsElectrically conductive

An interconnect for a solid oxide fuel cell includes a non-ionically and non-electrically conductive ceramic gas separator plate comprising at least two ceramic layers, a plurality of first vias extending through the first separator plate ceramic layer but not through the second separator plate ceramic layer and a plurality of second vias extending through the second separator plate ceramic layer but not through the first separator plate ceramic layer. The second vias are offset from the first vias. The interconnect also includes a plurality of electrically conductive first fillers located in the plurality of first vias and a plurality of electrically conductive second fillers located in the plurality of second vias. Each of the plurality of first fillers is electrically connected to at least one second filler.

Owner:BLOOM ENERGY CORP

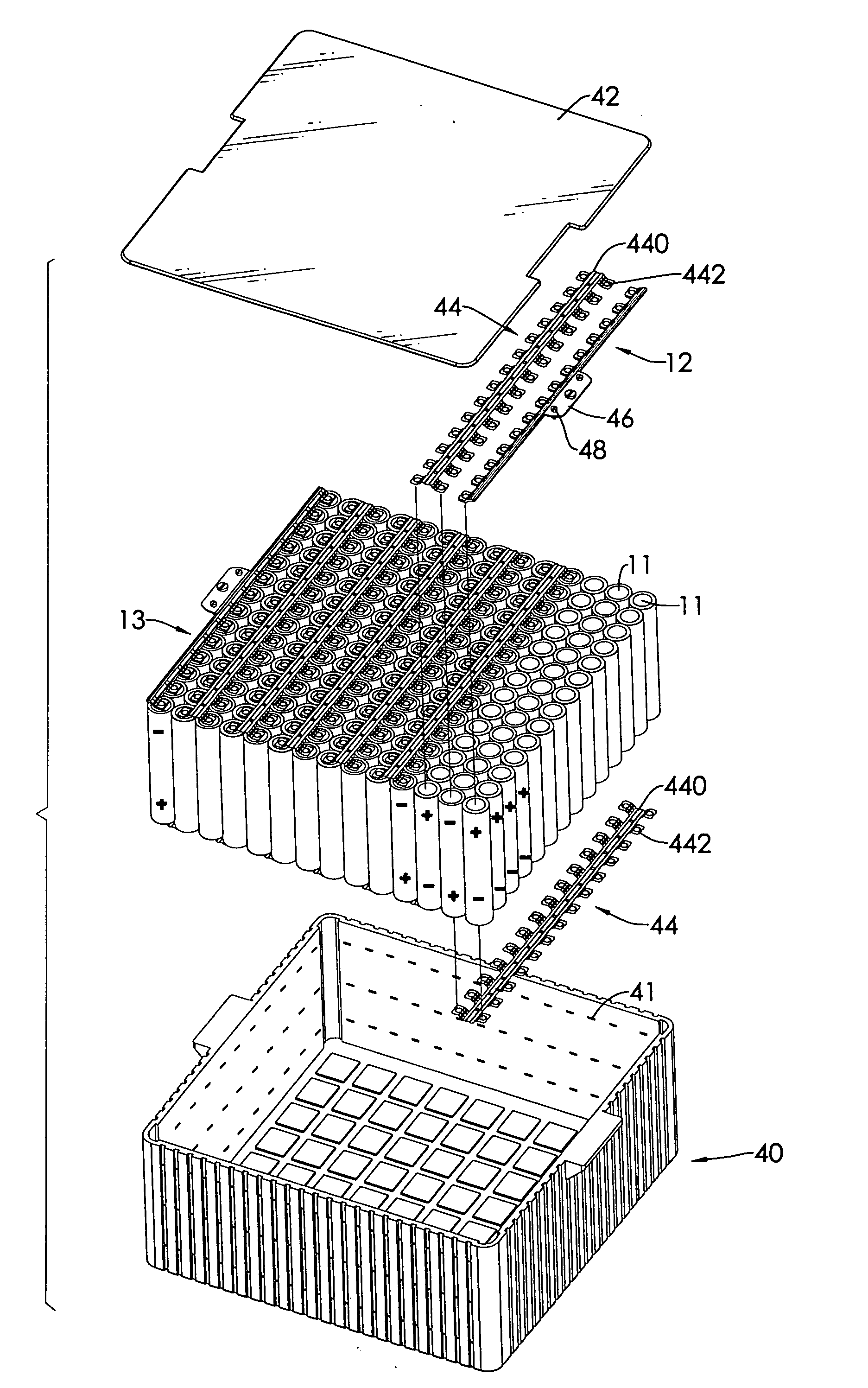

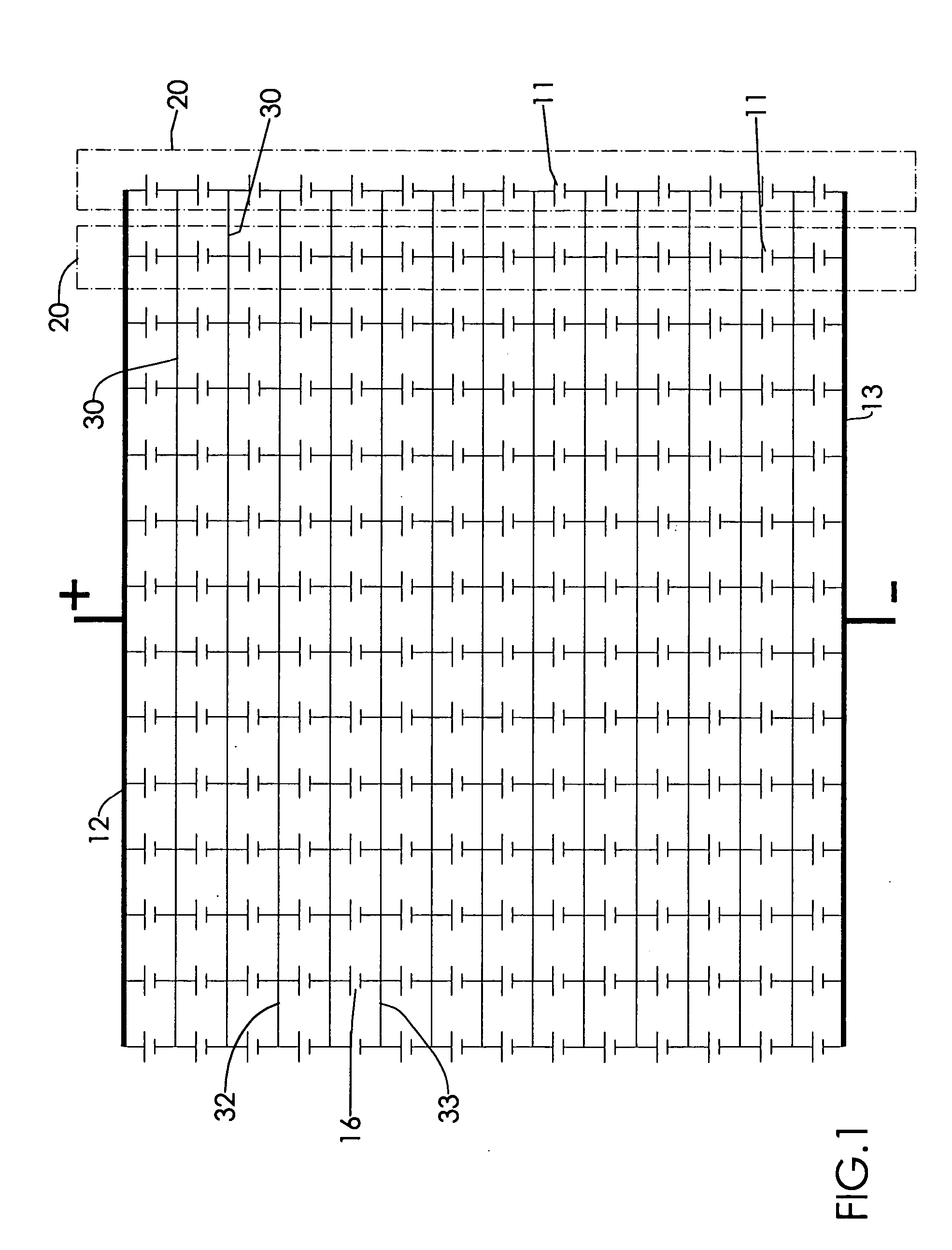

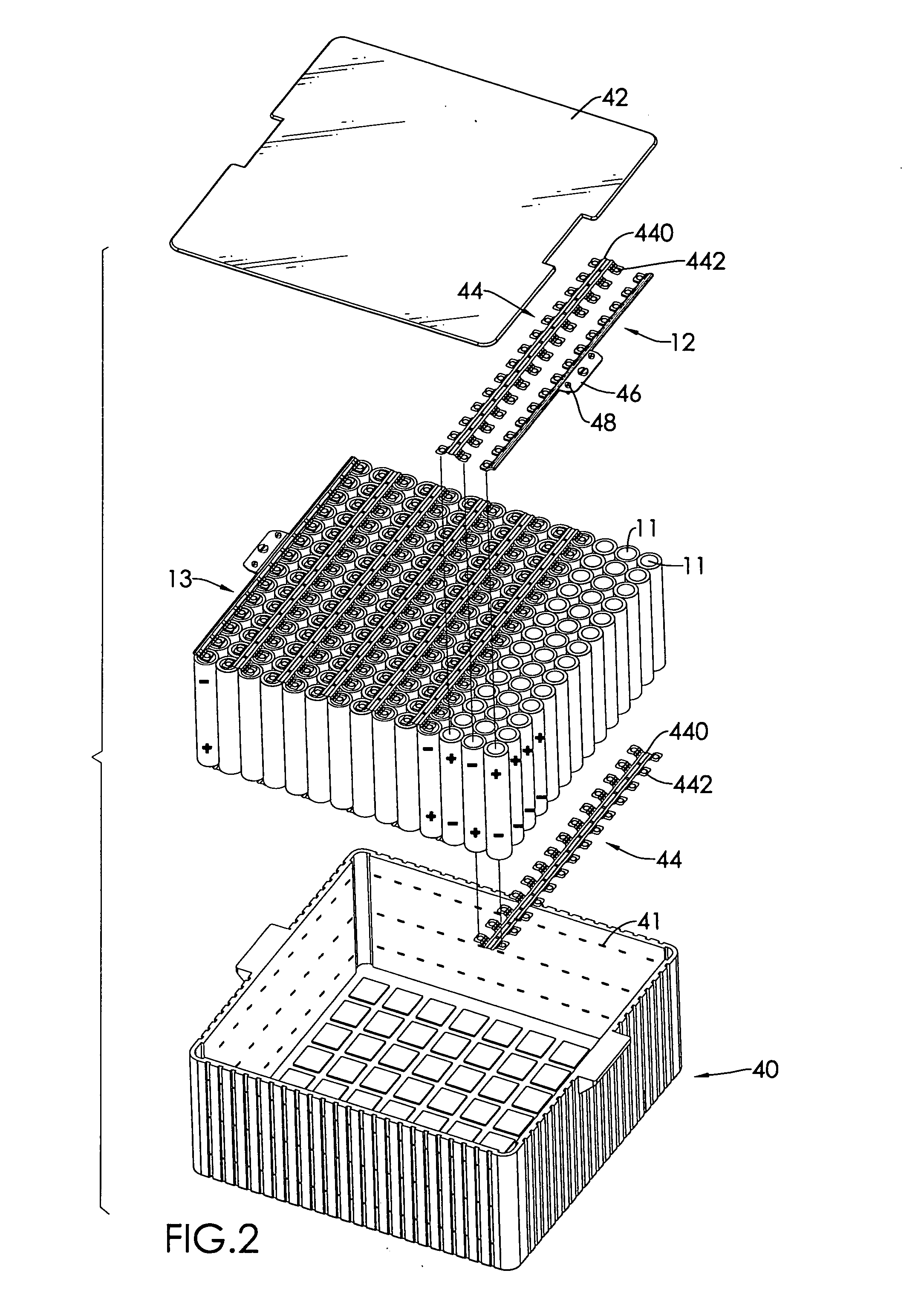

Battery assembly

InactiveUS20060177734A1Easy to produceImprove securityPrimary cell to battery groupingFuel cells groupingElectrical conductorEngineering

A battery pack includes multiple power bus lines connecting a quantity of cell strings in parallel, wherein each cell string includes multiple cells connected in series. The battery pack further has multiple conductors providing electrical communication between the cell strings such that a cell in one cell string is connected in parallel with a cell in other battery strings.

Owner:YAO LI HO

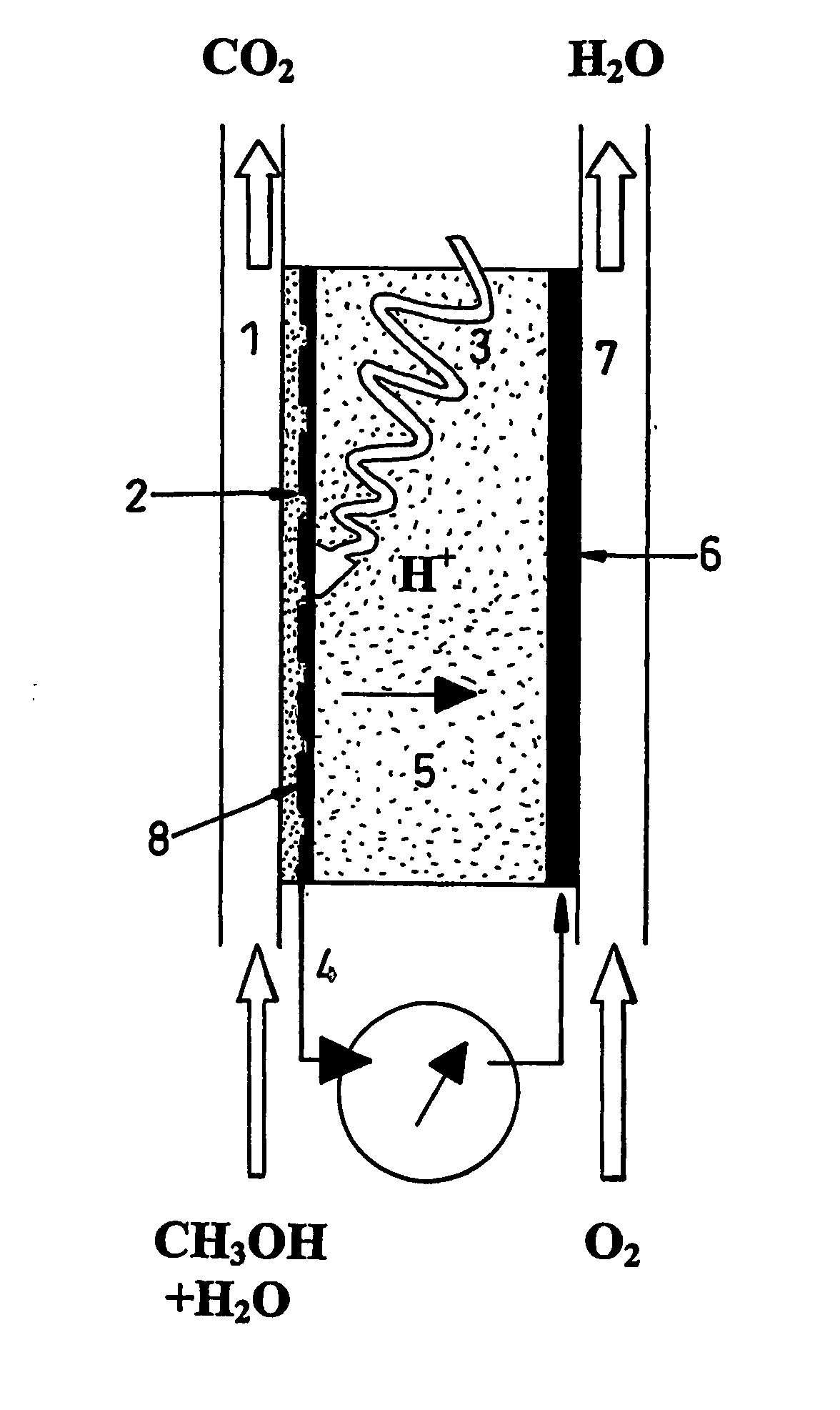

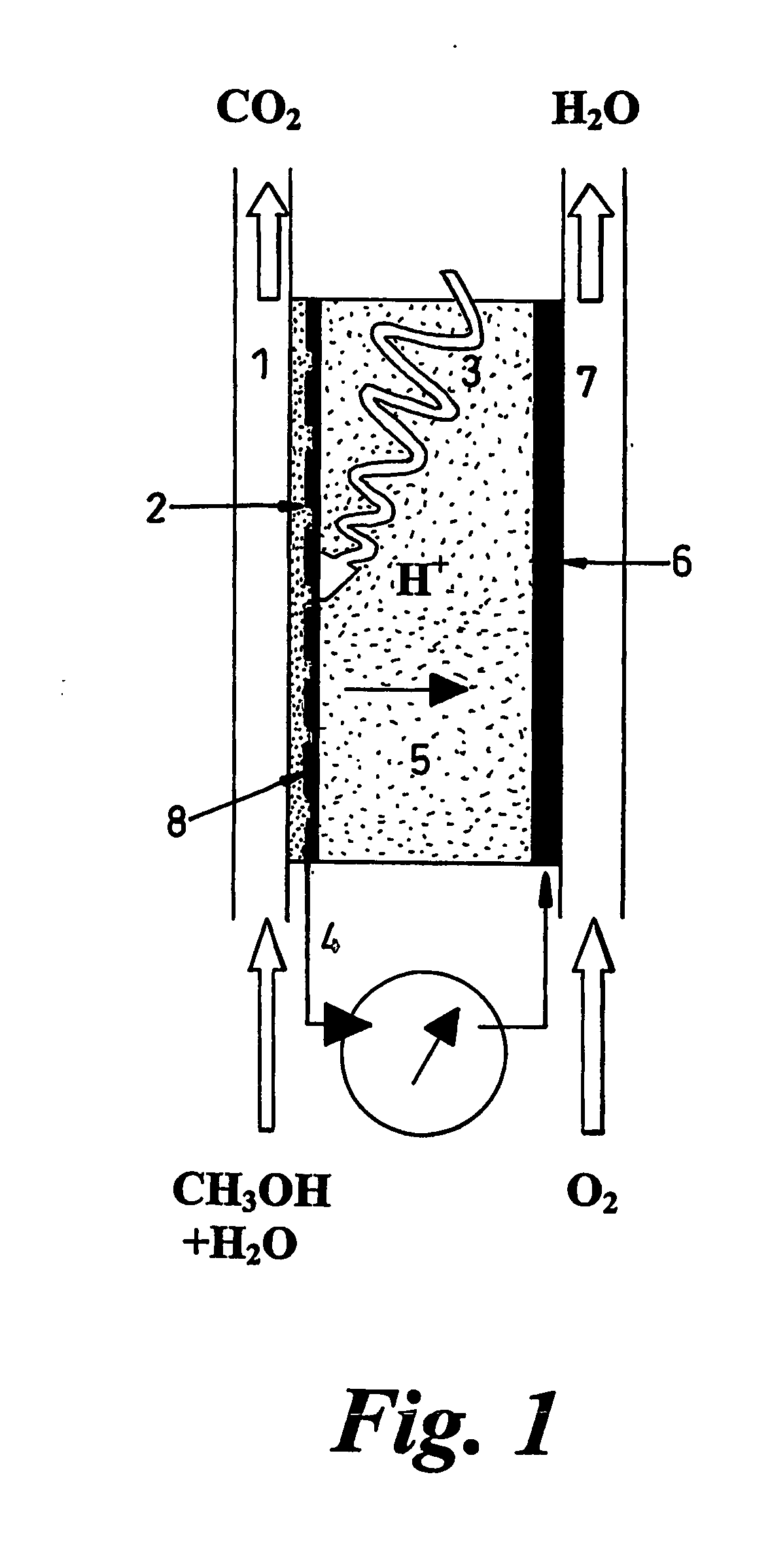

Photo-catalytic reactor

ActiveUS20060246342A1Reduce deliveryEasy to demonstrateDeferred-action cellsFuel cells groupingElectron holePhotocatalytic reaction

A photocatalytic reactor, capable of generating an electric current by consumption of a fuel containing organic material, comprises a direct oxidation fuel cell including an anode and a cathode. The anode is a photocatalysis-assisted anode which comprises a photocatalyst on a surface of an electrically-conductive substrate so arranged as to be receptive to light. A light-transmissive proton-conductive membrane is arranged between the anode and the cathode, such that light passes through said membrane as a final stage in the optical path to the photocatalyst. The photocatalyst promotes oxidation of organic material and generates electron-hole pairs. The reactor, configured to support multiple cells in a stacked array, is provided with inlet(s) for introducing said fuel and connector(s) for connection to an external electrical circuit.

Owner:THE UNIV COURT OF THE UNIV OF ABERDEEN REGENT WALK

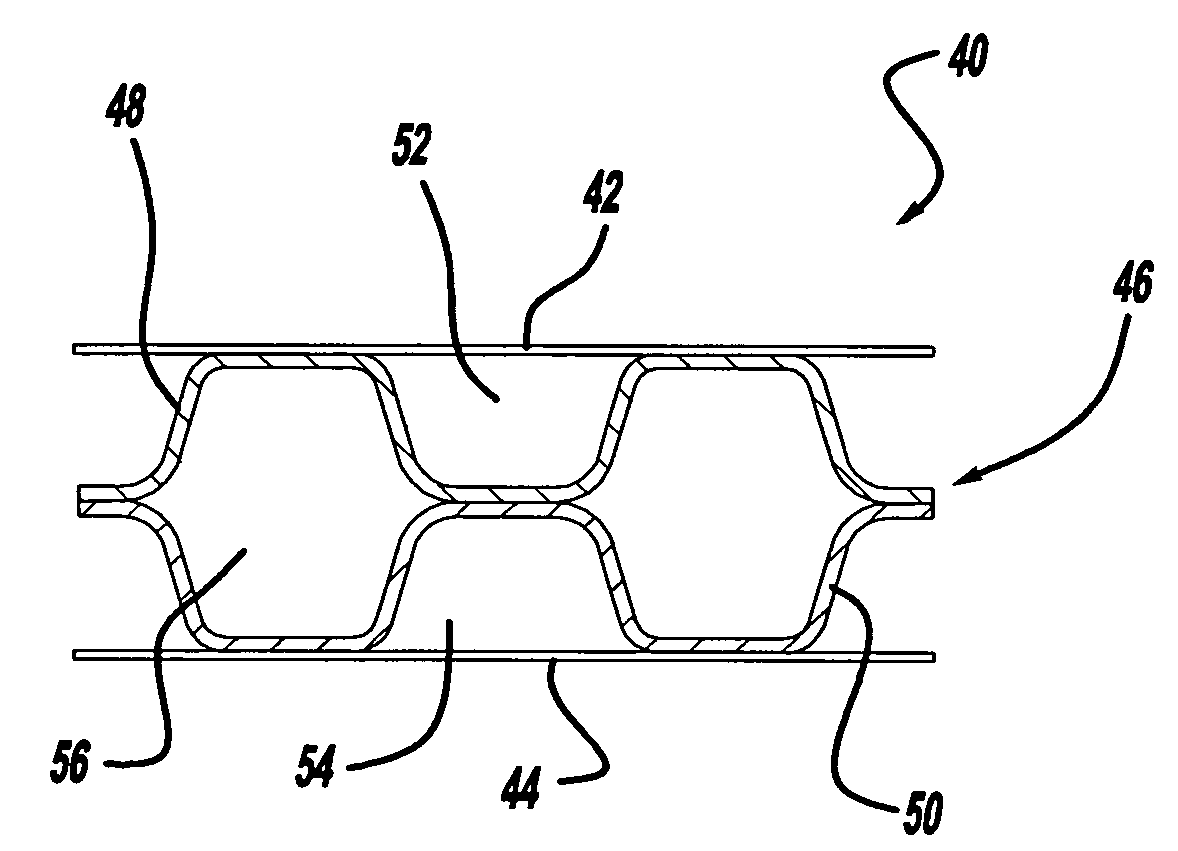

Reactant feed for nested stamped plates for a compact fuel cell

ActiveUS20060127706A1Reduce stack thicknessIncrease distanceFuel cells groupingCell electrodesFuel cellsMedia layer

A fuel cell in a fuel cell stack that provides a transition from nested bipolar plates in the active region of the stack to non-nested bipolar plates in the inactive regions of the stack without giving up the reduced stack thickness provided by the nested plates or changing the size of the flow channels. Particularly, the diffusion media layers in the fuel cells are removed in the inactive regions where the bipolar plates are non-nested so that the volume necessary to maintain the size of the flow channels is provided without the need to increase the distance between adjacent MEAs. A thin shim can be provided between the membranes and the plates in the inactive regions to support the membrane where the diffusion media layer has been removed to prevent the membrane from intruding into the flow channels and blocking the reactive flow.

Owner:GM GLOBAL TECH OPERATIONS LLC

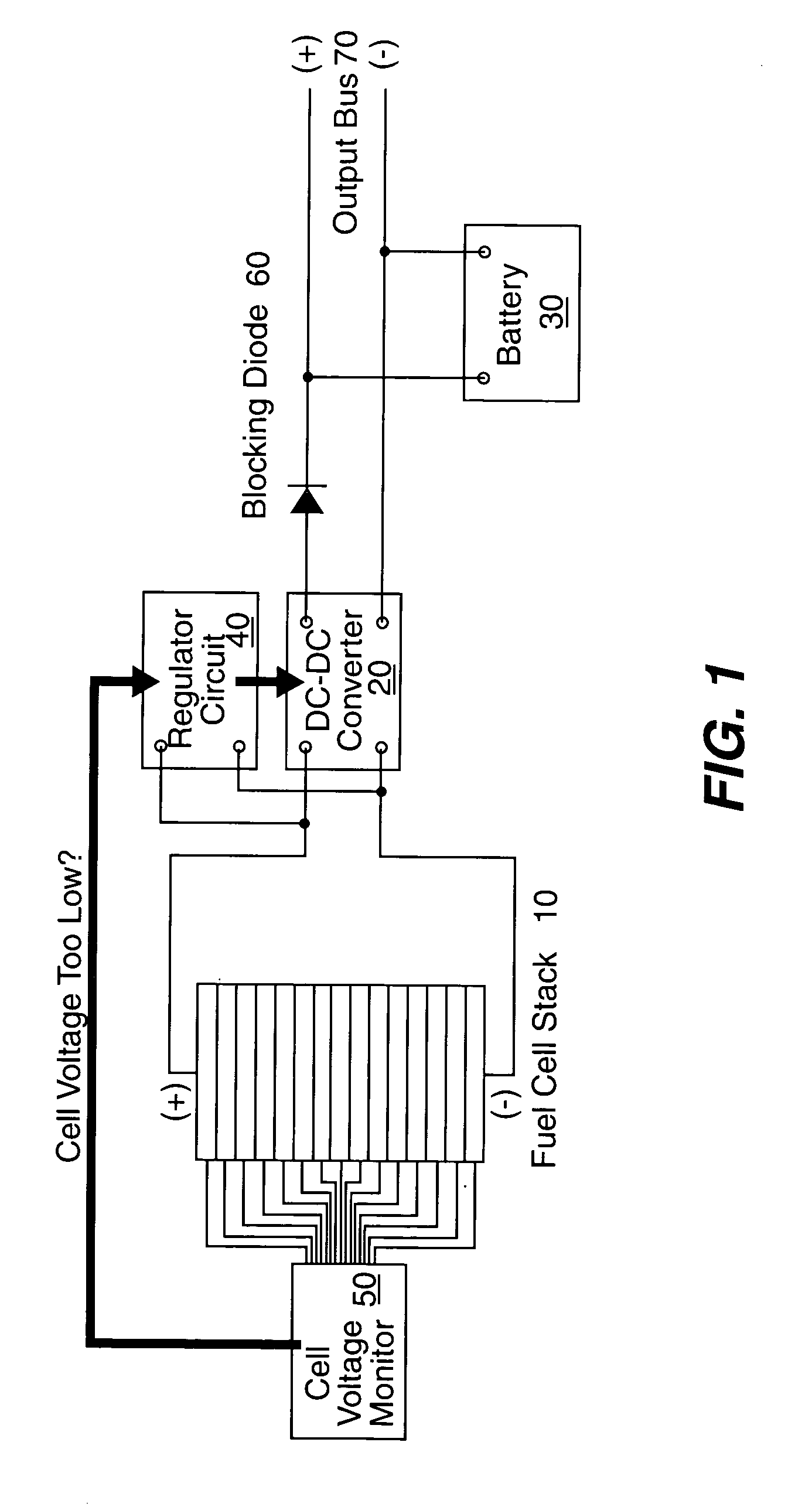

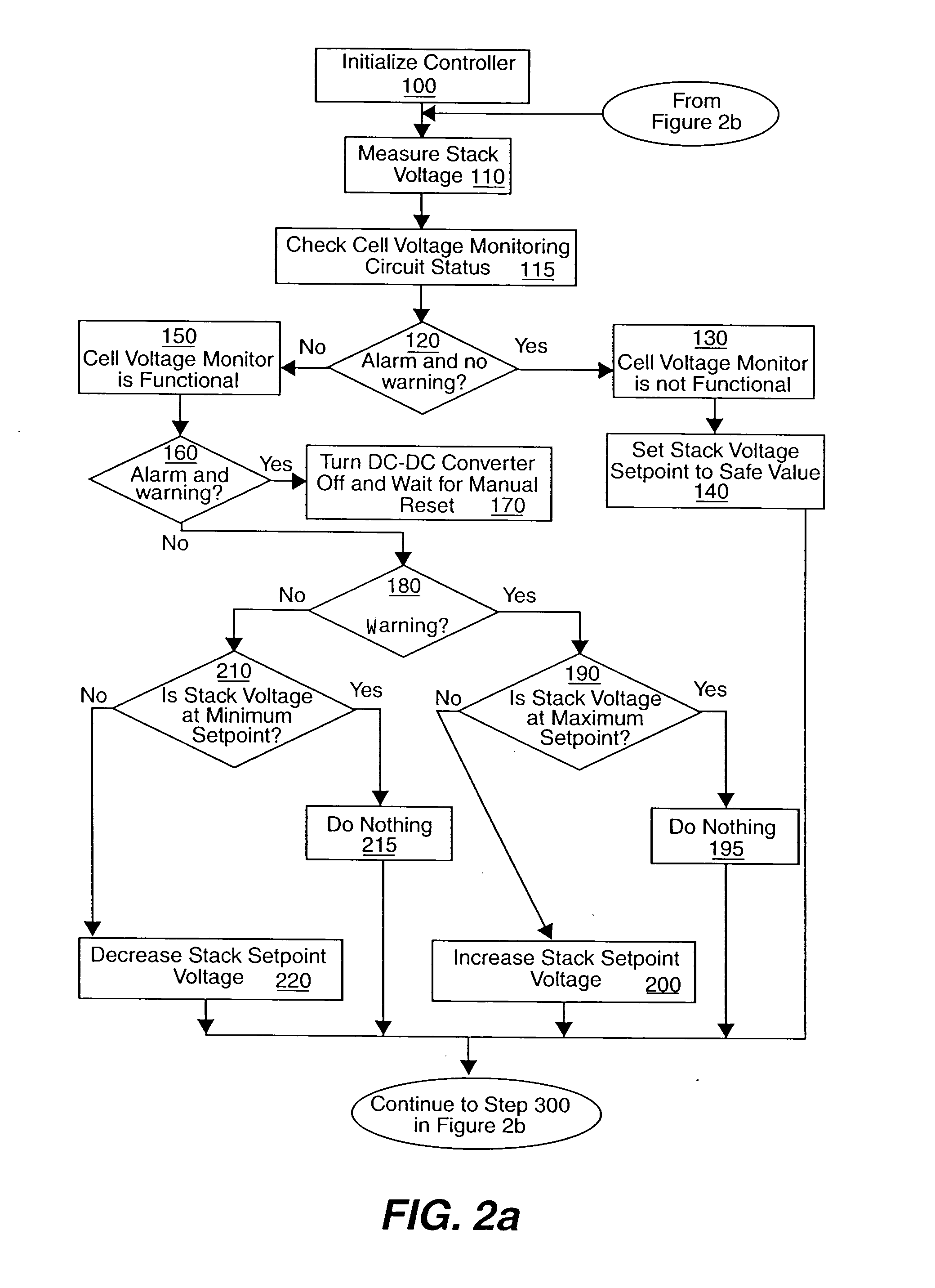

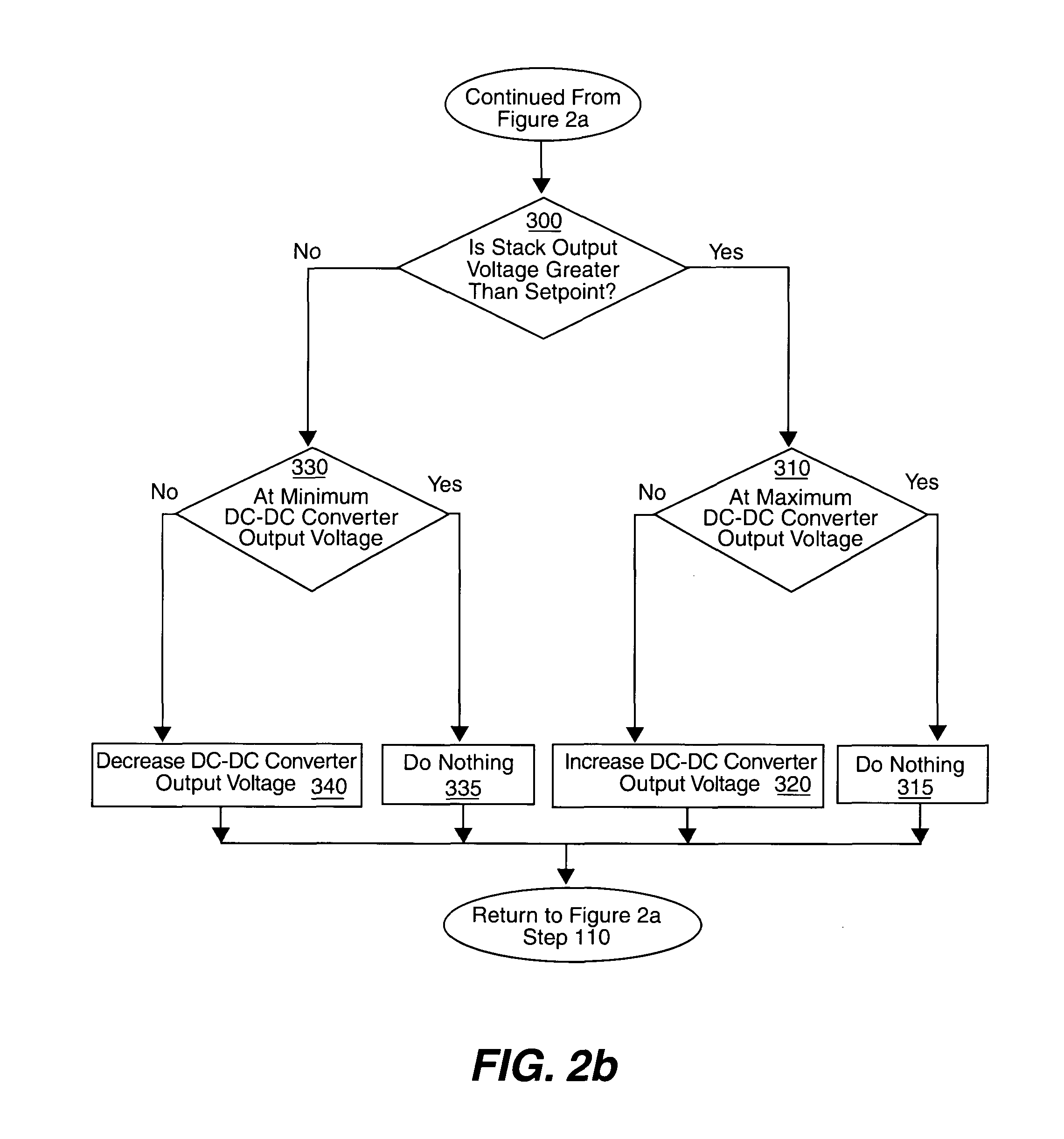

Apparatus and method for regulating hybrid fuel cell power system output

An apparatus and accompanying method for controlling a fuel cell power system having a fuel cell stack with a connected energy storage medium. A voltage monitoring circuit is connected to the individual fuel cells forming a fuel cell stack. A regulating circuit receives signals from the voltage monitoring circuit and outputs a control signal to a DC-DC converter connected between the fuel cell stack and an output bus and energy storage medium. The regulating circuit controls the DC-DC converter voltage output to a maximum power that the fuel cell stack can provide.

Owner:LOS ALAMOS NATIONAL SECURITY

Device for cooling a vehicle battery

InactiveUS20110132580A1Effective and reliable coolingImprove pressure resistanceFuel cell heat exchangeThermal insulationElectricityElectrical battery

A device for cooling a vehicle battery is provided that includes a plurality of electrical storage elements, and a cooling element having ducts for a fluid to flow through, wherein the electrical storage elements are in thermal contact with the cooling elements and heat can be transmitted from the storage elements to the fluid, and wherein the cooling element which comprises the ducts is embodied as at least one extruded profile.

Owner:BEHR GMBH & CO KG

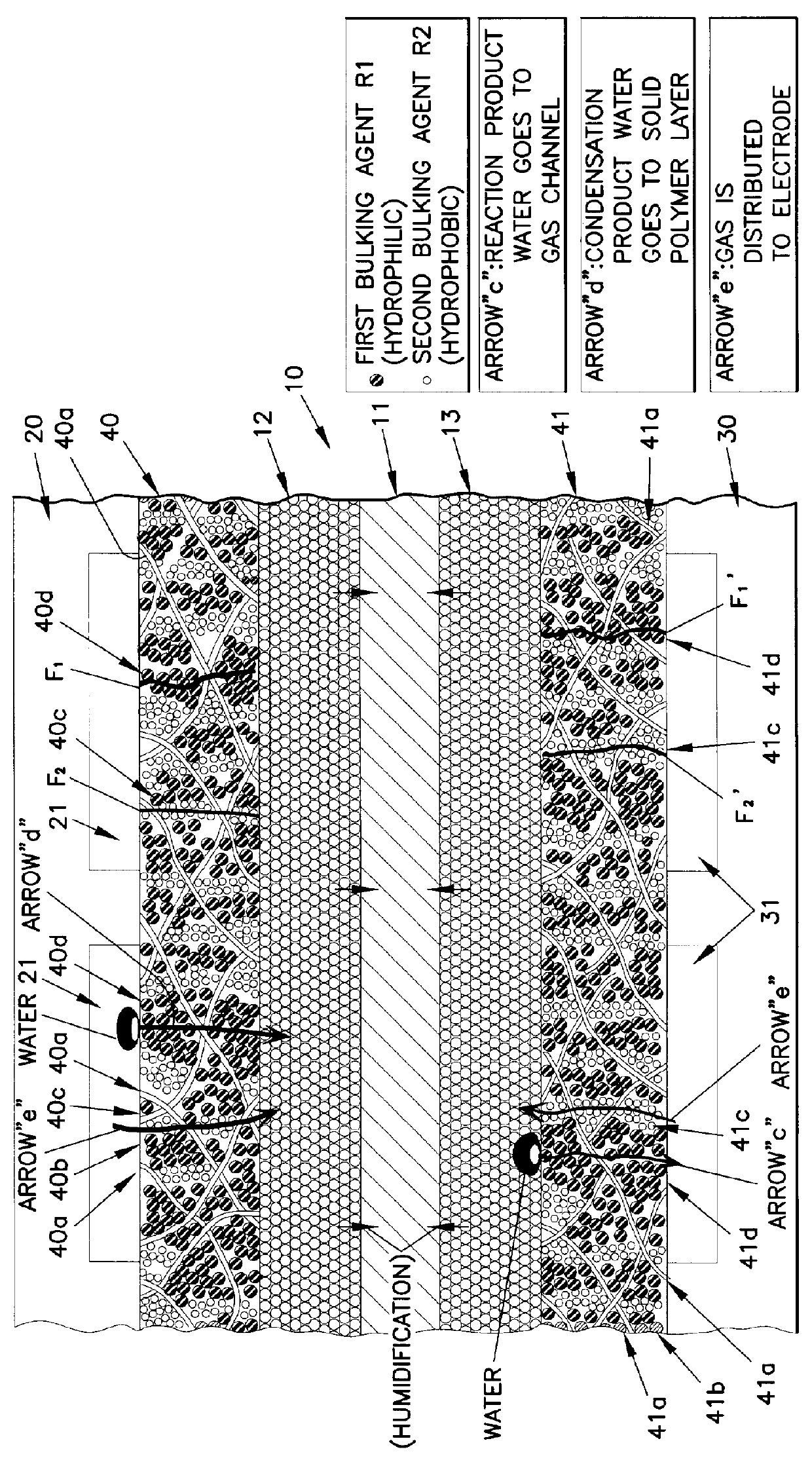

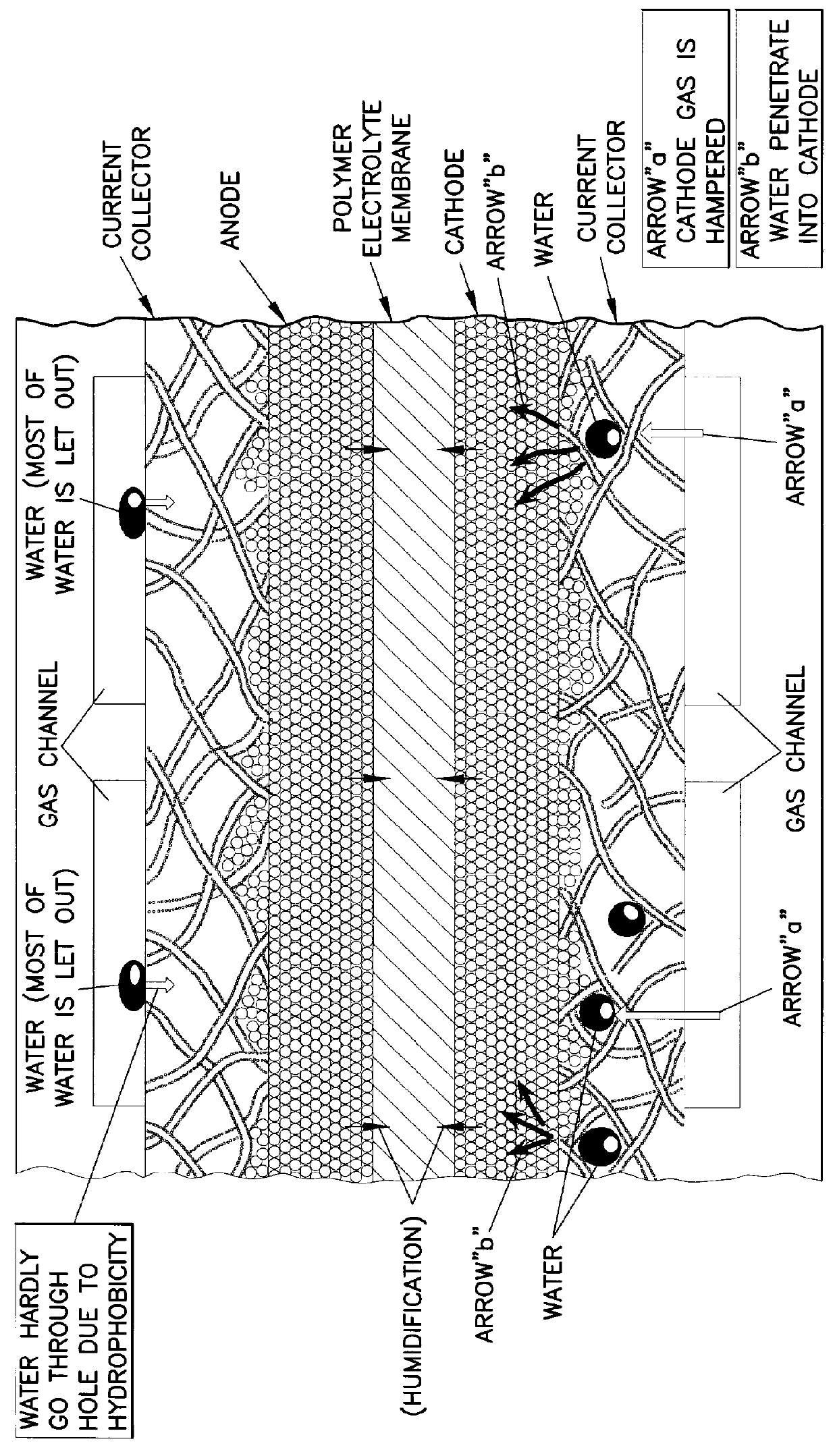

Fuel cell

InactiveUS6083638AEfficient humidificationSolid electrolytesFuel cells groupingPorous substratePolymer electrolytes

A current collector includes a thin porous substrate and a hydrophilic material, where the hydrophilic material is provided to holes of the thin porous substrate or surfaces of skeleton elements of the porous substrate so that hydrophilic areas formed by the hydrophilic material successively pass through the thin porous substrate between both surfaces of the thin porous substrate. In the current collector, water is let out through the hydrophilic areas and does not stay on an interface between an electrode and the current collector so that reaction gas is not hampered and is supplied, unlike a conventional current collector. When the current collector is applied to a polymer electrolyte fuel cell, water is supplied with reliability through the hydrophilic areas to a polymer electrolyte membrane so that the polymer electrolyte membrane is effectively humidified. The current collector applied to a cathode achieves a profound effect because reaction product water tends to stay around a cathode of any types of fuel cells. The current collector also includes gas flow paths which are surrounded by particles of a hydrophobic material and pass through the thin porous substrate between both surfaces of the thin porous substrate. As a result, gas permeability of the current collector is maintained with reliability.

Owner:SANYO ELECTRIC CO LTD

Manclaw-Harrison fuel cell

The Manclaw-Harrison Fuel Cell is a new Environmentally SAFE Fuel Cell (Lead Free, Acid Free, Mercury Free and has No Heavy Metals), and as such, it sets the definition of a new Class of Fuel Cell device because it has been verified to be a Non-Faraday device, making it the first such device discovered in the past 160+ years. See the “Preamble” for a more technical explanation.

Owner:MANCLAW RONALD R +1

Common Module Stack Component Design

A stack for use in a flow battery, the stack comprising an odd number of interior elements positioned between two end elements, the two end elements each including an electrode, and the odd number of interior elements including membrane elements alternating with electrode elements, wherein the membrane elements include an interior frame and a membrane, the electrode elements include the interior frame and an electrode, wherein the interior frame is rotated by 180° from the frame of the membrane elements.

Owner:IMERGY POWER SYST

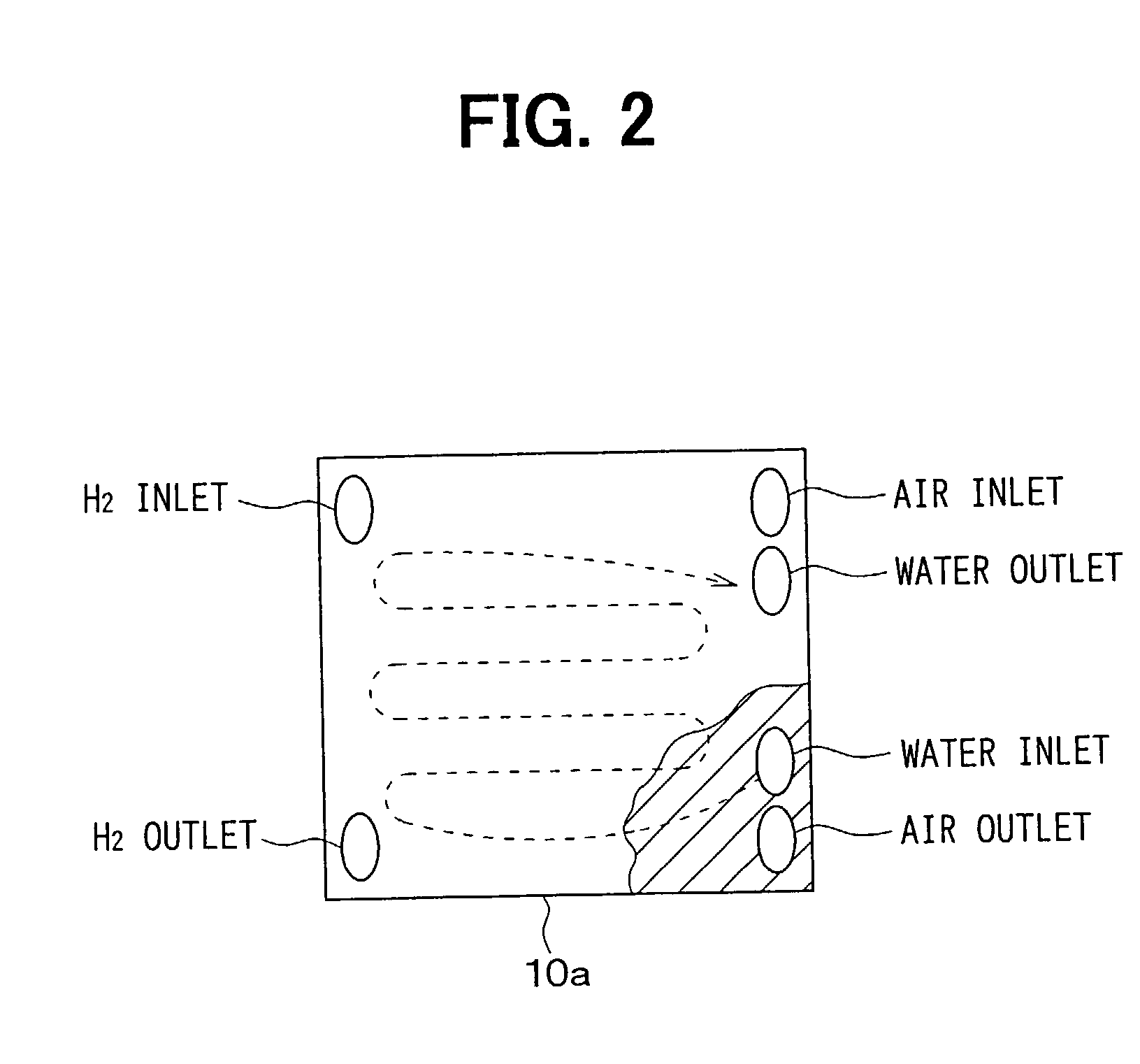

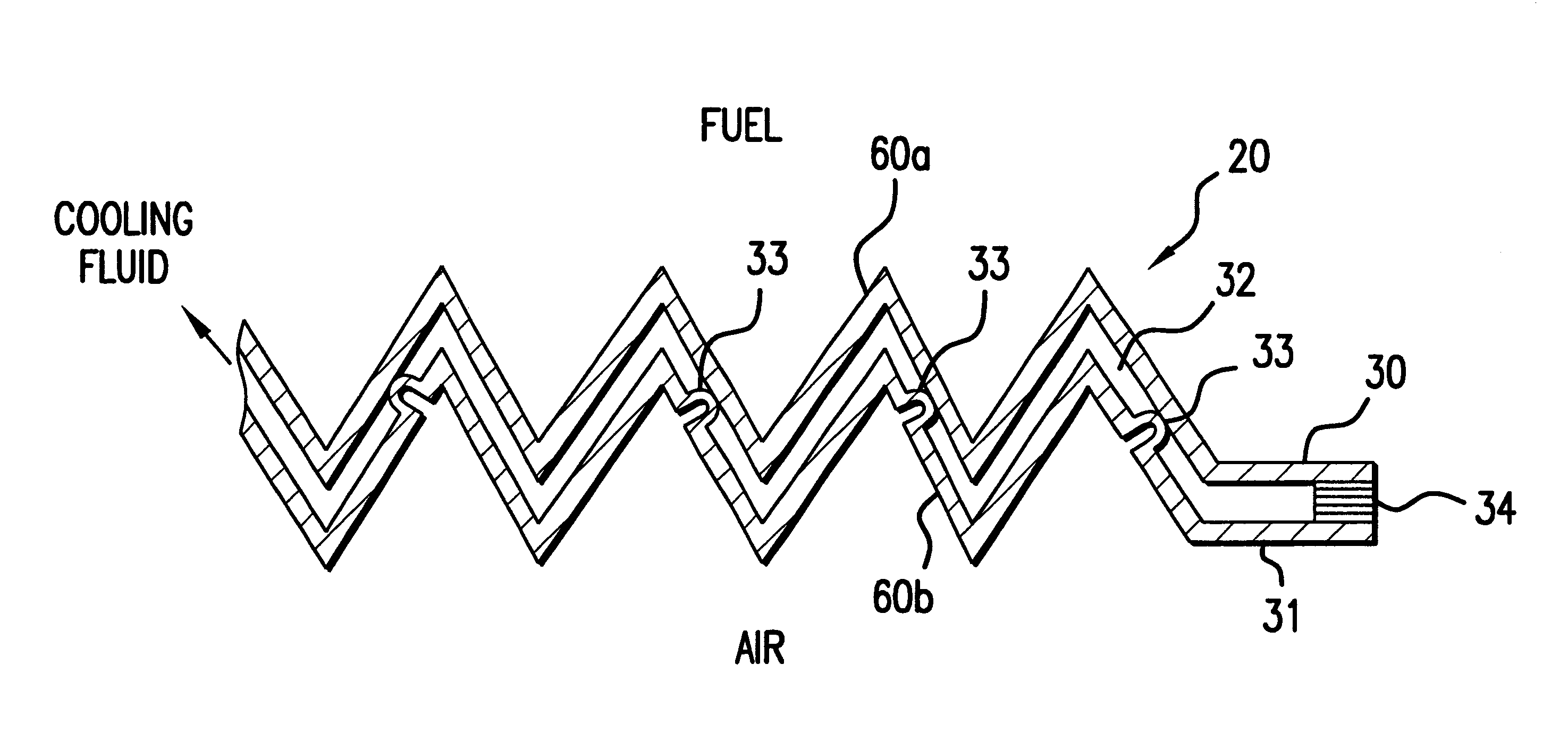

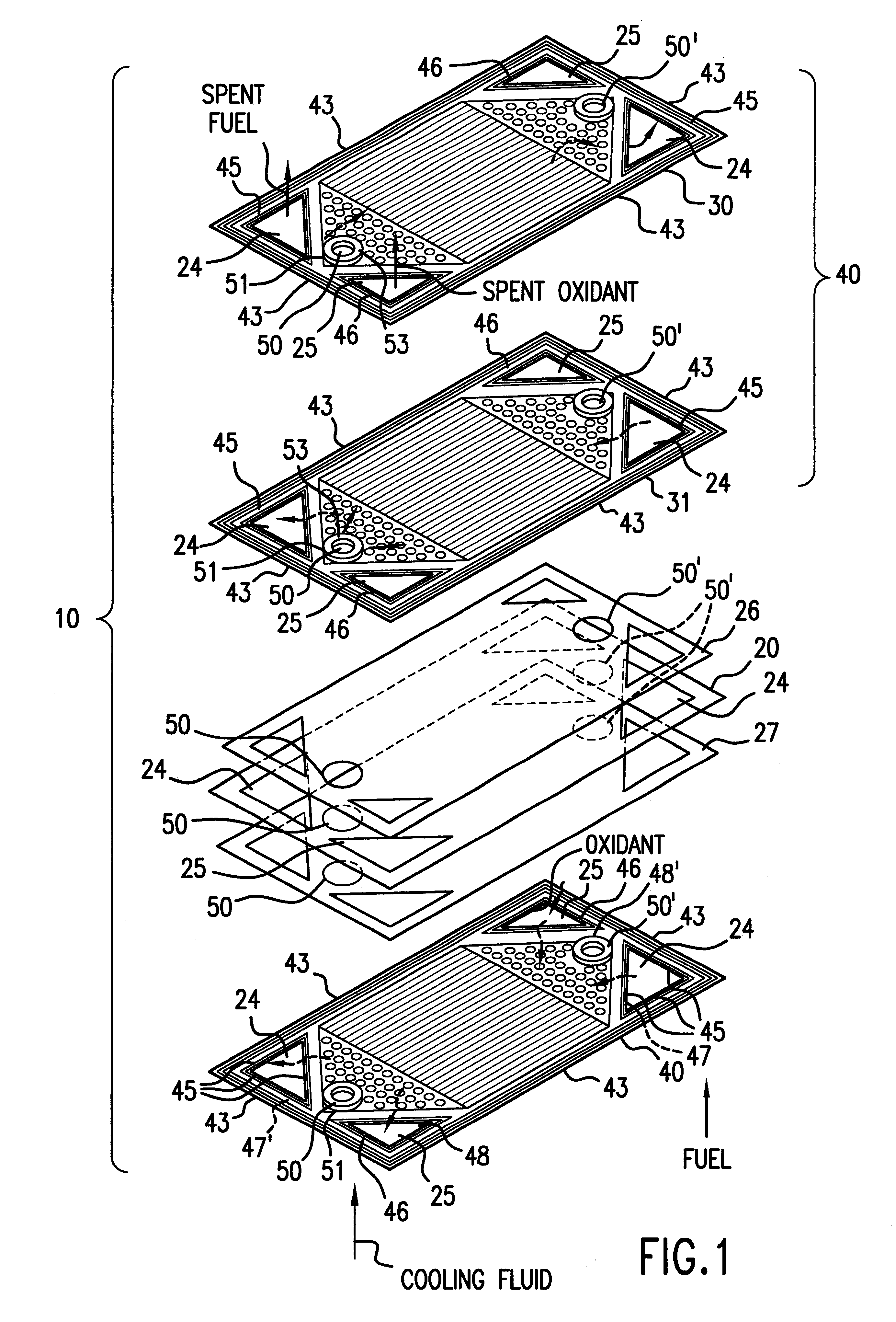

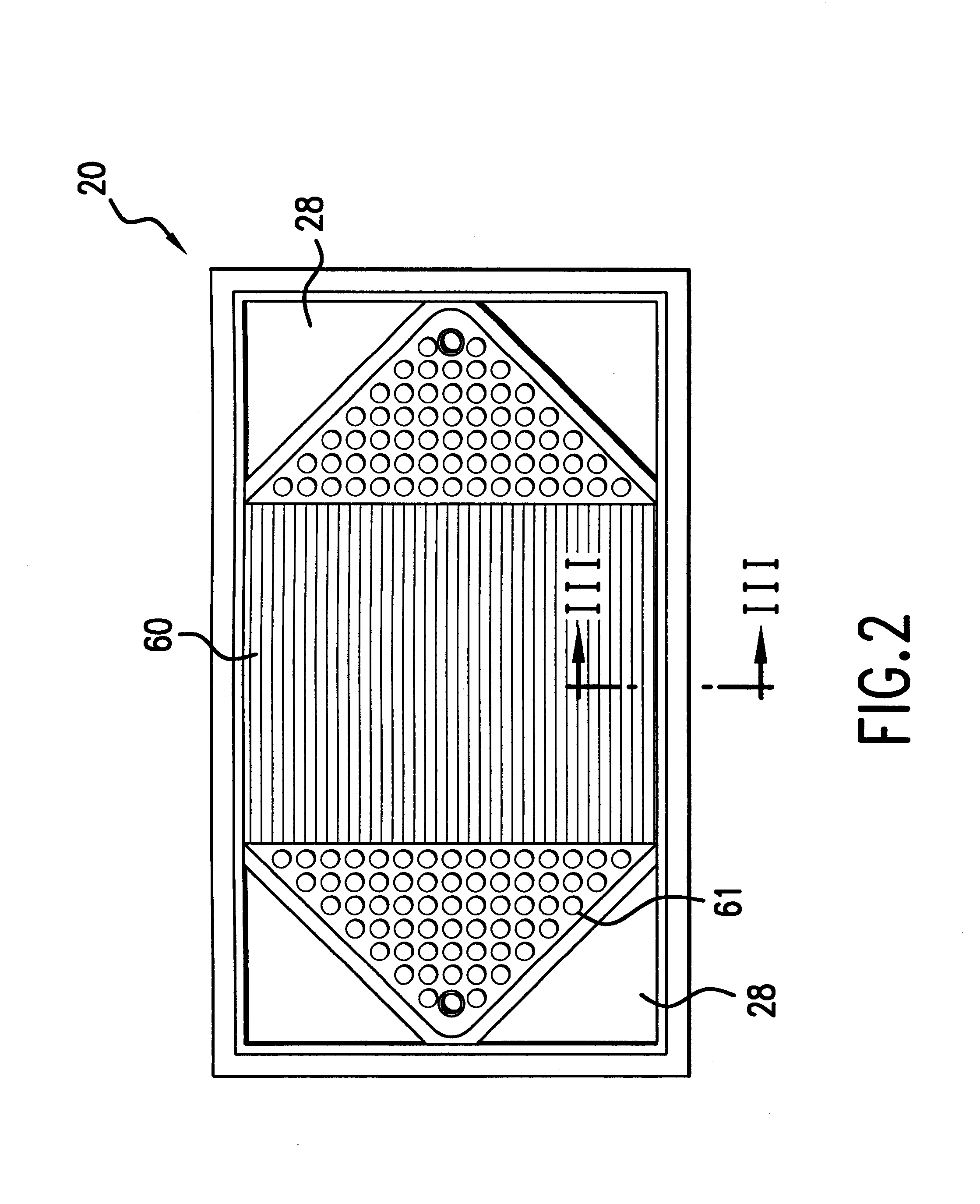

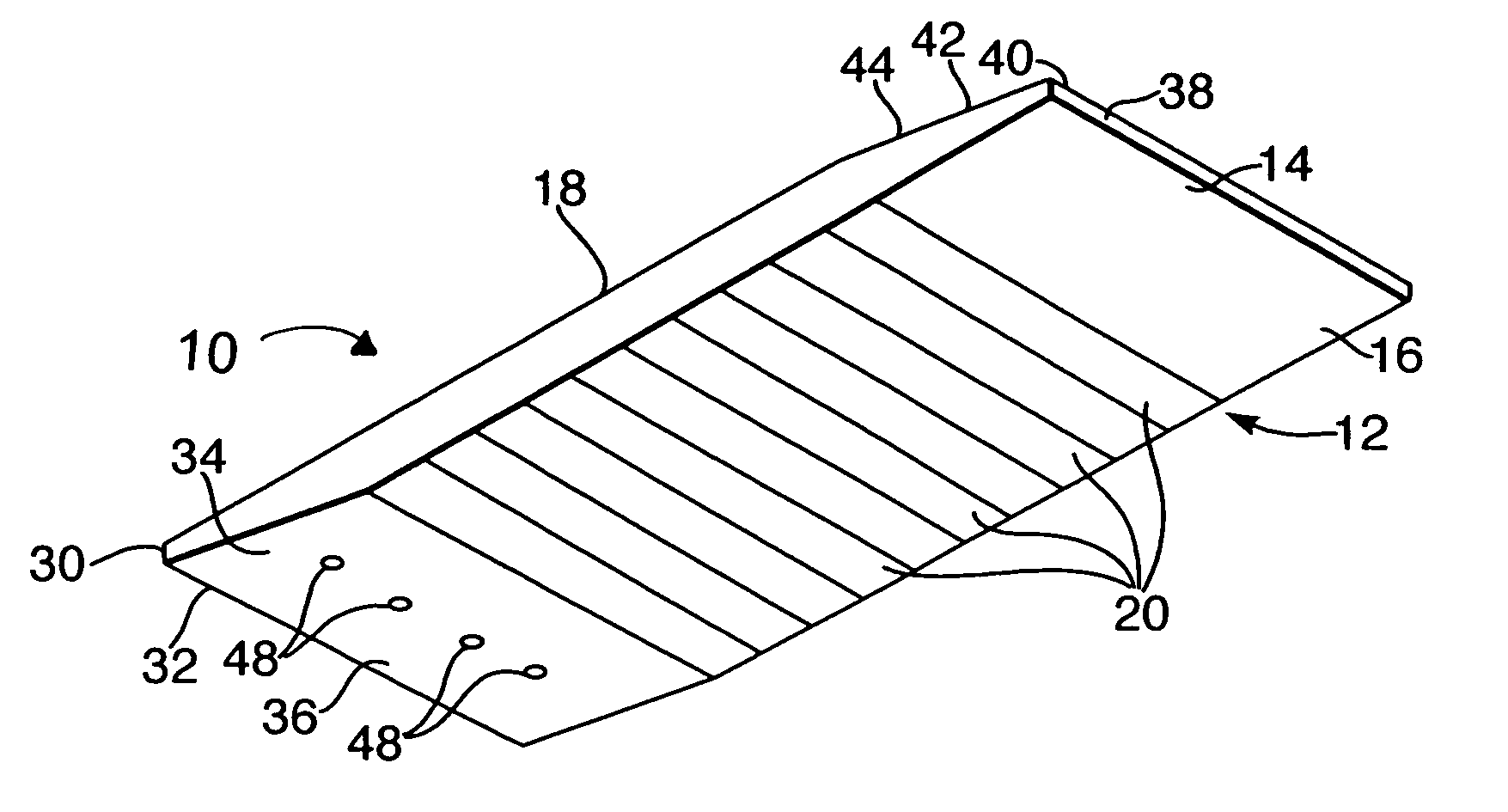

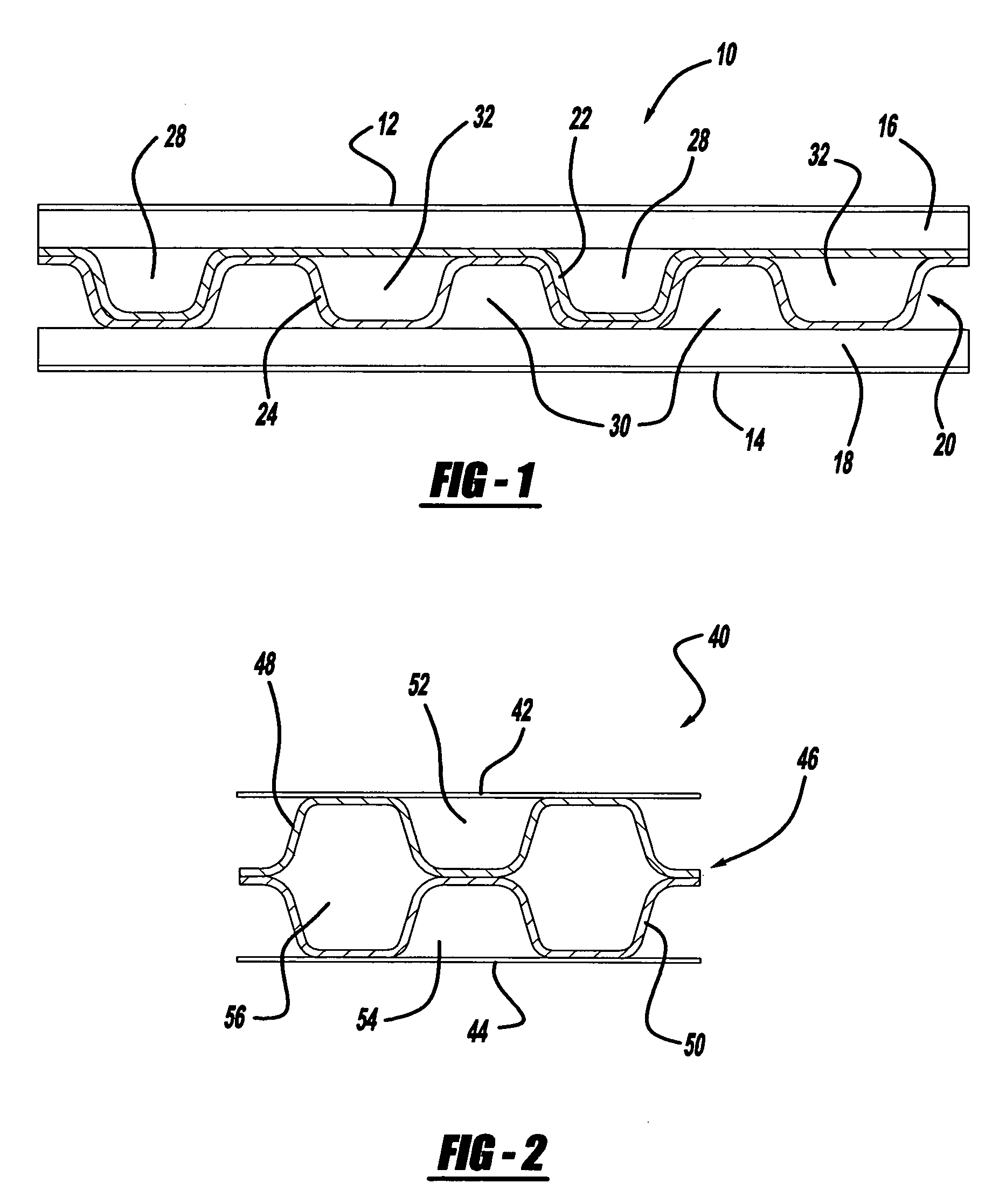

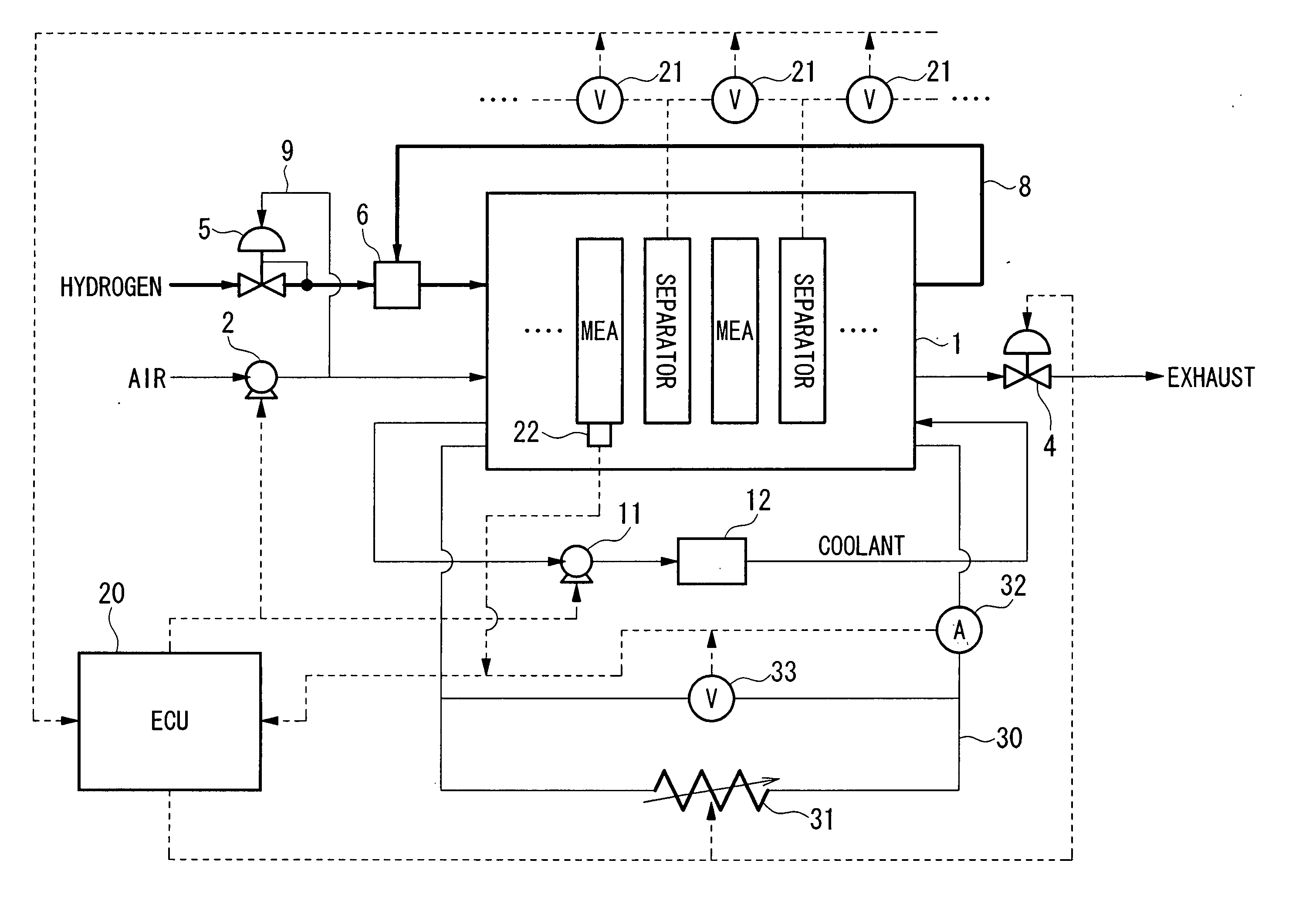

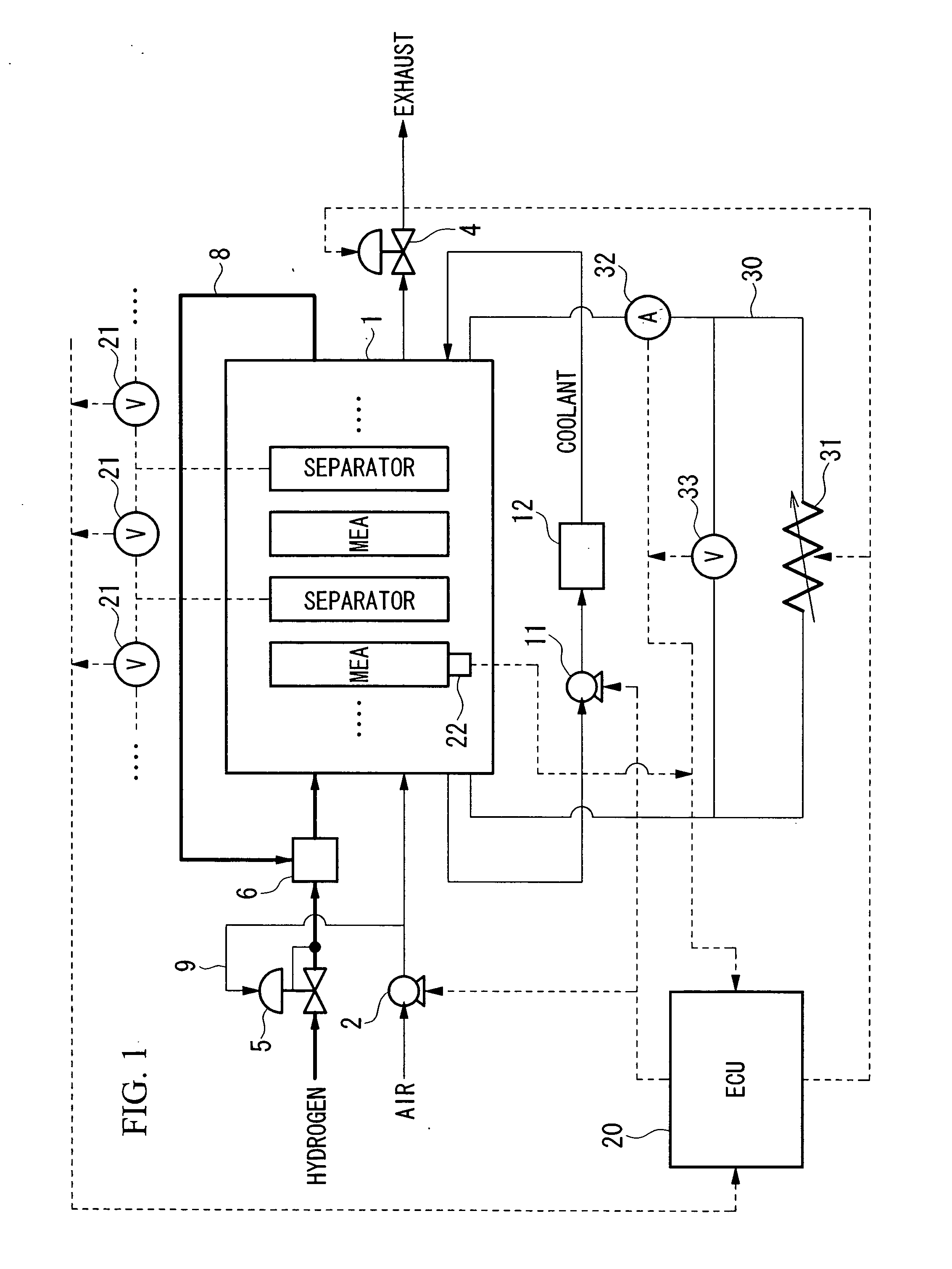

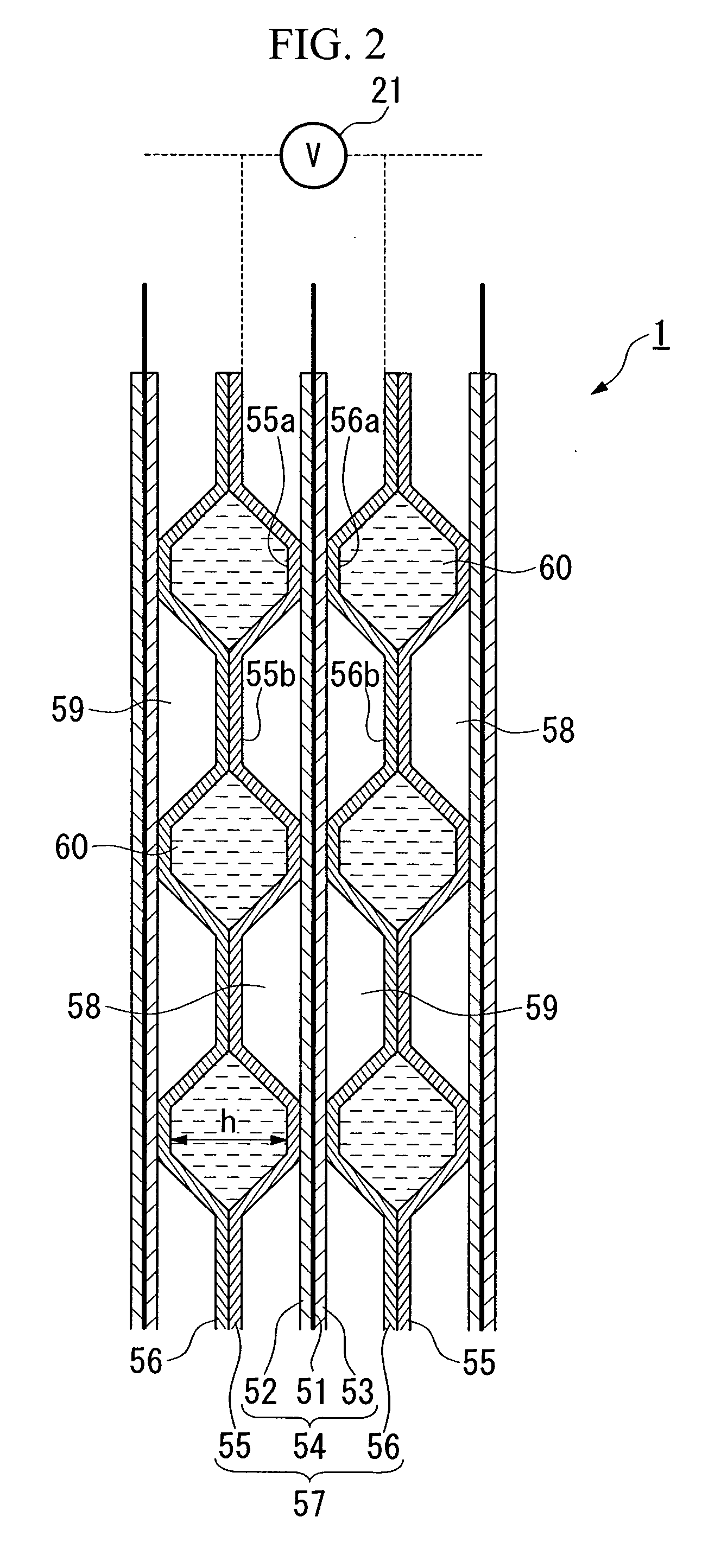

Method and system for starting up fuel cell stack at subzero temperatures, and method of designing fuel cell stack

InactiveUS20050053810A1Shorten warm-up timeSmall heat capacityFuel cells groupingFuel cell auxillariesPolymer electrolytesFuel cells

A method of starting up at a subzero temperature a solid polymer electrolyte fuel cell stack that is formed by stacking a plurality of layers of separators and membrane electrode assemblies having a solid polymer electrolyte membrane and electrodes. The method includes a step of using a solid polymer electrolyte fuel cell stack in which the separators are made from metal and have a cross-sectional waveform structure, and a space that is formed between at least a portion of the separators and separators that are placed adjacent to this portion of the separators is used as a coolant flow passage.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com