Reinforcement protection method for inner surface of tunnel

An in-tunnel, reinforcement technology, applied in tunnels, tunnel linings, earth-moving drilling, etc., can solve problems such as cracks, water seepage, high temperature, and bursting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0005] Specific embodiment one: this embodiment is realized by the following steps: 1. prepare cement waterproof mortar, cement waterproof mortar is fully mixed by the following components of weight ratio, cement: sand: water: polyacrylic acid emulsion=1: 0.5~0.7 : 0.4~0.6: 0.005~0.008; 2. According to the weight ratio of cement waterproof mortar: polypropylene fiber = 1: 0.006~0.008, fully mix polypropylene fiber in cement waterproof mortar to make modified cement mortar, polypropylene fiber The length of the fiber is 6-15 mm, and the diameter of the polypropylene fiber is 5-10 microns; 3. Spray the modified cement mortar on the inner surface of the tunnel of the concrete structure, and wait until the modified cement mortar solidifies to complete the inner surface of the tunnel. Strengthen protection work. The cement is selected from P.032.5 type products, and the sand is selected from medium sand with a particle size of less than 4.75 mm and a fineness modulus of 2.4 to 2.9....

specific Embodiment approach 2

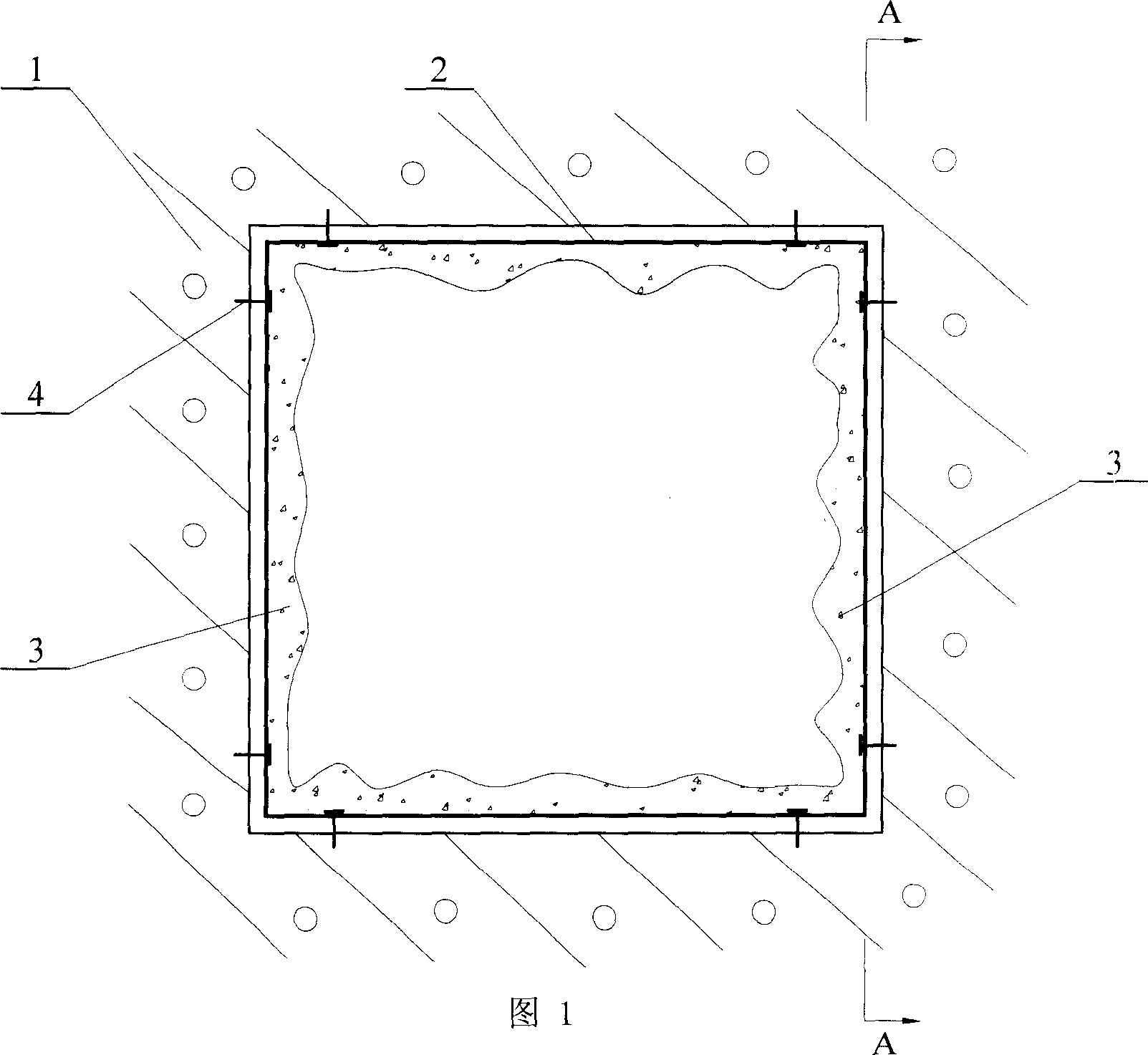

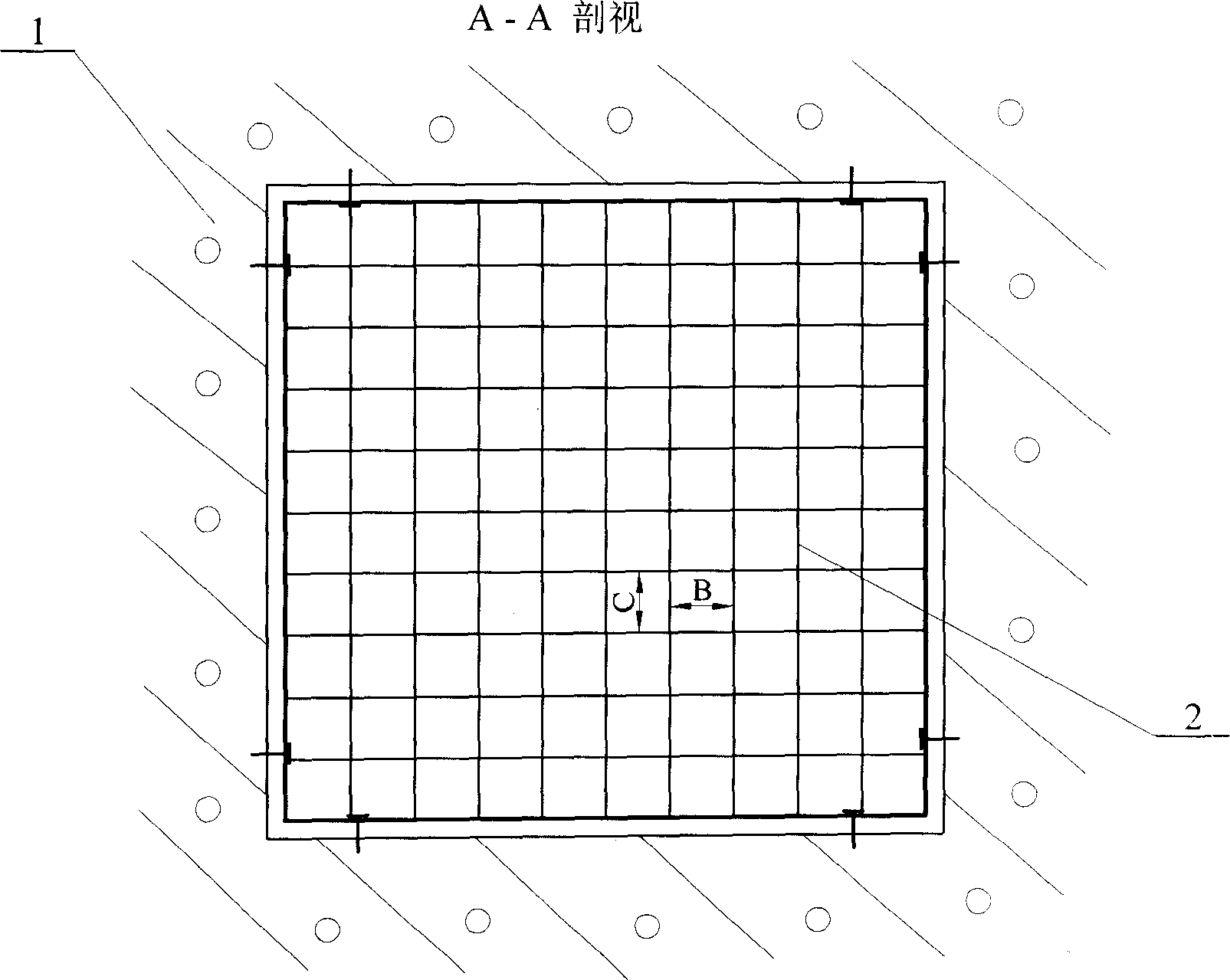

[0006] Specific embodiment two: below in conjunction with Fig. 1 and figure 2 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that the following steps are also included before step 1: covering and fixing the grid net 2 on the inner surface 1 of the tunnel, the grid grid net 2 is made of carbon fiber and epoxy Made of resin composite material. Other steps are the same as those in Embodiment 1. The grid-shaped grid net 2 is equivalent to the skeleton of the modified cement mortar, which improves the strength of the protective layer formed by the modified cement mortar after solidification. In addition, the electrical equipment in the subway system will generate stray currents during operation, and the stray currents will cause serious electrochemical corrosion to the steel bars of the main structure in the tunnel and various metal pipe networks within a certain range, causing certain harm. The present invention covers...

specific Embodiment approach 3

[0007] Specific embodiment three: the difference between this embodiment and embodiment two is: grid net 2 is made up of the component that volume ratio is carbon fiber: epoxy resin=30~35:100, and epoxy resin is used as base material, and carbon fiber is fully Mixed and cured in epoxy resin to form grid mesh 2. The carbon fiber can be selected from Japan Toray's T700 model product or the same domestic carbon fiber, and the epoxy resin can be selected from the product of the E54 model. The mesh size of the grid net 2 is B×C=100 mm×100 mm, and it can also be designed according to specific needs. Other steps are the same as the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com