Patents

Literature

98results about How to "Low cycle life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rechargeable lithium/water, lithium/air batteries

InactiveUS20070221265A1Improve protectionEasy to controlFinal product manufacturePV power plantsHigh energyOptoelectronics

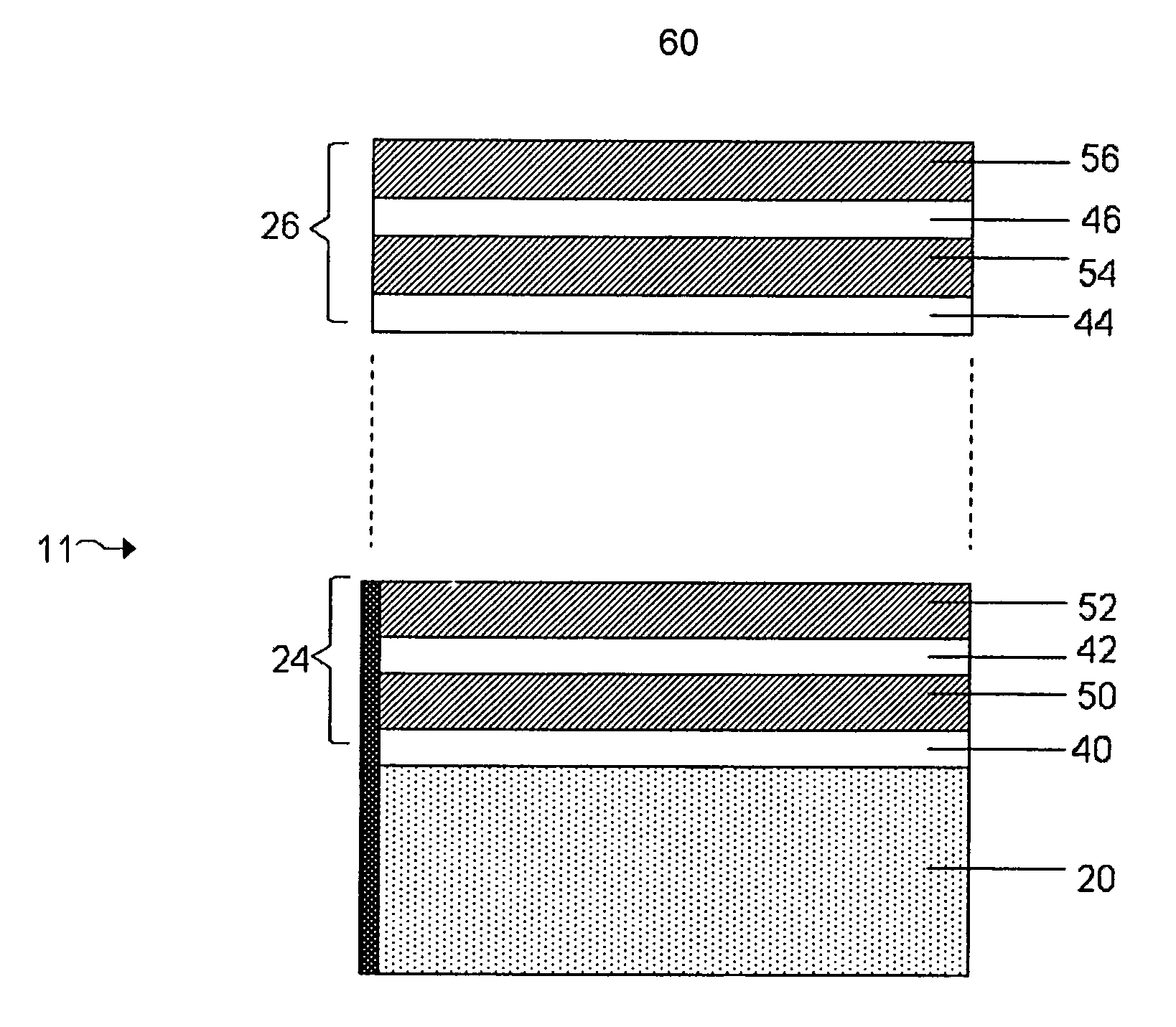

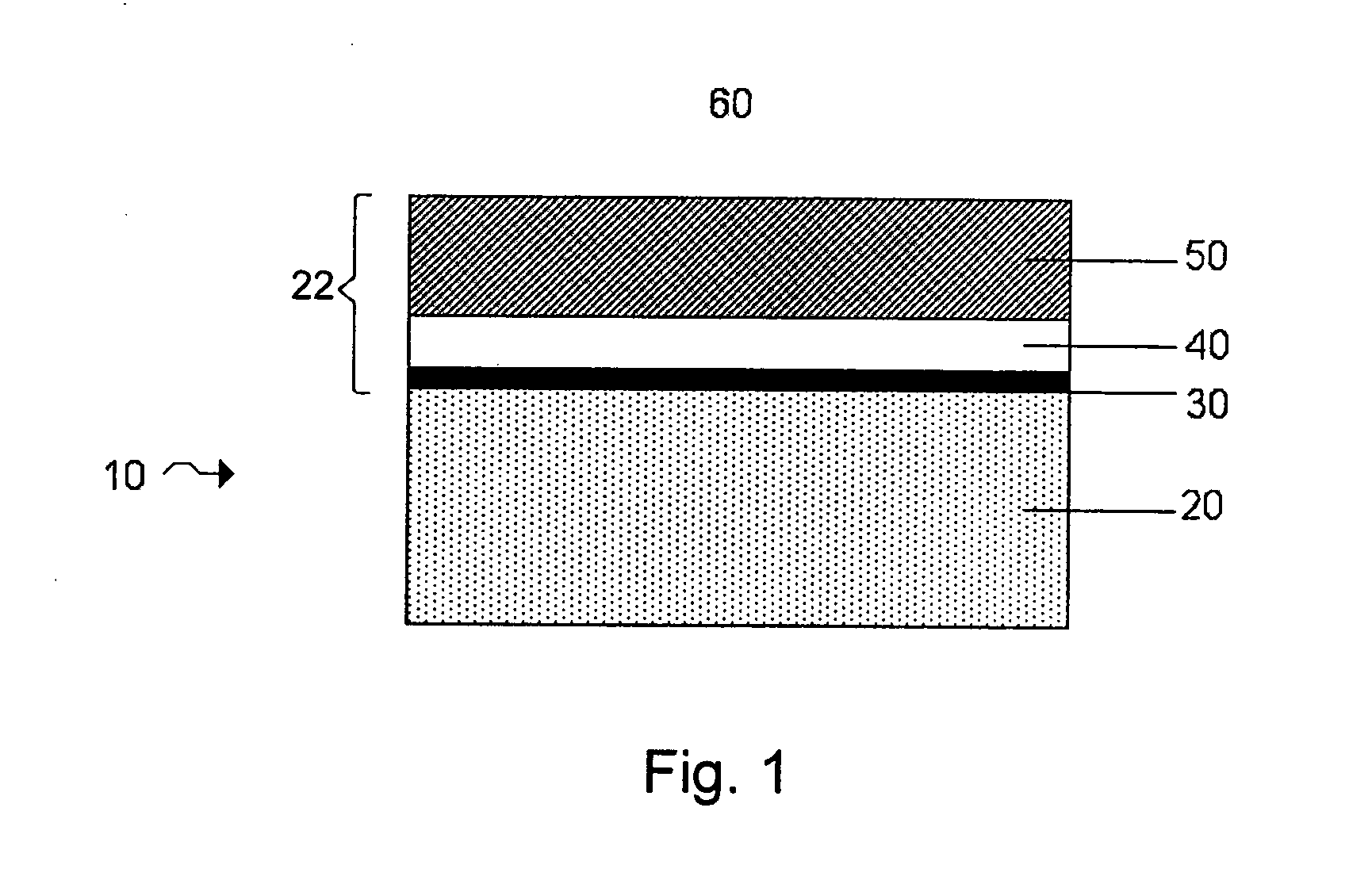

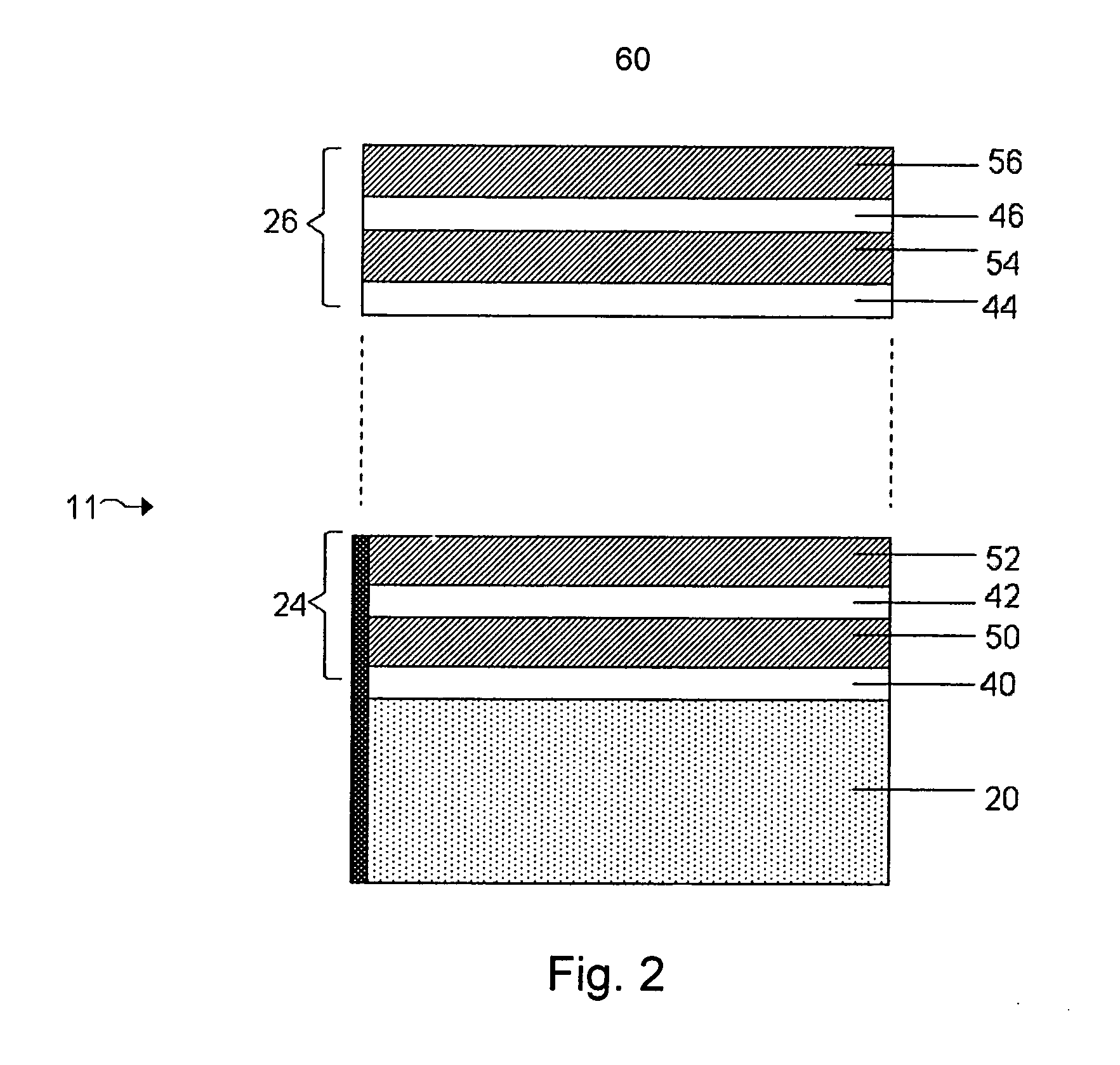

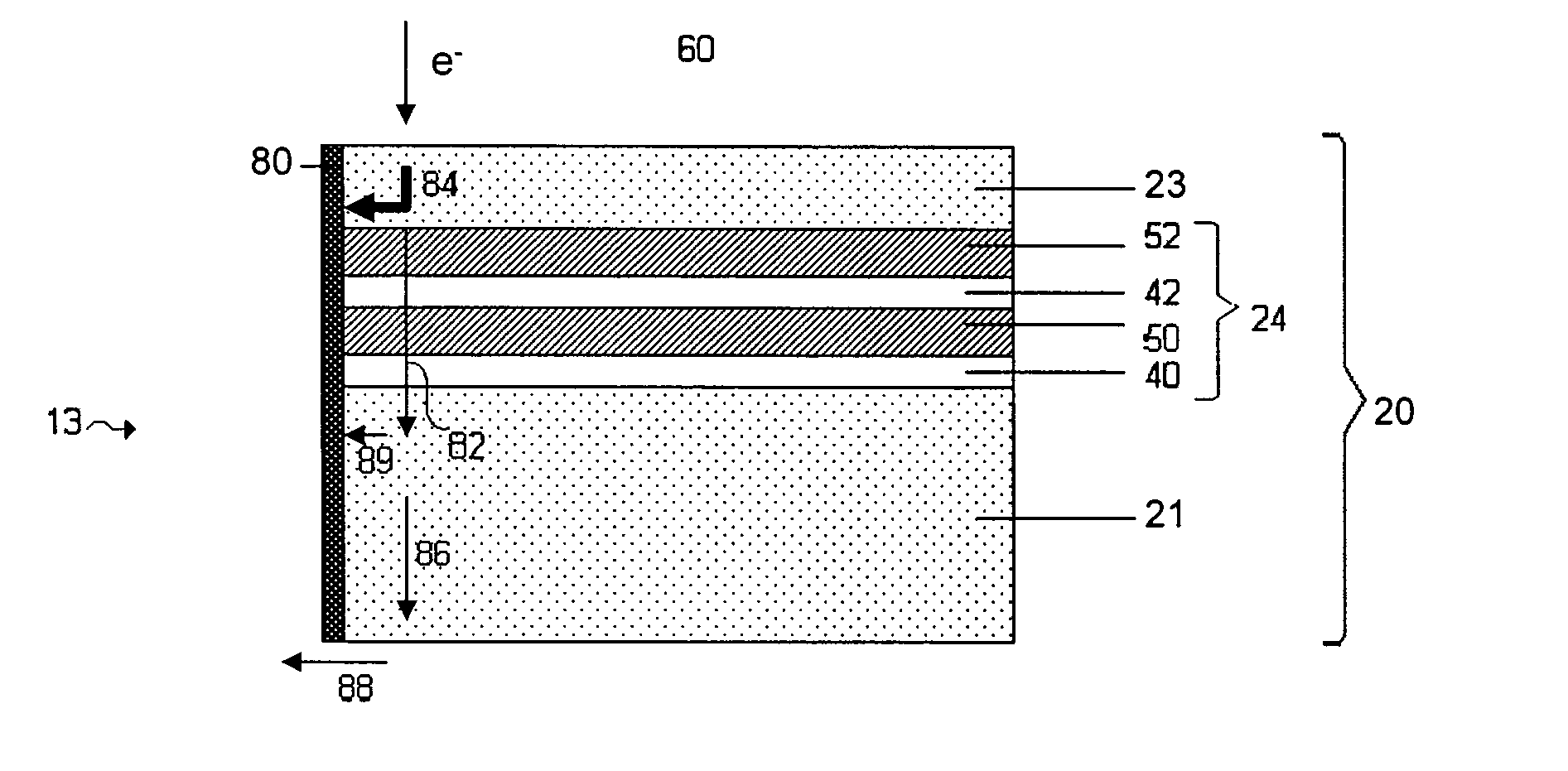

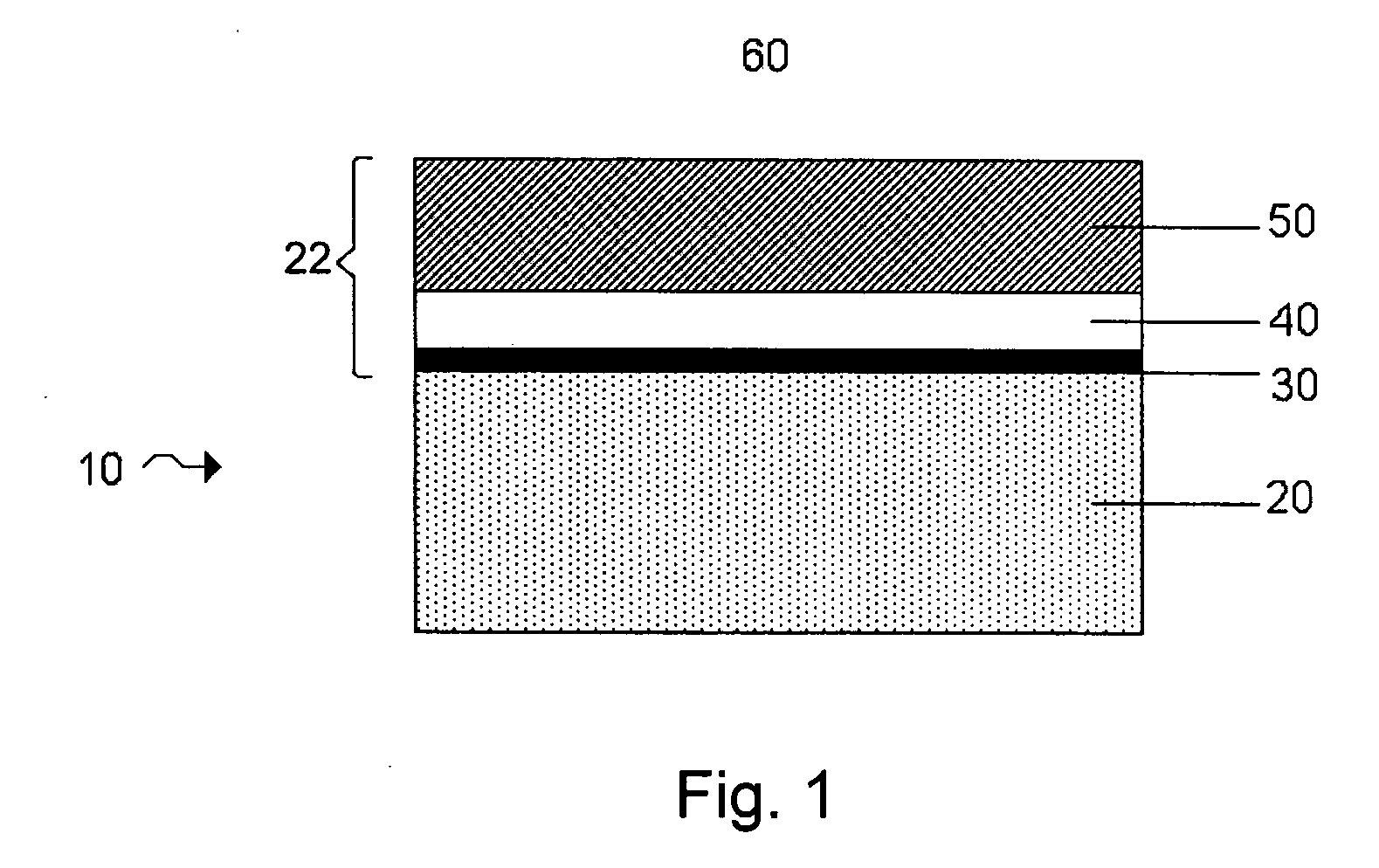

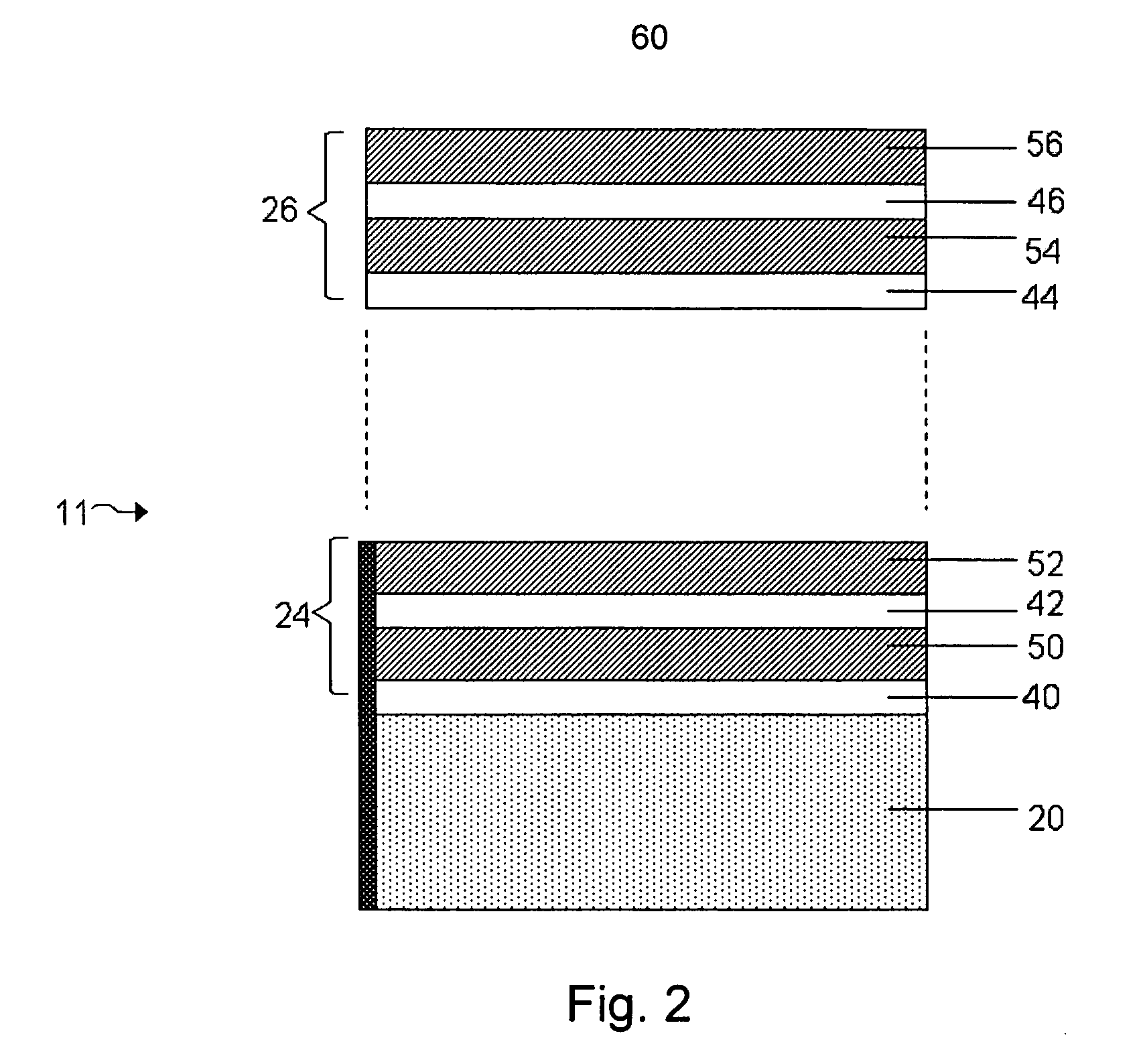

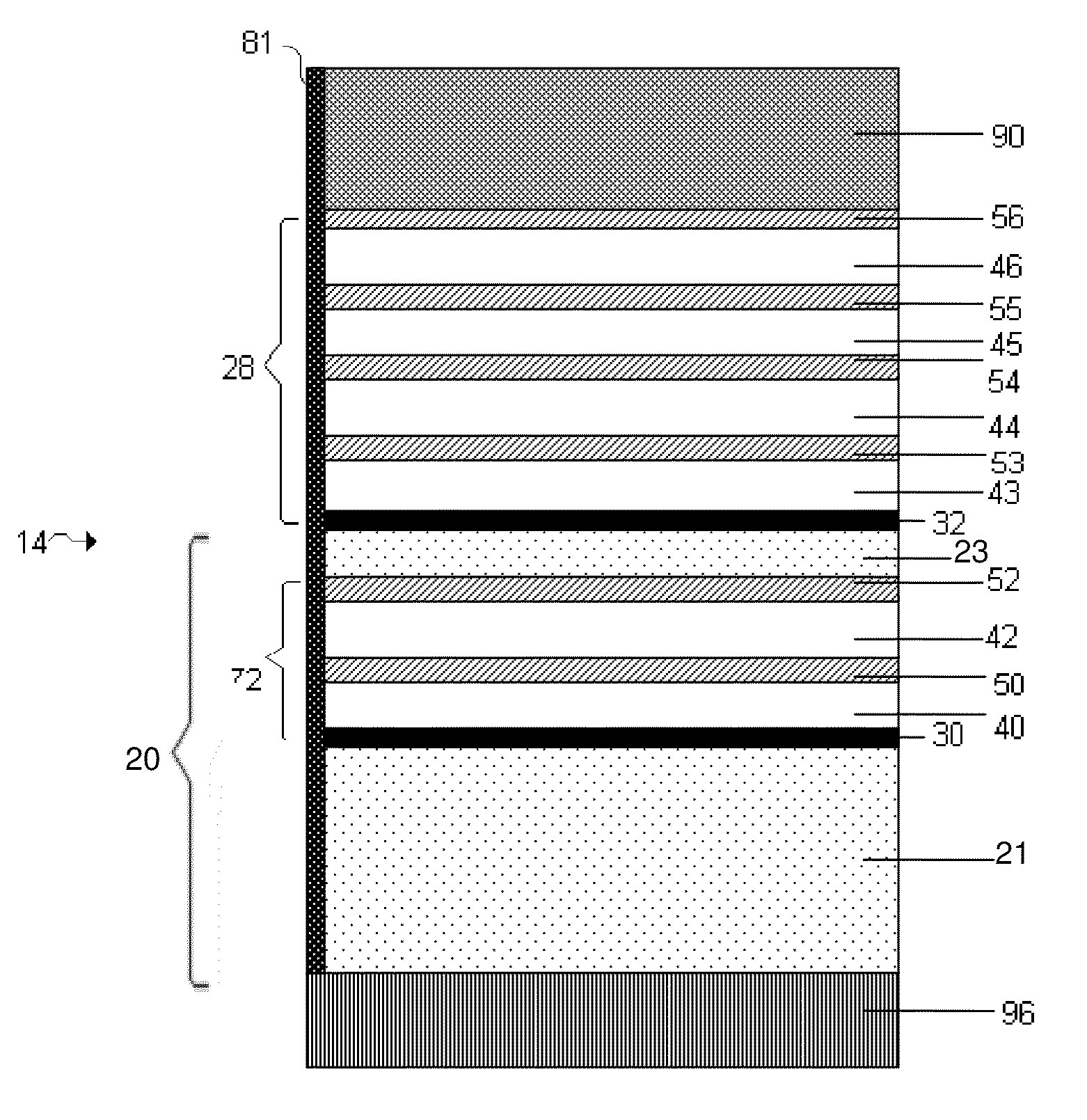

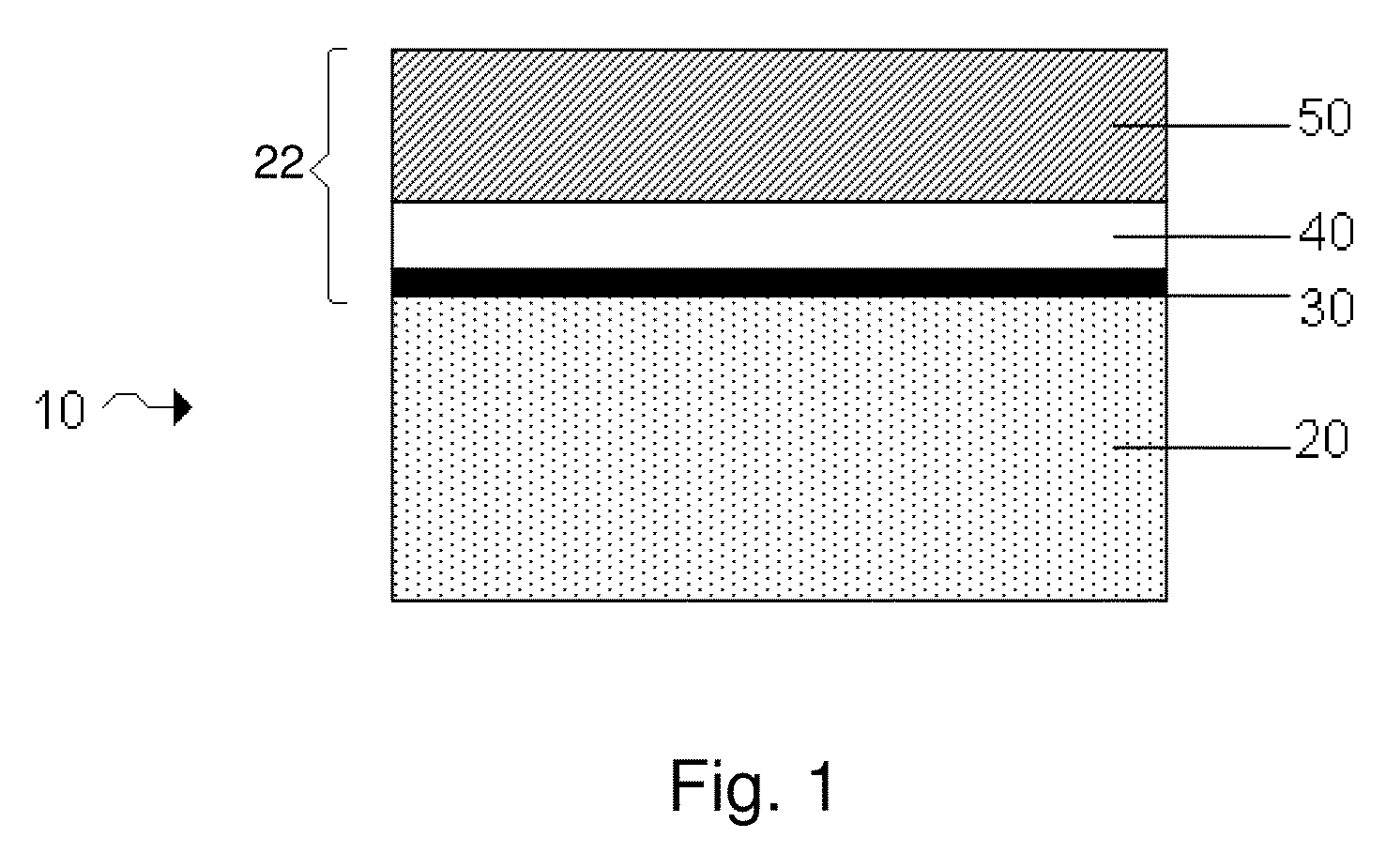

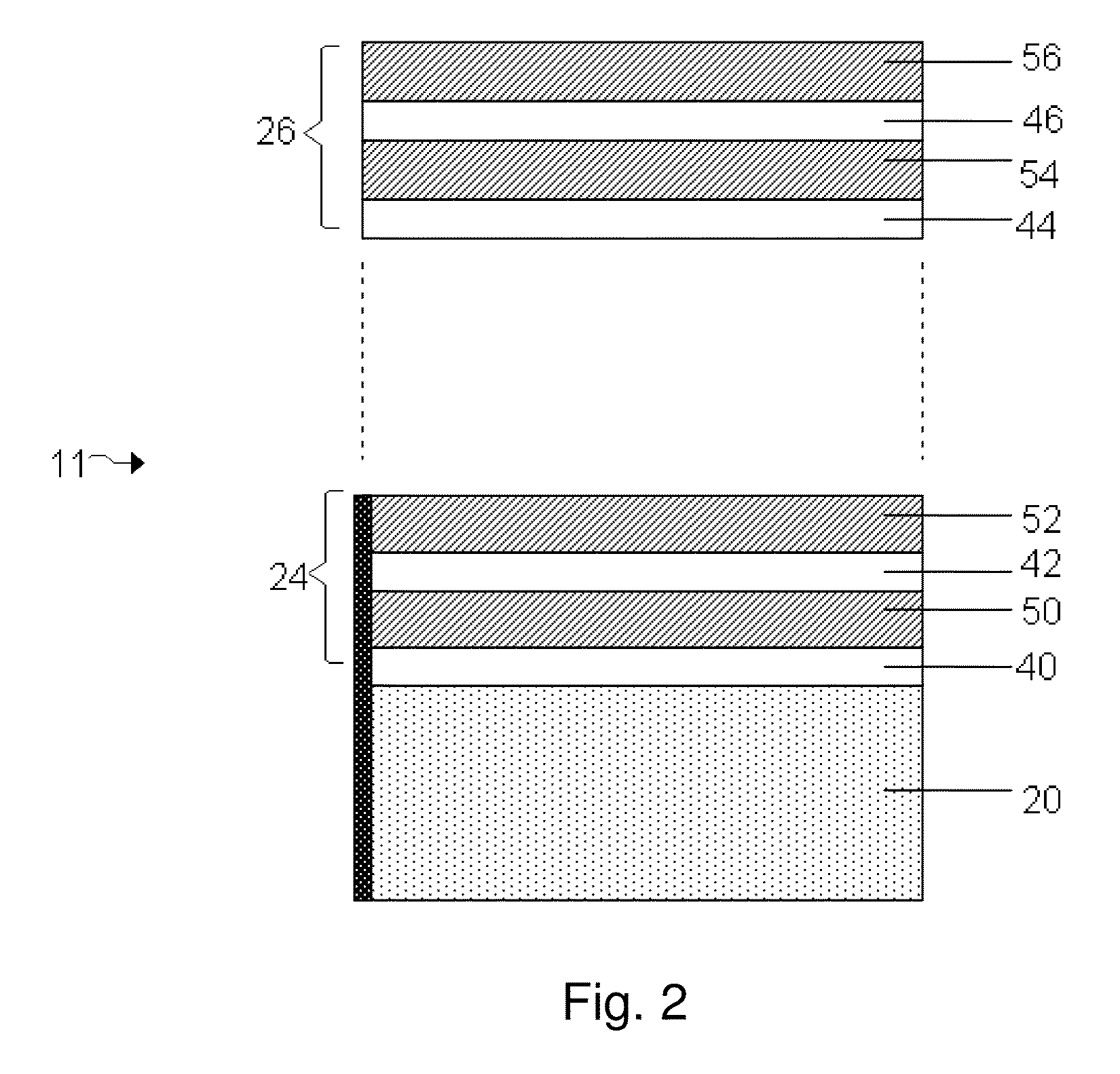

Electrochemical cells, and more specifically, rechargeable batteries comprising lithium anodes for use in water and / or air environments, as well as non-aqueous and non-air environments, are presented. In one embodiment, an electrochemical cell includes an anode comprising lithium and a multi-layered structure positioned between the anode and an electrolyte of the cell. A multi-layered structure can include at least a first single-ion conductive material layer (e.g., a lithiated metal layer), and at least a first polymeric layer positioned between the anode and the single-ion conductive material. The invention also can provide an electrode stabilization layer positioned within the electrode, i.e., between one portion and another portion of an electrode, to control depletion and re-plating of electrode material upon charge and discharge of a battery. Advantageously, electrochemical cells comprising combinations of structures described herein are not only compatible with environments that are typically unsuitable for lithium, but the cells may be also capable of displaying long cycle life, high lithium cycling efficiency, and high energy density.

Owner:SION POWER CORP

Electrode protection in both aqueous and non-aqueous electrochemical cells, including rechargeable lithium batteries

ActiveUS20070224502A1Preventing electronic communicationAvoid communicationFinal product manufactureElectrode carriers/collectorsHigh energyConductive materials

Electrode protection in electrochemical cells, and more specifically, electrode protection in both aqueous and non-aqueous electrochemical cells, including rechargeable lithium batteries, are presented. In one embodiment, an electrochemical cell includes an anode comprising lithium and a multi-layered structure positioned between the anode and an electrolyte of the cell. A multi-layered structure can include at least a first single-ion conductive material layer (e.g., a lithiated metal layer), and at least a first polymeric layer positioned between the anode and the single-ion conductive material. The invention also can provide an electrode stabilization layer positioned within the electrode, i.e., between one portion and another portion of an electrode, to control depletion and re-plating of electrode material upon charge and discharge of a battery. Advantageously, electrochemical cells comprising combinations of structures described herein are not only compatible with environments that are typically unsuitable for lithium, but the cells may be also capable of displaying long cycle life, high lithium cycling efficiency, and high energy density.

Owner:SION POWER CORP

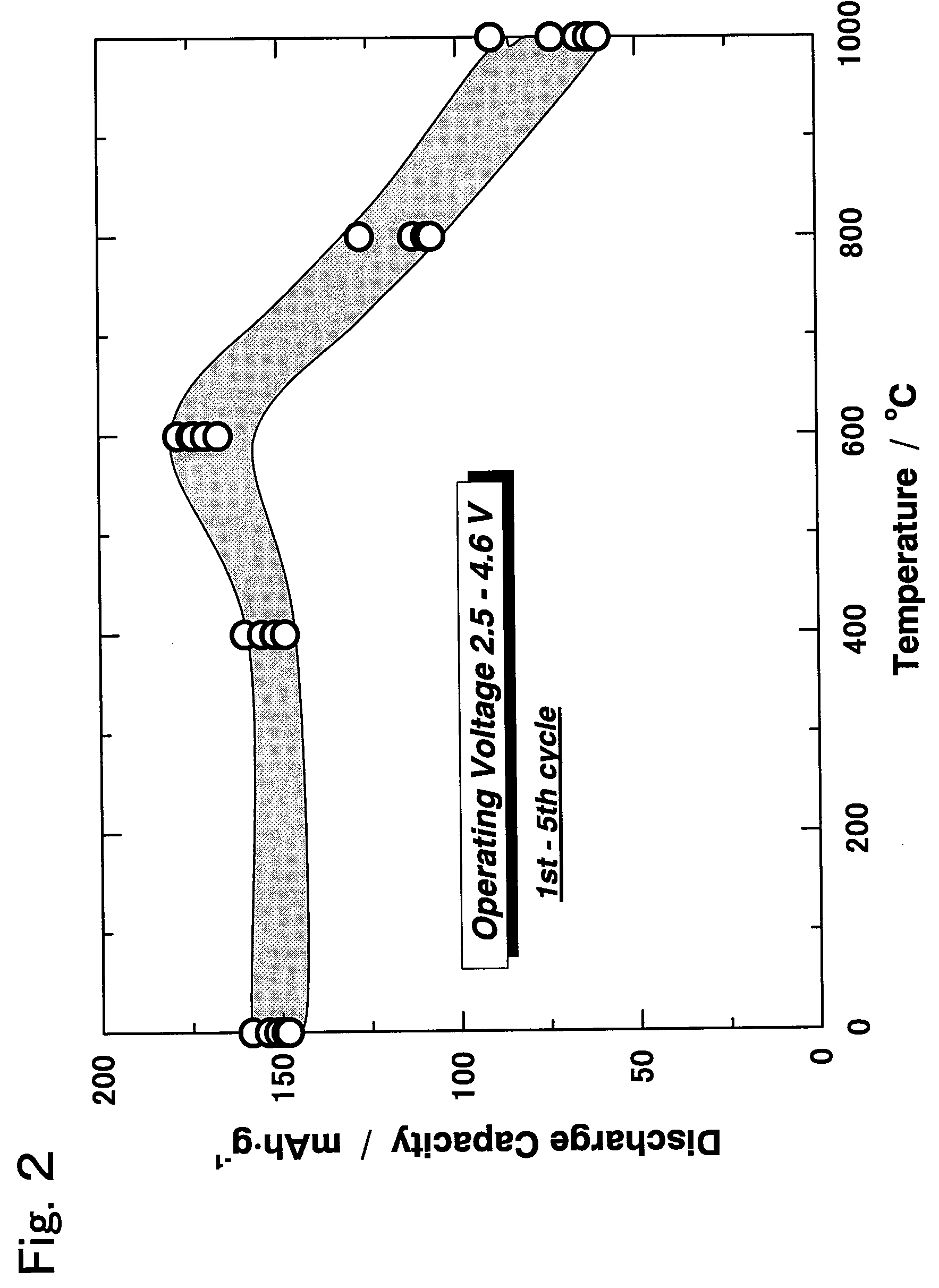

Active material for non-aqueous electrolyte secondary battery and manufacturing method therefore

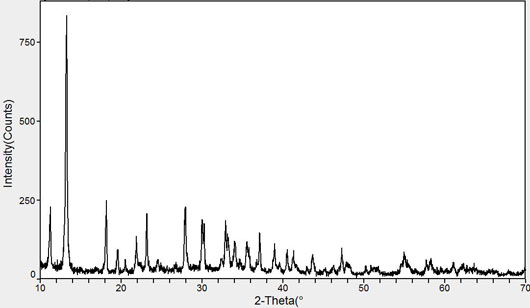

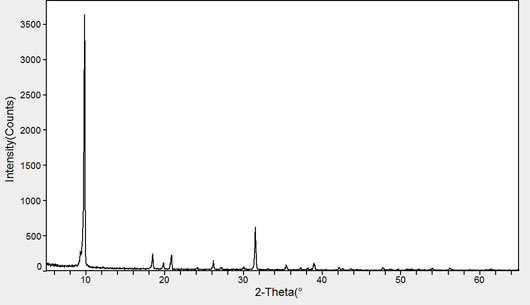

ActiveUS20080268347A1Increase capacityReduces electron conductivity and lithium diffusing abilityElectrode manufacturing processesNon-aqueous electrolyte accumulatorsDesorptionX-ray

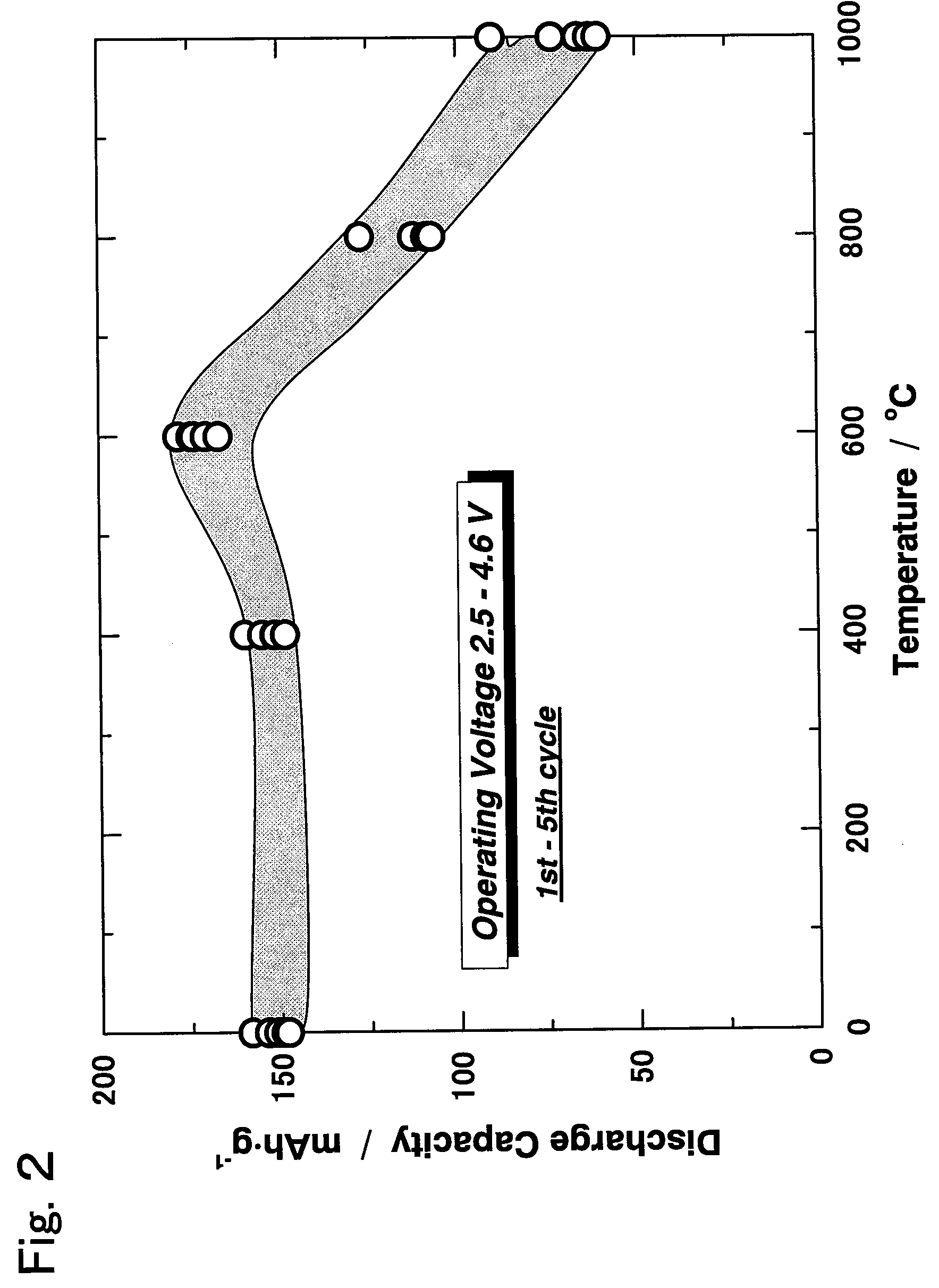

An active material for a non-aqueous electrolyte secondary battery including a lithium-containing transition metal oxide containing nickel and manganese and having a closest-packed structure of oxygen, wherein an atomic ratio MLi / MT between the number of moles of lithium MLi and the number of moles of transition metal Mt contained in the lithium-containing transition metal oxide is greater than 1.0; the lithium-containing transition metal oxide has a crystal structure attributed to a hexagonal system, and the X-ray diffraction image of the crystal structure has a peak P003 attributed to the (003) plane and a peak P104 attributed to the (104) plane; an integrated intensity ratio I003 / I104 between the peak P003 and the peak P104 varies reversibly within a range from 0.7 to 1.5 in association with absorption and desorption of lithium by the lithium-containing transition metal oxide; and the integrated intensity ratio varies linearly and continuously.

Owner:PUBLIC UNIVERSITY CORPORATION OSAKA CITY UNIVERSITY +1

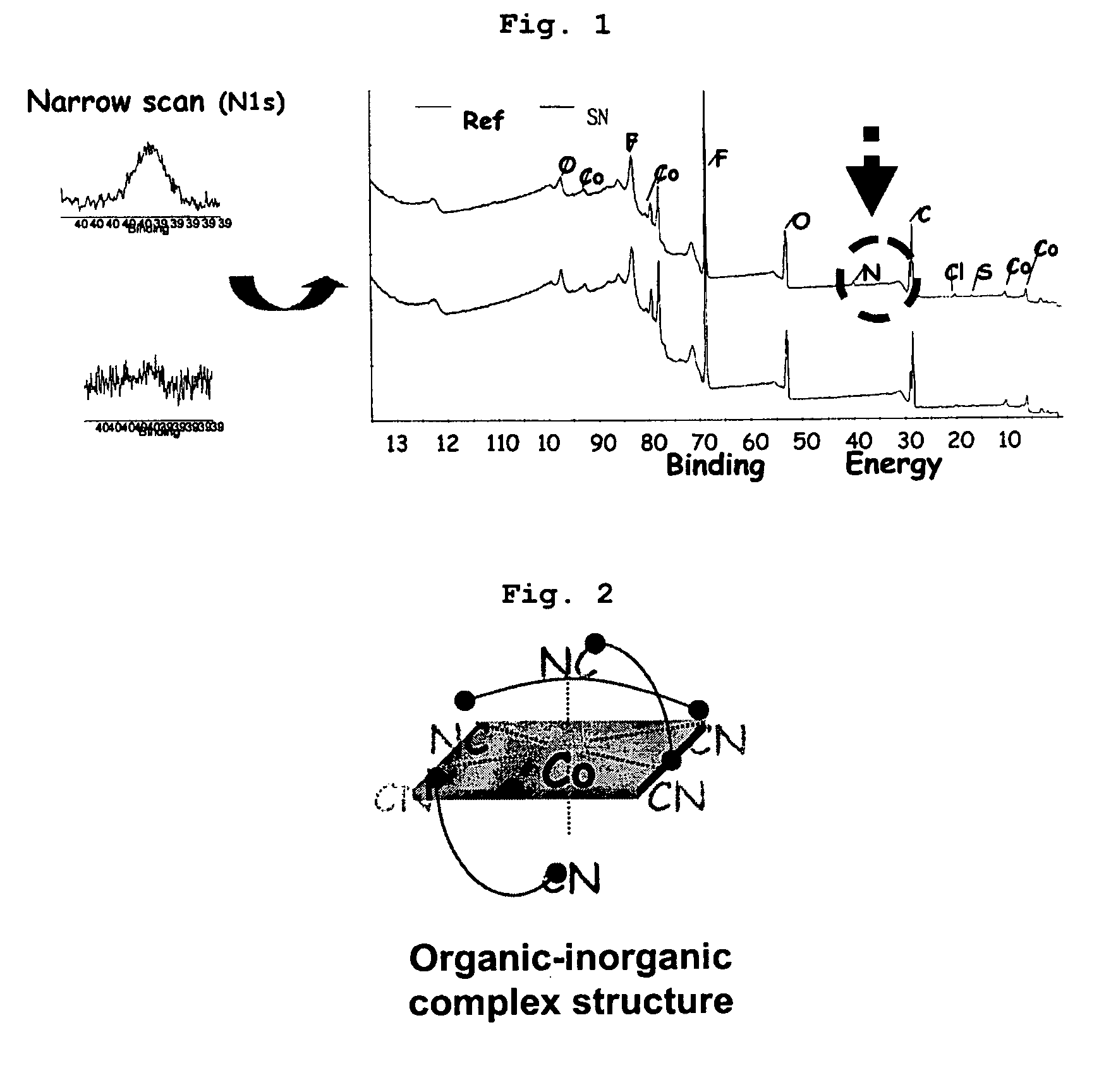

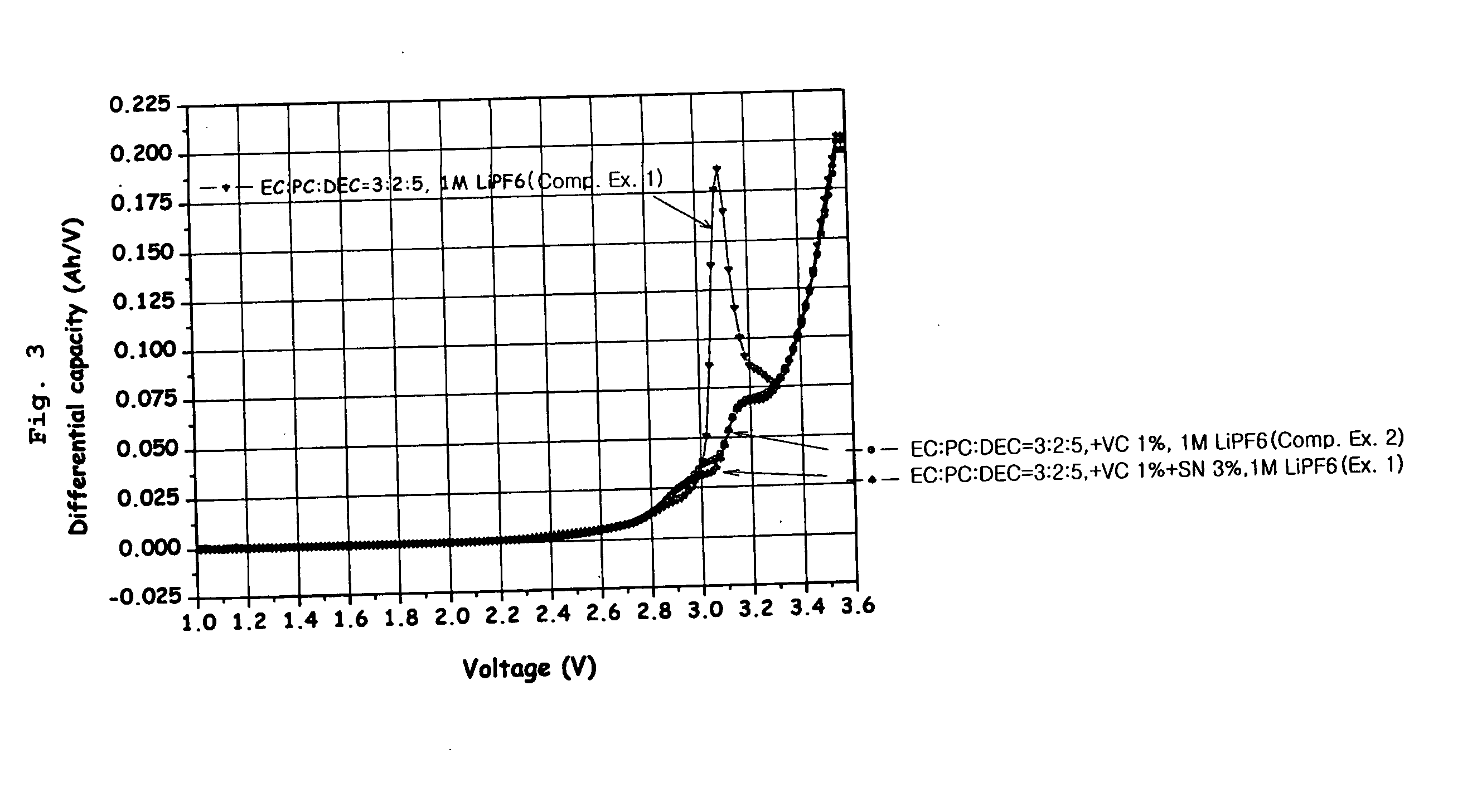

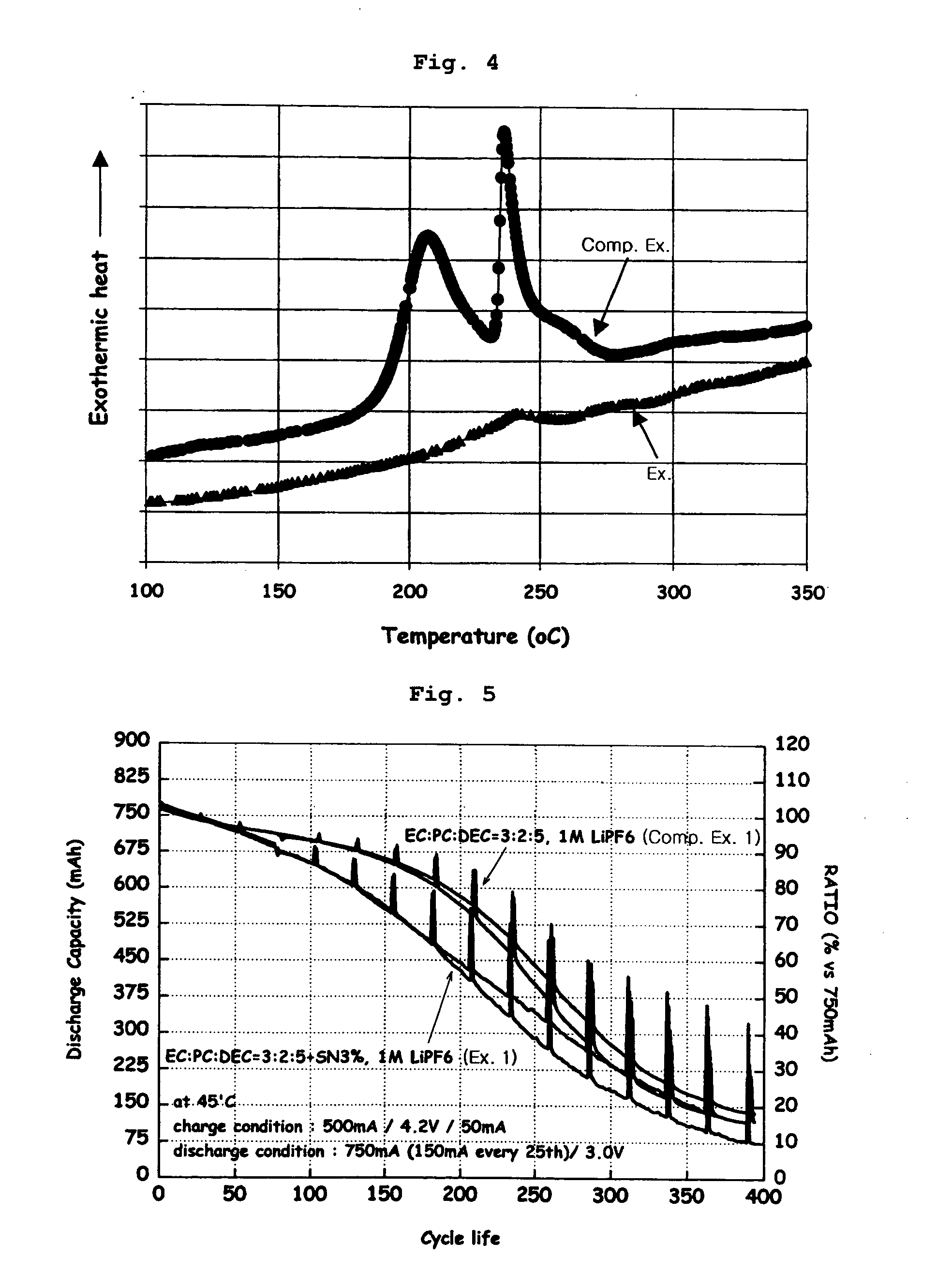

Electrochemical device comprising aliphatic nitrile compound

ActiveUS20050208371A1Low cycle lifeInhibit gas generationNon-aqueous electrolyte accumulatorsFinal product manufacturePhysical chemistryEther

The present invention provides a cathode having a protection layer formed by a complex between the surface of a cathode active material and an aliphatic nitrile compound, as well as an electrochemical device comprising the cathode. Also, the present invention provides an electrochemical device comprising: (1) a cathode having a protection layer formed by a complex between the surface of a cathode active material and an aliphatic nitrile compound; (2) an anode having a passivation layer formed by a compound selected from the group consisting of vinylene carbonate, its derivative and an ether compound; and (3) an electrolyte solution containing a lithium salt and a solvent.

Owner:LG ENERGY SOLUTION LTD

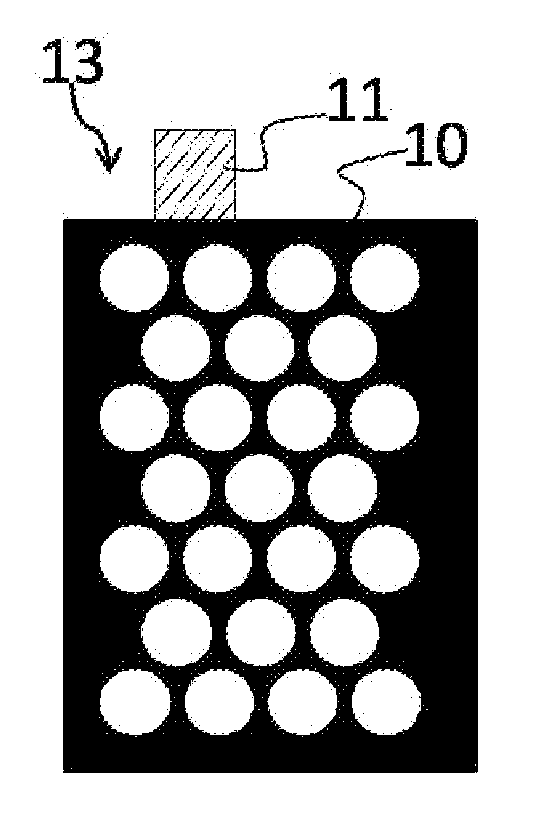

Solid state lithium-air based battery cell

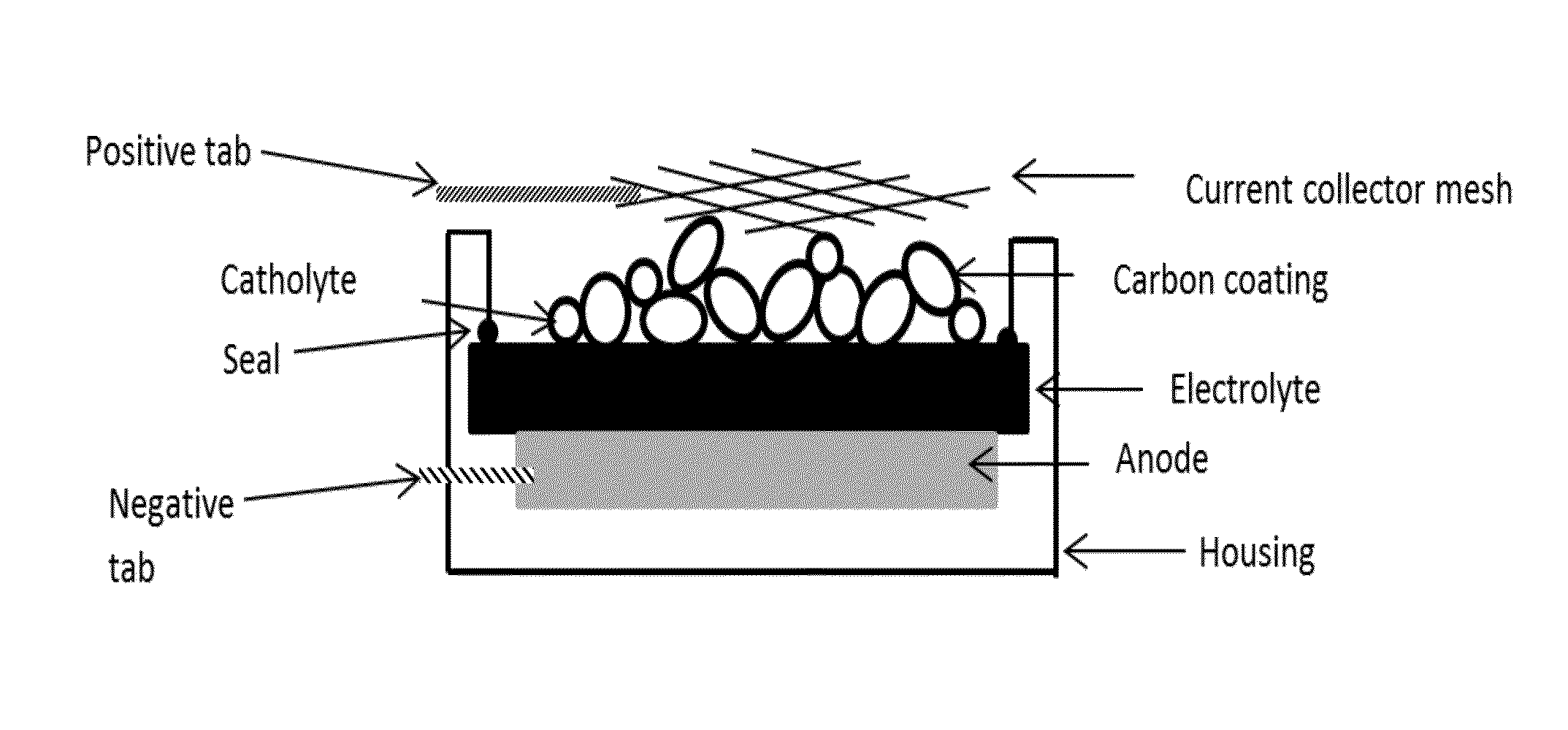

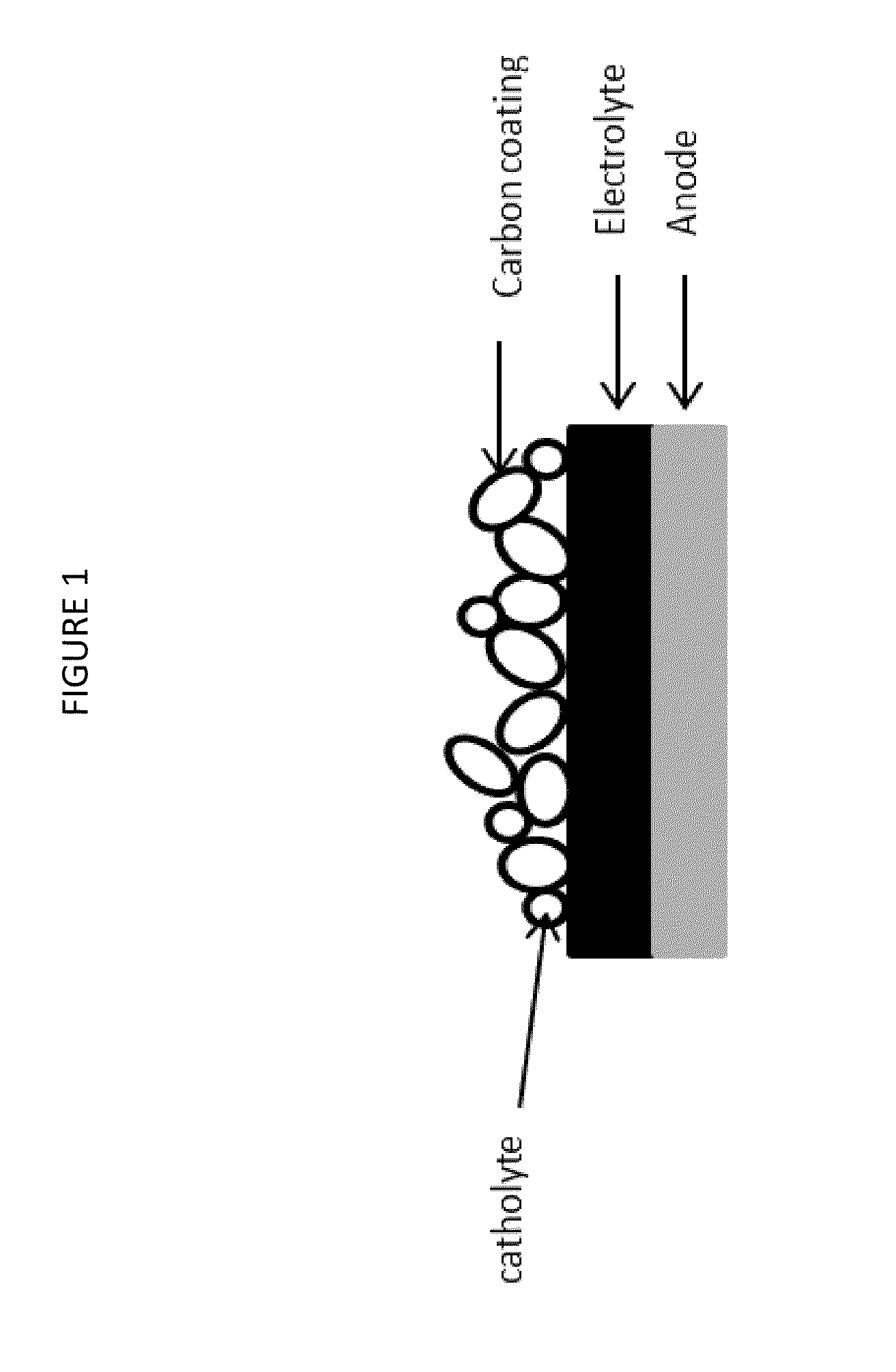

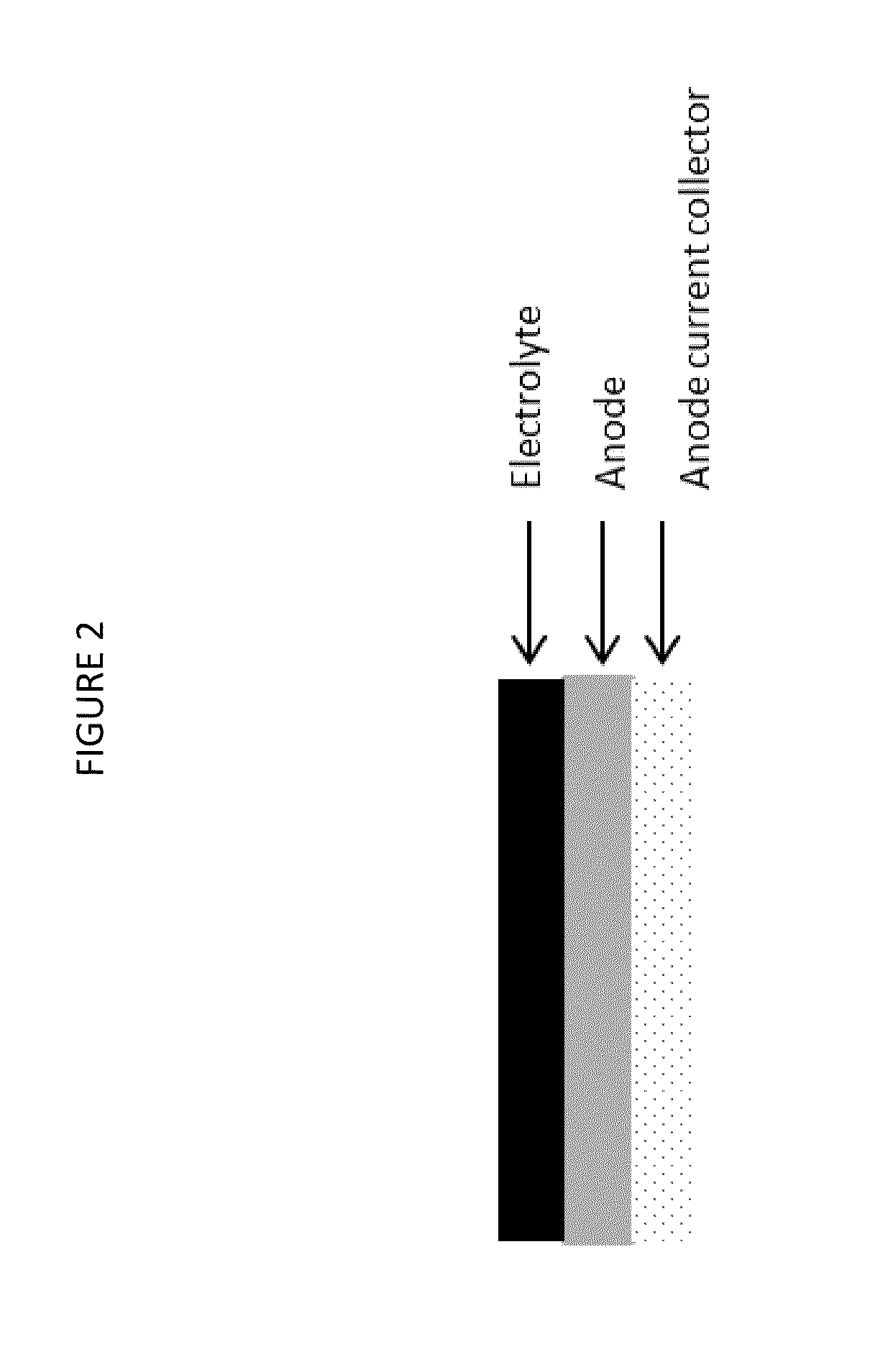

ActiveUS8940446B1High theoretical energy densityIncrease energy densityFuel and secondary cellsHybrid cell detailsPorositySolid-state battery

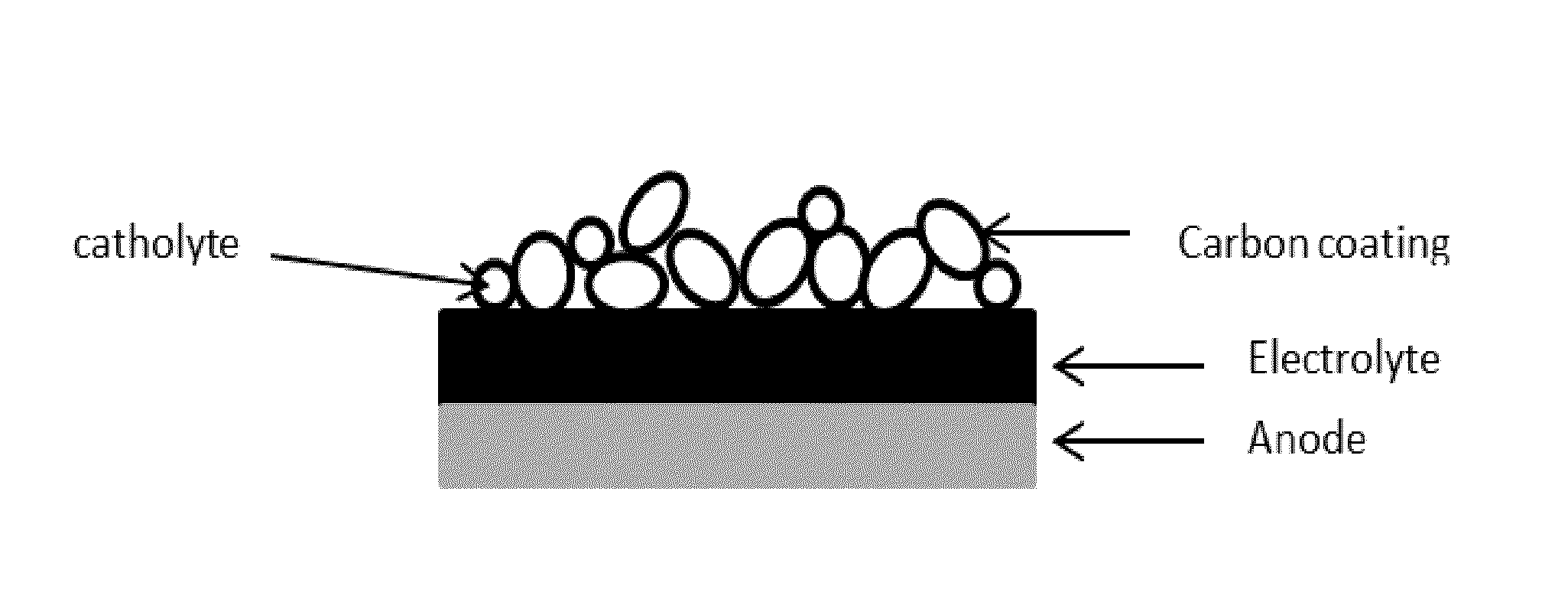

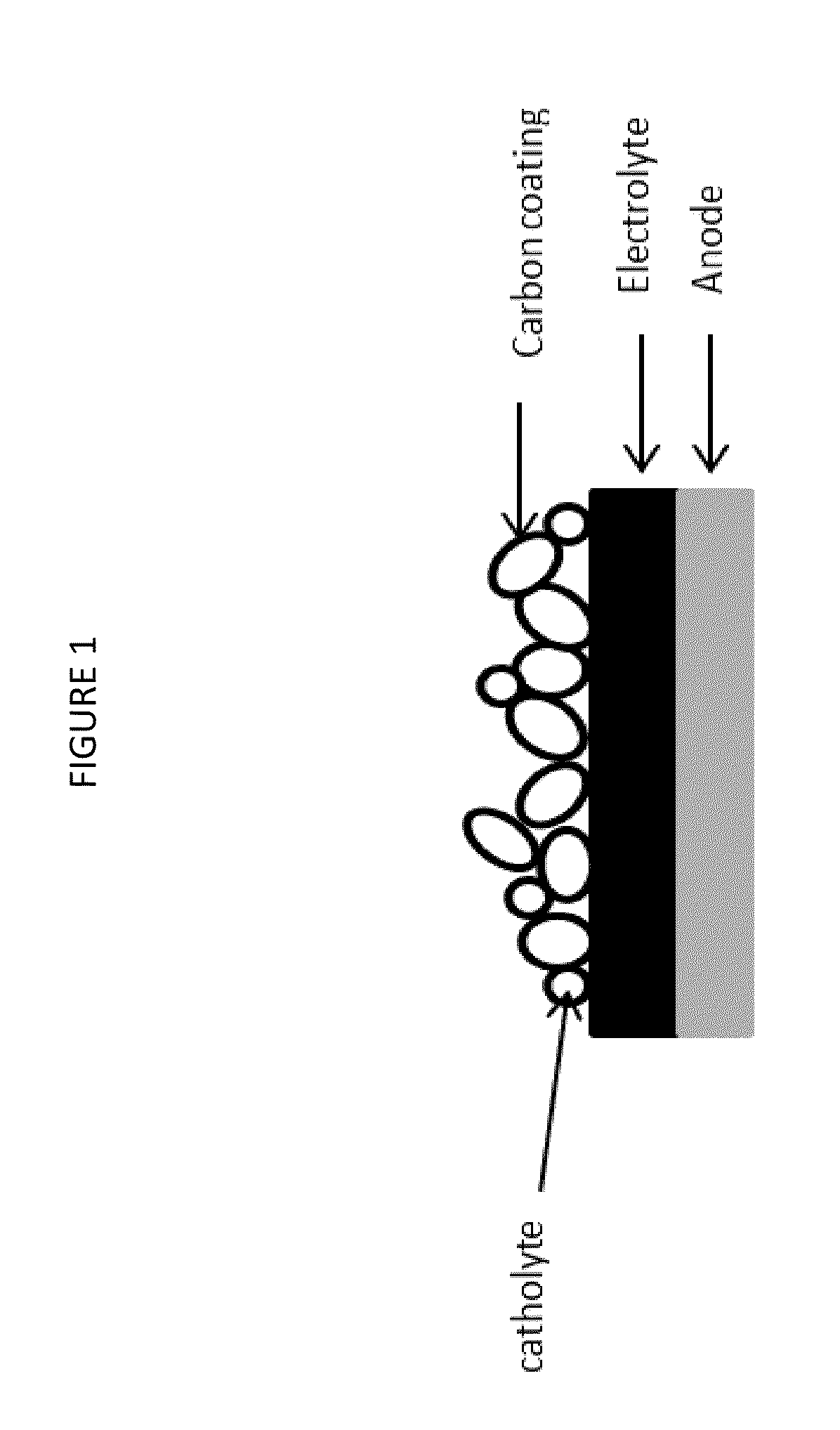

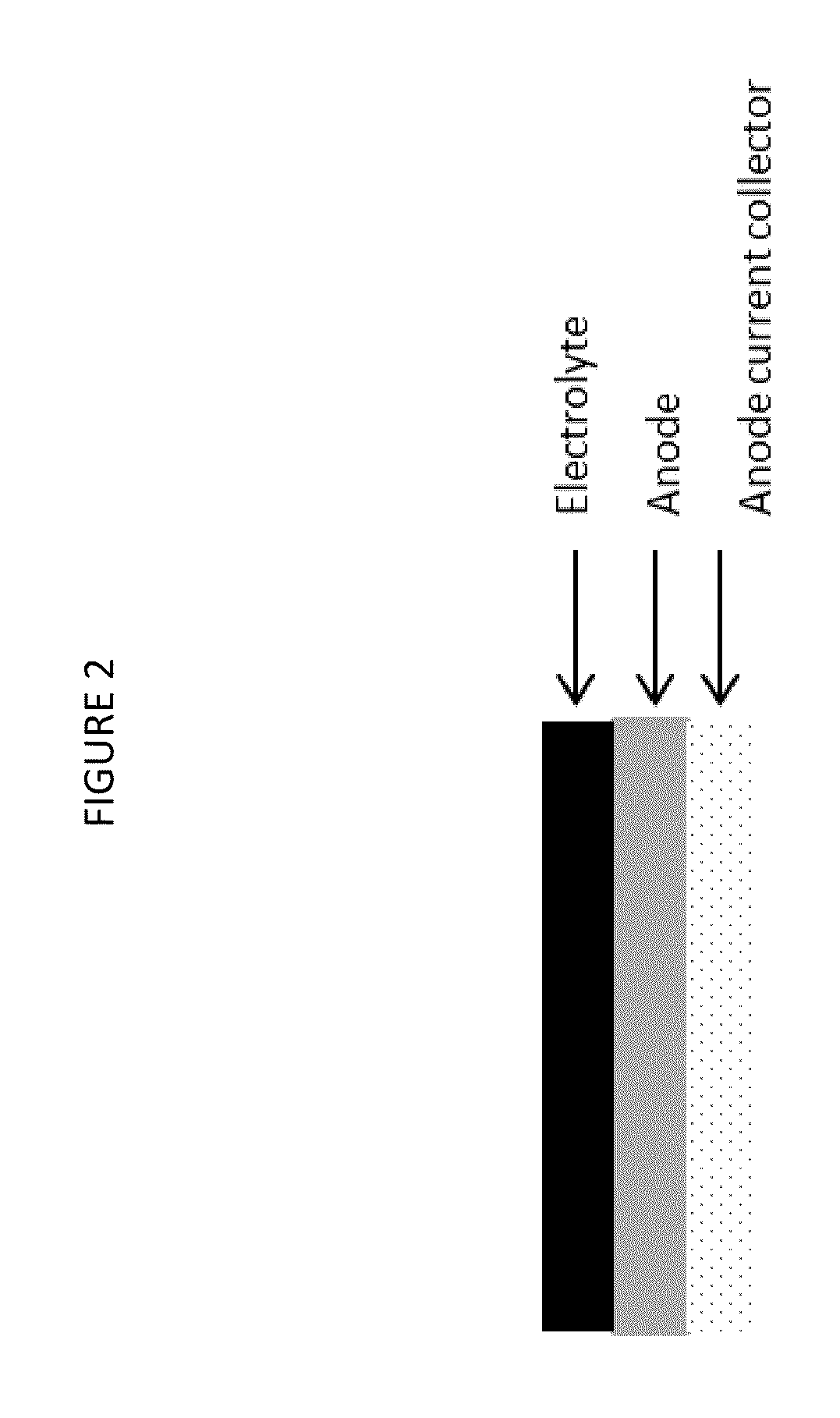

In an example, the present invention provides a solid state battery device, e.g., battery cell or device. The device has a current collector region and a lithium containing anode member overlying the current collector region. The device has a thickness of electrolyte material comprising a first garnet material overlying the lithium containing anode member. The thickness of electrolyte material has a density ranging from about 80 percent to 100 percent and a porous cathode material comprising a second garnet material overlying the thickness of electrolyte material. The porous cathode material has a porosity of greater than about 30 percent and less than about 95 percent and a carbon bearing material overlying a surface region of the porous cathode material. In an example, the carbon bearing material comprises substantially carbon material, although there can be variations.

Owner:QUANTUMSCAPE BATTERY INC

Electrode protection in both aqueous and non-aqueous electrochemical cells, including rechargeable lithium batteries

ActiveUS20090291353A1Improve protectionEasy to controlFinal product manufacturePrimary cellsHigh energyConductive materials

Electrode protection in electrochemical cells, and more specifically, electrode protection in both aqueous and non-aqueous electrochemical cells, including rechargeable lithium batteries, are presented. In one embodiment, an electrochemical cell includes an anode comprising lithium and a multi-layered structure positioned between the anode and an electrolyte of the cell. A multi-layered structure can include at least a first single-ion conductive material layer (e.g., a lithiated metal layer), and at least a first polymeric layer positioned between the anode and the single-ion conductive material. The invention also can provide an electrode stabilization layer positioned within the electrode, i.e., between one portion and another portion of an electrode, to control depletion and re-plating of electrode material upon charge and discharge of a battery. Advantageously, electrochemical cells comprising combinations of structures described herein are not only compatible with environments that are typically unsuitable for lithium, but the cells may be also capable of displaying long cycle life, high lithium cycling efficiency, and high energy density.

Owner:SION POWER CORP

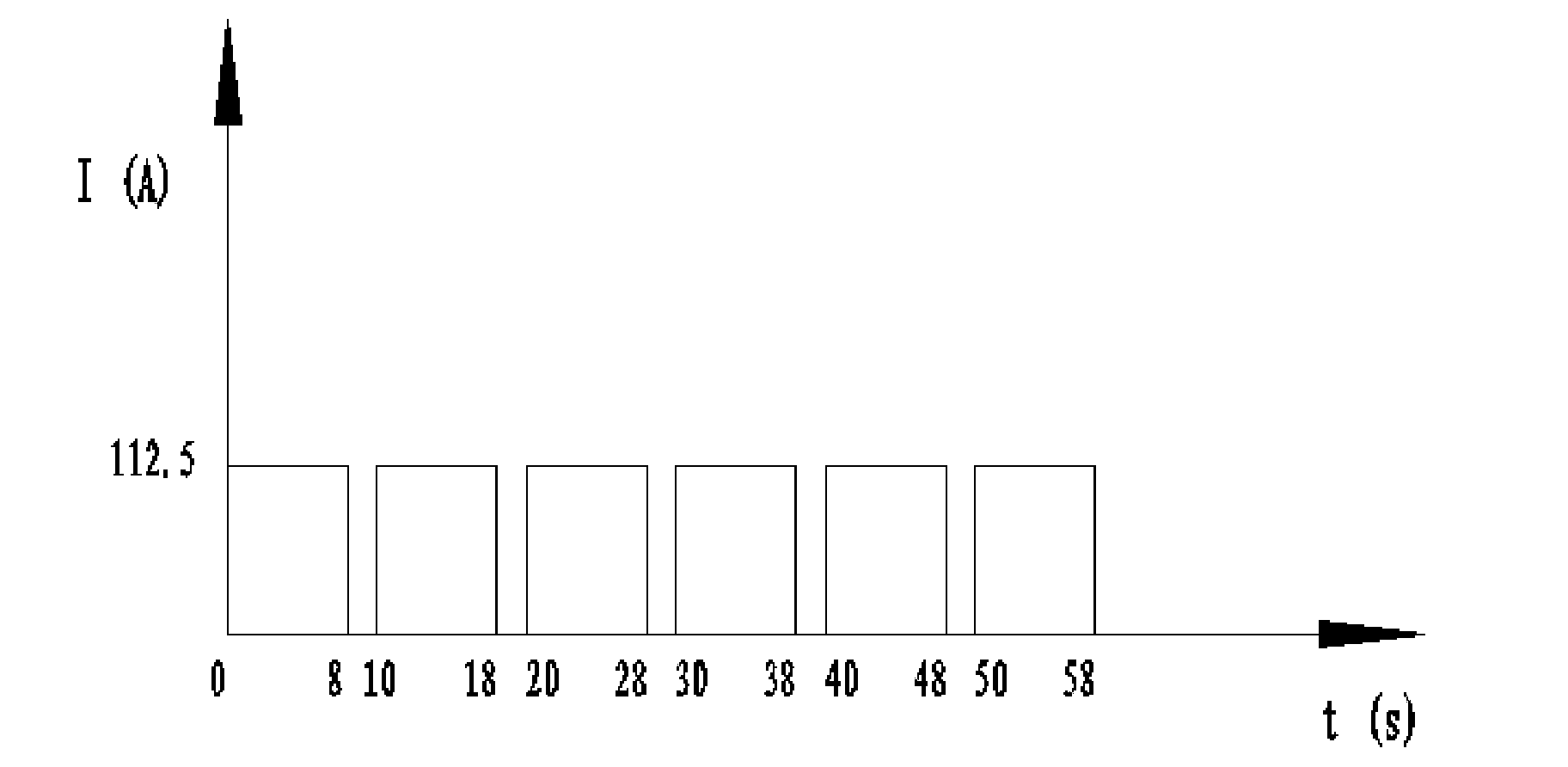

Pulse container formation method for high-capacity lead-acid battery

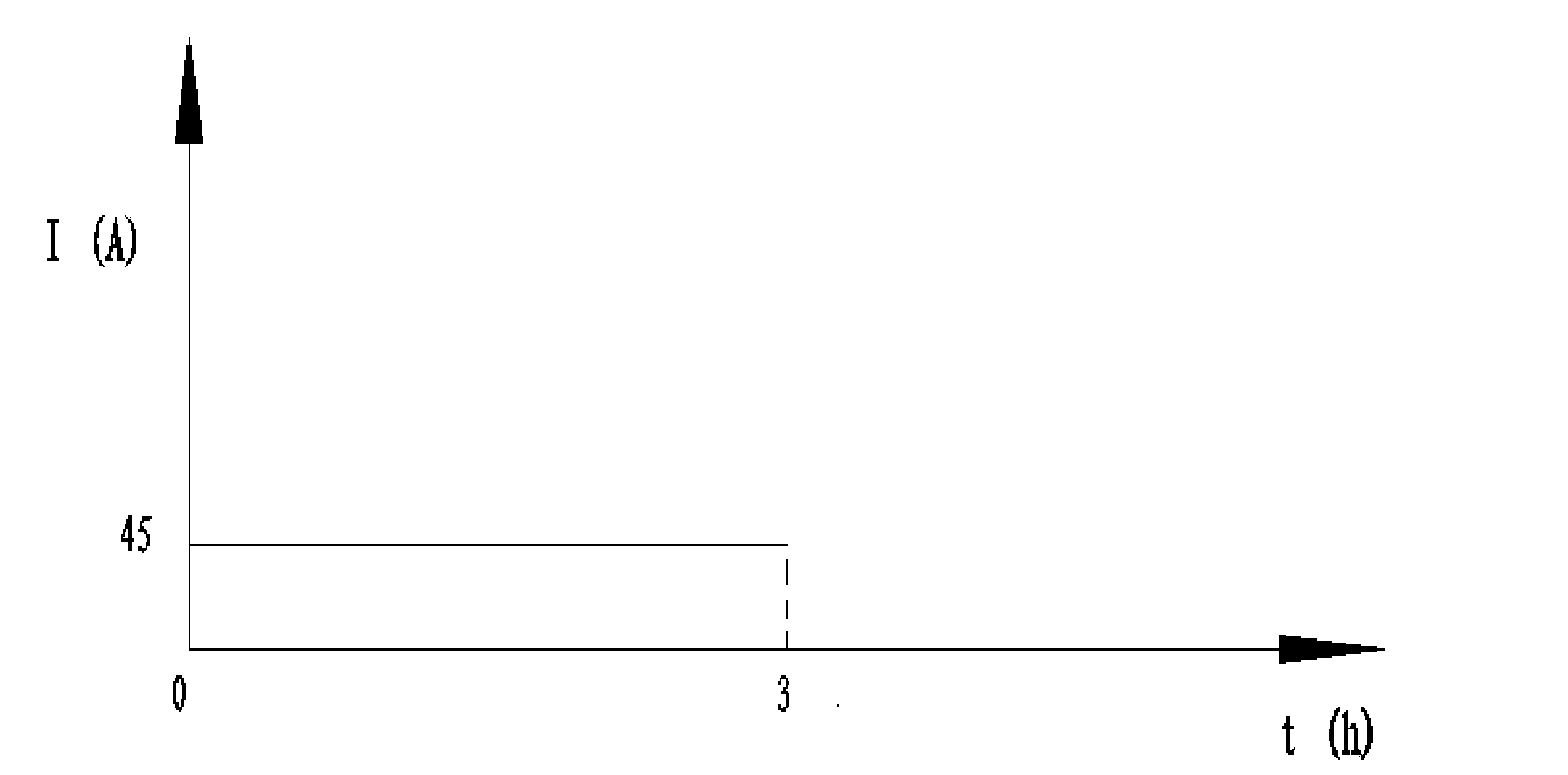

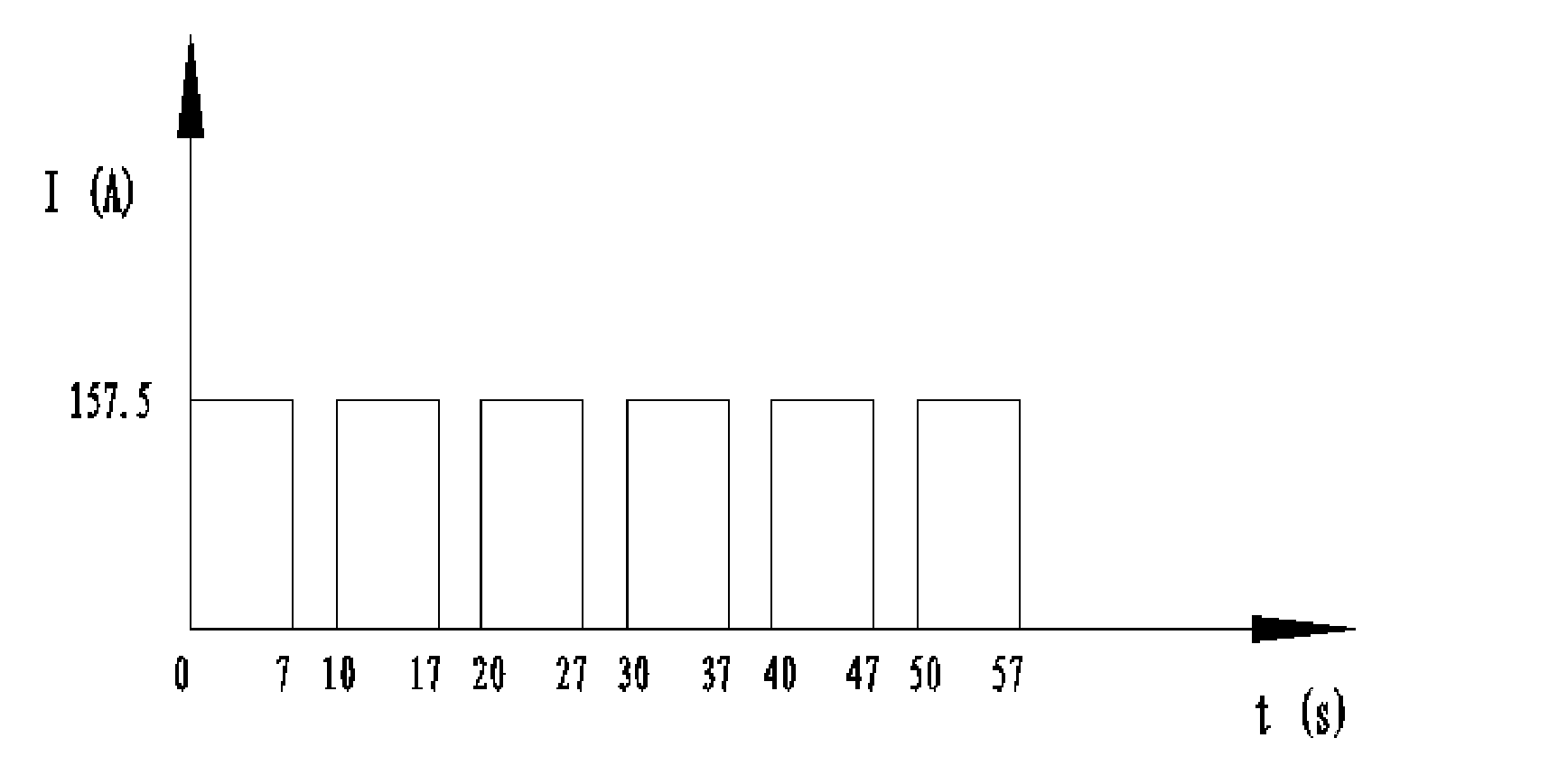

ActiveCN101877425AReduce shockImprove uniformityFinal product manufactureSecondary cells charging/dischargingEngineeringLow frequency

Owner:HUNAN FENGRI ELECTRIC GROUP

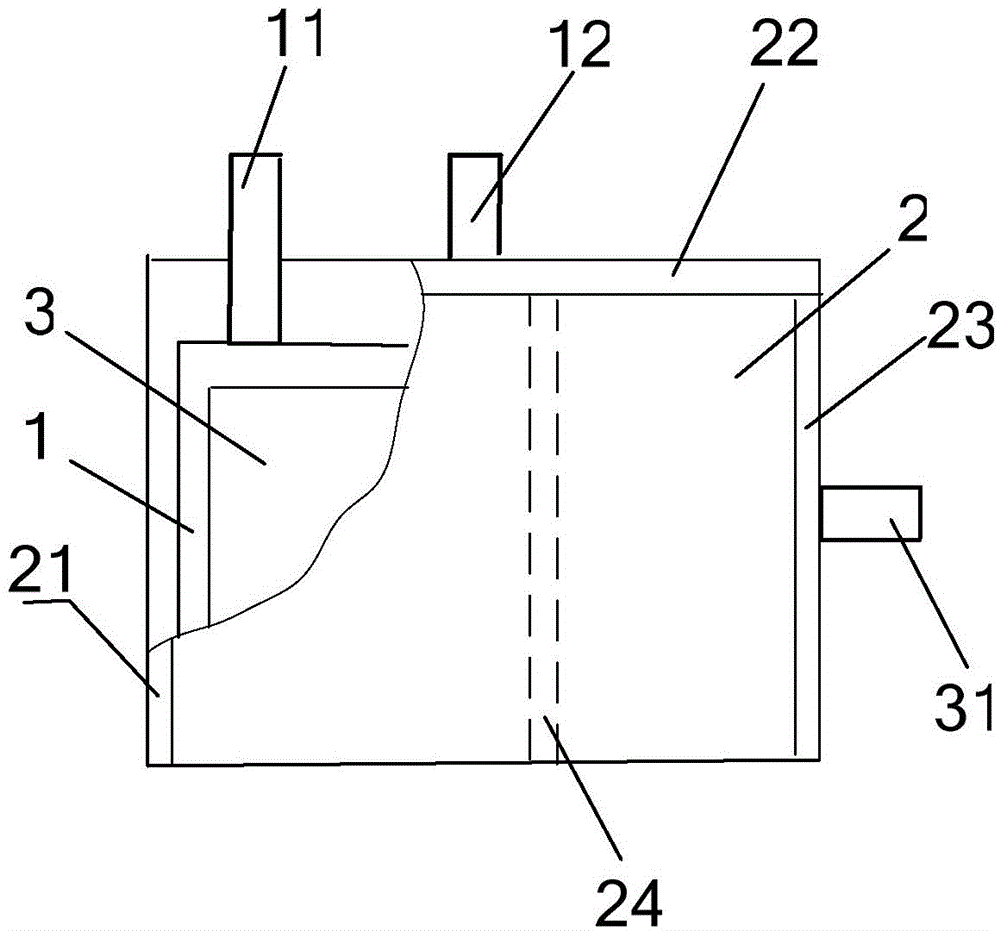

Manufacturing method of lithium ion mixed type capacitor and lithium ion mixed type capacitor

ActiveCN104008893AReduce decompositionLow cycle lifeDouble layer capacitorsHybrid/EDL manufacturePower flowEngineering

A manufacturing method of a lithium ion mixed type capacitor comprises the following steps that (a) electrode pieces and a separation film are stacked or wound to form a cell according to the sequence of positive electrode / separation film / negative electrode; (b) the cell is put into an aluminum compound packing film shell body, the top edge and a first lateral edge of the aluminum compound packing film shell body are sealed in a heating mode, the electrode lugs of the positive electrode and the negative electrode of the cell extend out of the aluminum compound packing film shell body from the top edge; (c) a metal lithium electrode is put into the aluminum compound packing film shell body, is adjacent to the cell and is separated from the cell by the separation film, and the electrode lug of the metal lithium electrode extends out of the aluminum compound packing film shell body from a second lateral edge; (d) excessive electrolyte is injected into the aluminum compound packing film shell body, and then the second lateral edge of the aluminum compound packing film shell body is sealed in a heating mode; (e) in a constant current mode, the negative electrode serves as a working electrode, the metal lithium electrode serves as a counter electrode, and the negative electrode is pre-embedded; (f) the metal lithium electrode is taken out, the superfluous electrolyte is poured out, the second lateral edge of the aluminum compound packing film shell body is sealed in a vacuum heating mode, and the lithium ion mixed type capacitor is obtained.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

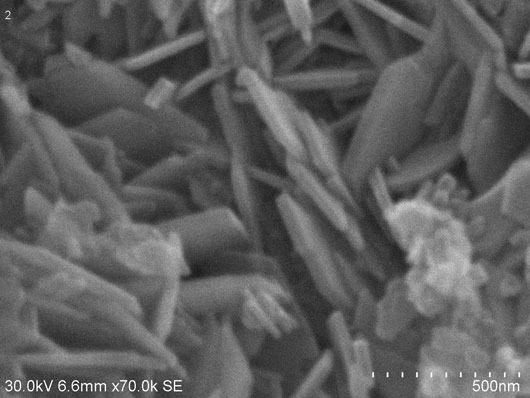

Preparation method of superfine nanometer lithium iron phosphate electrode material and application thereof

InactiveCN102674291AImprove electrochemical performanceIncrease capacityCell electrodesNanotechnologyLithium iron phosphatePhosphate

The invention discloses a preparation method of a superfine nanometer lithium iron phosphate electrode material, comprising the following steps of: firstly, taking an iron source compound and a phosphorus source compound as raw materials to obtain nanometer ferrous phosphate as a precursor; and secondly, using the ferrous phosphate and the lithium source compound to prepare the superfine nano lithium iron phosphate electrode material. The preparation method of ferrous phosphate, disclosed by the invention, has a simple production process; the obtained nanometer ferrous phosphate can be used for preparing the high-purity superfine nanometer lithium iron phosphate; and the ferrous valence state is not changed when the ferrous phosphate is used for preparing the lithium iron phosphate, thus, no carbon source compound or reducing agent needs to to be added to change the iron valence state, and then the carbon-coated lithium iron phosphate or non-carbon-coated lithium iron phosphate can be directly prepared. The nanometer lithium iron phosphate manufactured by the nanometer ferrous phosphate precursor has excellent performance, good discharge capacity and voltage platform performance under high capability and high multiplying power, and long cycle life.

Owner:GUANGXI NUOFANG ENERGY STORAGE TECH

Preparation method and application of carbon-based metal organic frame (MOF) compound derivative material

The invention discloses preparation method and application of a carbon-based metal organic frame (MOF) compound derivative material, and belongs to the technical field of preparation of a functional nanometer material. The preparation method comprises the steps of placing a carbon fiber / polyacrylonitrile (PAN) thin film in an MOF precursor solution, achieving self-assembly of different morphologies of an MOF on different substrates at a room temperature, mixing the obtained product and an appropriate amount of melamine, and then performing thermal reduction on in-situ catalytic growth carbon nanotube (CNT) in an inert atmosphere to obtain the carbon-based MOF derivative material. The function nanometer material prepared by the method has the physical characteristics of high conductivity, rapid ion transmission passage, good flexibility, favorable self-support structure and the like and shows long service lifetime, high-capacity electric storage performance and excellent electrochemicalstability during energy storage and conversion; and the preparation process of the whole material is simple, no toxic product during reaction is generated, and the material is green and environmental-friendly and is suitable for industrial production on a large scale.

Owner:NANJING UNIV OF TECH

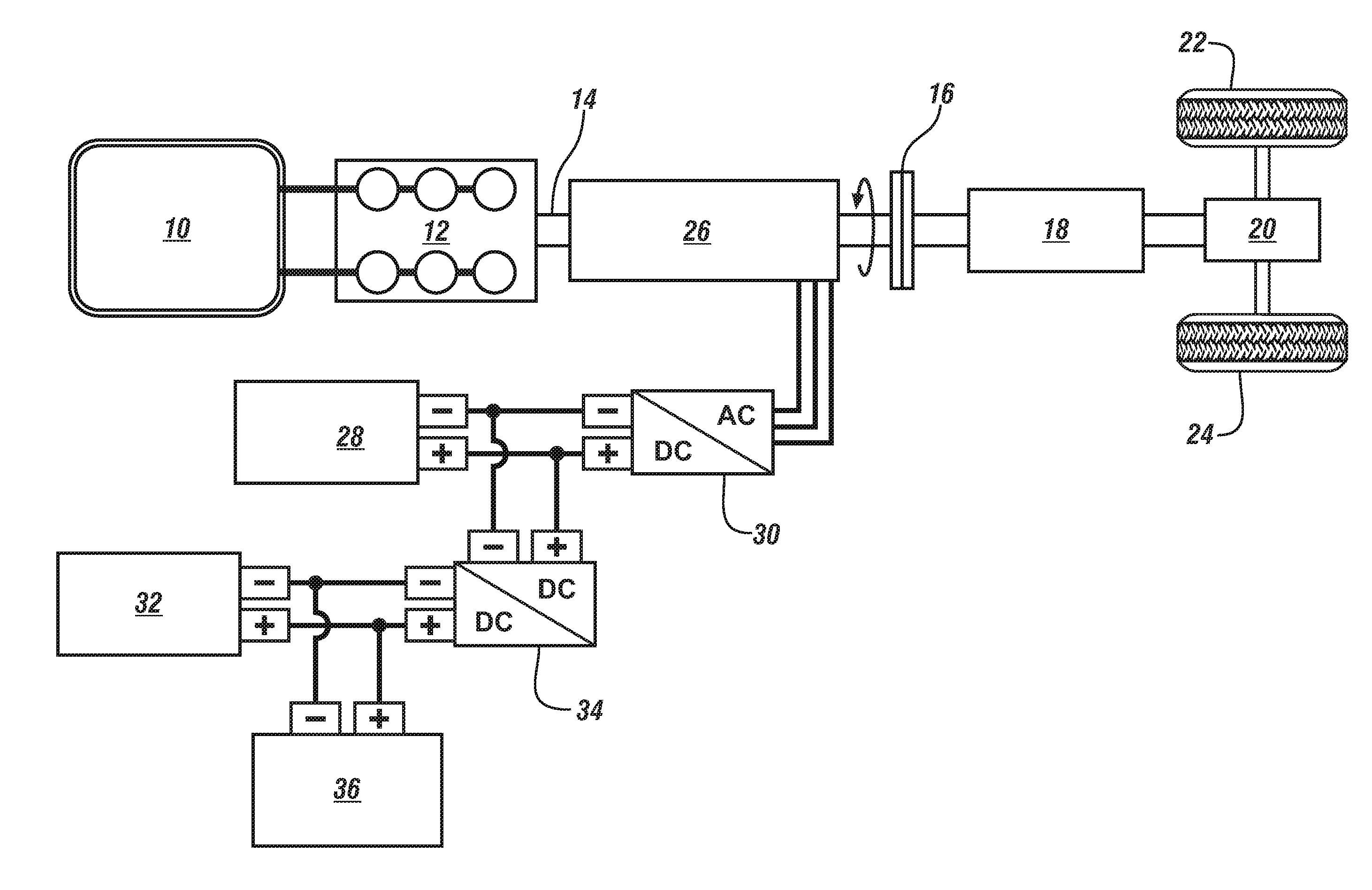

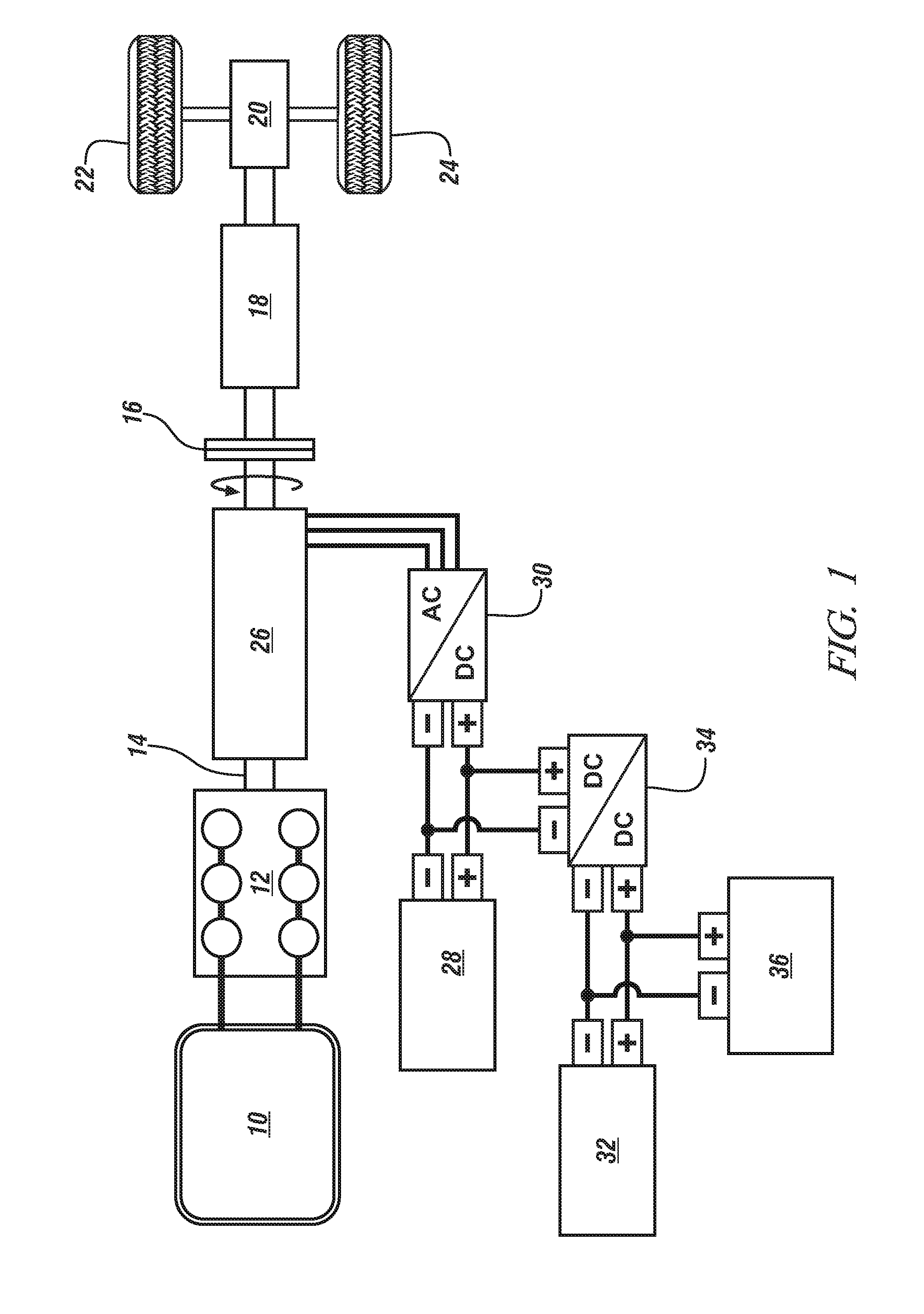

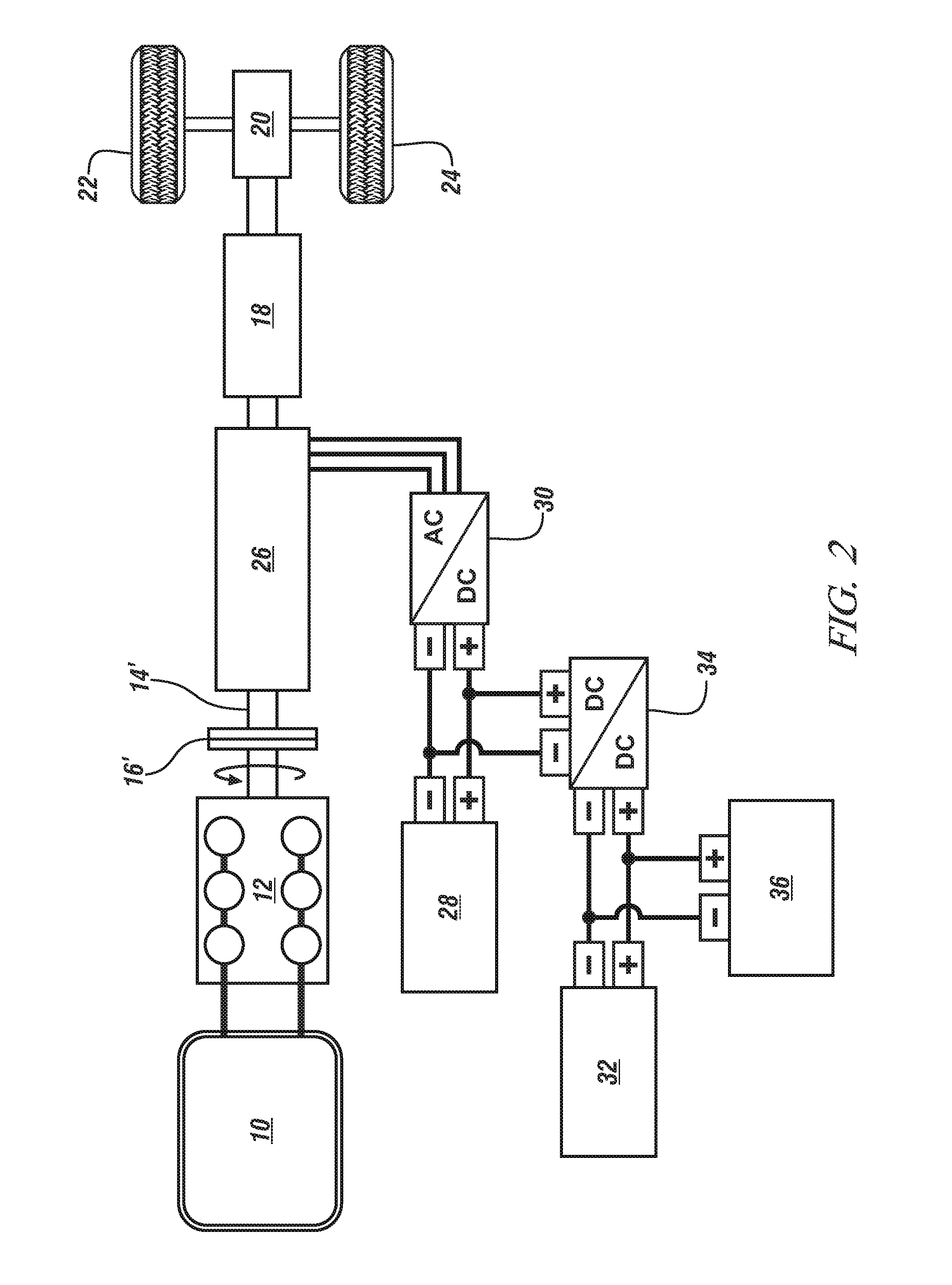

Li-ION BATTERY FOR VEHICLES WITH ENGINE START-STOP OPERATIONS

InactiveUS20120109503A1Reduce consumptionIncrease powerAnalogue computers for vehiclesCell electrodesCombustionStart stop

The operation of internal combustion, reciprocating engines in some automotive vehicles may be managed such that the engine operation is stopped each time the vehicle is brought to a stop, and then the engine is re-started when the operator presses the accelerator pedal to put the vehicle in motion. In some driving situations the engine of the vehicle may be stopped and re-started many times, which is a mode of engine operation for which the traditional 12 volt, lead-acid battery is not well suited. It is found that a six cell, lithium-ion battery combining LiFePO4 as the active positive electrode material and Li4Ti5O12 as the active negative electrode material, together with suitable separators and a suitable low freezing point electrolyte may be adapted to deliver starting power for repeated engine starting, despite short intervening charging periods.

Owner:GM GLOBAL TECH OPERATIONS LLC

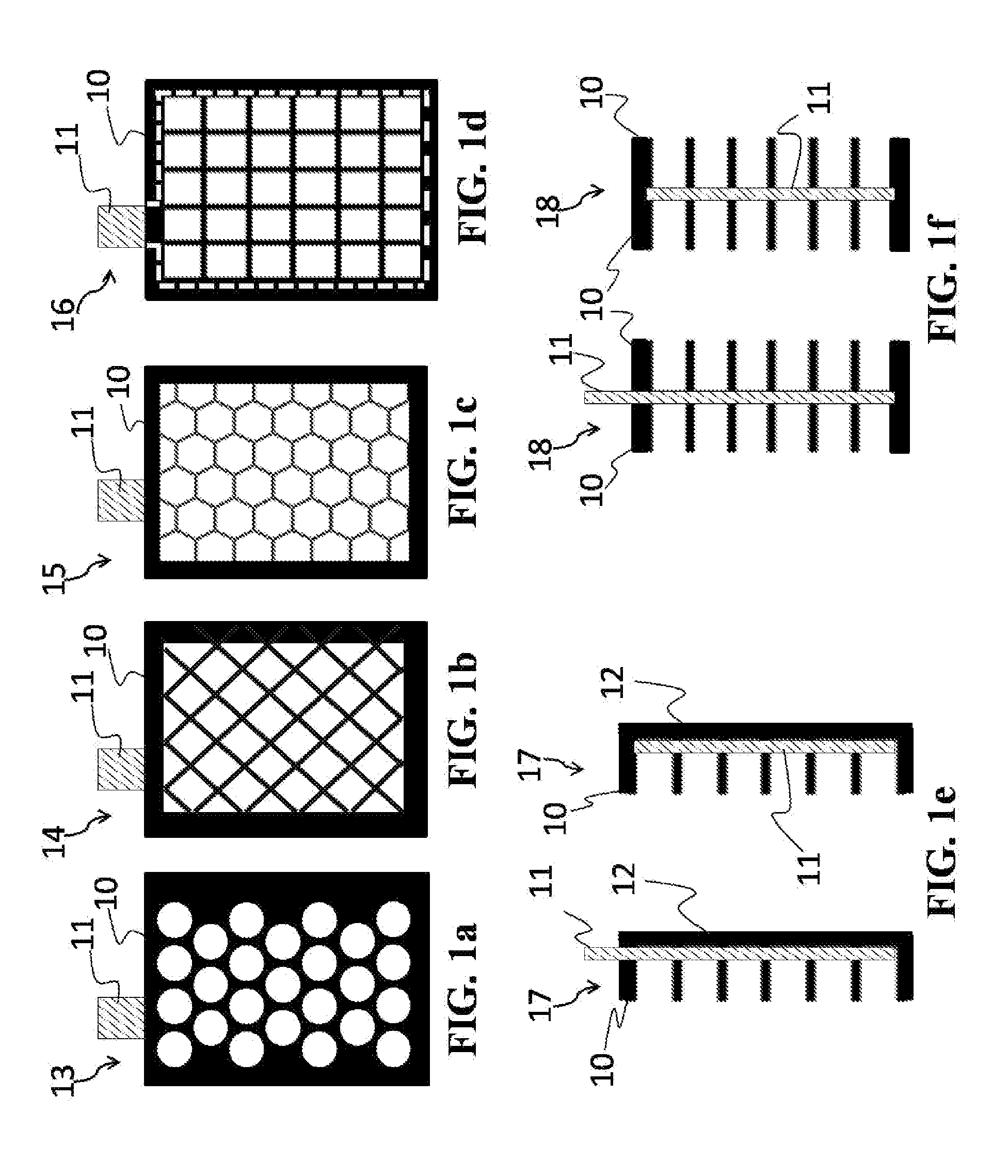

Current collector for lead acid battery

InactiveUS20110274969A1Low costHigh specific energyElectrode carriers/collectorsActive material electrodesMetal foilEngineering

A low cost, high specific energy and long cycle life lead acid battery includes polymer / metal current collectors. For intermediate electrodes, a current collector includes two polymer grids and a metal foil that is disposed between two grids, and for terminal electrodes, a current collector includes a polymer grid, a polymer sheet and a metal foil that is disposed between the polymer grid and sheet. The surfaces of the grids and metal foil are coated by different conductive and corrosion-resistant composites. The current collectors can be configured as monopolar or bipolar electrodes.

Owner:WANG XIAOGANG

Heat retention and distribution system for gas turbine engines

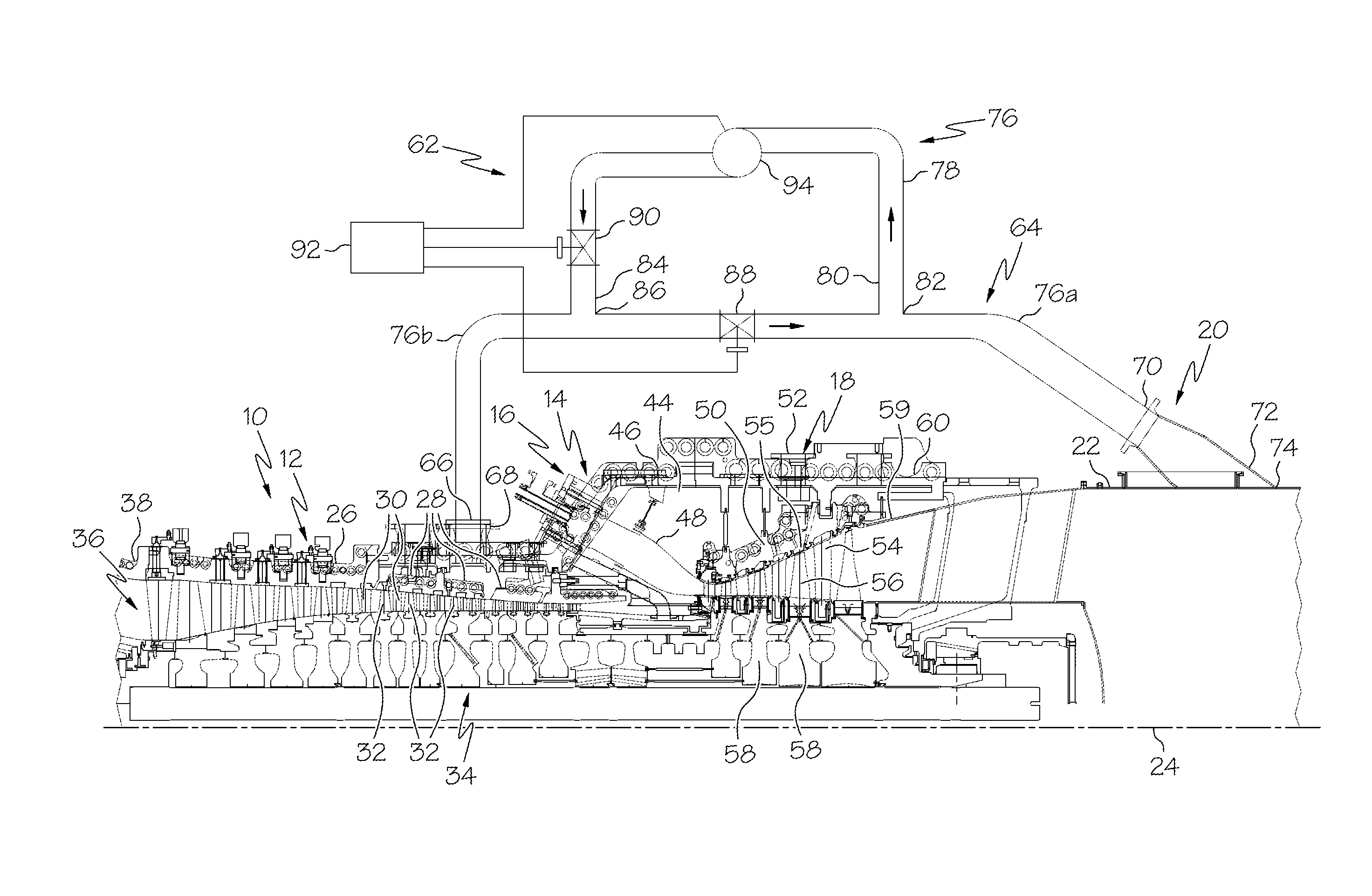

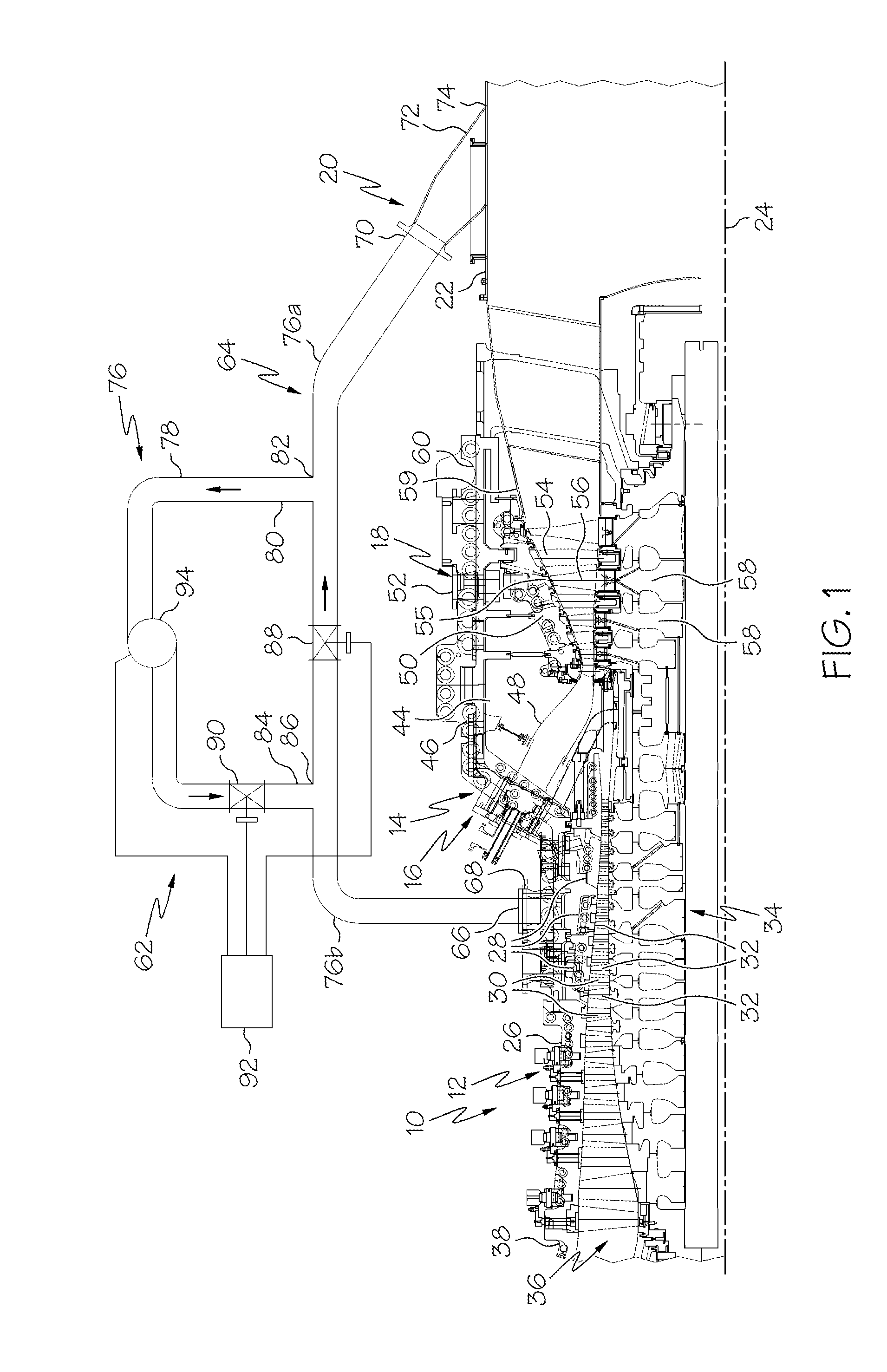

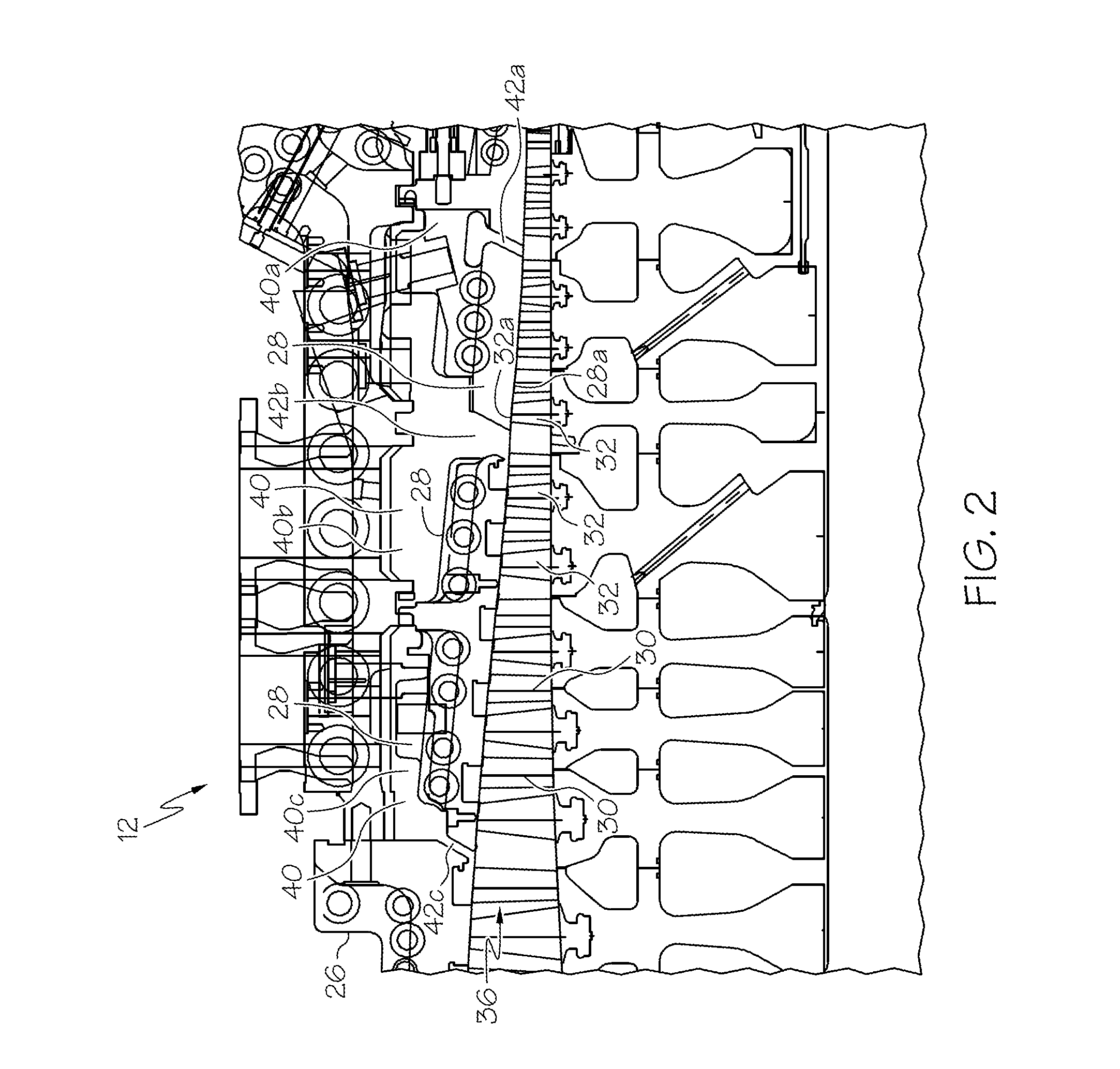

InactiveUS20140230400A1Extended maintenance intervalsReduce mechanical fatigueEngine fuctionsBlade accessoriesCombustorDistribution system

A gas turbine engine including a compressor section, a combustor section, and a turbine section operating to produce a power output during a first mode of operation. A heat retention and distribution system is provided to the engine wherein the heat retention system operates in a second mode of operation, following a shutdown of the engine, to maintain an elevated temperature in components of each of the compressor section, the combustor section and the turbine section in order to effect (1) a reduction in an effective cyclic life consumption of the components and extend a maintenance interval associated with the effective cyclic life consumption, and (2) clearances by maintaining a higher vane carrier temperature with time during a non-power producing mode and more uniform temperature of most stationary components in the circumferential orientation.

Owner:SIEMENS AG

Solid state lithium-air based battery cell

ActiveUS20150044581A1High theoretical energy densityIncrease energy densityFuel and secondary cellsHybrid cell detailsPorositySolid-state battery

In an example, the present invention provides a solid state battery device, e.g., battery cell or device. The device has a current collector region and a lithium containing anode member overlying the current collector region. The device has a thickness of electrolyte material comprising a first garnet material overlying the lithium containing anode member. The thickness of electrolyte material has a density ranging from about 80 percent to 100 percent and a porous cathode material comprising a second garnet material overlying the thickness of electrolyte material. The porous cathode material has a porosity of greater than about 30 percent and less than about 95 percent and a carbon bearing material overlying a surface region of the porous cathode material. In an example, the carbon bearing material comprises substantially carbon material, although there can be variations.

Owner:QUANTUMSCAPE CORP

Method for manufacturing battery negative pole piece

ActiveCN101552335AImprove consistencyImprove production efficiencyAlkaline accumulator electrodesState of artAlloy

The invention discloses a method for manufacturing battery negative pole piece, including drying and rolling, which is characterized in that the sizing before drying and rolling is continuous sizing, and adopting one-sided sizing at the no-powdering part of the cathode pole piece contacted to the steel shell. Compared with the prior art, the invention has beneficial effects that the inventive method adopts using steel belt matrix to position at the center of the smear paste die clearance, performs powder scraping continuous operation before pole piece rolling, which is in favor of reducing alloy oxidation of pole piece in the production process and impurity introduction in the pole piece, and is in favor of improving the consistency of pole piece production quality and production efficiency of the pole piece.

Owner:SHENZHEN HIGHPOWER TECH CO LTD

Preparation method of ion exchange membrane for alkaline redox flow battery

InactiveCN110534682AHigh ion selectivityHigh proton conductivityCell electrodesRegenerative fuel cellsKetoneCarbon felt

The invention relates to the field of alkaline redox flow battery energy storage, in particular to a preparation method of an ion exchange membrane for an alkaline redox flow battery, which is mainlyused for solving the problem of the high price of a Nafion diaphragm in the alkaline redox flow battery at the present stage, so that the cost of the redox flow battery is greatly reduced. An alkalineaqueous solution of ferricyanide (such as Na3[Fe(CN)6], K3[Fe(CN)6], (NH4)3[Fe(CN)6] and the like) is used as a positive electrolyte, and a strong alkaline solution (such as KOH, NaOH and the like) is used as a negative electrolyte; graphite felt and carbon felt are selected as positive electrode materials, and a zinc plate is selected as a negative electrode material; and the ionized sulfonatedpolyether ether ketone (SPEEK) diaphragm is used as an ion exchange membrane to assemble the battery. Therefore, the alkaline redox flow battery system with low cost and high performance is obtained.The flow battery system provided by the invention has the advantages of the high open-circuit voltage, the low cost, the high efficiency, the good cycling stability, safety, reliability and the like,and has a wide application prospect.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Paste type positive electrode for alkaline storage battery, and nickel-metal hydride storage battery

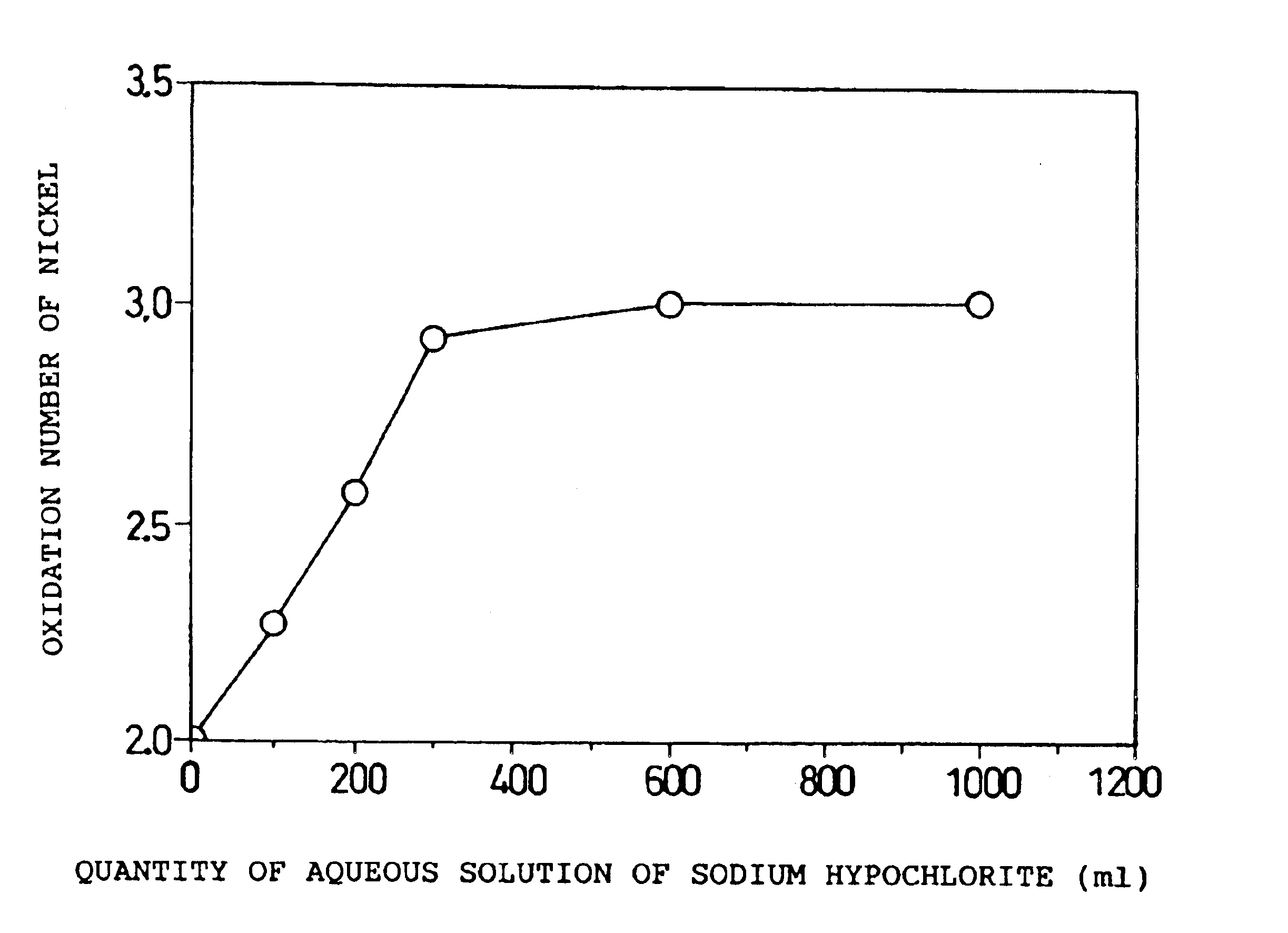

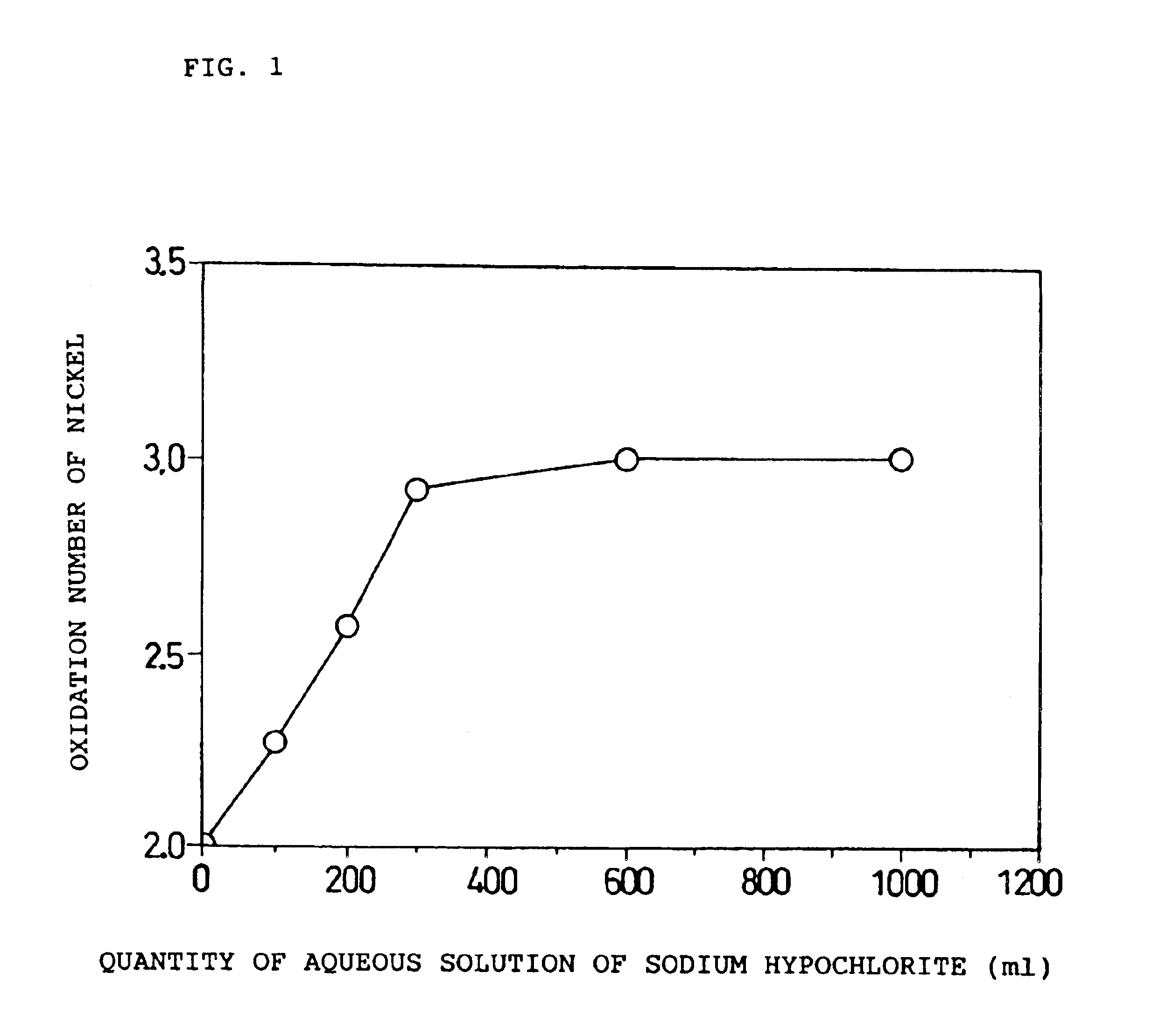

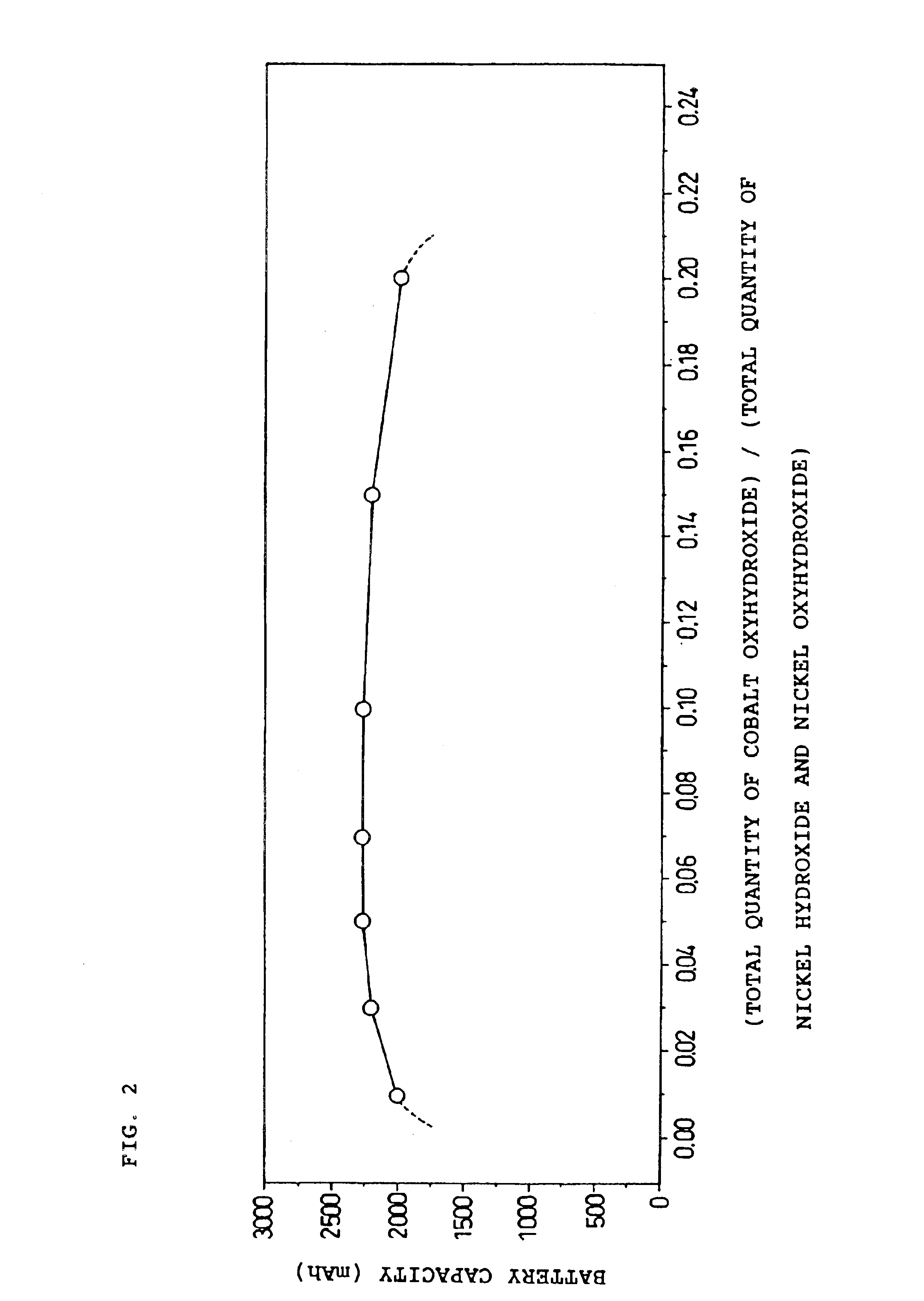

InactiveUS6858347B2Low cycle lifeReduce capacityFinal product manufactureAlkaline accumulator electrodesParticulatesNickel oxide hydroxide

The paste type positive electrode of the present invention contains a first active material and a second active material. The first active material comprises X parts by weight of particulate nickel hydroxide with aX / 100 parts by weight of cobalt oxyhydroxide carried thereon. The second active material comprises Y parts by weight of particulate nickel oxyhydroxide, of which an oxidation number of nickel is α, with bY / 100 parts by weight of cobalt oxyhydroxide carried thereon. Here, all the following relations are satisfied: (1) 2.5≦α<3.0, (2) 0.01≦(aX / 100+bY / 100) / (X+Y)≦0.20, (3) 0<b≦a≦10 or 0=b<a≦10, and (4) 2.1≦(2X+αY) / (X+Y)<2.2.

Owner:PANASONIC CORP

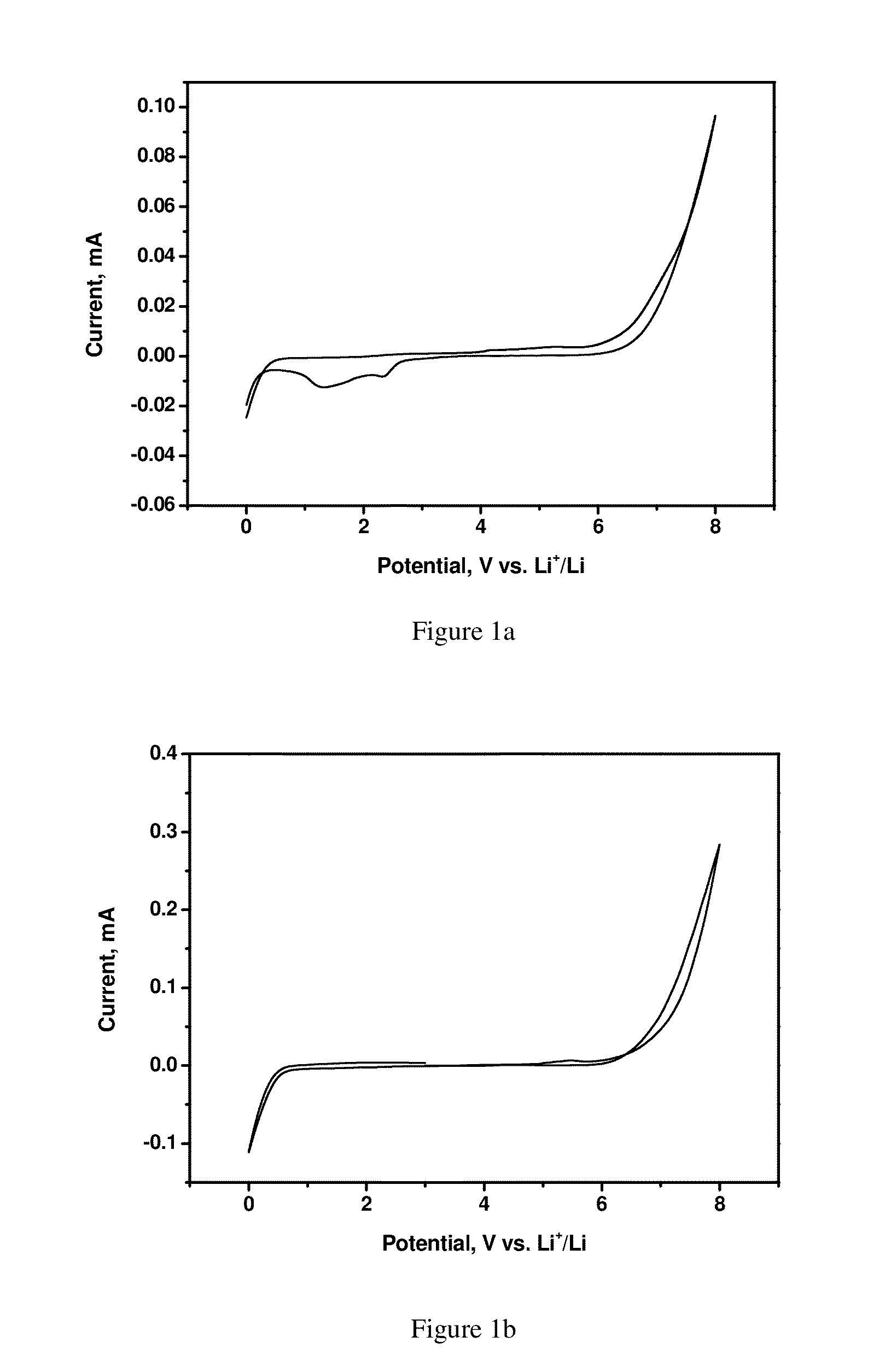

High voltage electrolyte and lithium ion battery

ActiveUS20150333373A1Improve securityImproving reliability and performanceOrganic electrolyte cellsSecondary cellsPhysical chemistryHigh pressure

The present application discloses a high voltage electrolyte including an electrolyte solvent which includes a mixture of a dinitrile solvent and a nitrile solvent and is stable at voltage of about 5 V or above. The dinitrile solvent may include at least one selected from the group consisting of malononitrile, succinonitrile, glutaronitrile, adiponitrile, pimelonitrile, suberonitrile, azelanitrile and sebaconitrile. The nitrile solvent may include at least one selected from the group consisting of acetonitrile, propionitrile, butyronitrile, pivalonitrile and capronitrile. The present application also discloses a lithium ion battery including the above high voltage electrolyte. The lithium ion battery exhibits a cyclic performance of greater than about 300 cycles and with a capacity retention of greater than about 80%.

Owner:NANO & ADVANCED MATERIALS INST

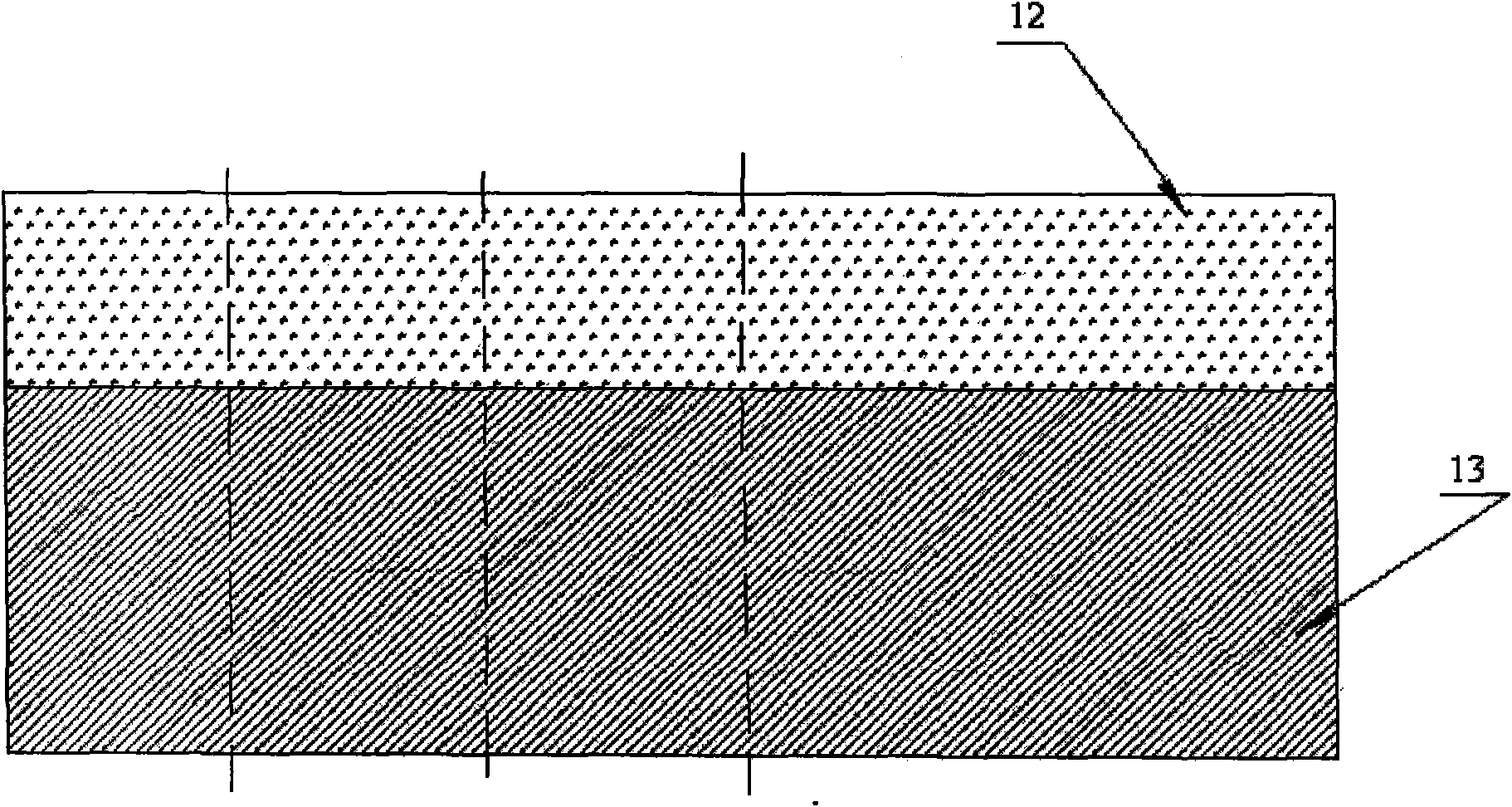

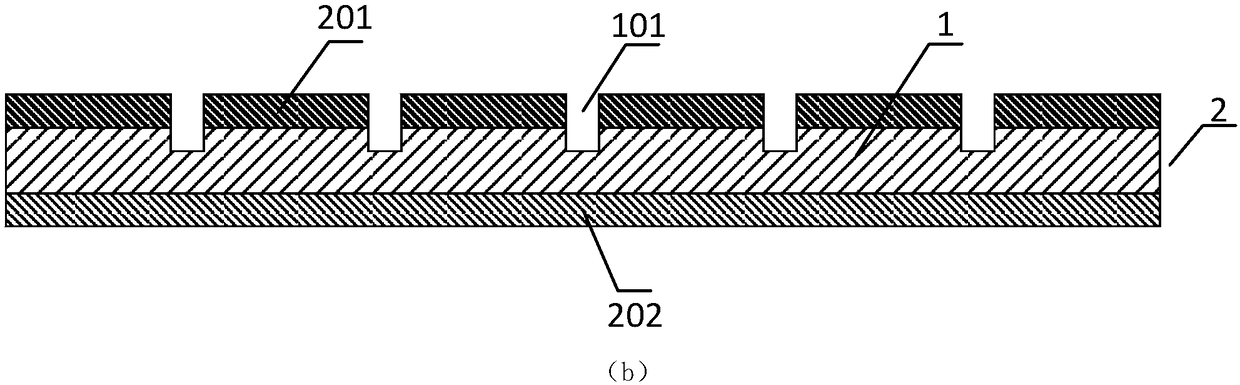

Bipolar electrode sheet, bipolar battery contain that electrode sheet, and maintenance and regeneration method thereof

ActiveCN109216647AEffectively complete uniform injectionImprove injection efficiencyLarge-sized flat cells/batteriesFinal product manufactureEngineeringElectrolyte

The invention provides a bipolar electrode sheet provided with an electrolyte flow channel and a bipolar battery including the bipolar electrode sheet, the bipolar electrode sheet comprises a bipolarplate and a positive electrode material layer and a negative electrode material layer respectively coated on both sides of the bipolar plate, one or more electrolyte flow channels are arranged on oneor both sides of the bipolar plate, and the electrolyte flow channels can effectively complete unified liquid injection of each battery unit in the bipolar battery, and are helpful for the electrolyteto flow in the battery, so as to facilitate the liquid injection, liquid exchange and liquid replenishment of the battery; The electrolyte flow channel can increase the contact surface between the electrolyte and the electrode material layer, so that the positive and negative electrode material layers can fully permeate and soak in the electrolyte.

Owner:BEIJING HAWAGA POWER STORAGE TECH

Active material for non-aqueous electrolyte secondary battery and manufacturing method therefore

ActiveUS8137847B2Increase capacityReduces electron conductivity and lithium diffusing abilityElectrode manufacturing processesNon-aqueous electrolyte accumulatorsDesorptionX-ray

An active material for a non-aqueous electrolyte secondary battery including a lithium-containing transition metal oxide containing nickel and manganese and having a closest-packed structure of oxygen, wherein an atomic ratio MLi / MT between the number of moles of lithium MLi and the number of moles of transition metal Mt contained in the lithium-containing transition metal oxide is greater than 1.0; the lithium-containing transition metal oxide has a crystal structure attributed to a hexagonal system, and the X-ray diffraction image of the crystal structure has a peak P003 attributed to the (003) plane and a peak P104 attributed to the (104) plane; an integrated intensity ratio I003 / I104 between the peak P003 and the peak P104 varies reversibly within a range from 0.7 to 1.5 in association with absorption and desorption of lithium by the lithium-containing transition metal oxide; and the integrated intensity ratio varies linearly and continuously.

Owner:PUBLIC UNIVERSITY CORPORATION OSAKA CITY UNIVERSITY +1

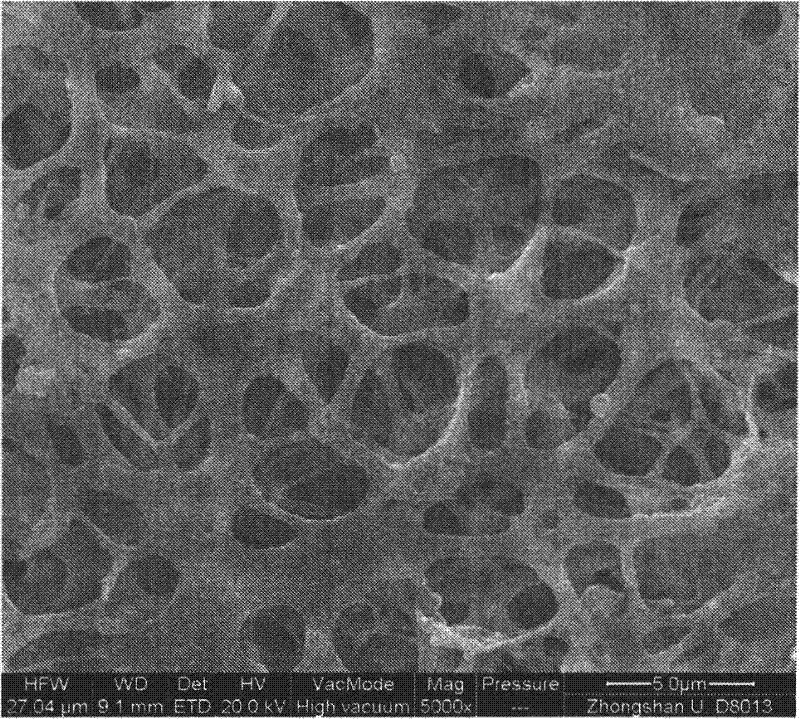

Novel PVC/rubber composite micropore partition board

InactiveCN102130314AIncrease elasticityImprove toughnessCell component detailsPolyvinyl chlorideCompressibility

The invention discloses a novel polyvinyl chloride (PVC) / rubber composite micropore partition board. The composite micropore partition board is characterized by consisting of the following components in percentage by weight: 30 to 80 percent of PVC resin, 0.1 to 20 percent of rubber, 0 to 50 percent of inorganic filling phase and 0.1 to 5 percent of conductive agent. The PVC / rubber composite micropore partition board provided by the invention has compressibility and high strength of plastic and resilience and high toughness of rubber, has good response to the volume change of a polar plate in the charge / discharge process of a battery, can play a good durable role in supporting active substances on the polar plate, effectively controls the separation of the active substances, and remarkably prolongs the service life of the battery.

Owner:SOUTH CHINA NORMAL UNIVERSITY

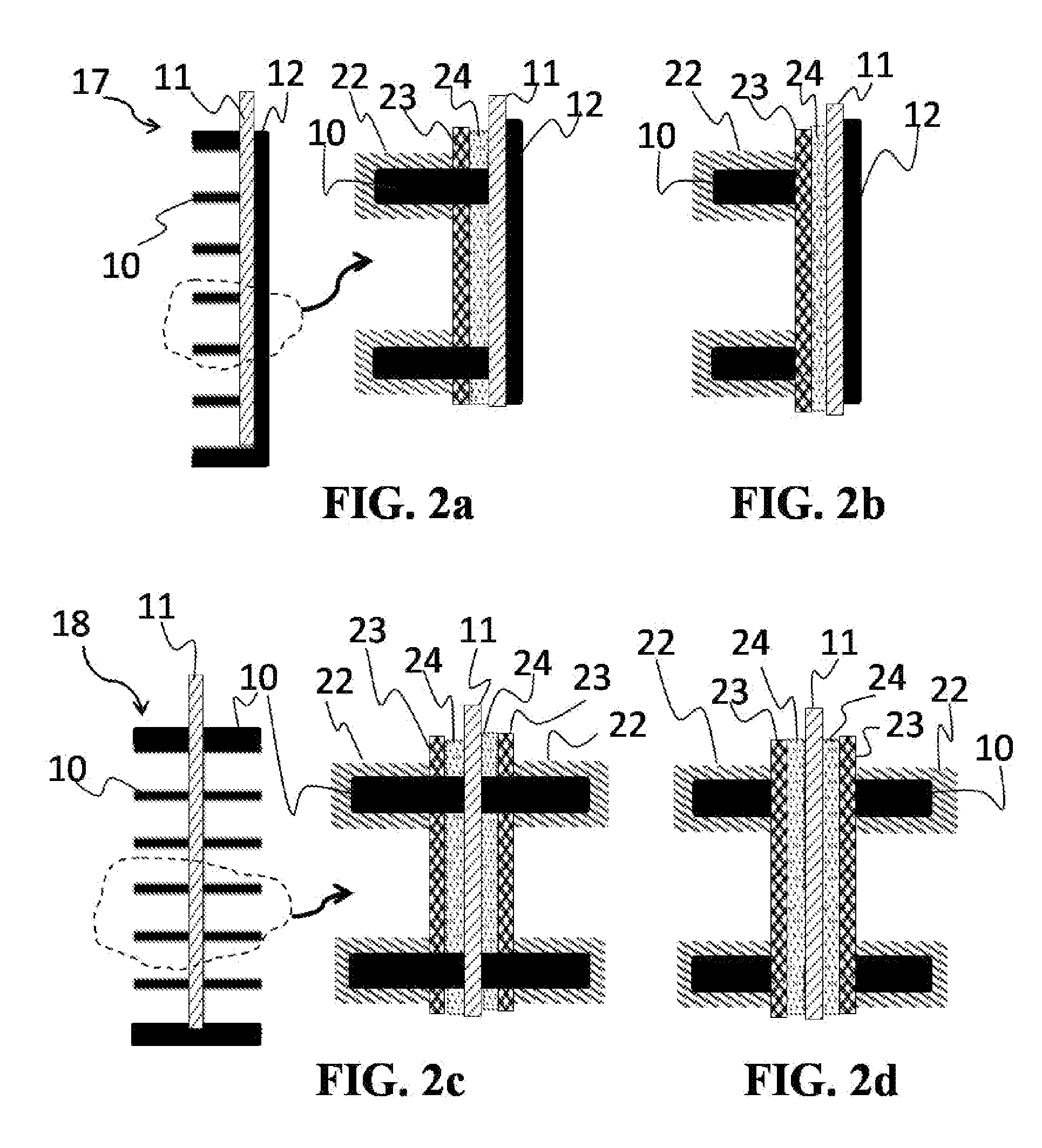

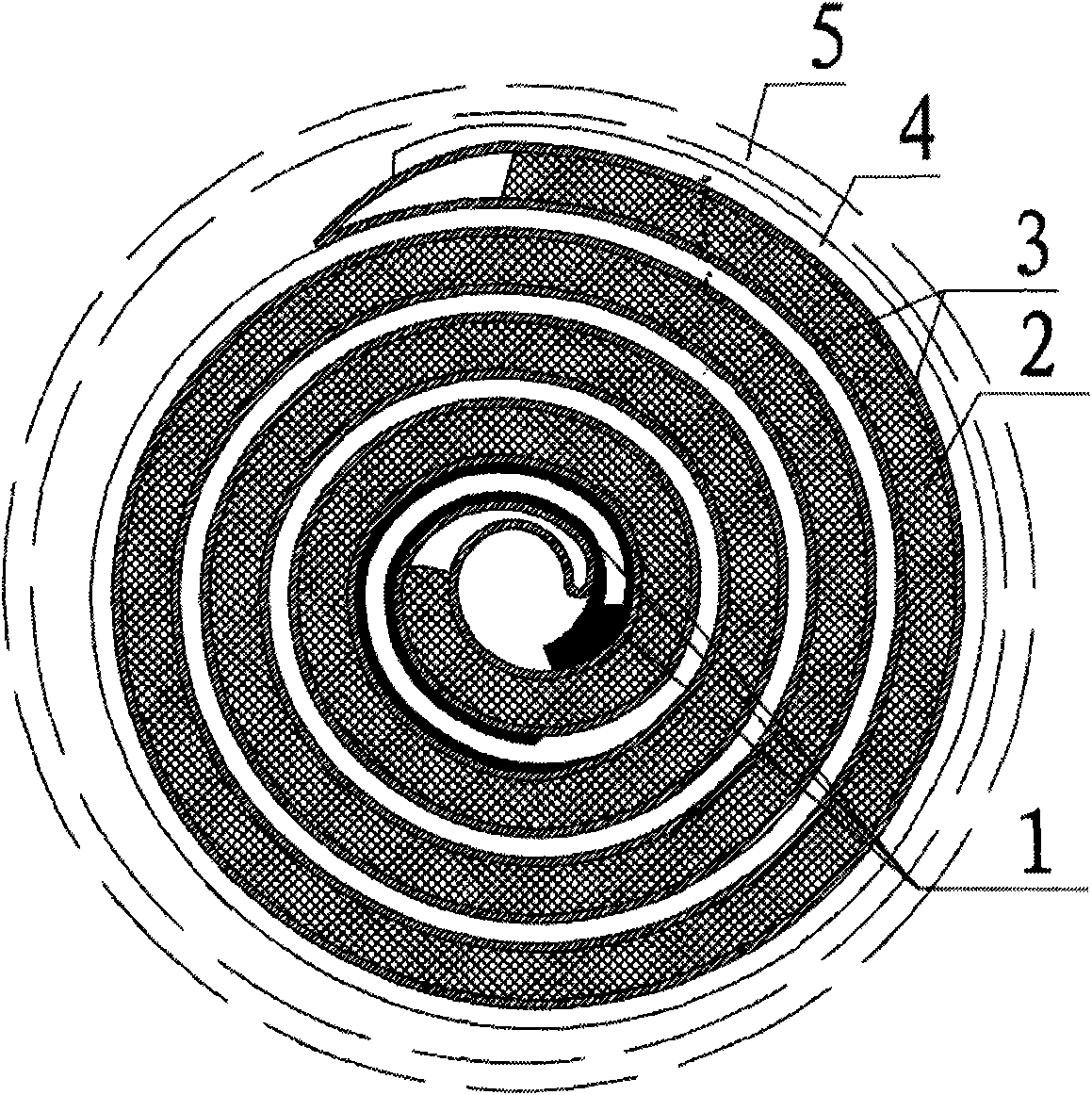

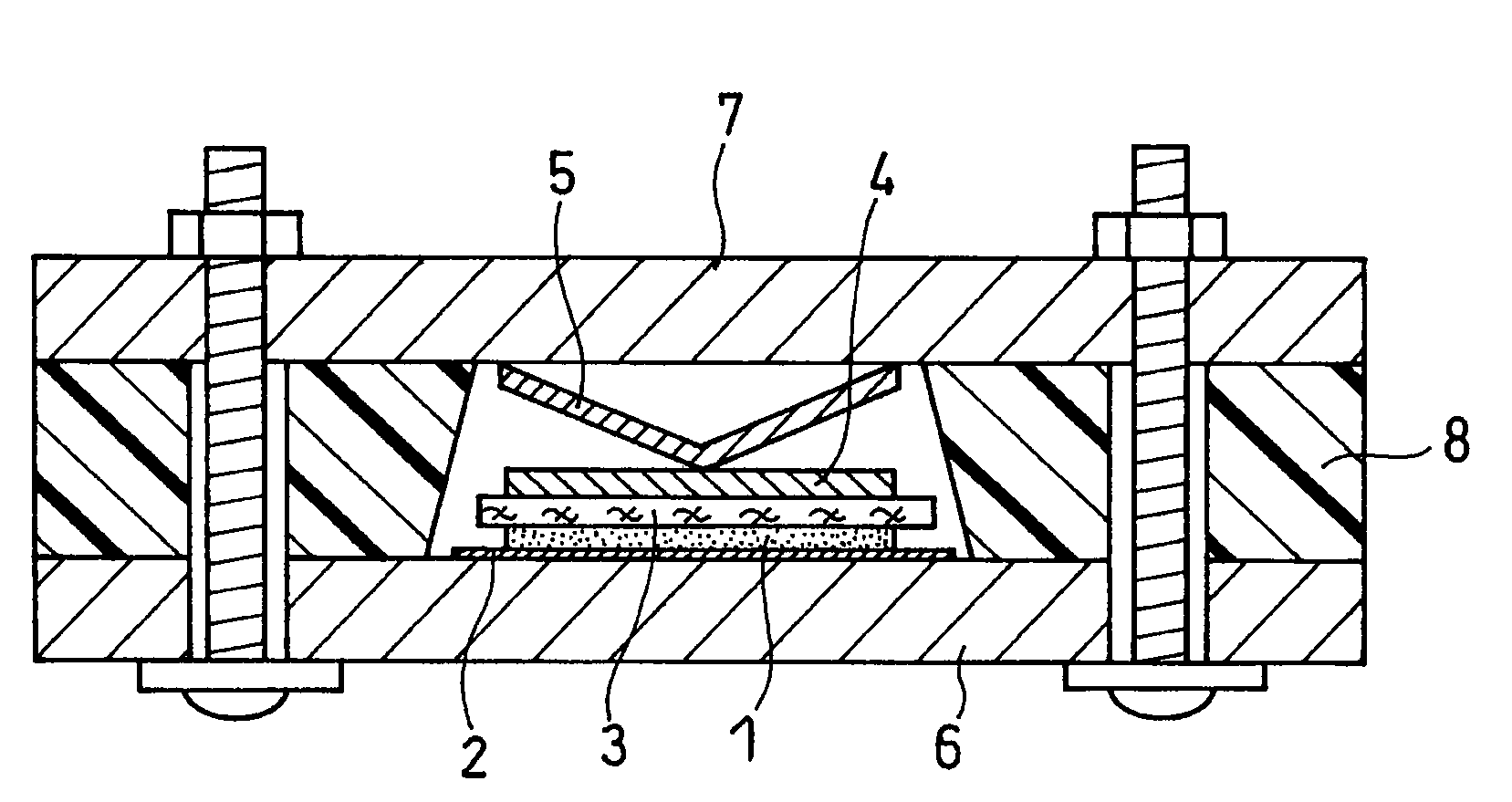

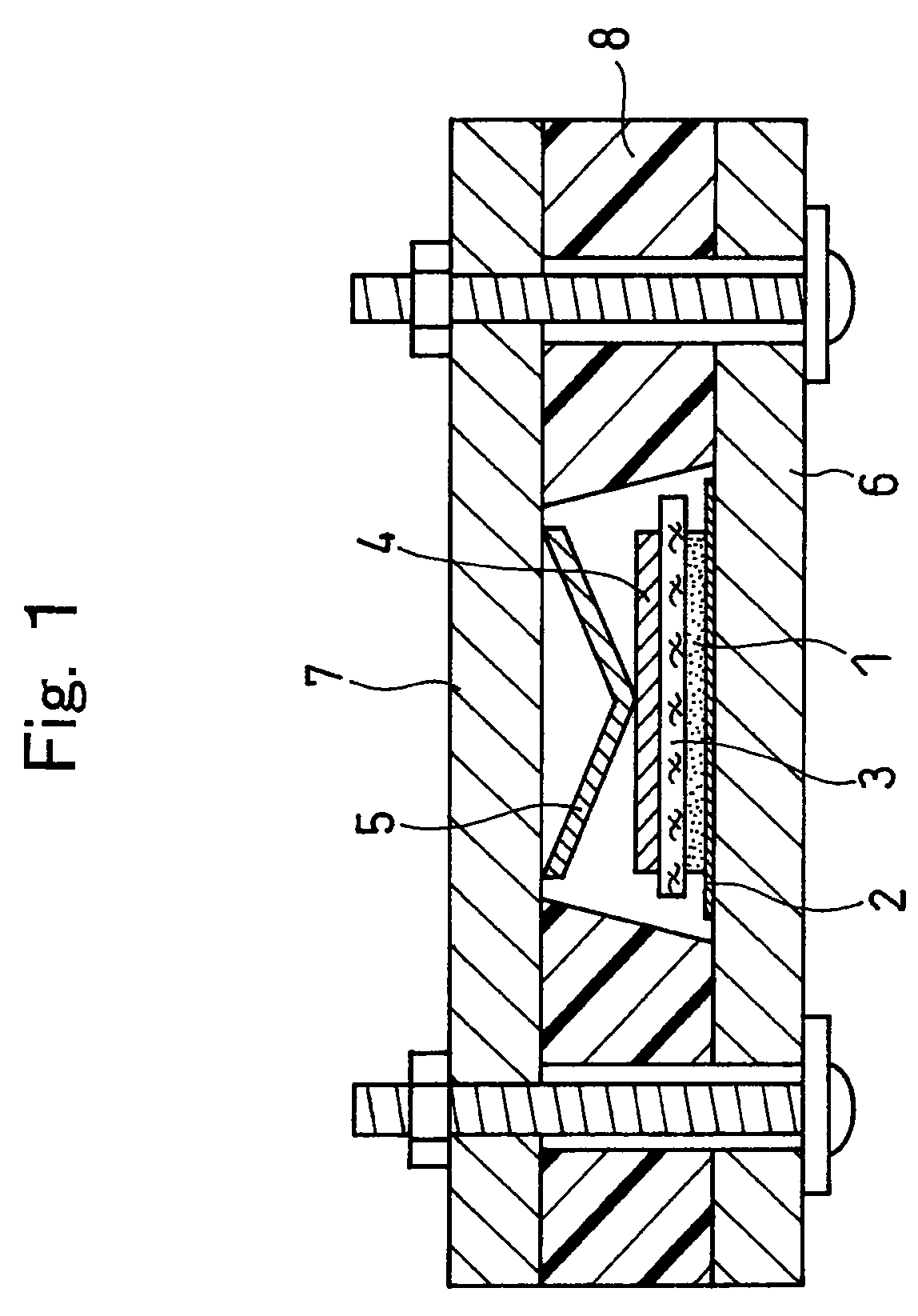

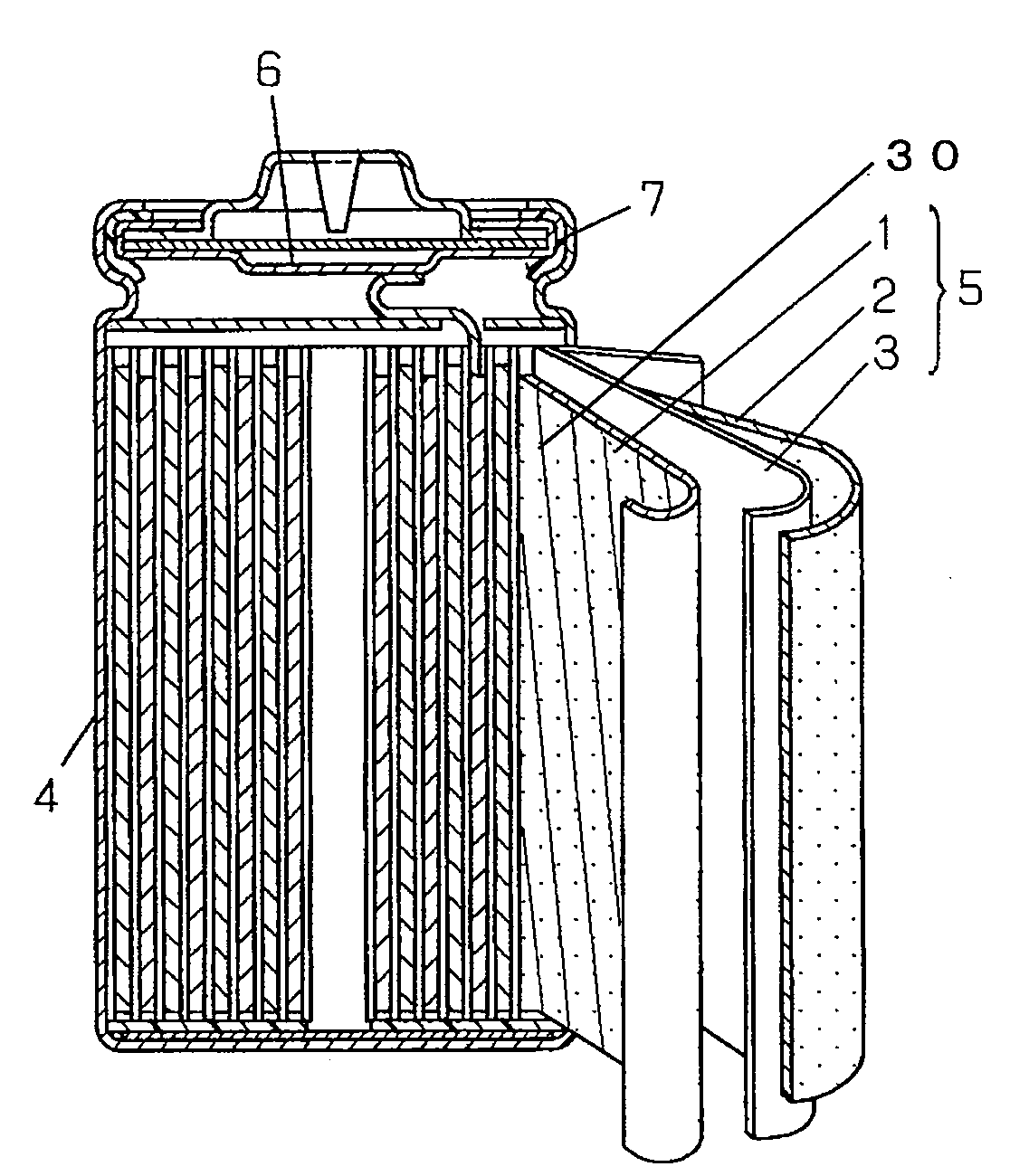

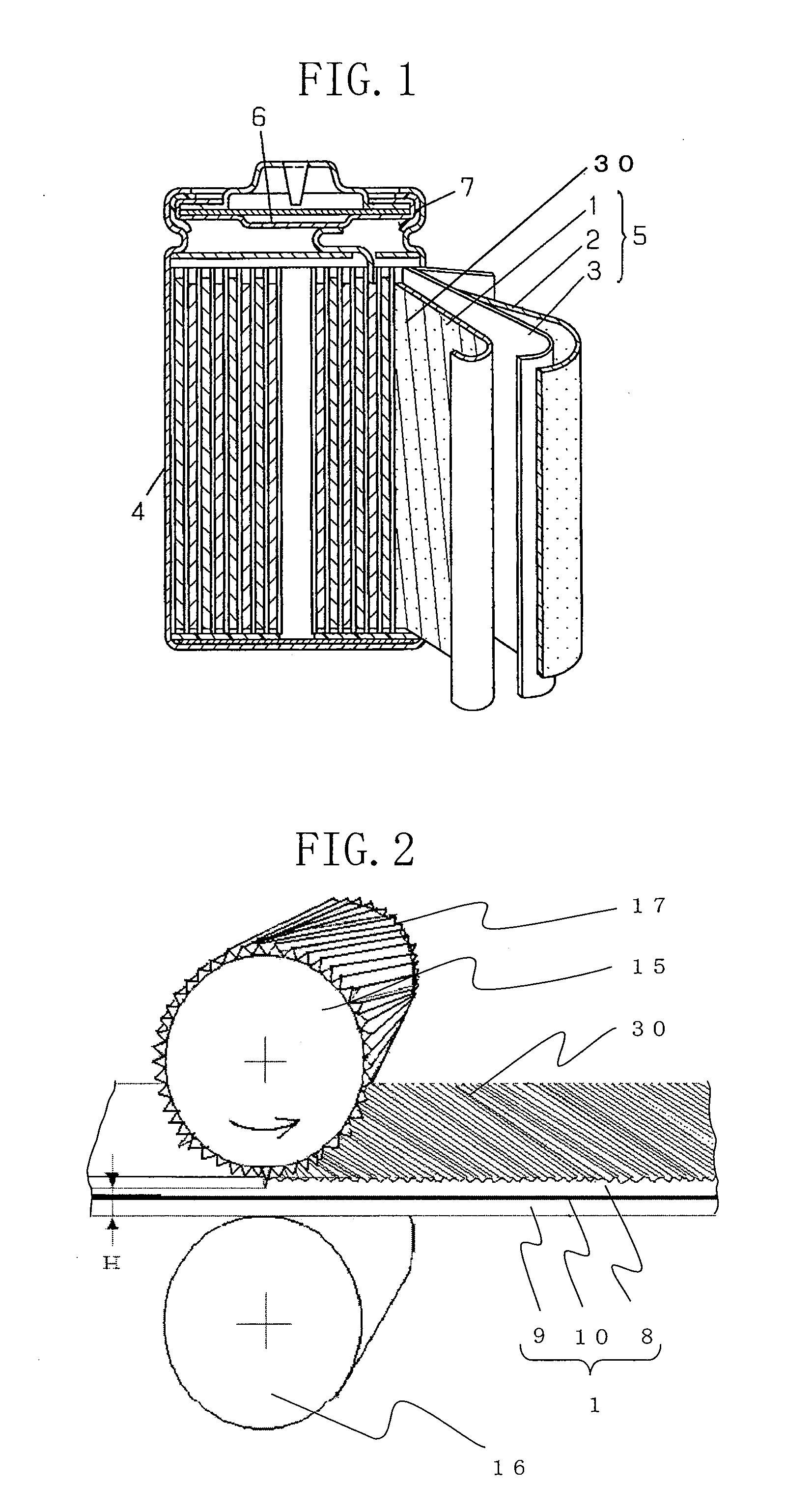

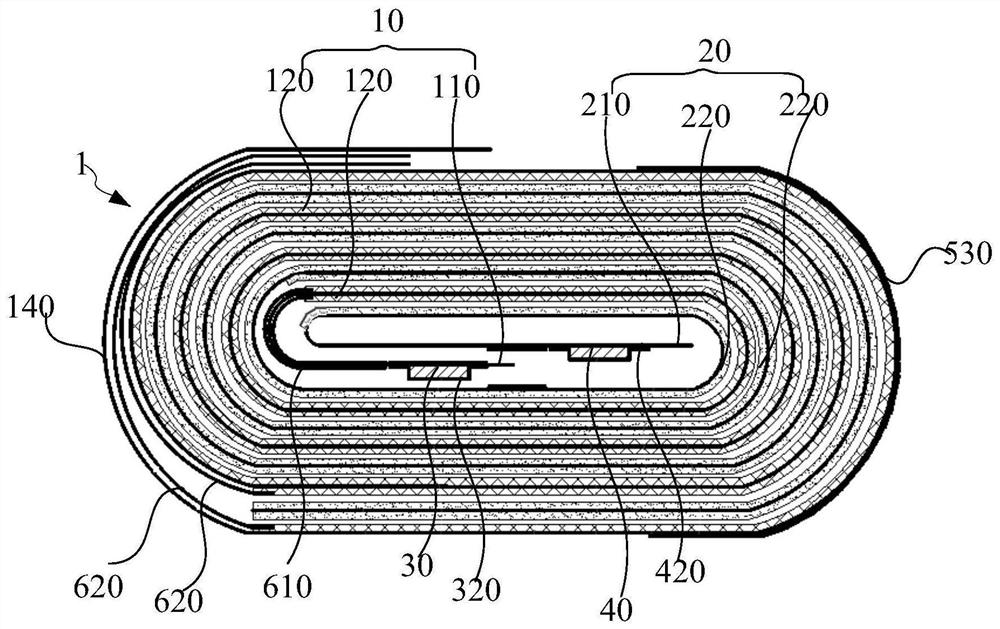

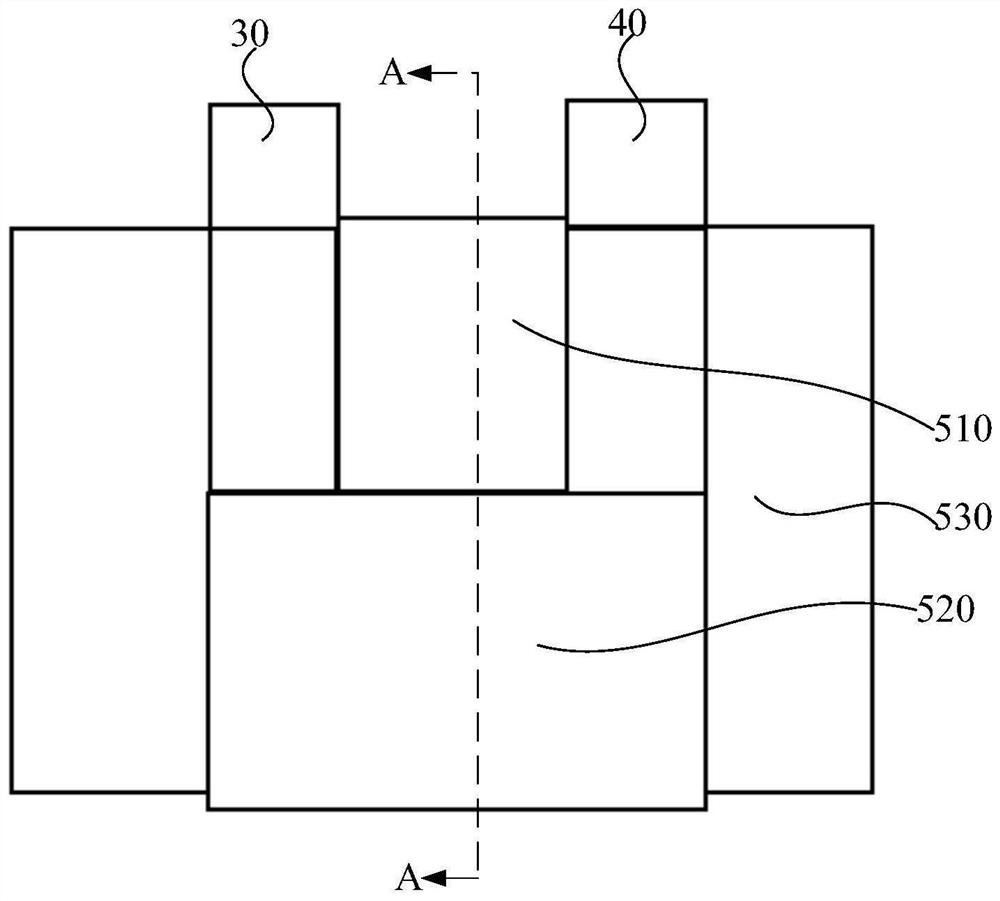

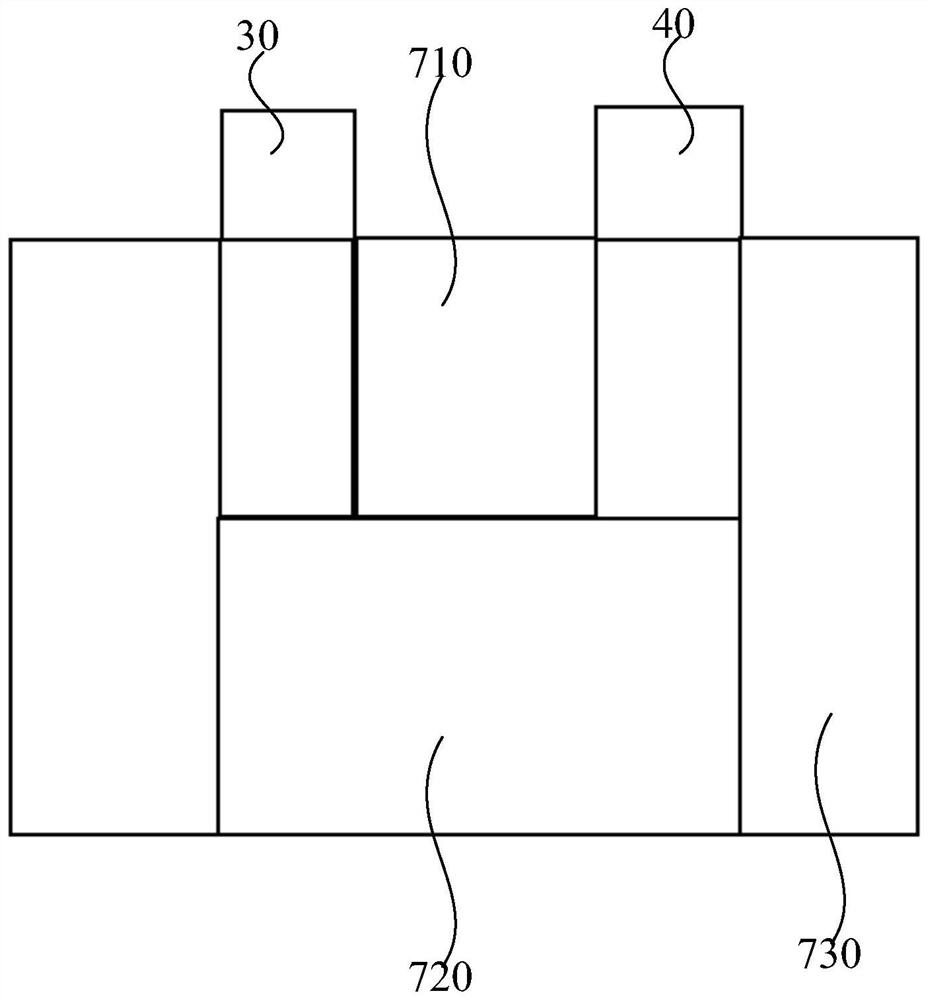

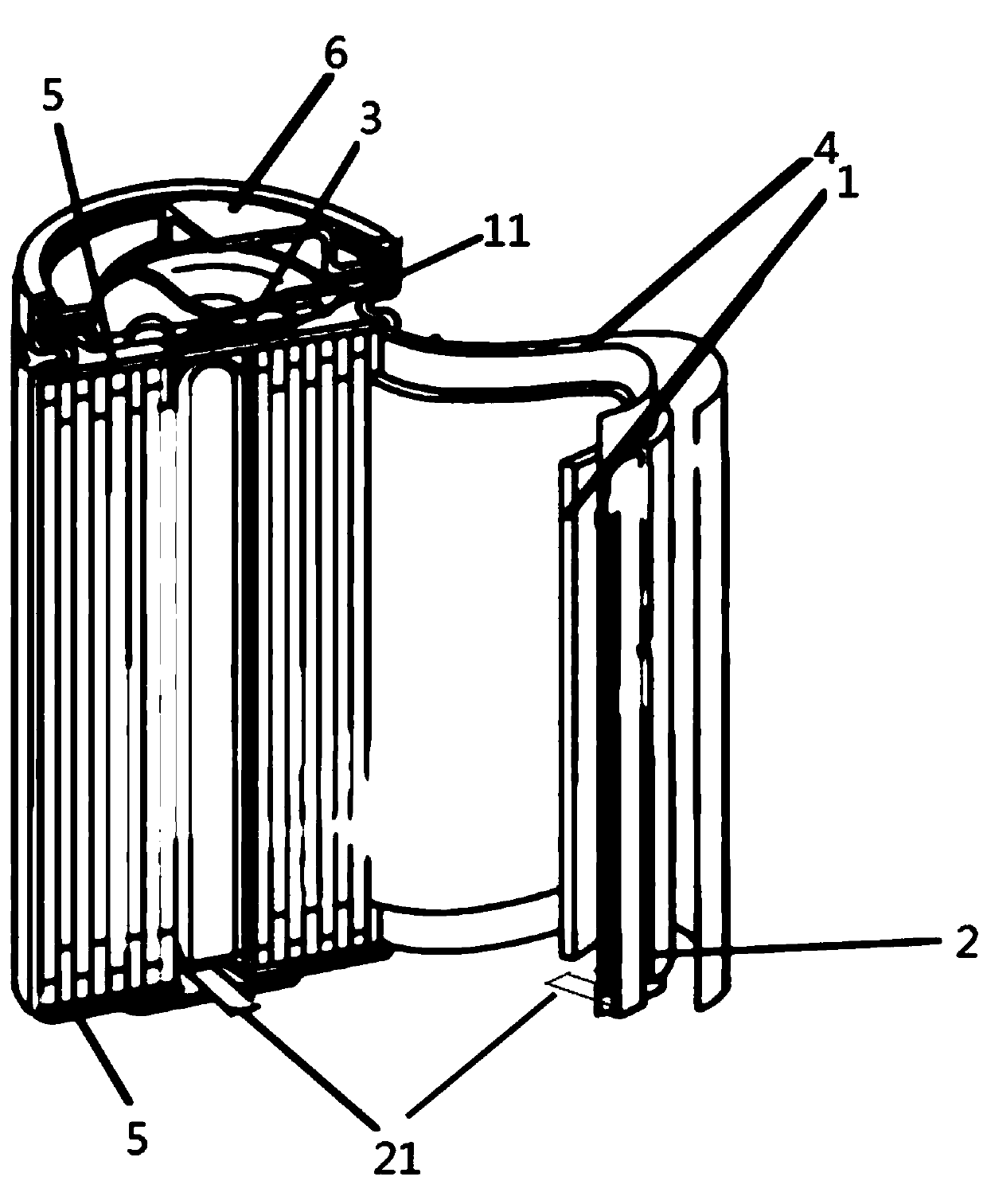

Secondary cell and its manufacturing method

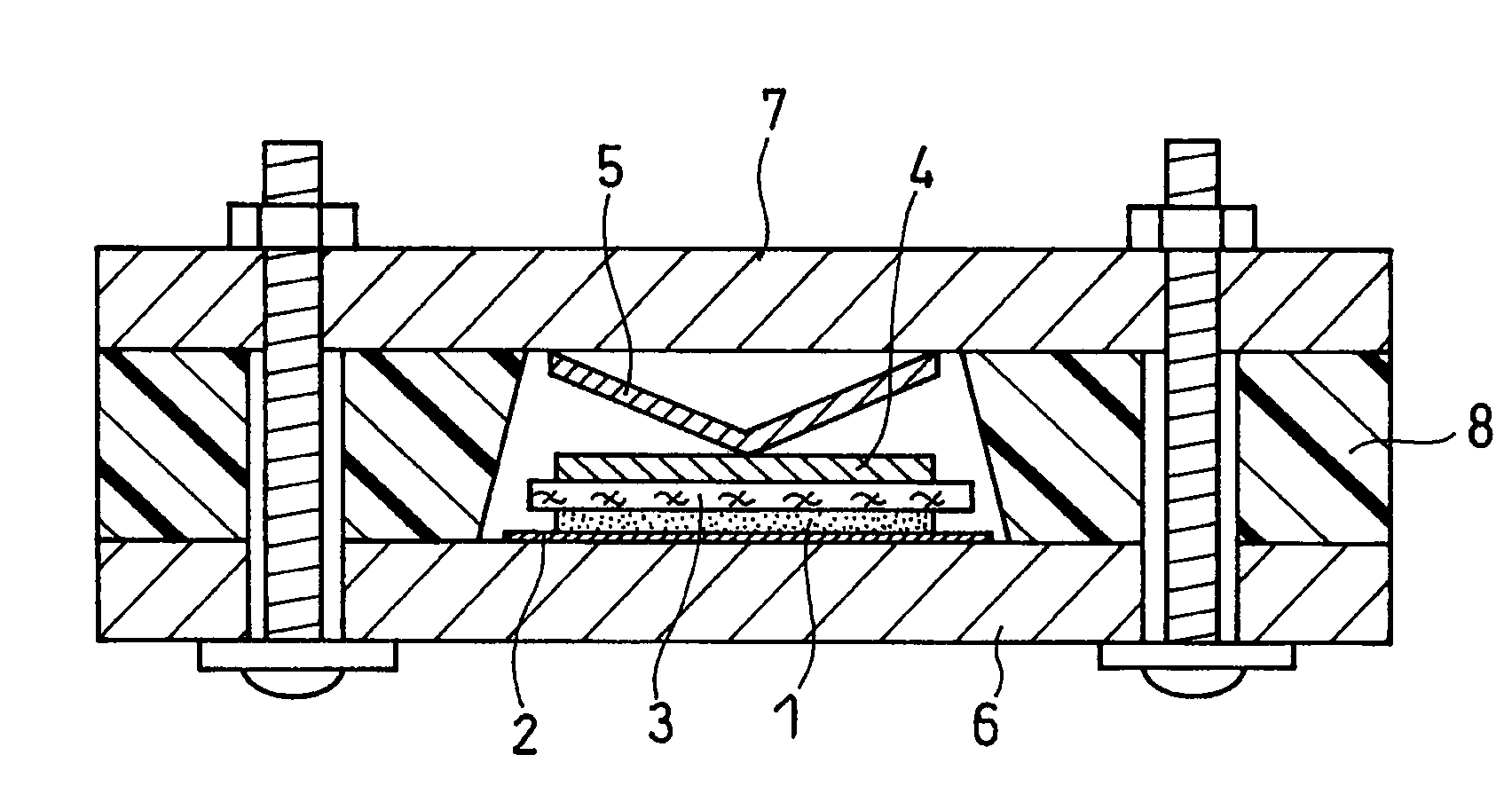

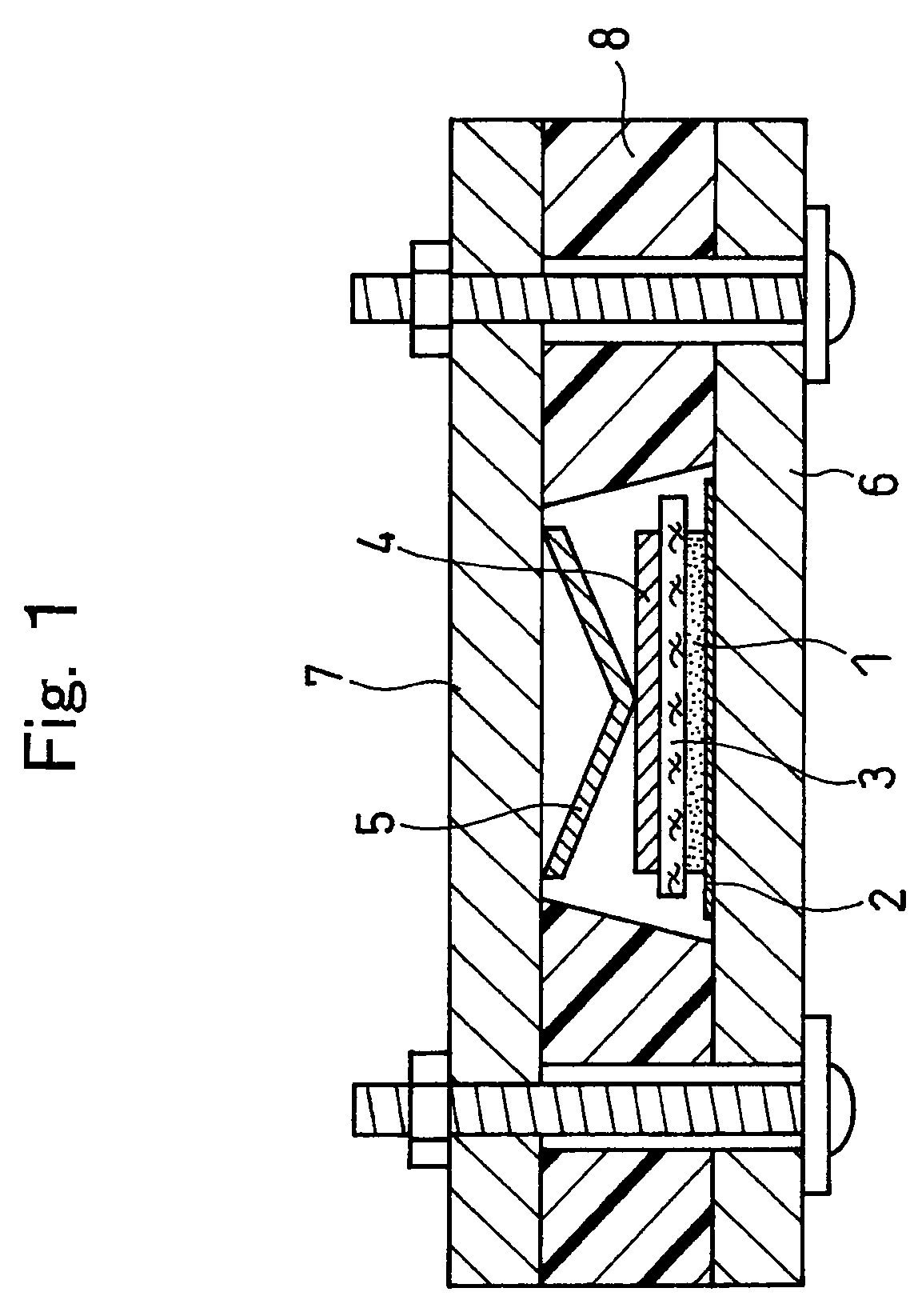

InactiveUS20100279158A1InhibitionPrevent peelingElectrode rolling/calenderingFinal product manufactureEngineering

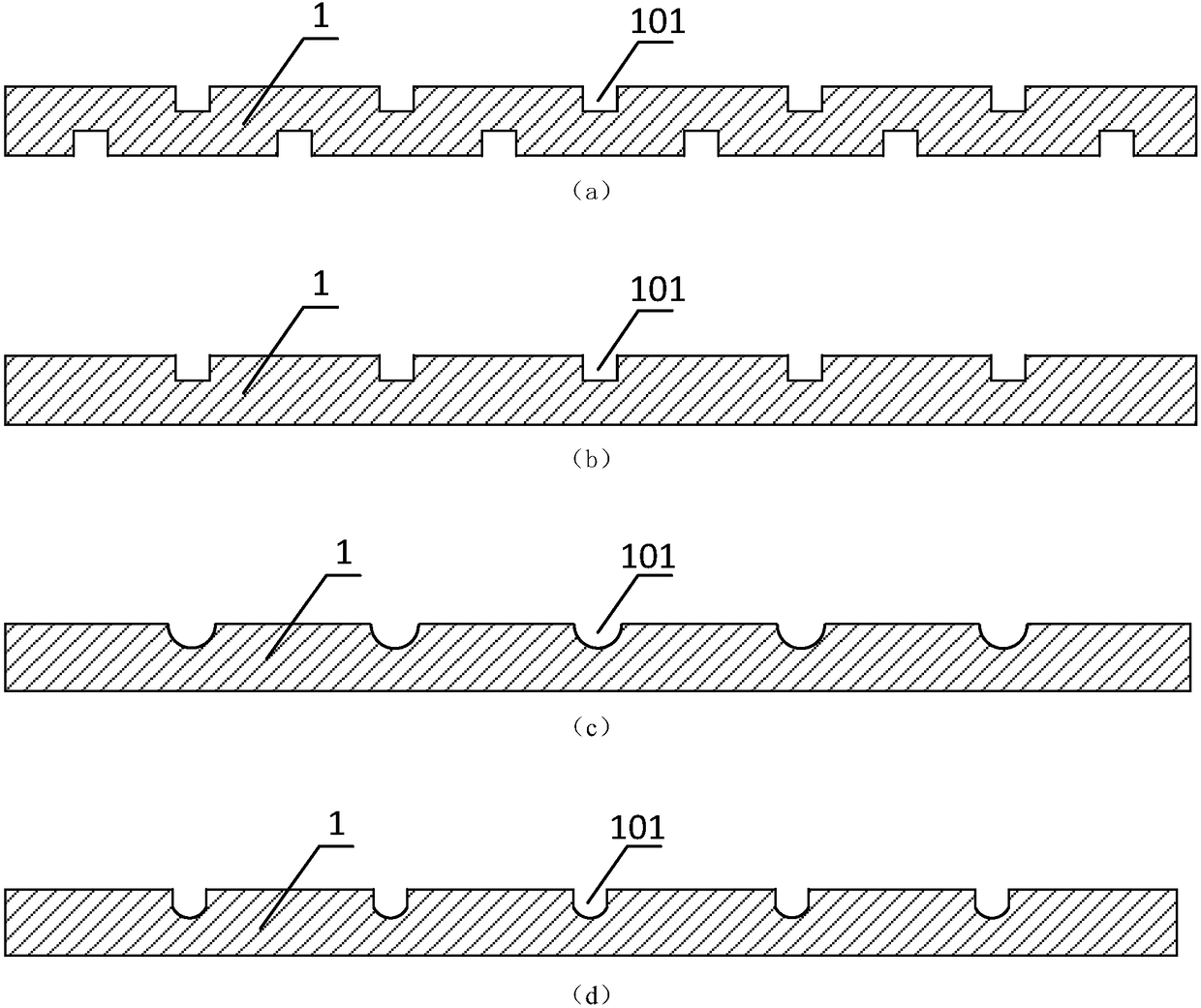

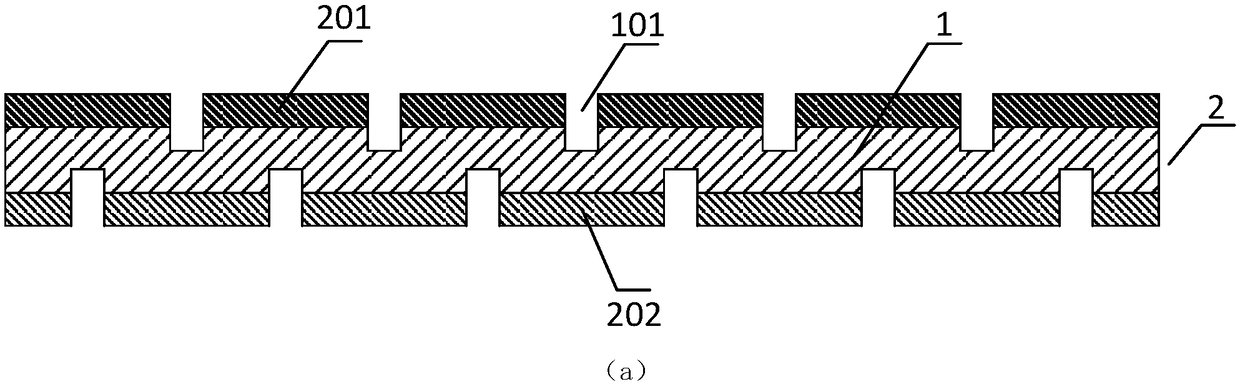

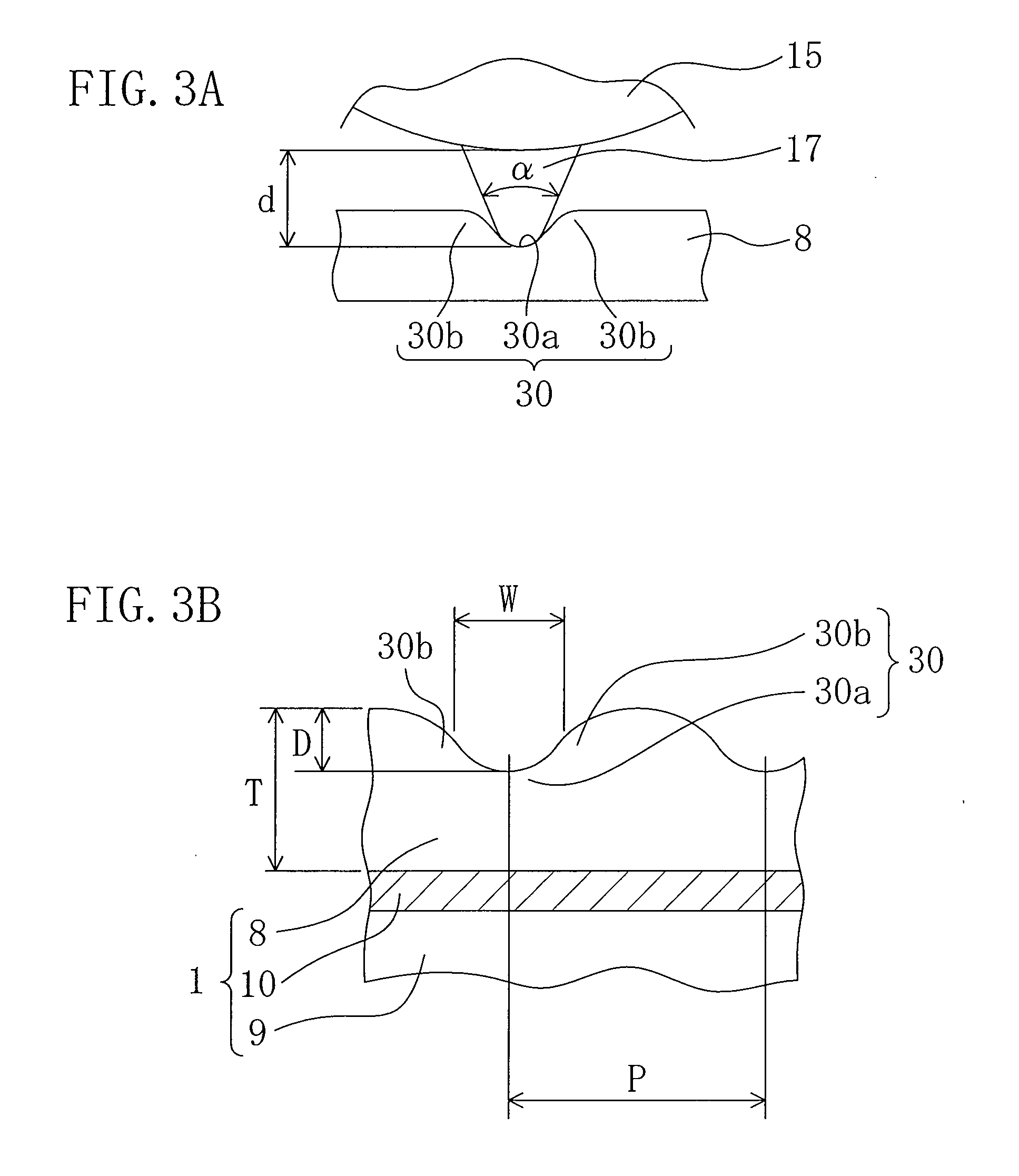

A secondary battery includes an electrode group 5 formed by winding a positive electrode plate 1 and a negative electrode plate 2 with a separator 3 interposed therebetween. Each of the positive and negative electrode plates 1 and 2 includes a current collector 1 and mixture layers 8 and 9 each containing an active material and formed on the surface of the current collector 1. A plurality of trenches 30 are formed in the surfaces of the mixture layers 8 and 9 of at least one of the positive electrode plate 1 and the negative electrode plate 2. The trenches 30 have curvature portions at side edges 30b and bottom centers 30a thereof.

Owner:GK BRIDGE 1

AB5 type negative pole hydrogen-storage material

InactiveCN1738082AEasy to useLow cycle lifeAlkaline accumulator electrodesNickel accumulatorsRare-earth elementElectrochemistry

The invention provides a AB5 type negative hydrogen storage material prepared by the rapid hardening band method, wherein, the atom proportions comprise: Mm1-zDyZnI3.55Co0.75-x-yFexCuyMn0.4Al0.3, in which the x + y ranges from 0-0.7, the z ranges from 0-0.039, the Mm is rare-earth compound formed by La, Ce, Pr and Nd elements etc., the weight of rare-earth compound Mm is selected as standard, the weight of La is 64.5-67.5 %, the weight of Ce is 22.0-24.0 %, the weight of Pr is 2.5-3.5 % and the weight of Nd is 7.0-9.0 %. The cooling rate of used rapid hardening band method is decided by the controlled linear speed 1-3 m / s of rotating surface of cooling roll and the thickness of product 0.2-0.5. Since the invention utilizes the rapid hardening band method, selects the correct cooling rate, uses a little rare-earth element Dy, and replaces the element Co with the more cheaper element Fe and Cu, the alloy can keep excellent active property, electrochemical charging and discharging capacity and cycle life, while the cost is reduced markedly.

Owner:北京宏福源科技有限公司

Large-capacity graphene battery capable of rapidly charging

InactiveCN108199039AImprove corrosion resistanceExtended service lifeCell electrodesSecondary cellsCorrosionEngineering

The invention provides a large-capacity graphene battery capable of rapidly charging, and relates to the technical field of batteries. The large-capacity graphene battery capable of rapidly charging,fabricated by the invention, comprises a positive pole plate, a negative pole plate, a separator, an electrolyte and a battery shell, the phenomena of small storage capacity and slow charging speed ofan existing graphene battery are solved, meanwhile, the corrosion resistance of the battery is improved, the service lifetime is prolonged, the large-capacity graphene battery is relatively good in stability, and no harm to a human body and an environment is generated; and compared with a traditional market graphene battery, it is verified that the charging time is obviously shortened by 34.94% under the same charging condition, and the charge-discharge efficiency of the battery can reach 87.73%.

Owner:长沙善道新材料科技有限公司

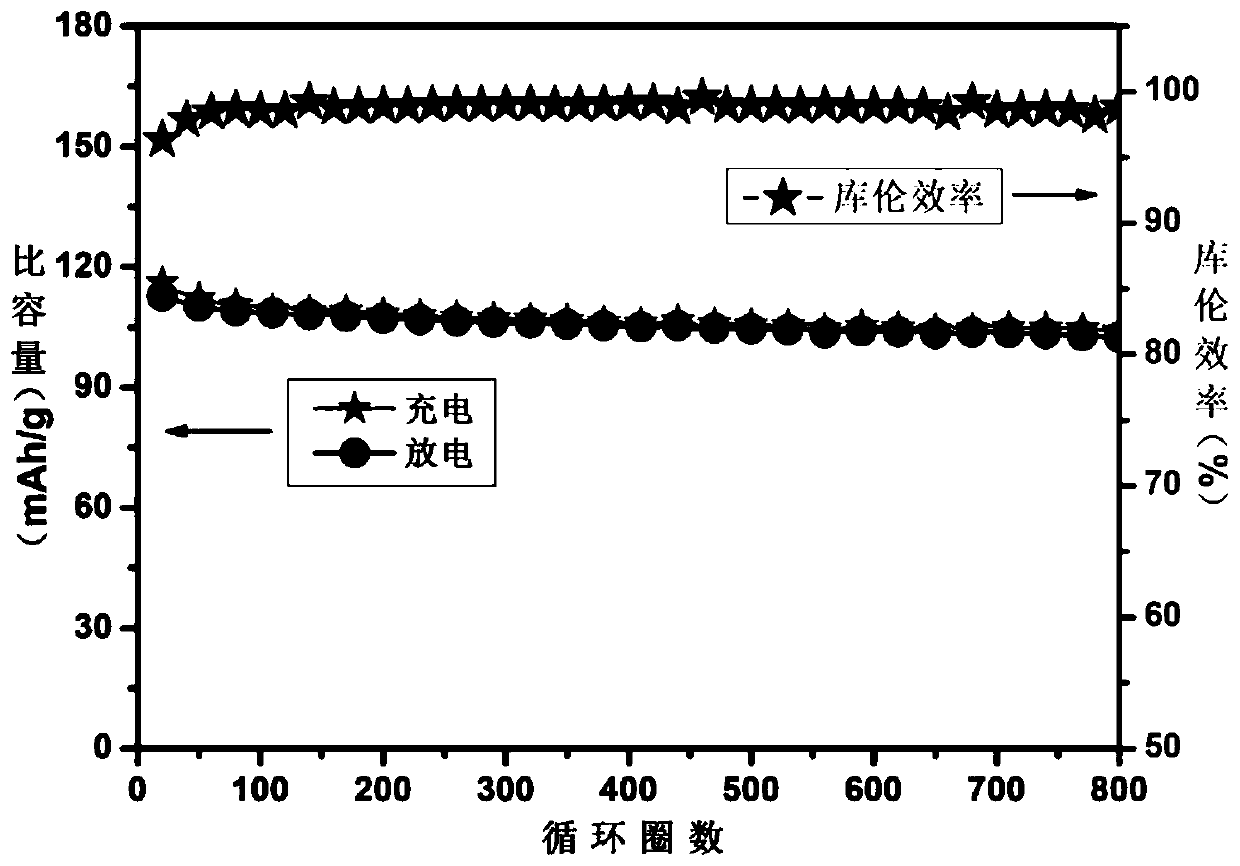

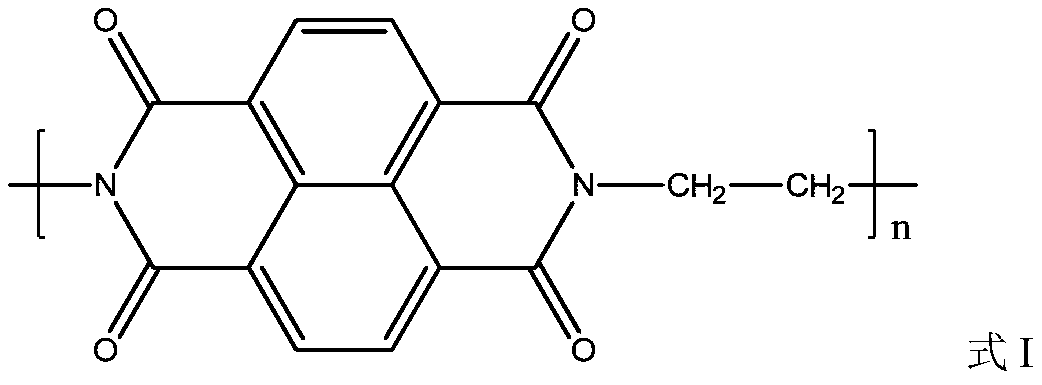

Aqueous ion battery and application thereof

ActiveCN110993944ALow cycle lifeLow specific capacitySecondary cellsNegative electrodesElectrolytic agentElectrical battery

The application discloses an aqueous ion battery. The aqueous ion battery comprises: an electrolyte which is an aqueous solution containing an electrolyte; a negative electrode containing a negative electrode active material; a negative electrode active material which includes polyimide containing a naphthalene ring; and a positive electrode, wherein a positive electrode comprises a positive electrode active material comprising a sodium-embedded material. The problems that the cycle life of the battery is short and the specific capacity of the battery is low due to poor matching (such as the mass ratio of positive and negative electrode material, process parameters of electrode preparation and a potential voltage window) of an existing negative electrode material and a positive electrode sodium-embedded material are solved; and moreover, the electrode preparation of the existing negative electrode material and battery assembly processes are complex, the condition requirements on an operation workshop are high, and the material preparation cost is high, so that the production and manufacturing cost of the whole battery is increased.

Owner:NINGBO FENGCHENG ADVANCED ENERGY MATERIALS RES INST

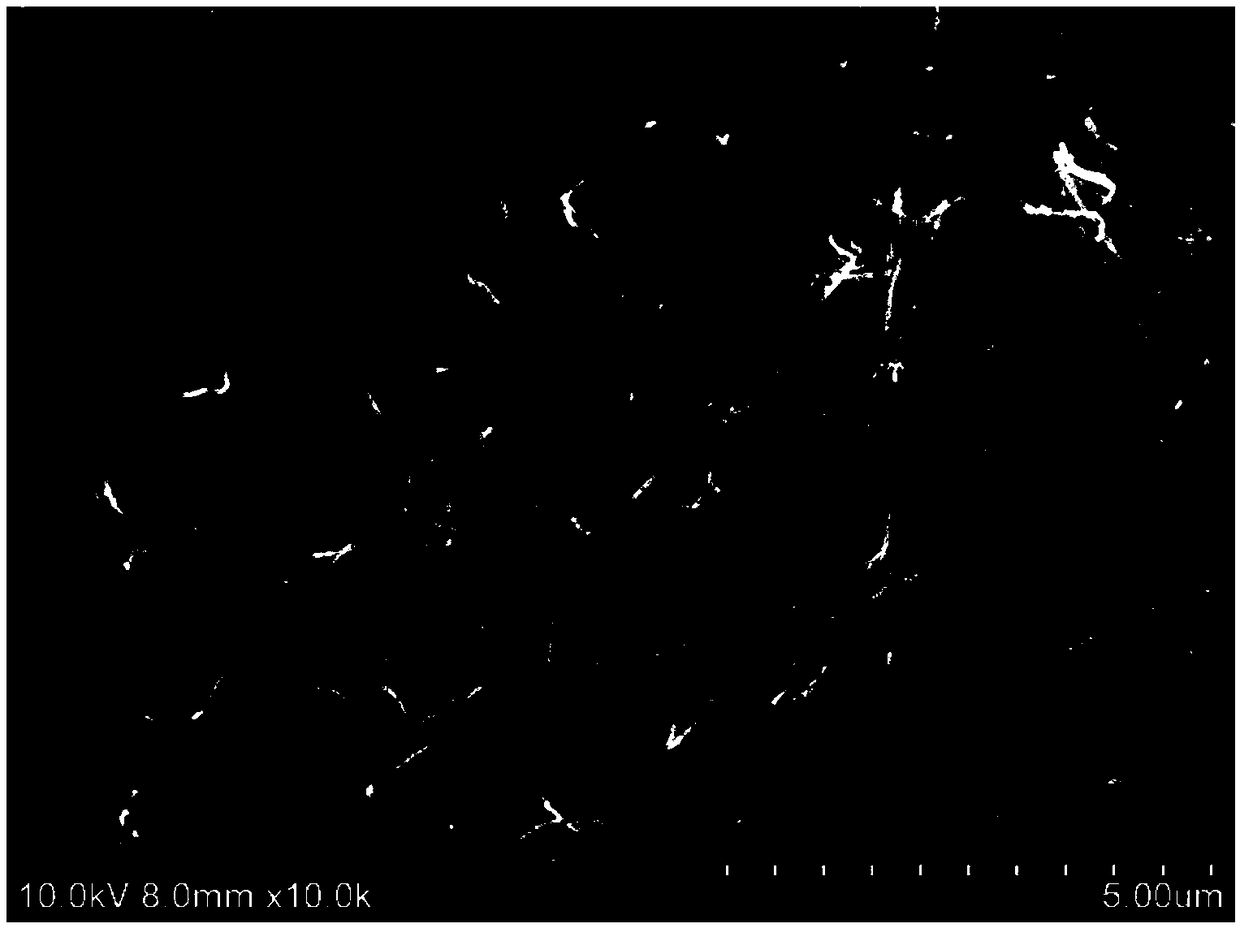

Carbon three-dimensional structural electrode of secondary battery and preparation method and application of carbon three-dimensional structural electrode

InactiveCN109411756AAvoid it happening againImprove Coulombic efficiencyMaterial nanotechnologyFuel and secondary cellsDendriteThree dimensional electrode

The invention provides a carbon three-dimensional structural electrode and a preparation method and application thereof. When the carbon three-dimensional structural electrode provided by the invention is adopted as an anode of a battery, active metal is deposited on or dissolved out of a carbon material three-dimensional skeleton, corresponding metallic dendrites are not generated, and the phenomenon that the dendrites puncture an electrolyte and consequently the battery is subjected to short circuit is avoided; rich holes in the three-dimensional electrode can accommodate the active metal deposited on a skeleton electrode and volume-expanded active metal, and the problems that the electrode structure collapses due to dissolving out of the active metal, consequently the size and shape ofthe battery are changed, the cycle life is shortened, and energy density is decreased are avoided through the rigid structure of the three-dimensional skeleton; and a carbon material can provide a space or a channel for embedding and stripping metal ions, and the storage capacity of the battery is increased. When the carbon three-dimensional structural electrode provided by the invention is used as the anode of the battery, the original assembly process of the battery does not need to be changed.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Battery

PendingCN113013377AImprove interfacial adhesionIncreasing the thicknessFinal product manufactureSecondary cellsElectrical batteryPole piece

The invention provides a battery. The battery comprises a roll core, the roll core comprises a first pole piece, a diaphragm and a second pole piece which are wound, the diaphragm is located between the adjacent first pole piece and second pole piece, the first pole piece is provided with a first tab, and the second pole piece is provided with a second tab; the first tab is close to a first bending part at the first end of the roll core, the second tab is close to a second bending part at the second end of the roll core, and the winding tail end of the roll core covers the first bending part and extends from the first bending part to the second bending part; and the area between the end head of the second end of the roll core and the second tab is opposite to the first part of the roll core, and the first outer-layer gummed paper covers the outer surface of at least one side of the first part. First outer-layer gummed paper has a certain thickness, so that the thickness of the part, which is attached to the first outer-layer gummed paper, of the roll core can be increased. Therefore, the battery provided by the embodiment of the invention solves the technical problem that the surface flatness of the roll core structure in the lithium ion battery is relatively poor.

Owner:ZHUHAI COSMX BATTERY CO LTD

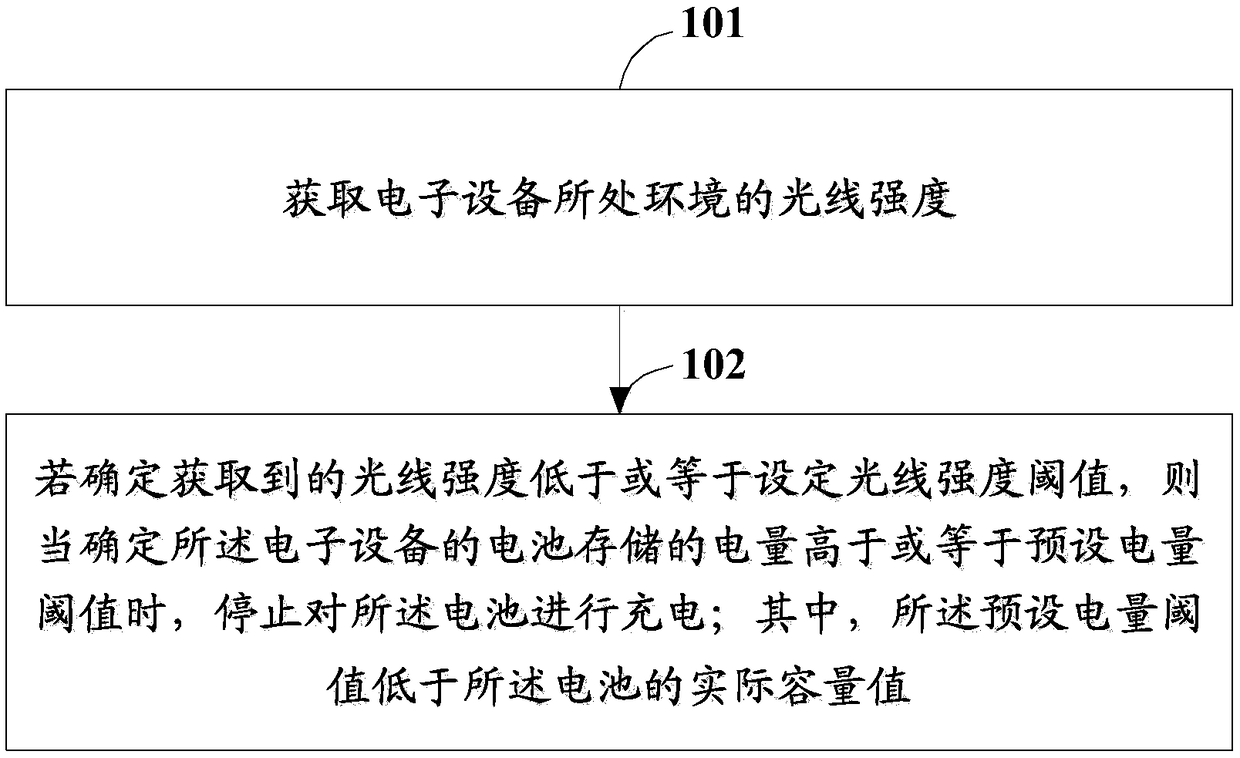

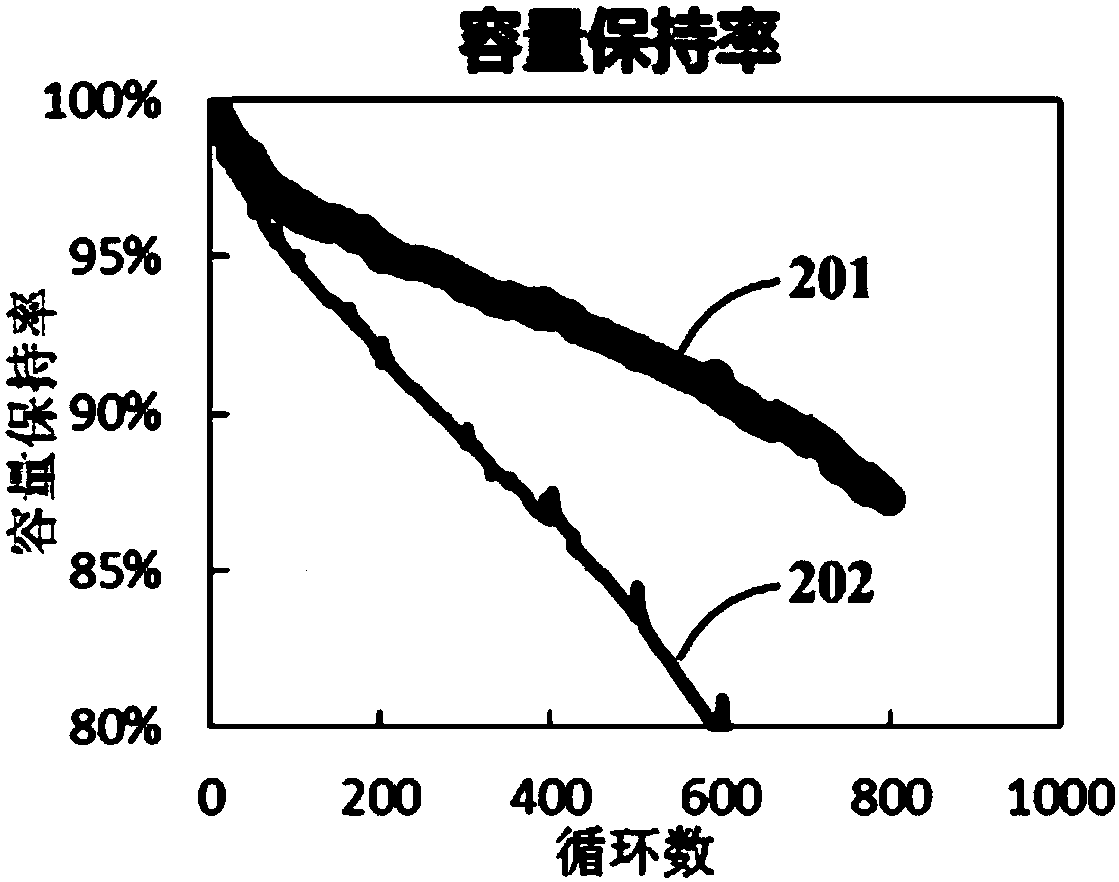

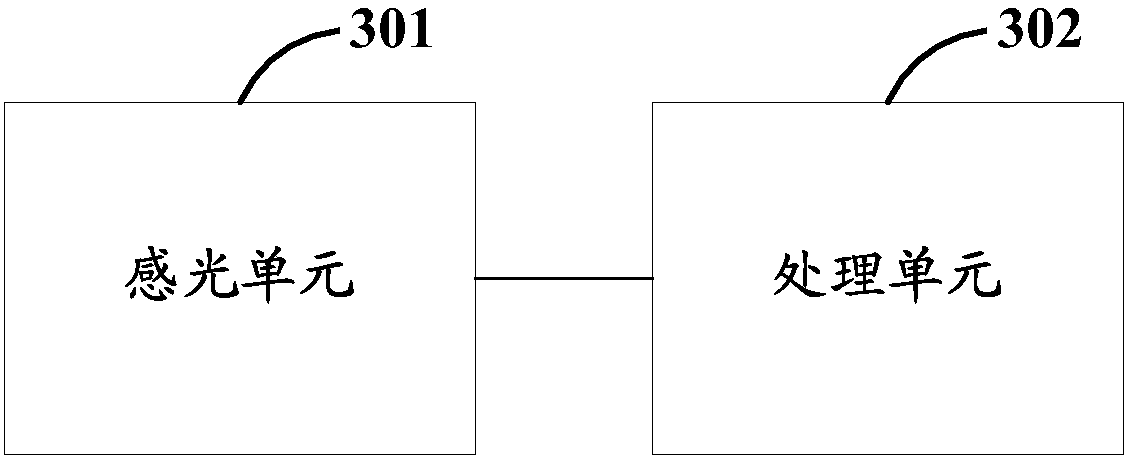

Charging method, charging device, and electronic device

ActiveCN109462260AImprove cycle lifeDecay cycle life for accelerated battery cycle lifeElectric powerBattery disconnect circuitsUltrasound attenuationCapacity value

The invention provides a charging method, a charging device, and an electronic device, and is applied to charging control of a battery arranged in the electronic device. The method includes steps: obtaining a light intensity of an environment in which the electronic device is located; and stopping charging of the battery if it is determined that the obtained light intensity is lower than or equalto a set light intensity threshold and it is determined that the capacity stored by the battery is higher than or equal to a preset capacity threshold, wherein the preset capacity threshold is lower than a practical capacity value of the battery. In other words, whether the current time for charging of the battery of the electronic device is night is determined through the obtained light intensityof the environment in which the electronic device is located, and if yes, the charging of the battery is stopped when the capacity stored by the battery of the electronic device is lower than the practical capacity value of the battery so that the acceleration of attenuation of the cycle life of the battery due to long-time full-charging state of the battery of the electronic device after charging at night is avoided, and the service lifetime of the battery is prolonged.

Owner:NINGDE AMPEREX TECH

Negative pole piece, lithium ion battery and manufacturing method of lithium ion battery

ActiveCN111048749AImprove conductivityImprove high-current discharge performanceCell electrodesFinal product manufacturePole pieceLithium-ion battery

The invention discloses a negative pole piece, a lithium ion battery and a manufacturing method of the lithium ion battery. Modified artificial graphite is selected as a negative electrode active substance, the artificial graphite is doped with one or more of Cu, Ni and Ag, the surface of the artificial graphite is coated with amorphous carbon subjected to phenolic resin pyrolysis, and the surfaceof the artificial graphite is further subjected to heat treatment, so that the high-current discharge capacity of the negative active substance, the negative pole piece coated with the negative active substance and the lithium ion battery taking the negative pole piece as a negative pole is effectively improved.

Owner:SHENZHEN ZHUONENG NEW ENERGY TECH

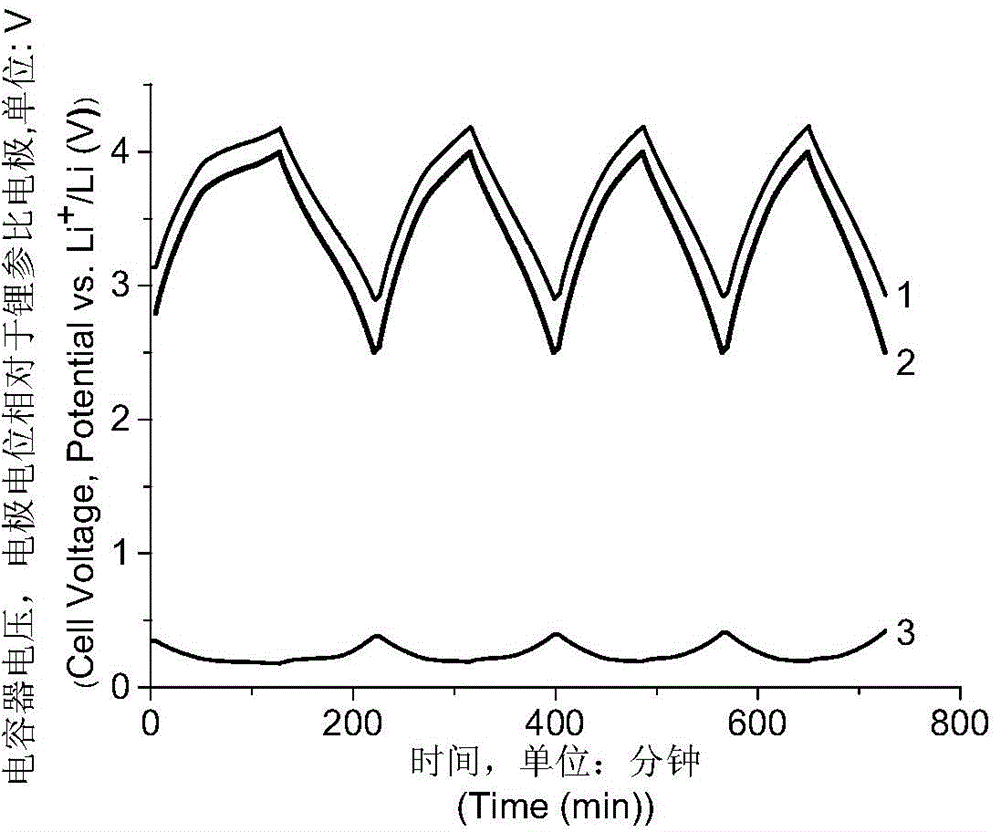

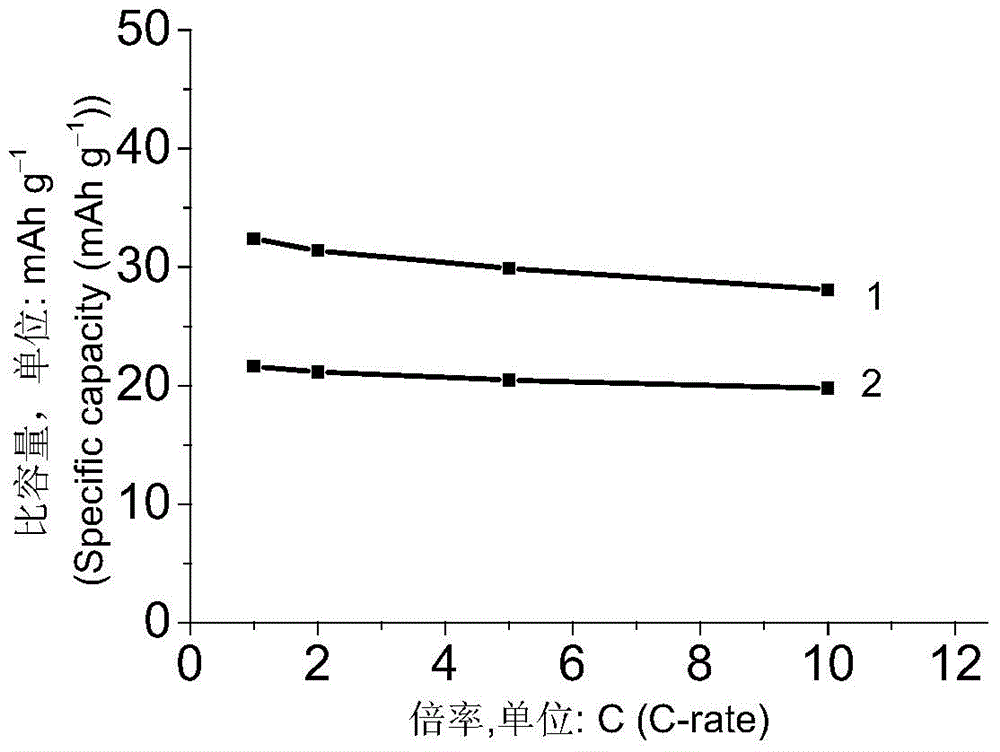

Lithium ion capacitor

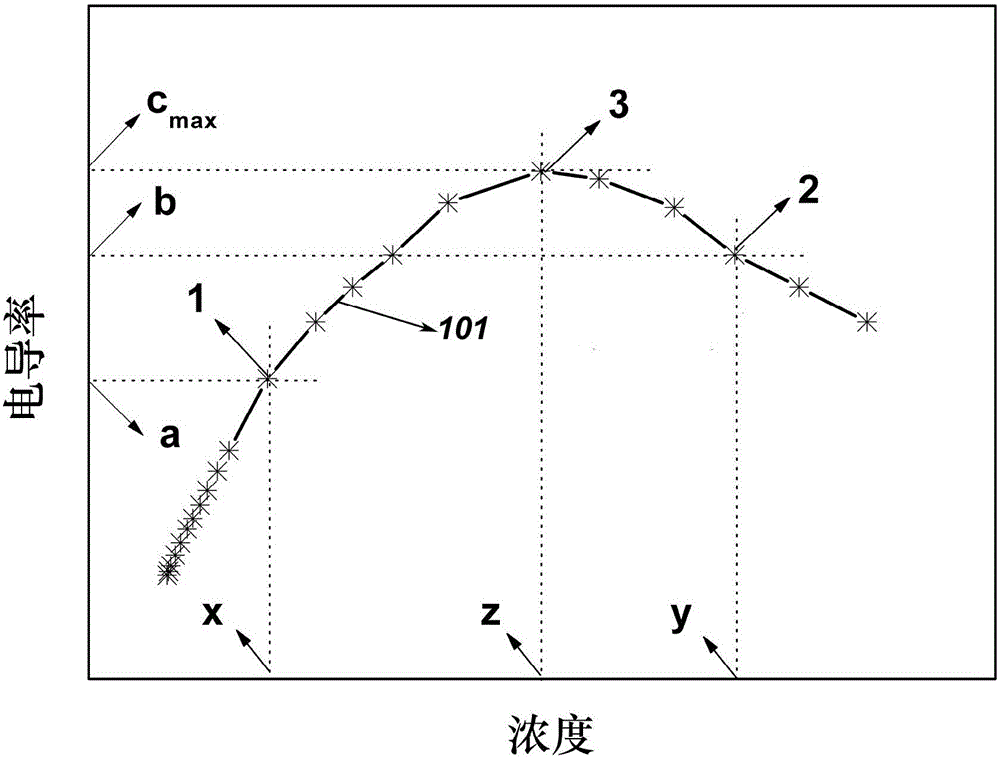

ActiveCN106158413ALower internal resistanceLow operating voltage and highest internal resistanceHybrid capacitor electrolytesHybrid capacitor electrodesHigh concentrationOrganic solvent

The invention discloses a lithium ion capacitor. An active material in a positive electrode material layer is a double-layer energy storage carbon material, an active material in a negative electrode material is a lithium inserted energy storage material, and electrolyte comprises soluble lithium salt and non-protonic organic solvent with soluble lithium salt dissolved. The concentration of the electrolyte is x when an open-circuit voltage of the lithium ion capacitor is equal to a maximum working voltage and is y when the open-circuit voltage is equal to a minimum working voltage, and a maximum conductivity concentration value of electrolytes of a same system is z at a temperature ranging from -20 DEG C to 60 DEG C, wherein z is larger than or equal to x and smaller than or equal to y. When the lithium ion capacitor is in operation under a voltage between the minimum working voltage and the maximum working voltage, concentration variation of the electrolyte corresponds to a high concentration range of conductivity values, the highest ionic conductivity range of the electrolyte is used to the greatest extent, and accordingly the lithium ion capacitor is low in internal resistance and excellent in power performance.

Owner:中船重工黄冈水中装备动力有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com