Patents

Literature

55results about How to "Excellent isomerization performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing para-xylene

InactiveUS6878855B2High yieldExcellent isomerization performanceHydrocarbon by isomerisationMolecular sieve catalystIsomerizationP-Xylene

Owner:EXXONMOBIL CHEM PAT INC

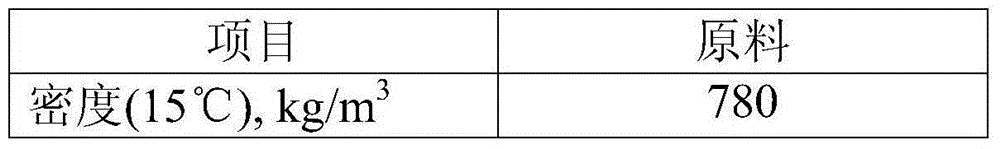

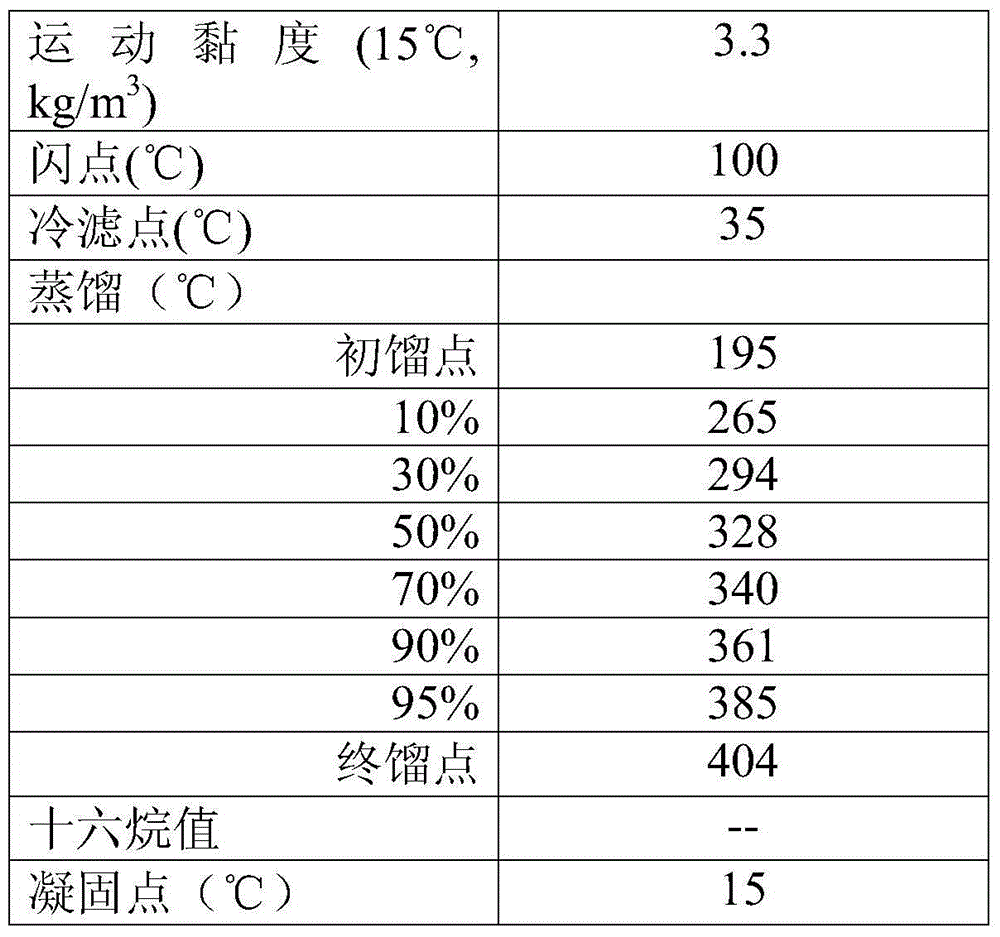

Method for producing chemical raw material by hydrocracking

ActiveCN102533317AHigh light oil selectivityImprove product qualityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

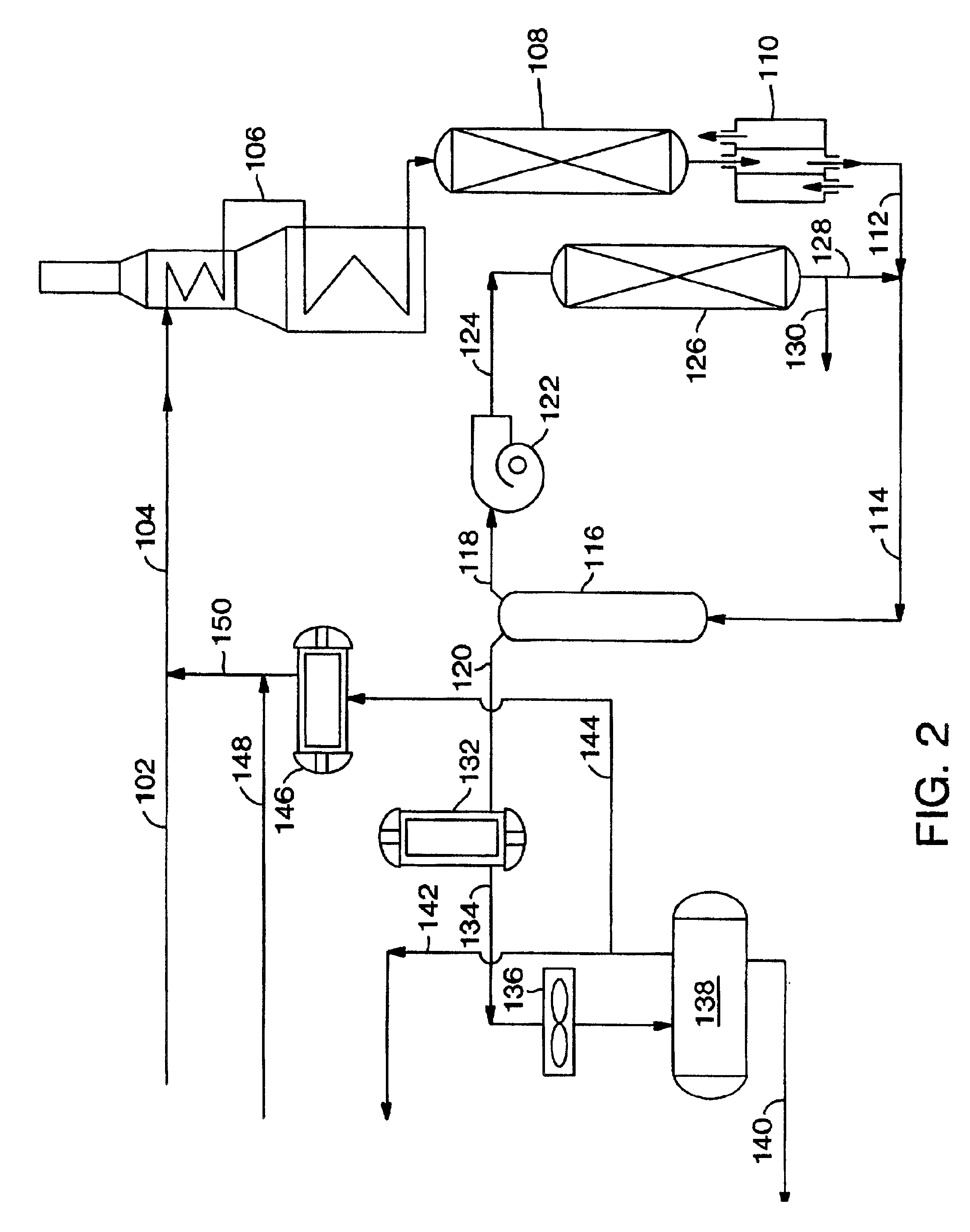

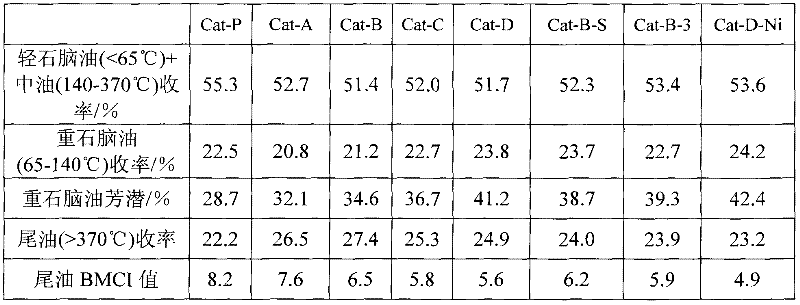

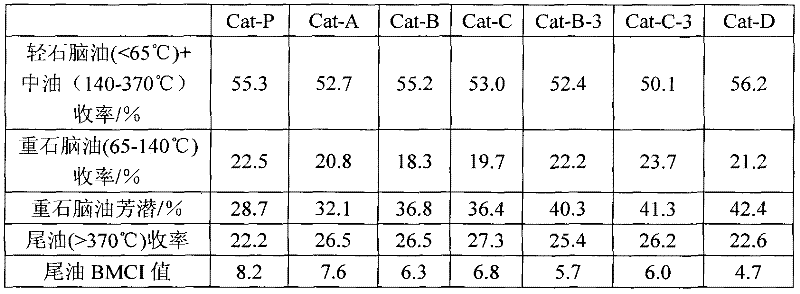

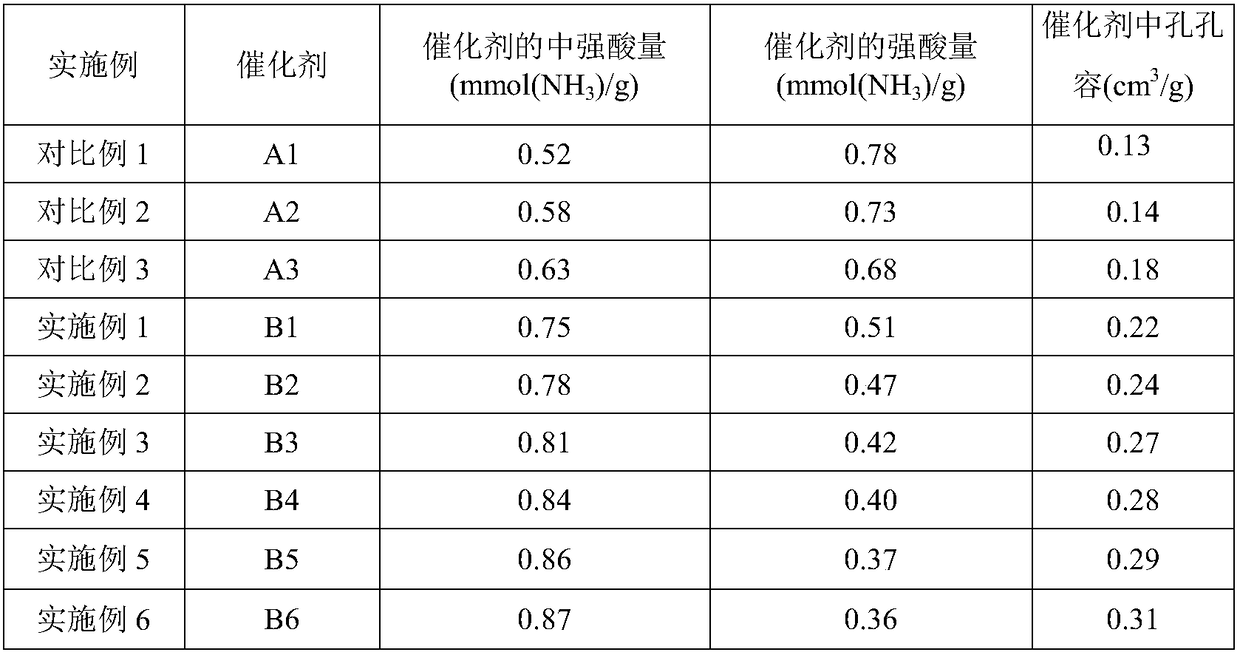

The invention relates to a method for producing a chemical raw material by hydrocracking. A catalyst for producing the chemical raw material by hydrocracking comprises the following components in percentage by weight according to 100 percent by weight of the catalyst: 30-70 percent of mesoporous amorphous silicon-aluminum, 10-30 percent of modified Y-type molecular sieve, 5-15 percent of Beta molecular sieve, 1-10 percent of NiO and 10-29 percent of WO3. The method for producing the chemical raw material by hydrocracking comprises the following steps of: loading metal components including Ni and W on a carrier by adopting a fractional infusion method, wherein a nickel acetate or nickel nitrate solution is used as a nickel source and ammonium meta-tungstate or ammonium tungstate is used as a tungsten source; adding a metric nickel salt solution in the preparation process of amorphous silicon-aluminum, wherein the addition amount of nickel accounts for 20-80 percent of the using amount of NiO in the catalyst; and preparing a mixed carrier and loading residual nickel salt solution and all tungsten salt solution by adopting a co-infusion isovolumetric method. The method disclosed by the invention has higher light oil recovery rate; meanwhile, heavy naphtha with high aromatic latent content and tail oil with BMCI (Bureau of Mines Correlation Index) value, which are respectively used as a favorable catalytic reforming raw material and a raw material for preparing ethylene by steam cracking, can be obtained.

Owner:PETROCHINA CO LTD +1

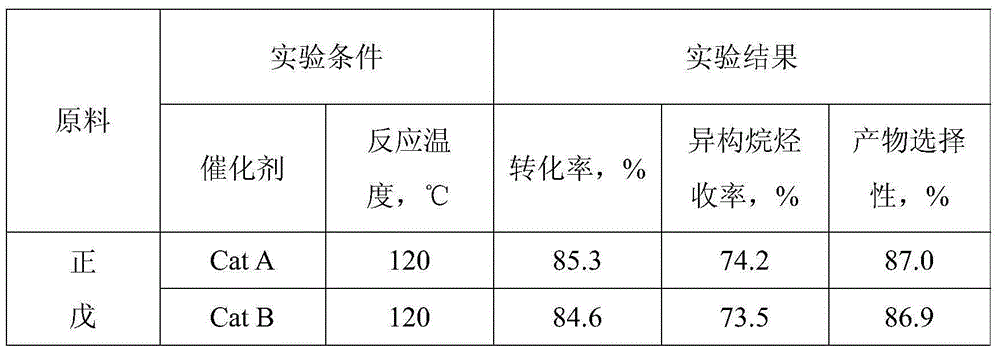

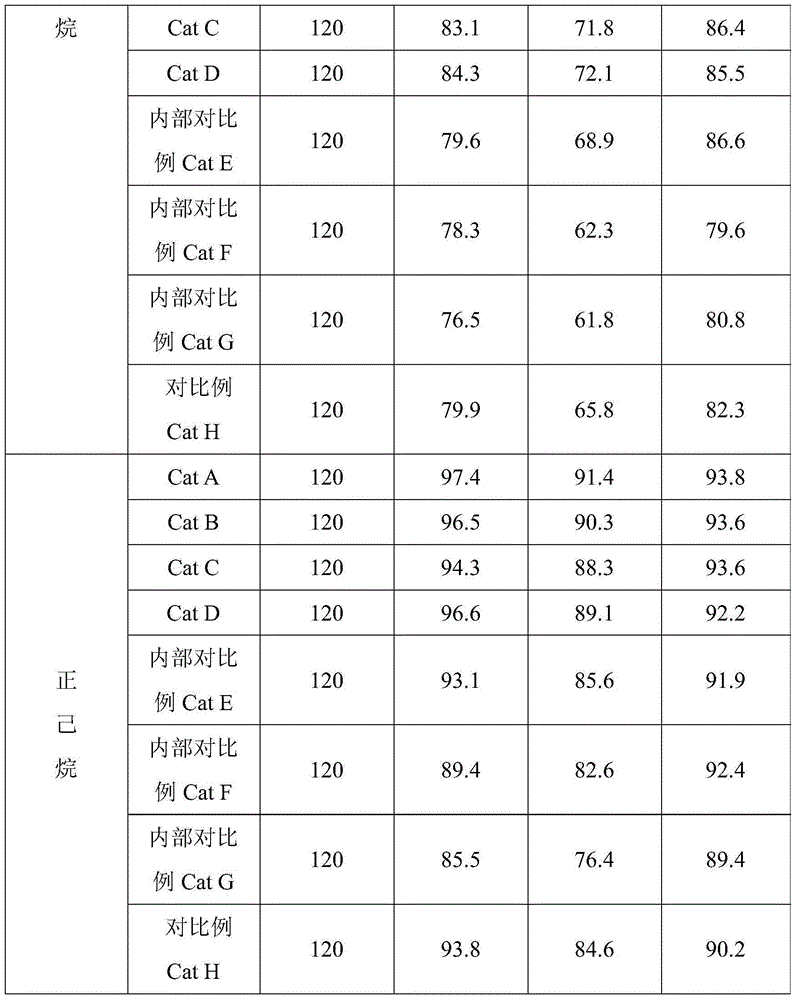

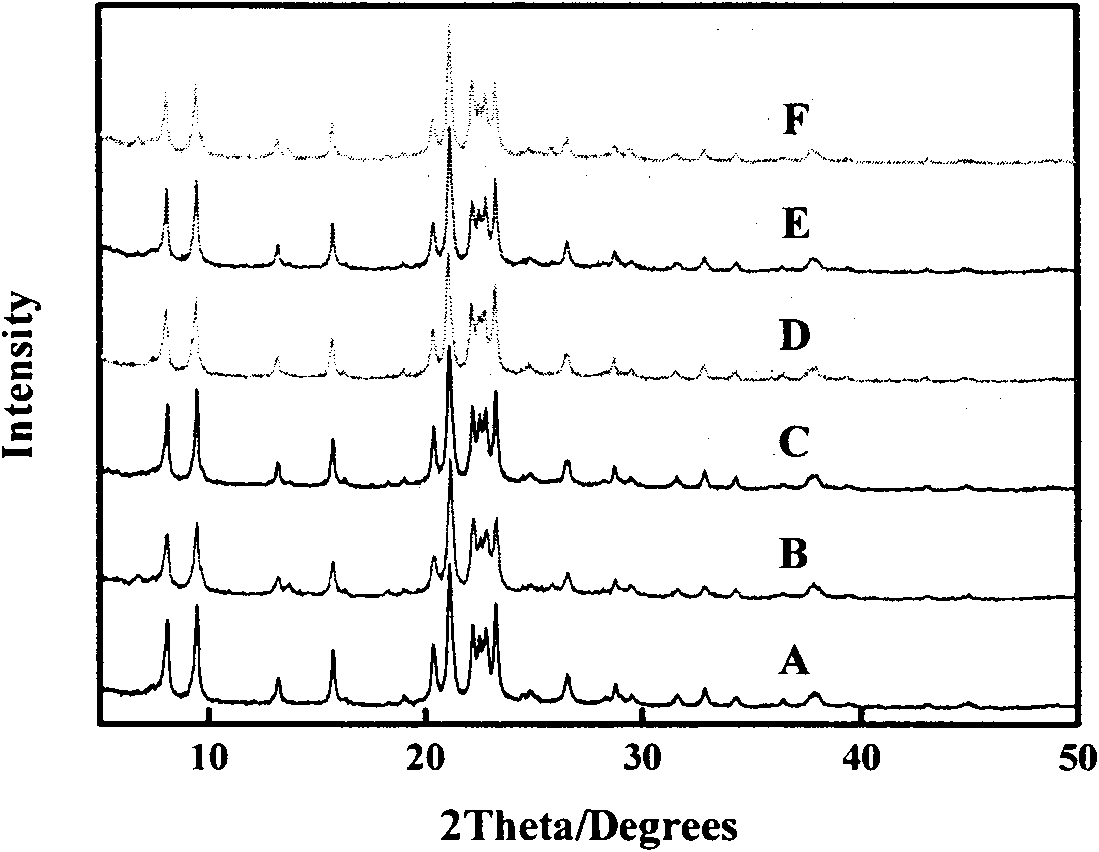

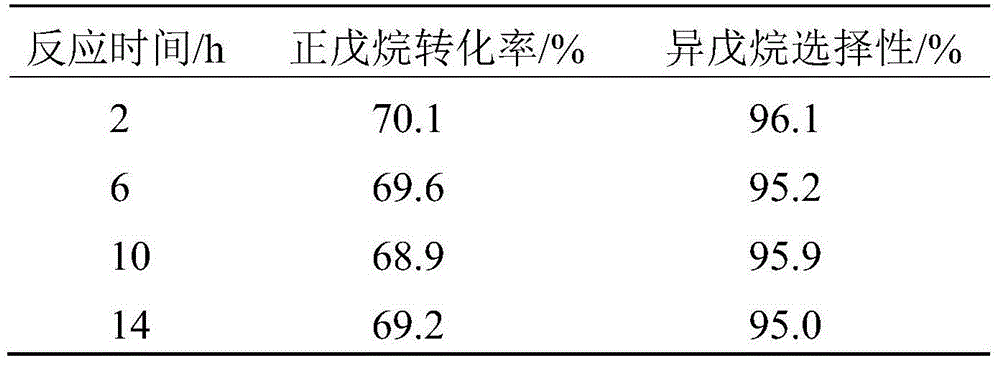

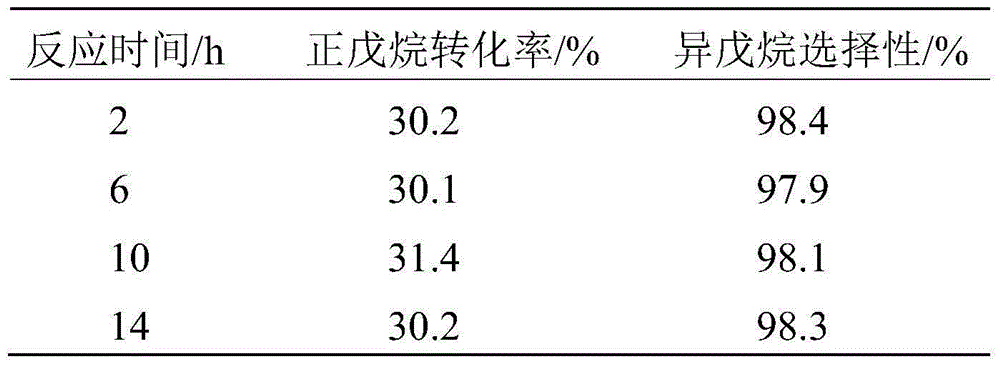

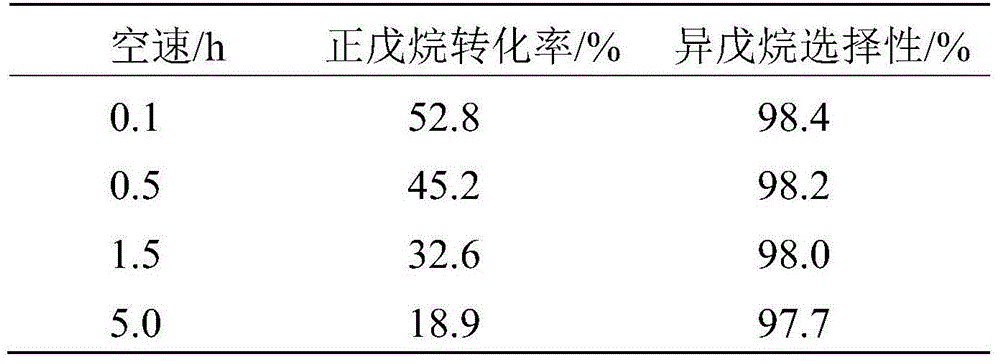

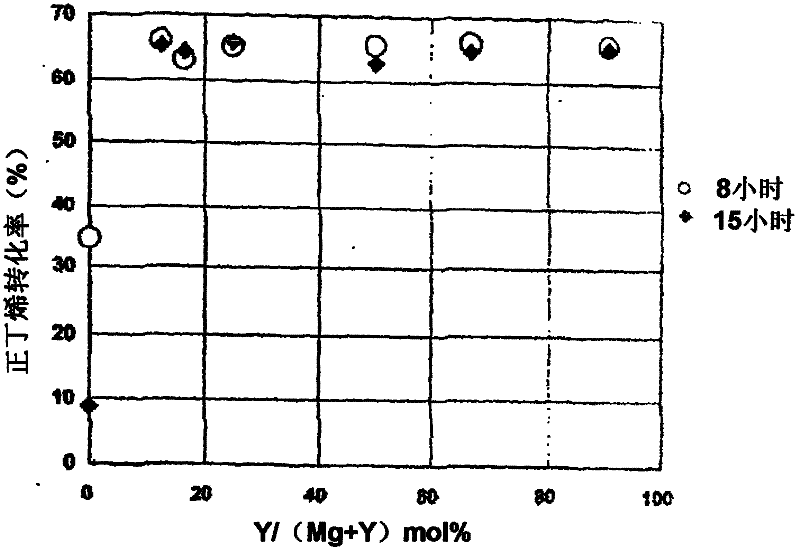

Catalyst for normal paraffin isomerization and use thereof

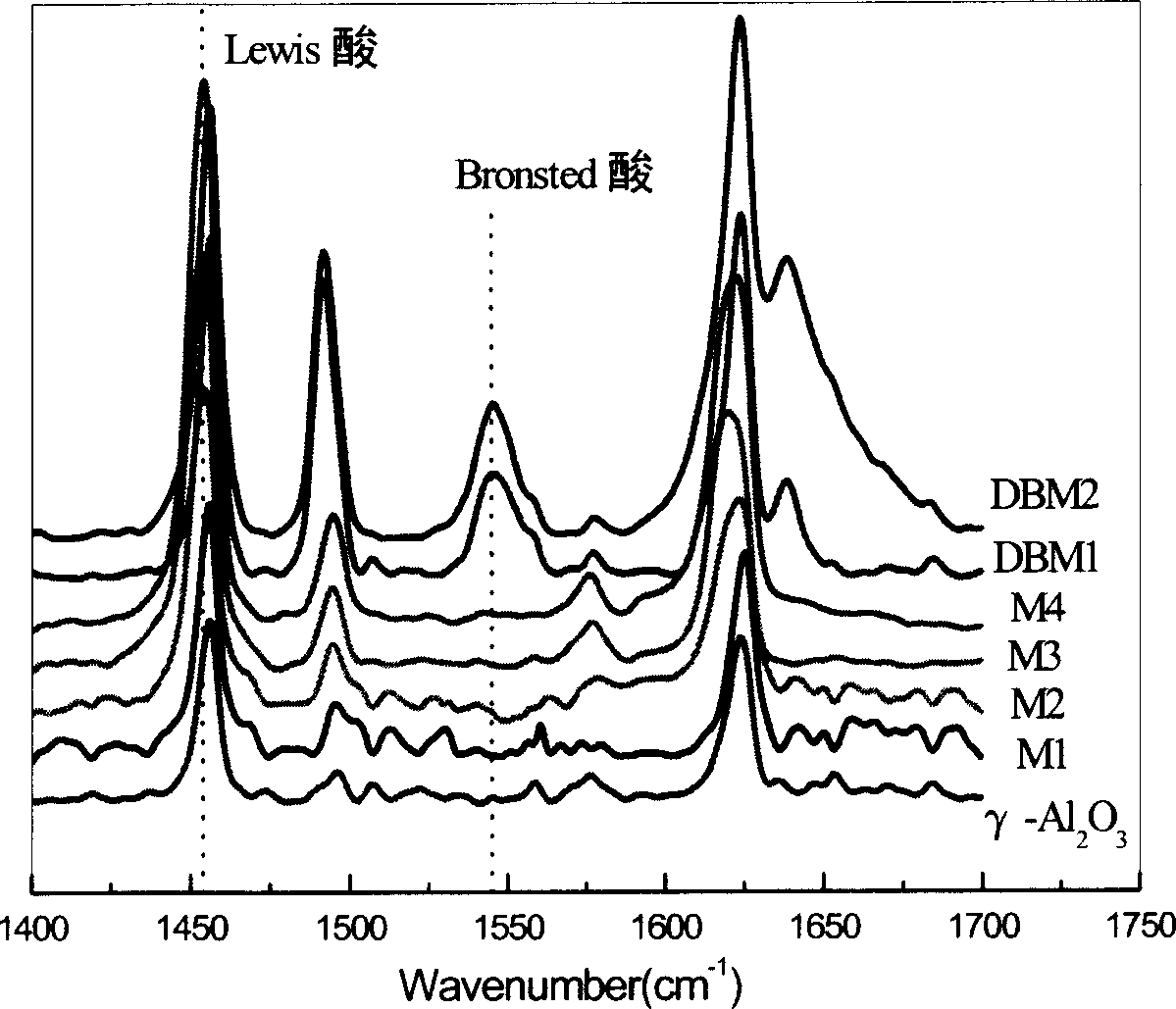

InactiveCN1465436AImprove catalytic performanceExcellent isomerization performanceHydrocarbon by isomerisationMetal/metal-oxides/metal-hydroxide catalystsParaffin oilsIsomerization

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

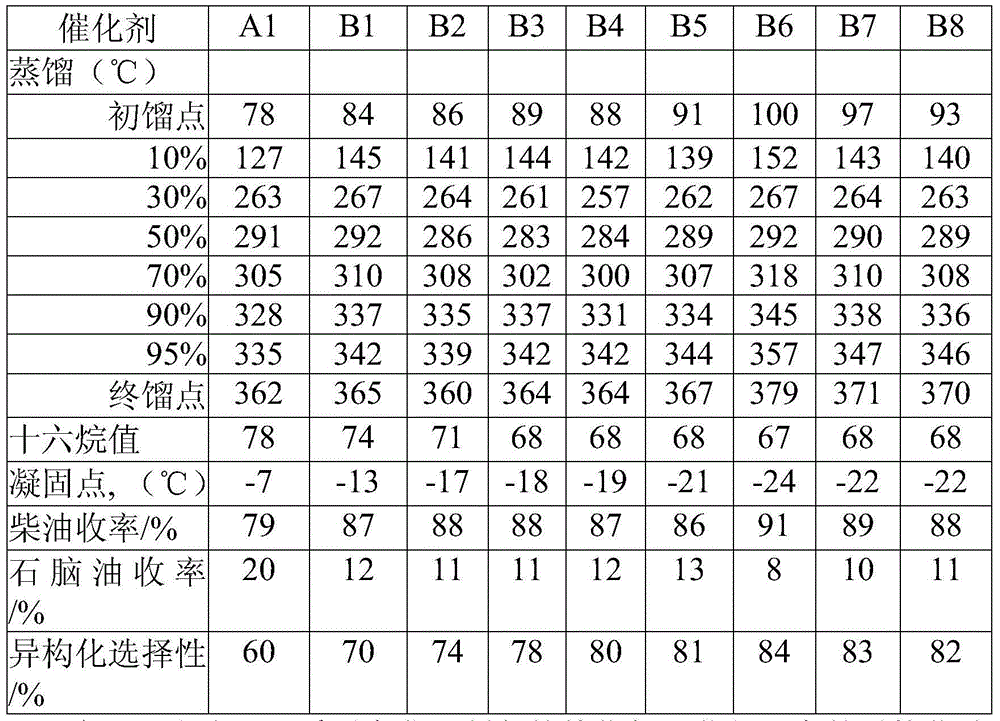

Hydrofining catalyst of diesel oil and preparation method thereof

InactiveCN101591560AIncrease cetane numberImprove desulfurization and denitrification activityRefining to eliminate hetero atomsMolecular sievePoor quality

The invention relates to a hydrofining catalyst of diesel oil, comprising a carrier and active constitutes. The active constitute is one or more of the VIB group metals and the VIII group metals, wherein, the carrier is composed of one or more of SAPO-5, SAPO-11, ZSM-22 and ZSM-23 molecular sieves which have one-dimensional pore canals, and gamma-Al2O3. The invention further discloses a preparation method of the catalyst on the basis of disclosing the hydrofining catalyst of diesel oil. The hydrofining catalyst prepared by the method in the invention can prevent the diesel oil distillates from cracking, realize the aromatics hydrogenation saturation of poor quality diesel oil, and simultaneously effectively realize the desulfuration and denitrification of poor quality diesel oil.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

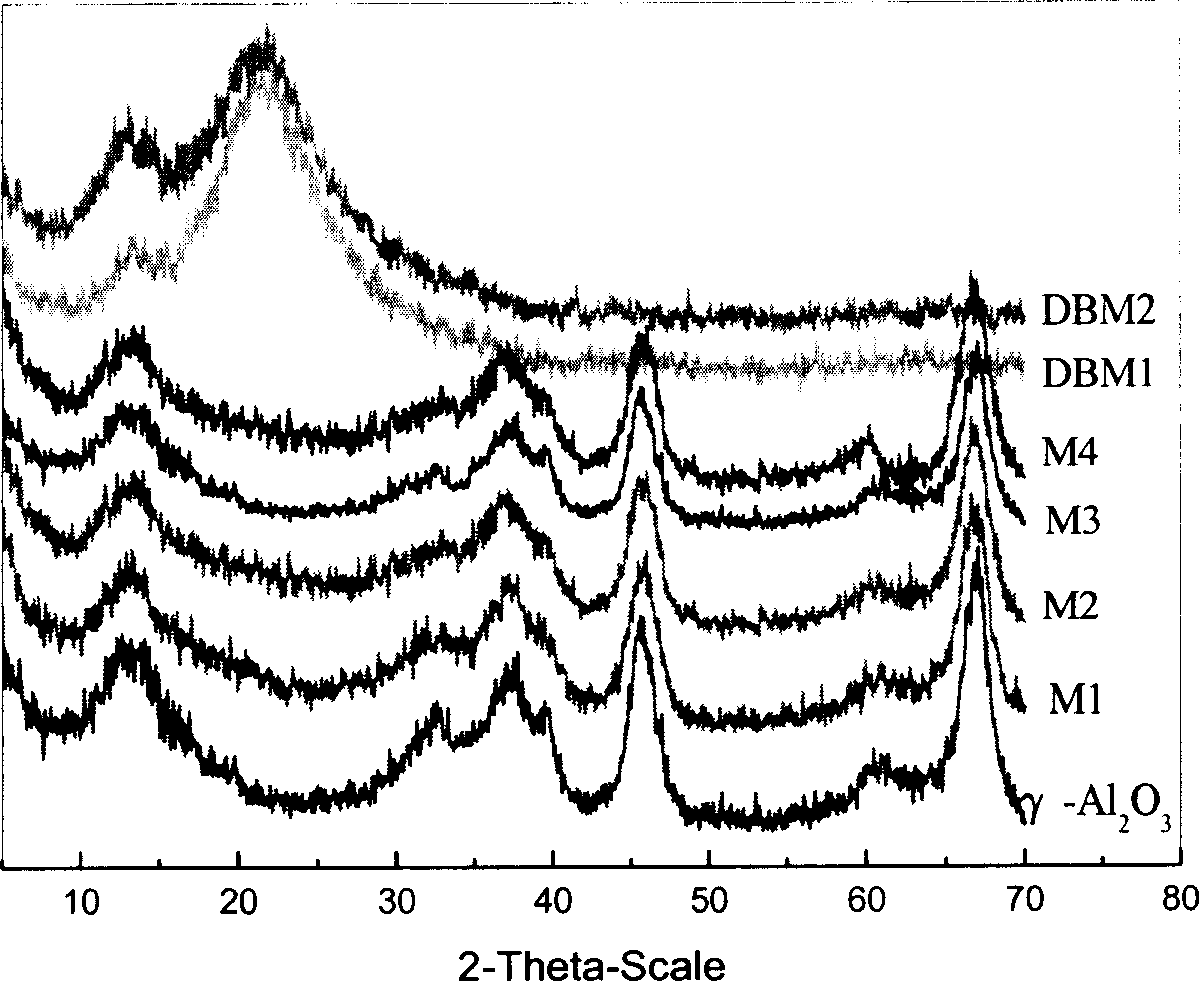

N-alkane low-temperature isomerization catalyst as well as preparation method and application thereof

ActiveCN105080578AHigh activityImprove stabilityHydrocarbon by isomerisationPhysical/chemical process catalystsAlkaneIsomerization

The invention discloses an n-alkane low-temperature isomerization catalyst as well as a preparation method and an application of the n-alkane low-temperature isomerization catalyst. The catalyst disclosed by the invention comprises the following components in percentage by weight: 0.1%-1.0% of loaded metal Pt, 5.0%-10.0% of an element Cl, and the balance of a carrier gamma-Al2O3. The preparation method of the catalyst disclosed by the invention comprises the following steps: dipping chloroplatinic acid on the carrier gamma-Al2O3, and then drying and roasting to obtain Pt / gamma-Al2O3 catalyst containing 0.1%-1% of the Pt; and firstly reducing a platinum-containing catalyst, then uniformly dipping a chlorinating agent on the surface of the Pt / gamma-Al2O3 catalyst by adopting a chlorinating way of liquid-phase dipping, and then carrying out programmed warming for curing the chlorinating agent to obtain the Pt / gamma-Al2O3-Cl n-alkane isomerization catalyst with high chloride loading quantity (5%) and uniform distribution of the chlorine element. The catalyst provided by the invention has relatively high chlorine content, also has good chlorine distribution, and achieves high acidity loading quantity, high isomerization activity and high stability of the catalyst.

Owner:BEIJING SINO SPHERE PETROCHEM TECH CO LTD

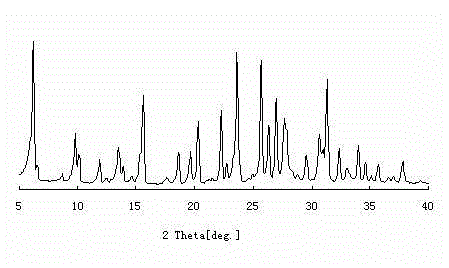

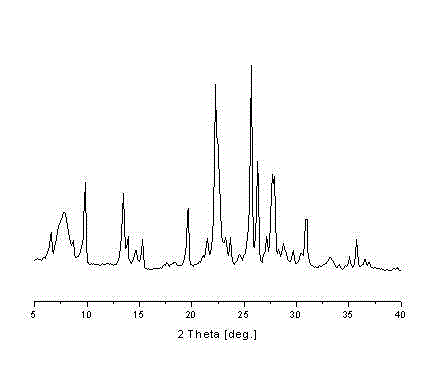

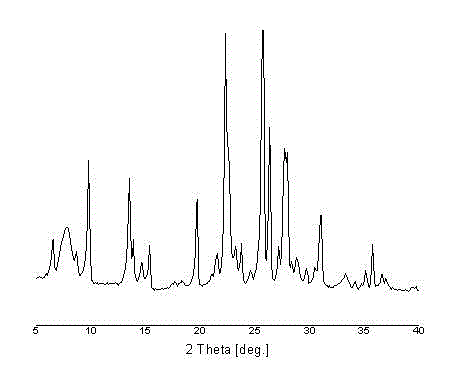

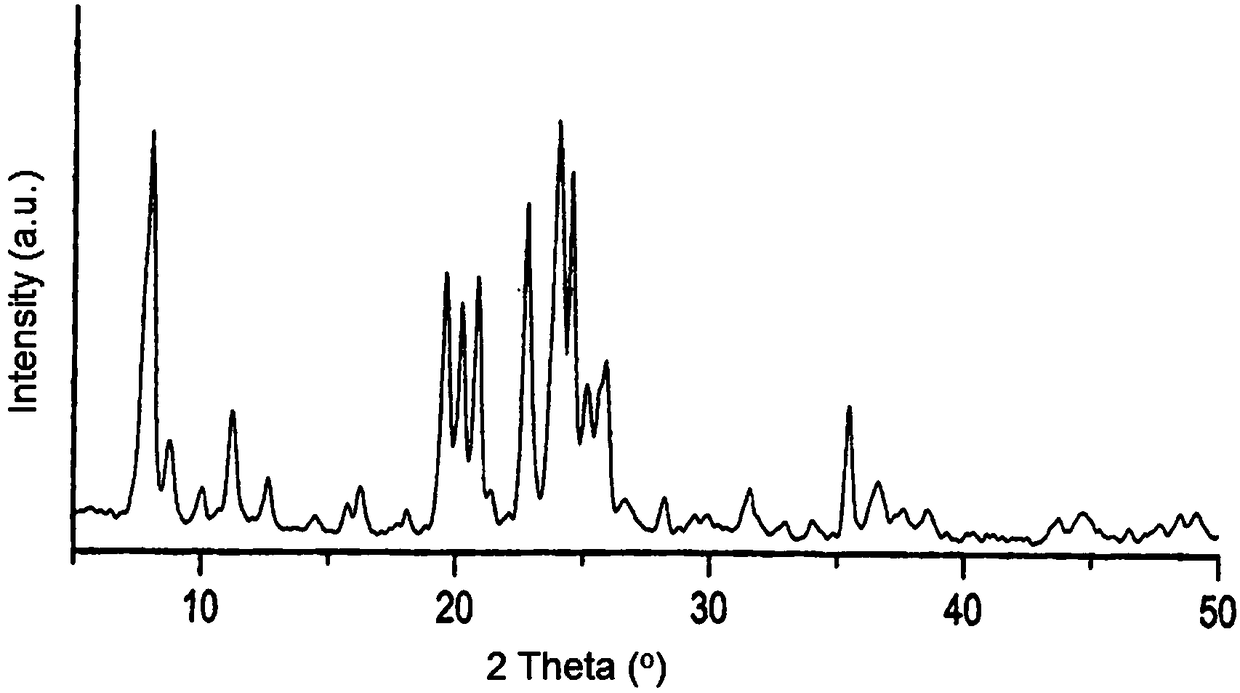

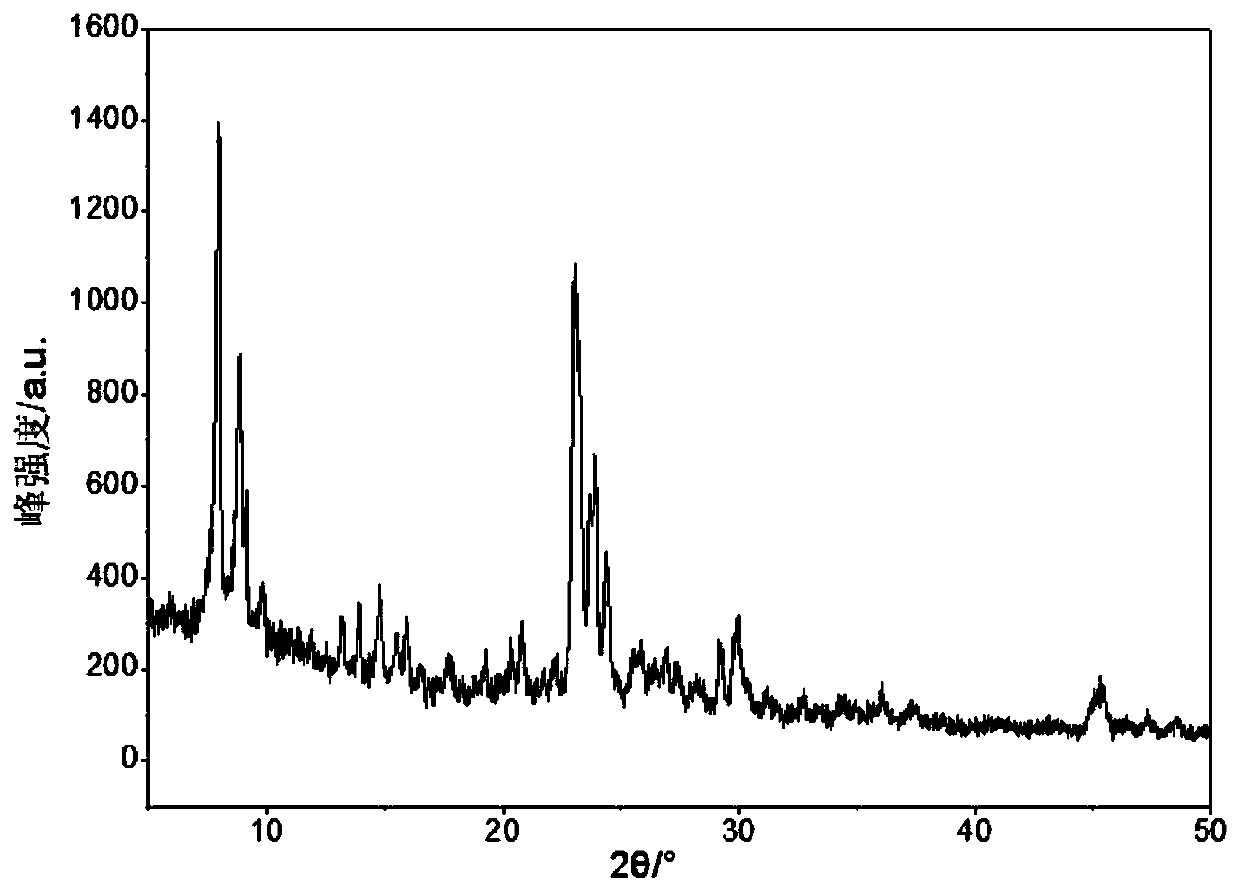

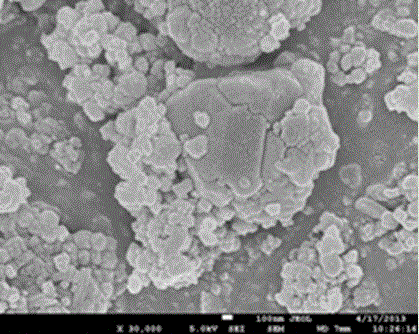

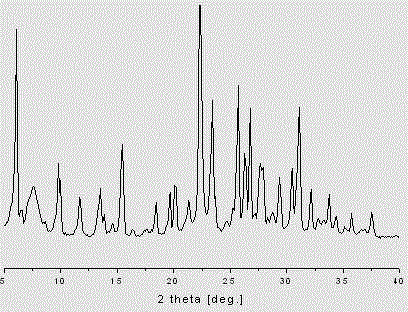

Preparation method of multistage pore canal SAPO-11 (silicoaluminophosphate-11) molecular sieve and application thereof in gasoline modification

ActiveCN101913622AEfficient removalIncrease the areaMolecular-sieve and base-exchange phosphatesHydrocarbon oils refiningPhosphoric acidAlkylation

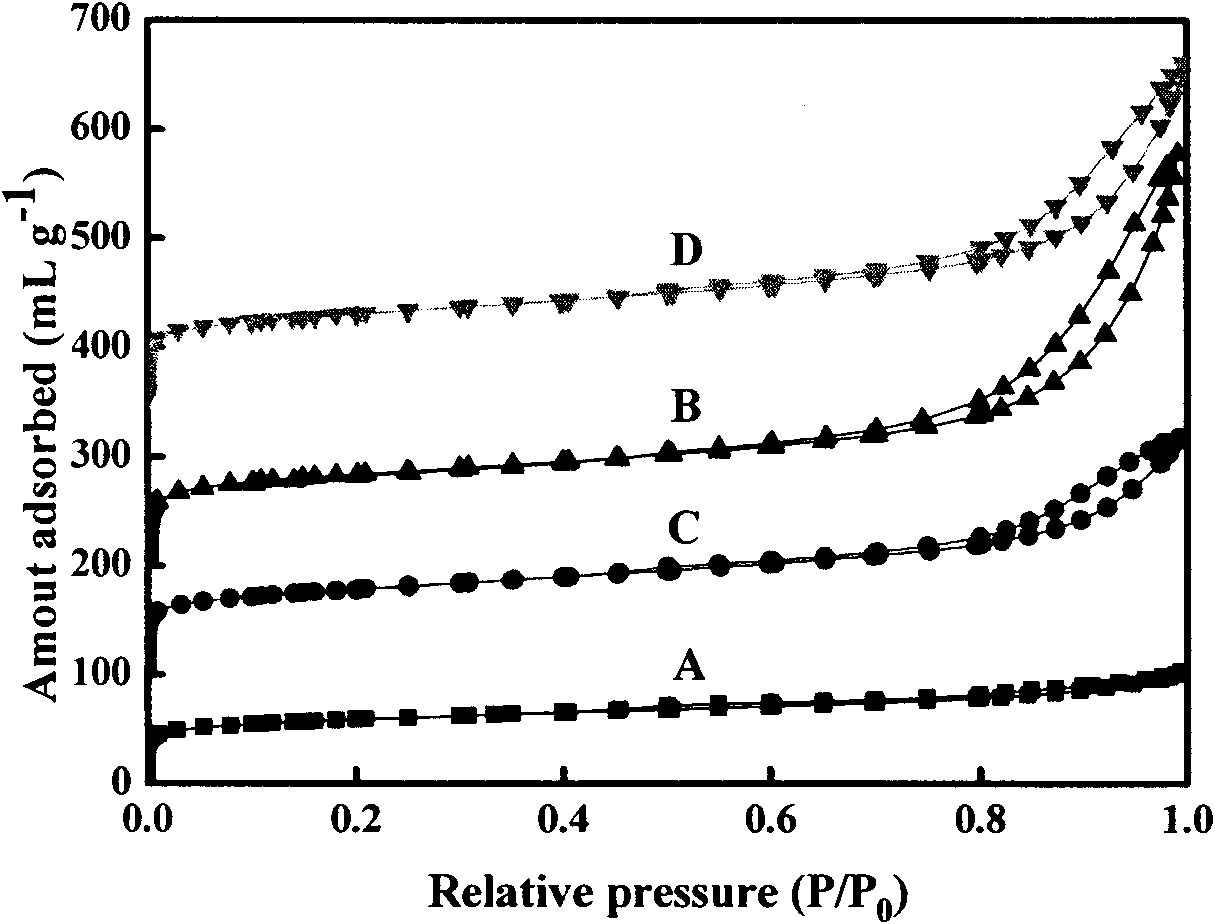

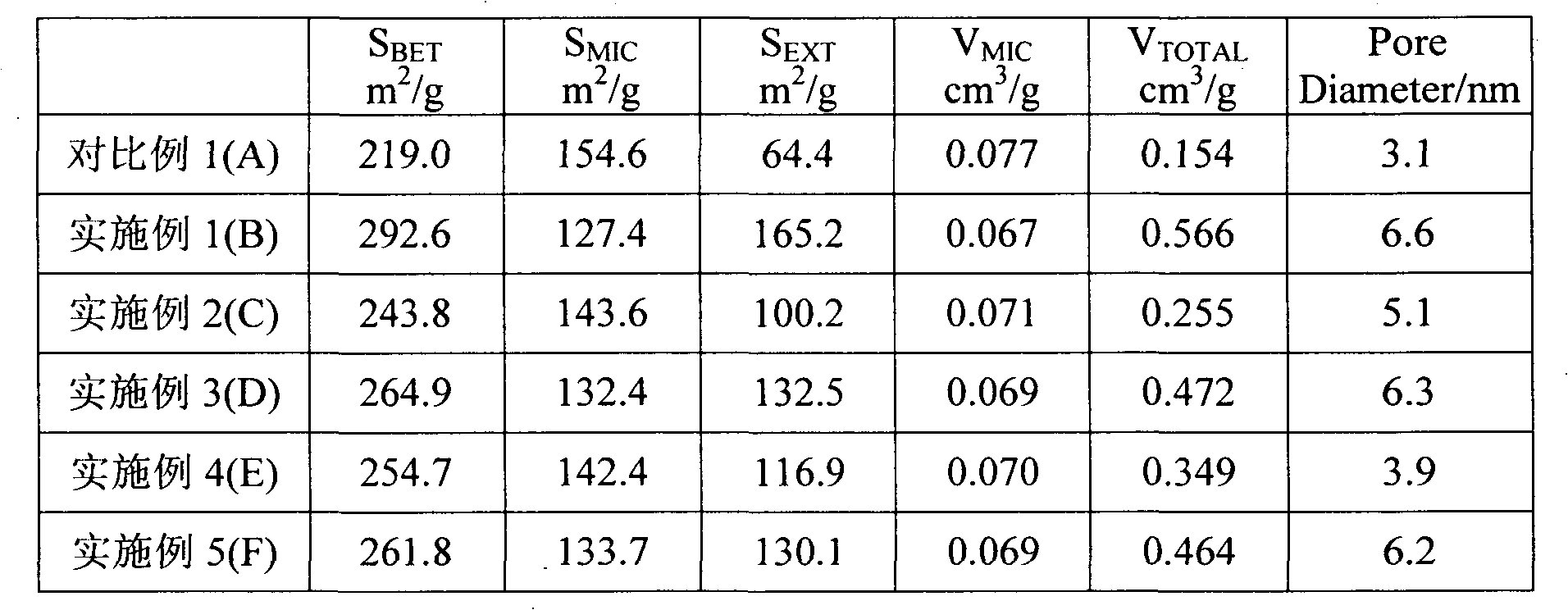

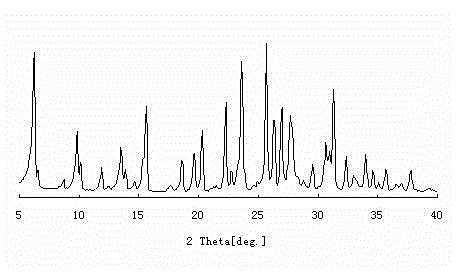

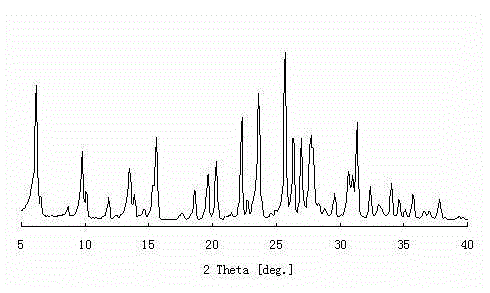

The invention relates to a preparation method of a multistage pore canal SAPO-11 (silicoaluminophosphate-11) molecular sieve and application thereof in gasoline modification. The preparation method comprises the following steps of: uniformly mixing alkylated organic phosphonic acid and deionized water, and sequentially adding phosphoric acid, an aluminum source, a template agent and a silicon source to obtain a mixed solution; carrying out crystallization, separating, washing and drying a solid product to obtain raw multistage pore canal SAPO-11 molecular sieve powder; and sintering to obtain the multistage pore canal SAPO-11 molecular sieve. In the invention, by introducing the amphiphilic alkylated organic phosphonic acid into a conventional SAPO-11 molecular sieve synthesis system and adjusting the chain length and the addition quantity of the alkylated organic phosphonic acid, the pore diameter of the molecular sieve is adjusted. The surfaces of an SAPO-11 molecular sieve product prepared with the preparation method is formed by small crystal grains, contains rich mesopore canals and has larger specific surface area and pore volume.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Synthesis method of Y-MOR composite molecular sieve

ActiveCN103058219AGood hydrocarbon molecular crackingExcellent isomerization performanceFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteEnvironmental resistanceMolecular sieve

The invention discloses a preparation method of a Y-MOR composite molecular sieve, which comprises the following steps: properly treating mordenite with an alkaline solution to serve as a structural guide agent; and mixing Y-type molecular sieve, inorganic alkali and water, sequentially adding the structural guide agent, aluminum source and silicon source, and carrying out hydrothermal crystallization to obtain the Y-MOR composite molecular sieve. The synthetic raw materials used by the method are conventional inorganic materials without any toxic or harmful substance; the whole preparation process is green and environment-friendly; and the operation steps are simple and easy to implement.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydroisomerization/cracking catalyst and catalyst

ActiveCN105749964AExcellent isomerization performanceGood cracking performanceMolecular sieve catalystsHydrocarbon oil crackingWaxAmorphous oxide

The invention relates to a preparation method of a hydroisomerization / cracking catalyst. The method specifically comprises the following steps: treating a sodium-type ZSM-23 molecular sieve containing a template agent with an alkaline solution having a certain concentration; washing the obtained product with deionized water, and performing drying and calcination to remove the template agent; performing replacement with an ammonium nitrate solution, performing filtration, washing the obtained product with deionized water, and performing drying and calcination to prepare a hydrogen-type ZSM-23 molecular sieve; mixing the hydrogen-type ZSM-23 molecular sieve with an amorphous oxide and an acid solution, and performing molding and calcination to prepare a carrier; and soaking the carrier in an aqueous solution of soluble salt, and performing drying and calcination to obtain the catalyst. Compared with a catalyst prepared in the prior art, the prepared catalyst can be used in a conversion process of wax in Fischer-Tropsch synthesis, and has favorable catalytic activity and selectivity of target products.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for selective hydrocracking of light oil

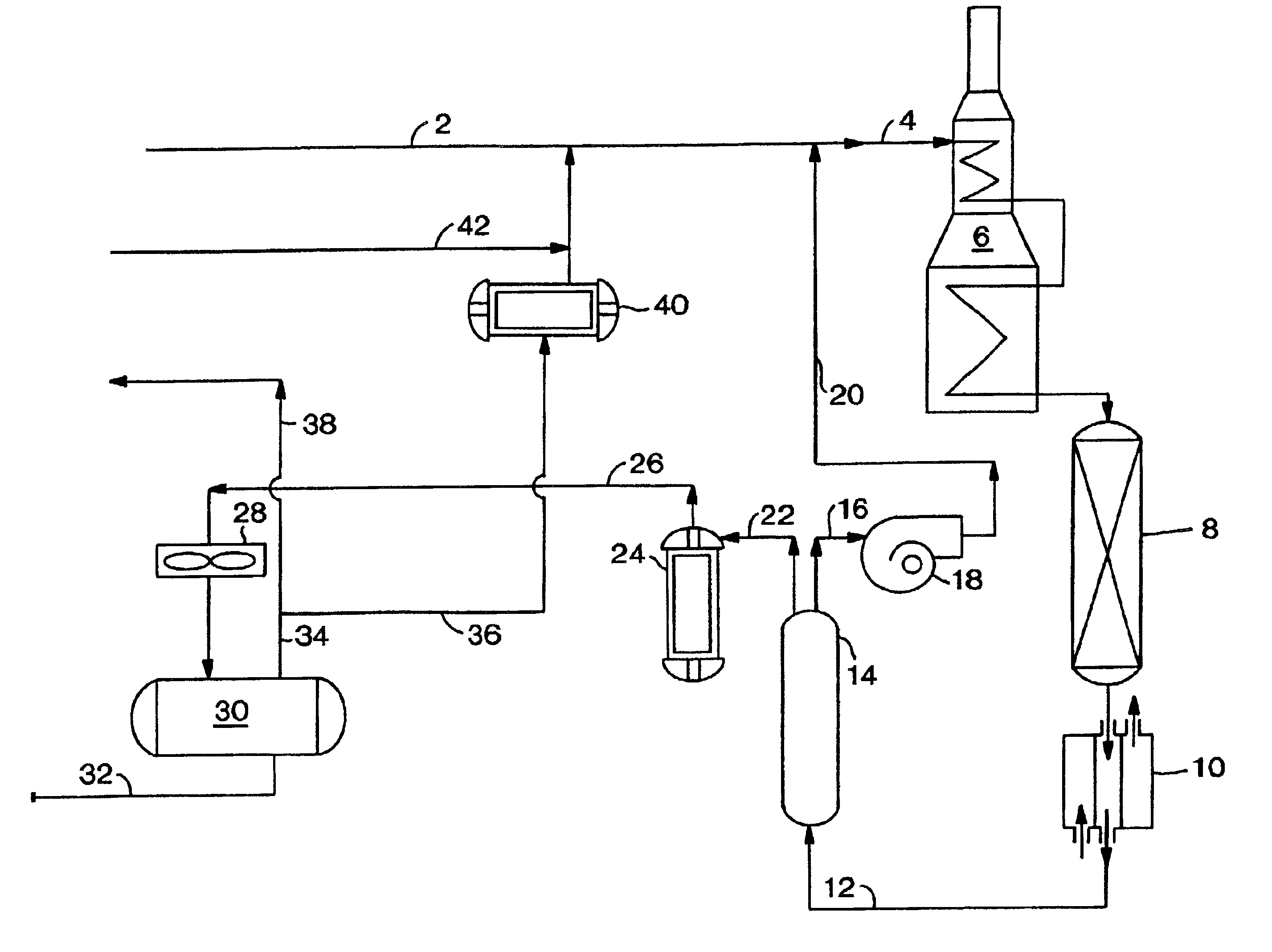

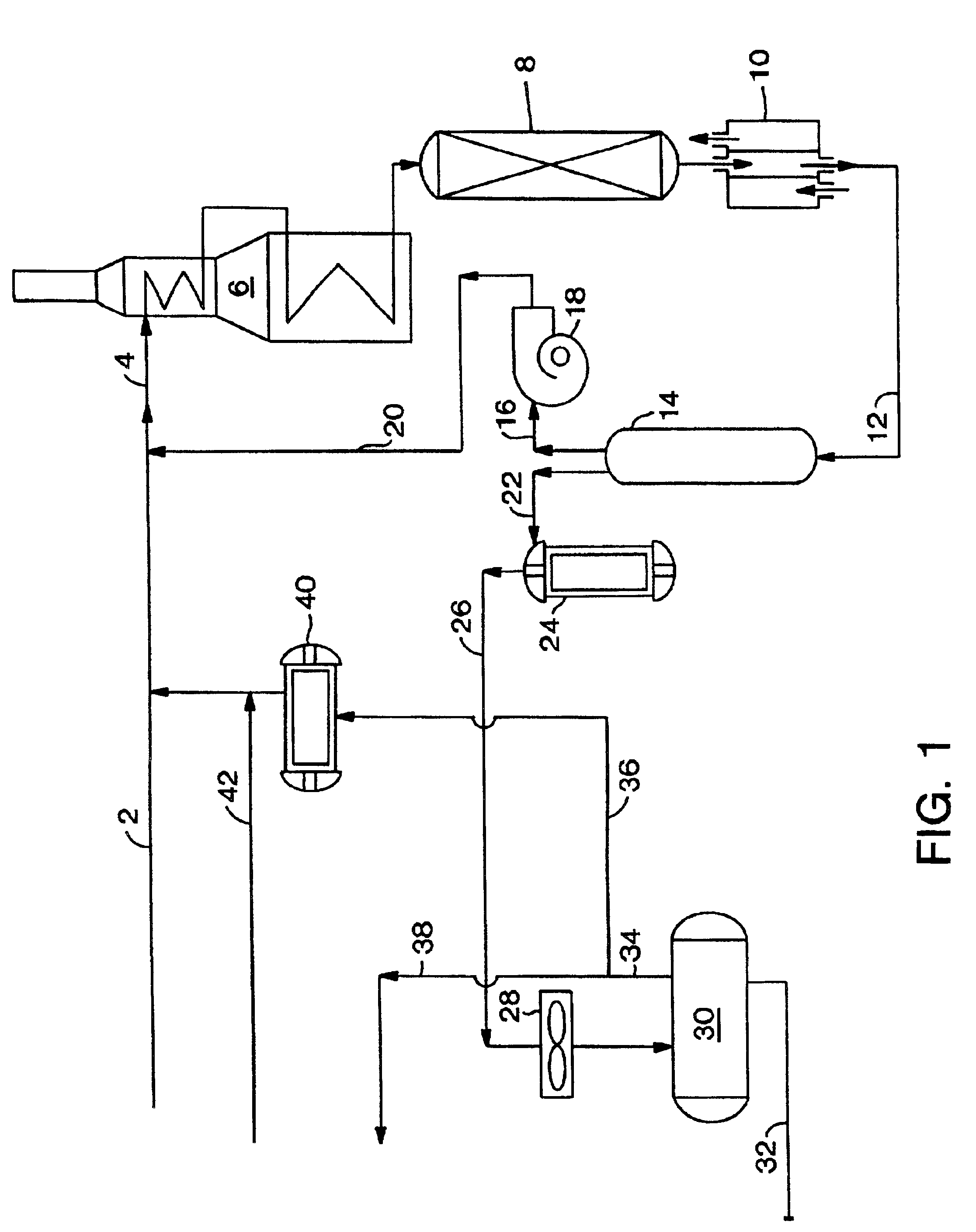

ActiveCN102533316AIncrease the potential content of aromaticsEnhance aromatizationMolecular sieve catalystsHydrocarbon oil crackingTreatment systemOxide

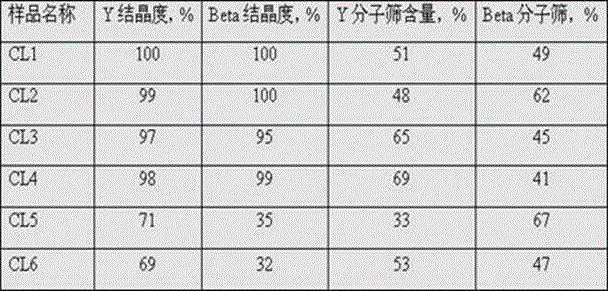

The invention relates to a method for selective hydrocracking of light oil. A catalyst used in the method comprises an acidic carrier and metal oxides NiO and WO3, wherein the acidic carrier comprises two porous beta / Y composite molecular sieves and a mesoporous amorphous silicon / aluminum, and the metal oxides are loaded on the acidic carrier; the two porous beta / Y composite molecular sieves are used for ammonium exchange and organic acid pretreatment, and the two treatment methods are carried out in one process; ammonium salt used in the ammonium exchange is NH4NO3 or NH4HCO3, and the mass ratio of the beta / Y composite molecular sieves and the ammonium salt solution is (1-10):1; the solution of one or mixture of any of citric acid, tartaric acid, acetic acid, malic acid and oxalic acid is used for treatment of the beta / Y composite molecular sieves, and the concentration of the organic acid in the treatment system is 0.5-2.0 mol.L-1; the potential content of aromatic hydrocarbon in heavy naphtha in products obtained in cracking is high, and the exhaust oil has a lower BMCI (Bureau of Mines Correlation Index) value.

Owner:PETROCHINA CO LTD +1

Light alkane isomerized ionic liquid catalyst and preparation method thereof

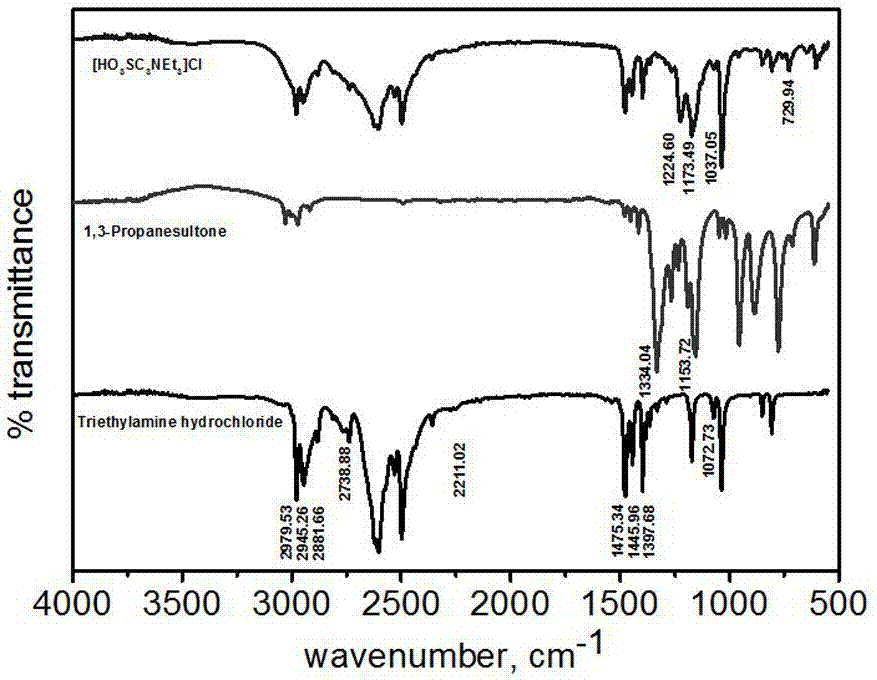

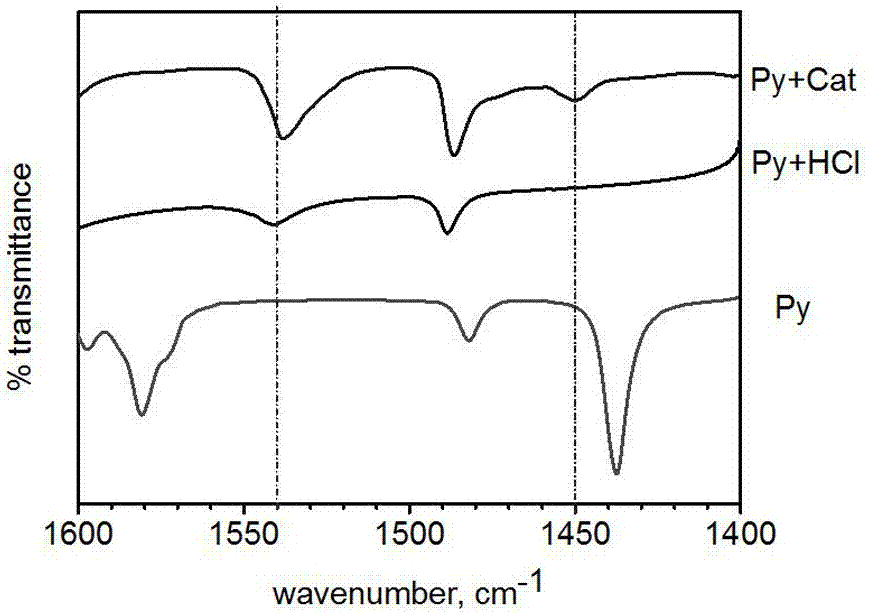

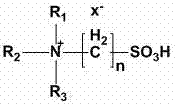

ActiveCN106964401AGood choiceHigh acid strengthOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oils refiningAlkaneIsomerization

The invention discloses a light alkane isomerized ionic liquid catalyst with a product distribution optimization function, and particularly relates to a preparation method of the Br-nsted-Lewis bi-acidity ionic liquid catalyst for catalyzing light alkane isomerization. Quaternary ammonium salt halide ionic liquid with kations partially containing sulfonate functional groups serves as a precursor to react with AlCl3 to form the ionic liquid catalyst with Br-nsted-Lewis bi-acidity performance. Compared with public ionic liquid catalysts for catalyzing light alkane isomerization, the catalyst prepared according to the method has the advantages of high hexane isomer selectivity, double-branch hexane isomer selectivity and liquid yield, so that the ionic liquid catalyst has better isomerization performance. In addition, the method has the advantages of simple process, simplicity and convenience in operation, low cost, good economic benefit and good industrialization potential.

Owner:FUZHOU UNIV

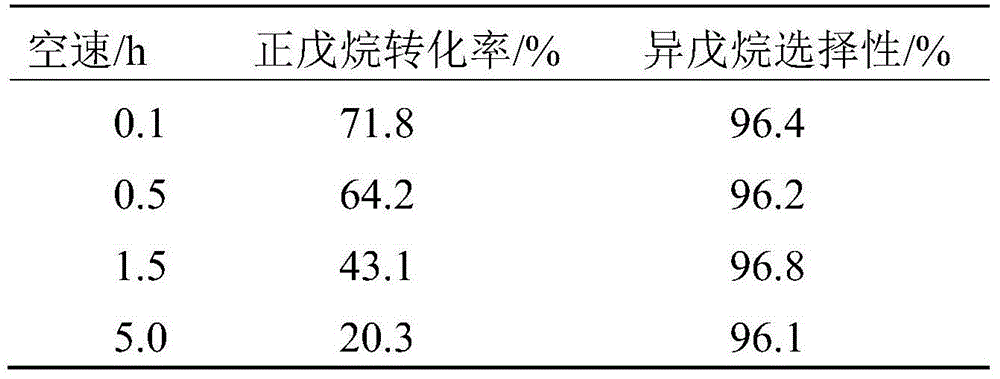

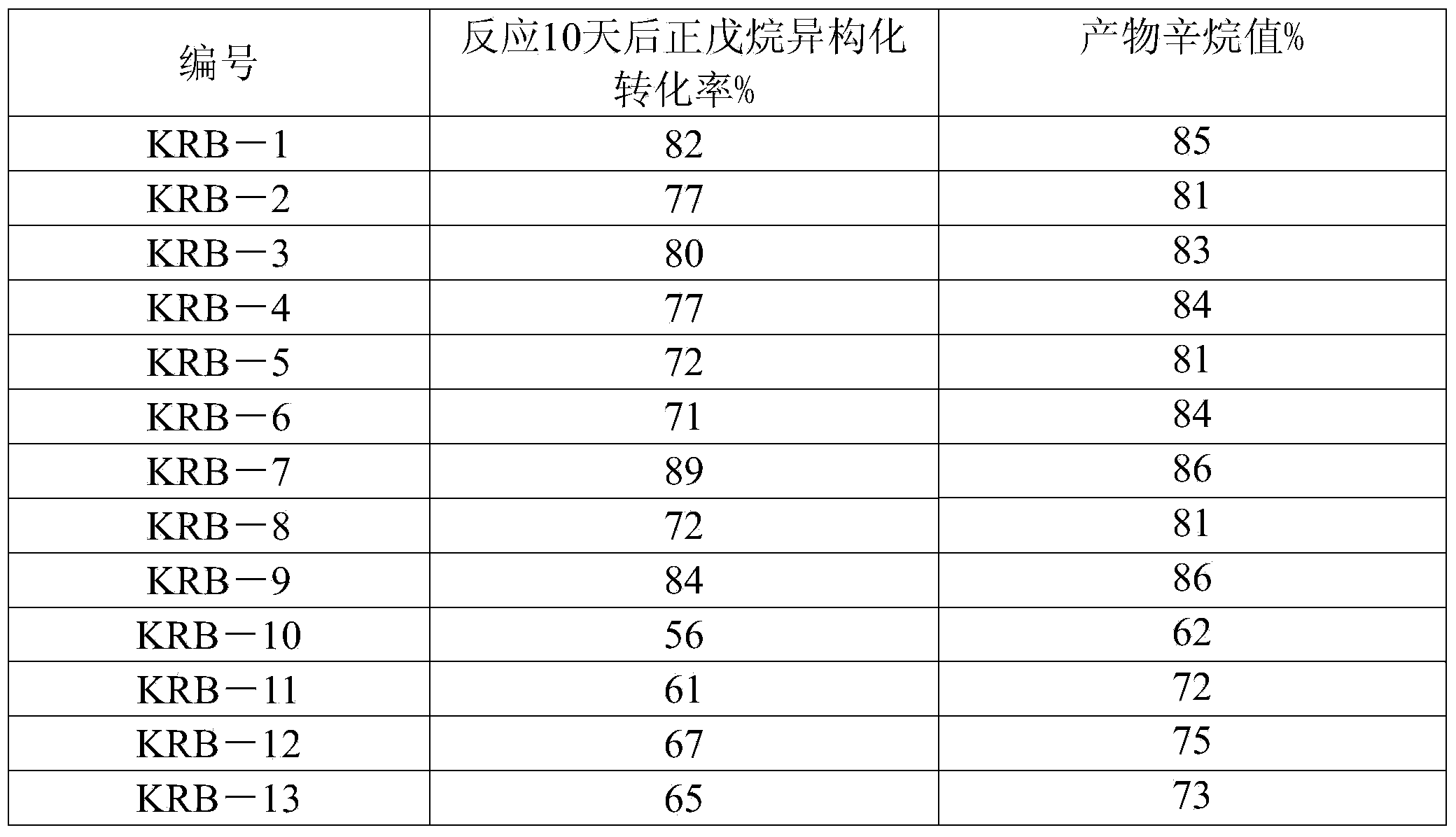

Solid superacid catalyst and preparation method thereof, and isomerization method of light n-alkanes

ActiveCN106140197AImprove stabilityExcellent isomerization performanceHydrocarbon by isomerisationPhysical/chemical process catalystsAlkaneIsomerization

The invention discloses a solid superacid catalyst and a preparation method thereof, and an isomerization method of light n-alkanes; the solid superacid catalyst comprises the following components: 5-20 wt% of W, 3-20 wt% of Ce, 3-20 wt% of Sn, 0.01-0.8 wt% of Pt, 1-10 wt% of SO4<2->, and the balance Zr with the balanced amount; the catalyst can be used for isomerization of C4-C8 n-alkanes, especially isomerization of C5 and C6 alkanes, and the reaction performance and stability of the catalyst can be significantly improved under hydroisomerization reaction conditions.

Owner:PETROCHINA CO LTD

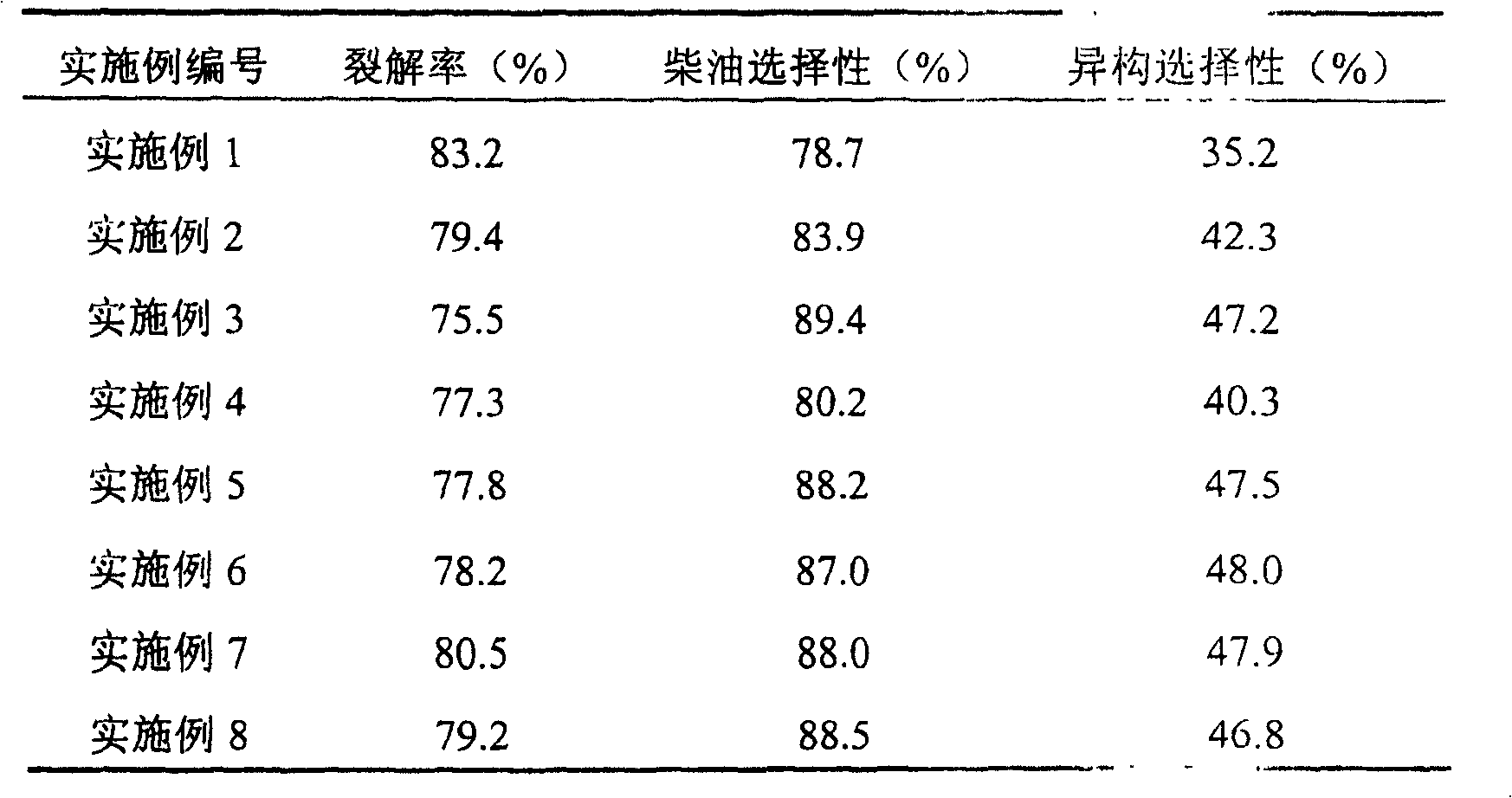

Hydrocracking catalyst for Tscher-Topsch synthesis of heavy wax, its preparation method and application thereof

The invention relates the hydrogenation-cracking catalyst used to synthesize heavy wax, comprising 10.0-24.0wt% HY molecular screen, 10.0-24.0wt% SAPO-11 molecular screen, 3.0-10.0wt% nickel oxide, 3.0-10.0wt% nickel oxide, 0.0-15.0wt% molybdenum oxide or tungsten oxide, 10.0-24.0wt% amorphous oxide compound and 5.0-65.0wt% diaspore. The method comprises preparing carrier and dipping active component. The catalyst has the advantages of good catalytic cracking property, high diesel selective, and good isomerization property.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Modified alumina composition and preparation thereof

ActiveCN1853774AGood linear olefin isomerization performanceExcellent isomerization performanceCatalytic crackingCatalyst activation/preparationAlkaneGasoline

A modified alumina composition used as the matrix of cracking catalyst to increase the content of isoalkane in gasoline contains alumina (80-99.5 Wt%) and silicon oxide (0.5-20 Wt%). Its preparing process includes such steps as adding the alkaline aqueous solution of silicate to the aqueous solution of Al salt for regulating pH value until gel is generated, heating the gel to 45-95 deg.C, ageing, filtering and washing.

Owner:CHINA PETROLEUM & CHEM CORP +1

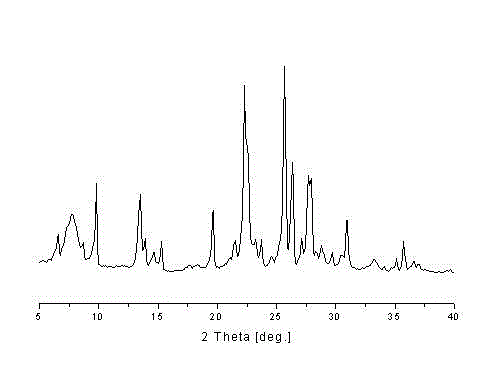

Preparation method of BETA-MOR symbiotic molecular sieve

ActiveCN103058220AExcellent isomerization performanceCo-growthMordenite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses a preparation method of a BETA-MOR symbiotic molecular sieve, which comprises the following steps: adding a BETA molecular sieve into an alkaline solution, stirring and mixing, and treating under sealed conditions to obtain a suspension product to serve as a structural guide agent; mixing inorganic alkali, aluminum source, silicon source and water according to a certain mol ratio to synthesize an initial silicon-aluminum gel; after evenly mixing, adding the structural guide agent; and after evenly mixing, carrying out two-step crystallization to obtain the BETA-MOR symbiotic molecular sieve. Compared with the process of directly adding the BETA molecular sieve crystal seed, the method disclosed by the invention greatly enhances the degree of crystallization of the BETA molecular sieve in the BETA-MOR symbiotic molecular sieve, and effectively avoids generation of stray crystals. The method disclosed by the invention is simple to operate and easy to implement, and the raw materials are cheap, accessible, nontoxic and harmless.

Owner:CHINA PETROLEUM & CHEM CORP +1

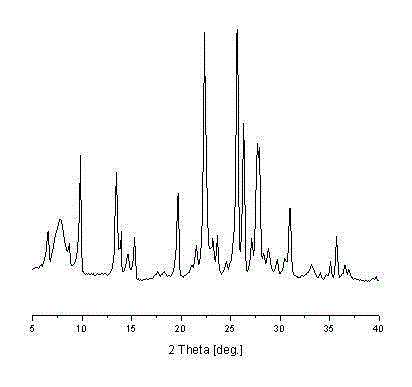

Hydro-upgrading catalyst for diesel oil with high content of aromatic hydrocarbons, and preparation method and application thereof

InactiveCN106853377AIncrease the speed of diffusionIncrease profitMolecular sieve catalystsHydrocarbon oil crackingLiquid productChemistry

The invention relates to a hydro-upgrading catalyst for diesel oil with high content of aromatic hydrocarbons, and a preparation method and application thereof. The catalyst comprises, by weight, 20 to 65% of a composite molecular sieve, 10 to 50% of alumina, 10 to 30% of VIB-group metal (in terms of oxide) and 3 to 8% of VIII-group metal (in terms of oxide), wherein the composite molecular sieve is composed of a small-grain modified Y molecular sieve and a SAPO-11 molecular sieve in a weight ratio of 2: 1 to 10: 1. The invention also discloses a preparation method for the small-grain modified Y molecular sieve. The preparation method comprises the following step: successively subjecting a raw material, i.e., a small-grain high-silica-alumina-ratio NaY molecular sieve with a SiO2 / Al2O3 mol ratio of 6.0 to 7.0, to primary ammonium exchanging, primary hydro-thermal treatment, secondary ammonium exchanging, secondary hydro-thermal treatment and primary acid treatment. With the catalyst prepared in the invention, high liquid product yield is obtained, and diesel oil with high content of aromatic hydrocarbons can be used for production of low-sulfur olefin-free high-octane-number gasoline and ultra-low-sulfur clean diesel oil.

Owner:PETROCHINA CO LTD

Synthesis method of BETA-MOR composite molecular sieve

ActiveCN103058212AThe preparation process is environmentally friendlyEasy to operateCrystalline aluminosilicate zeolitesEnvironmental resistanceMolecular sieve

The invention discloses a synthesis method of a BETA-MOR composite molecular sieve, which comprises the following steps: treating mordenite with an alkaline solution to serve as a structural guide agent; mixing inorganic alkali, silicon source, aluminum source and water to obtain a silicon-aluminum gel; and adding the structural guide agent, adding a BETA molecular sieve, and carrying out hydrothermal crystallization to obtain the BETA-MOR composite molecular sieve. The synthetic raw materials used by the method are conventional inorganic materials without any expensive template agent; the whole preparation process is green and environment-friendly; and the operation steps are simple and easy to implement.

Owner:CHINA PETROLEUM & CHEM CORP +1

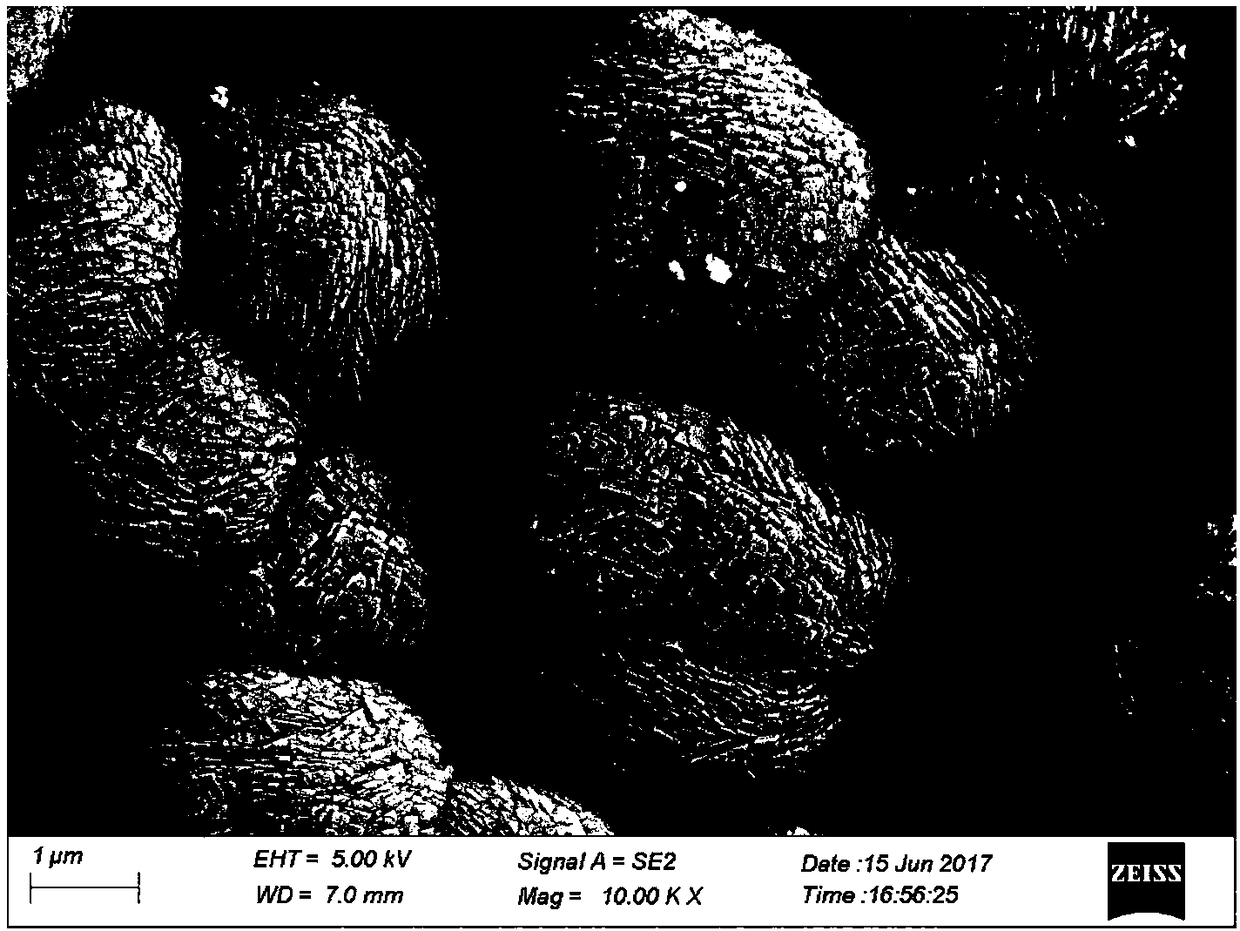

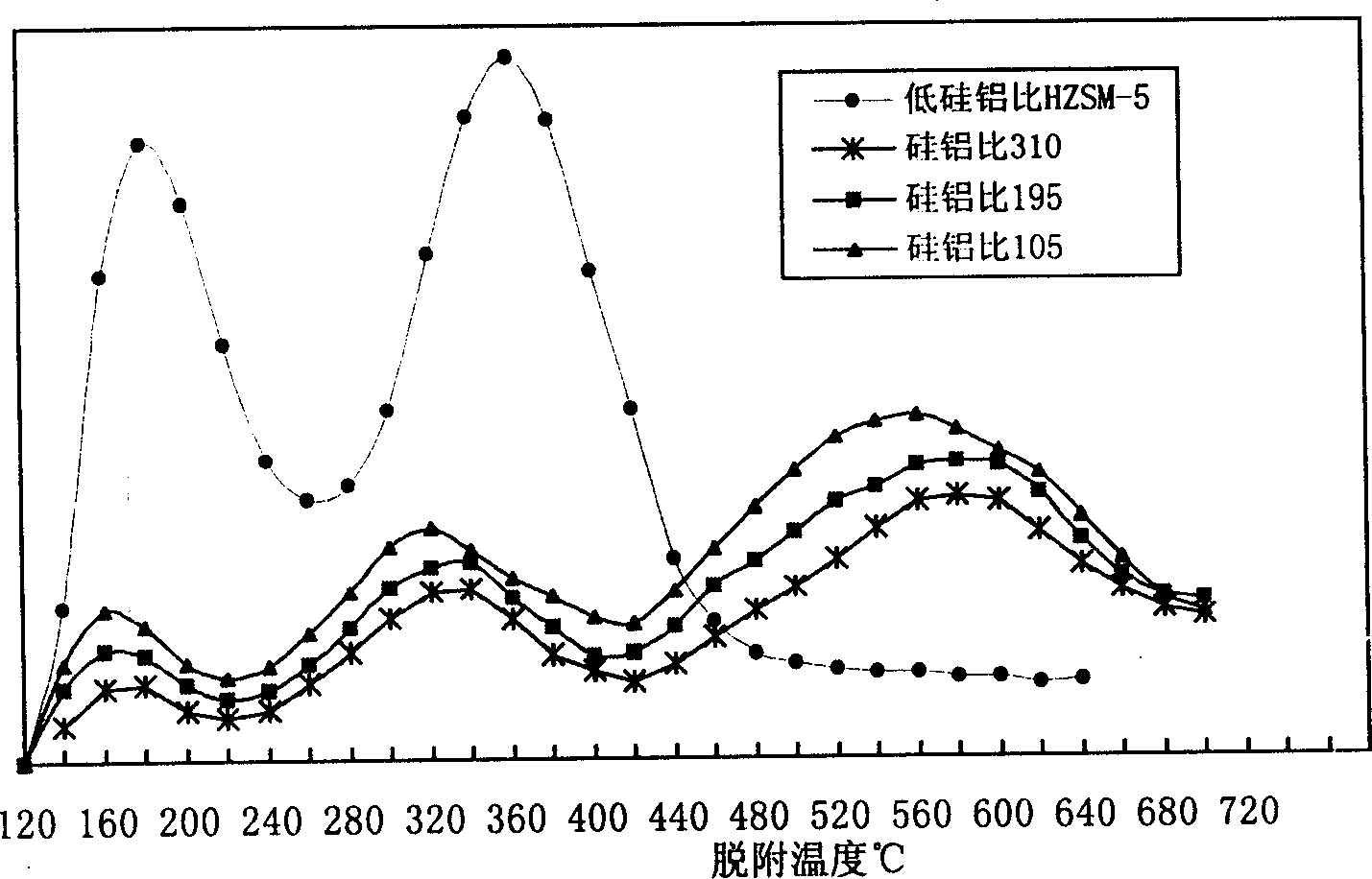

Low-silicon multistage structure ZSM-5 zeolite molecular sieve, and preparation method and application thereof

ActiveCN108178163AIncrease acidityExcellent mass transfer and diffusion propertiesMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sieveZSM-5 zeolite

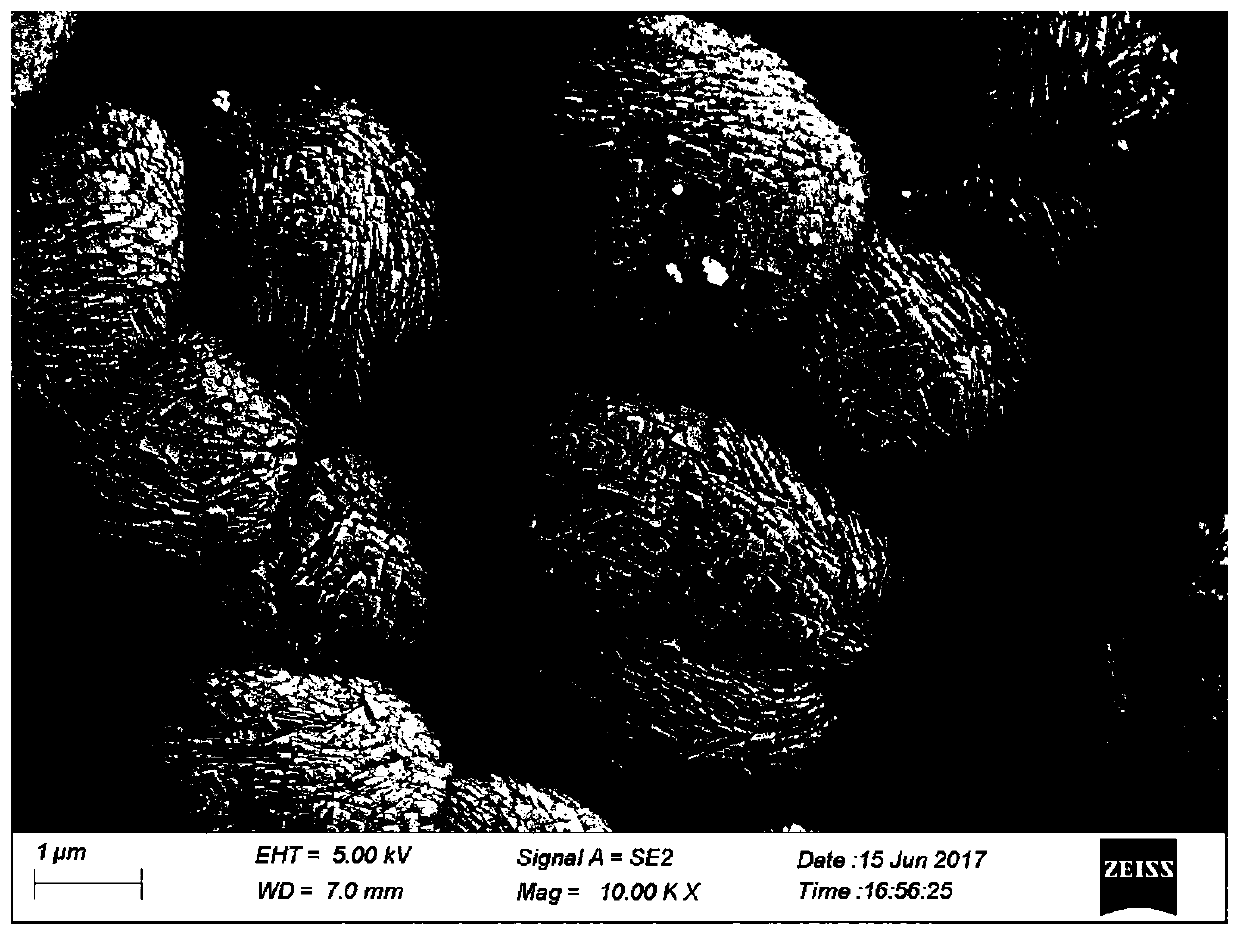

The invention relates to a low-silicon multistage structure ZSM-5 zeolite molecular sieve, and a preparation method and application thereof. The low-silicon multistage structure ZSM-5 zeolite molecular sieve is provided with a micropore-mesoporous multistage structure, wherein a one-time particle size is smaller than 300nm, and a secondary accumulation particle size is 300nm-4mu m; the silica-alumina ratio of the ZSM-5 zeolite molecular sieve is 10-80, the outer superficial area is greater than 100m<2> / g, mesoporous volume is not smaller than 0.1cm<3> / g, and total acid content is greater than1.5mmol / g. The low-silicon multistage structure ZSM-5 zeolite molecular sieve is high in acid content and reaction activity, more mesoporouses enable a reactant or products to be quickly diffused, side reaction and carbon deposition generation can be reduced, the carbon containing ability of the molecular sieve is increased, and the service life of the molecular sieve is prolonged.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Isomerization catalyst and preparation method thereof

InactiveCN105833900AImprove stabilityExcellent isomerization performanceHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationRare earth

The invention discloses an isomerization catalyst and a preparation method thereof. The isomerization catalyst is prepared from, by weight, 5-10 parts of tin oxide, 3-5 parts of titanium oxide, 4-8 parts of iron oxide, 3-8 parts of manganese oxide, 10-15 parts of silica, 10-15 parts of rare earth oxide, 8-10 parts of alkali earth oxide, 3-6 parts of titanium dioxide, 4-6 parts of tungsten trioxide, 4-8 parts of vanadium pentoxide, 4-6 parts of silicon fluoride, 2-3 parts of molecular sieve, 5-12 parts of silicon tetrachloride, 8-10 parts of titanium tetrachloride and 6-8 parts of a binder. The catalyst prepared through adopting the above technical scheme has 80% or above higher stability than present catalysts, and the stability of the catalyst in reactions can last for 1000h or above.

Owner:SHANDONG CHENGTAI CHEM IND

Hydrocarbon catalytic cracking catalyst and its preparation method

InactiveCN1478860AHigh cracking performance and isomerization performanceGood light oil yieldCatalytic crackingMolecular sieve catalystsMolecular sieveHydrocarbon

A catalyst for catalytic cracking of hydrocarbons contains carrier, adhesive, active cracking component and active isomerizing component. It features that said active isomerizing component is composed of modified HZSM-5 molecular sieve with high Si / Al ratio and small grain modified Y-type molecular sieve. Its advantages are high output rate of light oil, and high octane number of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP

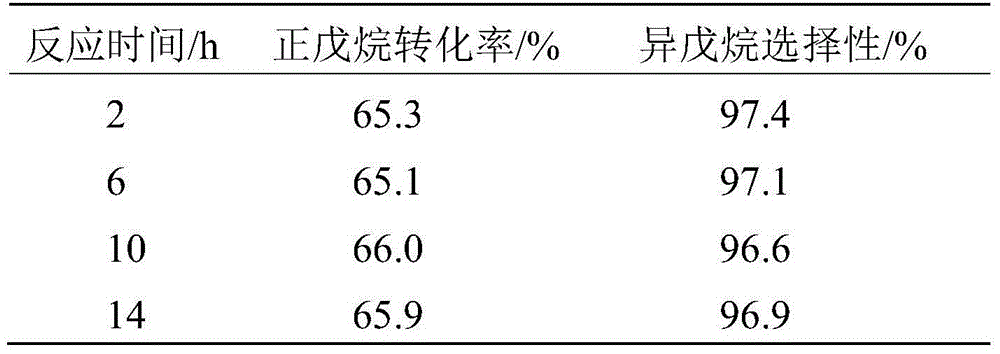

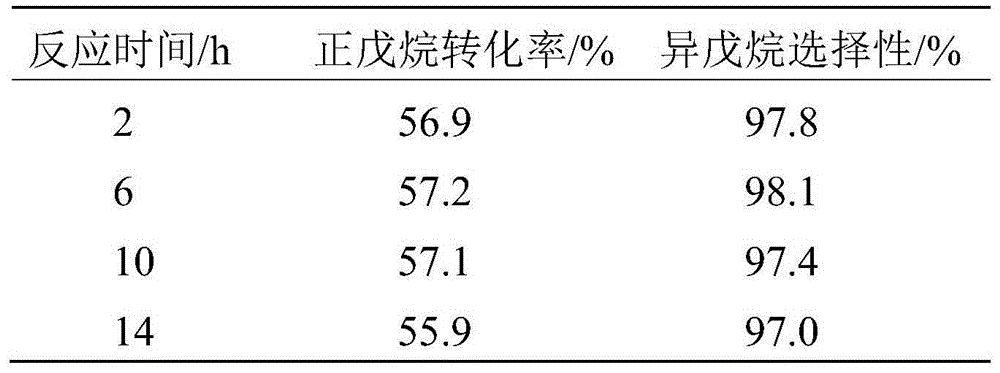

Preparation method of light alkane isomerization catalyst and isomerization method of light alkane

ActiveCN106140198AImprove stabilityExcellent isomerization performanceHydrocarbon by isomerisationPhysical/chemical process catalystsAlkaneIsomerization

The invention discloses a preparation method of a light n-alkane isomerization catalyst and an isomerization method of the light n-alkane. In the invention, a solid super-acidic catalyst is synthesized through a co-precipitation method and a hydrothermal method, wherein the catalyst is used for isomerization of C4-C8 n-alkanes, especially, n-pentane. Hydrogen exists in a reaction atmosphere, thus significantly improving reaction performance and stability of the catalyst. The n-alkane isomerization catalyst and the reaction process therewith are free of environment pollution and device corrosion, has high activity and selectivity, and has stable reaction performance.

Owner:PETROCHINA CO LTD

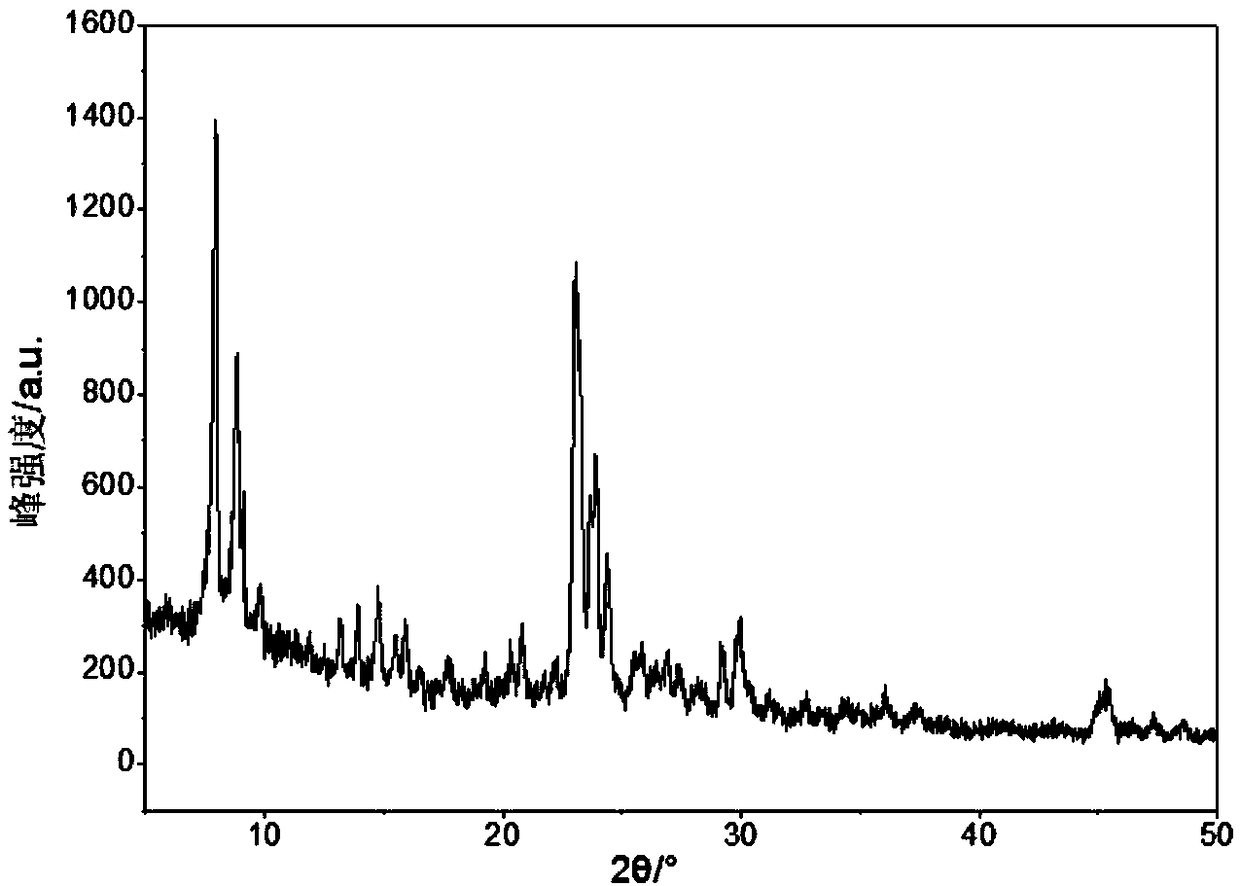

Preparation method of hydroisomerization/cracking catalyst

ActiveCN109420523AAdjustment of acid strength distributionIncrease acidityMolecular sieve catalystsHydrocarbon oils refiningWaxMolecular sieve

The invention relates to a preparation method of a hydroisomerization / cracking catalyst. The method includes the following concrete steps: treating a potassium type or sodium type ZSM-22 / ZSM-23 composite molecular sieve containing a template with an alkali solution of a certain concentration; washing an obtained product with deionized water and drying and roasting to remove the template; exchanging by using an ammonium nitrate solution, filtering, washing with deionized water, and drying and roasting to prepared a hydrogen type ZSM-22 / ZSM-23 composite molecular sieve; mixing kneading, formingand roasting the hydrogen type ZSM-22 / ZSM-23 composite molecular sieve, amorphous oxides and an acid solution to prepare a carrier; and immersing the carrier into an aqueous solution of soluble saltscontaining active components, and then drying and roasting to prepare the catalyst. Compared with a catalyst used by the prior art, the catalyst provided by the invention has better catalytic activityand target product selectivity in a hydroisomerization conversion process of Fischer-Tropsch synthetic wax.

Owner:PETROCHINA CO LTD +1

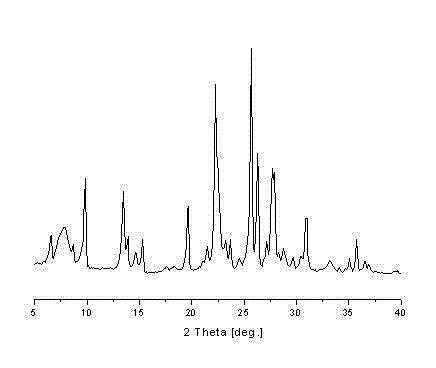

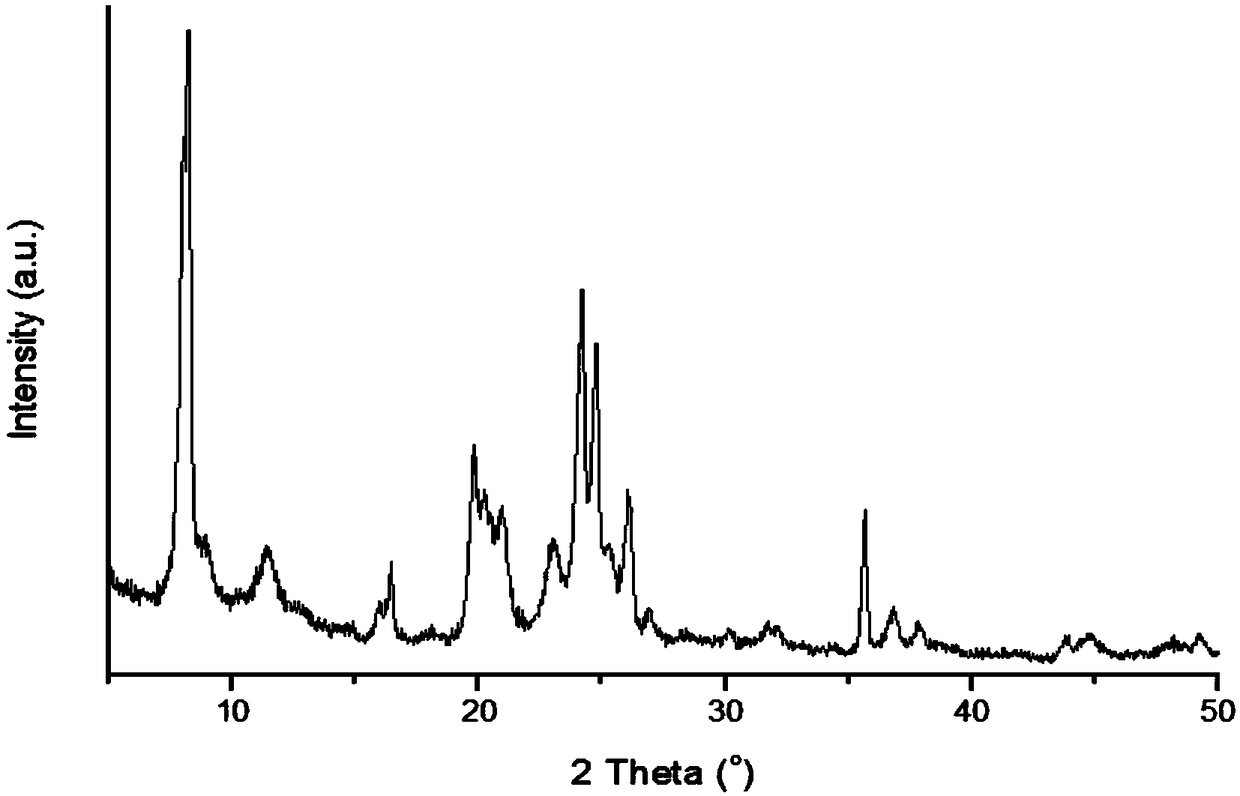

Isomerization catalyst and preparation method and application thereof

ActiveCN109395772AExcellent isomerization performanceEmission reductionHydrocarbon by isomerisationMolecular sieve catalystsMolecular sievePtru catalyst

The invention provides an isomerization catalyst and a preparation method and application thereof. The preparation method of the isomerization catalyst comprises the following steps: (1), mixing a rawmaterial for preparing an SAPO-11 molecular sieve and an active metal precursor of the isomerization catalyst to obtain a mixture A; (2), mechanically mixing the mixture A to obtain a gelatinous substance; (3), crystallizing the gelatinous substance, and washing, drying and calcinating a crystallized product to obtain the isomerization catalyst. According to a scheme provided by the invention, atechnology is simple and time-saving, and water is not required to be externally added as a mixed medium, so that a water resource is saved, sewage discharge is reduced and the environment is protected; the metal precursor is introduced into a carrier synthesizing system to achieve one-step synthesis of the catalyst, so that the drying and calcinating processes during metal loading are omitted andthe energy consumption is lowered; meanwhile, the catalyst shows relatively high n-hexane conversion rate and isomer selectivity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

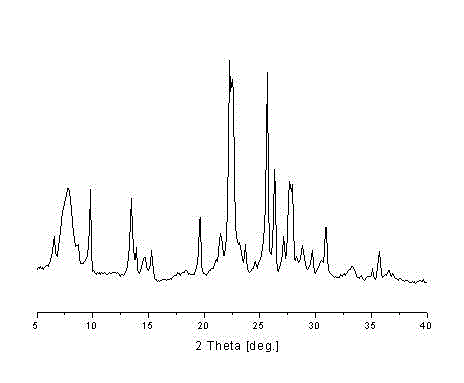

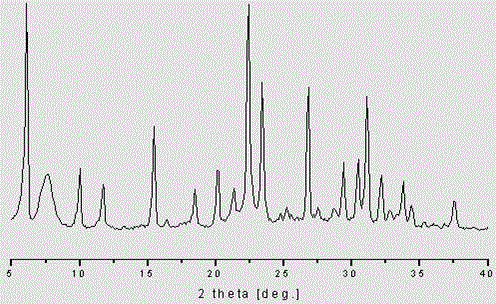

Beta-Y composite molecular sieve and synthetic method thereof

ActiveCN104591219AExcellent isomerization performanceGood physical propertiesFaujasite aluminosilicate zeoliteMolecular sieveCrystal structure

The invention provides a Beta-Y composite molecular sieve. The Beta-Y composite molecular sieve has the following two crystal forms at the same time: a Y type molecular sieve and a Beta molecular sieve. The invention also provides a synthetic method for the Beta-Y composite molecule sieve. The synthetic method comprises the following steps: (1) preparing a Y structure-directing agent; (2) adding the Beta molecular sieve into a glucose solution for pretreatment; (3) mixing a silicon source, an aluminum source, inorganic base and water and adding the Y structure-directing agent; and (4) adding the treated Beta molecular sieve under stirring, carrying out crystallization and then carrying out separating, washing, drying and roasting so as to obtain the Beta-Y composite molecular sieve. According to the invention, glucose is introduced into the micro pore channels of the Beta molecular sieve and becomes carbon after roasting; the carbon occupies the pore channels of the Beta molecular sieve to prevent alkali from entering the interior of Beta molecular sieve crystals, so the Beta molecular sieve is not destroyed in the process of crystallization and the integrity of crystal structure is maintained, which are beneficial for improvement of the physical and chemical properties and the catalytic activity of the Beta-Y composite molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

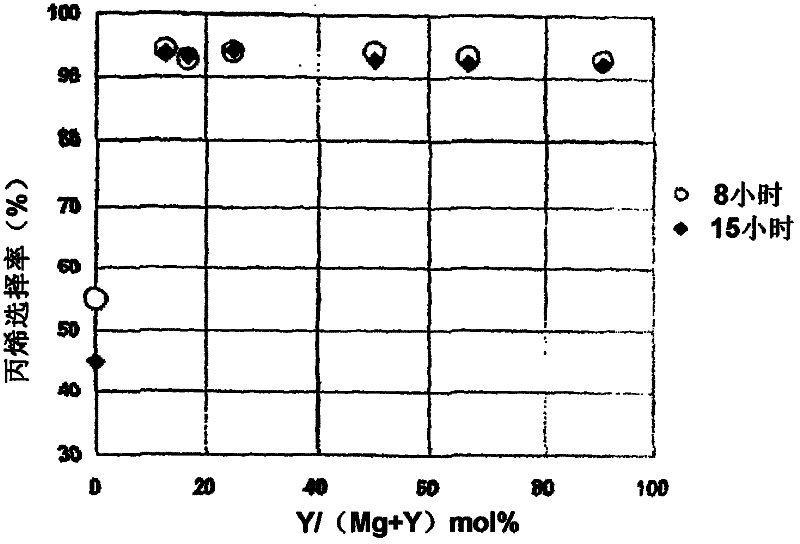

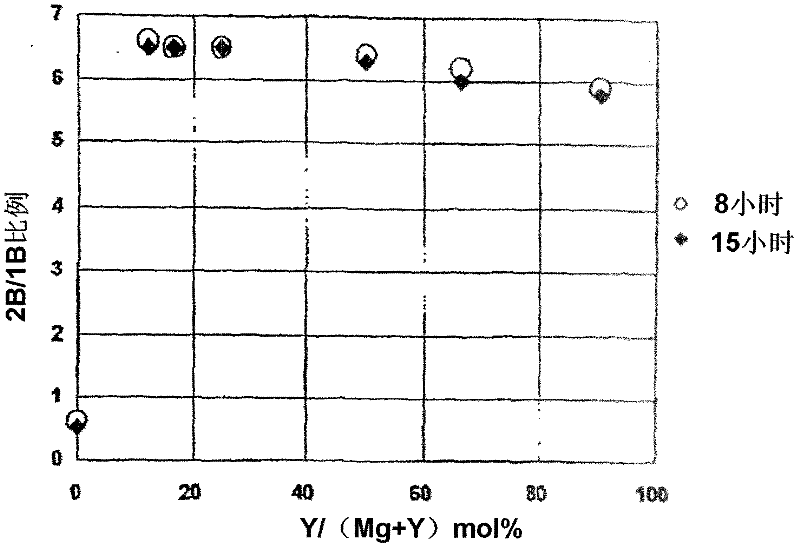

Method for manufacturing olefin

InactiveCN102361840AHigh selectivityReduce usageHydrocarbon by isomerisationOrganic chemistry methodsRheniumProduction rate

Disclosed is a process for producing an olefin, in which the double bond isomerization of starting material olefins can be promoted to inhibit a metathesis reaction, which is a side reaction, thereby increasing the selectivity for the desired product. Also disclosed is a process for producing an olefin, in which the activity of a metathesis catalyst can be maintained for a long period and the deterioration in performance of a catalyst for promoting the double bond isomerization of the starting material olefins (i.e., an isomerization catalyst) can be prevented, thereby producing the desired product with high productivity and high efficiency. Specifically disclosed is a process for producing an olefin, which comprises reacting the same types or different types of raw material olefins with each other to produce an olefin having a different structure from those of the starting material olefins, which is characterized by using both a catalyst comprising at least one metal element selected from tungsten, molybdenum and rhenium and another specific catalyst.

Owner:MITSUI CHEM INC

Hydrocracking catalyst for Tscher-Topsch synthesis of heavy wax, its preparation method and application thereof

The invention relates the hydrogenation-cracking catalyst used to synthesize heavy wax, comprising 10.0-24.0wt% HY molecular screen, 10.0-24.0wt% SAPO-11 molecular screen, 3.0-10.0wt% nickel oxide, 3.0-10.0wt% nickel oxide, 0.0-15.0wt% molybdenum oxide or tungsten oxide, 10.0-24.0wt% amorphous oxide compound and 5.0-65.0wt% diaspore. The method comprises preparing carrier and dipping active component. The catalyst has the advantages of good catalytic cracking property, high diesel selective, and good isomerization property.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

A kind of low-silicon multi-level structure ZSM-5 zeolite molecular sieve and its preparation method and application

ActiveCN108178163BImprove diffusivityHigh reactivityMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sieveCarbon deposit

The invention relates to a low-silicon multistage structure ZSM-5 zeolite molecular sieve, and a preparation method and application thereof. The low-silicon multistage structure ZSM-5 zeolite molecular sieve is provided with a micropore-mesoporous multistage structure, wherein a one-time particle size is smaller than 300nm, and a secondary accumulation particle size is 300nm-4mu m; the silica-alumina ratio of the ZSM-5 zeolite molecular sieve is 10-80, the outer superficial area is greater than 100m<2> / g, mesoporous volume is not smaller than 0.1cm<3> / g, and total acid content is greater than1.5mmol / g. The low-silicon multistage structure ZSM-5 zeolite molecular sieve is high in acid content and reaction activity, more mesoporouses enable a reactant or products to be quickly diffused, side reaction and carbon deposition generation can be reduced, the carbon containing ability of the molecular sieve is increased, and the service life of the molecular sieve is prolonged.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Light-hydrocarbon isomerization catalyst and method for preparing same

InactiveCN103464210AExcellent isomerization performanceLarge specific surface areaHydrocarbon by isomerisationCatalyst carriersHydrogen fluoridePolymer science

The invention discloses light-hydrocarbon isomerization catalyst and a method for preparing the light-hydrocarbon isomerization catalyst. Resin ribbon ball-shaped active carbon having high specific surface area and a micro-hole structure serves as the carrier, is roasted under high temperature and is activated through hydrogen fluoride to obtain a carrier with high specific surface area and a mesoporous structure, palladium loading is then carried out according to a liquid phase deposition method, and modifying is carried out through fluorine-containing chlorides at the same time to obtain the light-hydrocarbon isomerization catalyst. The light-hydrocarbon isomerization catalyst has extremely large specific surface area and a proper hole structure, and has good isomerization performance after modifying is carried out through the fluorine-containing chlorides. High activity of the light-hydrocarbon isomerization catalyst can still be kept after long-period operation and the light-hydrocarbon isomerization catalyst is long in service life.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

A kind of preparation method of hydroisomerization/cracking catalyst and catalyst

ActiveCN105749964BExcellent isomerization performanceImprove cracking performanceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveWax

The invention relates to a preparation method of a hydroisomerization / cracking catalyst. The specific steps are as follows: the sodium-type ZSM-23 molecular sieve containing the template is treated with a certain concentration of alkali solution; the obtained product is washed with deionized water, dried and roasted to remove the template; then exchanged with ammonium nitrate solution, filtered, and washed with deionized water, dried and roasted to make hydrogen ZSM‑23 molecular sieve; kneading, molding and roasting hydrogen ZSM‑23 molecular sieve with amorphous oxide and acid solution to make carrier; impregnating the carrier in soluble salt in an aqueous solution, and then dried and calcined to obtain the catalyst. Compared with the catalysts used in the prior art, the catalyst provided by the invention has better catalytic activity and target product selectivity when used in the conversion process of Fischer-Tropsch synthesis wax.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

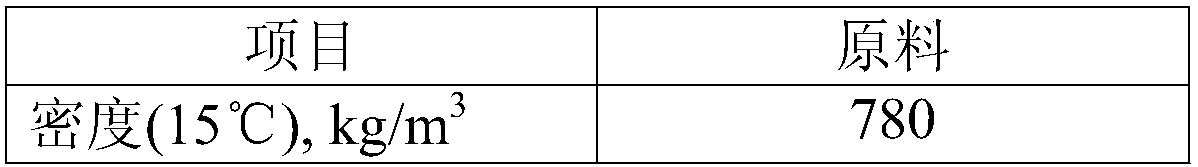

Bimetal supported catalyst, preparation method thereof and application of bimetal supported catalyst in preparation of biological aviation kerosene through hydrogenation conversion of palm oil

PendingCN114522716AThe preparation process is green and simpleLow costFatty acid hydrogenationMolecular sieve catalystsPtru catalystIsomerization

The invention designs and prepares a non-noble bimetal supported catalyst suitable for preparing biological aviation kerosene through grease hydro-conversion, and the non-noble bimetal supported catalyst is applied to palm oil hydrodeoxygenation and cracking / isomerization reaction to produce biological aviation kerosene in a C8-C16 hydrocarbon range. According to the bimetal supported catalytic material prepared by taking nickel as a main metal, adding a second transition metal and supporting the nickel on an acidic carrier in an alkali liquor precipitation manner, the metal is highly dispersed on the surface of the carrier, the hydrodeoxygenation performance of the catalyst is greatly improved, and in hydrodeoxygenation and cracking isomerization reactions of palm oil, the grease conversion rate reaches up to 100%, and the grease conversion rate reaches up to 100%. The yield of the biological aviation kerosene can reach 60%, and the carbon loss is reduced, so that the method has a good application prospect in a process for producing the biological aviation kerosene through oil hydrogenation conversion.

Owner:FUZHOU UNIV

Mordenite-Beta molecular sieve-Y molecular sieve composite material and synthesis method

ActiveCN104549464AGood hydrocarbon molecular crackingExcellent isomerization performanceCatalyst carriersMolecular sieve catalystsPore distributionMolecular sieve

The invention provides a mordenite-Beta molecular sieve-Y molecular sieve composite material and a synthesis method thereof. The mordenite-Beta molecular sieve-Y molecular sieve composite material contains a Y molecular sieve, a Beta molecular sieve and mordenite, takes a Y molecular sieve as a core, and the Beta molecular sieve and mordenite as a shell, and the Beta molecular sieve and mordenite coexist in the shell. The synthesis method of the composite molecular sieve material comprises the following steps: performing ultrasonic and thermal treatment to the nano-beta molecular sieve, nanometer mordenite and the Y molecular sieve, then mixing the treated zeolite mixture with inorganic base, distilled water, a template agent, an aluminum source and a silicon source, and synthesizing the mordenite-Beta molecular sieve-Y molecular sieve composite material by adopting a vapor phase method. The MOR-Beta-Y molecular sieve composite material has more reasonable acid property and pore distribution, and higher catalysis performance can be provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com