Patents

Literature

2130 results about "Freezing point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Freezing point, temperature at which a liquid becomes a solid. As with the melting point, increased pressure usually raises the freezing point. The freezing point is lower than the melting point in the case of mixtures and for certain organic compounds such as fats.

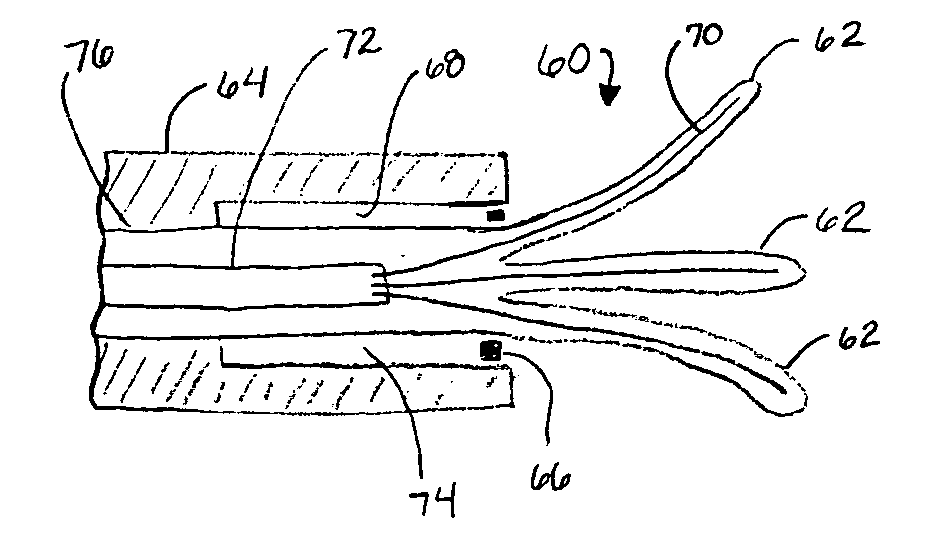

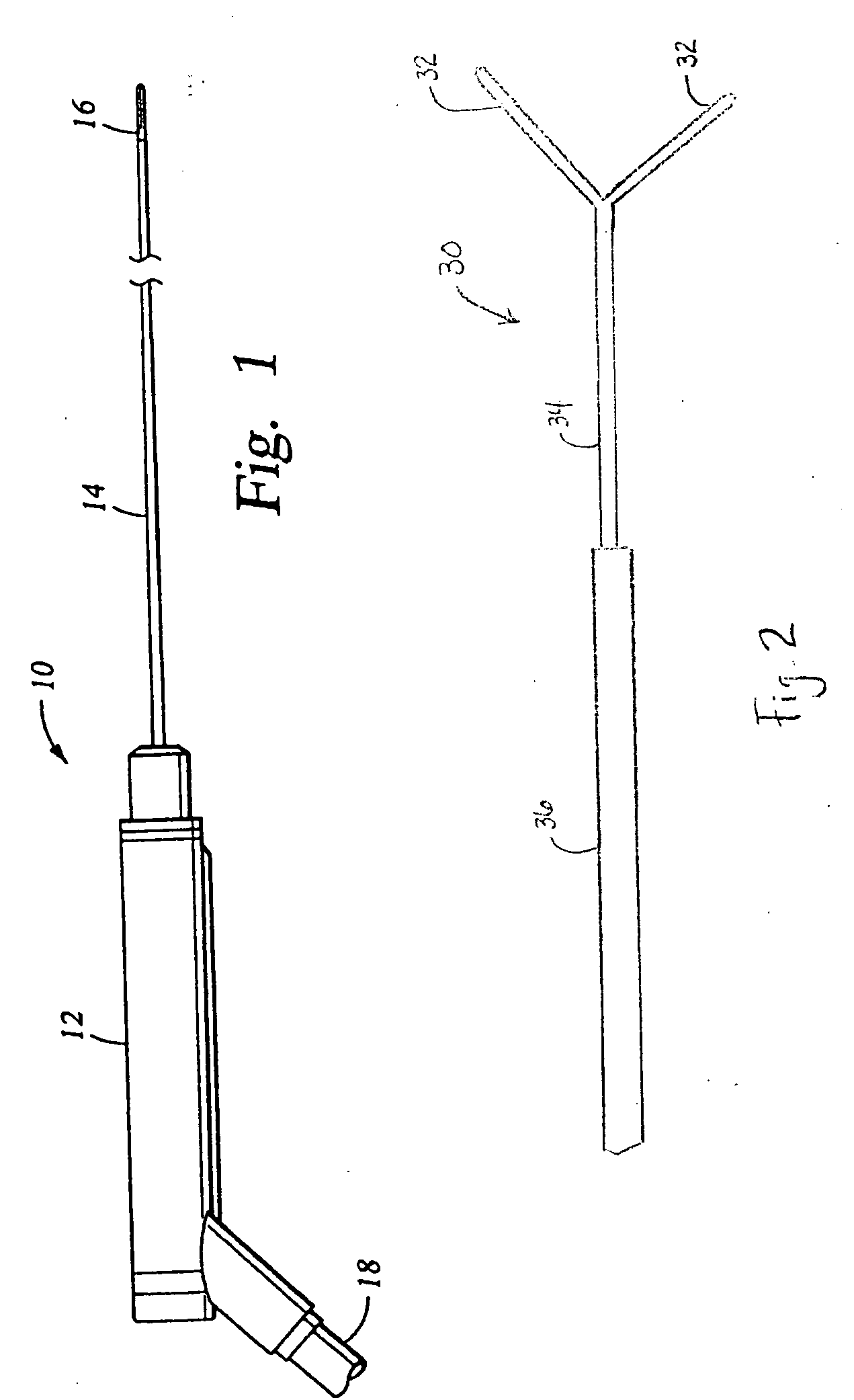

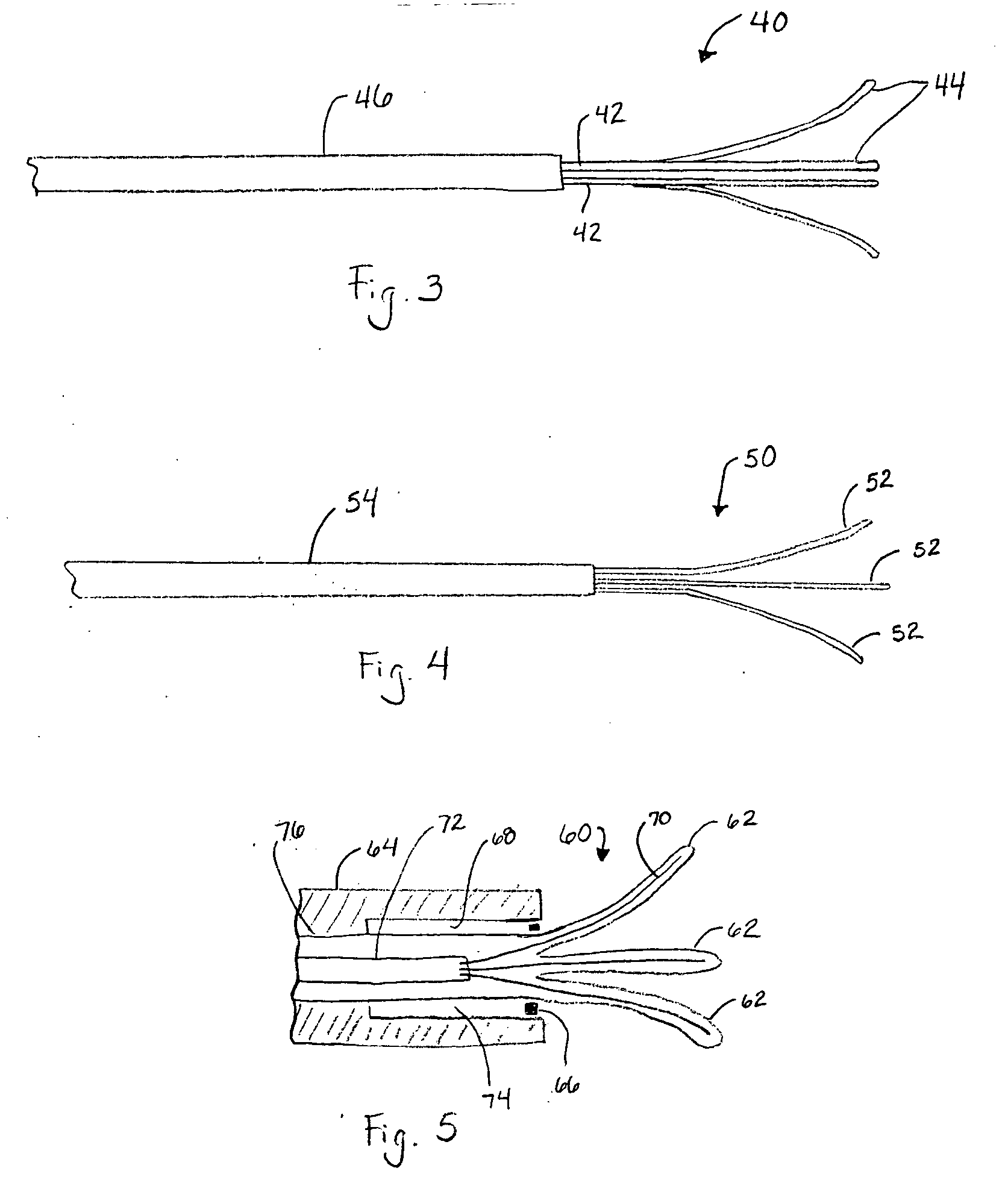

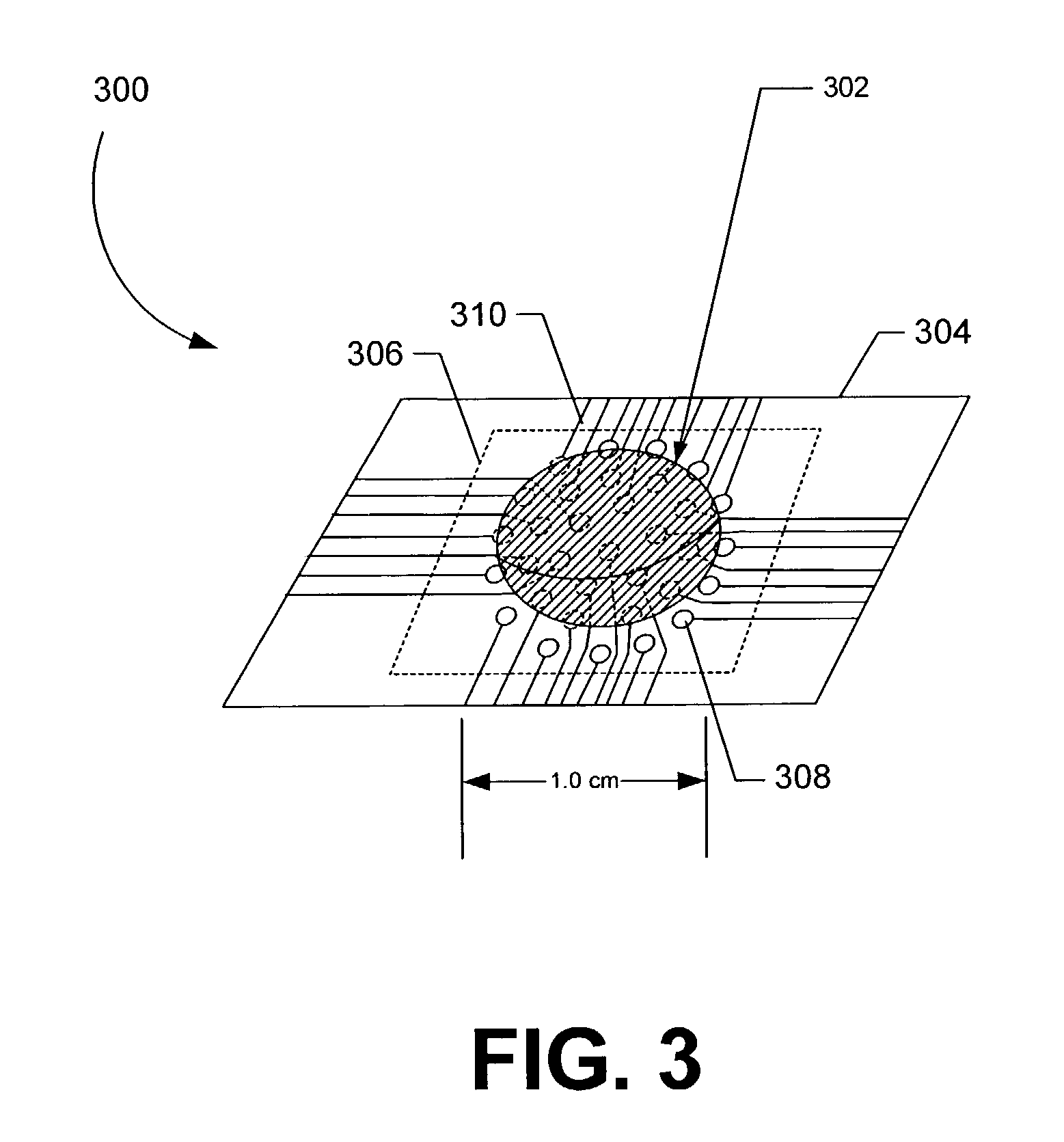

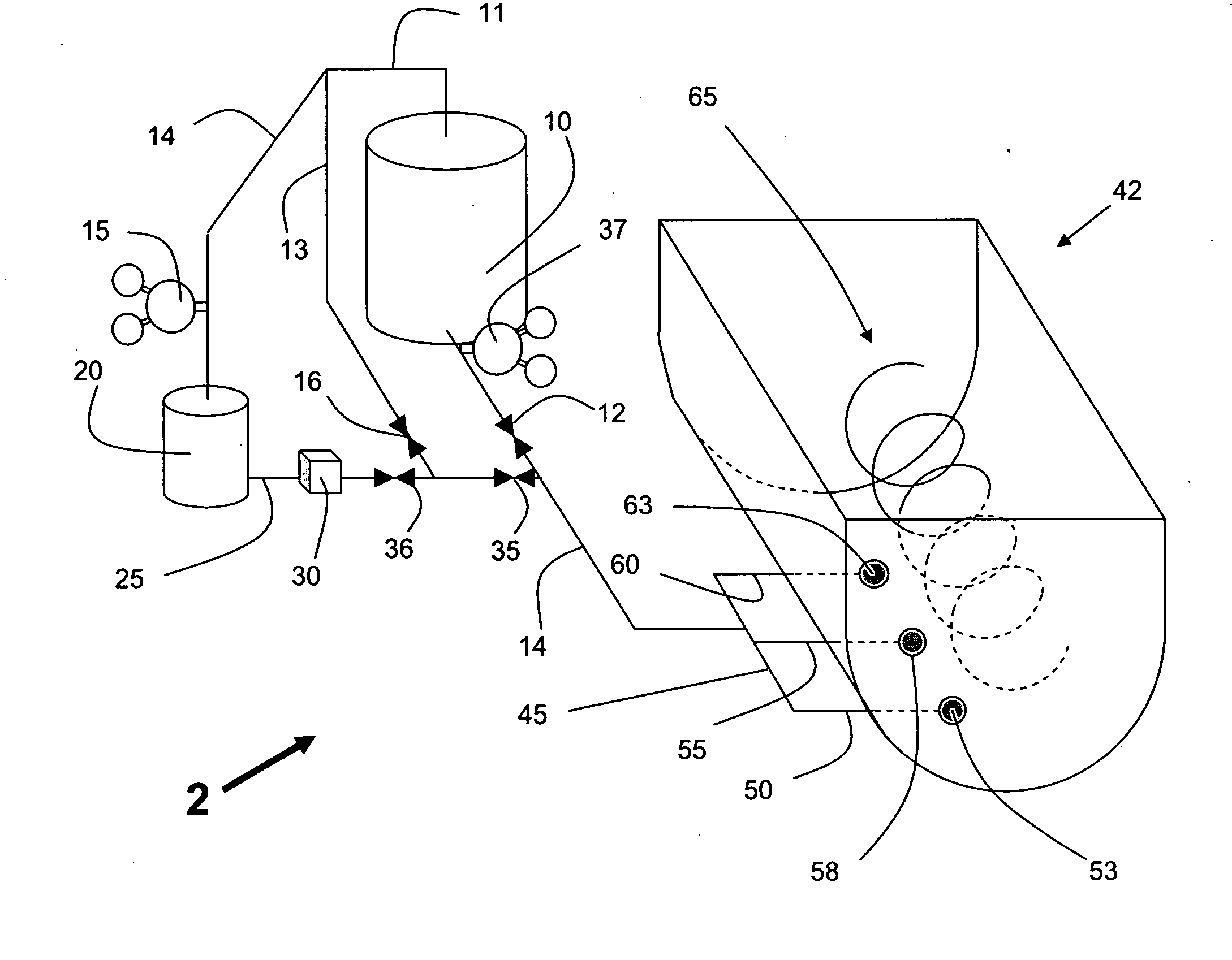

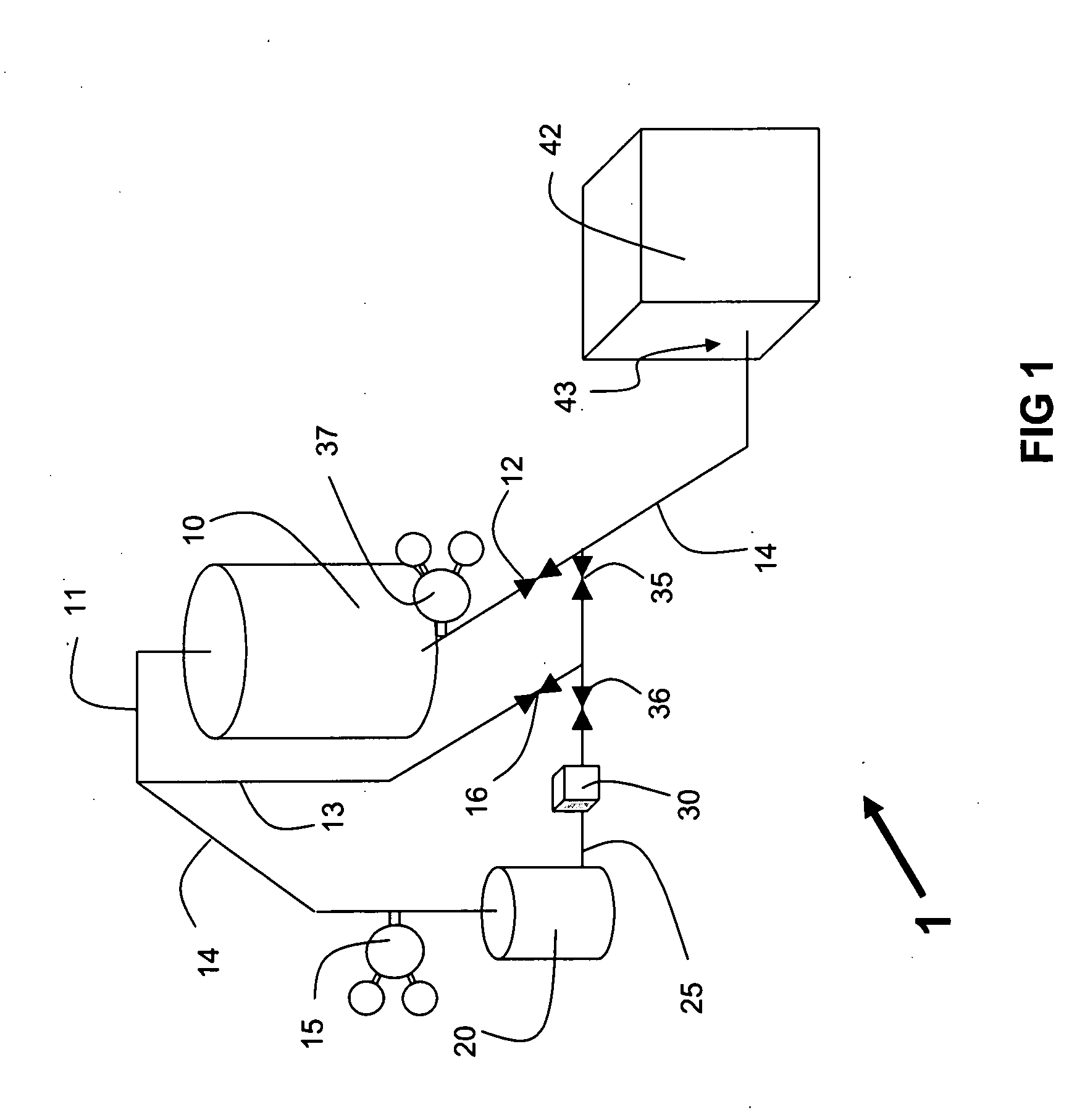

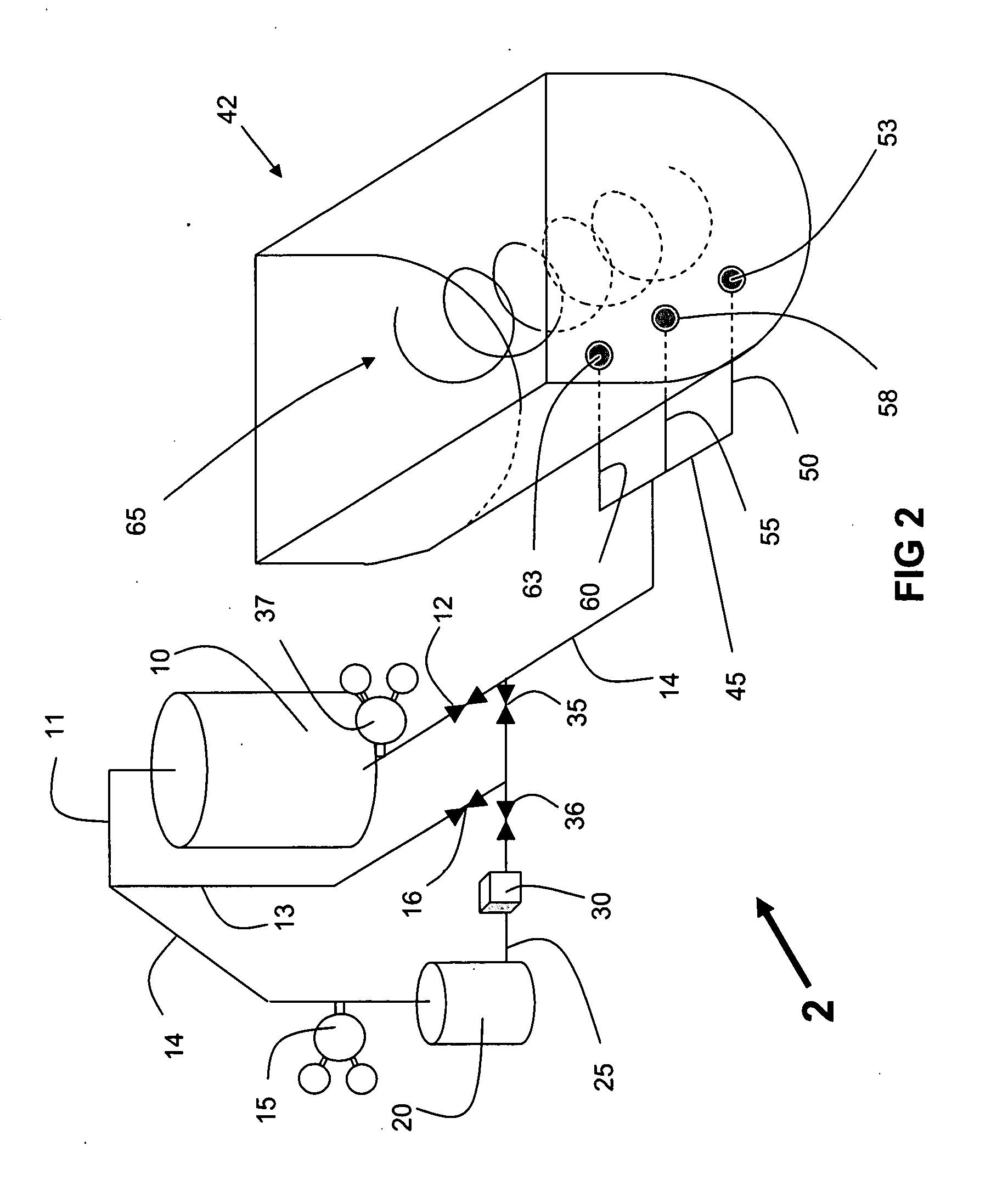

Cryosurgical devices and methods for endometrial ablation

A cryoablation system including a cannula having a proximal end, a distal end, and a longitudinal axis, an expandable balloon extending from the distal end of the cannula and fluidly connected to a source of heat transfer fluid by at least one fluid path, a pump for circulating the heat transfer fluid into and out of the balloon, a probe handle coupled to the proximal end of the cannula and in fluidic communication with the balloon through the cannula, and a heat exchanger for varying the temperature of the heat transfer fluid, wherein the heat exchanger is fluidly connected to a secondary refrigerant source. The heat exchanger may be positioned within the probe handle, within the cannula, or at least partially within the balloon. The heat transfer fluid of this cryoablation system preferably has a freezing point lower than about −110° C. and a boiling point greater than about 50° C.

Owner:COOPERSURGICAL INC

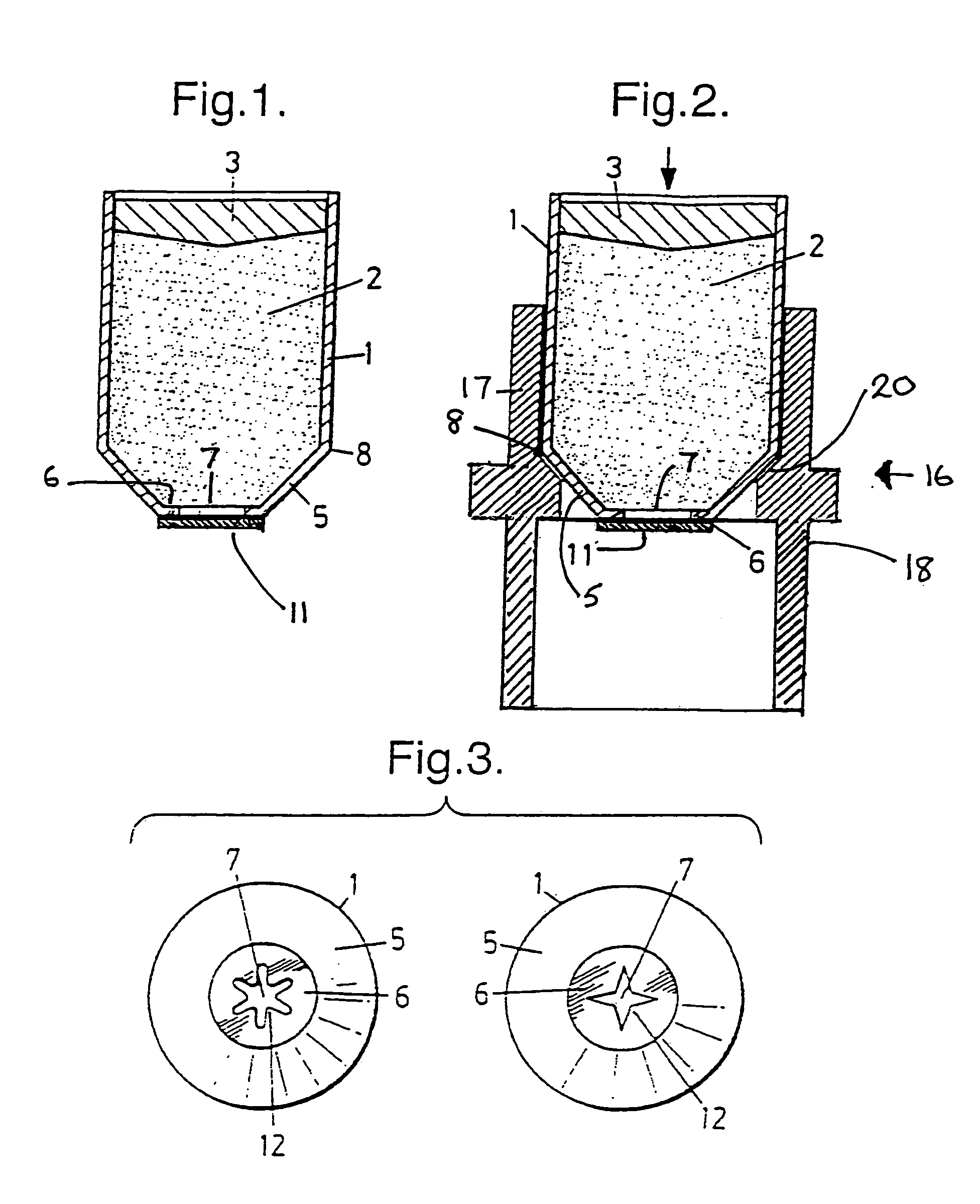

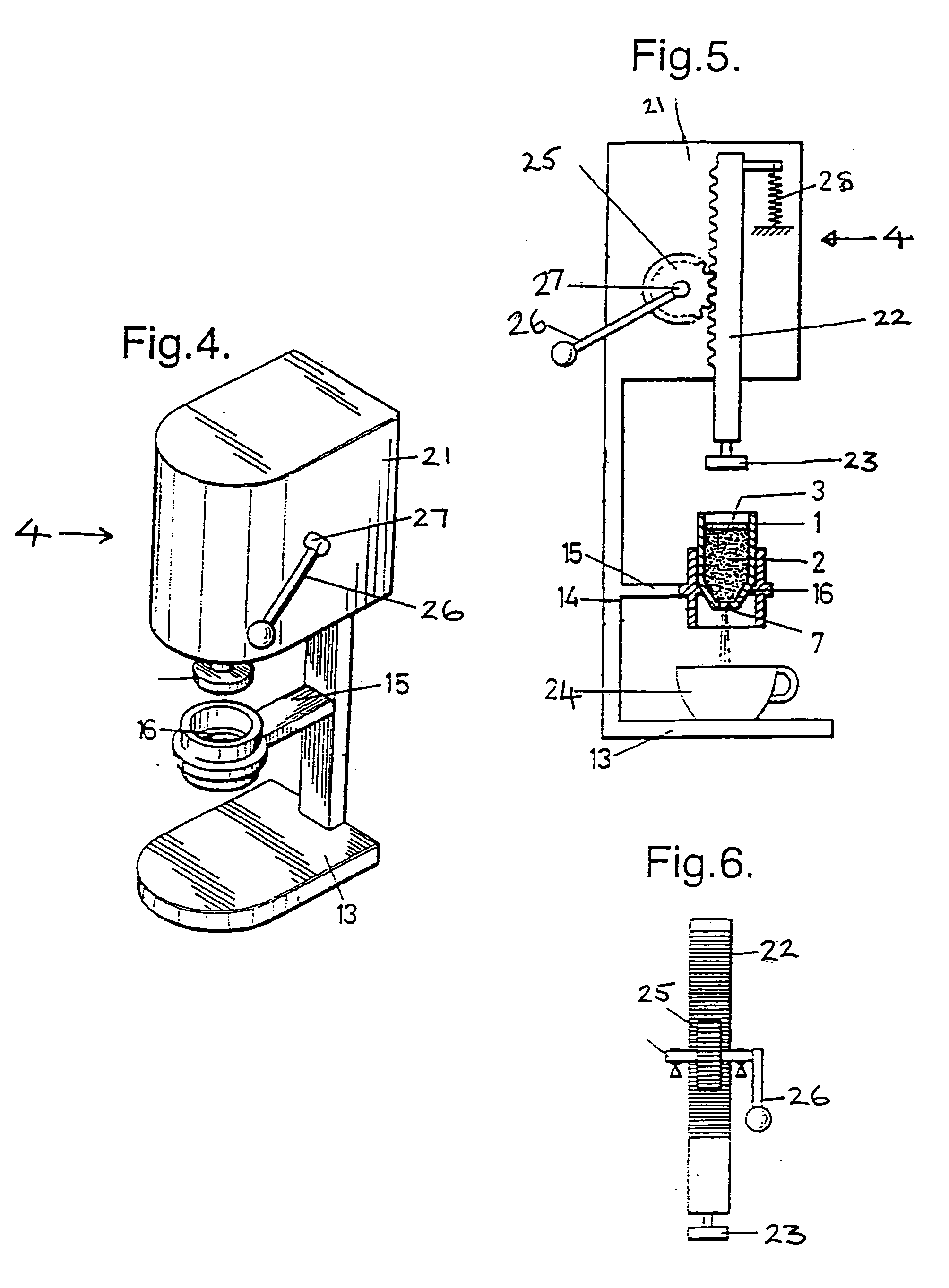

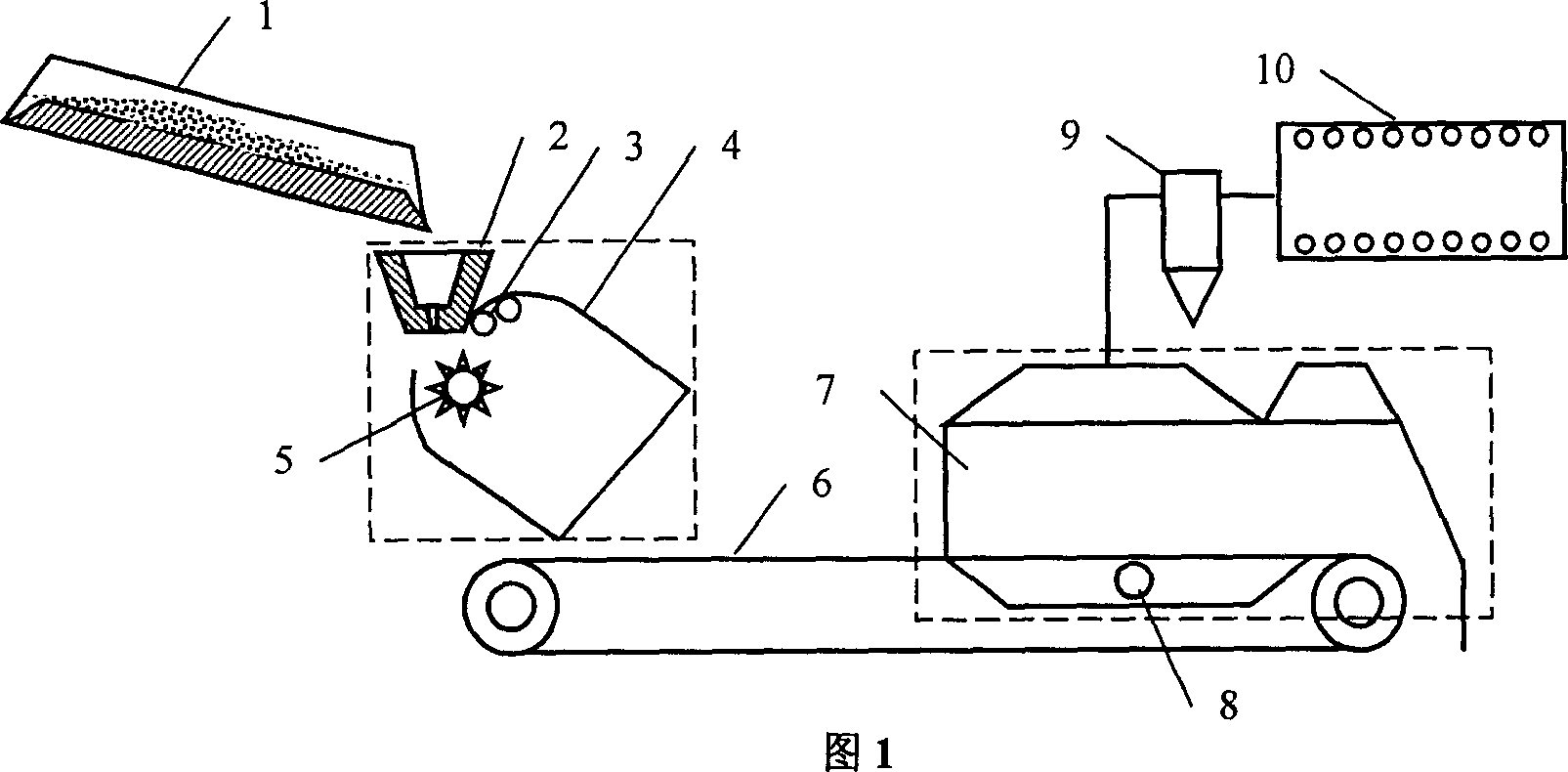

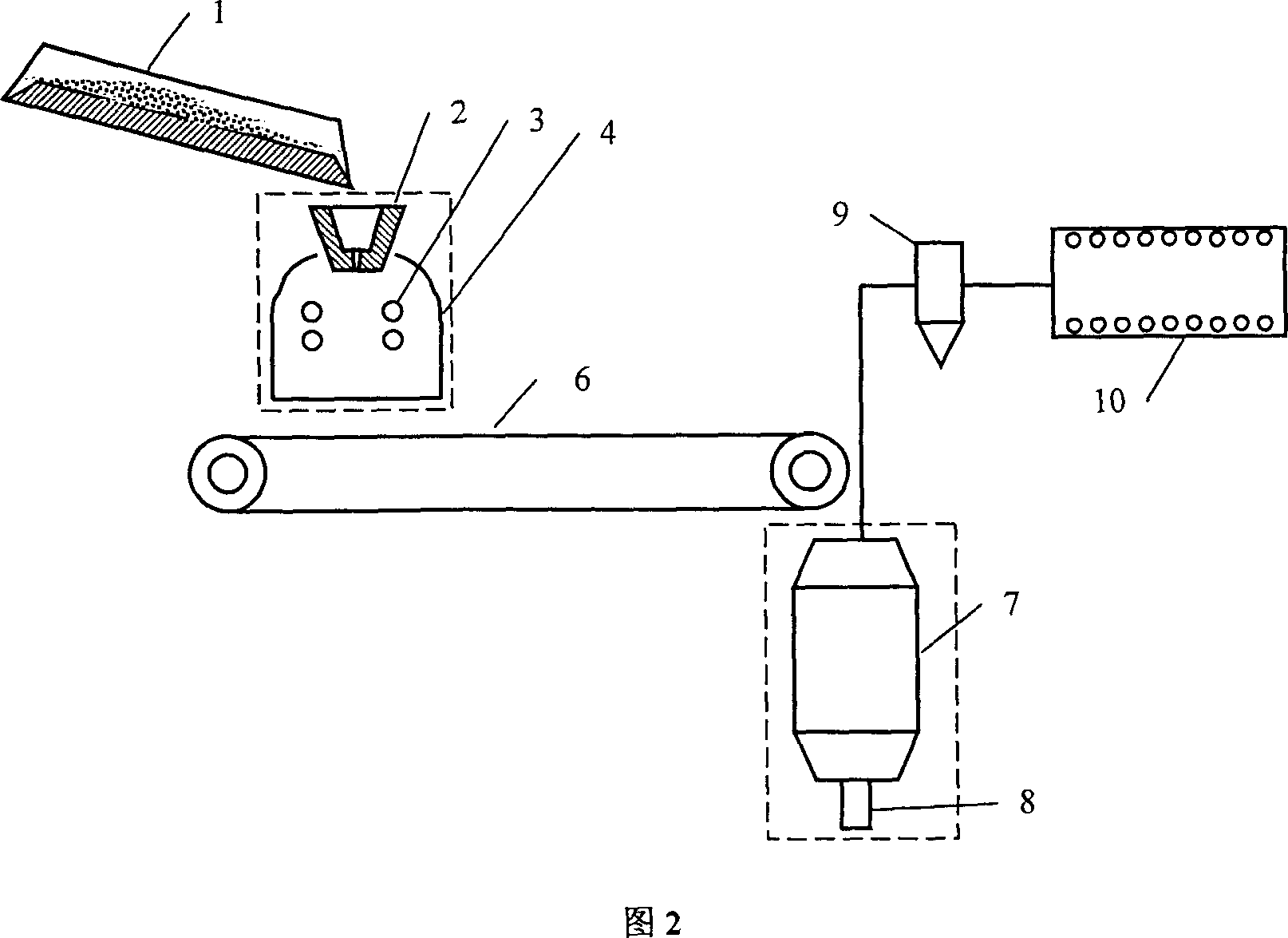

Process for the production of particles or powders

In a novel process for the production of particles or powders, a substance or mixture of substances to be treated is provided in a pressure vessel. A highly compressible fluid is dissolved under pressure in the substance or mixture of substances provided until a solution containing 5% to 90% by weight of said highly compressible fluid has formed. The melting point of said highly compressible fluid is at least around 40 K lower than the melting point of the substance or mixture of substances to be treated. The solution obtained by dissolving said highly compressible fluid in the substance or mixture of substances provided is adjusted to a temperature of up to around 50 K above or below the melting point under atmospheric pressure of the substance or mixture of substances to be treated and is then rapidly decompressed by means of a decompression device in such a way that the temperature falls, downstream of the decompression device, below the solidification point of the substance or mixture of substances to be treated and essentially all of the highly compressible fluid turns gaseous, whereby particles of the substance or mixture of substances provided form. Subsequently, the particles which have formed are removed from the stream of decompressed highly compressible fluid.

Owner:WEIDNER ECKHARD +2

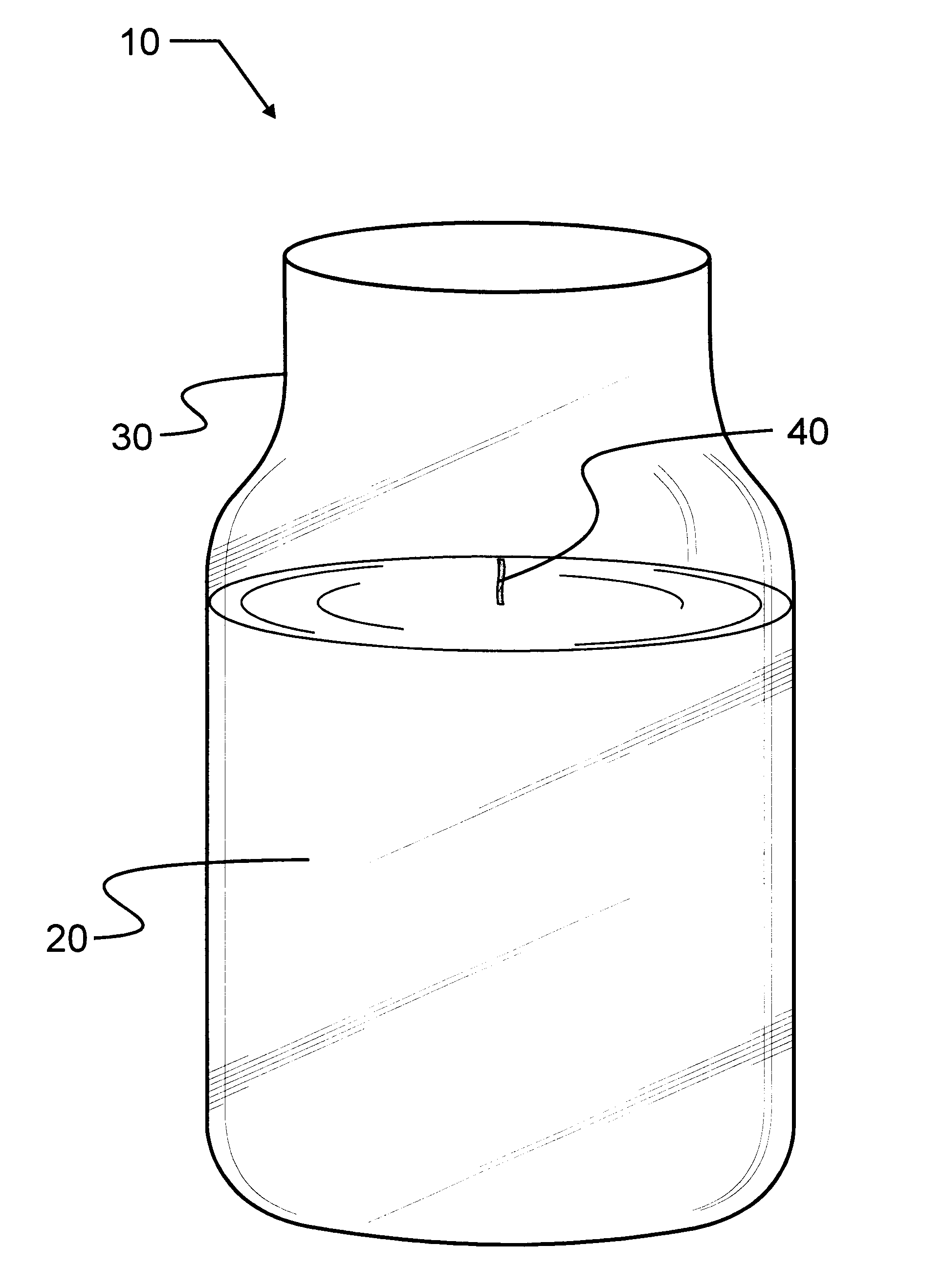

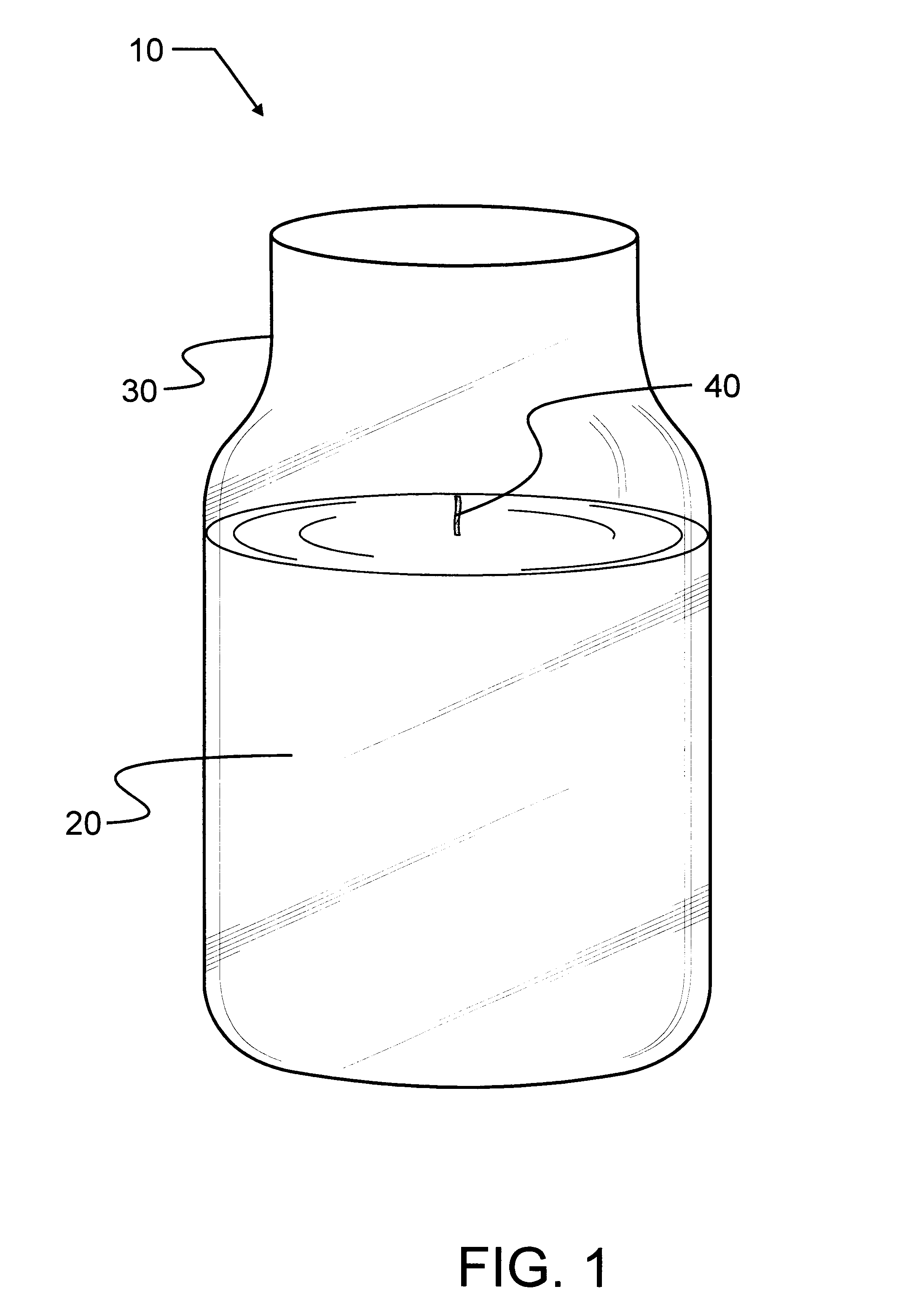

Soybean wax candles

InactiveUS6599334B1Increase profitWithout and crackingSolid fuelsCapillary burnersVegetable oilAlpha-olefin

A solid fuel candle which is highly adapted for use both in a container and also as a free-standing candle includes at least 85 percent hydrogenated soybean oil, approximately 0 to 4 percent synthetic wax composition, approximately 0 to 4 percent of a second hydrogenated vegetable or petroleum oil, approximately 0 to 10 percent fragrance or scent, and approximately 0 to 3 percent dye. The hydrogenated vegetable oil most preferably has an iodine value of approximately 50 and a melting point of approximately 125 degrees Fahrenheit, with a free fatty acid content of less than one-tenth of one percent. The synthetic wax composition is most preferably formed from alpha olefin monomers and oligomers under free radical conditions at relatively low pressures to yield a highly branched polymer wax having congealing and melting points lower than the starting alpha olefin material and a higher molecular weight.

Owner:ANDERSON JILL M

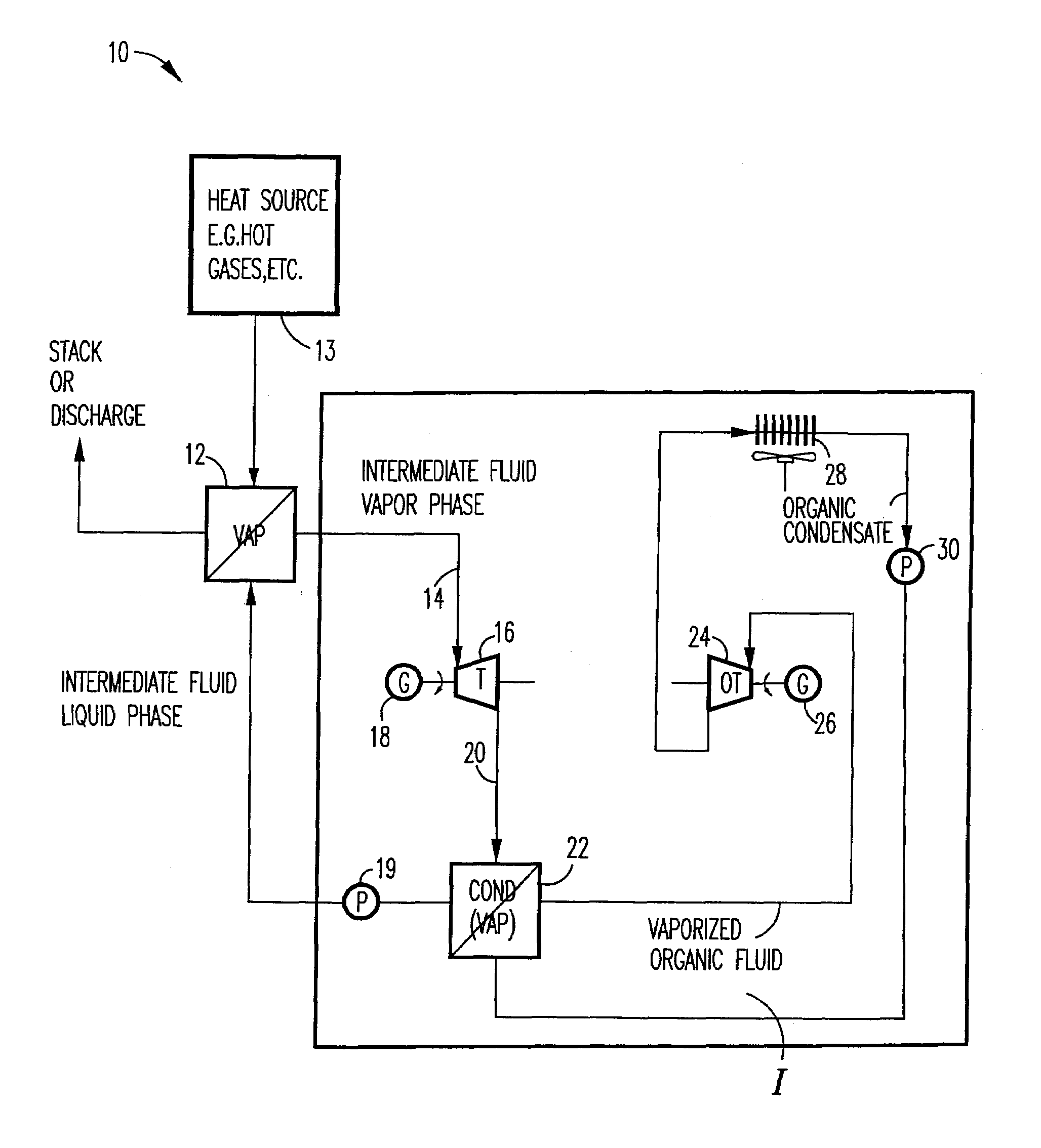

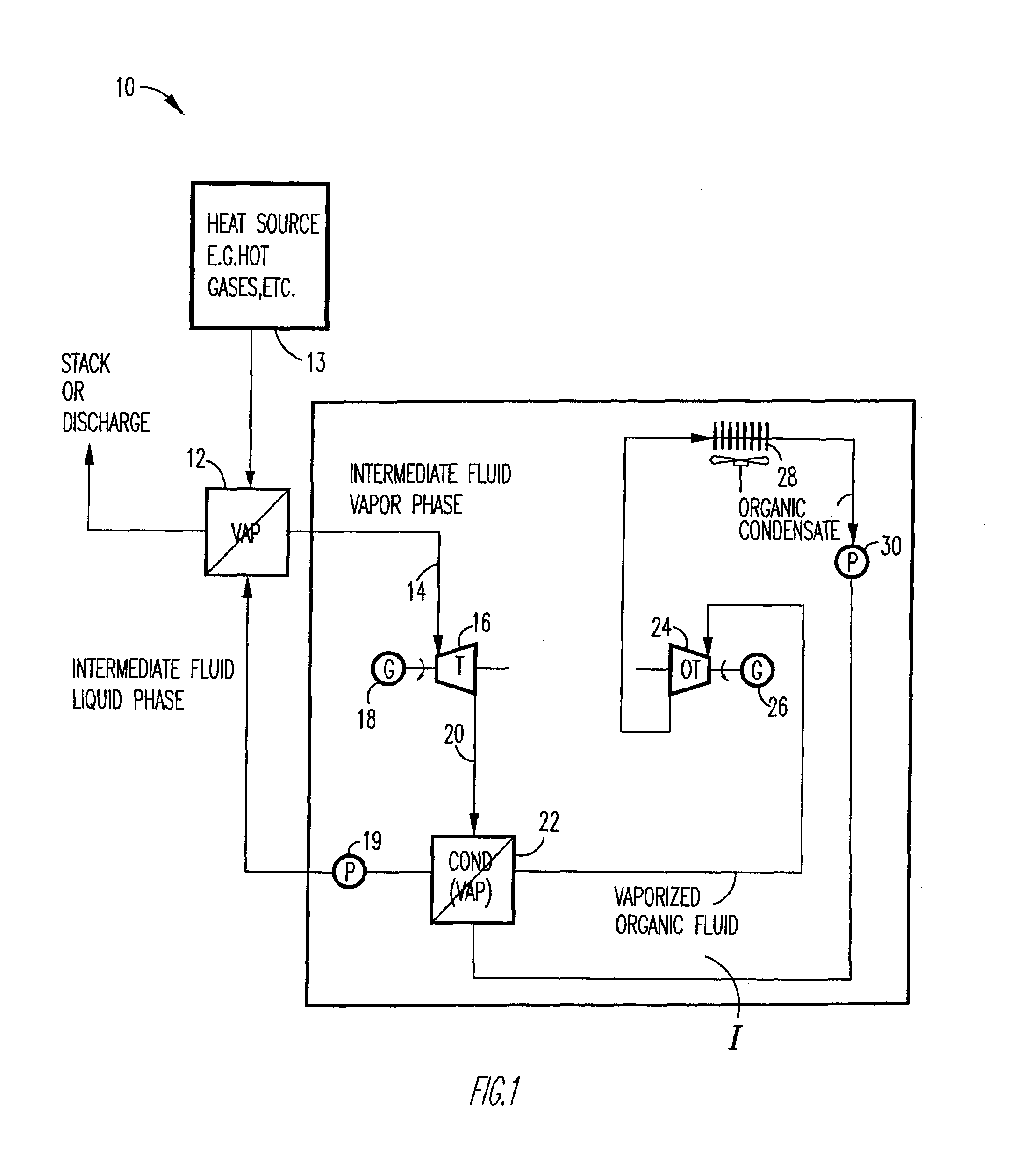

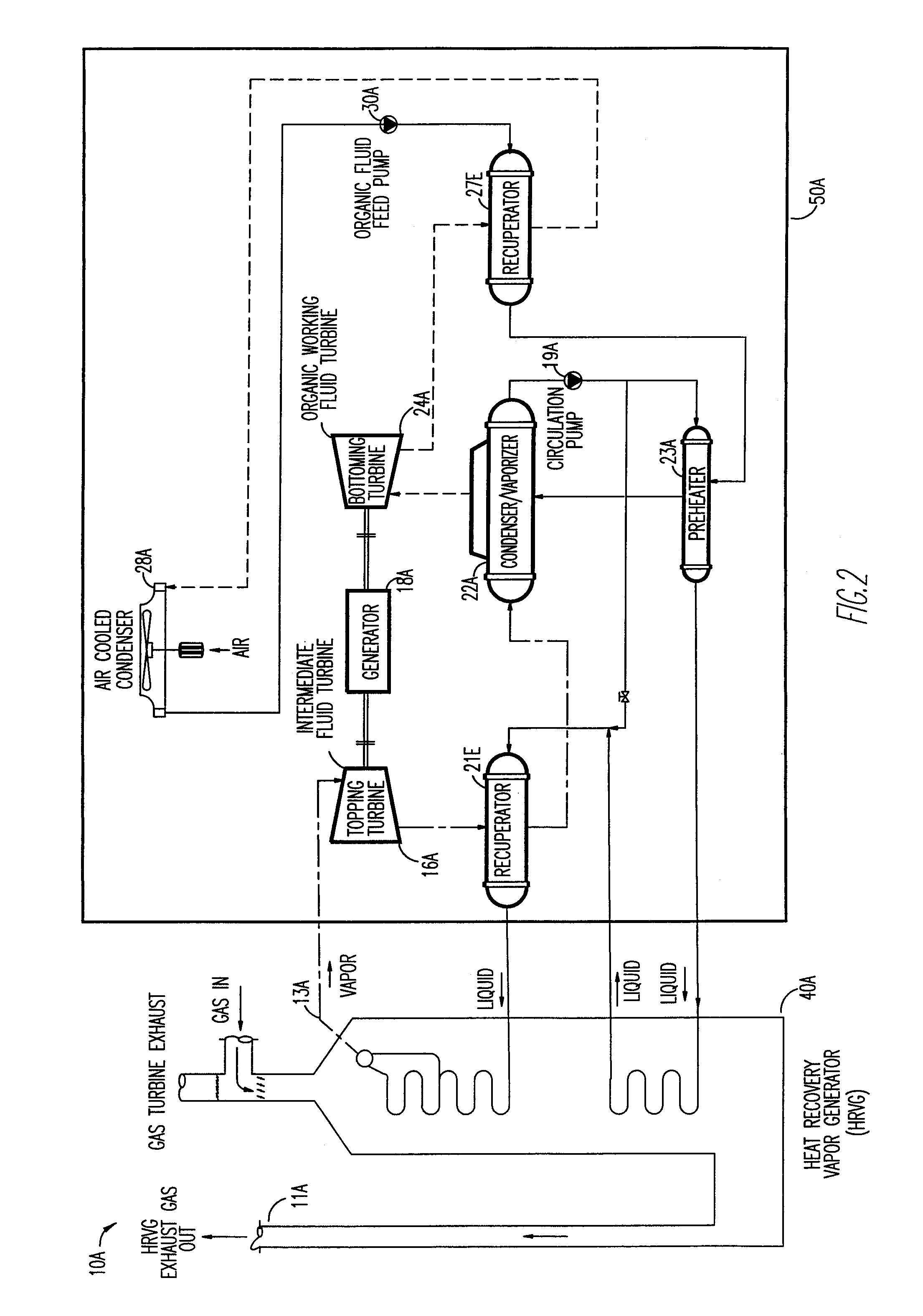

Organic working fluids

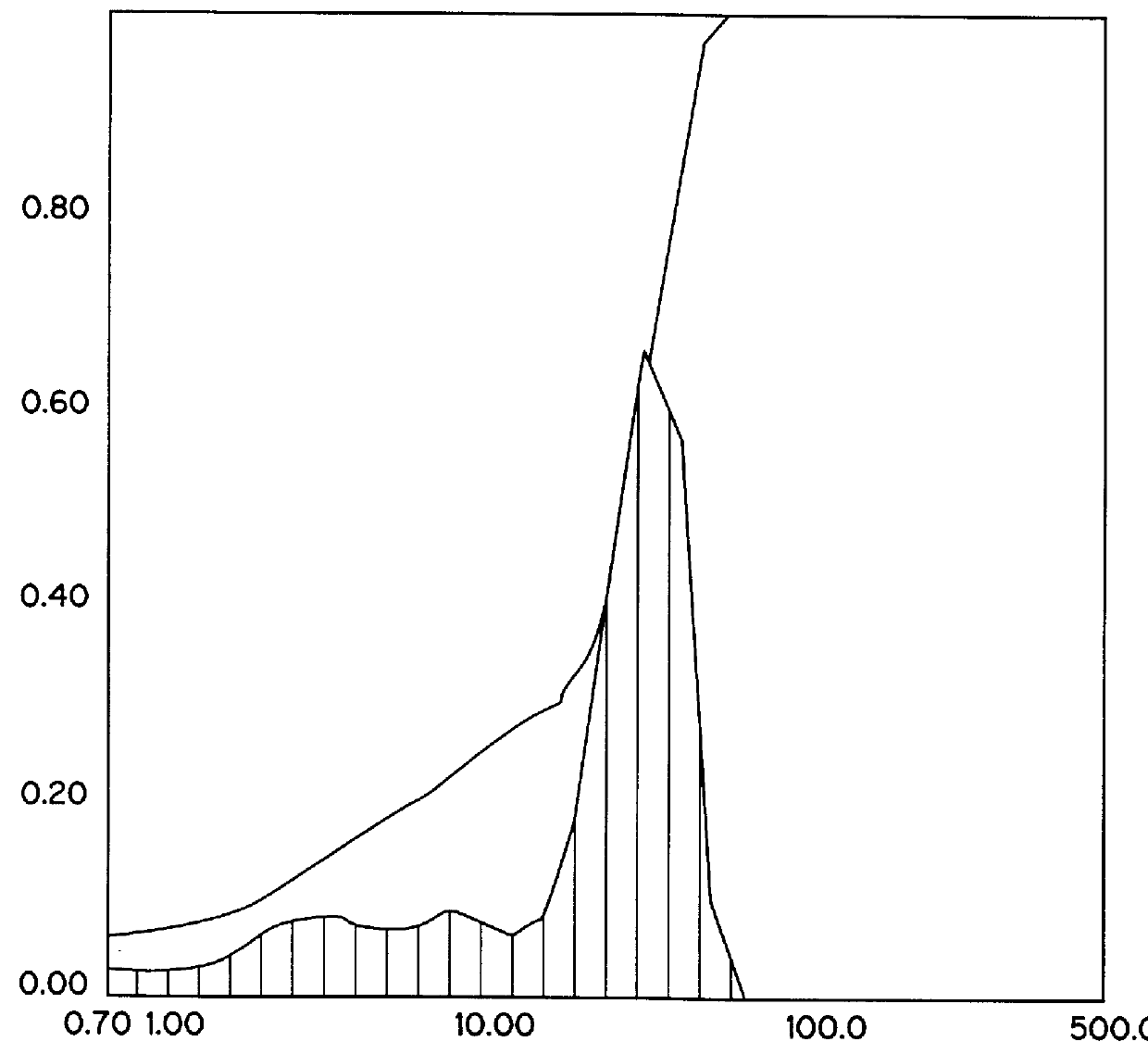

ActiveUS7225621B2Improve thermal stabilityStable compoundAuxillary drivesFrom solar energyHuman useAlkane

The present invention provides an improved, commercially available organic working fluid, which is operable under a broad range of temperatures, is thermally stable, has a high auto-ignition temperature, low freezing point and high critical temperature and is benign to the environment, and safe for human use. Such an organic working fluid is useful in organic Rankine cycle (ORC) power plants or units and other systems of the like; as an intermediate fluid for heat-recovery wherein heat from various heat sources is transferred using the intermediate fluid to a further working fluid and converted into work, and the intermediate fluid is also exploited to produce electricity. Such organic working fluids are also operable as heat transfer fluids either in ORC power plants or units or in other heat transfer systems. For this purpose the present invention presents a working fluid comprising at least one highly branched, heavy iso-paraffin hydrocarbons, or a mixture of two or more of such hydrocarbons. Preferably, at least one highly branched iso-paraffin hydrocarbon is present as the major component (i.e. at least 50% by volume) in the working fluid. A preferred sub-class of the class of the branched iso-paraffins which are suitable to be incorporated in organic working fluids of the present invention includes 8 to 20 carbon atom-containing hydrocarbons having at least one methyl radical (CH3) arranged to achieve a highly stable compound.

Owner:ORMAT TECH INC

Hydrodewaxing catalyst for diesel oil distillate and its preparing method

ActiveCN1952074AHigh yieldExcellent isomerization performancePetroleum wax recoveryWaxMolecular sieve

The invention disclosed a catalyst to lower the freezing point of the diesel oil. The catalyst includes carrier that contains reshaped molecular sieve and hydrogenated metal. The molecular sieve is reshaped by VIB group metal, the content of which in the molecular sieve is 1wt%-40wt% (by oxidation state). The content of the molecular sieve and the metal are 10wt%-90wt% (by oxidation state) and 0.1wt%-40wt% (by oxidation state) respectively. The reshaping agent can modify the acid substance and the bore size on the surface of the molecular sieve so as to match the catalyst's isomerizing function and structure-selective splitting function well; it can make the splitting reaction proceeds according to the lock-and-key mechnanism and ensure the reaction proceeds properly without over splitting; it can improve the quality of the diesel oil and increase its yield. The invention can be used in the deparaffinage of the material that contains wax, especially in the process to lower the freezing point of the diesel oil distillate. It can not only lower the freezing point, but also increase the diesel oil yield substantially.

Owner:CHINA PETROLEUM & CHEM CORP +1

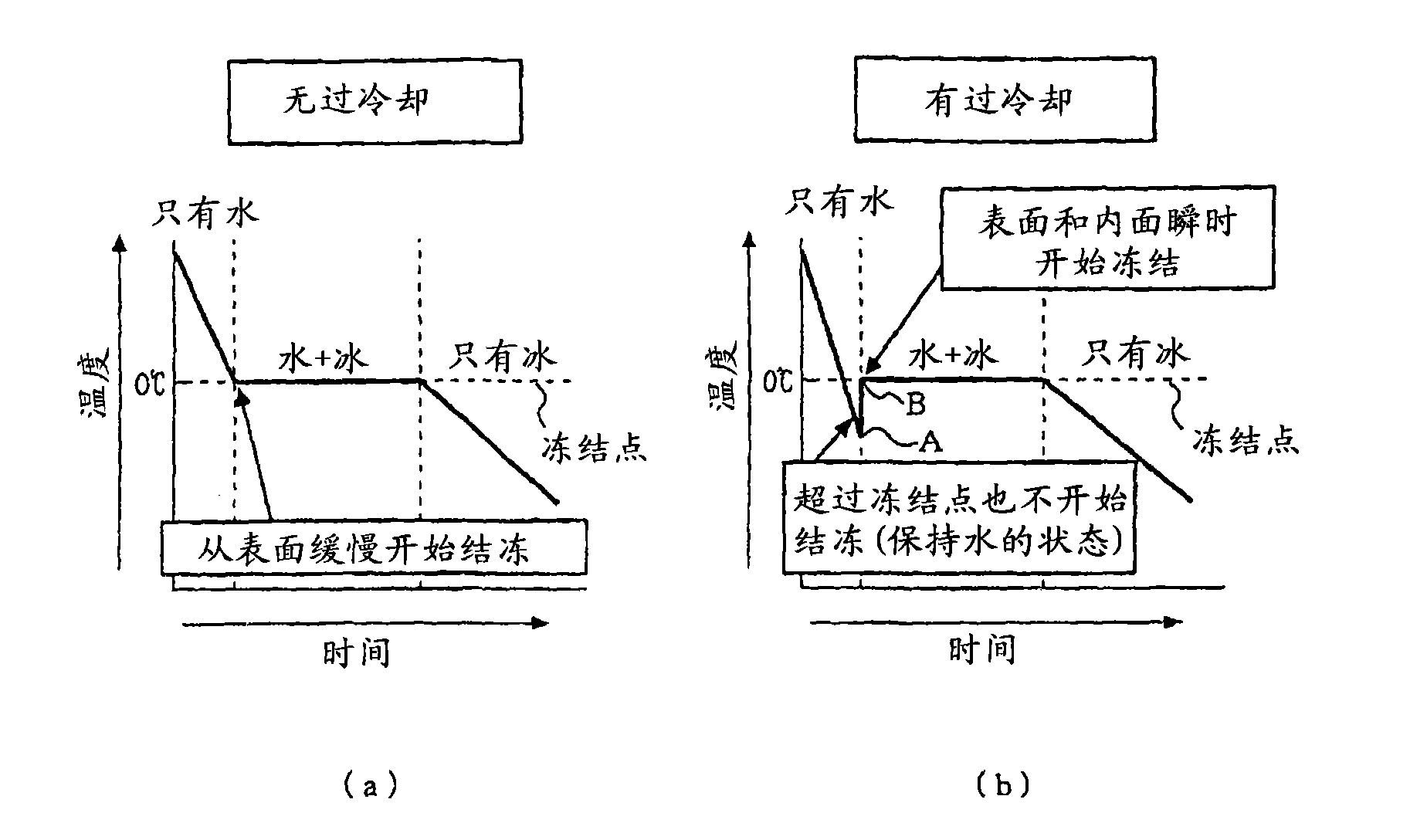

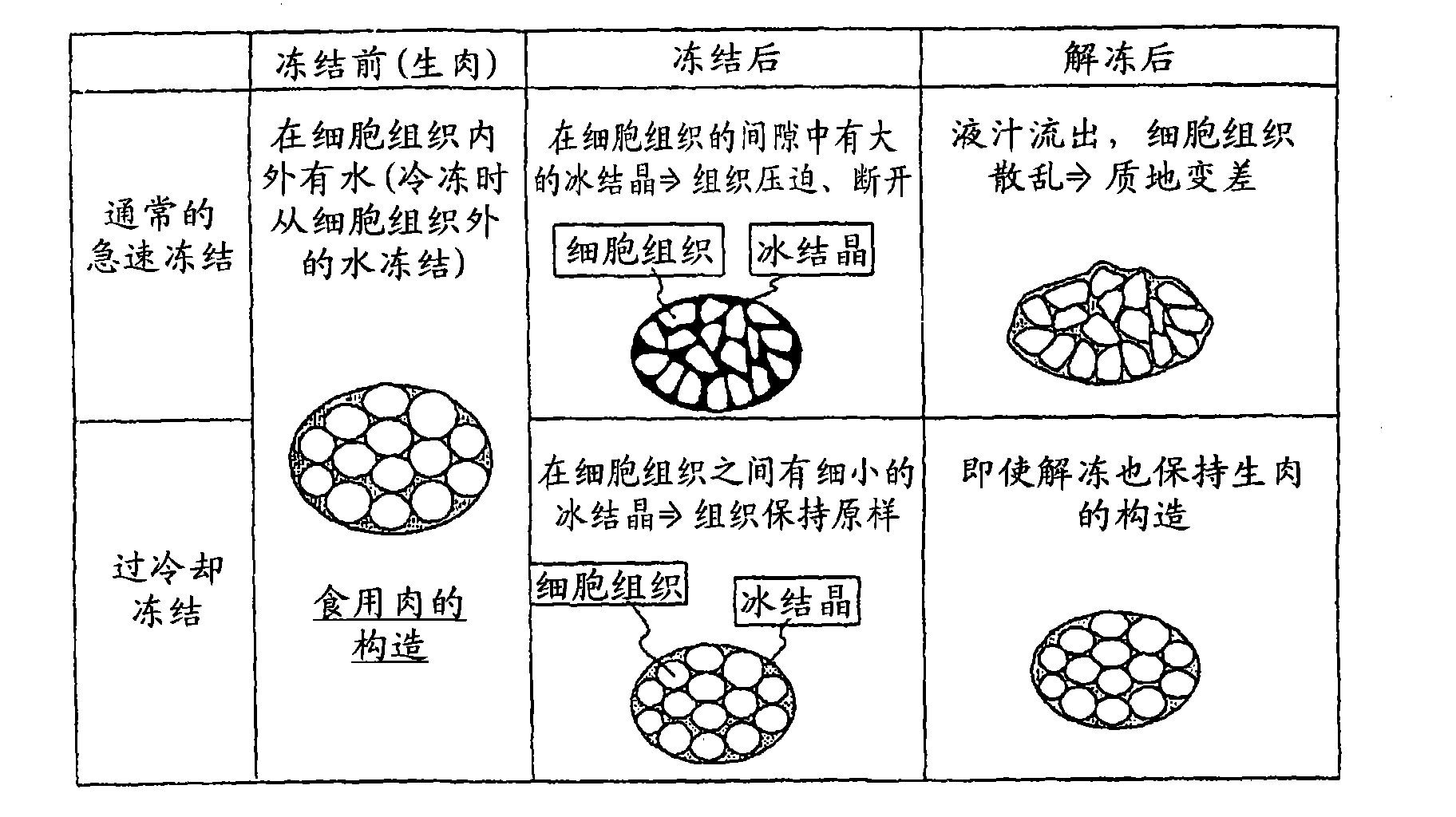

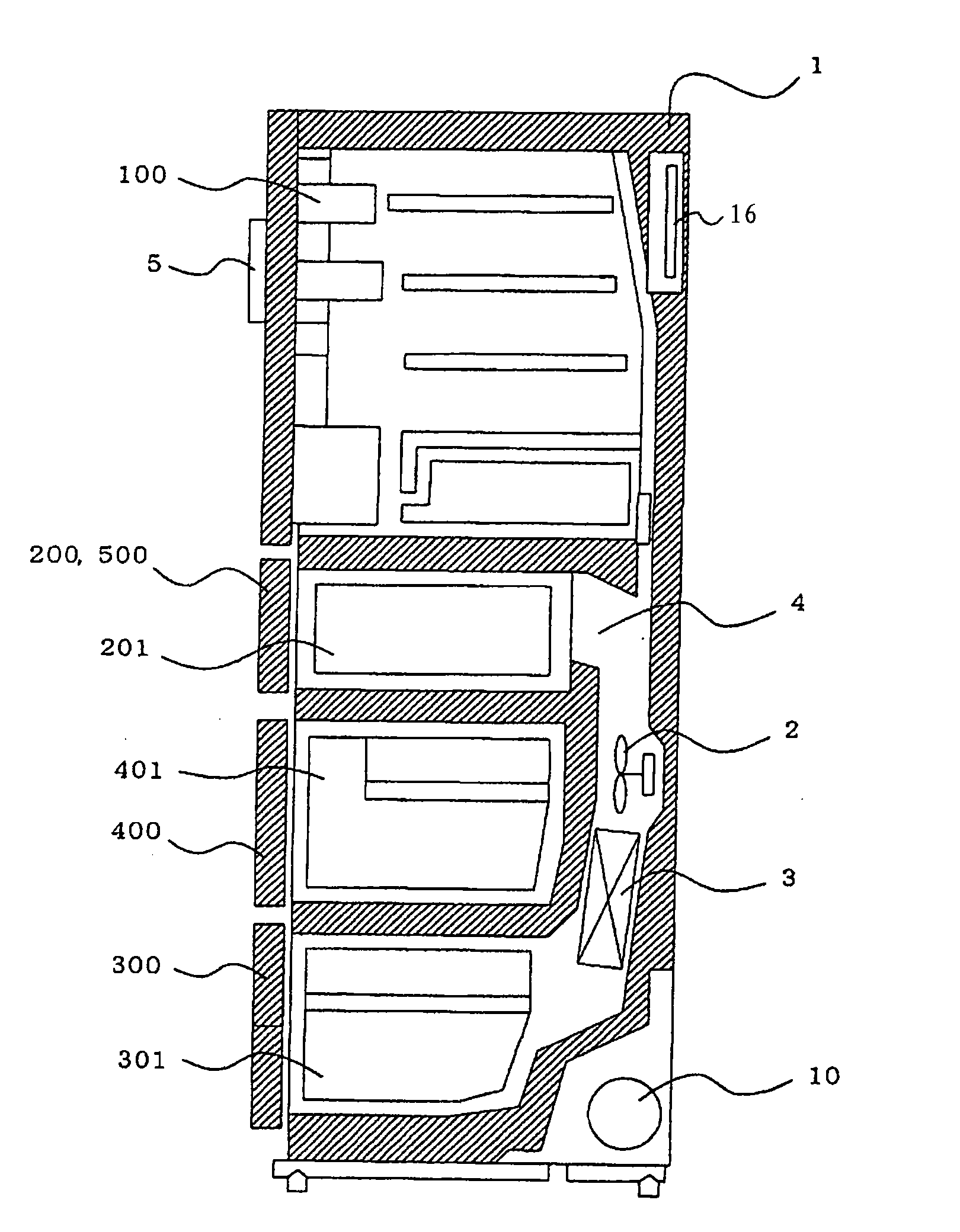

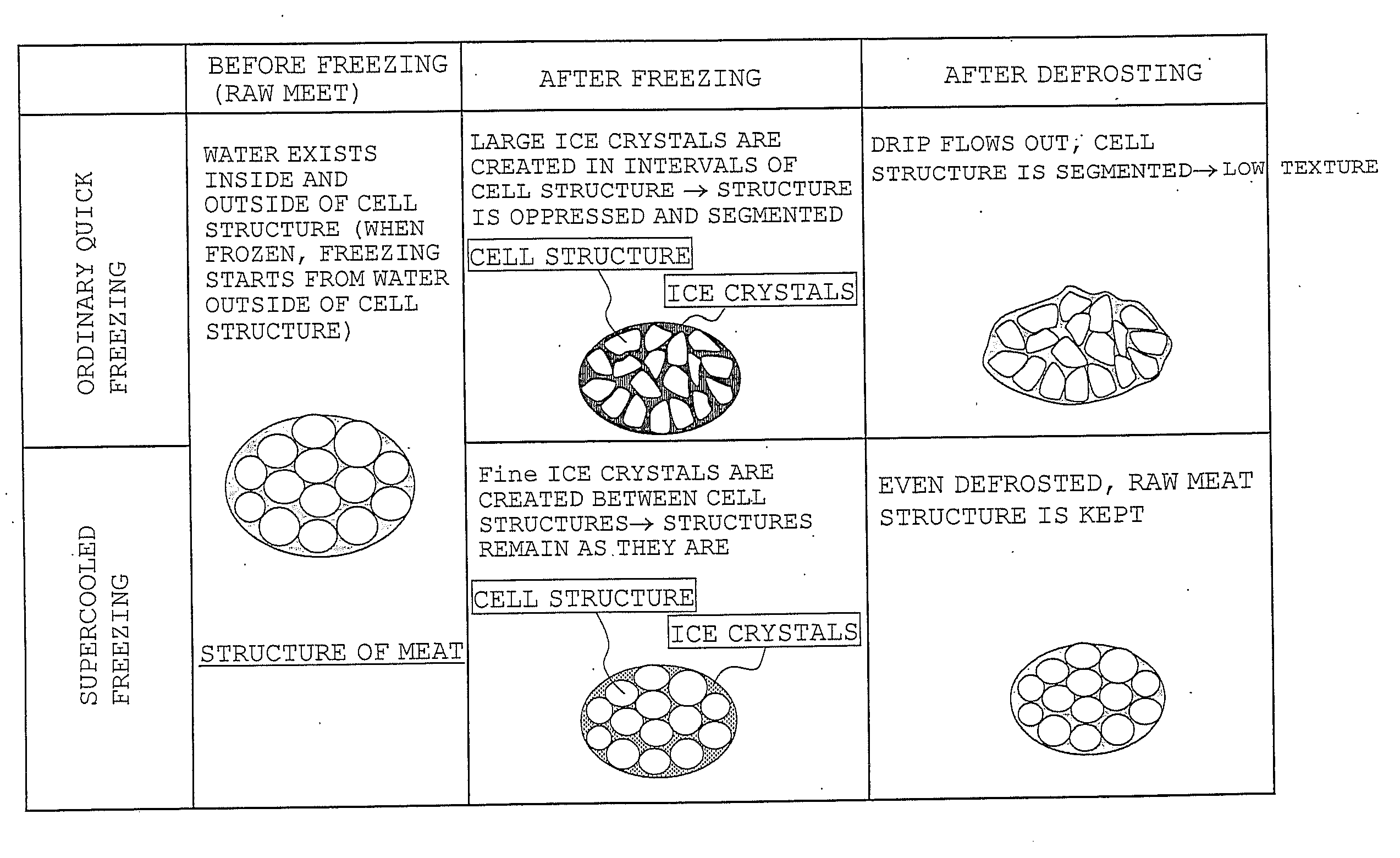

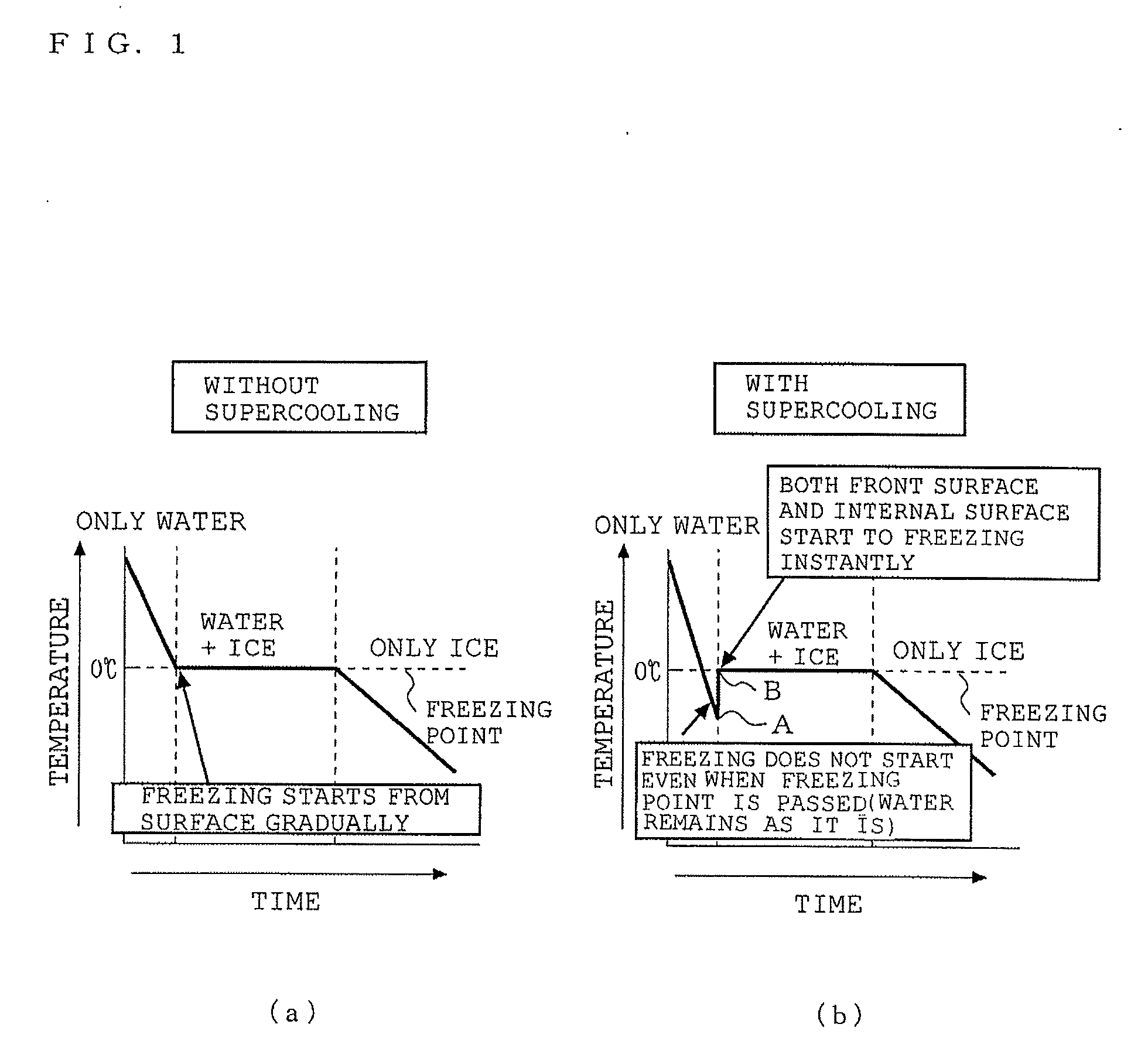

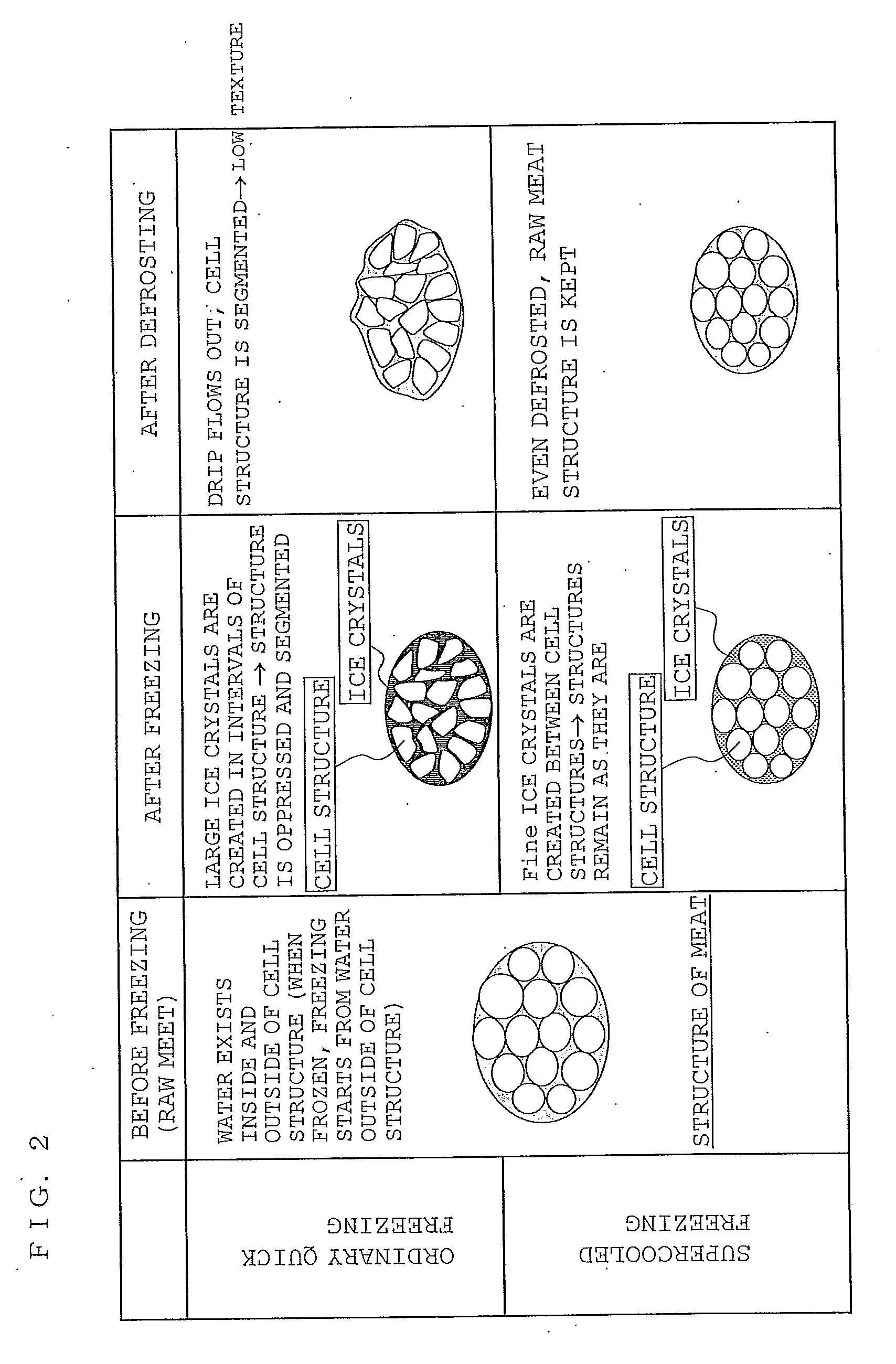

Refrigerator and method of refrigeration

ActiveCN101636625AHigh quality frozenRealize the effect of energy-saving refrigerationLighting and heating apparatusDomestic refrigeratorsCold airFood storage

Supercooling refrigeration being a method of enhancing the quality of food frozen other than the quick freezing method is realized by simple construction, and there are provided a refrigerator and method of refrigeration capable of realizing high-quality freezing by simple construction. The refrigerator is one capable of food storage utilizing cold air generated by cooler (3), comprising supercooling case (81) adapted to hold stored food in a supercooling state such that freezing does not occur even at its freezing point or lower temperature for at least a given period of time. The supercooling case (81) consists of, for example, the downside case of up-and-down two stage case disposed in switching chamber (200) capable of switching to multiple temperature zones.

Owner:MITSUBISHI ELECTRIC CORP

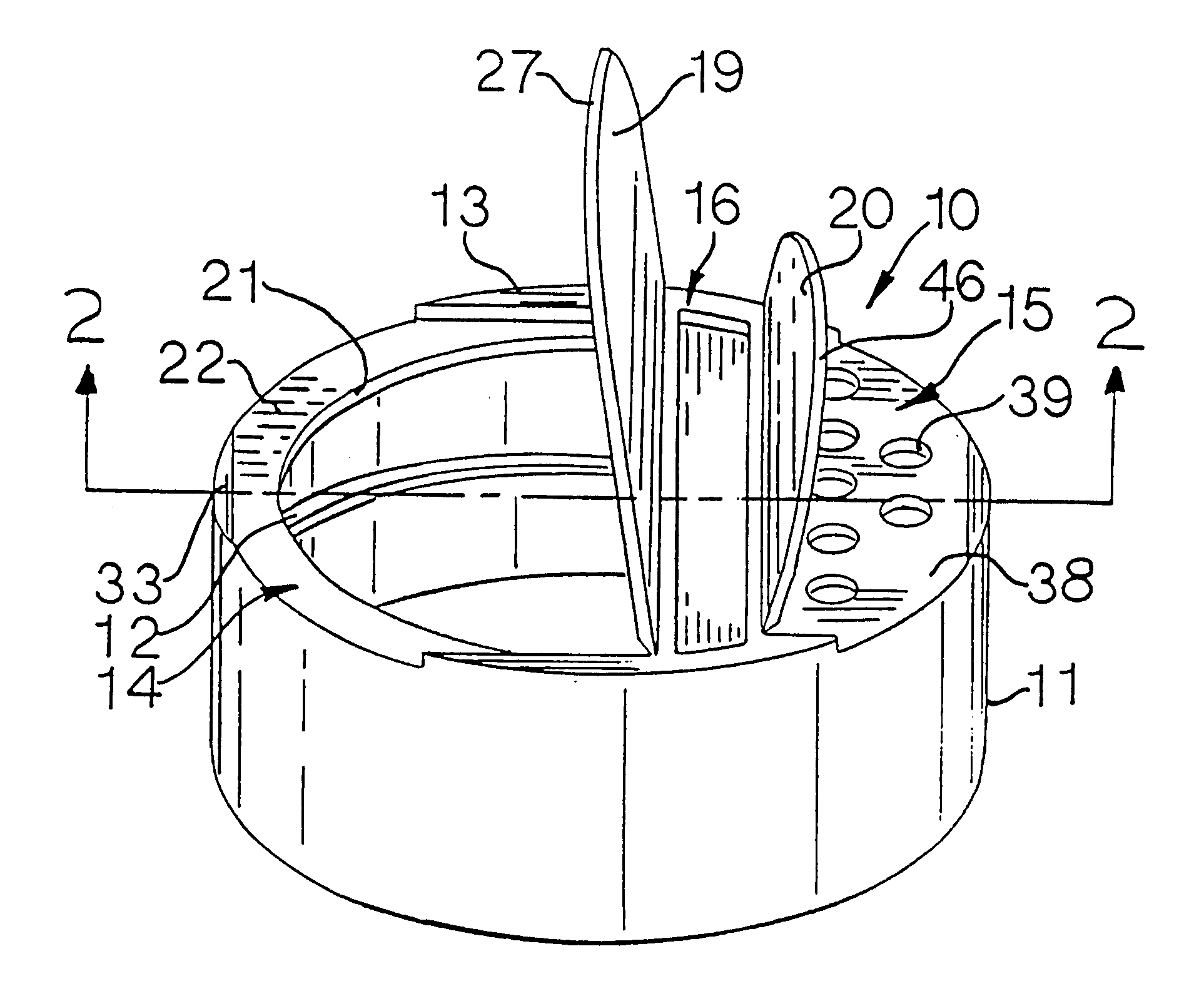

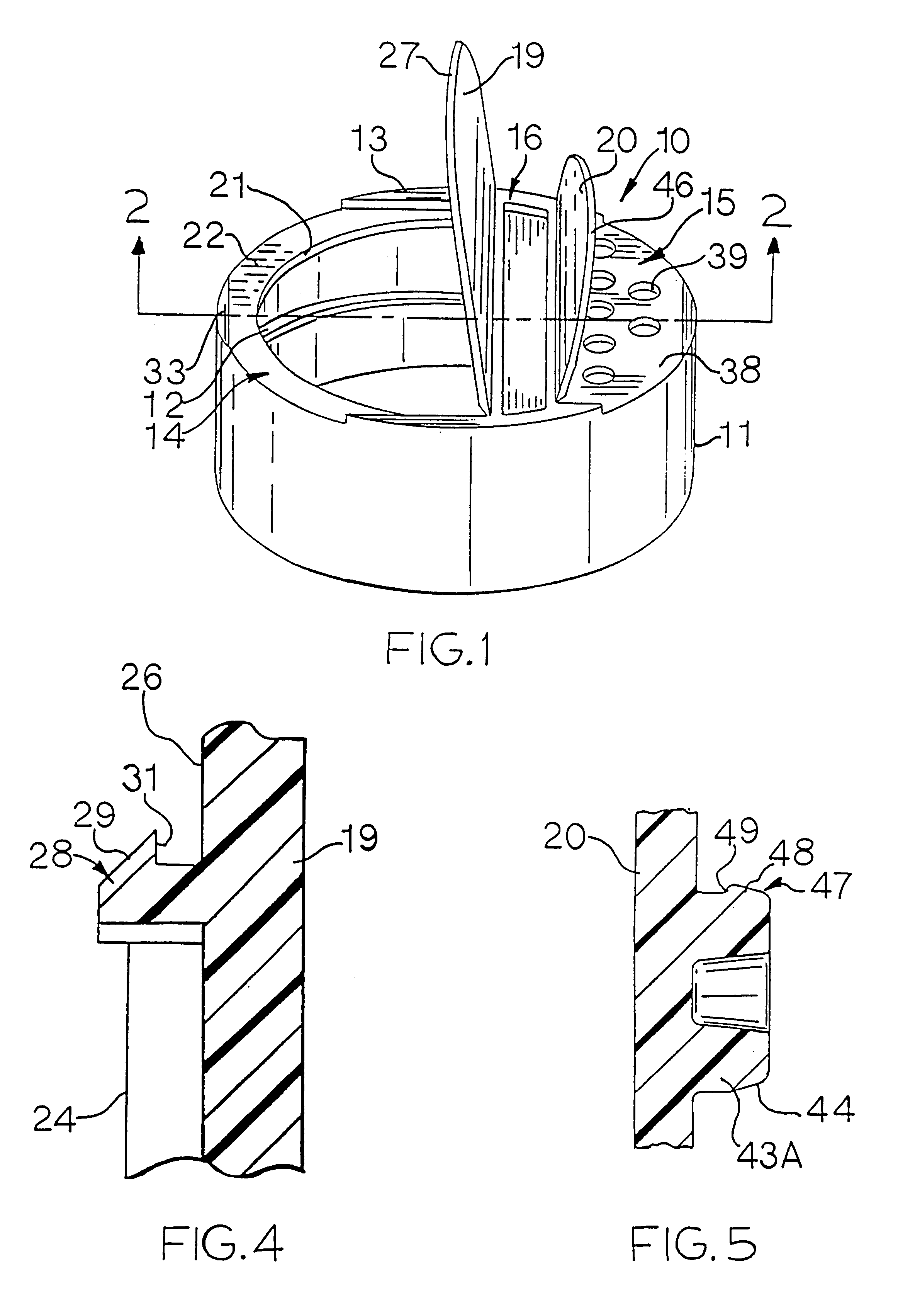

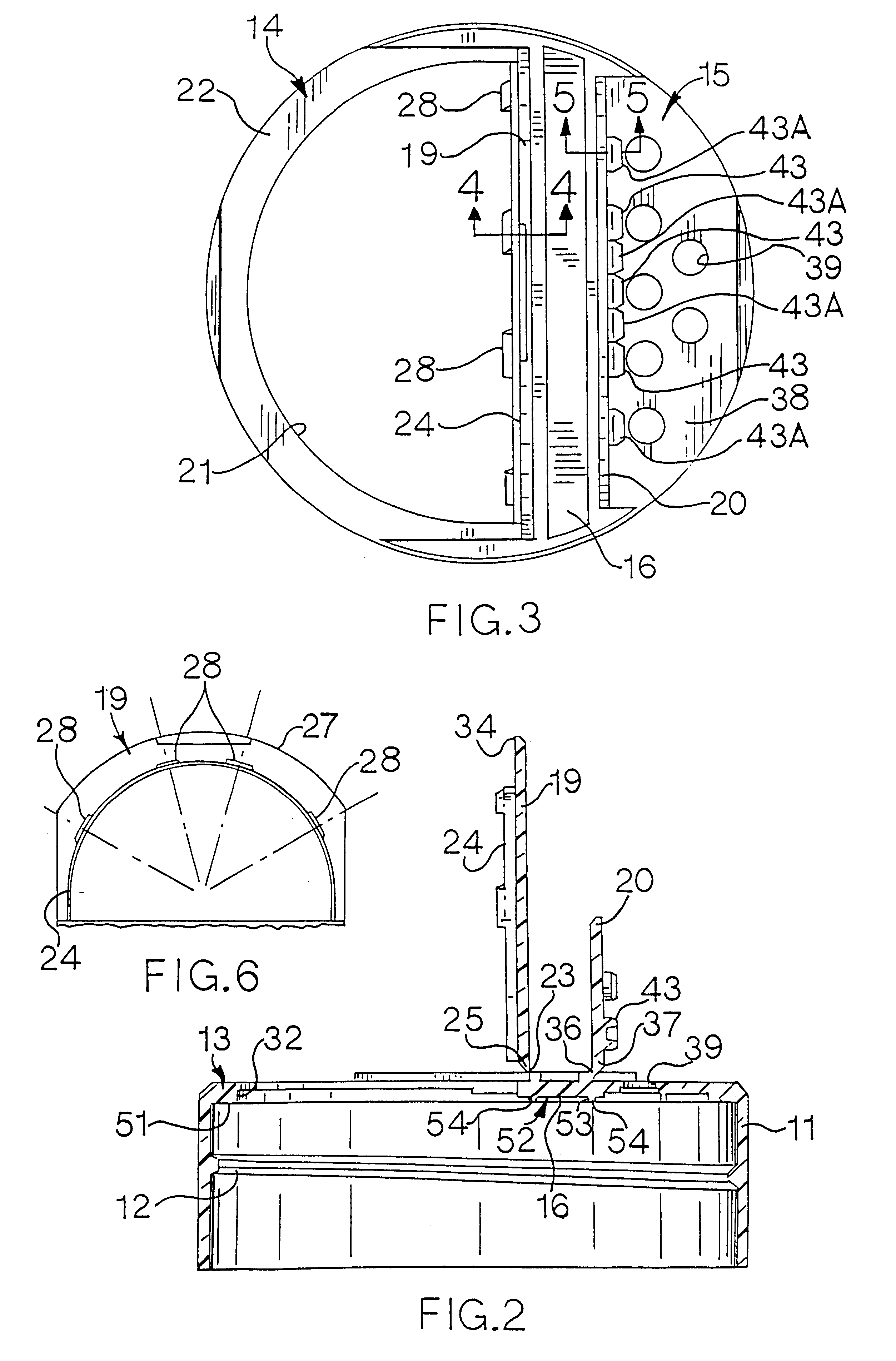

Two-flap closure

InactiveUSRE37634E1Reduce quality problemsImprove retentionCapsClosure using stoppersEngineeringInjection moulding

An injection-molded thermoplastic closure with shake-and-spoon apertures and associated flaps for selectively closing and opening the apertures. The flaps are releasably retained in their closed positions by catch elements which provide retention forces that are relatively insensitive to dimensional and shape variations in the body resulting from the molding process. In one embodiment, the cap has "freeze points" and a gate location that reduce the tendency of the cap to assume an oval condition when cooled from molding temperatures. A wide sealing ledge cooperates with a central support for a liner seal positioned in the cap to seal the mouth of a container.

Owner:WEATHERCHEM

Carbon naoparticle-containing hydrophilic nanofluid

InactiveUS20070158610A1Stabilize nanoparticle dispersionImprove thermal conductivityHeat-exchange elementsCarbon nanotubeHydrophile

The present invention relates to a process for preparing a stable suspension of carbon nanoparticles in a hydrophilic thermal transfer fluid to enhance thermal conductive properties and other characteristics such as freezing point of an antifreeze coolant. The process involves the step of dispersing carbon nanoparticles directly into a mixture of a thermal transfer fluid and other additives in the present of surfactants with intermittent ultrasonication. The present invention also relates to the composition of a hydrophilic nanofluid, which comprises carbon nanoparticles, particularly carbon nanotubes, a hydrophilic thermal transfer fluid, and at least one surfactant. Addition of surfactants significantly increases the stability of nanoparticle dispersion.

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

Antimicrobial salt solutions for food safety applications

ActiveUS7090882B2Reduce in quantityInhibit microorganismsMilk preservationDough treatmentBiologyFood processing

Owner:CARGILL INC

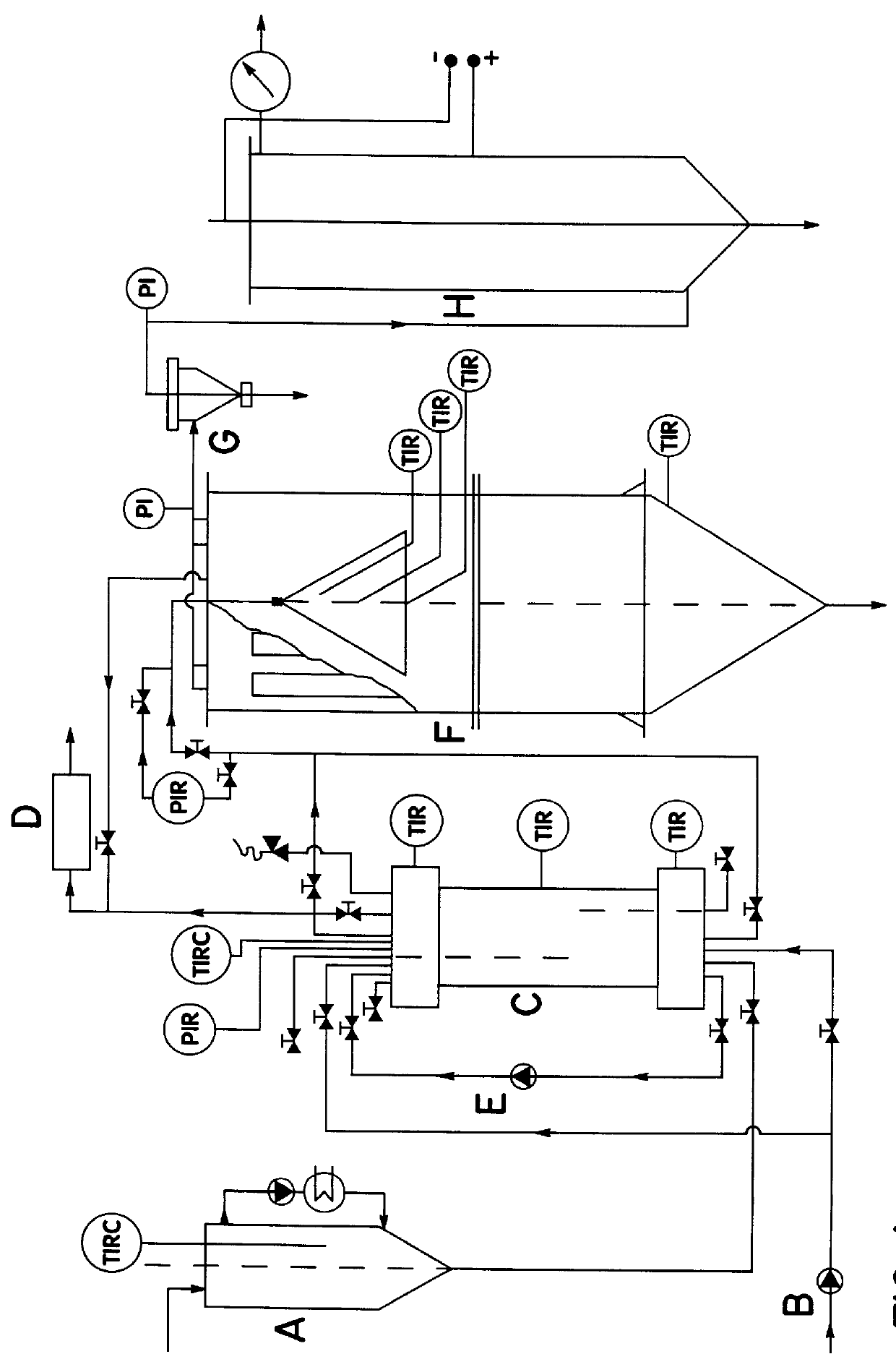

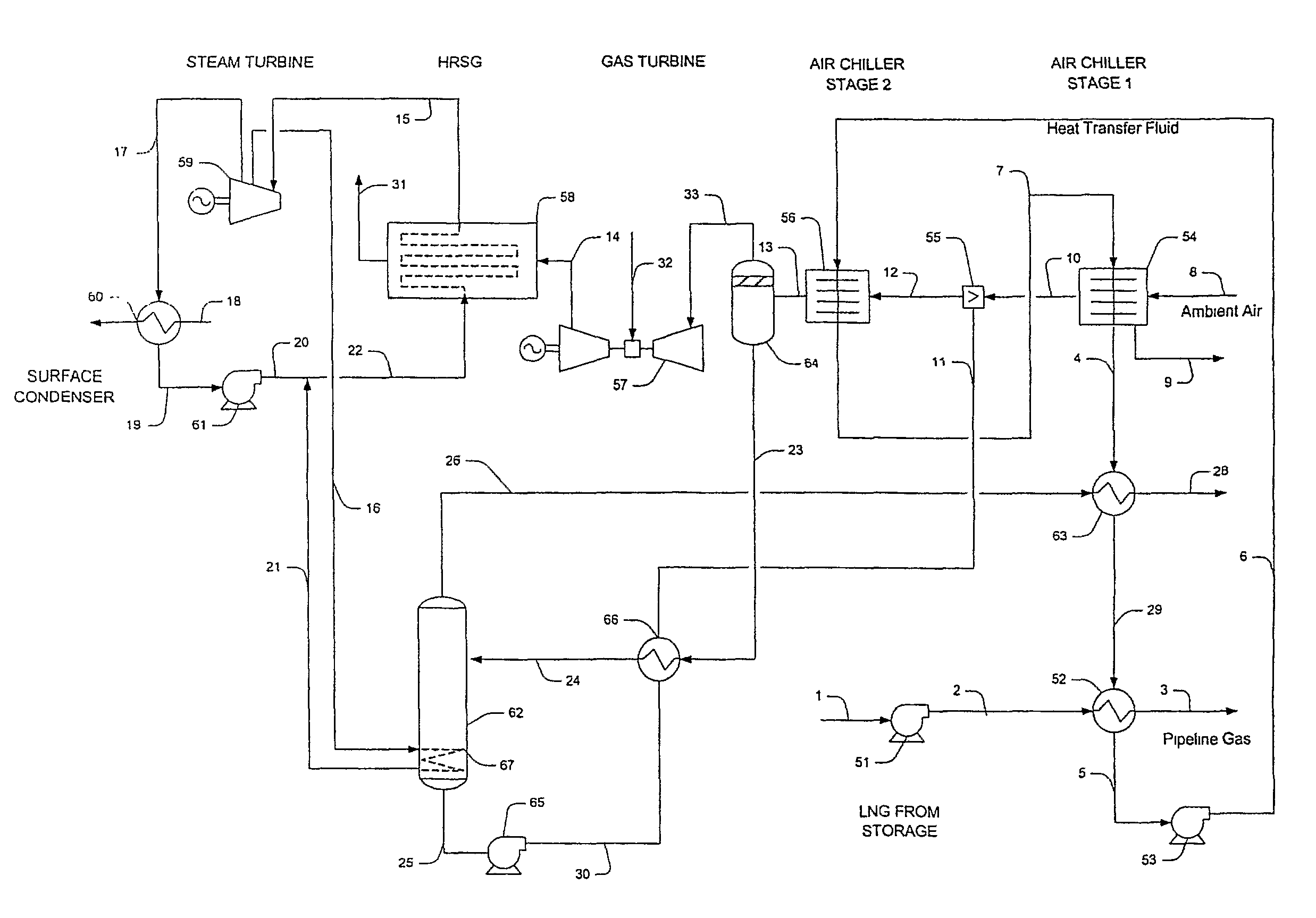

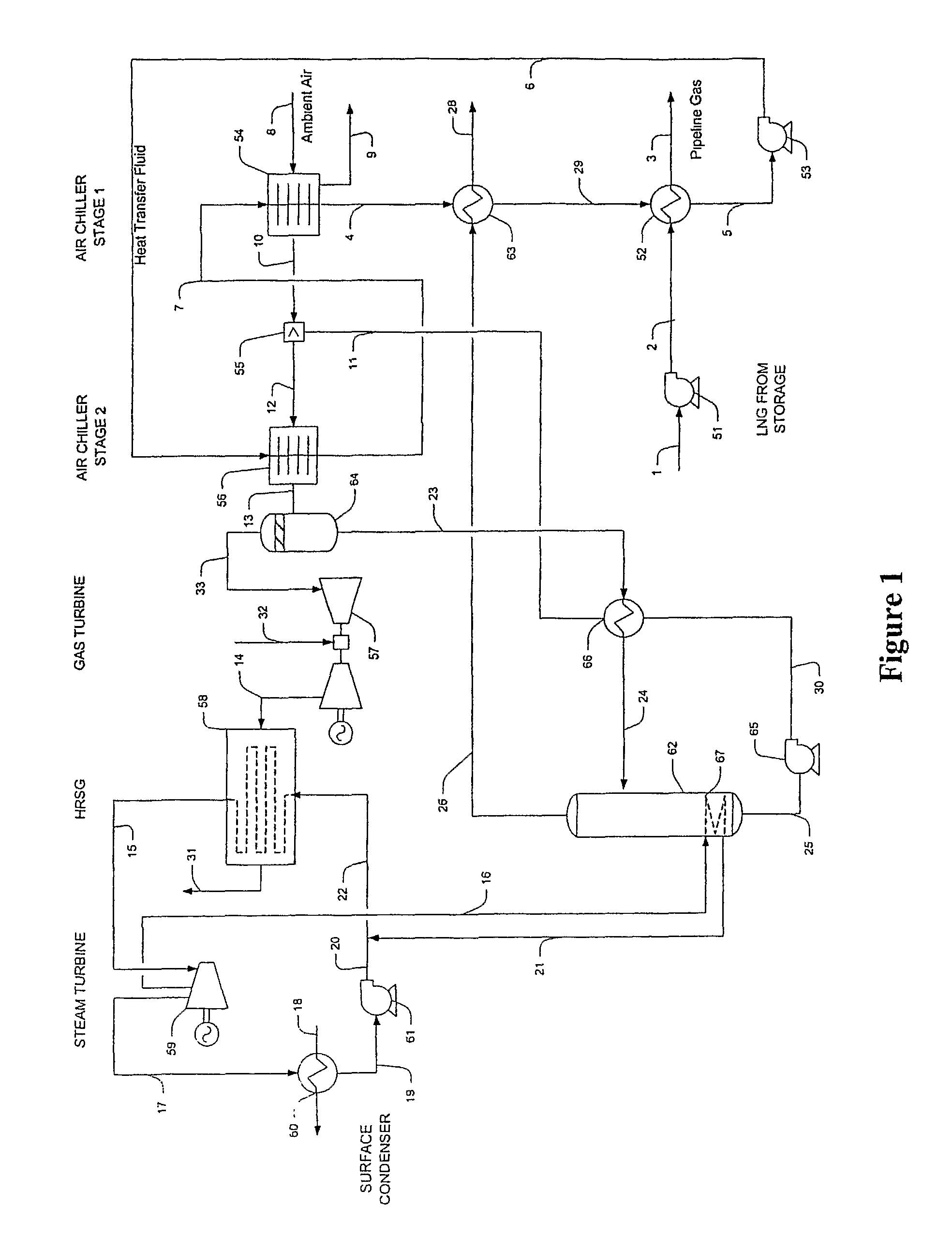

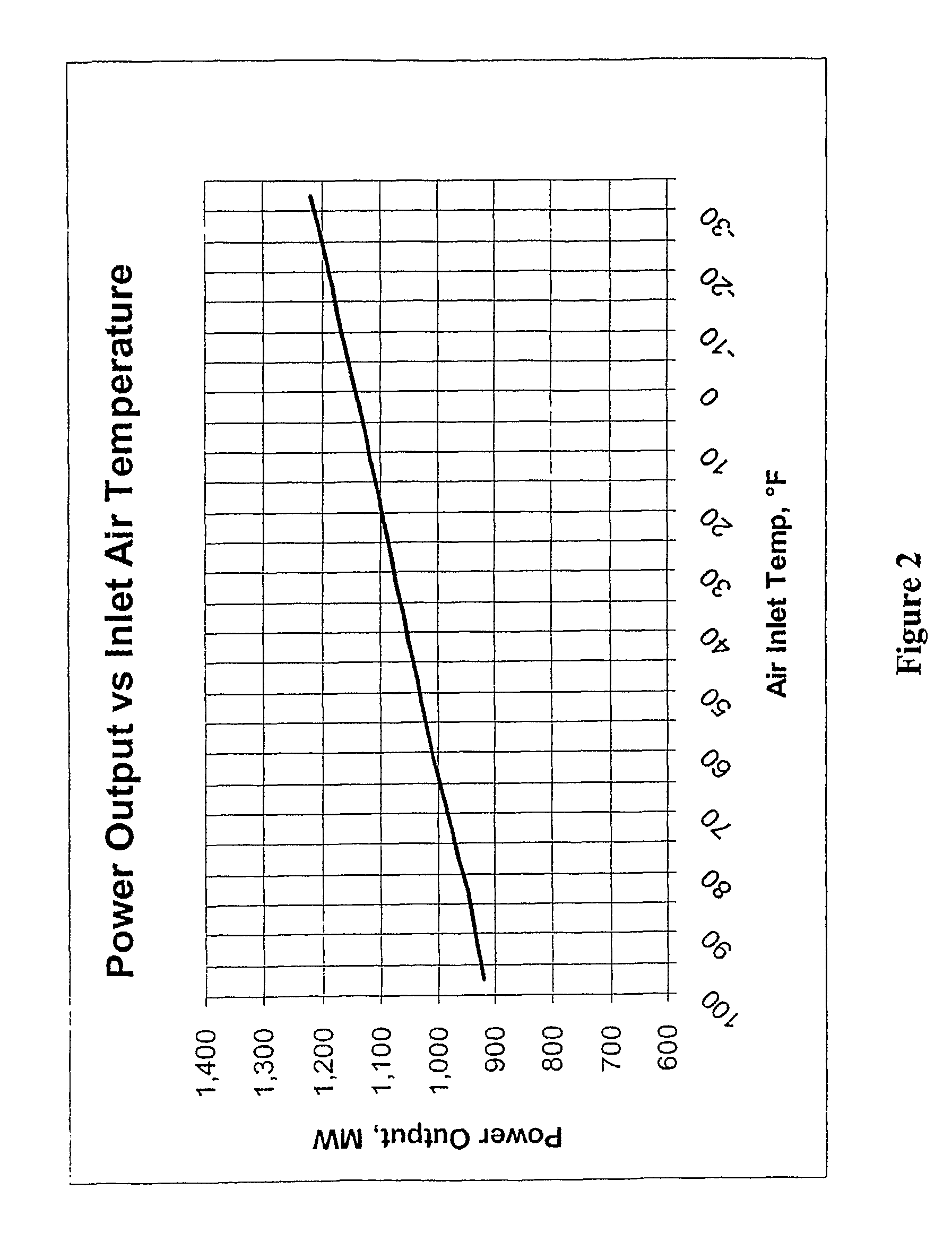

Configurations and methods for thermal integration of LNG regasification and power plants

Owner:FLUOR TECH CORP

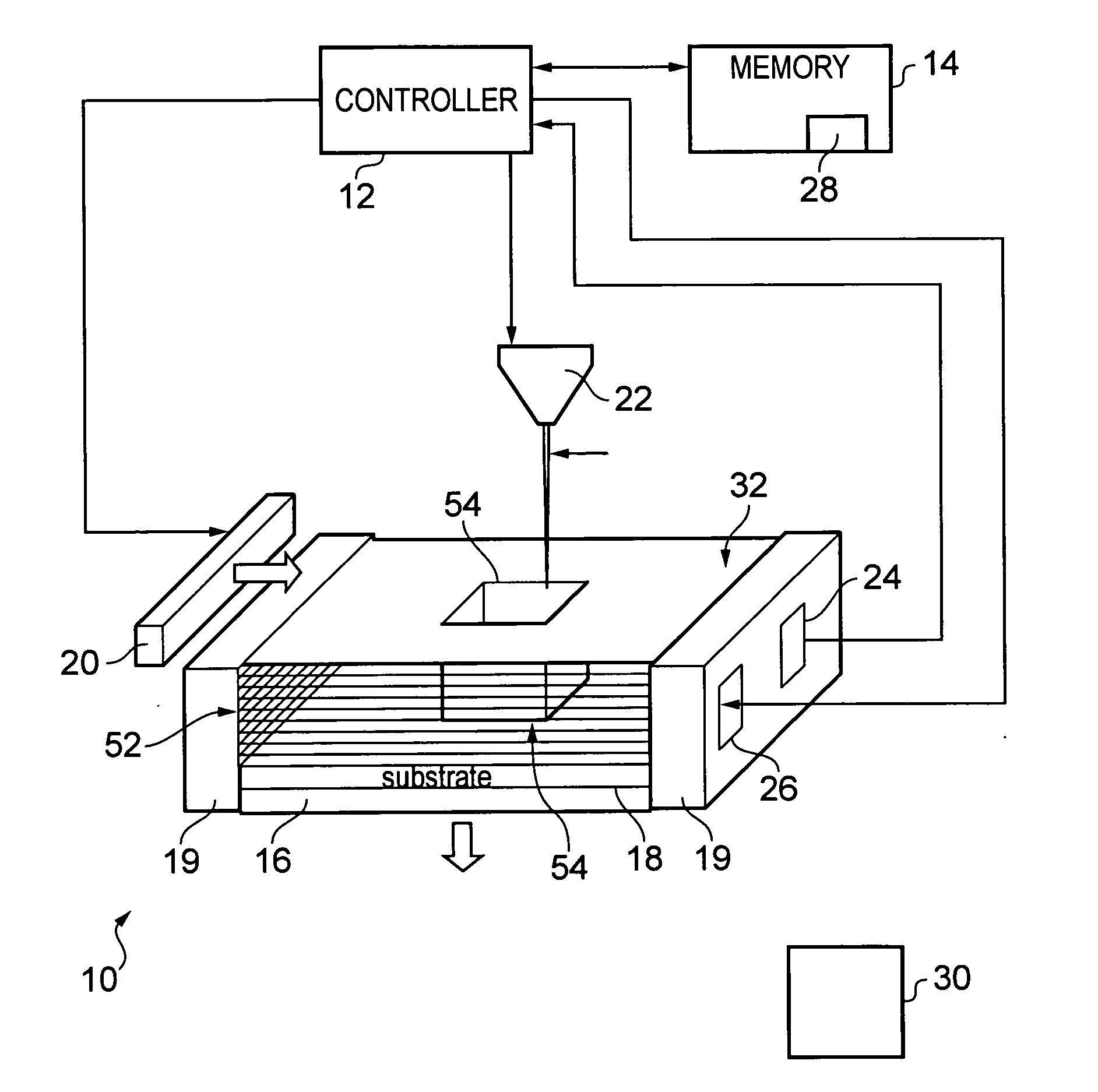

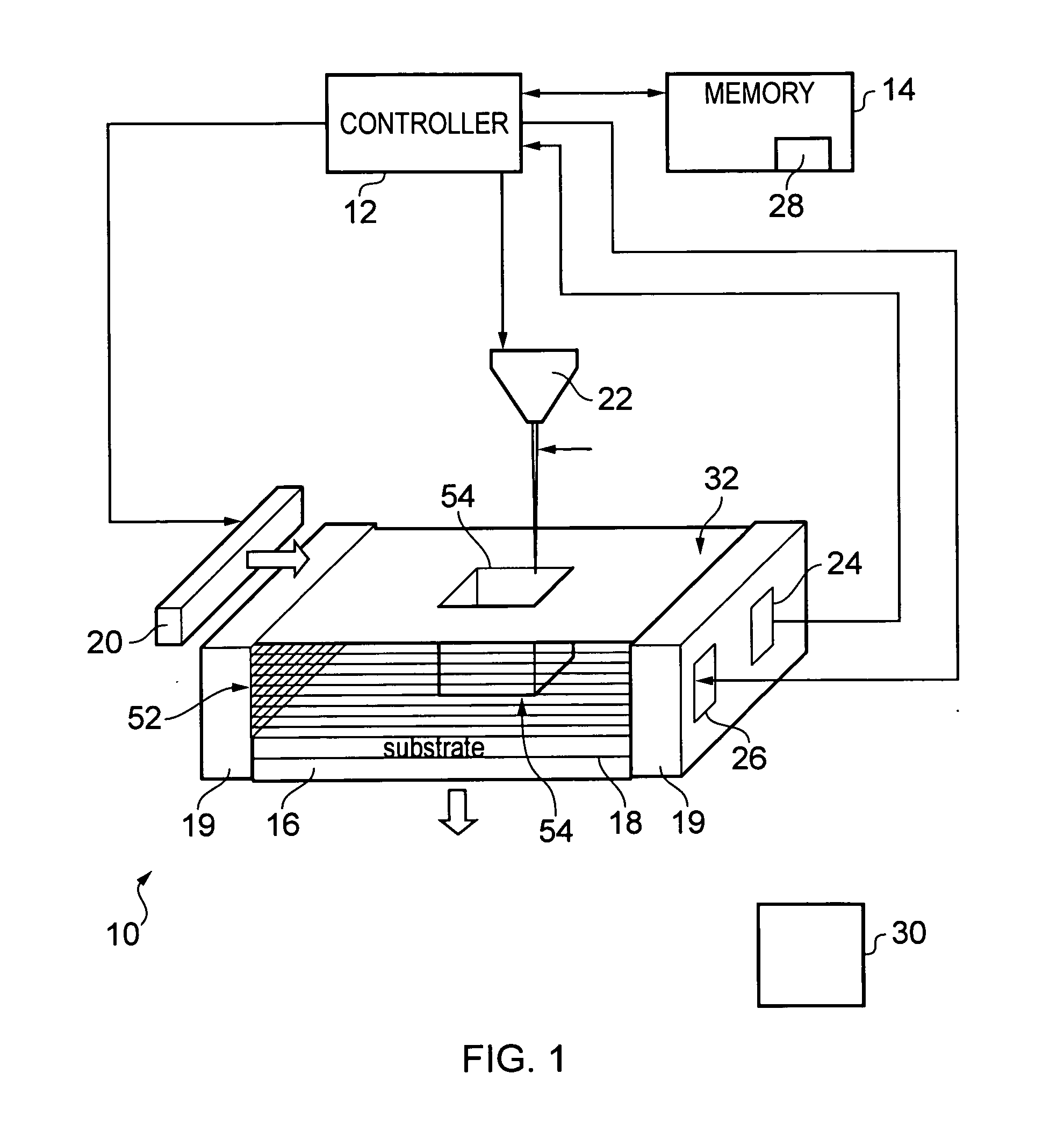

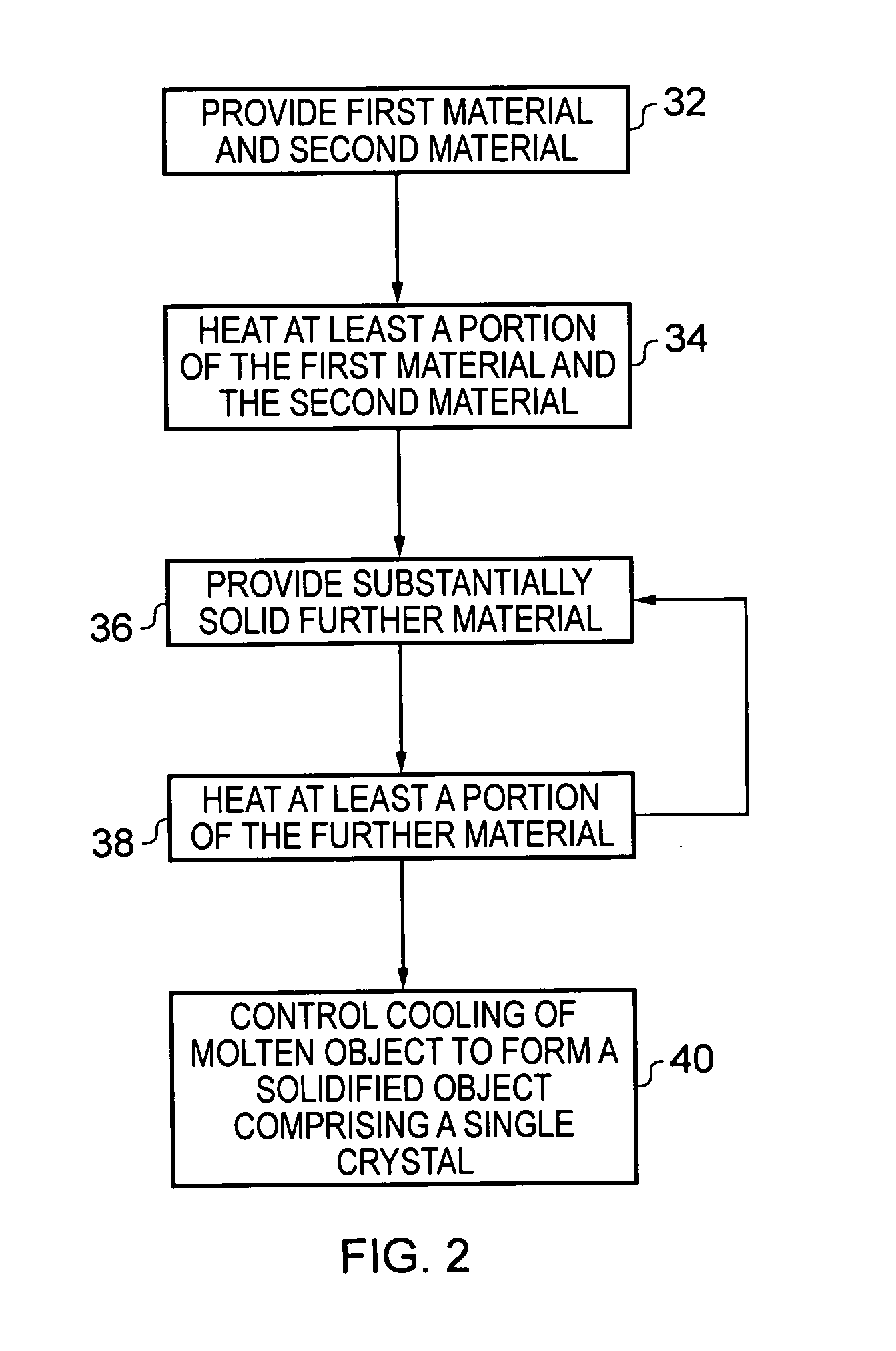

Method, apparatus, computer readable storage medium and computer program for forming an object

InactiveUS20110042031A1Polycrystalline material growthAdditive manufacturing apparatusComputer programFreezing point

A method for forming an object, including providing at least a first material having a melting point at a first temperature and a second material having a melting point at a second temperature; heating at least a portion of the first and second materials above the first and second temperatures to form a substantially molten alloy, the molten alloy having a solidifying point at a third temperature, the third temperature being less than the first temperature and the second temperature; and providing substantially solid further material to at least a portion of the molten alloy, the further material having a melting point at a temperature greater than the third temperature.

Owner:UNIV OF SHEFFIELD

Frozen aerated product

InactiveUS20040161503A1Reduce the temperatureAvoid damageSugar food ingredientsFrozen sweetsGlycerolSweet food

A frozen product comprises a cartridge containing a frozen aerated confection having an overrun of above 20% and below 100%, and containing less than 1.5% w / w glycerol, freezing point depressants in an amount of between 25% and 37% w / w, and between 2 and 12% fat, wherein the freezing point depressants have a number average molecular weight <M>n of less than 300. The frozen aerated confection has a soft structure and can be extruded from the cartridge at -18° C.

Owner:GOOD HUMOR BREYES ICE CREAM DIV OF CONOPCO

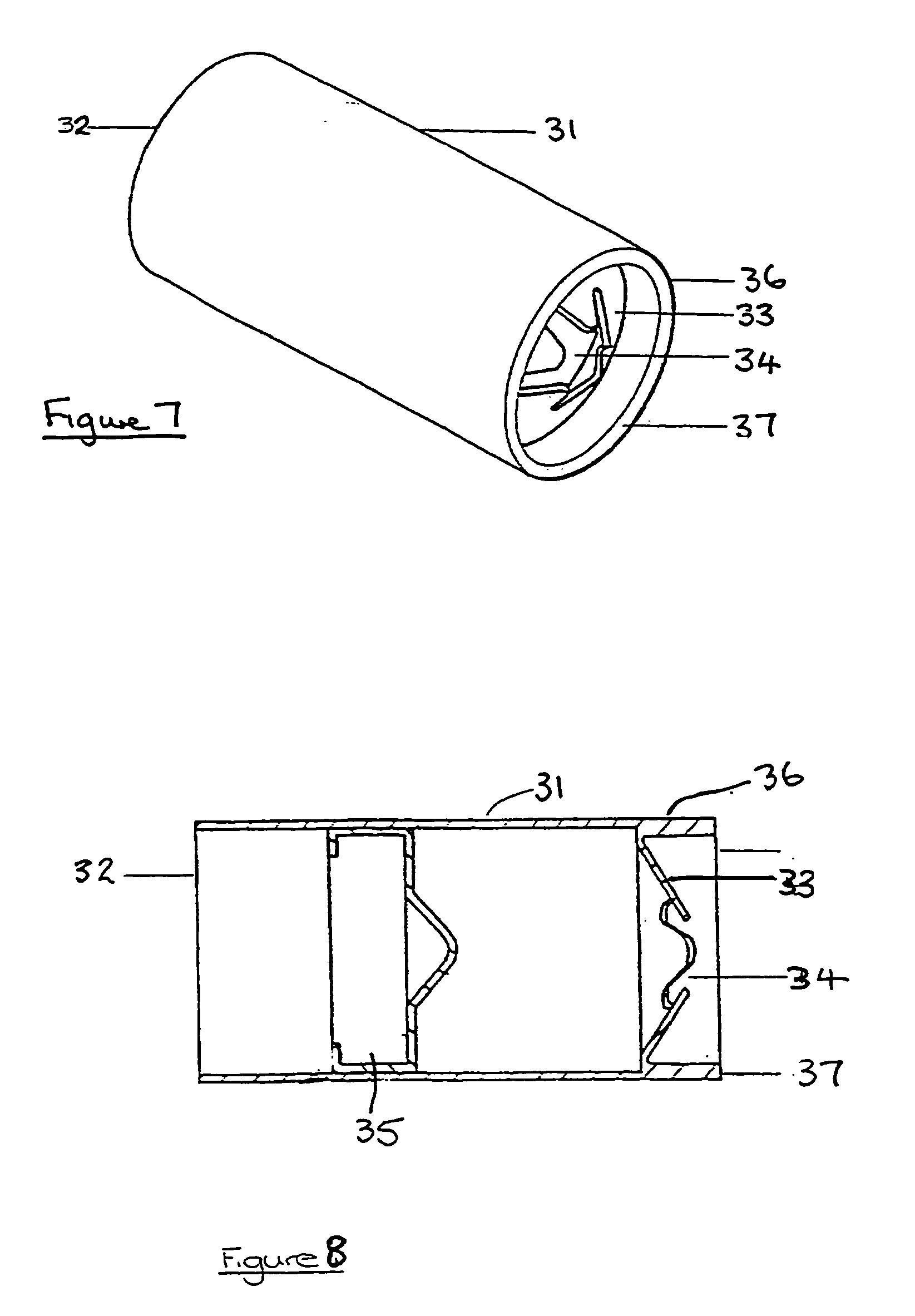

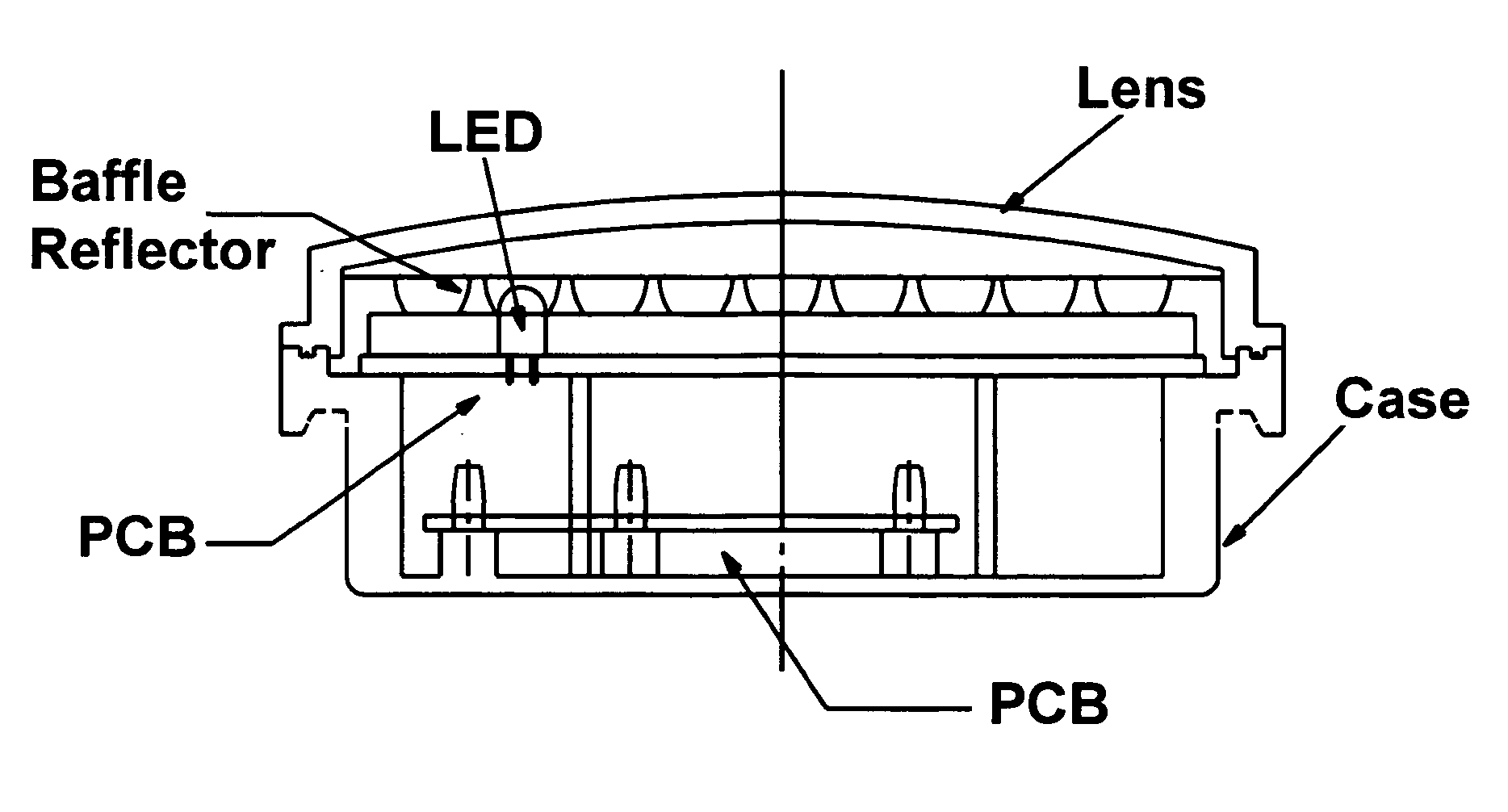

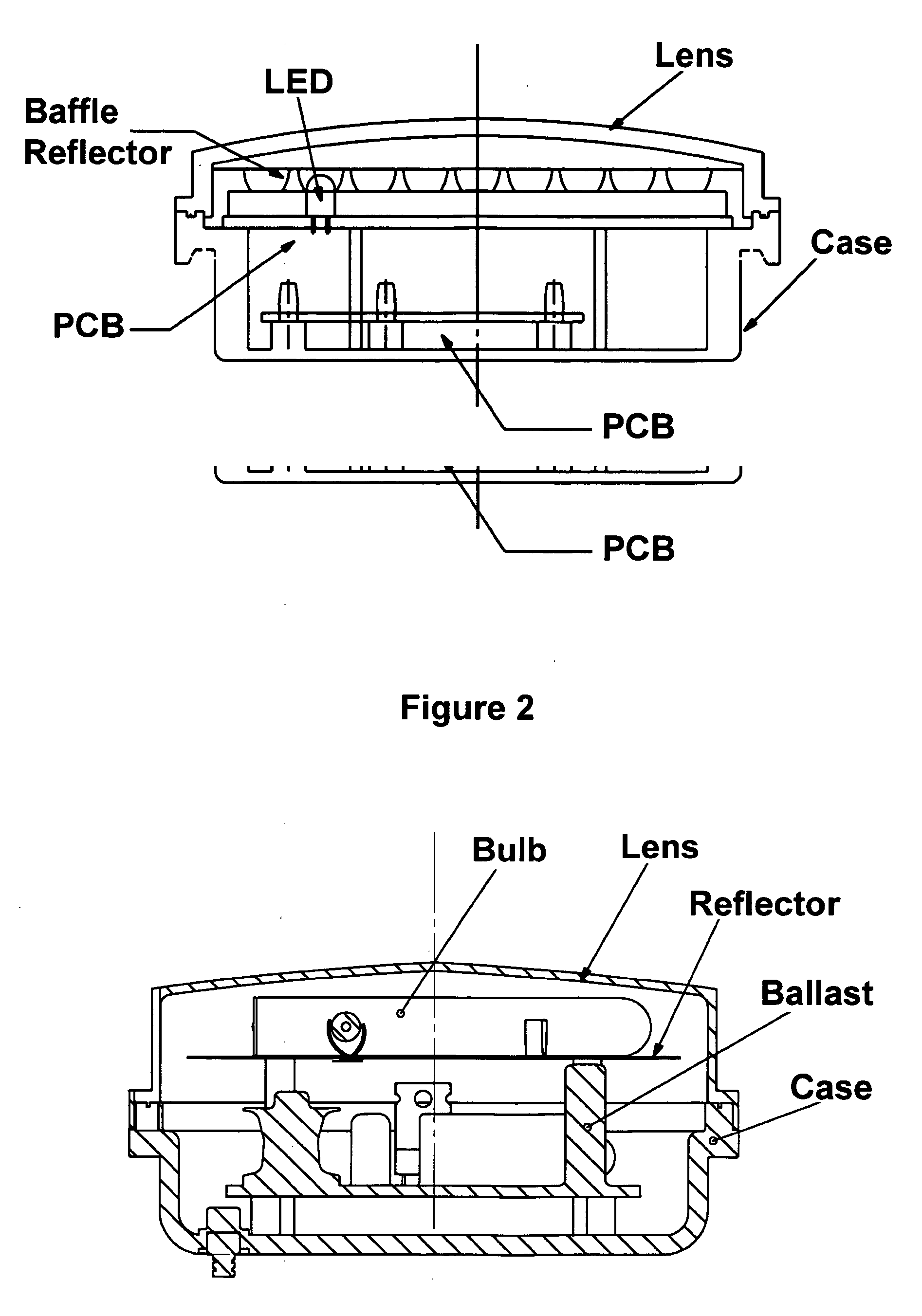

Fluid cooling lighting system

InactiveUS20060176699A1Way of increasePoint-like light sourceLighting heating/cooling arrangementsBoiling pointEffect light

A colorless, odorless, non corrosive, non conductive fluid, non toxic, environmentally safe available in different boiling points and freeze points, which will not burn and will be used for all types of lighting sources for purpose of anti freeze (to not freeze) and cooling, to removing heat in all type lighting products, which will allow all types of lighting products to be pushed at much higher limits extending the life in all types of lighting. This fluid type of lights can be used in home, business, auto, motorcycle, truck, trailer and can be LED, Fluorescent or other forms of lighting, which there components and lighting elements needs to be cooled extending the life and allow the light to be operated at far above the normal setting achieving the maximum output possible making the light fire resistant when using this non flammable fluid to produce wide intense super bright light generation for greater illumination. The lighting product can be self contained or in different components linked together that can utilize this fluid to cool the ballast, component and light generation source internal or external.

Owner:CRUNK PAUL DAVID

Method for improving solidifying point of Fischer-Tropsch wax

InactiveCN103980940AImprove stabilityHigh melting pointPetroleum wax recoveryChemical industryTwo step

The invention relates to a method for preparing high-melting-point refined wax capable of being applied to plastics, rubber processing, wood processing, food processing and other industries and particularly relates to a method for improving the solidifying point of Fischer-Tropsch wax. According to the method for preparing high-melting-point refined wax with excellent performances, distillation refining is carried out on light-weight oil serving as a raw material by means of continuous high-vacuum distillation, wherein the light-weight oil is produced by indirect coal liquefaction; According to the technical scheme, the method comprises two steps, namely, firstly, feeding the raw material in an evaporator by a feed pump so as to heat and evaporate the oil components and other low-boiling-point substances under the conditions of high temperature and high vacuum degree; secondly, feeding the coal-based synthetic oil without oil components and other low-boiling-point substances into a distiller, heating and evaporating the coal-based synthetic oil products by using heat-conduction oil under extremely high vacuum condition, condensing and capturing in a condenser to obtain the target product. The method disclosed by the invention can be widely used in the field of chemical industry.

Owner:SHANXI LUAN MINING GRP

Highly active midbarrel hydrocracking catalyst and the preparation thereof

InactiveUS20020094931A1High activityHigh yieldMolecular sieve catalystsHydrocarbon oil crackingSulfurNitrogen

The present invention relates to a highly active midbarrel hydrocracking catalyst and a process for the preparation thereof. The support of the catalyst comprises a modified zeolite-Y, a modified zeolite-beta, alumina, etc. The composite of the modified zeolite-Y and zeolite-beta exhibits a good synergistically catalytic effect. The catalyst prepared by supporting Group VIB and / or Group VIII metal components is useful in the hydrocacking of heavy oils with high content of sulfur and nitrogen to produce high quality middle distillates with maximum output. The activity of and selectivity to middle distillates of the catalyst are remarkably raised simultaneously. Moreover, the solidifying point of the produced diesel is remarkably lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for aviation kerosene

The invention relates to a new synthesis route of a liquid branched paraffin fuel, the method adopts a lignocellulose based platform compound as a raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as an aviation kerosene (or diesel) substitute or as an additive to increase the cetane number and cold resistance of fuel. The method provided by the invention includes two steps of: 1) under the promotion of a base catalyst, subjecting a lignocellulose based furfural compound (including furfural, methylfurfural or 5 hydroxymethylfurfural) and branched chain keto (including methyl isobutyl ketone, and mesityl oxide, etc.) to aldol condensation reaction so as to synthesize an oxygen-containing organic compound with a carbon chain length of 9-16; and 2) conducting hydrodeoxygenation on the aldol condensation product generated in step1 to obtain biomass aviation kerosene branched hydrocarbon with a carbon chain length of 9-16, higher energy density, stability and low freezing point.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

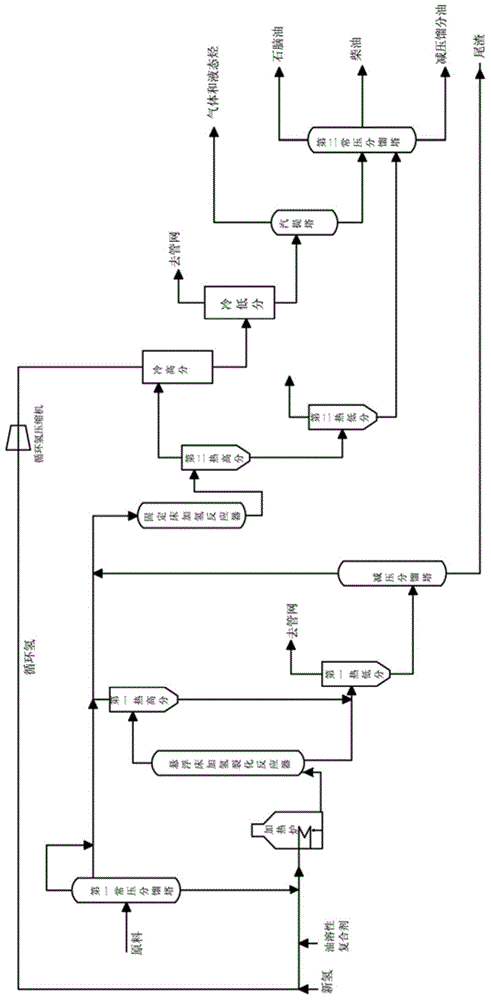

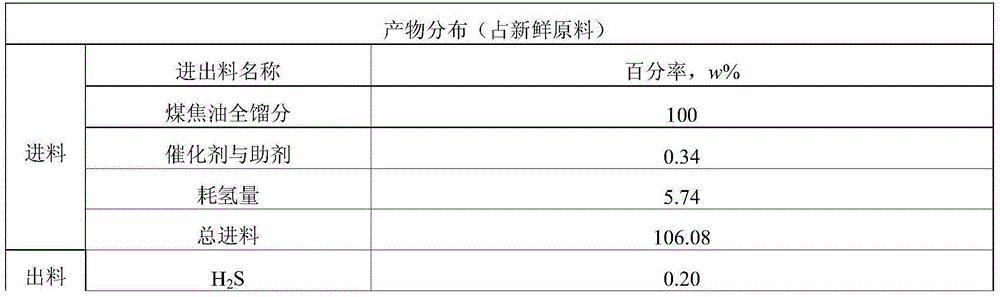

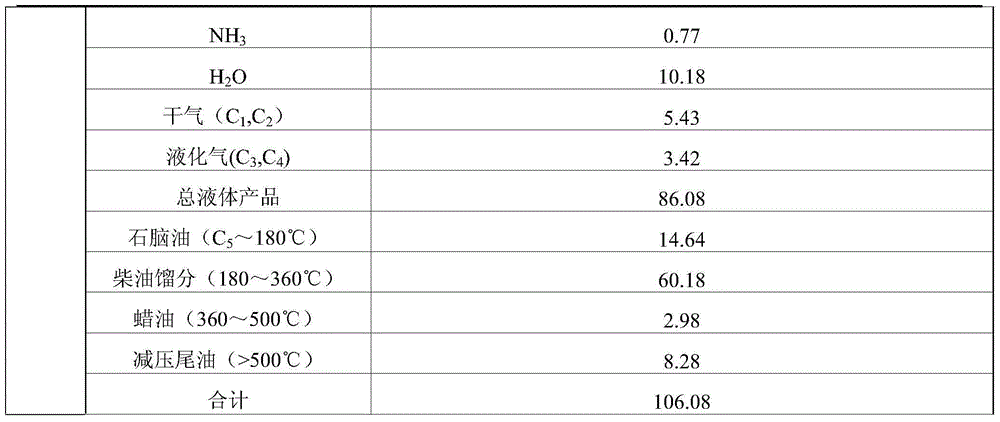

Combination method for hydrocracking of coal tar whole-fraction suspended bed and hydro-upgrading of fixed bed

ActiveCN104946306AImprove propertiesHigh yieldTreatment with hydrotreatment processesReaction temperatureFixed bed

The invention provides a combination method for hydrocracking of a coal tar whole-fraction suspended bed and hydro-upgrading of a fixed bed. In the method disclosed by the invention, a slurry-bed hydrocracking reactor is a circulating reactor, an adopted catalyst is a high-activity oil-soluble dispersible compound, and the adopted catalysts are a supported hydrorefining catalyst and a hydrocracking catalyst. In the process, the adopted reaction pressure is 12-20 MPa, the volume ratio of hydrogen to oil is 500-1200 Nm<3> / m<3>, the reaction temperature is 350-450 DEG C, and the volume space velocity is 0.3-1.5 / h. In the process, when coal tar whole-fractions are treated, the yields of naphtha, diesel oil and vacuum gas oil are 85-90 wt % higher than the yield of distillate oil, the yield of unconverted tail oil is less than 10 wt %, the obtained naphtha and diesel oil conform to the national V quality standards, and the vacuum gas oil can be used as a raw material of a catalytic cracking device or a raw material for producing base oil of low-freezing-point special lubricating oil.

Owner:INNER MONGOLIA SHENGYUAN TECH CO LTD

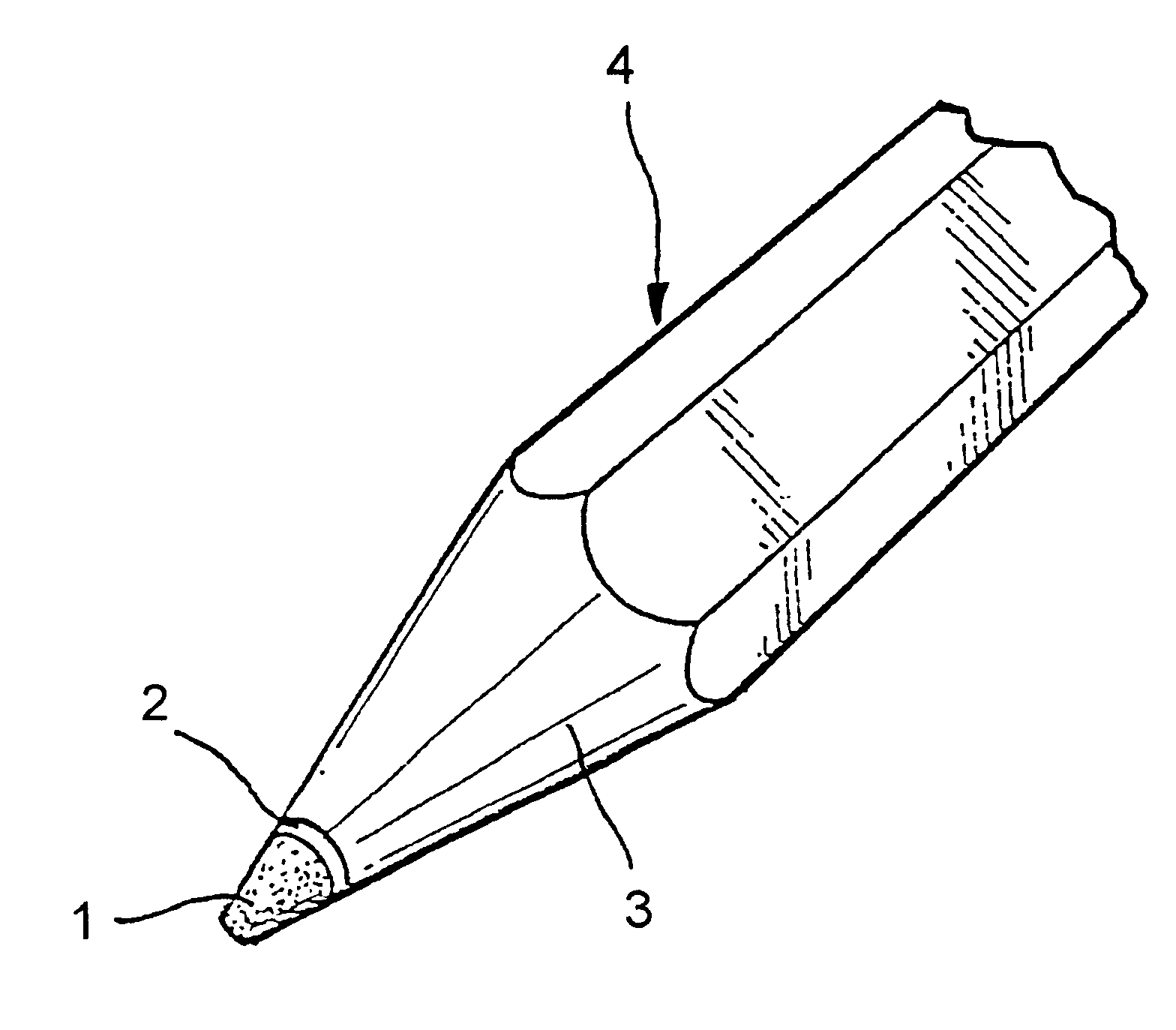

Method for making a writing or coloring pencil by triple extrusion and writing or coloring pencil comprising an intermediate protective layer

InactiveUS6572295B1Avoid problemsSynthetic resin layered productsNon-propelling pencilsMaterials sciencePlastic property

The method of continuously manufacturing pencils or crayons consists in coextruding a filled first thermoplastic material referred to as "lead" material, and around it both an intermediate "protective" layer of a thermoplastic material having no expanding agent and a second thermoplastic material containing an expanding agent and referred to as "wood" material, and in cooling said coextruded thermoplastic materials. According to the invention, the thermoplastic material constituting the protective layer is determined so that during cooling it remains deformable while the lead material shrinks. The pencil is constituted by superposing a core of a filled first thermoplastic material referred to as "lead" material, a protective layer of a non-expanded thermoplastic material, and a layer of an expanded second thermoplastic material referred to as "wood" material. According to the invention, the thermoplastic material constituting the protective layer has a solidification point which is lower than that of the thermoplastic material constituting the lead material.

Owner:CONTE SRL

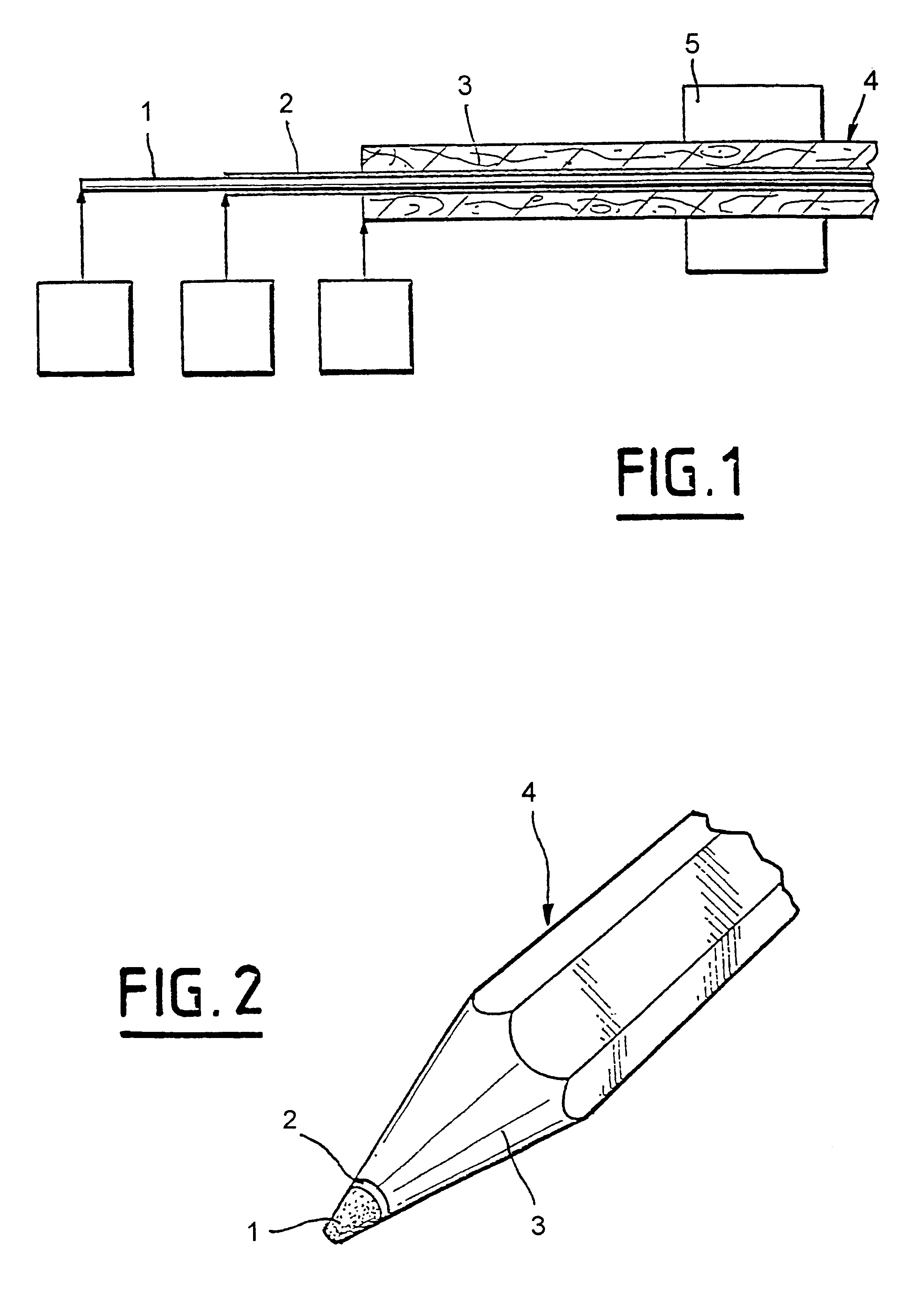

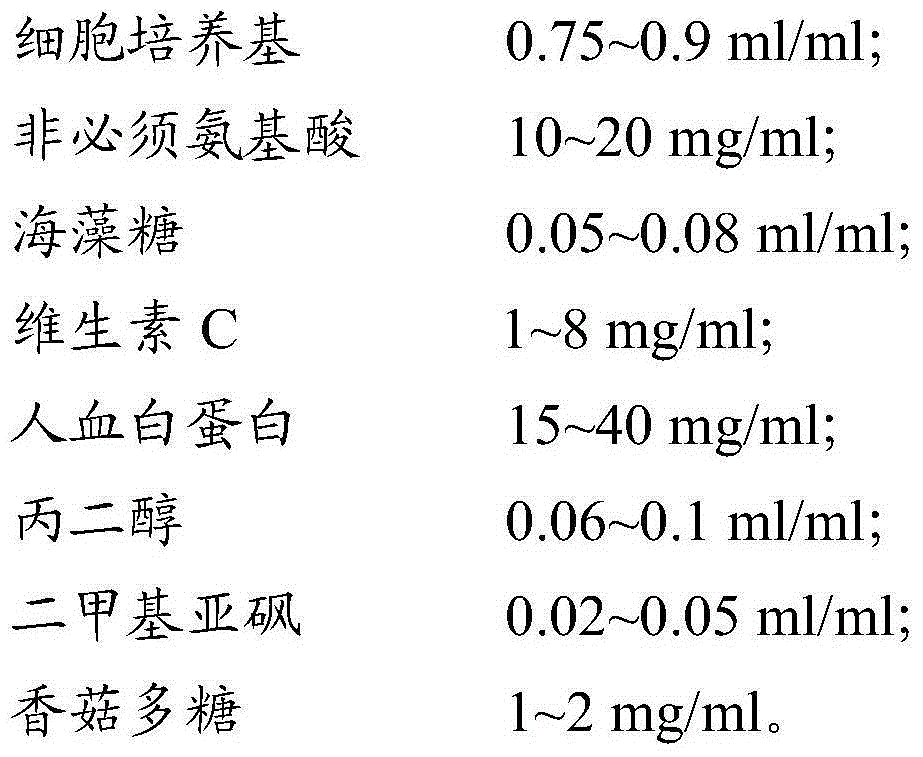

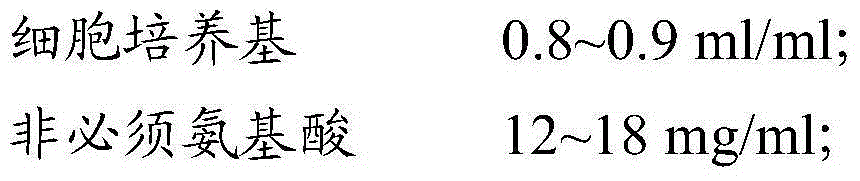

Cell cryo-preserved liquid, application, and immune cell cryo-preservation method

The invention provides a cell cryo-preserved liquid, an application, and an immune cell cryo-preservation method. The cell cryo-preserved liquid includes 0.7-0.9 ml / ml of a cell culture medium, 8-26 mg / ml of non-essential amino acids, 0.04-0.1 ml / ml of trehalose, 0.5-10 mg / ml of vitamin C, 10-50 mg / ml of human albumin, 0.04-0.12 ml / ml of propylene glycol, 0.01-0.07 ml / ml of dimethyl sulfoxide and 0.5-3 mg / ml of lentinan. Compared with a cell cryo-preserved liquid in the prior art, the human albumin can replace fetal calf serum to achieve the effects of the fetal calf serum in the cell cryo-preserved liquid, and meanwhile, the cell cryo-preserved liquid is added with the non-essential amino acids, the vitamin C and the lentinan, thereby ensuring cell proliferation vitality after recovery is not influenced. The trehalose and the propylene glycol can replace a protective effect of dimethyl sulfoxide, thereby ensuring moisture in cells to be not crystallized during approach of freezing point. The components are cooperated with each other to achieve cryo-preservation of immune cells.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

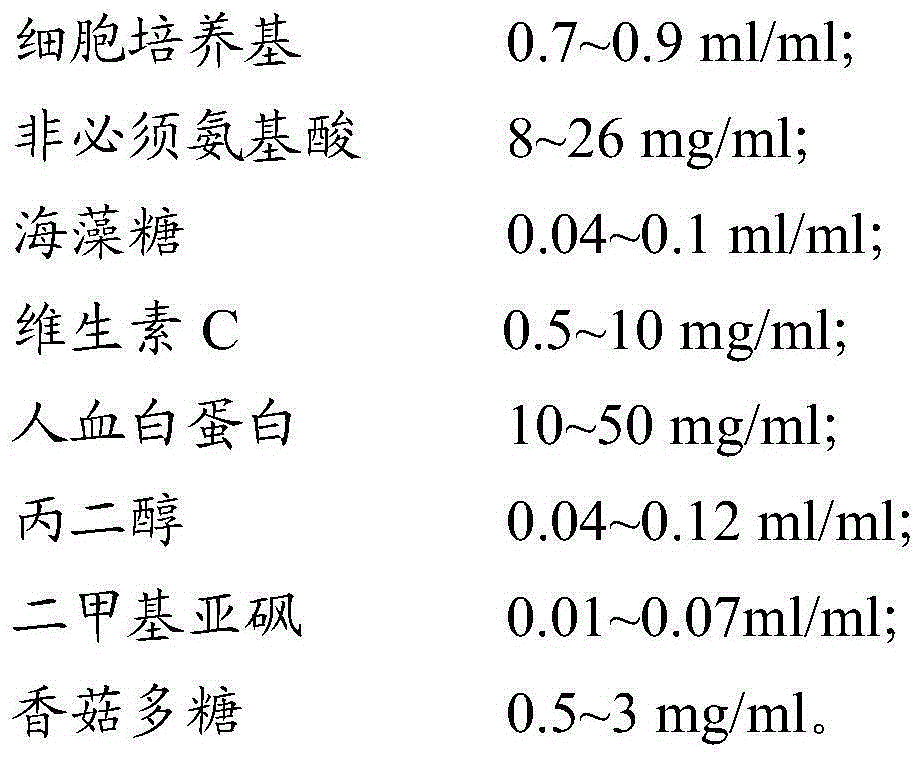

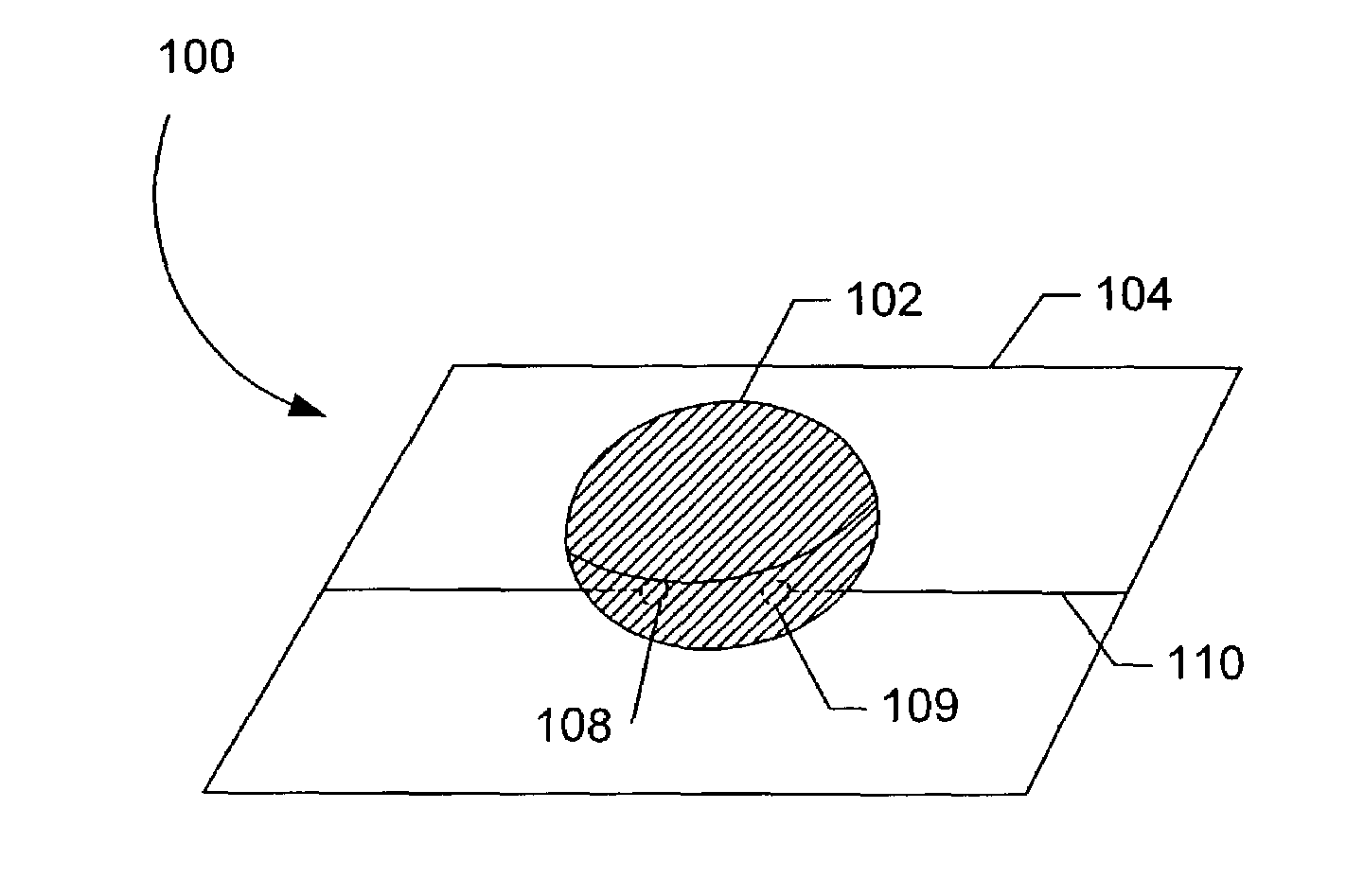

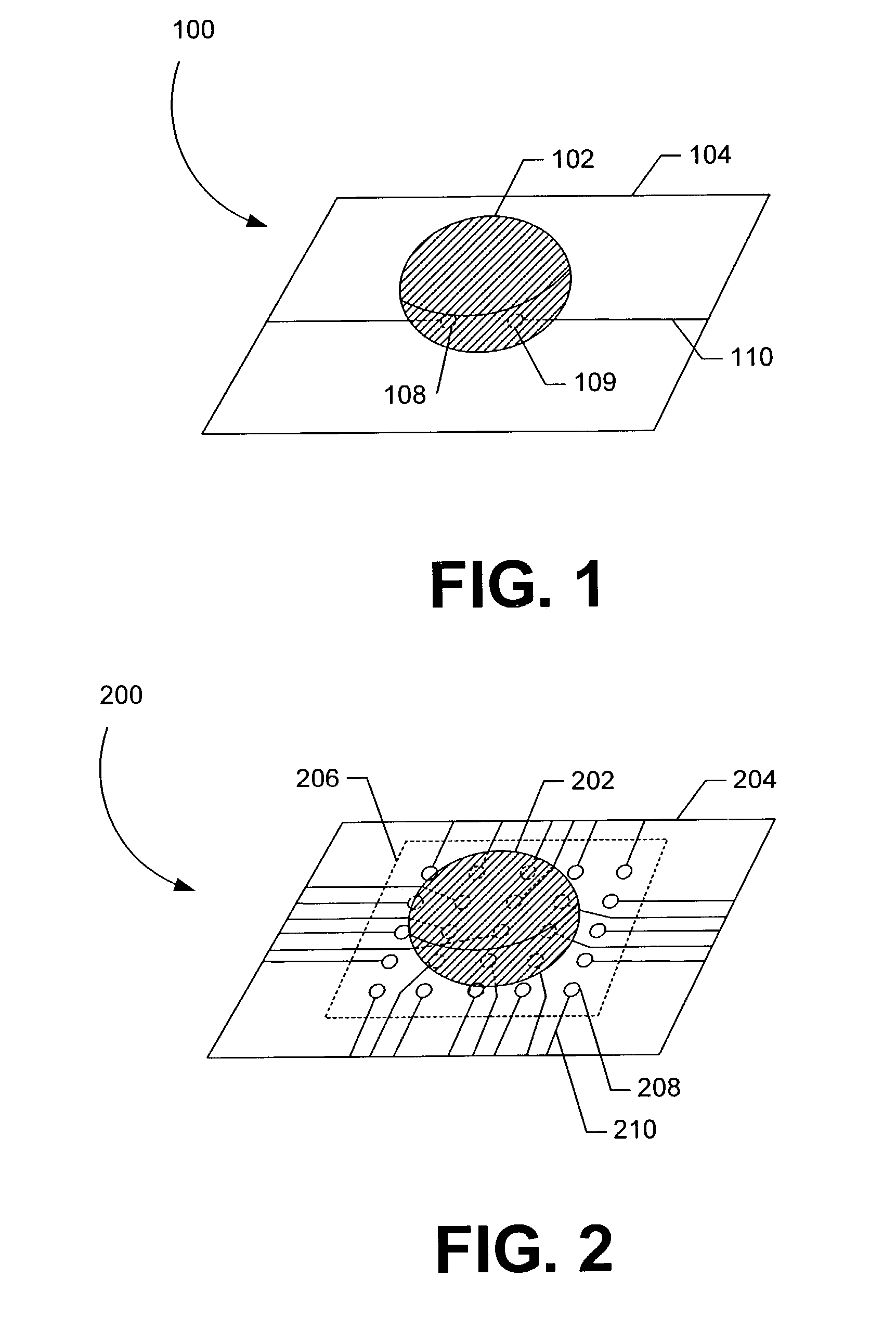

Tear film osmometry

ActiveUS7017394B2Quickly and easily obtainedAccurate measurementResistance/reactance/impedenceFlow propertiesThermal energyFluorescence

Osmolarity measurement of a sample fluid, such as tear film, is achieved by depositing an aliquot-sized sample on a sample receiving substrate. The sample fluid is placed on a sample region of the substrate. Energy is imparted to the sample fluid and energy properties of the fluid can be detected to produce a sample fluid reading that indicates osmolarity of the sample fluid. An aliquot-sized volume can comprise, for example, a volume of no more than 20 microliters (μL). The aliquot-sized sample volume can be quickly and easily obtained, even from dry eye sufferers. The imparted energy can comprise electrical, optical or thermal energy. In the case of electrical energy, the energy property of the sample fluid can comprise electrical conductivity. In the case of optical energy, the energy property can comprise fluorescence. In the case of thermal energy, the measured property can be the freezing point of the sample fluid. The substrate can be packaged into a chip, such as by using semiconductor fabrication techniques. An ex vivo osmolarity sensor system that uses the chip can detect energy from the sample region and can provide an accurate osmolarity measurement without user intervention.

Owner:RGT UNIV OF CALIFORNIA

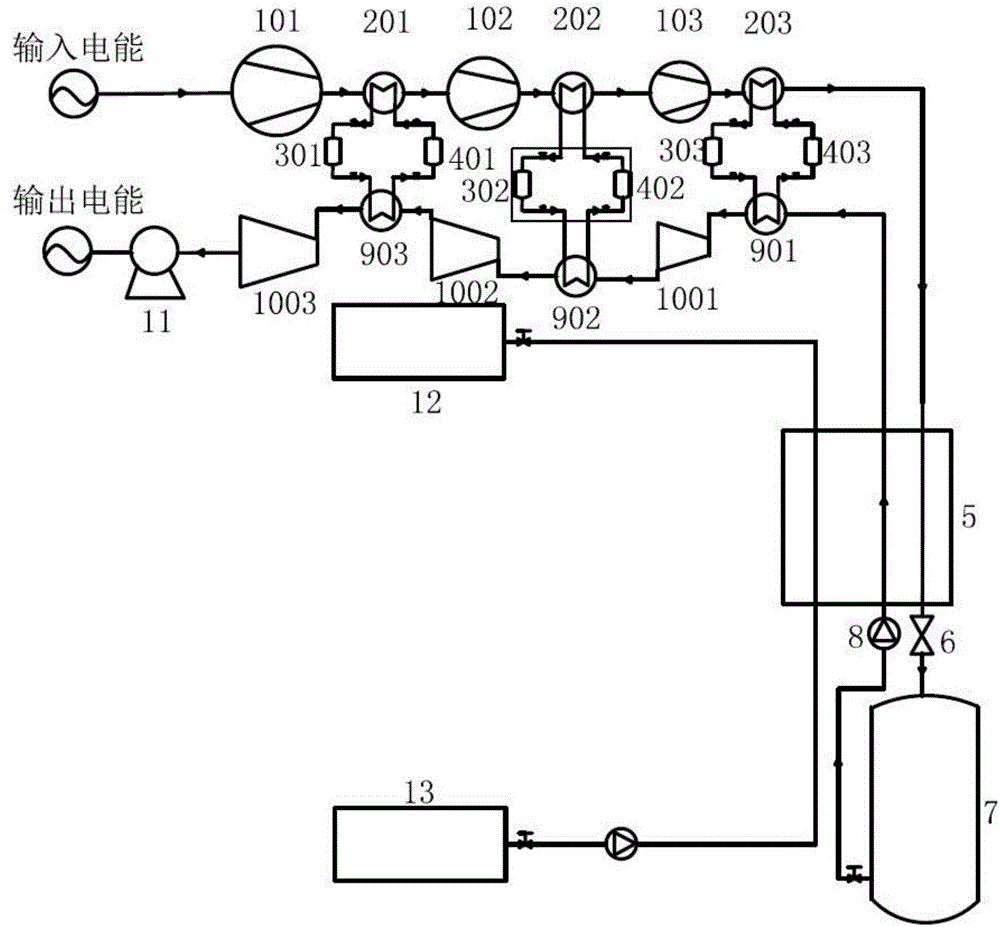

Liquefied compressed air energy storage system with cold-storage liquid media

ActiveCN105043147AHigh energy storage densityLow costHeat storage plantsMachines/enginesLiquid mediumThermal energy storage

The invention relates to a liquefied compressed air energy storage system with cold-storage liquid media. The liquefied compressed air energy storage system comprises compressor systems, a cold storage system, a heat storage system, a liquefying system and a turbine power generation system. During energy storage, the multistage compressor system is driven by renewable energy sources, so that compressed air is supercharged to exchange heat with a room-temperature cold-storage liquid medium, the cold quantity stored in the liquid medium is lowered to liquefying temperature, and the compressed air is liquefied through throttling; during energy releasing, the liquid air is supercharged to exchange heat with a high-temperature cold-storage liquid medium, the medium recycles cold energy to give to the liquefying process, and the air is warmed to be vaporized; room-temperature high-pressure air is input into a multi-stage turbine expander for acting, and a power generator is driven to output electric energy; the heat storage system reduces the power consumption of the next stage of compressor, and the stored heat is heated step by step before expansion to raise the intake air temperature; a cold-storage medium with a low freezing point and a high / low boiling point recycles the cold energy of the liquid air, the specific heat capacity of the liquid media is large, and the large-temperature-span heat exchange is realized. The liquefied compressed air energy storage system has the advantages of being simple in structure and stable in performance, can realize integration of energy storage and power generation, and can realize the large-scale grid-connection of renewable energy generation, therefore improving the capacity of a power grid accepting new energy power generation.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

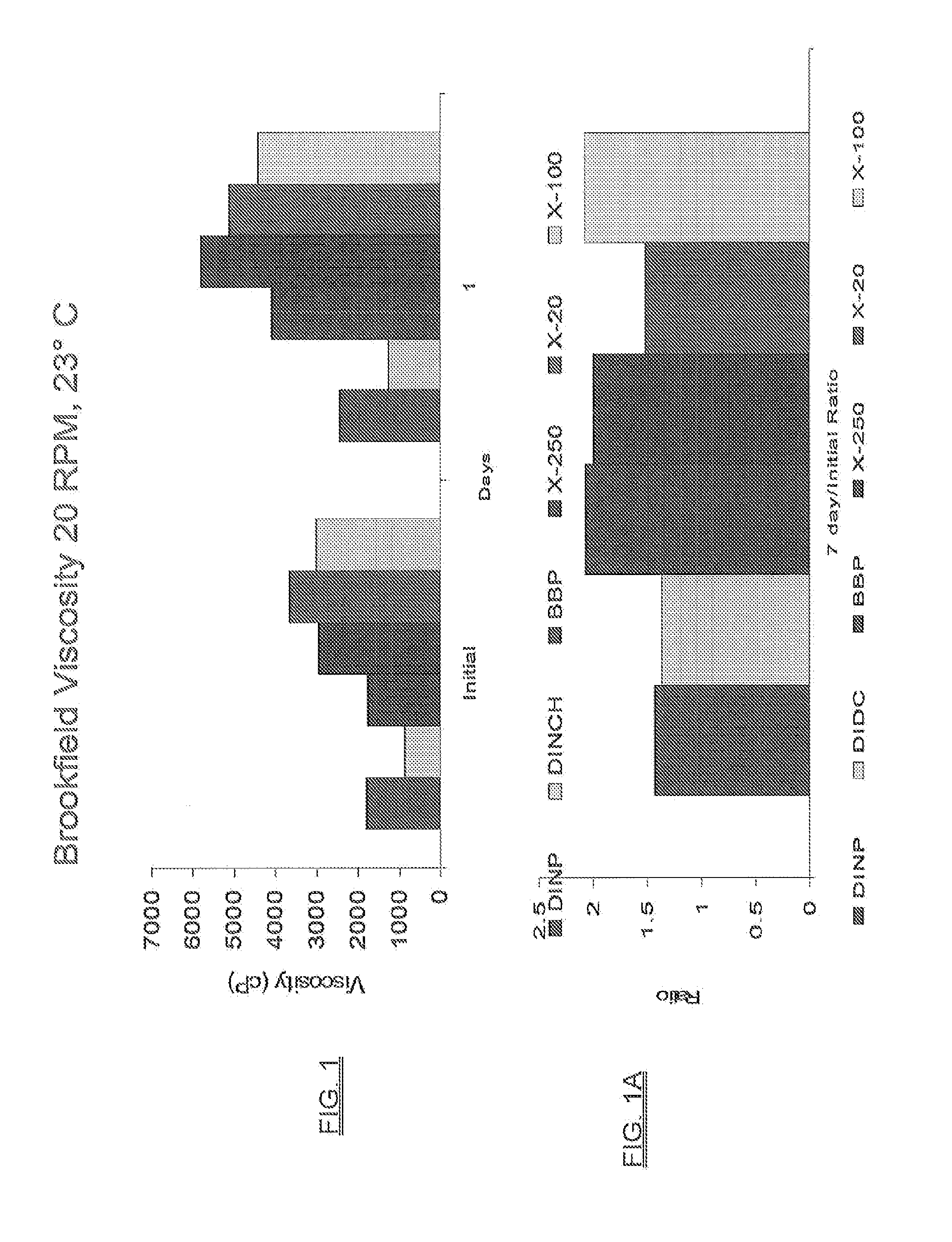

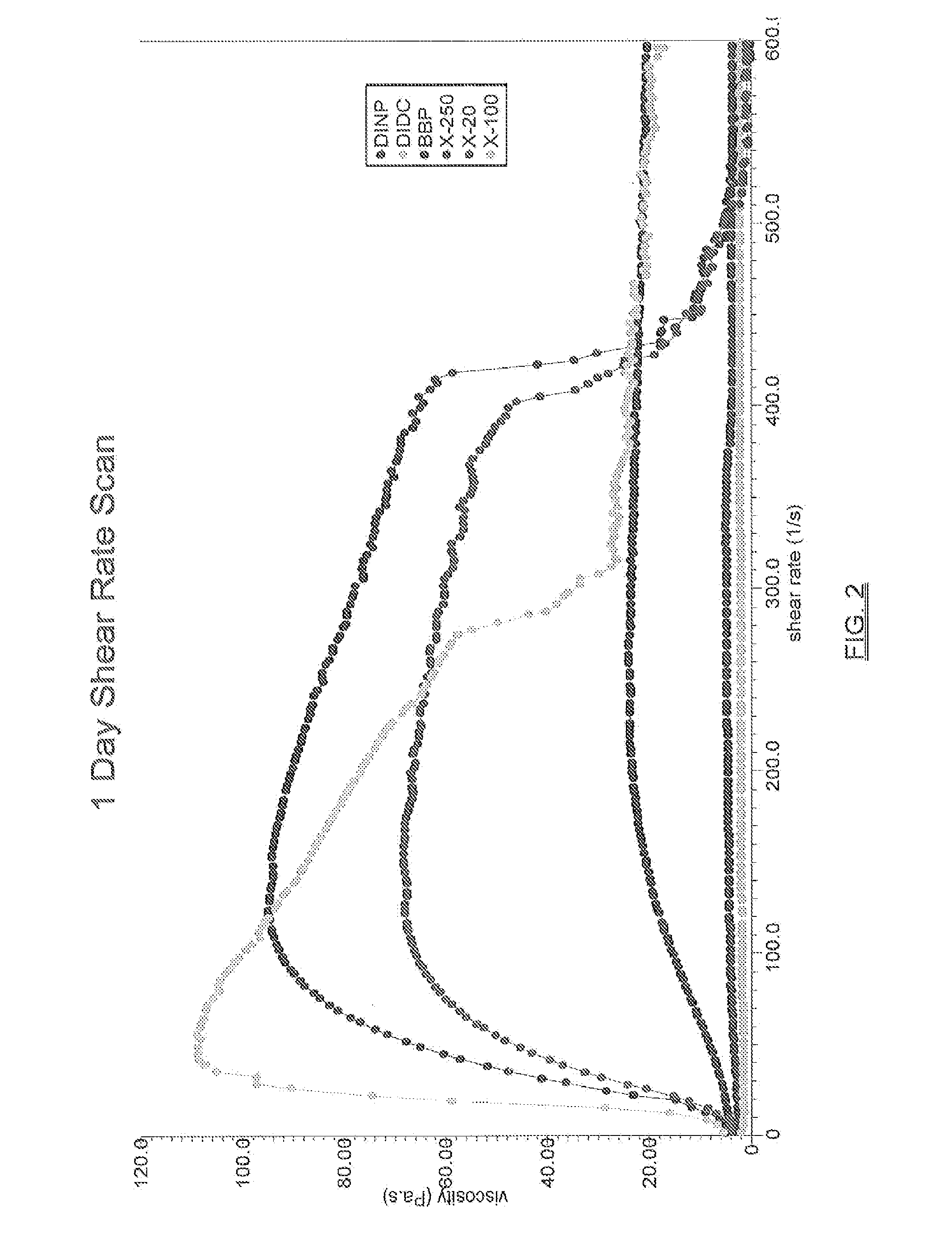

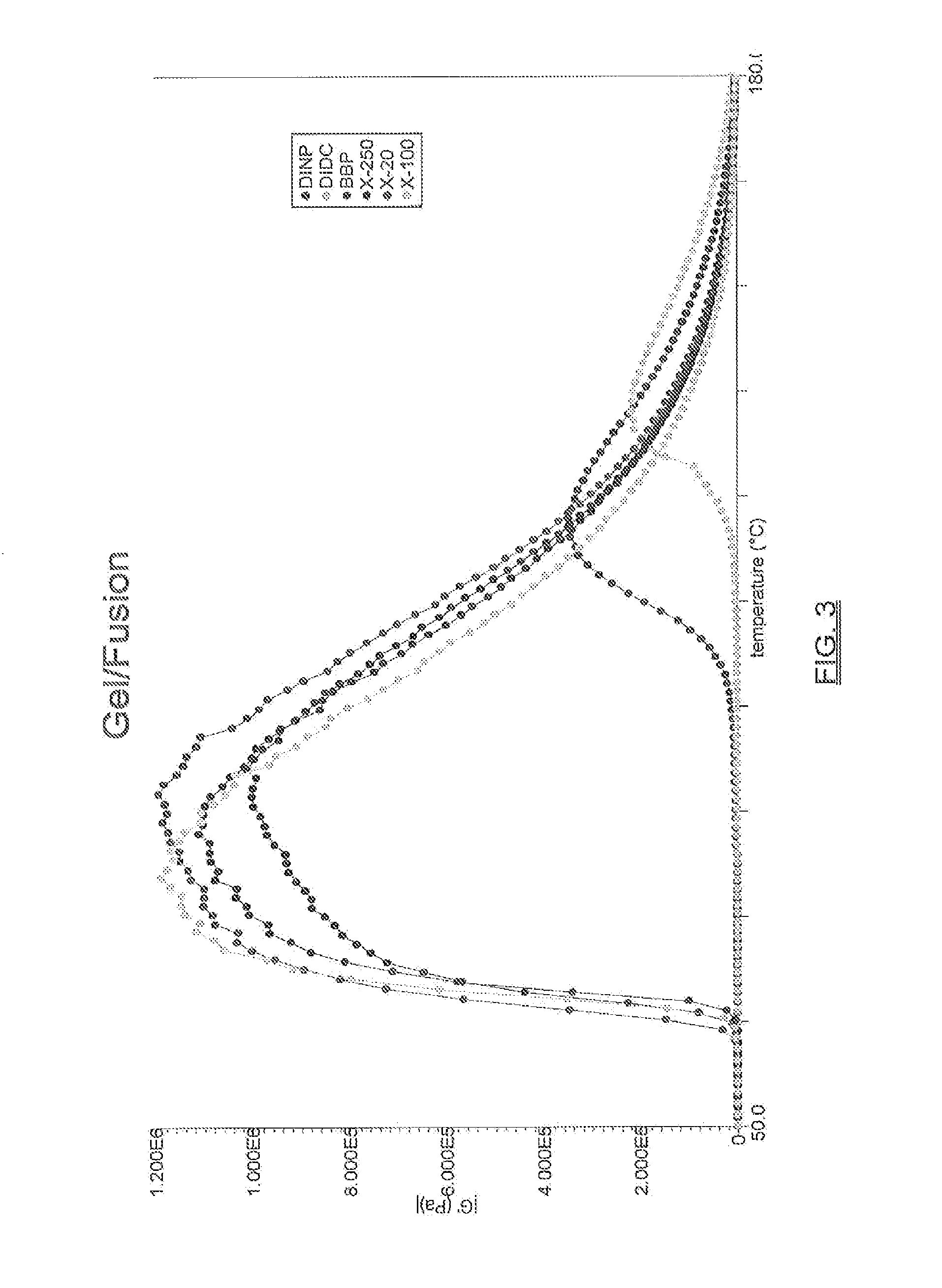

Blends of dibenzoate plasticizers

ActiveUS20130274396A1Efficient Tg suppressionFaster processing timeNon-macromolecular adhesive additivesInksElastomerAdhesive

Plasticizer blends comprise a triblend of diethylene glycol dibenzoate, dipropylene glycol dibenzoate, and 1,2-propylene glycol dibenzoate, in specified ratios, useful in combination with a multitude of thermoplastic polymers, thermosetting polymers, and elastomeric polymers and numerous applications, including but not limited to plastisols, adhesives, sealants, caulks, architectural coatings, industrial coatings, OEM coatings, inks, overprint varnishes, polishes, and the like. The advantages rendered by the use of the triblend depend on the type of polymer and application in which it is utilized and include among other advantages higher solvating power and lower processing time, low VOC's, reduced plasticizer freeze point, improved gelation and fusion characteristics, higher tensile strength, superior stain and extraction resistance, and improved rheology over traditional diblends of diethylene glycol dibenzoate and dipropylene glycol dibenzoate.

Owner:EMERALD KALAMA CHEM

Refrigerator and frozen food preservation method

InactiveUS20100083687A1Improvement of global environmentQuality improvementLighting and heating apparatusDomestic refrigeratorsCold airStore food

The present invention is to realize supercooled freezing as a method of enhancing the quality of frozen food with a simple arrangement by a method other than quick freezing. Further, the present invention is to obtain a refrigerator and a frozen food preservation method capable of realizing high quality freezing by a simple arrangement.The refrigerator, which stores food making use of the cold air generated by a cooler 3, includes a supercooling case 81 for keeping the stored food in a supercooled state, in which the food is not frozen even at a temperature equal to or less than the freezing point of the food, for at least a predetermined period of time. The supercooling case 81 is composed of, for example, a lower case of two-stage type upper and lower cases disposed in a switching chamber 200 capable of being switched to a plurality of temperature zones.

Owner:MITSUBISHI ELECTRIC CORP

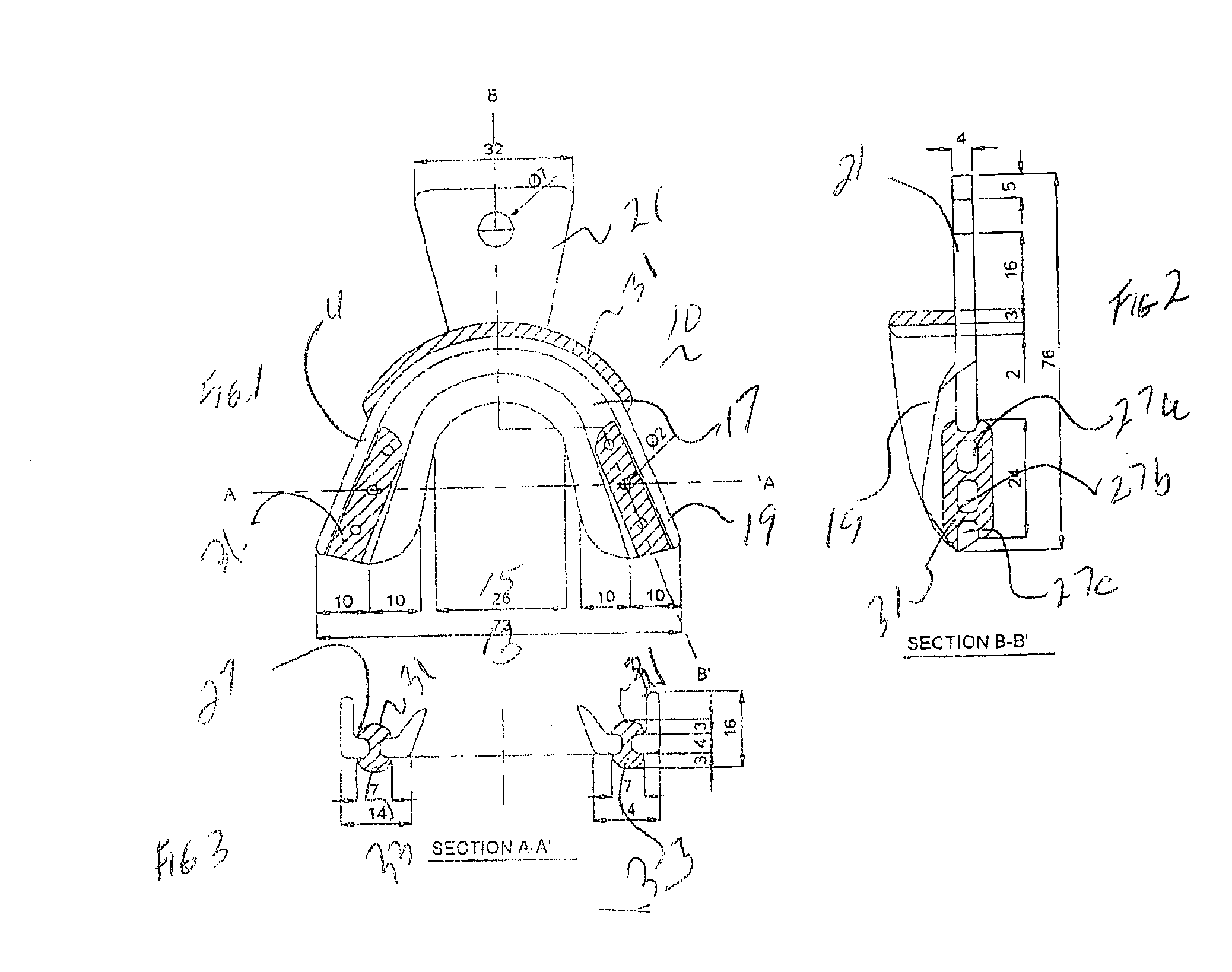

Mouthguard

InactiveUS20050115571A1Improve shock absorptionMaximum protectionTeeth fillingSport apparatusMouthguardEngineering

A mouthguard for use by athletes in competition and the like, including a first portion formed from a ethylene vinyl acetate copolymer material and having a teeth engaging shape and having a freezing point of less than 130° F. The first portion is formed into a tray having a generally U-shape with a tab extending out from the tray. The tray has a plurality of holes therein. A second portion formed from a block styrene copolymer is mounted on the first portion such that part of the second portion extends through the plurality of holes in the first portion to lock the two portions together. The second portion is formed from a gel material having sufficient softness to protect the user from damage during use in the athletic competition.

Owner:JACOBS SCOTT

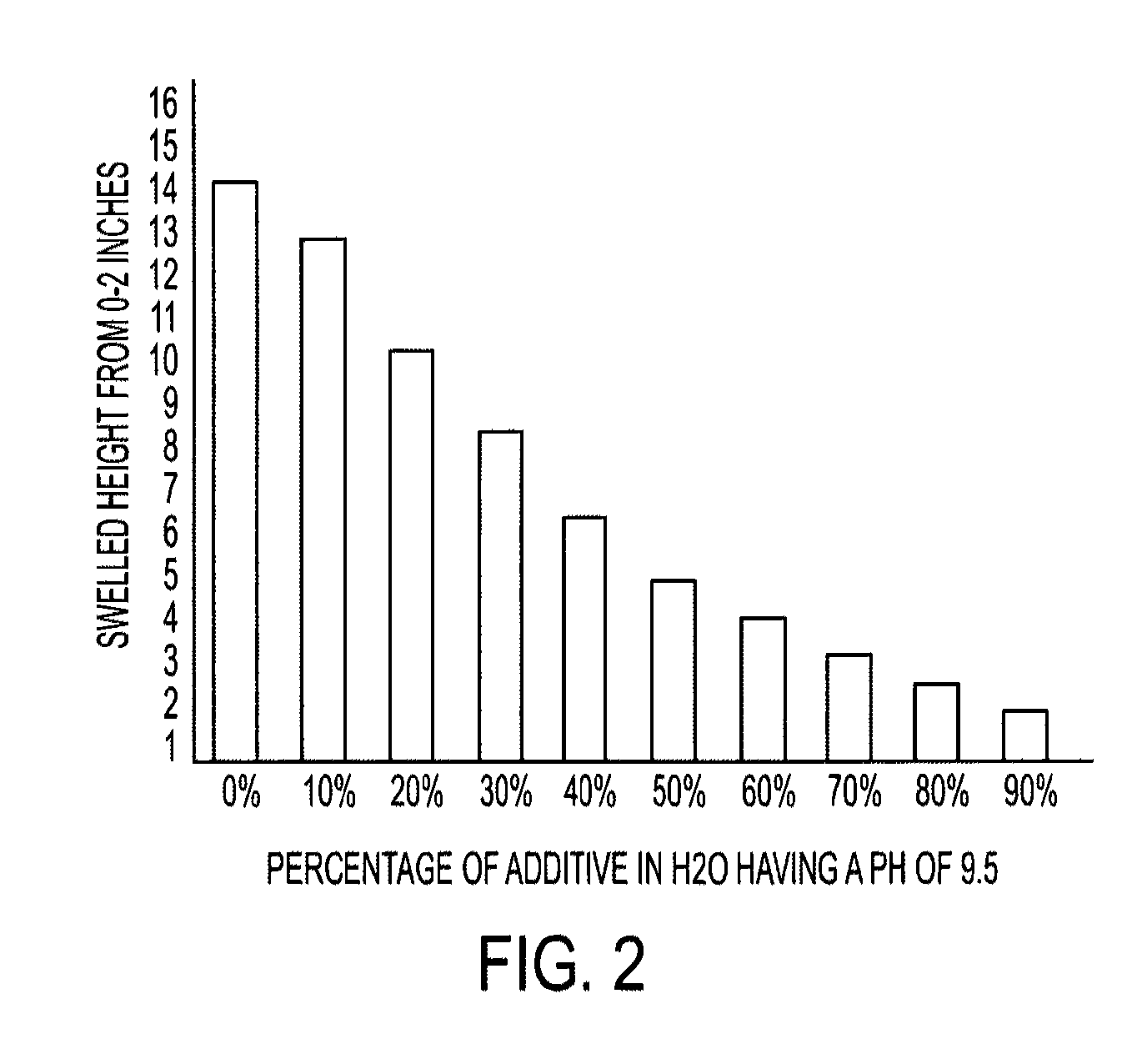

Drilling fluid additive with low freezing point

ActiveUS8673825B2Reduce coefficient of frictionImprove the lubrication effectSugar productsFlushingLiquid mediumSugar

A drilling fluid additive, is provided, and the additive comprises: syrup solids and a liquid medium; and the sugar content of the additive is directly proportionate to the freezing point of the additive.

Owner:MUD MASTERS ACQUISITION CORP

Blast-furnace cement sensible heat recovery system and its production process

InactiveCN1920380AReduce focal ratioRaise the hot air temperatureOther heat production devicesBlast furnace componentsSlagProduct gas

The invention relates to a blast furnace slag heat recycle system and relative production, wherein it is formed by cooling-breaking, gas-slag heat exchanger, and left-heat boiler units; the slag outlet has cooling-braking unit which will cool the slag to the solidify point 1200-1300Deg. C, to be broken into the slag particles whose diameter is less than 100mm; the transmitter is connected to the gas-slag heat exchanger to heat the air to 700-800Deg. C; the slag will be cooled under 150Deg. C; the heated air will be transmitted to the left-heat boiler; the water of heating tube of boiler will adsorb the heat of gas, to generate the steam whose pressure at 0.3-0.4MPa and temperature at 260-350Deg. C. The invention can improve the energy recycle efficiency more than 70%, to reduce the energy consumption of steel production, reduce the consumption of cooling water, and reduce the environment pollution.

Owner:ANGANG STEEL CO LTD +1

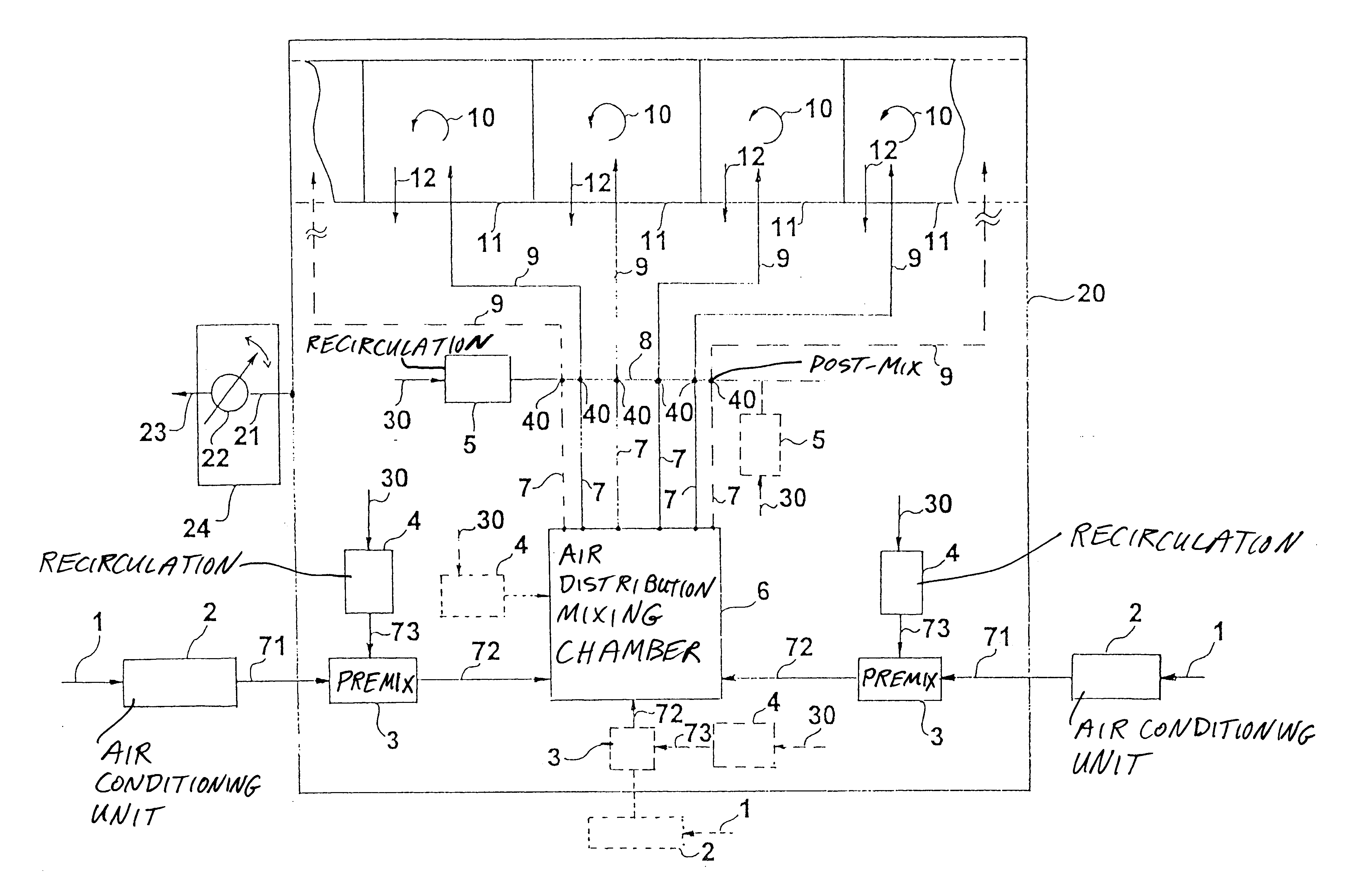

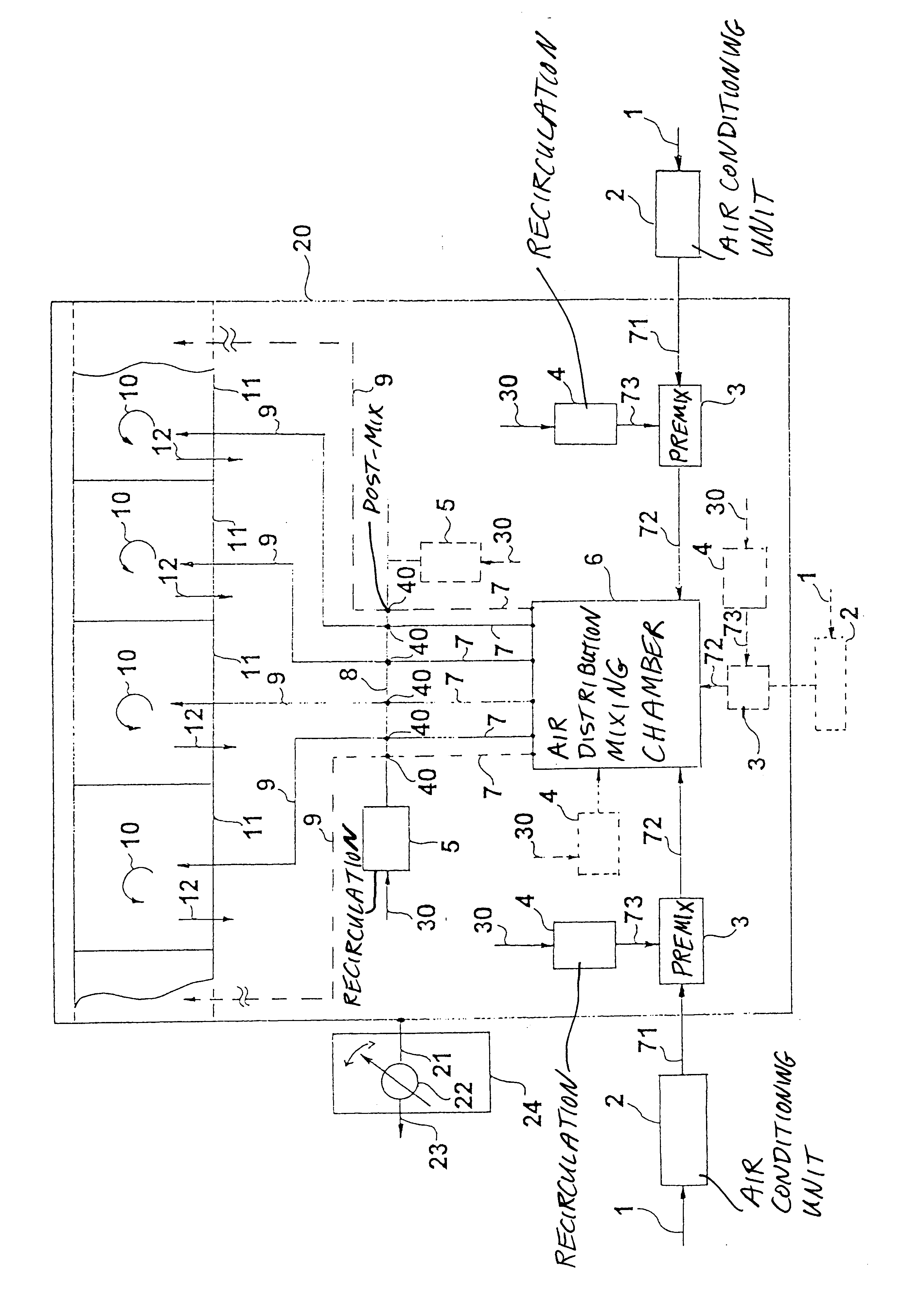

High capacity air conditioning system with redundant staged recirculation air mixing for an aircraft

InactiveUS6389826B2Improve cooling effectAvoid adjustmentAir-treatment apparatus arrangementsEnergy efficient board measuresCold airEngineering

In an air conditioning system for an aircraft, two pre-mixing units respectively mix cold air from two air conditioning units with recirculated fuselage interior air from two recirculation units, to prepare two pre-mixed air flows that are both directed into and mixed together in a common air distribution mixing chamber, from which mixed air distribution lines branch off to respectively associated separate air conditioning zones within the fuselage. Post-mixing units are respectively interposed in the mixed air distribution lines and respectively mix additional quantities of recirculated fuselage interior air into the mixed air distribution lines. Thereby, the admixture of recirculated air is divided into at least two stages, the system provides redundant failure tolerant operation, and the danger of ice formation in the air lines is reliably prevented even while the air conditioning units provide cold air at a temperature below the water freezing point.

Owner:AIRBUS OPERATIONS GMBH

Method and system for treating food items with an additive and solid carbon dioxide

ActiveUS20100293969A1Reduce pressureMixing methodsStationary refrigeration devicesLiquid carbonSolid carbon dioxide

Embodiments of the invention generally provide methods and systems that distribute an additive in solid carbon dioxide in an interior of food processing equipment. The additive may be injected into a flow of liquid carbon dioxide upstream of an expander at or adjacent to the interior. Injection of the additive into the interior may be alternated with directing a flow of expanded carbon dioxide into the interior. In some embodiments, the freezing point of the additive with or without a diluent composition and / or additive(s) is lower than a temperature of the liquid carbon dioxide.

Owner:AIR LIQUIDE AMERICA INC +1

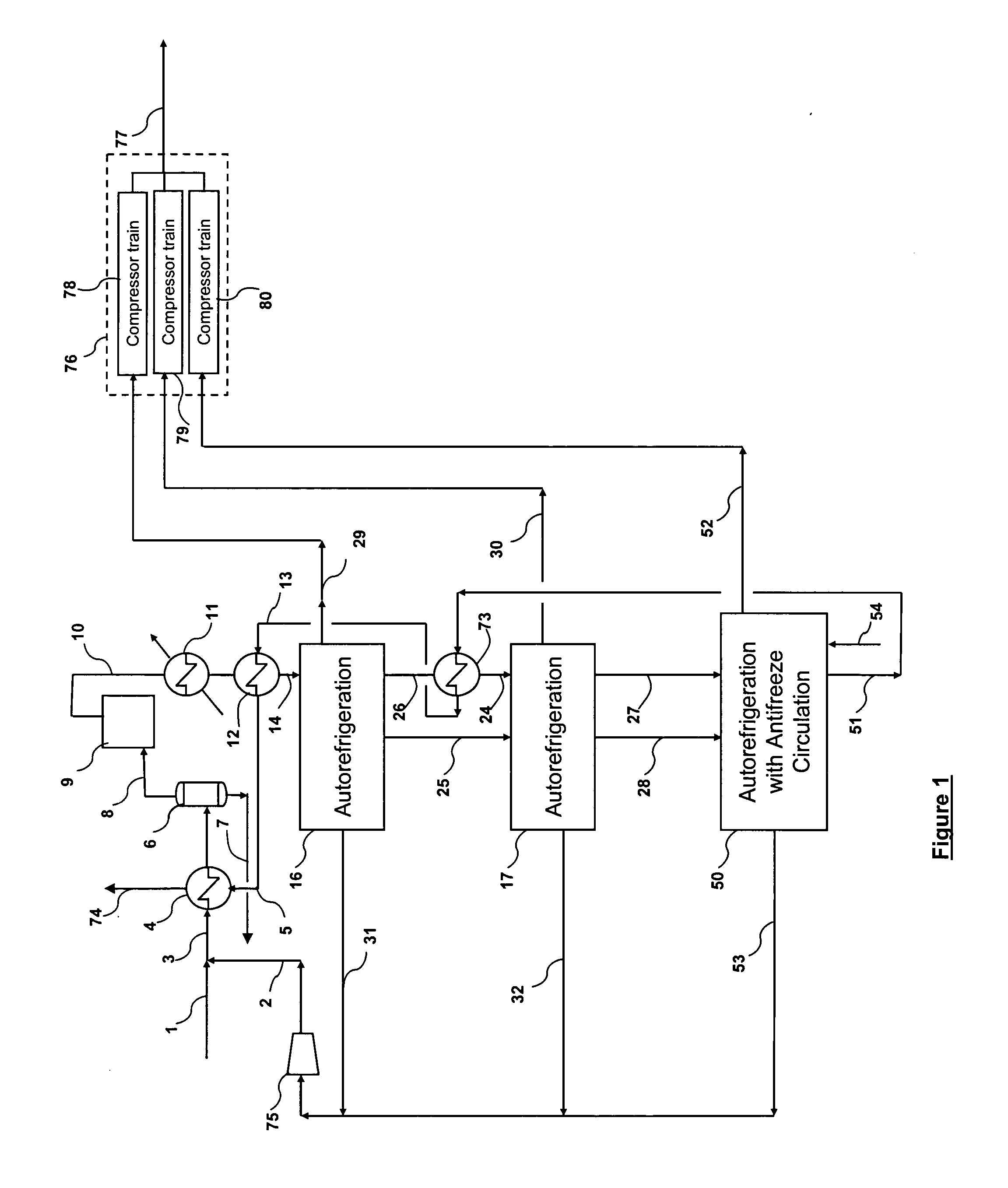

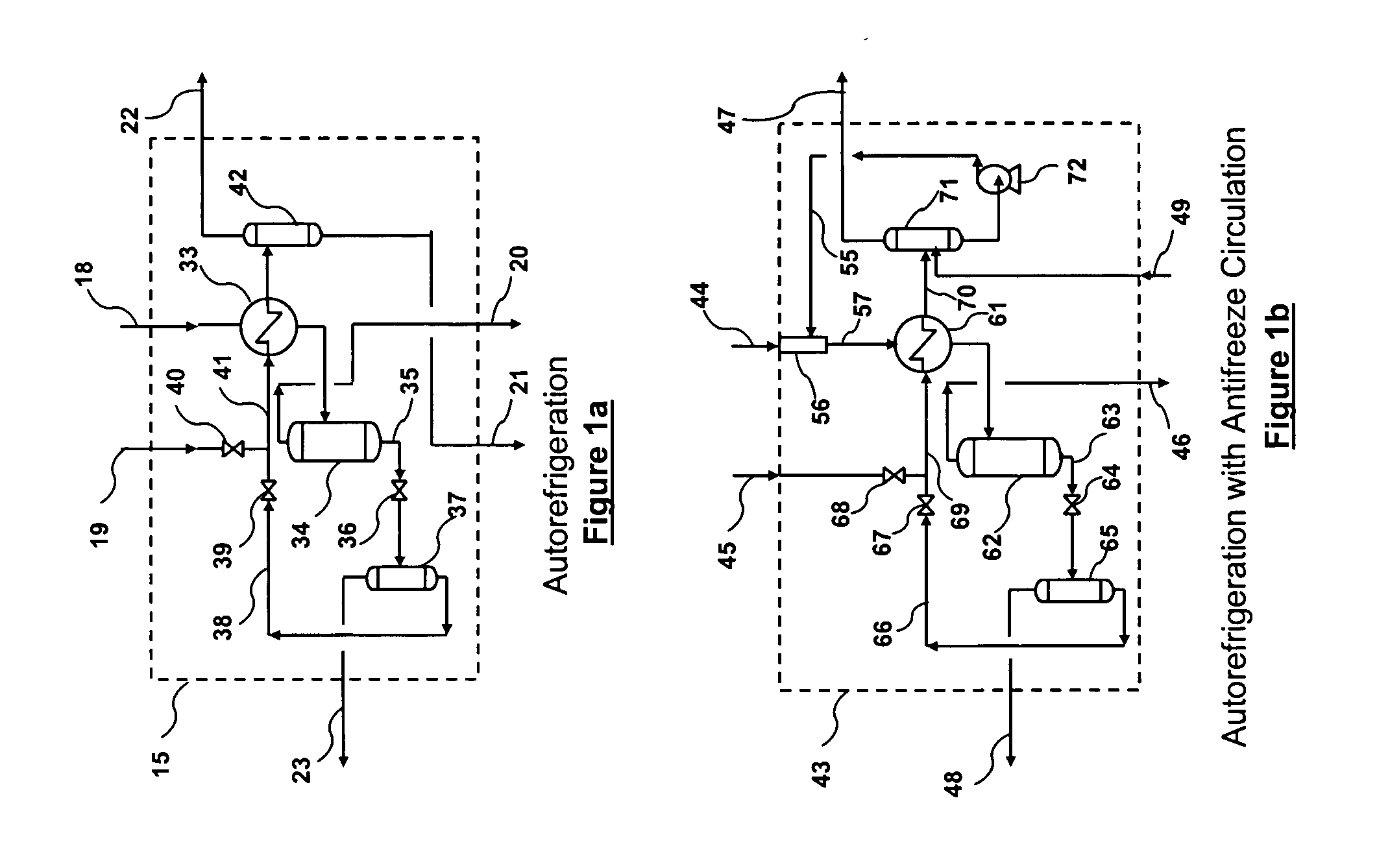

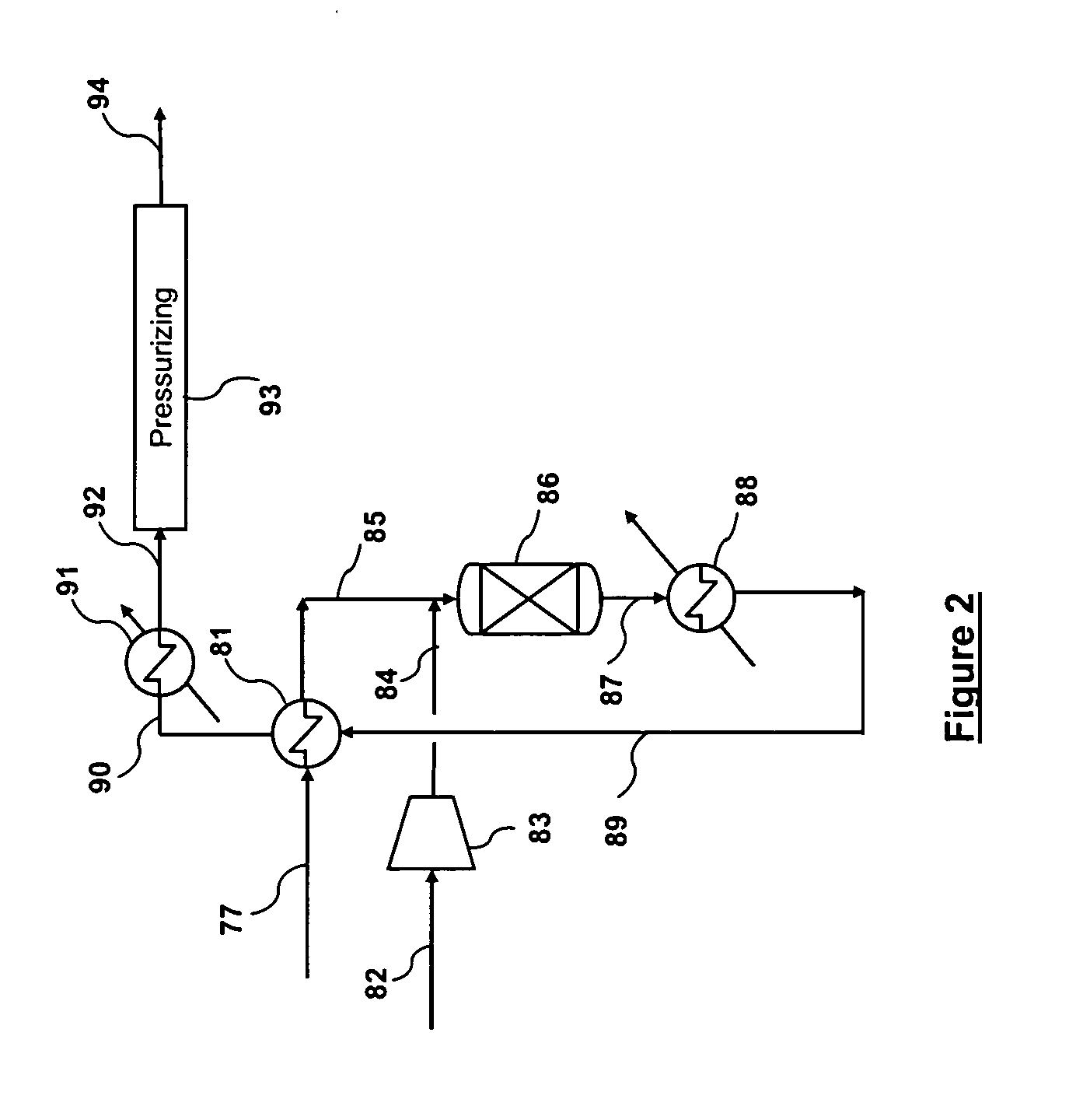

Multi-stage cryogenic acid gas removal

InactiveUS20070221541A1Alleviate power needsIncrease the number ofSolidificationLiquefactionPetroleumPetroleum coke

A relatively simple and energy efficient multiple stage cryogenic process for the purification of a hydrogen-rich stream by the removal of acid gases, mainly CO2 and H2S, by method of autorefrigeration and delivering or producing those acid gases, mainly CO2, at pressure sufficiently high for disposal by containment, commonly known as sequestration. Autorefrigeration is comprised of (a) condensing acid gases from the syngas stream by cooling the syngas, (b) separating the liquefied acid gases from the syngas, and (c) evaporating the liquefied acid gases at a pressure lower than that of the syngas to provide cooling. The process is composed of multiple autorefrigeration stages to generate multiple acid gas product streams with a pressure as high as practical in each stream so as to lessen the power needed to pressurize the acid gas streams for sequestration. The final autorefrigeration stage utilizes an antifreeze liquid that allows the final stage to operate below the freezing point of CO2; thus allowing more acid gas removal. The antifreeze liquid is an alcohol or a mixture of alcohols with a freezing point lower than about minus 110 degrees F. and a boiling point higher than about 100 degrees F. The process includes hydrogen recovery and recycle as well as recovery of the energy contained in the sulfur bearing compounds. The process is especially well suited for CO2 removal / sequestration from a coal (or petroleum coke) gasification process.

Owner:TENNESSEE VALLEY AUTHORITY

Diesel production from hydrogenation upgrading isomerizing pour-point reduction

ActiveCN1712499ALittle impact on yieldLowering the freezing pointRefining to change hydrocarbon structural skeletonIsomerizationCrystallinity

Production of hydrogenated and pour-point reducing modified isomerization diesel oil is carried out by using fraction oil as raw material from one-stage or series process flow, passing fraction oil raw material and hydrogen gas into catalyst bed which consists of beta molecular sieve 1í½9wt%, and obtaining clean high-quality diesel product and naphtha product with low sulfur nitrogen and high arene content. The beta molecular sieve has small crystal grain, low acidity, high silica-alumina ratio and crystallinity. It achieves simple process, higher productivity and less impurities, and improves density and freezing point.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com