Patents

Literature

651results about How to "Reduce mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

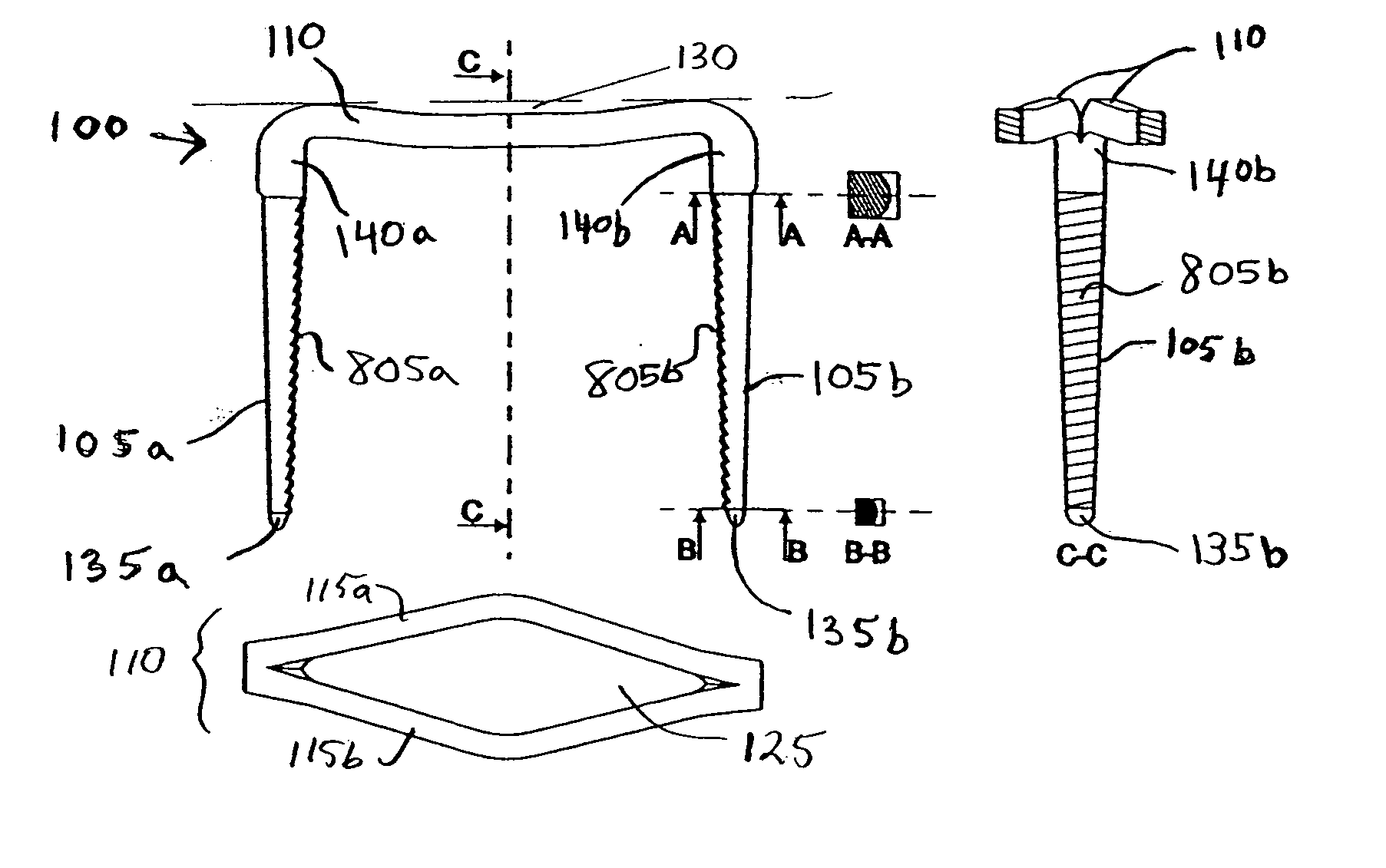

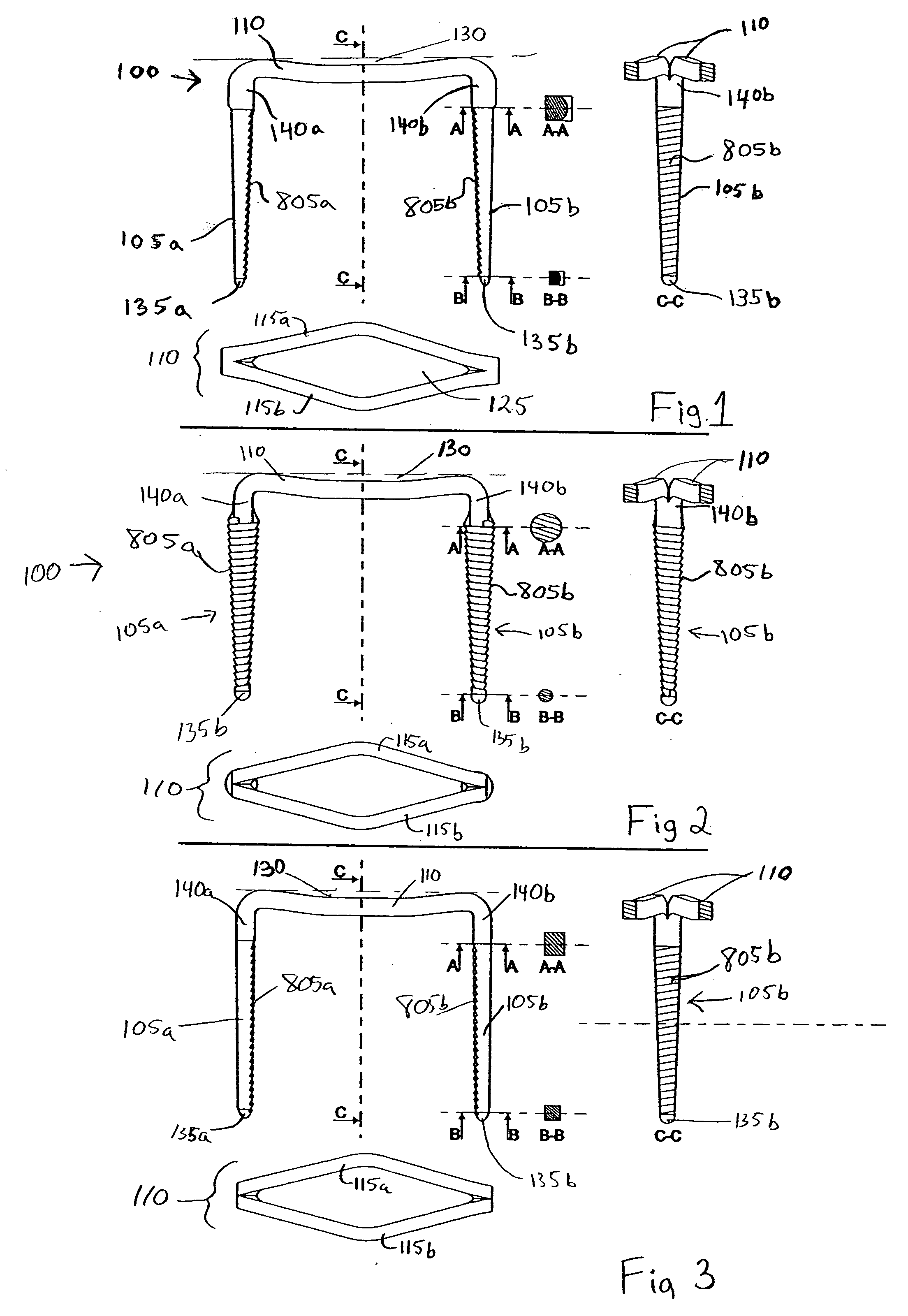

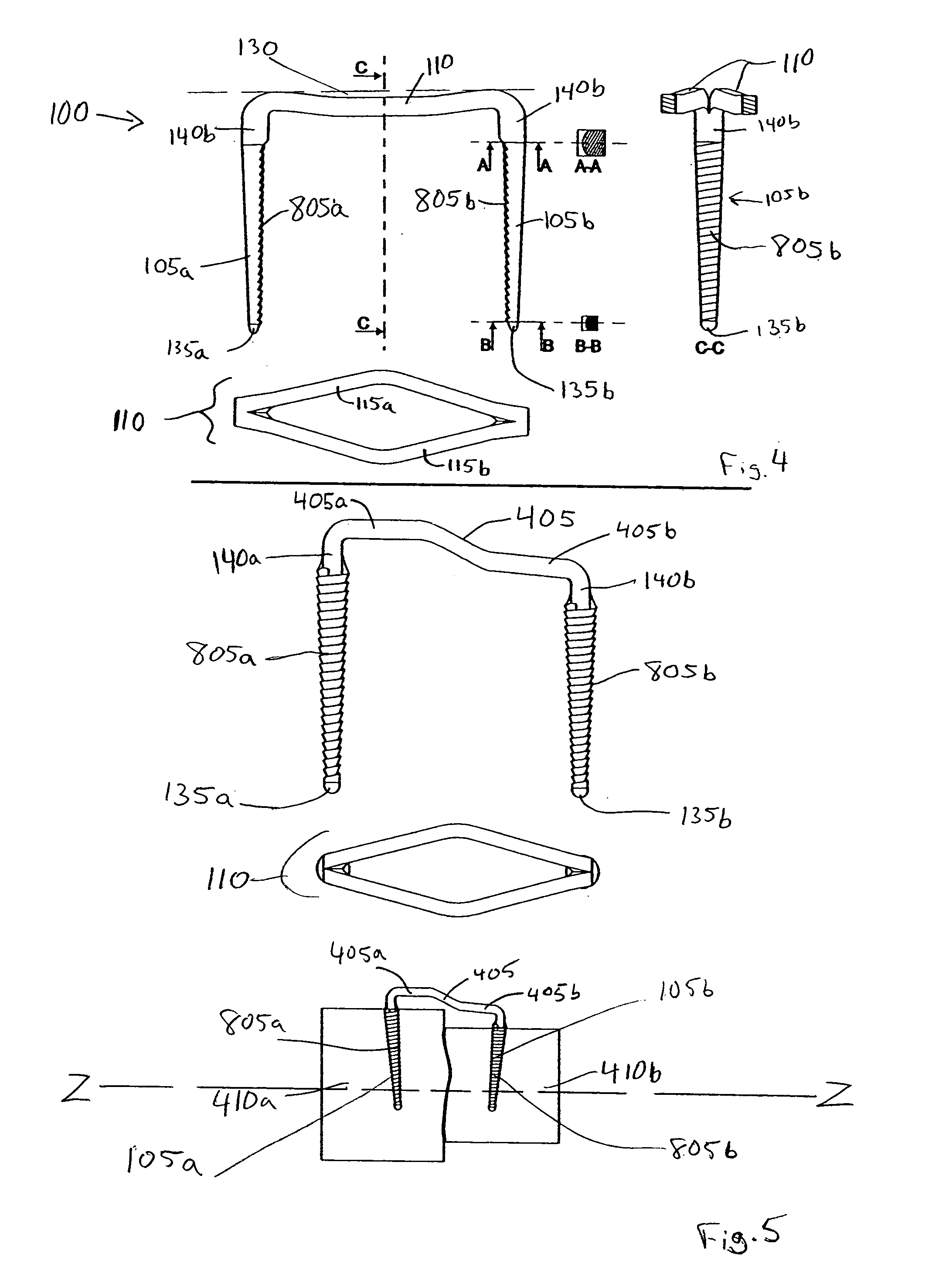

Osteosynthesis clip and insertion tool for inserting an osteosynthesis clip into bone tissue fragments

ActiveUS20050273108A1Easy to cutReduce miningInternal osteosythesisJoint implantsBone tissueBone splinters

An improved osteosynthesis clip for the cicatrization of bone fragments, an improved insertion tool and method for inserting the improved clip and a surgical system implementing the improved clip and insertion tool are provided. The clip includes at least two engagement legs extending approximately parallel to one another and including insertion tips to be inserted into the bone tissue fragments; and a connecting bridge coupled to the at least two engagement legs at portions opposite the insertion portions, the connecting bridge including at least two elongated sections extending along side one another, the elongated sections extending along a non-linear trajectory to form a non-linear deformable region, such as a depression or a dome, wherein the engagement legs having respective helical screw surfaces extending substantially an entire distance between respective insertion and opposite portions to facilitate removal of the clip after the bone tissue fragments have fused. The improved clip may be made of any biocompatible material, including shape memory alloys, such as Nitinol. The insertion tool is improved to apply force at the bridging tips of either a stepped on a non stepped clip.

Owner:MEDICREA INT SA

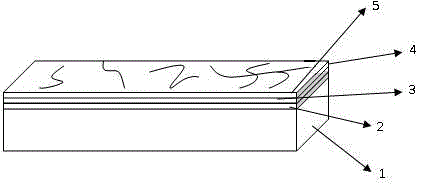

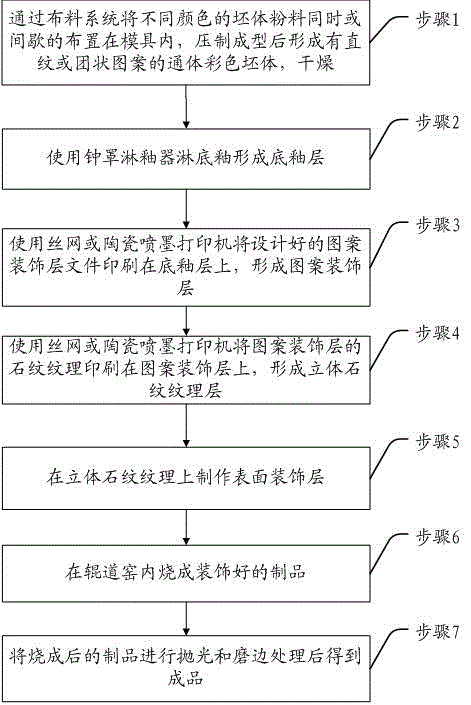

Whole-body polished porcelain tile having three-dimensional stone texture and production method of tile

The invention discloses a whole-body polished porcelain tile having three-dimensional stone texture and a production method of the tile. The tile comprises a whole-body colored blank layer, a ground coat layer, a pattern decoration layer, a three-dimensional stone texture layer and a surface decoration layer. The production method comprises steps as follows: 1) a whole-body colored blank is prepared; 2) the ground coat layer on the blank surface is formed; 3) the pattern decoration layer is formed; 4) ink or glaze having a dent effect is applied to the pattern decoration layer, a pattern corresponds to pattern texture of the decoration layer, and the three-dimensional stone texture layer is formed; 5) the surface decoration layer is formed; 6) a roller kiln is formed through sintering; 7) a finished product is obtained through polishing, edging and packaging. The surface color of the product produced with the scheme is integrated with the color of the blank, the stone texture changes naturally with the pattern texture of the product, the texture layer is protected by the surface decoration layer, and the tile has the decoration effect of natural stone. Properties of the product are superior to those of the natural stone, mining of the natural stone can be effectively reduced, and the natural environment is protected.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

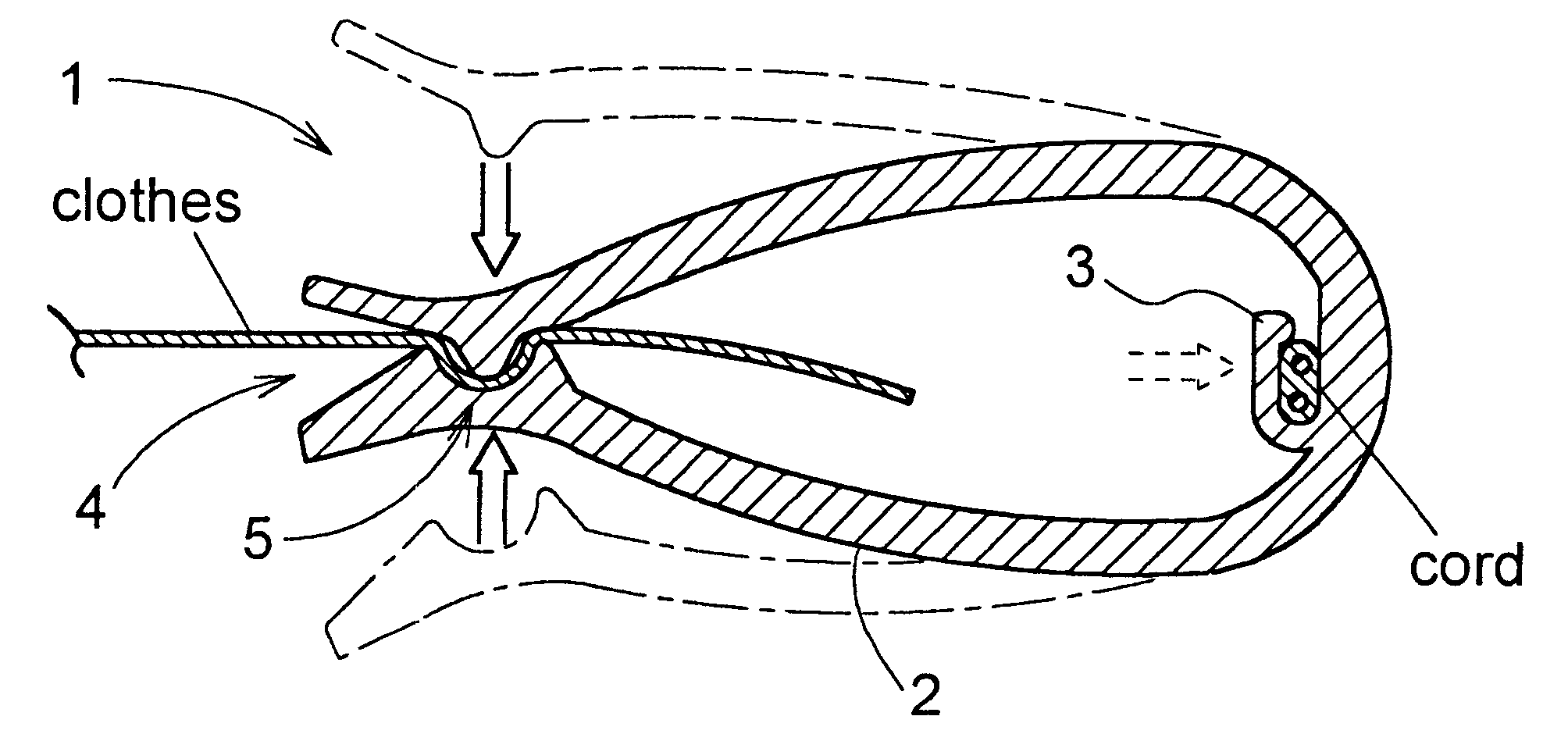

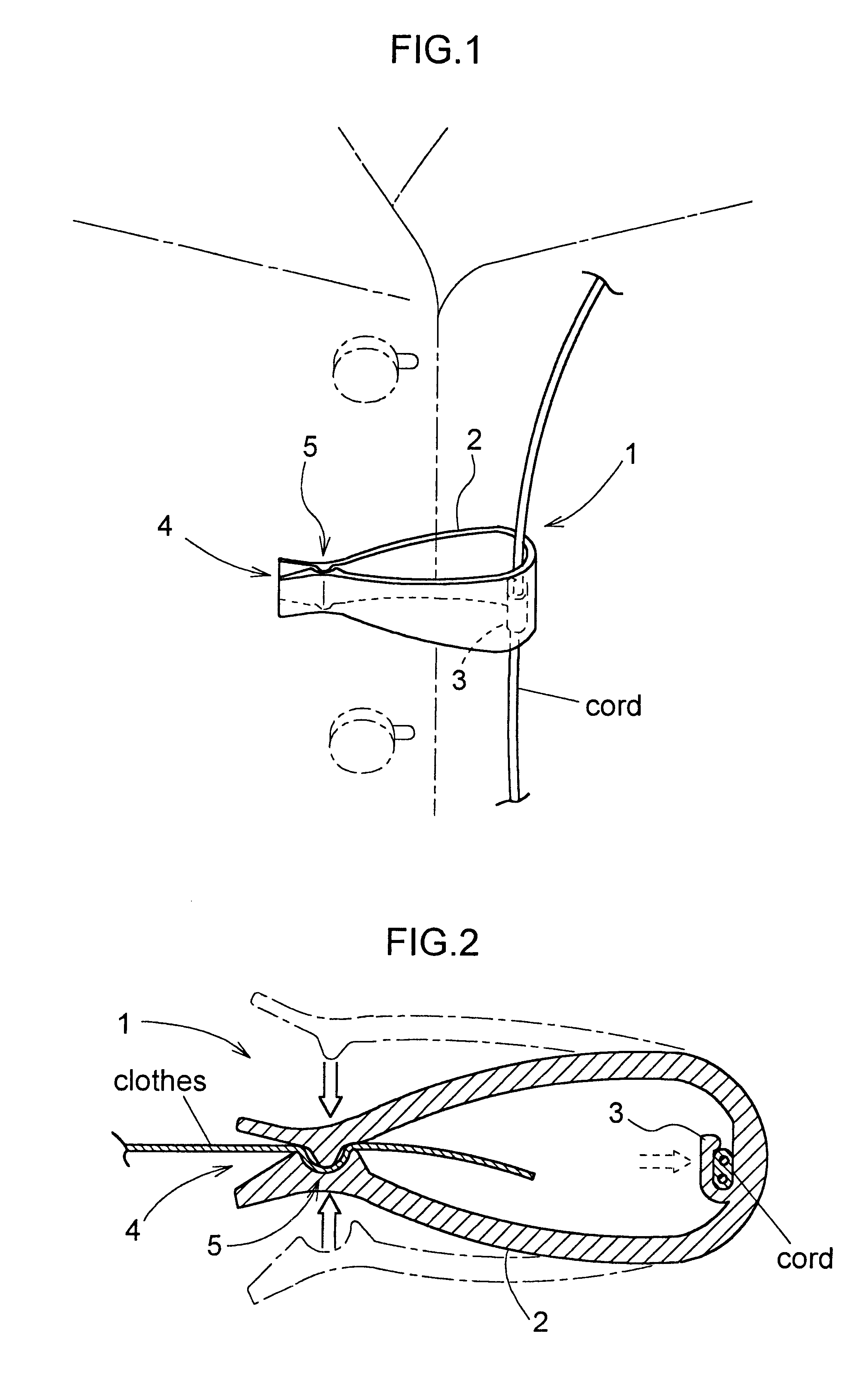

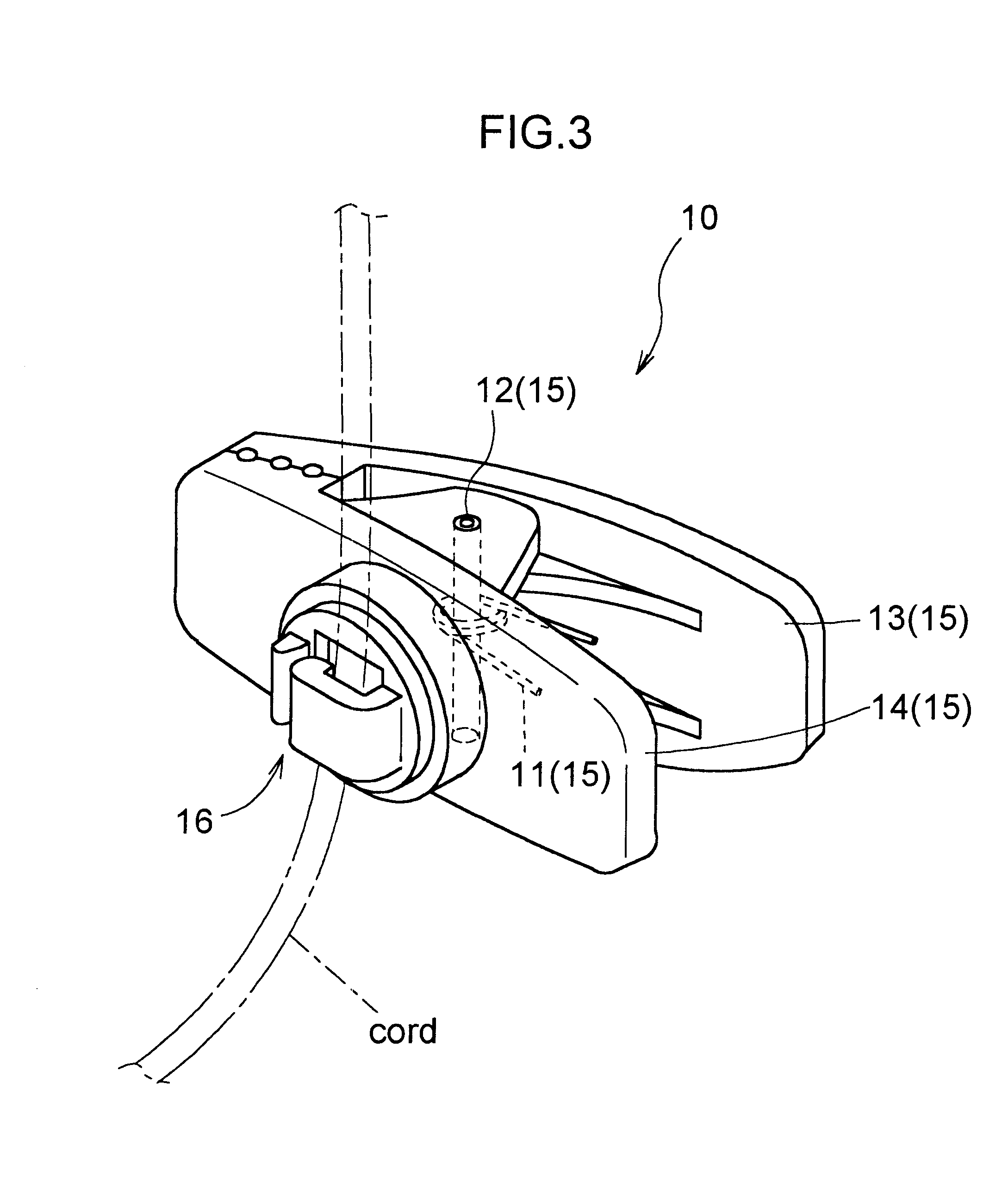

Cord clip

InactiveUS6526635B2Avoid mutual interferenceReduce part costSnap fastenersTravelling carriersEngineeringMechanical engineering

A cord clip for fastening a cord attached to e.g. an earphone to an object such as a clothes is disclosed. The cord clip includes a clipping portion for clamping the object and a cord holding portion for holding the cord. The clipping portion is formed by a first annular portion having a discontinuity at a part thereof. The clipping portion is capable of clamping the object at a clamping portion thereof provided by a narrow gap formed by the discontinuity of the first annular portion by means of an elastic resilient force of the first annular portion. The cord holding portion is formed by a second annular portion having a discontinuity at a part thereof. The cord holding portion is capable of holding the cord therein by means of an elastic resilient force of the second annular portion. This elastic resilient force of the second annular portion is independent of that of the first annular portion. The first annular portion and the second annular portion are formed integrally in a single member.

Owner:HOSIDEN CORP

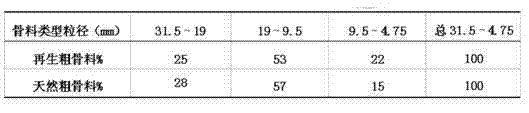

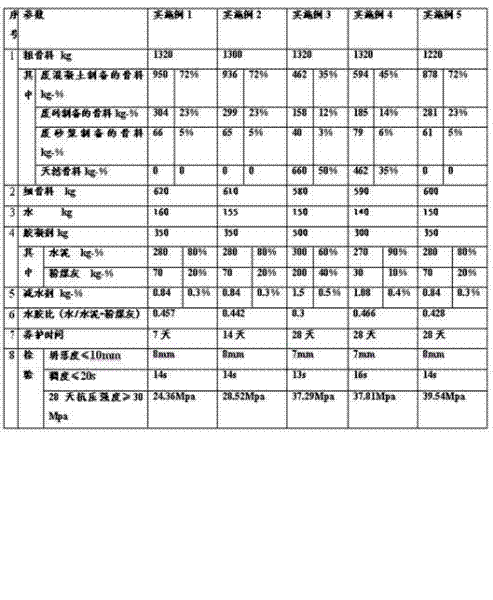

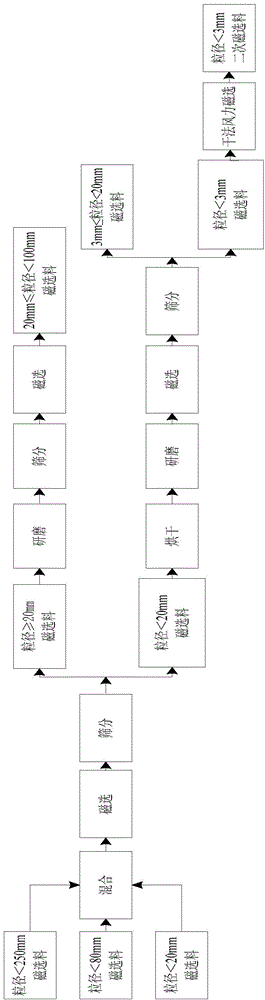

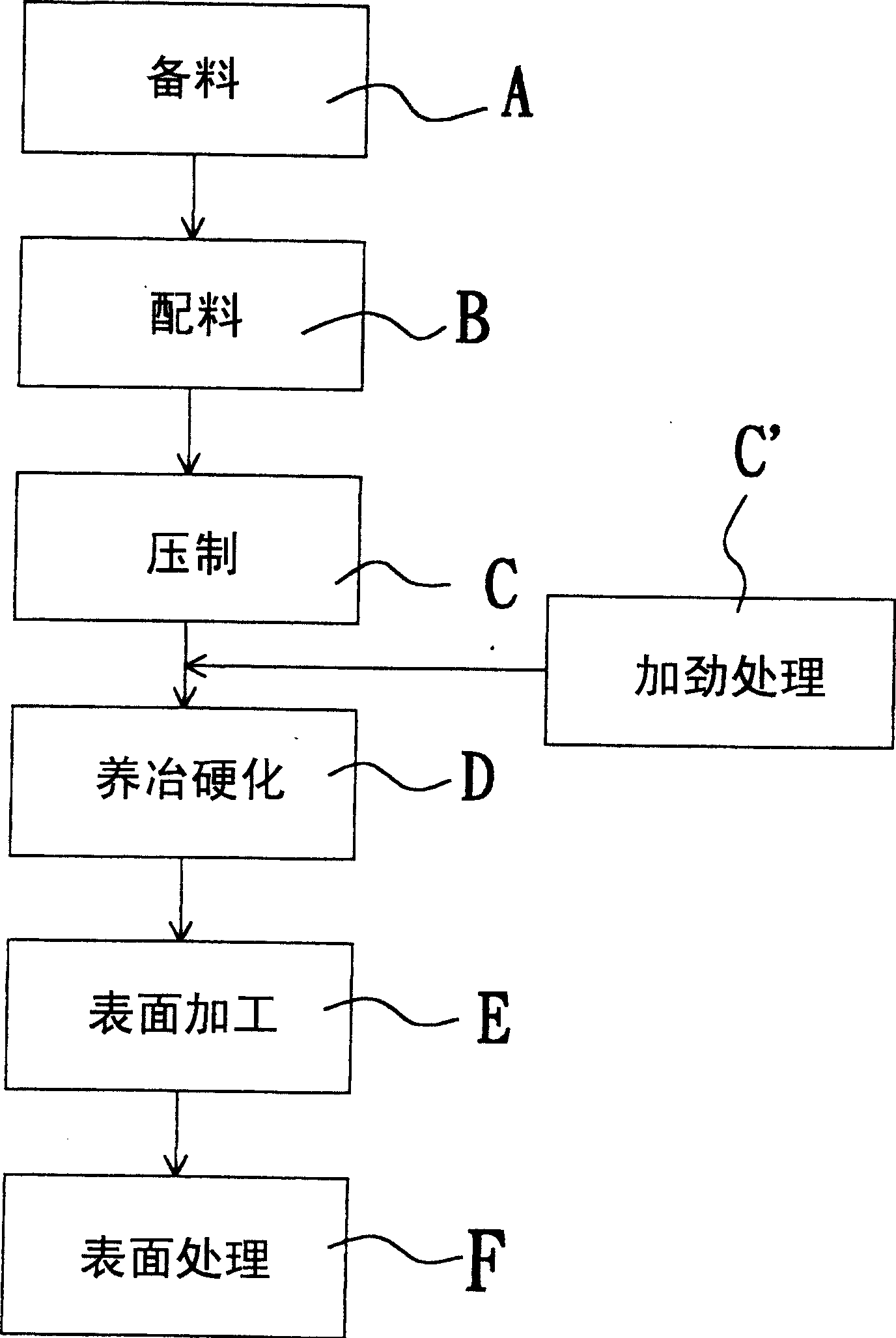

Recycled aggregate medium-dry hard concrete prepared by using building waste and preparation method of recycled aggregate medium-dry hard concrete

The invention discloses a recycled aggregate medium-dry hard concrete prepared by using building waste, which comprises the following raw materials of coarse aggregate, fine aggregate, a gelatinizing agent, a water reducing agent and water, wherein the gelatinizing agent comprises cement and coal ash, and the coarse aggregate comprises 50-100 percent of recycled coarse aggregate prepared from thebuilding waste. A preparation method of the recycled aggregate medium-dry hard concrete comprises the following steps of: pretreating the building waste, removing impurities, remaining waste concrete, waste bricks and the like; crushing and screening to prepare the recycled coarse aggregate; mixing the recycled coarse aggregate, natural sand, cement and water according to the proportion, adding the coal ash and the water reducing agent, stirring uniformly to obtain a mixture; and squeezing and forming the mixture, curing for 2 days to obtain the recycled aggregate medium-dry hard concrete. The invention solves the problems of worsening ecological environment and the like caused by difficulty in treating the building waste; and the building wastes are used for manufacturing the recycled aggregate for replacing natural aggregate, the increasingly deficient natural aggregate and damage degree to the ecological environment are reduced, and the living environment of human beings is protected. The recycled aggregate medium-dry hard concrete prepared by using the method has high strength and high abrasive resistance, and can be used for building base installations such as city roads, housing constructions and the like.

Owner:云南华威废弃物资源化有限公司

Geo-polymer recycled concrete and preparation method thereof

InactiveCN101570426ADelayed activationImprove liquiditySolid waste managementCement productionRoad engineeringSlag

The invention belongs to the fields of civil engineering and environmental material engineering, and in particular relates to geo-polymer recycled concrete and a preparation method thereof. The geo-polymer recycled concrete is prepared from raw materials of recycled coarse aggregate, recycled fine aggregate, fly ash, slag powder, water, sodium silicate, sodium hydrate, naphthalene sulfonate formaldehyde condensation compound and calcium saccharate according to certain mixing proportion by adopting a special stirring process. The product of the geo-polymer recycled concrete not only has simple preparation process, but also has good working performance, mechanical property, durability and heat-insulating property. Simultaneously, the geo-polymer recycled concrete and the preparation method can efficiently use a great deal of waste concrete and two industrial byproducts of the fly ash and blast furnace slag, are significant in saving resources, saving energy sources and protecting the environment, and accord with the sustainable development strategy of the building industry. The product of the geo-polymer recycled concrete can be widely applicable to road engineering, structural engineering and other various civil engineering constructions.

Owner:TONGJI UNIV

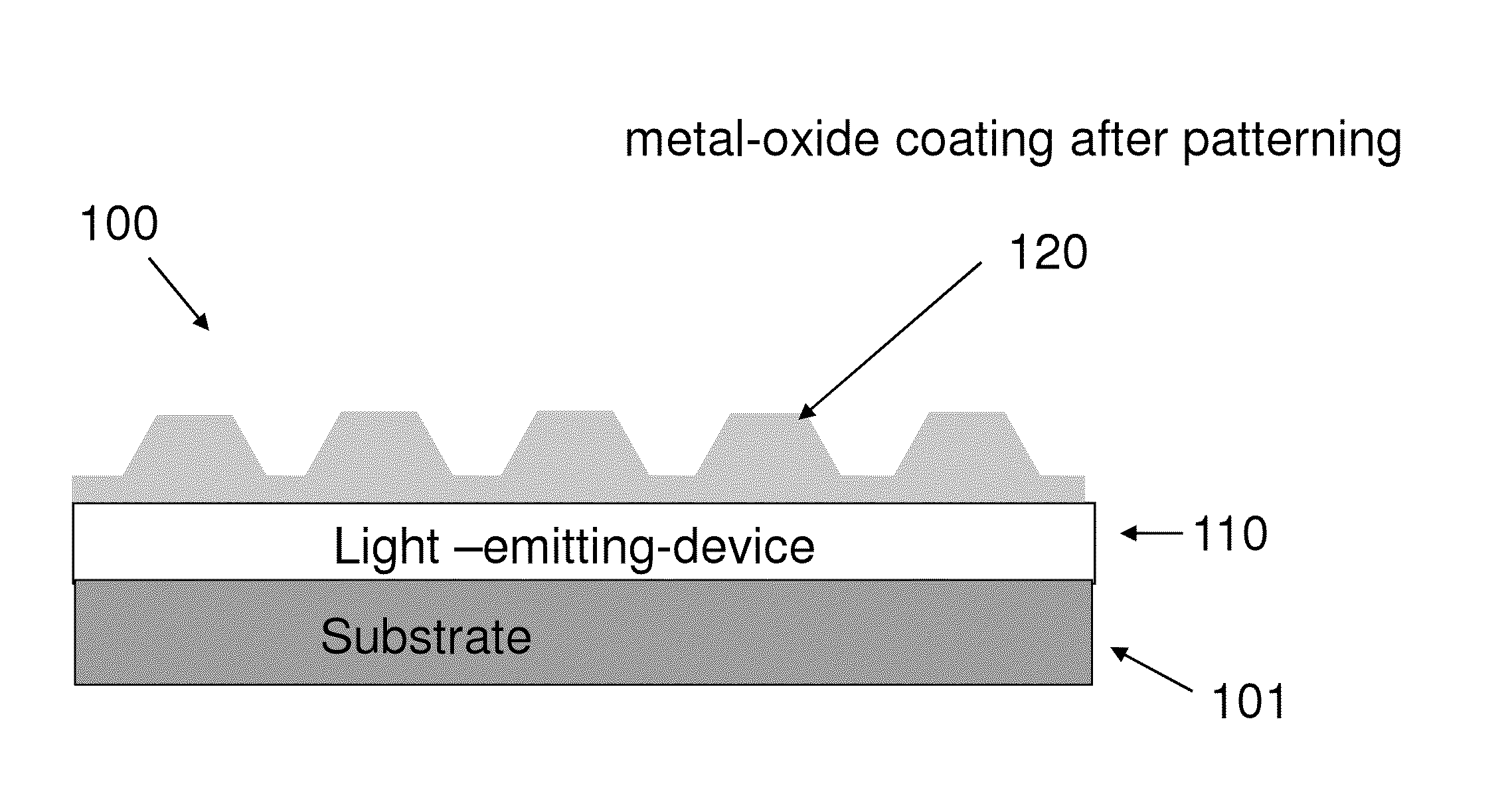

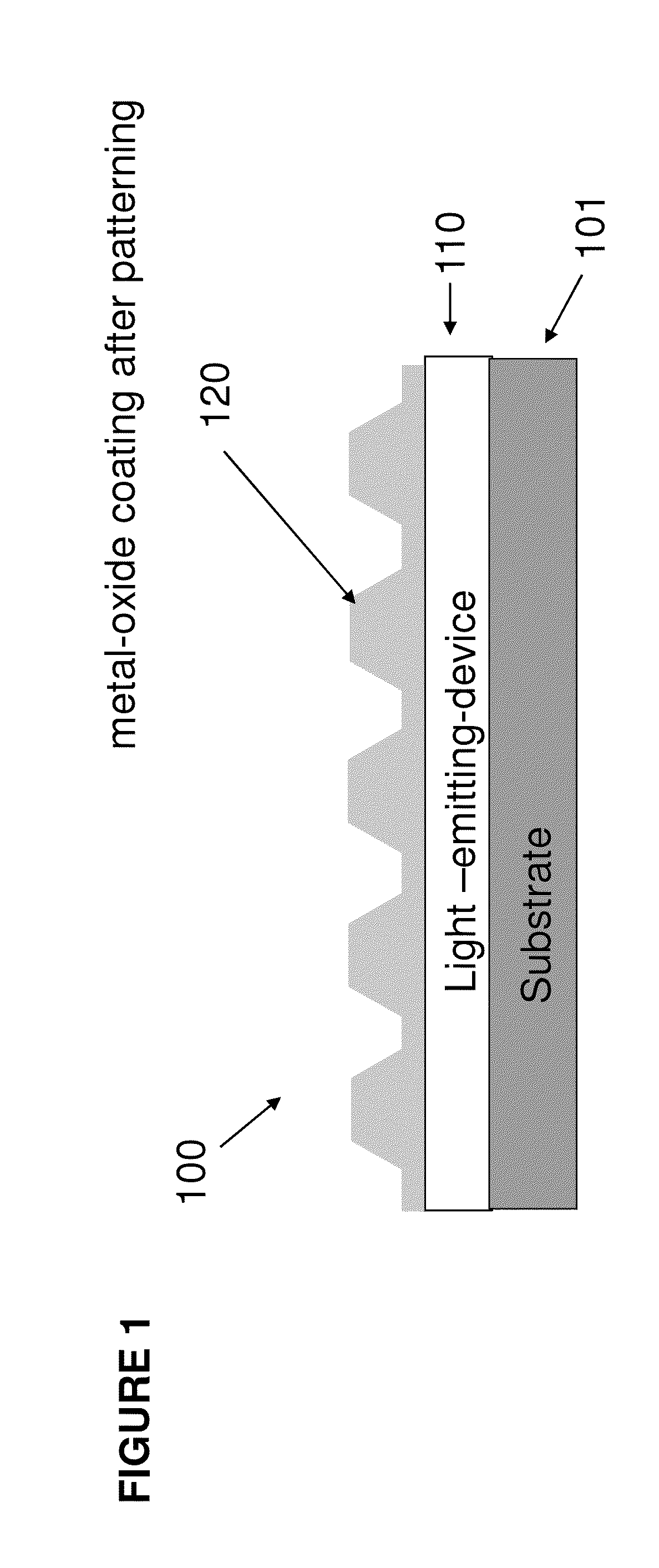

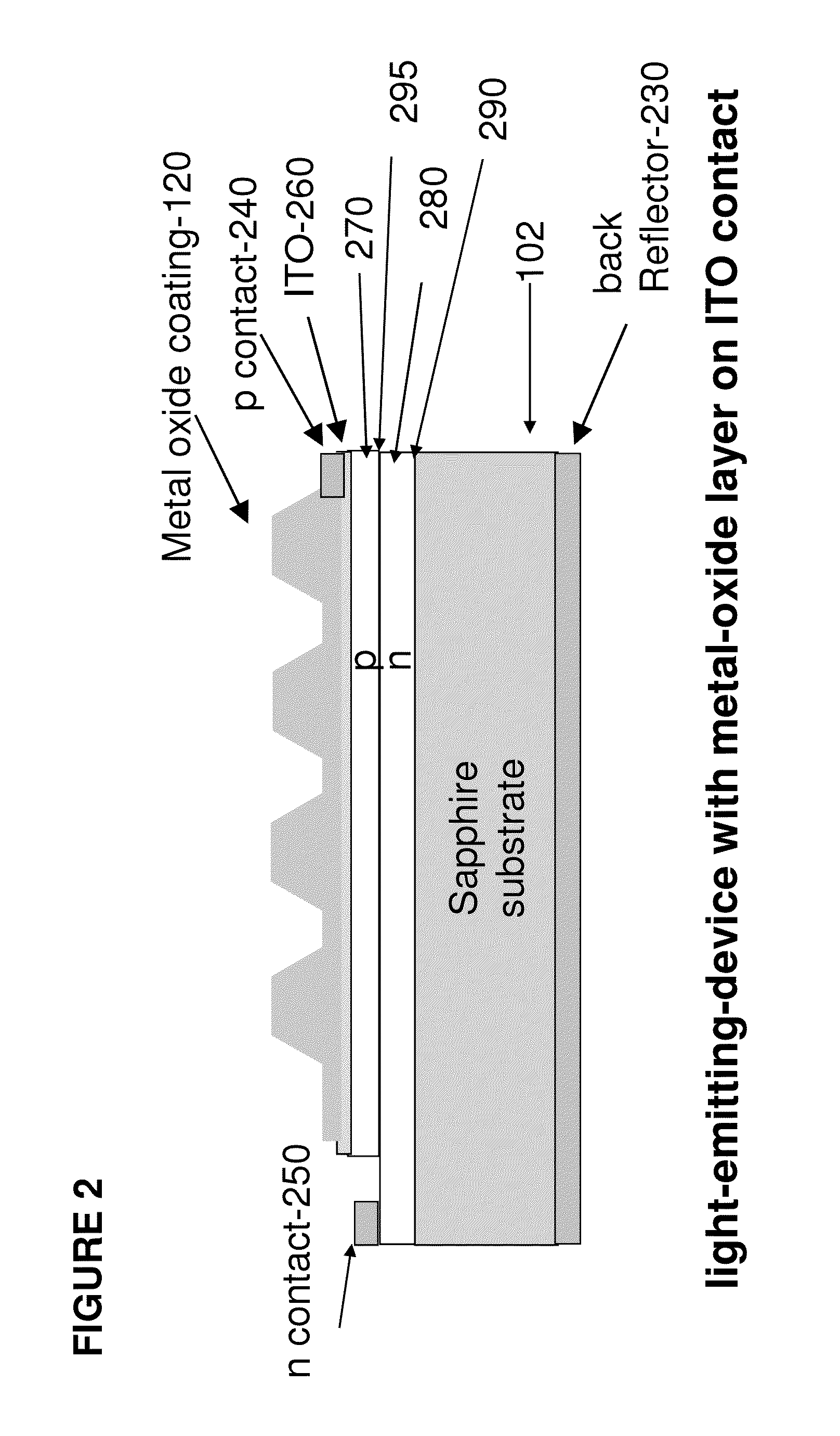

Light emitter with metal-oxide coating

InactiveUS20130228808A1Improve light outputLow costSemiconductor devicesRefractive indexProtection layer

A light emitting device based on a AlInGaN materials system wherein a coating is used to improve the extraction of light from a device. A coating has a very low optical loss and an index of refraction greater than 2. In a preferred embodiment the coating is made from Ta2O5, Nb2O5, TiO2, or SiC and has a thickness between about 0.01 and 10 microns. A surface of a coating material may be textured or shaped to increase its surface area and improve light extraction. A surface of the coating material can also be shaped to engineer the directionality of light escaping the layer. A coating can be applied directly to a surface or multiple surfaces of a light emitting device or can be applied onto a contact material. A coating may also serve as a passivation or protection layer for a device.

Owner:KK TOSHIBA

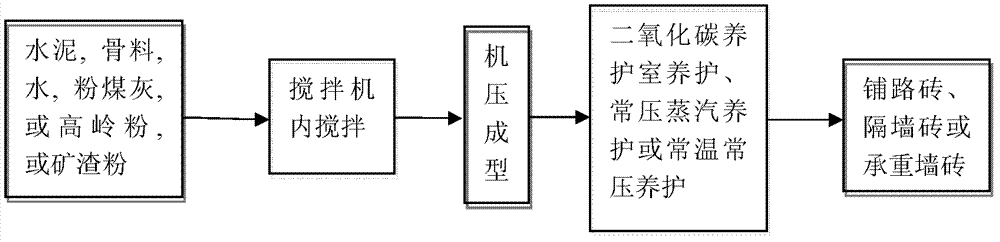

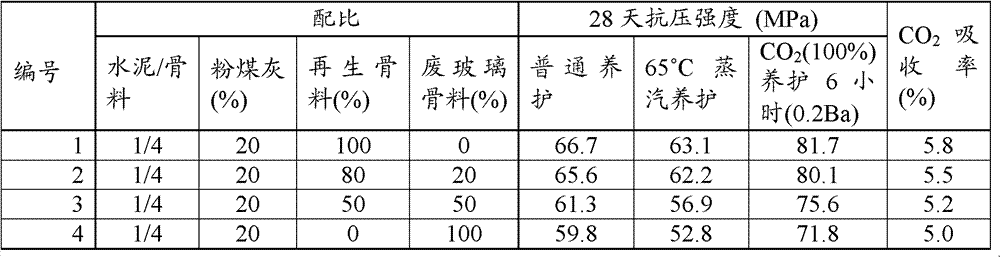

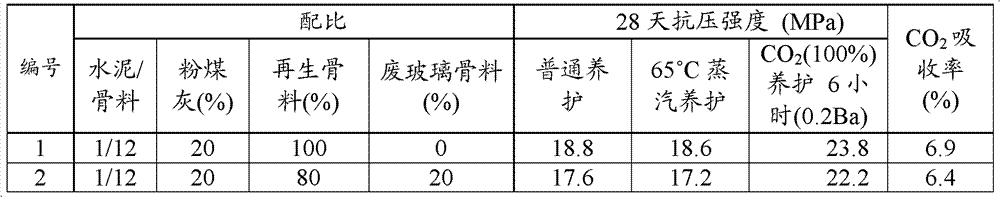

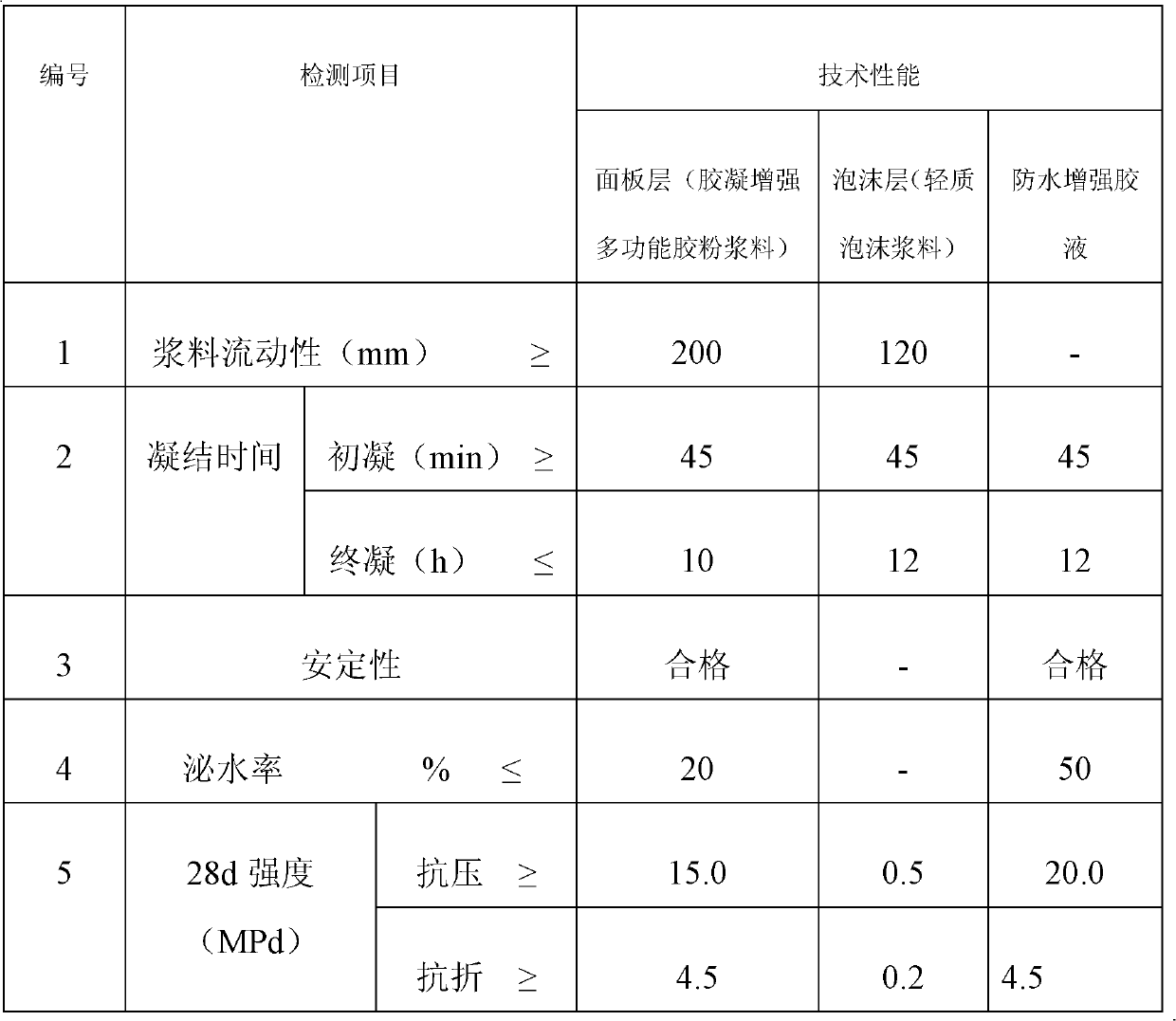

Method for preparing concrete brick

The present invention relates to a method for preparing concrete bricks. The concrete bricks are produced by using cement, aggregate, and fly ash or slag powder, kaolin powder or slag powder, blending through a blender and then pressing by a molding machine. The bricks are then fed into a carbon dioxide curing room for maintenance or are maintained at ambient pressure and room temperature or atmospheric pressure steam. The used aggregate includes recycled aggregates and cullet aggregates, and also may include sand or pebbles. The concrete bricks provided by the present inventions can be made into paving bricks, partition wall bricks and load bearing wall bricks due to different proportions. The performance of the concrete bricks fully meets the standard requirements. The concrete bricks have a good function of absorbing carbon dioxide.

Owner:THE HONG KONG POLYTECHNIC UNIV

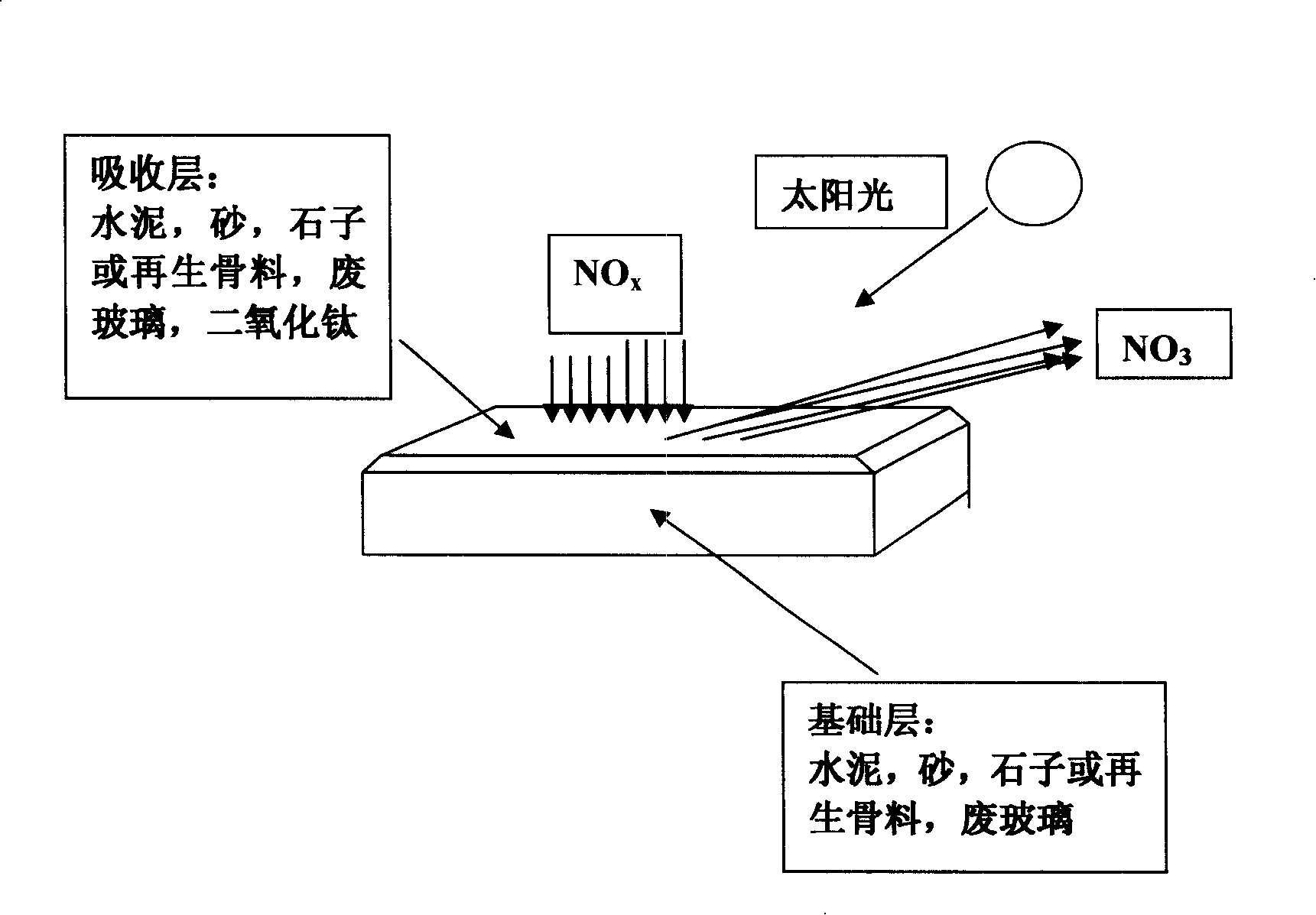

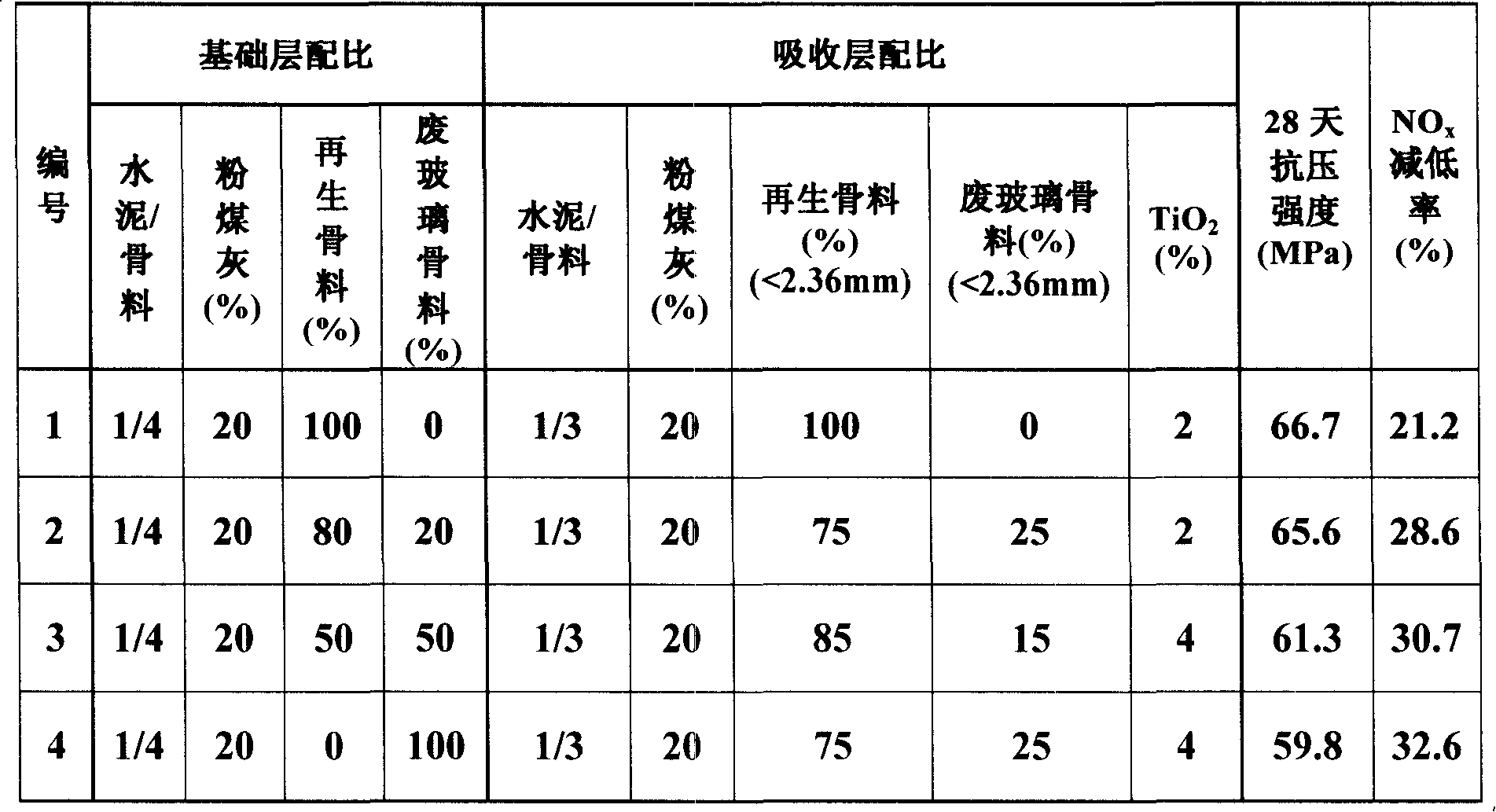

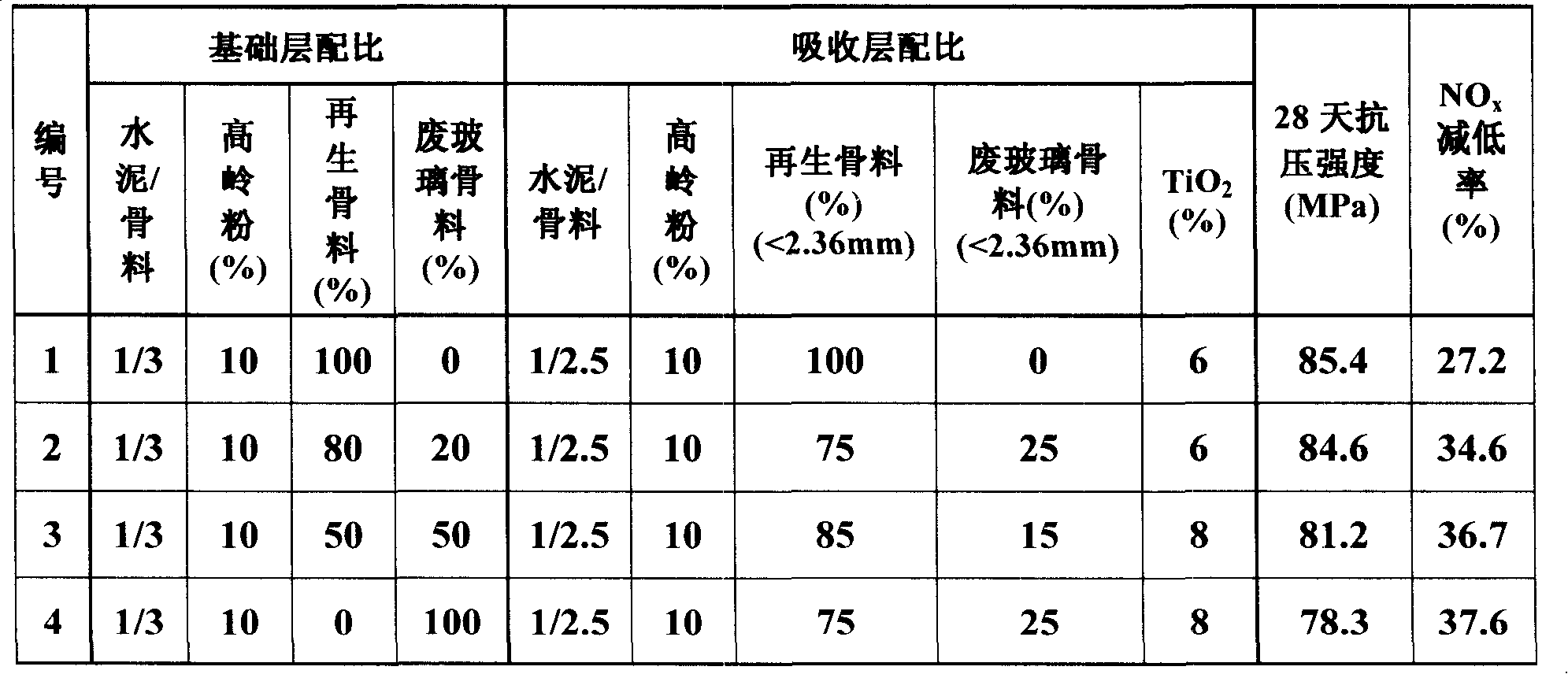

Concrete paving brick capable of purifying air and method for manufacturing the same

The invention provides a concrete paving brick capable of clarifying air produced by using building waste and recycled glass and the manufacturing method thereof. The paving brick comprises an absorption layer and a foundation layer, the absorption layer comprises cement, aggregate, titanium oxide and coal ash or kaolinite powder, the aggregate of the absorption layer comprises recycled aggregate, waste glass aggregate and sand or stones; the foundation layer comprises cement, aggregate and coal ash or kaolinite powder, the aggregate of the foundation layer comprises recycled aggregate, waste glass aggregate and sand or stones. The paving brick of the invention has good function of absorbing exhaust gas and good strength.

Owner:THE HONG KONG POLYTECHNIC UNIV

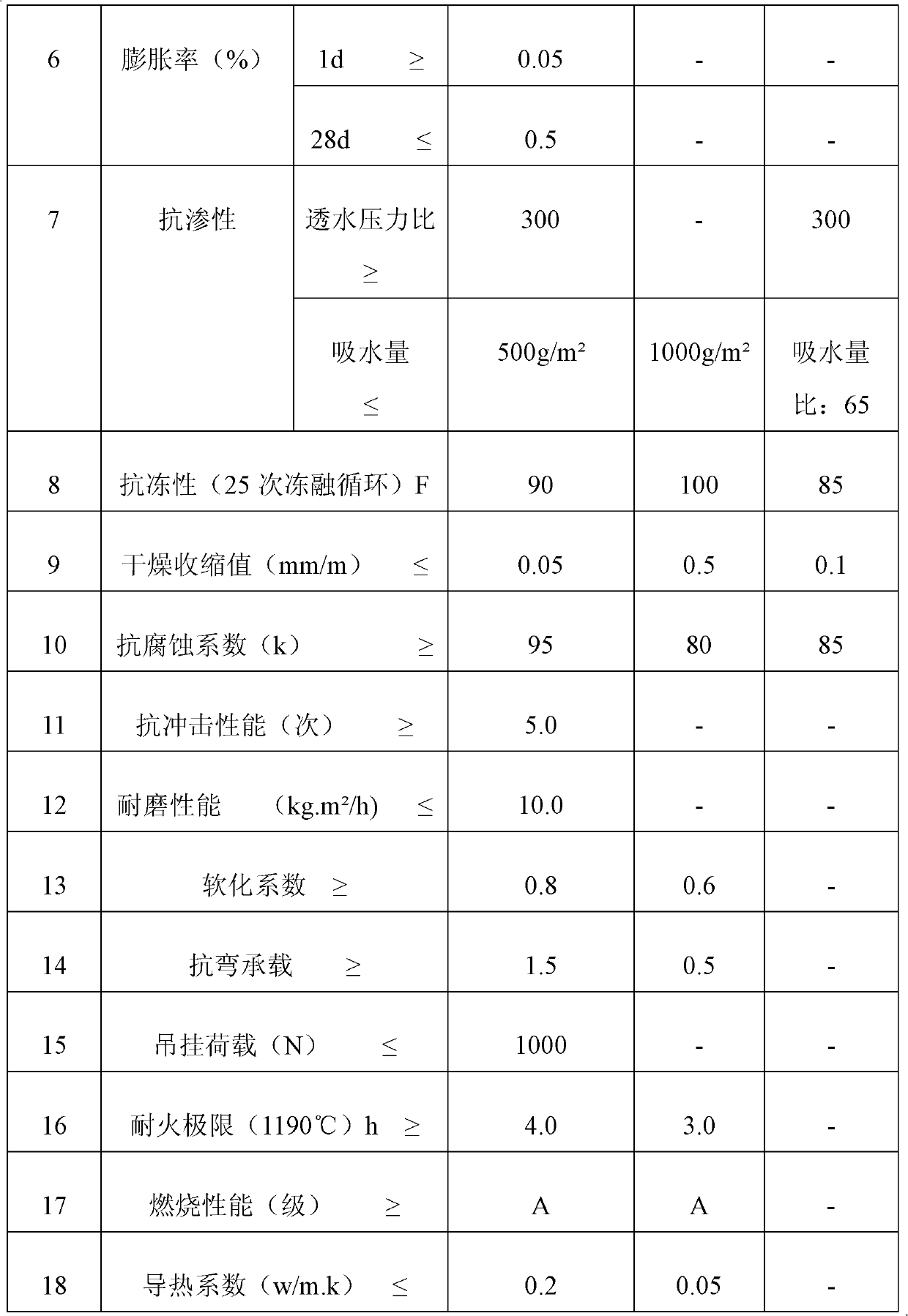

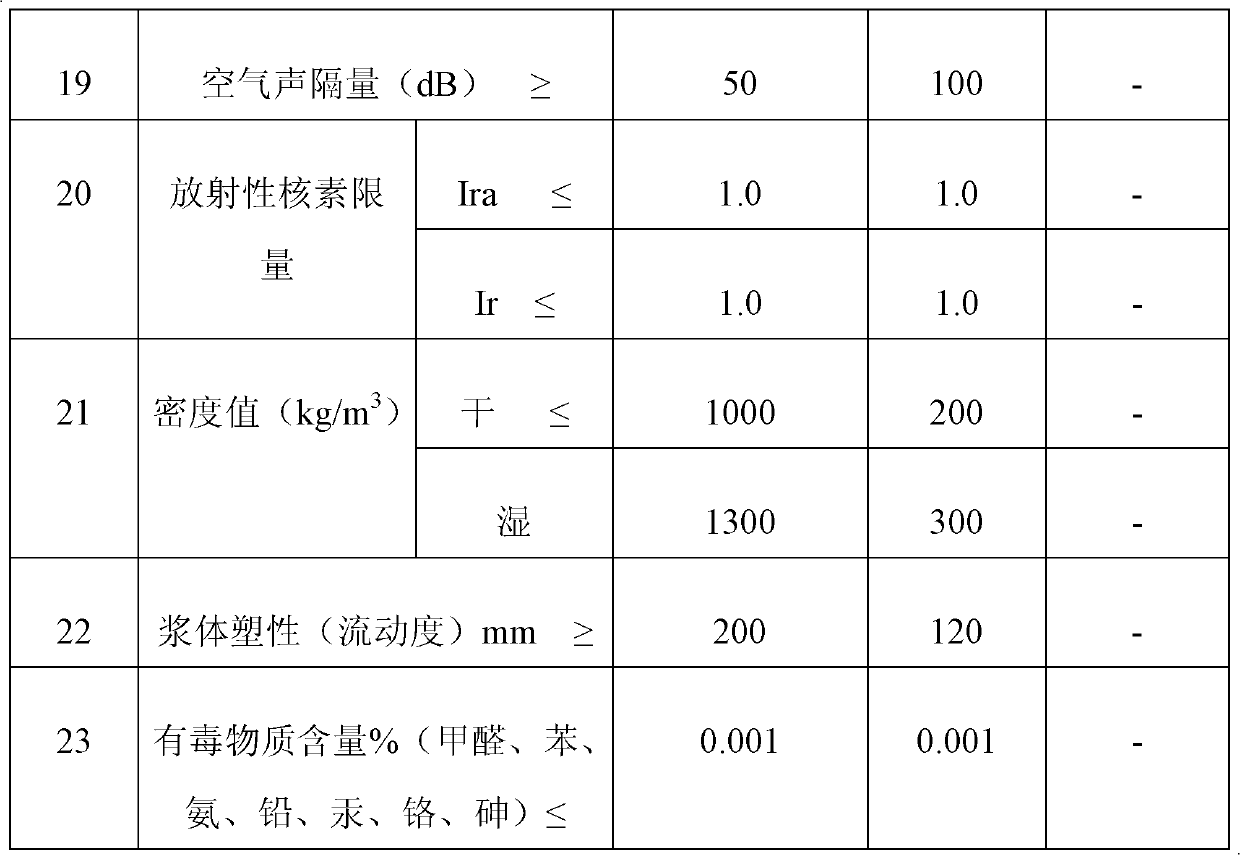

Multifunctional inorganic thermal insulation material composition, product comprising same and preparation method of product

The invention provides a multifunctional inorganic thermal insulation material composition, a multifunctional inorganic thermal insulation material product prepared from the multifunctional inorganic thermal insulation material composition and a preparation method of the multifunctional inorganic thermal insulation material product. By substantially utilizing industrial and construction wastes as a gel enhancement and inorganic thermal insulation system and adding a little amount of cement as well as a proper amount of regulator, the multifunctional inorganic thermal insulation material composition is molded in a casing mode by one step, thereby forming a wall plate, a block material (wall materials decorated by wall floor tiles) and a roof. Therefore, the wall body, the block material and the roof have the multifunction and the characteristics of thermal insulation, fire prevention, water resistance, freezing resistance, crack resistance, sound insulation, light weight, corrosion resistance, weather resistance, decoration, energy conservation, environmental friendliness, safety, sanitation, work saving, time saving, cost saving and the like.

Owner:苏琳

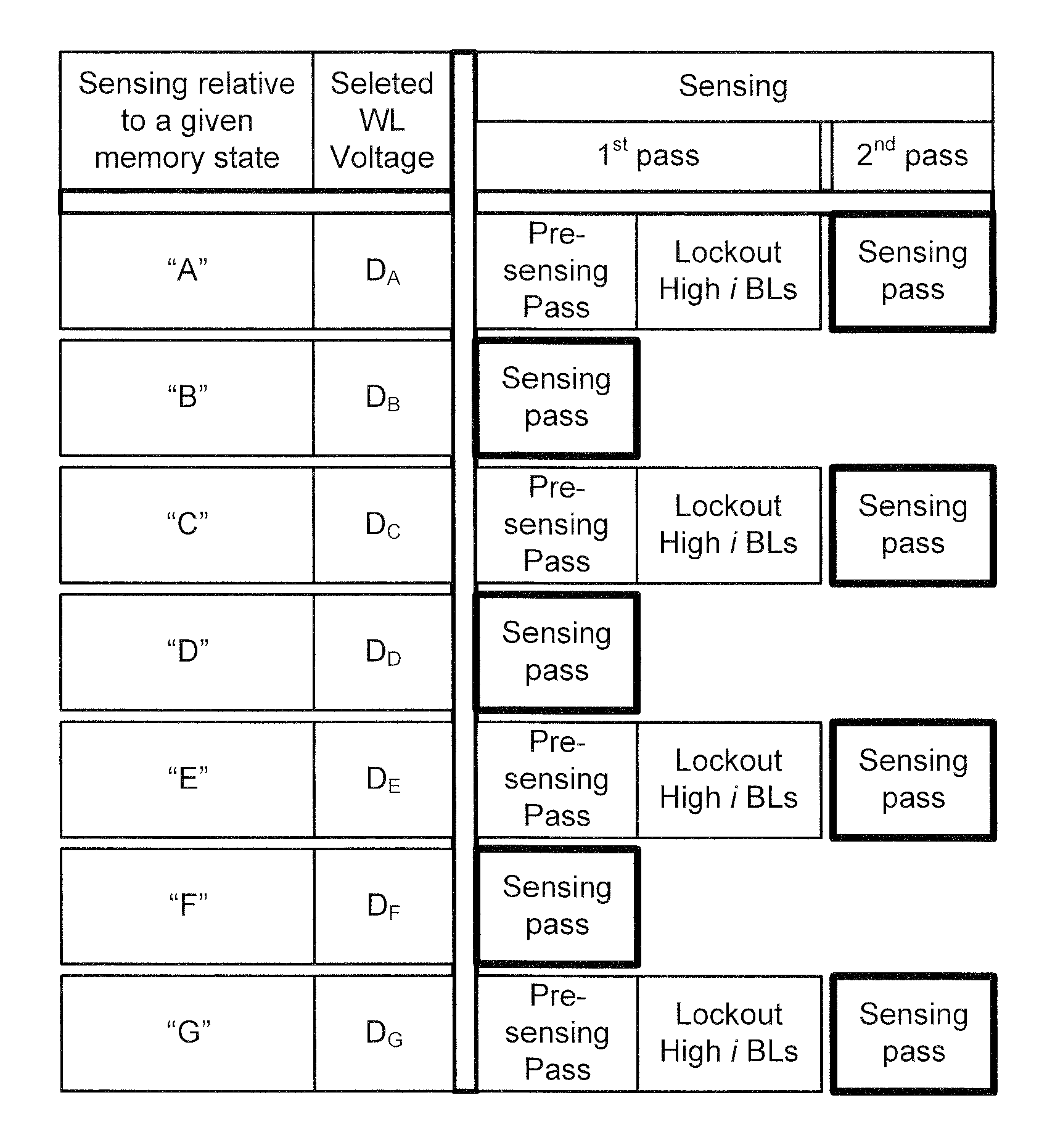

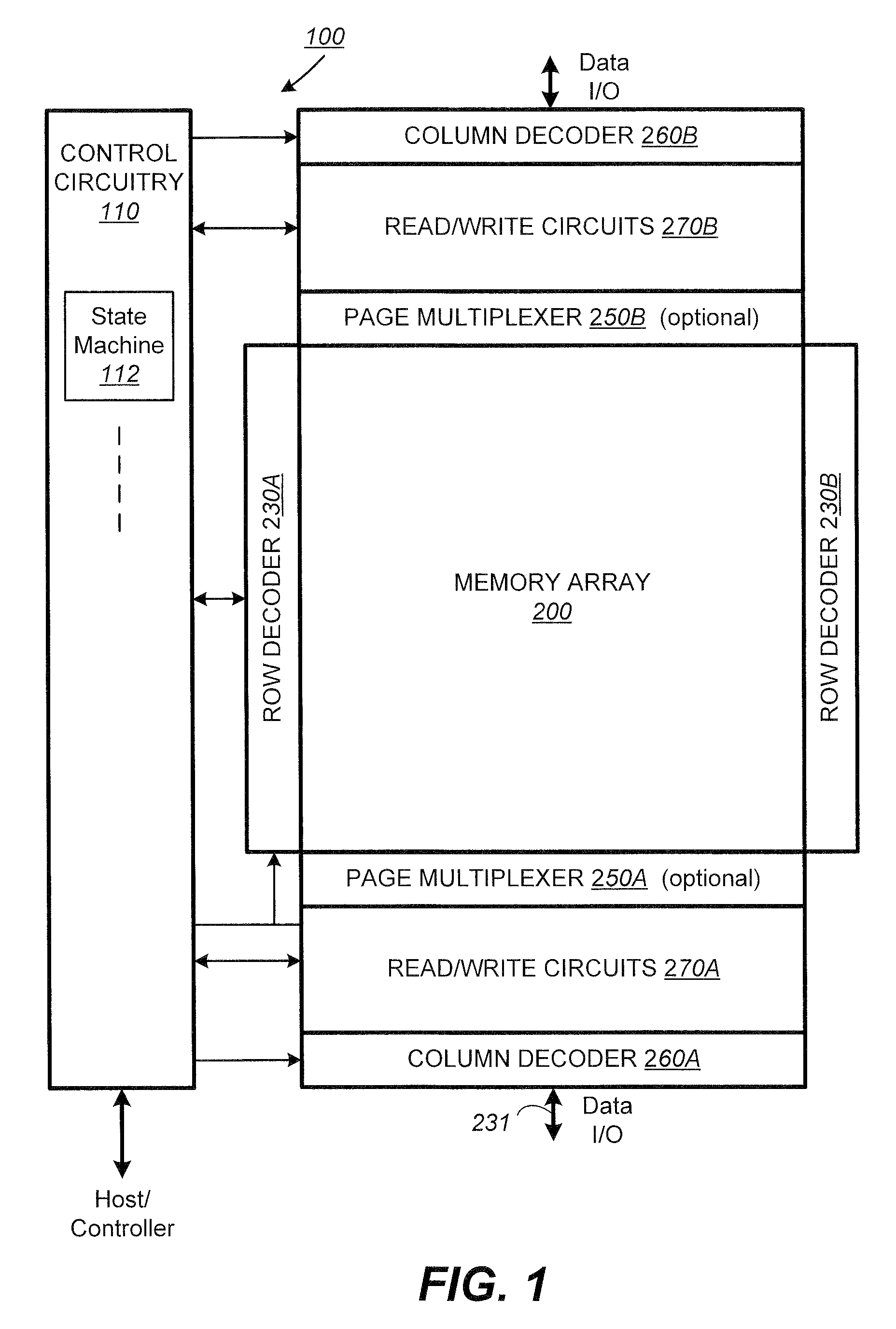

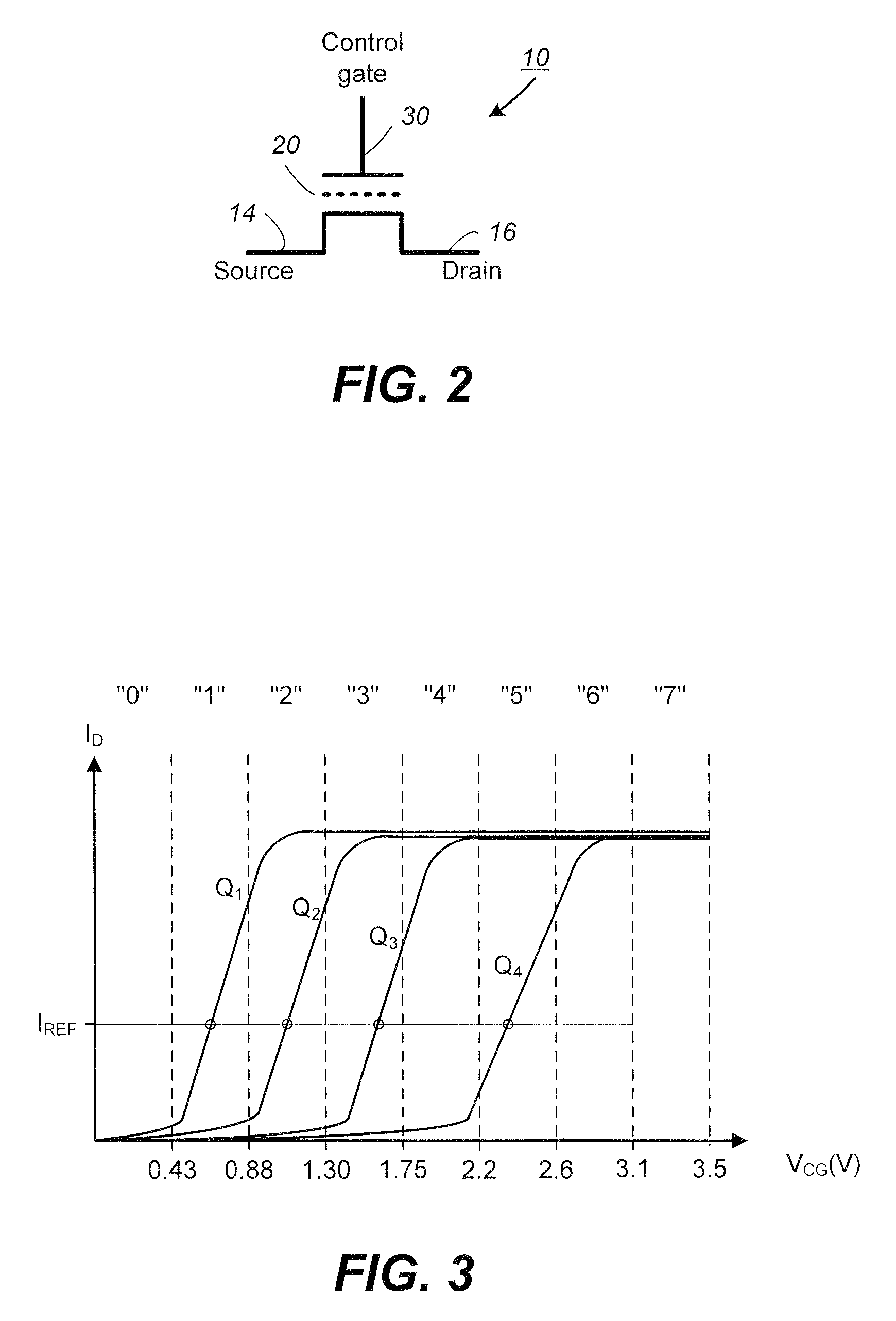

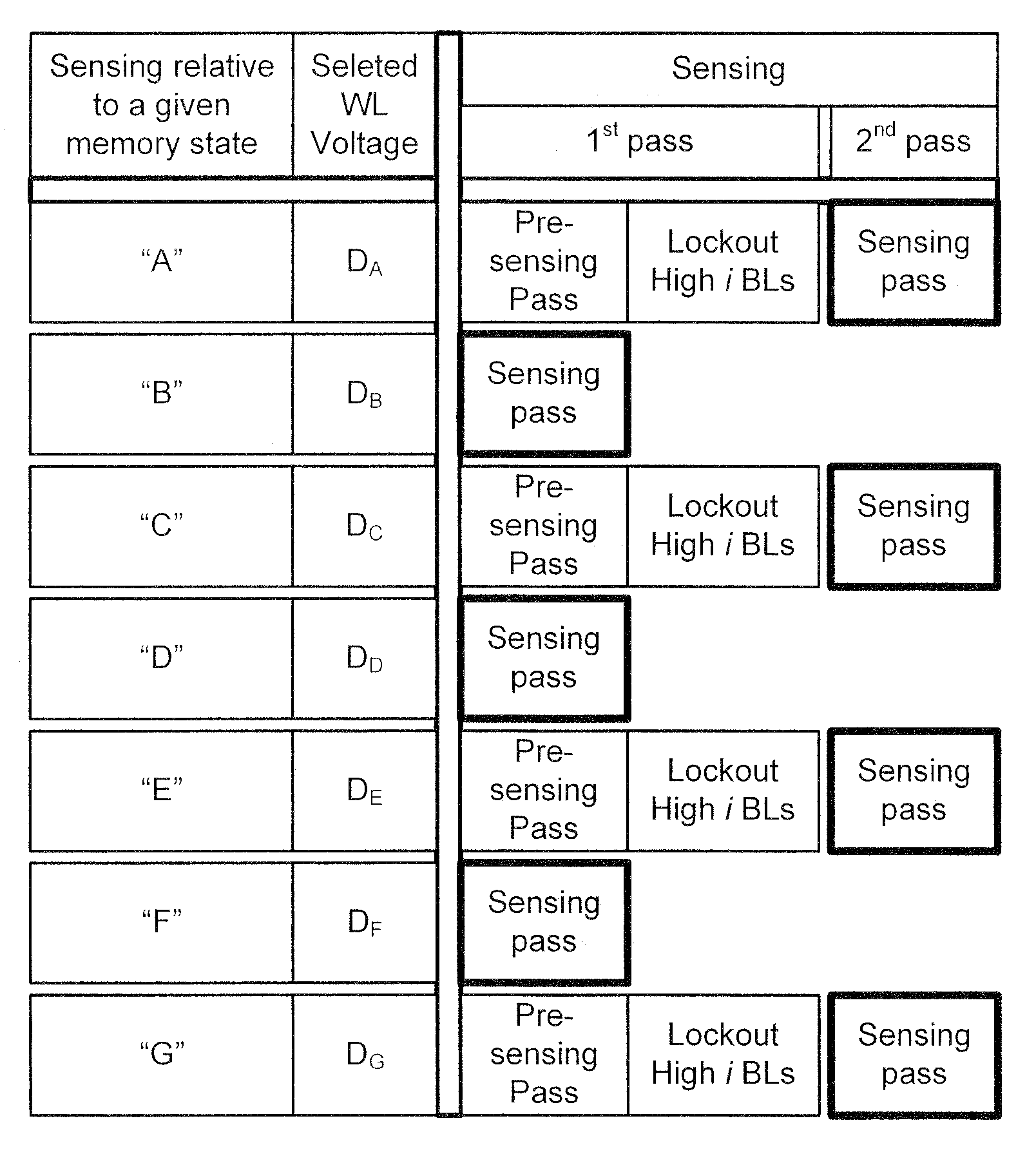

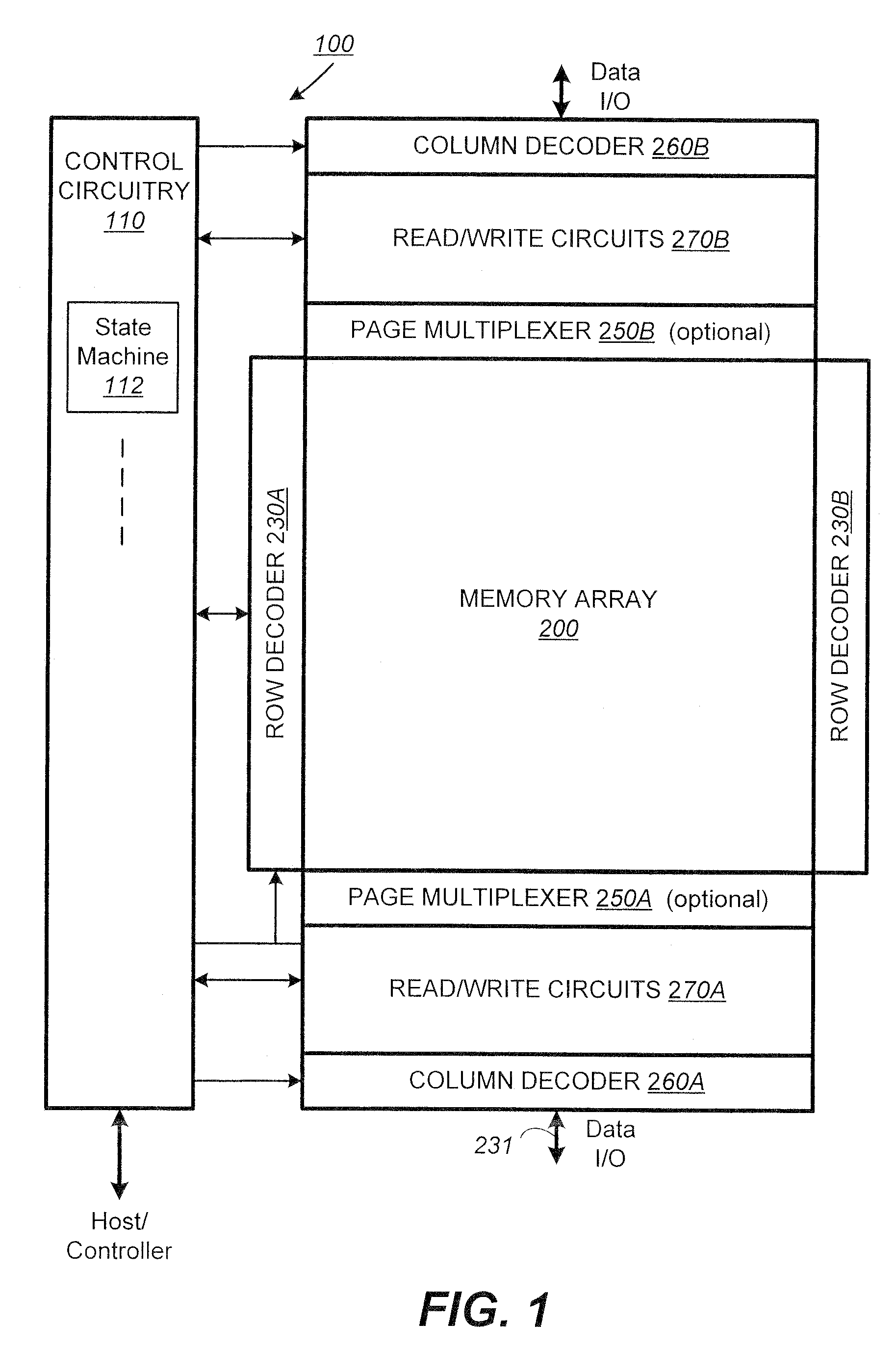

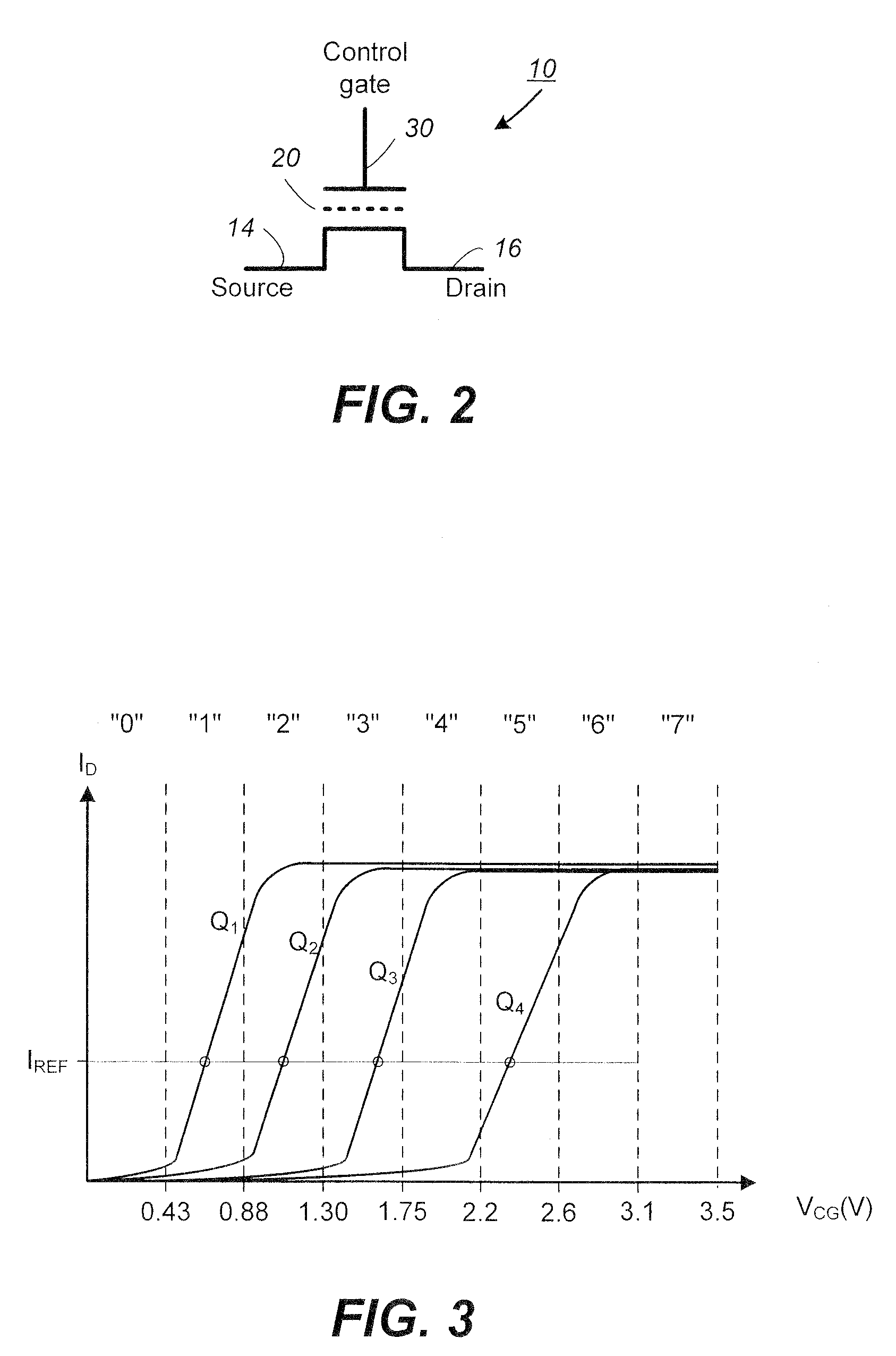

Sensing with bit-line lockout control in non-volatile memory

ActiveUS7492640B2Improve Sensing PerformanceReduce noiseRead-only memoriesDigital storageBit lineEngineering

Owner:SANDISK TECH LLC

Imitated wild gastrodia elata cultivation method through sexual propagation

The invention discloses an imitated wild gastrodia elata cultivation method through sexual propagation. The imitated wild gastrodia elata cultivation method comprises the steps of the preparation of fallen leaves and cut logs, the cultivation of germinating bacteria and armillariella twigs, the preparation of seeds, land selection and preparation, seeding, field management and harvesting. According to the cultivation method disclosed by the invention, forest resources are fully utilized to develop under-forest resources so as to harvest under-forest non-wood products, and therefore forest vegetation destruction is reduced; as the method adopts a growing environment the same as wild gastrodia elata, geoherbalism of the cultivated gastrodia elata is ensured, the excavation of wild gastrodia elata is also reduced, and therefore wild gastrodia elata resources are effectively protected.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

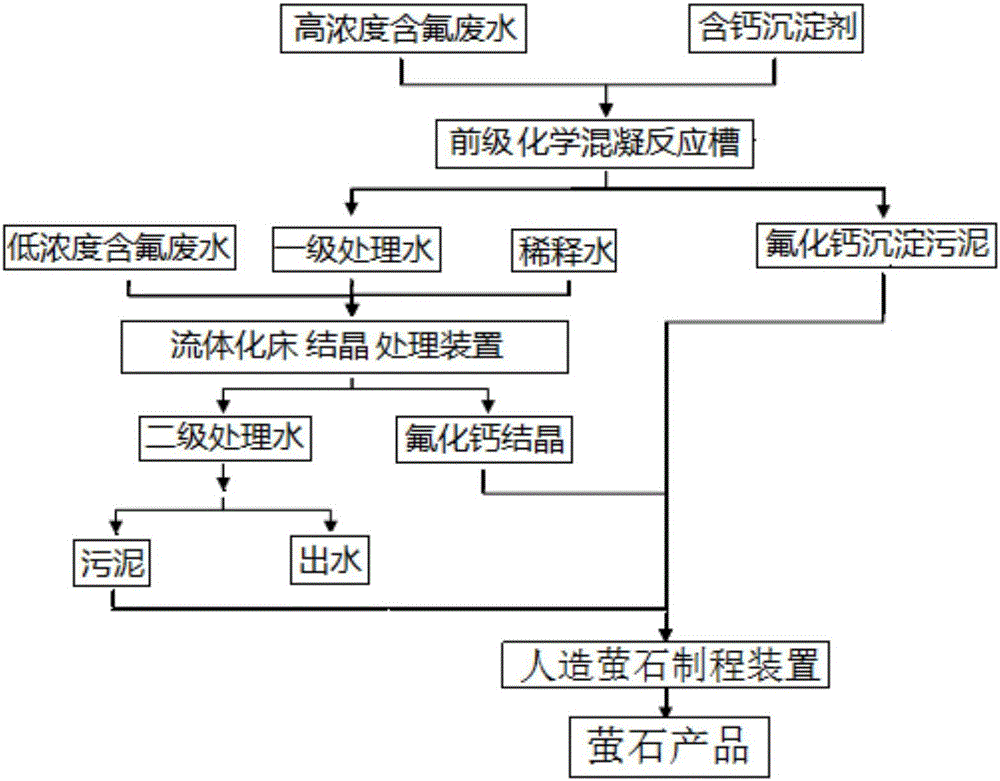

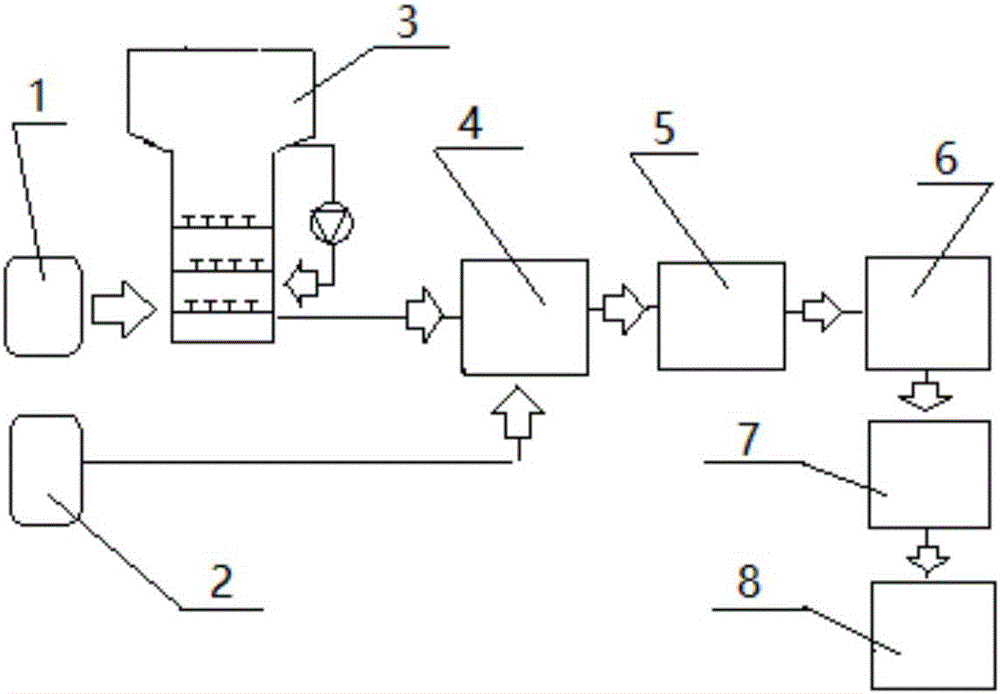

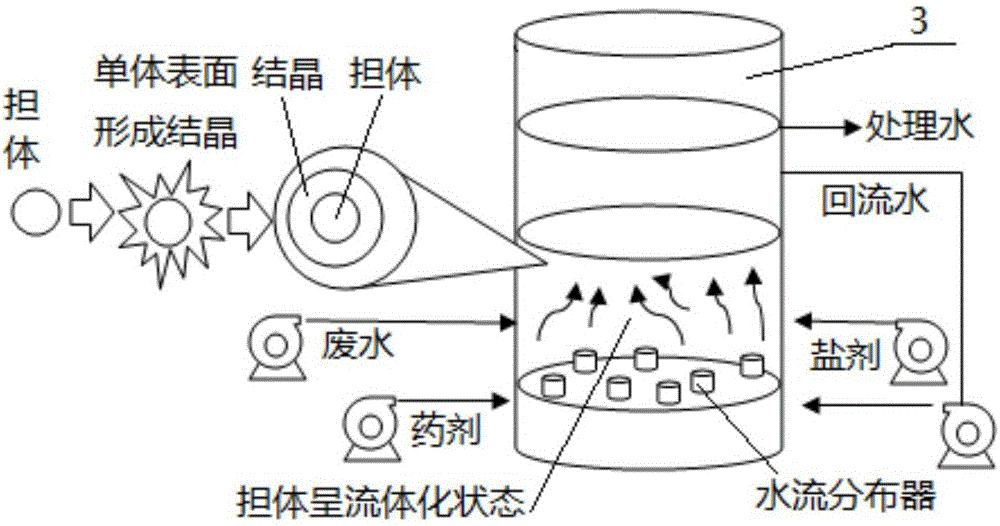

Process for preparing high-purity artificial fluorite by recovering fluoride-containing wastewater

ActiveCN105905933ASolve pollutionAvoid wastingCalcium/strontium/barium fluoridesWater contaminantsHigh concentrationPollution

According to a process for preparing high-purity artificial fluorite by recovering fluoride-containing wastewater, a fluidized bed serves as a crystallization treatment device, fluoride components in wastewater are efficiently extracted in a supporter crystallization mode, a high-purity calcium fluoride artificial fluorite product is prepared, fluoride-containing wastewater can be treated to reach the standard, no secondary pollution exists, the problems of land occupation and environment pollution of bottom mud produced during treatment of industrial fluoride-containing wastewater are solved, fluoride resources in the bottom mud are effectively used, circulation is short, operation is simple, implementation is easy, fluoride pollution and fluoride resource waste are reduced, and process efficiency is high; good balance can be achieved between making emission not exceed the standard and controlling wastewater treatment cost. Produced calcium fluoride crystals are suitable for preparing artificial fluorite to serve as the substitute of natural fluorite, calcium fluoride crystals produced in the technological process are low in water content, fluoride-containing waste reducing or resourceful using aim is effectively achieved, and the process is an environment-friendly method for treating high-concentration fluoride-containing wastewater and is wide in industrial application prospects.

Owner:KUNSHAN YANGCHENG LANGU ENVIRONMENTAL INST CO LTD

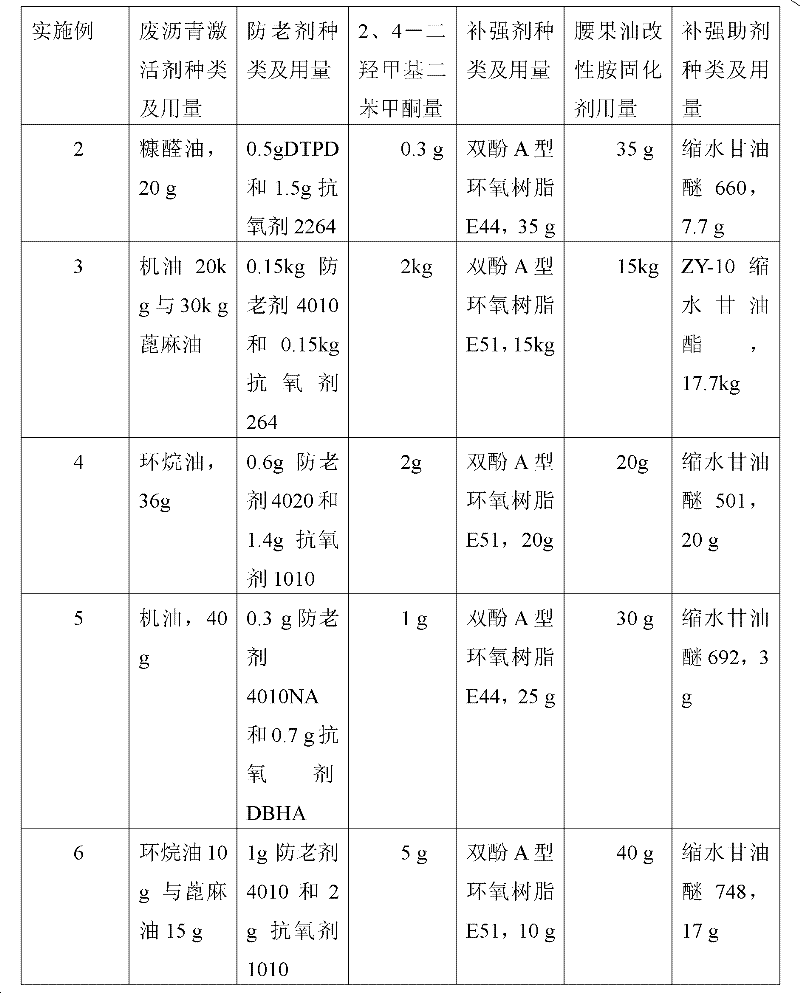

Asphalt cold recycling agent and preparation method thereof

ActiveCN102174267ANo pollution in the processImprove recycling ratesSolid waste managementBuilding insulationsCrack resistanceAntioxidant

The invention relates to an asphalt cold recycling agent, which is characterized by being prepared from a waste asphalt activator, an anti-aging agent, an ultraviolet absorbent, a reinforcing agent, a reinforcing curing agent and a reinforcing auxiliary agent serving as raw materials, wherein the waste asphalt activator consists of any one or more of engine oil, castor oil, naphthenic oil, aromatic hydrocarbon oil and furfural oil; the anti-aging agent is a mixture of an antioxidant and a p-phenylenediamine anti-aging agent; the ultraviolet absorbent is 2,4-dihydroxymethyl benzophenone; the reinforcing agent is bisphenol A epoxy resin E44 or E51; the reinforcing curing agent is a cashew nut oil modified amine curing agent; and the reinforcing auxiliary agent is a glycidyl ester epoxy active diluent. An asphalt recycled mixture prepared by adding the asphalt cold recycling agent into waste asphalt has high comprehensive performance, namely high bonding strength, high-temperature performance, low-temperature crack resistance and rheological performance, the actual service life of 8 years, and high aging resistance and weather resistance.

Owner:重庆市智翔铺道技术工程有限公司

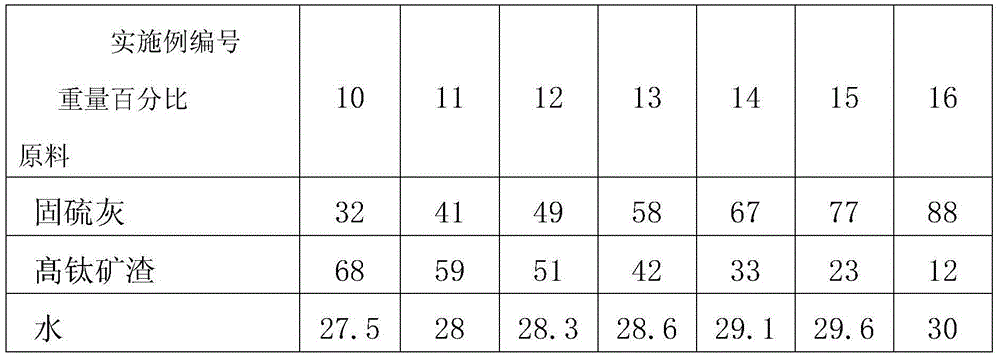

Fluidized bed combustion ash and high titanium slag compounded stable pavement base material

ActiveCN104003638AElicit activityHigh strengthSolid waste managementNatural resourceRoad engineering

The invention discloses a fluidized bed combustion ash and high titanium slag compounded stable pavement base material. The fluidized bed combustion ash and high titanium slag compounded stable pavement base material is formed by mixing 30-90wt% of fluidized bed combustion ash with 10-70wt% of high titanium slag. The fluidized bed combustion ash, the high titanium slag and water are stirred and mixed, and the obtained mixture is molded and maintained to make a fluidized bed combustion ash and high titanium slag compounded stable pavement base. The compounded stable pavement base material completely utilizes difficult-treatment and high-discharge-amount industrial wastes comprising the fluidized bed combustion ash and the high titanium slag, contains no lime or fly ash, and has better performances than traditional lime-fly ash stable pavement base material; and the compounded stable pavement base material has the advantages of low cost, no consumption of natural resources, simple and easy preparation method, suitableness for being used in areas short of traditional road engineering materials, substantial economic benefit, wide market prospect and strong practicality.

Owner:SOUTHWEAT UNIV OF SCI & TECH

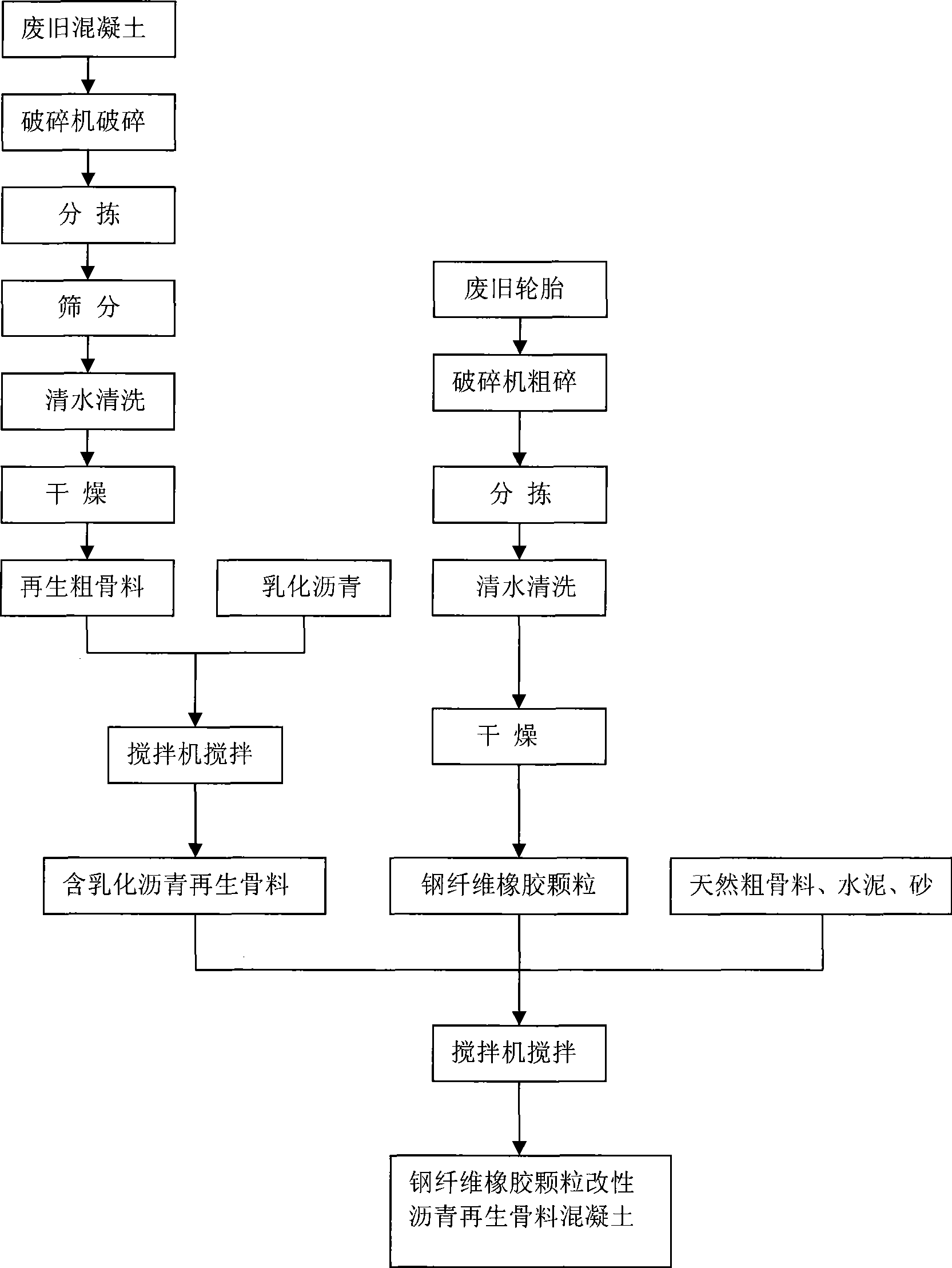

Method for regenerating aggregate concrete from steel fibre rubber granule modified asphalt

InactiveCN101381216AHigh dampingIncrease frictionSolid waste managementCrack resistanceEnergy absorption

The invention discloses a method for preparing steel fiber rubber particle modified asphalt recycled aggregate concrete. In the method, waste concrete is subjected to crushing, separating, screening, washing and drying to obtain the recycled aggregate, and the recycled aggregate is stirred with emulsified asphalt until the emulsified asphalt is covered on the surface of the recycled aggregate; waste tire is subjected to coarse crushing, separating, washing and drying to obtain the steel fiber rubber particle; and the recycled aggregate containing the emulsified asphalt, steel fiber rubber particles, natural aggregate, cement, sand and water are stirred according to certain ratio to obtain the steel fiber rubber particle modified asphalt recycled aggregate concrete. In the invention, the waste tire is subjected to crushing process to produce the steel fiber rubber, and the crack resistance, the heat preservation capability and the energy absorption and noise reduction capability of the asphalt recycled aggregate concrete are effectively improved by the modification of the steel fiber rubber; and the material is a circular economy building material, and by producing the material, the environmental pollution is reduced, and the performance of the material can be improved under the condition of not increasing cost.

Owner:GUANGDONG UNIV OF TECH

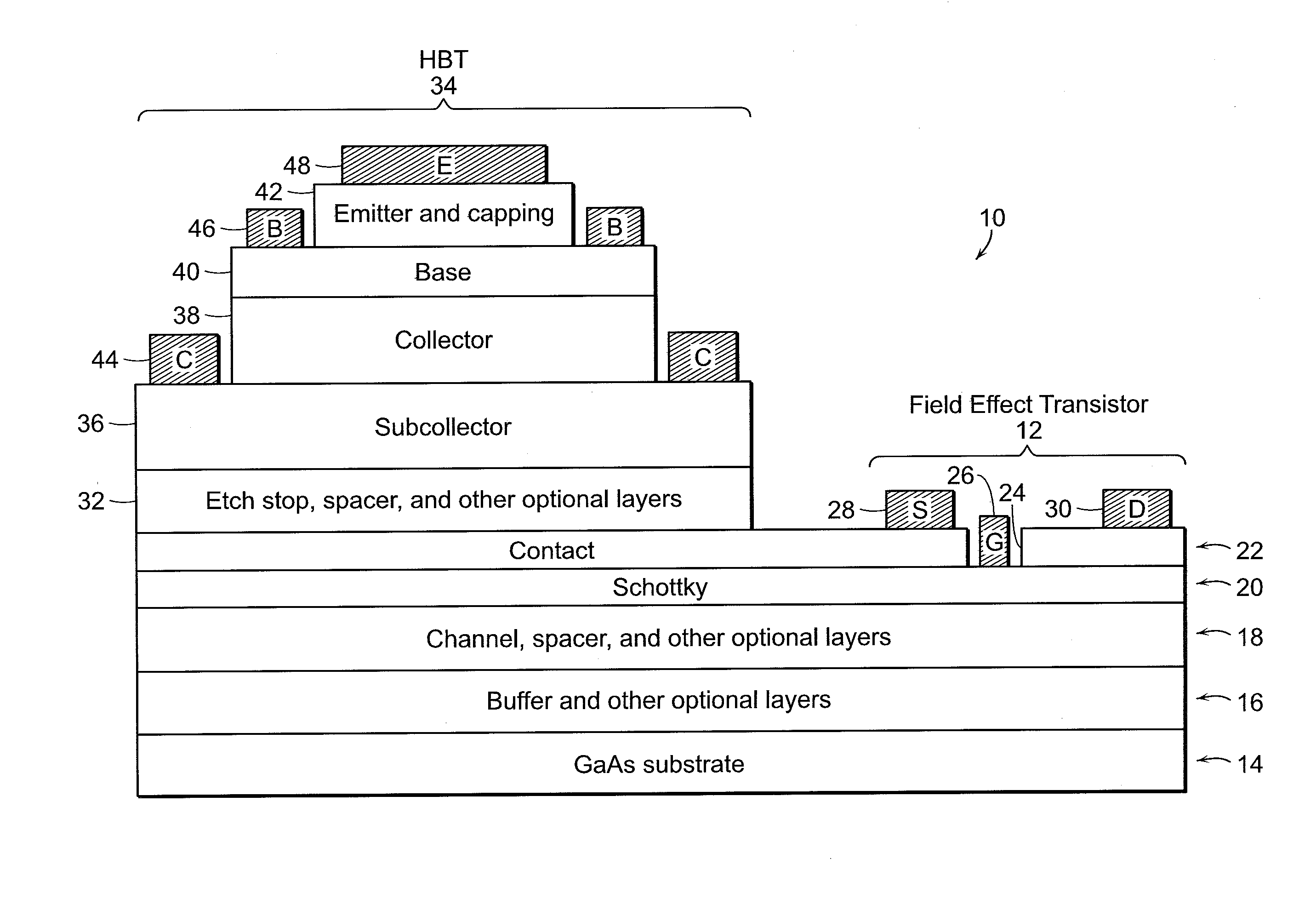

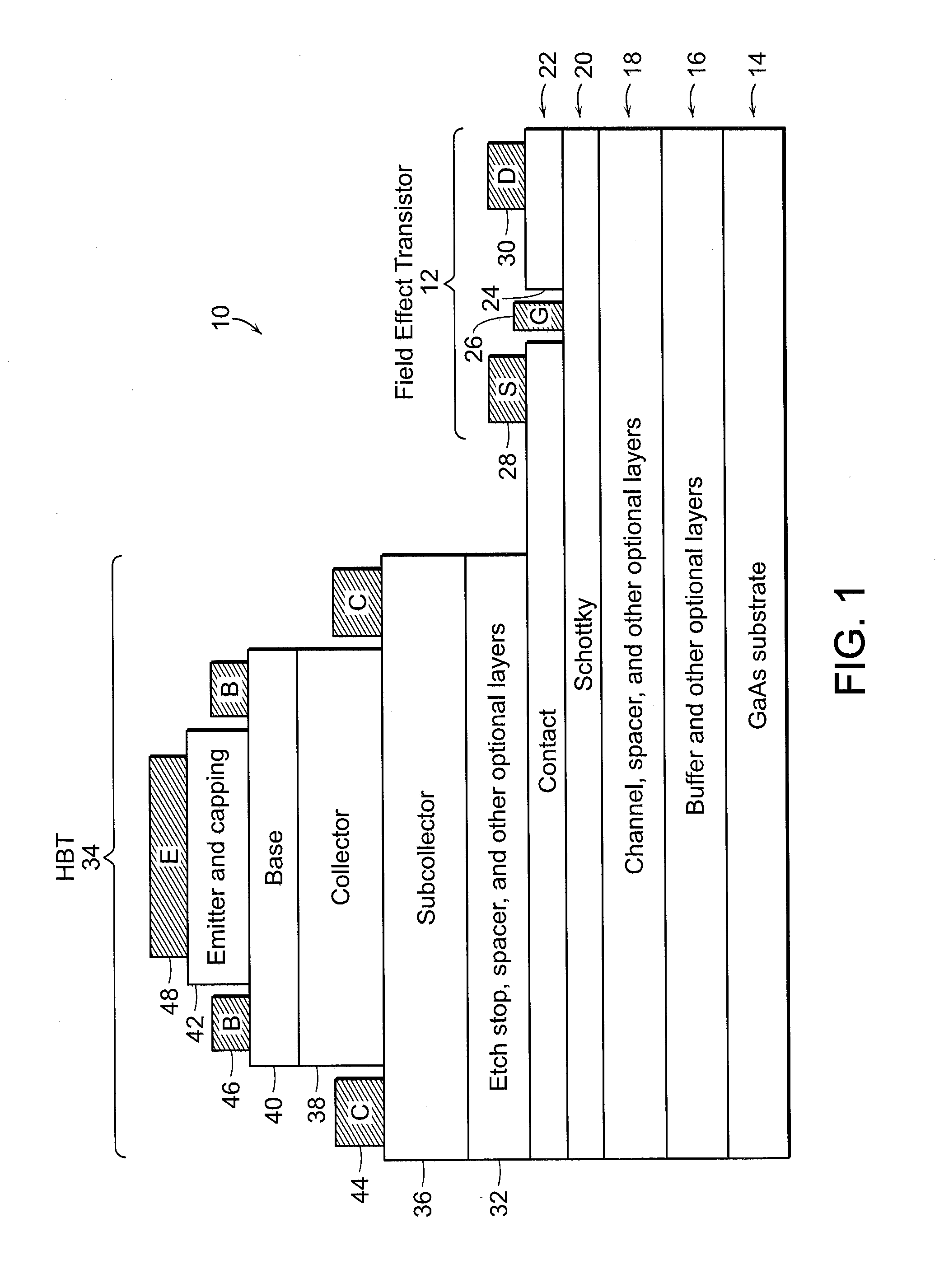

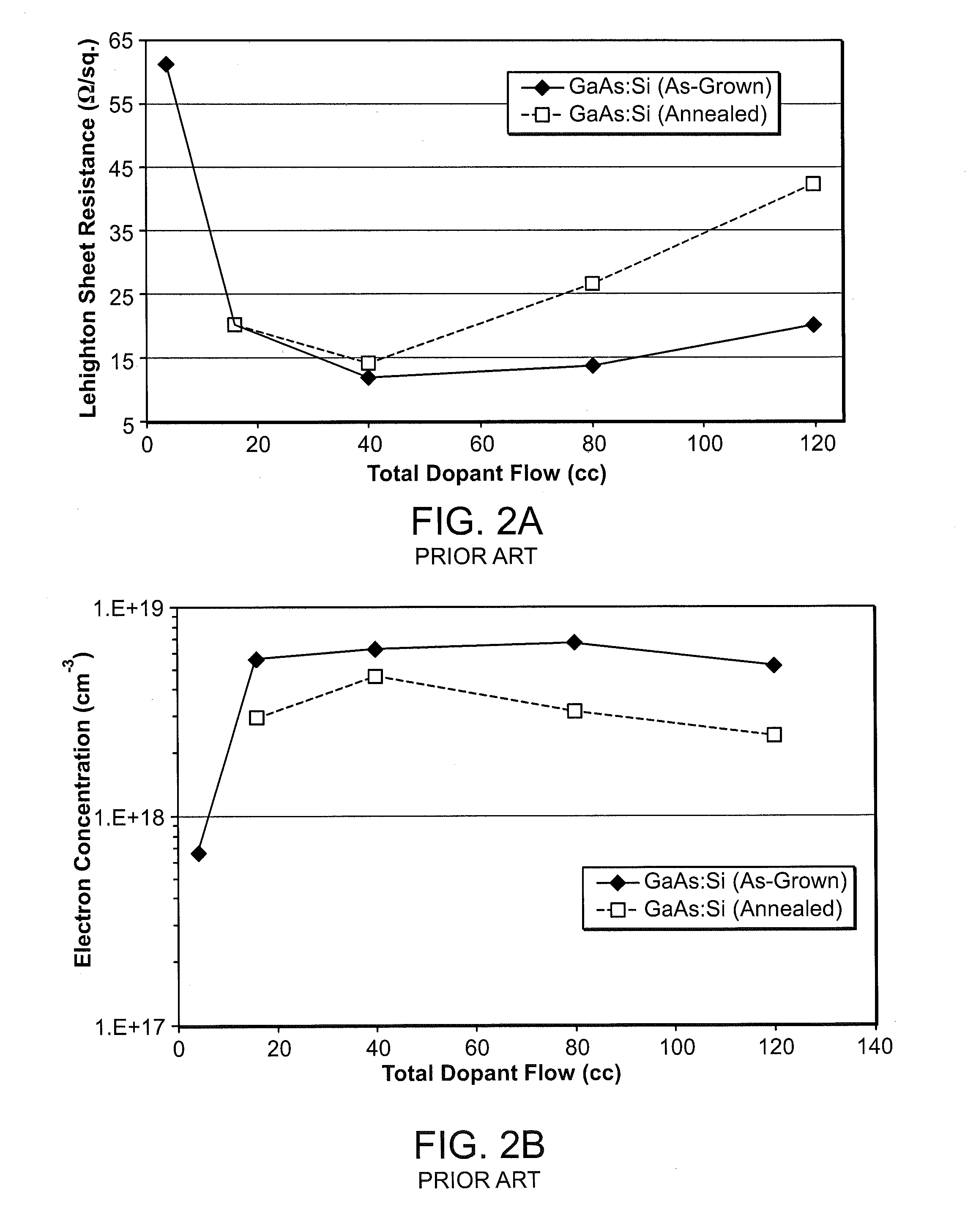

Bipolar high electron mobility transistor and methods of forming same

InactiveUS20120326211A1High electron mobilityIncrease maximum dopingTransistorSolid-state devicesSemiconductor materialsField-effect transistor

An epilayer structure includes a field-effect transistor structure and a heterojunction bipolar transistor structure. The heterojunction bipolar transistor structure contains an n-doped subcollector and a collector formed in combination with the field-effect transistor structure, wherein at least a portion of the subcollector or collector contains Sn, Te, or Se. In one embodiment, a base is formed over the collector; and an emitter is formed over the base. The bipolar transistor and the field-effect transistor each independently contain a III-V semiconductor material.

Owner:IQE KC

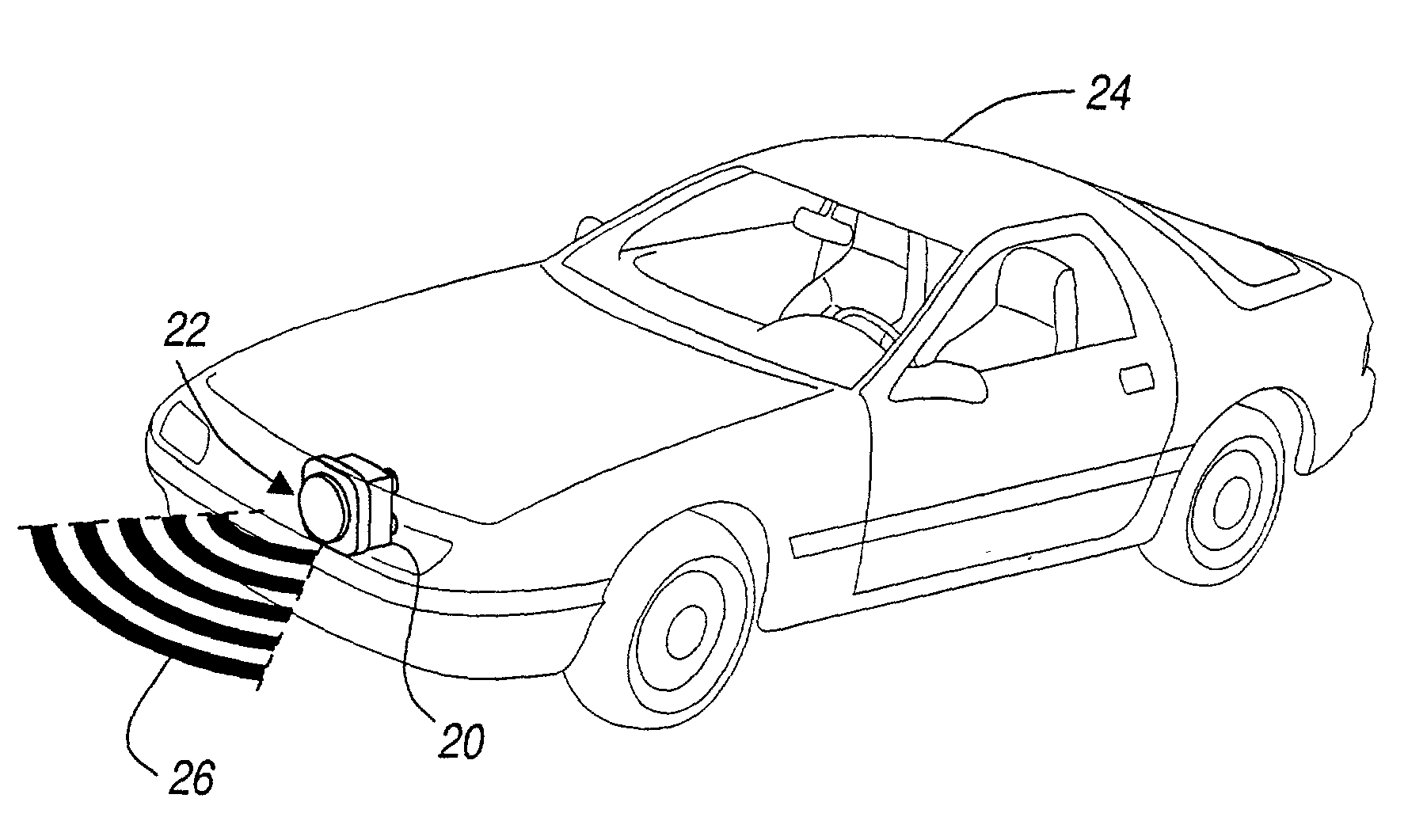

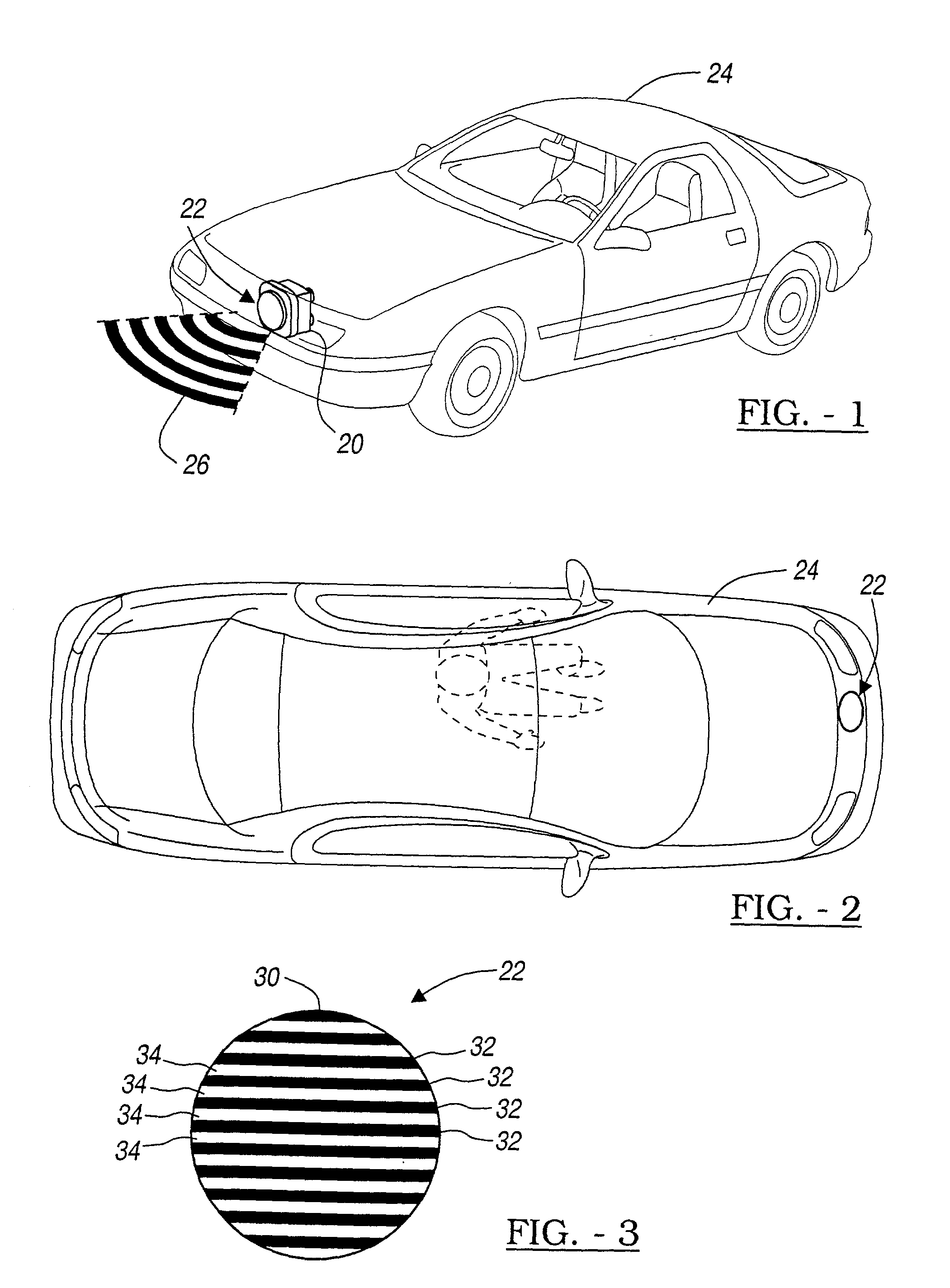

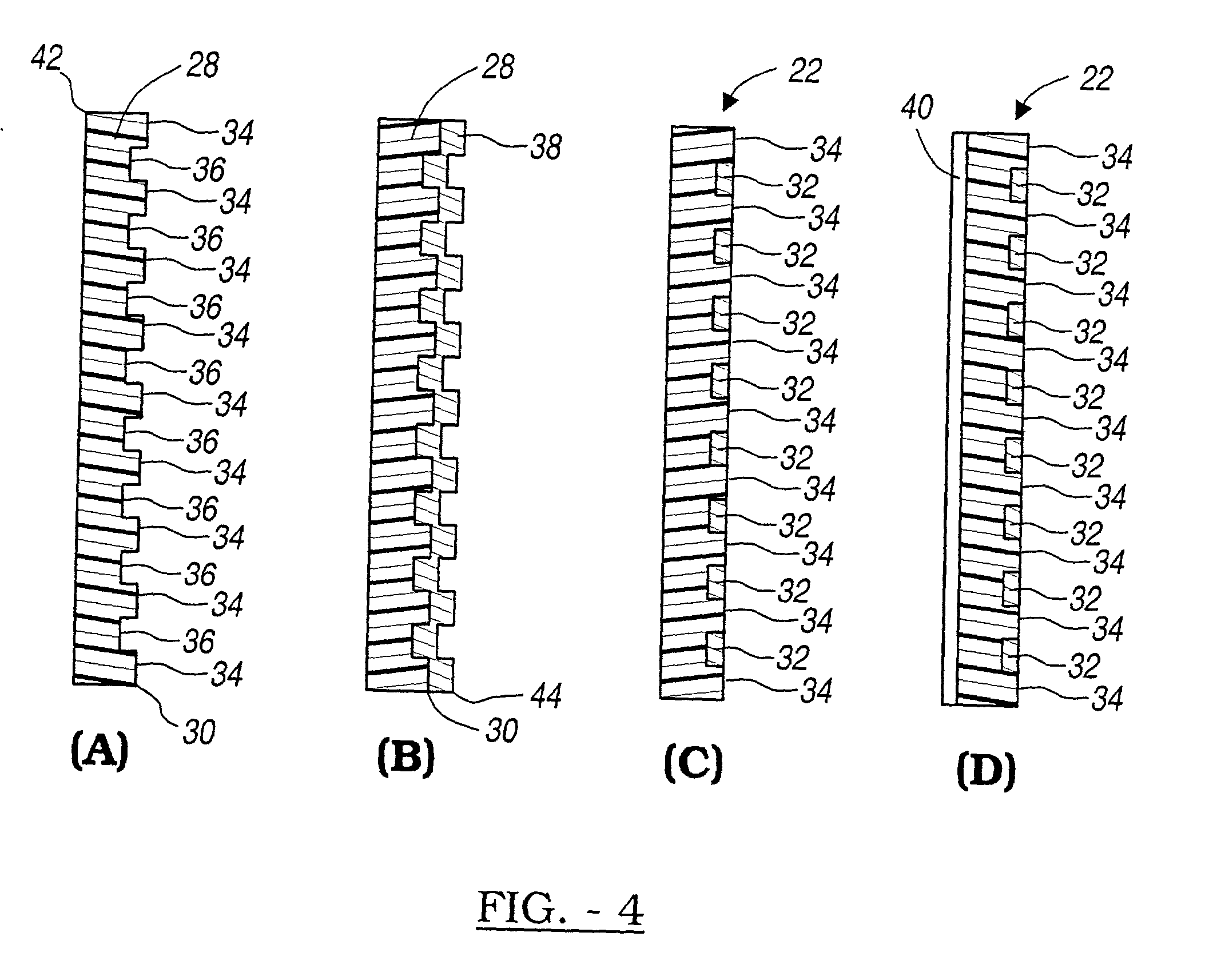

Sensor cover and method of construction thereof

InactiveUS20030128164A1Overcome disadvantagesAesthetically pleasingWave based measurement systemsSimultaneous aerial operationsRadarEngineering

A sensor cover is disclosed for camouflaging a high frequency sensor, including for example, a radar sensor. The sensor cover includes a substrate having a non-planar surface with non-signal transmitting regions and signal transmitting regions. A metal layer is disposed on each of the non-signal transmitting regions. Further, each of the non-signal transmitting regions is separated by one of the signal transmitting regions. The method of constructing such a sensor cover is also disclosed.

Owner:VEONEER US LLC

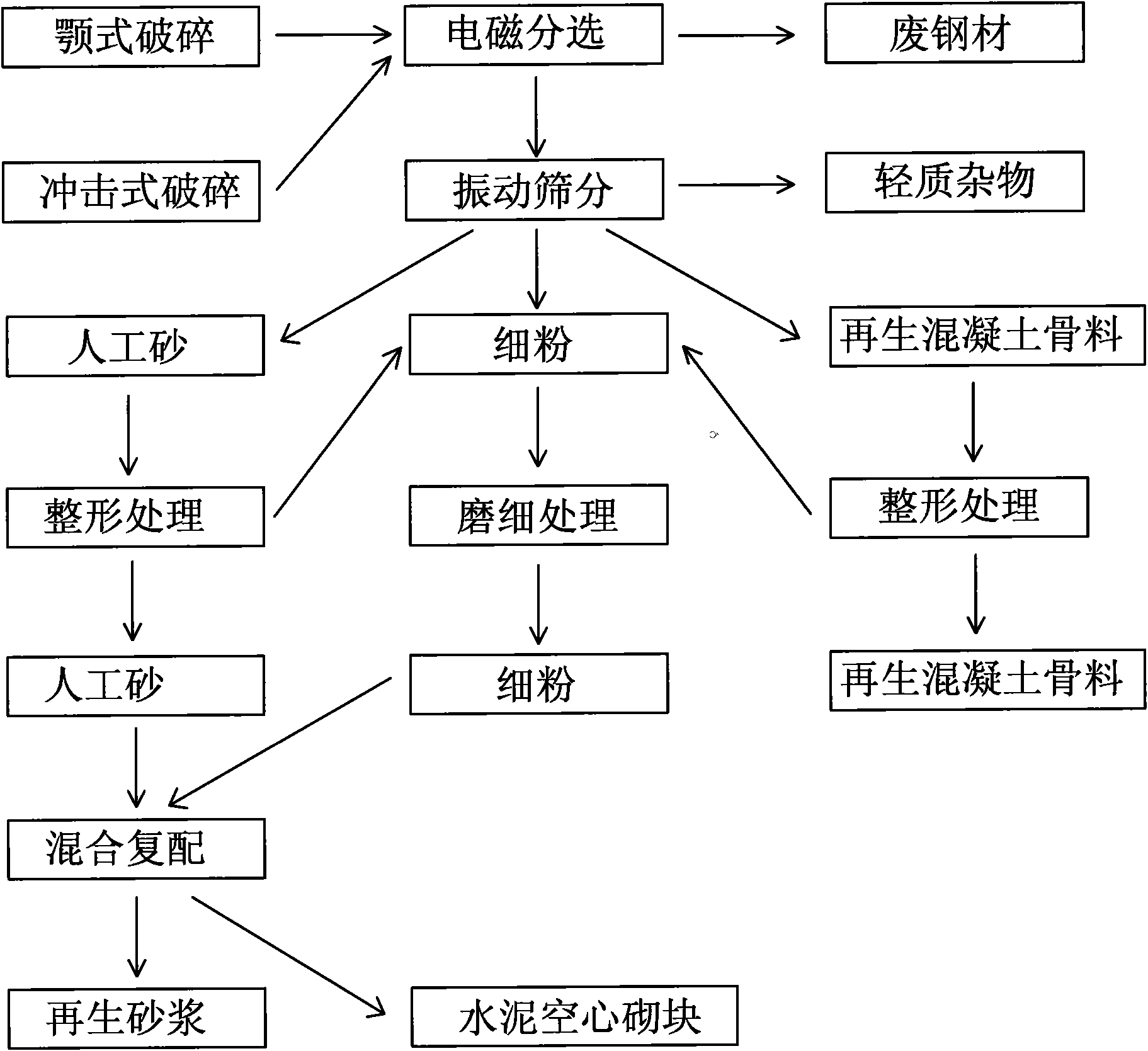

Method for recycling waste concrete

InactiveCN101560073ASolve processingSolve environmental problemsSolid waste managementEcological environmentCost of transport

The invention provides a method for recycling waste concrete, which comprises four steps of vibration screening, reshaping treatment, grinding treatment and mixing compounding. The method can reasonably solve the problem of the reutilization of the waste concrete; on the one hand, the problems of difficult treatment on a large amount of discarded waste concrete, adverse influence on the environment caused by the difficult treatment of a large amount of discarded waste concrete and the like are solved, so that the huge cost of transporting and treating wastes is saved; and on the other hand, the exploitation of natural sandstone is reduced, so that the method protects ecological environment and facilitates the sustainable development of human society.

Owner:长兴清华粉体及新材料工程中心有限公司

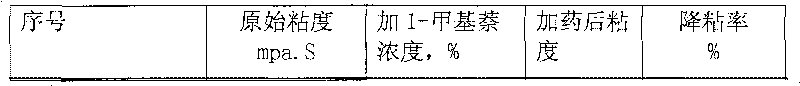

Application of methylnaphthalene in lowering viscosity of thickened oil

ActiveCN101717626ALow viscositySpeed up the flowFluid dynamicsFluid removalOil viscosityHigh surface

The invention discloses application of methylnaphthalene in lowering viscosity of thickened oil, which comprises application of 1-methylnaphthalene in lowering viscosity of thickened oil and the specific implementation steps, 2-methylnaphthalene in lowering viscosity of thickened oil and the specific implementation steps and mixed methylnaphthalene in lowering viscosity of thickened oil and the specific implementation steps. The invention enlarges the application method of methylnaphthalene, clearly demonstrates the specific application method of using methylnaphthalene to lower viscosity of thickened oil, solves the problems of great load and power consumption, frequent machinery accidents, high surface line return pressure, and the like of an oil extractor during extracting and outwards transporting thickened oil in the background art, and can effectively lower viscosity of thickened oil and reduce extraction and outward transportation cost of thickened oil.

Owner:盘锦河升大地石油科技有限公司

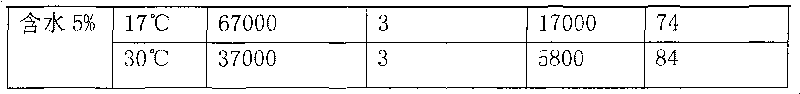

Steel slag recycling method

ActiveCN104789718AShort processHigh recycling purposeRecycling and recovery technologiesProcess efficiency improvementSlagPre treatment

The invention relates to a steel slag recycling method. The method comprises the following steps: carrying out mixing pretreatment on 100DEG C or above steel slag and 30-40DEG C steel slag, and carrying out multi-time magnetic separation, multi-time screening and multi-time fragmentation for recovery in order to obtain a low-iron metallurgy production auxiliary material substitute; and carrying out magnetic separation on a magnetic separation material in the steel slag, grinding, screening, and carrying out dry wind magnetic separation for recovery in order to obtain a high-iron metallurgy production auxiliary material substitute. The method reduces the smelting cost of a steel plant, reduces the exploitation and calcination of natural ore, reduces the discharge of greenhouse gas, has very good environmental protection benefit, and realizes short flow and high recovery utilization of the steel slag.

Owner:MCC BAOSTEEL TECH SERVICE

Polygonatum cyrtonema seed rapid emerging method

InactiveCN105660219AArtificial planting production cost reductionArtificial planting reductionSeed and root treatmentHorticulture methodsEpicotylPolygonatum cyrtonema

The invention discloses a polygonatum cyrtonema seed rapid emerging method. Polygonatum cyrtonema fruits are harvested and washed after the fruits are mature to obtain clean seeds for cold sand storage immediately, dormancy is removed from hypocotyl after storage treatment of 120 days, the seeds are treated with gibberellin with proper concentration and soaking time and are not sprouted, and emerging doesn't occur in the current year; gibberellin treated seeds are sown in a seedling plate loaded with a loose, fertile and moist substrate, primary roots of polygonatum cyrtonema are grown fully after four months, dormancy is removed from epicotyl after the primary roots are taken out and treated with cytokinin 6-BA with proper concentration and soaking time, the seeds are transplanted in a shading seedling field, emerging starts after about 15 days, the emerging is uniform, and the emergence rate can be as high as 70%. The polygonatum cyrtonema seed rapid emerging method has the advantages that the seed germination rate is high after treatment, the emergence rate is high, and the seedling culture time is reduced by one year.

Owner:GUIZHOU UNIV

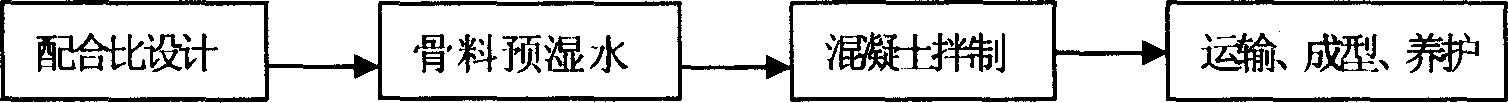

Whole-high valent titanium slag concrete

ActiveCN1880258AReduce total usageLow costSolid waste managementNational standardMechanical property

The invention discloses a concrete of high-titanium slag, including cement, high-titanium slag rubble, high-titanium slag sand, mineral admixture, matching designing according to national standard, the quantity of high-titanium slag sand matched in the concrete increases 3%-6% in the base of design, in which the content of ground-slag is 10%-18%, watering high-titanium slag rubble and high-titanium slag sand before agitating, then adding the compositions to the agitator according to the priority of block aggregate, cement, admixture, fine aggregate and agitating for the time that extends 10-30 seconds than normal concrete, the concrete not only makes use of waste resource effectively and also protects the environment and has good mechanical property.

Owner:攀枝花环业冶金渣开发有限责任公司

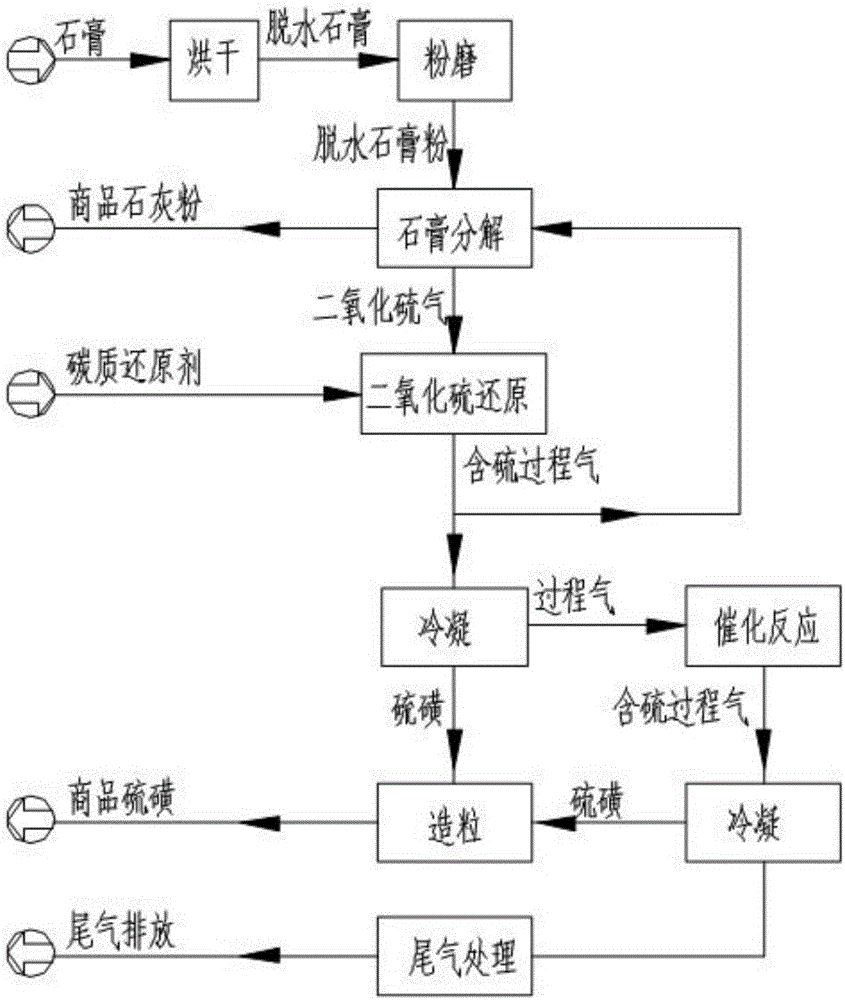

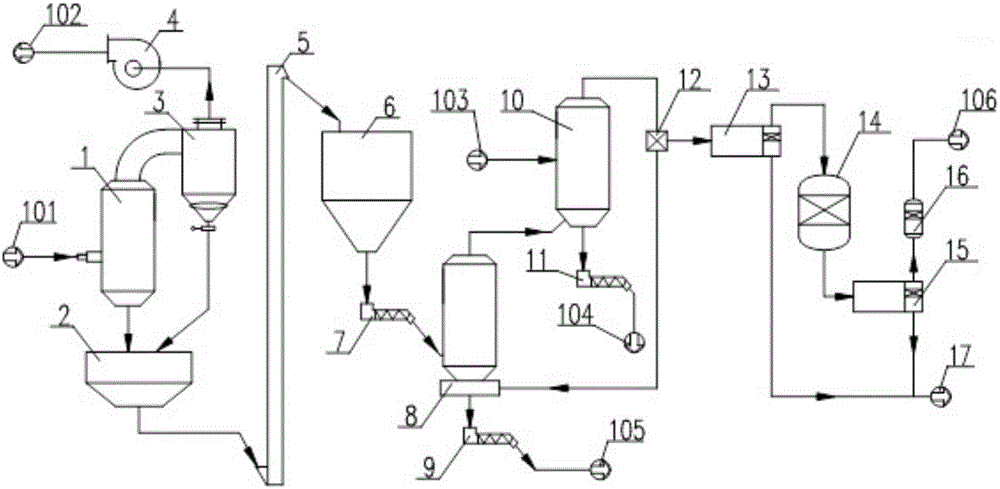

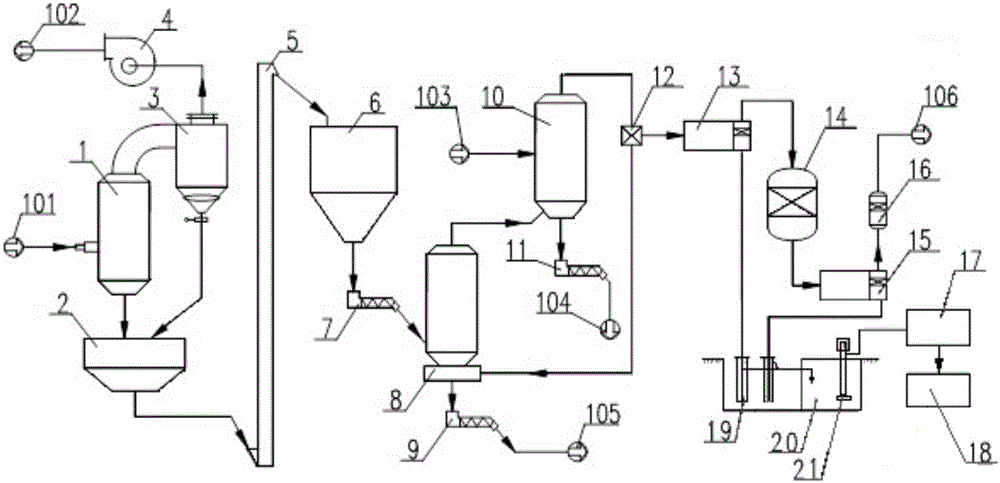

Method for preparing calcium oxide and sulfur from gypsum and system device

ActiveCN106745145AReduce miningHigh puritySulfur preparation/purificationCalcium/strontium/barium oxides/hydroxidesSulfurDecomposition

The invention relates to a method for preparing calcium oxide and sulfur from gypsum. The method comprises the following steps: (1) pretreating gypsum: drying dihydrate gypsum to form a dehydrated gypsum with the total water content of 2-10%, grinding the dehydrated gypsum into a gypsum powder; (2) decomposing the gypsum: enabling the gypsum powder in the step (1) to be in contact with a sulfur-containing process gas, reacting at the temperature of 700-1200 DEG C, and finally generating calcium oxide and a sulfur dioxide gas; (3) reducing the sulfur dioxide: enabling the prepared sulfur dioxide gas to be in contact with a carbonaceous reducing agent, reacting at the temperature of 600-1000 DEG C, and generating a sulfur-containing process gas. The sulfur-containing process gas is divided into two strands, one is used for the decomposition reaction of the gypsum in the step (2), and the other is used for producing sulfur through the processes of condensation, catalytic reaction, pelleting and the like. The conversion rate of the gypsum is high, the gypsum is consumed to produce the high value added calcium oxide and sulfur, the source of raw materials is wide, the energy consumption is low, and excellent environmental protection benefit and economic benefit are achieved.

Owner:JIANGSU DEYITONG ENVIRONMENTAL PROTECTION TECH CO LTD

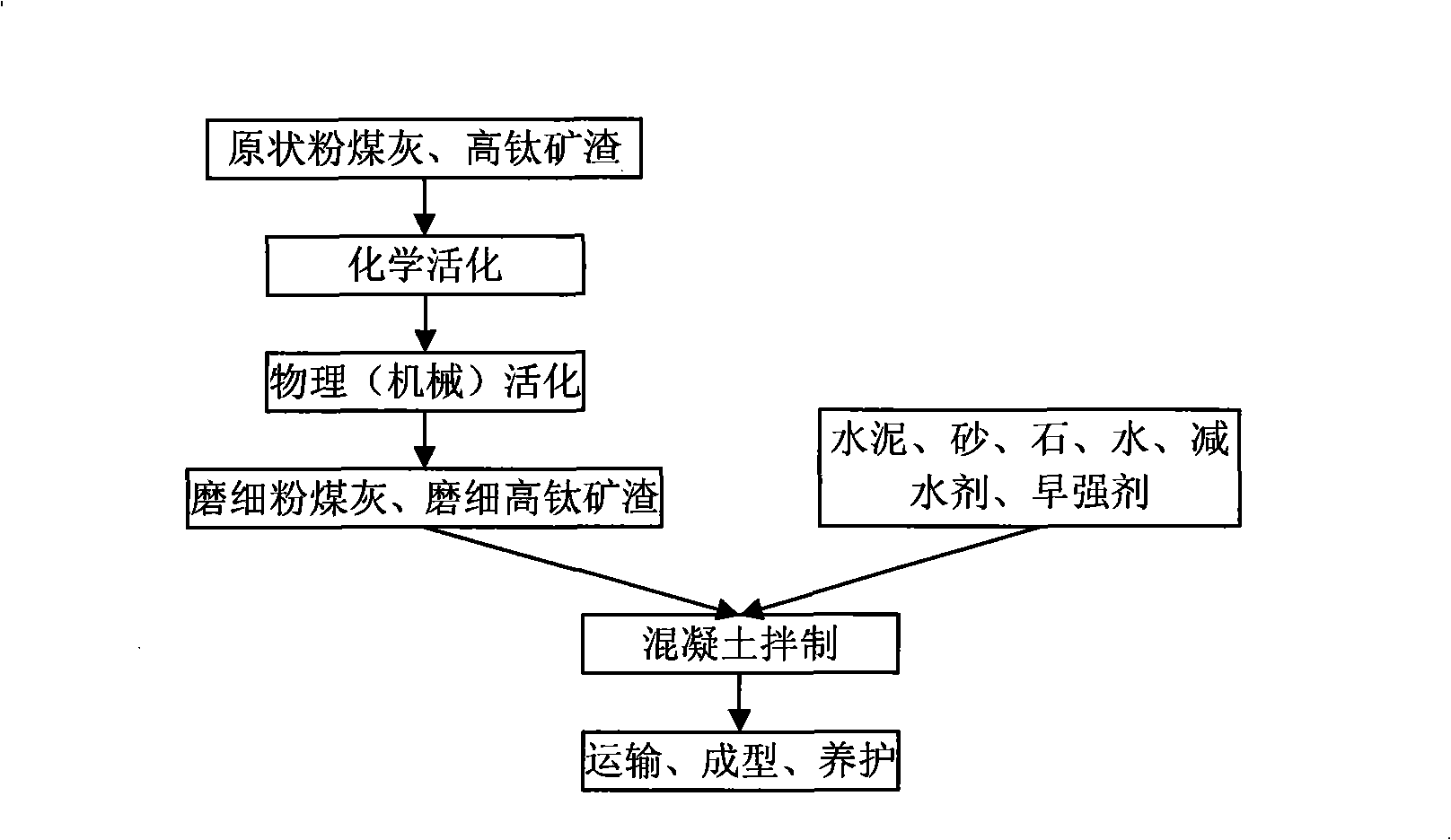

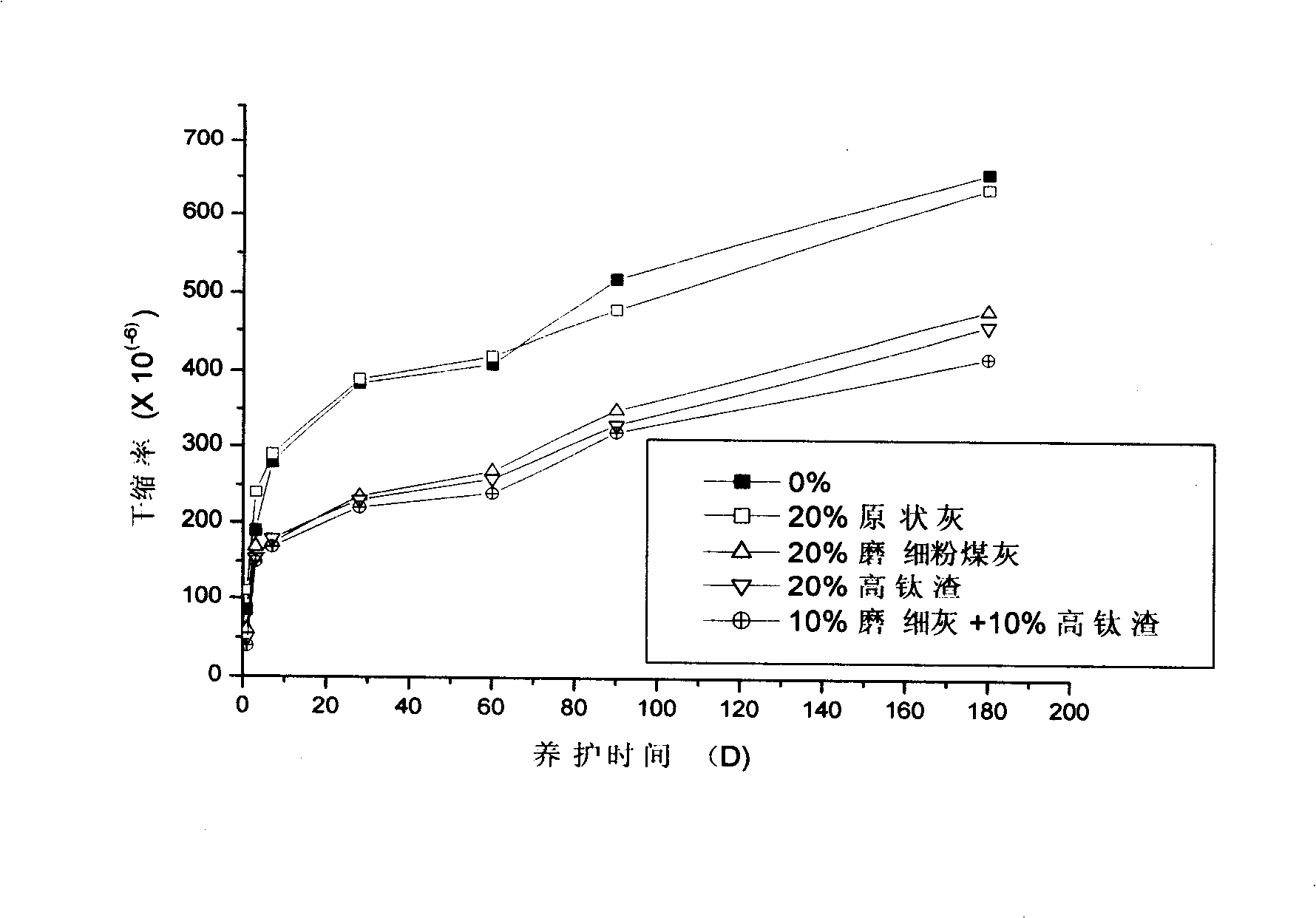

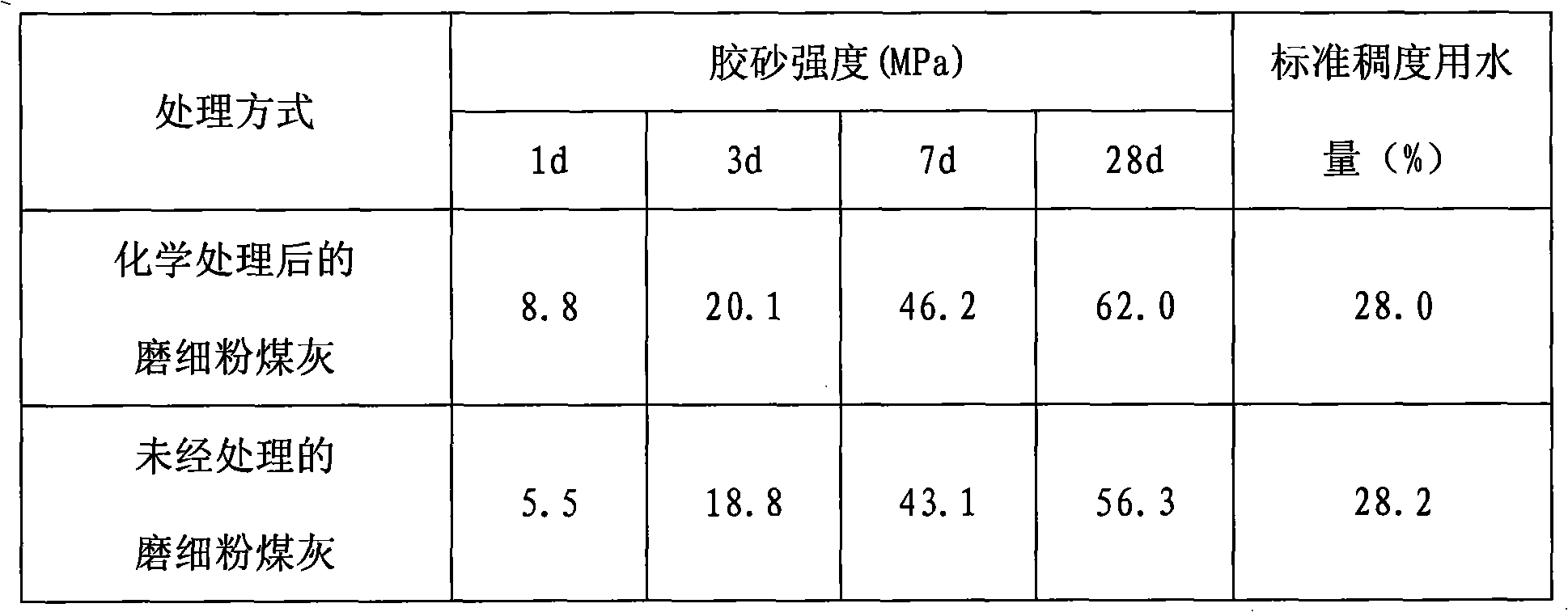

Finely ground high-titanium slag and fly ash composite high-performance concrete

InactiveCN101514088AIncrease profitEasy constructionSolid waste managementSuperplasticizerBiological activation

The invention discloses concrete, which is prepared by mixing cement, sand, stone and water which are mixed in common concrete, as well as finely ground high-titanium slag, fly ash, high-efficiency water reducing agent and hardening accelerator. The prepared concrete has high workability, durability, volume stability and excellent physical and mechanical performance. The concrete is activated by using mechanical (physical) activation and chemical activation and is used as excellent active additive to replace 10 to 25 percent of cement equally, so the workability and durability of the concrete are improved obviously without influencing the later strength of the concrete. The concrete has the advantages of improving the comprehensive utilization rate of high-titanium slag and fly ash, providing a high-performance concrete convenient in construction and high in quality, reducing construction cost and exploitation of natural sand and stone, and protecting environment.

Owner:陈加耘 +2

Method for preparing calcium sulfate hemihydrate whiskers by taking ardealite as main raw material

InactiveCN102925956AIncrease added valueReduce miningPolycrystalline material growthFrom normal temperature solutionsHemihydrate Calcium SulfateSulfate

The invention relates to a method for preparing calcium sulfate hemihydrate whiskers by taking ardealite as a main raw material. The technical scheme of the invention is as follows: firstly, mixing 40-50wt% of ardealite with 3-5wt% of hydrochloric acid, 1-3wt% of sulfuric acid and the balance of water as accessory materials, stirring the obtained mixture for 1-2 h at normal pressure and at a temperature of 80-110 DEG C, and filtering the obtained product so as to obtain a primary filter cake, and washing the primary filter cake; preparing 6-12wt% of habit modifier, 1-5wt% of sulfuric acid, 1-10wt% of primary filter cake subjected to washing and the balance of water into turbid suspension liquid; then, under the condition of normal pressure and 100-120 DEG C, stirring the turbid suspension liquid for 0.5-1 h, adding calcium sulfate whiskers accounting for 0.5-1wt% of ardealite and a whisker modifier accounting for 0.5-1wt% of ardealite while stirring, and then stirring for 4-8 h; carrying out filtering on the obtained product so as to obtain a finished filter cake product, and washing the finished filter cake product; and finally, drying the finished filter cake product for 2-4 hours so as to obtain the calcium sulfate hemihydrate whiskers. The method disclosed by the invention has the characteristics of mild operating condition, low production cost, green and environmental protection, and high product quality.

Owner:WUHAN UNIV OF SCI & TECH

Storing up and luminous dimension stoney and manufacturing method

InactiveCN1660712ABreak through the brittle characteristics and the bottleneck of secondary processingImprove featuresFilling materialsCeramic

A light-accumulating luminescent stone is prepared through choosing silicon contained aggregate (granite, quartz sand, marble, glass, or ceramics), pulverizing, classifying, proportionally mixing, adding light accumulating and emitting material, filler and functional material (nano material, pigment and resin or cement), stirring, vibration moulding, curing and drying. It has low luminous time.

Owner:李明禹

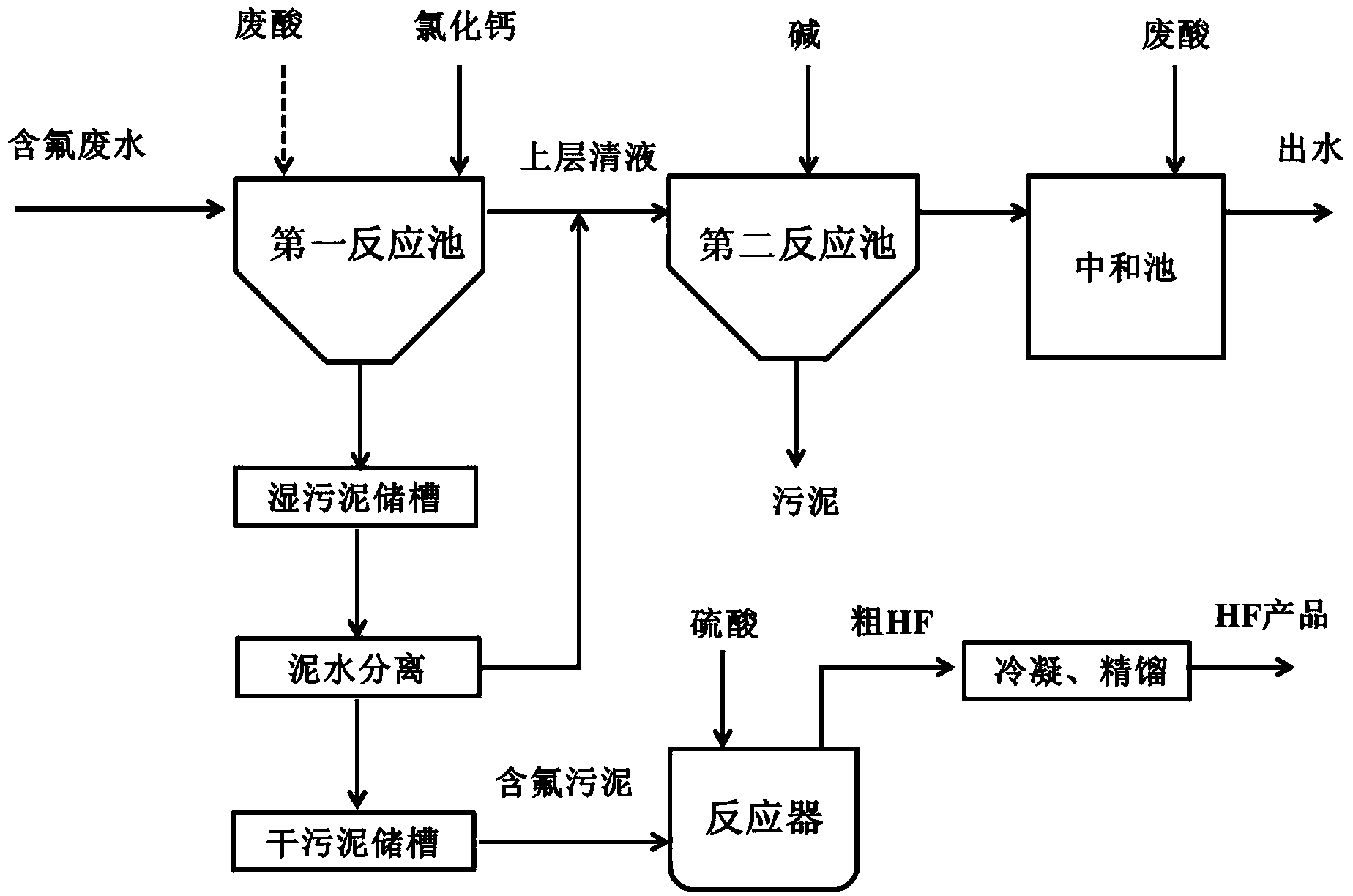

Method for treating fluorine-containing wastewater and recycling fluorine-containing sludge produced by treatment of fluorine-containing wastewater

ActiveCN103848522ATreatment up to standardReduce dosageSludge treatmentWater contaminantsSludgeImpurity

The invention discloses a method for treating fluorine-containing wastewater and recycling fluorine-containing sludge produced by treatment of fluorine-containing wastewater. The method comprises the steps of reacting the fluorine-containing wastewater with calcium chloride under the acidic condition formed by adding a waste acid matter, performing crystallization sedimentation to remove most fluorine ions from the wastewater to form high-purity fluorine-containing sludge, removing dissolved calcium fluoride and other impurities from supernate through alkali sedimentation to form a small amount of fluorine-containing sludge with relatively low purity, then neutralizing the supernate, and discharging effluent, wherein the concentration of fluorine ions of the effluent is lower than 10 mg / L and accords with national discharge standards; drying the high-purity fluorine-containing sludge, then adding the dried sludge and excessive sulfuric acid into a reactor with a stirring device, reacting at 150-300 DEG C to prepare hydrogen fluoride, and condensing and rectifying the obtained crude hydrogen fluoride gas to obtain an anhydrous hydrogen fluoride product.

Owner:ACAD OF ENVIRONMENTAL PLANNING & DESIGN GRP CO LTD NANJING UNIV

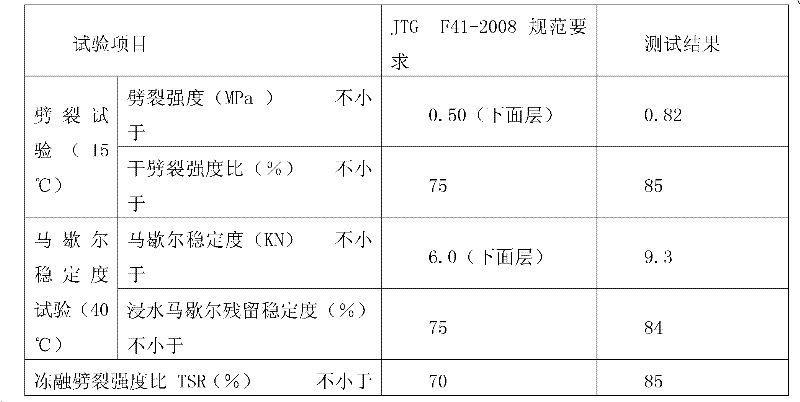

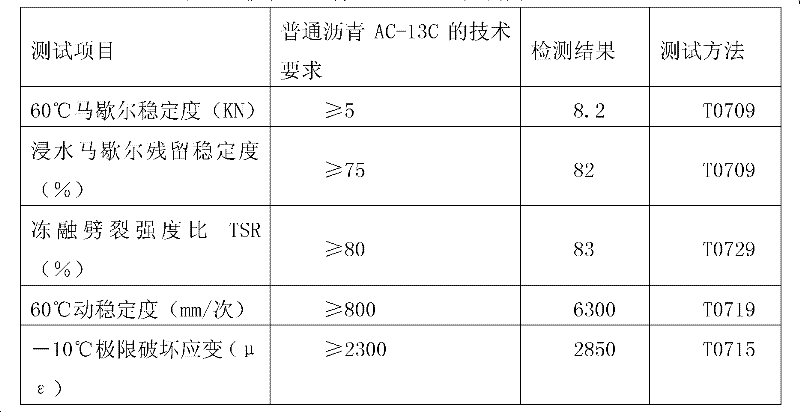

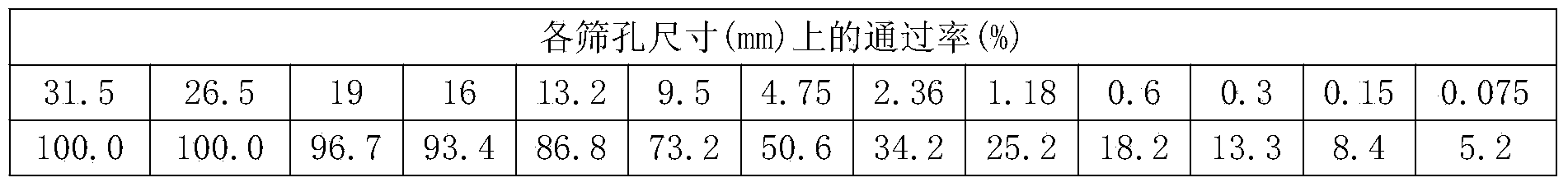

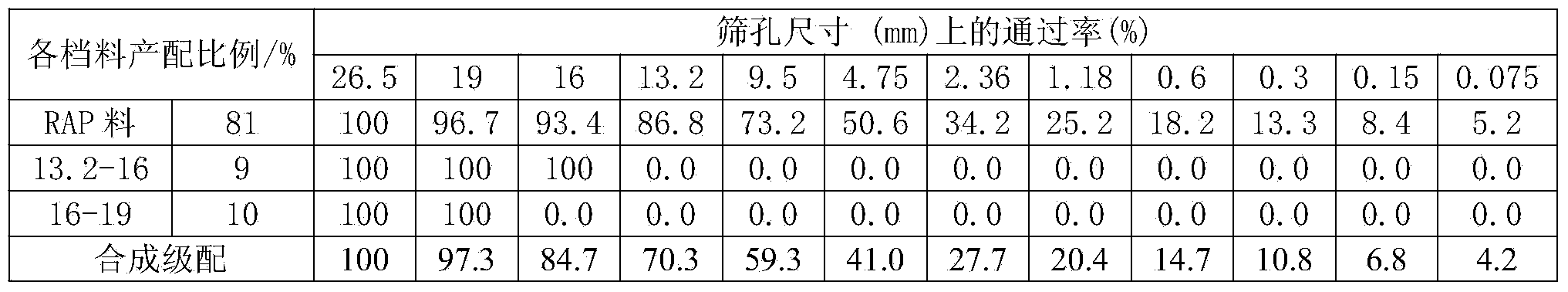

Preparation method of high-performance warm-mix regenerated asphalt mixture

InactiveCN103556560AImprove road performanceLower mixing temperatureClimate change adaptationRoads maintainenceIndex testTest specification

The invention discloses a preparation method of a high-performance warm-mix regenerated asphalt mixture, which comprises the following steps: extracting and screening an old asphalt mixture, determining the size distribution and asphalt content of the mixture, carrying out three-main-index testing on the asphalt, and evaluating old asphalt performance indexes in RAP; determining the doping proportion of the RAP according to the performance indexes of the asphalt in the RAP, wherein the doping proportion is generally 50-100%, and the doping proportion can be higher as the performance indexes of the asphalt in the RAP are higher; determining the optimal doped new asphalt consumption (OACn) of the asphalt mixture by a conventional asphalt mixture Marshall five-point process; and after calculating the doped new asphalt consumption, detecting according to according to the performance indexes specified in Asphalt Pavement Construction Technique Specifications (JTGF40-2004) by a testing method specified in Highway Engineering Asphalt and Asphalt Mixture Test Specifications (JTGE20-2011).

Owner:云南省公路科学技术研究院

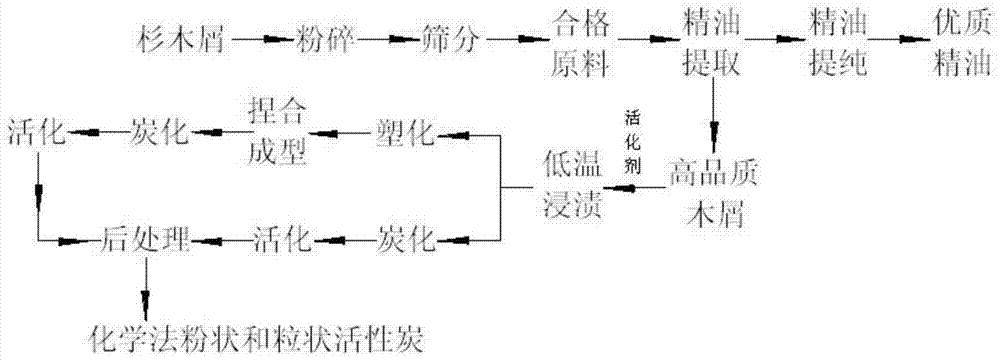

Method for extracting essential oil from wood processing waste Chinese fir chips to co-produce chemical method activated carbon

InactiveCN103756787AEfficient and comprehensive utilization of wasteReduce natural resource extractionCarbon compoundsEssential-oils/perfumesChemistryCarbonization

The invention proposes a method for extracting essential oil from wood processing waste Chinese fir chips to co-produce chemical method activated carbon. The method comprises the following steps: distilling fresh Chinese fir chips by water vapor; carrying out oil-water separation on condensate to obtain fir essential oil after cooling by obtained vapor; mixing the Chinese fir chips with a phosphoric acid according to the mass ratio of pure phosphoric acid to absolute dry sawdust of (1.8-3.0):1 after extracting oil; adding a cocatalyst concentrated sulfuric acid to fully mix according to the ratio of 1-8% of mass of the phosphoric acid, and then feeding to a sealed insulating barrel to carry out low-temperature osmotic treatment at 30-90 DEG C for 1-48 hours; carrying out carbonization, activation and post-treatment on the chemical method activated carbon; or carrying out plastifying, kneading, molding, drying and solidifying, carbon activation and post-treatment to obtain the chemical method granular activated carbon. Wooden column activated carbon can be prepared under the condition of not adding a binder, so that a plurality of purposes of efficient and comprehensive utilization of wastes, reduction of natural resource exploitation, reduction of environmental pollution, energy conservation and emission reduction are achieved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com