Patents

Literature

1999 results about "Charring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Charring is a chemical process of incomplete combustion of certain solids when subjected to high heat. Heat distillation removes water vapor and volatile organic compounds (syngas) from the matrix. The residual black carbon material is char, as distinguished from the lighter colored ash. By the action of heat, charring removes hydrogen and oxygen from the solid, so that the remaining char is composed primarily of carbon. Polymers like thermoset, or most solid organic compounds like wood or biological tissue, exhibit charring behaviour.

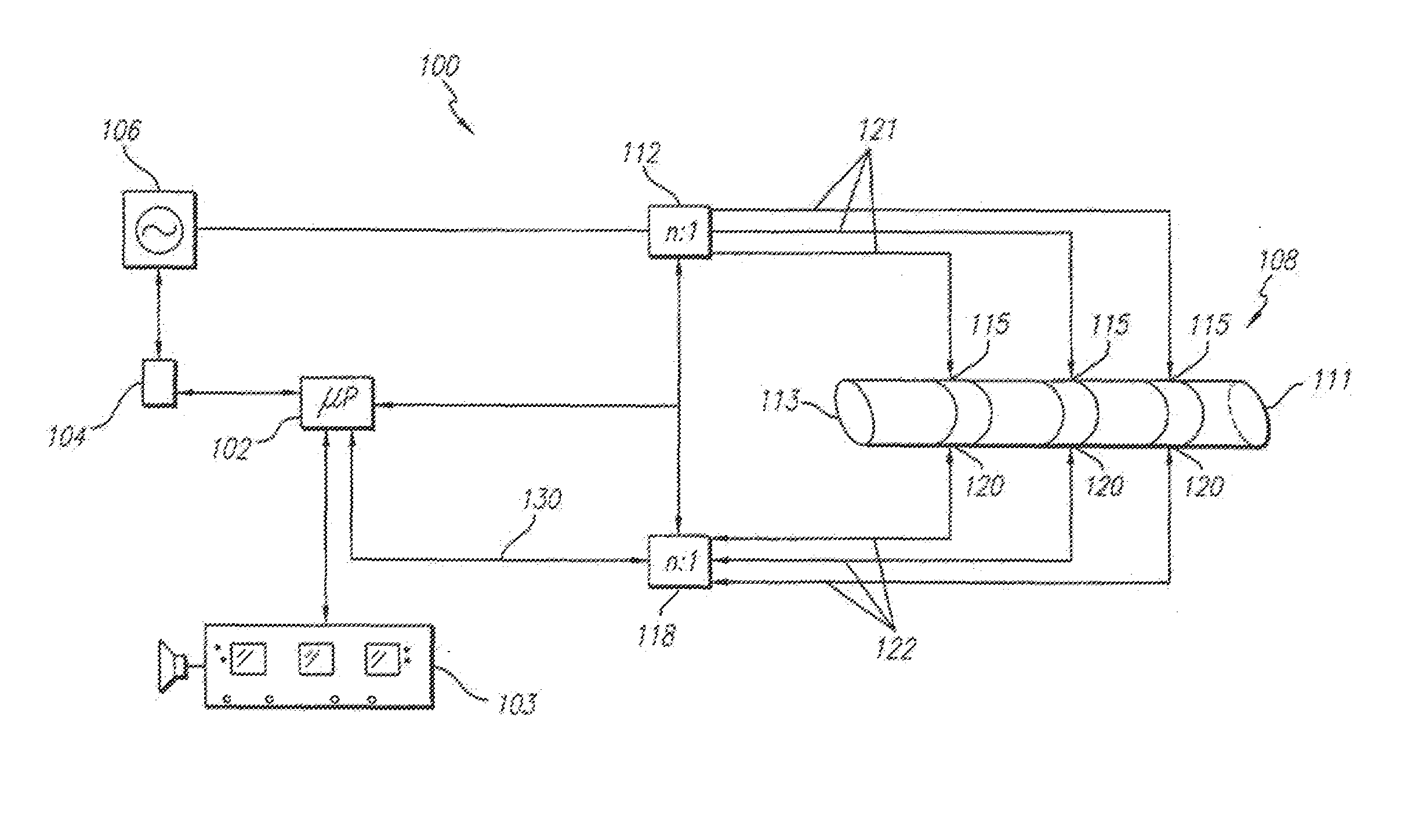

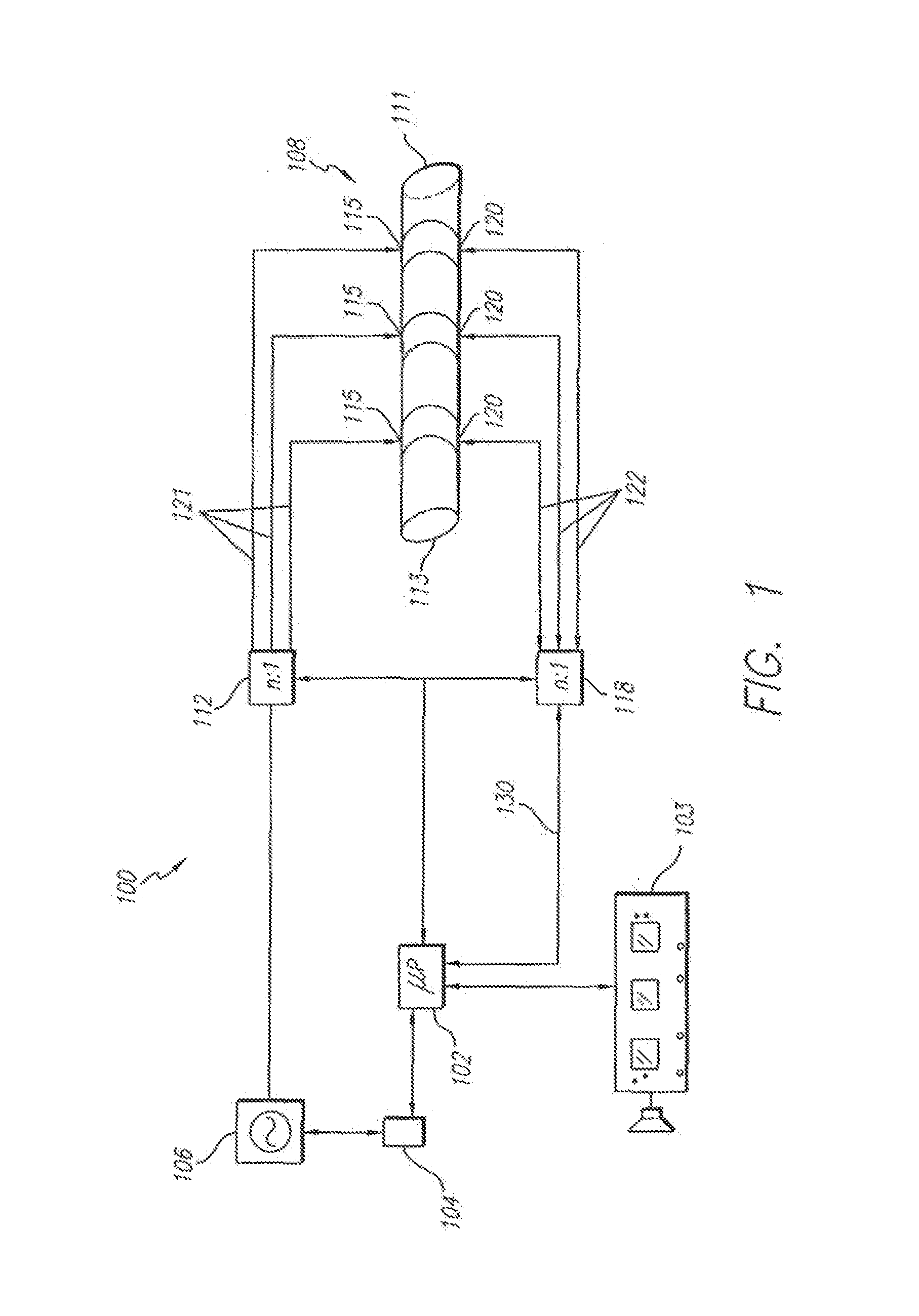

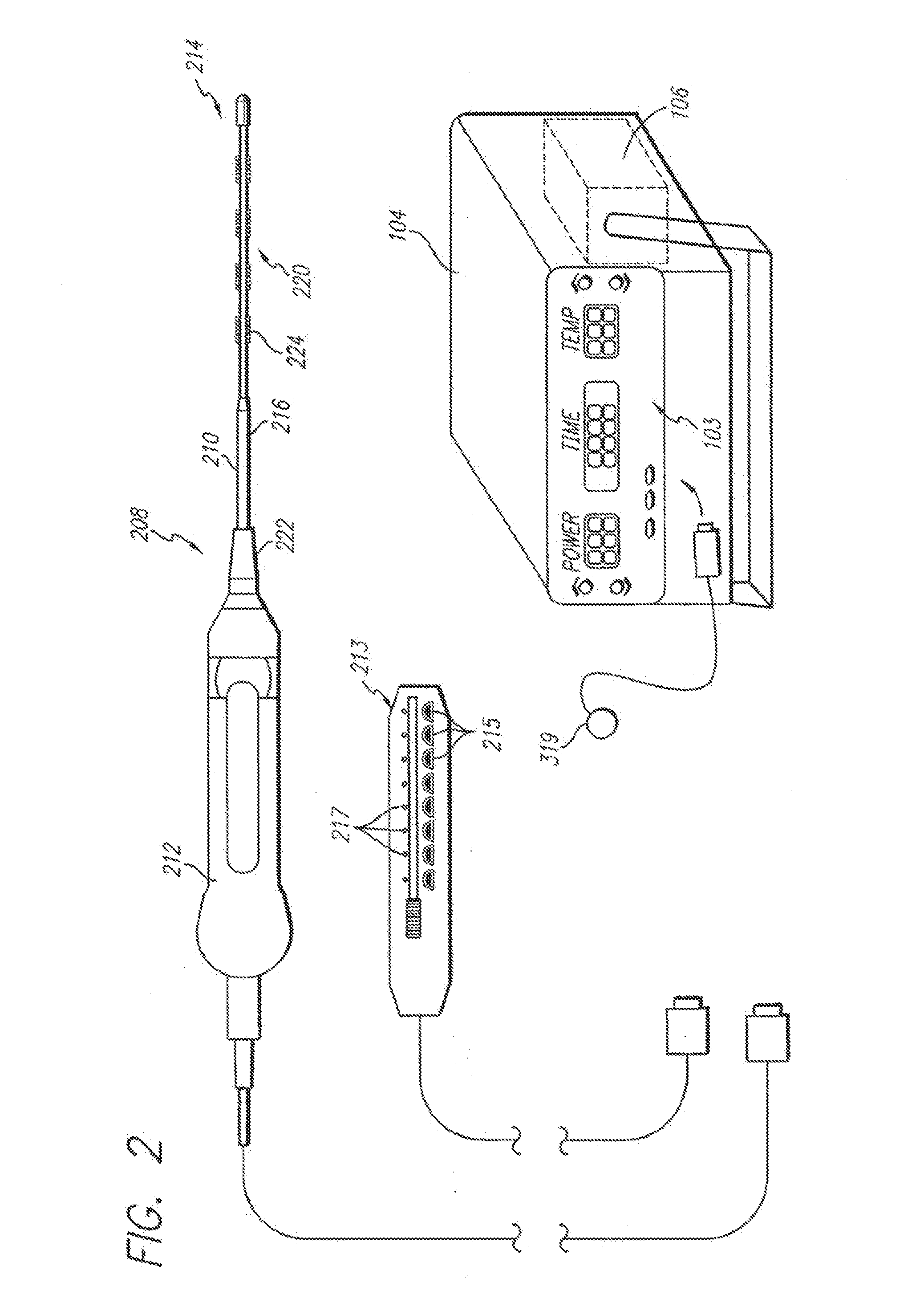

Systems and methods for controlling power in an electrosurgical probe

InactiveUS7582084B2Avoid problemsAccelerated programControlling energy of instrumentSurgical instruments for heatingControl powerCharring

Systems and methods for controlling the power supplied to an electrosurgical probe. The systems and methods may be used to monitor electrode-tissue contact, adjust power in response to a loss of contact, and apply power in such a manner that charring, coagulum formation and tissue popping are less likely to occur.

Owner:BOSTON SCI SCIMED INC

Flame retardant resin compositions

This invention relates to flame retardants for polyester and polyamide compositions, and specifically relates to compositions containing (1) about 30 to about 70 weight percent of a polyester or a synthetic, aliphatic polyamide and synthetic aliphatic, aromatic polyamide copolymers or a mixture thereof; (2) about 15 to about 40 weight percent of glass or mineral reinforcing agent; and (3) a flame retardant of (a) about 5 to about 45 weight percent of melamine polyphosphate; (b) about 15 to about 30 weight percent of melamine polyphosphate and up to about 10 weight percent of a charring catalyst; (c) about 15 to about 30 weight percent of melamine polyphosphate, up to about 10 weight percent of a charring catalyst and up to about 10 weight percent of a char former, wherein all percents by weight are based on the total weight of (1)+(2)+(3) only.

Owner:EI DU PONT DE NEMOURS & CO

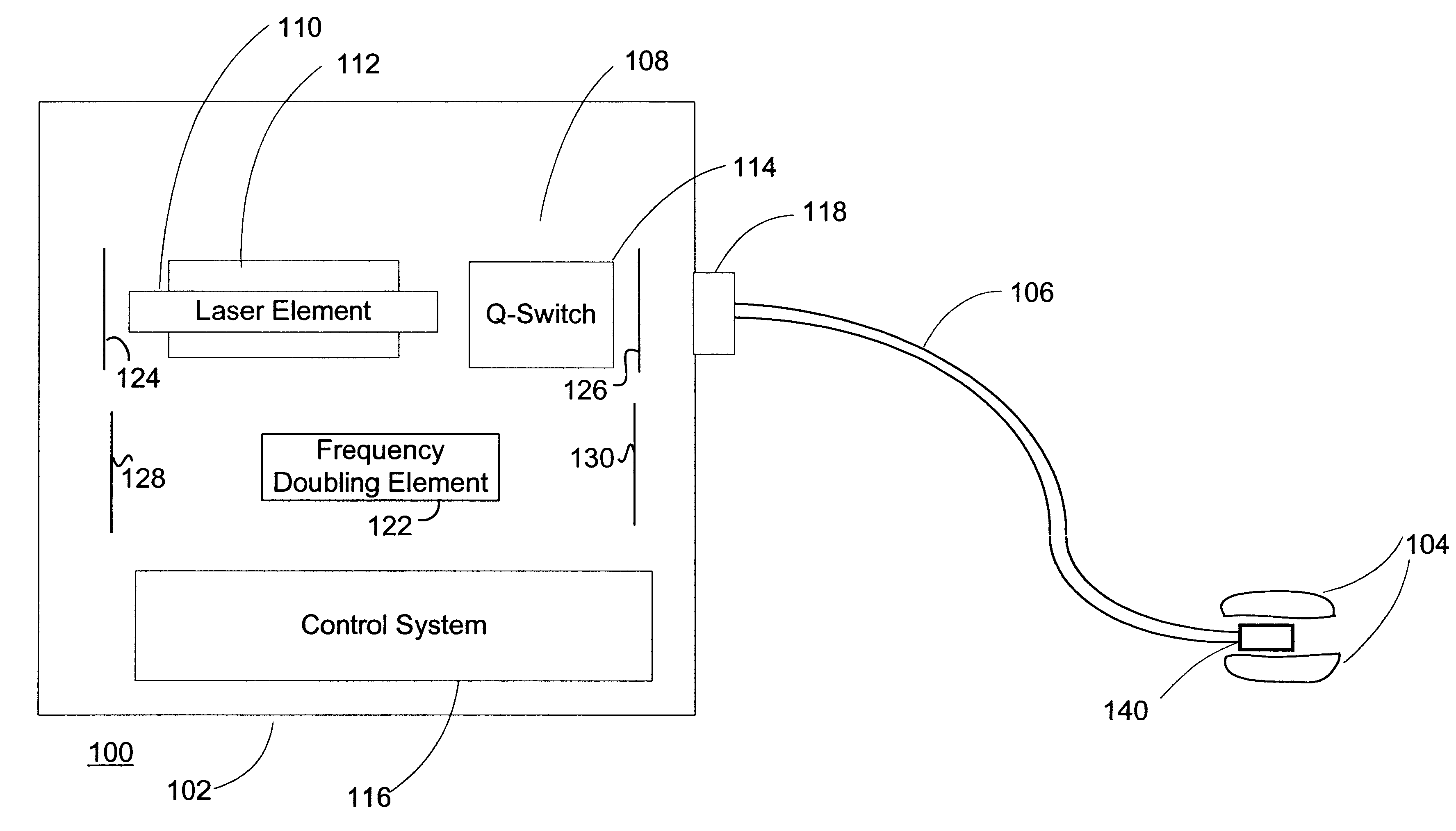

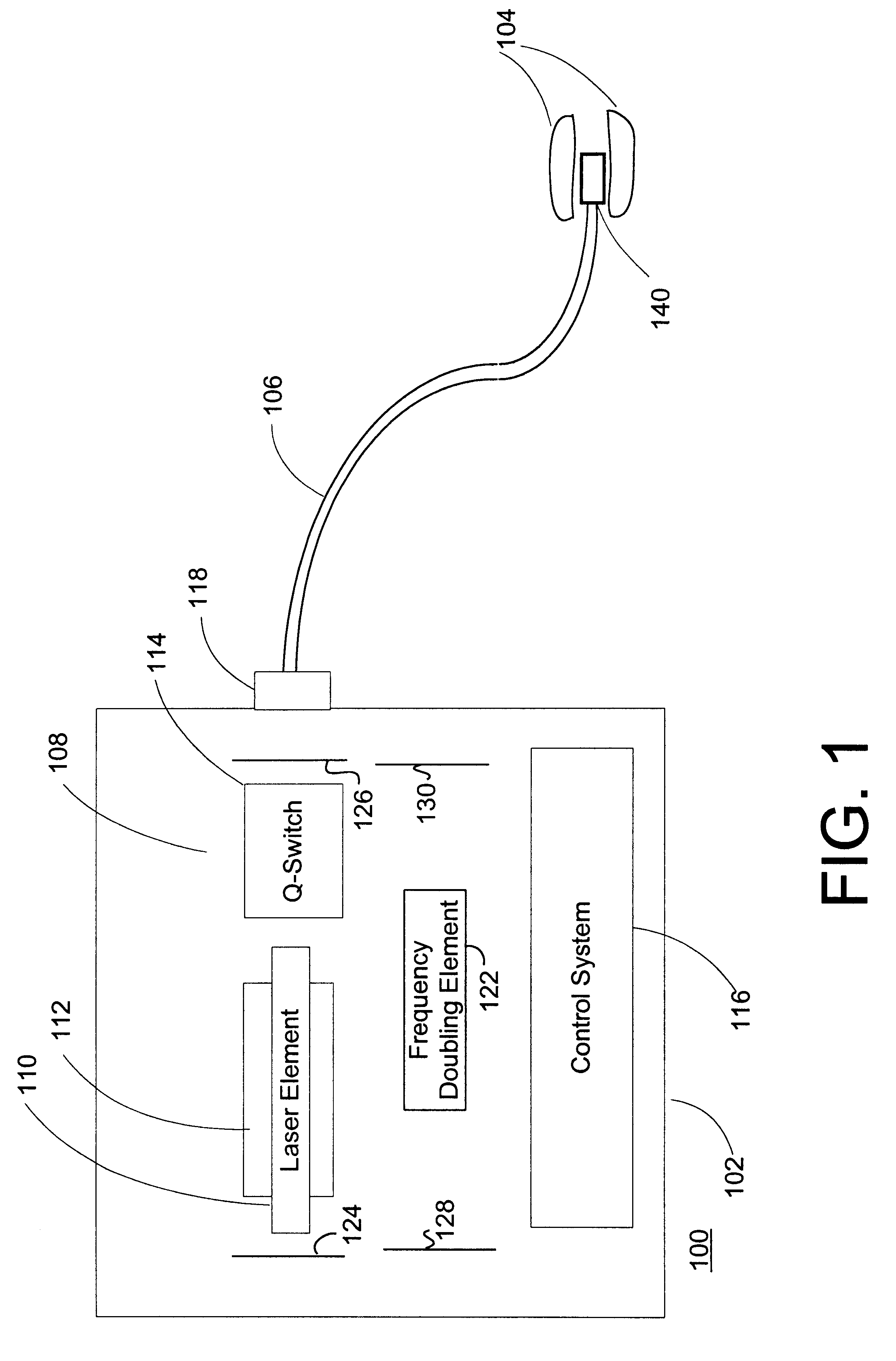

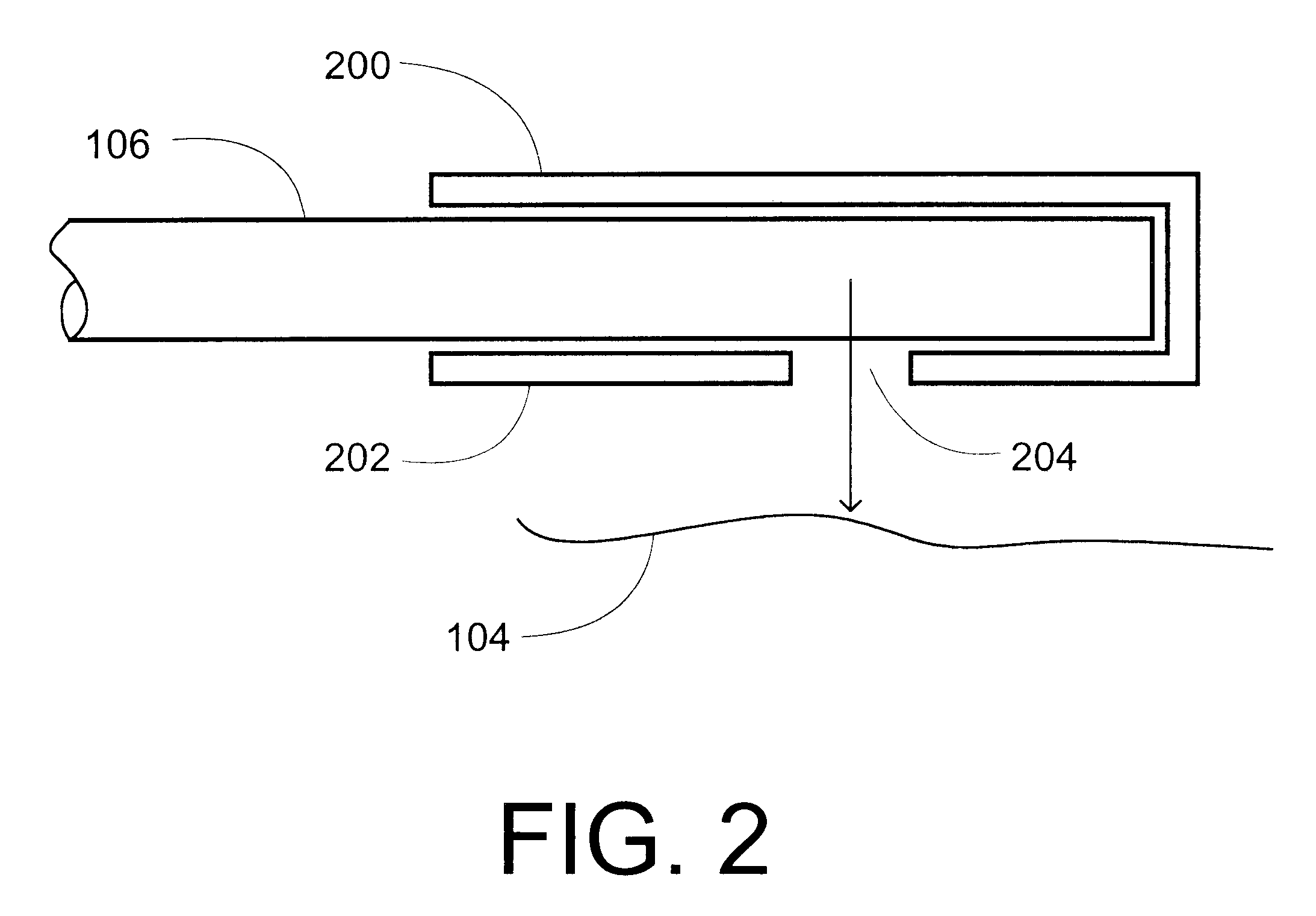

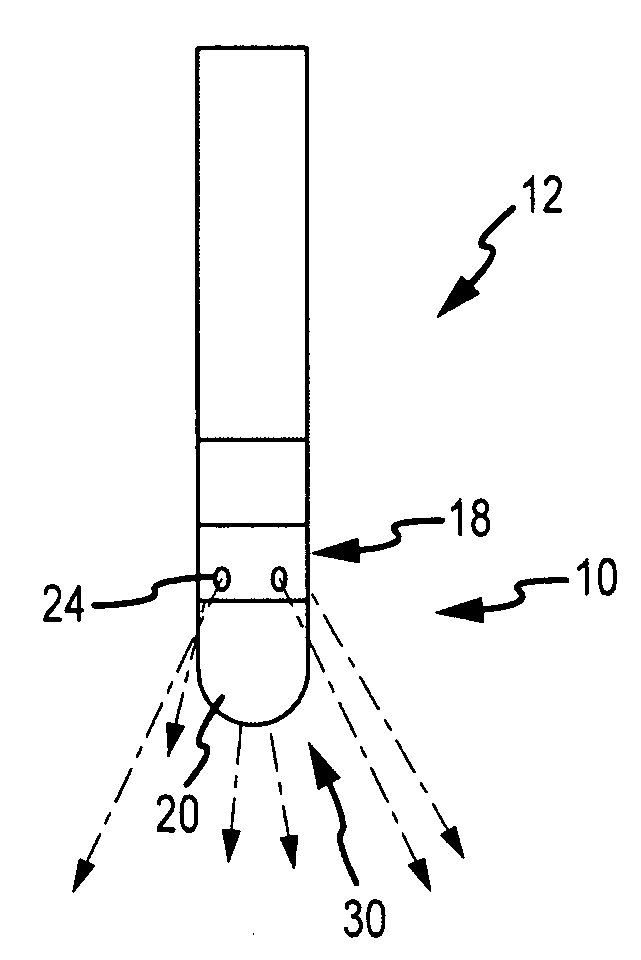

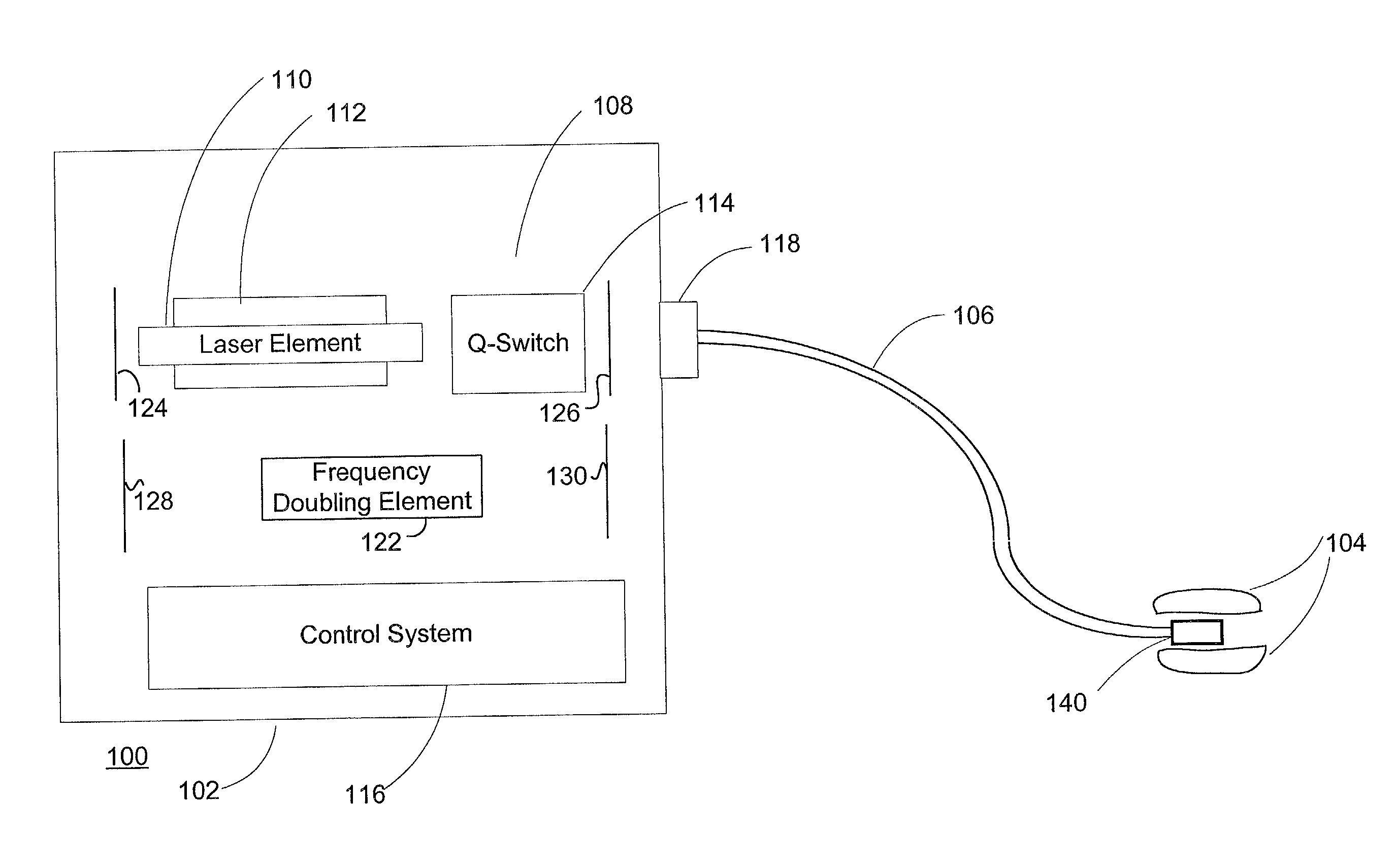

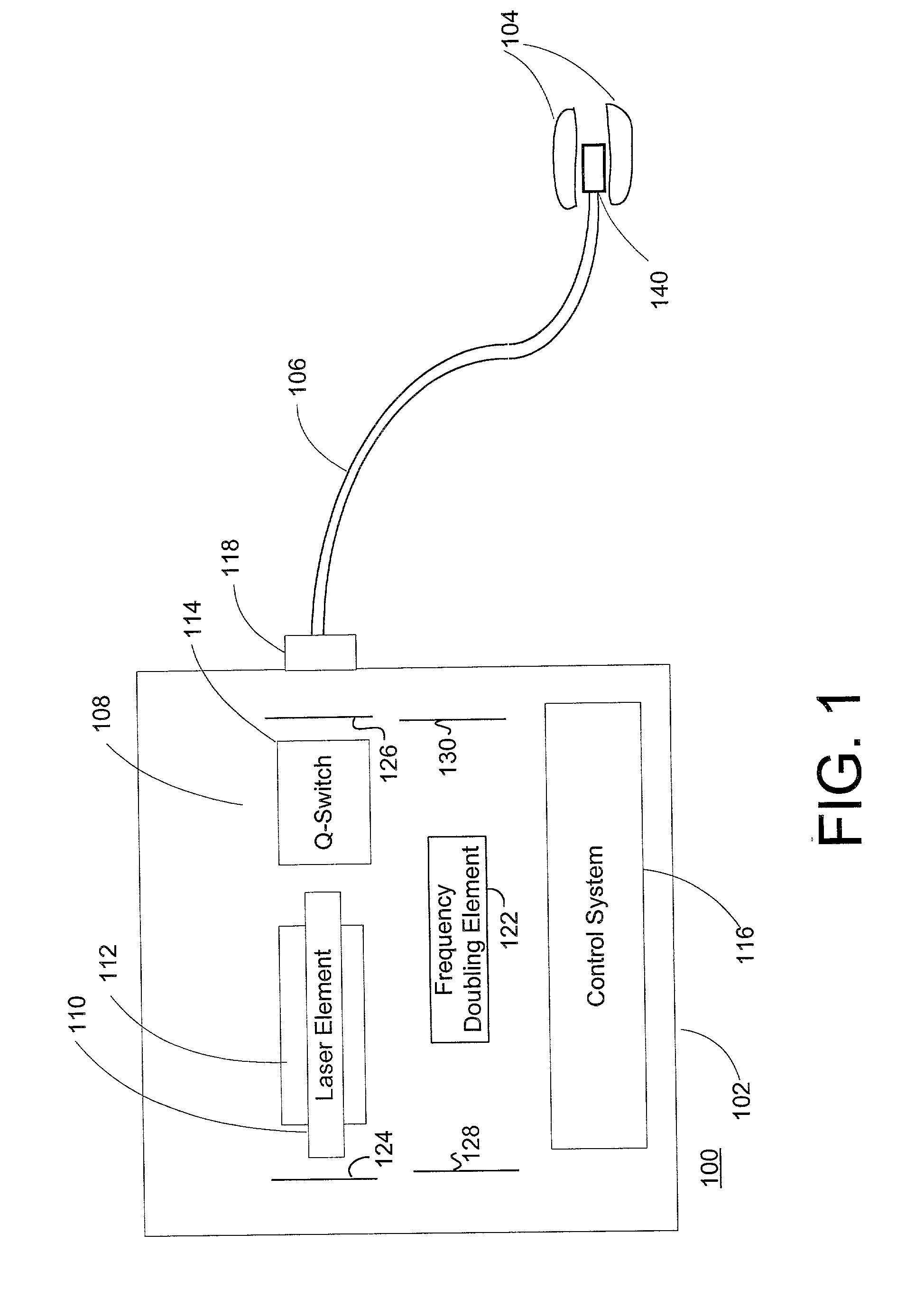

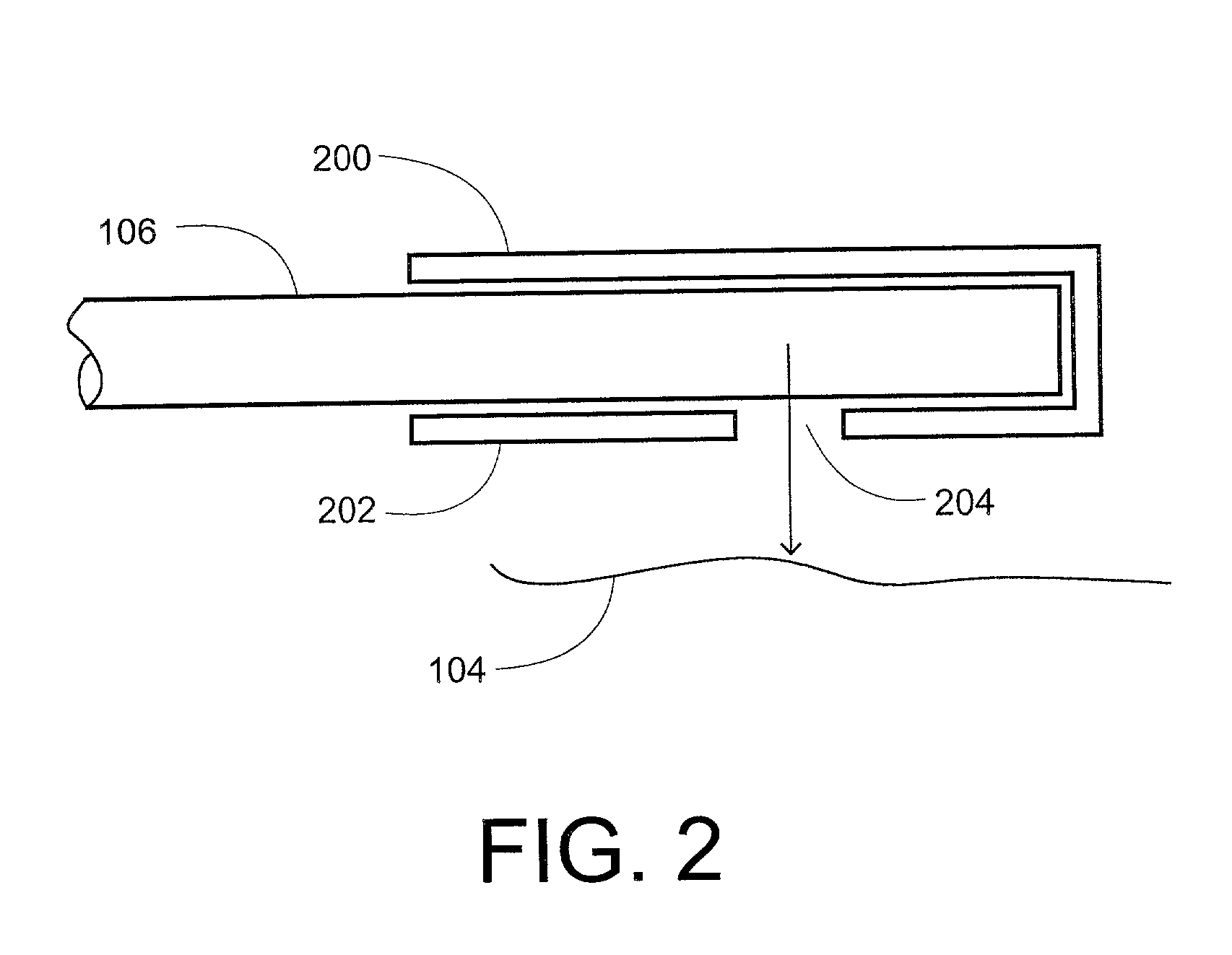

Methods for laser treatment of soft tissue

Methods are provided for treating prostate glands or other targeted soft tissue using a solid-state laser. The laser can be operated to generate a pulsed output beam having pulse durations of between 0.1 and 500 milliseconds. The output beam is delivered to the targeted tissue through an optical fiber, preferably terminating in a side-firing probe or diffusing tip. By operating the laser in a long-duration pulse mode, charring of the targeted tissue is initiated quickly, thereby increasing ablation rates and reducing overall procedure time.

Owner:BOSTON SCI SCIMED INC

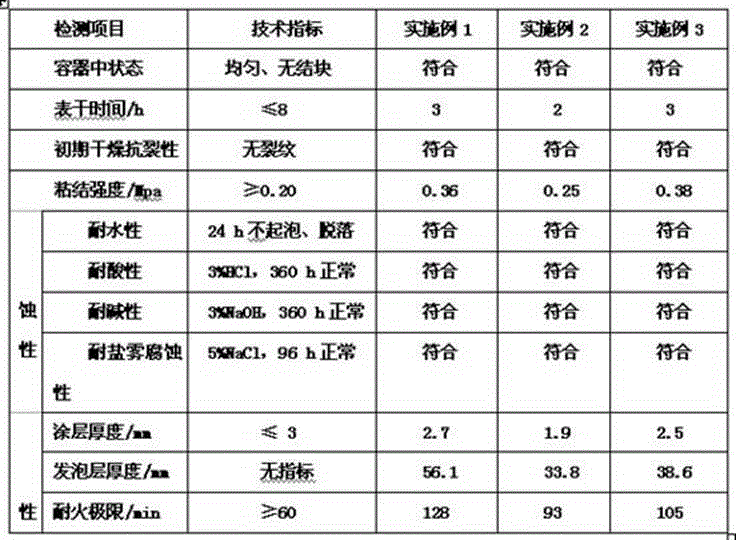

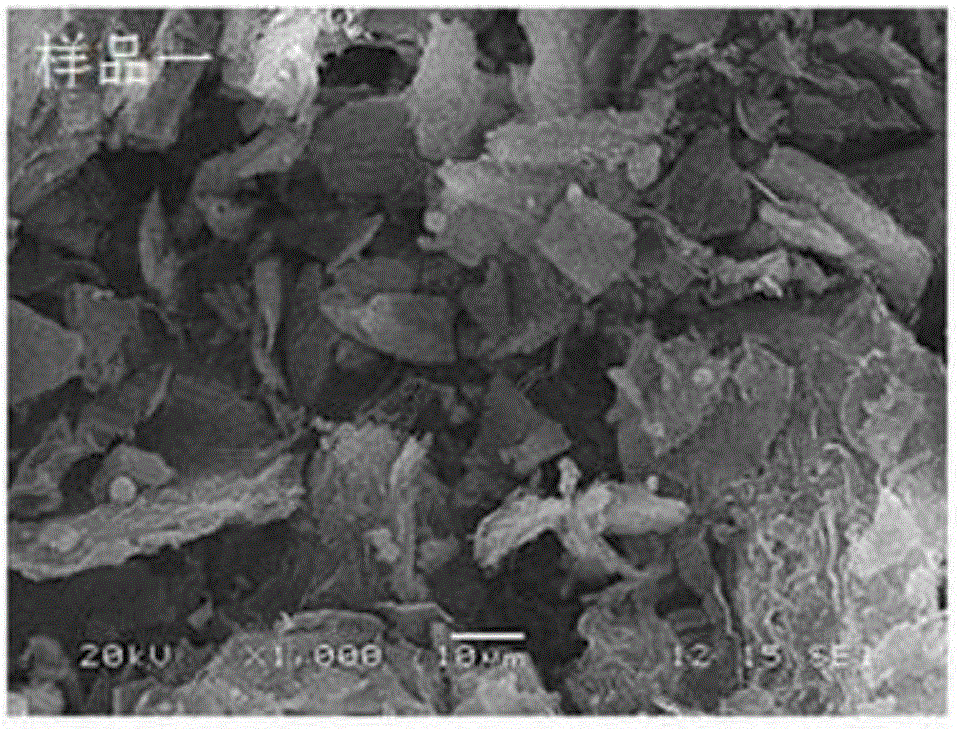

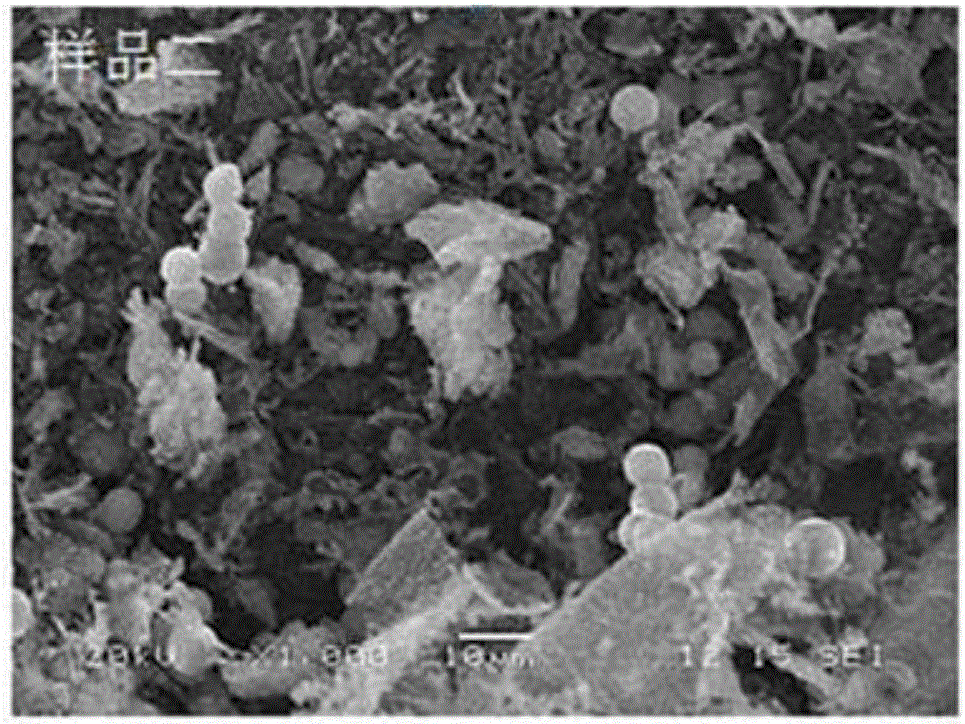

Aqueous fire-proof corrosion-proof paint for steel structure and preparation method thereof

ActiveCN104130638ATaking into account fire resistanceCompatible with anti-corrosionFireproof paintsAnti-corrosive paintsPtru catalystFoaming agent

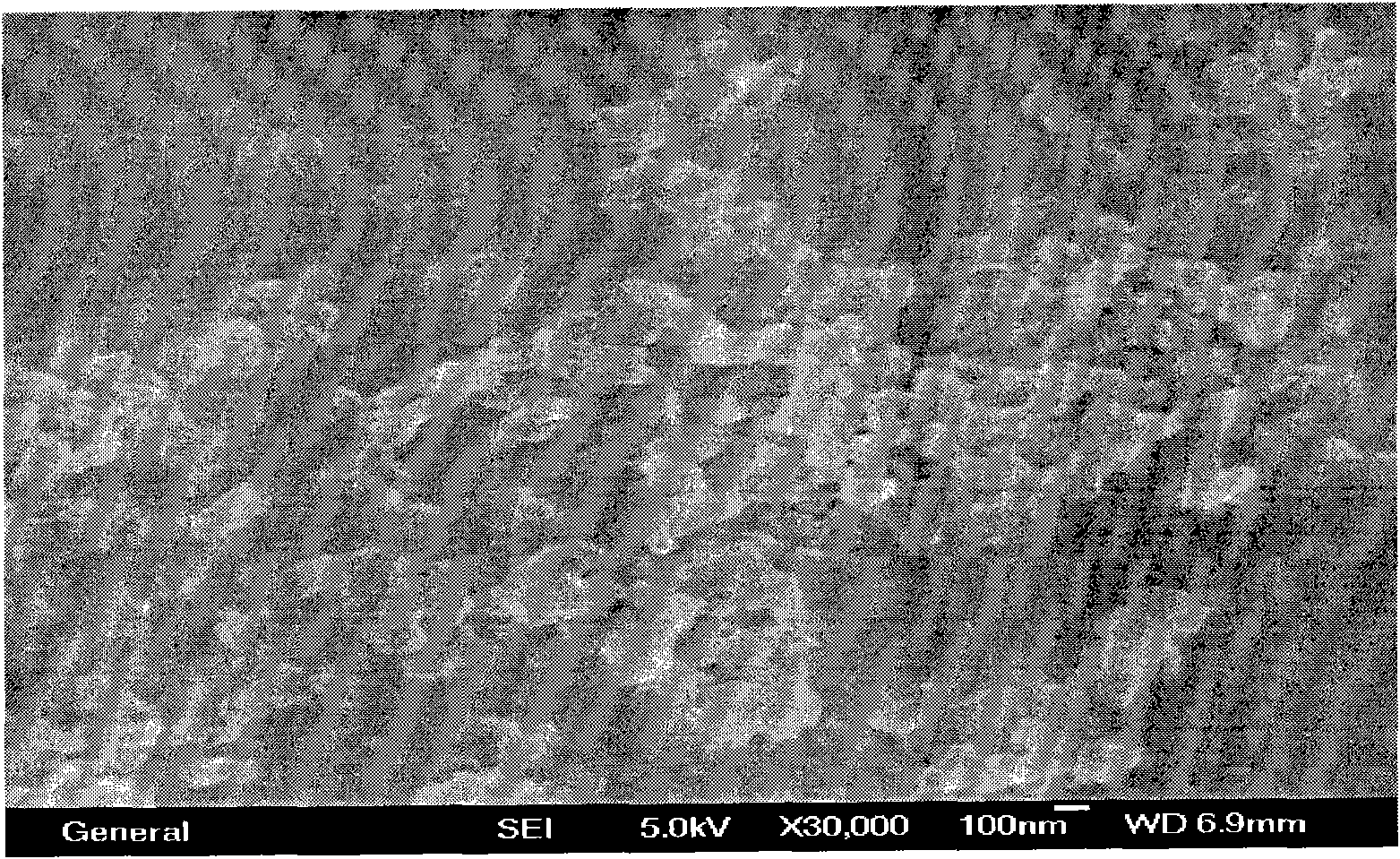

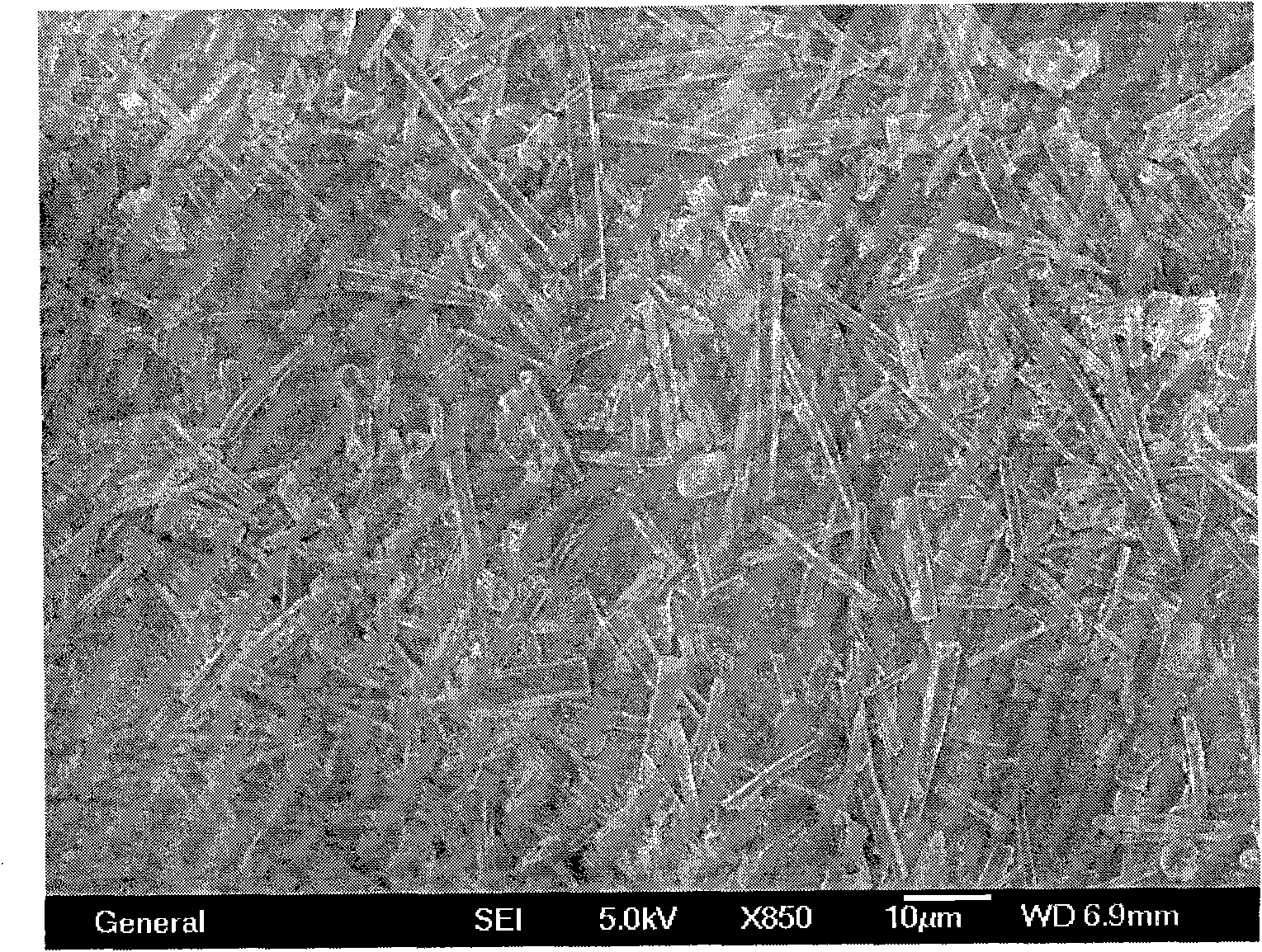

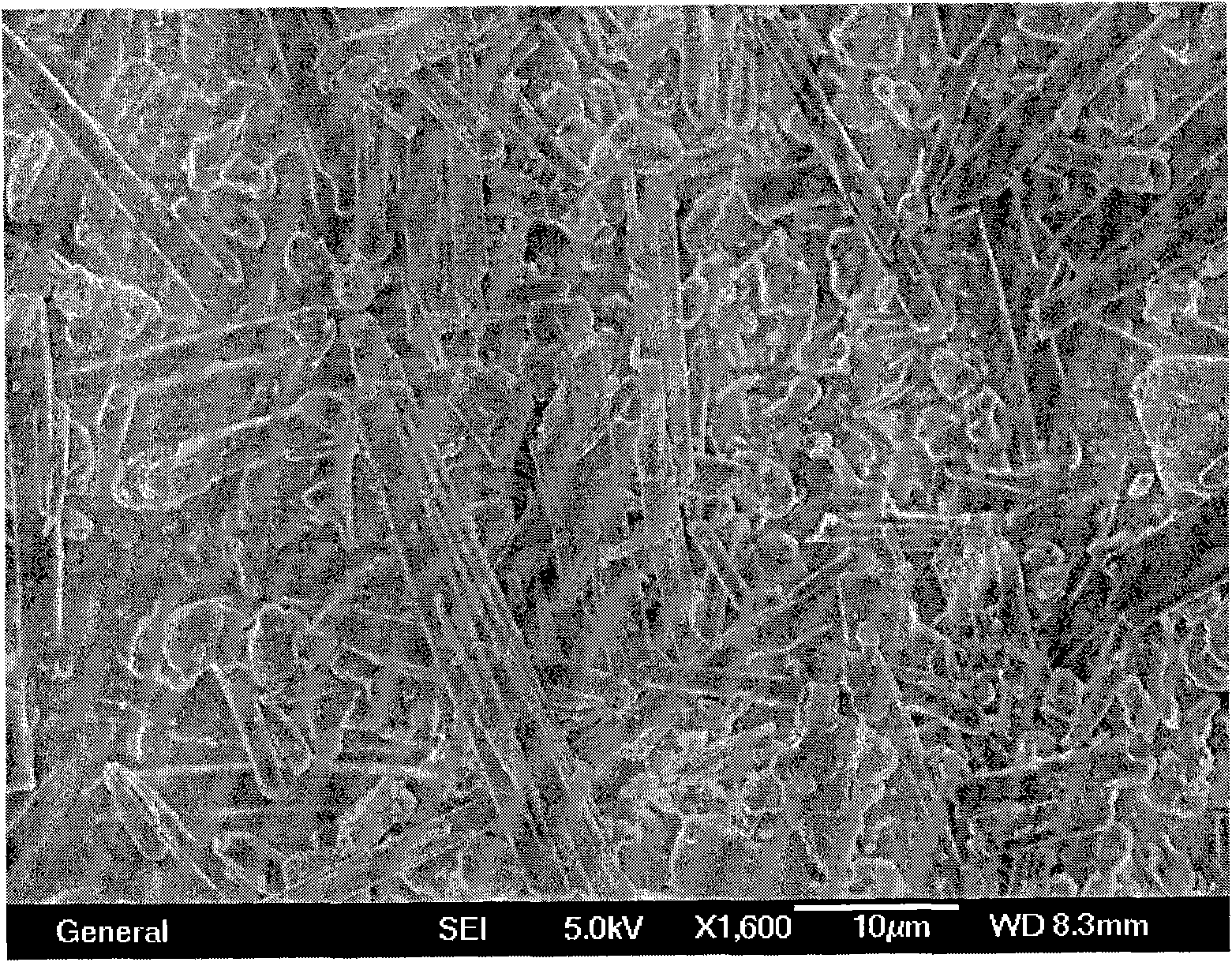

The invention discloses aqueous fire-proof corrosion-proof paint for a steel structure and a preparation method thereof, and belongs to the technical field of paint. The aqueous fire-proof corrosion-proof paint comprises, by mass, 20-45% of a composite emulsion, 12-25% of a charring catalyst, 6-12% of a foaming agent, 8-17% of a charring agent, 5-10% of a fire retardant, 1-5% of layered double hydroxide, 8-18% of an corrosion-proof filling material, 4-12% of a strengthening filling material, 1-5% of modified nano-powder, 0.5-6% of an assistant and 10-30% of water. Through use of the composite modified emulsion as a base material, coating flame resistance, corrosion resistance and decorativeness are obtained and coating defects caused by a single emulsion as a base material are overcome. Through use of a small amount of the nano-powder, the coating is compact because of filling effects of the nano-powder, the coating corrosion caused by O2, H2O and Cl <-> is avoided, good fire-proof and corrosion-proof effects are obtained under the condition of a small addition amount and a cost is reduced. The aqueous fire-proof corrosion-proof paint has the characteristics of green environmental protection and simple preparation processes.

Owner:山东七维新材料有限公司

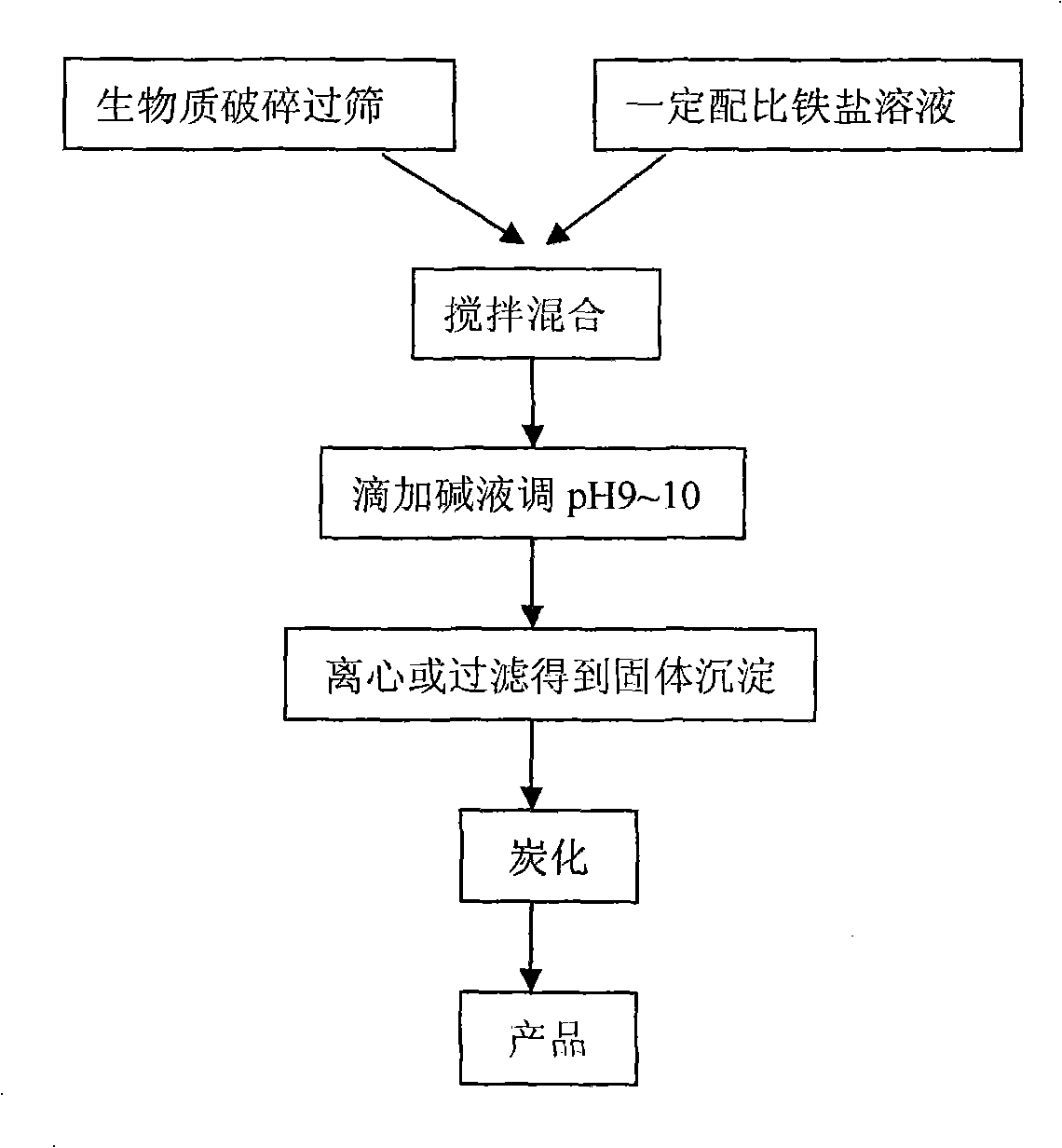

Method for preparing magnetic biological carbon adsorbing material and usage thereof

The invention discloses a method for preparing magnetic biological carbon adsorbing material and the usage thereof. The method comprises the steps: 1) drying and crushing waste biomass, and sieving by20-100 meshes; 2) putting the sieved biomass into 0.1-0.5mol / L of iron salt solution with the weight percent of the biomass being 1-10% of the total quantity; under stirring, dripping 3-6mol / L of NaOH solution until the pH value of the solution is 9-10; 3) filtering, drying and compacting the solid precipitate, and then limiting oxygen carbonizing for 1-5h at the temperature of 100-700 DEG C, thus obtaining the magnetic biological carbon adsorbing material; 4) putting the magnetic biological carbon adsorbing material into waste water, and simultaneously removing organic pollutant and phosphate radical in the waste water. The method realizes synchronization of preparation of the adsorbing material and the process of magnetization, and is simple in preparation process, rich in the source ofthe biomass material and low in cost; furthermore, the prepared magnetic adsorbent is covered by biological carbon or embedded with magnetic nano Fe3O4 granules, has special structure and stable existence, can effectively remove the organic pollutant and phosphate in the waste water, and is easy for magnetic separation.

Owner:ZHEJIANG UNIV

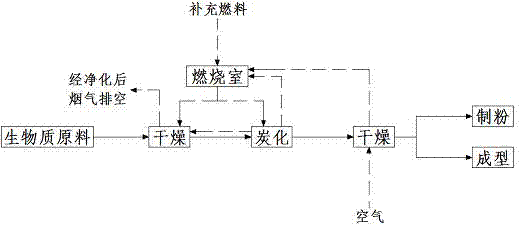

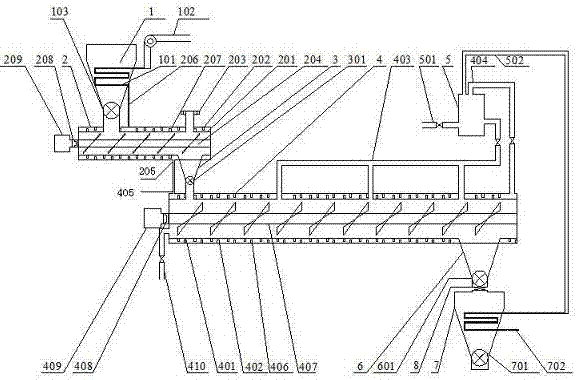

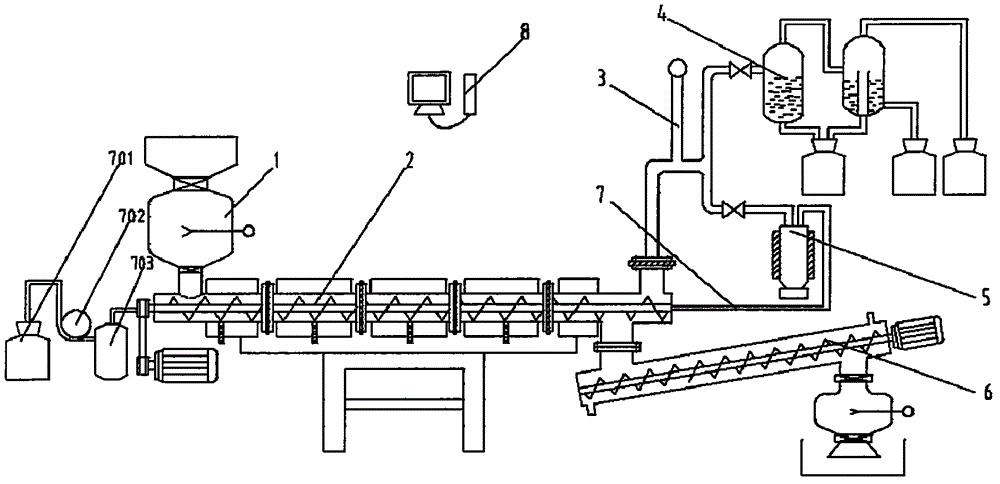

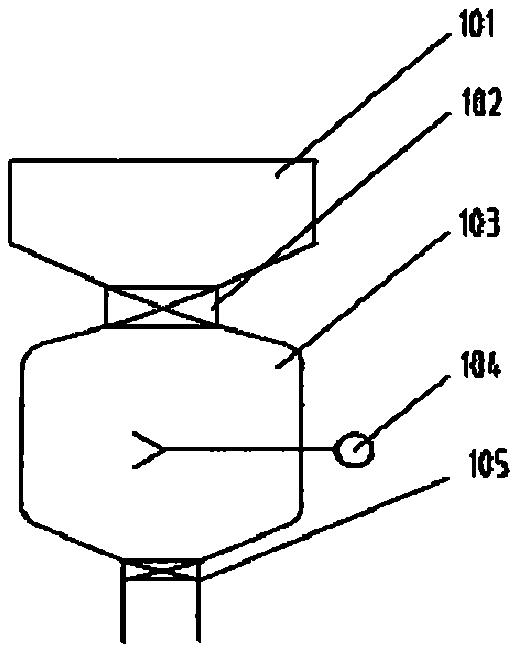

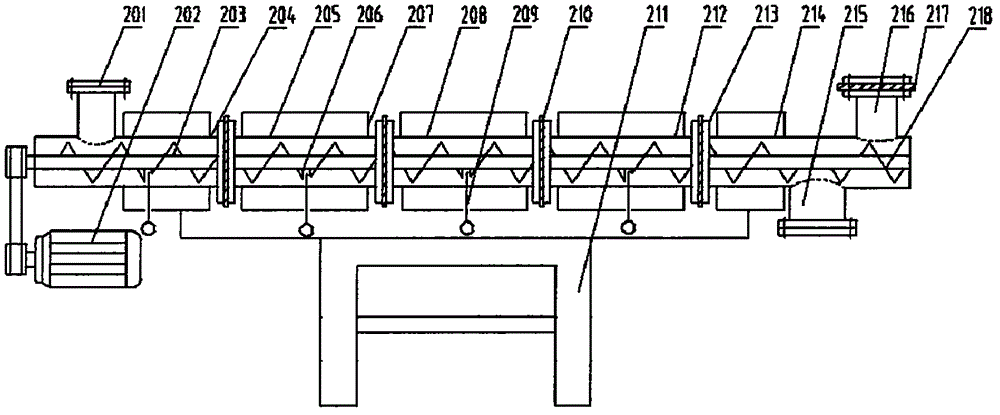

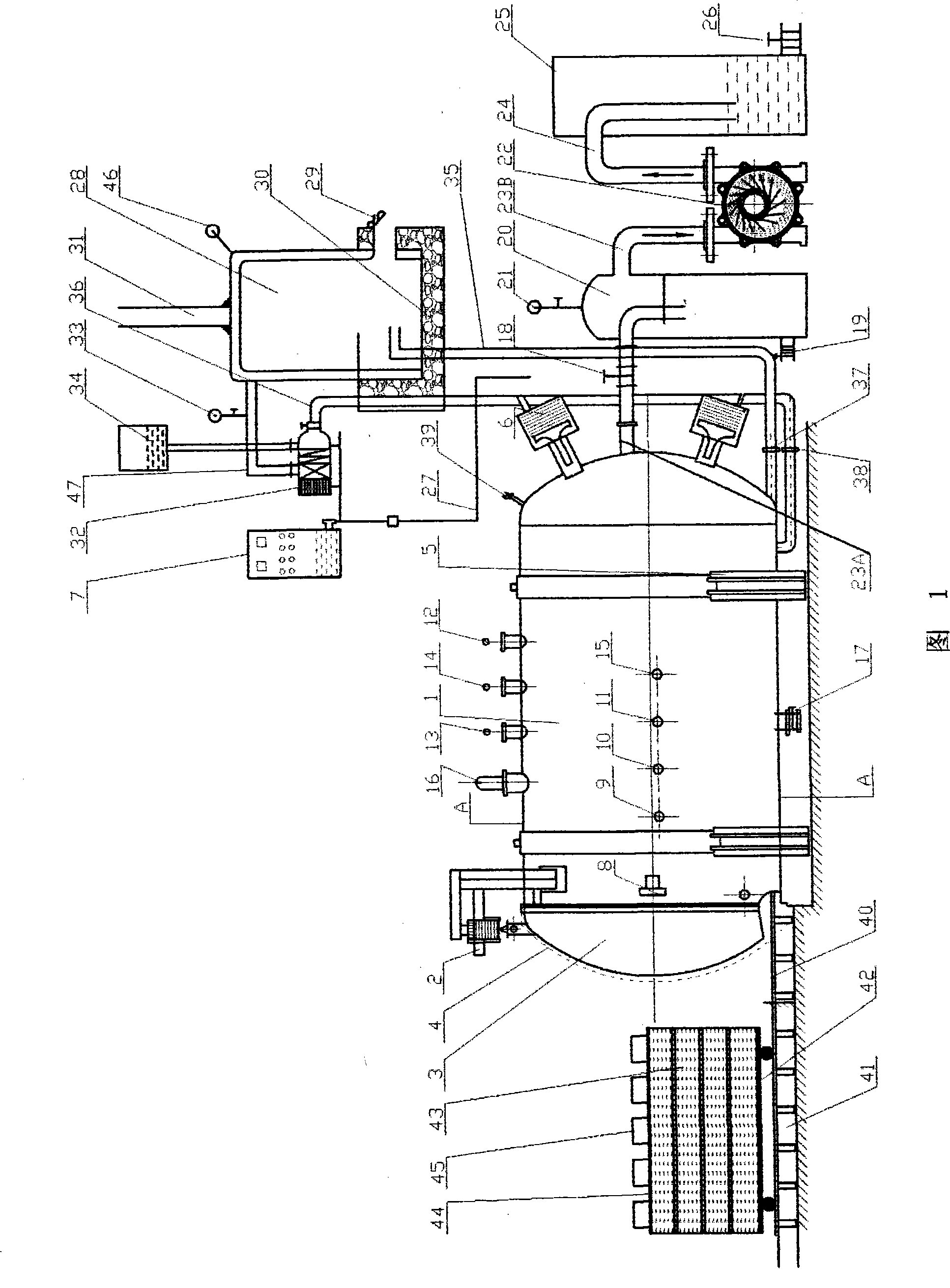

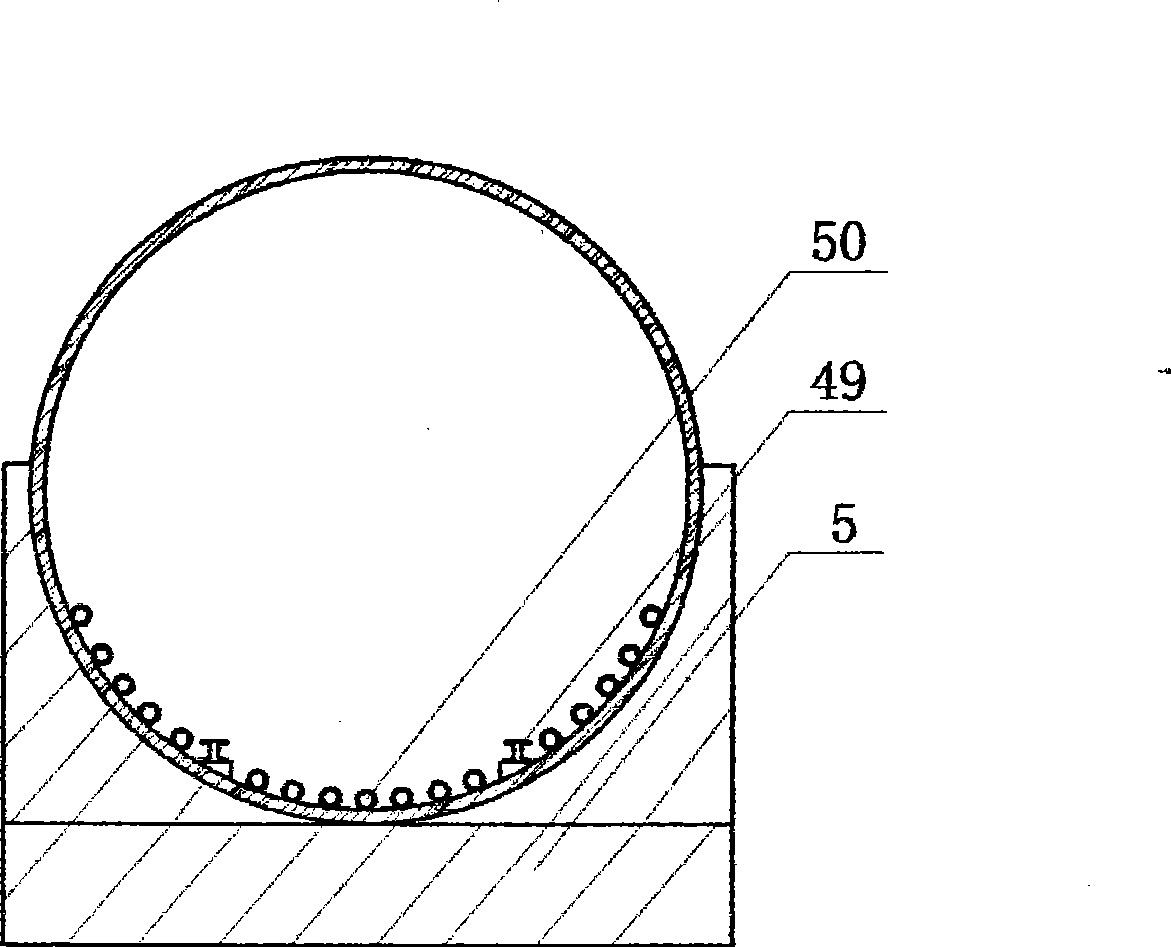

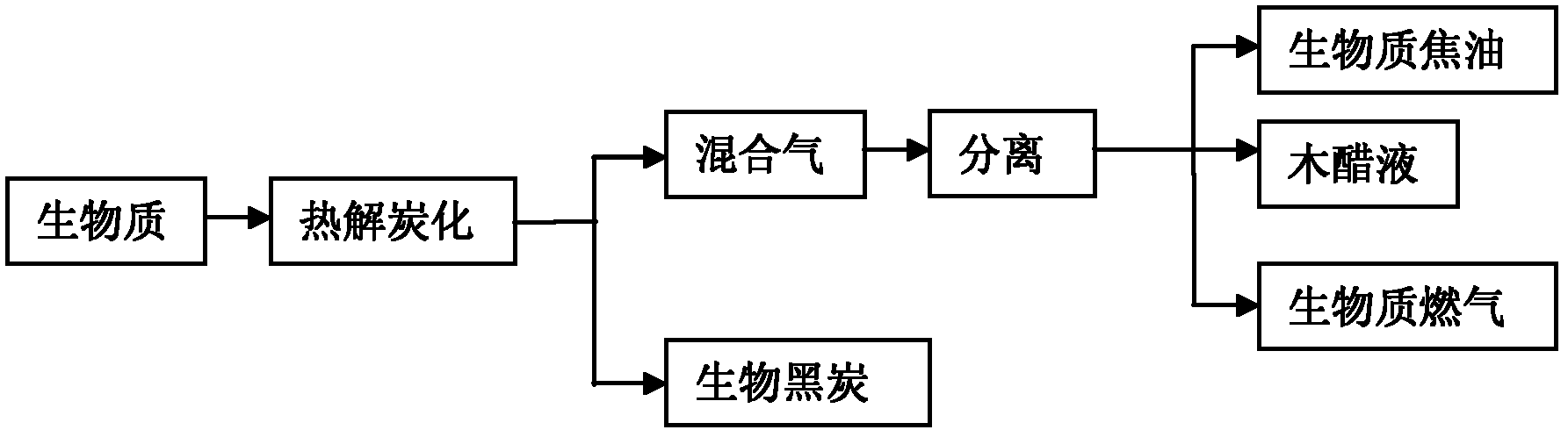

Continuous biomass low-temperature pyrolytic charring method and charring furnace thereof

InactiveCN102226092ARealize continuous carbonization productionImprove raw material adaptabilityDirect heating destructive distillationBiofuelsCombustion chamberRetention time

The invention discloses a continuous biomass low-temperature pyrolytic charring method and a charring furnace thereof, belonging to the fields of biomass charring and biomass energy source utilization. The furnace body of the charring furnace adopts a screw propelling feed mode, and the power is derived from the drive of a motor; an external heating cylinder is sheathed outside an internal heating cylinder of the furnace body, the internal cylinder and the external cylinder are spaced, and the internal flue inside the sleeve has a labyrinth path to ensure heat supply from hot flue gas to pyrolytic reaction to uniformly heat a biomass raw material; and during charring, the generated flue gas supplies heat to a reaction cylinder after combustion in a combustion chamber, and the hot flue gas enters a heat exchanger device to dry the raw material after flowing through the sleeve. Through screw propelling, the method disclosed by the invention realizes continuous low-temperature pyrolytic charring reaction, and realizes accuracy control of the retention time of the biomass inside the charring furnace; and the furnace body adopts a sleeve structure, which fully utilizes the afterheat of the charring flue gas, and the reaction cylinder adopts interior heating and outer wall heating together, which enhances the uniformity characteristic of the temperature inside the reaction cylinder and prolongs the service life of an auger shaft.

Owner:NANJING NORMAL UNIVERSITY

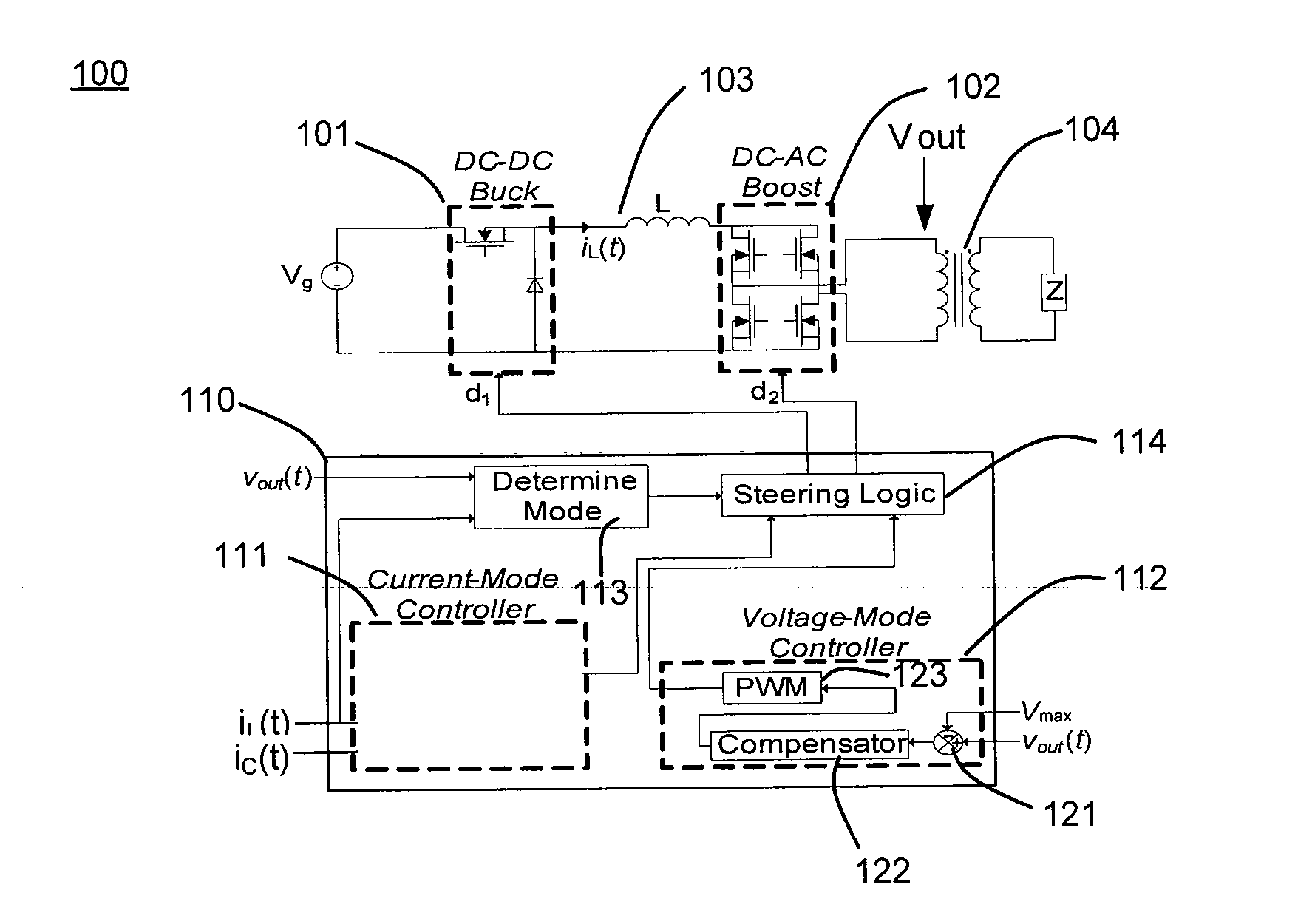

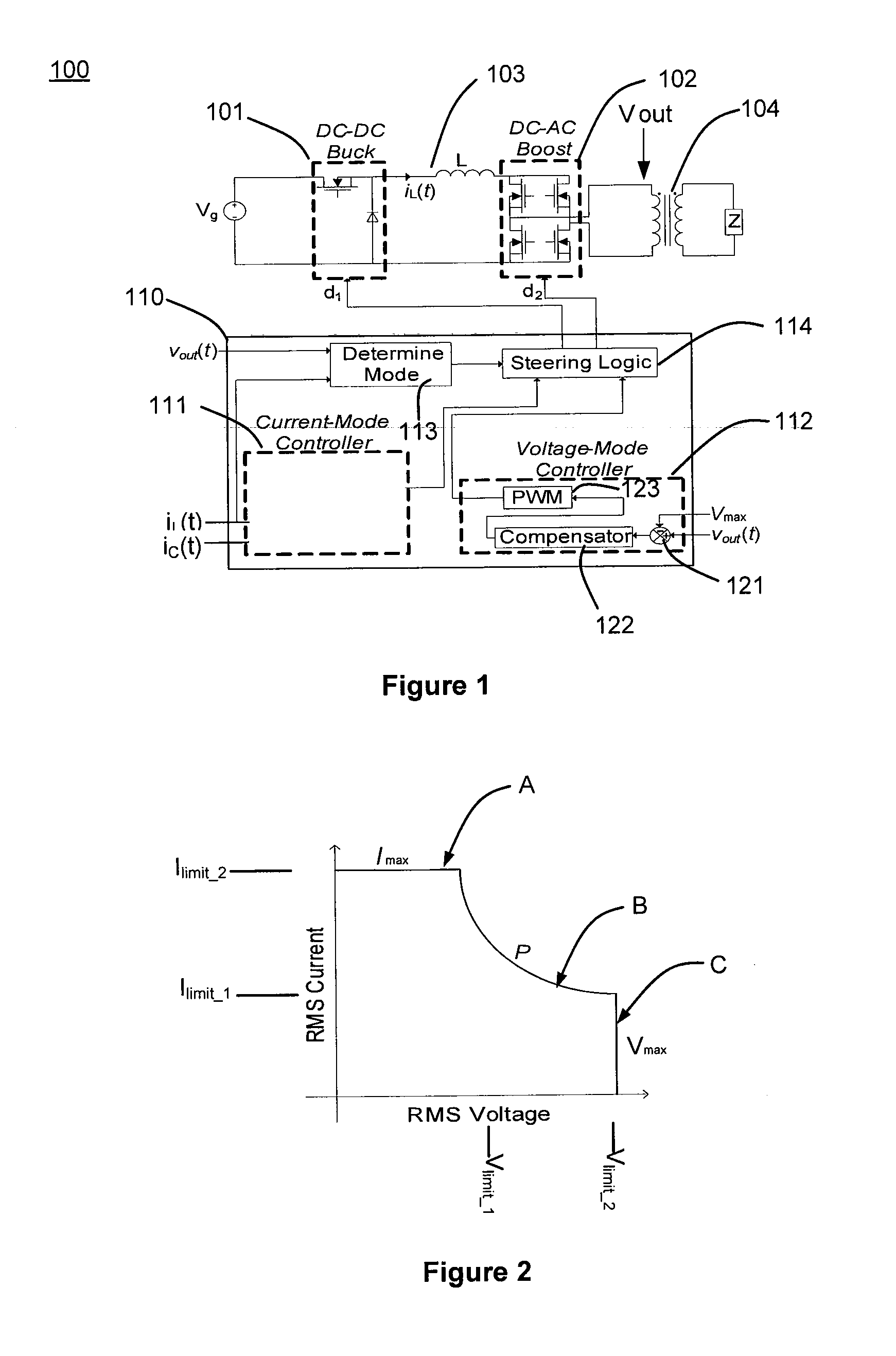

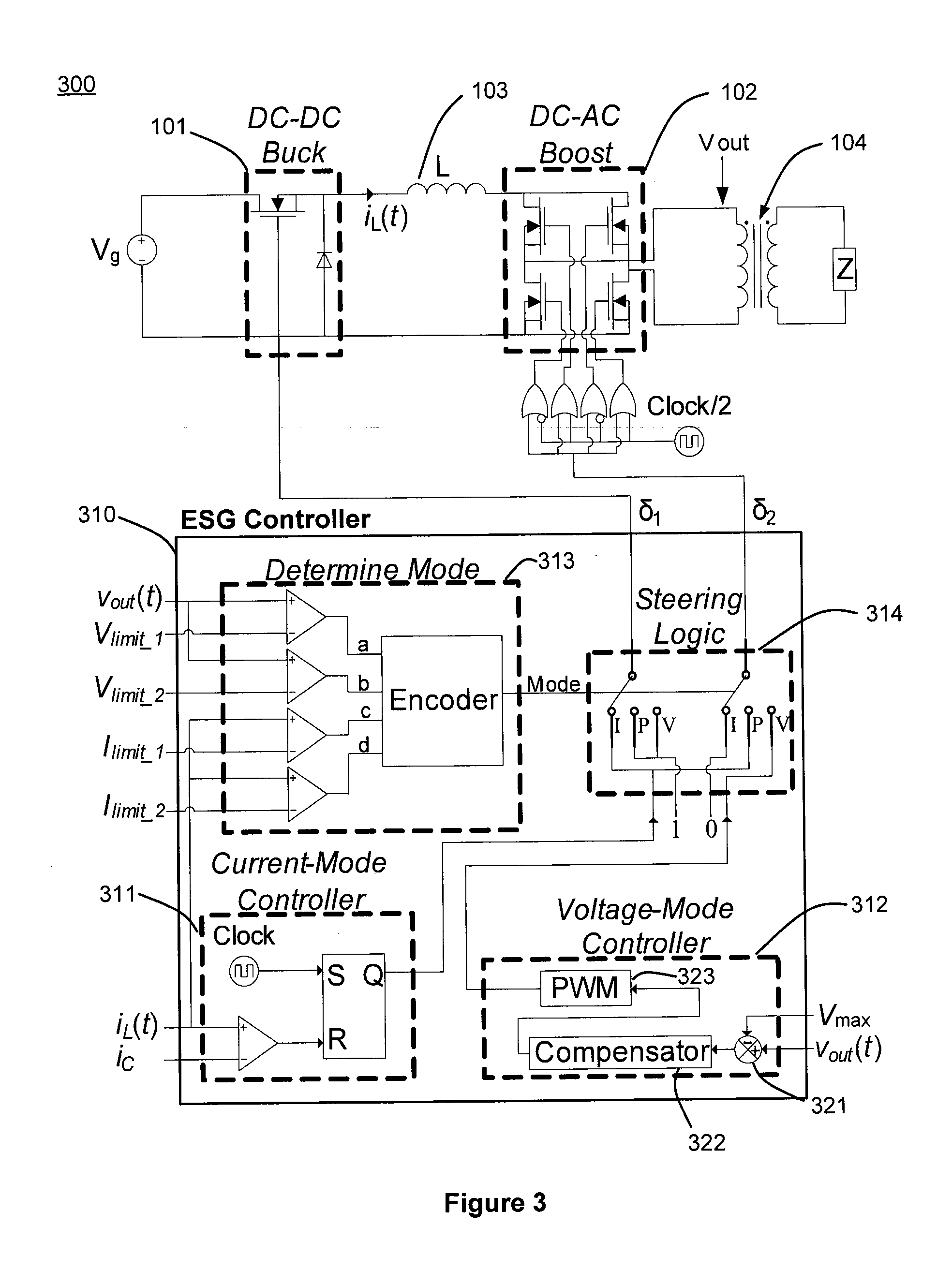

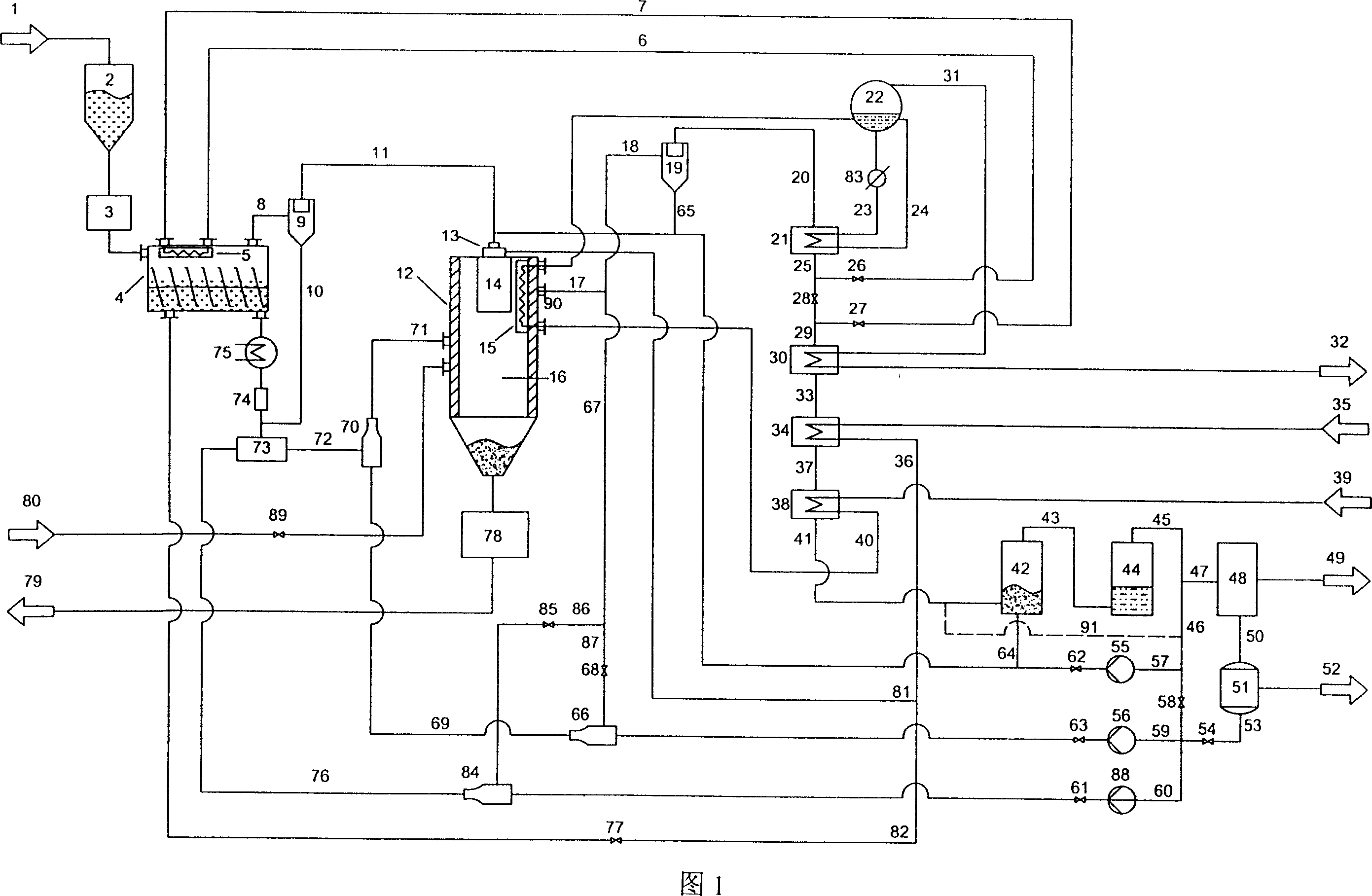

Electrosurgical generator controller for regulation of electrosurgical generator output power

ActiveUS20120215216A1Accurate power source output characteristicProcess safetyControlling energy of instrumentAc-dc conversionElectricityBuck converter

An electrosurgical generator may reduce unintended tissue damage by improving regulation of output power. The electrosurgical generator may control the power during a cycle, and react to a change in power if arcing occurs. Voltage sources, especially, demonstrate the tendency to have large, uncontrolled power excursions during normal electrosurgical use. The magnitude of the power excursions may be dependent on various factors. An exemplary electrosurgical generator control scheme reduces or minimizes the thermal spread by accurately supplying the specified power within a few cycles. Additionally, fast and accurate regulation provided by the constant voltage mode reduces or minimizes unintentional tissue charring. Thus, reduced thermal spread and charring should result in better surgical outcomes by reducing scarring and decreasing healing times. An electrosurgical generator controller may be configured to control both a DC-DC buck converter and a DC-AC boost inverter based in part on electrical parameters of the electrosurgical generator.

Owner:UNIV OF COLORADO THE REGENTS OF +1

Compositely circulating high temperature gasifying process for making synthetic gas with biomass

ActiveCN1931959AImprove grindabilityAvoid burnsBiofuelsSpecial form destructive distillationSyngasTar

The compositely circulating high temperature gasifying process for making synthetic gas with biomass includes the steps of low temperature charring, powdering, high temperature gasifying, separating carbon containing clinker, purifying synthetic gas, and circulating utilization of synthetic gas. Biomass material is first pyrolyzed into pyrolyzed gas and charcoal and the pyrolyzed gas is burnt incompletely in the high temperature gasifying furnace to produce gasifying agent and heat; the charcoal is powdered and fed to the reducing area in the high temperature gasifying furnace to produce reduction reaction with the gasifying agent; and the fly ash and residual carbon produced in the purification are returned to the burning area in the high temperature gasifying furnace. The present invention can produce synthetic gas with CO and H2 content up to 72 %, and has gasifying efficiency of 80-84 % and carbon converting rate over 99 %.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

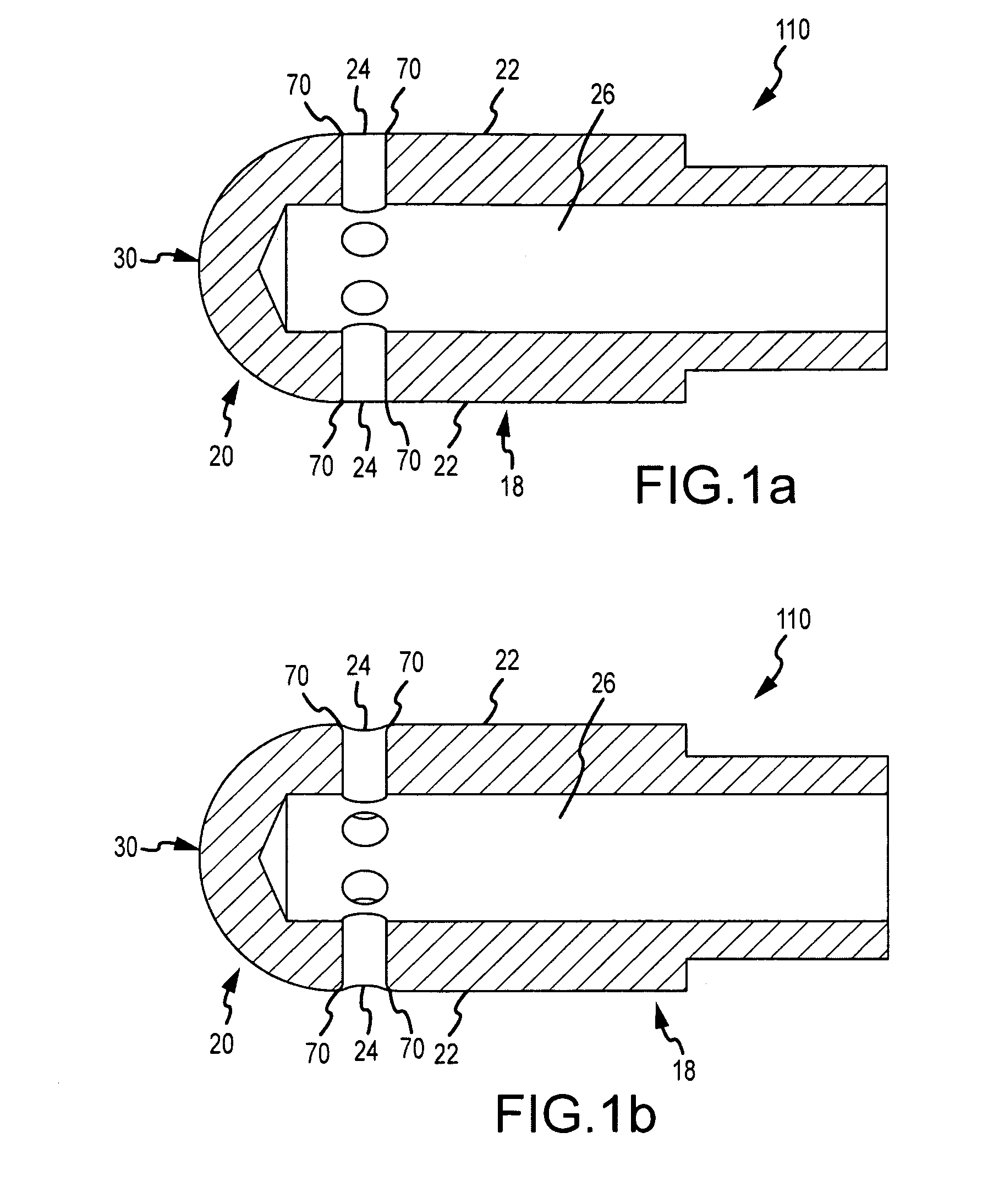

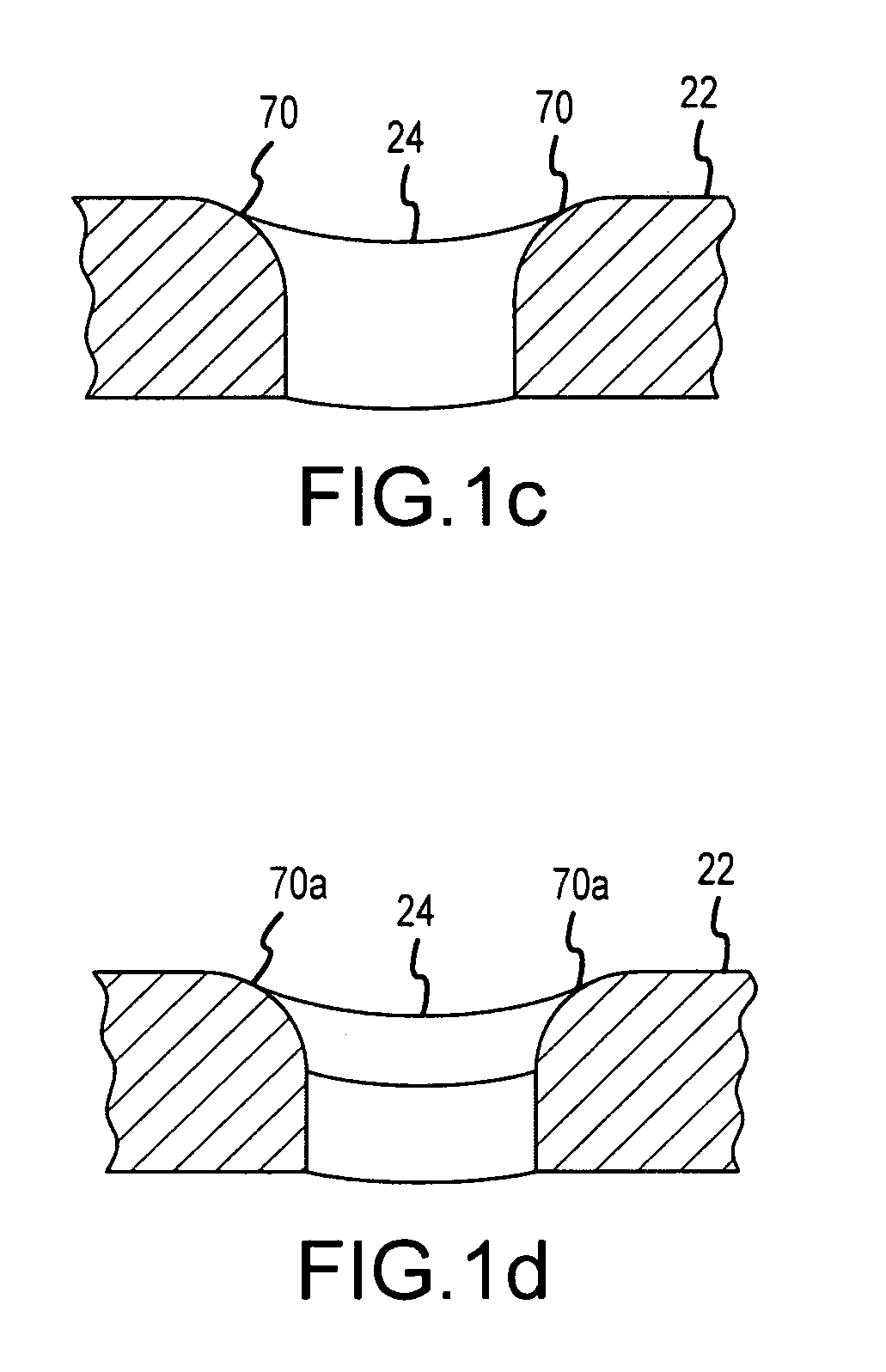

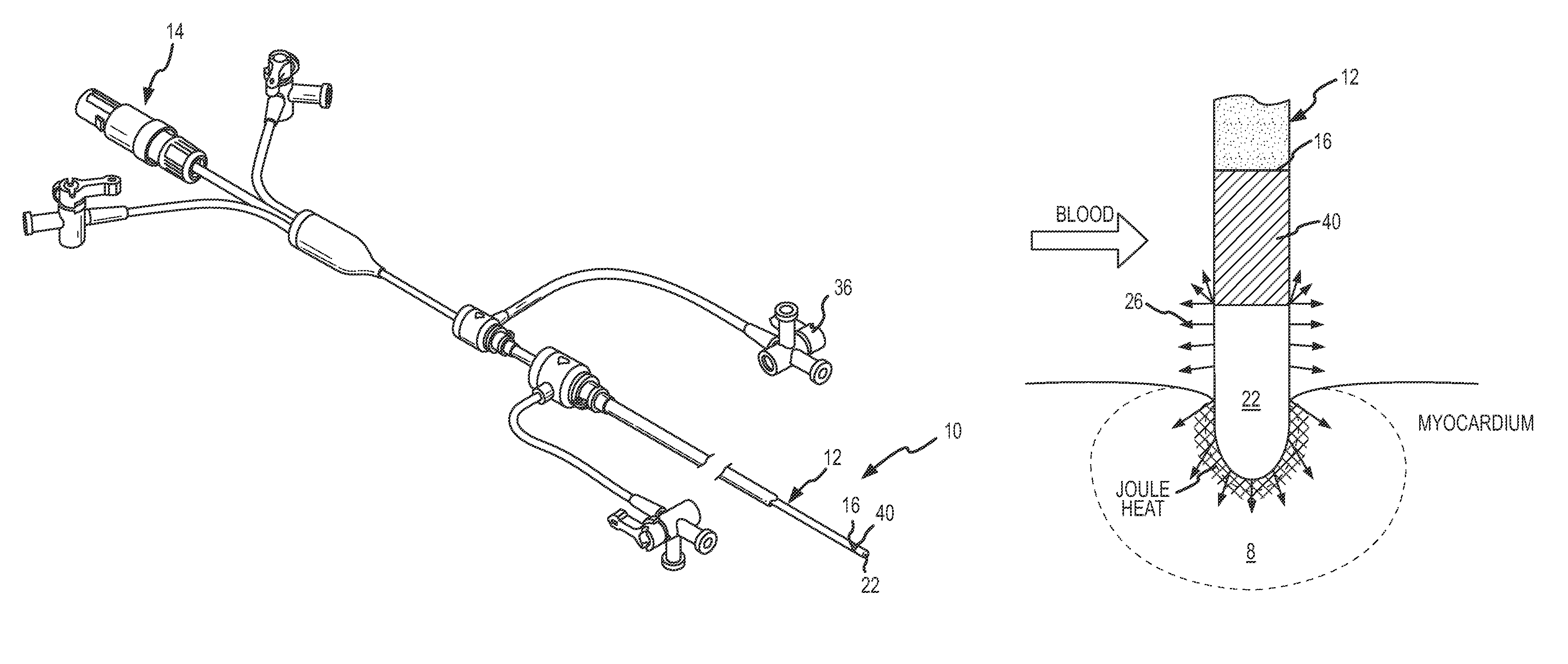

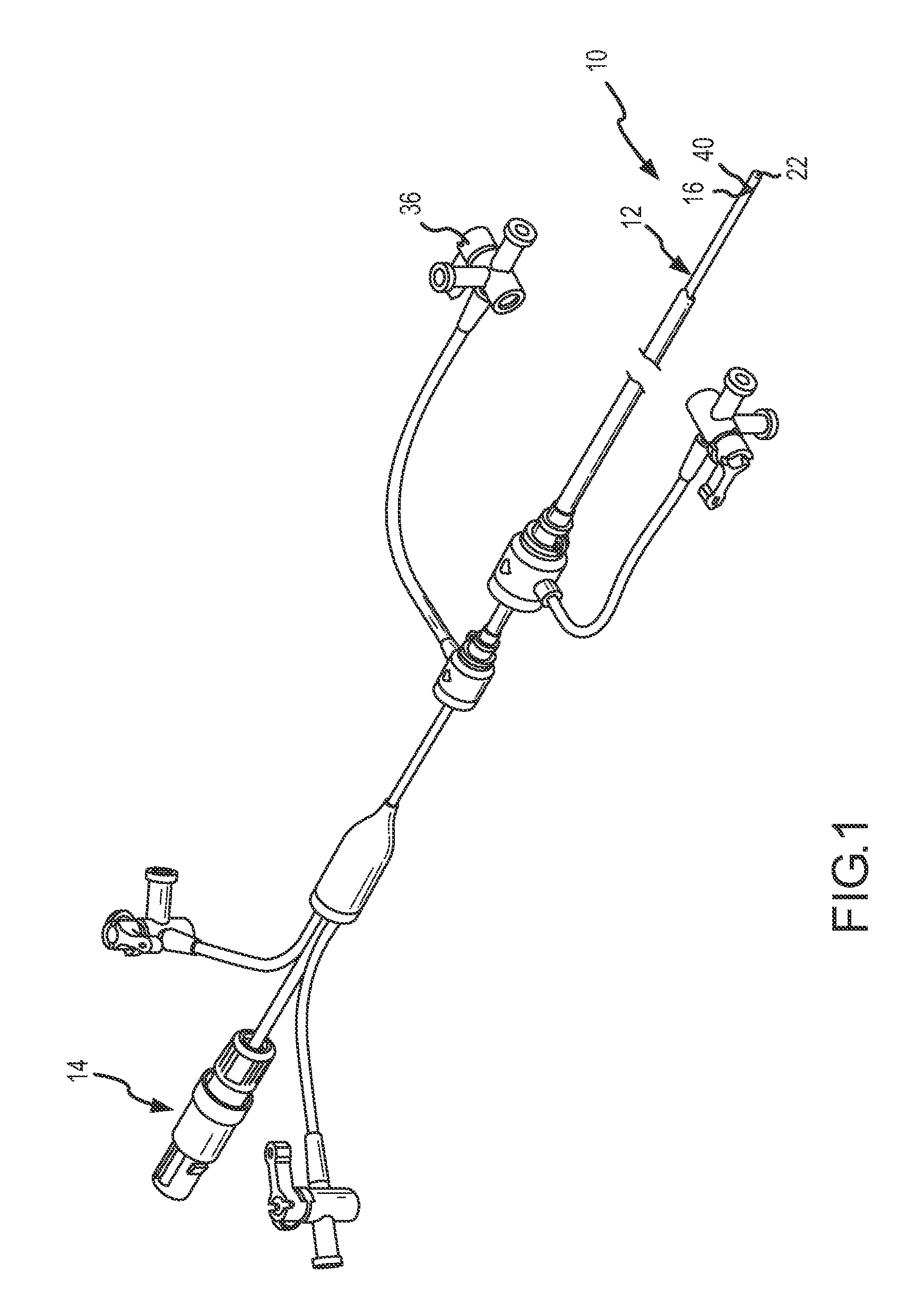

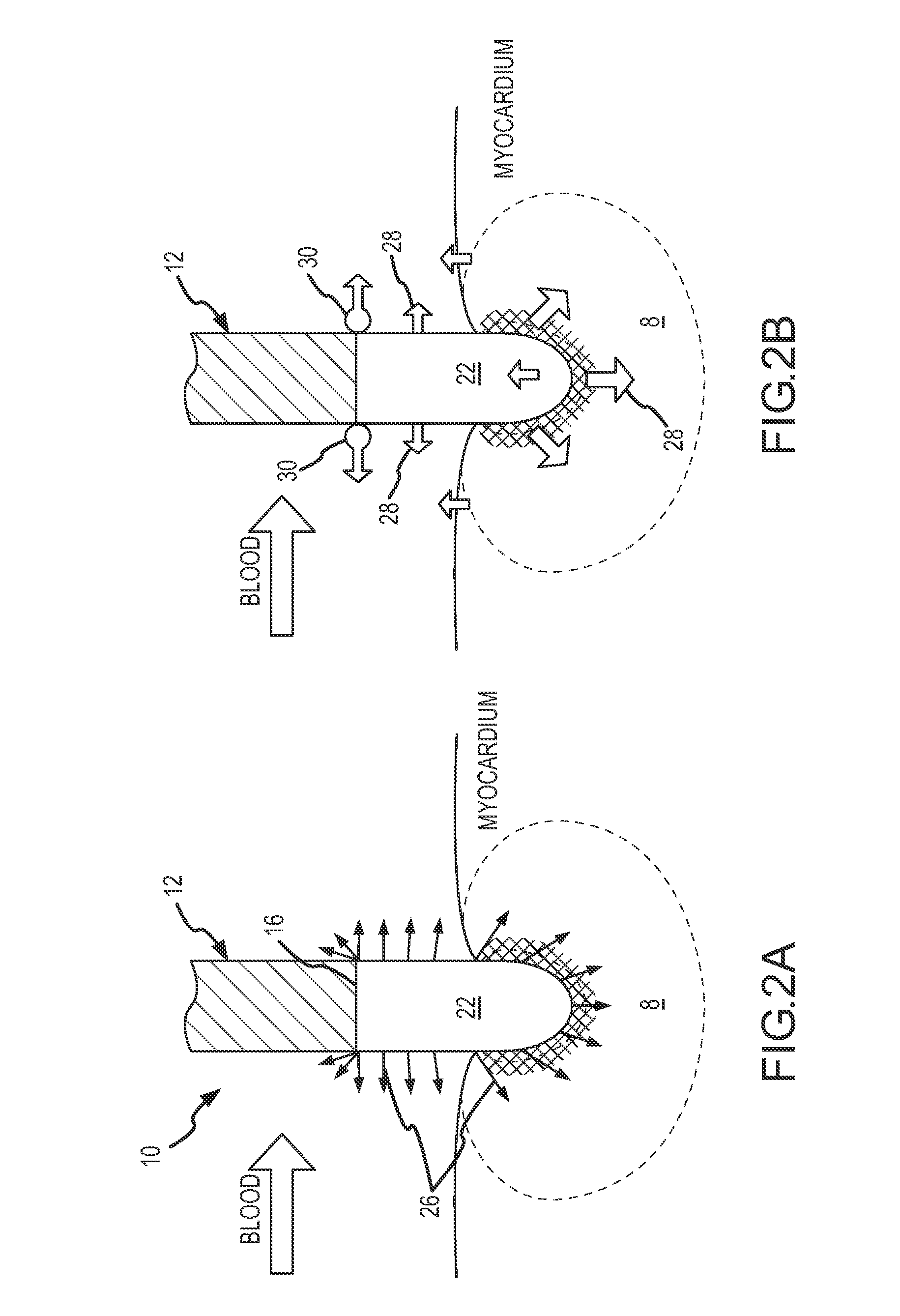

Irrigated ablation electrode having smooth edges to minimize tissue char

ActiveUS20090177193A1Tissue char is minimizedMinimize coagulationSurgical instruments for heatingRadiofrequency ablationCatheter electrode

The invention relates to ablation catheter electrodes that solve in part the problem of tissue charring during radiofrequency ablation. The electrode assemblies of the invention include passageways that lead from the inner lumen of the assemblies to the surface of the assemblies, wherein the passageways have a smooth conjunction with the outer surface. These smooth conjunctions comprise rounded edges or are camfered. In the case of rounded edges, the rounded edges can have fixed radii of about 0.002″ to about 0.008″.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

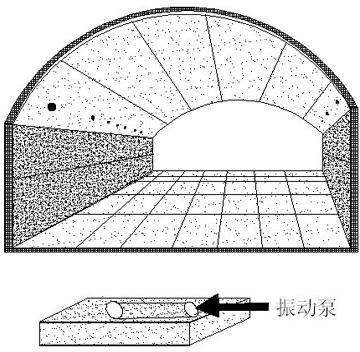

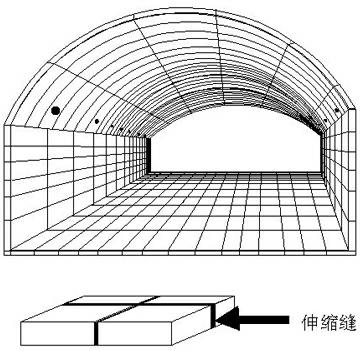

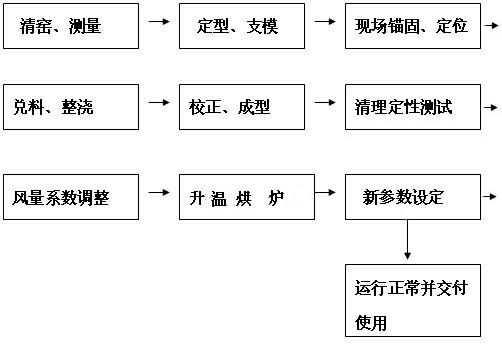

Composite fire-proof material with high refractoriness under load for coke ovens as well as furnace-building process and products thereof

InactiveCN102584294AImprove bindingWaste heat can be recovered for power generationCoke oven brickworkEnergy inputAdhesiveRefractory

The invention discloses a composite fire-proof material with high refractoriness under load for coke ovens. The preparation method of the material comprises the following steps of: evenly mixing and crushing 40%-60% of Al2O3, 15%-30% of SiC micro powder, less than 2% of Fe2O3, 5%-10% of Si micro powder and 1%-3% of cement as an additive; adding 3%-5% of Al(H2PO4)3 as an adhesive and stirring and mixing evenly; and pouring the mixture to a working region in 20-30 minutes. The furnace-building process comprises the following steps of: cleaning a kiln, measuring, molding, positioning and supporting a mould, adding materials, pouring and correcting, cleaning, starting for warming up and testing. The coke ovens newly built by pouring is characterized in that the top of the chamber of the furnace is fan-shaped, the chamber of the furnace is built by on-site seamless overall vibration pouring according to the process above with the furnace-building materials above, afterheat of the furnace can be recycled for power generation and no chemical residues exist. The furnace is short in charring time and higher in coke recovery and can be started and used at any time between the normal temperature and 1550 DEG C.

Owner:GUIYANG DONGJIBOYU REFRACTORY MATERIALS

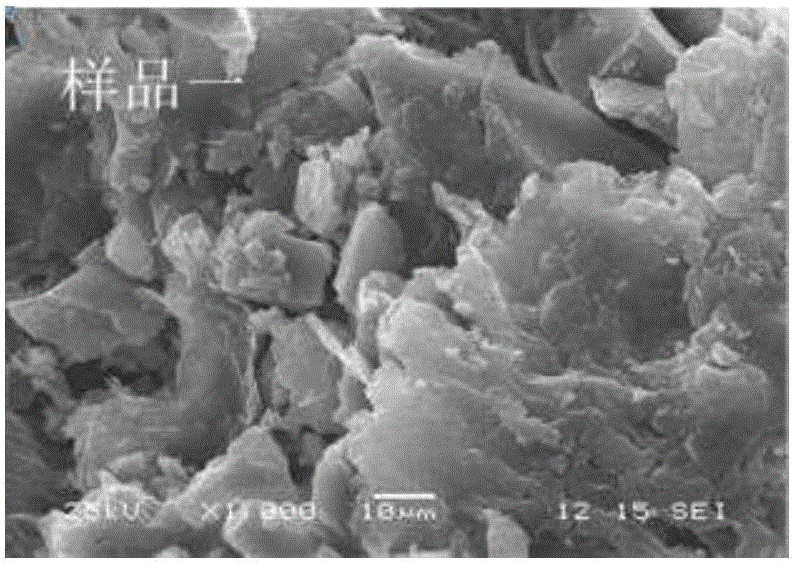

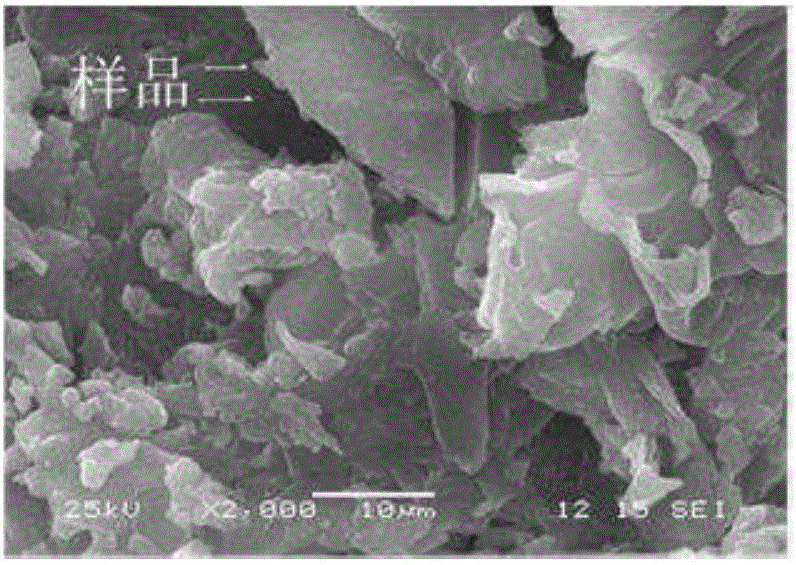

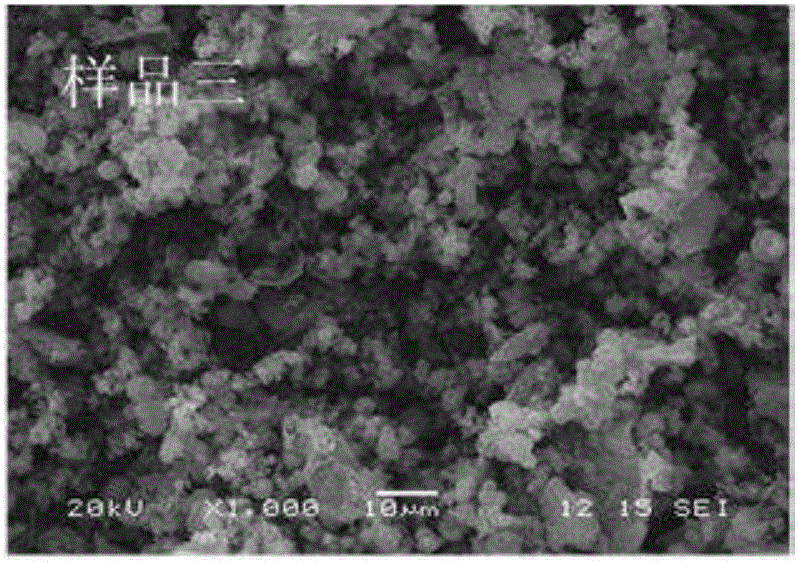

Preparation method and use of carbon molecular sieve

InactiveCN101935032ASolve the problem of difficult and efficient separation of methane-nitrogenNitrogen purification/separationOther chemical processesHigh concentrationLoss rate

The invention relates to a preparation method and use of a carbon molecular sieve. The preparation method comprises the following steps: preparing a conventional carbon molecular sieve; and expanding the pores in the conventional carbon molecular sieve by using a secondary activation technique and modifying the conventional carbon molecular sieve by adjusting the pores. The new carbon molecular sieve is prepared by using coal, coconut shell or phenolic resin, and the like as raw materials, by the conventional production steps of crushing, forming, carbonizing, steam activating, hydrocarbon settling and shrinking and the like and by secondary activation with KOH or CO2 as an activator. The activation temperature is between 550 and 850 DEG C; and the ignition loss rate of the product is kept be between 0.1 and 30 percent. In aspect of use, the carbon molecular sieve can be used for absorbing nitrogen molecules and can also be used for absorbing and separating methane and nitrogen in seam gas under a variable pressure while achieving an adsorption dynamic separation effect and allowing high-concentration methane gas to be collected at the exit of an adsorption tower directly; and thus, the methane in the seam gas can be used efficiently.

Owner:TONGJI UNIV

Method for preparing carbon material with high specific surface area by using metallic organic framework material as template

The invention relates to a method for preparing a carbon material with high specific surface area by using a metallic organic framework material as a template. The method comprises the following steps of: 1, synthesizing the metallic organic framework material template; 2, pre-treating the metallic organic framework material template; 3, introducing a carbon source into the metallic organic framework material template; 4, carbonizing the carbon source at a high temperature; and 5, removing the template. The method for preparing the carbon material with high specific surface area prepares the carbon material by adopting the metallic organic framework material as the template; the prepared carbon material has regular pore structure, uniform aperture distribution and good application value on the aspects of gas adsorption storage, industrial waste separation and the like; and the method has simple and feasible preparation process and good safety.

Owner:深圳市普迈达科技有限公司

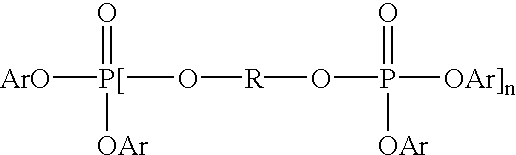

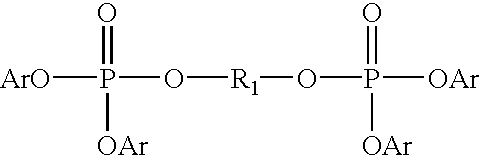

Phosphorus-containing fire retardant thermoplastic polyester composition

InactiveUS6569928B1Improve fire resistanceHigh charring polymerPhosphorus organic compoundsPolyesterFire resistance

A fire retardant thermoplastic polyester comprising a phosphorus containing additive and a high charring polymer containing benzene rings in its main polymer backbone and that has a softening point of no less than about 120° C. exhibits improved fire resistance and no plate out of fire retardant additive during aging.

Owner:ICL IP AMERICA INC

Sludge biological carbonizing technology based on hydrothermal reaction

ActiveCN102875005ALow running costImprove energy efficiencySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningPhysical chemistryCombustible gas

The invention discloses a sludge biological carbonizing technology based on hydrothermal reaction. The sludge biological carbonizing technology comprises the steps as follows: 1) dewatering the sludge, and transferring the sludge into a sludge pre-storage bin to be stored; 2) preheating the dewatered sludge; 3) transferring the preheated dewatered sludge into a hydrothermal reactor, thus obtaining hydrothermal lysis solution; 4) returning the hydrothermal lysis solution into a preheating system to preheat the dewatered sludge, and cooling the hydrothermal lysis solution so as to obtain a gaseous product; 5) transferring the cooled hydrothermal lysis solution into a filter press for filter pressing, thus obtaining a reacting filtrate and a solid product; 6) drying the solid product produced in previous step, and then transferring the solid product into a dry type carbonizing furnace to be carbonized, so as to obtain the solid biological carbon and other products, and transferring the other products into a gas-liquid separating device to be separated so as to obtain combustible gas and tar; and 7) transferring the gaseous product obtained in step 4) and the combustible gas and tar obtained in step 6) into a firebox to be burnt so as to generate heat; and supplying the generated heat to a hydrothermal reactor and the dry type carbonizing furnace. With the adoption of the sludge biological carbonizing technology disclosed by the invention, the product with high additional value can be obtained; and meanwhile, the energy can be saved.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Biological carbon prepared form grapefruit skin, preparation method and application thereof

ActiveCN106000303ALarge specific surface areaStrong adsorption capacityOther chemical processesWater contaminantsSodium polyacrylateAcrylic acid

The invention discloses a preparation method of biological carbon by using grapefruit skin. The method is as below: drying and pulverizing grapefruit skin, and mixing the grapefruit skin with an aqueous solution of catalyst, and conducting a hydrothermal carbonization reaction; after the hydrothermal carbonization reaction, washing and drying to obtain the biological carbon. The temperature of the hydrothermal carbonization reaction is 160 DEG to 260 DEG C; the catalyst is at least one selected from phosphoric acid, sulfuric acid, hydrochloric acid, acetic acid, citric acid, acrylic acid, sodium polyacrylate, sodium polystyrene sulfonate, zinc chloride, and stannic chloride. In addition, the invention also comprises the biological carbon which is prepared by the method and the application of the biological carbon in the adsorption of heavy metals. The biological carbon material obtained by the invention has the advantages of microsphere particle shape, uniform particle size and high adsorption capacity, and can be applied to the field of adsorption and remediation of heavy metal pollutants or organic pollutants.

Owner:HUNAN AGRICULTURAL UNIV

Saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer and use thereof

InactiveCN105384579AGood water permeabilityImprove breathabilityExcrement fertilisersBioloigcal waste fertilisersAlkali soilPotassium

The invention relates to saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer. The saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer has a low cost and high fertilizer efficiency, is economic and environmentally friendly, improves a soil water binding capacity and permeability, and has functions of keeping fertility, slowly releasing fertilizer and reducing paddy rice salinization. The saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer comprises biomass charcoal, chicken manure, pyroligneous liquor, fermented soybean meal and potassium humate. The biomass charcoal is prepared by thermal cracking charring of biomass raw materials under anoxic conditions. The saline-alkali soil paddy rice special-purpose carbon-based organic fertilizer can be used for paddy rice plantation, can improve a saline-alkali soil environment and can improve an organic paddy rice yield.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Ablation catheter with thermally mediated catheter body for mitigating blood coagulation and creating larger lesion

ActiveUS8449537B2Avoid overall overheatingIncrease surface areaSurgical instruments for heatingThermal contactBlood coagulations

An ablation catheter is provided for ablating internal tissue of a patient. The catheter includes a distal end that is adapted to be inserted into a body cavity relative to a desired location therein (e.g., within the heart). An ablation electrode is connected relative to the distal end of the catheter for providing ablation energy to patient tissue. A heat sink is provided that is in thermal contact with the ablation electrode. The heat sink, in addition to being in thermal contact with the ablation electrode, is electrically isolated from the ablation electrode. This allows the heat sink to conduct heat away from the ablation electrode without dissipating electrical energy from the electrode. In this regard, the heat sink may prevent build-up of excess heat within the electrode that may result in blood coagulation and / or tissue charring.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Biochar prepared from banana peel, preparation method and application thereof

ActiveCN106010601ASmall particlesLarge specific surface areaOther chemical processesWater contaminantsBanana peelEconomic benefits

The invention discloses a method for preparation of biochar from banana peel. The method comprises the steps of: (1) crushing banana peel, then mixing the crushed banana peel with an aqueous solution of an activator, and performing standing; then carrying out washing and drying to obtain a biochar precursor, wherein the activator is at least one of alkali metal hydroxide, lewis acid and peroxide; (2) mixing the biochar precursor with an acid solution, then carrying out hydrothermal charring reaction at 180DEG C-260DEG C, and at the end of the hydrothermal charring reaction, carrying out washing and drying to obtain the biochar. In addition, the invention also comprises the biochar prepared by the method and application of the biochar to adsorption of heavy metals. The method provided by the invention utilizes agricultural production waste to prepare a biochar adsorbent by simple and rapid hydrothermal charring method, turns waste into treasure, makes full use of resources, reduces environmental pollution, has good economic benefits, develops new technology, and is beneficial to industrial production.

Owner:HUNAN AGRICULTURAL UNIV

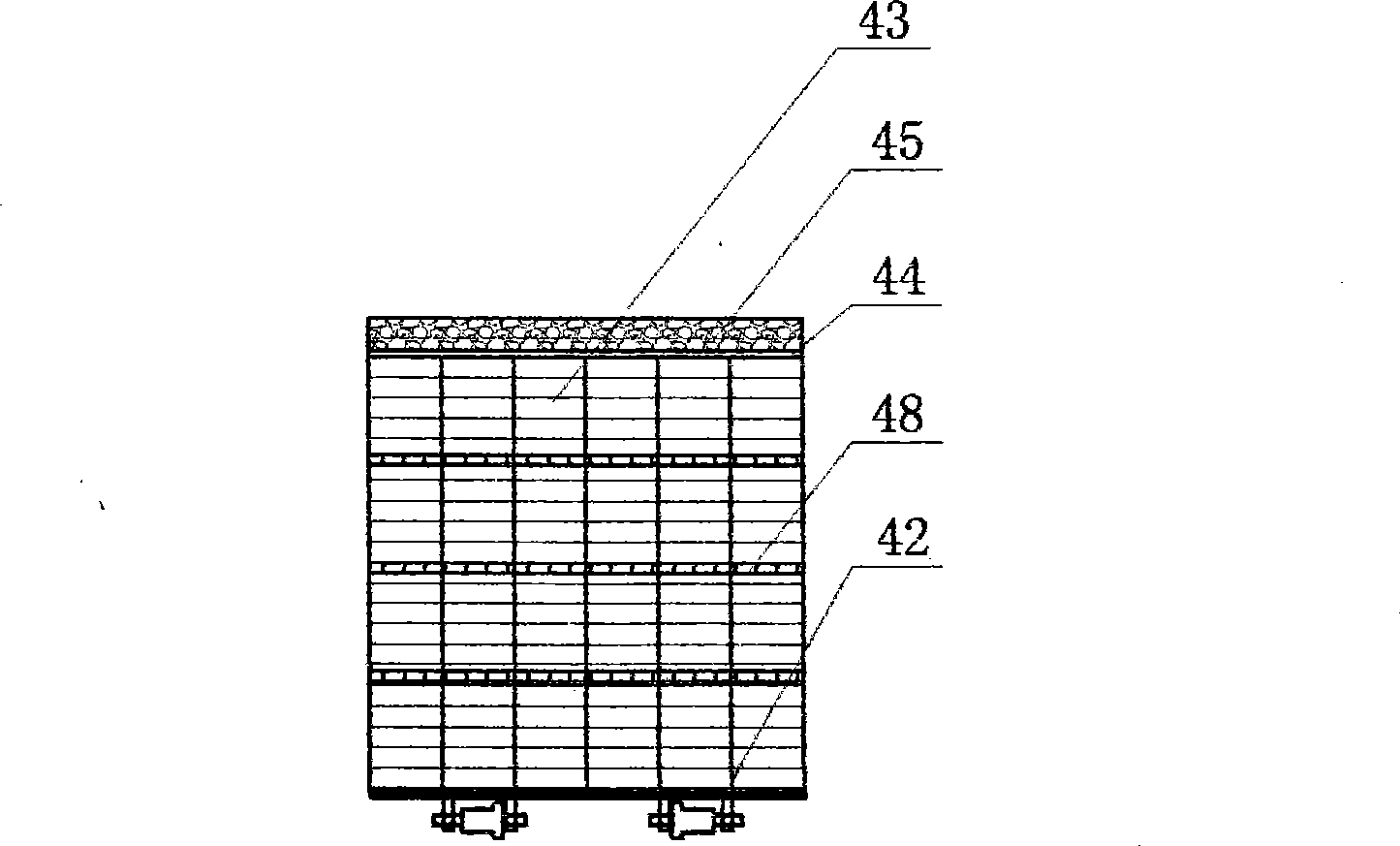

Simply corncob granule carbonization furnace and preparation method thereof

A simple charring furnace for corn cob particles and its charring process are disclosed. Said charring process features that the corn cob particles are dry-distilled and decomposed at 260-450 deg.C in anoxic condition and the quantity of supplied O2 is controlled by the thickness of raw material. The charred particles can be used as the matrix of slow-release compound fertilizer.

Owner:辽宁金和福农业科技股份有限公司

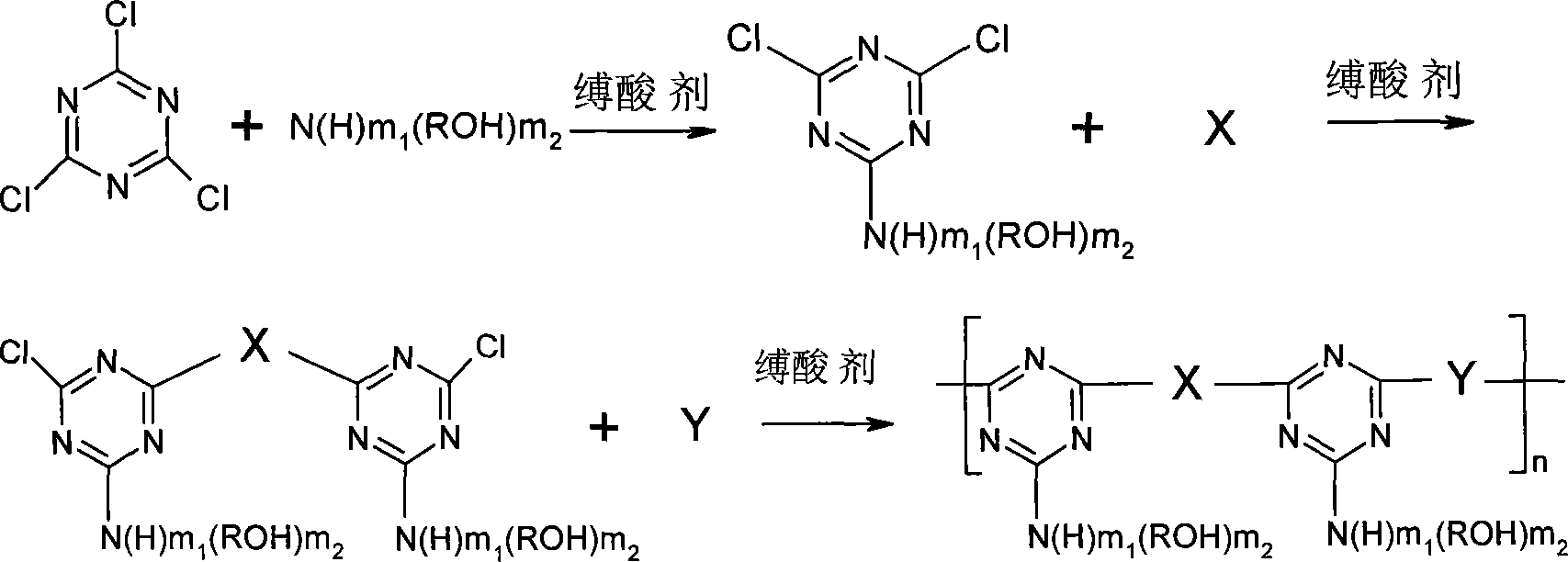

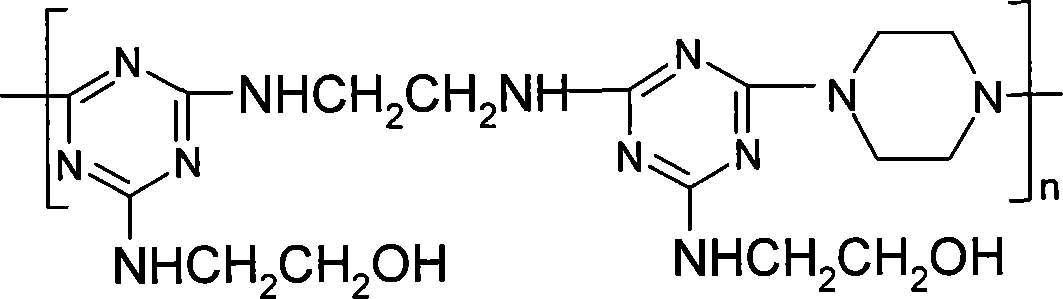

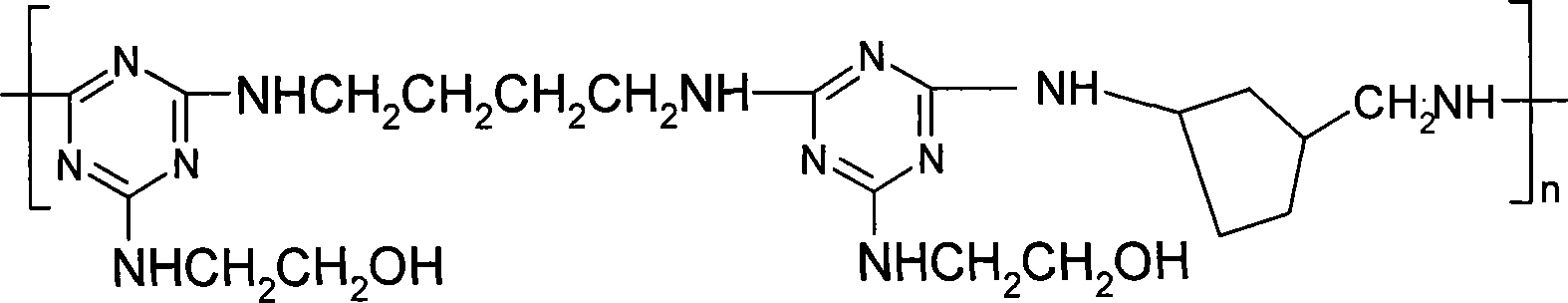

Triazine series oligomer and its synthesizing method

The invention relates to a triazine series oligomer and the compound method. The method has the following steps: adding solvent into cyanuric chloride, dropping alkylol amine and acid roping agent to gain substitute of cyanuric chloride; heating, dropping diamidogen and acid roping agent to gain the substitute of cyanuric chloride; adding diamidogen and acid roping agent into reaction solution, heating, pumping, washing, and drying to gain triazine series oligomer. The invention has strong charring and expanding ability, and good thermal stability. It has advantages of continuously reaction process, short reaction time, simple compounding technology, little organic solvent, and easy to recycle organic solvent.

Owner:NORTHEAST FORESTRY UNIVERSITY

Wooden wares surface archaizing treatment technology

InactiveCN1730255AEasy to produceVariety of colorsWood treatment detailsPretreated surfacesLacquerDiluent

The invention relates technology of surface treatment of wooden wares, comprising the following steps: drying the wood and blanking according to the requirement, processing and charring; brushing or spraying the archaized color priming paint which is compounded by diluent and mixture of yellow paint, red paint, black paint, and white paint in proper proportion, after drying, repairing the surface of the wood, then spraying the priming paint repeatedly twice or thrice, making it dry naturally; sanding the said wooden wares by fineness abrasive cloth, taking out the paint around 20%; spraying the press polish archaized paint to the surface of the wooden wares. The invention processes simple technology, good effect of imitation antique, convenience production, economy and utility.

Owner:DAKANG HLDG GROUP

Variable cascade temperature regulation biomass charring device

InactiveCN104861995AMeet the requirements of different heating ratesSolve the problem that the heating rate cannot be adjustedBiofuelsEnergy inputControl systemSeparation technology

The invention discloses a variable cascade temperature regulation biomass charring device. The device mainly comprises a feeding unit, a segmented pyrolysis unit, an oil-gas separation unit, a secondary catalytic cracking unit and a waste heat reuse unit. The whole process is regulated through a reaction control system, and the continuous performing of the pyrolytic reaction is guaranteed through continuous sealed feeding and discharging. According to the pyrolysis portion, a variable cascade segmented heating principle is used, so that multi-stage regulation among different heating sections of a pyrolyzing furnace is achieved, and the requirement for different heating speeds during pyrolysis is met. Meanwhile, the pyrolysis gas condensation separation technology, the secondary catalytic cracking tar removing technology, the charcoal continuous cooling technology, the high-temperature pyrolysis gas waste heat reuse technology, the internal and external combined heating pyrolysis charring technology and the like are integrated. The device is applicable to pyrolysis charring of various biomasses in different conditions.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

Methods for laser treatment of soft tissue

Methods are provided for treating prostate glands or other targeted soft tissue using a solid-state laser. The laser can be operated to generate a pulsed output beam having pulse durations of between 0.1 and 500 milliseconds. The output beam is delivered to the targeted tissue through an optical fiber, preferably terminating in a side-firing probe or diffusing tip. By operating the laser in a long-duration pulse mode, charring of the targeted tissue is initiated quickly, thereby increasing ablation rates and reducing overall procedure time.

Owner:BOSTON SCI SCIMED INC

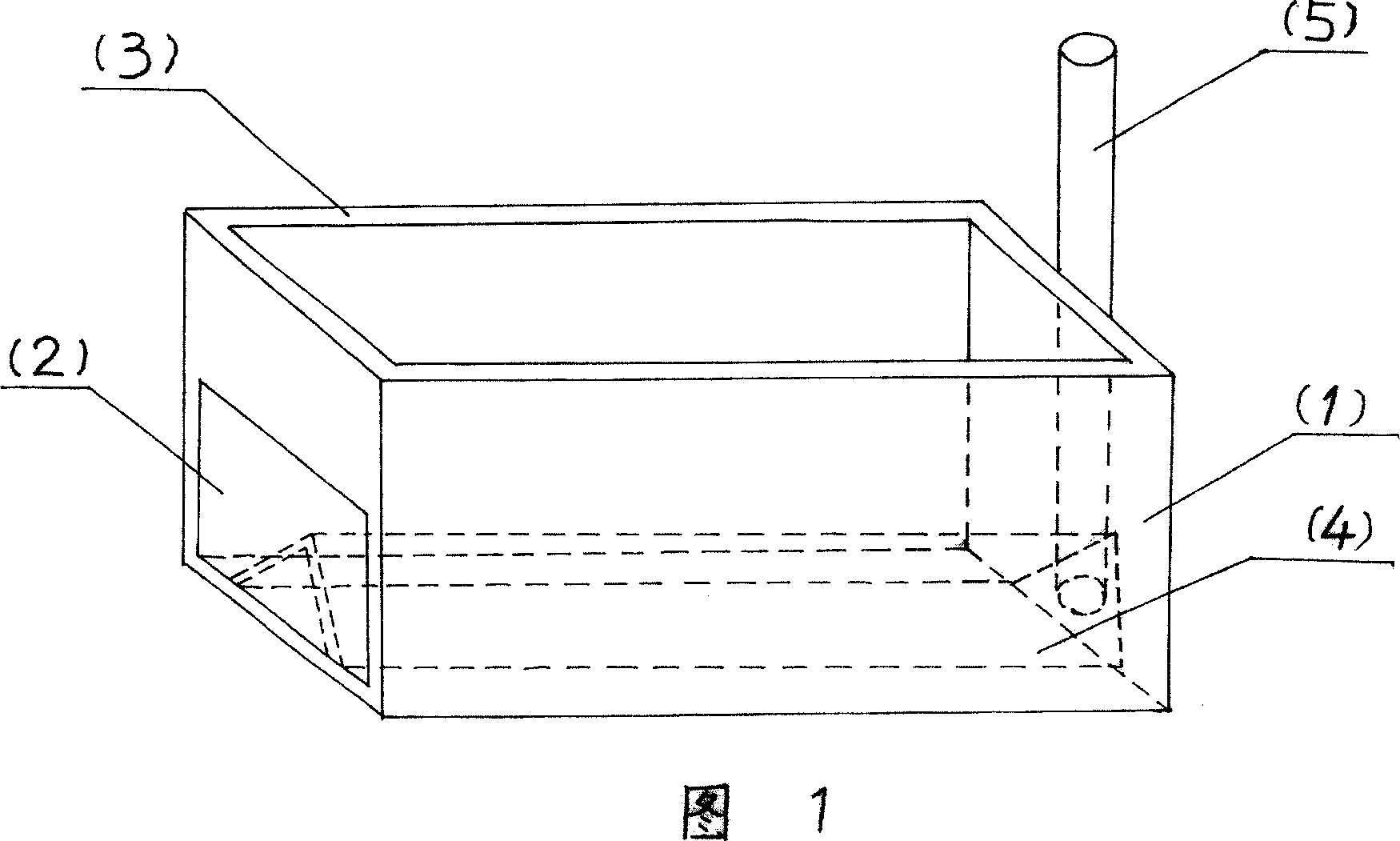

Microwave vacuum device for drying and charring lumber

ActiveCN101439529AConsistent heating inside and outsideDry evenlyWood treatment detailsWood dampingAir cycleFurnace temperature

The invention relates to a wood microwave vacuum drying and charring device and a drying and charring method thereof. The device comprises one charring tank (box) with a tank door (3), a tank door opener (2) and a charring chamber (1), a vacuum system, and one or more microwave sources (6) generating the microwave, a heat-conducting oil furnace system and a material preparation and feed system. The drying and charring method comprises the following steps: A. rising the temperature inside the tank to 30-50 DEG C, and then to 80-130 DEG C at the rate of 2-8 DEG C / h; B. preserving the temperature for 2-100 hours; C. vacuumizing the tank for 4-100 hours; D. starting a hot recycle pump to control the oil furnace temperature, the oil flow rate and the pressure inside the tank for 4-100 hours: E. turning off the microwave source and a heat source, opening an intake and exhaust valve (39) to discharge the pressure inside the tank to 0 and lower the temperature to 70-130 DEG C, and then closing the intake and exhaust valve (39); and F. starting a vacuum pump (22) to lower the temperature inside of the tank by air circulation and removing the wood from the tank when the temperature decreases to 30-70 DEG C. The device and the method help char the wood evenly, shorten the production cycle by 60% compared with the conventional method, and lower the energy consumption by 70%, thus greatly reducing the production cost.

Owner:罗玉成

Soft material solid-wood reinforced board and its producing method

ActiveCN101007415AImprove use valueOvercoming odd problemsCork treatment detailsVolumetric Mass DensityNormal conditions

A soft material quality wood material strengthening board is flat plate. It is characterized by: it has natural grains of raw wood, its color is the mixture color of raw wood self color, charring color and resin color, the density is 450-720kg / m<3>, surface hardness is 25-65MPa, vertical MOR is 35 - 90MPa, vertical elastic modulus is 1~10GPa, resin content (solid content) is 3% - 10%. The strengthening board can be produced floors or furniture raw materials after preliminary working, drying, rough planing, heating, resin soaking, hot pressing, placing in normal condition and fine finishing. The invention produces the strengthening board using soft material as raw material, covers the shortage of hardwood product raw materials, it increases the use-value of soft material, while meets the popular consumer demand of liking wood, and provides new materials for hardwood furniture and flooring manufacturing industry.

Owner:ZHEJIANG NENGFU TOURIST PRODS

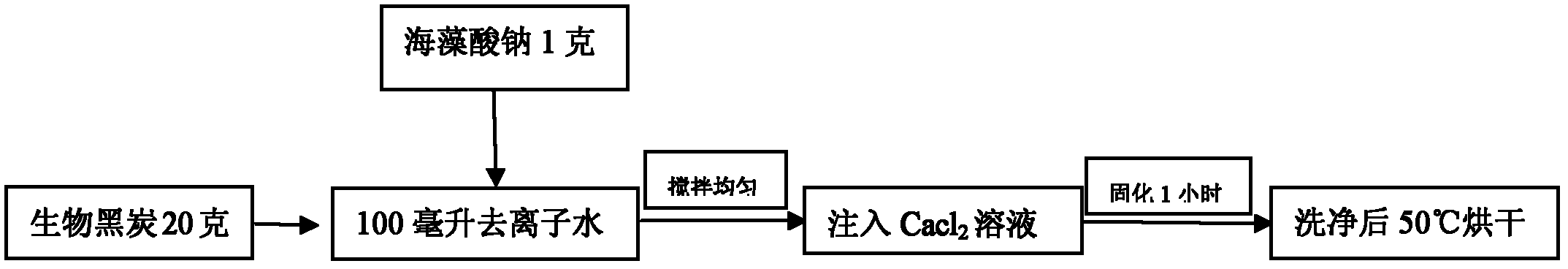

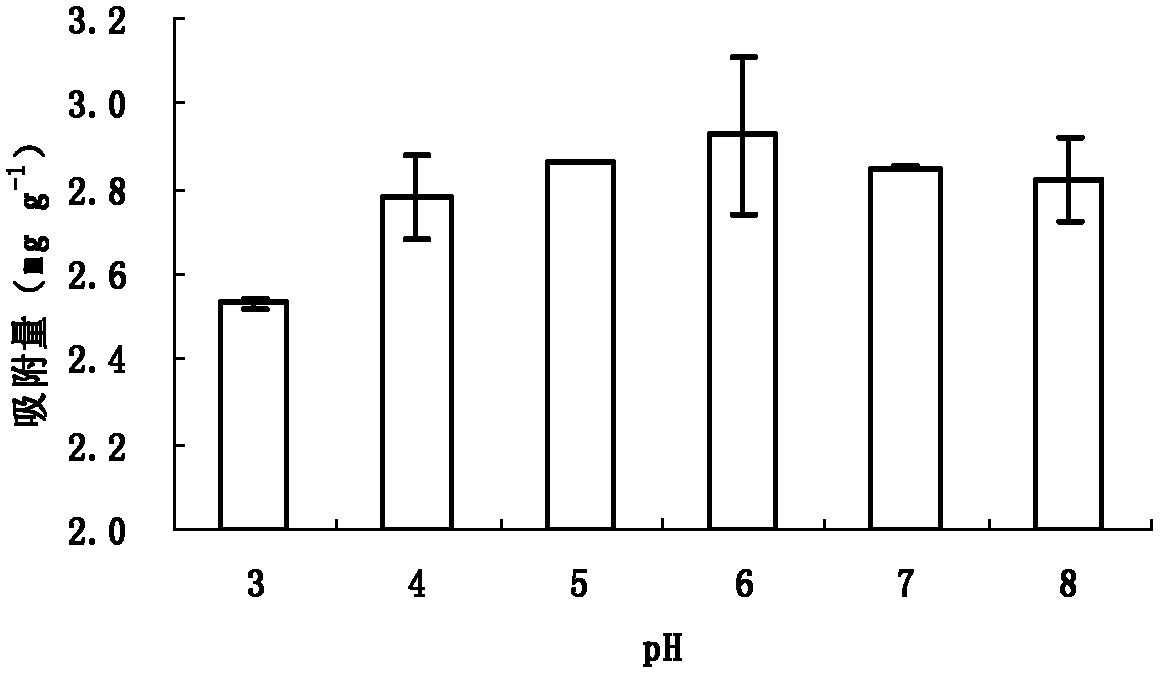

Biological black carbon treating agent for absorbing and curing cadmium and lead in water body polluted by heavy metals and preparation method thereof

ActiveCN102350308AImprove adsorption capacityHigh mechanical strengthOther chemical processesWater/sewage treatment by sorptionEnvironmental engineeringWaste management

The invention discloses a biological black carbon treating agent for absorbing and curing cadmium and lead in a water body polluted by heavy metals and a preparation method thereof. The preparation method comprises the following steps of: (1) collecting, namely collecting agricultural organic wastes; (2) air-drying, namely air-drying the agricultural organic wastes; (3) carbonizing, namely carbonizing the agricultural organic wastes at the temperature of 300-500 DEG C to obtain biological black carbon; (4) smashing, namely grinding and screening the biological black carbon; (5) modifying, namely adding the screened biological black carbon into a 12wt% sodium alginate solution and uniformly stirring; (6) granulating, namely dropping the biological black carbon-sodium alginate solution obtained in the step (5) into a 2wt% CaCl2 solution, curing and cleaning the mixture by using deionized water, thus obtaining biological black carbon granules; and (7) putting the biological black carbon granules obtained in the step (6) into a drying oven to dry the biological black carbon granules at the temperature of 40-60 DEG C until the biological black carbon granules are constant in weight. The biological black carbon treating agent can effectively absorb and remove the heavy metals, namely cadmium and lead, from the polluted water body, and simultaneously can fully use the agricultural organic waste resources.

Owner:南京农业大学资产经营有限公司

Biological carbon base compound fertilizer and preparing method thereof

InactiveCN102659474AImprove soil physical propertiesIncrease the granular structureFertilizer mixturesInorganic fertilizerFertilizer

The invention discloses a biological carbon base compound fertilizer which is mainly composed of biomass carbon black and a compound fertilizer. The preparing method of the biomass carbon black includes subjecting agricultural wastes which serve as biomass raw materials to a low-temperature carbonization so as to form the porous biomass carbon black. The invention also discloses a preparing method of the biological carbon base compound fertilizer. The biological carbon base compound fertilizer adopts microporous biomass carbon, has high adsorptive capacity, good light absorption, temperature increasing and sustained release effects, is capable of reducing leaching loss waste of the fertilizer effectively, can be stored for a long time at a normal temperature and subjected to mixing granulation and drying with other organic and inorganic fertilizers without being influenced, and has an obvious synergistic function.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +2

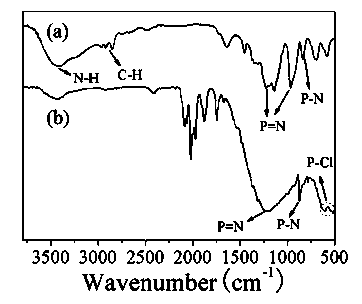

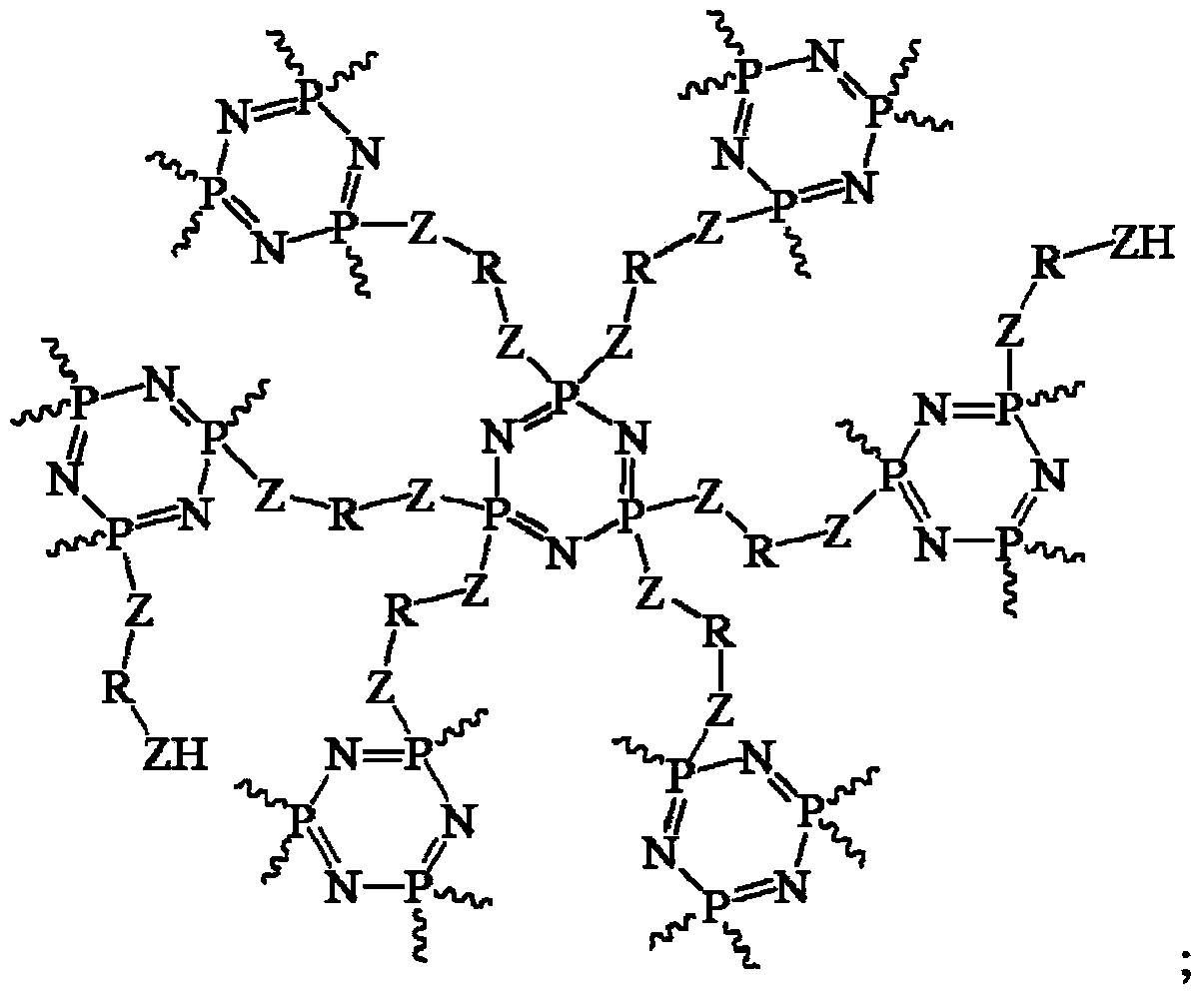

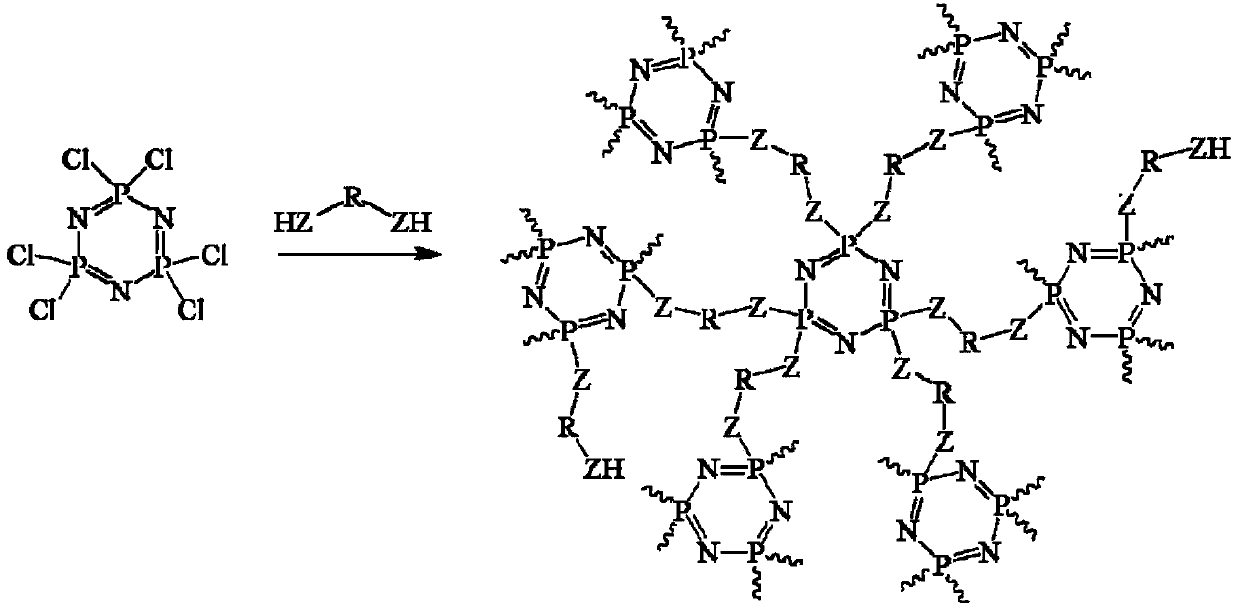

Hyperbranched polyphosphazene flame retardant charring agent and preparing method thereof

An efficient hyperbranched polyphosphazene flame retardant charring agent is prepared by reacting hexachlorocyclotriphosphazene with a binary compound containing two active groups. The charring agent has characteristics of good foaming charring performance, excellent flame retardant effects and good processing performance, and can be widely used in plastics, rubber, coating, adhesives, and other polymer materials. A preparing method adopts a one-pot method, and has characteristics of continuous reaction process, short reaction time and high production efficiency. By controlling the mole ratio of the hexachlorocyclotriphosphazene to the binary compound, no end-capping agent is added in the reaction process. When compared with the addition of end-capping agents in synthesis processes in triazine type charring agent patents, the synthetic process of the charring agent is simplified.

Owner:苏州安鸿泰新材料有限公司

Composite biological activated carbon and rapid preparation method thereof

InactiveCN101643208AExtended service lifeSolve the technical problems of long carbonization timeSpontaneous combustionBiological activated carbon

The invention discloses a composite biological activated carbon and a rapid preparation method thereof, raw materials thereof comprise coconut shell, bamboo, rice hull, sawdust, wheat straw or rice straw, or the raw materials thereof comprise the rice hull, the sawdust, the wheat straw or the rice straw, corn stalk or corn core, the raw materials are smashed to prepare columnar granules, the direct heating method of the spontaneous combustion type granules is adopted for preparing the carbon, a fixed layer is paved at the bottom of a furnace by taking the granules as the raw materials, the fixed layer is ignited by using ignition materials, the feeding is adopted at the upper part of the furnace and the air induction is carried out at the lower part of the furnace for accelerating carbonization of the granules, the air induction is stopped after the carbonization of the granules, the temperature in the furnace is kept at 430-700 DEG C, the spray cooling method is adopted for activatingand cooling the granular carbon, and a finished product is prepared after 20-30 minutes. A plurality of raw materials are mixed, and more pores are naturally formed, thereby expanding the specific surface area of the carbon, greatly increasing effective micropores, leading the absorption performance to be greatly better than the existing activated carbon of single material and reflecting the unique advantages of the composite material.

Owner:徐克文

Method of manufacturing active carbon for waste water treatment using waste tyre

InactiveCN101012059AReduce qualityImprove resource utilization efficiencyOther chemical processesWater/sewage treatment by sorptionThermal energyWaste treatment

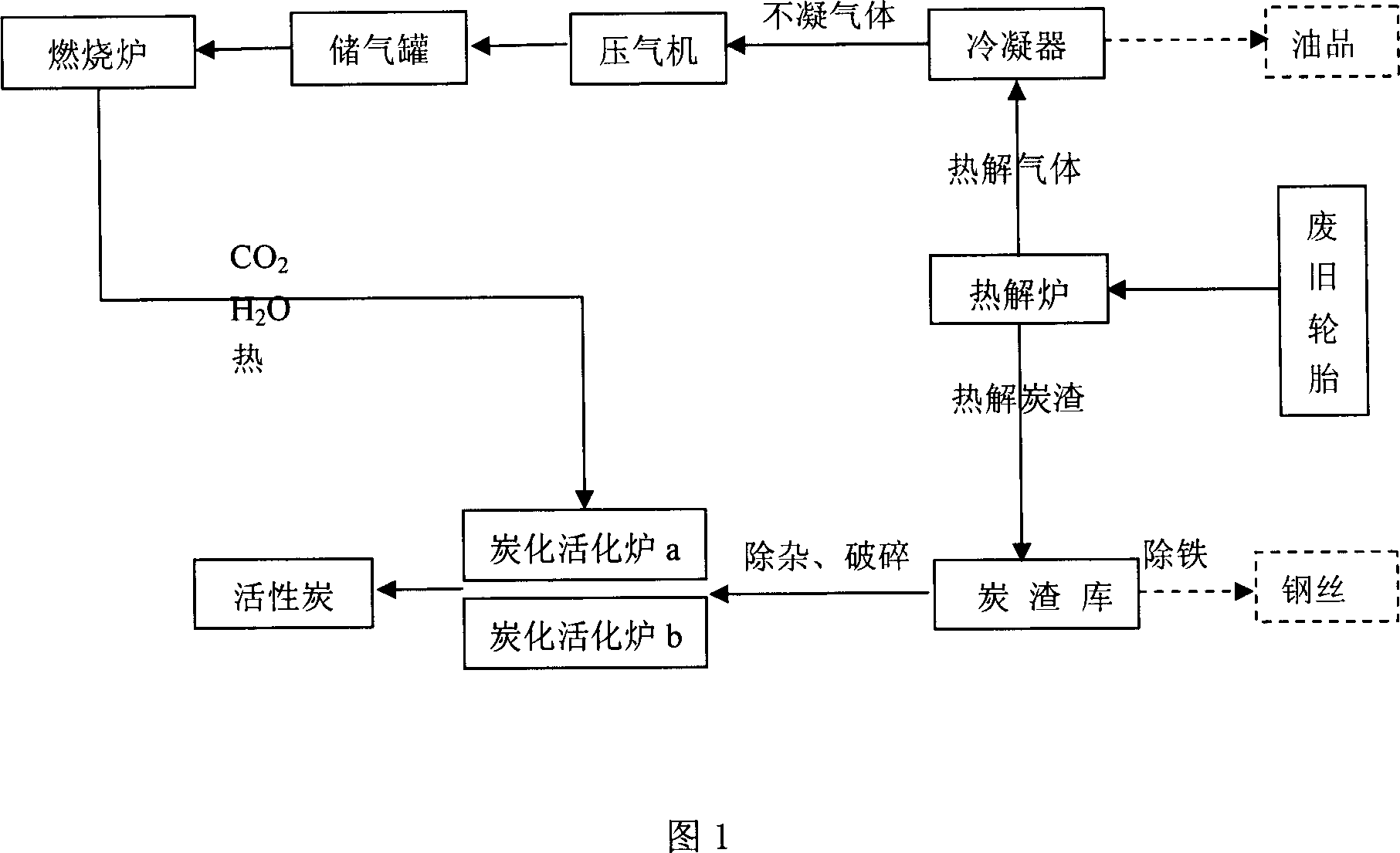

The invention discloses a making method of wastewater active charcoal through waste tyre in the processing method technical domain of environmental protective solid waste, which is characterized by the following: transmitting entire or broken waste tyre into pyrogenic stove; transmitting carbon waste in the charring activating furnace; sending non-condensed gas into combusting furnace; inducing high-hot CO2 and H2O flow into charring activating furnace to heat charring activating furnace; adopting incomplete combusting carbon black as new additional raw material; insulating the charring activating furnace from air; reducing to below 100 deg.c to obtain the product; alternating two stoves.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com