Patents

Literature

410results about How to "Improve hydrogenation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrocracking catalyst containing Y molecular sieve and preparation method thereof

ActiveCN101450320AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

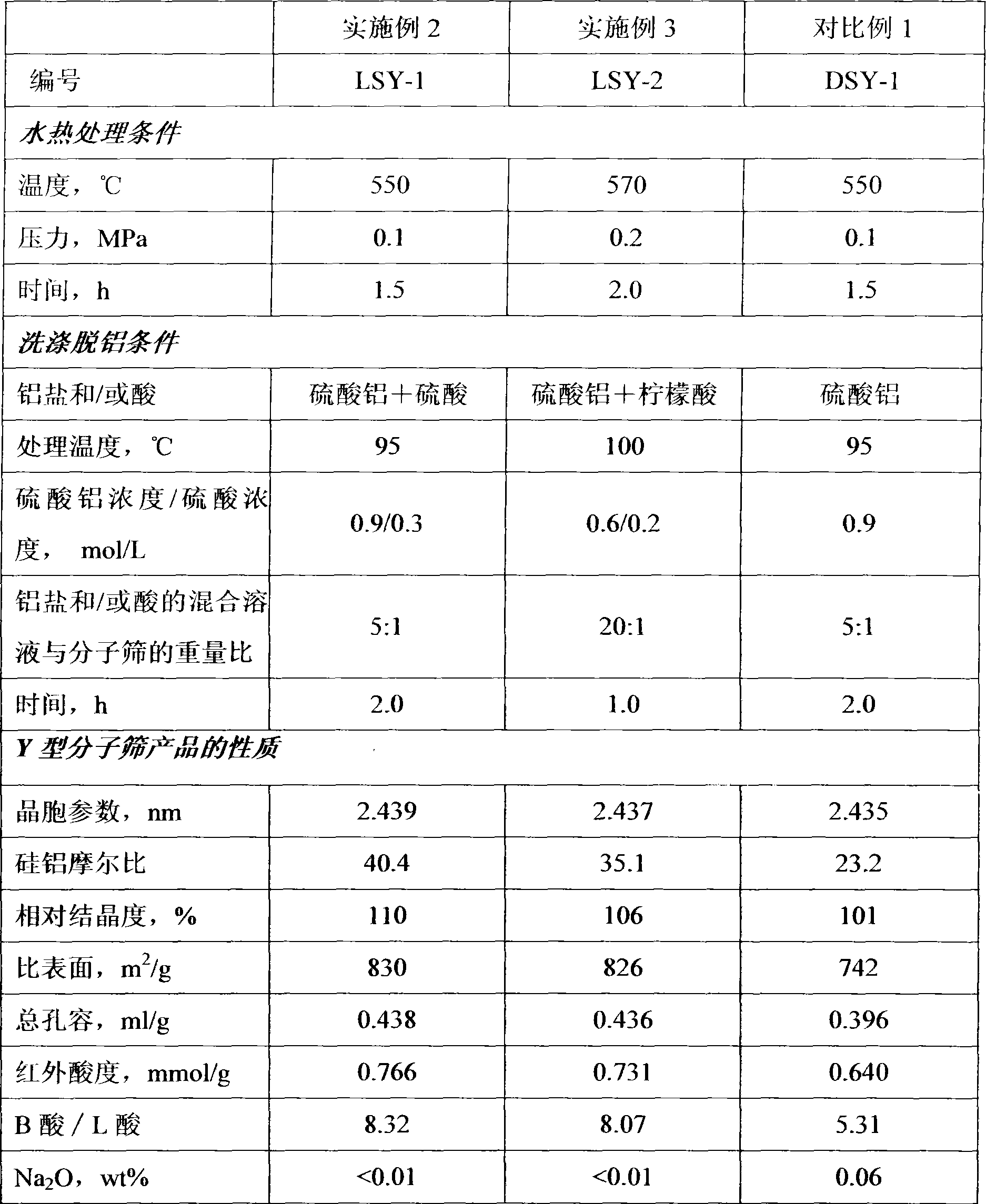

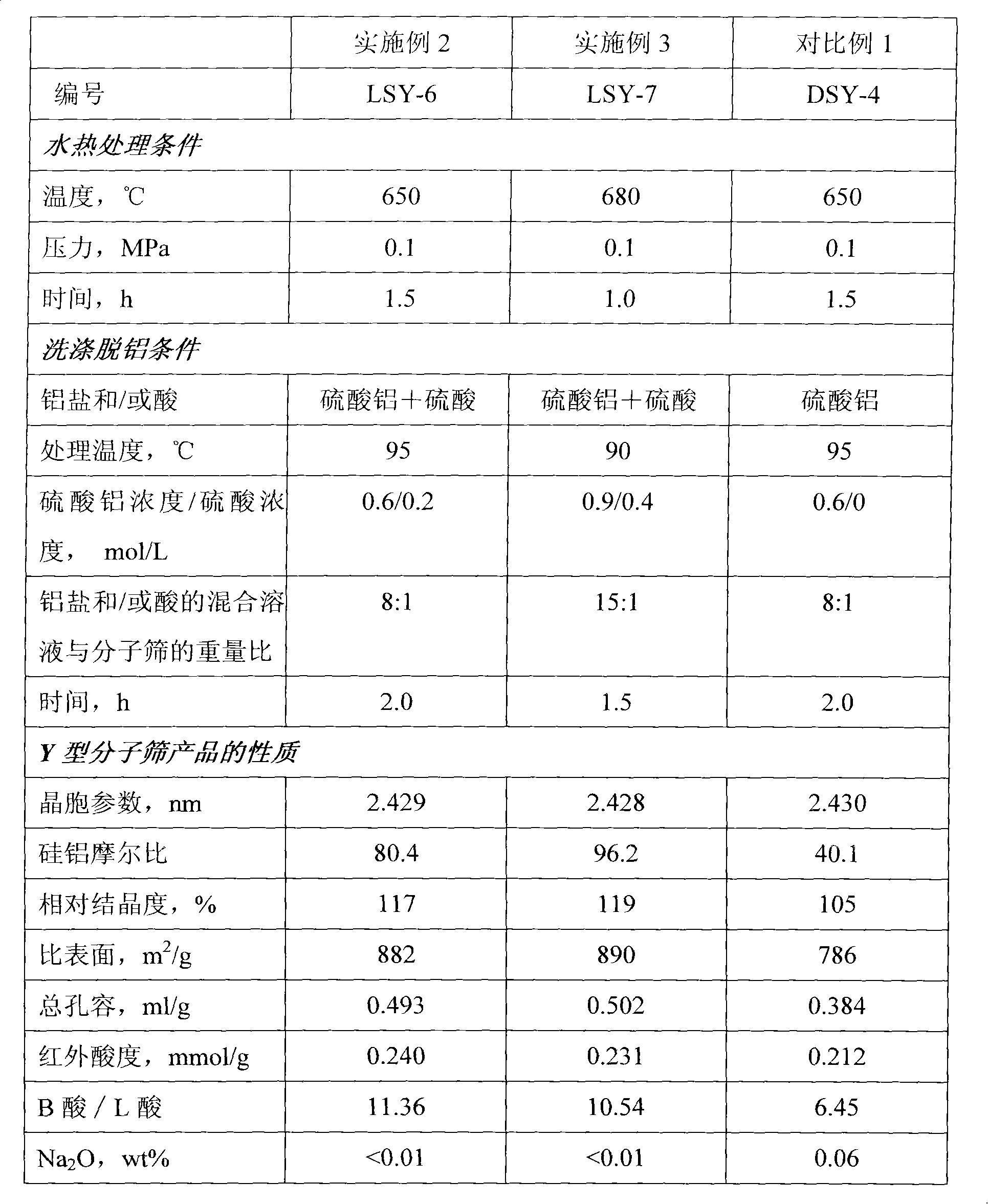

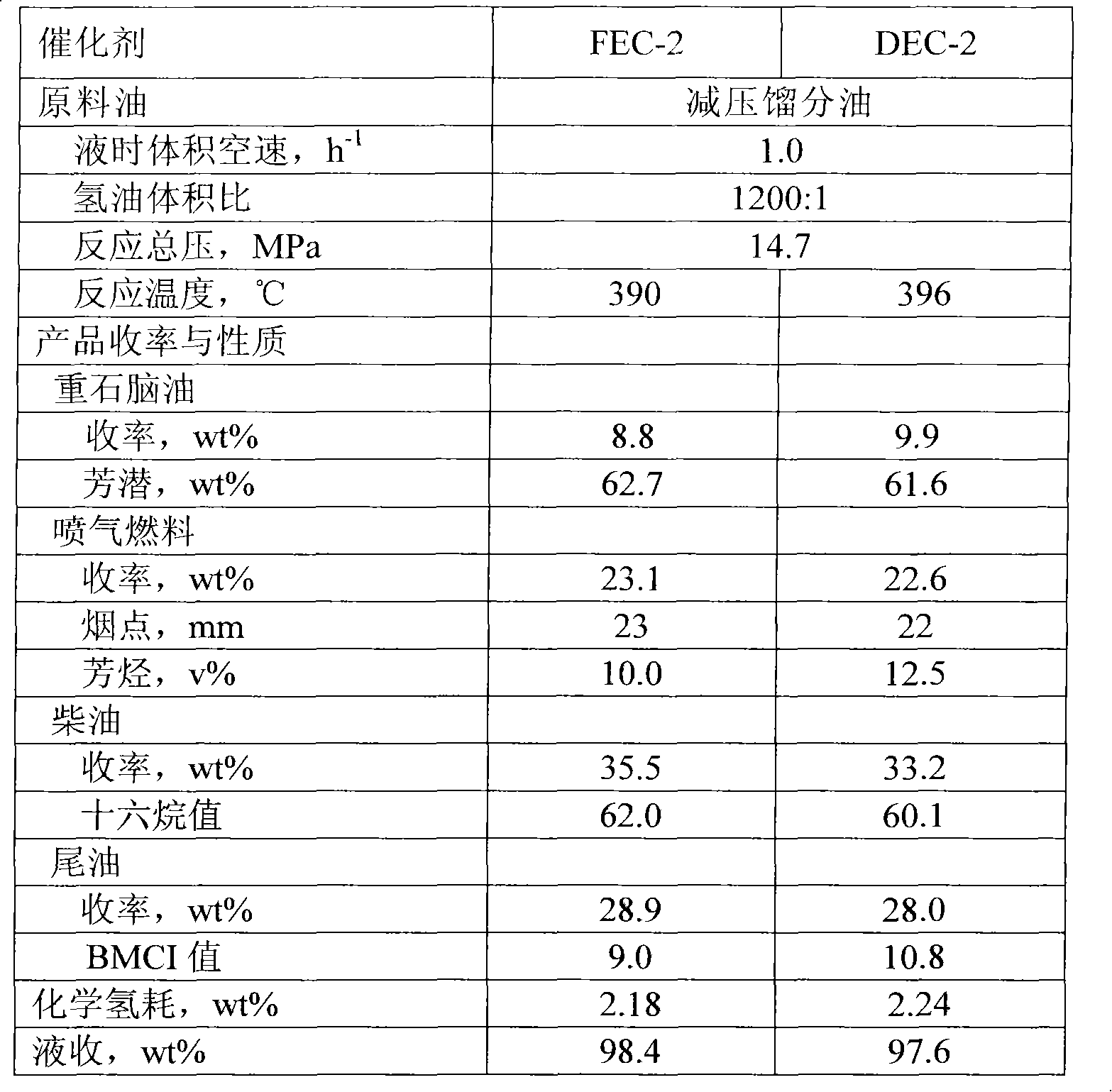

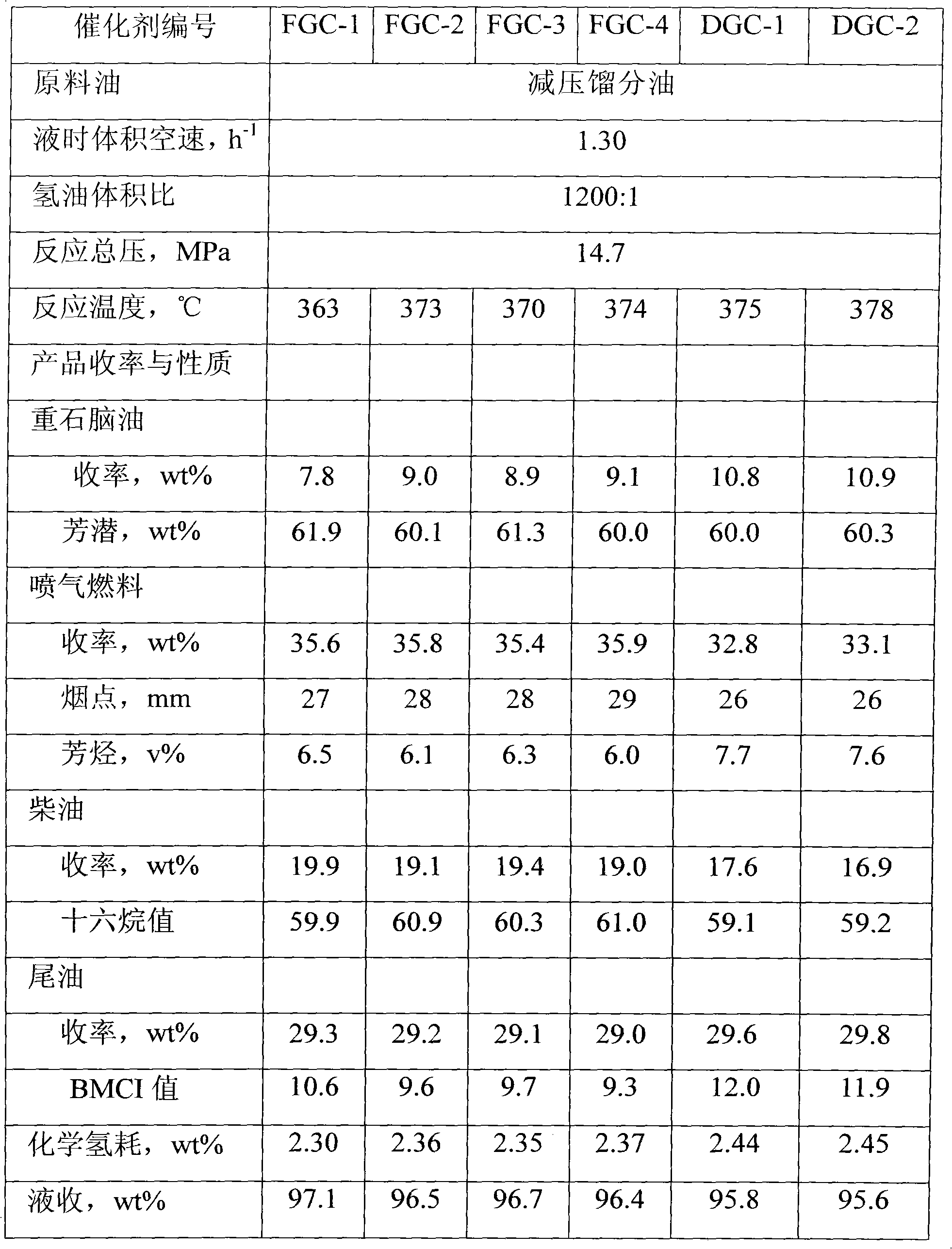

The invention discloses a hydrocracking catalyst for producing heavy naphtha in great abundance and a preparation method thereof. The catalyst contains hydrogenation active metals and a carrier which consists of modified Y molecular sieves and alumina, wherein the Y molecular sieves are obtained by using a mixed aqueous solution of aluminum salts and an acid to perform hydro-thermal treatment. The properties of the modified Y molecular sieves are as follows: the specific surface area is between 750 m<2> / g and 850 m<2> / g; the total pore volume is between 0.35 and 0.48 ml / g; the relative crystallinity is between 90 and 130 percent; the cell parameter is between 2.437 and 2.445 nanometers; the silicon-aluminum mol ratio is between 15 and 70; the infrared acid amount is between 0.5 and 1.0 mmol / g; the B acid / L acid is more than 7.0; and the content of sodium oxide is less than or equal to 0.05 weight percent. The hydrocracking catalyst has the characteristics of good catalytic activity, high heavy naphtha selectivity, high yield, high latent content of heavy naphtha arene, and so on.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618348AHigh activityHigh selectivityCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier comprises a modified Y-type molecular sieve, amorphous silica-alumina and alumina, wherein the modified Y-type molecular sieve is Y-type molecular sieve treated by mixed aqueous solution of an aluminum salt and an acid and by hydrothermal process. In the carrier, the modified Y-type molecular sieve has a high crystallinity, high silicon to aluminum ratio and proper total acidity and acid distribution and can form an acid component with the amorphous silica-alumina. Therefore, the carrier is particularly suitable for serving as a hydrocracking catalyst carrier to improve the activity of a hydrocracking catalyst and the selectivity of middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Highly active midbarrel hydrocracking catalyst and the preparation thereof

InactiveUS20020094931A1High activityHigh yieldMolecular sieve catalystsHydrocarbon oil crackingSulfurNitrogen

The present invention relates to a highly active midbarrel hydrocracking catalyst and a process for the preparation thereof. The support of the catalyst comprises a modified zeolite-Y, a modified zeolite-beta, alumina, etc. The composite of the modified zeolite-Y and zeolite-beta exhibits a good synergistically catalytic effect. The catalyst prepared by supporting Group VIB and / or Group VIII metal components is useful in the hydrocacking of heavy oils with high content of sulfur and nitrogen to produce high quality middle distillates with maximum output. The activity of and selectivity to middle distillates of the catalyst are remarkably raised simultaneously. Moreover, the solidifying point of the produced diesel is remarkably lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst containing small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN102049280ASkeleton silicon aluminum ratio is highLarger than surfaceMolecular sieve catalystsCatalyst activation/preparationMolecular sieveNaphtha

The invention discloses a hydrogenation catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metal components and a carrier consisting of the small crystal grain Y-shaped molecular sieve, amorphous silica-alumina and aluminum oxide, wherein the small crystal grain Y-shaped molecular sieve is a small crystal grain Y-shaped molecular sieve subjected to hydro-thermal treatment. The hydrocracking catalyst provided by the invention has the characteristics of high catalyst activity, excellent target product selectivity, great preparation flexibility, and the like, thus the catalyst can be used for preparing products such as heavy naphtha, aviation kerosene, diesel oil and the like with high yield and good product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for starting operation of catalyst for hydrocracking in oxidation state

InactiveCN101003749AStrong resistance to sulfur poisoningImprove hydrogenation performanceHydrotreatment operations starting-upOxidation stateNitrogen gas

This invention relates to a start-up method for oxidation-state hydrocracking catalyst used in oil refinery process. The method comprises: loading the oxidation-state hydrocracking catalyst into a reactor, introducing nitrogen to replace air in the reactor and pipelines, pressurizing to meet the pressure requirement of hydrocracking, switching to hydrogen after nitrogen flow is stable, raising the temperature of the catalyst bed to meet the temperature requirement of catalyst reduction after hydrogen flow is stable, keeping the temperature, adjusting the temperature of the catalyst bed to meet the temperature requirement of hydrocracking, adjusting hydrogen flux to meet the flux requirement of hydrocracking, and introducing hydrocarbon reactants. The method does not need pre-sulfurization of the catalyst with additional sulfurization agent, thus can avoid the problems caused by pre-sulfurization, and partially reduced catalyst has higher hydrocracking activity.

Owner:XIAMEN UNIV

Hydrogenation catalyst and preparation method thereof

InactiveCN102430406AWith hydrogen storage functionExtend your lifeLactams separation/purificationMetal/metal-oxides/metal-hydroxide catalystsHydrogenActive component

The invention discloses a hydrogenation catalyst, characterized in that: active components are loaded on a carrier, the active components comprise 0.2-5 wt% of metallic palladium and 0.1-2.5 wt% of rare earth oxide. The catalyst is prepared by the following steps: preparing water-soluble palladium-containing compound, water-soluble rare earth compound and water into a palladium-rare earth aqueous solution, dipping a carrier in the palladium-rare earth aqueous solution to loading the palladium-containing compound and rare earth compound on the carrier to obtain a catalyst precursor; drying and roasting the catalyst precursor, then carrying out reduction processing at a temperature of 50-200 DEG C in the presence of hydrogen to reduce oxidative divalent palladium in the palladium compound to metallic palladium.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydro-conversion catalyst for heavy oil and residual oil and its preparing process

The present invention belongs to the field of heavy oil and residual oil hydrotransforming technology. The heavy oil and residual oil hydrotransforming catalyst has siliceous alumina carrier, relatively strong acidity and especially protonic acid amount higher than that in available residual oil hydrotransforming catalyst. The siliceous alumina carrier is prepared through one colloid forming process, during and after which silicon is added to make alumina possess more strong acid centers and ideal pore structure. The catalyst of the present invention is used in the hydrotransforming treatment of heavy oil, residual oil and other inferior oil material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Full-cut fraction pyrolysis gasoline diolefin selective hydrogenation method

ActiveCN101429454AGood hydrogenation effectGood hydrogenation stabilityRefining by selective hydrogenationSilicon dioxideImpurity

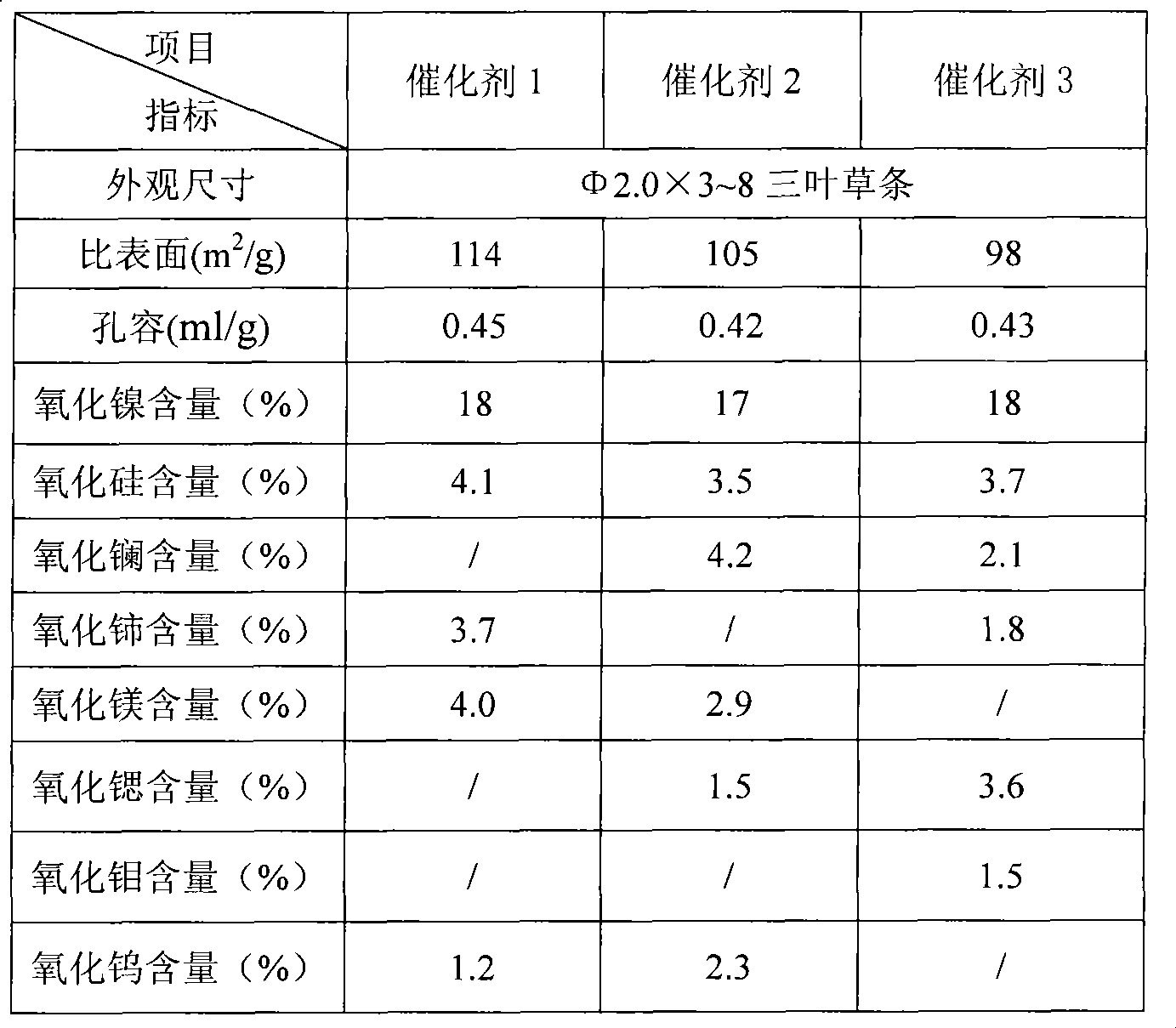

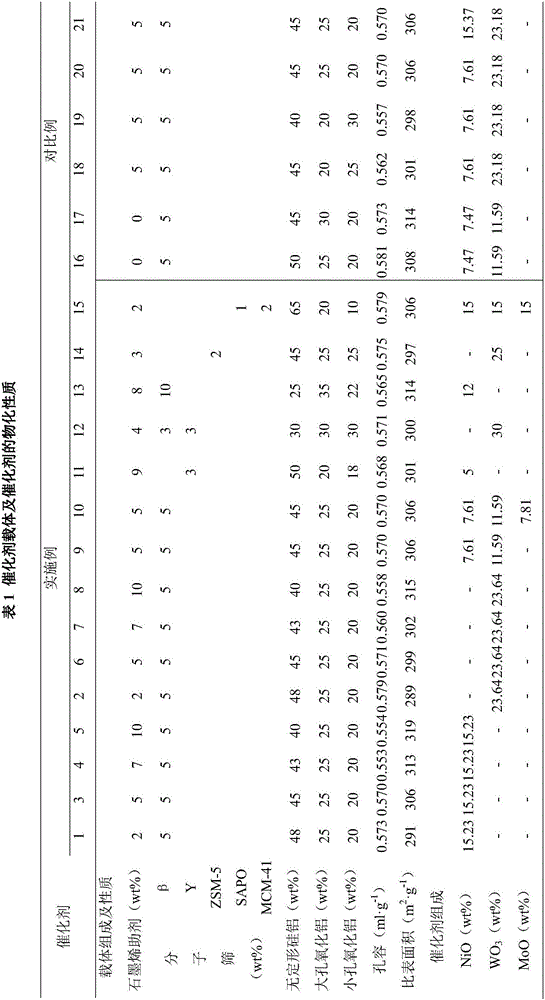

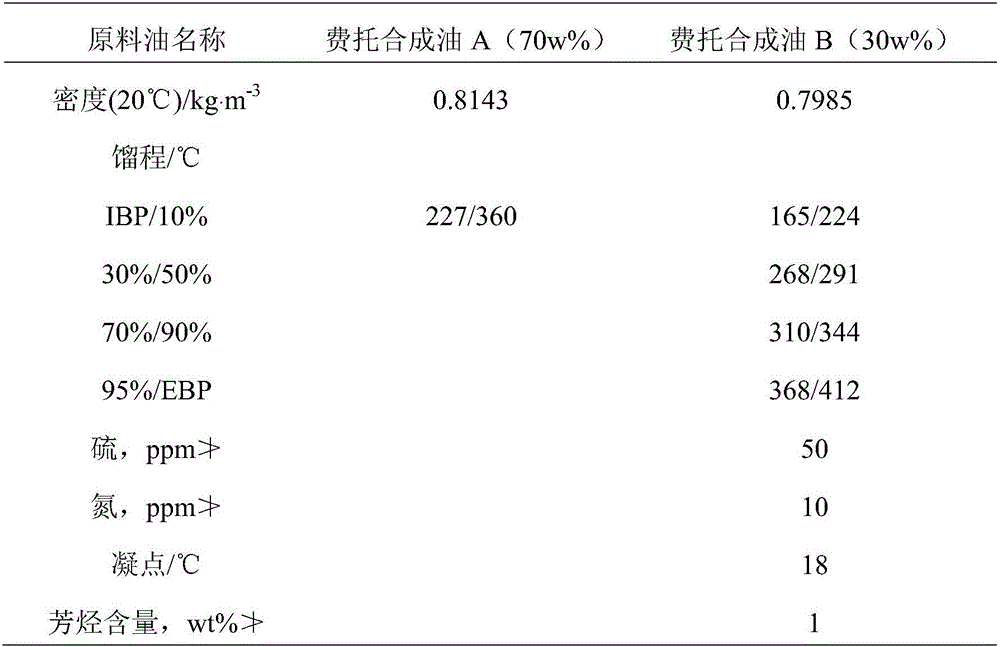

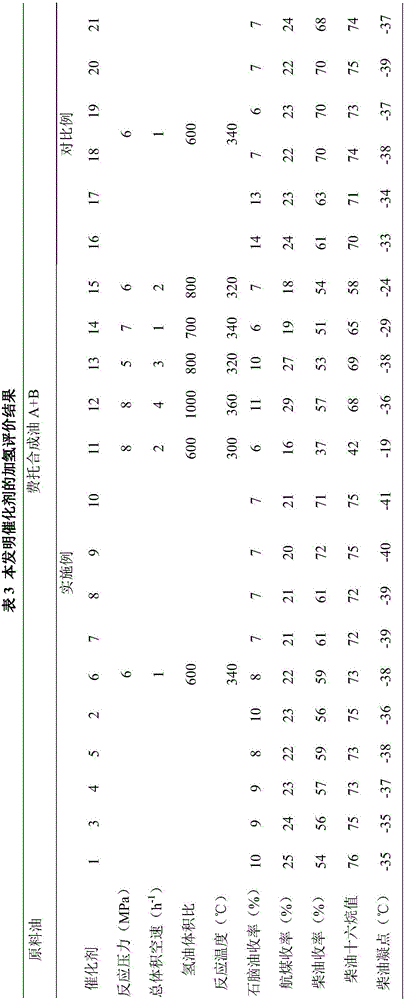

The invention provides a selectivity hydrogenation method for diolefin of full-fraction pyrolysis gasoline, which comprises reduction and passivation of catalyst and application of technological conditions. The catalyst is nickel series hydrogenation catalyst which is used after being reduced or being subjected to reduction and passivation. The selectivity hydrogenation method is characterized in that the hydrogenation technological conditions are as follows: the volume space velocity of a liquid is less than or equal to 4h<-1>, the inlet temperature of a reactor is between 40 and 130 DEG C, the reaction pressure is more than or equal to 2 MPa, and the hydrogen / oil ratio is between 100 and 500 (v / v); the nickel series catalyst takes alumina as a carrier, is prepared by the immersion method, and contains 14 to 20 percent of nickel oxide, 1 to 8 percent of lanthanum oxide and / or cerium oxide, 1 to 8 percent of 4B oxide auxiliary agent, 2 to 8 percent of silicon dioxide and 1 to 8 percent of alkaline earth oxide as calculated by 100 weight percent of the catalyst; and the specific surface of the catalyst is between 60 and 150 square meters per gram, and the pore volume of the catalyst is between 0.4 and 0.6 milliliter per gram. The invention also provides a method for performing reduction and passivation on the catalyst on a hydrogenation unit. Under the conditions of the application method and the technological conditions, the nickel catalyst has good hydrogenation performance, and particularly has strong impurity and colloid resistance and good hydrogenation stability.

Owner:PETROCHINA CO LTD

Highly active midbarrel hydrocracking catalyst and the preparation thereof

InactiveUS6670295B2High activityHigh yieldMolecular sieve catalystsHydrocarbon oil crackingSulfurNitrogen

The present invention relates to a highly active midbarrel hydrocracking catalyst and a process for the preparation thereof. The support of the catalyst comprises a modified zeolite-Y, a modified zeolite-beta, alumina, etc. The composite of the modified zeolite-Y and zeolite-beta exhibits a good synergistically catalytic effect. The catalyst prepared by supporting Group VIB and / or Group VIII metal components is useful in the hydrocacking of heavy oils with high content of sulfur and nitrogen to produce high quality middle distillates with maximum output. The activity of and selectivity to middle distillates of the catalyst are remarkably raised simultaneously. Moreover, the solidifying point of the produced diesel is remarkably lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

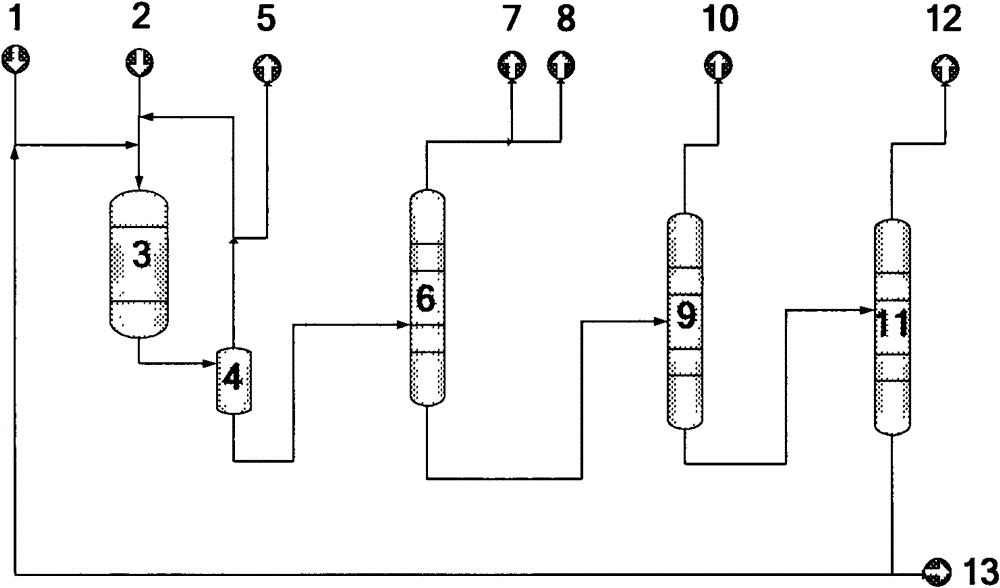

Selective hydrogenation catalyst for producing biodiesel and preparation method and application of selective hydrogenation catalyst

InactiveCN105903488AImprove thermal conductivityUniform temperature distributionMolecular sieve catalystsHydrocarbon oils refiningBiodieselFreeze-drying

The invention discloses a selective hydrogenation catalyst for producing biodiesel and a preparation method and application of the selective hydrogenation catalyst. The selective hydrogenation catalyst comprises a carrier and a main metal active ingredient loaded on the carrier, the main metal active ingredient accounts for 5-30% of the catalyst in weight and is one of or a combination of oxides containing Co, Mo, Ni and W, and the carrier is composed of, by weight, 1-8% of a molecular sieved, 25-65% of amorphous sial, 30-65% of alumina and 2-10% of a graphene auxiliary. The preparation method includes: disposing the carrier in a metal salt solution containing Co, Mo, Ni or / and W for soaking for 4-20 h to obtain a soaked carrier; freeze-drying and then calcining the soaked carrier to obtain the selective hydrogenation catalyst. With same carrying capacity of the carrier, active surface area represented by the carrier is large, the selective hydrogenation catalyst has more active sites, reaction temperature is lowered, and hydrogenation performance is improved.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

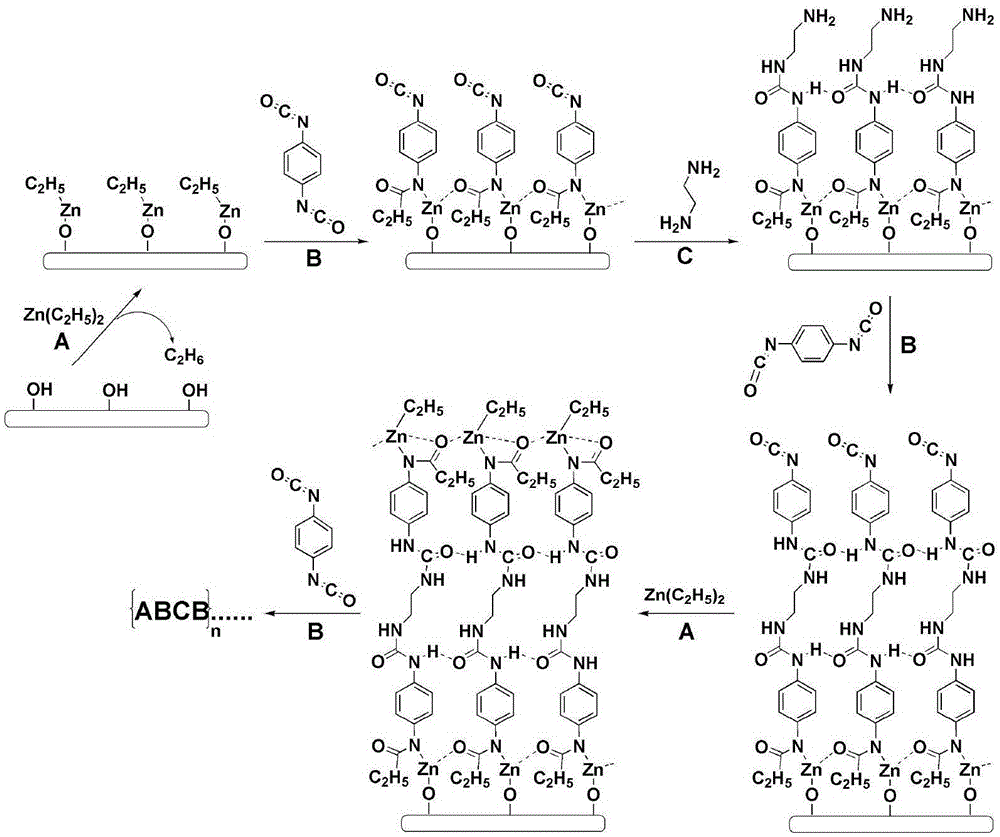

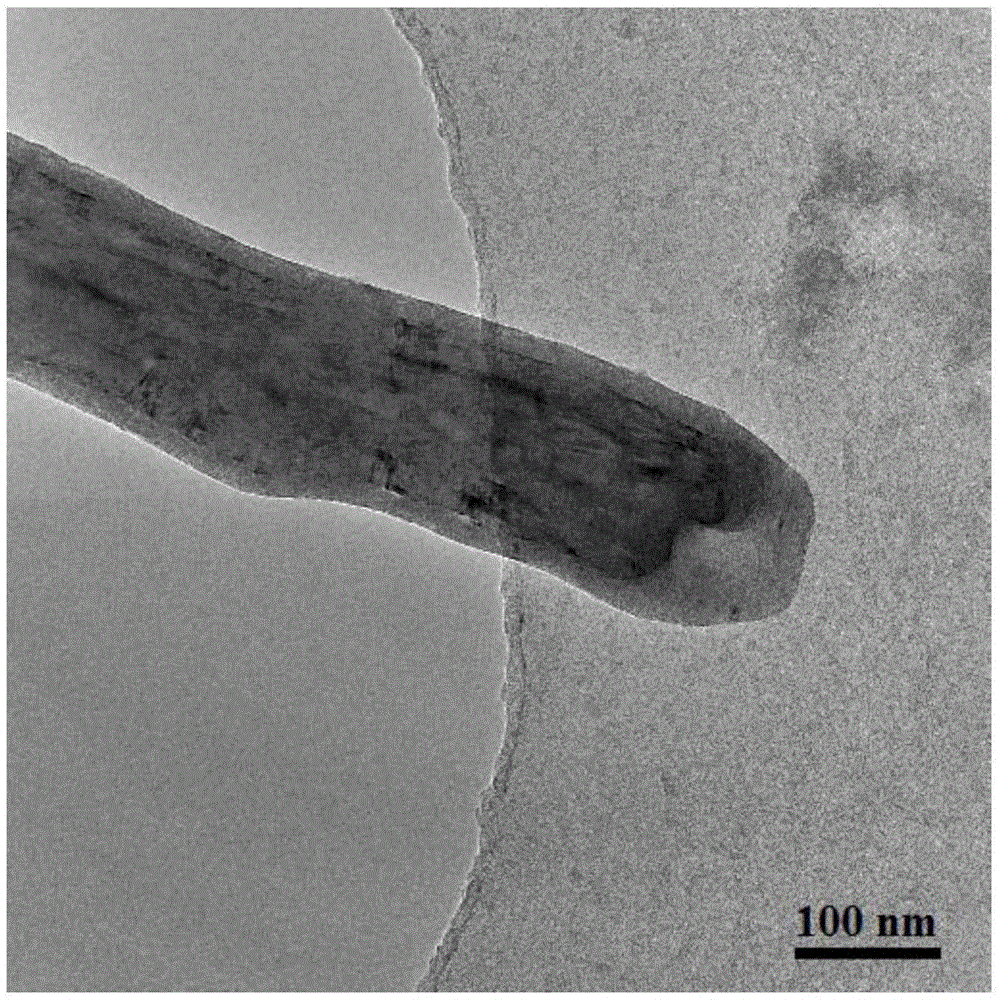

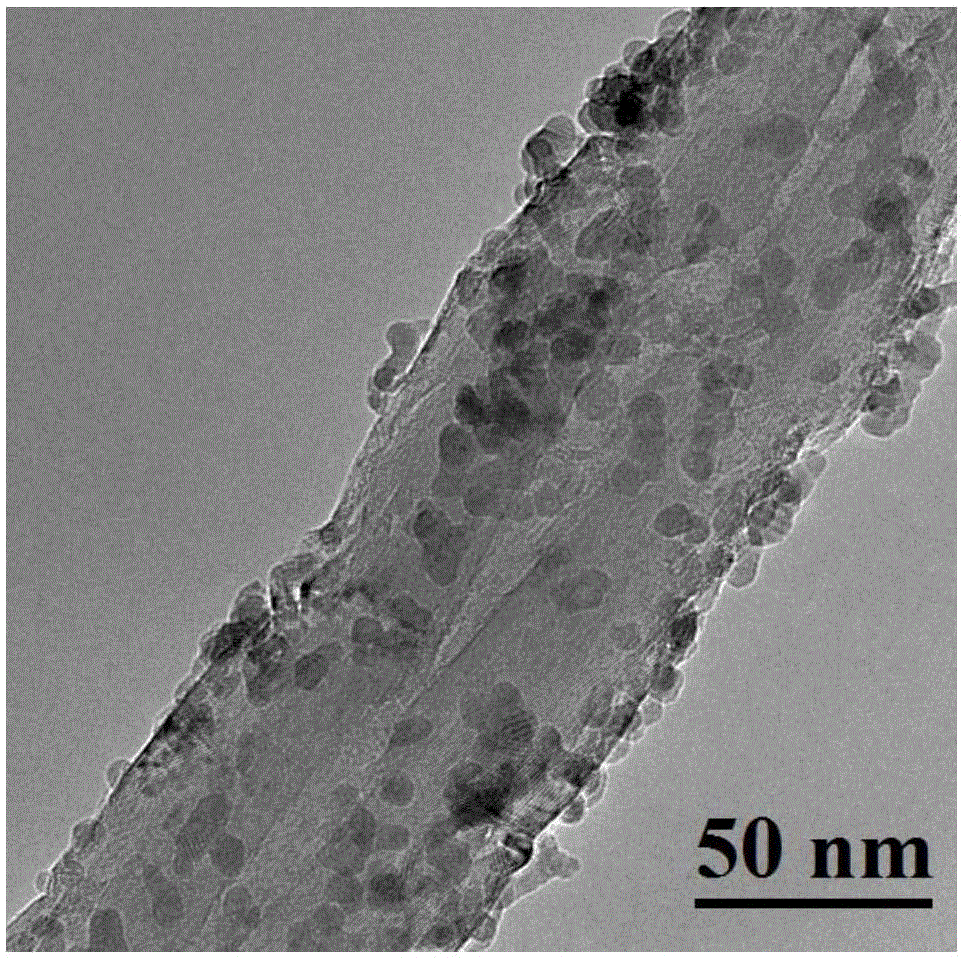

Preparation method for Cu-based hydrogenation catalyst

InactiveCN105148923AImprove hydrogenation performanceEnhanced interactionOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsReducing atmosphereGlass sheet

A preparation method for a Cu-based hydrogenation catalyst comprises the following steps: dissolving soluble copper salt into water, then adding a carrier into the solution, and uniformly loading a copper precursor on the surface of the carrier to obtain a precursor sample; mixing the precursor sample and ethanol to form a suspending liquid, coating the suspending liquid on the surface of a glass sheet, impulsing polyisocyanate into an MLD reaction cavity, then impulsing an M precursor to be subjected to monomolecular layer reaction on the sample surface in sequence to obtain a hybrid membrane coated copper precursor compound; conducting heat treatment on the compound in air to obtain a nanometer CuO-MOx compound, and then conducting reduction in the reducing atmosphere to obtain the Cu-MOx interface catalyst. The preparation method has the advantage that the Cu-MOx interface structure can be regulated and controlled.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Hydrocracking catalyst, and preparation method and application thereof

ActiveCN102909048AHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention describes a hydrocracking catalyst, and a preparation method and an application thereof. The hydrocracking catalyst comprises an acid component and an active metal component compound, wherein the acid component comprises at least one molecular sieve; the active metal component compound comprises a compound of Mo and / or W in a VIB group and a compound of Ni and / Co in a VIII group; and in a hydrocracking reaction state, the active metal component compound in the hydrocracking catalyst is in a metal phosphatizing state. The catalyst has excellent usage performance, good catalyst activity and high selectivity for medium oil under the condition of high nitrogen content in raw oil, is suitable for hydrocracking processes for increasing jet fuels and clean diesel oil, has stronger adaptability for nitrogen, and can reduce burden of a refining catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

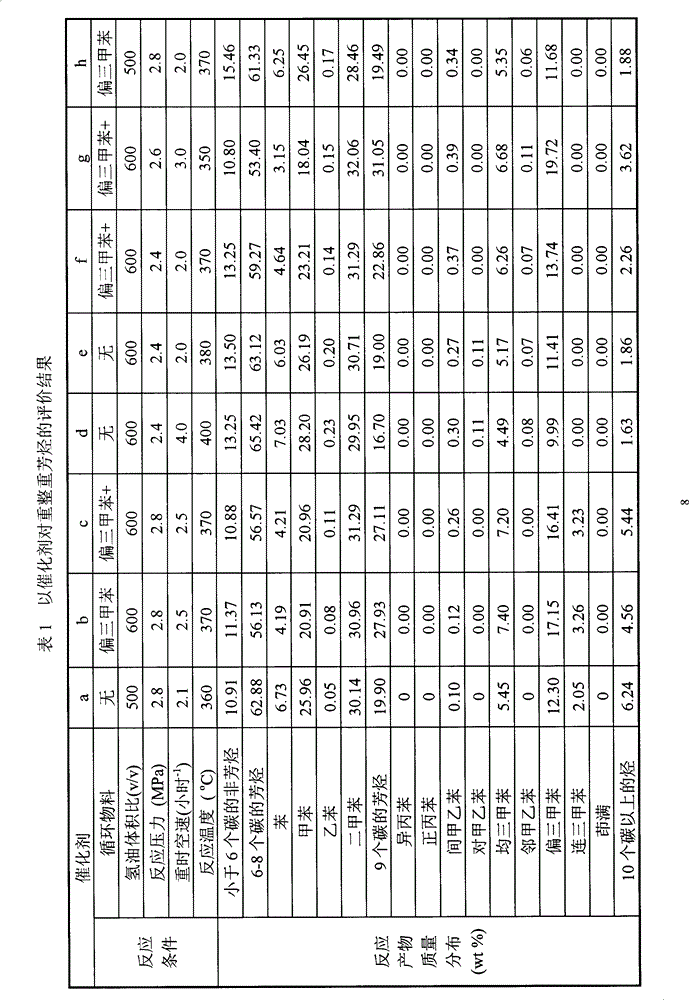

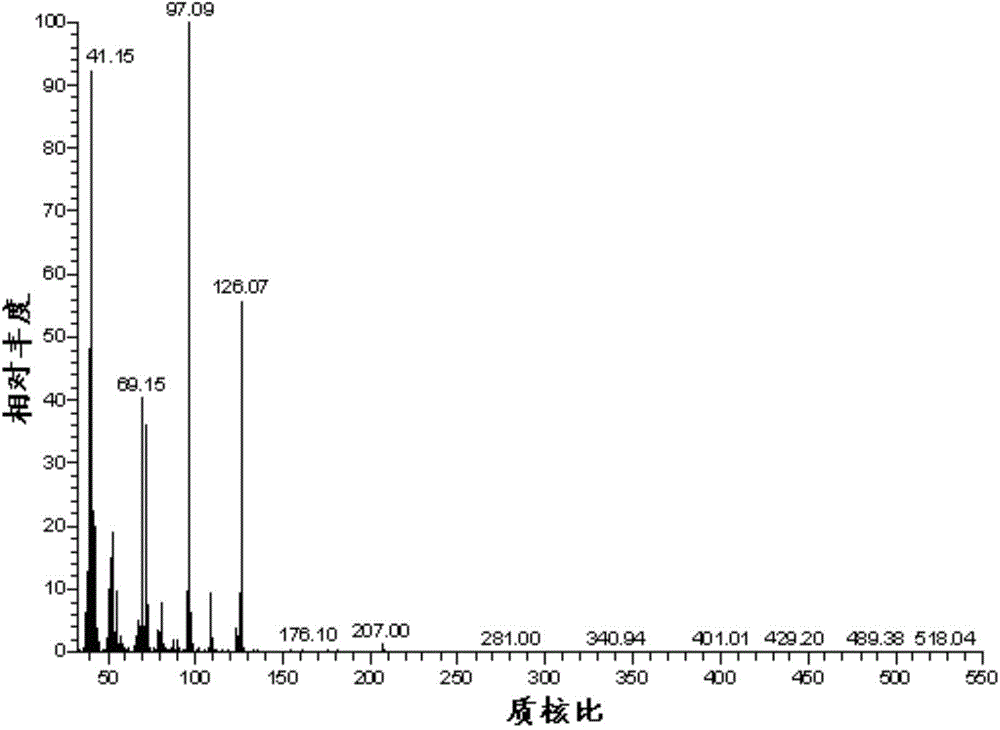

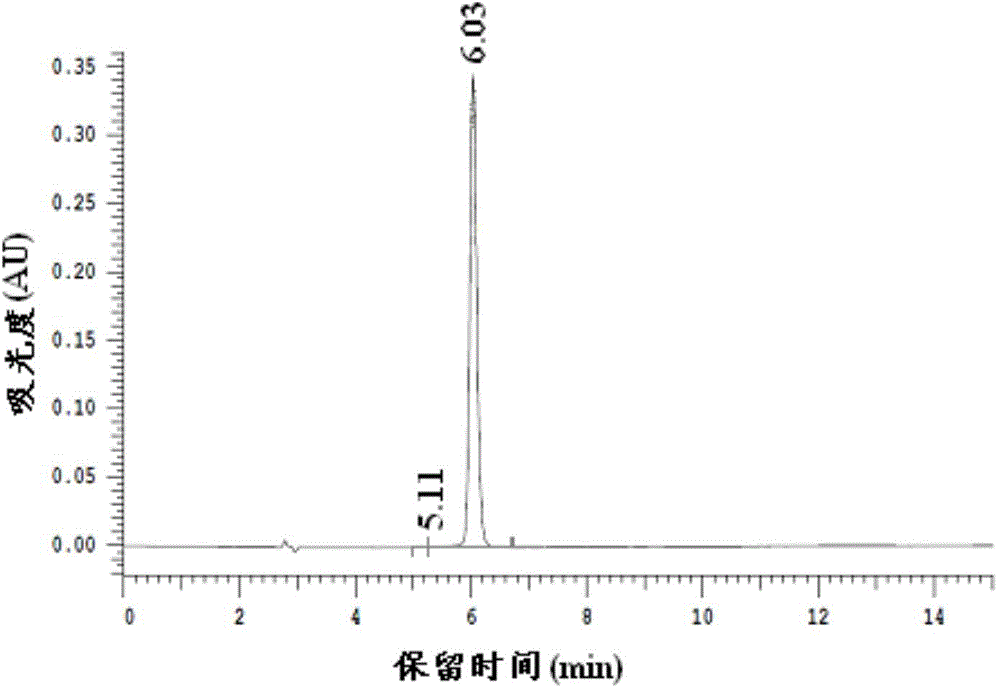

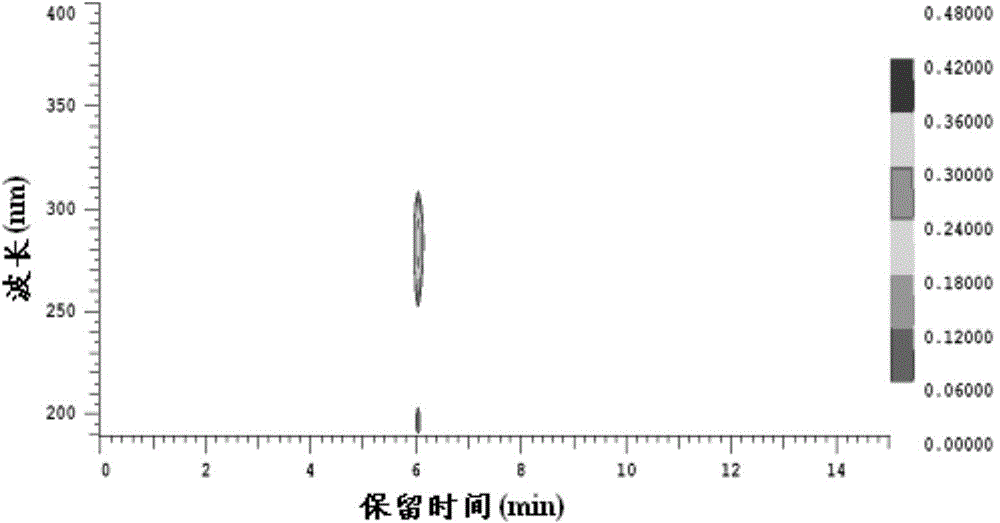

Method for separating and producing 1,3,5-trimethylbenzene through hydrocracking heavy aromatic hydrocarbons

ActiveCN102746092AEasy to removeHigh removal activityHydrocarbonsBulk chemical productionHydrogenBoiling point

The invention relates to a method for separating and producing 1,3,5-trimethylbenzene through hydrocracking heavy aromatic hydrocarbons to mainly solve technical problems of low added value of the heavy aromatic hydrocarbons, and complex flow, low product purity, low yield and the like in separation of 1,3,5-trimethylbenzene monomers from the heavy aromatic hydrocarbons. According to the method, hydrogen type binder-free ten-membered ring zeolite loading 0.005-0.5% by mass of Pt or Pd is adopted as a catalyst, hydrogen and the heavy aromatic hydrocarbons which are raw materials undergo hydrocracking treatment, and 1,2,4-trimethylbenzene and heavy aromatic hydrocarbons having boiling points greater than the boiling point of the 1,2,4-trimethylbenzene in products are returned to a reactor, so BTX aromatic hydrocarbon yield increase and 1,3,5-trimethylbenzene separation production are realized. The method well solves the problems, and can be used for the industrial production for yield increases of the BTX (benzene, toluene and xylol) aromatic hydrocarbon and the 1,3,5-trimethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking after-treatment catalyst and preparing method thereof

InactiveCN1508224AHigh Ni/(Ni+Mo) atomic ratioImprove hydrogenation performancePhysical/chemical process catalystsRefining to eliminate hetero atomsAfter treatmentActive component

The invention discloses a processing catalyzer after hydrogenated cracking and preparing method, adopting alumina as carrier, Mo and / or Wu as well as Ni and Co as active components, and P as catalyst promoting component. Firstly, it carries a part of Ni on the carrier by mixed kneading, and then uses Ni-Mo-Co-P mixed solution for dipping to make the catalyzer. It has higher NiO content, higher Ni / Ni+Mo atomic ratio, especially applied to processing the course of producing low-mercaptan product after hydrogenated cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing 2,5-dimethyl furan

The invention provides a method for preparing 2,5-dimethyl furan. The method comprises the following steps: under the action of a nickel metal catalyst, performing a hydrogenolysis reaction on 5-hydroxymethyl furfural in a solvent so as to obtain the 2,5-dimethyl furan, wherein the nickel metal catalyst is a loaded type double-metal catalyst; the nickel metal catalyst comprises effective active components including nickel and tungsten. According to the method provided by the invention, the nickel metal catalyst which takes nickel and tungsten as the effective components is adopted to catalyze HMF (Hydroxymethyl Furfural) to perform hydrogenolysis so as to obtain DMF (Dimethyl Formamide); the component nickel has a good hydrogenation capability, and can perform hydrogenation on an aldehyde group to be a hydroxymethyl group; the component tungsten has good Lewis acidity, can prompt breakage of a carbon-oxygen bond on the hydrogenolysis process of HMF, and can convert the hydroxymethyl group into a methyl group; under the dual functions of nickel and tungsten, the HMF can be efficiently and selectively converted into the DMF, and therefore, the yield of the DMF is relatively high.

Owner:UNIV OF SCI & TECH OF CHINA

Petroleum resin hydrogenation catalyst and preparation method thereof

ActiveCN103386302AImprove anti-coking performanceImprove stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHigh activityChemistry

The invention provides a petroleum resin hydrogenation catalyst and a preparation method thereof. The petroleum resin hydrogenation catalyst comprises an Al2O3 carrier, a precious metal Pd loaded on the Al2O3 and an assistant element oxide. The catalyst provided by the invention has high activity, and the steeping depth of active metals in the catalyst is controllable; and the preparation method of the catalyst is simple and suitable for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Diesel oil fraction upgrading and pour point reducing process

ActiveCN101089135AReduce usageReduce contentRefining to eliminate hetero atomsHydrogenOxidation stability

The diesel oil fraction upgrading and pour point reducing process has the mixture of diesel oil material and hydrogen passing through the hydroupgrading reaction region to result in diesel oil with low solidification point through reaction under certain condition. The catalyst in the hydroupgrading reaction region includes at least one kind of bulk phase catalyst comprising complex oxide NixWyOz and oxide MoO3 in the weight ratio 0.1-10 and accounting for 40-100 wt% of total catalyst, and at least one kind of upgrading catalyst containing beta-zeolite. The present invention can lower the solidification point, 95 vol% point temperature and sulfur content of diesel oil, and raise cetane number and oxidation stability under mild condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

In-situ hydrogenation method of acrylonitrile-butadiene rubber latex

InactiveCN101704909AOvercoming the problem of low degree of hydrogenationImprove hydrogenation performancePolymer scienceAcrylonitrile

The invention belongs to the field of hydrogenation of acrylonitrile-butadiene rubber latex. The hydrogenation of acrylonitrile-butadiene rubber latex is realized through the technical scheme as follows: the mixture of acrylonitrile-butadiene rubber latex and hydrazine hydrate is heated to 30 to 70 DEG C, and then constant temperature is kept for 2 to 8 h, and in the process with constant temperature, aqueous solution of sodium periodate is dripped into the mixture, the dripping rate is controlled, and the dripping is accomplished within 2 to 6 hours. The method has the advantages of simple process flow, low cost, less pollution, high hydrogenation rate, low cross linking level of the prepared hydrogenated acrylonitrile-butadiene rubber latex, and good processing property.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method for metal phosphide type hydrocracking catalyst

ActiveCN102909055AHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention describes a preparation method of a metal phosphide type hydrocracking catalyst. The method comprises the following steps of (1) preparing a catalyst carrier containing a molecular sieve and an inorganic refractory oxide; (2) preparing a dipping solution containing a VIB group metallic compound, a VIII group metallic compound and an inorganic phosphorus-containing compound; (3) dipping the catalyst carrier obtained for the step (1) with the dipping solution prepared by the step (2), and then drying the dipped material; and (4) performing hydrogen activation on the material obtained from the step (4), obtaining the hydrocracking catalyst used for hydrocracking reactions after the activation. The hydrocracking catalyst prepared by the method has outstanding usage performance, and is particularly suitable for a hydrocracking process of increasing middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

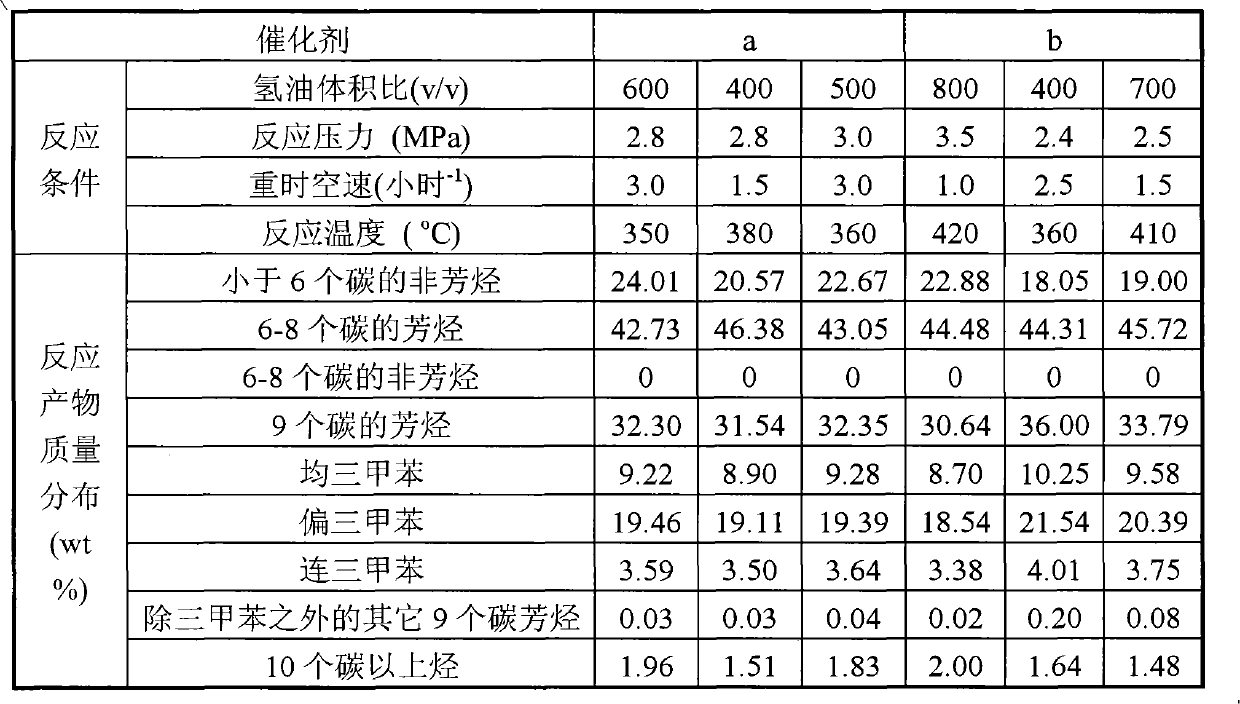

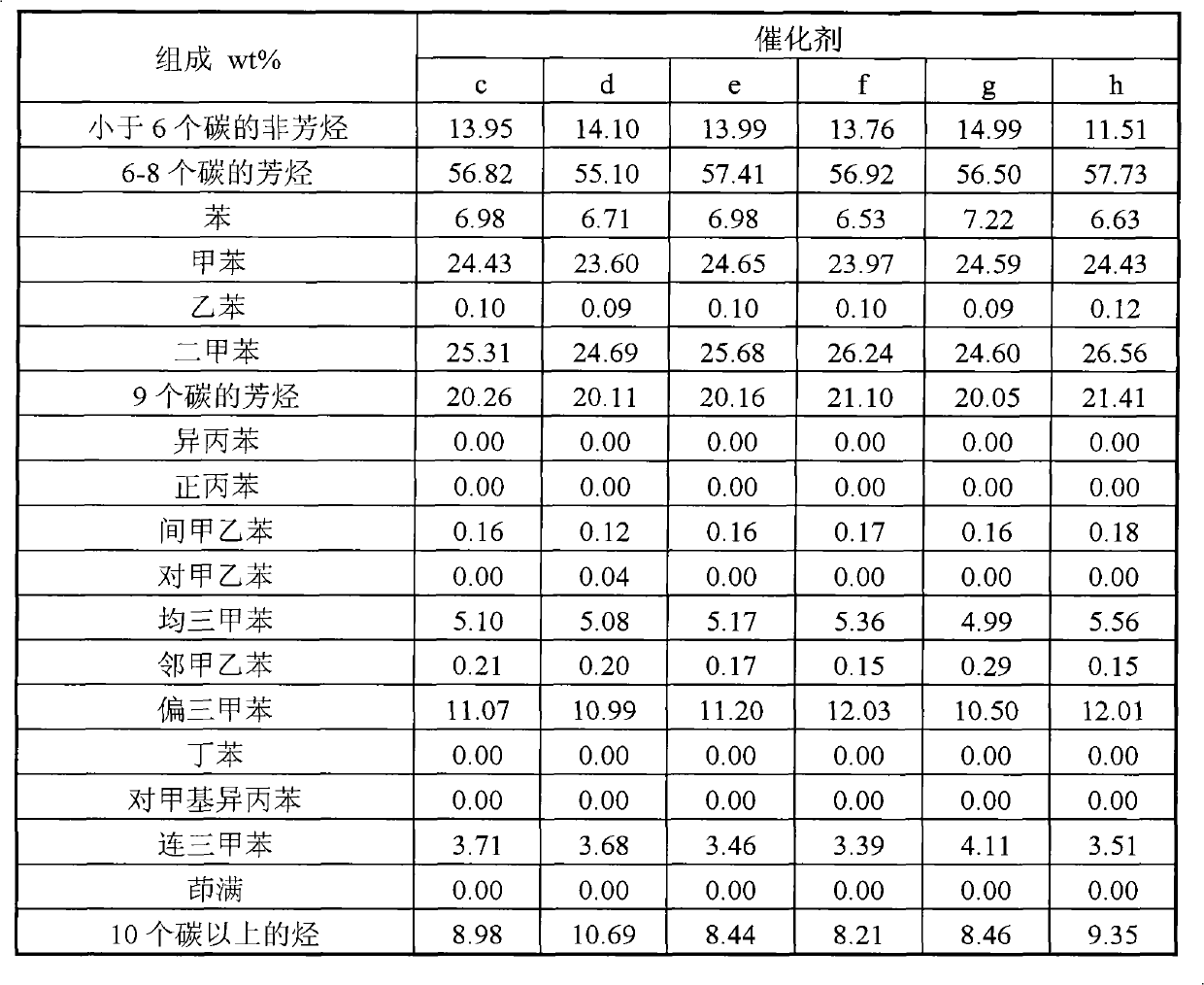

Method for increase production of BTX (benzene, toluene and xylol) aromatic hydrocarbons and trimethylbenzene through hydrocracking heavy aromatic hydrocarbons

ActiveCN102746093AEasy to removeHigh removal activityHydrocarbonsBulk chemical productionBenzeneHydrogen

The invention relates to a method for the increase production of BTX aromatic hydrocarbons and trimethylbenzene through hydrocracking heavy aromatic hydrocarbons to mainly solve technical problems of low heavy aromatic hydrocarbon added value and high cost for separating and producing trimethylbenzene monomers in the heavy aromatic hydrocarbons containing methylethylbenzene, propylbenzene and butylbenzene. The method comprises a step that the heavy aromatic hydrocarbons are subjected to a hydrocracking reaction through adopting Pt / Pd-loaded hydrogen type binder-free ten-membered ring zeolite as a catalyst under reaction conditions comprising that the reaction temperature is 320-450DEG C, the reaction pressure is 2.0-4.0Mpa, the hydrocarbons raw material weight hourly space velocity is 1.0-4.0h<-1> and the hydrogen / hydrocarbon raw material ratio by mole is 3-10:1. The method well solves the problems through above technical scheme, and can be applied to the industrial production of the BTX aromatic hydrocarbons and the trimethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Supported urushibara nickel catalyst and preparation method thereof

InactiveCN102744071AReduce manufacturing costIncrease the areaOrganic compound preparationAmino compound preparationCatalytic hydrogenationChemistry

A supported urushibara nickel catalyst comprises 1-20wt% of Ni, 0.5-9wt% of Fe, an assistant having a weight being 0-30wt% of the Ni content, and 65-98wt% of a carrier. The catalyst has the advantages of low price and excellent catalytic hydrogenation performance.

Owner:SEDIN ENG +1

Small crystal particle Y-shaped molecular sieve-containing hydrocracking catalyst carrier and preparation method thereof

ActiveCN102049306AImprove hydrogenation performanceHigh activityCatalyst carriersMolecular sieve catalystsCrystallinityCell parameter

The invention discloses a small crystal particle Y-shaped molecular sieve-containing hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier comprises a small crystal particle Y-shaped molecular sieve, amorphous silicon aluminium, and alumina, wherein the small crystal particle Y-shaped molecular sieve has the following properties: the SiO2 / Al2O3 molar ratio is 5.0-20.0; the average diameter of the crystal grains is 100 to 700nm; the crystal retention rate is over 95 percent; the specific surface area is 800 to 900m<2> / g; the pore volume is 0.35 to 0.45ml / g; the relative crystallinity is 90 to 130 percent; the cell parameter is 2.434 to 2.440nm; the infrared acid quantity is 0.3 to 0.8mmol / g; the B acid / L acid is more than 7.0; and the sodium oxide content isless than or equal to 0.05 weight percent. A hydrocracking catalyst prepared from the carrier has the characteristics of high catalytic activity, high target product selectivity, high production flexibility and the like, can be used for producing products such as heavy naphtha, aviation fuel and diesel oil, and ensures high yield and good product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of sulfurization type hydro-cracking catalyst

ActiveCN103769198AIncreased degree of vulcanizationImprove hydrogenation performanceMolecular sieve catalystsHydrocarbon oil crackingNickel saltTungstate

The invention discloses a preparation method of a sulfurization type hydro-cracking catalyst. The preparation method comprises the following steps: selecting a hydro-cracking catalyst carrier component, wherein the carrier component at least comprises an acidic cracking component; adding water into the carrier component powder, pulping so as to obtain slurry (c), then adding sulfo-molybdate and / or sulfo-tungstate slurry (a) and a nickel salt and / or cobalt salt solution (b) into the slurry (c), evenly stirring, filtering, washing, drying in the protection of inert gas, adding an adhesive, kneading, forming, and finally drying and burning in the protection of inert gas so as to obtain the sulfurization type hydro-cracking catalyst. The preparation method makes the active metal be evenly distributed on the carrier so as to generate more II type Ni(Co)Mo(W)S active phases with a higher activity; thus the catalyst has a high sulfurization degree and a high utilization rate of active metal, so that the hydrogenation performance of the catalyst is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

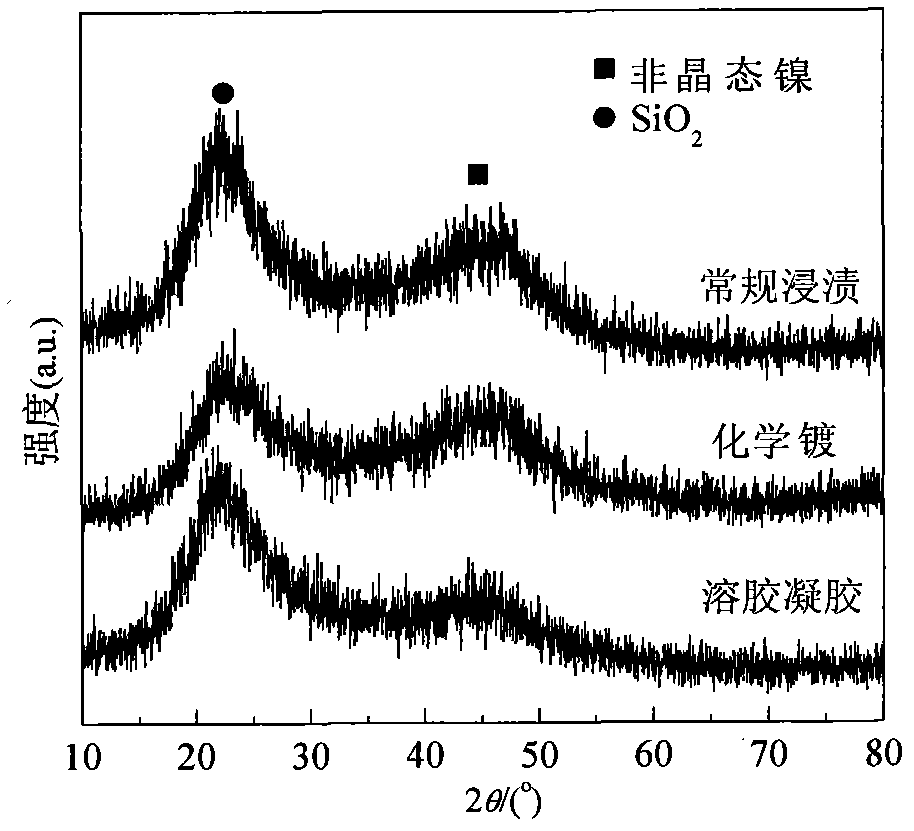

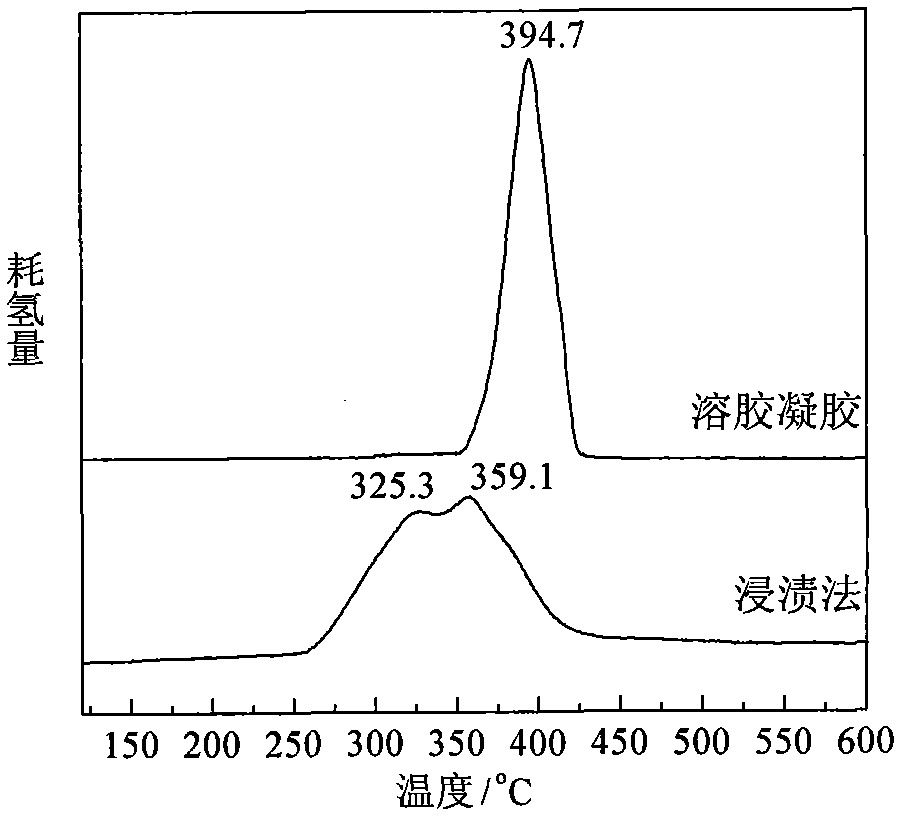

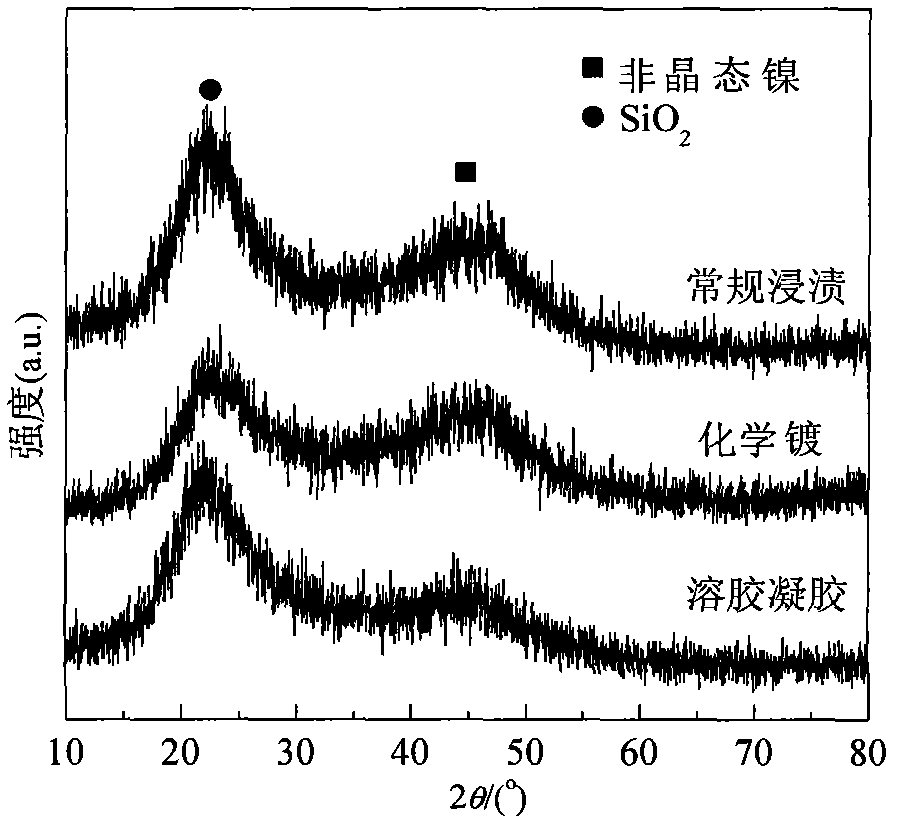

Amorphous alloy catalyst for hydrogenating dinitrotoluene and application of amorphous alloy catalyst

InactiveCN102580748ALow priceStrong interactionOrganic compound preparationAmino compound preparationDiamineSolvent

An amorphous alloy catalyst for hydrogenating dinitrotoluene comprises the following components according to catalyst composition: 5-30.0wt% of Ni, 5-30.0wt% of B, 0-5wt% of auxiliary and 40-90wt% of SiO2. The amorphous alloy catalyst is prepared by adopting a preparation method comprising the following steps of: dropwise adding a mixed aqueous solution containing soluble nickel salt and soluble salt of the auxiliary to an ethanol solution of tetraethoxysilane, and simultaneously, adding acetic acid and forming gel in a water bath; drying and grinding the gel, and then roasting the gel to obtain an NiO / SiO2 precursor; adjusting the pH value of 0.5-2.5 mol / L of KBH4 solution and adding the KBH4 solution to NiO / SiO2 according to the mol ratio of KBH4 to Ni being (1-5): 1, and then washing to obtain the catalyst. The catalyst provided by the invention is used for the reaction of synthesizing toluene diamine (TDA) by catalytically hydrogenising dinitrotoluene DNT; and the technical conditions of the application of the catalyst are as follows: the reaction temperature ranges from 80 to 150 DEG C; the reaction pressure is 0.8-1.2 MPa; methanol or ethanol is taken as a solvent; the initial concentration of the dinitrotoluene DNT is 2-20wt%; and the concentration of the catalyst is 0.1-5wt%. The amorphous alloy catalyst is low in cost, good in selectivity and high in conversion ratio.

Owner:TAIYUAN UNIV OF TECH +1

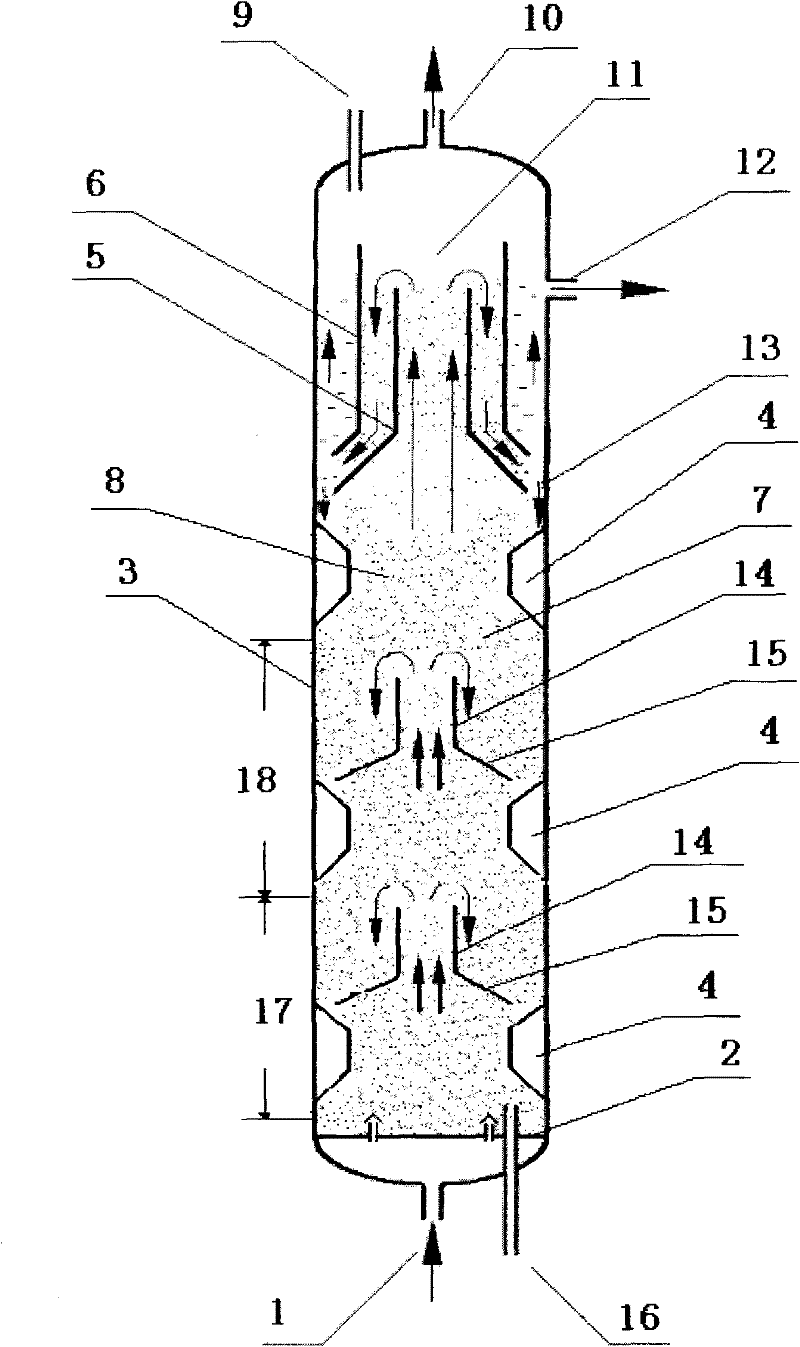

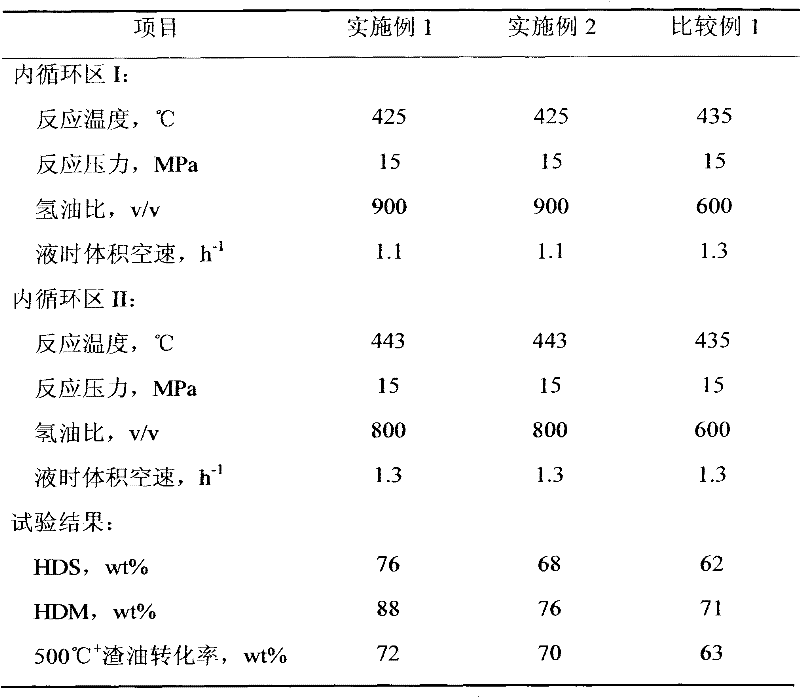

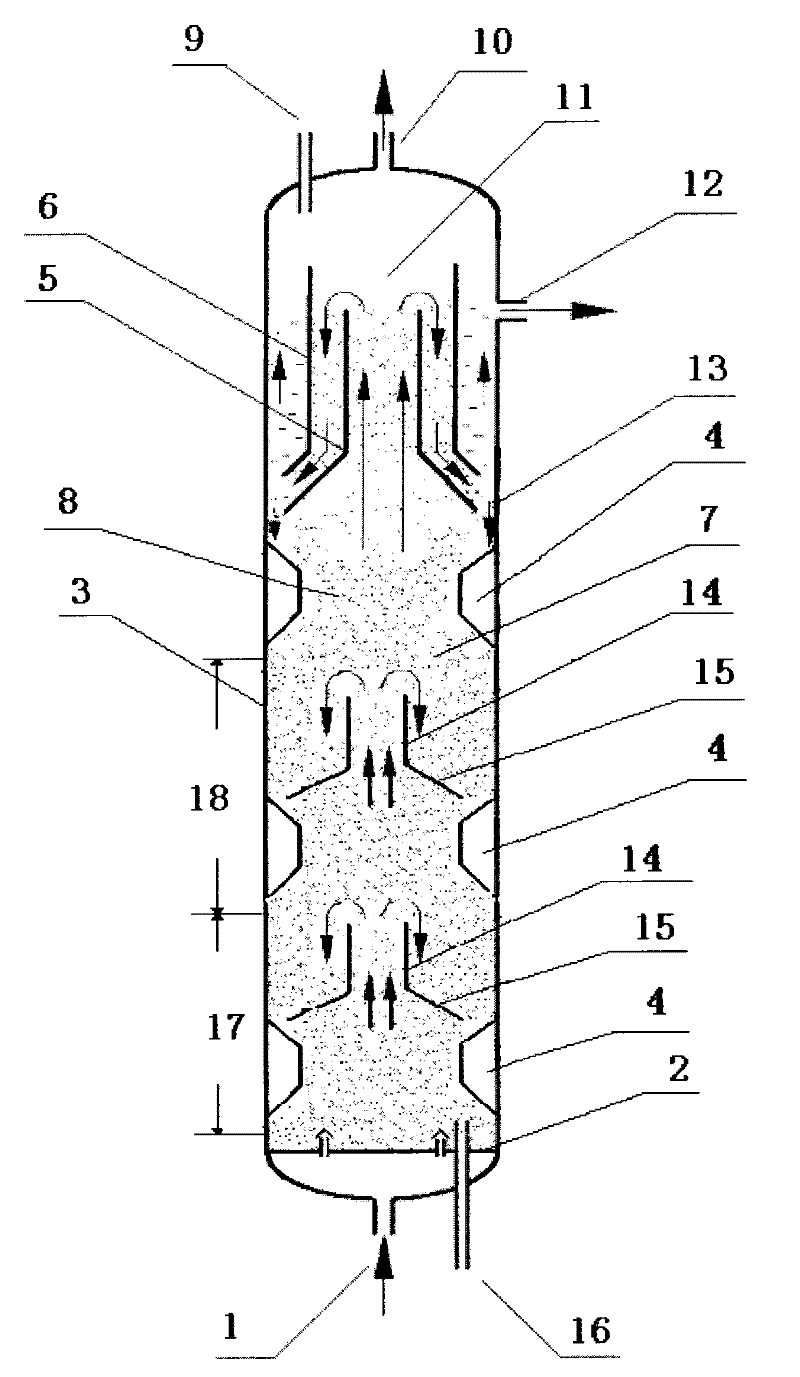

Multi-section boiling bed residual oil hydrogenation process method

ActiveCN102453528AReduce usageLarge voids between particlesTreatment with hydrotreatment processesHydrogenation processResidual oil

The invention discloses a multi-section boiling bed residual oil hydrogenation process method, which comprises the following steps of: mixing a hydrocarbon raw material with hydrogen, and feeding a mixture into a reactor from the bottom of a boiling bed reactor; and reacting under a hydrogenation treatment condition, wherein the boiling bed reactor comprises two or more internal circulation regions; and each internal circulation region is provided with different operation sections respectively. In the invention, a plurality of internal circulation regions are formed in the boiling bed reactor, and a plurality of different operation sections are formed, so that the entire boiling bed reactor is more flexible to operate, reasonable matching of the property of a reaction physical flow, operating conditions and catalyst performance can be realized, the activity of a catalyst is brought into full play, the yield of light oil is increased, the product quality is enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Wax oil hydrotreating method

ActiveCN102899081AAdaptableLow hydrogenation saturation rateTreatment with hydrotreatment processesPartial saturationCobalt

The invention relates to a wax oil hydrotreating method. According to the invention, under a hydrogenation reaction condition, a mixture of raw material oil and hydrogen is sequentially delivered into three hydrogenation reaction zones and is subjected to reactions. A first hydrogenation reaction zone is filled with a hydrogenation protective agent, and is used for removing metal, colloid and asphaltene from the raw material oil. The second hydrogenation reaction zone is filled with a hydrogenation refining catalyst I, and is mainly used for carrying out hydrodenitrogenation and polycyclic aromatic hydrocarbon partial saturation reactions. The active metal of the hydrogenation refining catalyst I is nickel-tungsten, nickel-molybdenum or nickel-molybdenum-tungsten. The third hydrogenation reaction zone is filled with a hydrogenation refining catalyst II, and is mainly used for carrying out a hydrodesulphurization reaction. The active metal of the hydrogenation refining catalyst II is cobalt-molybdenum. With the method provided by the invention, refined wax oil desulphurization rate can be improved, wax oil raw material cracking performance is improved, and conversion rate and light oil yield of a catalytic cracking device are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

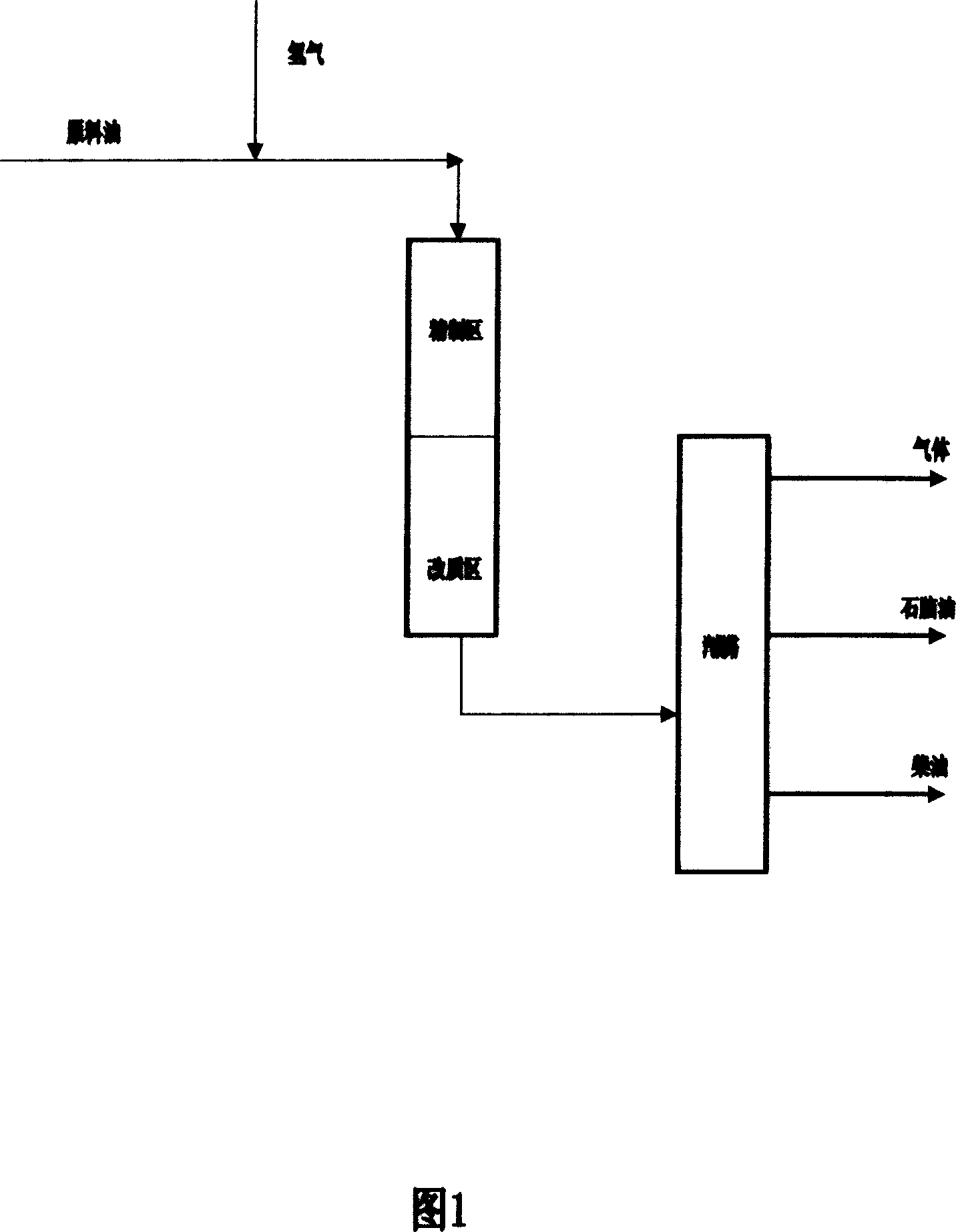

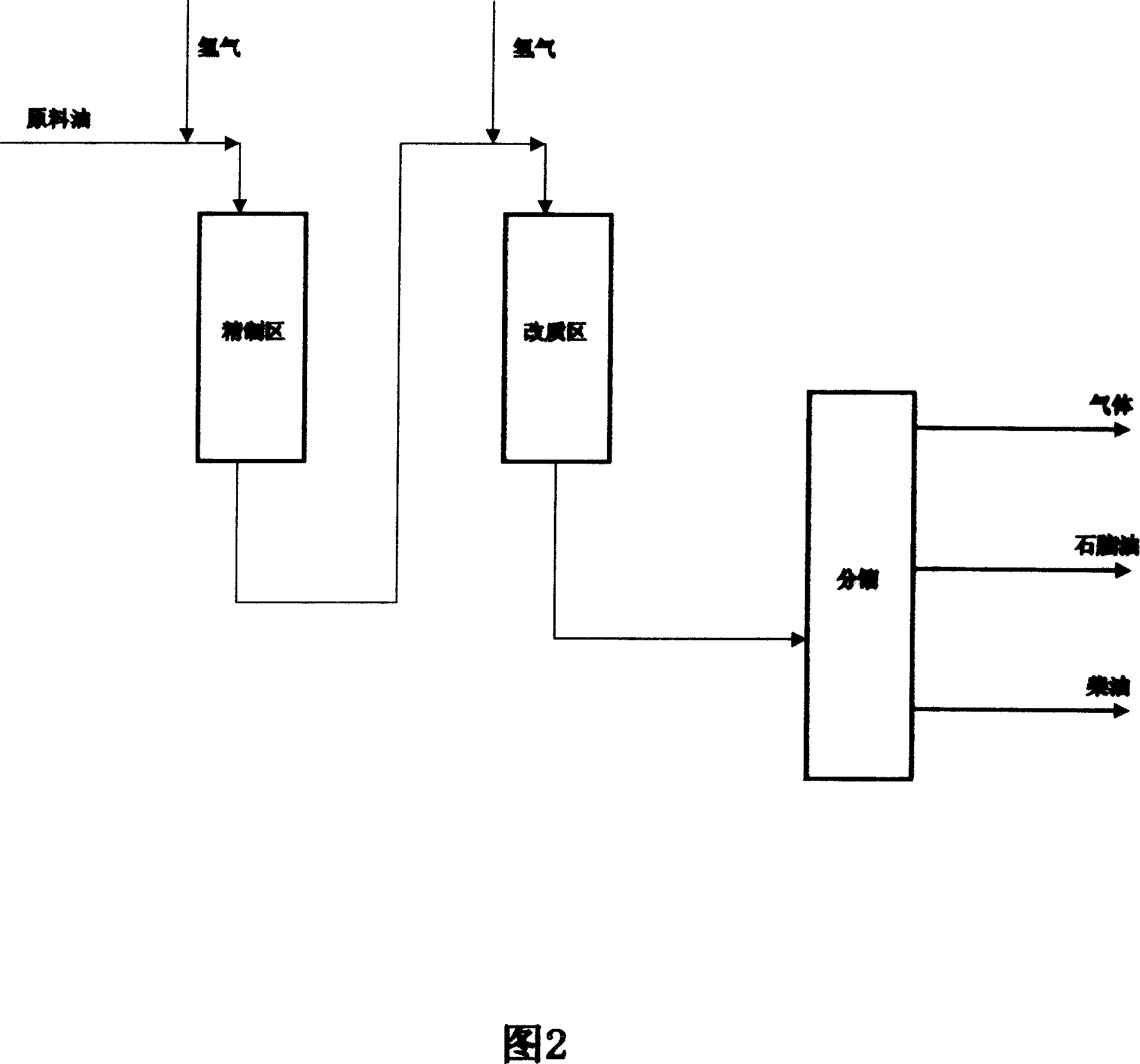

Hydrogenation modification method for coking gasoline and diesel distillates

ActiveCN102465023AAvoid Coking ProblemsFlexible production operationsTreatment with hydrotreatment processesChemistryKerosene

The invention discloses a hydrogenation modification method for coking gasoline and diesel distillates. A coking gasoline and diesel raw material is mixed with heated hydrogen and then introduced to pass through a low-temperature hydrorefining reactor and a hydrogenation modification reactor in sequence; a reaction effluent is separated and modified, and obtained liquid is distilled to obtain gas, gasoline, kerosene and diesel. In the method disclosed by the invention, a process flow of mixing hydrogen behind a furnace is adopted, the heating furnace is only used for heating the hydrogen, the mixed raw material does not pass through the heating furnace, and the temperature of the reactor is controlled based on the quantities of hot hydrogen and cold hydrogen. Compared with the prior art, the hydrogenation modification method disclosed by the invention has the advantage of saving equipment investment and being flexible in production scheme, can be used for flexible production by adjusting process conditions and production distribution according to the differences of raw material properties and product schemes; by implementation of hydrogen mixing behind the furnace, the coking raw material can be effectively prevented from being coked at a furnace tube; and by arrangement of a low-temperature protective agent reactor, olefin saturation is performed at lower temperature so as to reduce coking, meanwhile, coke powder is distributed at a protective agent bed as uniform as possible, so that the long-term operation of a hydrogenation device is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

Moderate hydrocracking process

ActiveCN101089137AReduce usageIncreased refining depthHydrocarbon oils refiningComplex oxideChemistry

The moderate hydrocracking process has the inferior diesel oil fraction, VGO or other heavy fraction oil as the material oil hydrocracked under moderate condition to result in high quality products, especially high quality hydrocracked tail oil. The catalyst in the hydrocracking reaction region includes at least one kind of bulk phase catalyst comprising complex oxide NixWyOz and oxide MoO3 in the weight ratio 0.1-10 and accounting for 40-100 wt% of total catalyst. The present invention facilitates the hydrocracking operation, increases the treating capacity of the apparatus, increases the service life of the catalyst and raises the quality of the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for middle distillate type hydrocracking catalyst containing metal nitride

ActiveCN103785440AHigh activityImprove nitrogen toleranceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveBiological activation

The invention discloses a preparation method for a middle distillate type hydrocracking catalyst containing metal nitride. The preparation method comprises the following steps: (1) preparing a catalyst carrier containing a molecular sieve and inorganic refractory oxide; (2) preparing a hydrazine derivative solution, dipping the catalyst carrier prepared in the step (1) in the hydrazine derivative solution and drying the catalyst carrier; (3) preparing a dipping solution containing a group VI-B metal compound and a group VIII metal compound; (4) dipping a material obtained in the step (2) in the dipping solution prepared in the step (3) and drying the material; and 5) subjecting a material obtained in the step (4) to hydrogen activation so as to obtain the hydrocracking catalyst used for a hydrocracking reaction. The hydrocracking catalyst provided by the invention is used for treating heavy hydrocarbon materials and can realize maximum production of intermediate distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst containing Y molecular sieve and preparation method thereof

ActiveCN101450320BHigh ratio of silicon to aluminumIncrease acidityMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a hydrocracking catalyst for producing heavy naphtha in great abundance and a preparation method thereof. The catalyst contains hydrogenation active metals and a carrier which consists of modified Y molecular sieves and alumina, wherein the Y molecular sieves are obtained by using a mixed aqueous solution of aluminum salts and an acid to perform hydro-thermal treatment. The properties of the modified Y molecular sieves are as follows: the specific surface area is between 750 m<2> / g and 850 m<2> / g; the total pore volume is between 0.35 and 0.48 ml / g; the relative crystallinity is between 90 and 130 percent; the cell parameter is between 2.437 and 2.445 nanometers; the silicon-aluminum mol ratio is between 15 and 70; the infrared acid amount is between 0.5 and 1.0 mmol / g; the B acid / L acid is more than 7.0; and the content of sodium oxide is less than or equal to 0.05 weight percent. The hydrocracking catalyst has the characteristics of good catalytic activity, high heavy naphtha selectivity, high yield, high latent content of heavy naphtha arene, and so on.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com