Patents

Literature

153 results about "Carbon fiber electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for electro-permeabilization of individual cellular and organellar structures and use thereof

InactiveUS7109034B2Accurate focusImprove spatial resolutionBioreactor/fermenter combinationsElectrotherapyFiberDisease

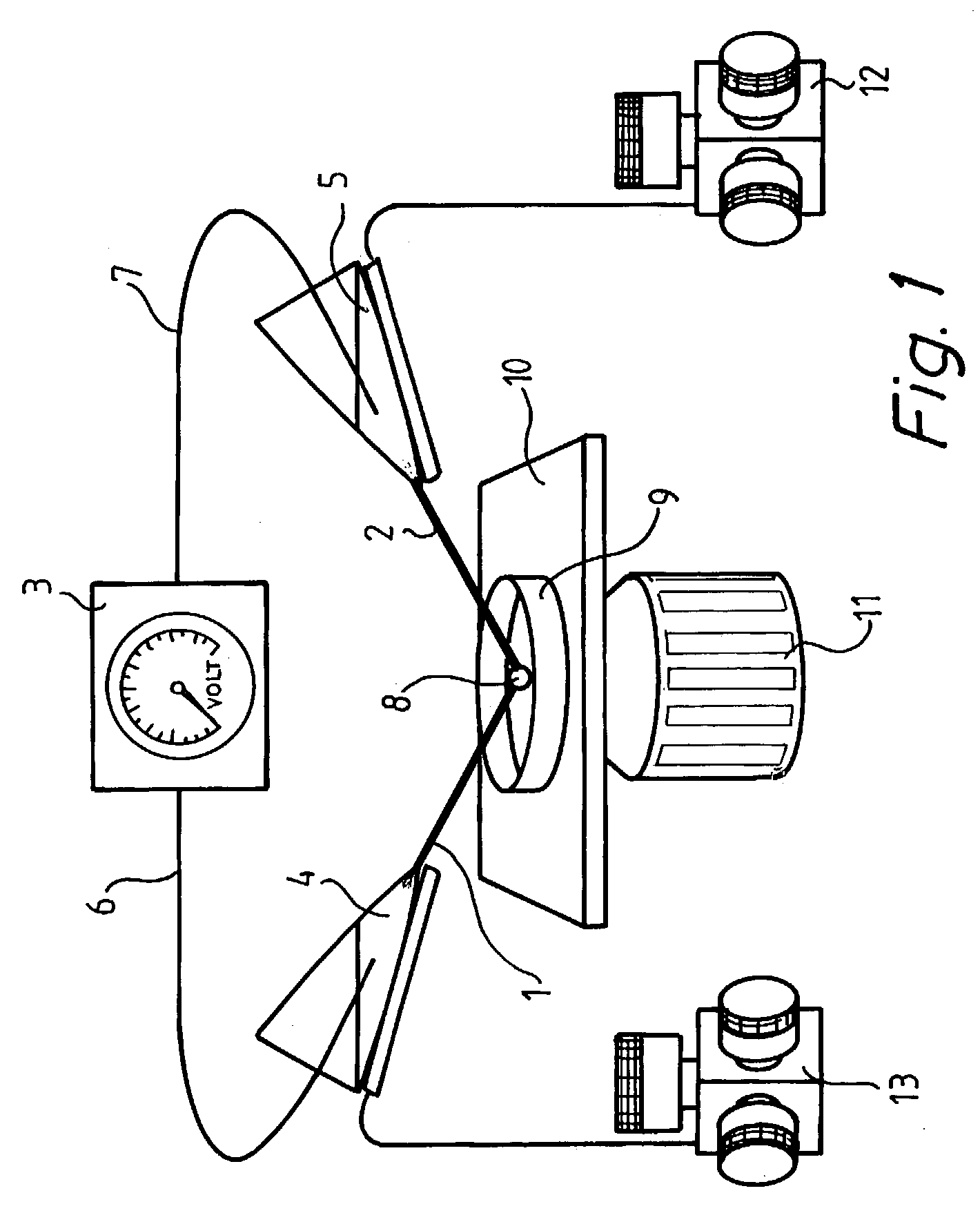

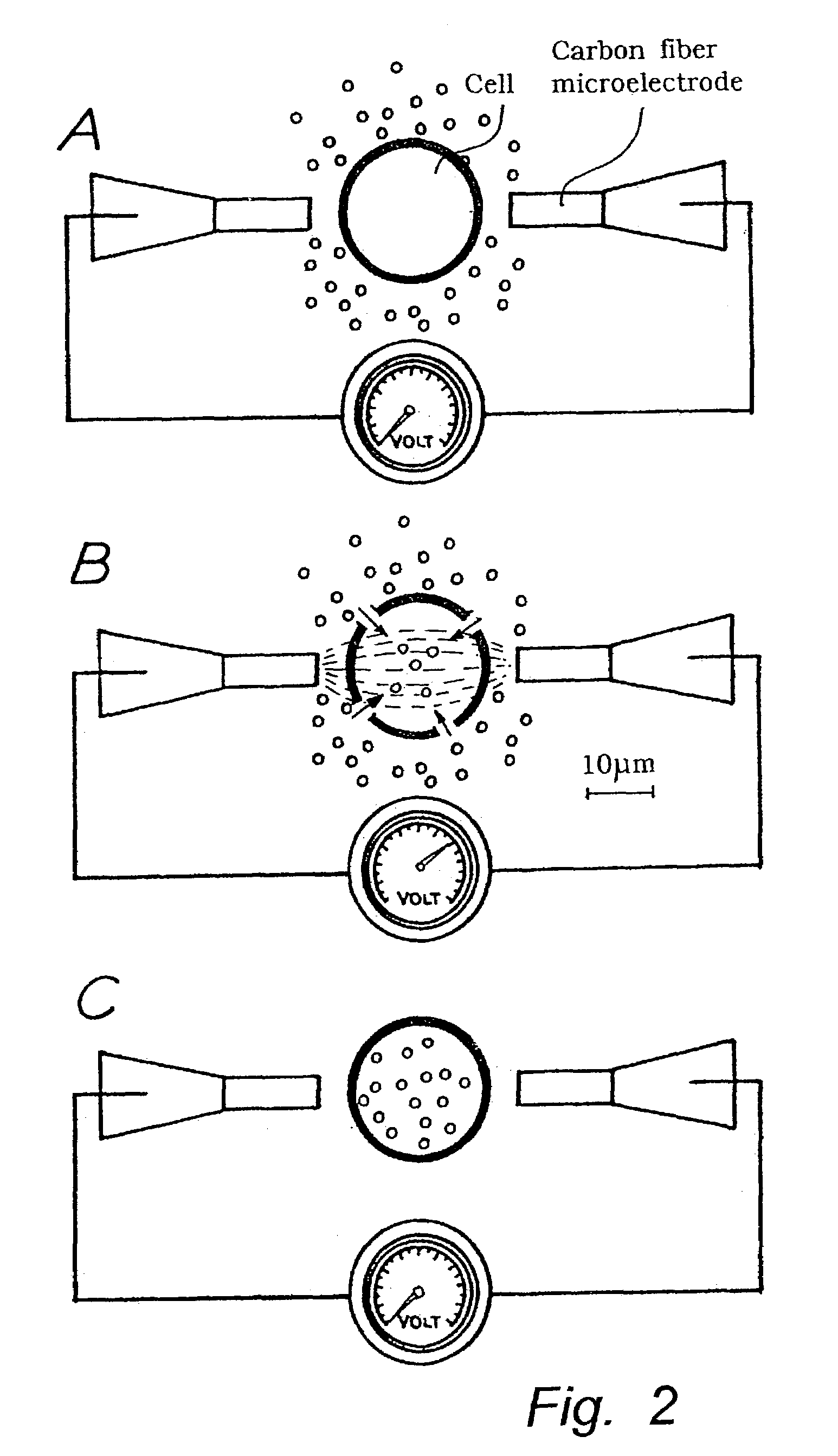

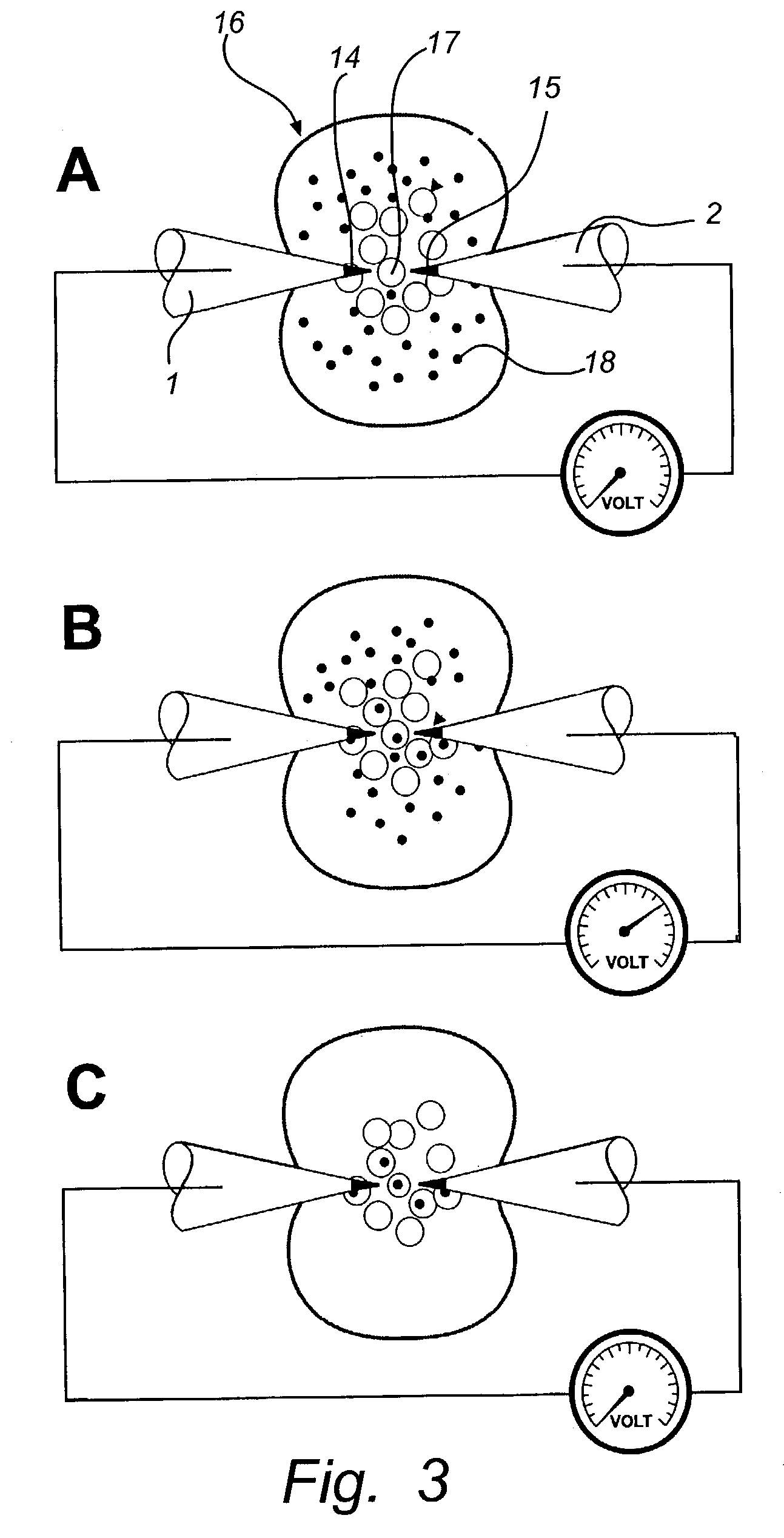

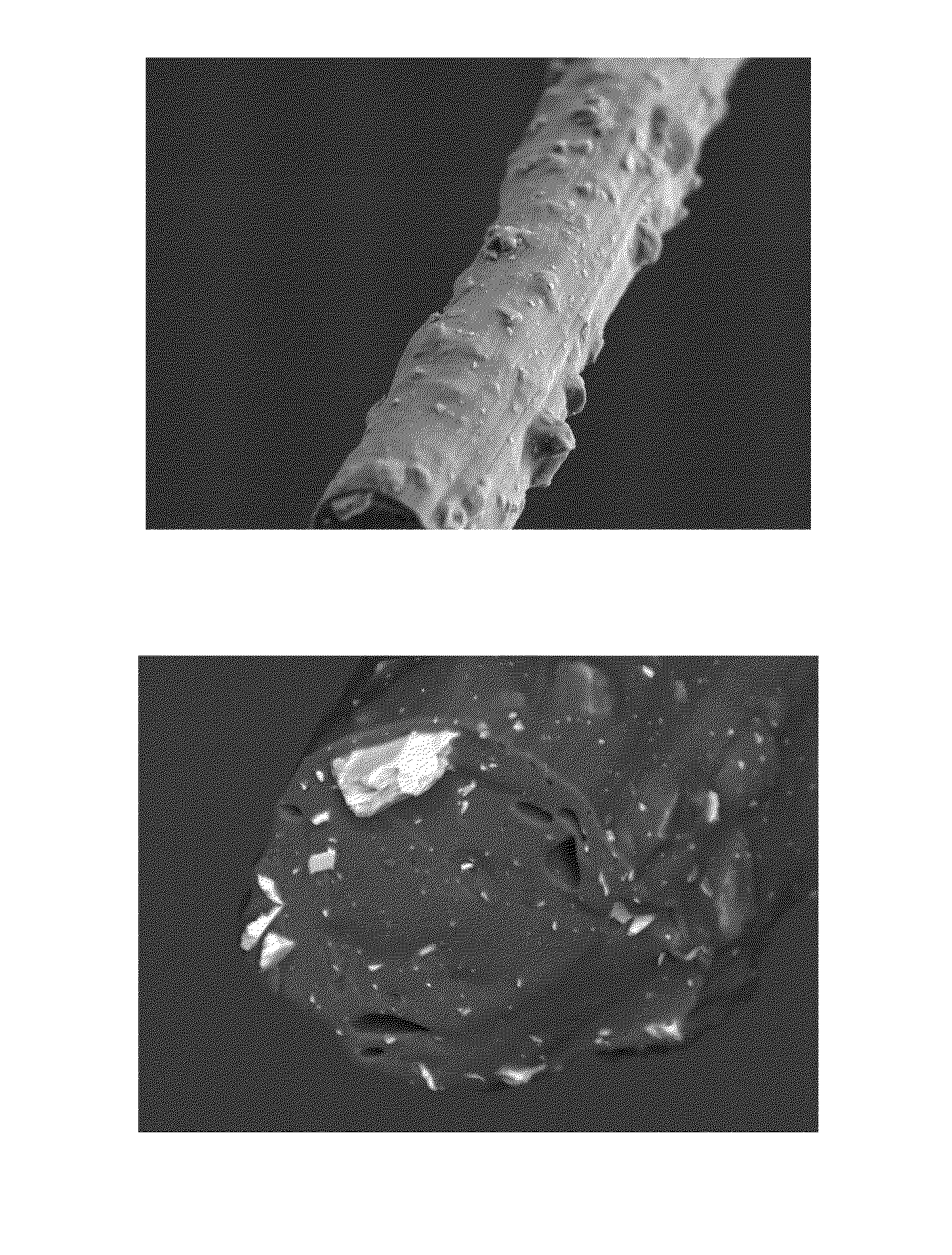

The invention relates to a method for permeabilization of a cell structure consisting of a single cell, an intracellular structure or an organelle comprising the following steps: (a) microelectrodes, preferably two carbon fiber electrodes or hollow fiber electrodes, are provided, (b) the microelectrodes are connected to a power supply, (c) the electrodes, individually controlled by high-graduation micromanipulators, are placed close to the cell structure at an appropriate inter-electrode distance, and (d) a highly focused electric field of a strength sufficient to obtain electroporation is applied between the electrodes. The method may be used in order to transfer cell impermeant solutes, such as drugs or genes, into the cell structure or out of the cell structure, in biosensors, in the treatment of tumours and neurodegenerative diseases and in the study of biophysical processes.

Owner:CELLECTRICON

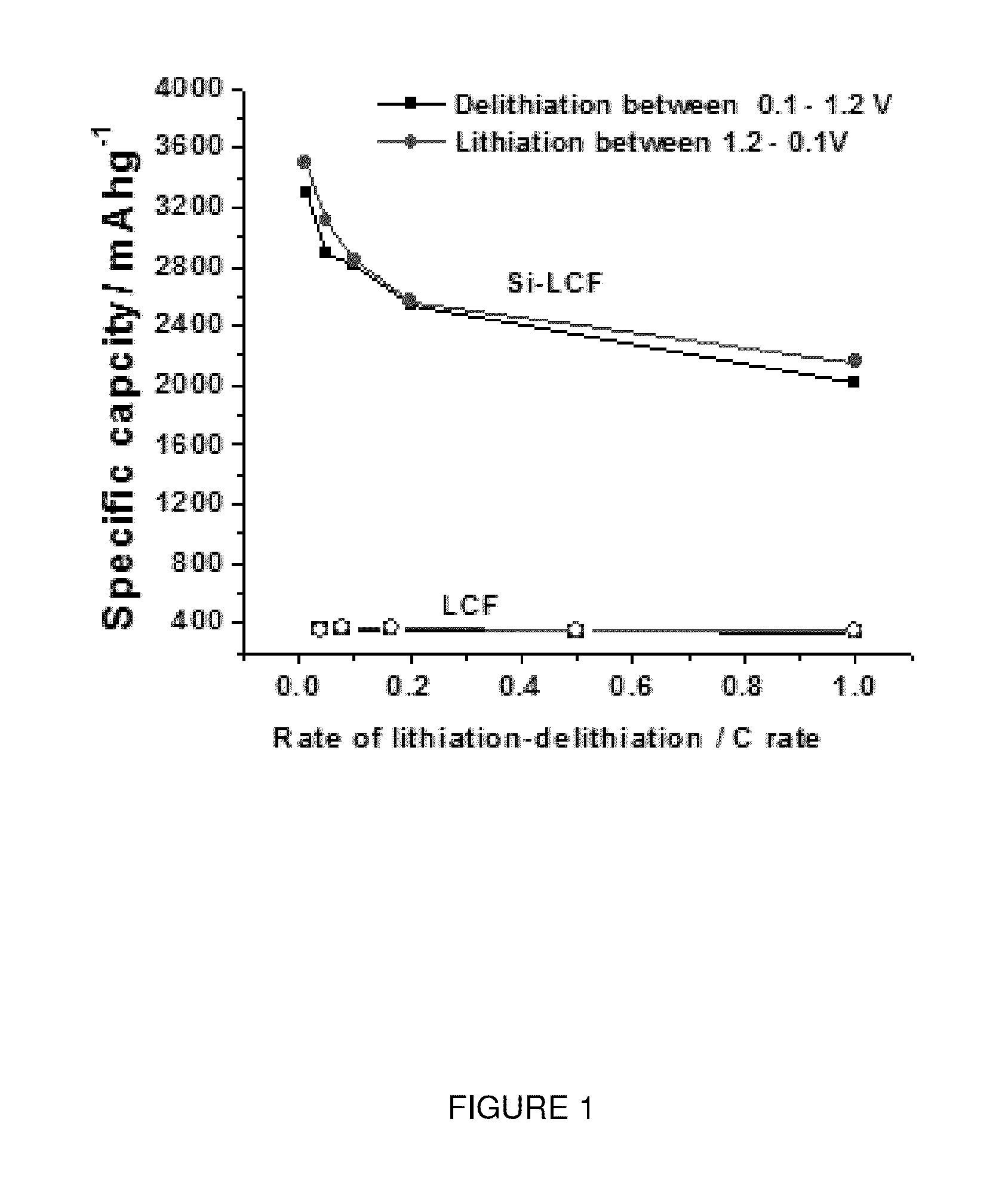

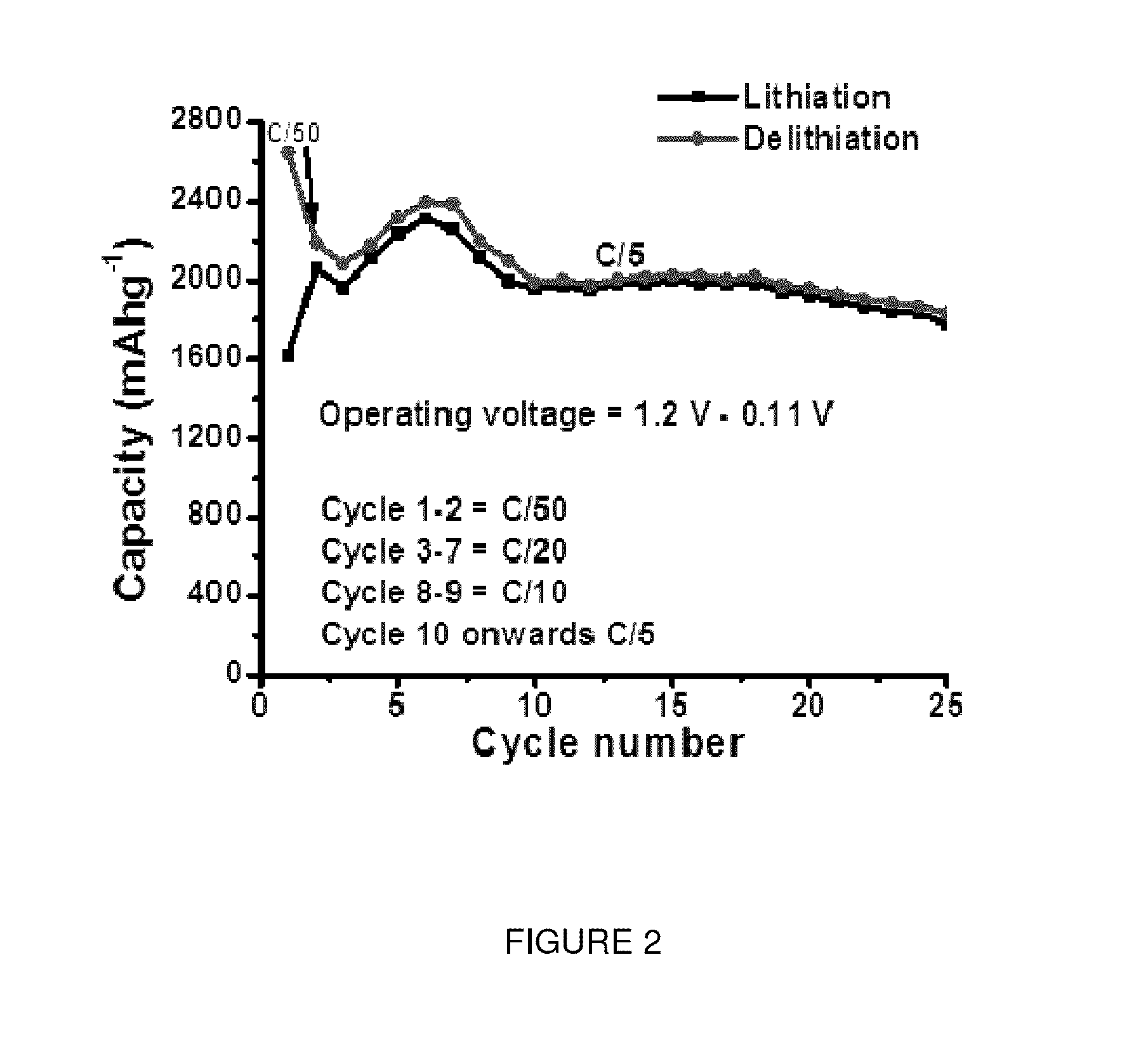

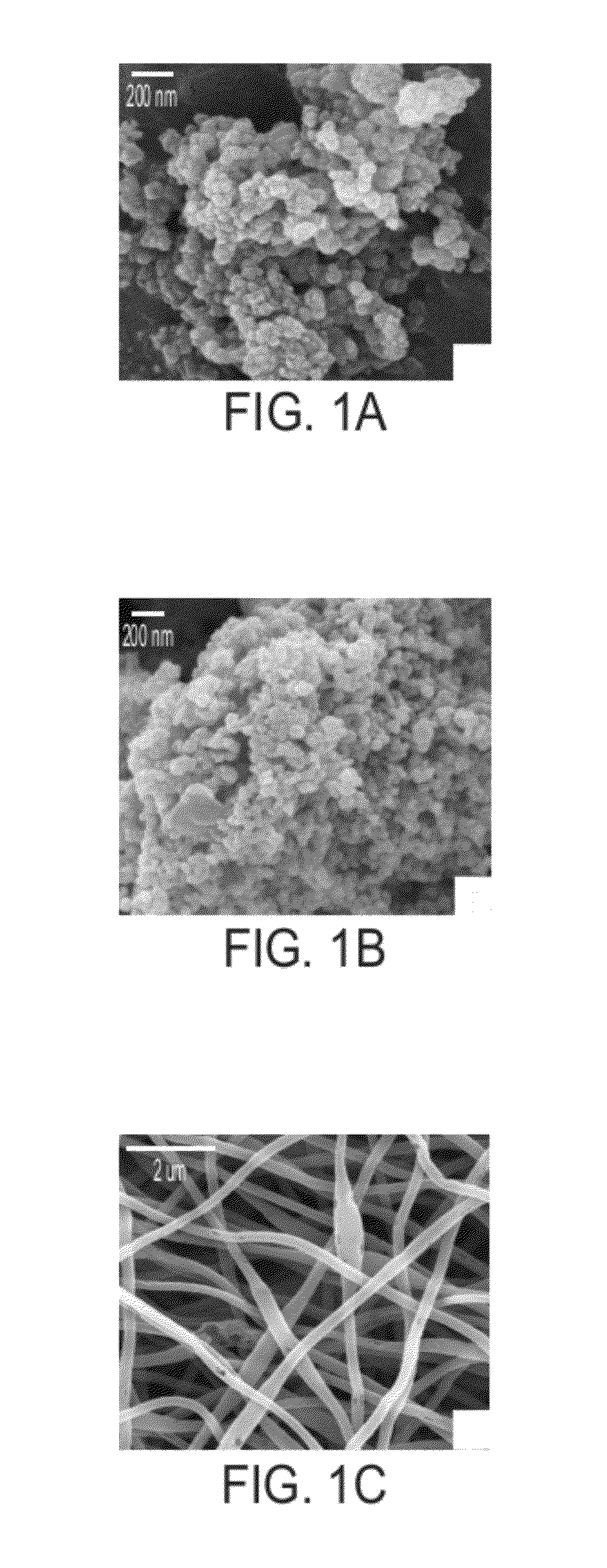

High capacity monolithic composite si/carbon fiber electrode architectures synthesized from low cost materials and process technologies

A composite Si-carbon fiber comprising a carbon matrix material with 1-90 wt % silicon embedded therein. The composite carbon fibers are incorporated into electrodes for batteries. The battery can be a lithium ion battery. A method of making an electrode incorporating composite Si-carbon fibers is also disclosed.

Owner:UT BATTELLE LLC

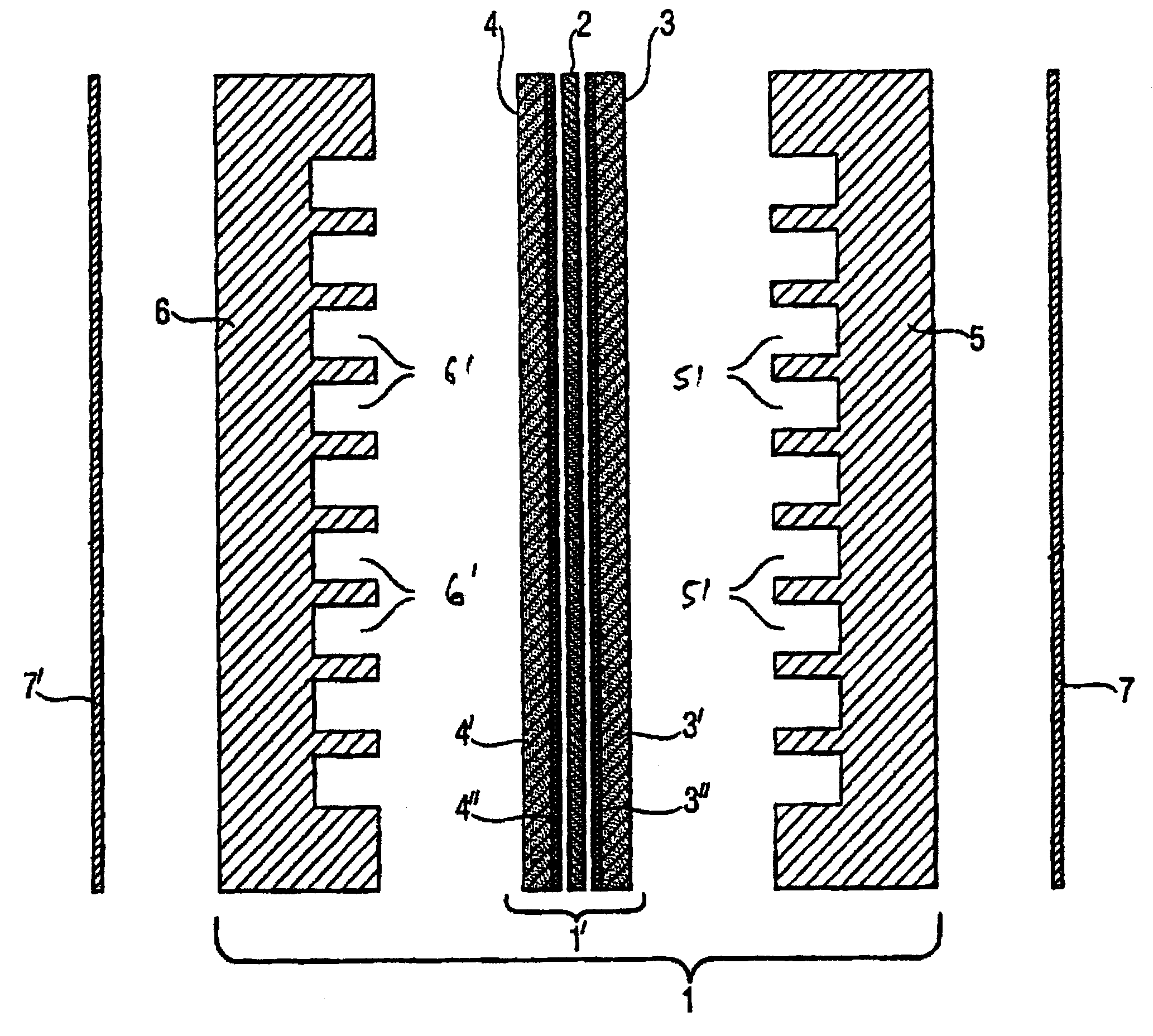

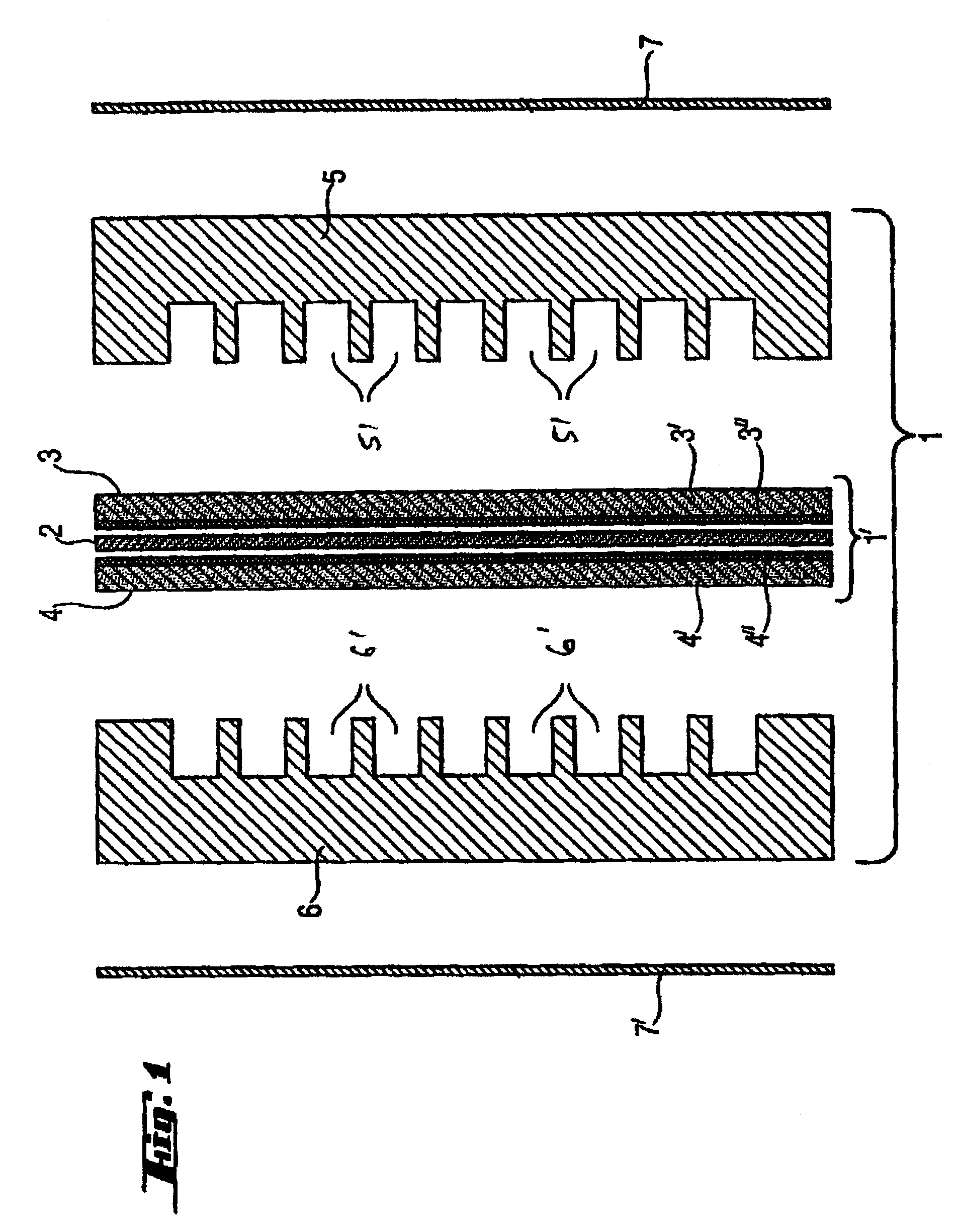

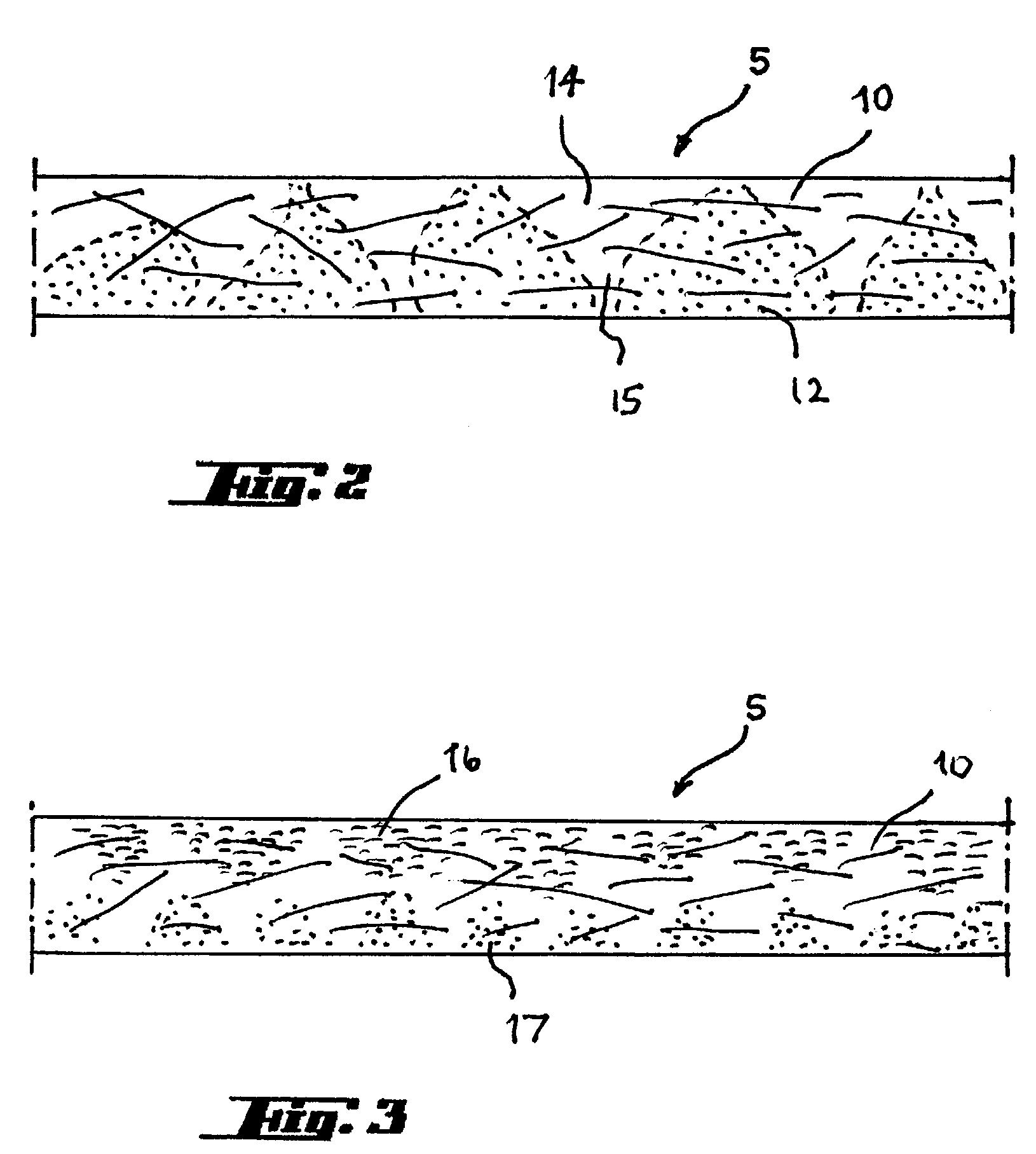

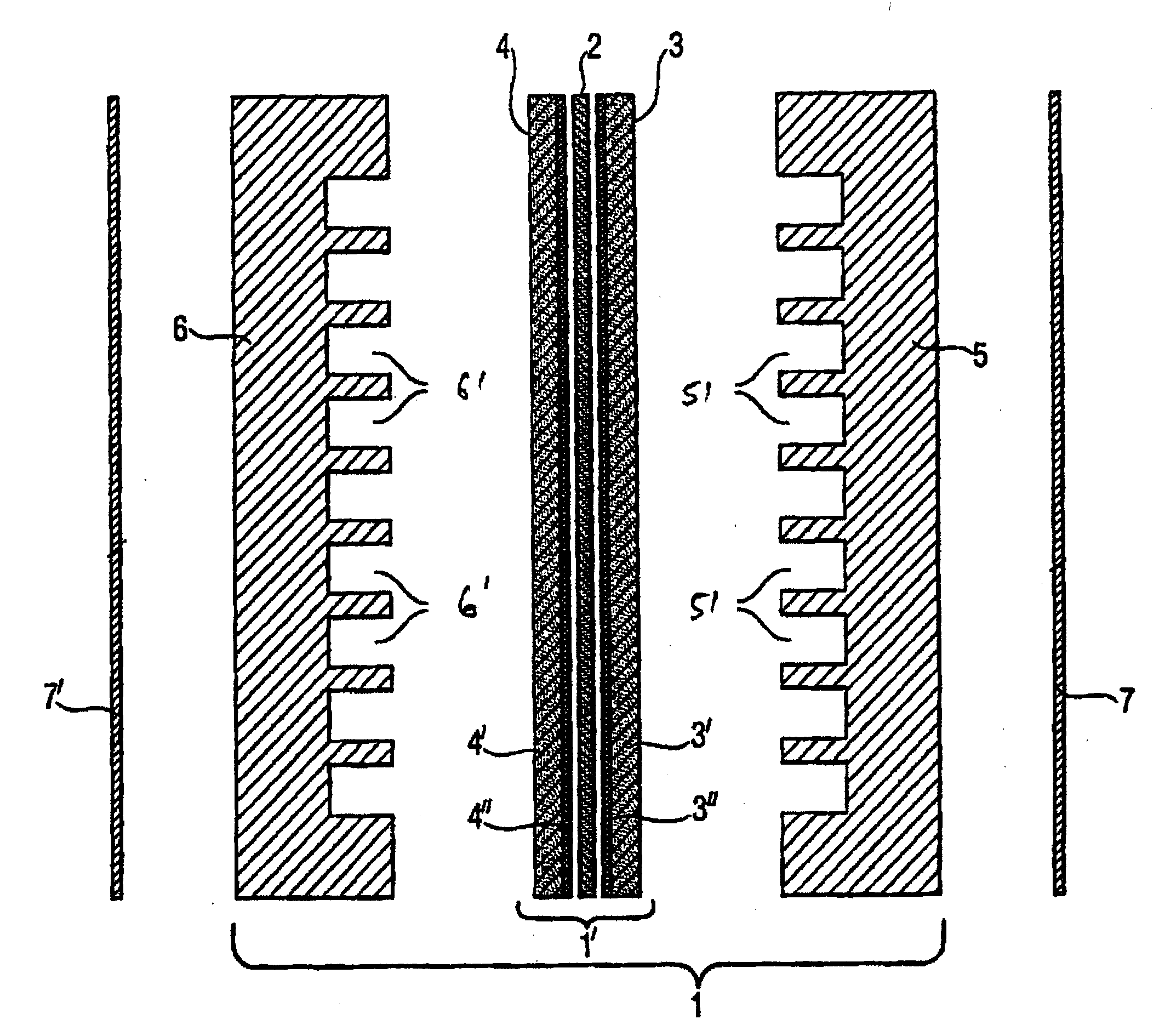

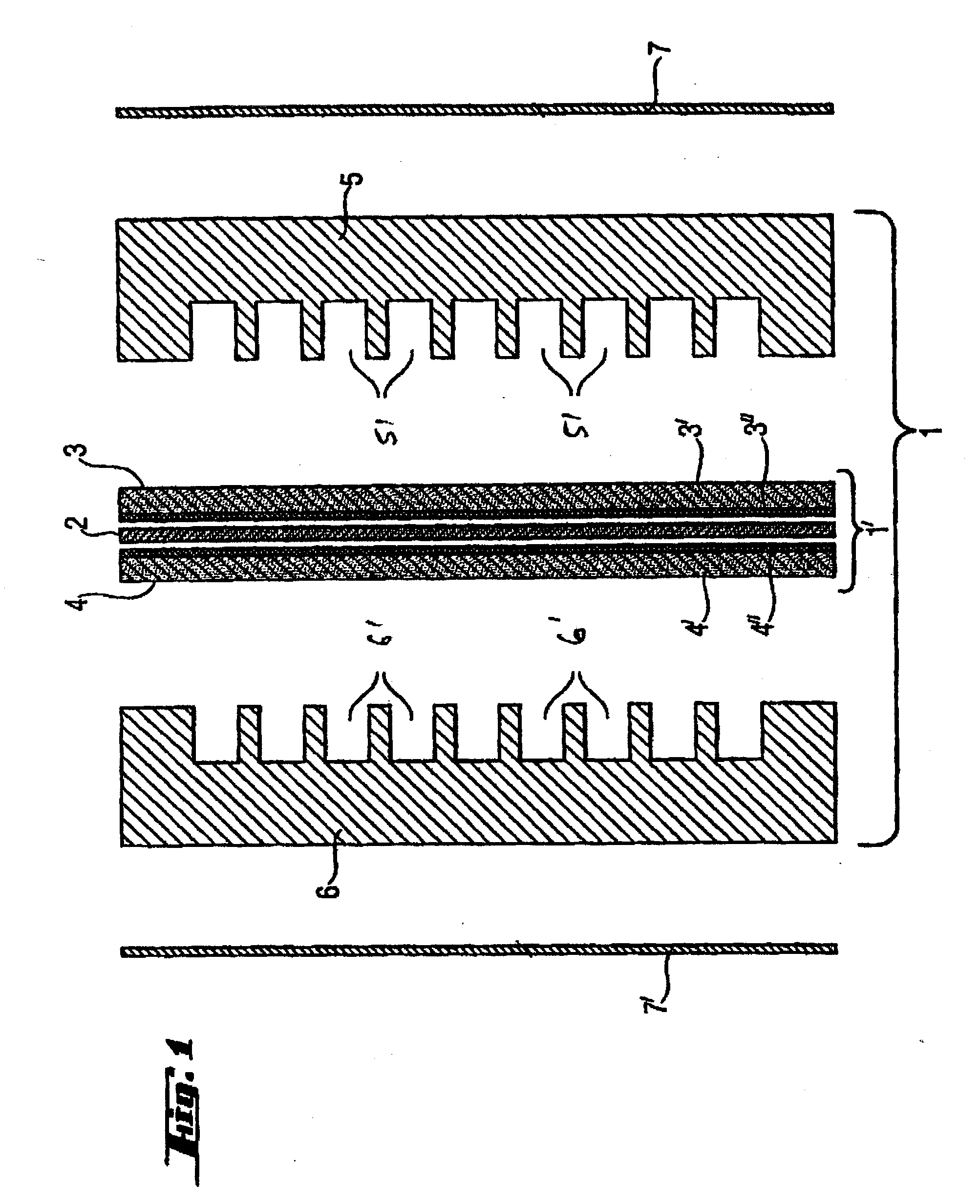

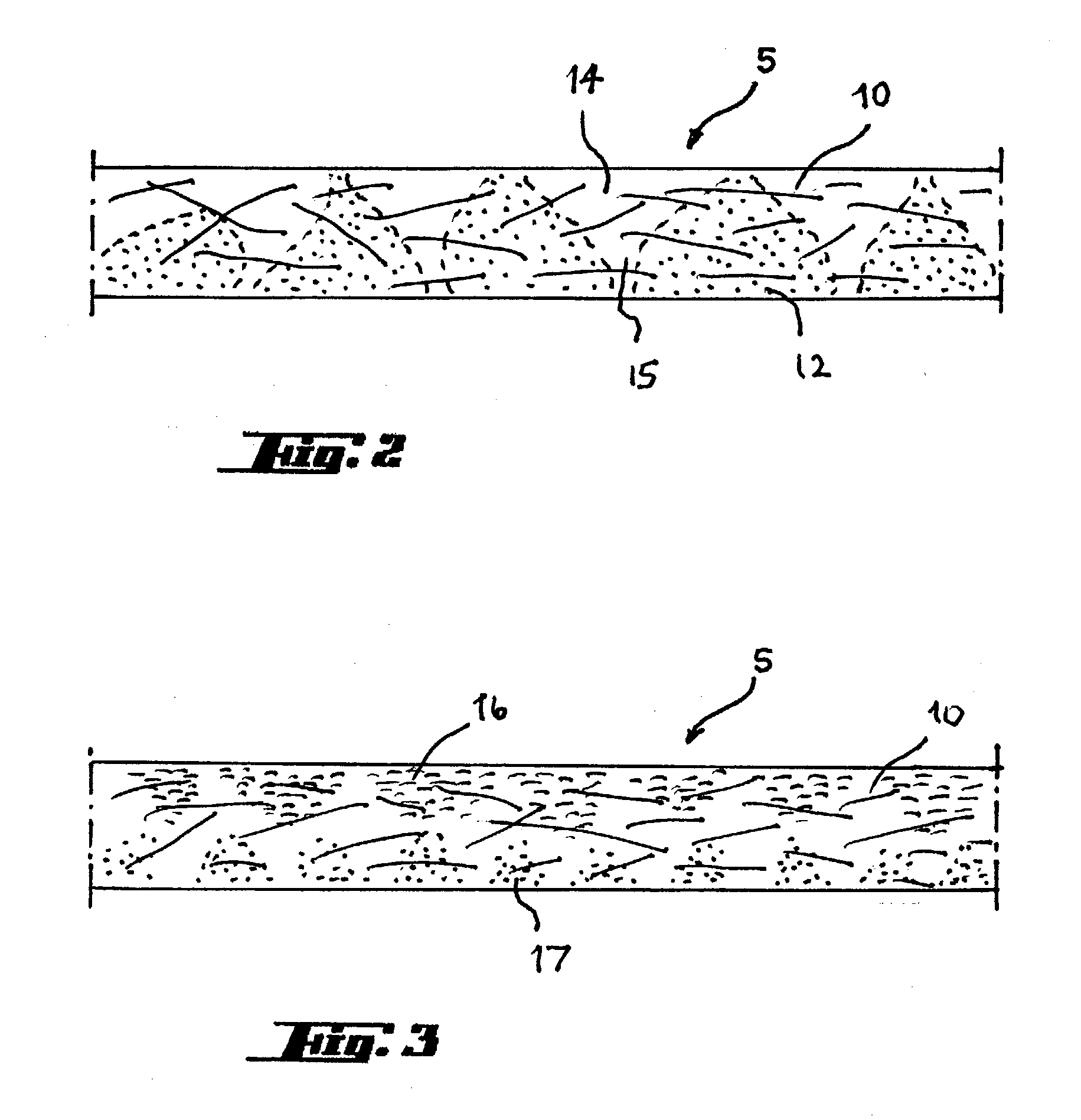

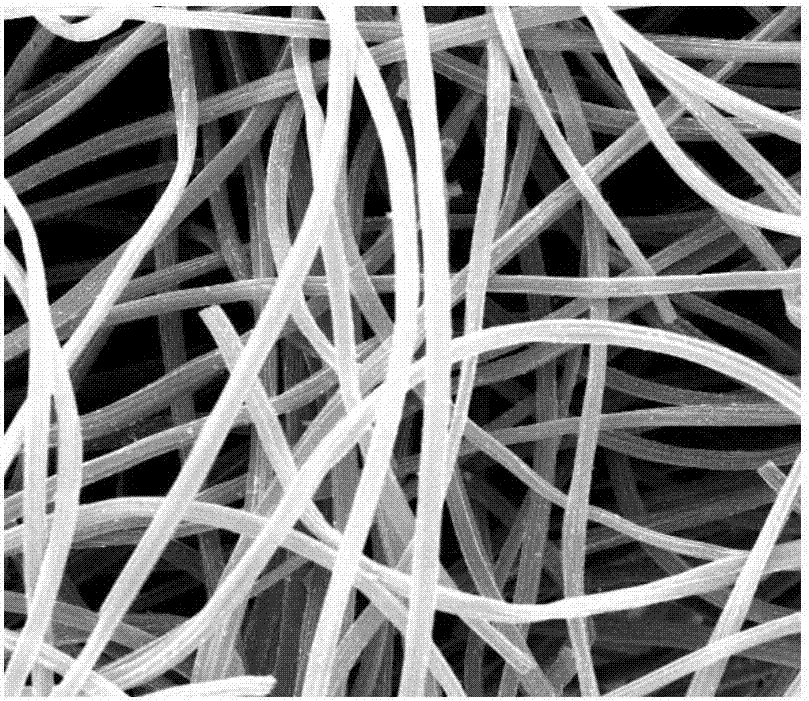

Carbon fiber electrode substrate for electrochemical cells

ActiveUS7144476B2High carbon contentImprove conductivityNon-fibrous pulp additionNatural cellulose pulp/paperFiberCarbon fibers

This invention relates to electrode substrates for electrochemical cells, particularly low-temperature fuel cells, and processes for their production. Low-cost carbon fiber paper structures are used as precursor for preparation of an all-carbon product that has a high electric conductivity and porosity and can be processed in a continuous reel-to-reel mode. These paper materials are further impregnated and processed to adjust the final product properties. This all-carbon electrode substrate is not brittle thereby avoiding the main disadvantage of the prior art.

Owner:SGL CARBON SE

Carbon fiber electrode substrate for electrochemical cells

ActiveUS20030194557A1Improve conductivityContinuous processabilityNon-fibrous pulp additionNatural cellulose pulp/paperPorosityFiber

This invention relates to electrode substrates for electrochemical cells, particularly low-temperature fuel cells, and processes for their production. Low-cost carbon fiber paper structures are used as precursor for preparation of an all-carbon product that has a high electric conductivity and porosity and can be processed in a continuous reel-to-reel mode. These paper materials are further impregnated and processed to adjust the final product properties. This all-carbon electrode substrate is not brittle thereby avoiding the main disadvantage of the prior art.

Owner:SGL CARBON SE

Method for preparing porous nitrogen-contained carbon fiber electrode material from melamine resin/polyvinyl alcohol aqueous solution through high-pressure static spinning technology

InactiveCN102797111AReduce pollutionLow costElectrolytic capacitorsHollow filament manufactureFiberCarbon fibers

The invention provides a method for preparing a porous nitrogen-contained carbon fiber electrode material from a melamine resin / polyvinyl alcohol aqueous solution through a high-pressure static spinning technology, relates to a preparation method of a supercapacitor electrode material, and solves the problems of poor pore-forming effect, complex operation, high cost and heavy pollution of current porous nitrogen-contained carbon fiber electrode material. The preparation method comprises the steps as follows: 1, adding a pore-forming agent into the mixed liquor of the polyvinyl alcohol aqueous solution and the melamine resin aqueous solution to prepare a basic spinning solution; 2, preparing a melamine resin / polyvinyl alcohol composite fiber film through the high-pressure static spinning technology; and 3, carbonizing the composite fiber film prepared in step 2 and foam nickel wrapped with a piece of graphite paper so as to obtain the porous nitrogen-contained carbon fiber electrode material. According to the method, the pore-forming agent is added to the basic spinning solution so that the preparation of the porous nitrogen-contained carbon fiber electrode material and the pore forming can be synchronously accomplished; and the method has the advantages of good pore-forming effect, simplicity in operation, low cost and little pollution and is applied to producing the porous nitrogen-contained carbon fiber electrode material.

Owner:HEILONGJIANG UNIV

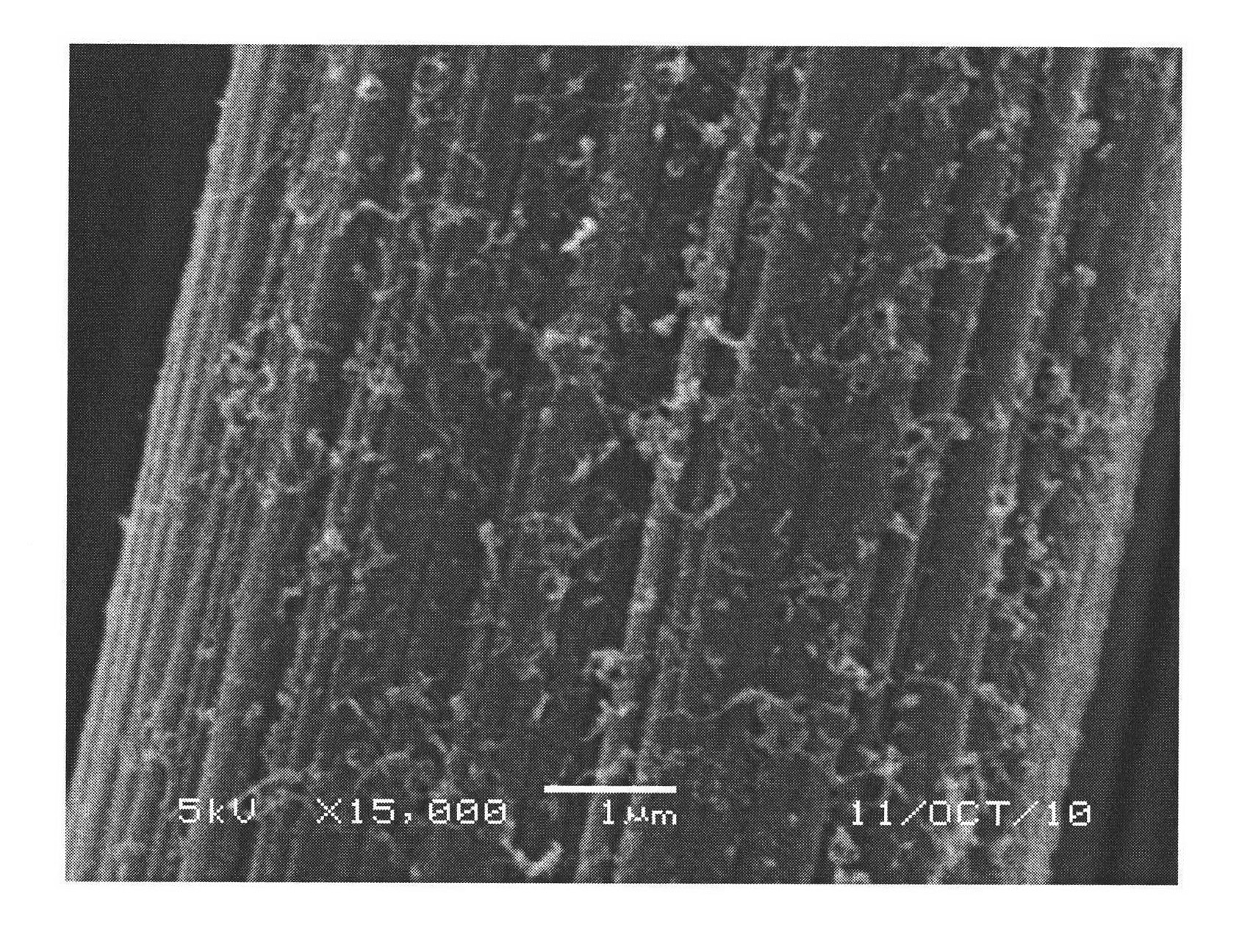

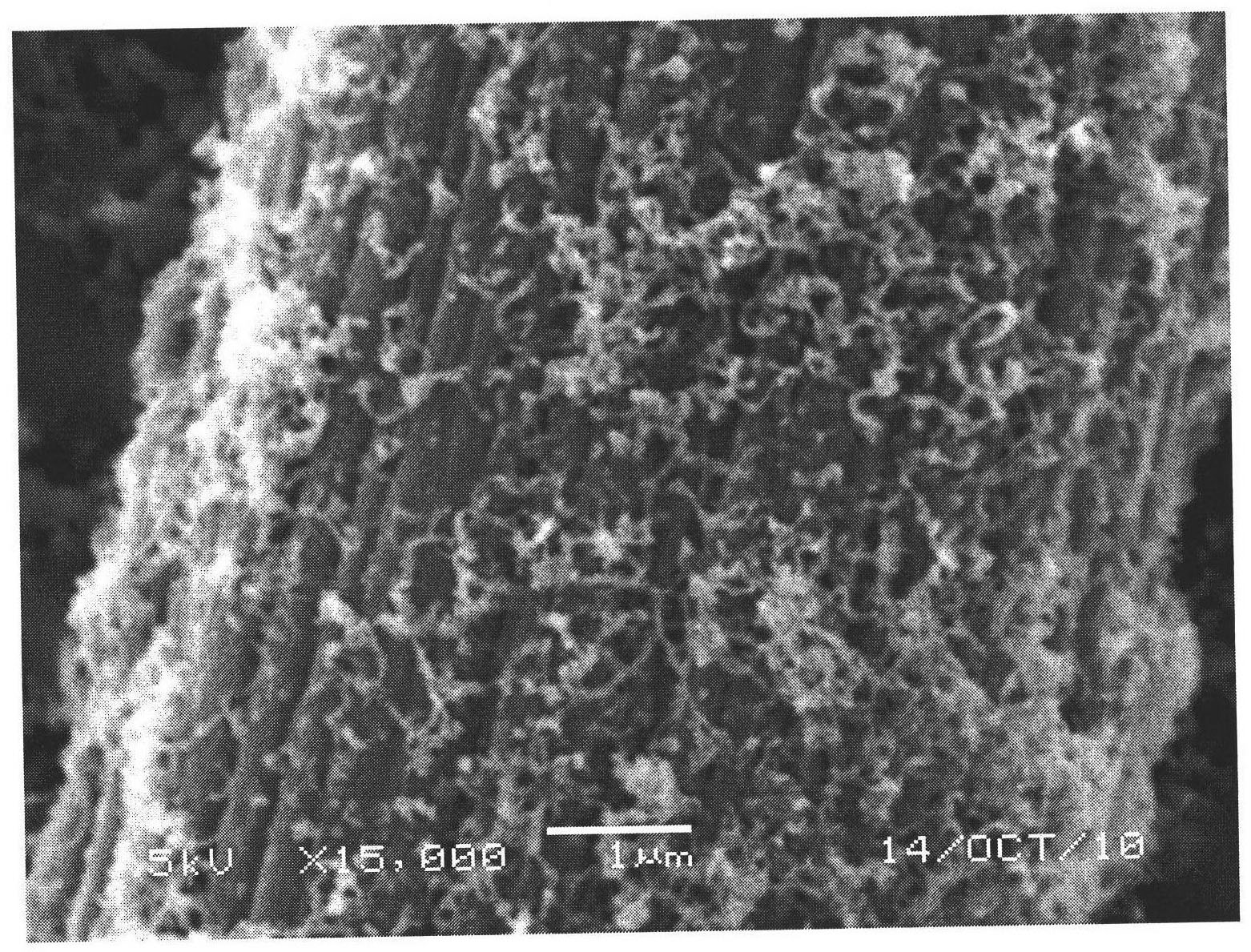

Method for modifying carbon fiber surface

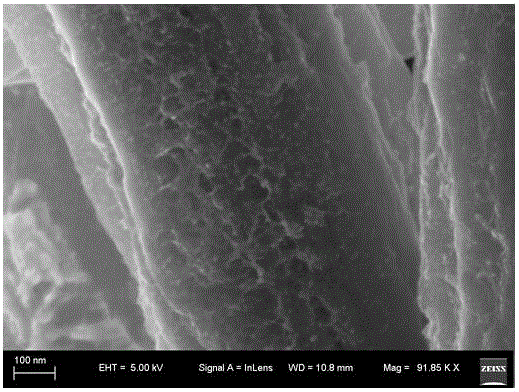

ActiveCN103243544AIncreased surface groovesImprove performanceAnodisationPhysical treatmentFiberCarbon fibers

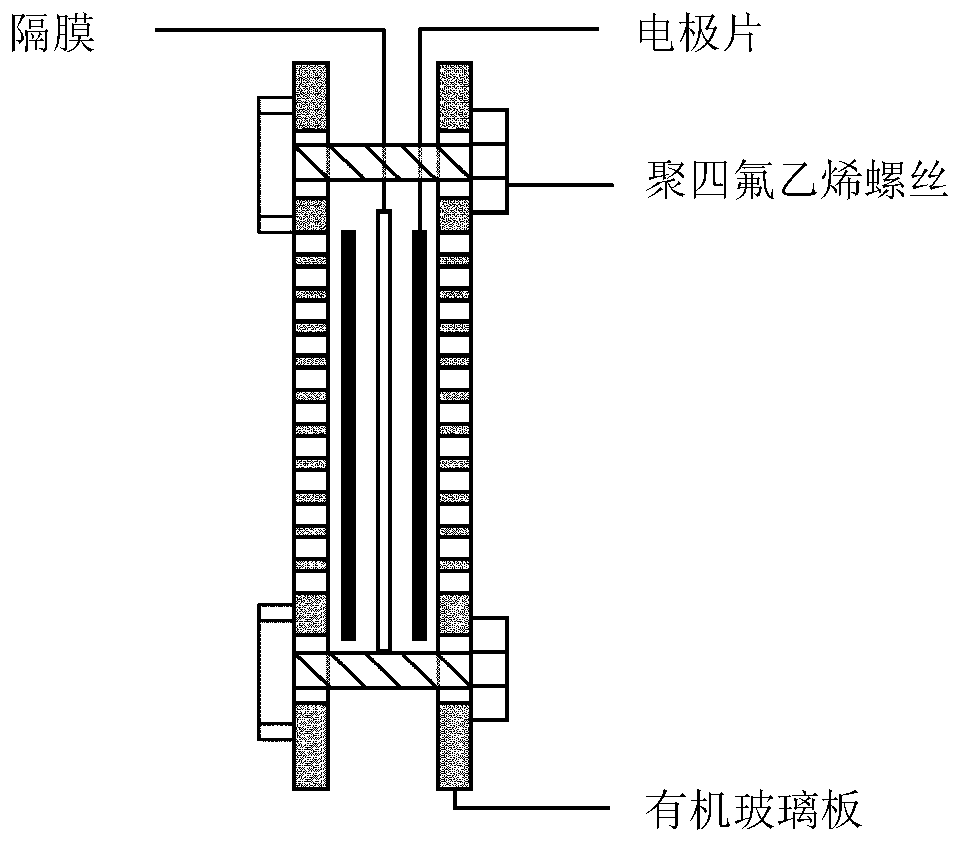

The invention discloses a method for modifying a carbon fiber surface. The method comprises the following steps of: dissolving graphene oxide in water, adjusting a pH value to 8.0-13.0, dispersing by mechanical agitation or an ultrasonic wave to obtain graphene oxide water solution; stewing the graphene oxide water solution into an electrolytic cell, taking a carbon fiber as an anode material of an electrode and conductive metal or a graphite material as a cathode material; exerting voltage or electricity on a carbon fiber electrode by a potentiostatic method or a galvanostatic method; and carrying out thermal treatment on the carbon fiber on which the graphene oxide is coated in a heating furnace to obtain the modified carbon fiber. The method has the advantages of being simple and practical, free of pollution, and industrial.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

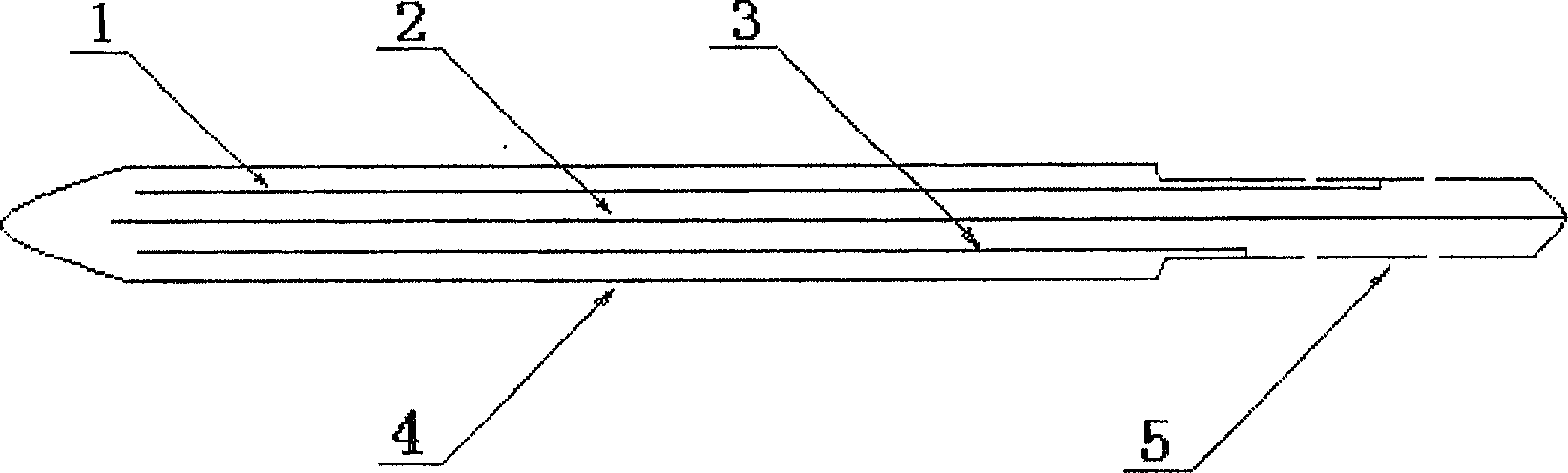

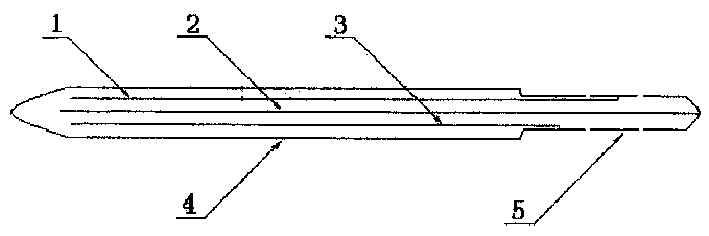

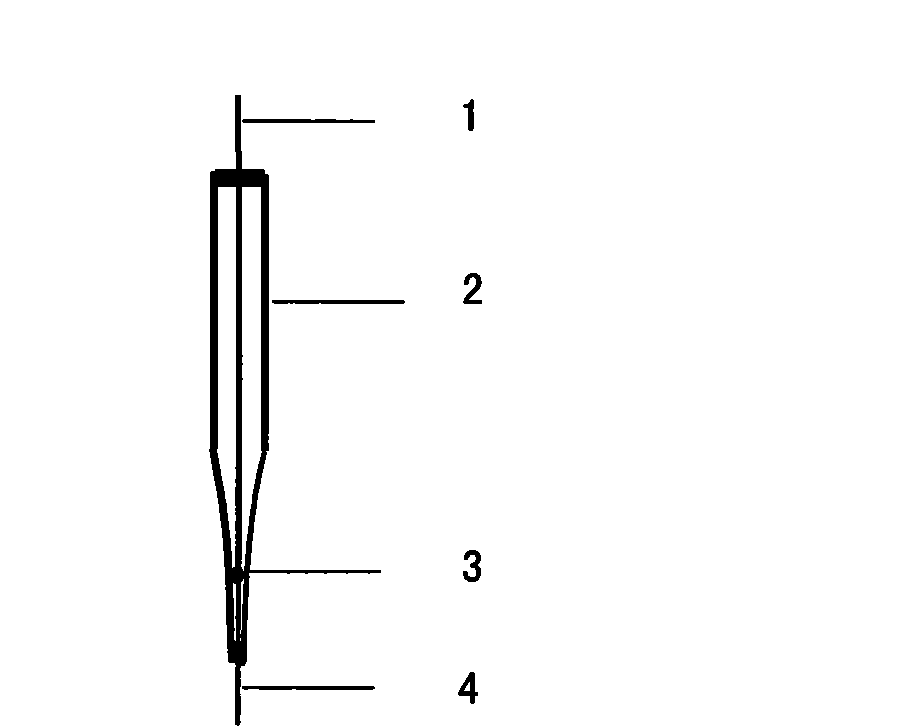

Method for producing complex type microelectrode

InactiveCN1462882AStable reference potentialLower resistanceMaterial electrochemical variablesParaffin waxCarbon fibers

A process for preparing a combined miniature electrode used for cell measurement features that the capillary glass tubes are used to load the micron-class Ag wire, Pt wire and carbon fibre in a fine metallic tube by insulating enclosure. The capillary glass tube for carbon fibre or Pt wire is enclosed by fused paraffin wax. The capillary glass tube contains the saturated potassium chloride solution of silver chloride to become an enclosed reference electrode.

Owner:袁倬斌 +1

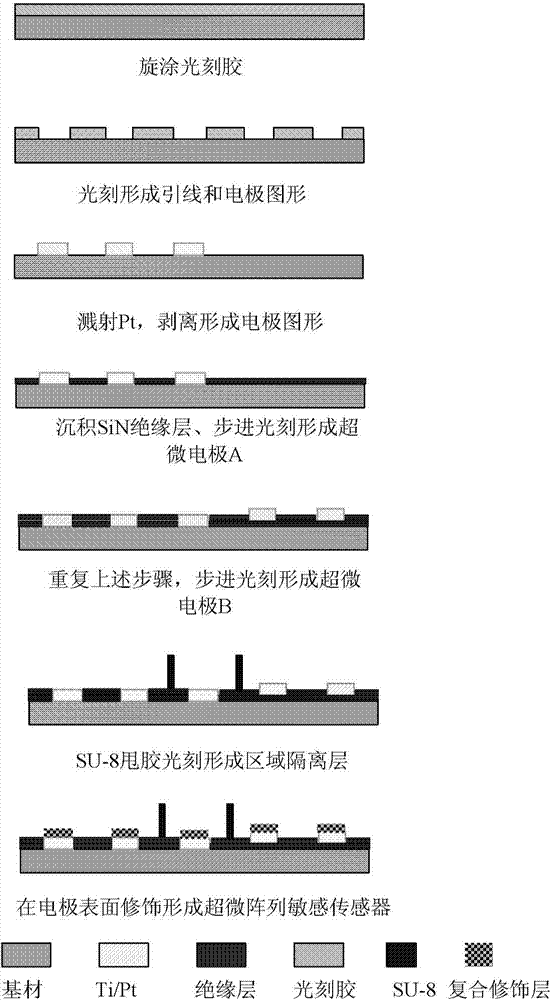

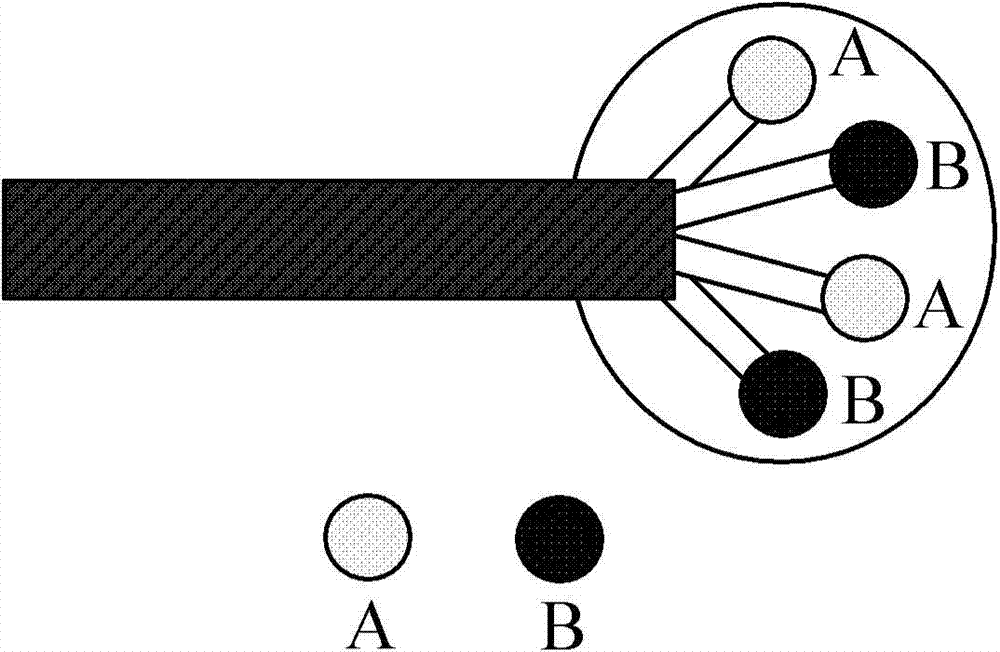

Ultramicro planar electrode array sensor and preparation method thereof

ActiveCN104760922AUniform performanceImprove performanceTelevision system detailsNanostructure manufactureDual modeNerve cells

The invention discloses a preparation method of a dual mode (two mode signals-electrophysiological signal and electrochemical signal) ultramicro planar array sensor for quantitative assay of nerve cell quantum release. An ultramicro planar electrode (0.5-5 mum) is prepared through combination of a double layer wiring design, a high precision stepping photolithography technique and a partition isolation design. According to the method, orientated nanometer modification, biological compatibility modification and specific recognition enzyme modification are combined and performed on the surface of an electrode array so as to prepare the dual mode planar ultramicro electrode array sensor. The dual mode planar ultramicro electrode array is prepared by the method combining a micro electromechanical system technique, a nanometer modification technique and a biological modification technique. Through adoption of the method, the limitations of large electrode site size (10-50 mum) of a conventional planar microelectrode and single site detection of a rodlike carbon fiber electrode are broken. The ultramicro planar electrode array prepared by the method has small electrode site and multiple recording points, does not damage nerve cells, and can simultaneously detect neurotransmitter quantum release of a plurality of nerve cells and dual mode information of an electrophysiological action potential signal in real time in situ.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Production method of multi-element transition metal hydroxide nuclear shell composite carbon filter electrode material

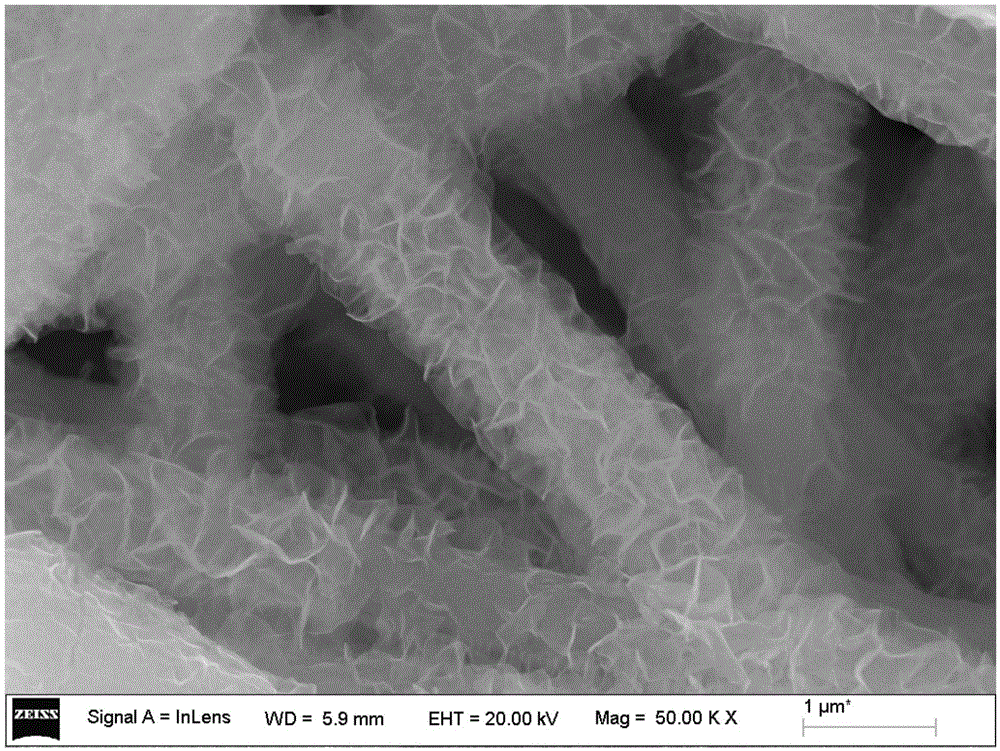

InactiveCN105590754AImprove conductivityImprove stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePorosity

The invention discloses a production method of a multi-element transition metal hydroxide nuclear shell composite carbon filter electrode material, and belongs to the electrode material production field. Nano-fibers can be produced by adopting the electrospinning method, and carbon fibers can be produced by adopting the high temperature carbonization method, and in addition, the surface functionalization can be realized by adopting the acid treatment, and the surface can be provided with the multi-element transition metal ions in a complexed manner, and then the in-situ growth transition metal hydroxide can be realized by adopting the base catalysis. The electrode material is advantageous in that the specific surface area of the nano-fiber film is large, and the porosity is high, and at the same time, the excellent electrochemistry performance is provided by combining with the high conductivity of the carbon fiber materials and the high capacitance of the multi-element metal hydroxide, and the important application value can be provided for the fields such as the lithium ion battery, the super capacitor, and other electronic devices.

Owner:BEIJING UNIV OF CHEM TECH

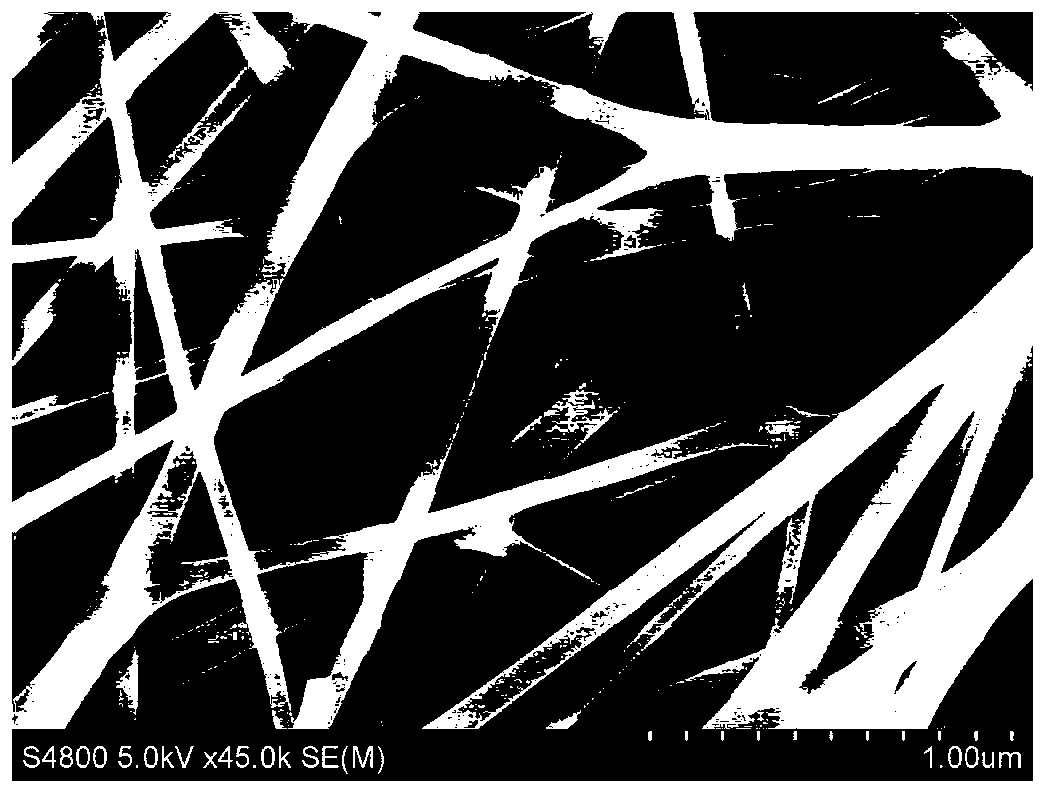

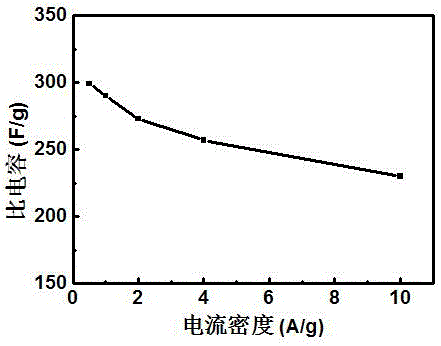

Preparation method of melamine resin modified nitrogen-rich porous carbon fiber electrode material

ActiveCN105671692AIncrease productivityReduce manufacturing costFibre chemical featuresHybrid/EDL manufactureCarbon fibersPorous carbon

The invention provides a preparation method of a melamine resin modified nitrogen-rich porous carbon fiber electrode material and relates to the technical field of production of functional materials. Melamine resin is synthesized by melamine and formaldehyde; polyacrylonitrile is dissolved in N,N-dimethyl formamide, and then the melamine resin is added to prepare a spinning solution; MF / PAN composite precursor fiber is prepared through electrostatic spinning; the MF / PAN composite precursor fiber is subjected to preoxidation, carbonization and other heat treatment to obtain nitrogen-rich carbon fiber; the NCNF is made into a super capacitor electrode. The problem that existing carbon fiber nitrogen doping and pore formation needs to be performed in a step-by-step mode, a production process is complicated and the cost is higher is solved.

Owner:YANGZHOU UNIV

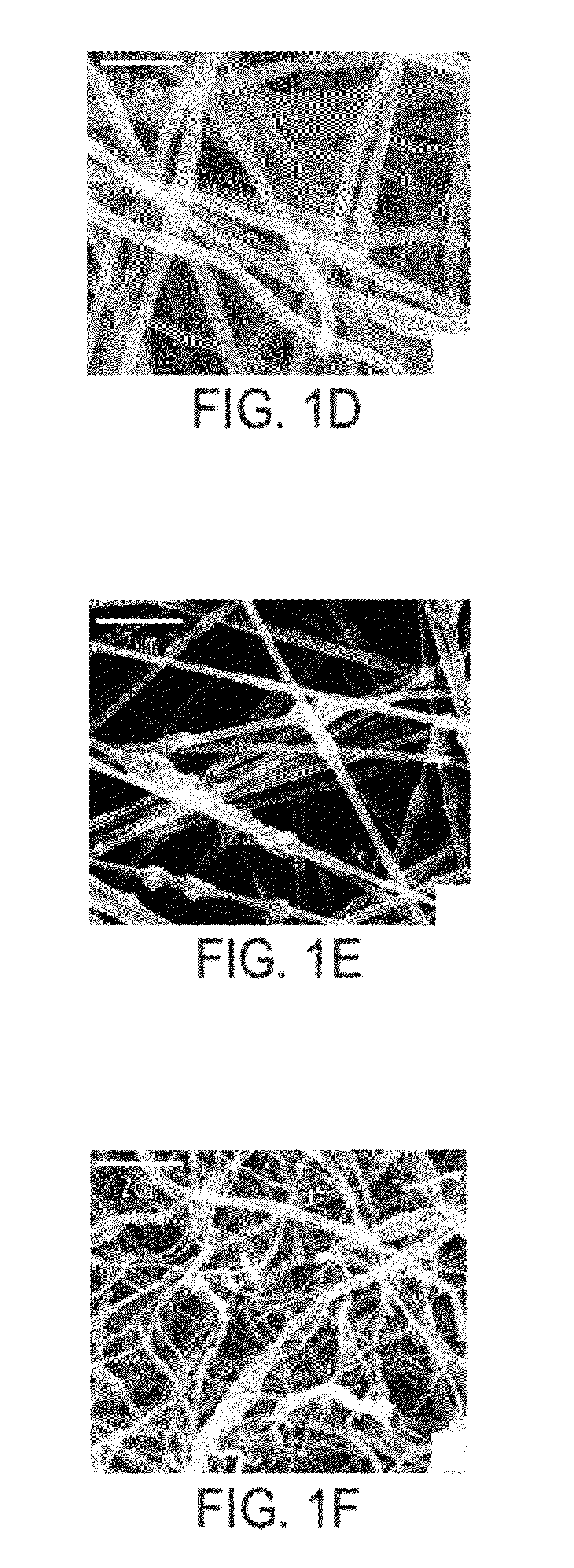

Composite carbon fiber electrodes incorporating porous high surface area carbon

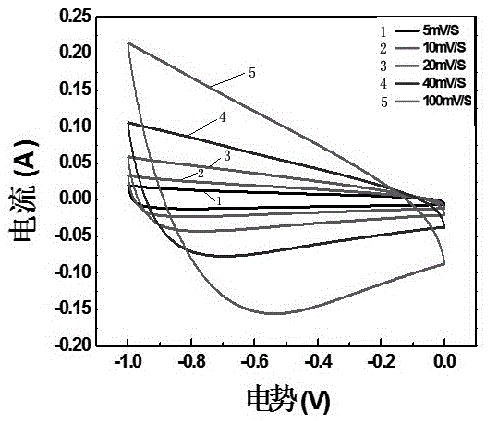

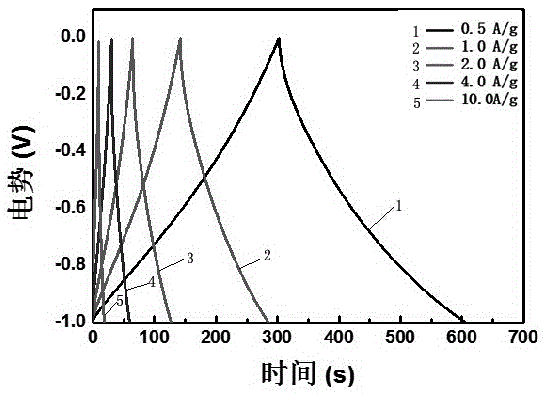

InactiveUS20120189877A1Increase surface areaMaterial nanotechnologyElectrolytic capacitorsCapacitanceFiber

The claimed invention uses activated carbon fibers that incorporate porous carbon with a suitable pore size to maximize capacitance. The porous carbon material is prepared using a template, followed by incorporation into a matrix polymer and electrospinning of the mixture. Subsequent thermal treatments retain the fiber form, and a composite carbon fiber incorporating templated porous carbon is attained. The resulting electrode is binder free and 100% electrochemically active. Energy densities up to 41 Wh / kg in energy density 1.5 kW / kg in power density (electrode weight only) have been achieved.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

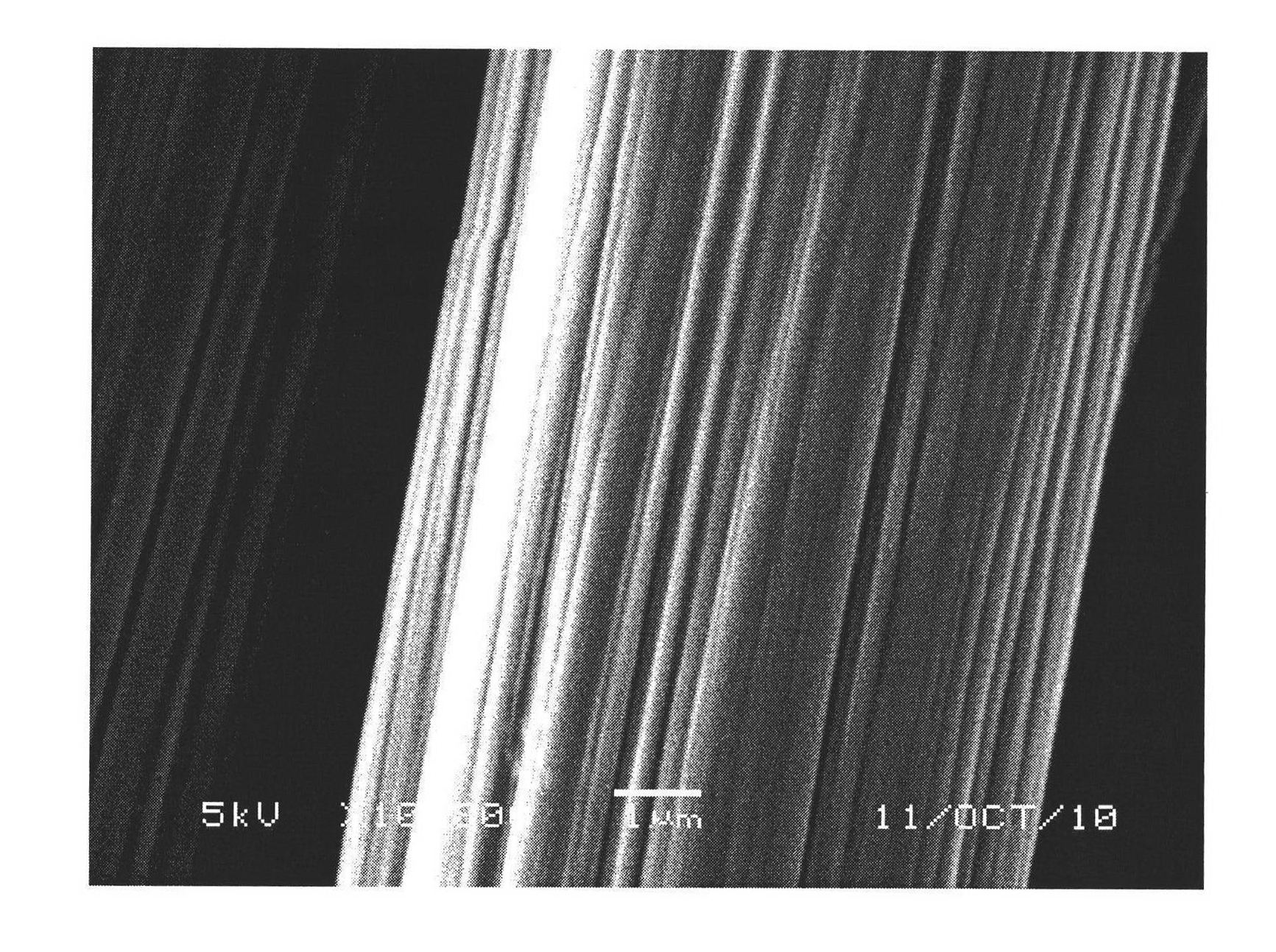

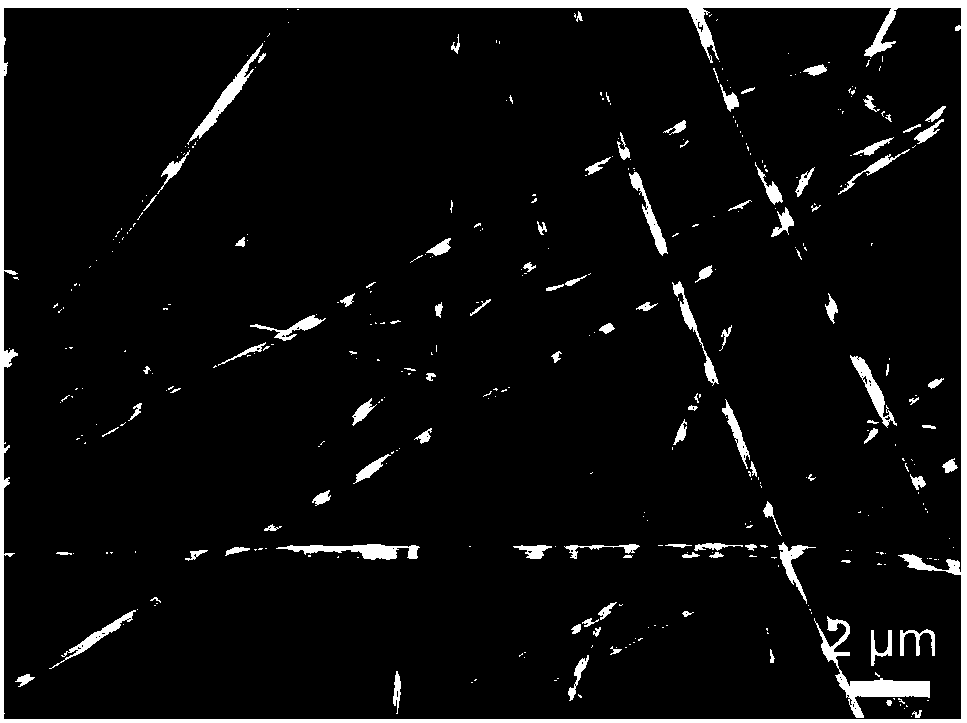

Electrochemical modification treatment method of carbon fiber surface

InactiveCN102505449AEasy to operateMild treatment conditionsAnodisationPhysical treatmentFiberCarbon fibers

The invention relates to an electrochemical modification treatment method of carbon fiber surface. The electrochemical modification treatment method comprises the steps of: modifying carbon nanotubes by adopting a nitric acid and sulfuric acid chemical oxidization method or an electrochemical method; dissolving modified carbon nanotubes in ethanol, acetonitrile, dimethyl formamide, dimethyl sulfoxide, tetrahydrofuran, protoporphyrin disodium, carbon tetrachloride, petroleum ether, acetone, chloroform or water, and carrying out ultrasonic treatment or stirring to form uniformly dispersed emulsion or suspension so as to prepare an electrolyte solution containing 0.01-10 mg / mL of carbon nanotubes; and applying voltage or current on a carbon fiber electrode in the electrolyte solution containing the carbon nanotubes with carbon fiber as an anode electrode and a conductive metal or graphite material as a cathode electrode while controlling the temperature of the electrolyte solution at 20-80 DEG C, then cleaning and drying. The electrochemical modification treatment method provided by the invention has the advantages of being simple, practical and capable of being industrialized.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

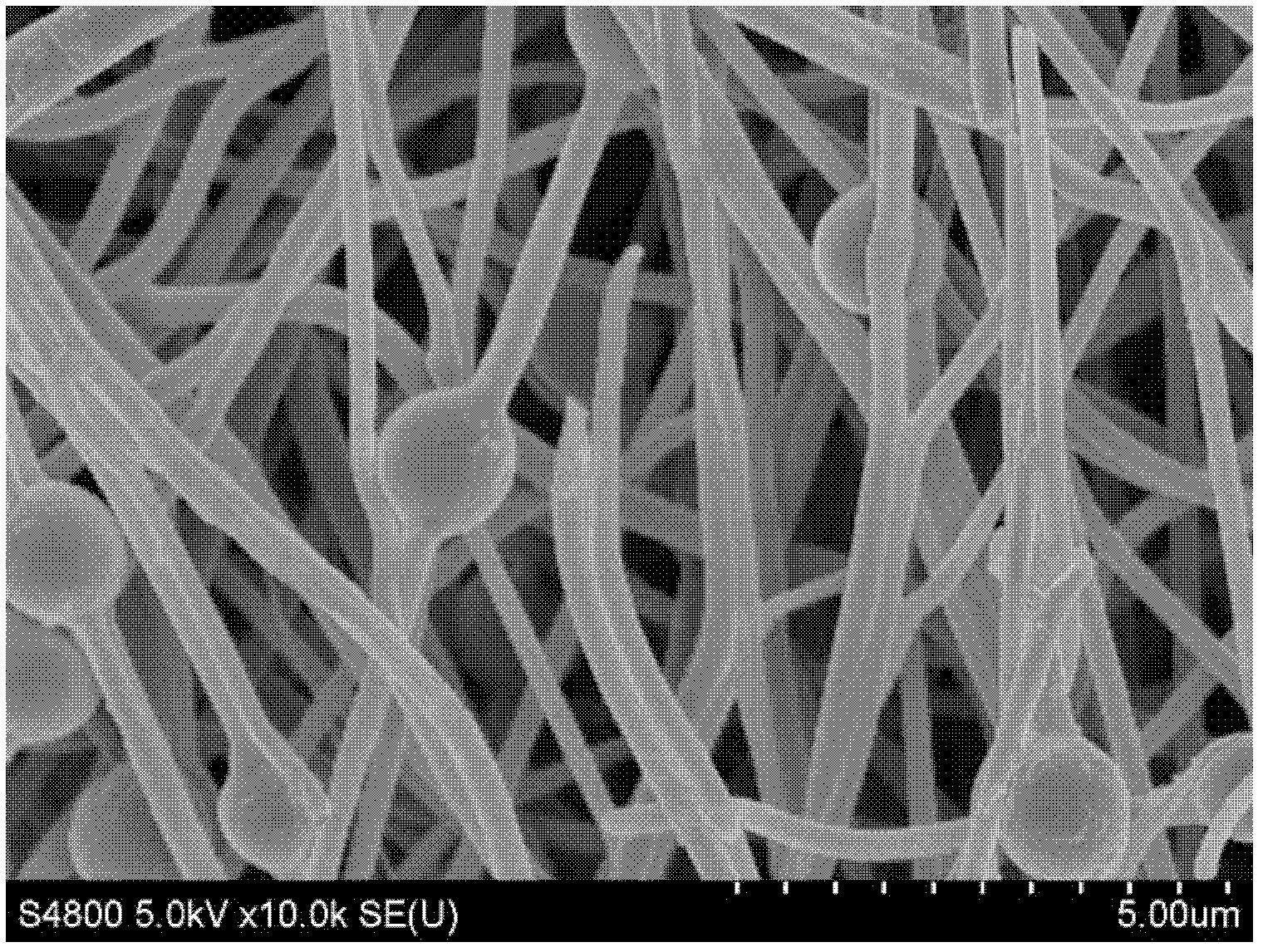

Method for producing bead-stringed PAN (polyacrylonitrile)-based carbon fiber electrode materials by electrostatic spinning

InactiveCN102560889ALarge specific surface areaIncrease the strength of the felt bodyElectrolytic capacitorsHeating/cooling textile fabricsCapacitanceResin microsphere

A method for producing controllable fibre diameter and sphere diameter bead-stringed PAN (polyacrylonitrile)-based carbon fiber electrode materials by electrostatic spinning relates to a method for producing PAN-based carbon fiber electrode materials. The method is to solve the problem in traditional carbon fiber preparation method process, the feature controllable carbon fiber electrode material is not easy to be obtained. By electrostatic spinning, phenolic resin microspheres are added into spinning dope to produce bead-stringed PAN-based carbon fiber felt electrode materials. The electrode materials have the advantages that the production method is simple and continuous, the diameter of fibers and sphere diameter ratio of bead strings are controllable, and the materials are high in specific capacitance, high in felt strength, large in specific surface area and the like.

Owner:HEILONGJIANG UNIV

Special electrode for in-vivo voltammetry analysis and preparation method thereof

InactiveCN101581690AAvoid artificial modificationImprove electrochemical catalytic performanceMaterial electrochemical variablesFiberCarbon fibers

The invention discloses a special electrode for in-vivo voltammetry analysis and a preparation method thereof. The preparation method of the special electrode comprises the following steps: 1) preparing carbon fiber coated with a carbon nanomaterial on surface; 2) preparing a carbon fiber microelectrode; 3) soaking the carbon fiber electrode prepared by the step 2) in solution for ultrasonic washing; and 4) subjecting the carbon fiber electrode prepared by the step 3) to electrochemical pretreatment to obtain the special electrode. Meanwhile, an electrochemical detection device for in vitro correction or in vivo real-time physiological activator monitoring is prepared by using the special electrode. The electrochemical detection device comprises the special electrode for physiological activator monitoring of the invention, a reference electrode and an auxiliary electrode. The electrochemical detection device prepared by using the special electrode of the invention can meet the requirements for the in-vivo voltammetry analysis of physiological activators and has a promising application prospect in researches in fields of neurophysiology, clinical medicine and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Electrode material preparation method

InactiveCN107633959AHigh specific surface areaImprove conductivityMaterial nanotechnologyHybrid capacitor electrodesAir atmosphereCarbon fibers

The invention provides an electrode material preparation method and relates to the technical field of a cell. The method comprises steps that a nanometer inorganic material is dispersed into N, N-dimethyl formamide to acquire dispersion liquid, polyacrylonitrile is then added, mixture is heated under 70 DEG C temperature condition for 1 hour to acquire mixture dense liquid, mass percentage of thepolyacrylonitrile of the mixture dense liquid is 15%, static spinning of the mixture dense liquid is carried out, thermal treatment of acquired protofilament is carried out under 250 DEG C condition in the air atmosphere for 0.5 hour, the protofilament after thermal treatment is heated in the nitrogen atmosphere under 800 DEG C condition for 3 hours, through cleaning and drying, an in-situ nitrogen doping carbon fiber / magnesium oxide composite material is acquired, and acid treatment of the composite material is carried out to acquire an in-situ nitrogen doping nano porous carbon fiber electrode material. The method is advantaged in that the process is simple, the preparation process is environmental friendly, the raw materials are cheap, the specific surface area of the material can be improved through adding the nano material, the polyacrylonitrile is added to acquire the in-situ nitrogen doping material, and electrochemical performance of the material can be improved.

Owner:深圳技术大学筹备办公室

Method for preparing bipolar plate of vanadium cell

ActiveCN103022531AImprove reliabilityThere will be no increase in surface resistanceFinal product manufactureFuel cell detailsCarbon fibersConductive materials

The invention relates to the field of manufacturing of vanadium cells, in particular to a method for preparing a bipolar plate of a vanadium cell, and solves the problems that the degree of mixing uniformity of materials is difficult to ensure, the resistivity of a polymer-carbon black composite bipolar plate is very high, the surface resistance of the bipolar plate is increased due to electrochemical corrosion and the like in the prior art. In order to solve the problems, according to the working requirement of the vanadium cell, a carbon fiber electrode with high corrosion resistance is taken as a conductive material to prepare the bipolar plate of the vanadium cell which is high in electric conductivity and simple in manufacturing procedure. The bipolar plate comprises a resin plate and an electrode; and the resin plate and the electrode are thermally pressed and molded to facilitate resin to completely permeate to the electrode so as to prepare the bipolar plate of the vanadium cell. According to the method, the resin is injected to the electrode to serve as a framework material, so that the conductivity is approximate to that of a graphite felt, the electrochemical corrosion resistance is high in the using process, the resistance is not increased and the reliability of the vanadium cell is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

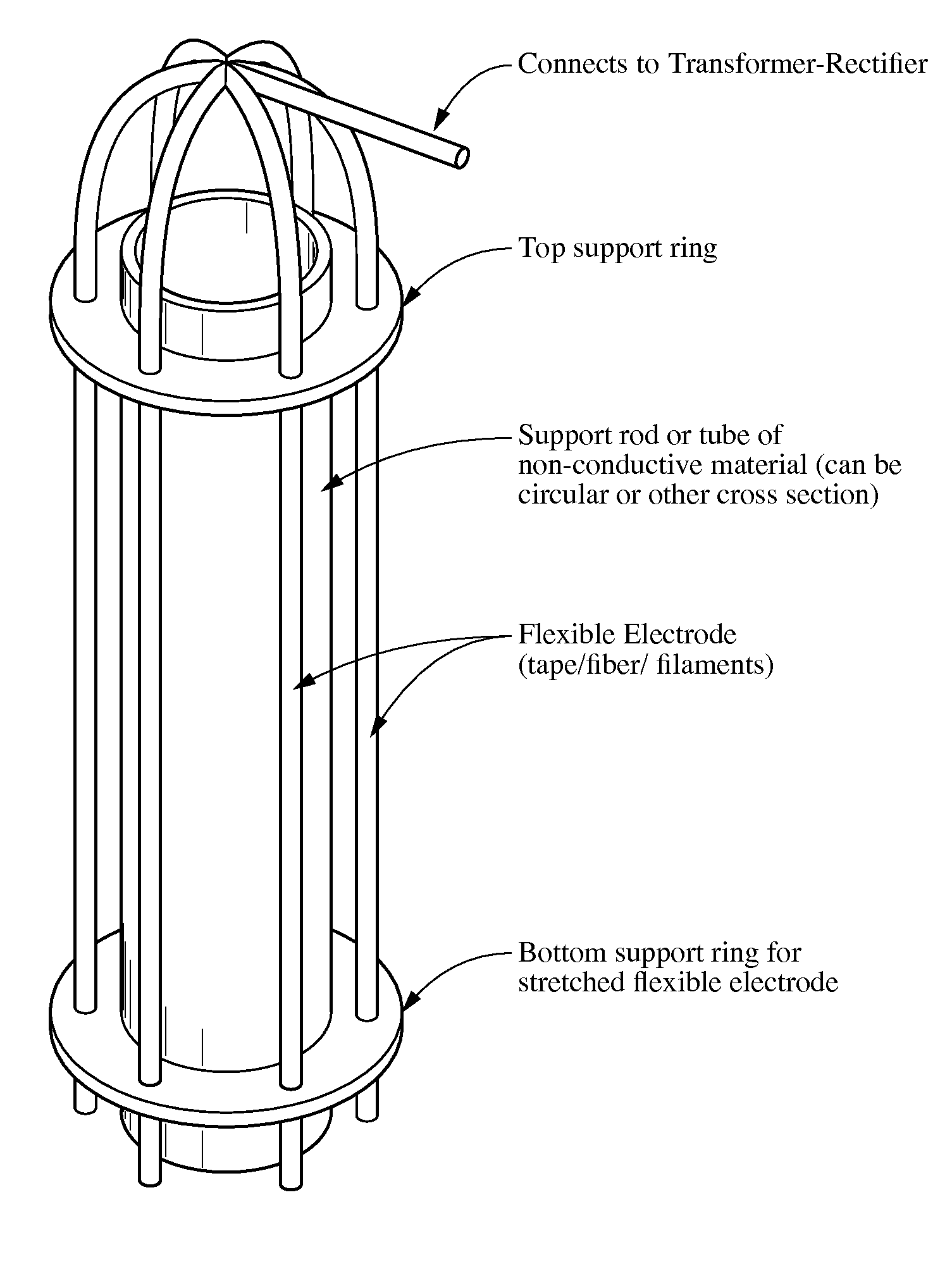

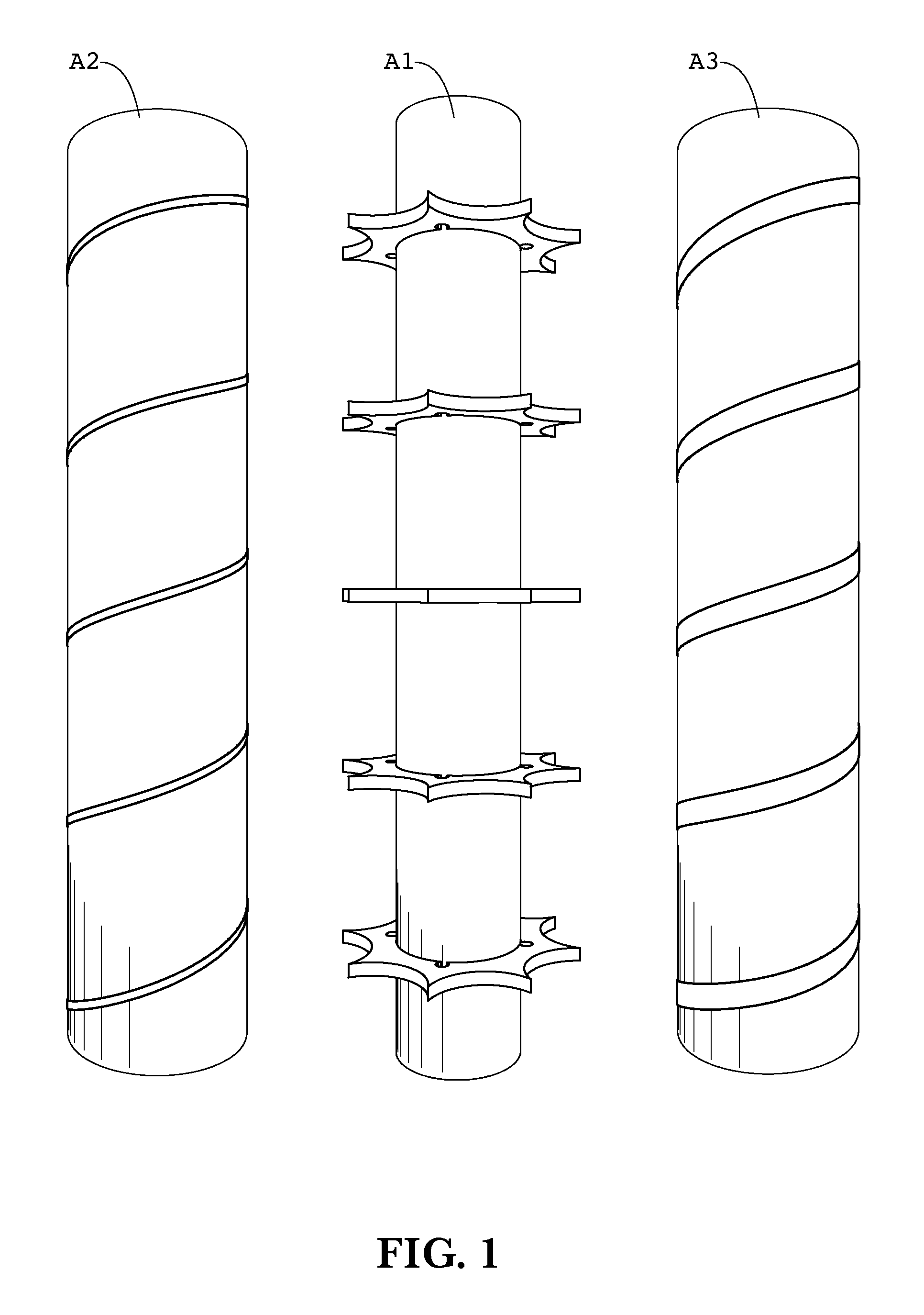

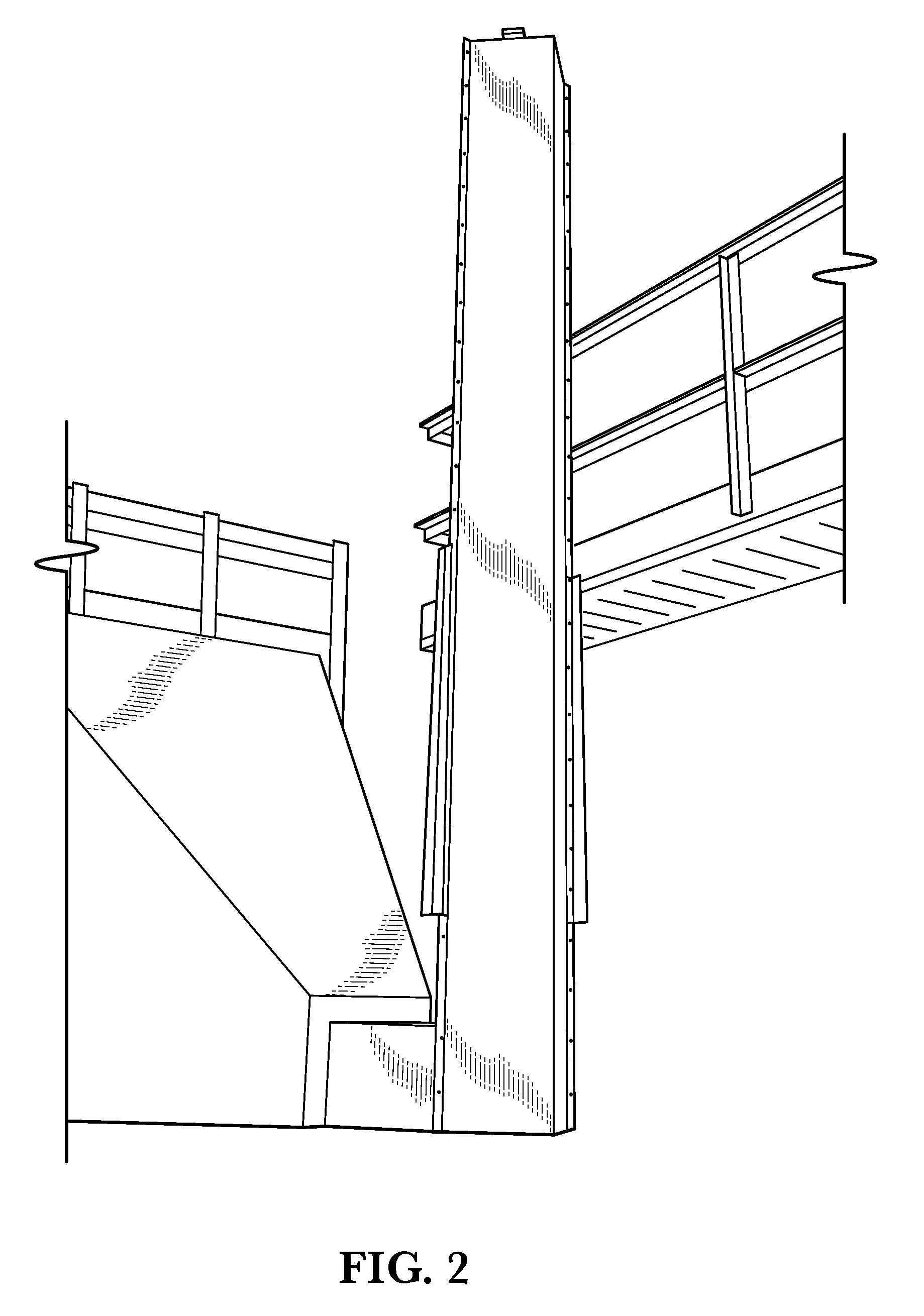

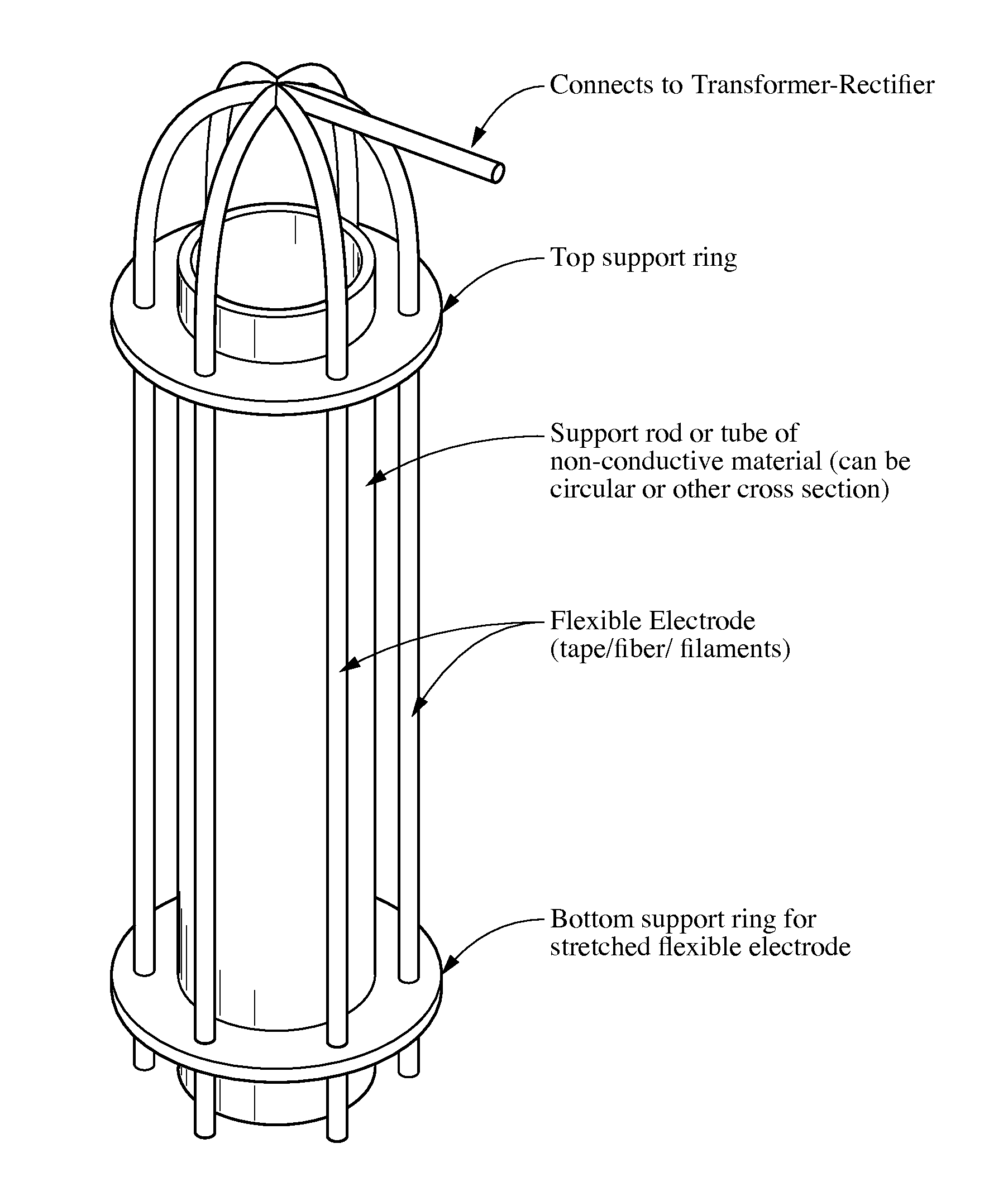

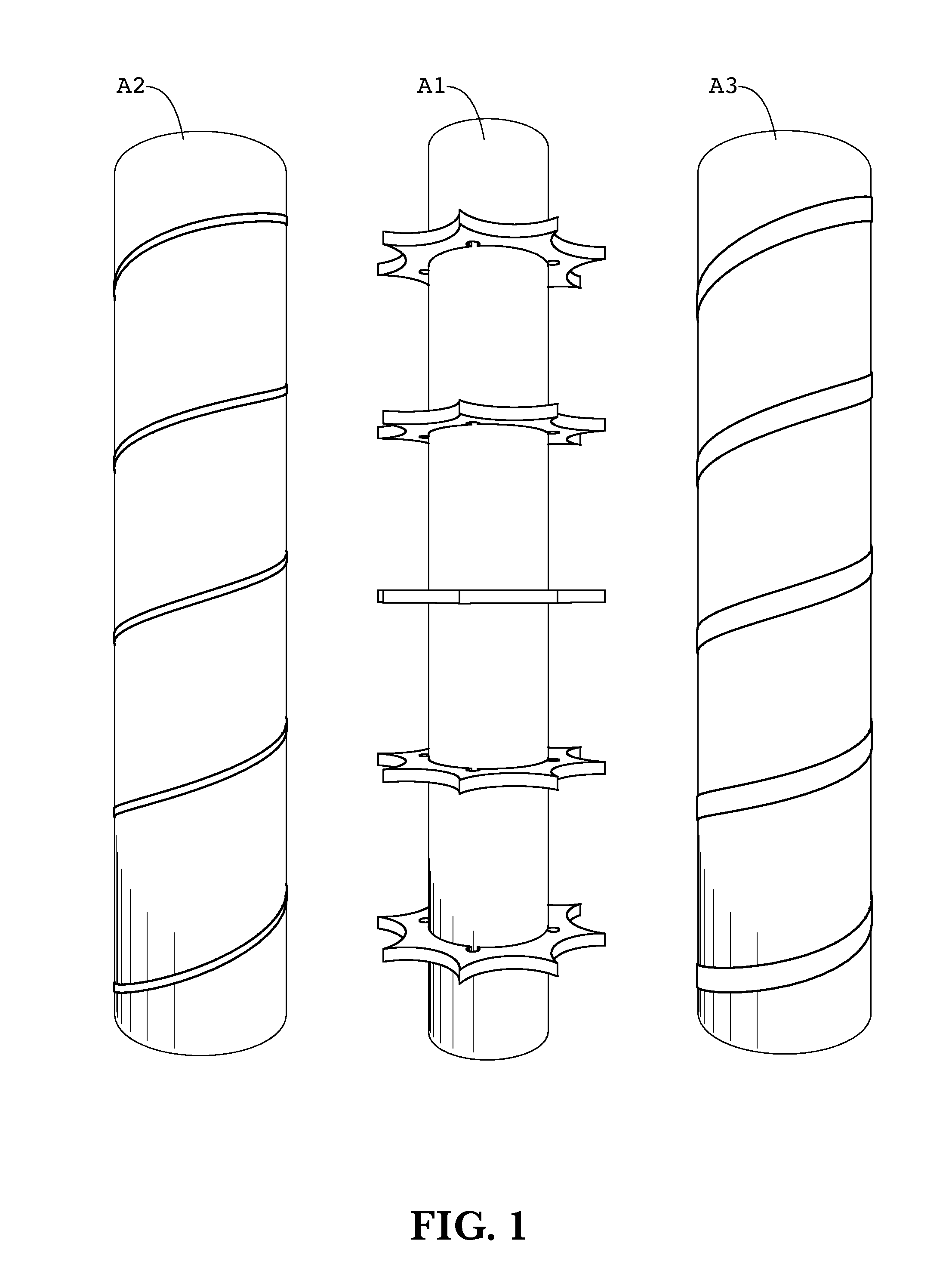

Carbon fiber composite discharge electrode

A discharge electrode using carbon fibers, nanofibers and / or nanotubes to generate the corona discharge. The invention contemplates carbon fiber electrodes with or without a polymer matrix to form a composite, and a supporting configuration in which the fibers are wrapped helically around a supporting rod that extends along the length of the electrode. Another supporting configuration includes the fibers stretched across the gas flow path. Yet another supporting configuration includes mounting the fibers along the length of the support rod substantially parallel to the rod.

Owner:OHIO UNIV

Production method of electrode material of high performance carbon fibre for fuel cell

InactiveCN101286565AImprove breathabilityCompact structureCell electrodesFibre chemical featuresCarbon fibersReduction treatment

The invention relates to a production method of high performance carbon fiber electrode material used for fuel cells, which pertains to the technical field of non-woven fabric and comprises the following processing steps: 1) glue-free polyacrylonitrile-based carbon fibre is selected and used as raw material, copying and manufacturing are carried out according to a non-woven technology, wherein, CMC is adopted as a dispersant and water-soluble polyvinyl alcohol fiber is taken as enhancing and bonding fiber; 2) water-soluble phenolic resin is selected and used by the copied and manufactured semi-finished product in the step 1), resin coating is carried out by adopting an impregnating method and drying processing is carried out; 3) a flat vulcanizing machine is adopted to carry out hot pressing processing; 4) high-temperature carbonizing treatment is carried out at the temperature of 2100-2300 DEG C and then heat preservation treatment and temperature reduction treatment are carried out. The method has simple and reasonable technology and easily-obtained raw material, and the manufactured high performance carbon fiber electrode material used for the fuel cells has compact structure, smooth surface, low resistivity, high air permeability and good strength. The use requirement of proton exchange membrane fuel cells can be met, and the method provides a special domestic assorted material for the research and development of the domestic fuel cells.

Owner:黄志达

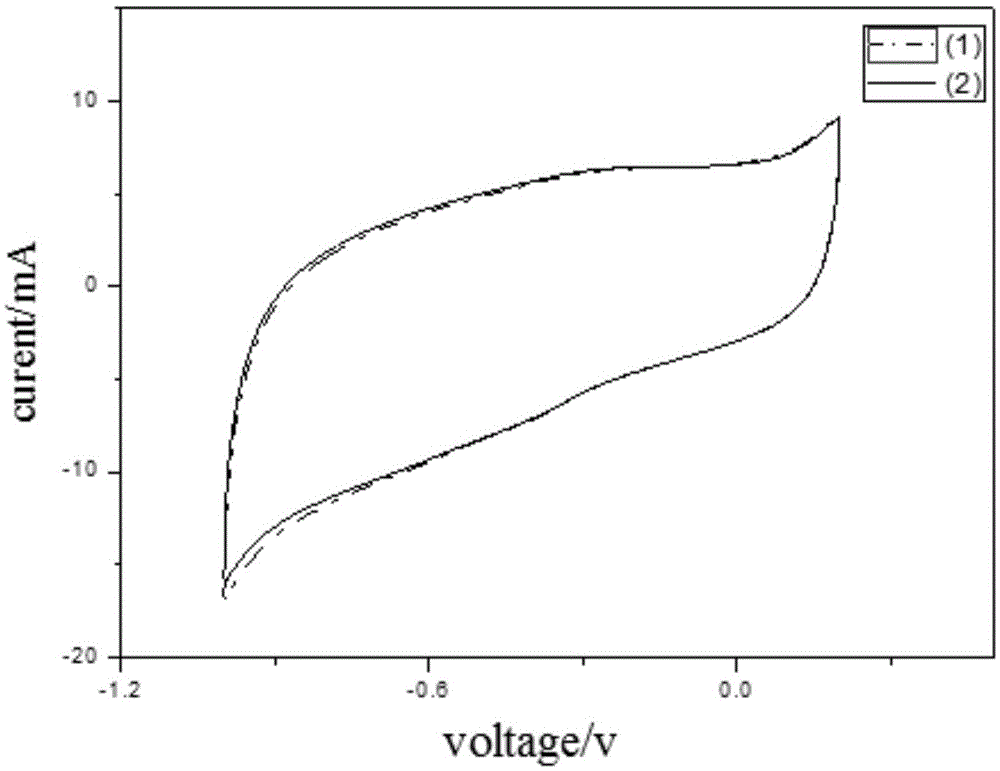

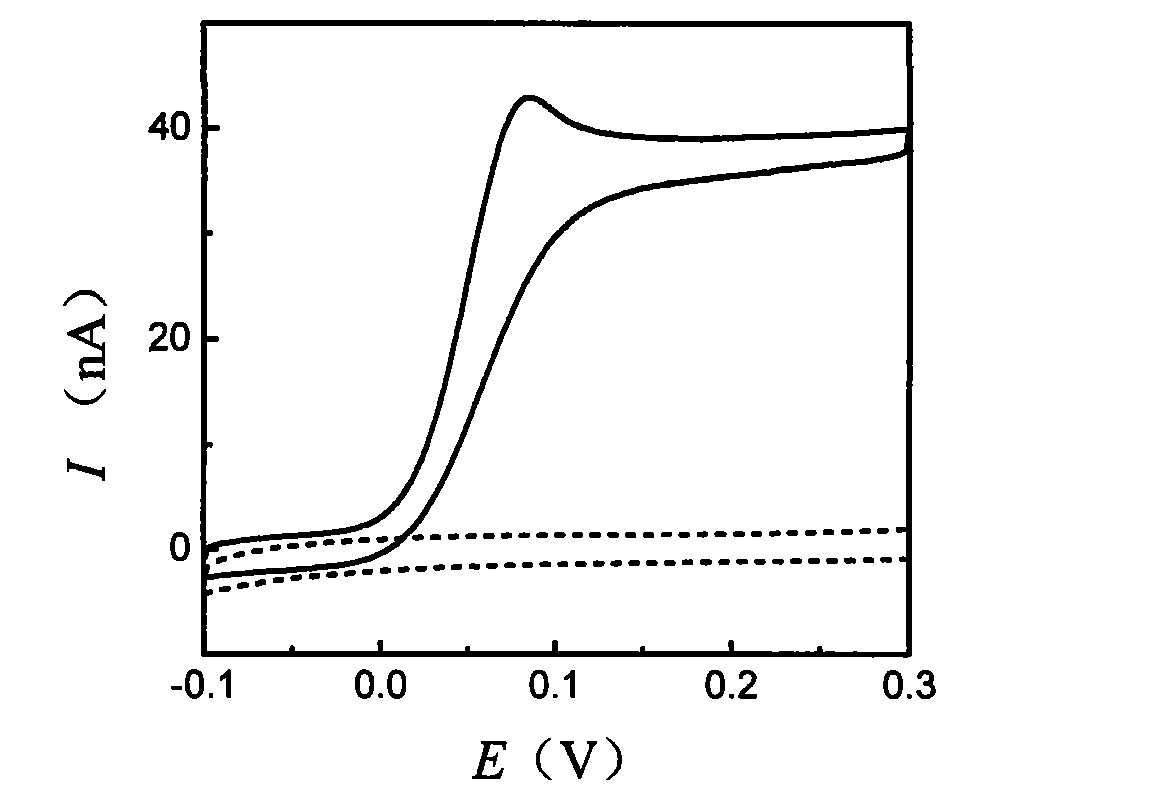

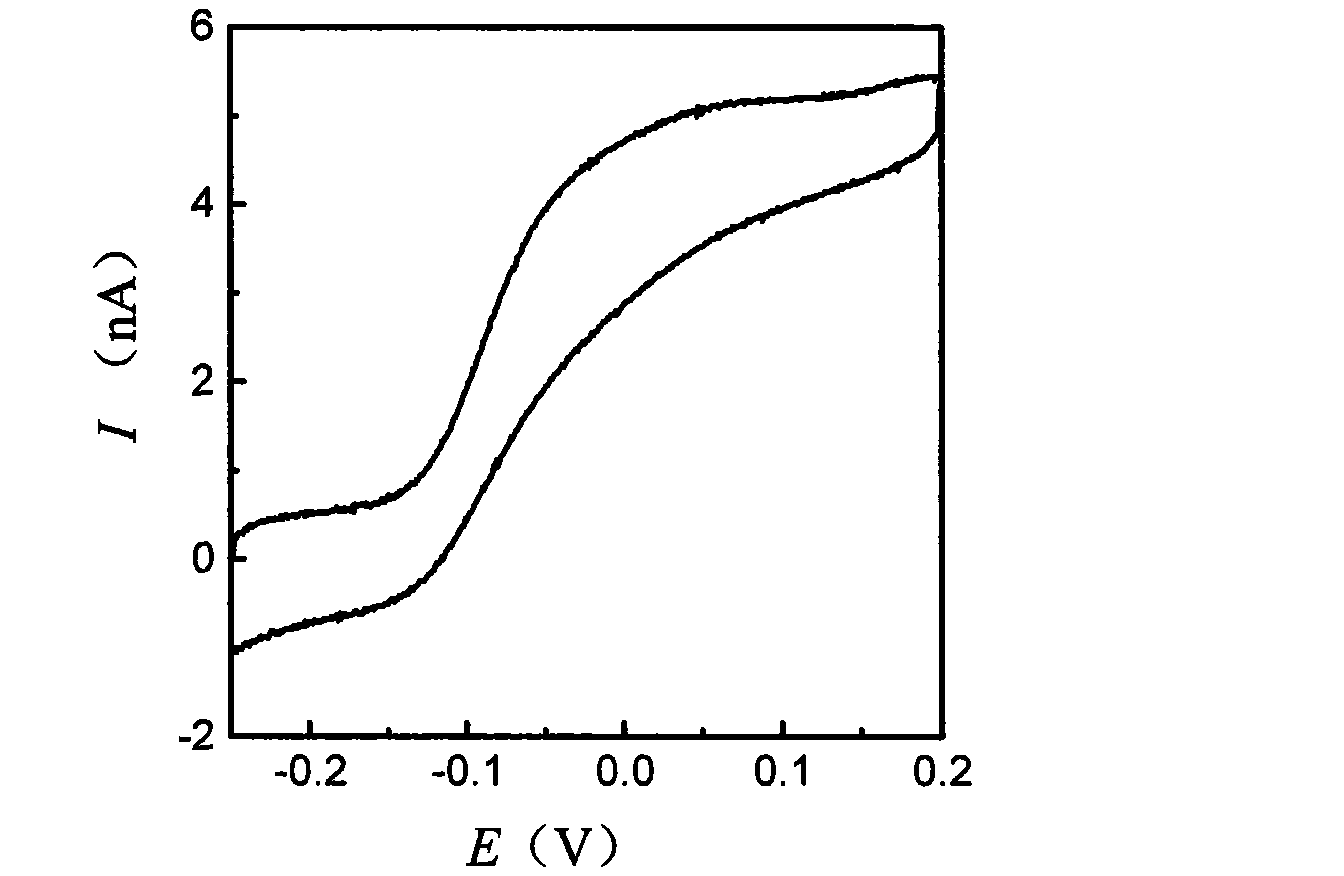

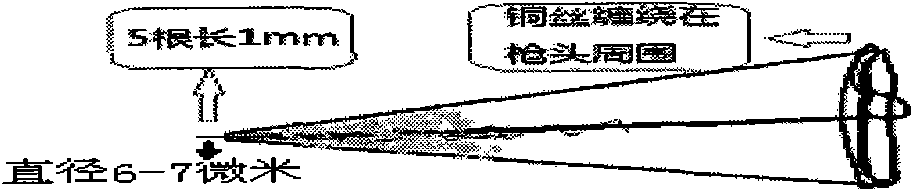

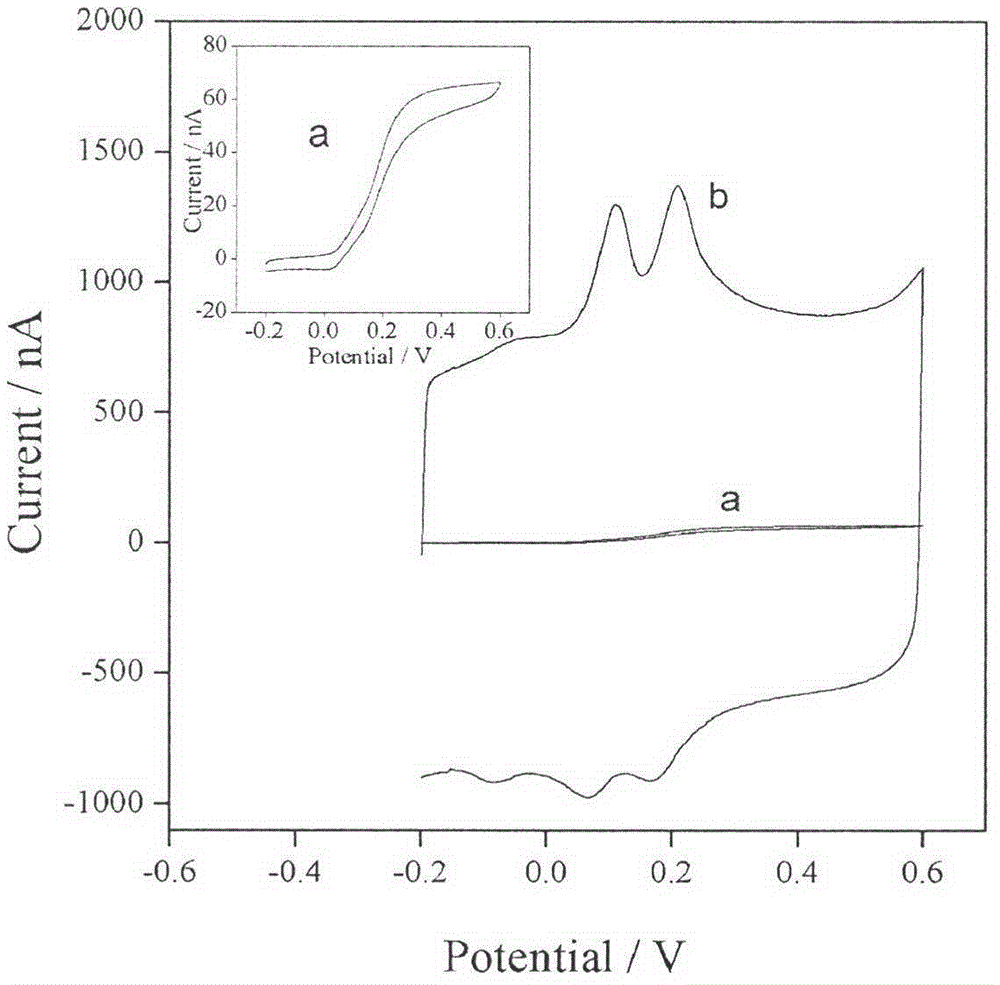

Manufacturing method of L-glutamic-acid-modified carbon fiber microelectrode, and application thereof in detecting neurotransmitters

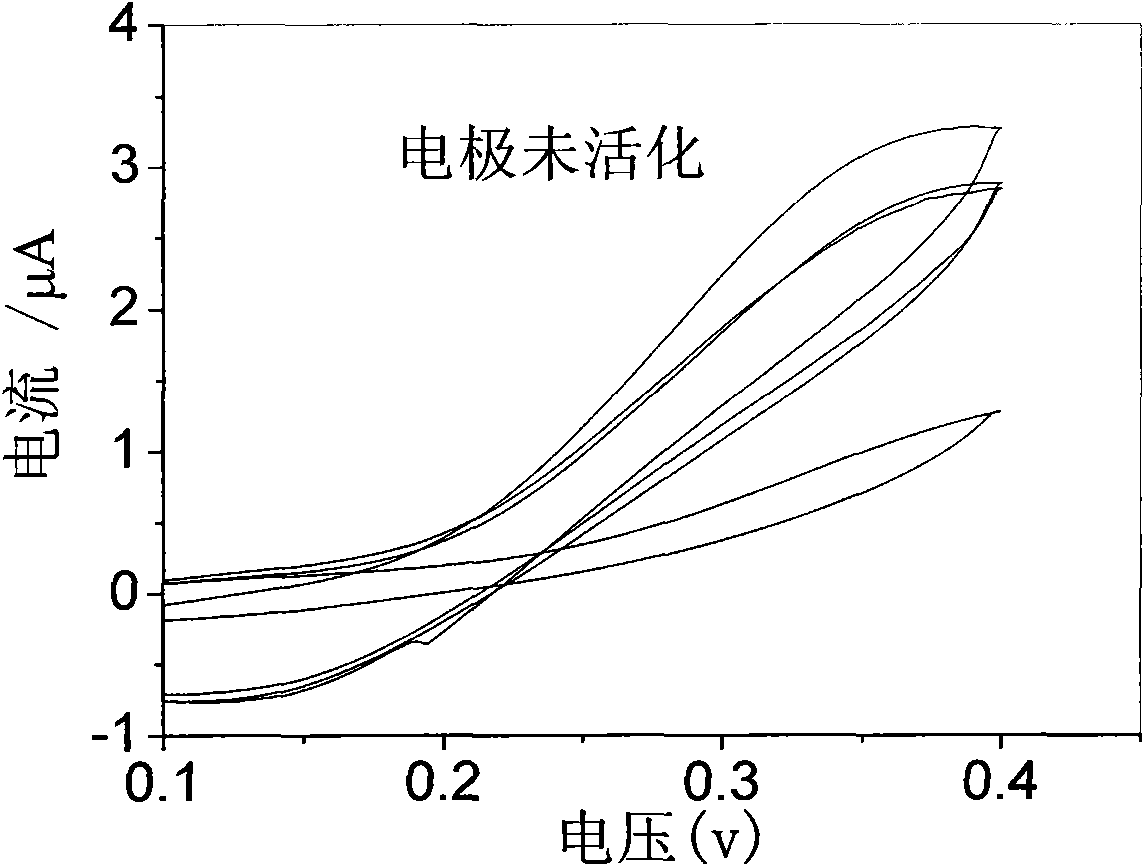

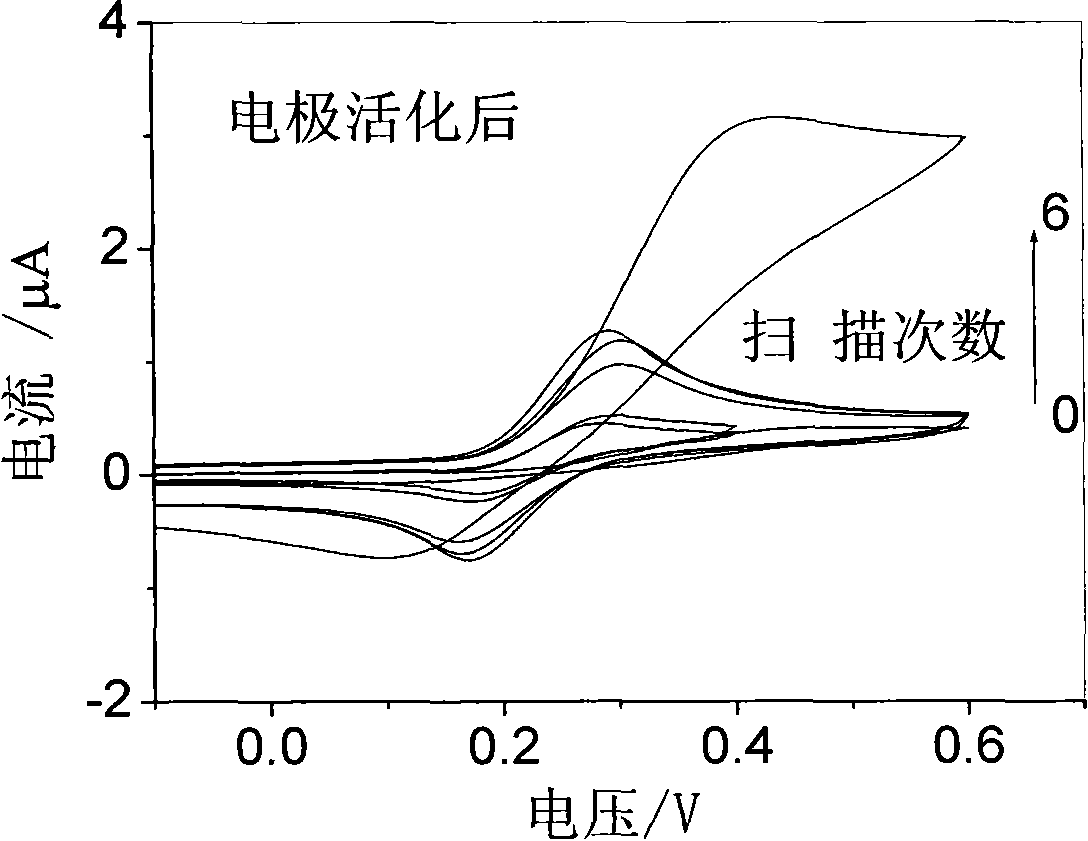

The invention relates to a project in which a research is carried out for simultaneously detecting dopamine and epinephrine by using carbon fiber modified microelectrode with a diameter of 7mum. As a result, L-glutamic-acid-modified carbon fiber microelectrode has a substantial catalytic effect upon electric oxidation-reduction of dopamine and epinephrine. In a phosphate buffer solution with a pH value of 6.0, a mixed solution of dopamine and epinephrine is detected by using a cathode differential pulse voltammetric method, and two relatively strong oxidation peaks are simultaneously detected. The peak with an electric potential located at 0.24V is dopamine, and the peak with an electric potential located at -0.14V is epinephrine. The peak currents thereof respectively have good linear relationships with the concentrations of dopamine and epinephrine. The linear range of dopamine is 5.0*10<-4>-1.0*10<7>mol / l, and a detection limit is 1.0*10<-8>mol / l. The linear range of epinephrine is 2.5*10<-4>-1.0*10<-5>mol / l, and a detection limit is 1.0*10<-7>mol / l.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Carbon fiber composite discharge electrode

ActiveUS20120227588A1Low costHigh strengthMaterial nanotechnologyElectrode carrying meansFiberNanofiber

A discharge electrode using carbon fibers, nanofibers and / or nanotubes to generate the corona discharge. The invention contemplates carbon fiber electrodes with or without a polymer matrix to form a composite, and a supporting configuration in which the fibers are wrapped helically around a supporting rod that extends along the length of the electrode. Another supporting configuration includes the fibers stretched across the gas flow path. Yet another supporting configuration includes mounting the fibers along the length of the support rod substantially parallel to the rod.

Owner:OHIO UNIV

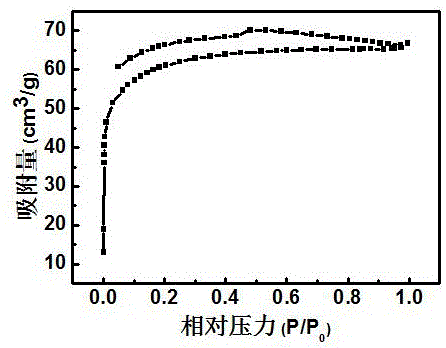

Preparation method of porous nitrogen-rich carbon fiber electrode

ActiveCN105761950ARich in nitrogenDoping method is simpleHybrid capacitor electrodesFibre chemical featuresCarbon fibersSpinning

The invention provides a preparation method of a porous nitrogen-rich carbon fiber electrode and relates to the field of production technologies of functional materials.Polyacrylonitrile is dissolved in N,N-dimethyl formamide, then melamine resin is added to serve as a nitrogen source, and polyethylene glycol serves as a pore-forming agent to prepare a spinning solution; a PEG / MF / PAN composite precursor fiber is produced through electrostatic spinning; the PEG / MF / PAN composite precursor fiber is subjected to preoxidation, carbonization and other heat treatment to obtain a porous nitrogen-rich carbon fiber (NACF); the NACF is made into the super-capacitor electrode, and the problem that existing carbon fiber nitrogen doping and pore forming need to be performed step by step, the specific surface area and the nitrogen content cannot be considered, a production process is complicated, the cost is higher and the like is solved.

Owner:YANGZHOU UNIV

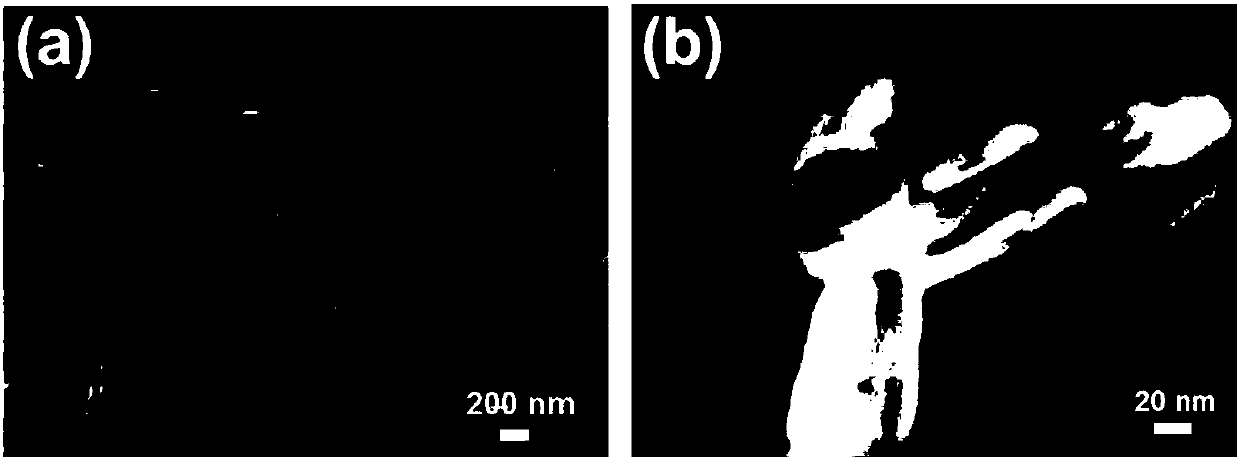

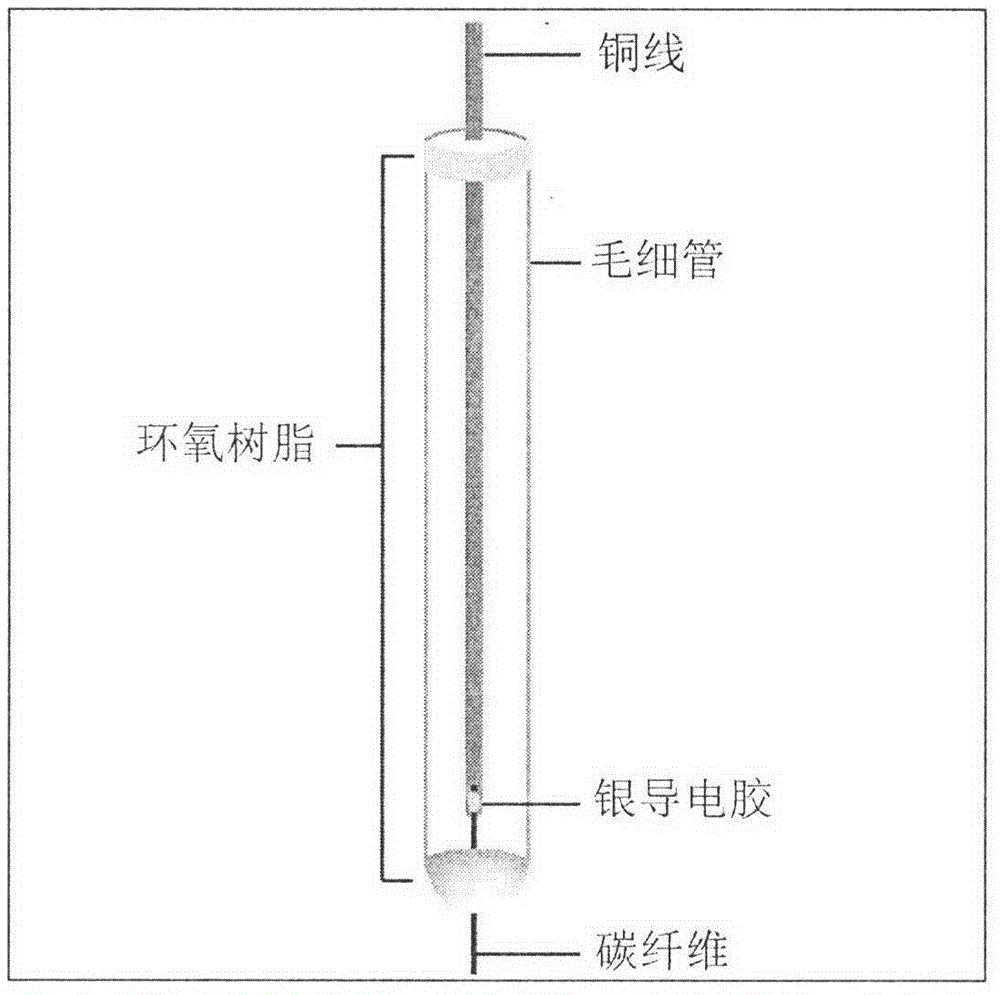

Carbon fiber electrode used for diphenol microsensor

InactiveCN104914149AImprove electrocatalytic activityReduce manufacturing costMaterial electrochemical variablesFiberEpoxy

The invention relates to modification for an electrode of a sensor, in particular to the assembly of a carbon fiber electrode and modification for the surface of the carbon fiber electrode so that the sensitivity and the signal intensity of the carbon fiber electrode for a to-be-detected article are enhanced. A specific preparation process comprises the following steps: (1) performing ultrasonic treatment on carbon fibers for 2-3min by using acetone and distilled water, drying, connecting copper wires and carbon fibers together by using silver conductive glue; (2) encapsulating the copper wires into a capillary tube by adopting epoxy resin without electrochemical catalytic activity, and completely drying under room temperature; (3) cutting the carbon fibers at the top end of the capillary tube so that the carbon fibers have suitable lengths, and dipping the electrode into dilute H2SO4 for electrochemical activation; (4) dipping the electrode subjected to electrochemical activation into acetonitrile solution containing 3,4-ethylenedioxythiophene (EDOT) and lithium perchlorate for potentiostatic electropolymerization; and (5) testing the performances of the prepared electrode by adopting an electrochemical workstation. The preparation process is easy to operate, the cost of the electrode is greatly reduced, and the prepared electrode has extremely high catalytic oxidation capacity for diphenol substance and has a very high practical value in the field of microelectrodes.

Owner:TIANJIN POLYTECHNIC UNIV

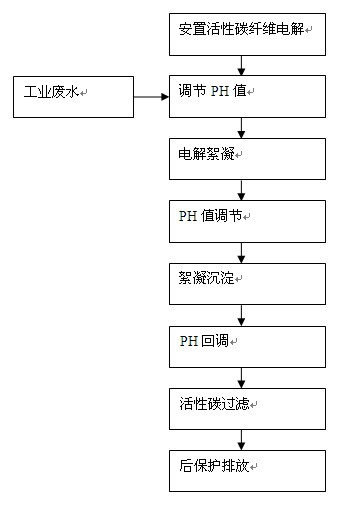

Application method of high-property activated carbon fibers in treatment of industrial waster water by electrocoagulation

InactiveCN102092821AAvoid secondary pollutionSecondary pollution will not occurWater/sewage treatmentMultistage water/sewage treatmentFiberElectrolysis

The invention discloses an application method of high-property activated carbon fibers in the treatment of industrial waster water by electrocoagulation. In the application method, the industrial waster water is treated by the electrocoagulation, the high-property activated carbon fibers are used as an electrode for electrolysis and has a composition of activated carbon. The high-property activated carbon fiber electrode has the advantages of high electrolysis efficiency, wide application range, low use cost and no secondary pollution, and is beneficial to water reuse treatment by reverse osmosis, thus the high-property activated carbon fibers have an extremely giant application prospect in the process of treating industrial waster water by high-frequency high-voltage impulse electrocoagulation.

Owner:吴国君 +1

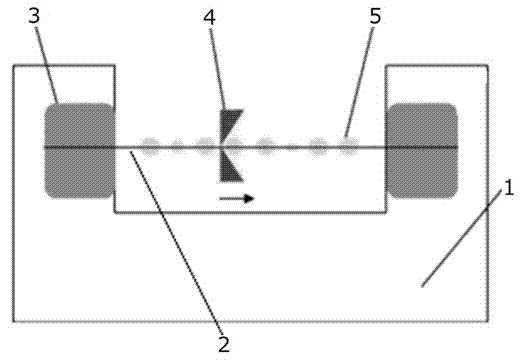

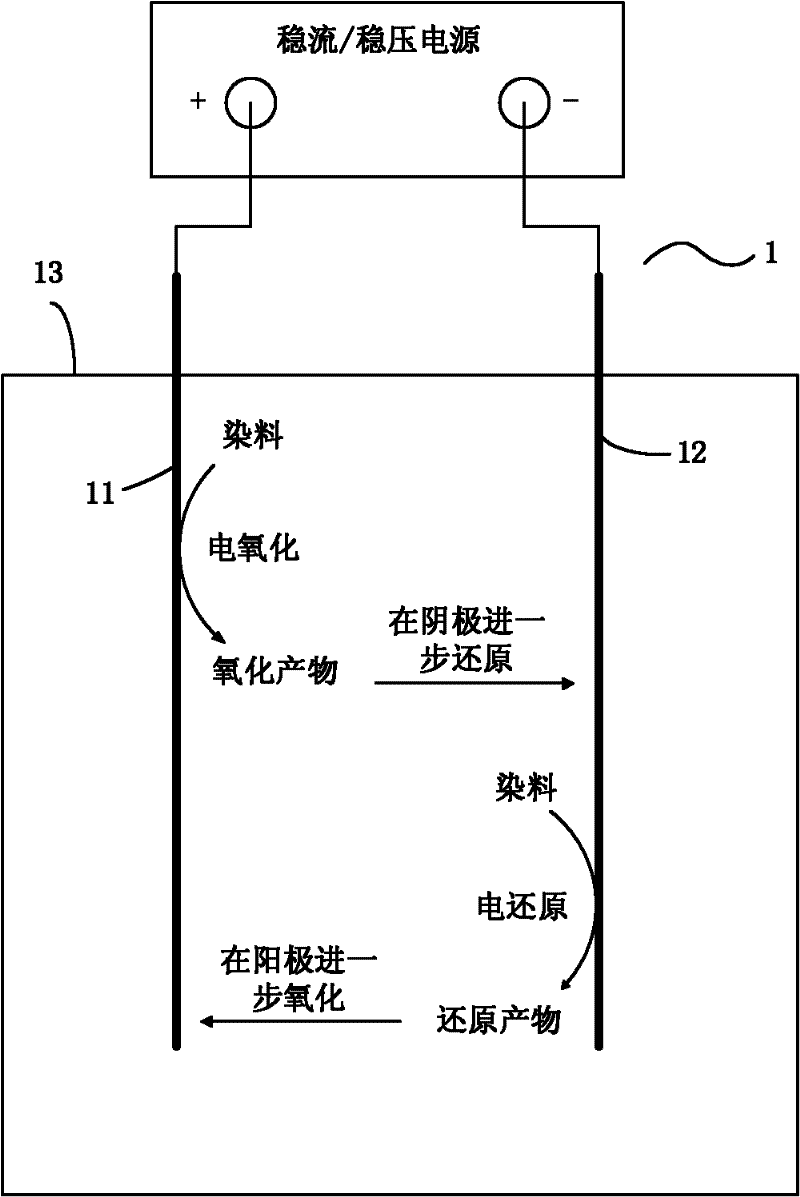

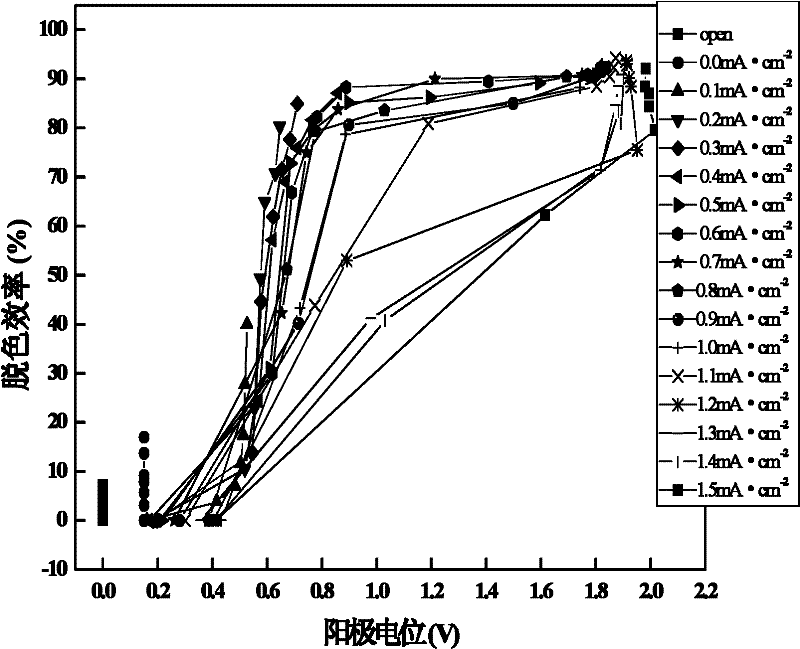

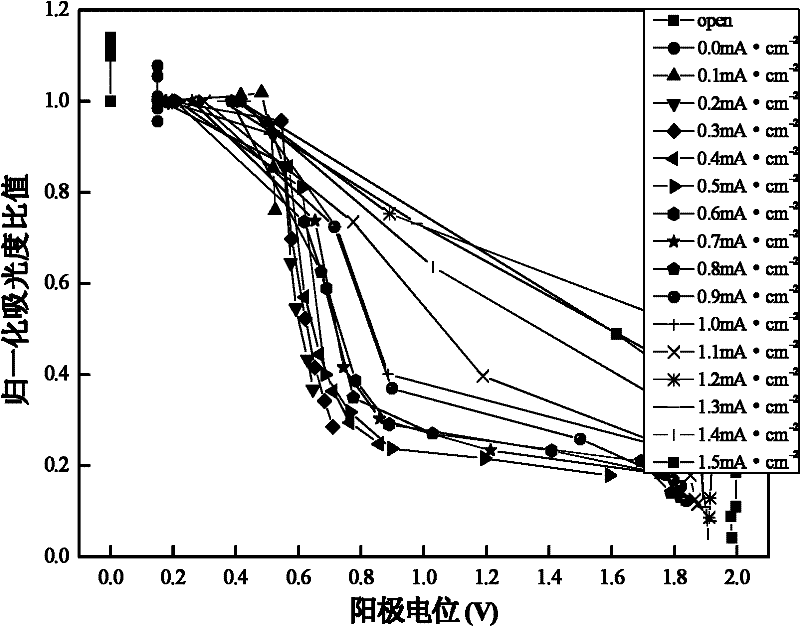

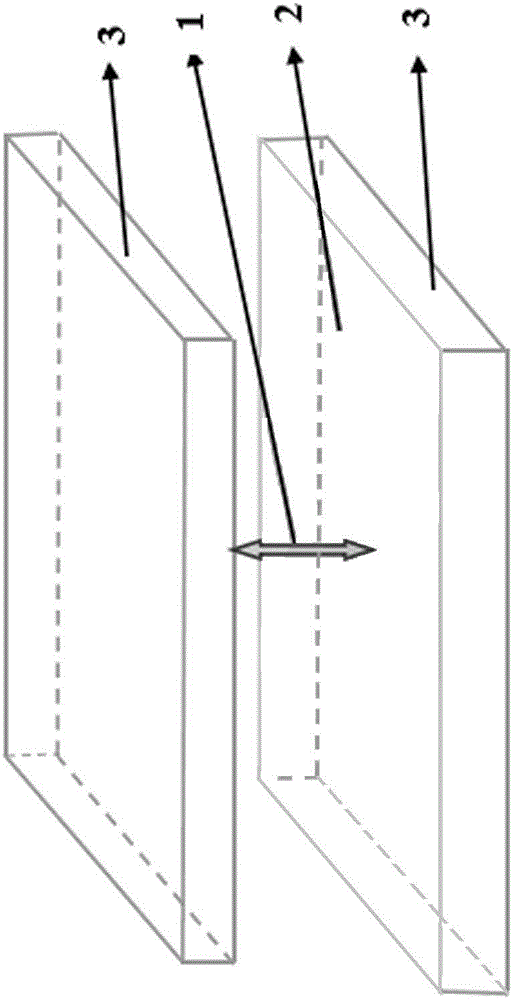

Active carbon fiber electrodes undivided paired direct electro-oxidation and electro-reduction decolorizing method

InactiveCN102225795ASolve the problem of high-efficiency and low-consumption decolorizationImprove current efficiencyWater/sewage treatment by reductionWater/sewage treatment by oxidationElectrochemical responseFiber

The invention provides an active carbon fiber electrodes undivided paired direct electro-oxidation and electro-reduction decolorizing method. According to the method, in an undivided electrochemical reactor, active carbon fiber (ACF) is adopted as an anode for electro-oxidation, and as a cathode for electro-reduction. After electrification, the ACF electrodes are polarized for 2 hours, and then dye waste water is electrolyzed. The undivided electrochemical reactor is a reaction tank provided with an ACF anode an ACF cathode, which are undivided. According to the present invention, ACF is adopted both in an anode for electro-oxidation, and in a cathode for electro-reduction. Direct electro-oxidation and electro-reduction occur between the anode and the cathode, such that electrolyzing and decolorizing can be carried out. With the method provided by the present invention, current efficiency and decolorizing efficiency can be improved, and power consumption can be reduced, such that the decolorizing of industrial dye wastewater can be carried out with high efficiency and low consumption.

Owner:FUJIAN UNIV OF TECH

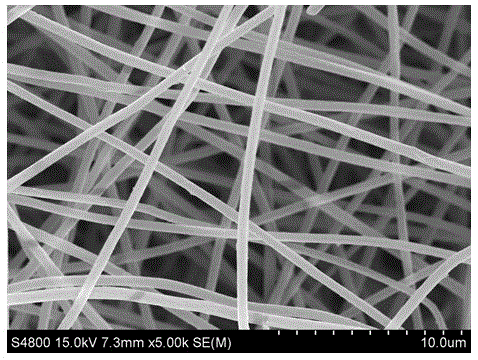

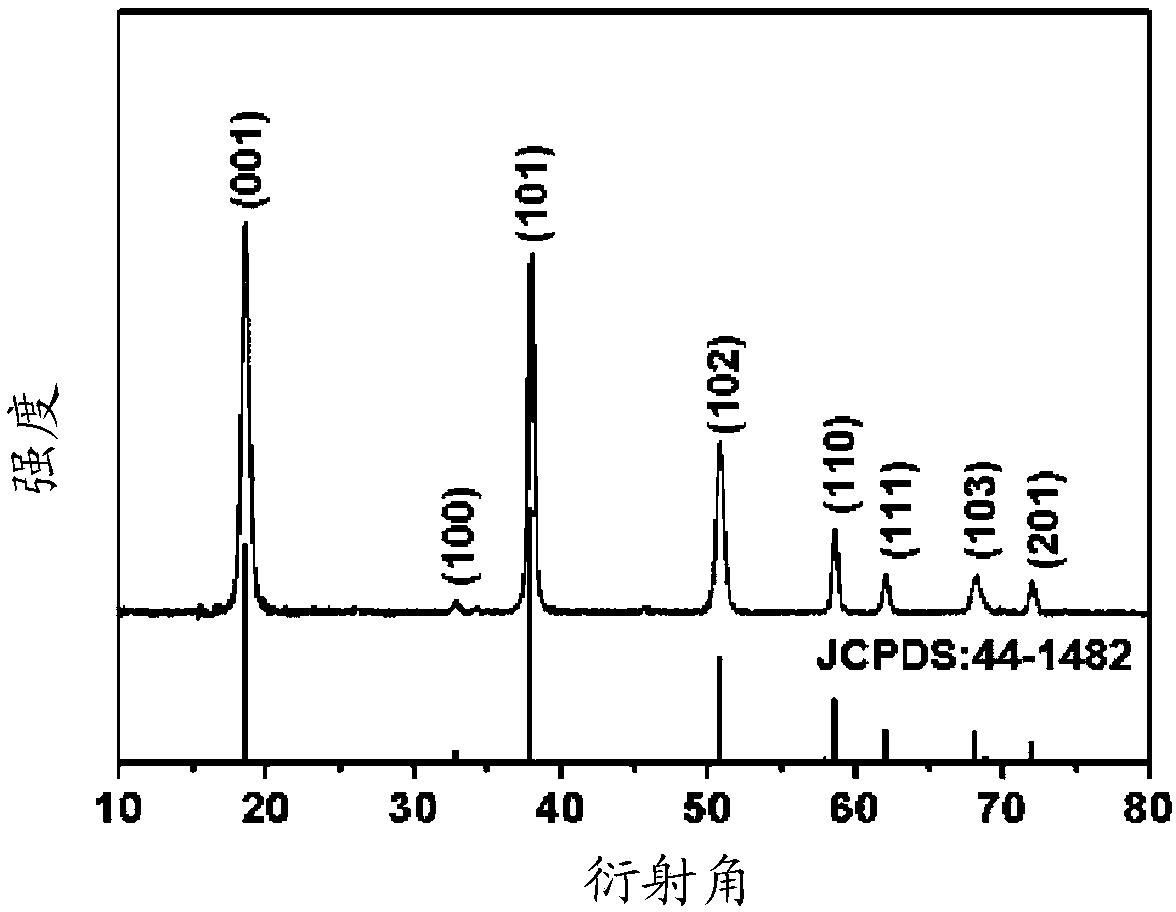

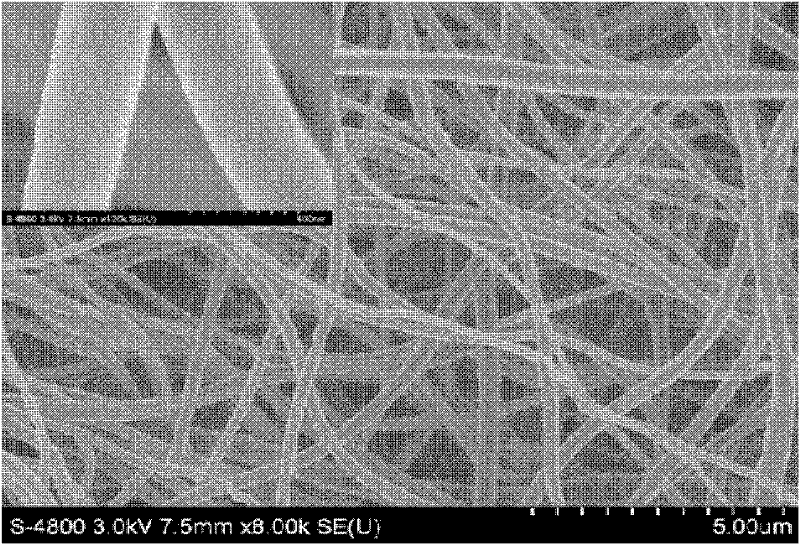

A preparation method of monolithic polyacrylonitrile carbon fiber electrode for desalination

InactiveCN102285706AHas a macroscopic integrityFine fiber diameterWater/sewage treatment by electrochemical methodsDispersed particle separationCapacitanceCarbonization

The invention relates to a preparation method for an integral polyacrylonitrile carbon fiber electrode for desalination, belonging to the technical field of novel carbon material preparation and water treatment. The method is based on an electrostatic spinning technique. Polyacrylonitrile is electro-spun into a film and then preoxidation, carbonization and activation are conducted. The prepared carbon fiber material has the characteristics of good macro integrity, small fiber diameter, large mass specific capacitance, high desalination capacity and the like. When electro-adsorption treatment is conducted to NaCl solution with initial concentration being 70mg / l under 1.6V direct-current voltage, the adsorption capacity of the carbon fiber electrode reaches 4.64mgNaCl / g and therefore a strong desalination capacity is reflected. The novel carbon fiber electrode can be widely used in fields such as bitter saline water and seawater desalination, water softening, heavy metal ion removal andthe like.

Owner:DALIAN UNIV OF TECH

Method for directly preparing carbon fiber electrode containing nitrogen with melamine formaldehyde resin/polyvinyl accohol water solution through high-voltage electrostatic spinning technology

InactiveCN102800490ALower internal resistanceSolve pollutionElectrolytic capacitorsCapacitanceCarbon fibers

The invention discloses a method for directly preparing a carbon fiber electrode containing nitrogen with melamine formaldehyde resin / polyvinyl accohol water solution through high-voltage electrostatic spinning technology, and relates to the method for preparing the fiber electrode containing nitrogen. The invention aims at solving the problems of environmental pollution, complex process of electrode preparation and high inner resistance caused by the fact that all of fiber films containing nitrogen take polyacrylonitrile organic solution as the original spinning solution. The preparation method is as follows: mixing the polyvinyl alcohol water solution and the melamine formaldehyde resin water solution to prepare the original spinning solution; preparing foam nickel attached with a melamine formaldehyde resin / polyvinyl alcohol compound fiber film through high-voltage electrostatic spinning technology; the film and the foam nickel are carbonized together to directly form the carbon fiber film containing nitrogen on the foam nickel; and tabletting the foam nickel attached with the carbon fiber film containing nitrogen to get the carbon fiber electrode containing nitrogen. According to the invention, the preparation of the carbon fiber film containing nitrogen and the preparation of electrode can be simultaneously completed. The method has the advantages of simple operation method, low pollution, low inner resistance of the electrode and high specific capacitance, and therefore is suitable for producing the carbon fiber electrode containing nitrogen.

Owner:HEILONGJIANG UNIV

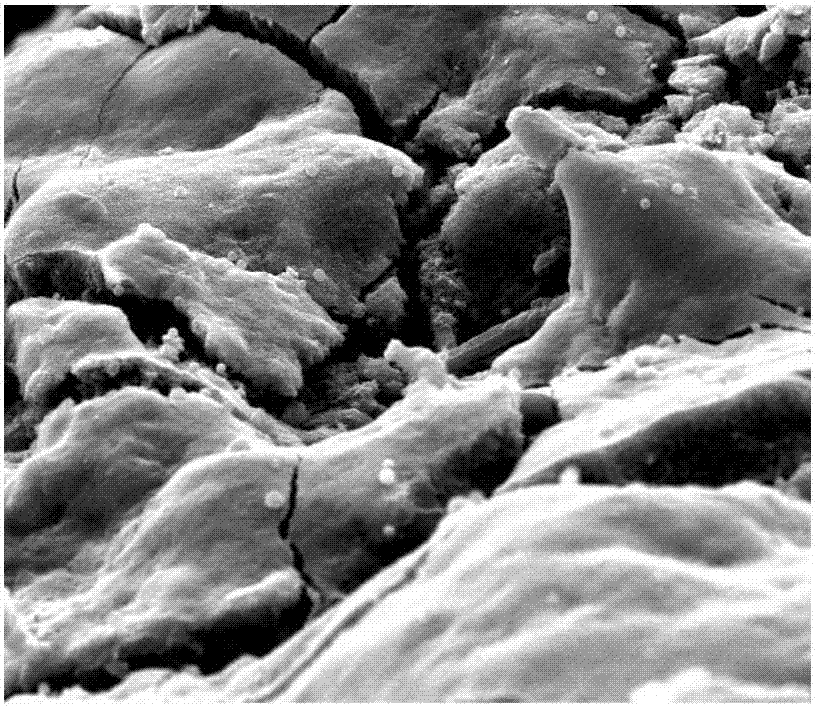

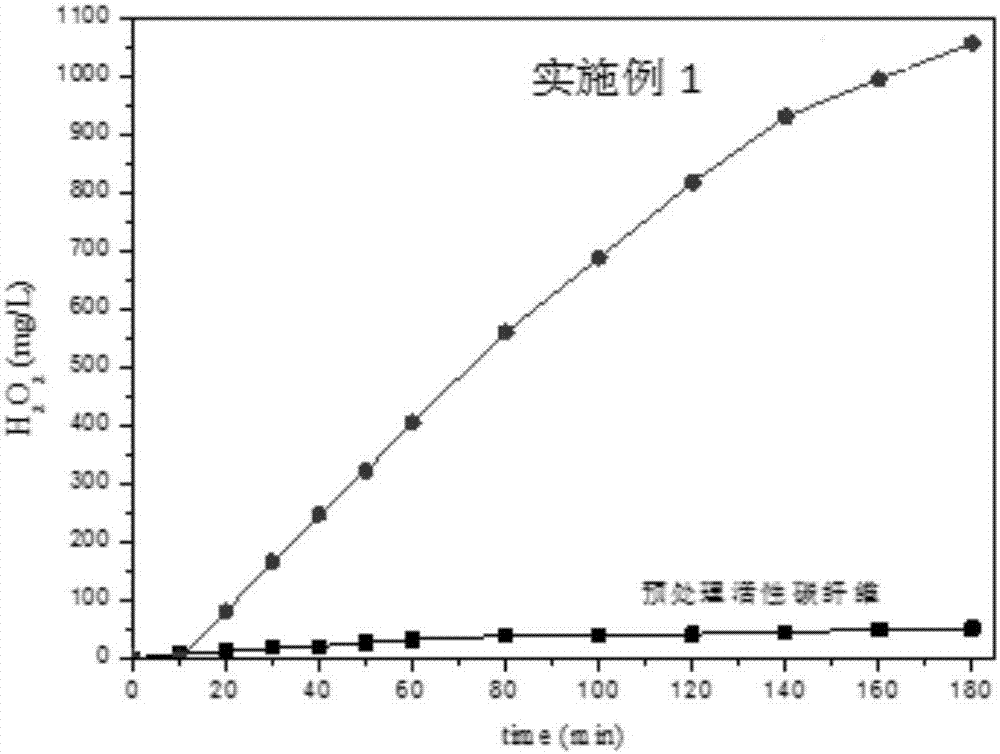

Preparation method of carbon fiber electrode efficiently producing hydrogen peroxide to treat organic wastewater

InactiveCN107200384AProduce efficientlyEasy to handleWater/sewage treatment by oxidationFiberCarbon fibers

The invention provides a preparation method of a carbon fiber electrode efficiently producing hydrogen peroxide to treat organic wastewater. The preparation method comprises the following steps of weighing carbon nanometer tube particles and teflon of a certain mass, adding the carbon nanometer tube particles and teflon into deionized water according to a mass ratio, adding isopropyl alcohol, performing ultrasonic treatment on the solution for 10-20 minutes so as to mix the solution uniformly to obtain a mixed solution A, immersing the cleaned commercialized carbon fiber material into the obtained mixed solution A for 20-40 minutes, performing ultrasonic treatment for 1-3 hours at a constant temperature of 40-60 DEG C so as to acquire a pre-treated carbon fiber material, maintaining the pre-treated carbon fiber material in a stove of 40-80 DEG C for 4-8 hours, then annealing in a muffle furnace at 300-400 DEG C for 1 hours, so as to obtain the carbon fiber material. The electrode carbon fiber electrode prepared by the method has the characteristic of long service life.

Owner:SHAANXI UNIV OF SCI & TECH

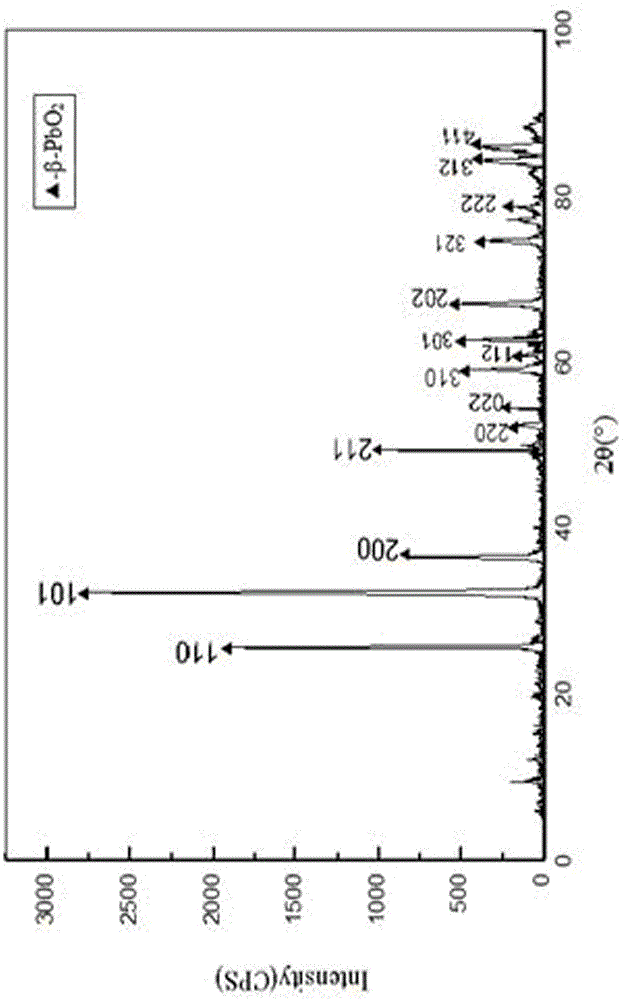

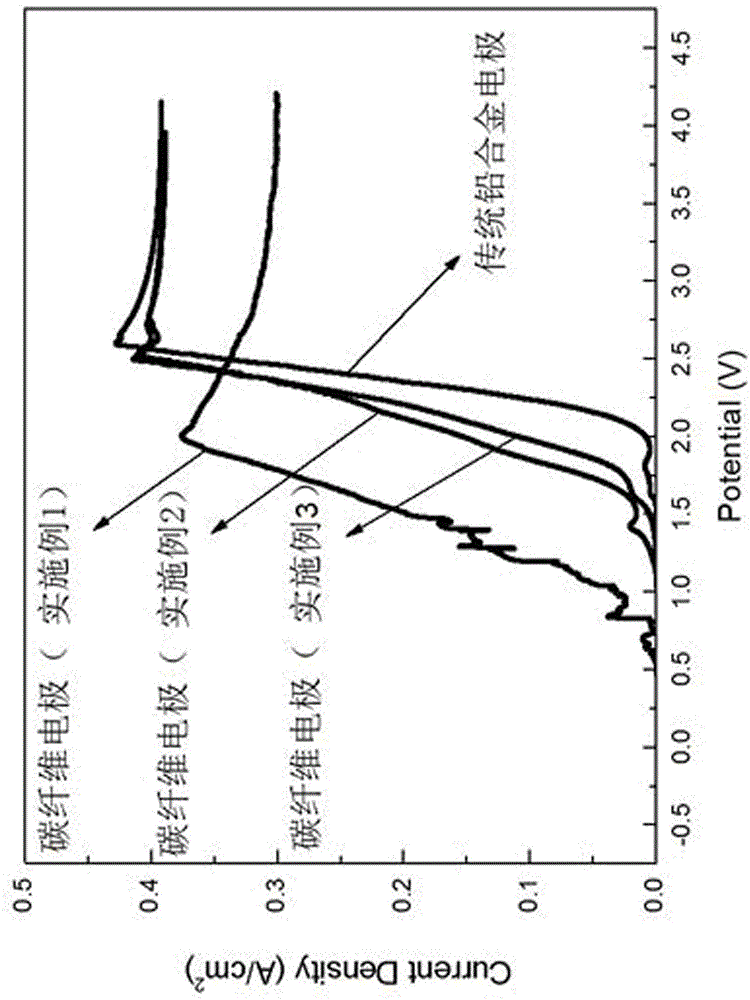

High-conductivity carbon fiber electrode material and preparation method

The invention discloses a preparation method of a high-conductivity carbon fiber electrode material. The preparation method comprises the following steps: performing alkaline oil removal to the surface of carbon fiber cloth, carrying out ultrasonic cleaning treatment, cleanly washing with distilled water, etching and activating with concentrated sulfuric acid, boiling off with distilled water and naturally airing, binding and sealing the pretreated carbon fiber cloth with a conductive resin adhesive, performing lead electric precipitation to a plurality of layers of sealed carbon fiber, and the like. According to the method, the oil contamination and impurities on the surface of carbon fiber cloth can be removed after pretreatment, so that the surface is clean, the binding property is improved, and the stability of the electrode material is improved; the compounding of activated substance lead dioxide on the surface of the carbon fiber can be directly realized without other binders or a middle layer, the internal resistance of an electrode is reduced, the activated substances are evenly distributed on the surface of the carbon fiber, and the conductivity of the electrode material is improved. The conductive layer of the carbon fiber electrode material prepared by adopting the method is smooth, strong in adhesion force, strong in catalytic activity, low in cost, simple in technology and good in stability.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

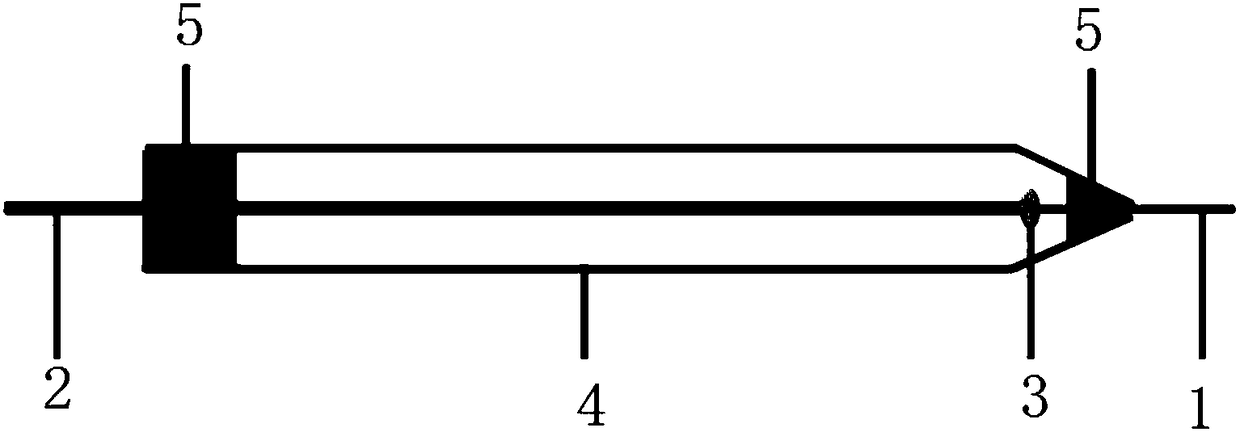

Novel carbon fiber microelectrode and preparation method thereof

InactiveCN108490052AImprove electrochemical performanceHigh yieldMaterial analysis by electric/magnetic meansFiberCarbon fibers

The invention belongs to the technical field of microelectrode preparation and relates to a novel carbon fiber microelectrode and a preparation method thereof. The novel carbon fiber microelectrode comprises carbon fiber wires and copper wires. One end of the carbon fiber wire and one end of the copper wire are connected and cured by a conductive adhesive. The cured carbon fiber wire-copper wire is sleeved by a glass capillary with a tip at one end. The thick end of the glass capillary and the copper wire are fixed through a short wax column. The gap between the tip end of the glass capillaryand the carbon fiber wire are sealed through a short wax column. Wax oil is used as a simple and efficient sealant. The carbon fiber microelectrode with good electrochemical performances can be prepared without a complicated instrument. The novel carbon fiber microelectrode has the characteristics of good sealing effects, high yield, no pollution, good electrochemical performance, etc. The carbonfiber microelectrode has no pollution to an analysis sample, good stability and high reproducibility, utilizes cheap and easily available raw materials, is prepared through simple processes and is suitable for mass production.

Owner:CHONGQING UNIV OF ARTS & SCI

Preparation method of lignin-based active carbon fiber for electrodes of supercapacitors

InactiveCN107604480AReduce manufacturing costIncrease energy densityHybrid capacitor electrodesArtifical filament manufactureCarbon fibersHigh energy

The invention discloses a preparation method of lignin-based active carbon fiber for electrodes of supercapacitors. The preparation method comprises the following steps: adding nano-scale manganese dioxide into a sodium alginate aqueous solution, then adding graphene oxide after ultrasonic stirring, then regulating the pH value of the solution to be 10-11, adding purified lignin, and carrying outdecompression and rotary evaporation to obtain a hybridized material; adding the hybridized material into a melt spinning machine to carry out spinning at the temperature 200-250 DEG C, and obtaininghybridized fiber; putting the hybridized fiber in a high-temperature furnace, raising the temperature to 280-300 DEG C at the temperature raising rate of 0.01-3 DEG C / min, keeping the constant temperature for 1-6 hours; and then raising the temperature to 1000-2000 DEG C to carry out carbonization for 0.5-12 hours, thus obtaining the carbon fiber for the electrodes of the supercapacitors. The electrode prepared by the lignin-based active carbon fiber has the beneficial effects of low production cost and high energy density and the like.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com