Patents

Literature

895 results about "Plenum chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A plenum chamber is a pressurised housing containing a fluid (typically air) at positive pressure. One function of the plenum is to equalise pressure for more even distribution, because of irregular supply or demand. Typically a plenum is relatively large in volume and thus has relatively low velocity (compared to other components of a system). In a wind tunnels, rockets, and many flow applications - the plenum is a chamber upstream on the fluid flow where the fluid initially resides (approximately at rest). A plenum chamber can also work as an acoustic silencer device.

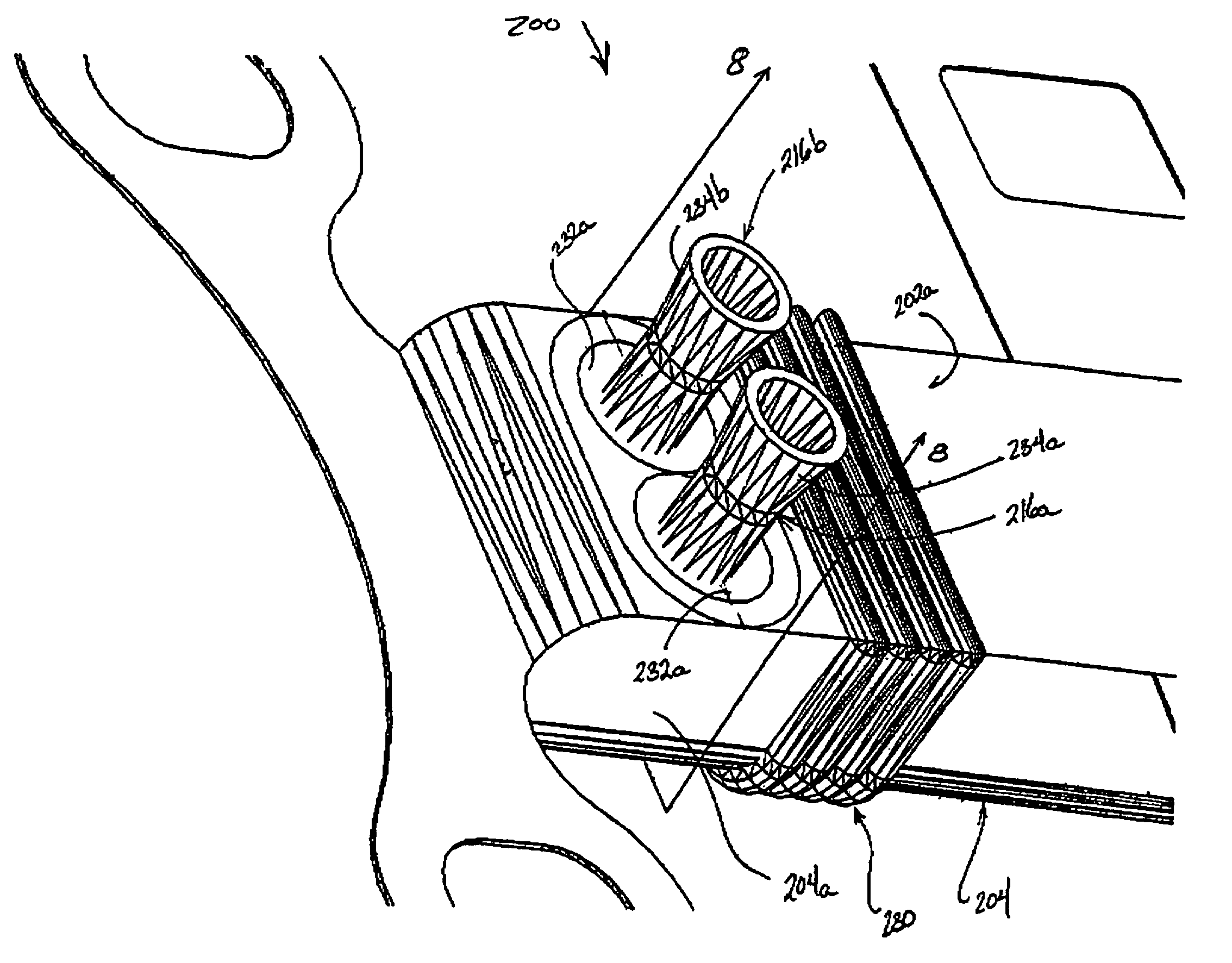

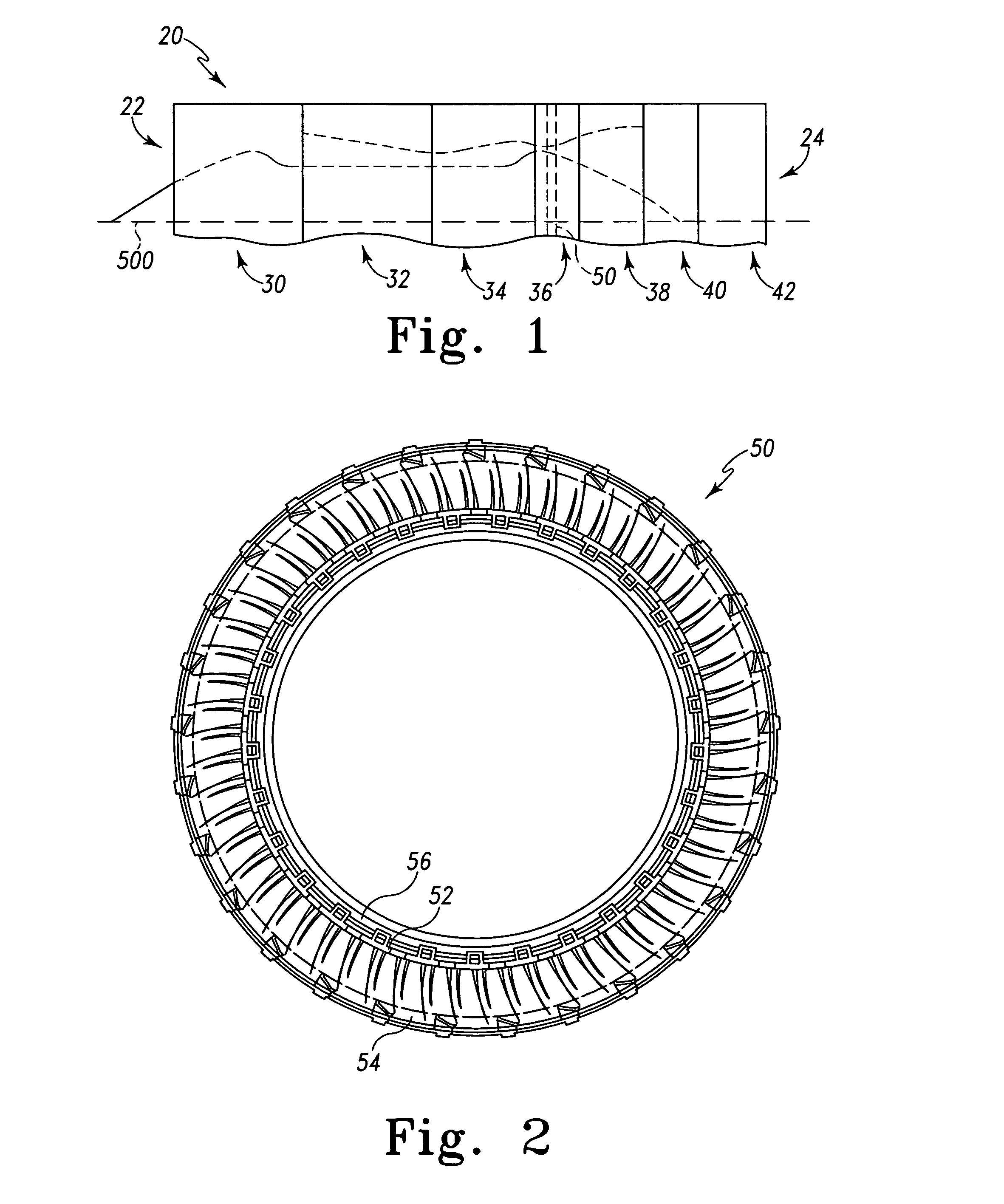

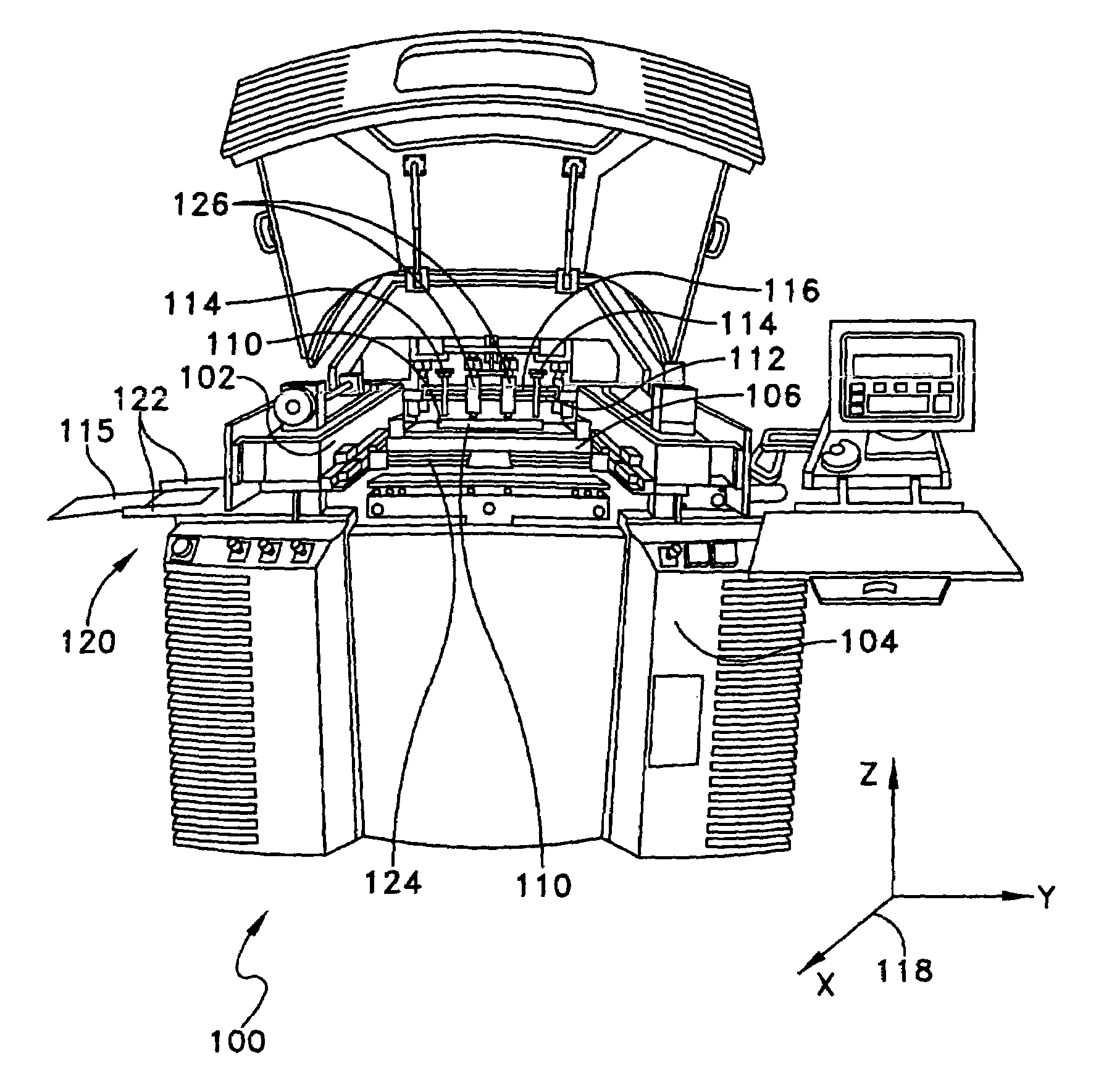

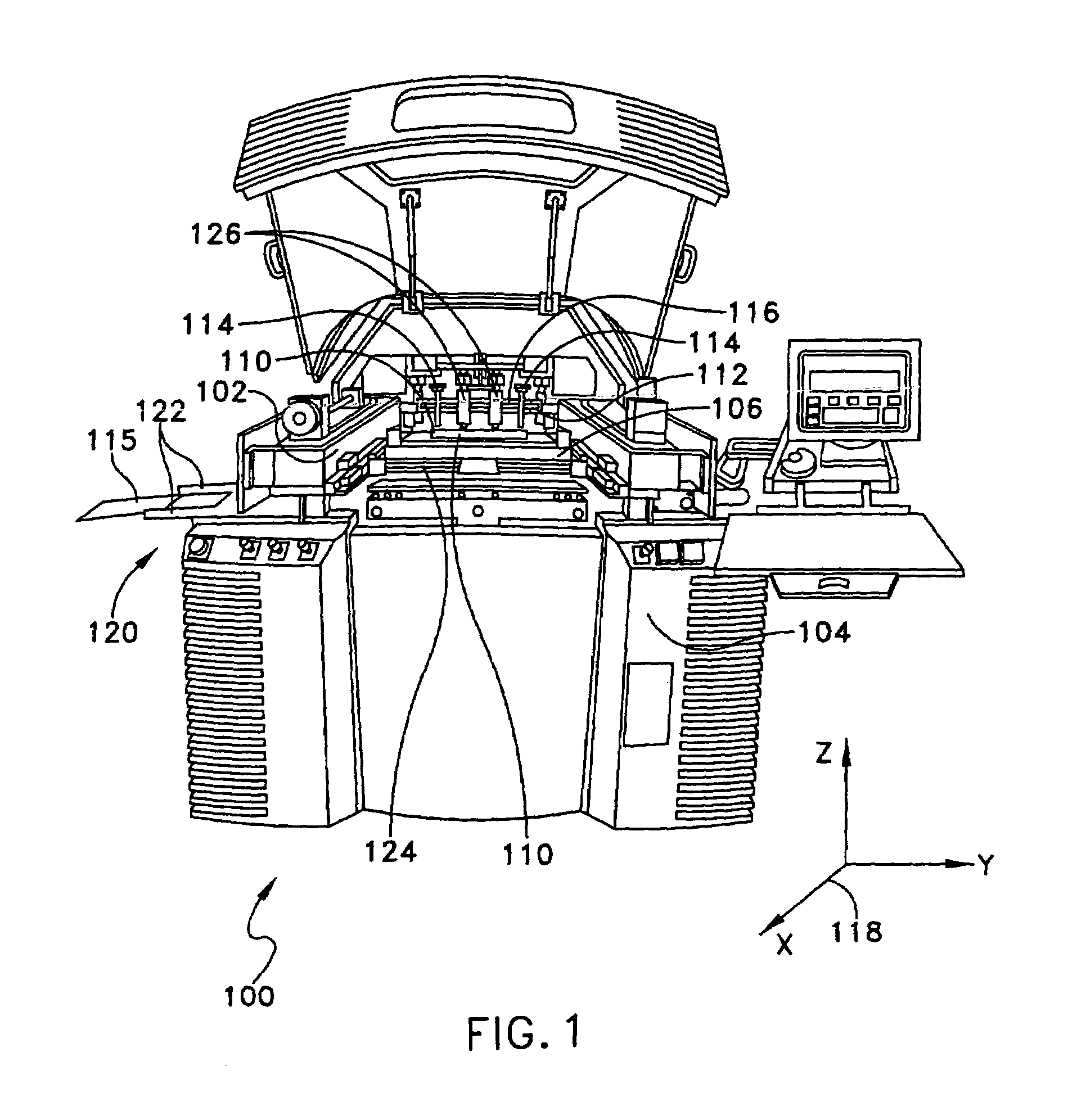

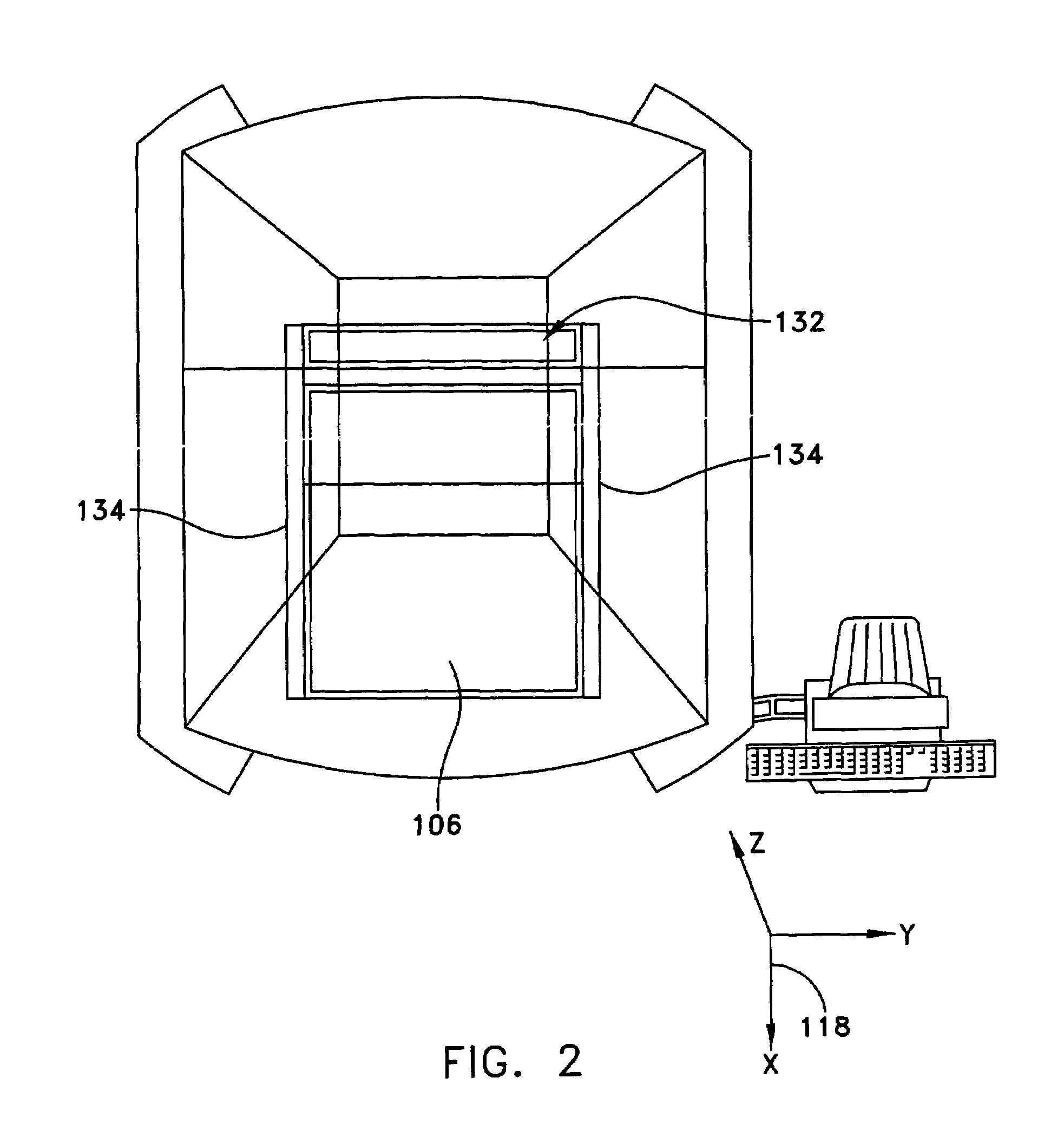

Method of and apparatus for tunable gas injection in a plasma processing system

InactiveUS6872259B2Control expansionElectric discharge tubesSemiconductor/solid-state device manufacturingElectronic communicationProduct gas

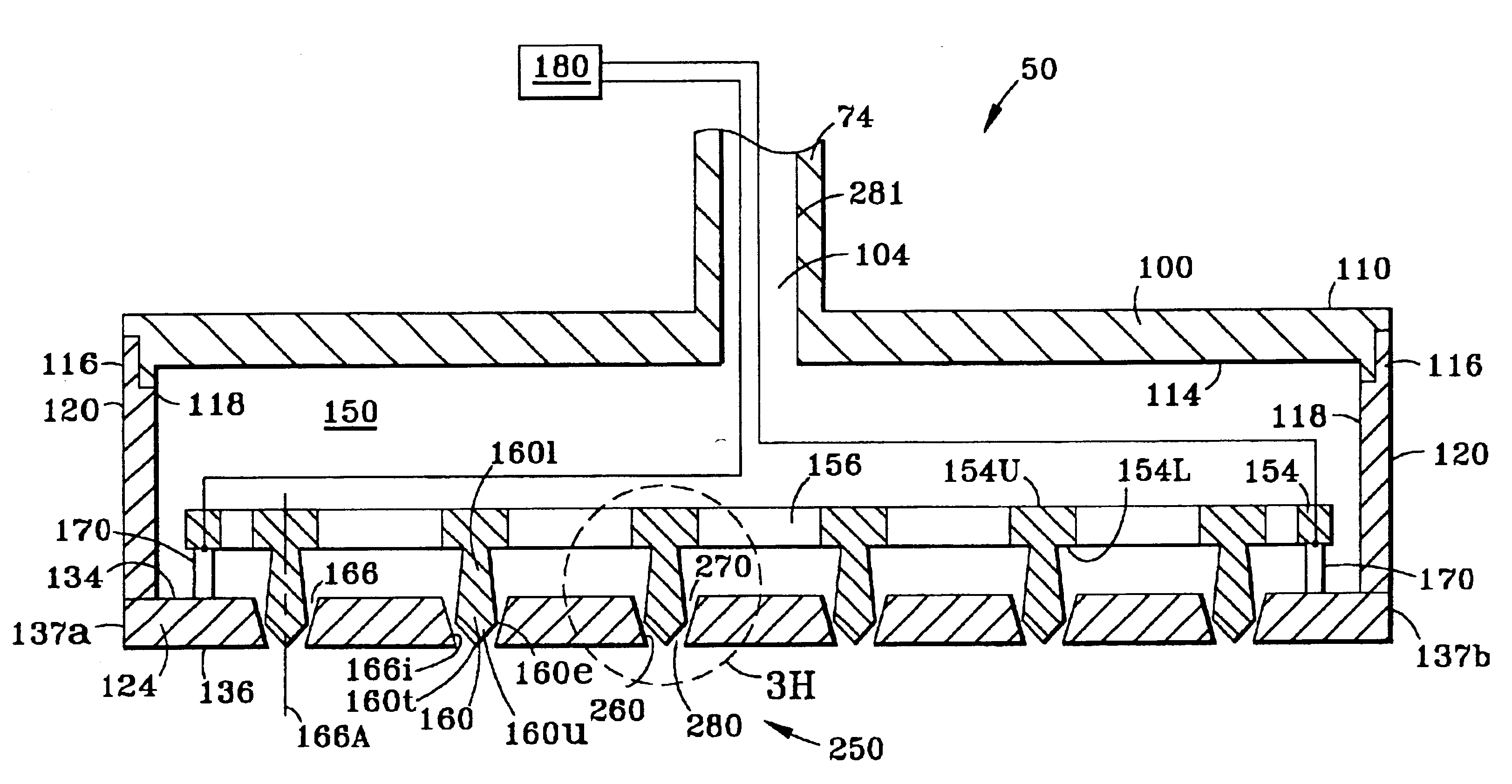

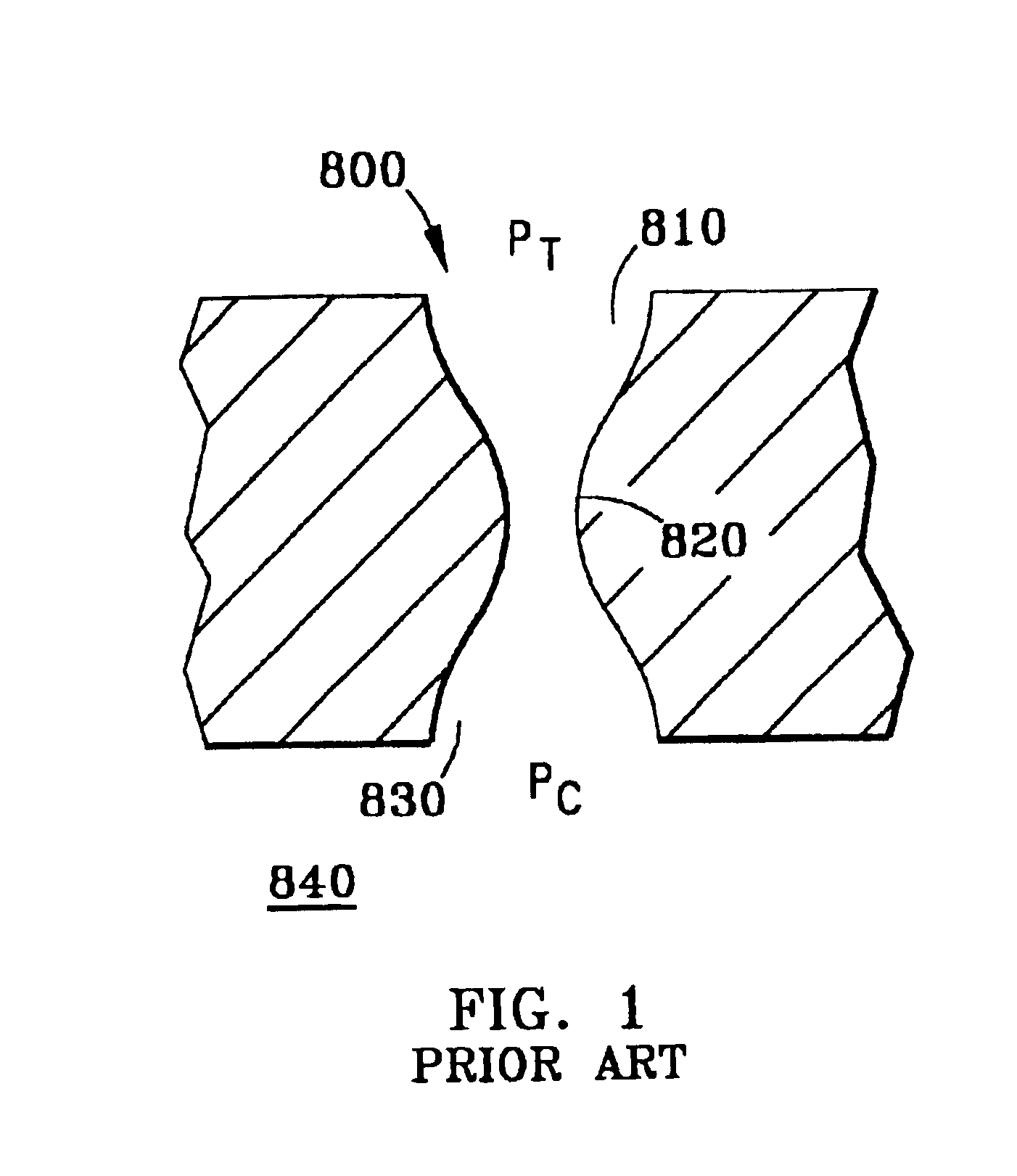

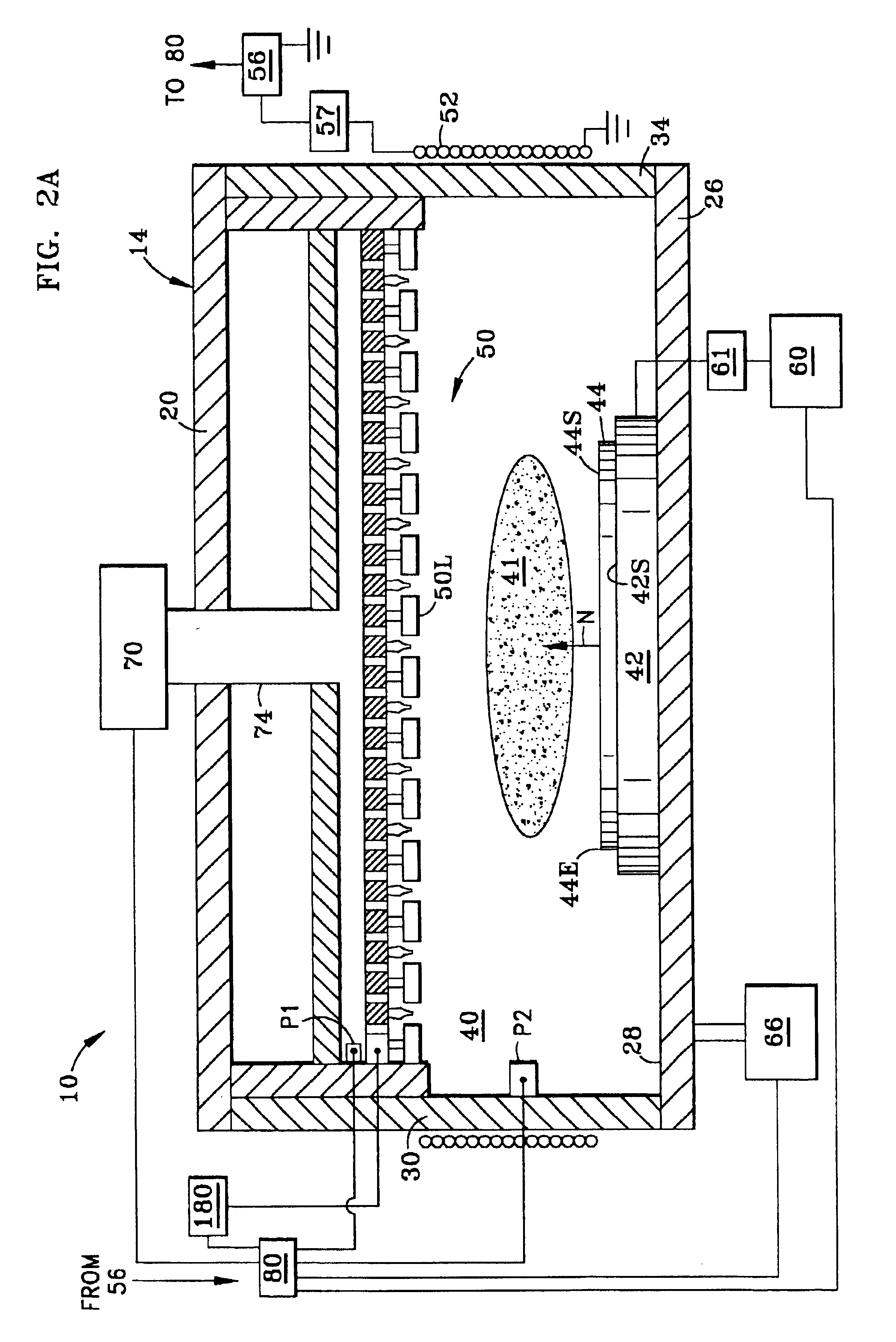

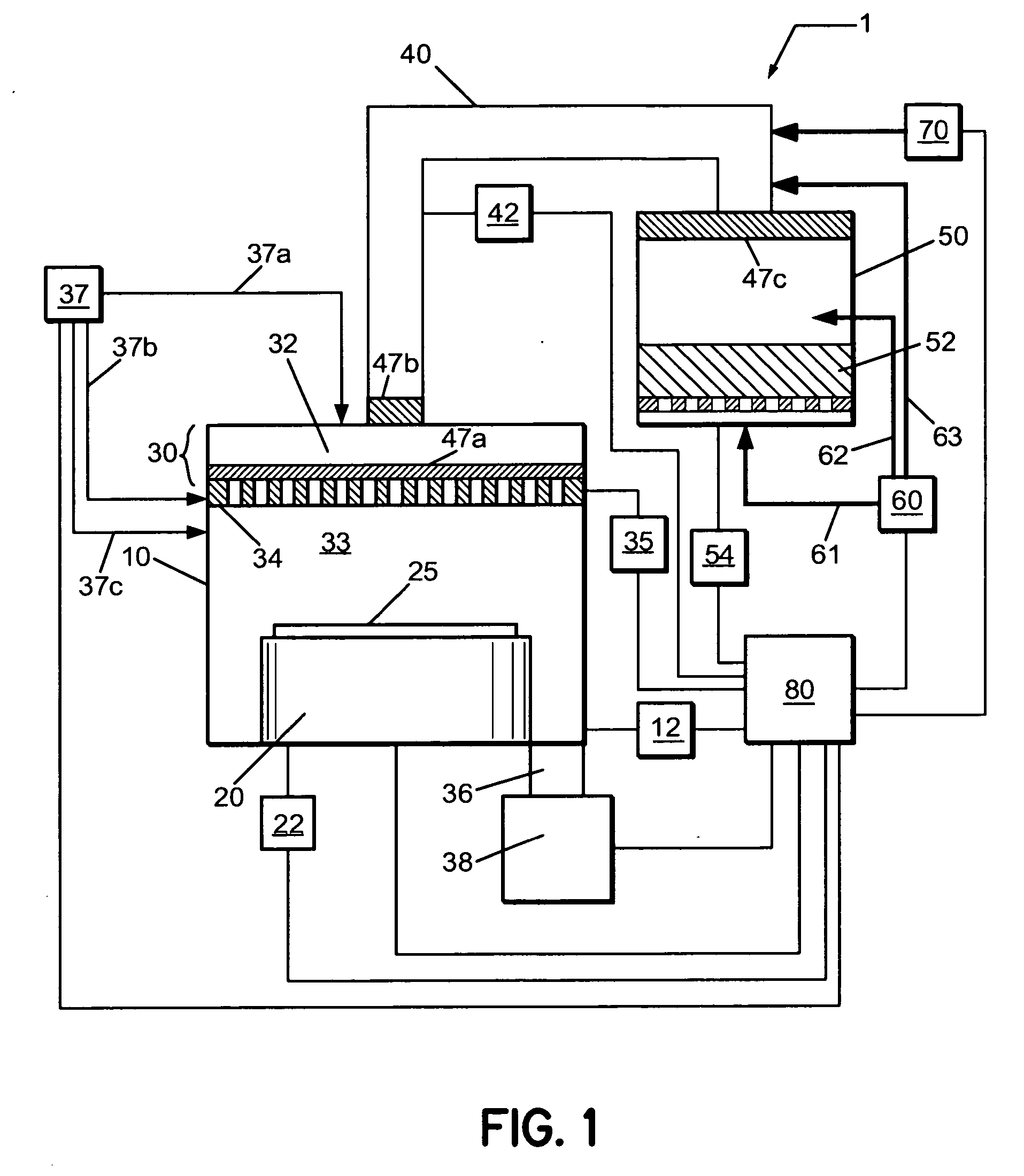

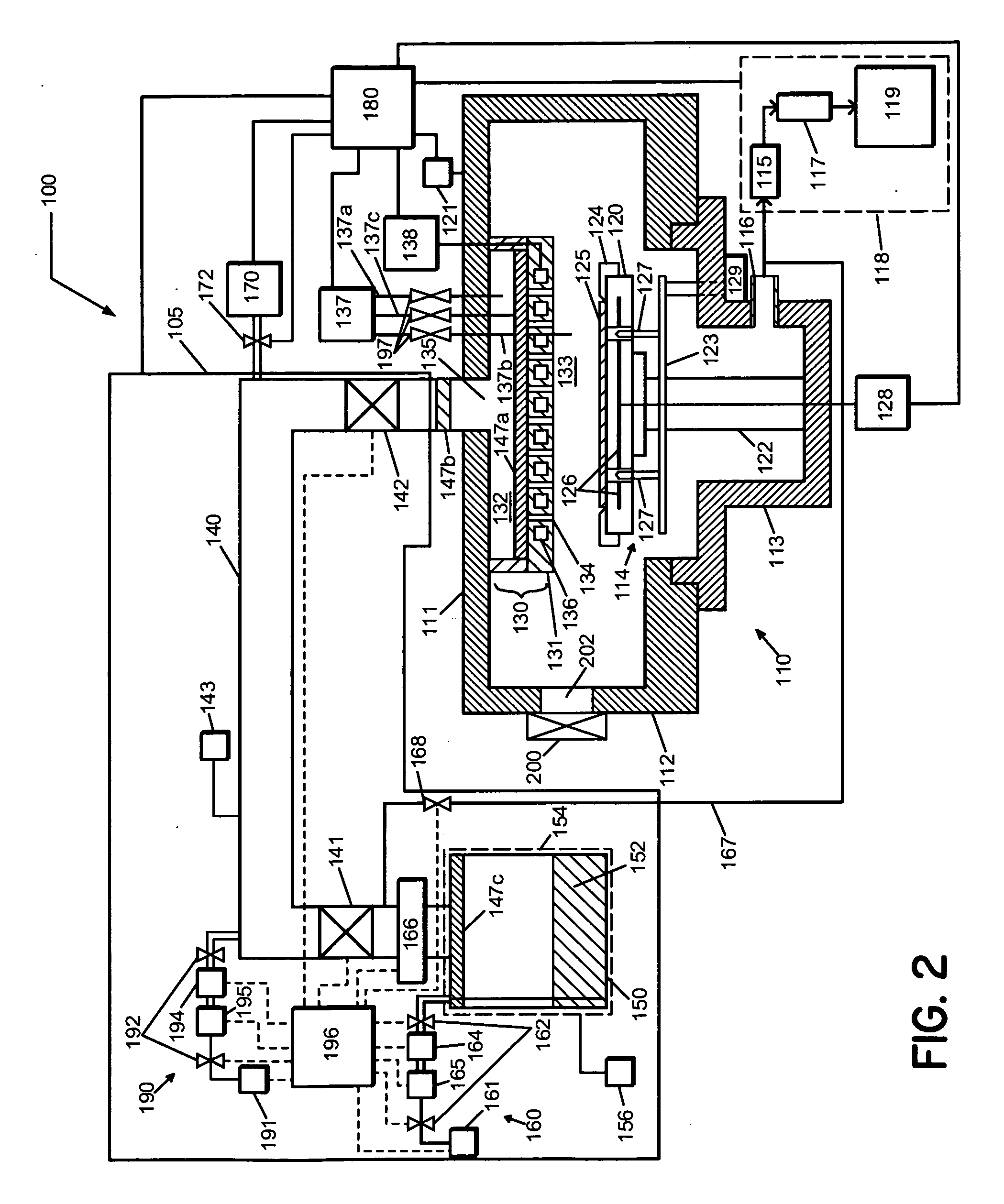

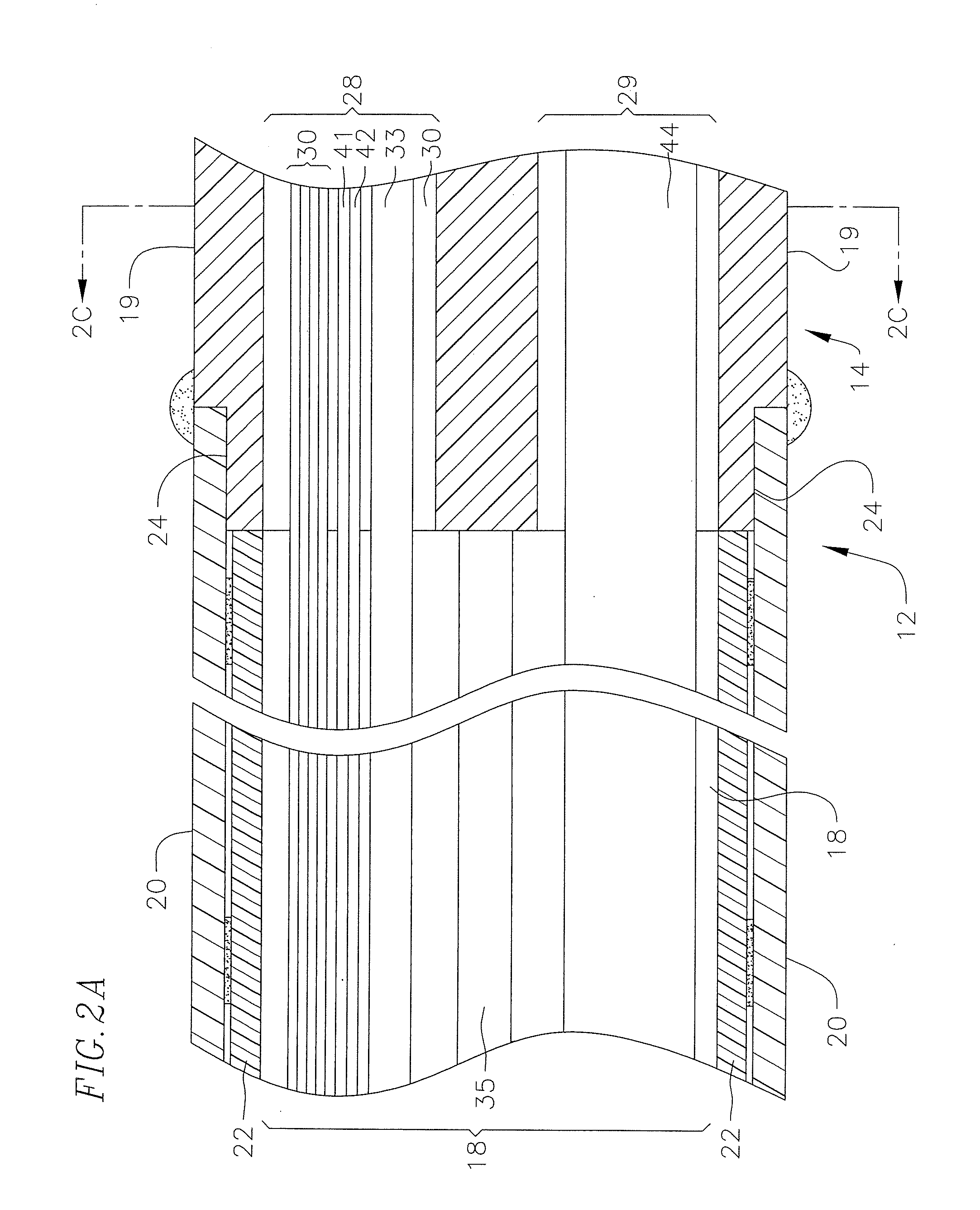

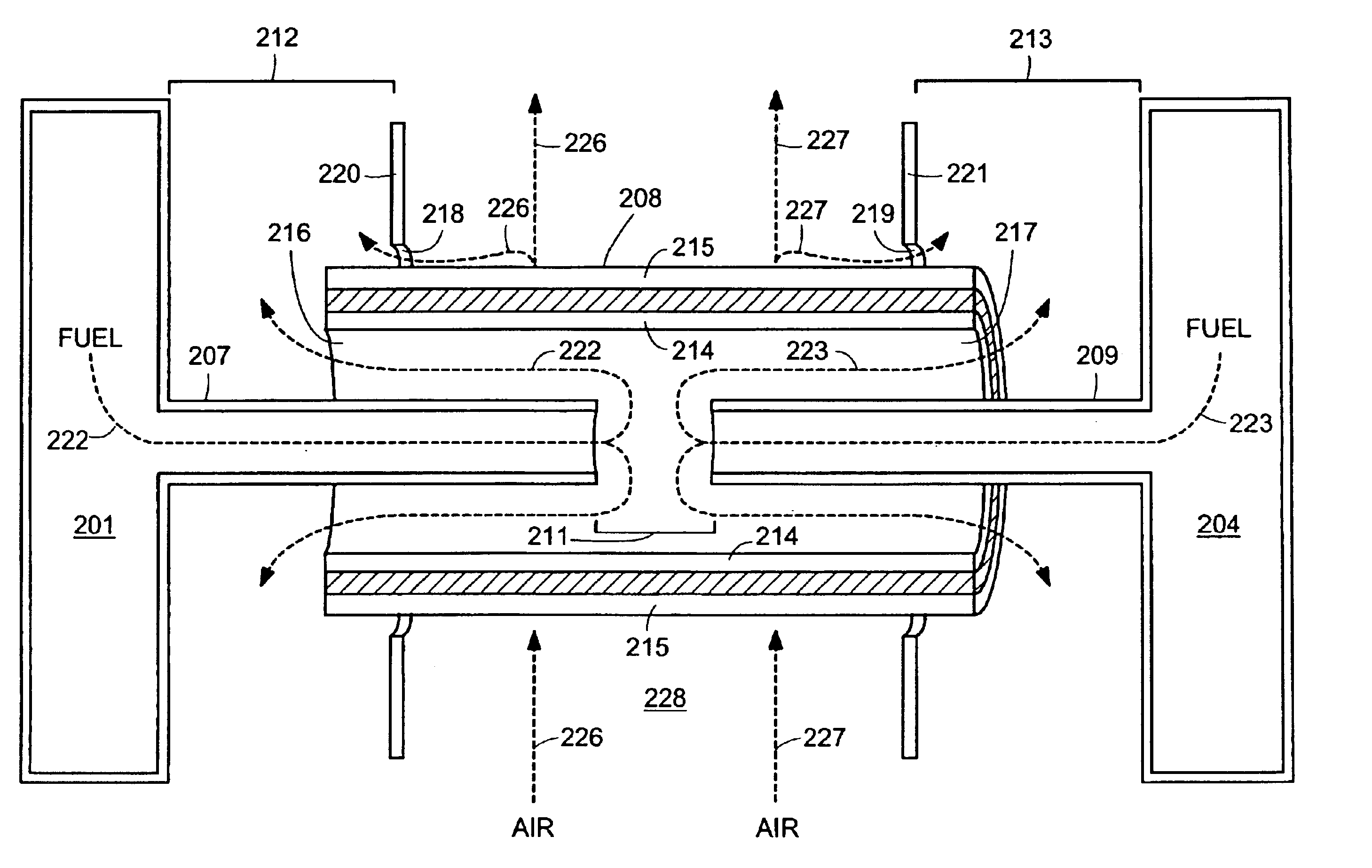

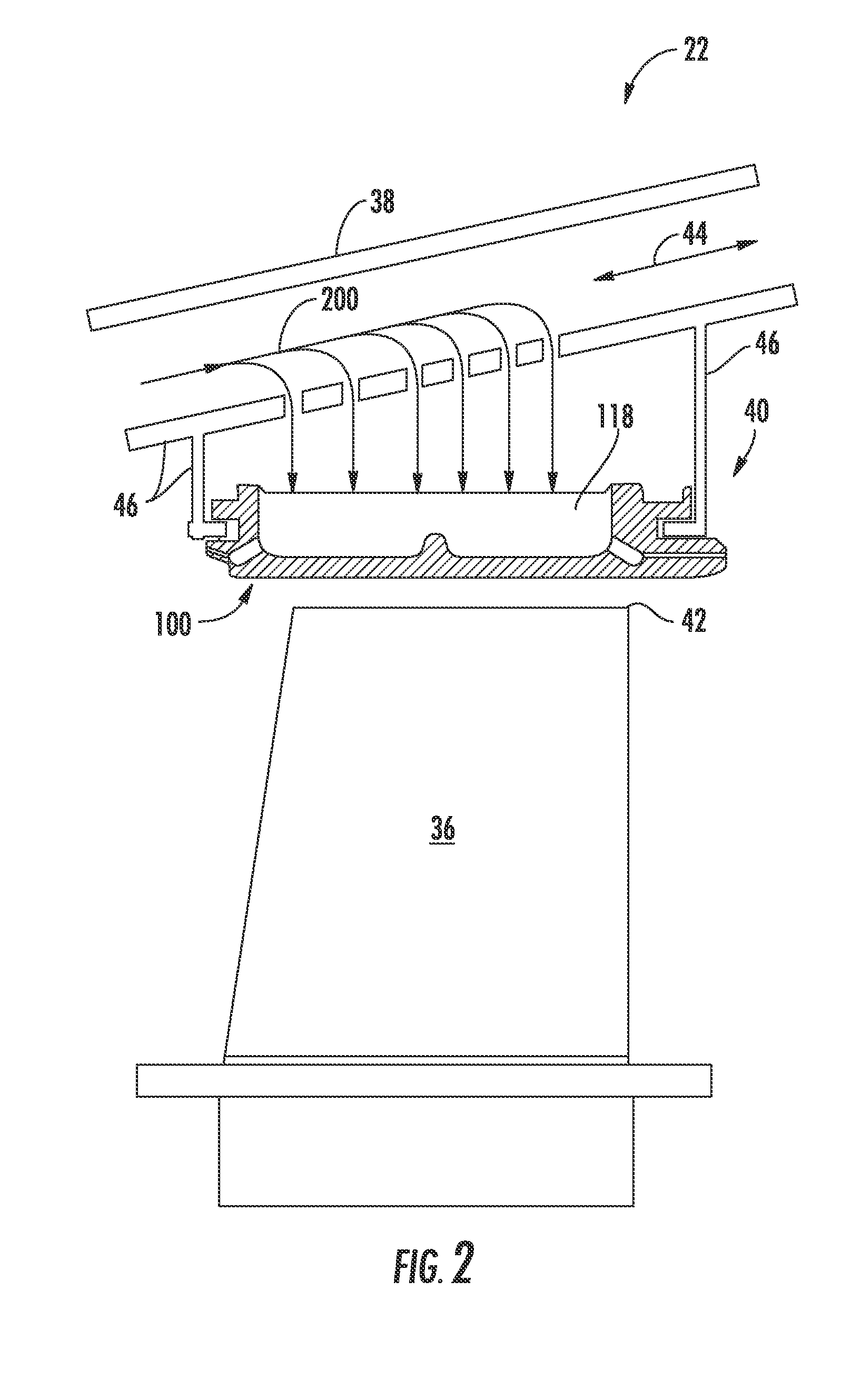

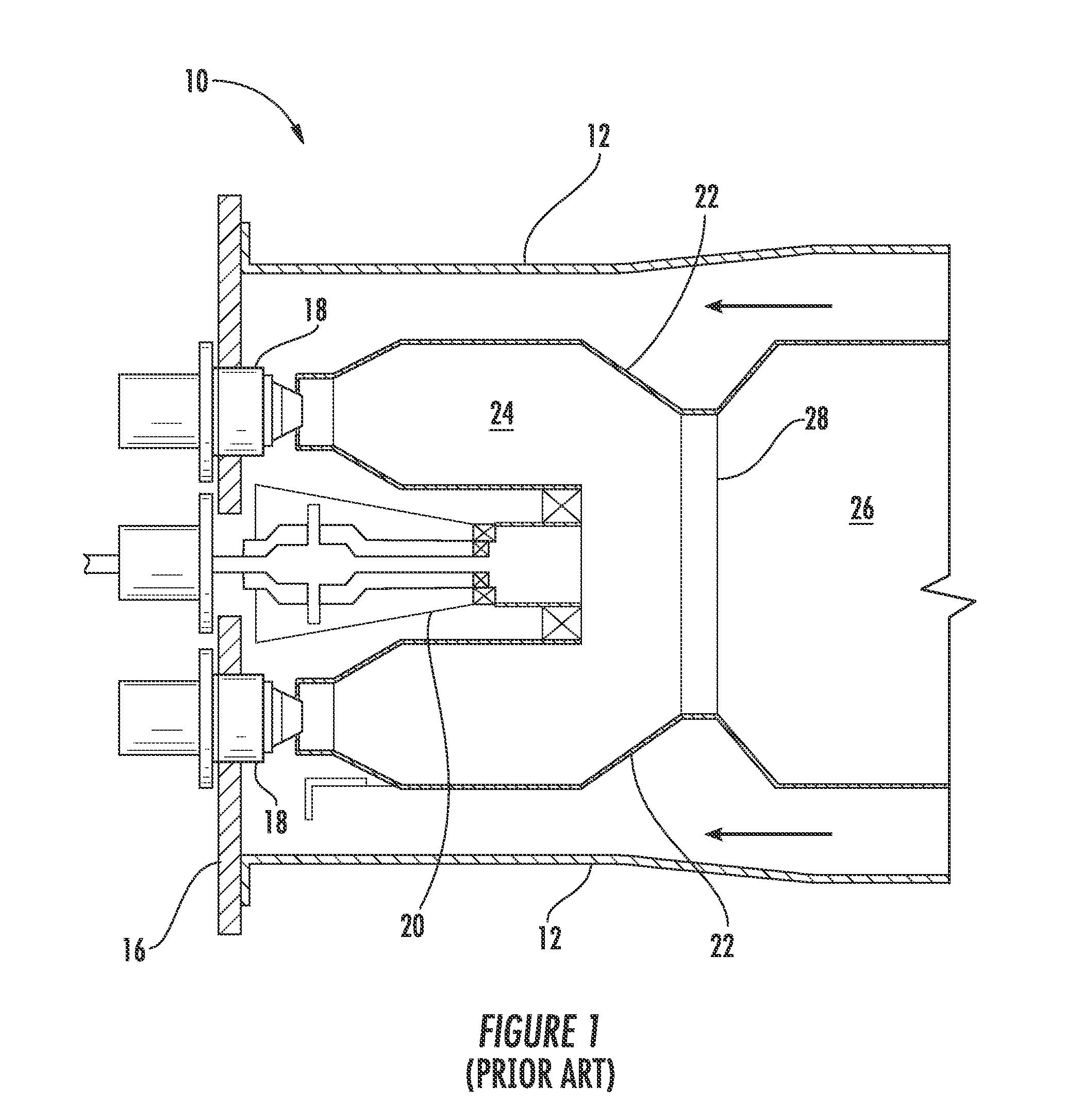

A method of and apparatus for providing tunable gas injection in a plasma processing system (10, 10′). The apparatus includes a gas injection manifold (50) having a pressurizable plenum (150) and an array of adjustable nozzle units (250), or an array of non-adjustable nozzles (502, 602), through which gas from the plenum can flow into the interior region (40) of a plasma reactor chamber (14) capable of containing a plasma (41). The adjustable nozzle units include a nozzle plug (160) arranged within a nozzle bore (166). A variety of different nozzle units are disclosed. The nozzle plugs are axially translatable to adjust the flow of gas therethrough. In one embodiment, the nozzle plugs are attached to a plug plate (154), which is displacable relative to an injection plate (124) via displacement actuators (170) connecting the two plates. The displacement actuators are controlled by a displacement actuator control unit (180), which is in electronic communication with a plasma processing system control unit (80). The gas flow into the chamber interior region is preferably controlled by monitoring the pressure in the plenum and in the chamber and adjusting the nozzle units accordingly. Where the nozzle units are not adjustable, a portion of the nozzles are sized to a first flow condition, and another portion of the nozzles are sized to a second flow condition.

Owner:TOKYO ELECTRON LTD

Method and apparatus for reducing particle formation in a vapor distribution system

InactiveUS20070218200A1Reduce particle pollutionChemical vapor deposition coatingDistribution systemEvaporation

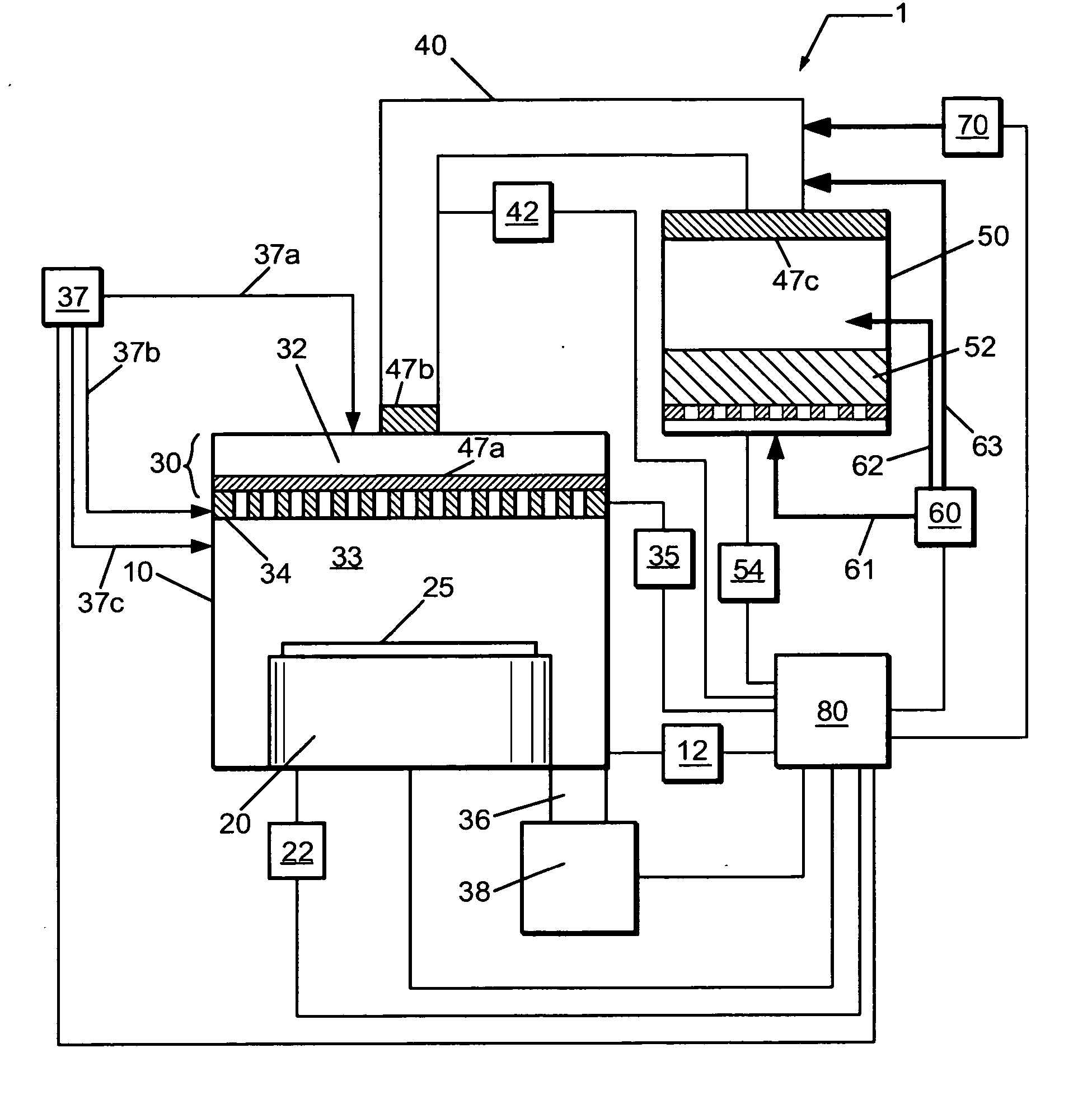

A method and system is described for reducing particle contamination in a vapor distribution system. The vapor distribution system comprises a housing and a vapor distribution head comprising a plurality of openings configured to introduce a film precursor vapor to a deposition system. The housing and vapor distribution head define a plenum coupled to a film precursor evaporation system, and configured to receive the film precursor vapor from the evaporation system and distribute the film precursor vapor within the deposition system through the plurality of openings. In order to reduce particle contamination, the vapor distribution system is designed to reduce the difference, or ratio, between the pressure in the plenum and the pressure in the deposition system. For example, the plenum pressure can be less than twice the pressure in the process space, or can be less than 50 mTorr, 30 mTorr or even 20 mTorr than the pressure in the process space.

Owner:TOKYO ELECTRON LTD

Manifold assembly for feeding reactive precursors to substrate processing chambers

InactiveUS20060249253A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingPlenum chamberBiomedical engineering

A reactive precursor feeding manifold assembly includes a body comprising a plenum chamber. A valve is received proximate the body and has at least two inlets and at least one outlet. At least one valve inlet is configured for connection with a reactive precursor source. At least one valve outlet feeds to a precursor inlet to the plenum chamber. A purge stream is included which has a purge inlet to the plenum chamber which is received upstream of the plenum chamber precursor inlet. The body has a plenum chamber outlet configured to connect with a substrate processing chamber. In one implementation, the plenum chamber purge inlet is angled from the plenum chamber precursor inlet. In one implementation, structure is included on the body which is configured to mount the body to a substrate processing chamber with the plenum chamber outlet proximate to and connected with a substrate processing chamber inlet.

Owner:MICRON TECH INC

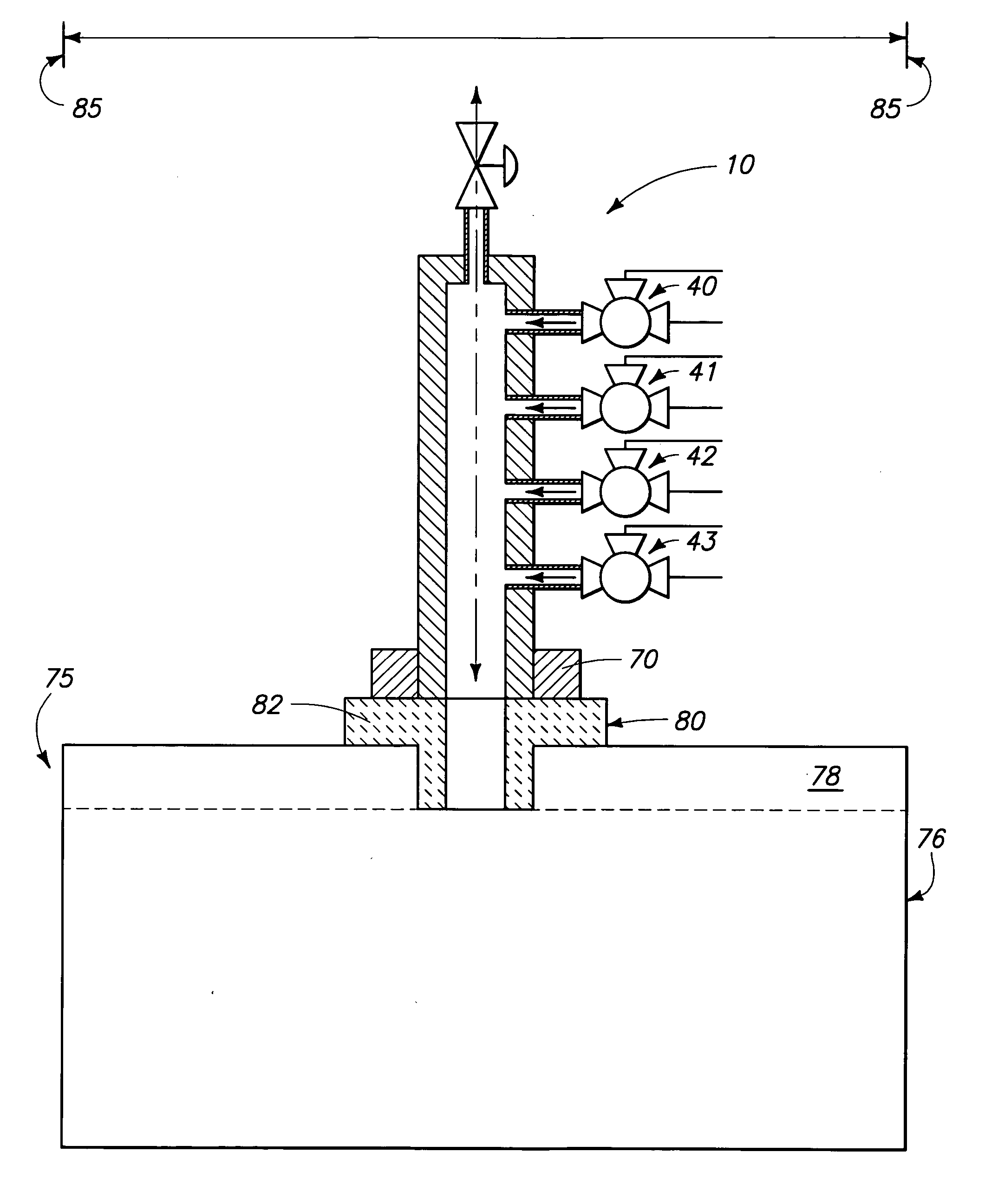

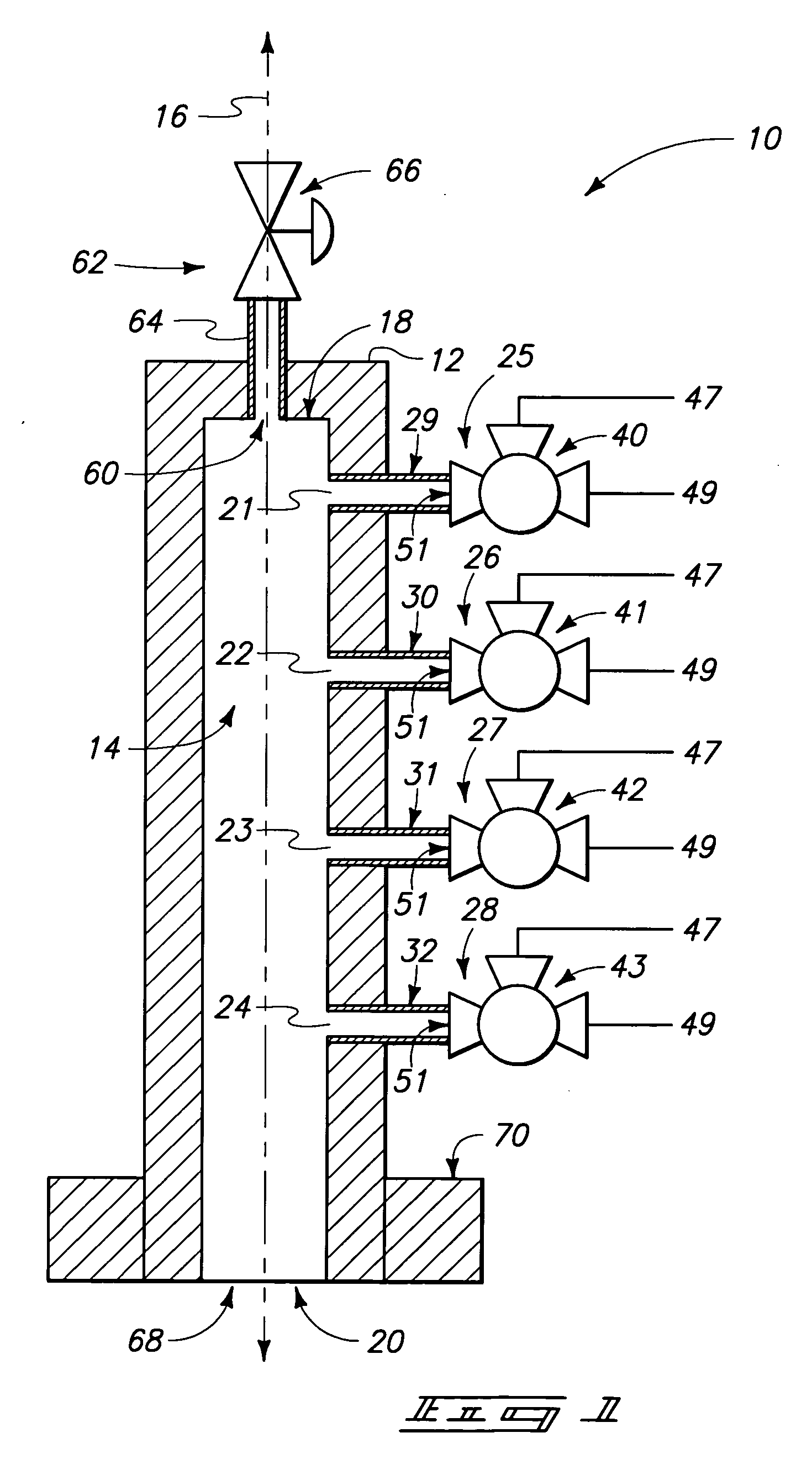

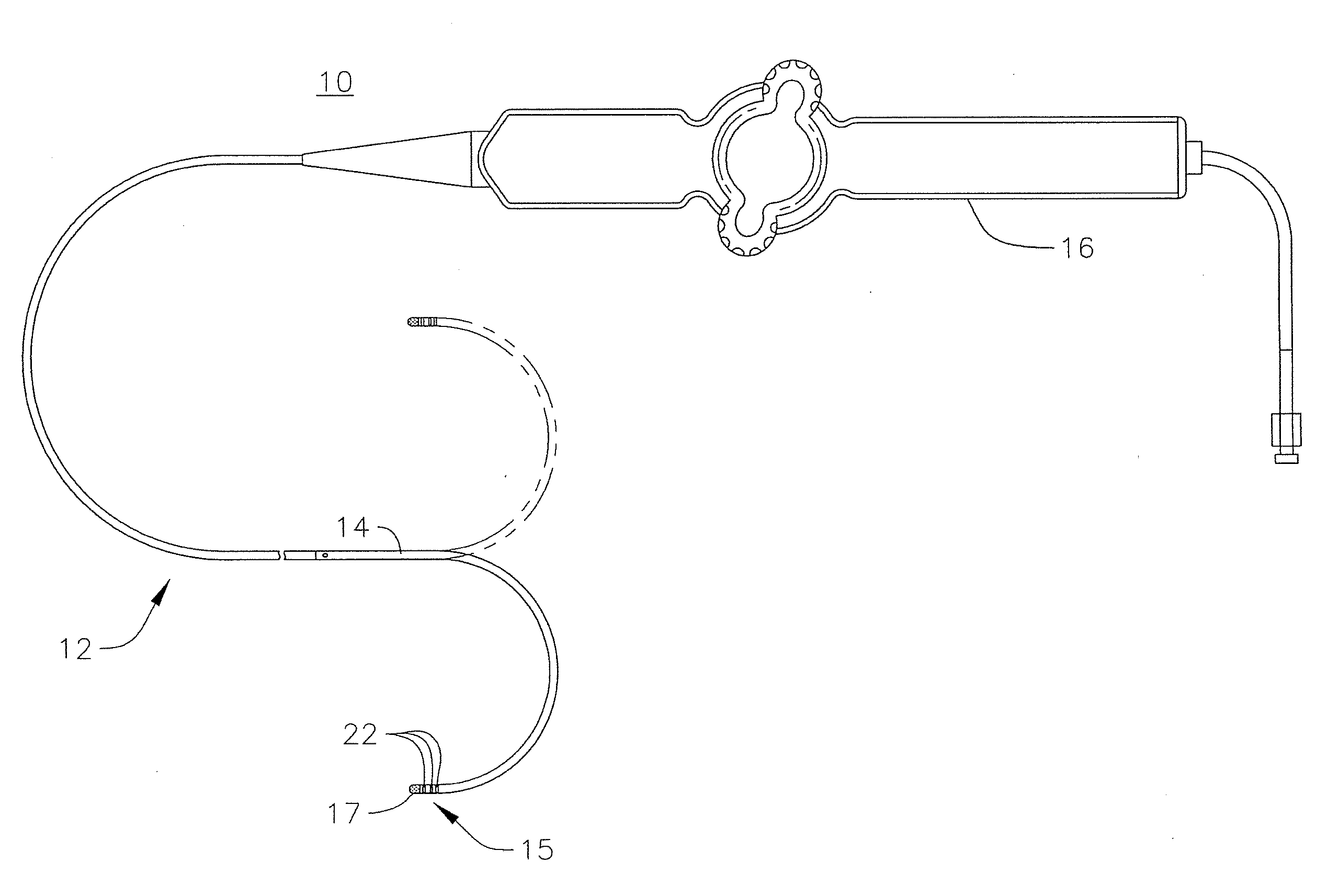

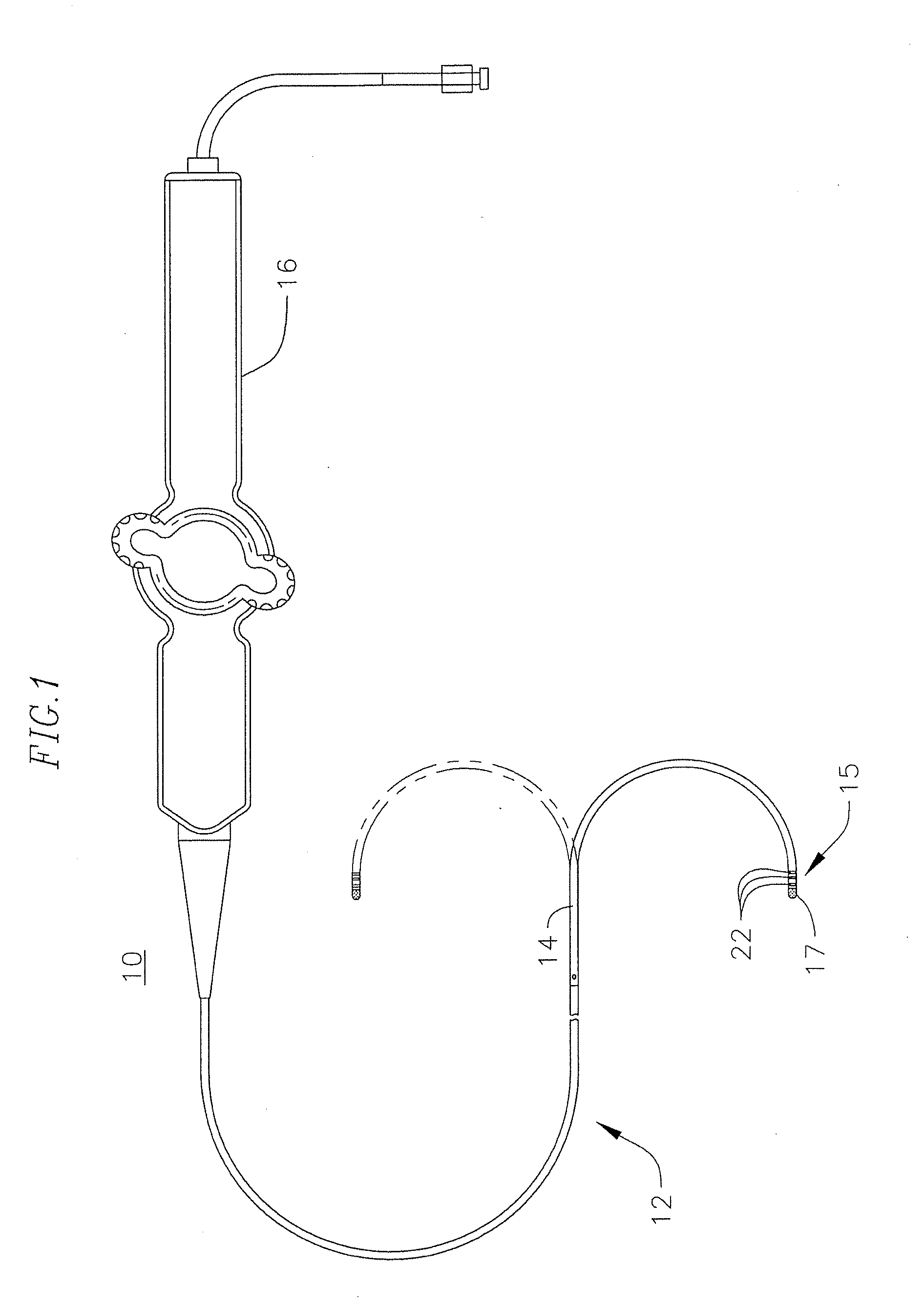

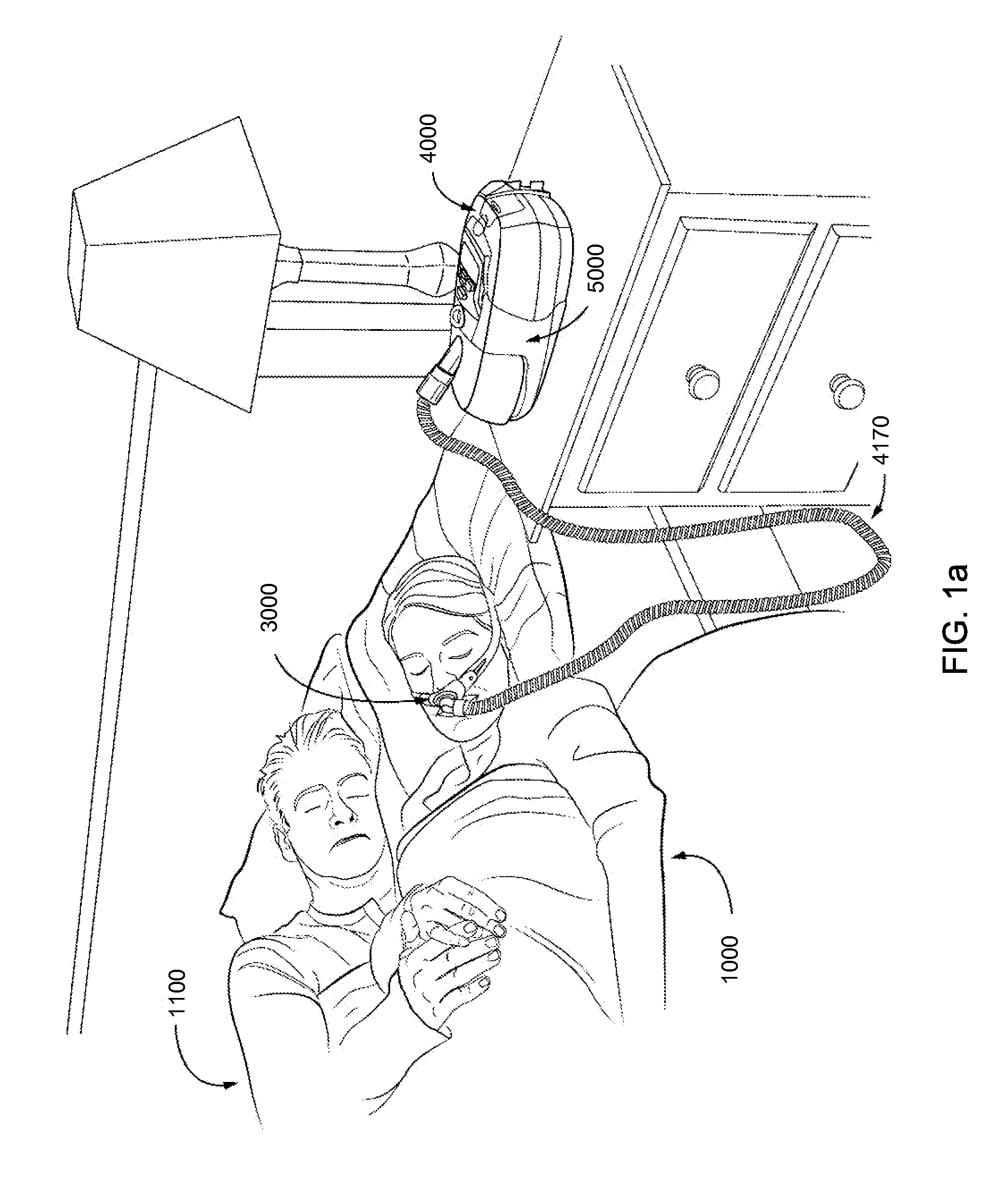

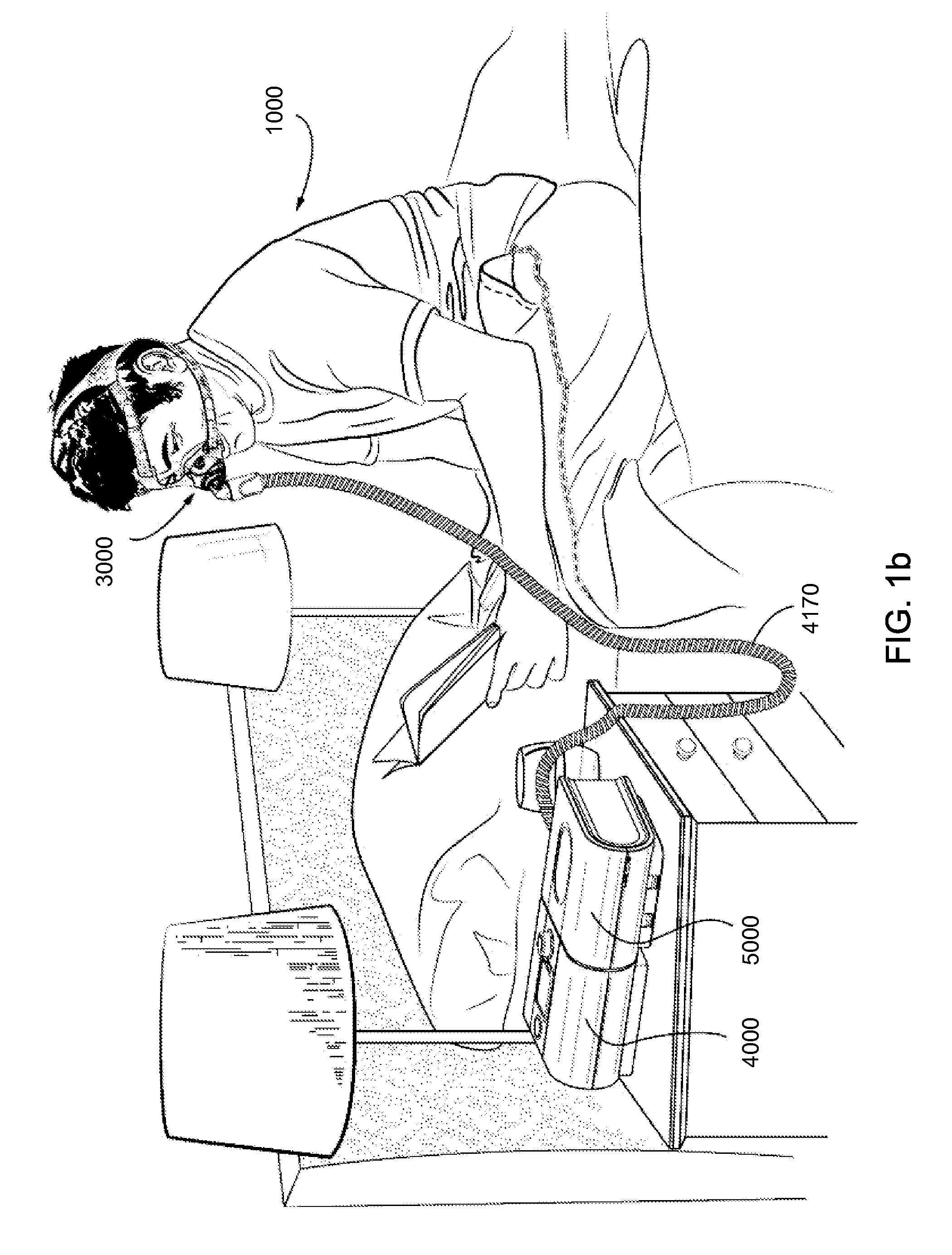

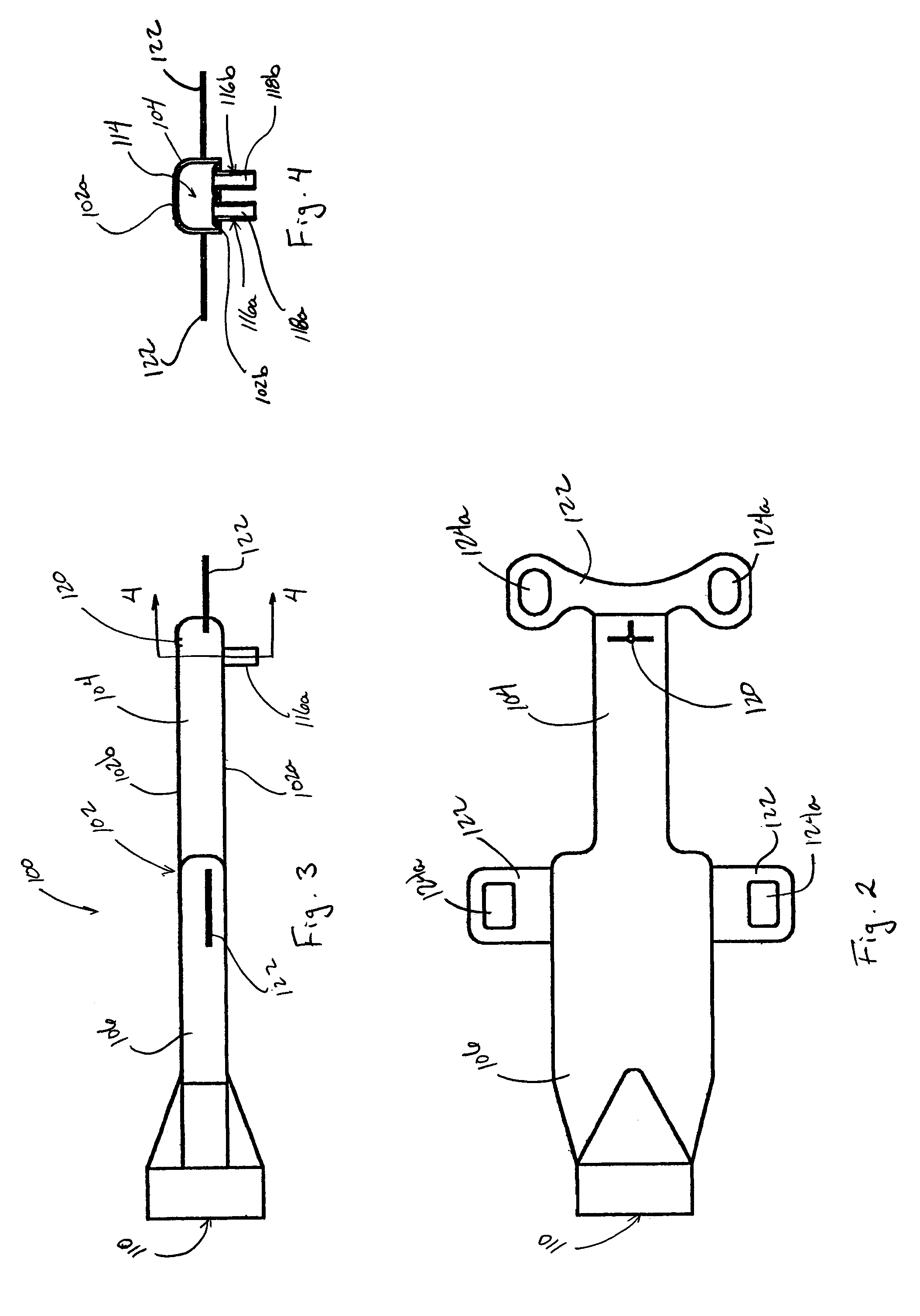

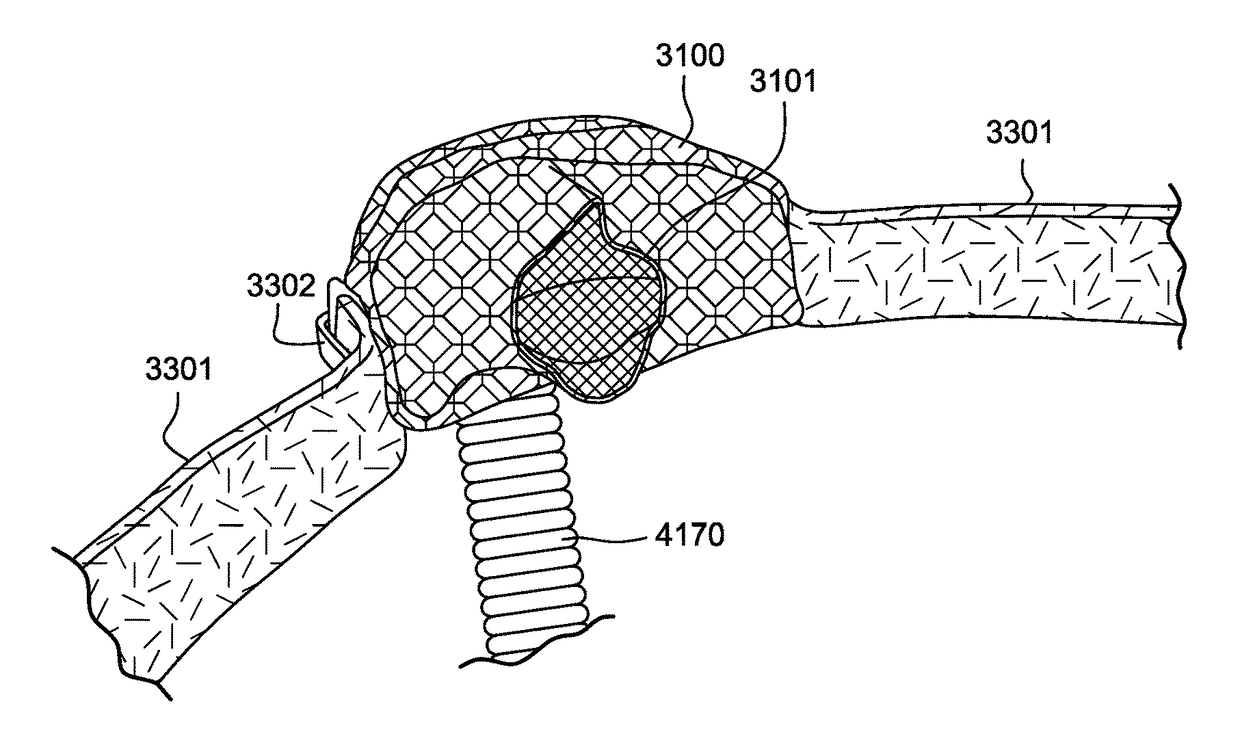

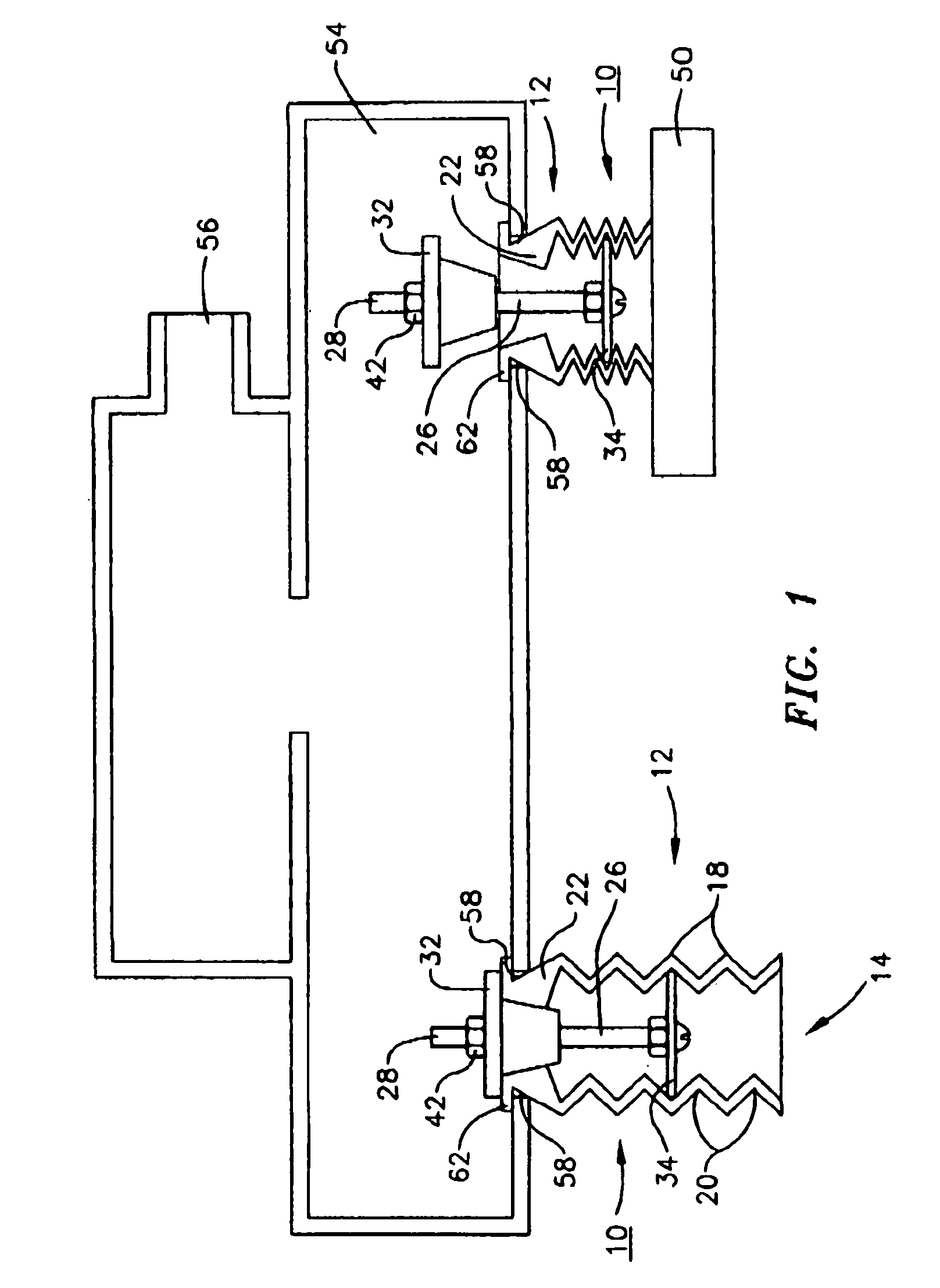

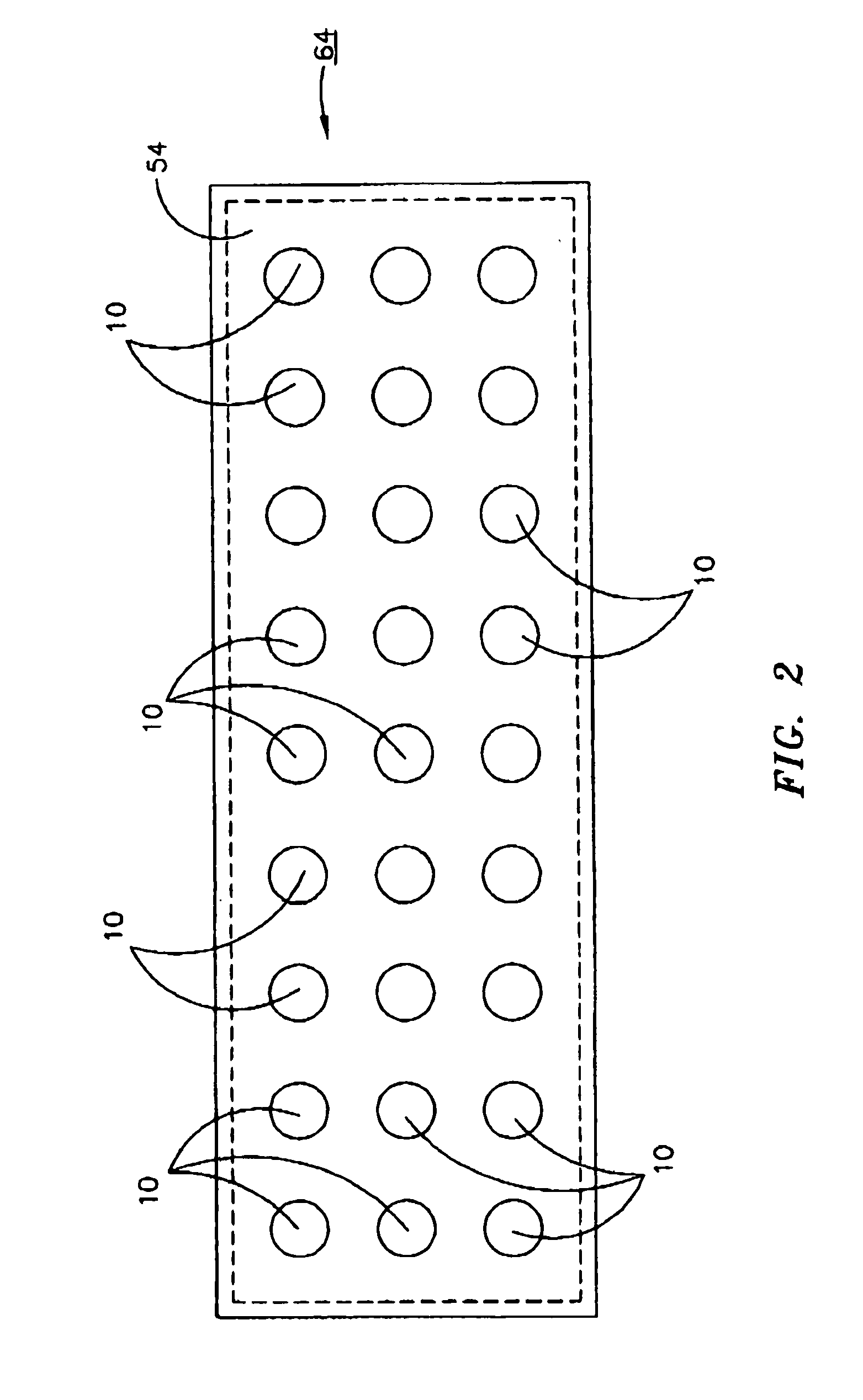

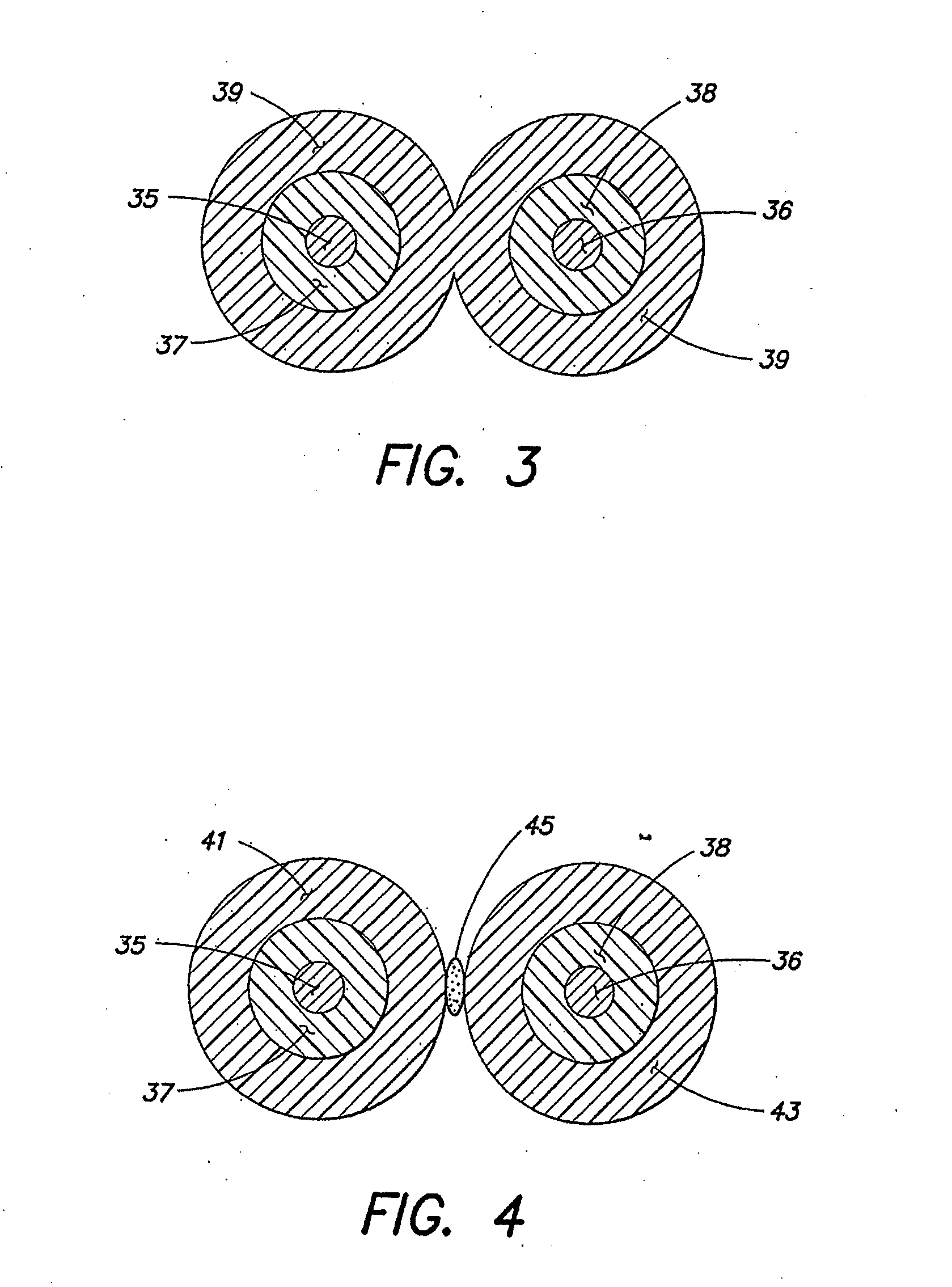

Trocar assembly with pneumatic sealing

A trocar assembly for creating a pneumatic seal during a minimally-invasive surgical procedure. The trocar assembly including an elongated body having a lumen extending therethrough. The proximal end portion of the body defining a housing. A fluid supply plenum is defined in the housing configured to deliver pressurized insufflation fluid to a nozzle. The nozzle configured for directing pressurized fluid into the lumen and creating a pneumatic seal. A fluid return plenum is defined in the housing configured to collect spent insufflation fluid from as patient's abdominal cavity. The fluid return plenum including a plurality of axially and radially oriented elongate vanes configured to permit spent insufflation fluid to proceed between the vanes and direct spent insufflation fluid back to the fluid return plenum.

Owner:SURGIQUEST

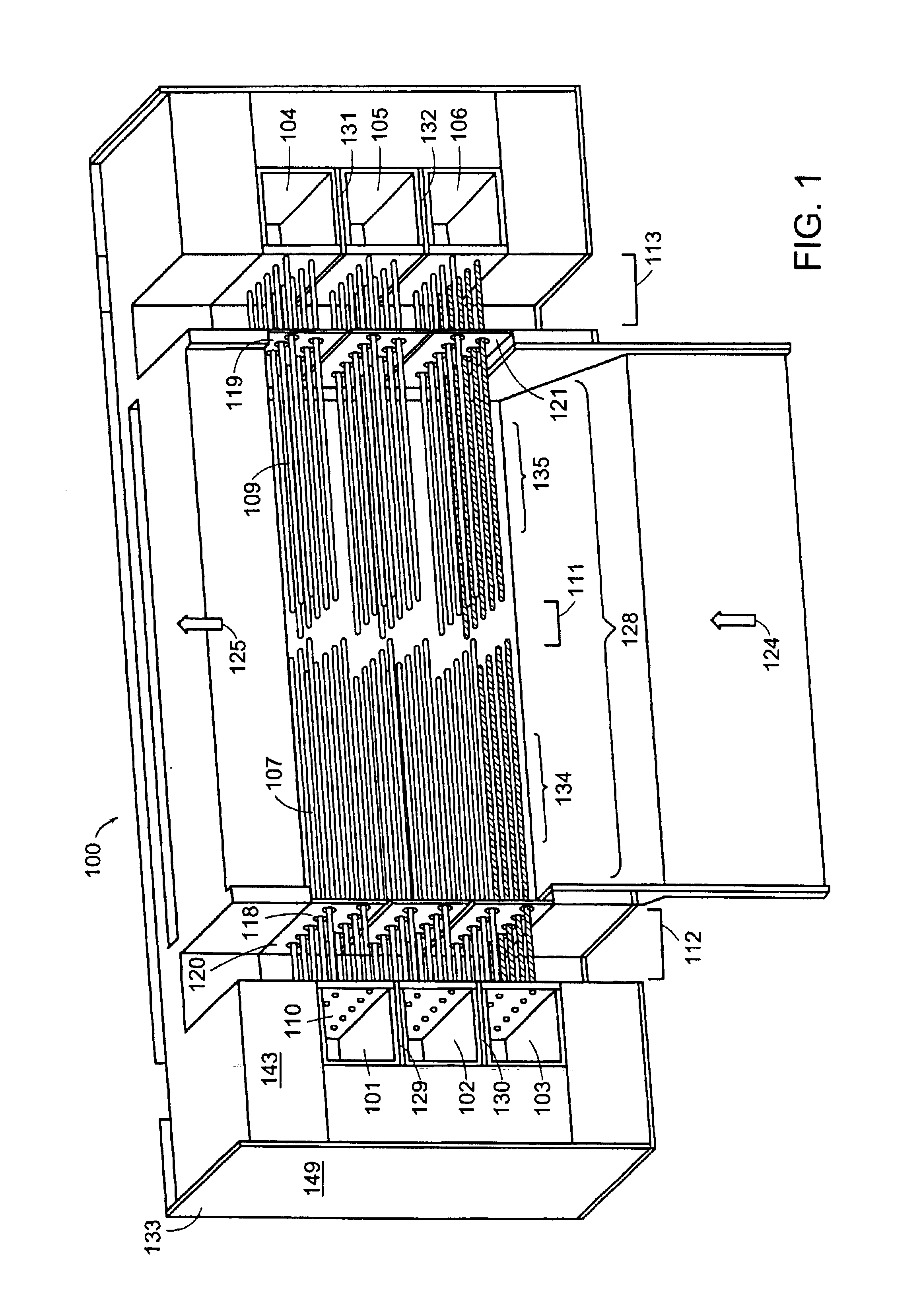

Integrated solid oxide fuel cell and reformer

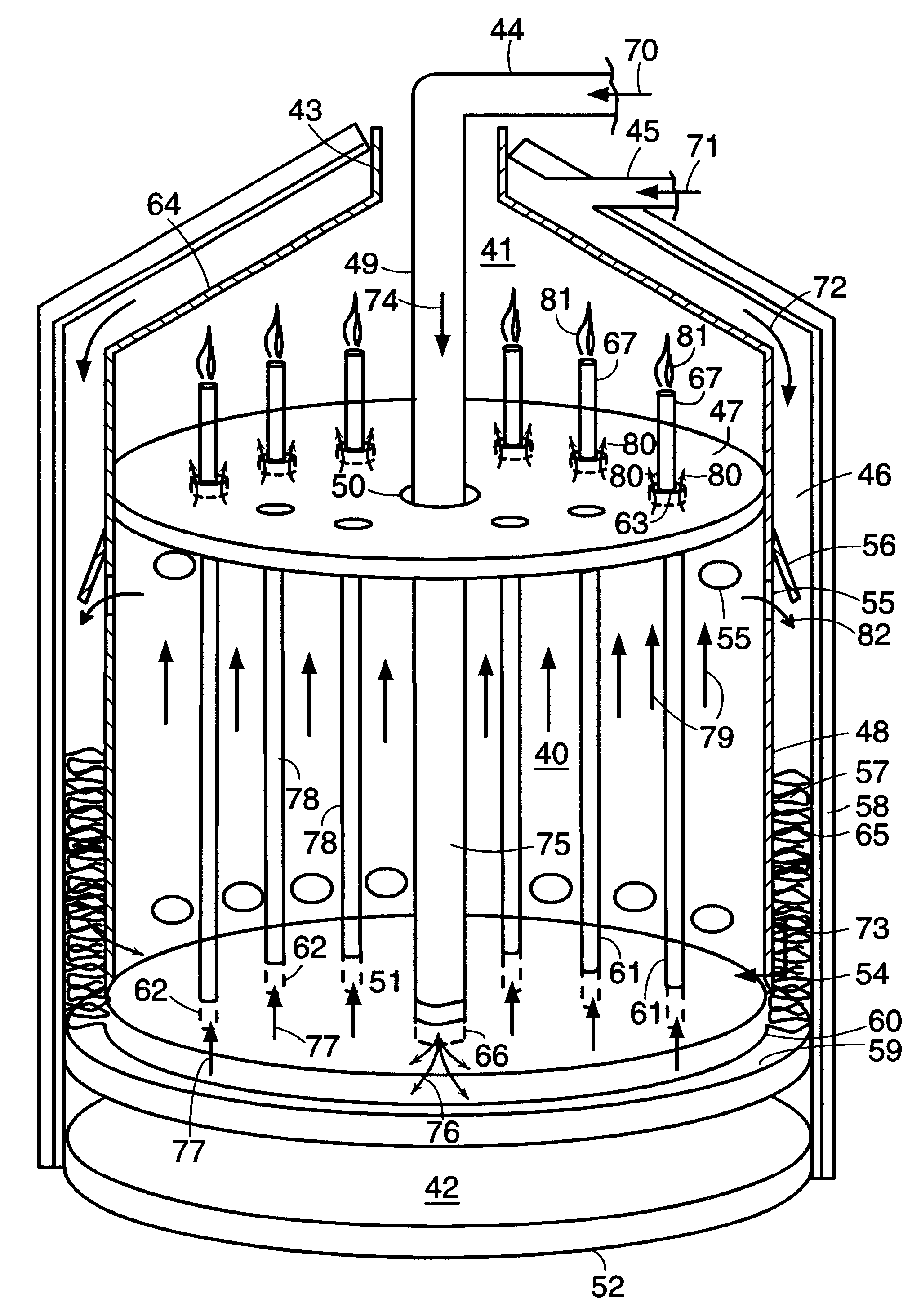

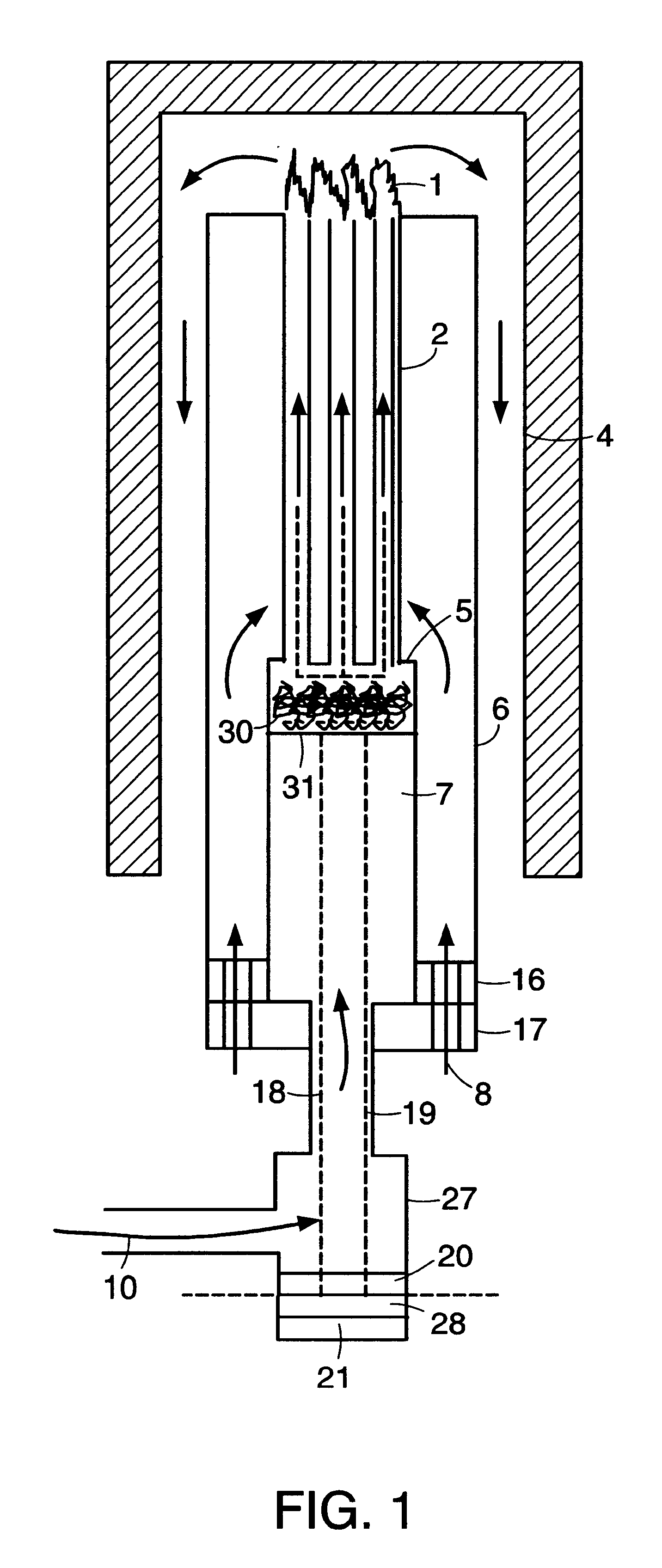

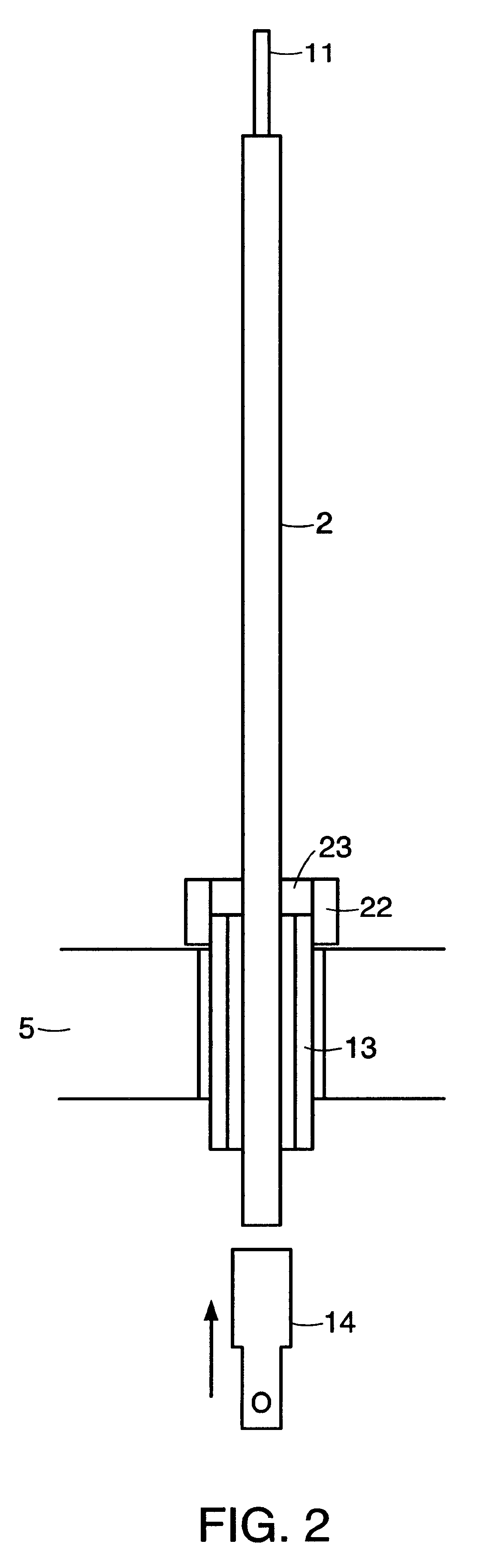

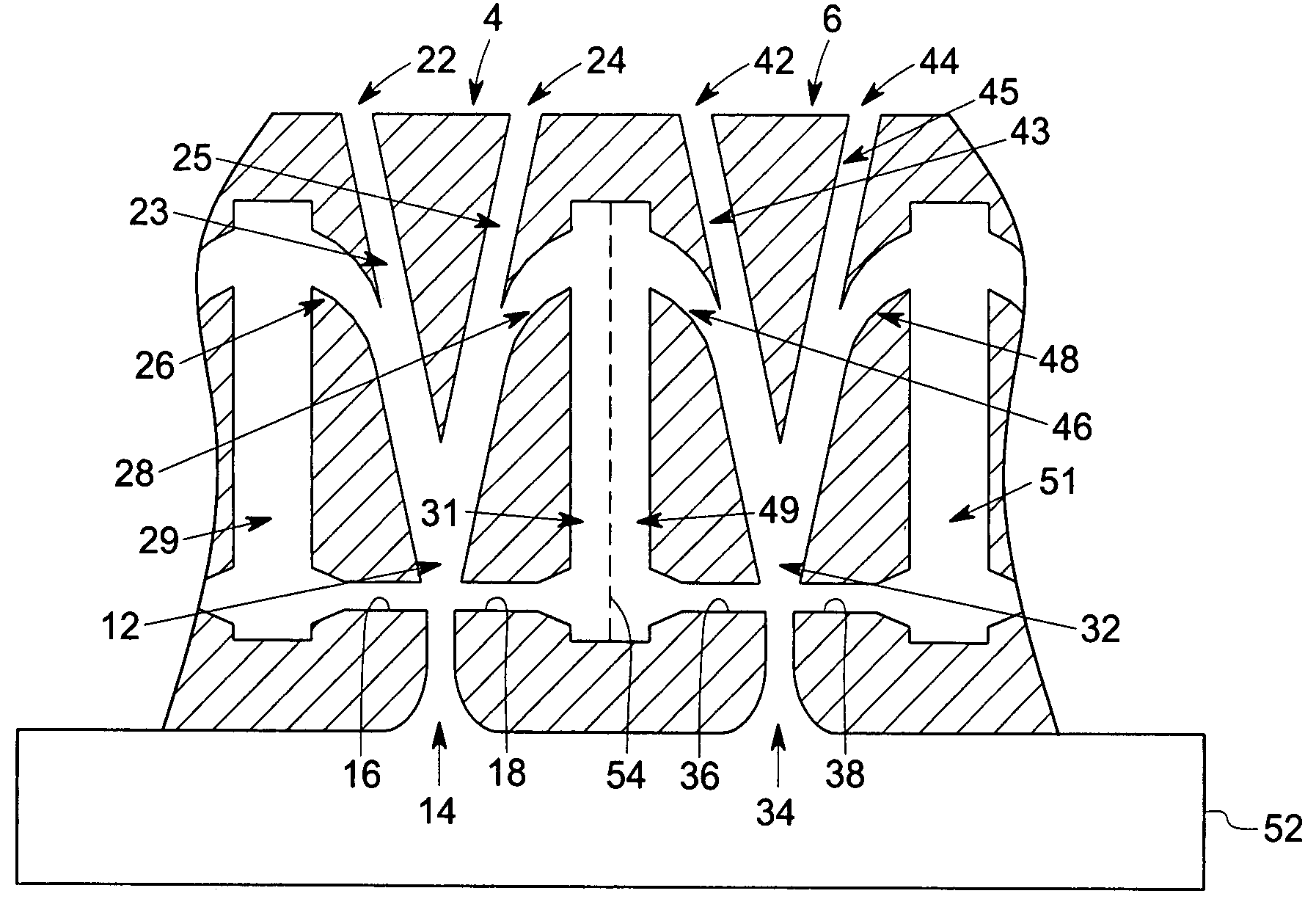

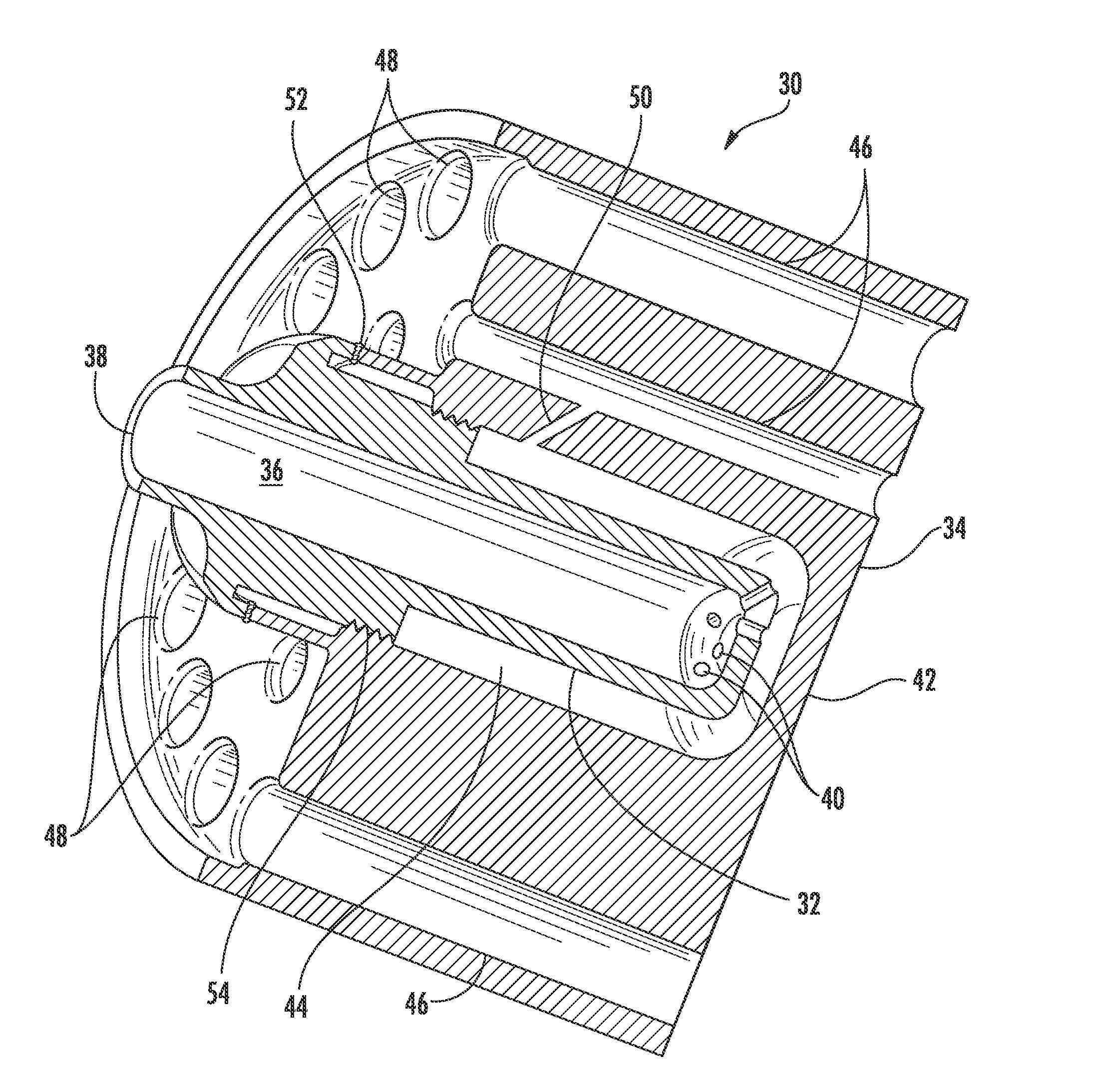

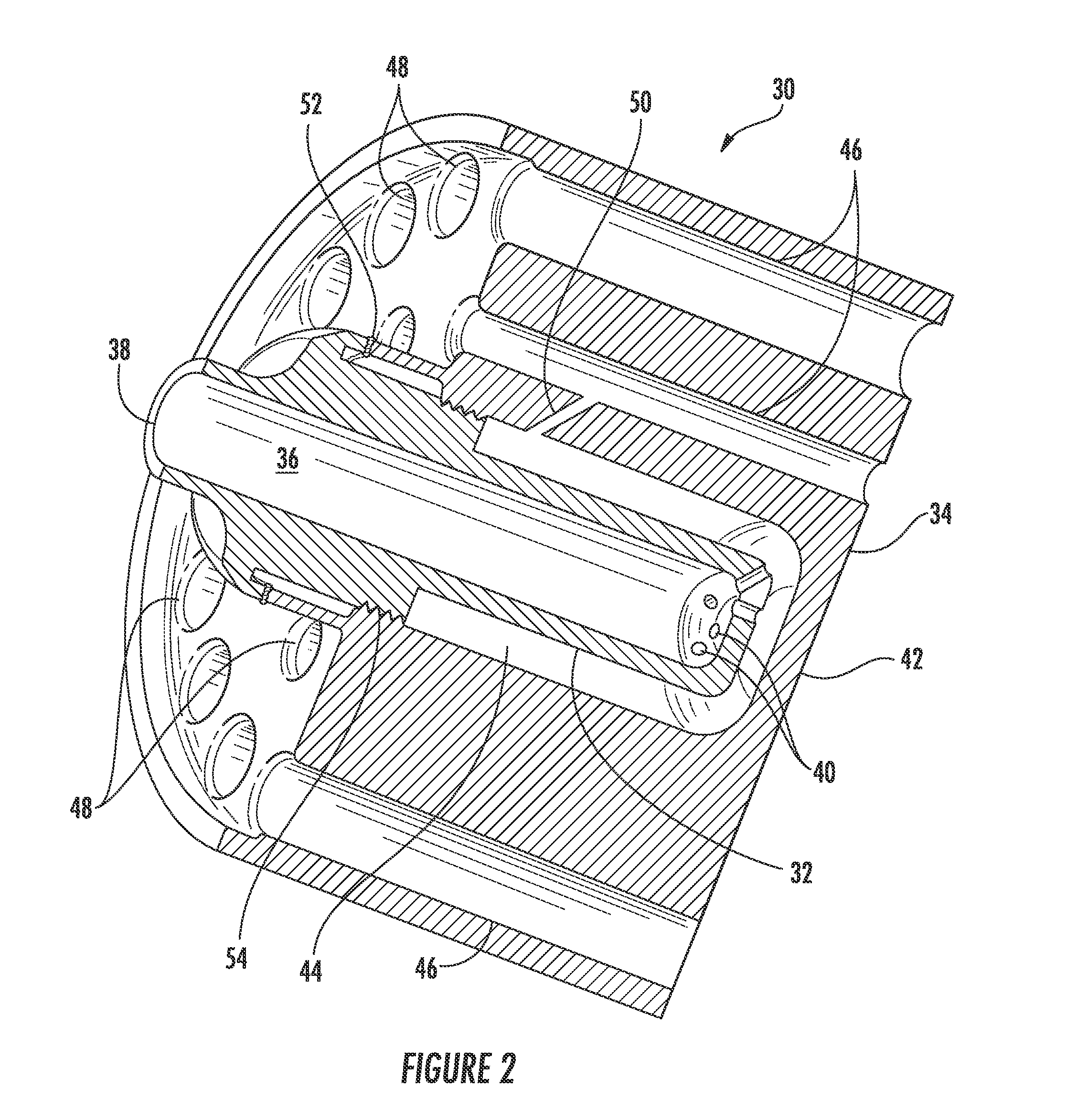

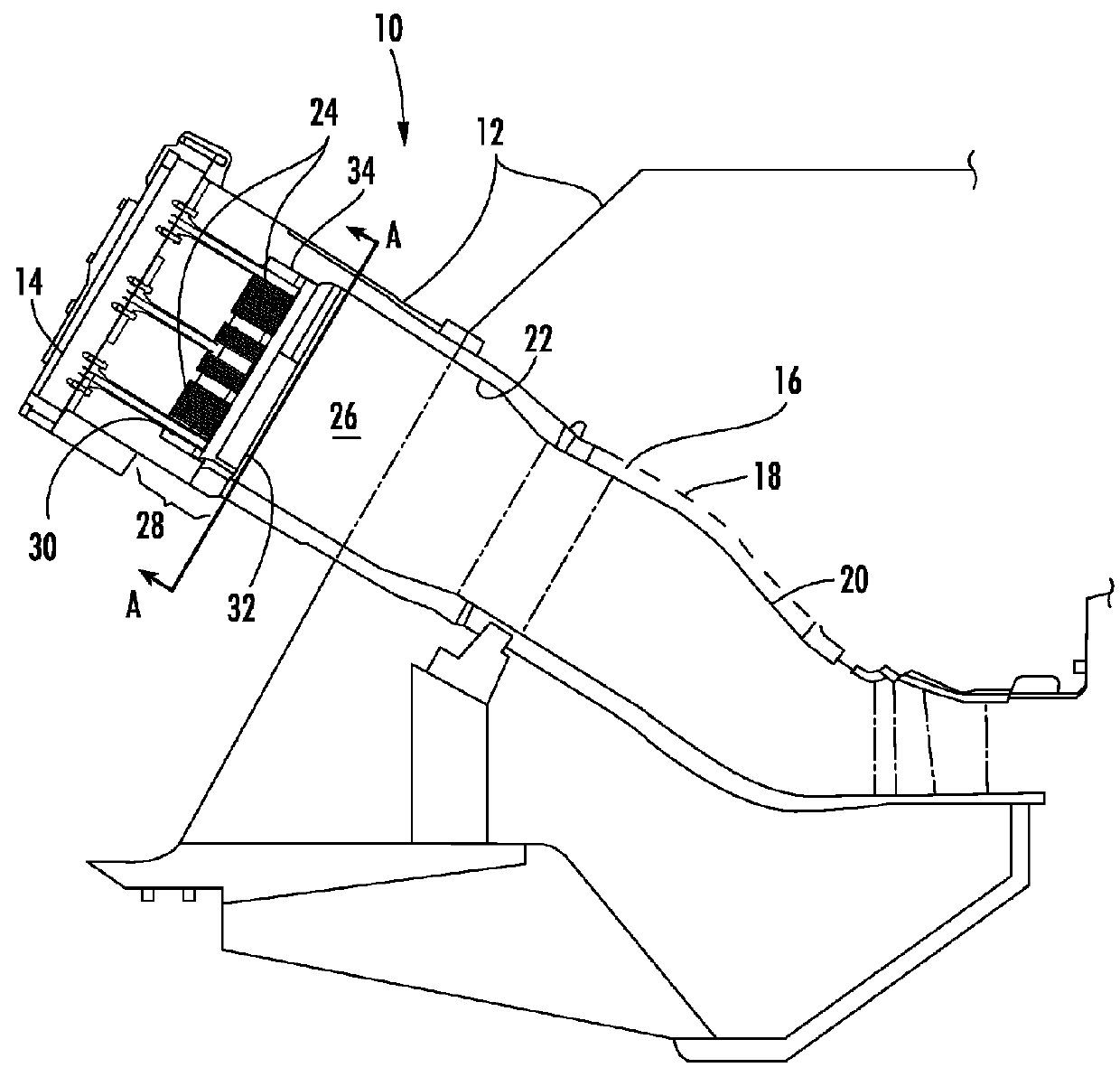

A disclosed apparatus for generating electrical power has, according to one embodiment of the invention, a plurality of tubular solid oxide fuel cells contained in a reaction chamber. The fuel cells are secured at one end thereof in a manifold block, the other ends thereof passing freely through apertures in a baffle plate to reside in a combustion chamber. Reaction gases are supplied to the insides of the tubular fuel cells from a plenum chamber below the manifold block and to the reaction chamber surrounding the outsides of the fuel cells through an annular inlet path, which may include a reformation catalyst. The gases inlet path to the plenum chamber, and the annular inlet path surround the reaction chamber, are both in heat conductive relation with the reaction chamber and the combustion chamber, and raise the gases to formation and reaction temperatures as appropriate.

Owner:ACUMENTRICS

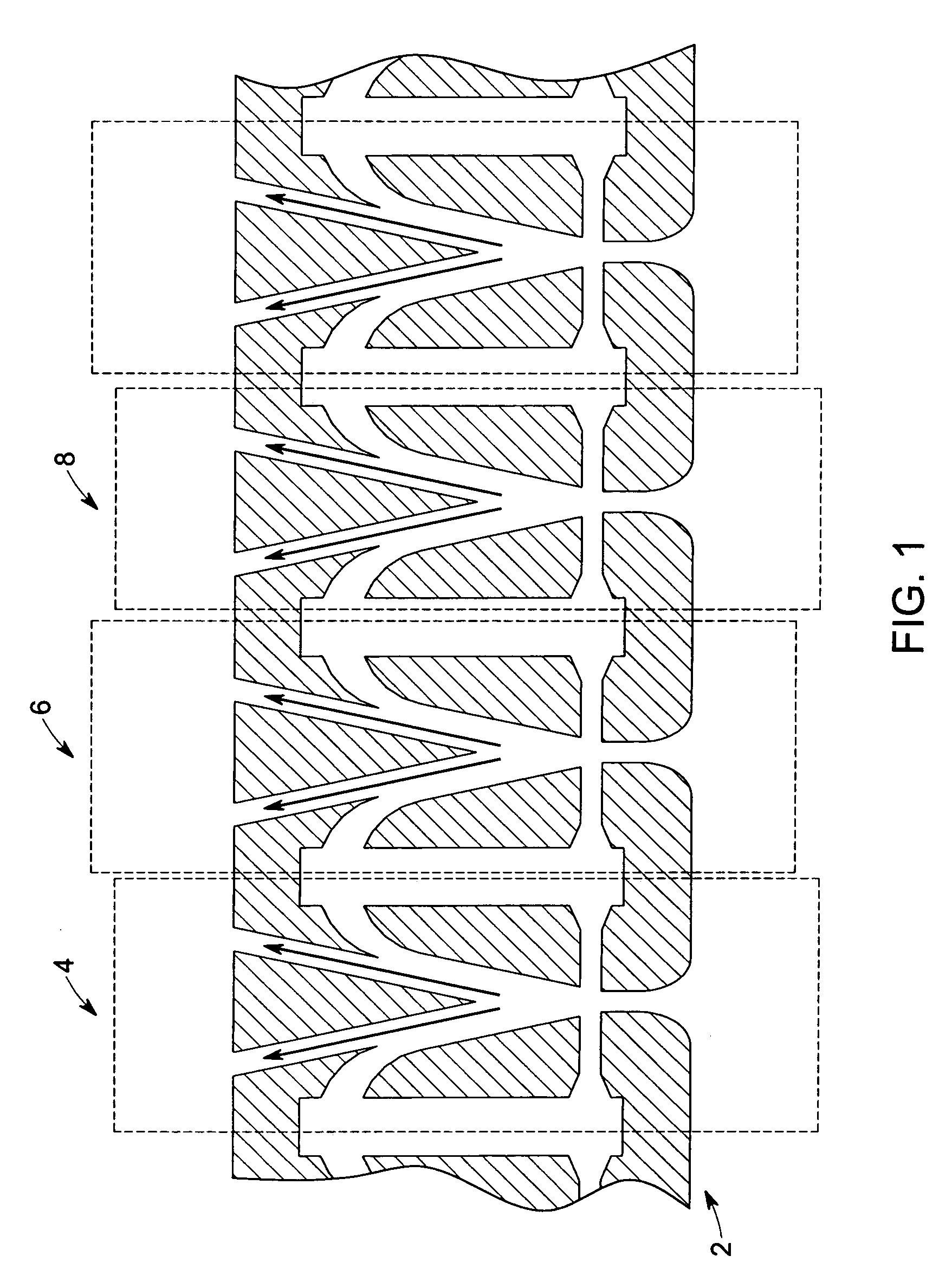

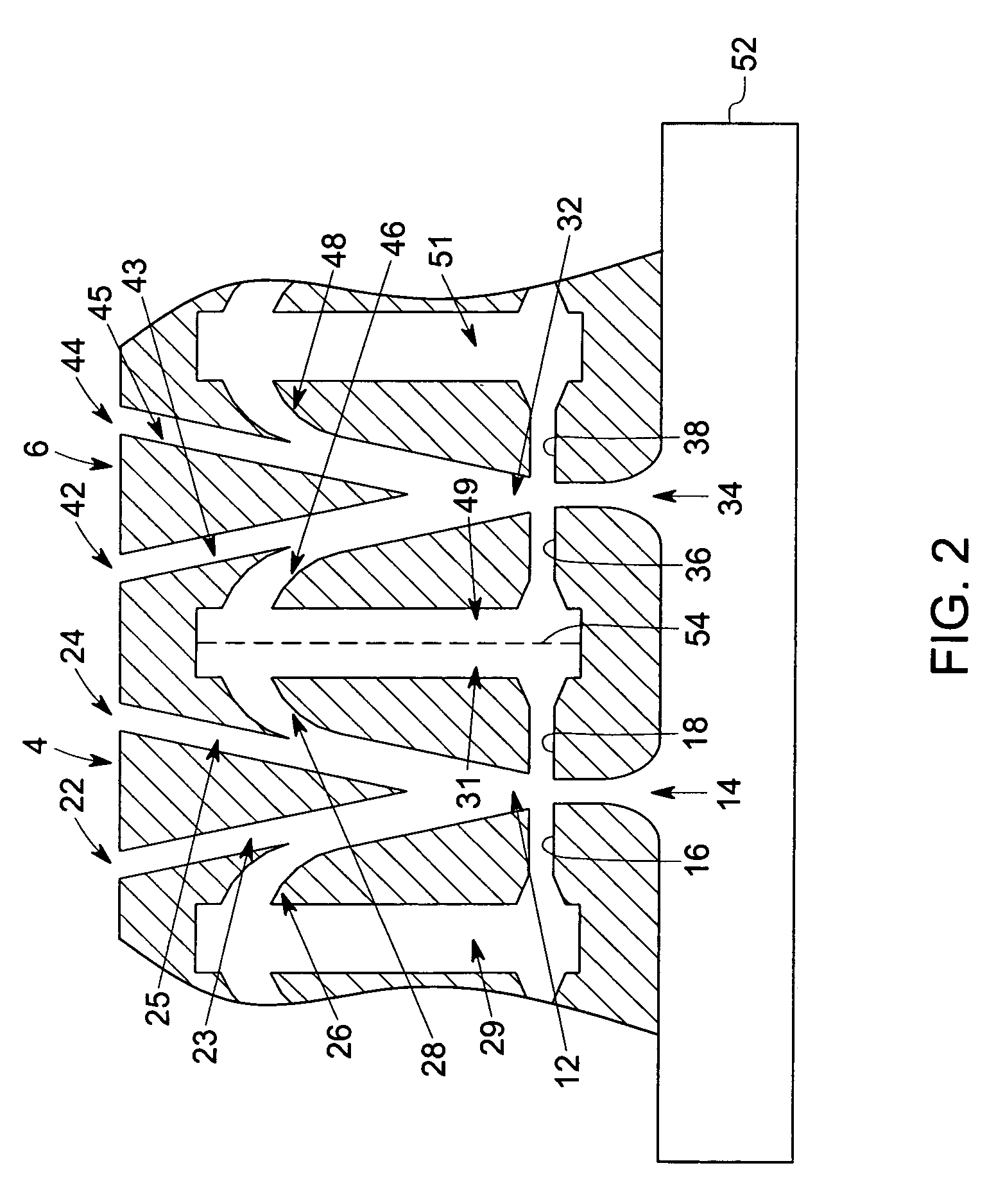

Method and system for flow control with fluidic oscillators

A system for control of a fluid flow. The system includes an array of fluidic oscillators. Each fluidic oscillator carries an oscillating flow of the fluid and includes a throat, an input port connected to the throat, two control ports connected to the throat and two output ports extending from the throat. A feedback line is connected to each of the two output ports and each of the two control ports. The system further includes a plenum connected to the input ports of the fluidic oscillators to supply the fluid to the fluidic oscillators and a feedback chamber disposed along each feedback line of each fluidic oscillator to provide a feedback path for the control fluid to cause oscillatory fluid motion between the first output port and the second output port, the frequency of which may be modulated by adjusting the volume of the feedback chamber.

Owner:GENERAL ELECTRIC CO

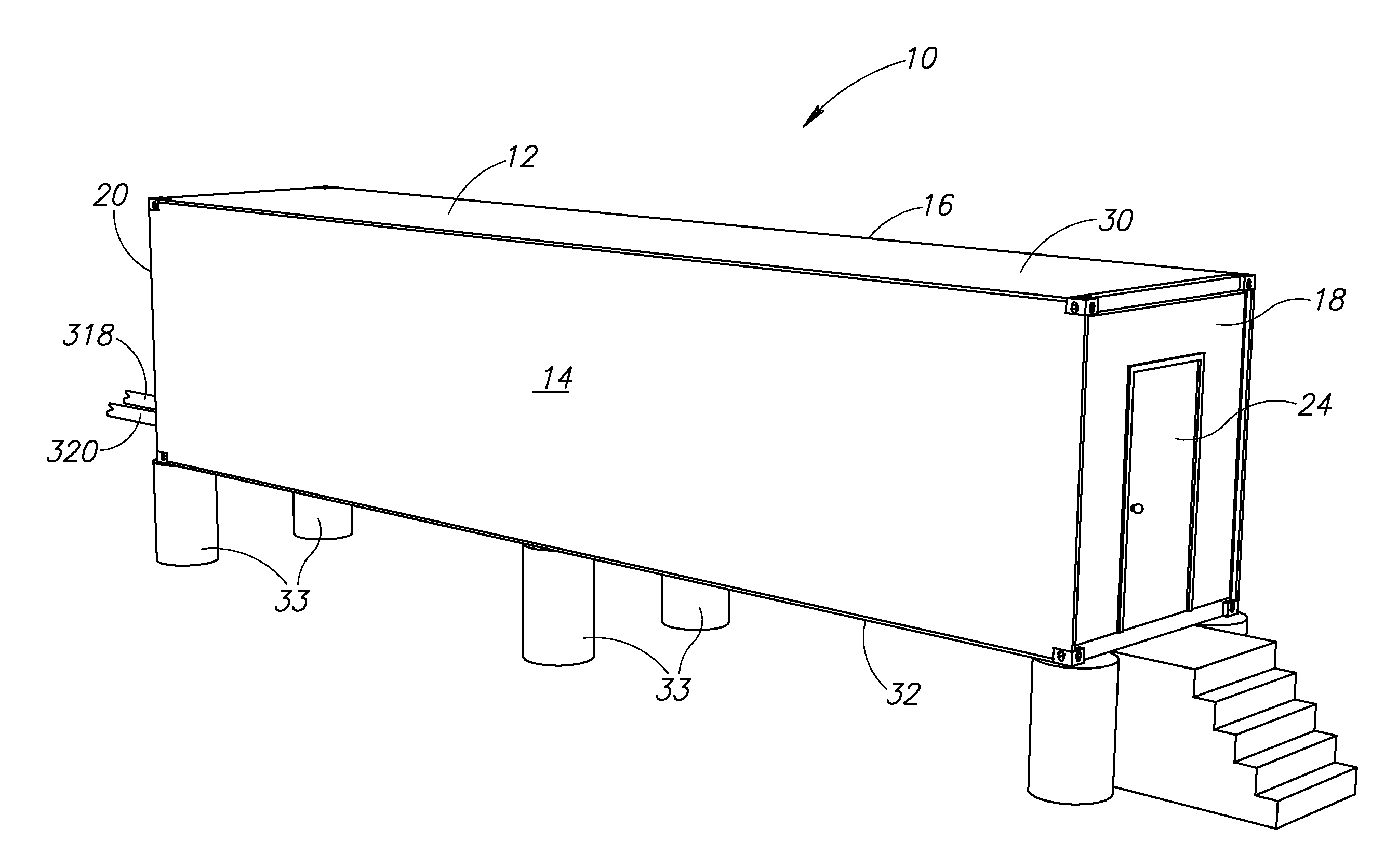

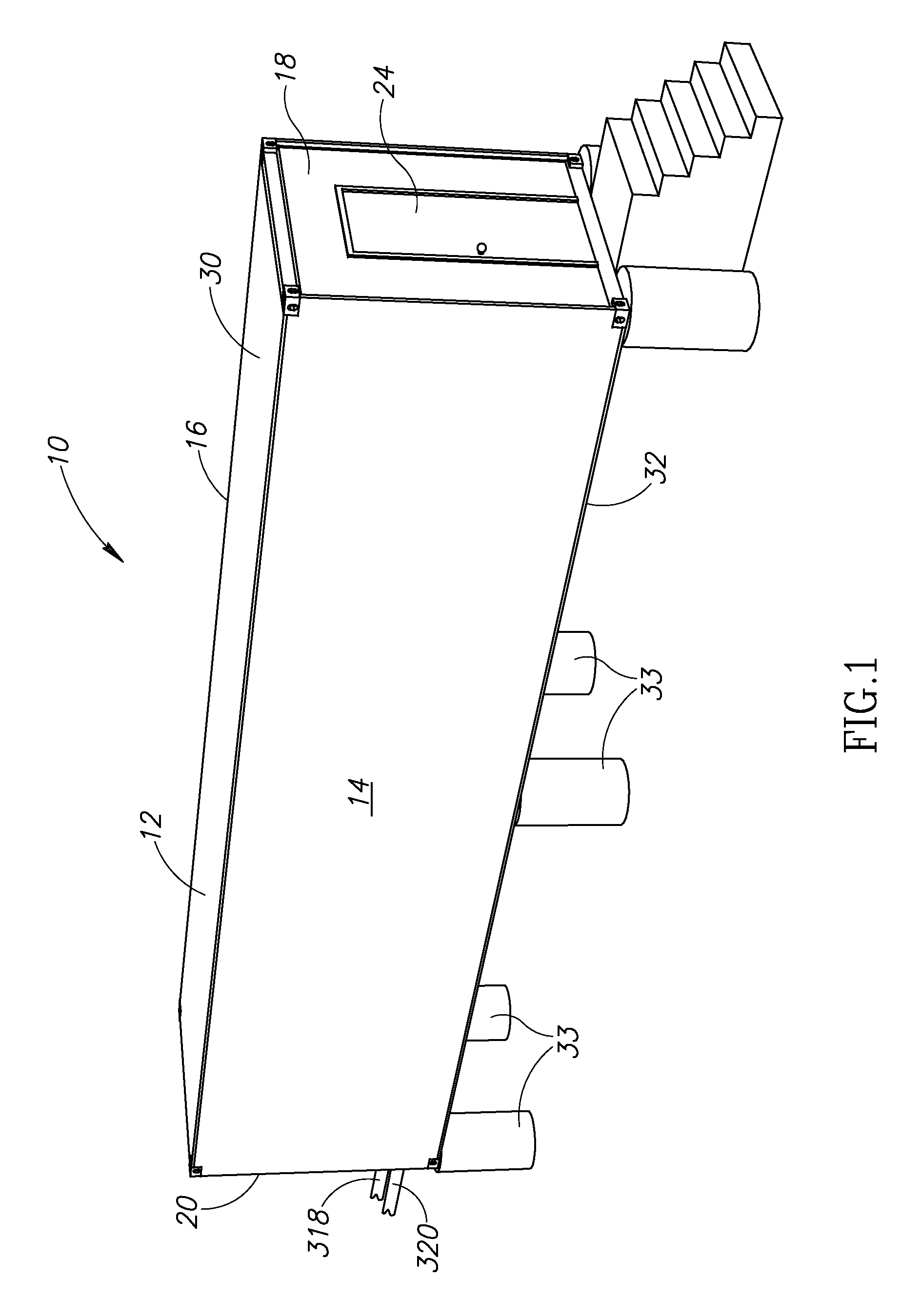

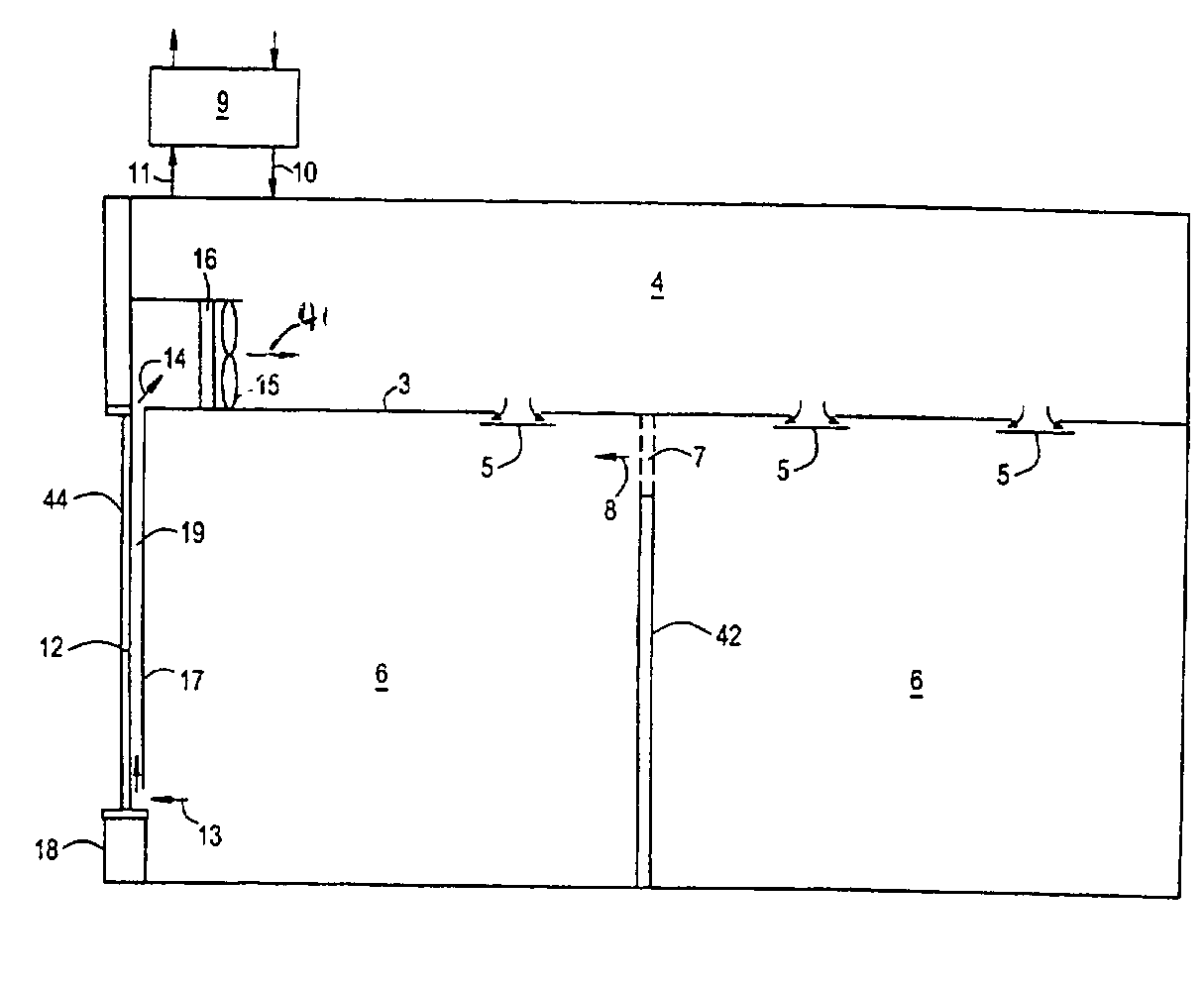

Data center

InactiveUS20100165565A1Electric signal transmission systemsMechanical apparatusData centerEngineering

A data center inside a shipping container having a lower plenum and an upper plenum in its interior. Heated air in the upper plenum exits therefrom into a plurality of heat exchangers adjacent thereto. Air cooled by the heat exchangers travels toward and enters the lower plenum. The data center includes a plurality of carriages each having an equipment receiving portion located between an open bottom portion in open communication with the lower plenum, and an open top portion in open communication with the upper plenum. Fans inside each of the carriages draw cooled air up from the lower plenum into the open bottom portion of the carriage, blow the cooled air up through the equipment receiving portion thereby cooling any computing equipment received therein, and vent the cooled air through the open top portion into the upper plenum.

Owner:CIRRASCALE

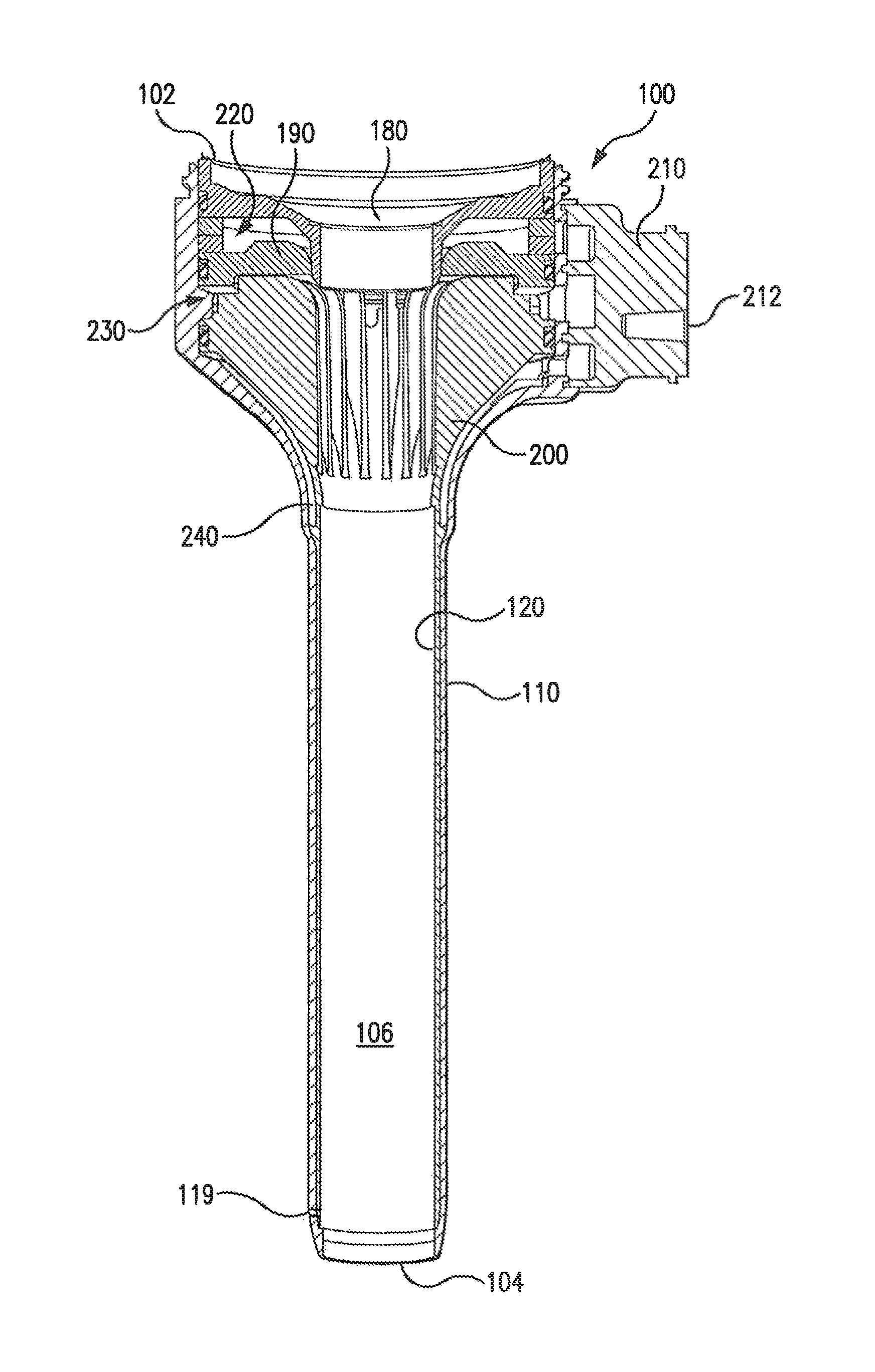

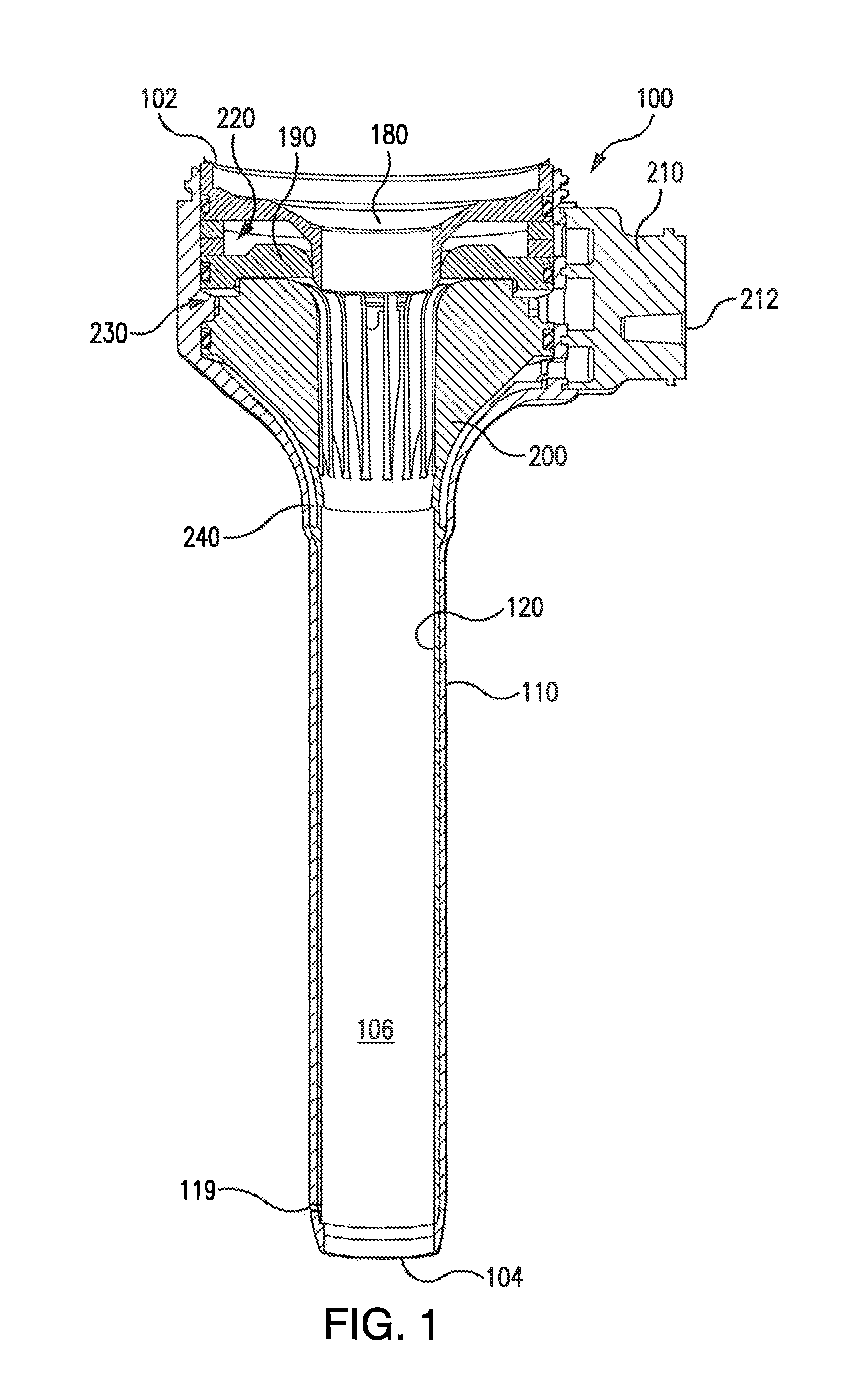

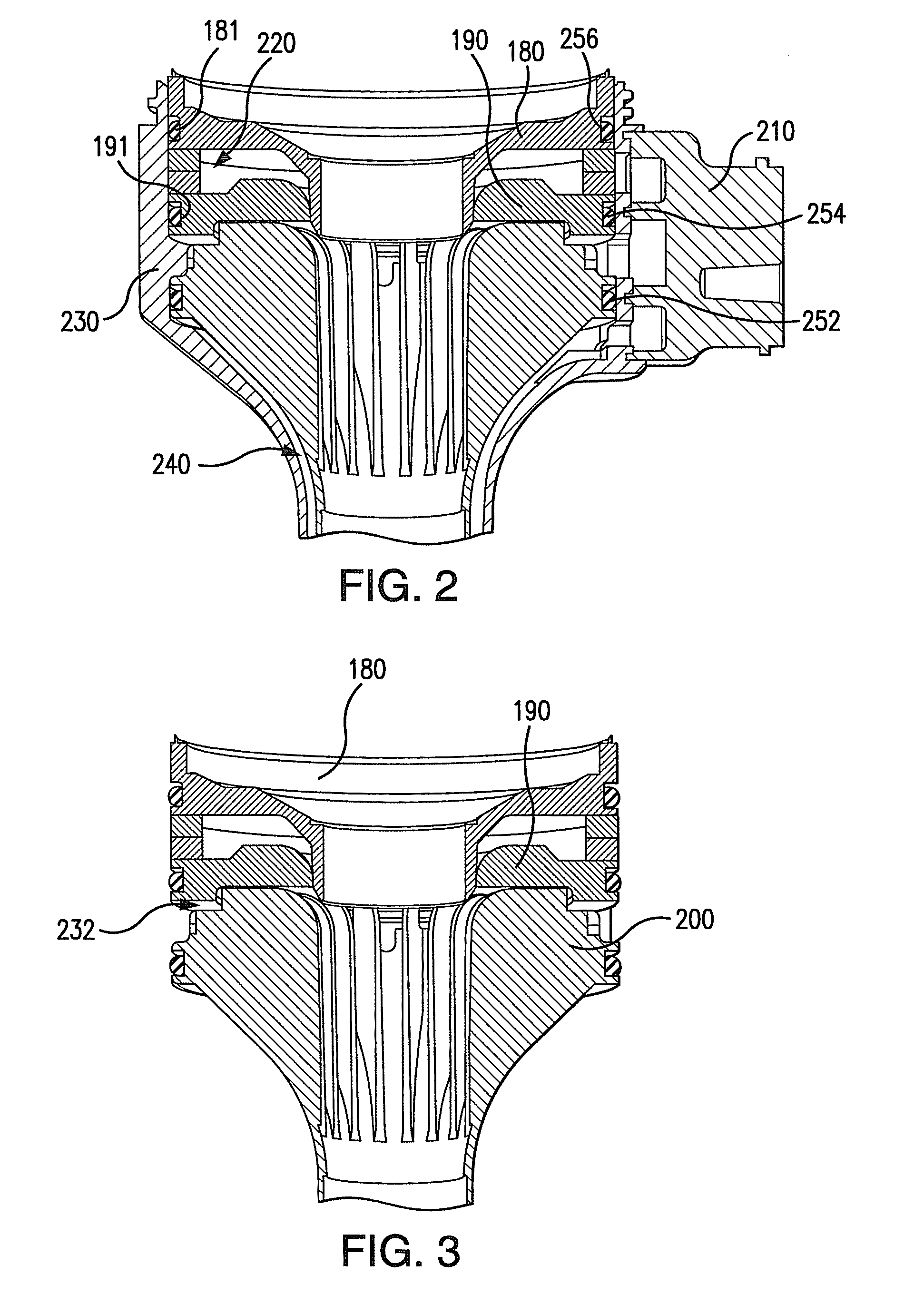

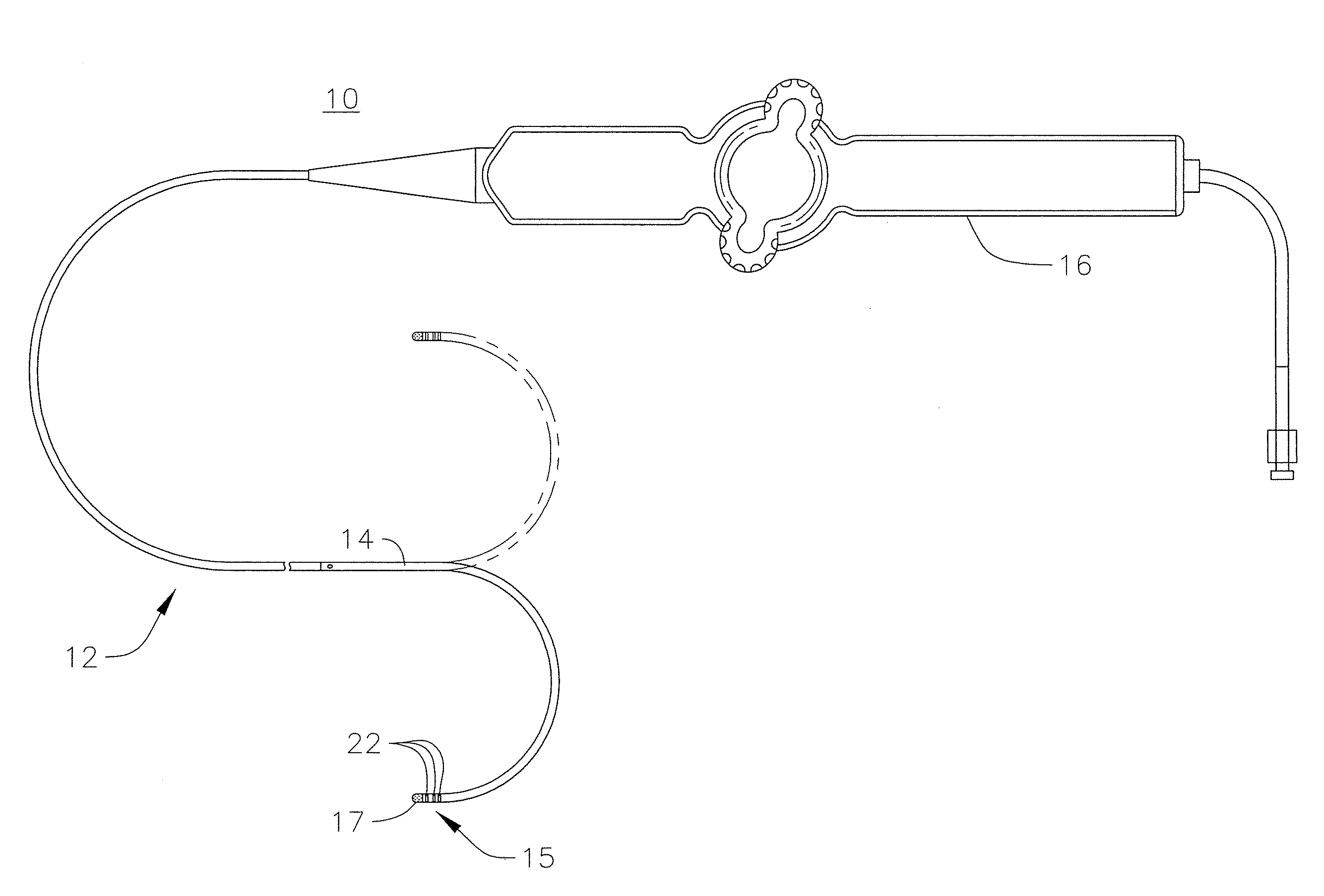

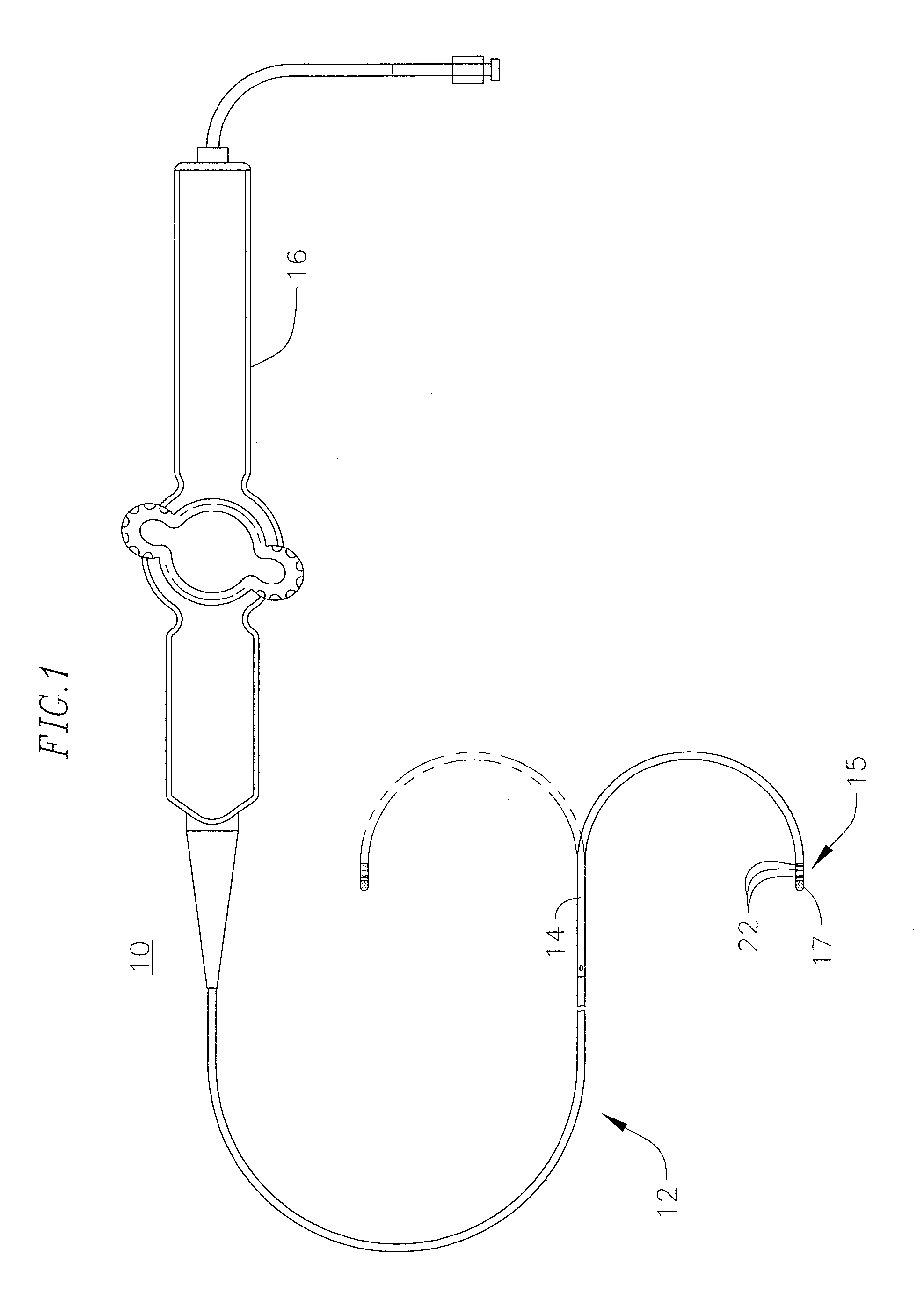

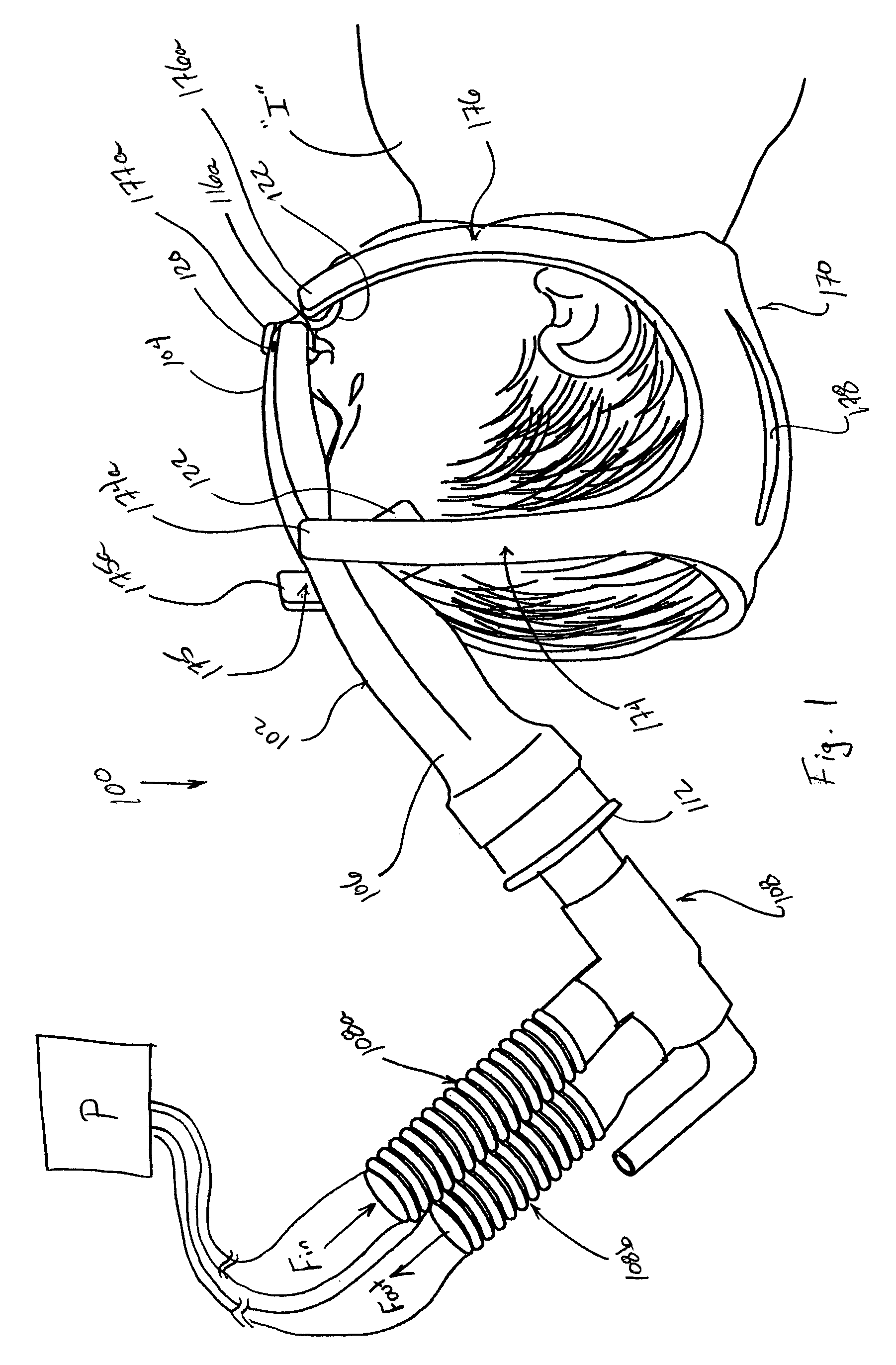

Irrigated ablation catheter with improved fluid flow

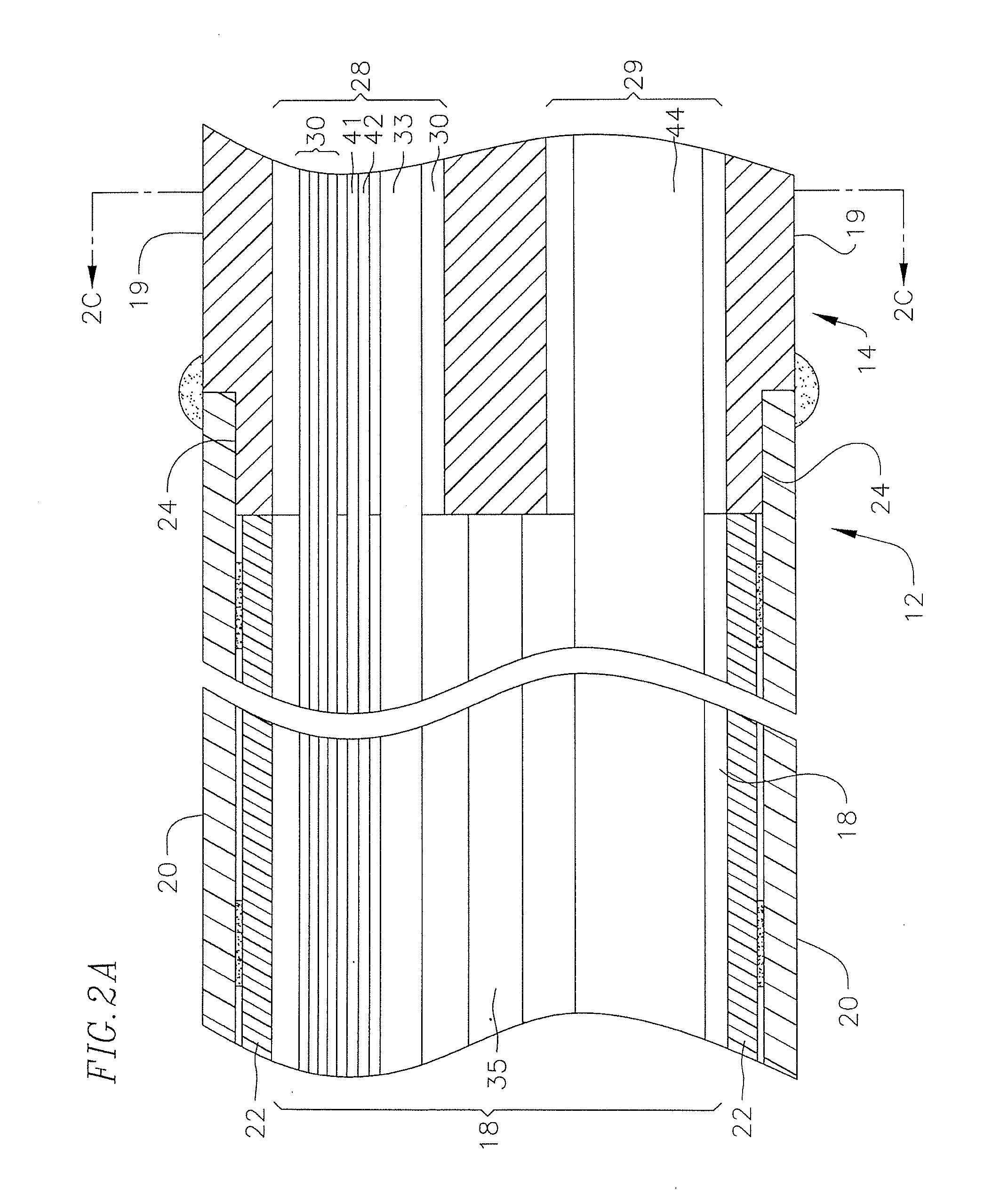

ActiveUS20110270246A1High trafficIncrease speedSurgical instruments for heatingComputer-aided surgeryFluid inputThin shells

An irrigated ablation catheter includes a tip electrode with a thin shell and a plug to provide a plenum chamber. The tip electrode has an inlet of a predetermined size and noncircular shape, and outlets in the form of fluid ports formed in the thin shell wall. The plurality of the fluid ports is predetermined, as is their diameter. The tip electrode thus considers a diffusion ratio of total fluid output area to fluid input area, and a fluid port ratio. The tip electrode also considers a fluid inlet aspect ratio where the fluid inlet has a noncircular (for example, oval or elliptical) radial cross-section. The plenum chamber has a narrow proximal portion opening to a wider distal portion so that fluid pressure decreases while fluid velocity increases with the desired effect of increased turbulence which decreases momentum for a more uniform distribution of fluid in the tip electrode. Extending distally from the plug is a baffle member shaped to diffuse fluid entering the tip electrode and to house an electromagnetic position sensor.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

Irrigated ablation catheter with improved fluid flow

ActiveUS20110270244A1Increase speedImprove fluid flowDiagnosticsSurgical instruments for heatingFluid inputThin shells

An irrigated ablation catheter includes a tip electrode with a thin shell and a plug to provide a plenum chamber. The tip electrode has an inlet of a predetermined size and noncircular shape, and outlets in the form of fluid ports formed in the thin shell wall. The plurality of the fluid ports is predetermined, as is their diameter. The tip electrode thus considers a diffusion ratio of total fluid output area to fluid input area, and a fluid port ratio. The tip electrode also considers a fluid inlet aspect ratio where the fluid inlet has a noncircular (for example, oval or elliptical) radial cross-section. The plenum chamber has a narrow proximal portion opening to a wider distal portion so that fluid pressure decreases while fluid velocity increases with the desired effect of increased turbulence which decreases momentum for a more uniform distribution of fluid in the tip electrode. Extending distally from the plug is a baffle member shaped to diffuse fluid entering the tip electrode and to house an electromagnetic position sensor.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

High-efficiency air handler

InactiveUS20030000230A1Lighting and heating apparatusCooling fluid circulationCeiling fanPressure rise

A high-efficiency air handler that is suitable for moving large volumes of air. The air handler comprises a coil and a fan. The total air volume moving through the unit is preferably over about 2000 CFM, with a total fan static pressure rise of less than about 0.5 inches and preferably less than 0.2 inches of water. The fan is preferably a modified ceiling fan with a rotational speed of less than about 450 rpm. The air handler is preferably part of a system where dehumidification and sensible cooling functions are separate. The separate dehumidification allows for much higher supply air temperatures, preferably within about 10° F. of the space temperature. Low-velocity air distribution through a ceiling plenum or a vent into the space allows for very low fan static pressures, which greatly reduces fan energy use compared to conventional ducted systems. The low static pressures and high supply-air temperatures allow the use of existing drop ceiling construction with little modification. The system can also include low-cost thermal storage. Latent thermal storage is in the form of a concentrated liquid desiccant solution. Chilled water storage is another option. The result is a major improvement in energy efficiency and comfort while reducing installed cost and peak electrical demand of the system.

Owner:KOPKO WILLIAM L

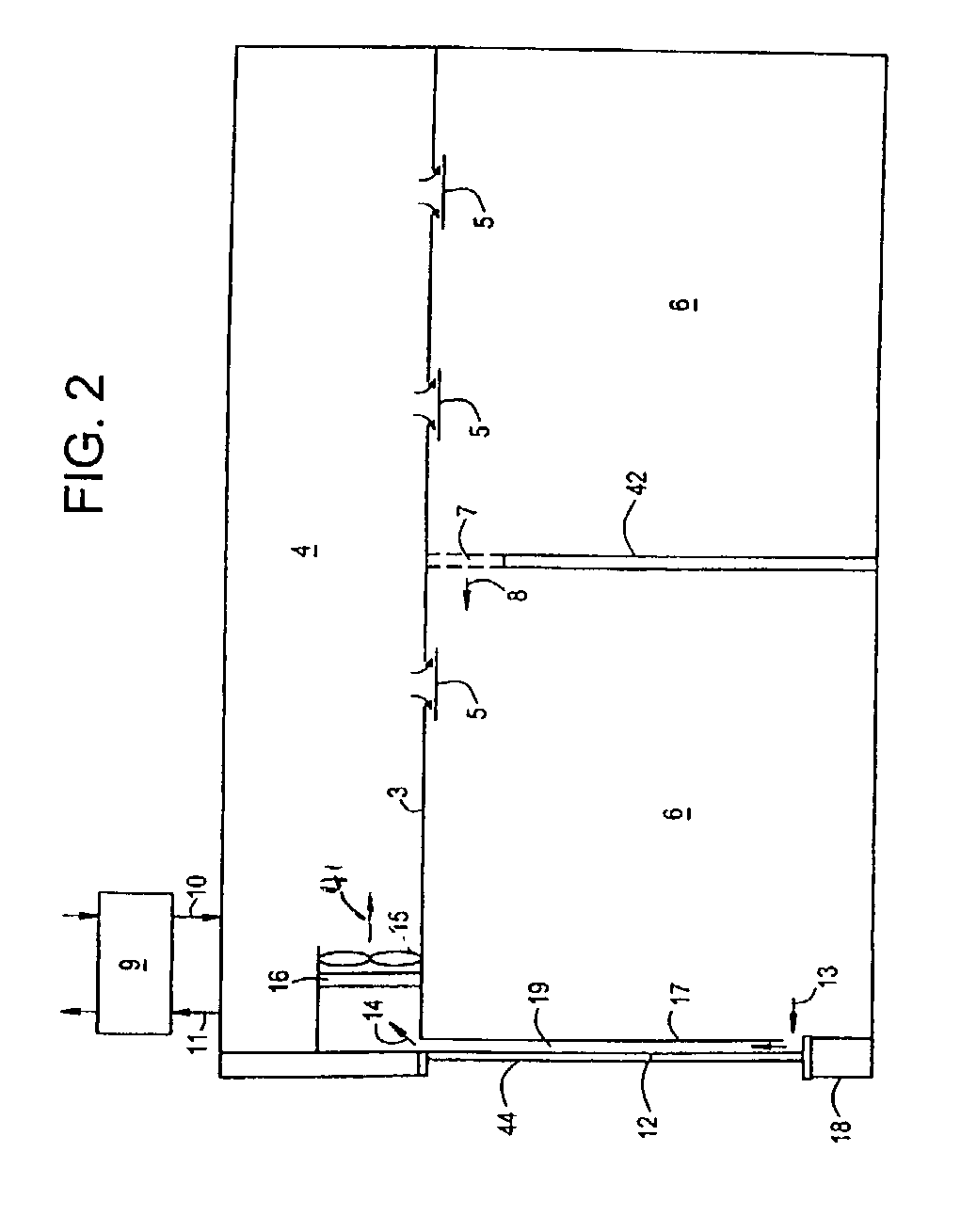

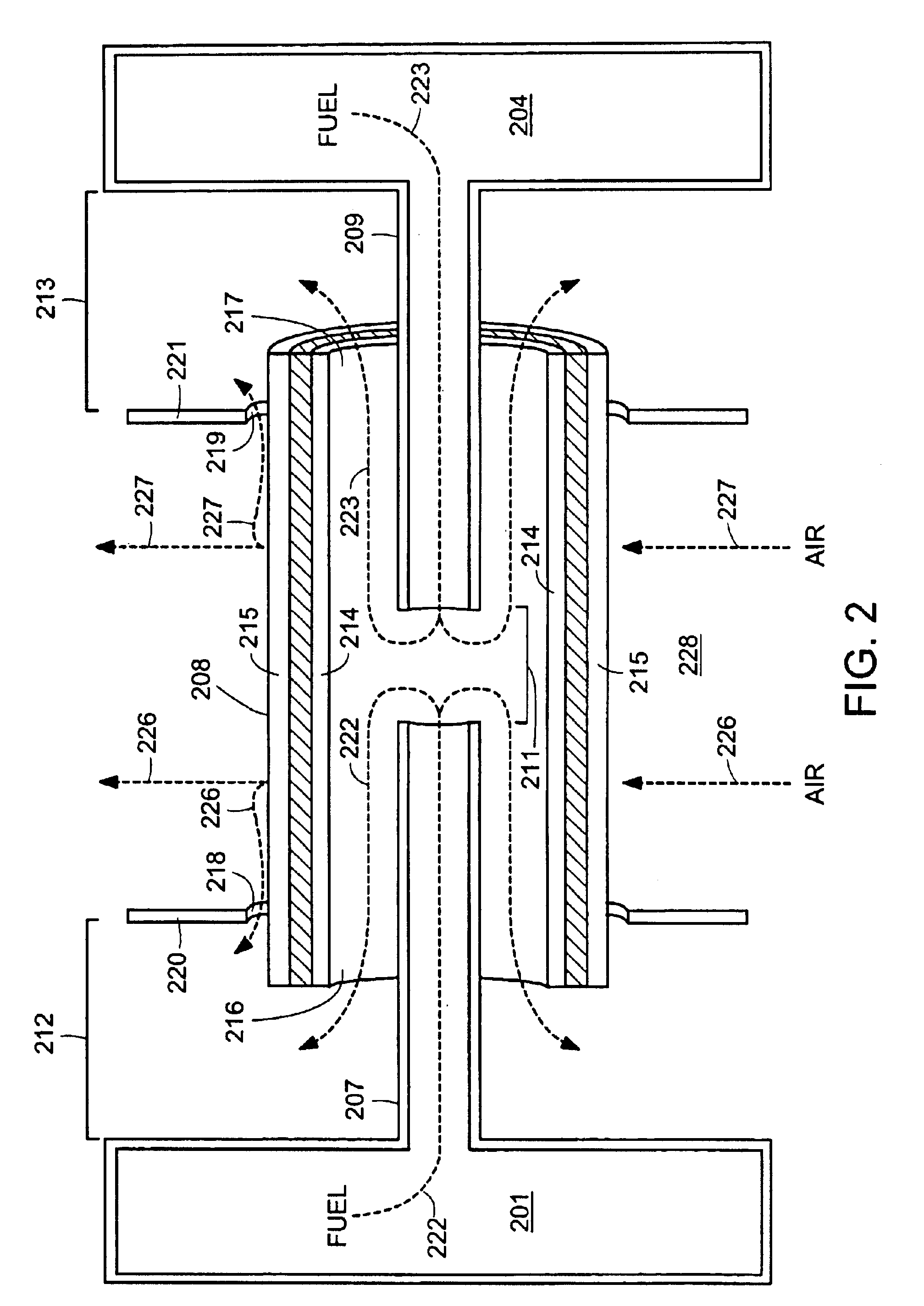

Horizontal fuel cell tube system and methods

In one disclosed embodiment according to the invention, a fuel cell system for generating electrical power comprises: an open-ended tubular solid oxide fuel cell; a first fuel injector tube extending from a first fuel plenum chamber through one open end of the fuel cell; and a second fuel injector tube extending from a second fuel plenum chamber through another open end of the fuel cell; wherein the first and second fuel injector tubes form a gap within the fuel cell from which a hydrogen-containing fuel gas may flow towards the open ends of the fuel cell. Further related systems and method are also disclosed.

Owner:ACUMENTRICS

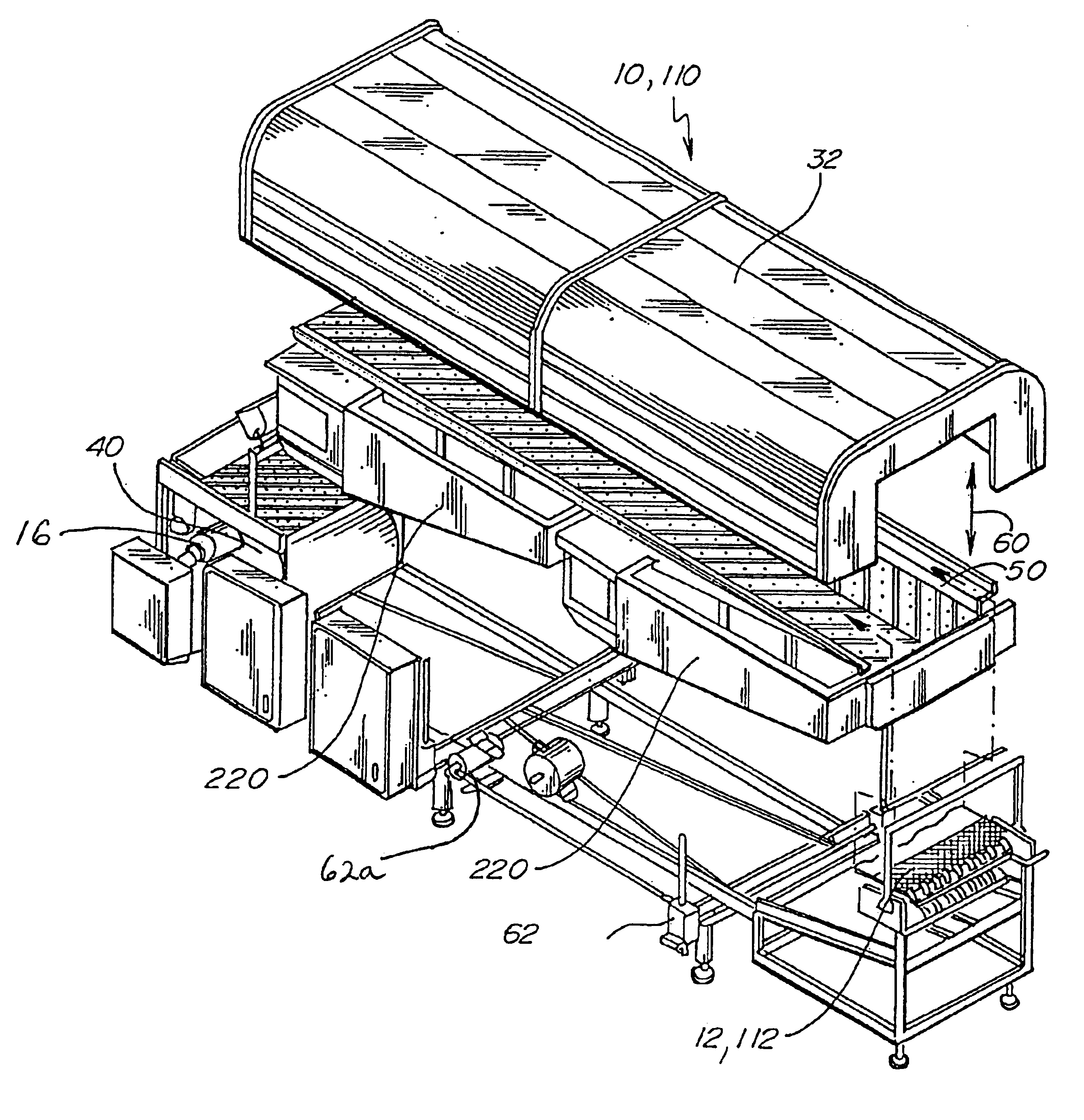

Heat tunnel for film shrinking

InactiveUS7155876B2Minimal distortionMinimum of wrinkles.Wrappers shrinkageFurnace componentsProcess engineeringShrink wrap

Owner:DOUGLAS MACHINE LIABILITY

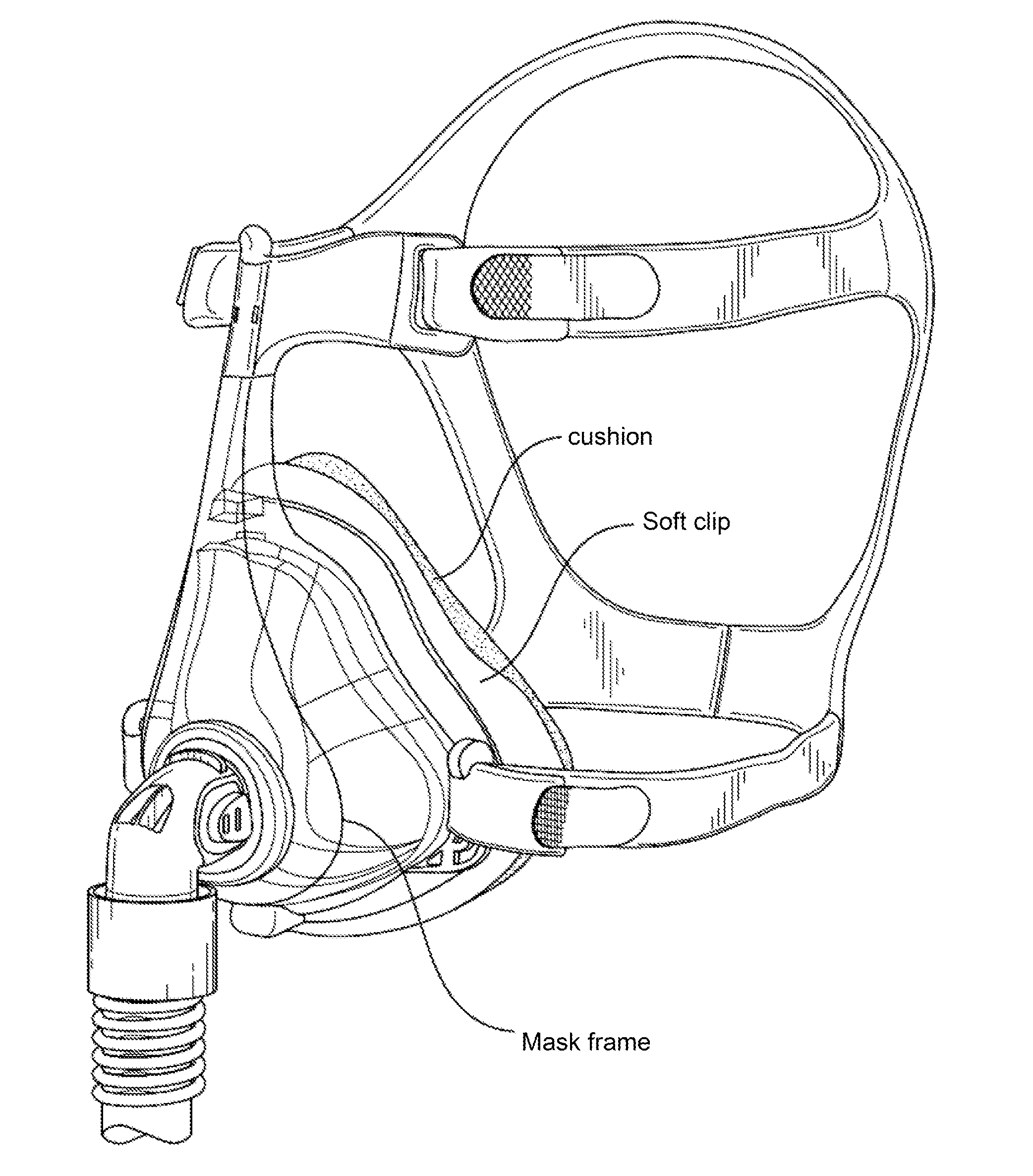

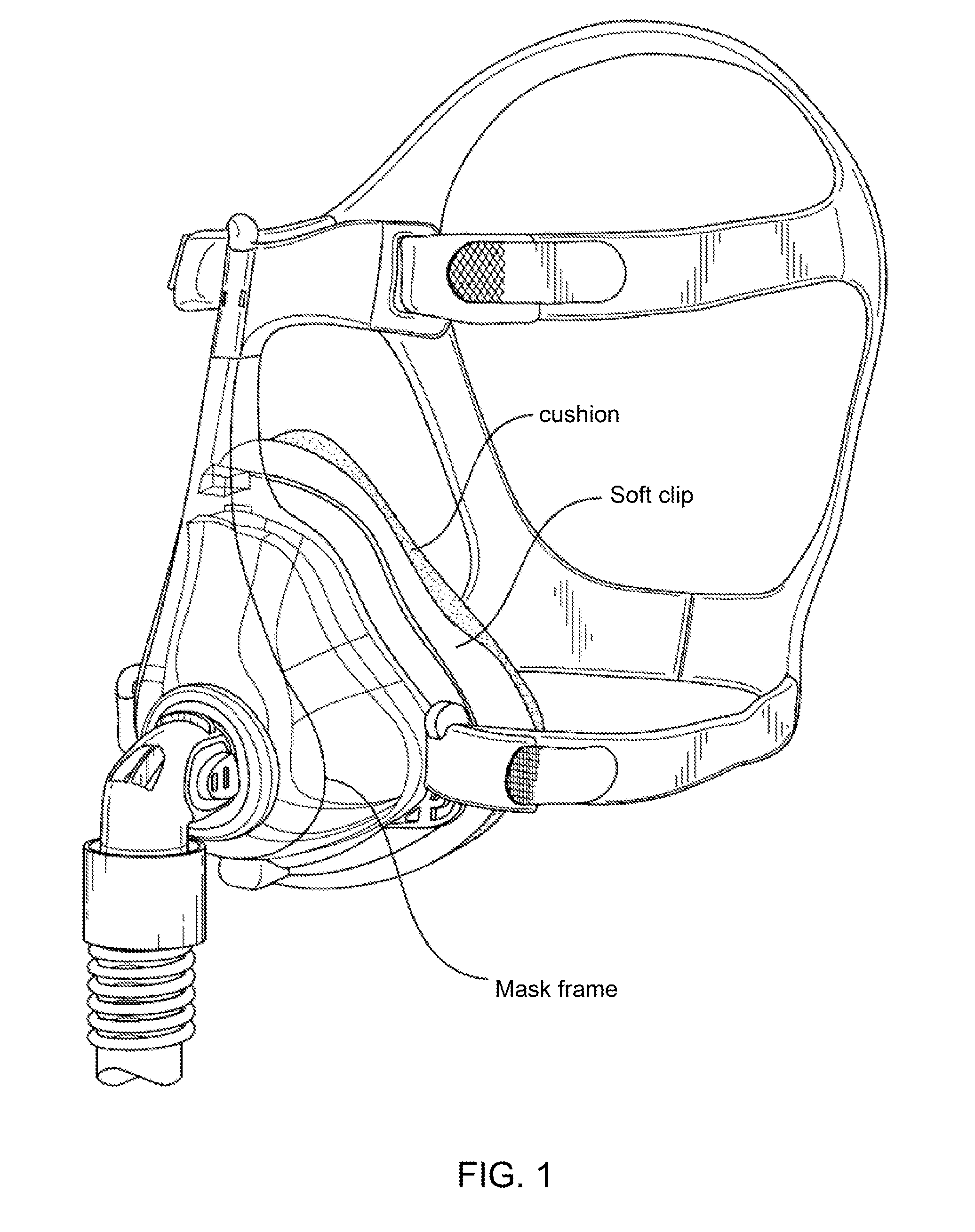

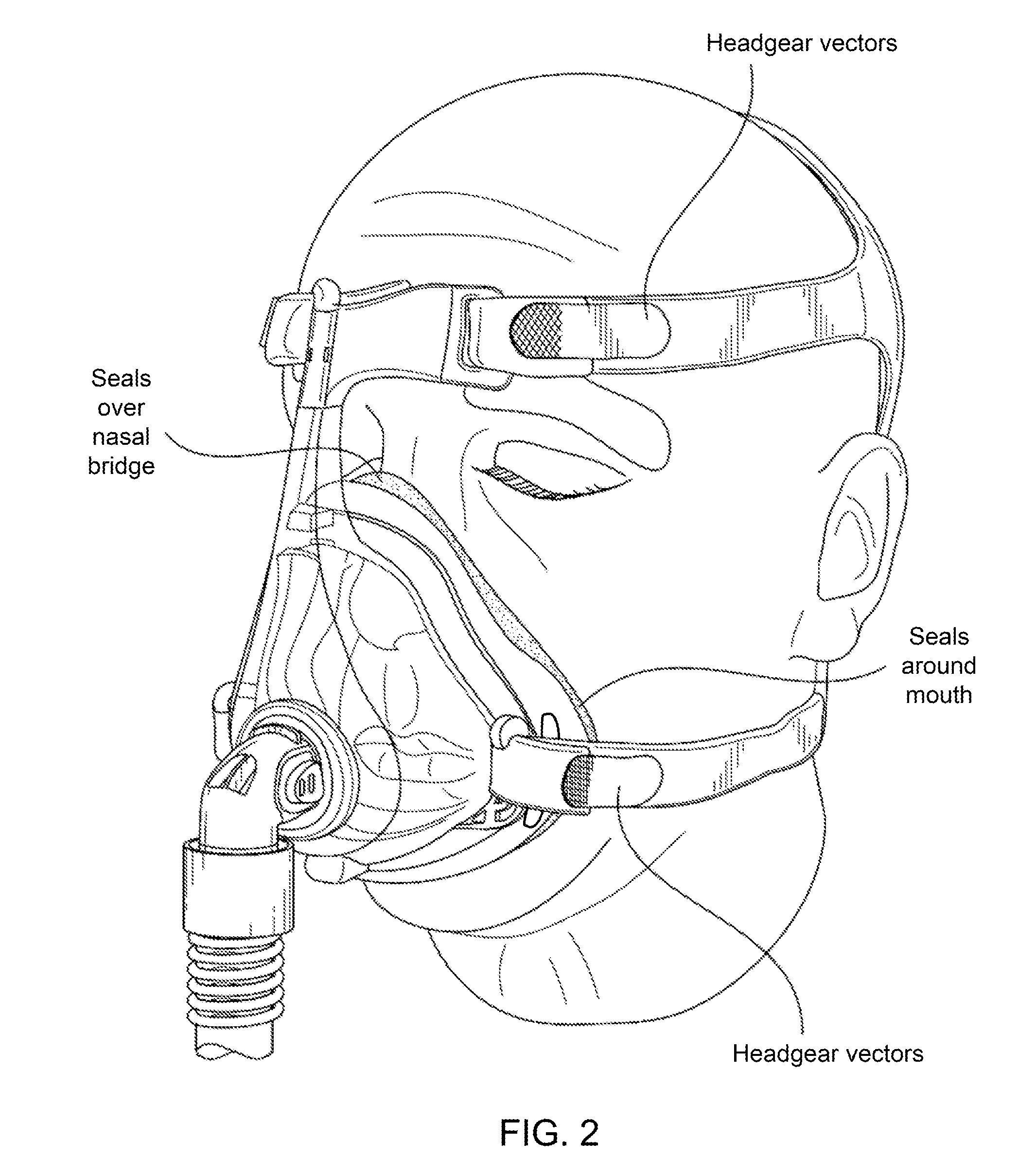

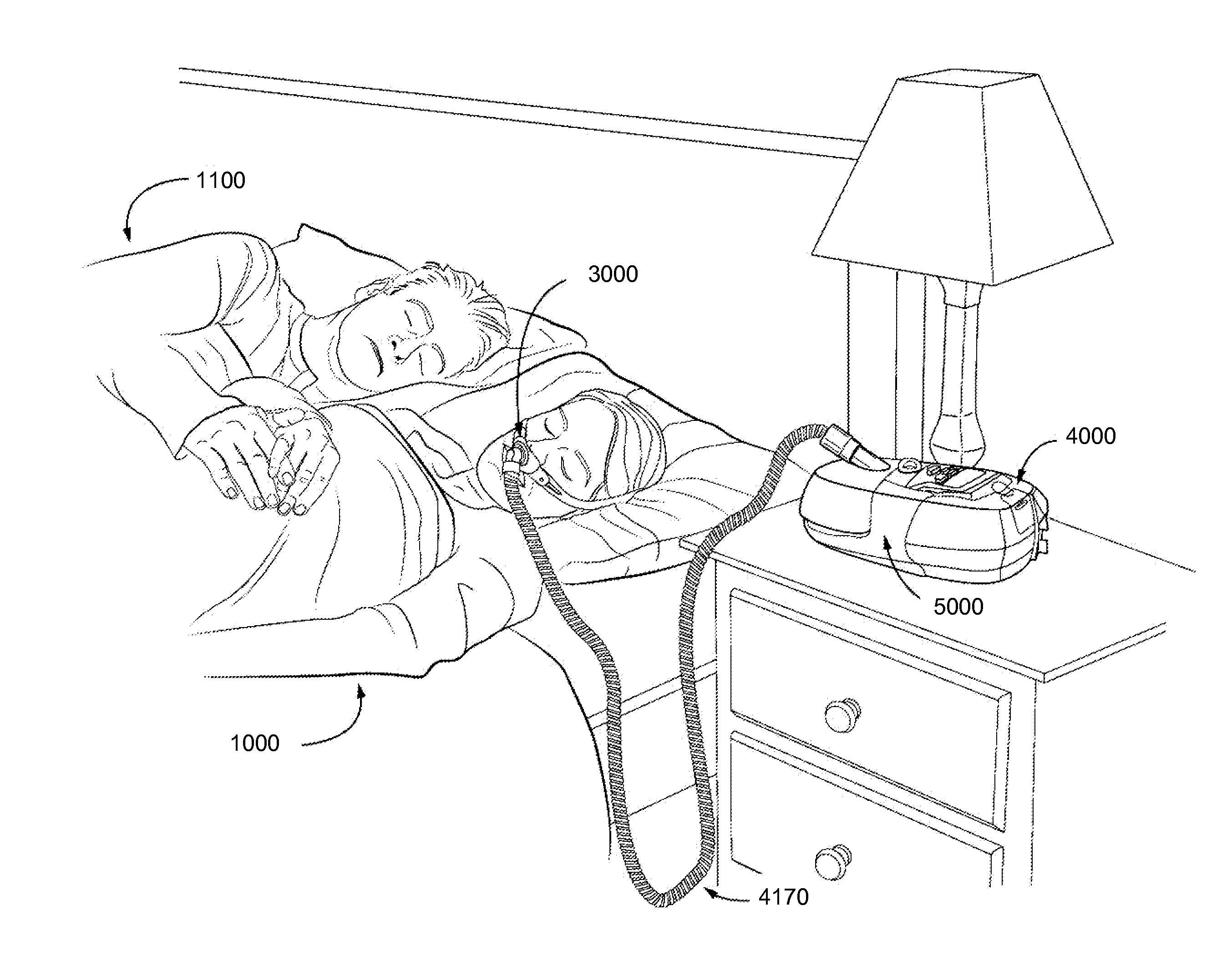

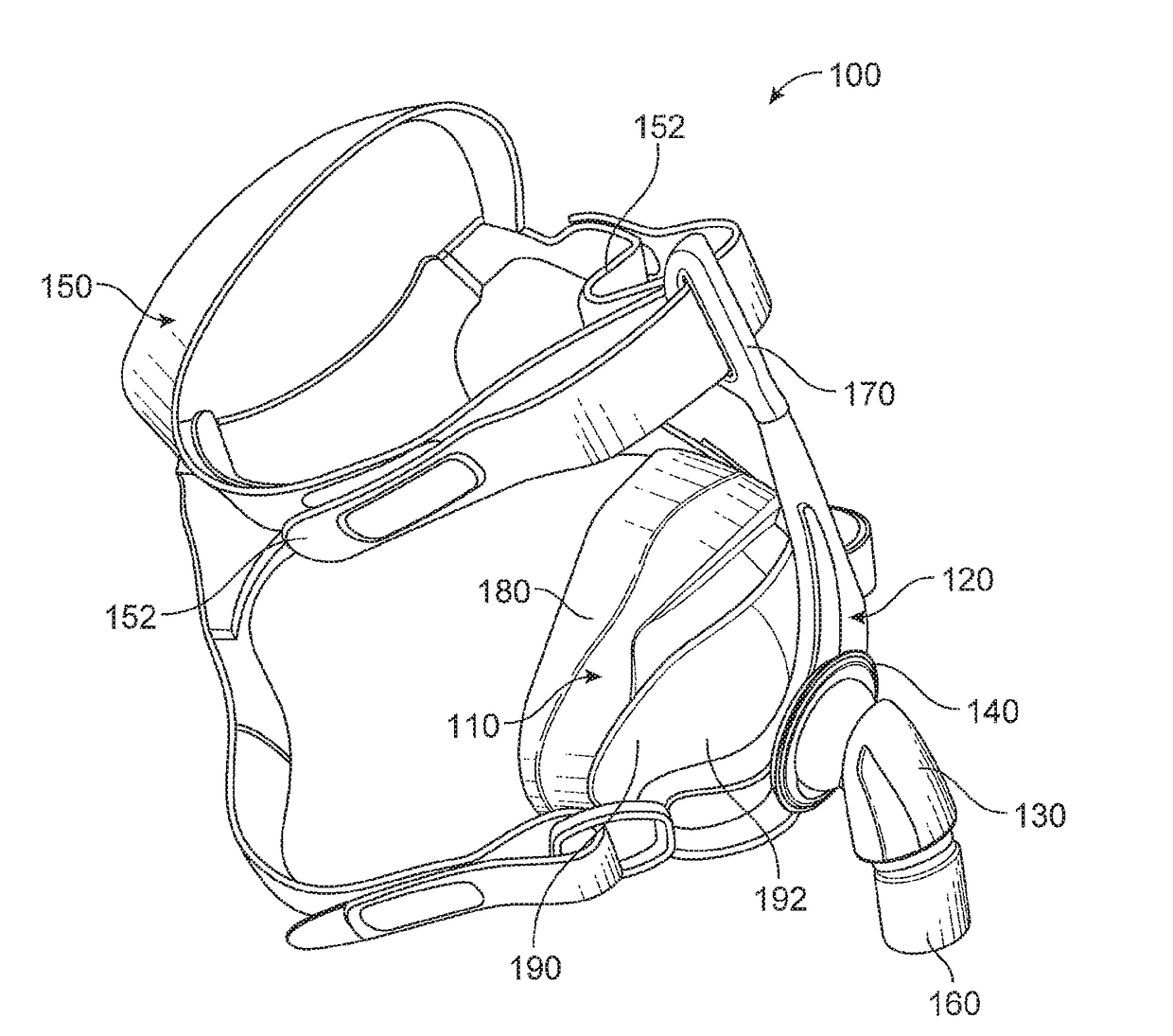

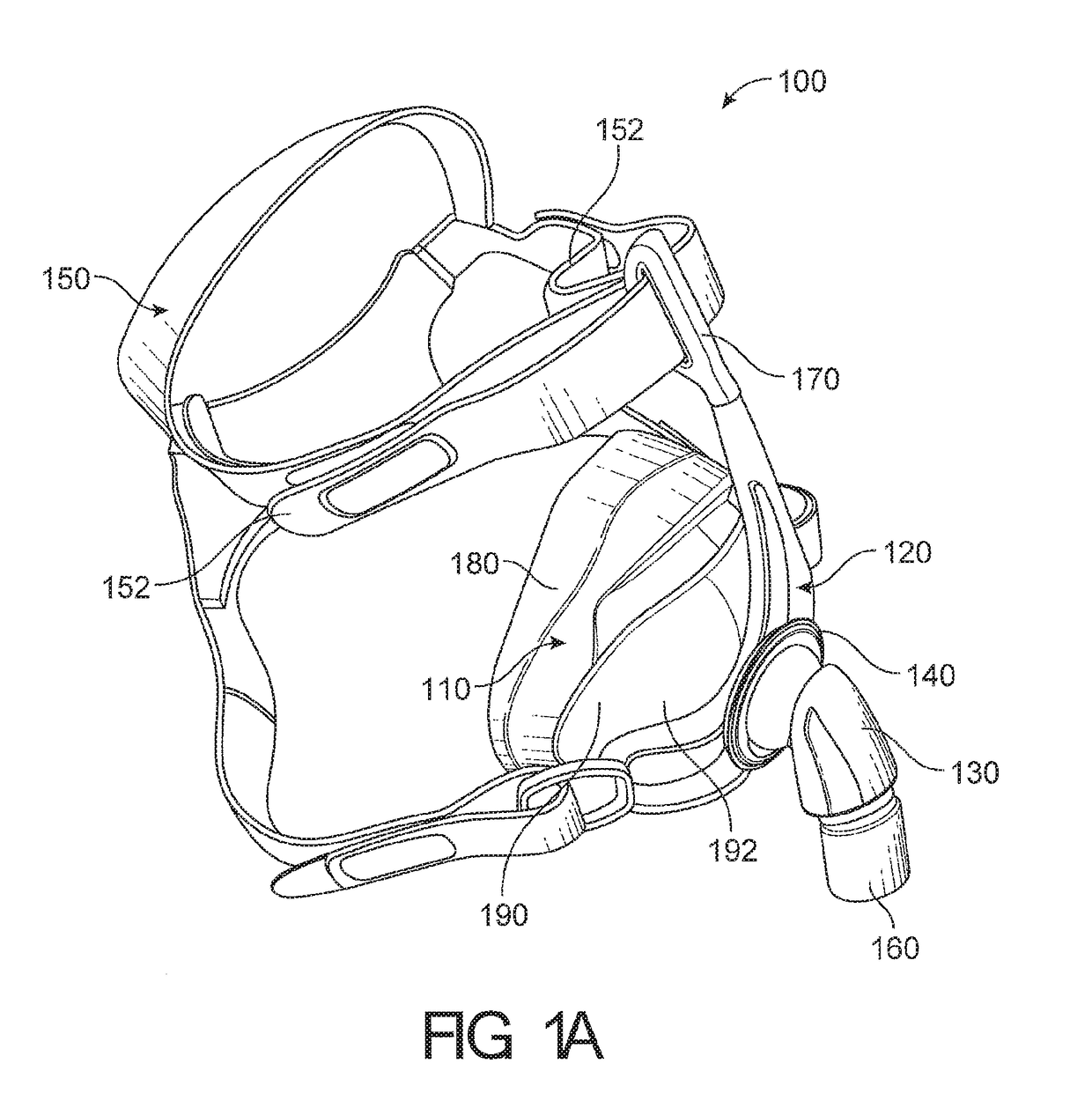

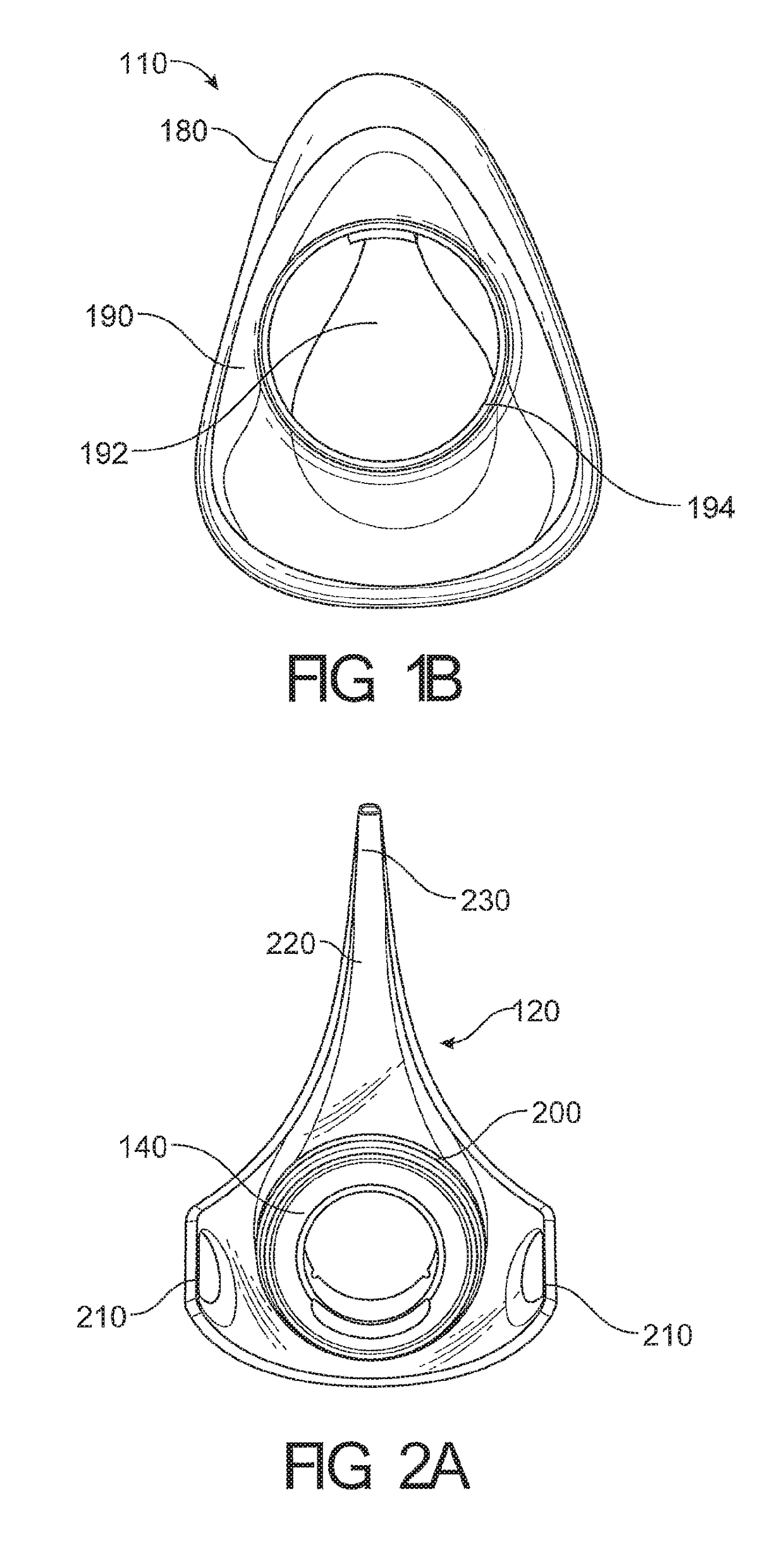

Cushion assembly

ActiveUS20140216462A1Comfortable and effective sealSmall sizeSleeve/socket jointsFluid pressure sealed jointsNoseEngineering

A foam cushion assembly for a patient interface, the foam cushion assembly being adapted to couple with a patient interface frame, the cushion assembly comprising a substantially above the nose seal portion and a mouth seal portion, wherein the cushion assembly comprises a foam cushion arranged to form with the frame a common plenum chamber for sealing about the nose and mouth.

Owner:RESMED LTD

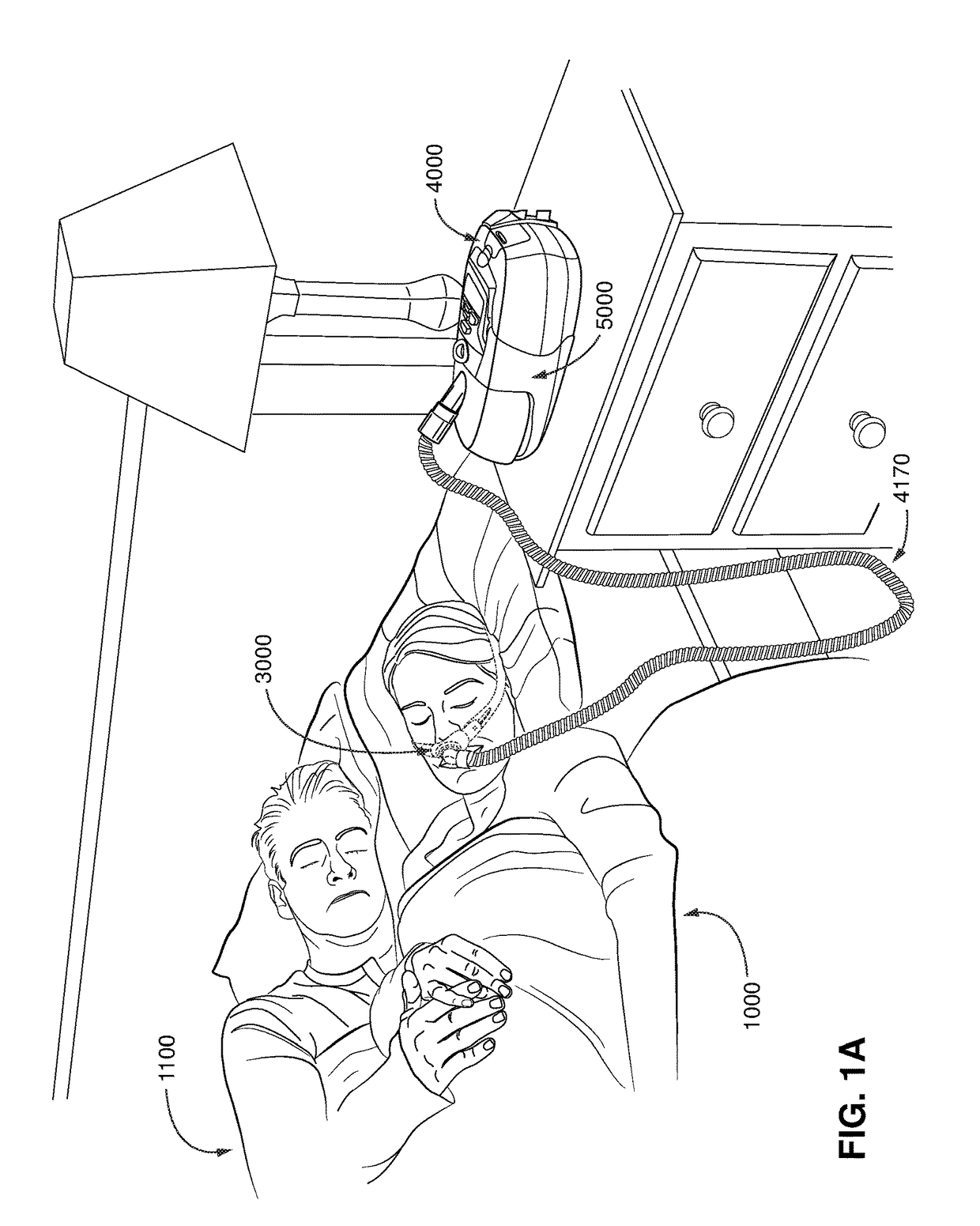

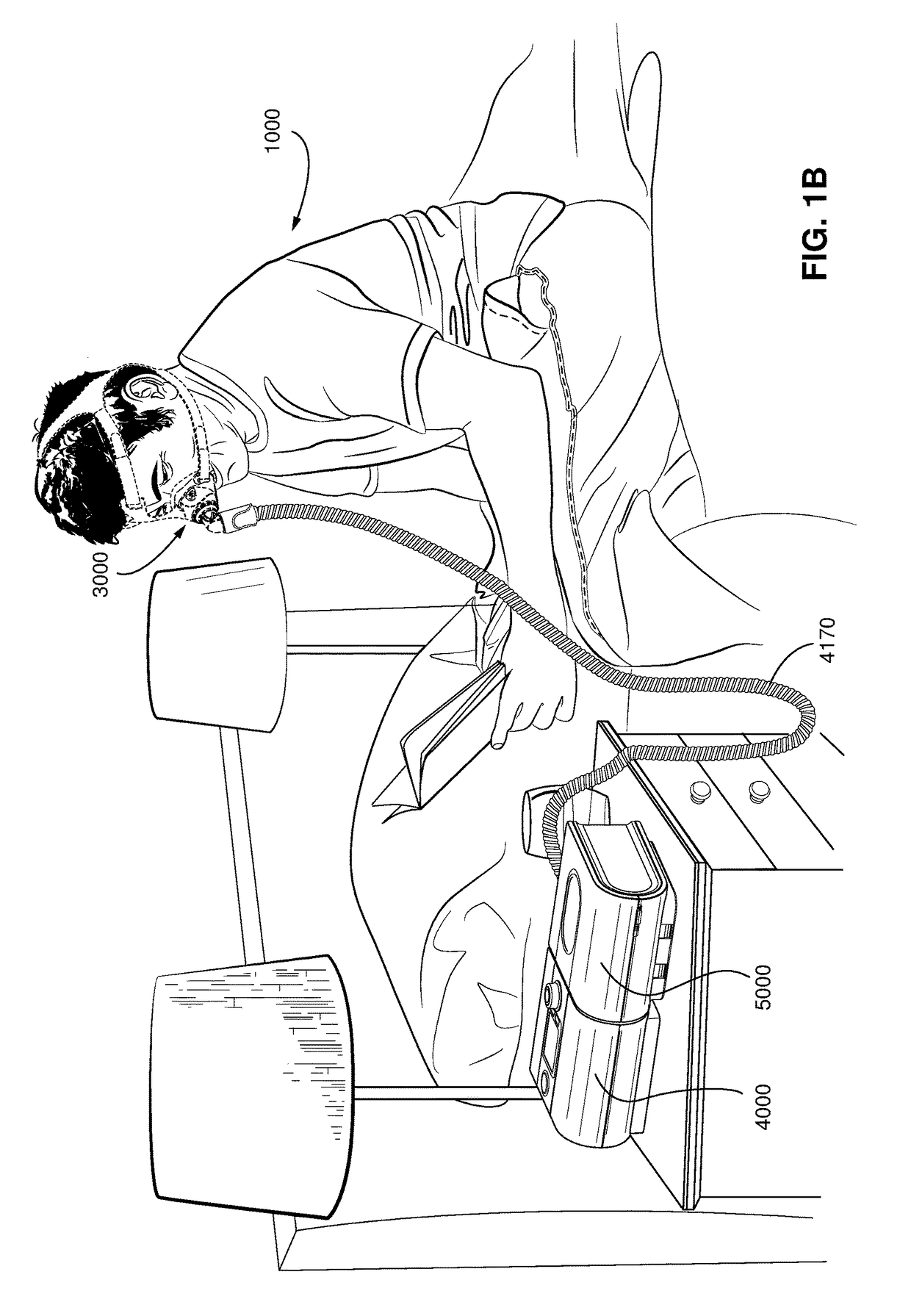

Respiratory apparatus

A mask apparatus for a respiratory treatment can permit delivery of breathable gas to a user. In one example, the mask may employ a frame and cushion to form a seal for both mouth and nose. The frame may be adapted for coupling with a respiratory treatment apparatus so as to permit communication of a pressurized gas from the respiratory treatment apparatus. The cushion, which may be foam, may have a substantially under the nose configuration or over the nose configuration. The mask may have a common plenum chamber for both nose and mouth. The cushion may further define a centrally open lip superior region. The cushion may be adapted to couple with the frame directly or to the frame in conjunction with a cushion support clip. Various features of the cushion may further promote sealing and comfort for the under the nose design.

Owner:RESMED LTD

Dynamic infant nasal CPAP system and method

Continuous positive airway pressure systems are provided including an interface defining a plenum chamber therein, and a pair of nasal cannulas connected to and in fluid communication with the plenum chamber of the interface. The nasal cannulas are configured and dimensioned to deliver pressurized air from the plenum chamber to the nares of a patient, wherein each nasal cannula is capable of off axis movement and / or pivoting.

Owner:WESTMED

Textile patient interface

ActiveUS20170326320A1Improve comfortIncrease costRespiratory masksMedical devicesPositive pressureAmbient pressure

A patient interface for sealed delivery of a flow of air at a continuously positive pressure with respect to ambient air pressure to an entrance to the patient's airways including at least entrance of a patient's nares to ameliorate sleep disordered breathing may include a seal-forming structure comprising a foam undercushion and a textile membrane for contact with the patient's face; a positioning and stabilising structure to maintain the seal-forming structure in sealing contact with an area surrounding an entrance to the patient's airways while maintaining a therapeutic pressure at the entrance to the patient's airways; and a plenum chamber pressurised at a pressure above ambient pressure in use.

Owner:RESMED LTD

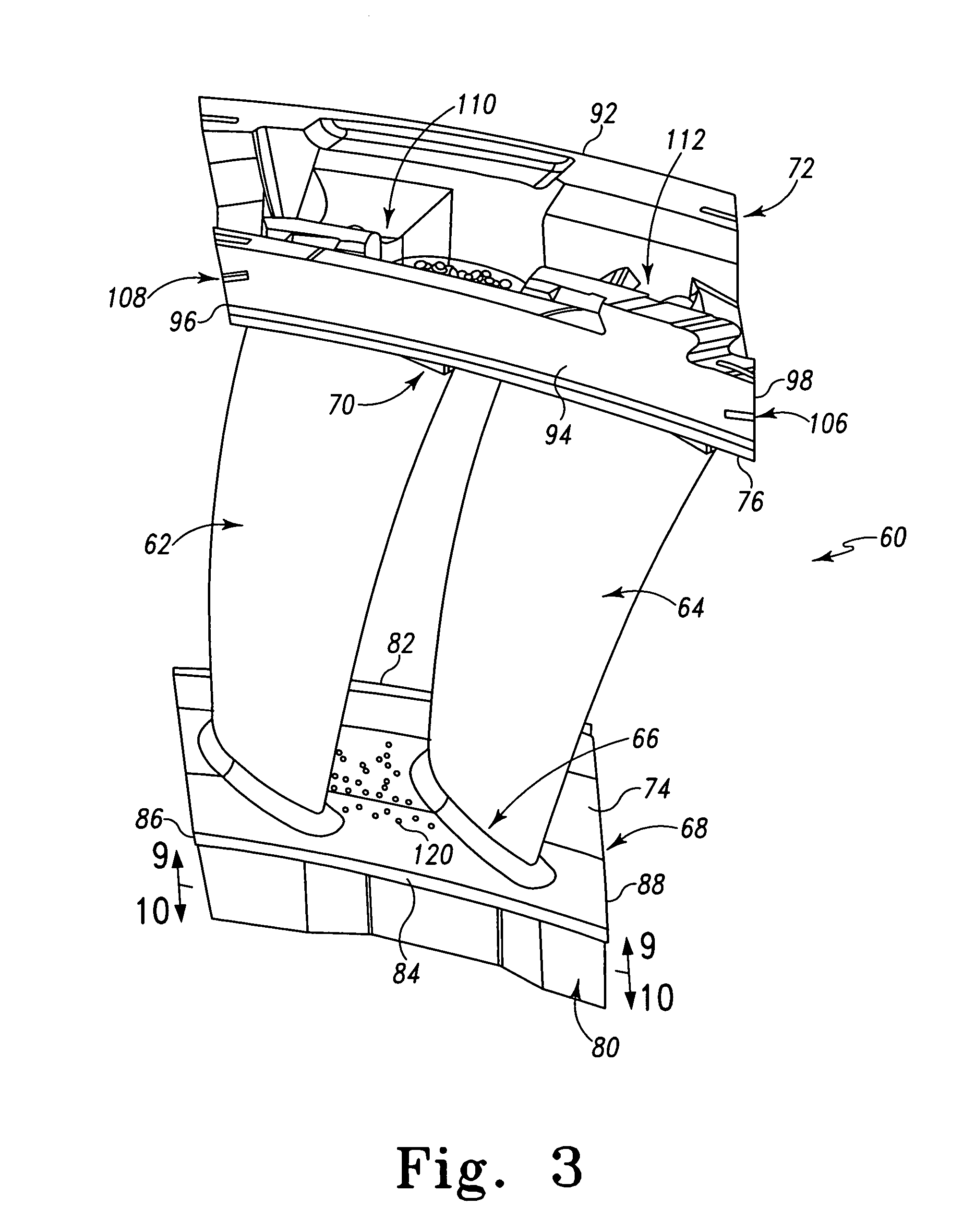

Vane platform cooling

A vane cluster has a platform, a shroud, and at least first and second airfoils extending between an outer face of the platform and an inner face of the shroud. Each airfoil has a pressure side and a suction side. The pressure side of the first airfoil faces the suction side of the second airfoil. The cluster includes a cooling passageway system. The system includes at least one inlet in the shroud. At least one first feed passageway extends from the shroud to the platform through the first airfoil. At least one second feed passageway extends from the shroud to the platform through the second airfoil. A first platform cooling plenum is to the pressure side of the first airfoil. A second platform cooling plenum is to the suction side of the first airfoil.

Owner:RTX CORP

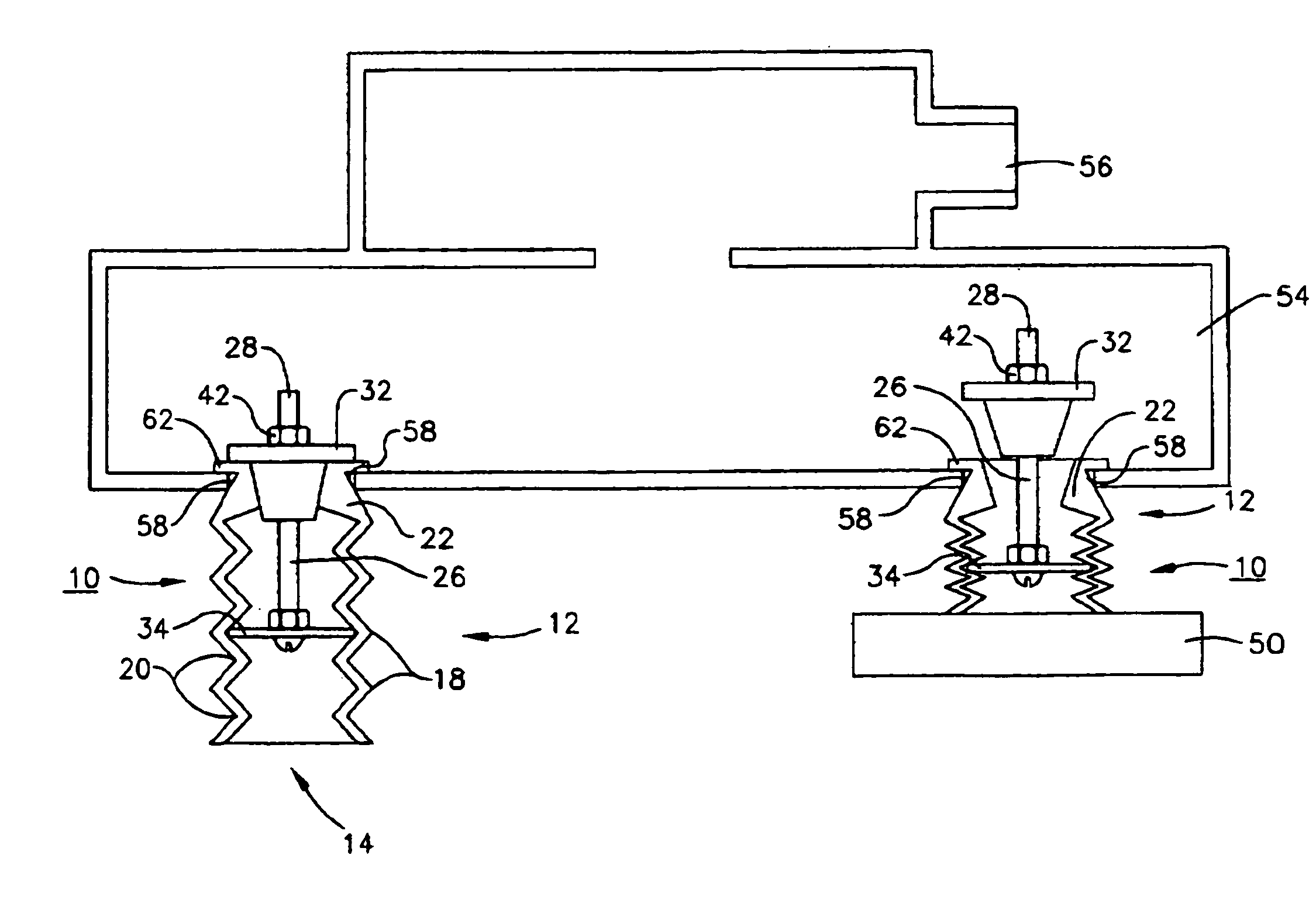

Vacuum flow suction cup assembly

A contact activated vacuum assisted suction cup assembly comprising: 1) a cylindrical bellowed or corrugated cup defining a plurality of interconnected bellows or corrugations of alternating, coaxial large and small diameter areas, hereinafter “bellows”, and having; A) an open contact end; and B) a valve end including a valve seat; 2) a valve stem having first and second extremities; 3) a valve plate intermediate the open contact end and the valve end in one of the large diameter areas attached to the first extremity; and 4) a valve stop attached to the valve stem at the second extremity that can engage the valve seat in the closed position. A picking device comprising a vacuum plenum having a plurality of the previously described contact activated vacuum assisted suction cup assemblies mounted therein in plenum apertures that engage a peripheral flange about the valve end is also described.

Owner:AMF AUTOMATION TECH

Shroud block segment for a gas turbine

A shroud block segment for a gas turbine includes a main body having a leading portion, a trailing portion, a first side portion and an opposing second side portion that extend axially between the leading portion and the trailing portion. The main body further includes an arcuate combustion gas side, an opposing back side and a cooling chamber defined in the back side. A cooling plenum and an exhaust passage are defined within the main body where the exhaust passage provides for fluid communication out of the cooling plenum. An insert opening extends within the main body through the back side towards the cooling plenum. A cooling flow insert is disposed within the insert opening. The cooling flow insert comprises a plurality of cooling flow passages that provide for fluid communication between the cooling chamber and the cooling plenum.

Owner:GENERAL ELECTRIC CO

Apparatus and method for a fuel nozzle

A fuel nozzle includes a fuel plenum, an outer body surrounding the fuel plenum, and bore holes that extend longitudinally through the outer body. The fuel nozzle also includes means for fixedly attaching the fuel plenum to the outer body and passages that provide fluid communication between the fuel plenum and the bore holes. A method for manufacturing a fuel nozzle includes drilling bore holes longitudinally through an outer body and drilling passages in the outer body to the bore holes. The method further includes inserting a fuel plenum into the outer body, wherein the passages provide a fluid communication between the bore holes and the fuel plenum, and attaching the fuel plenum to the outer body.

Owner:GENERAL ELECTRIC CO

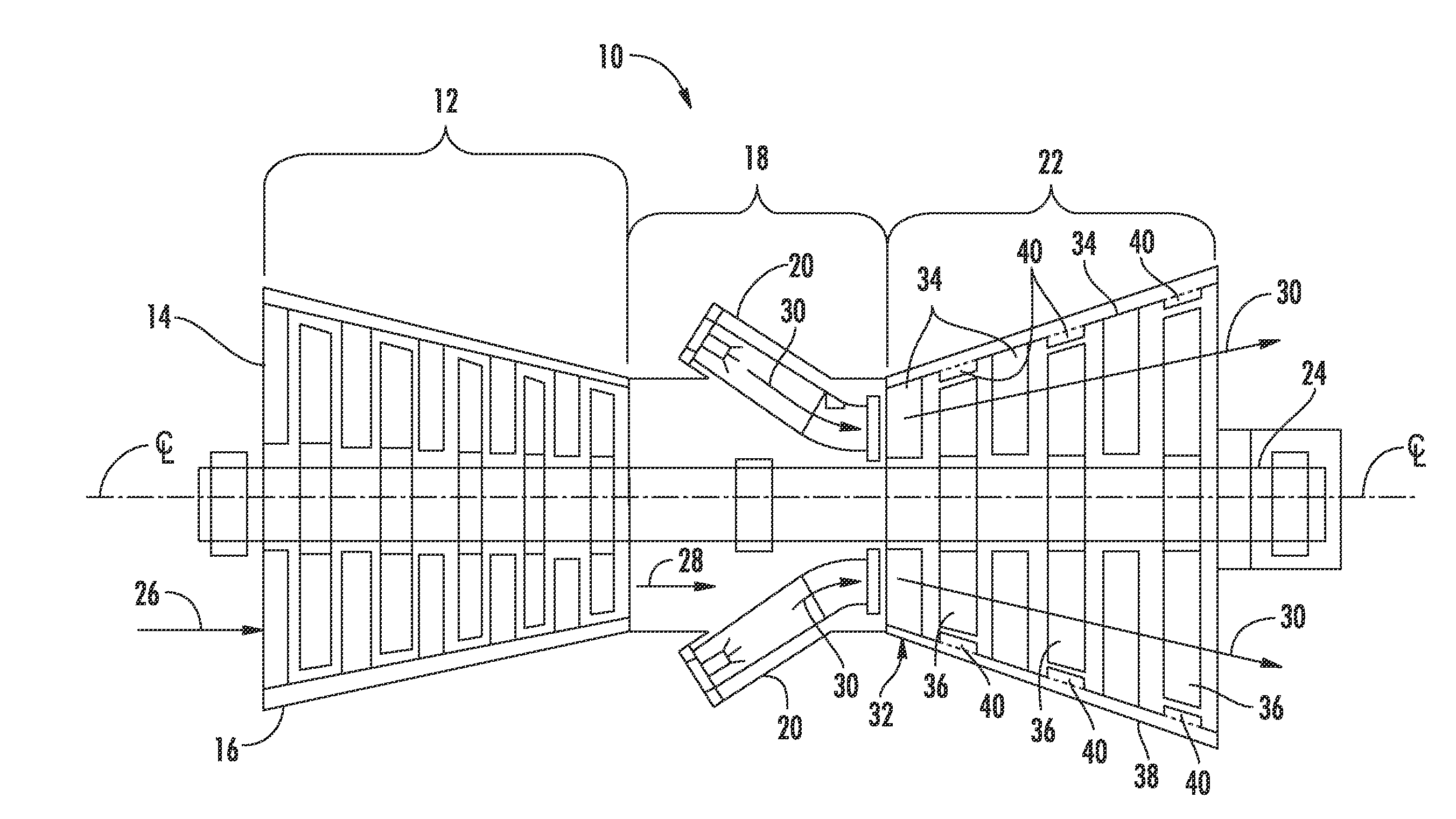

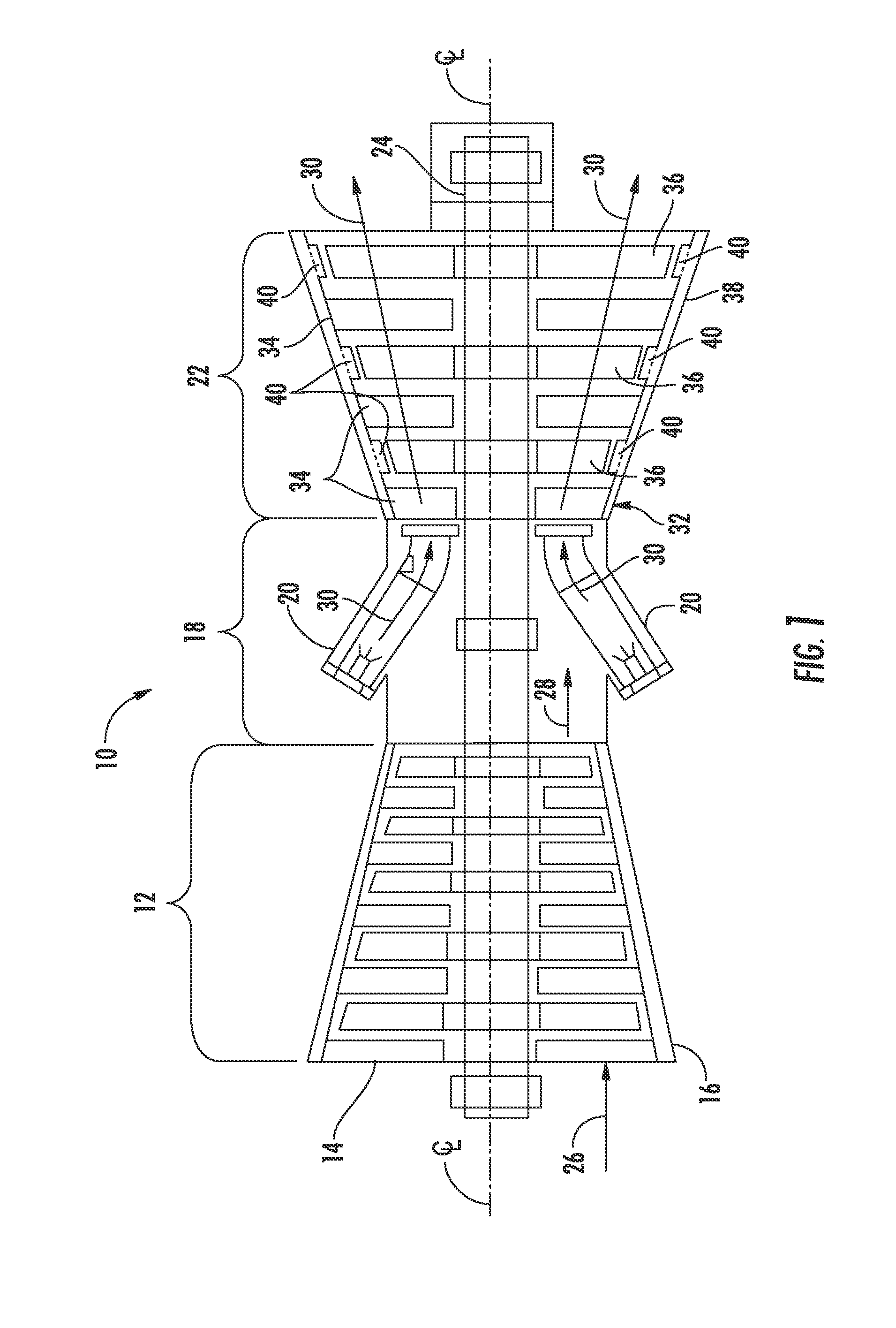

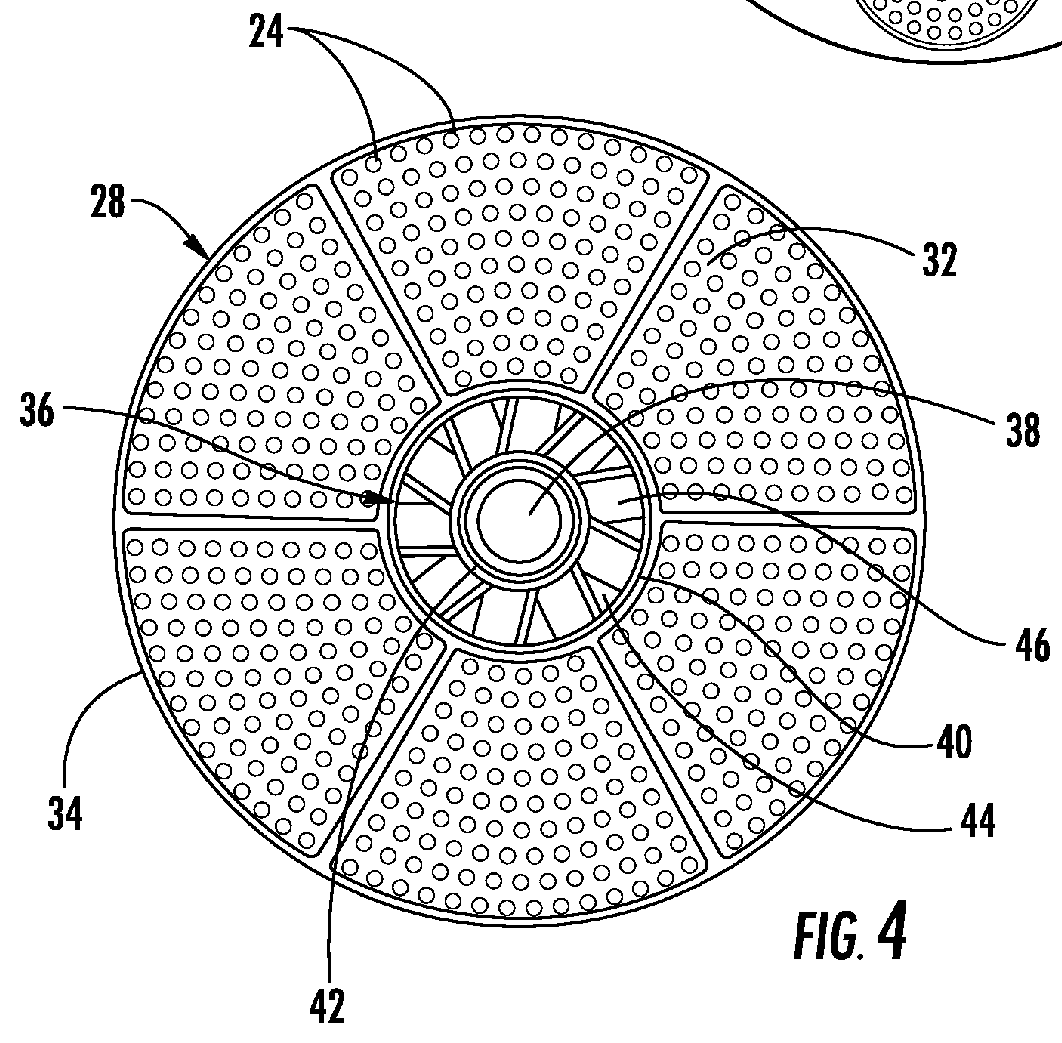

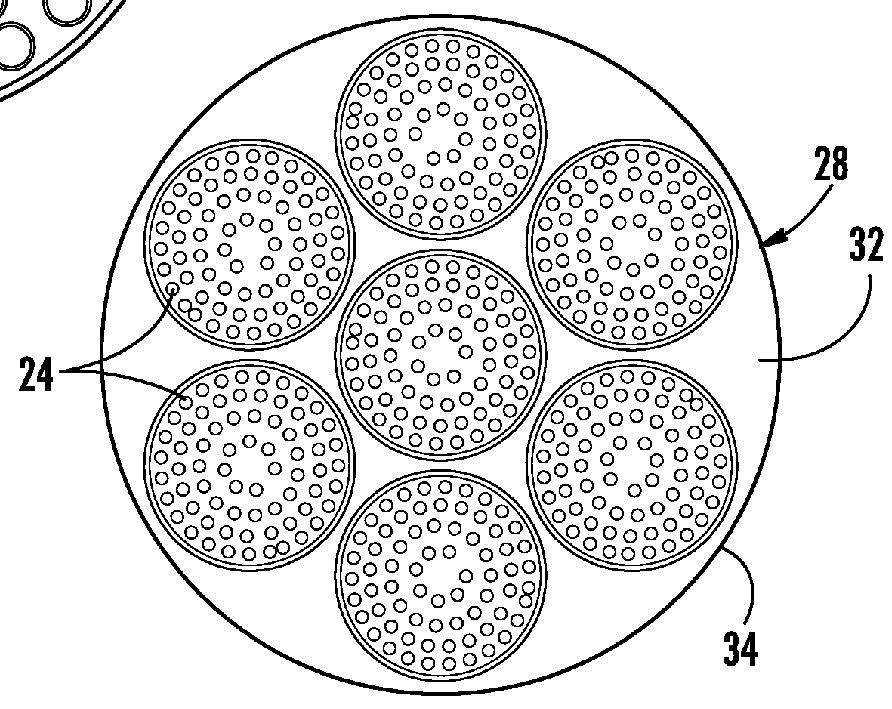

Combustor and method for supplying fuel to a combustor

A combustor includes an end cap having an upstream surface axially separated from a downstream surface and a cap shield circumferentially surrounding the upstream and downstream surfaces. A first circuit of tubes extends from the upstream surface through the downstream surface. A first fuel plenum is in fluid communication with the first circuit of tubes. A second circuit of tubes extends from the upstream surface through the downstream surface. A second fuel plenum downstream from the first fuel plenum is in fluid communication with the second circuit of tubes. A method for supplying fuel to a combustor includes flowing a working fluid through tubes, flowing fuel or diluent from a first fuel plenum through a first circuit of tubes, and flowing fuel or diluent from a second fuel plenum through a second circuit of tubes, wherein the second fuel plenum is downstream from the first fuel plenum.

Owner:GENERAL ELECTRIC CO

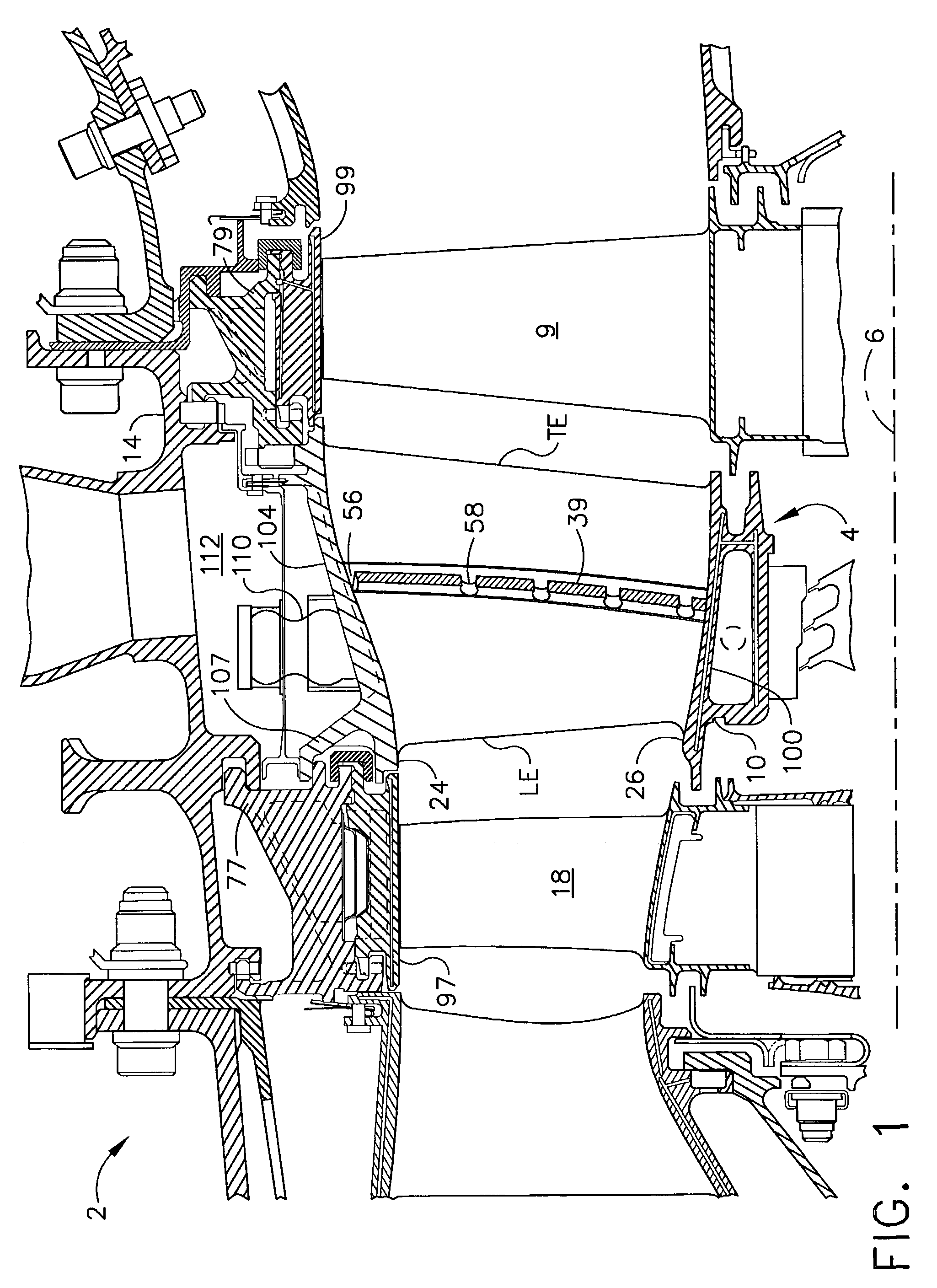

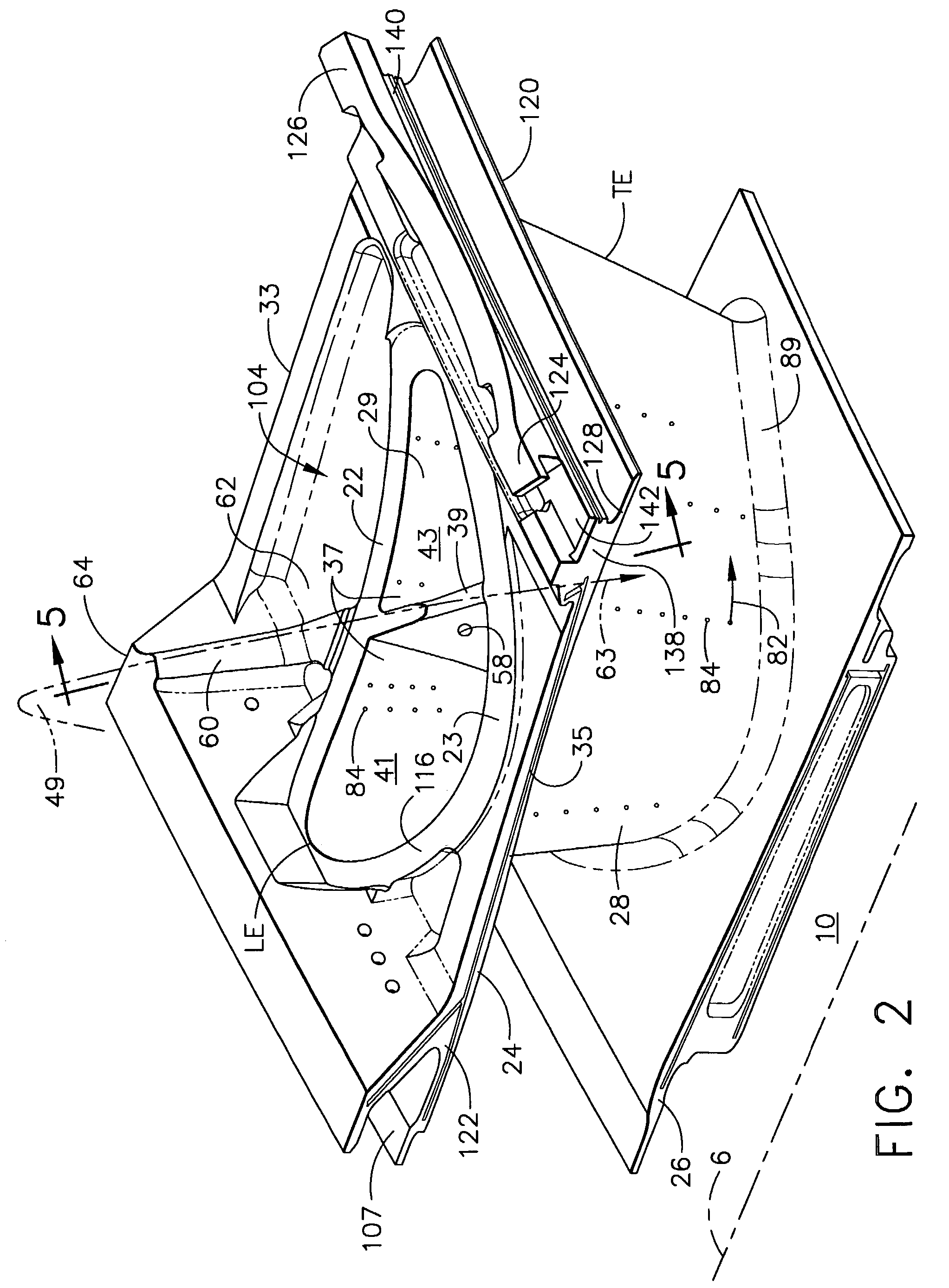

Gas turbine engine turbine nozzle bifurcated impingement baffle

InactiveUS7008185B2Reduce leakageReduce complexityEngine manufacturePump componentsPlenum chamberTurbine

A turbine nozzle bifurcated impingement baffle includes axially forward and aft chambers with a gap therebetween, impingement holes through forward and aft baffle walls of the forward and aft chambers respectively, and a plenum chamber in fluid flow communication with the forward and aft chambers. An exemplary embodiment of the bifurcated impingement baffle further includes a single cooling air inlet to the plenum chamber enclosed within a plenum chamber enclosure the plenum chamber. A sealing plate is mounted between and sealed to the plenum chamber enclosure and the forward and aft chambers. The sealing plate has forward and aft inlet apertures disposed between the plenum chamber and the forward and aft chambers respectively. Forward and aft end plates cap radially inner ends of the forward and aft chambers. An outlet aperture in the forward end plate has an interstage seal cavity feed tube disposed therethrough.

Owner:GENERAL ELECTRIC CO

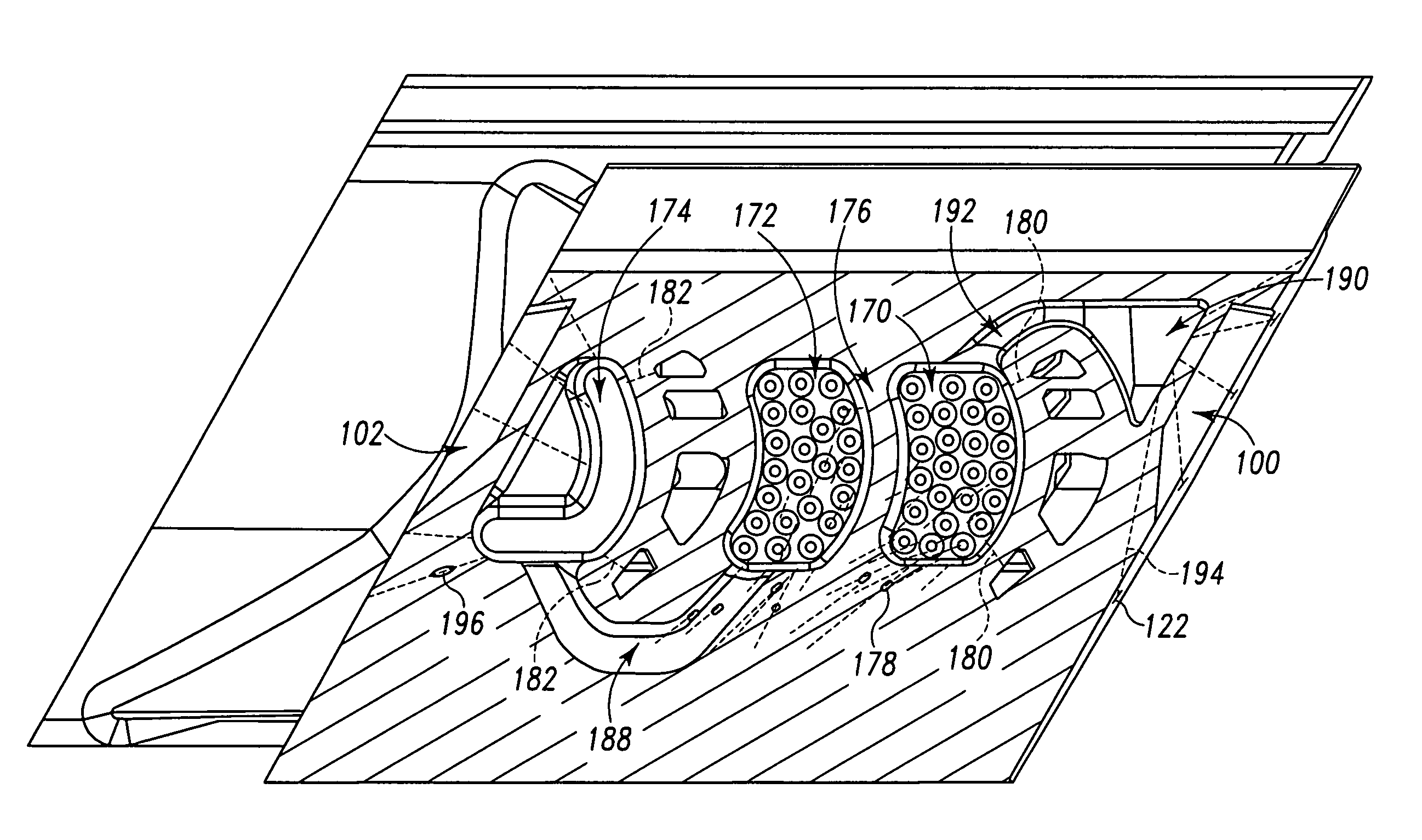

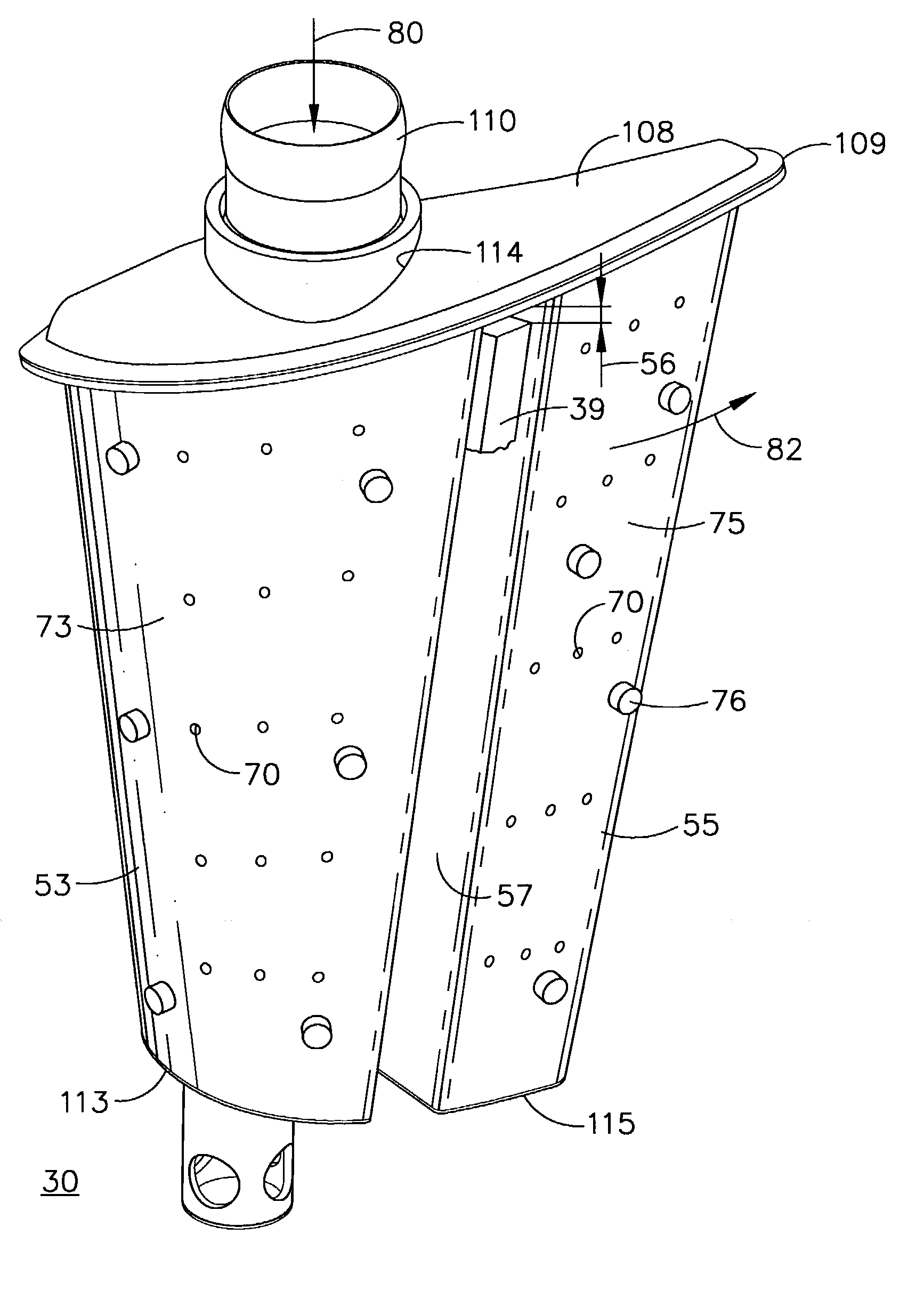

Self-contained vacuum module for stencil wiper assembly

A vacuum plenum module of a stencil wiper assembly for wiping and removing excess material from a stencil of a stencil printer includes a wiper blade to wipe the stencil, a plenum chamber in fluid communication with the wiper blade, and a vacuum generator attached to and in fluid communication with the plenum chamber to create a vacuum within the plenum chamber. The vacuum plenum module further includes a fluid supply to introduce pressurized fluid into the vacuum generator, and an exhaust to exhaust fluid from the vacuum generator. The vacuum generator includes at least one vacuum ejector adapted to create the vacuum. The vacuum plenum module is further configured to move between a first position in which the vacuum plenum is spaced away from the stencil and a second position in which the vacuum plenum engages the stencil. A method of cleaning a stencil is further disclosed.

Owner:KPS SPECIAL SITUATIONS FUND II LP

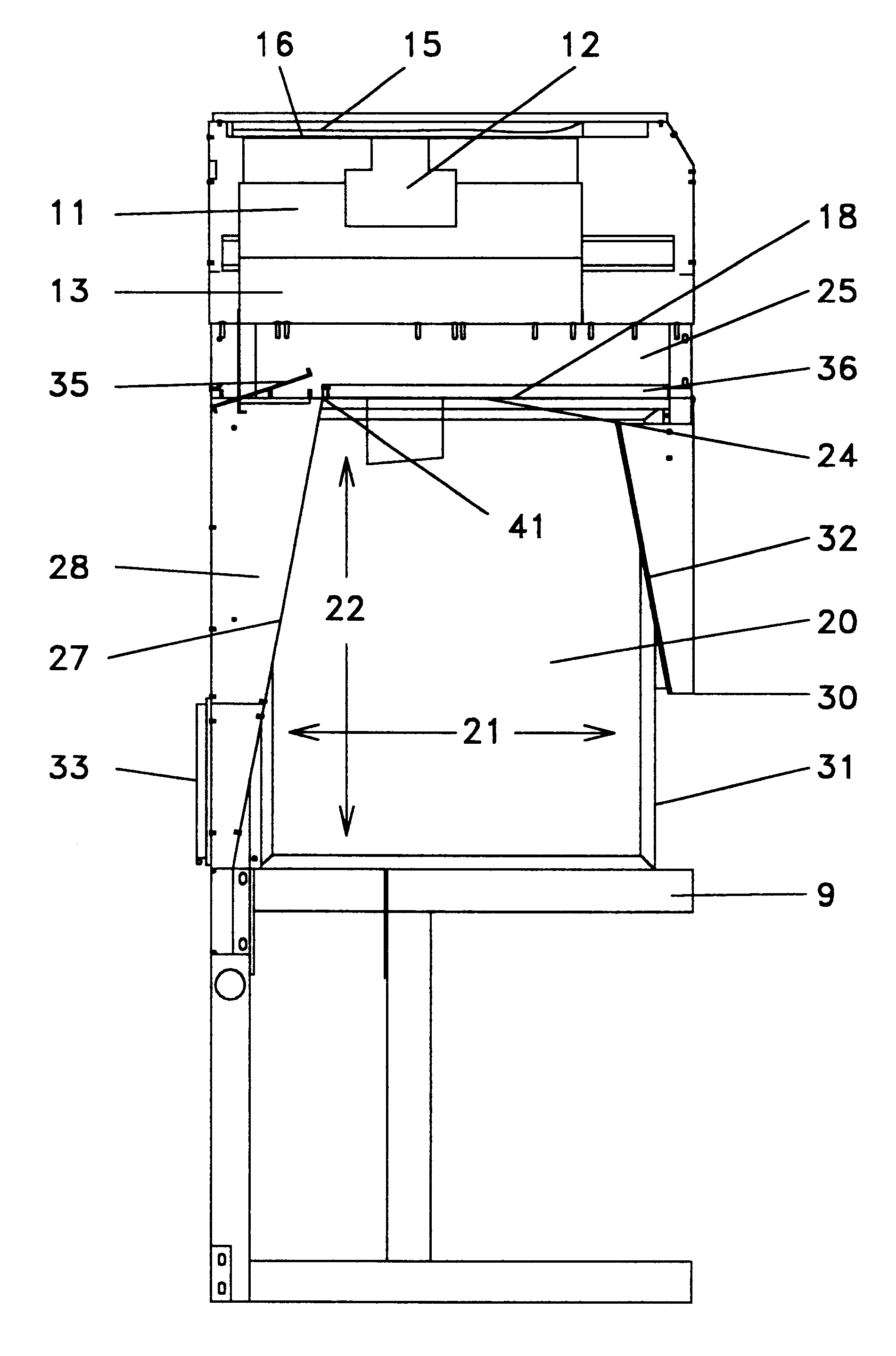

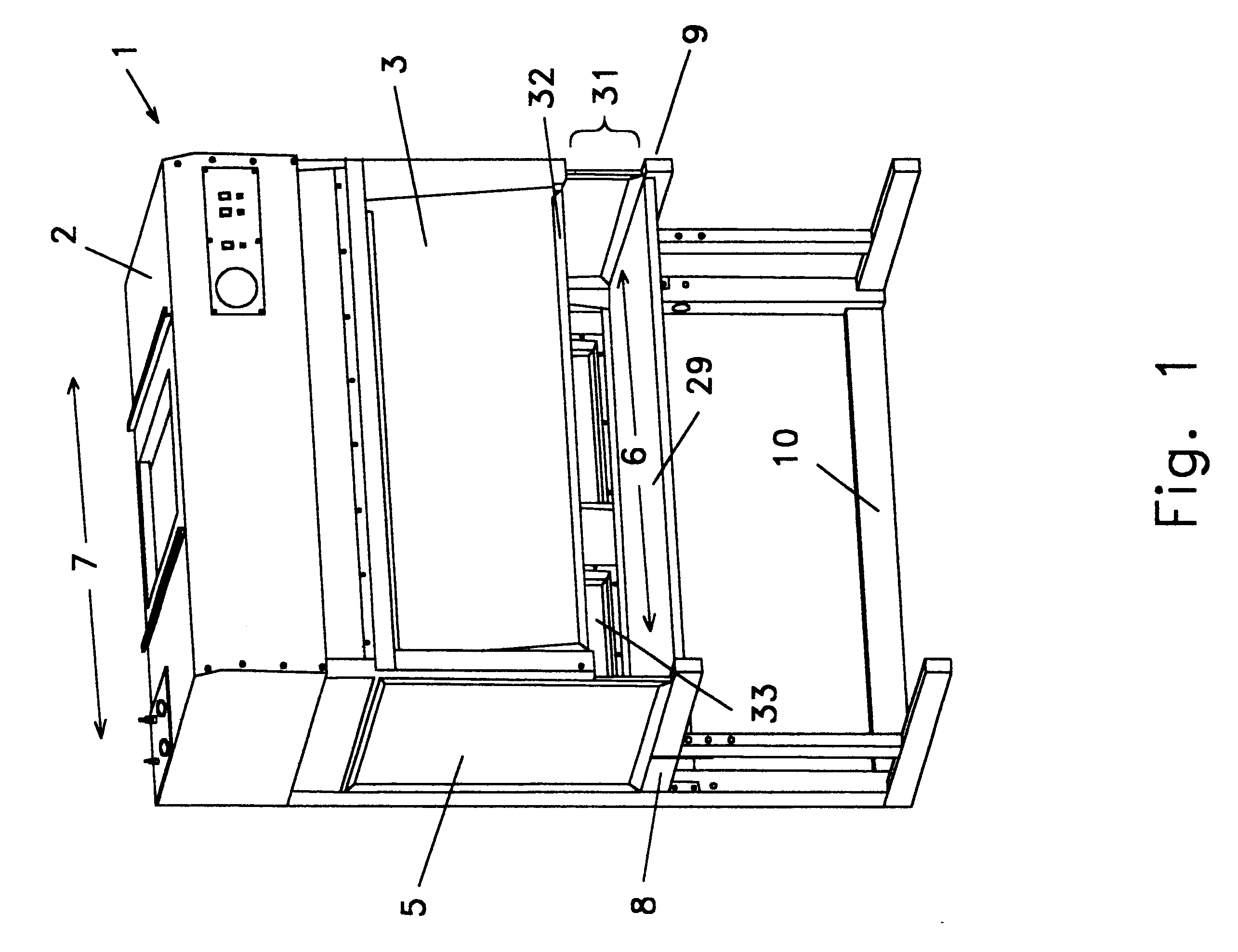

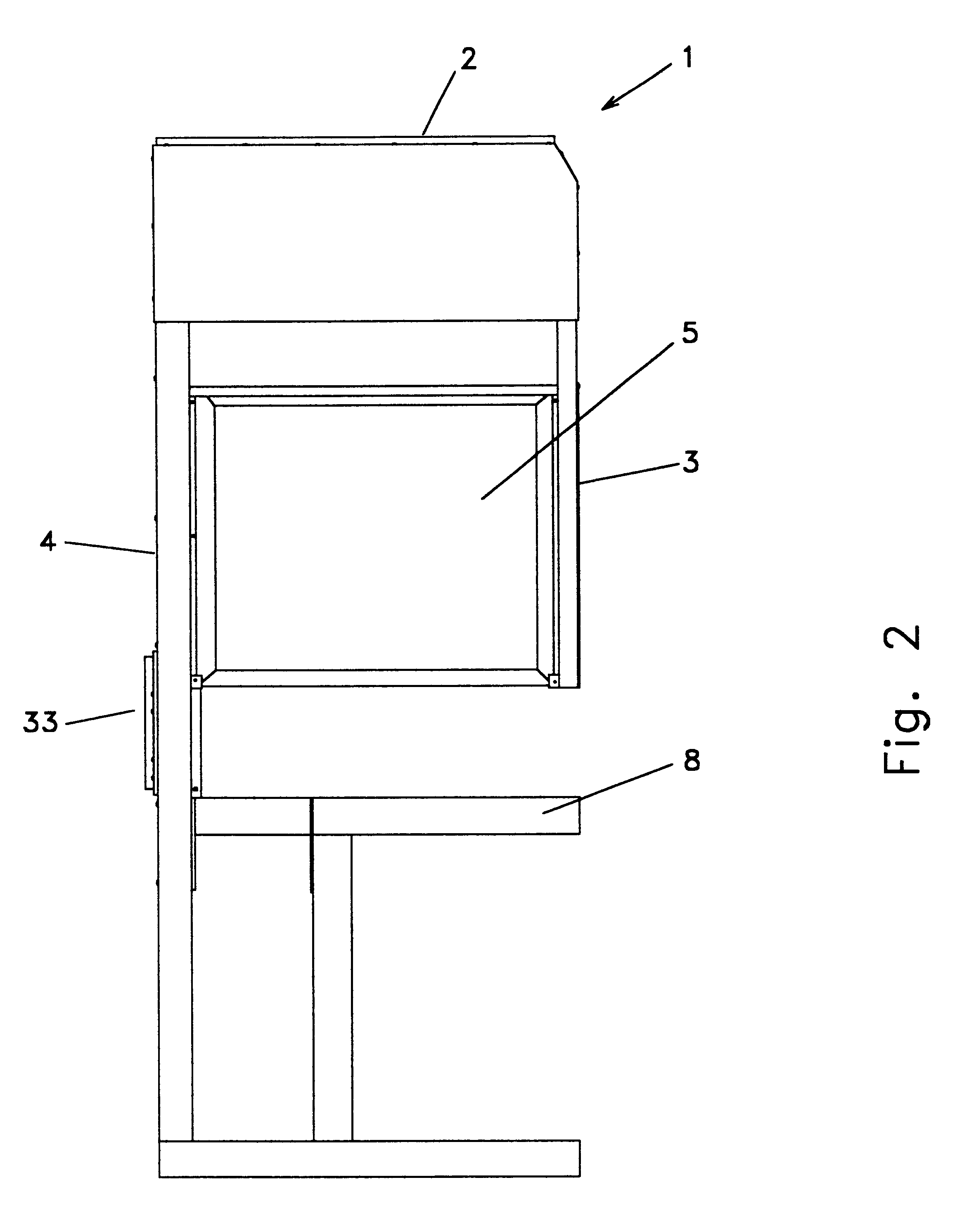

Adjustable clean-air flow environment

InactiveUS6632260B1Free from pollutionMany of constraintCombination devicesDomestic stoves or rangesEngineeringSmall footprint

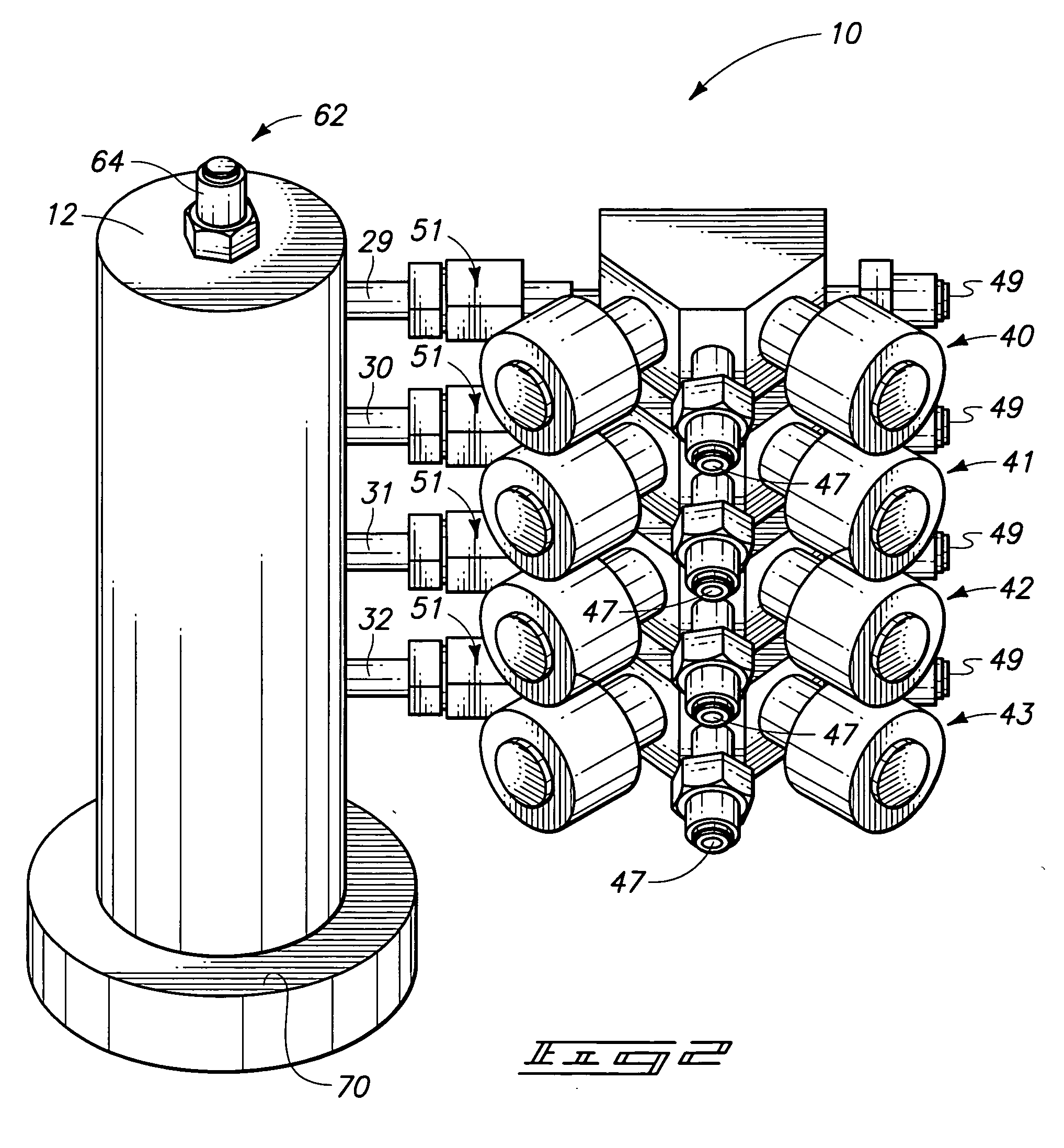

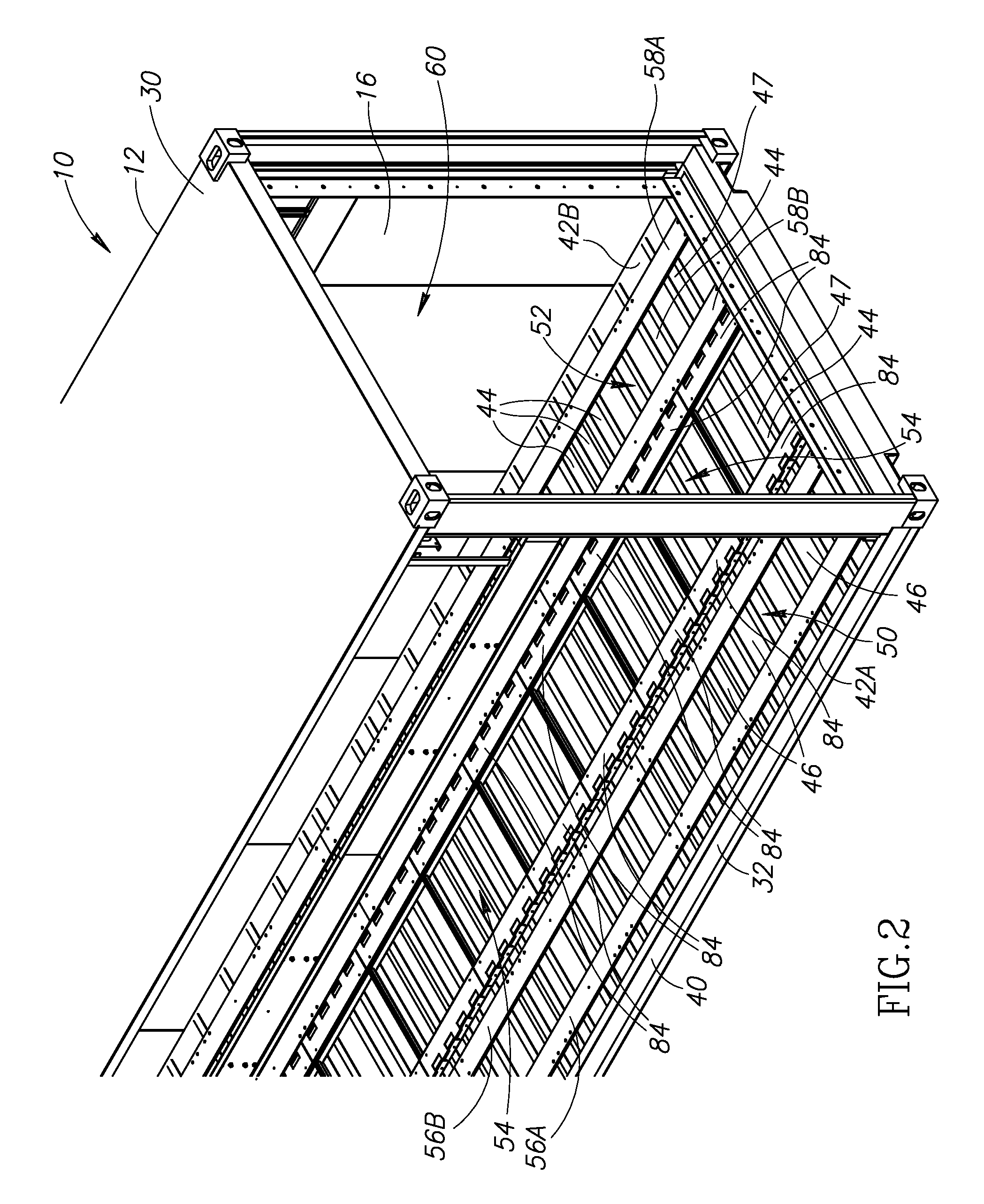

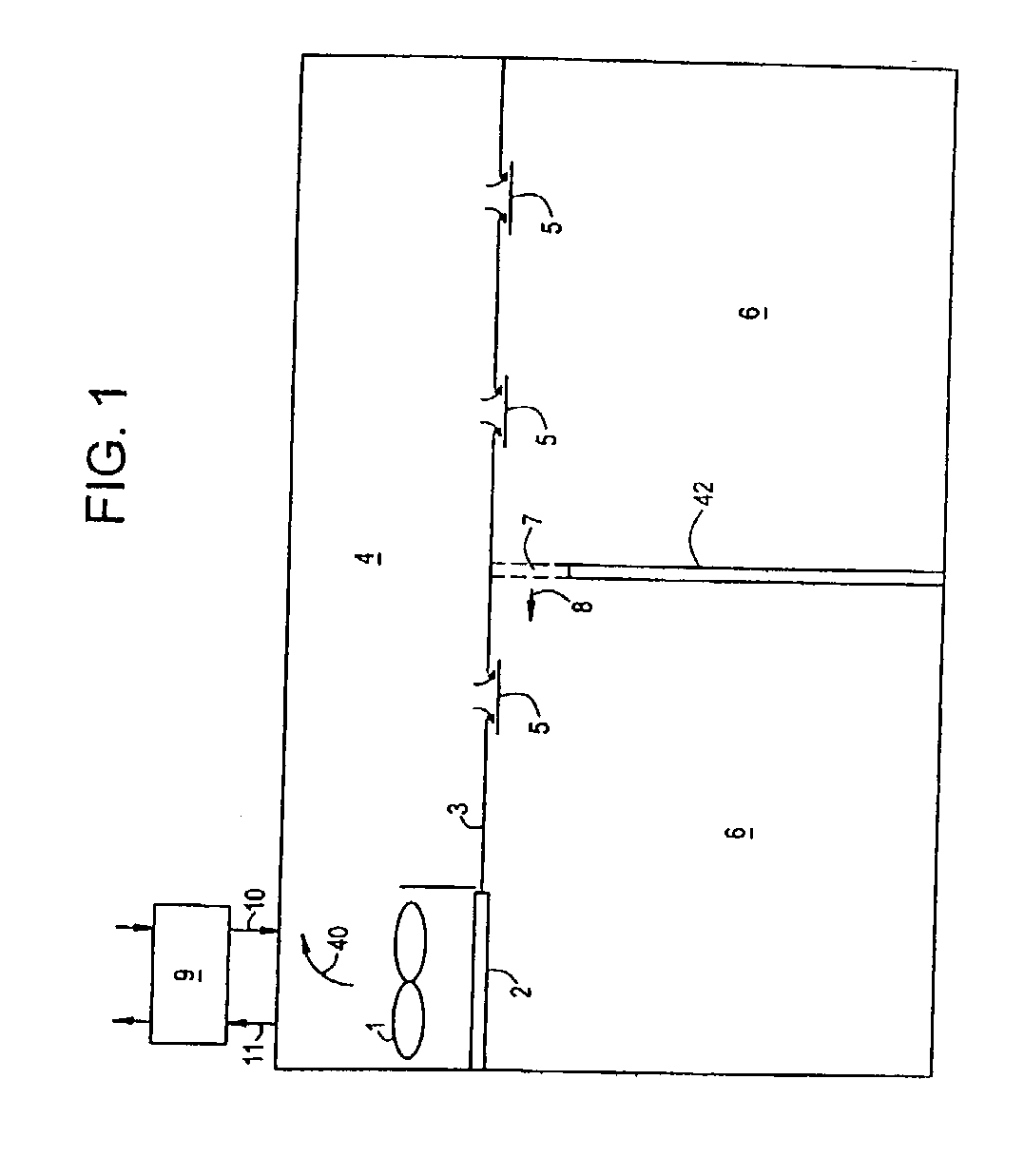

Enclosures having adjustable clean gas flow environments and methods of enclosed pressure differential distribution technology. Specifically, clean gas flow enclosures, which provide for the isolation of materials from airborne micro-particulate contamination. An embodiment of the invention utilizes a small footprint, modular, selectable, clean-gas flow environment for handling and isolating materials. The environment can be a clean room class environment by providing filtered gas from a gas flow generator (12) through a gas filter (13) to a filtered gas flow space (20). An embodiment of the invention provides a first plenum (23) and a second plenum (26) so that both a horizontal filtered gas flow and vertical filtered gas flow may be used separately or in combination within the same filtered gas flow space (20).

Owner:STRATOTECH CORP

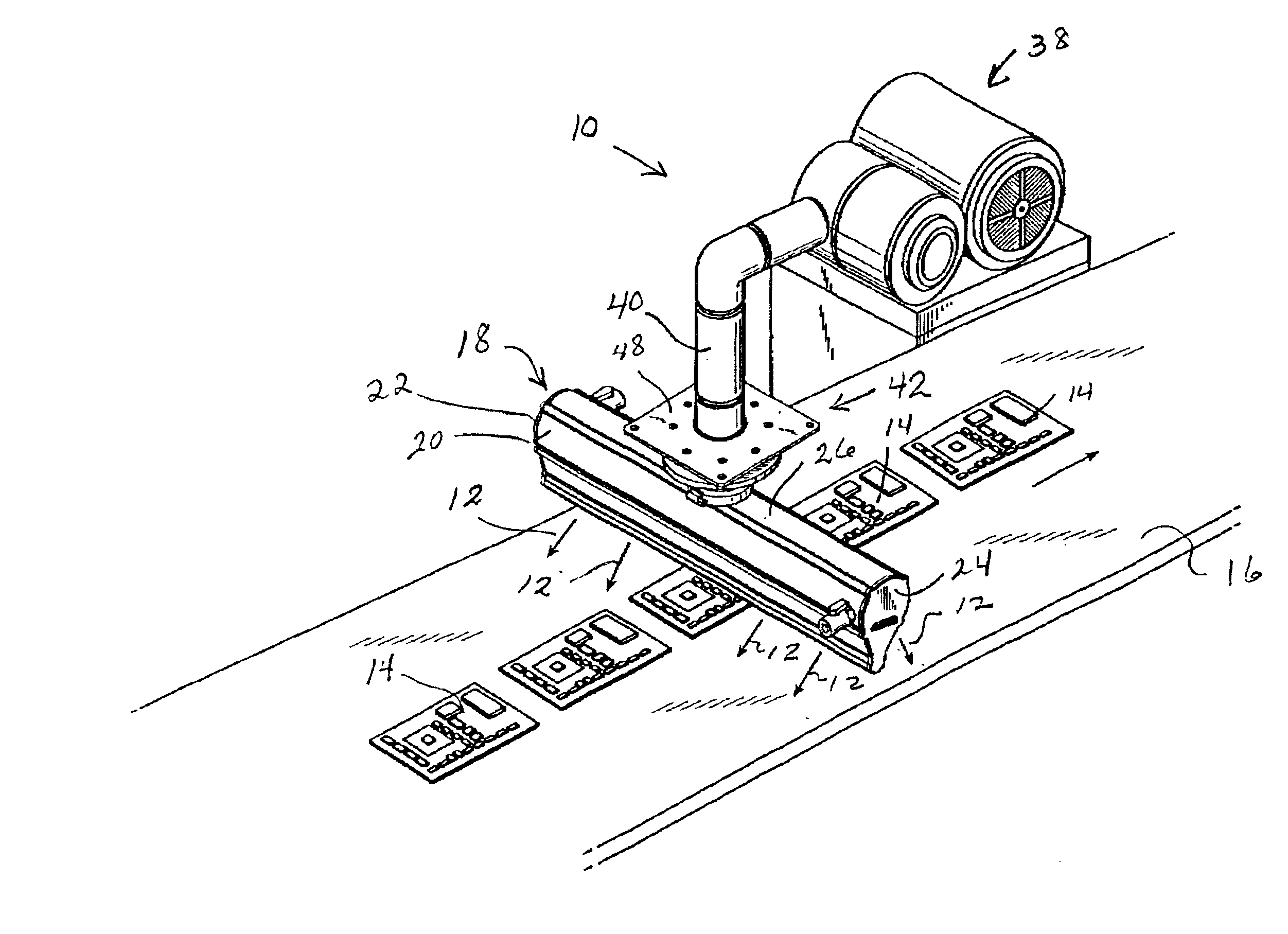

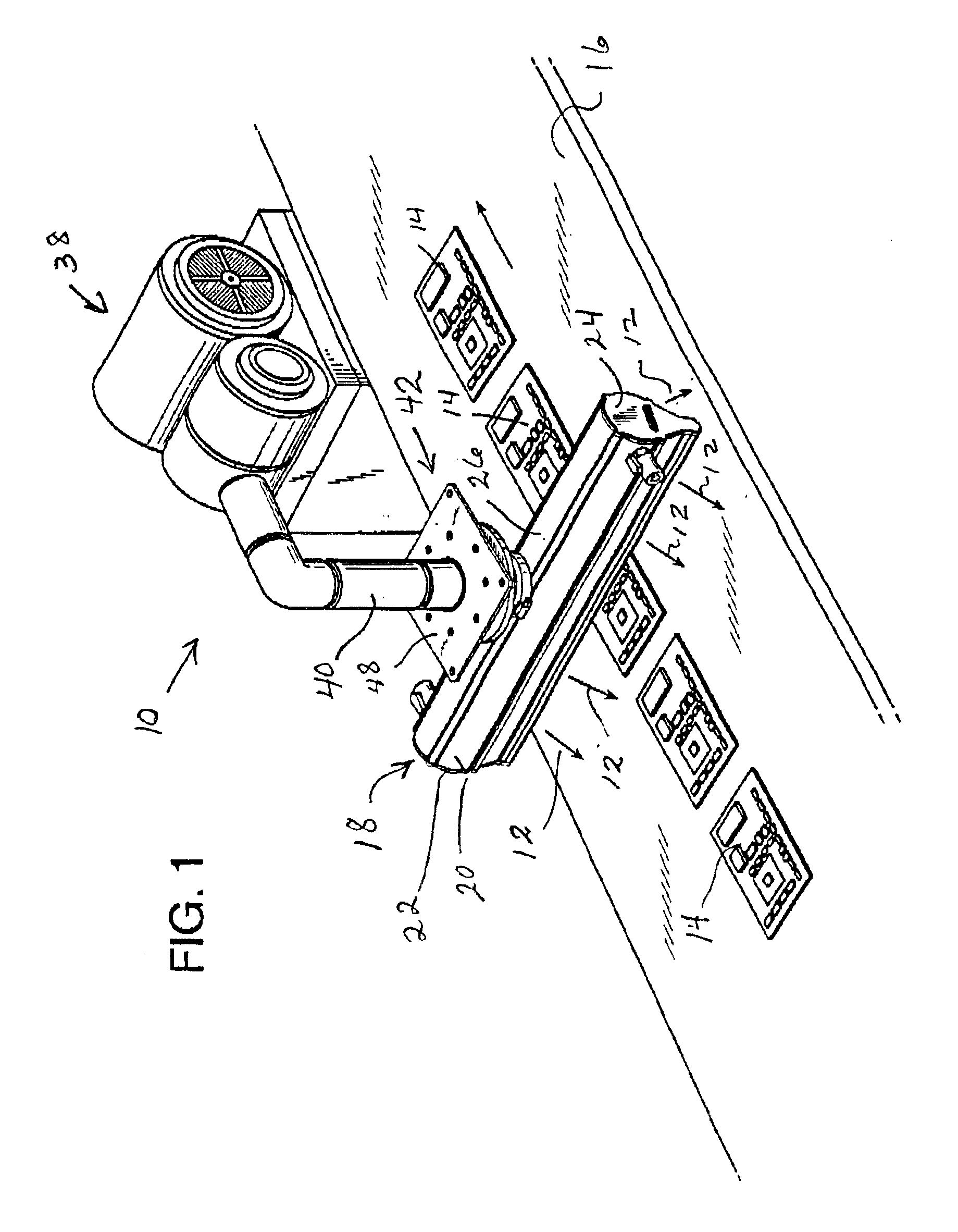

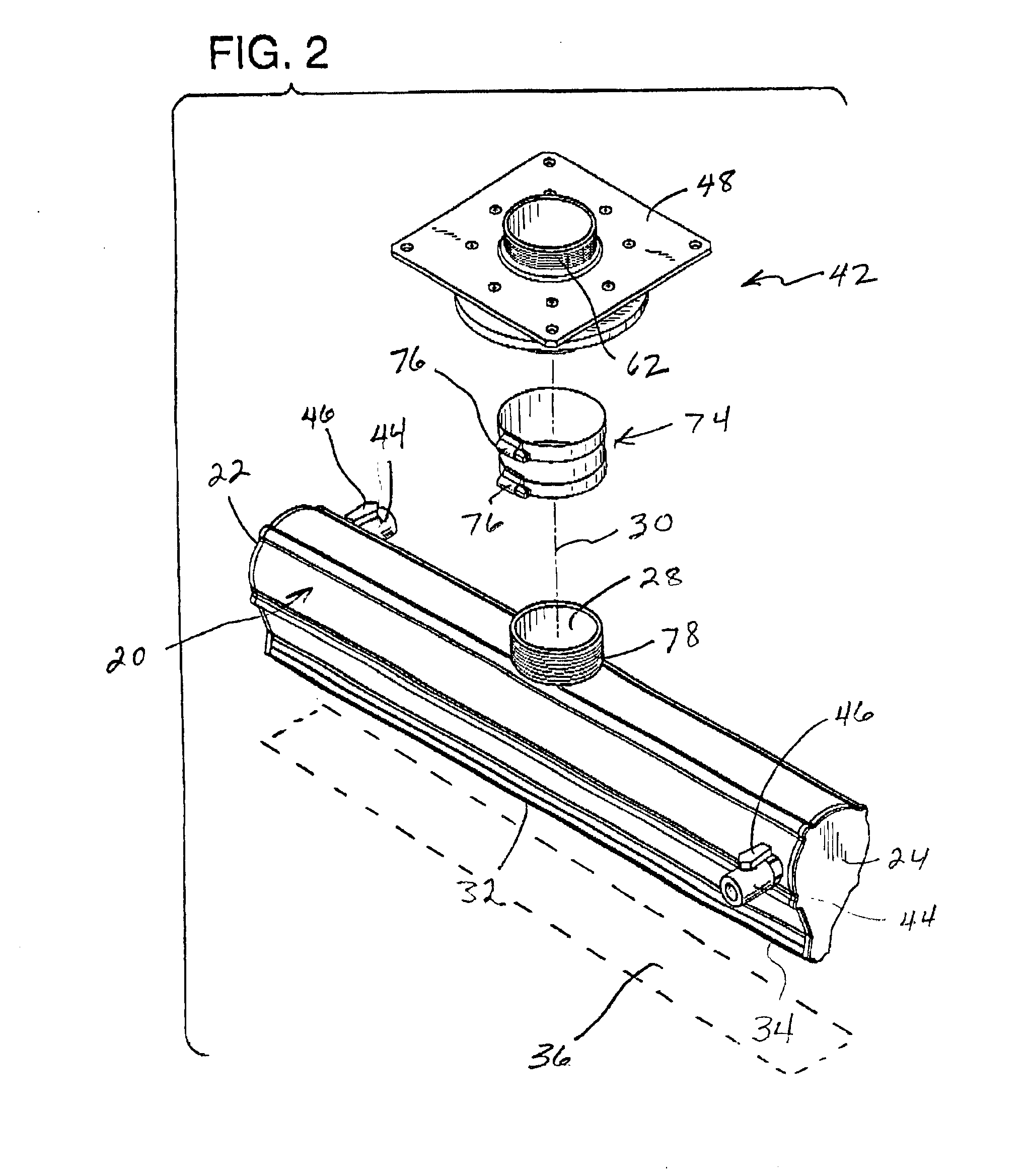

Rotatable air knife

InactiveUS6990751B2Extended stayDried or blown off more effectivelyDrying solid materials with heatDrying gas arrangementsCouplingEngineering

An air knife or air nozzle manifold for drying or blowing off passing articles moved by a conveyor system is provided with a coupling that permits rotation of the air knife or air nozzle manifold relative to the air inlet duct leading from a blower. The air knife or air nozzle manifold has opposing ends located equidistant from a longitudinal axis of rotation relative to a stationary element of the coupling. Thrust nozzles are provided at each of the opposing ends of the air knife or air nozzle manifold to deflect a certain portion of the air from the plenum chamber to provide thrusting jets of air that rotate the air knife or air nozzle manifold about the longitudinal axis. The flow of air emitted from the air knife or air nozzle manifold is thereby directed onto the passing articles from different directions as the articles move by. The efficiency of drying and blowing off the articles to be processed is thereby significantly improved.

Owner:SONIC AIR SYST

Respiratory mask and related portions, components or sub-assemblies

A respiratory mask for providing positive pressure therapy and a bias-flow venting system configured to reduce discernable draft generated by exhausted air are disclosed herein. The respiratory mask has a ball jointed elbow, one or more detachable forehead pieces and a headgear with a spacer fabric region. The elbow is configured to be removable when oriented to a predetermined position. The forehead pieces are provided in one or more sizes. The spacer fabric region having two or more layers wherein the raw edges are turned to the inside of the layers. The seal having improved seal performance and accommodating a wider variety of facial geometries. The bias-flow system having a tube and exhaust holes radially aligned on a bead of the tube. The bias-flow system also having an annular component exhaust holes and a shroud having a plenum chamber around the exhaust holes.

Owner:FISHER & PAYKEL HEALTHCARE LTD

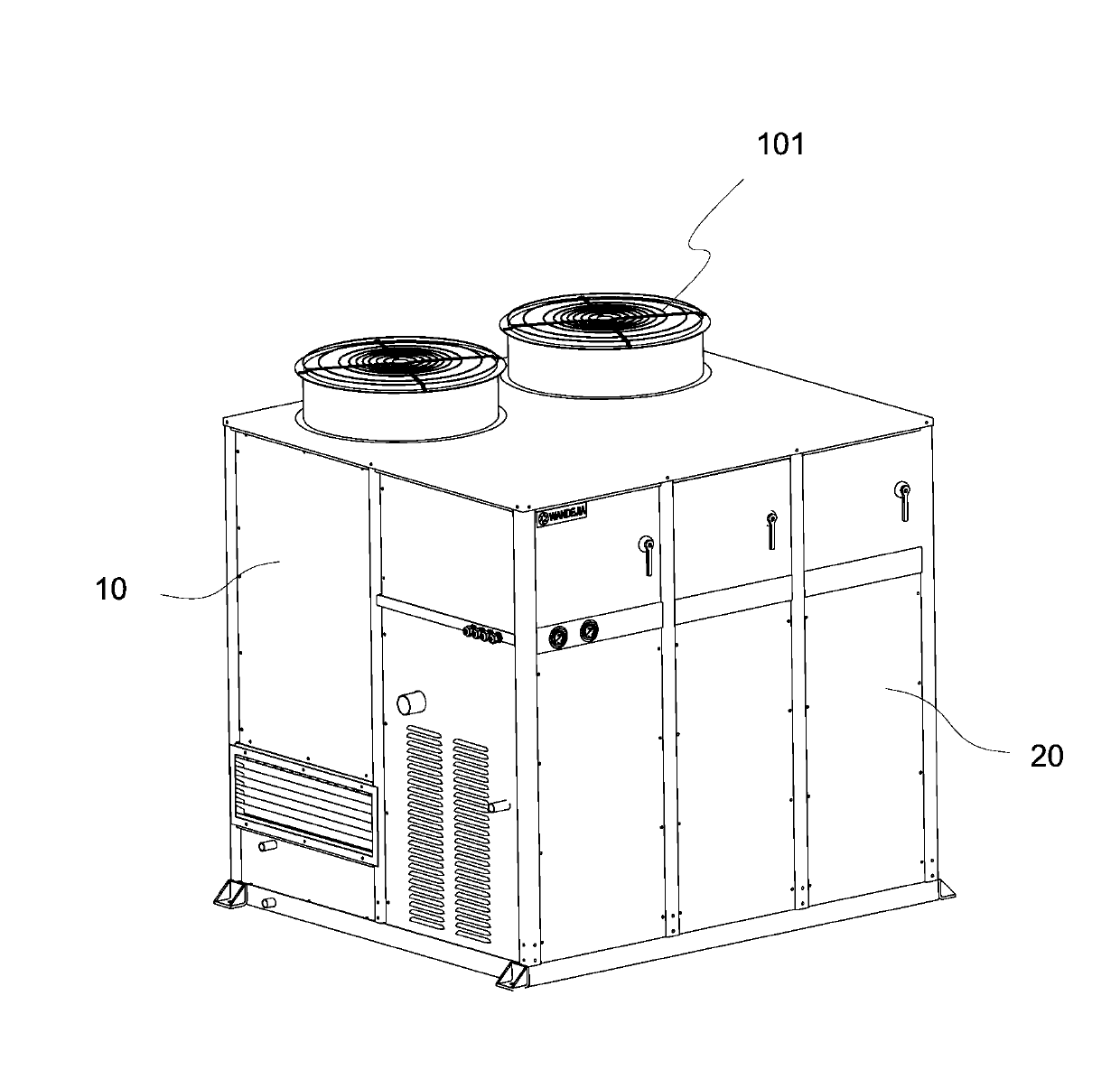

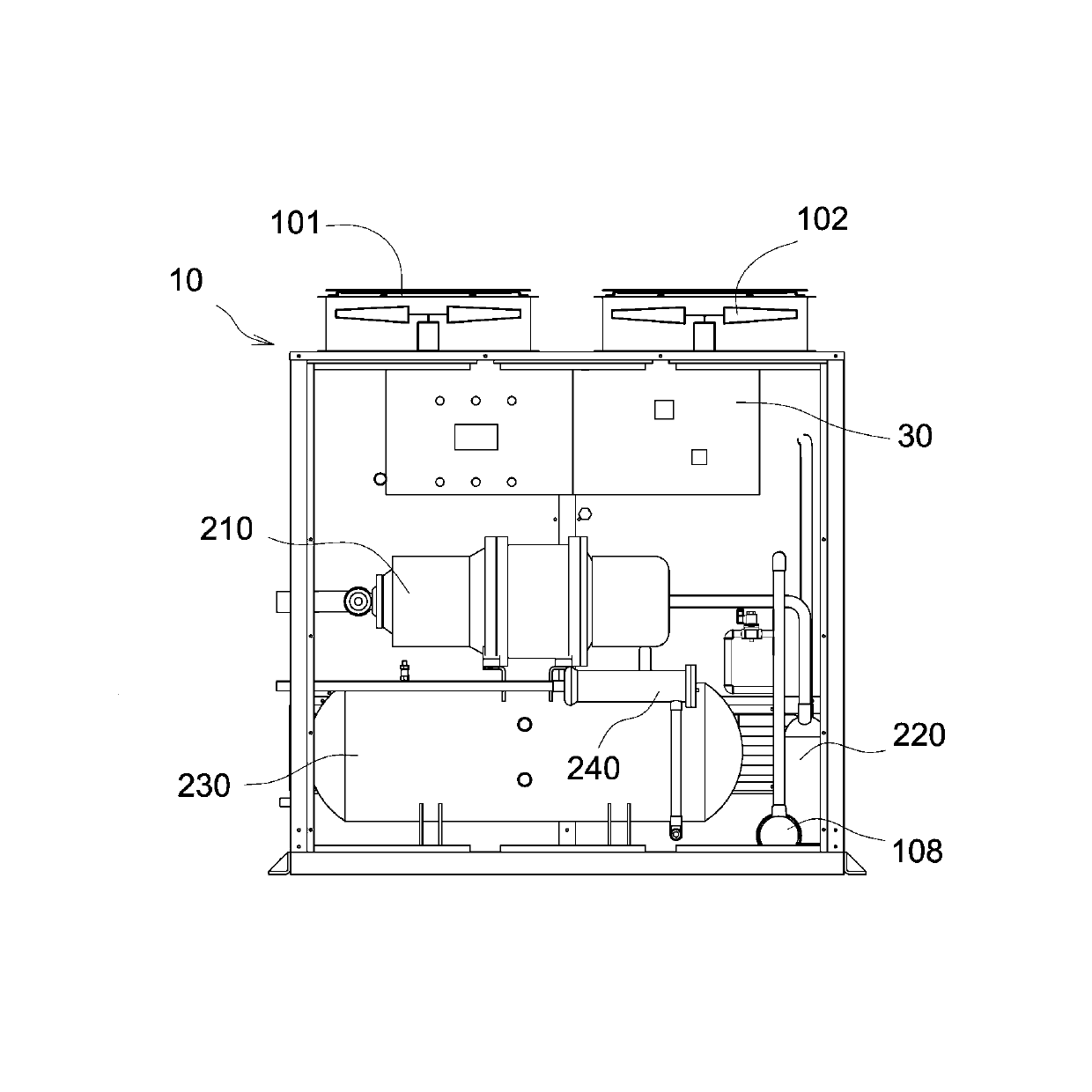

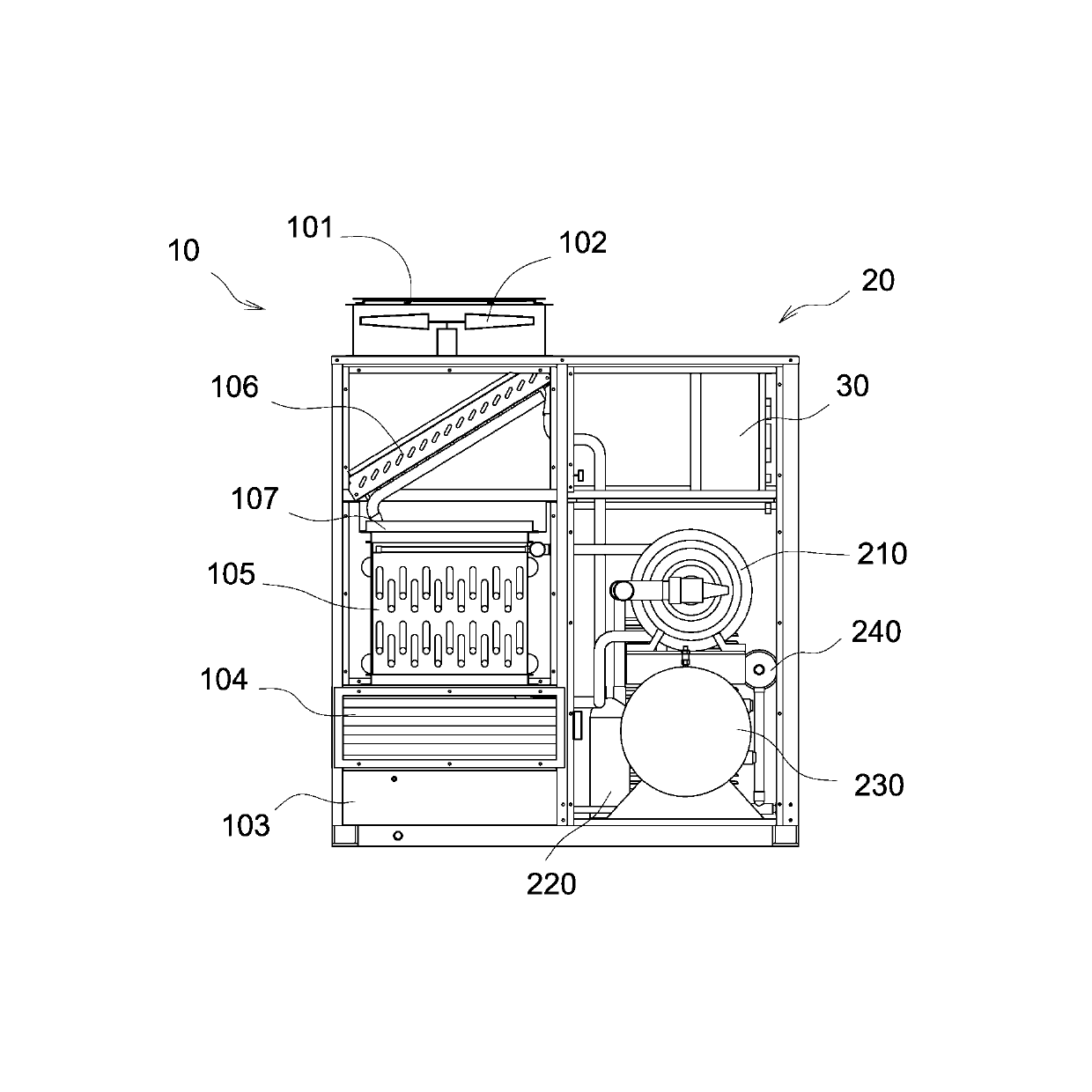

Evaporative type condenser, refrigeration and air conditioning unit applies the same and control method thereof

ActiveCN102997510AReduce circulationReduce power consumptionEvaporators/condensersRefrigeration safety arrangementCommon baseControl system

The utility model relates to an evaporative type condenser. Inside the plenum chamber of the upper box body of the evaporative type condenser is provide with a second heat exchanger used for removing frog, the lower box body is provided with a first heat exchange connected in series and used for condensation. The invention also relates to an evaporative cooled condensing unit applies the evaporative type condenser and a water chilling unit, mainly to achieve the function of a first mode in the cooling and condensation of a refrigerating fluid and to achieve the function of a second mode and a controlling system in the suction and compression of the refrigerating fluid. Wherein the first mode integrated in parallel by at least one evaporative type condenser, the second mode comprises at least one compressor, and the first mode and the second mode are combinedly installed on a common base seat, the number of the evaporative type condensing devices comprises by the first mode corresponds to the number of the compressor comprises by the second mode corresponds or the power steps of at least one compressor. The invention controls the start of the evaporative type condenser and the fan and water pump of the evaporative type condenser through temperature; adjusting and controlling the working state of the evaporative type condenser and the fan and water pump of the evaporative type condenser through the environment temperature and the exhaust pressure value of the compressor to maintain the pressure of the compressor within the scope of the preset pressure value; minimizing the operating power of the fan and the water pump to achieve the dynamic match between the heat dissipation capacity of the evaporative condensing unit and the needed heat dissipation of the compressor in operation.

Owner:上海二冷能源科技有限公司

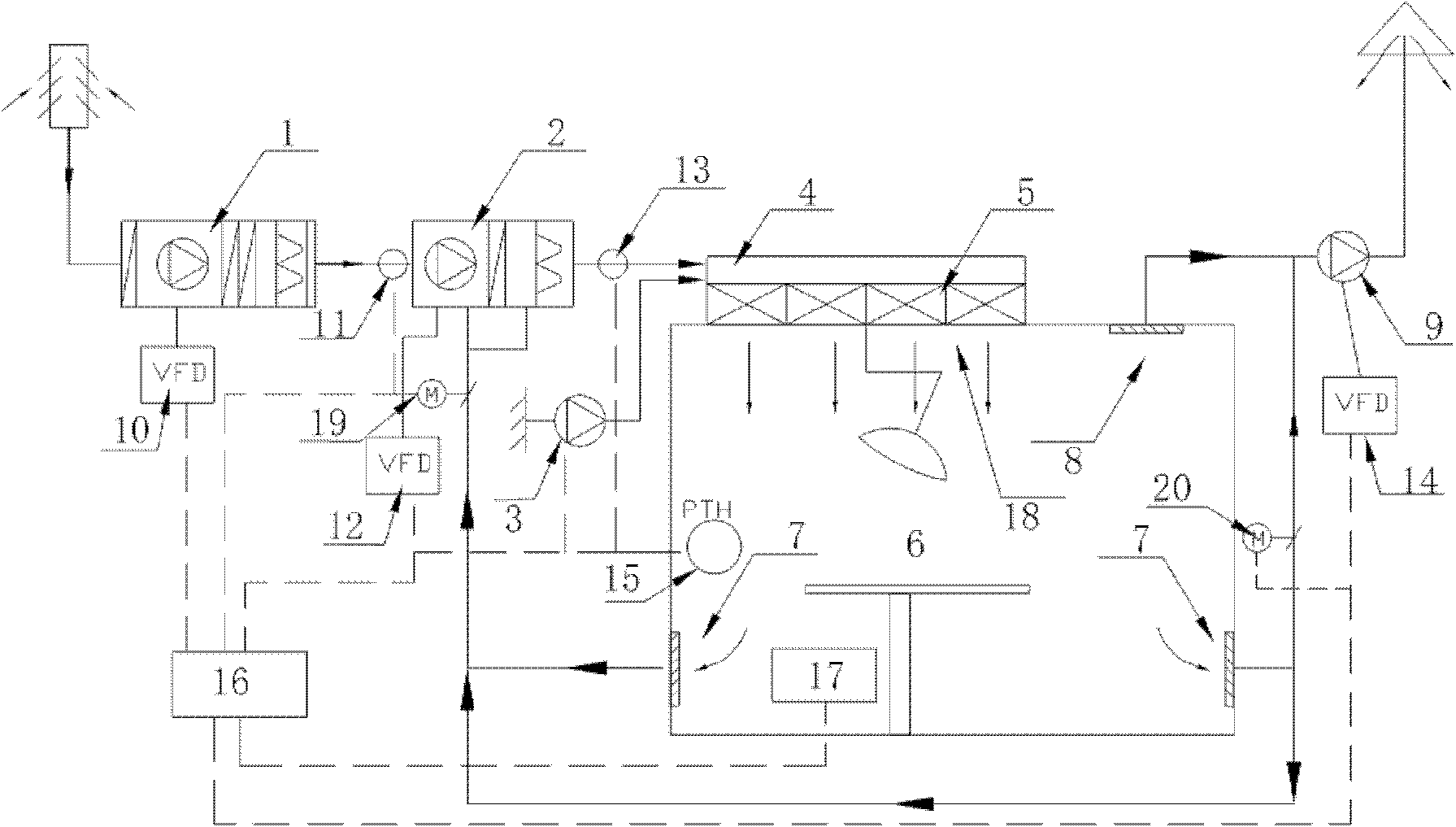

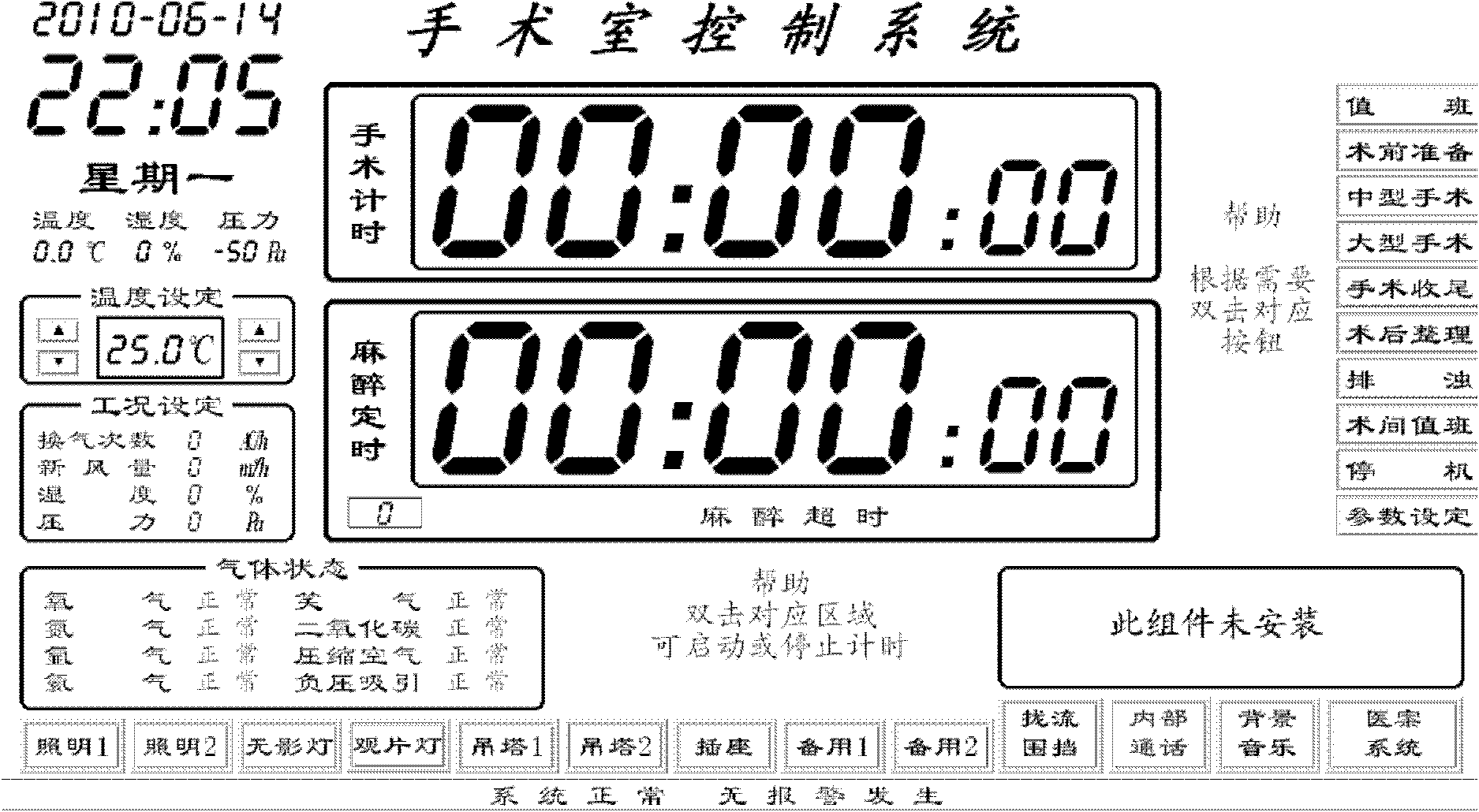

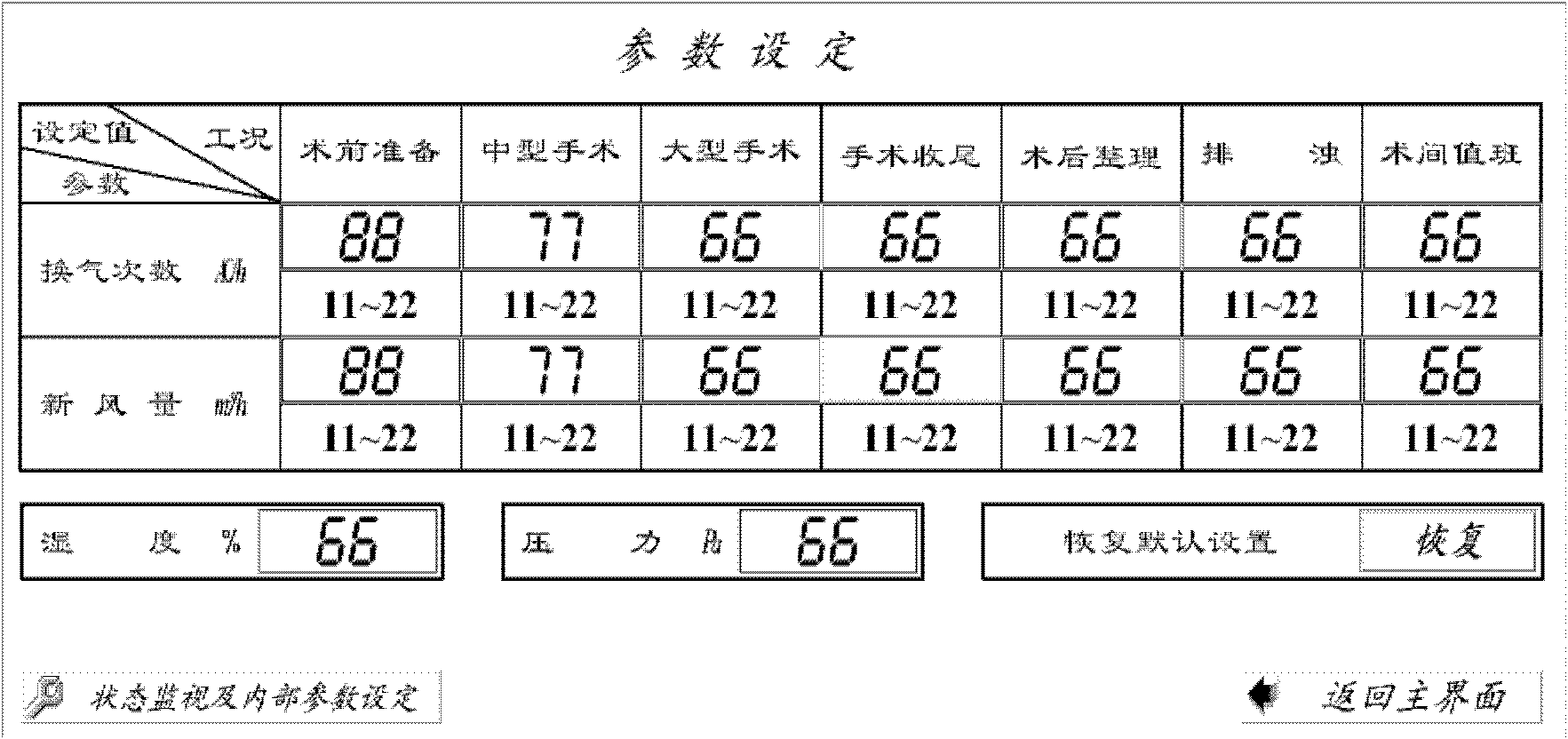

Clean operating room with air cleaning and conditioning system with intelligent adjustment and control

InactiveCN101915444AReduce drive energy consumptionReduce heating and cooling energy consumptionSpace heating and ventilation safety systemsLighting and heating apparatusFrequency changerAir volume

The invention relates to a clean operating room with an air cleaning and conditioning system with intelligent adjustment and control. A humiture and pressure difference combination sensor and a control unit are installed in an aseptic clean space; an air conditioning, cleaning and ventilating system comprises a fresh air conditioning unit and a transducer thereof, a cycling cleaning unit and a transducer thereof, a duty fan, an air supply plenum chamber, a high efficiency filter, an exhaust fan and a transducer thereof, an embedded controller and a control panel, wherein the fresh air conditioning unit, the cycling cleaning unit and the air supply plenum chamber are sequentially connected in series through air flues; the high efficiency filter is connected with the plenum chamber into a whole; and the high efficiency filter is arranged at the top of the clean operating room and the air outlet of the high efficiency filter is the input port of cleaned air after adjustment and control at the top of the aseptic clean space. In the invention, a plurality of typical working conditions can be respectively set according to different operation types or working processes, air parameters such as temperature, humidity, air delivery volume, fresh air volume and the like can be preset by the control unit in the aseptic clean space, and the working conditions can be combined for operation according to the actual use load, so the energy saving effect is very obvious.

Owner:TIANJIN LONGCHUAN PURIFICATION ENG

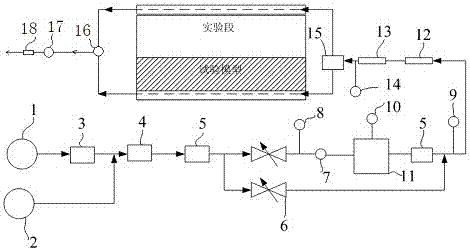

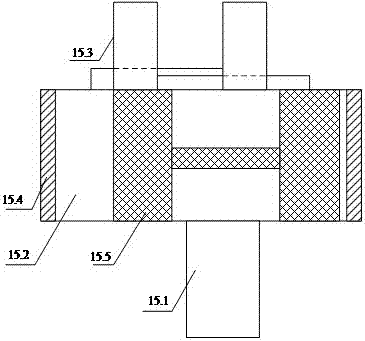

Icing wind tunnel hot gas anti-icing test high-precision simulation method and device

ActiveCN107271134AAvoid low temperature freezing and other problemsReduce high pressure heatAerodynamic testingWind energy generationThermodynamicsTemperature conditioning

The present invention discloses an icing wind tunnel hot gas anti-icing test high-precision simulation method and device. The device comprises a gas source, a pressure reduction device, a filter, an air heater, a multistage electric heating device and a test section in order from a gas input direction to a gas output direction. The gas path behind the pressure reduction device is divided into two paths, one path is heated and then is subjected to flow mixing with the other unheated path, a pneumatic switching valve in an icing wind tunnel plenum chamber is configured to divide the gas path into two paths, gas of one path enters a test section and flows out after passing through a test model to perform flow measurement, gas of the other path is flown through from the external portion of the test section and performs flow measurement, and gas of a model main path and gas of a simulation bypass path are combined into one path after passing through the wind tunnel test section and are exhausted through a flowmeter and a silencer; a cold and hot gas mixing mode is employed to rapidly reduce the high-pressure hot gas behind the air heater so as to reach the effect of rapid temperature adjustment; and the multistage electric heating device is employed to perform high-precision temperature regulation and control so as to perform high-precision temperature adjustment of high-pressure hot gas prior to the high-pressure hot gas entering a test model step by step.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

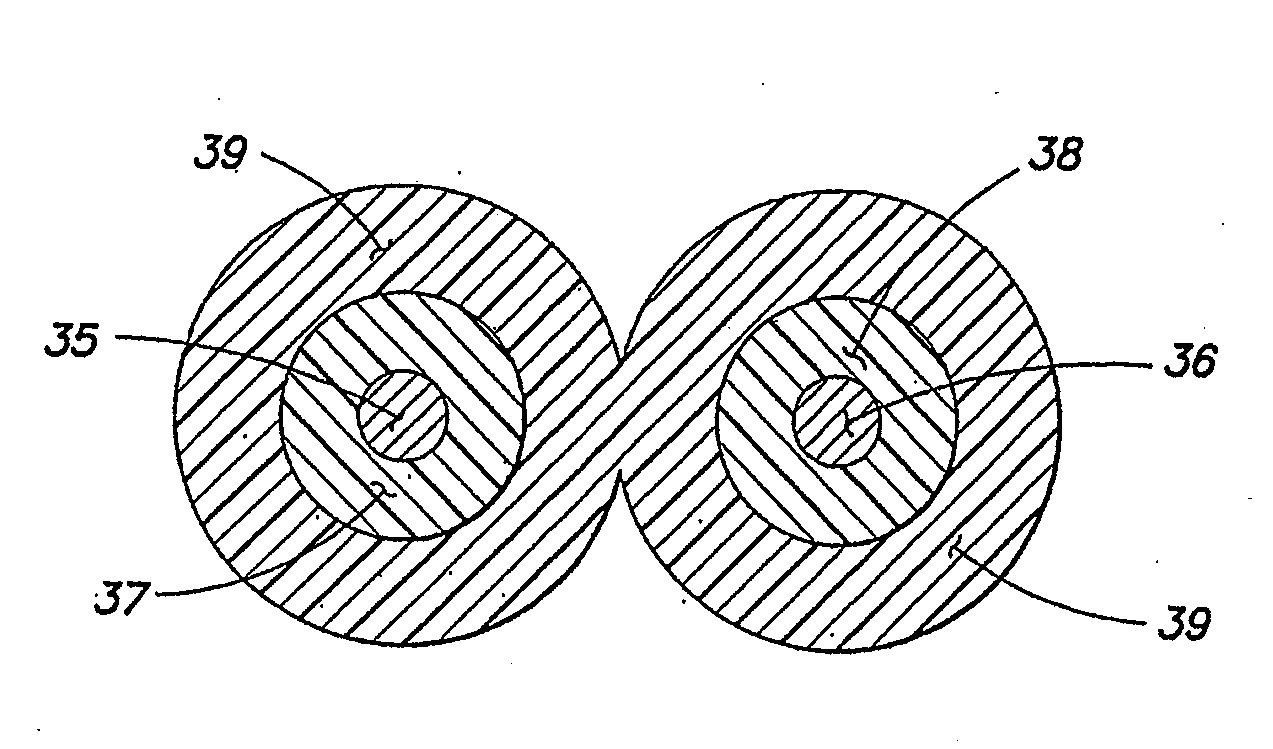

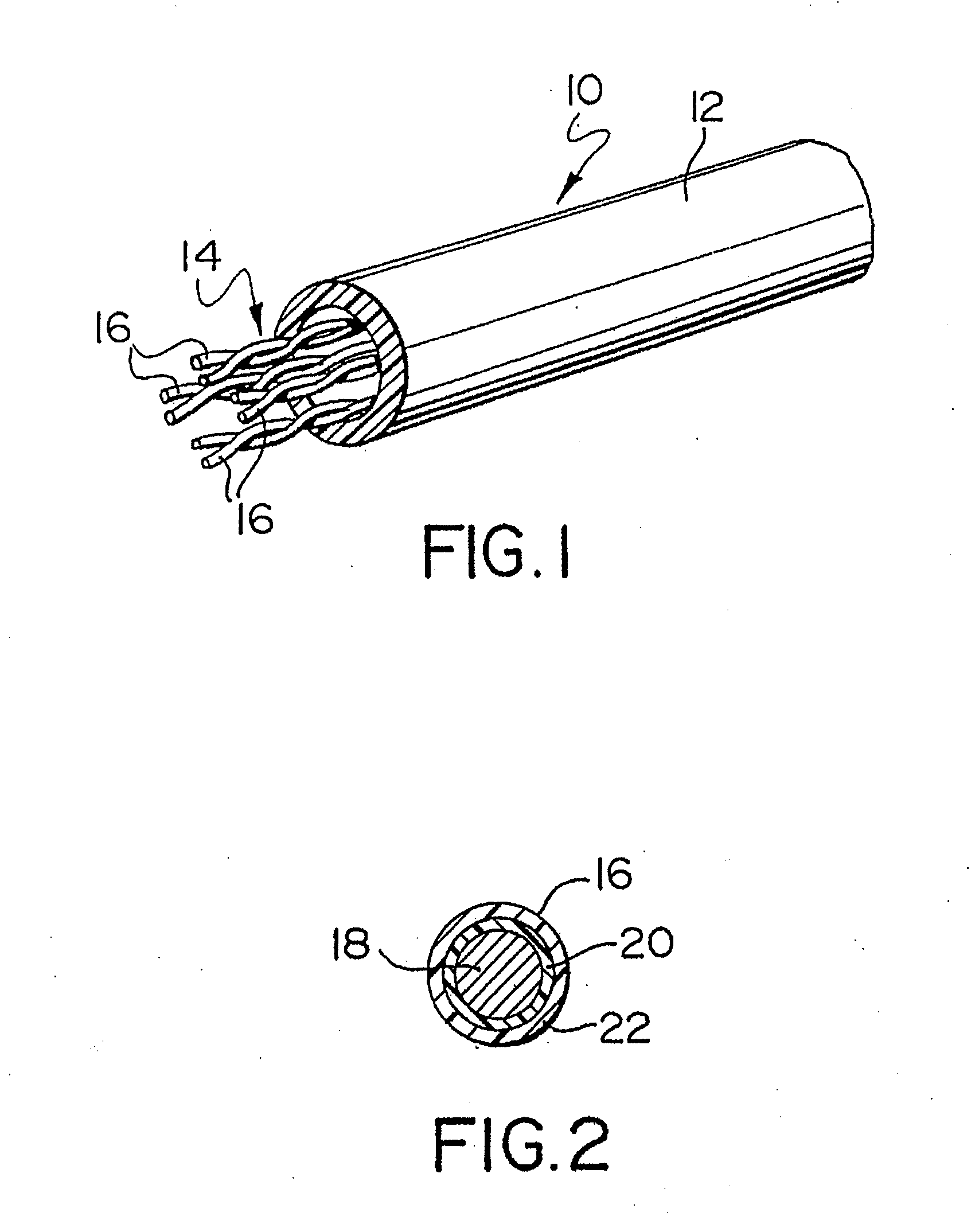

Telecommunications cable

ActiveUS20080073105A1Suppress generationDampens spreadEmergency protective circuit arrangementsInsulated cablesElectrical conductorPolyolefin

A telecommunications cable having a cable core in which each conductor is surrounded by an individual dual layer insulation of an inner layer of flame retardant polyolefin and an outer layer of fluorinated ethylene propylene. The cable is for plenum chamber usage in which smoke is to be minimized. Although the flame retardant polyolefin is a known smoke generating substance which does not satisfy plenum test smoke requirements, its use in this structure is entirely suitable for plenum chamber use because little or no smoke is actually generated as the outer layer protects the inner layer from combustion.

Owner:BELDEN TECHNOLOGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com