Preparation method of superfine nanometer lithium iron phosphate electrode material and application thereof

A lithium iron phosphate, ultra-fine nano technology, applied in battery electrodes, nanotechnology, chemical instruments and methods, etc., can solve the problems of complex preparation process, uneven particle distribution, and low product purity of lithium iron phosphate precursors, and achieve Excellent electrochemical performance, simple preparation method and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Example 1: Solution A1: Mix 55.8 grams of 85% concentrated phosphoric acid with 400ml of water. Solution B1: 139 g FeSO 4 ·7H 2 O mixed with 500ml of water. Pour solution B1 into A1 under stirring, adjust the pH to about 5.5 with sodium hydroxide, and heat the resulting mixed solution at about 70°C for about 4 hours. Centrifuge the precipitate, wash it with deionized water, and dry it in an oven at 104°C to obtain the ferrous phosphate precursor Fe 3 (PO 4 ) 2 .8H 2 O.

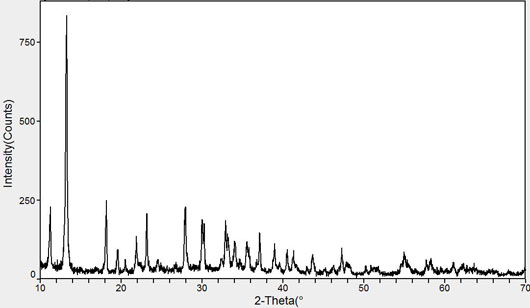

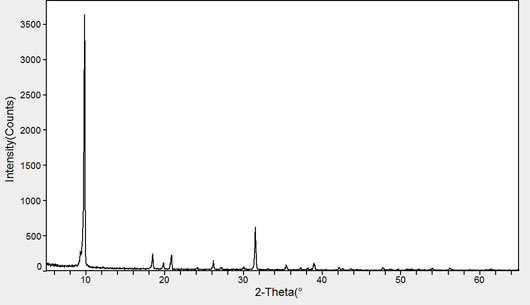

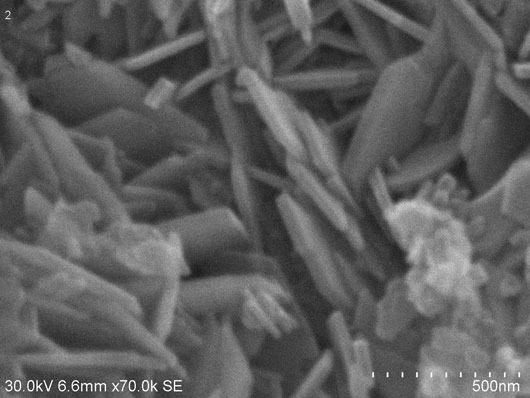

[0051] figure 1 For the obtained Fe 3 (PO 4 ) 2 .8H 2 O X-ray powder diffraction pattern, image 3 for Fe 3 (PO 4 ) 2 .8H 2 O high-resolution electron microscopy image. It can be seen from the figure that the primary particles of the precursor are flakes with a size of about 50-800 nanometers.

[0052] Li with a Li:Fe:P molar ratio of about 1:1:1 2 CO 3 , Fe 3 (PO 4 ) 2 .8H 2 O, H 3 PO 4 Add about 15 g of cellulose acetate per mole of LFP and mix in water, stir and mix evenly t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com