Icing wind tunnel hot gas anti-icing test high-precision simulation method and device

A simulation method and high-precision technology, applied in the field of wind tunnel testing, can solve the problems of destroying aerodynamic performance, increasing the weight of the aircraft, and reducing the maximum lift of the aircraft, so as to avoid low-temperature freezing of lubricating oil and the effect of avoiding low-temperature environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] All the features disclosed in this specification, or all disclosed methods or steps in the process, except for mutually exclusive features and / or steps, can be combined in any manner.

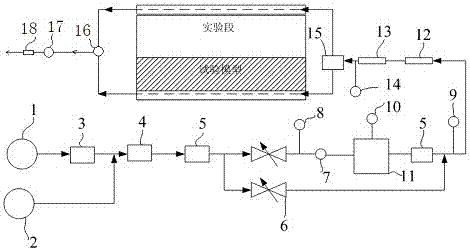

[0046] Such as figure 1 As shown, for the key technology of high-precision temperature adjustment, the present invention adopts a strategy that combines two methods: one is a method of mixing and adjusting cold and hot air, which separates a small flow cold air branch from the air supply pipeline at the front end of the air heater The cold air of this branch is to provide mixed air flow for the hot air at the outlet of the air heater, and the main purpose is to adjust the temperature of the hot air in the main air supply pipeline. Since the air heater itself has a certain degree of hot air temperature control accuracy, such as ±5°C, the compressed air flow of the branch must be small to prevent excessive mixing. Since the mixing of cold air and hot air to adjust the temperature is faster an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com