Steel slag recycling method

A technology of iron and steel slag and tailing slag, which is applied in the field of recycling and utilization of iron and steel slag, which can solve the problems of polluting the surrounding environment, occupying farmland land, and increasing the pH value, and achieves the effects of reducing smelting costs, reducing greenhouse gas emissions, and reducing steel scrap consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

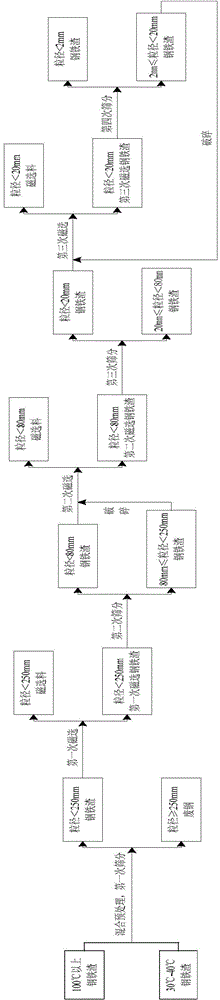

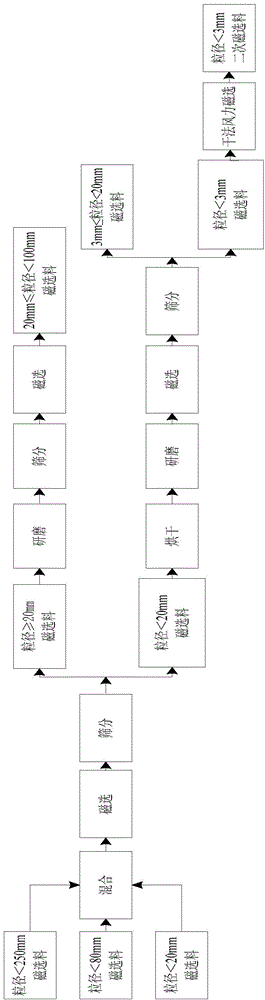

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1 pretreatment

[0068] A steel plant has 100 tons of steel slag and iron slag at 40°C with a moisture content of 10wt%. There are 4 pieces of slag with a maximum diameter of 300mm on the surface, and the surface area of slag is 8-12mm. After fully mixing 50 tons of 300°C high-temperature slag and pretreatment for 8 hours, it was found that the steel slag on the surface of the slag iron and steel was completely peeled off, and the effective separation of slag and iron was realized. At the same time, it was also found that the large pieces of steel slag were naturally pulverized and completely turned into small pieces And granular, the water content after mixing pretreatment is 4wt%, the calcium oxide content is 40wt%, and the total iron content is 32wt%.

Embodiment 2

[0069] Embodiment 2 pretreatment

[0070] A steel plant has 250 tons of steel slag and iron slag at 35°C with a moisture content of 10wt%. There are 5 pieces of slag with a maximum diameter of 280mm on the surface. After fully mixing 100 tons of high-temperature slag at 230°C and pretreatment for 10 hours, it was found that the steel slag on the surface of the slag iron and steel was completely peeled off, realizing the effective separation of slag and iron. At the same time, it was also found that the large pieces of steel slag were naturally pulverized and completely turned into small pieces And granular, the water content after mixing pretreatment is 3wt%, the calcium oxide content is 50wt%, and the total iron content is 30wt%.

Embodiment 3

[0071] Embodiment 3 pretreatment

[0072] 150 tons of 30°C steel slag and iron slag from a steel plant, with a moisture content of 10wt%, were fully mixed with 50 tons of 100°C high-temperature slag and pretreated for 12 hours. It was found that the steel slag on the surface of the slag steel was completely peeled off, and the slag and iron were effectively separated. At the same time, it is also found that the large pieces of steel slag are naturally pulverized and completely become small pieces and granules. After mixing and pretreatment, the moisture content is 5wt%, the calcium oxide content is 62wt%, and the total iron content is 31wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com