Biochar prepared from banana peel, preparation method and application thereof

A technology of biochar and banana peel, applied in the field of agricultural chemistry, can solve the problems of environmental pollution, negative impact of production, waste of resources, etc., and achieve the effect of large specific surface area, strong adsorption capacity, and full utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

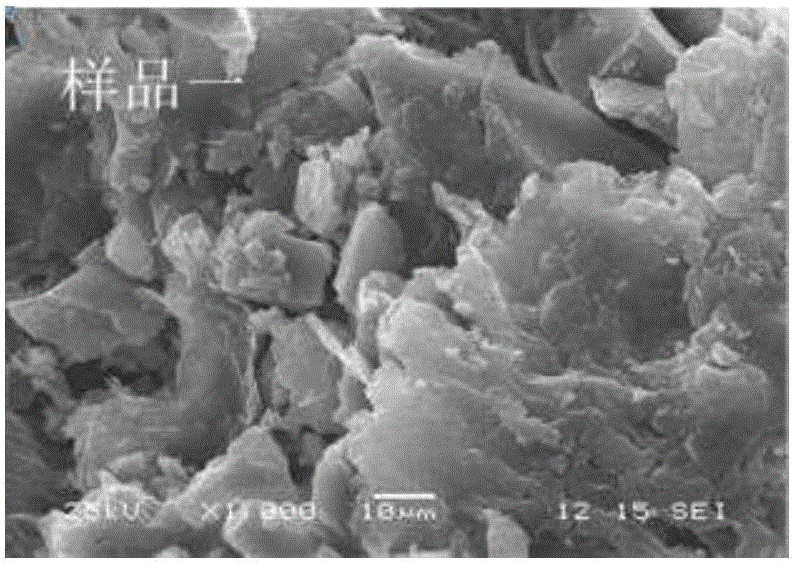

[0047] After the banana peel waste was pulverized, 40 mesh particles were selected, and 5 g of banana peel biomass was mixed with 25 g of 20% KOH aqueous solution according to the mass ratio of banana peel biomass and KOH aqueous solution as 1:5, stirred evenly and then left to stand for 2 h. Wash with deionized water until neutral, filter and dry, stir 5g of biochar precursor and 10ml of 60% hydrochloric acid aqueous solution according to the ratio of solid / liquid ratio of 1g:2ml, and then seal them into an autoclave. Under the condition that the heating rate of the electric furnace is 10-20°C / min, conduct hydrothermal carbonization at 180°C for 16 hours, wash with deionized water until neutral after natural cooling, filter, dry at 110°C for 12 hours, and grind to obtain biological Carbon material, the SEM image of the prepared biochar is shown in figure 1 . The FTIR spectrum of the prepared biochar is shown in Figure 10 The spectrum of "sample 1" ( Figure 10 1st spectra...

Embodiment 2

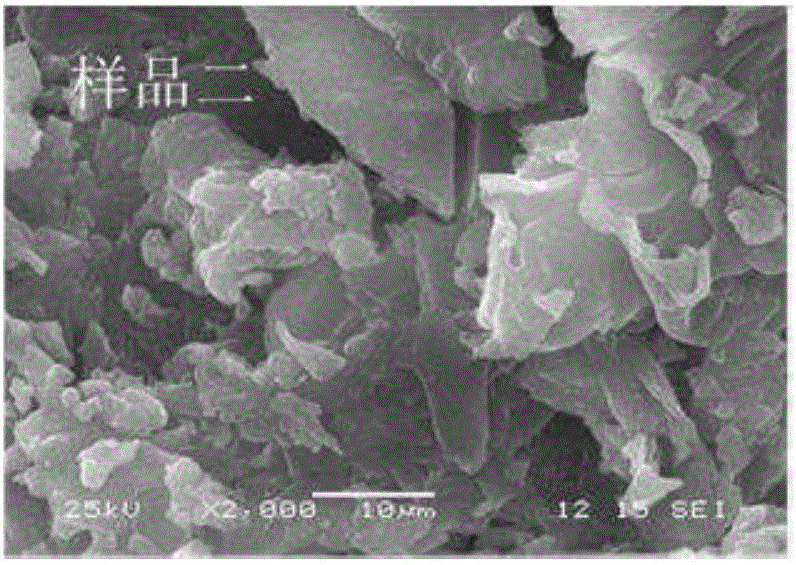

[0050] After the banana peel waste was pulverized, 50 mesh particles were selected, and 5 g of banana peel biomass was mixed with 15 g of 10% KOH aqueous solution according to the mass ratio of banana peel biomass and KOH aqueous solution as 1:3. Wash with deionized water until neutral, filter and dry, stir 5g of biochar precursor and 20ml of phosphoric acid solution with a concentration of 20% according to the ratio of solid / liquid ratio of 1g:4ml, and then seal them into a high-pressure reactor. Under the condition that the heating rate of the electric furnace is 10-20°C / min, conduct hydrothermal carbonization at 190°C for 14 hours, wash with deionized water until neutral after natural cooling, filter, dry at 110°C for 12 hours, and grind to obtain biological Carbon material, the SEM image of the prepared biochar is shown in figure 2 . The FTIR spectrum of the prepared biochar is shown in Figure 10 The spectrum of "sample 2" ( Figure 10 2nd spectral line from top to bo...

Embodiment 3

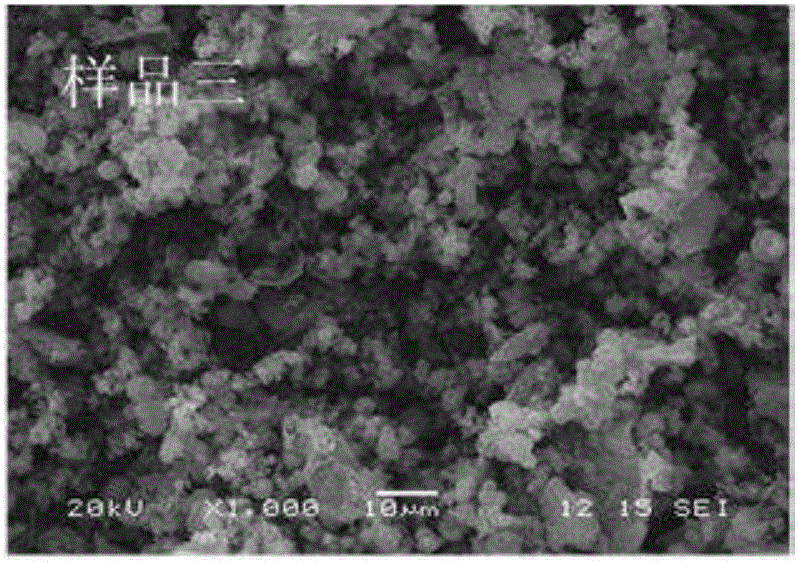

[0053] After the banana peel waste is pulverized, select 60-mesh particles, mix 10g of banana peel biomass with 40g of 20% NaOH aqueous solution according to the mass ratio of banana peel biomass and NaOH aqueous solution as 1:4, stir evenly and let stand for 3h, use Wash with deionized water until neutral, filter and dry, stir 5g of biochar precursor and 30ml of sulfuric acid aqueous solution with a concentration of 20% according to the solid / liquid ratio of 1g: 6ml, and then seal them into a high-pressure reactor. Under the condition that the heating rate of the electric furnace is 10-20°C / min, conduct hydrothermal carbonization at 200°C for 12 hours, wash with deionized water until neutral after natural cooling, filter, dry at 110°C for 12 hours, and grind to obtain biological Carbon material, the SEM image of the prepared biochar is shown in image 3 . The FTIR spectrum of the prepared biochar is shown in Figure 10 The spectrum of "sample 3" ( Figure 10 3rd spectral l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com