Wafer edge protection ring and method for reducing particles at wafer edge

An edge protection and protection ring technology, which is applied in the manufacture of discharge tubes, electrical components, semiconductors/solid-state devices, etc., can solve problems such as damage to chip quality, and achieve the effects of easy control, quality assurance, and particle reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

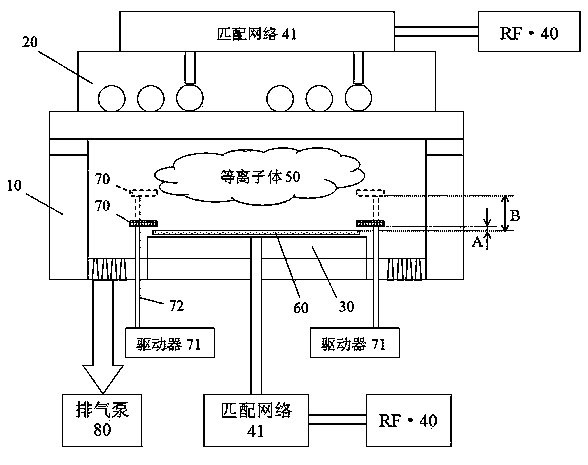

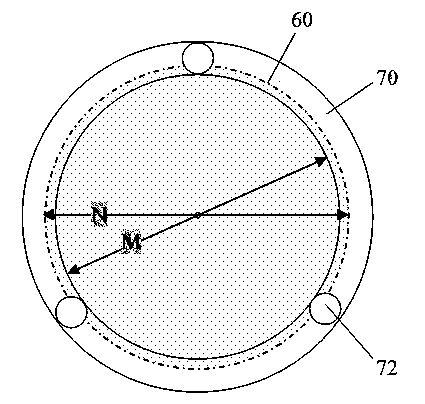

[0033] Cooperate see figure 1 , figure 2 As shown, the first embodiment of the present invention provides a wafer edge protection ring (hereinafter referred to as the protection ring 70 for short), which is located in the reaction chamber 10 of the plasma processing apparatus. The protection ring 70 covers the edge of the wafer 60 .

[0034] The inner diameter M of the protective ring 70 is equal to or slightly smaller than the diameter N of the wafer 60: for example, if the diameter of the wafer 60 is 200mm, the inner diameter of the protective ring 70 can be 196mm~200mm; if the diameter of the wafer 60 is 300mm Yes, the inner diameter of the protection ring 70 may be 294mm~300mm.

[0035] A driver 71 (for example, including a motor, a cylinder, etc.) is provided on the atmospheric side of the reaction chamber 10 . The driver 71 can connect the protective ring 70 through several connecting rods 72 penetrating into the reaction chamber 10 , so as to control the rising or f...

Embodiment 2

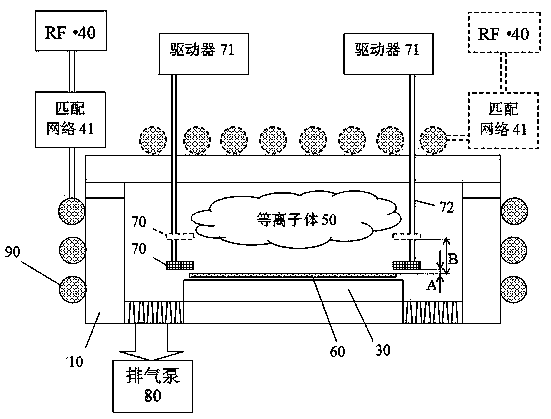

[0040] Such as image 3 As shown, the protective ring 70 provided in the second embodiment of the present invention is characterized in that the driver 71 of the protective ring 70 is located above the top of the plasma processor reaction chamber 10 and is on the atmospheric pressure side. A plurality of connecting rods 72 penetrate into the reaction chamber 10 from top to bottom to connect the protection ring 70 , and the protection ring 70 is suspended above the wafer 60 and covers the edge of the wafer 60 . Under the action of the driver 71, the protection ring 70 can be lowered to the first state, so that there is a first gap A between the bottom surface of the protection ring 70 and the top surface of the wafer 60 (edge position); it is also possible to make the protection ring 70 pulled up to the second state ( image 3 Indicated by a dotted line), the distance between the bottom surface of the guard ring 70 and the top surface of the wafer 60 (edge position) is inc...

Embodiment 3

[0044] The present invention also provides another structure of the protective ring, which can be applied to Embodiment 1 or 2. The characteristic is that the protective ring is composed of equal or non-equal segments of arcs, and the driver controls these arc segments to spread out or gather in the horizontal direction through corresponding connecting rods instead of making them lift up and down. . The circular arc segments can be supported from below or suspended from above by means of vertically arranged connecting rods, and can also be driven by means of horizontally arranged connecting rods.

[0045] Such as Figure 4 As shown, for example, in a protective ring provided, there are two semi-circular arc segments 70-1, 70-2, and the two are in a state of gathering during wafer processing, so as to form a complete cover on the A ring structure at the edge of the wafer to hold process reaction by-products including polymers. While releasing the wafer, the two semicircle ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com