Patents

Literature

52 results about "Propylbenzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propylbenzene may refer to: Cumene n-Propylbenzene

Method for increase production of BTX (benzene, toluene and xylol) aromatic hydrocarbons and trimethylbenzene through hydrocracking heavy aromatic hydrocarbons

ActiveCN102746093AEasy to removeHigh removal activityHydrocarbonsBulk chemical productionBenzeneHydrogen

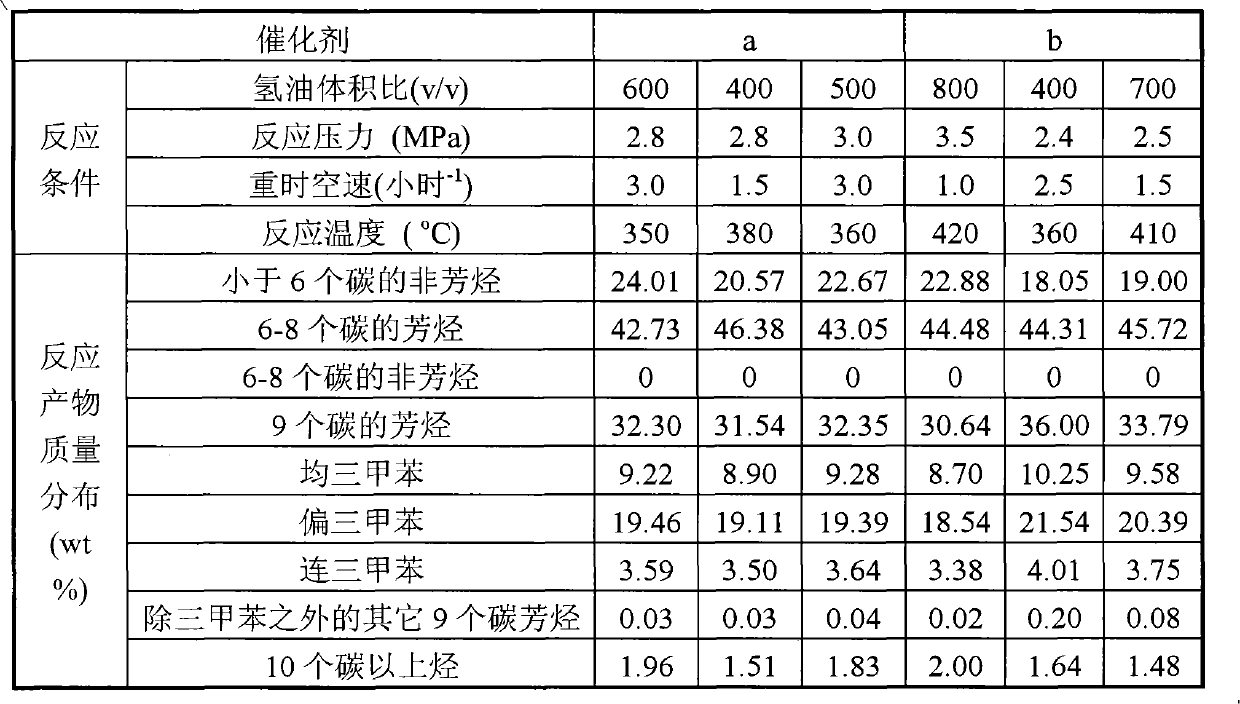

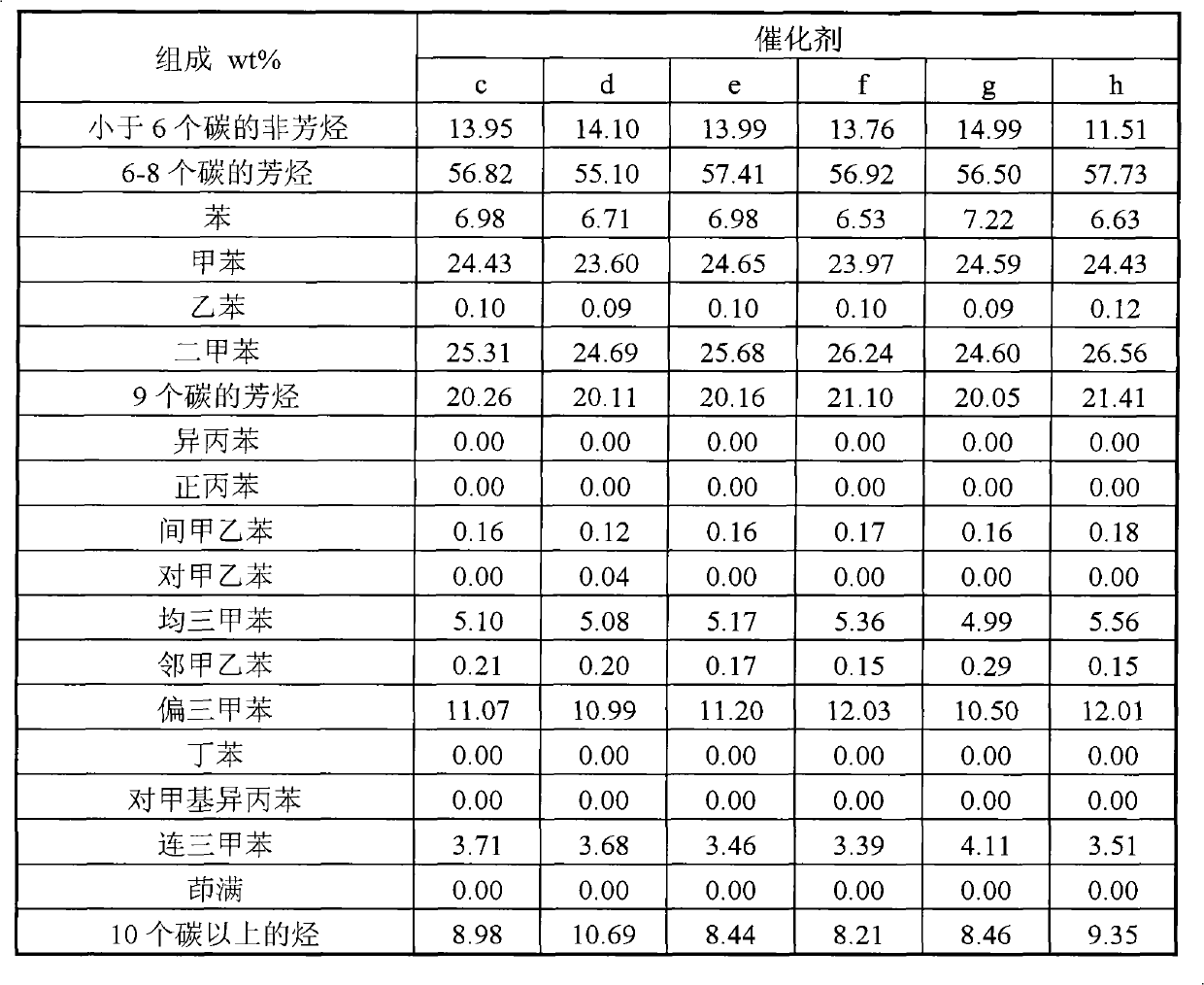

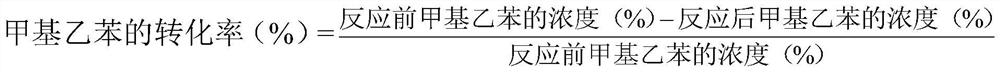

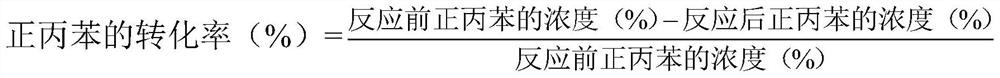

The invention relates to a method for the increase production of BTX aromatic hydrocarbons and trimethylbenzene through hydrocracking heavy aromatic hydrocarbons to mainly solve technical problems of low heavy aromatic hydrocarbon added value and high cost for separating and producing trimethylbenzene monomers in the heavy aromatic hydrocarbons containing methylethylbenzene, propylbenzene and butylbenzene. The method comprises a step that the heavy aromatic hydrocarbons are subjected to a hydrocracking reaction through adopting Pt / Pd-loaded hydrogen type binder-free ten-membered ring zeolite as a catalyst under reaction conditions comprising that the reaction temperature is 320-450DEG C, the reaction pressure is 2.0-4.0Mpa, the hydrocarbons raw material weight hourly space velocity is 1.0-4.0h<-1> and the hydrogen / hydrocarbon raw material ratio by mole is 3-10:1. The method well solves the problems through above technical scheme, and can be applied to the industrial production of the BTX aromatic hydrocarbons and the trimethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Propyl benzene latex with fine grain diameter for coating paper surface paint and preparation method and application thereof

The invention discloses propyl benzene latex with fine grain diameter for coating paper surface paint and a preparation method and application thereof. The latex is prepared by taking the following components as the raw materials in parts by weight in the mode of emulsion polymerization: 4-15 parts of seed emulsion, 100 parts of mixed monomer, 0.7-4.5 parts of emulsifier, 0.4-4.5 parts of initiator, 2-4 parts of accelerator, 2-8 parts of cross linking monomer, 4-20 parts of aqueous alkali and 90-290 parts of water, wherein the mixed monomer is composed of the following monomers in parts by weight: 20-44 parts of metacrylic acid ester, 50-74 parts of alpha methyl styrene and 6-10 parts of methacrylic acid. The propyl benzene latex with fine grain diameter for coating paper surface paint of the invention is an environmental-friendly high-property product which can be used by paper making paint. The product is applied in coating paper surface paint, can obviously strengthen the surface strength of the coating surface and improves paper coating glossiness.

Owner:JINING MING SHENG NEW MATERIALS CO LTD

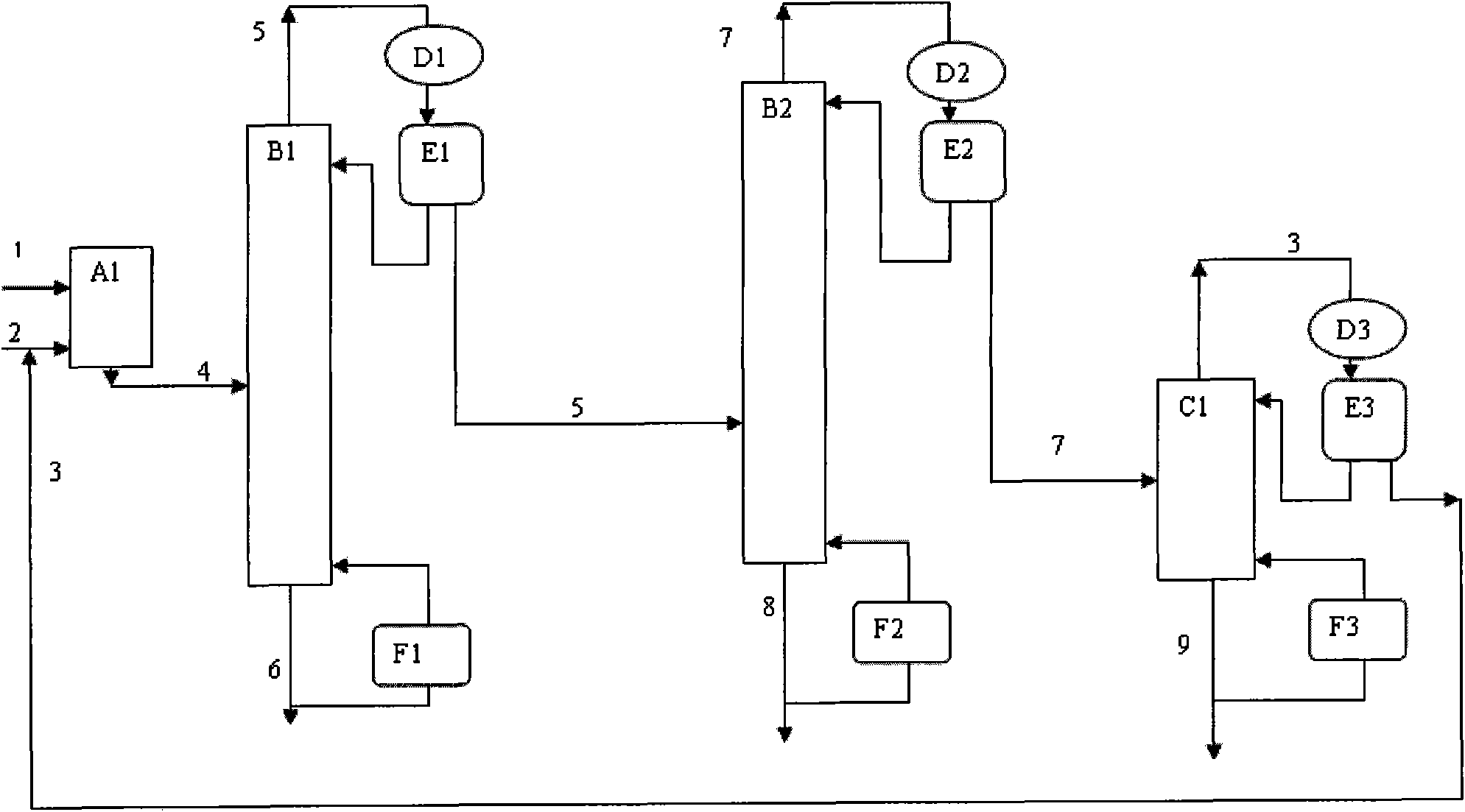

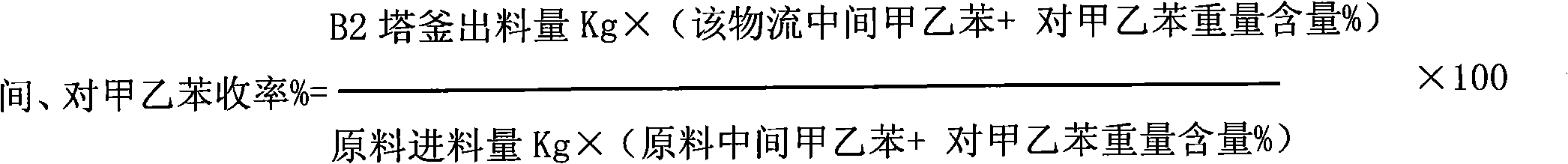

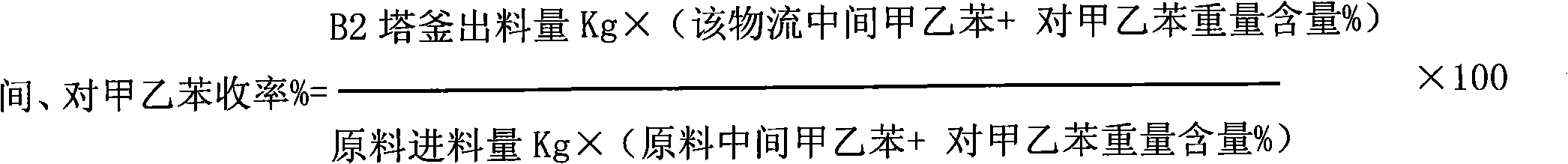

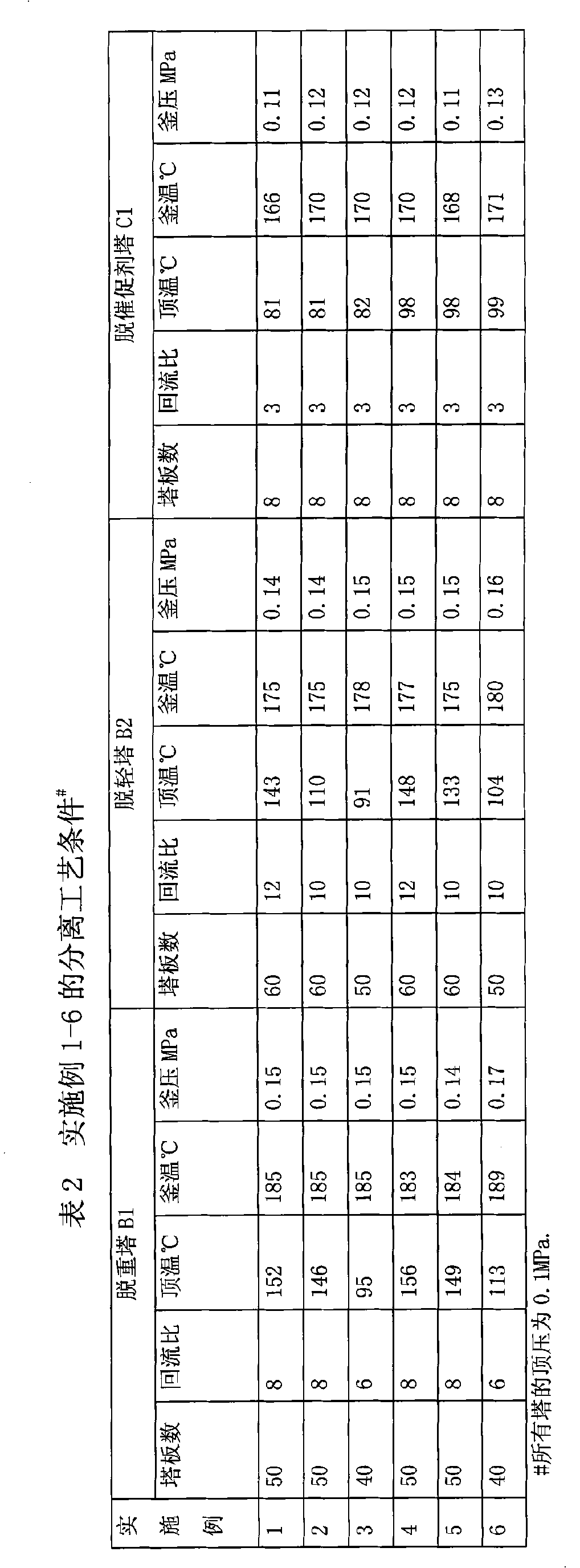

Method for separating mixture of m-ethyltoluene and p-ethyltoluene from C9 aromatics

ActiveCN102399125ALow boiling pointGood compatibilityDistillation purification/separationBulk chemical productionBenzenePropylbenzene

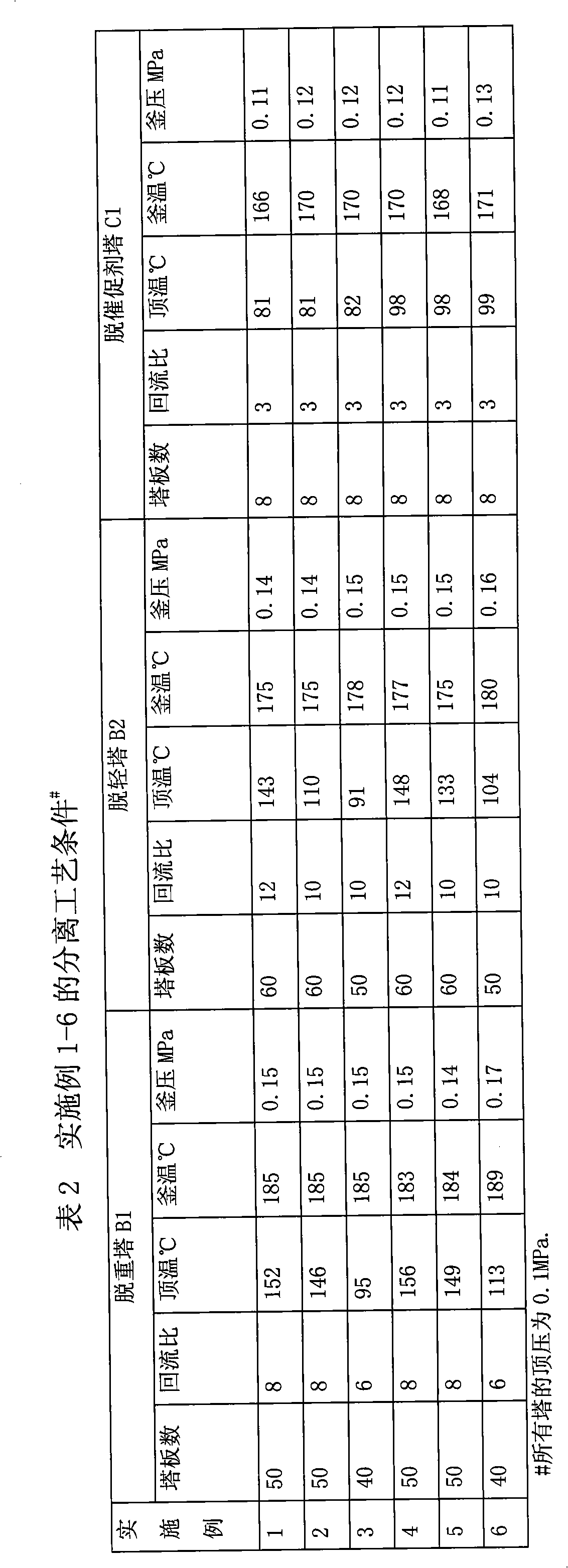

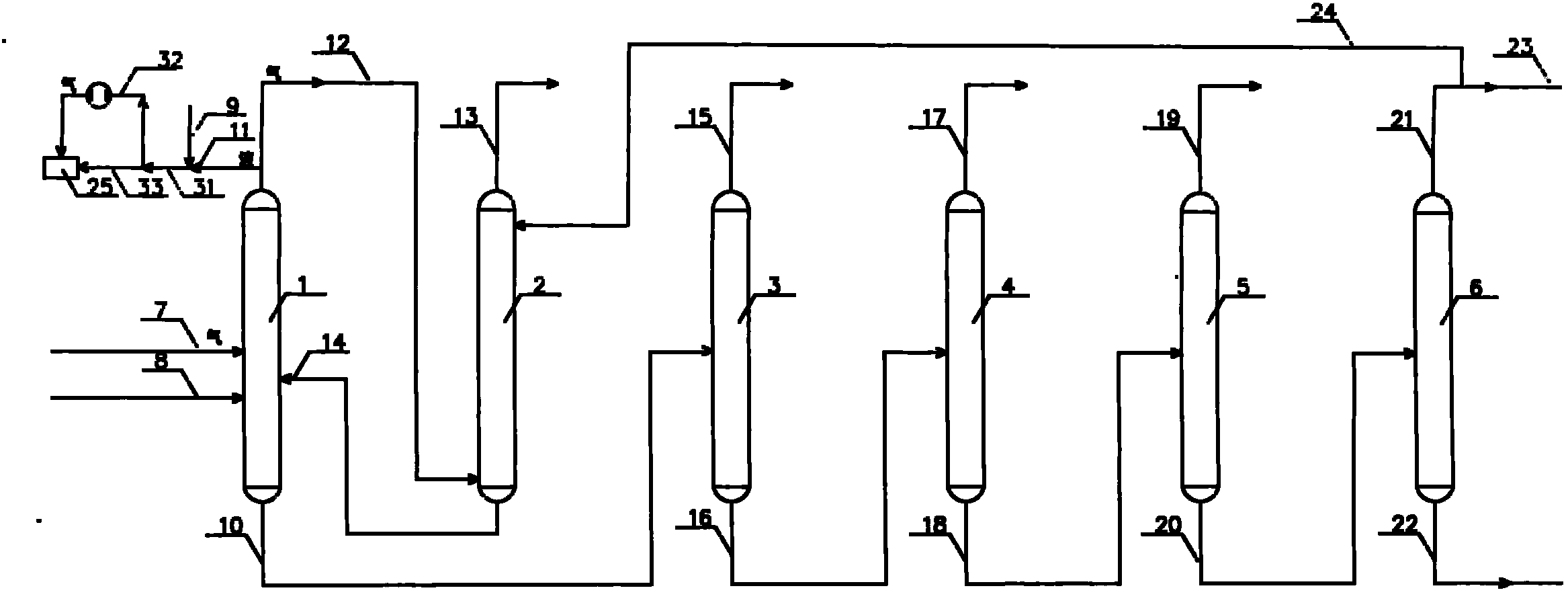

The invention discloses a method for separating a mixture of m-ethyltoluene and p-ethyltoluene from C9 aromatics. The method comprises the following steps of: (1) mixing a C9 aromatics mixture and an accelerator, and sending into a heavy component eliminating tower, introducing a light component from the top of the tower, introducing a heavy component from a tower kettle; wherein the weight ratio of the C9 aromatics mixture to the accelerator is 1:0.05-0.5; (2) sending the light component from the step (1) into a light component eliminating tower, introducing the mixture of m-ethyltoluene and p-ethyltoluene from the tower kettle; (3) sending material flow introduced from the light component eliminating tower in the step (2) to an accelerator removal tower, introducing the accelerator from the tower top, introducing the material flow containing normal propylbenzene and isopropylbenzene from the tower kettle. The accelerator is acetonitrile and propionitrile. The mixture of m-ethyltoluene and p-ethyltoluene obtained by the method of the invention has the advantages of high purity, high yield and obvious separation effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel nanometer antifungus energy-conserving wall material

InactiveCN101333358AHas absorptionWith thermal insulationAntifouling/underwater paintsPaints with biocidesSodium BentoniteMoisture

Disclosed is nano anti-mildew energy-saving wall material, containing organic solvent, water, bentonite, diatomite, inorganic dye and filler, and addition agent. The organic solvent is one or more from polyvinyl alcohol, propyl benzene, propyl alcohol, ethylene glycol, alcohol ester and organic silicon resin; the bentonite is ca-bentonite; the inorganic dye and filler is one or more from titanium dioxide, talcum powder, light calcium carbonate, lithopone, wollastonite powder and wollastonite. The nano anti-mildew energy-saving wall material has the functions of absorbing and releasing moisture, adjusting room temperature, resisting mildew and bacteria, absorbing osmyl, noise and harmful substances, insulating and preserving heat, and resisting water and fire, and has water resistance and adhesive force, so the nano anti-mildew energy-saving wall material is a new environment-friendly paint better than latex paint.

Owner:唐子林

Catalyst for synthesizing iso-propylbenzene

ActiveCN101045209AImprove reaction stabilityImprovement of dealuminationMolecular sieve catalystsHydrocarbonsMolecular sieveReaction temperature

A catalyst for synthesizing isopropylbenzene with low reaction temp (120-170 deg.C) and benzene / hydrocarbon ratio (2-5) and high stability is a modified molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for alkylation reaction of aromatic hydrocarbons and low-carbon alkanes and use thereof

A catalyst for the alkylation reaction of aromatic hydrocarbon and light alkane contains Mo element and ZSM-5 molecular sieve, wherein the weight ratio of the Mo element and the ZSM-5 molecular sieve is 1-16%. A binder of 5-40 wt% is added into the catalyst. In accordance with the embodiment of the catalyst in the alkylation reaction of aromatic hydrocarbon and light alkane, the reaction temperature is 250-450 DEG C, the material molar ratio of the aromatic hydrocarbon and light alkane is 0.5-3, the weight space-velocity is 0.2-5 h<-1>, accordingly, toluene, ethyl benzene, isopropyl benzene and n-propylbenzene can be prepared with high selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Sulfosalicylic acid silver plated additive, preparation method of sulfosalicylic acid silver plated additive and electroplating liquid including sulfosalicylic acid silver plated additive

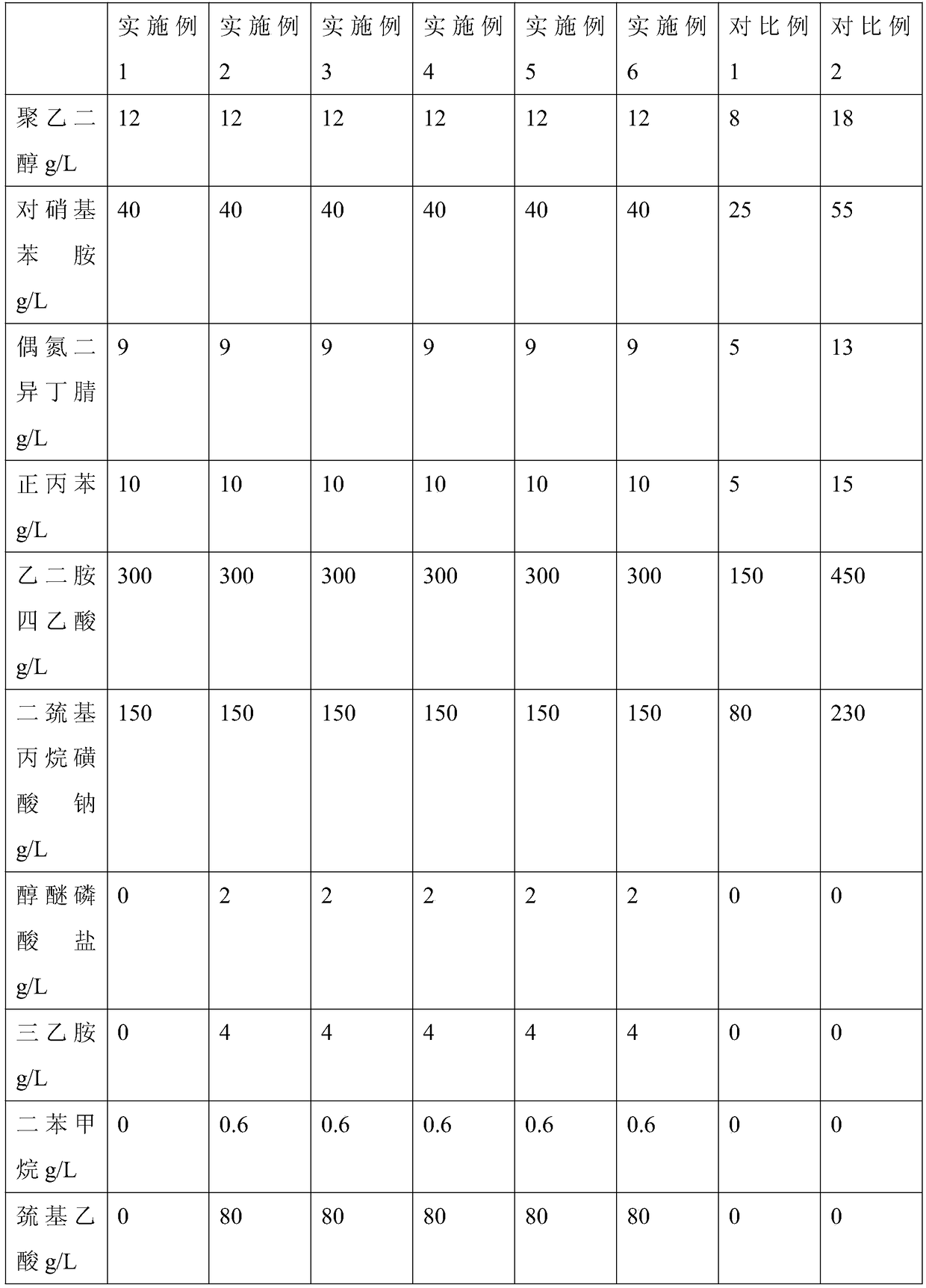

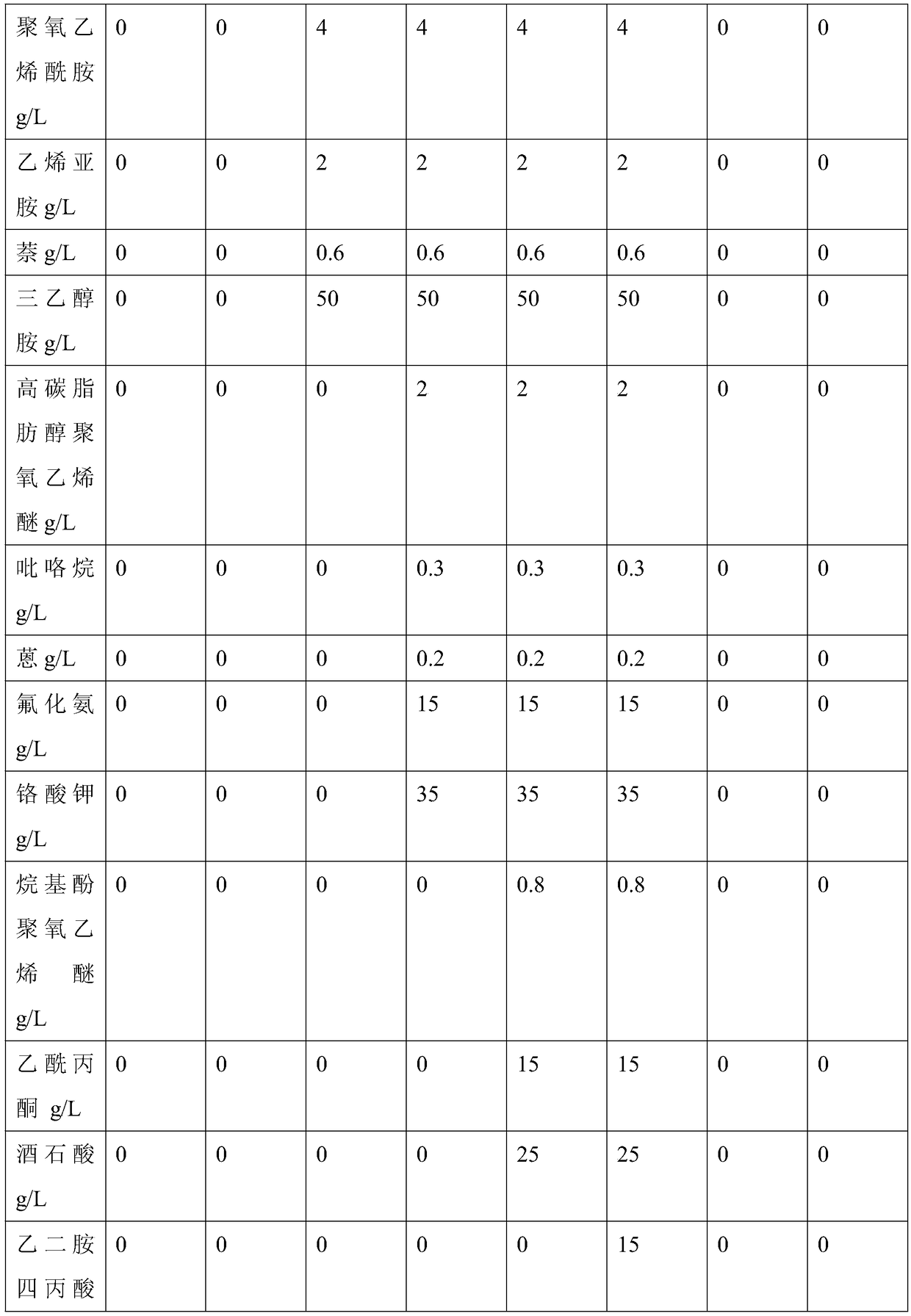

The invention discloses a sulfosalicylic acid silver plated additive, a preparation method of the sulfosalicylic acid silver plated additive and electroplating liquid including the sulfosalicylic acidsilver plated additive. The sulfosalicylic acid silver plated additive comprises 10 g / L-15 g / L of polyethylene glycol, 30 g / L-50 g / L of paranitroaniline, 8 g / L-10 g / L of azodiisobutyronitrile, 8 g / L-12 g / L of propylbenzene, 200 g / L-400 g / L of EDTA, 100 g / L-200 g / L of sodium dimercaptosulphonate and the balance water. By means of the silver plated additive, the dispersibility, stability, electroplating performance and the like of the electroplating liquid are improved quite remarkably, the pH value does not need to be repeatedly adjusted in the electroplating process, meanwhile, the smoothness, adhesive force, glossiness color change resistance and other performance of a silver plated layer are improved remarkably, the thickness of the plating layer is reduced, and the phenomena of fracturing and the like are avoided. The electroplating liquid includes no cyanide, the plating layer is bright in mirror surface, small in brittleness, good in adhesive force, level in surface, bright, goodin color change resistance and high in heat resistance, application to multiple fields such as decorative electroplating and functional electroplating can be met, the electroplating liquid can be directly sued for brass, copper, chemical nickel and other workpieces, pre-plating is not needed, and the binding force can be guaranteed.

Owner:NANJING INST OF PROD QUALITY INSPECTION +1

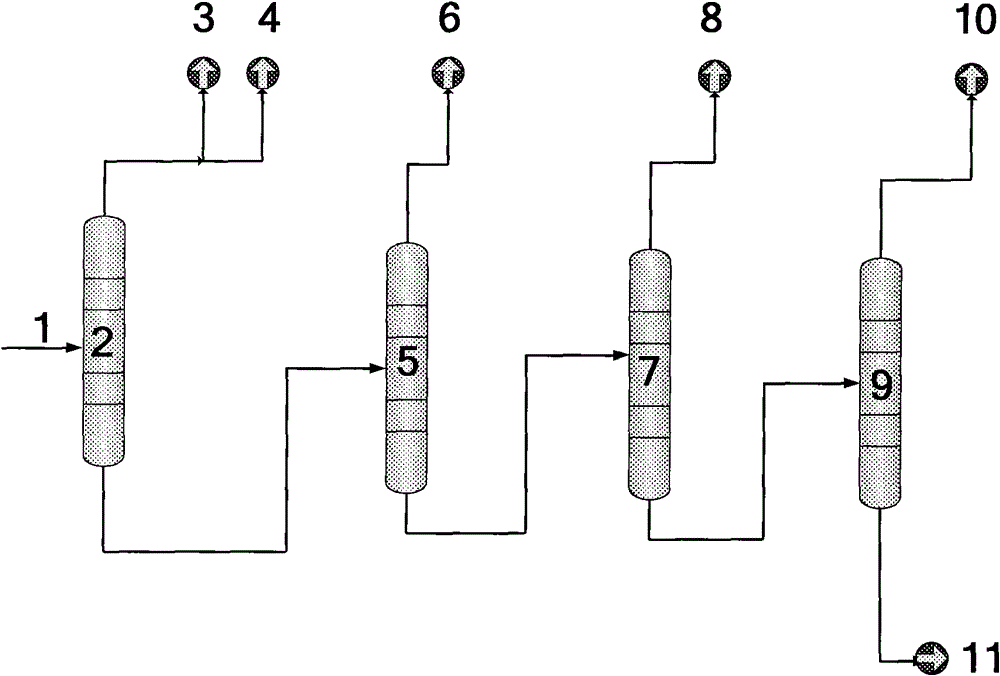

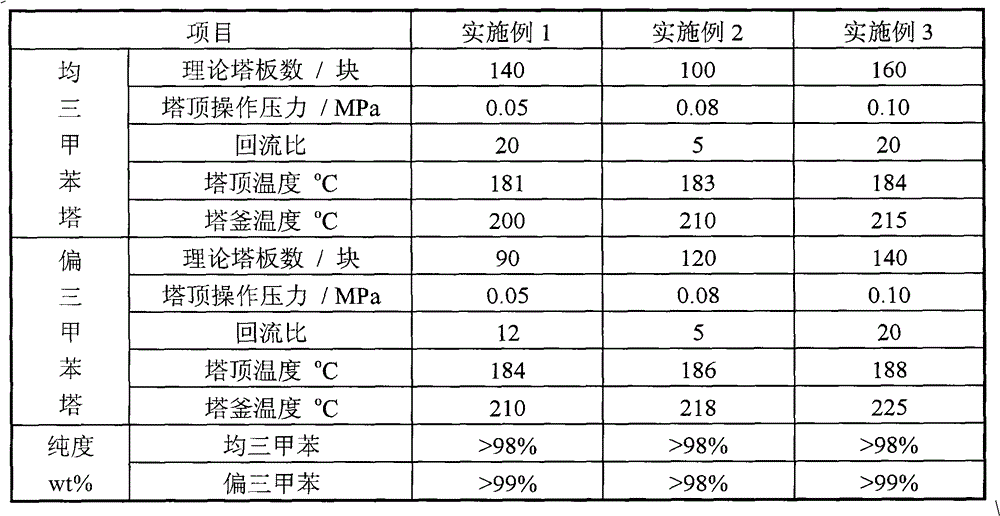

Trimethylbenzene separation method

The invention relates to a trimethylbenzene separation method to mainly solve technical problems of long flow and high cost of previous separation of trimethylbenzene monomers from a heavy aromatic hydrocarbon material containing propylbenzene, methylethylbenzene and butylbenzene. The method, which adopts a technical scheme that the heavy aromatic hydrocarbon material which is C9 aromatic hydrocarbons with the content of aromatic hydrocarbons except trimethylbenzene being less than 0.5% sequentially enters a 1,3,5-trimethylbenzene tower and a 1,2,4-trimethylbenzene tower for being rectified and separated to obtain 1,3,5-trimethylbenzene products and 1,2,4-trimethylbenzene products, well solves the problems, and can be applied to the industrial production of trimethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

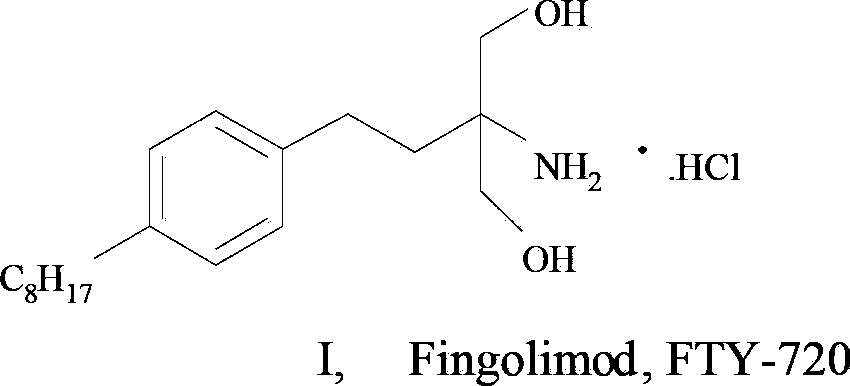

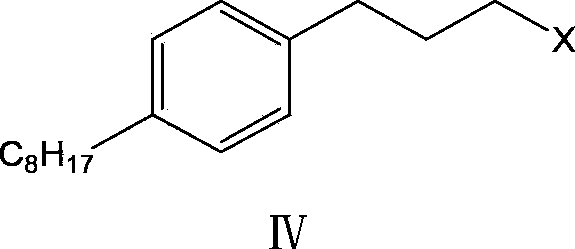

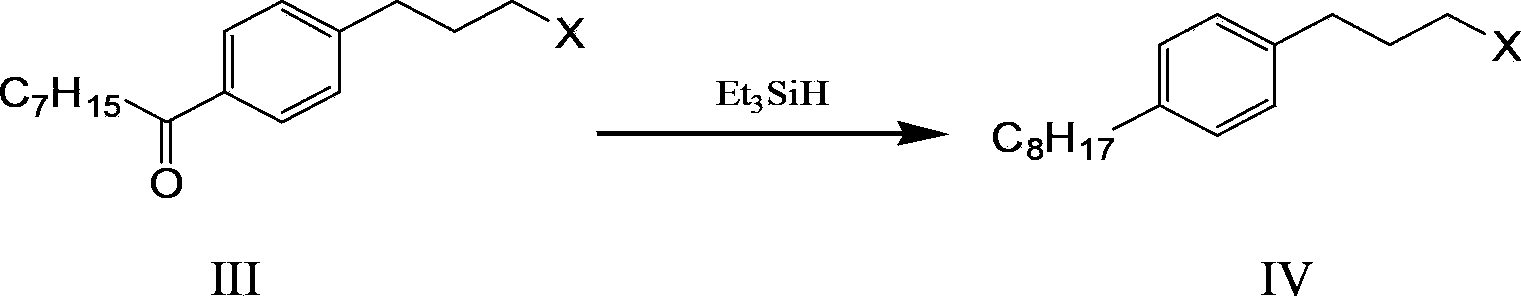

Method and intermediate for synthesizing Fingolimod hydrochloride

ActiveCN103804123AEasy to operateSuitable for industrialized mass productionOrganic compound preparationCarbonyl compound preparation by condensationFingolimod HydrochloridePropylbenzene

The invention provides a method and an intermediate for synthesizing Fingolimod hydrochloride. The method comprises the following steps: performing nitro-substitution, formaldehyde condensation, reduction and salification on octyl halogenated propylbenzene by using a novel intermediate, thereby obtaining the Fingolimod hydrochloride. The synthetic method is short in route, high in yield, low in cost, mild in reaction conditions, simple and convenient in operation and high in product purity and has high application value in large-scale industrial production.

Owner:四川弘远药业有限公司

Anti-corrosion coating capable of emitting aromatic odor for glass door and preparation method of anti-corrosion coating

InactiveCN104342002AImprove water resistanceImprove anti-corrosion performanceAnti-corrosive paintsPolyurea/polyurethane coatingsCellulosePolymer science

The invention discloses an anti-corrosion coating capable of emitting aromatic odor for a glass door. The anti-corrosion coating is characterized by being prepared from the following raw materials in parts by weight: 46-52 parts of a transparent polyurethane emulsion, 1-2 parts of a polyethylene wax emulsion, 20-24 parts of a modified styrene-acrylic emulsion, 1-3 parts of methoxy-1-methylethylacetate, 0.2-0.5 part of propanediol butyl ether bi(2-octyloxy pyrophosphate-yl) ethylene titanate, 0.2-0.4 part of a polyacrylate flatting agent, 1-2 parts of ethyl acetate, 0.2-0.3 part of ethyecellulose, 0.2-0.5 part of polyether-modified polyethylene organic siloxane, 0.3-0.6 part of propyl triethoxy siloxane, 0.3-0.7 part of menthyl acetate, 0.2-0.5 part of polyoxyethylene oleate, 0.3-0.5 part of phenoxyaethanol, 1-3 parts of a pigment, 1-2 parts of nano ceramic powder and 10-15 parts of deionized water. The water-based coating disclosed by the invention has excellent water resistance, rot resistance and adhesive force, also has fresh aromatic odor, and is refreshing; the coating has the effects of sterilizing, preventing dust, resisting static electricity and the like due to the added modified styrene-acrylic emulsion; and the quality of the coating is further improved.

Owner:凤阳徽亨商贸有限公司

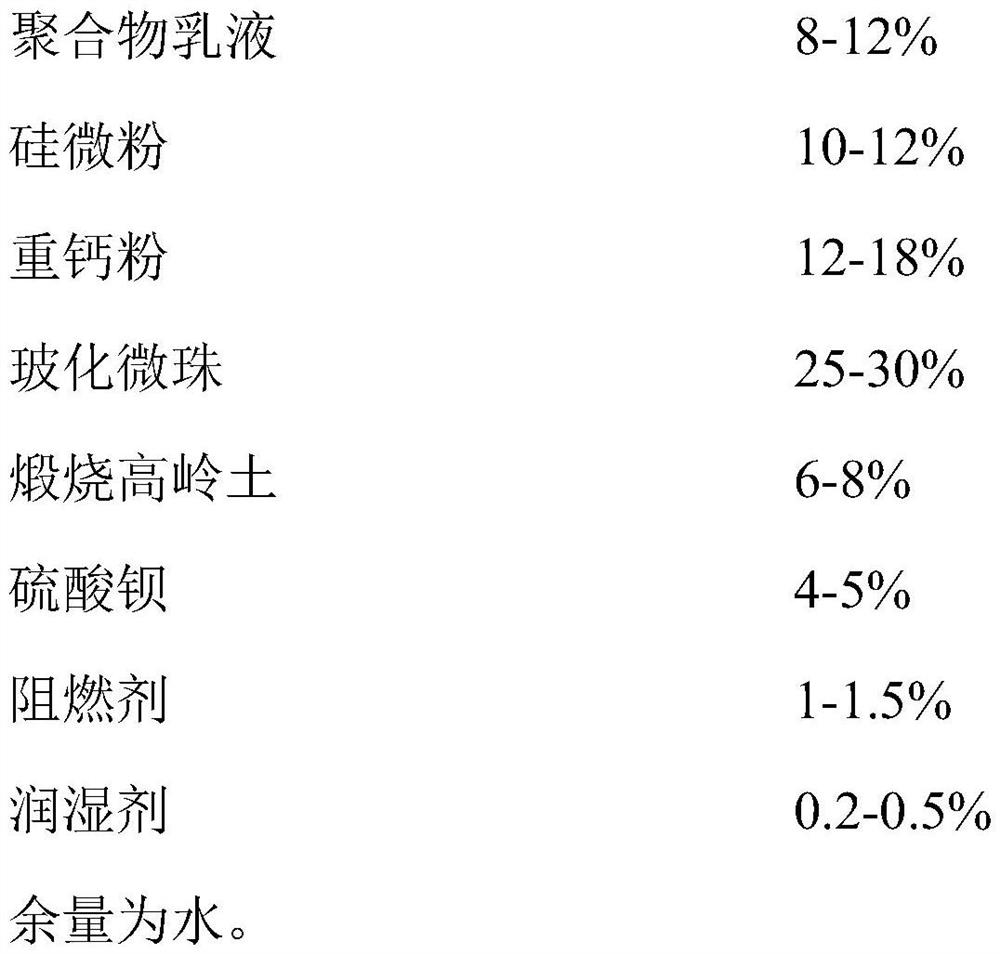

Elastic thermal insulation slurry and preparation method thereof

The invention relates to elastic thermal insulation slurry and a preparation method thereof. The elastic thermal insulation slurry is prepared from the following raw materials in percentage by weight:8-12% of polymer emulsion, 10-12% of silica powder, 12-18% of coarse whiting powder, 25-30% of glass micro-beads, 6-8% of calcined kaolin, 4-5% of barium sulfate, 1-1.5% of a flame retardant, 0.2-0.5% of a wetting agent and the balance of water. According to the invention, the silica powder is used as a light skeleton, the polymer emulsion and the calcined kaolin are added at the same time, so that the binding power of slurry is improved, the slurry can be quickly coagulated, strong binding strength with a base material is generated and is up to 0.11 MPa, the cured propylbenzene emulsion is high in strength, good toughness of the product can be guaranteed, and after being mounted on a wall, the elastic thermal insulation slurry is not easy to crack and fall off; and the slurry is good inheat preservation performance, the vitrified micro bubbles are added, so that the heat conductivity coefficient of the obtained slurry is smaller than 0.053 W / (m.K), and the slurry has good flame retardance.

Owner:JIANGSU TEYOUNUO NEW MATERIALS TECH

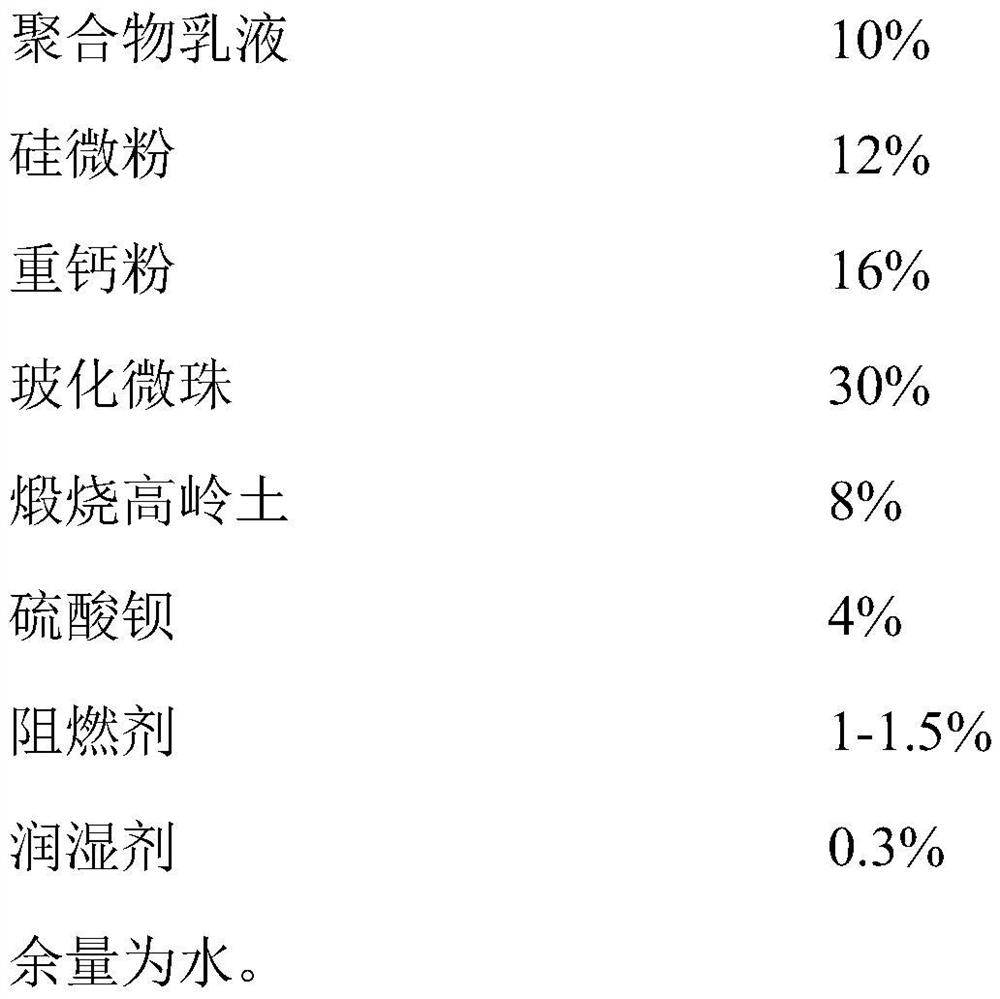

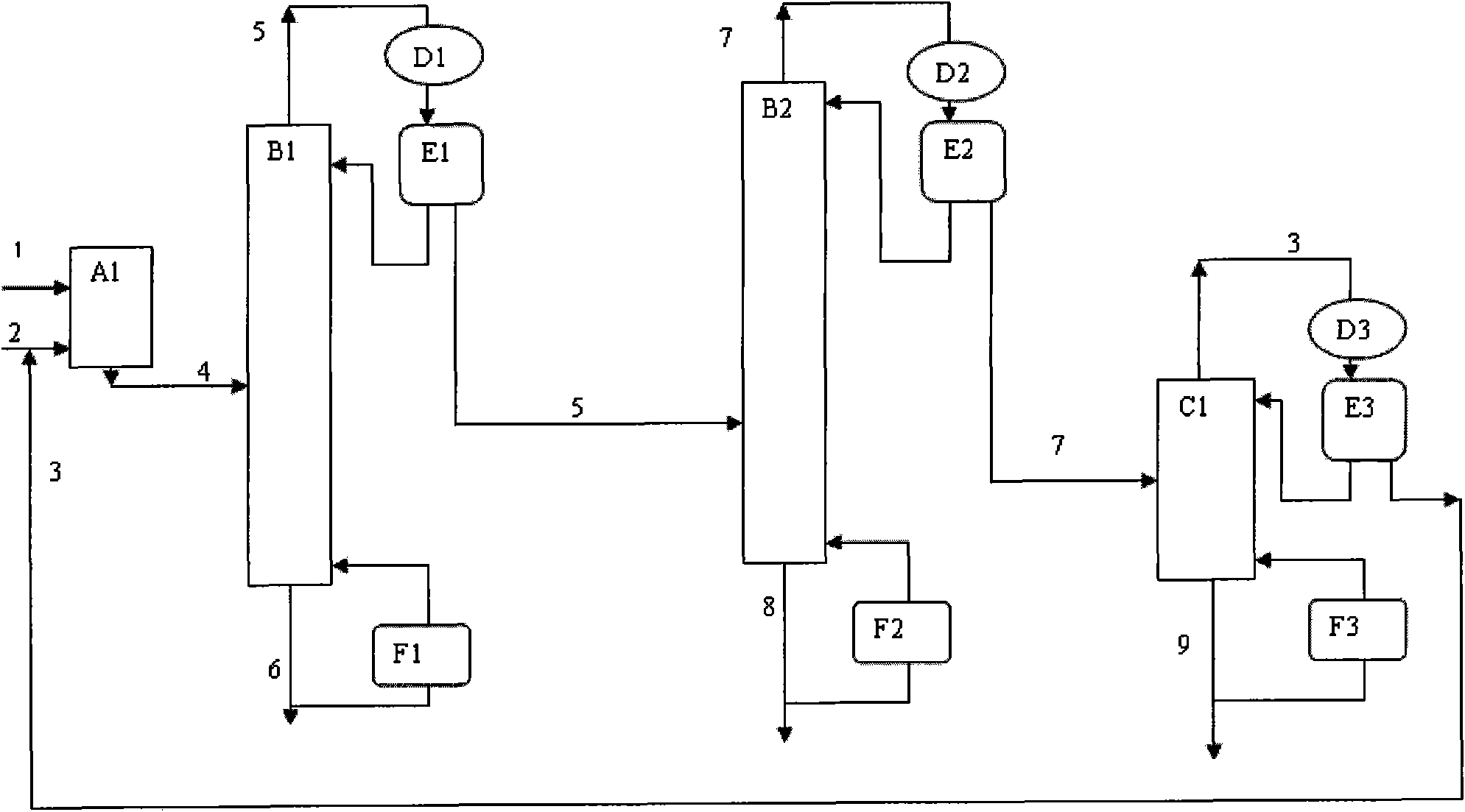

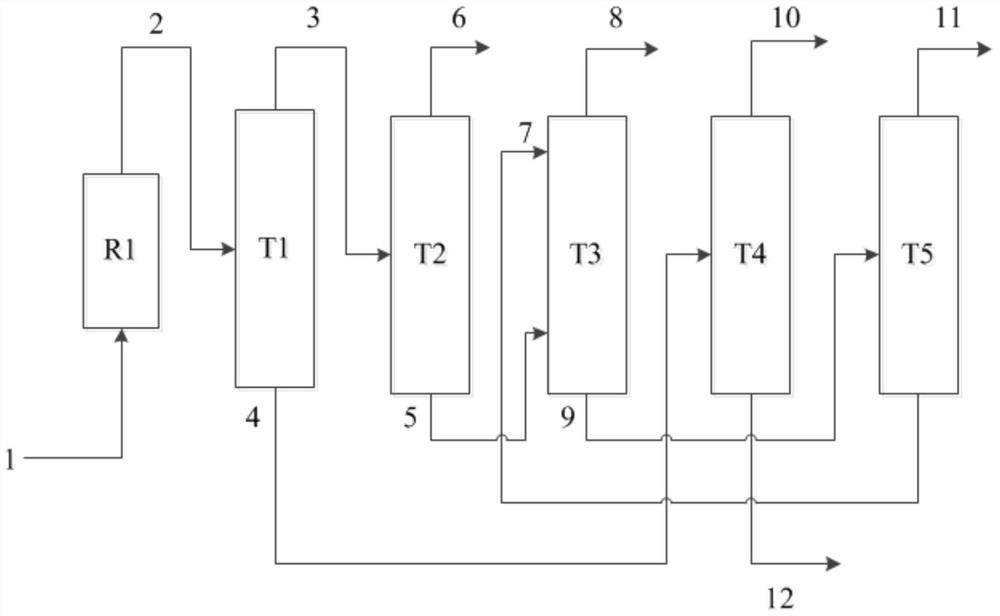

Methods and apparatuses for producing xylene from propylbenzene

InactiveUS20150307412A1Hydrocarbon by isomerisationHydrocarbon by metathesis reactionIsomerizationPropylbenzene

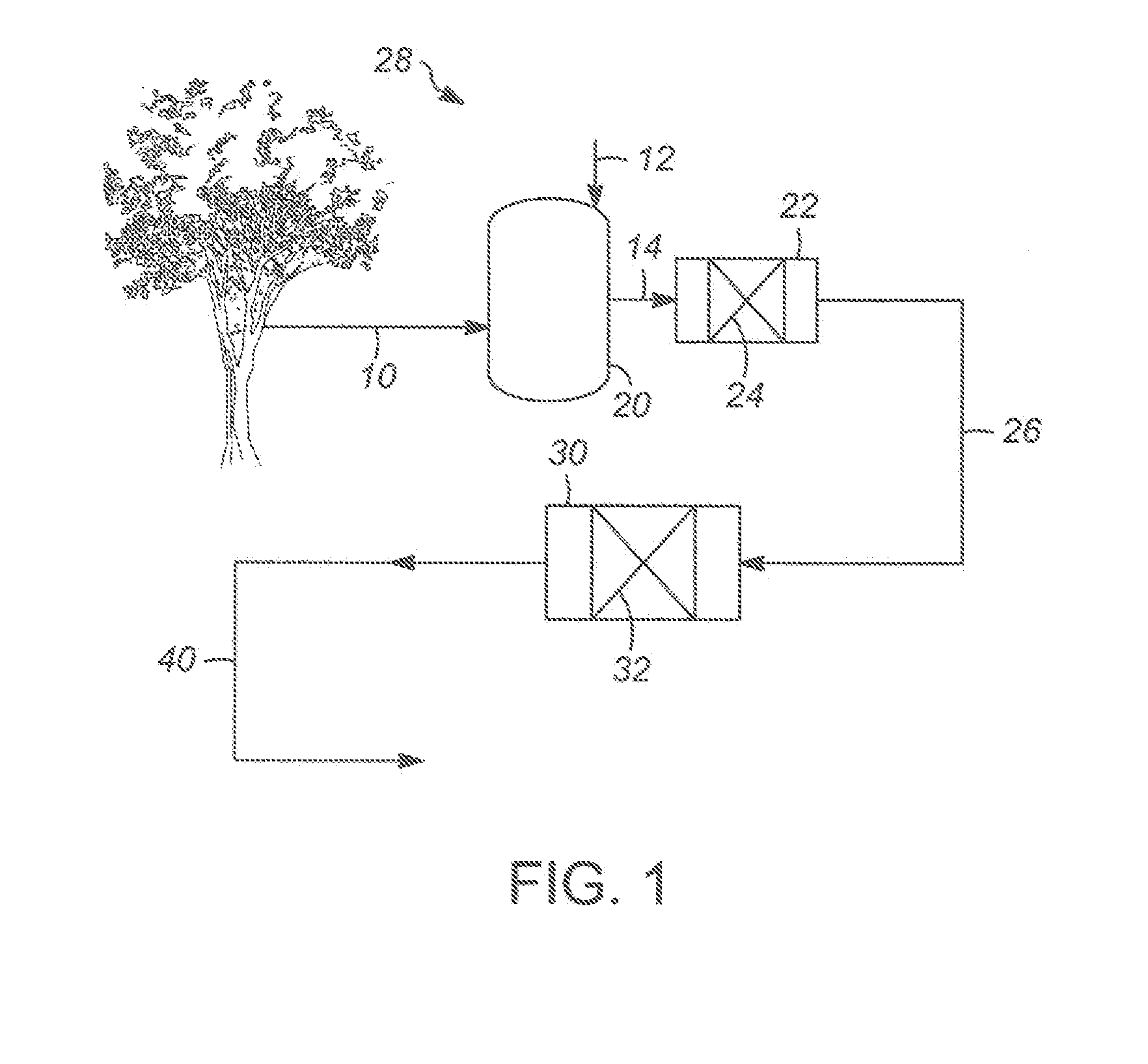

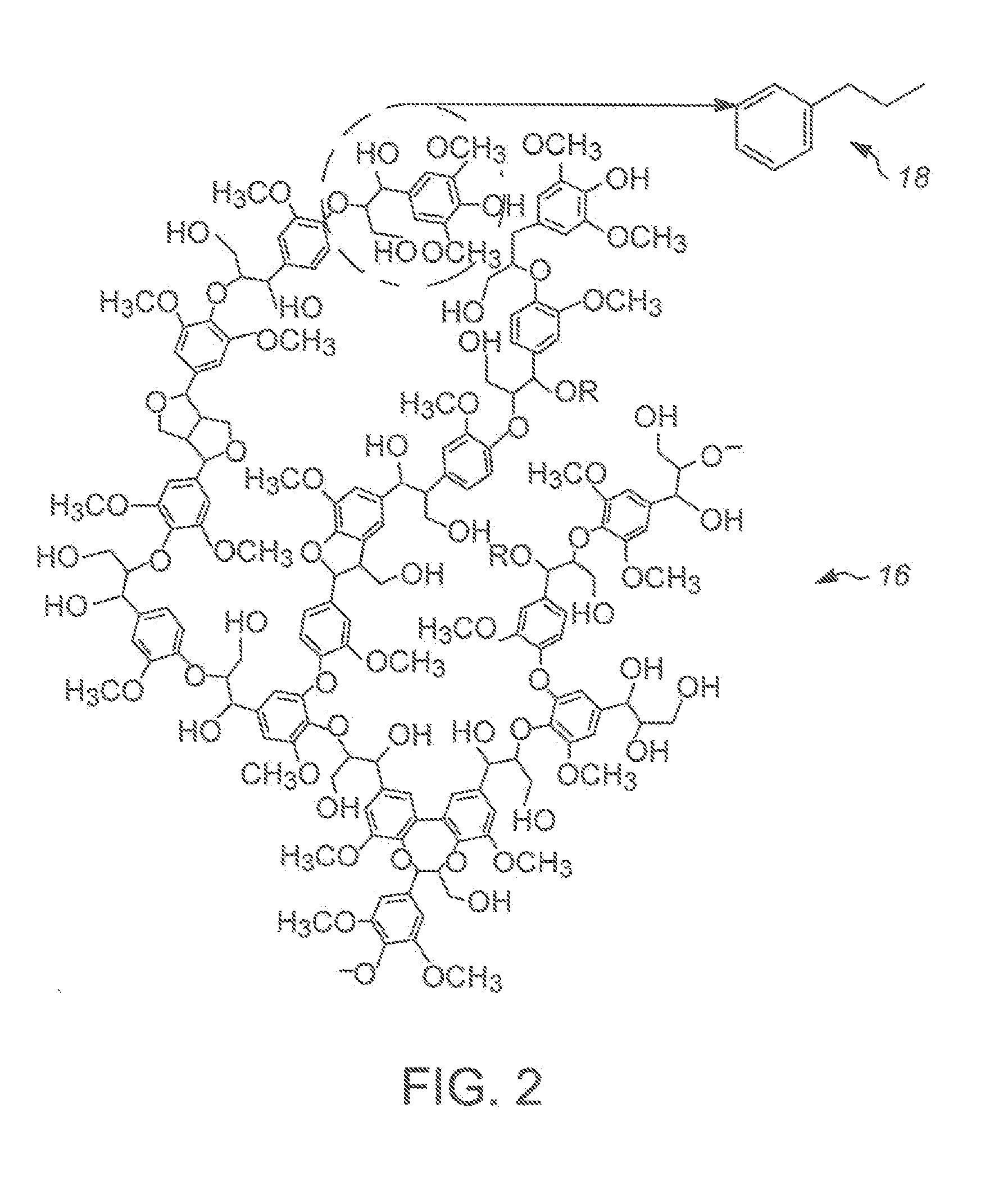

Methods and apparatuses are provided for producing xylene. A method includes combining a propylbenzene containing feed with a xylene raffinate stream, where the xylene raffinate stream is provided from a xylene recovery unit. The xylene raffinate stream and the propylbenzene containing feed are isomerized in an isomerization unit to produce an xylene isomerization effluent stream, where the xylene isomerization effluent stream includes aromatic compounds having 8, 9, or 10 carbons atoms. The aromatic compounds having 8 carbon atoms are separated from the aromatic compounds having 9 or 10 carbons, and the aromatic compounds having 8 carbons are fed to the xylene recovery unit. The aromatic compounds having 9 or 10 carbons are transalkylated with toluene to produce xylene.

Owner:UOP LLC

Anticorrosive anti-yellowing coating for glass door and preparation method of coating

InactiveCN104341944AImprove dustproofImprove antistatic performanceAntifouling/underwater paintsPaints with biocidesPolymer scienceMaterials science

The invention discloses an anticorrosive anti-yellowing coating for a glass door. The coating is characterized by being prepared from the following raw materials in parts by weight: 8 to 12 parts of water-based vinyl polyurethane, 30 to 35 parts of amino resin emulsion, 0.1 to 0.3 part of water-based silane coupling agent KH460, 26 to 32 parts of modified styrene-acrylic emulsion, 1 to 3 parts of dipropylene glycol dimethyl ether, 0.3 to 0.5 part of alcohol amine alkoxy titanate ester, 0.2 to 0.4 part of fluoro-alkyl polyether modified polysiloxane, 0.1 to 0.3 part of lauroyl diethanolamide, 0.2 to 0.3 part of white oil, 0.2 to 0.4 part of polyoxyethylene sorbitan monooleate, 0.1 to 0.2 part of ammonium polyphosphate, 0.3 to 0.7 part of ethylparaben, 0.2 to 0.5 part of glycerin, 0.3 to 0.6 part of quartz powder, 1 to 3 parts of pigment and 10 to 15 parts of deionized water. The sterilization, the dust prevention, the anti-static performance and the like of the coating are improved due to the added modified styrene-acrylic emulsion; the coating has the functions of sterilization and anticorrosion due to the added ethylparaben; and on the basis of water resistance, acid resistance and an excellent adhesive force of the water-based coating, the water-based coating is also good in weatherability, aging resistance and anticorrosion.

Owner:凤阳徽亨商贸有限公司

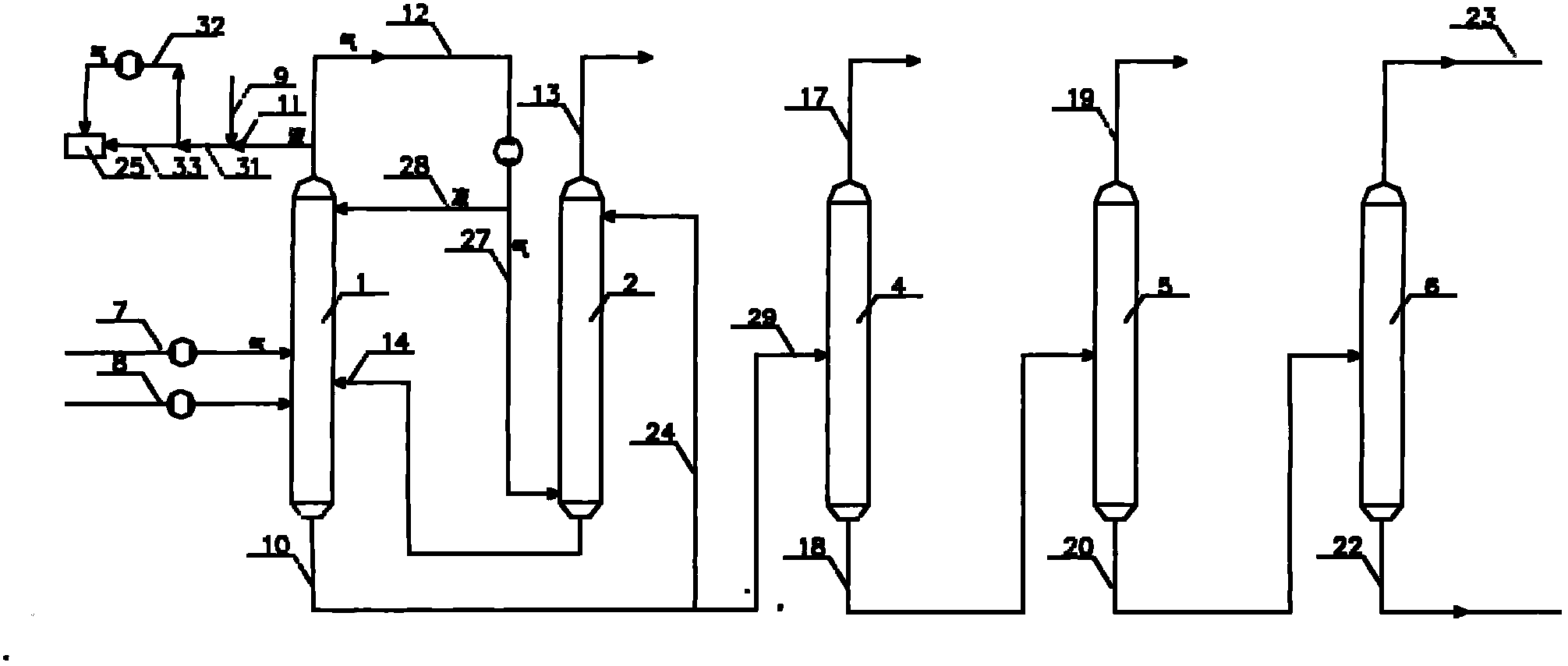

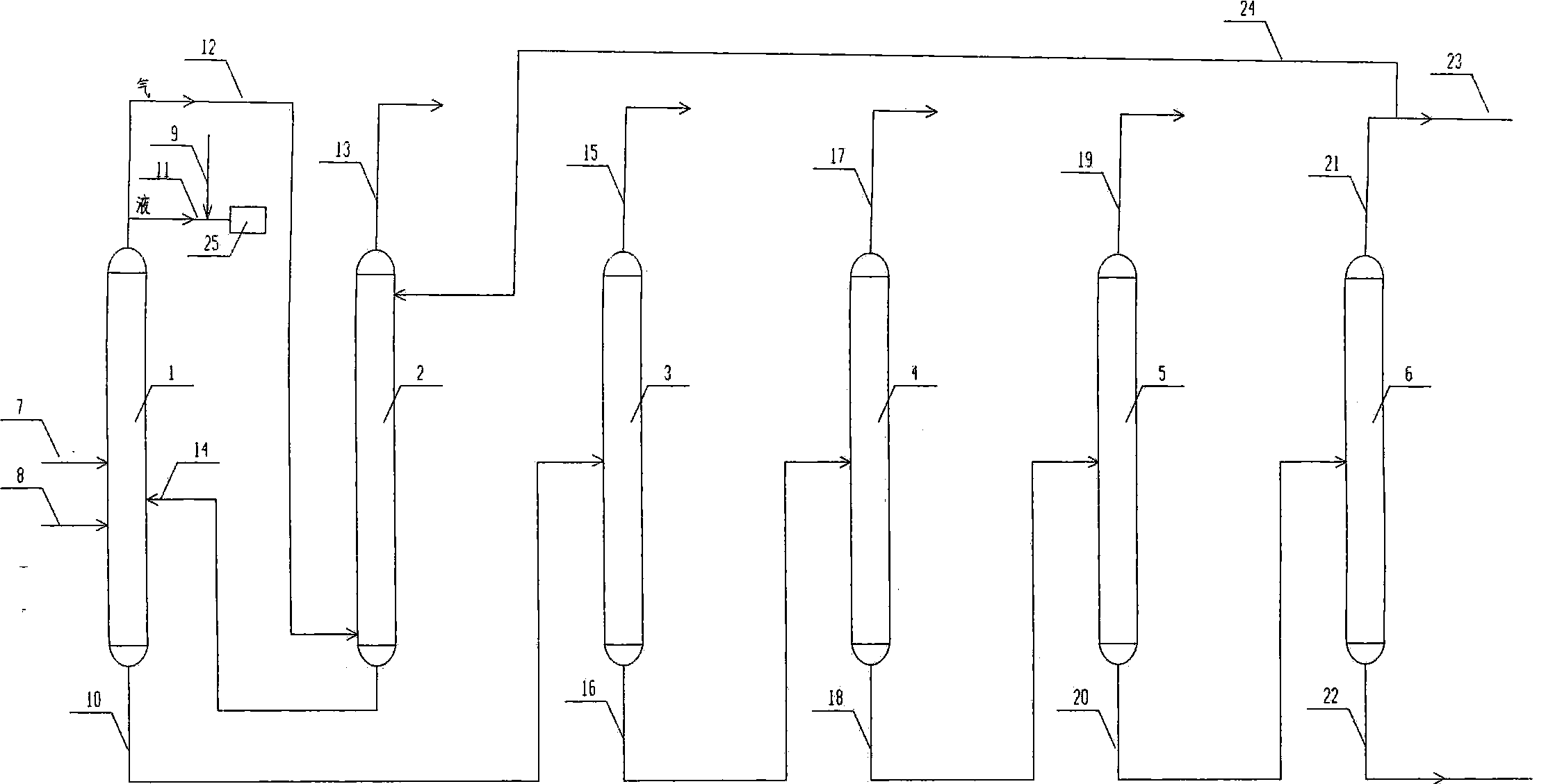

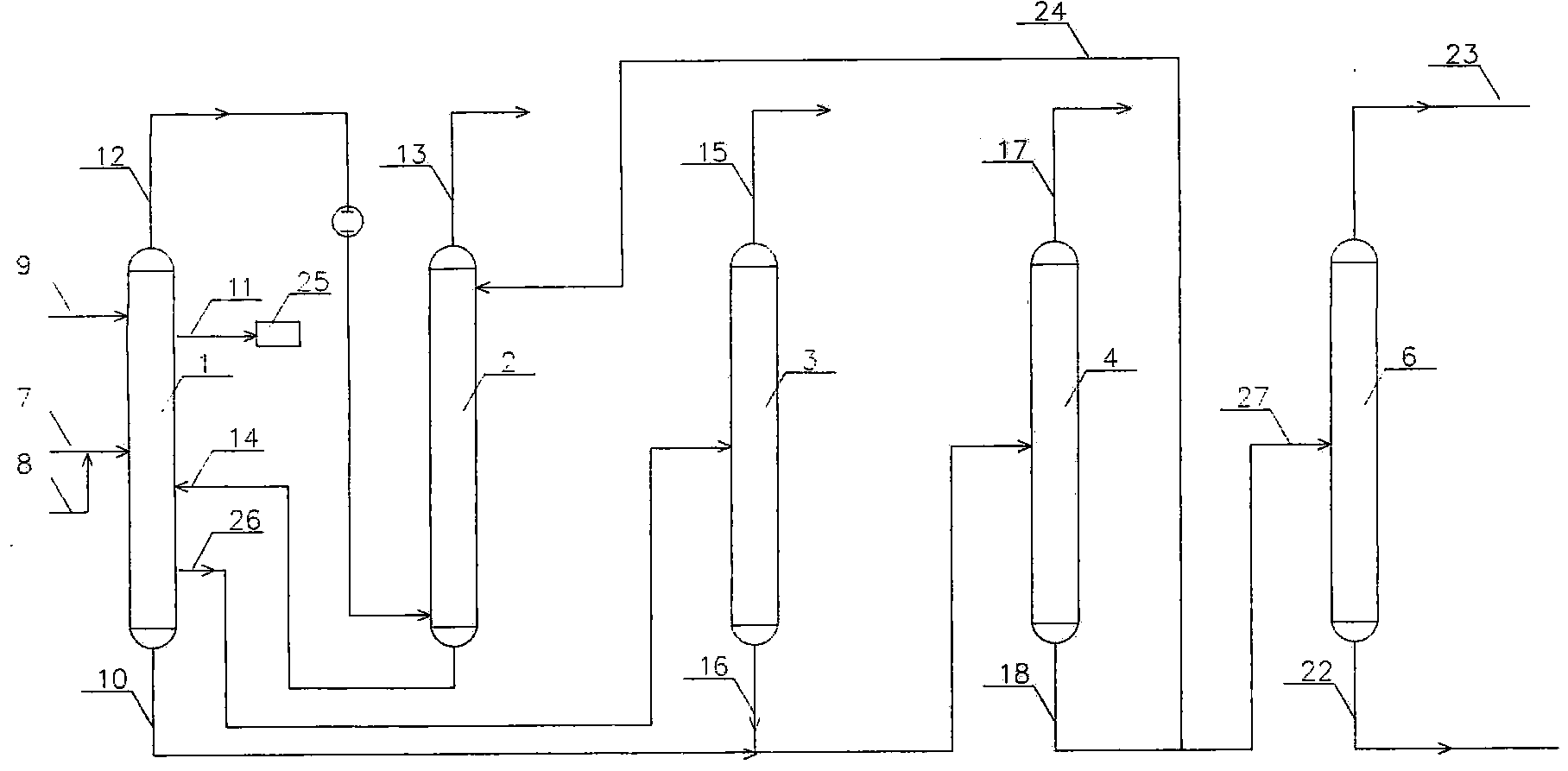

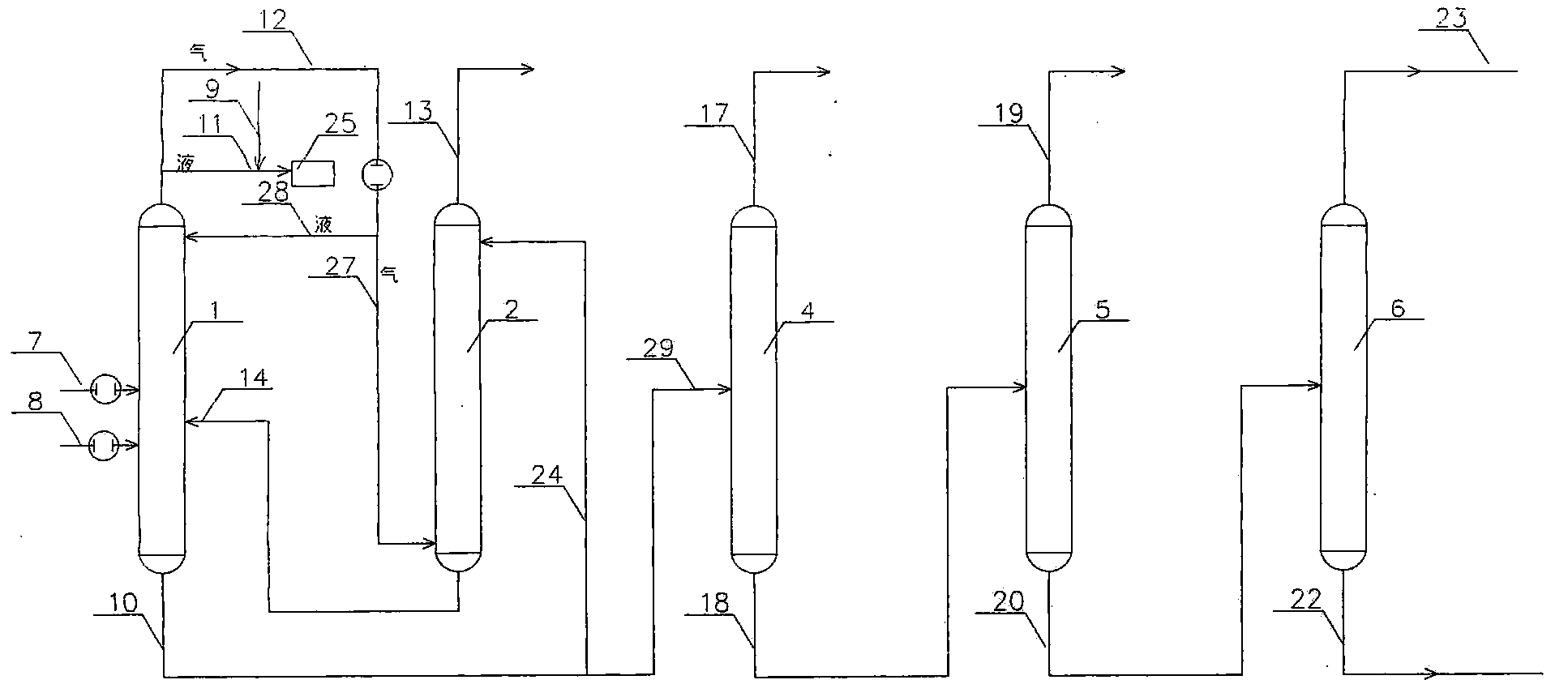

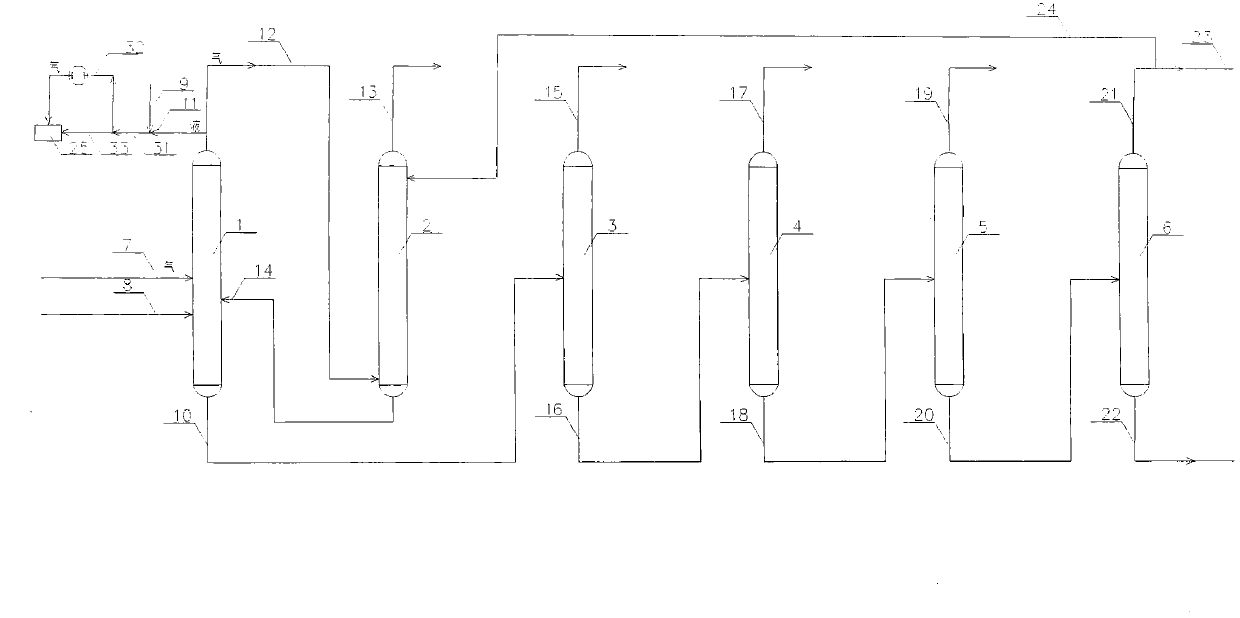

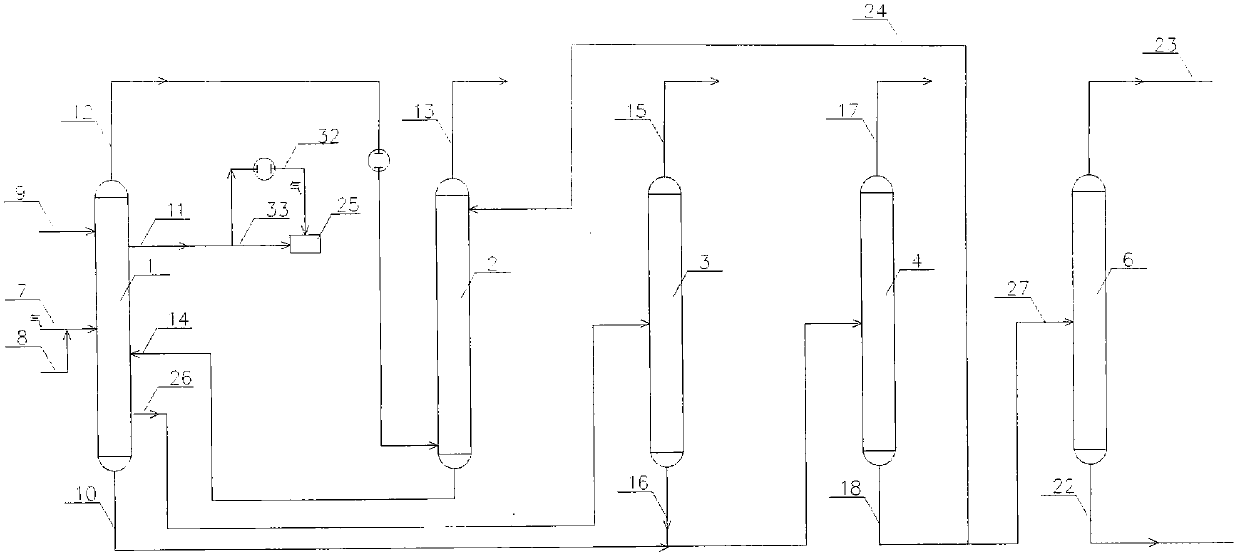

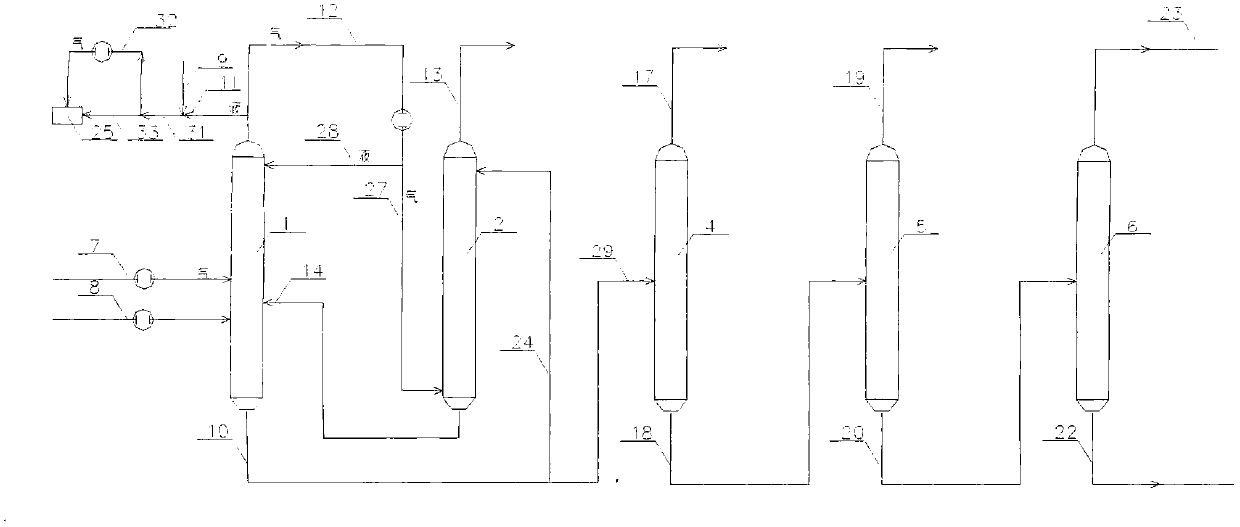

Separation process for producing ethylbenzene and/or propylbenzene product from gas containing ethylene and/or propylene by gas phase process

ActiveCN104341264ASimple processLess investmentHydrocarbon purification/separationHydrocarbonsGas phasePetrochemical

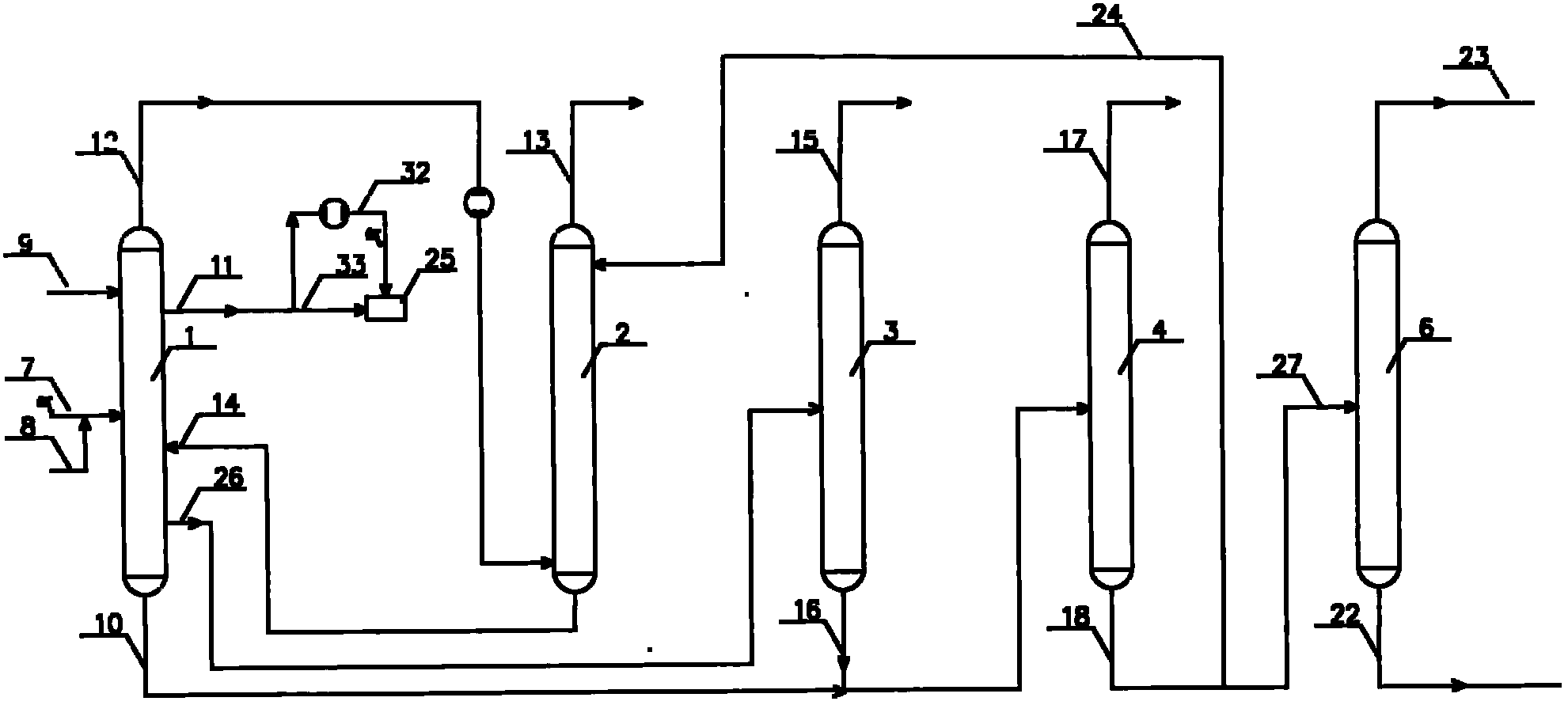

The invention belongs to the field of petrochemical industry and discloses a separation process for producing an ethylbenzene and / or propylbenzene product from gas containing ethylene and / or propylene by a gas phase process. The separation process comprises the following steps: 1) feeding alkylation reaction products getting out of an alkylation reactor and anti-alkylation reaction products getting out of an anti-alkylation reactor into a benzene tower respectively or after mixing; 2) feeding gas-phase materials at the top of the benzene tower after separation into an absorption tower after the gas-phase materials are drawn out of the tower top of the benzene tower; 3) drawing out liquid-phase materials at the upper part of the benzene tower after separation from the tower top or the side of the benzene tower and then returning the liquid-phase materials into the reaction part; and 4) performing corresponding separation on the materials at the tower bottom of the benzene tower by a subsequent separation tower to obtain several or all of methylbenzene, ethylbenzene, propylbenzene, diethylbenzene and high-boiling residues. By adopting the separation process disclosed by the invention, by directly bringing heat of the reaction products, including reaction heat, into the benzene tower, the heat supply at the tower bottom of the benzene tower is reduced and the energy consumption is reduced; and the utilization of the heat is reasonable. By adopting the separation process disclosed by the invention, the number of the towers required for separation is not increased, and indirect heat exchange equipment is reduced.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

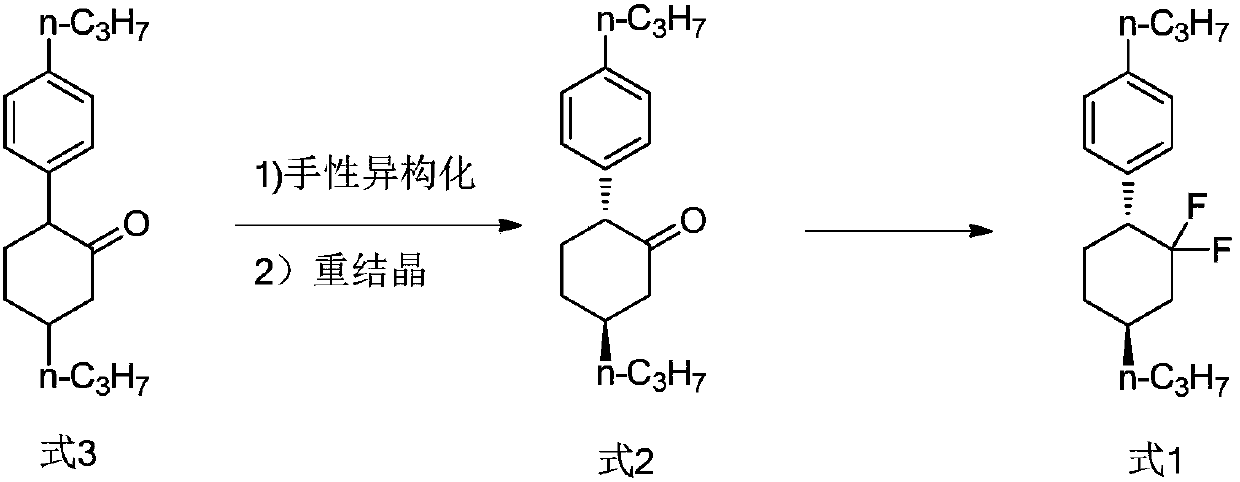

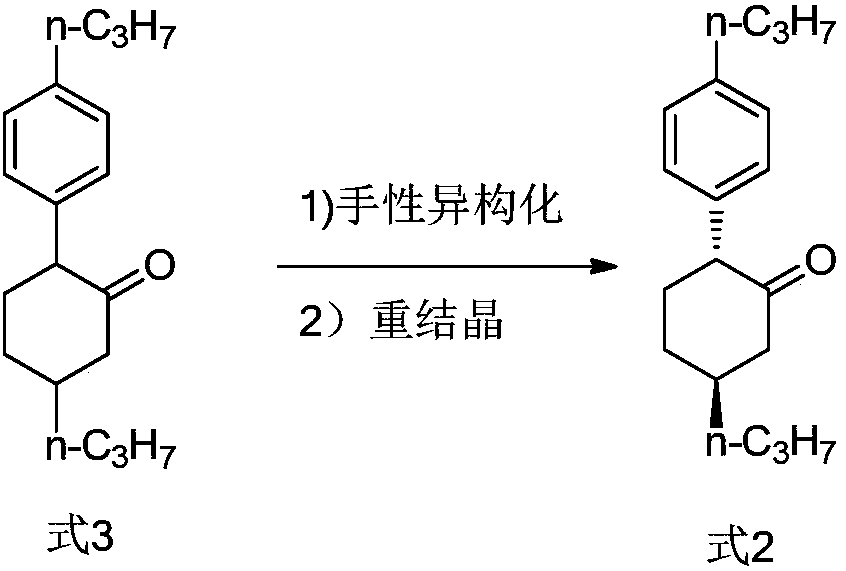

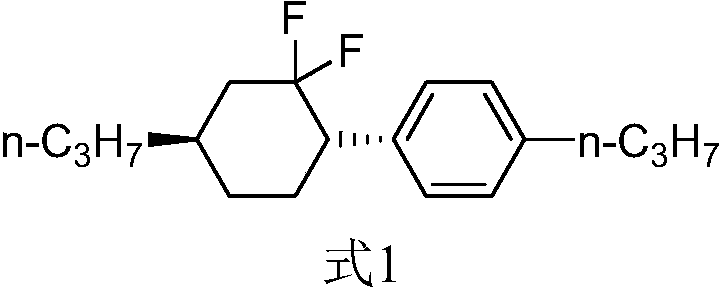

Method of preparing high-purity trans-1-(2,2-difluoro-4-propylcyclohexyl)-4-propylbenzene

ActiveCN109651078ARaise the ratioEasy to operateOrganic compound preparationOrganic chemistry methodsIsomerizationLewis acid catalysis

The present invention provides a method for preparing high-purity trans-1-(2,2-difluoro-4-propylcyclohexyl)-4-propylbenzene at a high yield. The method comprises the following steps: a Lewis acid is used to catalyze a chiral isomerization reaction of a mixture formula 3 to obtain high-purity (trans:cis > 90:10) trans-2-(4-propylphenyl)-5-propylcyclohexanone (formula 2); and the high-purity (trans:cis > 90:10) trans-2-(4-propylphenyl)-5-propylcyclohexanone (formula 2) undergoes a fluorination reaction to prepare the high-purity trans-1-(2,2-difluoro-4-propylcyclohexyl)-4-propylbenzene (formula1). The method has the advantages of high yield, easiness in separation and purification of the product, few wastes, low cost and easiness in industrialization.

Owner:HUANGGANG LUBAN PHARM

Auxiliary paint for steel ring of automobile hub

InactiveCN107880657APerformance optimization and releaseFree from harmPolyamide coatingsEpoxy resin coatingsPolyesterGlycoluril

An auxiliary paint for steel rings of automobile wheels, relating to the technical field of automobile wheel processing and production, characterized in that: it is made of the following materials in parts by weight: 11-17 parts of resin, 6-10 parts of phenol, diisoperoxide 4-9 parts of propylene, 125-10 parts of nylon, 4-9 parts of accelerator DM, 1-5 parts of polyester acrylate, 1-3 parts of triethanolamine, 6-12 parts of modified fluorite, 1-6 parts of bamboo charcoal , 5‑10 parts of hexamethylenetetramine, 2‑8 parts of tetramethoxymethyl glycoluril, 8‑15 parts of defoamer, 8‑15 parts of antiaging agent, 5‑10 parts of biomass auxiliary materials, deionized 20‑27 parts of water. The invention has the advantages of reasonable method, convenient operation, high strength and corrosion resistance.

Owner:ANHUI HENGXING WHEEL

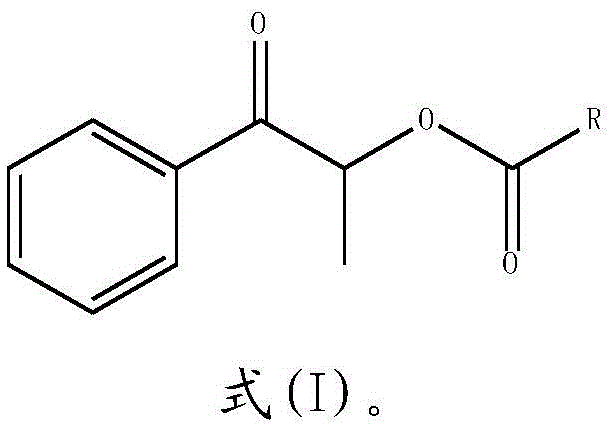

Synthesizing method of propiophenone compound

ActiveCN105646220AEasy to operateThe synthetic route is simplePreparation by caroxylic acid/anhydride-hydrocarbon reactionOrganic acidOrganic solvent

The invention provides a synthesizing method of a propiophenone compound, and belongs to the technical field of organic synthesizing. The synthesizing method has the advantages that the reaction steps for synthesizing the propiophenone compound can be simplified, and the reaction cost is reduced. The synthesizing method of the propiophenone compound comprises the following steps of adding propylbenzene, organic acid, iodine and tert-butyl hydroperoxide into a reaction kettle, and reacting for 8-24h at the temperature of 80-120 DEG C; after the reaction is finished, extracting a reaction solution by an organic solvent, and drying, so as to obtain the propiophenone compound. The synthesizing method can be used for the synthesizing and preparation of the propiophenone compound.

Owner:吉林中科研伸科技有限公司

Product separation process for preparing ethylbenzene and/or propylbenzene from gas containing ethylene and/or propylene

InactiveCN104341263AAvoid coolingAvoid heatingHydrocarbon purification/separationHydrocarbonsGas phasePetrochemical

The invention belongs to the field of petrochemical engineering, and discloses a separation process for preparing ethylbenzene and / or propylbenzene from gas containing ethylene and / or propylene. The product separation process comprises the following steps: 1) feeding alkylated product from an alkylation reactor and trans-alkylated product from a trans-alkylation reactor into a benzene tower in a respective mode or a mixed mode; 2) extracting separated benzene tower top gas phase material from the top of the benzene tower to be fed into an absorption tower, removing the reaction part through heat exchange; 3) extracting the separated benzene tower upper part liquid phase material from the benzene tower top or side, and then returning the reaction part; and 4) correspondingly separating multiple or all of methylbenzene, ethylbenzene, propylbenzene, diethylbenzene and high-boiling residue from benzene tower bottom material through a subsequent separation tower. The aim of reducing energy consumption is achieved without adding equipment, the flow is simple and the investment is low.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

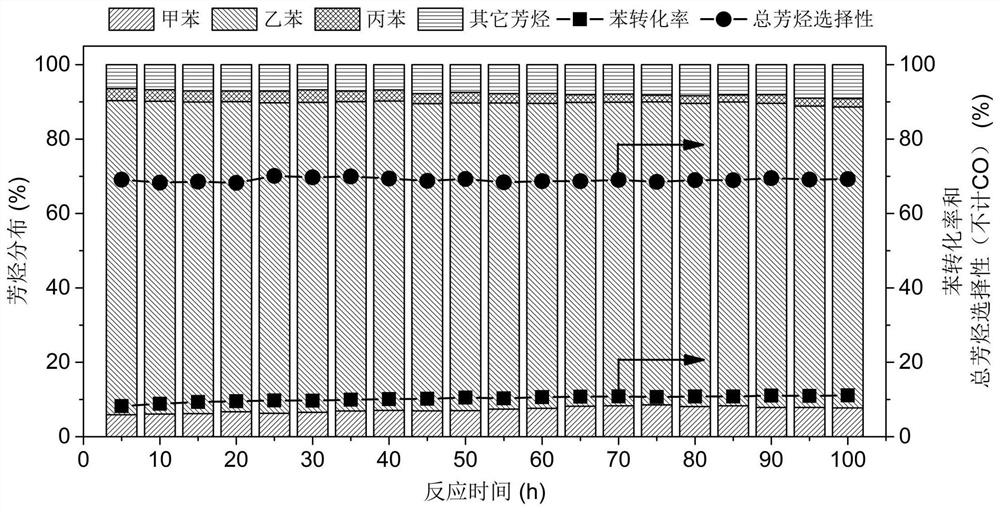

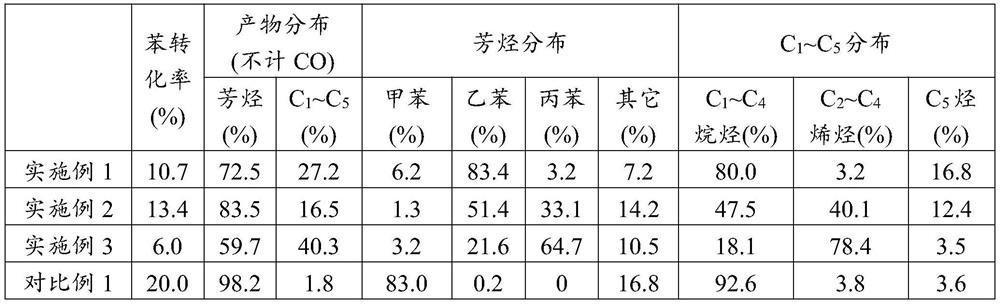

Composite double-layer catalyst and method for preparing ethylbenzene and/or propylbenzene through carbon dioxide/carbon monoxide hydrogenation coupling benzene alkylation

ActiveCN113600229AHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sievePtru catalyst

The invention belongs to the technical field of catalyst preparation, and particularly relates to a composite double-layer catalyst and a method for preparing ethylbenzene and / or propylbenzene through carbon dioxide / carbon monoxide hydrogenation coupling benzene alkylation. The invention provides a composite double-layer catalyst for preparing ethylbenzene and / or propylbenzene through CO2 / CO hydrogenation coupling benzene alkylation, the composite double-layer catalyst comprises a first-layer catalyst and a second-layer catalyst, the first-layer catalyst comprises a metal oxide catalyst and a CHA molecular sieve, the second-layer catalyst comprises an acidic molecular sieve, the acidic molecular sieve comprises an MFI molecular sieve or a phosphorus-modified MFI molecular sieve. The composite double-layer catalyst provided by the invention not only can be used for coupling low-carbon olefin prepared by CO2 / CO hydrogenation and ethylbenzene and / or propylbenzene prepared by alkylation of benzene and low-carbon olefin, but also has high content of the target product ethylbenzene and / or propylbenzene in aromatic hydrocarbon products.

Owner:XIAMEN UNIV

A gas-phase process for the separation of ethylbenzene and/or propylbenzene from gas containing ethylene and/or propylene

ActiveCN104341264BReduce consumptionSimple processHydrocarbon purification/separationHydrocarbonsGas phasePetrochemical

The invention belongs to the field of petrochemical industry. The invention discloses a process for separating ethylbenzene and / or propylbenzene products from gas containing ethylene and / or propylene by gas phase method, which comprises the following steps: 1) alkylation reaction from an alkylation reactor The product and the anti-alkylation reaction product from the anti-alkylation reactor enter the benzene tower separately or after being mixed; 2) the separated benzene tower top gas phase material enters the absorption tower after being extracted from the benzene tower top; 3) the separated The liquid phase material in the upper part of the benzene tower is withdrawn from the top or side of the benzene tower and then returned to the reaction part; 4) The bottom material of the benzene tower is separated from toluene, ethylbenzene, propylbenzene, diethylbenzene, and high-boiling substances through the subsequent separation tower. some or all of them. By adopting the present invention, by directly bringing the heat of the reaction product including the reaction heat into the benzene tower, the heat supply at the bottom of the benzene tower is reduced, and the energy consumption is reduced; the heat utilization is reasonable. Adopting the present invention does not increase the number of towers required for separation, and reduces the equipment for indirect heat exchange.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

Method for separating mixture of m-ethyltoluene and p-ethyltoluene from C9 aromatics

ActiveCN102399125BLess investmentHigh purityDistillation purification/separationBulk chemical productionBenzenePropylbenzene

The invention discloses a method for separating a mixture of m-ethyltoluene and p-ethyltoluene from C9 aromatics. The method comprises the following steps of: (1) mixing a C9 aromatics mixture and an accelerator, and sending into a heavy component eliminating tower, introducing a light component from the top of the tower, introducing a heavy component from a tower kettle; wherein the weight ratio of the C9 aromatics mixture to the accelerator is 1:0.05-0.5; (2) sending the light component from the step (1) into a light component eliminating tower, introducing the mixture of m-ethyltoluene and p-ethyltoluene from the tower kettle; (3) sending material flow introduced from the light component eliminating tower in the step (2) to an accelerator removal tower, introducing the accelerator from the tower top, introducing the material flow containing normal propylbenzene and isopropylbenzene from the tower kettle. The accelerator is acetonitrile and propionitrile. The mixture of m-ethyltoluene and p-ethyltoluene obtained by the method of the invention has the advantages of high purity, high yield and obvious separation effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

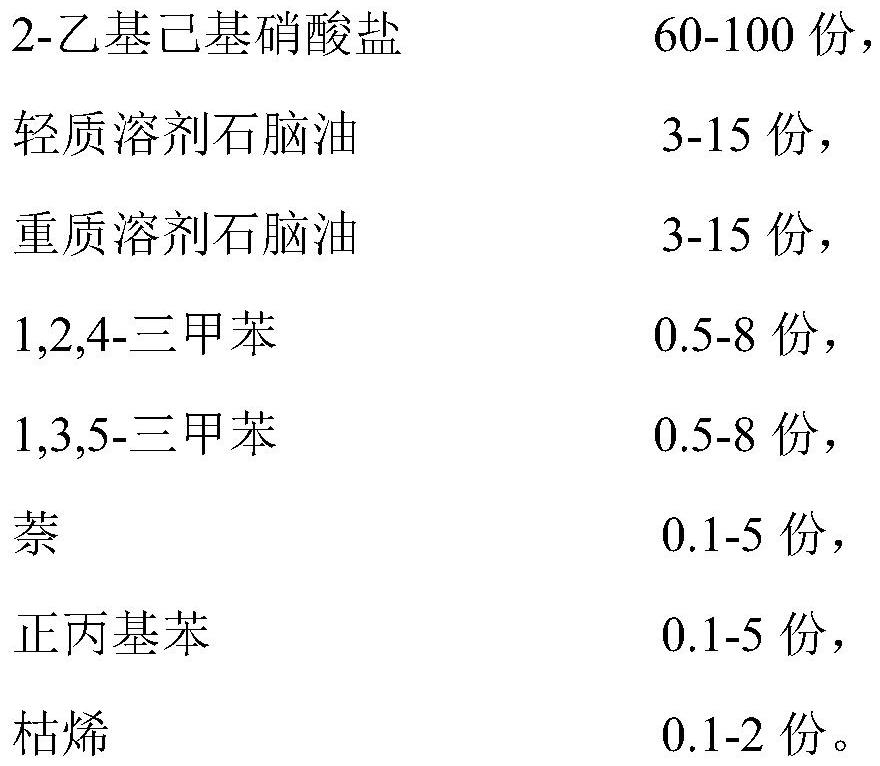

A kind of diesel oil additive and preparation method thereof

ActiveCN109294640BImprove utilization efficiencyBurn completelyLiquid carbonaceous fuelsFuel additivesBiodieselInjector nozzle

The invention discloses a diesel oil additive and a preparation method thereof. The diesel oil additive includes a multifunctional agent and aviation kerosene with a mass ratio of 1:1-5, in parts by mass, wherein the multifunctional agent includes the following components : 60-100 parts of 2-ethylhexyl nitrate, 1-20 parts of light solvent naphtha, 1-20 parts of heavy solvent naphtha, 0.1-10 parts of 1,2,4-trimethylbenzene, 1, 0.1-10 parts of 3,5-trimethylbenzene, 0.05-8 parts of naphthalene, 0.05-8 parts of n-propylbenzene, and 0.05-5 parts of cumene. The diesel additive of the present invention can clean the carbon deposits in the fuel injector, make the combustion more complete, improve the fuel utilization efficiency, increase the power, restore the good atomization effect of the fuel, improve the difficult condition of cold start, and can effectively improve the stability of diesel oil. Fully compatible.

Owner:开平保驰捷汽车用品科技有限公司

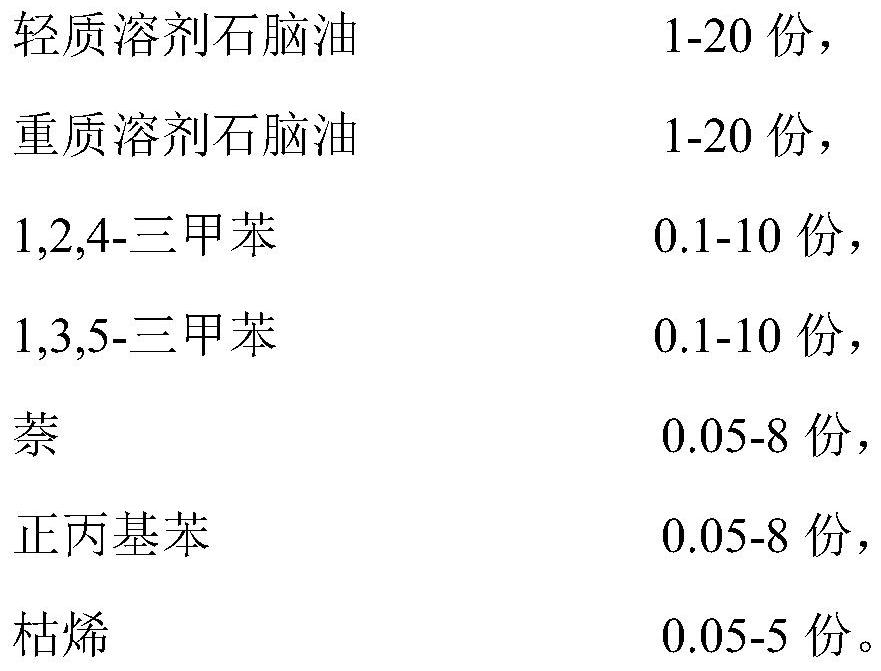

Oil-saving cleaning agent

InactiveCN110041973AReduce resistanceReduce running fuel consumptionLiquid carbonaceous fuelsCombustion chamberN-Butanol

The invention discloses an oil-saving cleaning agent. The oil-saving cleaning agent comprises the following components, by weight: 35-40 parts of polyetheramine, 2-3 parts of n-butanol, 5-8 parts of n-propylbenzene, 1-2 parts of methyl tert-butyl ether, 3-5 parts of isooctyl alcohol, 15-20 parts of polyisobutene amine, 0.2-0.5 part of isoamyl alcohol, 3-5 parts of xylene, 2-3 parts of isobutylbenzene, 8-10 parts of polyetheramine, 1-2 parts of di-tert-butyl-p-cresol, 10-15 parts of an auxiliary additive, 2-3 parts of apricot tree branches, 10-15 parts of honeysuckle flowers, and 3-5 parts of roots of slender dutchmanspipe. The oil-saving cleaning agent can reduce combustion chamber deposits, reduce engine resistance and reduce engine operating oil consumption through the synergistic effectof the components.

Owner:国久新能源科技有限公司

Catalyst for synthesizing iso-propylbenzene

ActiveCN100453178CImprove reaction stabilityImprovement of dealuminationMolecular sieve catalystsHydrocarbonsMolecular sieveReaction temperature

A catalyst for synthesizing isopropylbenzene with low reaction temp (120-170 deg.C) and benzene / hydrocarbon ratio (2-5) and high stability is a modified molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

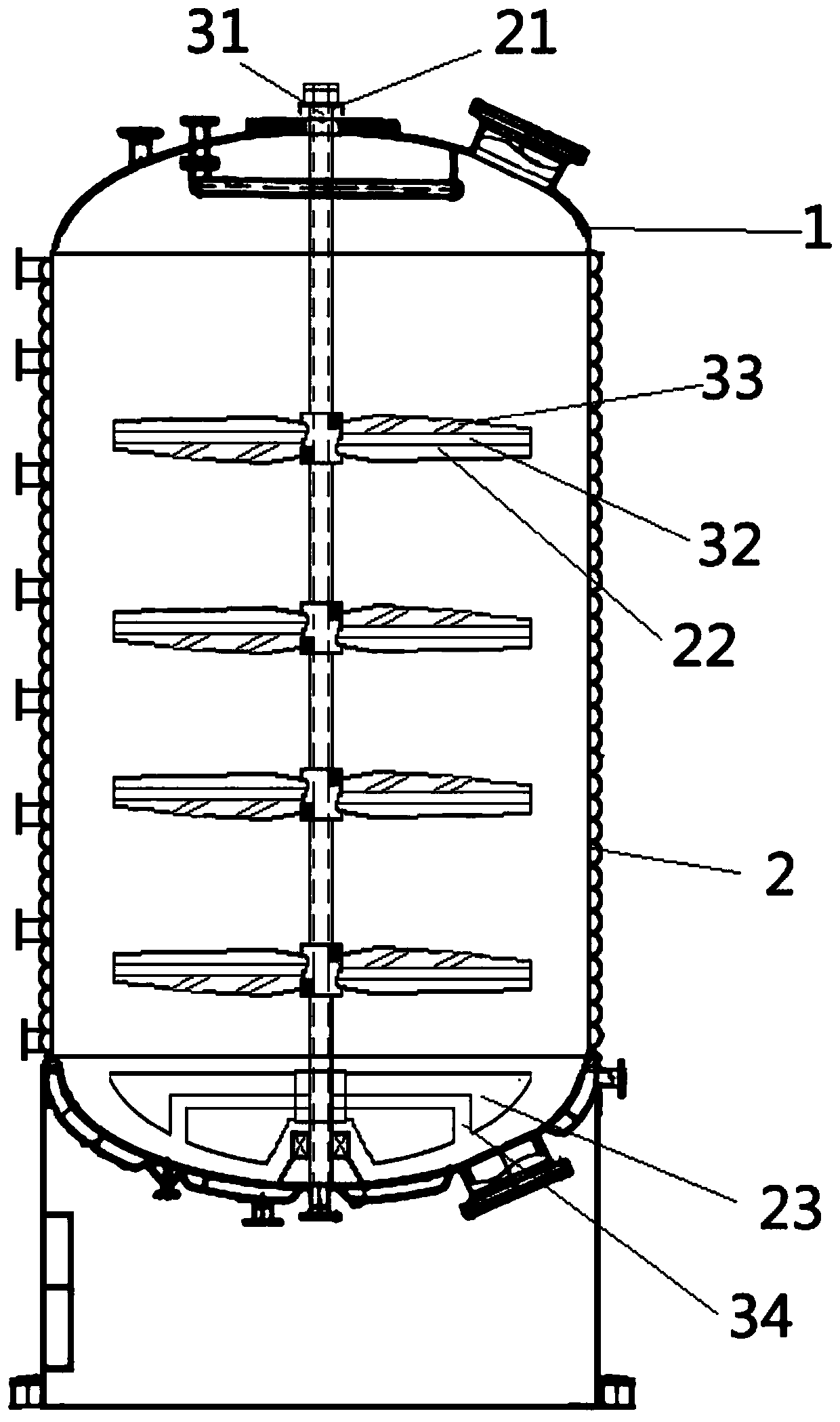

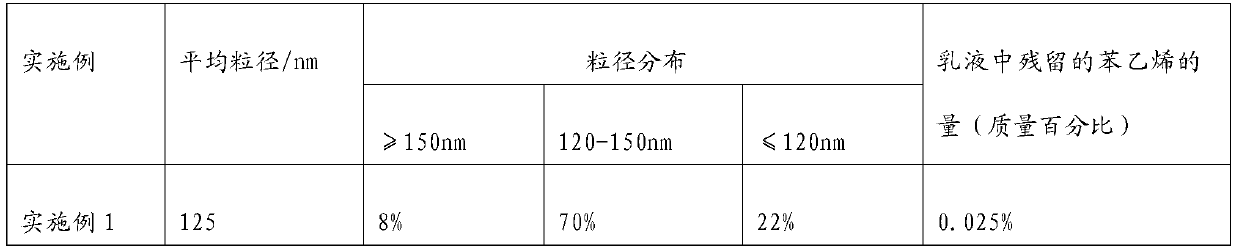

A kind of preparation method of styrene-acrylic latex and propylbenzene latex

The invention relates to a preparing method of styrene-acrylate latex. Reaction heat energy is provided for a reaction of styrene-acrylate latex through high-speed steam which is transformed into high-temperature deionized water after being cooled; in addition, the high-speed steam drives liquid in a reaction vessel to rotate, the liquid in the reaction vessel is dispersed by the steam flow to form a large number of tiny steam and water combined bodies, and materials in the reaction vessel are pushed to flow rapidly; furthermore, mechanical stirring is conducted for cooperation, the materials and the temperature in the reaction vessel are uniformly distributed, and a polymerization reaction is also very uniform, so that the end product styrene-acrylate latex is stable in molecular structure, molecular weight is easy to control, particle size distribution is more concentrated, the conversion rate of monomers can reach 99% or above, the content of unreacted polymerization monomers in latex is very small, and prepared styrene-acrylate latex is more environmentally friendly.

Owner:ZHEJIANG TIANCHEN PLASTIC IND

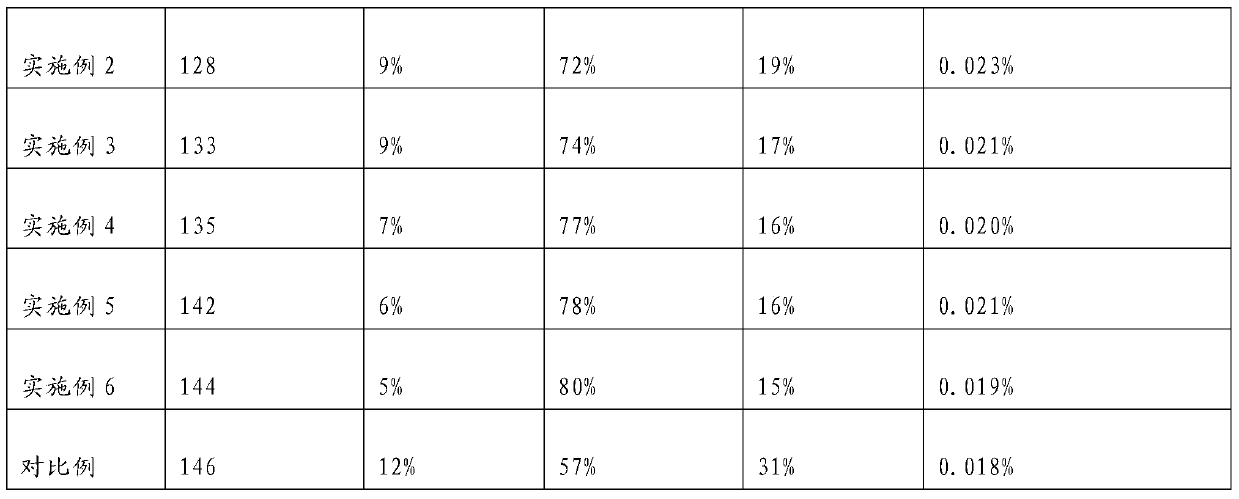

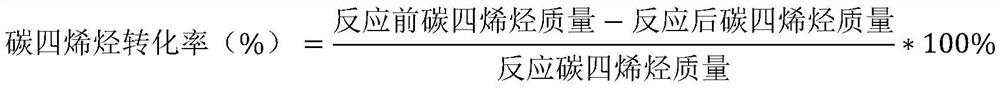

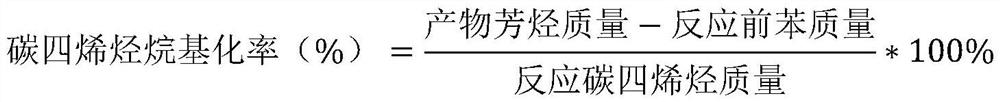

Preparation method and application of catalyst for producing mixed propylbenzene through alkylation of benzene and C4 olefin

PendingCN114762832AImprove conversion rateQuick responseMolecular sieve catalystsHydrocarbonsPtru catalystReaction temperature

The preparation method of the catalyst comprises the following steps: mixing at least one zeolite with a binder, adding water and a peptizing agent, kneading, extruding and molding, and then sequentially drying and roasting, finally, the roasted catalyst is subjected to metal or nonmetal oxide modification through an impregnation method, and the required catalyst is obtained. According to the present invention, benzene and C4 olefin are adopted as reaction raw materials, the catalyst obtained by using the preparation method is adopted to catalyze the reaction of benzene and butene so as to generate the target product mixed propylbenzene, the reaction can be performed under the mild reaction condition, the reaction speed is high, and the olefin conversion rate is high. Through measurement, under the conditions that the reaction temperature is 360 DEG C, the reaction pressure is 0.8 MPa, the total weight hourly space velocity is 5.0 h <-1 > and the molar ratio of benzene to alkene is 5.5: 1, the conversion rate of C4 olefin reaches 99.8%, the selectivity of the product mixed propylbenzene reaches 72.6%, the proportion of isopropyl benzene in the mixed propylbenzene is 52.69%, and the proportion of n-propylbenzene in the mixed propylbenzene is 47.31%.

Owner:洛阳市科创石化科技开发有限公司

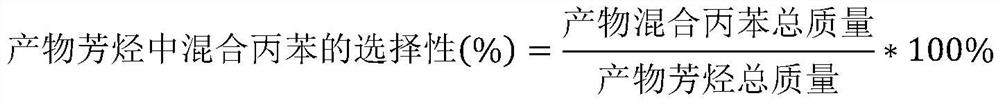

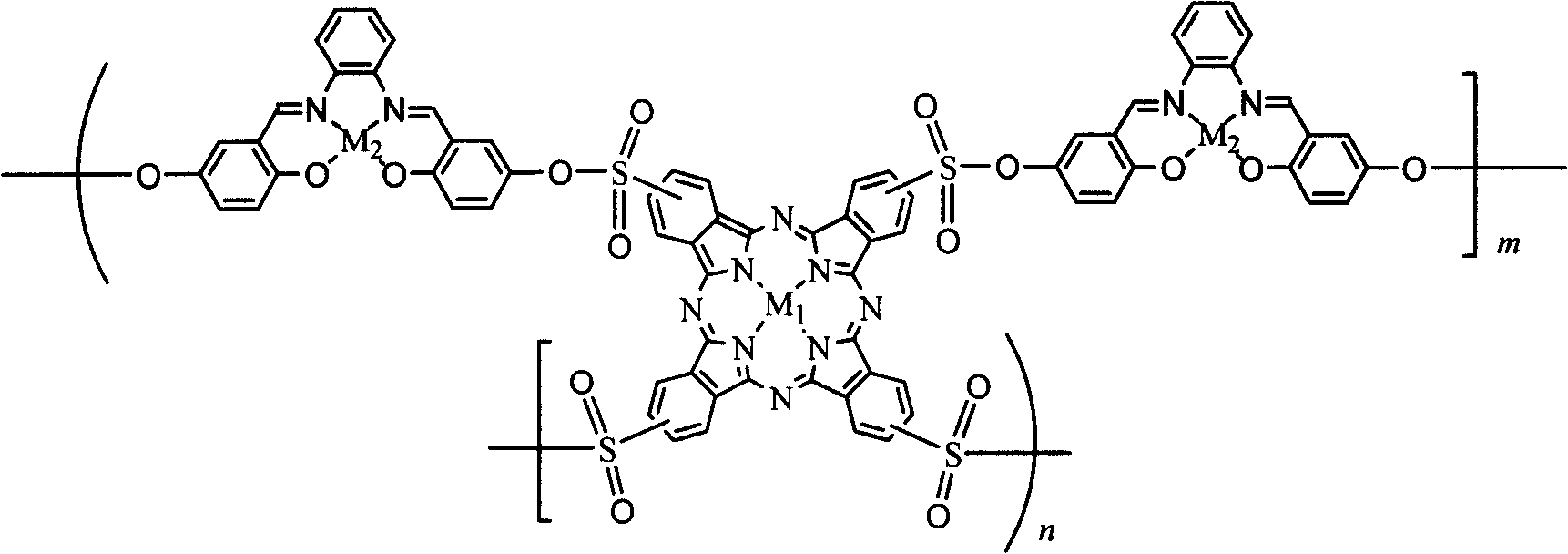

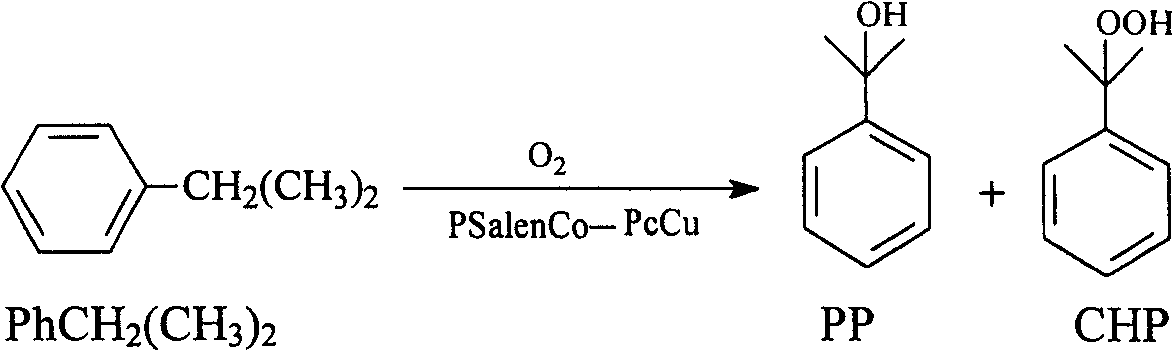

Polymer xifualkali phthalocyanin bimetal compound, its preparation method and application

InactiveCN100441610CImprove conversion rateHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSalicylaldehydePtru catalyst

This invention discloses a giant molecule Schiff's base-phthalocyanine thermometal coordination compound and its preparation. The preparation of this giant molecule Schiff's base-phthalocyanine thermometal coordination compound is made by interface fasculation of orth-benzene di-imido mini-(4,4'-di-hydroxy group )salicylaldehyde Schiff's base transition metal coordination compound and phthalocyanine sulfochlorides transition metal coordination compound. This giant molecule Schiff's base-phthalocyanine thermometal coordination compound contains double active center, possessing very strong Catalytic Properties.it can be used to catalyze molecule oxidizing reaction, especially to produce catalyst of allotri-propylbenzene hydrogen dioxide.

Owner:NORTHWEST NORMAL UNIVERSITY

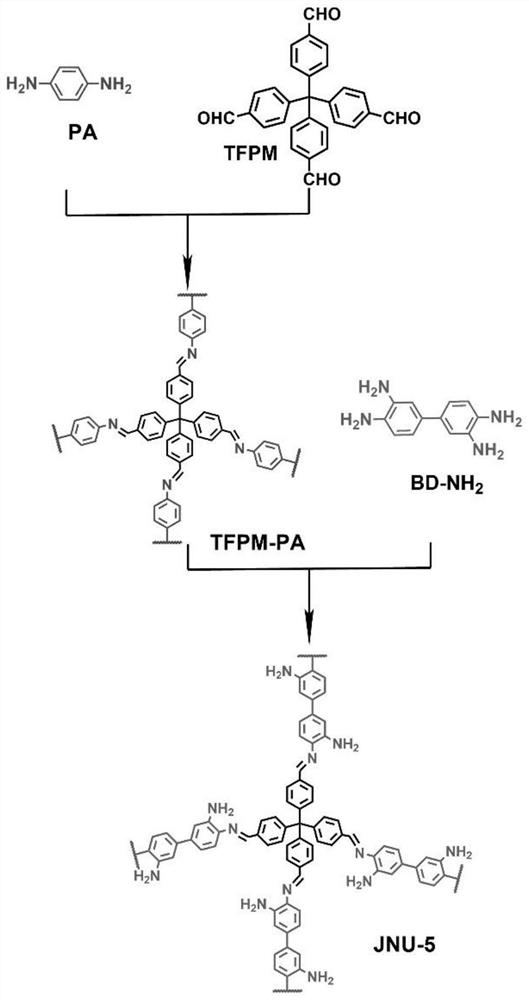

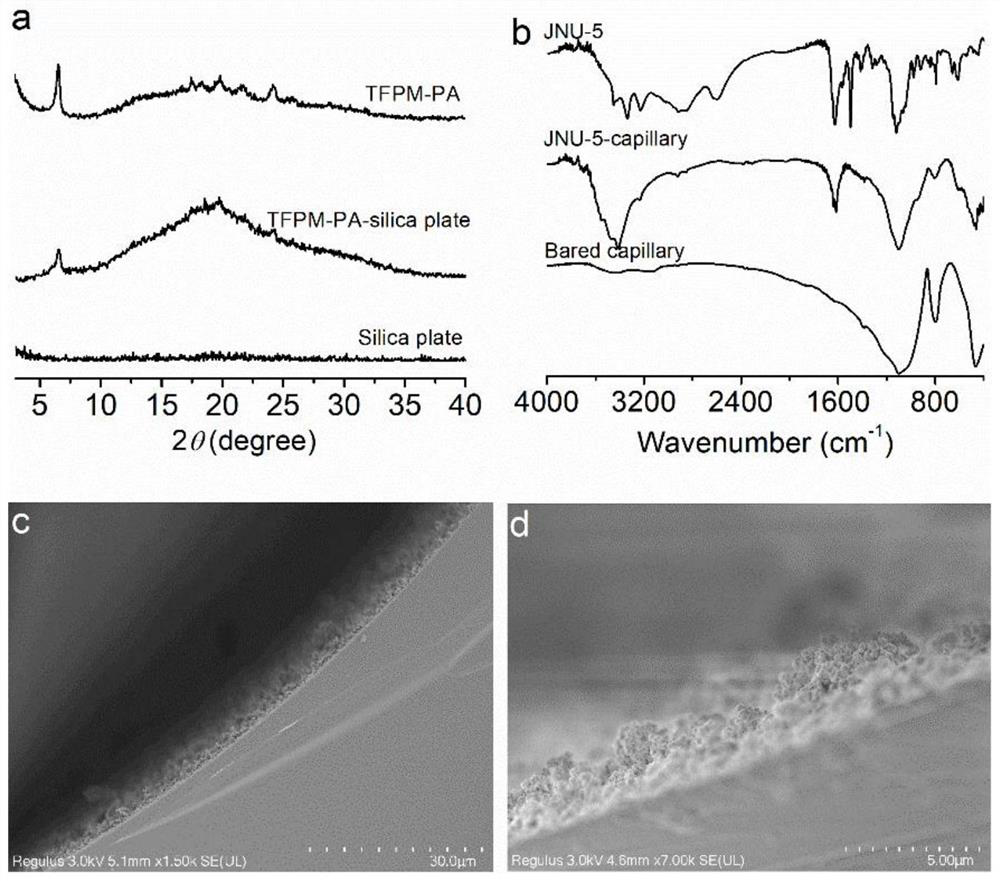

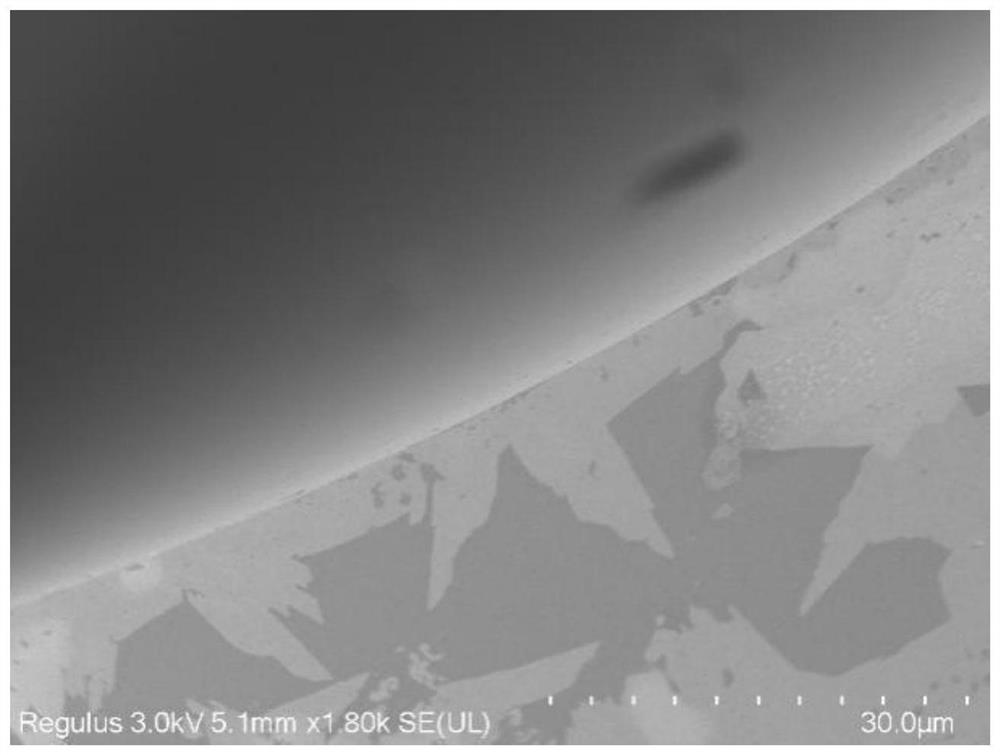

Bonded three-dimensional covalent organic framework chromatographic column and separation application thereof

ActiveCN114192118AHigh resolutionEasy to separateIon-exchange process apparatusOther chemical processesAlkaneCapillary gas chromatography

The invention discloses a bonded three-dimensional covalent organic framework chromatographic column and separation application thereof. An aromatic structure three-dimensional covalent organic framework JNU-5 with high thermal stability and rich amino groups is prepared as a gas chromatography stationary phase, a JNU-5 covalent bonded capillary column is further prepared through an in-situ growth method, and high-performance gas chromatography separation of xylene, dichlorobenzene, propylbenzene and other isomers is successfully achieved. Besides the isomeride, the prepared JNU-5 covalent bonding capillary column also has a good separation effect on common substances such as n-alkanes, benzene homologues, normal alcohols and the like, and the chromatographic column can be repeatedly used for multiple times. The invention not only provides a preparation method of the bonded three-dimensional covalent organic framework-based capillary gas chromatographic column, but also provides a new solution for efficient separation of isomeride.

Owner:JIANGNAN UNIV +1

Enamelled wire paint for resisting high-frequency pulse

InactiveCN102993920AAppropriate viscosity coefficientUniform surfacePolyester coatingsPhenolMaterials science

The invention discloses enamelled wire paint for resisting high-frequency pulse. The viscosity efflux time of the enamelled wire paint is 20-50 seconds; and the enamelled wire paint consists of the following components in percentage by mass: 9-9.8% of glycol, 15.8-16.82% of dimethyl terephthalate, 13.1-16.9% of trimellitic acid trimethyl, 0.83-0.9% of propylbenzene, 15-16.22% of 1,2,3-trimethylbenzene, 4.1-4.38% of phenol, 14.07-15.27% of 3-methylphenol, 13.96-14.87% of 1,3-dimethyl benzene, 7.4-8.2% of 1,2-dimethyl benzene, 1.9-2.1% of tetrabutyl titanate and 0.95-1.05% of thickening agent. When the enamelled wire paint for resisting high-frequency pulse is coated in the subsequent process, the paint is beneficial to the forming of paint films with even, dense and smooth surfaces; the micropores are greatly reduced; and the anti-scratch performance and the hardness of the paint films are prominently enhanced.

Owner:江苏芯盛半导体科技有限公司

A method for preparing methyl styrene and co-producing mesitylene from C9 aromatic hydrocarbon mixture dehydrogenation and alkyl aromatic hydrocarbon dehydrogenation catalyst

ActiveCN107304159BLow costHigh activityHeterogenous catalyst chemical elementsDistillation purification/separationPtru catalystMethyl benzene

Owner:曹炳铖

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com