Carbon three-dimensional structural electrode of secondary battery and preparation method and application of carbon three-dimensional structural electrode

A three-dimensional structure and electrode technology, applied in the electrodes of primary batteries, secondary batteries, battery electrodes, etc., can solve the problems of battery short circuit, battery failure, combustion and explosion, etc., to improve metal dendrites, ensure integrity, and improve energy. The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] This example is used to illustrate the electrode of the present invention and its preparation method and application.

[0081] 1. Fabrication of carbon nanotube three-dimensional structure electrodes for lithium secondary batteries

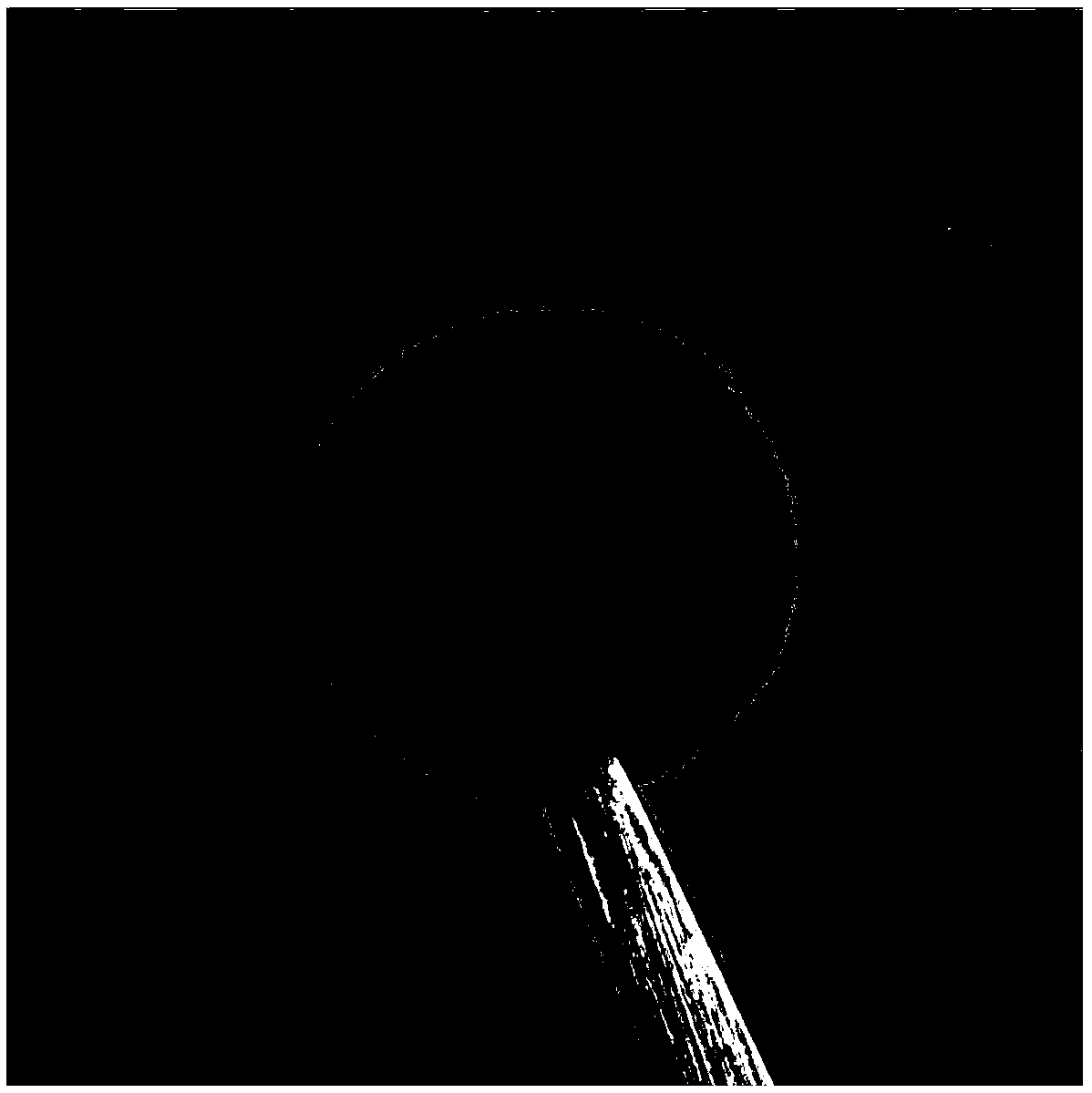

[0082] Commercialized carbon nanotube sponges were punched into discs with a diameter of 14 mm and a thickness of 2 μm. Wherein, the inner diameter of the carbon nanotube is 20nm, the outer diameter is 40nm, and the ratio of amorphous carbon and graphitic carbon in the material is 0.74. A carbon nanotube sponge electrode with a diameter of 14 mm such as figure 1 shown.

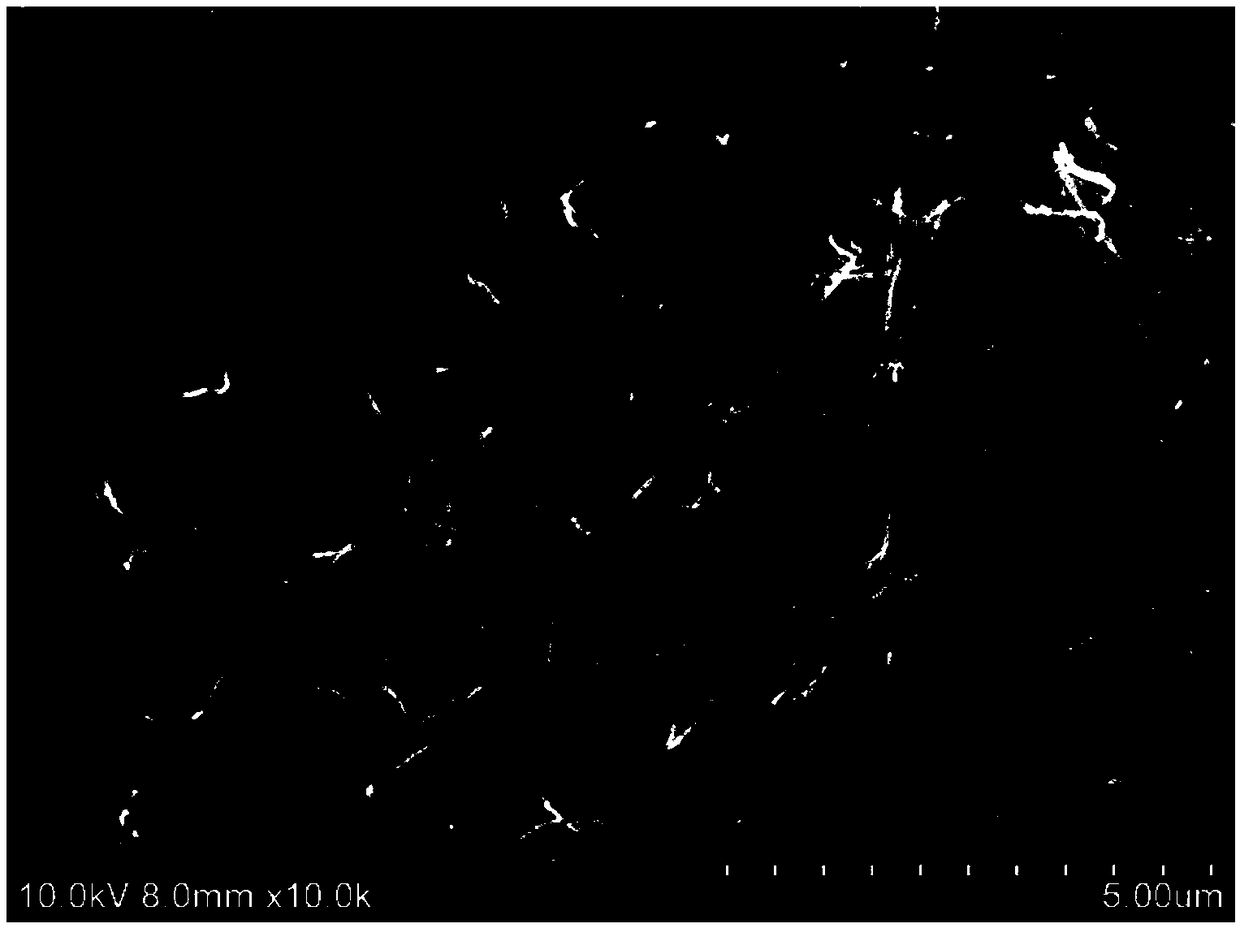

[0083] Such as figure 2 As shown, the prepared carbon nanotube sponge electrode has a three-dimensional structure, and its porosity is 95%. The above-mentioned carbon nanotube sponge electrode was cleaned with dilute hydrochloric acid, deionized water and alcohol respectively, and then the cleaned carbon nanotube sponge electrode was placed in a vacuum chamber and evac...

Embodiment 2

[0093] This example is used to illustrate the electrode of the present invention and its preparation method and application.

[0094] 1. Fabrication of graphitized carbon fiber three-dimensional structure electrodes for lithium secondary batteries

[0095] Commercially available graphitized carbon fibers were punched into discs with a diameter of 14 mm and a thickness of 3 μm. Among them, the diameter of the carbon fiber is 500nm, and the ratio of amorphous carbon and graphitic carbon in the material is 0.51.

[0096] Observing the graphitized carbon fiber electrode of Example 2 through a scanning electron microscope showed that the graphitized carbon fiber had a three-dimensional structure with a porosity of 90%.

[0097] The above-mentioned graphitized carbon fiber electrode was cleaned with citric acid, deionized water and alcohol respectively, and then the cleaned graphitized carbon fiber electrode was placed in a vacuum chamber for 12 hours at room temperature to make it...

Embodiment 3

[0107] This example is used to illustrate the electrode of the present invention and its preparation method and application.

[0108] 1. Fabrication of carbon nanowire three-dimensional structure electrodes for lithium secondary batteries

[0109] Commercialized carbon nanowire sheets were punched into discs with a diameter of 14 mm and a thickness of 2 μm. Wherein, the diameter of the carbon nanowire is 70nm, and the ratio of amorphous carbon and graphitic carbon in the material (calculated according to the integral area of the D peak representing the amorphous carbon and the G peak representing the graphitic carbon in the Raman spectrum of the corresponding material) is 0.65.

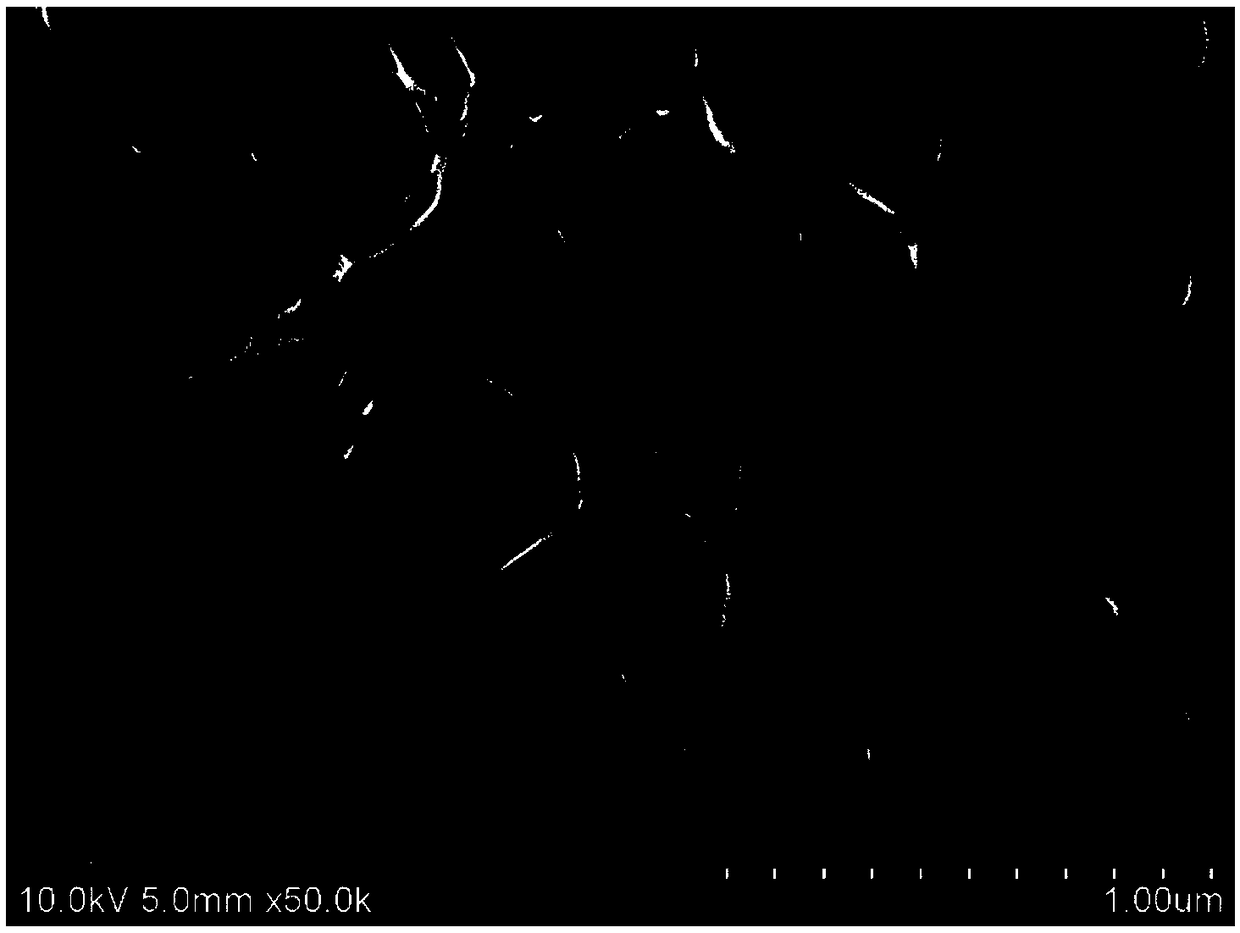

[0110] Such as Image 6 As shown, the prepared carbon nanowire electrode has a three-dimensional structure with a porosity of 92%.

[0111] The above-mentioned carbon nanowire electrodes were cleaned with dilute hydrochloric acid, deionized water and alcohol respectively, and then the cleaned carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com