Patents

Literature

59results about How to "Excellent heat shrinkage resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

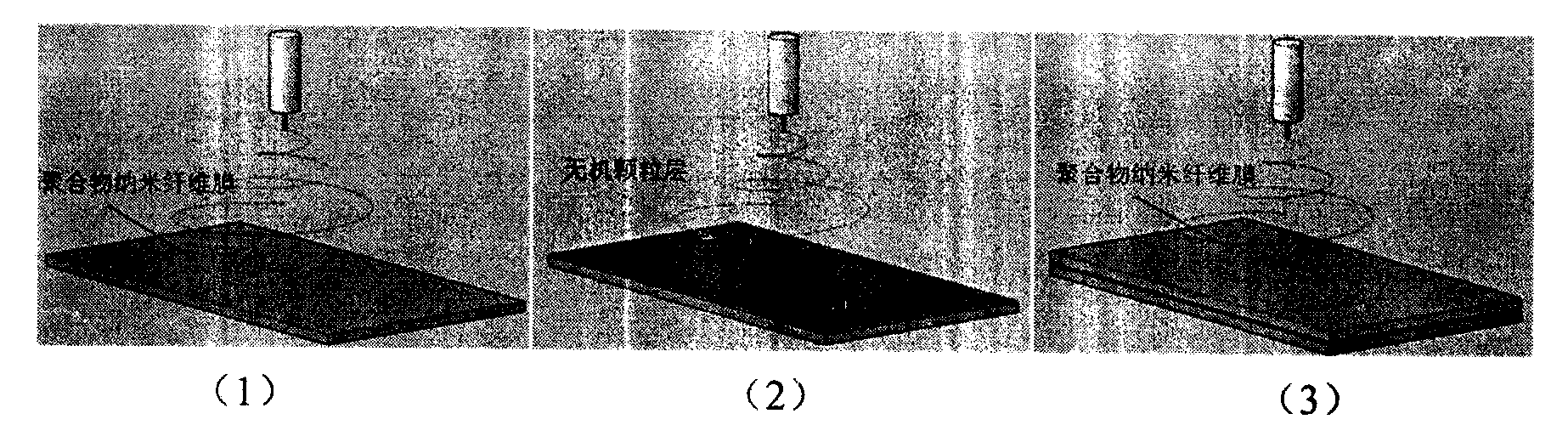

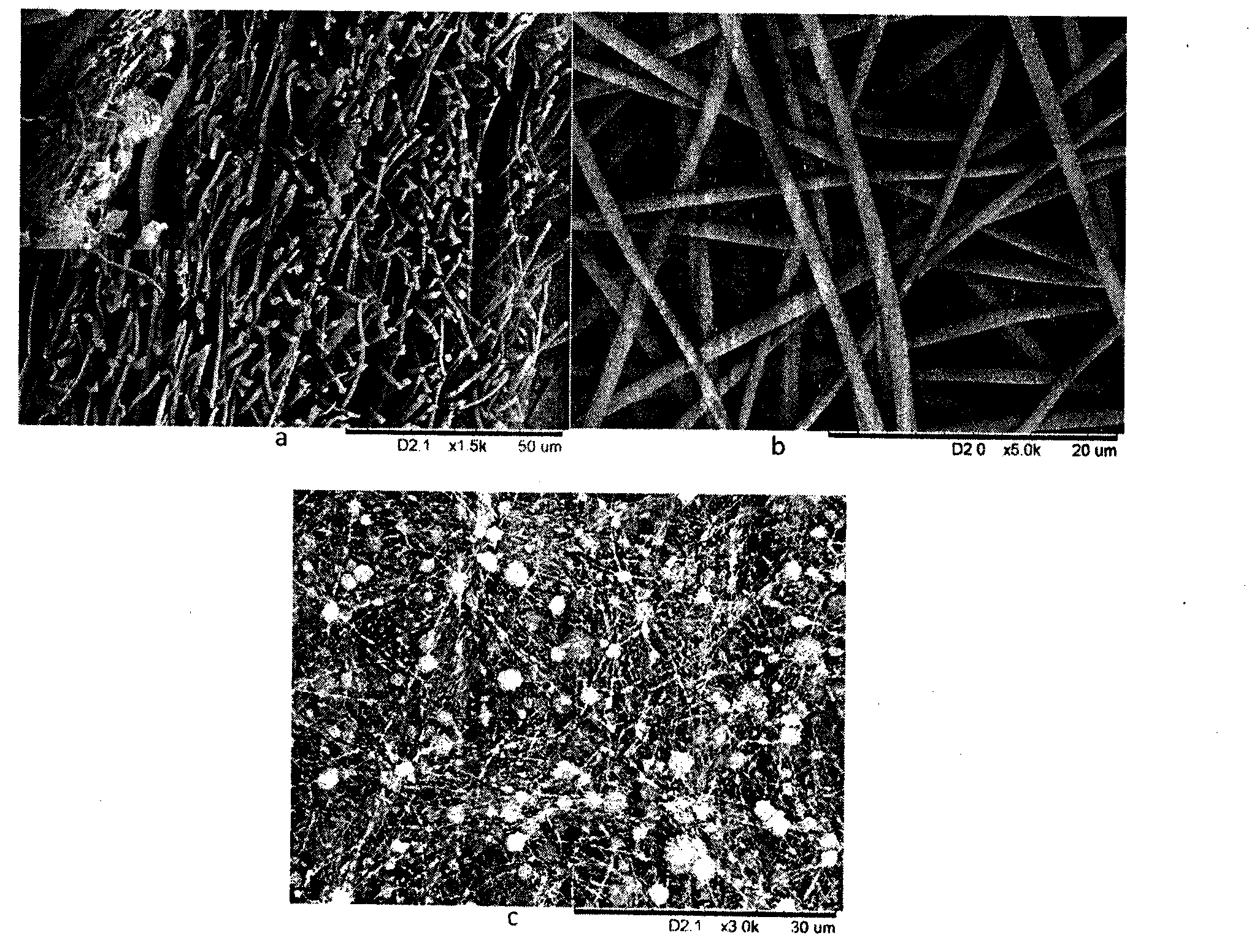

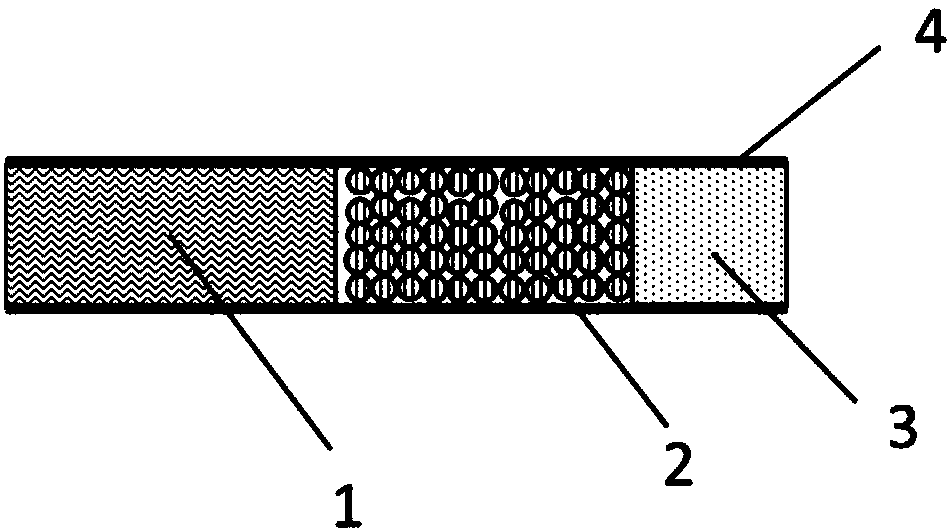

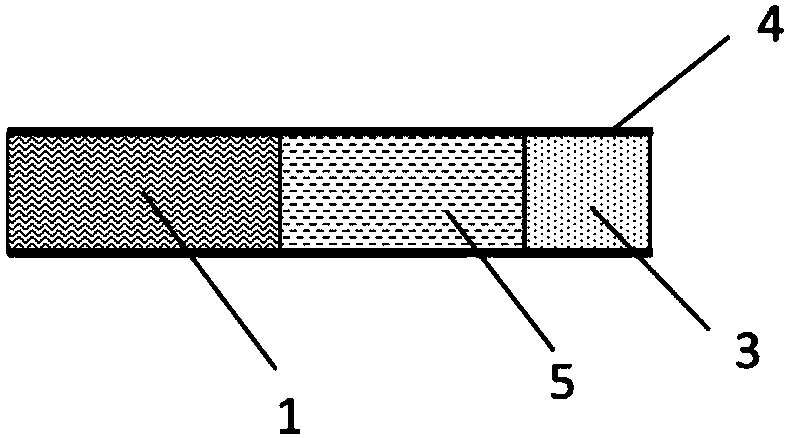

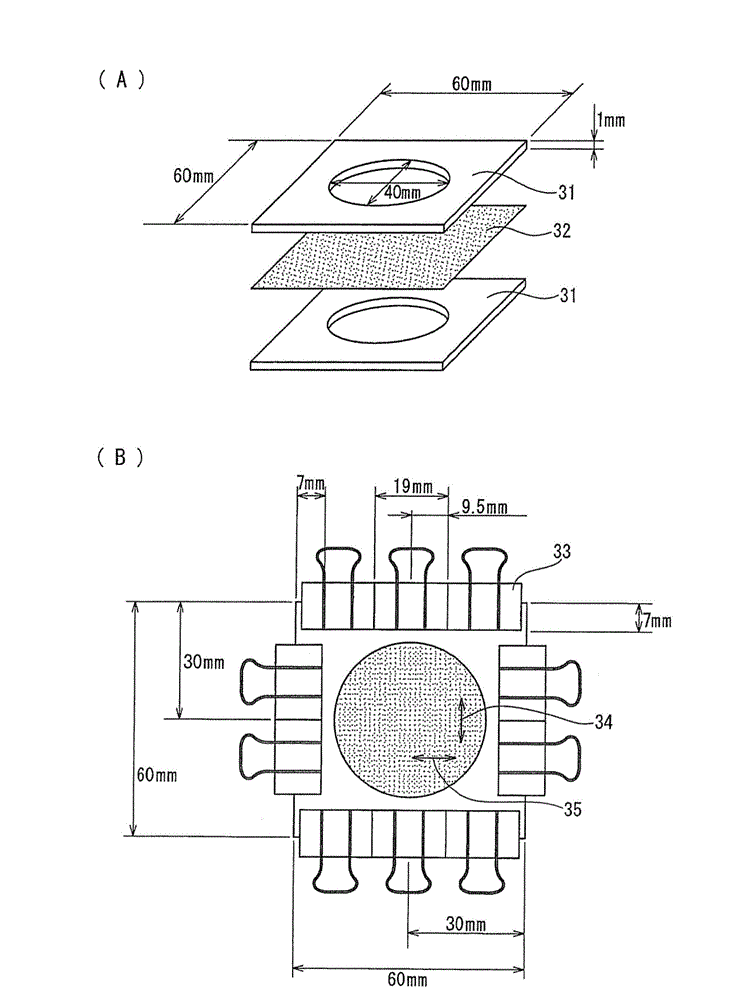

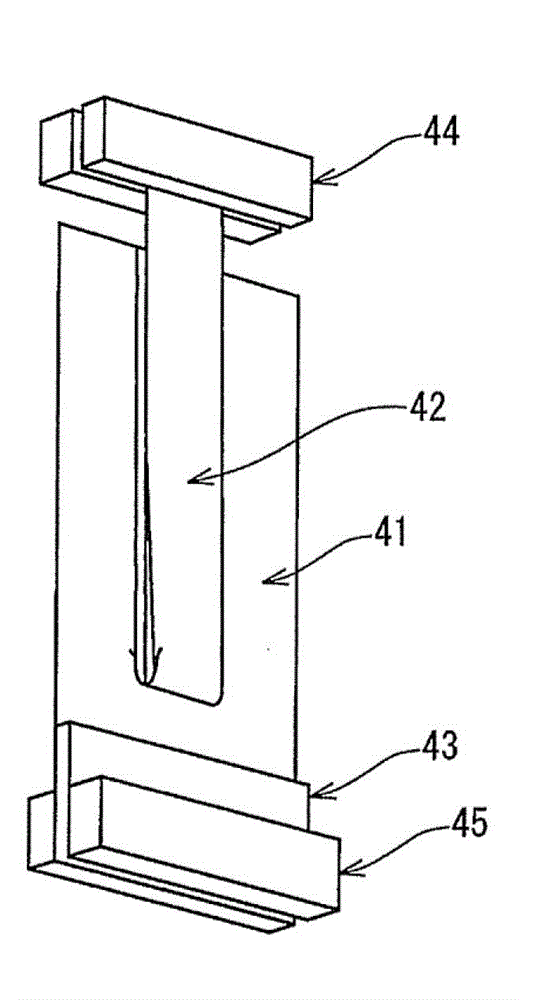

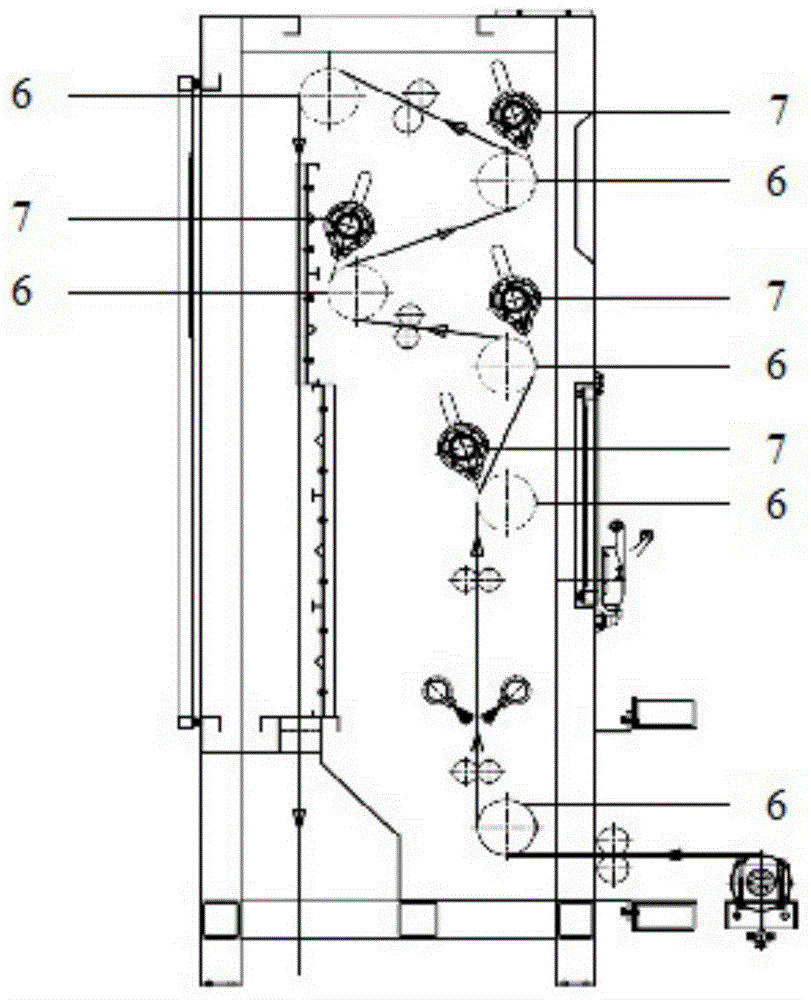

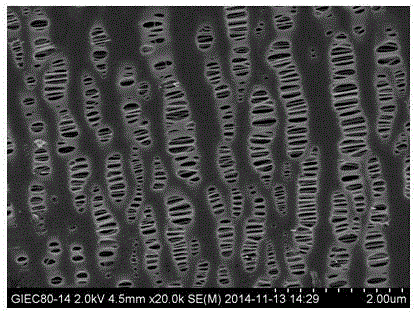

Method for preparing composite lithium-ion battery separator through electrostatic spinning/electrostatic spraying

InactiveCN103474610AExcellent heat shrinkage resistanceIncrease fluid retentionCell component detailsNon-woven fabricsFiberOrganic solvent

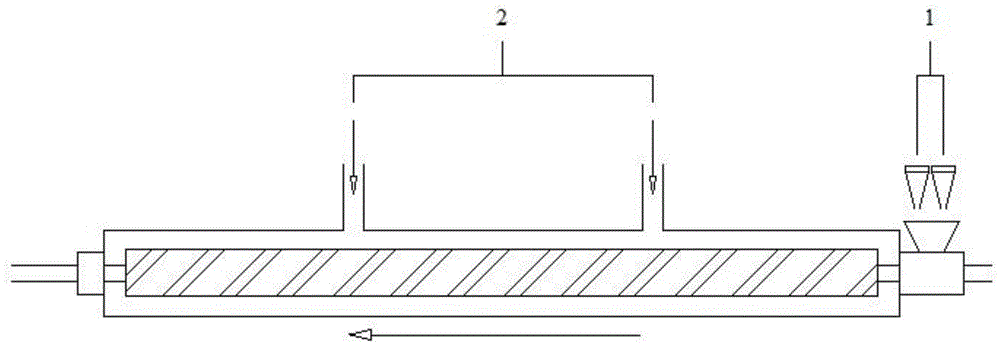

The invention relates to the field of lithium-ion batteries, in particular to a method for preparing a composite lithium-ion battery separator through electrostatic spinning / electrostatic spraying. The method specifically includes the steps of firstly, adding high molecular polymer into an organic solvent, dissolving the high molecular polymer through mechanical stirring to form a transparent solution, and obtaining an electrostatic spinning solution; secondly, mixing inorganic nanometer particles with the high molecular polymer and adding the mixture into the organic solvent, and conducting mechanical stirring to obtain inorganic nanometer particle suspension liquid; thirdly, conducting electrostatic spinning on the spinning solution prepared in the first step to prepare a lower layer nanometer fiber film, and enabling the inorganic nanometer particle suspension liquid prepared in the second step to be deposited on the lower layer nanometer fiber film through electrostatic spraying to obtain an interlayer; finally, receiving an electrostatic spun nanometer fiber layer on an inorganic particle layer to obtain the composite lithium-ion battery separator. The composite lithium-ion battery separator has the high imbibing rate and good electrochemical stability under the room temperature and has good heat shrinkage resistance performance at the same time.

Owner:TIANJIN POLYTECHNIC UNIV

Heat-not-burn cigarette smoke cooling material and application thereof

ActiveCN108143004AAvoid heat shrinkage defectsExcellent heat shrinkage resistanceTobacco devicesCooling effectHeat not burn

The invention discloses a heat-not-burn cigarette smoke cooling material and application thereof. The heat-not-burn cigarette smoke cooling material is prepared from, by mass, polymer 50-75%, layerednano material 5-15%, fibrous nano material 4-15%, phase change material 5-10% and metal powder 3-10% by adopting screw extrusion processing. The heat-not-burn cigarette smoke cooling material has highheat resistant shrinkage by means of addition of the layered nano material and the fibrous nano material, and the defect that a polylactic acid cooling material shrinks due to heat is avoided; the exogenous phase change material is added, so that the heat-not-burn cigarette smoke cooling material has a better cooling effect; in addition, the heat-not-burn cigarette smoke cooling material has a low interception rate of smoke, and the suction experience is not affected basically.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Composite microporous film, and production method and use thereof

ActiveCN1882436AGood adhesionHigh mechanical strengthSemi-permeable membranesFinal product manufactureDebyePolyolefin

Disclosed is a composite microporous film which is obtained by applying a liquid mixture containing (a) a fluororesin which can be gelated, (b) a good solvent therefor and (c) a poor solvent therefor having a dipole moment of not more than 1.8 Debye to at least one surface of a polyolefin microporous film and drying it, thereby forming a coating layer composed of a porous body of the fluororesin on the surface. The composite microporous film has columnar through holes in the coating layer, and has an excellent balance among permeability, adhesion to electrodes, mechanical strength, thermal shrinkage resistance, shutdown characteristics and meltdown characteristics.

Owner:TORAY IND INC

Lithium ion battery diaphragm with hydrophilic cross-linking surface layer and manufacture method of lithium ion battery diaphragm

ActiveCN102779965AExcellent heat shrinkage resistanceGood dimensional stabilityCell component detailsLithium electrodeGraft reaction

The invention relates to a lithium ion battery diaphragm with a hydrophilic cross-linking surface layer and the manufacture method of the lithium ion battery diaphragm. The battery diaphragm is a polyolefin microporous film; and the manufacture method comprises: (1) surface pretreatment of the polyolefin microporous film, (2) surface grafting reaction of the polyolefin microporous film, (3) cross-linking of a surface hydrophilic layer of the polyolefin microporous film; and (4) post-treatment of the polyolefin microporous film. The prepared microporous film can still keep the original porosity and penetration rate, and is improved obviously in the surface hydrophilicity so as to facilitate the full wetting of electrolyte on the surface of the diaphragm, thereby lowering the internal resistance of the lithium ion battery and realizing the excellent cycling performance and higher charging-discharging efficiency of the battery. Meanwhile, the heat-resistant contraction performance and the size stability of the diaphragm under heating are improved, thereby improving the use safety of the lithium ion battery.

Owner:扬州市永佳车辆配件有限公司

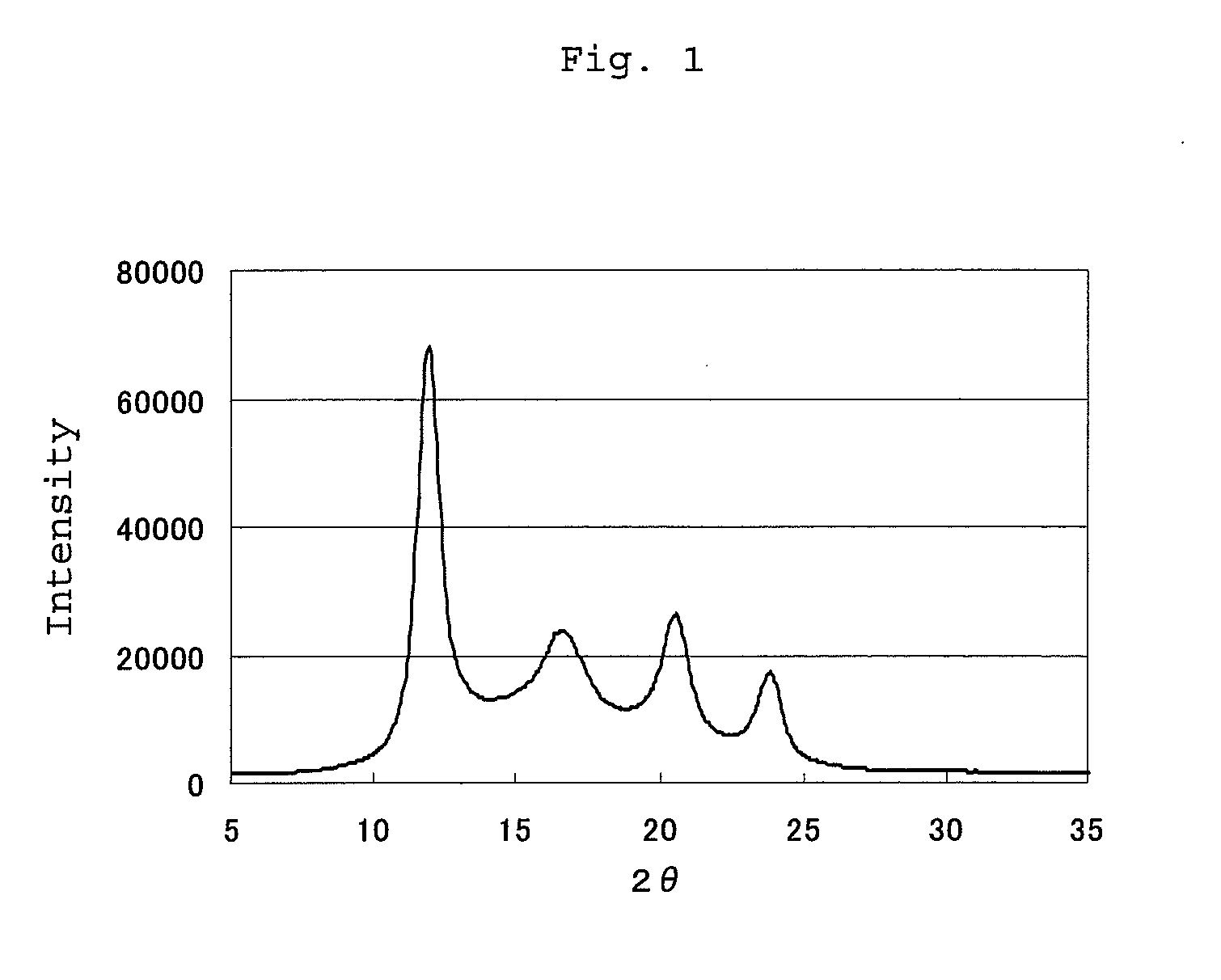

Highly crystalline silver powder and production method of highly crystalline silver powder

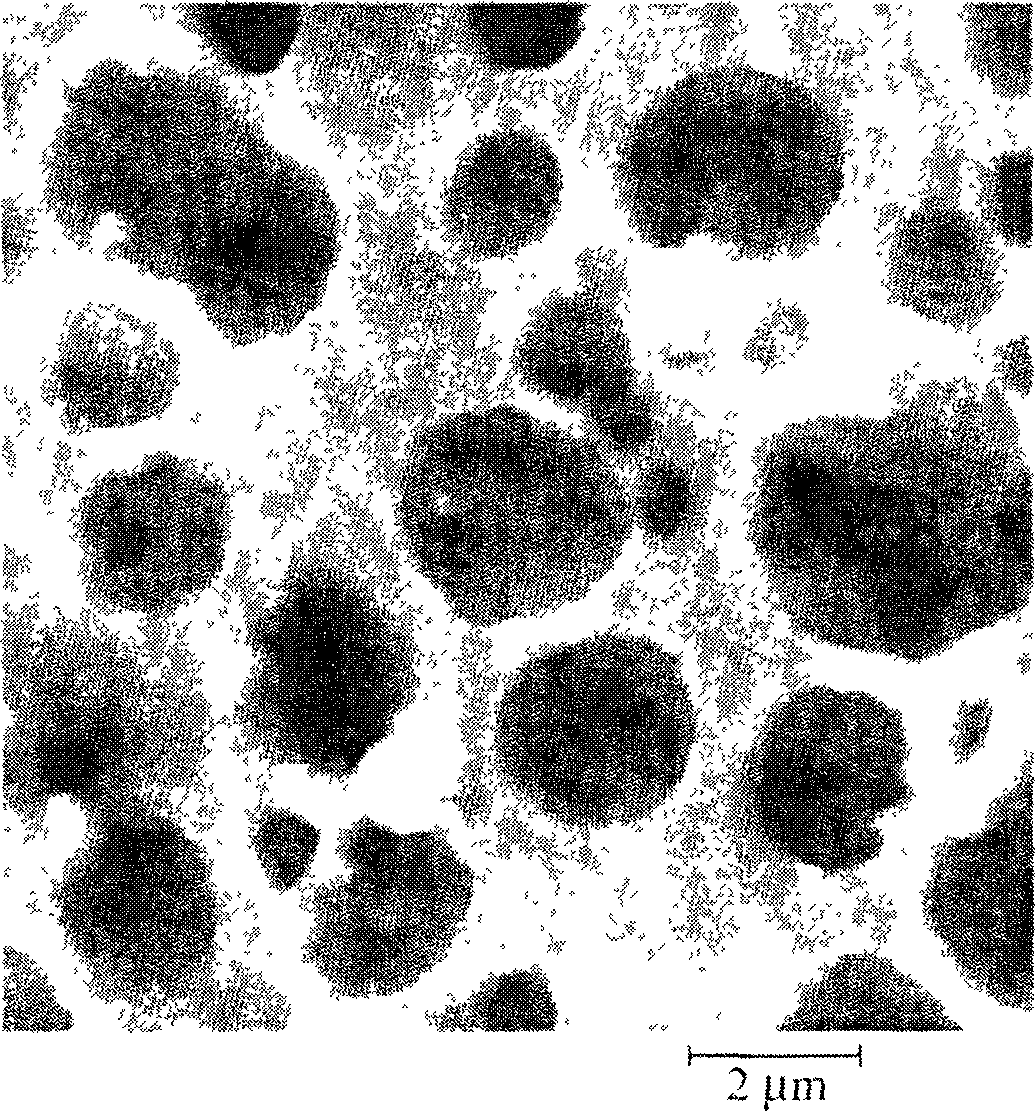

InactiveUS20090116998A1High yieldLarge crystallite diameterTransportation and packagingMetal-working apparatusOrganic acidSilver particles

Object of the present invention is to provide a production method of a highly crystalline silver powder containing powder particles in fine particle region and having a good particle size distribution as well as the highly crystalline silver powder obtained by the production method. In order to achieve the object, the present invention adopts a production method characterized in that the method comprises preparation of a first aqueous solution in which gelatin, silver nitrate and nitric acid are dissolved in water, preparation of a second aqueous solution in which L-sorbic acid and / or ascorbic acid and a water-soluble organic acid are dissolved, adding of the second aqueous solution slowly to mix with the first aqueous solution, stirring of the mixture to grow the silver particles after finishing the mixing, keeping of the mixture still to settle the silver particles, discarding of the supernatant, filtration and rinsing to obtain the highly crystalline silver powder.

Owner:MITSUI MINING & SMELTING CO LTD

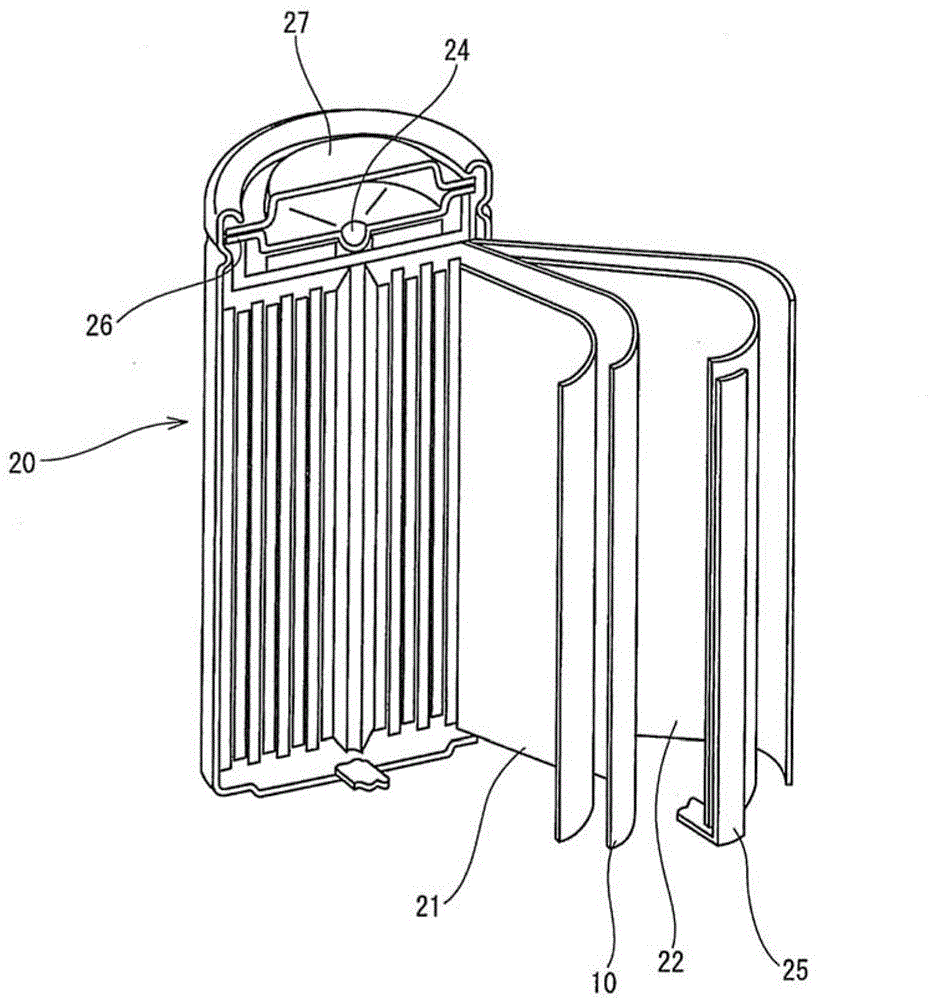

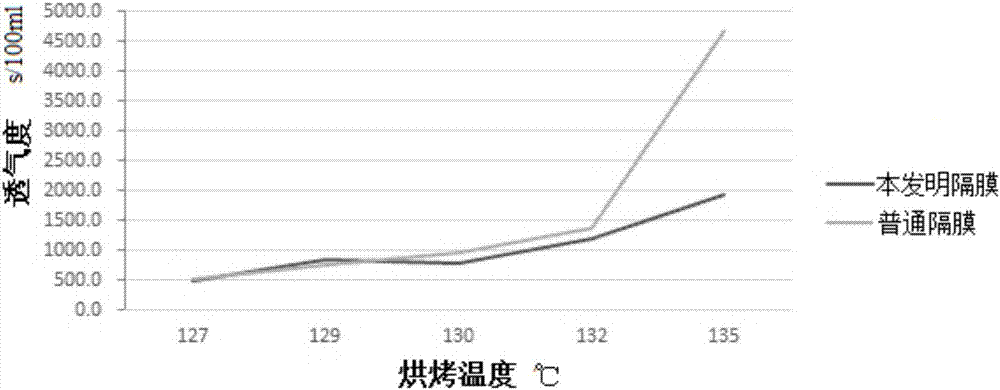

Battery separator

InactiveUS20140315065A1Improve physical stabilityHigh rateSemi-permeable membranesCell component detailsPolymer sciencePolyolefin

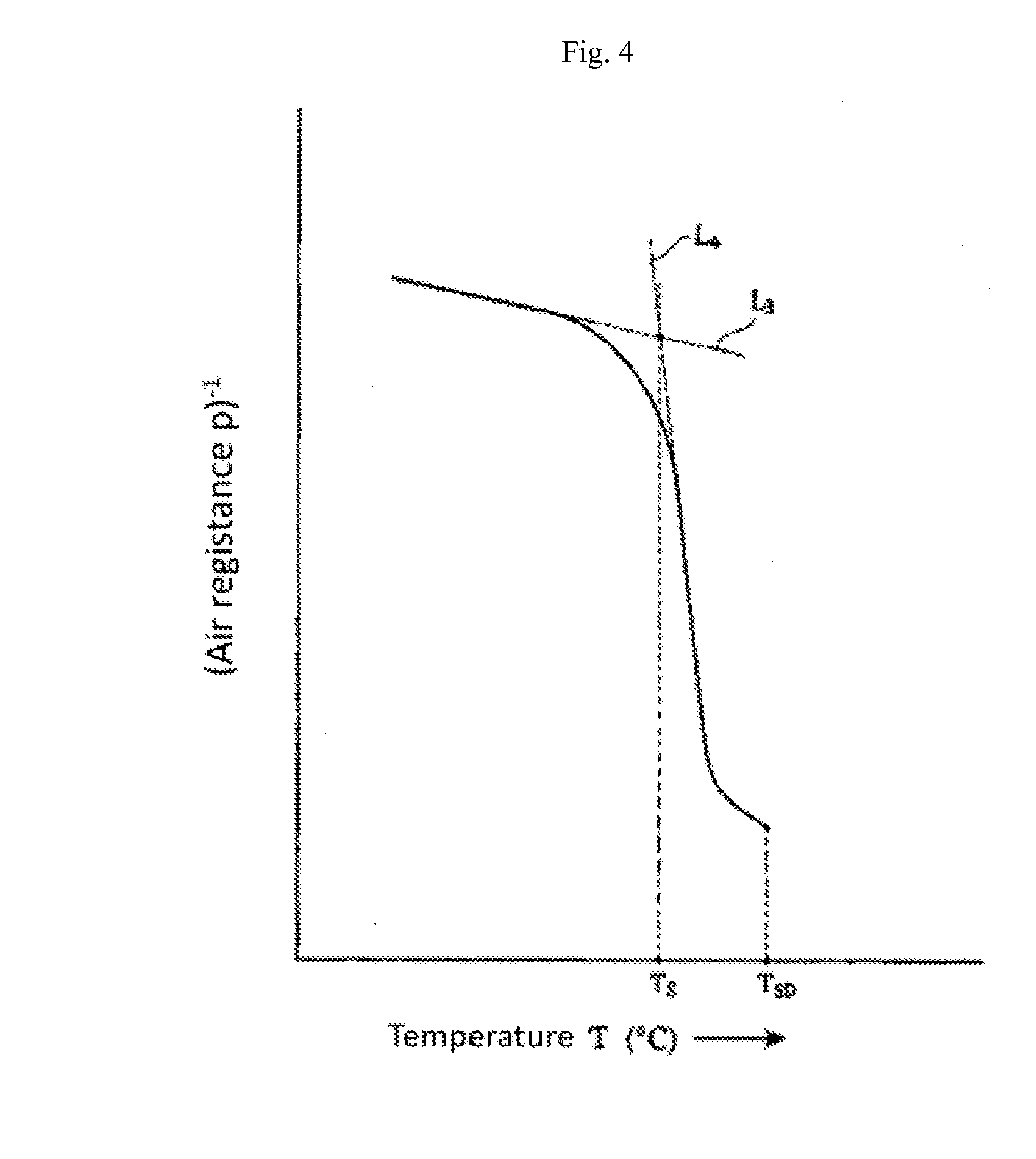

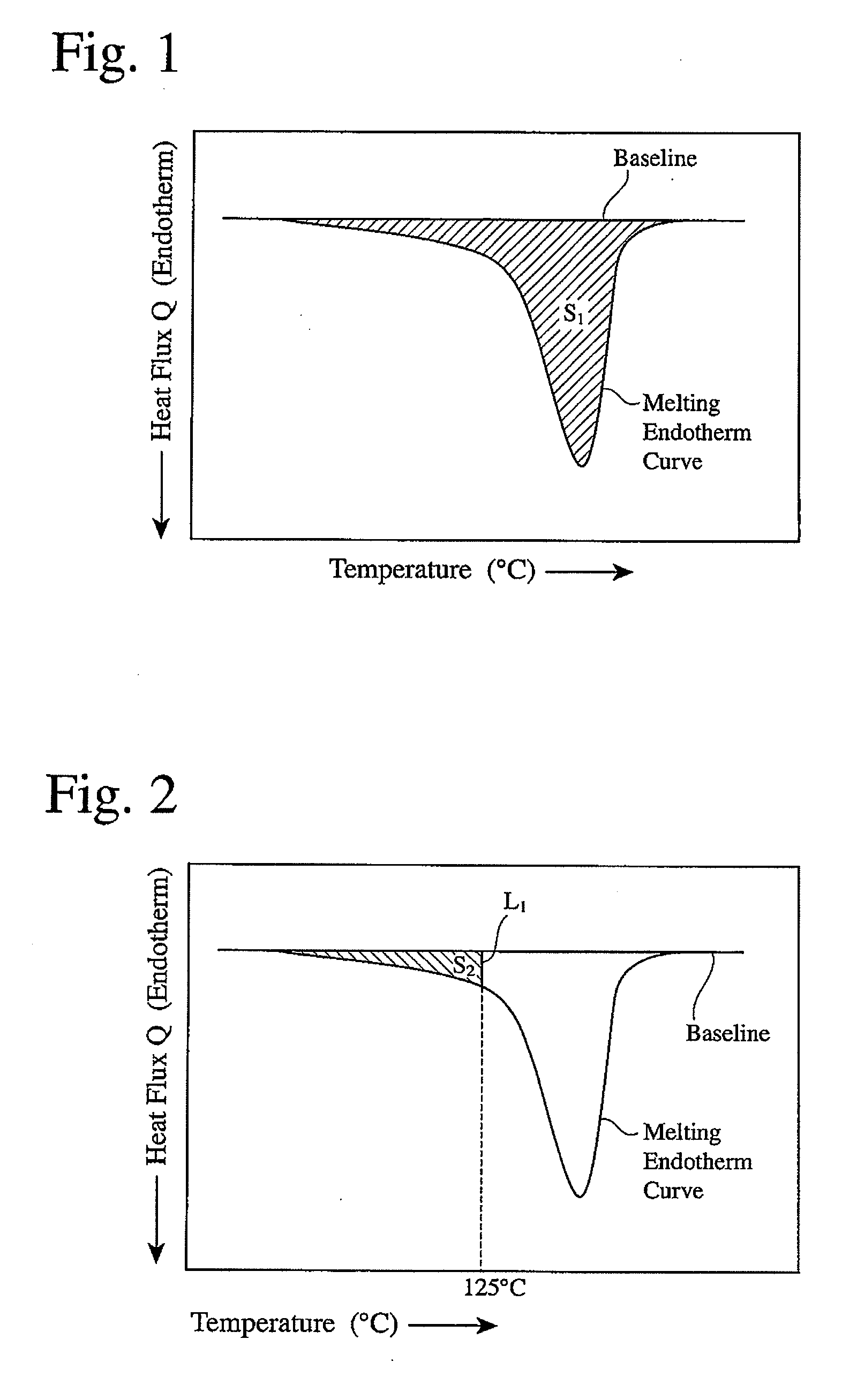

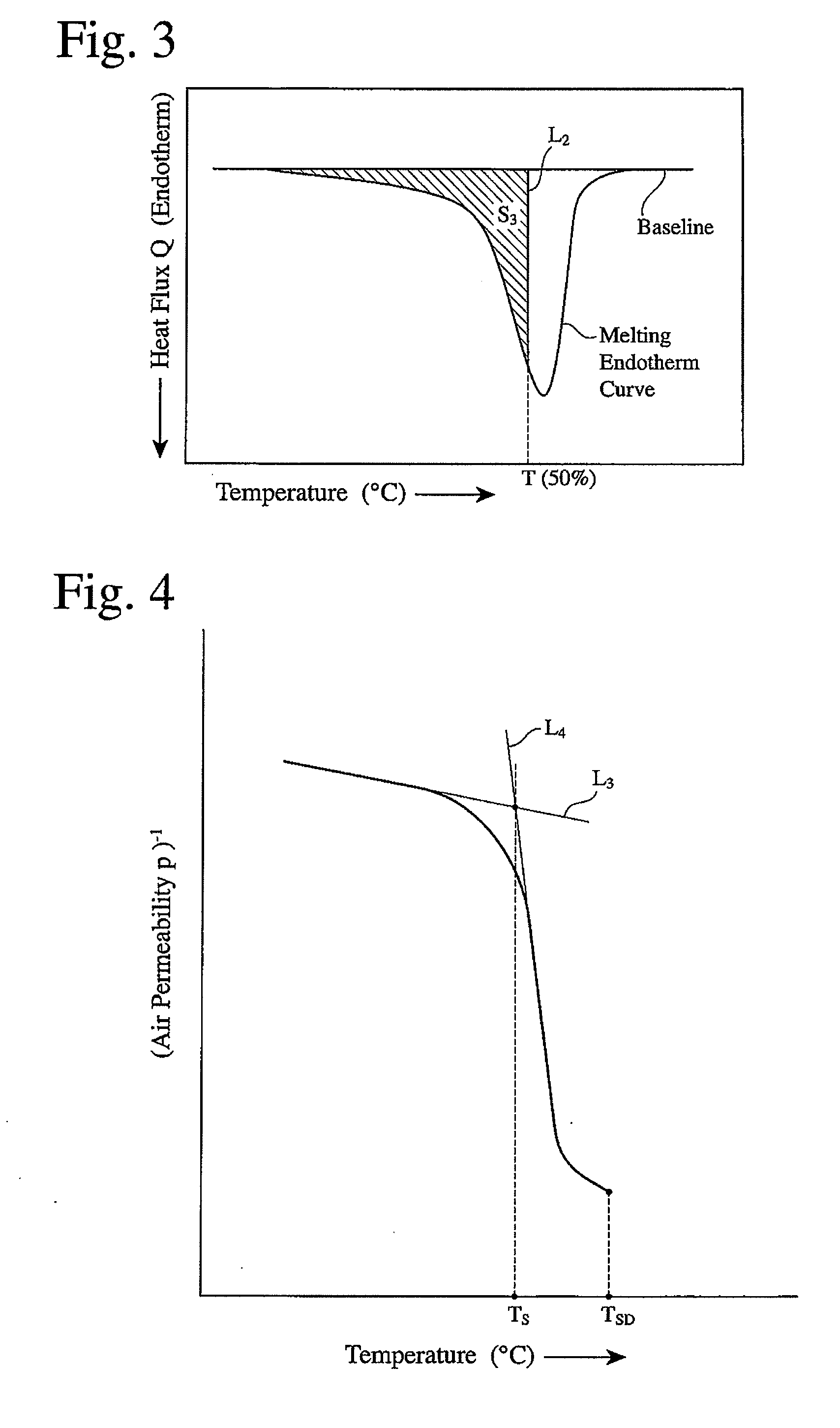

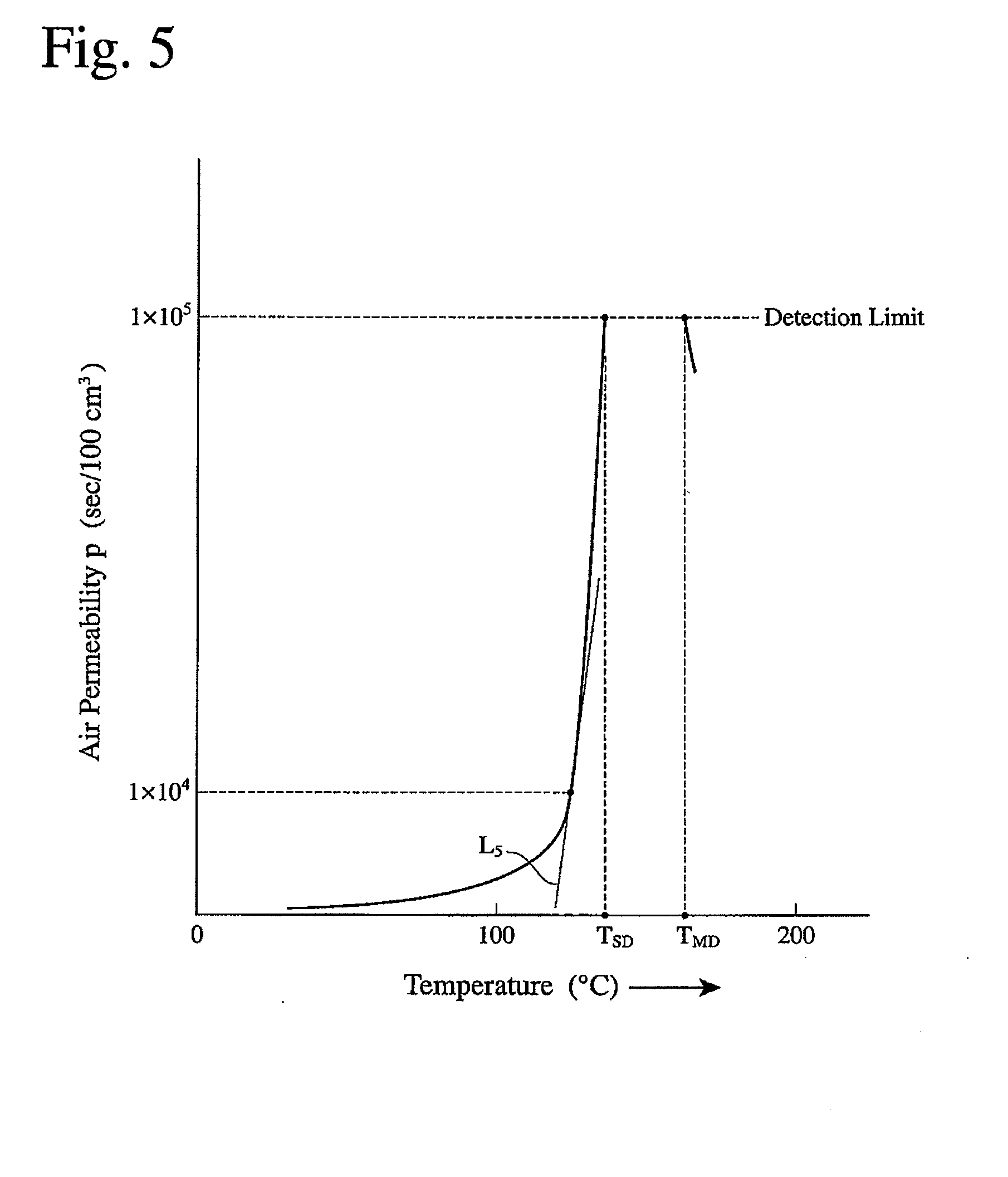

A battery separator includes a microporous polyolefin membrane and a modifying porous layer laminated on at least one surface of the microporous polyolefin membrane, wherein the microporous polyolefin membrane comprises a polyethylene resin, and the modifying porous layer is laminated on at least one surface of the microporous polyolefin membrane having (a) a shutdown temperature of 135° C. or lower, (b) a rate of air resistance change of 1×104 sec / 100 cc / ° C. or more, and (c) a transverse shrinkage rate at 130° C. of 20% or less.

Owner:TORAY BATTERY SEPARATOR FILM

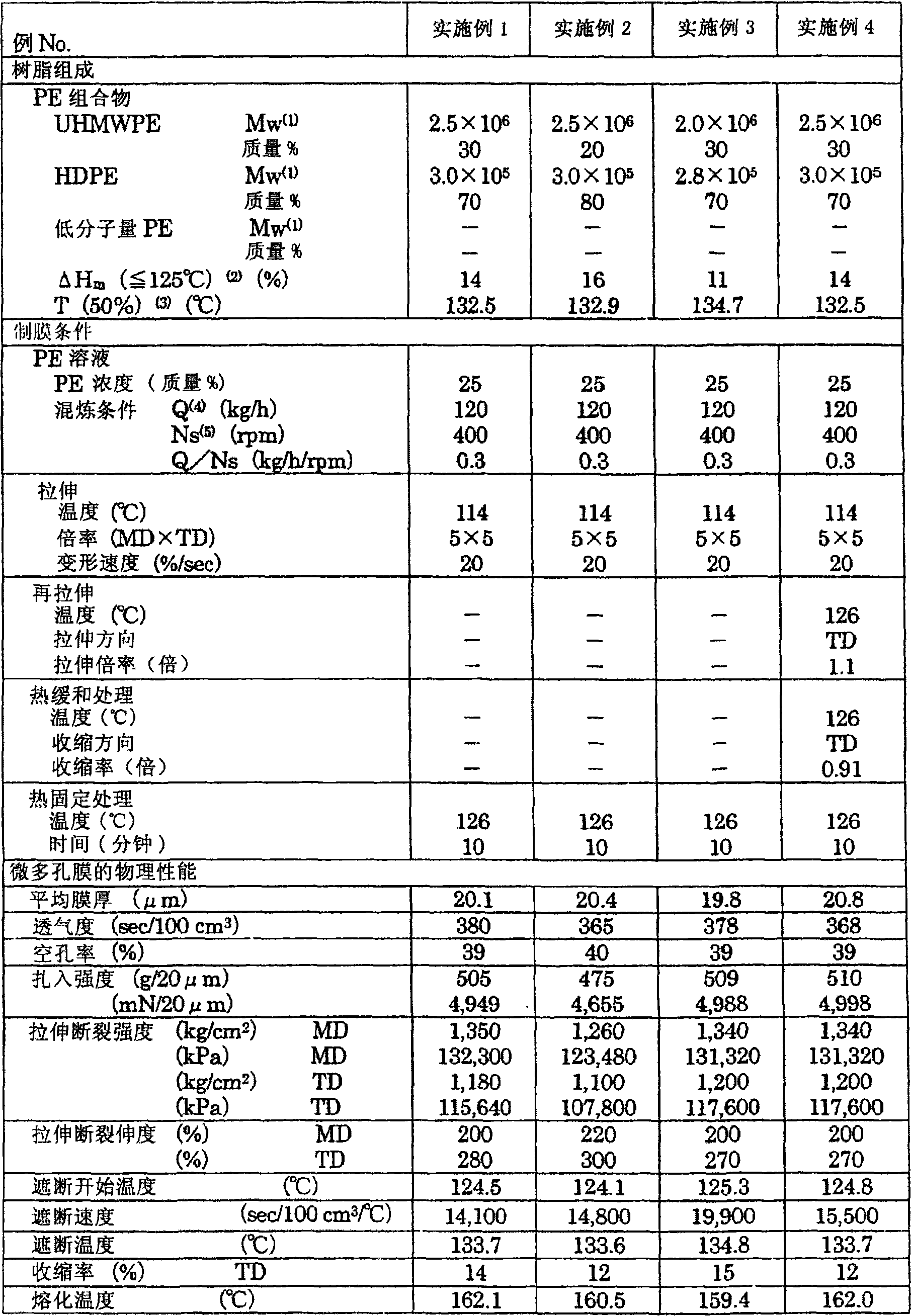

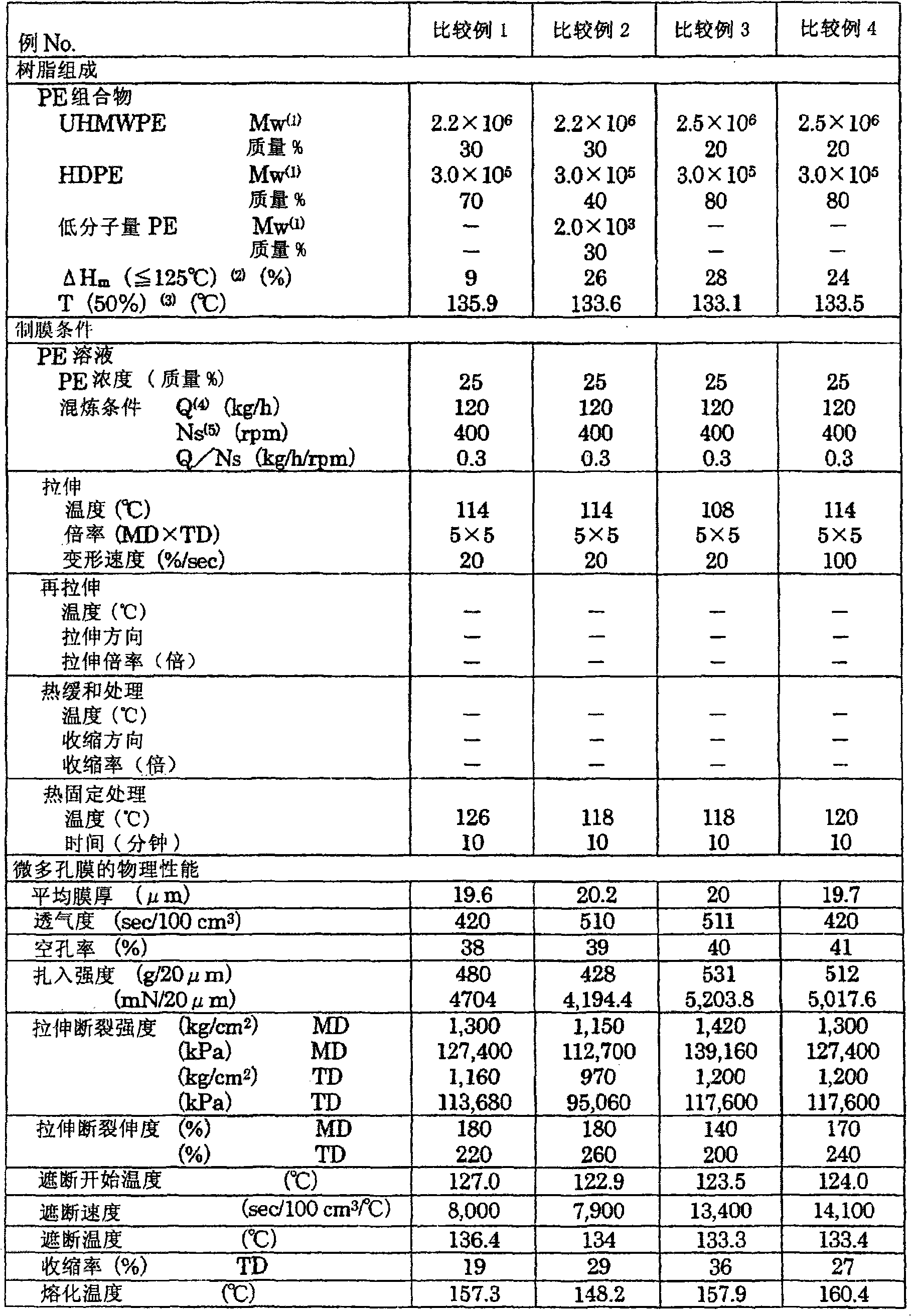

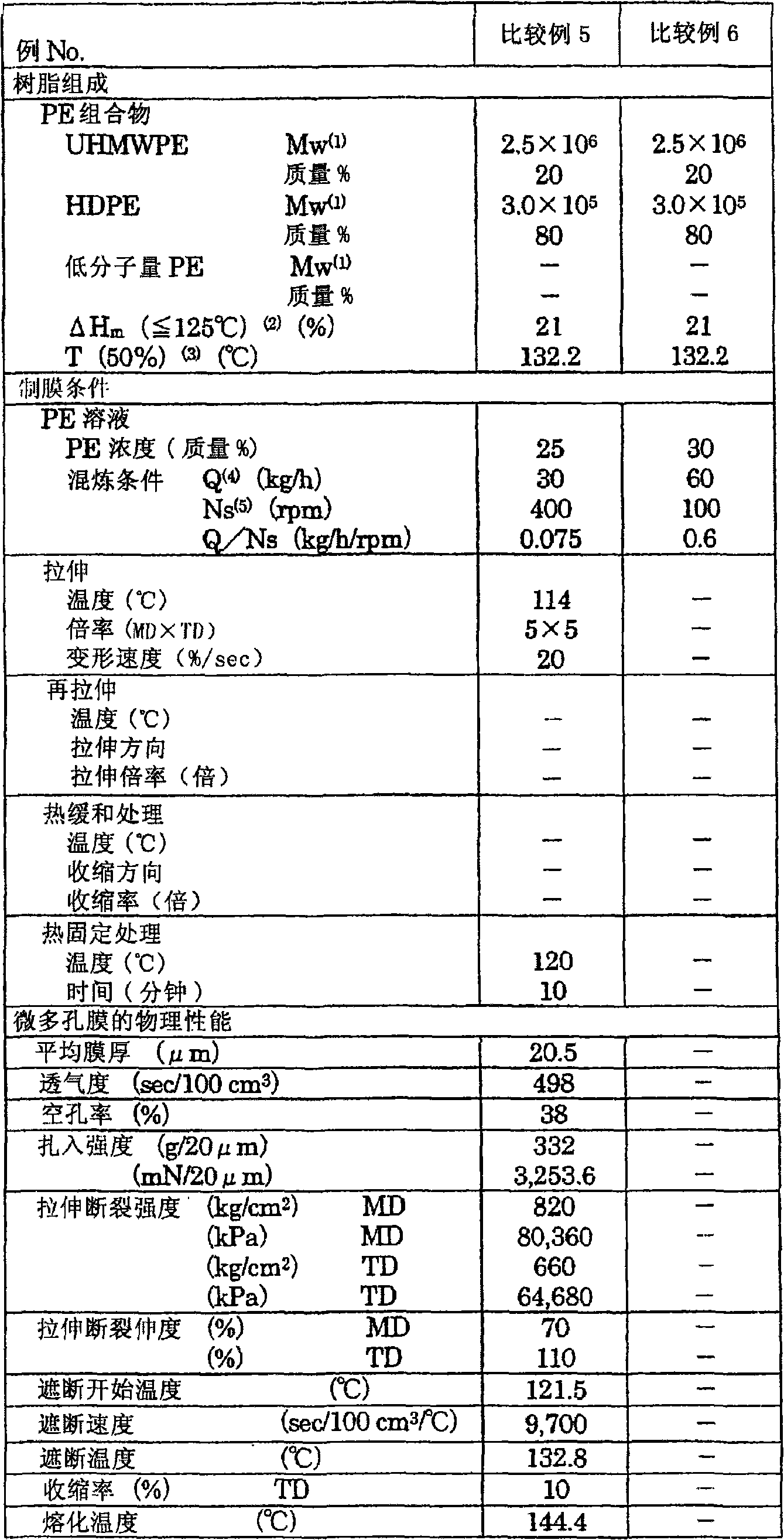

Microporous polyolefin membrane, its production method, battery separator and battery

InactiveUS20090042008A1Improve breathabilityExcellent heat shrinkage resistanceAlkaline accumulatorsAnimal housingPolymer sciencePolyolefin

A microporous polyolefin membrane comprising a polyethylene resin, and having (a) a shutdown temperature of 135° C. or lower, at which the air permeability measured while heating at a temperature-elevating speed of 5° C. / minute reaches 1×105 sec / 100 cm3, (b) a maximum melting shrinkage ratio of 40% or less in a transverse direction in a temperature range of 135 to 145° C., which is measured by thermomechanical analysis under a load of 2 gf and at a temperature-elevating speed of 5° C. / minute, and (c) a meltdown temperature, at which the air permeability measured while further heating after reaching the above shutdown temperature becomes 1×105 sec / 100 cm3 again, being 150° C. or higher.

Owner:TORAY BATTERY SEPARATOR FILM

Lithium battery diaphragm for power battery and preparation method thereof

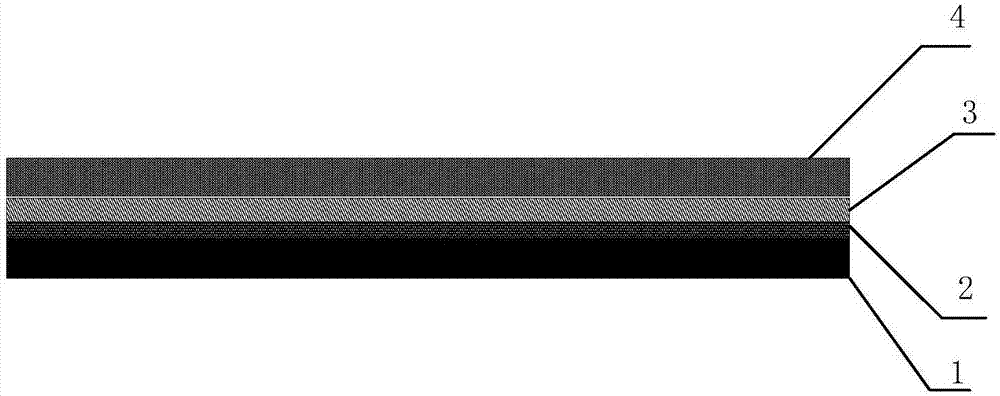

InactiveCN106935772AExcellent heat shrinkage resistanceAvoid large area short circuitLi-accumulatorsCell component detailsElectrospun nanofiberElectrical battery

The invention provides a lithium battery diaphragm for power vehicles. The diaphragm has four layers, the layers are respectively from bottom to top a base diaphragm, a nanometer flame retarding layer, an electrospun nanofiber layer and a thermal closed layer, wherein the base diaphragm is a PET nuclear pore membrane with a thickness of 5 microns-20 microns, the nano meter flame retardant layer is a flame retardant ceramic slurry with a thickness of 0.5 micron-10 microns, the thickness of the electrospun nano-fiber layer is 2 microns-5 microns, and the heat closed layer is a heat-resistant epoxy resin with a thickness of 5 microns-10 microns. The invention also provides a preparation method of the lithium battery diaphragm; the heat-resistance and shrinkage performance of the prepared lithium battery diaphragm can be greatly improved, the thermal stability and thermal closed property are significantly improved, and the security is very good.

Owner:湖南中智优库科技有限公司

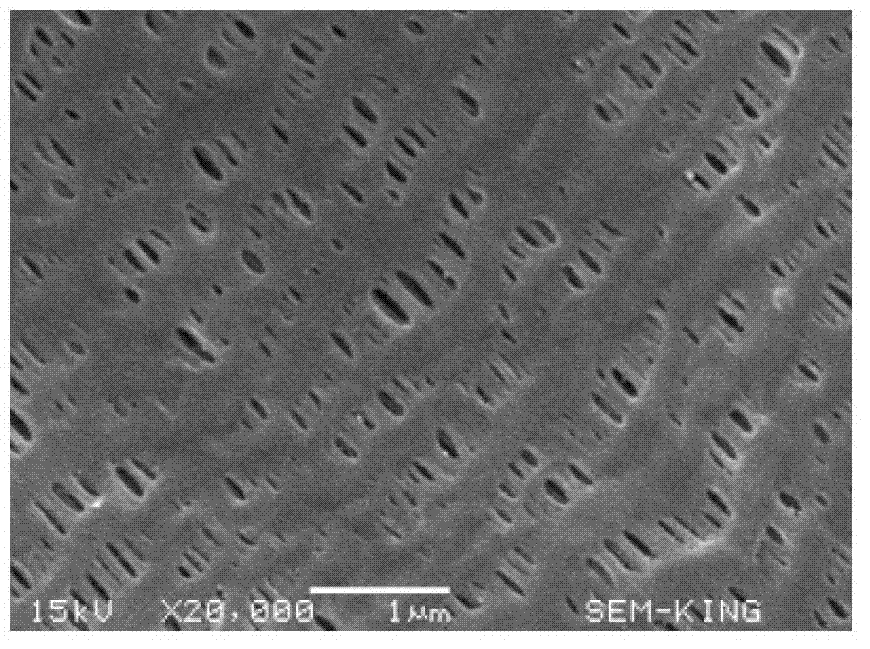

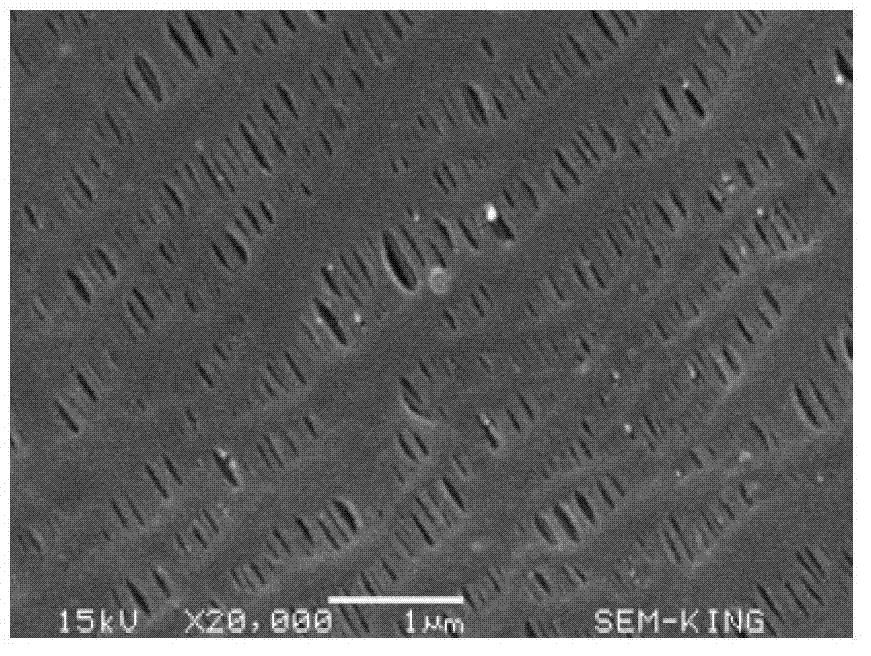

Highly crystalline silver powder and process for production of the same

InactiveCN101218051AExcellent heat shrinkage resistanceSmooth surface roughnessTransportation and packagingMetal-working apparatusFiltrationMicroparticle

The invention aims at providing a process for the production of highly crystalline silver powder which comprises silver particles falling within the fine particle region and has an excellent particle size distribution and highly crystalline silver powder obtained by the process. The aim is attained by a process for the production of highly crystalline silver powder which is characterized by preparing the first aqueous solution containing gelatin, silver nitrate and nitric acid and having a temperature of 45 to 55 C and the second aqueous solution containing erythorbic acid and / or ascorbic acid and a water-soluble organic acid, adding the second aqueous solution mildly to the first aqueous solution, stirring the mixed solution after the completion of the addition to form silver particles through particle growth, allowing the resulting system to stand to settle the silver particles, removing the supernatant, and then subjecting the remainder to filtration and washing to recover the silver particles.

Owner:MITSUI MINING & SMELTING CO LTD

Battery separator

ActiveCN104823304AExcellent electrode adhesionHigh rate of change in air tightnessSemi-permeable membranesCell component detailsHigh ratePolyolefin

Provided is a battery separator comprising a microporous polyolefin membrane and a modifying porous layer laminated on at least one surface of the microporous polyolefin membrane, wherein the microporous polyolefin membrane comprises a polyethylene resin, and the modifying porous layer is laminated on at least one surface of the microporous polyolefin membrane having (a) a shutdown temperature of 135°C or lower, (b) a rate of air resistance change of 1 × 10 4 sec / 100 cc / °C or more, and (c) a transverse shrinkage rate at 130°C of 20% or less. Provided is a battery separator having high physical stability before the start of shutdown, a high rate of air resistance change after the start of shutdown, excellent heat shrinkage resistance in a temperature range from a shutdown start temperature to a shutdown temperature, a low shutdown temperature, and excellent adhesion to electrode.

Owner:TORAY IND INC

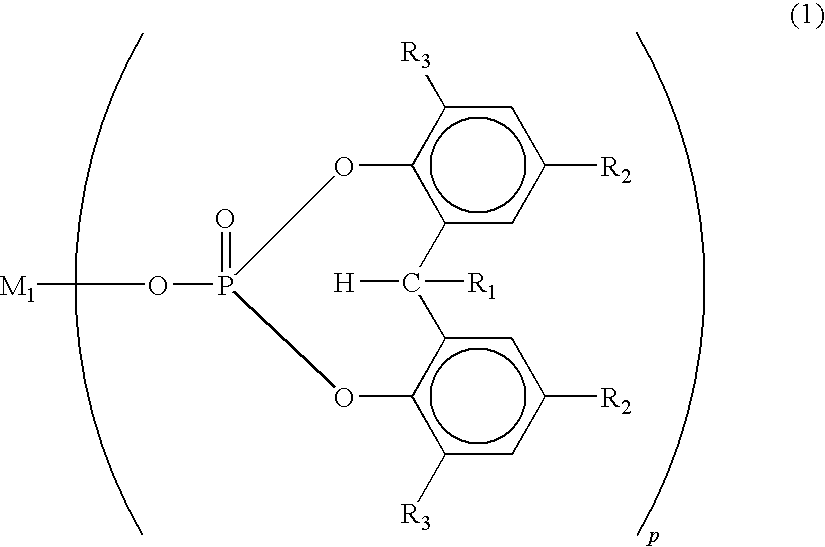

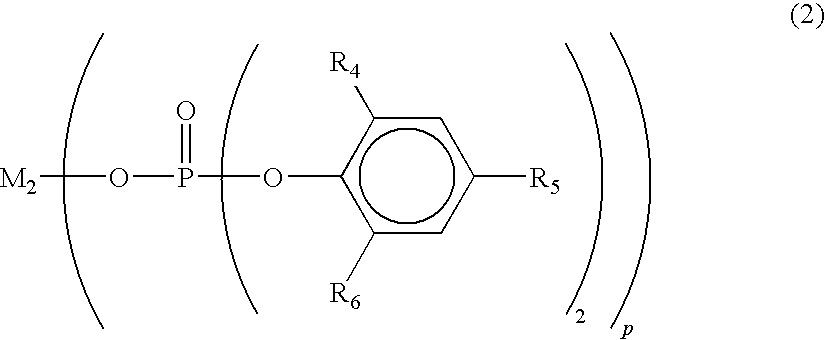

Slurry for secondary batteries

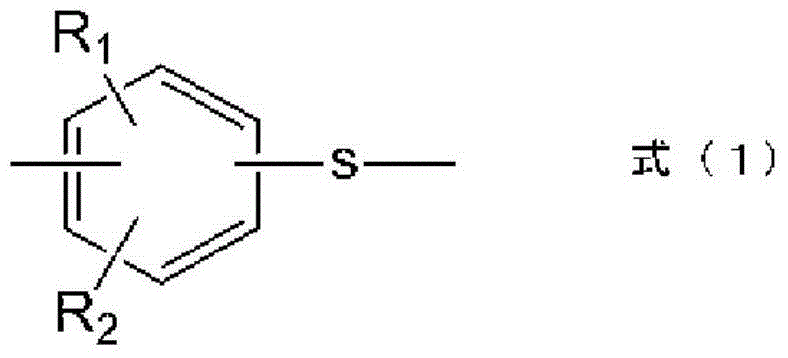

ActiveCN103797613AImprove securityExcellent cycle characteristicsElectrode manufacturing processesFinal product manufactureSlurryPhenyl group

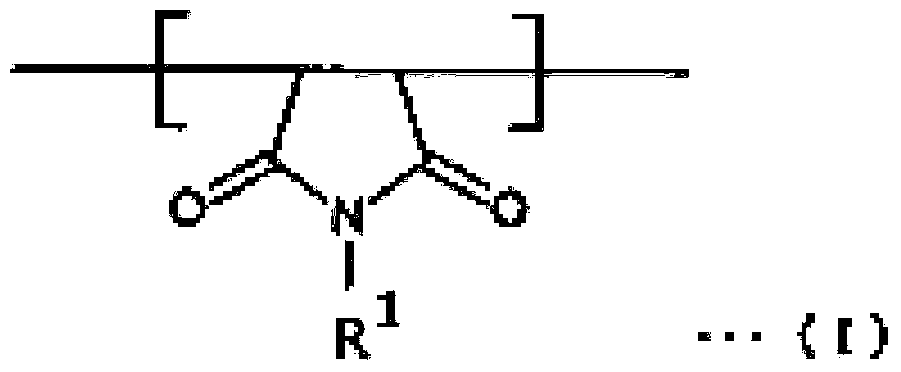

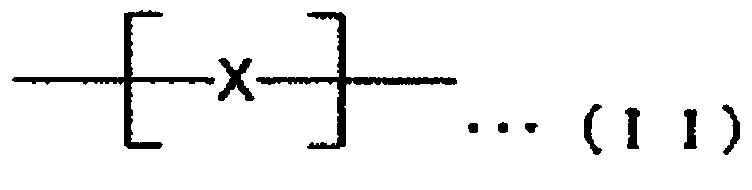

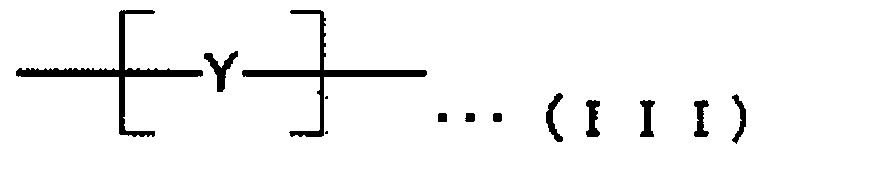

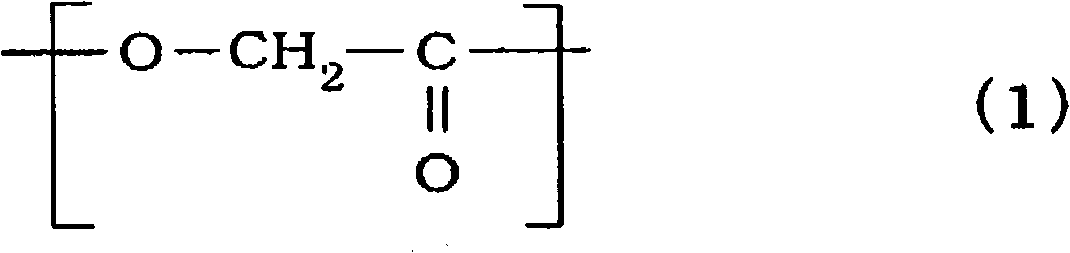

Slurry for secondary batteries, which is used for the production of a porous film that has excellent resistance to thermal shrinkage, is provided. The slurry contains non-conductive particles and a water-soluble polymer, wherein the water-soluble polymer is a maleimide-maleic acid copolymer that contains a structural unit (a) represented by general formula (I) and a structural unit (b) represented by general formula (II). In the formulae, R1 represents a hydrogen atom or a substituent selected from the group consisting of an alkyl group having 1-6 carbon atoms, a cycloalkyl group having 3-12 carbon atoms, a phenyl group and a hydroxyphenyl group; and X represents a maleic acid residue which may be neutralized by an ion other than a hydrogen ion, dehydrated or esterified.

Owner:ZEON CORP

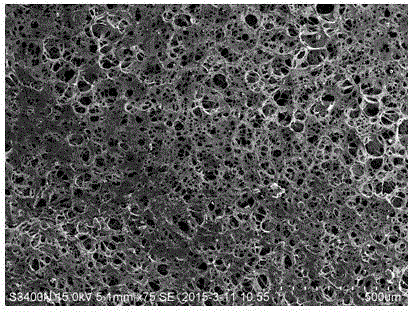

Multilayer porous film, separator for batteries, and battery

ActiveCN102917876AInhibit sheddingExcellent adhesionCell seperators/membranes/diaphragms/spacersSynthetic resin layered productsPolyolefinElectrical battery

The present invention is capable of providing a multilayer porous film which has high adhesion between a base layer and a coating layer and excellent heat resistance and exhibits excellent characteristics when used as a separator for a nonaqueous electrolyte secondary battery. A multilayer porous film which is obtained by laminating a coating layer that contains a filler and a resin binder on at least one surface of a polyolefin resin porous film that serves as a base layer. The ratio of the average particle diameter (Du) of the filler within 25% of the thickness of the coating layer from the surface of the multilayer porous film to the average particle diameter (Db) of the filler within 25% of the thickness of the coating layer from the interface with the base layer, namely, Du / Db is 1.2-10; and the average particle diameter (Du) is 0.5 [mu]m or less.

Owner:MITSUBISHI CHEM CORP

Heat-shrinkage-resistant lithium ion battery diaphragm and polyethylene composition adopted by same

ActiveCN106328859ALow costWide variety of sourcesCell seperators/membranes/diaphragms/spacersSecondary cellsHigh diaphragmPhysical chemistry

The invention provides a polyethylene composition for preparing a heat-shrinkage-resistant lithium ion battery diaphragm. The composition comprises high-molecular polyethylene, ultra-high-molecular polyethylene and an optional additive. The lithium ion battery diaphragm prepared from the composition has high heat shrinkage resistance, high tensile strength, high puncture strength, relatively high diaphragm-rupture temperature and relatively low closed-hole temperature, thereby ensuring safety in preparation and usage of the lithium ion battery.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

Successively biaxially stretched polyglycolic acid film, process for producing the successively biaxially stretched polyglycolic acid film, and multilayered film

InactiveCN101945749AExcellent gas barrier performanceHigh mechanical strengthSynthetic resin layered productsMedical devicesStretch ratioArea ratio

Disclosed is a process for producing a successively biaxially stretched polyglycolic acid film comprising a step (1) of unidirectionally stretching an amorphous polyglycolic acid sheet at a stretching temperature of 40 to 70 DEG C and at a primary stretch ratio of 2.5 to 7.0 to form a uniaxially stretched film, a step (2) of passing the uniaxially stretched film through an environment having a temperature which is in a range of 5 to 40 DEG C and is at least 5 DEG C below the stretching temperature of the step (1), a step (3) of stretching the uniaxially stretched film in a transverse direction transversely to the stretching direction in the step (1) at a stretching temperature, which is in a range of 35 to 60 DEG C and is at least 3 DEG C above the temperature adopted in the step (2), to form a biaxially stretched film having an area ratio of 11 to 30, and a step (4) of heat treating the biaxially stretched film at 70 to 200 DEG C.

Owner:KUREHA KAGAKU KOGYO KK

Preparation method of high-temperature-resistant low-resistivity lithium ion battery diaphragm

InactiveCN107342386AIncrease specific energyLow shrinkageSecondary cellsCell component detailsCarbon nanotubeSlurry

The invention relates to a preparation method of a high-temperature-resistant low-resistivity lithium ion battery diaphragm, and belongs to the technical field of battery diaphragms. A slurry layer is coated on one side end face or two side end faces of a basal membrane; then, after the slurry layer is dried, the high-temperature-resistant low-resistivity lithium ion battery diaphragm is obtained; the slurry layer is ceramic slurry or carbon nano tube modified ceramic slurry; and furthermore, the carbon nano tube modified ceramic slurry is at least coated on one side end face of the basal membrane. The invention further discloses a specific method for preparing the carbon nano tube modified ceramic slurry. By means of the preparation method in the invention, a steady and high-efficiency process is provided for producing the high-temperature-resistant low-resistivity lithium ion battery diaphragm; the prepared carbon nano tube modified ceramic slurry has low shrinkage ratio and high security of the ceramic slurry at high temperature, and also has high electric conductivity at normal temperature and low electric conductivity at high temperature of a carbon nano tube material; therefore, when the high-temperature-resistant low-resistivity lithium ion battery diaphragm is used in the field of electric automobiles, the charging time consumption problem of the electric automobiles can be solved; and the technical support is provided for development of clean energy automobiles.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

Polyolefin microporous film and its manufacture method, and spacer for battery and battery

ActiveCN101313016AImprove securityImprove productivityAlkaline accumulatorsLi-accumulatorsPolyolefinPorous membrane

Owner:TORAY IND INC

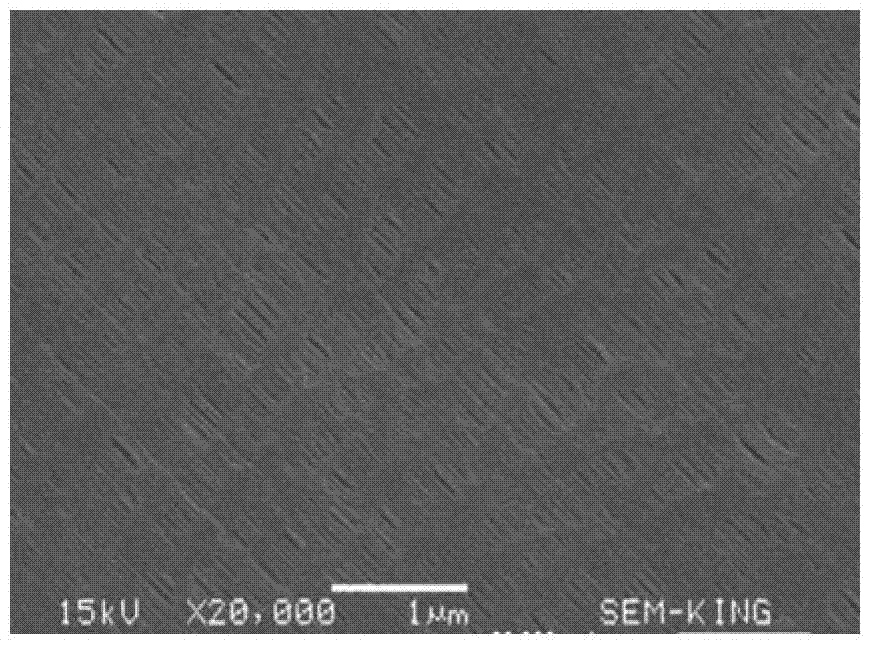

Highly crystalline silver powder and method for producing the same

InactiveUS20090023007A1Good dispersionEasy to fillMetal-working apparatusThin material handlingAqueous solutionParticle-size distribution

An object of the present invention is to provide highly crystalline silver powder which is characterized in fine particles, showing high dispersibility, it's particle size distribution is not excessively sharp but relatively broad and crystallites are large; and a method for producing the same. In order to achieve the object, a method for producing highly crystalline silver powder is characterized in that mixing a first aqueous solution and a second aqueous solution, wherein the first aqueous solution contains silver nitrate, a dispersing agent and nitric acid, and the second solution contains ascorbic acid. For dispersing agent, polyvinylpyrrolidone or gelatin is preferred. Highly crystalline silver powder produced by the above-described method is preferred to be a crystallite diameter of 300 Å or more, an average particle diameter D50 in the range from 0.5 μm to 10 μm, and a thermal shrinkage rate for the length direction after heating at 700° C. in the range from −3% to 3%. For ratio D90 / D10 of the silver powder is preferred to be in the range from 2.1 to 5.0.

Owner:MITSUI MINING & SMELTING CO LTD

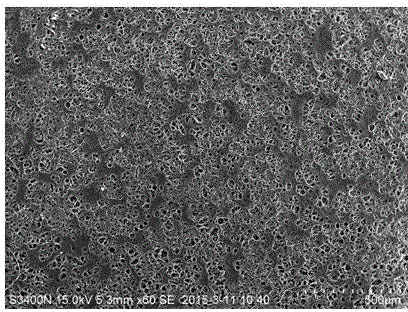

Microporous member, method for producing same, battery separator, and resin composition for nonaqueous electrolyte secondary battery separator

InactiveCN104583288AExcellent heat shrinkage resistanceCell component detailsPolyolefinElectrical battery

Provided are: a microporous membrane which contains a polyolefin and a thermoplastic resin (a) having a melting point of 220°C or more, said thermoplastic resin (a) having a needle-like structure; and a method for producing the microporous membrane. Since this microporous membrane uses a polyolefin and a high-melting-point thermoplastic resin having a needle-like structure, this microporous membrane has excellent thermal shrinkage resistance. Consequently, there can be provided a nonaqueous electrolyte secondary battery separator, especially a single layer separator for nonaqueous electrolyte secondary batteries, which has excellent shut-down function and thermal shrinkage resistance.

Owner:DIC CORP

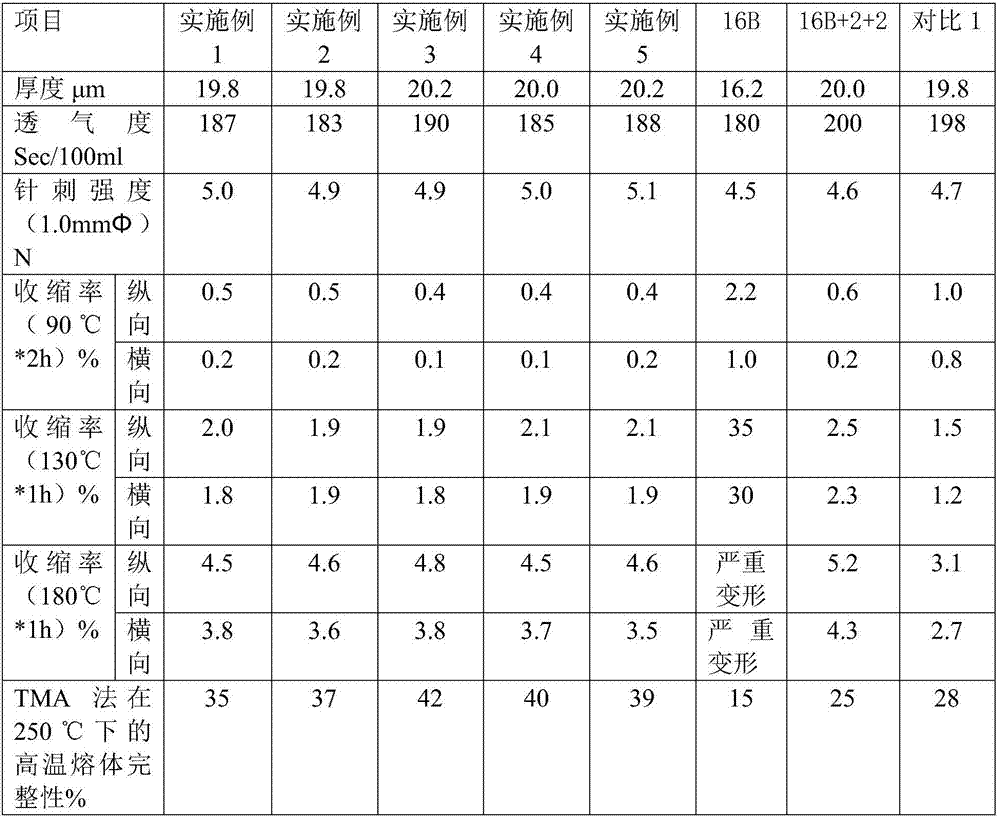

Heat shrinkage-resistant lithium-ion battery separator

ActiveCN106328867AExcellent heat shrinkage resistanceImprove performanceSecondary cellsCell component detailsPorosityInternal resistance

The invention discloses a heat shrinkage-resistant lithium-ion battery separator, which comprises a first outer layer, a second outer layer and an inner layer clamped between the first outer layer and the second outer layer, wherein the first outer layer, the second outer layer and the inner layer have different micropore structures. The heat shrinkage-resistant lithium-ion battery separator disclosed by the invention has excellent heat shrinkage resistance and good overall performance, has high puncture strength and tensile strength when reaching a relatively low thickness, can be applied to a relatively small battery and is not easily damaged in the installation process; a plurality of physical properties are taken into account; meanwhile, the heat shrinkage-resistant lithium-ion battery separator has good air permeability and porosity and small internal resistance; the capacity and the cycle performance of the battery are improved; and furthermore, the heat shrinkage-resistant lithium-ion battery separator also has relatively low closed pore temperature and membrane rupture temperature and high safety.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

POLYLACTIC ACID FIBER AND MANUFACTURING METHOD THEREOF( as amended

ActiveUS20100004362A1Improve heat resistanceExcellent heat shrinkage resistanceGroup 5/15 element organic compoundsDyeing processFiberPolymer science

An object of the present invention is to provide a fiber made of polylactic acid and having excellent strength, heat resistance and heat shrinkage resistance and a manufacturing method thereof.The present invention relates to the fiber is made of a composition which comprises (i) poly(L-lactic acid) having a weight average molecular weight of 50,000 to 300,000 (component A), (ii) poly(D-lactic acid) having a weight average molecular weight of 50,000 to 300,000 (component B) and (iii) 0.01 to 5 parts by weight of a phosphate metal salt (component C) based on 100 parts by weight of the total of the components A and B and has a strength of 2.5 to 10 cN / dTex and a manufacturing method thereof.

Owner:TEIJIN LTD

Ultrafine diamond coated diaphragm and lithium ion battery using diaphragm

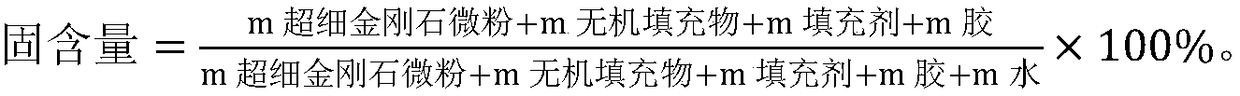

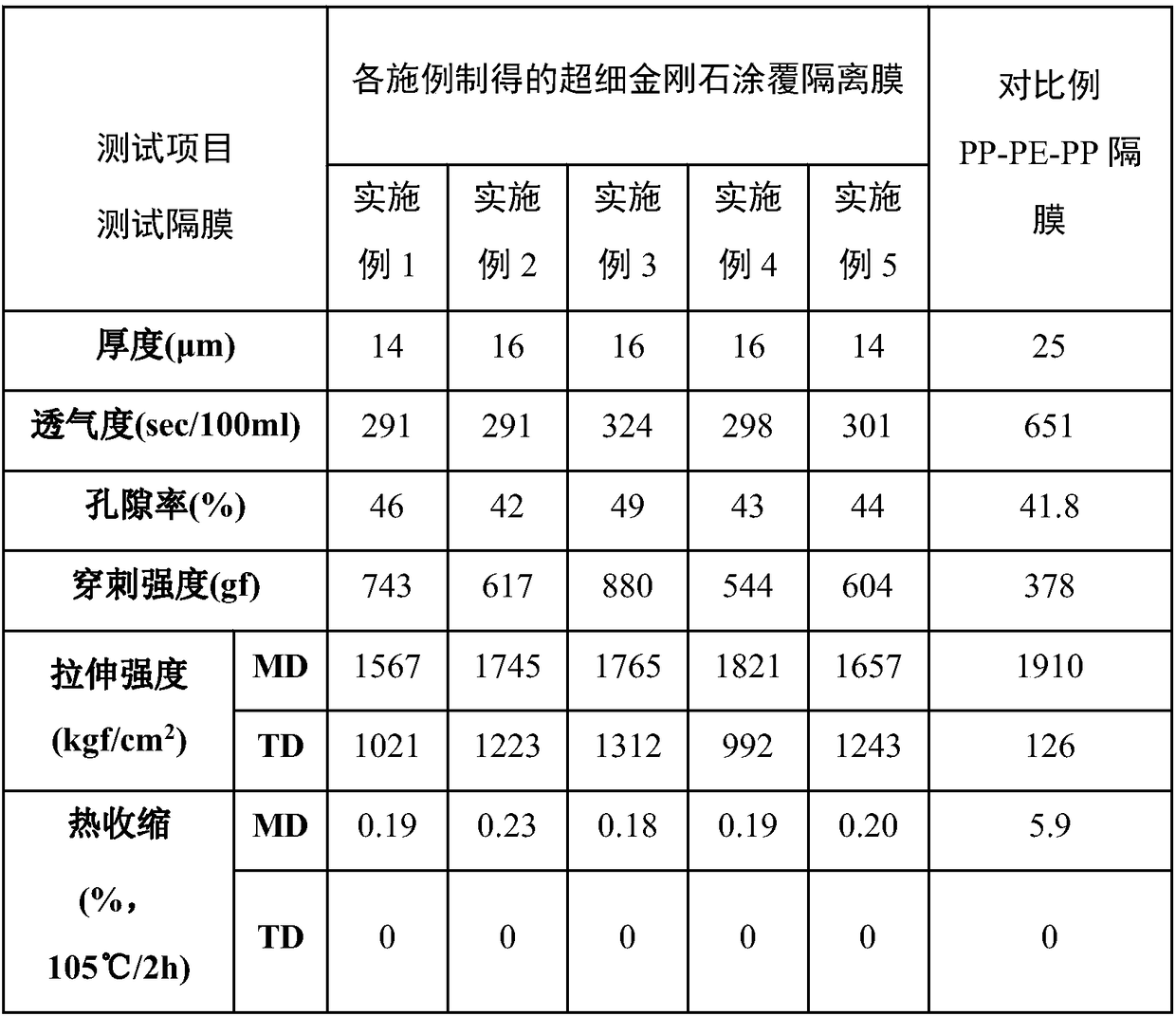

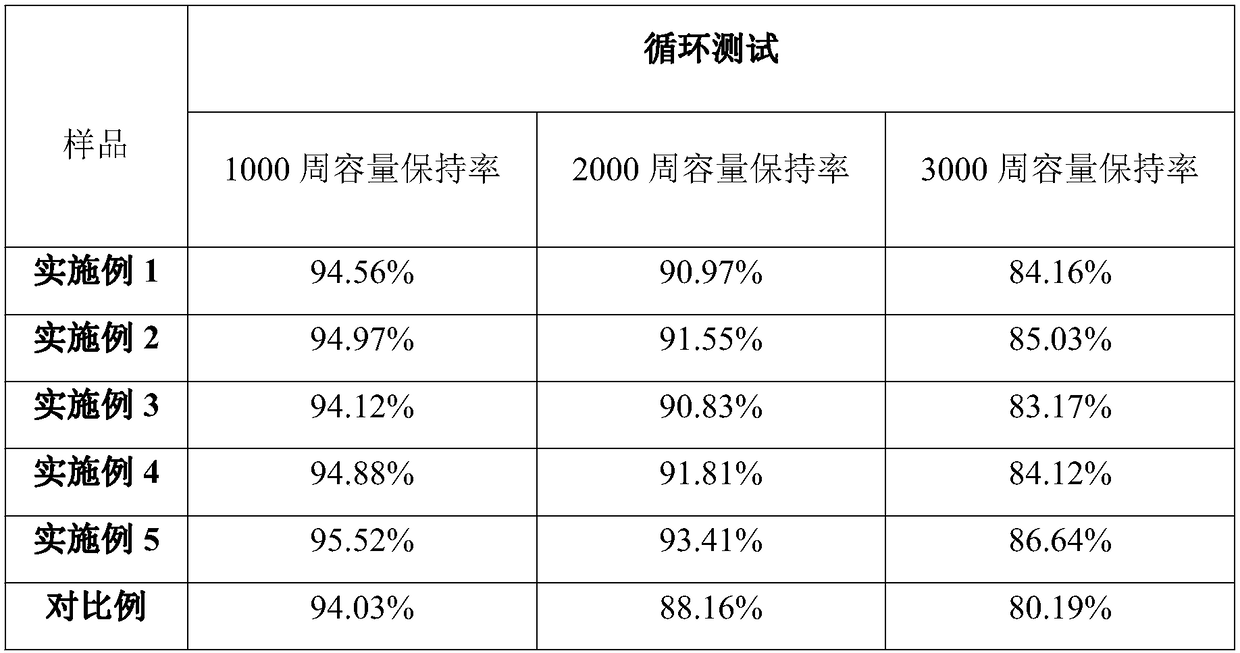

ActiveCN108550764AImprove microporous structureExcellent heat shrinkage resistanceSecondary cellsCell component detailsLithium electrodeInorganic filler

The invention belongs to the technical field of lithium ion batteries, and relates to an ultrafine diamond coated diaphragm, a preparation method thereof, and a lithium ion battery using the diaphragm. The ultrafine diamond coated diaphragm is prepared through the following steps: coating a base film with a slurry, and drying the coated base film, wherein the slurry contains, by mass, 65-85% of ultrafine diamond micro-powder and am inorganic filler, 10-25% of a filler and 3-15% of glue; and the mass of the ultrafine diamond micro-powder is 0.5-100% of the total mass of the ultrafine diamond micro-powder and the inorganic filler. The diaphragm makes micron-sized diamond crystal particles uniformly dispersed on the surface of the base film, so the micro-porous structure of the diaphragm is effectively strengthened, and the heat shrinkage resistance and the puncture strength are improved. The lithium ion battery using the diaphragm improves the transfer state of lithium ions in an electrode sheet interface, inhibits the lithium ions from accumulating into lithium element dendrite after the lithium battery is repeatedly circulated, and improves the safety and the cycle performances ofthe battery.

Owner:河南力旋科技股份有限公司

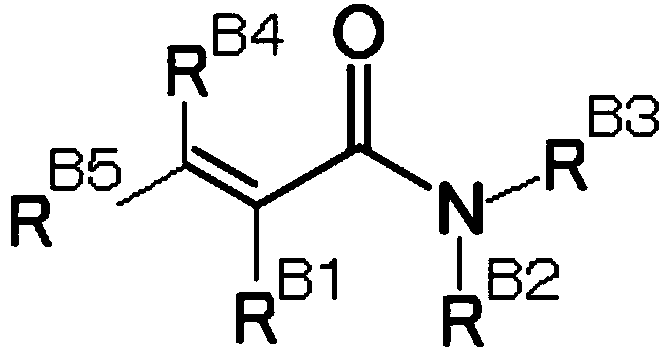

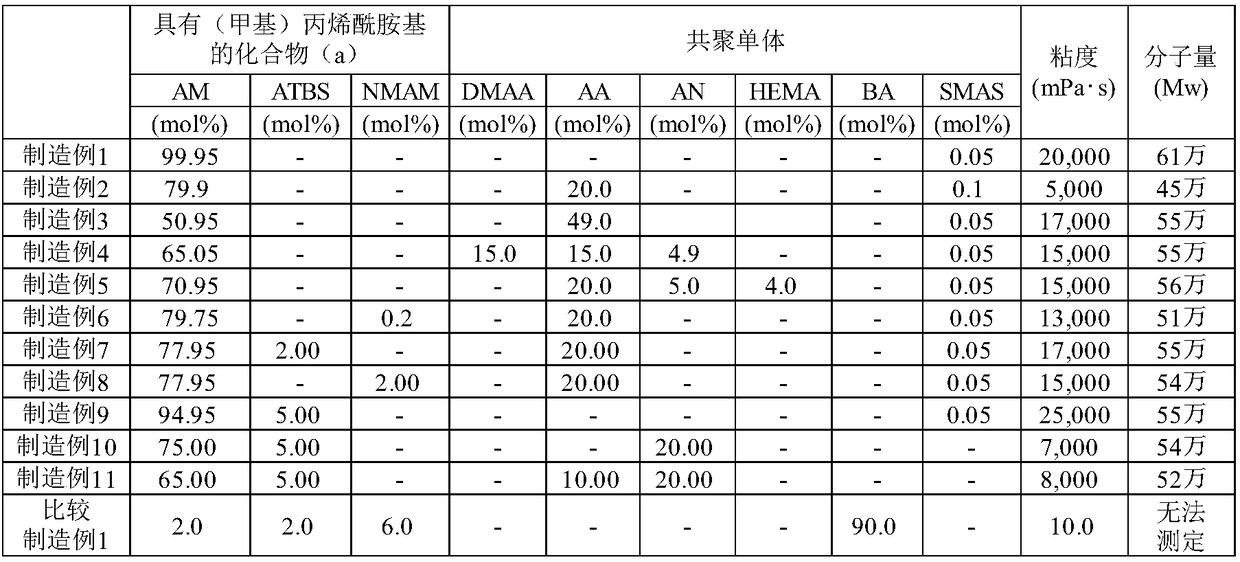

Thermal crosslinking type slurry for lithium ion battery, electrode, separator, separator/electrode laminate, and lithium ion battery

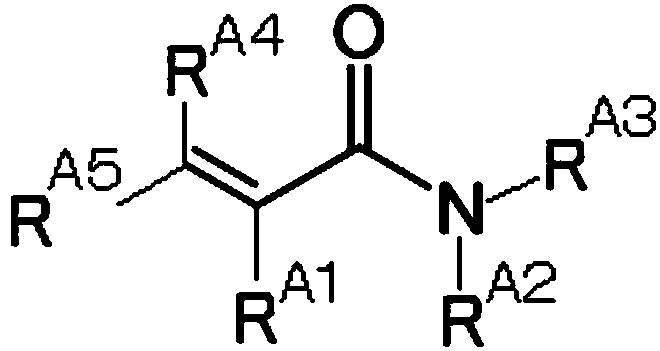

ActiveCN108666499AImprove battery lifeIncrease elasticityElectrode thermal treatmentCell seperators/membranes/diaphragms/spacersMeth-Hexamethylenetetramine

The present application provides a thermal crosslinking type slurry for a lithium ion battery, a method for producing the same, an electrode for a lithium ion battery, a separator for a lithium ion battery, a separator / an electrode laminate for a lithium ion battery, and a lithium ion battery. The present application provides the thermal crosslinking type slurry for the lithium ion battery, comprising: a water-soluble poly(meth)acrylamide (A), which is 100% by mole based on the structural unit, wherein the water-soluble poly(meth)acrylamide (A) contains 50% by mole or more of a structural unit derived from the compound (a) having an N-unsubstituted or monosubstituted (meth)acrylamide group; a water-soluble crosslinking agent (A1), wherein the water-soluble crosslinking agent (A1) containsone or more selected from the group consisting of formaldehyde, glyoxal, hexamethylenetetramine, urea-formaldehyde resin, and methylol melamine resin; and water.

Owner:ARAKAWA CHEM IND LTD

Preparation method of self-cooled and hole-closing-resistant lithium ion battery diaphragm

The invention discloses a preparation method of a self-cooled and hole-closing-resistant lithium ion battery diaphragm, and belongs to the technical field of the battery diaphragm. The slurry layer is arranged at one side end surface or two side end surfaces of a basement membrane, thereby obtaining the self-cooled and hole-closing-resistant lithium ion battery diaphragm after the drying; the slurry layer is the ceramic slurry or the erythritol modified ceramic slurry, the erythritol modified ceramic slurry is at least coated at one side end surface, and the specific method for preparing the erythritol modified ceramic slurry is disclosed. The preparation method disclosed by the invention provides the stable and efficient process of the self-cooled and hole-closing-resistant lithium ion battery diaphragm; the prepared erythritol modified ceramic slurry has low shrinkage and high security at the high temperature of the ceramic slurry.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

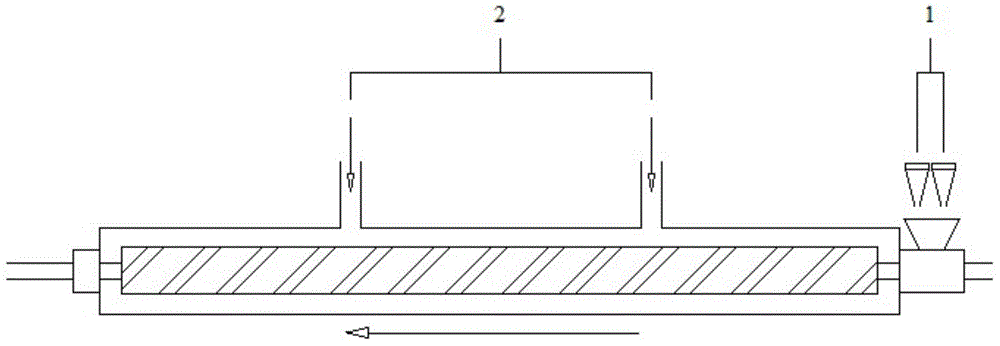

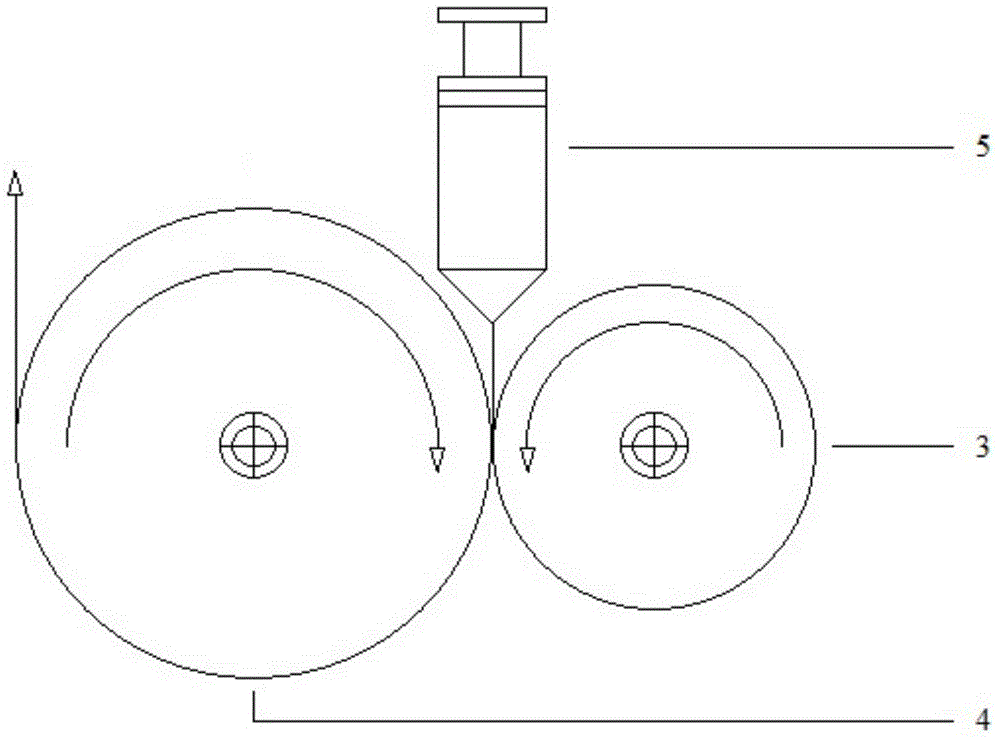

Preparation method of heat shrinkage-resistant lithium-ion battery separator

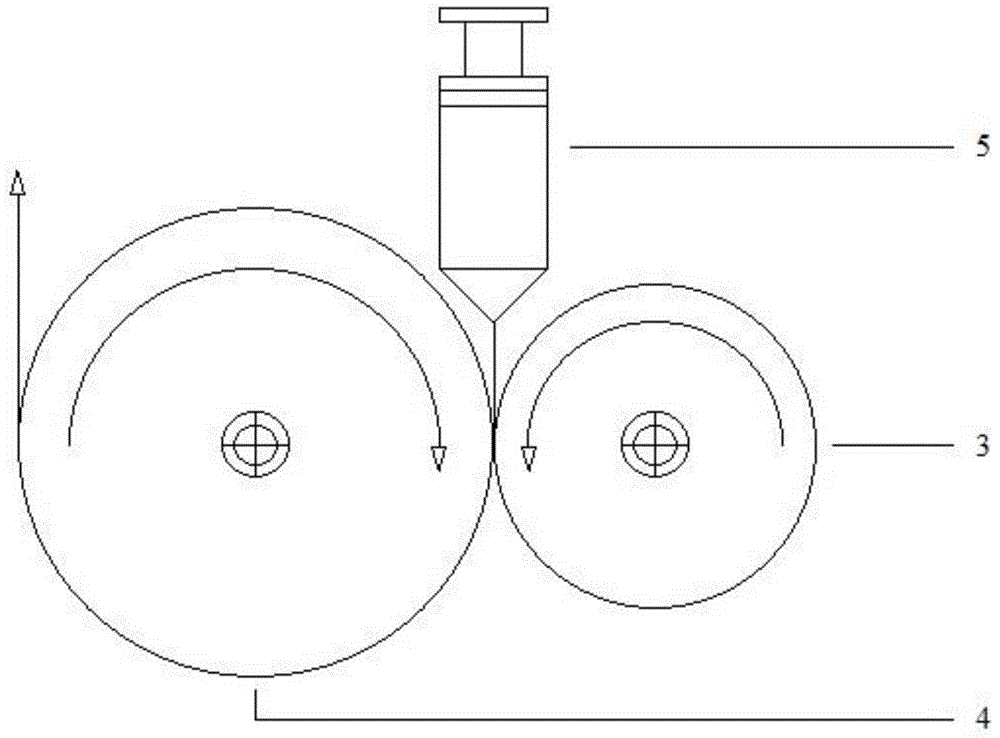

ActiveCN106328861AExcellent heat shrinkage resistanceImprove performanceCell component detailsStretch zoneLithium electrode

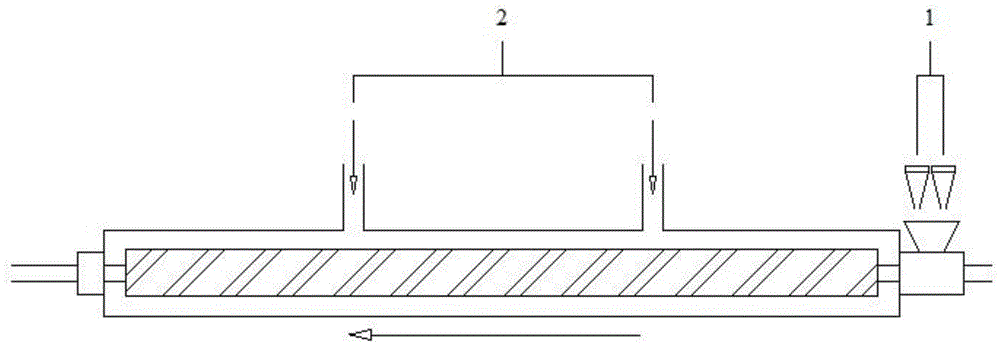

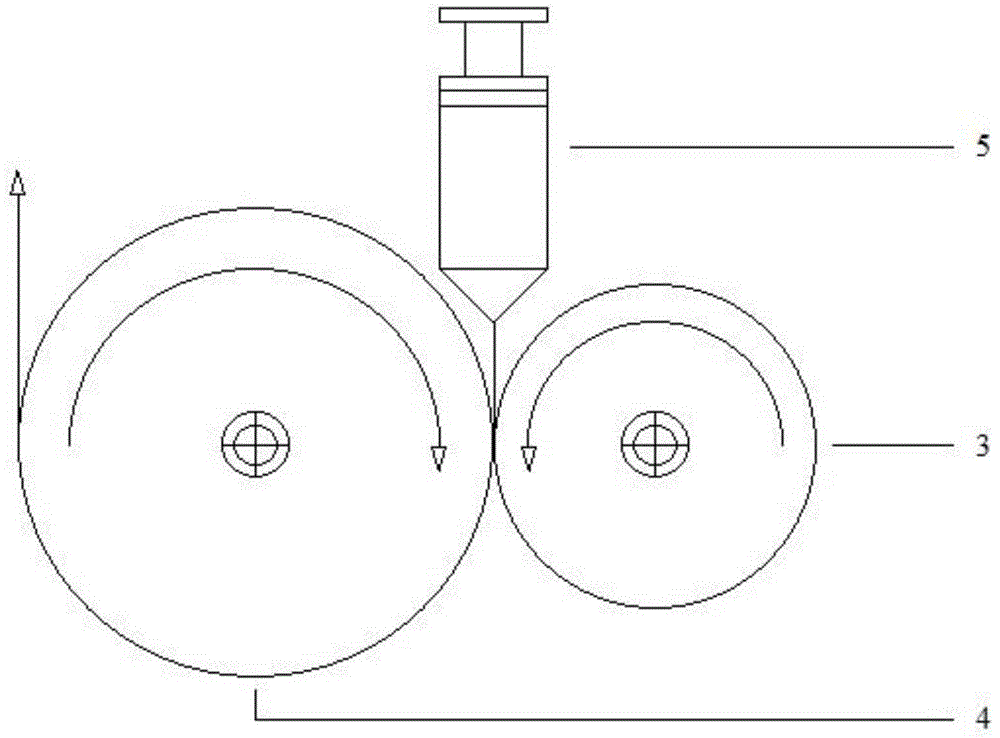

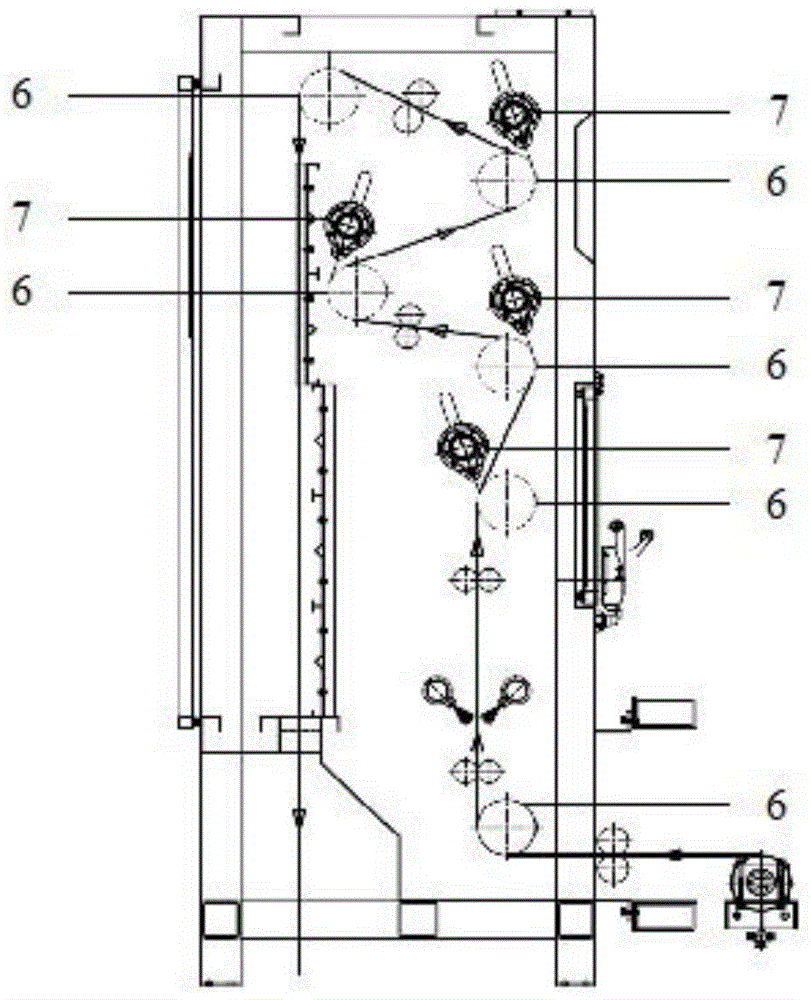

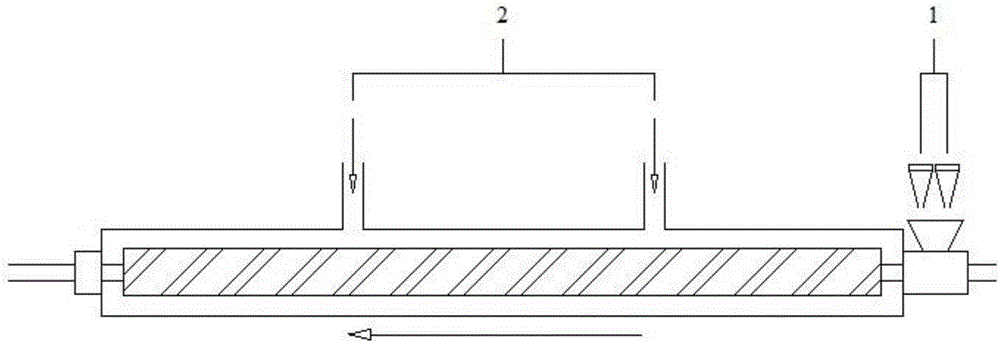

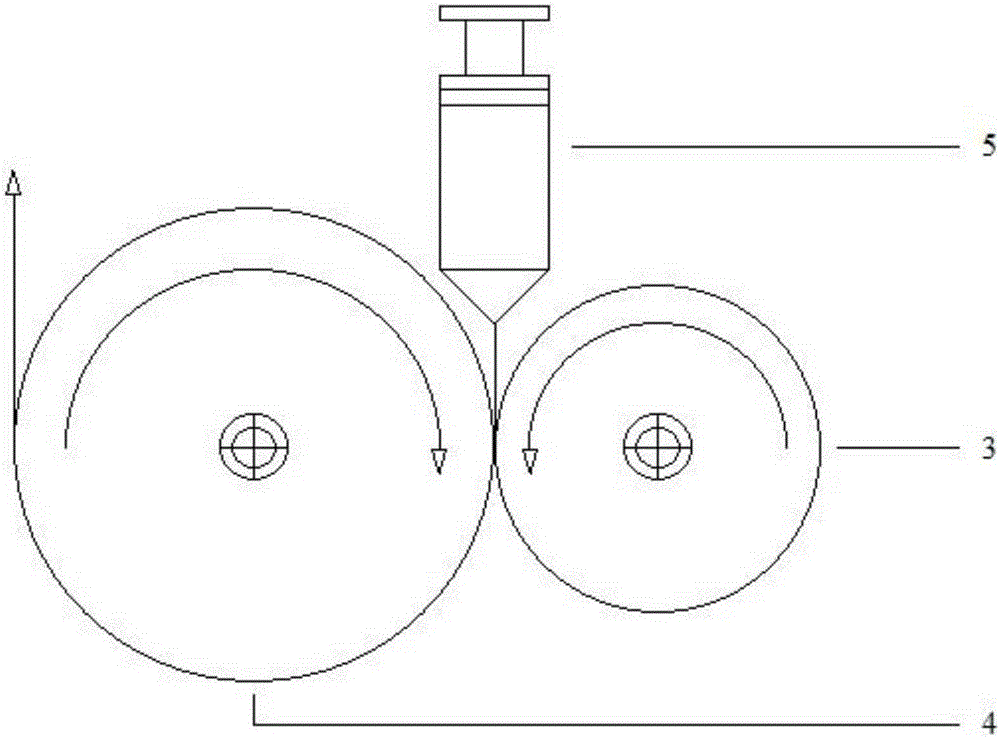

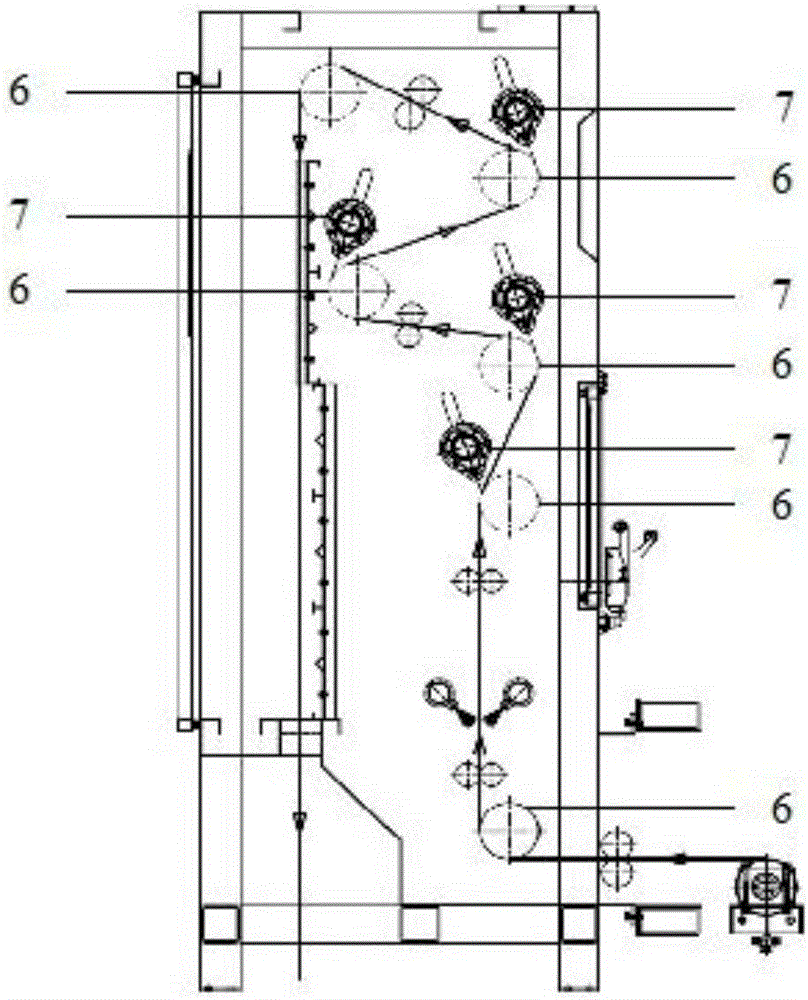

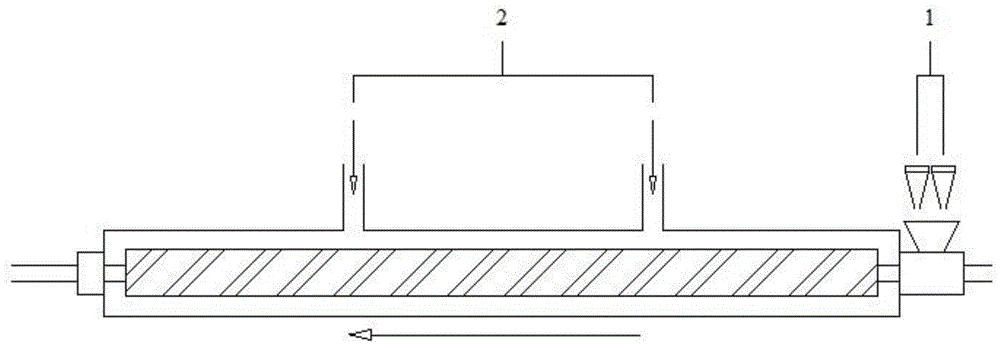

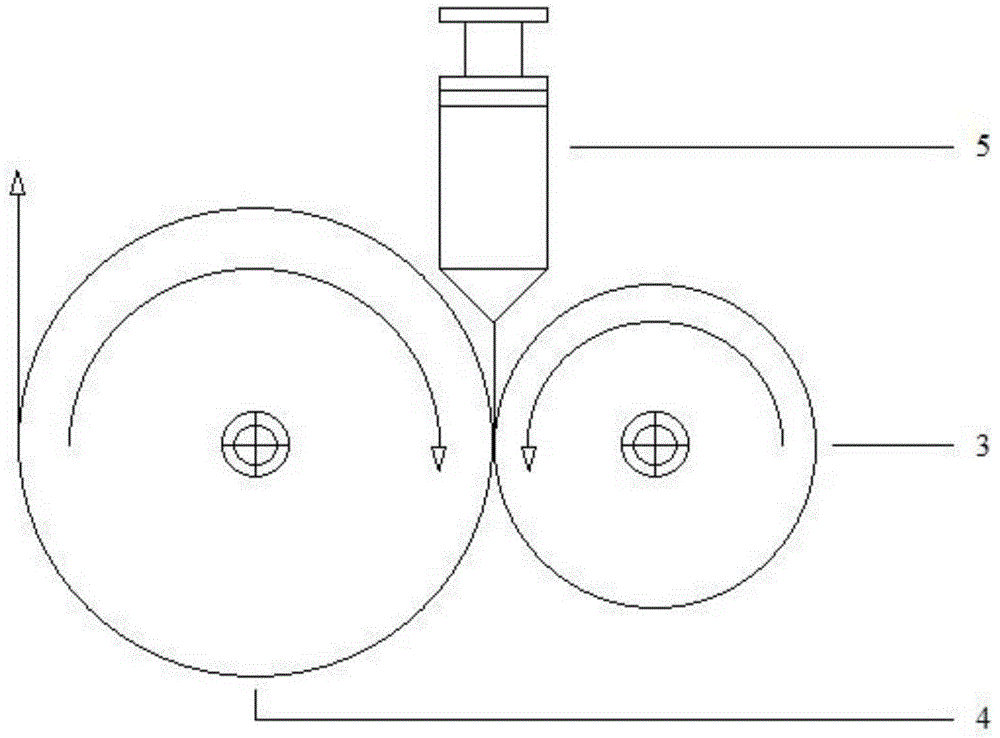

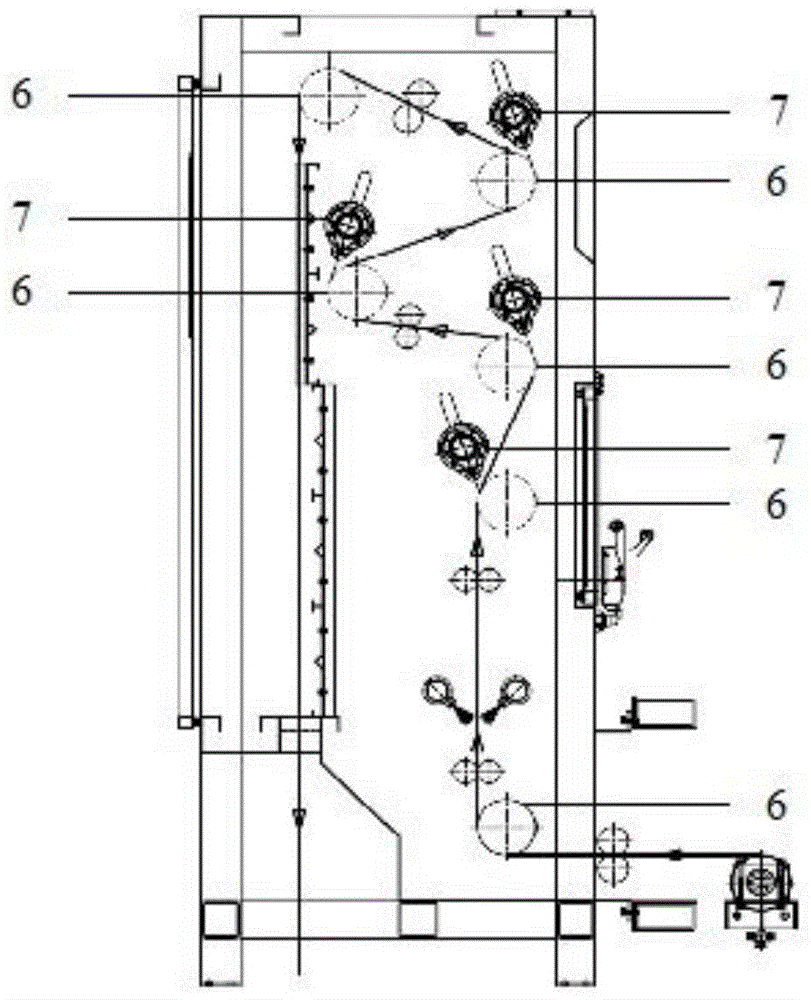

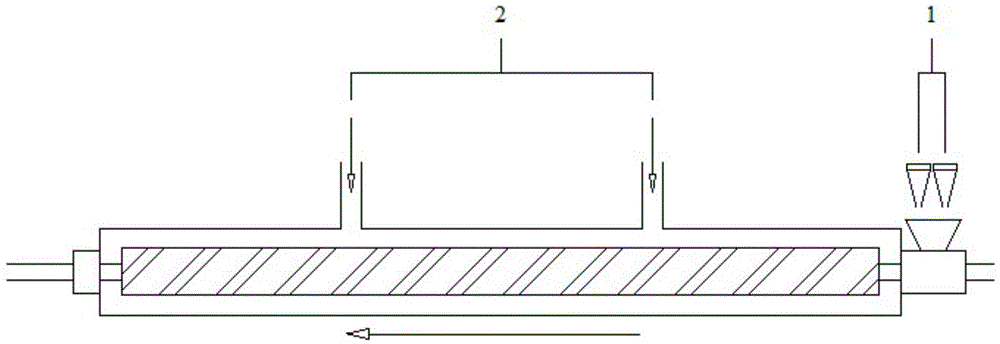

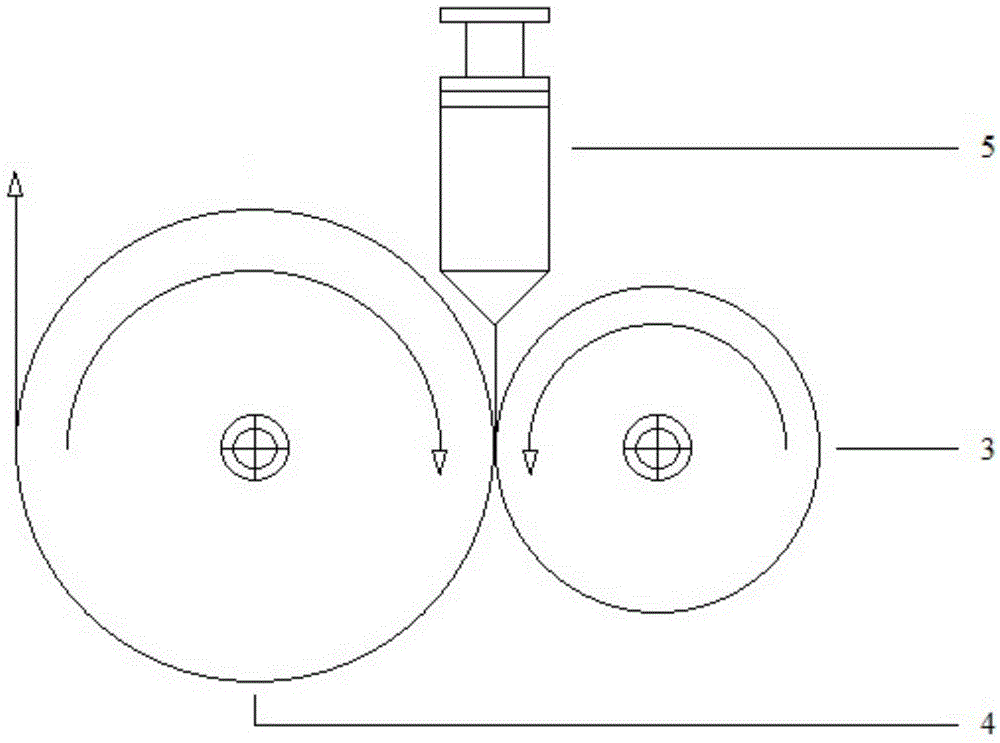

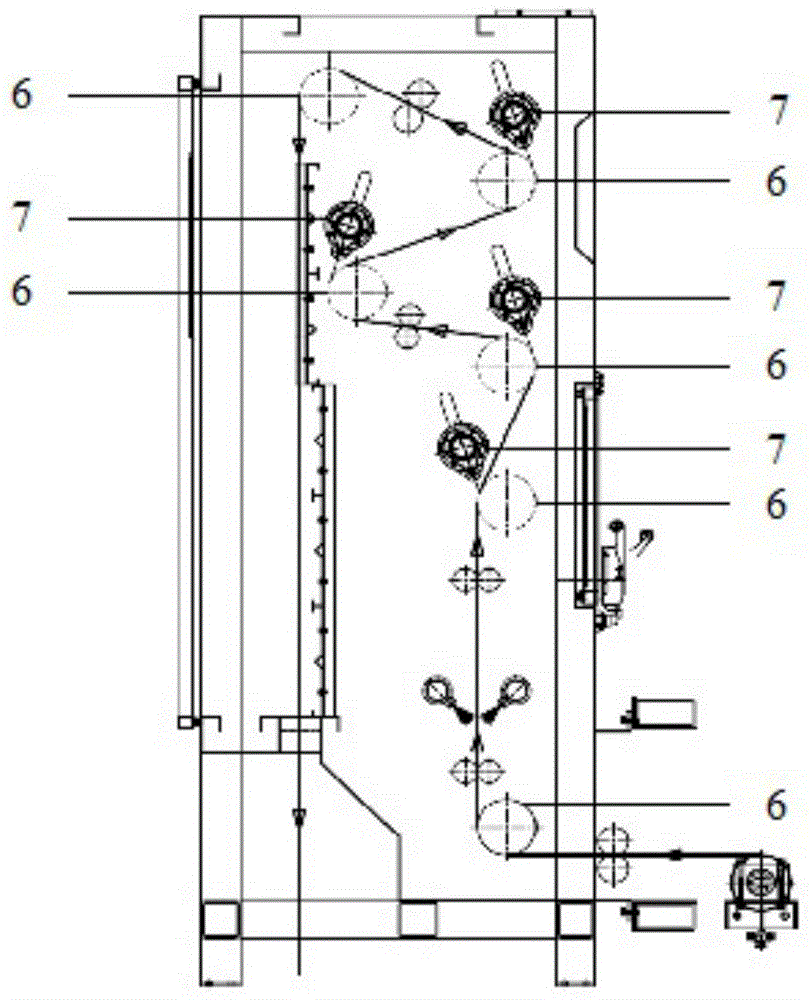

The invention discloses a preparation method of a heat shrinkage-resistant lithium-ion battery separator. The method comprises the steps of melting and mixing a polyethylene composition, a pore-forming agent and an optional additive, extruding a cast film and casting a thick sheet through a first sheet casting roller and a second sheet casting roller; and carrying out longitudinal stretching through a preheating roller, a stretching roller and a cooling roller, carrying out first transverse stretching through a first preheating zone, a first stretching zone and a first cooling zone, carrying out extracting, pore-forming and drying and then carrying out second transverse stretching through a second preheating zone, a second stretching zone and a second cooling zone to obtain the heat shrinkage-resistant lithium-ion battery separator. The preparation method of the heat shrinkage-resistant lithium-ion battery separator is simple and convenient to operate, high in controllability and wide in application; and the battery separator prepared by the method has excellent heat shrinkage resistance and good overall performance.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

Battery separator with three micropore structures

ActiveCN106299215AImprove performanceIncrease capacityCell seperators/membranes/diaphragms/spacersPorosityInternal resistance

The invention discloses a battery separator with three micropore structures. The separator comprises a first outer layer, a second outer layer and an inner layer clamped between the first outer layer and the second outer layer, wherein the first outer layer, the second outer layer and the inner layer have different micropore structures. The battery separator with the three micropore structures disclosed by the invention has a plurality of physical and chemical properties and good overall performance, has high puncture strength and tensile strength when reaching a relatively small thickness, can be used for a relatively small battery, and is not easily damaged in the installation process and has good air permeability and porosity and small internal resistance; the capacity and the cycle performance of the battery are improved; and furthermore, the battery separator also has relatively low closed pore temperature and membrane rupture temperature and high safety.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

Preparation method for battery diaphragm with three kinds of microporous structures

ActiveCN106328866ALow closed cell temperatureHigh membrane rupture temperatureSecondary cellsCell component detailsControllabilityMetallurgy

The invention discloses a preparation method for a battery diaphragm with three kinds of microporous structures. The preparation method comprises the steps of performing fusing and mixing on a polyethylene composition, a pore-forming agent and an optional additive; extruding a cast film, and casting a thick sheet through a first sheet-casting roller and a second sheet-casting roller; next, performing longitudinal stretching through a preheating roller, a stretching roller, and a cooling roller; performing transverse stretching for the first time by passing through a first preheating region, a first stretching region and a first cooling region; performing extracting and pore-forming, and drying; and performing transverse stretching for the second time by passing through a second preheating region, a second stretching region and a second cooling region to obtain the battery diaphragm with the three kinds of microporous structures. The preparation method for the battery diaphragm with the three kinds of microporous structures is simple and convenient to operate, high in controllability and wide in application; and the battery diaphragm prepared by the method is good in comprehensive performance.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

Heat-shrinkage-resistant lithium ion battery diaphragm and pore-forming agent composition adopted by same

ActiveCN106328860AHigh porosityImprove ventilationCell seperators/membranes/diaphragms/spacersHigh diaphragmBoiling point

The invention discloses a heat-shrinkage-resistant lithium ion battery diaphragm and a pore-forming agent composition adopted by the same. The pore-forming agent composition comprises an organic pore-forming agent and an inorganic pore-forming agent, wherein the organic pore-forming agent is high-boiling-point low molecular weight organic matter preferably; the inorganic pore-forming agent is water-soluble inorganic nanoparticles preferably; and the pore-forming agent and the optional additive are jointly added to a film-forming material to form a lithium ion battery diaphragm with three kinds of microporous structures through processing of casting pieces. In addition, the heat-shrinkage-resistant lithium ion battery diaphragm has relatively low closed-hole temperature, high heat shrinkage resistance, high tensile strength, high puncture strength and relatively high diaphragm-rupture temperature, thereby ensuring safety in preparation and usage of the lithium ion battery.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

Method for preparing environment-friendly hydrophilic porous coating used for modifying surface of porous membrane

ActiveCN104861199ASolve the hydrophilic problemExcellent heat shrinkage resistanceCoatingsHydrophilic coatingPorous coating

The invention relates to a method for preparing an environment-friendly hydrophilic porous coating used for modifying the surface of a porous membrane, and belongs to the technical field of porous membrane coating production. The method includes the following steps: soaking the porous membrane subjected to oxidation by a potassium permanganate / hydrochloric acid solution into a hydroxy ethyl cellulose (HEC) emulsion containing or without containing aluminium oxide particles for 10-14 hours; taking out and placing into a refrigerator for 10-14 hours; then freeze-drying for 2-4 hours to obtain the hydrophilic porous coating. The preparation technology of the coating is simple and environment-friendly; the hydrophilic coating provided by the invention not only has a porous structure but also enables the porous membrane to have excellent wettability; in addition, the heat-shrink resistance of the holes is greatly improved; the coating has a wide application prospect in membrane separation of hydrophilic mediums and the battery industry.

Owner:GUANGDONG UNIV OF TECH

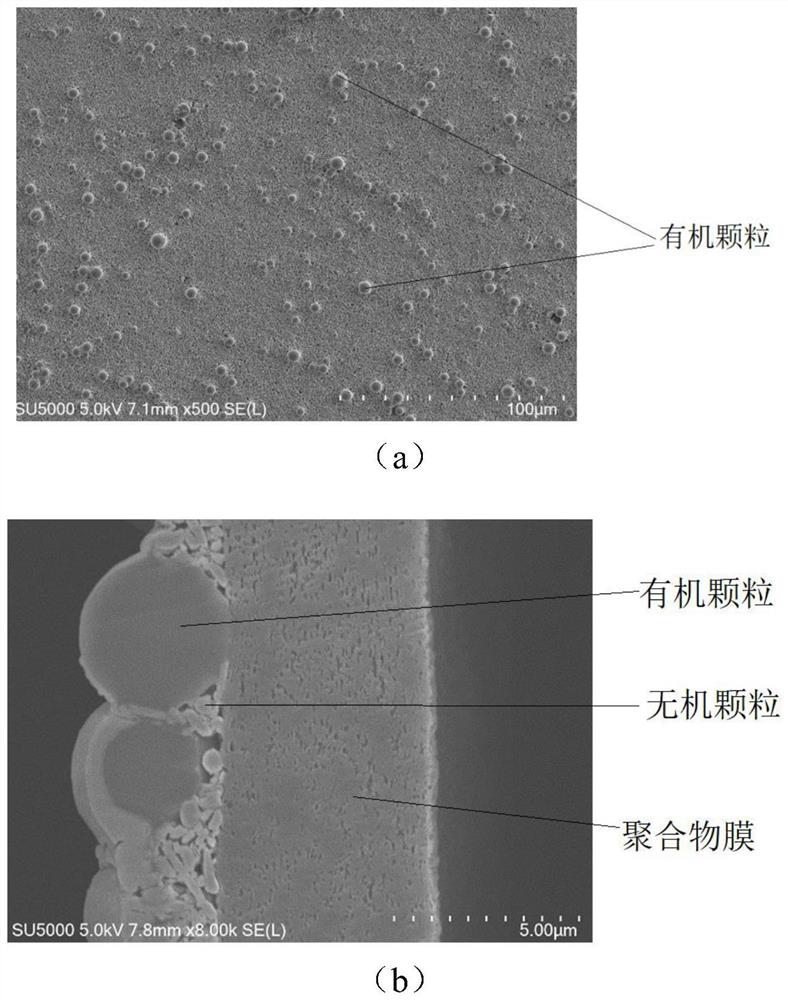

Composite membrane and electrochemical device

PendingCN114361717AHigh strengthImprove structural stabilitySecondary cellsCell component detailsHigh energyElectrochemistry

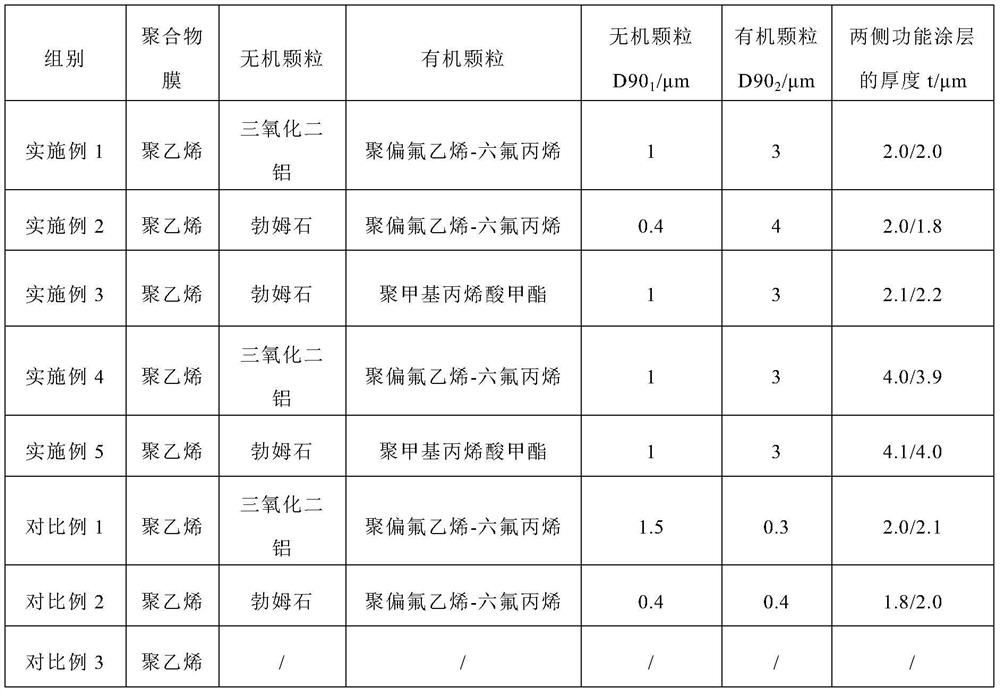

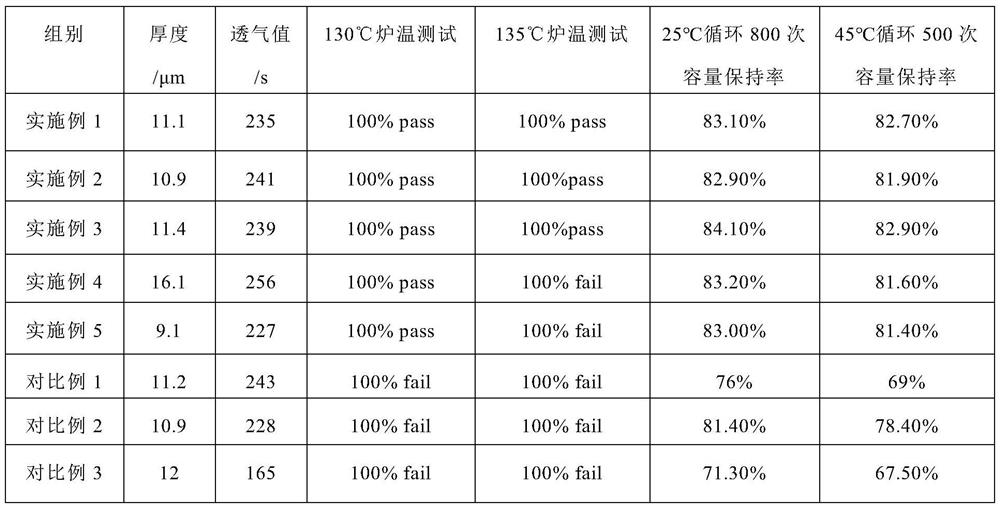

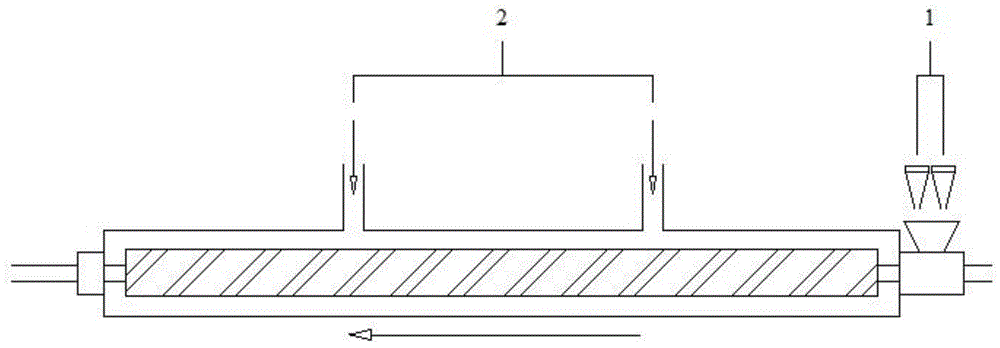

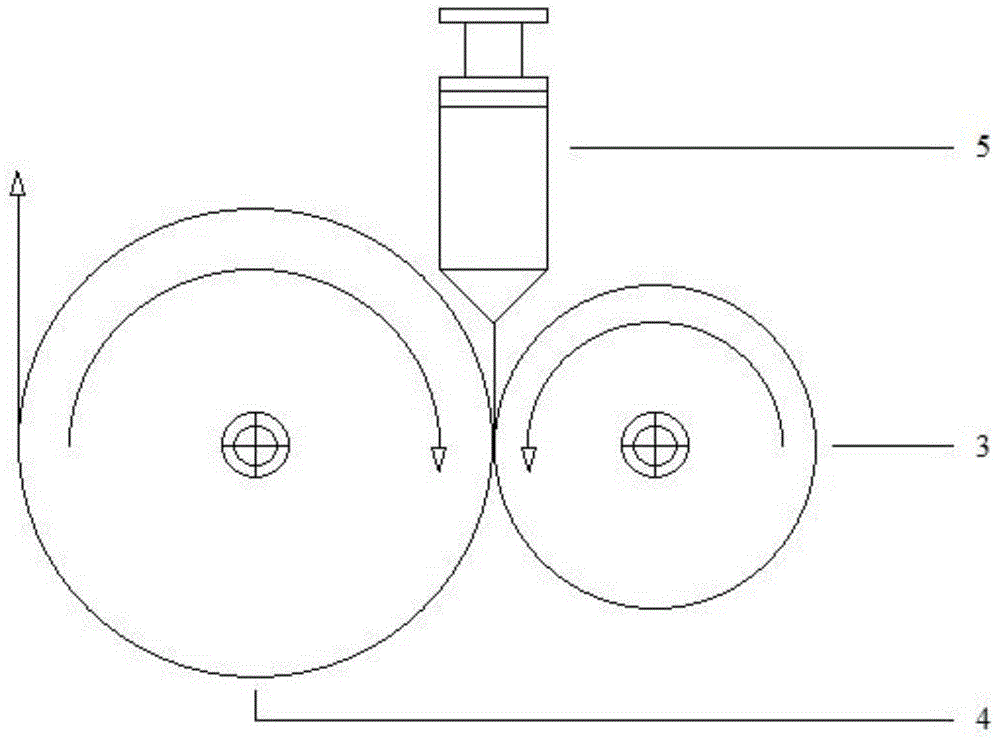

The invention provides a composite diaphragm and an electrochemical device, the composite diaphragm comprises a polymer film and a functional coating arranged on at least one surface of the polymer film, and the functional coating comprises inorganic particles and organic particles; the particle size D901 of the inorganic particles and the particle size D902 of the organic particles meet the following conditions: 0.01 * D902 < = D901 < = 0.5 * D902, and D901 is the particle size of the inorganic particles reaching 90% of the volume accumulation from the small particle size side in the volume-based particle size distribution, and D902 is the particle size of the organic particles reaching 90% of the volume accumulation from the small particle size side in the volume-based particle size distribution. D902 is that in volume-based particle size distribution, the particle size of the organic particles reaches 90% of volume accumulation from the small particle size side. The composite diaphragm has excellent heat-resistant shrinkage performance and interface bonding performance, and can give consideration to high energy density and high safety of an electrochemical device when being applied to the electrochemical device.

Owner:ZHUHAI COSMX BATTERY CO LTD

Heat shrinkage-resistant lithium ion battery diaphragm and extractant composition used by diaphragm

ActiveCN106328868AReduce problems such as open circuitHigh tensile strengthSecondary cellsCell component detailsLithium-ion batteryNuclear chemistry

The invention discloses a heat shrinkage-resistant lithium ion battery diaphragm, a production method of the diaphragm, and an extractant composition used by the diaphragm. The extractant composition comprises a first extractant and a second extractant, the first extractant is a mixture comprising dichloromethane and phosphate ester, and the second extractant is water. The extractant composition provided the invention has a complete extraction effect on pore forming agents, and realizes less residual of the pore forming agents, and the battery diaphragm with good comprehensive performances can be produced from the pore forming agent, a specific pore forming agent and a specific ratio of macromolecular polyethylene and ultra-macromolecular polyethylene through a specific device by using a processing technology.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com