Patents

Literature

598results about How to "Little impact on mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

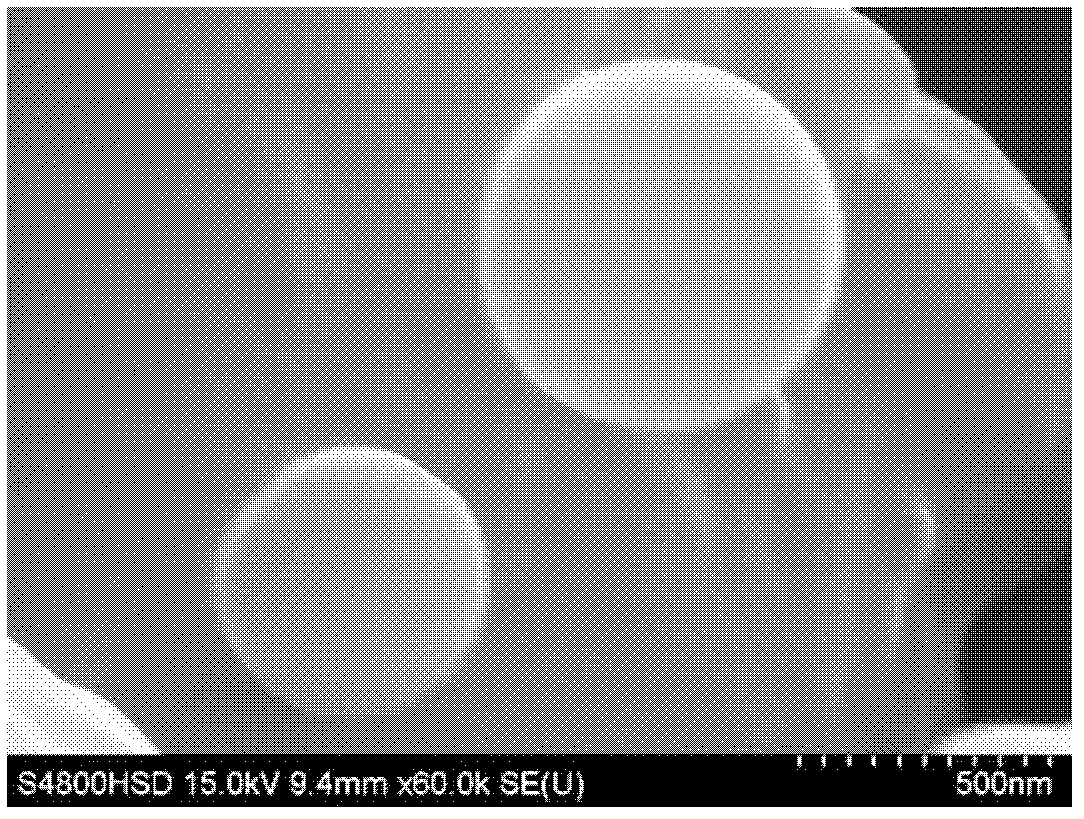

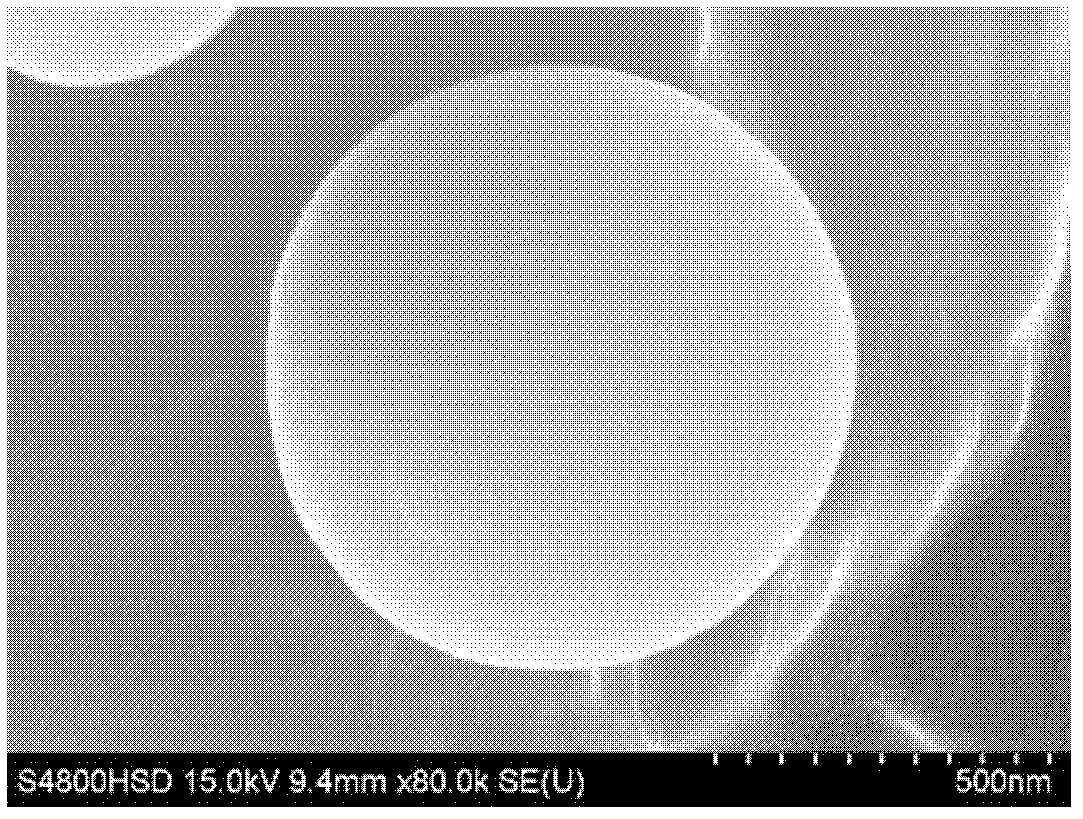

Phase-change energy-storage material nanocapsule and preparation method thereof

ActiveCN104449590ASmall sizeImprove stabilityHeat-exchange elementsMicroballoon preparationTetraethyl orthosilicateNanocapsules

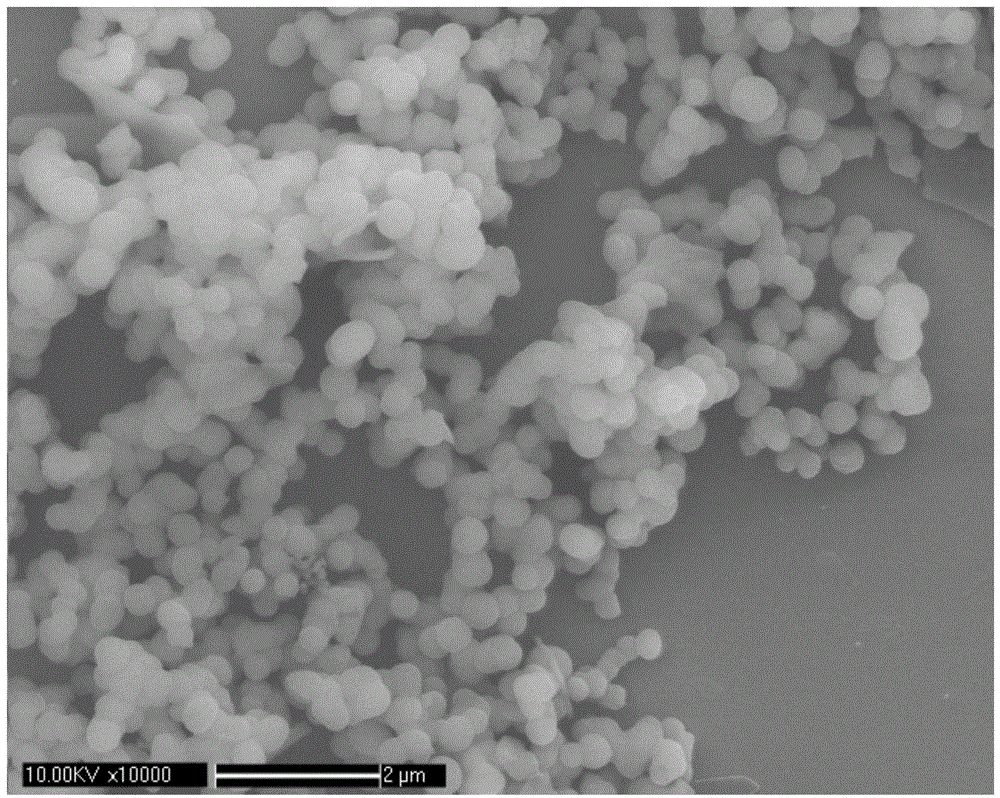

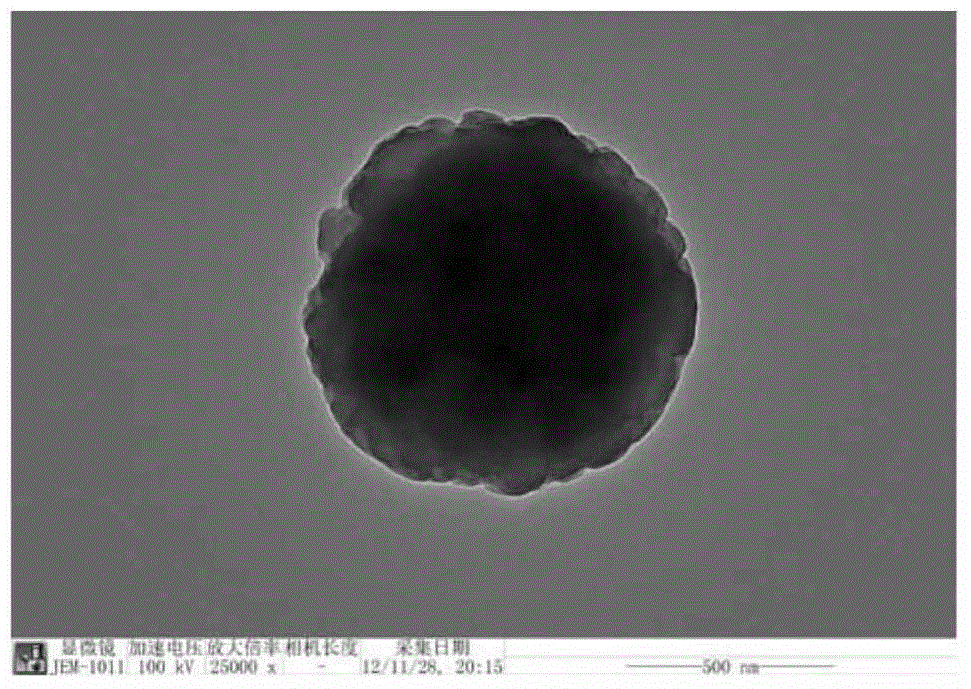

The invention discloses a phase-change energy-storage material nanocapsule and a preparation method thereof and particularly relates to a phase-change energy-storage material capsule using an inorganic material as a shell layer and a preparation method of the capsule. By dispersing an oil phase formed by mixing the phase-change energy-storage material and tetraethyl orthosilicate in an aqueous phase formed by water and ethanol in a shape of nanoscale droplets, carrying out hydrolysis-condensation reaction on tetraethyl orthosilicate in the presence of a basic catalyst, and forming a silicon oxide shell layer on the surface of each of oil phase droplet to coat the phase-change energy-storage material, thus obtaining the phase-change energy-storage material nanocapsule of which the particle size is less than 1mu m. The nanocapsule has the advantages of uniform particle size distribution, large surface area and high enthalpy of phase change. The preparation method is simple and feasible, is high in preparation yield and is conductive to prepration of the phase-change energy-storage material having high heat storage / release efficiency in a large scale.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

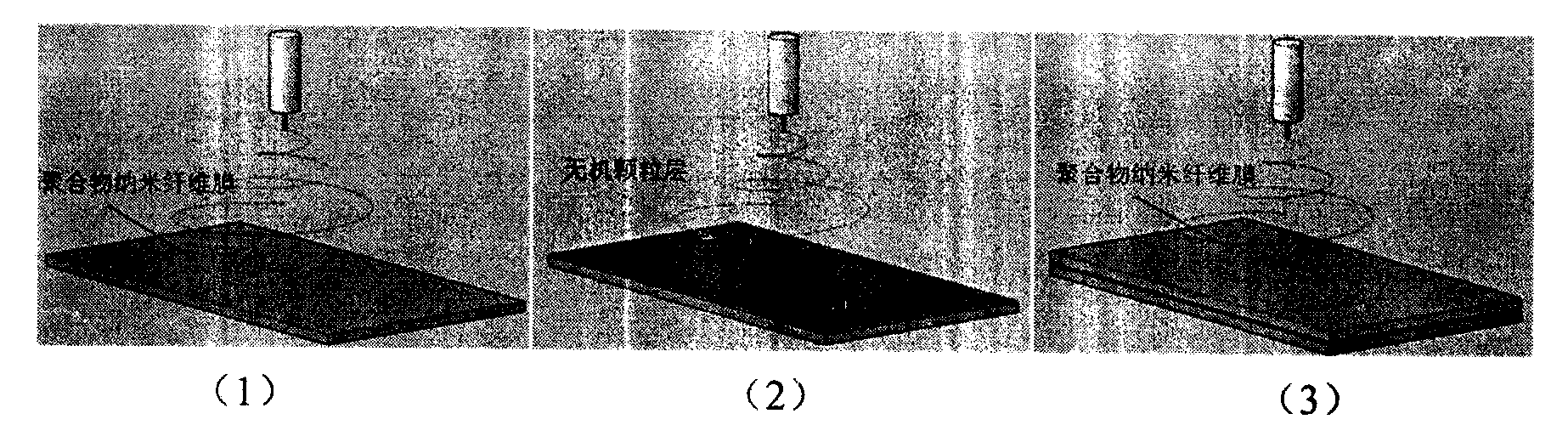

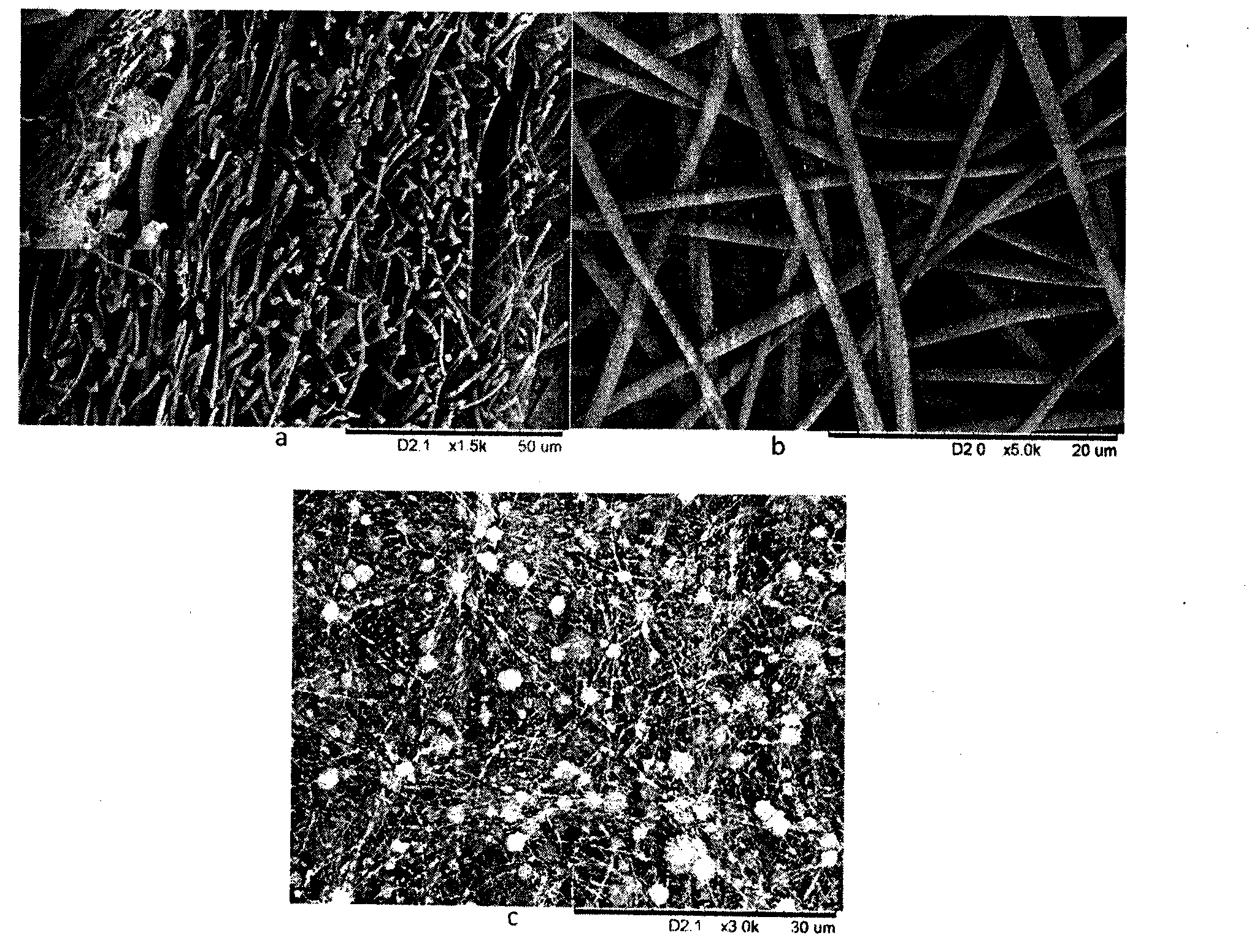

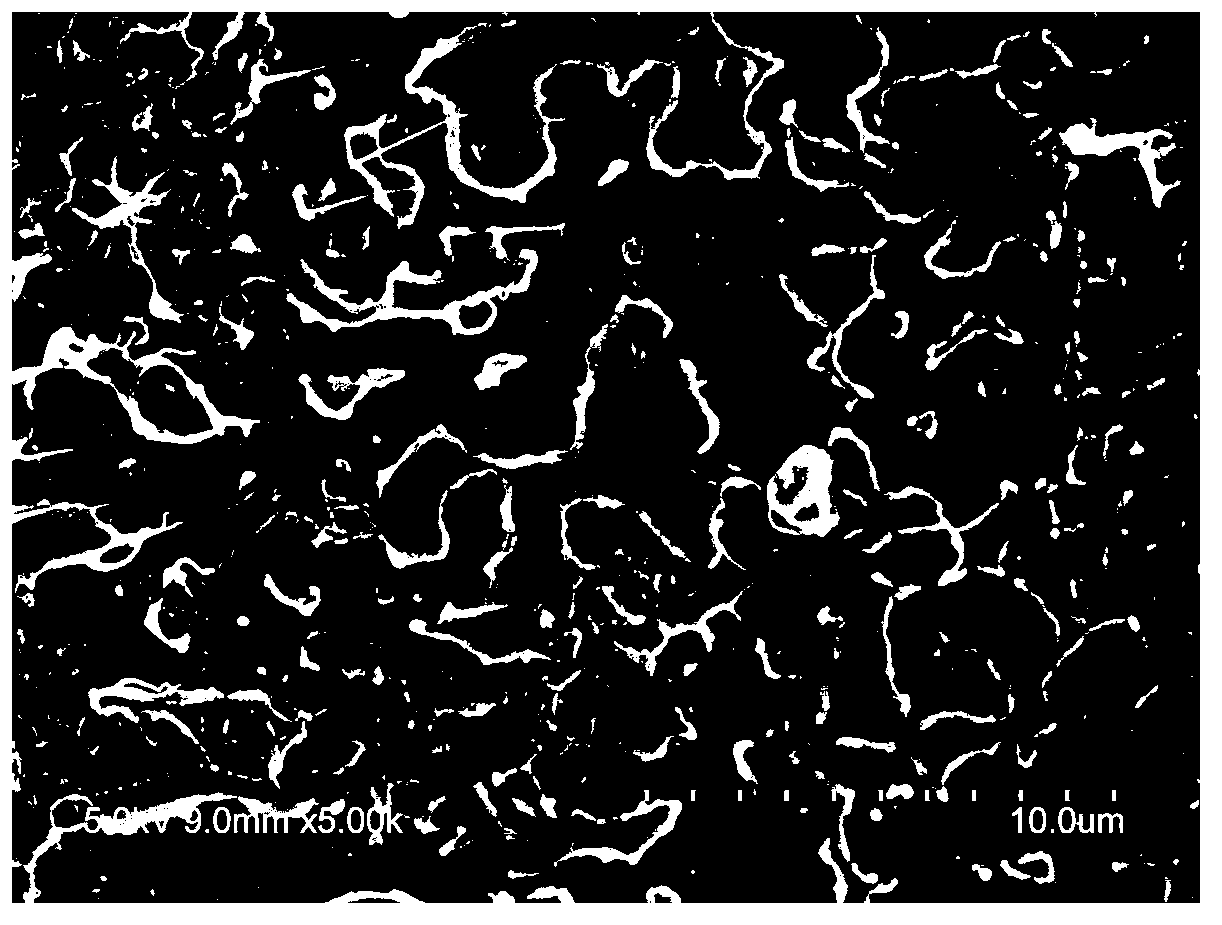

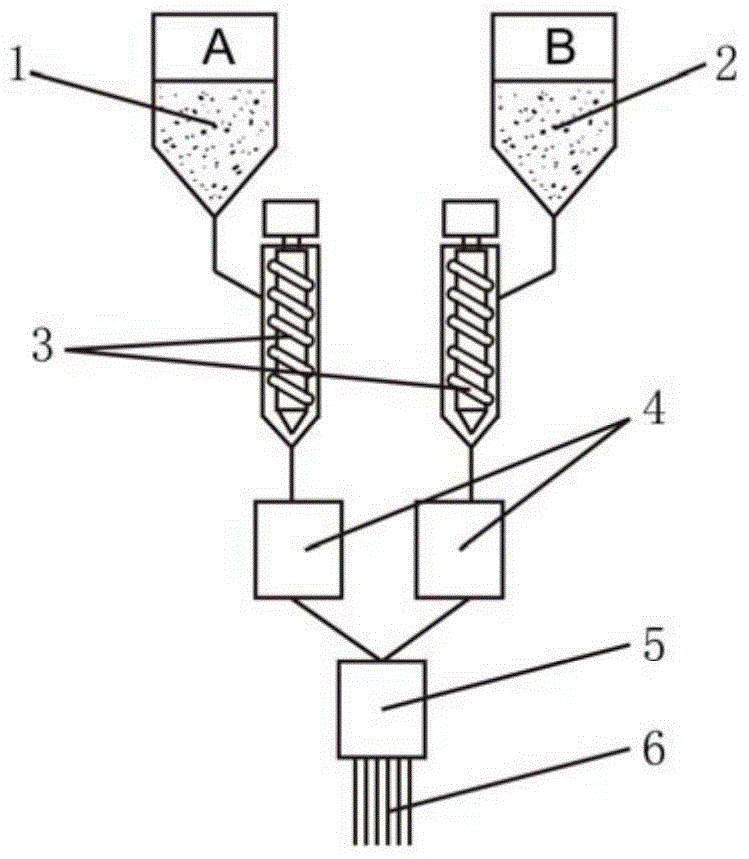

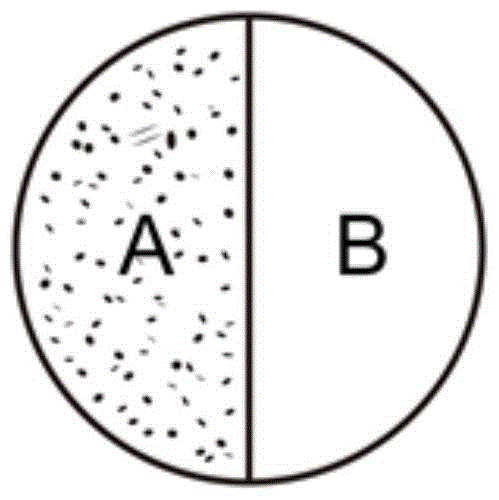

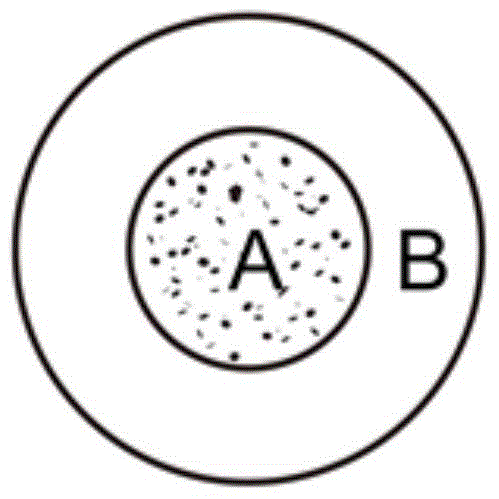

Method for preparing composite lithium-ion battery separator through electrostatic spinning/electrostatic spraying

InactiveCN103474610AExcellent heat shrinkage resistanceIncrease fluid retentionCell component detailsNon-woven fabricsFiberOrganic solvent

The invention relates to the field of lithium-ion batteries, in particular to a method for preparing a composite lithium-ion battery separator through electrostatic spinning / electrostatic spraying. The method specifically includes the steps of firstly, adding high molecular polymer into an organic solvent, dissolving the high molecular polymer through mechanical stirring to form a transparent solution, and obtaining an electrostatic spinning solution; secondly, mixing inorganic nanometer particles with the high molecular polymer and adding the mixture into the organic solvent, and conducting mechanical stirring to obtain inorganic nanometer particle suspension liquid; thirdly, conducting electrostatic spinning on the spinning solution prepared in the first step to prepare a lower layer nanometer fiber film, and enabling the inorganic nanometer particle suspension liquid prepared in the second step to be deposited on the lower layer nanometer fiber film through electrostatic spraying to obtain an interlayer; finally, receiving an electrostatic spun nanometer fiber layer on an inorganic particle layer to obtain the composite lithium-ion battery separator. The composite lithium-ion battery separator has the high imbibing rate and good electrochemical stability under the room temperature and has good heat shrinkage resistance performance at the same time.

Owner:TIANJIN POLYTECHNIC UNIV

Fire-retardant polyolefin based wood plastic composite material and preparation method thereof

ActiveCN102321374AGood smoke suppression performanceExcellent flame retardancy and mechanical propertiesPolyolefinEnvironmentally friendly

The invention discloses a fire-retardant polyolefin based wood plastic composite material and a preparation method thereof, and relates to a wood plastic composite material and a preparation method thereof, and the composite material and method provided by the invention can be used for solving problems that the existing fire-retardant wood plastic composite material has high heat release efficiency in burning and high smoke production, and can generate CO harmful gas easily. The flame-retardant polyolefin based wood plastic composite material is prepared from wood fiber materials, plastics, acoupling agent, a lubricant, an antioxidant, a nano inorganic fire retardant and a mineral filler. The method comprises the following steps: putting the wood fiber materials, the coupling agent and the lubricant into a high-speed mixing machine for hot mixing; then putting into a cold mixing machine for cold mixing, sending the plastics, the antioxidant, the nano inorganic fire retardant and the mineral filler into the cold mixing machine and then mixing; and then carrying out fusing and extruding for granulation by adopting extruding, injection, hot compressing or mold compression for molding, thus the fire-retardant polyolefin based wood plastic composite material is obtained. The wood plastic composite material provided by the invention has low heat release rate in burning and less smoke production, and is healthy and environmentally-friendly, and can be widely applied to the fields of indoor construction, decoration and furnishing materials and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

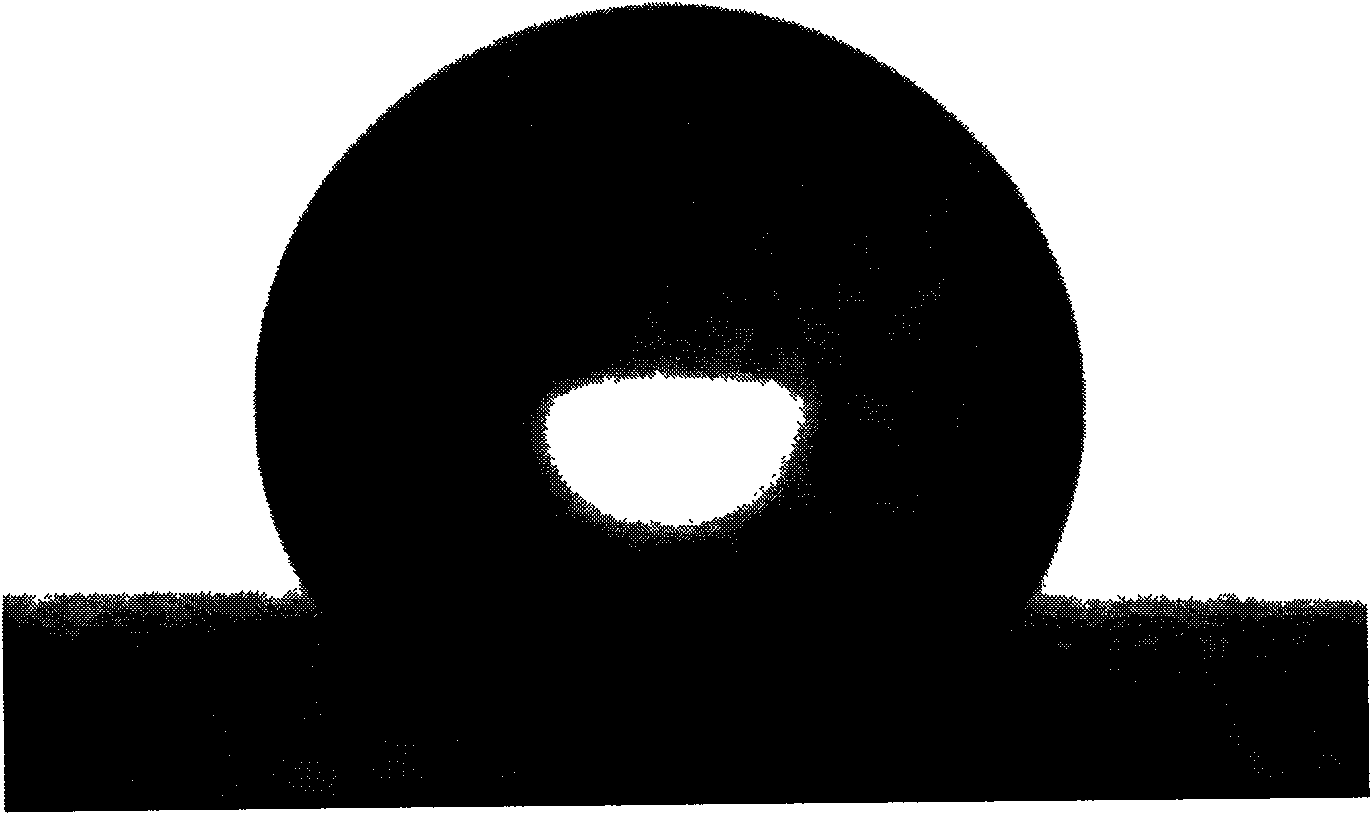

Surface modification method for polytetrafluoroethylene product

ActiveCN101979429AImprove permeabilityImprove wettabilityCoatingsPolyethylene glycolTherapeutic effect

The invention discloses a surface modification method for a polytetrafluoroethylene product. The method comprises the following steps of: coating polyethylene glycol on the surface of the polytetrafluoroethylene product, and then performing surface modification on the polytetrafluoroethylene product coated with the polyethylene glycol by adopting a plasma treatment method. Compared with the prior art, the polyethylene glycol element is introduced on the surface of the polytetrafluoroethylene product so as to effectively improve the surface activity of the polytetrafluoroethylene product, reduce the contact angle, improve the surface energy, remarkably improve the wetting property and the adhesion property of the polytetrafluoroethylene product and keep the polytetrafluoroethylene product for long time; and in addition, the method has little influence on the chemical property of the polytetrafluoroethylene product, has the advantages of convenient for operation, simple process, high processing speed, good treatment effect, low cost, energy conservation and emission reduction, is not easy to cause environmental pollution, and is more suitable for industrialized production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

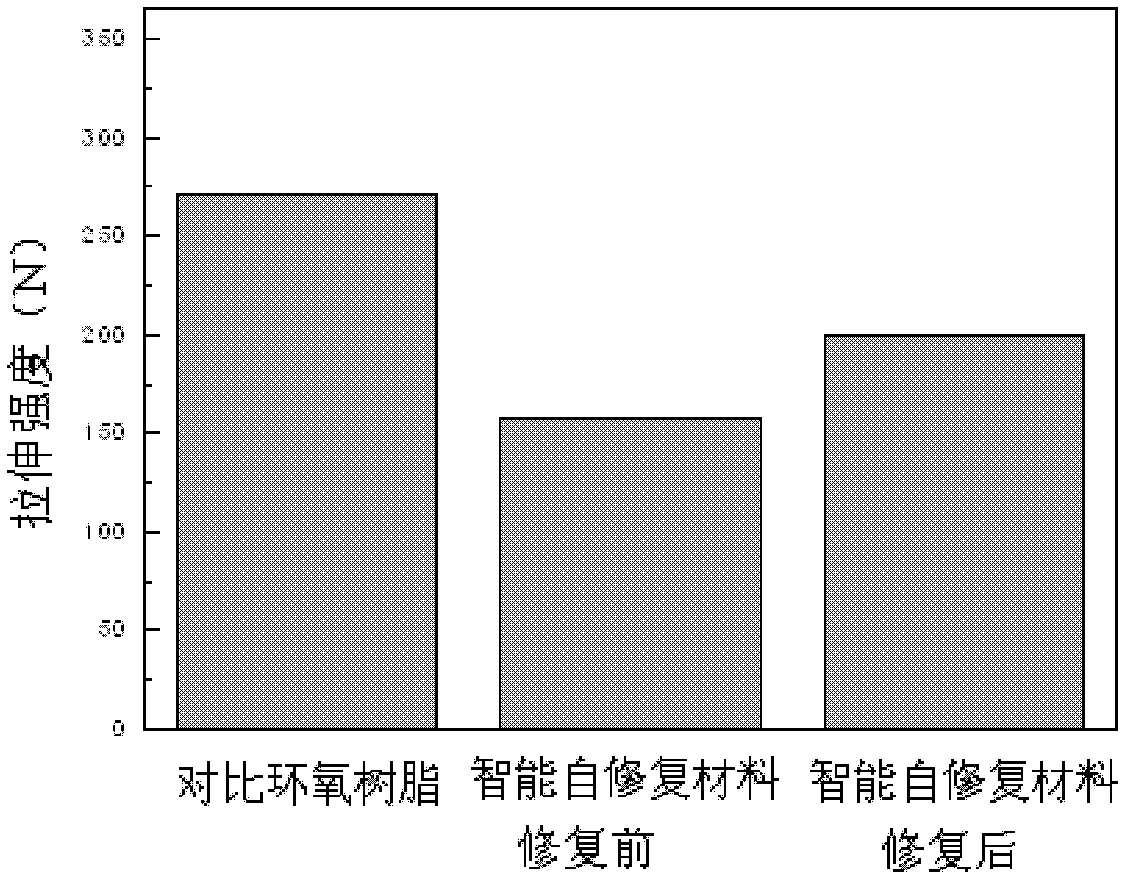

Epoxy resin self-repairing microcapsule and preparation method thereof

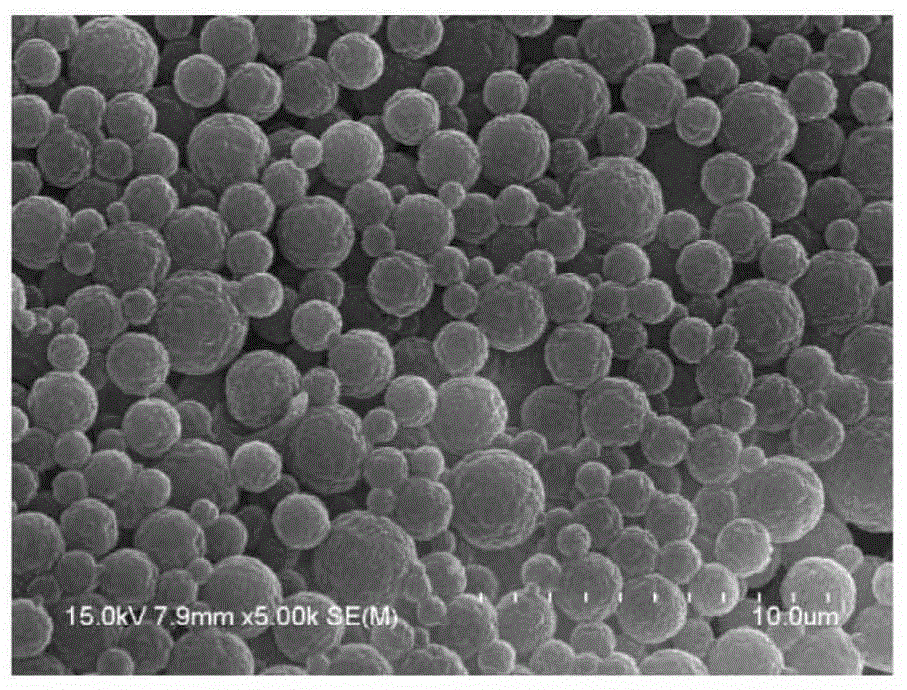

InactiveCN104624132AComposition is easy to controlImprove stabilityMicroballoon preparationMicrocapsule preparationEpoxyEmulsion polymerization

The invention provides an epoxy resin self-repairing microcapsule and a preparation method thereof. The method comprises the following steps: mixing a water phase containing inorganic nanoparticles and water with an oil phase containing epoxy resin, monoolefin monomer, a polyene cross-linking agent and an initiator to form a stable oil-in-water emulsion; and heating the emulsion to realize emulsion polymerization in order to form the epoxy resin self-repairing microcapsule. The epoxy resin self-repairing microcapsule is prepared by adopting the inorganic nanoparticles as an emulsifier through an emulsion polymerization process via the method; and compared with methods adopting molecular emulsifiers, the method provided by the invention has the advantages of no need of subsequent emulsifier removal, simple process, and no pollution to environment. The epoxy resin self-repairing microcapsule prepared in the invention has the advantages of excellent stability, excellent leakproofness and high cladding rate.

Owner:INST OF CHEM CHINESE ACAD OF SCI

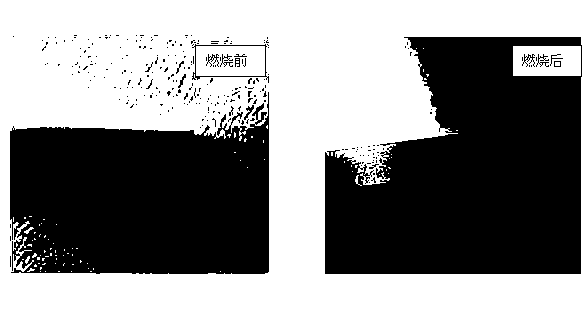

Flame-retardant anti-dropping resin composition

InactiveCN101348603AExcellent and durable flame retardantLittle impact on mechanical propertiesPolyesterFiber

The invention discloses a flame-retardant anti-dripping resin compound, consisting of 100 weight portions of thermoplastic resin, 0.01-5 weight portions of modified polytetrafluoroethylene anti-dripping agents and 20 to 40 weight portions of environment-friendly flame retardant containing phosphorus and / or nitrogen. The resin compound has strong anti-dripping effect and heat resisting performance, is level and smooth in exterior appearance, and can endow polyester fiber products with excellent enduring flame retardancy without using halogen (Cl and Br) flame retardant. The resin compound has the advantages of high oxygen index, droplet resistance, low heat release rate, no halogen, little toxicity, low smoke dust emission, little influence on the mechanical properties of base materials, etc.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Flame-retardant polypropylene composition with high glow-wire ignition temperature

The invention discloses a flame-retardant polypropylene composition with high glow-wire ignition temperature (GWIT). The composition is characterized by comprising the following components in percentage by weight: 35.0 to 66.5 percent of polypropylene, 15.0 to 20.0 percent of brominated flame retardants, 3.0 to 8.0 percent of flame-retardant synergist, 15.0 to 35.0 percent of high-efficiency composite flame retardant, 0.1 to 0.5 percent of primary antioxidant, 0.1 to 0.5 percent of auxiliary antioxidant and 0.3 to 1.0 percent of processing aid. The composition has the advantages that: a) the composite flame retardant can achieve a microcapsule coating effect around the composite flame retardant, and the heat is taken away and the heat conduction is reduced by isolating oxygen; b) ultrafine magnesium hydroxide can generate metal oxide to reduce heat conduction in the heating process of a glow wire, and produce steam which can take away the heat, and the surface treatment of the precipitated ultrafine magnesium hydroxide slightly affects the mechanical properties of the flame-retardant modified polypropylene composition; and c) an organosiloxane polymer with high polymerization degree can form a silicon carbide gel isolation layer to isolate oxygen and achieve a flame-retardant effect, the GWIT is higher than required 750 DEG C, and the composition is widely applied to the fields of machinery, industry and the like.

Owner:KINGFA SCI & TECH CO LTD +2

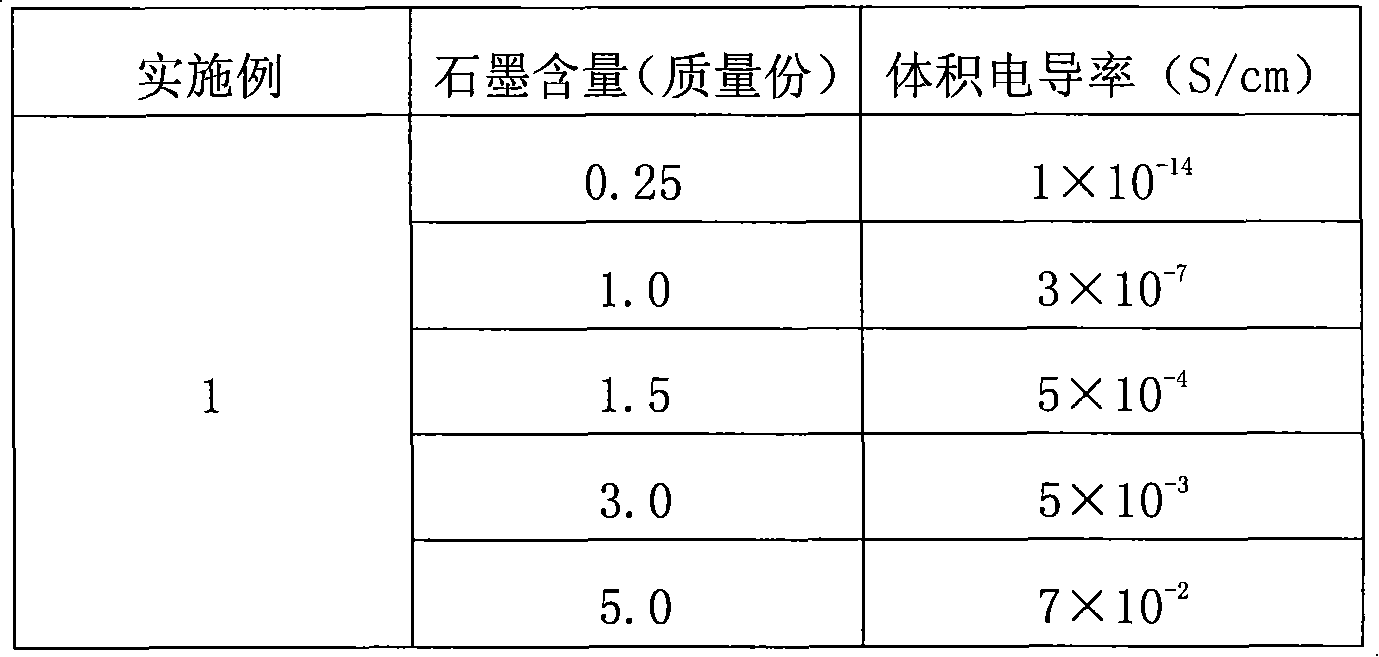

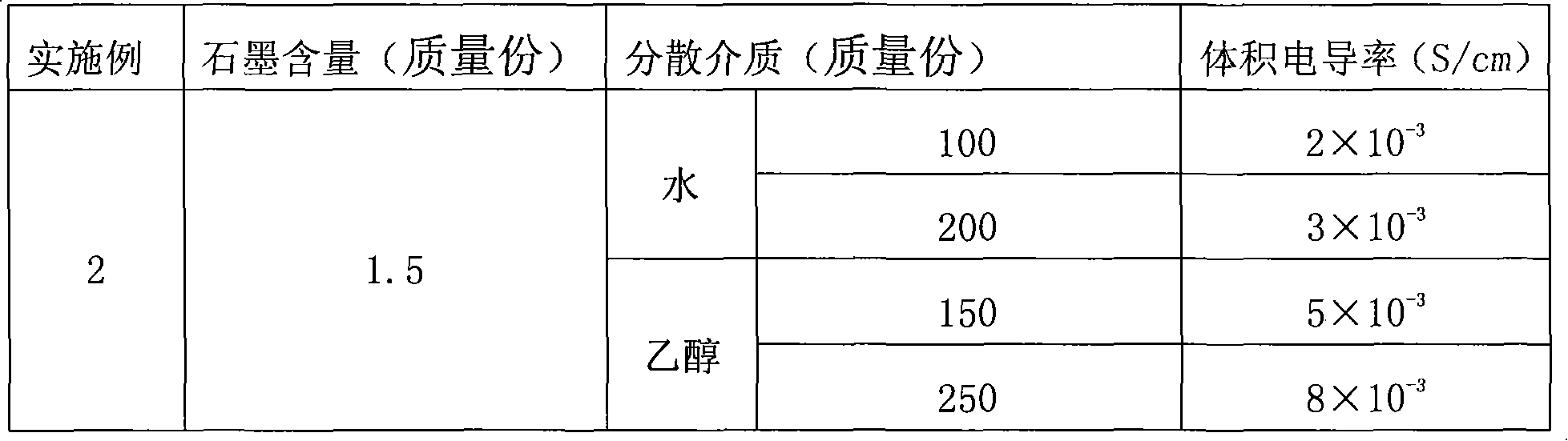

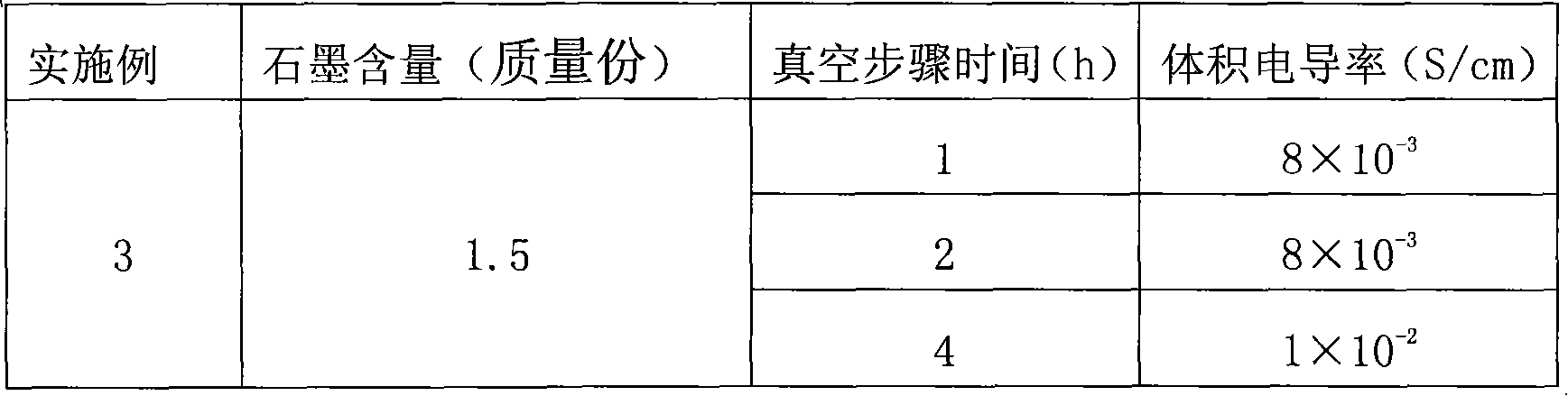

Polyamide/oxidized graphite composite material with high conduction performance and preparation method thereof

InactiveCN101608061AImprove conductivityReduce the amount of fillerIn situ polymerizationConductive polymer

The invention discloses a polyamide / graphite composite material with high conduction performance and a preparation method thereof. The composite material consists of a polyamide substrate and nanometer graphite and is prepared through in-situ polymerization. The nanometer graphite has high diameter-to-thickness ratio; and an effective conduction network can be formed in a polymer by using little nanometer graphite. With the low content of a conduction filling of the nanometer graphite, a conduction polymer material keeps original good mechanical performance. The volume conductivity of the polyamide / graphite composite material with high conduction performance can reach 8*10S / cm; and compared with a conventional natural graphite and expanded graphite conductive composite material, the polyamide / graphite composite material has excellent properties of low filling amount and high conductivity.

Owner:TORAY IND INC

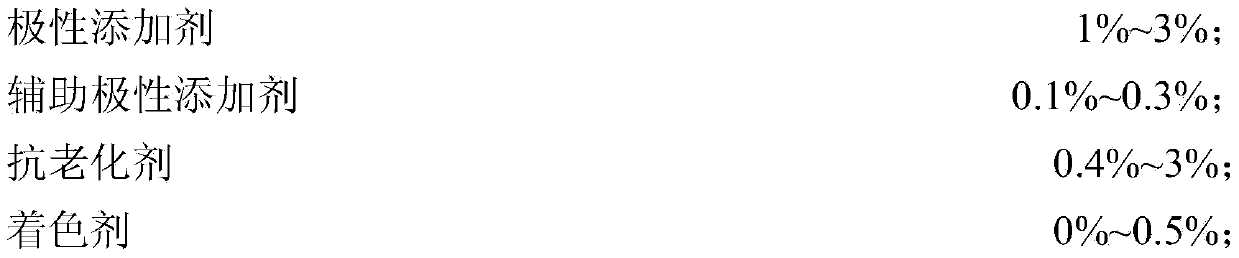

A polarity-modified polypropylene composite material and a preparing method thereof

InactiveCN104086894AIncrease polarityHigh retention rate of mechanical propertiesPolypropylene compositesAdhesion force

A polarity-modified polypropylene composite material and a preparing method thereof are disclosed. The composite material comprises following components by weight: 60-90% of polypropylene, 5-15% of a flexibilizer, 0-30% of a mineral filling material, 1-3% of a polarity additive, 0.1-0.3% of an assistant polarity additive, 0.4-3% of an anti-ageing agent and 0-0.5% of a coloring agent. The assistant polarity additive is a nonionic ester type surfactant. According to the composite material and the preparing method thereof, by addition of an extremely low amount of the polarity additive and the assistant polarity additive, the adhesion force of the composite material and a coating is enhanced and the composite material maintains excellent mechanical properties. The method can be performed by adoption of a double-screw extruder at present and has characteristics of simple preparation, easy implementation and operation, easy industrial production and wide application prospect.

Owner:CGN JUNER NEW MATERIALS +1

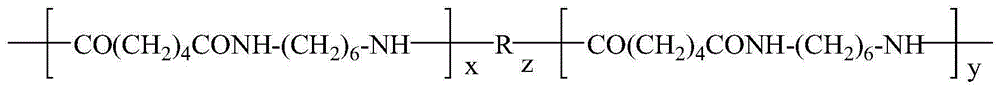

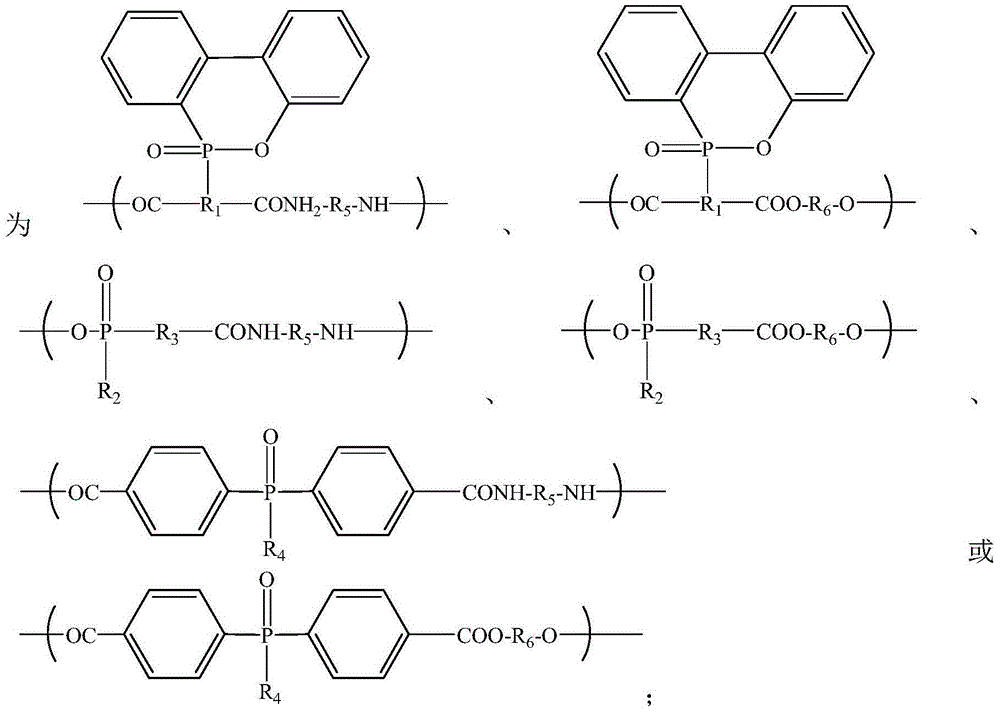

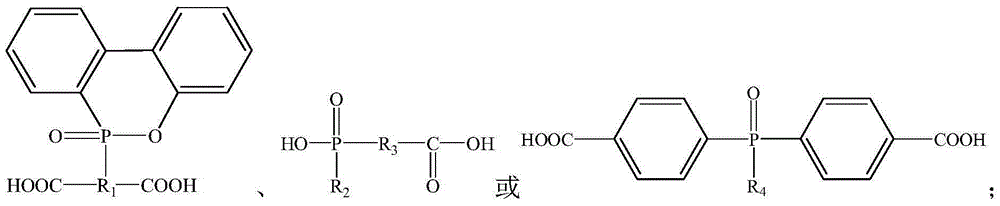

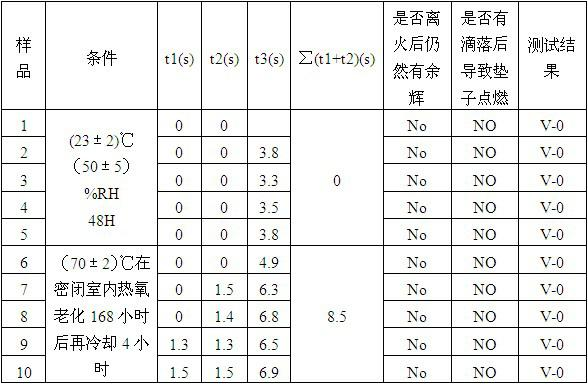

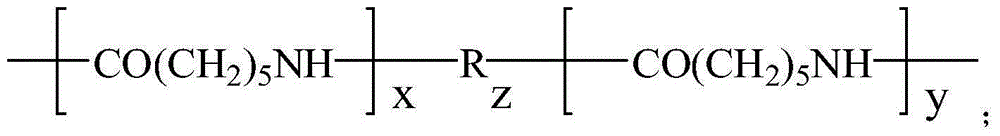

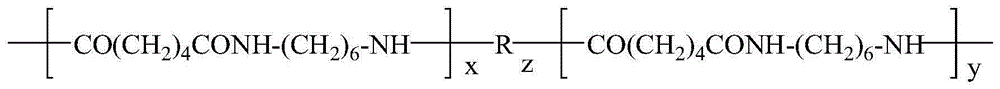

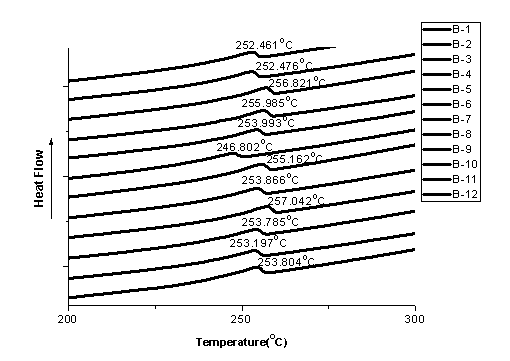

Flame-retardant nylon 66 copolymer material and preparation method therefor

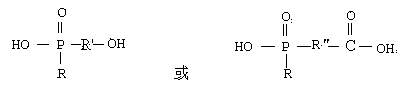

The invention relates to a flame-retardant nylon 66 copolymer material and a preparation method therefor and particularly relates to a block flame-retardant nylon 66 copolymer material obtained through polymerization reaction of a phosphoric reactive flame retardant and a preparation method therefor. The method is characterized by comprising the steps of firstly enabling the flame retardant to react with diamine or dibasic alcohol so as to obtain a flame retardant prepolymer, and then, enabling the flame retardant prepolymer to react with a prepolymer of nylon 66, thereby obtaining the flame-retardant nylon 66 copolymer material. The flame-retardant nylon 66 copolymer material prepared by the method has the advantages of low flame retardant addition level, excellent mechanical properties, good flame retardant durability and the like, the vertical firing test can reach UL94V-0, and the limiting oxygen index is over 32%. The flame-retardant nylon 66 copolymer material not only can be subjected to injection molding directly or form films, but also can be prepared into flame-retardant fibers through melt spinning so as to be applied to the fields of clothing, fabrics and the like.

Owner:DONGHUA UNIV

Halogen-free antiflaming polylactic acid material and produciotn method of same

The invention discloses a halogen-free antiflaming polylactic acid material which comprises the following components according to weight percentage: 50 to 80 percent of polyactic acid base stock, 5 to 40 percent of halogen-free flame retardant, 0.1 to 1.5 percent of dispersing aid, and 10 to 30 percent of degradable toughening resin. The invention also discloses a production method of the halogen-free antiflaming polylactic acid material, which comprises the steps of blending all the components of the halogen-free antiflaming polylactic acid material and then extruding for granulation. The polylactic acid material reduces the flame retardant additive amount of an antiflaming system, ensures the antiflaming effect and simultaneously guarantees the mechanical property of the material, and can be used for injection molding type electronic products, sheet grade decoration boards and the like.

Owner:SHENZHEN ESUN IND

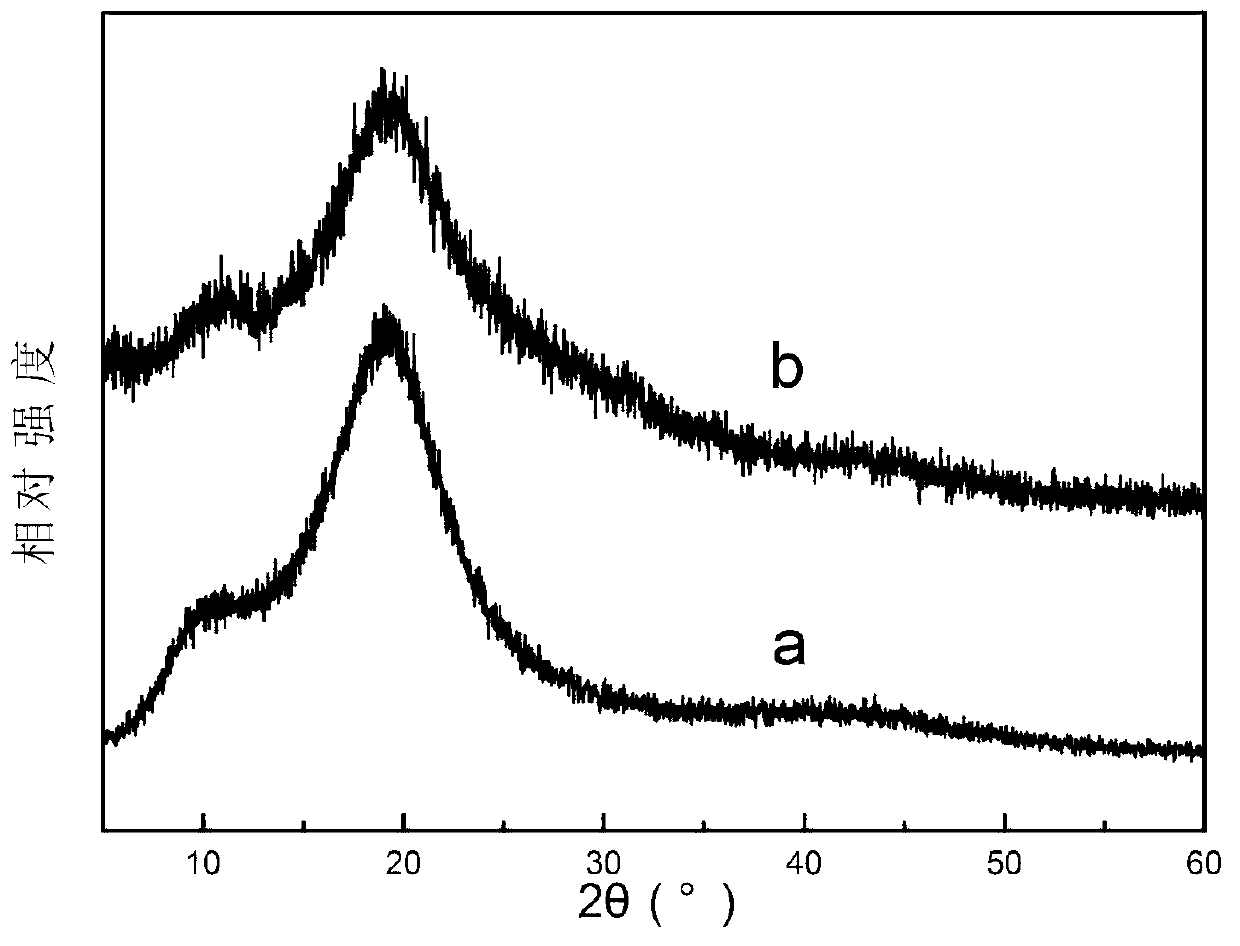

Graphene/layered double hydroxide composite flame retardant and preparation method of polystyrene nanometer flame-retardant composite material

InactiveCN103275408AReduce Secondary HazardsMeet the requirements of green environmental protectionNano compositesCarbon nanotube

The invention relates to a graphene / layered double hydroxide composite flame retardant and a preparation method of a polystyrene nanometer flame-retardant composite material. The preparation method comprises the following steps of: dissolving a carbon nanotube into graphene oxide colloid; stirring and performing ultrasonic dispersion until the materials are dispersed uniformly; adding M<2+> salt and Al<3+> salt; adding urea; performing a reflux reaction to obtain a graphene / carbon nanotube / layered double hydroxide composite assembling body; mixing the composite assembling body and polystyrene resin; and performing melt extrusion to obtain the polystyrene nanometer flame-retardant composite material. The graphene / carbon nanotube / layered double hydroxide composite assembling body is prepared by dispersing carbon nanotubes by a graphene oxide nanosheet, controlling the pH value of the solution by the urea and reducing the graphene oxide into the graphene. The polystyrene nanometer flame-retardant composite material prepared by the melt extrusion method has excellent flame resistance and mechanical properties.

Owner:HOHAI UNIV

Environment-friendly halogen-free flame-proof copolymerized methanal complex and method for producing the same

InactiveCN101508820AImprove flame retardant performanceReduce the degree of toughness lossAntioxidantHeat rejection

The invention relates to an environment-friendly halogen-free flame-retardant copolyoxymethylene compound and a preparation method thereof, belonging to the field of the preparation of flame-retardant polymer material. The compound comprises the components with the mass percentage as follows: 56.0-69.0 percent of copolyoxymethylene resin, 15.0-22.0 percent of flame retardant, 5.0-7.0 percent of flame retardant synergist, 3.0-7.0 percent of char-forming agent, 3.0-5.0 percent of toughener, 0.1-0.5 percent of formaldehyde absorbent, 0.1-1.0 percent of antioxidant and 0.5-3.0 percent of heat rejection and dripping-resistant agent. In the invention, the flame retardant, the flame retardant synergist and the heat rejection and dripping-resistant agent are coated by the toughener to manufacture compound flame retardant; then the compound flame retardant is mixed with the copolyoxymethylene, the formaldehyde absorbent, the char-forming agent and the antioxidant uniformly and the mixture is extruded from a double-screw extruder and granulated; and the copolyoxymethylene compound is obtained. The compound has good flame-retardant performance, the flame-retardant grade reaches UL94V-0 grade, and the compound is friendly to the environment.

Owner:BEIJING UNIV OF CHEM TECH

Urea resin wrapped dicyclopentadiene nanometer microcapsule, and synthetic method and application thereof

InactiveCN102492174AEasy to prepareEasy to operateMicroballoon preparationMicrocapsule preparationRepair materialPrepolymer

The invention discloses a urea resin wrapped dicyclopentadiene nanometer microcapsule, and a synthetic method and application thereof, and relates to a self-repair material, and a synthetic method and application thereof. The urea resin wrapped dicyclopentadiene nanometer microcapsule is a nanometer spherical granule prepared from urea resin used as a wall shell, and dicyclopentadiene used as a core material. The method comprises the following steps of: adding urea and a formaldehyde solution into a reactor, stirring uniformly, adding resorcinol and NH4Cl, regulating a pH value, and heating and reacting to obtain a prepolymer; and adding a sodium dodecyl benzene sulfonate solution into the dicyclopentadiene and the prepolymer, mixing the dicyclopentadiene and the prepolymer, regulating the pH value until the solution is acidic, heating, cooling the obtained suspension, washing, filtering and drying to obtain the urea resin wrapped dicyclopentadiene nanometer microcapsule. The self-repair efficiency of the nanometer microcapsule is over 60 percent, the preparation method is simple and easy to operate, and the yield is between 80 and 85 percent. The urea resin wrapped dicyclopentadiene nanometer microcapsule can be used for composite materials of aerospace.

Owner:HARBIN INST OF TECH

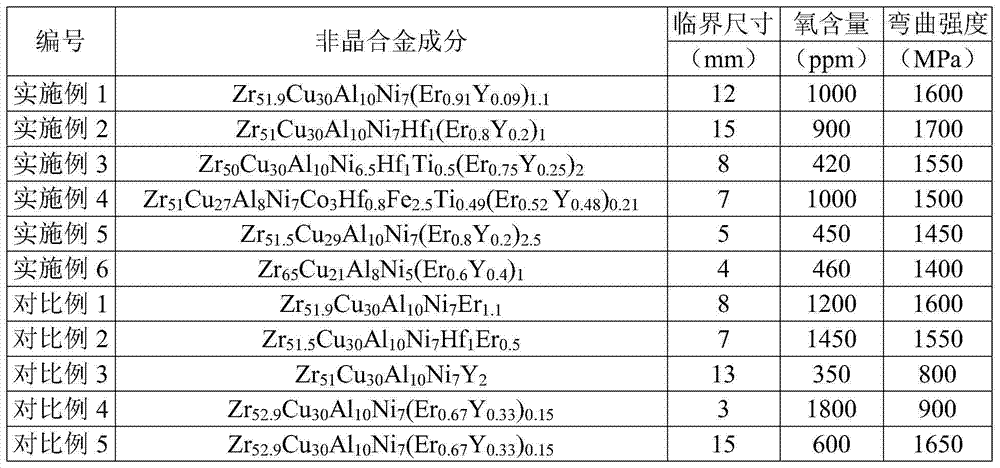

Zr-based amorphous alloy and manufacturing method thereof

InactiveCN104745973ALittle impact on mechanical propertiesEnhanced Amorphous Formation AbilityAlloyZirconium

A zirconium-based amorphous alloy and a preparation method therefor. The composition of the amorphous alloy is ZraCubAlcMd(Er1-xYx)e, wherein M is at least one selected from Ni, Fe, Co, Mn, Cr, Ti, Hf and Ta, 40≤a≤70, 15≤b≤35, 5≤c≤15, 3≤d≤15, 0.2<e≤2.5, and 0<x<0.5, and the amorphous alloy is obtained by smelting and cooling molding under the protection of an inert gas or a vacuum condition.

Owner:BYD CO LTD

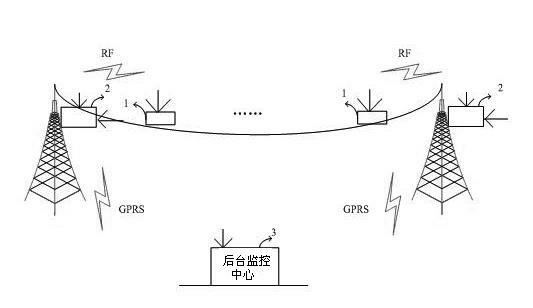

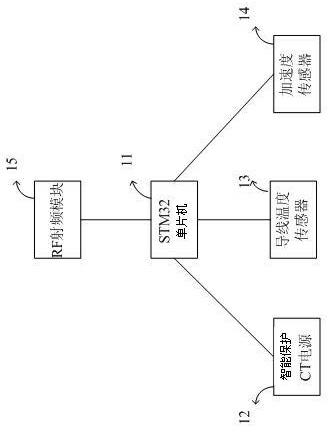

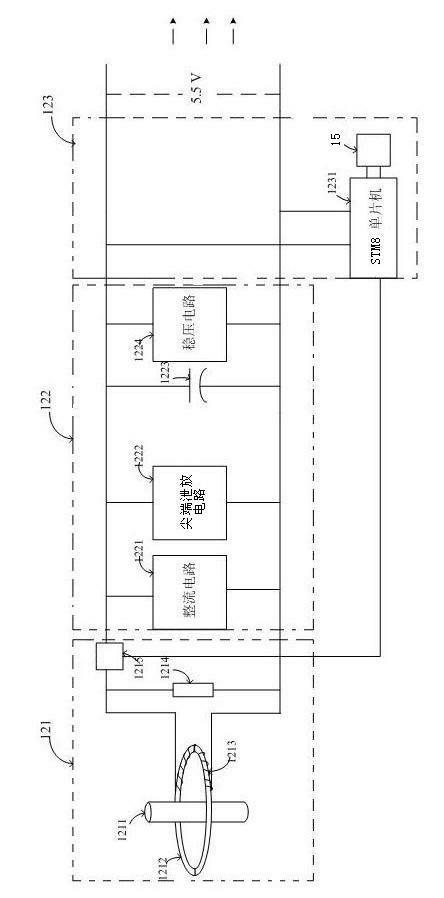

Online monitoring system for galloping of overhead power transmission line

ActiveCN102564493ALittle impact on mechanical propertiesGuaranteed synchronicityMeasurement devicesGeneral Packet Radio ServiceEngineering

The invention belongs to the technical field of power transmission line state monitoring, and discloses an online monitoring system for galloping of an overhead power transmission line. The online monitoring system is characterized in that the online monitoring system for the line of each span consists of a plurality of monitoring substations, two monitoring master stations and a background monitoring upper computer, wherein the monitoring substations are arranged on the transmission line; the two monitoring master stations are arranged on towers respectively; the background monitoring upper computer is arranged in a monitoring center; the two master stations and the plurality of substations monitor the galloping state of the line of each span; the substations accurately position the galloping of the line by utilizing acceleration sensors, and upload positioning data to the master stations through short-range radio frequency; each master station receives galloping monitoring data from four nearby substations, and uploads the monitoring data and environmental meteorological data to the background monitoring upper computer through a general packet radio service (GPRS); and when each master station synchronizes a clock through a global positioning system (GPS) module, the synchronism of the uploaded data is ensured. The online monitoring system has a small volume, low influence on mechanical properties of the line, high dynamic performance and high data monitoring accuracy, is low in cost, and can work round the clock.

Owner:STATE GRID CORP OF CHINA +1

Permanent-flame-retardant nylon 6 material and preparation method therefor

InactiveCN105153414AAdd lessGood and long-lasting flame retardantFireproof paintsFiberPolymer science

The invention relates to a permanent-flame-retardant nylon 6 material and a preparation method therefor and particularly relates to a preparation method for a block copolymerized flame-retardant nylon 6 material obtained through continuously and respectively carrying out two-step polymerization reaction on a phosphoric reactive flame retardant. The method is characterized by comprising the steps of firstly enabling the flame retardant to react with diamine or dibasic alcohol so as to obtain a flame retardant prepolymer, and then, enabling the flame retardant prepolymer to react and copolymerize with a prepolymer of nylon 6, thereby obtaining the permanent-flame-retardant nylon 6 material. The flame-retardant nylon 6 material prepared by the method has the characteristics of low flame retardant addition level and durable flame-retardant effect, the limiting oxygen index is over 30%, the vertical firing test reaches UL94V-0, and the mechanical properties are excellent; and the nylon 6 material can be subjected to injection molding directly or form films and can also become into fibers so as to further prepare flame-retardant fabrics.

Owner:DONGHUA UNIV

Glass fiber reinforced halogen-free flame-retardant PA66 and preparation thereof

The invention discloses a glass fiber reinforced halogen free flame retardation PA66 material and a preparation method thereof. The glass fiber reinforced halogen free flame retardation PA66 comprises the following components by weight percentage: 36 to 60 percent of PA66 resin, 15 to 50 percent of non-alkali glass fiber, 12 to 25 percent of halogen free flame retardant, 0.5 to 1 percent of borate, 0.5 percent of antioxidant and 0.5 to 1 percent of processing additive. The glass fiber reinforced halogen free flame retardation PA66 has high flame retardation grade which reaches vertical firing (0.8mm)FV-0, excellent mechanical properties: a tensile strength reaching 145MPa, bending strength reaching 215MPa and cantilever notch impact strength reaching 12kj / m for a 30 percent glass fiber reinforced product and good thermal endurance: heat distortion temperature (1.82MPa) reaching 250 DEG C. The borates are added to improve the thermal stability, and consequently the end product has excellent thermal stability property. The preparation method for the glass fiber reinforced halogen free flame retardation PA66 material has the advantage of simple operation.

Owner:KINGFA SCI & TECH CO LTD +1

ABS (Acrylonitrile Butadiene Styrene) modified material with high heat resistance, high gloss and flame retardance and preparation method thereof

The invention discloses an ABS modified material with high heat resistance, high gloss and flame retardance and a preparation method thereof. The material comprises ABS, SAN (Styrene Acrylonitrile), a flame retardant, a heat resistant agent, a compatibilizer, an antioxidant and a lubricating agent. The preparation method comprises the steps of: weighing raw materials; sequentially adding the raw materials into a high mixing machine in a material mixing sequence; stirring and mixing for at least 2 minutes; putting the mixed raw materials into a double-screw extruder for extruding and granulating, wherein the screw rotating speed is 200 to 450 revolutions / minute, the screw temperature is 180 DEG C to 220 DEG C, the residence time is 1 to 2 minutes and the melt pressure is 10 to 20MPa; extruding to obtain particles; and drying the particles at 60 DEG C to 90 DEG C for 2 to 4 hours. The invention provides the ABS modified material which achieves high heat resistance, flame retardance and high gloss.

Owner:SHENZHEN KEJU NEW MATERIAL

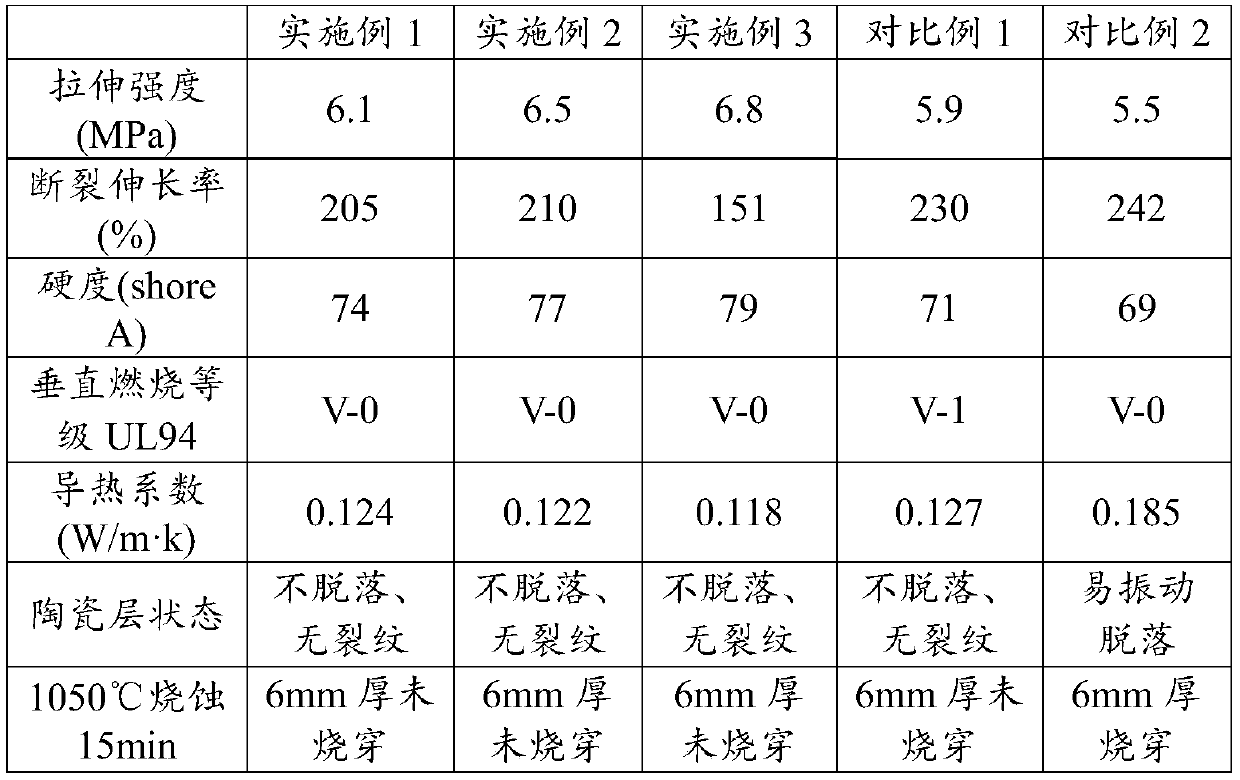

Low-thermal-conductivity flame-retardant fireproof silicone rubber composite material and preparation method thereof

The invention provides a low-thermal-conductivity flame-retardant fireproof silicone rubber composite material. The material, in parts by weight, comprises 60-80 parts of methyl vinyl silicone rubber,20-40 parts of methyl vinyl phenyl silicone rubber, 15-25 parts of hydrophobic silica aerogel powder, 20-30 parts of metal oxide powder, 5-10 parts of a fluxing agent, 3 parts of a crosslinking aid,20-30 parts of fumed silica, 3 parts of hydroxyl silicone oil, 20-30 parts of an organic-inorganic compound flame retardant and 1 part of an antioxidant. The metal oxide is selected from one or more of ferric oxide, calcium carbonate and zirconium dioxide; the organic-inorganic compound flame retardant is selected from a mixture of modified pentaerythritol phosphate and silane coupling agent modified aluminum hydroxide; and the modified pentaerythritol phosphate is prepared by reacting pentaerythritol phosphate modified by phosphorus oxychloride with aminopropyl-terminated dimethyl silicone oil. The composite material has good fireproof and heat-insulating effects and mechanical properties.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Copolymerized flame-retardant polyamide 66 fiber and preparation method thereof

InactiveCN105155018AAdd lessImprove flame retardant performanceMonocomponent copolyamides artificial filamentMelt spinning methodsPolymer sciencePolyamide

The invention relates to a copolymerized flame-retardant polyamide 66 fiber and a preparation method thereof, especially to a method for preparing the flame-retardant polyamide 66 fiber by preparing a block flame-retardant polyamide 66 copolymer through polymerization of a phosphorus-containing reactive flame retardant, then pelletizing and drying the polyamide 66 copolymer and then carrying out melt spinning. The method is characterized in that the flame-retardant reacts with diamine or dihydric alcohol to produce a flame-retardant prepolymer, then the flame retardant prepolymer reacts with polyamide 66 prepolymer so as to obtain the flame-retardant polyamide 66 copolymer, and finally, the flame-retardant polyamide 66 copolymer is subjected to melt spinning so as to prepare the copolymerized flame-retardant polyamide 66 fiber. The copolymerized flame-retardant polyamide 66 fiber prepared in the invention has excellent mechanical properties, good flame retardation durability and a limit oxygen index of more than 30%. The flame-retardant polyamide 66 fiber can be used for fabricating civil filaments like clothes, carpets, curtains, cloth for furniture, etc. and fabricating industrial filaments like cord fabrics, transport belts, fishing nets, cables, military fabrics, etc.

Owner:DONGHUA UNIV

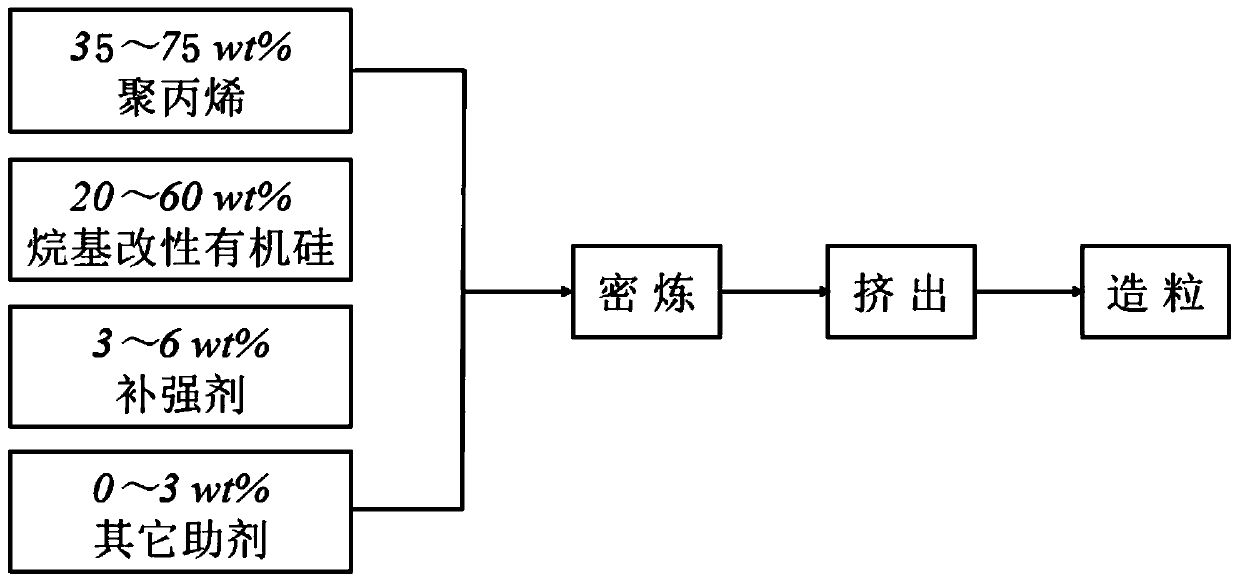

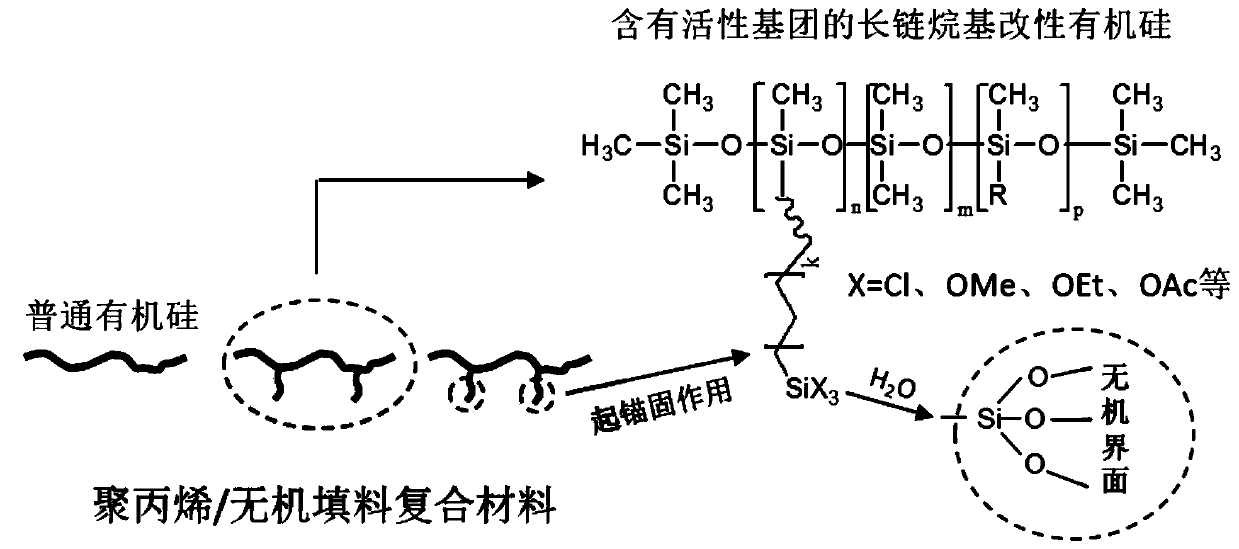

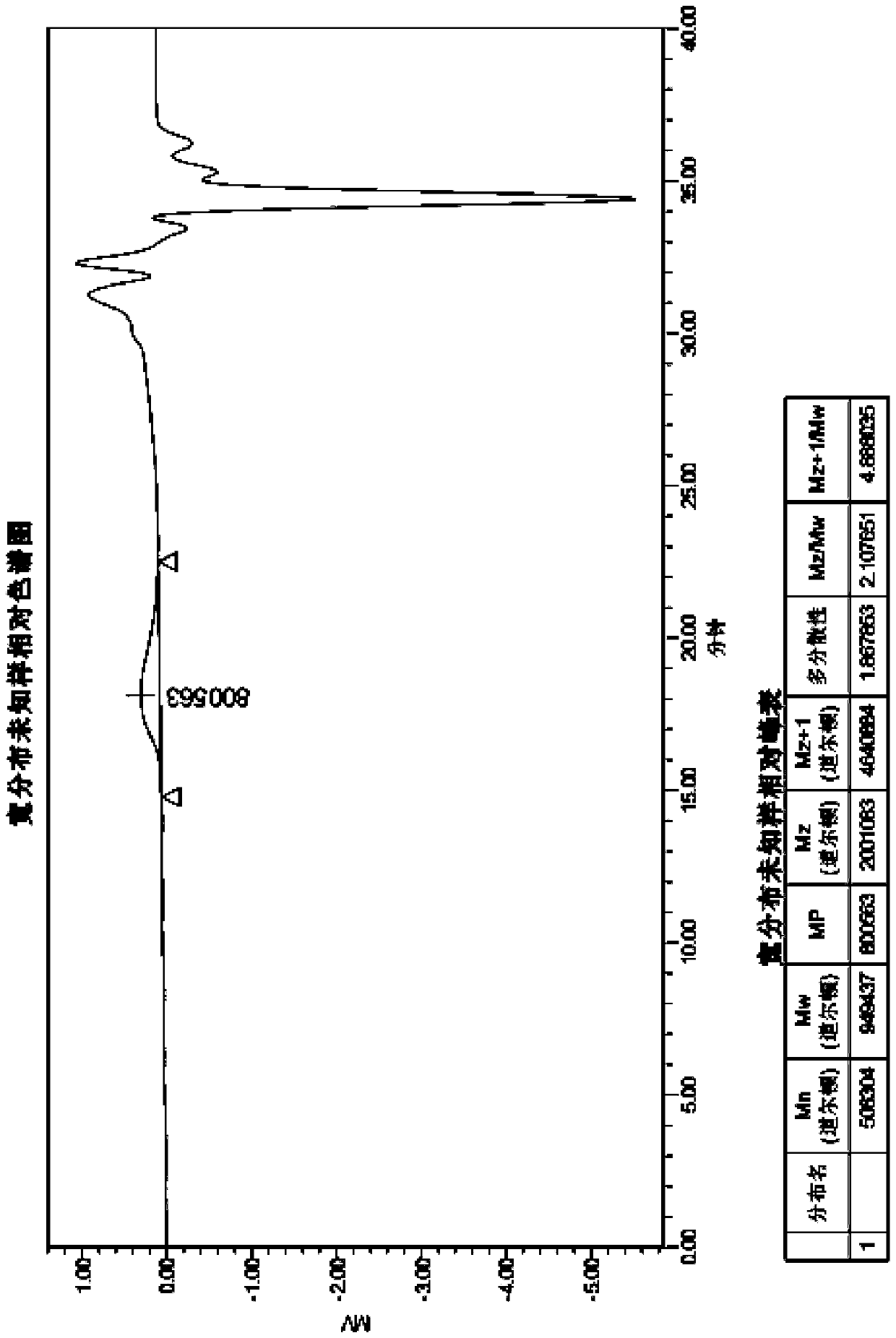

Silicone master batch with long-lasting scratch resistance, and preparation method thereof

The invention discloses a silicone master batch with long-lasting scratch resistance, and a preparation method thereof. The raw materials of the master batch contain modified silicone, the modified silicone is an active group-containing long side chain-grafted high molecular weight polysiloxane, and the raw materials also contain polypropylene, a reinforcing agent, an anti-aging agent and other assistants. The raw materials are internally mixed at 200-220 DEG C, and then are extruded and granulated under certain conditions by a twin-screw extruder to obtain the silicone master batch with long-lasting scratch resistance. The silicone master batch prepared by the invention contains the active group-containing long side chain-grafted high molecular weight polysiloxane, so the problems of unabiding scratch resistance and stress whitening of common silicone are well solved, the plastic processing performance is improved, and the device wearing is reduced. The preparation method of the invention has the advantages of simple process, environmental protection, safety, good repeatability, and easiness in industrialization. The silicone masterbatch prepared in the invention is mainly used for preparing a scratch-resistant automotive interior polypropylene composite material.

Owner:CHENGDU GUIBAO SCI & TECH

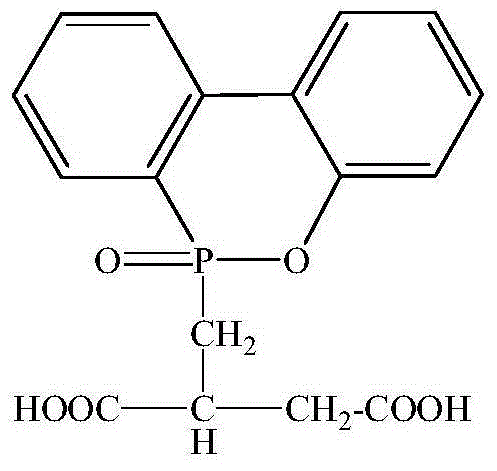

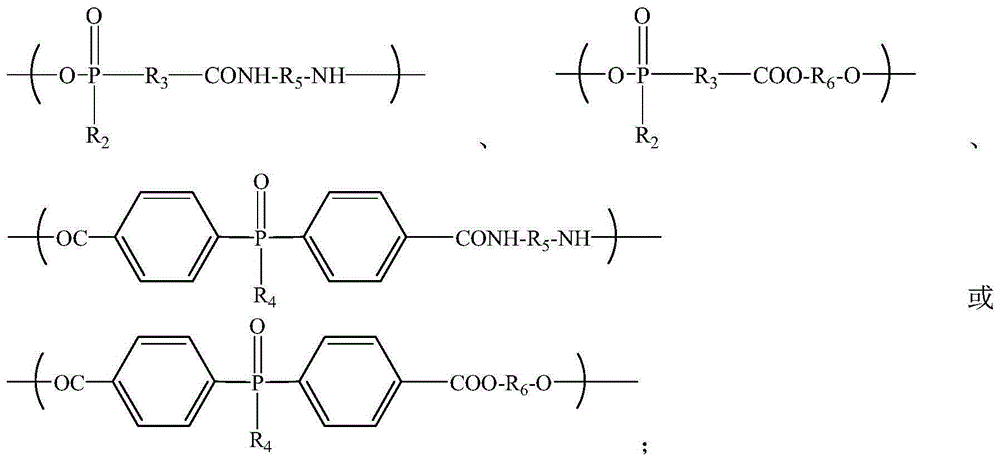

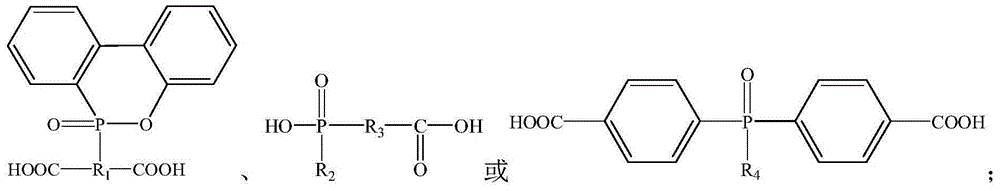

Reaction type nylon flame retardant and preparation method

ActiveCN104311877AHigh flame retardant efficiencyLittle impact on mechanical propertiesGroup 5/15 element organic compoundsPolymer scienceAlcohol

The invention belongs to the field of flame retardants, and especially relates to a reaction type nylon flame retardant and a preparation method. The technical scheme is characterized in that the halonge-free phosphorus-containing nylon flame retardant is synthesized by a two-step process, a first step is preparation of a flame-retardation esterification liquid, the formula comprises 5-52 parts by mass of a halogen-free phosphorus-containing copolymerization type flame retardant and 20-65 parts of a dihydric alcohol, and the flame-retardation esterification liquid is obtained by reacting the above two compositions under a certain condition; and a second step is preparation of the halogen-free phosphorus-containing nylon flame retardant, based on the mass quantity of the flame-retardation esterification liquid, the formula comprises 18-60 parts of the flame-retardation esterification liquid and 5-48 parts of a dibasic acid, and the halogen-free phosphorus-containing nylon flame retardant is obtained by reacting the above two compositions under a certain condition. The obtained flame retardant is resistant to a high temperature of 250 DEG C, satisfies the polymerization temperature of nylon, is polymerized onto a nylon molecular chain in a monomer form in a nylon polymerization process, and has persistent flame retardation effect. The prepared nylon flame retardant has the limit oxygen index of 30% or more, has excellent flame retardation performance, is applicable to produce flame-retardant nylon with the flame retardation performance of UL94V-0 grade or more, and is an efficient environment-friendly nylon flame retardant.

Owner:CHENGDU TALY TECH CO LTD

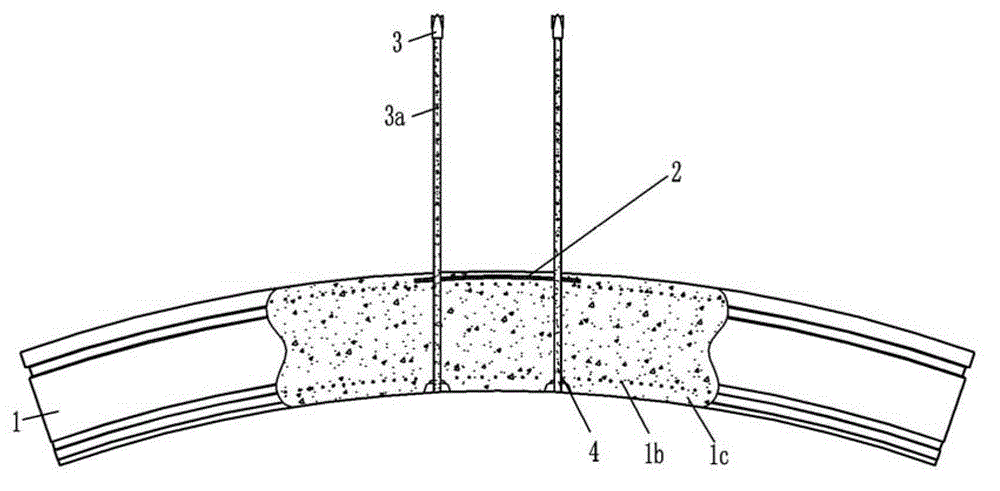

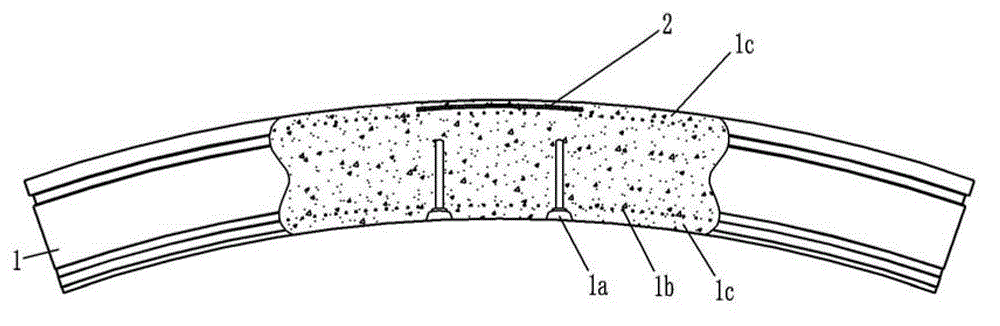

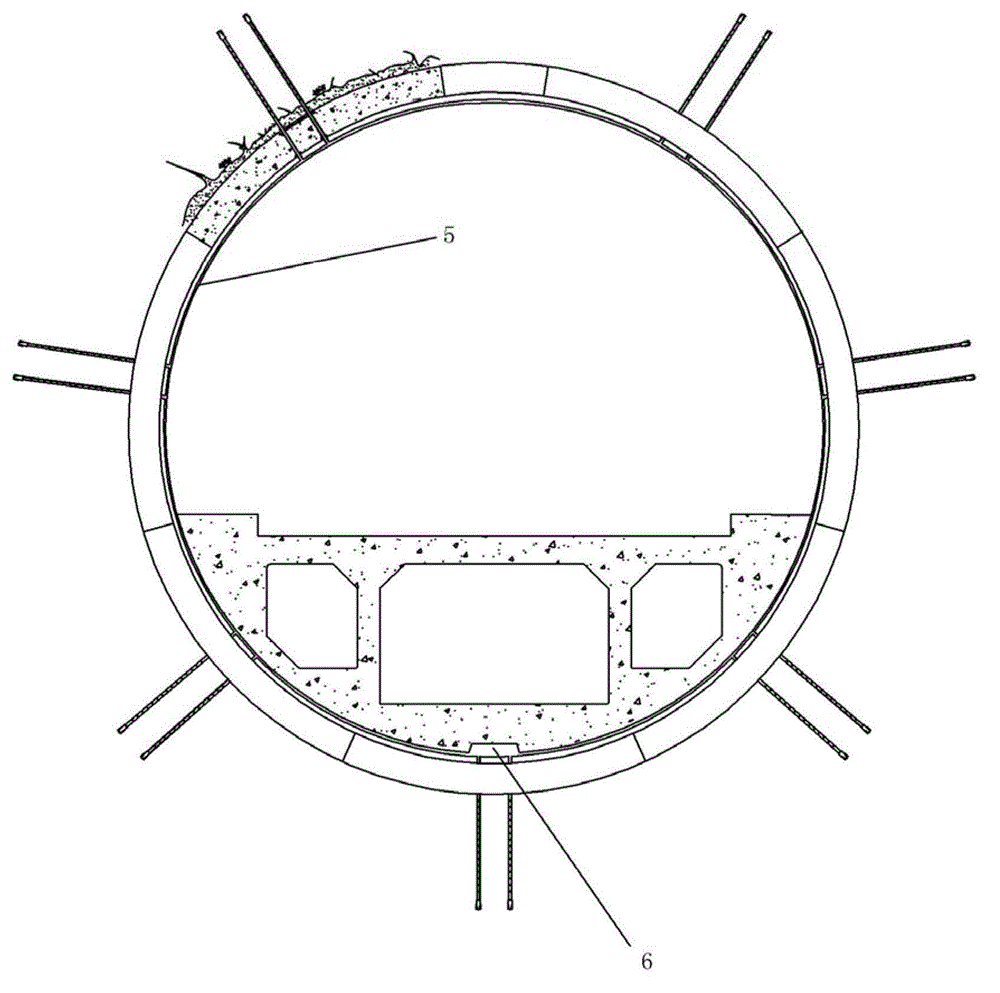

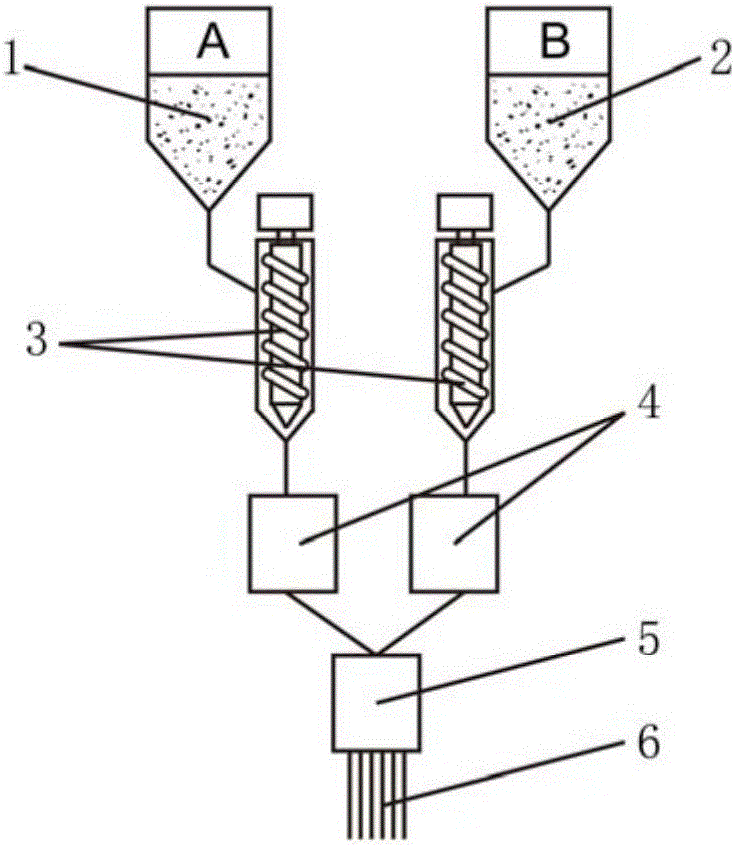

Drain-type pipe piece for tunnel lining

ActiveCN102979535ANo need to increase intensityEnsure safetyUnderground chambersDrainageReinforced concreteSlurry

The invention discloses a drain-type pipe piece for tunnel lining. The drain-type pipe piece comprises a reinforced concrete pipe piece (1), a slurry injection hole (or a hoist hole) (1a) in the pipe piece (1), a load bearing steel bar (1b), and a concrete protective layer (1c) on the outer side; a water stop rubber block (2) capable of being expanded when being in contact with water is preburied in the concrete protective layer (1c) right opposite to one or two slurry injection holes (1a) of the pipe piece (1); a self-advancing type hollow anchor rod (3) is inserted in the slurry injection holes (or the hoist hole) (1a) of the pipe piece (1), then penetrates the water stop rubber block (2), and shoots out of the concrete protective layer (1c); and drain holes (3a) are formed in the rod wall of the outer end of the self-advancing type hollow anchor rod (3), and a filter column (4) used for filtering sand is plugged in the inner cavity of the self-advancing type hollow anchor rod (3). Lining built with the pipe pieces has a reliable drain function, and can reduce water pressure around the structure to ensure tunnel safety; and construction is convenient, small damage is caused to the pipe piece lining structure, and construction cost of the pipe piece lining is low.

Owner:SOUTHWEST JIAOTONG UNIV

Flame-retardant polyamide 6 composite fiber and preparation method thereof

InactiveCN105155033AAdd lessGood and long-lasting flame retardantConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention relates to a flame-retardant polyamide 6 composite fiber and a preparation method thereof, especially to a method for preparing the flame-retardant polyamide 6 composite fiber by continuously and separately carrying out two-step polymerization on a phosphorus-containing reactive flame retardant to prepare block copolymerized flame-retardant polyamide 6 and then subjecting the block copolymerized flame-retardant polyamide 6 and a fiber forming polymer to melt composite spinning. The method is characterized in that the flame retardant reacts with diamine or dihydric alcohol to produce a flame-retardant prepolymer, then the flame-retardant prepolymer and polyamide 6 prepolymer undergo copolymerization so as to obtain a flame-retardant polyamide 6 material, and finally, after pelletizing of a cast strip, extraction and drying, the flame-retardant polyamide 6 material and the sliced fiber forming polymer are subjected to melt composite spinning so as to prepare the flame-retardant polyamide 6 composite fiber. The flame-retardant polyamide 6 composite fiber prepared by using the method has the characteristics of a small addition amount of the addition, long-lasting flame retardation effect and fluffy and comfortable feel, can be used for preparation of fabric products, and is mainly applicable to knitting wool, blankets, wool fabrics, warm-keeping wadding fillers, silk fabrics, non-woven fabrics, medical and sanitary products, special working clothes, etc.

Owner:DONGHUA UNIV

Preparation method for flame-retardant acrylic rubber

ActiveCN104262528AImprove flame retardant performanceLittle impact on mechanical propertiesCross-linkPolymer science

The invention relates to a preparation method for flame-retardant acrylic rubber. According to the preparation method, the problem that the flame-retardant performance of the acrylic rubber in the prior art is poorer is mainly solved. The preparation method for the flame-retardant acrylic rubber, disclosed by the invention, comprises the following steps: under an inert gas atmosphere, adding a main acrylate monomer, a flame-retardant monomer, a cross-linking monomer and a chain transfer agent in a water system containing an emulsifying agent; emulsifying the mixture at the temperature of 40-90DEG C; then adding an initiator for reacting; finally, coagulating, washing and drying the emulsion obtained by reacting to obtain the flame-retardant acrylic rubber, wherein the flame-retardant monomer is a monomer containing double bonds and a phosphate ester group; according to the technical scheme adopted by the invention, the problems are better solved; the preparation method can be used for preparing the flame-retardant acrylic rubber.

Owner:SHANGHAI HUAYI GRP CO

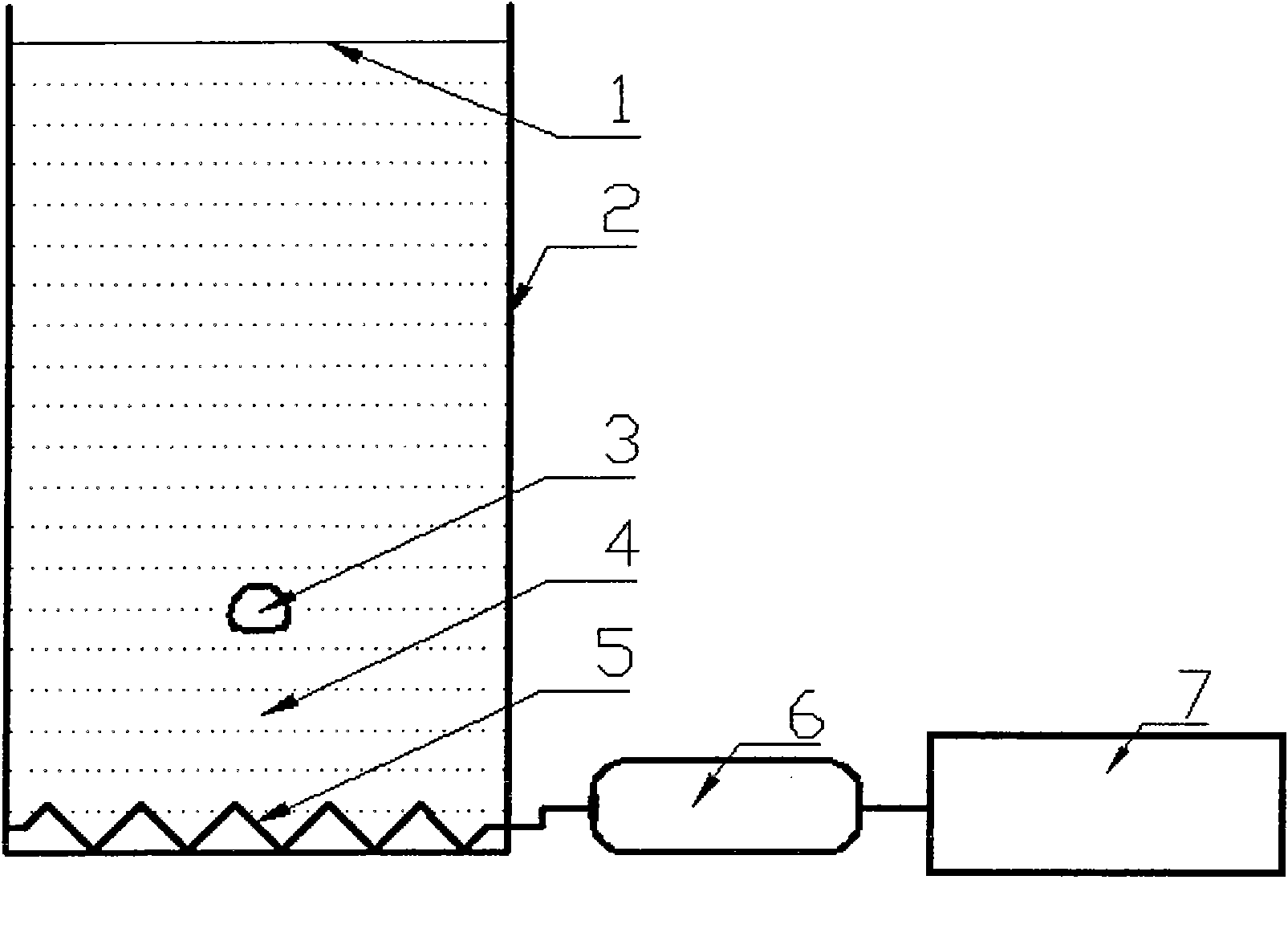

Control system of hydraulic boundary conditions in water bearing layer during similar model test

InactiveCN101644701AGuaranteed successful layingReduce volumeMaterial analysisControl systemEngineering

The invention relates to a control system of hydraulic boundary conditions in a water bearing layer during a similar model test, which comprises a test bench, a booster pump and a data processing device, wherein similar materials are laid in the test bench; a tunnel and a non-watertight film bag are arranged in the similar materials; a cavity in the non-watertight film bag is connected with the booster pump through a water inlet pipe; and the booster pump is connected with the data processing device. The invention has the advantages that: (1) the hydraulic boundary conditions in any selected position under any geological condition during the similar model test can be successfully controlled; (2) successful laying of the similar materials can be ensured, and the non-watertight film bag canbe laid in any position according to any shape, thereby simulating groundwater seepage or water inrush under special conditions; (3) the film bag has small volume and large flexibility, thus, after the film bag is embedded in the similar materials, the film bag can synchronously deform along with the similar materials, and the influence on the mechanical property of the similar materials at the periphery of the current position is less; and (4) the data processing device can control the hydraulic boundary conditions in the position of the film bag in the similar materials through the booster pump according to the engineering background and simulating requirements.

Owner:SHANDONG UNIV

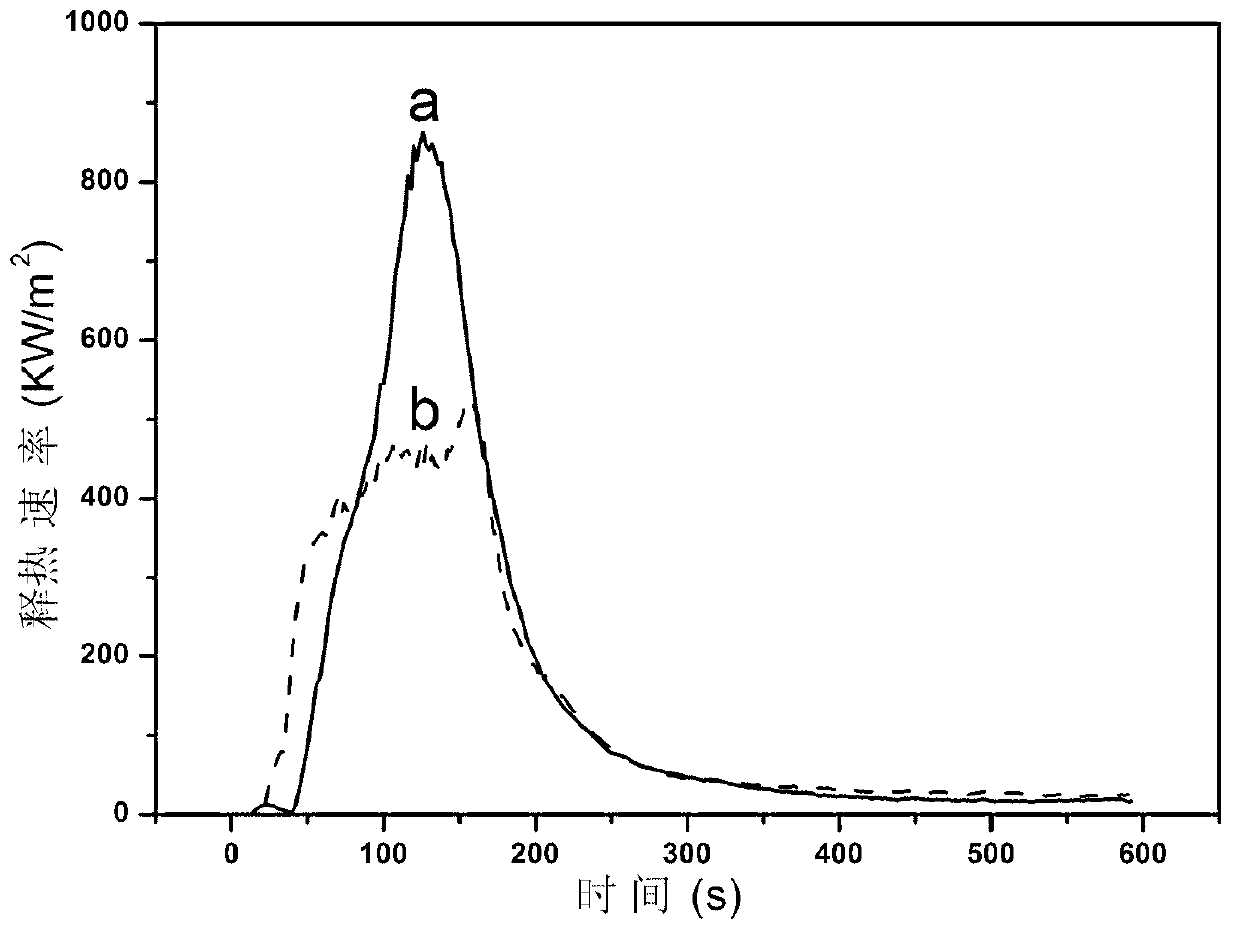

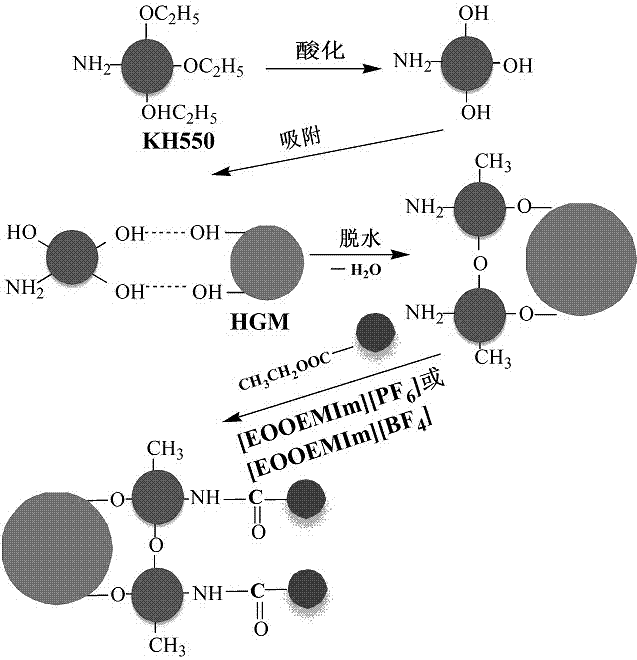

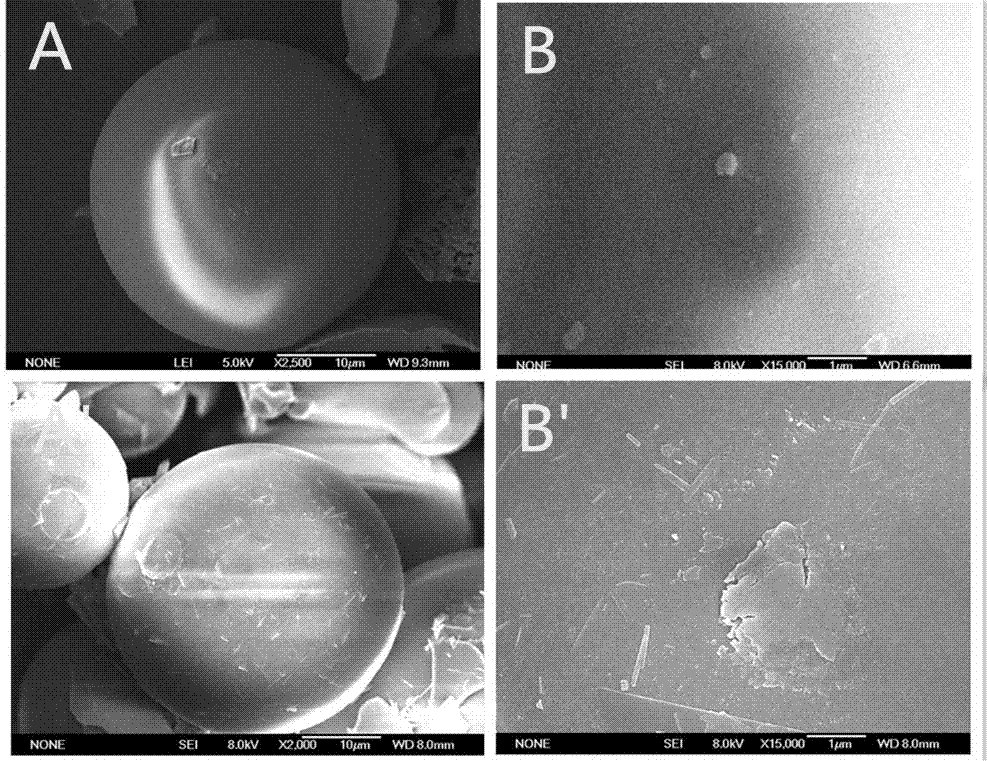

Method of modifying hollow glass microbeads with ionic liquid and flame-retarding thermoplastic polyurethane elastomer with the modified hollow glass microbeads as flame retardant

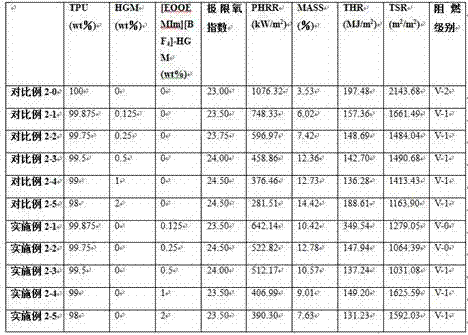

The invention discloses a method of modifying hollow glass microbeads with an ionic liquid and a flame-retarding thermoplastic polyurethane elastomer with the modified hollow glass microbeads as a flame retardant. The method includes the steps of: 1) treating the hollow glass microbeads with a hydrochloric acid solution; 2) after the acid treatment, repeatedly washing and drying the hollow glass microbeads; 3) activating the hollow glass microbeads, adding a silane coupling agent, and performing mechanical stirring reflux; 4) stopping the reaction and cooling the reaction product to room temperature, and performing suction filtration with acetonitrile, ethanol and deionized water and drying the reaction product; 5) adding the ionic liquid to the silanized hollow glass microbeads and performing mechanical stirring reflux; 6) stopping the reaction and cooling the reaction product to room temperature, performing suction filtration successively with ethanol, a mixed solution of ethanol and deionized water, and ethanol, and drying the reaction product. By means of the hollow glass microbeads modified with the ionic liquid as the flame retardant for preparing flame-retarding thermoplastic polyurethane (TPU) elastomer, not only is oxygen index of the composite material improved, but also the vertical combustion performance, which reflects melt-dripping resistance, is improved, so that heat release rate is reduced and smoke is significantly inhibited.

Owner:JIANGSU STERRIC CHEM IND

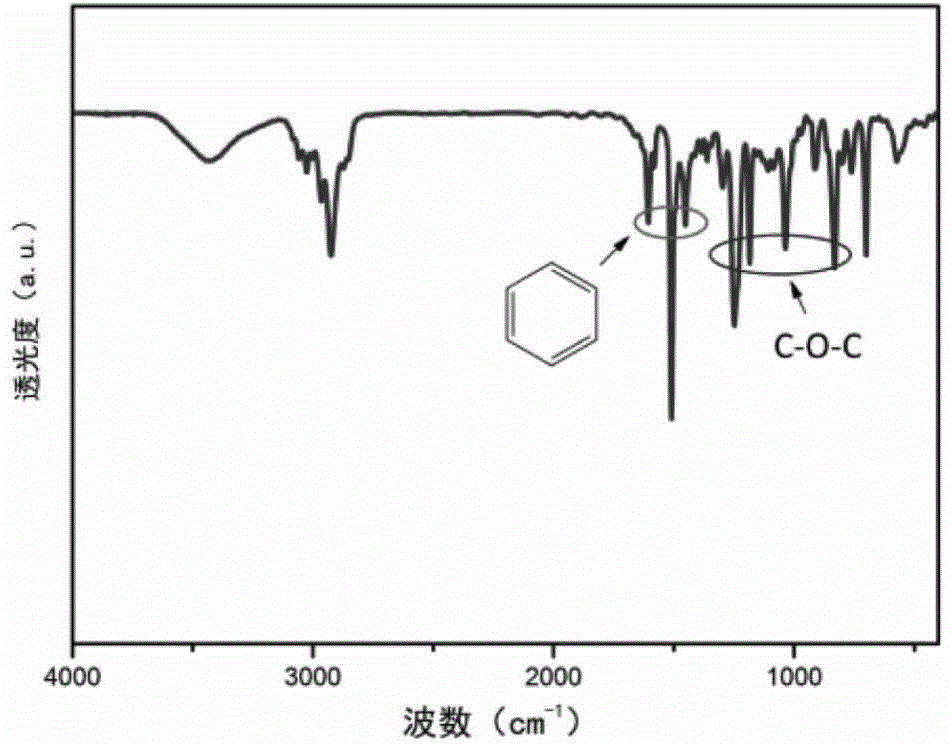

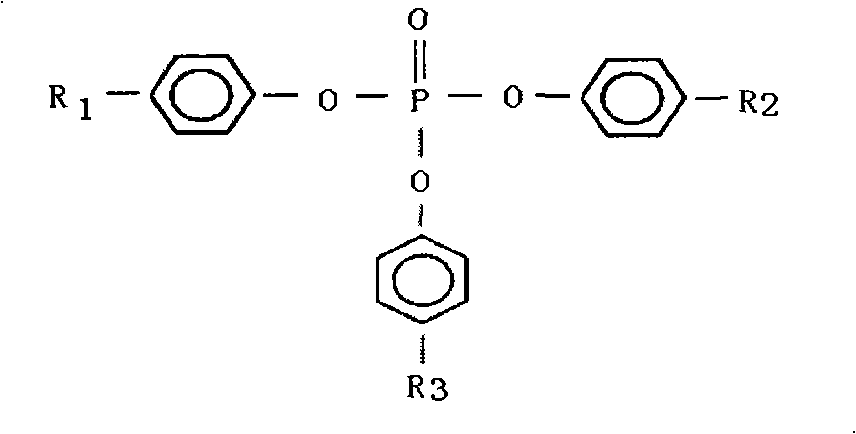

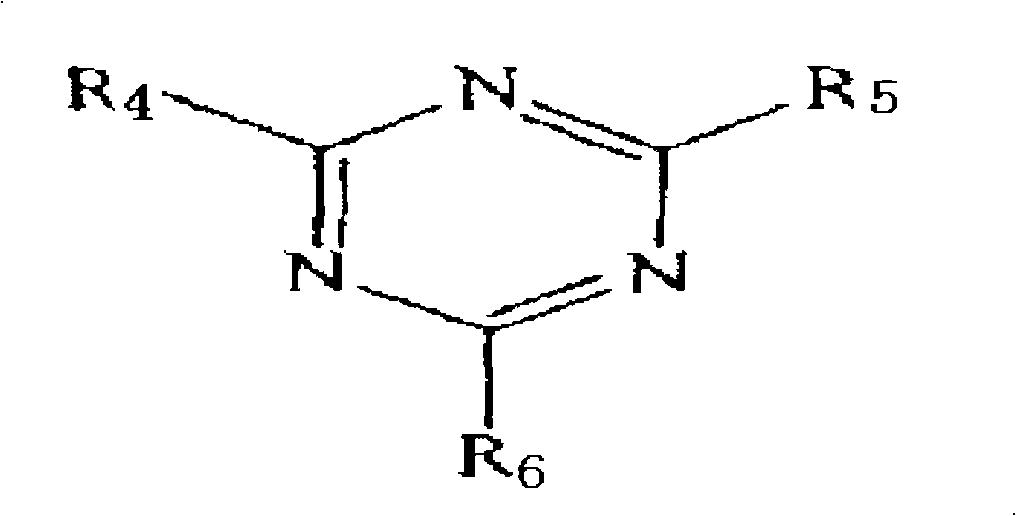

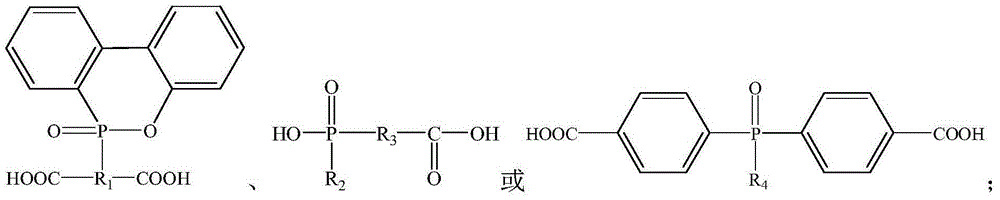

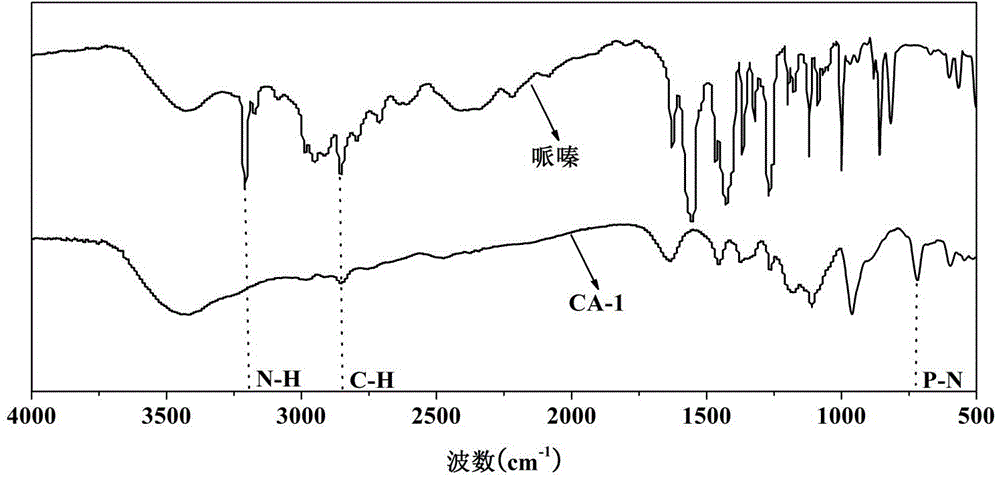

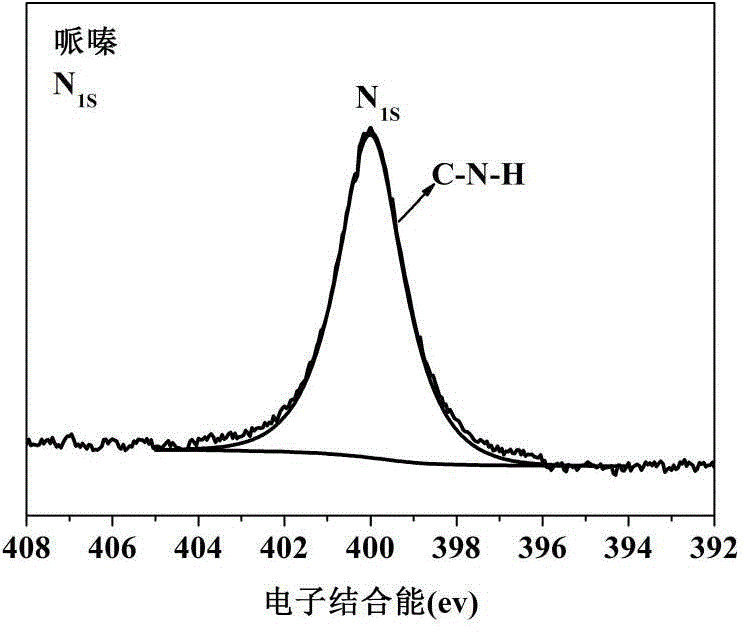

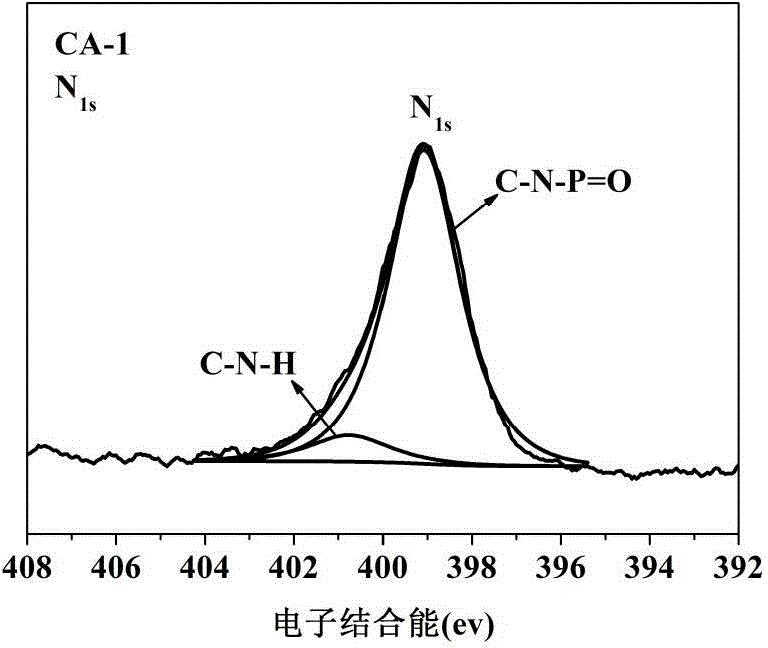

Phosphorus-containing macromolecular intumescent flame-retardant charring agent with cross-linked structure as well as preparation method and application thereof

ActiveCN104559204ASolve the problems caused by poor water resistanceImprove solubilityEpoxyCross-link

The invention discloses a phosphorus-containing macromolecular intumescent flame-retardant charring agent with a cross-linked structure as well as a preparation method and an application thereof. A structural general formula of the phosphorus-containing macromolecular intumescent flame-retardant charring agent is as shown in the specification, wherein X, Y and Z are any one of diamine, diol group, alkylol amine or diphenol, and can be the same, and can also be different. The invention further relates to a preparation method of the flame-retardant charring agent, and an application of the flame-retardant charring agent as a carbon source of a novel intumescent flame-retardant system, and an application of novel intumescent flame-retardant system in polyolefin, polyurethane, polylactic acid, polyamide and epoxy resin. The intumescent flame-retardant charring agent prepared by the method has good charring property, and is free of halogen, low in toxicity and high in water resistance, good in compatibility with a plurality of flame-retardant high polymers, relatively small in effects on mechanical property, simple in synthesis process, easy to control, and easy to put into industrial production.

Owner:SICHUAN UNIV

Flame-retardant polyamide 66 complex fiber and preparation method thereof

InactiveCN105040154AAdd lessImprove flame retardant performanceConjugated synthetic polymer artificial filamentsFiberYarn

The invention relates to a flame-retardant polyamide 66 complex fiber and a preparation method thereof, in particular to a method that a phosphorus-containing reactive type fire retardant is subjected to polymerization reaction to prepare a blocked flame-retardant polyamide 66 copolymer, and the blocked flame-retardant polyamide 66 copolymer is fused with a fiber forming polymer for composite spinning to prepare the flame-retardant polyamide 66 complex fiber. The method is characterized in that firstly, the fire retardant reacts with diamine or dihydric alcohol to obtain a fire retardant prepolymer; secondly, the fire retardant prepolymer reacts with a polyamide 66 prepolymer to obtain the flame-retardant polyamide 66 copolymer; finally, the flame-retardant polyamide 66 copolymer is fused with the fiber forming polymer for composite spinning to prepare the flame-retardant polyamide 66 complex fiber. The flame-retardant polyamide 66 complex fiber prepared by means of the method has the advantages of being lasting in flame-retardant effect, fluffy and comfortable in hand feeling and the like. The flame-retardant polyamide 66 complex fiber can be used in the fields of woolen yarns, woolen blankets, silk fabrics, non-woven fabrics, special working clothes and the like.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com