Patents

Literature

5454 results about "Polypropylene fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polypropylene Fiber. a synthetic fiber formed from a polypropylene melt. Polypropylene fiber is generally superior to polyamide fibers in elasticity and resiliency, but it has lower wear resistance. It displays good heat-insulating properties and is highly resistant to acids, alkalies, and organic solvents.

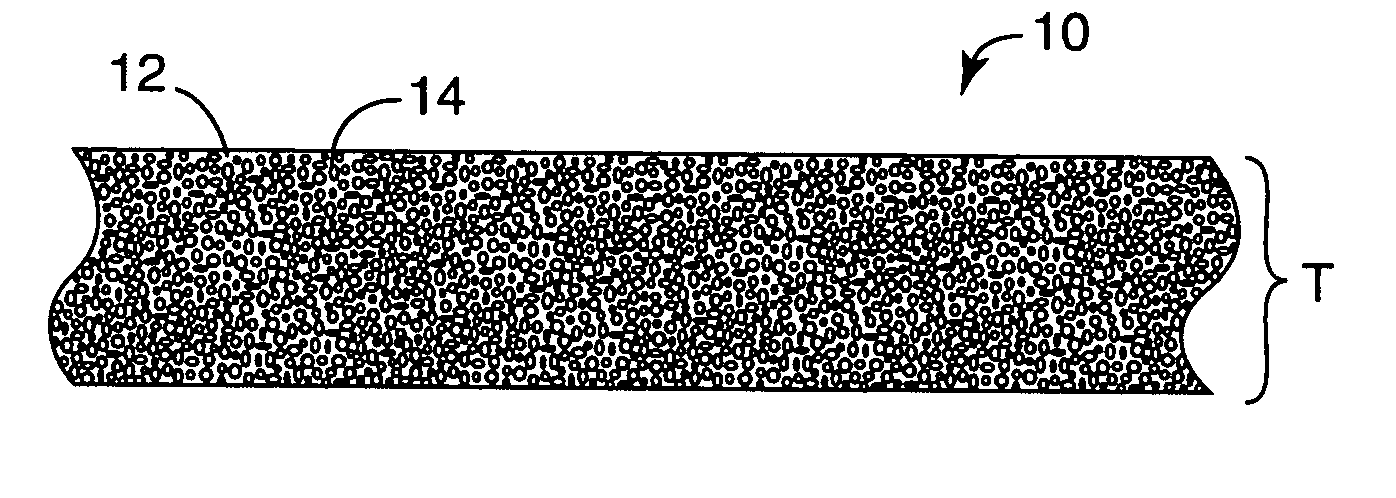

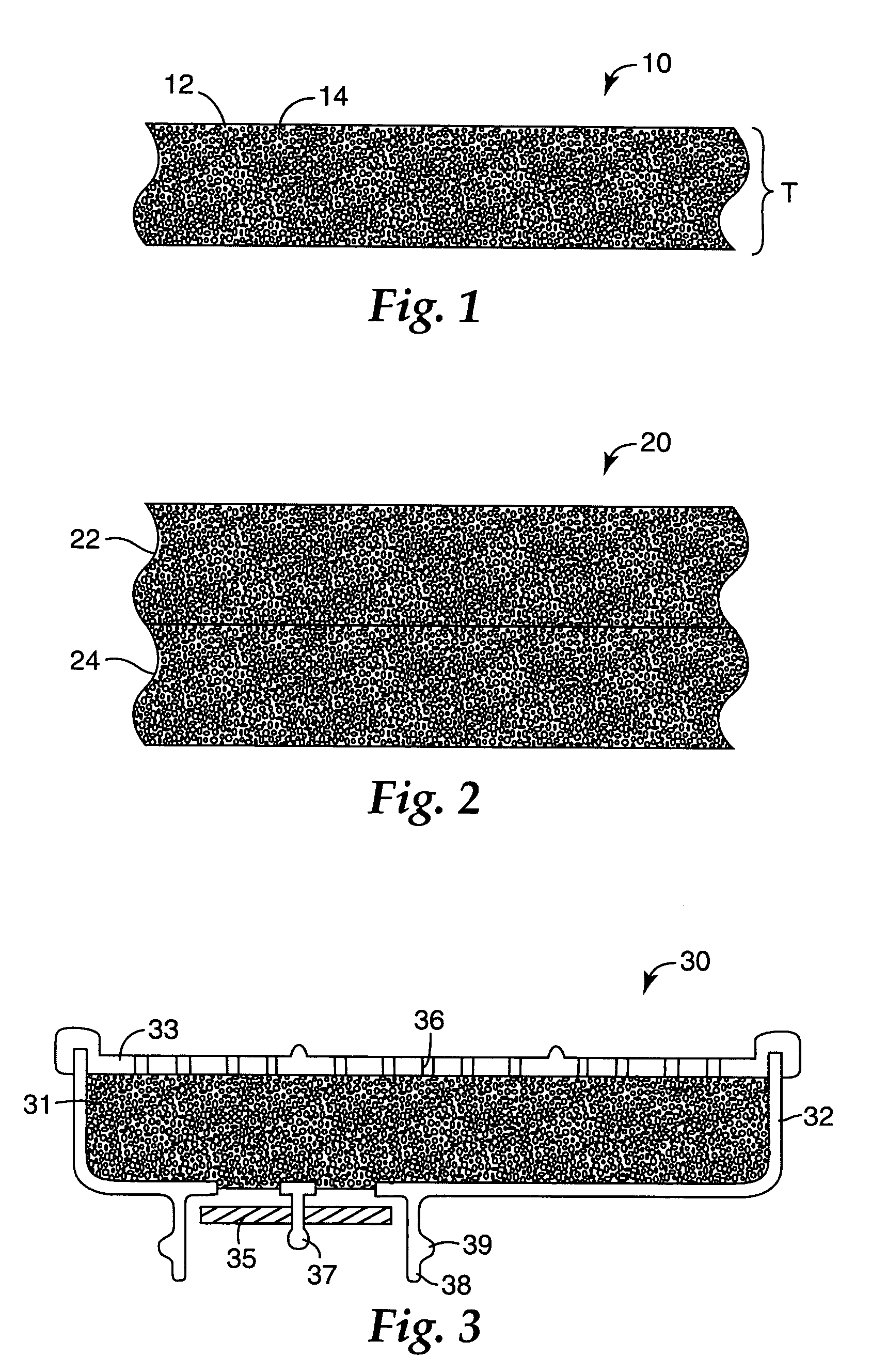

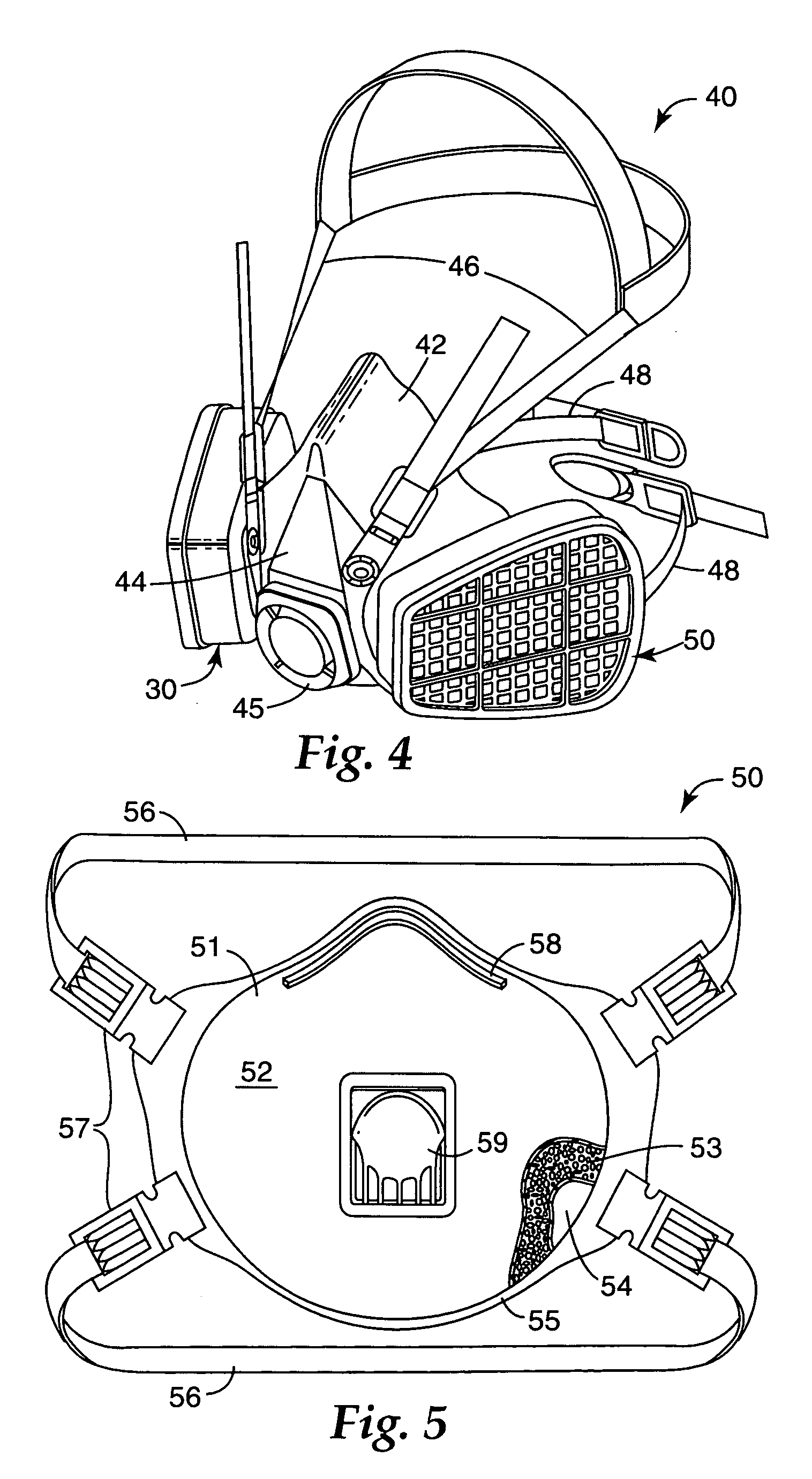

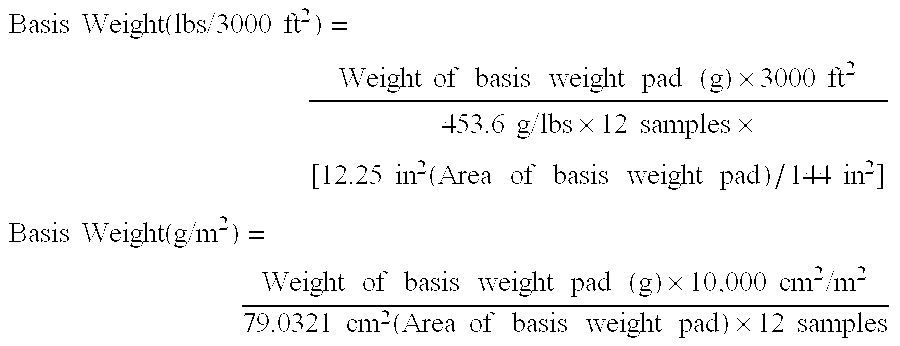

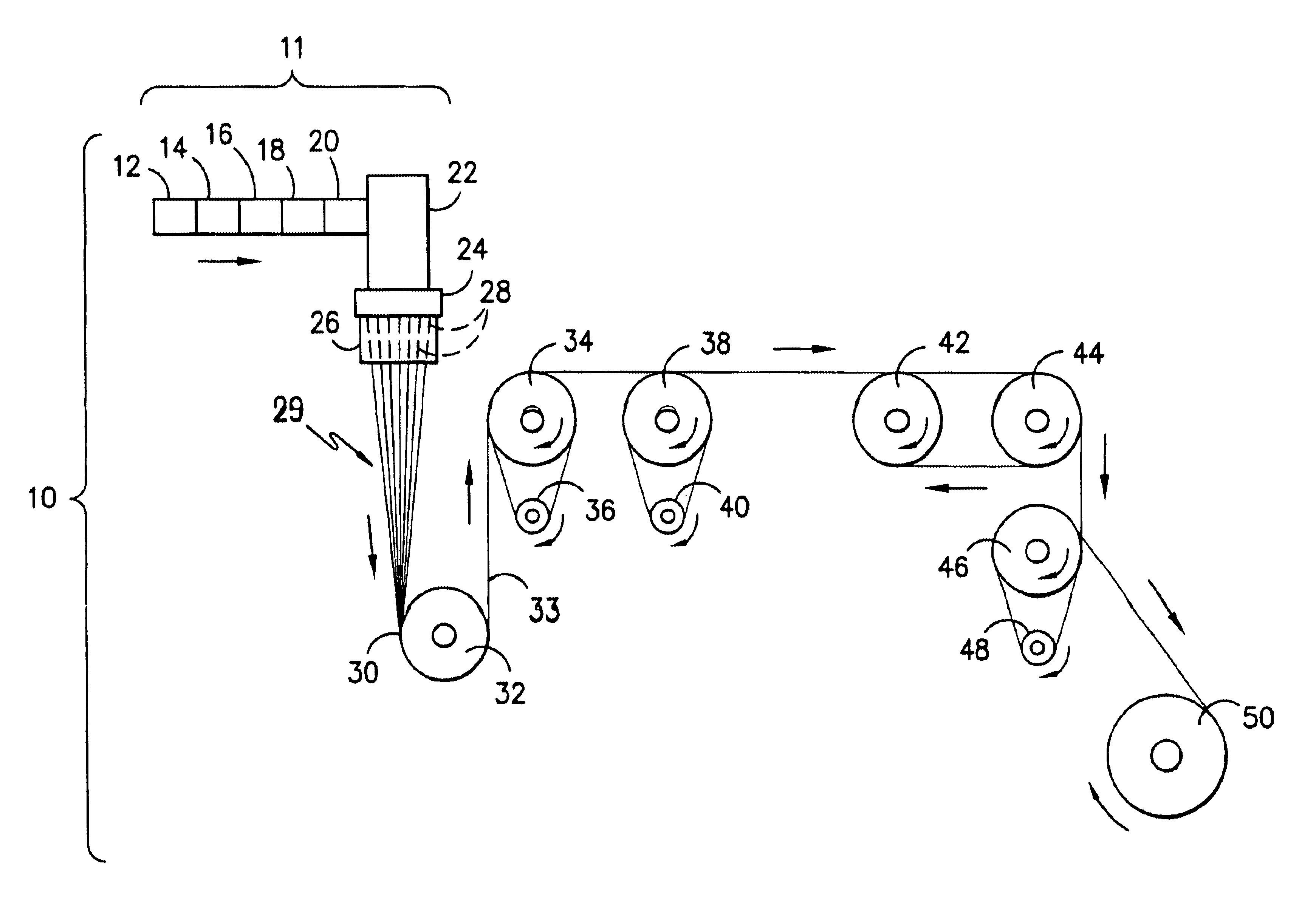

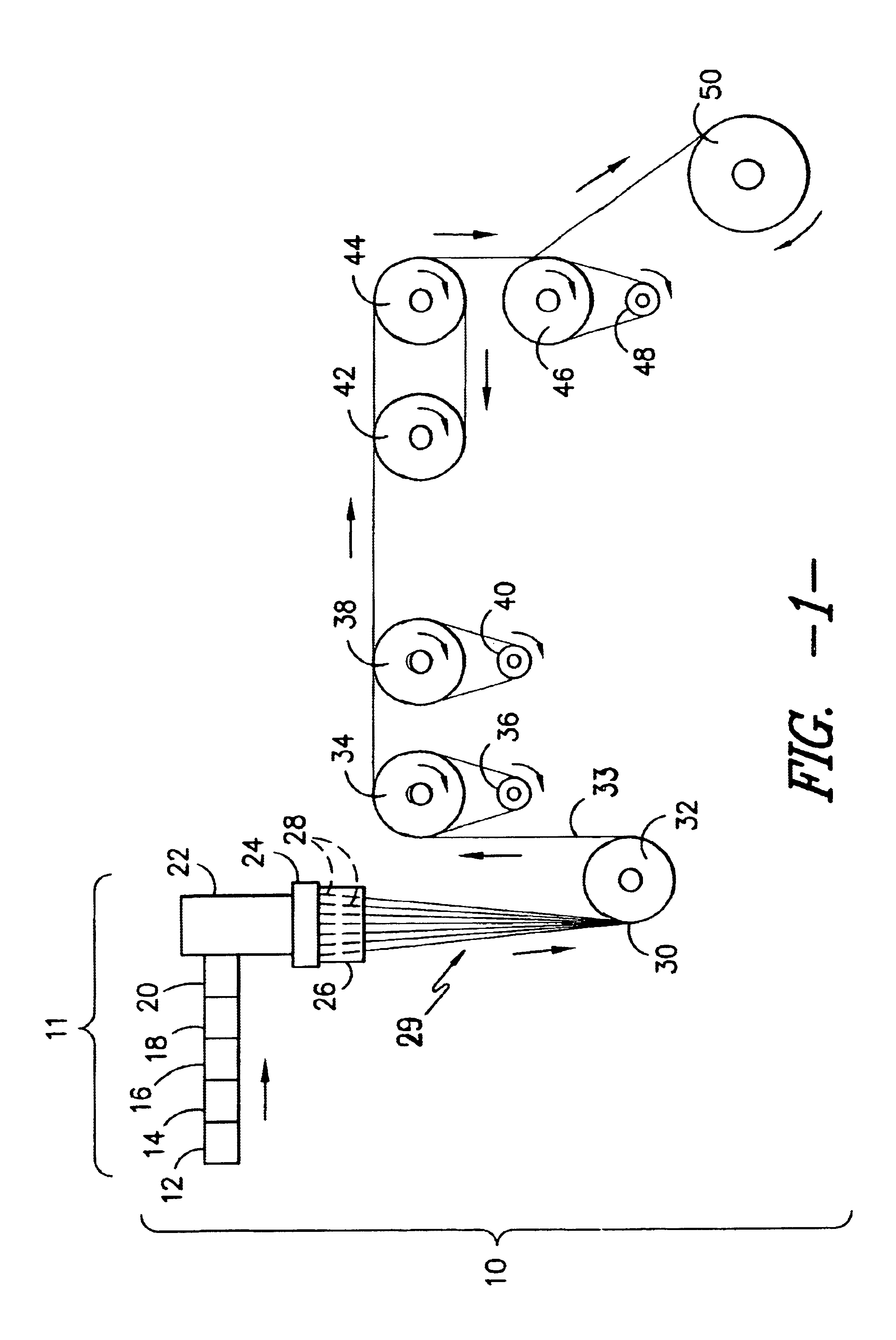

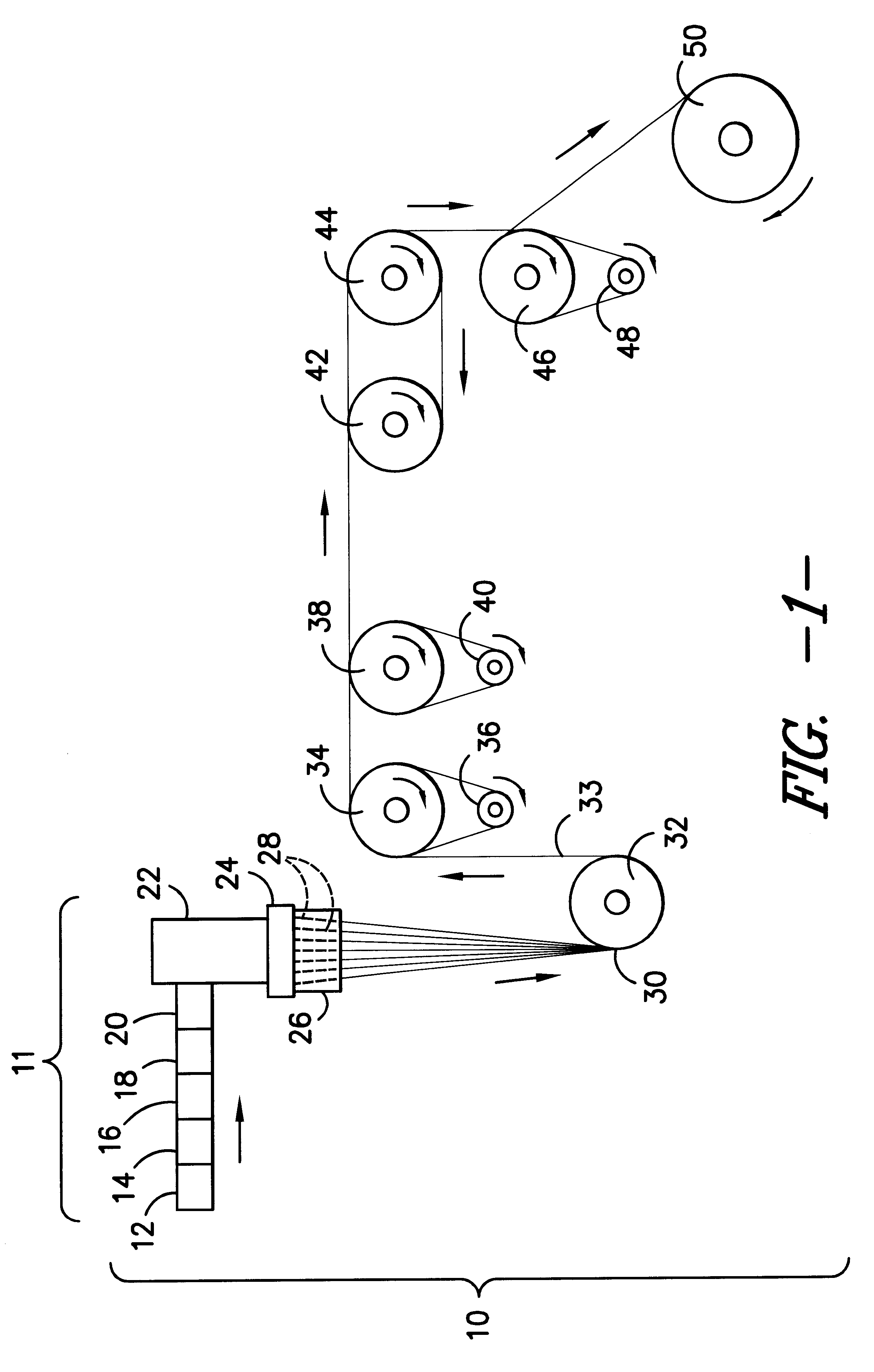

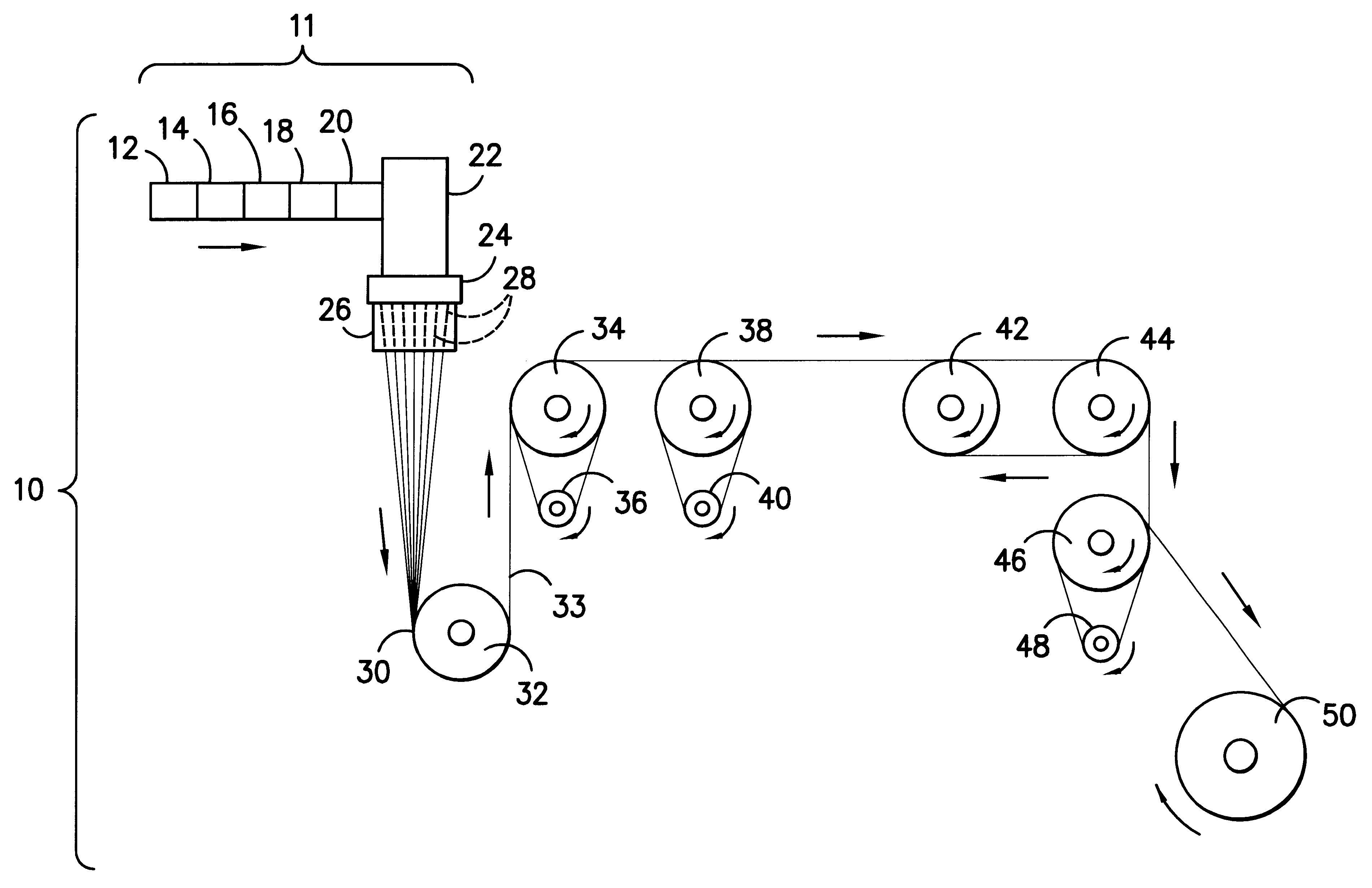

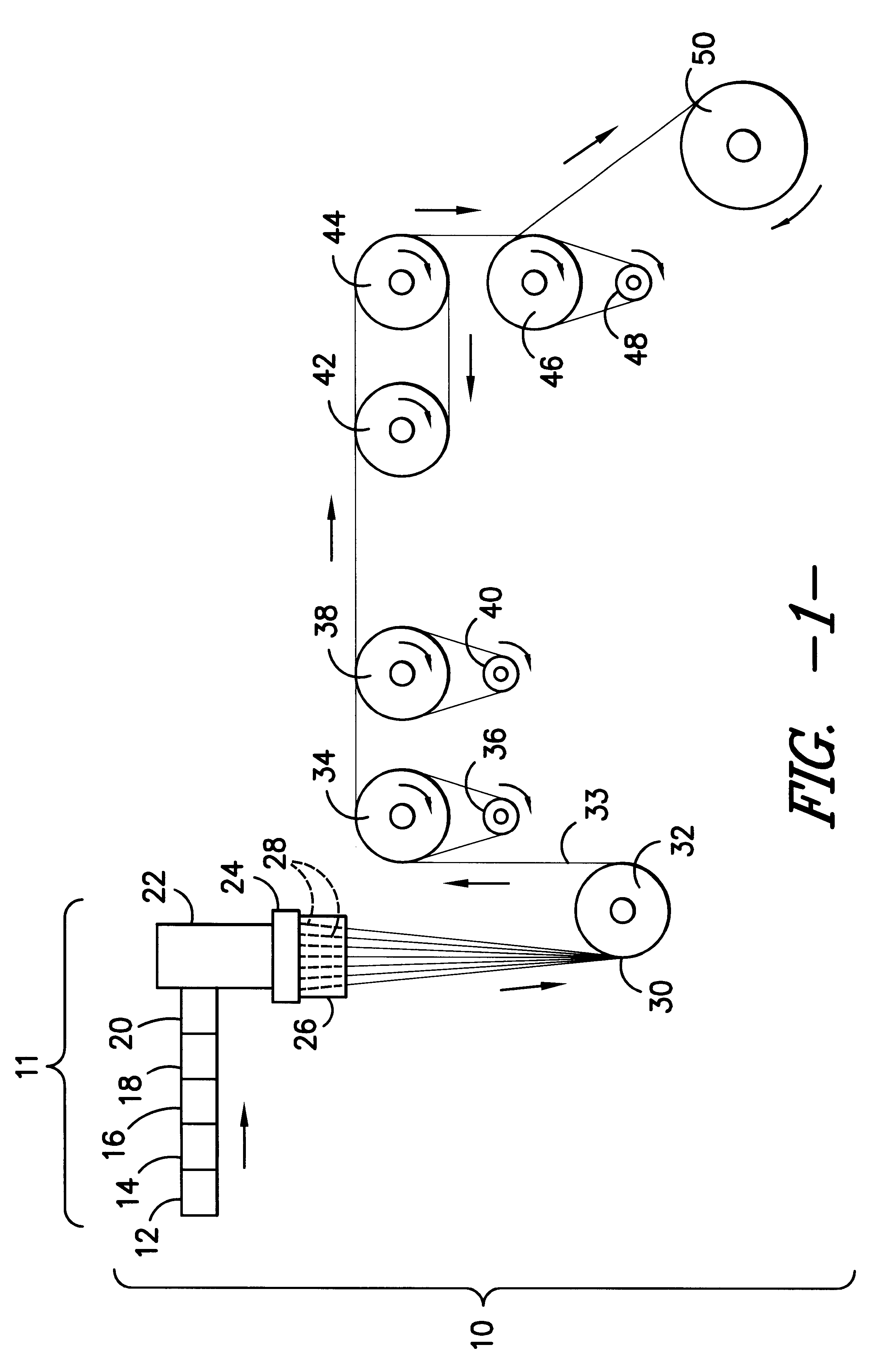

Particle-containing fibrous web

InactiveUS20060096911A1Lower overall pressure dropLow carbon shedding tendencyBreathing filtersDispersed particle separationPolymer scienceSorbent

A porous sheet article comprising a self-supporting nonwoven web of polymeric fibers and at least 80 weight percent sorbent particles enmeshed in the web, the fibers having sufficiently greater elasticity or sufficiently greater crystallization shrinkage than similar caliper polypropylene fibers and the sorbent particles being sufficiently evenly distributed in the web so that the web has an Adsorption Factor A of at least 1.6×104 / mm water. The articles have low pressure drop and can provide filter elements having long service life and an Adsorption Factor approaching and in some instances exceeding that of a packed carbon bed.

Owner:3M INNOVATIVE PROPERTIES CO

Polyolefin containing polyetheramine modified functionalized polyolefin

InactiveUS6093496AGood paintabilityExcellent mold flowabilityFilm/foil adhesivesSynthetic resin layered productsPolymer sciencePolyolefin

This invention concerns a composition comprising a blend of polyolefin with the reaction of a functionalized polyolefin and polyetheramine in which the polyetheramine is grafted into the functionalized polyolefin in a customary mixing apparatus. A process for producing the reaction product of functionalized polypropylene and polyetheramine by melting with polypropylene in a customary mixing apparatus is also disclosed. Blends of the present invention are advantageously useful to prepare paintable automotive body parts. This invention further includes dyeable polyolefin compositions containing the reaction product of functionalized polyolefin and polyetheramine. Dyeable polyolefin fibers, including polypropylene fibers, are disclosed, which may be made by melt spinning, and which may be employed to make woven and non-woven fabric. The polyolefin employed in the practice of this invention may be a flexible polyolefin.

Owner:HUNTSMAN PETROCHEMICAL LLC +1

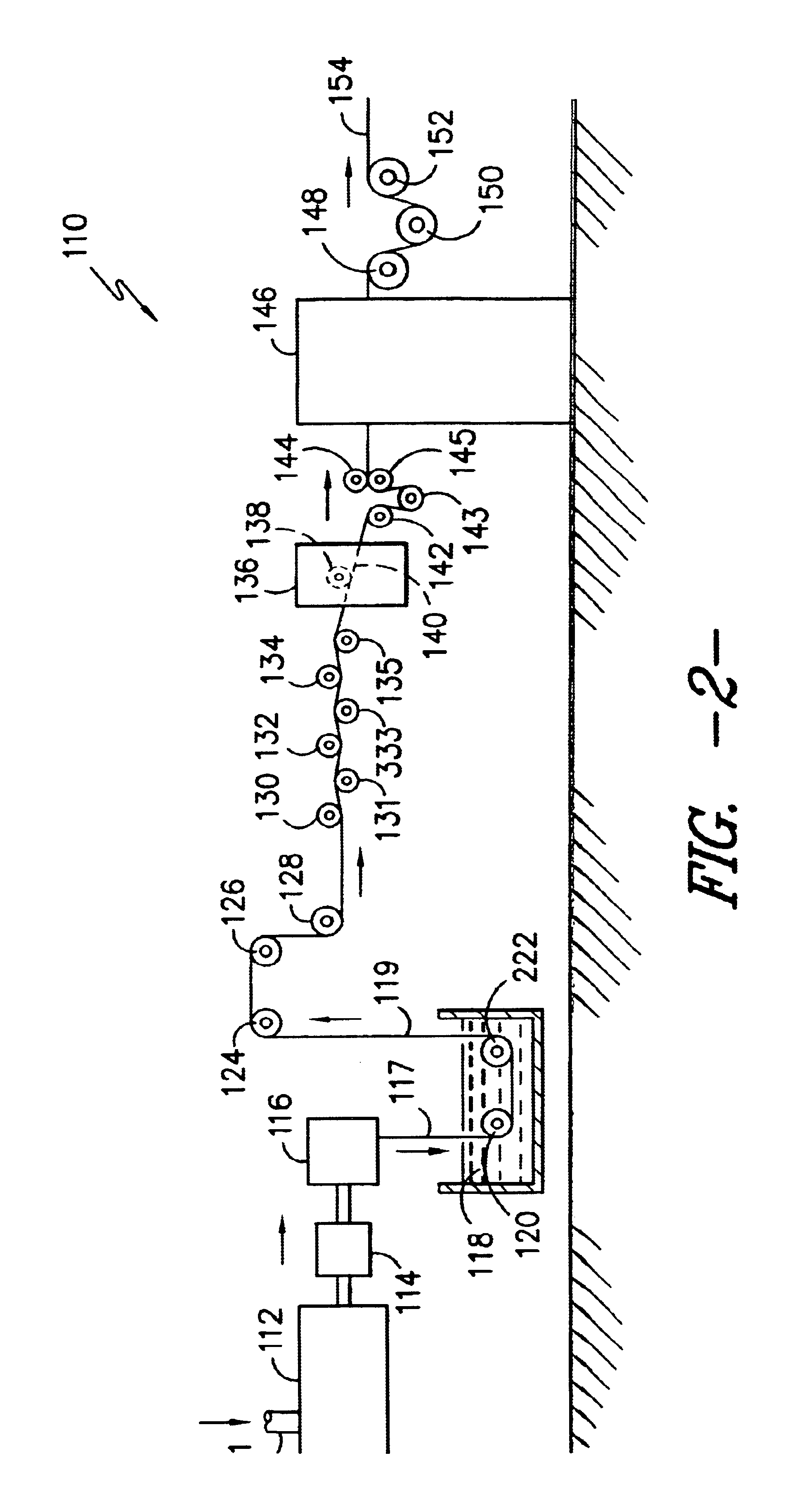

Polypropylene fibrous elements and processes for making same

InactiveUS20110104493A1High elongationImprove spinnabilityMixingConjugated synthetic polymer artificial filamentsPolymer scienceFiber structure

Polypropylene fibrous elements and more particularly polypropylene microfiber fibrous elements, fibrous structures including polypropylene fibrous elements, and processes for making same are provided.

Owner:THE PROCTER & GAMBLE COMPANY

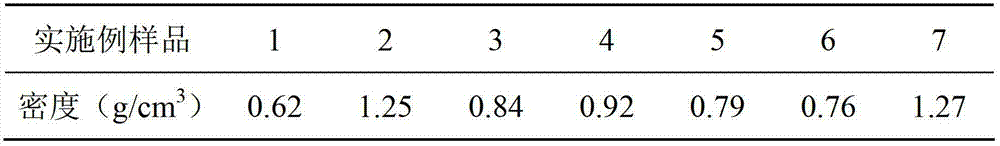

Light composite material

InactiveCN103087463ASolve the insulation performanceSolve the sound insulationGlass fiberCarbon fibers

The invention relates to a light composite material, and in particular relates to a hollow microspheres and fiber body composite material. The light composite material consists of a base material, the fiber body and hollow microspheres which are uniformly distributed. The proportion of the total volume of the fiber body and hollow microspheres and the base material is (1:5)-(1:1). The base material is thermoplastic or thermosetting resin. The fiber body is at least one of fibrilia, carbon fiber, glass fiber, polypropylene fiber, aramid fiber and basalt fiber. The hollow microspheres are at least one of hollow glass microspheres and hollow ceramic microspheres. The volume ratio of the fiber body and the hollow microspheres is (1:5)-(1:1). The fiber body and the hollow microspheres are bonded together through the base material. According to the light composite material provided by the invention, the problem that current composite material is unsatisfactory in heat insulation, sound insulation, shock absorption and the like because the inner structure is almost a solid structure can be solved.

Owner:CHERY AUTOMOBILE CO LTD

Thermoplastic fibers exhibiting durable high color strength characteristics

InactiveUS6849330B1Reduce extractionQuick and efficient changeoverFireproof paintsSynthetic resin layered productsYarnPolymer science

Improvements in permitting brighter colorations within polypropylene fibers and / or yarns while simultaneously providing more efficient production methods of manufacturing of such colored fibers as well are provided. Generally, such fibers and / or yarns have been colored with pigments, which exhibit dulled results, or dyes, which exhibit high degrees of extraction and low levels of lightfastness. Such dull appearances, high extraction levels, and less than stellar lightfastness properties negatively impact the provision of such desirable colored polypropylene fibers and / or yarns which, in turn, prevents the widespread utilization of such fibers and yarns in various end-use applications. Thus, it has surprisingly been determined that brighter colorations, excellent extraction, and more-than-acceptable lightfastness characteristics can be provided, preferably, through manufacture with certain polymeric colorants that include poly(oxyalkylene) groups thereon. Fabric articles comprising such novel fibers and / or yarns are also encompassed within this invention.

Owner:MILLIKEN & CO

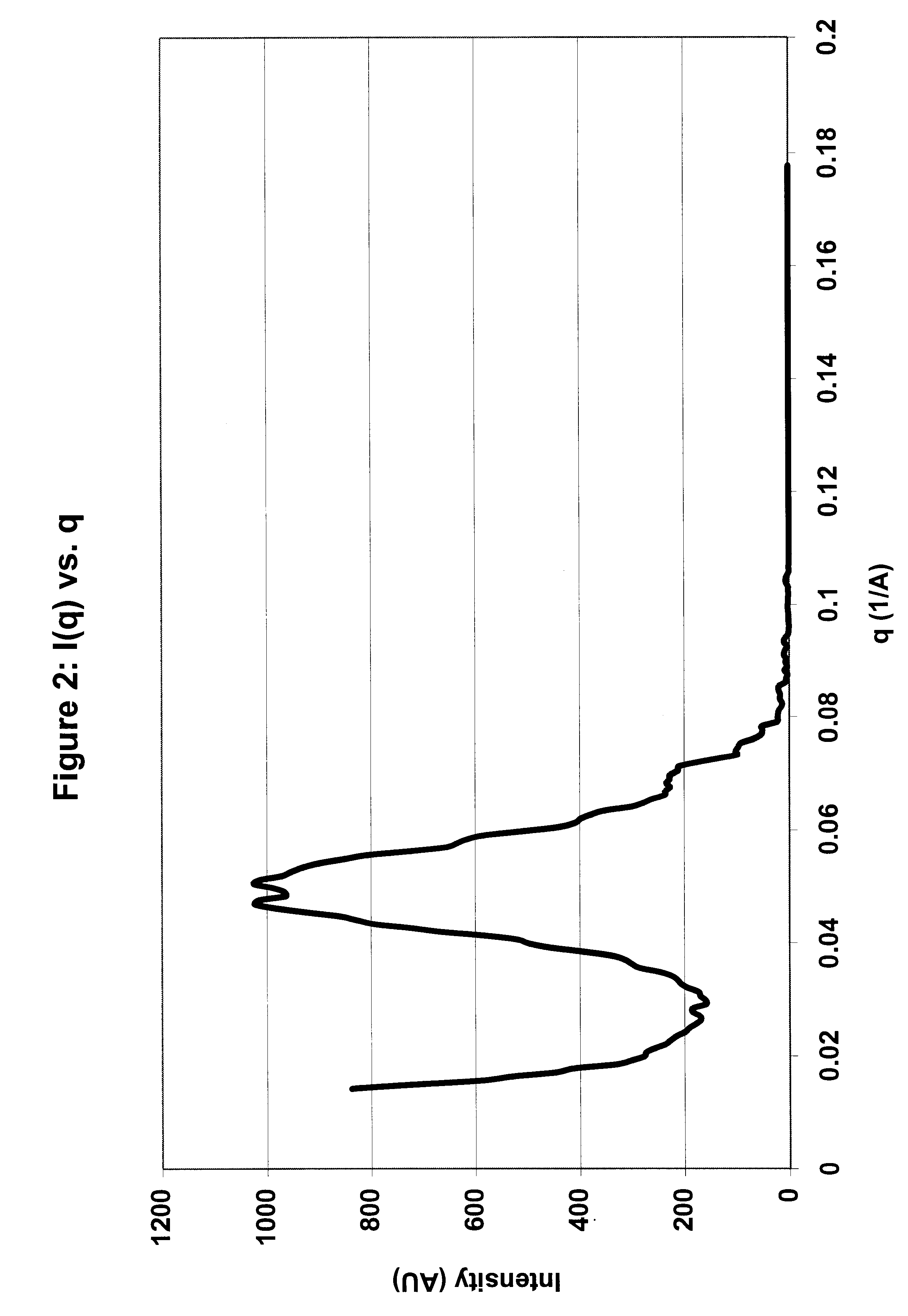

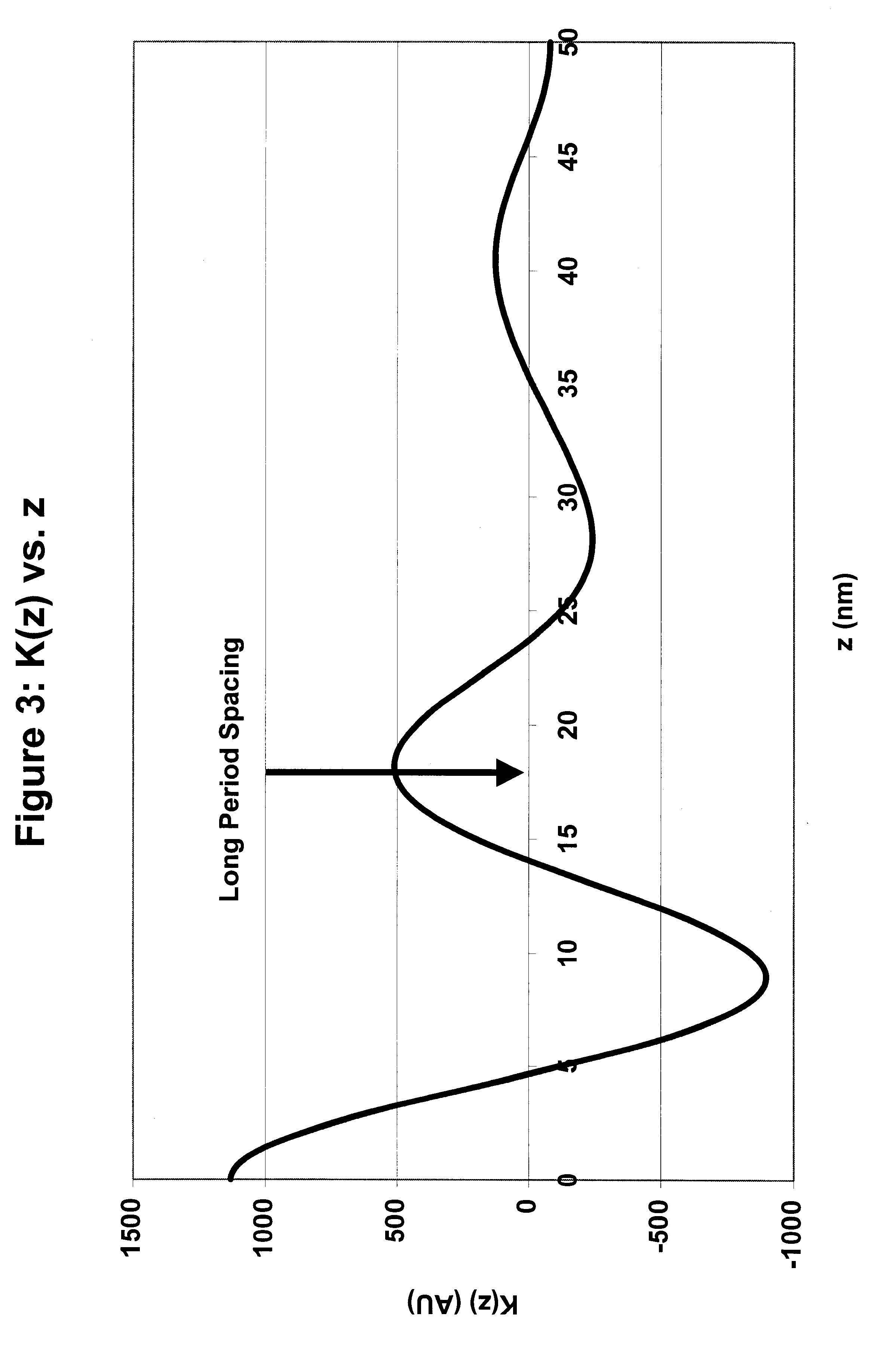

Low-shrink polypropylene fibers

This invention relates to improvements in preventing heat- and moisture-shrink problems in specific polypropylene fibers. Such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target polypropylene fiber after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target polypropylene after exposure to sufficient heat to melt the initial pelletized polymer and upon allowing such a melt to cool. The compounds must nucleate polymer crystals at a higher temperature than the target polypropylene without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for polypropylene crystal growth. After drawing the nucleated composition into fiber form, the fiber is then exposed to sufficient heat to grow the crystalline network, thus holding the fiber in a desired position. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as sodium benzoate, certain sodium and lithium phosphate salts (such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11). Specific methods of manufacture of such fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

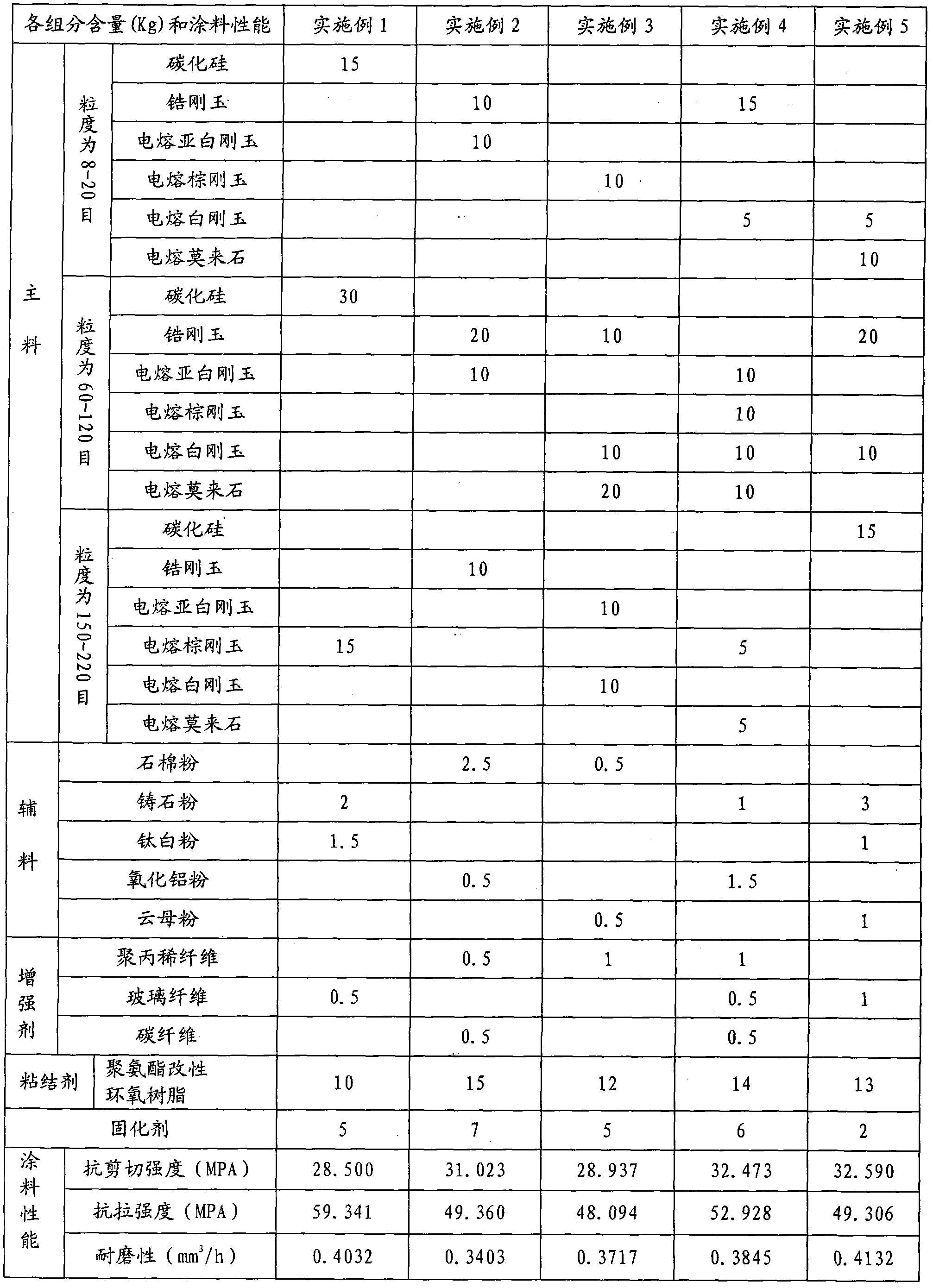

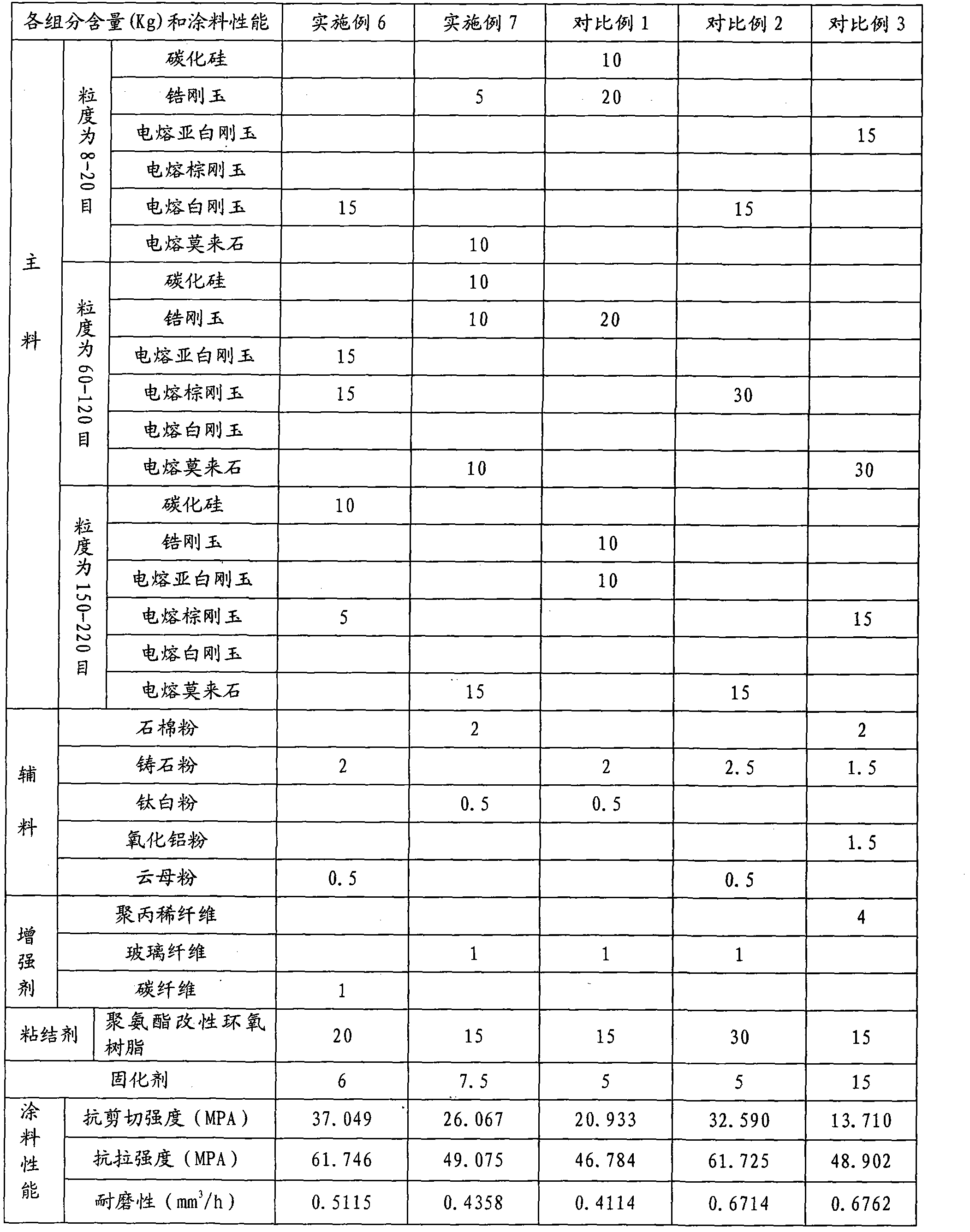

Polymer wear-resistance coating material

ActiveCN102040901AReduce operating costsReduce labor intensityEpoxy resin coatingsEpoxyCarbon fibers

The invention relates to a polymer wear-resistance coating material, which is a coating material consisting of a component A and a component B, wherein the component B is a solidifier, and the weight part of the component B is 2 to 10 percent of that of the component A; the component A consists of 40 to 80 weight parts of a main ingredient which is one or more mixed in random ratio of silicon carbide, fused zirconia alumina, fused sub-white corundum, fused brown aluminium oxide, fused white corundum and fused mullite, 1 to 5 weight parts of an auxiliary material which is one or more mixed in a random ratio of asbestos powder, glass-ceramic powder, titanium white, aluminium oxide powder and mica powder, 0.5 to 2 weight parts of reinforcing agent which is one ore more mixed in a random ratio of polypropylene fibers, glass fibers and carbon fibers, and 10 to 20 weight parts of a bonding agent which is polyurethane modified epoxy resin. The construction and use of the coating material are convenient and quick, the bonding strength of the coating material is high and the use cost of the coating material is low; and the coating material has high wear resistance, corrosion resistance and air corrosion resistance.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Anti-bacterial bamboo charcoal nano-fiber and production method thereof

ActiveCN101440533AImprove adsorption capacityGood moisture absorptionMonocomponent polypropylene artificial filamentMelt spinning methodsRenewable resourceProcess conditions

The invention relates to a nanometer bamboo charcoal antibacterial fiber and a method for producing the same, in particular to a melt-spinning method for producing the nanometer bamboo charcoal antibacterial fiber. The nanometer bamboo charcoal antibacterial fiber consists of nanometer bamboo charcoal, nanometer silver and a carrier slice, wherein the carrier slice is one of terylene, polypropylene fiber or chinlon. An antimicrobial master batch is prepared first and is mixed with the carrier slice according to certain proportion, and then the mixture is used for preparing the required nanometer bamboo charcoal antibacterial fiber through the melt-spinning method. The nanometer bamboo charcoal antibacterial fiber has the advantages that the bamboo charcoal is a renewable resource which is rich, can be produced through adjusting part of the process conditions by using the prior equipment, and passes test and detection with the antibacterial rate of more than 98 percent; and the nanometer bamboo charcoal antibacterial fiber is not only applied in the aspect of dress, but also widely applied to transportation, environmental protection, medical treatment and other industries.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

Article manufacture using polyolefin containing polyetheramine modified functionalized polyolefin

InactiveUS6146574AIncrease stiffnessReduce void volumeSynthetic resin layered productsWood working apparatusPolyolefinPolymer science

This invention concerns a composition comprising a blend of polyolefin with the reaction of a functionalized polyolefin and polyetheramine in which the polyetheramine is grafted into the functionalized polyolefin in a customary mixing apparatus. A process for producing the reaction product of functionalized polypropylene and polyetheramine by melting with polypropylene in a customary mixing apparatus is also disclosed. Blends of the present invention are advantageously useful to prepare paintable automotive body parts. This invention further includes dyeable polyolefin compositions containing the reaction product of functionalized polyolefin and polyetheramine. Dyeable polyolefin fibers, including polypropylene fibers, are disclosed, which may be made by melt spinning, and which may be employed to make woven and non-woven fabric.

Owner:HUNTSMAN PETROCHEMICAL LLC +1

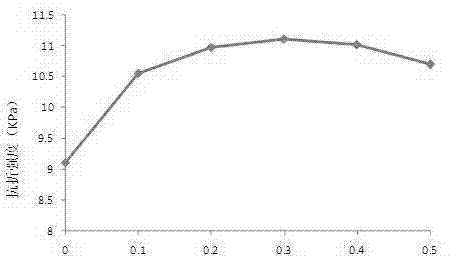

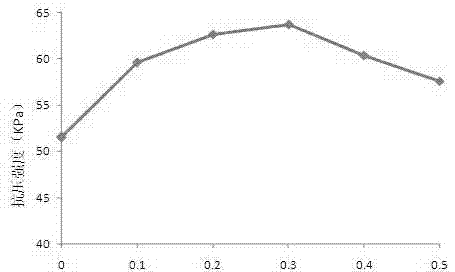

High-strength polypropylene fiber polymer cement mortar and preparation method thereof

The invention discloses a high-strength polypropylene fiber polymer cement mortar and a preparation method thereof. The mortar is composed of the following components in parts by mass: 0.28-0.3 part of silica fume, 0.68-0.7 part of cement and 1.97-2 part of sand. The SiO3 content in the silica fume is higher than 95%; the water-cement ratio is 0.31; the volume content of the polypropylene fiber is 0.9 kg / m<3>; the water reducer:cementing material ratio is 0.9-1%; the defoaming agent:cementing material ratio is 0.5-0.55%; the coupling agent and diluter:cementing material ratio is 0.3%; the polymer modifier:cementing material ratio is 10-11%; and the reducer:cementing material mass ratio is 3-3.5%. By combining the excellent physical and chemical characteristics of the silica fume, when the silica fume is substituted for cement, the consumption of the cement clinker is saved, and the industrial waste is reutilized, thereby greatly enhancing the pressure resistance and bending resistance of the modified cement mortar.

Owner:ZHENGZHOU UNIV

Plugging flexibilizer

ActiveCN103740346AImprove flexural strengthGood toughening effectDrilling compositionCellulosePetroleum

The invention discloses a plugging flexibilizer, comprising the components in parts by weight: 5-12 parts of polypropylene fiber, 20-30 parts of rubber particles, 1-5 parts of high molecular polyacrylamide, 2-8 parts of toughened nylon, 2-8 parts of asbestos section, 5-12 parts of plant fibers, 4-7 parts of calcium hydroxide, and 0.1-0.4 part of polyanionic cellulose PAC-HV. A preparation method of the plugging flexibilizer comprises the following steps: orderly adding the components in parts by weight to a kneading machine according to a conventional preparation method at constant temperature and constant pressure; evenly mixing and stirring; and crushing into a 0.05-1mm granular product. The plugging flexibilizer has the characteristics of being wide in material source, free of toxicity and pollution, simple and convenient in construction technology, good in rheological property, good in pillar-forming property, strong in tenacity, not easy to fragilely fall off, high in plugging success rate and the like, does not easily generate a rupture and a brittle fracture in the drilling process after plugging, and is widely applied to pressure-loaded plugging engineering of low-pressure fractured formation, large cracks, large caves, subterranean rivers and serious voidage formation in petroleum and geological drilling.

Owner:DONGYING TAIER GASOLINE TECH

Light cast-in-situs concrete wallboard

InactiveCN1530501AStrong and durable connectionImprove the seismic performance of structuresSolid waste managementWallsFiberglass meshGlass fiber

A light concrete wall slab cast in-situ is composed of main body and welded reinforcing steel bar net in said main body. Said main body is made up of water, cement, powdered coal ash, slag powder, silicon powder, efficient composite water-reducing agent, polypropylene fibres, glass fibre fabric or alkali-resistant plastic-coated glass staple, modified cement polymer emulsion (or powder), haydite, and sand. Its advantages are light weight, high strength, low shrinkage, not deforming and cracking, and low cost.

Owner:张英保

Pervious concrete and construction method thereof

ActiveCN104402339AImprove workabilityIncreased intensityIn situ pavingsRoad surfaceUltimate tensile strength

The invention discloses pervious concrete and a construction method thereof. The pervious concrete comprises the following raw materials in percentage by weight: 13.1-15.9% of cement, 12.7-15.6% of river sand, 59.6-66.0% of stones, 3.7-3.9% of water and 4.5-5.0% of admixtures, wherein the admixtures comprise the following raw materials in percentage by weight: 45-50% of ultrafine mineral powder, 15-20% of heavy calcium carbonate, 15-20% of gypsum powder, 3-5% of polypropylene fiber, 5-10% of a polycarboxylate water reducing agent, 4.2-8.4% of adhesive powder and 2-5% of a pigment. The pervious concrete provided by the invention has relatively high water permeability, strength and durability; after the pervious concrete is applied to a practical engineering, the pervious concrete can greatly improve the problem of poor drainage of a hardened road surface, so that the development of the pervious concrete can be promoted.

Owner:TIANYUAN CONSTR GROUP

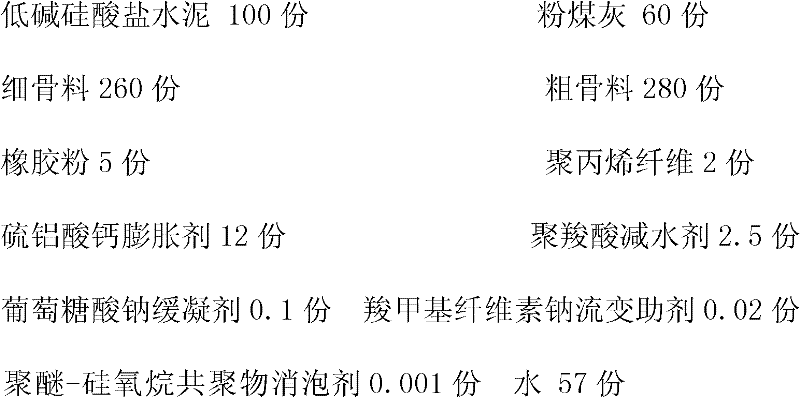

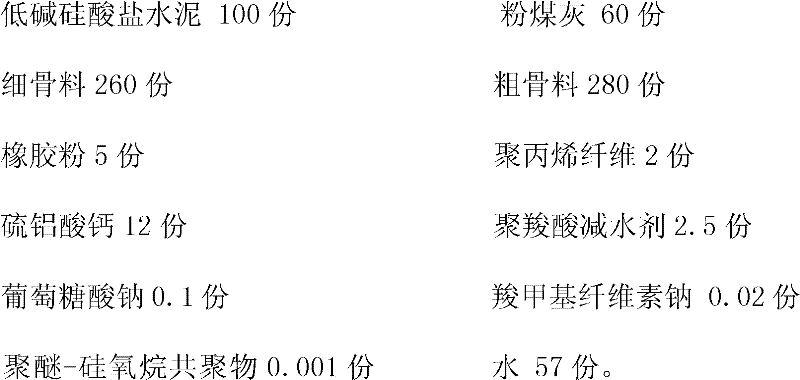

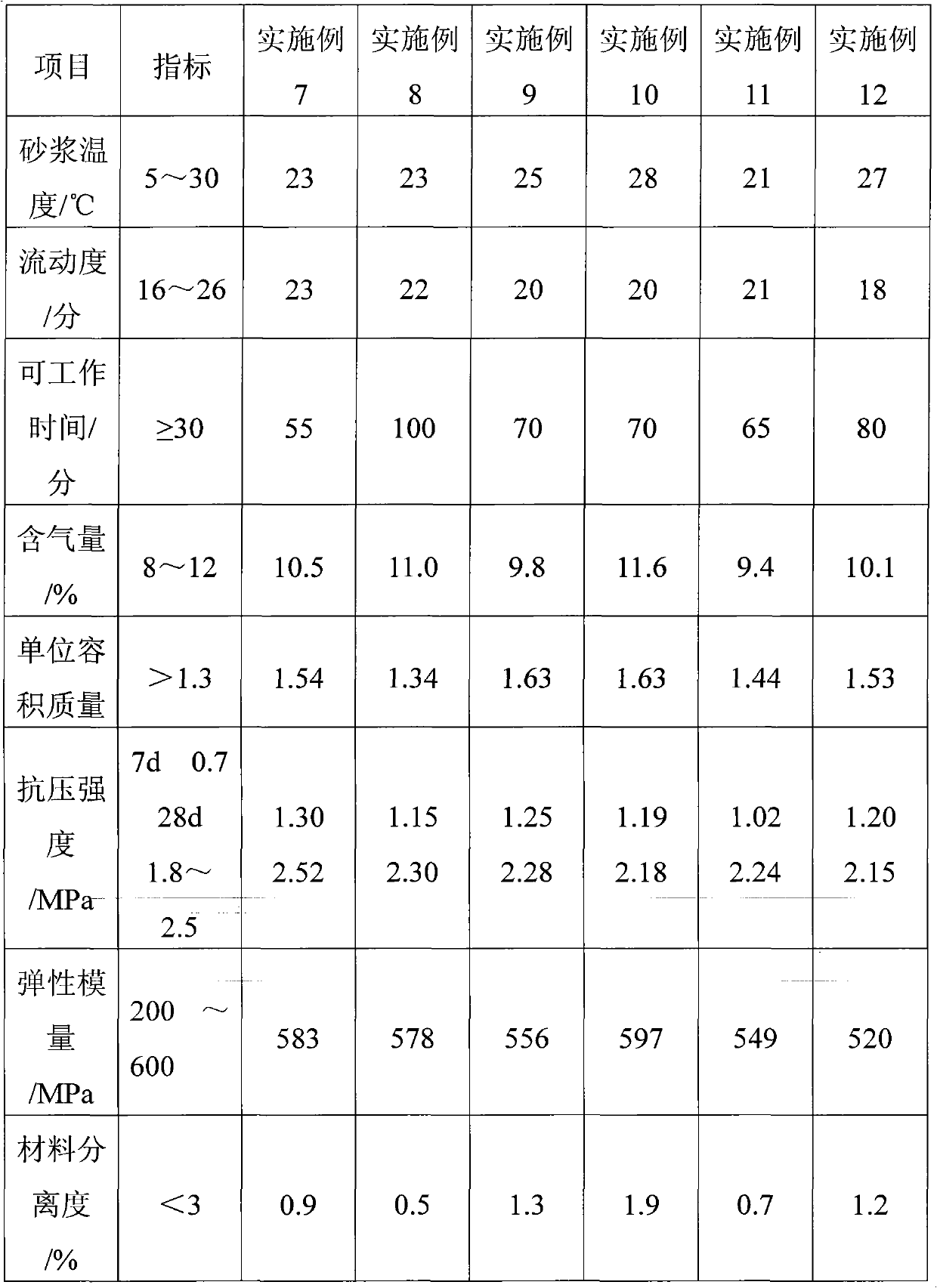

Self-compacting concrete mixture for plate-type ballastless track of railway

The invention discloses a self-compacting concrete mixture for a plate-type ballastless track of a railway, which is composed of the following ingredients in part by weight: 100 parts of cement, 20-80 parts of mineral admixture, 200-300 parts of fine aggregate, 250-350 parts of coarse aggregate, 2-10 parts of parts of rubber powder, 1-3 parts of polypropylene fiber, 10-25 parts of expansion agent, 1.0-3.0 parts of water reducing agent, 0.1-1 part of retarder, 0.01-0.05 parts of rheology accessory agent, 0.001 part of antifoaming agent and 60-80 parts of water; and the self-compacting concretemixture is prepared by blending and stirring the materials. The self-compacting concrete mixture disclosed by the invention has the advantages of large flow state, self-compacting property, non-segregation, low shrinkage, high anti-cracking property and vibration adsorption, and the like, so that the self-compacting concrete mixture can be used as filler between a rail board and a soleplate in a plate-type ballastless track and can also be used as filler between a turnout board and the soleplate in a turnout structure.

Owner:SOUTHWEST JIAOTONG UNIV

Thermal-insulation loading recycled concrete

The invention relates to a concrete commonly used in building materials, and especially relates to a thermal-insulation loading recycled concrete. A technical problem to be solved is to provide a recycled concrete which is an integration of thermal insulation, loading, quake resisting, and energy saving and emission reduction. A technical scheme adopted is characterized in that a weight ratio (kg / m<3>) of a composite lightweight aggregate admixture: cement: recycled fine aggregate: sand: recycled coarse aggregate: cobblestone: ceramsite: coal ash: water: additives is (5-250):(200-800):(20-500):(5-800):(30-600):(5-1400):(50-800):(10-600):(50-500):(0.1-200); the composite lightweight aggregate admixture is a mixture of glazed hollow beads and an aerogel, and the weight part ratio of the glazed hollow beads to the aerogel is 1:(0.7-1.5); and the additives comprise the following components, by weight, 10-150 parts of silica fume, 4-40 parts of an air entraining agent, 5-30 parts of a foaming agent, 3-30 parts of a water reducing agent, 1-30 parts of a polypropylene fiber, and 10-150 parts of waste slag. The technical scheme is used for making the recycled concrete.

Owner:TAIYUAN UNIV OF TECH

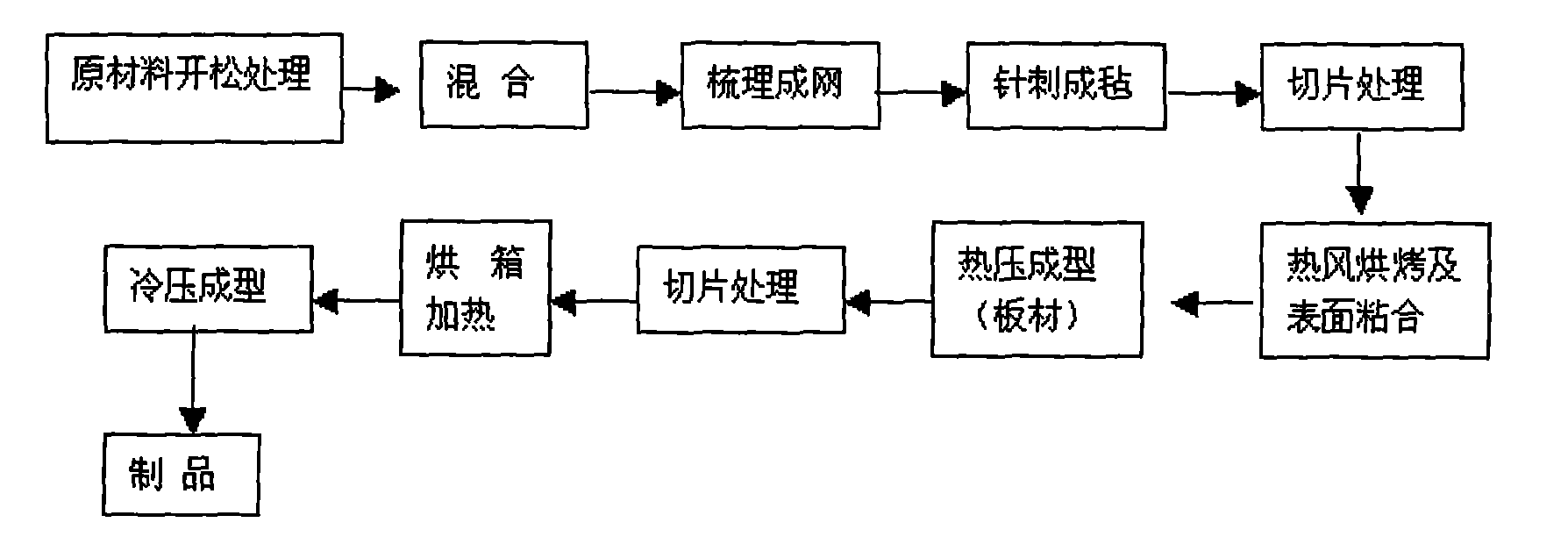

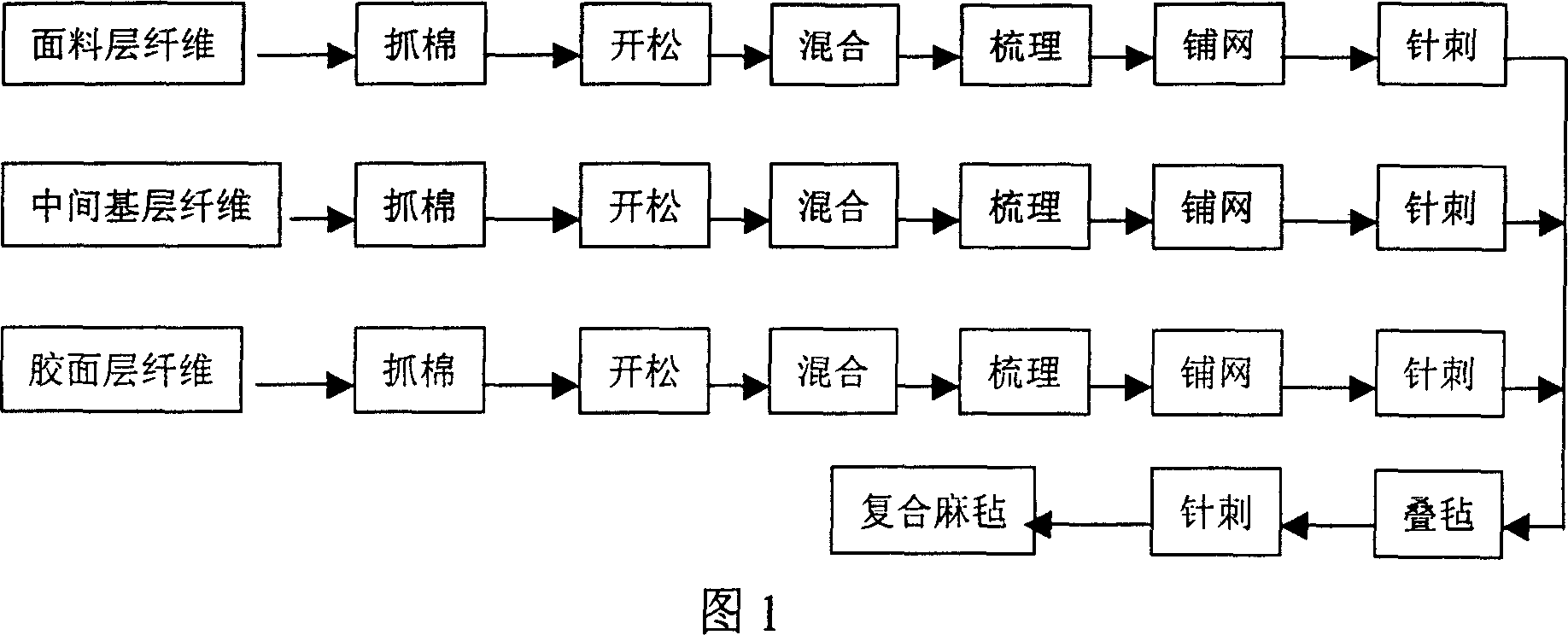

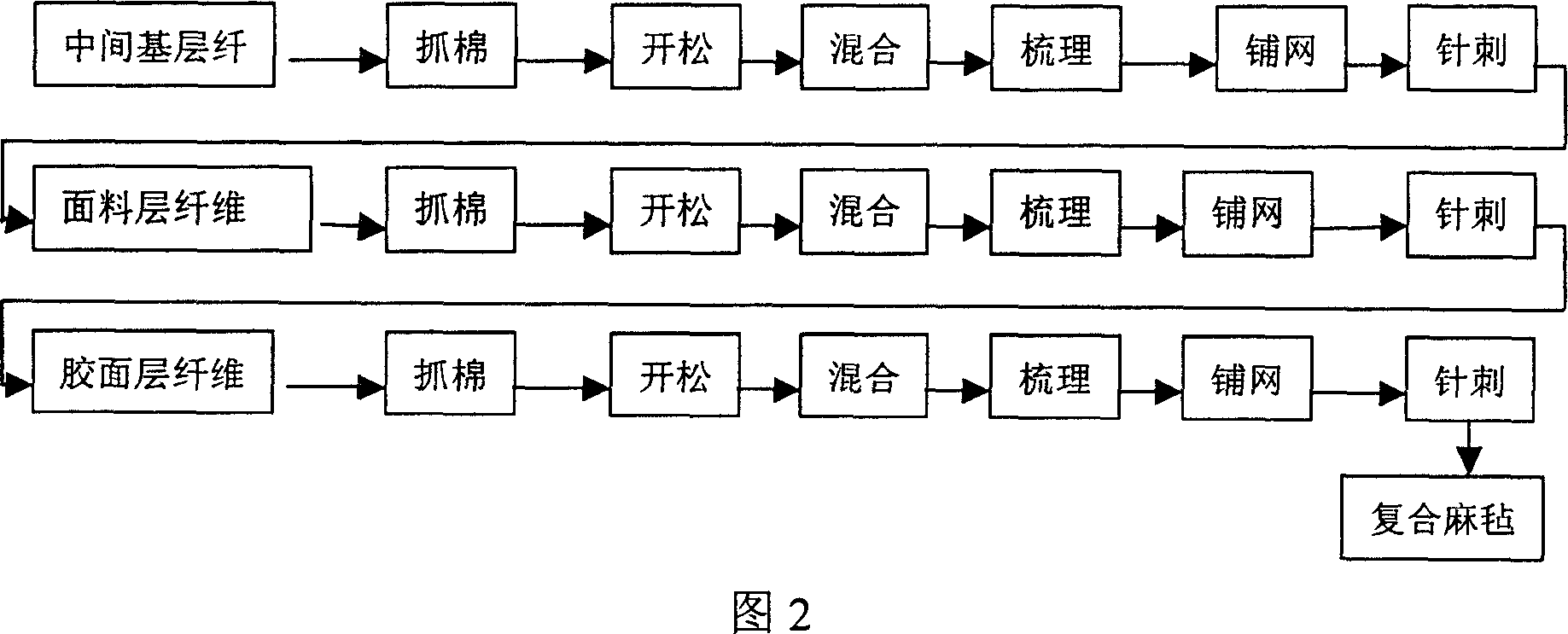

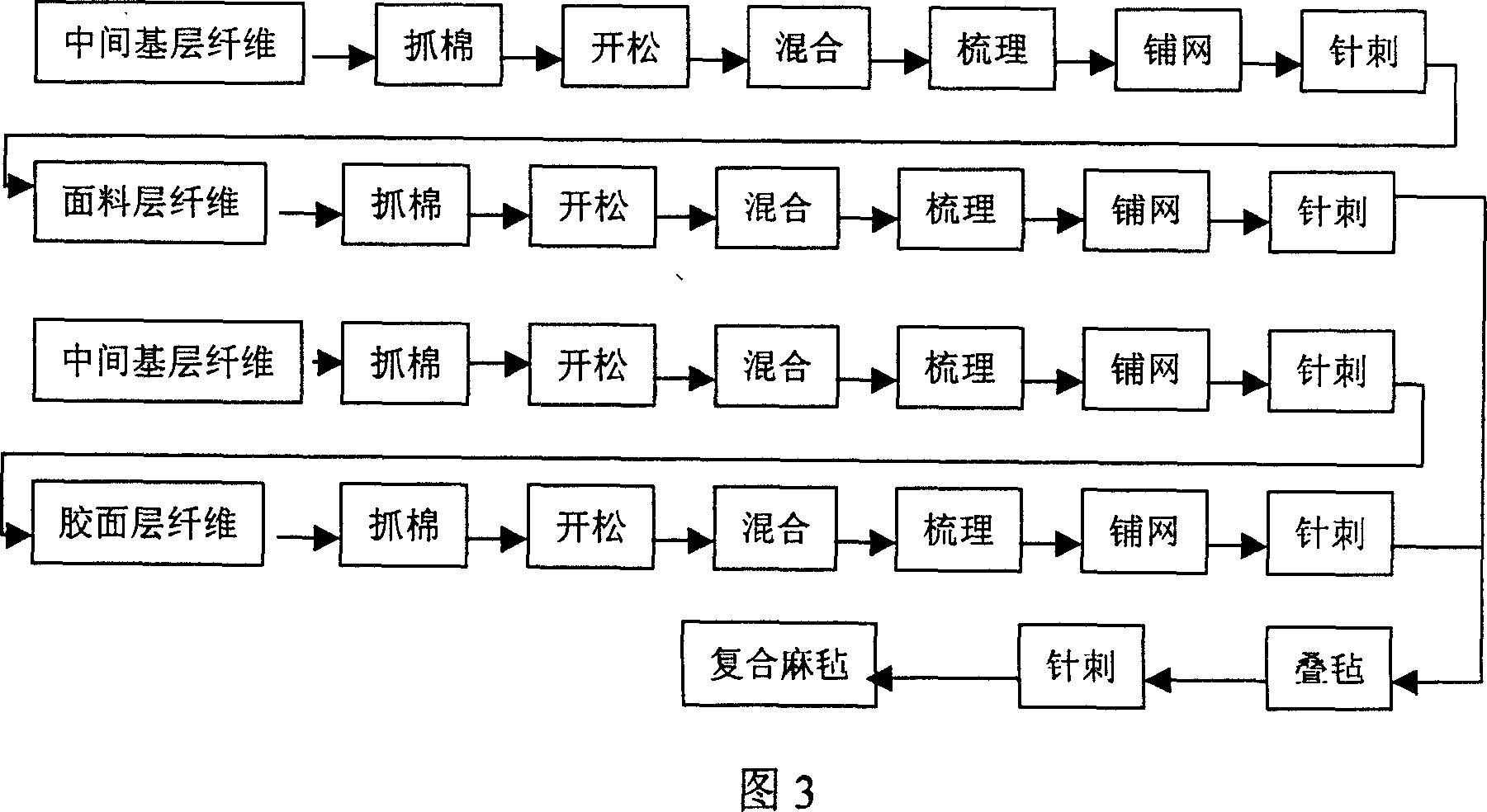

Fibrilia automobile inner decoration member and method of manufacturing the same

ActiveCN101549671ANo pollution in the processReduce lossMonocomponent cellulose artificial filamentSuperstructure subunitsRaw materialPolypropylene fiber

The present invention relates to a fibrilia automobile inner decoration member and a method of manufacturing the same, the steps is that implementing a opening treatment to packaged raw material, mixing jute fiber and polypropylene fiber according to proportionality in a cotton opener, and fiber netting simultaneously; then needling to form a felt by a needle machine, and implementing a sliced sheet treatment to the product after felting; baking and heating the felt directly in a baking oven to bond the surface, the baking temperature is from 180 to 200 DEG C; then cold press molding by a product mold, finally manufacturing a finished product; or preparing the belt into a sheet material to store, then baking and heating the sheet material, and a corresponding product molding according to requirements.

Owner:CHERY AUTOMOBILE CO LTD

Methods of making low-shrink polypropylene fibers

InactiveUS6656404B2Monocomponent polypropylene artificial filamentWoven fabricsPhosphateLITHIUM PHOSPHATE

Improved polypropylene fibers exhibiting greatly reduced heat- and moisture-shrink problems and including certain compounds that quickly and effectively provide rigidity to the target polypropylene fiber after heat-setting are disclosed herein. In such a manner, the "rigidifying" compounds provide nucleation sites for polypropylene crystal growth. After drawing the nucleated composition into fiber form, the fiber is then exposed to sufficient heat to grow the crystalline network, thus holding the fiber in a desired position. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as sodium beuzoate, certain sodium and lithium phosphate salts (such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11).

Owner:MILLIKEN & CO

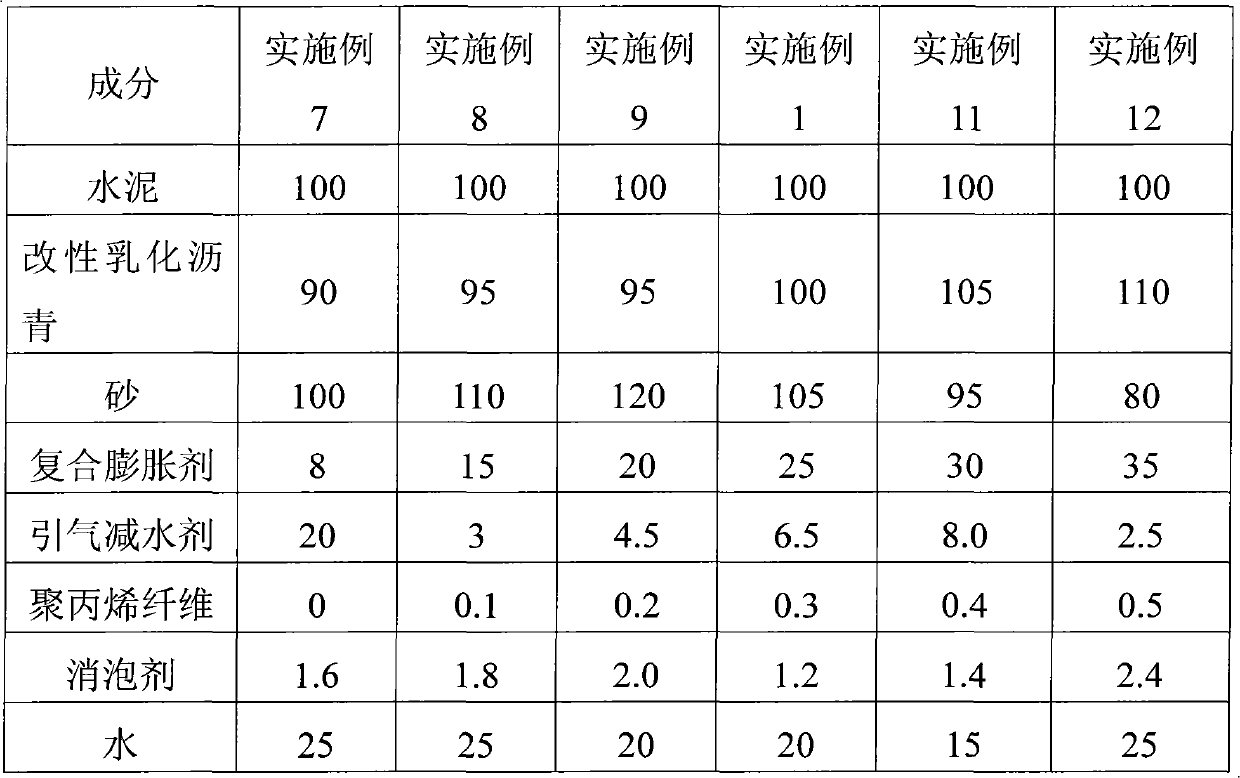

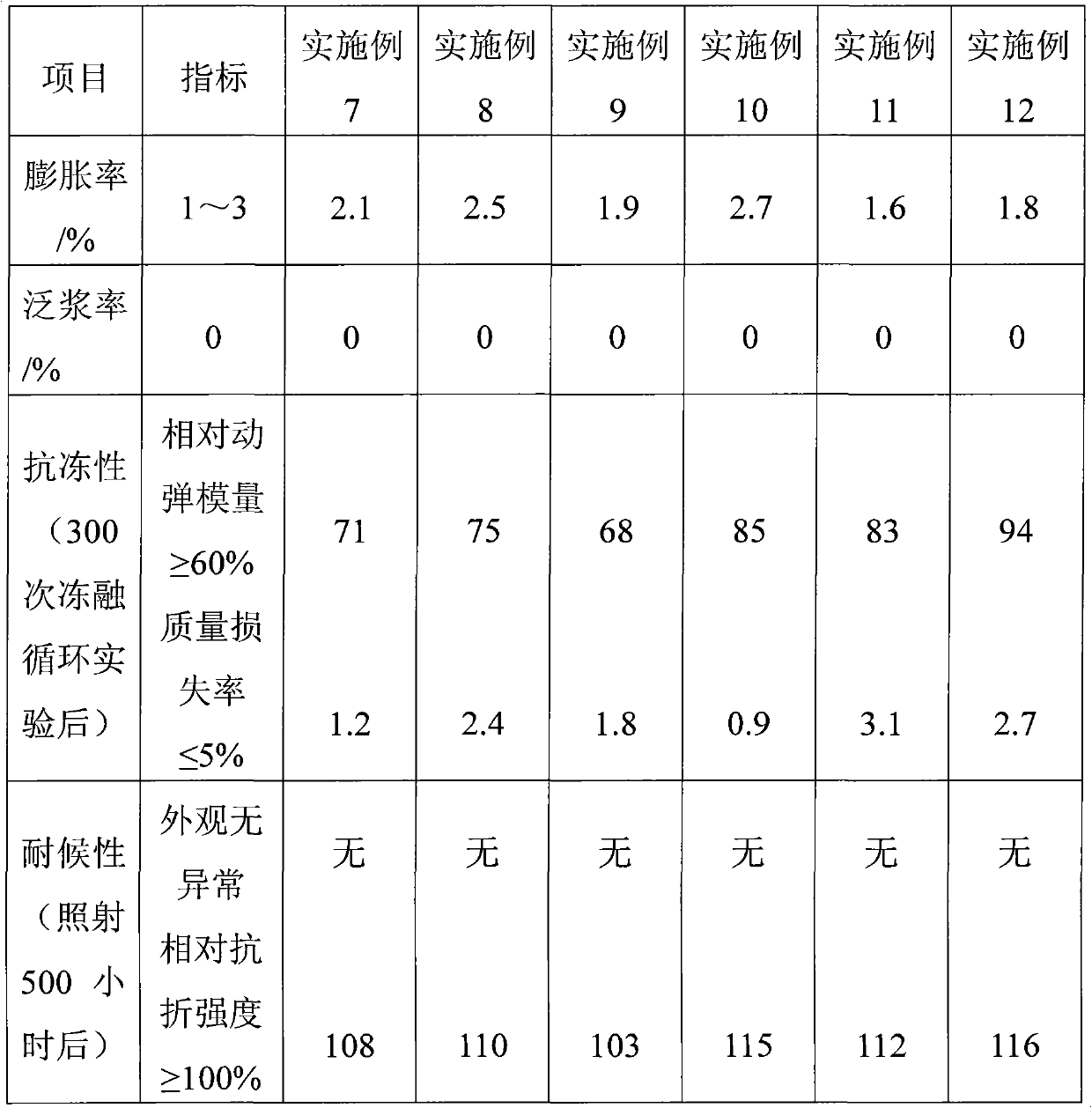

Rubber powder modified emulsified asphalt and preparation method thereof and CA mortar prepared by emulsified asphalt

InactiveCN101948623AGood compatibilitySolving the technical key to difficult emulsificationBuilding insulationsPolymer scienceAsphalt

The invention provides rubber powder modified emulsified asphalt and a preparation method thereof and CA mortar prepared by the emulsified asphalt. The rubber powder modified emulsified asphalt is prepared from 30-50% of base asphalt, 15-30% of rubber powder, 0.5-3.0% of coupling agent, 0.2-0.5% of thickening agent, 0.5-3% of diluting dispersing agent, 2.0-6.0% of emulsifying agent, 0.5-3% of emulsifying auxiliary by mass and the balance water through the steps of diluting, stirring and shearing. The CA mortar can be further prepared by adding cement, sand, a compound expansion agent, an air entraining and water-reducing agent, polypropylene fibers, a defoaming agent and other substances to the rubber powder modified emulsified asphalt. The invention solves the technical problem that the rubber powder is difficult to emulsify. The prepared rubber powder modified emulsified asphalt has high dispersibility and stability and the high / low temperature performance and the weatherability of the asphalt are improved. The prepared CA mortar not only has higher elasticity but also does not produce segregation and the storage stability of the CA mortar is obviously improved.

Owner:江苏省苏安能节能建材科技有限公司

Dyeable polyolefin containing polyetheramine modified functionalized polyolefin

InactiveUS6127480AGood paintabilityExcellent mold flowabilityEngine sealsCellulosic plastic layered productsPolymer sciencePolyolefin

This invention concerns a composition comprising a blend of polyolefin with the reaction of a functionalized polyolefin and polyetheramine in which the polyetheramine is grafted into the functionalized polyolefin in a customary mixing apparatus. A process for producing the reaction product of functionalized polypropylene and polyetheramine by melting with polypropylene in a customary mixing apparatus is also disclosed. Blends of the present invention are advantageously useful to prepare paintable automotive body parts. This invention further includes dyeable polyolefin compositions containing the reaction product of functionalized polyolefin and polyetheramine. Dyeable polyolefin fibers, including polypropylene fibers, are disclosed, which may be made by melt spinning, and which may be employed to make woven and non-woven fabric.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT

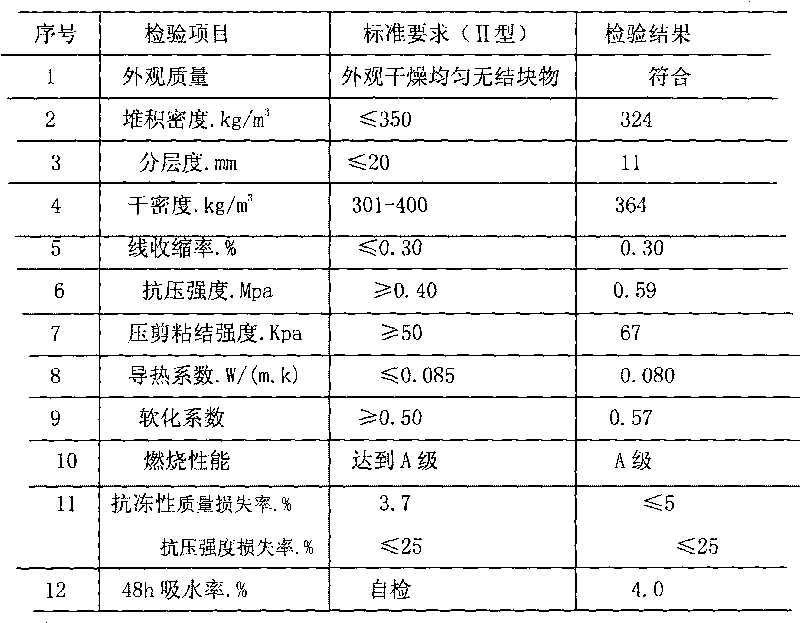

Heat-preservation and heat-insulation crack-resisting brick made from modified vitrified micro beads

ActiveCN101725208ASolve the weakness of high water absorptionNo pollution in the processSolid waste managementBuilding componentsSocial benefitsBrick

The invention relates to a heat-preservation and heat-insulation crack-resisting brick made from modified vitrified micro beads and effectively resolves the problems of large contractibility rate, poor stability, easy cracking and high cost of masonry walls. According to parts by weight, the brick is composed of the following raw materials: 100 parts of cement, 5-20 parts of coal ash, 0.005-0.015 part of polypropylene fiber, 10-50 parts of modified vitrified micro beads, 10-30 parts of activating agent, 1-5 parts of sodium silicate, 10-50 parts of sand, 10-200 parts of fine stone and 110-330 parts of water. The method for preparing the brick comprises the following steps: evenly stirring and mixing the modified vitrified micro beads, 50 parts of the cement and the activating agent to form material A, then evenly stirring and mixing the fine stone, the sand, the coal ash, the polypropylene fiber and the remaining 50 parts of cement to form material B; adding water to stirring the material A and material B into uniform brick material; pressing the brick material into block-shaped bricks by a die and curing the block-shaped bricks at 10-40 DEG C for 7-30 days, thus obtaining the final product. The brick of the invention features scientific and reasonable components, simple process, stable quality, low contractibility rate, low coefficient of heat conductivity, good heat-preservation and heat-insulation property, low cost, environmental friendliness, economy and tremendous economic and social benefits.

Owner:BEIJING TIANJI NEW MATERIALS

Thermal insulation building mortar and preparation process thereof

InactiveCN101759416AWith thermal insulationWith phase change energy storageCement mixing apparatusSodium BentoniteThermal insulation

The invention discloses a thermal insulation building mortar. The thermal insulation building mortar is prepared by the mixing portland cement, pulverized fuel ash, calcium bentonite, re-scattering glue powder, hypromellose, polyacrylamide powder, polypropylene fibre, wood fiber, permeating crystal waterproof agent, air entraining agent, vitrified micro-bead, sizing phase-change material and hollow glass bead. A preparation process thereof comprises the steps of: a) preparing the sizing phase-change material, b) preparing the permeating crystal waterproof agent and c) preparing the thermal insulation building mortar. The mortar of the invention is characterized by the functions of thermal insulation, phase-change energy storage, temperature control, water resistance and energy saving, the wide application scope and low cost. The mortar is widely applied in thermal insulation work inside or outside the buildings and has a broad prospect.

Owner:唐山市思远涂料有限公司

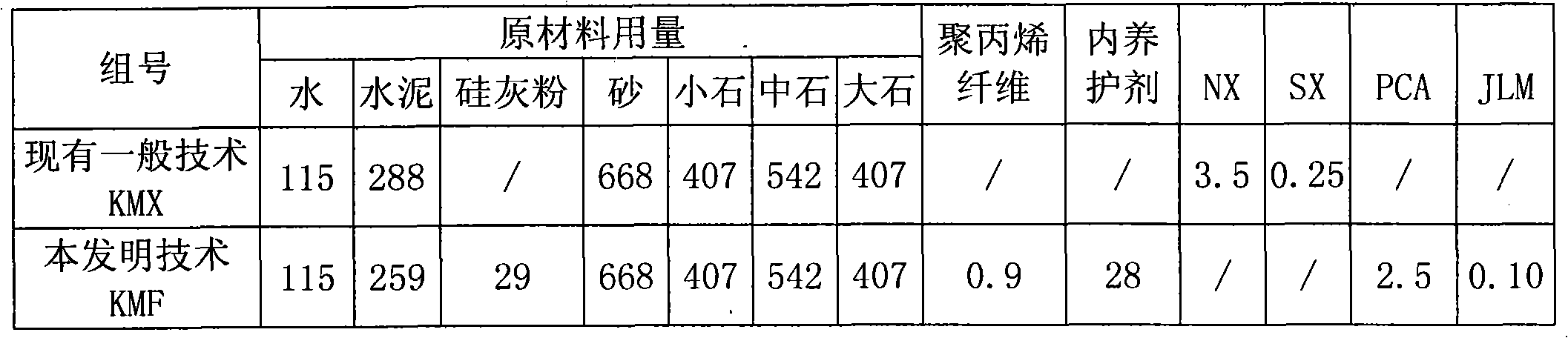

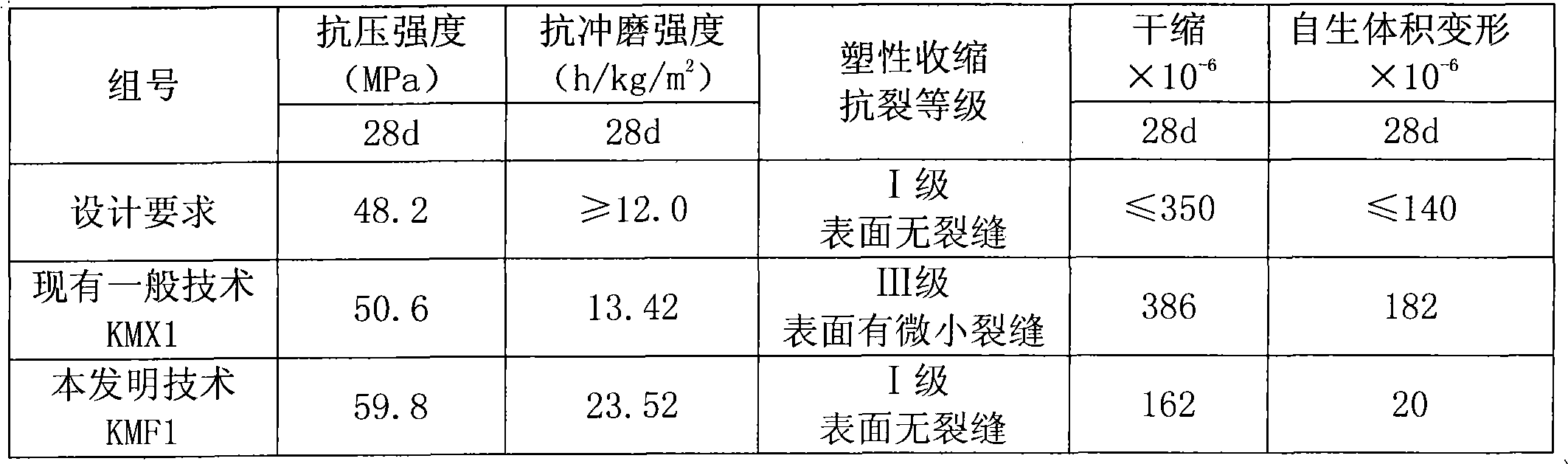

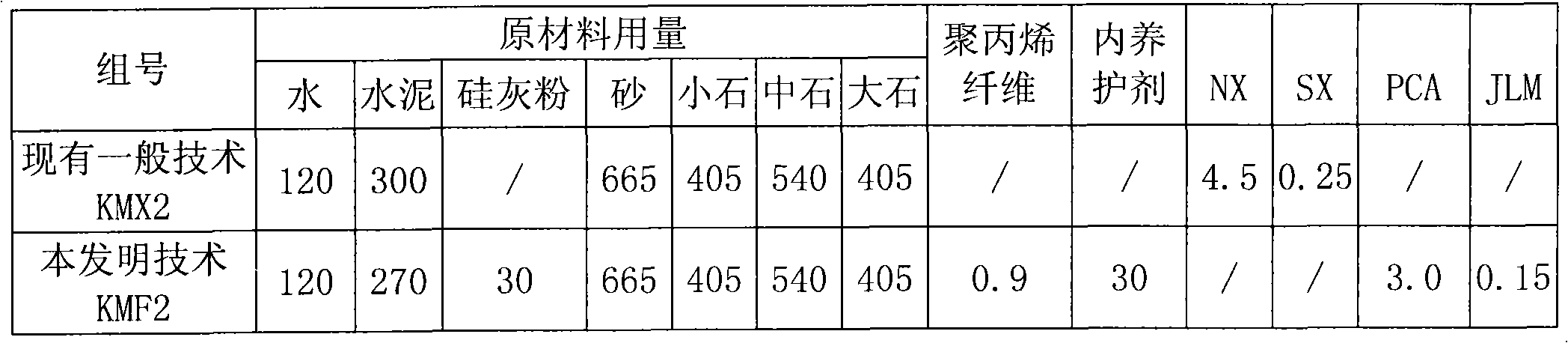

Crack-resistant abrasion-resistant hydraulic concrete and preparation method thereof

InactiveCN102010160AImprove performanceImprove abrasion resistanceSolid waste managementCrack resistanceVolume deformation

The invention discloses crack-resistant abrasion-resistant hydraulic concrete and a preparation method thereof. The hydraulic concrete comprises materials of cement, sand, stones, a polypropylene fiber, a water reducing agent, an air entraining agent and water, and is characterized in that: an internal curing agent and silica fume powder are added; by adopting the internal curing agent as a super absorbent resin, internal maintenance of the concrete is enhanced, the concrete shrinkage is reduced, the abrasion resistance of the concrete is improved, and the crack resistance of the concrete is improved; by adopting the silica fume powder, the concrete mixture performance and abrasion resistance are improved, the comprehensive utilization of industrial wastes and resource and energy conservation are realized, and the environment is protected; and taking concrete at C40 strength grade as an example, the abrasion resistance is 23.52h / kg / m<2>, the early plastic shrinkage crack resistance reaches the first grade, cracks are not formed on the surface of the concrete, an air shrinkage value within 28 days is 162*10<-6>, and the autogenous volume deformation within 28 days is 20*10<-6>. The technical scheme is simple in technical operation, readily available in raw materials, lower in production cost and better in economic and social benefits.

Owner:广西壮族自治区水利科学研究院

Foam concrete with desulfurized gypsum as main cementing material and preparation method of foam concrete

The invention belongs to the technical field of building materials, in particular relates to foam concrete with desulfurized gypsum as a main cementing material. The foam concrete comprises desulfurized gypsum, slag powder, coal ash, cement, a foaming agent, a foam stabilizer, an alkali-activator, an early strength agent, water glass, a water reducer and polypropylene fibre. The desulfurized gypsum in the foam concrete is uncalcined desulfurized gypsum; by using the foam concrete, the desulfurized gypsum can be recycled, a great number of industrial wastes such as slag powder and coal ash canbe digested, and a favorable environmental benefit is achieved. In addition, the foam concrete provided by the invention has the excellent performances such as light weight, heat insulation, noise isolation and absorption, flame retardance, seismic resistance and energy adsorption, can be used for casting in situ and producing blocks and plates and is suitable for casting a roof heat insulating layer, a floor heating heat insulating layer, a light wall heat insulating building block, a road absorbent lined barrier and the like in situ.

Owner:TONGJI UNIV

Self-compacting fiber reinforcement active powder concrete and method for making same

ActiveCN101139192AImprove liquidityNo need to vibrateSolid waste managementCompressive strengthUltimate tensile strength

The present invention belongs to the building material technology field, in particular to relate to a self-compact strengthened fibre active concrete and the corresponding preparation method. The present invention is made of cement, silicon ash, quartz powder, quartz sand, water reducer and steel fibre or polypropylene fibre or the mixing fibre between the steel fibre and the polypropylene fibre according to the weight ratio. By using the new type water reducer, the present invention makes the concrete not need any vibration when being molded and the concrete can rely on the self weight to be filled in each angle of the building mould. Besides, the concrete can rely on the self weight to reach the compact situation. By using the rational fibre, both the compression strength and the folding strength can be enhanced greatly, especially for the folding strength, the enhanced degree is much greater. And moreover, the tenacity of the RPC is also enhanced greatly. The self-compact strengthened fibre active concrete in the present invention can simplify the manufacturing process greatly and provide much wider application foreground for manufacturing thin-wall products, slight components or other components with novel structure shape.

Owner:广东利盈投资集团有限公司

Multifunctional aromatic type element fiber fabric protective clothing

ActiveCN103233287ASpinning solutions preparationArtifical filament manufactureAcute hyperglycaemiaSesamum orientale

The invention discloses multifunctional aromatic type element fiber fabric protective clothing. The multifunctional aromatic type element fiber fabric protective clothing comprises vitamin mineral substance nutrient element group, a free radical-scavenging anti-electromagnetic wave energy-accumulated heat-insulating material, natural antibiosis mite-proof traditional Chinese medicine fluid extract aroma nano microcapsule, and cotton, sesame, silk, wool, polypropylene fiber, nylon, acrylic fiber and a terylene viscose fiber spinning solution. The multifunctional aromatic type element fiber fabric protective clothing can entirely supplement and regulate the element balance of a human body, as well as the vitamin balance, release trace element negative ions, purify air, resist heavy metal elements and air, powerfully scavenge free radicals, enhance the immunity of the human body, and prevent electromagnetic wave pollution, is energy-accumulated, cold-proof and heat-insulating, as well as antimicrobial and mite-proof, can effectively prevent the infection of various pathogenic bacteria, influenza and skin pruritus, is anti-cancer, and resists hypertension, hyperlipidemia, hyperglycemia, cerebral thrombosis and the like, thus building the human body, and enabling the human body to emit natural and pleasant aroma.

Owner:中山巨邦科技集团有限公司

Method for preparing strong acidic ion-exchange fibers

ActiveCN104499281AImprove mechanical propertiesImprove hydrophilicityCation exchanger materialsFibre typesCross-linkPolymer science

The invention provides a method for preparing strong acidic ion-exchange fibers. The method comprises the steps of performing vacuum packaging for polyolefine fibers; pre-irradiating through a radiation source; feeding pre-irradiated polyolefine fibers into a grafting solution under the protection of inert gas to react to obtain a polyolefine fiber grafting copolymer; then sulphonating through chlorosulfonic acid to obtain strong acidic ion-exchange fibers; a cross-linking agent is fed into the grafting solution to enable high mechanical strength and relatively high exchange capacity of the sulphonated fibers. According to the method, the process is simple, the polyolefine fiber grafting copolymer is easily prepared under a low temperature condition; the prepared polyolefine fiber-styrene copolymer is low in styrene autopolymer (less than 2%); the dichloroethane solution of chlorosulfonic acid is treated as a sulphonating agent, so that little chlorosulfonic acid is used, and the post-processing is simple.

Owner:SHENZHEN QIANHAI ZHONGSHENG ENVIRONMENTAL PROTECTION TECH

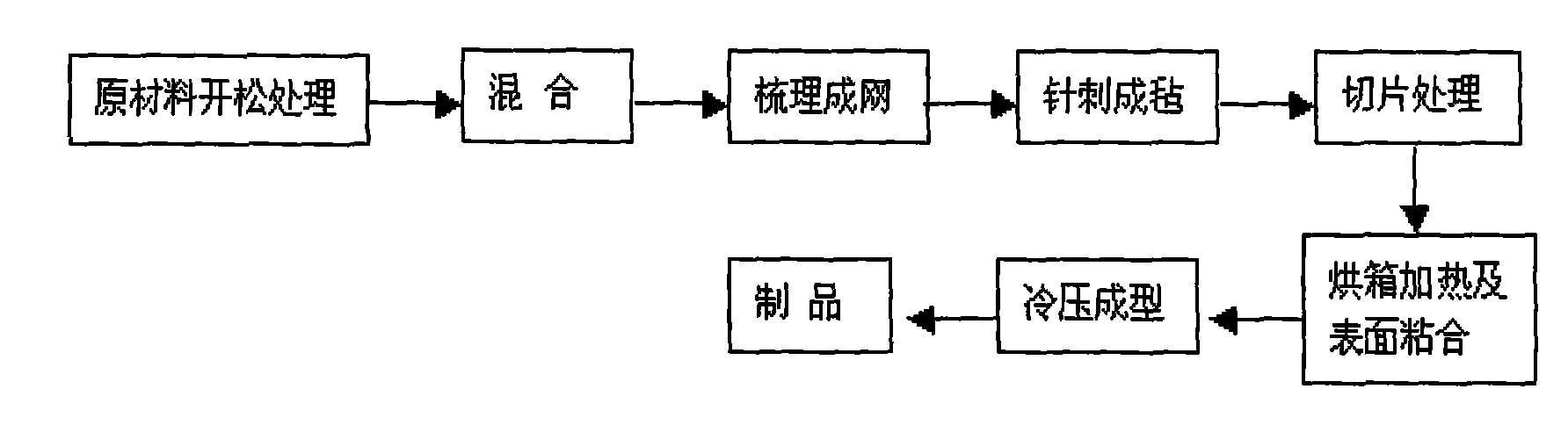

Composite board made of natural firilia for automobile inner decoration use and its producing method

ActiveCN101045310AImprove rigidityAvoid warpingWood working apparatusDomestic articlesPolyesterPolymer science

A composite bast fiber board for the internal decoration of car is composed of adhesive layer, sandwich substrate layer and surface layer, and is prepared through sequentially spreading said three layers, needling to become a composite bast felt, and hot pressing. Said sandwich substrate is made of the mixture of bast fibers (37-45%), polyester fibers (10-20%) and polypropylene fibers (35-53%).

Owner:铜陵华源汽车内饰材料有限公司

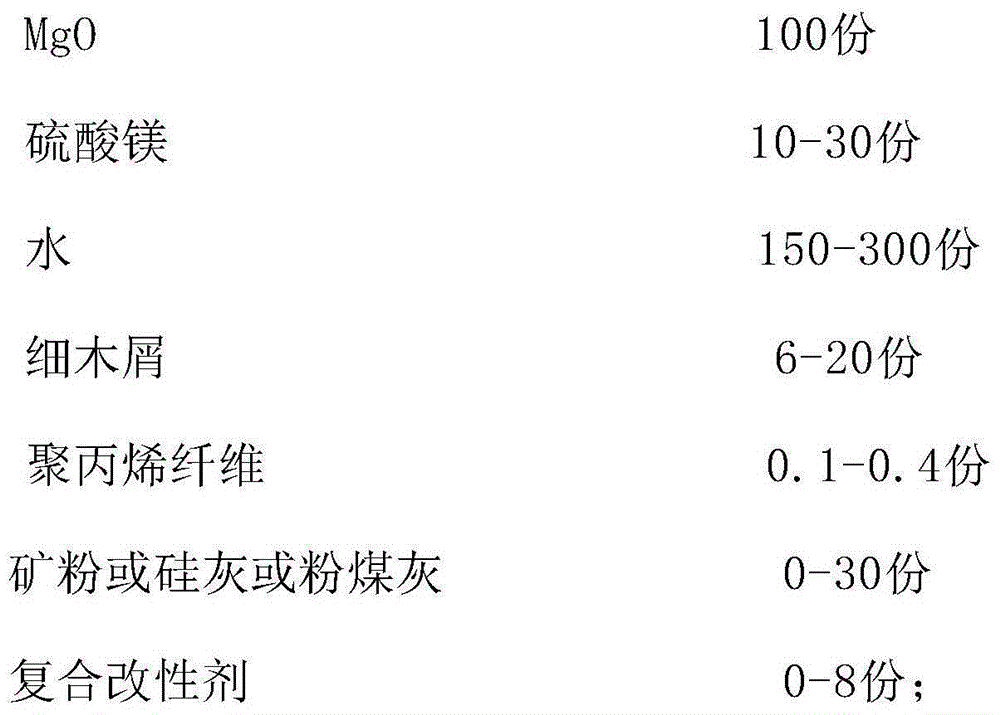

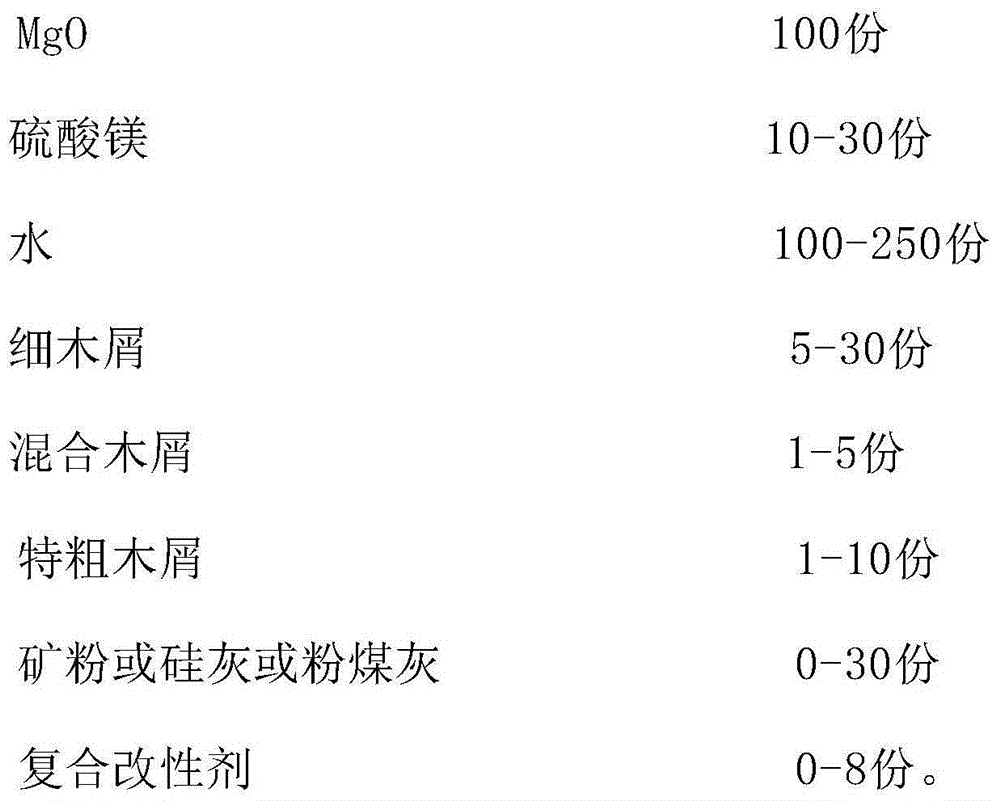

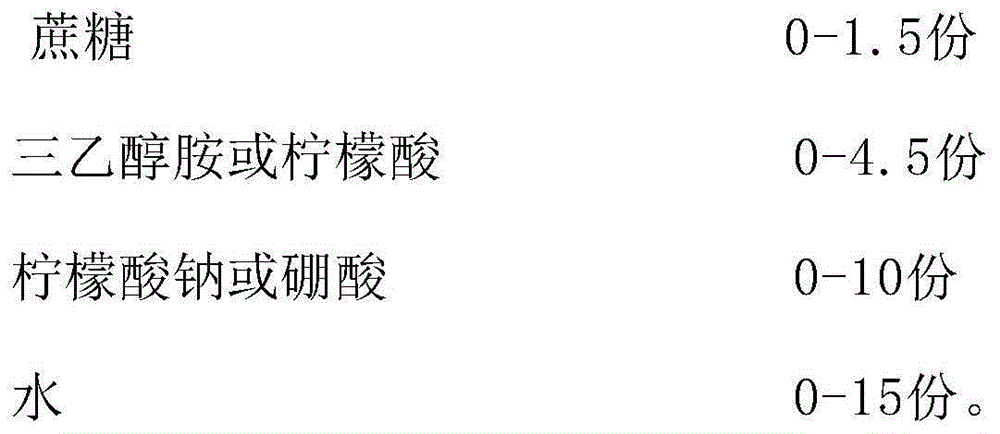

Prefabricated high-strength floor deck and preparation method thereof

InactiveCN105110743AQuick releaseIncrease profitSolid waste managementSurface layerMaterials science

The invention discloses a prefabricated high-strength floor deck and a preparation method thereof. The floor deck comprises an upper surface layer, a middle material layer and a bottom surface layer, wherein the upper and bottom surface layers are both composed of MgO, magnesium sulfate, water, fine wood chip, and polypropylene fibre, and the middle material layer is composed of MgO, magnesium sulfate, water, fine wood chip, mixed wood chip, and extra thick wood chip. Compared with the prior art, the floor deck can realize industrialization of building the floor deck, and overcome the disadvantages of intensive labor force, need for various work types, long completion period, and heavy workload in a traditional floor deck installation process.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Energy-saving type concrete crack repairing agent

The invention discloses an energy-saving type concrete crack repairing agent which comprises the following components in parts by weight: 12-18 parts of sand, 5-10 parts of a quartz powder, 20-35 parts of ordinary portland cement, 10-18 parts of sulphoaluminate cement, 6-12 parts of sodium silicate, 5-9 parts of a polyvinyl acetate emulsion powder, 3-7 parts of silica fume, 7-10 parts of a slag powder, 6-9 parts of fly ash, 8-10 parts of an expansive agent, 0.4-0.6 part of a polycarboxylic acid type high-efficiency water-reducing agent, and 0.2-0.4 part of polypropylene fiber. The concrete repairing agent has high bonding strength, and significantly improves the binding force between a new concrete interface and an old concrete interface; the concrete repairing agent is short in congealing curing time, fast in development of strength after congealing, and suitable for rapid repairing; the concrete repairing agent has the advantages of environmental protection, no toxicity, no smell, harmlessness to human bodies, single-component construction, and no pollution to the environment; and the concrete repairing agent can be used for repairing of concrete cracks, holes, honeycombs and pock marks, and drawing repairing of seams of face bricks and mosaic.

Owner:HUNAN CONSTR ENG GRP COR +1

Foamed concrete and preparation method thereof

ActiveCN103304200AReduce voidsImprove waterproof performanceCeramicwareIsolation effectFoam concrete

The invention provides foamed concrete and a preparation method thereof, and belongs to the technical field of building materials. The foamed concrete provided by the invention consists of the following components in percentage by mass: 25-55 percent of a gel material, 18-50 parts of light aggregate, 13-36 parts of water, 0.5-5 parts of a foaming agent, 0.03-0.5 part of a thickening agent and 0.03-0.5 part of enhanced fiber, wherein the gel material consists of cement and coal ash or superfine slag powder; the light aggregate consists of coarse light aggregates and fine light aggregates; the foaming agent is a hydrogen peroxide solution or an ammonium hydrogen carbonate; the thickening agent is powdered carboxymethylcellulose; the enhanced fiber is a lignin fiber or a polypropylene fiber or an alkali resistance glass fiber which is 5-20 mm long. The water prevention, sound isolation and heat isolation effects of the foamed concrete prepared by the invention are better than those of the existing foamed concrete. According to the method, the foaming process of processing various batches and scales of foamed concrete can be precisely controlled by in-situ foaming; the method can be suitable for large-scale production of high-quality foamed concrete.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com