Patents

Literature

1167 results about "Surface strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface Strength Agents. Surface strength agents are commonly used to enhance surface strength of fine paper, coated paper, coated board, linerboard, newsprint etc. They also can reduce fuzz that sometimes appears on the paper surface after printing. It enhances surface strength of paper / paperboard.

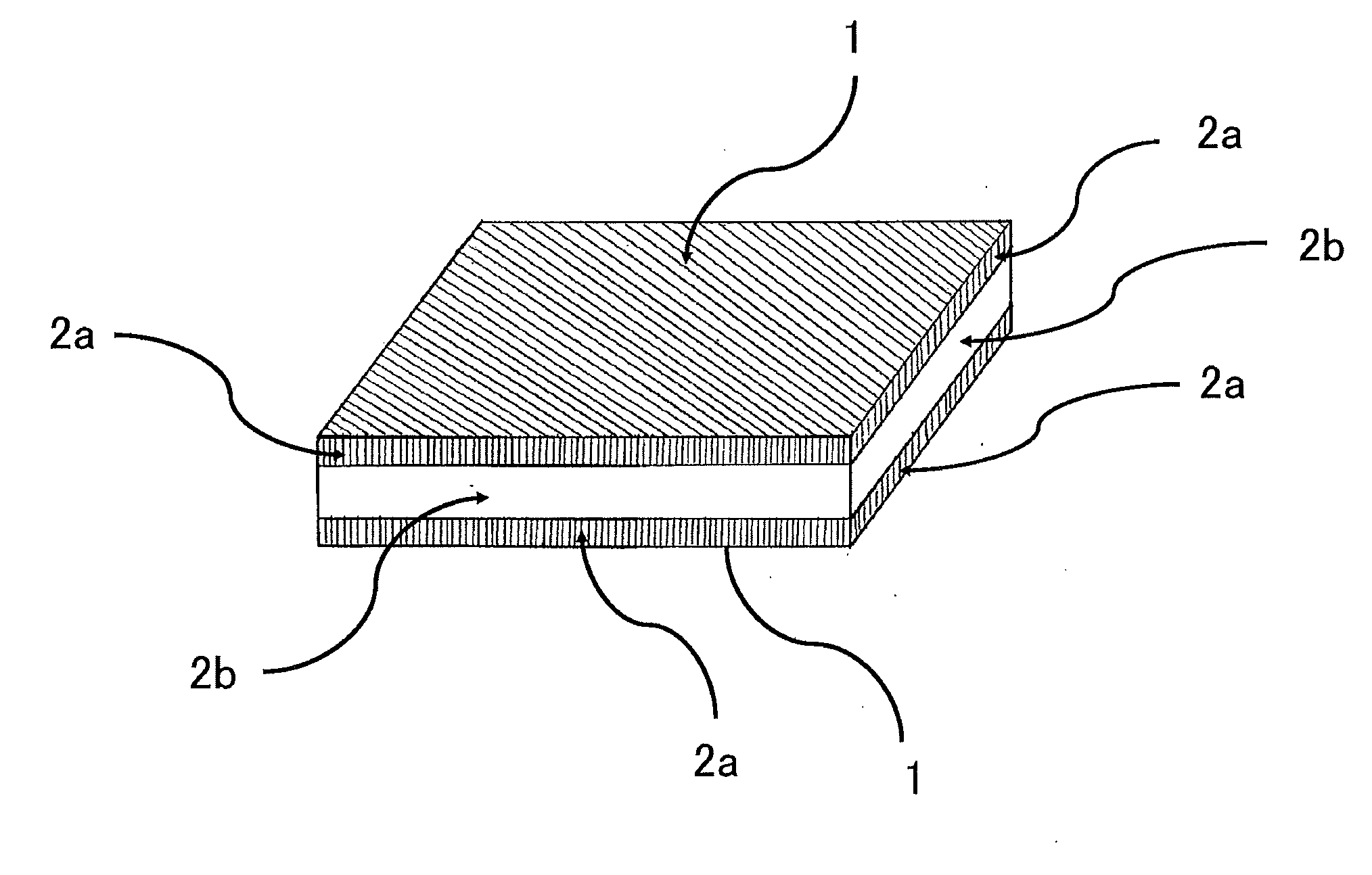

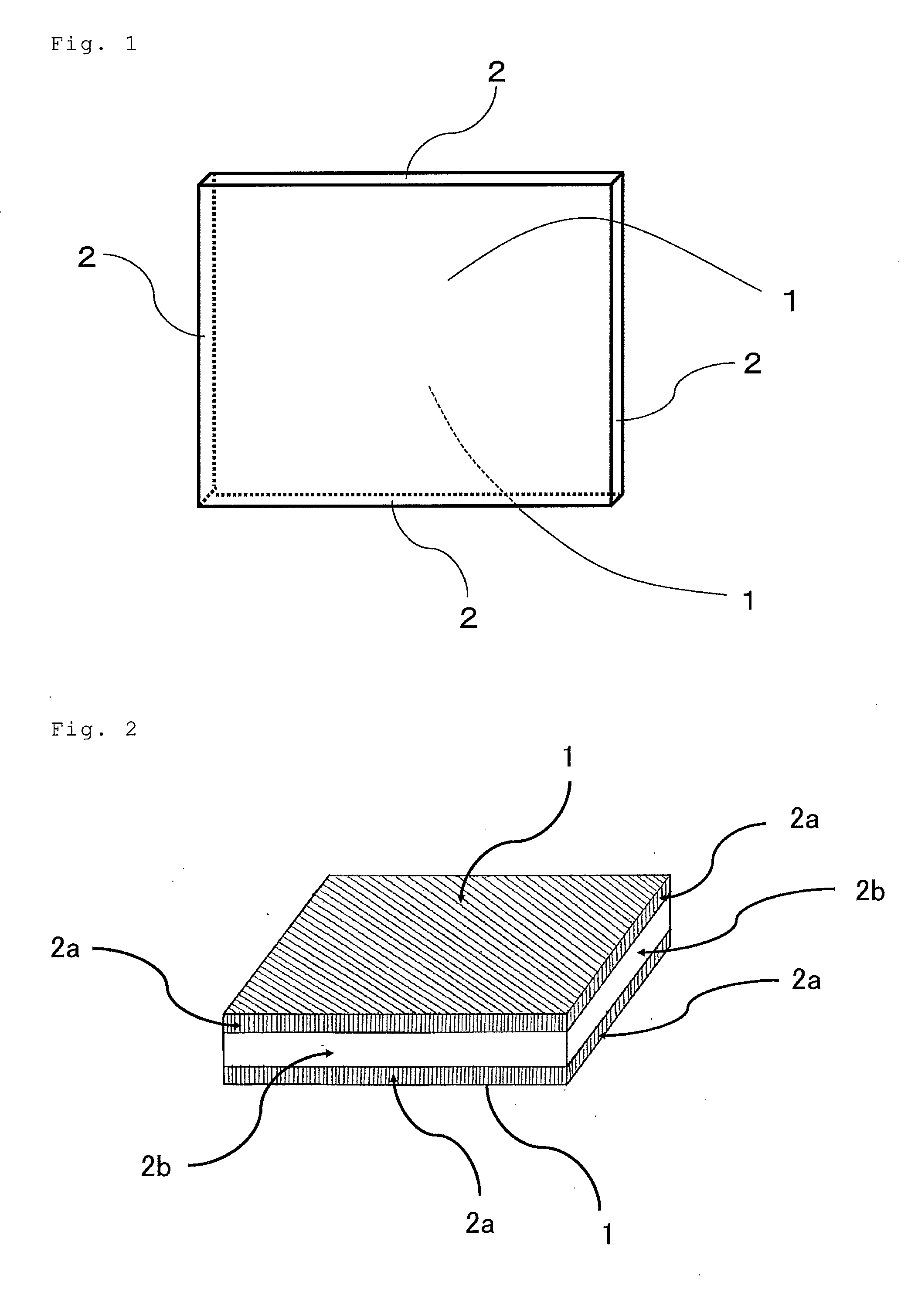

Reinforced plate glass and method for manufacturing the same

InactiveUS20100119846A1Quality improvementStrength of plate glass surfaces opposed to each otherGlass/slag layered productsGlass severing apparatusFlat glassUltimate tensile strength

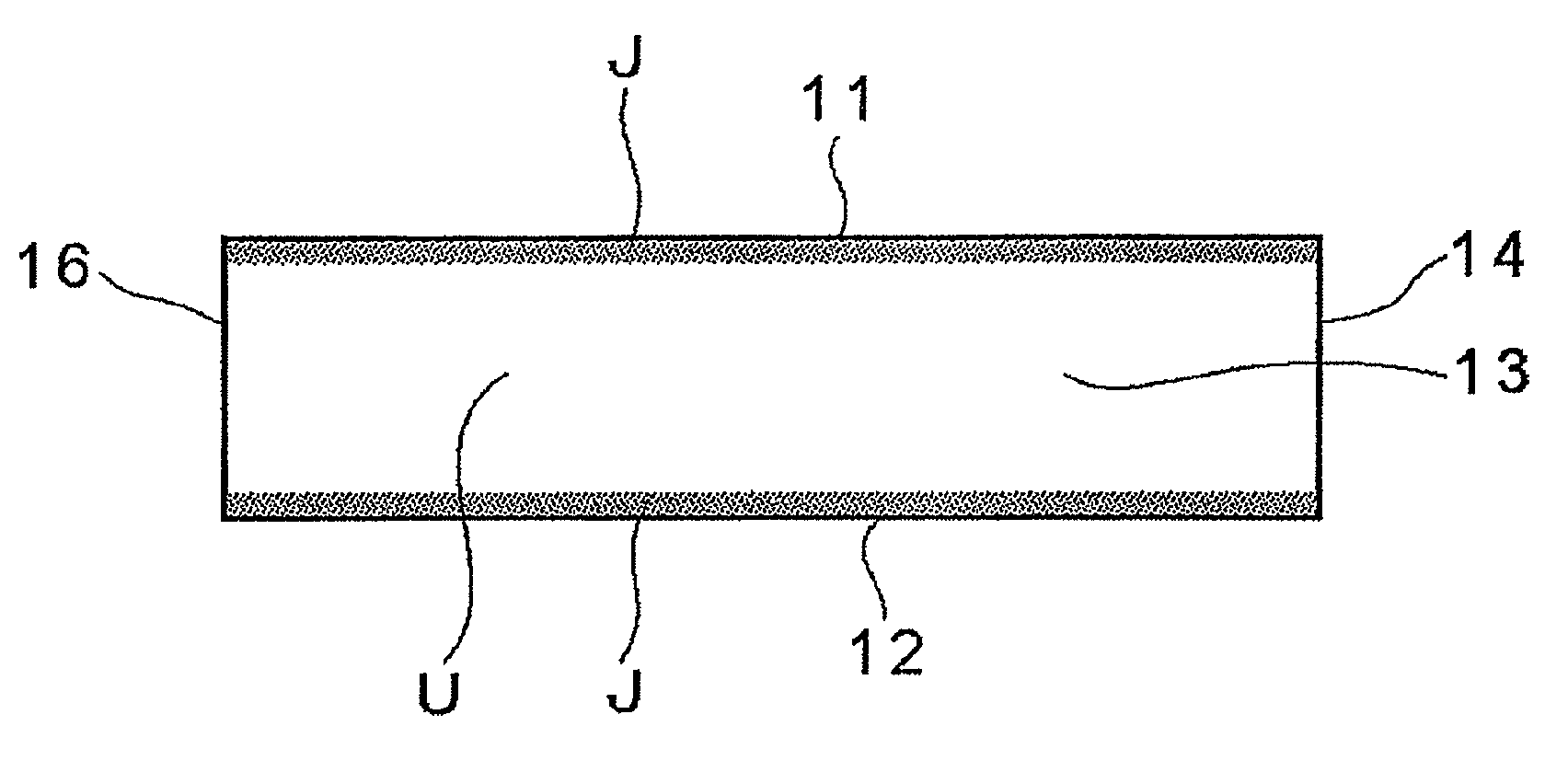

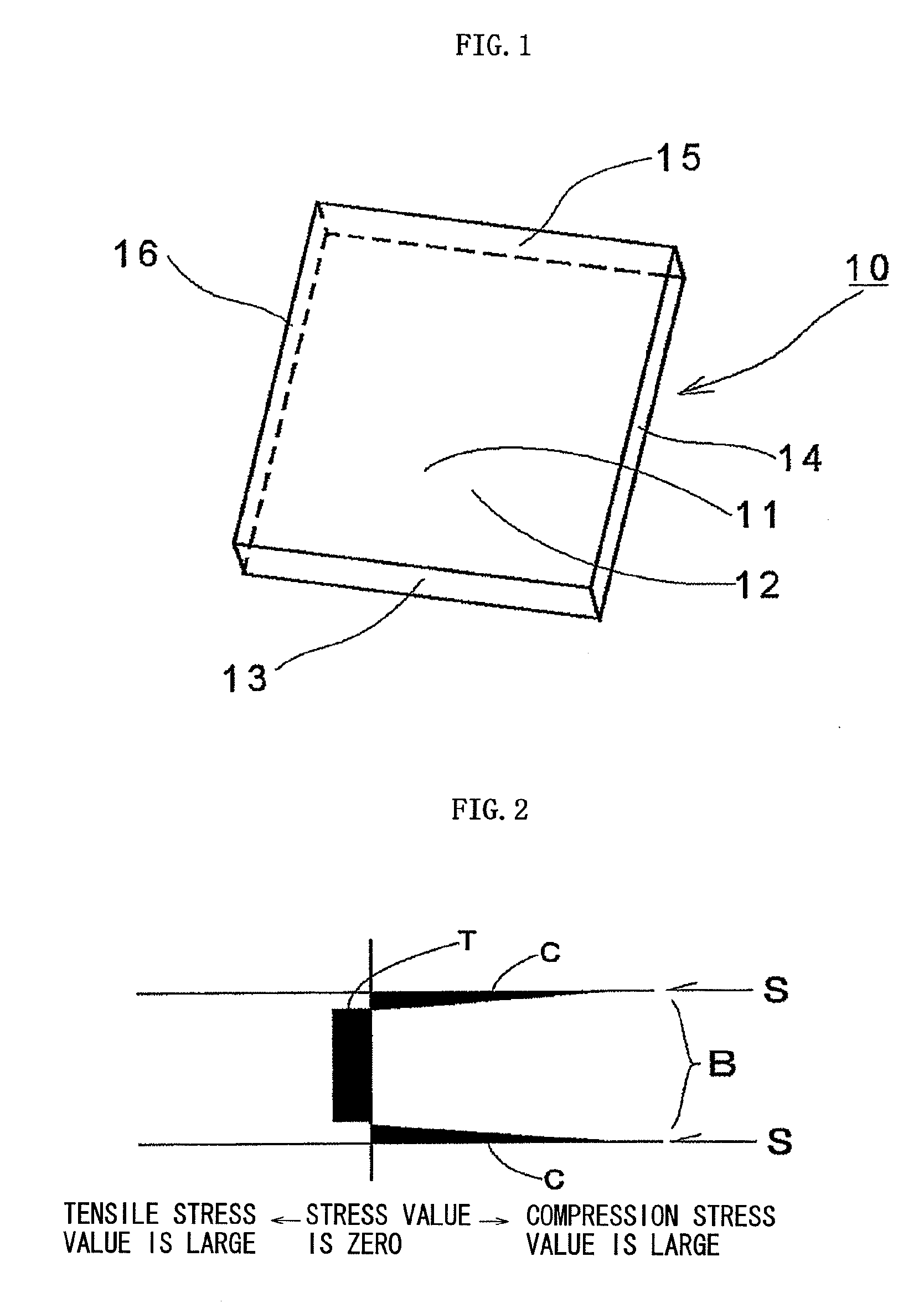

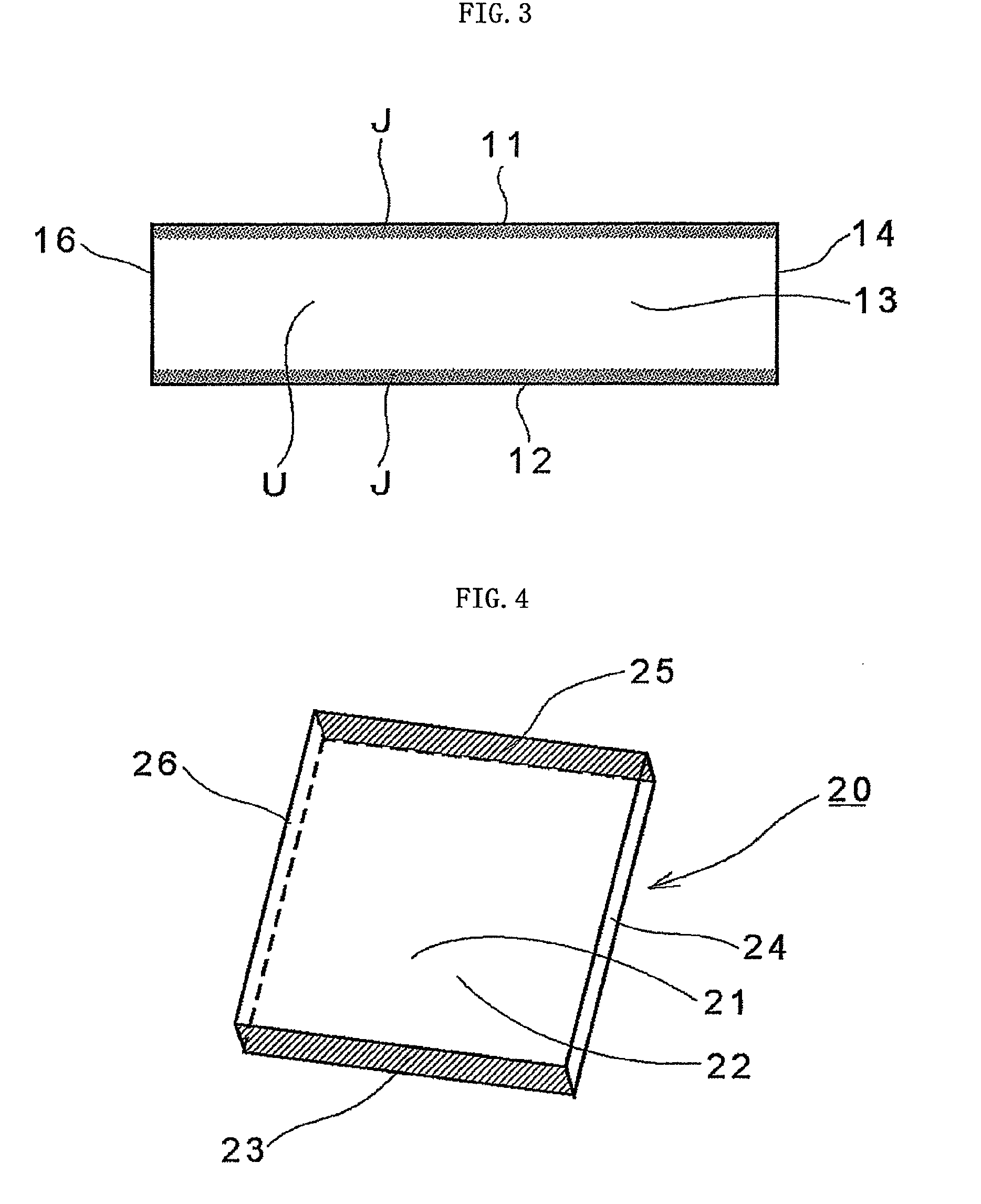

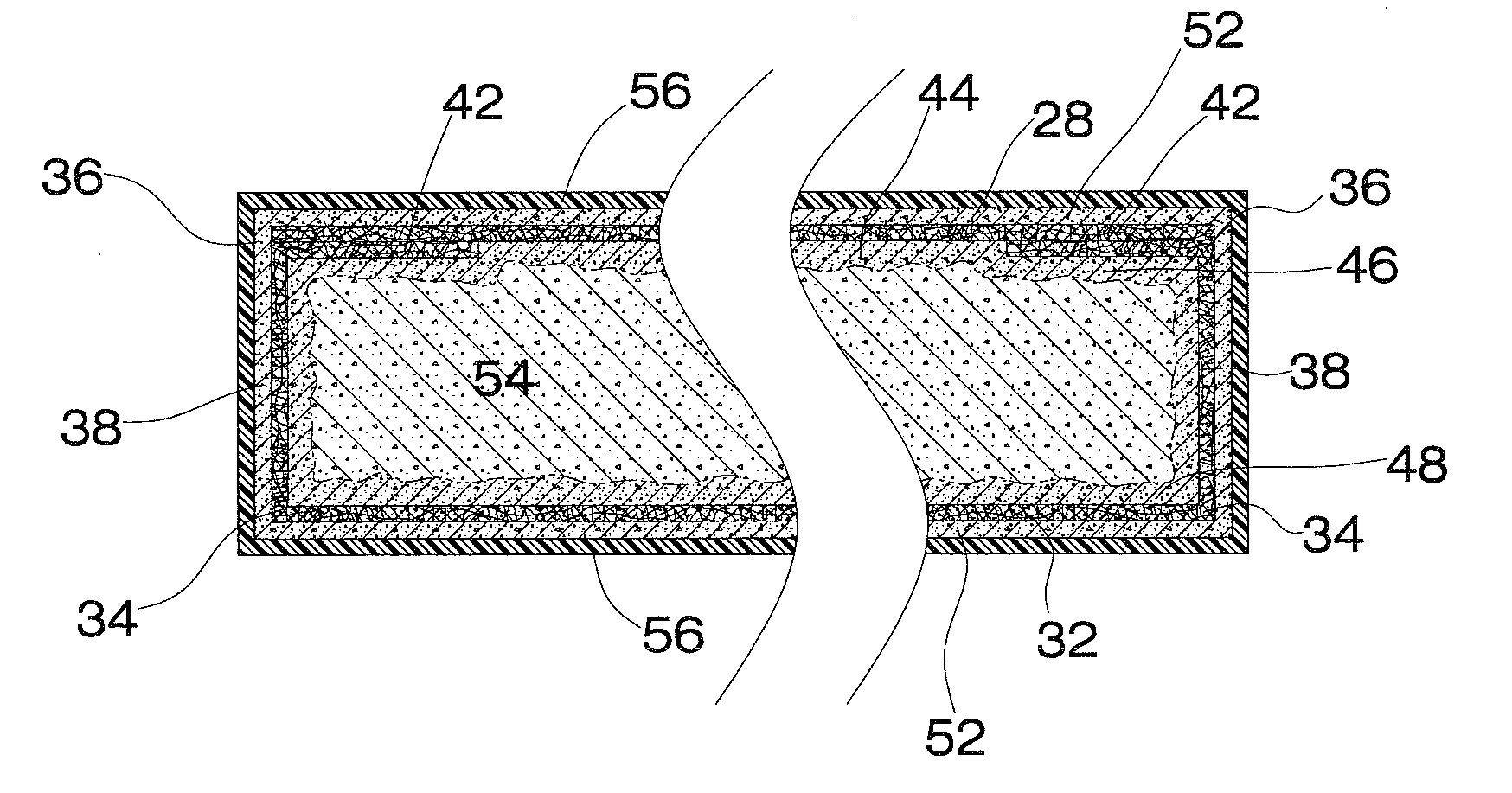

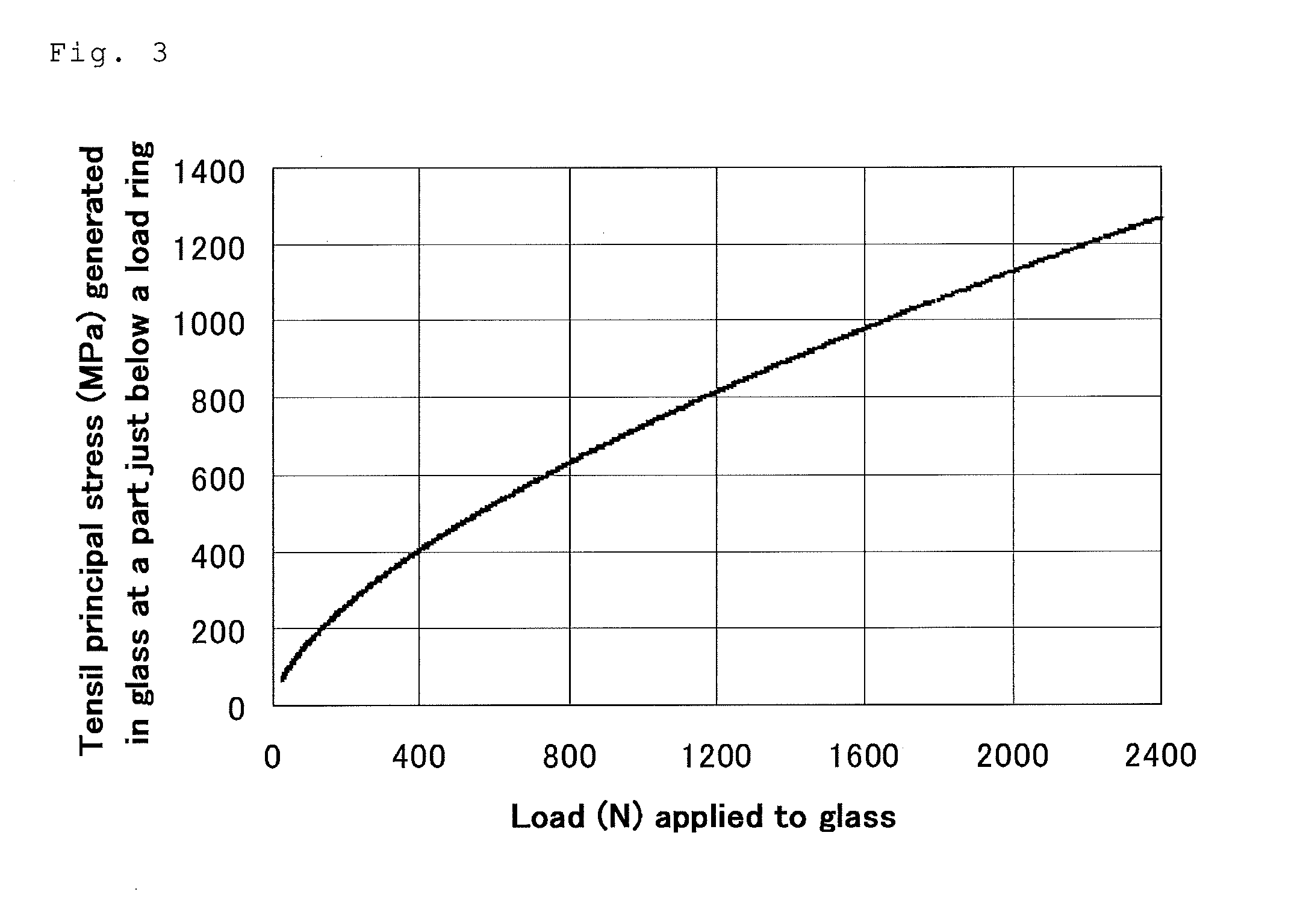

[Object] To provide a method of manufacturing a reinforced plate glass by which glass surface strength can be sufficiently increased, and a stable quality reinforced plate glass is manufactured at high production efficiency, and to provide a reinforced plate glass manufactured by the manufacturing method.[Solving Means] A reinforced plate glass (10) is formed of an inorganic oxide glass, and is provided with a compression stress layer by chemical reinforcement on plate surfaces (11, 12) opposed to each other in a plate thickness direction. Plate end faces (13, 14, 15, 16) have regions where a compression stress is formed and regions where no compression stress is formed.

Owner:NIPPON ELECTRIC GLASS CO LTD

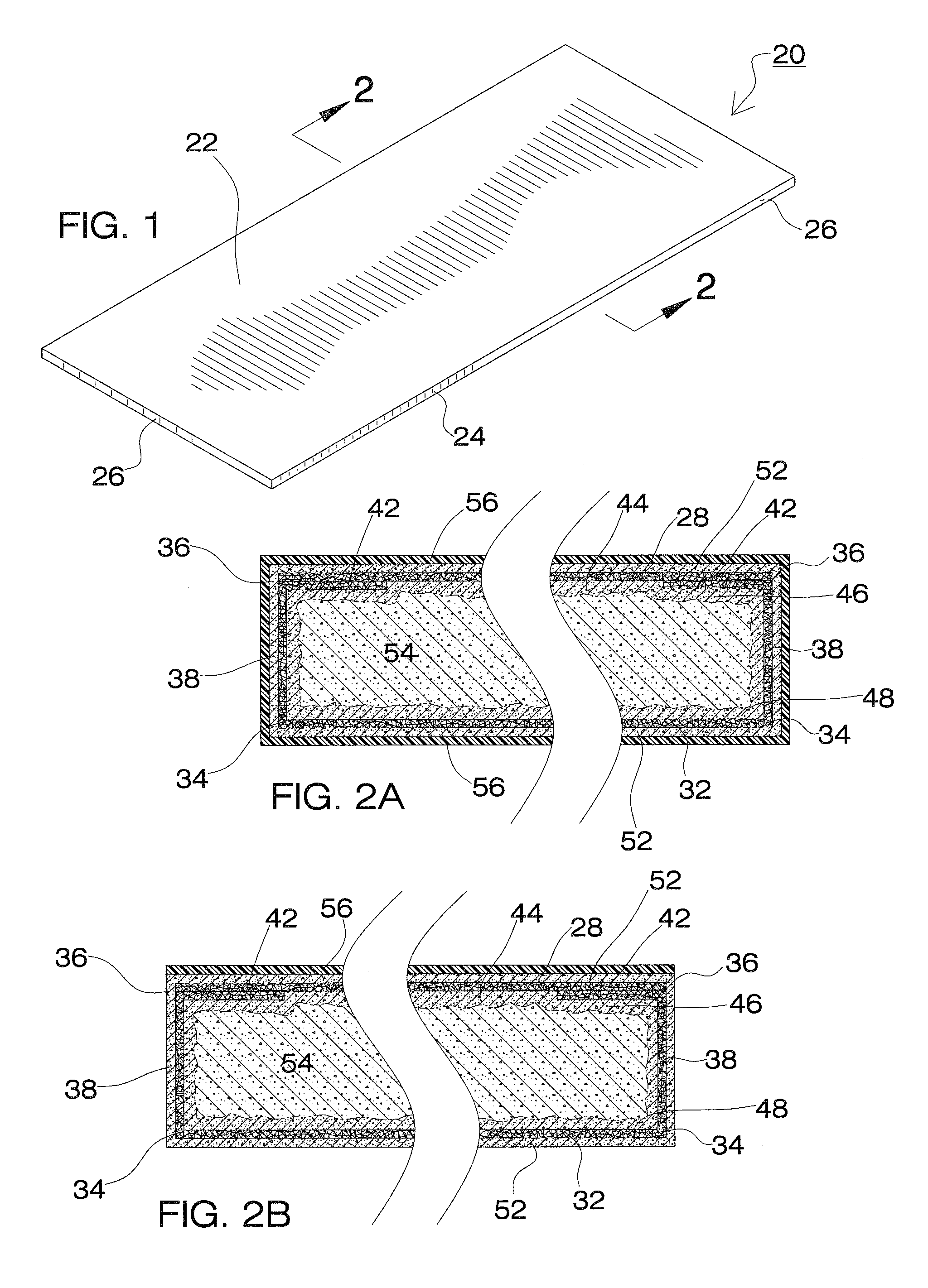

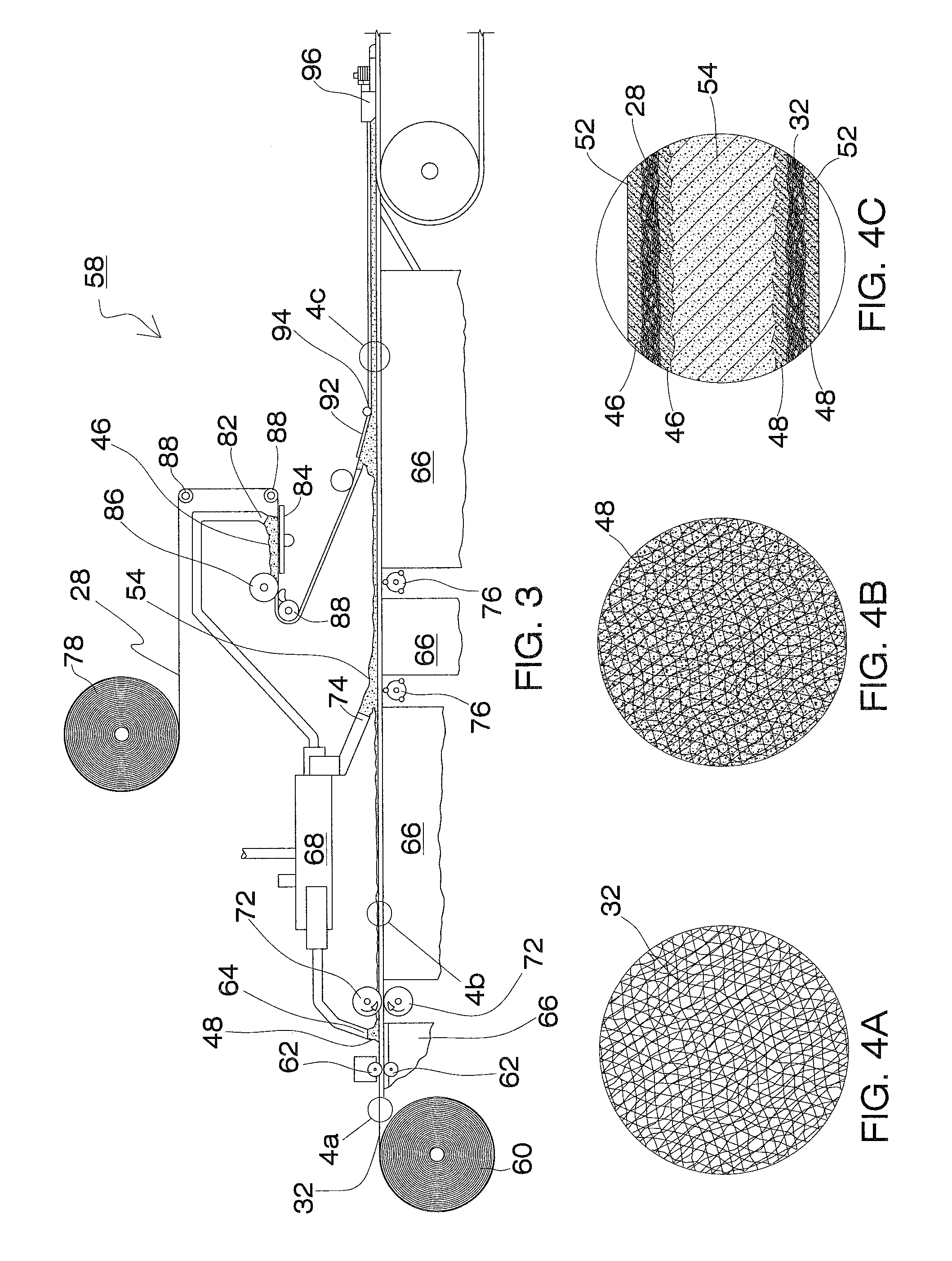

Plastic Coated Composite Building Boards and Method of Making Same

ActiveUS20100055431A1Improve physical propertiesIncrease durability and load carrying capacityGlass/slag layered productsCoatingsCross-linkSlurry

Disclosed are composite building boards and associated manufacturing methods. The composite boards may include, for example, one or more slurry layers with embedded fibrous mats. An exterior plastic coating is mechanically adhered to the underlying slurry layer. The plastic layer chemically bonds and cross-links with polymer additives within the slurry layer. The result is an integrated polymer matrix with greatly improved durability and surface strength.

Owner:CERTAINTEED GYPSUM INC

Cover glass for display device, and manufacturing method for same

InactiveUS20140227525A1High mechanical strengthHigh strengthGlass/slag layered productsDisplay deviceIon exchange

The present invention aims to provide a cover glass for display devices, made of soda-lime glass, excellent in cutting easiness and reliability of surface strength. The cover glass for display devices of the present invention includes a chemically strengthened glass, and has a compressive stress layer having a depth of 6 to 15 μm.In the cover glass, a shape parameter determined in accordance with JIS R 1625 (1996) based on analysis of a facture stress of the cover glass measured by a coaxial double ring test is not less than 7, and strength of the cover glass when a cumulative fracture probability is 1% is not less than 450 MPa.The glass plate before the ion exchange is made of soda-lime glass.

Owner:CENT GLASS CO LTD

Double layer sandwich foamed concrete composite solid wall plate

InactiveCN1987008AShort demoulding timeIncrease productivityConstruction materialSolid waste managementFiberFoam concrete

A dual-layer sandwich-type solid wall slab is composed of two surficial thin cement slabs and a foam concrete core layer. It is proportionally made of fast hardening sulphoaluminate cement, powdered coal ash, river sand, fibers, hydrogen peroxide as foaming agent, and stabilizer. Its advantages are light weight, high surface strength and high insulating effect.

Owner:贵州华骏集团节能环保材料有限公司

Antifogging coating, special antifogging coating composition and antifogging product thereof

InactiveCN101591494AGood anti-fog performanceImprove water resistanceCoatingsEthylene HomopolymersHigh surface

The invention discloses an antifogging coating, a special antifogging coating composition and a special antifogging product thereof. The antifogging coating composition comprises the following components: 0.5 to 58 mass portions of homopolymer or copolymer taking acrylic acid or methylacrylic acid as a monomer, 0.05 to 6 mass portions of aziridine crosslinking agent, 0.5 to 58 mass portions of inorganic nano-particles and 40 to 98 mass portions of solvent. The coating composition has excellent antifogging property and excellent water resistance; the coating has high bonding strength with a substrate; and the antifogging coating formed by coating the substrate of the coating has good surface hardness. The antifogging product coated with the antifogging coating has excellent surface smoothness and clearness, excellent appearance, high surface strength and good wear resistance, and can be used for bathroom mirrors, eyeglasses, helmets, safety glasses, automobile lampshades, instrument panels and the like.

Owner:BEIJING RIBIO BIOTECH

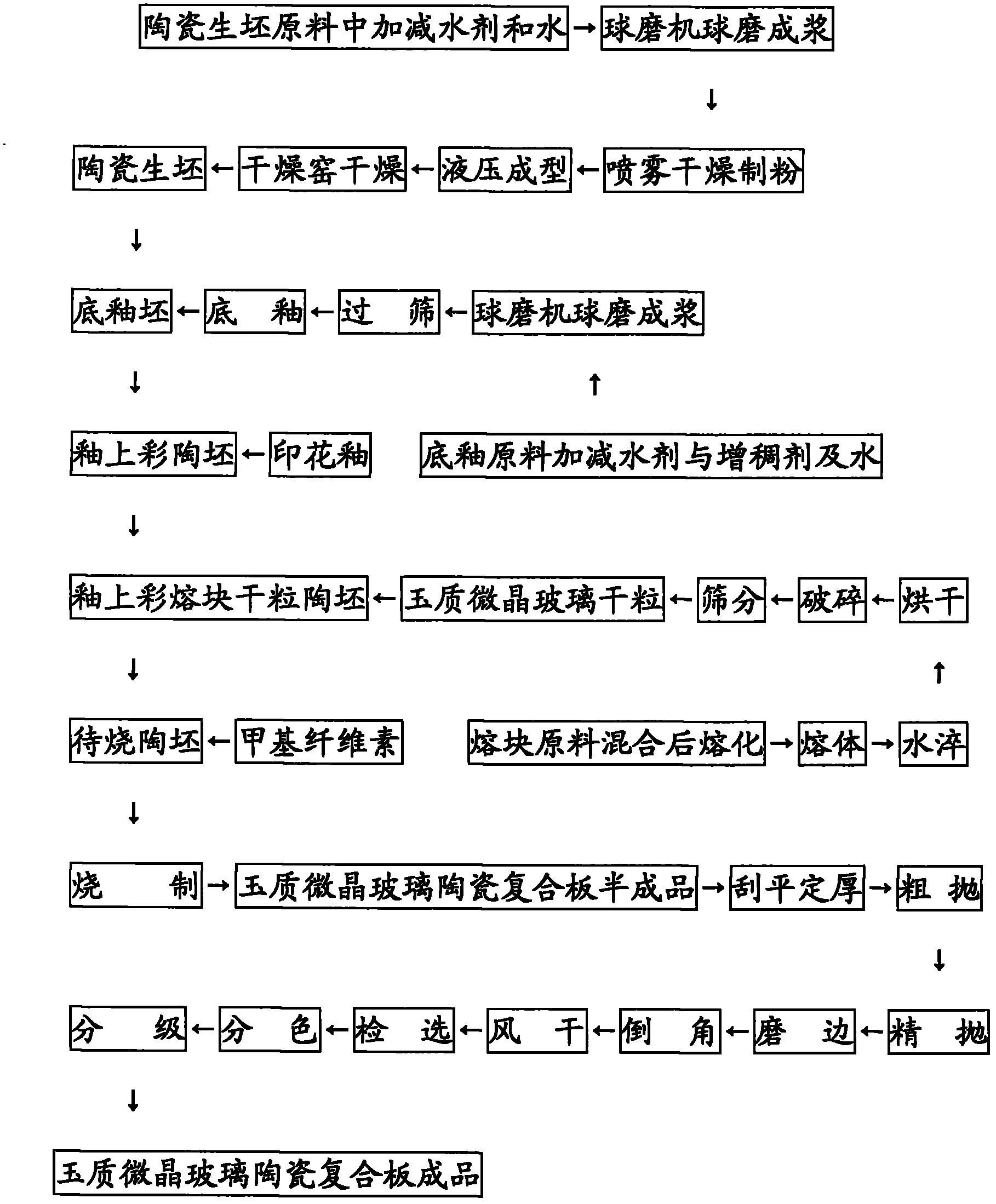

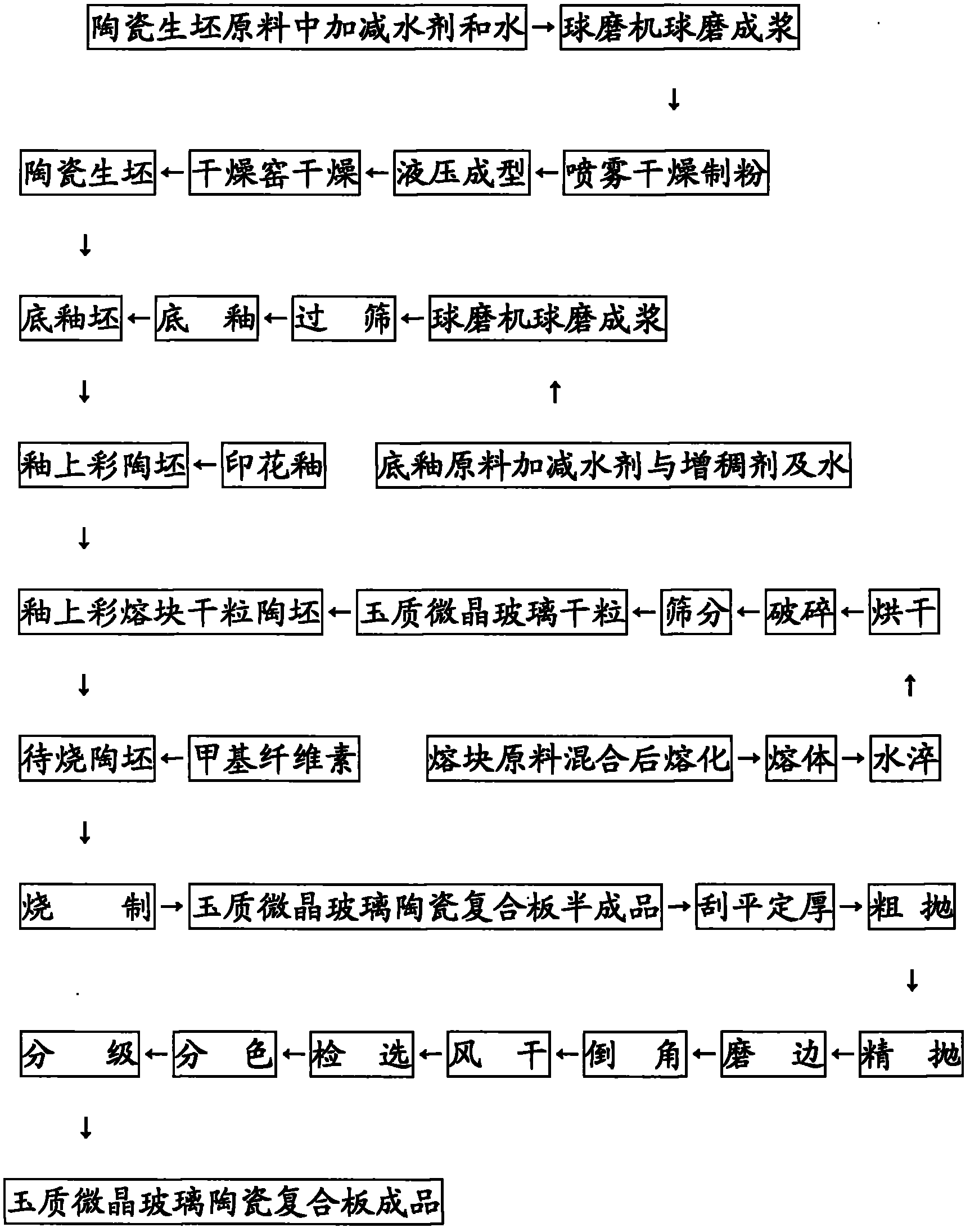

Method for preparing jadeite microcrystal glass ceramic composite board

The invention relates to a method for preparing a jadeite microcrystal glass ceramic composite board, and relates to the technical field of building materials. The method comprises the following steps of: on the basis of a key technology of 'jadeite microcrystal glass clinker dry granules obtained by selecting materials within a preset range of product ingredients', applying a ground coat on a ceramic blank to obtain a ground coat blank, and printing textile printing glaze on the ground coat blank to obtain an over-glaze colored ceramic blank; applying the jadeite microcrystal glass clinker dry granules on the over-glaze colored ceramic blank to obtain over-glaze colored clinker dry granular greenware, spraying methylcellulose for fixing to obtain greenware to be fired; and firing the greenware to be fired to obtain a semi-finished product, strickling, calibrating thickness, polishing coarsely, polishing finely, edging, chamfering, airing, sorting, performing color separation, and grading to prepare a finished product of the jadeite microcrystal glass ceramic composite board. The method is used for producing jadeite microcrystal glass ceramic composite boards, and adapts to a primary or secondary sintering process; and the product is high in quality, high in surface strength and wear resistance and wide in application range, and has a unique jadeite texture and a high comprehensive benefit.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

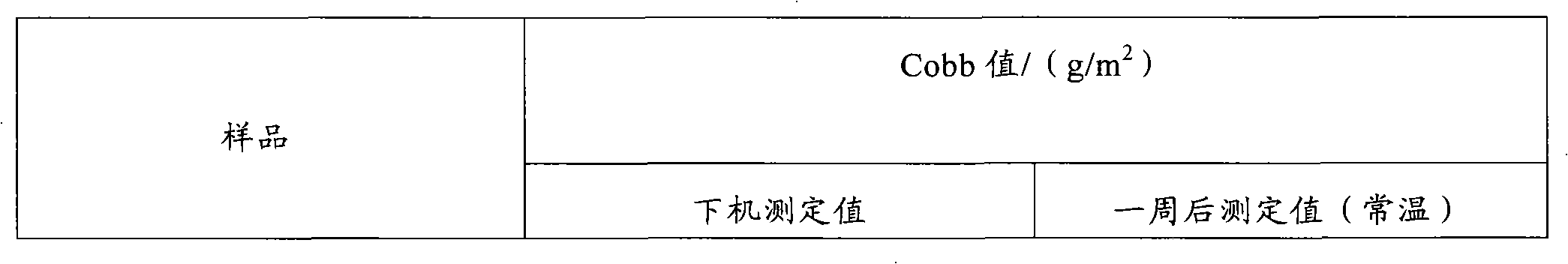

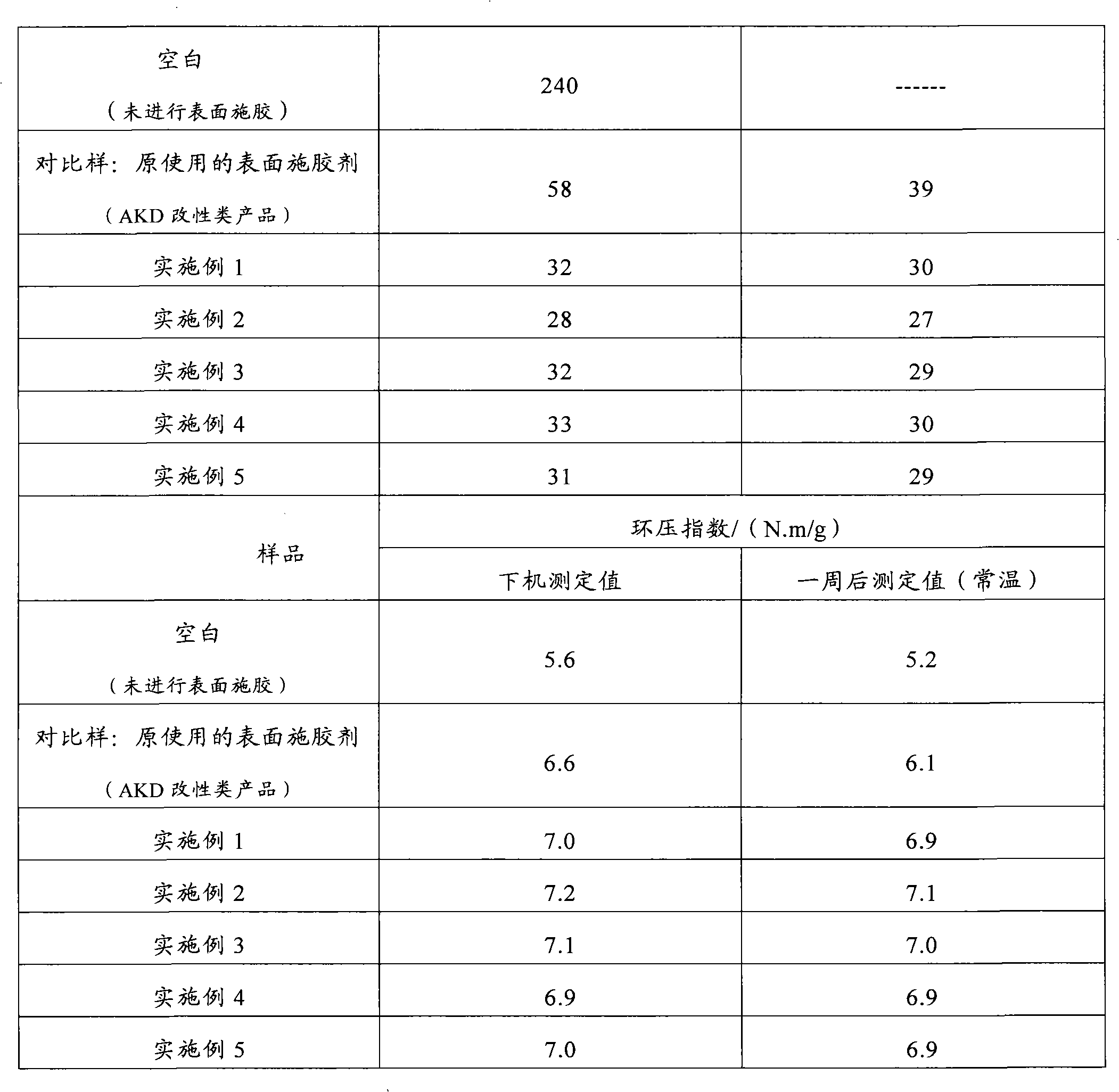

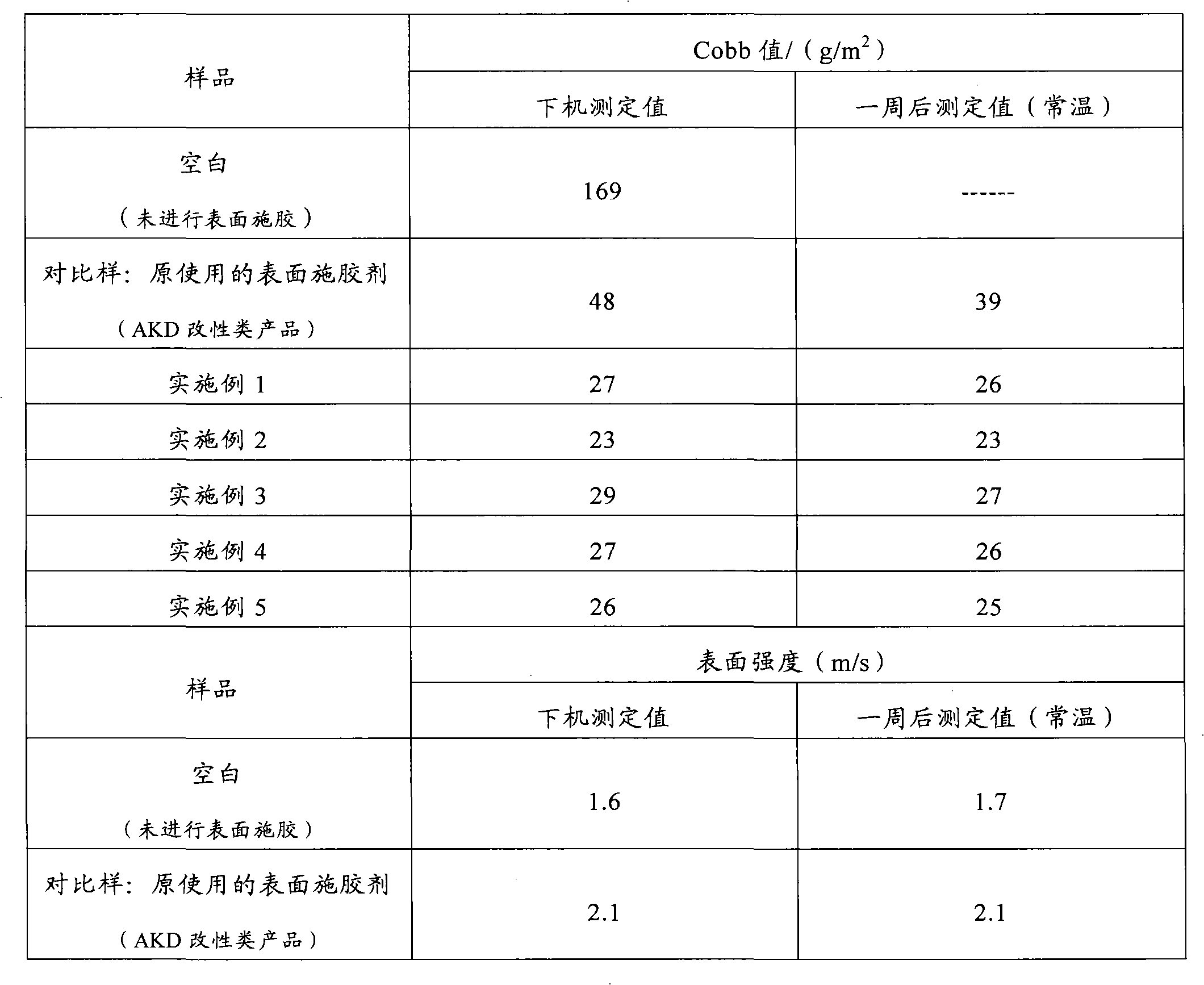

Styrene-acrylate emulsion for surface coatings of coated paper

ActiveCN101704930AImprove surface strengthHigh glossPaper coatingCoatingsEmulsionEmulsion polymerization

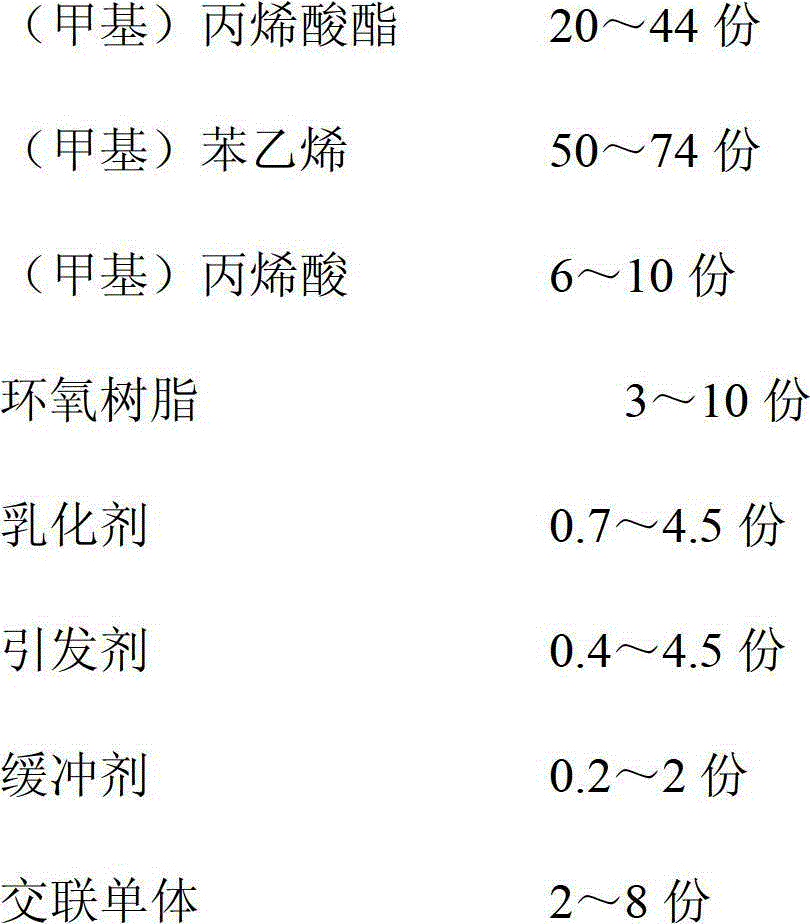

The invention provides a styrene-acrylate emulsion for surface coatings of coated paper, which is prepared in emulsion polymerization mode by mixing the following raw materials in part by weight: 100 parts of mixed monomers; 0.7 to 4.5 parts of emulsifying agent; 0.4 to 4.5 parts of initiating agent; 2 to 4 parts of accelerating agent; 2 to 8 parts of crosslinking monomers; 4 to 20 parts of aqueous alkali; and 90 to 290 parts of water. The mixed monomers comprise the following monomers in part by weight: 20 to 44 parts of (methyl) acrylic ester; 50 to 74 parts of (methyl) styrene; and 6 to 10 parts of (methyl) acrylic acid. The styrene-acrylate emulsion for the surface coatings of the coated paper of the invention is a high-performance and environmentally-friendly product which can be used for paper coatings. When applied to the surface coatings of the coated paper, the product can obviously increase the surface strength of the coated paper and improve glossiness of paper coatings.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Cation surface sizing agent and preparation method thereof

InactiveCN101649583AReduce manufacturing costPrevent penetrationWater-repelling agents additionPaper/cardboardAmylaseSizing

The invention provides a cation surface sizing agent and preparation method thereof. Raw materials are as follows by weight percent: 8-17% of styrene, 5-15% of butyl acrylate, 0.5-5% of acrylamide, 0.5-5% of N-hydroxymethyl acrylamide, 1-5% of methyl acryloyl ethyl trimethylammonium chloride, 2-8% of starch, 0.001-0.003% of amylase, 0.2-0.7% of organic acid, 0.2-0.8% of emulsifier, 1-5% of 27% hydrogen peroxide, 0.01-0.05% of iron dichloride, the balance water. The cation surface sizing agent is prepared by starch pasting, monomer pre-emulsion and emulsion polymerization. The invention is usedfor surface sizing of paper and achieves the aim of improving physical performances of paper such as water-resistance, ring crush compression resistance, surface strength and the like.

Owner:东莞市清正合成高新材料有限公司 +1

Light coated printing paper and manufacturing method thereof

InactiveCN1455047AEase the strain on resourcesAdjustable structurePaper/cardboardSulfatePulp and paper industry

The present invention discloses a light-weight coated printed paper and its making method. It includes the following steps: using bleached sulfate needle wood (pulp (BKP). Italia poplar alkaline hydrogen peroxide hot-ground mechanical wood pulp (APMP), bleached sulfate reed pulp (BKP) or commercial bleached hard wood pulp; respectively beating, proportioning and making them into mixed pulp; adding auxiliary material to obtain material for making paper and making paper. Said invention adopts the advanced making process of AKD neutral sizing, internal coating and calendering by using soft roll, so that said printing paper has good surface strength, bulkness and air permeability, and is suitable for implementing various colour printing.

Owner:YUEYANG FOREST & PAPER CO LTD

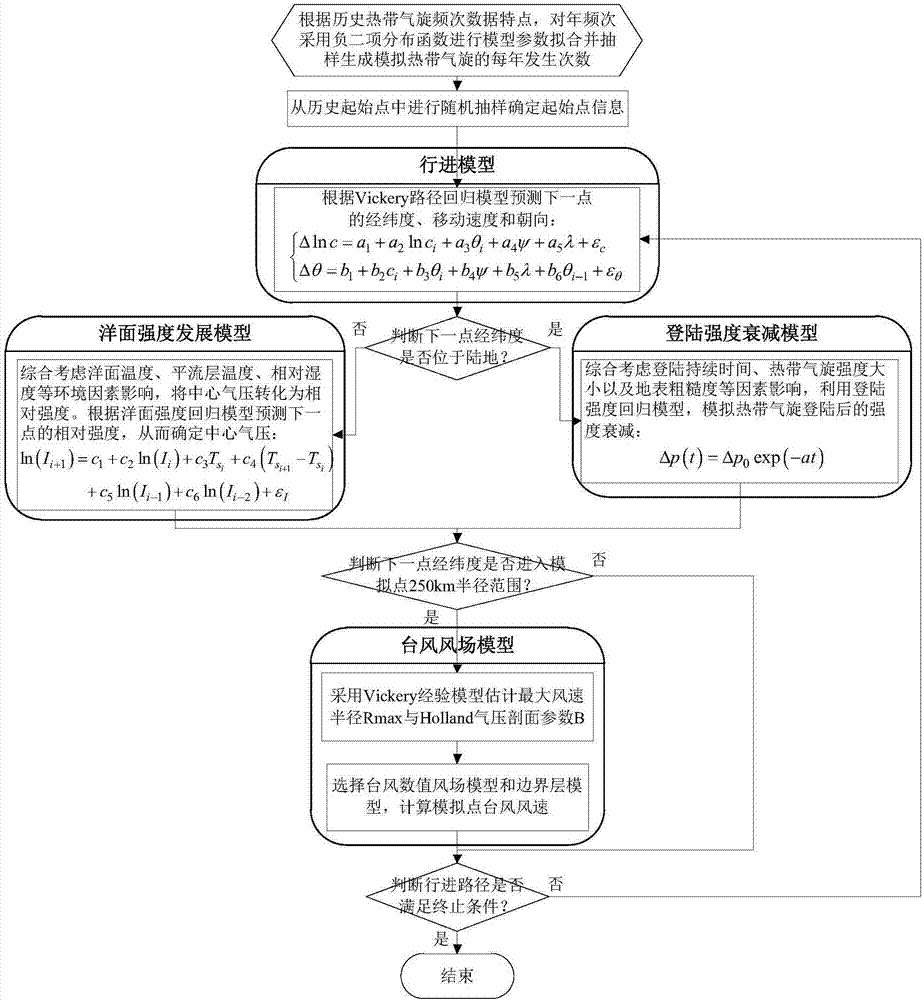

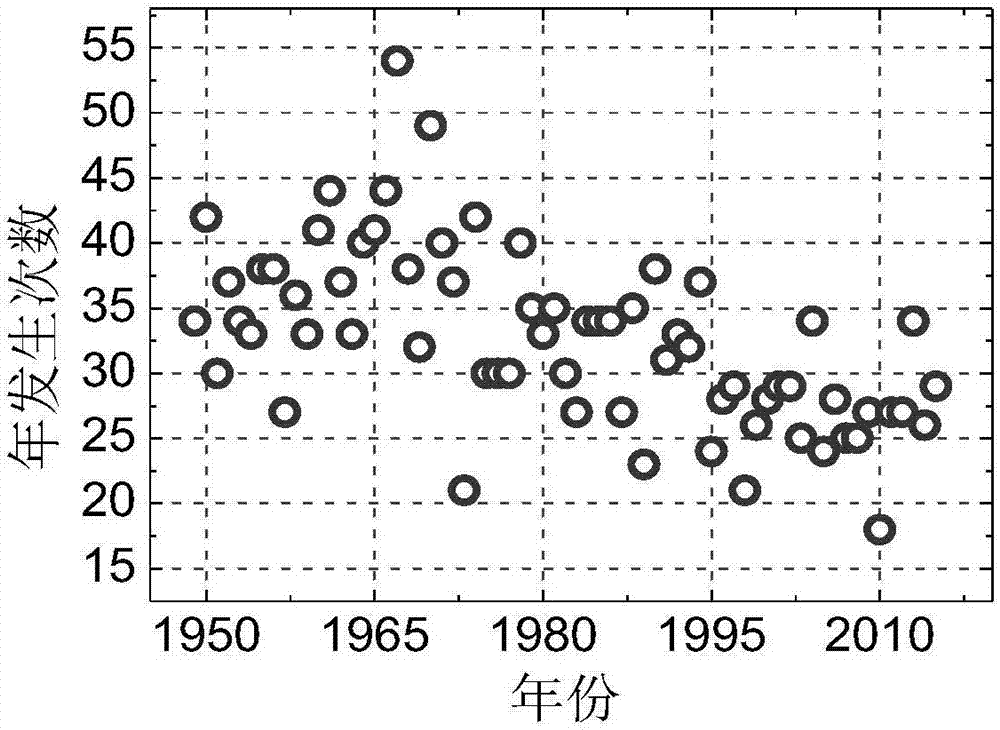

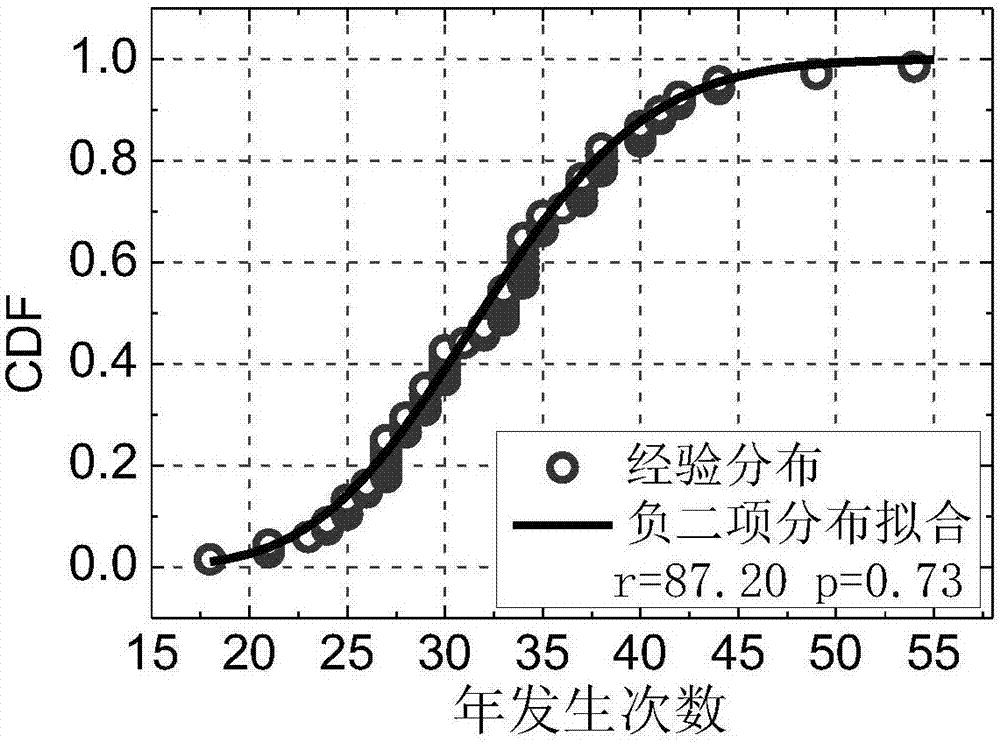

Tropical cyclone full path simulation method facing disaster risk assessment

InactiveCN107229825AThe result is accurate and reliableImprove computing efficiencySpecial data processing applicationsInformaticsLongitudeSimulation

The invention relates to a tropical cyclone full path simulation method facing disaster risk assessment. The tropical cyclone full path simulation method comprises concrete steps: a first step of establishing a start point model, and taking samples to simulate yearly occurrence frequency of tropical cyclones and generate start point information; a second step of establishing a marching model, and simulating the moving speed and orientation of the tropical cyclones to form a tropical cyclone path; a third step of establishing strength models including an ocean surface strength development model and a land strength attenuation model, and selecting the corresponding strength model in dependence on the latitude and longitude of the next point in the tropical cyclone path; a fourth step of examining the path simulation result, and carrying out statistical result examination and statistical rule analysis on the randomly-generated tropical cyclone path and the strength large sample; and a fifth step of establishing a typhoon wind field engineering model and a boundary layer model, calibrating wind field model key parameters, calculating the typhoon wind speed on the simulated point, and carrying out typhoon risk disaster assessment. The tropical cyclone full path simulation method facing disaster risk assessment can achieve refined evaluation, and is accurate and reliable in result, high in calculating efficiency and wide in application scope.

Owner:ZHEJIANG UNIV

Surface sizing agent for paper making

InactiveCN101225623AImprove qualityMeet quality requirementsWater-repelling agents additionNon-macromolecular organic additionIsooctyl acrylateEmulsion

The invention relates to a surface sizing agent for paper making, which has the material formula with a plurality of components and weight percentages as follows: starch 6.5-8%, styrene 4.5-6%, acrylonitrile 4-5%, n-butyl methacrylate 5.5-6.5, methacrylic acid iso-octyl 2-3.5, iso-octyl acrylate 0.4-1%, hydrogen peroxide 0.2-0.5%, formic acid0.5-1%, ferrous sulfate 0.5-4%, n-dodecyl mercaptan 0.5-3%, amylase 0-0.2% and water the rest, wherein at least one is chosen from n-butyl methacrylate, methacrylic acid iso-octyl and iso-octyl acrylate. The appearance of the surface sizing agent is slight yellow emulsion, and the main component is styrene-acrylic copolymer which is easily soluble at normal temperature. The surface sizing agent for paper making has the advantages of greatly increasing paper surface intensity, decreasing hair and powder shedding, and improving the sizing degree, smoothness and printability of paper.

Owner:杨春先

Production method of high-performance latex paper

InactiveCN102191725AImprove beating degreeHigh tensile strengthSpecial paperPaper/cardboardFiberTemperature resistance

The invention discloses a method for producing latex paper by using a circular-net multi-cylinder paper machine. 50 to 60 percent of bleached sulfate soft wood pulp, 35 to 45 percent of non-bleached sulfate soft wood pulp and 5 percent of manmade fiber are adopted, and the following technology is used at the same time so as to make the product better: defibrinating by using a previous-low-concentration fiberizer and a rear-middle-concentration fiberizer so that the beating degree is higher and the length of the fiber can be retained to the maximum extent, and the body paper has higher tensile strength and flexibility and is hard to break during use; besides the two different soft wood pulps, a certain amount of manmade fiber is added into the fiber raw material, so that the strength and the anti-abrasion performance of latex paper are enhanced; the body paper subjected to dipping treatment according to an optimized latex formula has higher strength and water, oil and high temperature resistance performance; a specific surface coating and back coating mode is performed on the dipped body paper, so the tensile strength, the bending resistance and the liquid resistance of the finished paper are enhanced; meanwhile, the latex paper is softer and durable, and higher in the surface strength.

Owner:郭友实

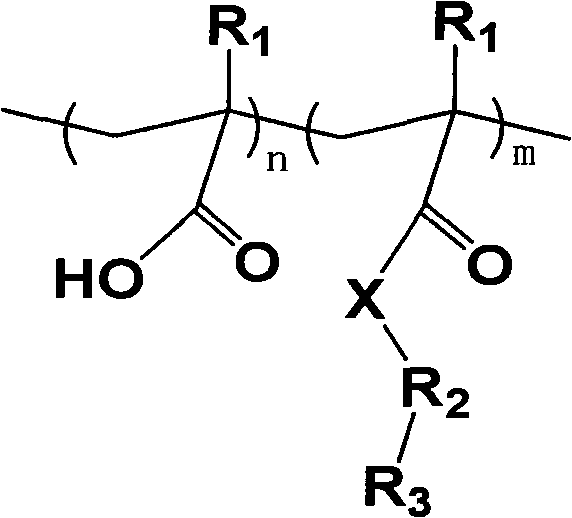

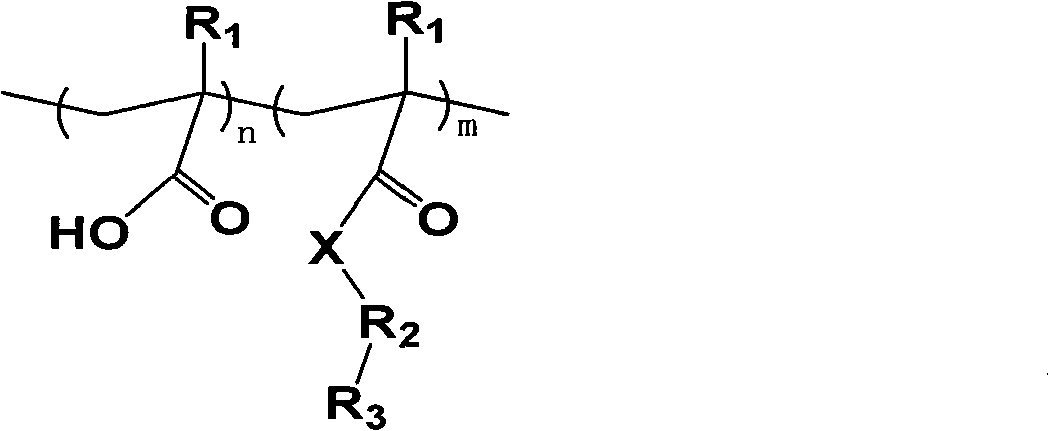

Surface sizing agent as well as preparation method and application thereof

InactiveCN102086614AHigh strengthImprove surface strengthWater-repelling agents additionPaper coatingCardboardEnvironmental resistance

The invention relates to a surface sizing agent as well as a preparation method and an application thereof. The surface sizing agent comprises the following components: siloxane, a cationic monomer, an acrylate monomer, a crosslinking monomer, styrene, a dispersant, an emulsifier, an initiator and deionized water. The surface sizing agent has good starch crosslinking strength and good hydrophobic property, thus paper prepared from the surface sizing agent has the advantages of better surface strength, better water resistance, better printing performance and environmental protection; and in addition, the surface sizing agent is also applicable to neutral and alkali paper, and can generate good ring crush strength on cardboard paper and corrugated paper. The surface sizing agent can fully replace an internal sizing agent, and has the advantages of less spillage, good film-forming performance, good system compatibility and the like.

Owner:长春市筱悦印刷有限公司

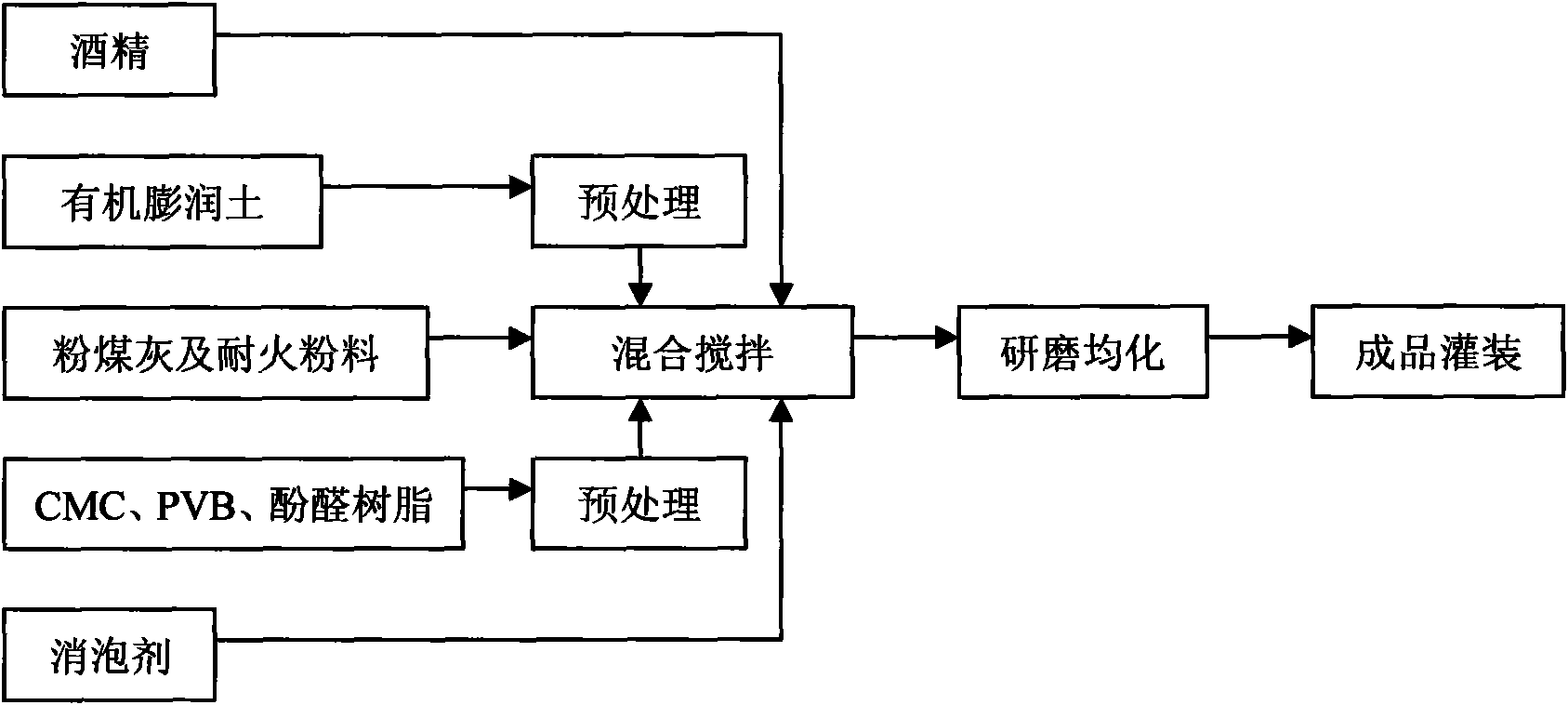

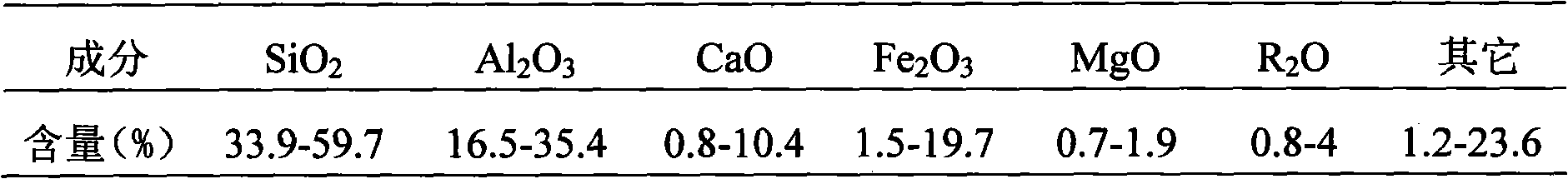

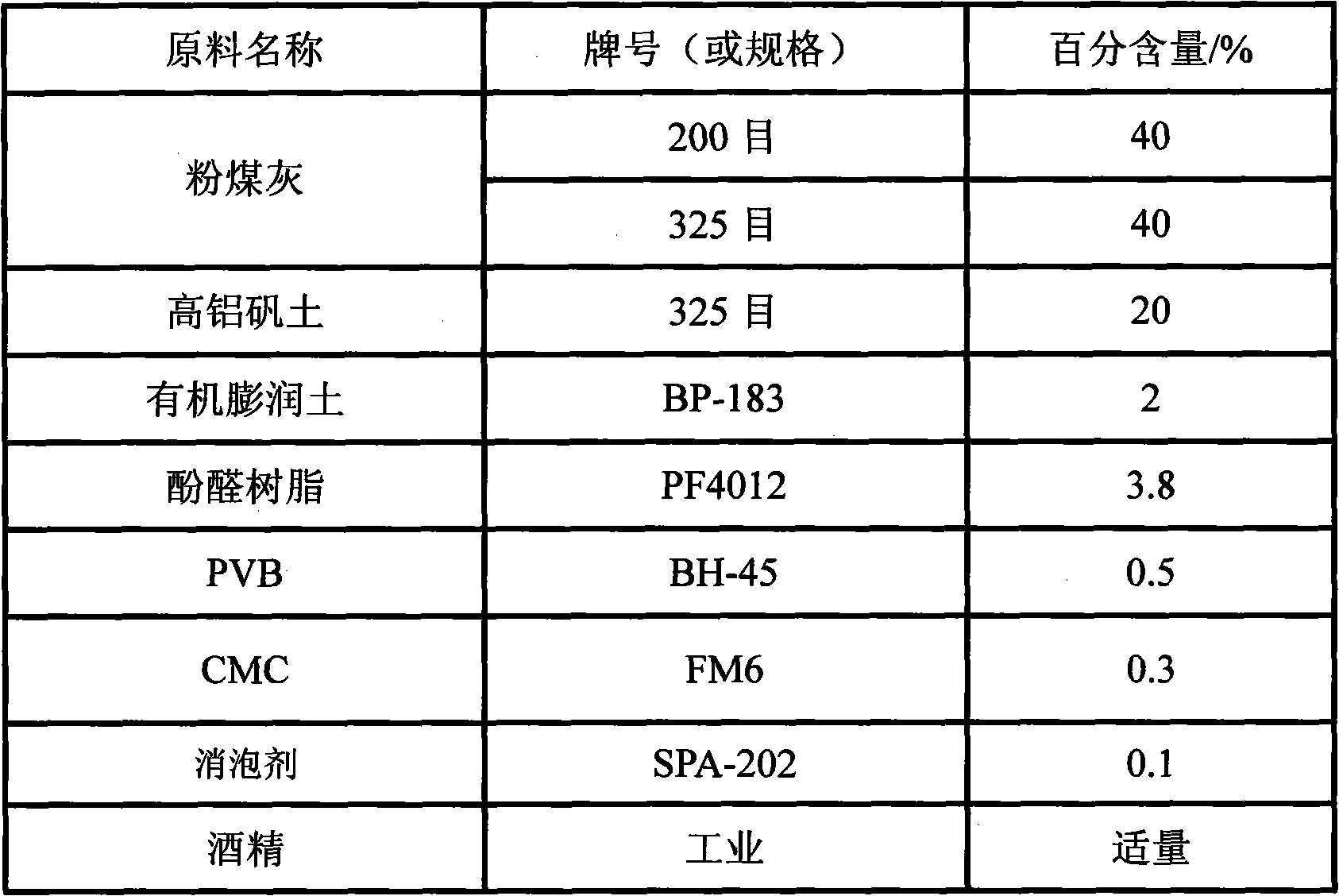

Method for preparing iron casting coating by flyash

InactiveCN101602088AEasy to peelSand cleaning is easyFoundry mouldsFoundry coresSodium BentoniteVolumetric Mass Density

The invention discloses a method for preparing iron casting coating by flyash. The iron casting coating prepared by the method comprises refractory powder, an additive and carrier liquid; wherein, the refractory powder comprises flyash and high-alumina bauxite; the additive comprises organic bentonite, phenolic resins, PVB, CMC and a defoaming agent; the carrier liquid is alcohol. The preparation process comprises the following steps: pretreating the organic bentonite, CMC, PVB and phenolic resins, mixing the above materials with other raw materials, stirring and dispersing the mixture in an agitator, grinding and homogenizing the mixture and regulating the density and viscosity of the coating, packing the coating in a barrel special for coatings and sealing the barrel, thus preparing the finished product. The coating is coated on the surface of a sand mould (core) and then is ignited and quickly dried to form a coat so as to enhance the casting mould surface strength and sand-burning resistance. The coat is easily stripped and sand is easily cleared after casting pouring. Use of the coating can achieve the effect of fine casting surface quality.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

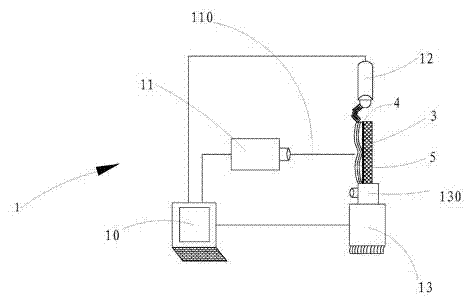

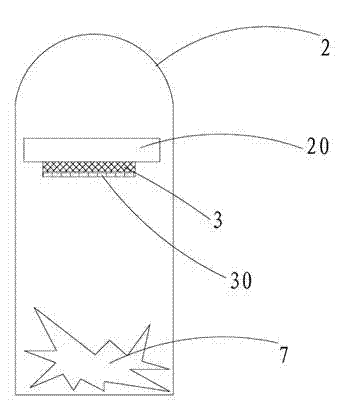

Laser shock method

ActiveCN102212655AReduce porosityImprove corrosion resistanceVacuum evaporation coatingSputtering coatingComputer control systemHigh power lasers

The invention discloses a laser shock method. The method comprises the following steps: (A) providing a laser shock device and a vacuum ion plating machine, wherein the laser shock device comprises a computer control system, a high-power laser, an automatic water sprayer and a worktable, the worktable is equipped with a first fixture and the vacuum ion plating machine is equipped with a second fixture; (B) covering an aluminum foil absorbing layer on the surface of a metal material; (C) controlling the automatic water sprayer to spray water to the surface of the aluminum foil absorbing layer by means of the computer control system; (D) controlling the worktable to move by means of the computer control system; (E) controlling the high-power laser to emit laser beams to the aluminum foil absorbing layer by means of the computer control system; and (F) finally removing the aluminum foil absorbing layer, placing the metal material in the vacuum ion plating machine and forming a graphite coating on the surface of the metal material by utilizing a physical vapor deposition method. By utilizing the laser shock method, surface strength and hardness of the metal material can be improved and cavitation erosion can be effectively avoided.

Owner:ZHANGJIAGANG FURUI SPECIAL EQUIP CO LTD

Method for preparing surface coating reinforcing agent for secondary fibre paper

InactiveCN101649584AAddressing Surface Performance RequirementsMeet the requirements of surface propertiesReinforcing agents additionPaper/cardboardFiberSolvent

The invention relates to a method for preparing a surface coating reinforcing agent for secondary fibre paper. The method comprises the following steps: under the emulsifying action of a maleic anhydride polyoxyethylene ester polymeric emulsifying agent, taking a copolymer of soft monomers, such as acrylic acid long-chain fatty ester and the like, as a core (or casing) component, taking a copolymer of hard monomers, such as styrene, methyl methacrylate and the like, as a casing (or core) component, taking an organic silane coupling agent as a core-casing crosslinking component, taking silicasol as a surface reinforcing crosslinking component and preparing a high molecular / inorganic hybridization surface coating reinforcing agent. The product not only can solve various problems caused by the strength decay of the secondary fibre paper, reduce the use quantity of a reinforcing retention aid in pulp and improve the foaming performance, but also can meet the requirement of paper surface properties (such as surface strength, smoothness, oil-taking property, ink-taking property and the like) and overcome the phenomena of hair slipping, powder slipping, cross color and printthrough in multicolor printing, and the like; simultaneously, by the invention, the secondary fibre paper can meet the required indexes of high-grade paper or special type paper, such as the washing resistance andthe solvent resistance of chromatic paper.

Owner:SHAANXI UNIV OF SCI & TECH

Styrene-acrylic emulsion for priming paint as well as preparation method and application thereof

ActiveCN101704913AImprove surface strengthImprove the phenomenon of hair loss and powder lossPaper coatingCoatingsCross-linkAccelerant

The invention provides a styrene-acrylic emulsion for priming paint as well as a preparation method and an application thereof. The preparation method comprises the following steps: by using a surfactant compound from an anionic surfactant and a nonionic surfactant as an emulsifier and using peroxide as an initiator, carrying out free-radical emulsion polymerization on (methyl) acrylic monomer, (methyl) acrylate monomer, (methyl) styrene, cross-linking monomer and an accelerant under the conditions of 50-95 DEG C and normal pressure to obtain an emulsion; and then, neutralizing the obtained emulsion with aqueous alkali, and regulating the pH value to be 7-10 to obtain a finished product. The styrene-acrylic emulsion for priming paint is a product which can be used for paper-making paint and has high performance and environmental protection. When the product is applied to the priming paint of coated paper, the surface strength of the coated paper can be obviously increased, and the phenomena of fur falling and powder falling can be improved.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Method for preparing full-mold casting coating

ActiveCN102500745AImprove performanceIncrease stiffnessFoundry mouldsFoundry coresHigh surfaceTemperature resistance

The invention discloses a method for preparing a full-mold casting coating. The full-mold casting coating prepared by the method is high in anti-burn-on capacity and capable of improving rigidity and high-temperature resistance of molds, while cost is reduced to the utmost extent. A high-current rheological fluid is formed by optimizing blending of aggregates and various additives, and has betterwettability and brushing property to foamed plastic molds. According to practices, the coating thickness of the coating can be at least 1.7mm after the coating is brushed by twice and is capable of meeting requirements for anti-burn-on capacity and transporting of large-size castings. The full-mold casting coating has excellent suspended property, thixotropy, breathabililty and higher surface strength, the method for preparing the full-mold casting coating is simple, convenient in operation and low in cost, and raw materials for preparing the full-mold casting coating are rich. In addition, surfaces of the full-mold castings produced by the full-mold casting coating are smooth and bright and free of defects of wrinkles, carbon black and the like, and coating layers on the surfaces are easy to be stripped and convenient to be cleaned.

Owner:南通市通州区俊朗建筑工程有限公司

Refined light weight coated paper and its production process

InactiveCN1769587ASimple preparation processSimple surface strengthCoatings with pigmentsPaper/cardboardSurface strengthPre treatment

This invention discloses a fine smearing cloth and its making technology, the charater of which is that it uses the bleaching sulfate chemical paddle, the pasta pretreatment alkalescence hydrogen peroxide bleaching thermomechanical pulp (P-RC APMP), the wastepaper de-ink plasm, and the most advanced plasm making and transimitting system, the diluting stream case, the vertical web nipping frame, the straight-through shoe type grinding, membrane type surface gluing machine or applying machine, the infrared drier, the 8 roller soft calendar, the strip type duplicate reel machine. The obtained refine light coated paper is 48í½80g / m2ú¼the moisture is 5.0í½7.0úÑú¼the whiteness (ISO) is 75í½90úÑ, the untransparency is more than 82úÑú¼the breakage length (longitudinal ) is more than 4200m; the horizontal breaking bearing is more than 12 times, the roughness of the press surface(PPS) is 1.3í½1.8ª

Owner:YUEYANG FOREST & PAPER CO LTD

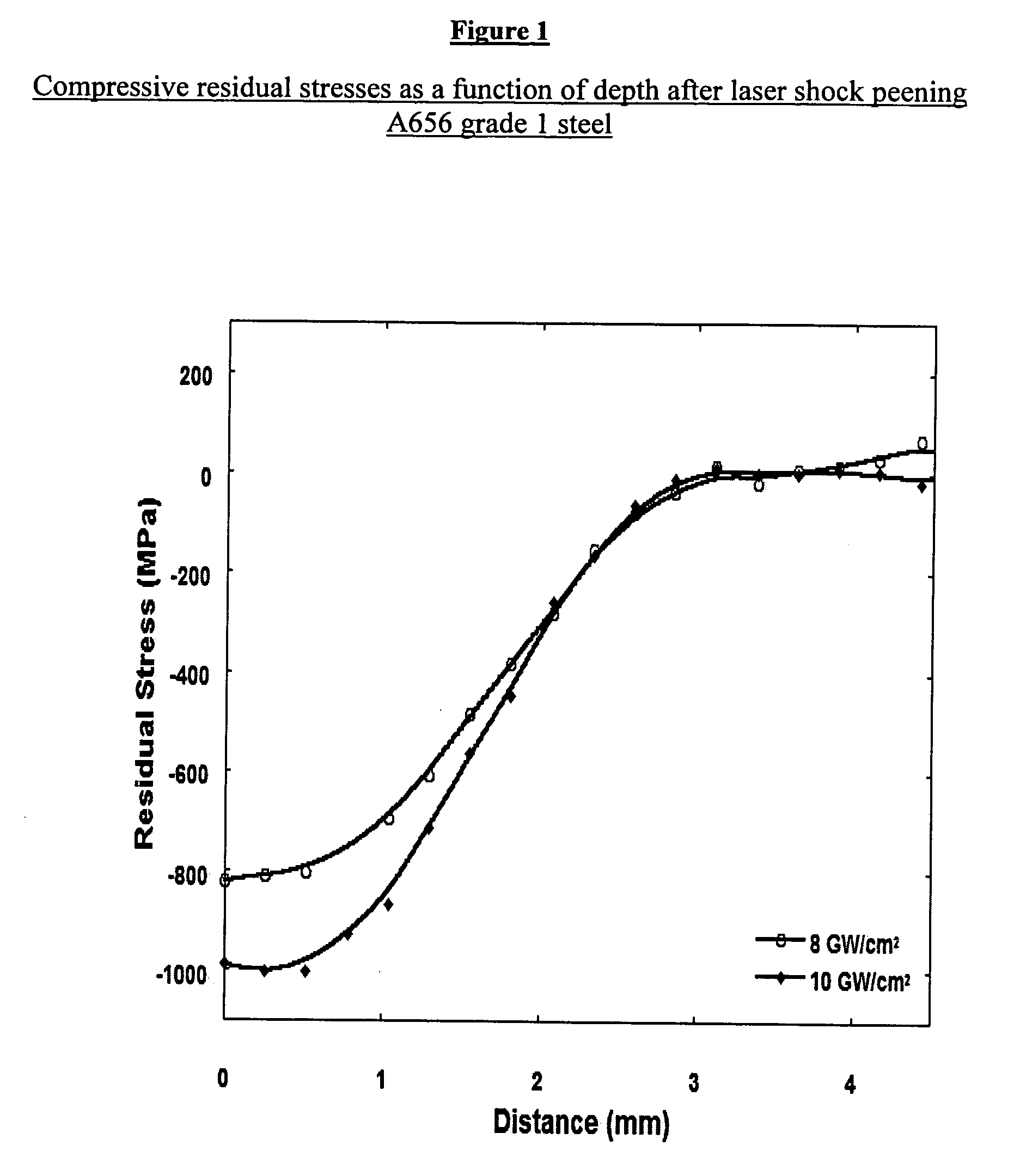

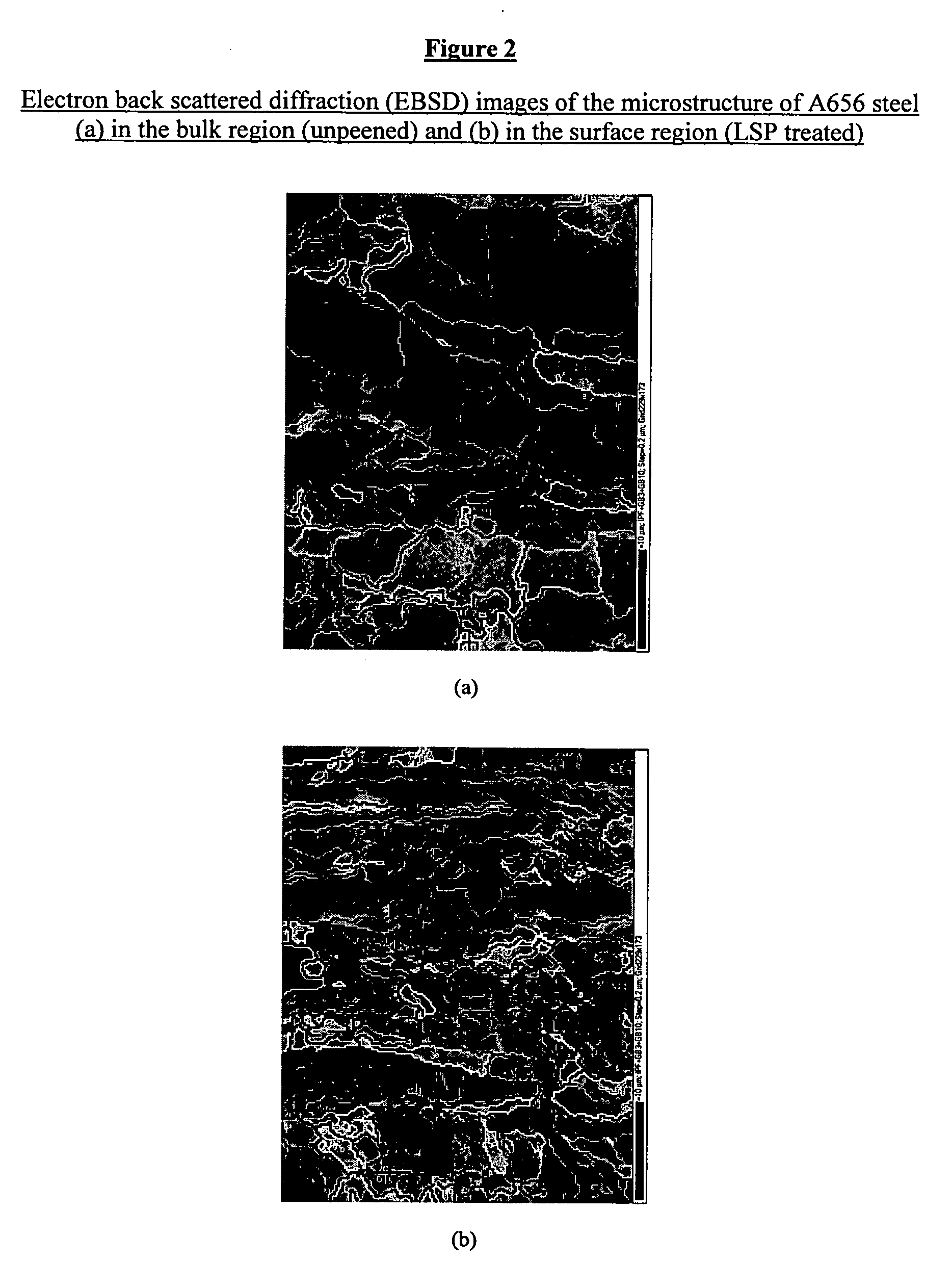

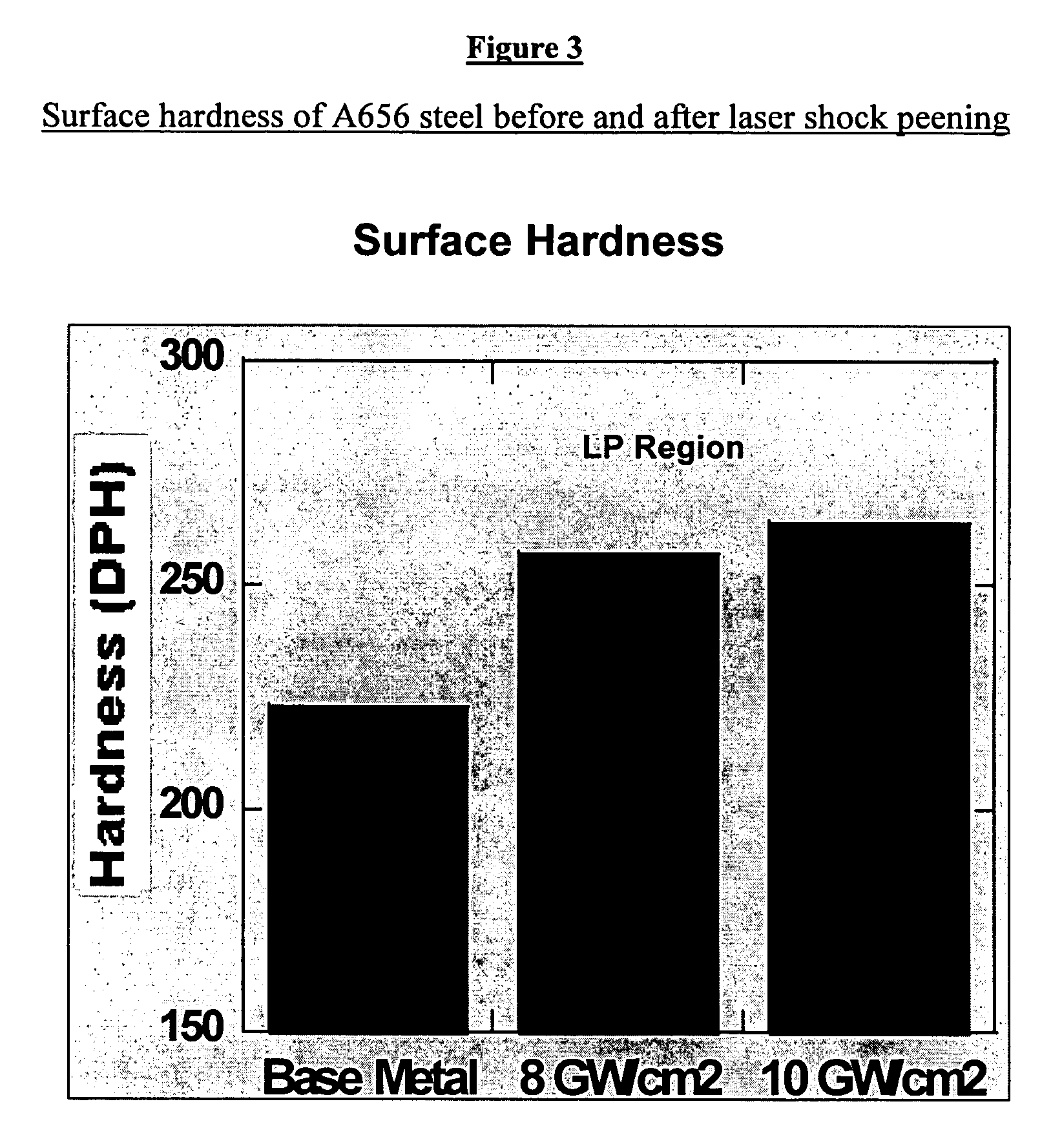

Use of friction stir and laser shock processing in oil & gas and petrochemical applications

InactiveUS20080032153A1Reduce the thickness of the structureDecreases gradeFurnace typesThin material handlingAlloyPetrochemical

The use of friction stir and laser shock processing in oil & gas and / or petrochemical applications is provided by the present invention. The use includes subjecting friction stir weldments, fusion weldments, and other critical regions of ferrous and non-ferrous alloy components used in oil & gas and petrochemical applications to laser shock processing to create residual compressive stresses near the surface of the treated area. The residual compressive forces in the ferrous or non-ferrous components improve properties including, inter alia, surface strength, fatigue life, surface hardness, stress corrosion resistance, fatigue resistance, and environmental cracking resistance. Friction stir and laser shock processing find particular application in high strength pipelines, steel catenary risers, top tension risers, threaded components, liquefied natural gas containers, pressurized liquefied natural gas containers, deep water oil drill strings, riser / casing joints, and well-head equipment.

Owner:EXXON RES & ENG CO

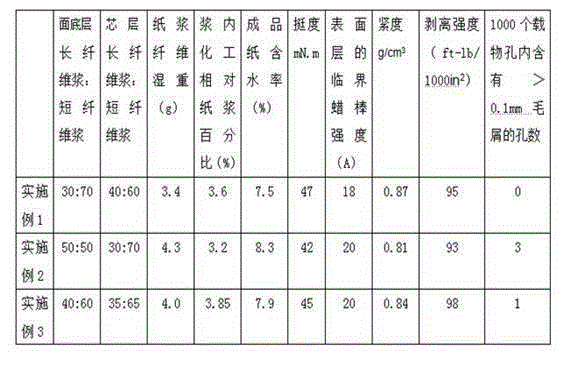

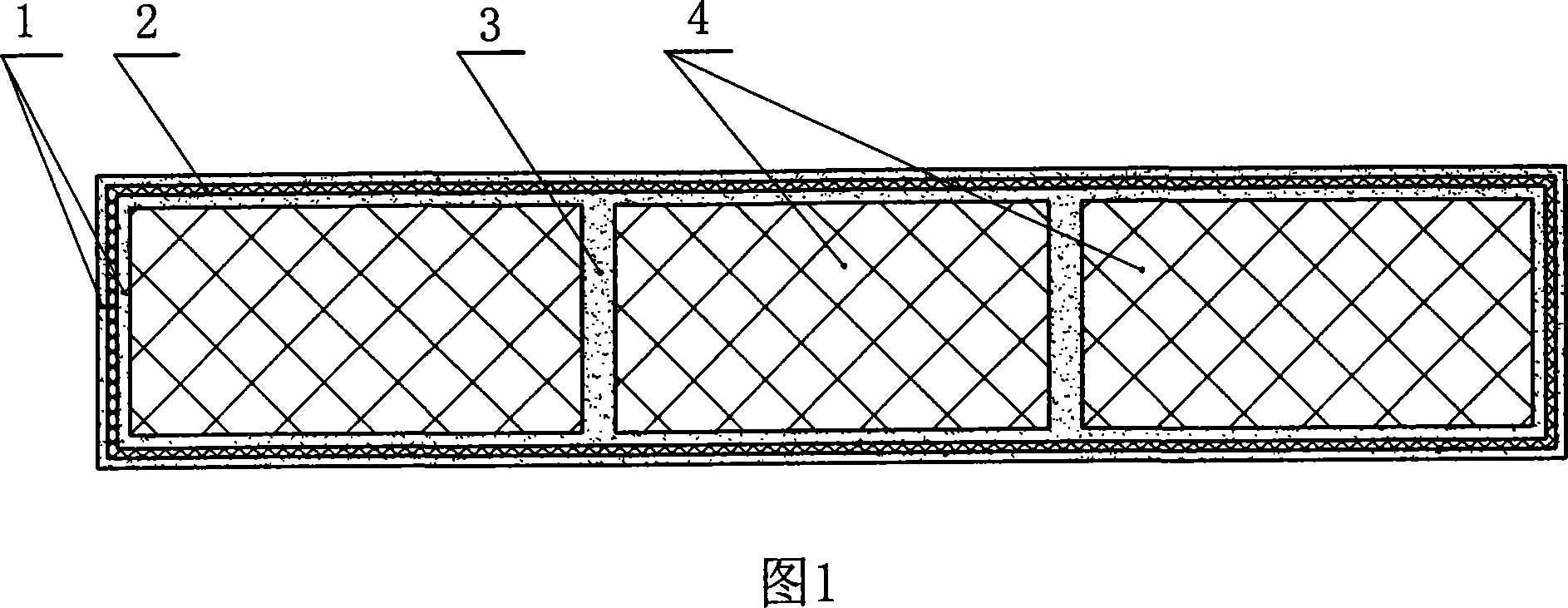

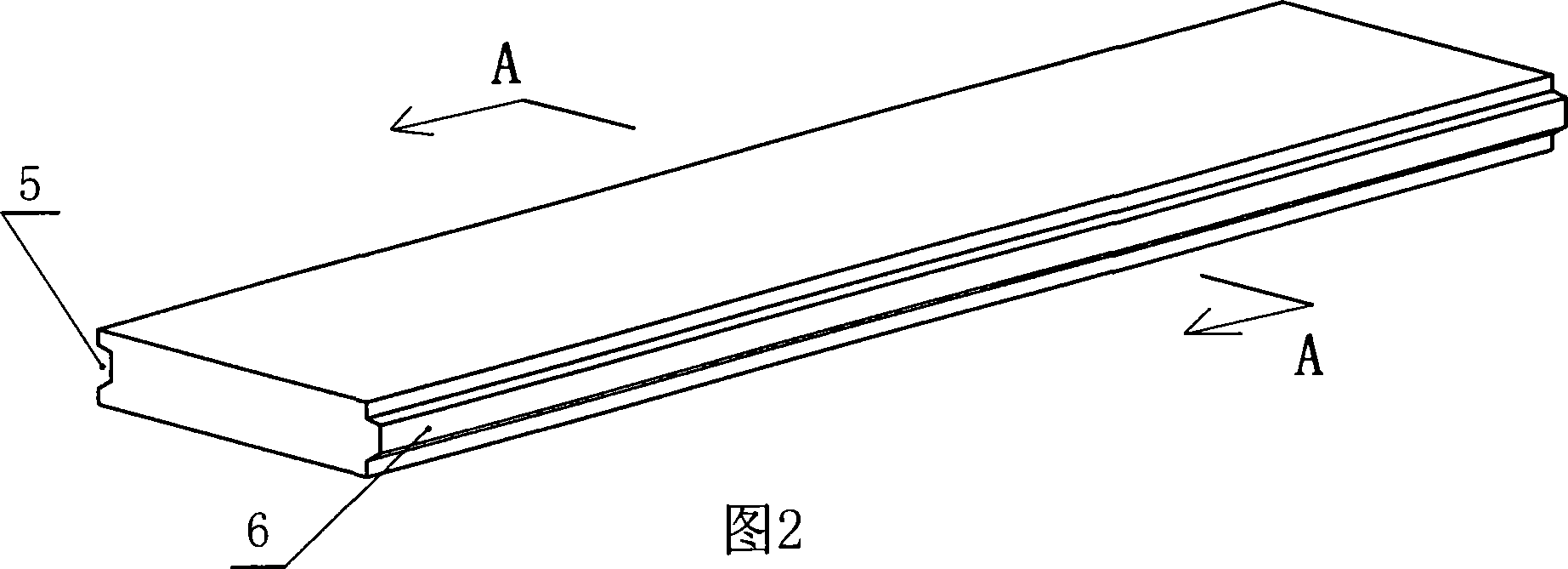

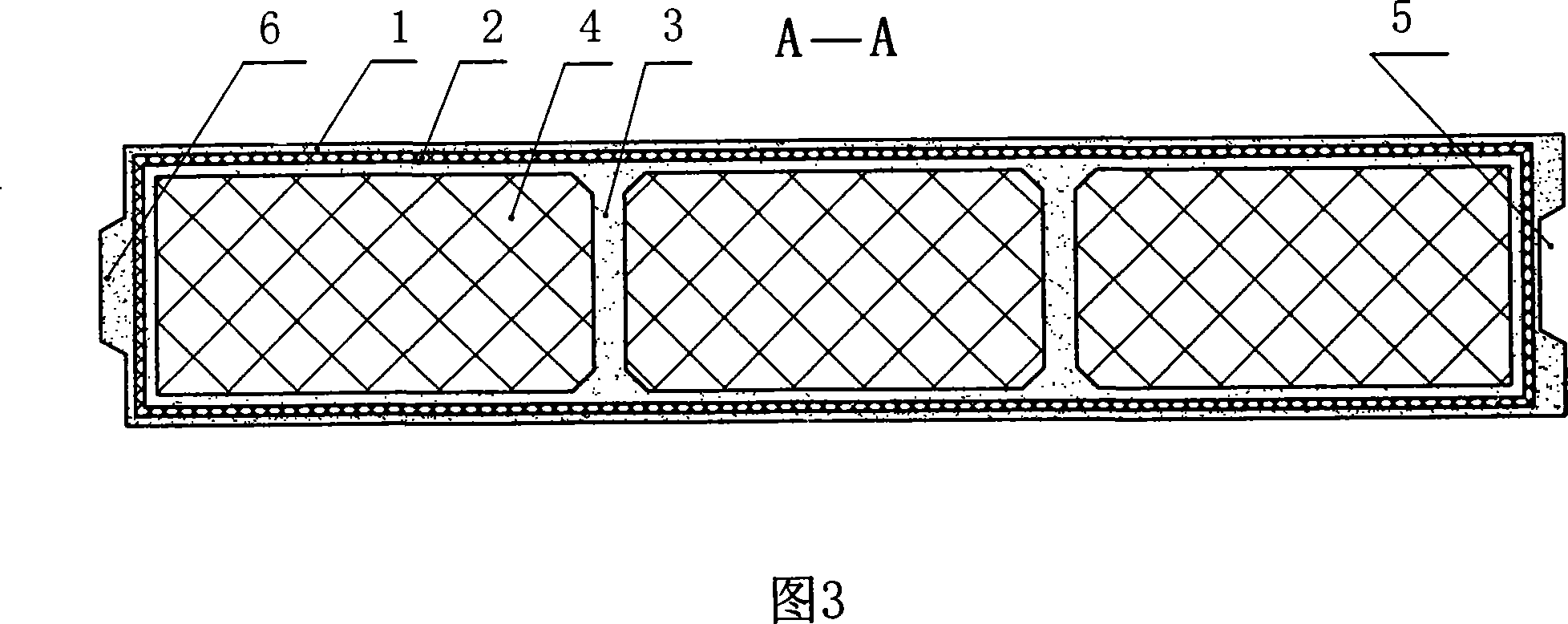

Paper for packaging carrier tape and preparation method thereof

ActiveCN104088199AHigh bonding strength between layersImprove surface strengthFlexible coversWrappersCardboardFiber

The invention discloses paper for packaging a carrier tape and a preparation method thereof. The paper and the preparation method are characterized in that the thickness of the paper for packaging the carrier tape is 0.25mm-1.00mm, the thickness deviation is plus or minus 0.02mm, the compactness is 0.80-0.95g / cm<3>, the moisture content is 6.0%-9.0%, the deflection is greater than or equal to 30mN.m, the peel strength between all the layers is greater than or equal to 80ftlb / 1,000in2, the critical wax rod strength of a surface layer is greater than or equal to 18A, and the residual rate of burrs (soft flocks) greater than 0.1mm in a carrying hole punched by using a punching mould is less than 5 / 1000. According to the paper for packaging the carrier tape and the preparation method thereof, by utilizing short fiber paper pulp subjected to pulp grinding treatment, and adding and spraying a high-molecular polymer resin adhesive, dry-strength resin, wet-strength resin, a stiffening agent, a sizing agent and the like into the paper pulp and between made wet paper sheet layers, a three-dimensional network structure is formed by bonding paper pulp fibers with various polymer resin macromolecules, so that paper boards have relatively high interlayer bonding strength, surface strength and stiffness, and the fibers are easier to cut off during punching to reduce the production of the soft flocks, so as to meet the quality requirements for the packaging the carrier tape.

Owner:JIANGXI JIEMEI ELECTRONICS INFORMATION MATERIAL CO LTD

Surface sizing agent for improving paper deflection and paperboard circular press stength

InactiveCN101050611ARaise the gradeNo change in product qualityWater-repelling agents additionNon-macromolecular organic additionPaperboardPulp and paper industry

The present invention related to a surface sizing agent for raising stiffness of paper and ring crush of board. It is a mixture made up by using (by wt %) 80-99.5% of water-soluble thermosetting resin adhesive and 0.5-20% of solidifying agent. Said invention also provides its application method.

Owner:NANJING FORESTRY UNIV

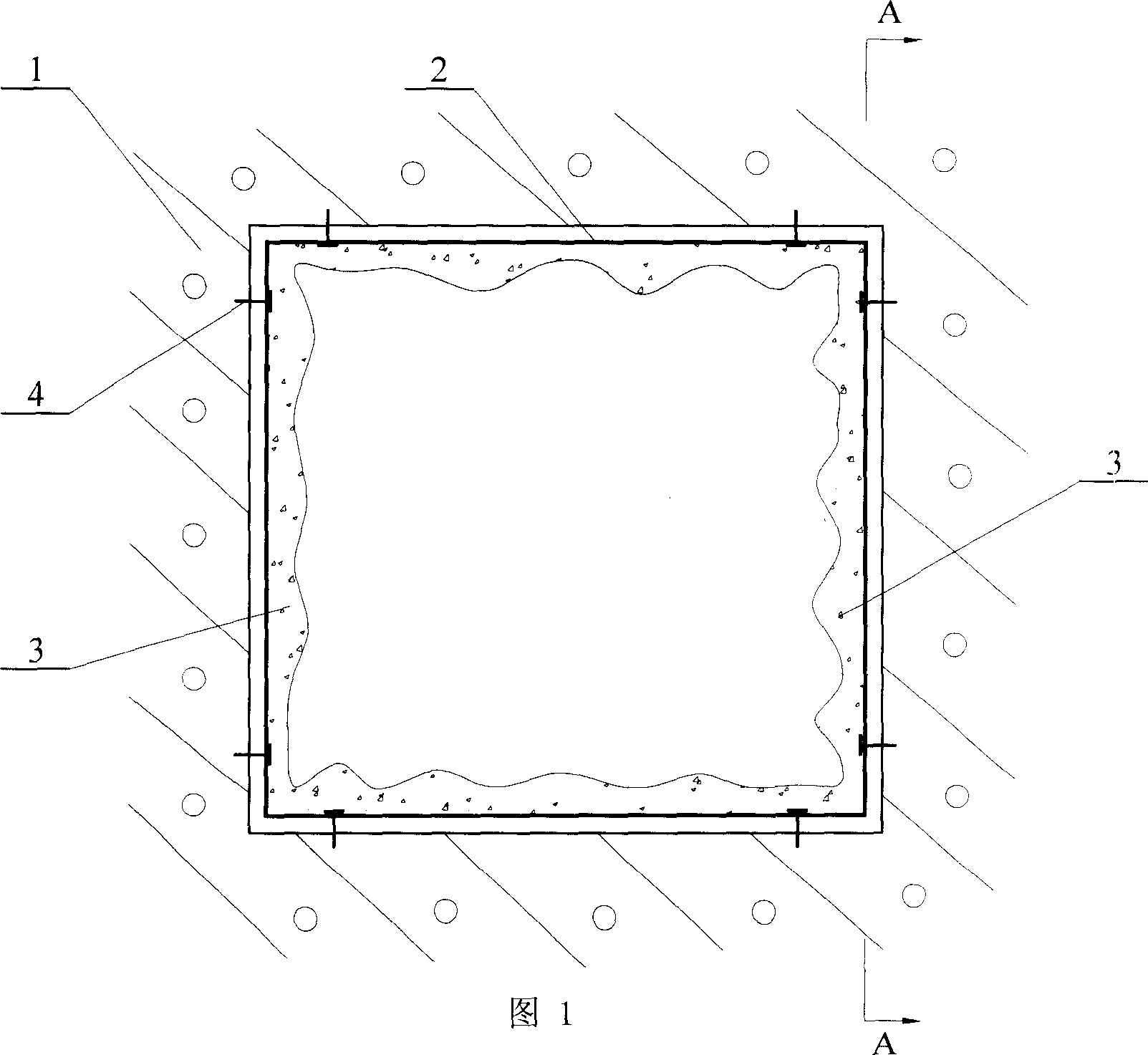

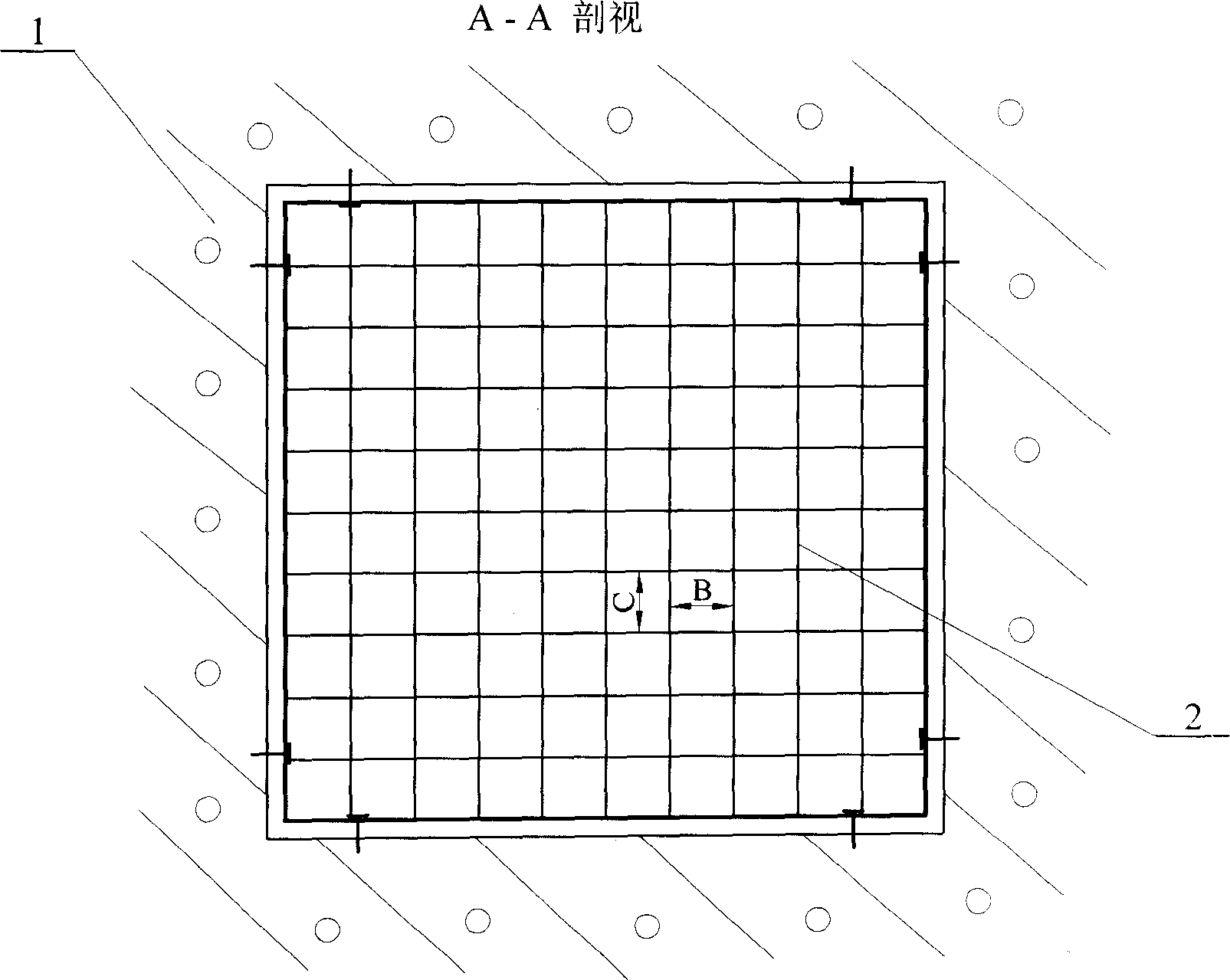

Compact composite light internal and external wall plate

InactiveCN101050658AImprove surface strengthGuaranteed not to deformSolid waste managementBuilding componentsPolystyreneSlurry

The present invention relates to a compact composite light-weight internal and external wall panel. It includes slurry material layer of external layer. Said slurry material layer is made up by using (by weight portion) 100 portions of quick-hardening early-strength sulphoaluminate cement, 0-35 portions of fly-ash, 0-10 portions of building glue and 0.2 portions as raw material through the processes of mixing, adding water and making slurry. It the slurry material layer interior a plastic-coated glass fiber mesh fabric is filled, and the slurry material layer interior is covered with a foamed plastic layer, said foamed plastic layer is a high-foamed polystyrene foam plastic plate. In the foamed plastic layer several through holes are set, in every through hole a column slurry material body is injected, and two sides of said panel body are equipped with tongue and slot mortise.

Owner:周胜利

Glaze composition for redware products

The invention provides a glaze composition for redware products and relates to the technical field of redware. The glaze composition is prepared from the following components in parts by weight: 1-3 parts of copper oxide, 5-9 parts of barium oxide, 4-6 parts of silicon carbide, 25-35 parts of quartz, 10-20 parts of borax, 0.1-0.5 part of graphene, 0.005-0.03 part of ferric oxide, 0.01-0.06 part of titanium carbide, 10-20 parts of dolomite, 5-15 parts of shell and 0.1-1 part of glass. According to the invention, lead material is removed and the quartz and glass are added, the quartz is used for increasing the surface strength of glazing color, the glass is used for increasing smoothness, and the hand feeling is good. The graphene and titanium carbide are added, so that the adsorption capacity among materials is great, and a layer of mesh structure can be formed on the surface of a green body and cannot fall off after firing.

Owner:卢群山

Epoxy resin modified styrene-acrylic emulsion and preparation method thereof

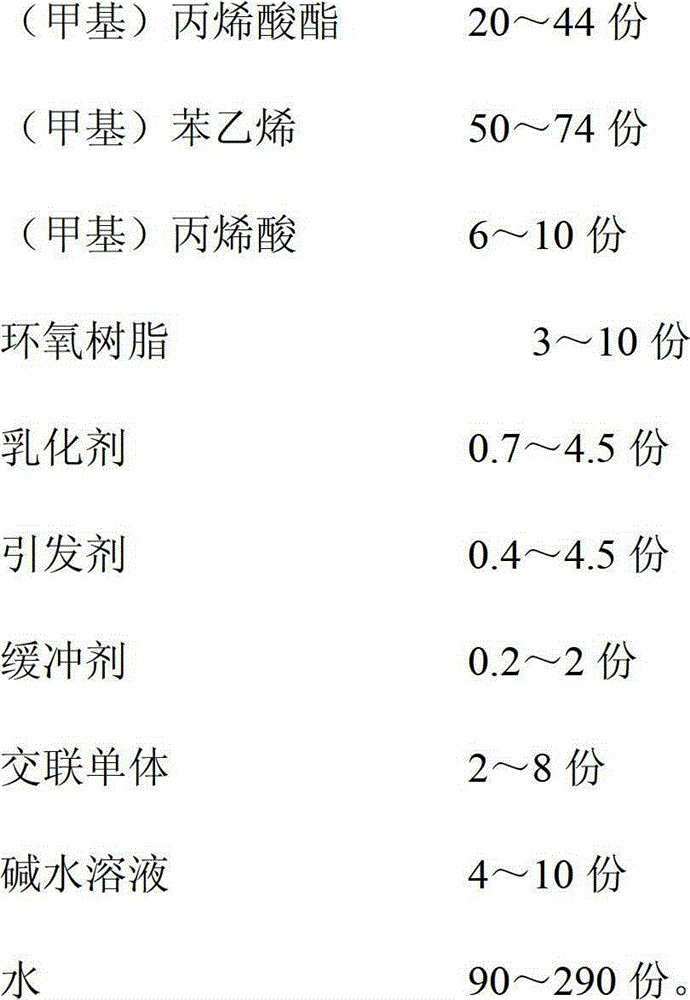

The invention discloses epoxy resin modified styrene-acrylic emulsion and a preparation method thereof. The epoxy resin modified styrene-acrylic emulsion comprises, by weight, 20-44 parts of (methyl) acrylate, 50-74 parts of (methyl) styrene, 6-10 parts of (methyl) acyclic acid, 3-10 parts of epoxy resin, 0.7-4.5 parts of emulsifier, 0.4-4.5 parts of initiator, 0.2-2 parts of buffer agent, 2-8 crosslinking monomer, 4-10 parts of aqueous alkali and 90-290 parts of water. The epoxy resin modified styrene-acrylic emulsion is high in fiber binding force and fine in film-forming property and water resistance. The epoxy resin modified styrene-acrylic emulsion is applied to paint of coated paper. Compared with common emulsion, the epoxy resin modified styrene-acrylic emulsion can evidently improve surface strength and gloss of paper. The epoxy resin modified styrene-acrylic emulsion is high in performance, environment-friendly and applicable to surface sizing of papermaking coating printing.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Color ink-jet print paper and its producing method

InactiveCN1458337AImprove surface strengthPrint with rich and vivid colorsNon-fibrous pulp additionSulfatePulp and paper industry

The color ink-jetting print paper is produced with bleached sulfate needle leaved wood pulp, mechanical milled Italian poplar, bleached sulfate reel pulp or bleached broadleaf wood pulp and proper supplementary material and through making base paper, applying AKD glue, painting special paint, soft roller burnishing and finishing. The color ink-jetting print paper product has areal weight 70-100 g / sq m, black light density not lower than 1.2, drying time less than 20 s, color optical density not lower than 0.75, ink water dispersing time not less than 60 s, and whiteness higher than 88 %. Ithas high surface strength, and is level and smooth and results in images with bright color and clear netted points. It is suitable for color jetting printing.

Owner:YUEYANG FOREST & PAPER CO LTD

Reinforcement protection method for inner surface of tunnel

InactiveCN1730908AHigh strengthReduces the possibility of crackingUnderground chambersBuilding repairsEmulsionUltimate tensile strength

The inner tunnel surface reinforcing and protecting method includes adding polyacrylic emulsion and polyacrylic fiber into waterproof cement mortar to raise the surface strength of inner tunnel surface and to prevent crack, water permeation and high temperature blowout. The method includes the first compounding waterproof cement mortar with cement, sand, water and polyacrylic emulsion in the ratio of 1 to 0.5-0.7 to 0.4-0.6 to 0.005-0.008; the subsequent mixing polyacrylic fiber in the amount of 0.006-0.008 of cement mortar weight with cement mortar to form modified cement mortar; and final spraying the modified cement mortar to the inner surface of the concrete structure. The polyacrylic fiber resists the stresses of cement shrinking in different directions to raise the strength of solidified waterproof mortar and raise the fireproof limit. In addition, the grille net has crack resisting reinforcing effect.

Owner:HARBIN INST OF TECH

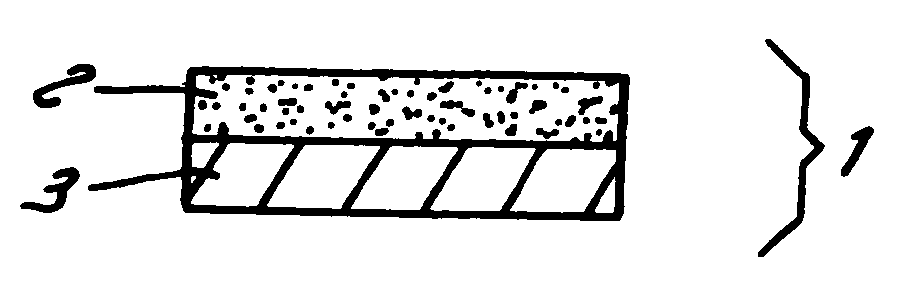

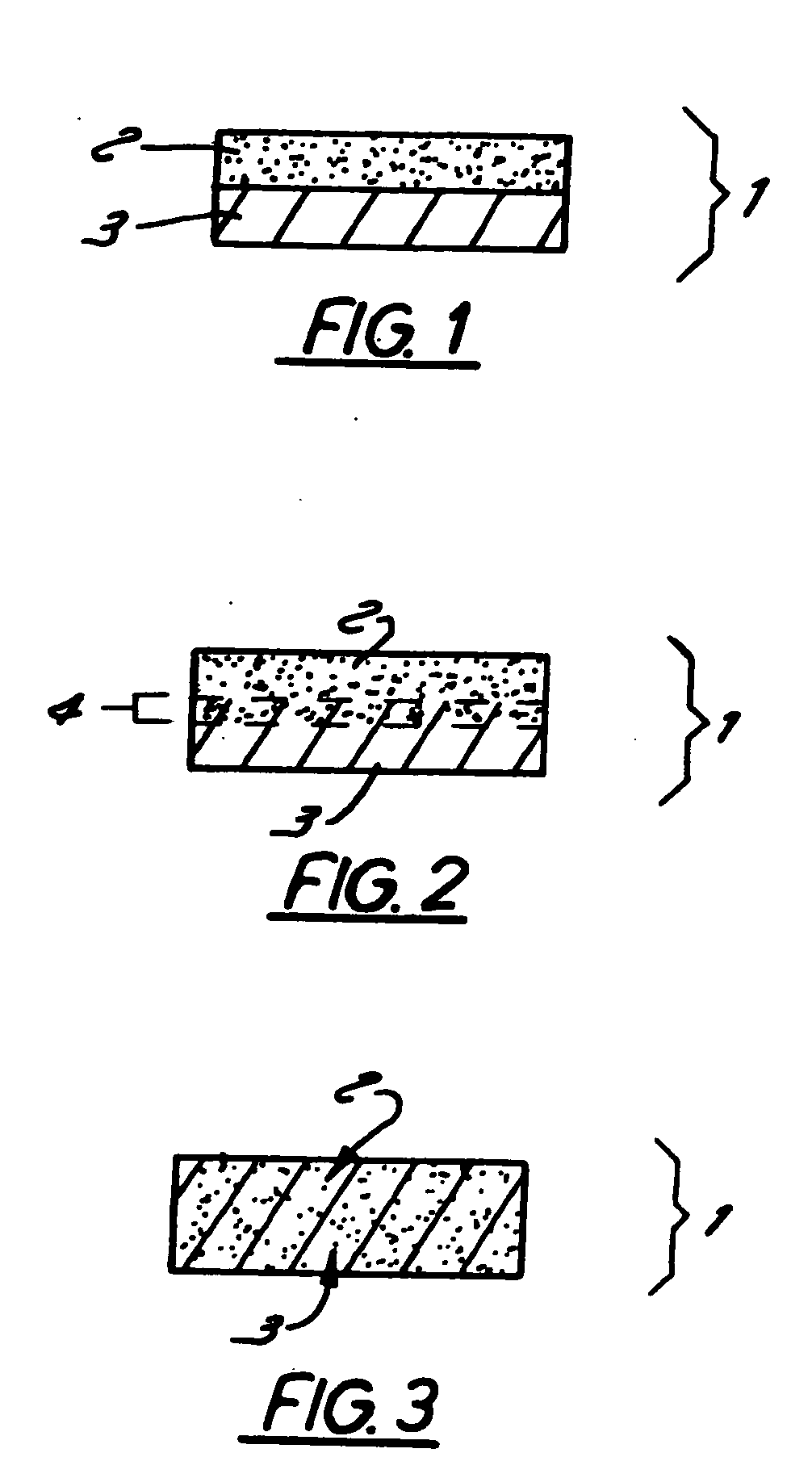

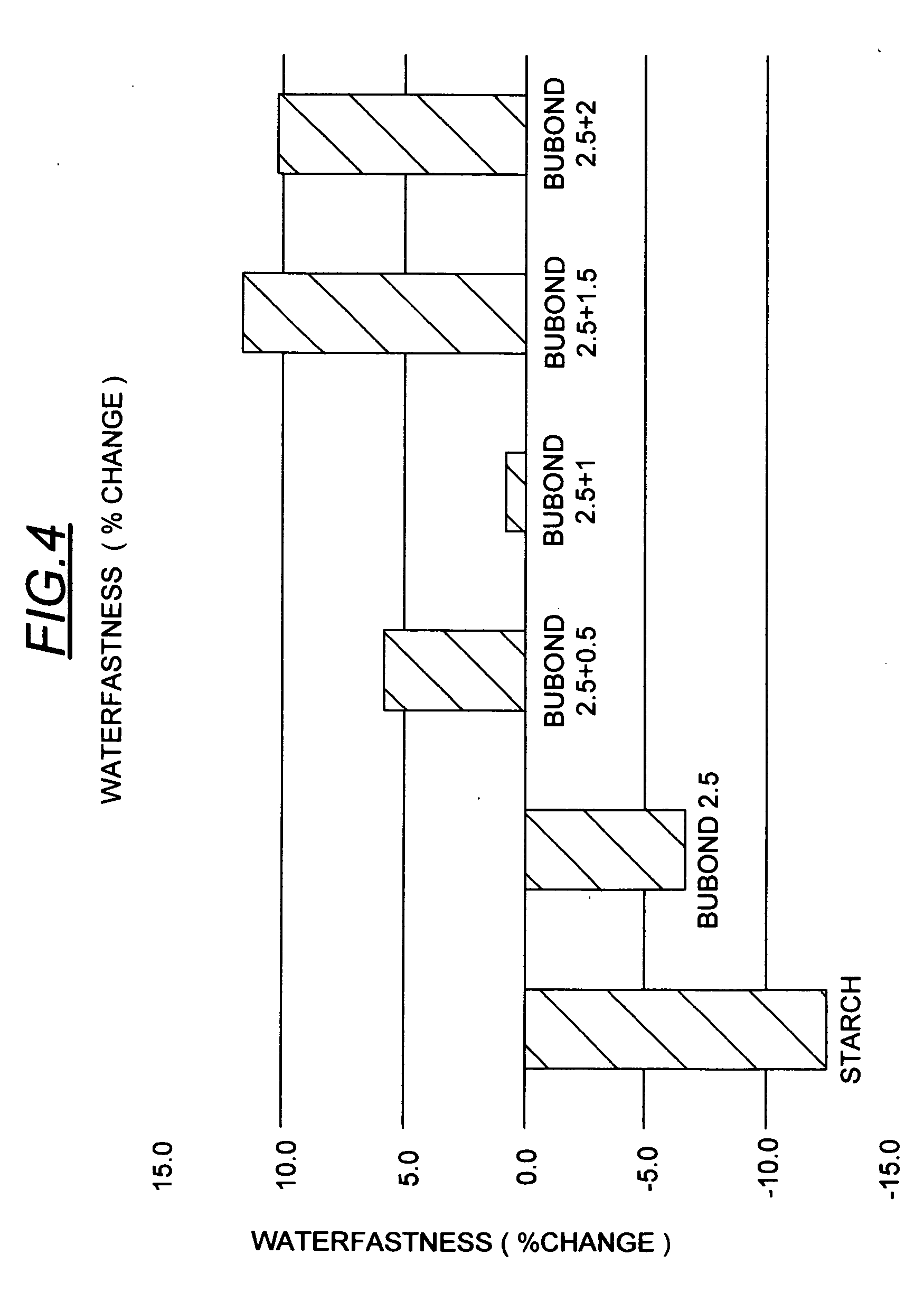

Recording sheet with improved image waterfastness, surface, strength, and runnability

The present invention relates to a sizing or coating composition that, when applied to paper substrate, creates a substrate having improved waterfastness, surface strength, and surface strength as measured by resistance to abrasion. In addition, the present invention relates to paper substrates containing the composition, as well as methods of using and making the paper substrate and composition.

Owner:GLOBAL HLDG II INC

Organosilicone emulsion-silica gel permeable crystallization type waterproof material and preparation method thereof

The invention provides an organosilicone emulsion-silica gel permeable crystallization type waterproof material which is prepared from the following raw materials: an organosilicone monomer, an emulsifier, silica sol, a silane coupling agent, a defoamer, a coalescing agent and water. The waterproof material is excellent in waterproof performance, strong in resistance to harmful ion invasion and excellent in weather ability and durability, so that the surface strength of concrete is improved, and the waterproof material is suitable for surface waterproof treatment of materials such as concrete, mortar, cement paste and stones and particularly suitable for surface treatment of concrete structures in severe environments such as harbor wharfs, roads working under a condition of deicing salt and removing corrosion of salt mist, and flyovers.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Technique of manufacturing artificial cultured stone

InactiveCN101229661AHigh densityLow water absorptionMouldsMixing operation control apparatusHigh densityUltraviolet

The invention discloses a production process for an artificial cultural stone, comprising the following steps: preparation of a die, preparation of slurry, preparation of stuffing, die-coloring, guniting or grouting, filler-filling, secondary guniting or grouting, vibration and shaping, ustulation and shaped product-packing. The invention has the advantages that the artificial cultural stone manufactured according to the technical scheme of the invention has a surface with high density, low water absorption, a good weatherability, a high strength surface, a strong anti-ultraviolet ability, good forest resistance, good anti-aging property and a uniform and coordinated color; the artificial cultural stone can floats in the water due to the hard surface and a low specific gravity in the middle; the pasting surface pasting to the building surface is rough which is in favor in pasting, therefore, the pasting is more stable and dose not exfoliate easily; the invention also has a good heat-insulation and a preservation which can replace the insulating layer, thus not only reducing the building cost, but also conforming with the requirement of the national environmental protection and energy conservation.

Owner:成都市福美来艺术装饰材料厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com